Patents

Literature

72results about How to "Reduce sorting error rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

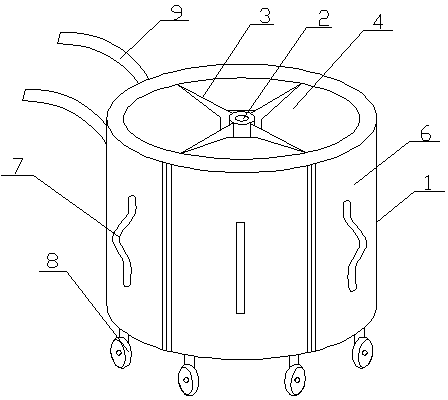

Rotating tower type quick sorting unit

InactiveCN105883370AReduce workloadReduce sorting error rateConveyorsSortingSmall footprintEngineering

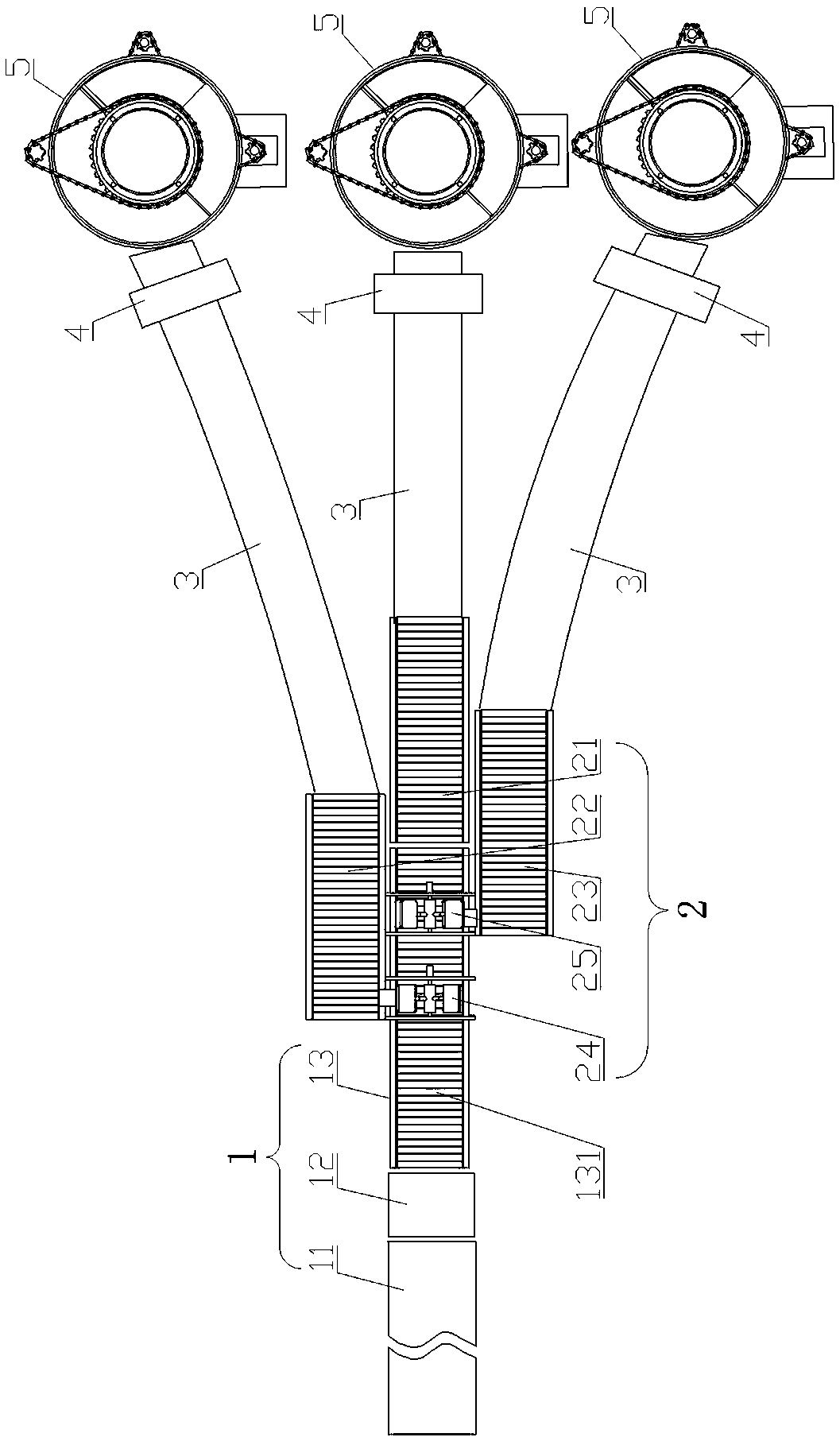

The invention discloses a rotating tower type quick sorting unit which comprises a stepping motor A, a vertical rotating shaft, a horizontal sweep plate, a movable plate, an upper base, a lower base and a driving mechanism C for driving the movable plate to move, wherein the stepping motor A drives the vertical rotating shaft to rotate; the two ends of the vertical rotating shaft are movably mounted on the upper base and the lower base respectively; at least three sweep arms are arranged on the horizontal sweep plate; the upper base is divided into a plurality of stations by the sweep arms of the horizontal sweep plate; a region between every two adjacent sweep arms is one station; the stations comprise a material feeding station and a plurality of rotary conveying stations; a package falling opening is formed in each rotary conveying station; the movable plate moves under the driving of the driving mechanism C, to open or close the package falling opening. The rotating tower type quick sorting unit has the advantages of capability of sorting packages in the vertical direction and conveying the packages into package collection cases corresponding to addresses on the packages under the control of a main control computer. Compared with a conventional automatic sorting system, the rotating tower type quick sorting unit occupies a small area, and is high in intelligence degree and high in sorting efficiency.

Owner:NANHUA UNIV

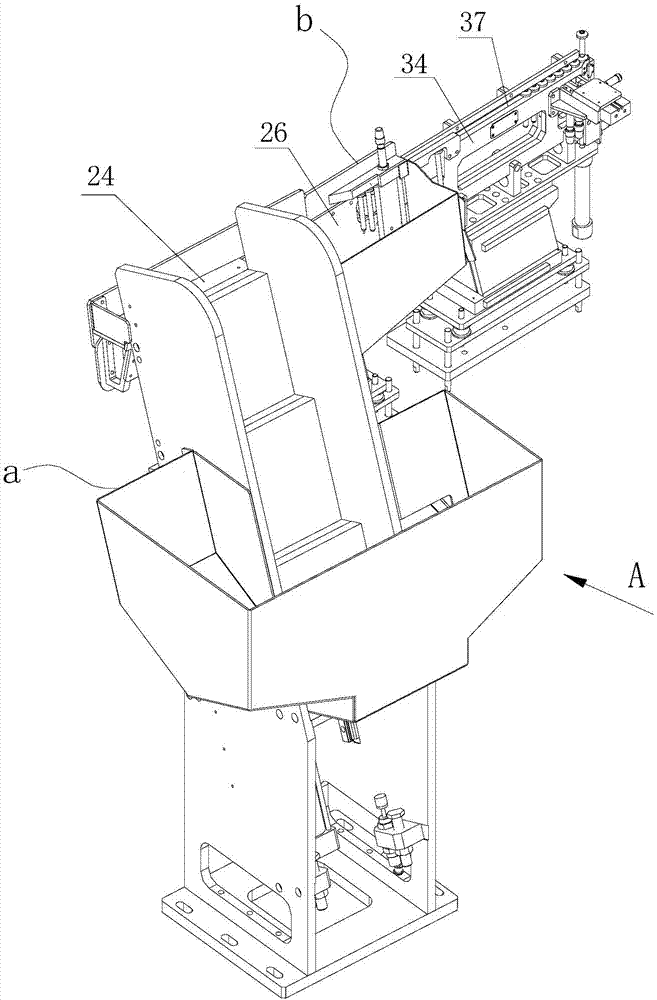

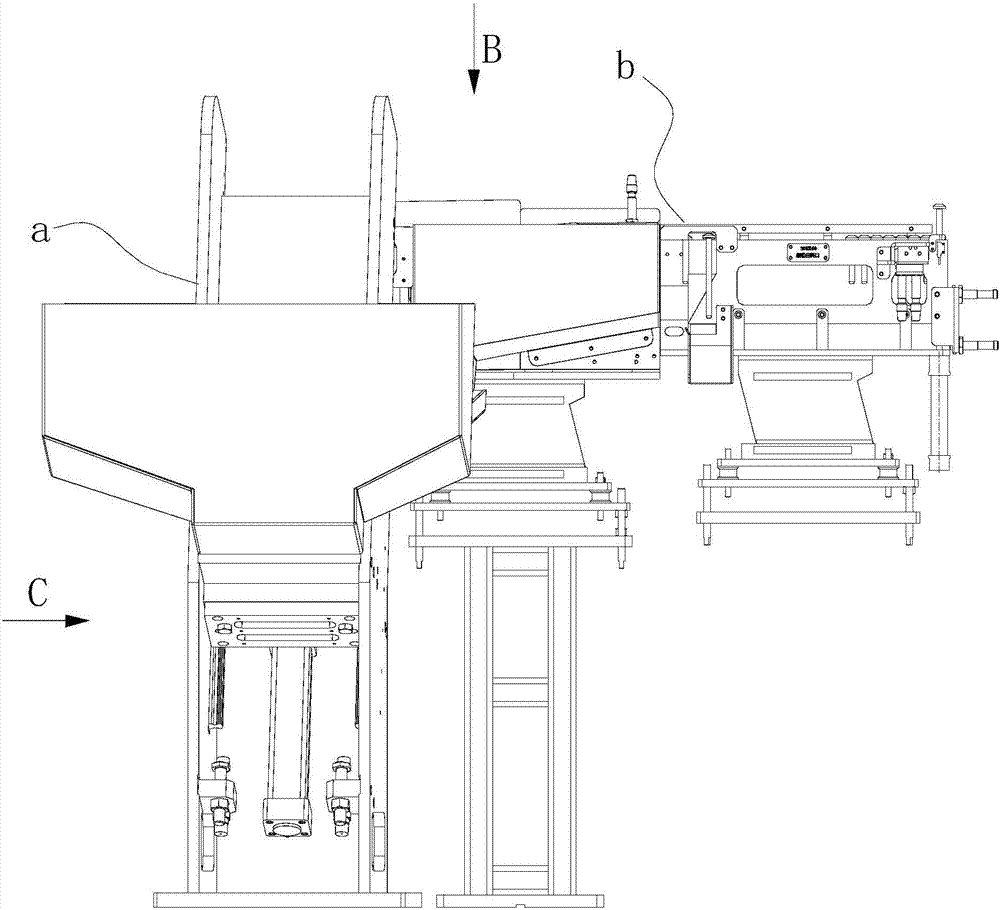

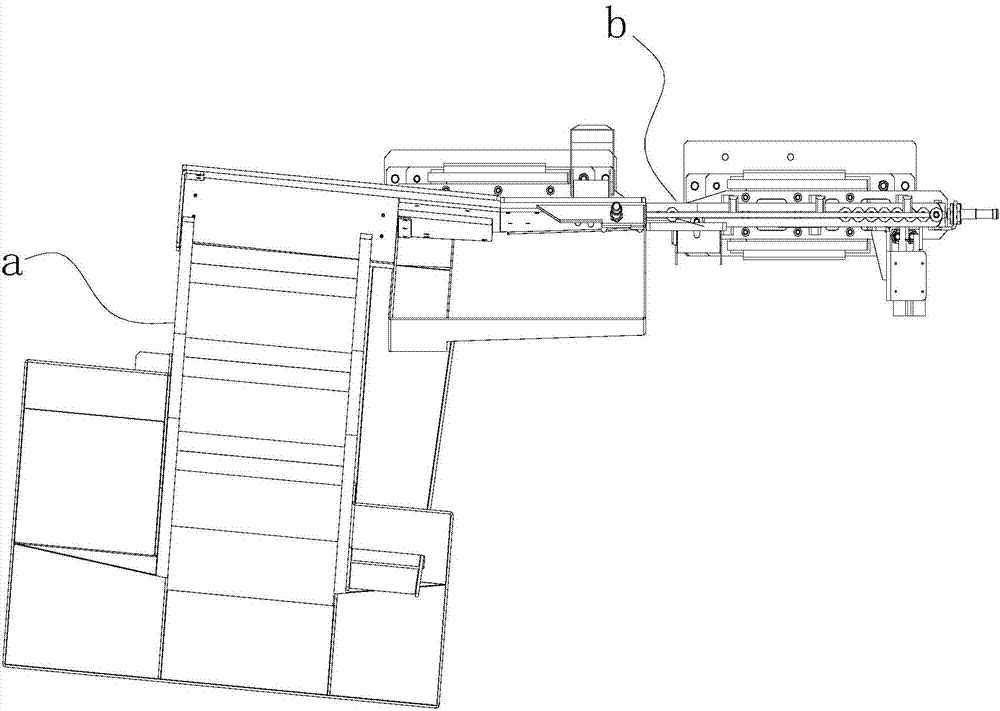

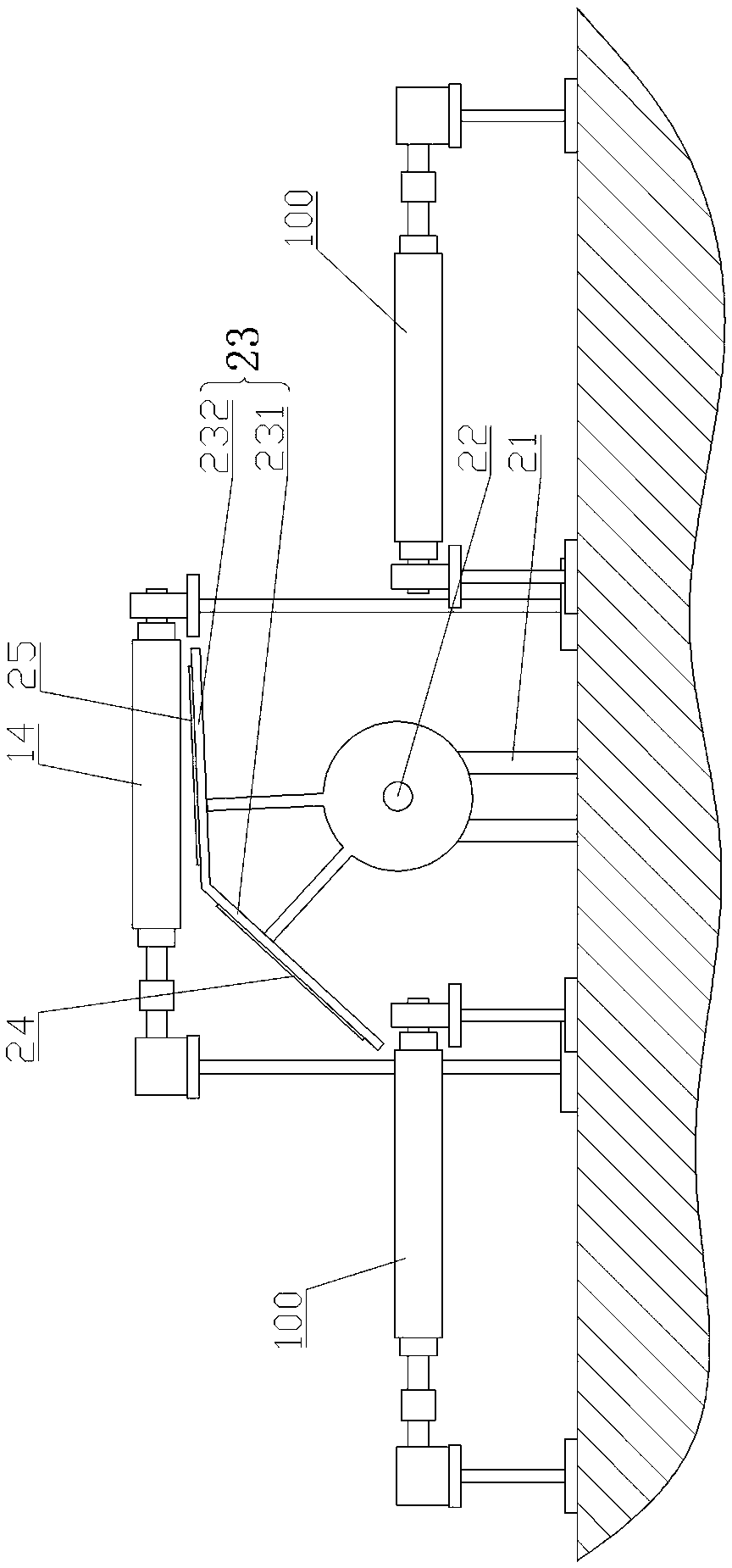

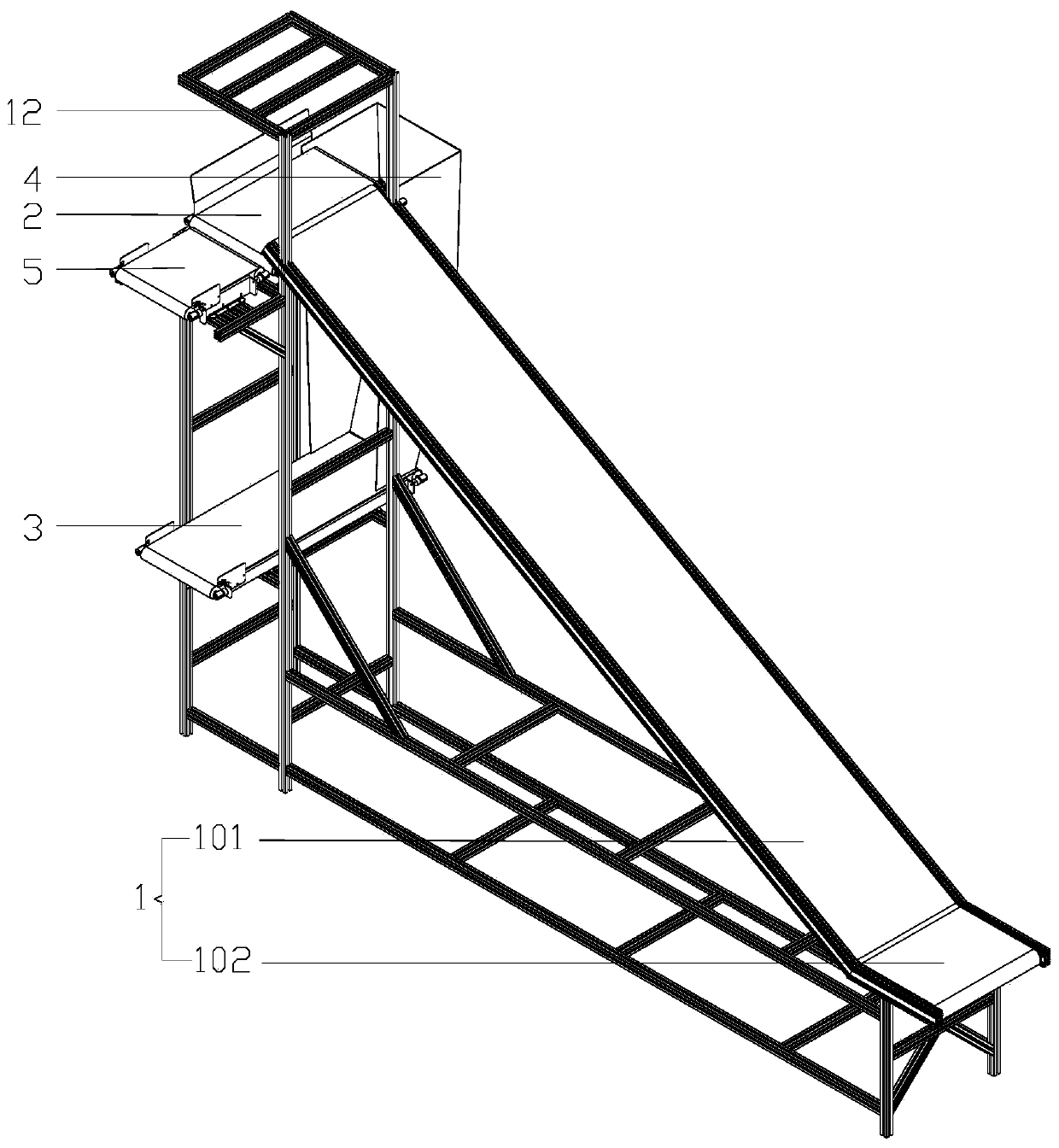

Automatic bolt feeding device

ActiveCN107032095AQuick exclusionRealize automatic feeding processMetal working apparatusConveyor partsLagMechanical engineering

The invention discloses an automatic bolt feeding device which comprises a stepped feeding mechanism and a vibratory screening mechanism which are connected, wherein the vibratory screening mechanism comprises a lag bolt screening component and a stay bolt screening component; the stepped feeding mechanism, the lag bolt screening component and the stay bolt screening component are connected in sequence in the conveying direction of bolts; the stepped feeding mechanism is used for automatically extracting bolts from a feed hopper and conveying the bolts to the follow-up vibratory screening mechanism; the lag bolt screening component is used for screening out and excluding too-short bolts from the bolts; the stay bolt screening component is used for screening out and excluding too-long bolts from the bolts, so as to obtain bolts with qualified specifications. The automatic bolt feeding device completely replaces manual operation, realizes automatic bolt feeding and screening, realizes quick feeding while quickly excluding bolts with unqualified specifications, effectively improves the working efficiency, reduces the production cost of the equipment, and meanwhile meets the requirements of the equipment on high speed assembly.

Owner:广州市嘉特斯机电制造有限公司

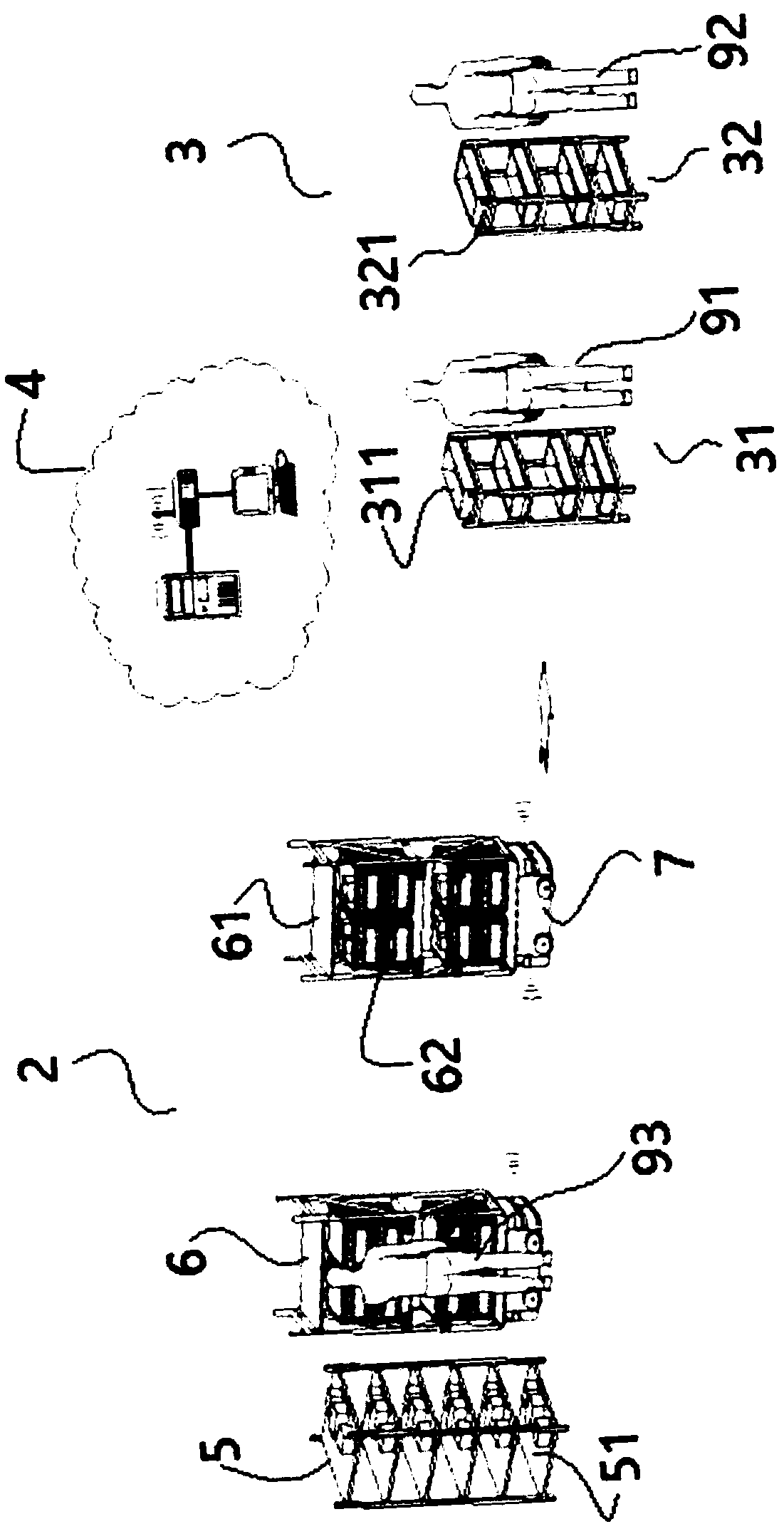

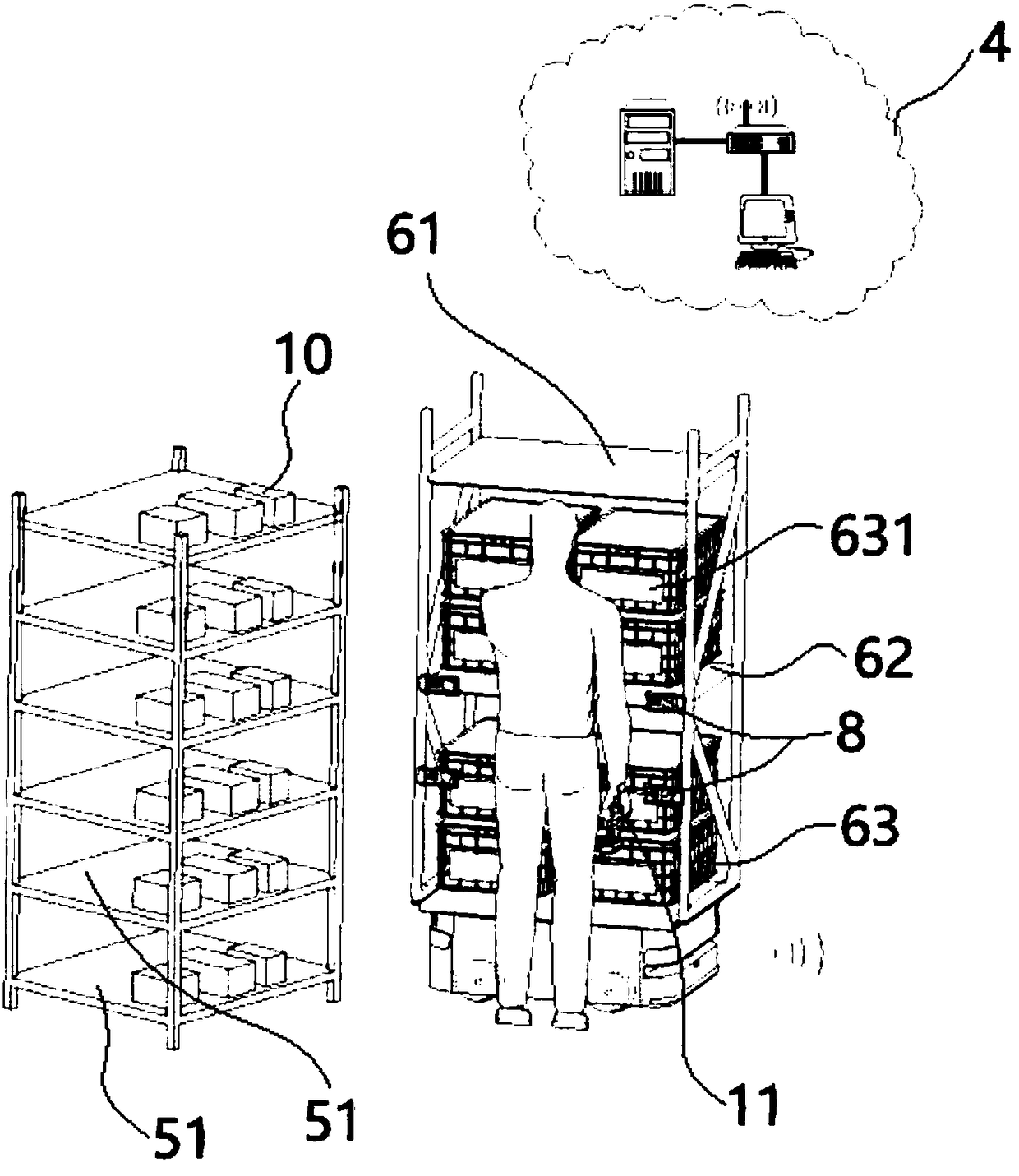

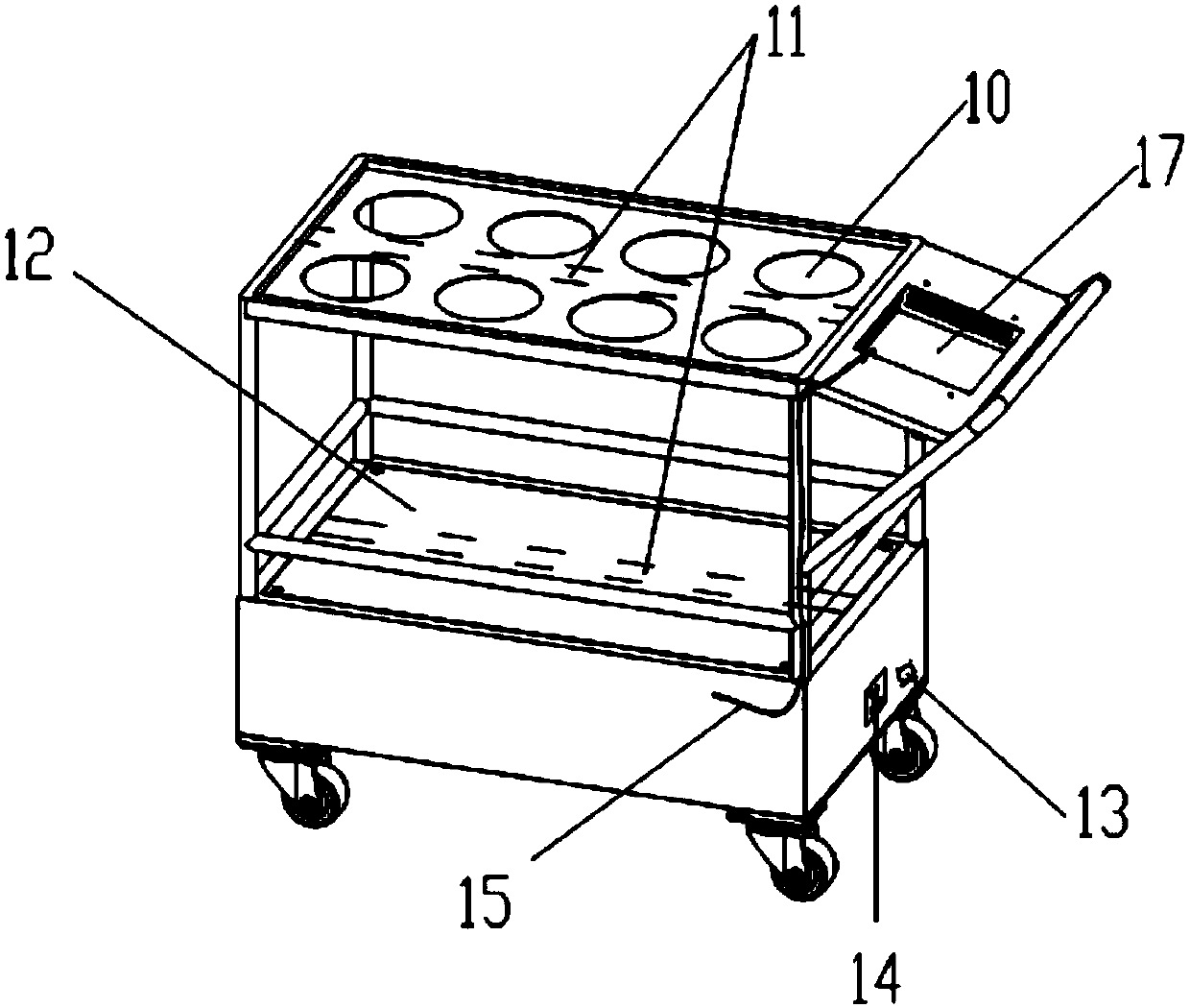

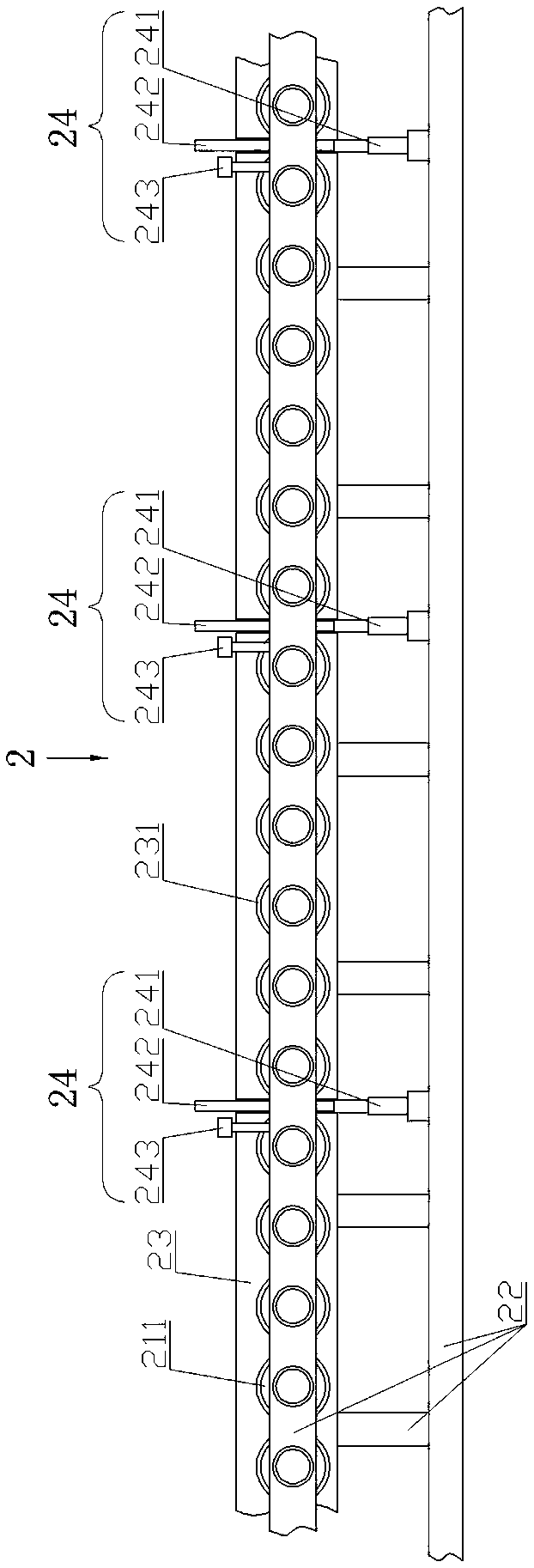

Intelligent warehousing sorting system, goods shelf and AGV

PendingCN108382779ASave labor costSave material costsStorage devicesHuman–machine interfaceMaterial resources

The invention discloses an intelligent warehousing sorting system, a goods shelf and an AGV. The intelligent warehousing sorting system comprises a storage goods shelf body, a carrying goods shelf body, the AGV, an upper computer and controller provided with a human-computer interface, wherein the upper computer is connected with the AGV and the controller in a communication mode; and the carryinggoods shelf body comprises a main goods shelf body which is provided with a plurality of first goods stations used for storing goods. The upper computer is in communication connection with the controller and the AGV to monitor the product information (position, quantity and the like) in the whole course, then the resources (the goods shelf and the AGV) can be reasonably distributed, and the warehousing conveying and sorting efficiency is improved. Product partitioning, centralized goods loading and partitioning unloading are formed, modular and regional management and monitoring of the wholewarehousing are achieved, enterprises can conveniently and comprehensively monitor the process from order making to order finishing, data are obtained fast, the manpower, material resource and time cost of the enterprises are reduced, and intelligent and automatic management and monitoring of the warehousing process are facilitated.

Owner:SHANGHAI ATOVO ROBOTICS CO LTD

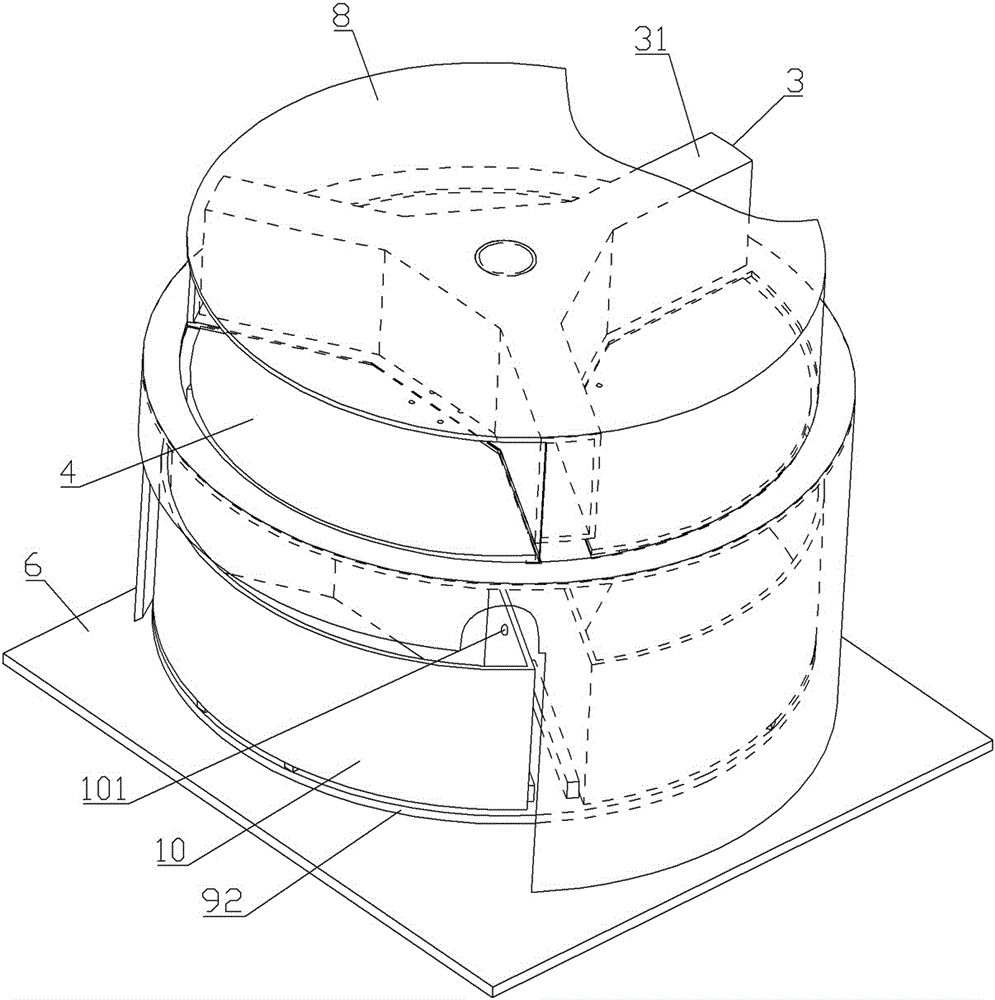

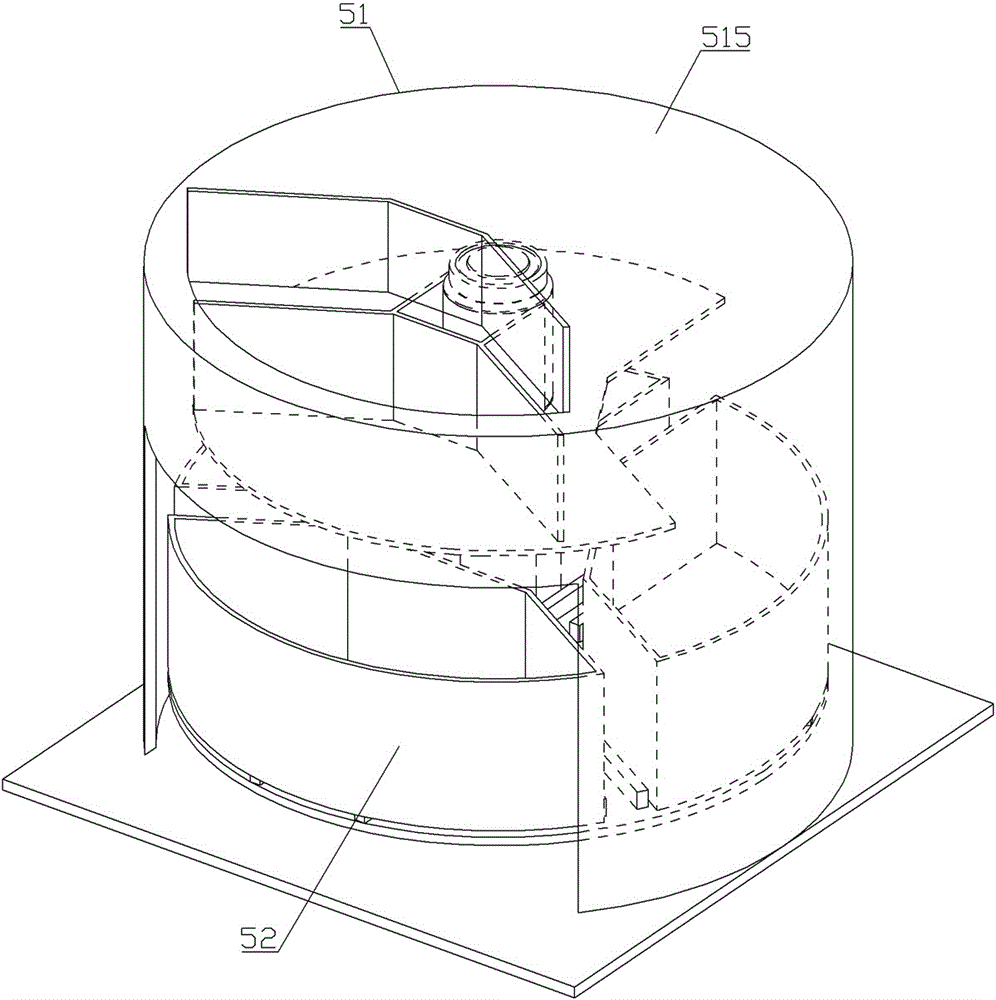

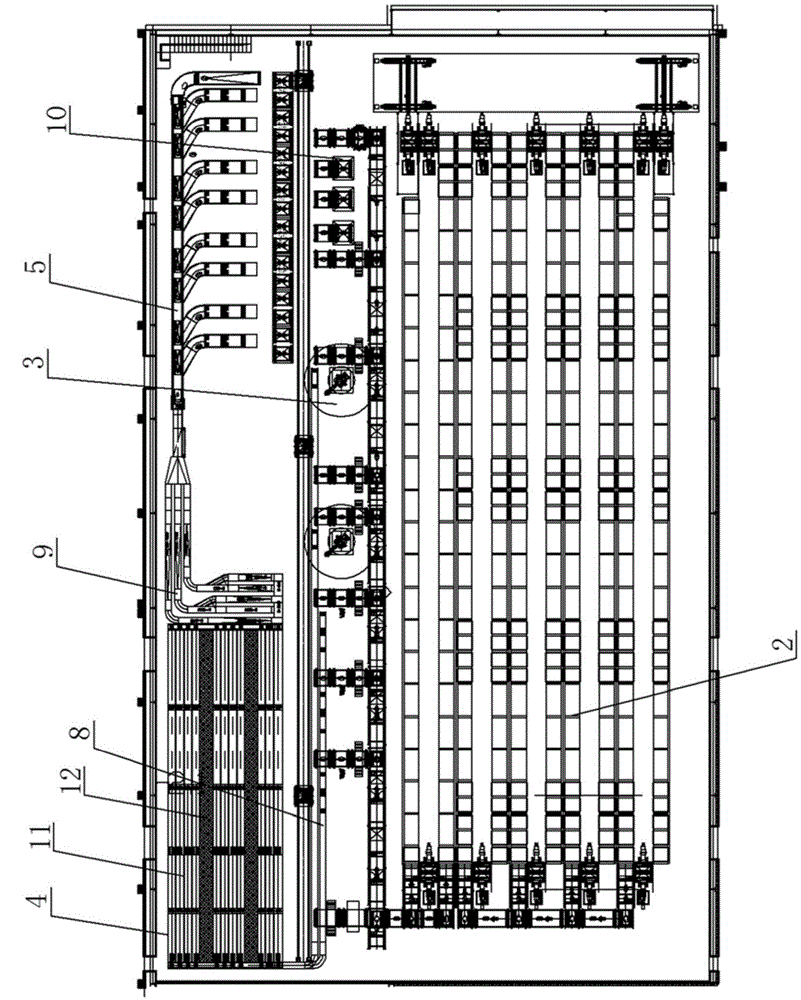

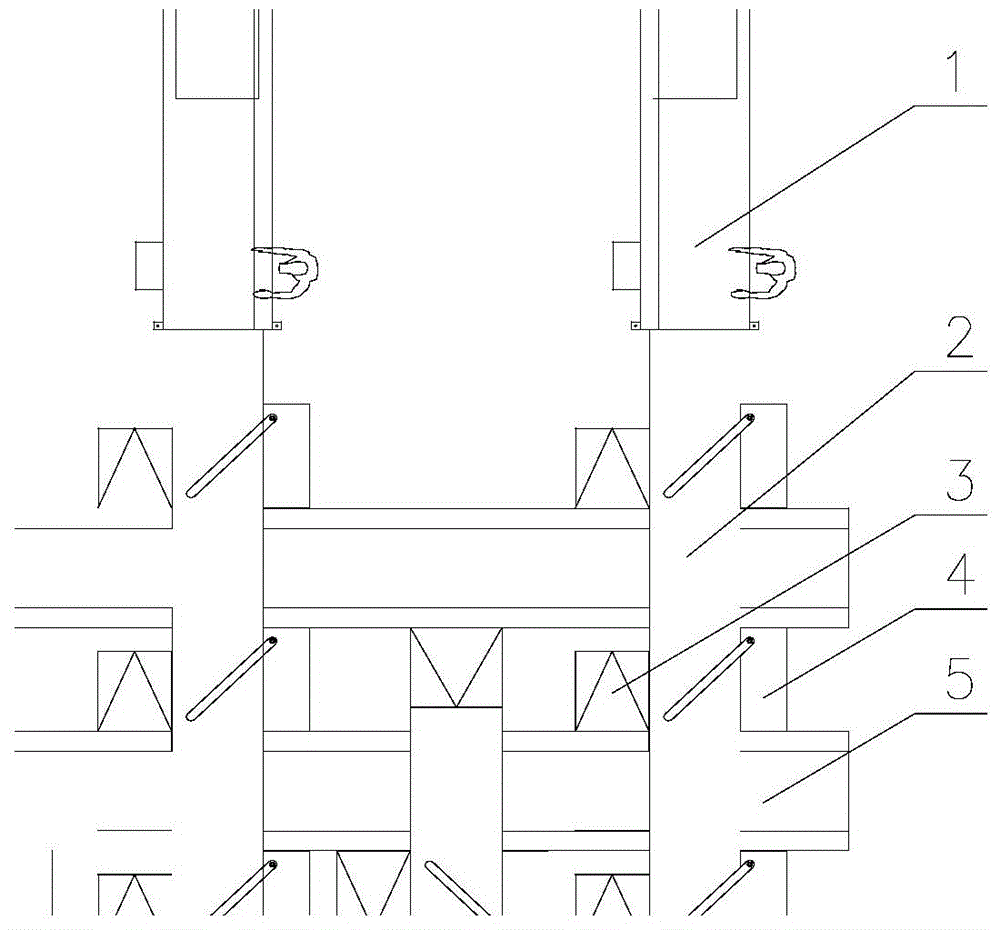

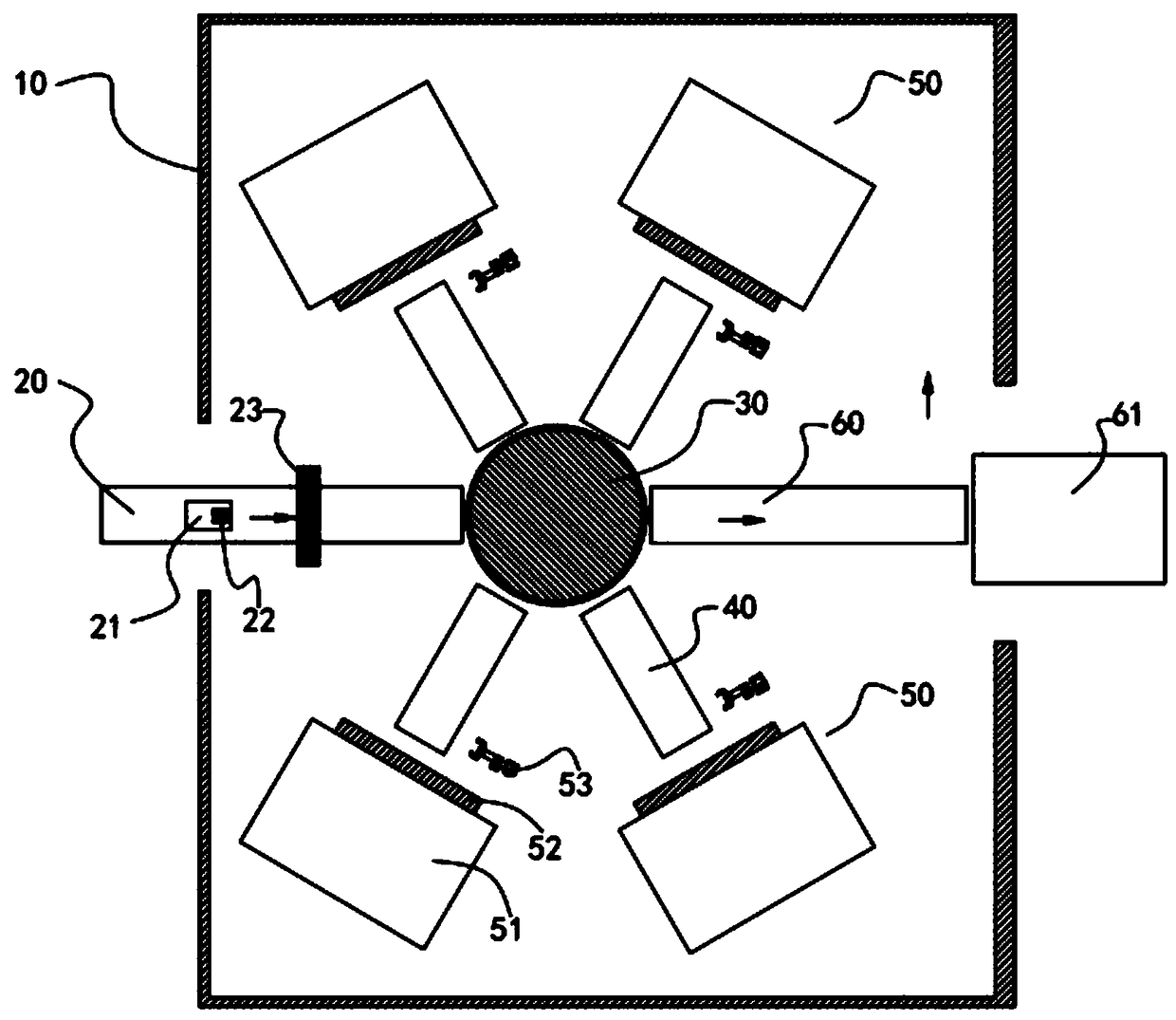

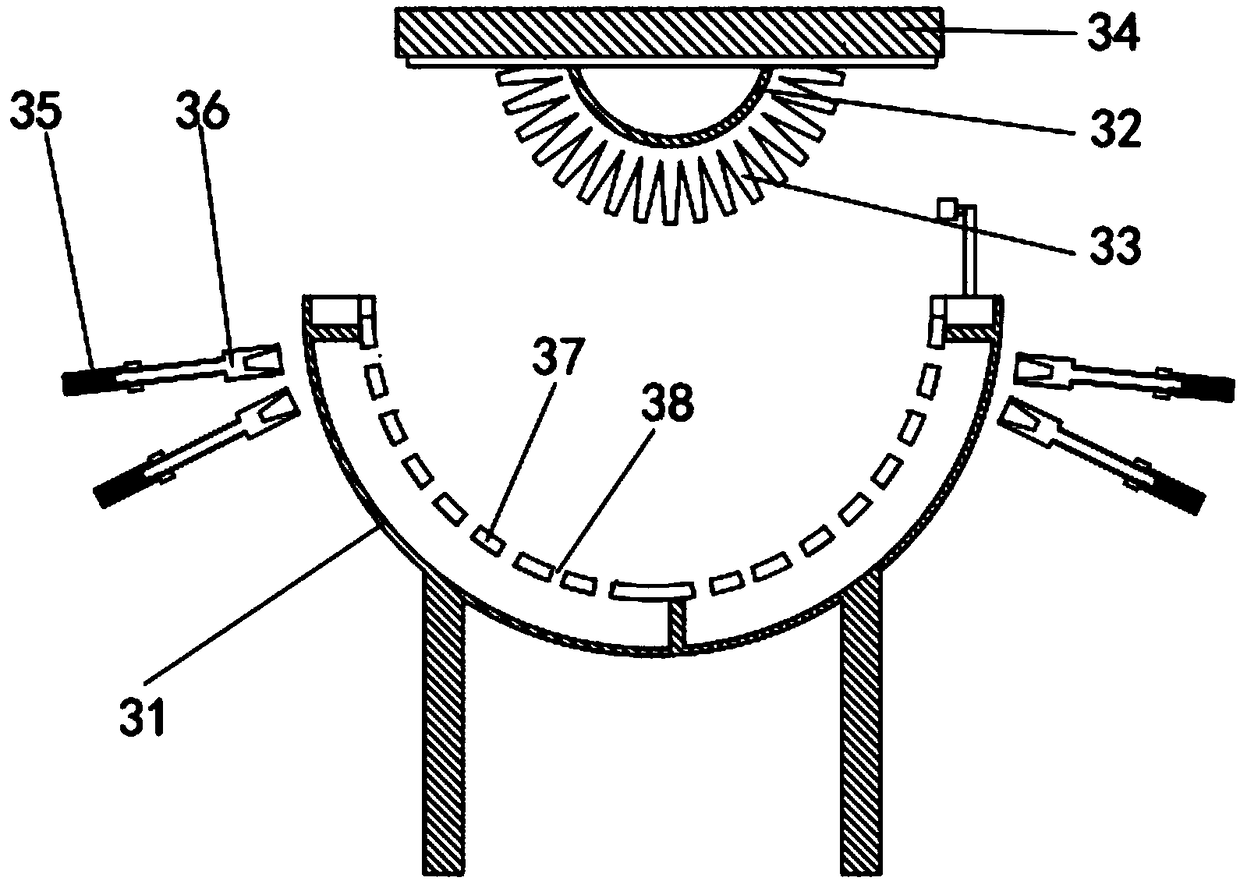

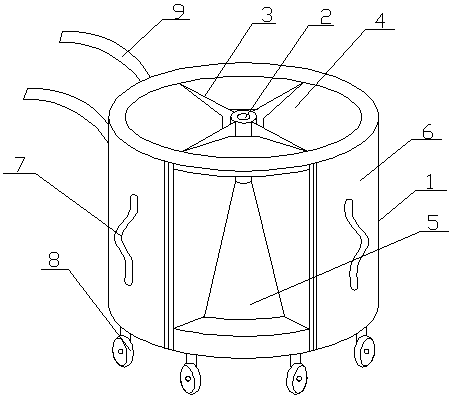

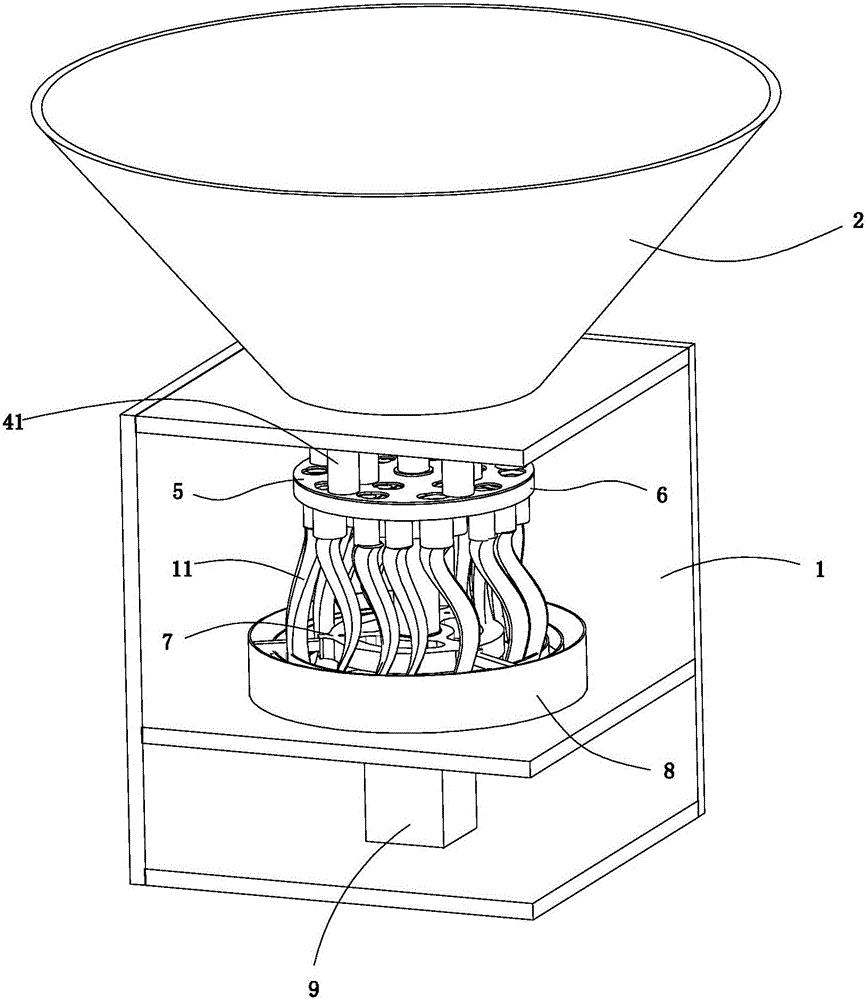

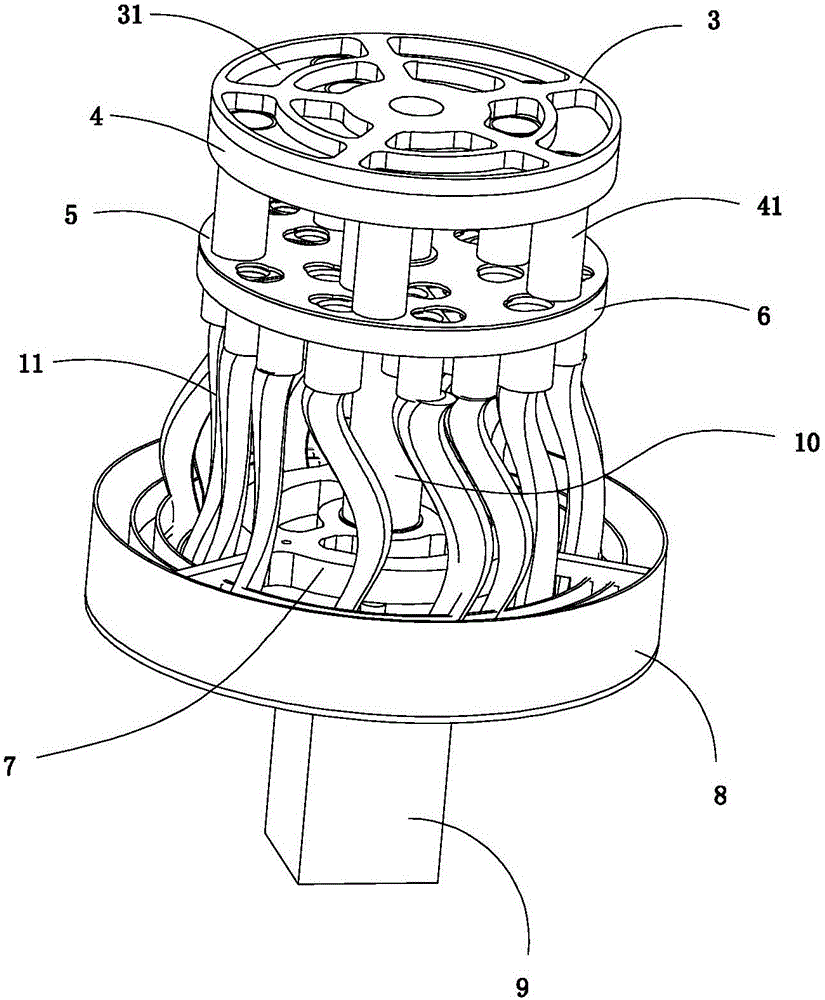

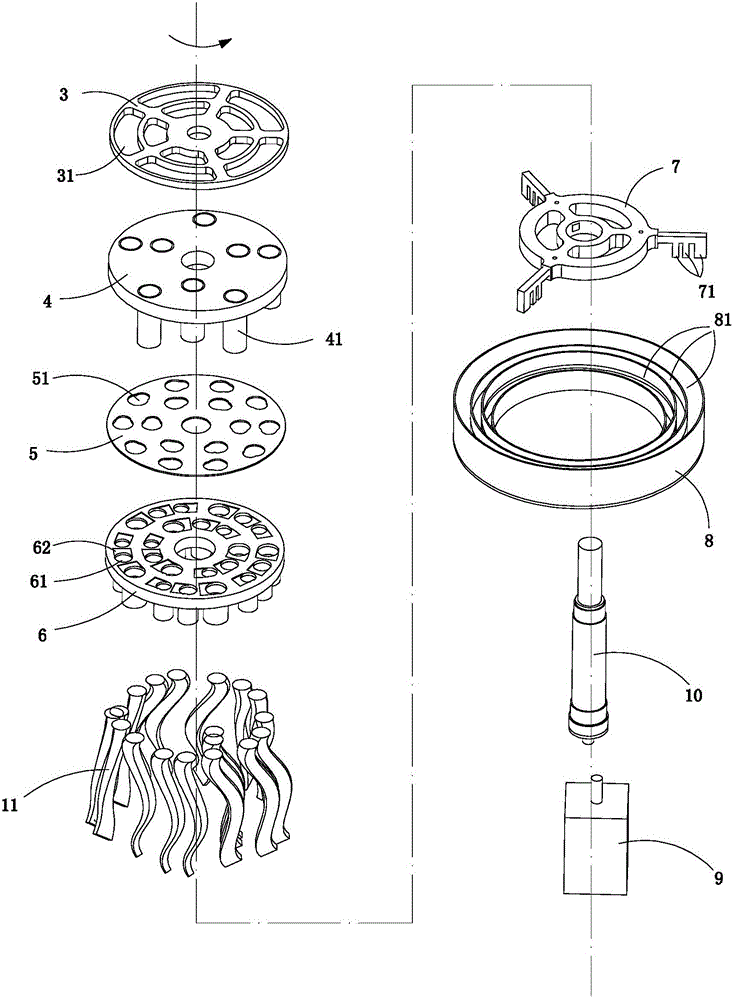

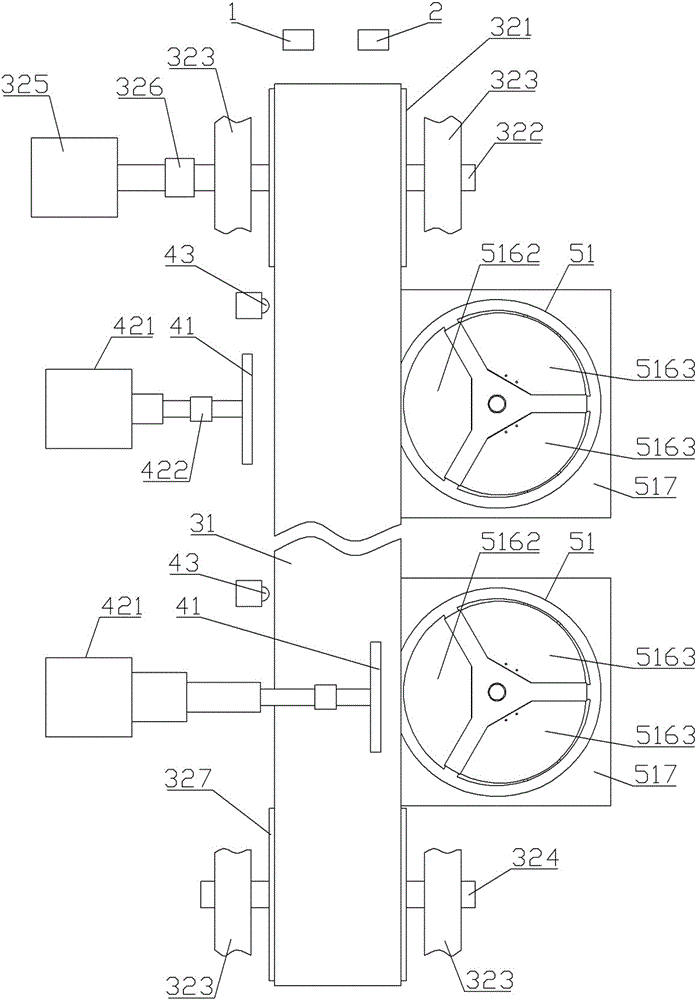

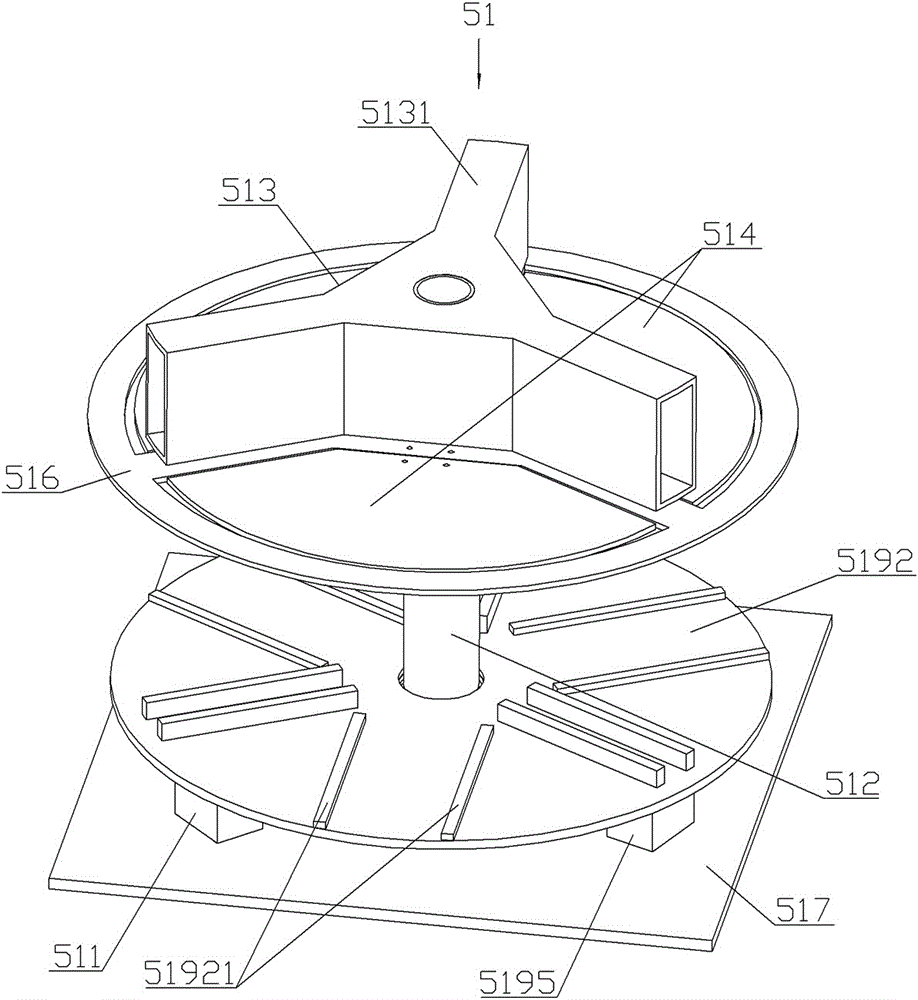

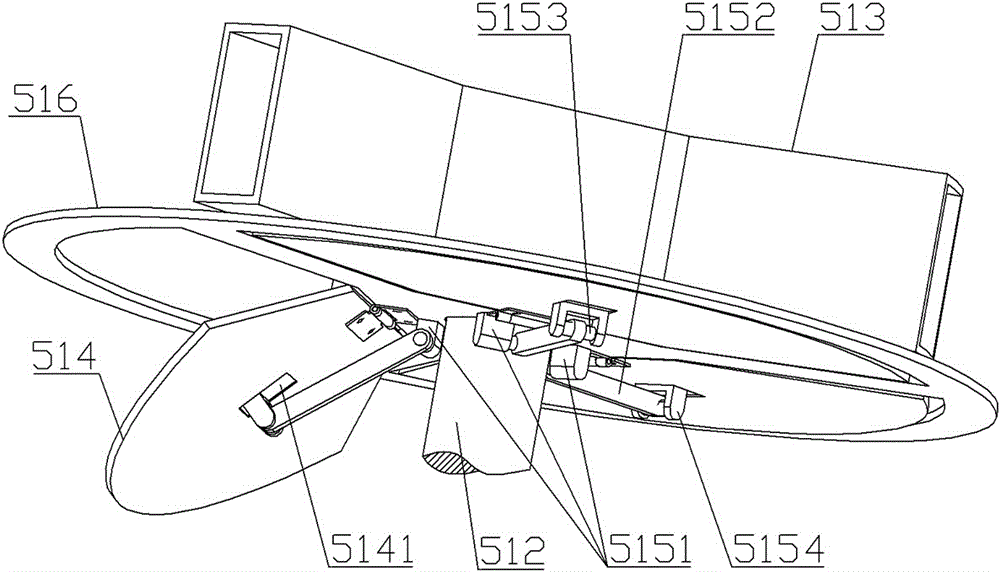

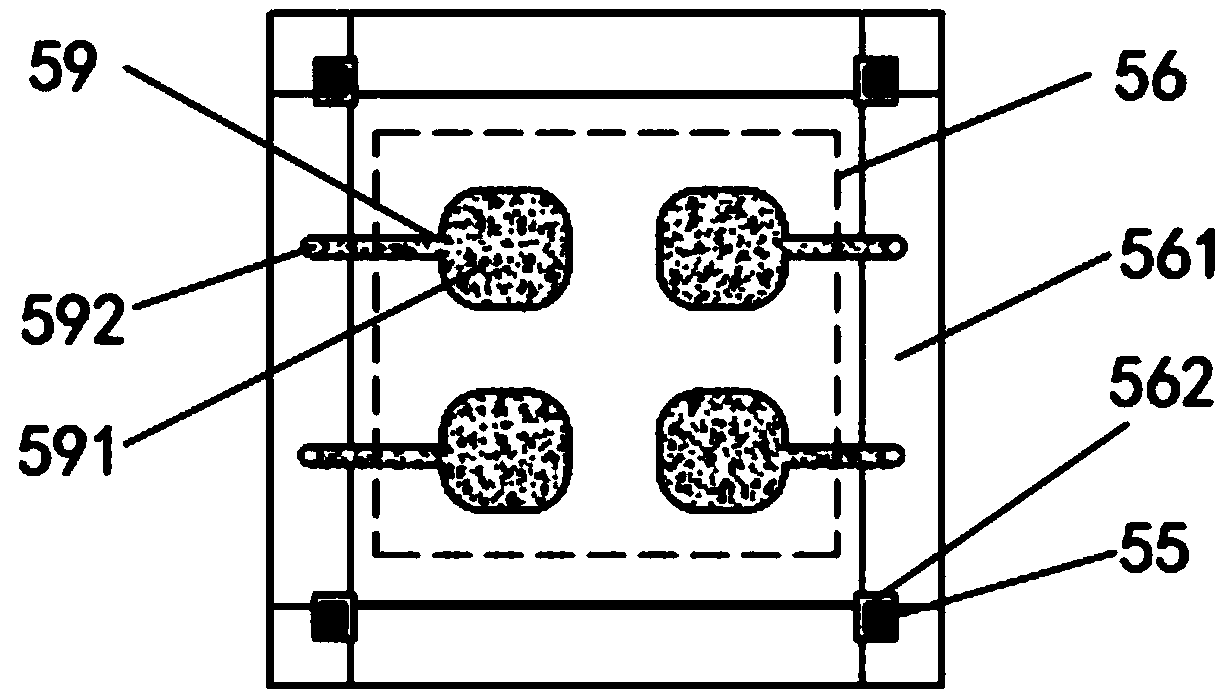

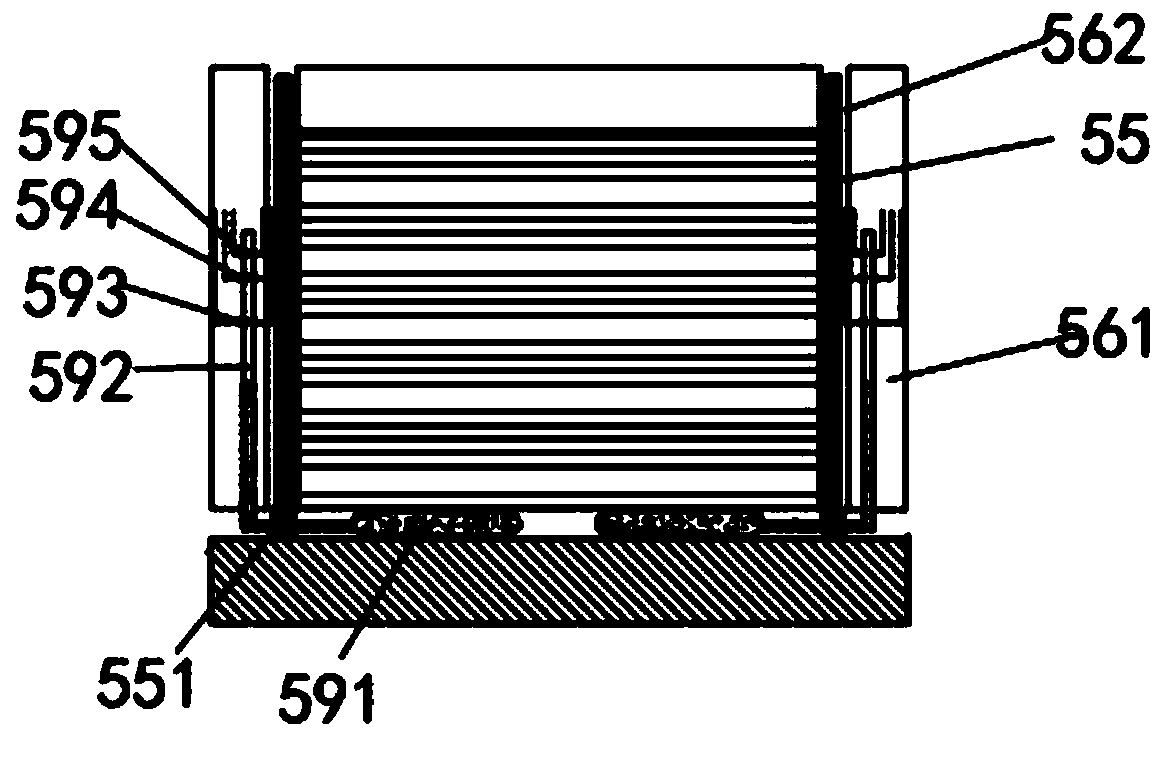

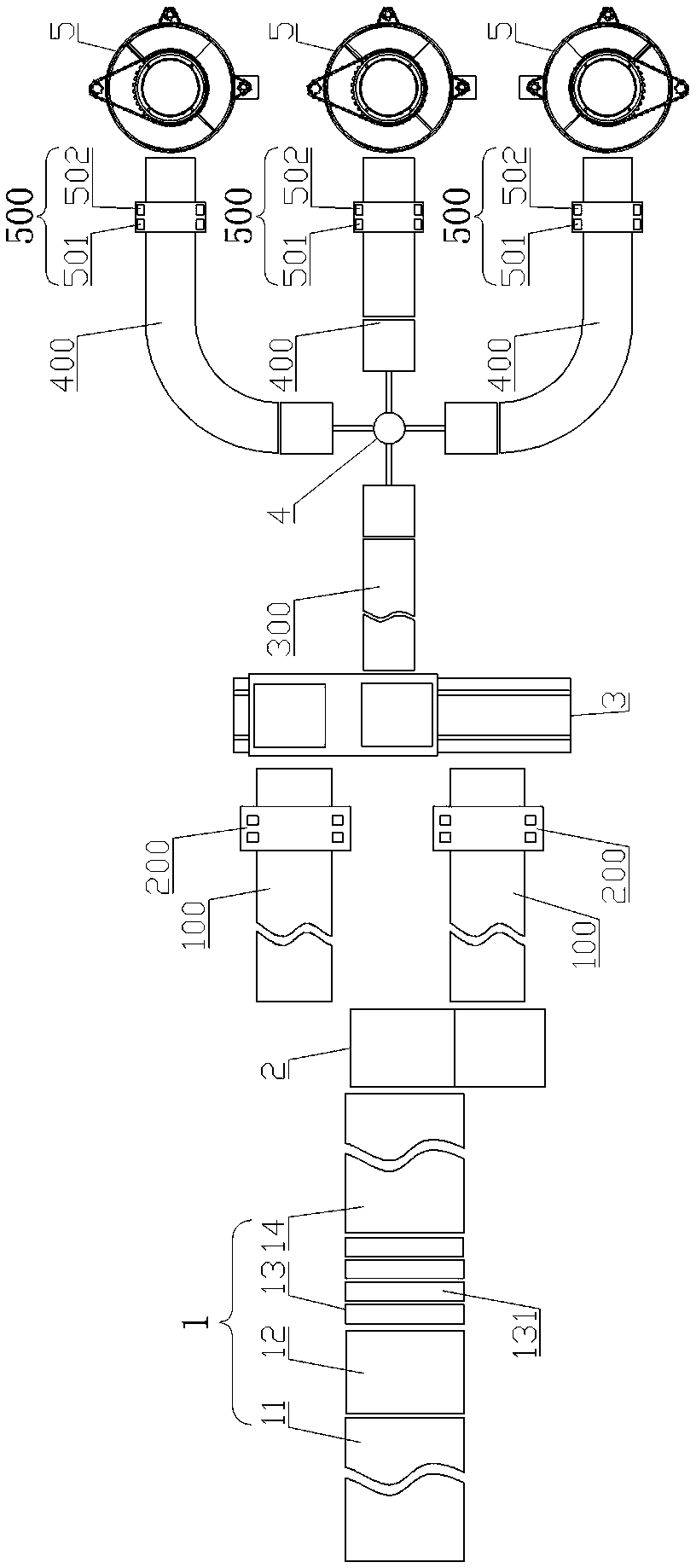

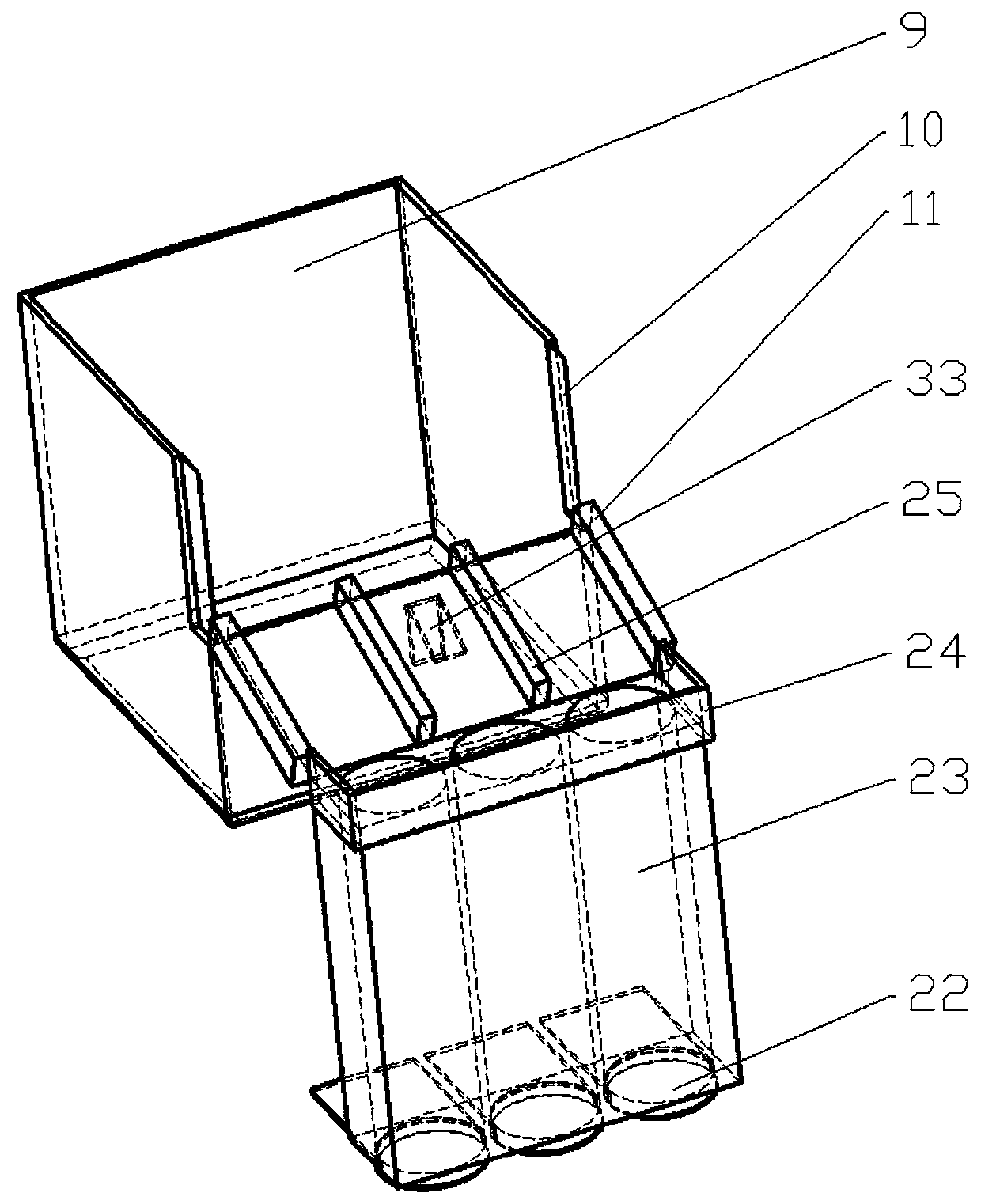

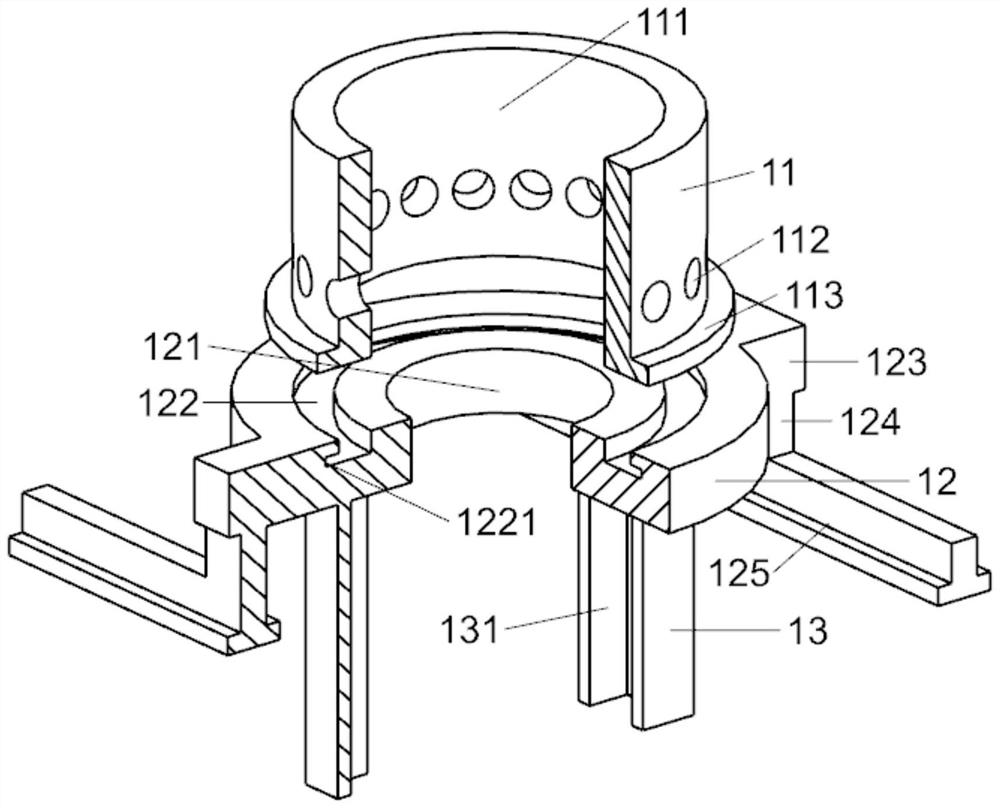

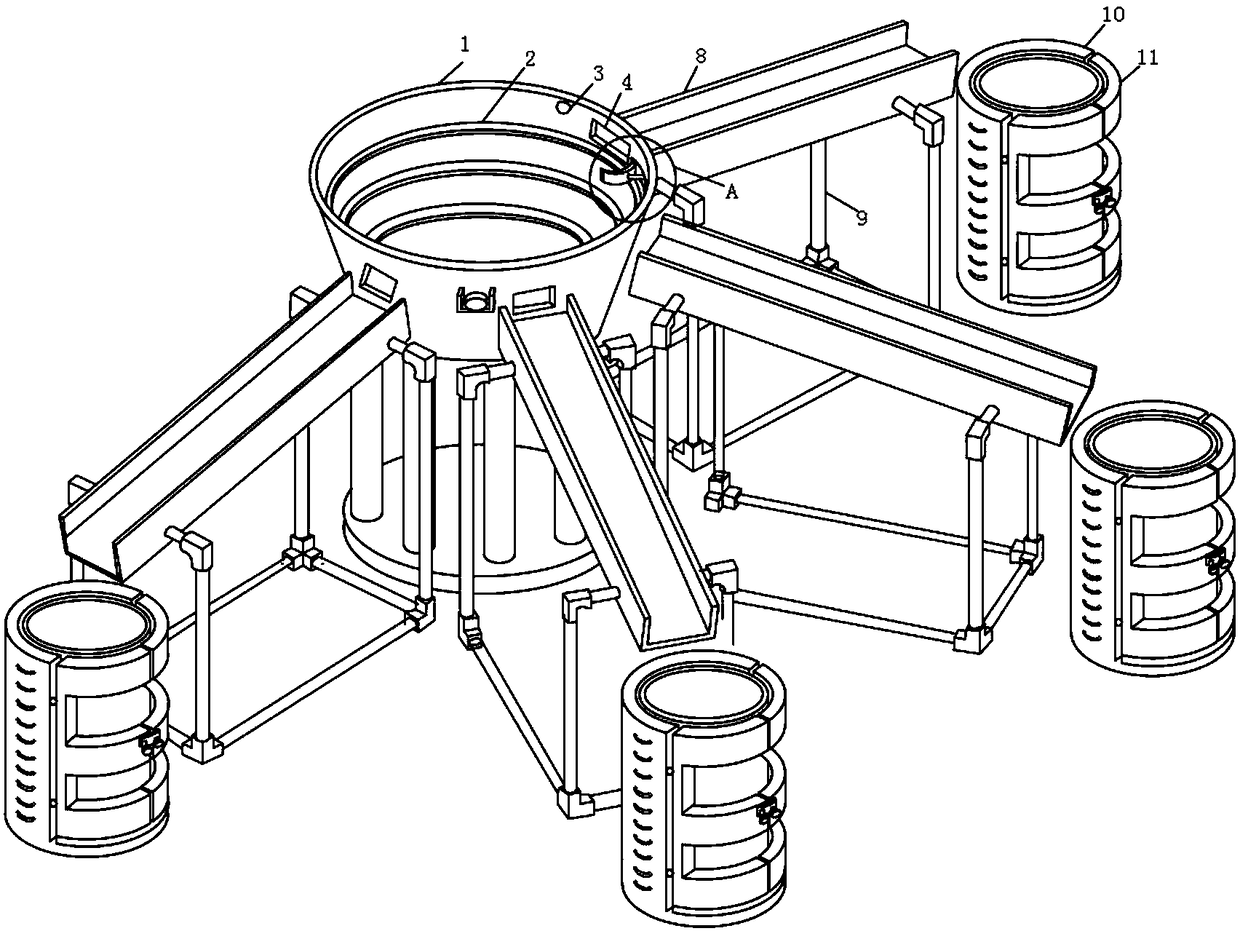

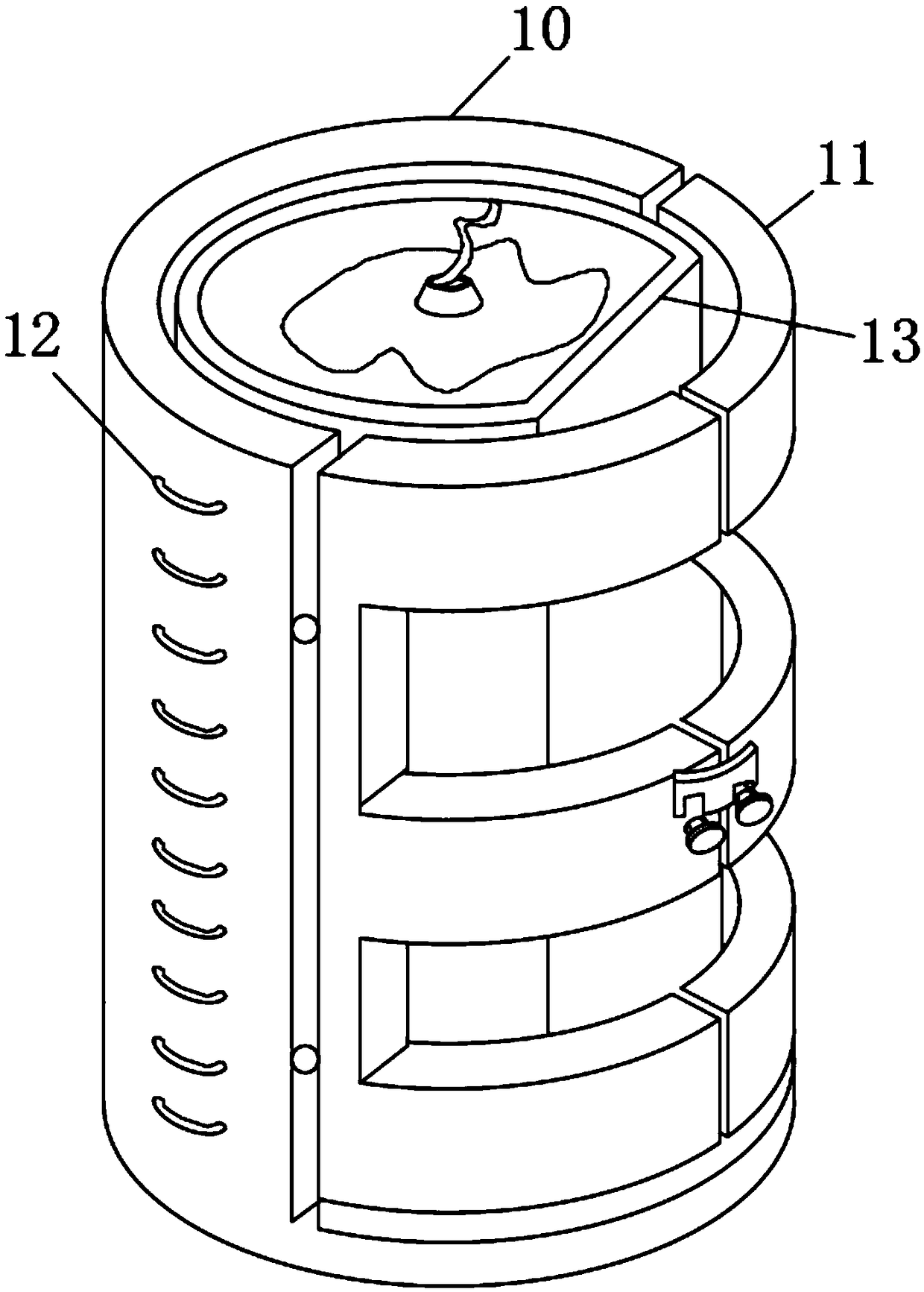

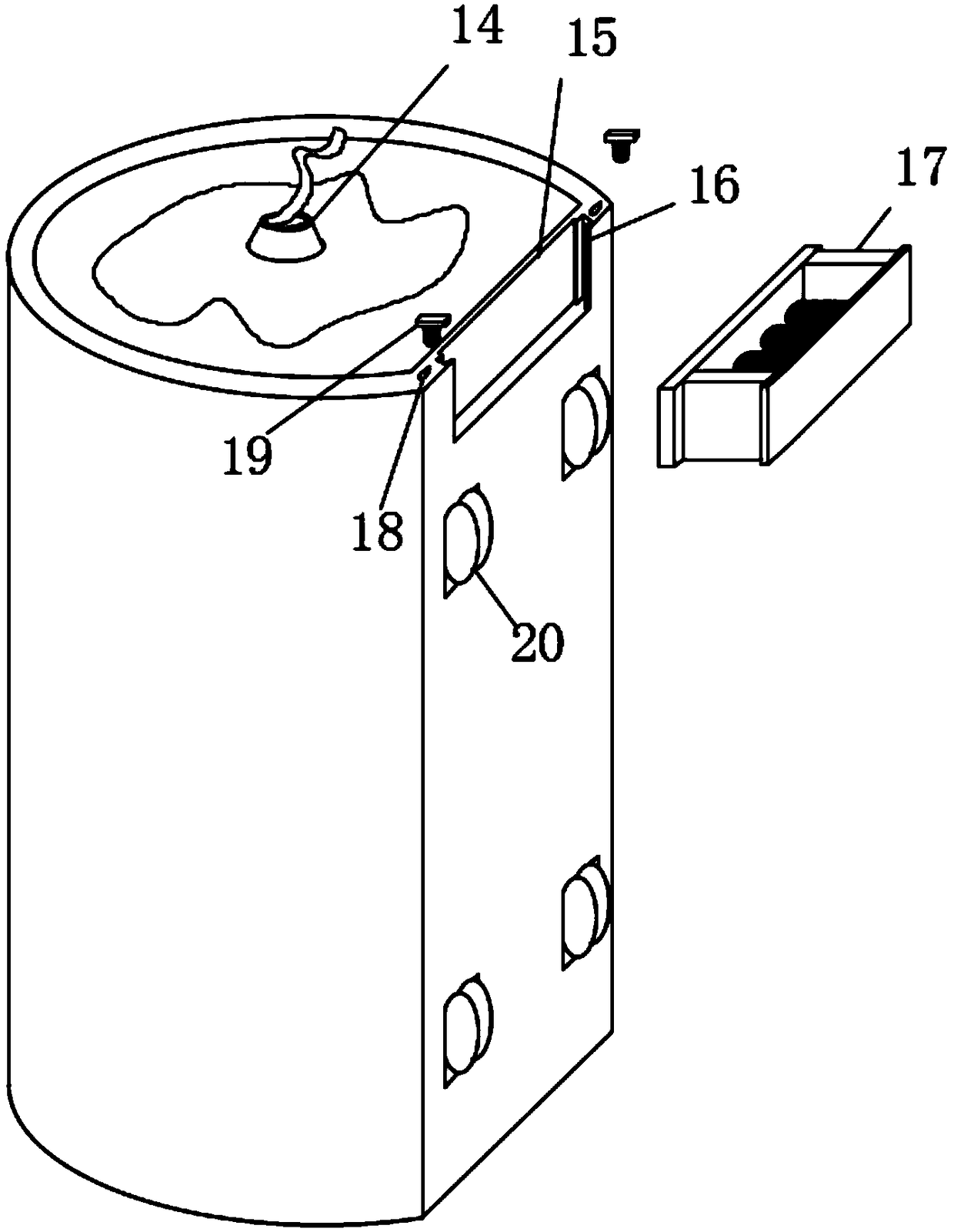

Three-dimensional turret express sorting system

InactiveCN106076856AReduce workloadReduce sorting error rateConveyorsSortingSmall footprintEngineering

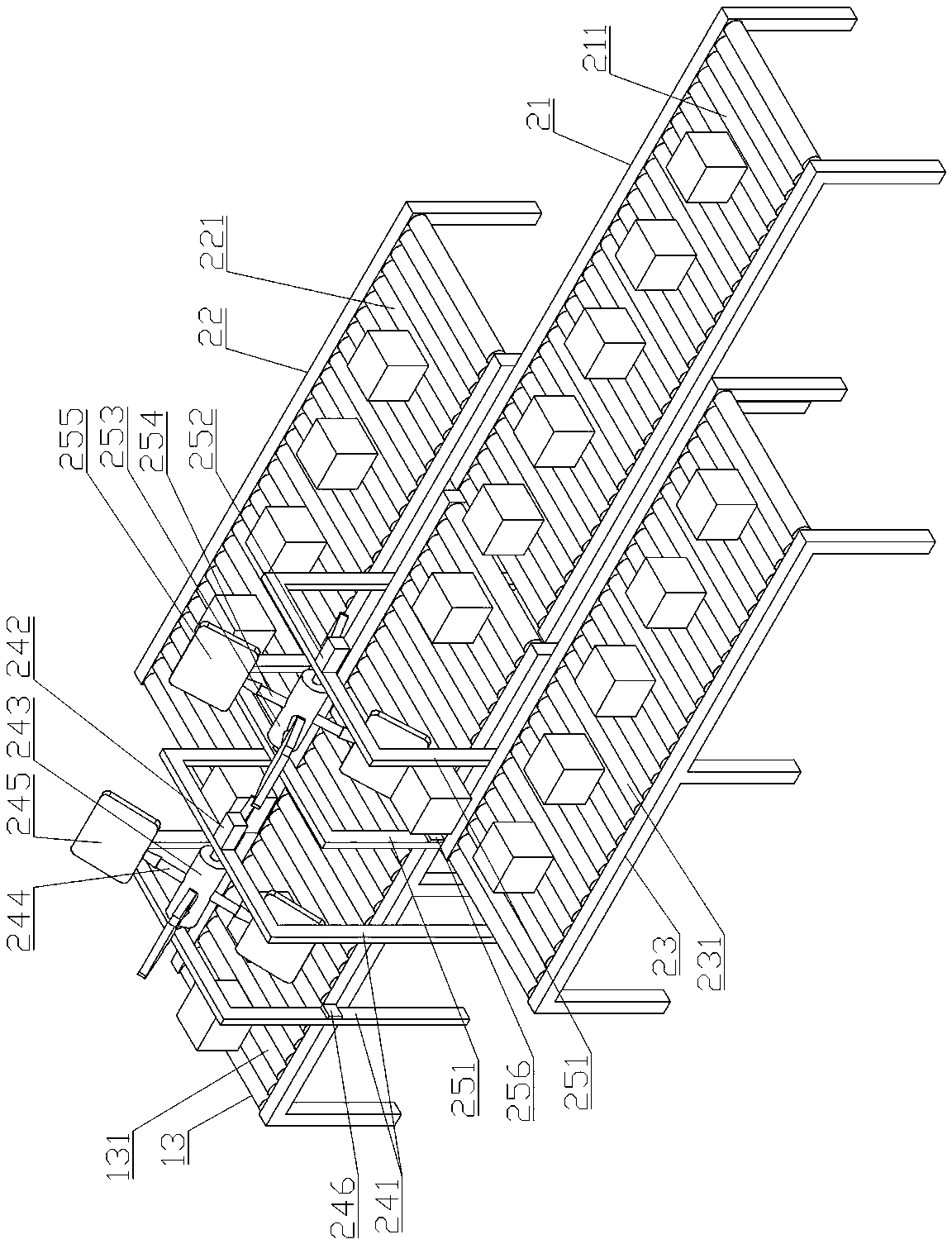

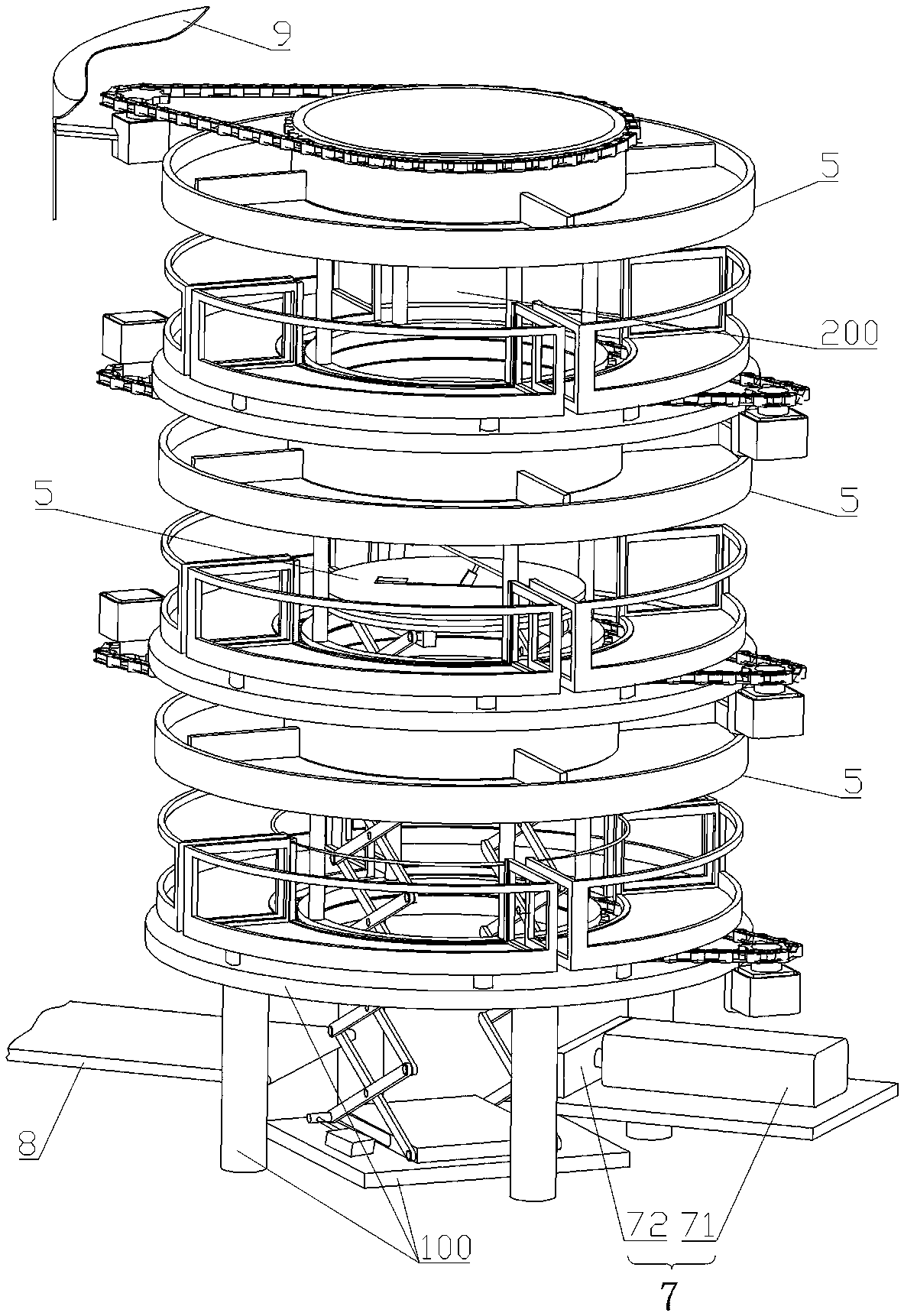

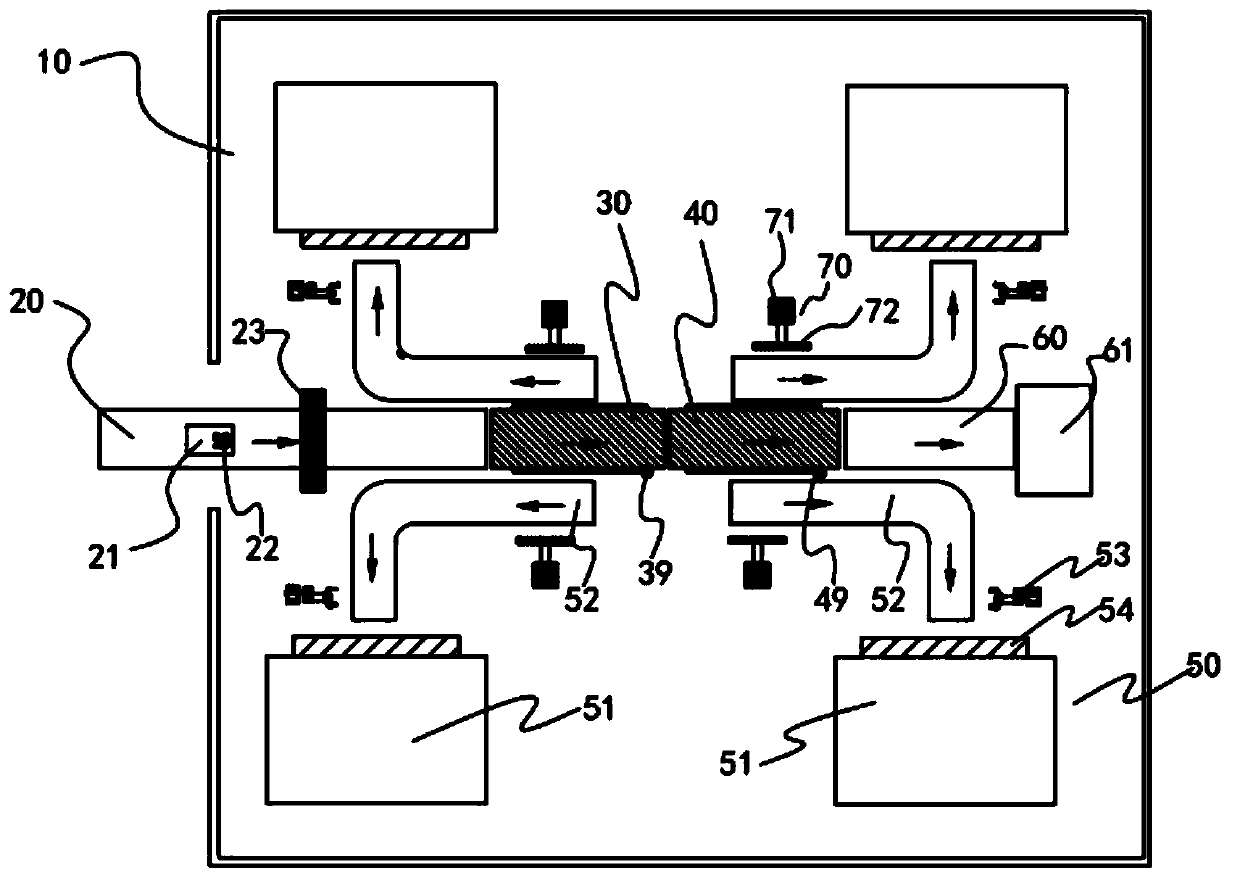

The invention discloses a three-dimensional turret express sorting system. The three-dimensional turret express sorting system comprises a main control computer, a package information recording device, a conveying belt device, a package pushing device and a turret sorting device; the turret sorting device includes a sorter and multiple package receivers; and the sorter includes a vertical inner rotating shaft, a vertical outer rotating shaft, a horizontal sweeping disc, a horizontal upper turntable, a lower base, an outer cover, a stepper motor A and a stepper motor B. The vertical outer rotating shaft movably coats the vertical inner rotating shaft; a package falling port is formed in the horizontal upper turntable; two adjacent sweeping arms of the horizontal sweeping disc form a package wrapping station; the stepper motor A drives the vertical inner rotating shaft to rotate; the stepper motor B drives the vertical outer rotating shaft to rotate; and the multiple package receivers surround the vertical outer rotating shaft by one lap. Compared with a traditional automatic sorting system, the three-dimensional turret express sorting system has the advantages of small floor area, high intelligent degree and high sorting efficiency.

Owner:NANHUA UNIV

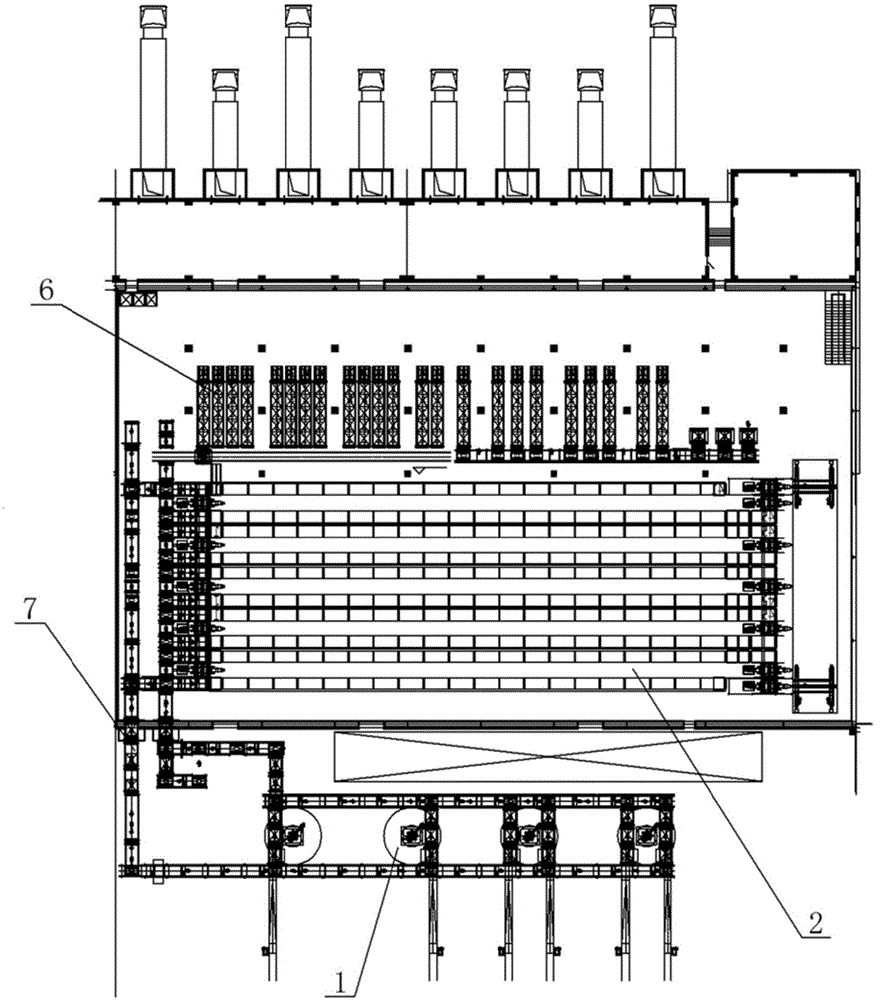

Yoghourt refrigerating automatic storage and transport sorting system based on sliding stocking up channel

InactiveCN104960830AReduce sorting error rateAchieve traceabilityStacking articlesDe-stacking articlesTransport systemAutomatic control

The invention discloses a yoghourt refrigerating automatic storage and transport sorting system based on a sliding stocking up channel. The system comprises a robot stacking system, an automatic three-dimensional warehouse, a robot destacking system, a sliding stacking up channel, a sorting system, a gravity type shelf, an automatic control system and a bar code information management system. The robot stacking system is connected with the automatic three-dimensional warehouse through a pallet conveyer line, the robot destacking system is connected with the automatic three-dimensional warehouse and connected with the sliding stacking up channel through a box-type conveyer line, the sliding stacking up channel is connected with the sorting system through an warehouse in-out transport system, and a transportation device can automatically transport temporarily stored warehouse-out yoghourt in to the gravity type shelf. The yoghourt refrigerating automatic storage and transport sorting system based on the sliding stocking up channel employs a densely-stored sliding stocking up channel, automatic unmanned operation is adopted, the error rate of bar code sorting is lower than 0.03%, and the traceability of food can be provided.

Owner:WUXI ZHONGDING INTEGRATION TECH CO LTD

Full-automatic total-package sorting system and method

The invention discloses a full-automatic total-package sorting system. The system comprises importing rubber belt conveyors, sorting rubber belt conveyors, chutes, micro-resistance switches and branch convergence rubber belt conveyors, wherein the importing rubber belt conveyors are connected with the sorting rubber belt conveyors connected with the branch convergence rubber belt conveyors through the chutes, each sorting rubber belt conveyor is equipped with multiple micro-resistance switches, and the micro-resistance switches transfer total packages sent from the importing rubber belt conveyors to the sorting rubber belt conveyors to the branch convergence rubber belt conveyors through the chutes. The full-automatic total-package sorting system is mainly used for increasing the automation degree of a handling center of the logistics industry, decreasing the manpower usage cost and the sorting error rate in a sorting link in the logistics industry and reducing the labor intensity of workers.

Owner:SHANGHAI RES INST OF CHINA POST GROUP

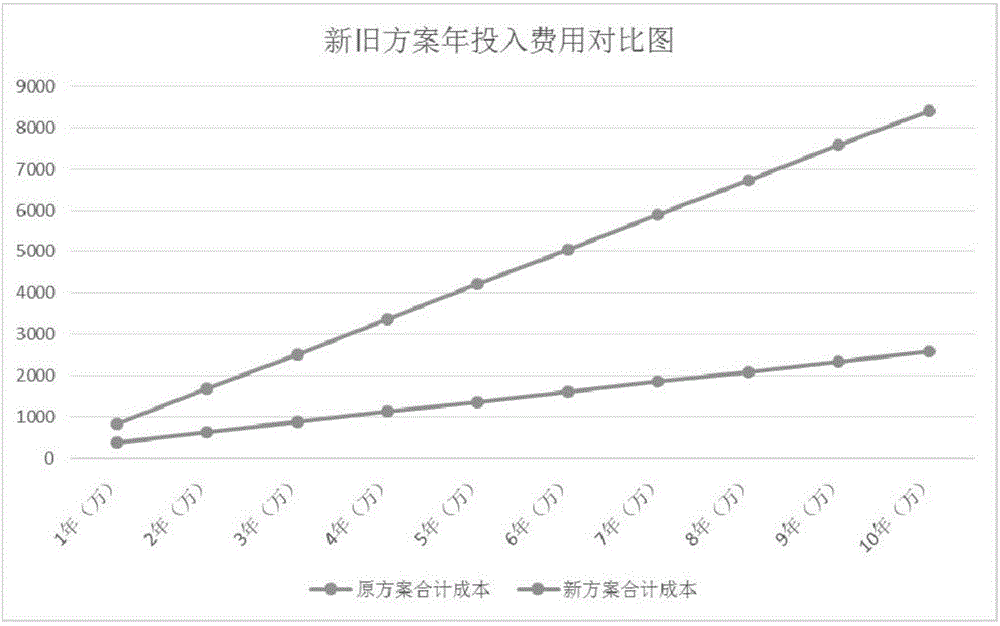

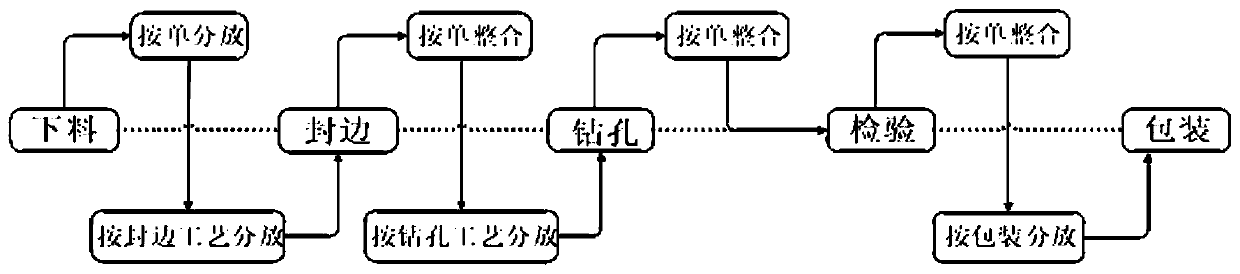

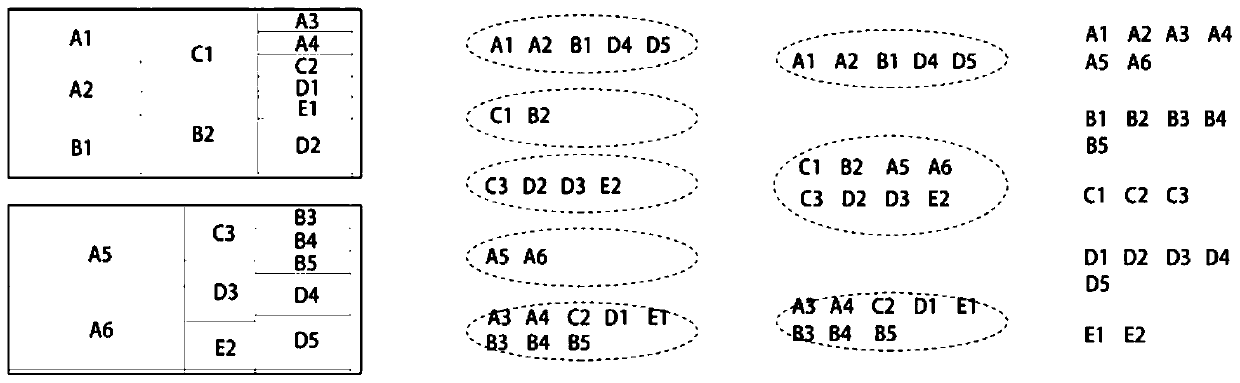

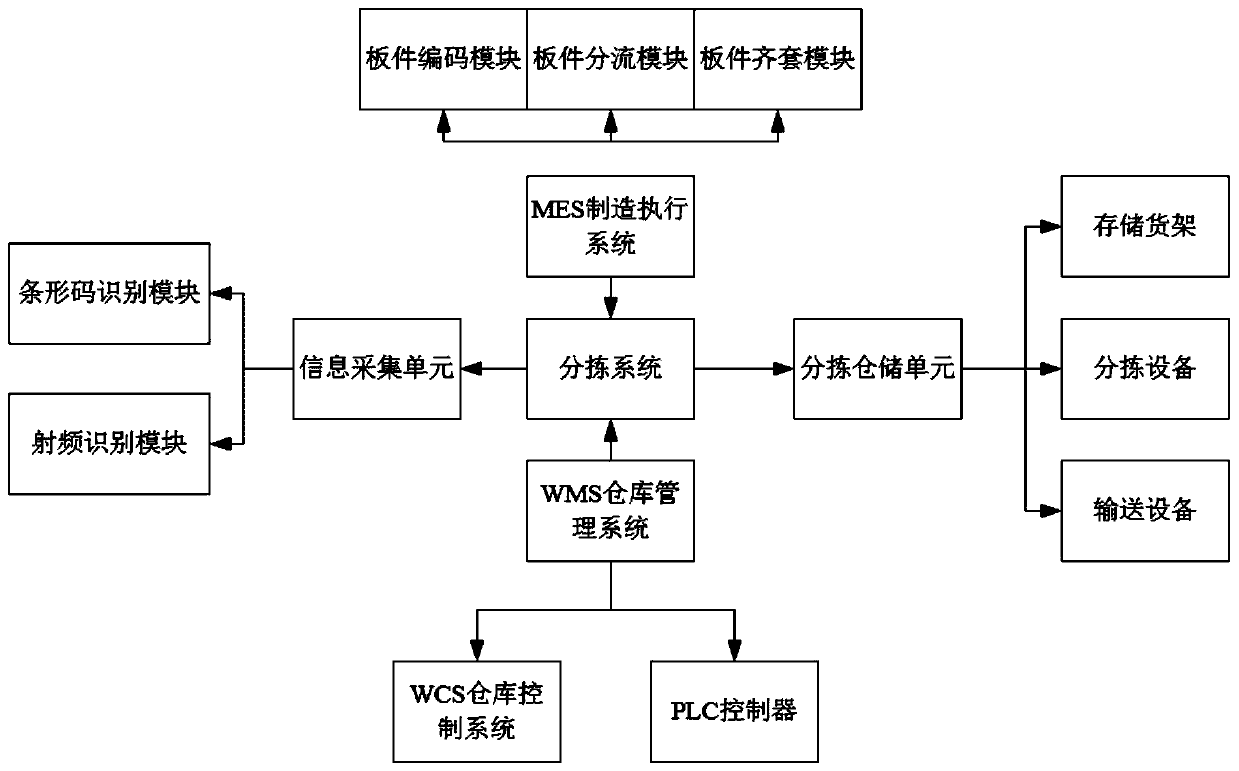

Sorting system and process for plate-type custom-made furniture

The present invention discloses a sorting system and process for plate-type custom-made furniture, and the sorting system includes a control unit, an information acquisition unit and a sorting and storage unit that communicate with the control unit; the control unit includes an MES manufacturing execution system and a WMS warehouse management system that communicate with each other, the MES manufacturing execution system includes a plate encoding module, a plate shunting module and a plate assembly module; the WMS warehouse management system includes a WCS warehouse control system and a PLC controller that communicate with each other, and the sorting and storage unit includes a sorting robot, a stacking machine, annular warehouse inbound lines, vertical warehouse inbound and outbound lines, annular storage racks and vertical storage racks. By using the system and the process, sorting operation and information feedback are intelligently and orderly -executed, thereby contributing toprevent the storage racks from warehouse blasting and significantly improving the sorting efficiency; in the whole process, information is in real time scanned and collected by a plate QR code, a plate batch code and a complete plate sorting code, and shunting and sorting are orderly performed so that the sorting error rate is significantly reduced.

Owner:南京多兰德家具有限公司

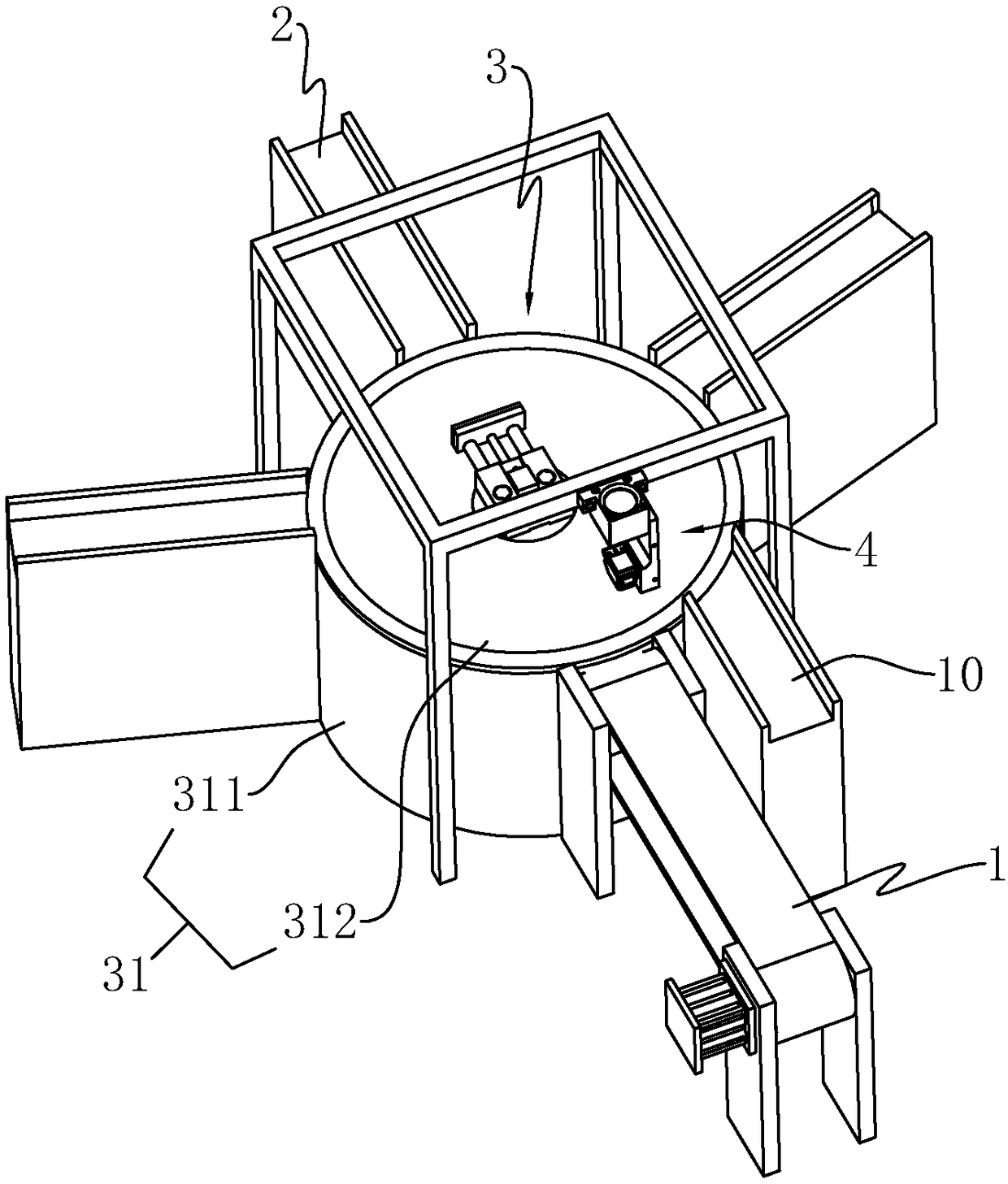

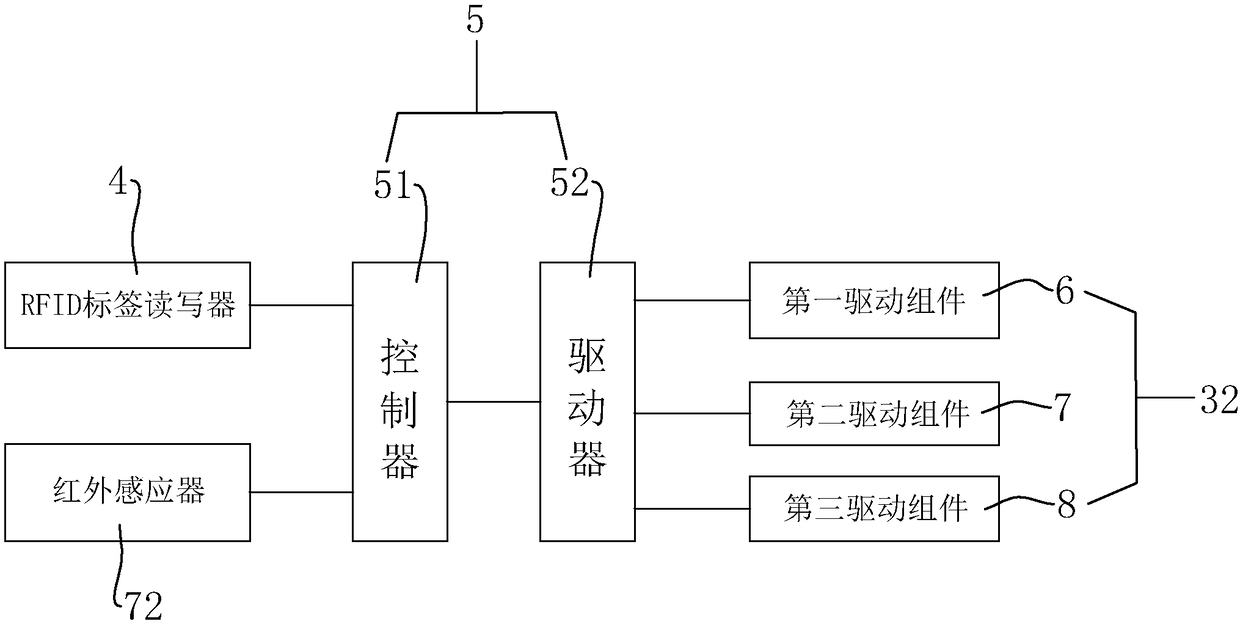

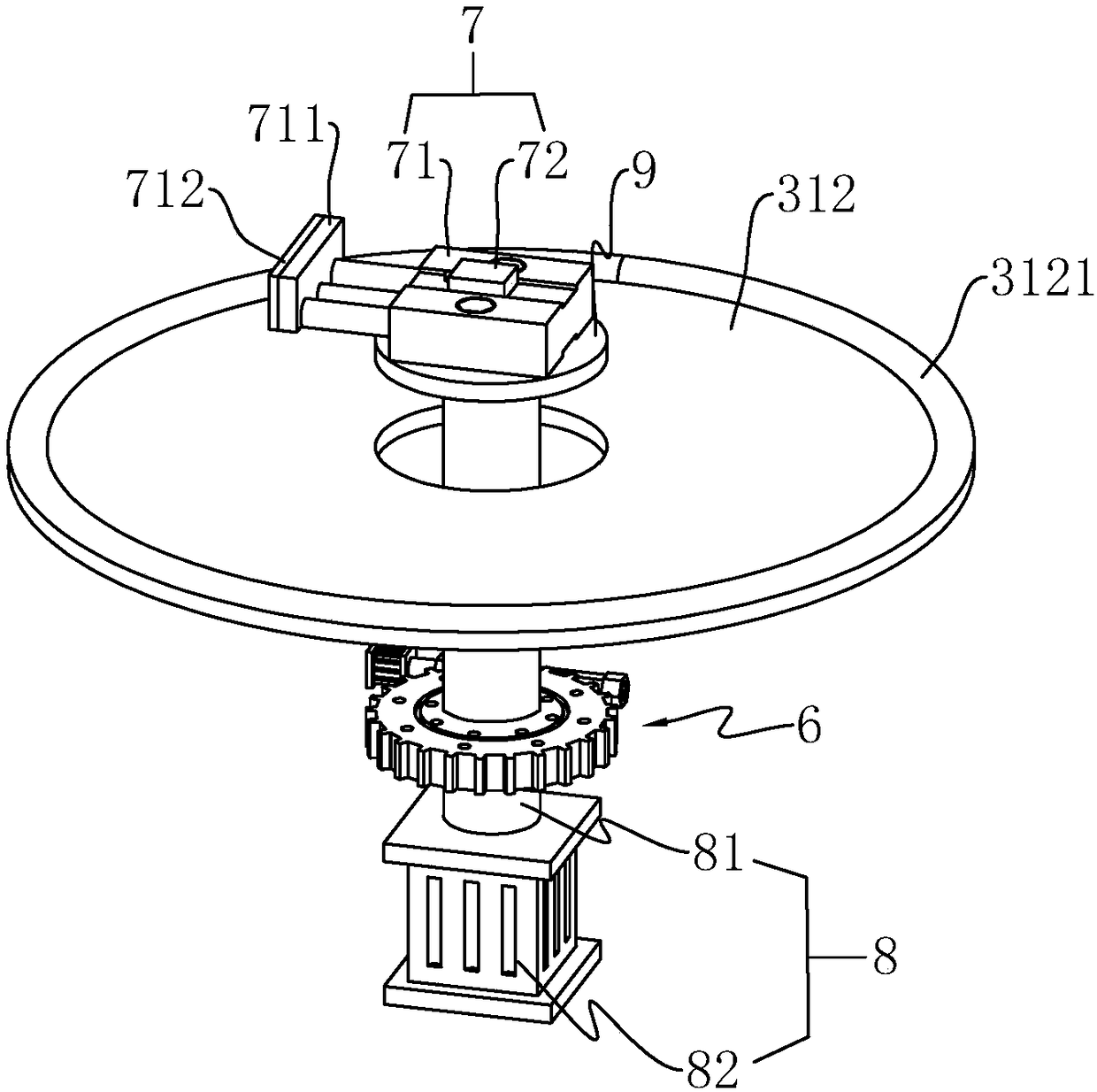

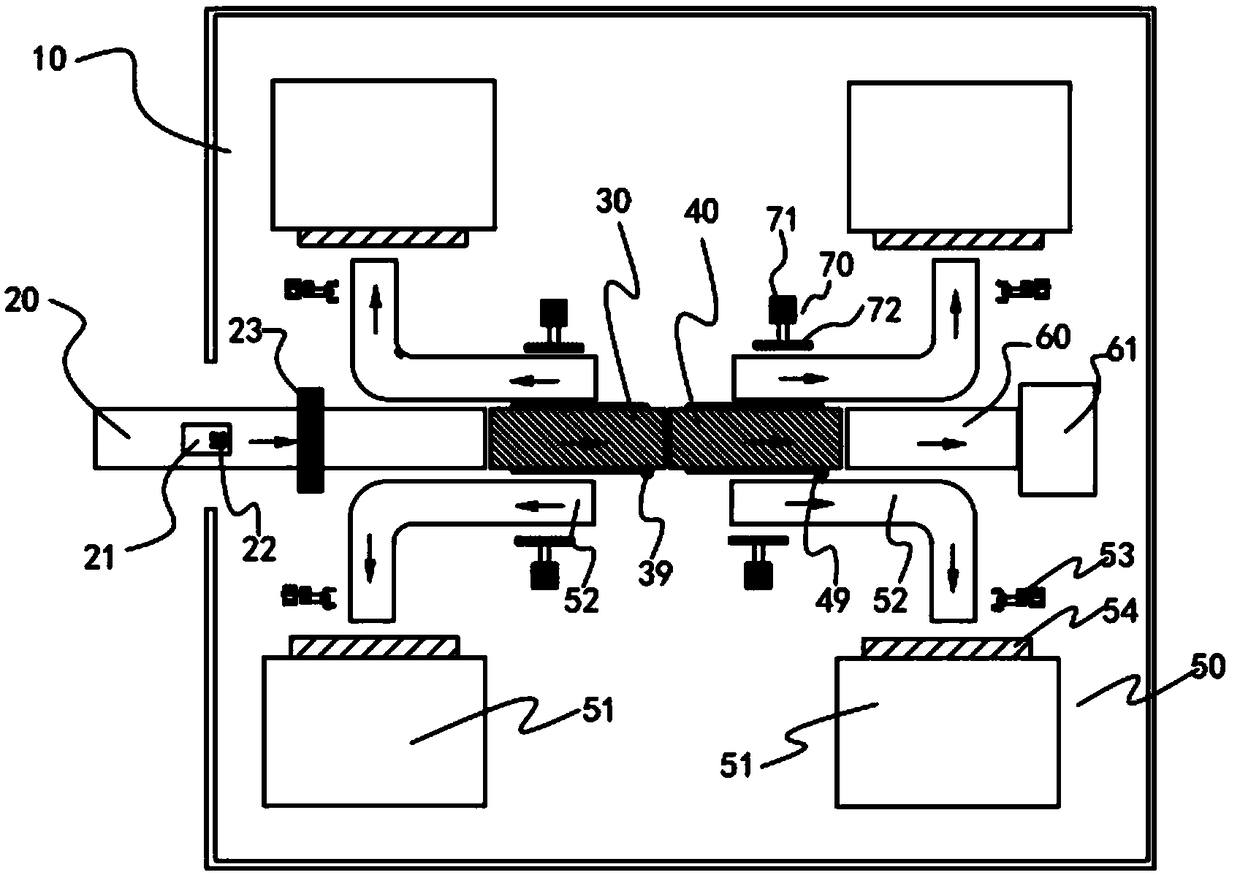

Cargo sorting system and sorting method

InactiveCN108438694ARealize fully automatic sortingImprove sorting efficiencyStorage devicesEngineeringReader writer

The invention discloses a cargo sorting system and sorting method, and relates to the technical field of logistics storage. The cargo sorting system comprises a put-into-storage line body, a pluralityof sets of sorting lines, a bearing device, a cargo identification module and a control module; the bearing device comprises a conveying carrier and driving assemblies, the cargo identification module is an RFID label reader-writer, and the control module comprises a controller and a driver; and the conveying carrier comprises a base and a rotary disc, and the driving assemblies comprise the first driving assembly and the second driving assembly. According to the cargo sorting method, the above cargo sorting system is adopted, and full-automatic cargo sorting is achieved. The cargo sorting system is extremely high in automation and intelligent degree, the labor intensity of workers can be greatly reduced, the cargo sorting efficiency and the sorting accuracy are greatly improved, responseto the trend of modern logistics development is achieved, and the market competitiveness of logistics enterprises is better improved.

Owner:上海诺尔国际物流有限公司

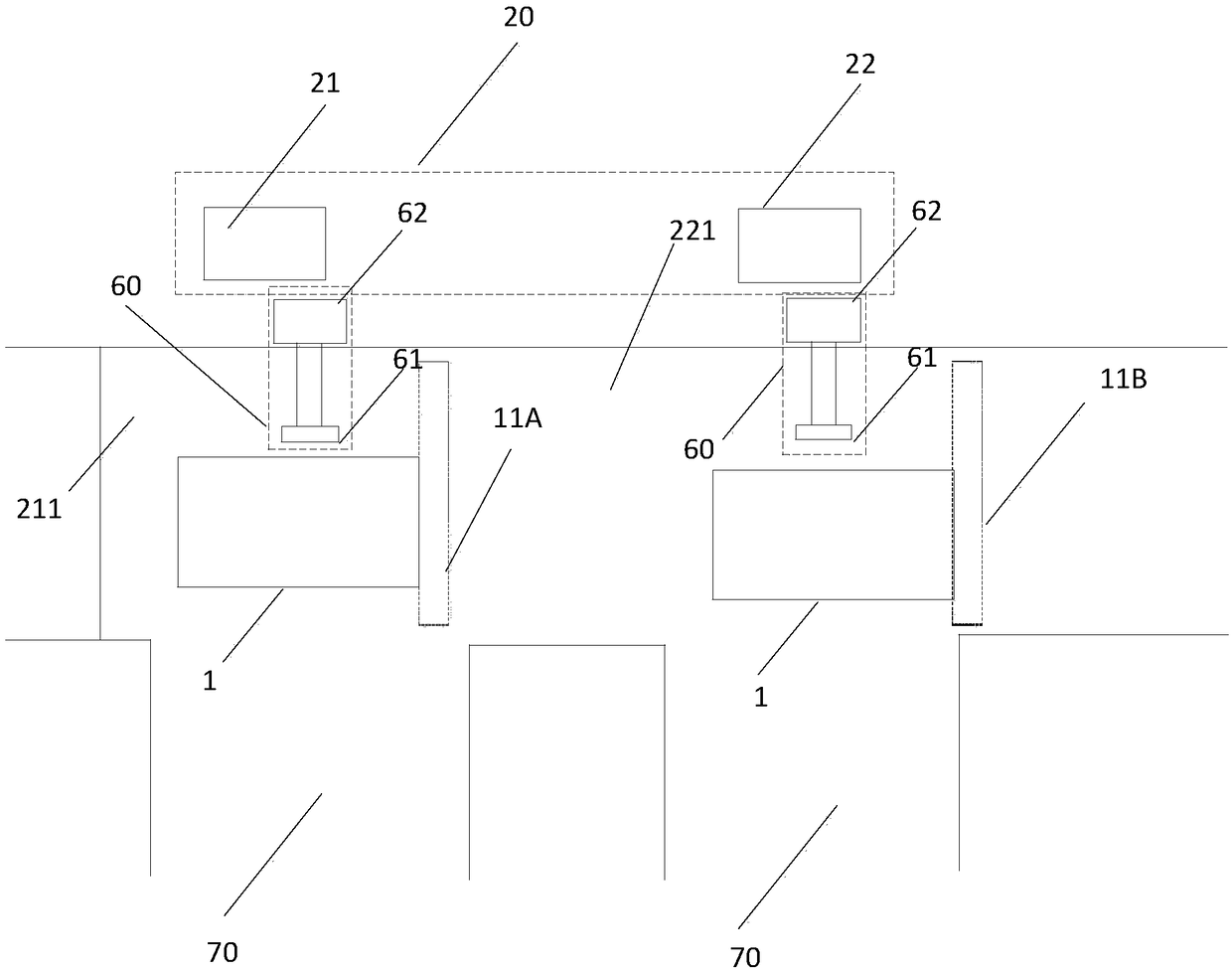

Independent address scanning sorter-based package sorting method

ActiveCN108499883AReduce the probability of misalignmentShorten the conveying distanceSortingLogistics managementBarcode

An independent address scanning sorter-based package sorting method is applied to a scanning rear-set logistics system. The package sorting method comprises the following steps: 1, packages input in adistantly unordered manner are output in an equidistant array manner; 2, the packages are divided into three division conveyors in an ordered manner; 3, barcode information of the packages on the division conveyors are scanned by a scanning device; 4, the packages are sorted and enter corresponding collecting boxes; 5, the collecting boxes bind off collecting bags reaching bind-off standards; 6,the bound collecting bags are transferred to an objective table; 7, one of the collecting bags is distracted after the collecting bag is transferred; and 8, the collecting bags on the objective tableare transferred to the conveyor B through a pusher. An independent address code scanning link is arranged at the near front end of every sorting link, so a conveying distance between address code scanning and sorters is reduced, the dislocation probability between the code scanning address and the address of a package, caused by dropping of the package, is reduced, and the sorting accuracy is improved.

Owner:NANHUA UNIV

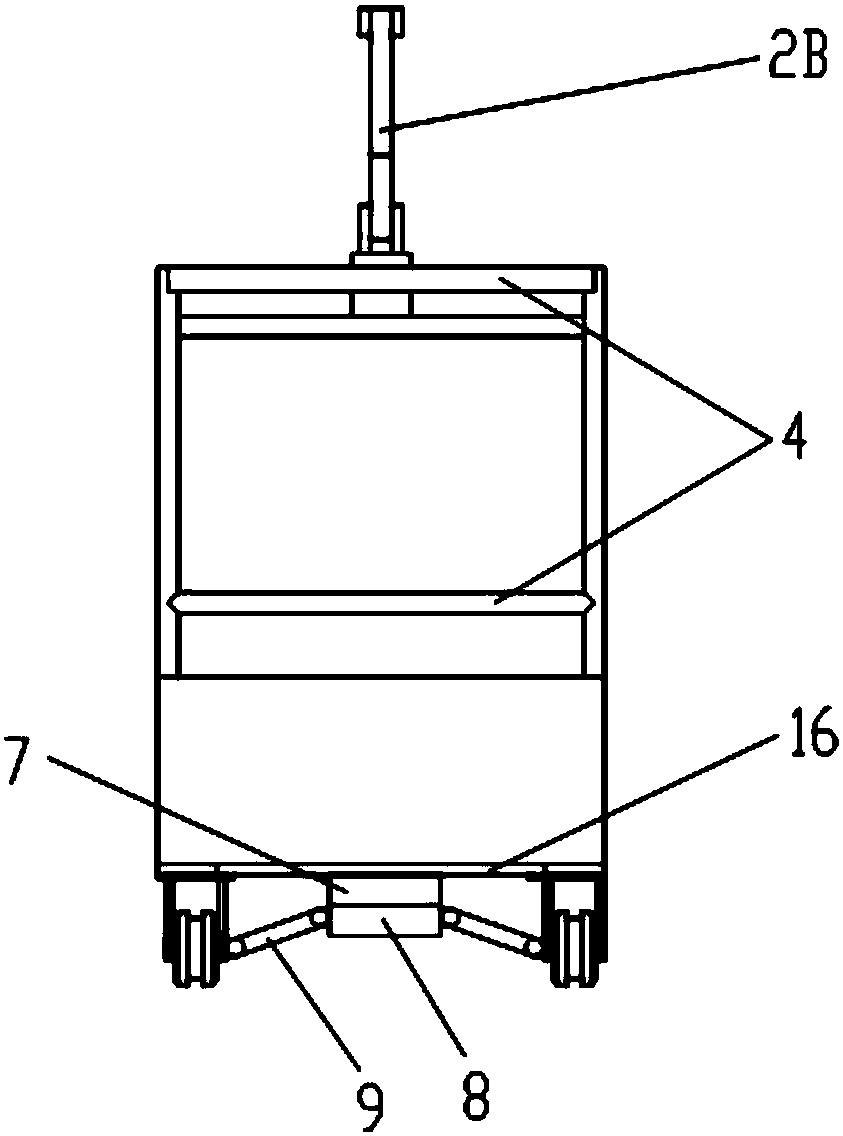

Sorting trolley

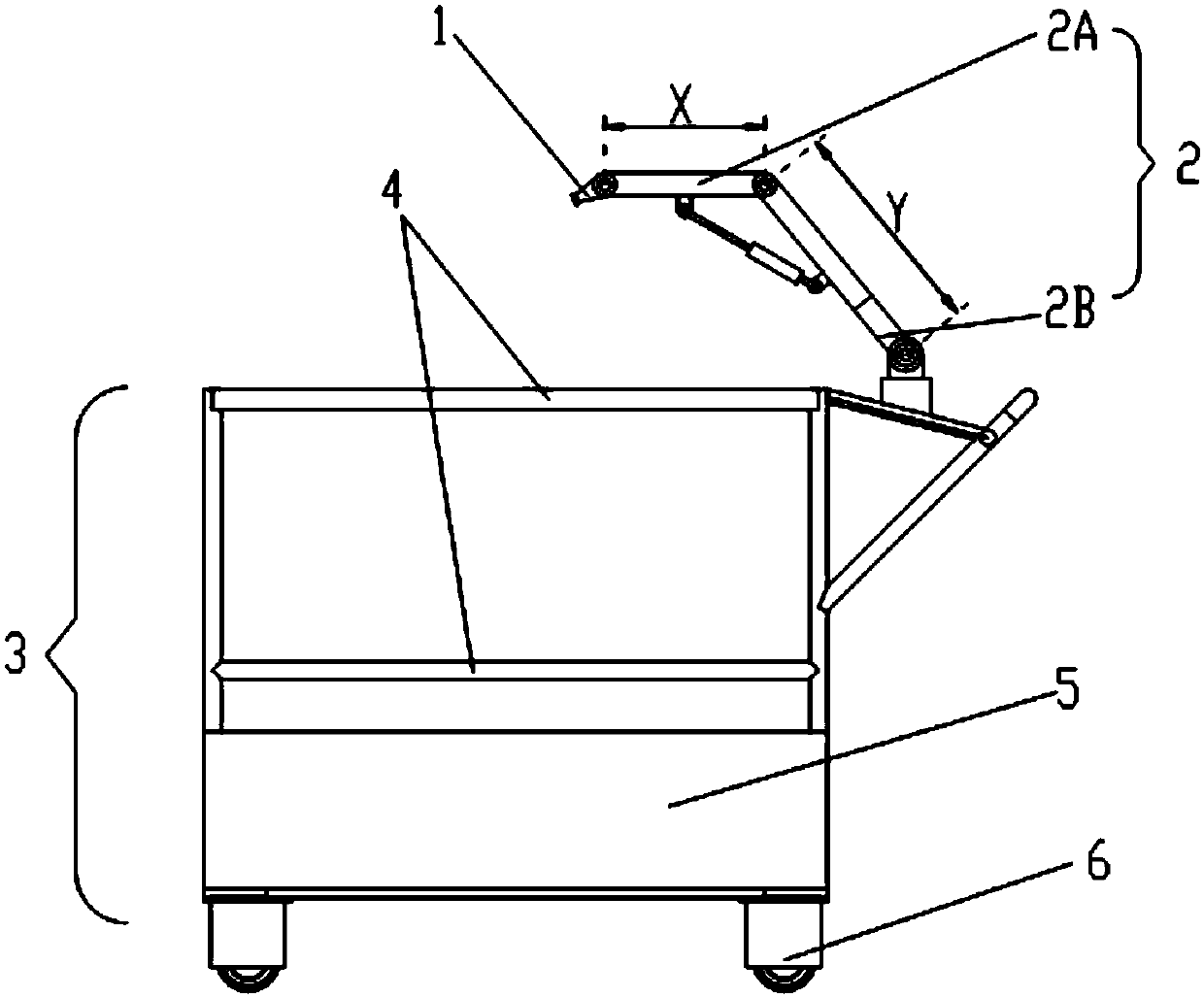

PendingCN107774579AOrderly operationReduce error rateGripping headsSortingEngineeringIntelligent control

The invention relates to a sorting trolley. The sorting trolley comprises a trolley body (3), wherein a mechanical arm (2) is arranged on the trolley body (3), a negative pressure device (1) is arranged on the mechanical arm (2), the trolley body is also provided with a camera shooting identification system, an image transmission module, an industrial control computer, a signal receiver and a tablet computer. The sorting trolley also relates to a mobile device thereof, and the mobile device comprises a roller conveyor belt and a wheel (6). The sorting trolley provided by the invention has thecharacteristics of intelligent control, ordered operation, prescription correctness checking, real-time checking on prescription and medicinal materials, real-time monitoring, low medicine sorting error rate, low labor intensity and high sorting efficiency.

Owner:SINOPHARM GRP DEZHONG (FOSHAN) PHARM CO LTD +1

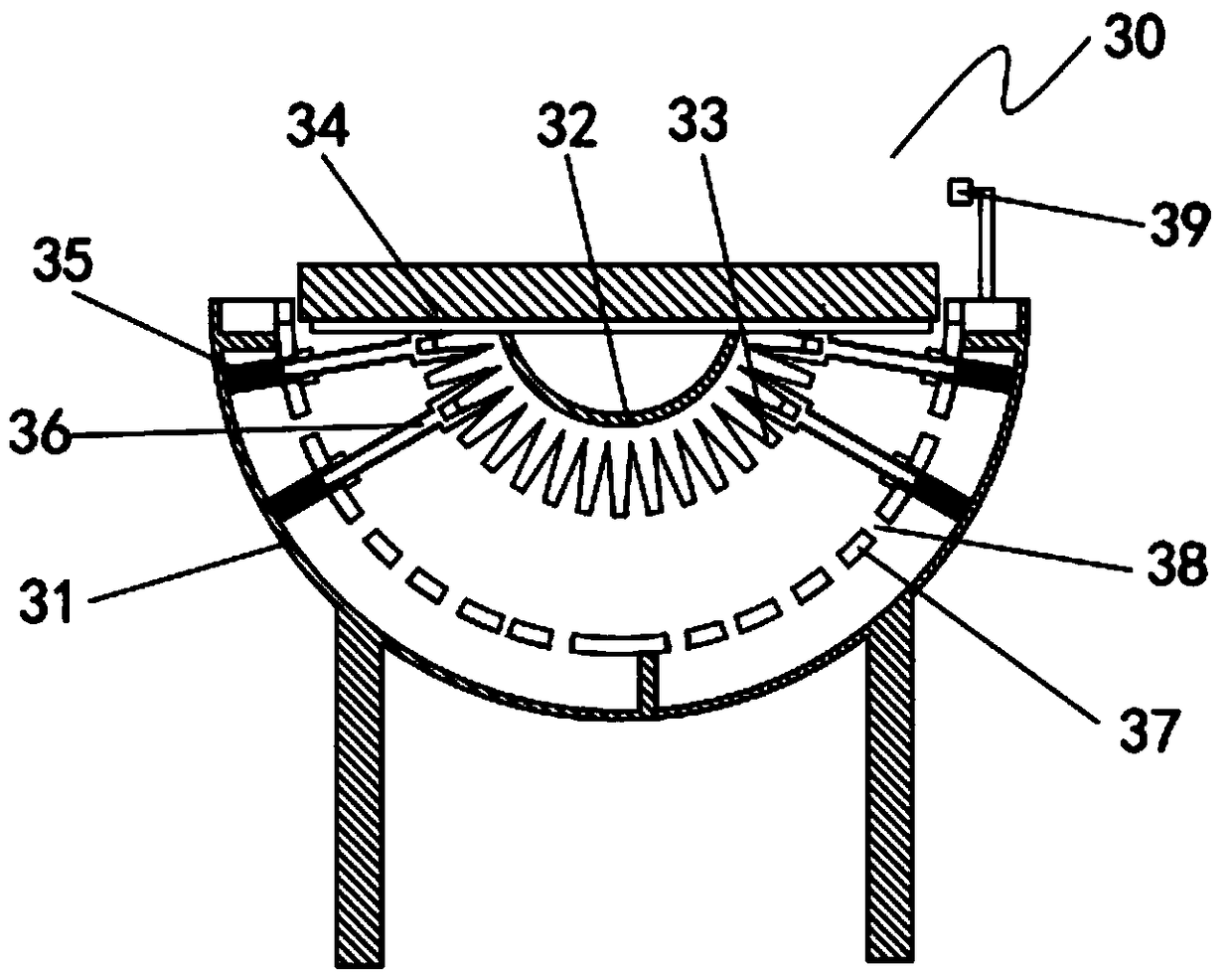

Internal circulation type automatic sorting storing and taking device

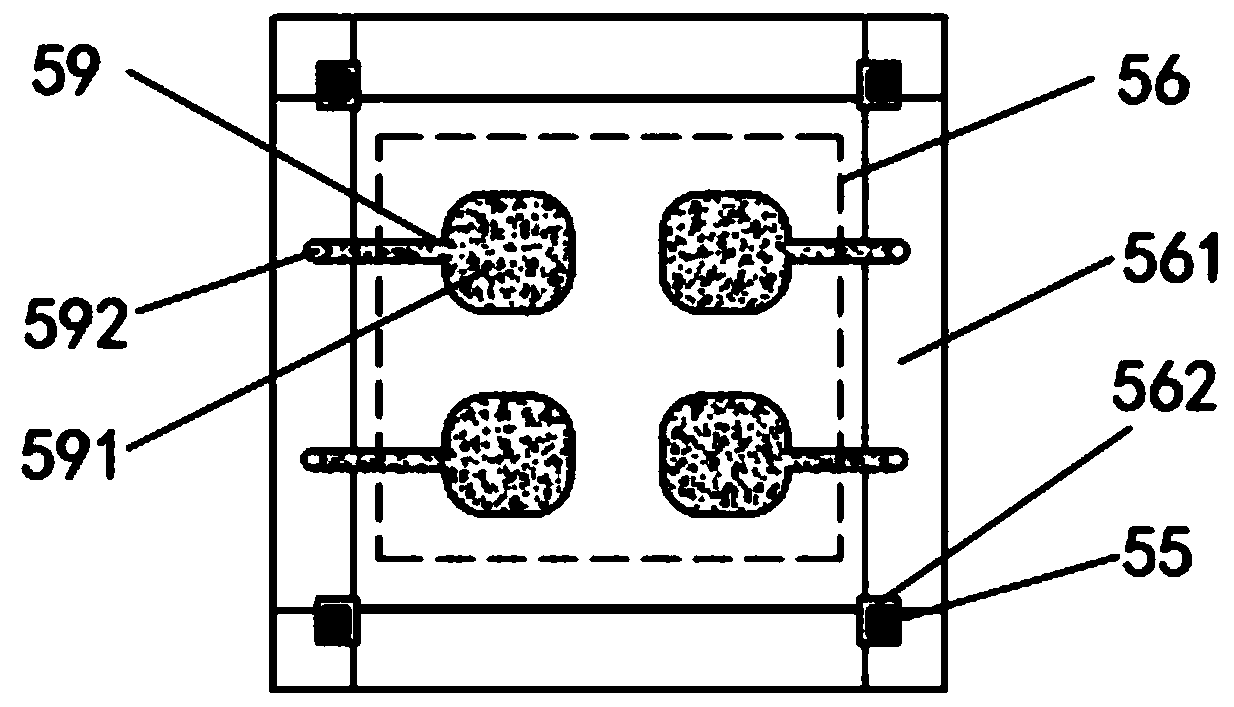

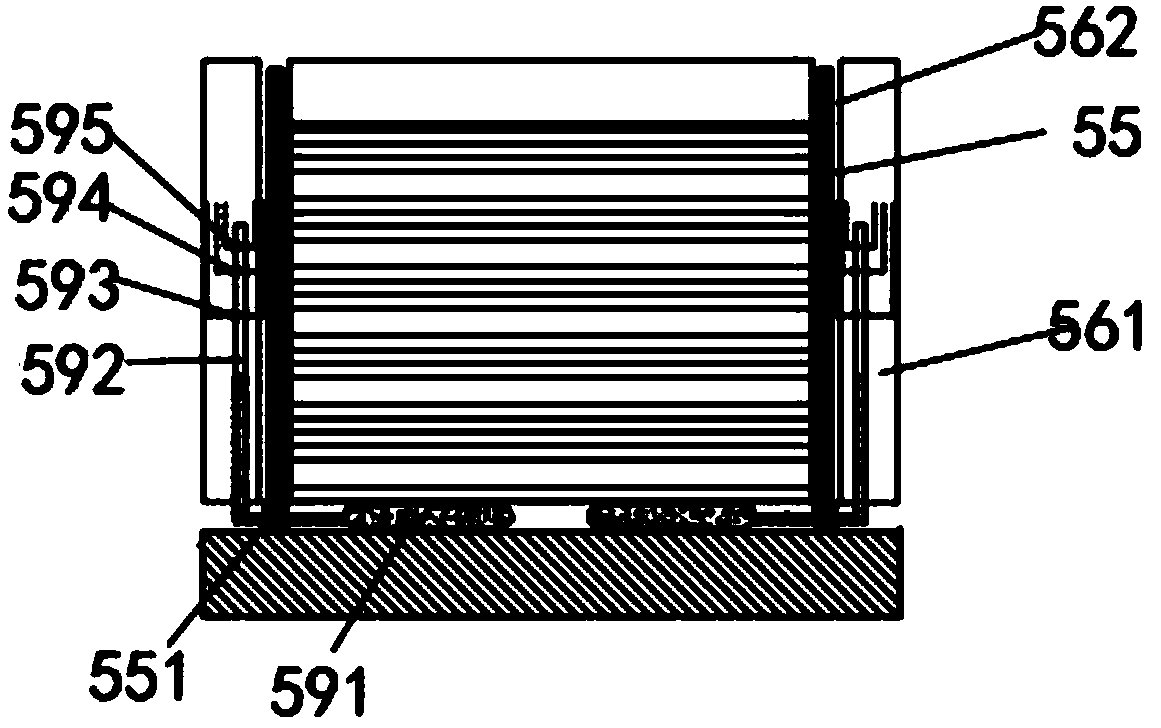

ActiveCN108455150AProtection securityRealize fully automatic closed managementStorage devicesEngineeringSmall footprint

The invention discloses an internal circulation type automatic sorting storing and taking device. The internal circulation type automatic sorting storing and taking device comprises a warehouse, a front end conveying belt, an overturning sorting mechanism and a distributing conveying belt, and the front end conveying belt, the overturning sorting mechanism and the distributing conveying belt are sequentially arranged in the warehouse, wherein a plurality of two-way sorting conveying belts are uniformly distributed around the periphery of the overturning sorting mechanism, and a warehousing device is arranged at the tail ends of the two-way sorting conveying belts; and the overturning sorting mechanism comprises a semispherical supporting frame, a semispherical overturning plate, a plurality of overturning columns distributed at the bottom of the semispherical overturning plate, a plurality of telescopic cylinders fixed to the supporting frame and an overturning platform installed on the semispherical overturning plate. The internal circulation type automatic sorting storing and taking device achieves automatic circulation in the warehouse, manual operation is not needed, full-automatic closed type management on a stereoscopic warehouse is achieved, and the goods safety is fully guaranteed; and the internal circulation type automatic sorting storing and taking device is compactin structural design, reasonable in arrangement, small in occupied area and low in cost.

Owner:LONLINK SMART STORAGE SOLUTION SHANGHAI CO LTD

Sorting device and method

The invention discloses a sorting device and method. The sorting device stops finished air conditioners in a detecting area, and then a detecting unit detects the state of barcodes and / or coolant leakage to determine qualified products and non-qualified products; a sorting unit is connected with the detecting unit for sorting out the qualified products and the non-qualified products of the finished air conditioners from the detecting area. Therefore, the sorting device can fully-automatically sort out the qualified products and the non-qualified products to prevent the non-qualified products from being mixed into the qualified products and further avoid batch quality problems, thereby saving labor, improving the sorting efficiency and reducing sorting errors.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

Book pre-sorting device

InactiveCN103433223ASimple structureIngenious ideaSortingHand carts with multiple axesEngineeringWorkload

A book pre-sorting device comprises a body and a central shaft arranged in the body, wherein the body can rotate freely around the central shaft; the body consists of a bottom plate and a side wall; a plurality of partitions are arranged between the central shaft and the side wall; a sorting plate inclined inwards is arranged between every two adjacent partitions; a notch is formed between the end part of each sorting plate and the central shaft; an inclined slide rail is arranged between each sorting plate and the bottom plate; a notch is formed at the top end, corresponding to a position between each sorting plate and the central shaft, of each slide rail; a movable door is arranged on the side wall, corresponding to each sorting plate, of the body; a handle is arranged on each movable door; sterilization and disinfection devices are arranged on inner wall surfaces of the movable doors; and a plurality of casters are arranged at the bottom of the body. The book pre-sorting device is simple in structure and convenient to use, greatly reduces the workload in a book organization process, improves the neat quality of books, and is suitable for popularization and application in various large libraries.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

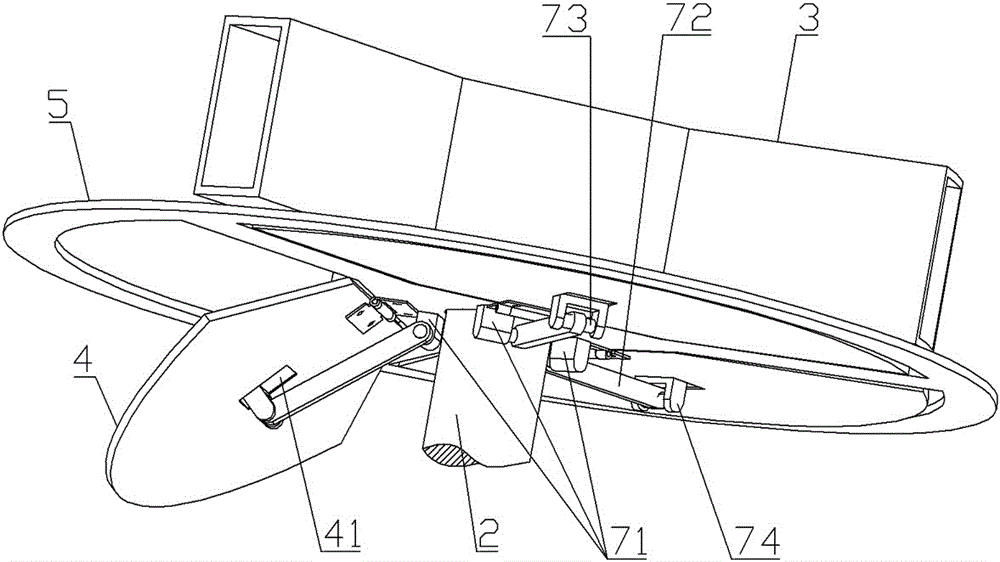

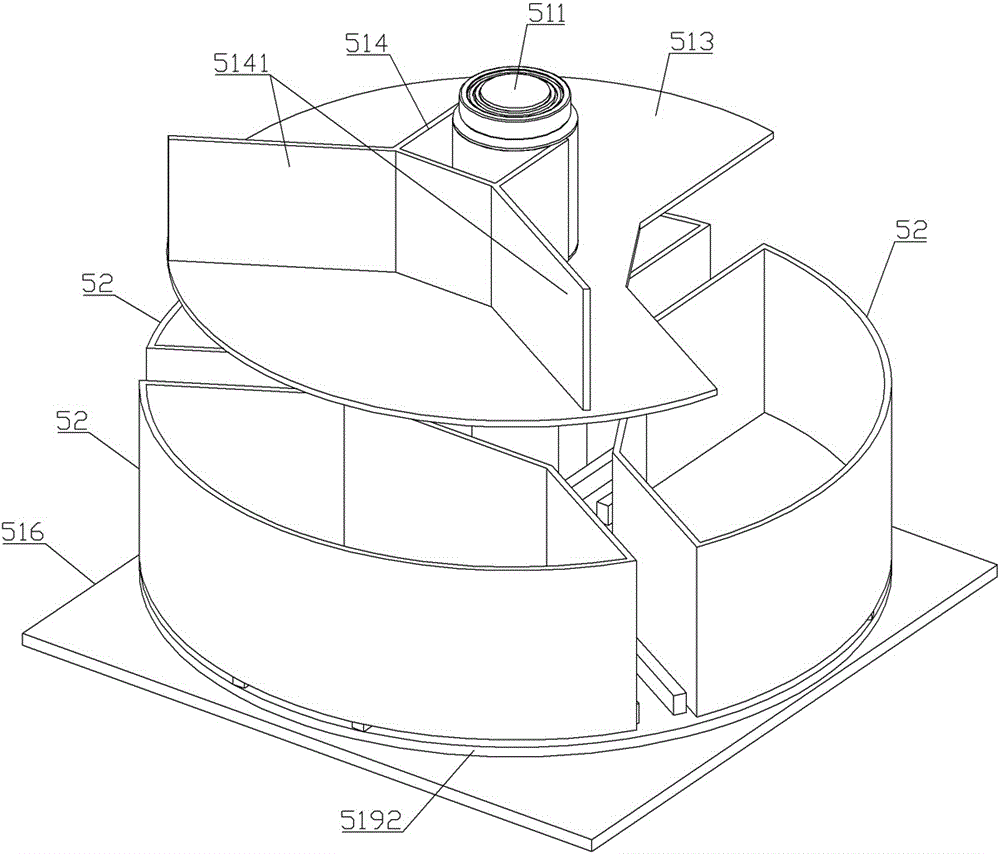

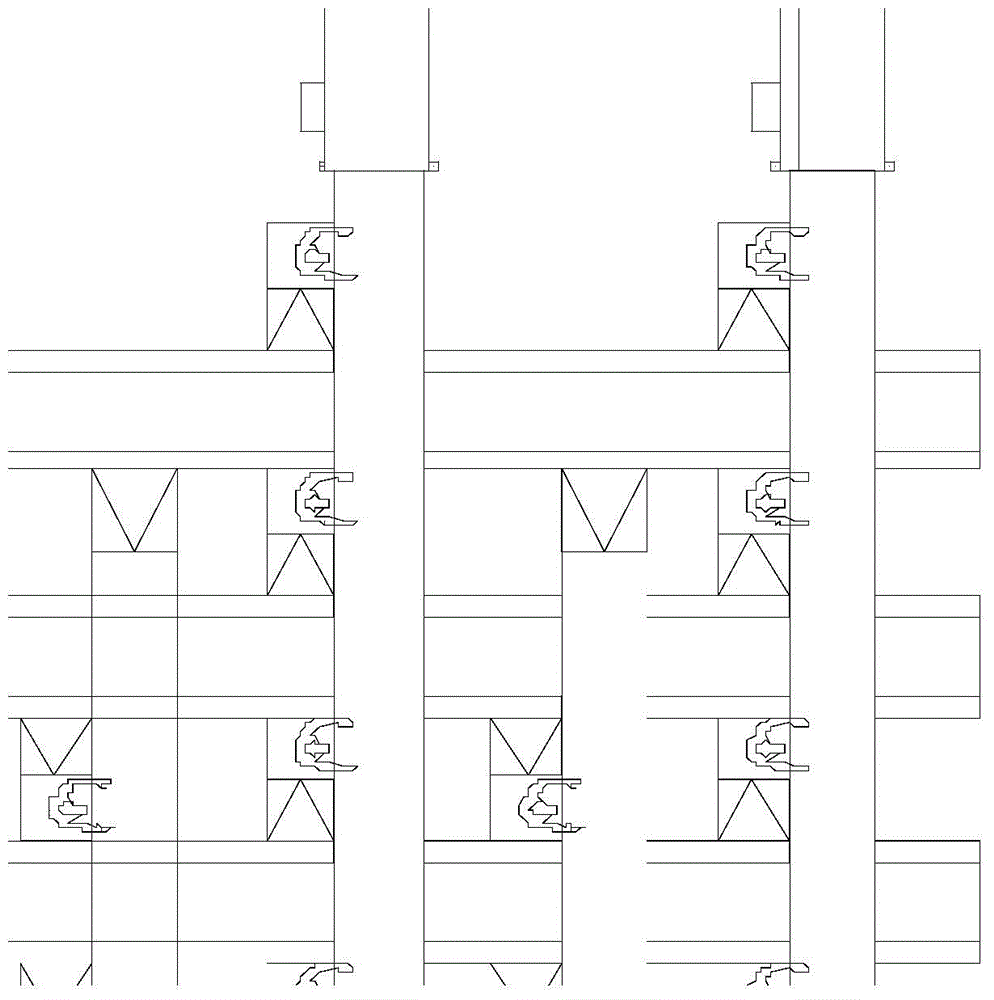

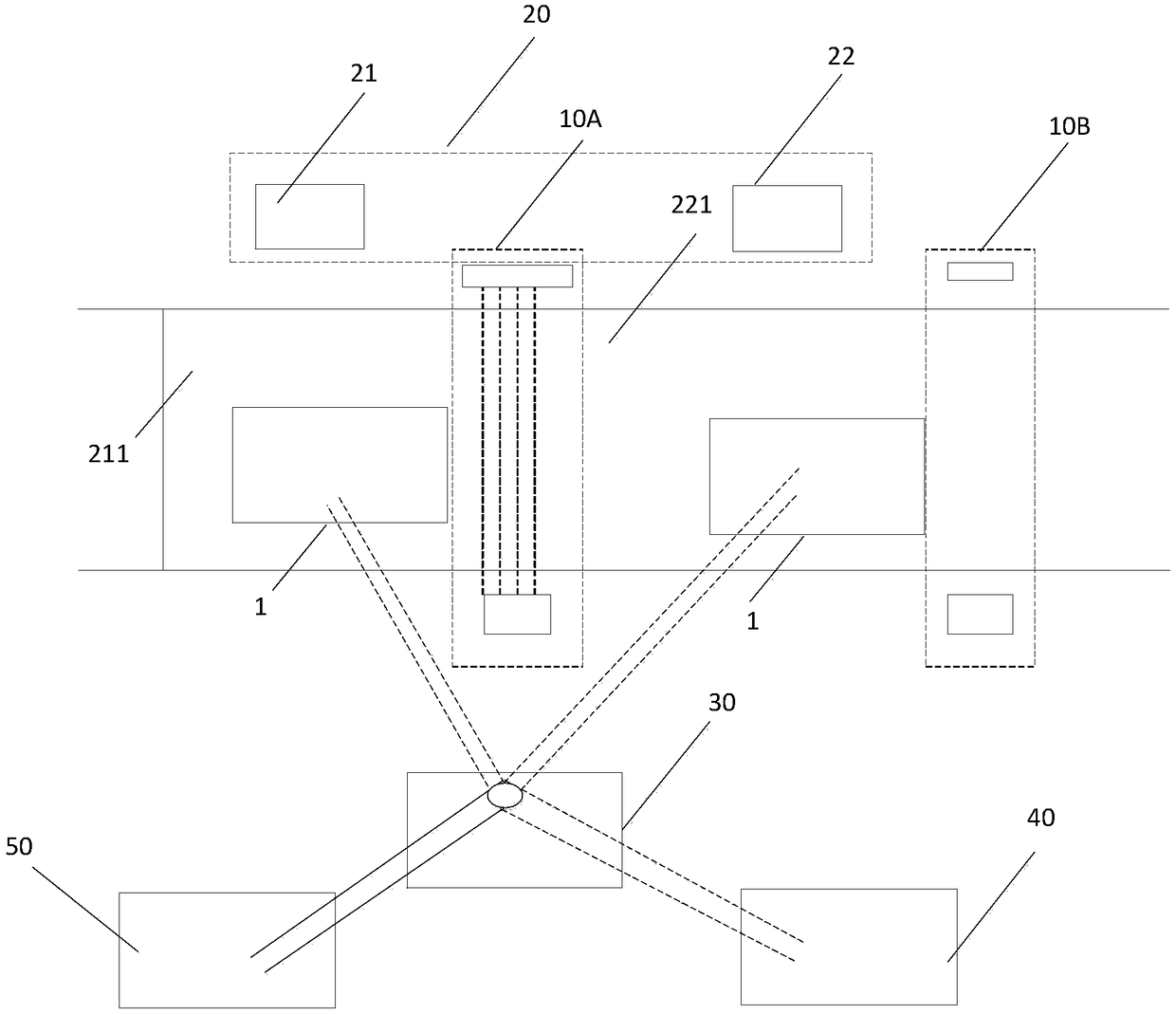

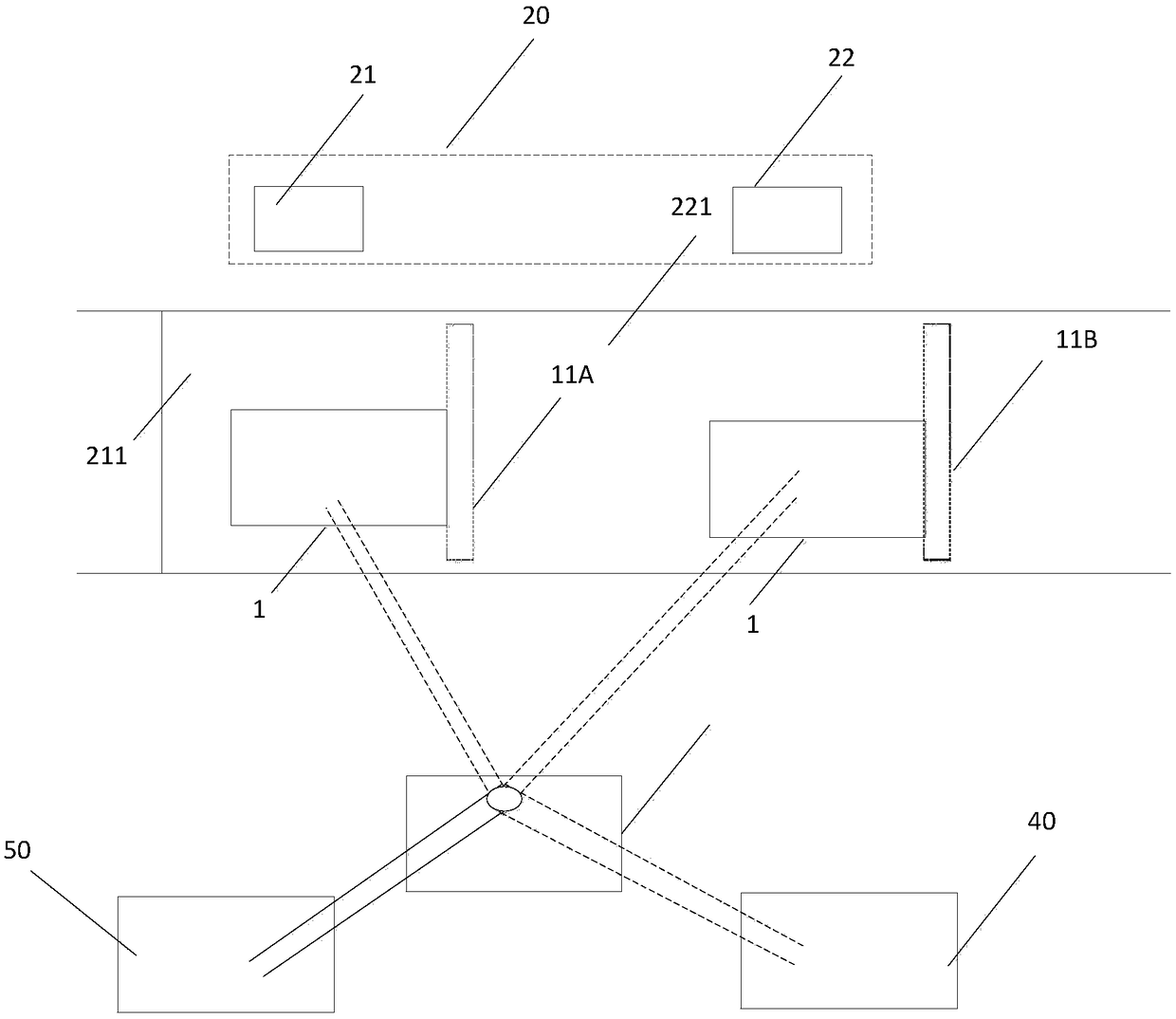

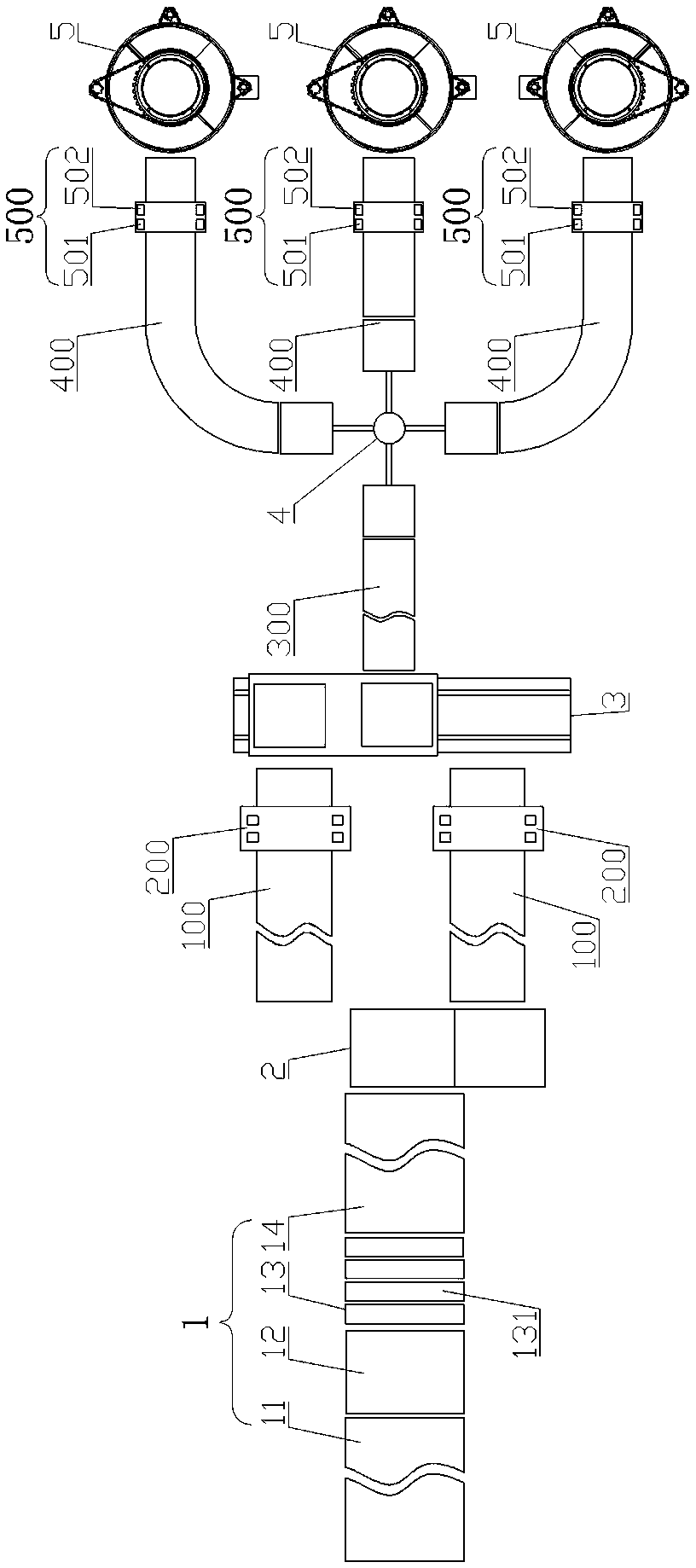

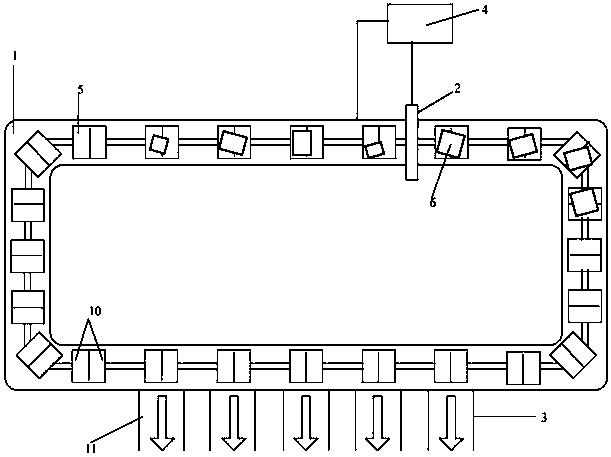

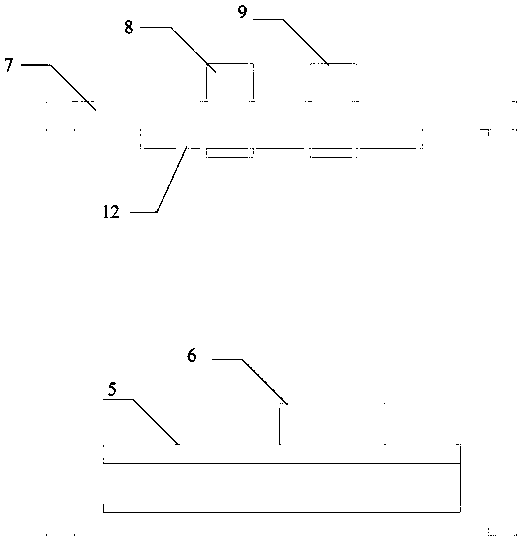

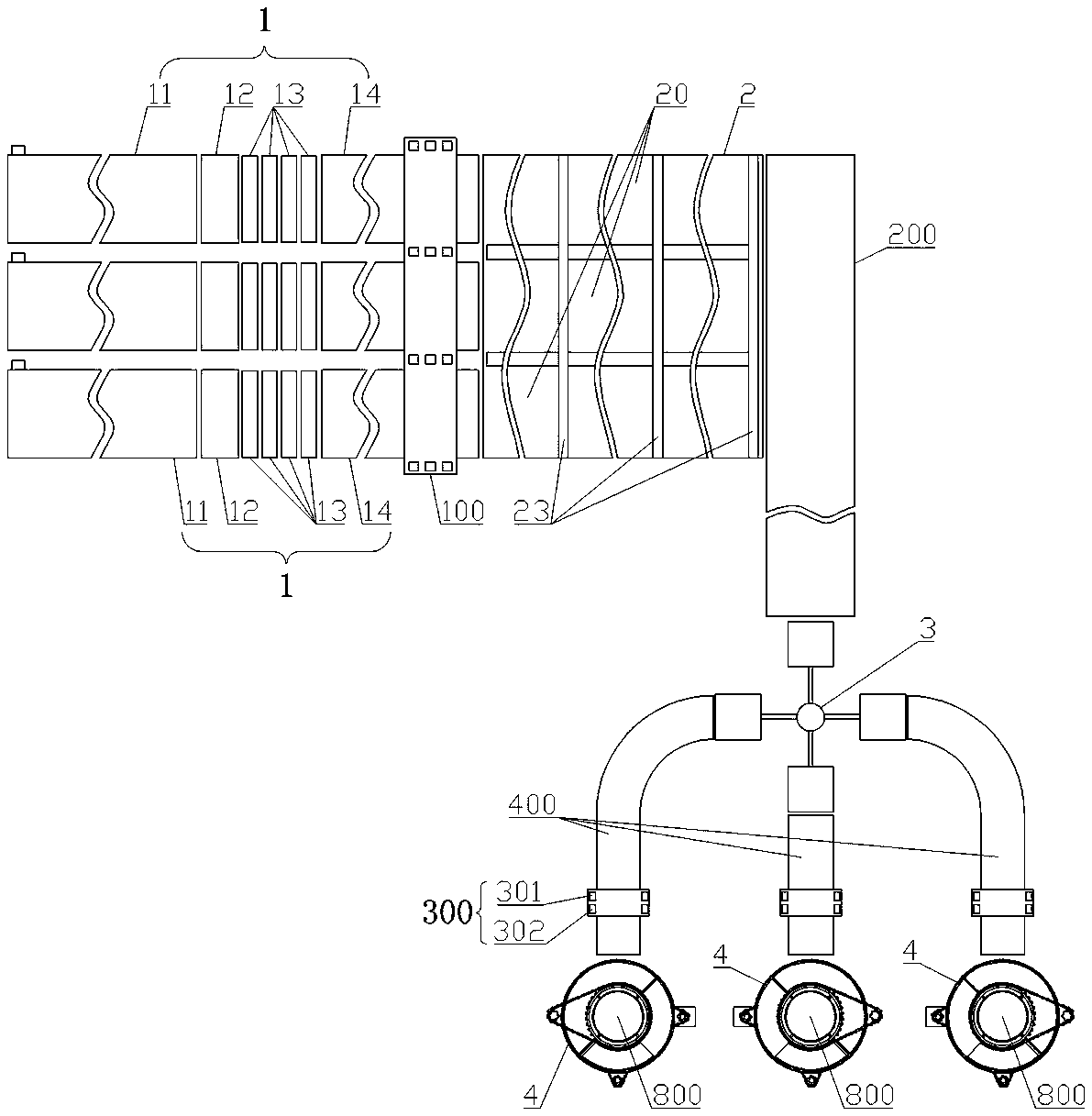

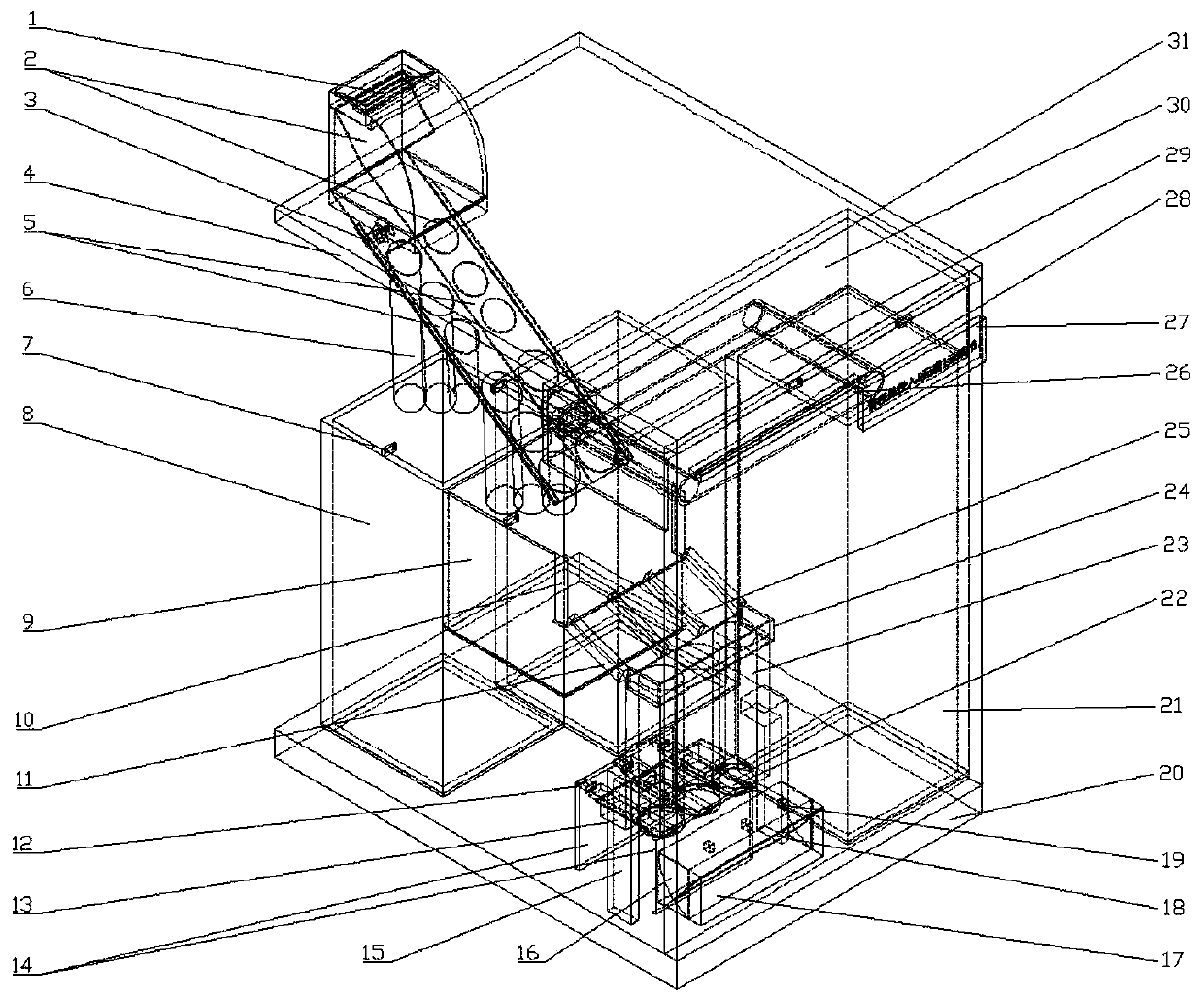

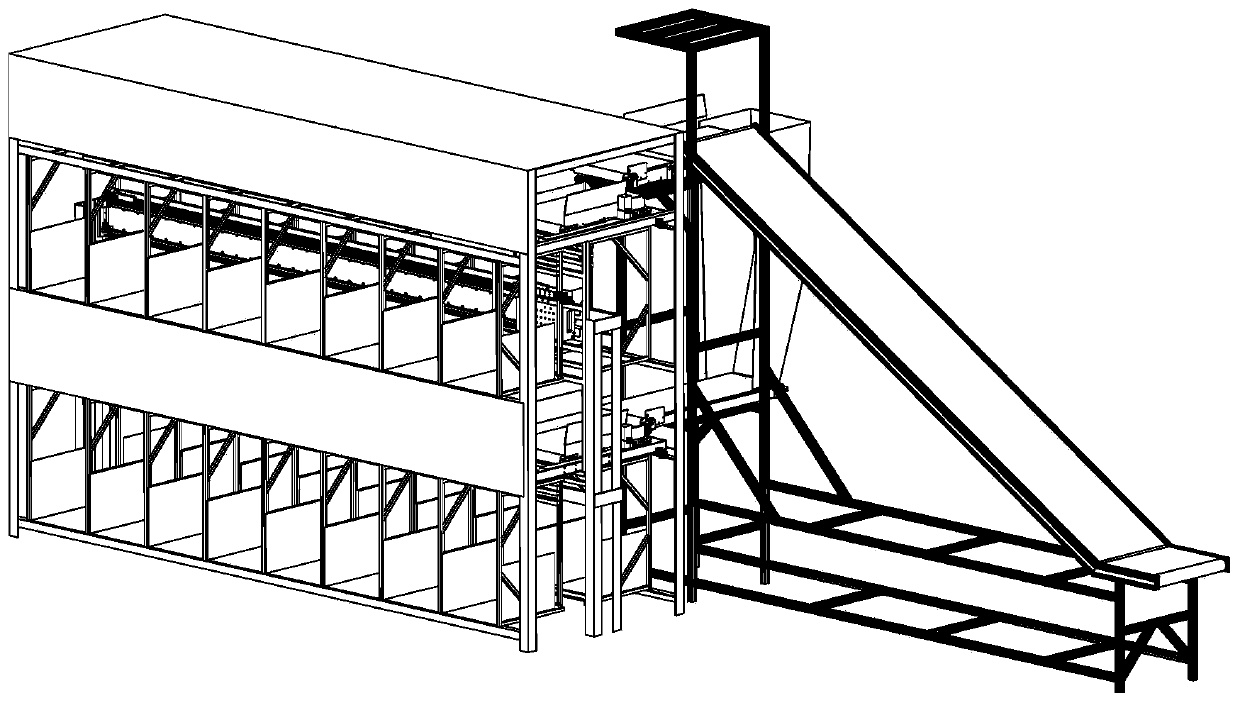

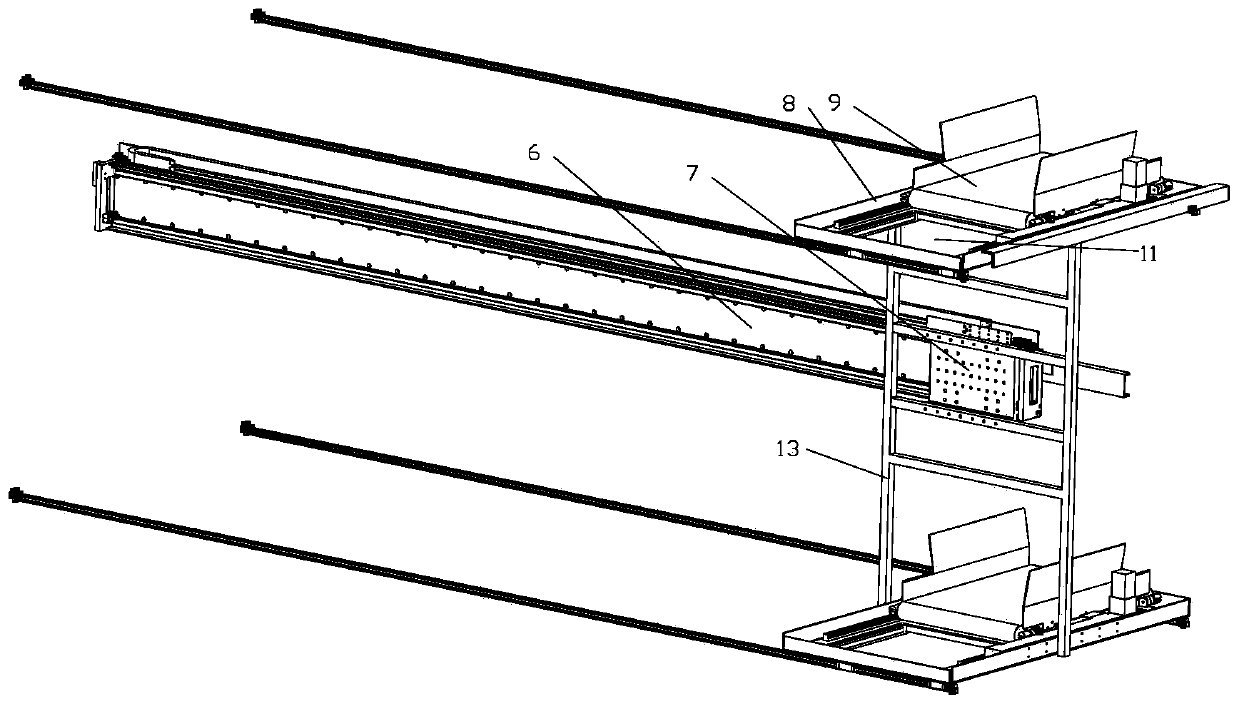

Logistics sorting system based on tower type sorting device

The invention discloses a logistics sorting system based on a tower type sorting device. The system comprises a gradual taking separation device, a front flow dividing device, a front flow dividing conveyor, a code scanning device, a flow combining device, a flow gathering conveyor, a rear flow dividing device, a rear flow dividing conveying belt, an error correcting device and the tower type sorting device. The tower type sorting device comprises sorters, a parcel taking device, a pushing device, a conveyor C, an outer cover and a base; the multiple sorters are overlapped in the vertical direction, the sorters are directly or indirectly fixedly mounted on the base, a cylindrical central channel is formed in the central area of one sorter, central channels of the sorters are sequentially communicated, and a vertical coherent parcel transport channel is formed; the problem that an existing common logistics sorting assembly line carries out plane laying and sorting through the conveyingbelt, and the occupied area is large is solved. Through the design, overlapping in the vertical direction is achieved, and the tower type sorting device with the automatic packaging function is integrated in function, compact in mechanism and small in occupied area.

Owner:NANHUA UNIV

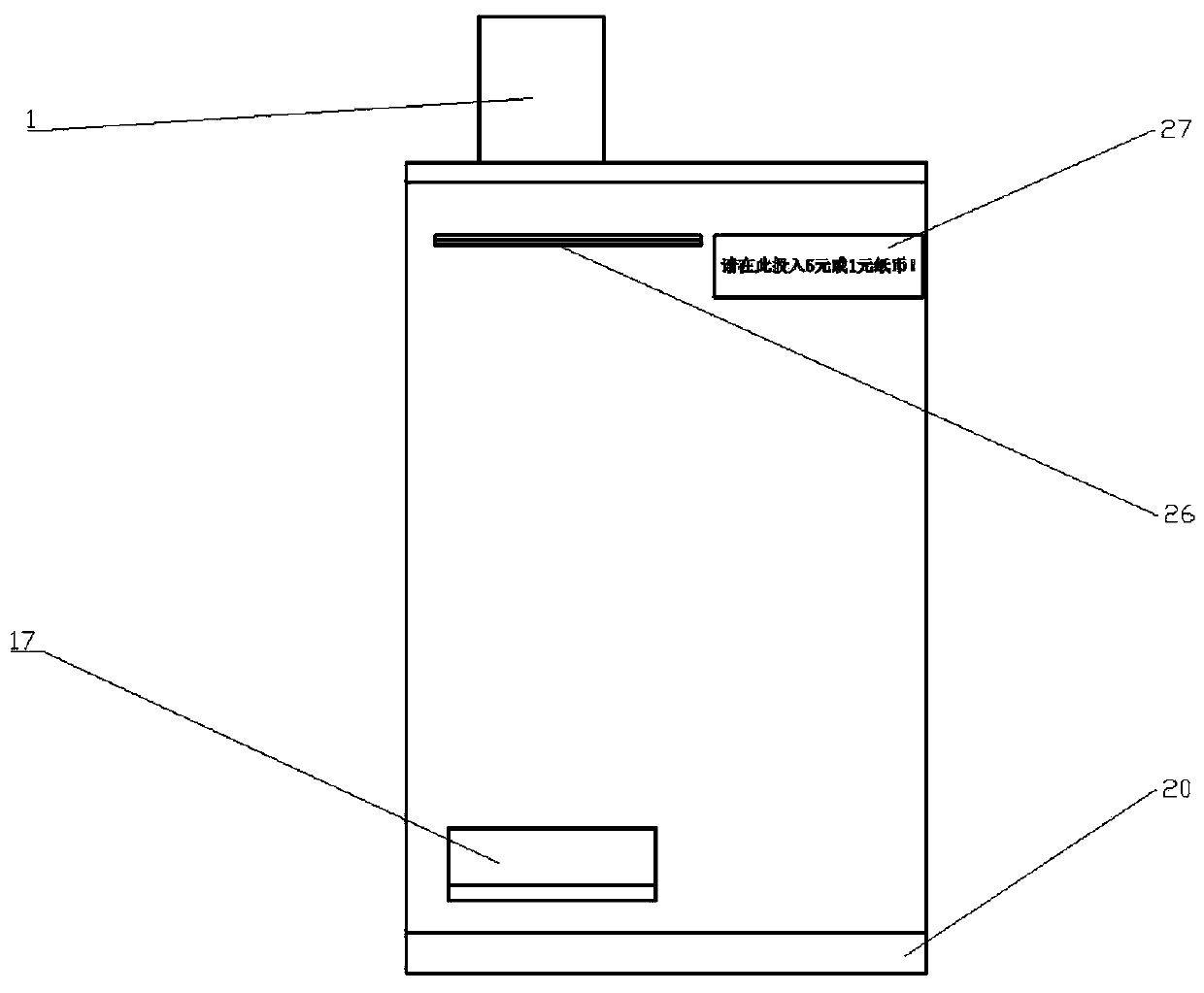

Coin sorter

ActiveCN105913542AThe structure is simplified and reasonableEasy to useCoin/paper handlersEngineeringElectric motor

The invention discloses a coin sorter. A machine shell is provided with a coin inlet funnel, a coin pushing disc, a coin guiding disc, a screening disc, a classification disc, a coin sweeping wheel and a coin blocking ring that are all orderly arranged from top to bottom coaxially; a main shaft which is driven by an electric motor to rotate is arranged on axis positions of the coin pushing disc, the coin guiding disc, the screening disc, the classification disc, the coin sweeping wheel and the coin blocking ring in a penetrating manner; the main shaft drives the coin pushing disc, the screening disc and the coin sweeping wheel to rotate synchronously; the coin guiding disc, the classification disc and the coin blocking ring are fixed and cannot rotate along with the main shaft; the coin pushing disc is provided with a coin pass hole through which coins can pass, the coin guiding disc is provided with coin falling tubes, the screening disc is provided with coin inlet holes, the classification disc is provided with coin separating holes, side parts of all the coin separating holes are connected with a coin guiding grooves, the coin blocking ring is provided with annular accommodating chambers, lower ends of all the coin separating holes are connected with coin guiding tubes, the coin sweeping wheel are provided with coin sweeping teeth, bottom parts of all the annular accommodating chambers are provided with coin falling holes, and lower parts of the coin falling holes are connected with the coin falling tubes. The coin sorter disclosed in the invention is simple and reasonable in structure, low in manufacture cost, and low in sorting error rate.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

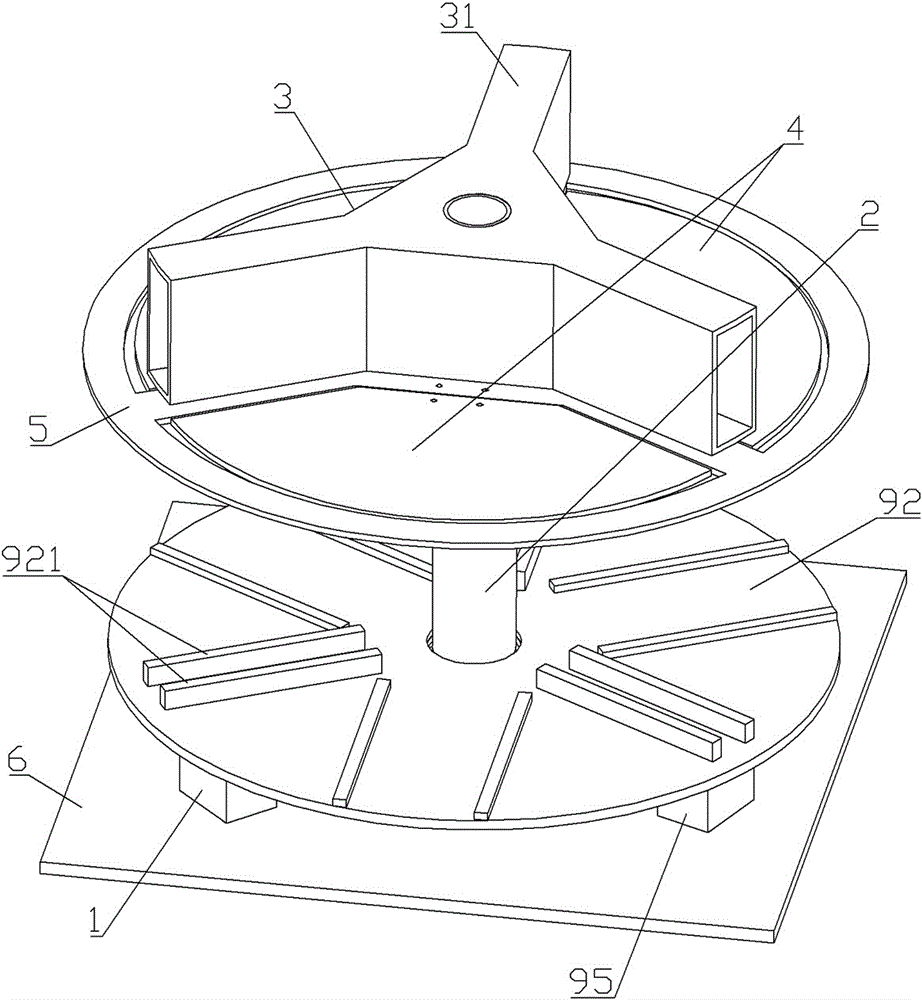

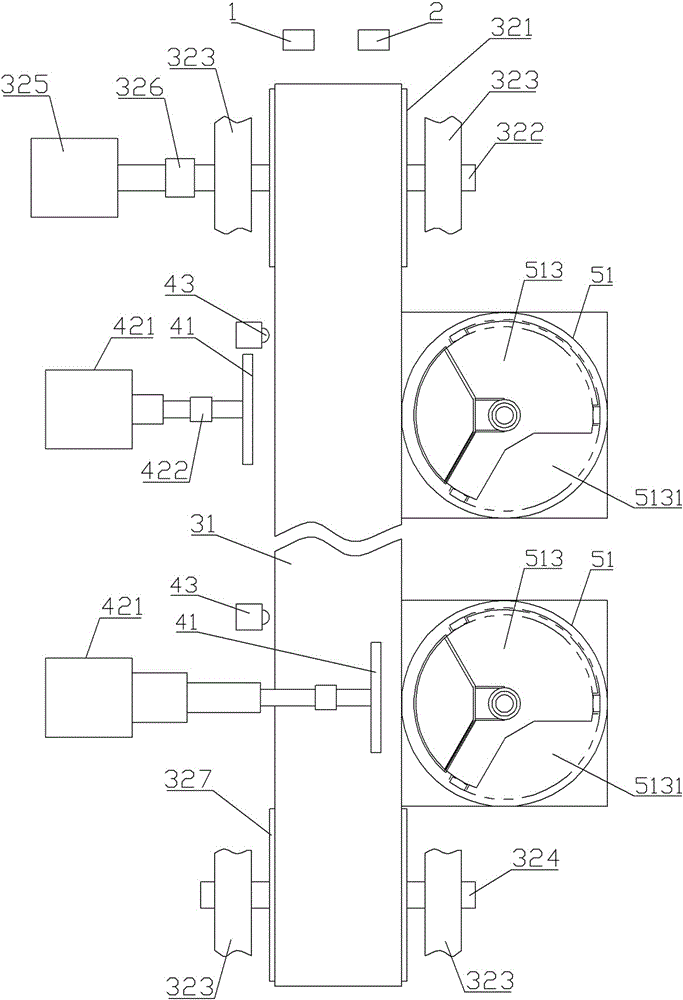

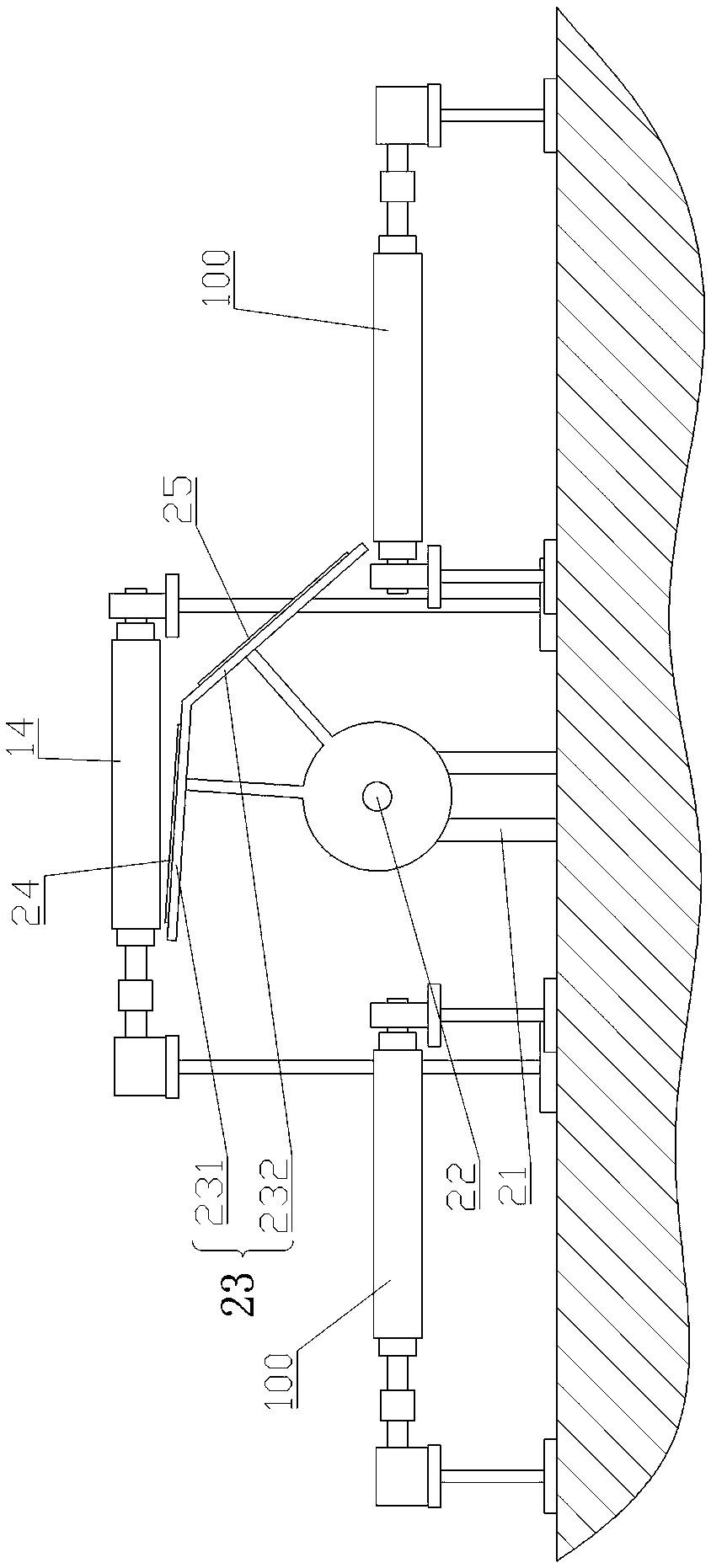

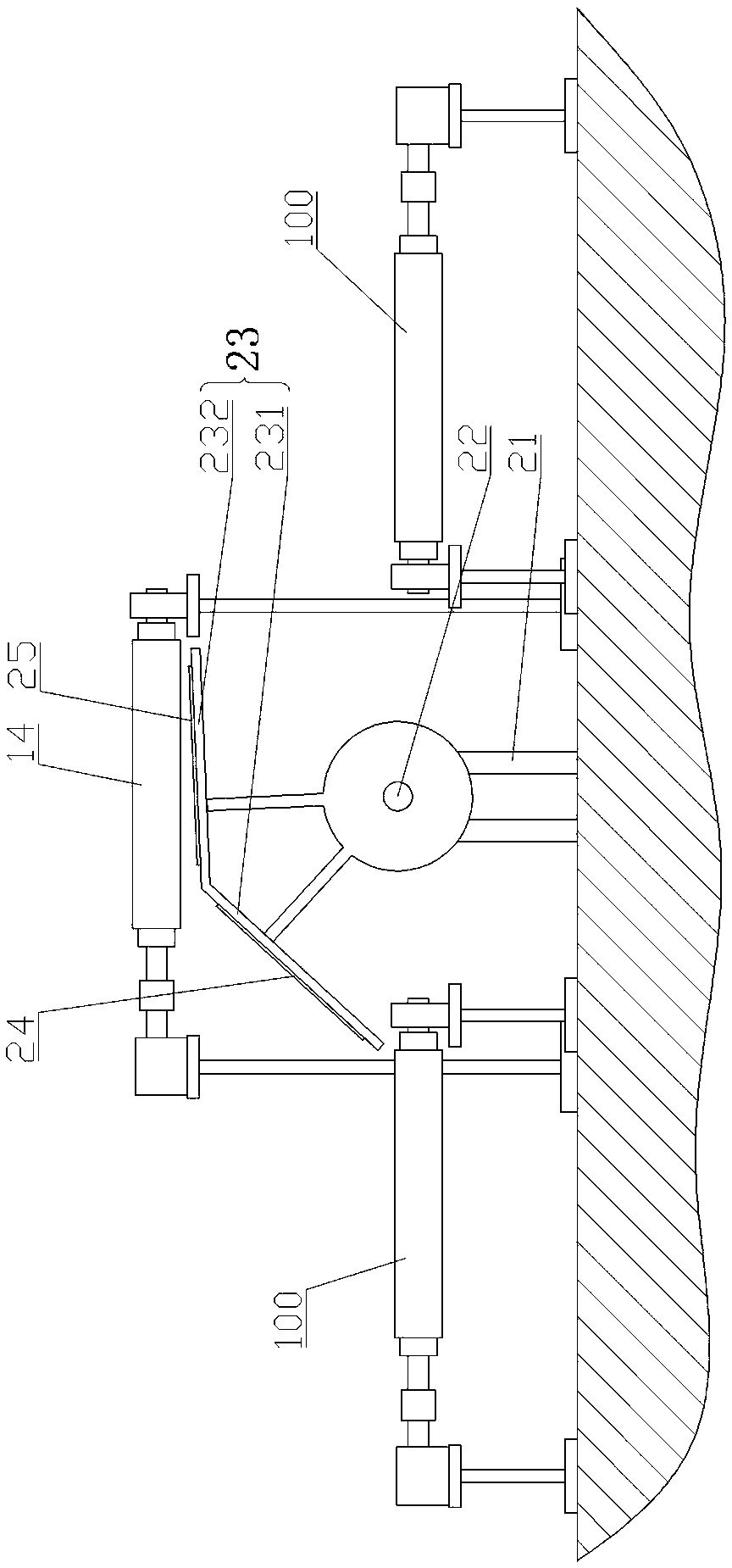

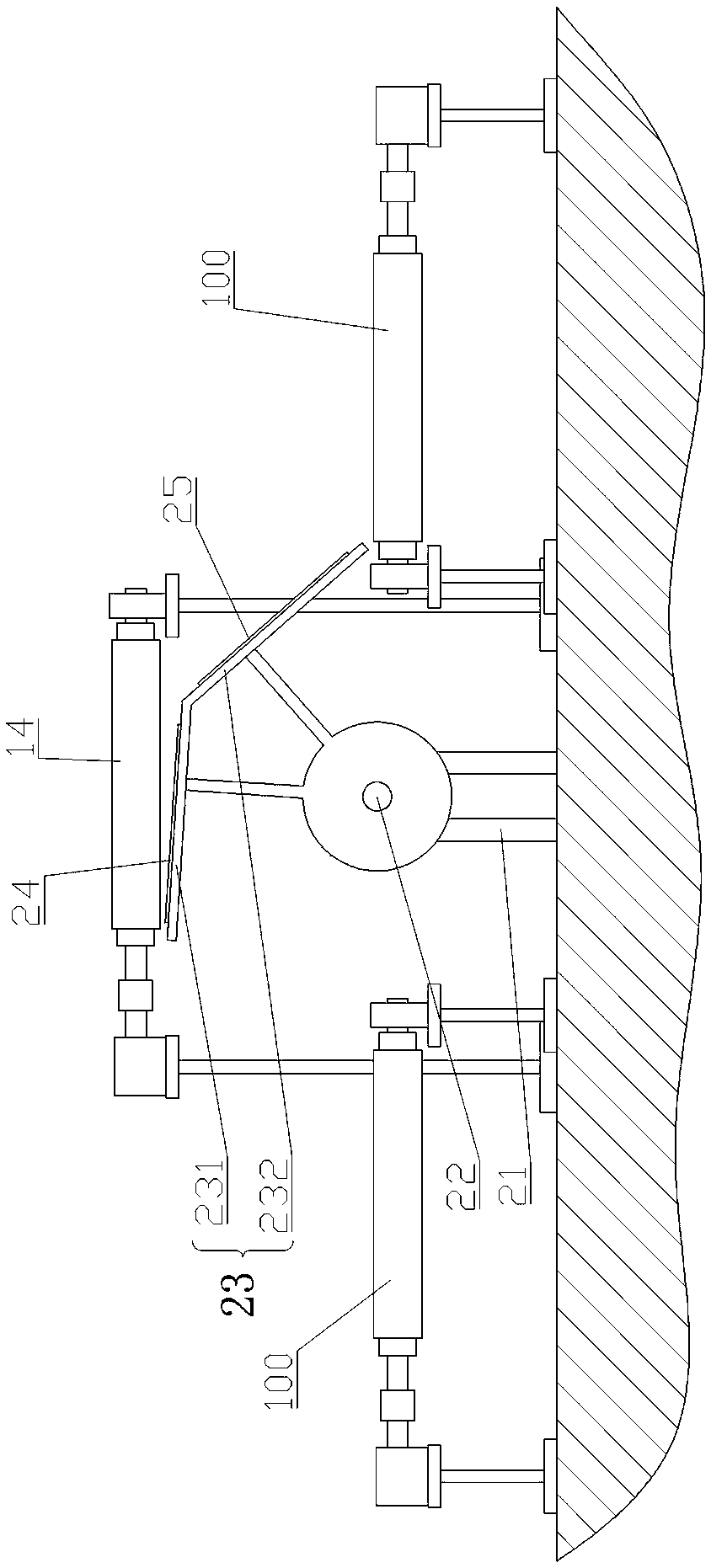

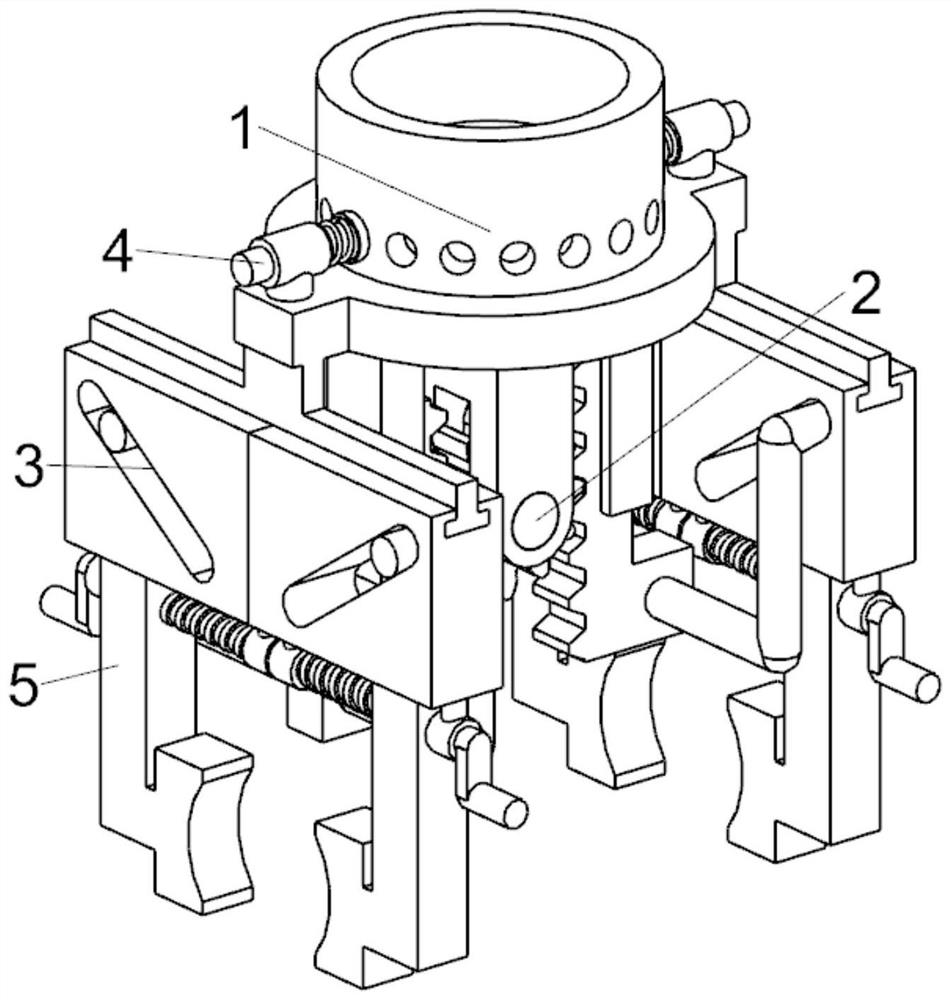

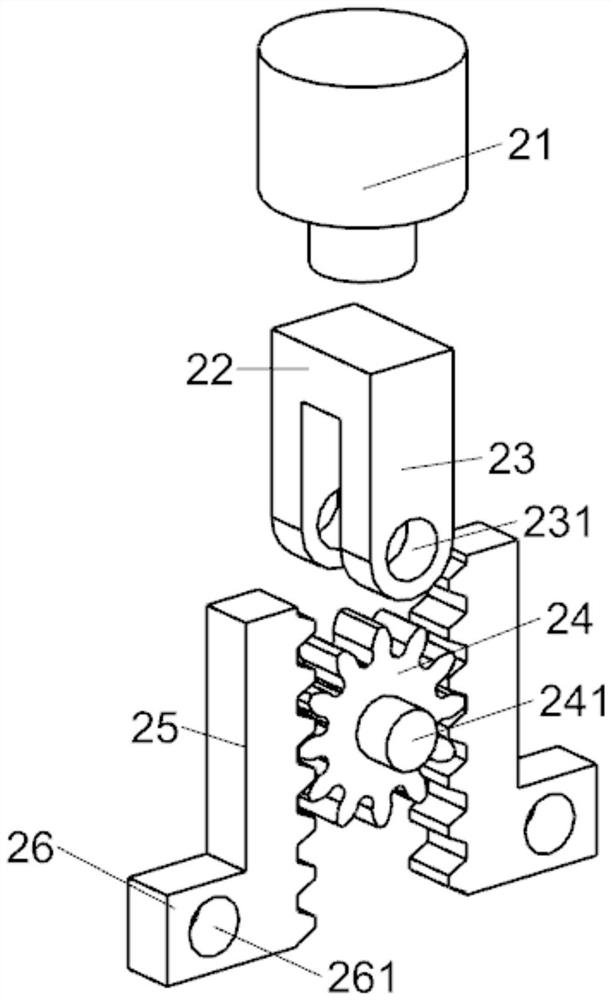

Turret type express sorting system

A turret type express sorting system comprises a main control computer, a package information entry device, a conveying belt device, package pushing devices and turret sorting devices. Each turret sorting device comprises a sorter and a plurality of package receivers. Each sorter comprises a stepping motor A, a vertical rotating shaft, a horizontal sweeping disc, a movable plate, a drive mechanism C for driving the movable plate to move, an upper base and a lower base. Each upper base is divided by sweeping arms of the corresponding horizontal sweeping disc into a plurality of stations, and the area between every two adjacent sweeping arms serves as one station. The stations of each upper base comprise the feeding station and the multiple transfer stations, each feeding station is adjacent to a conveying belt and right faces a pushing arm, and each transfer station is provided with a package falling opening. The movable plates are driven by the drive mechanisms C to move, and then the package falling openings are opened or closed. The corresponding package receiver is arranged under each package falling opening. The turret type express sorting system has the beneficial effects that compared with an existing automatic sorting system, the turret type express sorting system is small in occupied area, high in intelligent degree and high in sorting efficiency.

Owner:NANHUA UNIV

Intelligent storage shelf device for logistics storage

The invention discloses an intelligent storage shelf device for logistics storage. The intelligent storage shelf device for logistics storage comprises a warehouse and a front-end conveyer belt, a first turning sorting mechanism, a second turning sorting mechanism and a distributing conveyer belt which are sequentially arranged in the warehouse; the two sides of the first turning sorting mechanismand the two sides of the second turning sorting mechanism are each provided with a storage device; and each storage device comprises a stereoscopic warehouse, two-way sorting conveyer belts arrangedamong the stereoscopic warehouse, the first turning sorting mechanism and the second turning sorting mechanism, a first manipulator and a circular conveying device. According to the intelligent storage shelf device for logistics storage, a stereoscopic warehouse department can adjust the capacity of the stereoscopic warehouses according to the cargo quantity, and storing or conveying of cargoes onstorage grids is achieved through a horizontal conveying mechanism; meanwhile, the condition that the service life of the intelligent storage shelf device is influenced, and potential safety hazardsare caused due to the fact that the stereoscopic warehouse department is locally overloaded is avoided through a bearing early warning protection mechanism arranged at the bottom.

Owner:LONLINK SMART STORAGE SOLUTION SHANGHAI CO LTD

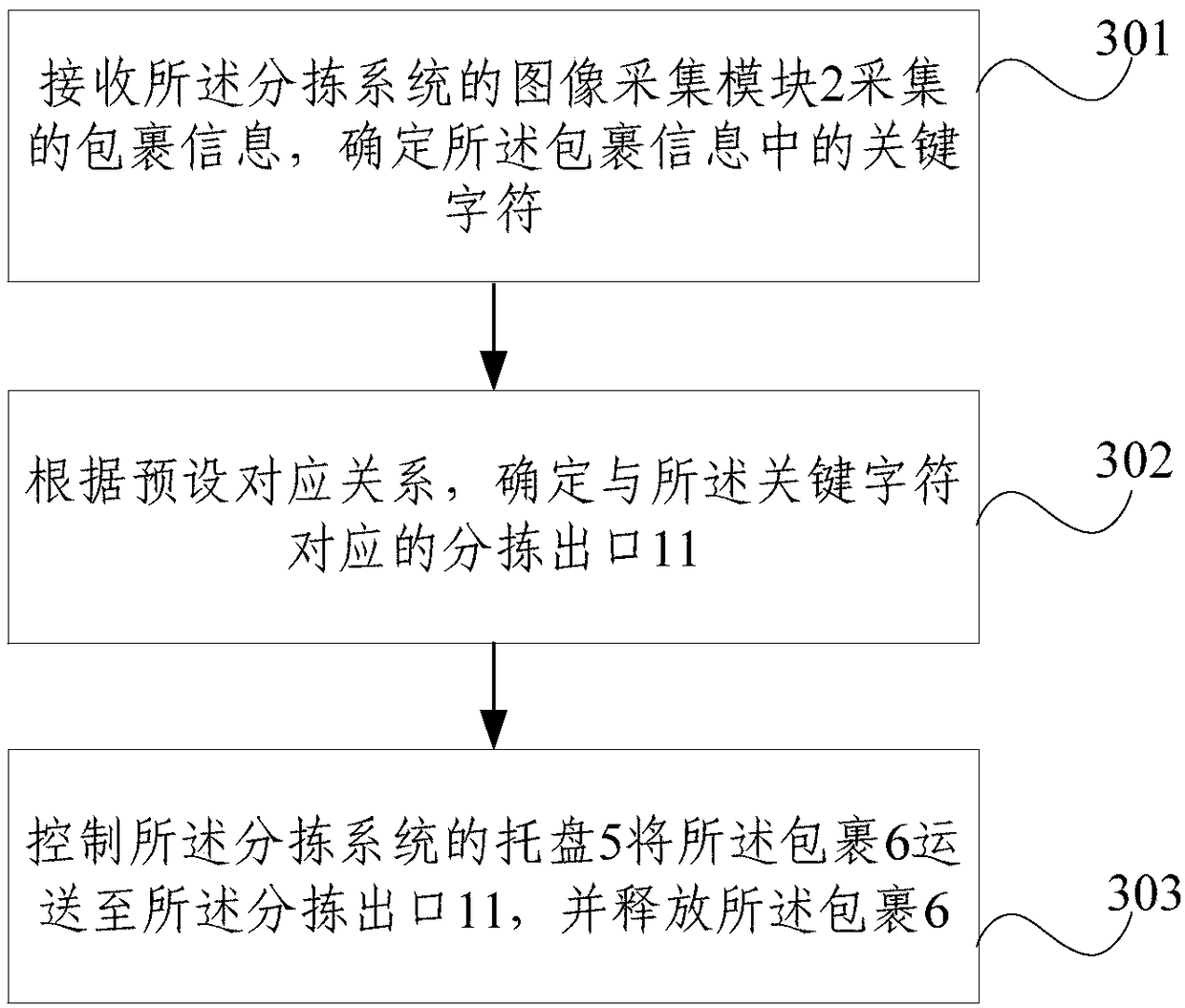

Sorting system and sorting method

The embodiment of the invention provides a sorting system and a sorting method. The sorting system comprises a conveying belt which comprises at least two trays used for carrying packages, an image collecting module used for collecting package information of the packages facing the image collecting module on the trays and collecting first identification numbers of the trays of the packages, an exit module which is arranged in the second preset direction of the conveying belt and comprises at least two sorting exits, and a system controlling module which is used for receiving the package information and the first identification numbers collected by the image collecting module to determine key characters in the package information. According to preset corresponding relationship, the sortingexit corresponding to the key characters is determined. The target tray corresponding to the first identification numbers is controlled to convey the packages to the sorting exits and release the packages. The integration and automation degree is high, the sorting cost and breaking rate can be lowered, and sorting efficiency can be improved.

Owner:杭州视语智能视觉系统技术有限公司

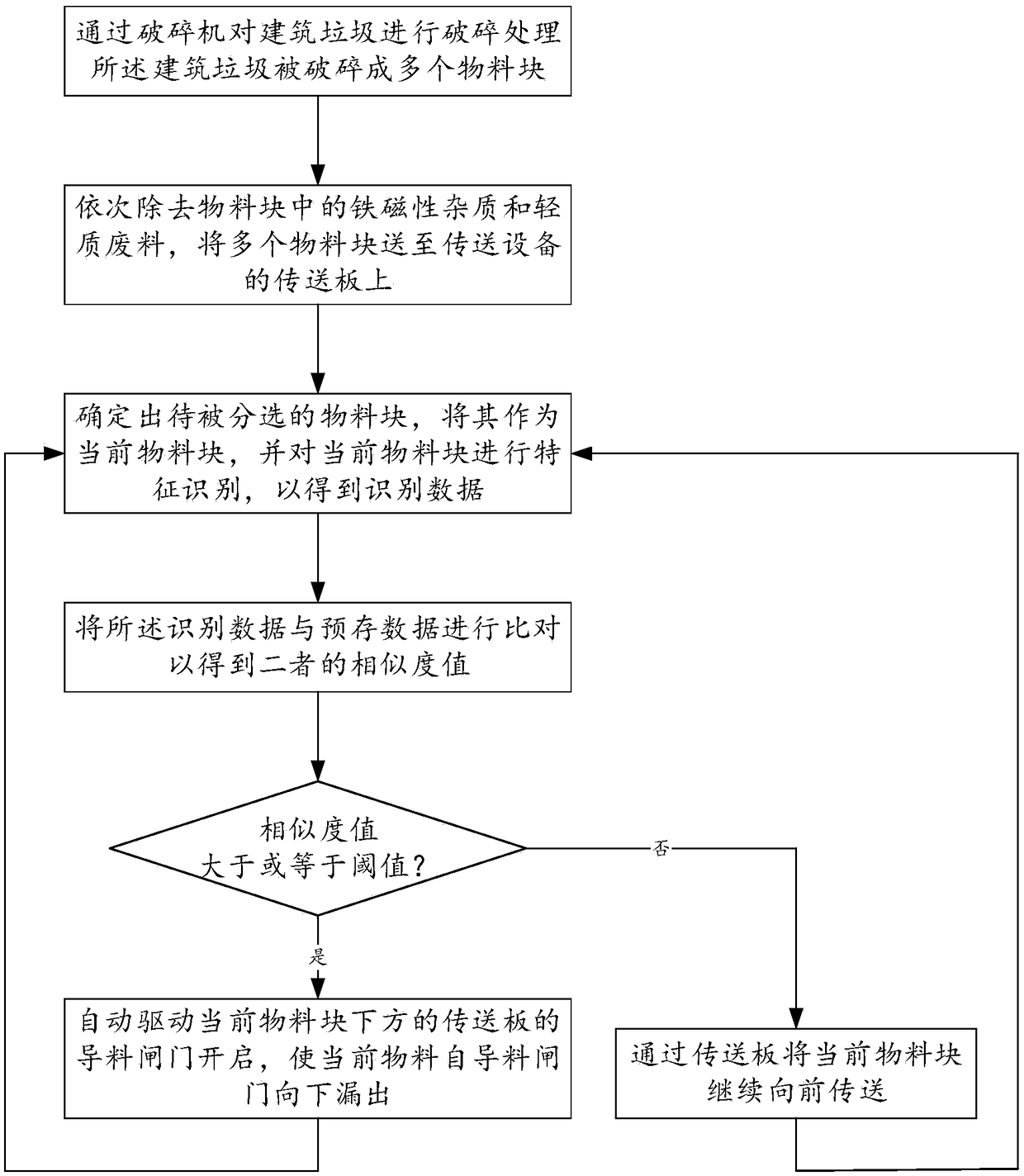

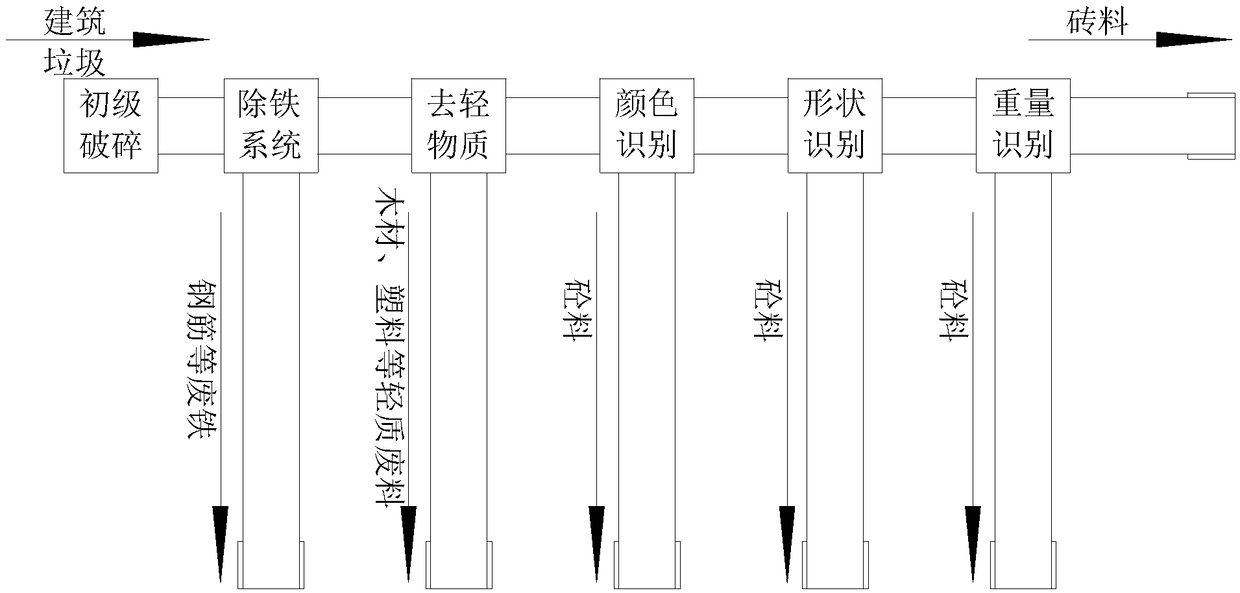

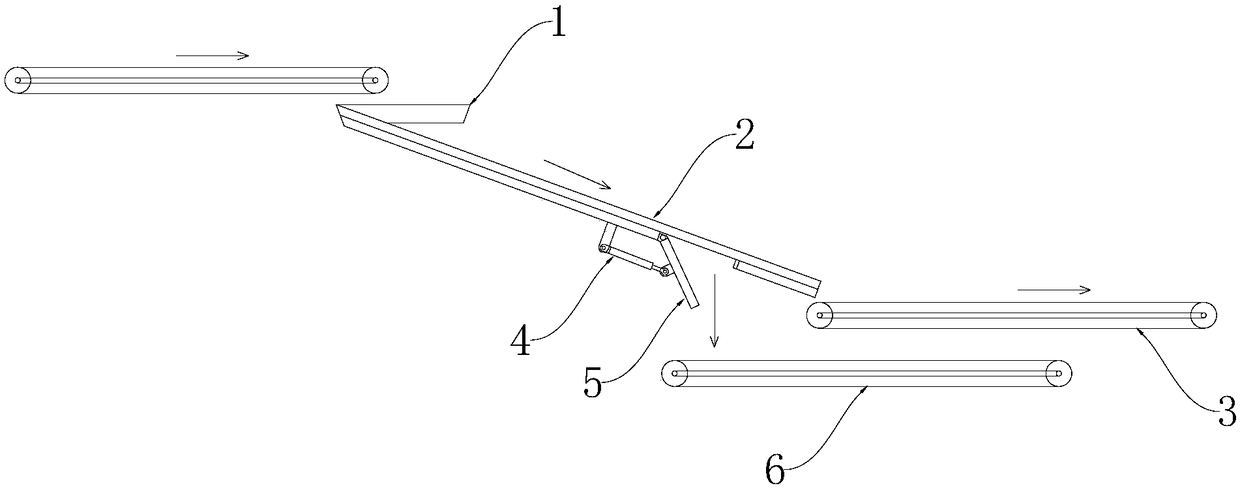

Automatic sorting method for construction waste

PendingCN108837936AAchieve separationAvoid personal harmCleaning using gasesGrain treatmentsBrickEngineering

The invention discloses an automatic sorting method for construction waste. The automatic sorting method comprises the following steps that firstly, the construction waste is crushed into material blocks; secondly, ferromagnetic impurities and light waste materials are removed, and the material blocks are conveyed to a conveying plate of conveying equipment; thirdly, feature identification is carried out on the current material blocks to obtain identification data; fourthly, the identification data are compared with the pre-stored data, and the similarity value of the identification data and the pre-stored data is obtained; if the similarity value is greater than or equal to the threshold value, the fifth step is executed; and otherwise, the sixth step is executed; fifthly, a material guide gate of the conveying plate below the current material blocks is driven to open so that the material guide gate can leak the current materials downward and the third step can be executed; and sixthly, the current material blocks are continuously conveyed forward, and the third step is executed. By the adoption of the automatic sorting method for the construction waste, the construction waste canbe effectively identified and sorted, the automatic diversion of brick materials and concrete materials is effectively realized, the sorting efficiency is improved, the harm to workers is avoided, and the labor cost is reduced.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

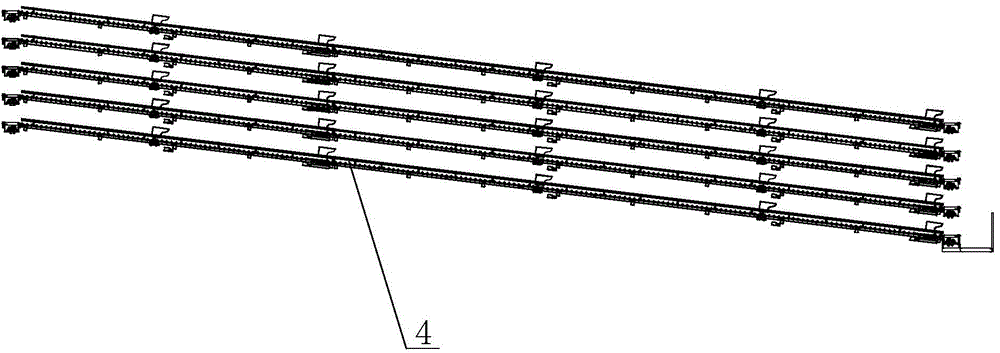

Package sorting method based on speed matching principle

ActiveCN108453062AImprove sorting efficiencyReduce workloadPackagingSortingLogistics managementLow speed

A package sorting method based on a speed matching principle is applied to a logistics sorting system based on a tower type sorting device. The process includes the following steps that 1, packages atdisordered intervals are output at equal intervals; 2, the packages are divided orderly on a front diversion conveyer; 3, the packages are scanned through a scanning device; 4, the packages are gathered orderly on a gathering conveyer; 5, the packages are divided orderly on a rear conveyer; 6, whether the packages are missing or not is checked through a correction device; 7, the packages are sorted and enter a collection box; 8, collection bags are sealed by the collection box; 9, the sealed collection bag are transferred to a carrying table; 10, one collection bag is automatically opened inthe collection box; 11; the collection bags on the carrying table are transferred to a conveyer C through a pusher. According to the problem that low-speed links (such as address scanning) in an existing logistics sorting assembly line causes slowness of the whole sorting assembly line, a sorting mode that a plurality of package low-speed line are in parallel connection is used, so that the sorting efficiency of the whole logistics sorting line is improved.

Owner:NANHUA UNIV

Time difference principle-based address error correction package sorting method

A time difference principle-based address error correction package sorting method is applied to a logistics sorting system having debugging-error correction-error checking functions. The method comprises the following steps: 1, packages which are input in a distantly disordered manner are output in an equidistant array manner; 2, barcode information of the packages is scanned by a scanning device;3, the packages are converged to a converging conveyor in an ordered manner; 4, the packages are divided into a plurality of division conveyor belts by a divider in an ordered manner; 5, whether thepackages are deleted or not is checked; 6, the packages are sorted and enter a corresponding collecting box; 7, collecting bags reaching bind-off standards are bound off; 8, the collecting bags are transferred to an objective table; 9, one of the collecting bags in the collecting box is automatically distracted after the collecting bag is transferred out; and 10, the collecting bag is transferredto the conveyor C by a pusher. An error correction link having address debugging-error correction-error checking functions is added before a package classifying and bagging link to prevent the dislocation of a code scanning address and the address of a package, so the sorting accuracy is improved.

Owner:NANHUA UNIV

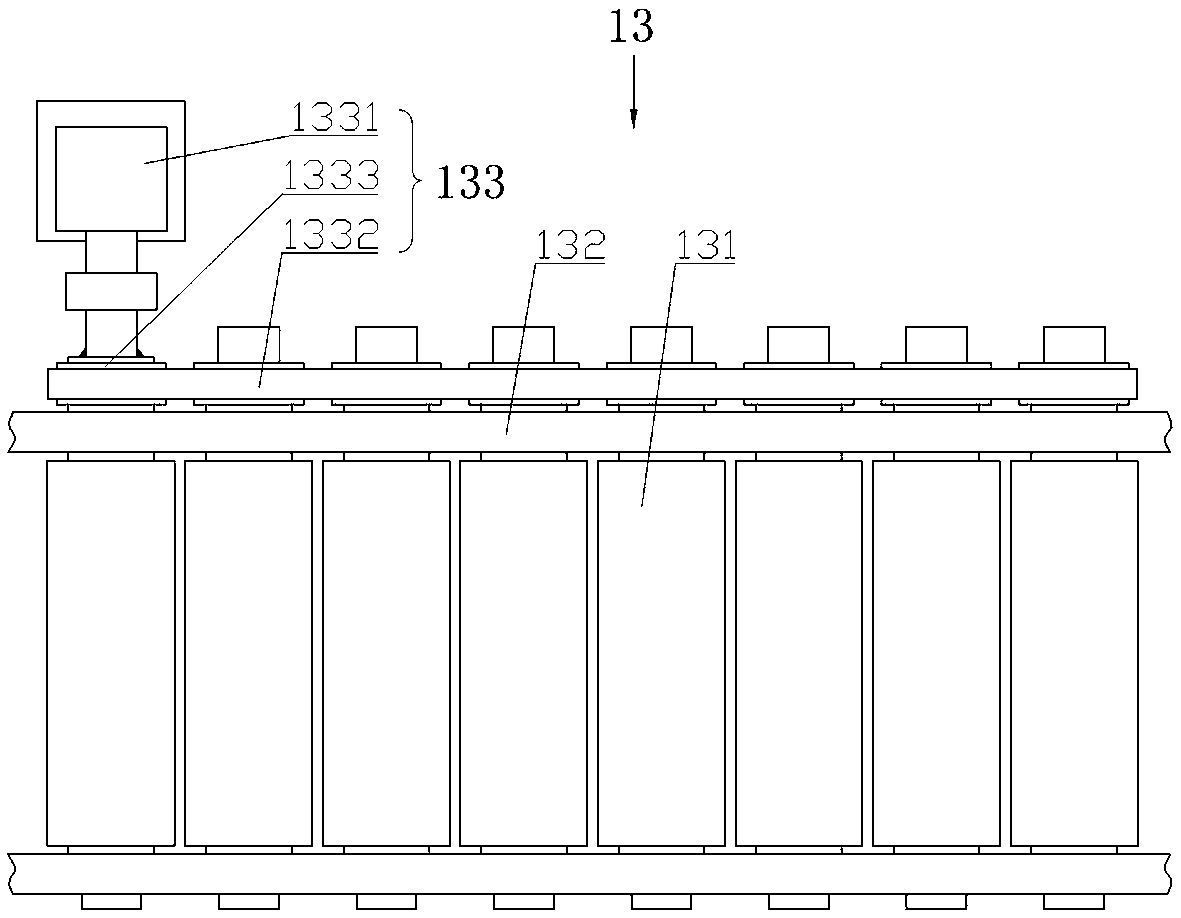

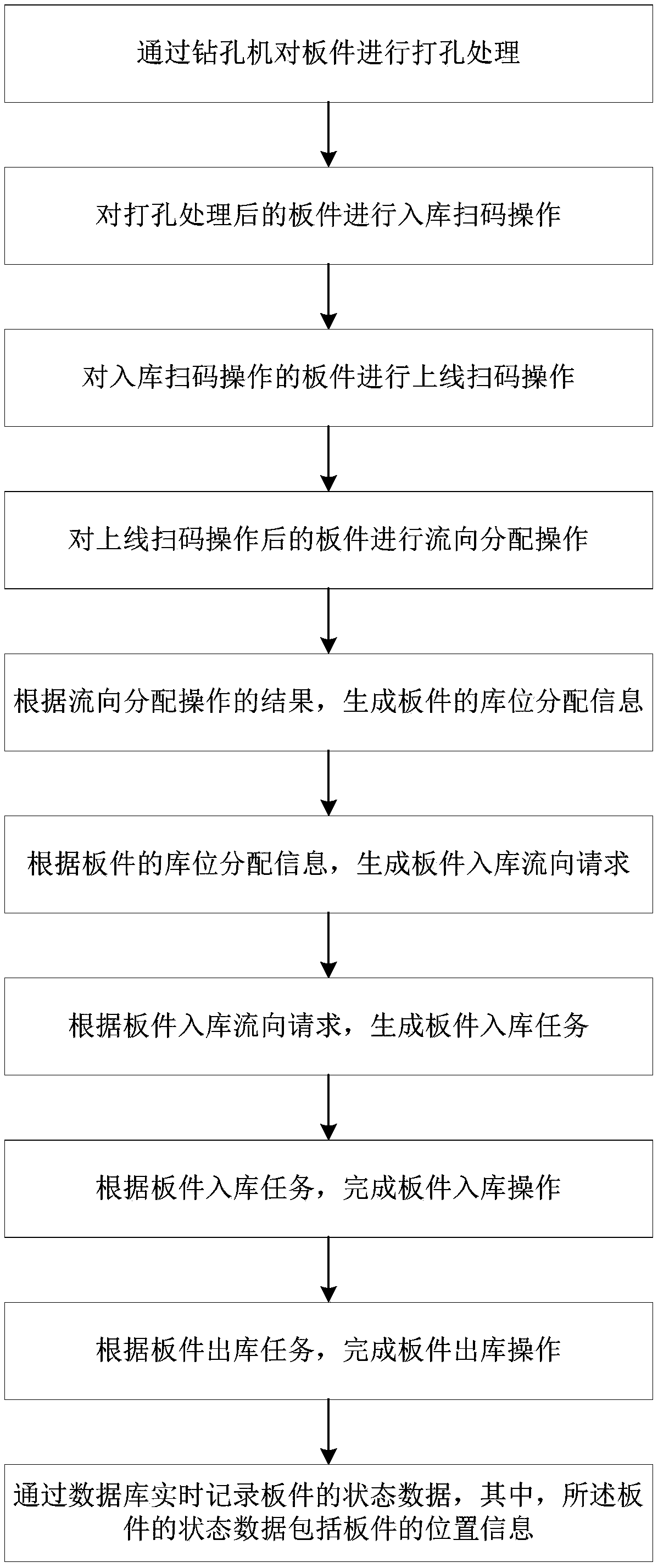

Intelligent sorting method and system and storage medium

PendingCN109615344AImprove work efficiencyReduce sorting error rateOffice automationLogisticsData warehouseDrilling machines

The invention discloses an intelligent sorting method and system and a storage medium. The method comprises the steps that a plate is punched through a drilling machine; carrying out warehousing and code scanning operation on the punched plate; carrying out online code scanning operation on the plate subjected to the warehousing code scanning operation; carrying out flow direction distribution operation on the plate subjected to the online code scanning operation; according to a result of the flow direction distribution operation, generating storage location distribution information of the plate; generating a plate warehousing flow direction request according to the storage location distribution information of the plate; generating a plate warehousing task according to the plate warehousing flow direction request; completing plate warehousing operation according to the plate warehousing task; according to the plate warehouse-out task, plate warehouse-out operation is completed; and recording state data of the plate in real time through the database. According to the invention, the working efficiency is improved, and the sorting error rate is reduced; each state record in the platesorting process can be recorded, a historical state record tracing function is provided, and the method can be widely applied to the technical field of plate sorting.

Owner:广州宁基智能系统有限公司

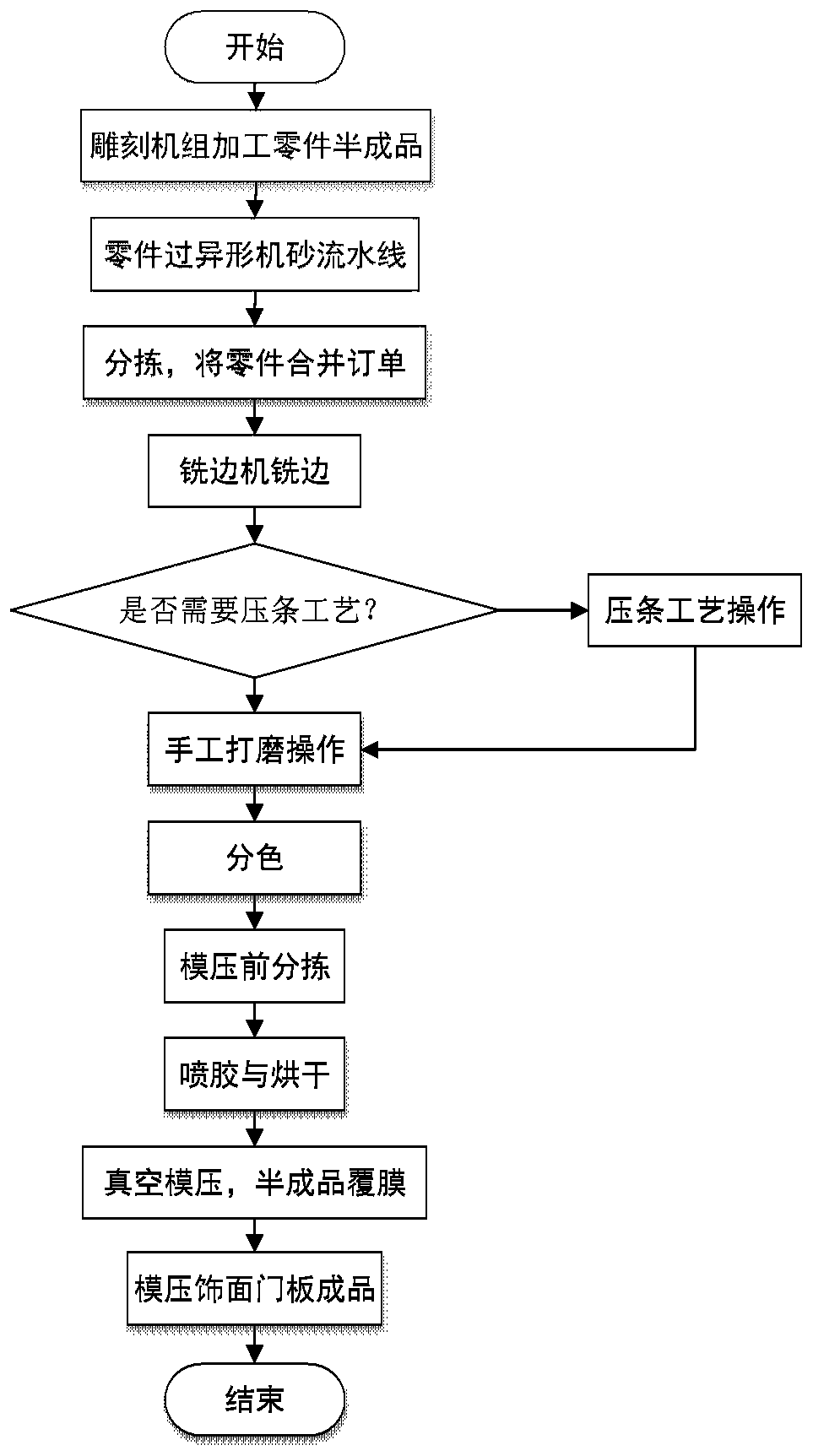

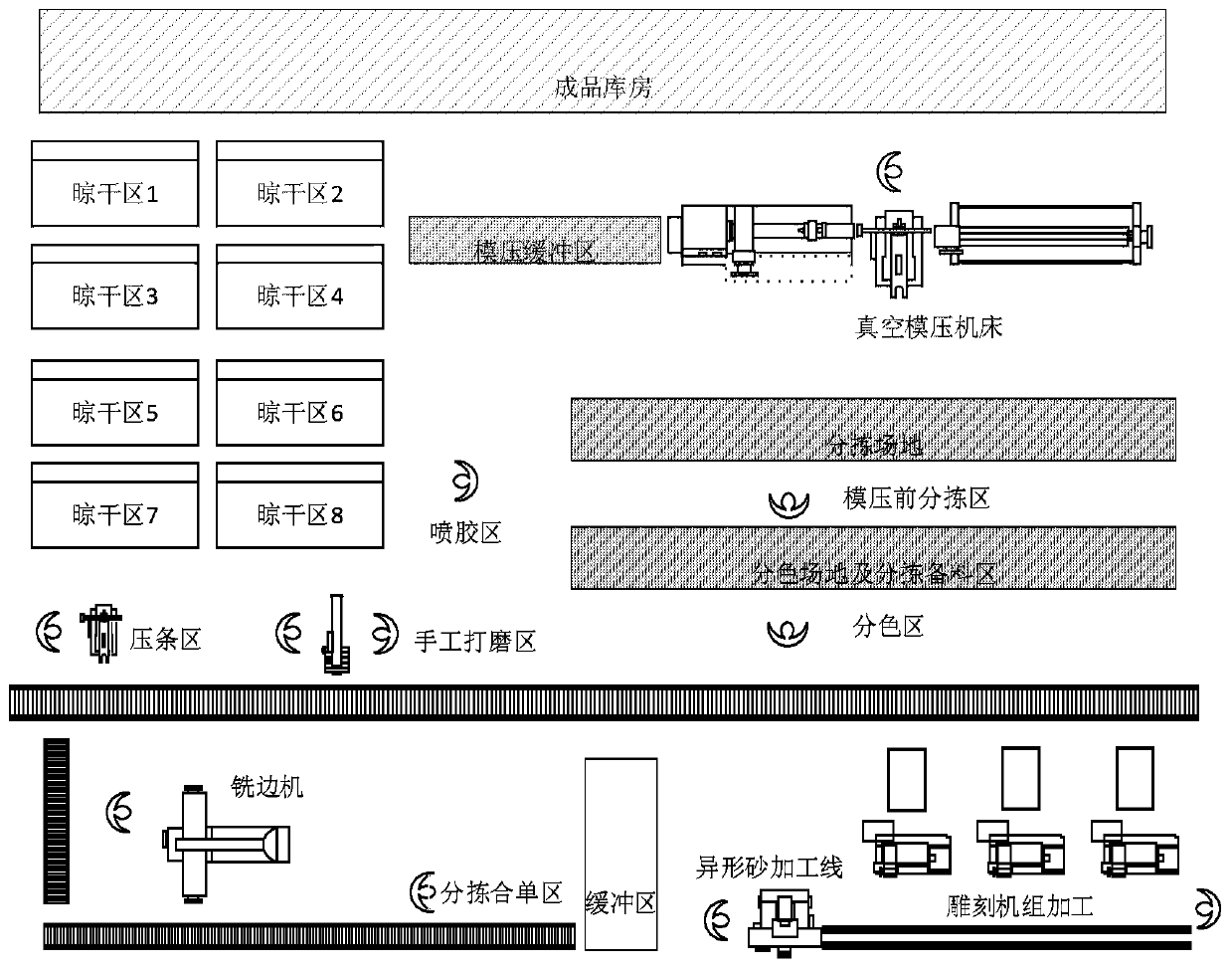

Production method and production system for die pressing veneer door panels

ActiveCN110315615AReduce manual operationsImprove operational efficiencyWood working apparatusWork in processAssembly line

The invention provides a production method and a production system for die pressing veneer door panels, and belongs to the technical field of door panel production. The production method for the die pressing veneer door panels comprises the steps that an engraving machine processes original plates into door panel part semi-finished products with hinge holes and sends the door panel part semi-finished products to a special-shaped machine sand assembly line to remove rough parts and burrs of the door panel part semi-finished products; according to the condition whether the door panel part semi-finished products need to be subjected to strip pressing, whether the door panel part semi-finished products are sent to a strip pressing station for strip pressing operation or not is selected; the door panel part semi-finished products are sorted according to the to-be-laminated color at a color separation station, the door panel part semi-finished products in each laminating color are subjectedto tool separation operation at a sorting station before die pressing; the door panel part semi-finished products on each tool are subjected to glue spraying operation, and then the door panel part semi-finished products are sent to a drying room for drying; and the dried door panel part semi-finished products on each tool are sent to a vacuum die pressing station for vacuum die pressing operation, and the finished products of the die pressing veneer door panels are obtained. By means of the production method and the production system, the production efficiency is improved, and production is more smooth.

Owner:TIANJIN UNIV

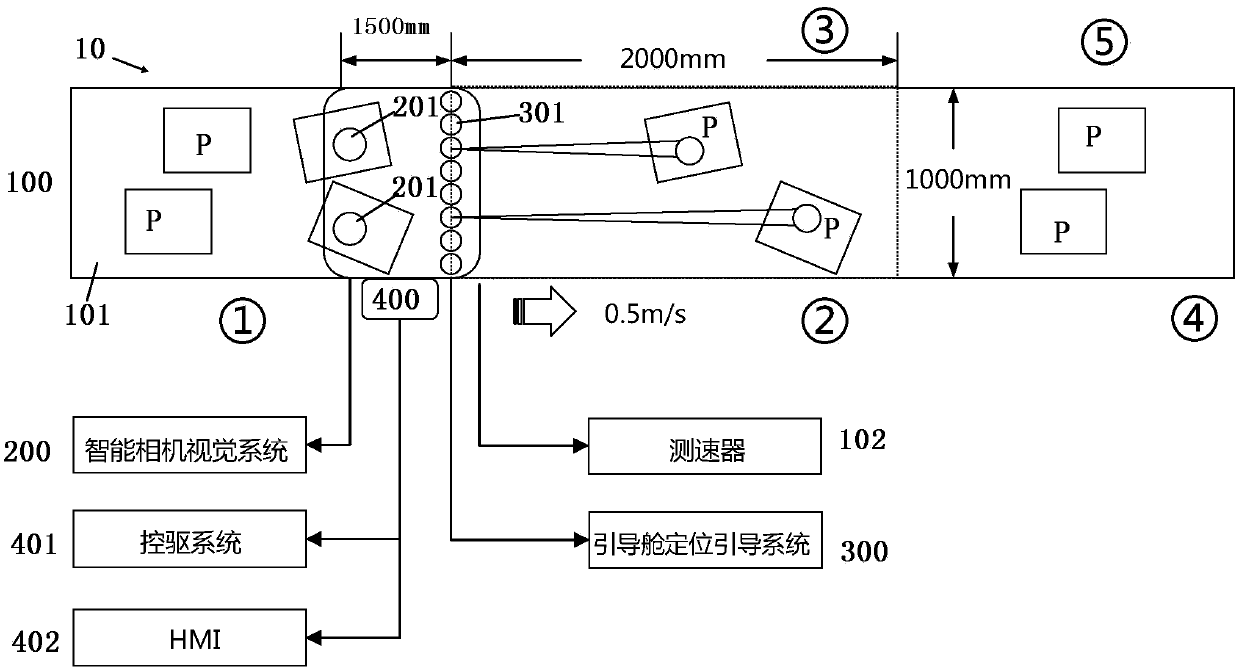

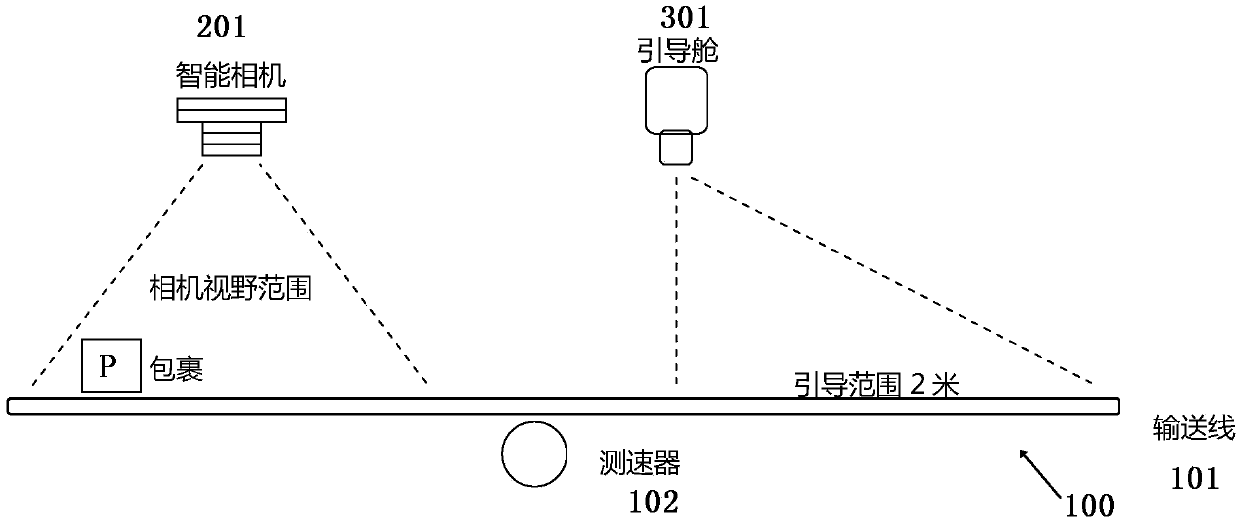

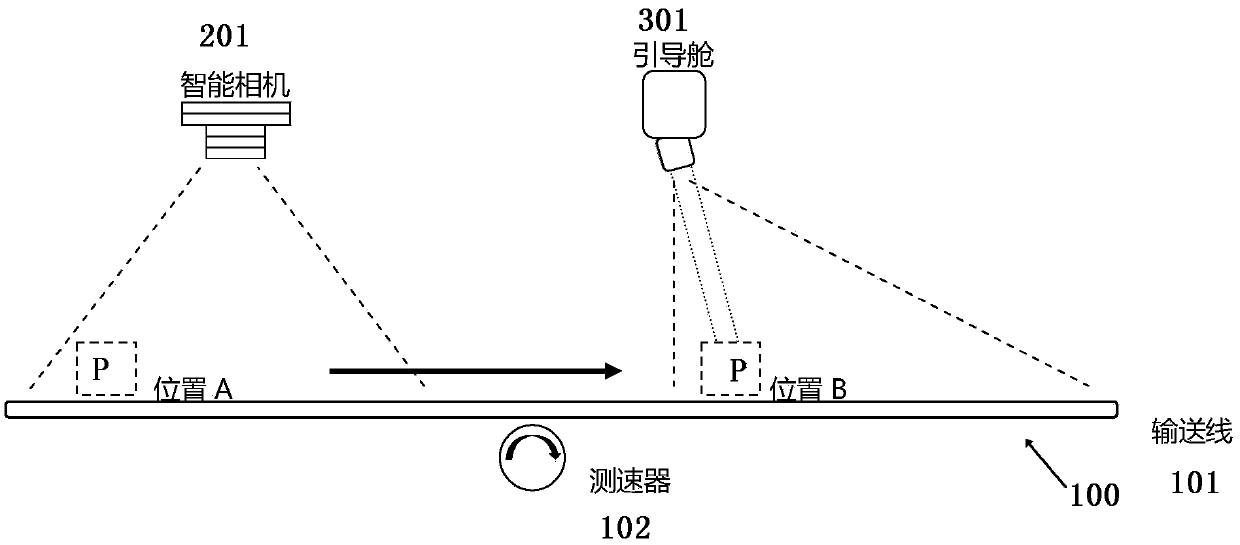

Visual localization guidance system and method for sorting

InactiveCN110813768AOvercoming the problem of prone to visual fatigueReduce sorting error rateSortingLogistics managementVisual localization

The invention discloses a visual localization guidance system and method for sorting, and relates to the field of warehouse logistics. The visual localization guidance system for sorting comprises a package transfer system, a smart camera vision system, a guidance bin localization guidance system and a controller, wherein the package transfer system comprises a conveyor line for transferring packages and a speedometer for measuring the speed of the conveyor line, the smart camera vision system comprises one or more smart cameras arranged above the conveyor line and is used for scanning and localizing the packages on the conveyor line and transmitting information of the packages to the controller, the guidance bin localization guidance system comprises a plurality of visual guidance bins arranged above the conveyor line at a certain distance from the downstream of the smart cameras and used for projecting color light onto target packages in a guidance area according to an instruction ofthe controller so as to provide visual localization guidance, and the controller is used for assigning guidance tasks to the visual guidance bins based on the information of the packages so as to instruct that visual localization guidance is conducted on the target packages. The visual localization guidance system and method for sorting reduce the error rate of manual sorting and improve the sorting efficiency.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

An intelligent storage shelf device for logistics warehousing

ActiveCN108502430BImplement storageRealize deliveryStorage devicesLogistics managementProtection mechanism

The invention discloses an intelligent storage shelf device for logistics storage. The intelligent storage shelf device for logistics storage comprises a warehouse and a front-end conveyer belt, a first turning sorting mechanism, a second turning sorting mechanism and a distributing conveyer belt which are sequentially arranged in the warehouse; the two sides of the first turning sorting mechanismand the two sides of the second turning sorting mechanism are each provided with a storage device; and each storage device comprises a stereoscopic warehouse, two-way sorting conveyer belts arrangedamong the stereoscopic warehouse, the first turning sorting mechanism and the second turning sorting mechanism, a first manipulator and a circular conveying device. According to the intelligent storage shelf device for logistics storage, a stereoscopic warehouse department can adjust the capacity of the stereoscopic warehouses according to the cargo quantity, and storing or conveying of cargoes onstorage grids is achieved through a horizontal conveying mechanism; meanwhile, the condition that the service life of the intelligent storage shelf device is influenced, and potential safety hazardsare caused due to the fact that the stereoscopic warehouse department is locally overloaded is avoided through a bearing early warning protection mechanism arranged at the bottom.

Owner:LONLINK SMART STORAGE SOLUTION SHANGHAI CO LTD

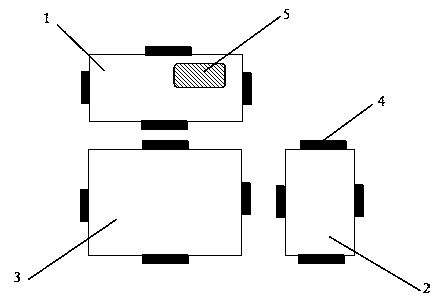

Intelligent box for changing, classifying and counting bus coins

PendingCN107622558AEasy rideImprove work efficiencyCoin/currency accepting devicesCoin dispensersEngineeringHuman error

The invention provides an intelligent box for changing, classifying and counting bus coins and belongs to the technical field of mechanical electronic equipment. The intelligent box comprises a coin changing device and a coin classifying counting device, wherein the coin changing device is arranged in a coin inserting box and on the outer surface; a coin classifying device is arranged in the coininserting box; a fifty-cent coin inlet, a one-yuan coin inlet, a one-yuan paper currency inlet, a one-yuan and five-yuan paper currency receiving port, a one-yuan coin changing port and an informationprompt display screen are formed in the outer surface of the coin inserting box; a coin classifying plate, an electric fan, a receiving box for various coins of a counter, a changing device and a coin splitting pipe are arranged in the coin inserting box. The intelligent box provided by the invention is capable of automatically changing the coins, guaranteeing the sufficient changing quantity, automatically classifying at par and automatically counting and recording the income, so that the working efficiency of the bus company can be increased, the human error rate in the classifying countingprocess is reduced, the intelligent box is convenient for passengers without small change for taking a bus and the time of the passenger is saved.

Owner:山东大学深圳研究院

Express delivery containerization box

InactiveCN103466160AEasy to carryReduce pollutionRigid containersExternal fittingsContainerizationEngineering

The invention provides an express delivery containerization box. The express delivery containerization box comprises 6 rectangular plates, wherein the 6 rectangular plates comprise two same plates A, two same plates B and two same plates C; the length of the plate A is the same with that of the plate B; the length of the plate C is equal to the width of the plate A; the width of the place C is equal to that of the plate B; lengths of the plates A, B and C are respectively integral multiples of widths of the plates A, B and C; connecting ends are arranged on four sides of each rectangular plate; and an electronic tag is arranged on at least one rectangular plate. By improving the express delivery containerization box through the technical scheme, the problem of how to provide a hard express delivery packaging material which can be reused is solved.

Owner:马晓璐

Intelligent express delivery sorting machine and sorting method

The invention provides an intelligent express delivery sorting machine. The intelligent express delivery sorting machine comprises a scanning device, a transport device, a sorting device and a sortingbasket frame, wherein the scanning device, the transport device, the sorting device and the sorting basket frame are sequentially arranged according to the station sequence. The intelligent express delivery sorting machine further comprises a control center which is in signal connection with each device and the sorting frame. The invention further provides a corresponding sorting method. By meansof the intelligent express delivery sorting machine, the sorting speed can be effectively increased. The intelligent express delivery sorting machine is particularly applicable to the distribution ofmedium and small express delivery packages. Sorting is convenient, express delivery sorting is rapid and accurate, the occupied space is small, the labor cost is reduced, express delivery sorting isin order, the sorting efficiency is high, and the error rate is very low. Moreover, because a large number of sorting baskets exist, a larger number of categories of express delivery sorting are available, and more convenience is brought. Meanwhile, by means of the express delivery sorting method, the positions of the sorting baskets can be confirmed in advance, so that a large number of packagesto be delivered in the same delivery station can be sorted into the sorting baskets as soon as possible, and the sorting baskets are carried away by transportation tools after being fully loaded.

Owner:FOSHAN UNIVERSITY

Static grabbing and transferring automatic sorting and conveying equipment

PendingCN114873245AImprove sorting efficiencyReduce sorting error rateConveyorsConveyor partsComputer hardwareEngineering

The static grabbing and transferring automatic sorting and conveying equipment comprises a supporting and fixing assembly, a power assembly is installed below the supporting and fixing assembly, transmission assemblies are symmetrically installed on the two sides of the power assembly, and angle limiting assemblies are symmetrically installed on the two sides of the supporting and fixing assembly; the supporting and fixing assembly comprises a connecting and fixing column and a rotating disc, a through receding hole is formed in the top end of the connecting and fixing column, limiting inserting holes in a circular array are formed in the peripheral side of the connecting and fixing column, a protruding disc is fixedly connected to the bottom end of the connecting and fixing column, and a fixing and mounting hole is formed in the center of the top end of the rotating disc. And a rotating groove rotationally matched with the rotating disc is formed in the top end of the rotating disc outside the fixed mounting hole. By arranging the driving assembly, objects in irregular shapes can be grabbed, manual sorting is replaced, the sorting efficiency is improved, and the sorting error rate is effectively reduced.

Owner:赛那德科技有限公司

Sorting device for sorting logistics parcels

ActiveCN109080888ARealize automatic sortingImprove sorting efficiencyWrapper twisting/gatheringButt jointBarrel Shaped

The invention discloses a sorting device for sorting logistics parcels. The sorting device comprises a barrel-shaped sorting device, a disc ring type conveyor belt, a sliding plate and an enclosure barrel. A carrying plate is welded to the inner wall of the barrel-shaped sorting device, the disc ring type conveyor belt is fixedly connected to the panel of the carrying plate, a scanning device is fixedly connected to the inner wall of the barrel-shaped sorting device, a delivery port is formed in the inner wall of the barrel-shaped sorting device, the delivery port is formed by penetrating theouter wall of the barrel-shaped sorting device, a supporting plate is welded to the outer wall of the barrel-shaped sorting device, a hydraulic rod is carried on the supporting plate, and the outer wall, penetrating the outer wall, of the barrel-shaped sorting device, of the hydraulic rod is fixedly connected to the panel of a distributary panel; the enclosure barrel is arranged on a storage device and is matched with a butt joint door plank to enclose the storage device, so that the sorting device is prevented from toppling over in the sorting process; a shock absorbing part and a pulley arearranged on the storage device, so that the storage device is unloaded and transferred conveniently.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com