Patents

Literature

295 results about "Wood splinter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood: this type of splinter is contracted from lumber or other vegetative materials. Wood splinters must be removed from wounds because they are associated with inflammation and risk of infection. Larger or deeper splinters can result in difficult removal, or localization of the foreign body.

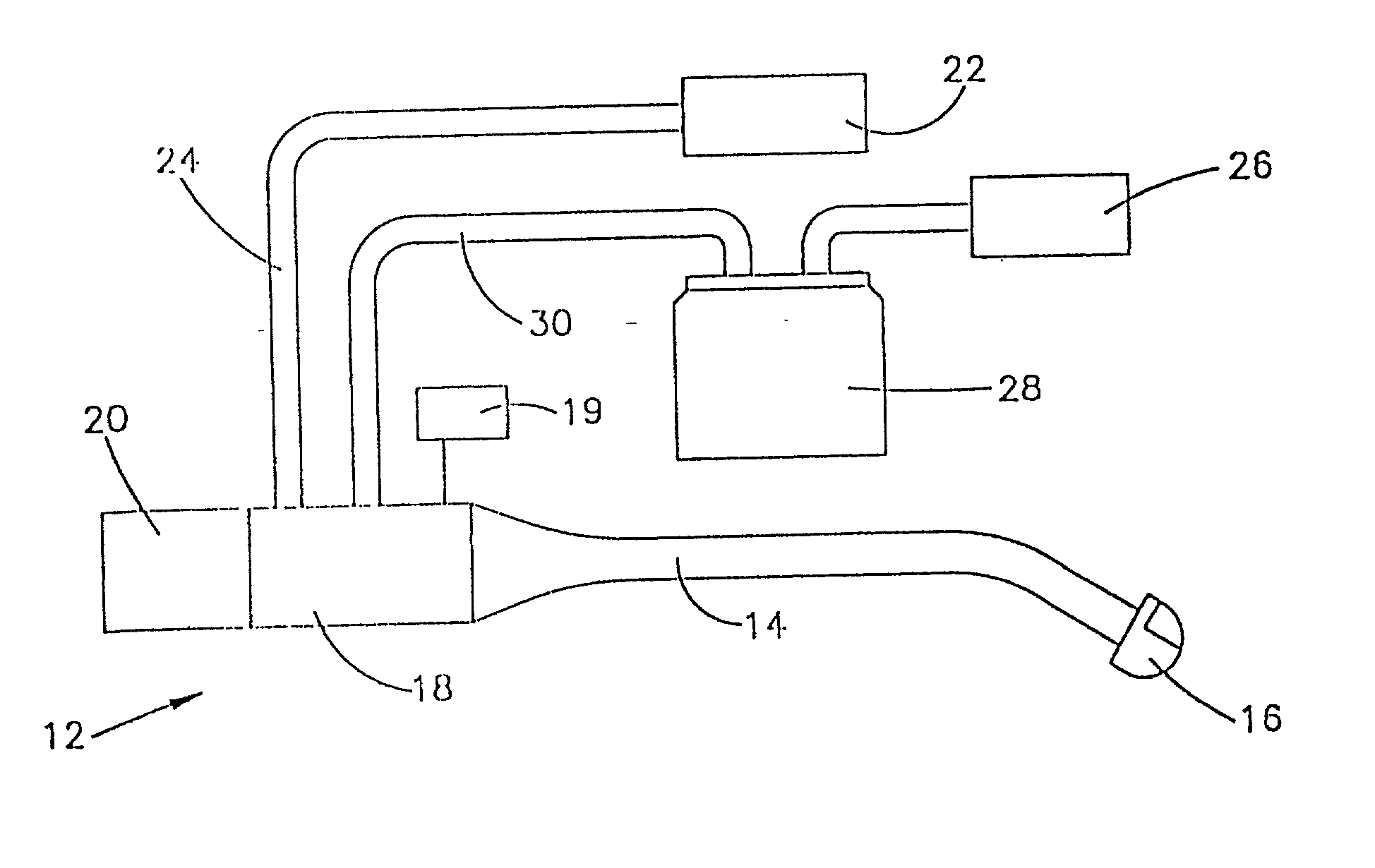

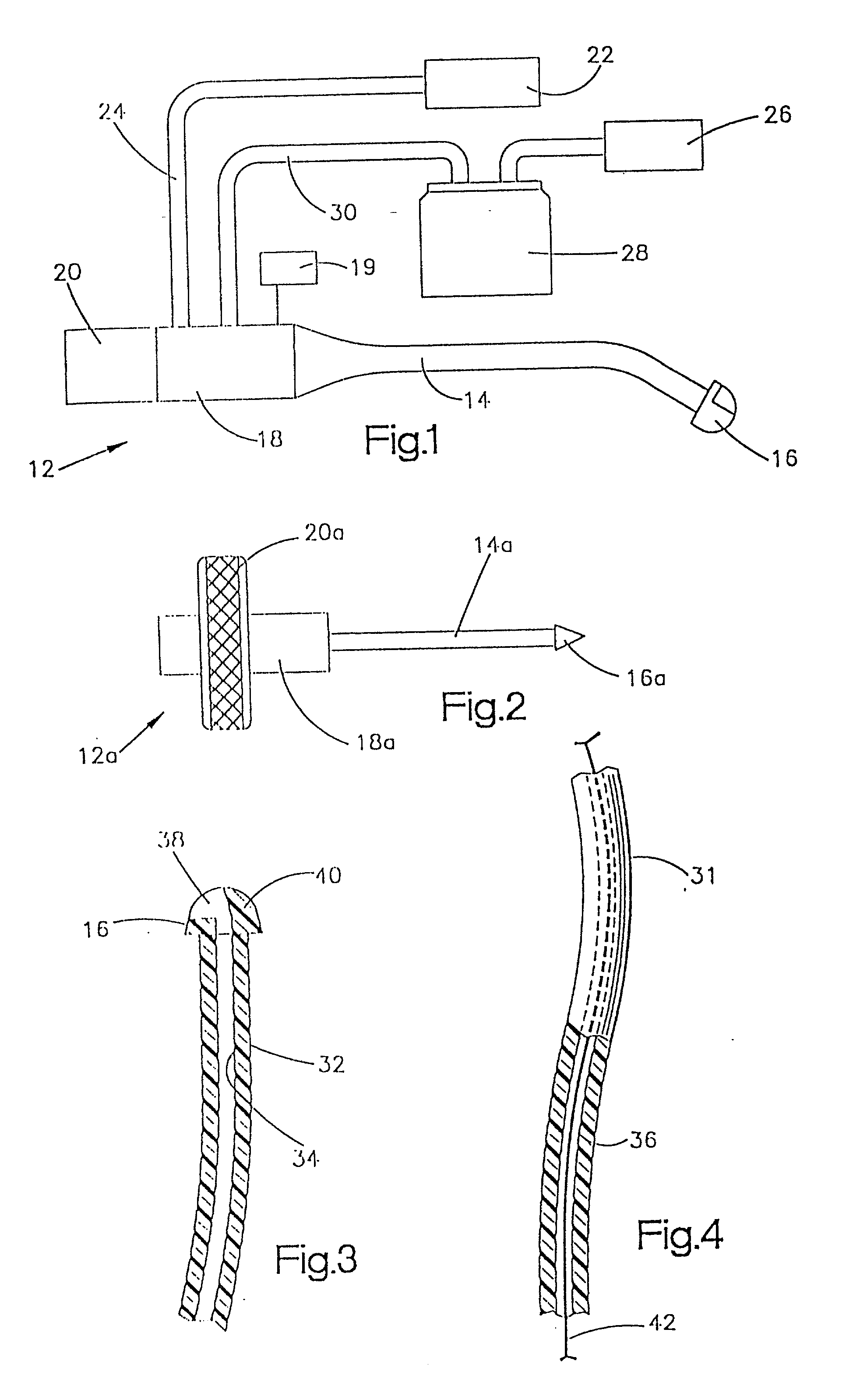

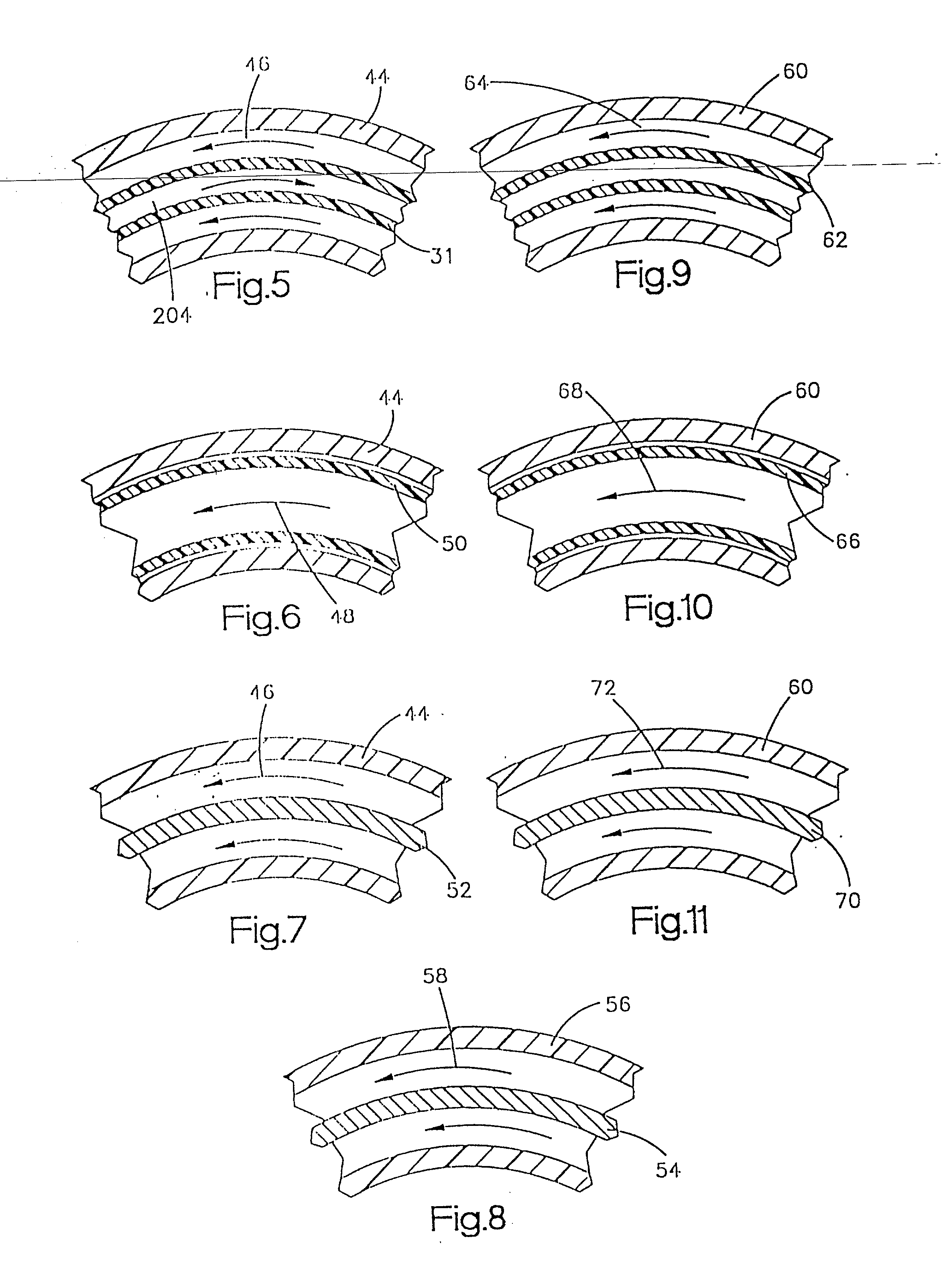

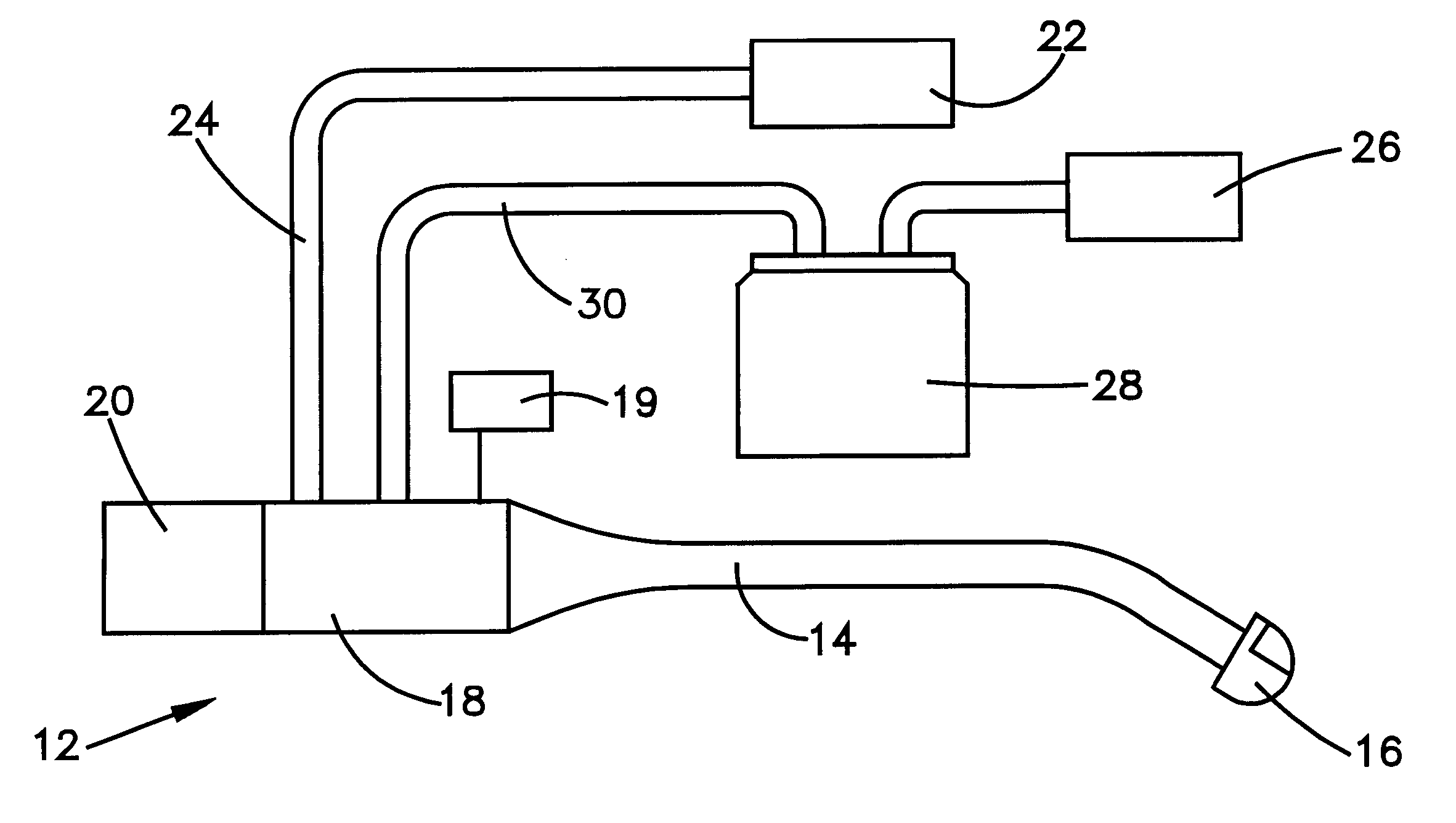

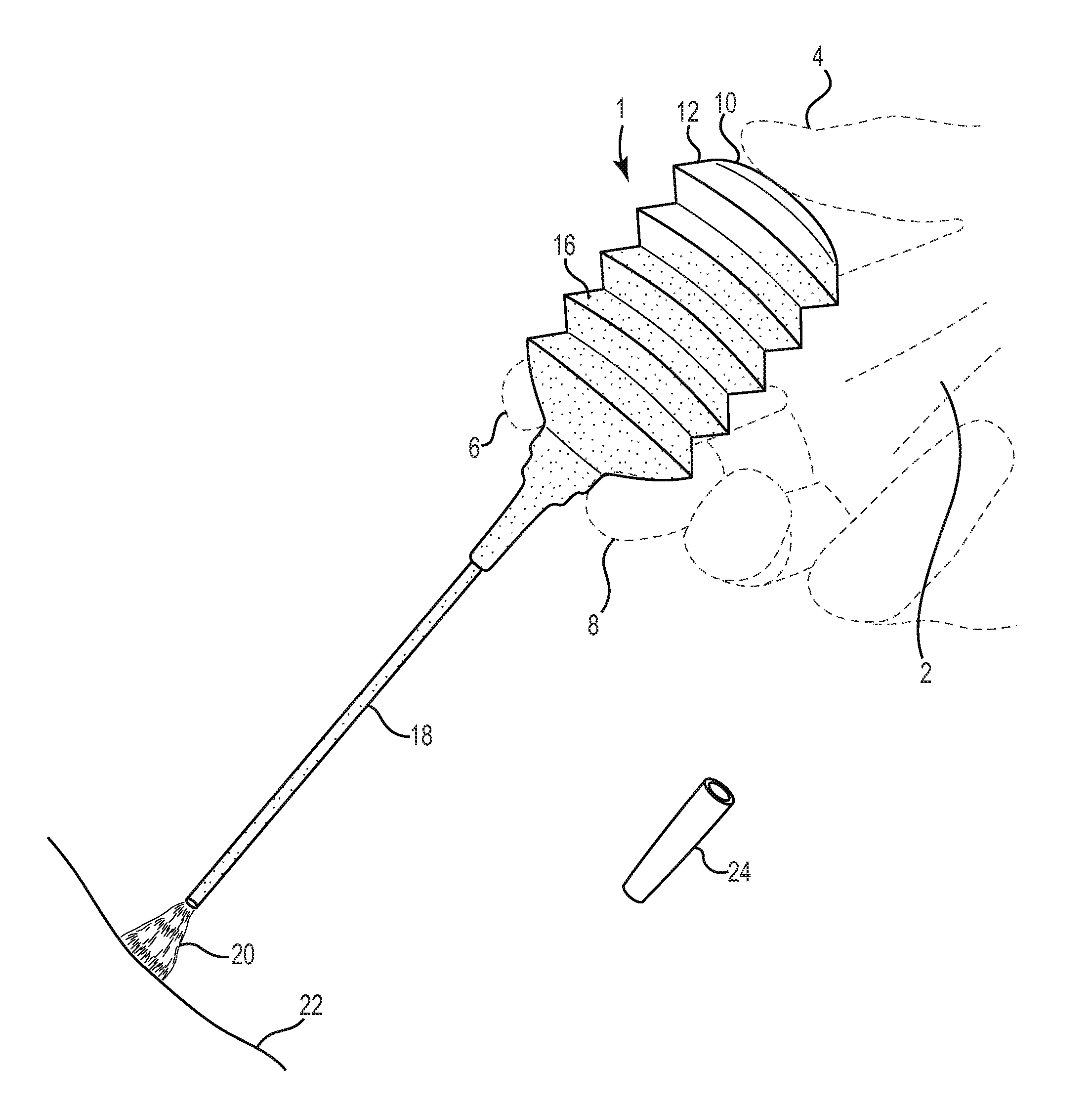

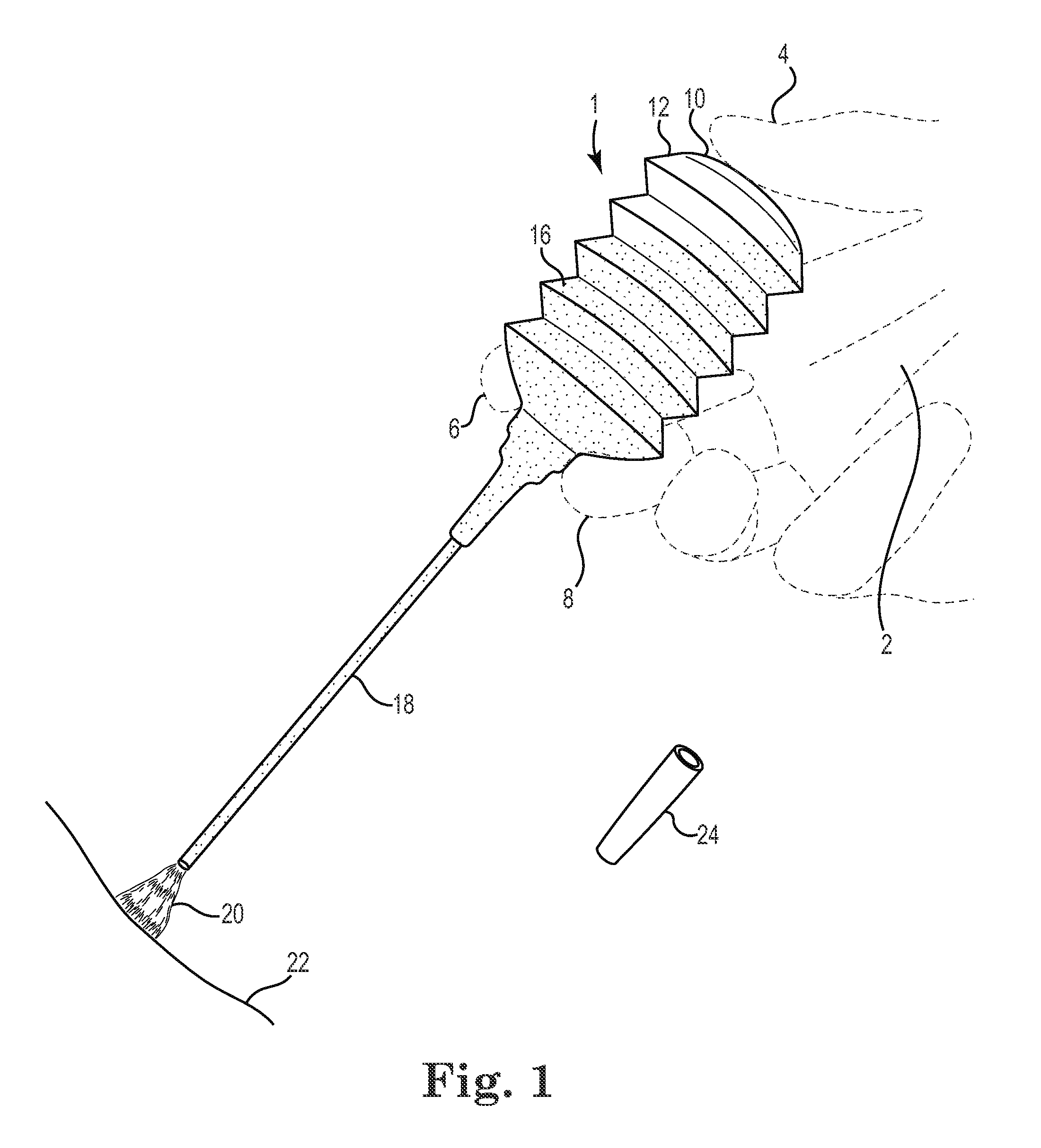

Apparatus and method for tissue removal

InactiveUS20020029055A1Less energyReduce frictionSurgical needlesVaccination/ovulation diagnosticsWood splinterMotion transfer

Percutaneous tissue removal apparatus comprises a flexible drill shaft, a cutting tip mounted on the shaft for placement adjacent a tissue mass for cutting the tissue, means for transmitting motion to the shaft to move the cutting tip against the tissue to cut tissue fragments from the tissue, and means for removing the tissue fragments along the shaft by suction to a location outside the tissue mass while cutting. The apparatus may include means for collecting one or more selected components of the harvested tissue fragments for implantation of the fragments preferably into the body of the patient from whom they were removed. Where the tissue to be cut is bone, a cutting tip is preferably made of a polymeric material which is softer than the cortical portion of the bone, although the cutting tip may be made of a ceramic or a composite material. A second flexible shaft may be provided either within or about the flexible drill shaft. The harvested tissue fragments may be implanted in the donor patient's body.

Owner:BONUTTI SKELETAL INNOVATIONS +2

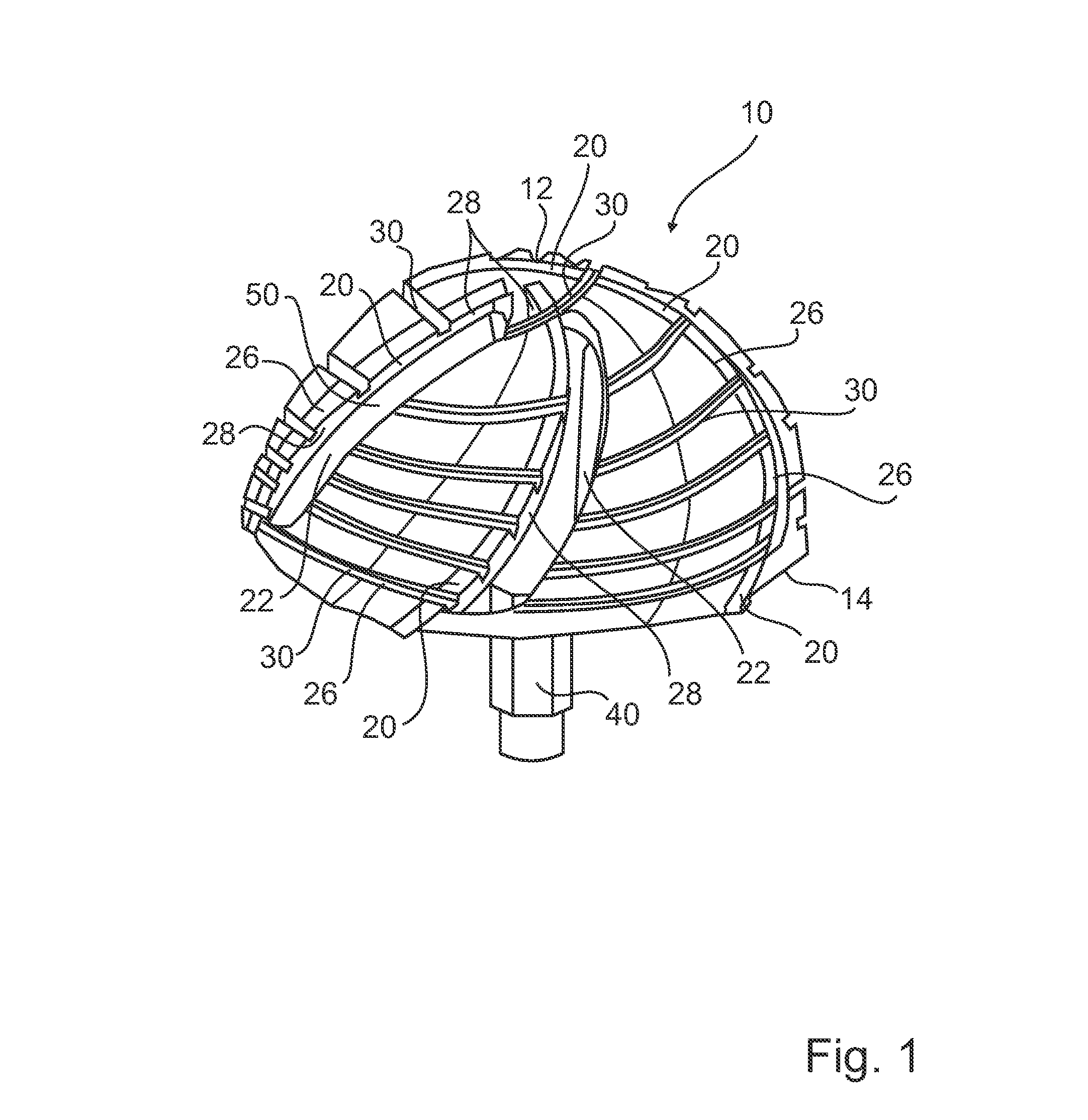

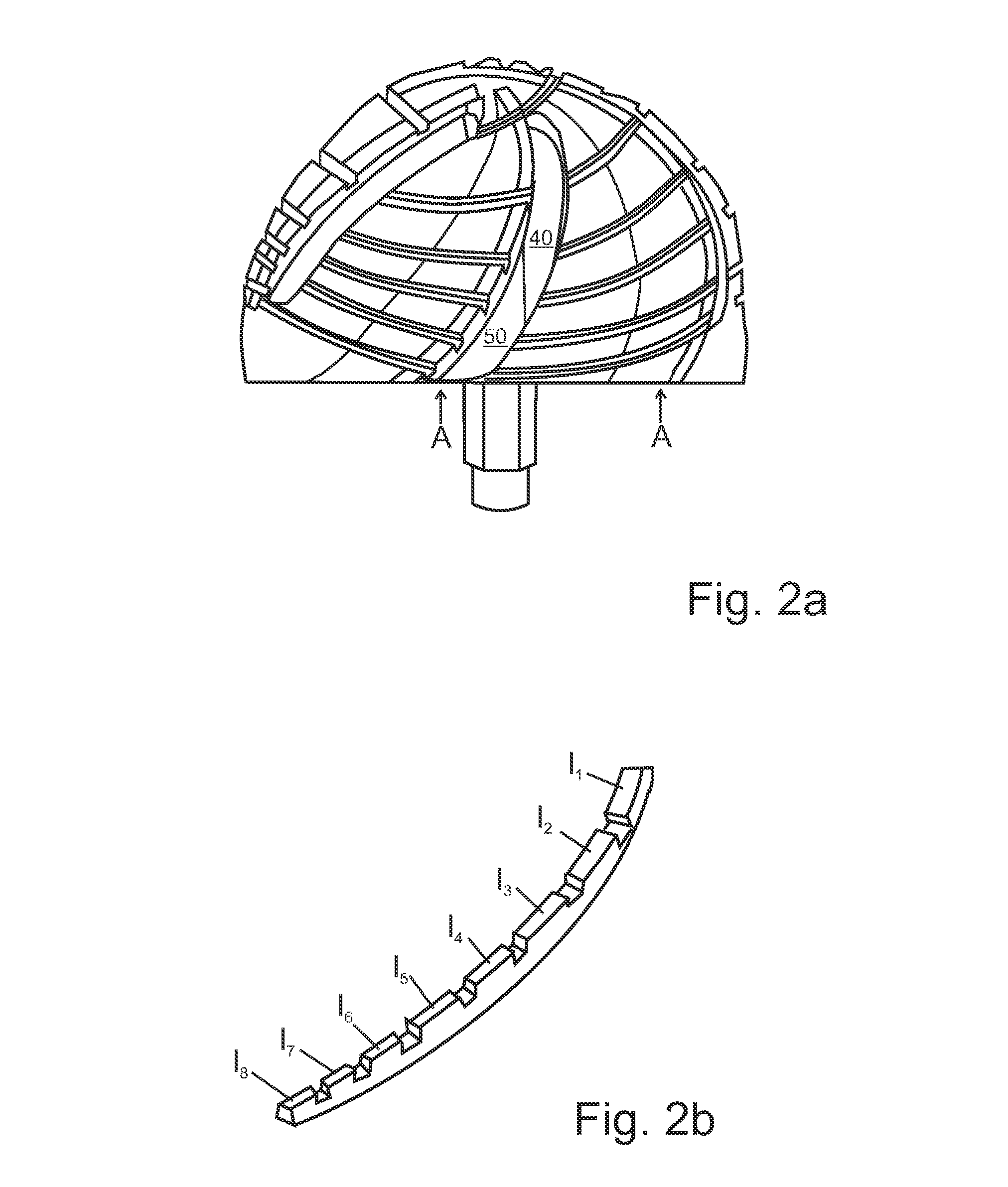

Surgical cutting tool

Surgical cutting tool for manufacturing of a recess in a firm body tissue, in particular in a bone and / or in a cartilage, with a milling range rotatable around a central axis of rotation, with an outside lateral surface and an internal area substantially defined by the lateral surface and turned away from the worked on body tissue. The lateral surface is formed with at least two machining cutting edges, which proceed at the lateral surface from a machining center to a machining edge of the milling range and which are in particular spiral curved. Apertures are arranged adjacent to the cutting edges for the transport of the cutting splinters into the internal area, whereby the cutting edges are interrupted by means of recesses in such a way that the cutting edges are formed by individually cutting elements.

Owner:MULLER ERICH JOHANN

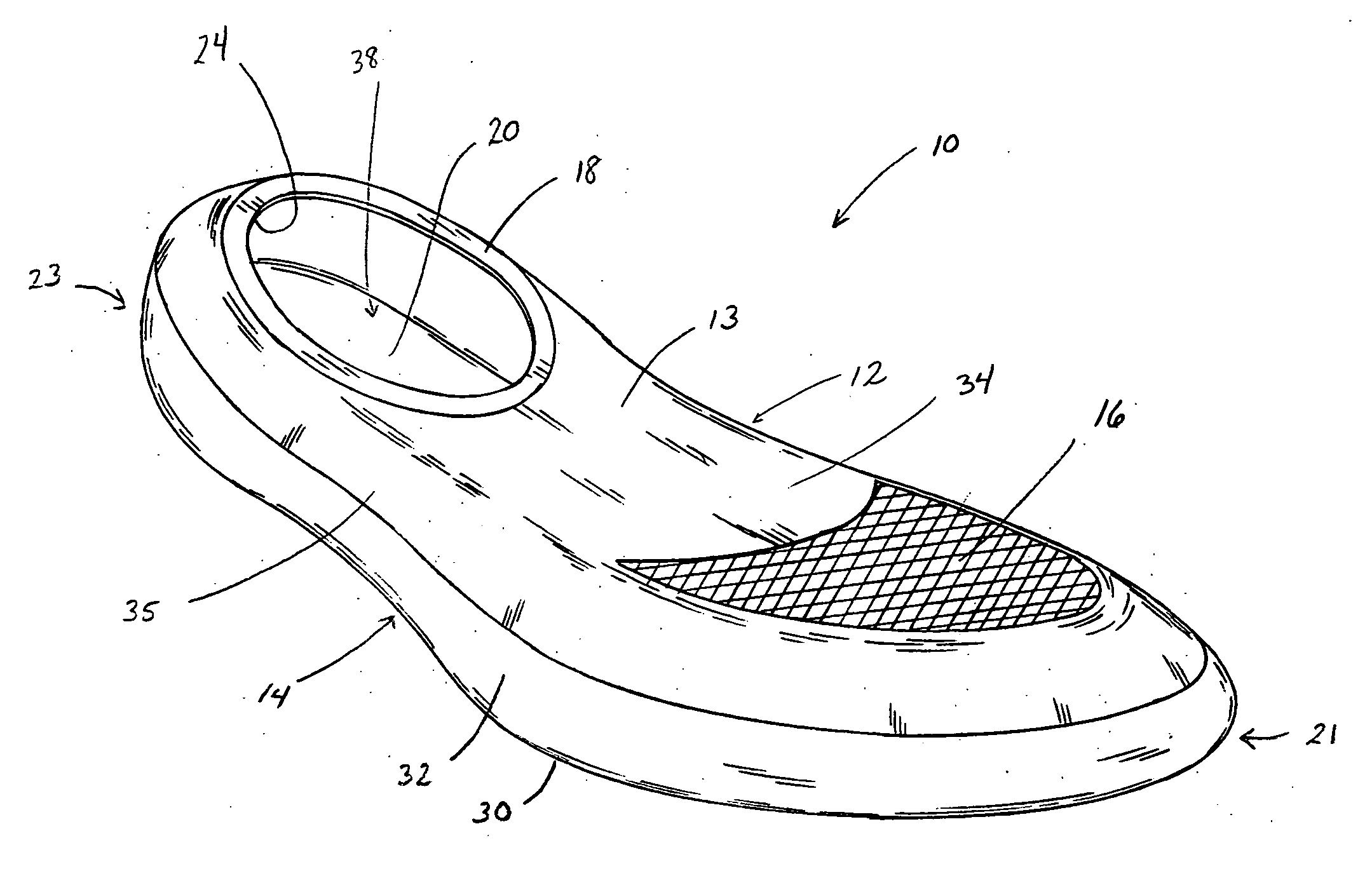

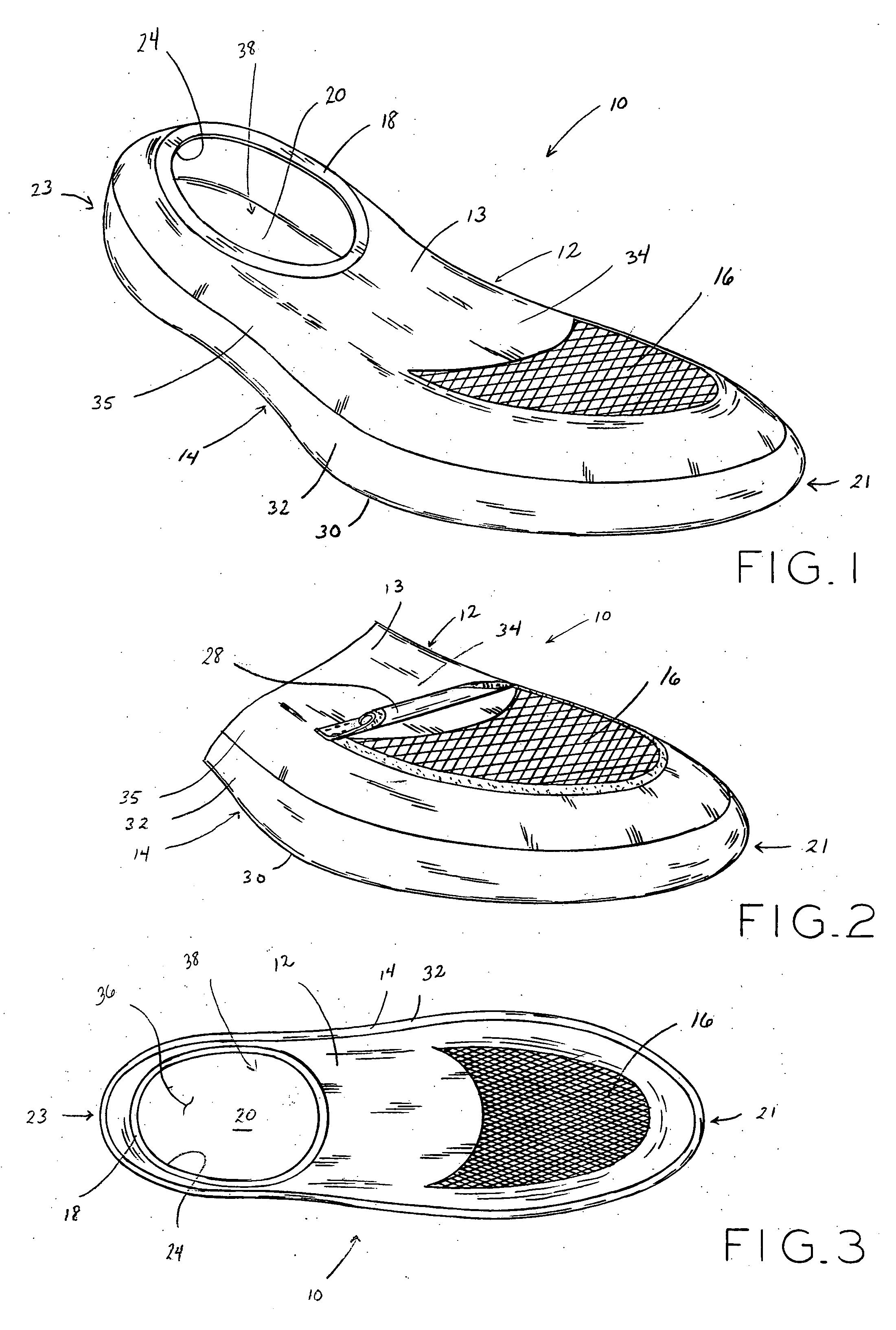

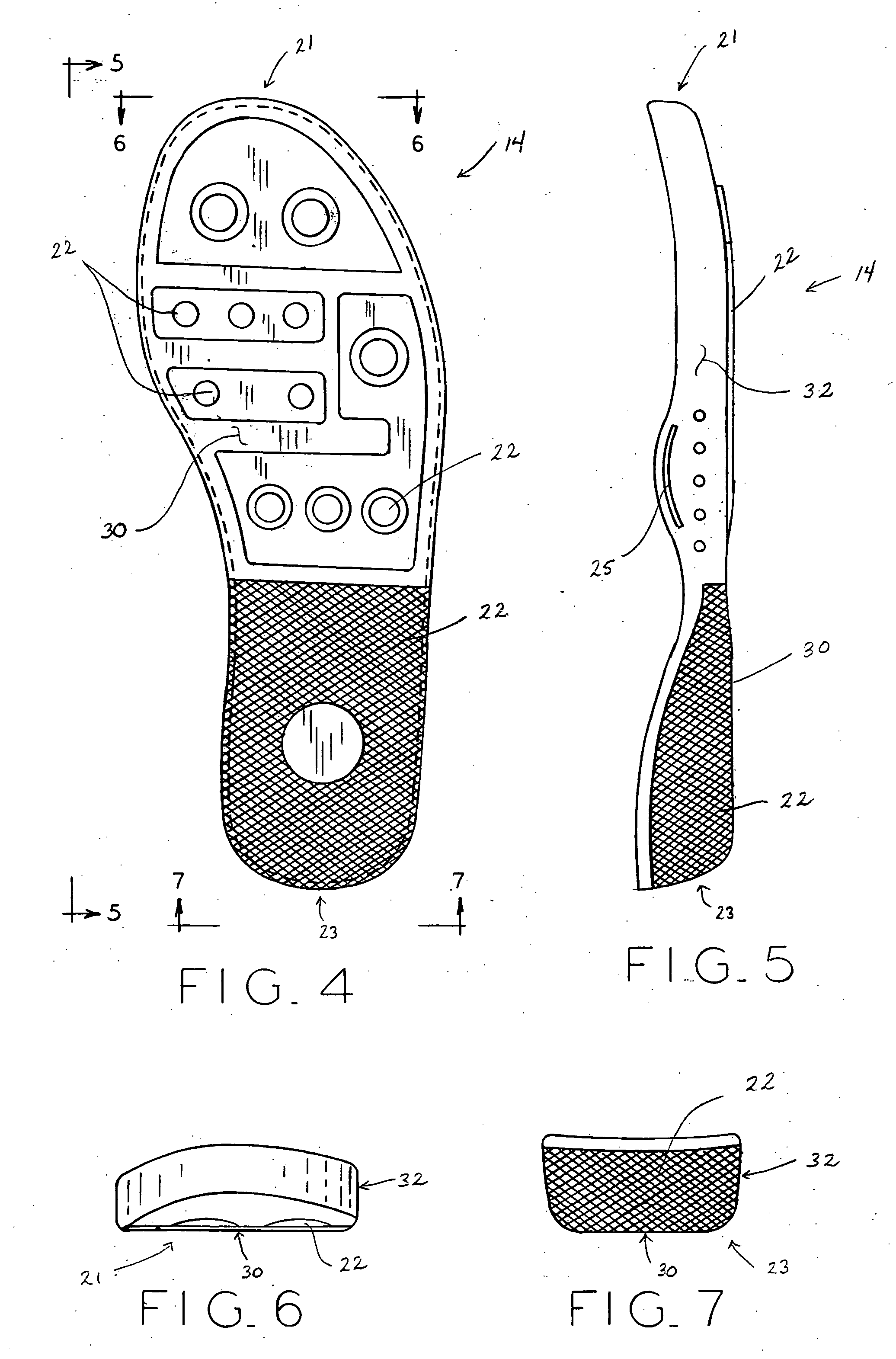

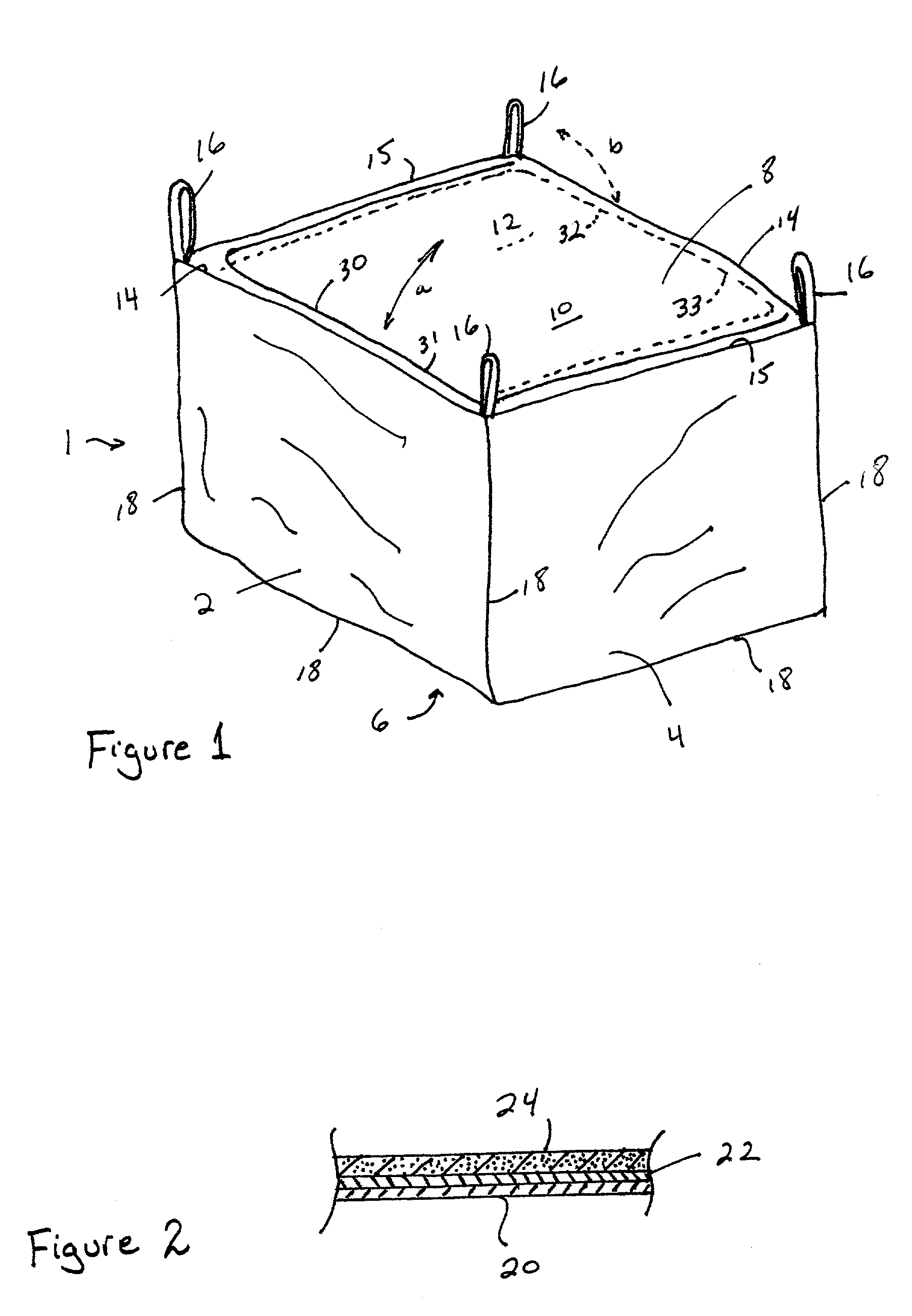

Pocket slipper

A foot covering in the form of a pocket or lodge slipper that allows outer footwear, e.g., shoes or boots to be removed and, with the covering in place, the conventional sock and / or foot will be protected from dirt, moisture, and other elements of nature such as thorns, rocks, splinters, etc. The slipper may be formed at least in part from elastic material which is stretchable to fit over a conventional sock. The slipper may also be formed at least in part from a rubberized material. The slipper may be flexible and foldable into a small package to be carried in a pant or coat pocket, for example. Alternatively, the slipper may be tightly rolled and carried in a small package such as a pouch or nylon bag.

Owner:SLOAN DALE A

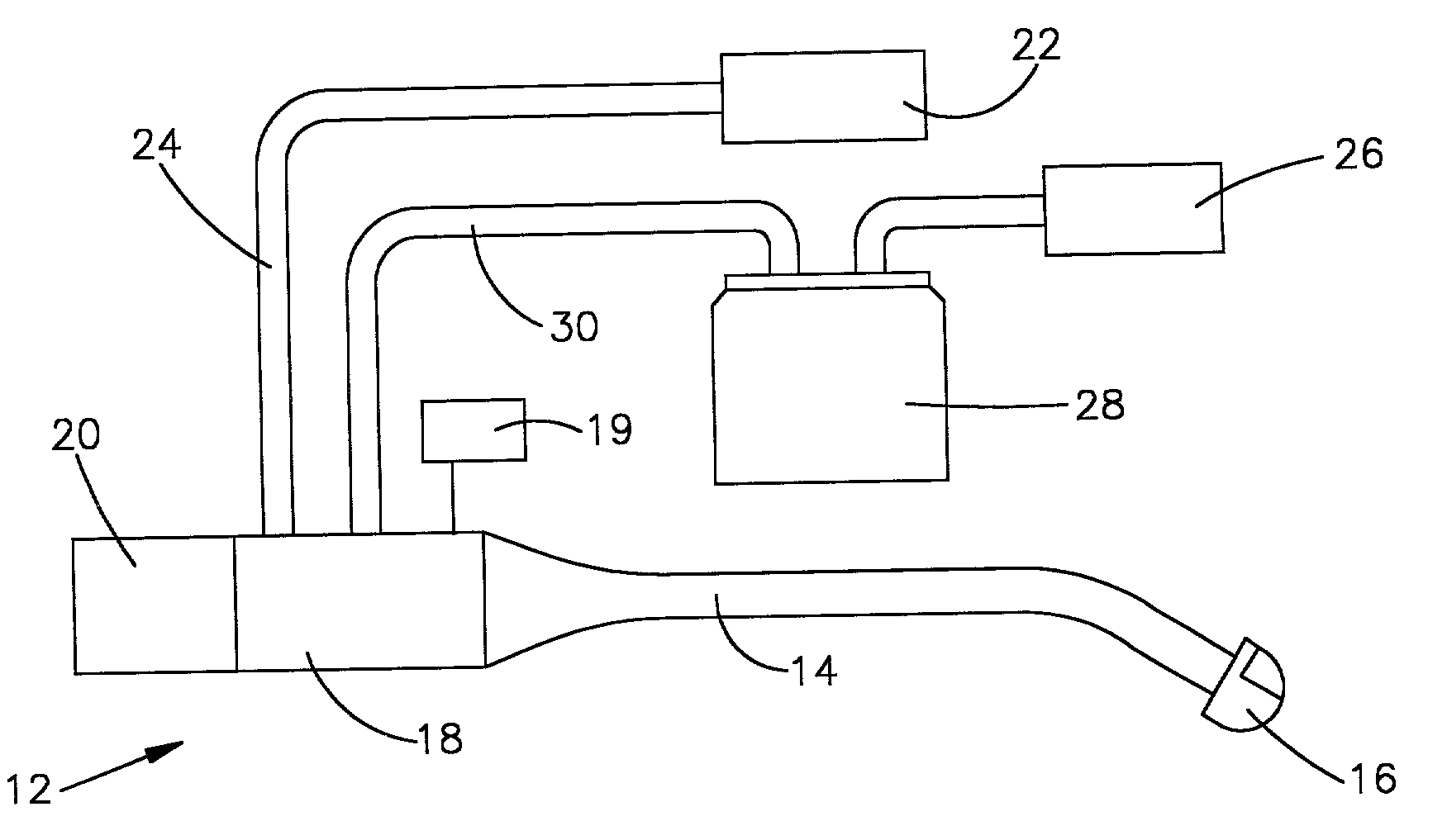

Apparatus and method for tissue removal

InactiveUS6174313B1Various locationsReduce frictionSurgical needlesVaccination/ovulation diagnosticsWood splinterMotion transfer

Percutaneous tissue removal apparatus comprises a flexible drill shaft, a cutting tip mounted on the shaft for placement adjacent a tissue mass for cutting the tissue, means for transmitting motion to the shaft to move the cutting tip against the tissue to cut tissue fragments from the tissue, and means for removing the tissue fragments along the shaft by suction to a location outside the tissue mass while cutting. The apparatus may include means for collecting one or more selected components of the harvested tissue fragments for implantation of the fragments preferably into the body of the patient from whom they were removed. Where the tissue to be cut is bone, a cutting tip is preferably made of a polymeric material which is softer than the cortical portion of the bone, although the cutting tip may be made of a ceramic or a composite material. A second flexible shaft may be provided either within or about the flexible drill shaft. The harvested tissue fragments may be implanted in the donor patient's body.

Owner:BONUTTI SKELETAL INNOVATIONS +1

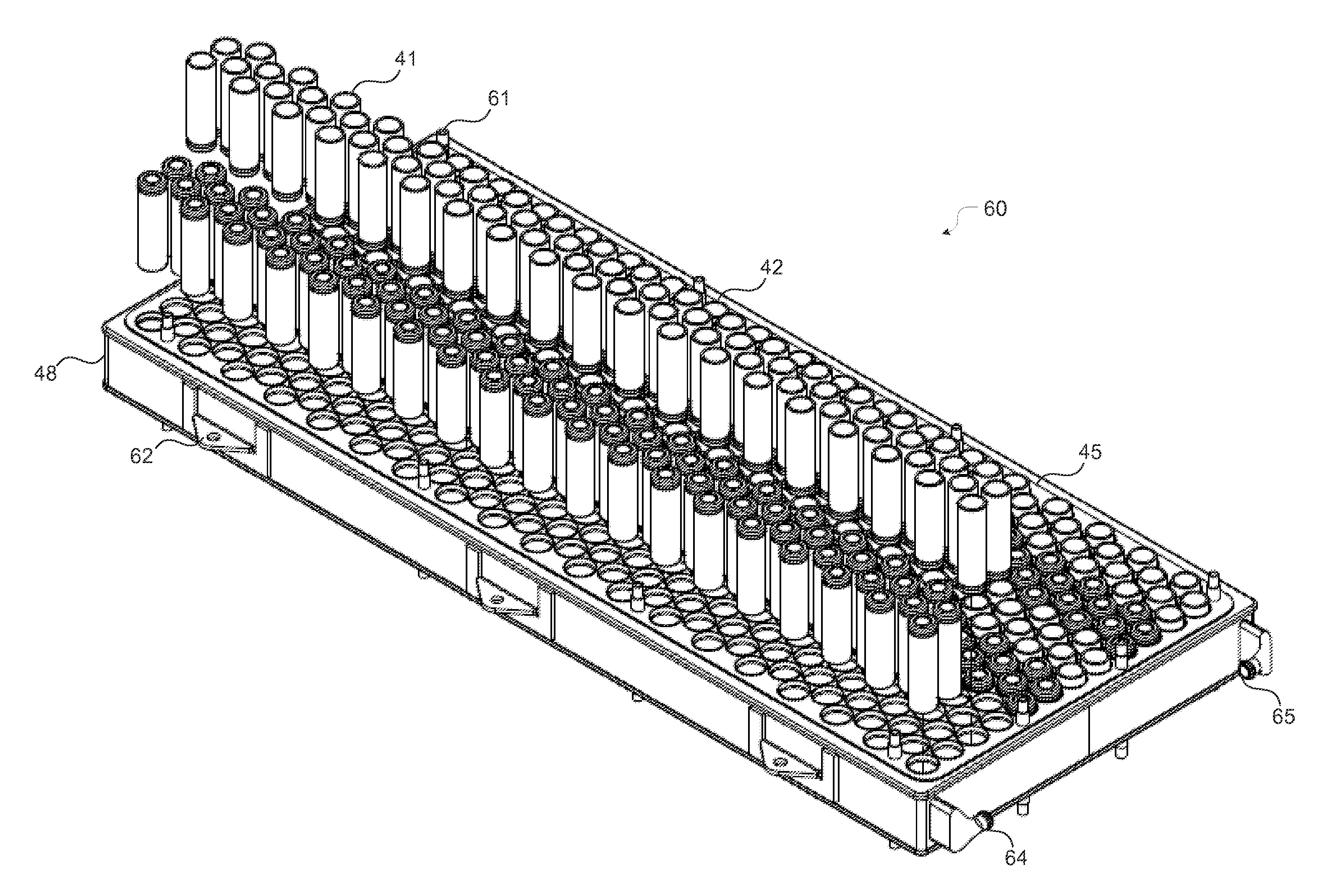

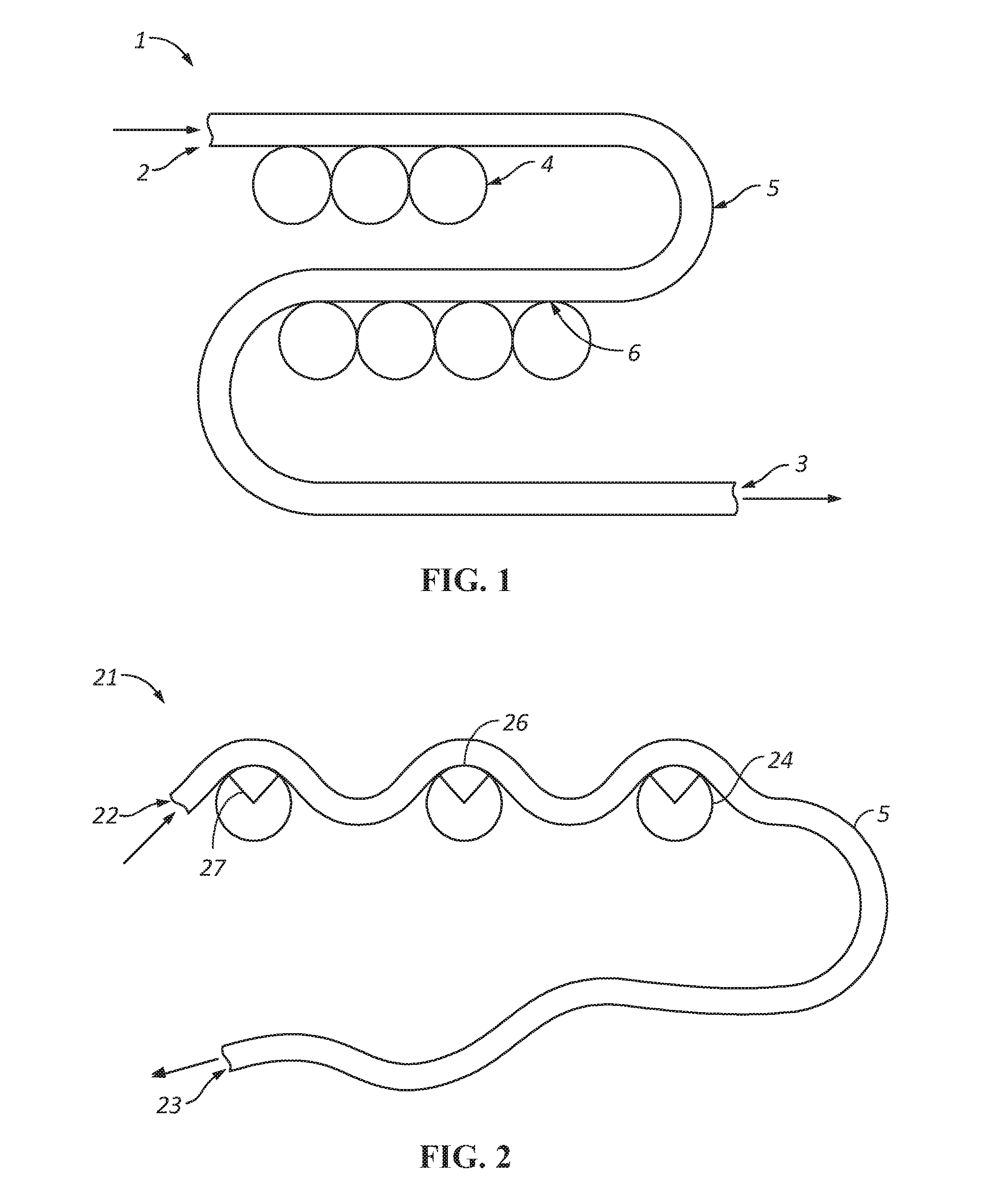

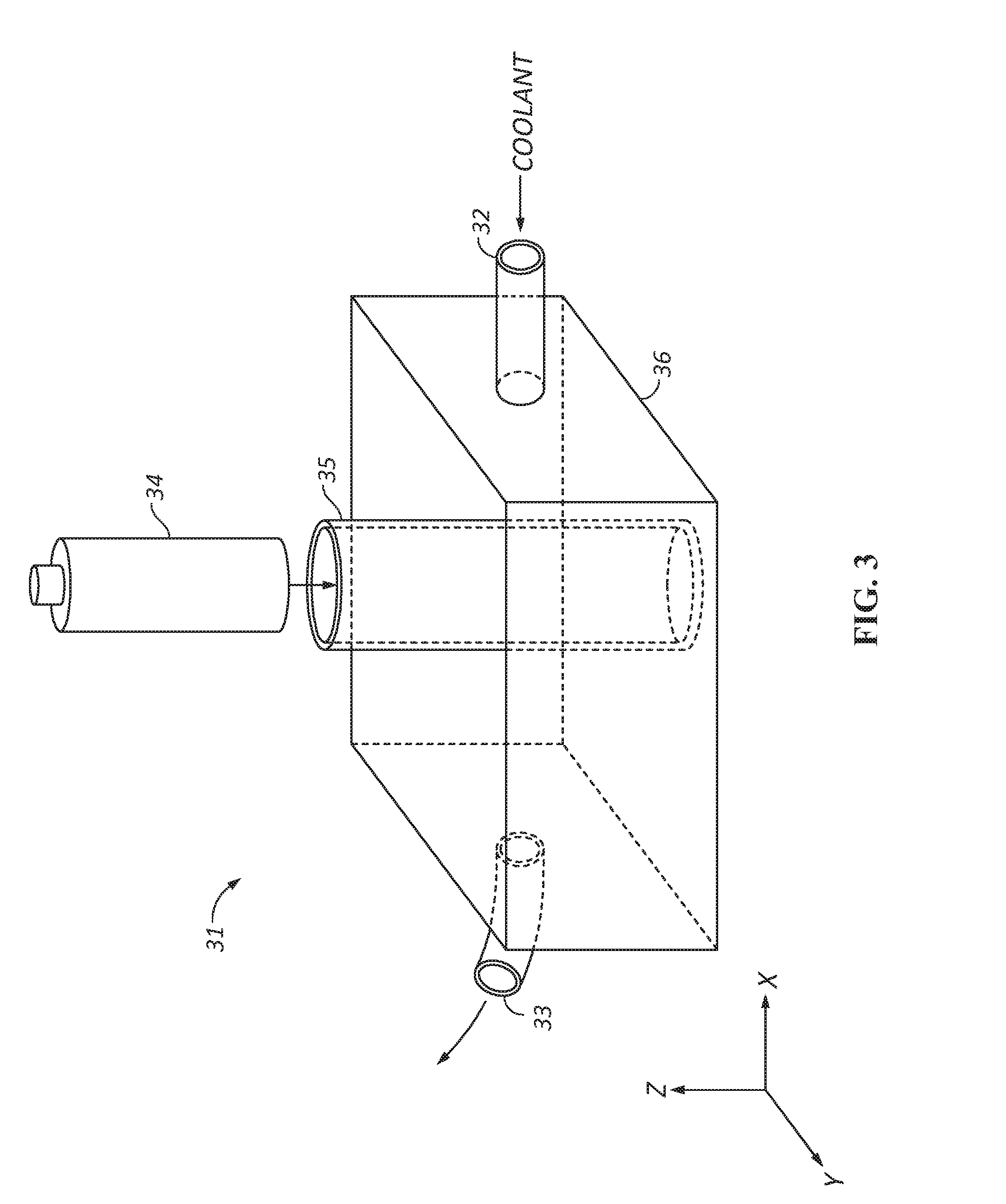

Vehicle Battery Module with Cooling and Safety Features

A battery pack apparatus is disclosed that reduces the possibility of thermal runaway by improving the transfer of heat from the battery body and apparatus to the coolant by increasing the surface area of contact between the two. Principles of shape charge are used to drive debris, splinters and other particles towards the ground in an automobile in the event of an explosion, thereby reducing the possibility of harm to the driver, occupants and automobile. Fire retardant cartridges are suitably embedded to deter fire and incidental harm to person and automobile.

Owner:ANHUI XINEN TECHNOLOGY CO LTD

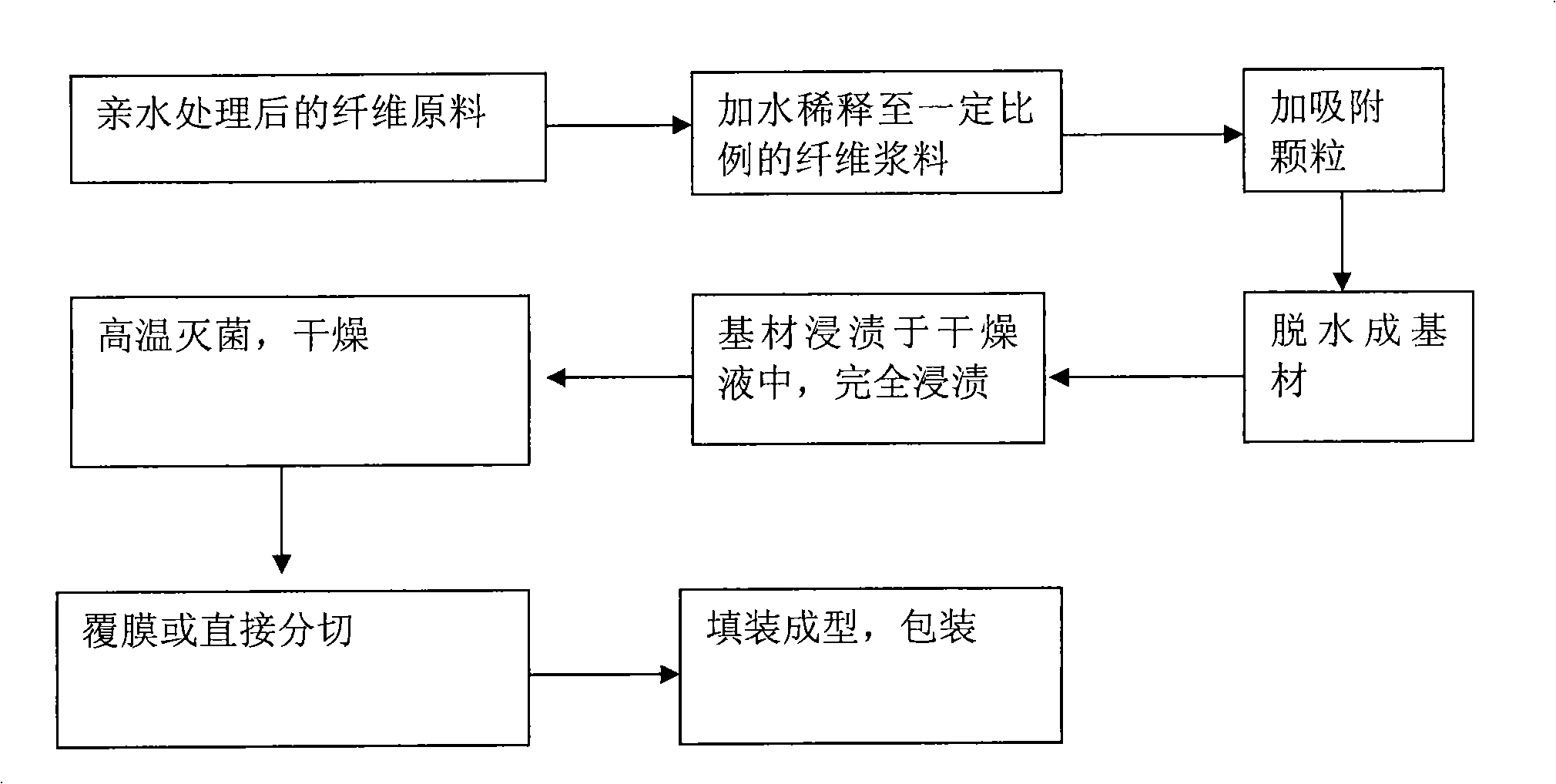

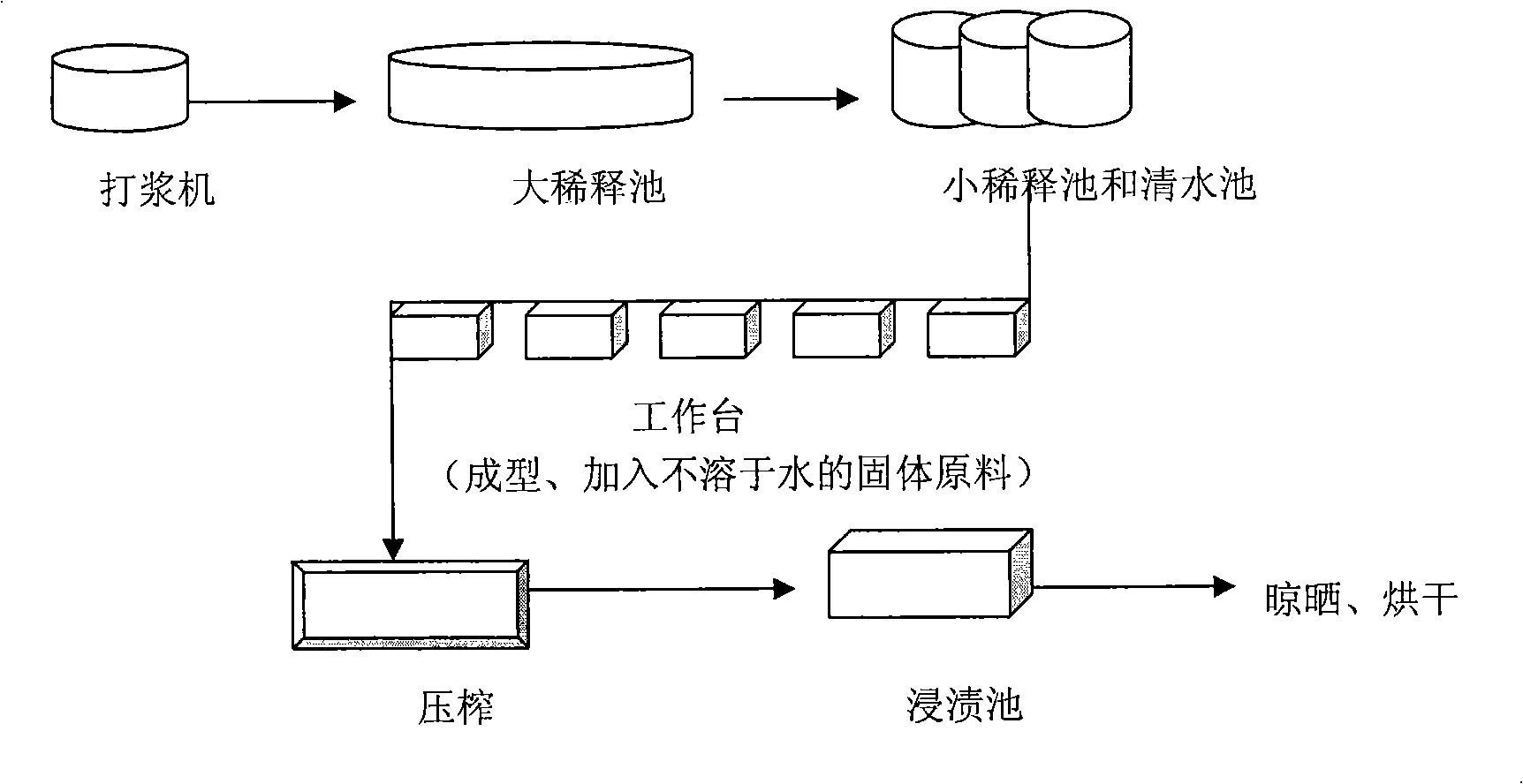

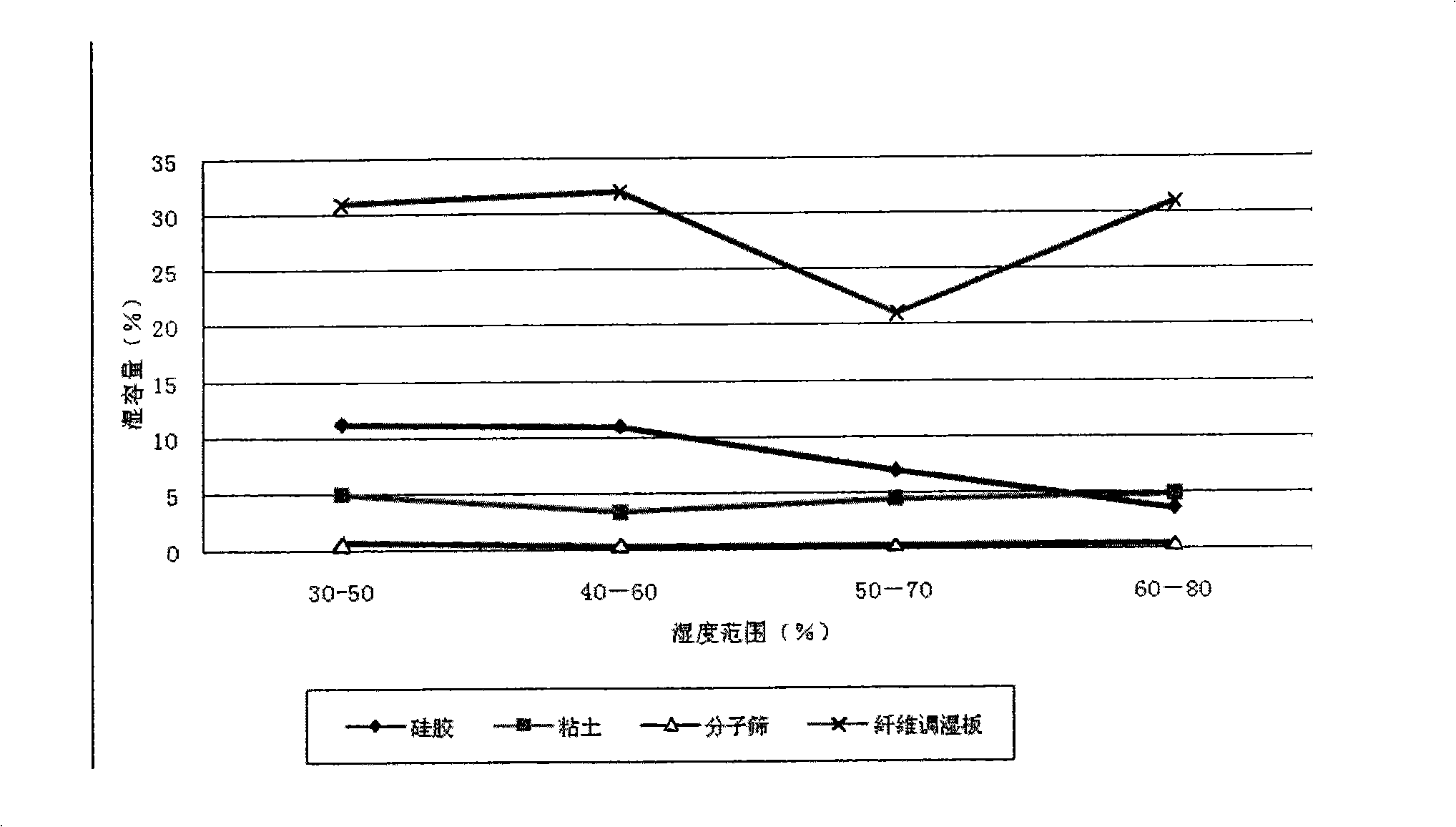

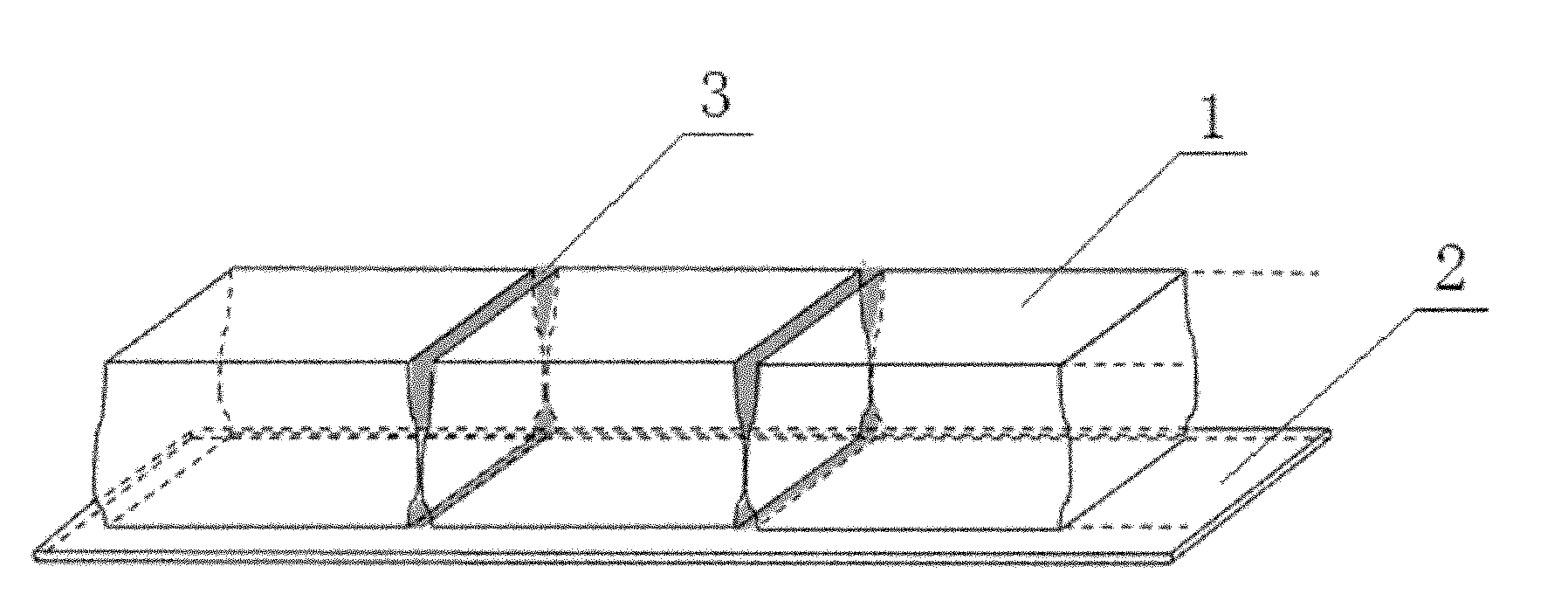

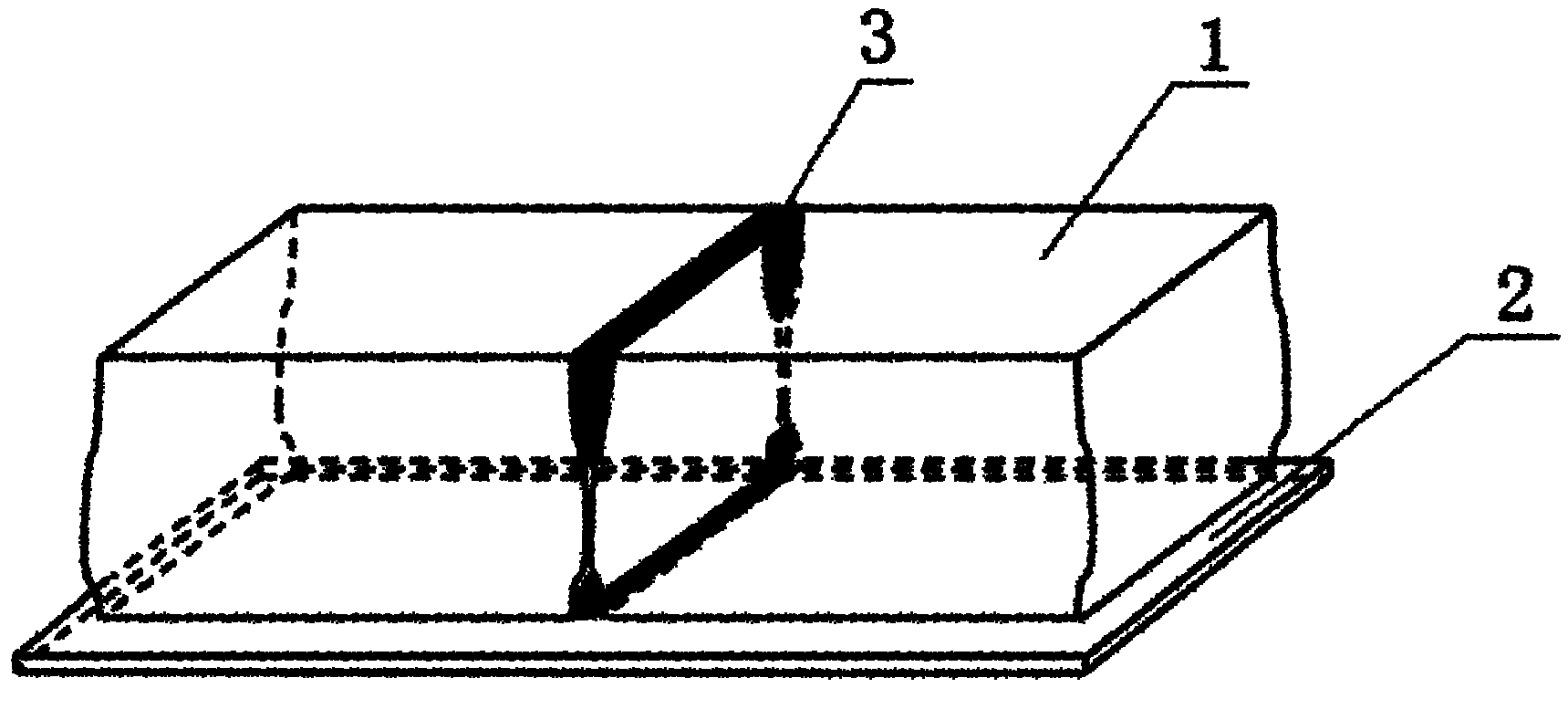

Method for preparing fibre humidity-controlling board and apparatus

The invention provides a method for making a fiber humidity-adjusting board and equipment thereof. The fiber humidity-adjusting board comprise fiber materials, inorganic material or inorganic and organic materials mixing humidity-adjusting agent and adsorption particles, among which fiber materials are taken as the base material component; the method comprise the following steps that: hydrophilic fiber materials are made into water dispersion; the water dispersion is drained on a web plate, and solid adsorption particles are dispersed in the water dispersion, and the water dispersion is dewatered and turned into fiberboard base materials; the fiberboard base materials are soaked in drying fluids; after drying, forming plates or splinter-shaped products are obtained. The humidity-adjusting board has the advantages that because the fiber humidity-adjusting board is splinter-shaped, the fiber humidity-adjusting board can be cut into different shapes; the fiber humidity-adjusting board has the function of adjusting the humidity and reaches and exceeds international seminal humidity-adjusting products in wet volume capacity; nontoxic, harmless and recyclable materials are used; due to the adoption of closed cycle process, no waste gas, waste water and waste slag are generated and discharged, so that the fiber humidity-adjusting board is new-generation green environment friendly product; due to the adoption of the environmental protection process, no waste gas, waste water and waste slag are discharged, and all added solids are not drained, so that the controllability is good.

Owner:SHANGHAI HENGYUAN MACROMOLECULAR MATERIALS CO LTD

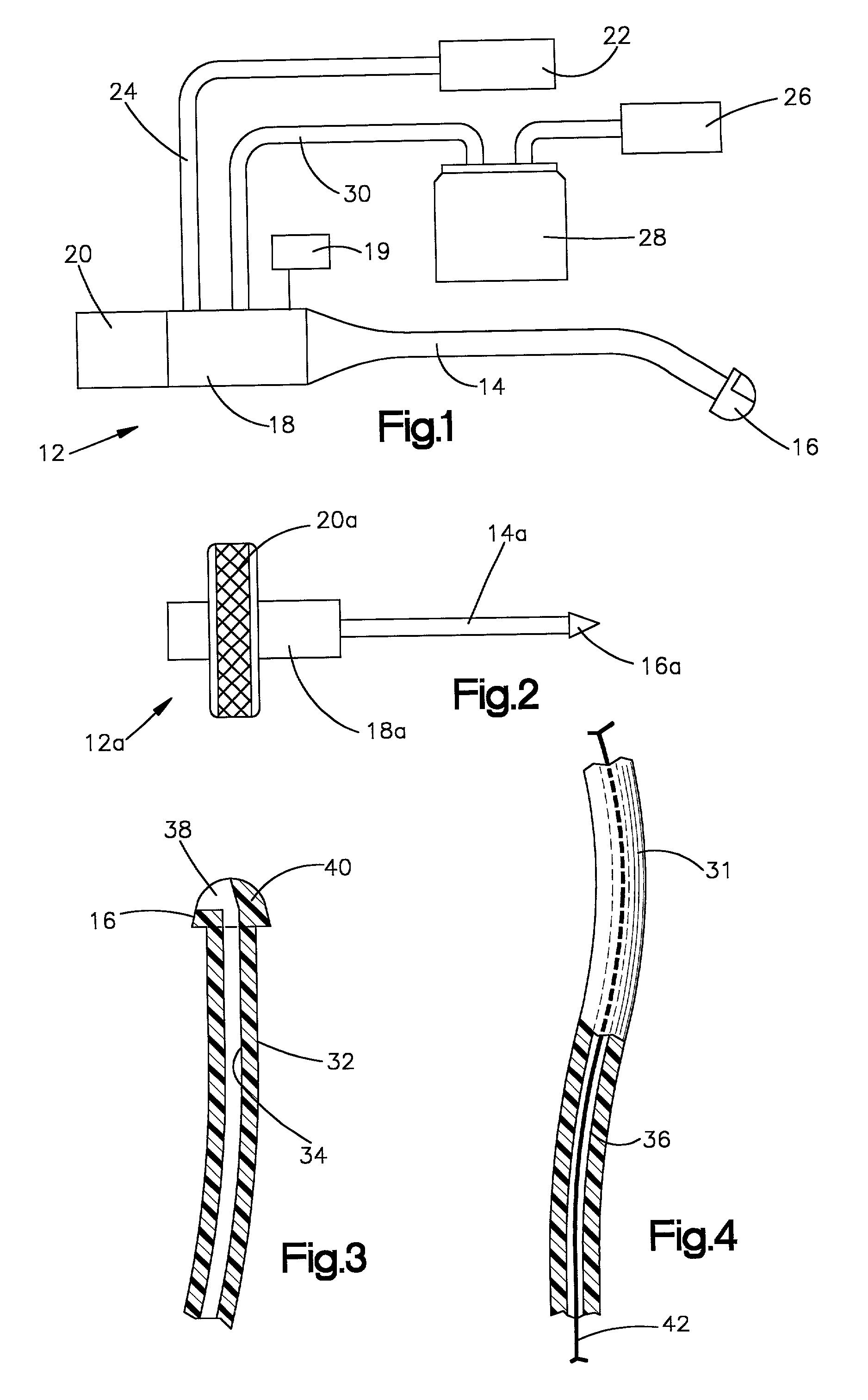

Apparatus and method for tissue removal

InactiveUS20020045903A1Less energyReduce frictionSurgical needlesVaccination/ovulation diagnosticsWood splinterEngineering

Percutaneous tissue removal apparatus comprises a flexible drill shaft, a cutting tip mounted on the shaft for placement adjacent a tissue mass for cutting the tissue, means for transmitting motion to the shaft to move the cutting tip against the tissue to cut tissue fragments from the tissue, and means for removing the tissue fragments along the shaft by suction to a location outside the tissue mass while cutting. The apparatus may include means for collecting one or more selected components of the harvested tissue fragments for implantation of the fragments preferably into the body of the patient from whom they were removed. Where the tissue to be cut is bone, a cutting tip is preferably made of a polymeric material which is softer than the cortical portion of the bone, although the cutting tip may be made of a ceramic or a composite material. A second flexible shaft may be provided either within or about the flexible drill shaft. The harvested tissue fragments may be implanted in the donor patient's body.

Owner:BONUTTI SKELETAL INNOVATIONS +1

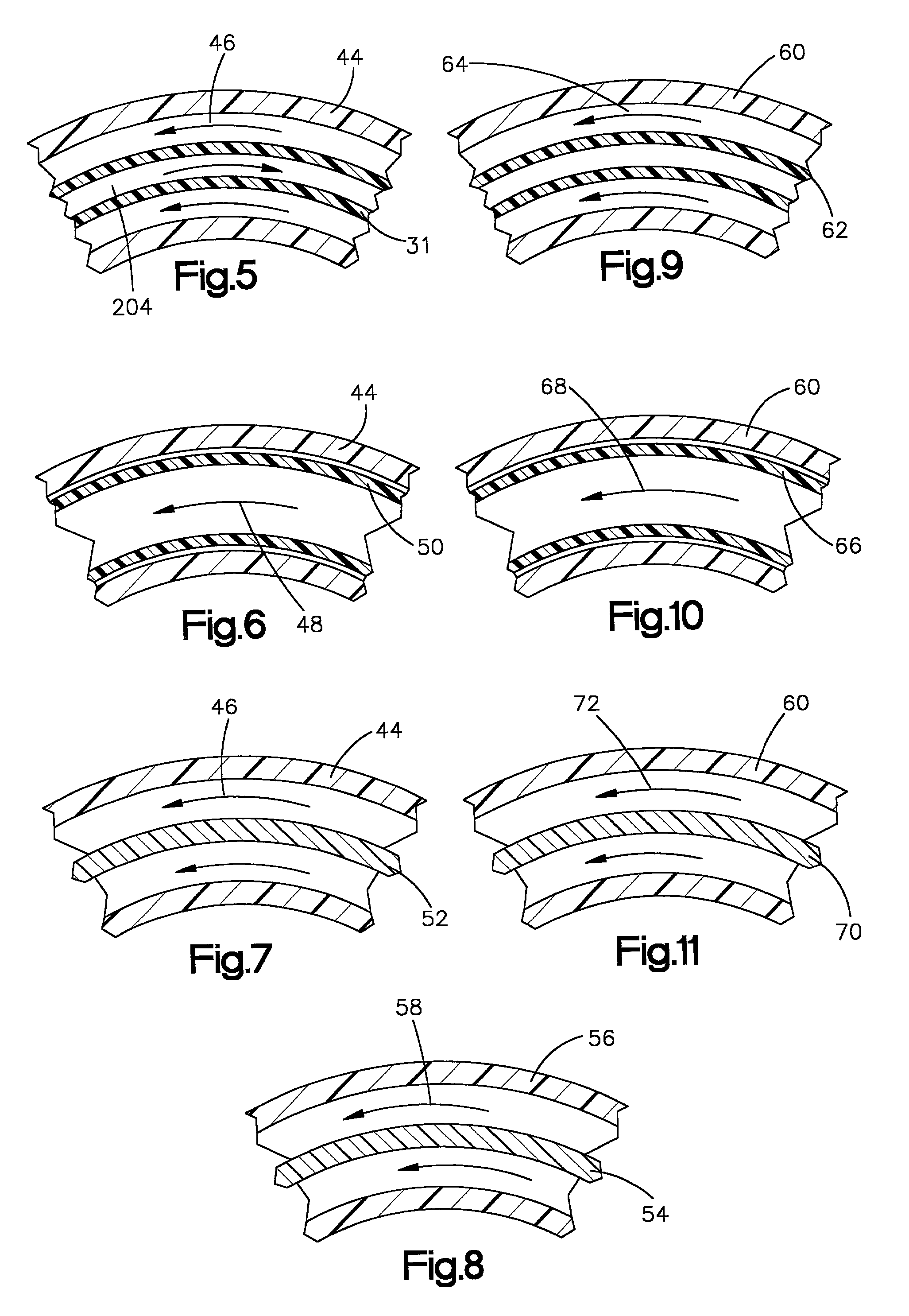

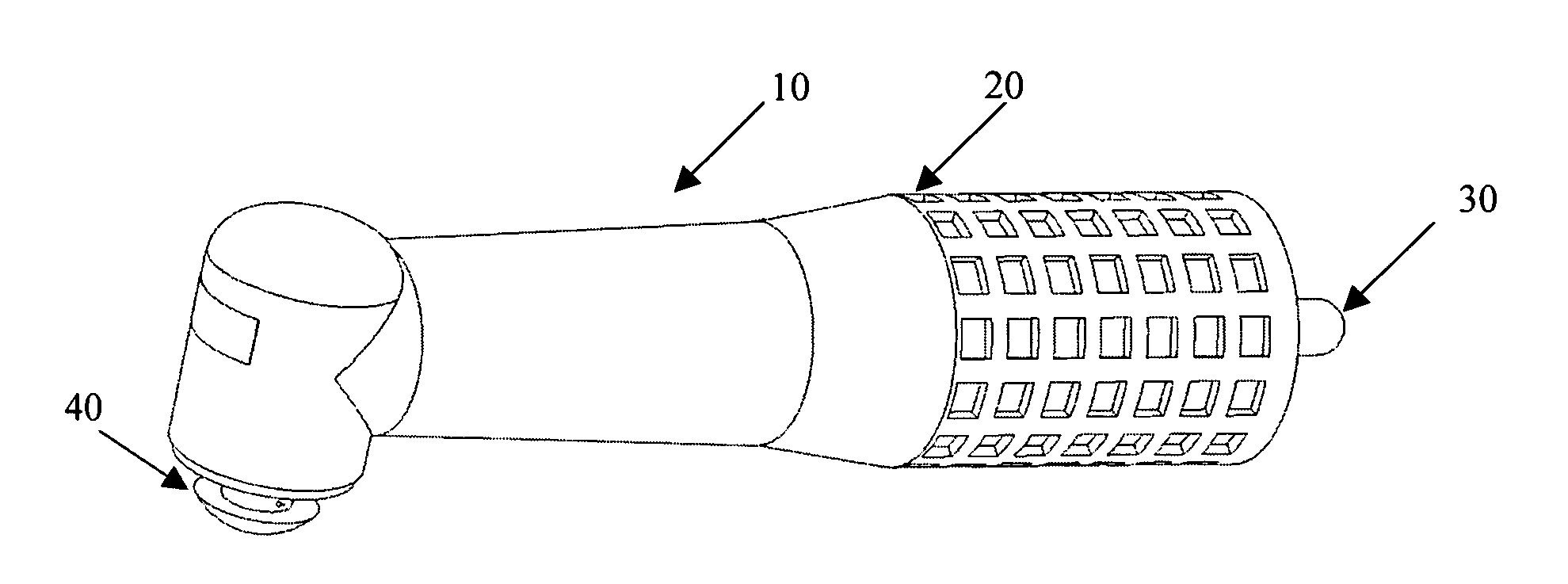

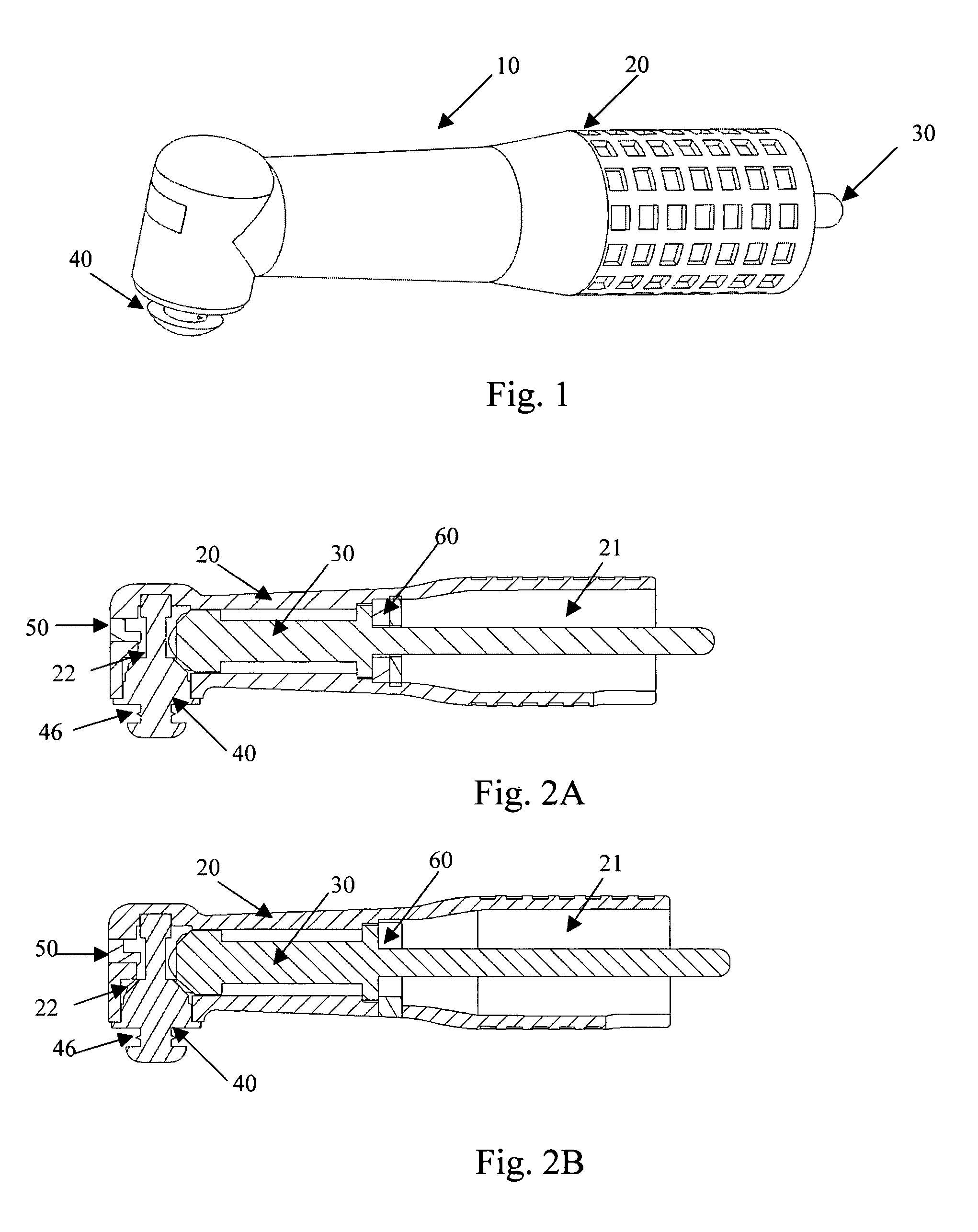

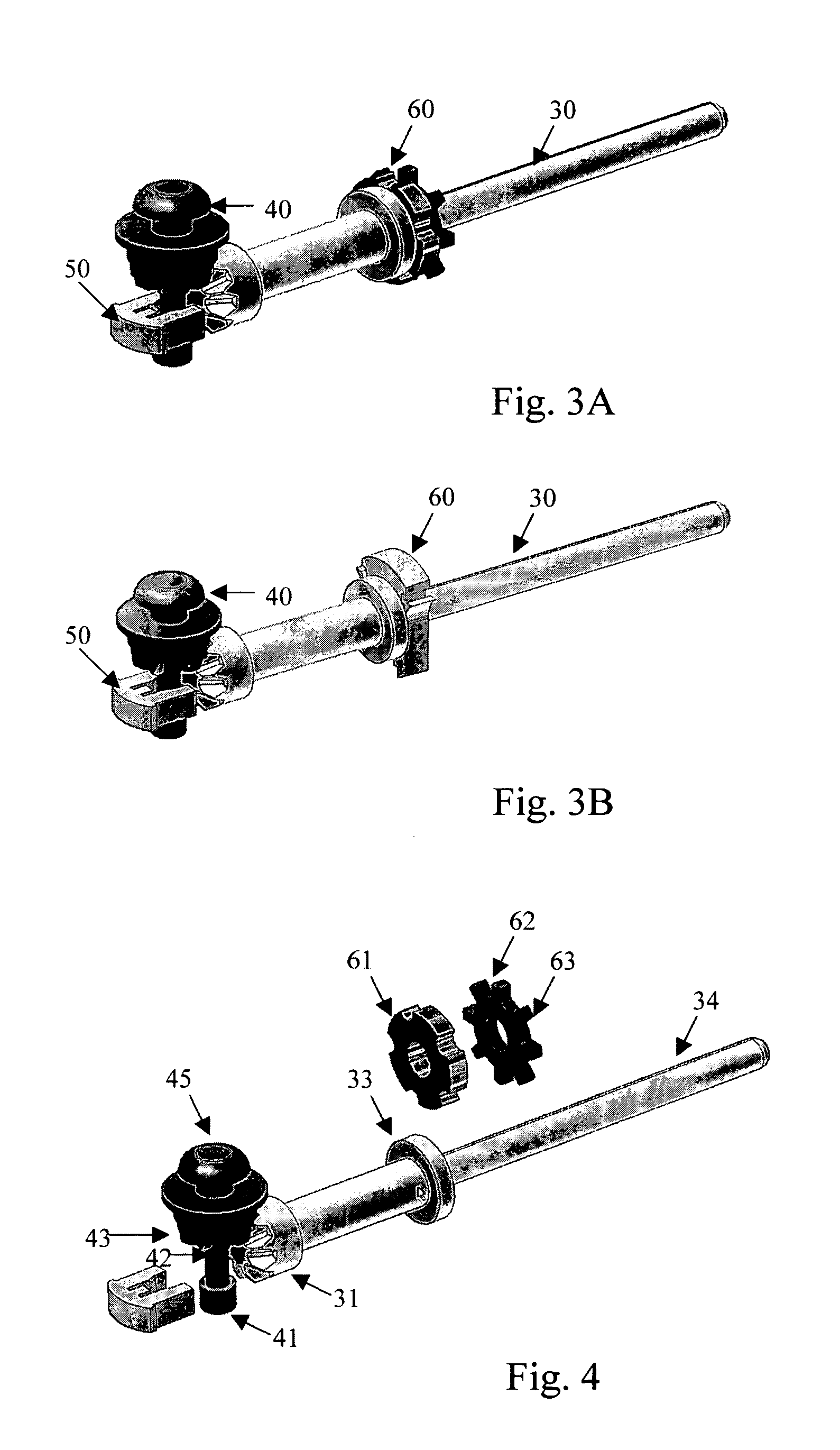

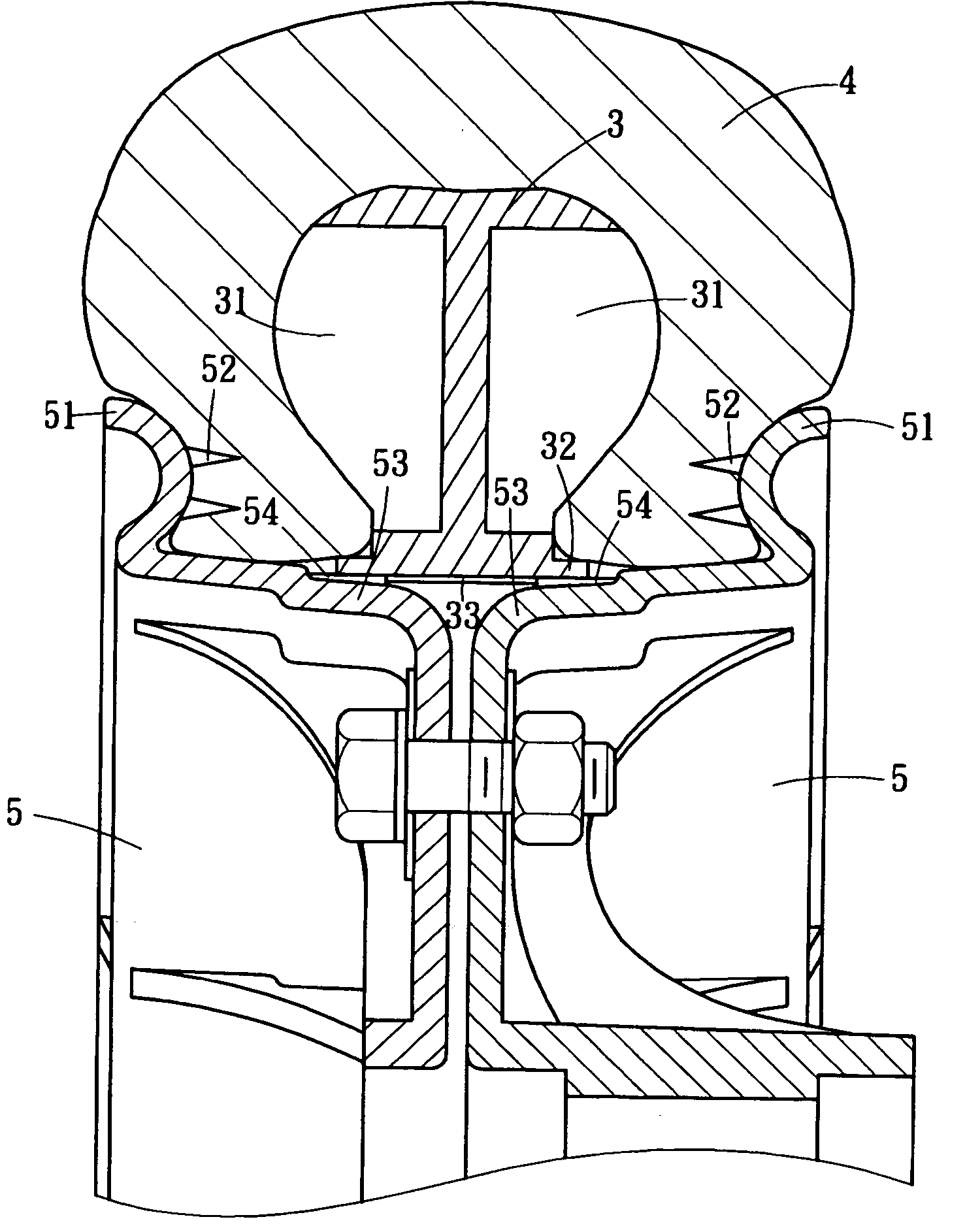

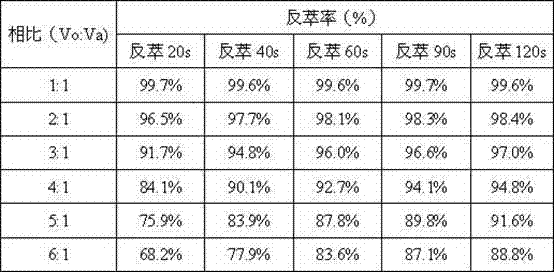

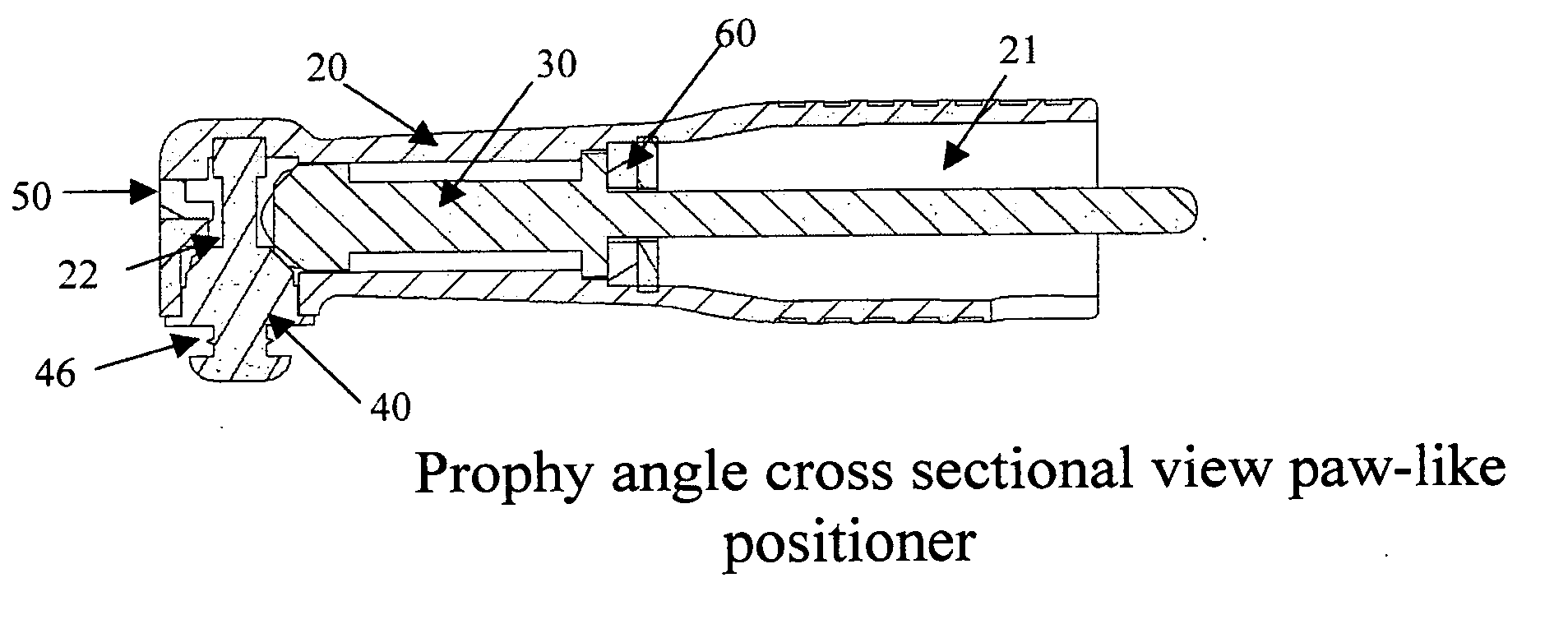

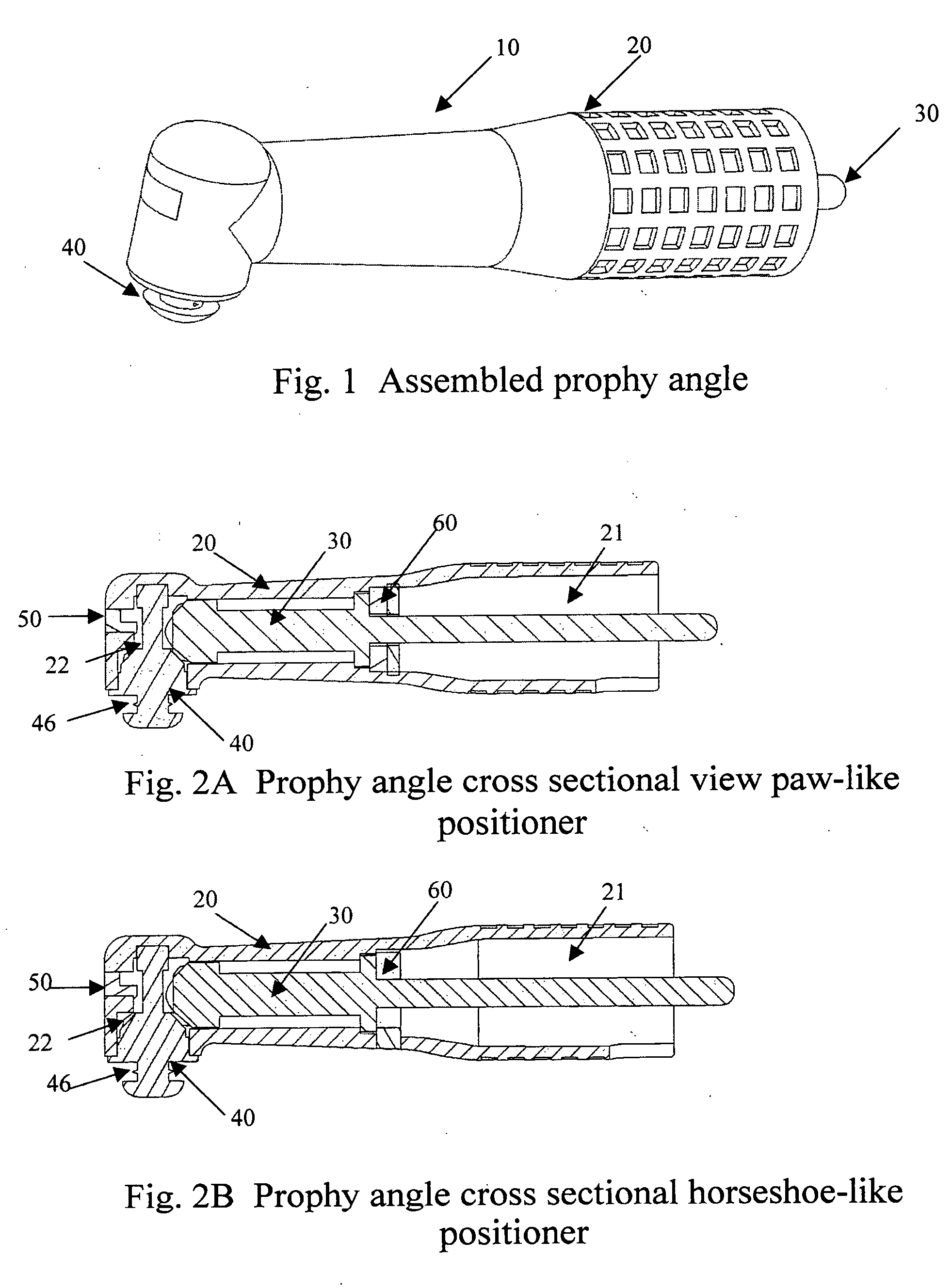

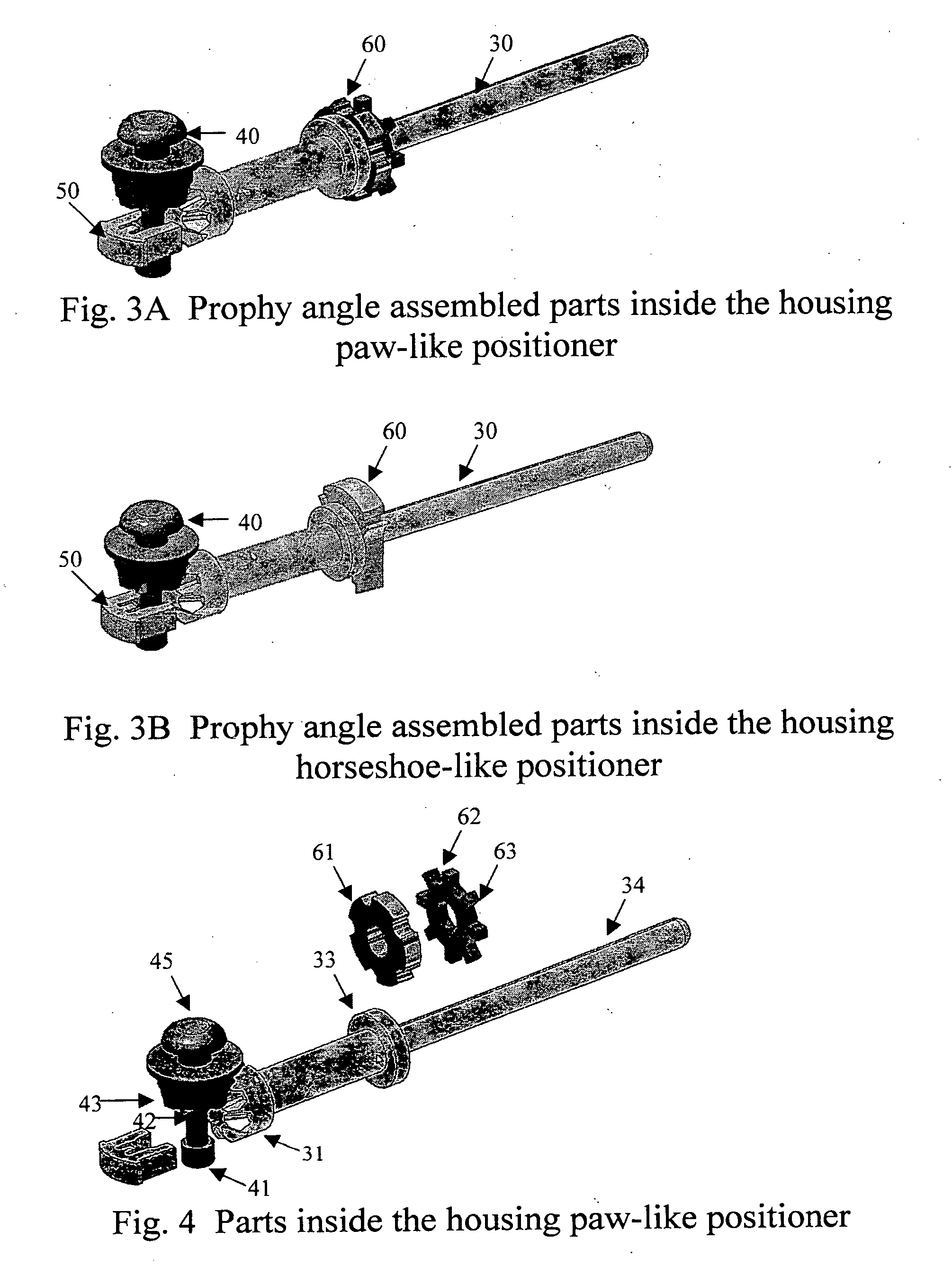

Disposable dental prophy angle with secure retention mechanism

ActiveUS7255559B2Improve convenienceImprove performanceTooth pluggers/hammersBoring toolsDrive shaftWood splinter

A disposable, securely retained dental angle is provided. The angle includes a one-piece hollow housing having a short leg at its front end, which is angled with respect to the long leg. Both the short and long legs have a through bore. The short leg has an aperture, which is connected to the bore of the long leg to allow insertion of a driving shaft through the short leg of the angle. A driven rotor is inserted in the short leg. A horse-shoe-like snap rotor retainer fits within the short leg over the driven rotor to retain the driven rotor in the angle. A paw-like or, alternately, a horse-shoe-like locking means fits within the long leg over the driving shaft to lock the driving shaft in the angle and to retain the angle together. In one embodiment, a pair of splinters on the driven rotor provides the function to retain the rubber prophy cup firmly while the driven rotor is in operation.

Owner:PAC DENT INC

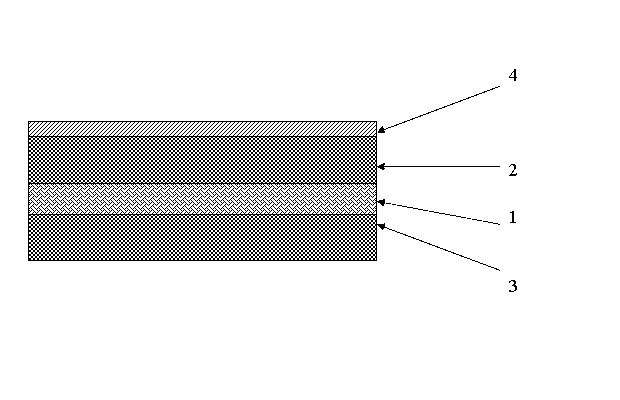

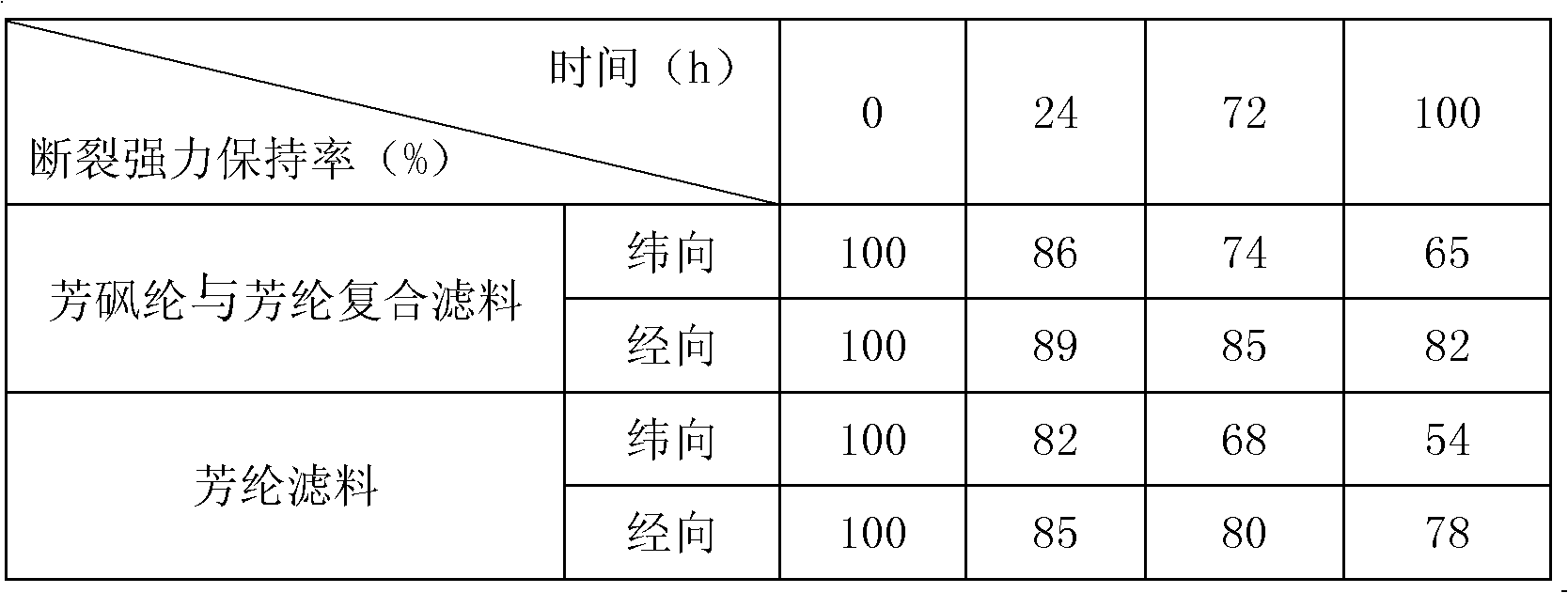

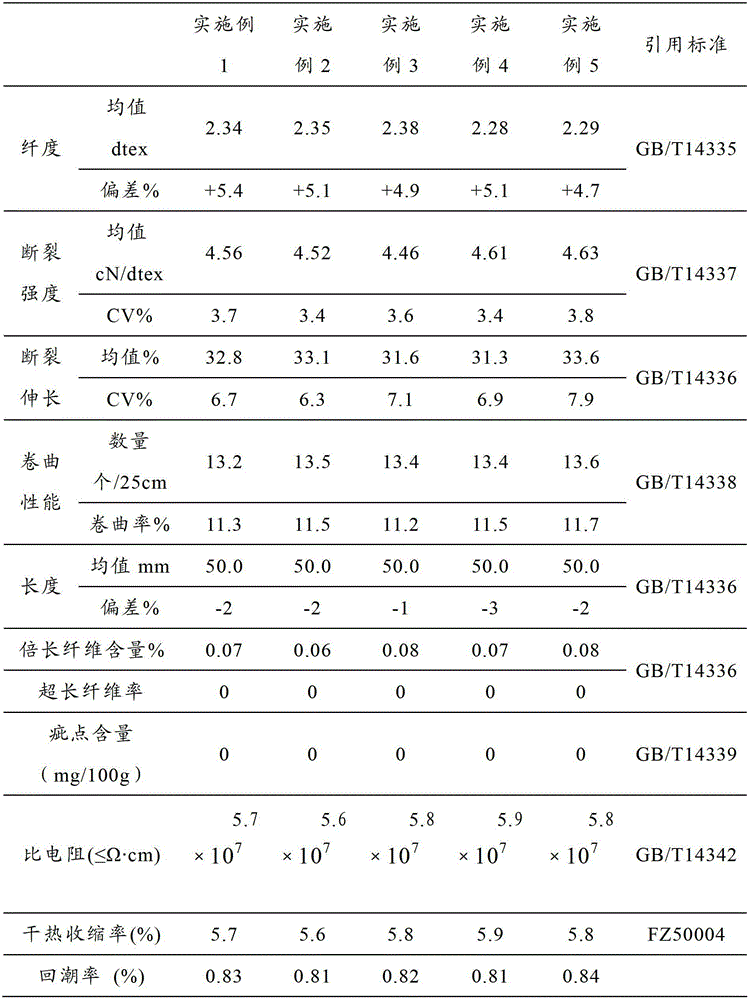

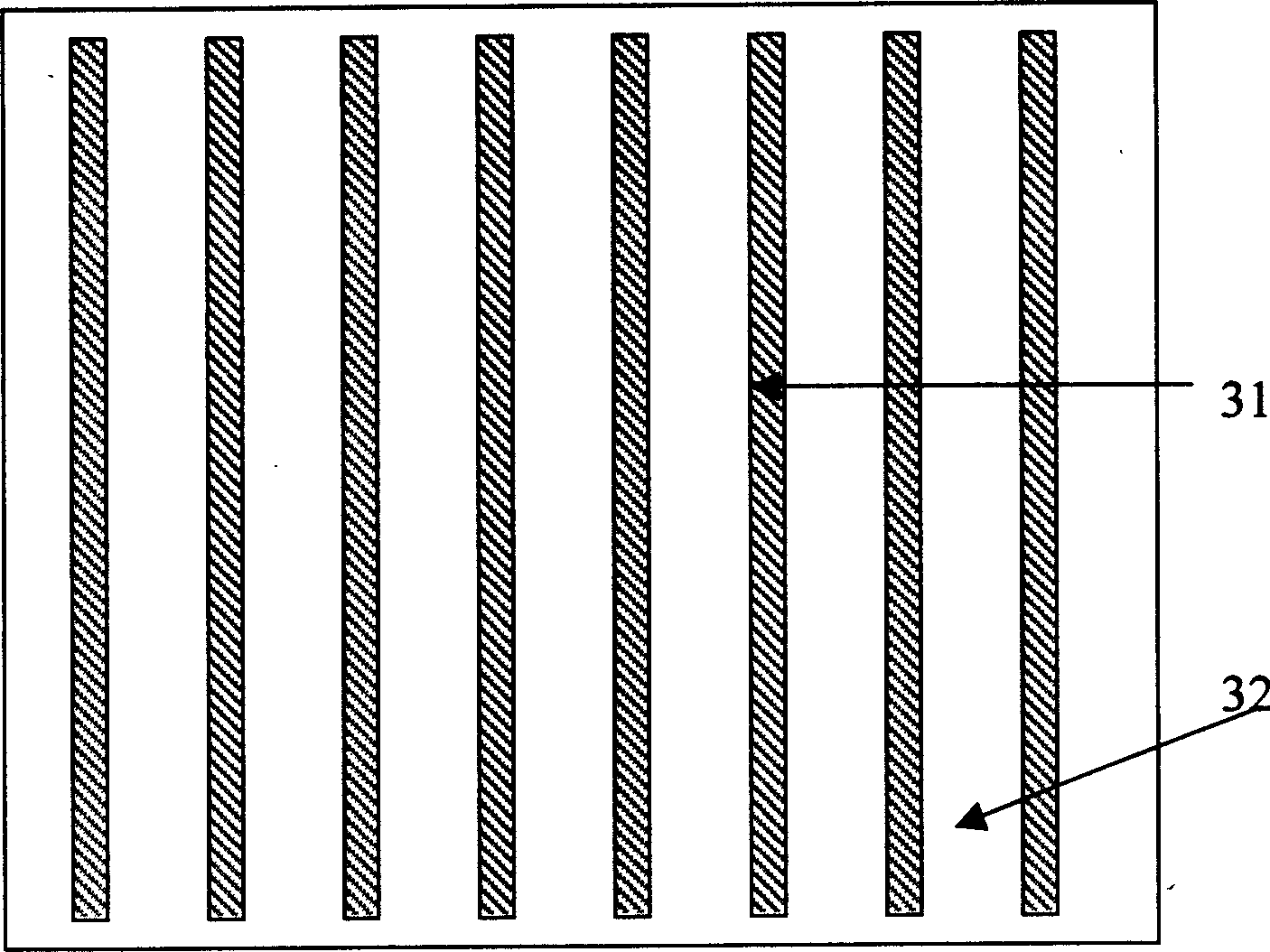

Compound filter material for high-temperature flue gas bag-type dust removal system and preparation method of same

ActiveCN102872649AHigh strengthImprove stabilityLamination ancillary operationsDispersed particle filtrationYarnChemical industry

The invention provides a compound filter material for a high-temperature flue gas bag-type dust removal system and a preparation method of the compound filter material, belongs to the field of the chemical industry and solves the technical problems of high heat shrinkage, poor high temperature impact resistance, high system running resistance and short service life of a filter bag of a bag-type of a filtering material product of a bag-type dust collector. The compound filter material comprises a base fabric, wherein the base fabric is formed by weaving polysulfonamide and aramid blended yarns; a dust facing surface formed by polysulfonamide and aramid mixed fibers is arranged on the upper surface of the base fabric; a bottom layer formed by the polysulfonamide and aramid mixed fibers is arranged on the lower surface of the base fabric; and the dust facing surface, the base fabric layer and the bottom layer are connected by closing splinters. The preparation method disclosed by the invention comprises a process of compounding the air-laid and acupuncture / hydroentangle combination base fabric with the polysulfonamide and aramid mixed fibers. The filter material disclosed by the invention has high strength; the high temperature strength stability and the high temperature size stability of the filter material disclosed by the invention are obviously superior to those of an aramid filter material; and the compound filter material resists to the impact of 250 DEG C to 280 DEG C high temperature flue gas and the impact of high temperature particles.

Owner:AFCHINA CORP CO LTD

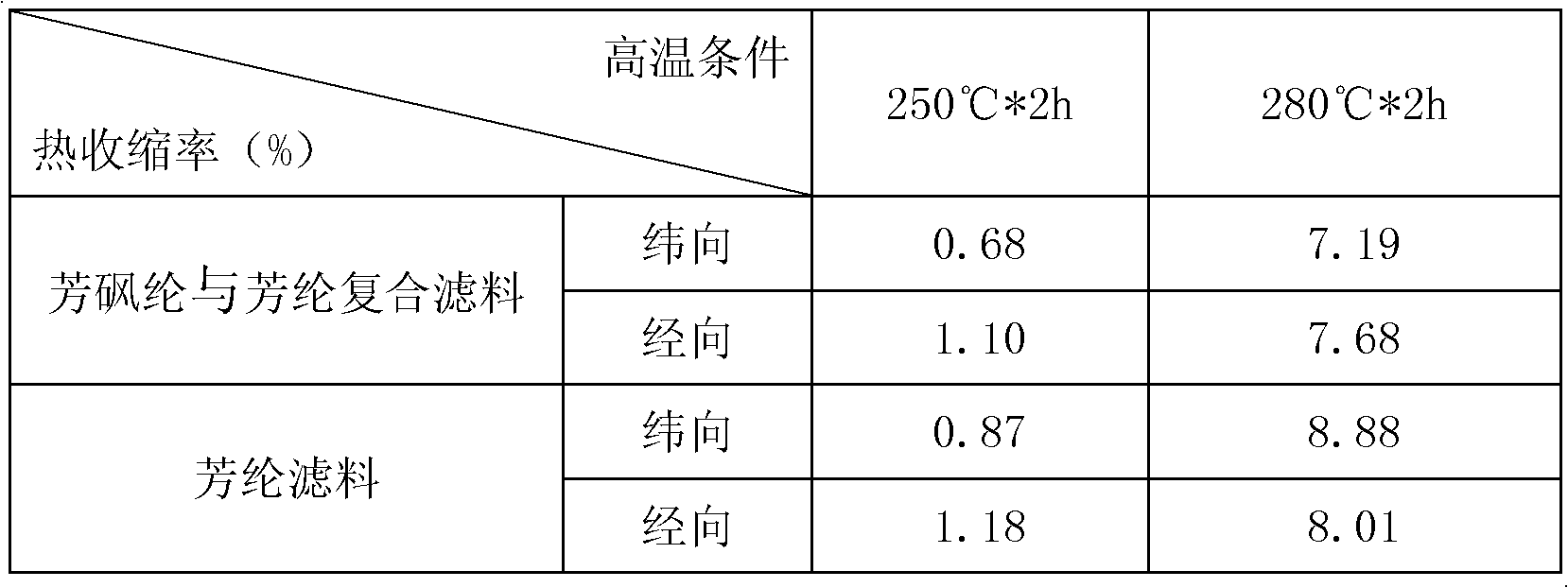

Methods and apparatus for encapsulating hazardous debris

InactiveUS7074174B2Reduce exposureReduce LeachabilitySludge treatmentSolid waste disposalWood splinterLitter

A method of collecting, treating, transporting and disposing of hazardous debris which combines the standards of macroencapsulation and microencapsulation and involves the use of a liner to contain hazardous debris together with reagents that reduce leachability of a constituent of the hazardous debris. The liner is supported in a rolloff box or other transportable container on site where the hazardous debris is collected. Prior to placing hazardous debris into the liner, a layer of reagent(s) is provided in the bottom of the liner. Once hazardous debris is loaded in the liner, addition free flowing reagent(s) is / are added to fill void space in and around the hazardous debris, after which the top of the liner is sealed for disposal in a landfill.

Owner:HESS ENGINEERING INC +1

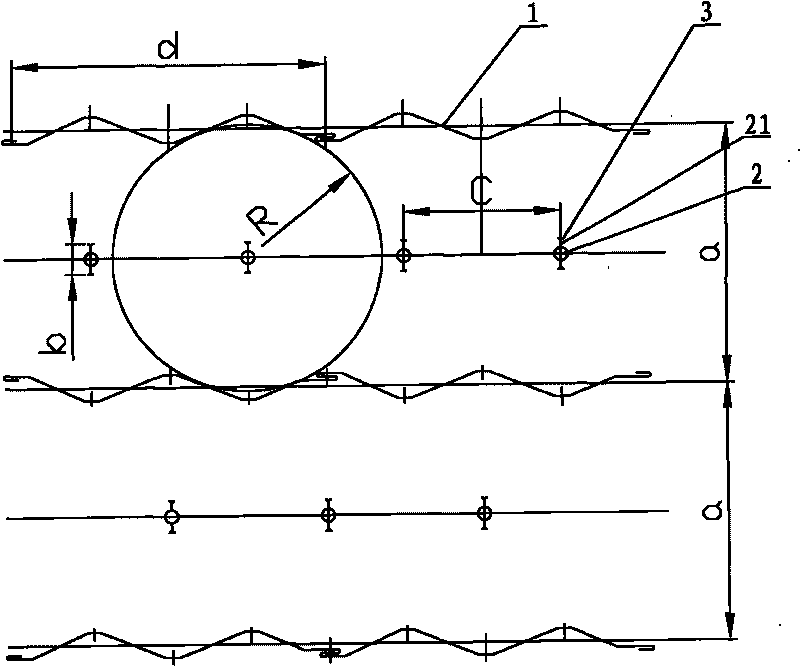

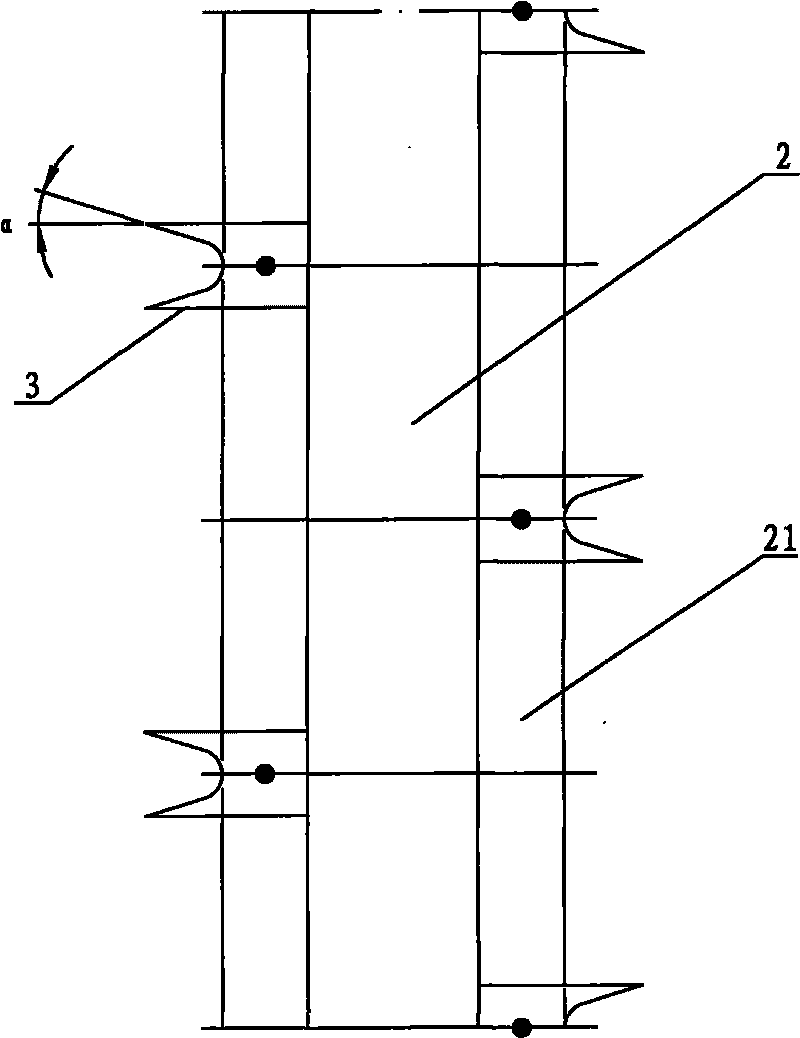

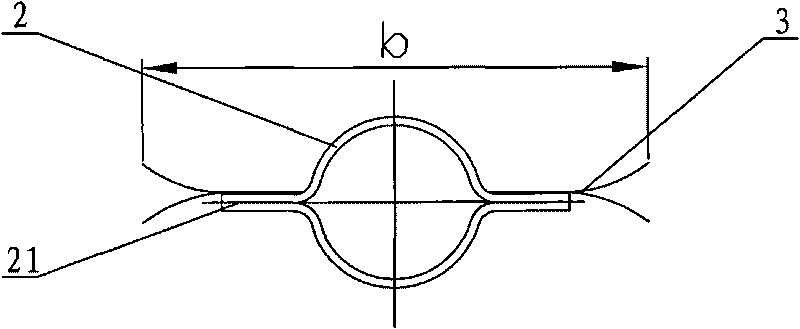

Graded efficient electric precipitator

InactiveCN101757980AImprove breakdown voltageImprove dust removal efficiencyElectrode constructionsWood splinterCathode ray

The invention relates to a graded efficient electric precipitator, comprising a cathode ray, a baffling plate type anode plate with a dust collection ditch; wherein the cathode ray is a tube with two symmetrical edges, a transverse section of each anode plate is folded into four folds to form two concave zones and two convex zones, concave zones of the two adjacent rows of anode plates are corresponding to concave zones of the two adjacent rows of anode plates and convex zones of the two adjacent rows of anode plates are corresponding to convex zones of the two adjacent rows of anode plates; symmetric center points of the two concave zones of the two adjacent rows of the anode plates are vertically arranged on the cathode ray, the two symmetrical edges of the cathode ray are respectively faced the concave zones of the two adjacent anode plates, multiple 'Y'-shaped bent splinters are welded on the two symmetrical edges of the cathode ray from top to bottom at uniform spacing, two bent cuspidal points at the head part of the 'Y'-shaped bent splinters are respectively faced with the two board surfaces of the concave zones of the anode plates. In the invention, the two bent cuspidal points at the head part of the 'Y'-shaped bent splinters are respectively faced with the anode board surfaces, so that critical coronal current and breakdown voltage of the cathode ray is increased, which in turn improves efficiency of dust collection; in addition, height of the two bent cuspidal points of the 'Y'-shaped bent splinters can be adjusted, requirements on dust collection of different power can be met and the application range is wide.

Owner:江苏蓝电环保股份有限公司

Artificial scab for use in an airway

Body tissue and structures in an airway may be treated with an artificial scab comprising an inhomogeneous, uncohesive, solid sheet-like body comprising a granular mixture of chitosan and polysaccharide particles. The artificial scab breaks apart into smaller pieces if peeled away from the surgical site or wound, thus reducing the risk of airway occlusion.

Owner:MEDTRONIC INC

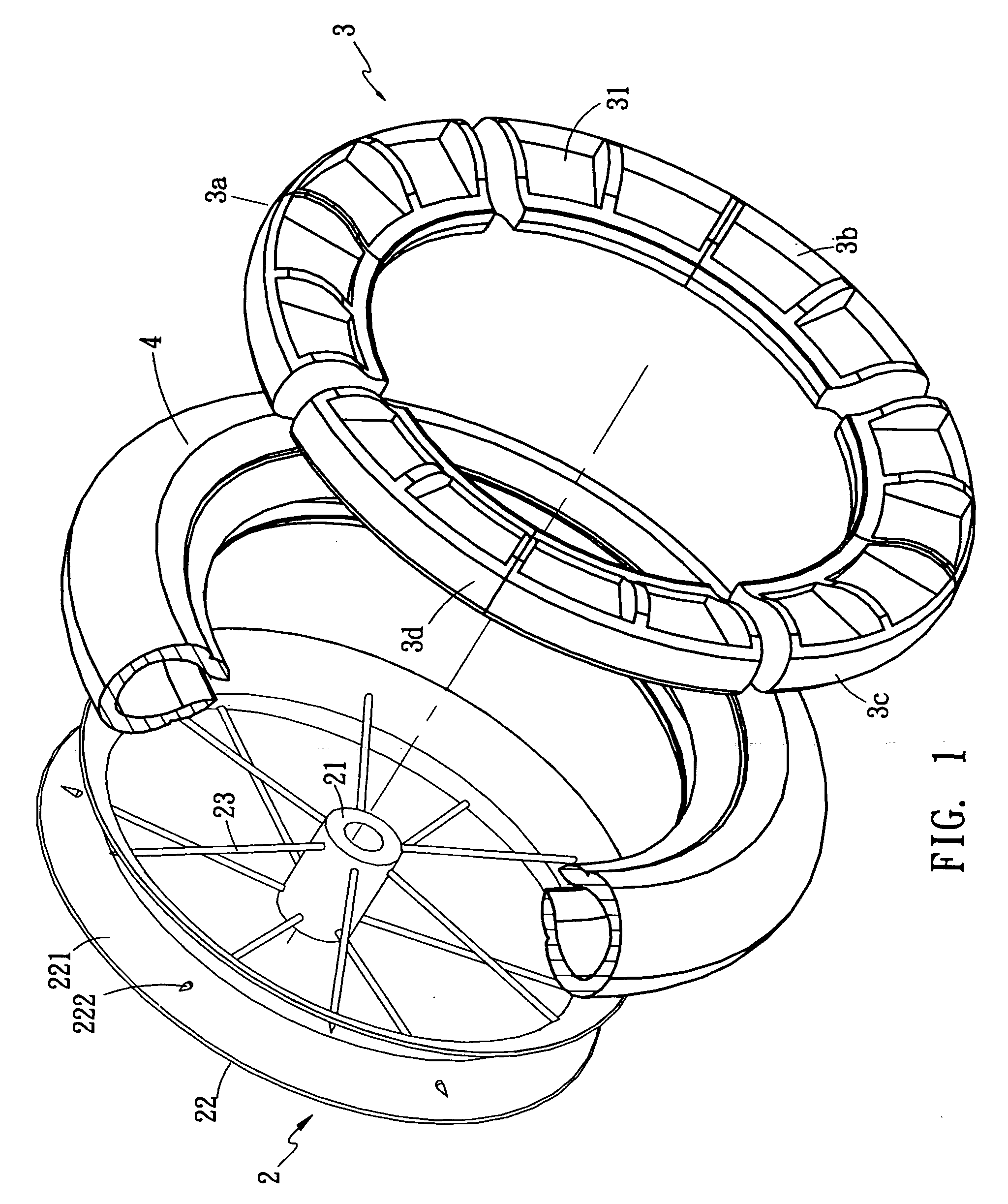

Enhanced hollow foam tire structure

InactiveUS20060027298A1Improve abilitiesSimple structureWithout separate inflatable insertsRimsCarrying capacityWood splinter

This invention discloses a hollow EVA foam tire structure capable of carrying heavy loads, particularly a hollow EVA form tire having an accommodating space between the inboard sides of the tire. The tire is comprised of a plurality of sections substantially arranged into an annular shape, and a wheel core being hollow on both sides, such that a plurality of protruded block sections is disposed on the internal side of the flange section extended from the accommodating space and both sides of the tire are covered by a rim having two corresponding external flange surfaces at the external sides, and a pointed splinter is disposed on the internal side of the external flange surface and a protruded block section is protruded from the surrounding surface of the flange end at the internal side of the rim, so that the protruded block sections of the wheel core are alternatively and mutually engaged. Therefore, when the two corresponding rims are securely coupled, the pointed splinters of the rim can be pierced and fixed into the tire, and the internal side of the tire is embedded into the hollow section of the wheel core by the compressed force. Therefore, the tire, the wheel core and the two side rims can be coupled more securely so as to enhance the carrying capacity of the tire by the wheel core.

Owner:HAN WEN YAO

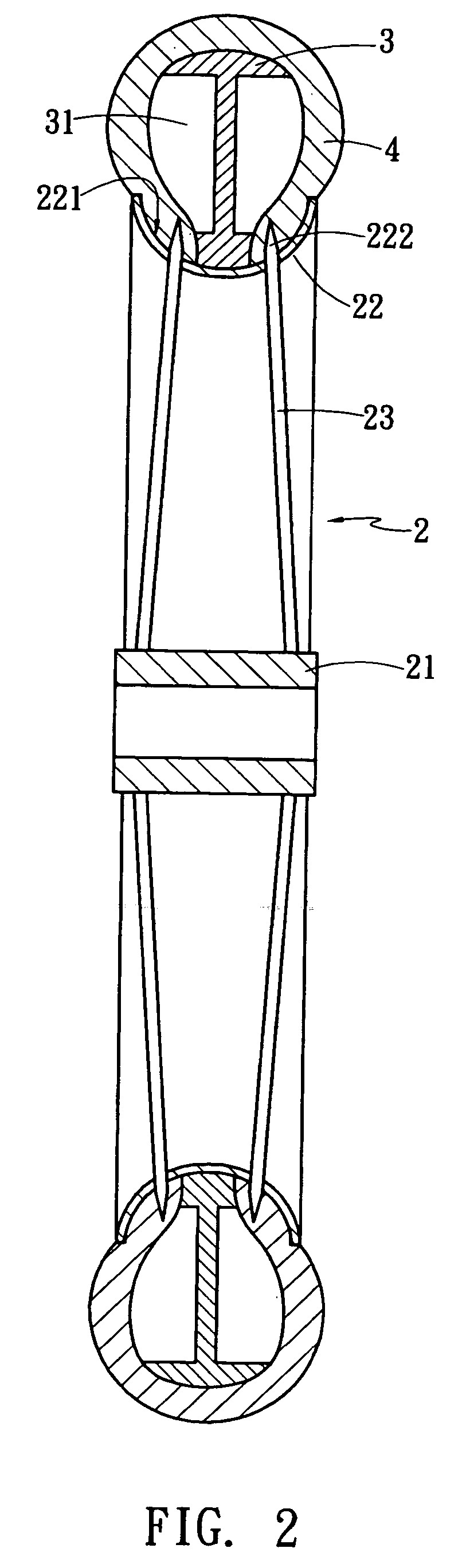

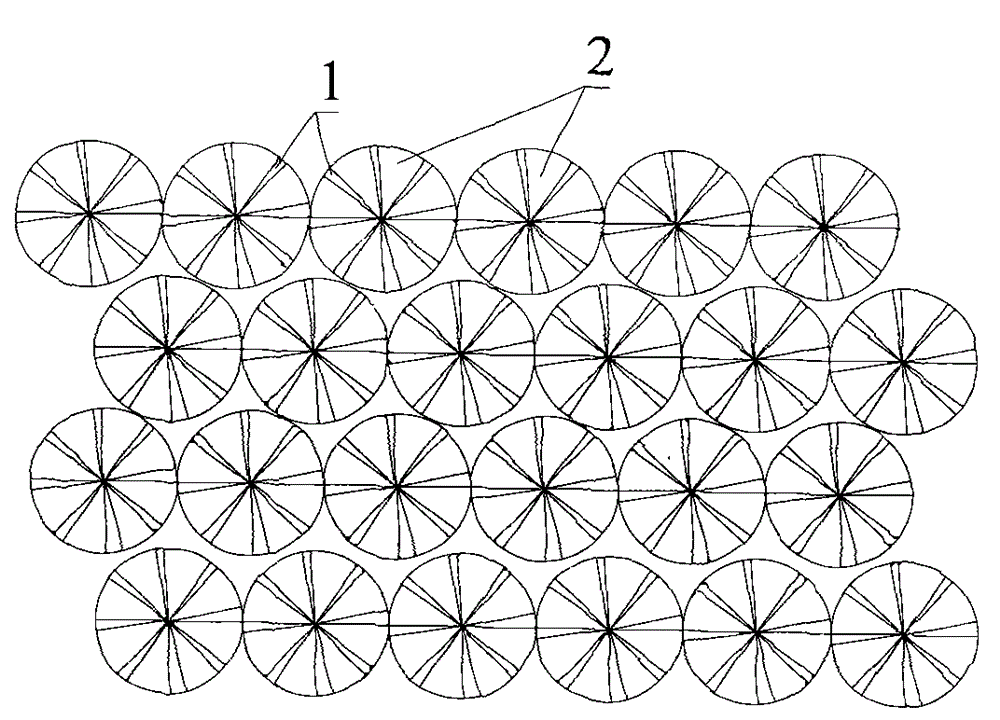

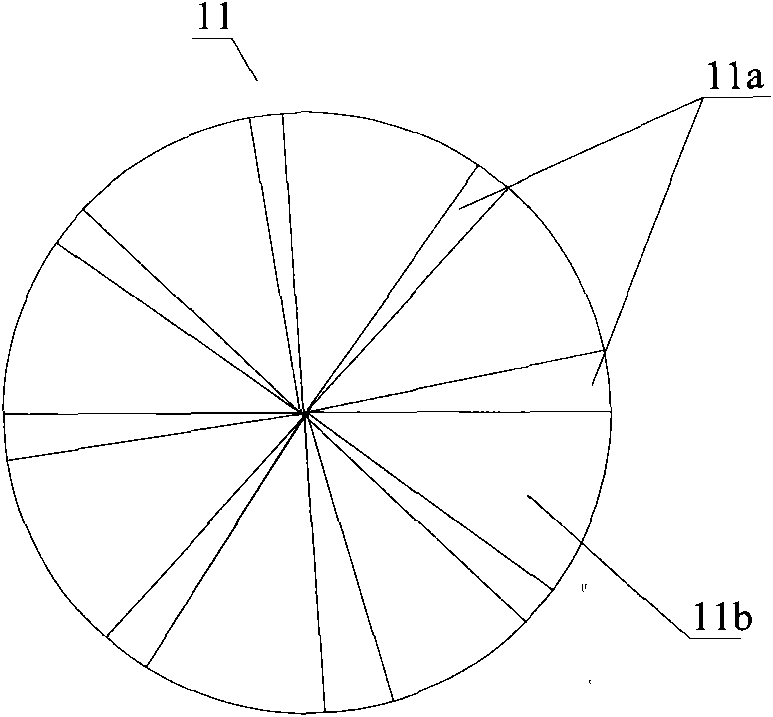

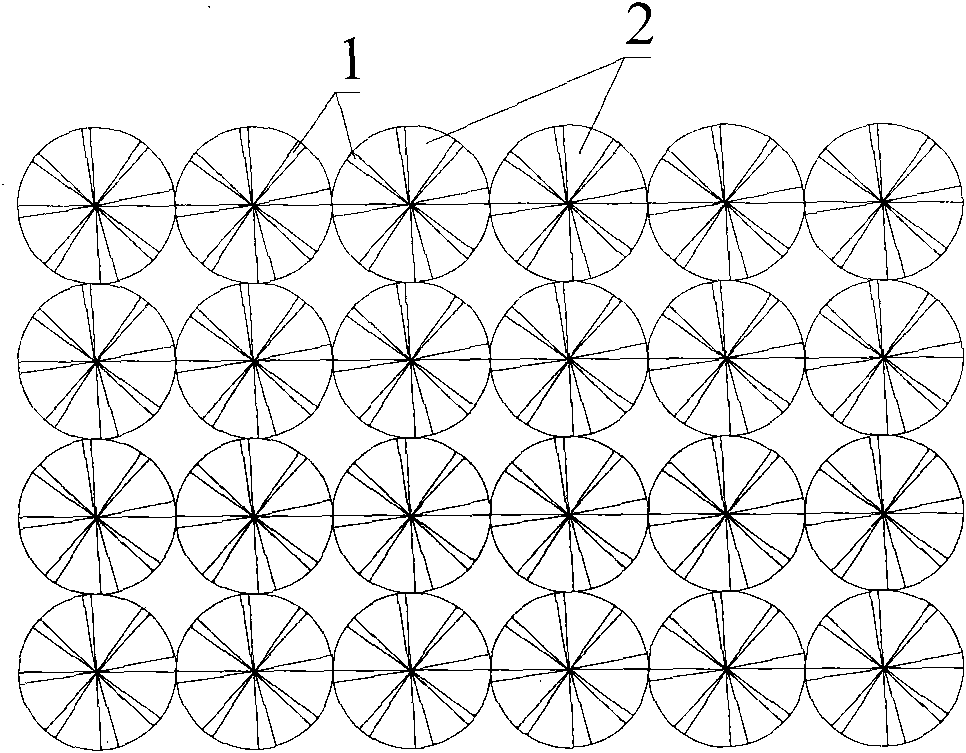

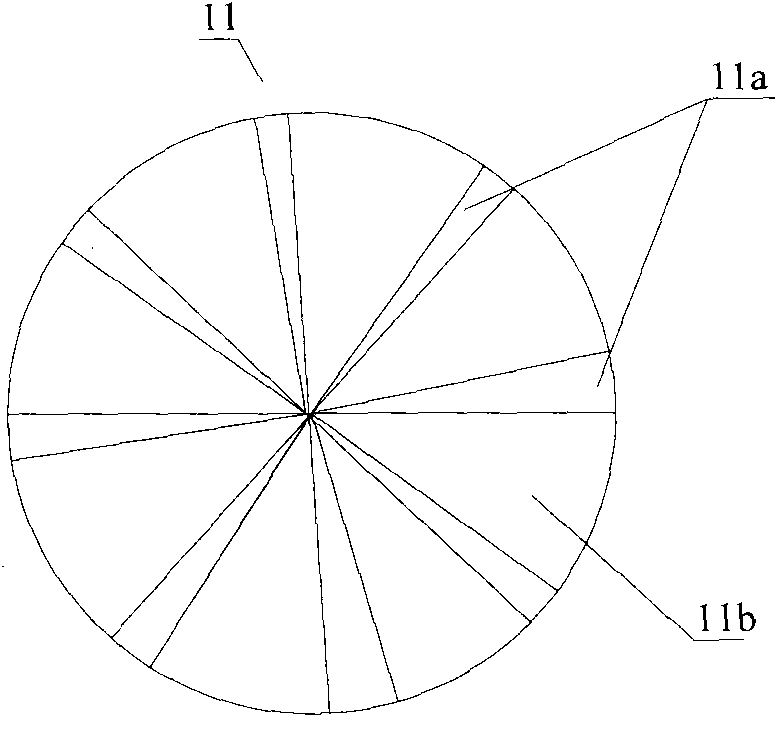

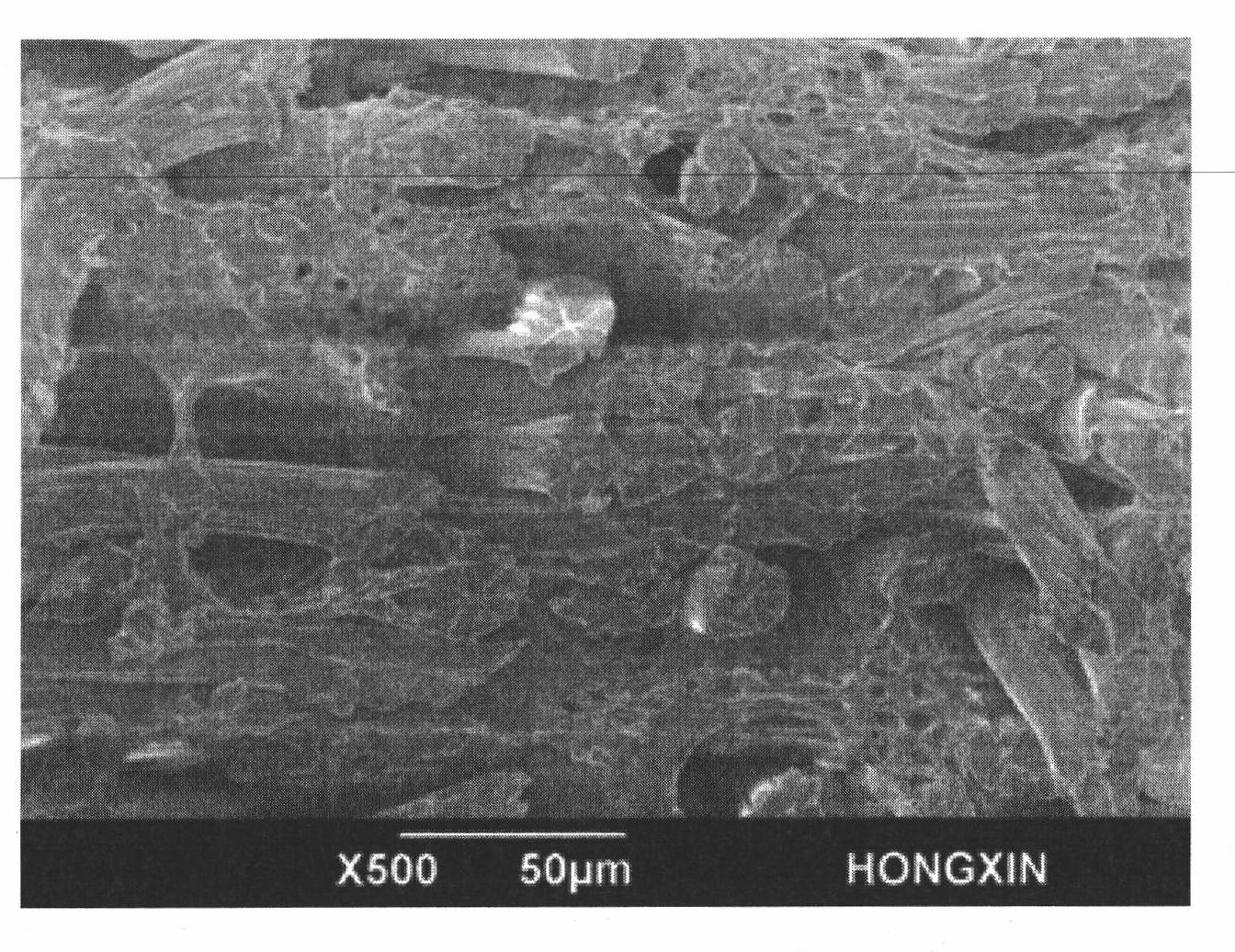

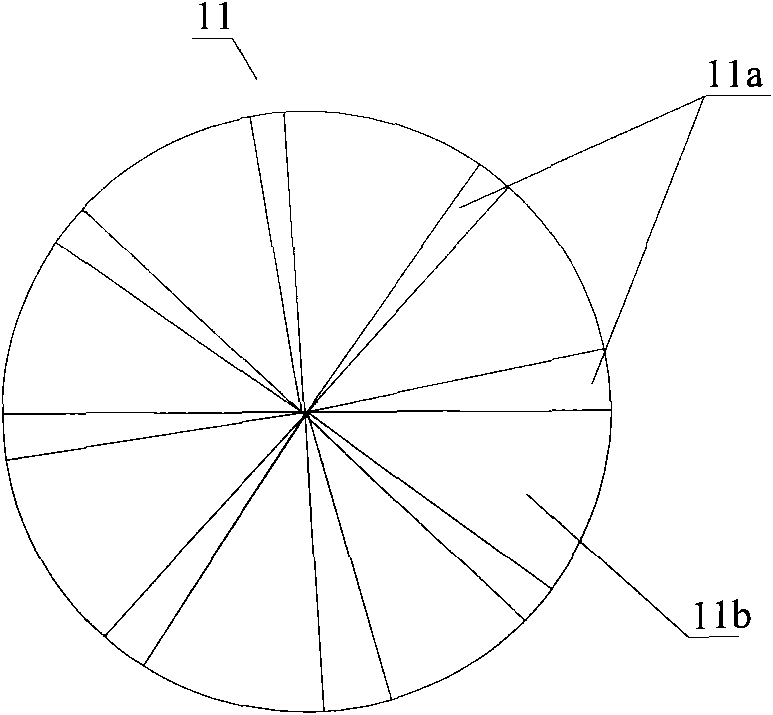

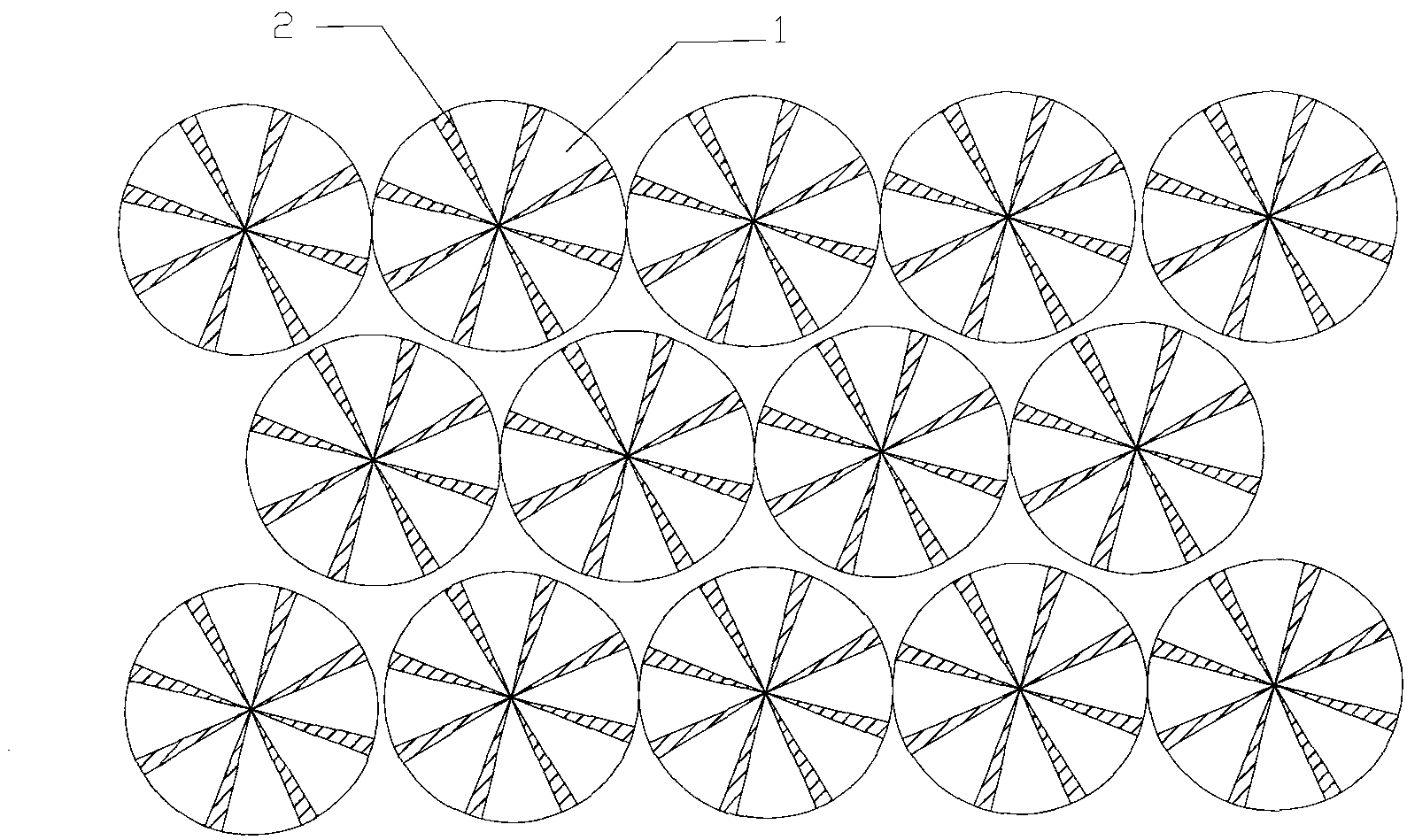

Bi-component composite fiber and preparation method thereof

ActiveCN101798714BIncrease physical bond strengthGuaranteed smooth productionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterWood splinter

The invention provides a bi-component composite fiber. The two components in the bi-component composite fiber comprise a polyester component and a polyamide component. The bi-component composite fiber comprises skeleton parts arranged in a radioactive mode and splinter parts filled in the skeleton parts; the two components form the skeleton parts and the splinter parts respectively; and the polyester component comprises polyester and a fluxing agent, and the fluxing agent accounts for 0.1 to 4 percent of the weight of the bi-component composite fiber. The fluxing agent is mixed into the polyester, and because the fluxing agent can increase the physical bonding strength between the polyester and the polyamide, when the bi-component composite fiber is loosened and carded, the two componentscan be prevented from performing fiber opening in advance to ensure the smooth progression of non-woven fabric production.

Owner:厦门象屿兴泓特种材料有限公司

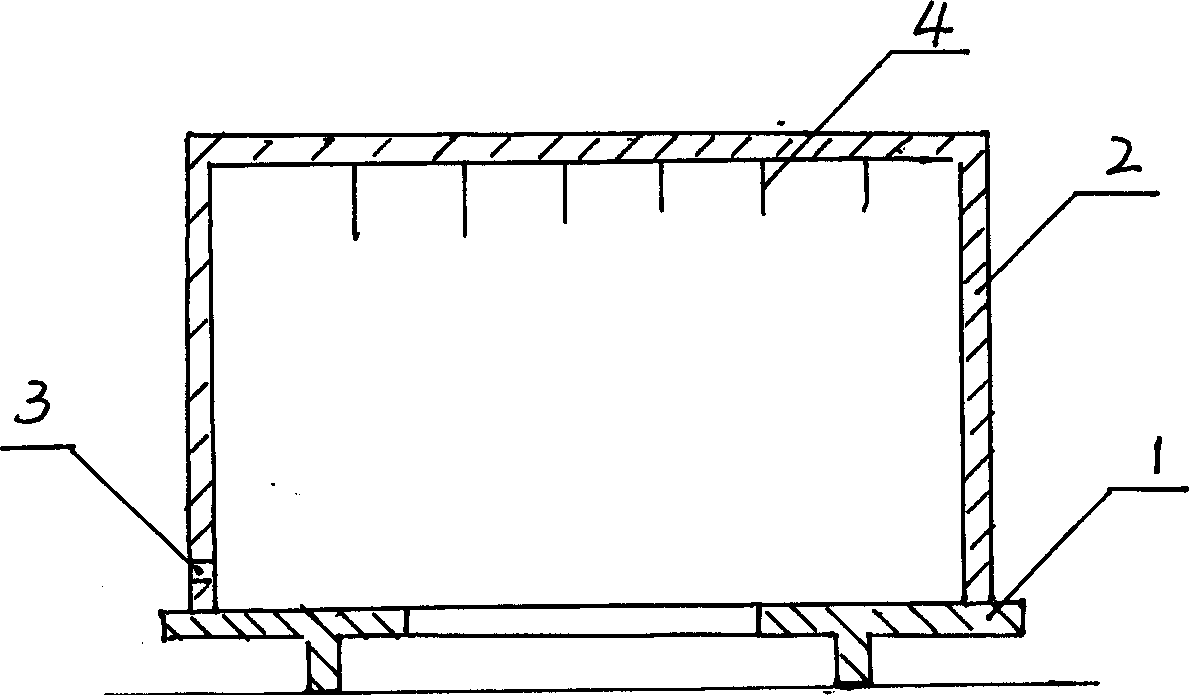

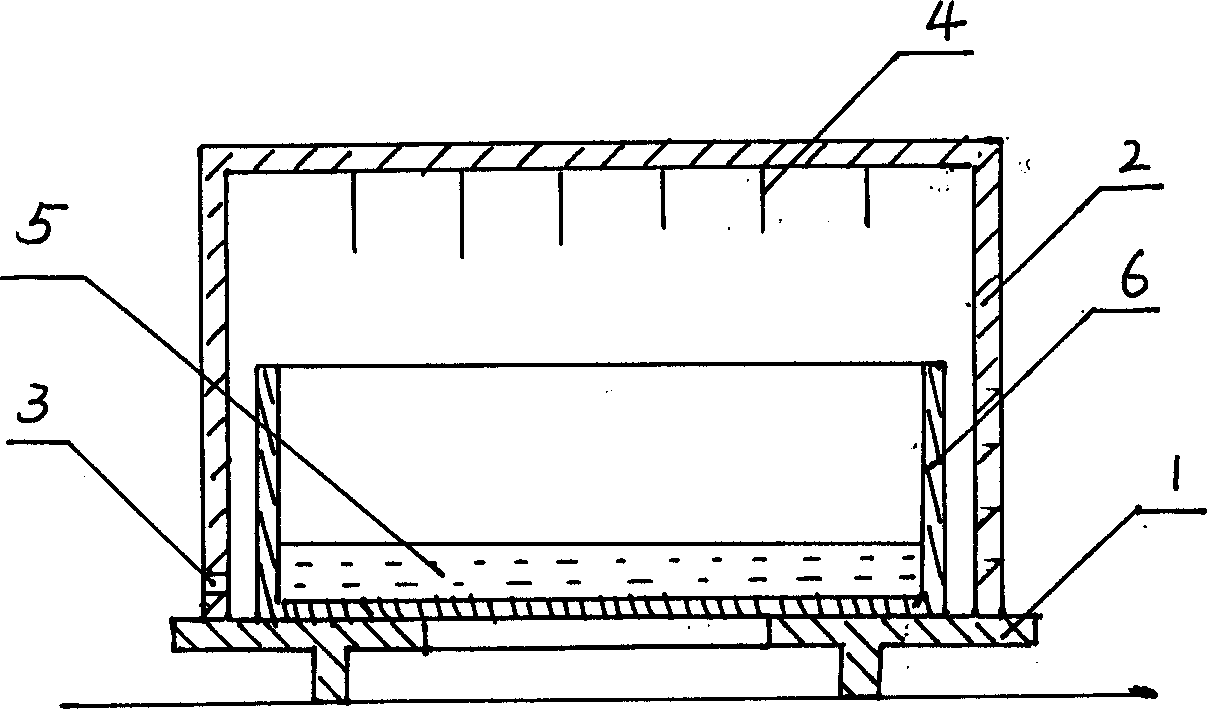

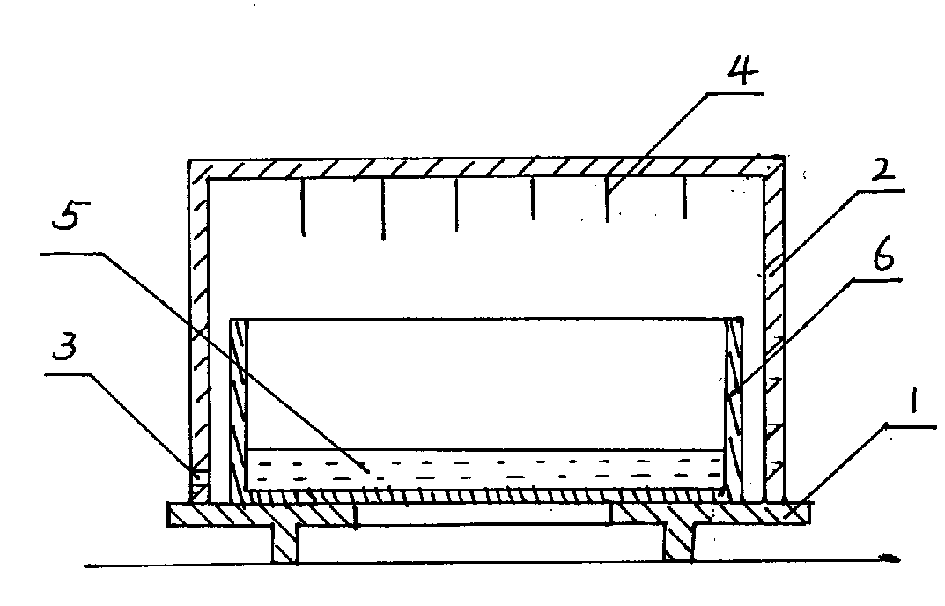

Microwave heating process and special moisture maintainer for producing rice bran stably

InactiveCN1347661AImprove cooling effectPromote passivationFood preservationFood preparationWood splinterFree cooling

The rice bran producing process of regulating the moisture content of rice bran to 15-24 % includes spreading sieved rice bran in a container, setting the container inside one special moisture maintainer, microwave heating for 2.5-3.5 min to 101-120 deg.c and final natural cooling. The special moisture maintainer consists of one horizontal hollow shelf and one cover with pendulous splinters. The present invention is superior in that heating rice bran in a special moisture maintainer to form stable steam environment is favorable to deactivation of enzyme in rice bran, reduce water and microwave power consumption.

Owner:南京经济学院

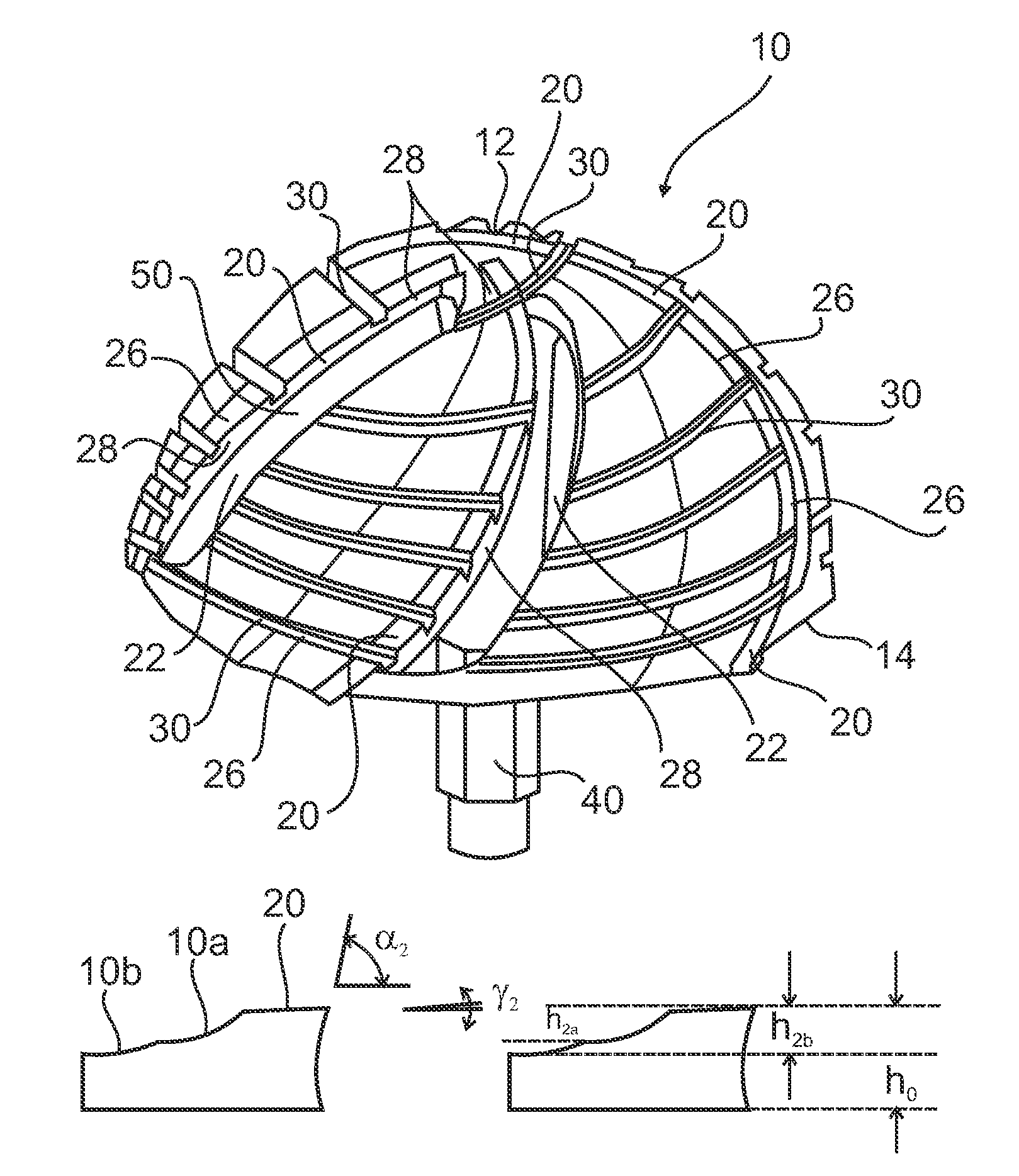

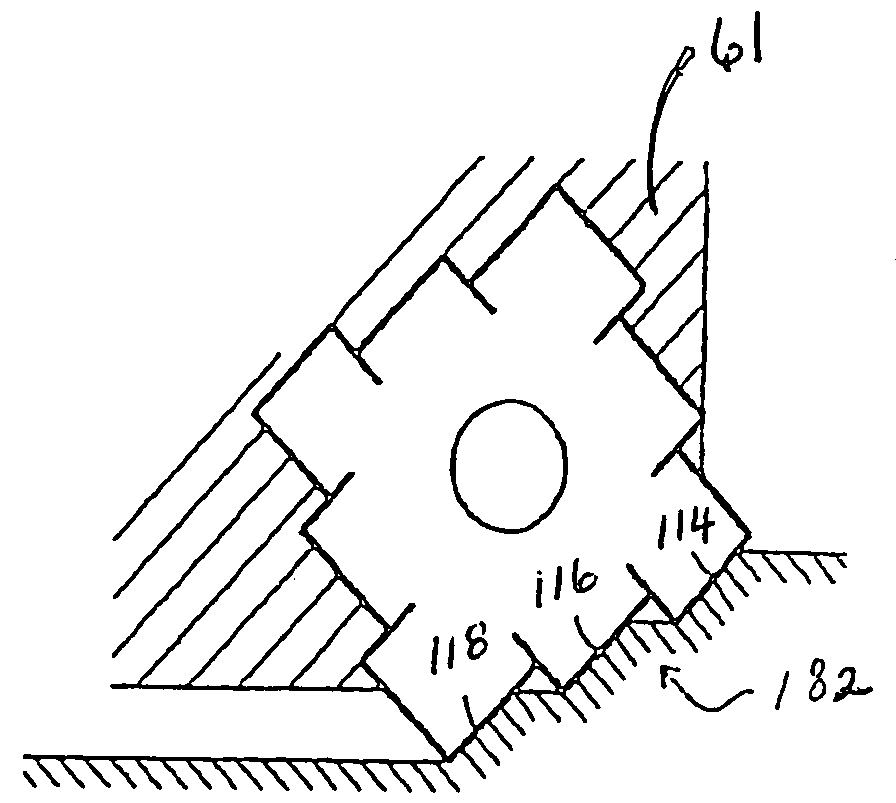

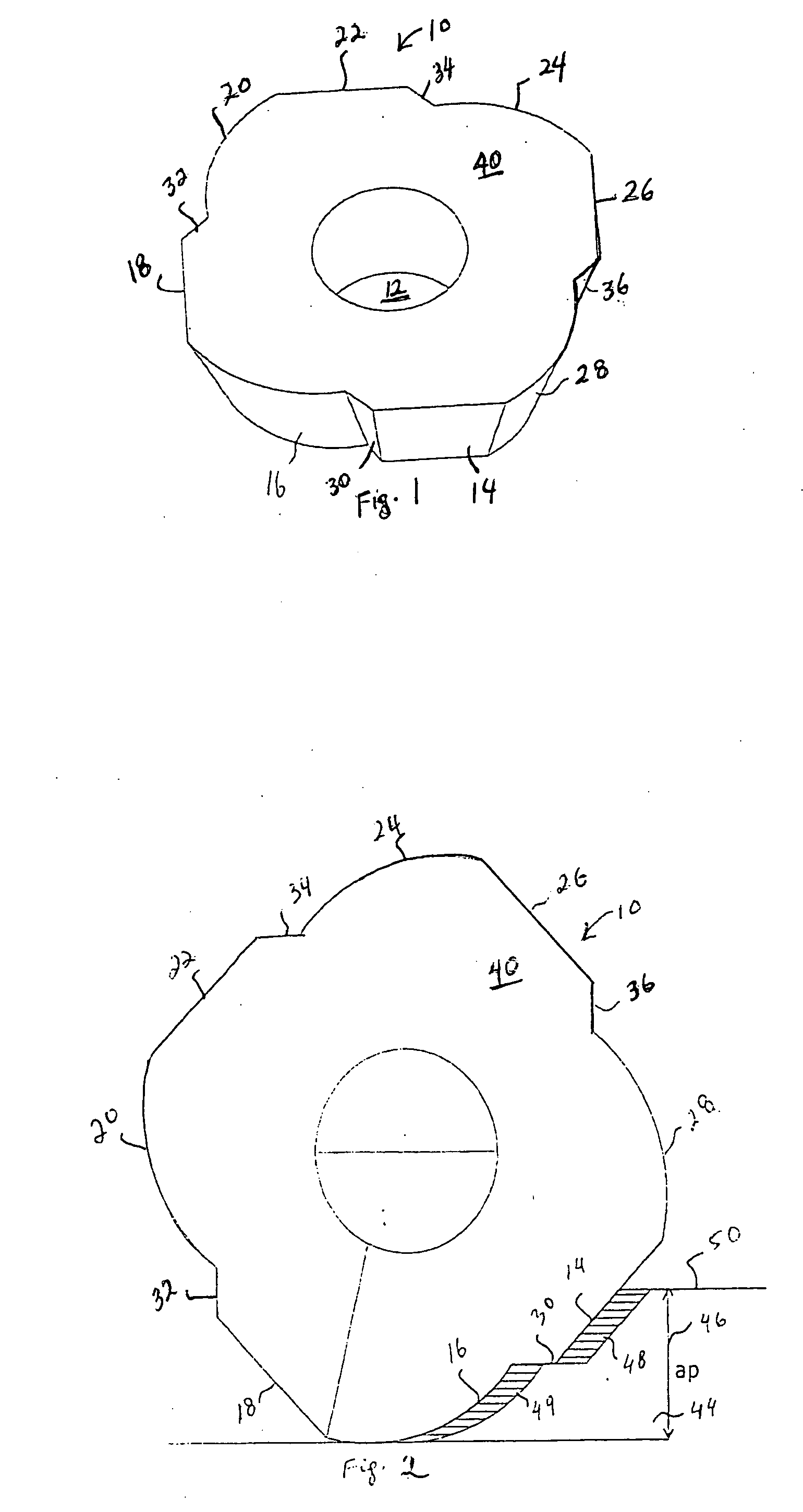

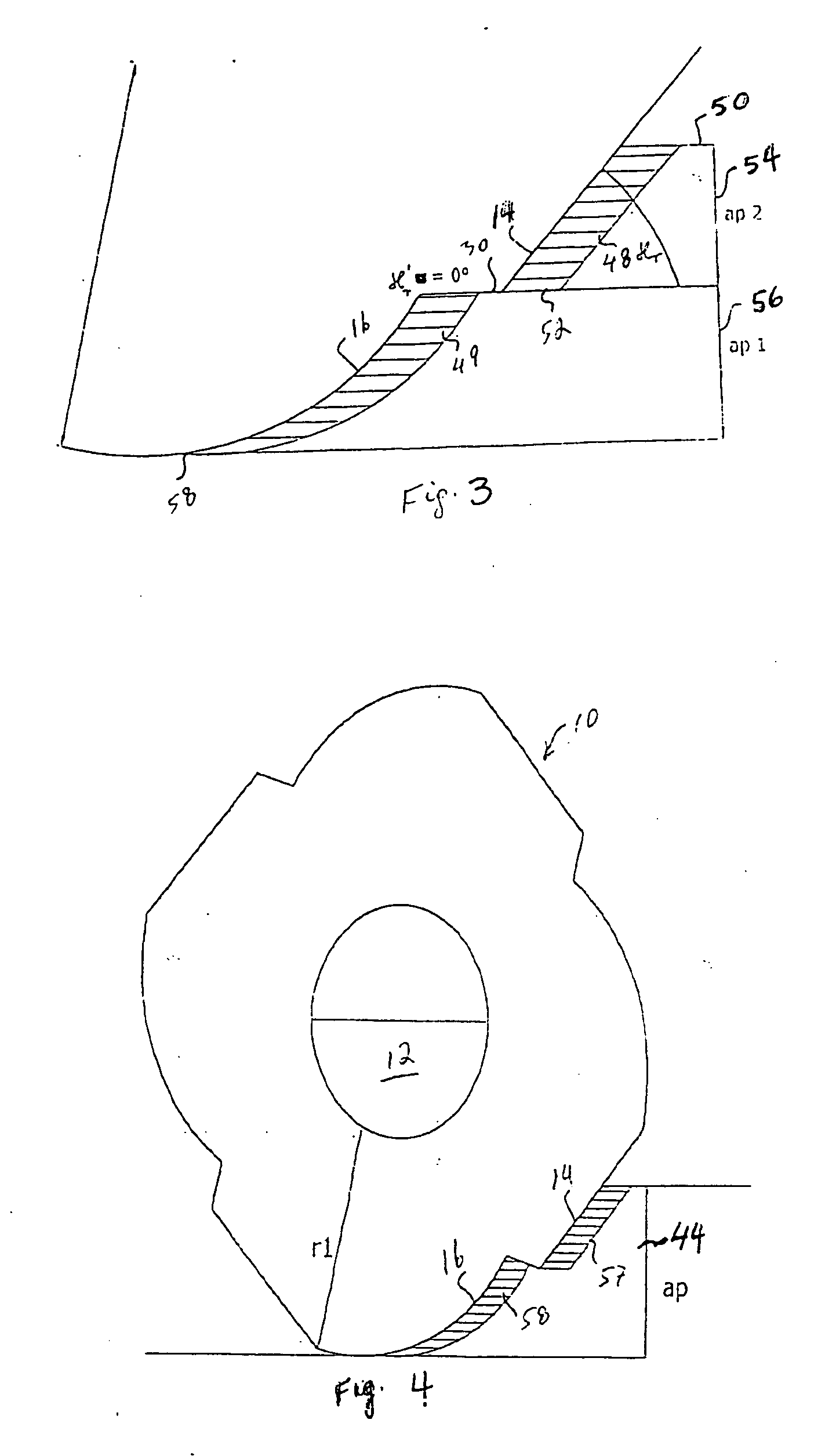

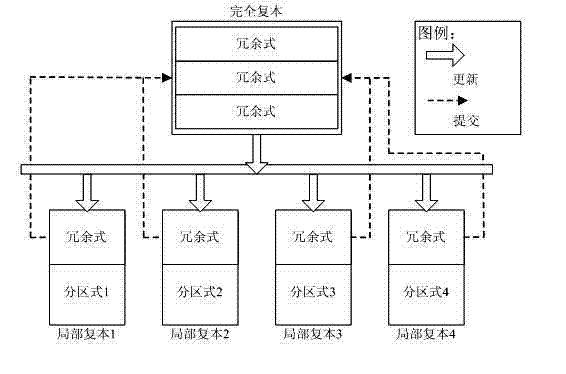

Cutting tool

InactiveUS20050111928A1Eliminate vibrationEliminates clatterMilling cuttersMilling machinesWood splinterEngineering

A cutting tool for a milling, drilling or turning machine has a body with a plurality of sides and a central opening. Each side has a perimeter along which cutting planes or edges are formed. Each side has at least two such cutting planes or edges. The planes may have a straight or curved profile, or a combination of straight and curved profiles along one side. The tool may have a plurality of such cutting planes formed along each side of the tool body. The cutting planes may be located at different levels in relation to each other, entering a work piece in sequence, or may be aligned to enter the work piece simultaneously. Preferably, the cutting planes are staggered in two directions—in a feeding direction and in a cutting direction. By dividing each surface being cut into a plurality of segments, the cutting tool creates a plurality of distinct shavings, or splinters that have shorter length in comparison with conventional splinters formed by indexable tips. Shorter cuts require less cutting force, which saves wear on the cutting tool and the machine. At the same time, the cuts can be made deeper and smoother when dividing the cutting surface into a plurality of segments.

Owner:S J S

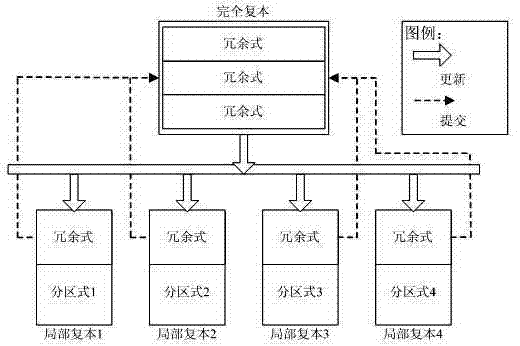

Asynchronous collecting method for maintaining consistency of database replicas

ActiveCN102402600AAvoid dependenceReduce dependenceSpecial data processing applicationsWood splinterApplication software

The invention discloses an asynchronous collecting method for maintaining consistency of database replicas, comprising the steps of: 1) dividing a database differential replica into a complete replica type and a partial replica type; dividing the data into splinters according to the application requirement and storing them into two types of data replicas; 2) comparing the database contents to find the differential data in the complete replica and the partial replica, before modifying the local data, renewing the data and synchronizing the data from the complete replica to the partial replica;3) after modifying the local data, executing a committing operation, and synchronizing the data from the partial replica to the complete replica. The asynchronous collecting method provided by the invention supports multi-database concurrent changes, overcomes the dependence on the dump file and greatly reduces the dependence on the network stability compared with the online synchronous method realized via an application software.

Owner:NARI TECH CO LTD +1

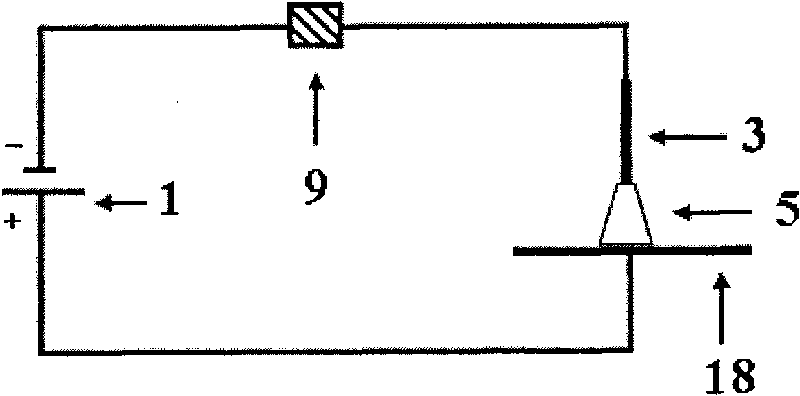

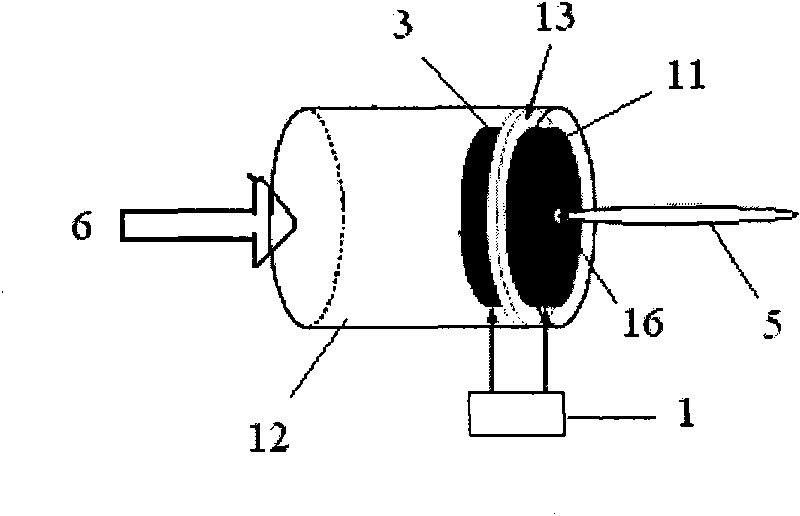

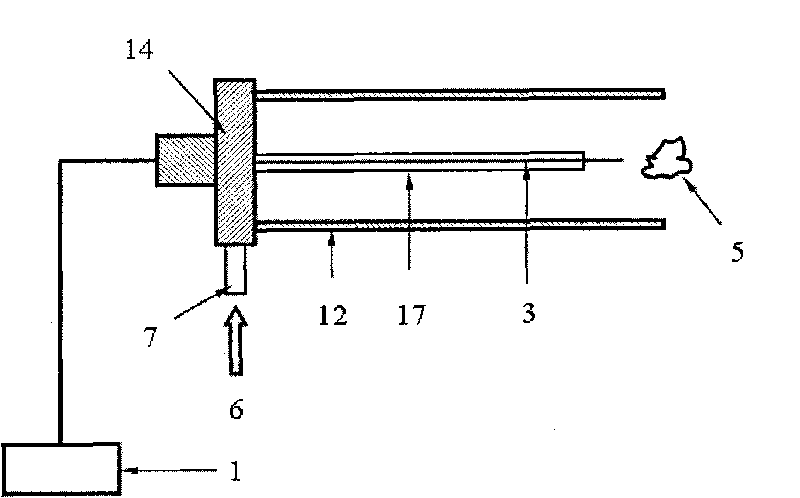

Plasma needle device

The invention relates to a plasma needle device belonging to the field of plasma generation devices and solving the problems that the traditional corona discharging device can not be directly touched by human bodies, and the electrode of a plasma jet device is unsafe or arc discharge is probably generated between the electrode and the ground. The plasma needle device comprises a pulse power source and an electrode, wherein the electrode is connected with the pulse power source through serially connected resistors and capacitors; the radial section of the electrode is in the shape of one of a circle and a ring or a polygon; and the end part and the outer surface or the inner surface of the electrode are provided with needle-shaped or splinter-shaped bulges. The invention has the advantages of easy manufacture and maintenance, convenient use, low cost and easy carrying; the generated temperature of plasma needles can be different by adopting the resistors with different resistance values, the capacitors with different capacitance values and different driving power sources and working gases; and the plasma needles can be applied to sculpture, deposition, surface treatment, surface cleaning, purification, food treatment, biomedical disinfection, tooth cleaning, root canal therapy, and the like.

Owner:武汉海思普莱生命科技有限公司

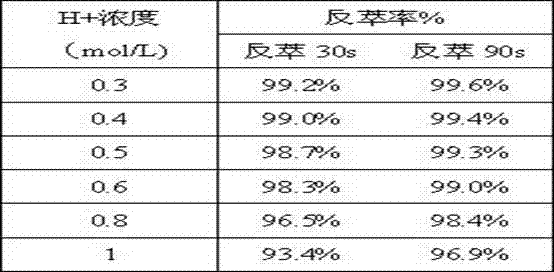

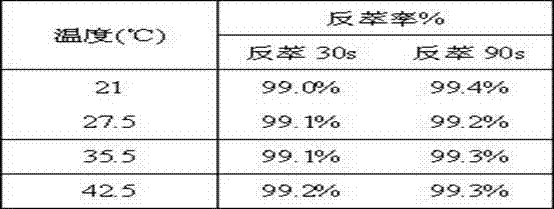

Method for separating U (uranium) from Pu (plutonium) in Purex process

The invention which belongs to the technical field of radioactive post-treatment concretely relates to a method for separating U from Pu in a Purex process. The method comprises the following steps: 1, removing nuclear reaction splinters except U and Pu; 2, coextracting codecontaminated U and Pu to a TBP (tributyl phosphate) / kerosene mixed liquor with a volume percentage of 30%; and 3, adding a reducing agent HSC (hydroxysemicarbazide) to the mixed liquor in step 2, and fully mixing to back-extract Pu (III) which is reduced from Pu (IV) in an organic phase to an aqueous solution of hydrogen nitrate, wherein the ratio of the molar concentration of the HSC in an aqueous phase solution to the molar concentration of Pu in an organic phase solution is 5-60, the volume ratio of the organic phase solution to the aqueous phase solution is 1:1-6:1, the temperature is 21-42.5DEG C, and the concentration of H<+> is 0.3-1mol / L. A technical scheme provided by the invention allows Pu (IV) in the organic phase to be rapidly reduced and back-extracted to the aqueous phase, the reaction time is two magnitudes shorter than the reaction time of the prior art, the technological process is simplified, and the separation efficiency is improved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Disposable dental prophy angle with secure retention mechanism

ActiveUS20060046227A1Improve performanceImprove operational convenienceTooth pluggers/hammersBoring toolsDrive shaftWood splinter

A disposable, securely retained dental angle is provided. The angle includes a one-piece hollow housing having a short leg at its front end, which is angled with respect to the long leg. Both the short and long legs have a through bore. The short leg has an aperture, which is connected to the bore of the long leg to allow insertion of a driving shaft through the short leg of the angle. A driven rotor is inserted in the short leg. A horse-shoe-like snap rotor retainer fits within the short leg over the driven rotor to retain the driven rotor in the angle. A paw-like or, alternately, a horse-shoe-like locking means fits within the long leg over the driving shaft to lock the driving shaft in the angle and to retain the angle together. In one embodiment, a pair of splinters on the driven rotor provides the function to retain the rubber prophy cup firmly while the driven rotor is in operation.

Owner:PAC DENT INC

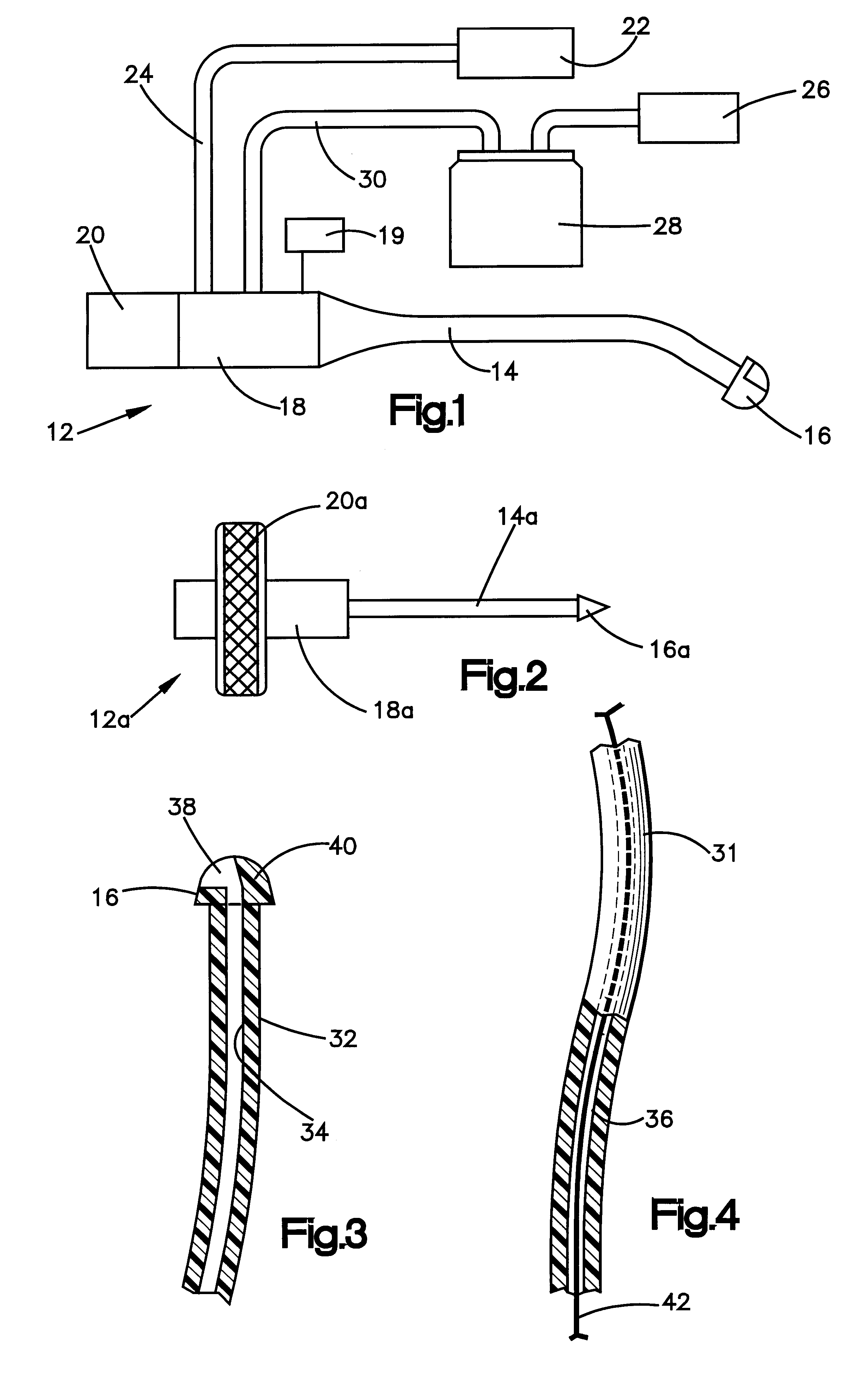

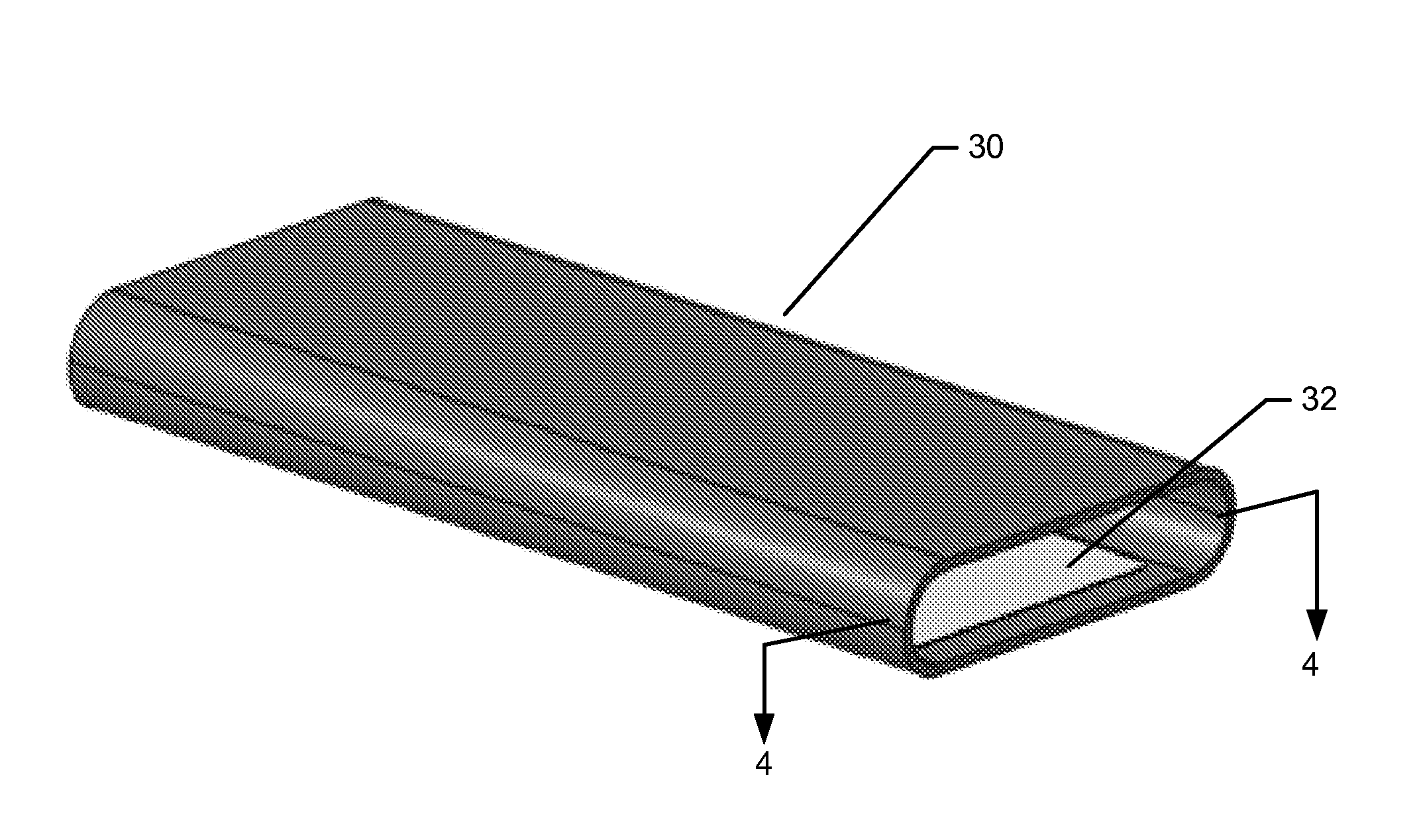

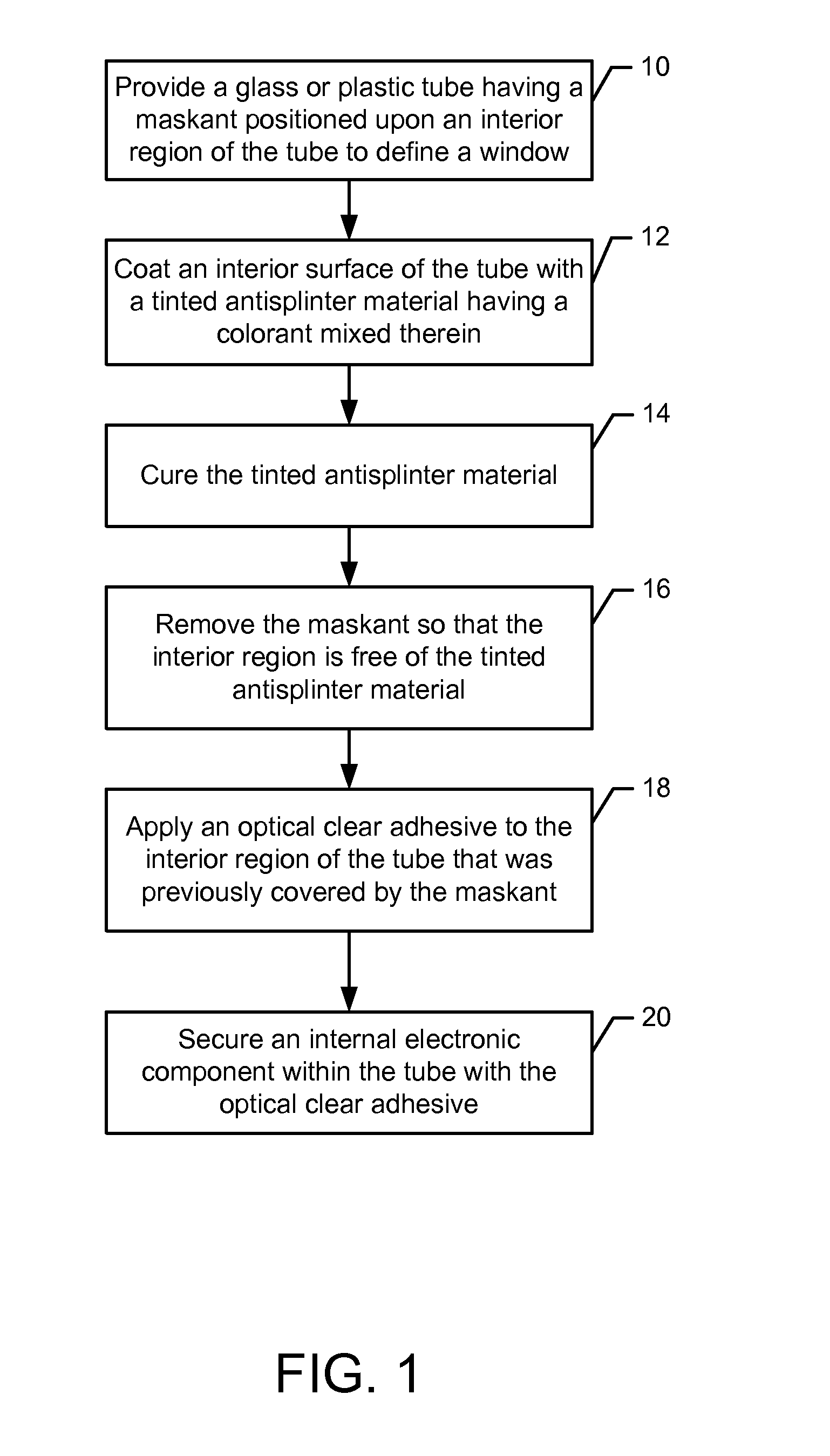

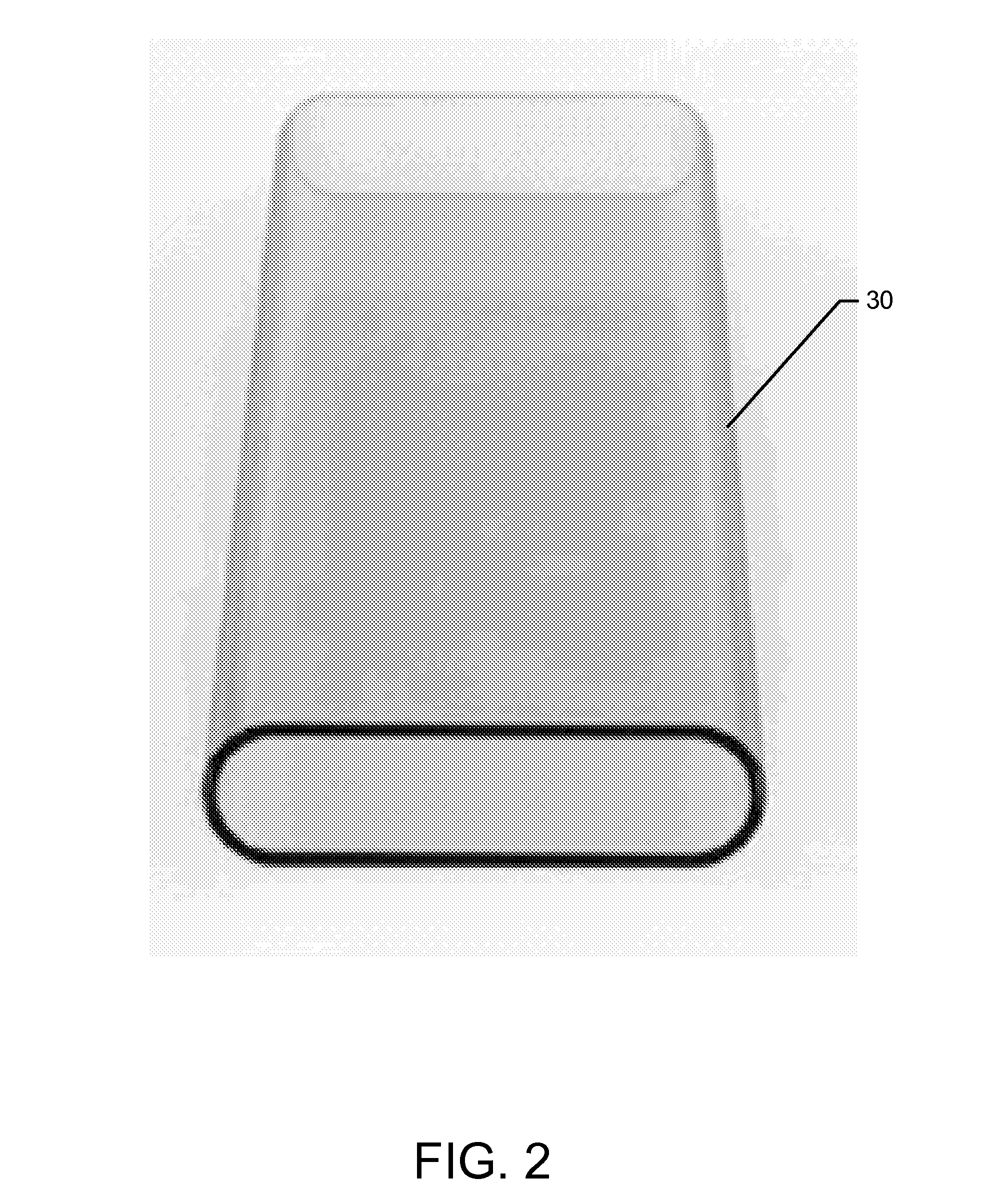

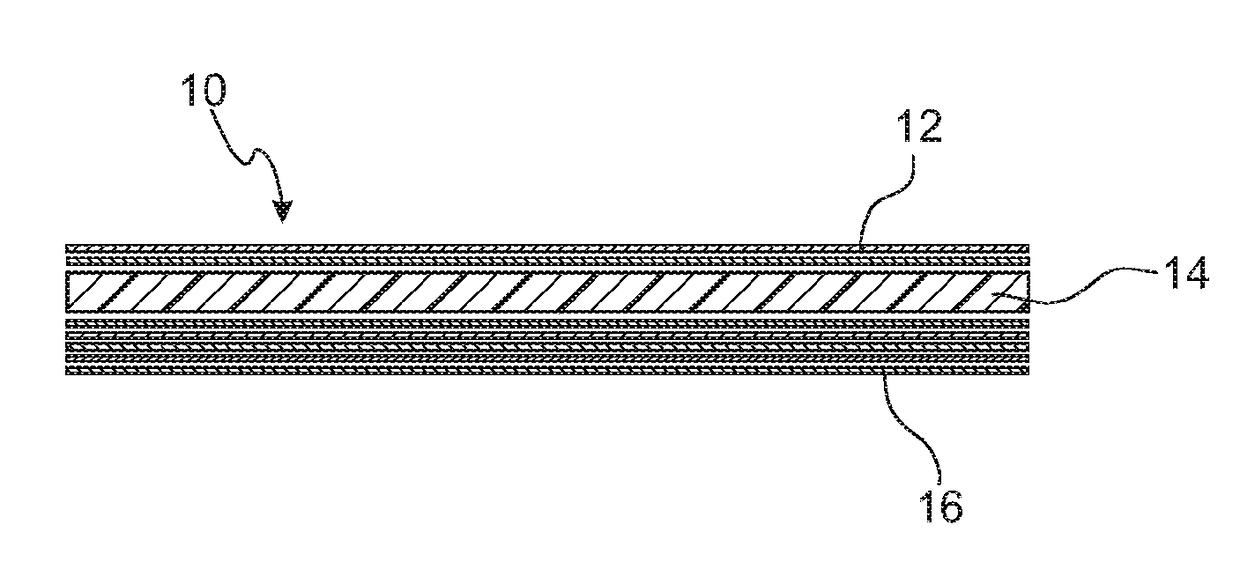

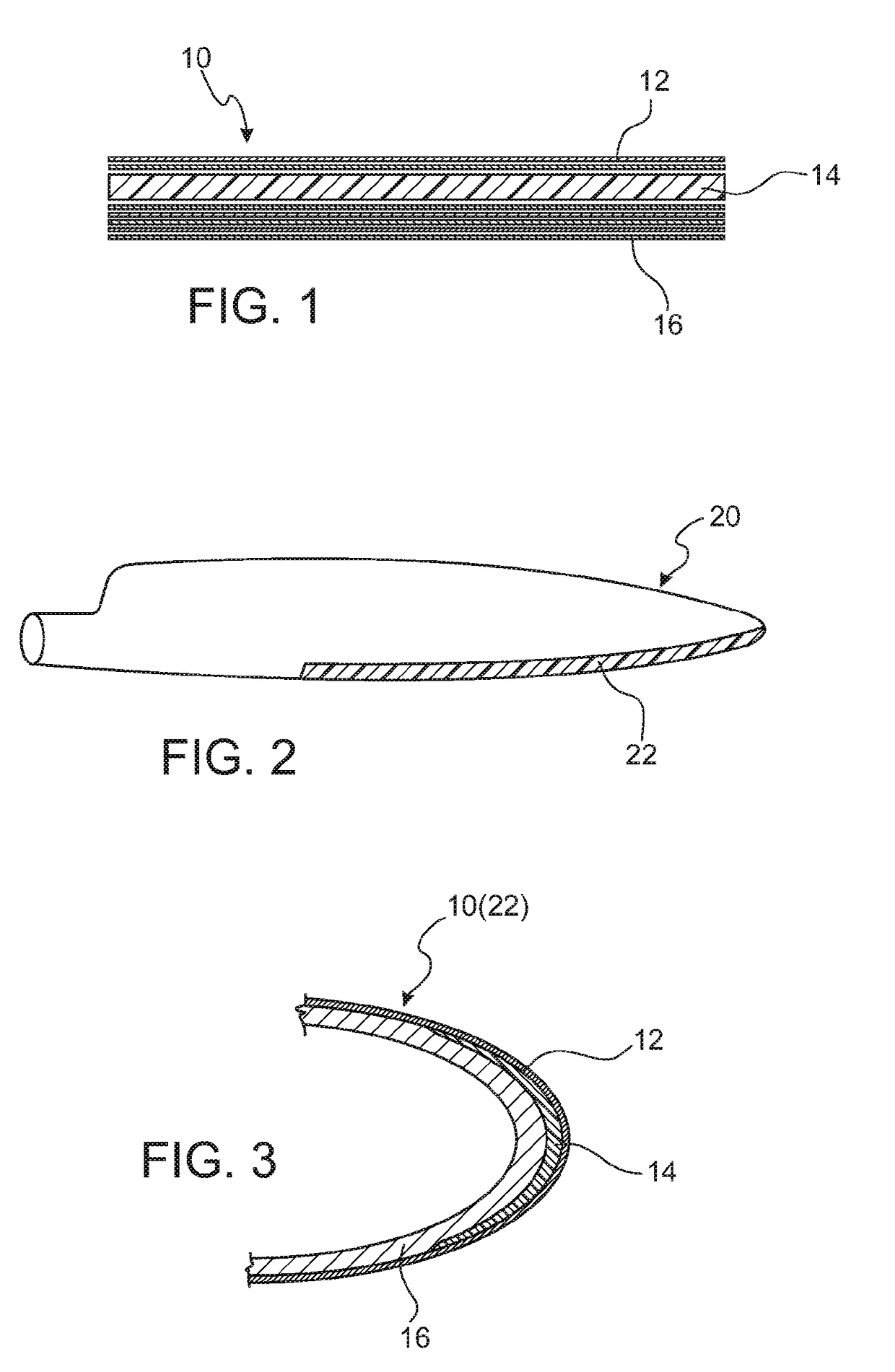

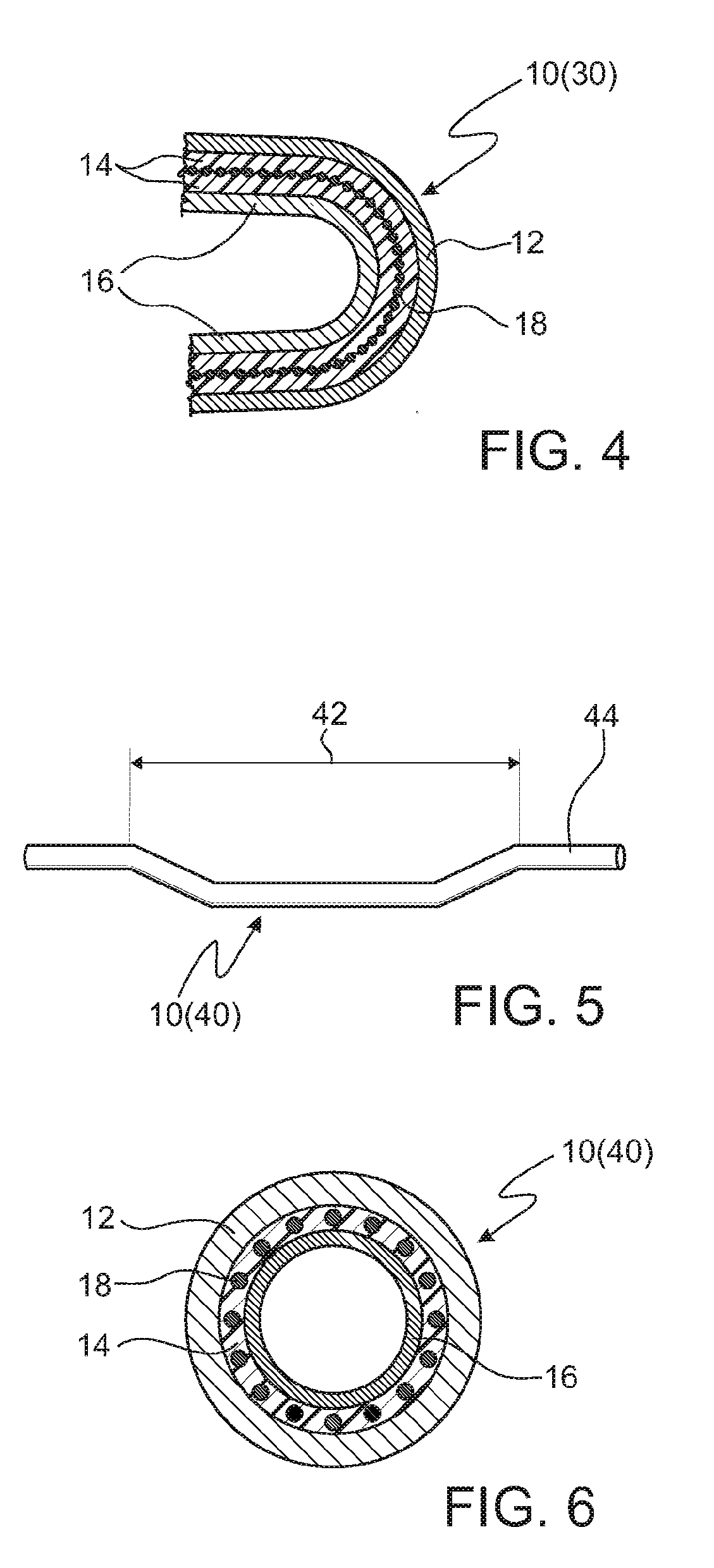

Tube-shaped part and an associated method of manufacture

ActiveUS20140000747A1Efficient manufacturingLamination ancillary operationsLaminationWood splinterEngineering

A tube-shaped assembly, a tube-shaped part and an associated method of manufacturing the same are provided. In regards to a method, a glass or plastic tube is provided that has a maskant positioned upon an interior region of the tube to define a window. The method also includes coating an interior surface of the tube with a tinted anti-splinter material having a dye or pigment mixed therein. The method also includes curing the tinted anti-splinter material and removing the maskant such that the interior region is free of the tinted anti-splinter material. A tube-shaped part is also provided that includes a glass or plastic tube and a maskant positioned upon an interior region of the tube to define a window. The tube-shaped part also includes a tinted anti-splinter material having a dye or pigment mixed therein.

Owner:NOKIA TECHNOLOGLES OY

Impregnation method of non-woven fabric

The invention provides an impregnation method of non-woven fabric, which comprises the following steps of: providing the non-woven fabric made of double-component composite fiber, wherein the double components are polyester component and polyamide component; using framework parts arranged in a radioactive way and splinter parts filled among the framework parts to form the non-woven fabric, wherein the splinter parts and the framework parts are respectively formed by the double components; carrying impregnation treatment on the non-woven fabric by using polyvinyl alcohol impregnation liquid, and obtaining first impregnation base fabric; then, carrying out impregnation treatment by using polyurethane impregnation liquid, and obtaining second impregnation base fabric, wherein the polyurethane impregnation liquid comprises the components based on mass concentration: 12-20 percent of polyurethane, 1-3.2 percent of impregnation auxiliary agent and balance DMF; and finally, leading the second impregnation base fabric to enter coagulating liquid for coagulating, water washing and drying. By adopting the method, the impregnation treatment can be carried out on the non-woven fabric, so that the double-component composite fiber can be reserved inside the leather, the double components can be prevented from being adhered with the leather, and the finally obtained PU synthetic leather not only has stiffness of terylene, but also has softness of nylon.

Owner:厦门象屿兴泓超细材料有限公司

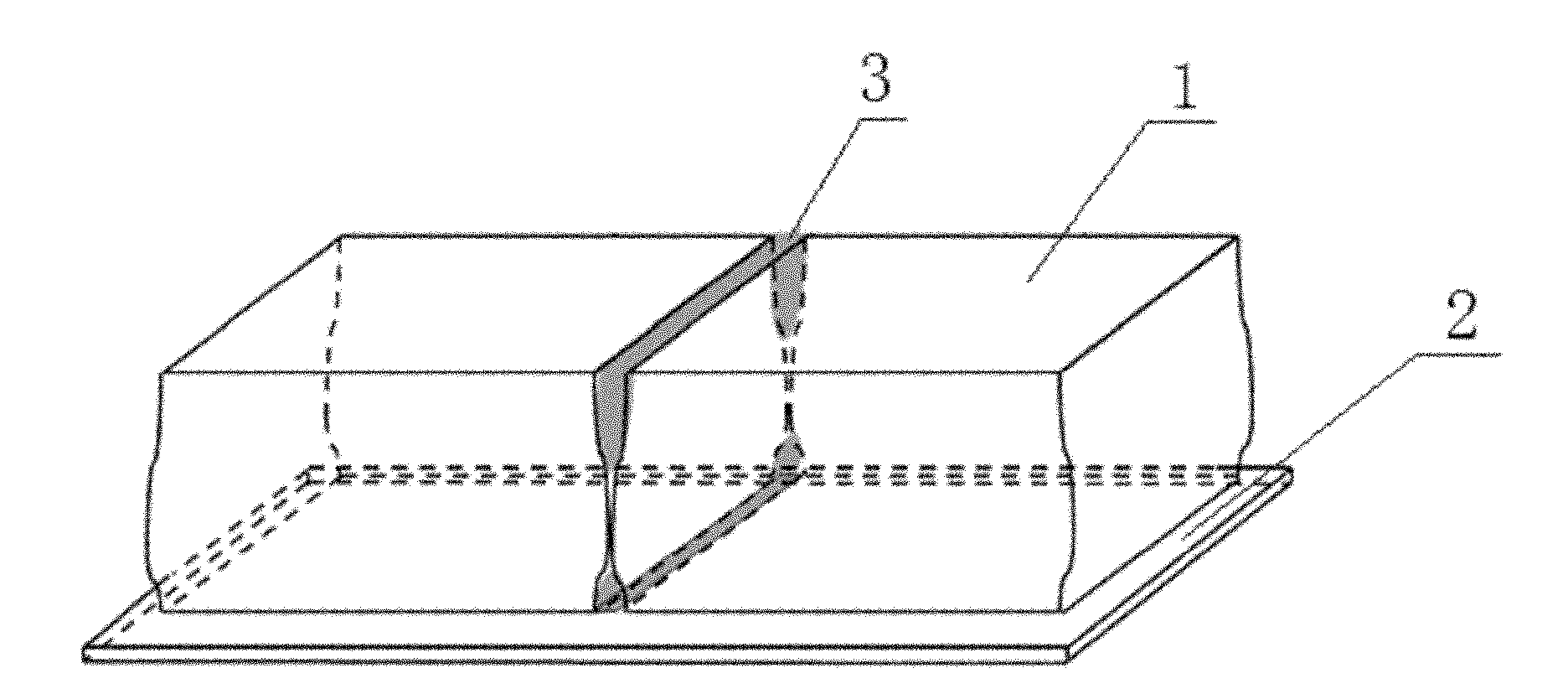

Crystal-block bonding rod slicing process

ActiveCN102092102AEliminate knife marksAvoid disconnectionFine working devicesWood splinterEngineering

The invention relates to a crystal-block bonding rod slicing process. The process comprises the following steps: adhering more than two crystal blocks on the same glass plate to form a crystal-block bonding rod, wherein unqualified semi-finished product crystal blocks which are not cut are arranged on two ends of the crystal block; unqualified parts of the two adjacent crystal blocks are closely connected, and the connecting gap of the unqualified parts of the two adjacent crystal blocks is filled with glue; and the crystal block is sliced by a slicing machine after the glue is solidified. The crystal-block sliced bonding rod is a seamless bonding rod, and the unqualified parts on two ends of the crystal block are not required to be cut before the crystal block is sliced so as to save a cutting process and eliminate bevel, line trace and cut trace caused by cutting two ends of the crystal block; therefore, the problem of high proportion of hidden splinters, thick and thin slices, line traced slices, notch slices and fragment on two ends of the crystal block in a slicing process is fundamentally solved, occurrence of broken line is avoided, yield and capacity of silicon slices is greatly improved, and quality guarantee is provided for the silicon slices on a battery end.

Owner:TRINA SOLAR CO LTD

Non-woven fabric and preparation method thereof

ActiveCN101798726ATo achieve the purpose of initial fiber openingFiber opening is beneficialFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterWood splinter

The invention provides a non-woven fabric, which is characterized in that the non-woven fabric is made of bi-component composite fibers in which the two components are polyester and polyamide respectively, and the bi-component composite fibers comprise radially-arrayed skeletons and splinters filled in the skeletons, which are respectively formed by the two components. The polyester comprises 0.1 to 4 percent of flux based on the total weight of the bi-component composite fibers. The flux in the polyester can increase the physical cohesive strength between the polyester and the polyamide, so that the advance fiber opening of the two components can be prevented when the two components are loosen and carded, and the smooth production of the non-woven fabric is guaranteed.

Owner:厦门象屿兴泓超细材料有限公司

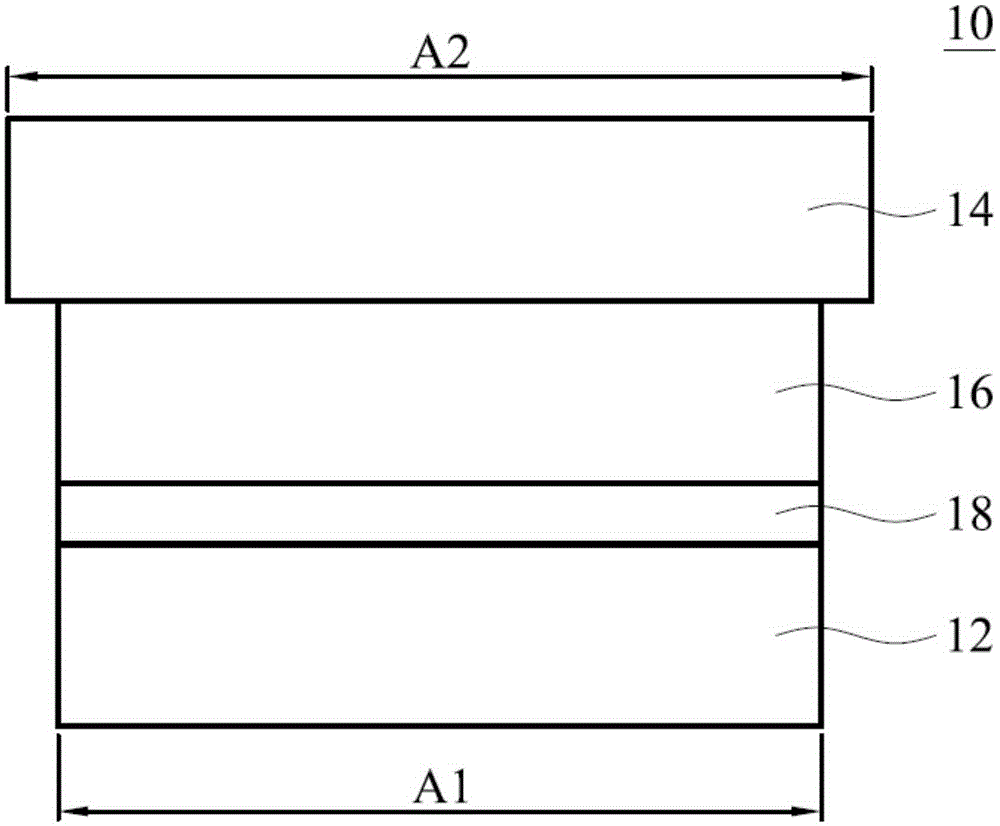

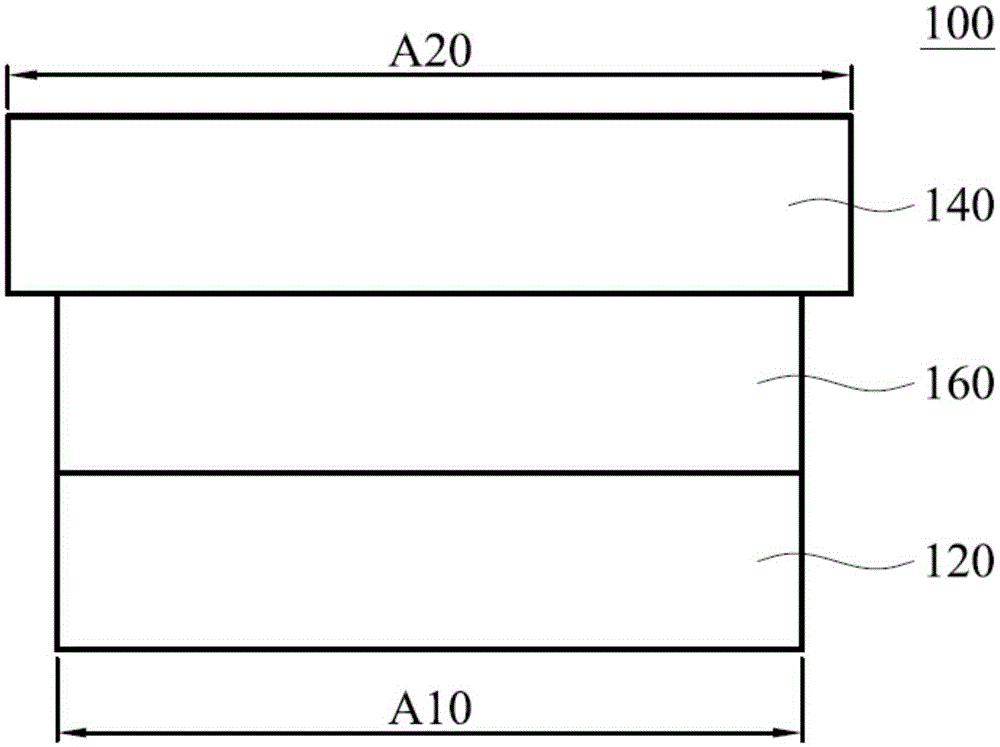

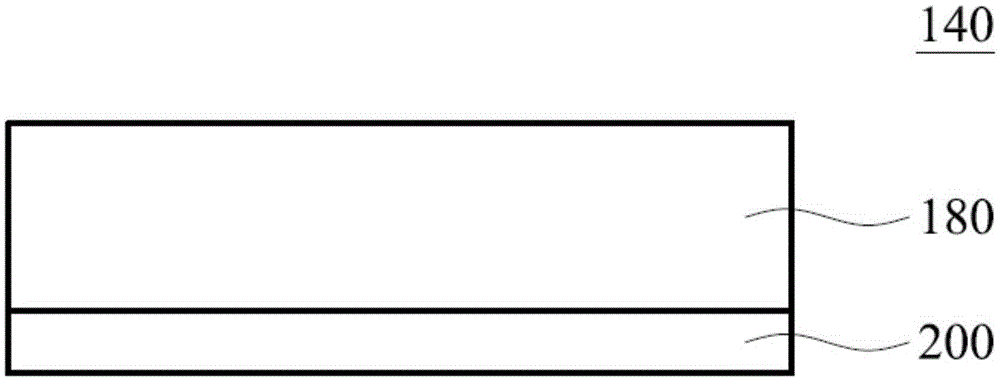

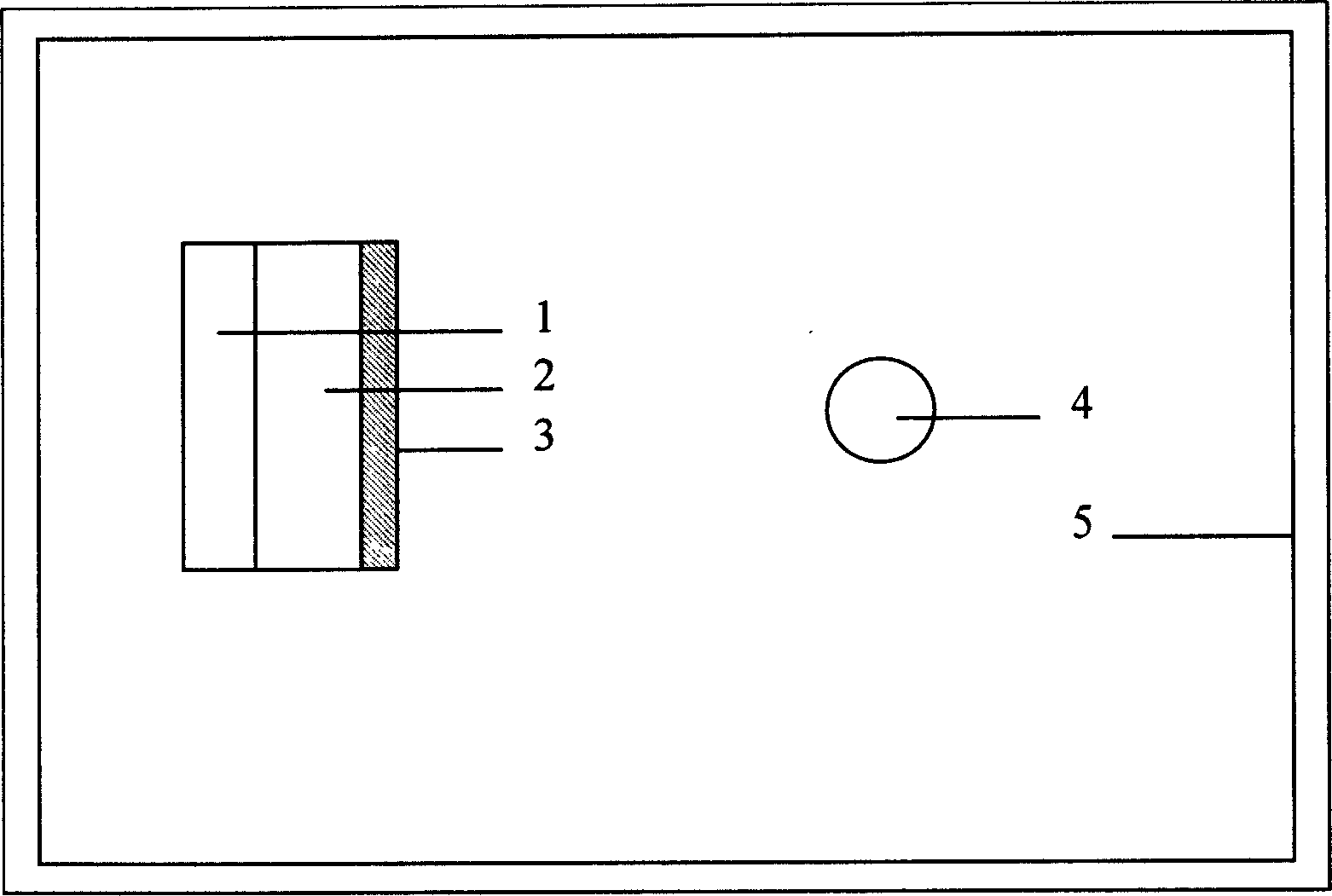

Touch panel, touch display device and display device

PendingCN106557188AReduce splashReduce harmElectrical equipmentGlass/slag layered productsTouch SensesWood splinter

The present invention provides a touch panel. The touch panel comprises: a substrate; a cover plate provided on the substrate; an optical glue disposed between the substrate and the cover plate, wherein an elastic modulus of the optical glue is between 1x10<7> Pa and 1x10<10> Pa; and a touch sensing layer disposed an upper surface or a low surface of the substrate or the upper surface and the low surface of the substrate. The present invention further provides a touch display device and a display device. The present invention further provides a touch display device and a display device, which both comprise an optical glue with a relatively great elastic modulus. Therefore, anti-drop strength of products can be effectively improved, the rupture of the edge of the cover plate or the touch panel is reduced so that the splinters are not easy to spread, and damage to the human body is reduced.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

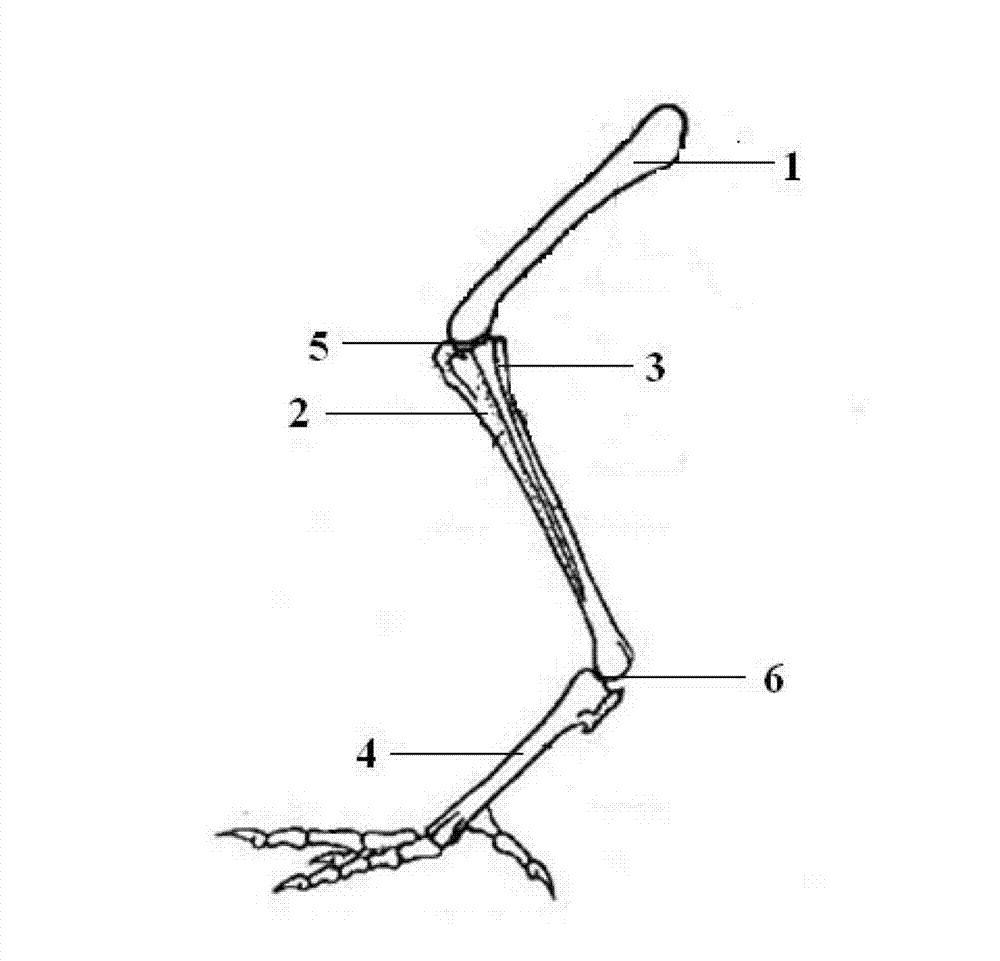

Removing method for chicken leg bone

The invention provides a removing method for a chicken leg bone. The removing method comprises the following steps: (a), forming a first longitudinal cut by adopting the lower end of a shin bone to longitudinally cut up the inner side of the chicken leg through a cutter along the shin bone and a thigh bone; (2), cutting off tendons which are connected with the thigh bone by a cutter under the condition of rotation to remove the thigh bone by using the connected part of the thigh bone and the shin bone as the circle center, as well as adopting the cut at the connected part of the thigh bone and the shin bone as an inlet; and (c), breaking the tendons which are connected with the meat at the tarsal joint by enabling the cutter to pass through a splinter bone, so that the shin bone is removed. The chicken leg meat obtained by the removing method disclosed by the invention is complete without wasting the leg chicken or leaving the leg bone.

Owner:SHANDONG FENGXIANG

Saphire base nitride chip scribing method

InactiveCN1529347ADifferent absorptionPrevent penetrationLaser detailsSemiconductor/solid-state device manufacturingWood splinterGamma ray

The method includes following steps: based on scribing requirement, using lead plate makes irradiation baffle with several slots in middle; adhibiting rear face of sapphire crystal with GaN being developed on the irradiation baffle closely, carrying out irradiation of Gamma ray by using Co60 in irradiation dose about 10 to the power 7 Rad; then, rotating baffle at 90 degree, carrying irradiation with same dose forms meshy irradiation lines on substrate of sapphire; scribing is carried out for exposured GaN / sapphire LED chip along irradiation line by using KrF quasi molecule laser in 248nm; splinting is carrier out for GaN / sapphire LED chip scribed by using splinter device, then testing chip through probe and sorting chips. Advantages of the invention are smooth edge, not affecting on photoelectric properties of GaN.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

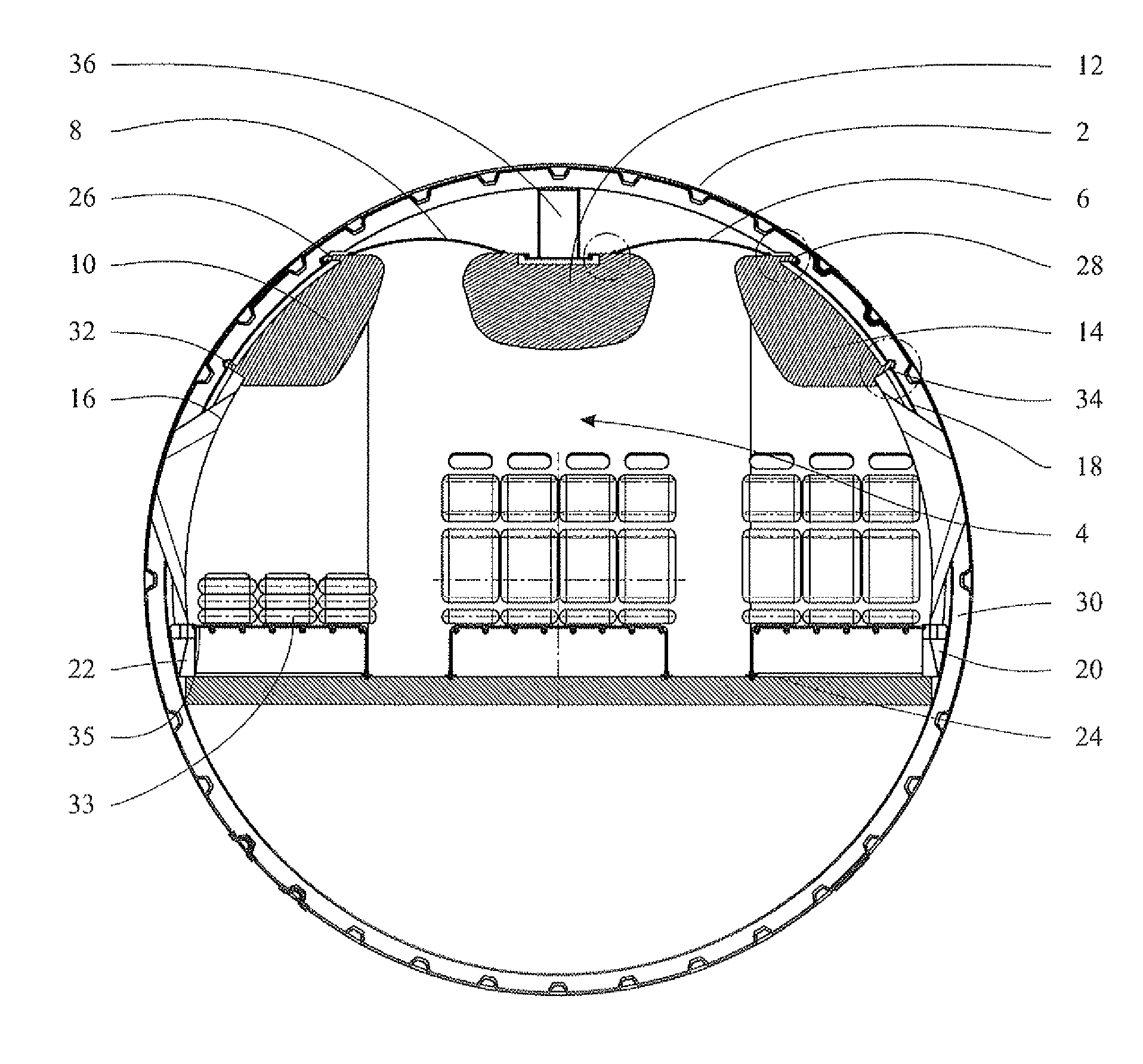

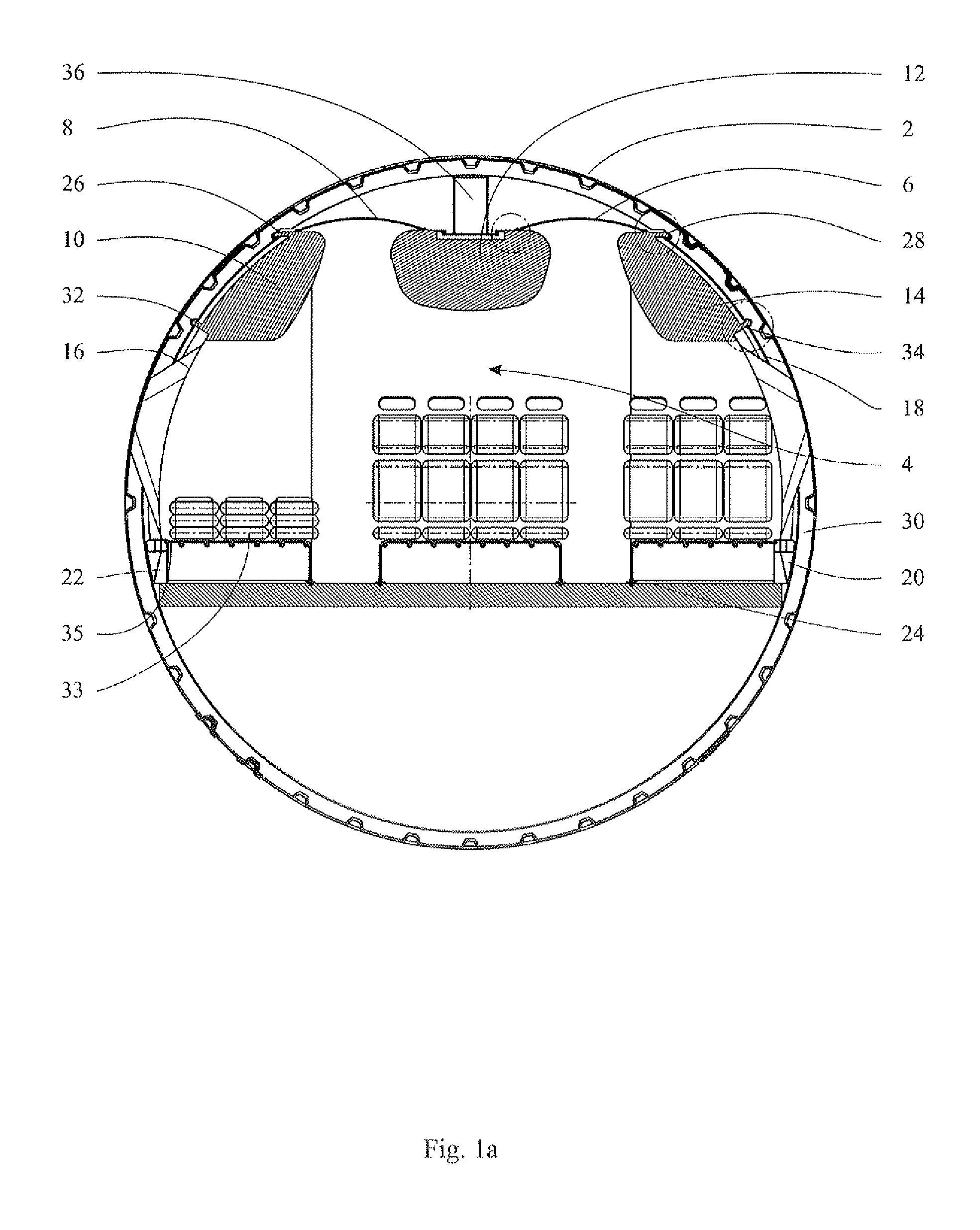

Safety cabin

InactiveUS20100264268A1High mechanical strengthQuality improvementAir-treatment apparatus arrangementsFuselagesNacelleWood splinter

The invention relates to a cabin system for an aircraft fuselage, having one or more lining components for interior lining, and optionally one or more cabin equipment components, wherein the lining component can be installed either separately or in combination with a further lining component and / or a cabin equipment component under tension in the aircraft fuselage such that a cabin that is under tension in the circumferential direction and attaches to the aircraft fuselage is defined. In this manner a passenger cabin configured as a closed safety cell is created in a fuselage, which is of particular advantage in an aircraft fuselage made of a fiber composite material because no splinters or the like can penetrate the self-supporting passenger cabin in case of damage to the same.

Owner:AIRBUS OPERATIONS GMBH

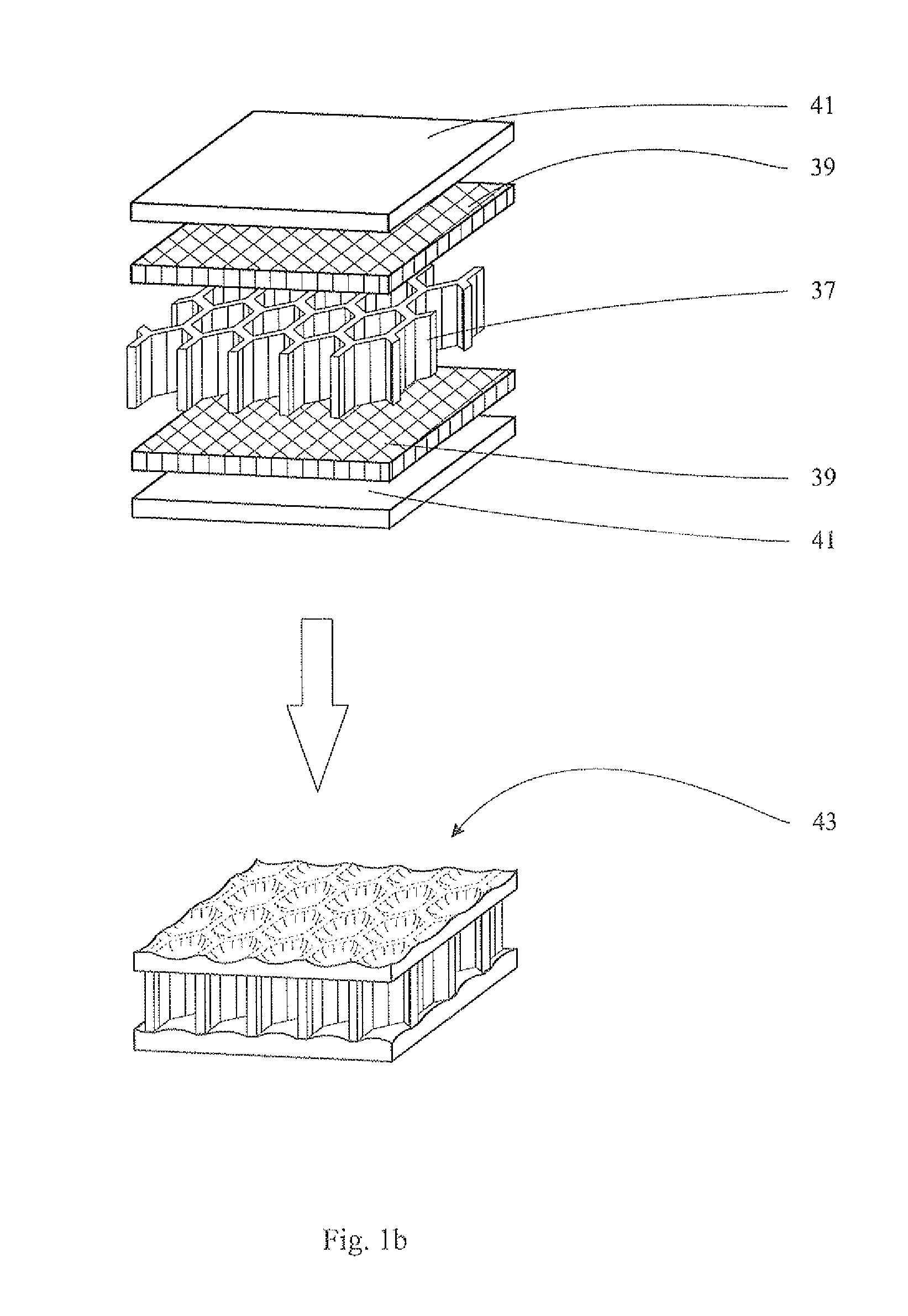

Composite components made of heat-curing resins and elastomers

InactiveUS20180208302A1Increase material costAbsorb energyWater sport boardsCanoes/kayaksElastomerGlass fiber

A plastic composite component which is formed by a thin hard plastic outer layer, at least one elastomer layer adjoining the former on the inside, and at least one metal and / or plastic carrier layer adjoining said elastomer layer on the inside and made of a fibre reinforced plastic (RFP). A carbon fibre reinforced plastic (CRP) or glass fibre reinforced plastic (GRP), is arranged on the component or at least partly forms the latter, as an impact protection part, as a splinter protection part, as a protective part against sudden total failure or as a protective part against vibrations and vibration damages, against resonance, for the purpose of damping oscillations or for the purpose of acoustic damping.

Owner:GUMMIWERK KRAIBURG

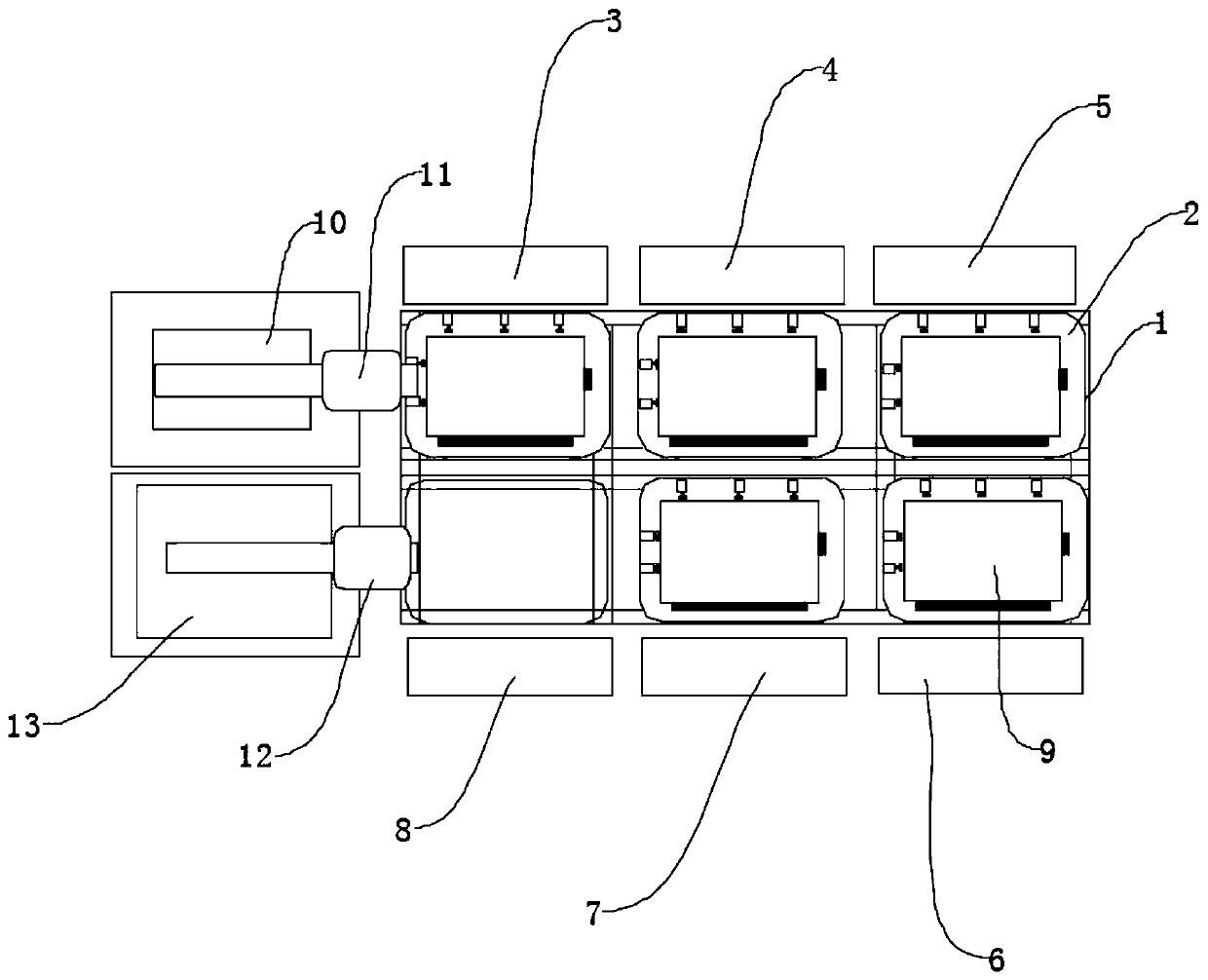

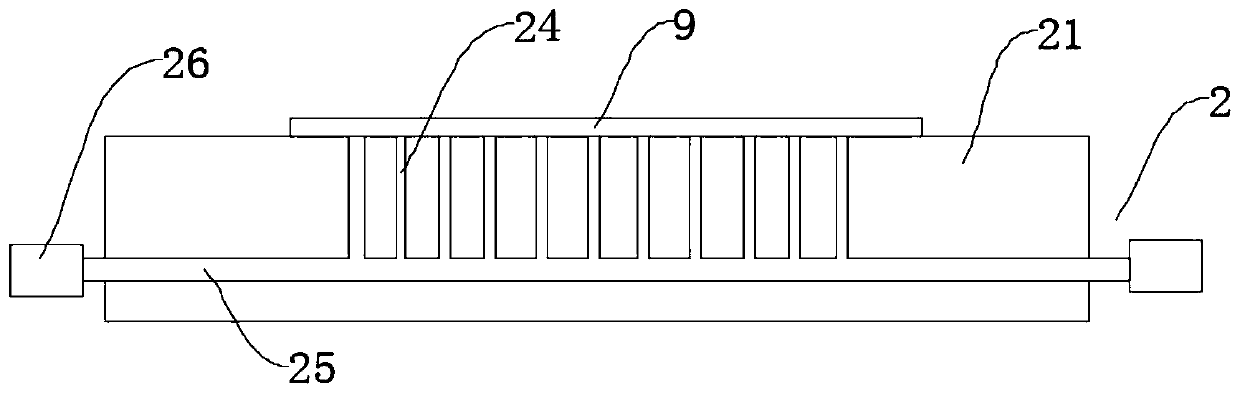

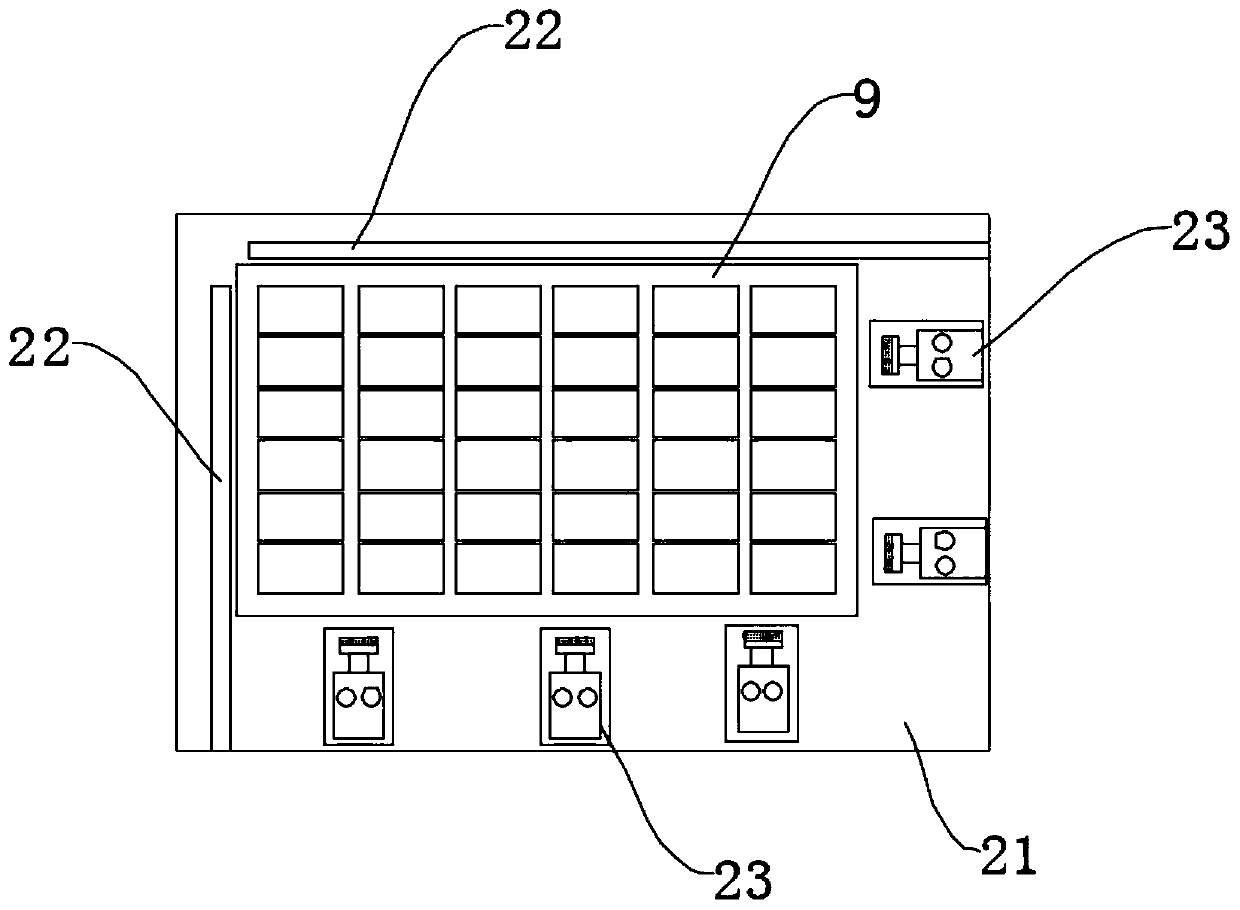

Circular track type cell cutting system for manufacturing flexible OLED (Organic Light Emitting Diode) display panel

InactiveCN110181180AHigh degree of automationImprove cutting efficiencySolid-state devicesSemiconductor/solid-state device manufacturingWood splinterLaser cutting

The invention relates to the technical field of display screens. According to the technical scheme of the invention, a circular track type cell cutting system for manufacturing a flexible OLED (Organic Light Emitting Diode) display panel comprises an annular guide rail and a plurality of positioning jigs arranged on the annular guide rail, wherein a CO2 laser cutting station, a protective film tearing-off station, an UV (ultraviolet) laser cutting station, an IR (infrared) laser cutting station, a splinter station and a discharging station are arranged on the annular guide rail. The circular track type cell cutting system integrates the tearing-off of protective films and the cutting of an OLED display panel master slice with a glass substrate for the first time, and has high degree of automation, high cutting efficiency and high precision.

Owner:AENEQ CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com