Patents

Literature

34results about How to "Avoid personal harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene oxide for electrochemical reduction and preparation method of graphene

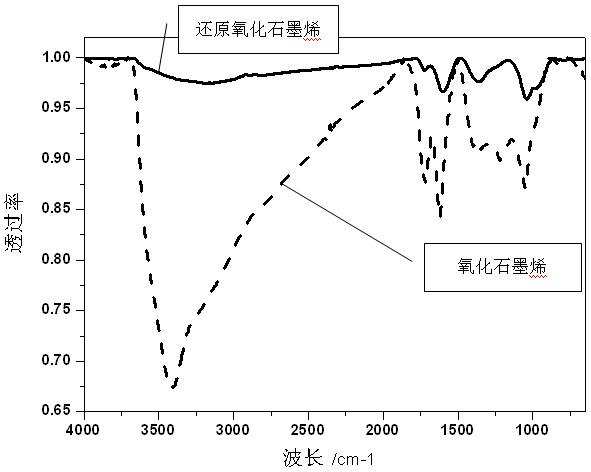

InactiveCN102181877AQuality improvementElectrochemical reduction is effectively realizedElectrolysis componentsCopper conductorGraphite

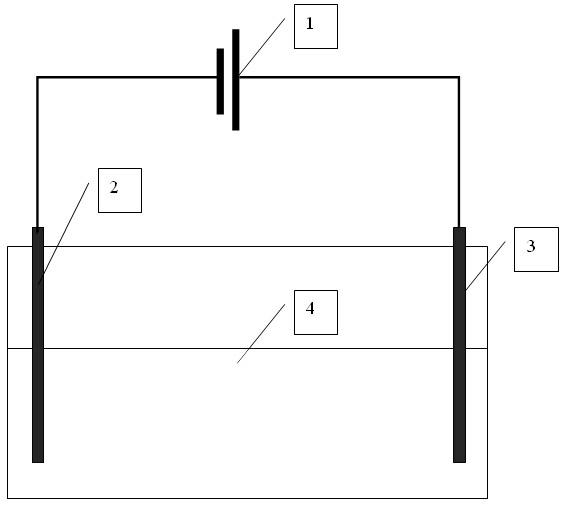

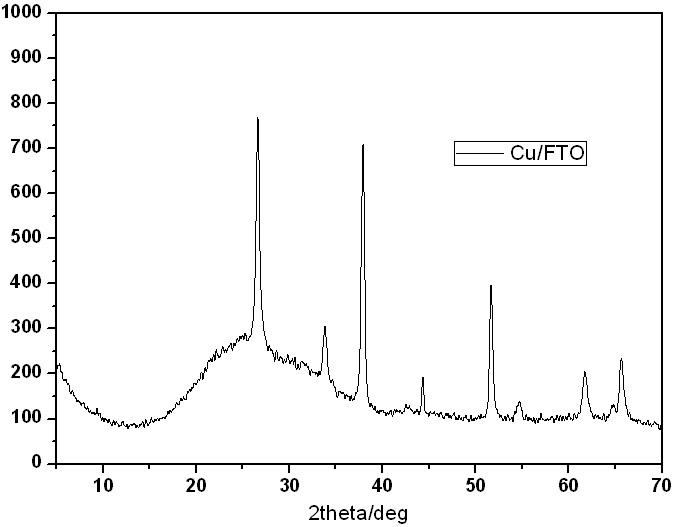

The invention belongs to the technical field of nano materials, and particularly relates to a graphene oxide for electrochemical reduction and a preparation method of graphene. The method comprises the following steps: dissolving graphite oxide in deionized water, and carrying out ultrasonic peeling to obtain a graphene oxide solution; cleaning electrodes and a glass container; adding the graphene oxide solution into the glass container; connecting one end of a copper conductor with cathode and anode materials, putting the electrodes into the graphene oxide solution, and respectively connecting the other end of the copper conductor with positive and negative poles of a direct-current stabilized voltage supply; switching on the direct-current stabilized voltage supply, wherein the voltage is controlled at 10-50V, and the temperature is controlled at 25-90 DEG C; and carrying out electrochemical reduction for 1-60 minutes, thereby obtaining the graphene. The graphene prepared by the method provided by the invention has the advantages of high quality; and the method is simple to operate, and has the advantages of low cost, high safety, no pollution, high-efficiency and the like.

Owner:TONGJI UNIV

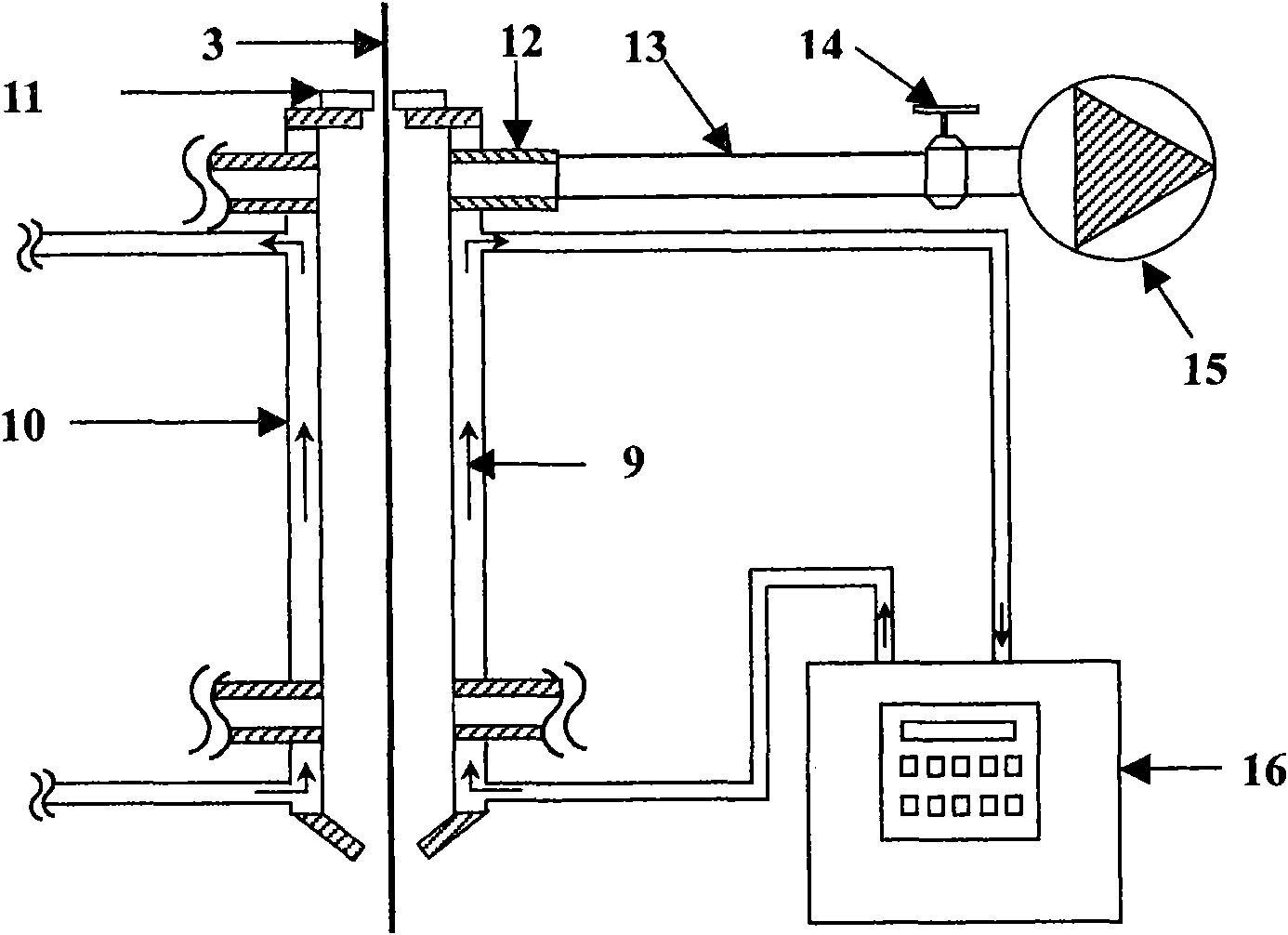

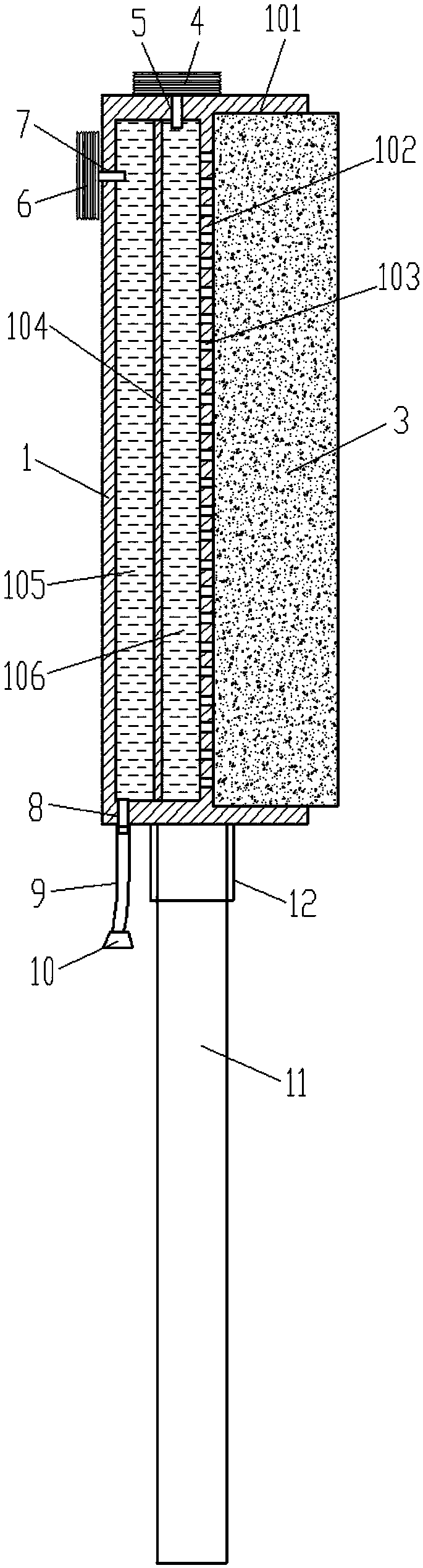

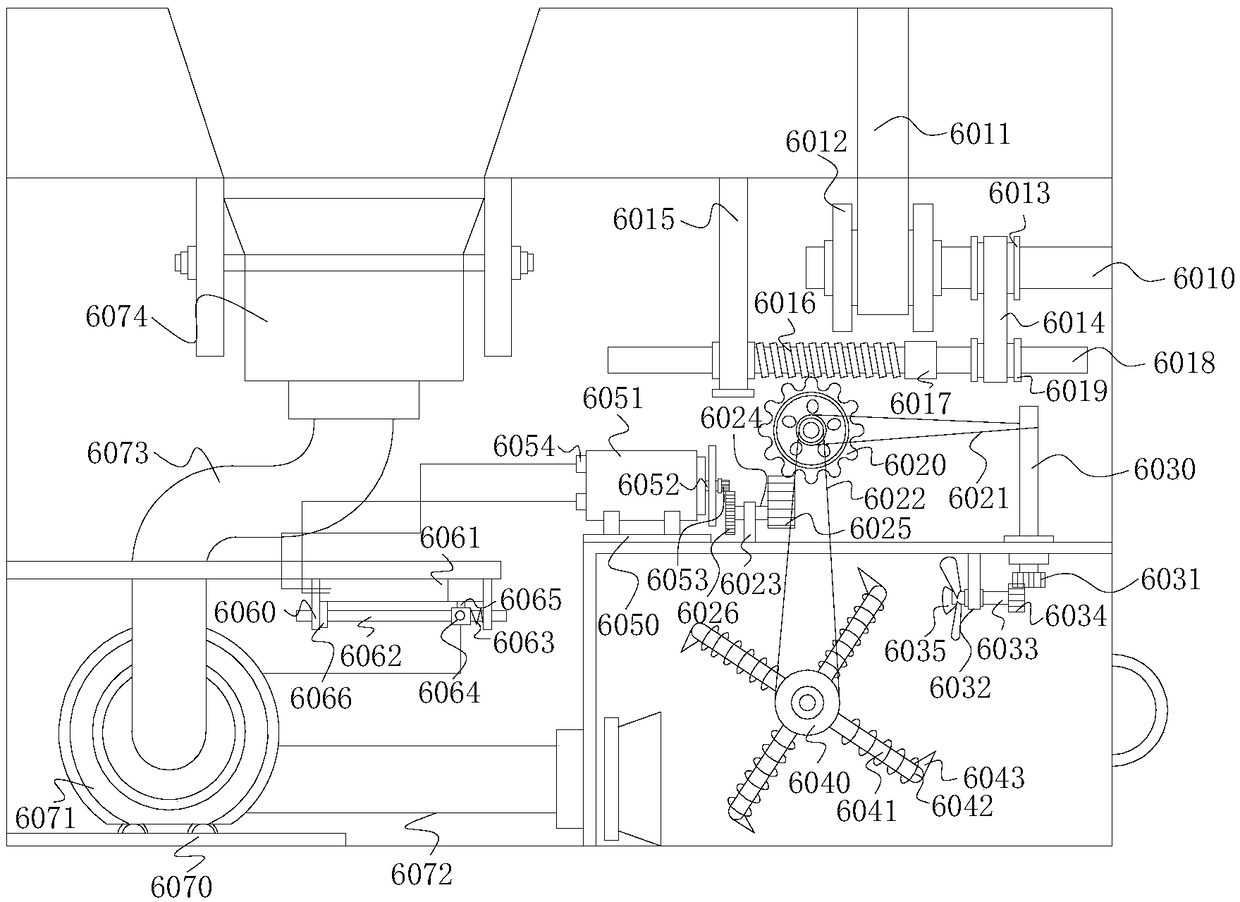

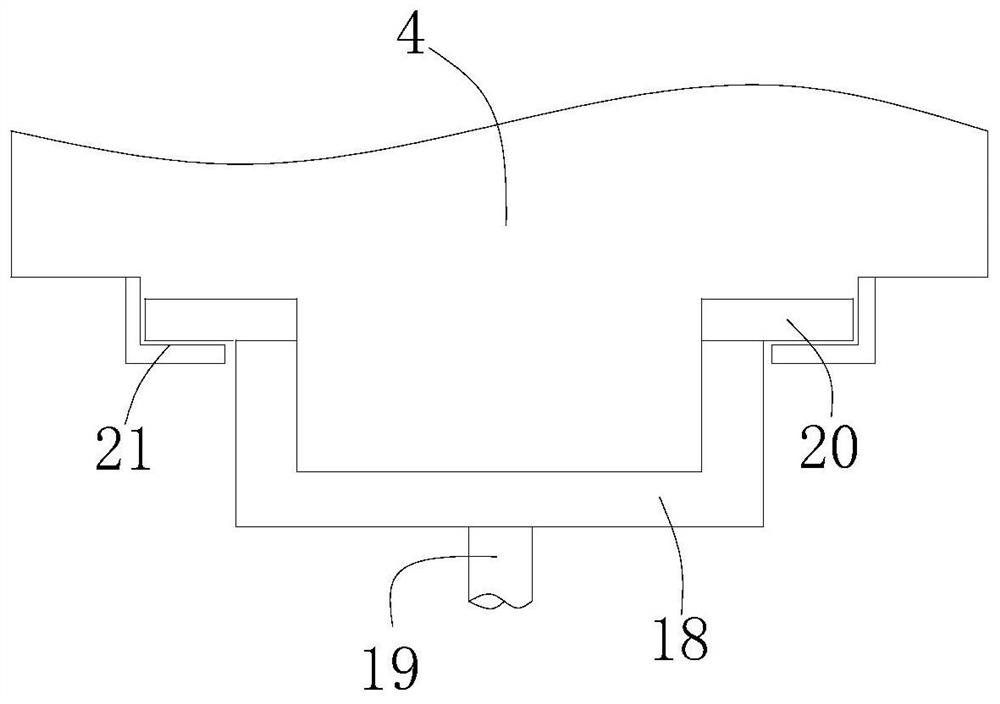

Method and device for removing coating solidifying volatile material in optical fibre drawing process

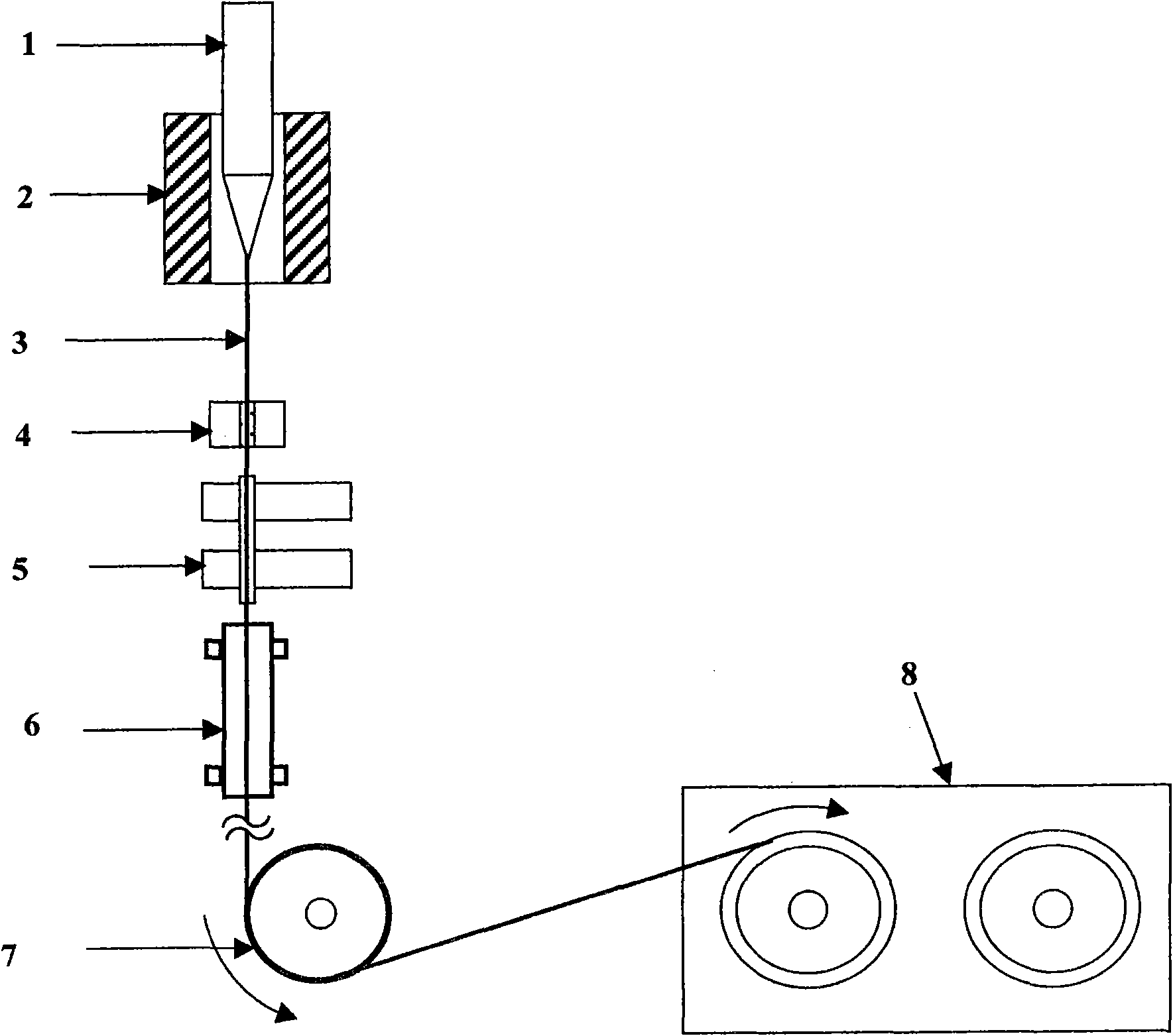

The present invention relates to a method and a device for removing coating solidifying volatile material in optical fibre drawing process. The method includes steps as follows: insulating optical fibre with surrounding environment after coating solidifying in a channel of the optical fibre drawing process, processing negative-pressure absorbing to air in the insulated region for generating gaseous current with high speed to scour and absorb to the optical fibre surface coating, then removing the solidifying volatile matter. The insulated region is a device for removing the solidifying volatile matter which includes a slightness cylinder, an upper end and a down end of the cylinder are equipped with a fibre inlet and a fibre outlet, an extract opening is set on the cylinder, the extract opening communicates with an air extract system through a connecting pipeline. The method can remove the optical fibre surface coatings solidifyin volatile matter in optical fibre drawing process efficiently, increase processing quality of the optical fibre and avoid volatile matter polluting surrounding environment and causing personal damage. The device has simple structure and reasonable design which can satisfy requirement for removing the solidifying volatile matter sufficiently.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD

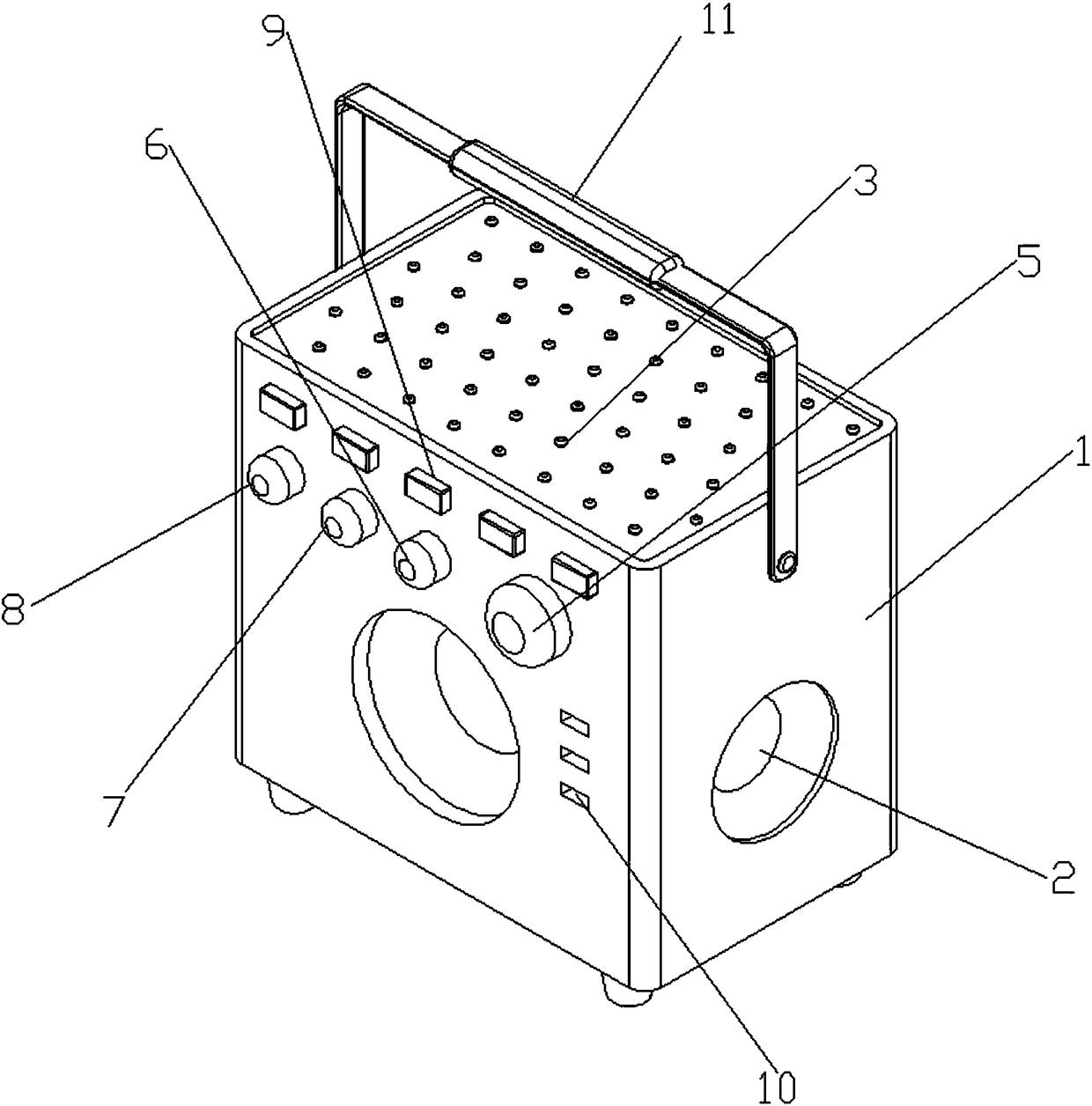

Laser photoelectric fireworks and crackers

InactiveCN108106502ABeautiful patternNo noise pollutionFirework simulationsLaser transmitterFireworks

The invention discloses laser photoelectric fireworks and crackers. The laser photoelectric fireworks and crackers comprise a body and is characterized in that loudspeakers are arranged on the periphery of the body, a plurality of laser emission heads are evenly arranged at the top of the body, and laser emitters are arranged inside the laser emission heads; a volume regulating button, a distanceregulating button, a color regulating button, a sound imitation regulating button and a color system selecting module are arranged on the body. The laser photoelectric fireworks and crackers have theadvantages that various different fireworks forms are written into a program, the program is used to control the laser emitters to emit laser of different colors, different heights and different positons to form different patterns, and the forms and sounds of various fireworks are simulated; the simulated electronic fireworks and crackers can increase festive atmosphere and do not generate smoke and gunpowder smell, and pollution and burden to atmosphere and environments are avoided; in addition, personal injury caused by fire caused by the fireworks is avoided.

Owner:中合国际知识产权股份有限公司

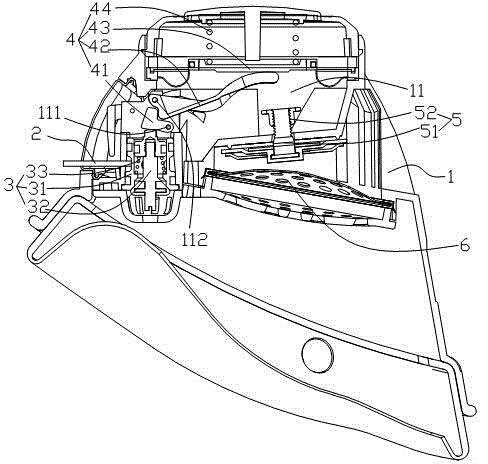

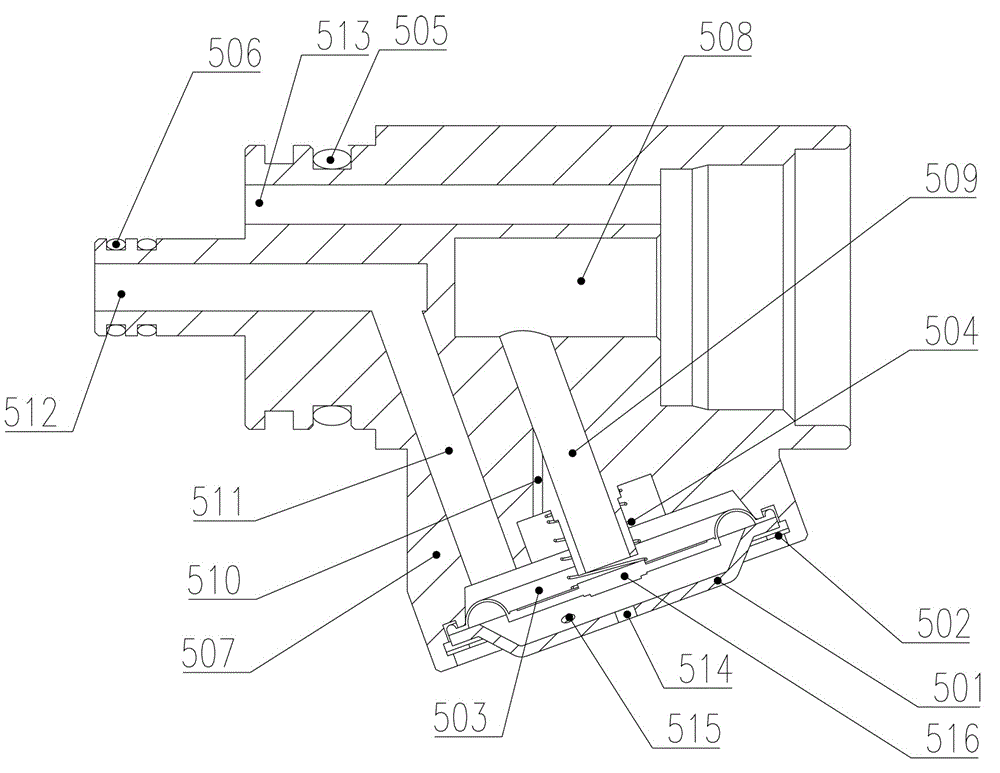

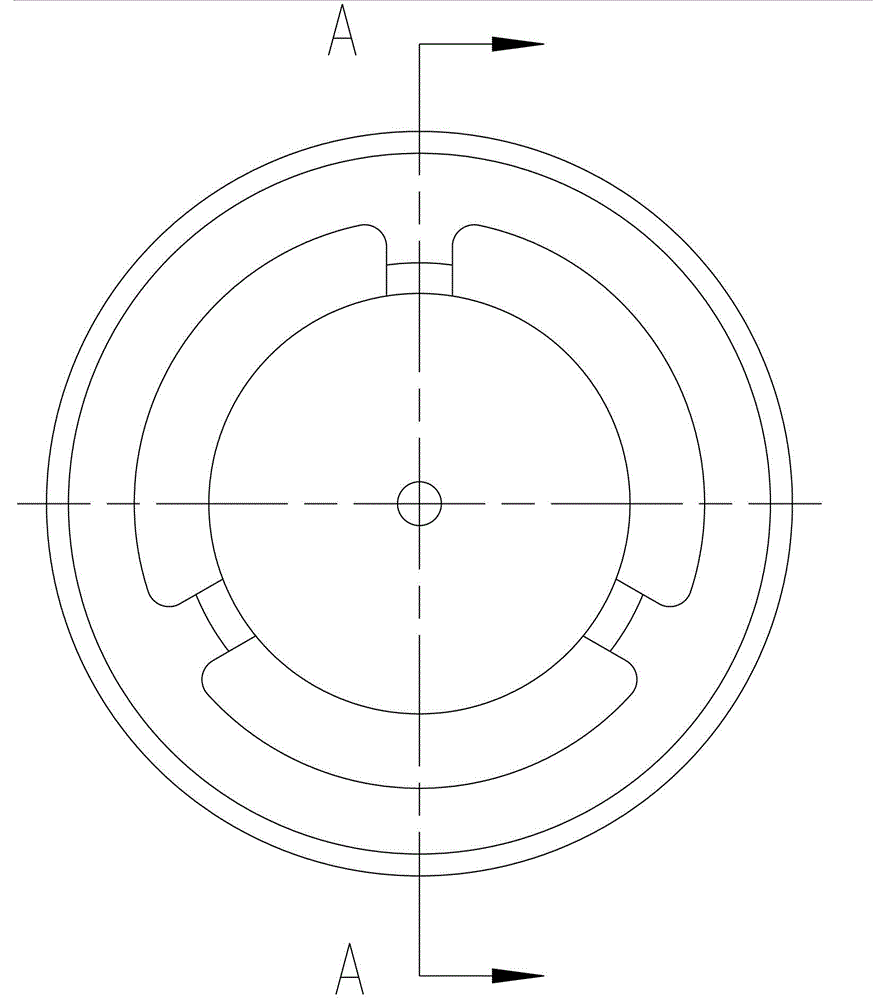

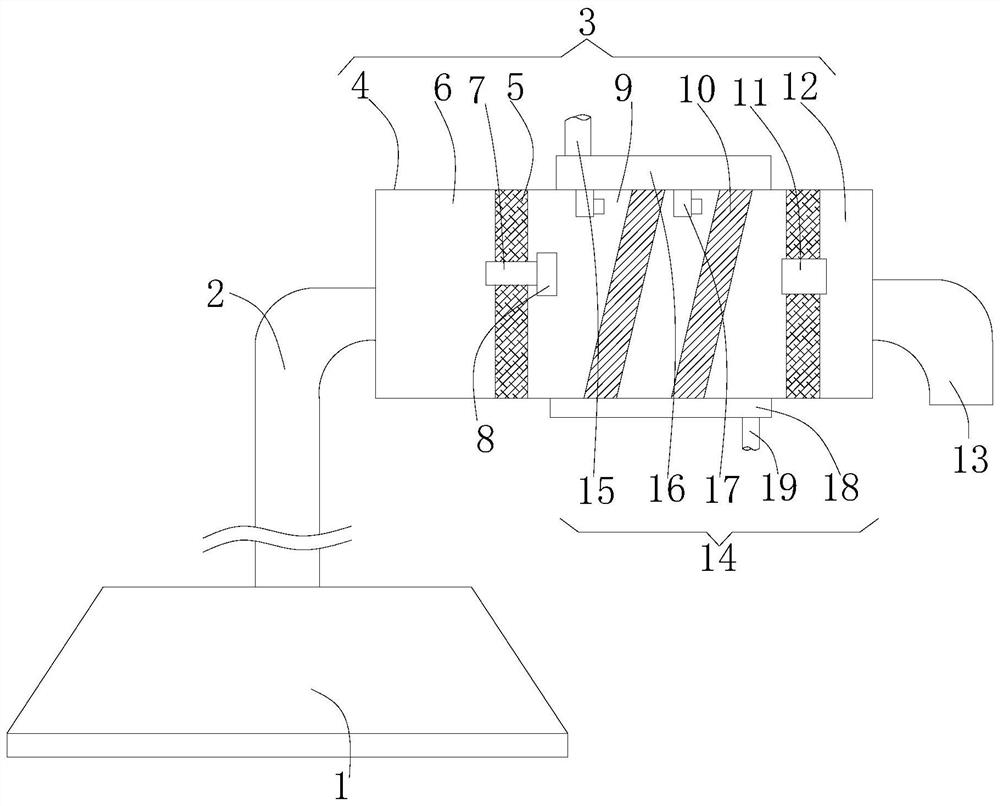

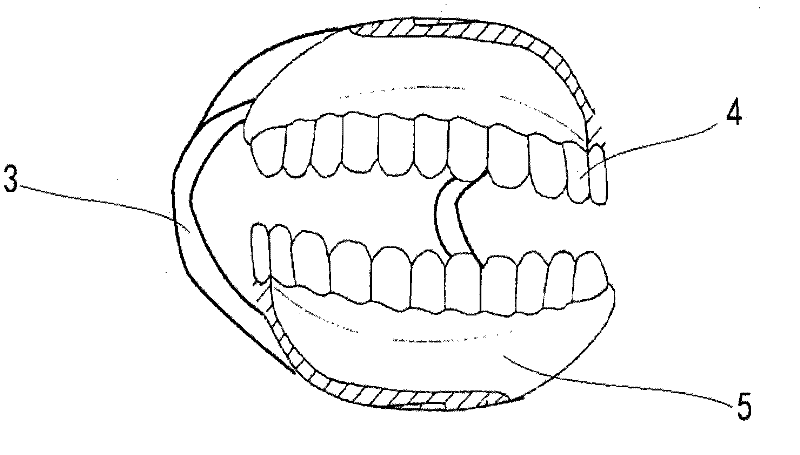

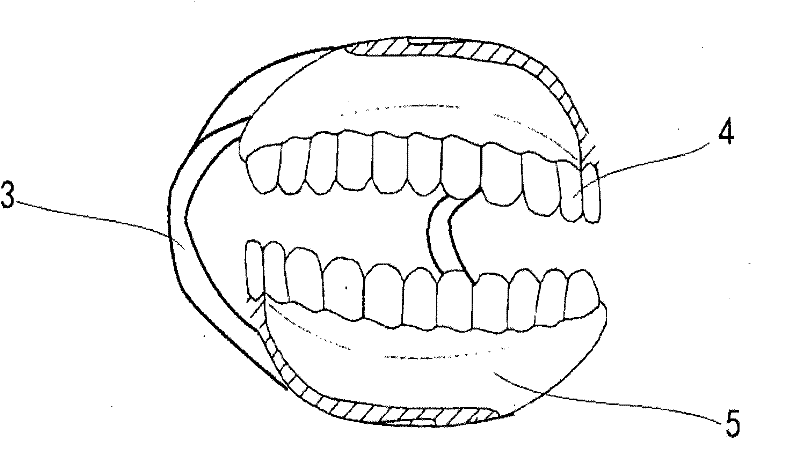

Positive pressure type breathing mask

InactiveCN104436455AAvoid personal harmFire rescueRespiratory apparatusEngineeringMechanical engineering

The invention discloses a positive pressure type breathing mask. The positive pressure type breathing mask comprises a mouth and nose cover. An air supply system which can supply air into a breathing cavity in the mouth and nose cover is arranged in the mouth and nose cover. The air supply system mainly comprises an air inlet connector, an air inlet valve and an air inlet valve opening device, wherein the outer end of the air inlet connector is connected with an air pump or a pipeline air source, and the inner end of the air inlet connector is connected with the air inlet of the air inlet valve. The air inlet valve is composed of a valve body, a valve element and a reset spring, wherein the valve element is movably arranged in the valve body, the valve element abuts against and seals the air outlet of the valve body through the reset spring, and the head of the valve element extends out of the valve body and enters the breathing cavity. The air inlet valve opening device pushes the valve element to contract inwards to make the air outlet of the valve body communicated with the breathing cavity only when the pressure in the breathing cavity is reduced. According to the positive pressure type breathing mask, air outside a severe environment is directly used as an air source, safety of the air source is ensured, the defects of an existing mask are effectively overcome, the positive pressure type breathing mask can be used in any environment, and the breathing safety of workers in the severe environment is ensured.

Owner:江再青 +1

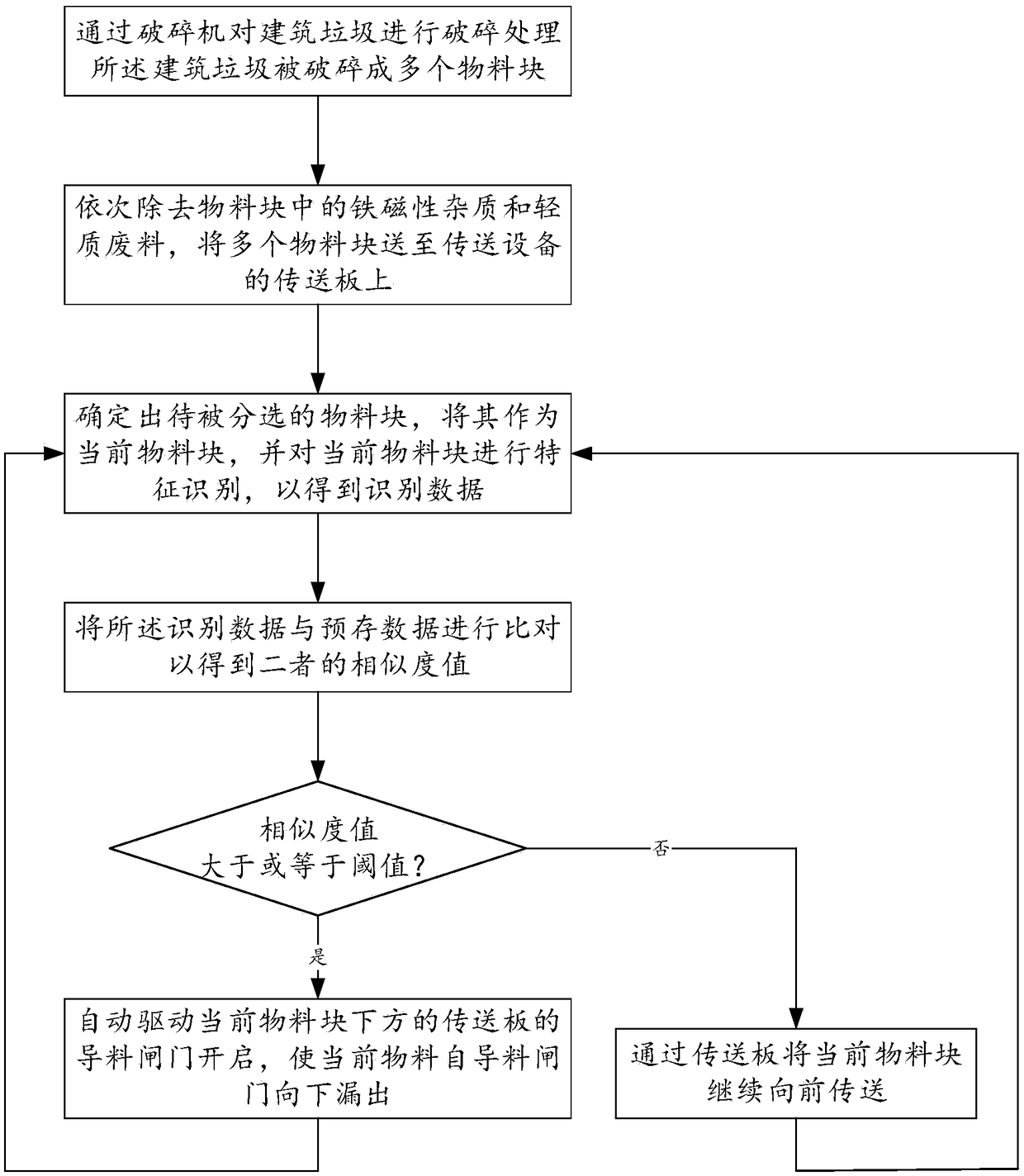

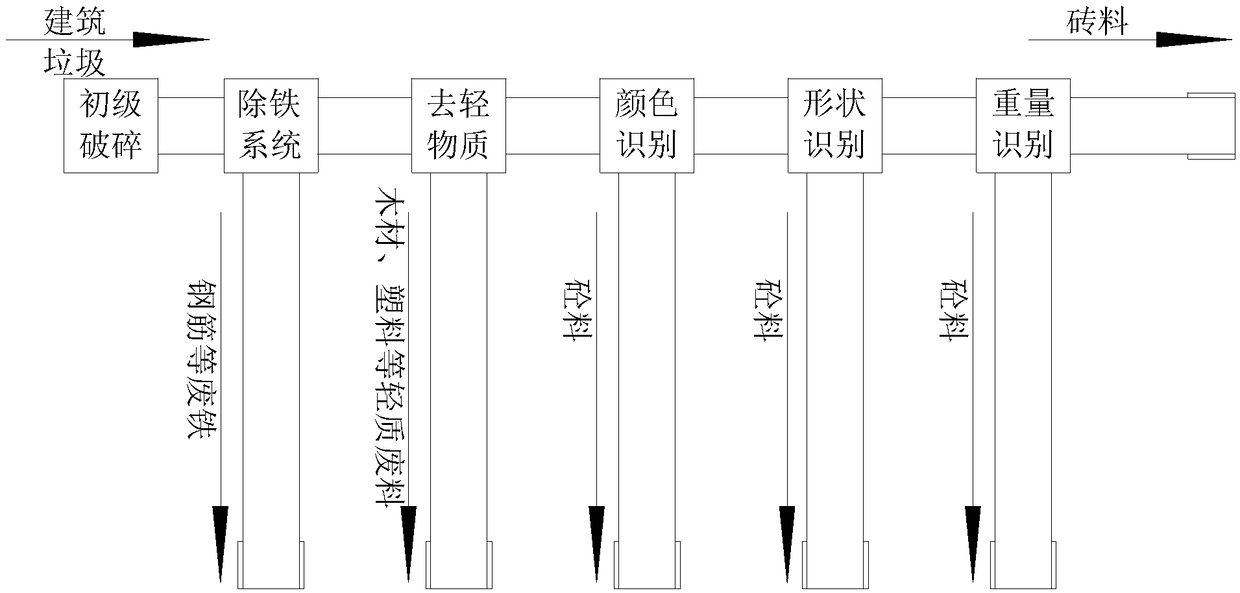

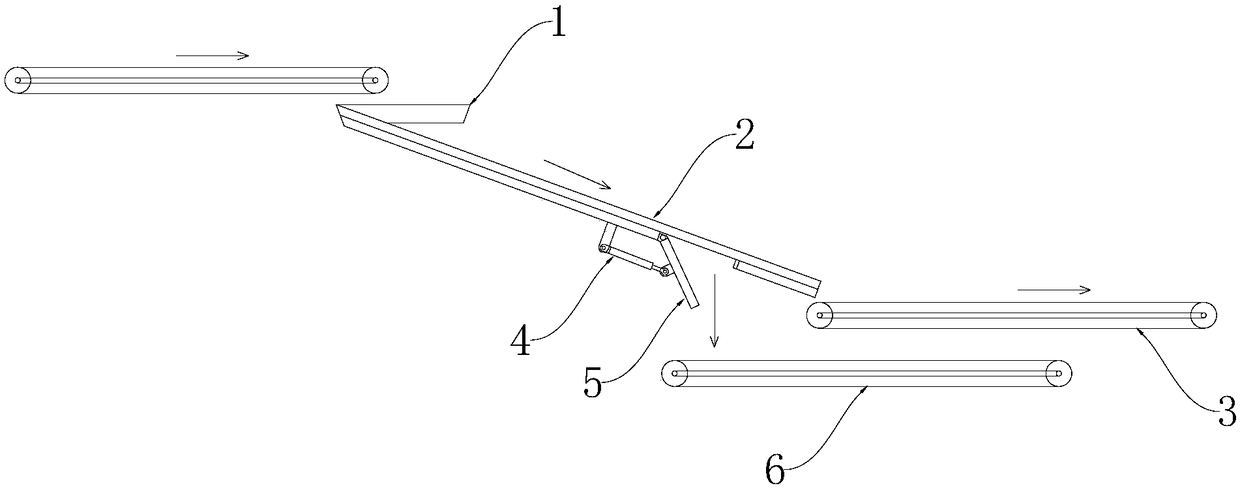

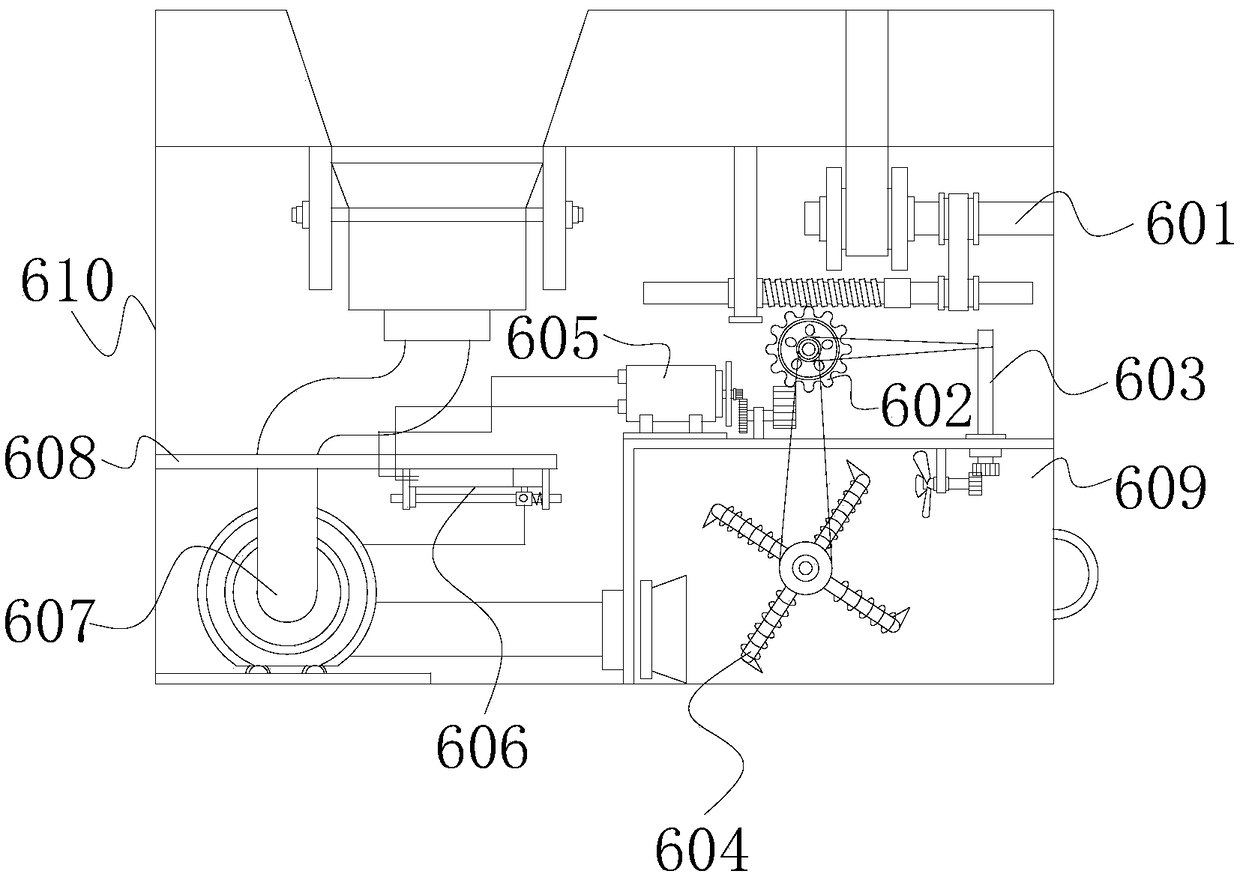

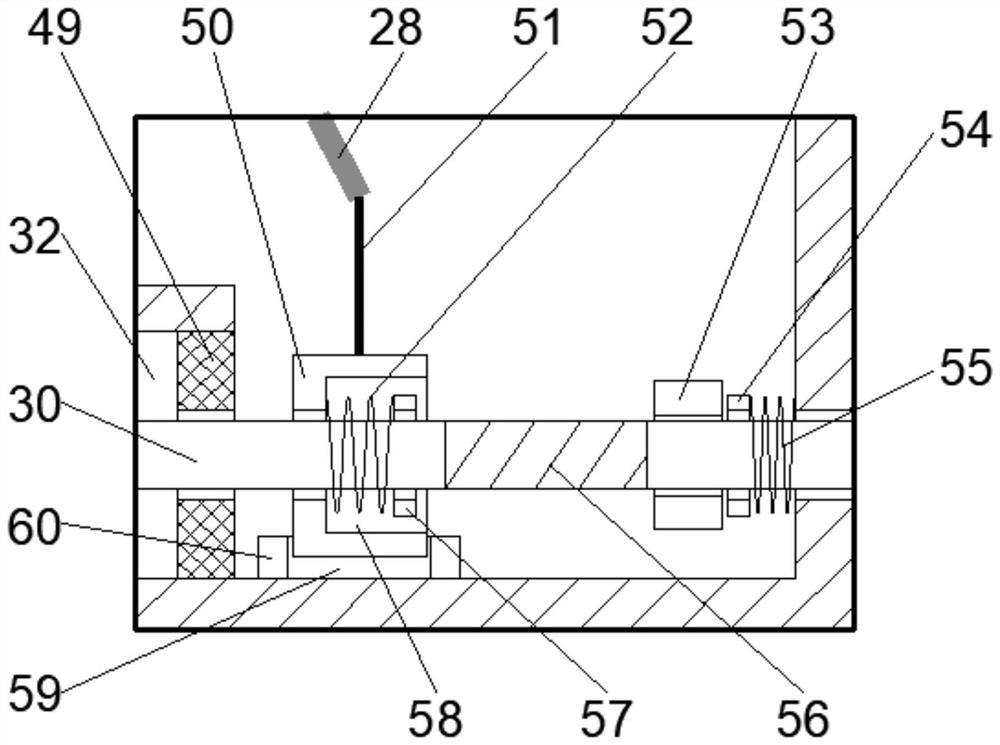

Automatic sorting method for construction waste

PendingCN108837936AAchieve separationAvoid personal harmCleaning using gasesGrain treatmentsBrickEngineering

The invention discloses an automatic sorting method for construction waste. The automatic sorting method comprises the following steps that firstly, the construction waste is crushed into material blocks; secondly, ferromagnetic impurities and light waste materials are removed, and the material blocks are conveyed to a conveying plate of conveying equipment; thirdly, feature identification is carried out on the current material blocks to obtain identification data; fourthly, the identification data are compared with the pre-stored data, and the similarity value of the identification data and the pre-stored data is obtained; if the similarity value is greater than or equal to the threshold value, the fifth step is executed; and otherwise, the sixth step is executed; fifthly, a material guide gate of the conveying plate below the current material blocks is driven to open so that the material guide gate can leak the current materials downward and the third step can be executed; and sixthly, the current material blocks are continuously conveyed forward, and the third step is executed. By the adoption of the automatic sorting method for the construction waste, the construction waste canbe effectively identified and sorted, the automatic diversion of brick materials and concrete materials is effectively realized, the sorting efficiency is improved, the harm to workers is avoided, and the labor cost is reduced.

Owner:HEBEI ZHUODA BUILDING MATERIALS RES INST CO LTD

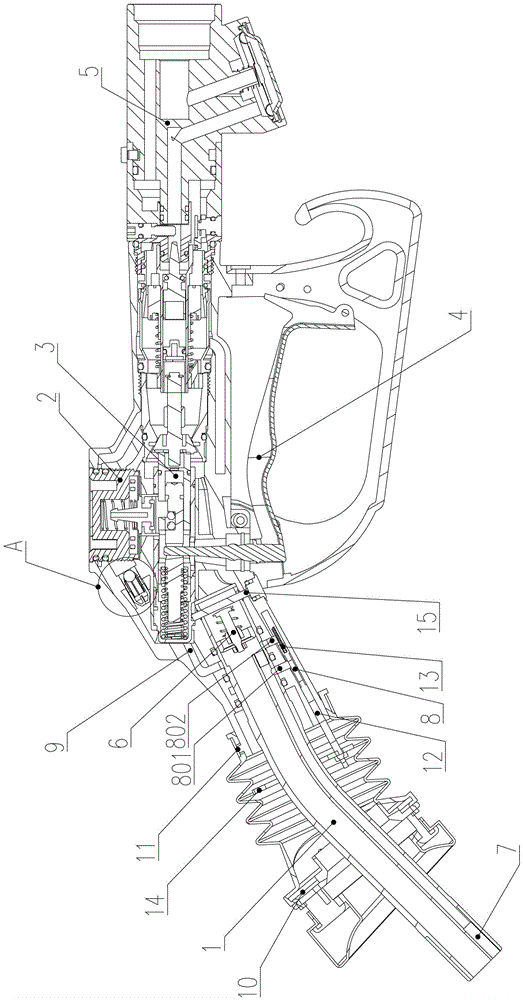

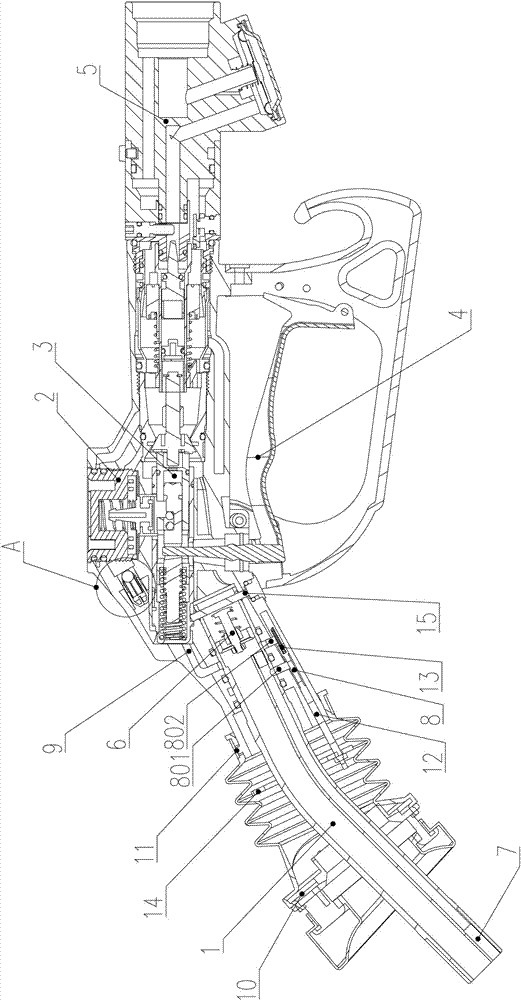

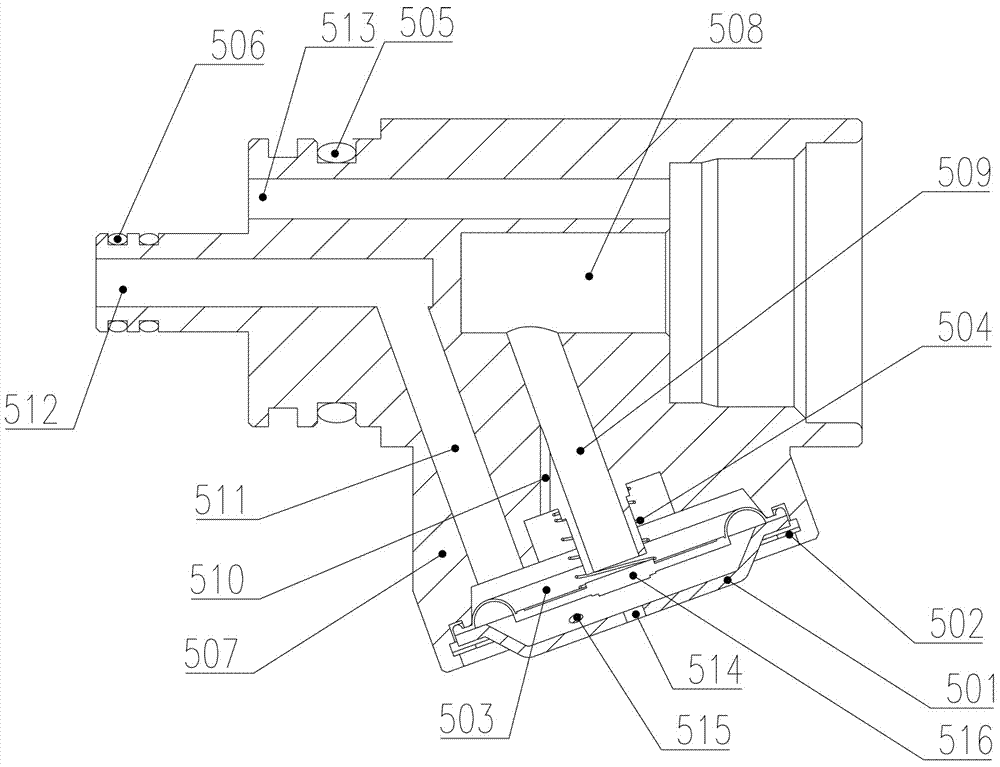

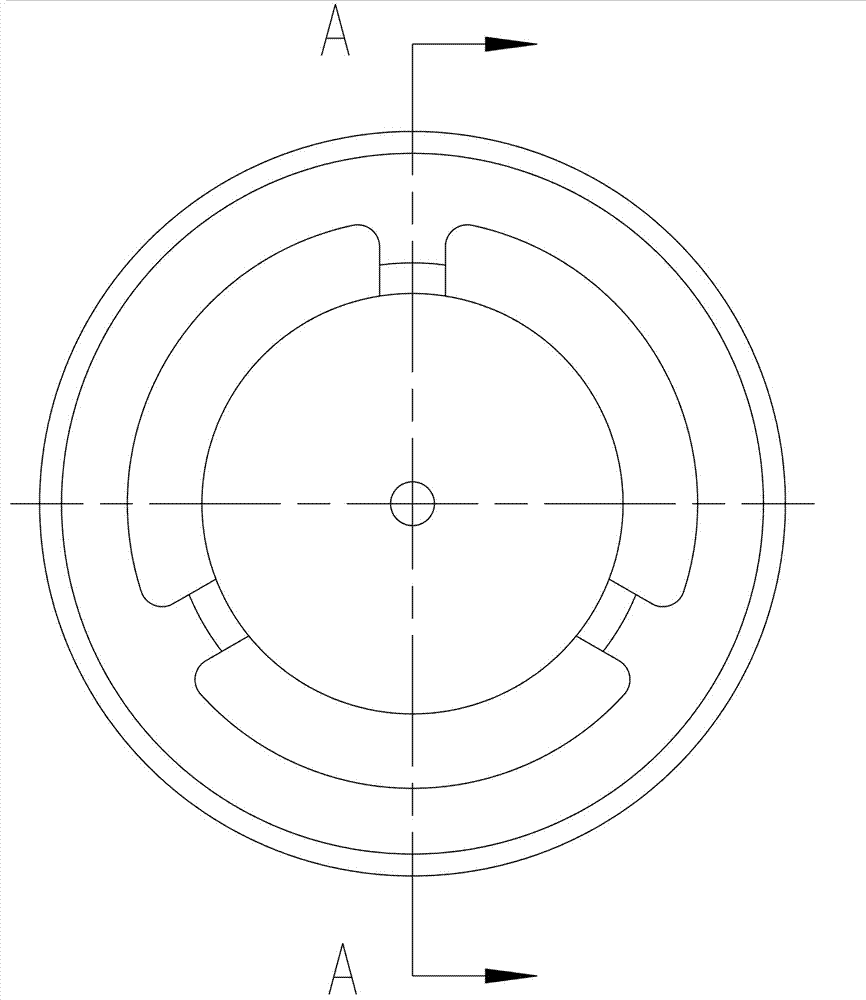

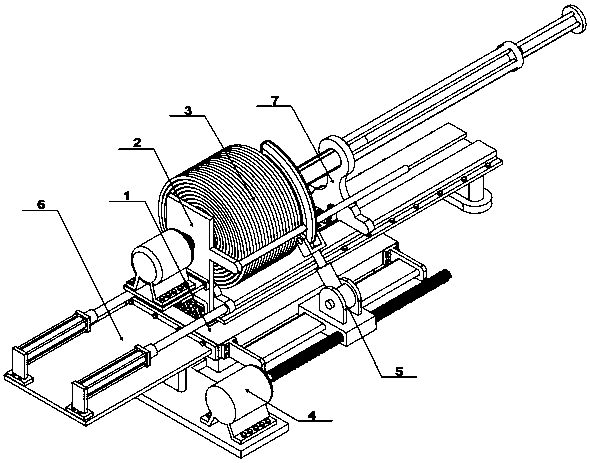

Oil gun with oil and gas recovery structure

ActiveCN105000527AAvoid pollutionAvoid wastingLiquid transferring devicesGasoline stationProcess engineering

The invention relates to an oil gun, in particular to an oil gun with an oil and gas recovery structure. The oil gun comprises an oil and gas recovery oil gun and a mechanical gas and liquid ratio regulating valve, wherein an inlet of the oil and gas recovery oil gun is connected with the mechanical gas and liquid ratio regulating valve in a sealing manner, and both a gun barrel and a pull rod of the oil and gas recovery oil gun are communicated with a gas chamber; the inlet end of the mechanical gas and liquid ratio regulating valve is connected with a vacuum flow regulating valve in a sealing manner; the gun barrel is sleeved with a gas collecting hood in a sealing manner, an auxiliary valve is mounted in the gun barrel in a pressing manner, and the gas collecting hood is connected with a push rod mechanism; a gas returning pipe is arranged on the side face in the gun barrel, and a gas returning channel I communicated with the gas returning pipe is formed in a gun body on the outer side surface of the gun barrel. The oil gun has the advantages of being safe, environmental-friendly and energy-saved and is the necessary equipment of a secondary oil and gas recovery system and a vehicle-mounted oil and gas recovery system of a gasoline station.

Owner:郑州永邦环保科技有限公司

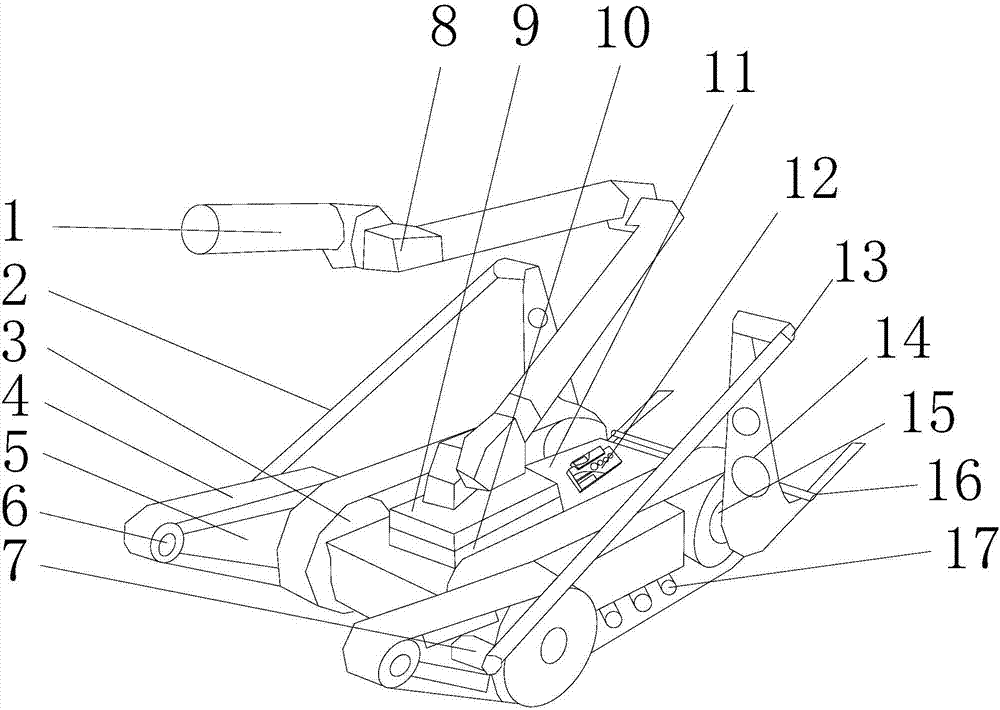

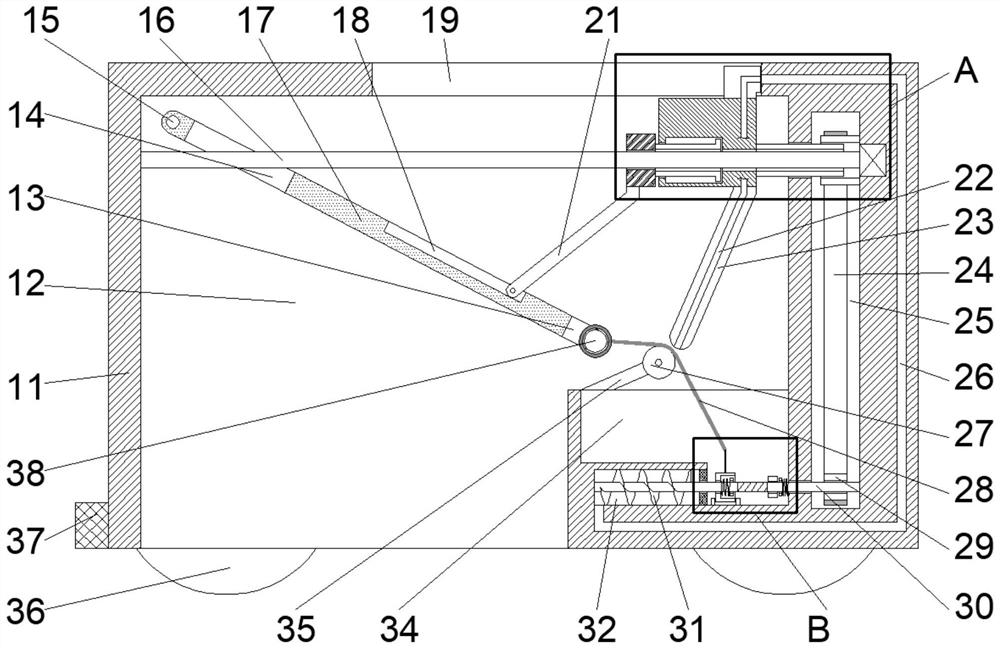

Detecting rescuing robot capable of being remotely controlled

InactiveCN107322604AAvoid personal harmRealize remote wireless operationManipulatorRescue robotRemote control

The invention discloses a detection and rescue robot capable of remote control, the structure of which includes a clamp, a linkage rod, a main wheel, a track, a bracket, a secondary wheel, a fixed head, a mechanical arm, an electric control box, a large battery, a main engine, Infrared control device, transition lever, drive frame, hub motor, synchronous lever, auxiliary wheel, the lower part of the electric control box and the upper part of the large battery form an integrated structure, the hub motor is welded to the left and right sides of the main engine, the hub motor is located inside the main wheel, the main The wheel forms an integrated structure through the bracket and the auxiliary wheel. The beneficial effect of the present invention is that by adding an infrared control device, remote wireless operation is realized, which avoids the need for people to take risks in some dangerous places, causing other personal hazards .

Owner:陈雯娣

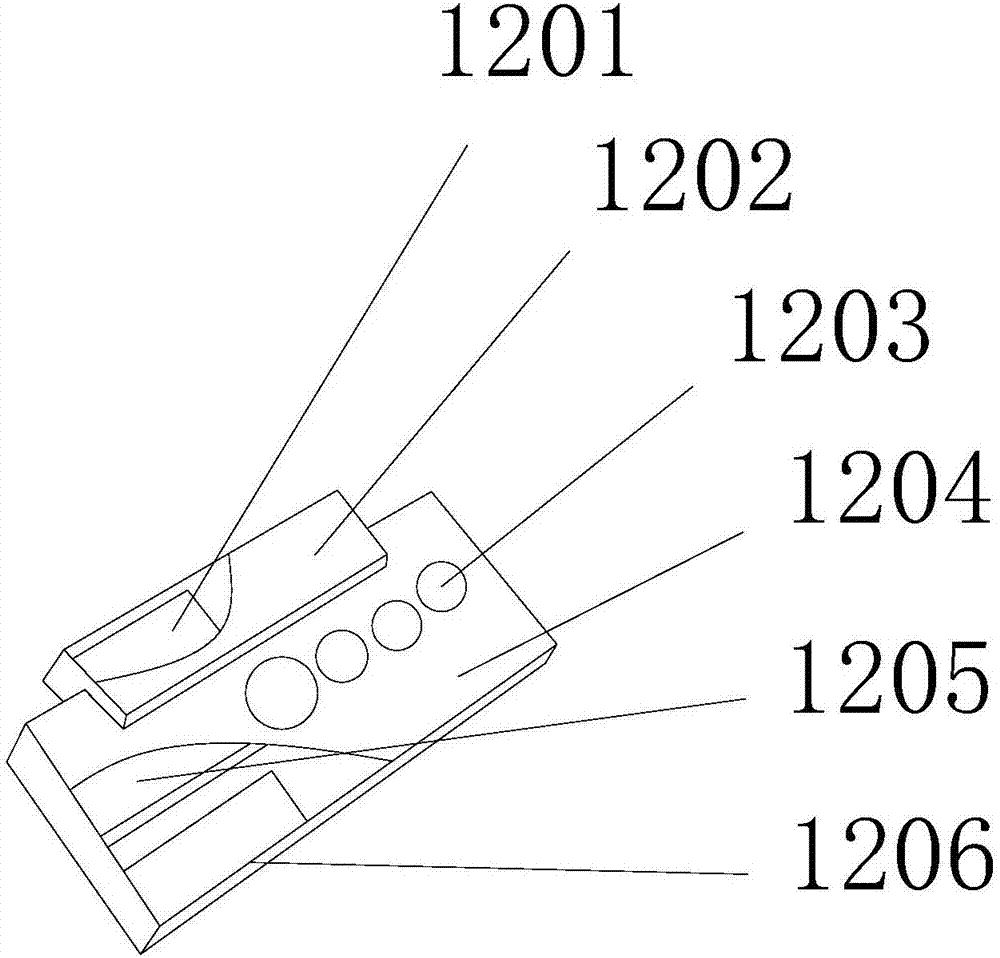

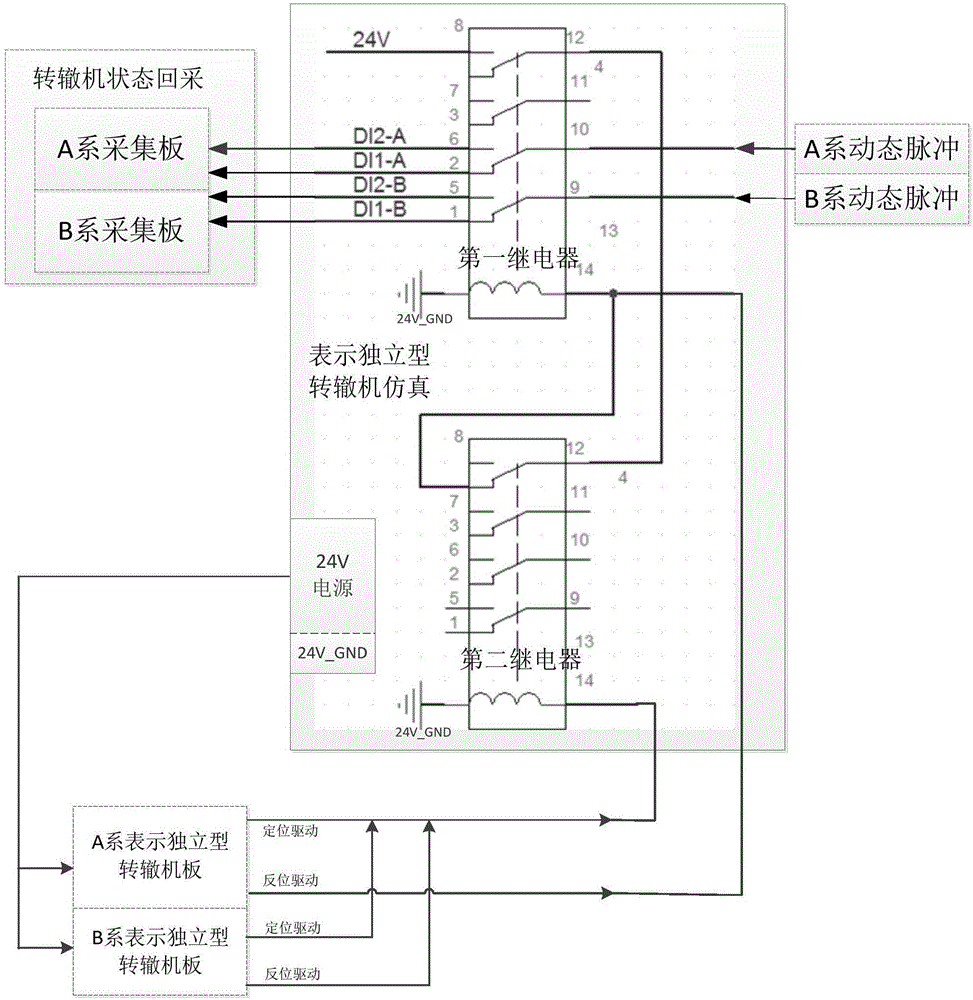

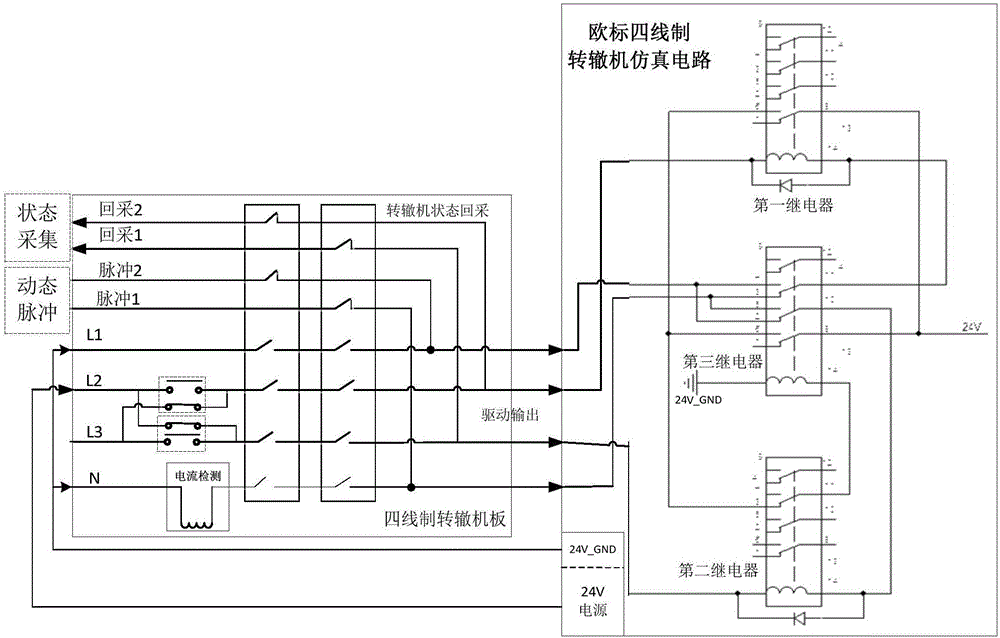

Point machine electronic simulation circuit

PendingCN106371332ASimple operation and maintenanceReduce failure rateSimulator controlFailure rateOperational maintenance

The present invention relates to a point machine electronic simulation circuit. The circuit comprises: a node unit provided with a relay and at least one relay node, wherein the relay is configured to control the connection or disconnection of the relay node; a collection circuit configured to detect the connection or disconnection of the relay node; and a driving loop configured to drive the relay. The collection circuit includes a first collection circuit configured to detect the connection of the relay node and a second collection circuit configured to detect the disconnection of the relay node. The electronic circuit replaces a mechanical point machine. The point machine electronic simulation circuit is simple in circuit, low in failure rate, low in cost, low in space usage, simple in operation and maintenance and easy to extend; the 24V voltage is employed to replace the heavy voltage and is taken as the driving voltage so as to avoid the personal danger.

Owner:浙江众合科技股份有限公司

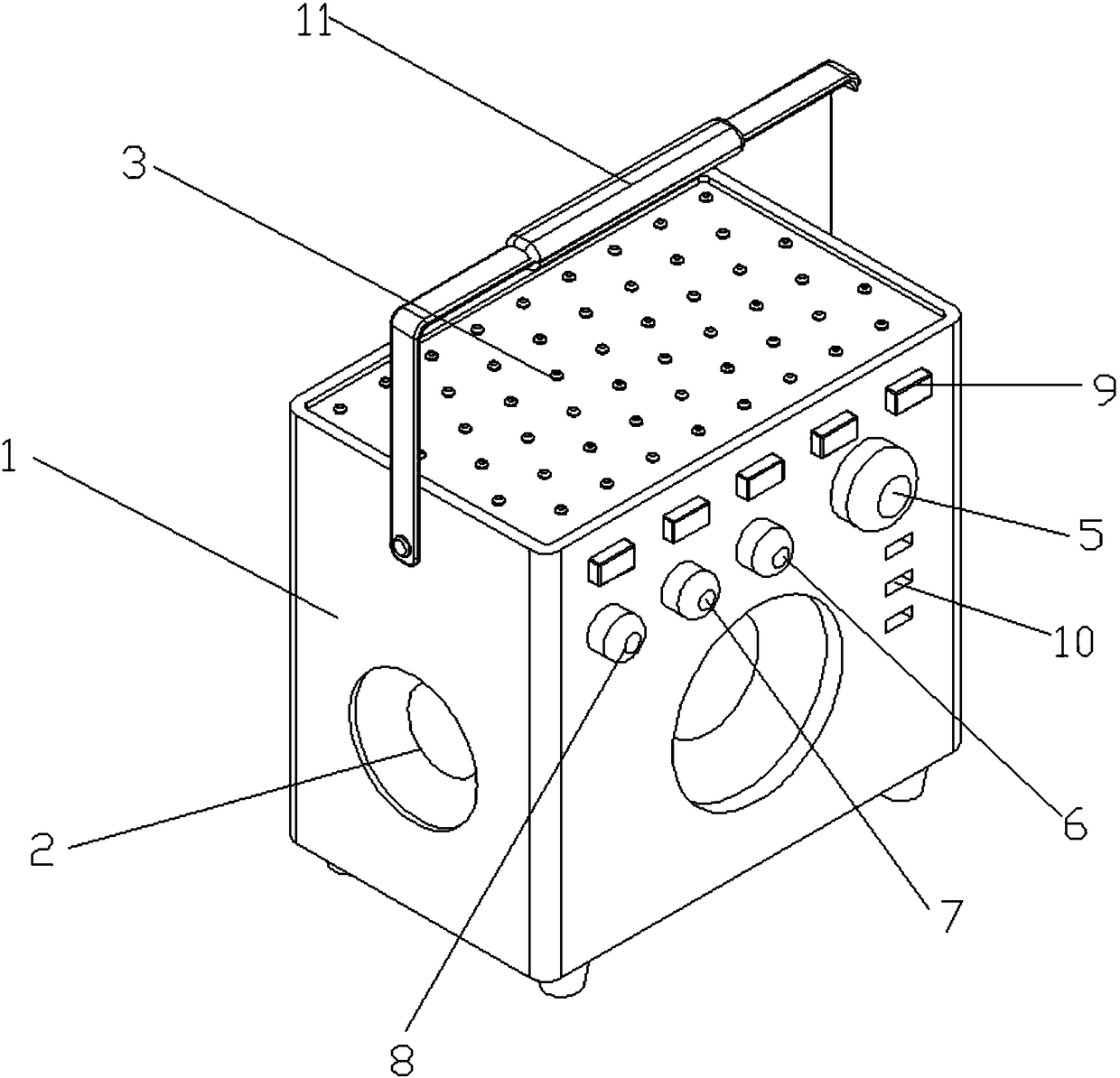

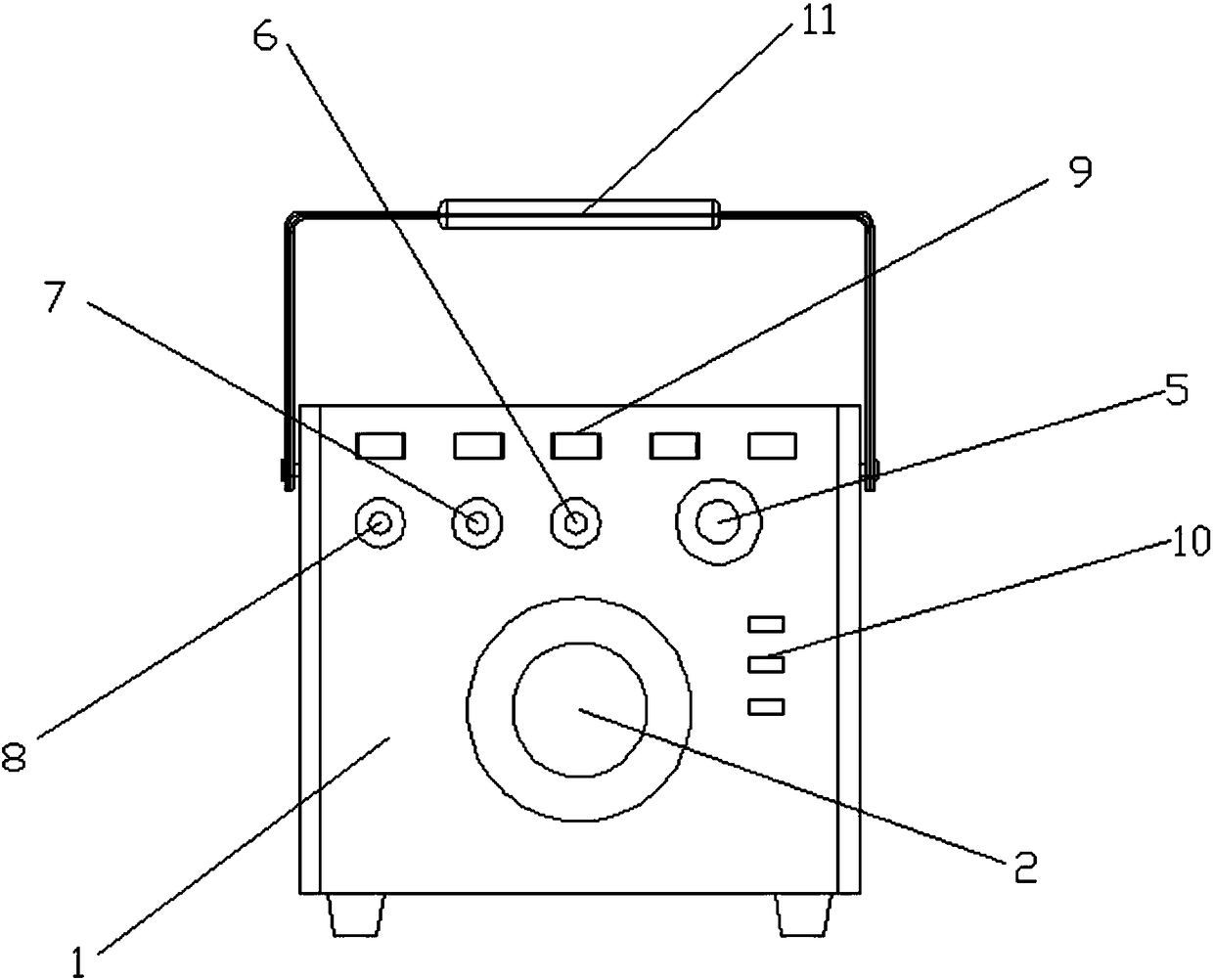

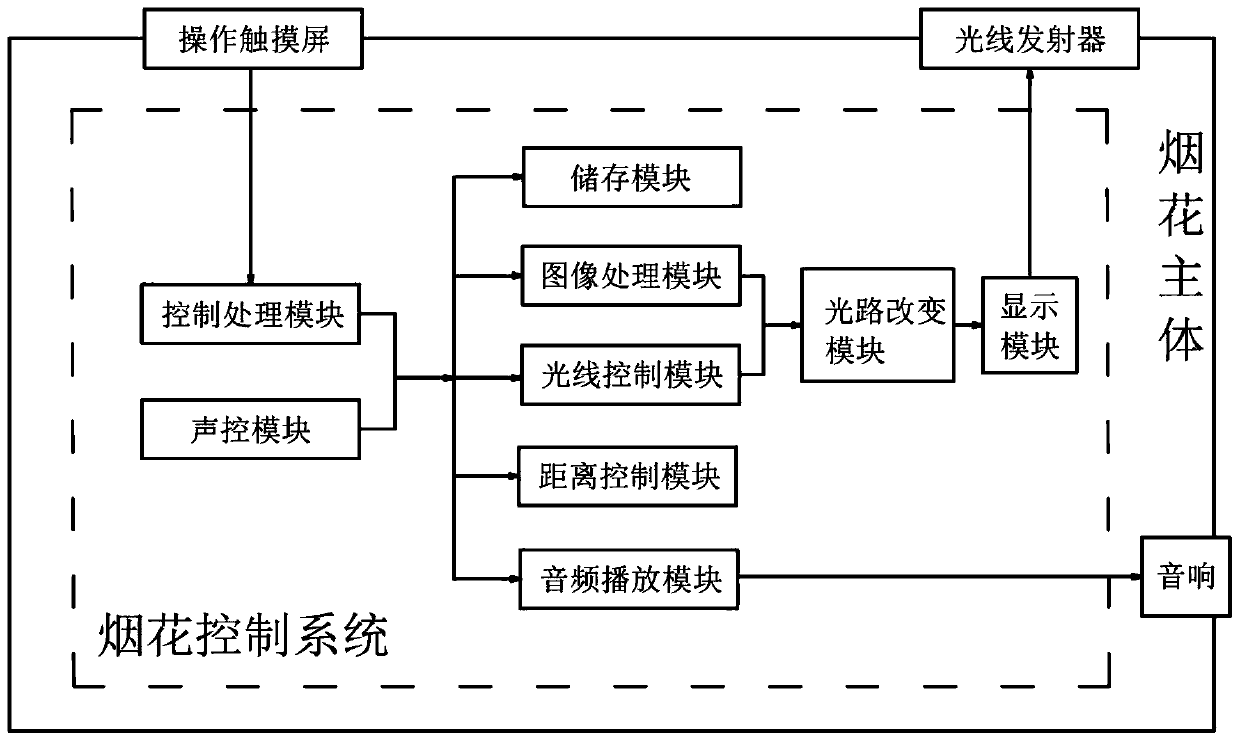

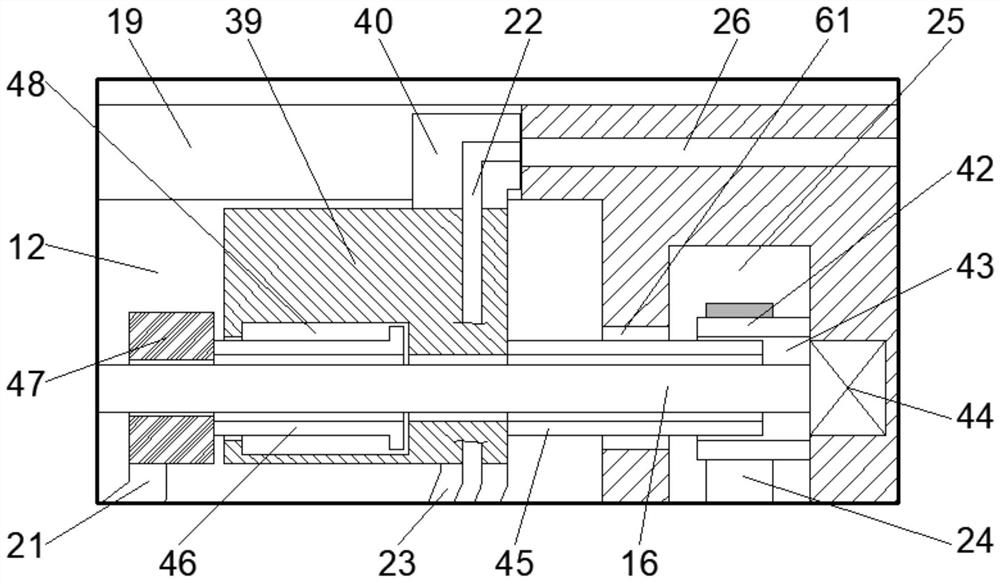

Electronic firework capable of projecting display image

InactiveCN109780942ACreate pollutionCause a burdenFirework simulationsLaser transmitterImaging processing

The invention provides an electronic firework capable of projecting a display image. The electronic firework comprises a firework main body; the firework main body is provided with a loudspeaker; thetop part of the firework main body is evenly provided with a plurality of light ray emitters; the firework main body is further provided with an operating touch screen; a firework control system usedfor controlling the light color, the distance and the image of each light ray emitter is arranged in the firework main body; and the firework control system comprises an audio playing module, an imageprocessing image, a light ray control module, a display module, a distance control module, a storage module and a control processing module, wherein the audio playing module is used for simulating the different sounds of the firework or playing music; the image processing module is used for processing an image formed after laser emission; the light ray control module is used for controlling the color and the brightness of an emitted laser beam; the display module is used for displaying a projected pattern or subtitle; the distance control module is used for controlling the laser emission distance; the storage module is used for storing a preset scene, a preset sound effect and preset music, and thus, rapid selected operation is facilitated; and the control processing module is used for receiving an operating command, controlling the light ray emitters to perform projection, and controlling a firework launching effect through the operating touch screen.

Owner:张天亮

A refueling gun with an oil and gas recovery structure

The invention relates to a refueling gun, in particular to a refueling gun with an oil-gas recovery structure, including a fuel-gas recovery refueling gun and a mechanical gas-liquid ratio regulating valve. The regulating valve is sealed and connected, the gun barrel and the pull rod part are connected with the gas chamber part, the inlet end of the mechanical gas-liquid proportional regulating valve is sealed and connected with a vacuum flow regulating valve, and the sealing sleeve of the gun barrel has a gas absorbing valve Cover, the inside of the gun barrel is press-fitted with a pair of valves, the air receiving cover is connected with a push rod mechanism, the inner side of the gun barrel is provided with a return pipe, and the gun body part of the outer side of the gun barrel is provided with a Return air channel 1 connected to the return air pipe. This product has the advantages of safety, environmental protection, and energy saving. It is an indispensable equipment for the secondary oil vapor recovery system of the gas station and the vehicle oil vapor recovery system.

Owner:郑州永邦环保科技有限公司

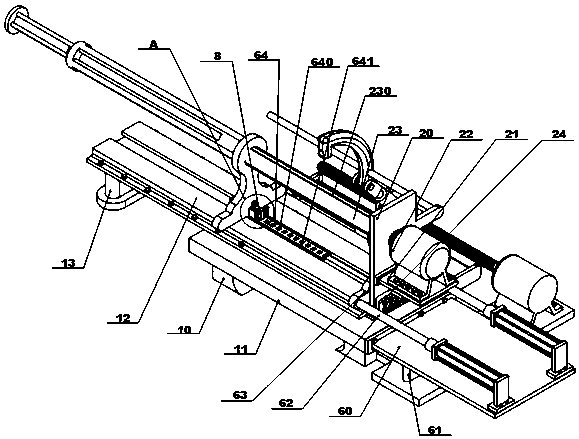

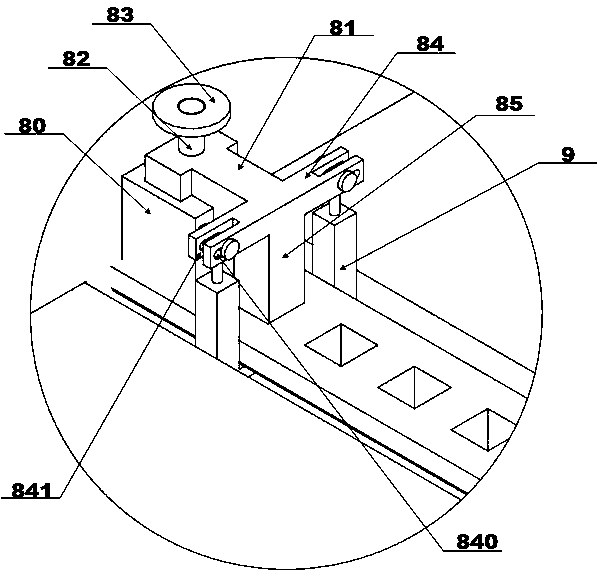

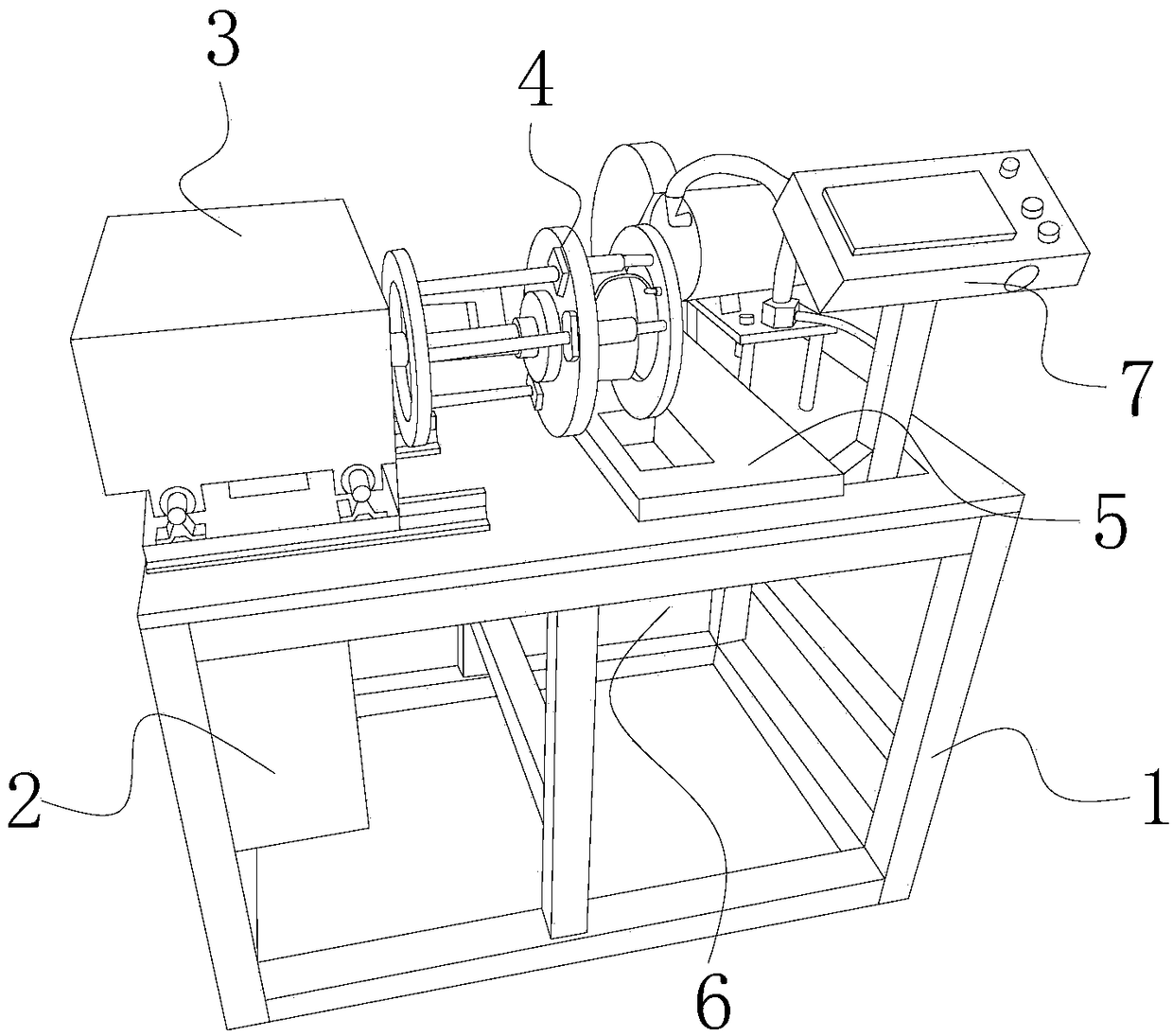

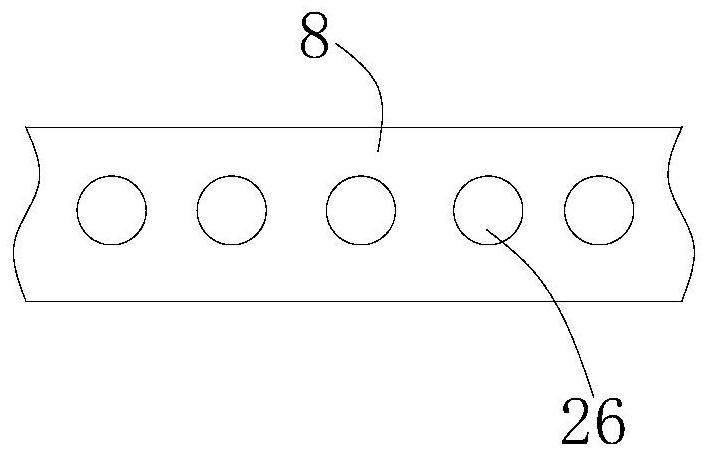

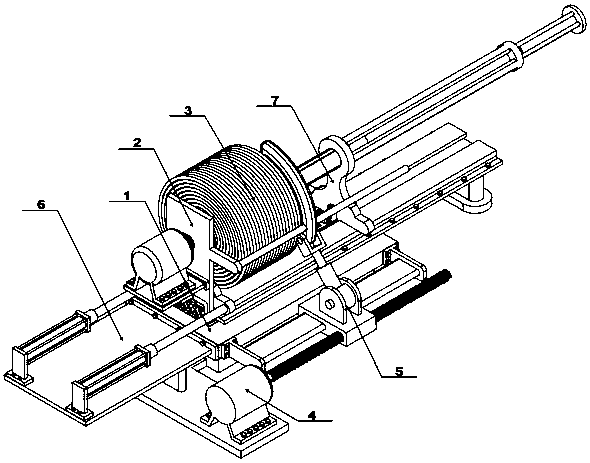

Wire-twisting-preventing coiling device for electrotechnical round aluminum rod

ActiveCN108821002AImprove stabilityImprove practicalityFilament handlingEngineeringMechanical engineering

Owner:眉山市博眉启明星铝业有限公司

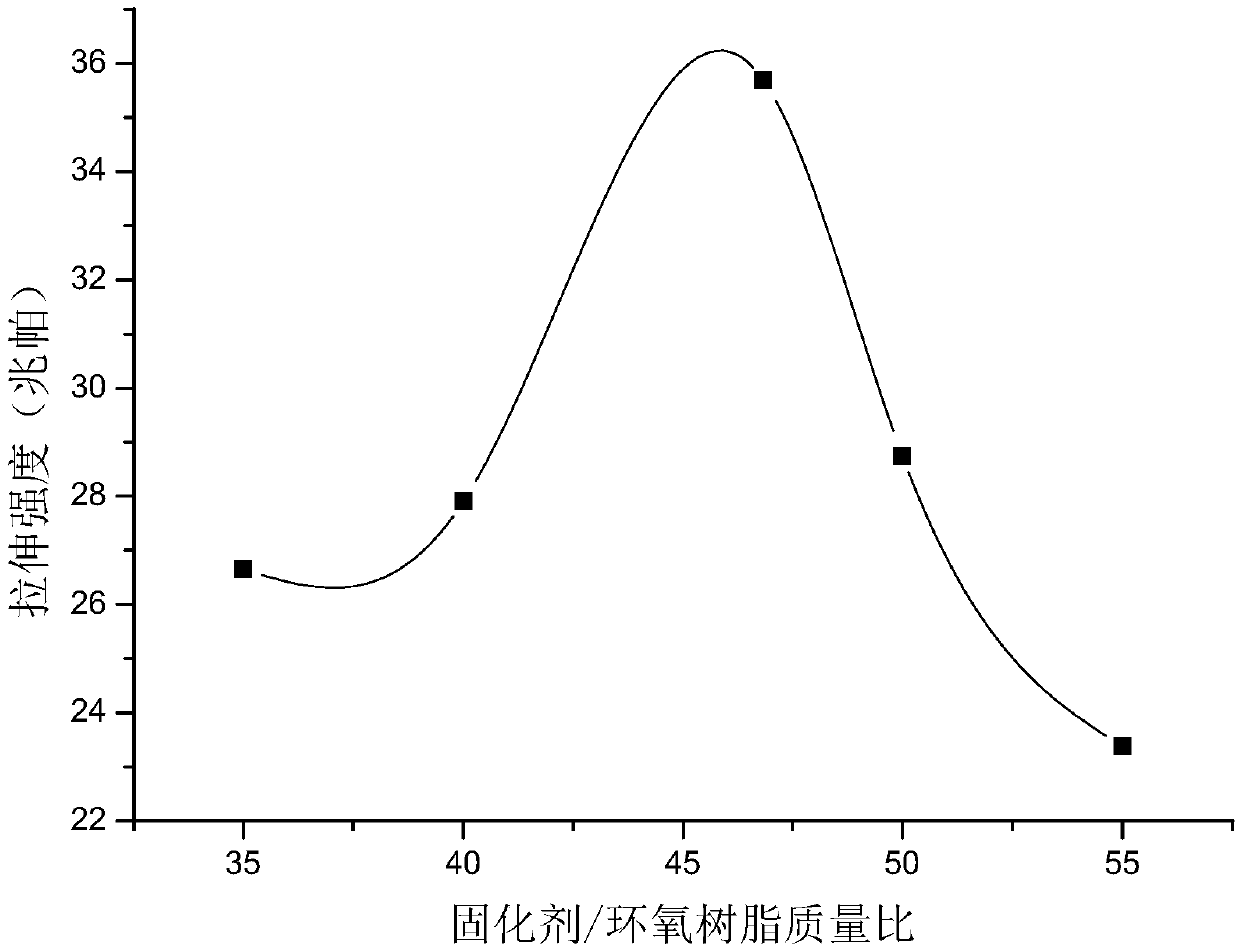

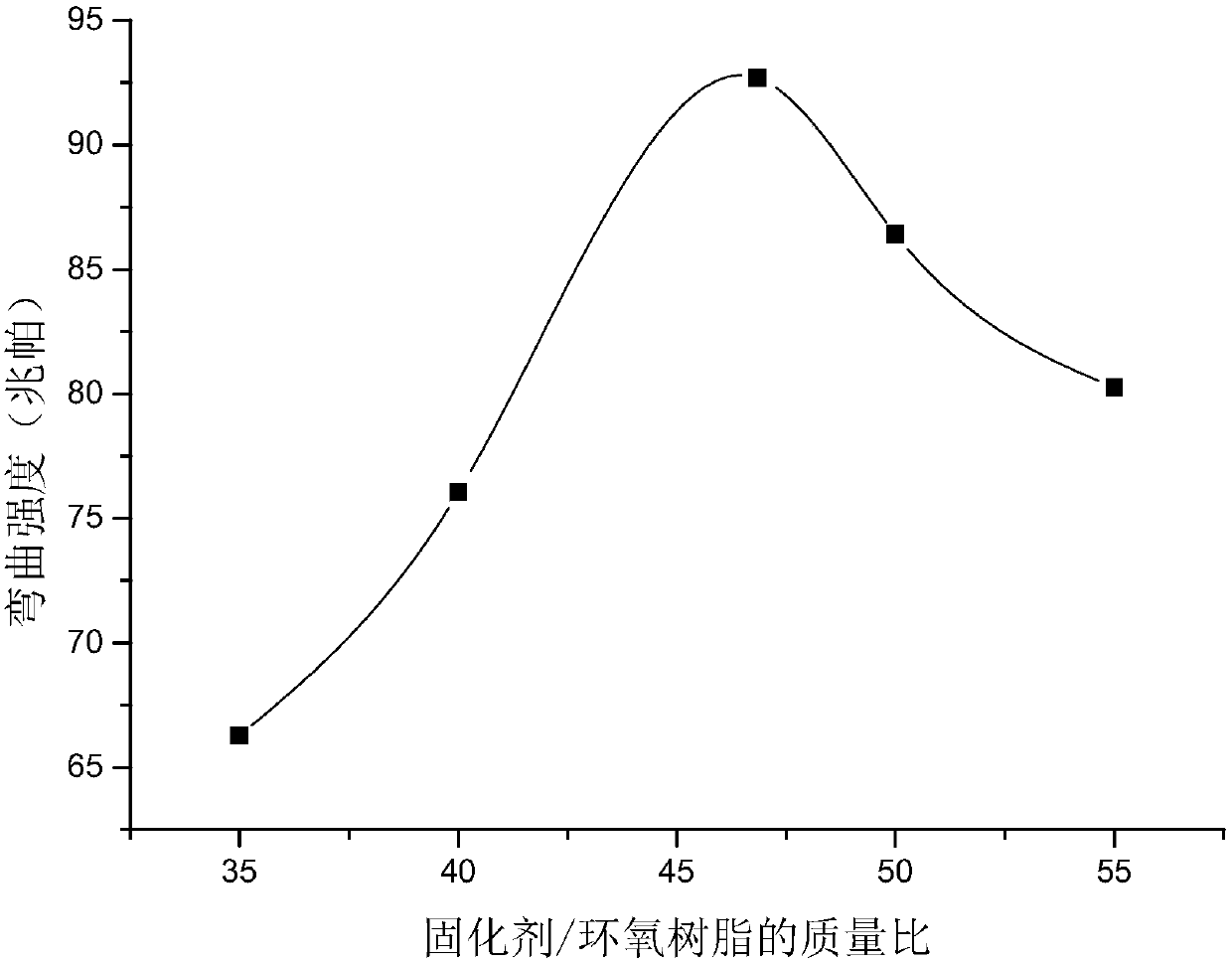

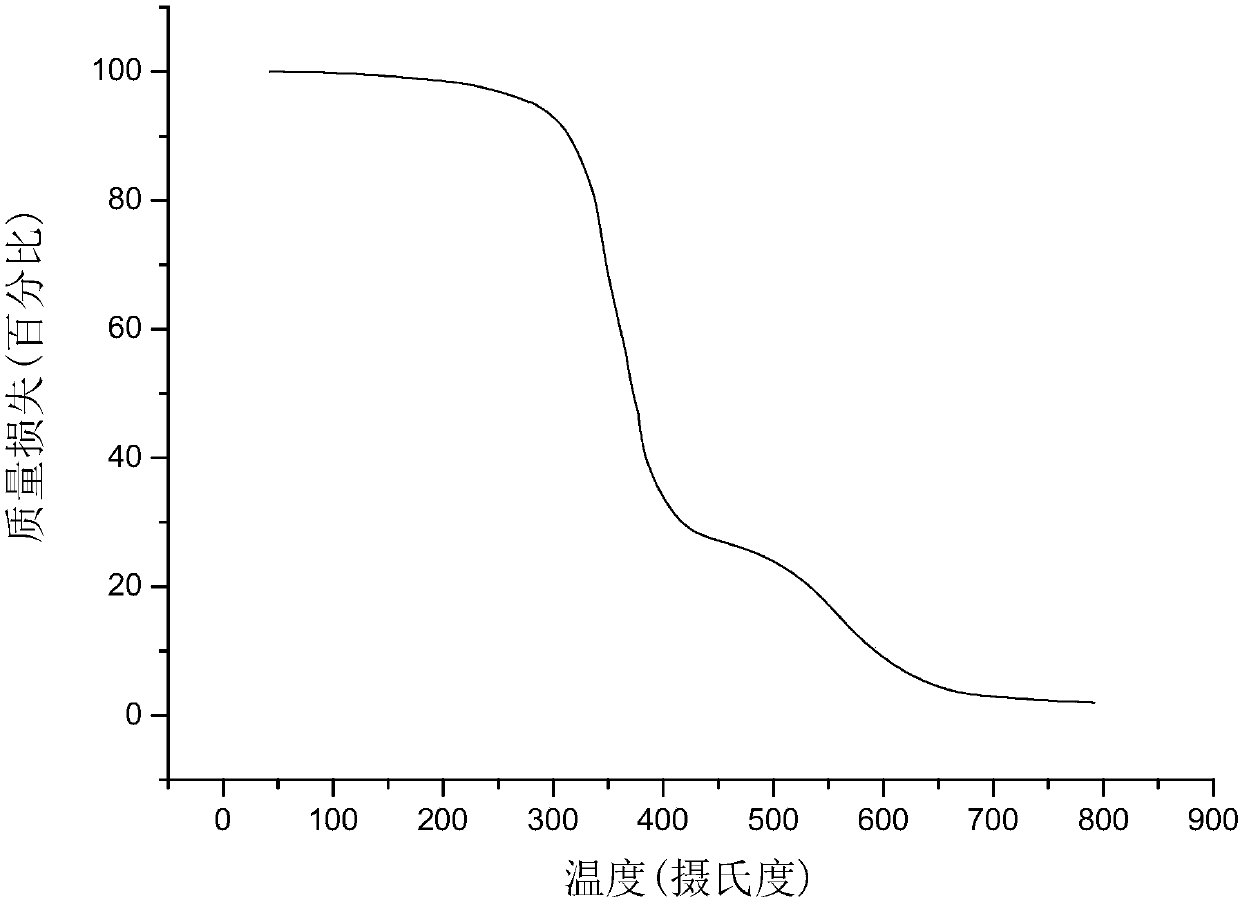

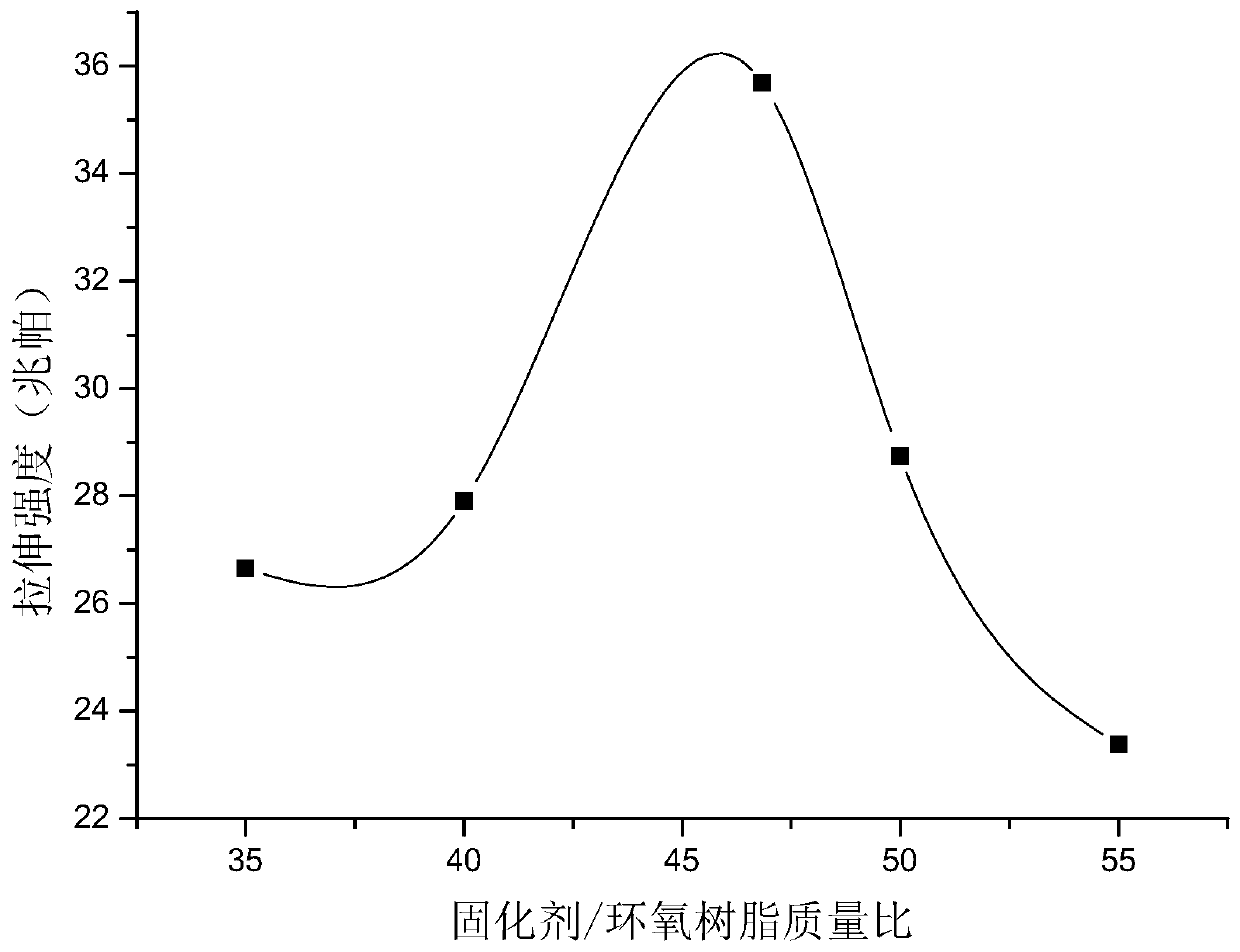

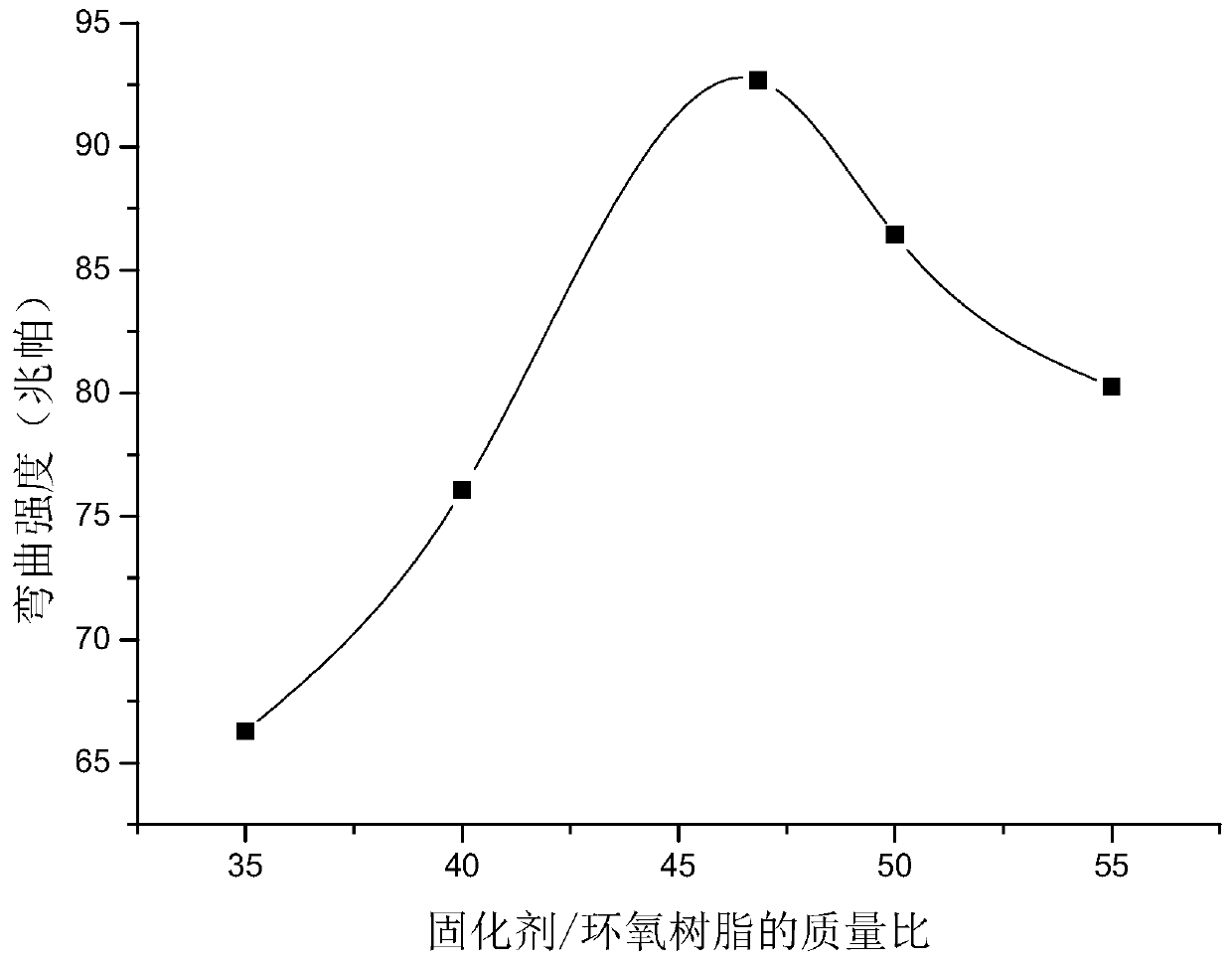

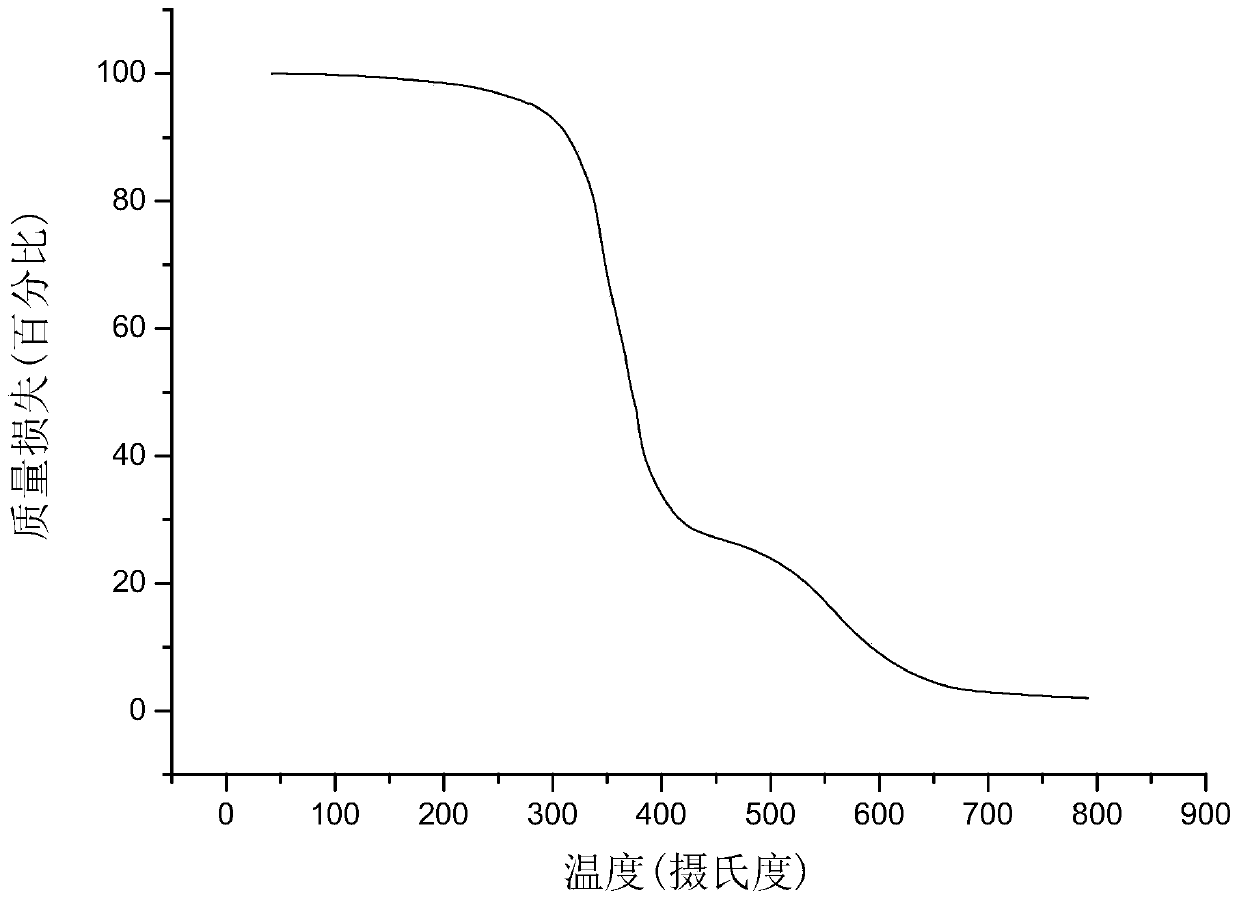

Epoxy resin curing agent based on methyl methacrylate reactor bottom waste materials and preparation method and application thereof

ActiveCN107722242AImprove thermal stabilityThe synthesis method is simpleOrganic compound preparationCarboxylic acid amides preparationMethacrylateStructural formula

The invention discloses an epoxy resin curing agent based on methyl methacrylate reactor bottom waste materials and a preparation method and application thereof, and belongs to the field of curing agents. The epoxy resin curing agent aims to solve the technical problems that the environment pollution of the methyl methacrylate reactor bottom waste materials is caused and a huge harm is brought tohuman and also can solve the pollution problem in a use process of a low-molecular-weight polyethylene polyamine. The structural formula of the curing agent disclosed by the invention is shown in thespecification. The preparation method comprises the following steps: 1: taking waste materials generated by producing methacrylate, adding polyethylene polyamine, taking cyclohexane as a water-carrying agent, and carrying out heating reflux until no methyl alcohol is in reactant; 2: then, adding AGE (Alkyl Glycidyl Ether), and carrying out heating reaction for 30min to obtain the curing agent. Thecuring agent is used for curing epoxy resin.

Owner:青岛哈工资源环境技术有限公司

Self-washing dustproof blackboard eraser

The invention discloses a self-washing dustproof blackboard eraser. The blackboard eraser comprises a shell, wherein a water seepage plate is arranged in the middle of an inner cavity of the shell, aneraser cotton mounting groove for installing a eraser cotton is formed in the part, at the front part of the water seepage plate, of the inner cavity of the shell, and the part, at the rear part of the water seepage plate, of the inner cavity of the shell is divided into a cleaning water cavity and a water seepage water cavity through a separation plate, wherein the cleaning water cavity is usedfor cleaning the eraser cotton, and the water seepage water cavity is used for enabling the blackboard eraser to be free of dust when the blackboard eraser is used for wiping by water seeping into theeraser cotton . According to the self-washing dustproof blackboard eraser, the problem that environment of a classroom is polluted due to chalk dust flies is prevented, and therefore personal hazardscaused by the fact that dust is inhaled by people can be avoided; and the blackboard eraser is provided with the structure for cleaning the eraser cotton, so that the eraser cotton is convenient to clean, and the eraser cotton can be kept neat and clean.

Owner:高天宇

Spare brake beam having replaceable brake heads

ActiveCN101484345AQuick installationEasy to installRail brake actuationBrake padAutomotive engineering

Owner:STUCKI DE MEXICO S DE R L DE C V

Back striking lighter safety lock

The present invention relates to a back-lighted type lighter safety lock. It is characterized by that a secret pin is set in the interior of machine head, said secret pin is a lever mechanism, the pivot of said lever is the pin shaft set on the machine head, the right arm of said lever is extended towards outer side wall of machine body, the left arm of said lever is extended into the machine head interior; on the top cover of said machine head a long hole is set along the sliding direction of machine head, the top cover of said machine head is covered by using an opening-closing knob, said opening-closing knob is slide-fit with the top cover of machine head, a starting bar is fixedly-placed in the bottom portion of said opening-closing knob, said starting bar is passed through long hole and is placed in the machine head interior, the bar end of said starting bar is used as drive end for driving left arm of said lever; on the pin shaft a torsion spring is set, the bottom end of said torsion spring is fastened on the right arm of lever, the upper end of said torsion spring is formed into 'V'-shaped elastic structure. Said invention also provided the working principle of said back-lighted type lighter safety lock and its concrete operation method.

Owner:尚诚德

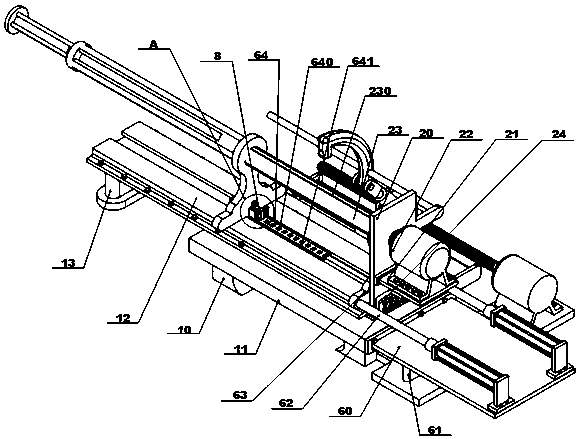

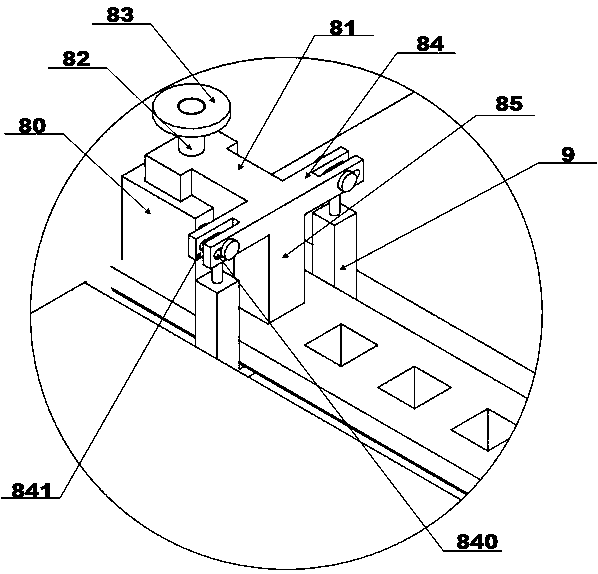

Glass product automatic notching machine

InactiveCN108818977AAvoid personal harmAvoid wasting resourcesWorking accessoriesStone-like material working toolsWood splinterEngineering

The invention discloses a glass product automatic notching machine. The glass product automatic notching machine structurally comprises a working frame, a motor, a transmission protective cover, a cutting component, an object placing plate, a glass splinter recovery device and a control panel, wherein the motor is arranged on the left wall of the inner lower part of the working frame and is connected to the left wall through a bolt; the transmission protective cover is arranged at the left side of the upper surface of the working frame and is connected to the left side rotatably and movably through the bolt; the left end of the cutting component is connected to the motor through the transmission protective cover; the glass splinter recovery device is arranged at the right side of the innerupper wall of the working frame, is located below the object placing plate and is connected to the working frame by electric soldering; and the control panel is arranged at the right side of the object placing plate and is connected to the right end of the object placing plate by electric soldering. When the glass product automatic notching machine works, the glass product automatic notching machine can collect glass splinters generated in work automatically and centrally through the arranged glass splinter recovery device so as to prevent the glass splinters from doing harm to operating personnel, causes the glass splinters to be used again and avoids the wasting of resources.

Owner:FOSHAN HUAPU RUILIAN ELECTROMECHANICAL TECH CO LTD

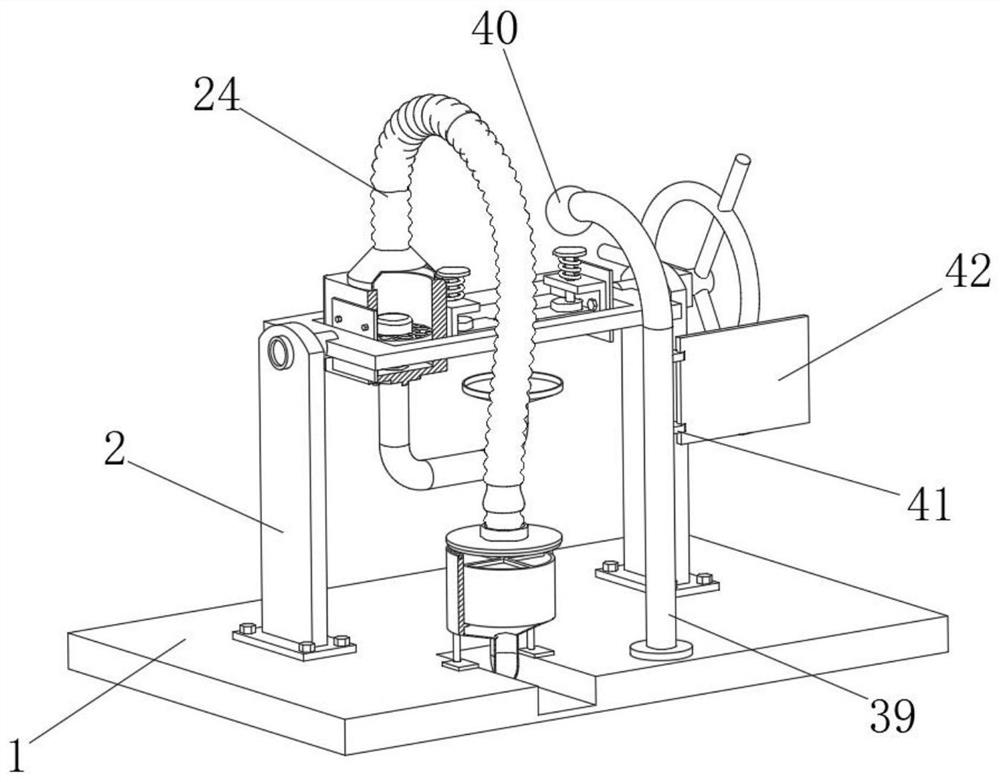

Dust removal system for rubber mixing mill

InactiveCN111702979AIncrease contact areaGuaranteed Filtration EfficiencyDispersed particle filtrationTransportation and packagingThermodynamicsDust control

The invention relates to the technical field of rubber mixing mill dust removal, and discloses a dust removal system for a rubber mixing mill. The dust removal system comprises a dust cover, the top end of the dust cover is connected with a communicating pipe, the tail end of the communicating pipe communicates with a dust prevention mechanism, the dust prevention mechanism comprises a box body, and partition plates are arranged on the two sides in the box body; the partition plates divide the interior of the box body into a dust collection cavity, a dust removal cavity and a purification cavity, a first through pipe is arranged on the partition plate between the dust collection cavity and the dust removal cavity, a plurality of filter plates are arranged in the dust removal cavity, and acirculating dust removal mechanism is further arranged in the dust removal cavity. According to the dust removal system, the contact area between a filter plate arranged on the inclined plane and airflow is large, and the filtering effect is good; the arranged circulating dust removal mechanism can flush dust accumulated on the filter plate, and the filtering efficiency of the filter plate is guaranteed; and meanwhile, water circulation is arranged, the dust can be attached to the filter plate when meeting water, and the filtering effect is enhanced.

Owner:河北汇海橡塑材料股份有限公司

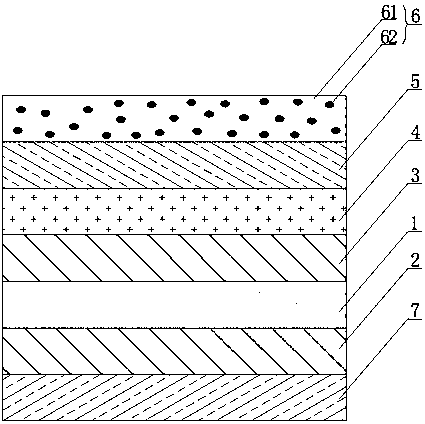

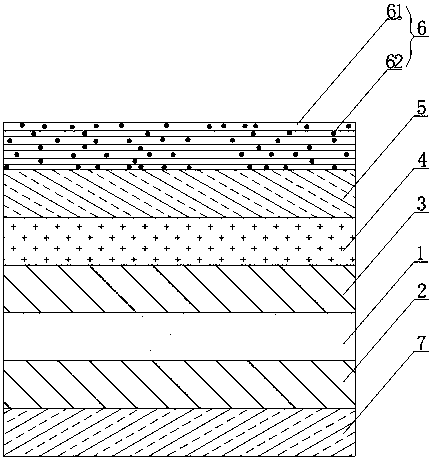

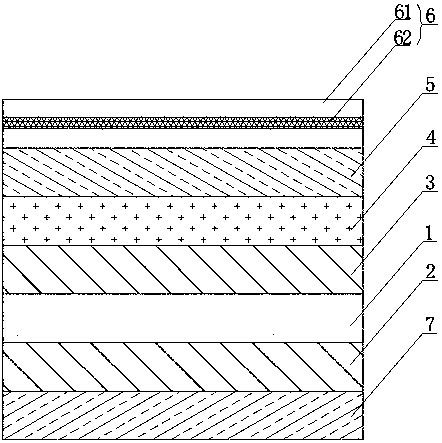

A self-cleaning curtain wall decorative board and its processing technology

ActiveCN106088422BGood spreadabilityImprove superhydrophilicityAntifouling/underwater paintsCovering/liningsWeather resistanceFluoropolymer

The invention relates to a self-cleaning curtain wall decorative sheet and a manufacturing technique thereof and belongs to the technical field of building materials. The self-cleaning curtain wall decorative sheet is composed of a substrate layer, a first passivation layer, a second passivation layer, a backing paint layer, a primer layer, a finish paint layer and a self-cleaning layer. The first passivation layer and the second passivation layer are located on the lower surface and the upper surface of the substrate layer correspondingly. The backing paint layer is located under the first passivation layer. The primer layer is located on the second passivation layer. The primer layer, the finish paint layer and the self-cleaning layer are sequentially arranged from bottom to top. The self-cleaning layer is a titanium dioxide / silicon dioxide composite layer, and fluoropolymer formed by water-soluble fluorine-containing polymer is arranged in the self-cleaning layer. The self-cleaning curtain wall decorative sheet is applied to the building decoration field such as high-rise building outer walls and large exhibition halls and has the advantages of weather resistance, corrosion resistance, self-cleaning and the like.

Owner:浙江墙煌新材料有限公司

Bathroom safety protection vehicle for removing surface accumulated water

A bathroom safety protection vehicle for removing surface accumulated water, disclosed in the invention, and comprises a vehicle body, a working cavity with a downward opening is formed in the vehicle body, a belt cavity is formed in the right side of the working cavity, a motor is arranged in the right wall of the belt cavity, and the left end of the motor is in power connection with a motor shaft; and the motor shaft is rotatably connected between the belt cavity and the working cavity in a leftward through manner. The vehicle is used in bathrooms in various occasions and serves as safety protection to avoid personal injury caused by wet and slippery ground, the vehicle advances on the ground, when water is accumulated on the ground, a towel can be automatically and flatly laid on the ground to suck the accumulated water dry, sewage is discharged and collected by squeezing the towel after water absorption, and then the action is repeated, so that the device can continuously remove accumulated water in the bathroom, time and labor are saved, and convenience and rapidness are achieved.

Owner:湖北普谦云科技有限公司

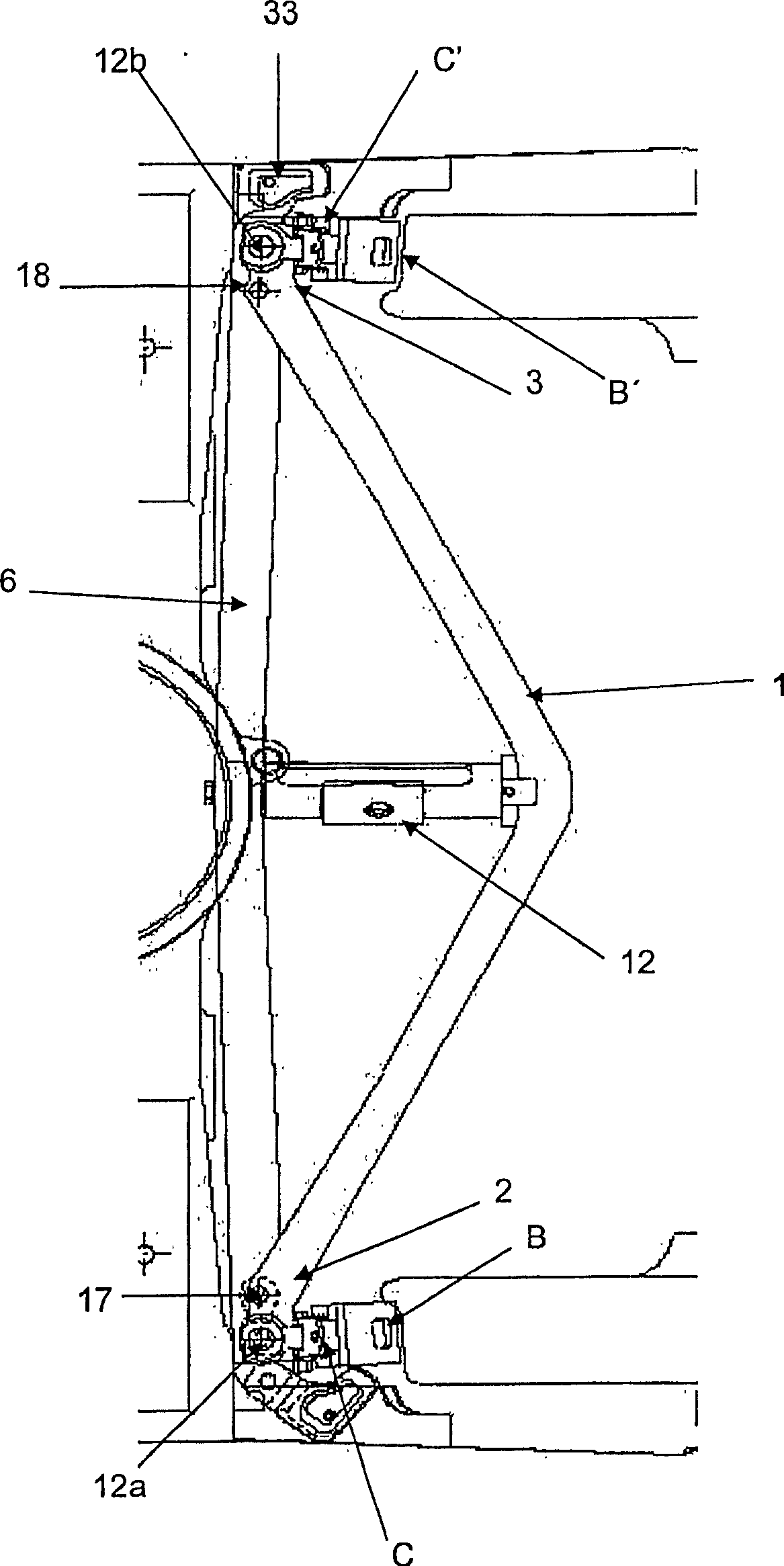

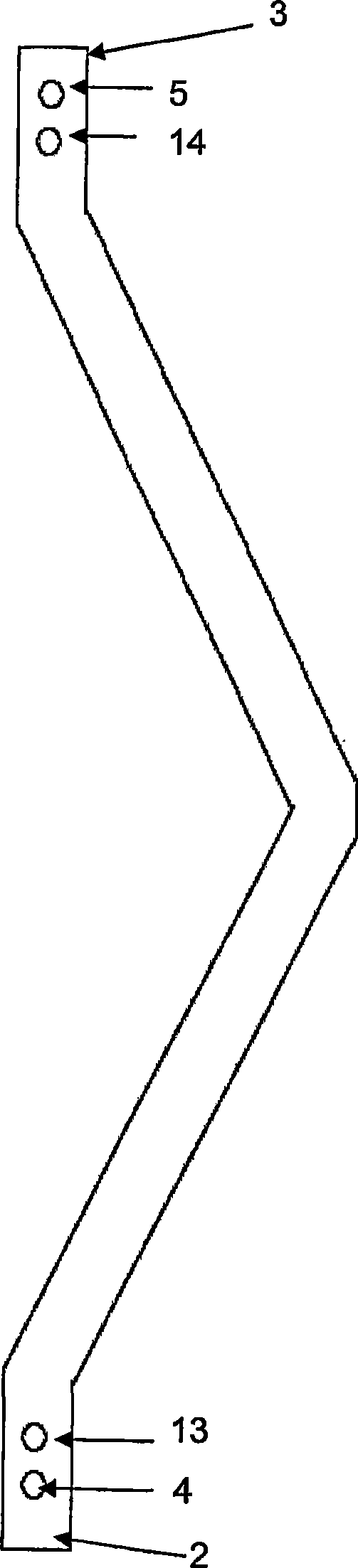

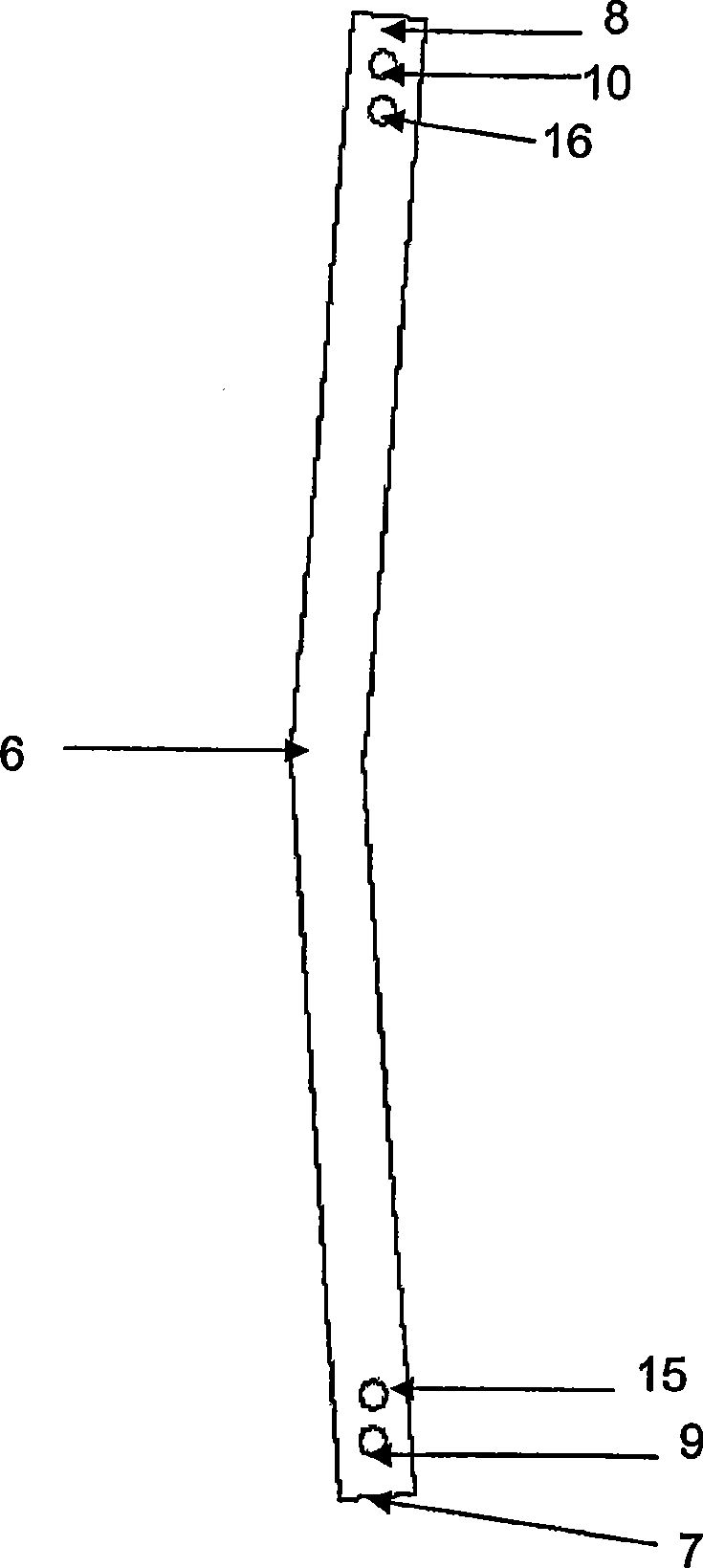

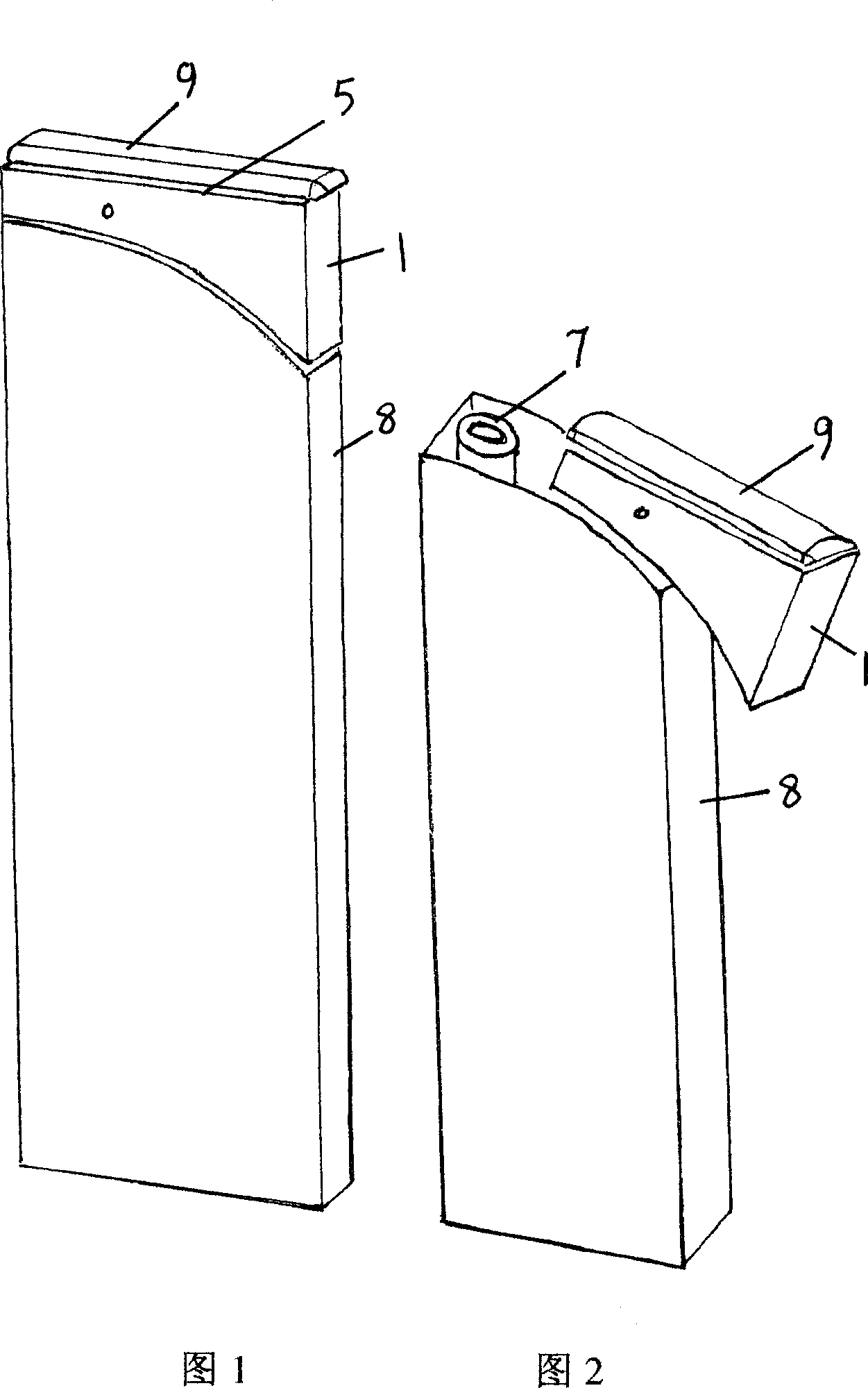

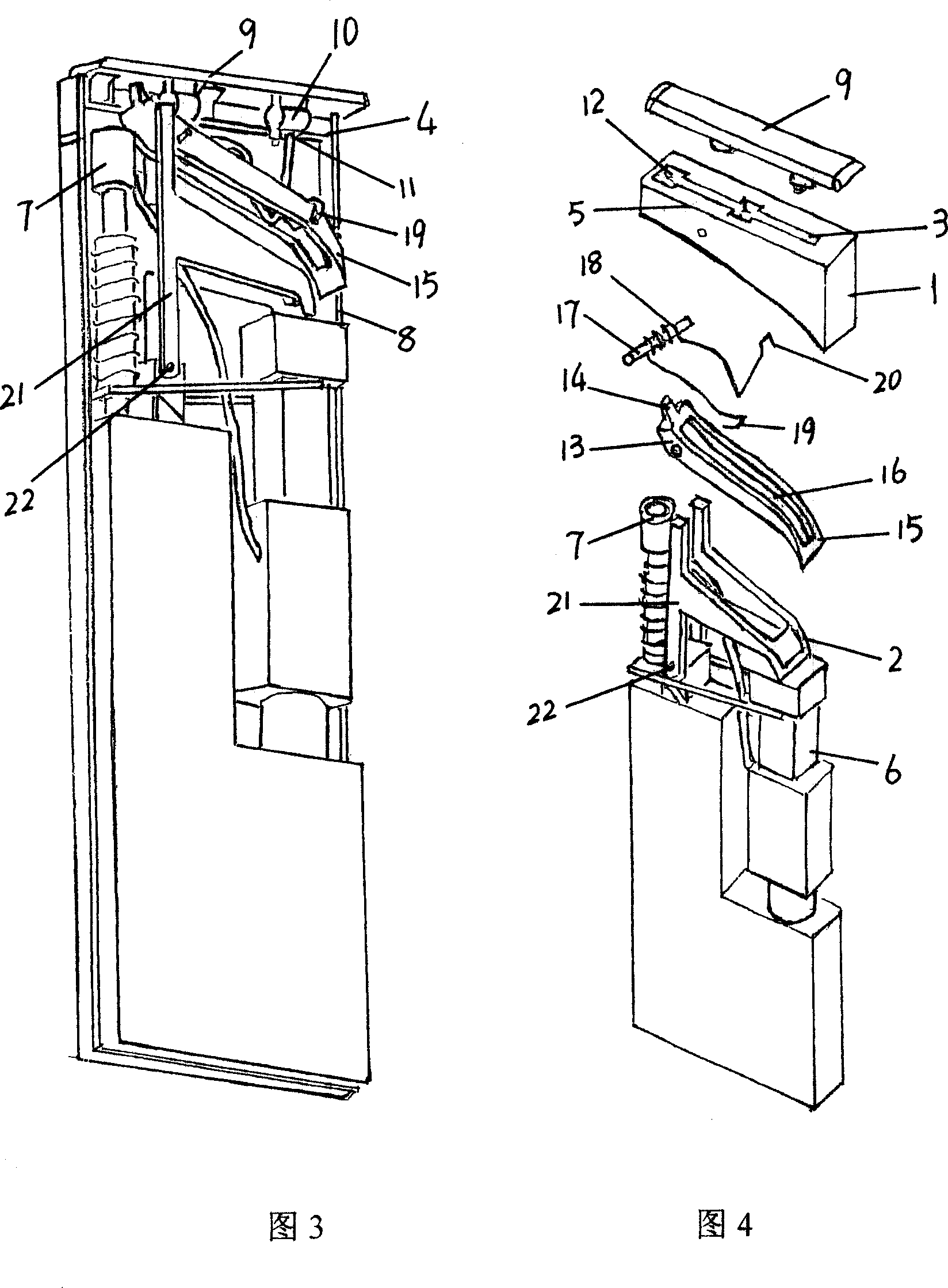

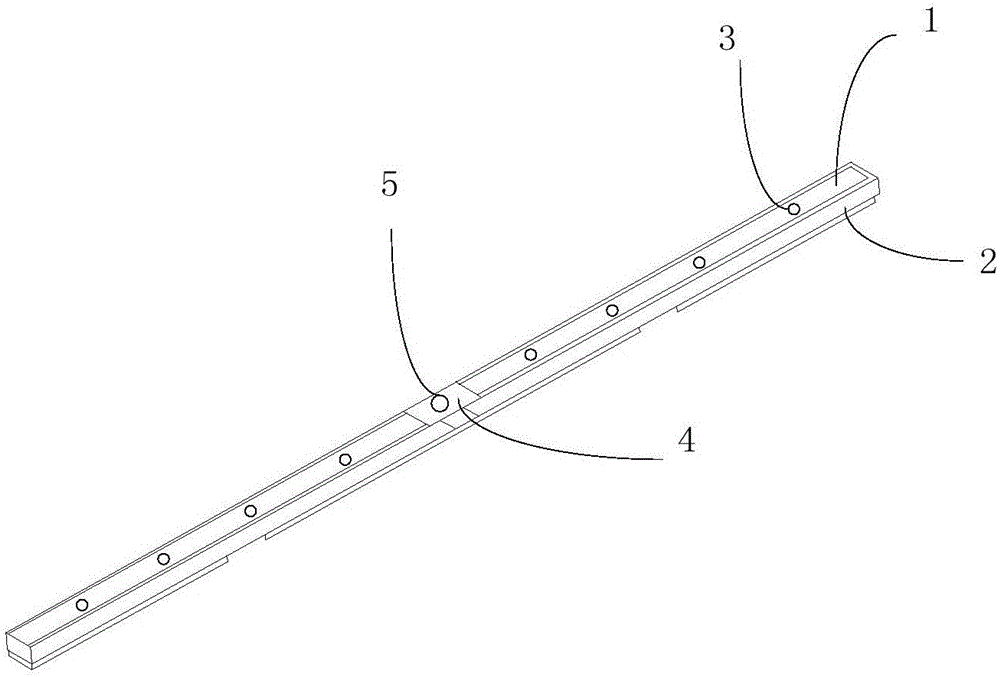

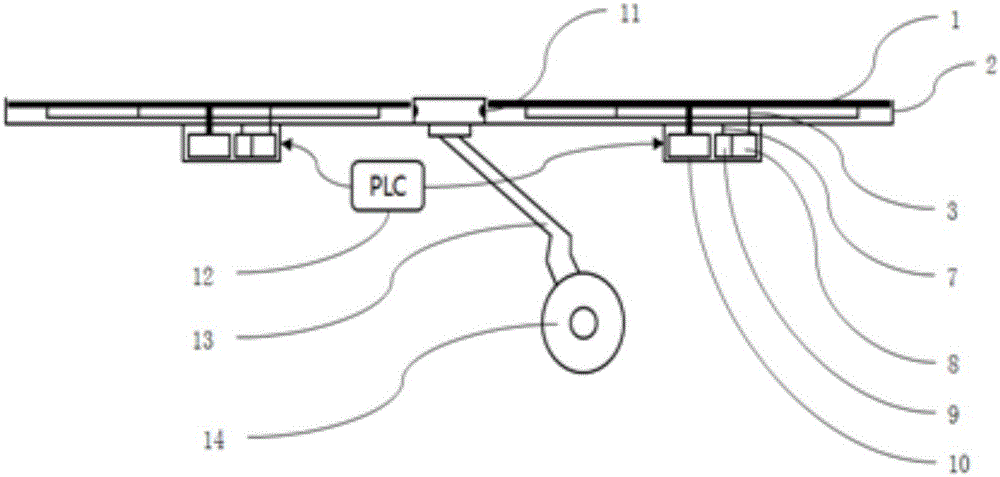

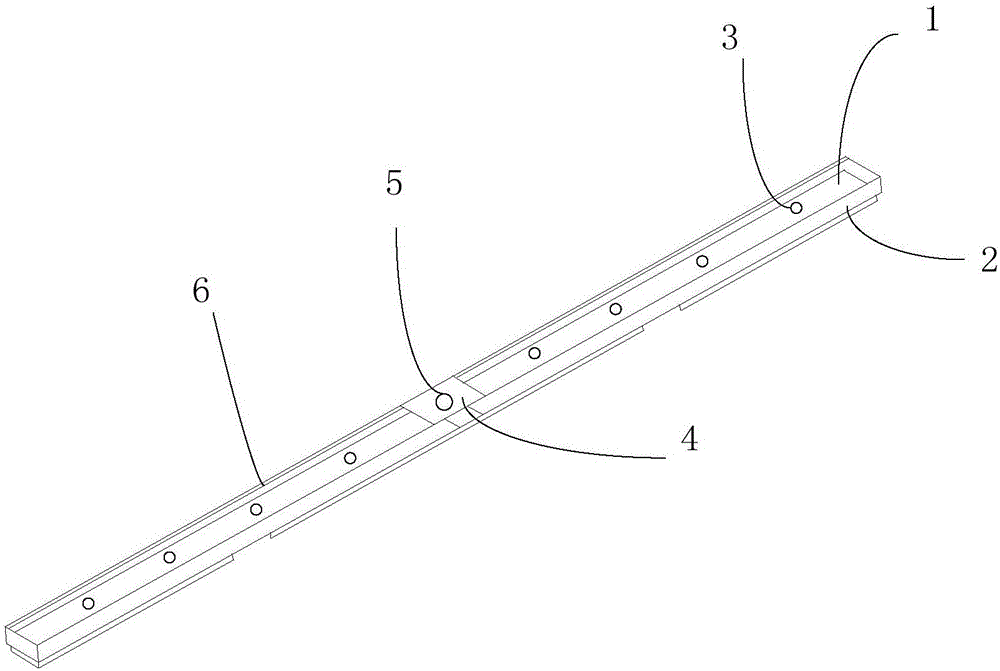

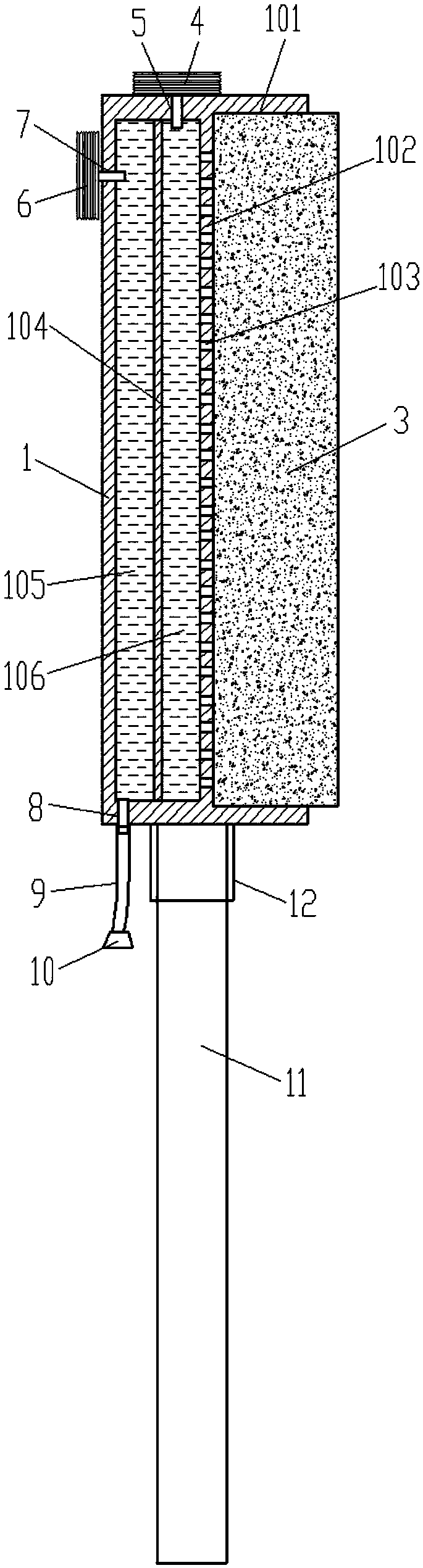

Substrate supporting rod and antistatic liquid coating method

ActiveCN106444110ARealize automatic coatingAvoid pollutionLiquid surface applicatorsSemiconductor/solid-state device manufacturingSoftware engineeringSupport surface

The invention relates to a substrate supporting rod. The substrate supporting rod comprises an outer supporting rod, an inner supporting rod, a lifting structure and an antistatic liquid coating structure, wherein the outer supporting rod adopts a box structure with an opening in one surface; the inner supporting rod is accommodated inside the outer supporting rod, and has a supporting surface for supporting a substrate; the lifting structure is used for controlling the inner supporting rod to do lifting movement so as to change the inner supporting rod between a first state and a second state; the lifting structure comprises a connecting rod running through the bottom of the outer supporting rod so as to support the inner supporting rod; the antistatic liquid coating structure is used for coating antistatic liquid onto the inner supporting rod when the inner supporting rod is in the first state; in the first state, the inner supporting rod is completely positioned inside the outer supporting rod; in the second state, the supporting surface of the inner supporting rod is flush with the surface, having the opening, of the outer supporting rod. The invention further relates to an antistatic liquid coating method. With the antistatic liquid coating method, automatic coating of the antistatic liquid is achieved, and during antistatic liquid coating, pollution to the substrate and the like is prevented and personal hazards are avoided.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

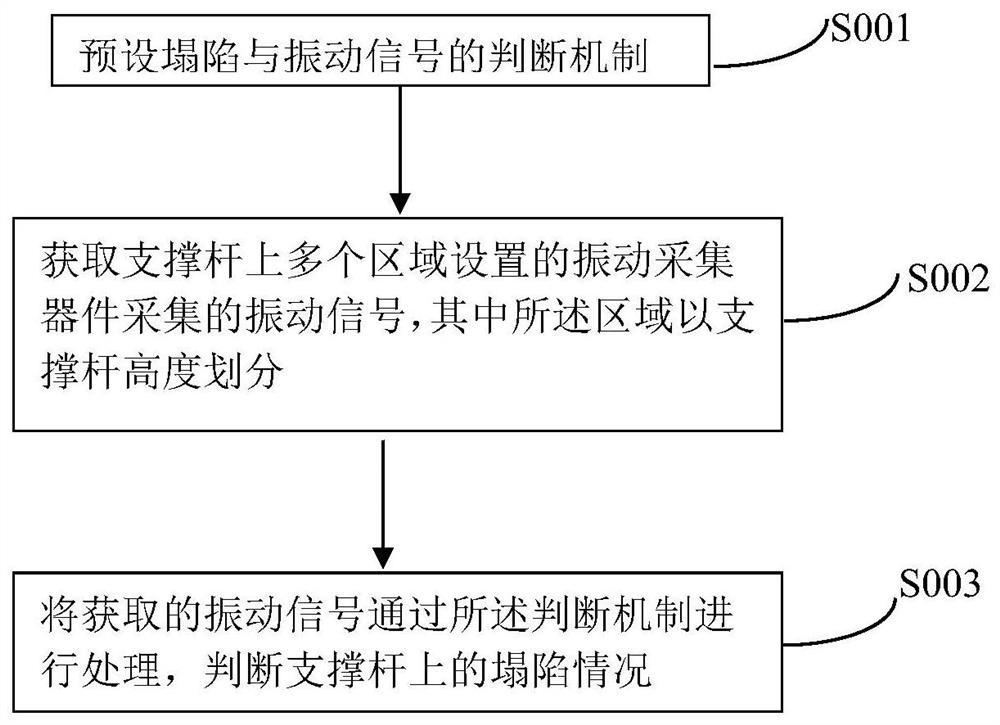

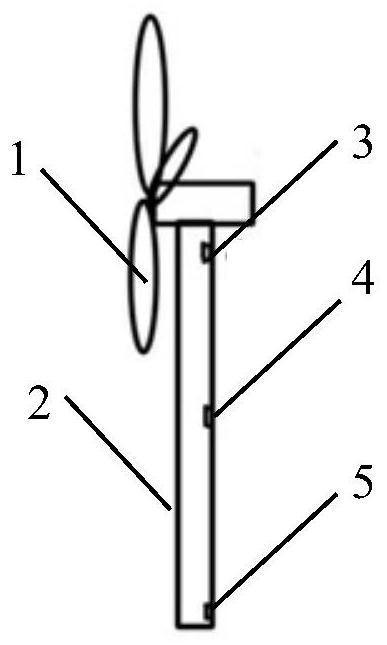

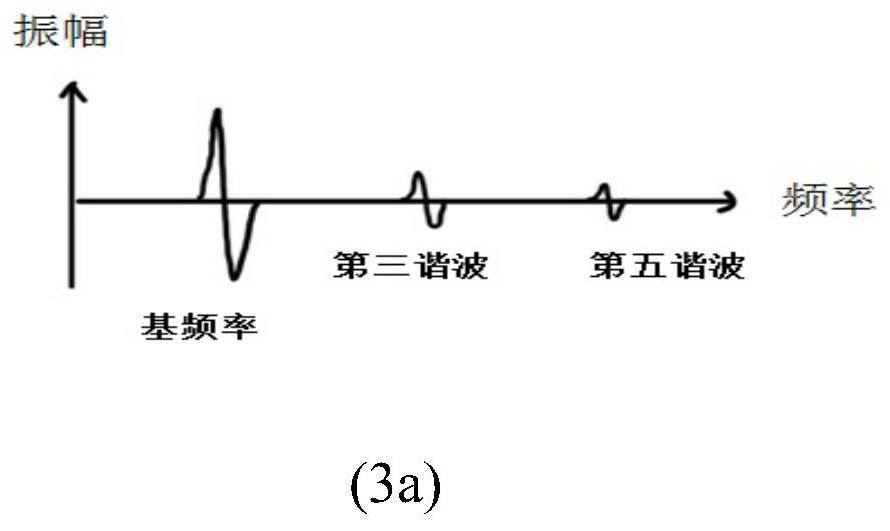

Fan supporting rod collapse monitoring method and device

PendingCN112257516AReduce economic lossAvoid personal harmCharacter and pattern recognitionMachines/enginesStructural engineeringMechanical engineering

The invention discloses a fan supporting rod collapse monitoring method and device. The method comprises the steps of presetting a collapse and vibration signal judgment mechanism; acquiring vibrationsignals acquired by vibration acquisition devices arranged in a plurality of areas on the support rod, wherein the areas are divided according to the height of the support rod; processing the acquired vibration signals through the judgment mechanism, and judging the collapse condition of the supporting rod; according to the method and the device, the vibration acquisition devices are distributedto acquire the vibration signals of different height areas on the supporting rod, collapse analysis is automatically performed based on a judgment mechanism to obtain a judgment result of the collapsecondition, early warning is timely sent to inform workers to take maintenance measures in time, economic losses are reduced, and personal injury caused by collapse of the fan supporting rod is effectively avoided.

Owner:北京致感致联科技有限公司

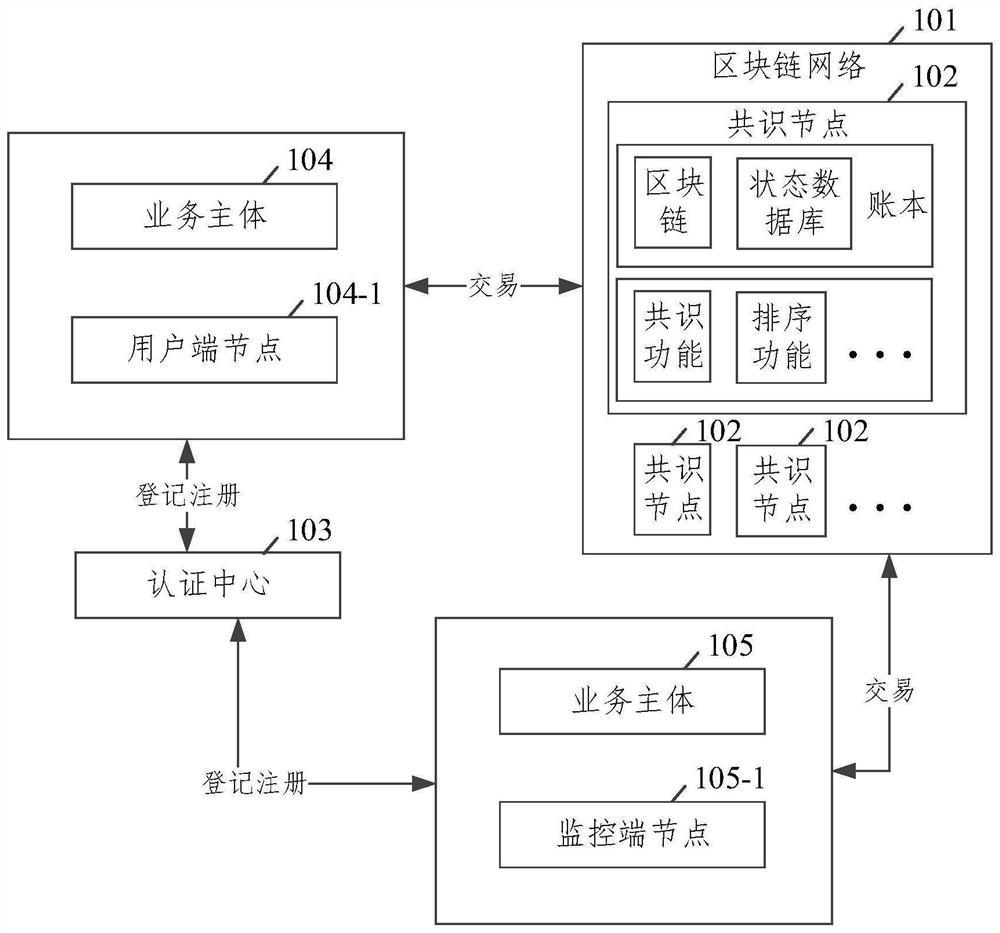

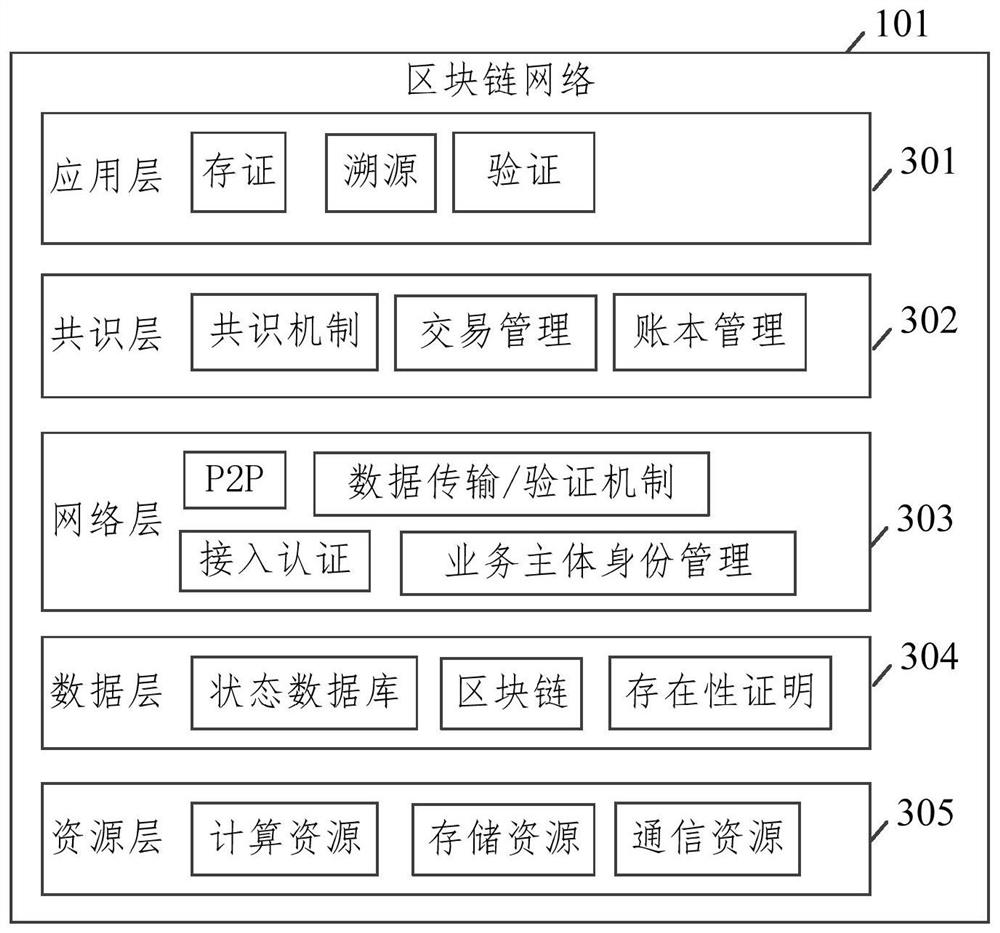

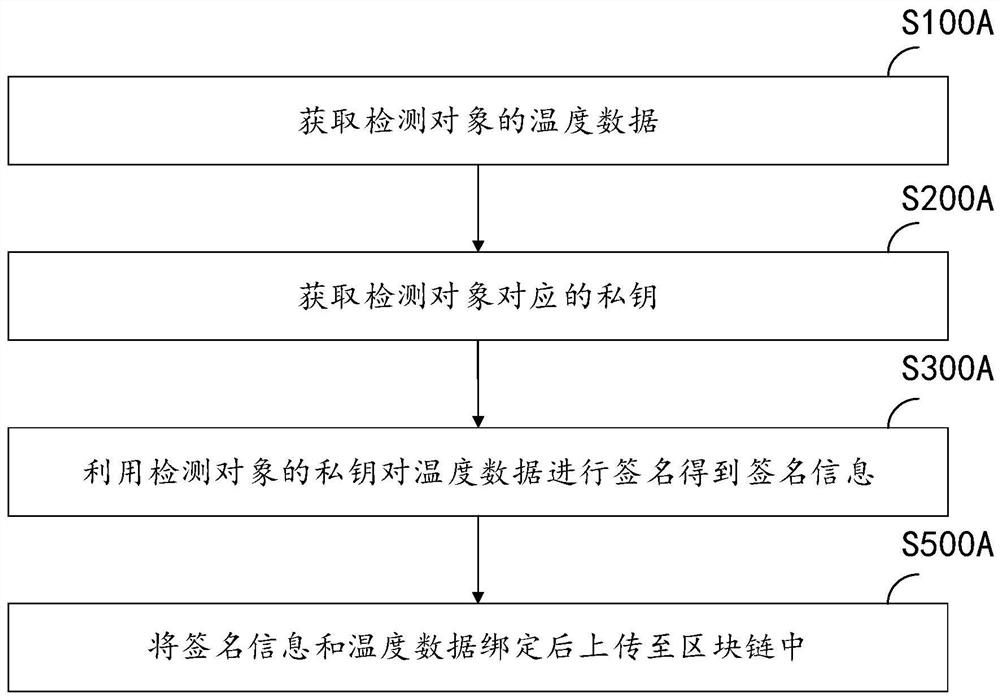

Temperature data management and control method and device based on block chain and storage medium

ActiveCN112597512AAvoid troubleAvoid personal harmDatabase distribution/replicationDigital data protectionData managementReliability engineering

The invention relates to a temperature data management and control method and device based on a block chain and a storage medium. The method comprises the steps of obtaining temperature data of a detection object; obtaining a private key corresponding to the detection object; signing the temperature data by using a private key of the detection object to obtain signature information; binding the signature information and the temperature data, and uploading the bound signature information and temperature data to a block chain. The temperature privacy data of the user is strictly controlled in the temperature detection process, safety and reliability are achieved, and the situation that the temperature privacy data of the user is directly exposed to cause trouble and personal harm to the usercan be prevented.

Owner:HANGZHOU QULIAN TECH CO LTD

Self-cleaning dustproof blackboard eraser

InactiveCN108528110AAvoid flyingAvoid pollutionBoard cleaning devicesCleaning using liquidsEngineeringCOTTON WOOL

The invention provides a self-cleaning dustproof blackboard eraser. The self-cleaning dustproof blackboard eraser comprises a shell. A water seepage plate is arranged in the middle of an inner cavityof the shell. A board wiping cotton mounting groove for mounting board wiping cotton is formed in the portion, at the front of the water seepage plate, of the inner cavity of the shell. The portion, at the rear of the water seepage plate, of the inner cavity of the shell is divided into a cleaning water cavity for cleaning the board wiping cotton and a water seepage cavity for infiltrating water into the board wiping cotton so as to avoid dust when the blackboard eraser is used for wiping. According to the self-cleaning dustproof blackboard eraser, the chalk dust can be well prevented from flying, the classroom environment pollution can be avoided, and personal hazards caused by dust inhalation can be avoided; and the structure for cleaning the board wiping cotton is arranged on a blackboard eraser body, so that the board wiping cotton is convenient to clean, and the board wiping cotton is kept clear and clean.

Owner:李思蓓

An anti-twisting coiling device for electrical round aluminum rods

ActiveCN108821002BImprove stabilityImprove practicalityFilament handlingEngineeringMechanical engineering

Owner:眉山市博眉启明星铝业有限公司

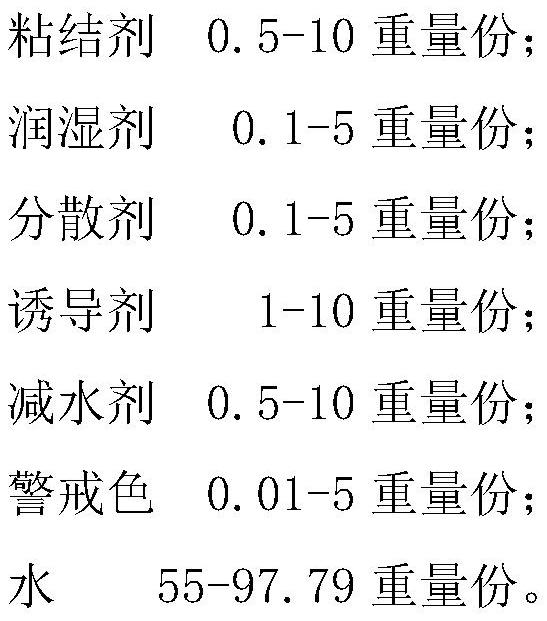

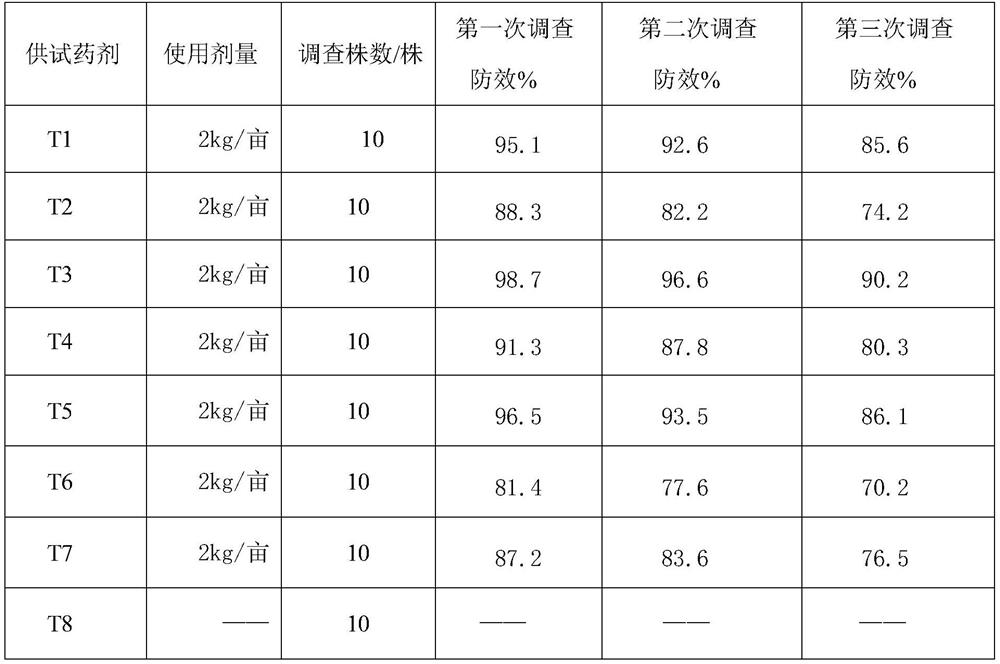

Granule containing indole butyric acid and lentinan as well as preparation method and application thereof

The invention relates to a granule containing indole butyric acid and lentinan. The granule comprises the following components in parts by weight: a phase A component: 60-95 parts by weight of a granule carrier; a B-phase component: pesticide active ingredient mother powder, wherein the pesticide active ingredient mother powder comprises two components, one component is 0.1-10 parts by weight of indole butyric acid, and the other component is 0.1-1 part by weight of lentinan; and a phase C component: 1-30 parts by weight of functional slurry. Indole butyric acid and lentinan are matched to prepare the indole butyric acid and lentinan combined granule, crop virus diseases are mainly represented as the symptoms of shrinking, dwarfing, yellowing and the like of newly born leaves at the top ends of plants, lentinan has good plant virus resisting activity, meanwhile, lentinan serves as a sugar source to activate the plant nutrition transfer process, indole butyric acid is helped to be transmitted upwards and is transmitted to the apical growth part of a plant, apical growth is stimulated, and the obvious control effect on crop virus diseases is achieved.

Owner:TIANJIN HIGHPOINT PLANT PROTECTION

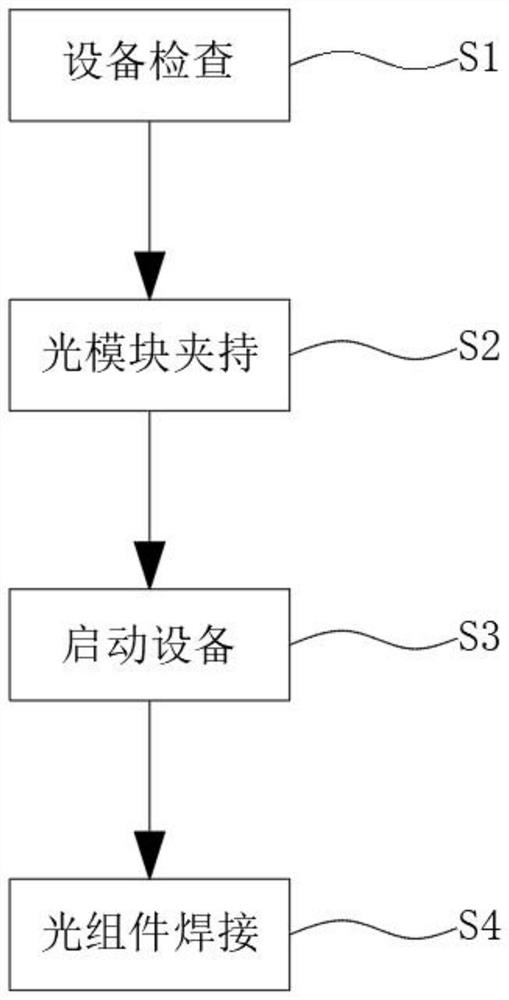

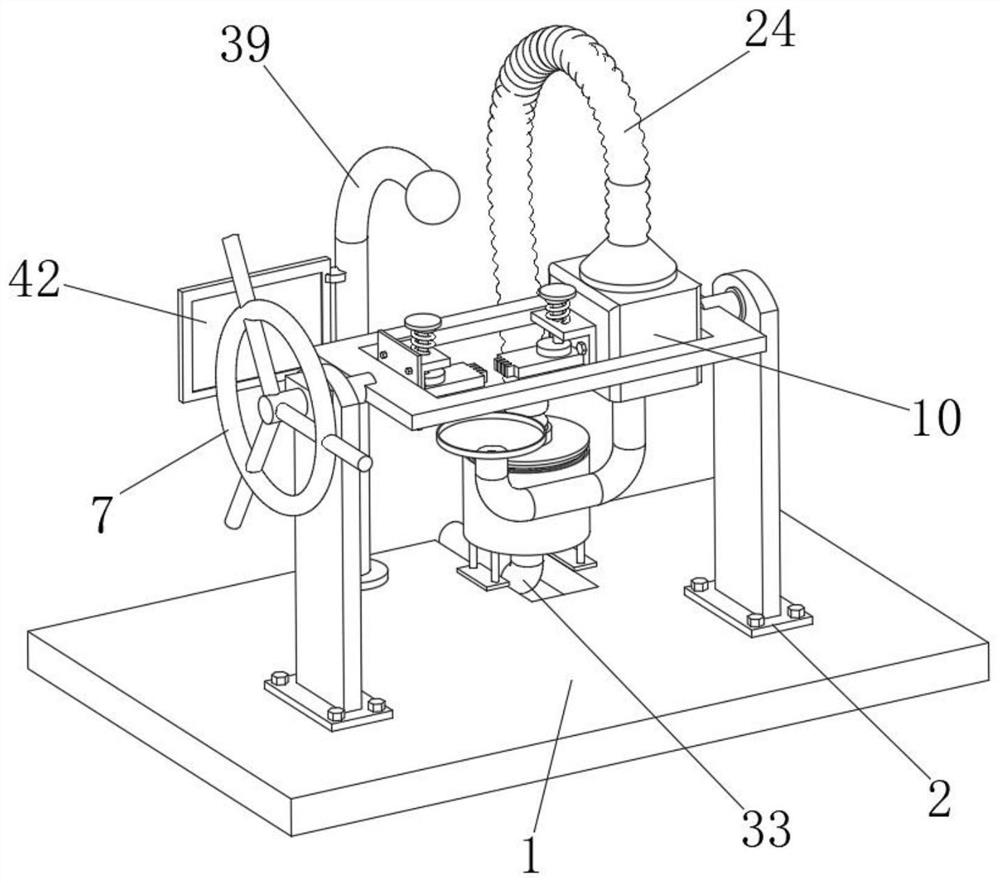

A kind of optical module production process

ActiveCN112935638BAvoid sorenessFacilitate subsequent weldingDispersed particle separationWelding/cutting auxillary devicesActivated carbonOptical Module

Owner:福弼通科技有限公司

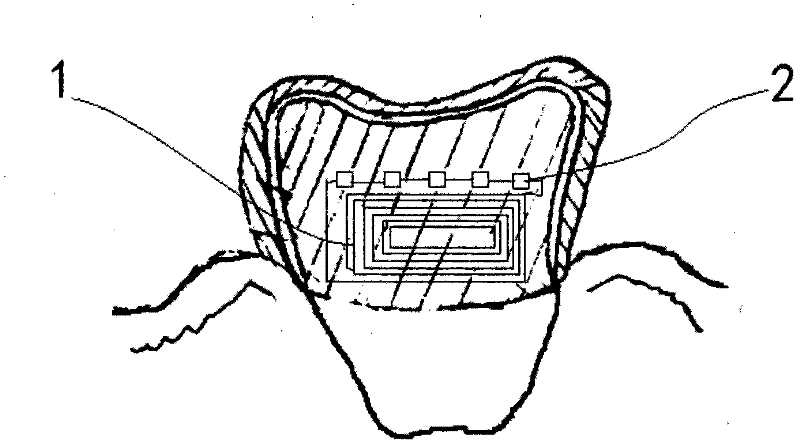

LED (Light-Emitting Diode) artificial teeth

The invention discloses LED (Light-Emitting Diode) artificial teeth, which comprise an induction coil, an LED luminous chip, artificial teeth, teeth and a gum, and is characterized in that: the induction coil is connected in series with the LED luminous chip, and is attached to the inside of the teeth; the induction oil is a radiofrequency IC (Integrated Circuit) card induction coil; and the artificial teeth consist of the teeth and the gum. The LED artificial teeth have the advantages that: environmental pollution and personal injuries caused by the use of a button cell can be avoided; and the LED artificial teeth have a simple structure and a unique luminous effect, and are convenient to manufacture.

Owner:XIAN COMEN ELECTRONICS TECH

Epoxy resin curing agent based on methyl methacrylate bottom waste and its preparation method and application

ActiveCN107722242BThe synthesis method is simpleLow costOrganic compound preparationCarboxylic acid amides preparationMethacrylateReflux

Owner:青岛哈工资源环境技术有限公司

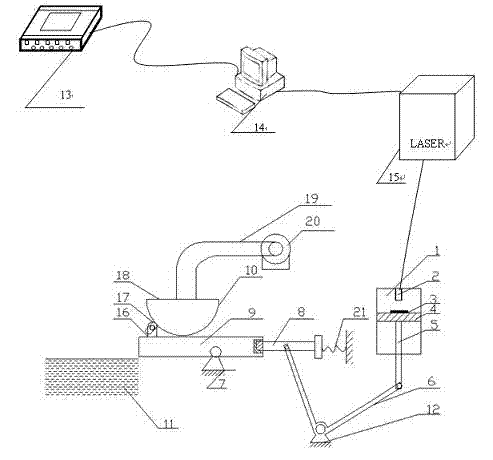

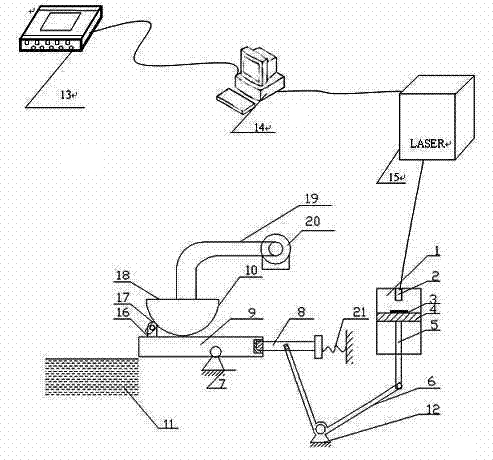

Laser-driven gas defense device

InactiveCN102042479BPrevent proliferationImprove controllabilityMachines/enginesPressure vesselsChemical industryHigh energy

The invention relates to the technical field of security protection in the chemical industry, in particular to a laser-driven gas defense device. Laser with high energy is conducted through an optical fiber, and the laser is radiated on the surface of a metal material, ablates partial metal film and makes the surface of the metal material instantly vaporized, high temperature and high pressure plasmas and a gas mixture are generated, and high air pressure is formed in an enclosed space, so that a piston is driven to move, a piston rod and a connecting rod drive a positioning pin to move rightwards, a bracket loses balance, and a storage bottle on the bracket rotates around a pin in a pin seat; therefore, liquid chlorine leaked from the storage bottle is poured into a bath of alkaline solution. Body harm caused by manually operating the device is avoided, and the storage bottle is not needed to be manually captured. The laser is used as a power source, the energy controllability is high, and super long-distance control can be performed by adopting laser drive.

Owner:JIANGSU UNIV

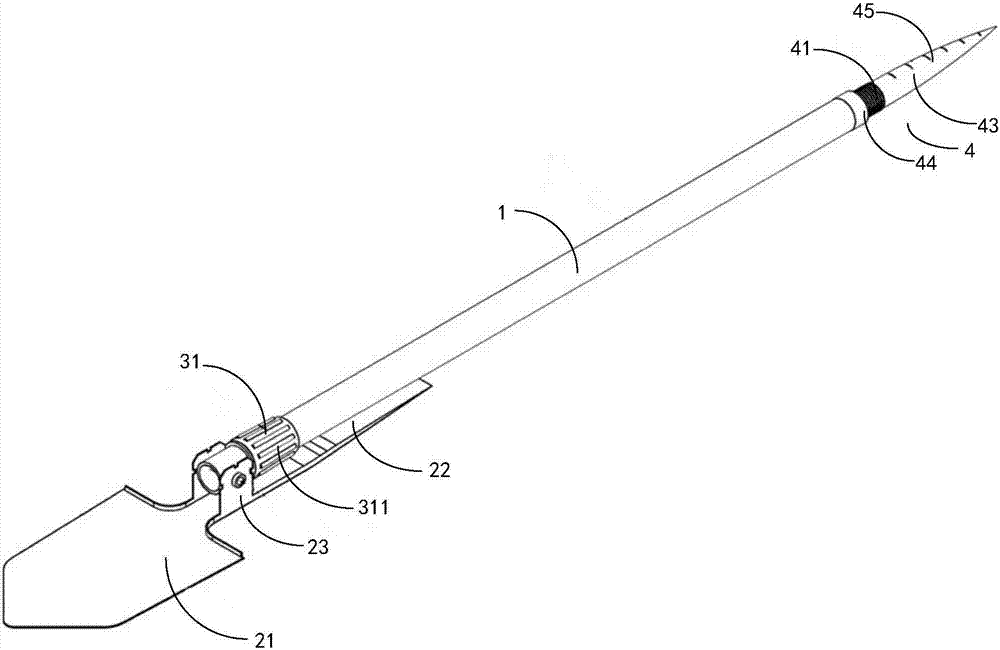

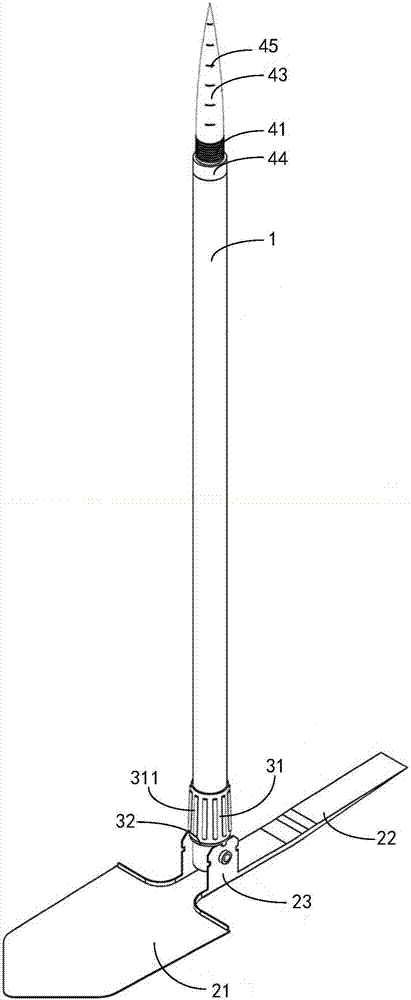

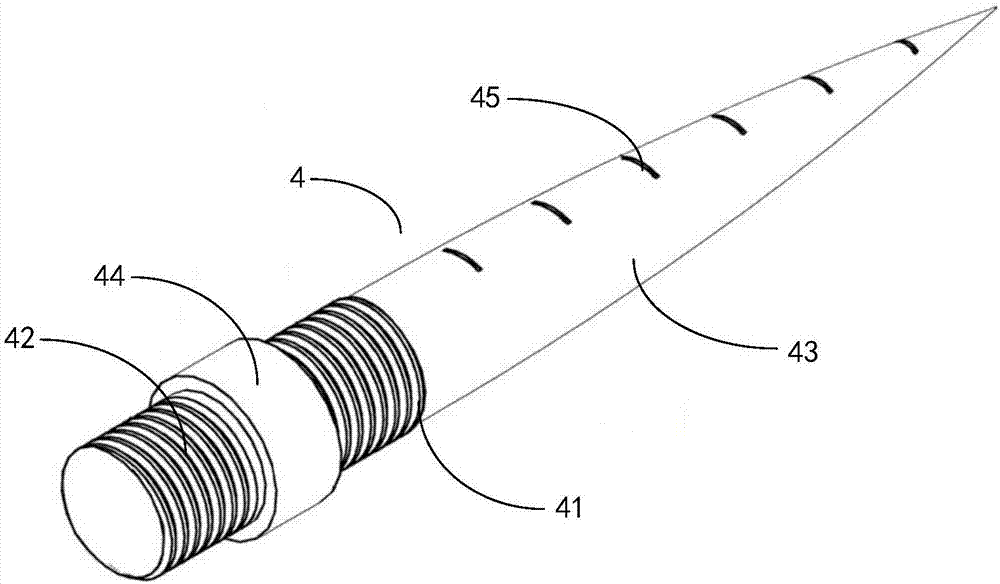

Afforestation tool for region of difficult-site type

PendingCN107258111AWith opening functionEasy to excavateSpadesManure treatmentPlant rootsEngineering

The invention relates to an afforestation tool for a region of a difficult-site type. The afforestation tool comprises a handle, a nursery-grown plant root pitting device, a digging device and a locating device, wherein the two ends of the handle separately comprise a first end and a second end, the nursery-grown plant root pitting device is detachably connected to the first end of the handle, and the middle part of the digging device is rotatably connected to the second end of the handle; and the locating device is mounted on the handle and is used for locating the digging device when the digging device is rotated to a preset position. According to the afforestation tool, the nursery-grown plant root pitting device and the digging device are separately arranged at the two ends of the handle, so that the afforestation tool has a pitting function and also has a digging function, the digging of nursery-grown plant planting platforms and planting holes in slopes of arsenic rock is facilitated, and the survival rate and working efficiency of afforestation are increased.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com