Saphire base nitride chip scribing method

A sapphire and nitride technology, applied in the dicing field of sapphire-based nitride chips, can solve the problems of low laser absorption, unfavorable laser dicing efficiency, and influence on the optoelectronic properties of GaN/sapphire LED chips, so as to improve production efficiency and ensure The effect of optoelectronic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

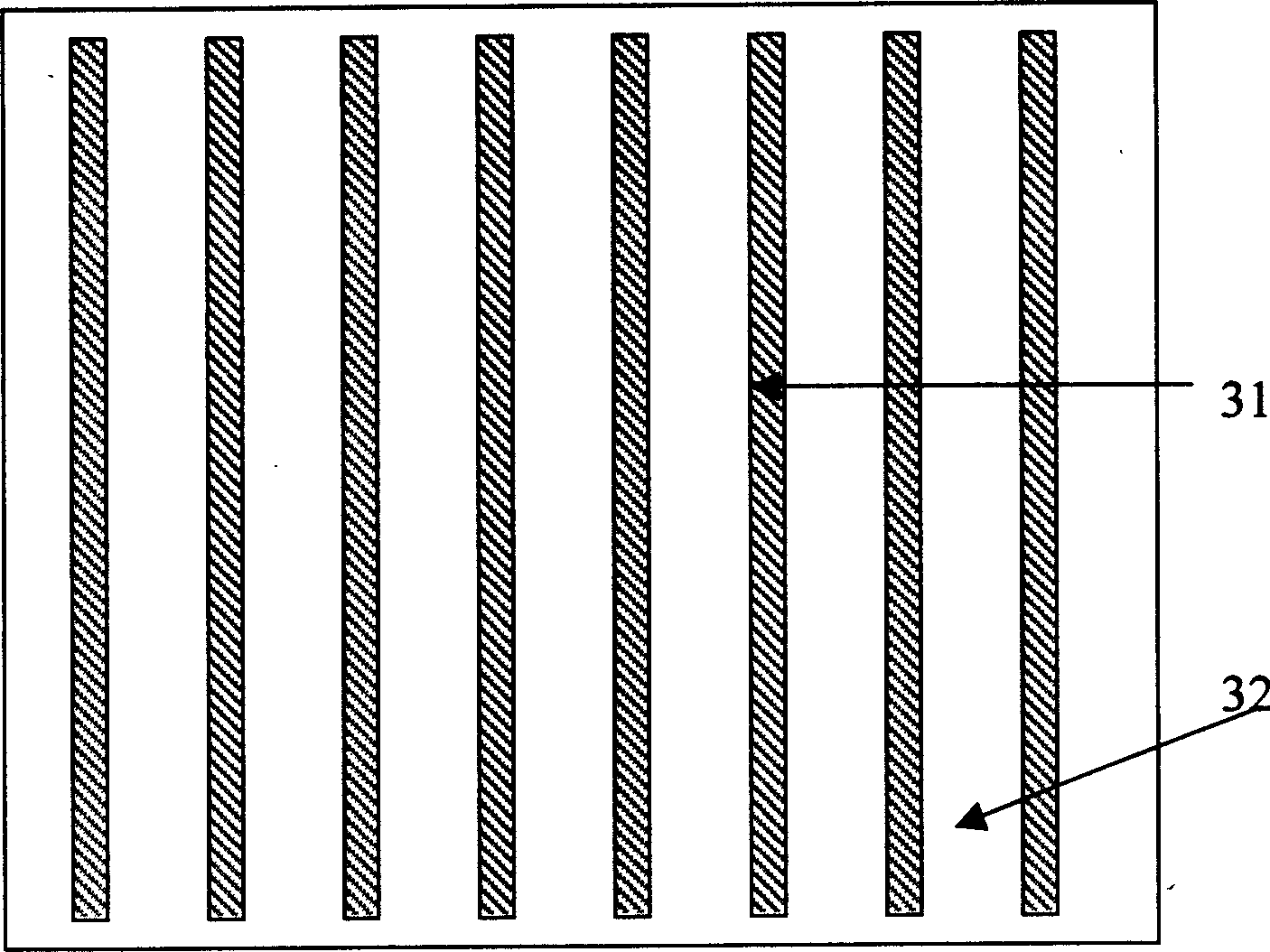

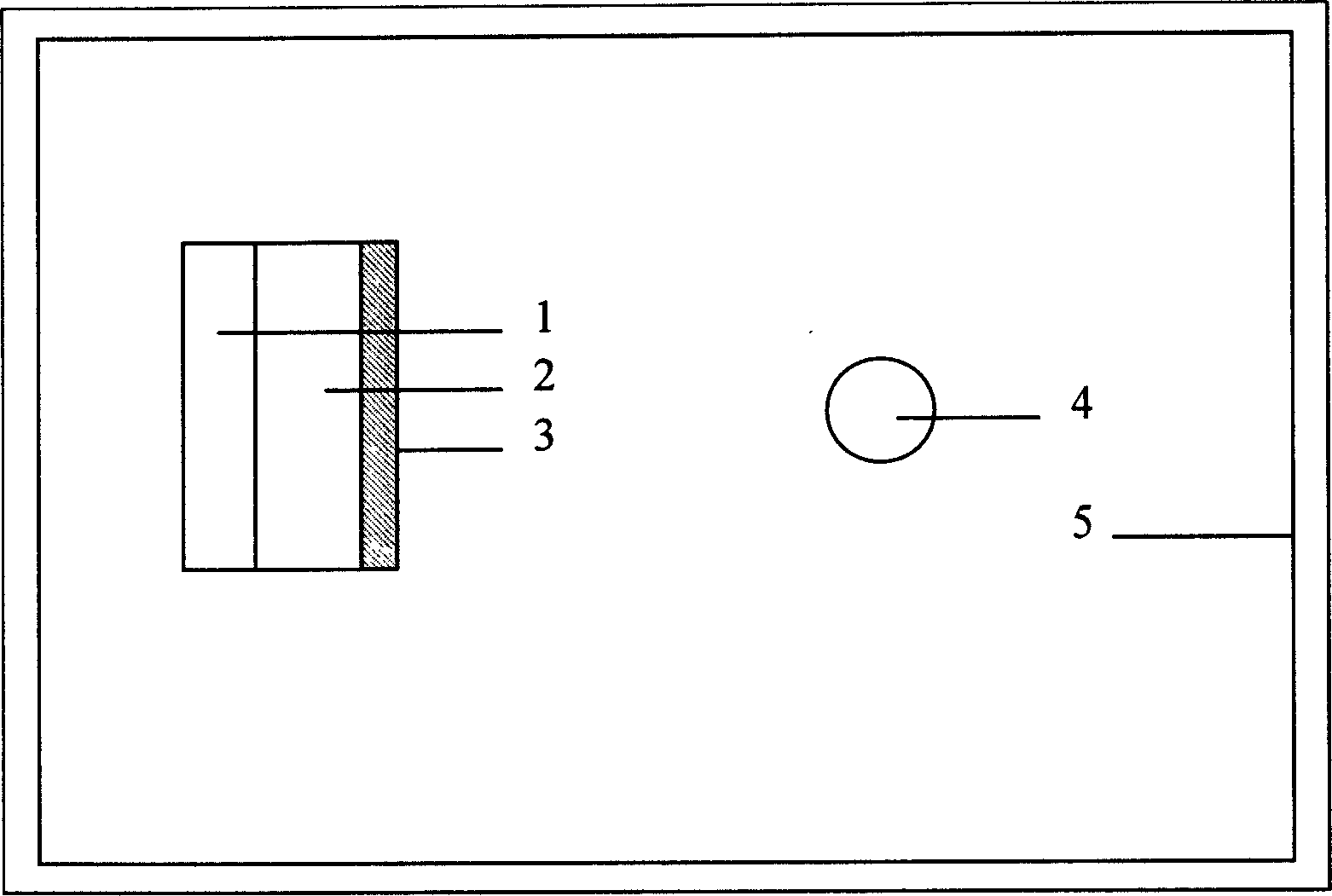

[0022] see first figure 1 and figure 2 , figure 1 and figure 2 They are the schematic diagram of the irradiation baffle and the schematic diagram of the irradiation device according to the embodiment of the present invention, respectively.

[0023] The scribing method of the sapphire-based nitride chip in the embodiment of the present invention is characterized in that it includes the following steps:

[0024] According to the size of the chip to be scribed, a 300×300×3mm irradiation baffle 3 is made of a lead plate. The size of the baffle is the same as that of the chip. The width of the slit 31 in the baffle is about 0.2mm. The slit spacing 32 is 35nm, and the thickness of the baffle is about 3-10mm, see figure 1 ;

[0025] The back side of the sapphire substrate 2 that has grown GaN is closely attached to the radiation baffle 3, and the Co 60 The irradiation source 4 performs Gamma ray irradiation in the irradiation room 5, and the irradiation dose is 10 8 Rad; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com