Cleaning device

A jig and body technology, applied in cleaning methods and utensils, manufacturing tools, cleaning flexible objects, etc., can solve the problems that the optical element 40 is not clean, the optical element 40 is not easy to put in, damaged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

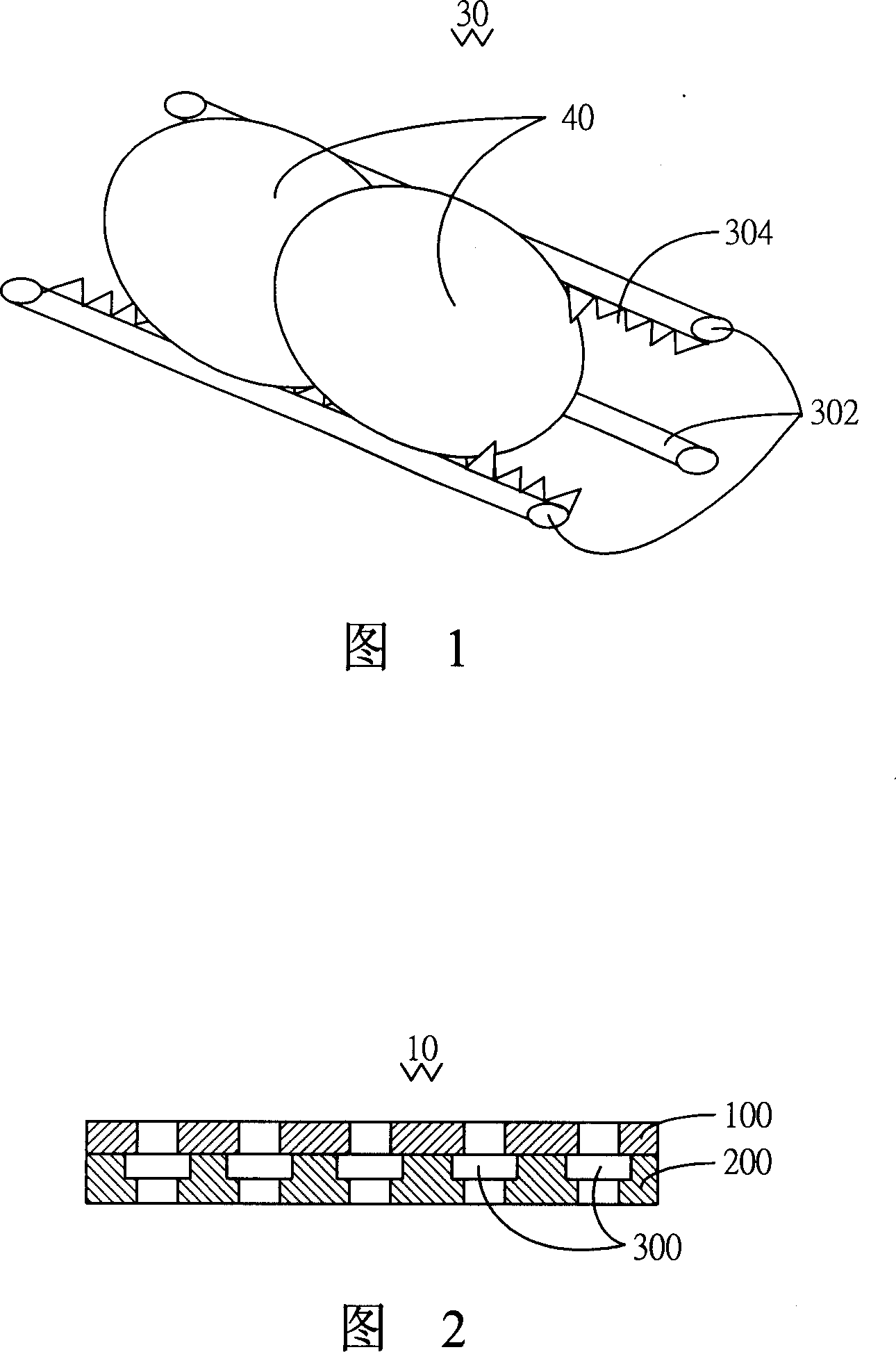

[0020] Referring to FIG. 2 , the first embodiment of the present invention provides a jig 10 , the jig 10 includes a cover 100 and a body 200 . The material of the jig 10 is one of aluminum, aluminum alloy, stainless steel, titanium alloy, copper and heat-resistant engineering plastics, and the jig 10 can be manufactured by using CNC processing technology.

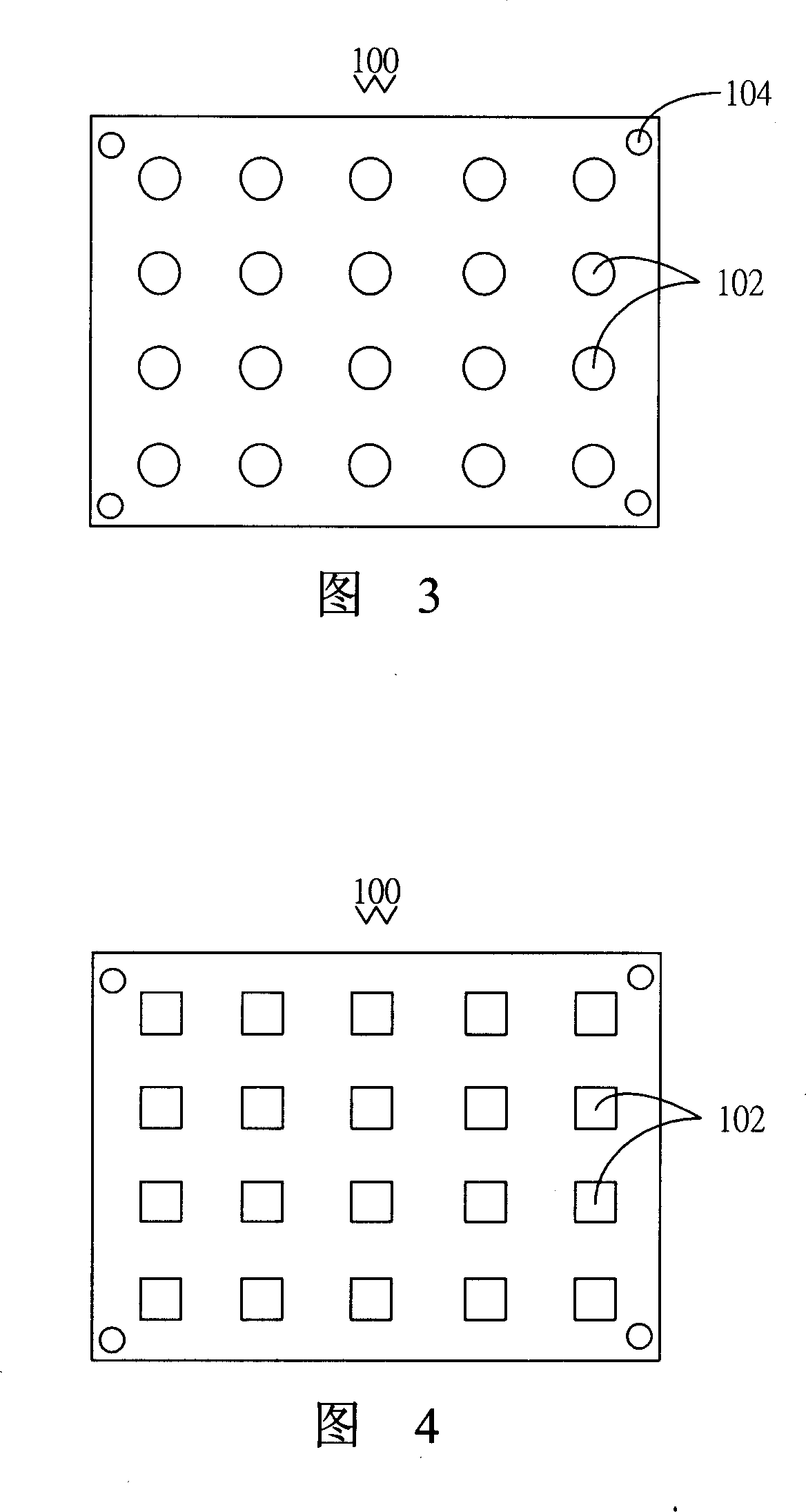

[0021] The cover body 100 defines a plurality of first through holes 102 , and the plurality of first through holes 102 are opened on the cover body 100 at a certain distance. In this embodiment, as shown in FIG. 3 , the plurality of first through holes 102 are circular holes. Certainly, the plurality of first through holes 102 may also be square holes, as shown in FIG. 4 , or other shapes, such as triangular holes, rhombus holes, and the like.

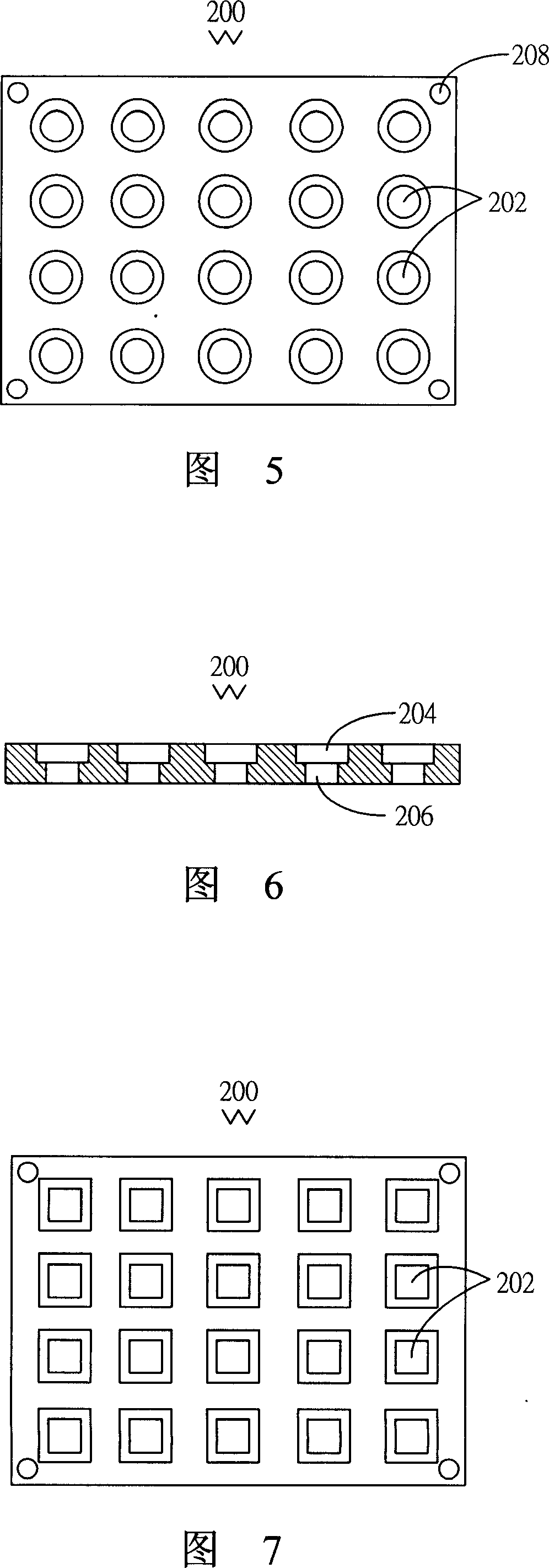

[0022] The body 200 defines a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com