Patents

Literature

152results about How to "Will not cause shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mortar

InactiveCN1951858AOvercoming brittlenessOvercome defects such as cracking and drummingFiberCellulose

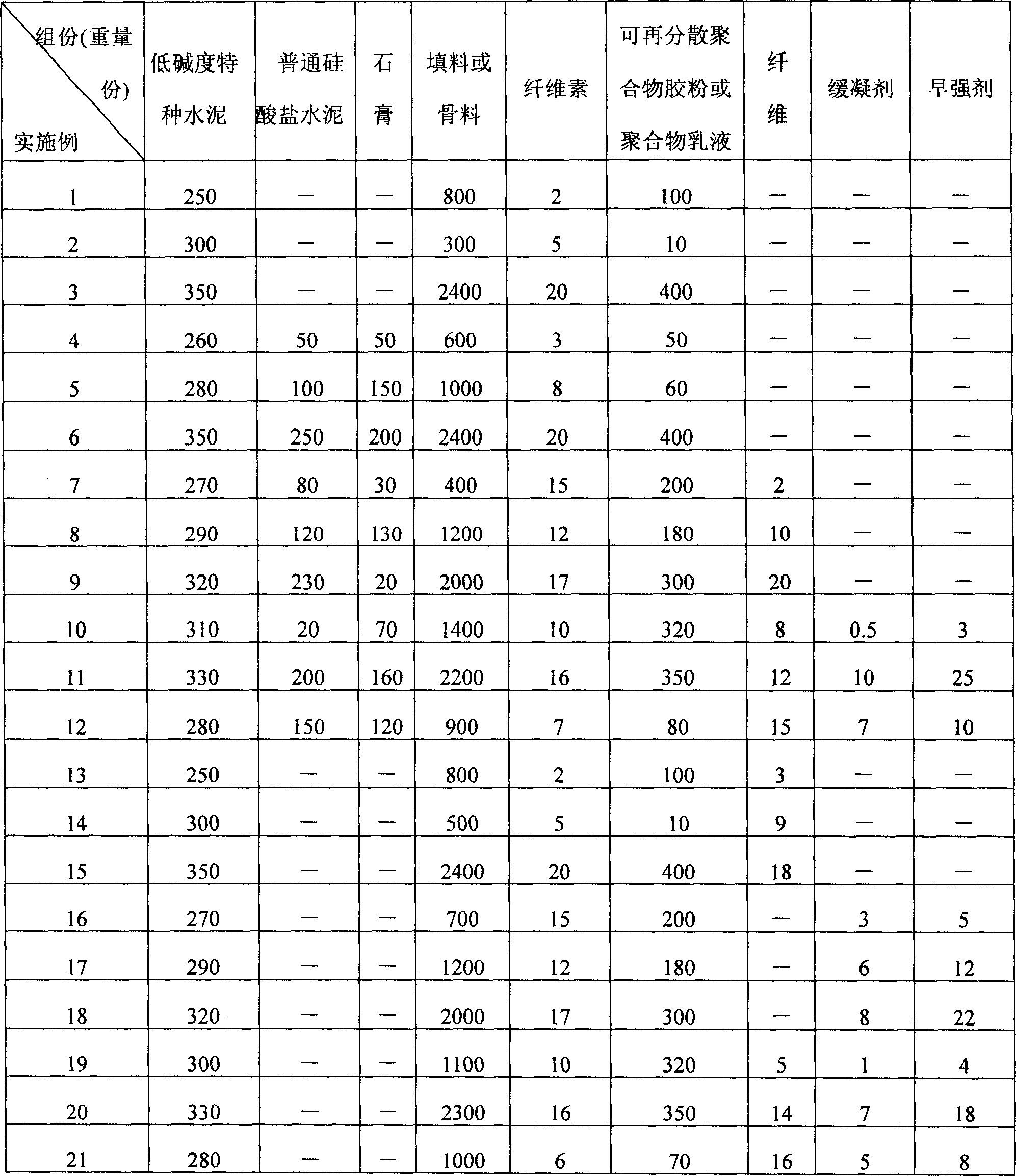

The invention discloses a mortar, which comprises the following parts: 250-350 parts of low-alkaline special typed cement, 0-250 parts of common silicate cement, 0-200 parts of calcium sulfate, 300-2400 parts of filler or aggregate, 2-20 parts of cellulose, 10-400 parts of redispersion polymer gel powder or 10-400 parts of polymer emulsion, 2-20 parts of fiber, 0.5-10 parts of retarder and 3-25 parts of instant coagulant. The low-alkaline cement contains the following clinker with 15%-35% C4A3S, 15%-35% C2S, 0%-35% C3S, 4%-15% CaSO4, 0%-15% C4AF and 0%-5% C3A . The mortar with low-alkaline cement and water can be preserved for 1-7d, whose pH value is 8-9.5.

Owner:王红

Laser melting rehabilitation method for titanium alloy thin-wall case

InactiveCN1966201AHigh hardnessQuality improvementLaser beam welding apparatusHeat inorganic powder coatingHydrogenThermal deformation

The invention relates to a method for using laser fusion to repair titanium alloy frame, wherein the inventive method comprises that: smoothing the abrasive area of element surface; cleaning out the solder electrolytic corrosion layer and solder vacuum anneal hydrogen removing treatment; at 750-800Deg. C, for 40-60min, 0.2-0.4MPa, using argon gas to cool down to 80Deg. C, discharging from furnace; laser fusion, while fusion frequency f=5-6Hz, time t=4-5m, under argon gas whose flux Q-4.5-5.5L / min, the fusion solder fills the abrasive part higher than 0.2-0.4mm, to cove 40-75%; abrading to needed size and roughness. The invention has simple operation and high rigidity, without thermal deformation.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

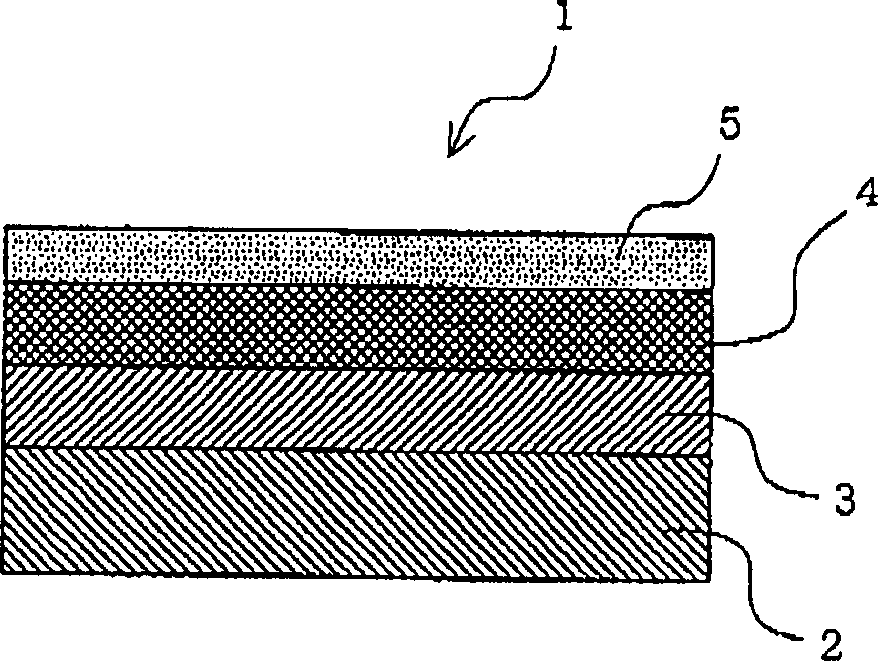

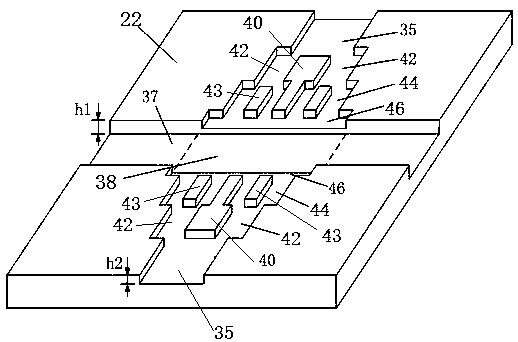

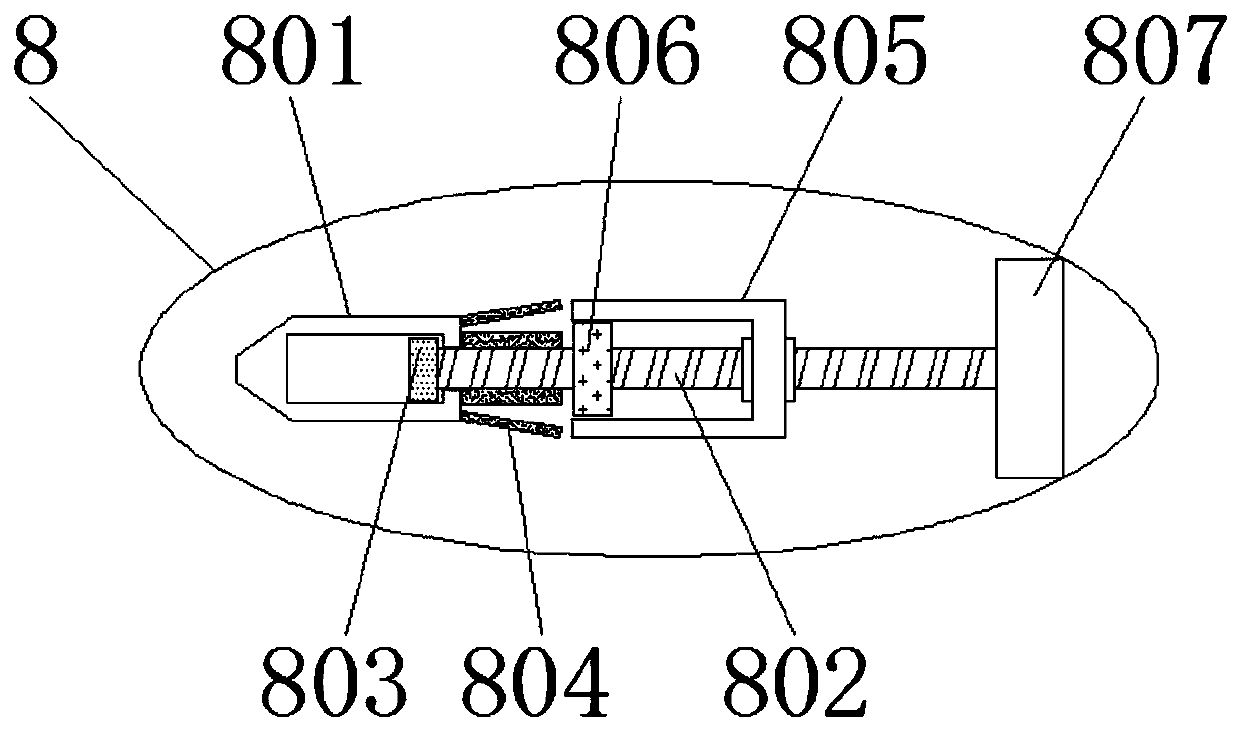

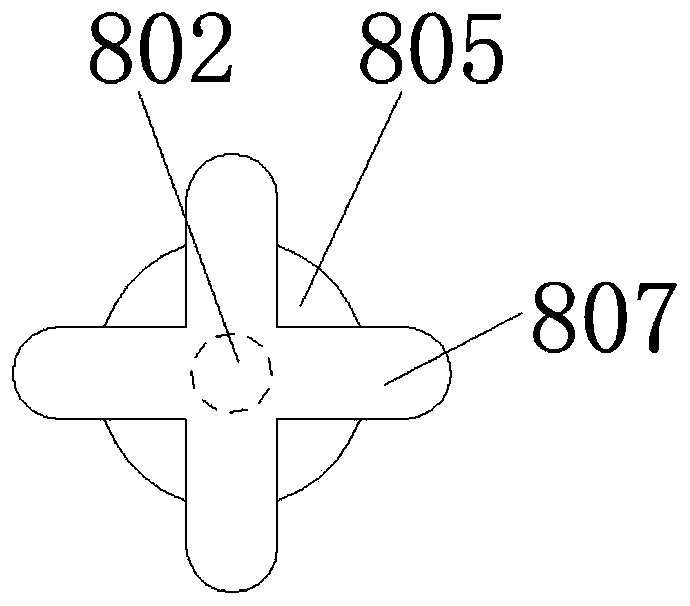

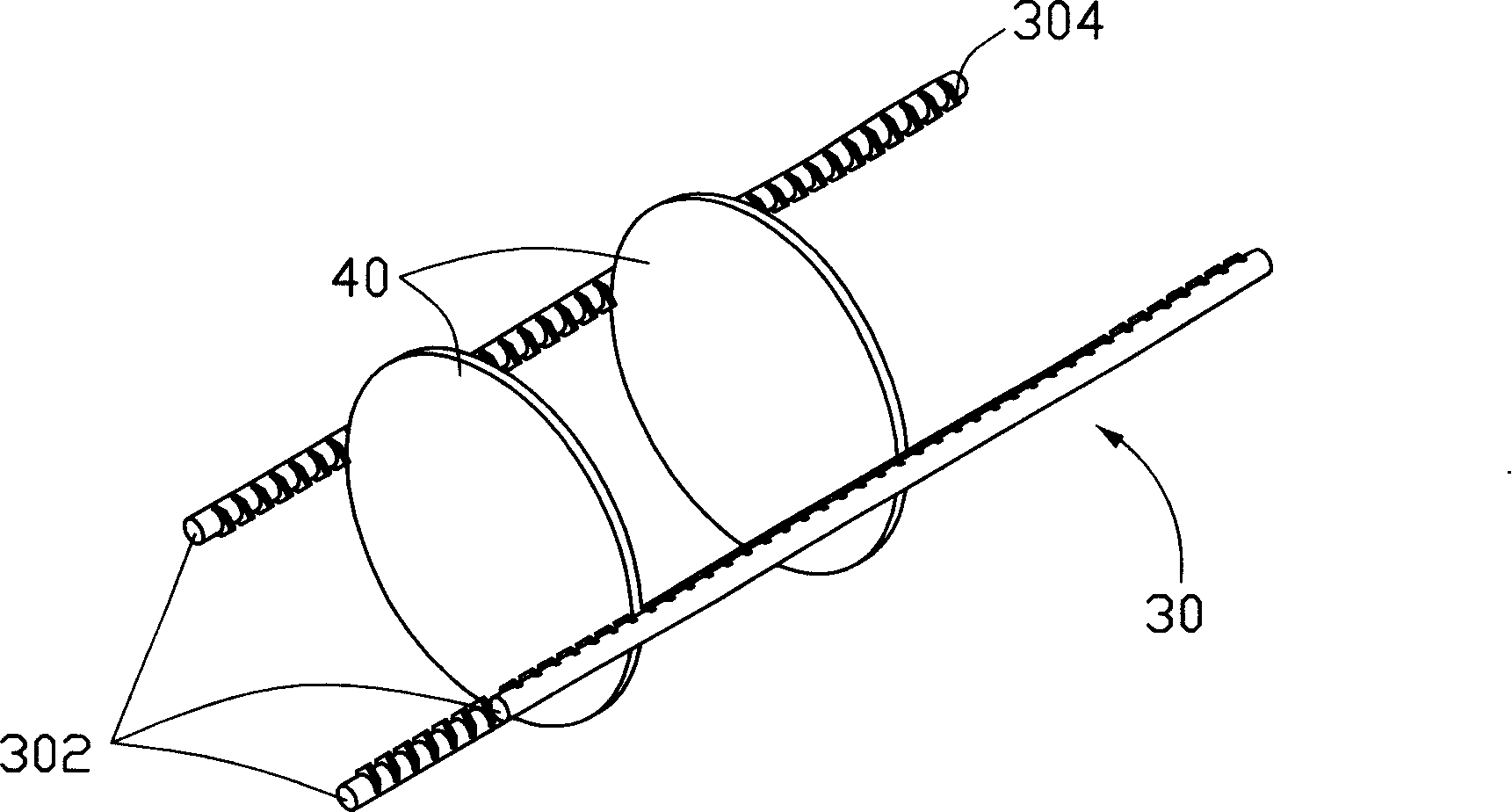

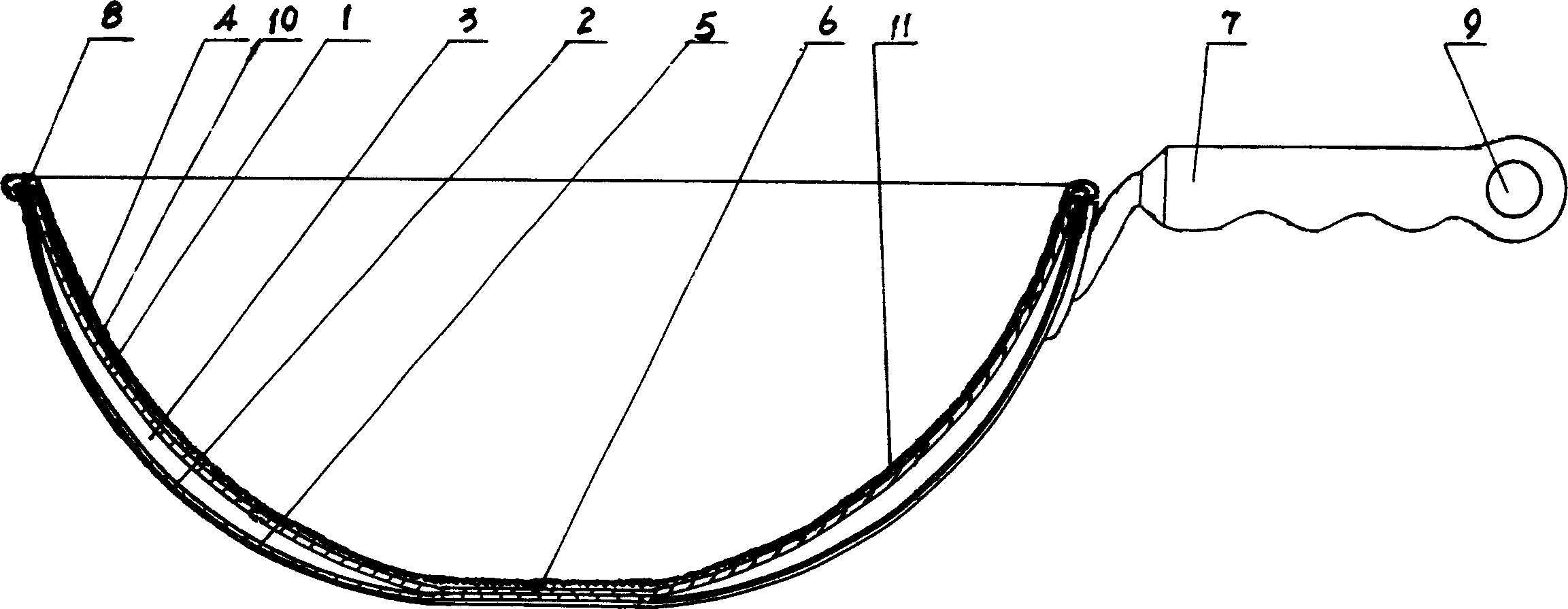

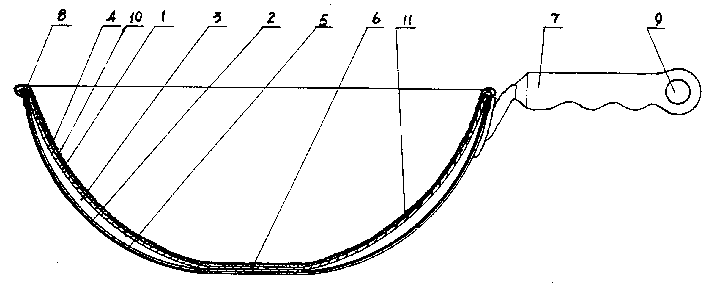

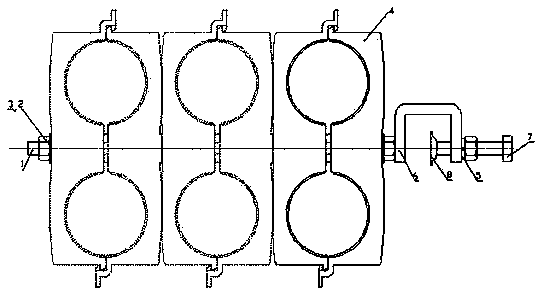

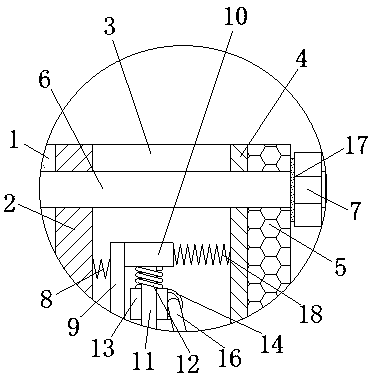

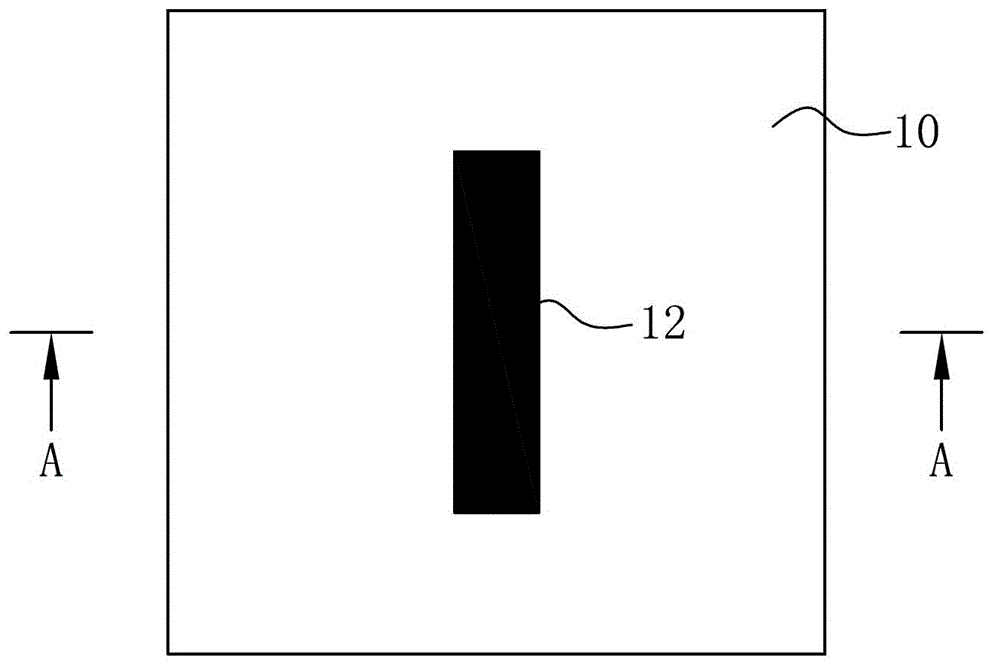

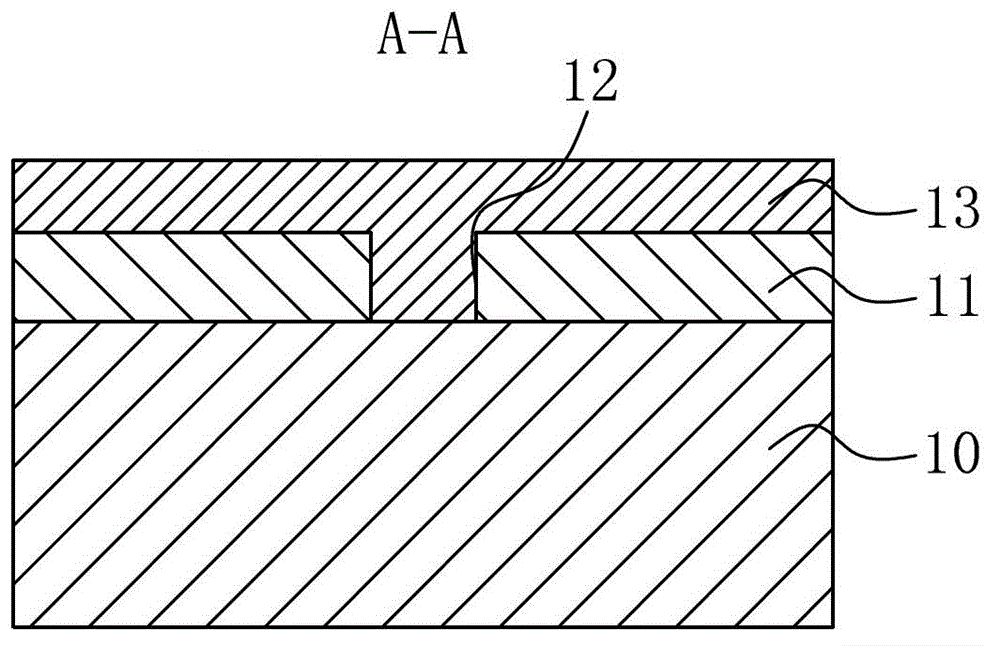

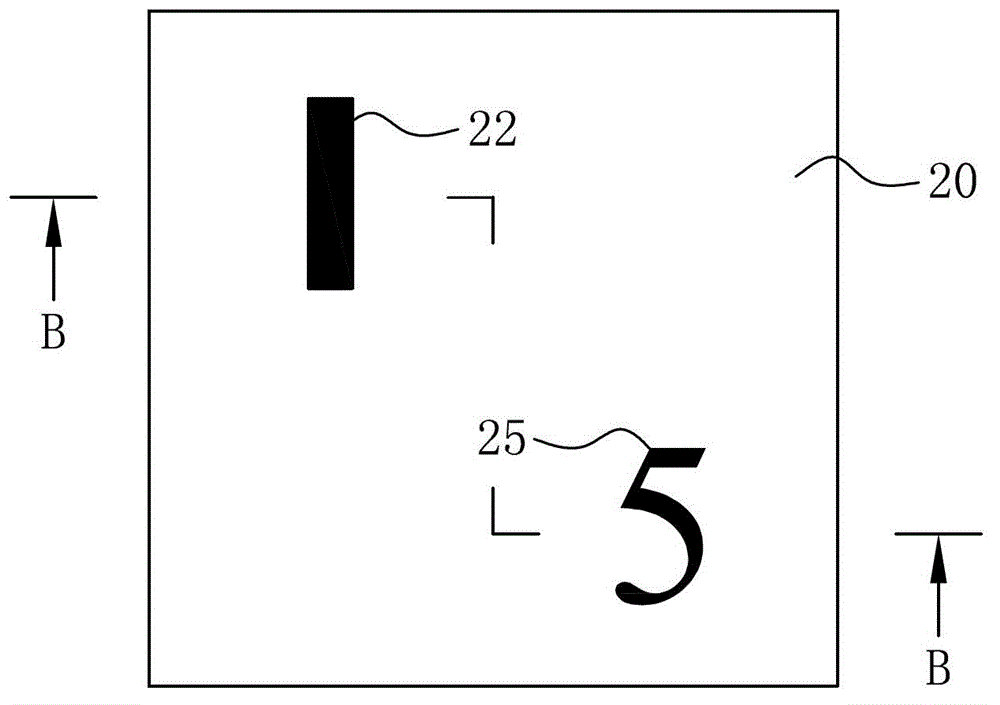

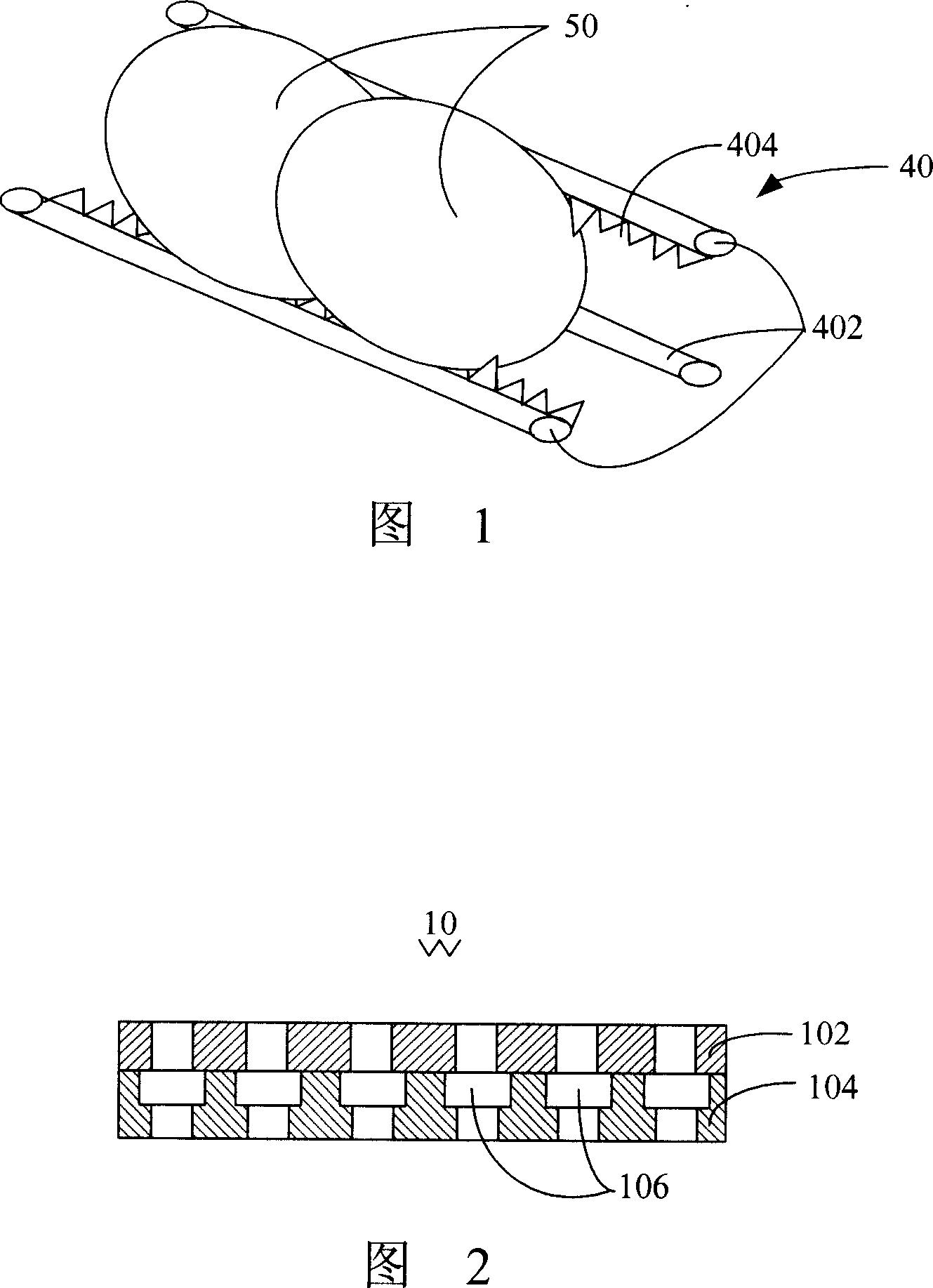

Coiled laminate square lithium-ion battery cell and preparation method thereof

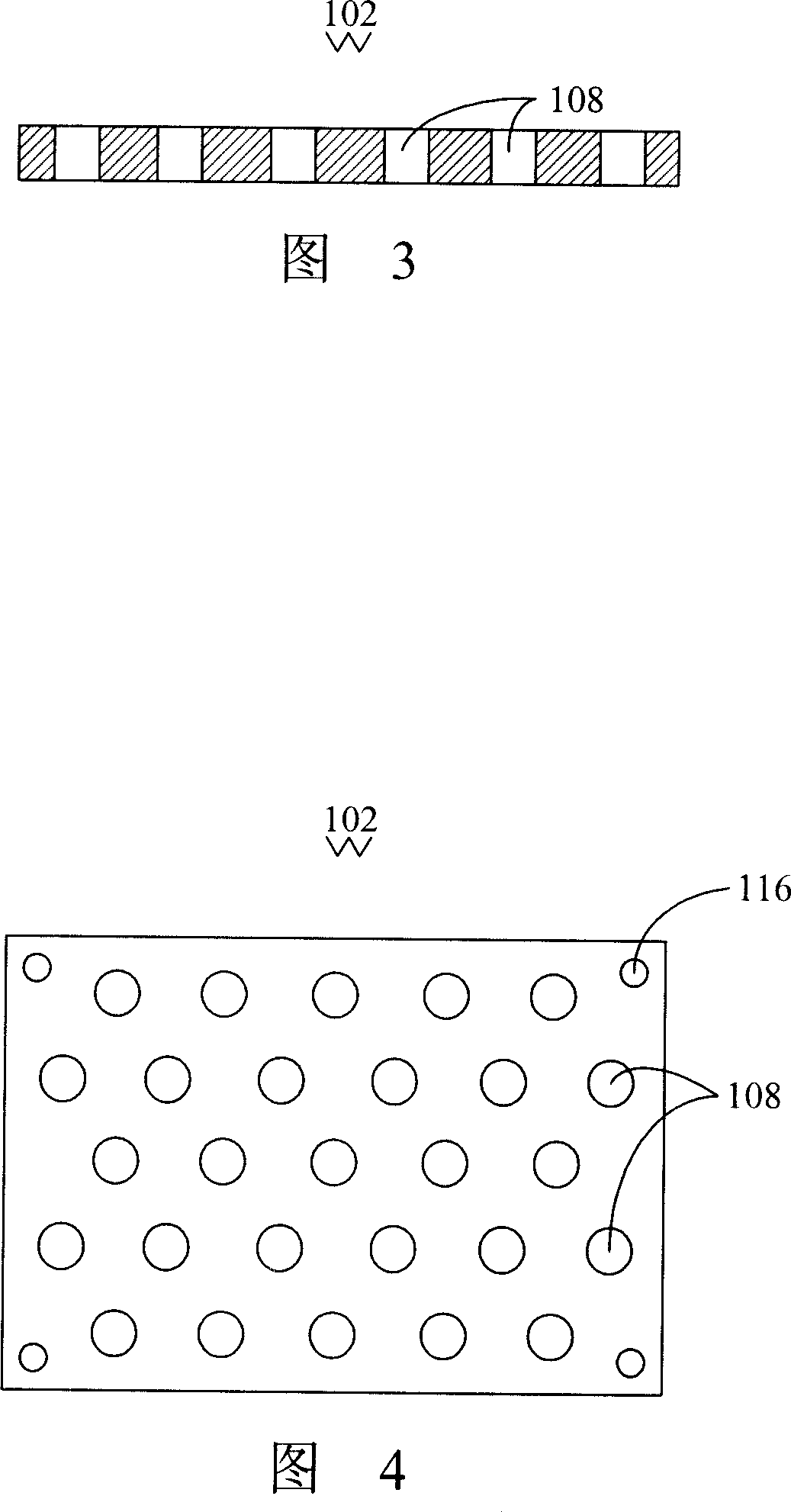

InactiveCN101901934AWill not cause sheddingWill not cause cracksFinal product manufactureSecondary cellsEngineeringPole piece

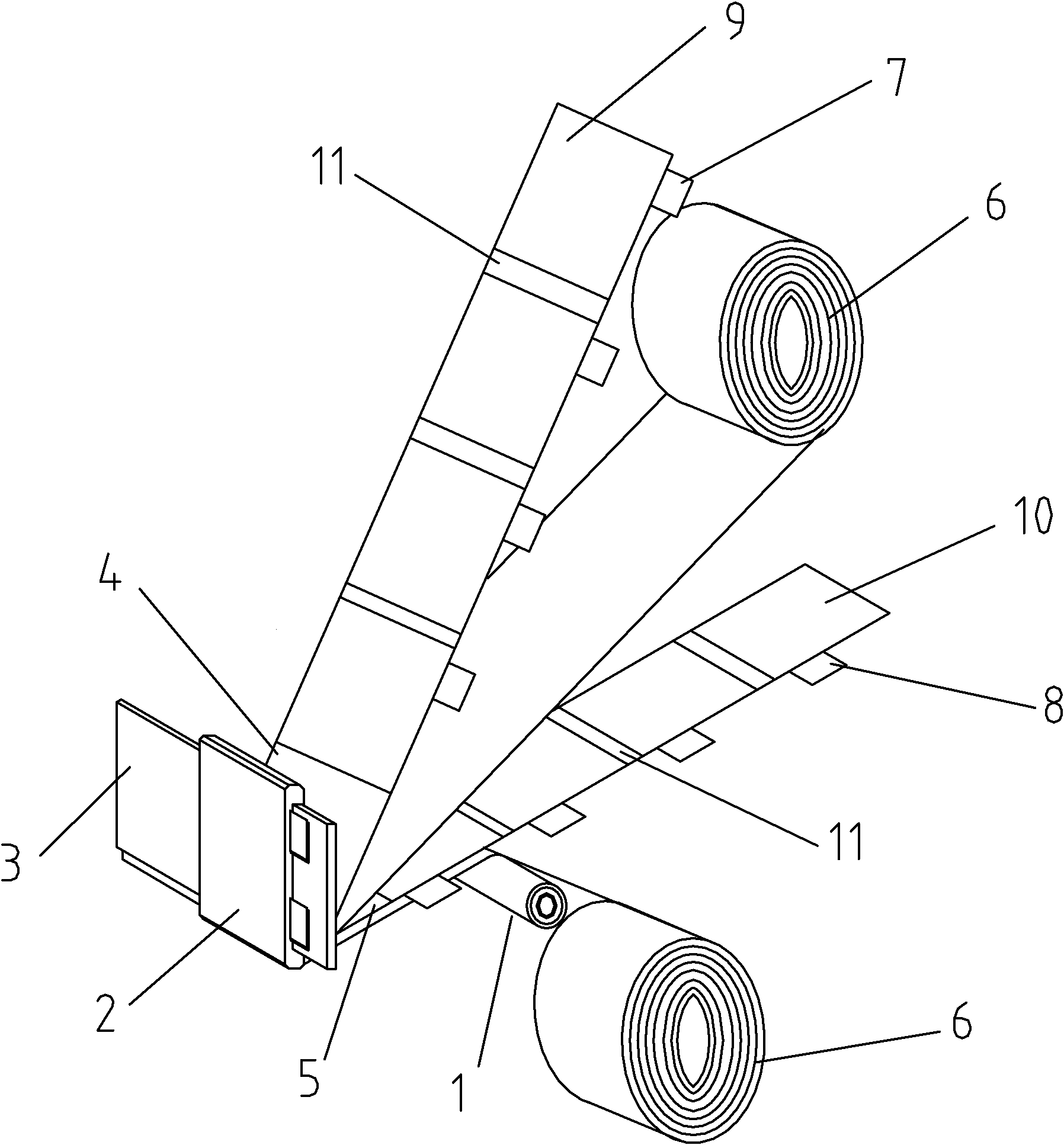

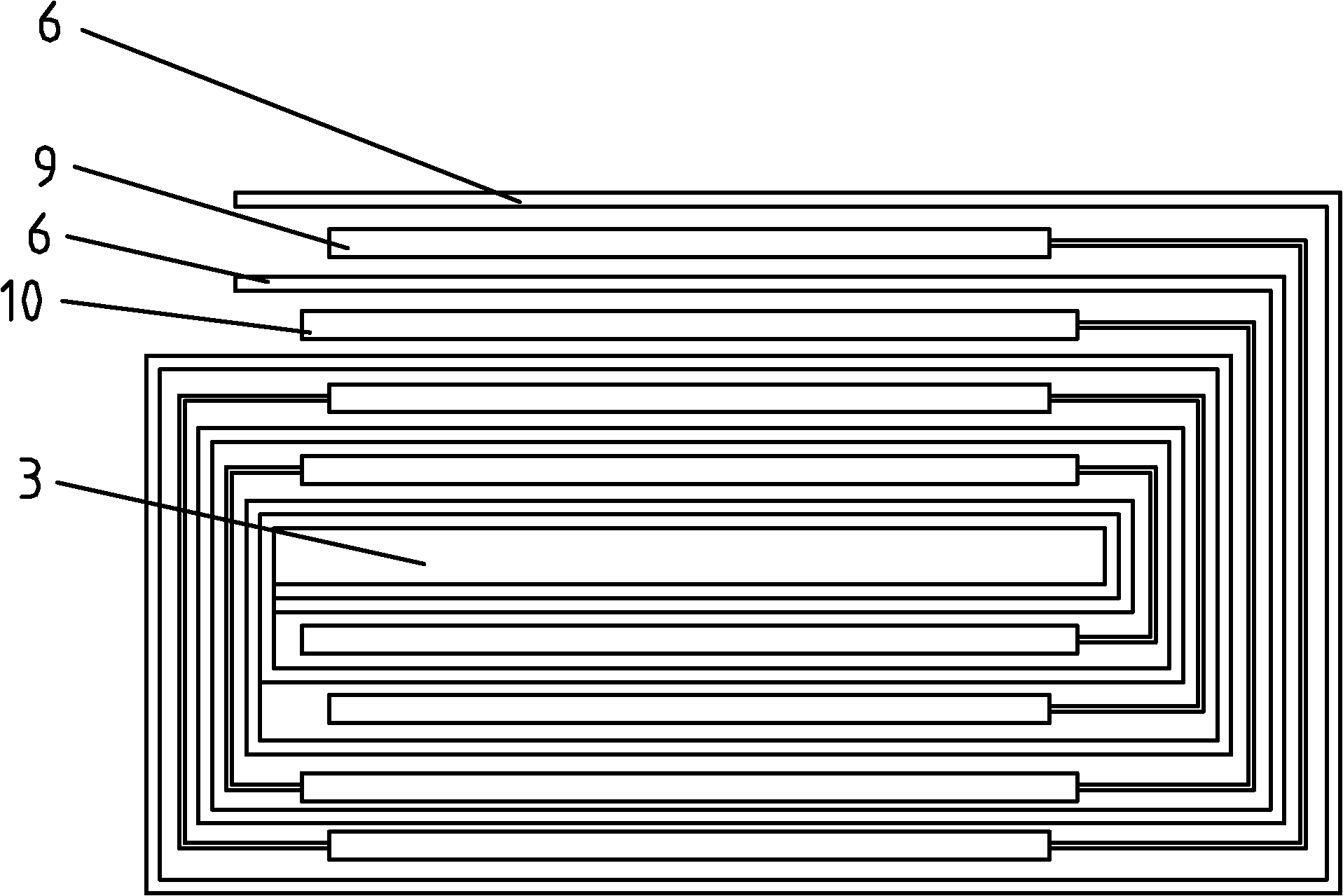

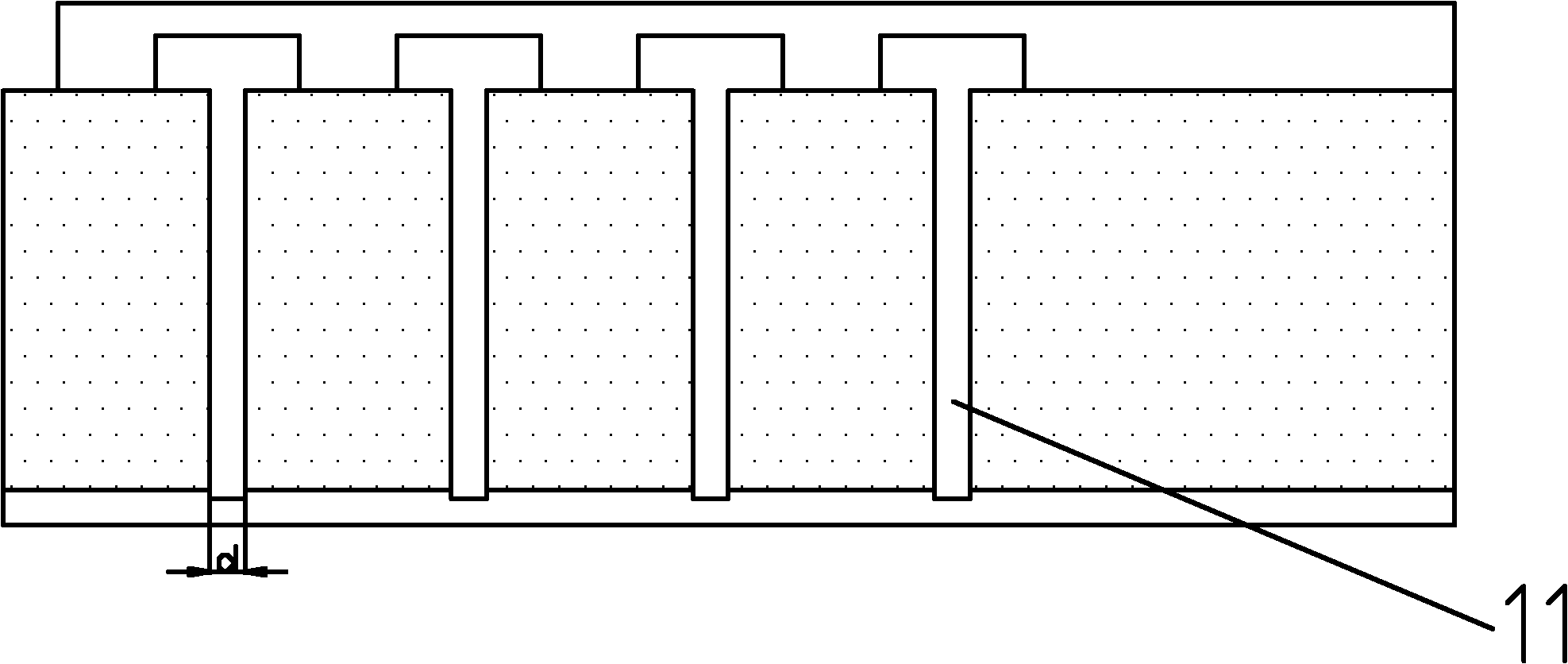

The invention relates to a coiled laminate square lithium-ion battery cell and a preparation method thereof. The coiled laminate square lithium-ion battery cell comprises a platelike coiling needle (3), wherein the coiling needle (3) is coiled with strip-shaped pole pieces; the pole piece comprises a strip-shaped basal layer the surface of which is coated with an electrode material; the pole piece is provided with a coating area for the electrode material and an isolation area (11) used for disconnecting the coating areas; the isolation area (11) is positioned on the pole piece coiled on the two side edges of the coiling needle (3); and the range of the isolation area (11) comprises the whole pole piece coiled on the two side edges of the coiling needle (3). The pole pieces at the corner pieces of the two end side surfaces (the two side edges of the coiling needle) of the coiled laminate square lithium-ion battery cell are easy to yield, thus preventing the electrode material on the pole piece from dropping off or generating cracks.

Owner:武汉慈惠捷高能源装备有限公司

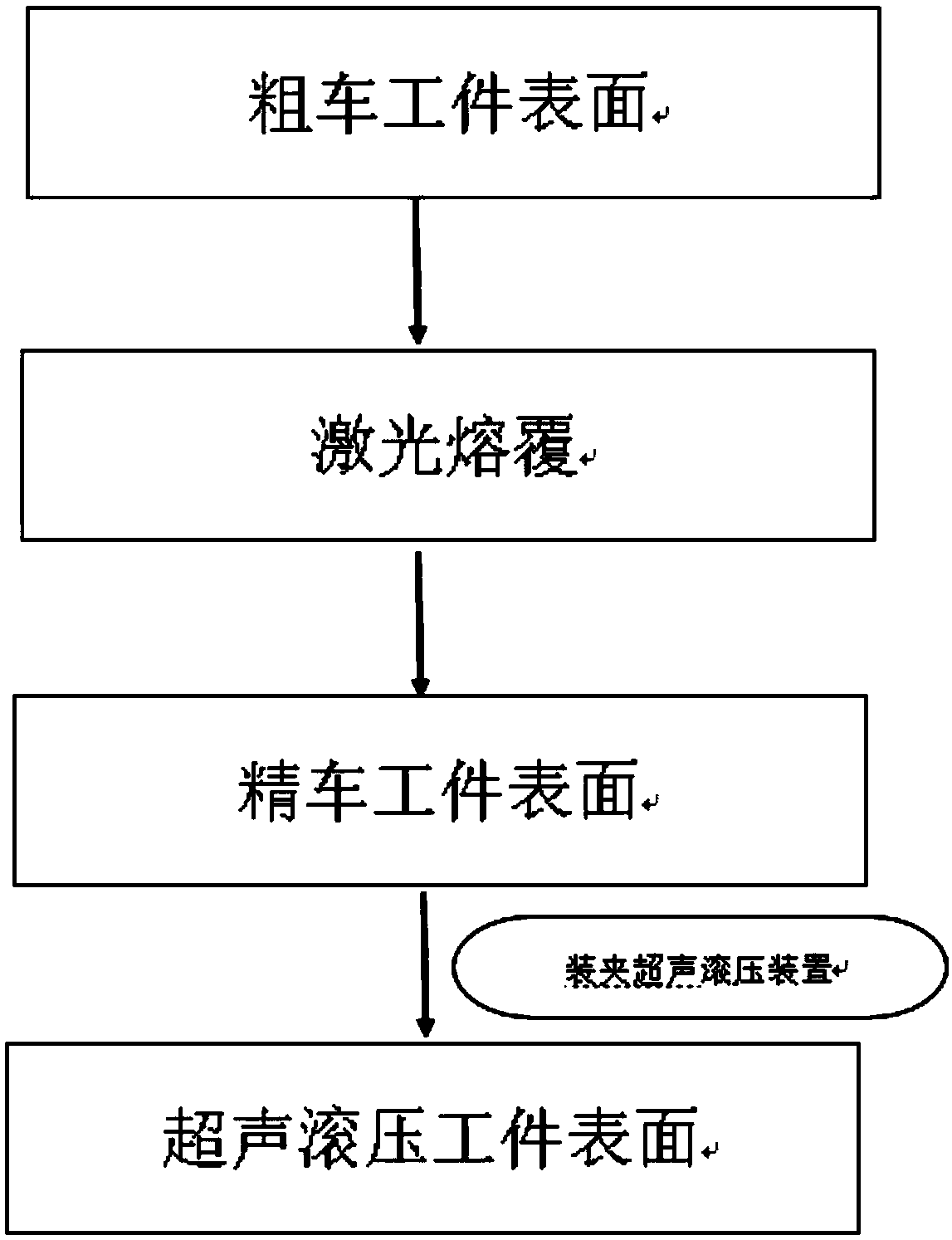

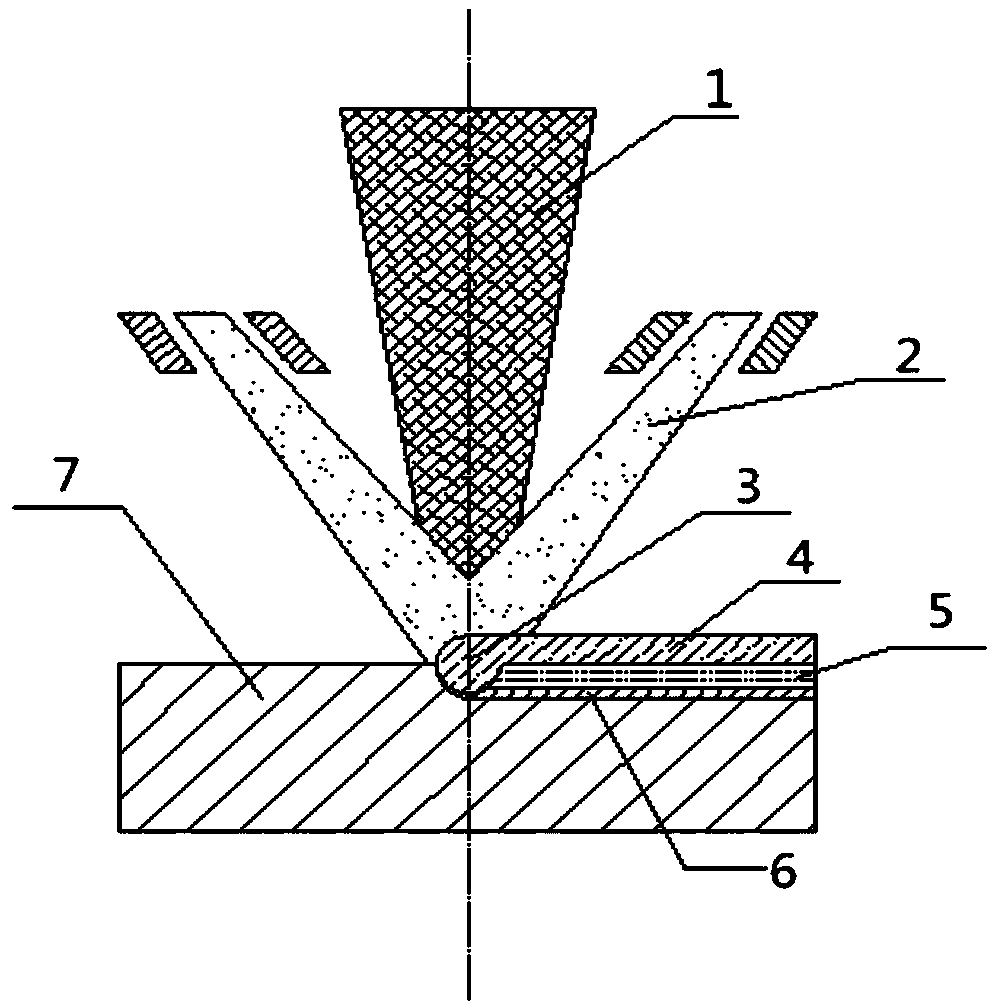

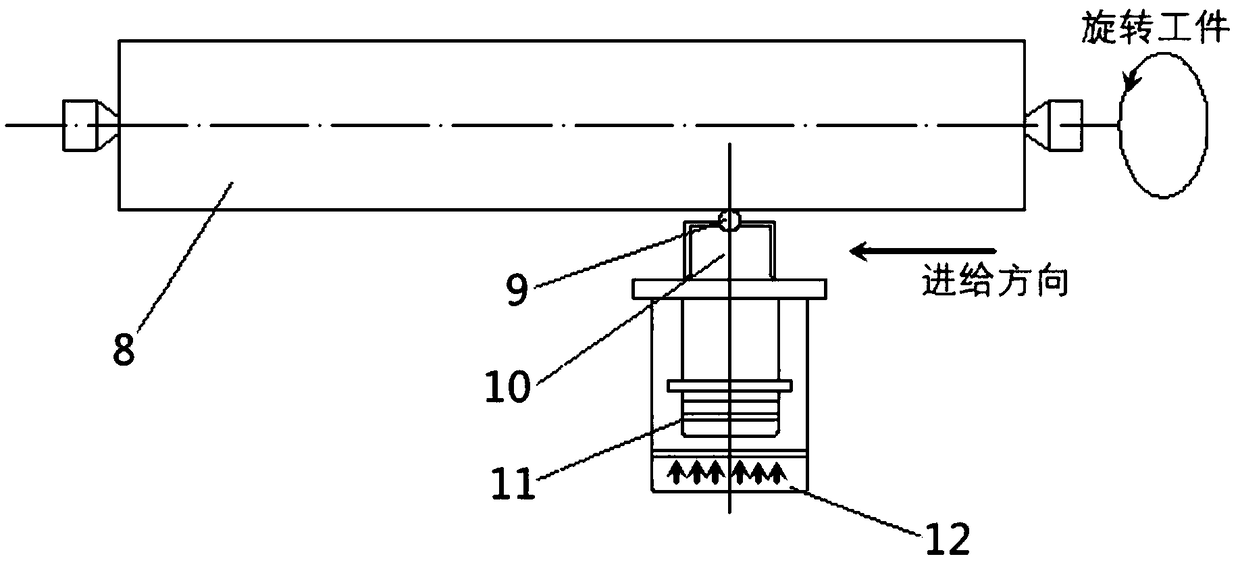

Repairing technology for ultrasound rolling strengthening of shaft type component surface laser cladding layer

InactiveCN109338358AAdd ultrasonic rolling processSmall grain sizeMetallic material coating processesSurface layerHardness

The invention discloses a repairing technology for ultrasound rolling strengthening treatment of a shaft outer circle surface laser cladding layer, and belongs to the technology of shaft type component repairing and strengthening. The repairing technology specifically comprises the steps that to remove surface impurities and make the cladding layer and a base body have good bonding strength, first-time turning machining is conducted on the surface of a shaft needing to be repaired, a certain amount of outer circle surface layer is removed, then, laser cladding is conducted, the diameter of theshaft obtained after laser cladding is slightly larger than the diameter of the surface of the finally-repaired shaft, then, second-time turning machining is conducted on the cladding surface, finally, ultrasound rolling strengthening is conducted, and accordingly the final repairing diameter is formed. According to the repairing technology, operation is simple, the repairing layer is high in hardness, good metallurgy bonding is formed between the repairing layer and the base body, and disengaging is avoided; and after ultrasound rolling, surface-layer grains are fine, large residual compressive stress is formed, accordingly, the fatigue performance of the shaft is improved, and the shaft can be a stirring shaft with a stirring function in mine machines.

Owner:NANCHANG UNIV

Method of thermal adherend release and apparatus for thermal adherend release

InactiveCN1787169AWill not cause sheddingStripping does not causeSolid-state devicesSemiconductor/solid-state device manufacturingFoaming agentSwelling pressure

A heat-adherent peeling method, wherein a part of an adherend adhered to a heat-peelable pressure-sensitive adhesive sheet having a heat-expandable layer containing a foaming agent is partially heated by partially heating the heat-peelable pressure-sensitive adhesive The adhesive sheet is selectively peeled from the pressure-sensitive adhesive sheet, wherein the method comprises preheating the adherend to be peeled off at a temperature at which the heat-expandable layer of the heat-peelable pressure-sensitive adhesive sheet does not expand. The adherend is then heated at the temperature at which the heat-expandable layer expands, thereby selectively peeling the adherend.

Owner:NITTO DENKO CORP

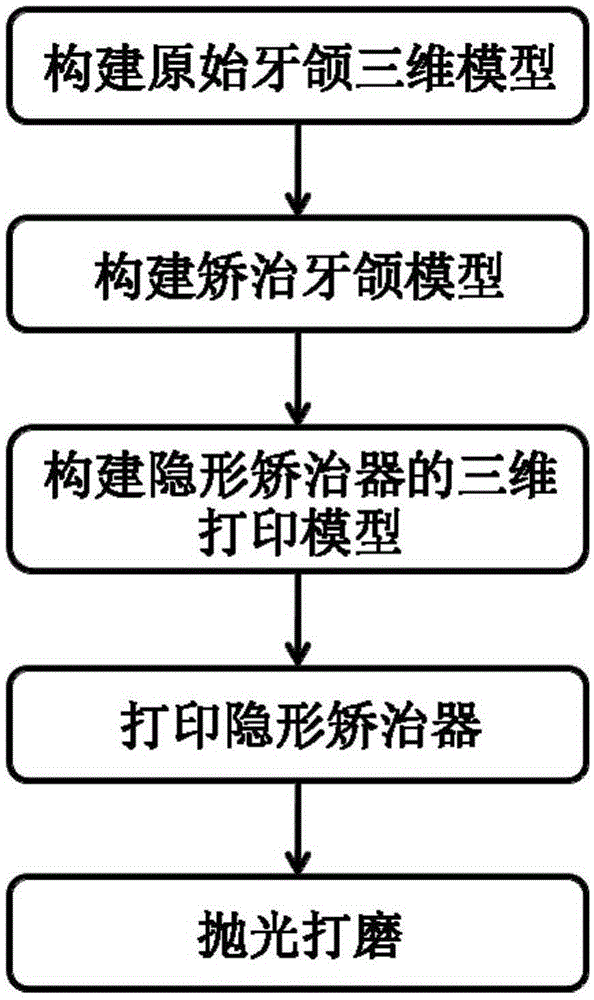

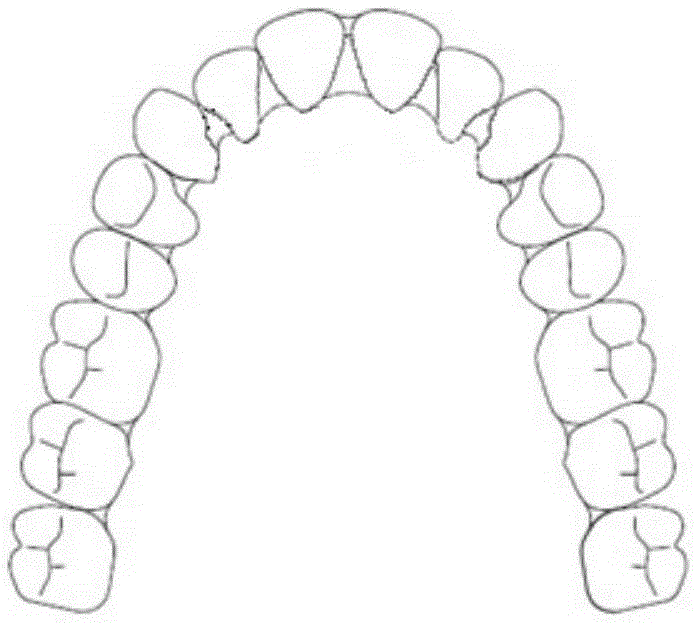

Manufacturing method of invisible tooth correcting treatment devices

InactiveCN105266906AReduce model materialSimplify production stepsOthrodontics3 dimensional printingObjective model

The invention discloses a manufacturing method of invisible tooth correcting treatment devices. According to the method, firstly, an original odonto-maxillary three-dimensional model of a patient is built through a correcting treatment objective and an original odonto-maxillary three-dimensional model; secondly, correcting treatment odonto-maxillary models in different stages of the correcting treatment process are built; then, corresponding three-dimensional printing models are built; corresponding invisible tooth correcting treatment devices are respectively printed out by medial polyethylene according to the three-dimensional printing models; and finally, the invisible tooth correcting treatment devices are polished and ground and are delivered to the patient to be used. By using the method, the invisible tooth correcting treatment devices are directly manufactured without using a solid body objective model, so that the consumption of a great number of light-cured resin materials is avoided; and the problems of high cost and complicated production process of the invisible tooth correcting treatment devices are solved.

Owner:肖然 +1

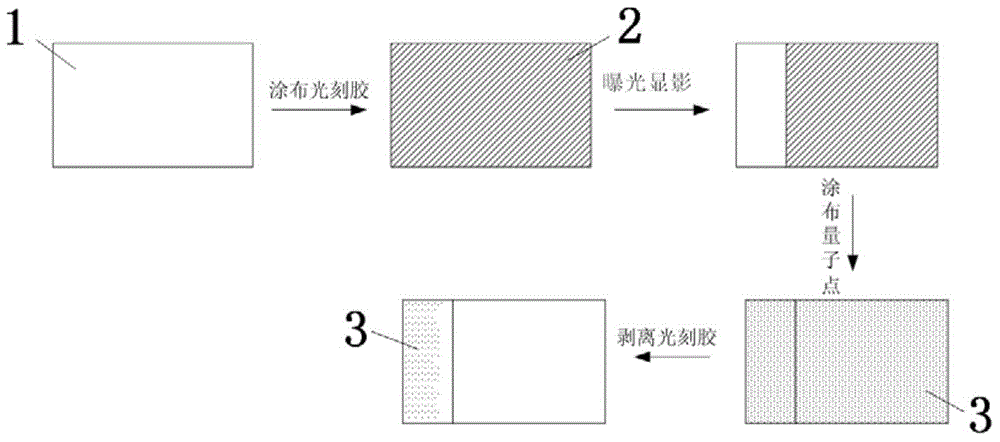

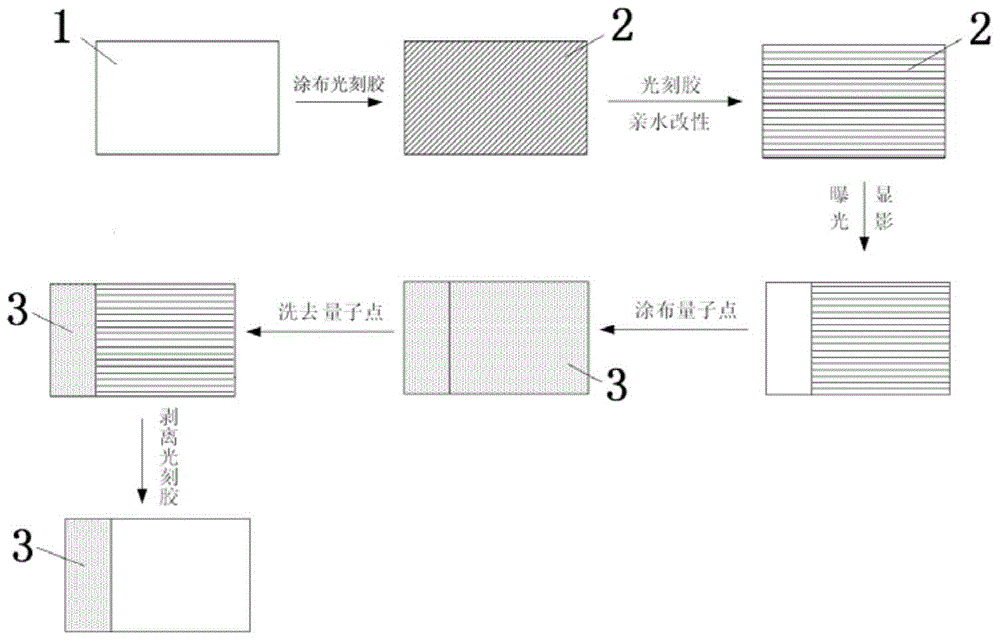

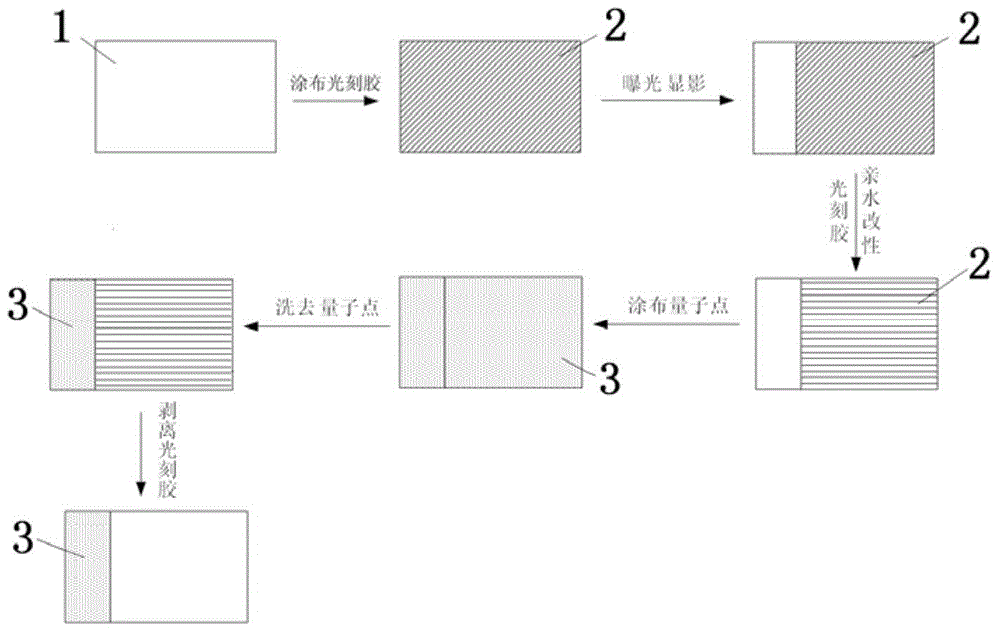

Photoresist, quantum dot layer patterning method, quantum light-emitting diode (QLED), quantum dot color film and display device

ActiveCN105098002ALipophilicReduce adhesionPhotomechanical coating apparatusPhotomechanical exposure apparatusLED displayColor film

The invention provides a photoresist, a quantum dot layer patterning method, a quantum light-emitting diode (QLED), a quantum dot color film and a display device, which belongs to the technical field of display and can be used for solving the problem of quantum dot damage by the traditional patterning method. The quantum dot layer patterning method comprises the following steps of: forming a photoresist material layer on a substrate; carrying out pattern composition on the photoresist; carrying out hydrophilic treatment on the photoresist; coating quantum dots; removing the quantum dots on the residual photoresist; and stripping the photoresist. By the quantum dot layer patterning method, the hydrophilic performance of the photoresist can be improved, and the adhesive force of the quantum dots with lipophilicity onto the photoresist is reduced. During stripping the photoresist, the quantum dots at the target position of the substrate cannot fall off. The quantum dot layer patterning method is suitable for a light-emitting diode displayer containing the quantum dot layer, the quantum dot color film and the display device applying the quantum dot color film.

Owner:BOE TECH GRP CO LTD

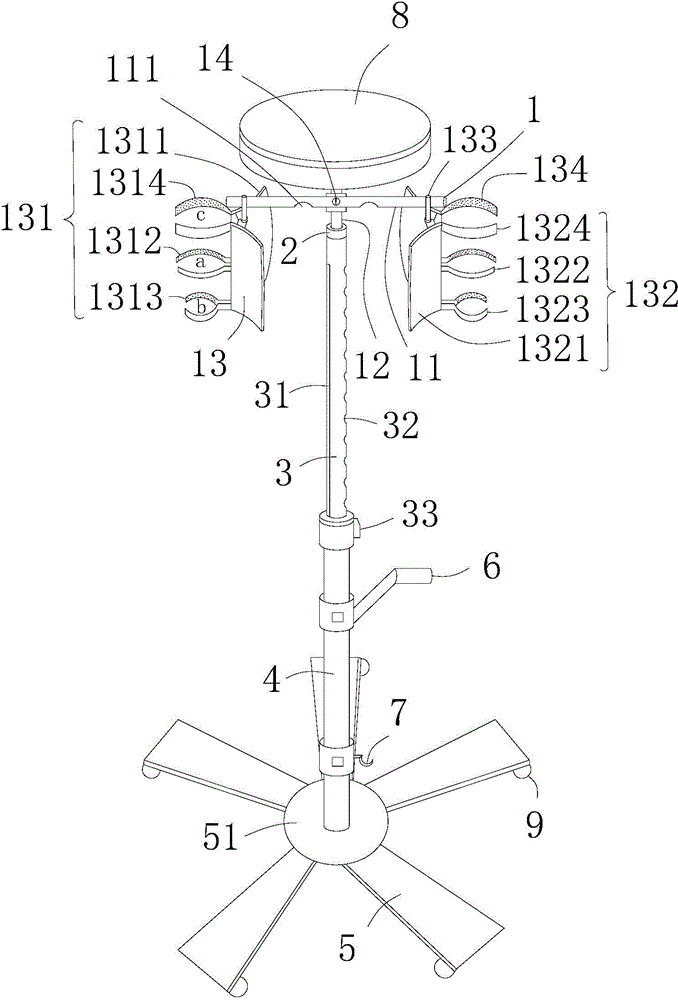

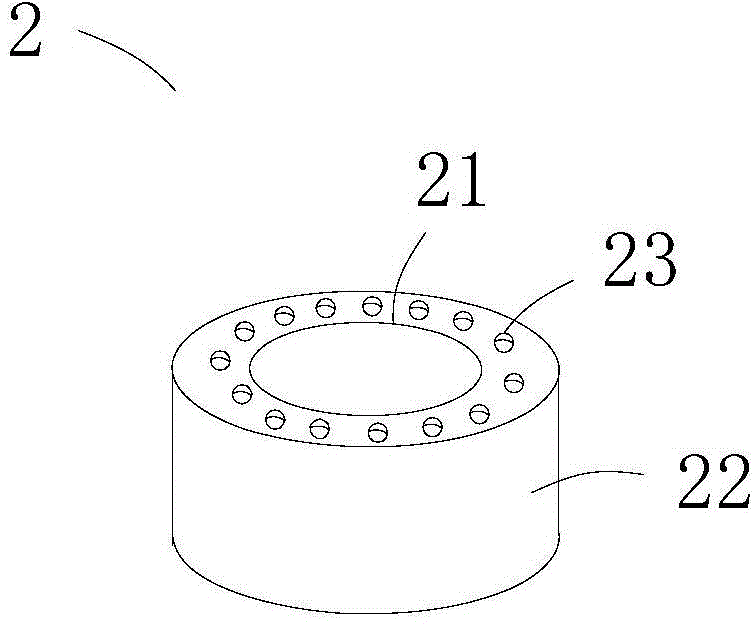

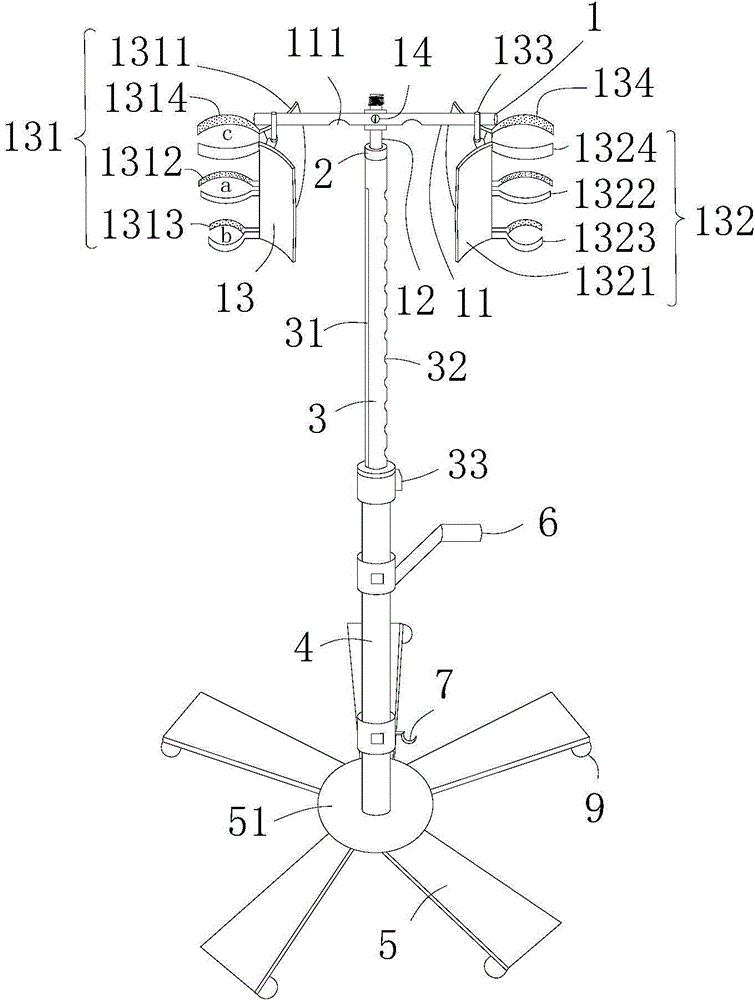

Movable infusion support used in cardiovascular surgical department

The invention provides a movable infusion support used in the cardiovascular surgical department. The movable infusion support comprises an infusion bottle clamping device, a telescopic rod, a fixing rod and a base, wherein a height-adjustable armrest and a hook are arranged on the fixing rod, a guide groove and a plurality of sunken grooves opposite to the guide groove are formed in the surface of the telescopic rod in a concave mode, bolts of a micro-injection pump are matched with the guide groove and the sunken grooves and are clamped on the telescopic rod, and the infusion bottle clamping device is provided with upper elastic clamps and lower elastic clamps which are different in size and are used for clamping infusion bottles. The movable infusion support is simple in structure and good in stability, integrates multiple functions and can be freely moved. For a patient, the movable infusion support brings convenience to the patient to early get out of a bed for activities. For a nursing worker, the movable infusion support is convenient to operate, nursing safety is ensured, and the amount of nursing work is reduced.

Owner:陕西智宇寰宸医疗器械有限公司

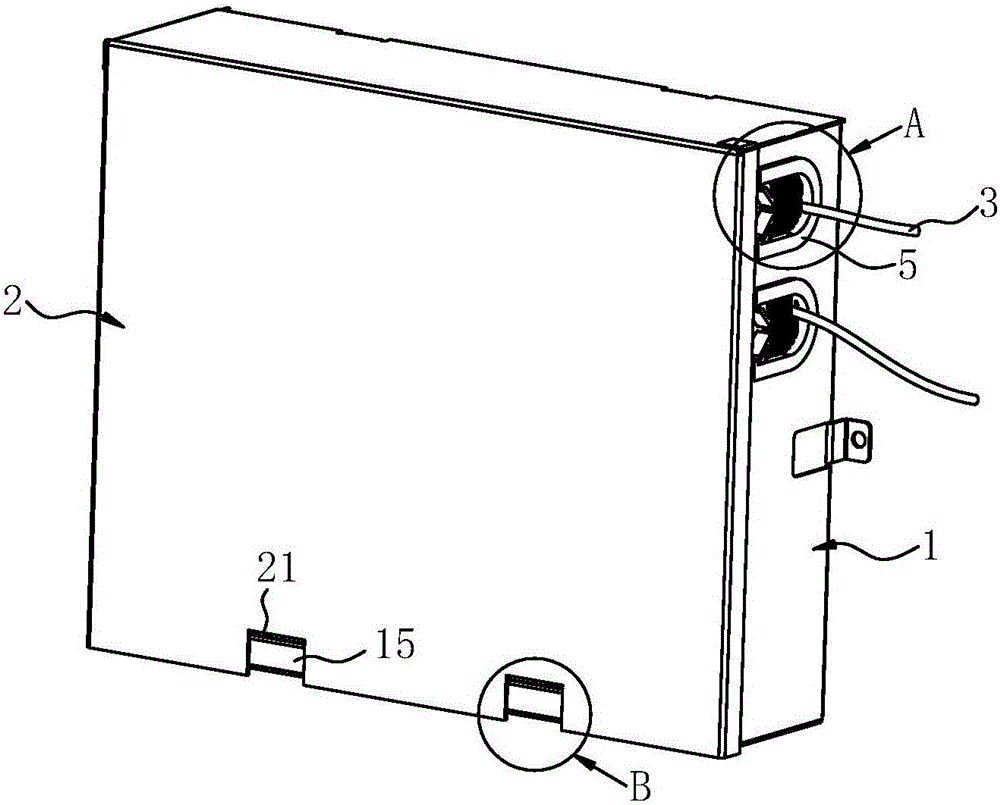

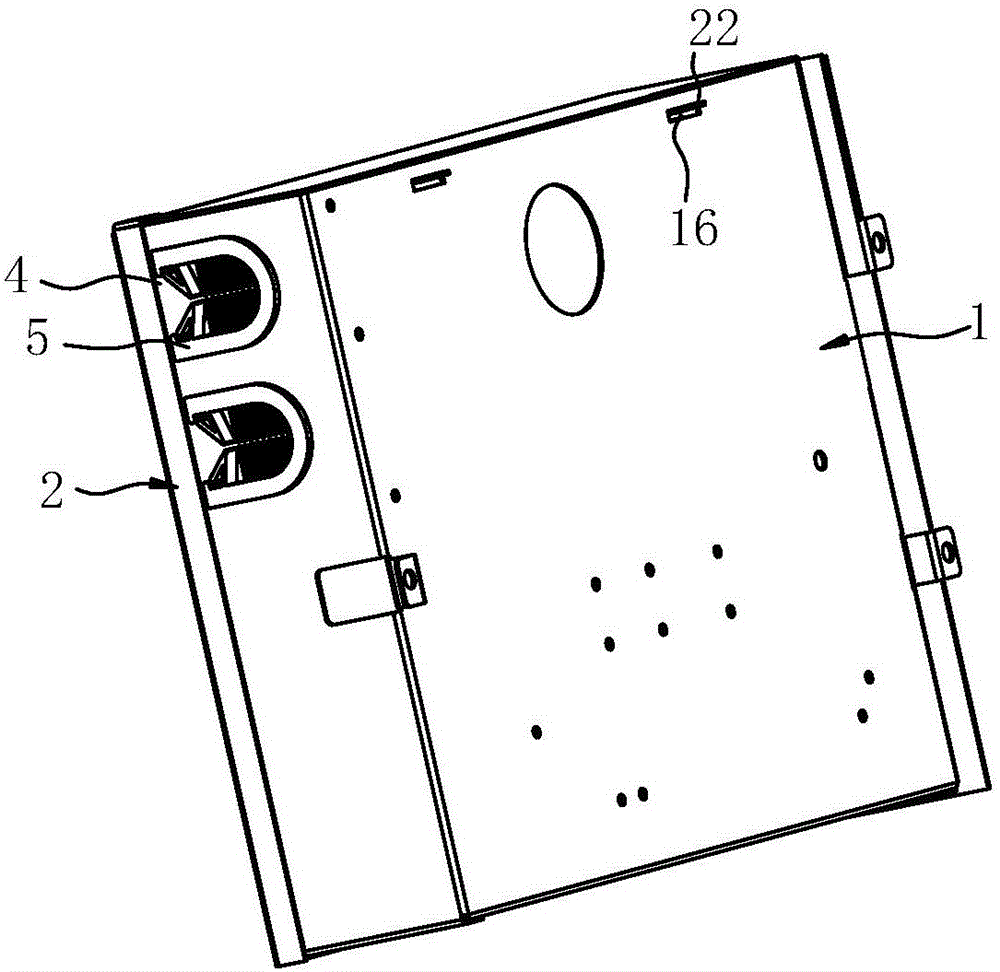

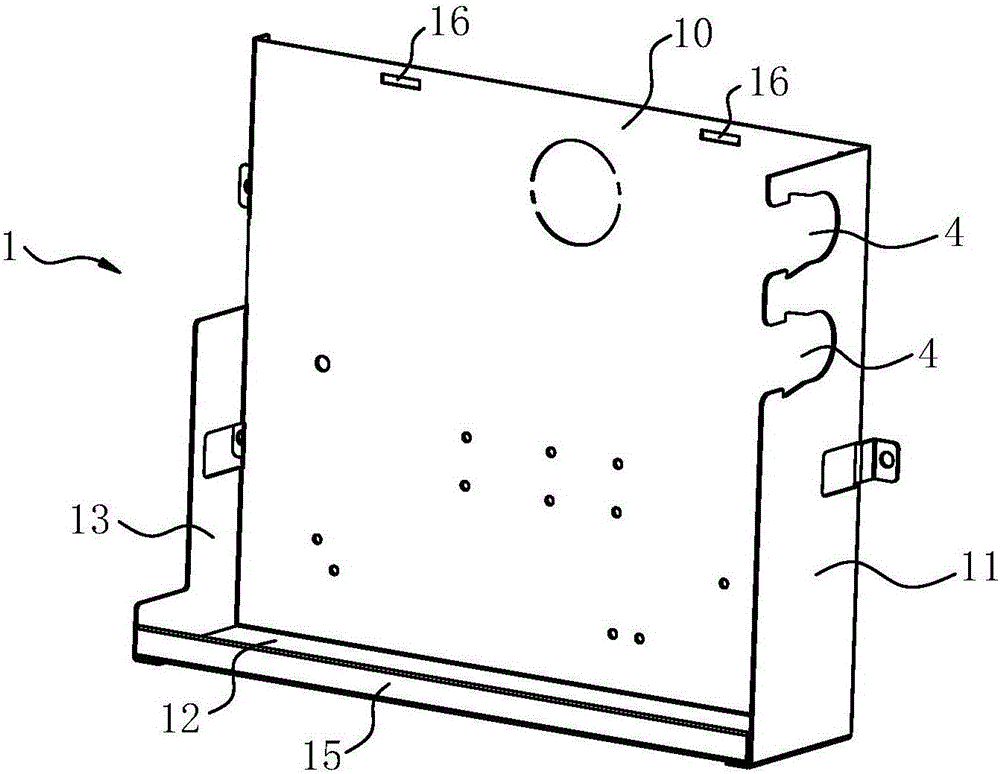

Electric appliance box, indoor unit and air conditioner

ActiveCN105910242AEasy maintenanceSimple structureMechanical apparatusSpace heating and ventilation safety systemsWire cuttingEngineering

The invention discloses an electric appliance box, an indoor unit and an air conditioner, wherein the electric appliance box comprises a box body, a box cover, a control circuit and an electric connecting wire; the box cover and the box body are detachably connected; the control circuit is arranged in the box body; a wire passing port is formed in the box body; a wire passing ring is detachably arranged in the wire passing port; one end of the electric connecting wire is connected with the control circuit, and the other end penetrates through the wire passing ring to extend out of the box body; and at least one parts of the box body and the box cover are connected through a buckle module. As the wire passing port is formed in the box body of the electric appliance box, and the wire passing ring is mounted in the wire passing port, the box cover of the electric appliance box is convenient for disassembly without causing coil falling in maintenance, and the wire cutting hidden troubles are eliminated; the electric connecting wire is fixed on the box body of the electric appliance box through the wire passing ring to prevent looseness of a wiring terminal caused by frequent pulling of the electric connecting wire in maintenance; and the box body and the box cover are connected by using the buckle module, so that the use of a screw can be reduced, or even the screw has no need to be used, and the disassembly difficulty and cost are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

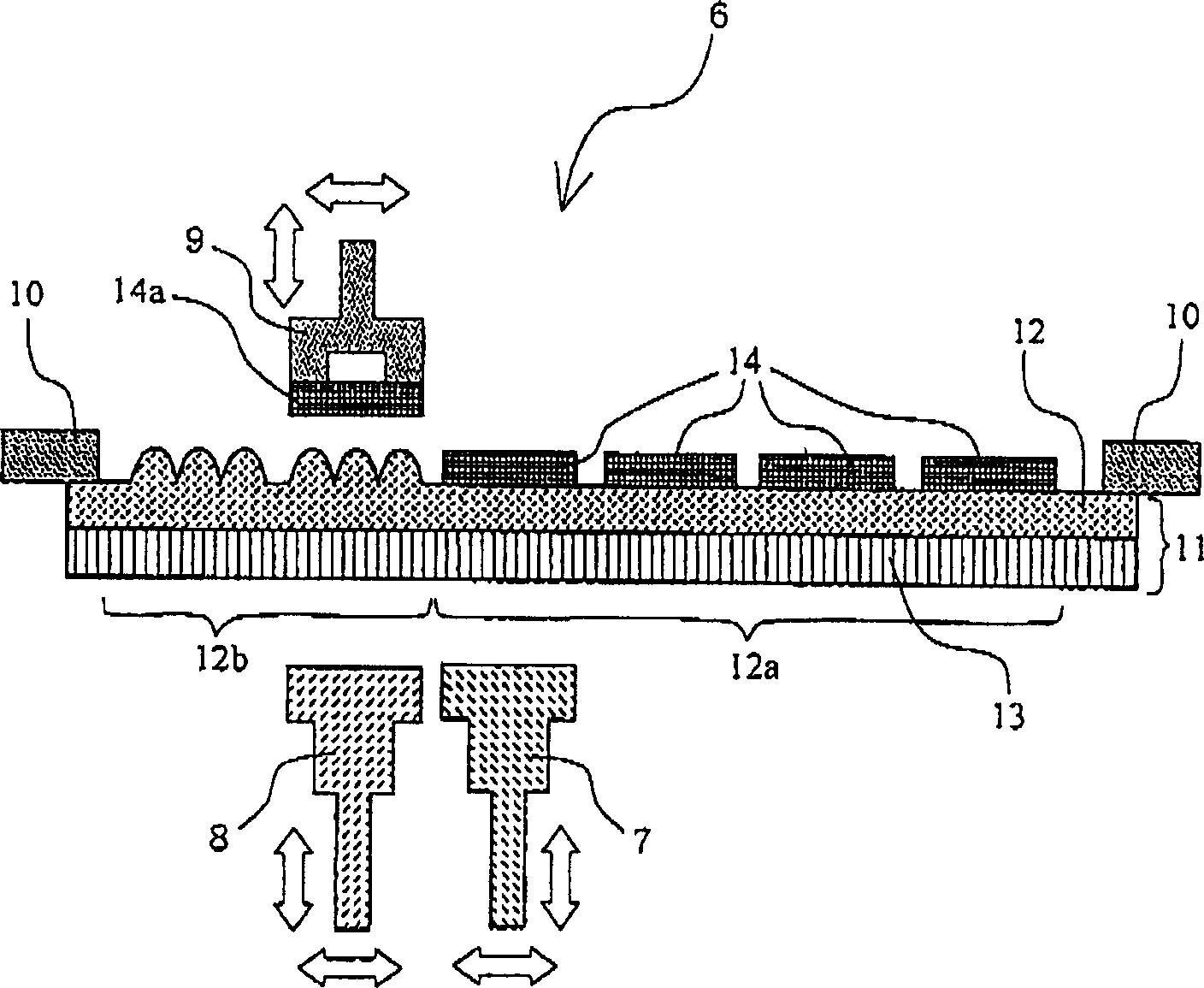

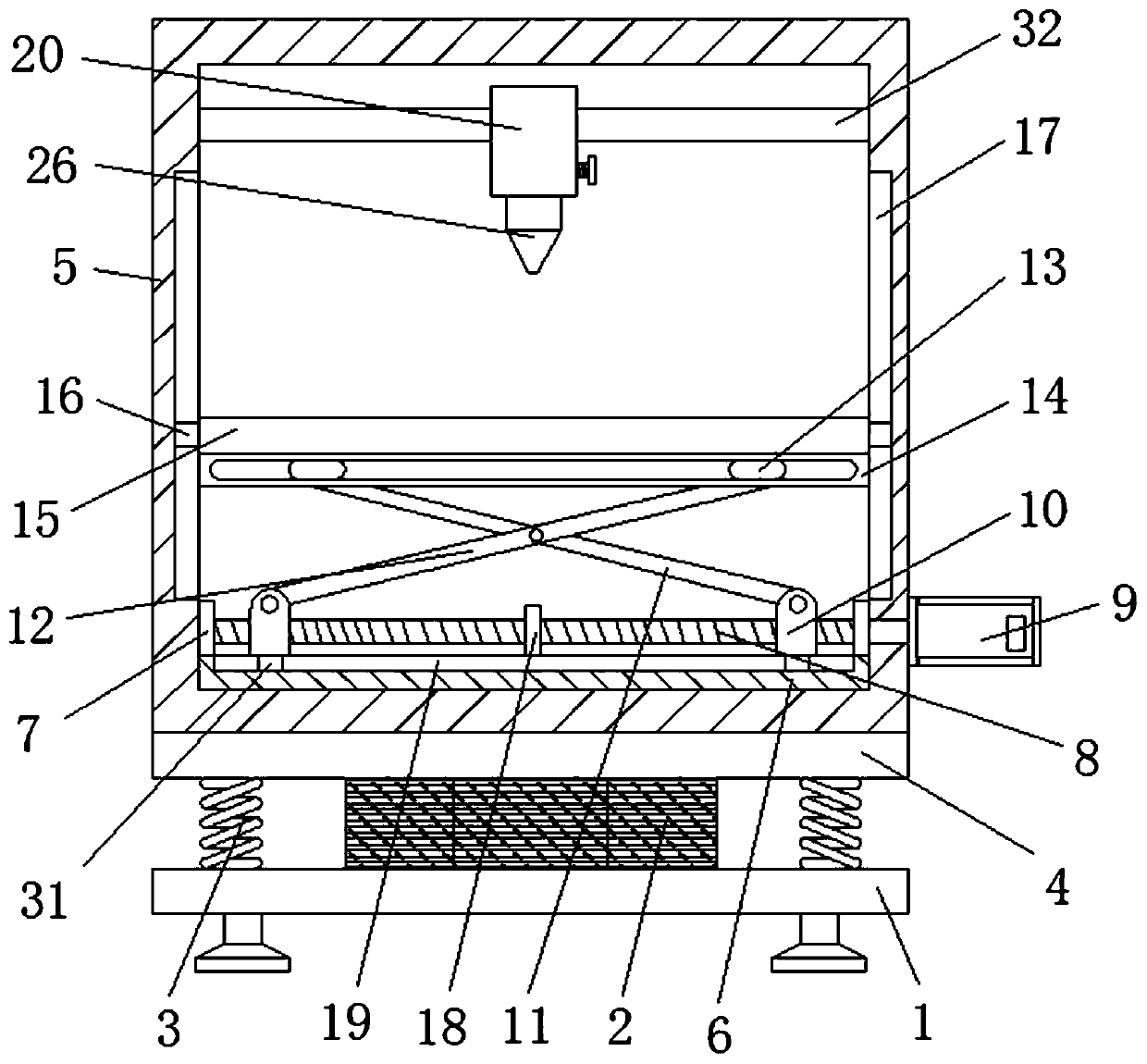

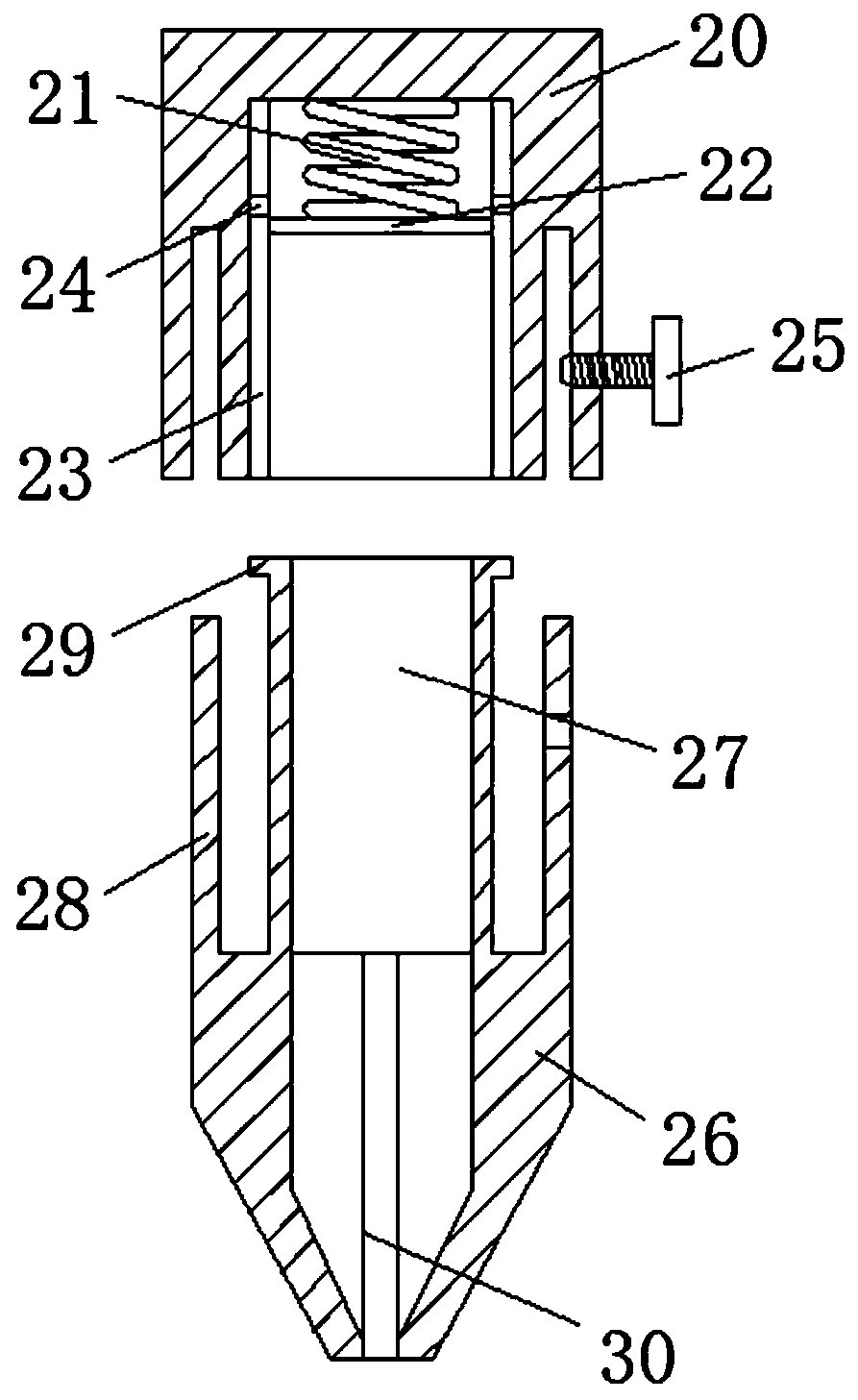

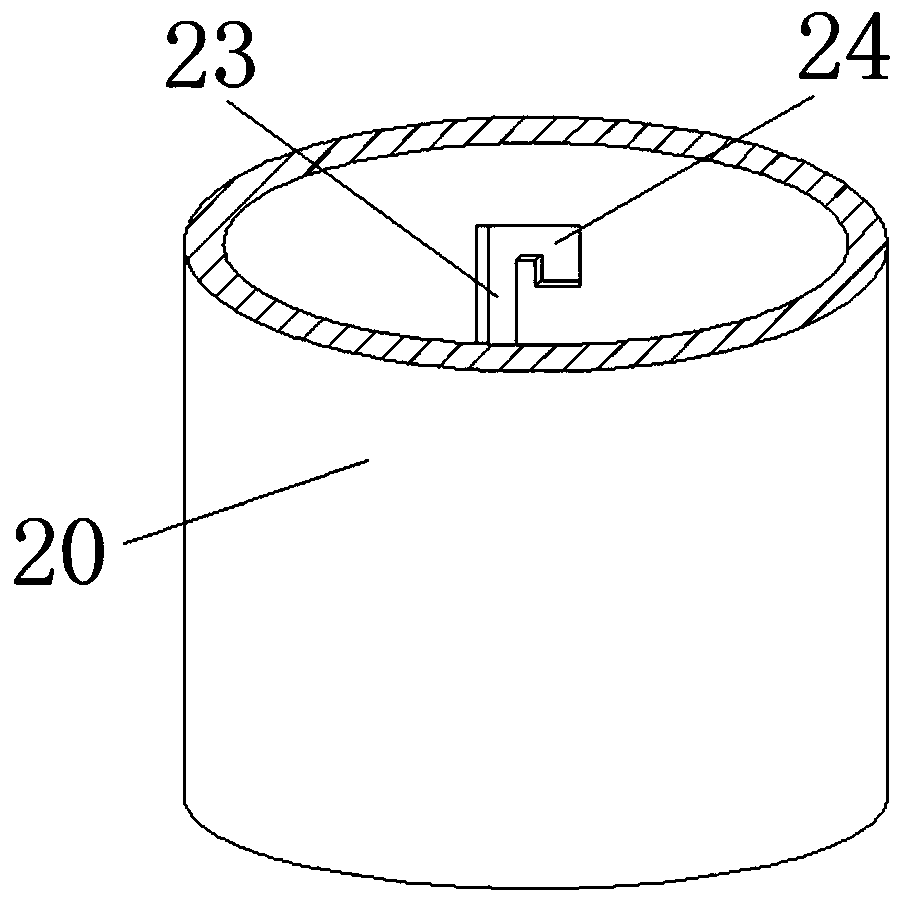

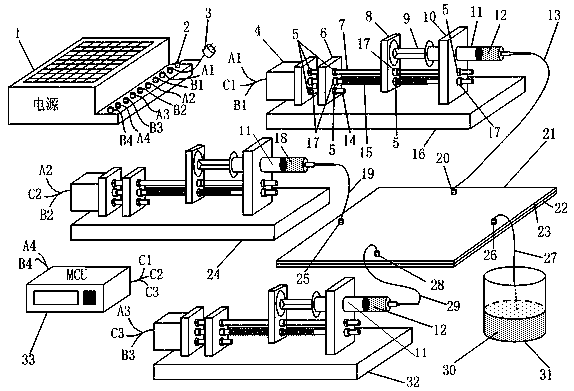

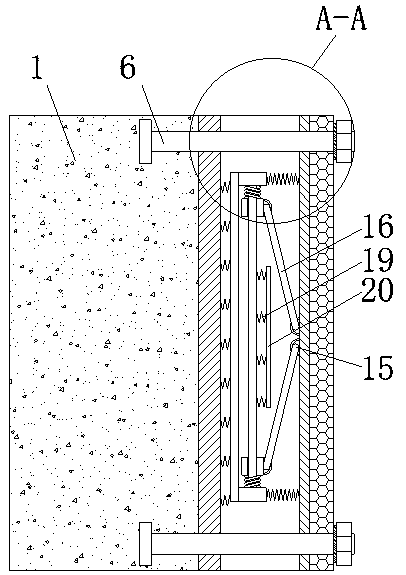

Ascending and descending mechanism of 3D printer and ascending and descending method thereof

InactiveCN110587987AWill not cause sheddingSimple structureManufacturing platforms/substrates3D object support structuresEngineeringSlide plate

The invention discloses an ascending and descending mechanism of a 3D printer and an ascending and descending method thereof. The ascending and descending mechanism of the 3D printer comprises a support seat, wherein a high-elasticity rubber buffer pad is fixedly connected to the middle of the upper surface of the support seat; a support plate is also fixedly connected to the upper surface of thehigh-elasticity rubber buffer pad; vibration reduction springs are fixedly connected between the support plate and the support seat; the upper surface of the support plate is fixedly connected to a printing cabin; a fixing plate is fixedly connected to the lower surface of the inside of the printing cabin; the two ends of the fixing plate are fixedly connected with a rotating seat; a lead screw isrotationally connected onto the rotating seat; a motor is fixedly connected to a position, corresponding to the lead screw, of one side of the printing cabin; the output end of the motor is fixedly connected with the lead screw; a printing platform is glidingly connected inside the support seat; the lower surface of the printing platform is fixedly connected with a slide plate; a first slide block is glidingly connected inside the slide plate; and two sliding seats are rotationally connected onto the lead screw. The ascending and descending mechanism has the advantages that the use is convenient; the structure is simple; the ascending and descending movement is stable; the printing effect is not influenced; meanwhile, a spray head can be conveniently dismounted and repaired; and the vibration reduction effect is good.

Owner:JINLING INST OF TECH

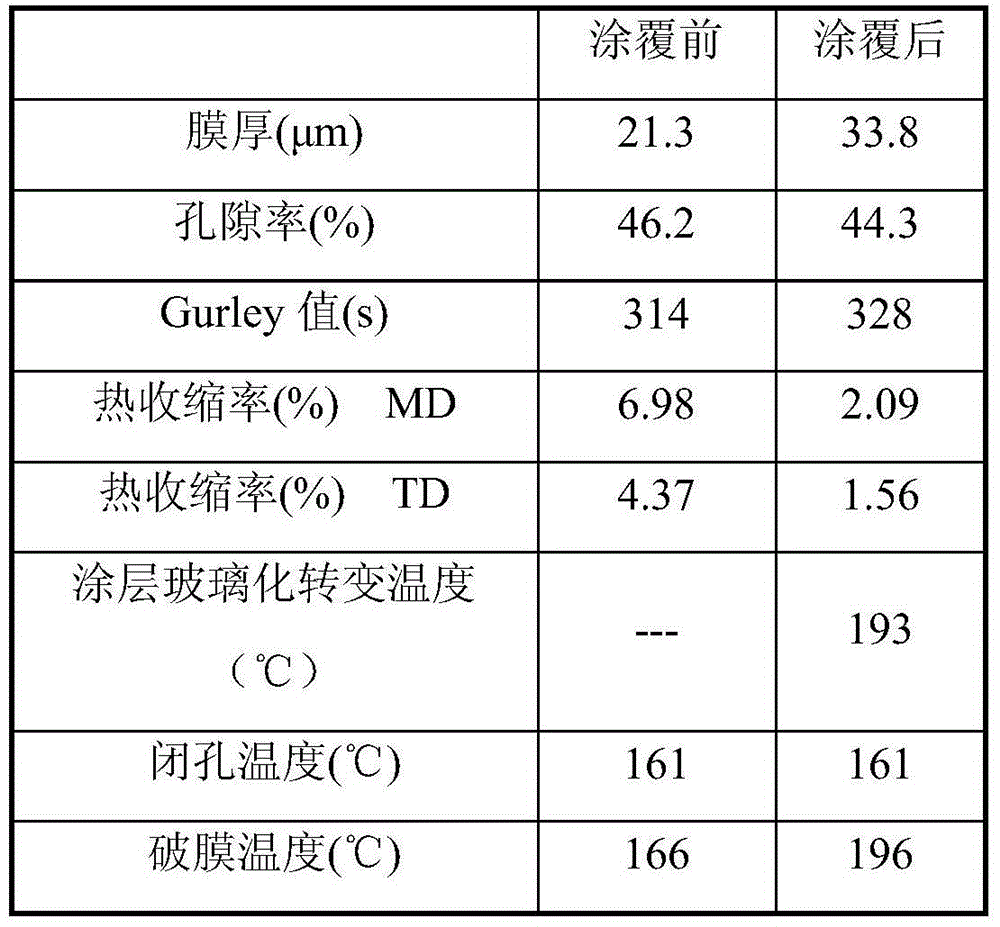

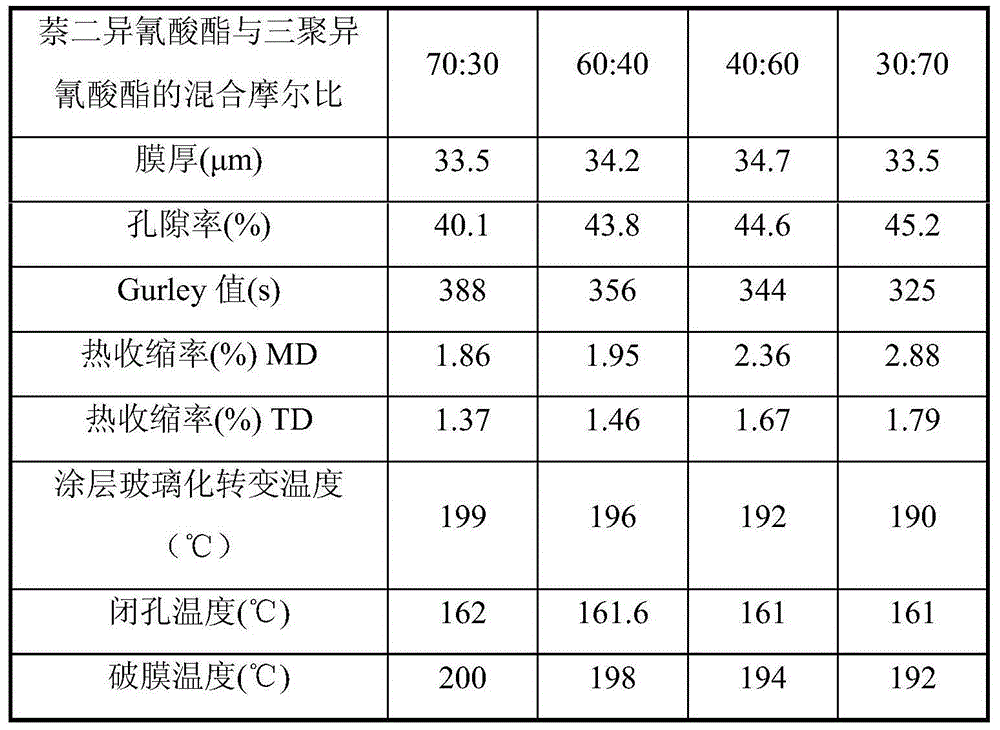

Polyethylene micropore diaphragm containing organic/inorganic composite cross-linking coating and preparation method of polyethylene micropore diaphragm

ActiveCN104701479AHigh mechanical strengthDoes not affect permeabilityCell seperators/membranes/diaphragms/spacersPolyesterPorosity

The invention belongs to the field of functional polymer membrane preparation, and in particular relates to a polyethylene micropore diaphragm which is used for improving the use security of a lithium ion battery and contains an organic / inorganic composite cross-linking coating, and a preparation method of the polyethylene micropore diaphragm. The preparation method comprises the following steps: by taking aromatic polyester polyhydric alcohol and aromatic isocyanate as basic components, preparing a coating liquid by combing with a cross-linking agent, a foaming agent, a catalyst and inorganic nano packing at a certain ratio, coating at least one surface of the polyethylene micropore diaphragm with the coating liquid, and curing at certain temperature, thereby forming an organic polymer / inorganic nanoparticle composite cross-linking coating of a pored foamed structure on the surface of the polyethylene micropore diaphragm. Relatively high porosity and air permeability of the polyethylene micropore diaphragm are maintained, at the same time the thermal shrinkage membrane breaking temperature is greatly improved, and the use security property of the battery can be remarkably improved when the polyethylene micropore diaphragm is used as a power lithium ion battery diaphragm material.

Owner:扬州市永佳车辆配件有限公司

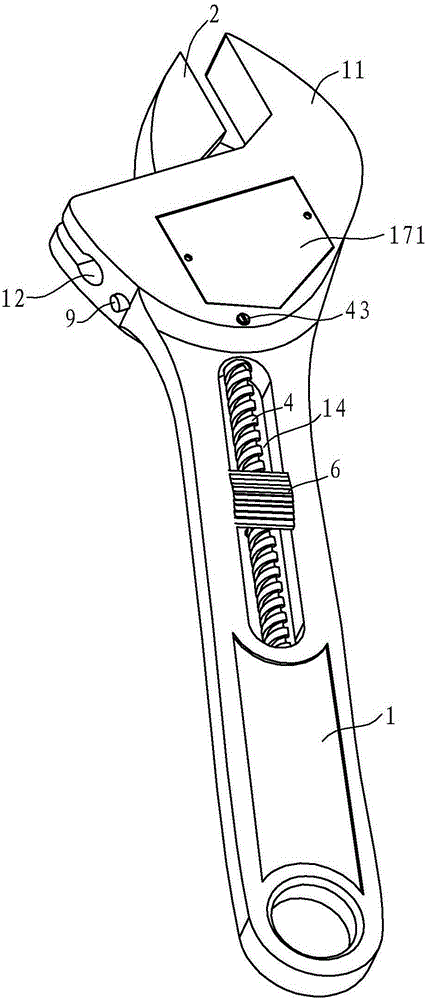

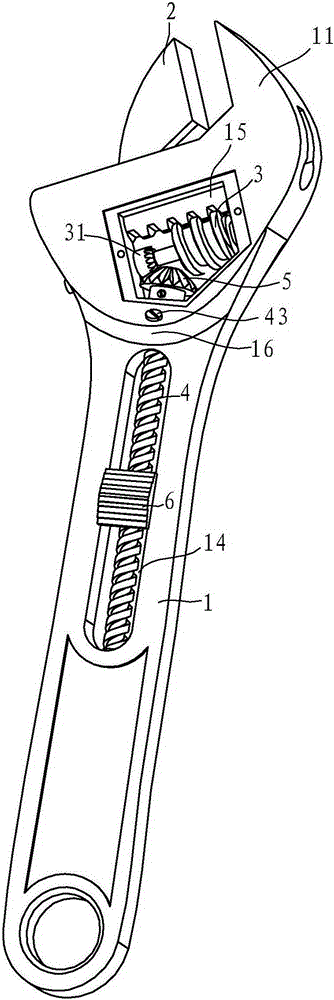

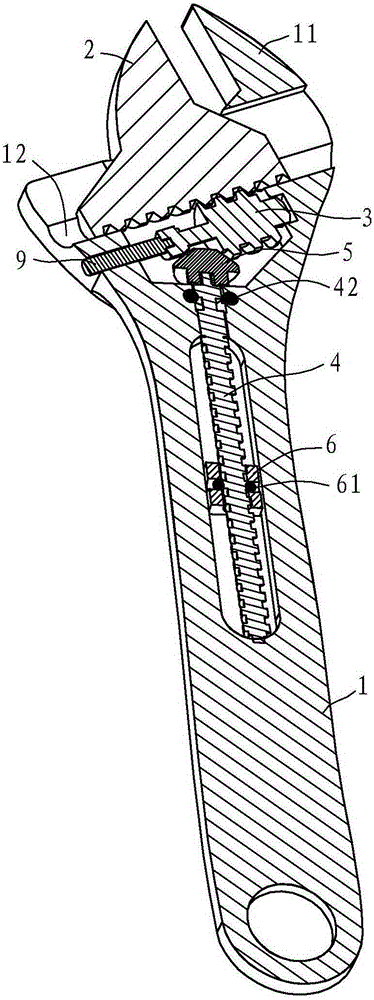

Adjustable wrench

InactiveCN105171655AWill not cause sheddingAvoid damageSpannersWrenchesEngineeringFront and back ends

An adjustable wrench comprises a handle, an adjustable wrench lip, a transmission mechanism and a screw rod, and is characterized in that a strip-shaped hole or a strip-shaped groove is formed in the handle in the length direction; a separating part is formed between the front end of the strip-shaped hole or strip-shaped groove and a mounting cavity; the screw rod is inserted from the end opening of a sliding groove, and then penetrates through the separating part; the front and rear ends of the screw rod can be rotationally arranged in the separating part and on the inner wall at the rear end of the strip-shaped hole or strip-shaped groove respectively; a pushing button is positioned in the strip-shaped hole or strip-shaped groove, and can slide up and down to drive the screw rod to rotate. Compared with the prior art, the adjustable wrench provided by the invention has the advantages that as the screw rod is inserted from the end opening of the sliding groove, and then penetrates through the separating part, grooving in the separating part is not needed, and the damage to the whole adjustable wrench is relatively low; the adjustable wrench is uniform in stress and high in overall strength, so that the screw rod is prevented from falling off when the adjustable wrench is broken at random.

Owner:陆亚明

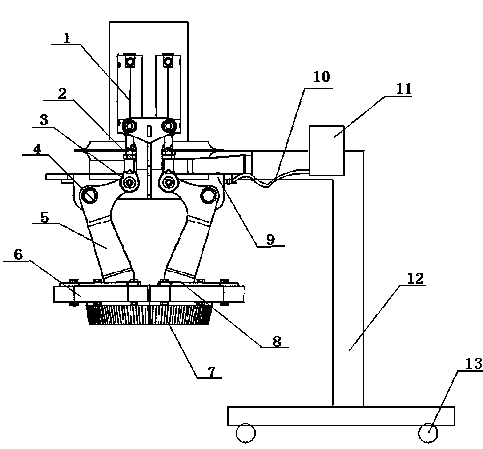

Bag-clamping device for opening bag packing machine

The invention relates to a bag-clamping device for an opening bag packing machine. The bag-clamping device comprises a support provided with two bag-clamping arms; the middles of the bag-clamping arms are hinged to the support; first free ends of the bag-clamping arms are connected with a lifting device respectively; when the lifting devices drive the first free ends of the bag-clamping arms to ascend, second free ends of the bag-clamping arms rotate around the middle hinging points to realize the clamping. The bag-clamping arms are clamped or opened by using a cylinder to drive the lifting devices to lift up and down, when the bag-clamping arms are opened, an opening of the packing bag can be properly opened to avoid the material leaking phenomenon of the packing bag. The bag-clamping device for the opening packing machine is strong in clamping strength without causing the stripping of the packing bag, and due to the scheme, bag packing can be performed without assisting manpower, and the full automation of the packing machine can be realized.

Owner:CHINA WEIGHING EQUIP SUZHOU FACTORY

Stone polishing wax and method for producing the same

A polishing wax for stone material features that it can effectively penetrate into porous surface of stone material, and after its volatile components including tetrachlorethylene fully volatilize its polishing component stays in the pores and on the surface of stone material for polishing the stone surface by grinding or rubbing. Its advantages are high lustre, high resistance to water, dust, harmful gas and liquid, and abrasion.

Owner:王兴玺

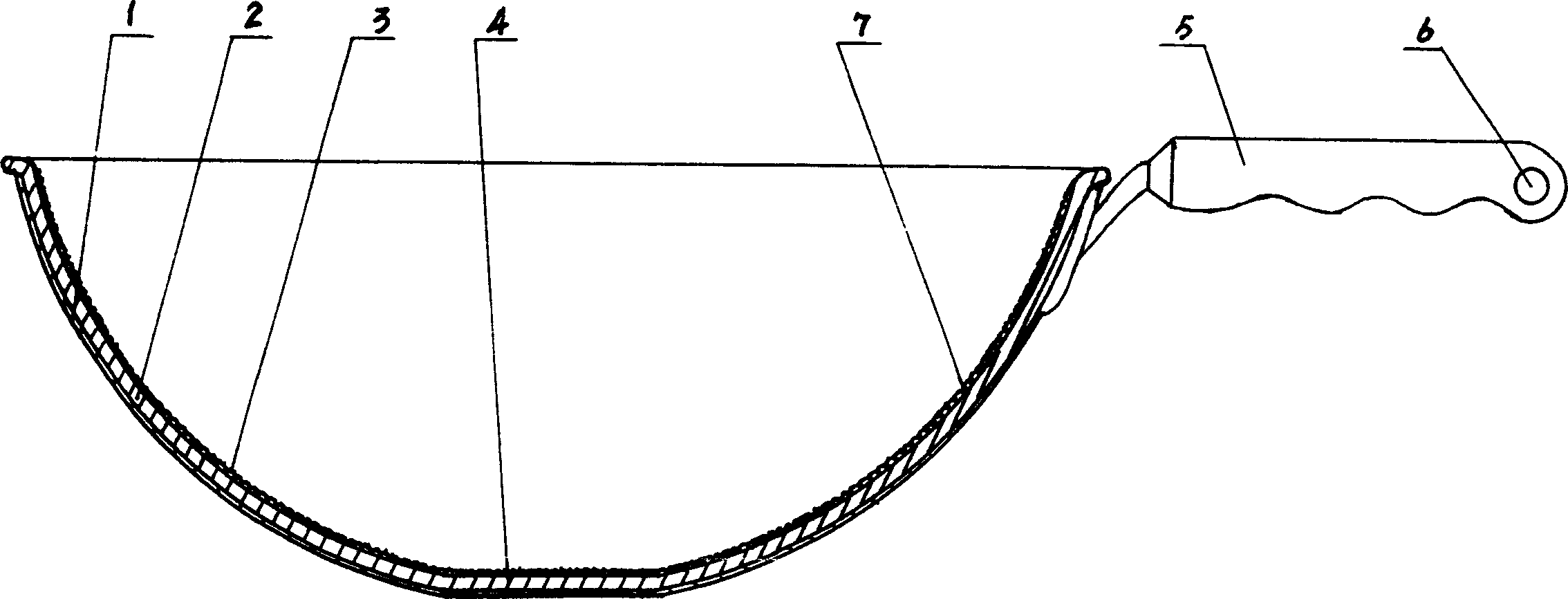

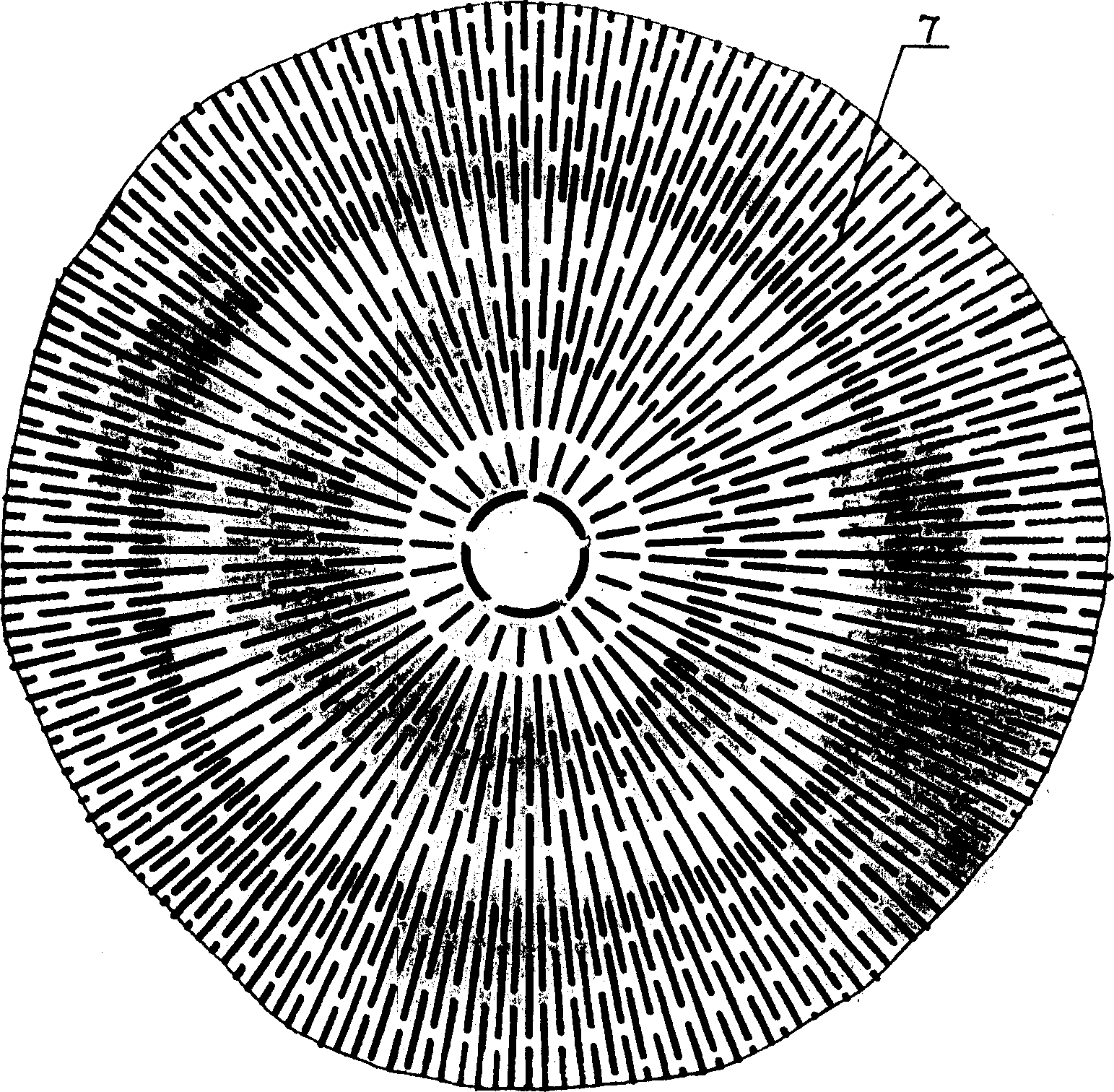

Quick-heating fume-free pan used in sauteing food and making method thereof

InactiveCN1465317AIncreasing the thicknessFast heat transferCooking-vessel materialsMetal layered productsSand blastingCooking process

The present invention discloses a quickly-heating fume-free pan used for stir-frying dish, consisting pan body and pan handle fixed on the pan body, several radial microsmall projections are formed on the internal surface of the pan body, and said internal surface is coated with an inadhesive layer, and the external surface of the pan body is coated with an inadhesive layer or high-temp. resistant paint. Said pan body is made of aluminium alloy, and its thickness is 4-5 mm. Its making method incldues the following procedures: forming procedure, sand-blasting procedure, cleaning procedure, coating procedure and packaging procedure.

Owner:胡金高

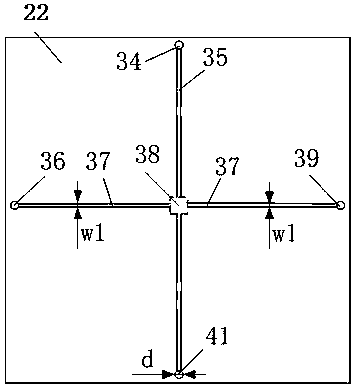

Microfluidic cell culture chip guaranteeing uniform cell distribution and cell sample introduction method

ActiveCN107354094AStable living environmentWill not remainBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidEngineering

The invention discloses a microfluidic cell culture chip guaranteeing uniform cell distribution and a cell sample introduction method. A main flow channel and auxiliary flow channels which are cross and vertical to the main flow channel are formed in a substrate, each auxiliary flow channel is a step-shaped flow channel which is granularly widened from the outer end to the middle, and the bottom surfaces of the auxiliary flow channels are higher than the bottom surface of the main flow channel; firstly, a culture solution is injected into a culture chamber, a cell suspension solution is injected into the culture chamber after the bottom of the culture chamber is filled with the culture solution, the culture solution is injected into the main flow channel after a certain quantity of the cell suspension solution is injected into the main flow channel, the culture solution pushes the injected cell suspension solution to the culture chamber, mixed gas enters buffer zones on two sides of the culture chamber through the auxiliary flow channels, the bottom of the culture chamber in the middle of the main flow channel is enabled to be filled with the cell suspension solution while the other space of the main flow channel is filled with the culture solution, therefore, cells are just distributed at the bottom of the culture chamber, no cells remain in the non-culture-chamber zone, and the cells are uniformly distributed at the bottom of the culture chamber.

Owner:南京九川科学技术有限公司

Cleaning device

InactiveCN101088637AEasy to take outWon't block the flowWork holdersFlexible article cleaningEngineeringBiomedical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation method of aluminum alloy extrusion material for metro rigid suspension busbar

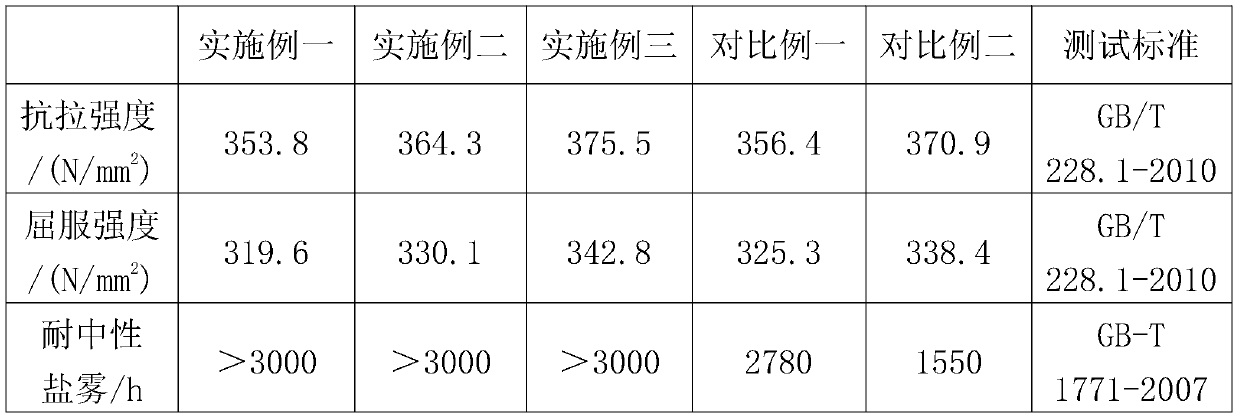

ActiveCN111334691AHigh tensile strengthHigh yield strengthAnodisationElectrophoretic coatingsUltimate tensile strengthMaterials science

The invention relates to the technical field of aluminum profiles and provides a preparation method of an aluminum alloy extrusion material for a metro rigid suspension busbar. Mass fractions of all elements in the aluminum alloy extrusion material are 0.65-0.8% of Mg, 0.6-0.75% of Si, 0.1-0.15% of Zn, 0.02-0.04% of Fe, 0.06-0.08% of Cu, 0.04-0.06% of Mn, 0.01-0.03% of Cr, 0.01-0.03% of Zr, 0.02-0.04% of La, 0.01-0.03% of Sc, 0.015-0.025% of Y and the balance of Al. The preparation method comprises the steps of casting, extrusion, quenching, aging treatment, anodic oxidation, electrophoresis treatment and spraying of an anticorrosion coating. The prepared aluminum alloy extrusion material has excellent tensile strength and yield strength as well as good corrosion resistance, and the requirement of the metro rigid suspension busbar on the aluminum alloy extrusion material can be met.

Owner:FUJIAN MINFA ALUMINUM

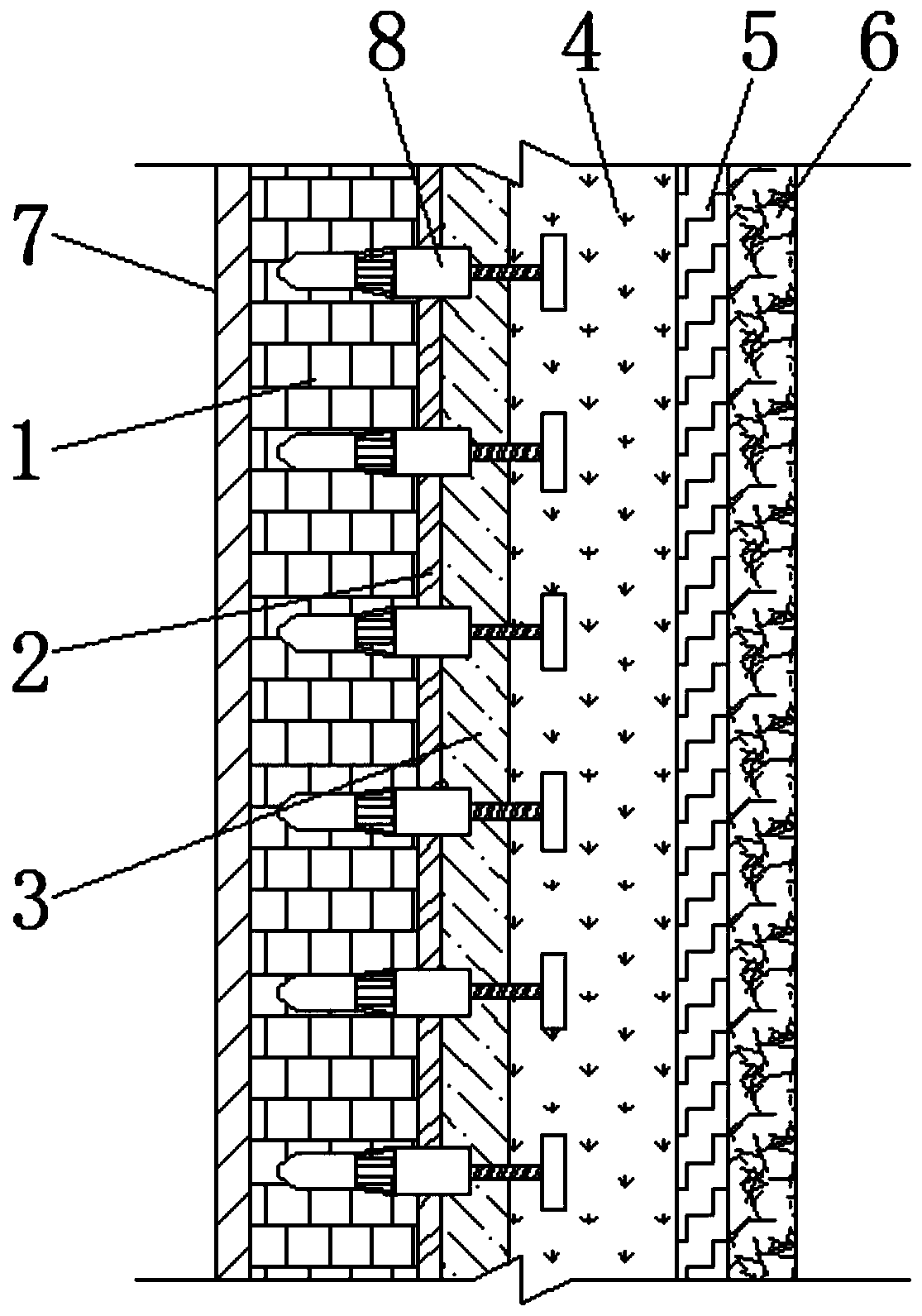

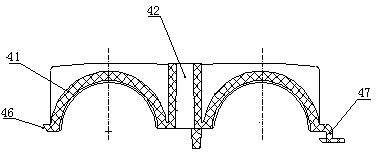

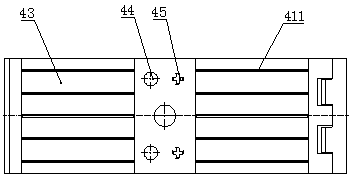

Building thermal insulation outer wall

InactiveCN111042363AImprove connection stabilityEasy to installElectrical apparatusHeat proofingAdhesive cementThermal insulation

The invention discloses a building thermal insulation outer wall. The building thermal insulation outer wall comprises a basic layer wallboard and a wire placement groove. An interface mortar layer isconnected with the right side of the basic layer wallboard. A thermal insulation board comprises a bonding layer and an expanded polystyrene board. The right side of the thermal insulation board is connected with an anti-crack protective plate. The anti-crack protective plate comprises anti-crack adhesive cement, a hot-dip galvanized steel wire mesh and anti-crack mortar. The hot-dip galvanized steel wire mesh is connected with the left side of the anti-crack adhesive cement, and the anti-crack mortar is connected with the left side of the hot-dip galvanized steel wire mesh. A flexible puttylayer is laid on the surface of the right side of the anti-crack protective plate. An interior trim surface layer is laid on the surface of the left side of the basic layer wallboard, and connecting pieces are installed inside the basic layer wallboard. According to the building thermal insulation outer wall, the stability of the connection between interior structures is high, installation and construction of wall bodies are facilitated, the stability of the connection between the wall bodies is conveniently guaranteed, laying operation of wires inside the wall bodies is facilitated, the phenomenon that the wires fall off cannot happen, and the attractiveness of the interiors of the wall bodies is enhanced.

Owner:浙江辉腾建设有限公司

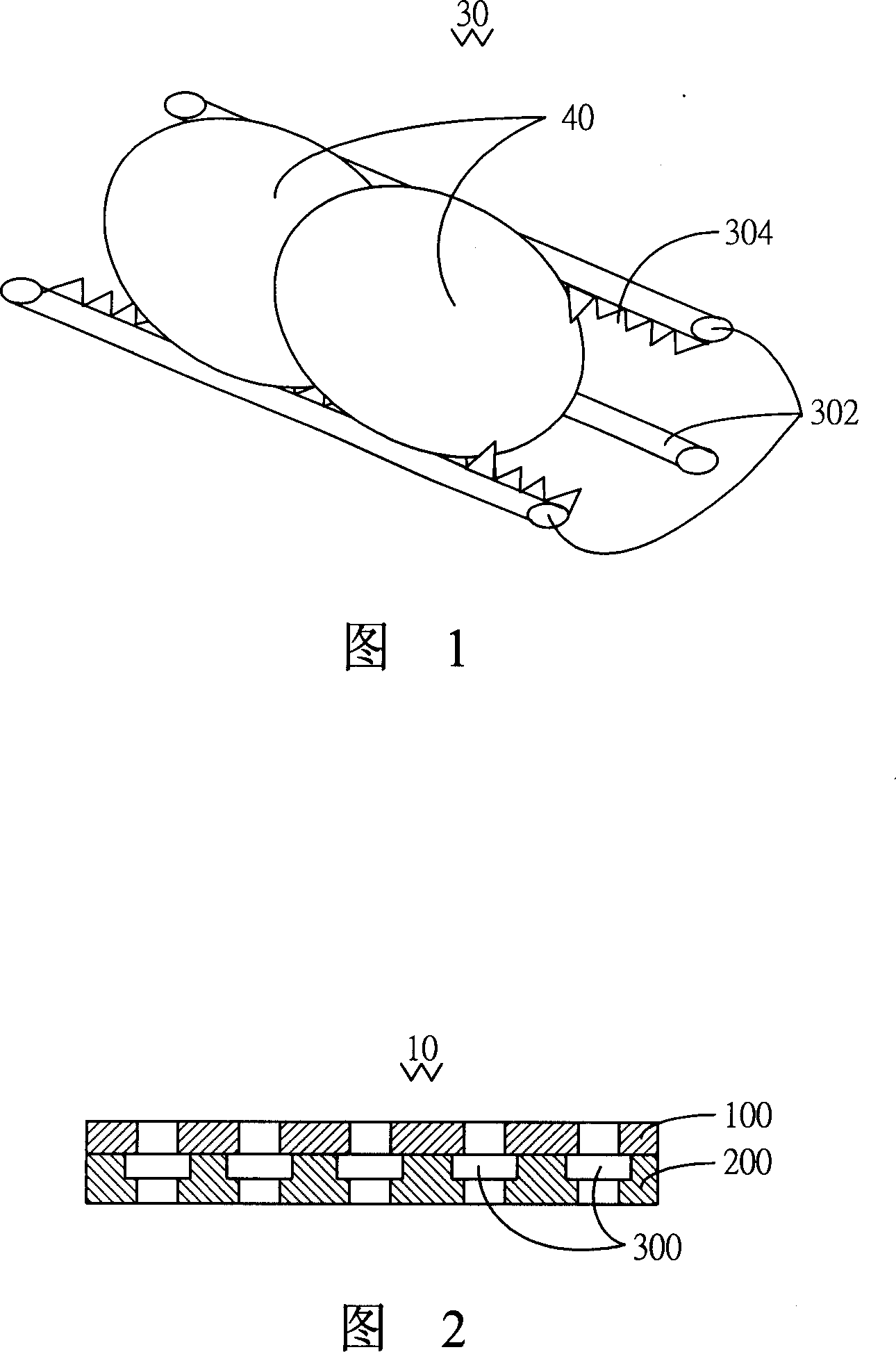

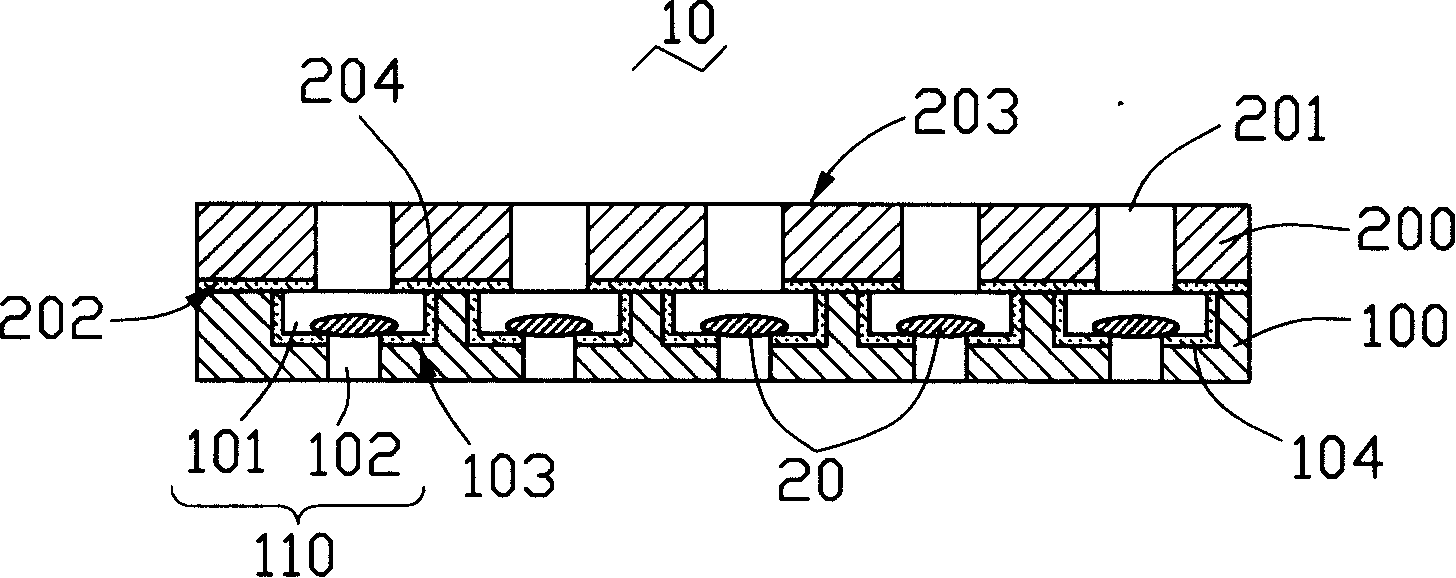

Cleaning fixture

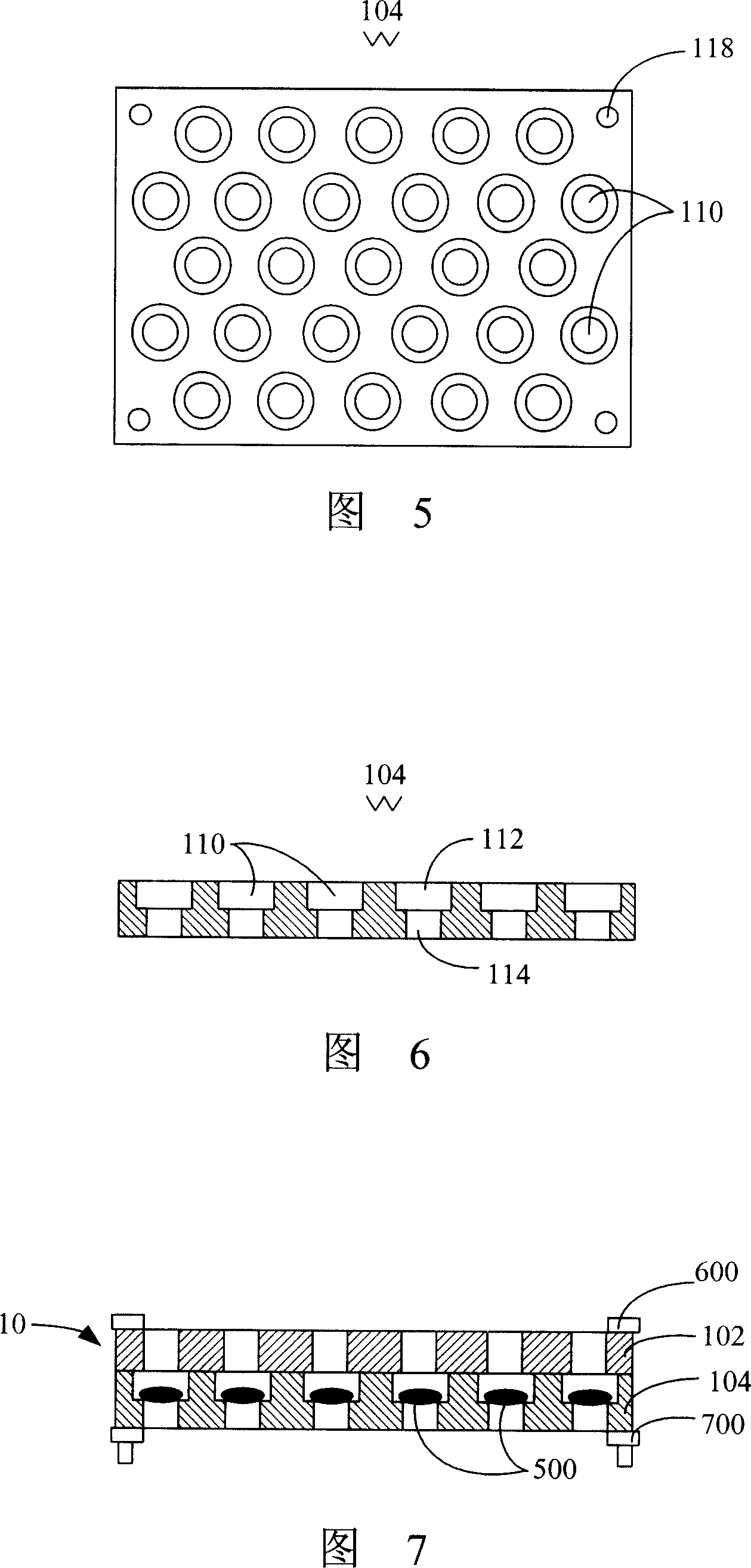

InactiveCN101172281AEasy to take outEasy to remove water and dry processWork holdersFlexible article cleaningEngineering

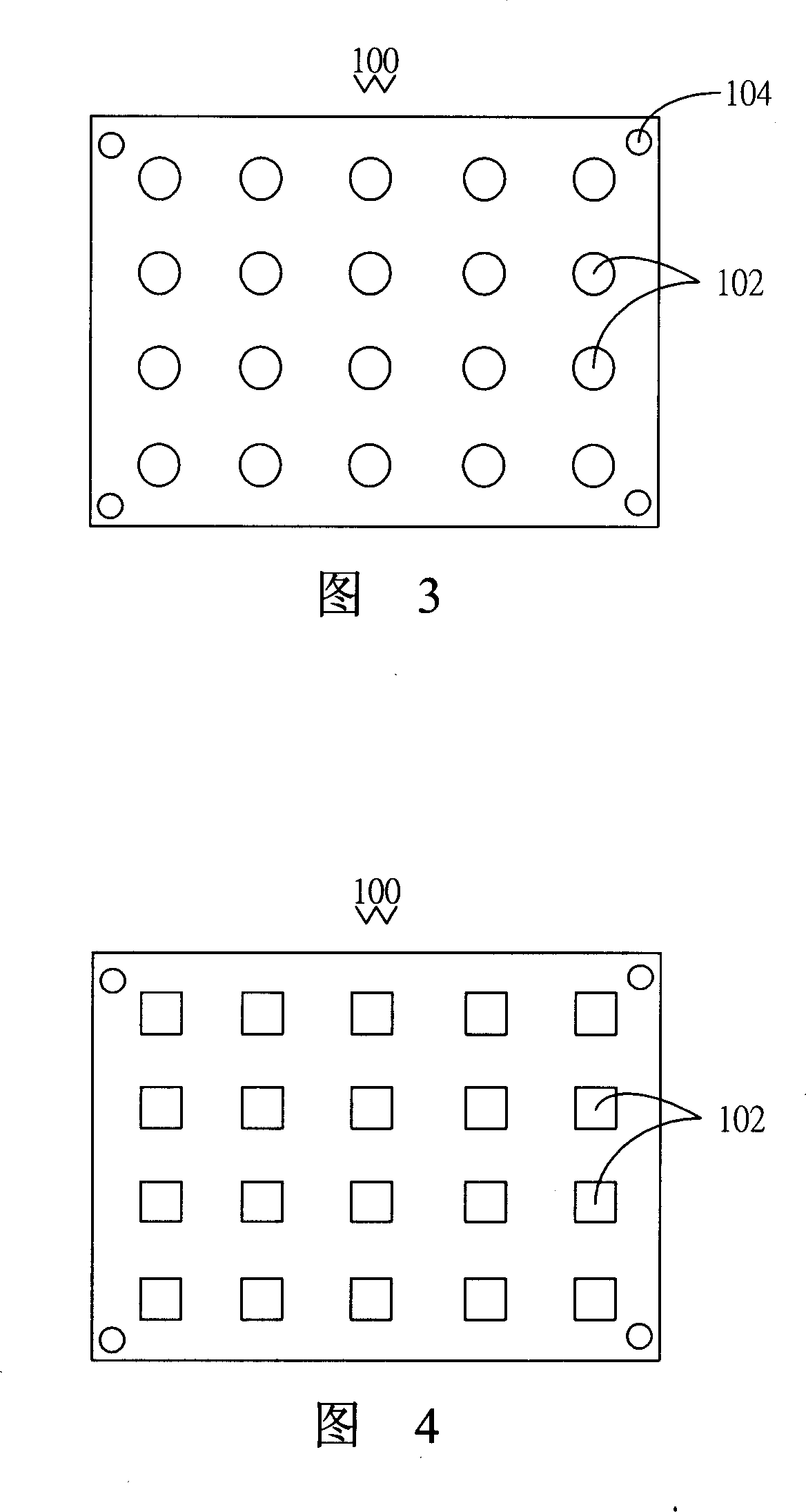

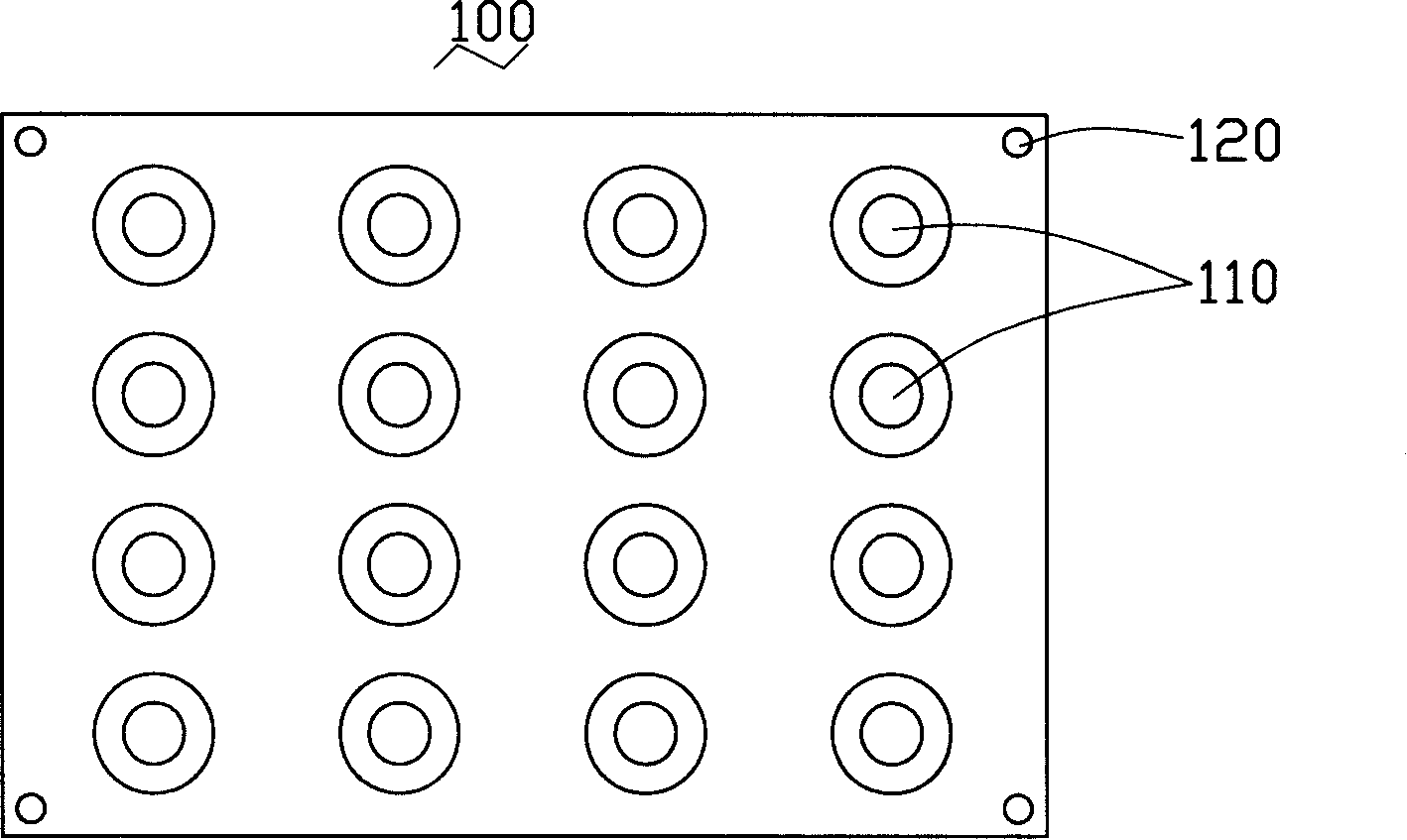

An apparatus (10) for holding optical lenses (20) provided herein generally includes a holding member (100) and a cover member (200) coupling with the holding member. The holding member comprises a plurality of first through holes (110). Each of the plurality of the first through holes comprises a first portion (101) for receiving an optical lens (20) therein and a second portion (102) communicating with the first portion. A minimum breadth of the first portion is greater than a minimum breadth of the second portion. The cover member comprises a plurality of second through holes (201) corresponding to the first through holes of the holding member. The second through holes communicate with their corresponding first portions of the first through holes. A breadth of the second through holes is less than that of the first portions of the first through holes of the holding member.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Laser etching method for watch 3D glass watch cover scales

The invention, which belongs to the technical field of watch cover decoration processing, relates to a laser etching method for watch 3D glass watch cover scales, thereby solving a problem that ink scales of the existing watch cover are not clear and are prone to falling off. The laser etching method comprises the steps: arranging a 3D glass watch cover on a marking machine jig; introducing a watch cover scale pattern required to be marked into a software system, carrying out filling and setting parameters; after position and distance judgment and successful alignment through snapshot by a CCDcamera, carrying out marking processing to enable corresponding scales to be formed at the corresponding positions of the front surface of the 3D glass watch cover; and taking out the 3D glass watchcover, transferring the 3D glass watch cover into an ink filling system, filling all engraved scales with ink, and carrying out cleaning and baking after filling. According to the invention, the marking accuracy can be realized, the line profile of the formed scale is clear and distinct, the aesthetic property is good, the defects of burrs and edge breakage are overcome, and the effect of not being easy to fall off is realized.

Owner:ZHEJIANG XINGXING TECH CO LTD

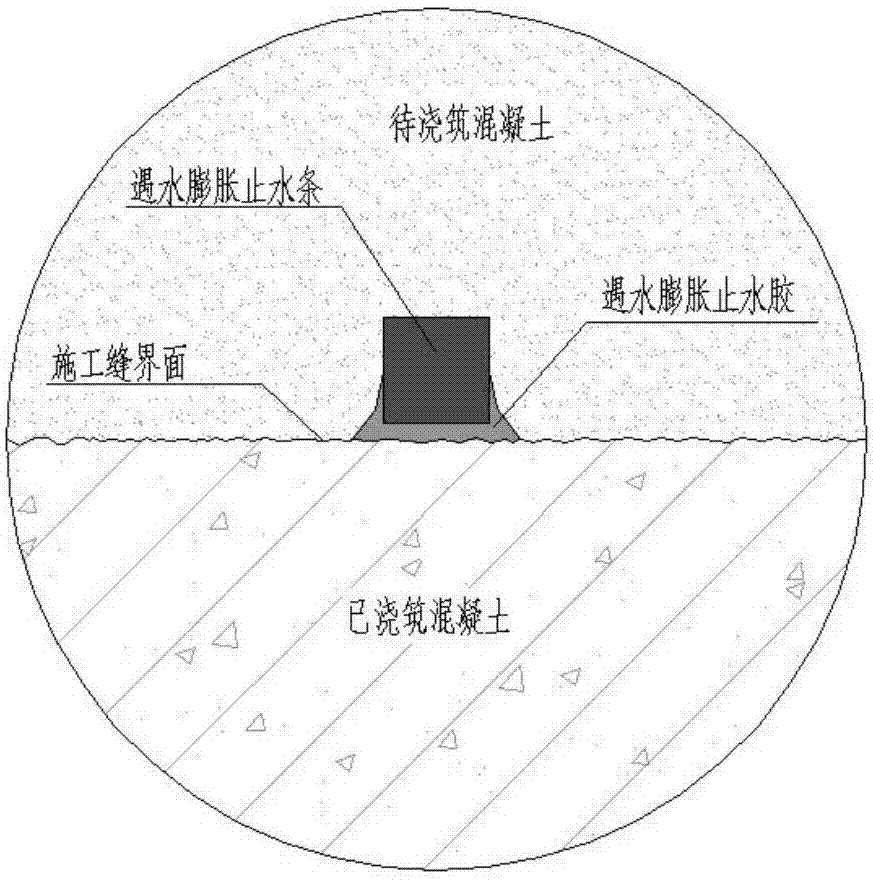

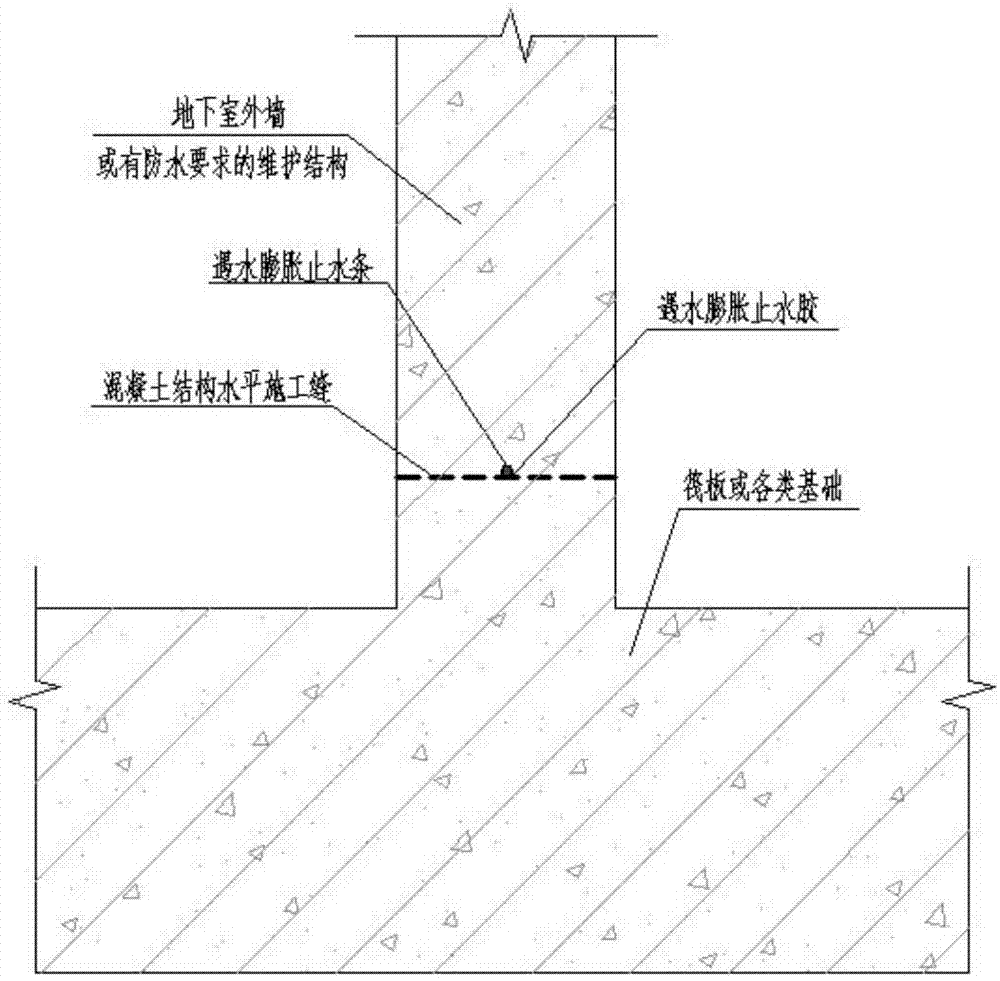

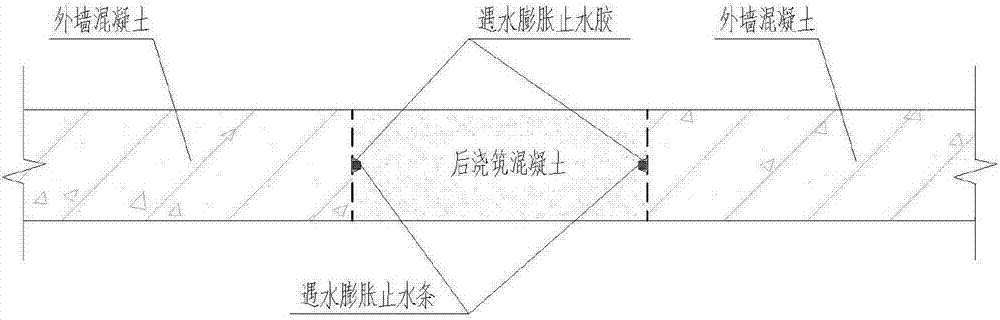

Construction method for combination of water swelling sealing rod and water swelling glue

ActiveCN107143046ARepair operation is simpleQuality improvementArtificial islandsUnderwater structuresSocial benefitsBuilding construction

The invention discloses a construction method for combination of water swelling sealing rod and water swelling glue, which relates to the technological field of waterproof construction. In the construction method for combination of water swelling sealing rod and glue, the water swelling sealing rod is used as a main water stopping material and the water swelling glue is used as a bonding and fixing material as well as an auxiliary water stopping material on a lap joint. At the same time, the combination of water swelling rod and water swelling glue is applied to the construction of the waterproof part in a building. The construction method for combination of swelling sealing rod and water swelling glue can be extensively applied to concrete construction joints, late poured bands, wall pipes, pile crowns in underground projects and other joints which is suitable for the waterproof method. The construction method for combination of water swelling sealing rod and water swelling glue has much more polarization and application value. Besides, the economic and social benefits of the construction method for combination of water swelling rod and water swelling glue are extremely notable.

Owner:王军

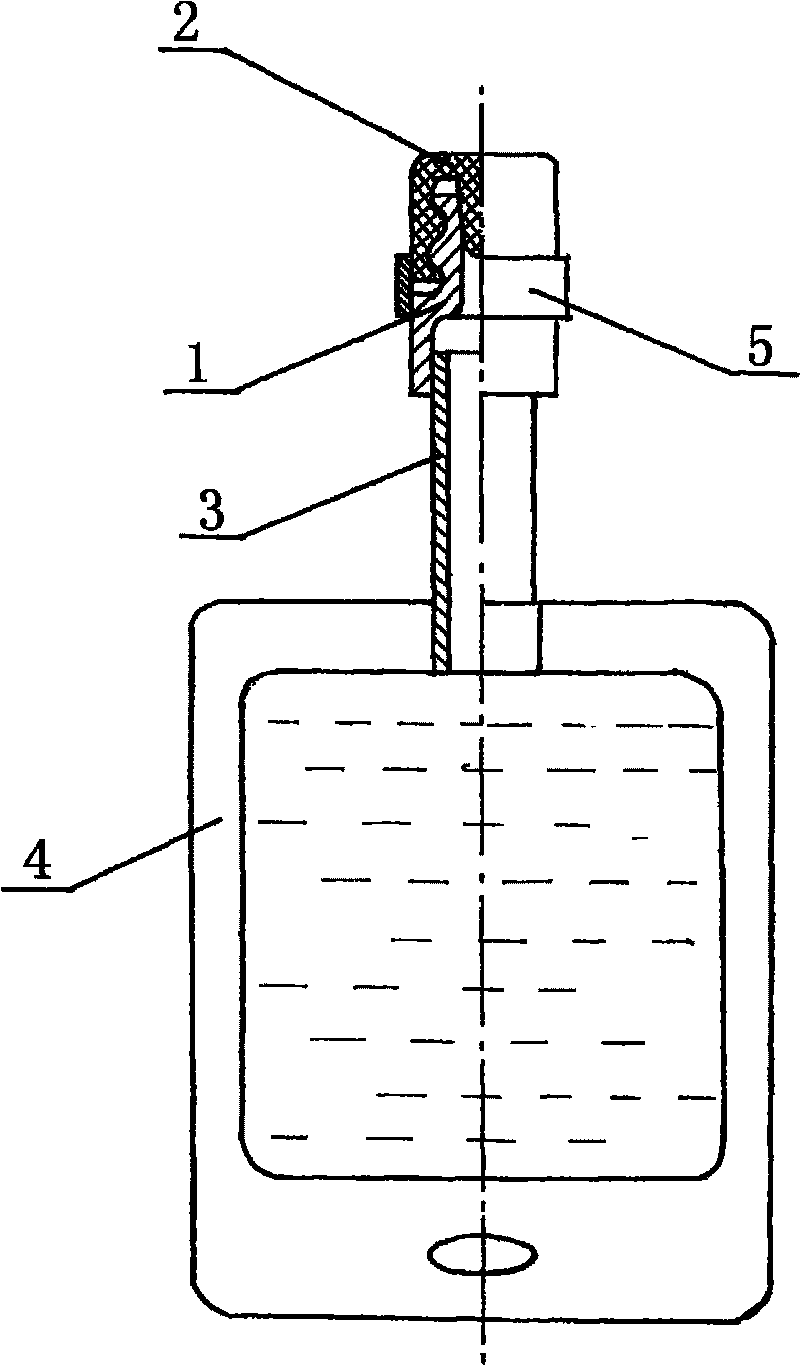

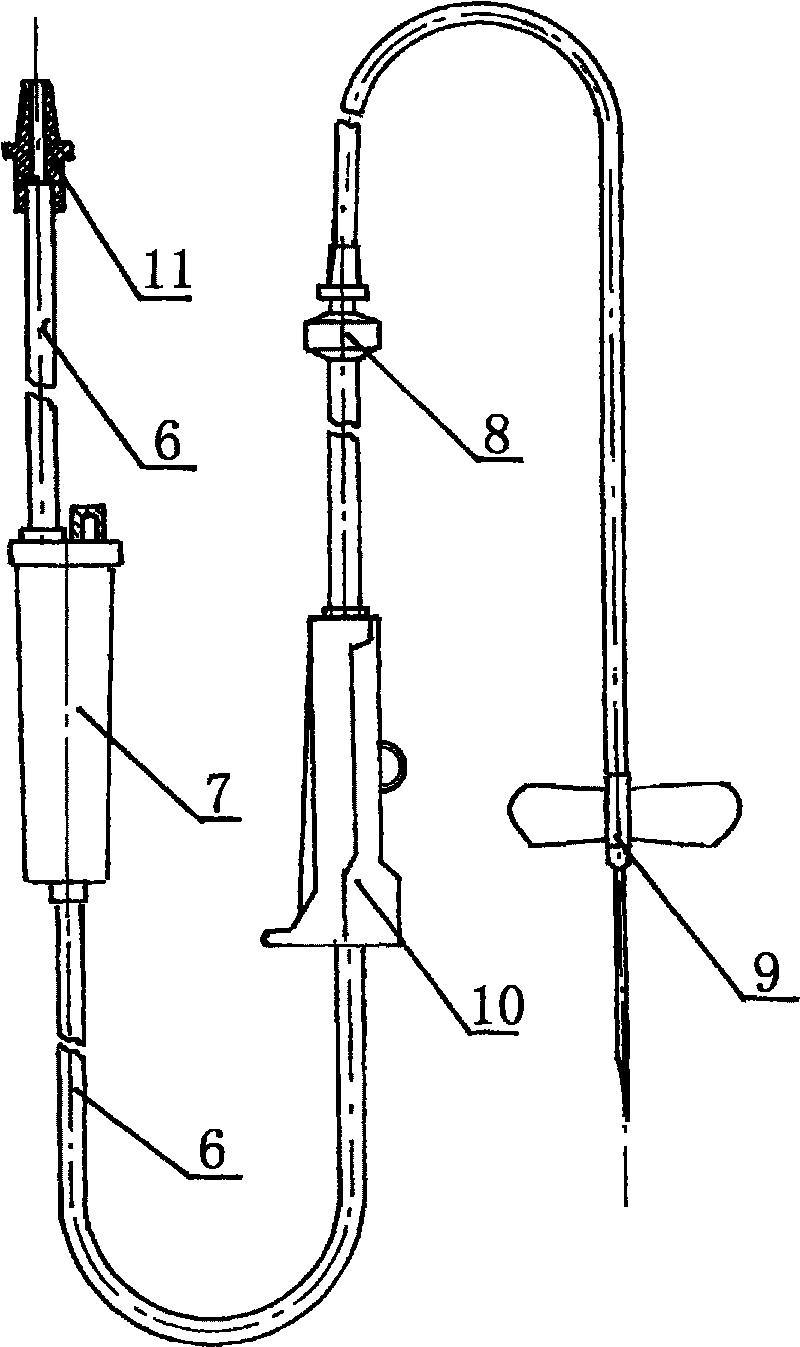

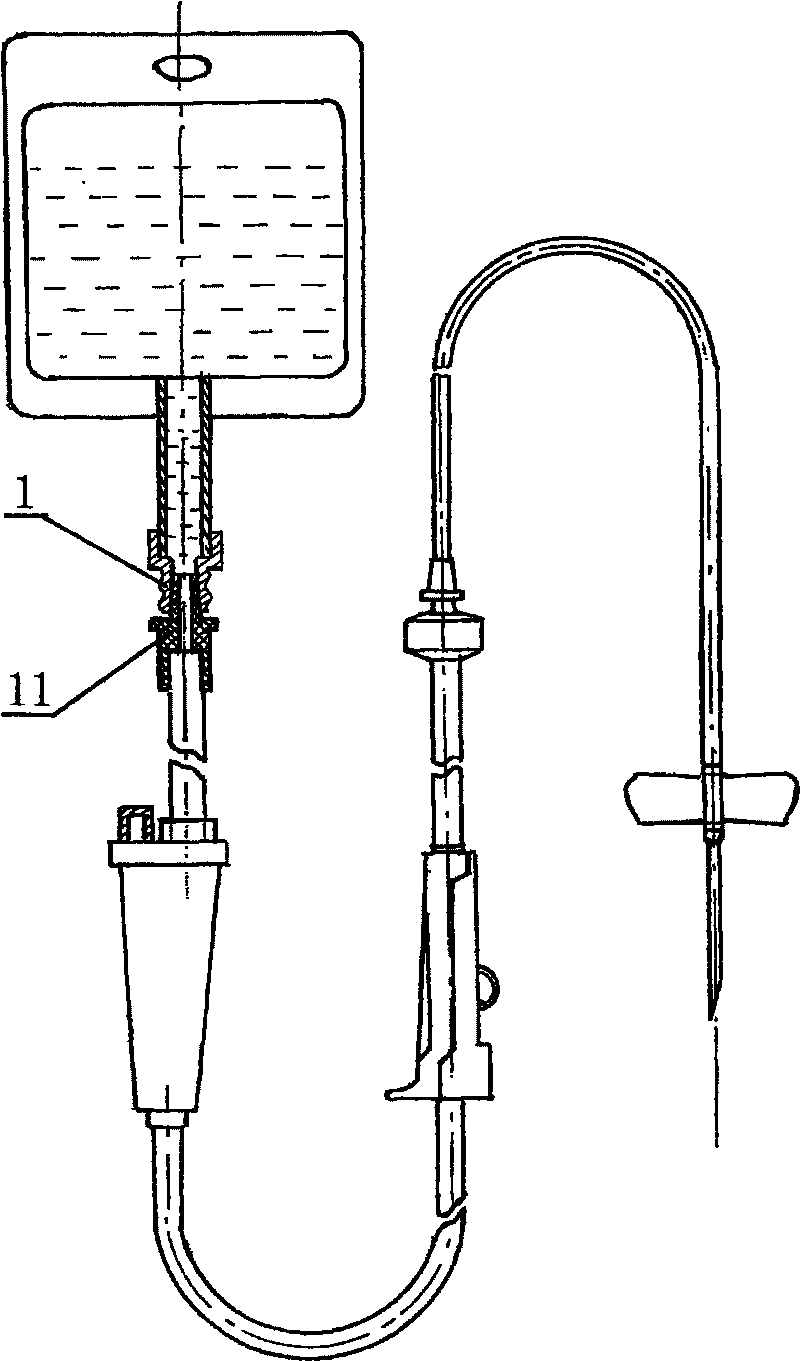

Infusion bag and infusion apparatus matched with same

InactiveCN101721309ACause spilloverCreate pollutionInfusion devicesPharmaceutical containersBottleSurgery

The invention provides a single-opening infusion bag which comprises a combination cover, an interface pipe and a bag, wherein the combination cover consists of a drug outlet mouth and a plugging cover; particularly, the upper section of the drug outlet mount is internally provided with a tapered hole matched with a tapered nipple of an infusion apparatus and externally provided with a thread; the annular wall of the plugging cover is internally provided with an inner thread matched with the thread outside the upper section of the drug outlet mouth; the center of a top plate of the plugging cover is provided with a plugging piece matched with the tapered hole in the upper section of the drug outlet mouth; and after the plugging cover is screwed on the drug outlet mouth to seal the drug outlet mouth, a sealing ring which can be torn off is used for sealing a gap between the plugging cover and the drug outlet mouth. The packaging structure of the infusion bag cannot loosen in conveying and transportation processes to cause the leakage and the pollution of liquid medicine. The infusion bag is used together with a matched infusion apparatus provided with the invention and can avoid plug scrap dropping and nurse accidental injuries which are caused by using a bottle inserting needle or an infusion apparatus puncturing combination cover in the process of an infusion operation.

Owner:马伟博

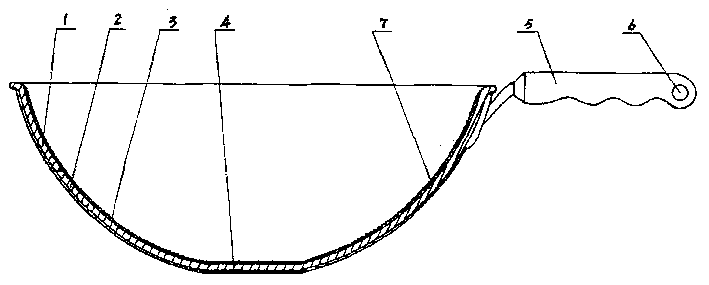

Fume-free pan used in sauteing food and making method thereof

InactiveCN1465318AImprove thermal efficiencyWill not cause sheddingCooking-vessel materialsBiomedical engineeringThermal efficiency

The present invention discloses a fume-free pan for stir-frying food and its making method. It includes pan body formed from internal pan body and external pan body and pan handle. The bottom portions of the internal pan body and external pan body have flat bottom portions which are combined together, and between two pan bodies a hollow sandwich layer is formed, and the surface of the internal pan body is coated with base enamel with several microsmall projections on which an inadhesive layer is formed, and the surface of the external pan body is covered with enamel layer. Its making method includes the procedures of forming, pickling, glazing, sand-blasting, spray-coating and packaging.

Owner:胡金高

Cleaning-free external pasting film

InactiveCN101544873AColorless and transparentWaterproofFilm/foil adhesivesPolyureas/polyurethane adhesivesPolymer scienceEvaporation

A cleaning-free external pasting film is composed of a basal layer, a glue layer and a film layer, wherein the basal layer is made of a smooth synthetic papers surface coating silicon oil layer with toughness; the film layer is made by dissolving 35 shares of HO-(CH2CH2O)18-COOH and 10 shares of EuCl2 6H2O into methanol to mix, a [HO-(CH2CH2O)18-COO]2Eu complexes is obtained through oil bath heating, inverse flow, filtrating, decompression rotary evaporation to remove dissolvent and cooling, then the film layer will be obtained by adding the complexes into polyethylene; for the glue layer, a suspending liquid is obtained by agitating 50 shares of graphite and 200 shares of N-2-hydroxyethylamino; a glue is obtained by agitating a mixture of 1 shares of the suspending liquid and 49 shares of polyurethane glue by weight, the glue layer will be obtained by jetting the glue on the film layer. The pasting film of the invention is economic and environment protection, operation is easy and safe. The film has characteristics of colorless transparent, water-proof, oil-proof, sun-prevention, high temperature resistant, chilliness resistance and easy operation, the glue may be applied at a temperature range from -30 DEG C to 110 DEG C, and it is capable of resisting summer sweltering high-temperature and winter chilliness low-temperature.

Owner:陈新

Double-ring self-locking type feeder clamp

The invention relates to a double-ring self-locking type feeder clamp. The double-ring self-locking type feeder clamp is characterized by comprising a screw, a C-shaped fixture and a plurality of self-locking double-ring plastic clamps, wherein one end of the screw is connected with the C-shaped fixture, the other end of the screw is sleeved with the self-locking double-ring plastic clamps which are clamped through locking nuts, the center of the buckling side face of a plastic clamp body of each self-locking double-ring plastic clamp is provided with a smooth through hole which is matched with the screw in outer diameter, semicircular through grooves are arranged on the two sides of each through hole, one end of each plastic clamp body is provided with a claw, the other end of each plastic clamp body is provided with a C-shaped locking piece, and the non-buckling side face of each plastic clamp body is provided with structure reinforcing ribs. The double-ring self-locking type feeder clamp has the advantages that the phenomenon that an operator needs to lock the locking nuts when the operator clamps the plastic clamp bodies is not needed, and installation is convenient and rapid; in addition, due to the fact that each self-locking double-ring plastic clamp is provided with a self-locking structure to clamp a feeder, after the locking nuts are loose, the feeder can still be well fixed to the self-locking double-ring plastic clamps, and disengagement is avoided.

Owner:RUGAO KK TELECOM MATERIALS

Energy-saving and heat-preservation wall for building

ActiveCN109083300AWill not cause ruptureWill not cause sheddingWallsHeat proofingEngineeringLoad-bearing wall

The invention discloses an energy-saving and heat-preservation wall for a building. The wall comprises a load bearing wall body, a waterproof plate is fixedly connected to the right side of the load bearing wall body, a sponge heat-preservation plate is fixedly connected to the right side of the waterproof plate, a fireproof plate is fixedly connected to the right side of the sponge heat-preservation plate, and an energy-saving and heat-preservation plate is fixedly connected to the right side of the fireproof plate; embedded rods are symmetrically arranged in the load bearing wall body, the right end of each embedded rod sequentially penetrates through the load bearing wall body, the waterproof plate, the sponge heat-preservation plate, the fireproof plate and the energy-saving and heat-preservation plate from left to right and extends to the outside of the energy-saving and heat-preservation plate, and the portion, located outside the energy-saving and heat-preservation plate, of thesurface of each embedded rod is in threaded connection with a fastening buckle. The wall is simple in structure, low in cost and good in impact resistance; it is ensured that after the wall is subjected to large impact force, the heat-preservation plates cannot be broken or shed; moreover, it is ensured that the body of people who the impact force is applied to cannot be injured, and the household or office use needs can be completely met.

Owner:安徽百维新材料有限公司

Self-luminous key, keyboard and manufacturing method thereof

InactiveCN104103445AWill not cause sheddingLong luminous lifeElectric switchesLaser etchingKey pressing

The invention discloses a self-luminous key, keyboard and a manufacturing method thereof. The key includes: a body of light color to which luminescent material is added when the body is molded; and a primer layer which is sprayed on the body, adopts dark color paint, and has a laser etching area which exposes a corresponding part of the body and thereby displays a key symbol. The self-luminous keyboard is equipped with the self-luminous keys. The manufacturing method includes: molding a body of a key doped with luminescent materials; spraying dark color paint on the body to form a primer layer; and performing laser etching on the body to form a laser etching area, exposing a corresponding part of the body to display a key symbol. The key has luminescent materials in the body, the key symbol is formed by exposing the corresponding part of the body through laser etching, so falling of the luminescent materials is not easily caused, and the key has a long luminous life; and an LED lamp does not need to be used to emit light, so manufacturing cost and using cost are relatively low.

Owner:SHENXUN COMP KUNSHAN

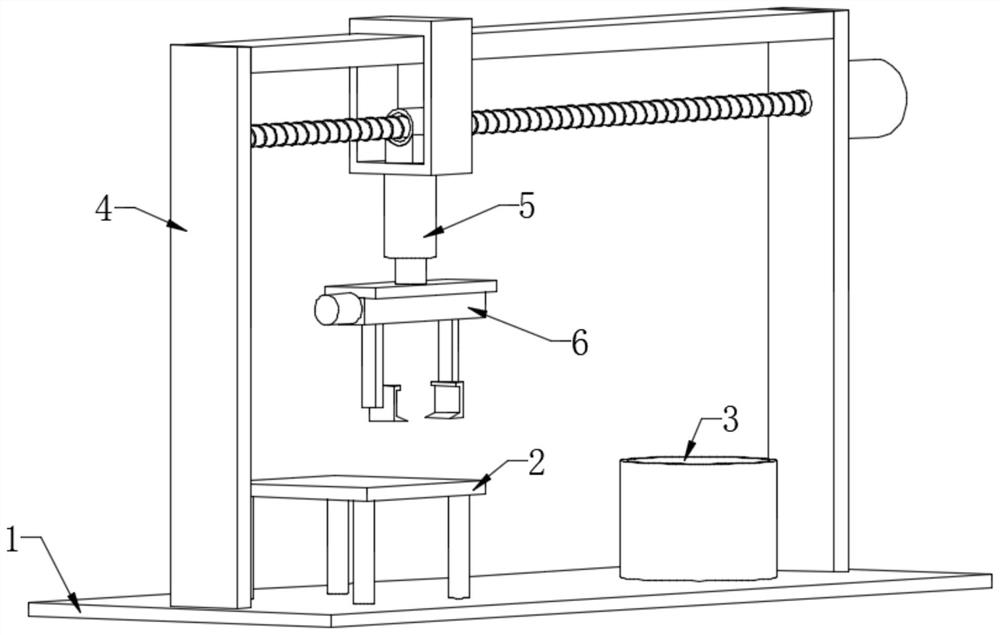

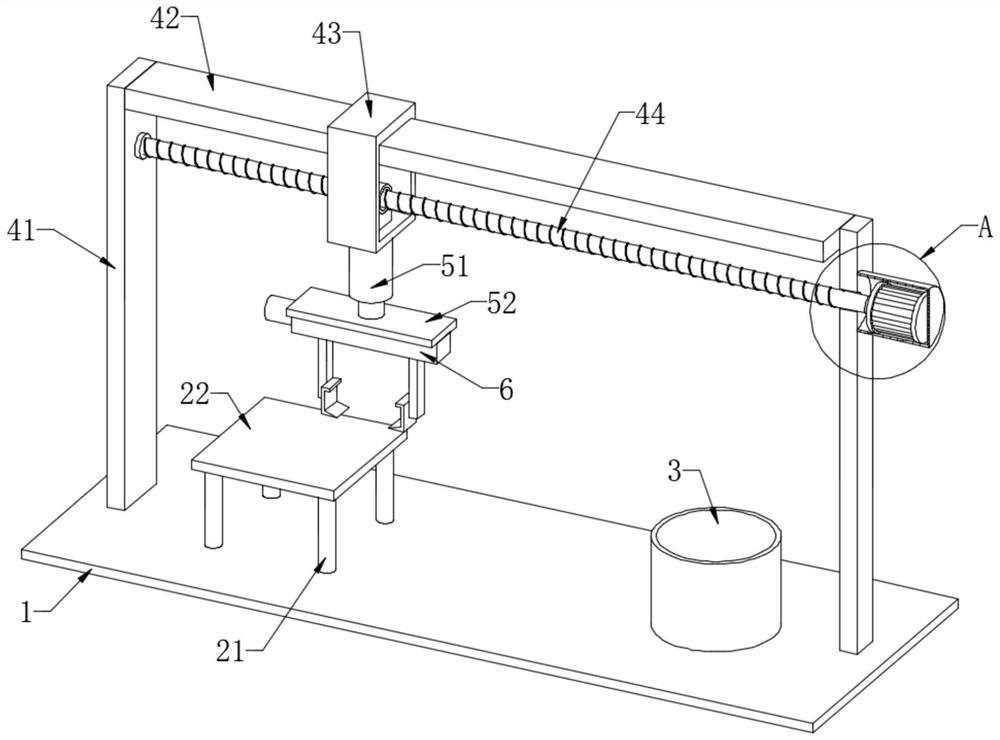

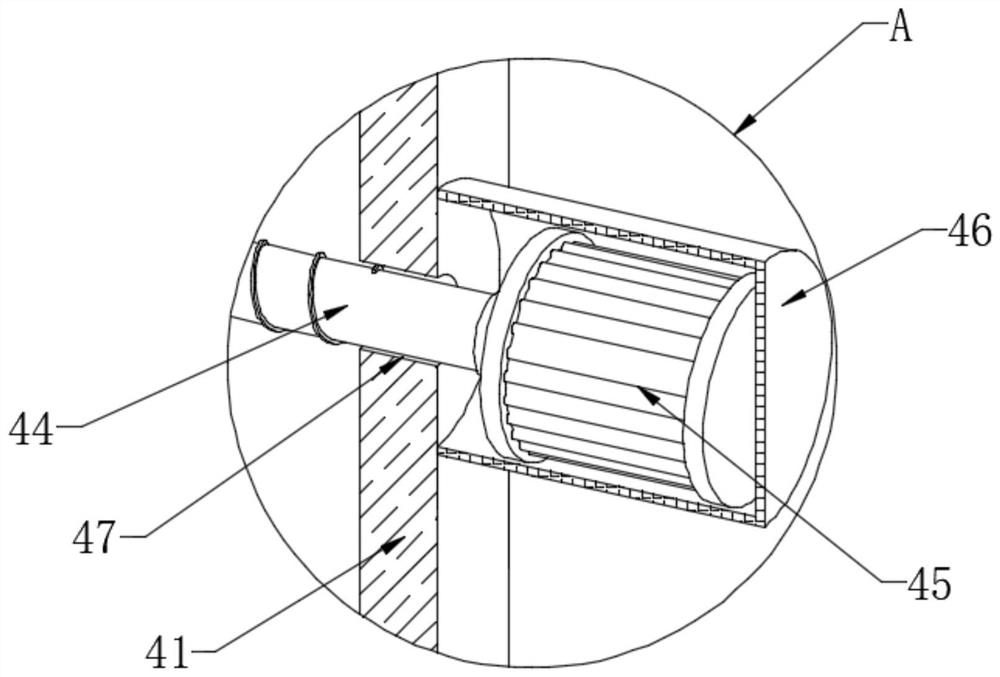

Heat treatment device for precision forging

ActiveCN113106216AWill not cause sheddingStable clamping effectFurnace typesIncreasing energy efficiencyEngineeringMachining

The invention discloses a heat treatment device for precision forging. The heat treatment device comprises a base, a machining table, a quenching barrel, a translation assembly, a lifting assembly and a clamping assembly, the translation assembly is welded to the top of the base, the lifting assembly is fixedly installed at the bottom of the translation assembly, and the clamping assembly is fixedly installed at the bottom of the lifting assembly; and the machining table and the quenching barrel are welded to the two sides of the top of the base correspondingly, the machining table and the quenching barrel are located on the inner side of the translation assembly, and the translation assembly comprises two stand columns, a cross beam and a sliding sleeve. According to the scheme, through mutual cooperation of the translation assembly, the lifting assembly and the clamping assembly, a workpiece placed on the top of the machining table can be transferred to the inner cavity of the quenching barrel for quenching, the workpiece is transferred to the top of a table plate after quenching, the workpiece does not need to be manually clamped for quenching, and the safety during quenching is greatly improved.

Owner:蒙阴县常发矿山机械有限公司

Cleaning fixture

InactiveCN101108388AEasy to take outWon't block the flowWork holdersFlexible article cleaningHoneycombEngineering

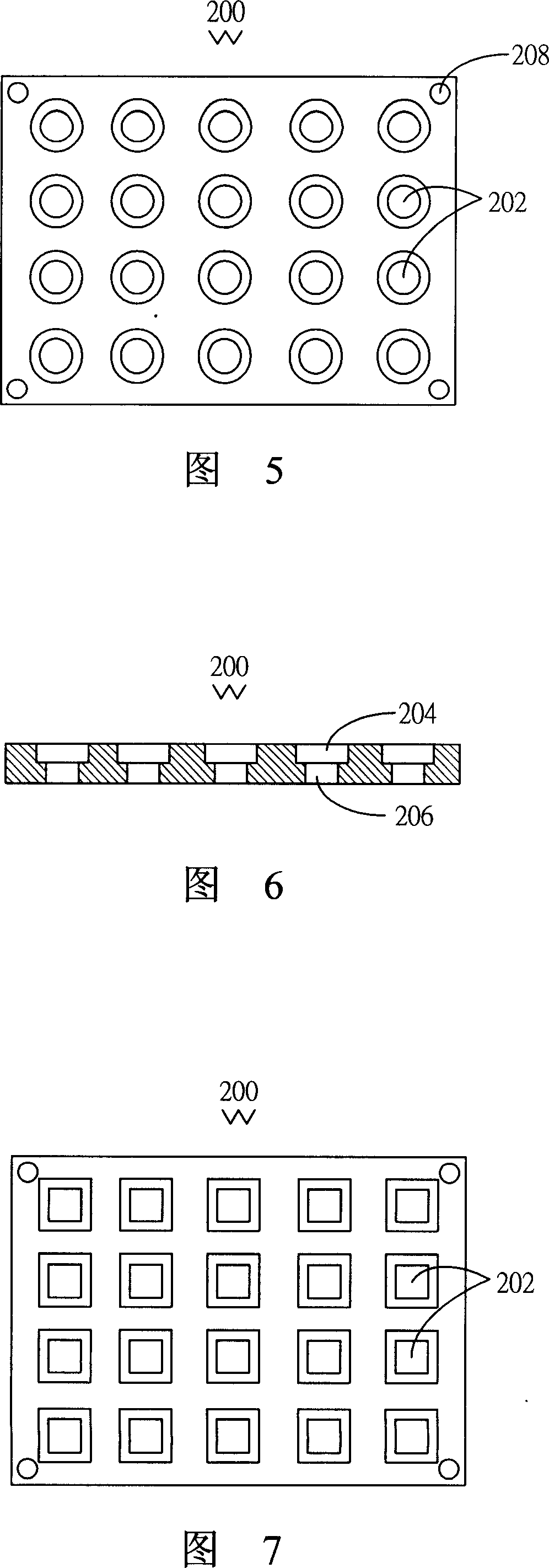

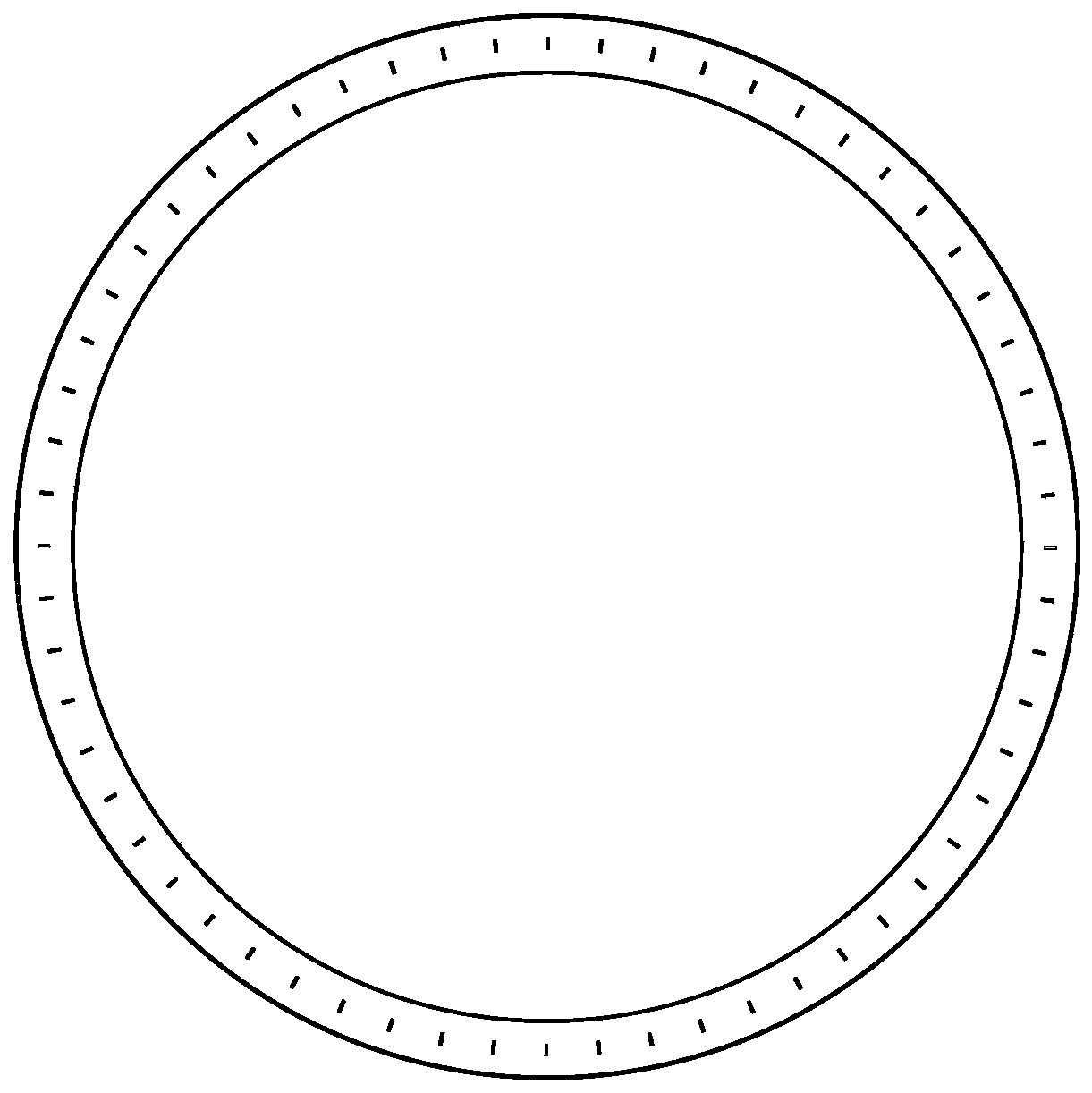

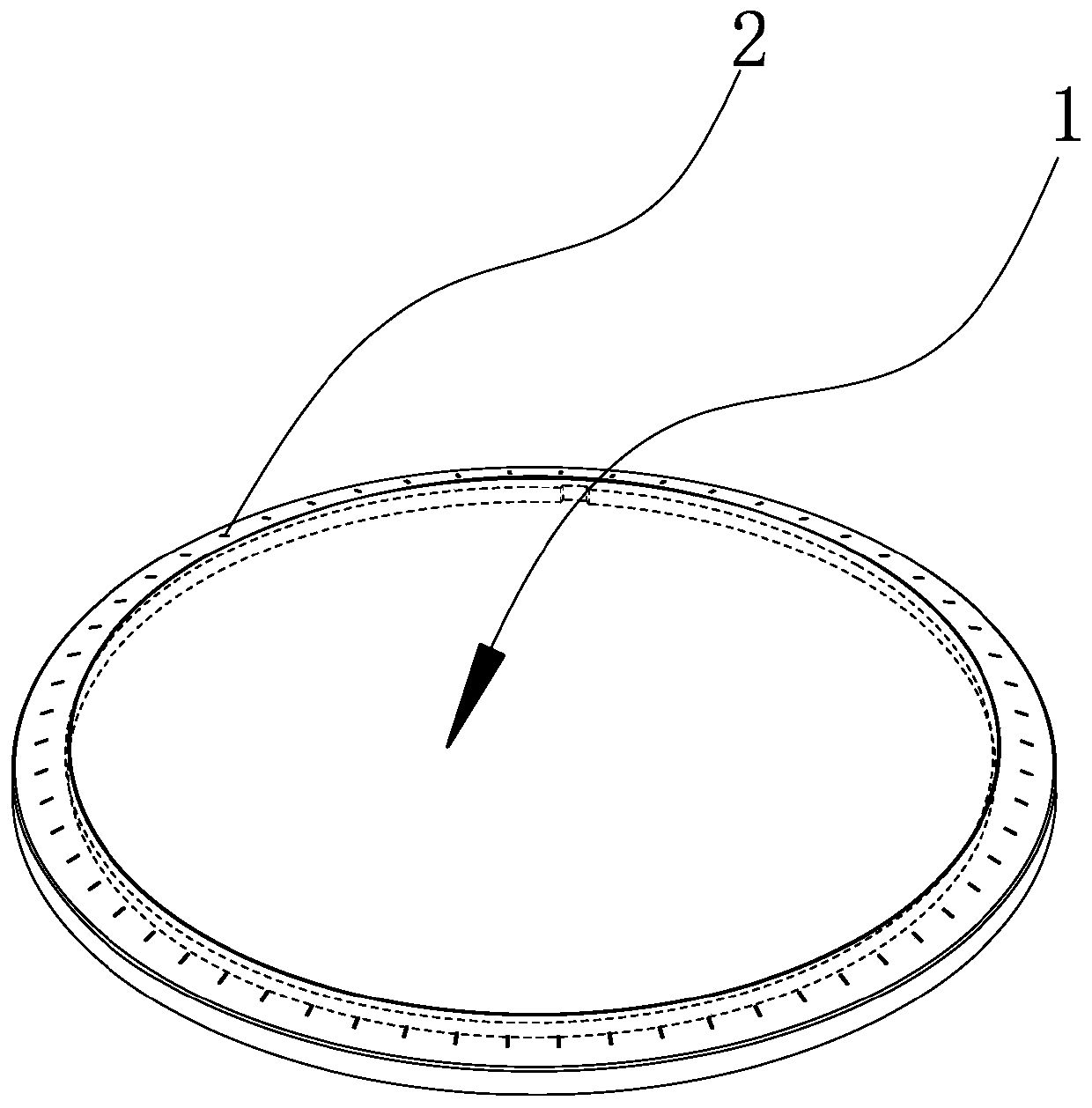

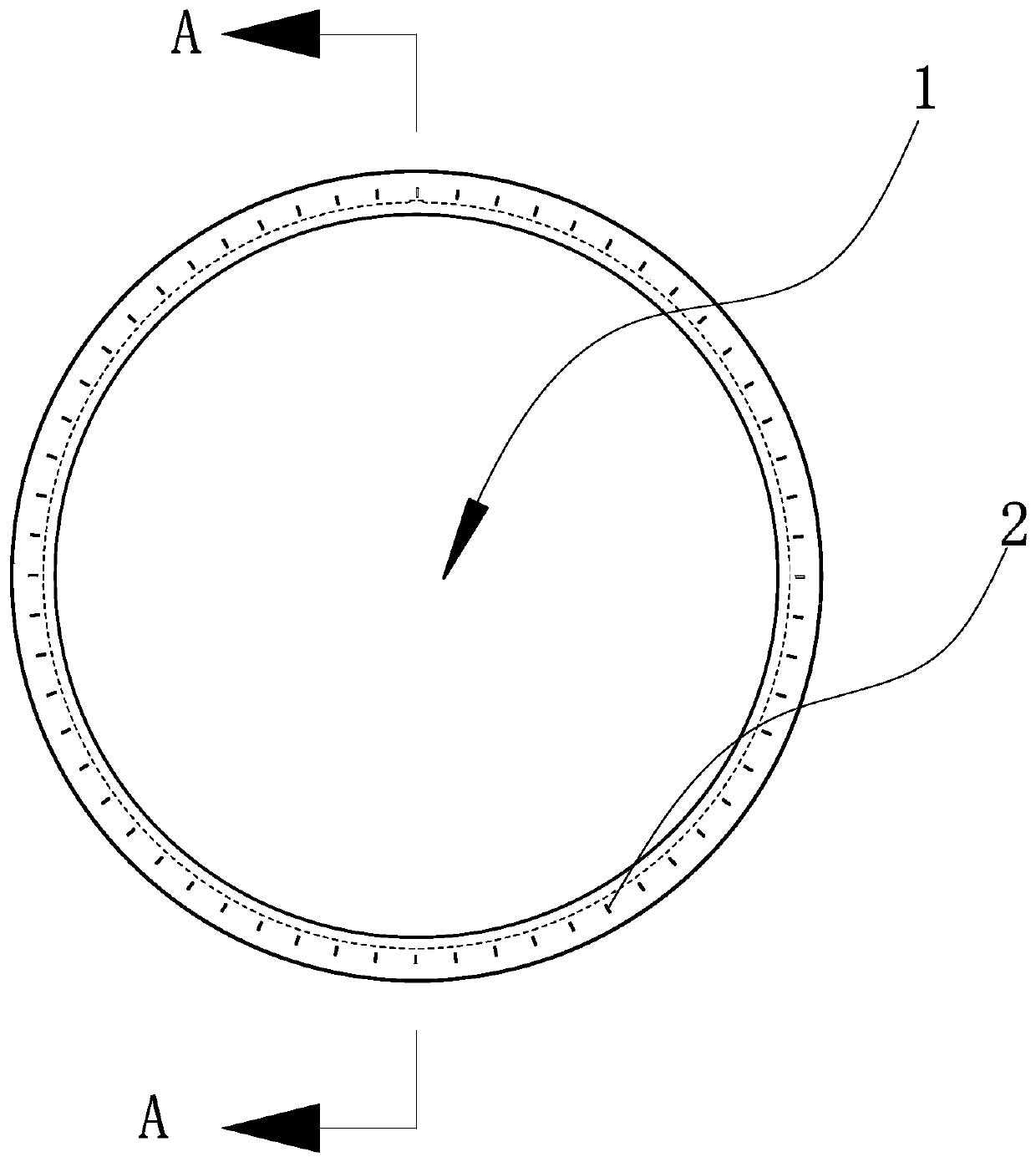

The invention relates to a washing fixture used for washing optical member, which comprises a lid and a main body. A plurality of first through holes are opened on the lid, which takes honeycomb shape array and are distributed on the lid. A plurality of second through holes which corresponds with the first through holes are opened on the main body, which takes honeycomb shape array and are distributed on the lid, each second through hole is provided with a first opening and a second opening, when the lid is coordinated with the main body, the first opening is more closer to the lid than the second opening, when the lid and the main body are washed together, a plurality of containing spaces which is used for collecting optical member are formed on the fixture. The containing space limits the optical member, to prevent the optical member fall off from the second openings of the first through hole and the second hole. The washing fixture, the honeycomb array way of the through holes can reach the large quantity of the through holes in the same fixture area, therefore increase the quantity of the collecting optical member for washing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com