Yoghourt refrigerating automatic storage and transport sorting system based on sliding stocking up channel

A sorting system, fully automatic technology, applied in the direction of chutes, storage devices, stacking of objects, etc., can solve the problems of environmental temperature, lack of product temperature, inability to trace food, etc., to achieve traceability, error The effect of low rate and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

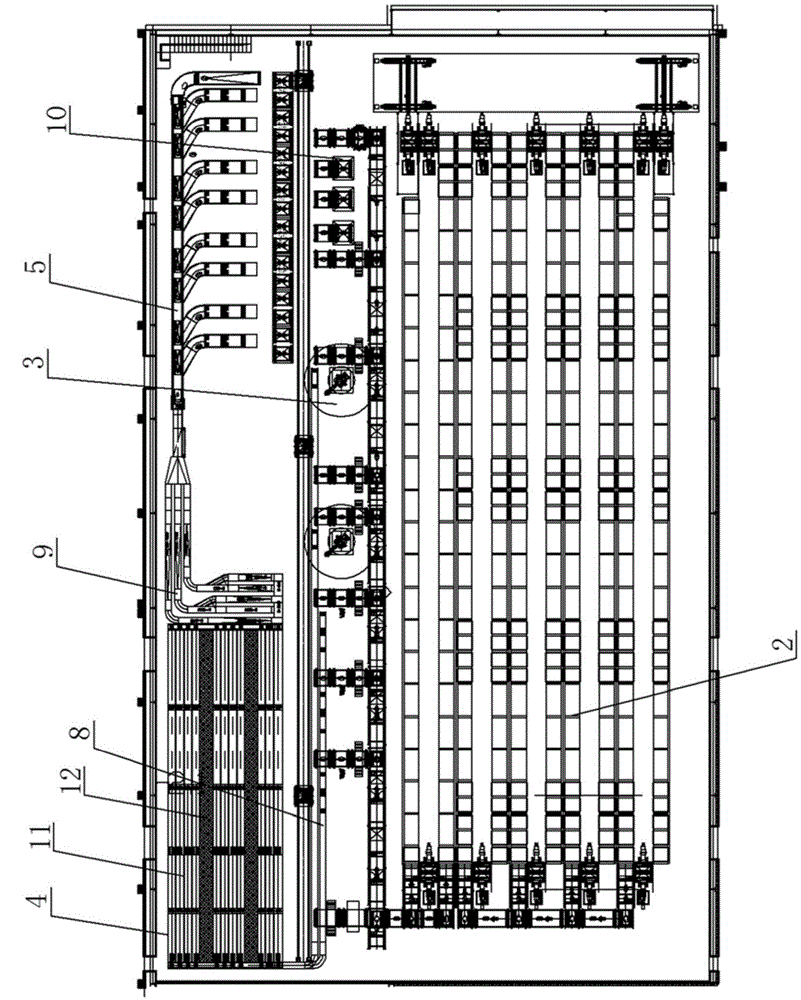

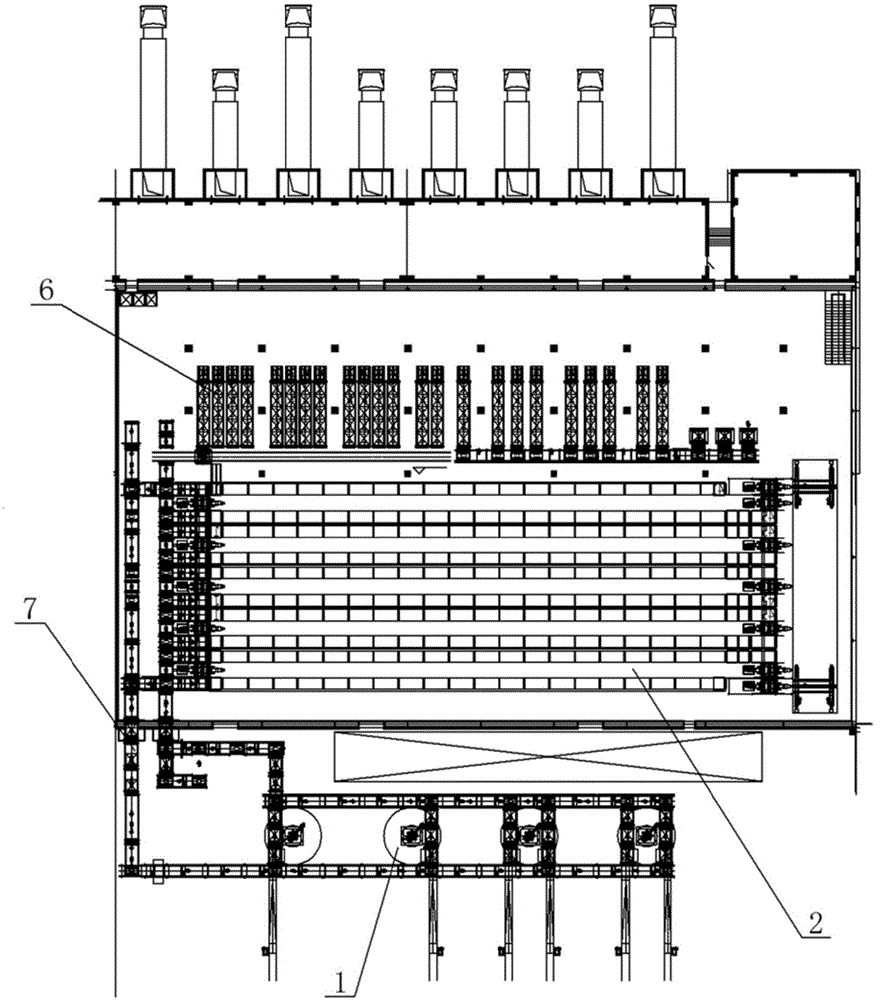

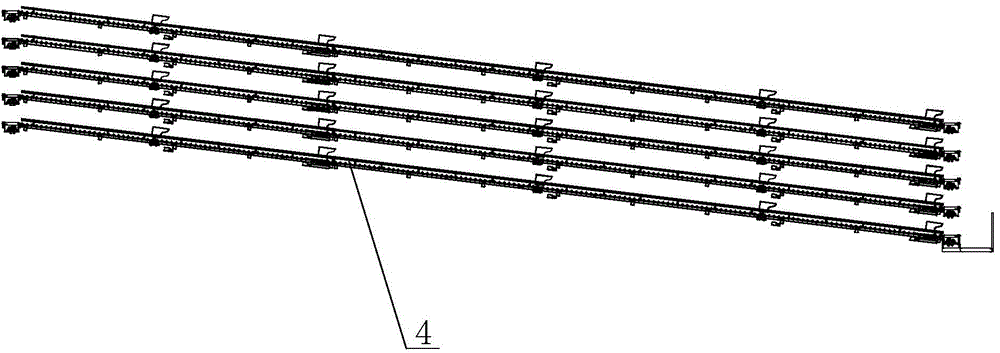

[0017] see Figure 1 to Figure 3 As shown, in this embodiment, a yoghurt refrigerated automatic storage, conveying and sorting system based on a fluent stocking lane is arranged in the upper and lower floors, including a robot palletizing system 1, an automated three-dimensional warehouse 2, Robot unstacking system 3, fluent stocking lane 4, high-speed sliding shoe sorter 5, gravity shelf 6, automatic control system and barcode information management system, the automatic three-dimensional warehouse 2 runs through the upper and lower floors, and the The robot palletizing system 1 and the gravity rack 6 are arranged on the first floor, and the robot depalletizing system 3, the fluent stocking lane 4 and the sorting system 5 are arranged on the second floor. The robot palletizing system 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com