Patents

Literature

678 results about "Laser scribing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser scribing apparatus, systems, and methods

InactiveUS20080029152A1Final product manufactureWelding/soldering/cutting articlesLaser scribingEngineering

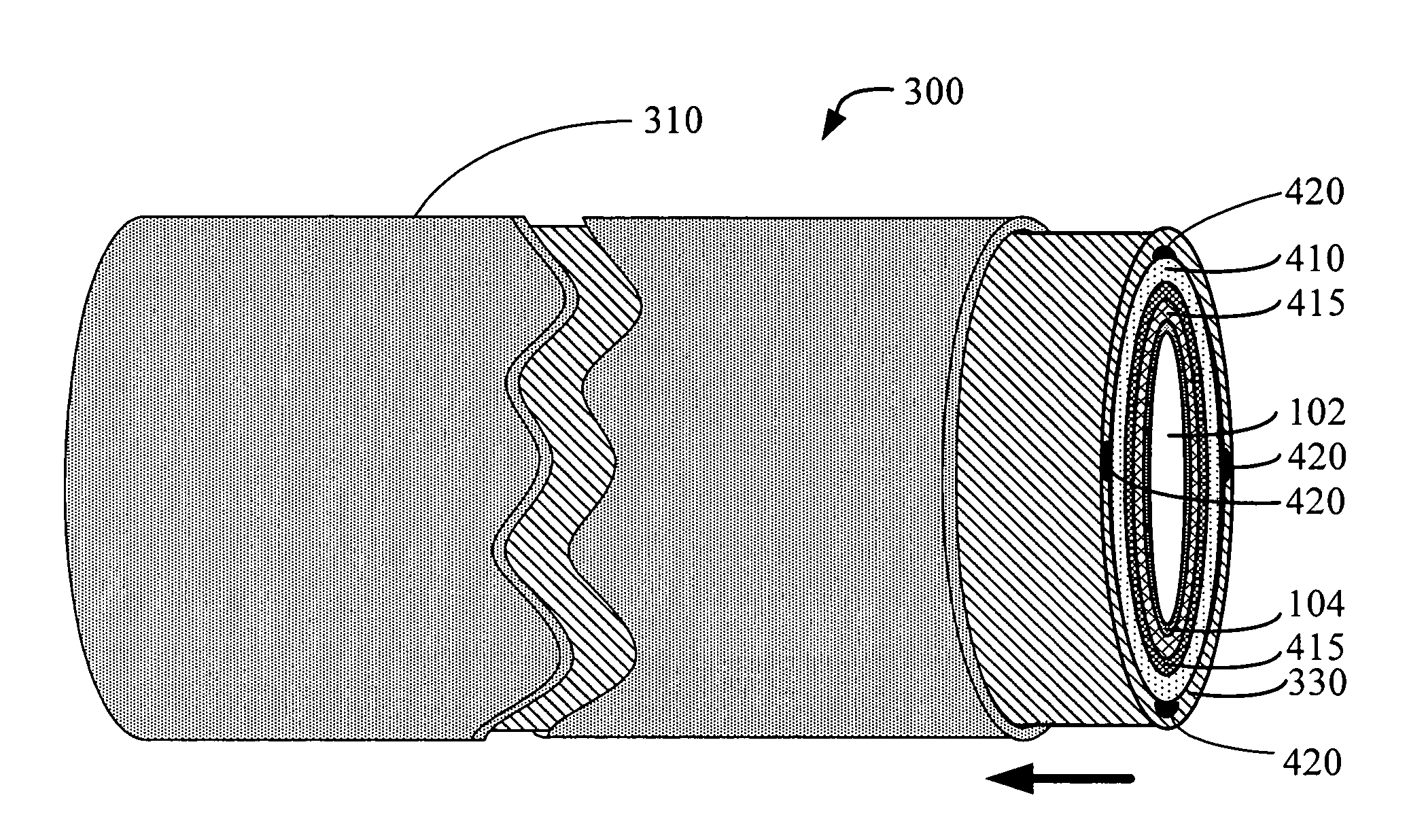

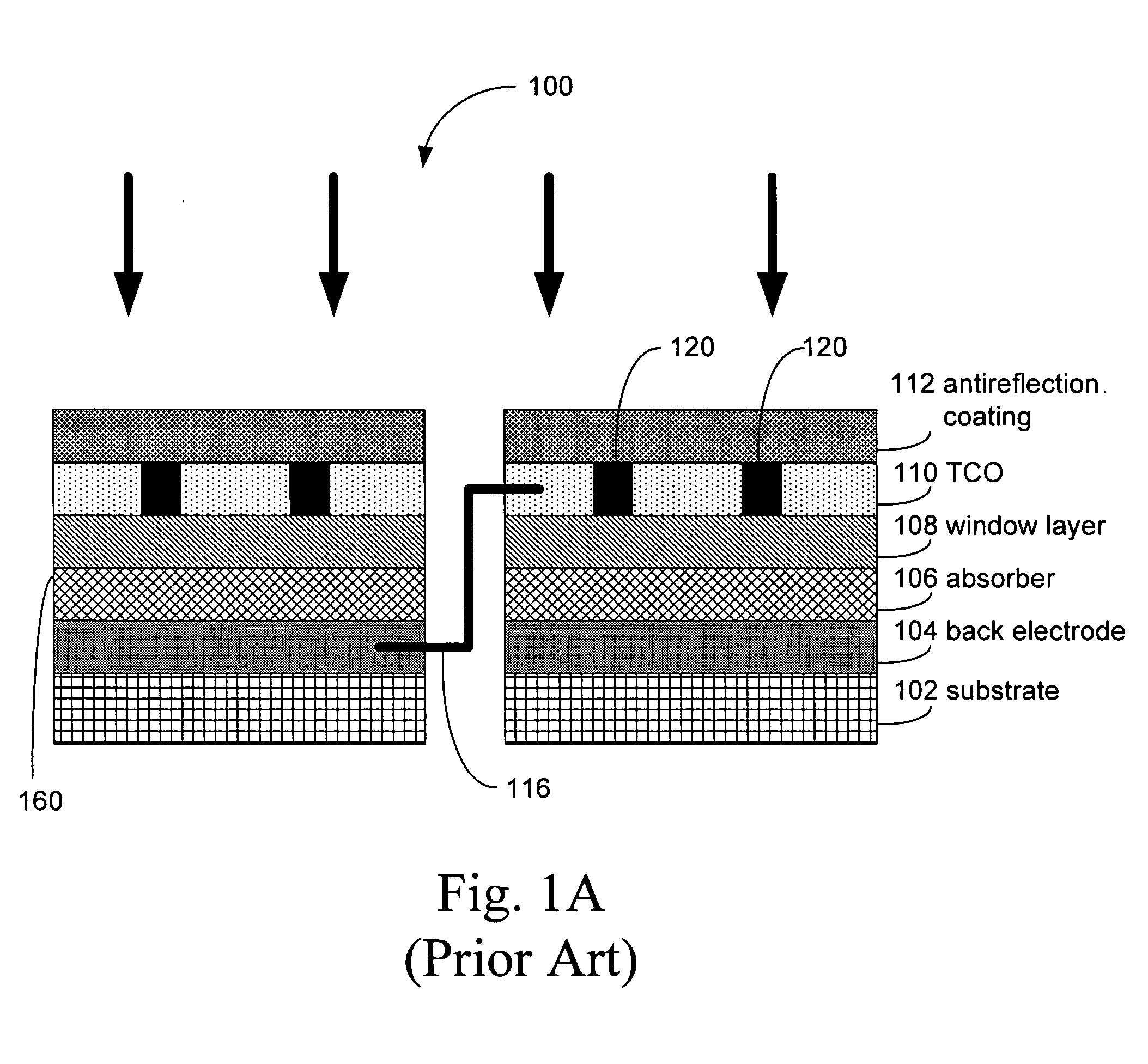

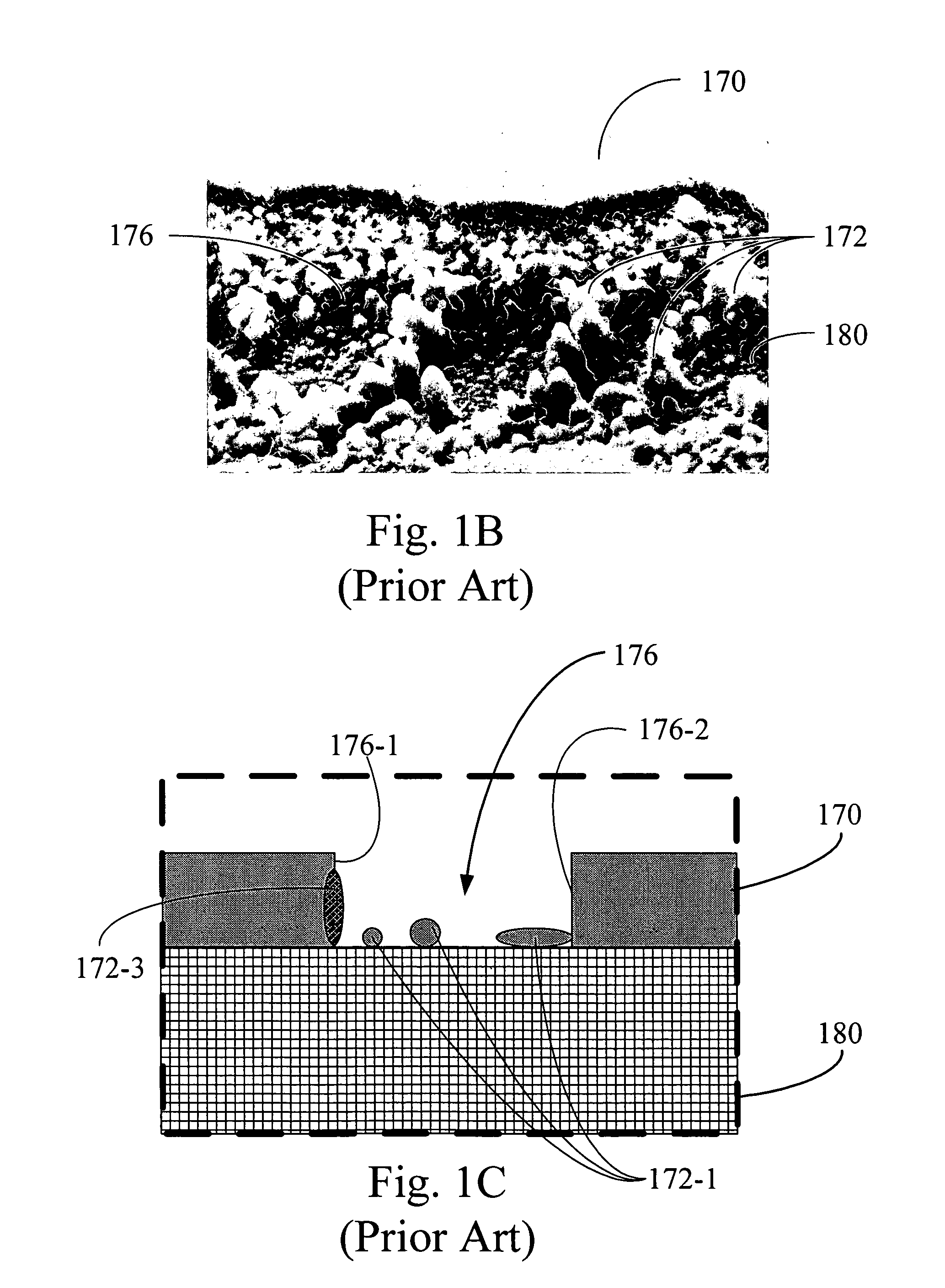

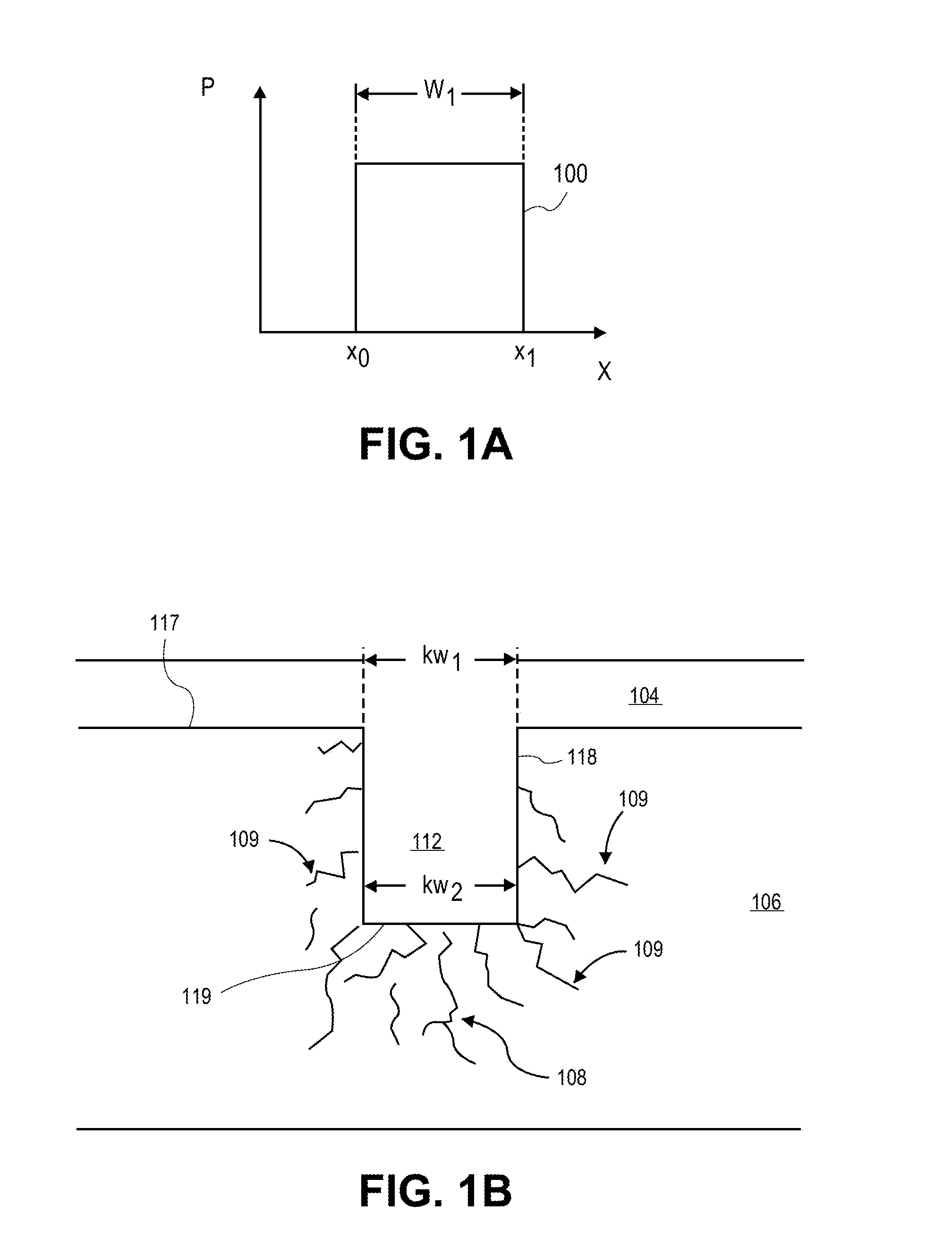

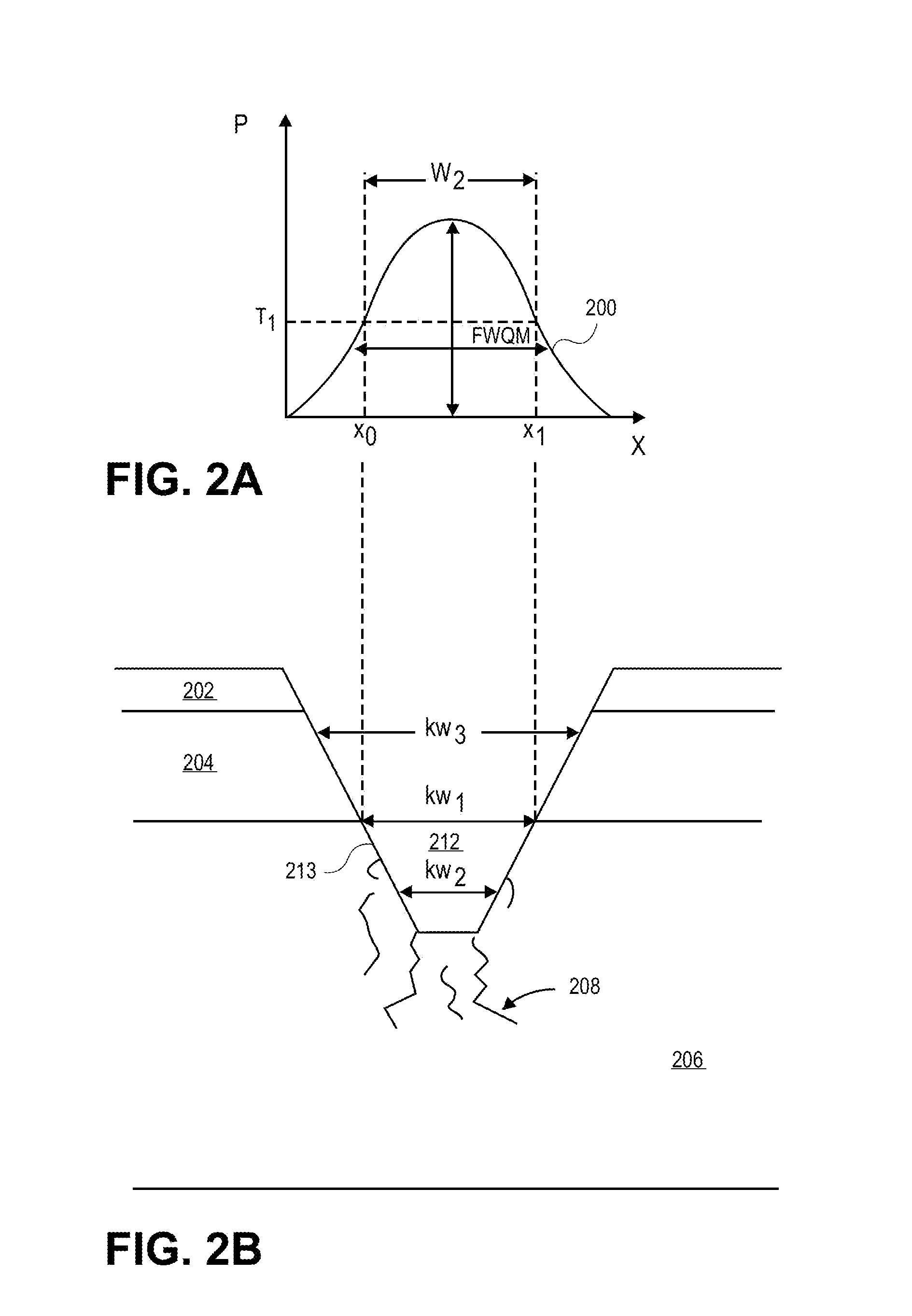

Apparatus, systems, and methods for forming a photovoltaic cell from a common layer on a substrate are provided. A first pass is made with a first laser beam over an area on the common layer. The first pass forms a groove in the common layer. The first pass forms within the common layer a first edge and a second edge. The first edge is separated from the second edge by the groove. The groove provides a first level of electrical isolation between the first edge and the second edge. A second pass is made with a second laser beam over approximately the same area on the common layer. The second pass provides a second level of electrical isolation between the first edge and the second edge. The second level of electrical isolation is greater than the first level of electrical isolation.

Owner:SOLYNDRA

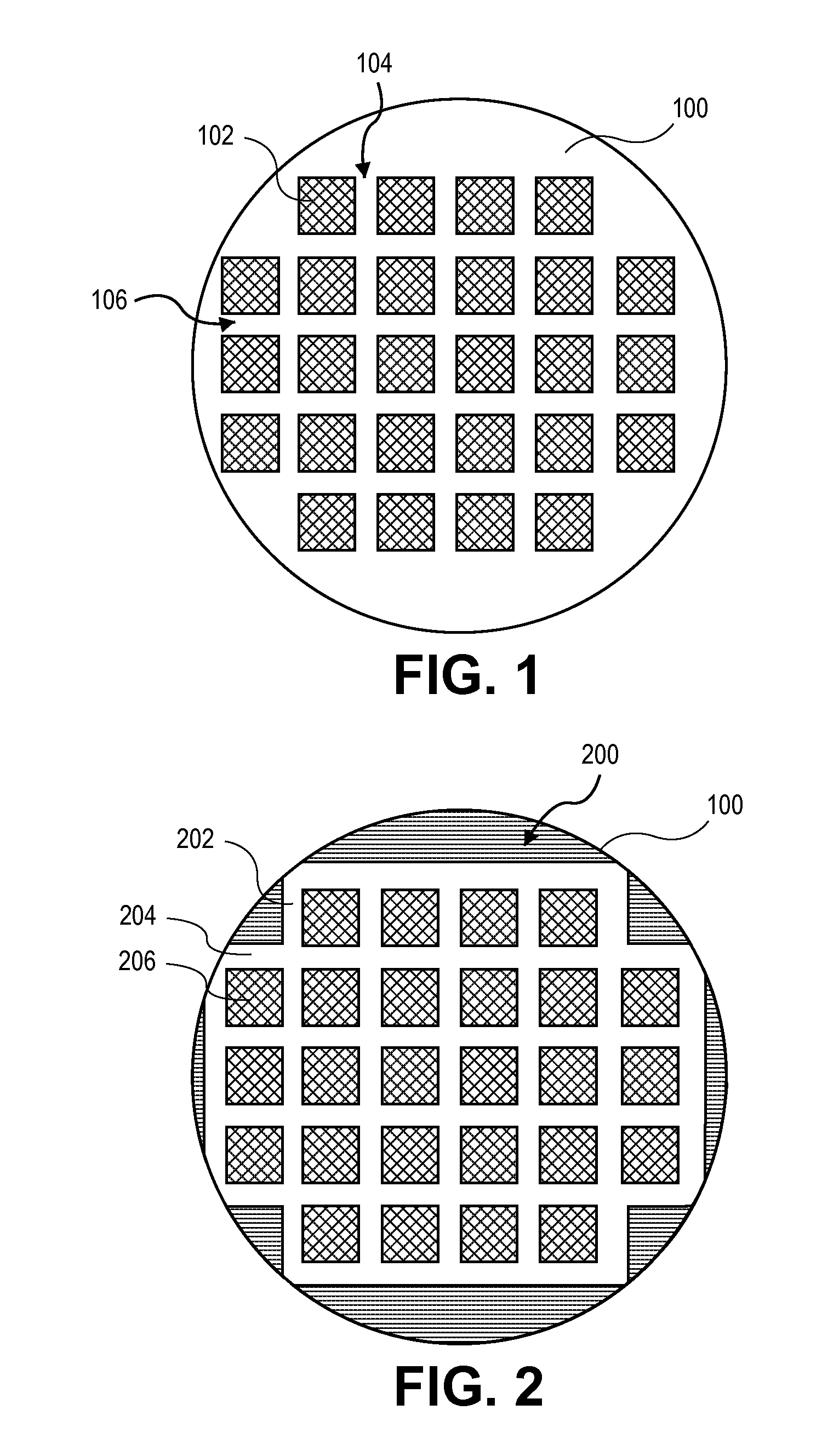

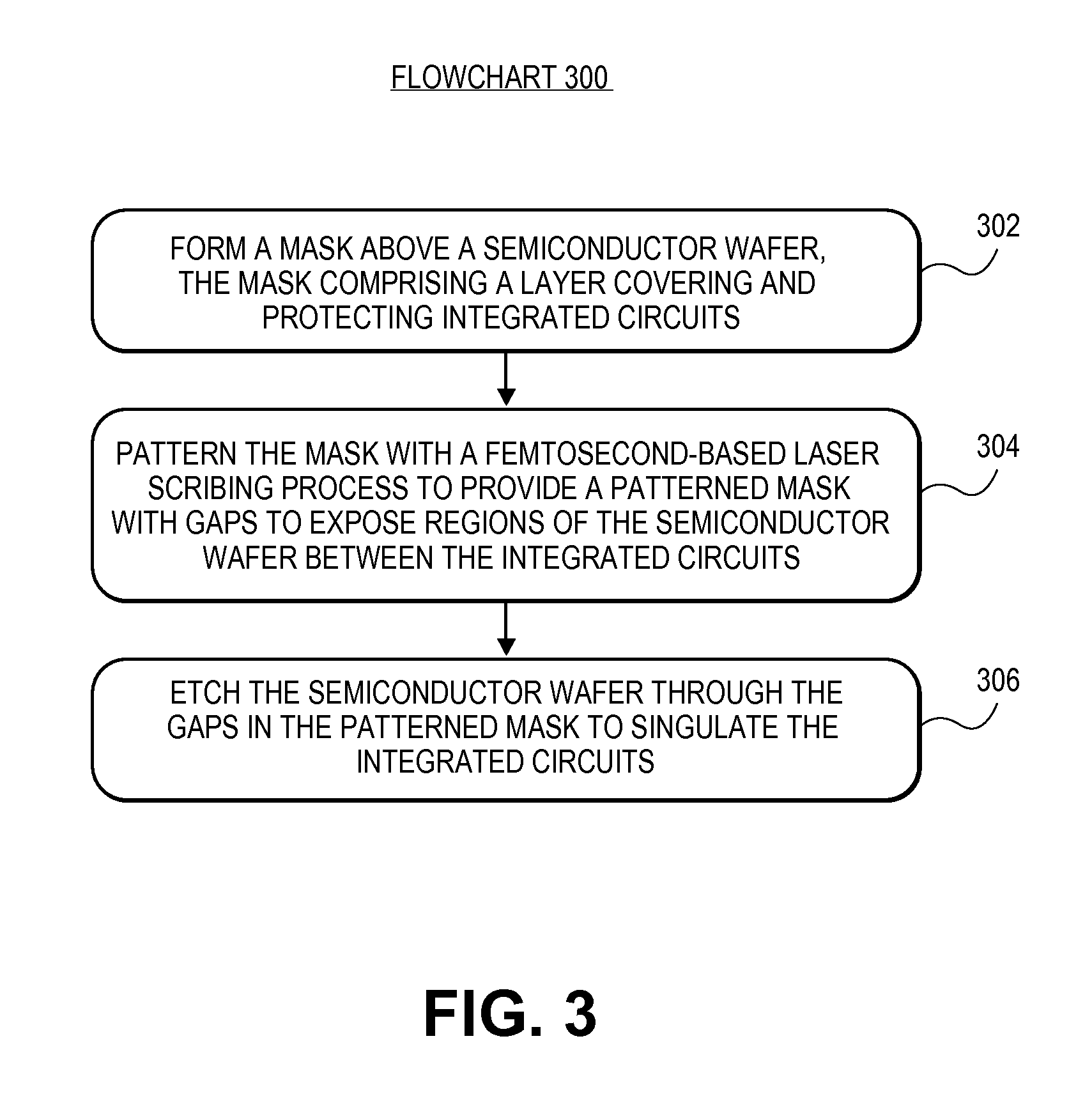

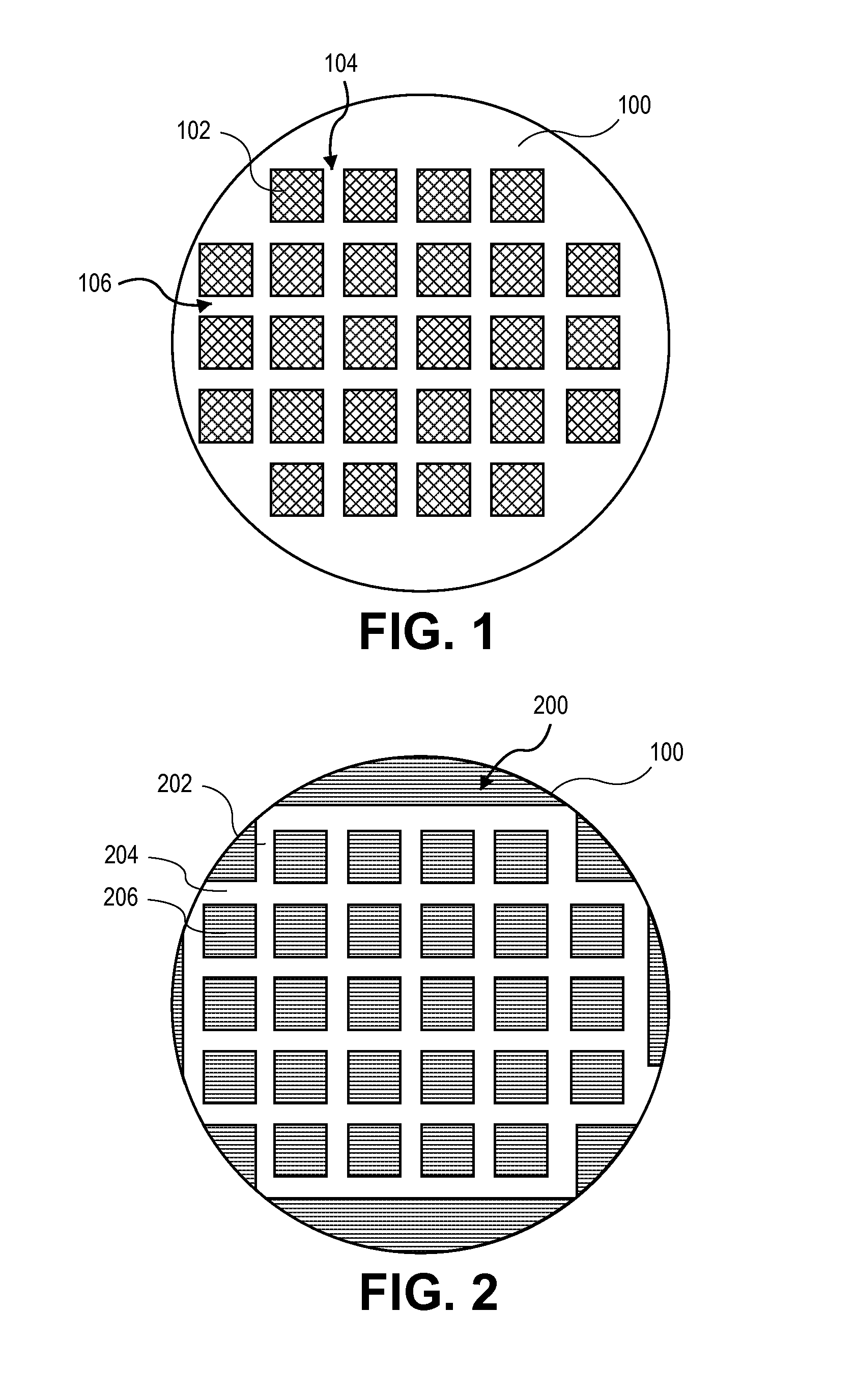

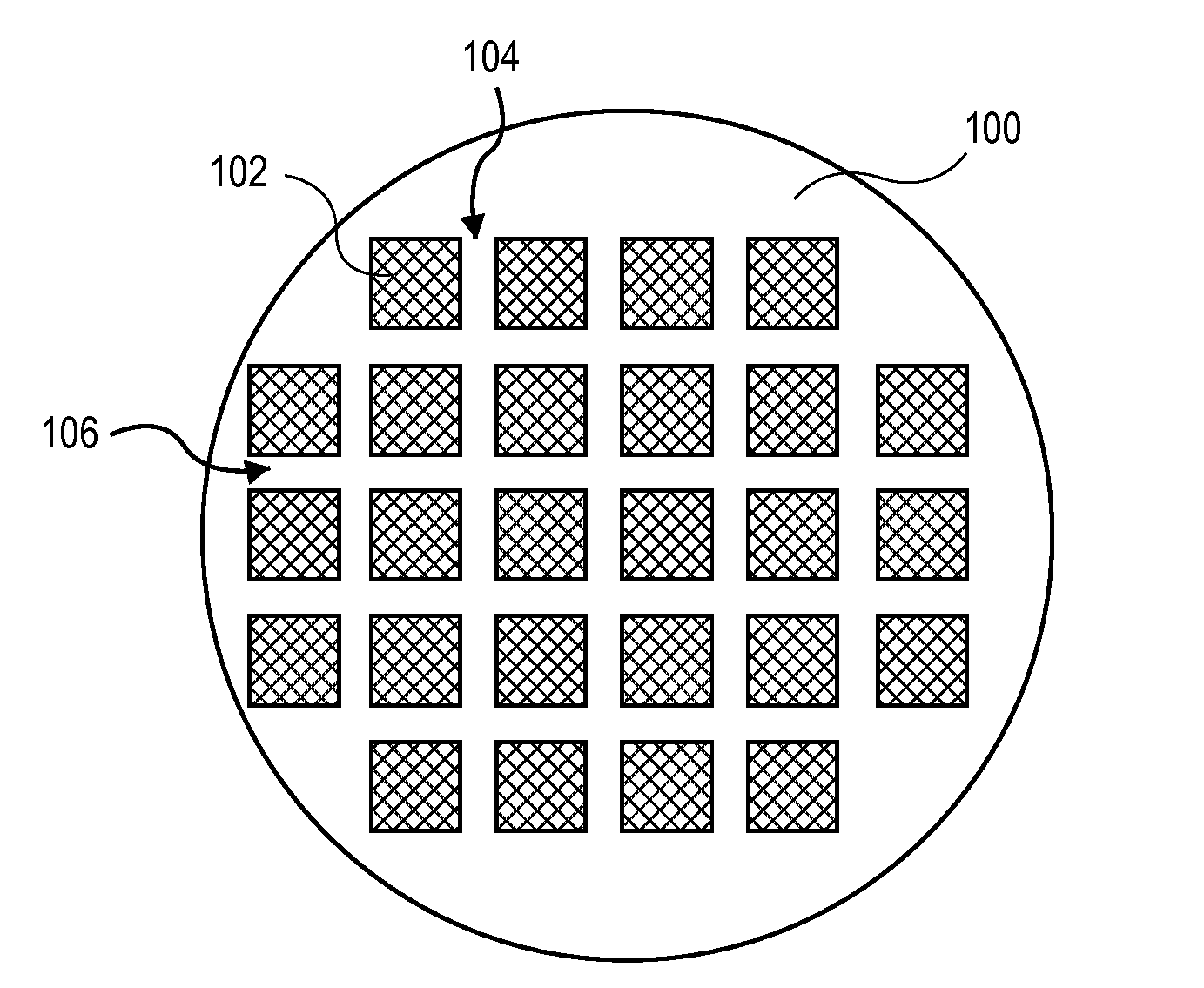

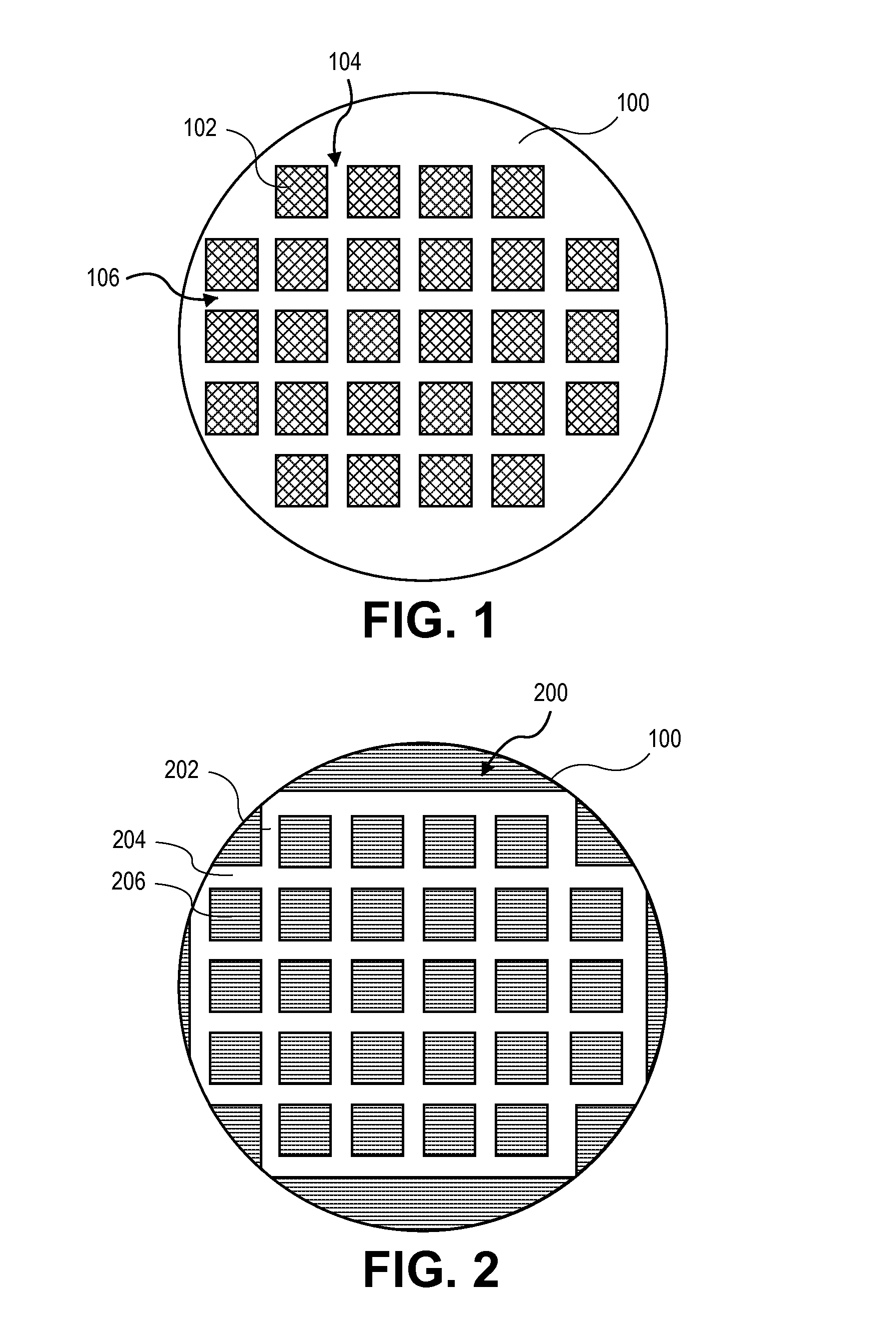

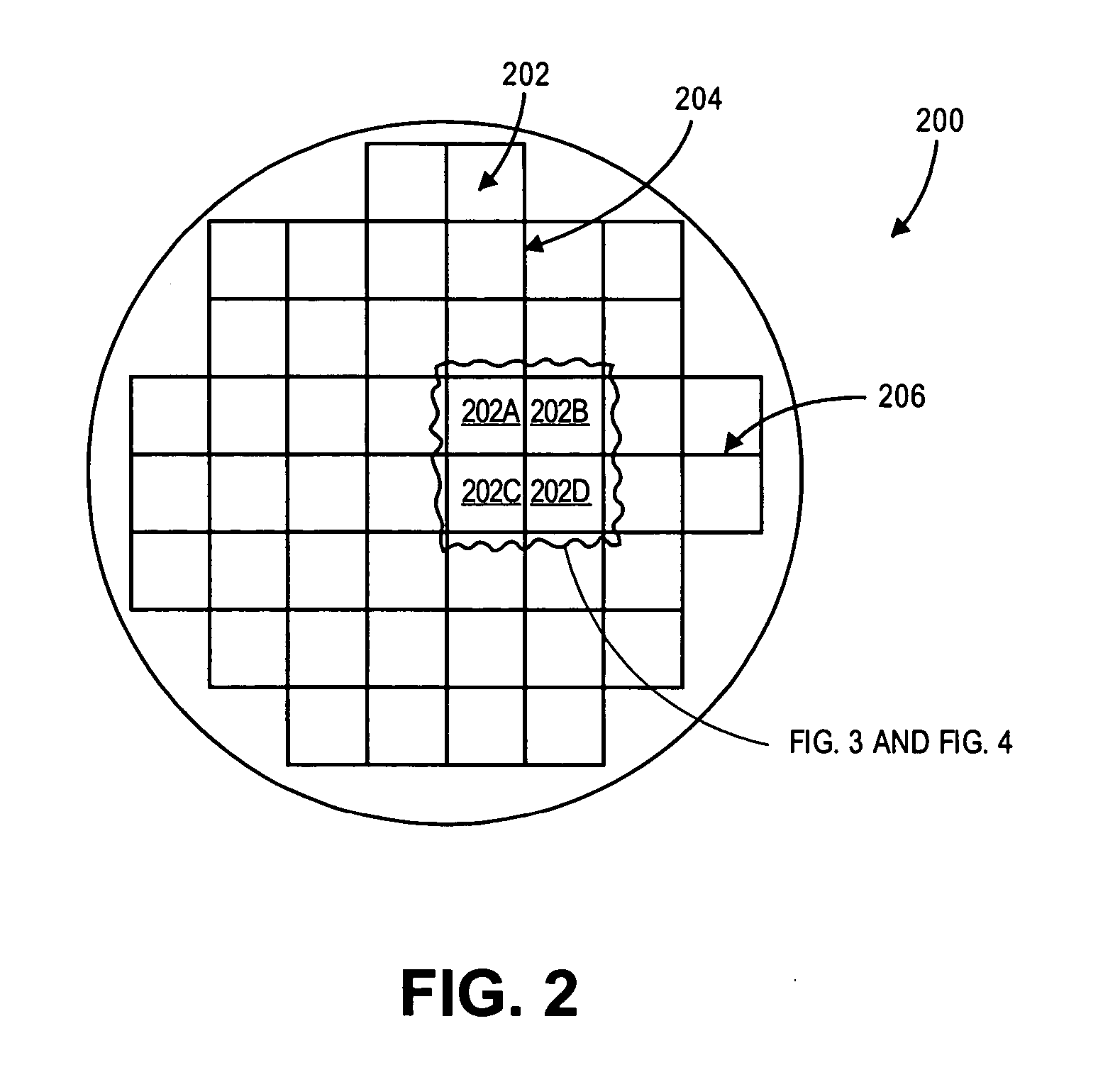

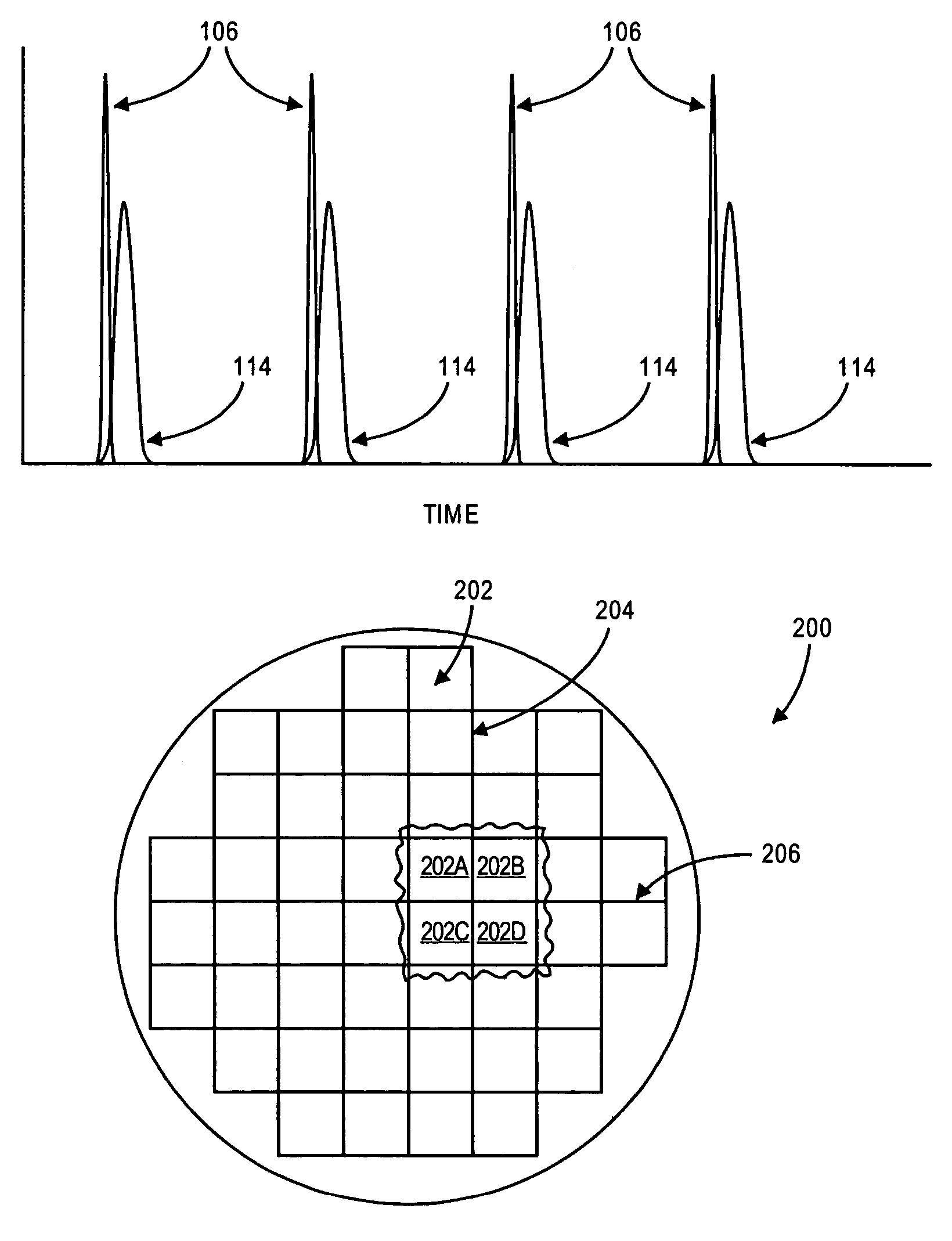

Wafer dicing using femtosecond-based laser and plasma etch

ActiveUS20110312157A1Electric discharge tubesSemiconductor/solid-state device detailsWafer dicingEngineering

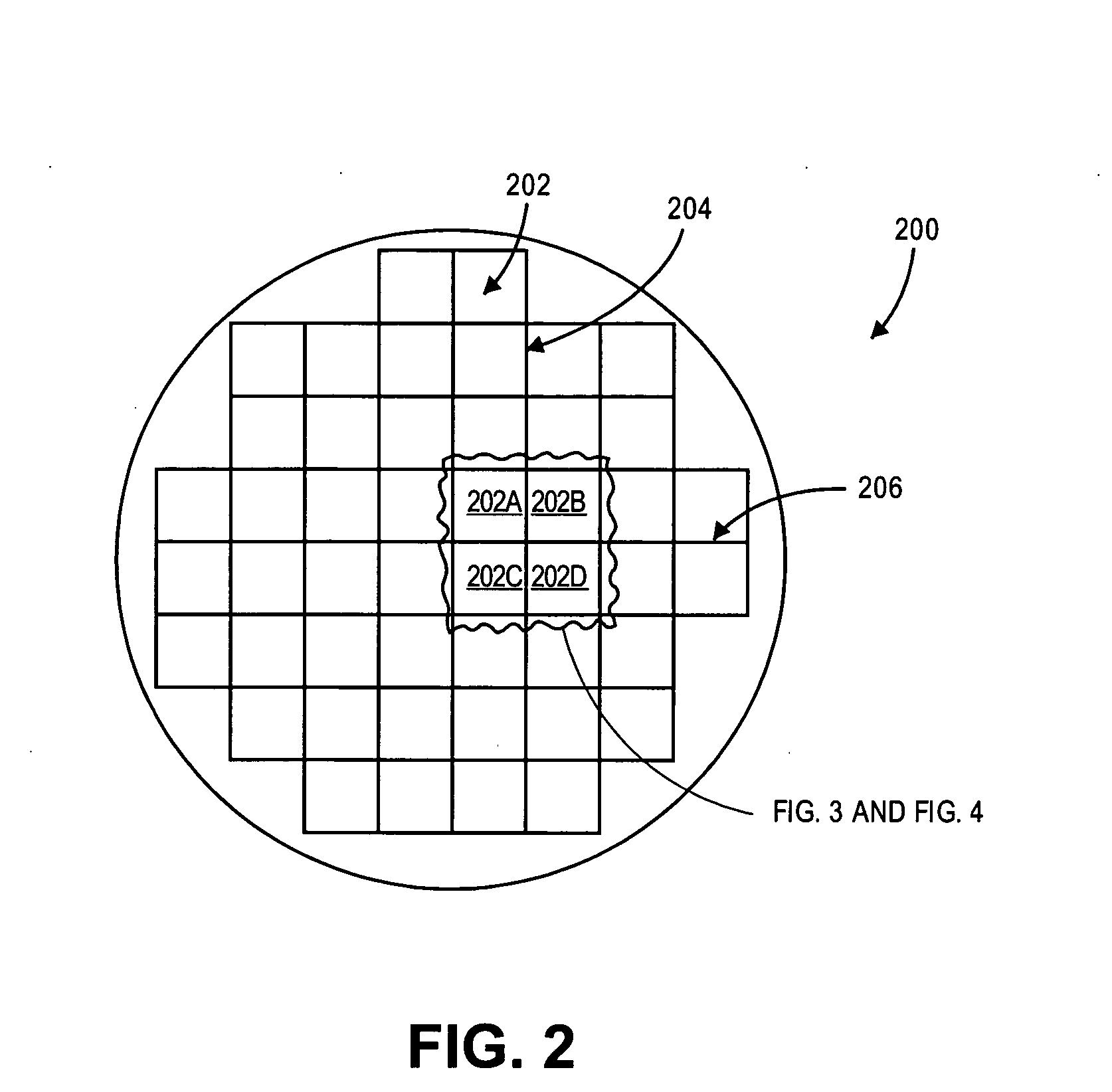

Methods of dicing semiconductor wafers, each wafer having a plurality of integrated circuits, are described. A method includes forming a mask above the semiconductor wafer. The mask is composed of a layer covering and protecting the integrated circuits. The mask is patterned with a femtosecond-based laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the semiconductor wafer between the integrated circuits. The semiconductor wafer is then etched through the gaps in the patterned mask to singulate the integrated circuits.

Owner:APPLIED MATERIALS INC

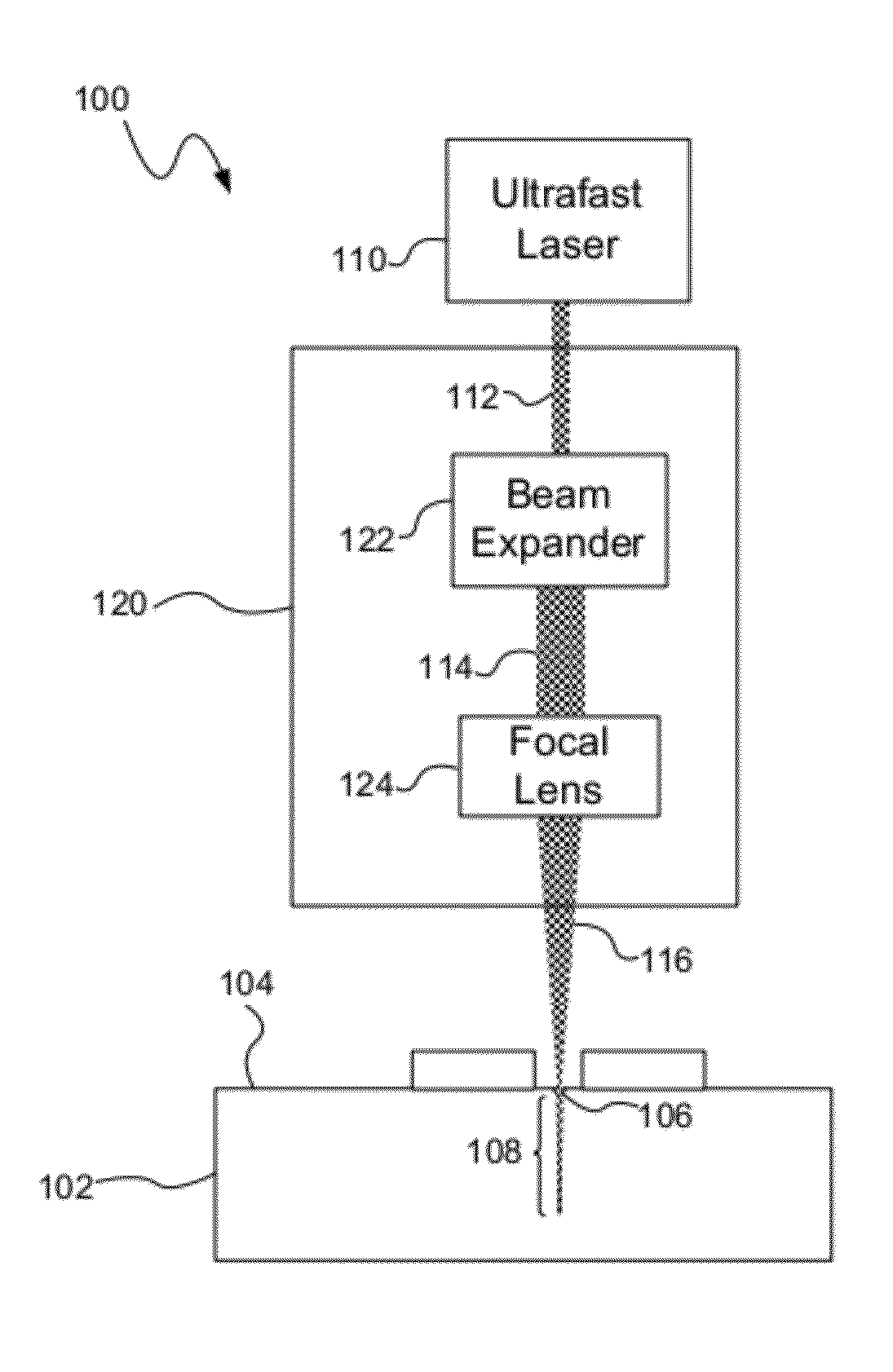

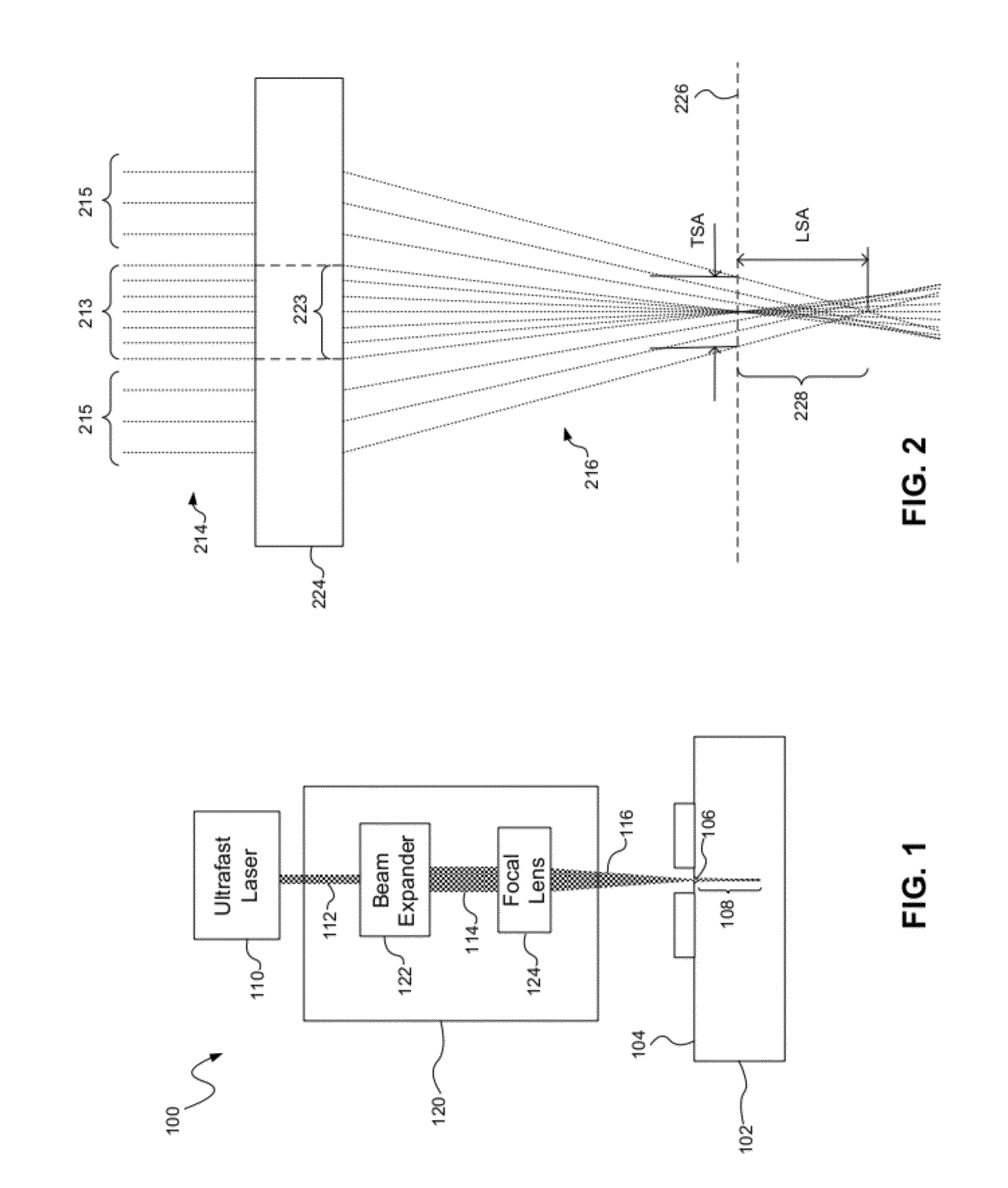

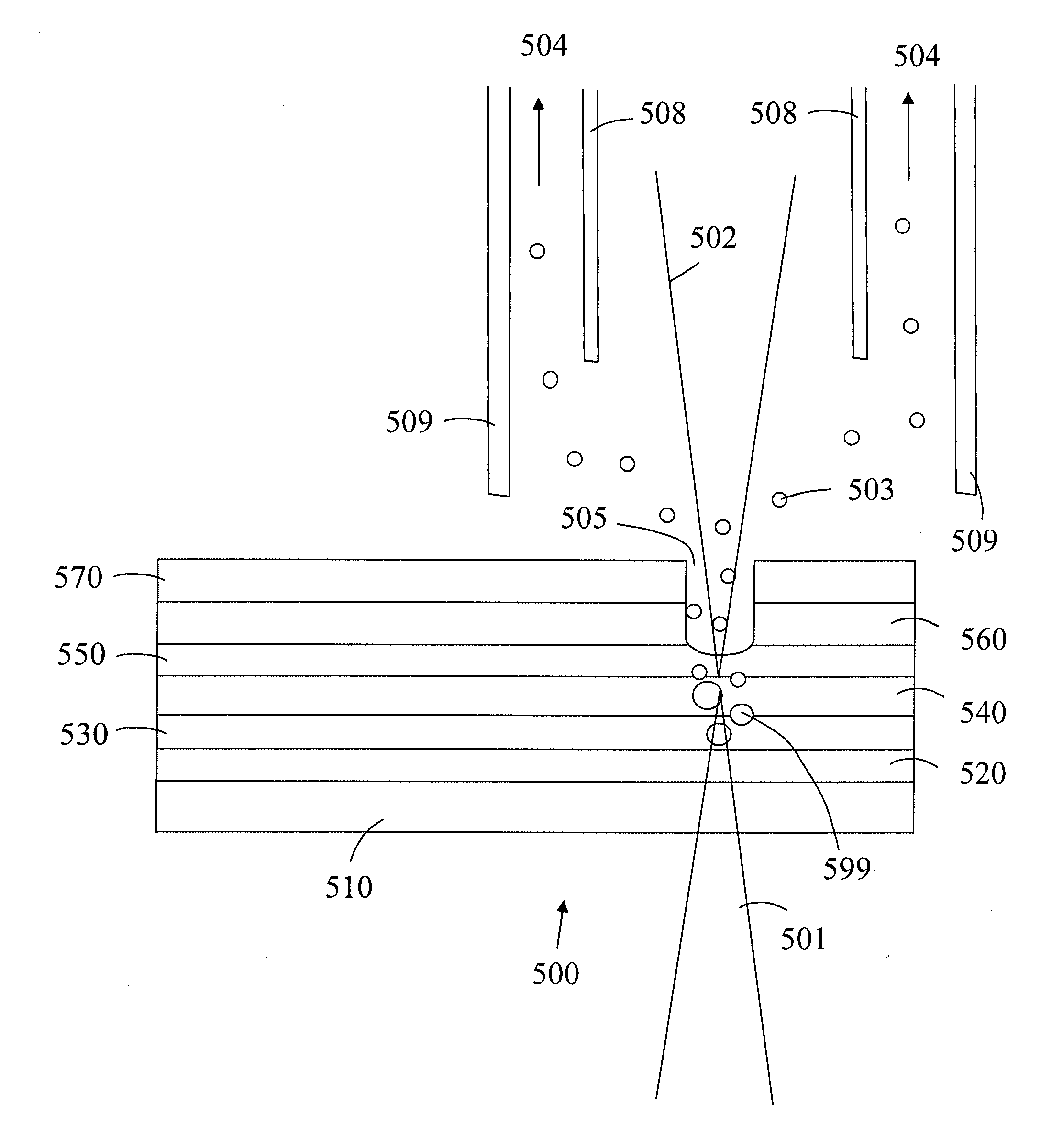

Laser scribing with extended depth affectation into a workplace

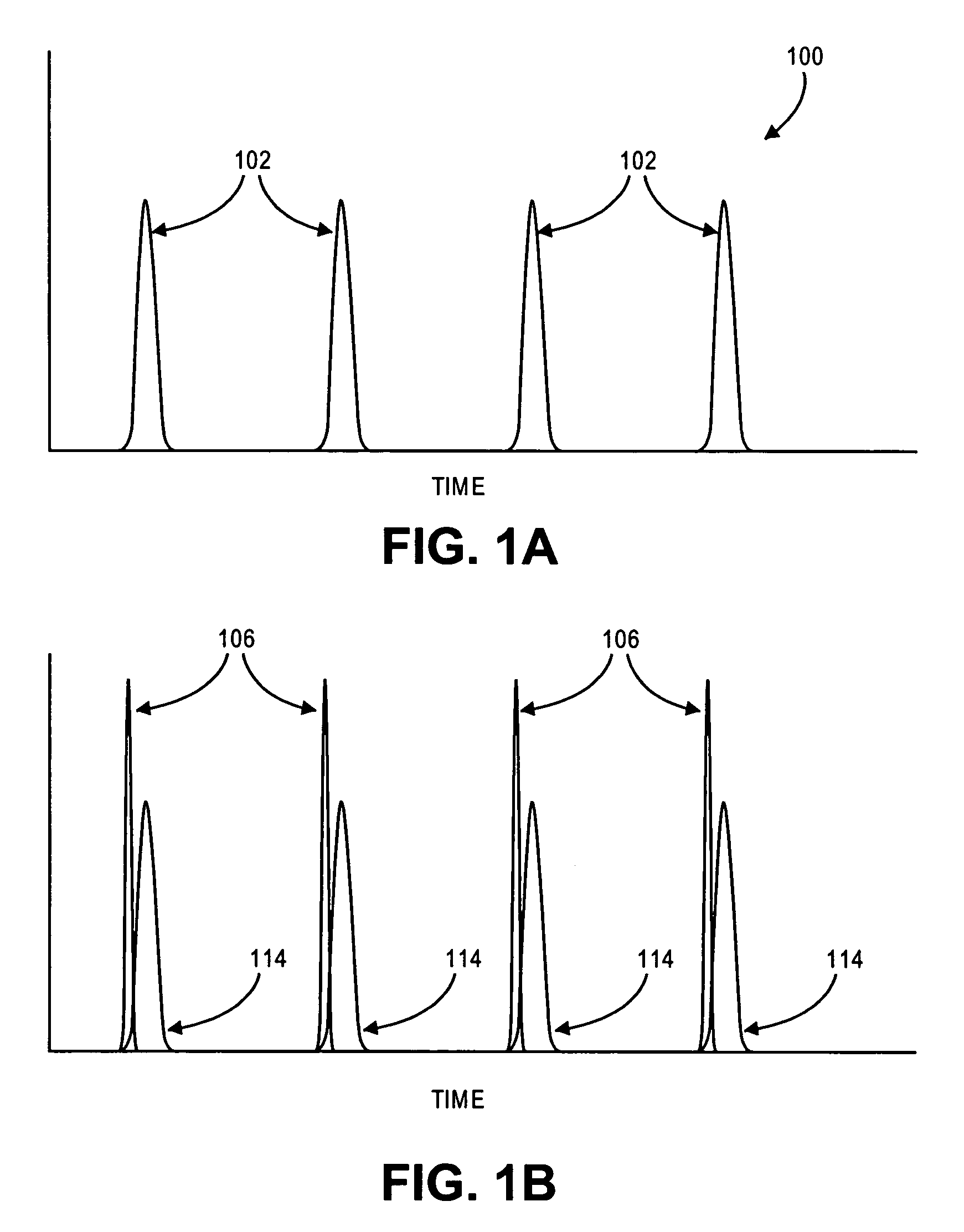

InactiveUS20120234807A1Welding/soldering/cutting articlesMetal working apparatusPulse energyLight beam

Systems and methods for laser scribing provide extended depth affectation into a substrate or workpiece by focusing a laser beam such that the beam passes into the workpiece using a waveguide, self-focusing effect to cause internal crystal damage along a channel extending into the workpiece. Different optical effects may be used to facilitate the waveguide, self-focusing effect, such as multi-photon absorption in the material of the workpiece, transparency of the material of the workpiece, and aberrations of the focused laser. The laser beam may have a wavelength, pulse duration, and pulse energy, for example, to provide transmission through the material and multi-photon absorption in the material. An aberrated, focused laser beam may also be used to provide a longitudinal spherical aberration range sufficient to extend the effective depth of field (DOF) into the workpiece.

Owner:IPG PHOTONICS CORP

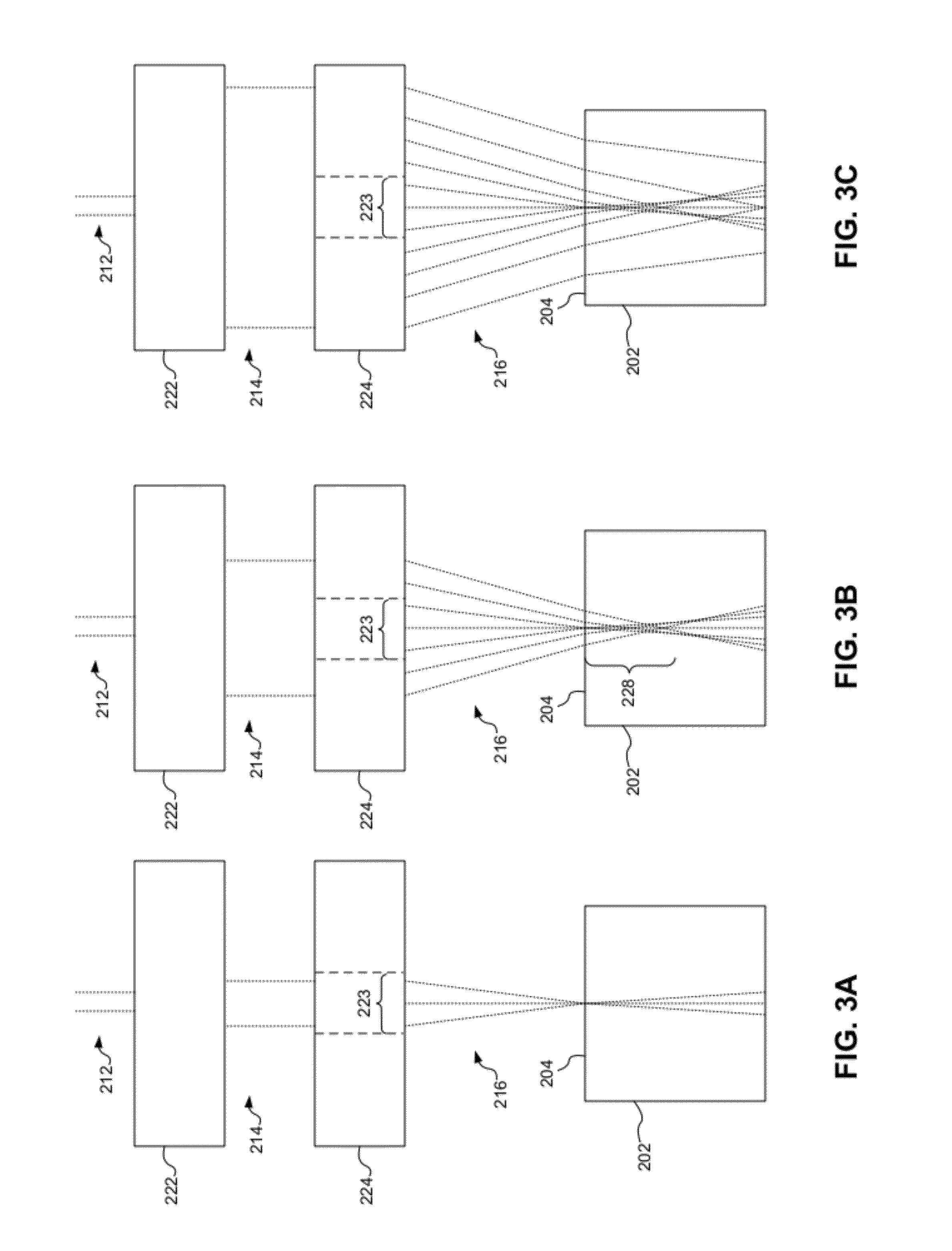

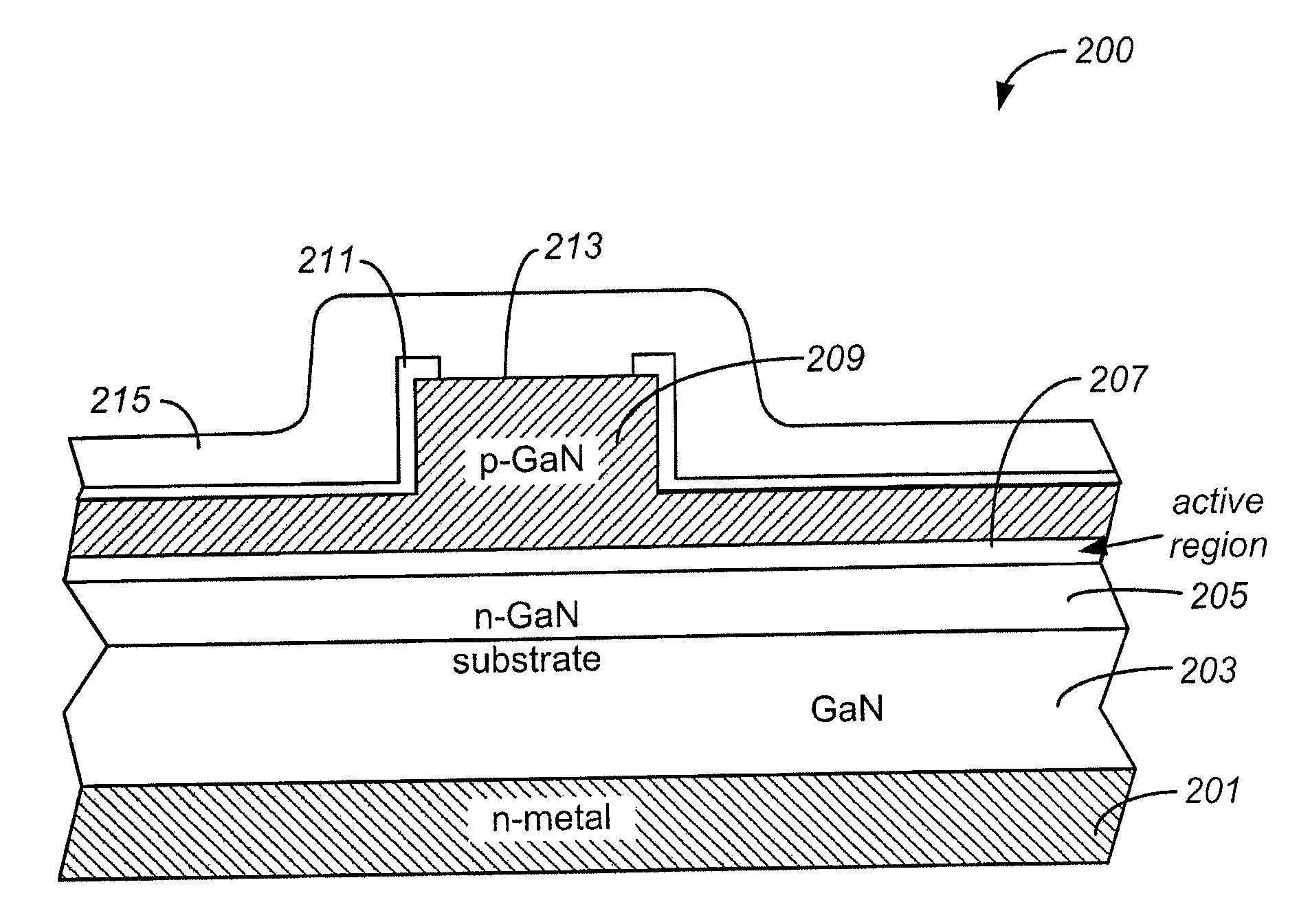

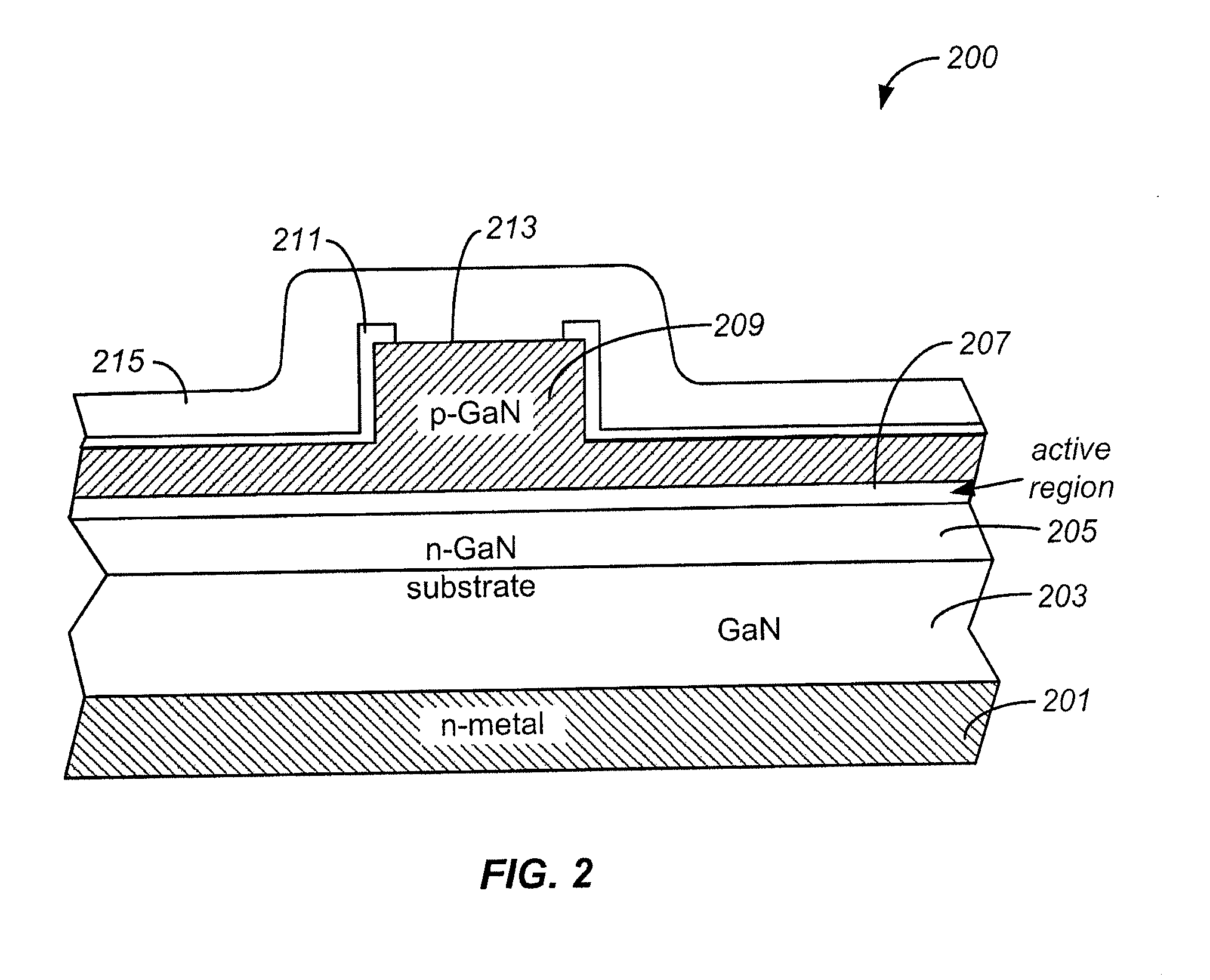

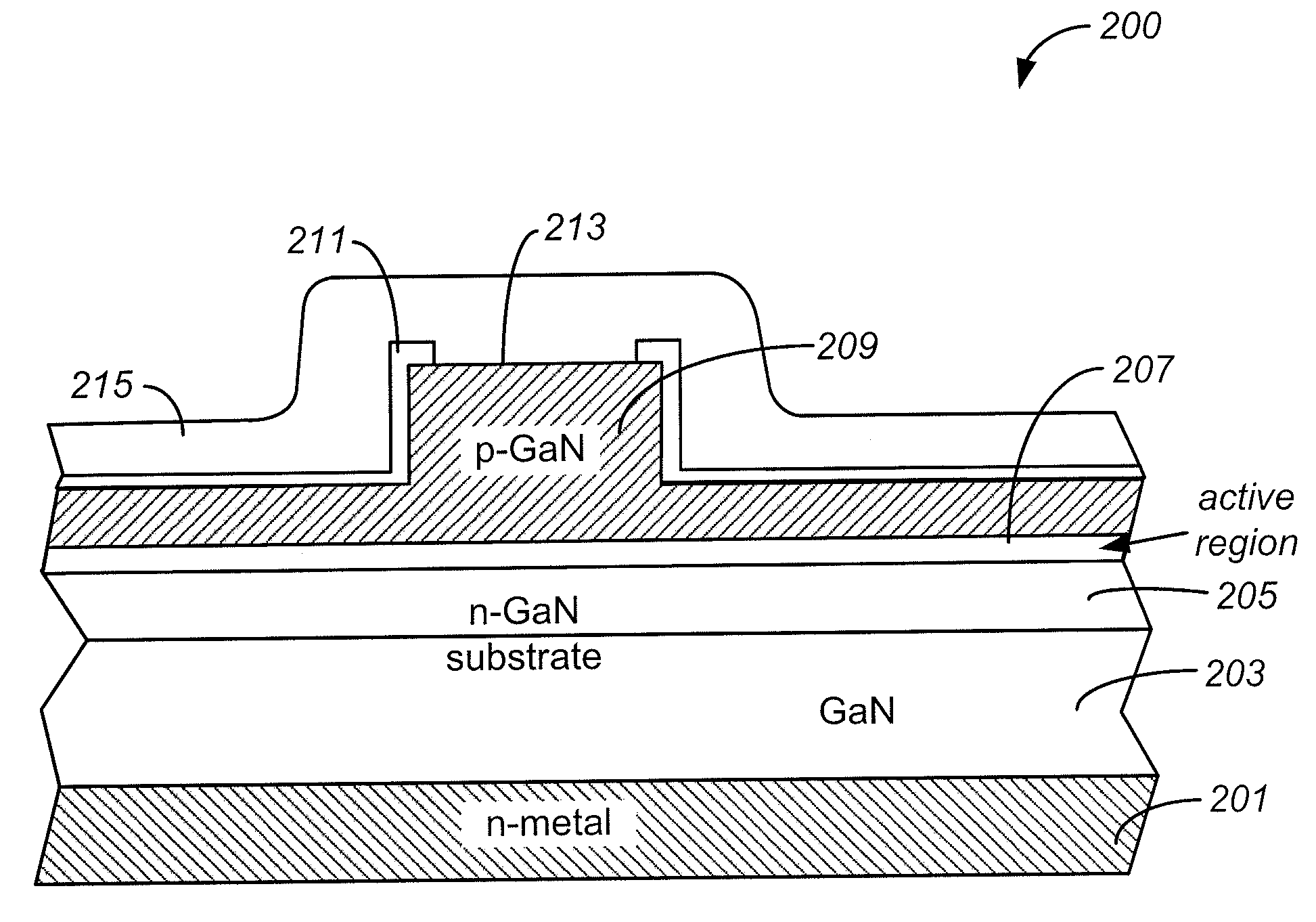

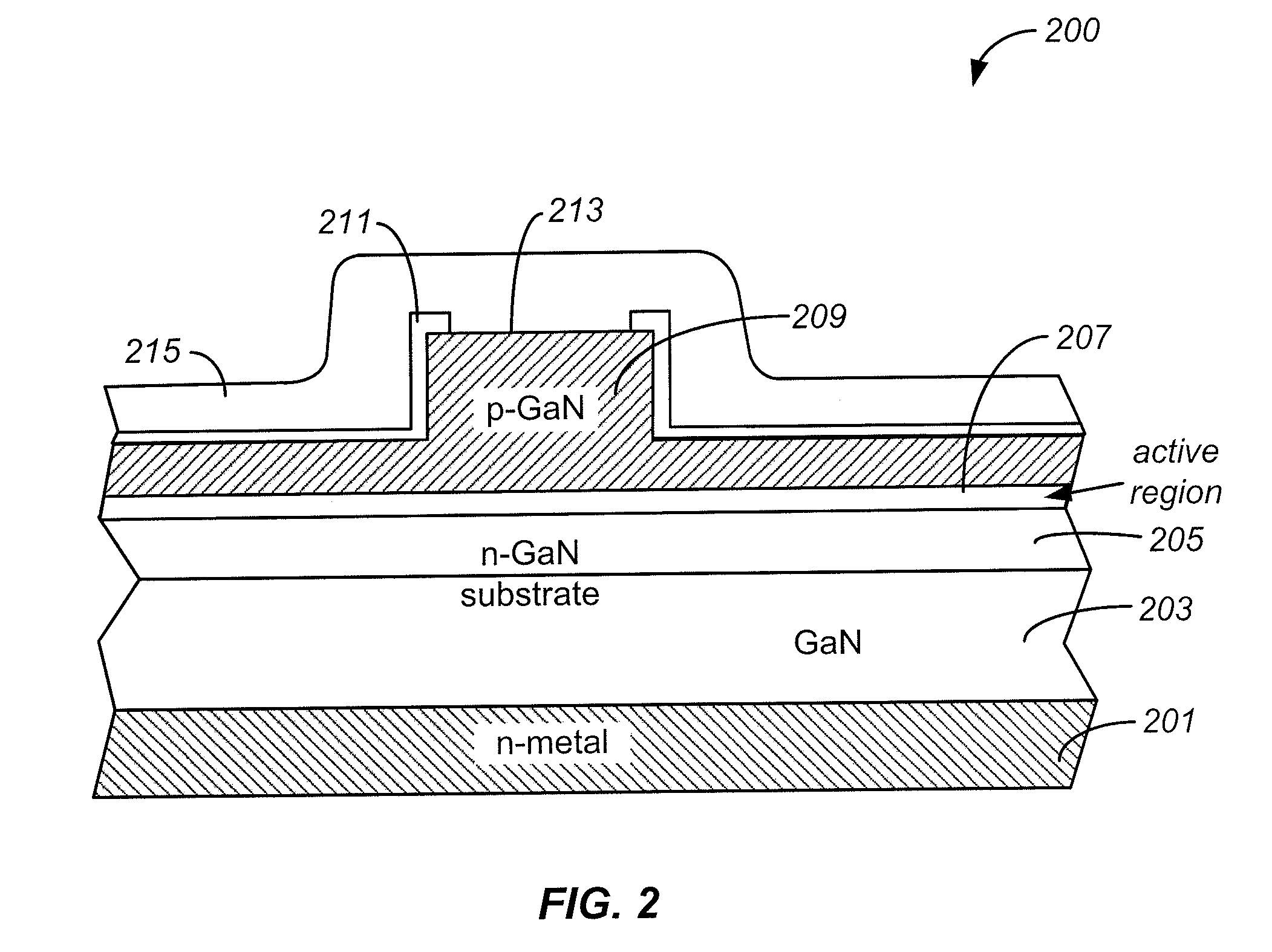

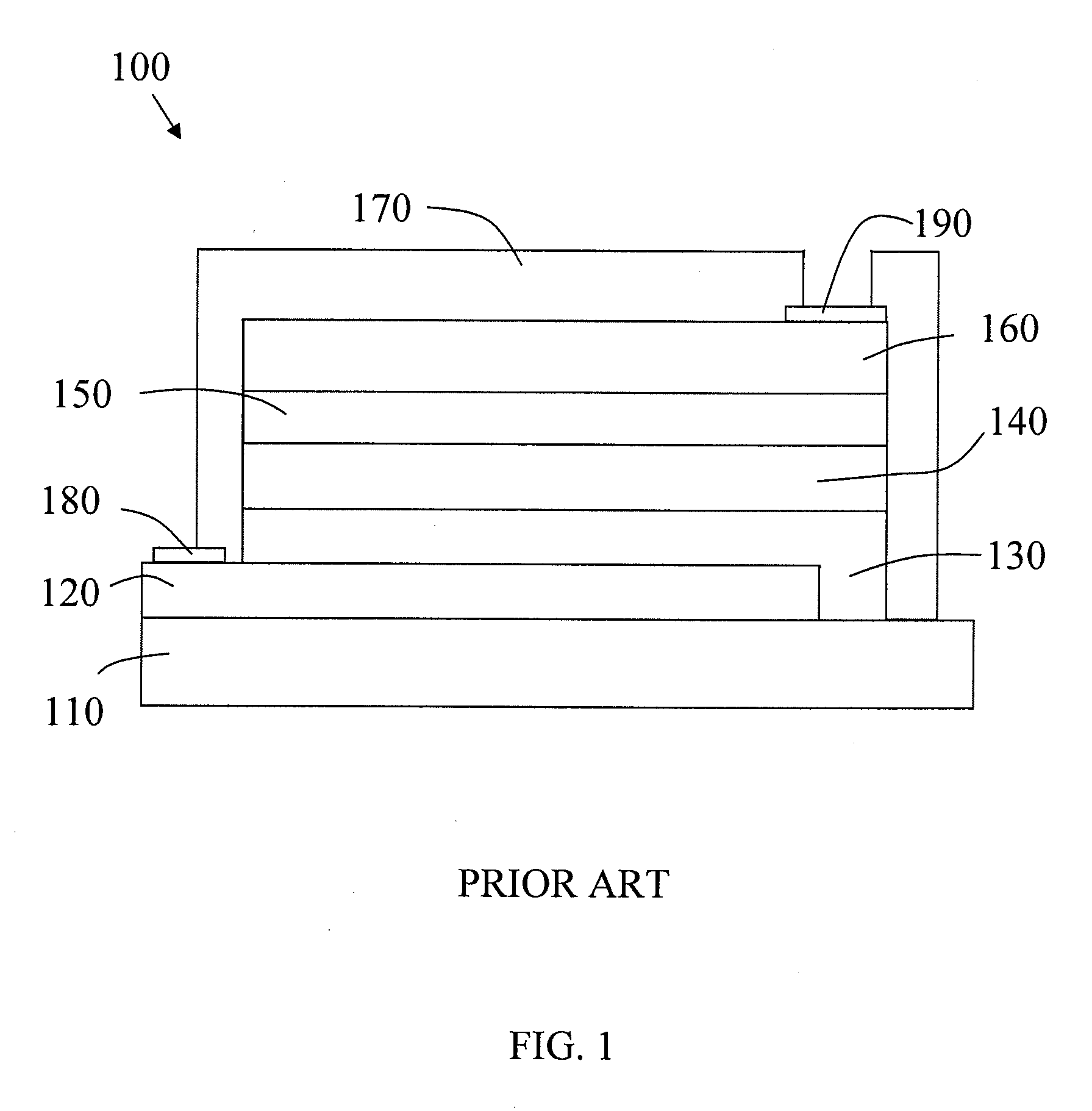

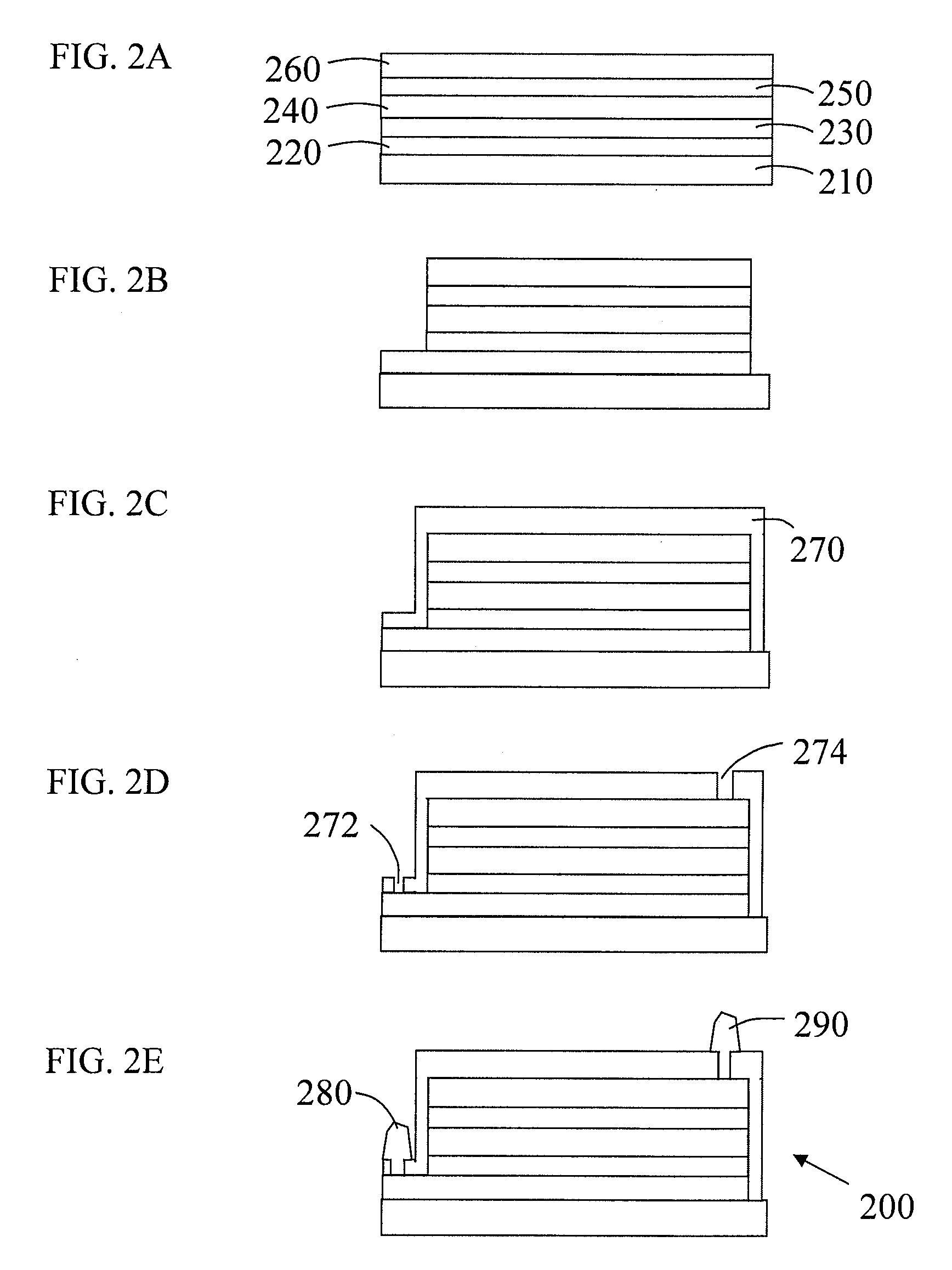

Method of Fabricating Optical Devices Using Laser Treatment of Contact Regions of Gallium and Nitrogen Containing Material

ActiveUS20120104359A1Improve device performanceSmooth connectionSolid-state devicesSemiconductor/solid-state device manufacturingNitrogenGallium

Owner:KYOCERA SLD LASER INC

Laser ablation method

InactiveUS20060088984A1Semiconductor/solid-state device manufacturingMetal working apparatusLaser scribingLaser pulse duration

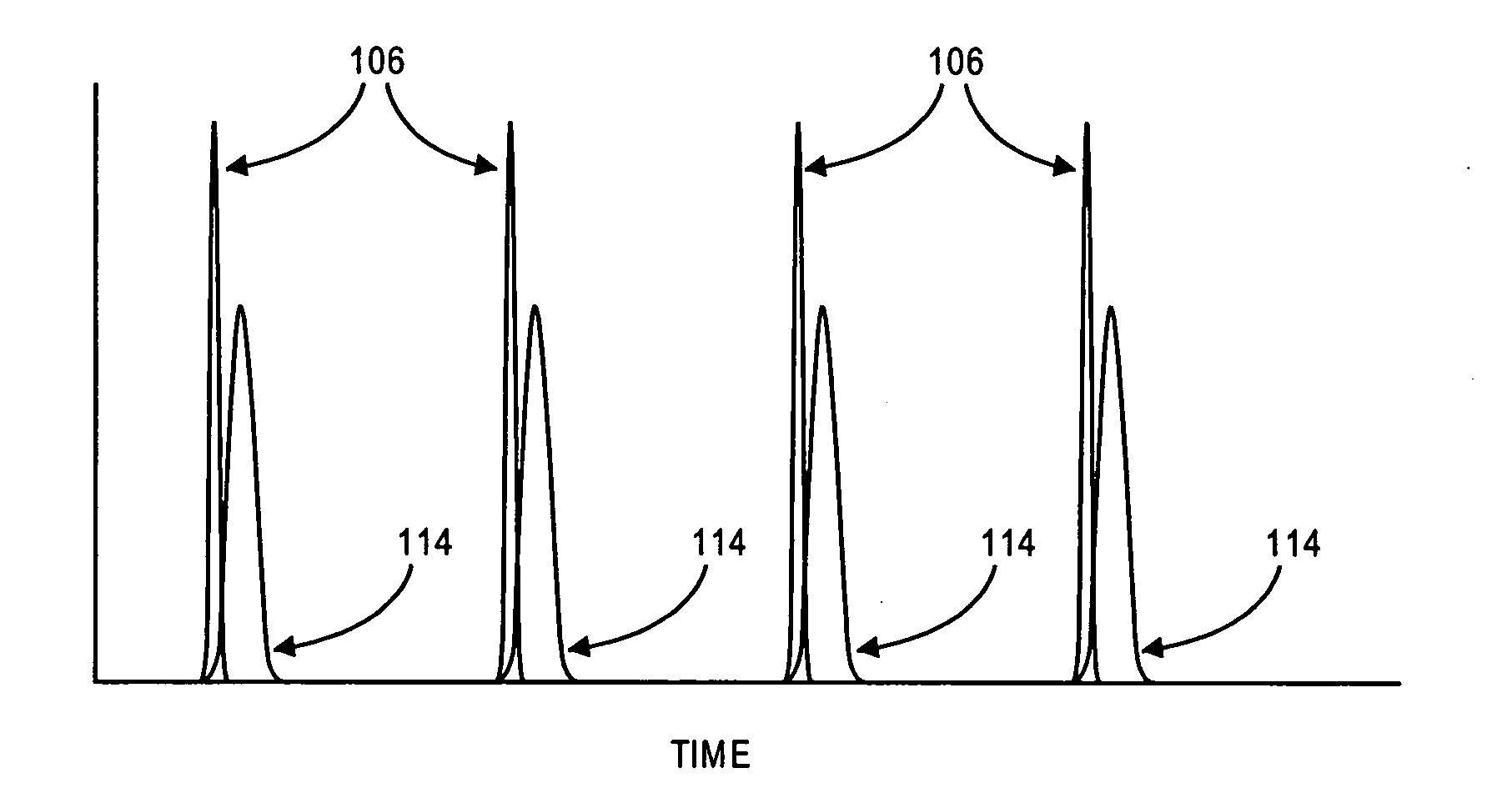

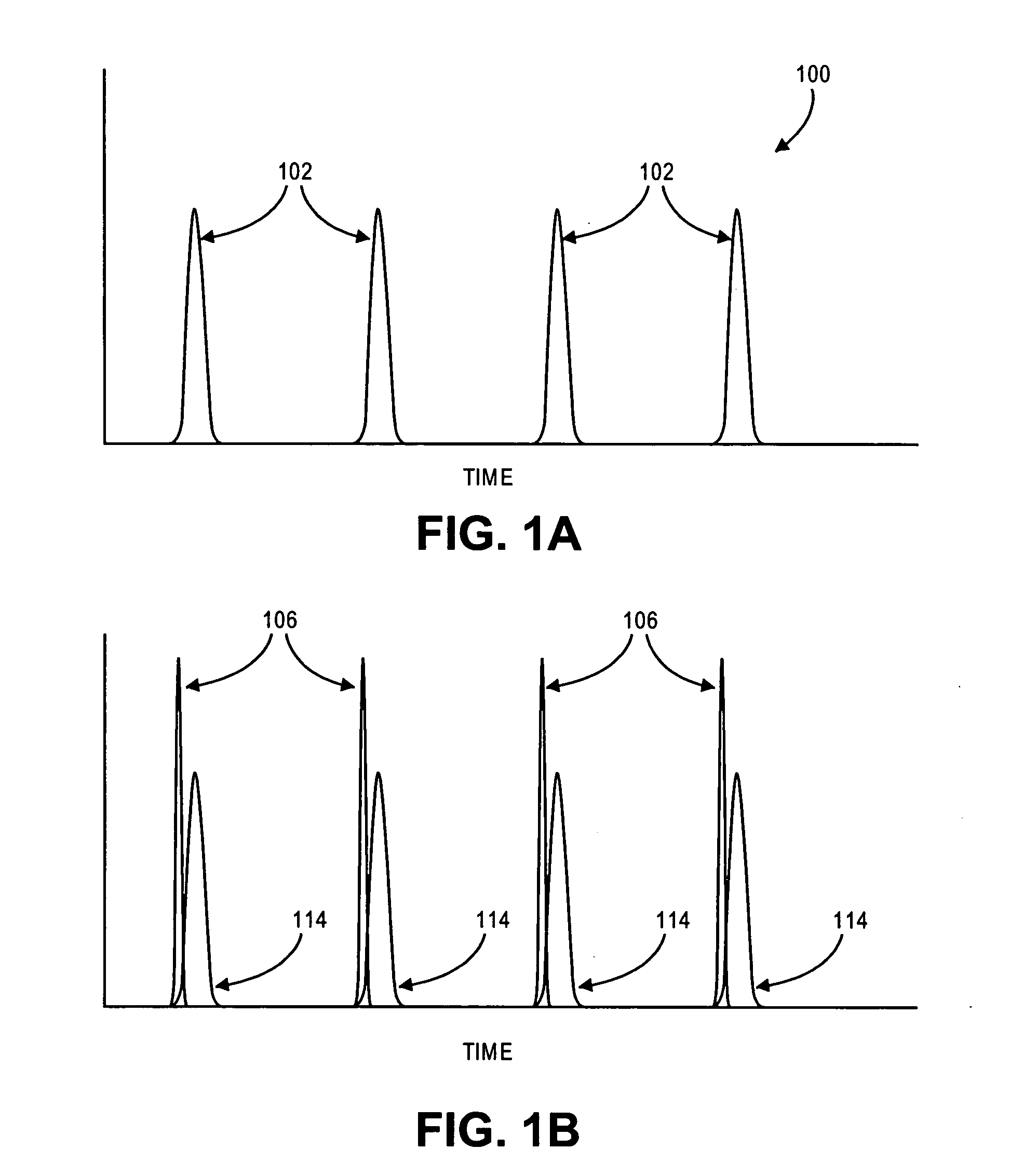

A combination of specific laser pulse durations and repetition rates are incorporated into a semiconductor wafer laser scribing / dicing process. The disclosed combination can reduce factors that contribute to thermal effects, explosive melting and evaporation, and laser / plasma interactions, thereby reducing problems with microcracks, delamination, and particles that can affect semiconductor die yields and reliability.

Owner:INTEL CORP

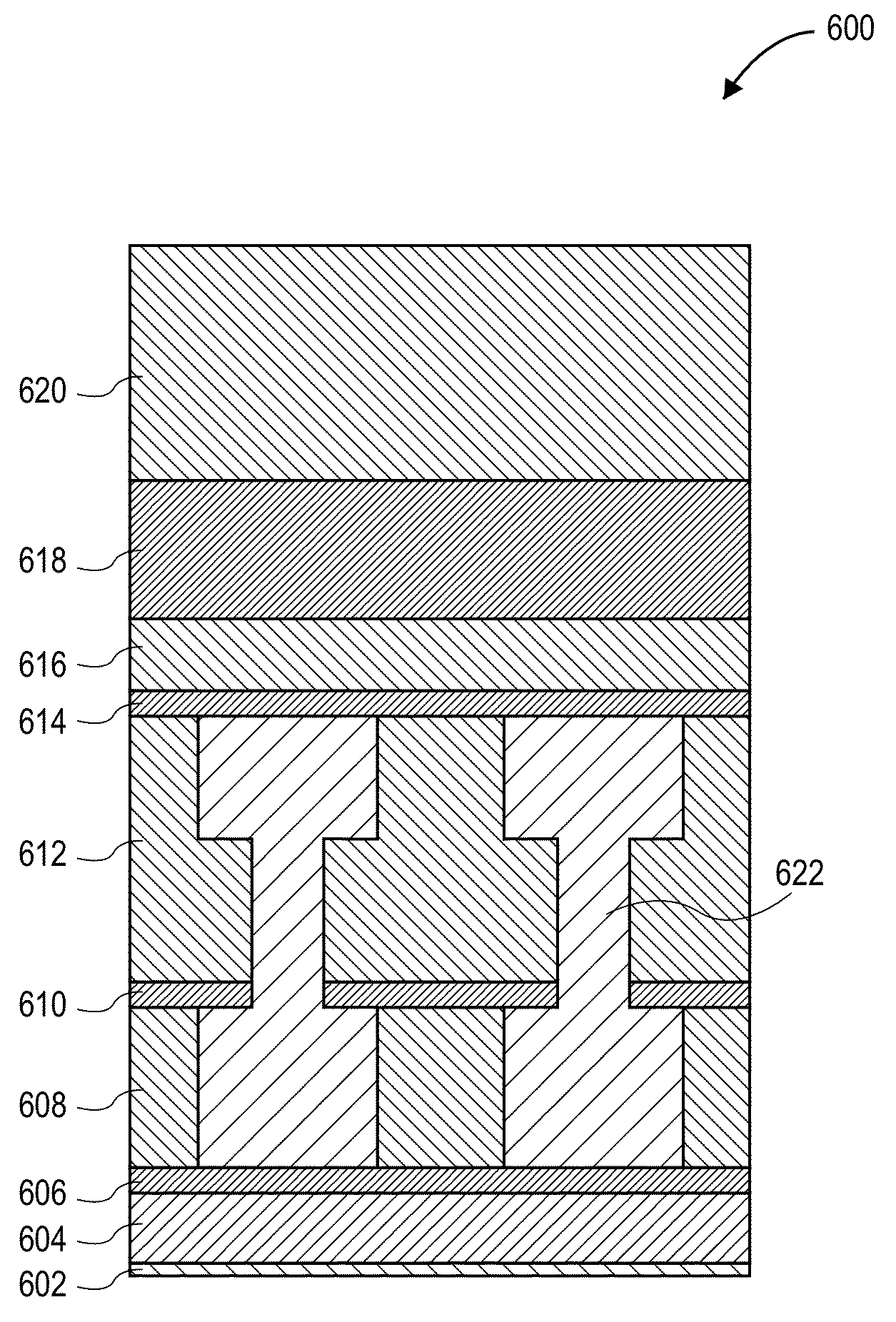

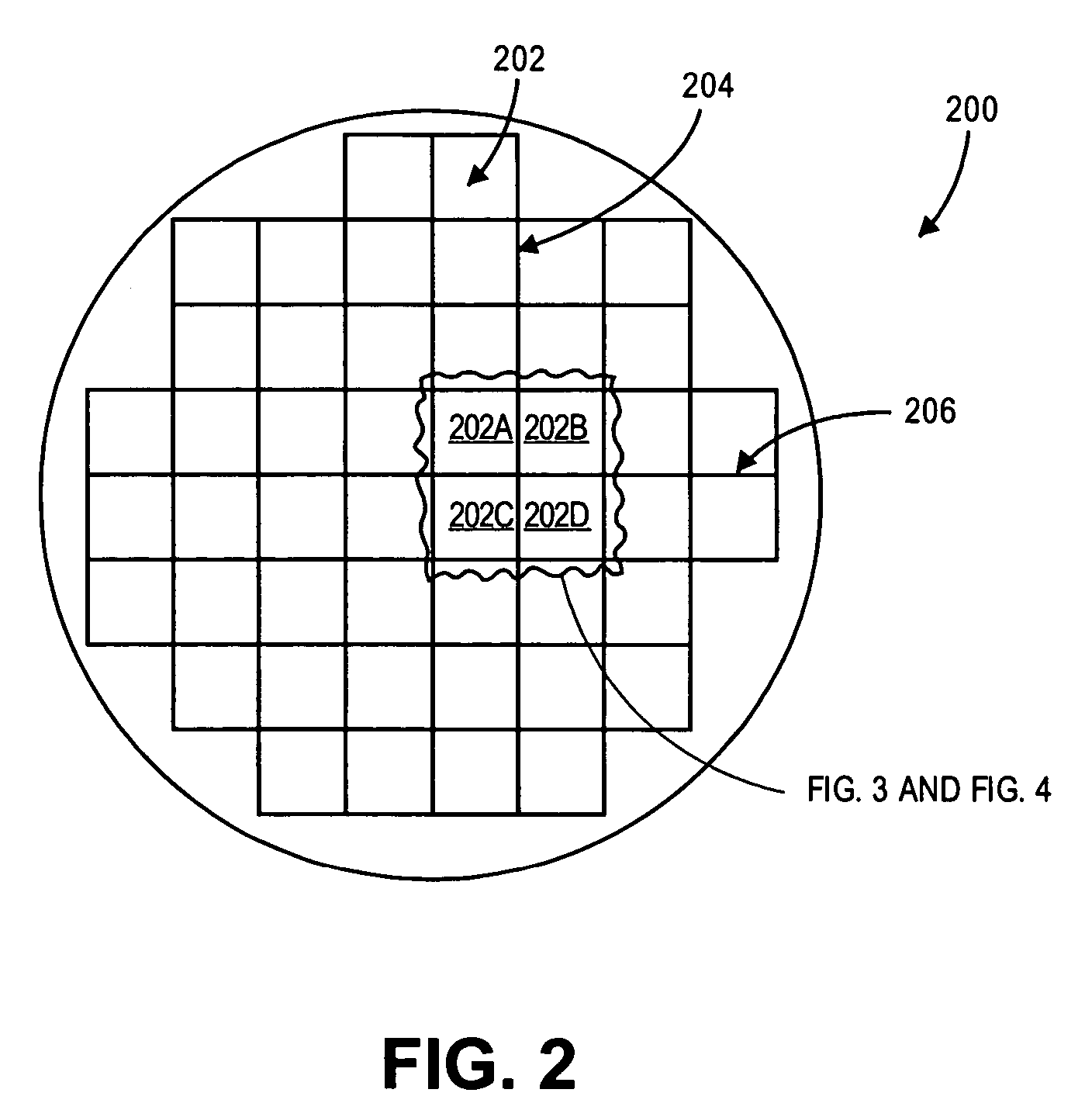

Laser scribing platform and hybrid writing strategy

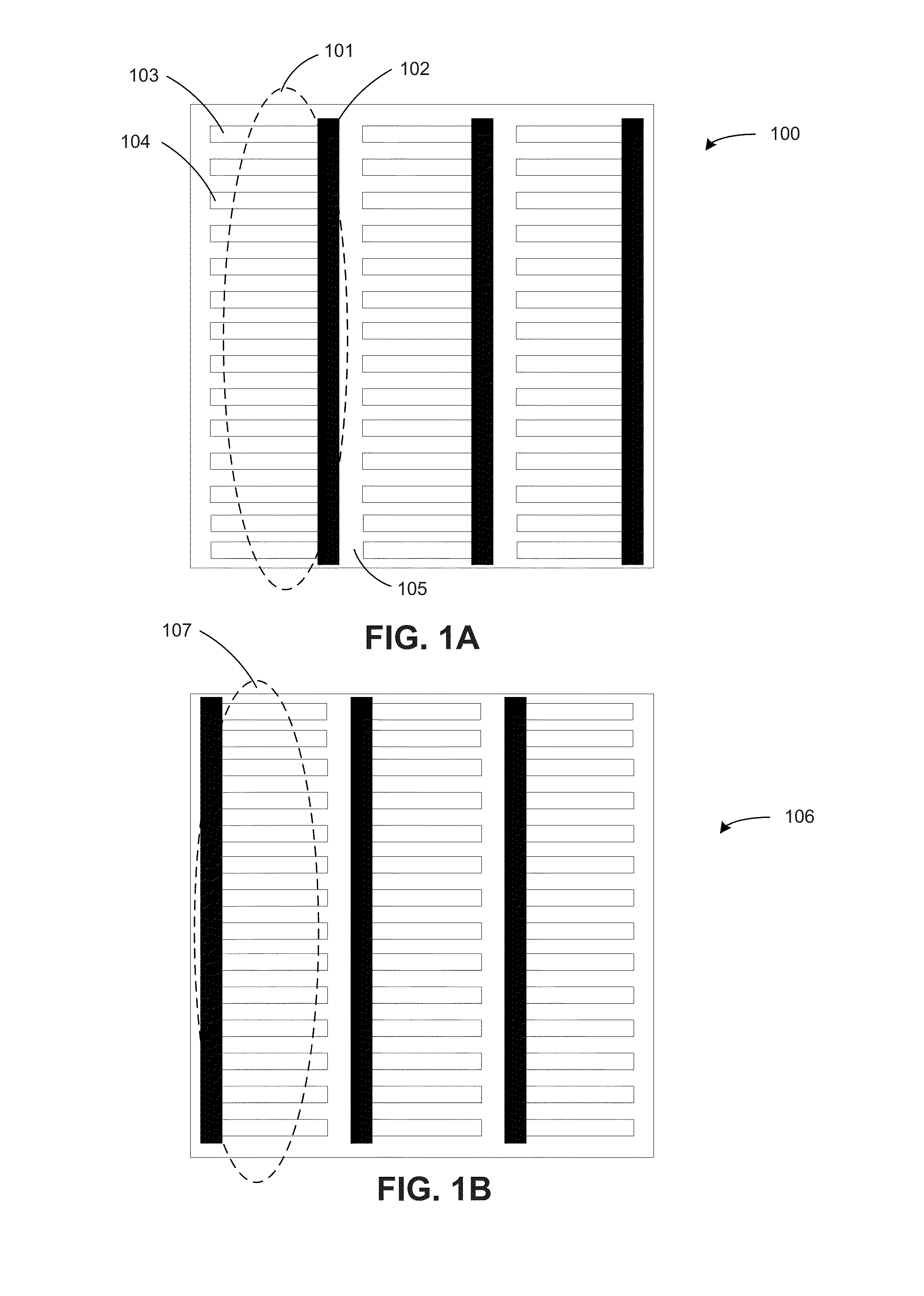

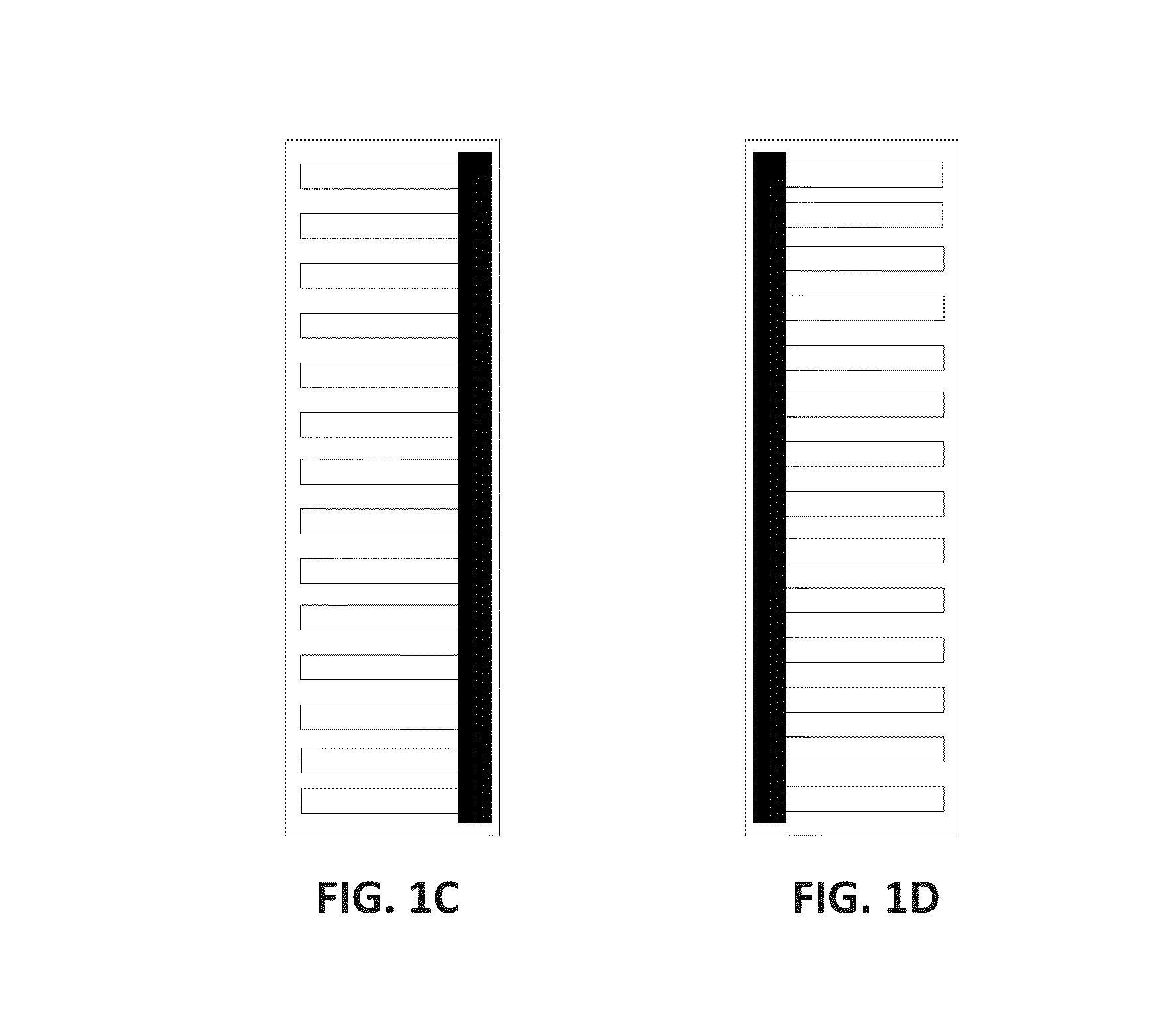

InactiveUS20090255911A1Easy to controlWelding/soldering/cutting articlesMetal working apparatusLight beamLaser scribing

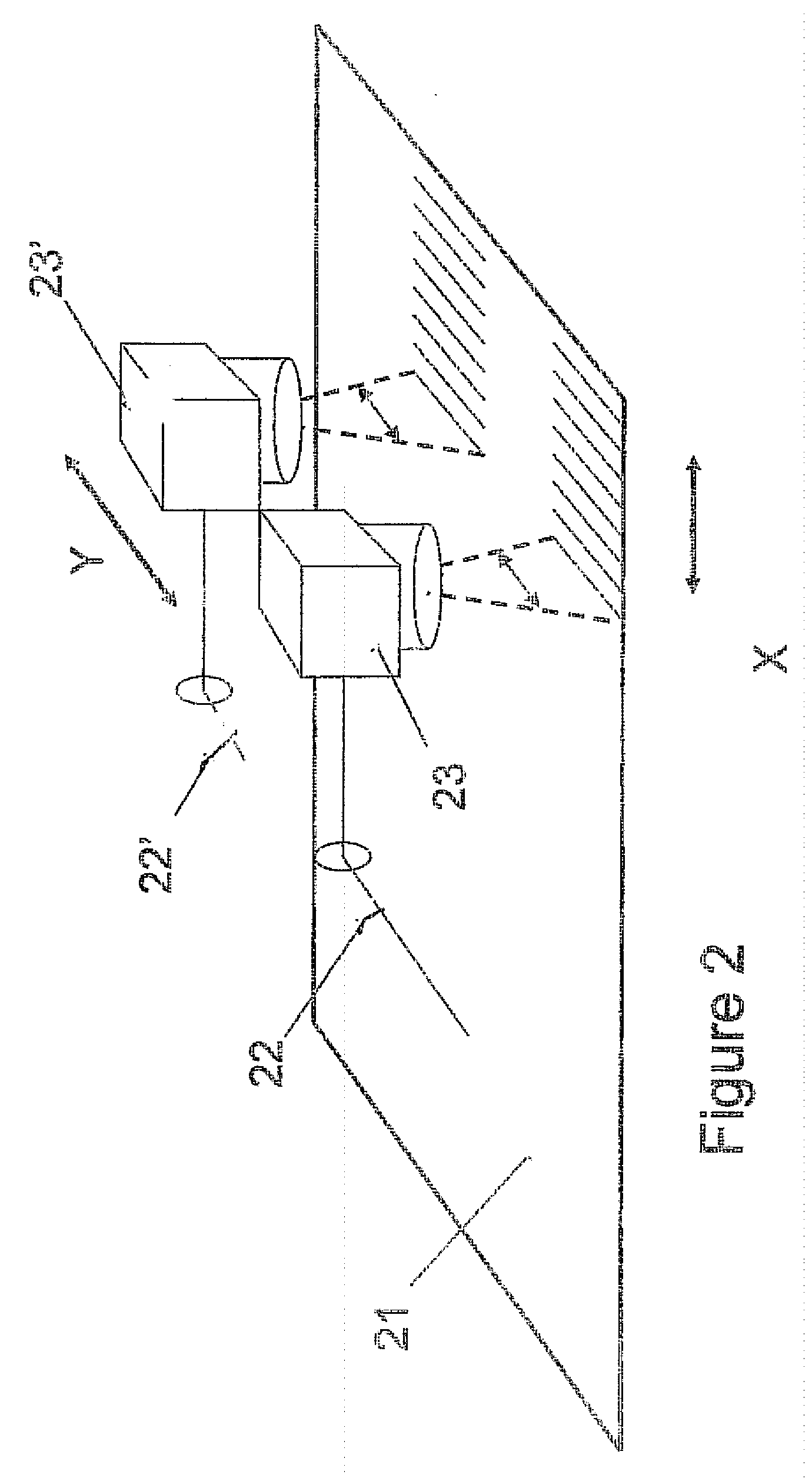

Laser scribing can be performed on a workpiece (104) such as substrates with layers formed thereon for use in a solar panel without need to rotate the workpiece (104) during the scribing process. A series of lasers (602, 622) can be used to concurrently remove material from multiple positions on the workpiece (104). Each laser (602, 622) can have at least one scanning device (614, 630, 632) positioned along a beam path thereof in order to adjust a position of the laser output relative to the workpiece (104). By adjusting the beam or pulse positions using the scanning devices (614, 630, 632) while translating the workpiece (104), substantially any pattern can be scribed into at least one layer of the workpiece (104) without the need for any rotation of the workpiece (104).

Owner:FORTIX

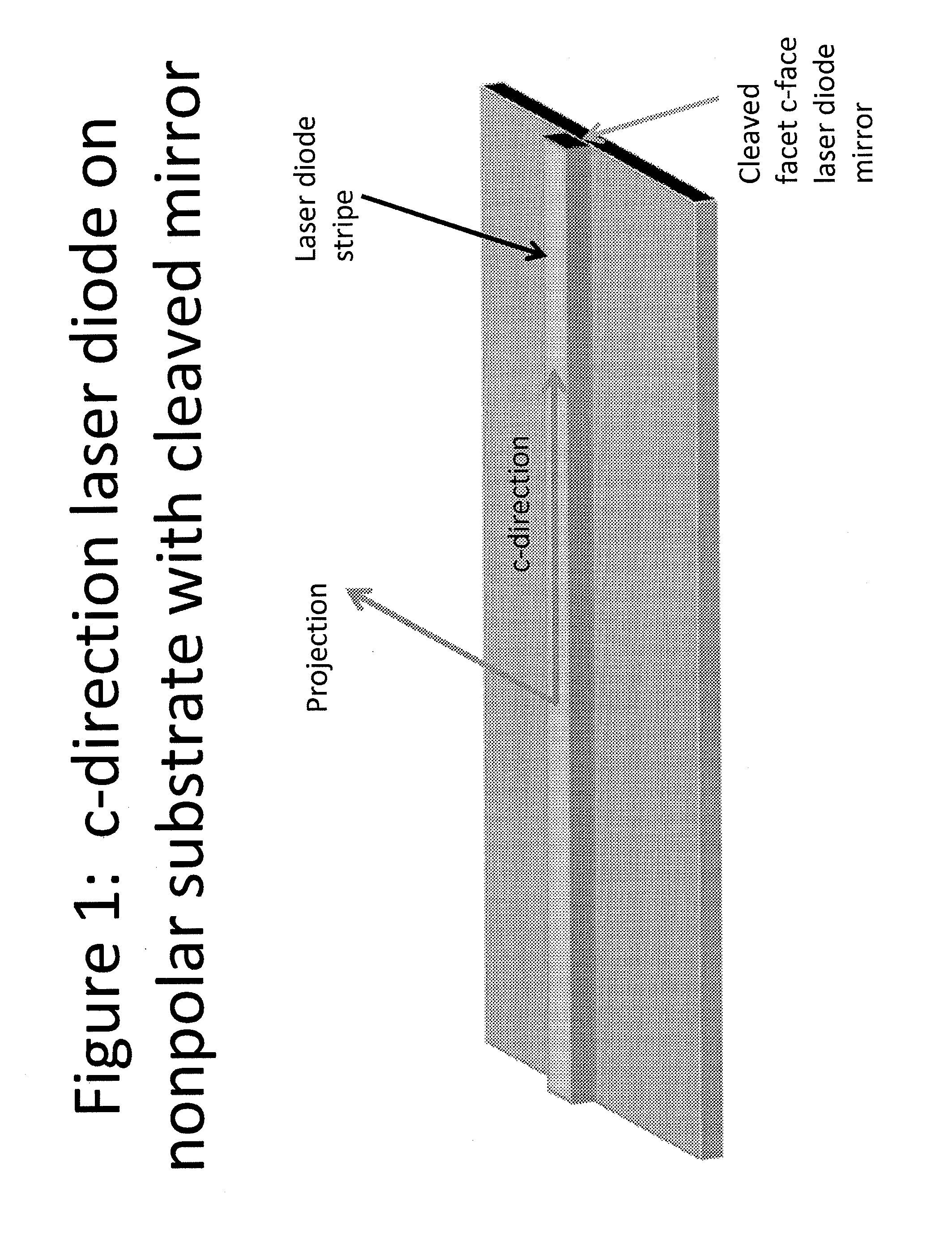

Method of Fabricating Optical Devices Using Laser Treatment

ActiveUS20130234111A1Smooth connectionLower resistanceSemiconductor/solid-state device manufacturingSemiconductor lasersLaser scribingGallium nitride

A method for forming optical devices. The method includes providing a gallium nitride substrate member having a crystalline surface region and a backside region. The method also includes subjecting the backside region to a laser scribing process to form a plurality of scribe regions on the backside region and forming a metallization material overlying the backside region including the plurality of scribe regions. The method removes at least one optical device using at least one of the scribe regions.

Owner:KYOCERA SLD LASER INC

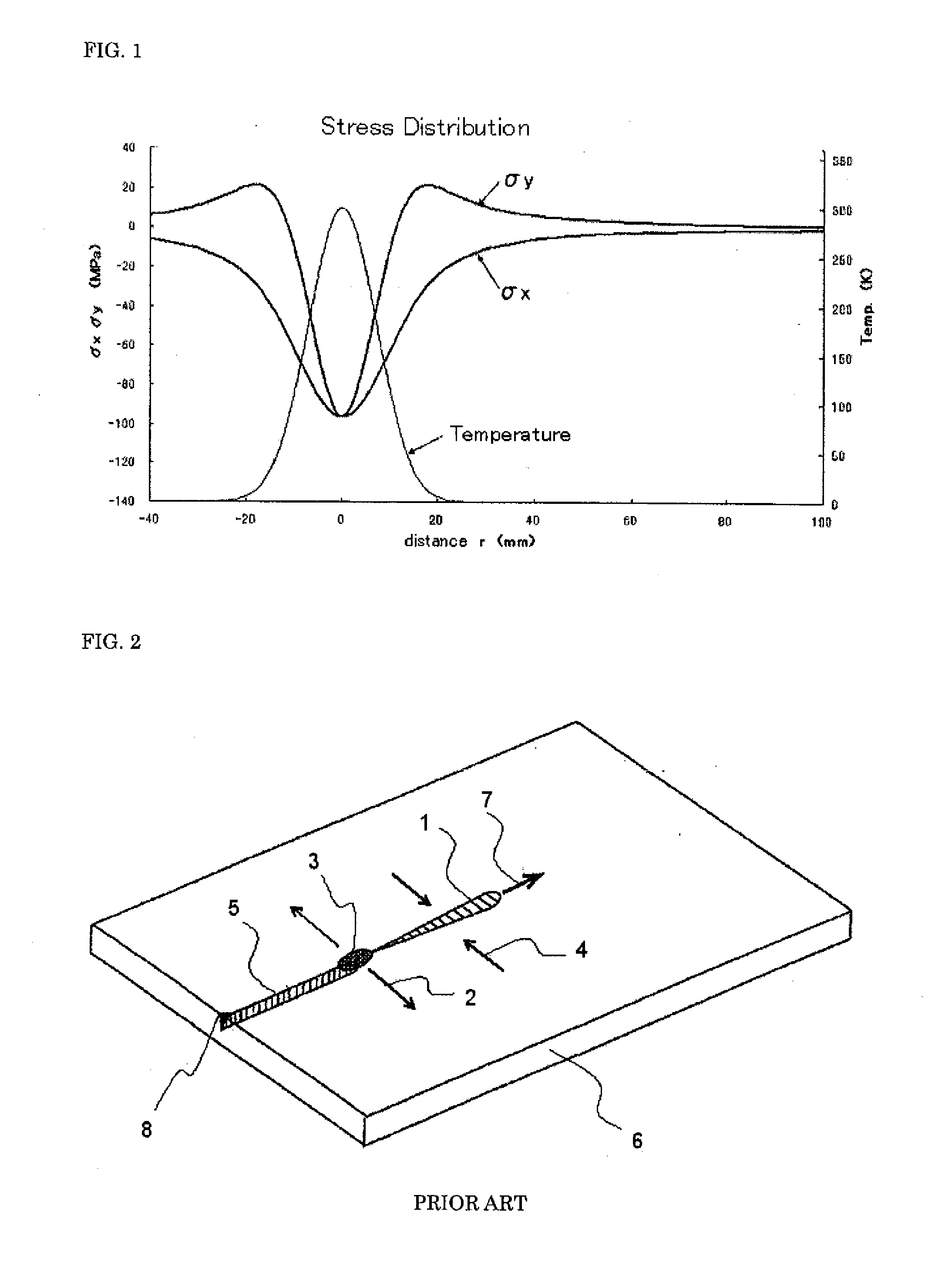

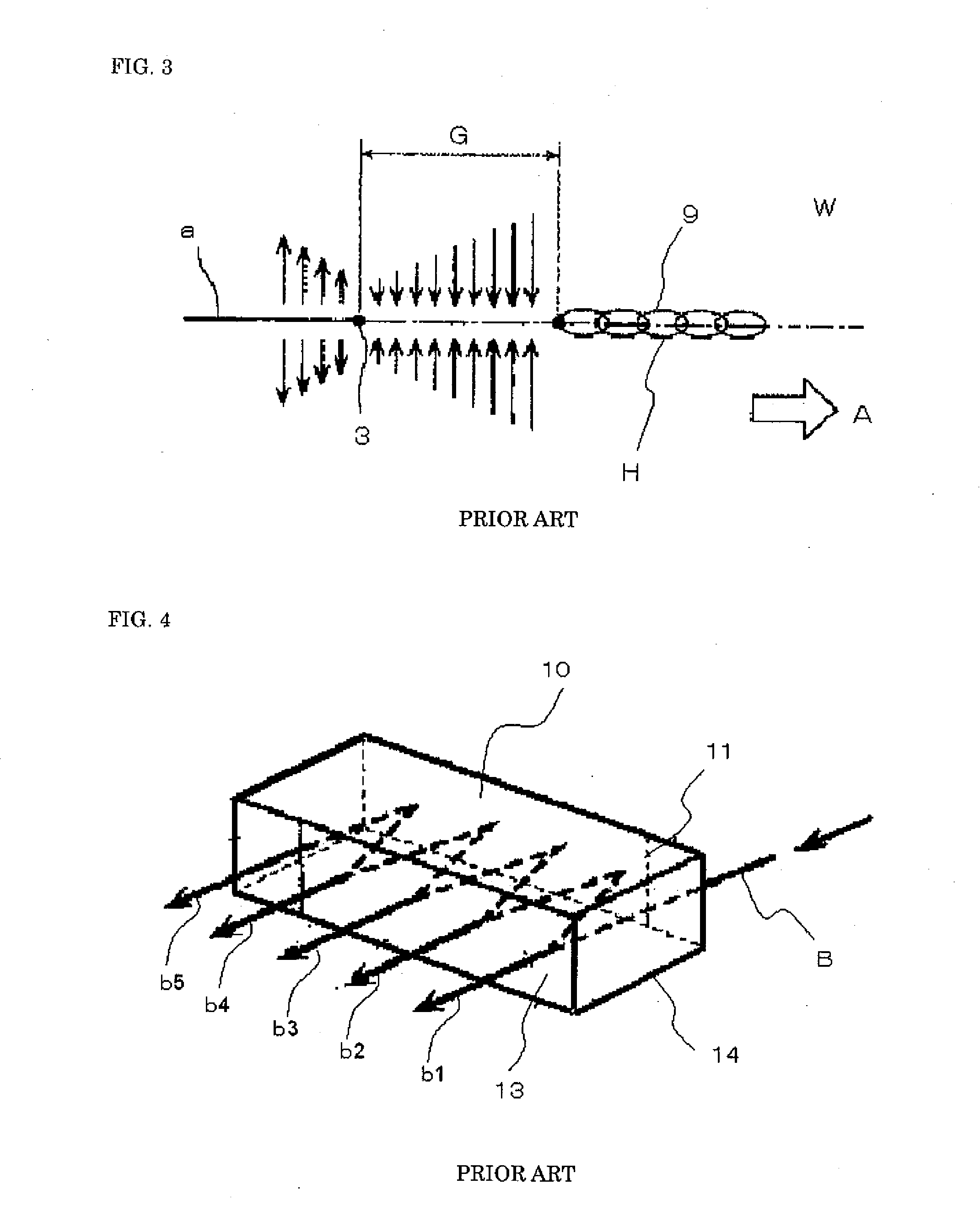

High speed laser scribing method of fragile material

InactiveUS20100089882A1Accelerate thermal stress scribingAvoid disadvantagesFine working devicesGlass severing apparatusLight beamOptoelectronics

In a method for scribing fragile material, a laser beam is irradiated onto a work plate of the fragile material. The work plate is heated by absorption of the irradiated laser beam and generating thermal stress by the heating. The laser beam is formed by a plurality of laser beam groups arranged along a beam scanning direction on a same line, and the plurality of laser beam groups are divided into two groups. One takes charge of initial heating and rising up temperature of the work plate, and another takes charge of temperature holding of the work plate. The laser beam intensity corresponding to each of the laser beam groups is adjusted so as to obtain optimum values.By the method, it is possible to remarkably increase scribing speed of the work plate of the fragile materials without increasing heating temperature.

Owner:GLOBALY TECH CO LTD

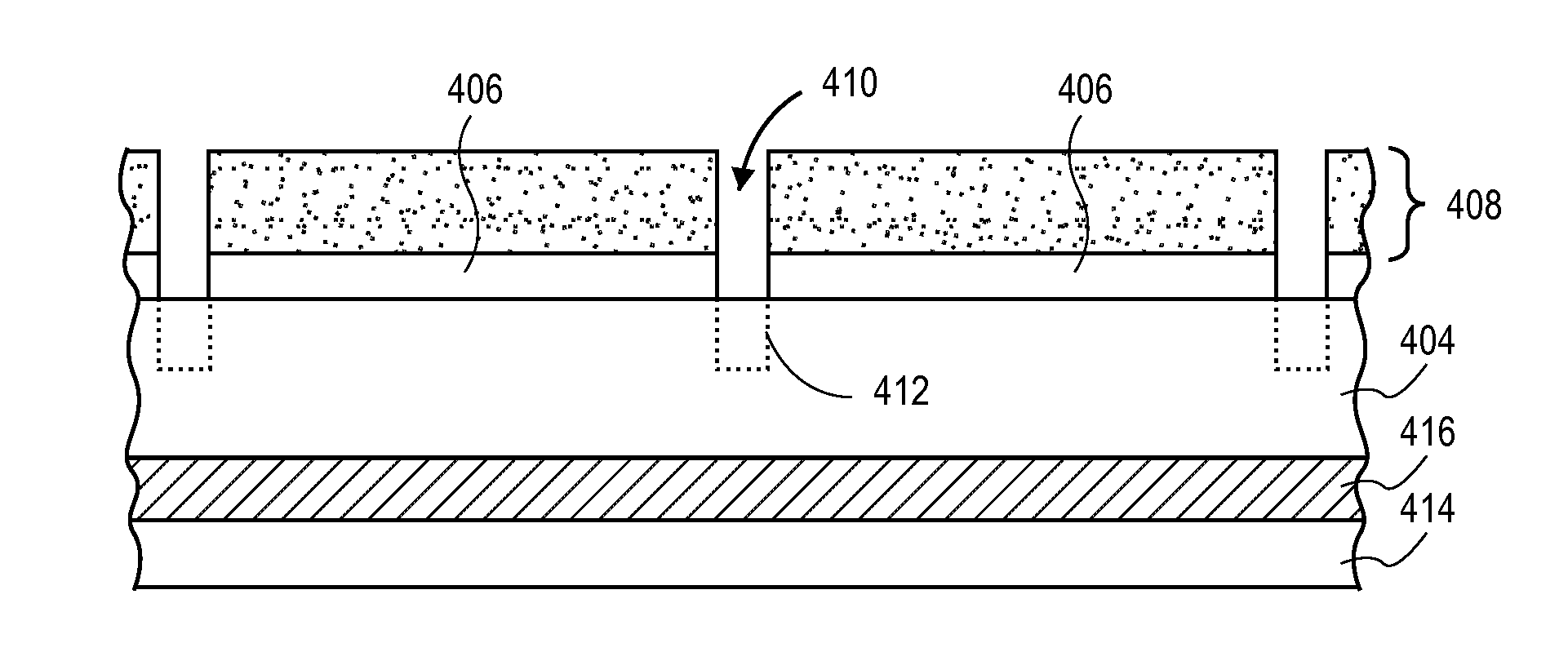

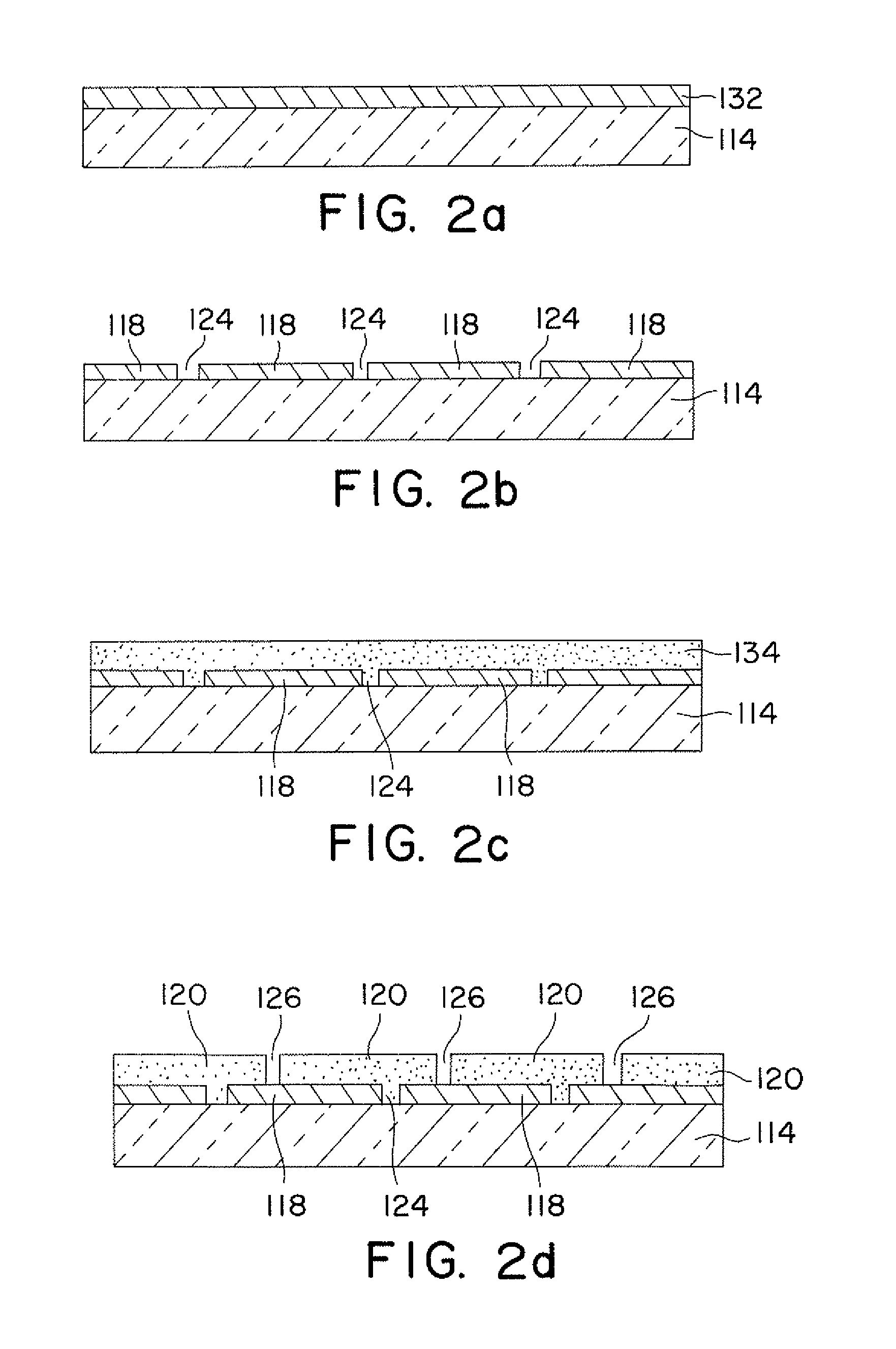

Method for high volume manufacturing of thin film batteries

ActiveUS20090148764A1Improve manufacturabilityLow costFinal product manufacturePrinted batteriesHigh volume manufacturingEngineering

Concepts and methods are provided to reduce the cost and complexity of thin film battery (TFB) high volume manufacturing by eliminating and / or minimizing the use of conventional physical (shadow) masks. Laser scribing and other alternative physical maskless patterning techniques meet certain or all of the patterning requirements. In one embodiment, a method of manufacturing thin film batteries comprises providing a substrate, depositing layers corresponding to a thin film battery structure on the substrate, the layers including, in order of deposition, a cathode, an electrolyte and an anode, wherein at least one of the deposited layers is unpatterned by a physical mask during deposition, depositing a protective coating, and scribing the layers and the protective coating. Further, the edges of the layers may be covered by an encapsulation layer. Furthermore, the layers may be deposited on two substrates and then laminated to form the thin film battery.

Owner:APPLIED MATERIALS INC +1

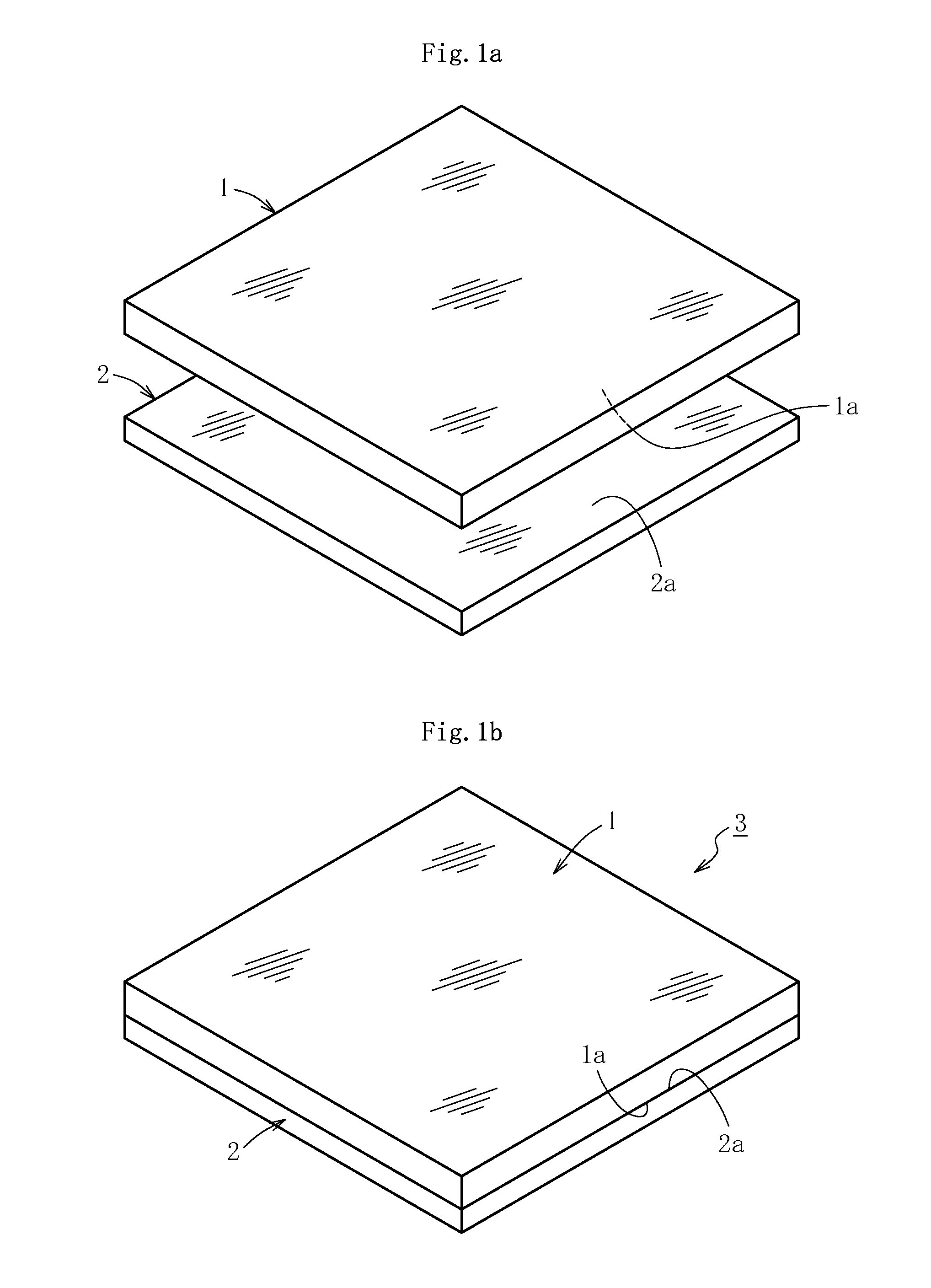

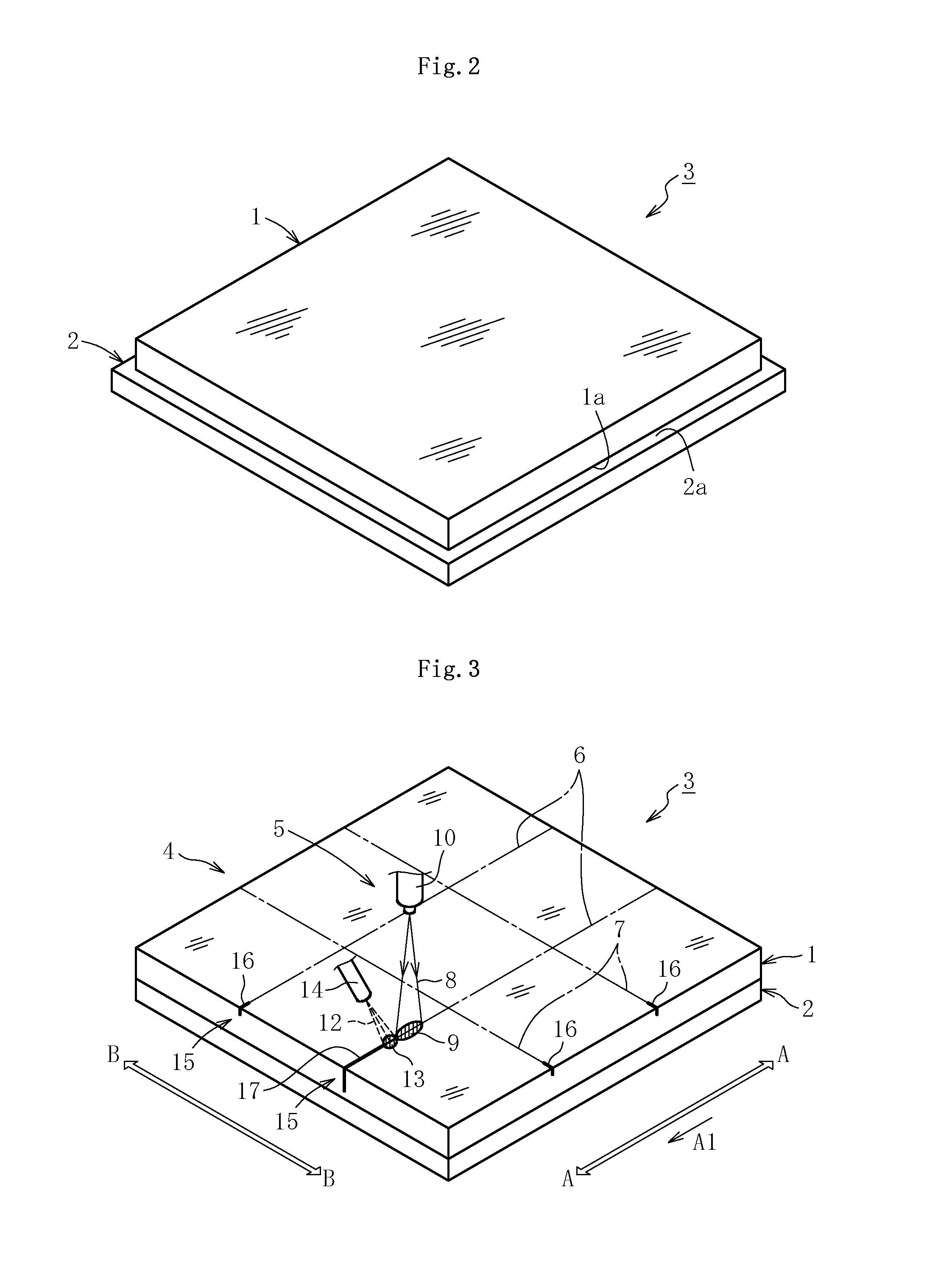

Glass film cutting method and glass film laminate

InactiveUS20130280495A1Appropriate adhesionGlass/slag layered productsGlass reforming apparatusSurface roughnessLaser scribing

Owner:NIPPON ELECTRIC GLASS CO LTD

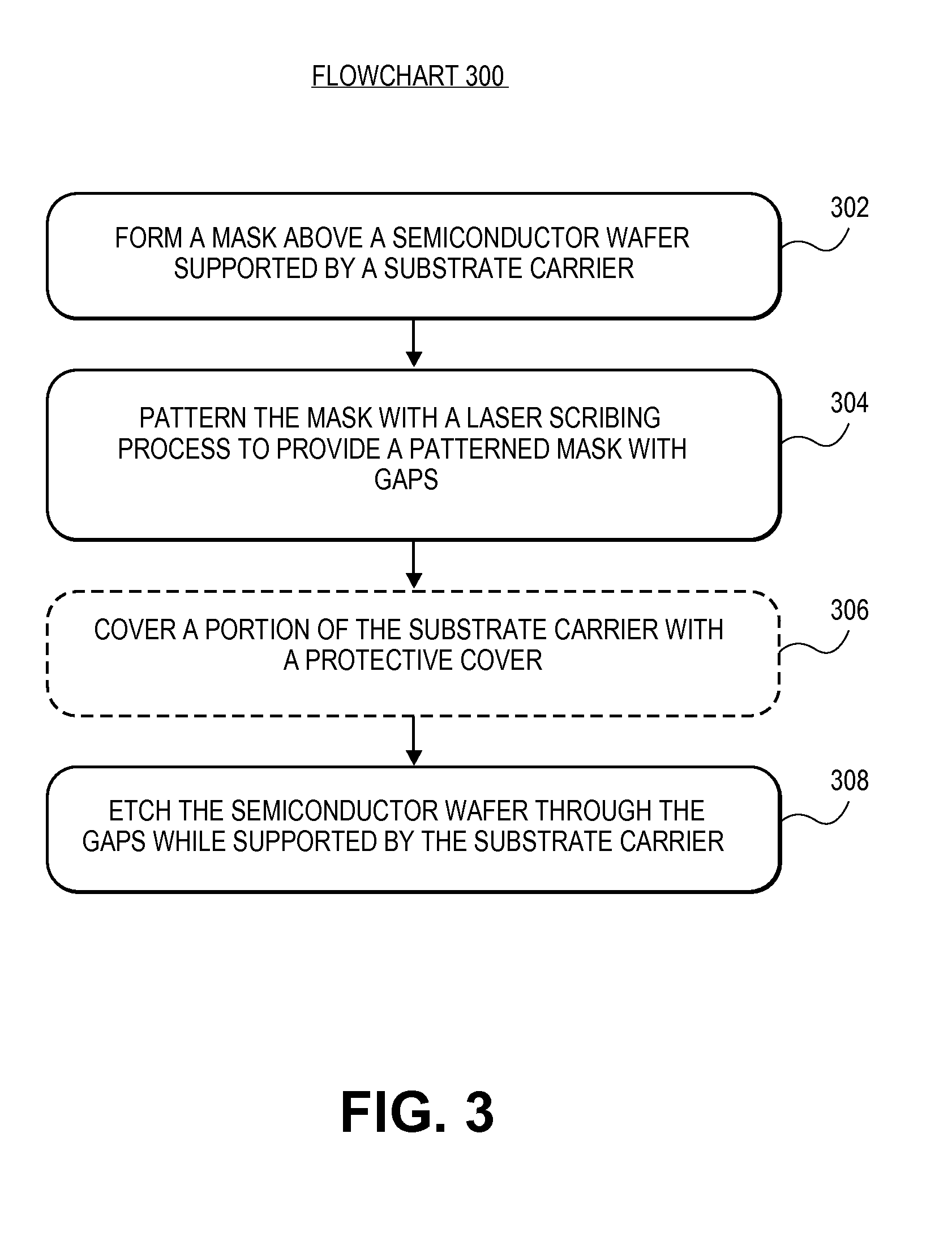

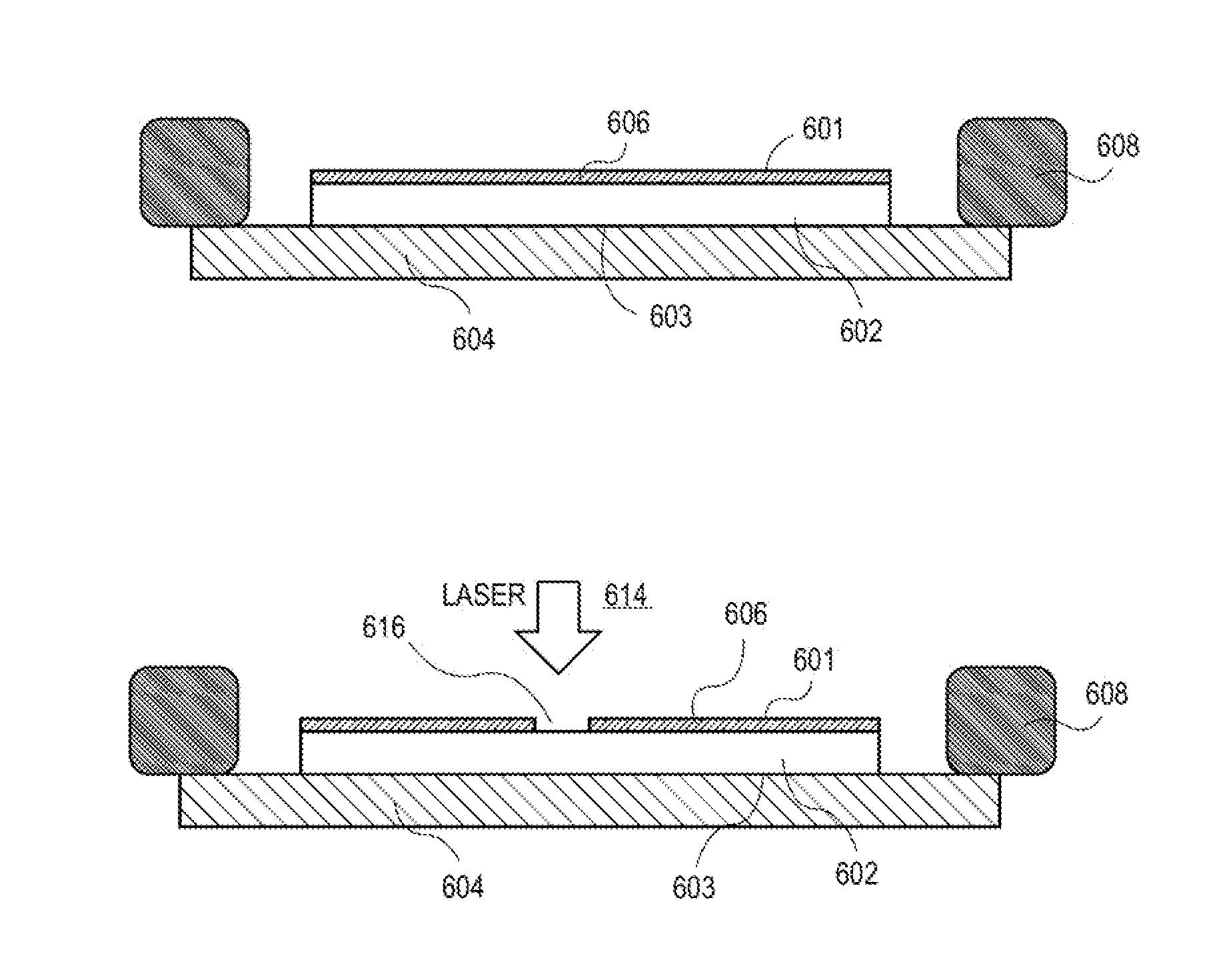

Hybrid laser and plasma etch wafer dicing using substrate carrier

ActiveUS20120322239A1Solid-state devicesSemiconductor/solid-state device manufacturingWafer dicingLaser scribing

Methods of dicing semiconductor wafers, each wafer having a plurality of integrated circuits, are described. A method includes forming a mask above the semiconductor wafer, the mask composed of a layer covering and protecting the integrated circuits. The semiconductor wafer is supported by a substrate carrier. The mask is then patterned with a laser scribing process to provide a patterned mask with gaps, exposing regions of the semiconductor wafer between the integrated circuits. The semiconductor wafer is then etched through the gaps in the patterned mask to singulate the integrated circuits while supported by the substrate carrier.

Owner:APPLIED MATERIALS INC

Method for manufacturing electrochromic devices

ActiveUS20090304912A1Improve manufacturabilityReduce complexityRadiation applicationsPretreated surfacesDevice materialLaser patterning

This invention contemplates the use of laser patterning / scribing in electrochromic device manufacture, anywhere during the manufacturing process as deemed appropriate and necessary for electrochromic device manufacturability, yield and functionality, while integrating the laser scribing so as to ensure the active layers of the device are protected to ensure long term reliability. It is envisaged that the laser is used to pattern the component layers of electrochromic devices by directly removing (ablating) the material of the component layers. The invention includes a manufacturing method for an electrochromic device comprising one or more focused laser patterning steps. To minimize redeposition of laser ablated material and particulate formation on device surfaces a number of approaches may be used: (1) ablated material generated by the focused laser patterning may be removed by vacuum suction and / or application of an inert gas jet in the vicinity of the laser ablation of device material; (2) spatial separation of the edges of layers and patterning of lower layers prior to deposition of upper layers; and (3) the laser patterning step may be performed by a laser beam focused directly on the deposited layers from above, by a laser beam directed through the transparent substrate, or by a combination of both.

Owner:APPLIED MATERIALS INC

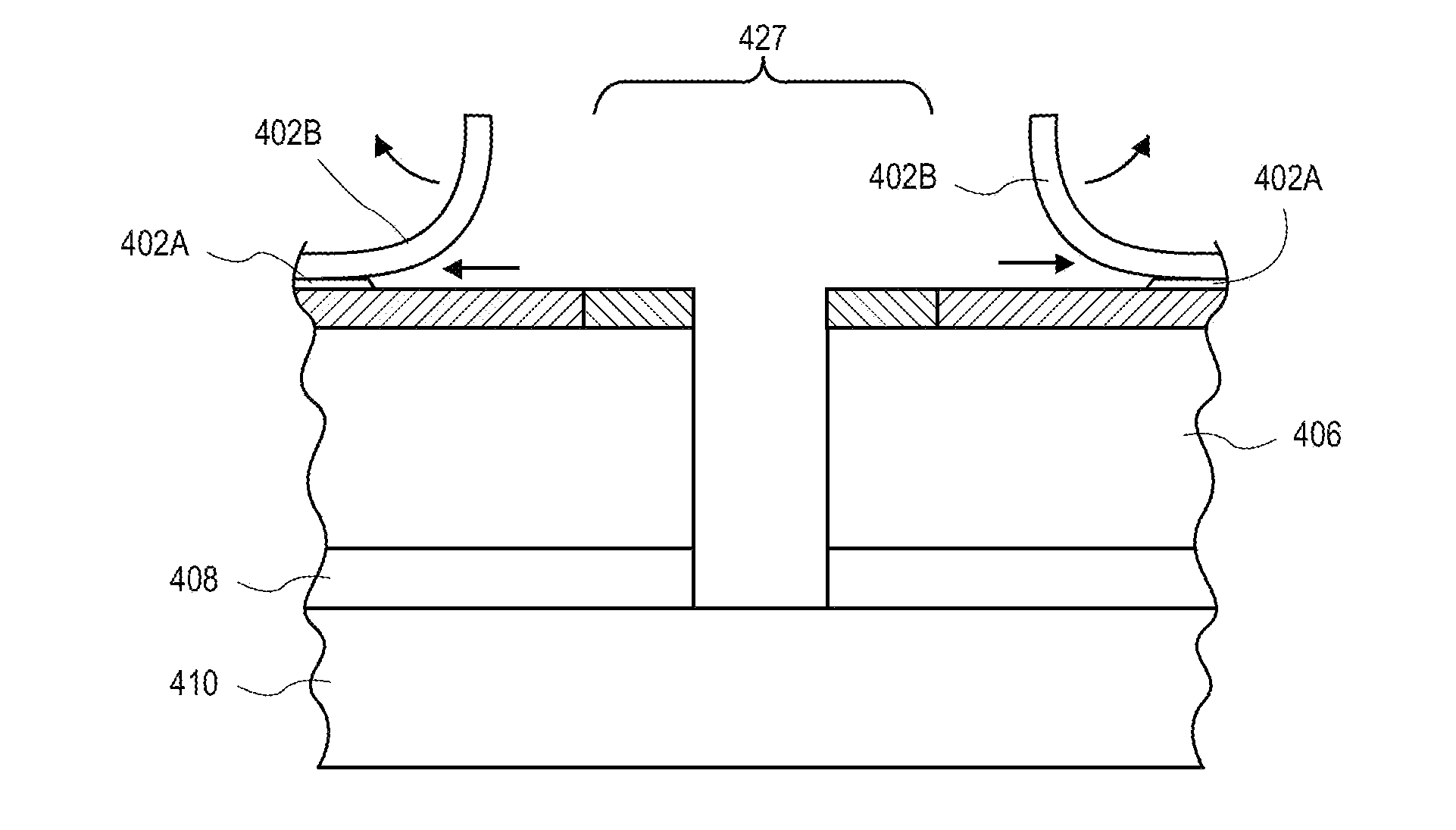

Damage isolation by shaped beam delivery in laser scribing process

ActiveUS20120322240A1Electric discharge tubesSemiconductor/solid-state device manufacturingShaped beamOptoelectronics

Owner:APPLIED MATERIALS INC

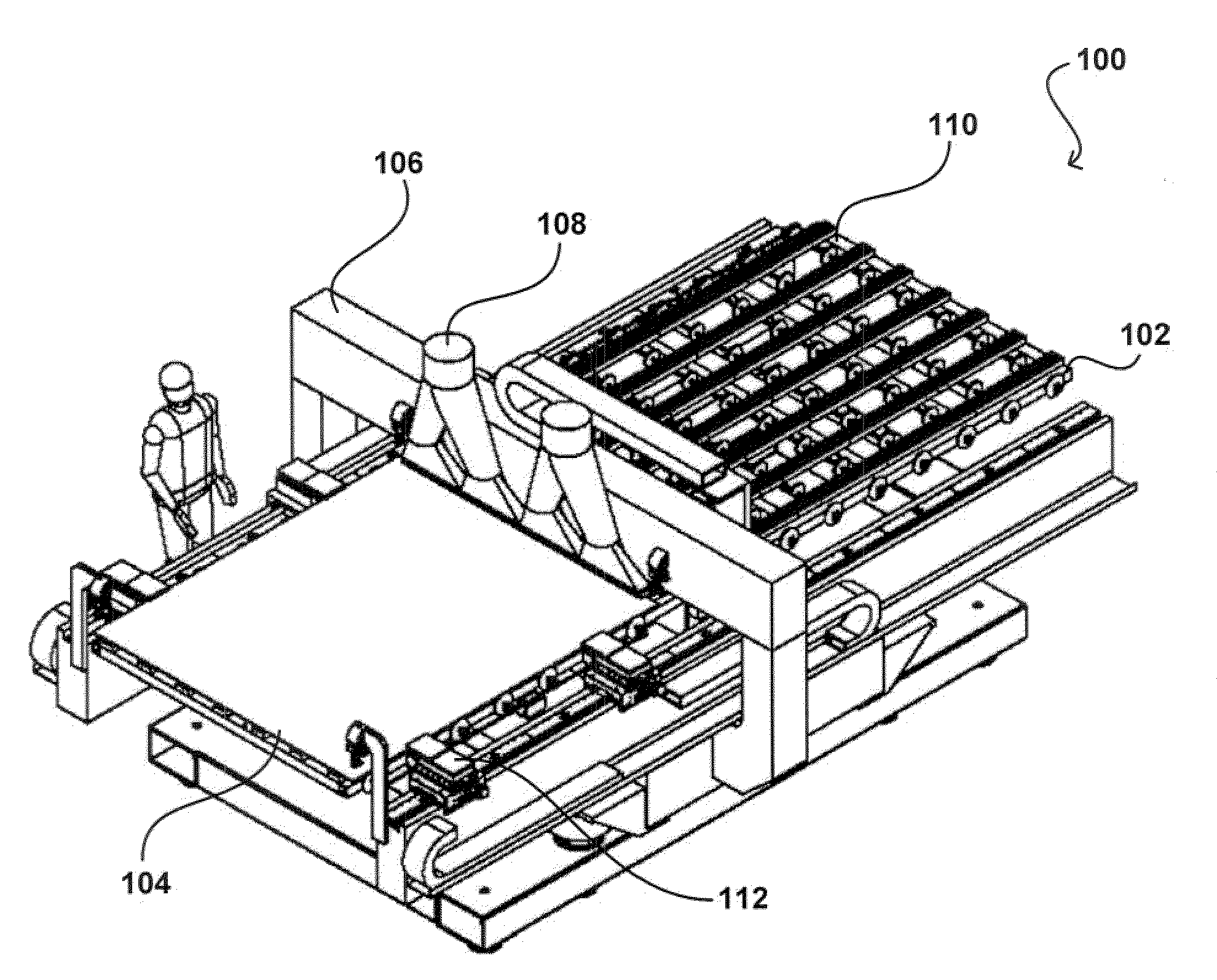

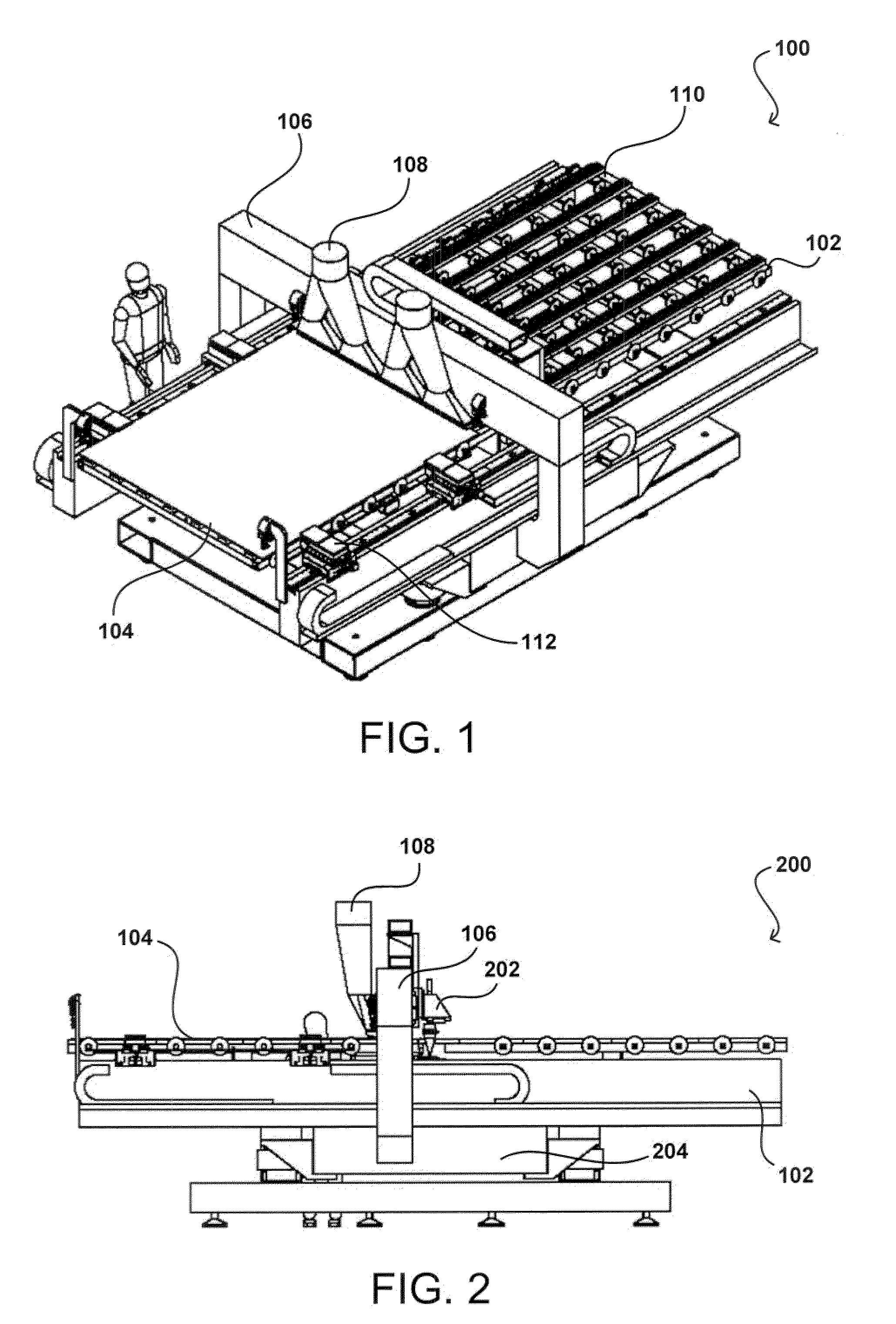

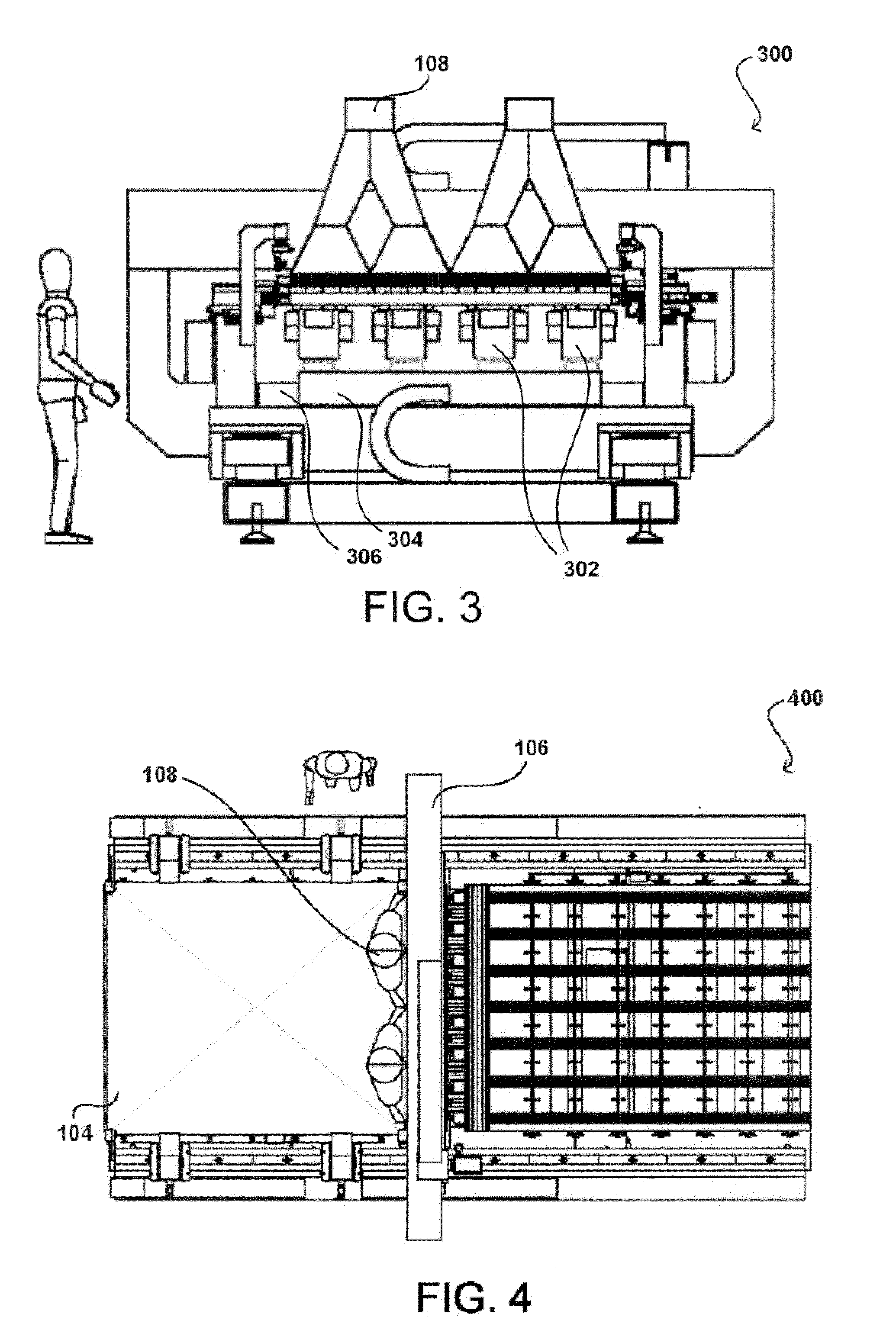

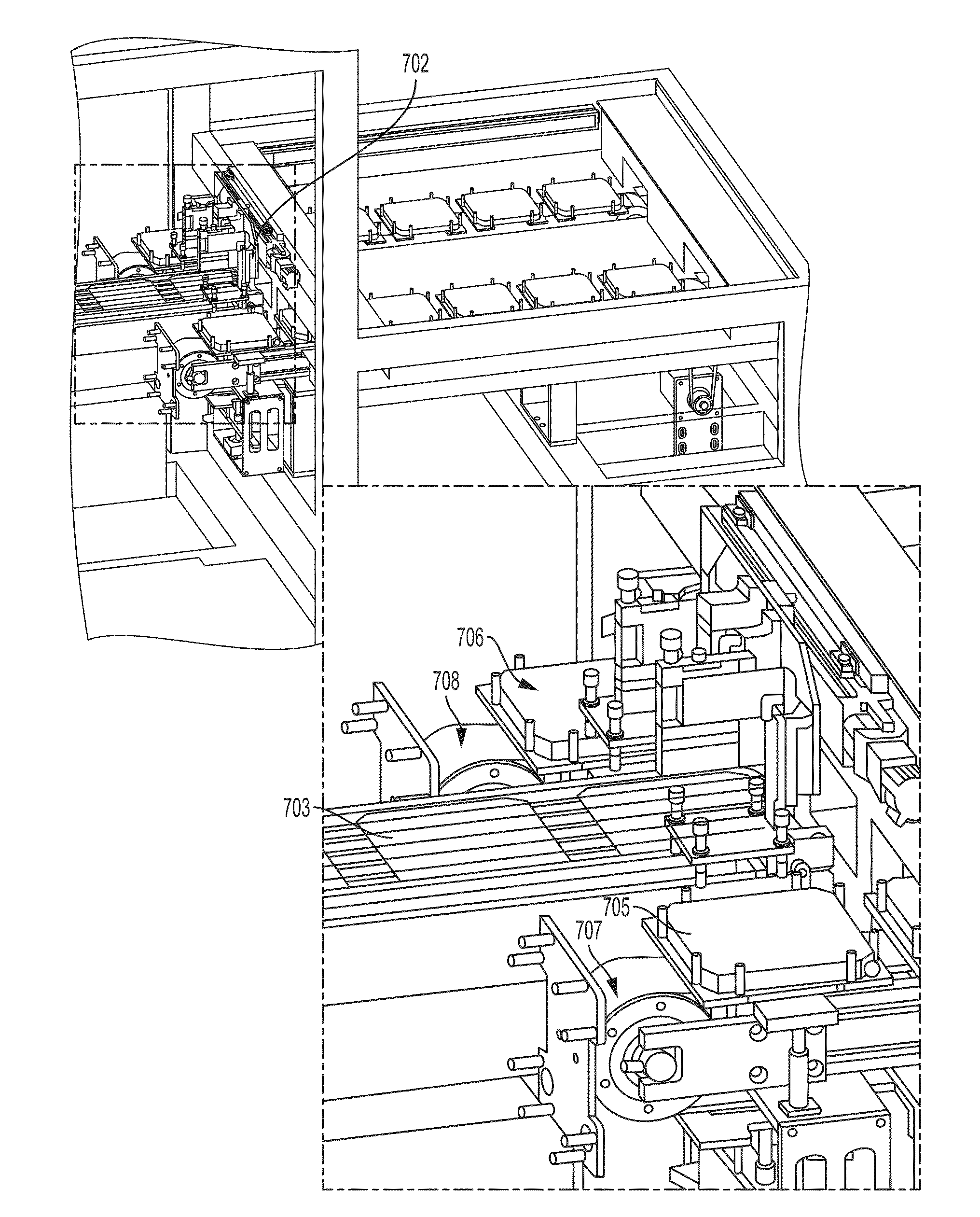

Systems, methods and apparatus for precision automation of manufacturing solar panels

Systems and methods for manufacturing solar panels are disclosed. Solar cells are placed on a conveyor that transports the cells from a start point to an end point. A laser scribing module scribes the cells at a predetermined depth. A paste dispensing module deposits a predetermined amount of conductive paste on the surface of the solar cells. A cleaving apparatus divides the cells into smaller strips. A shingling module creates a string of cells by overlapping the strips. A targeted annealing module cures the paste, and a layup module places the strings on a backsheet. A glass cover is then added to one side of the strings.

Owner:TESLA INC

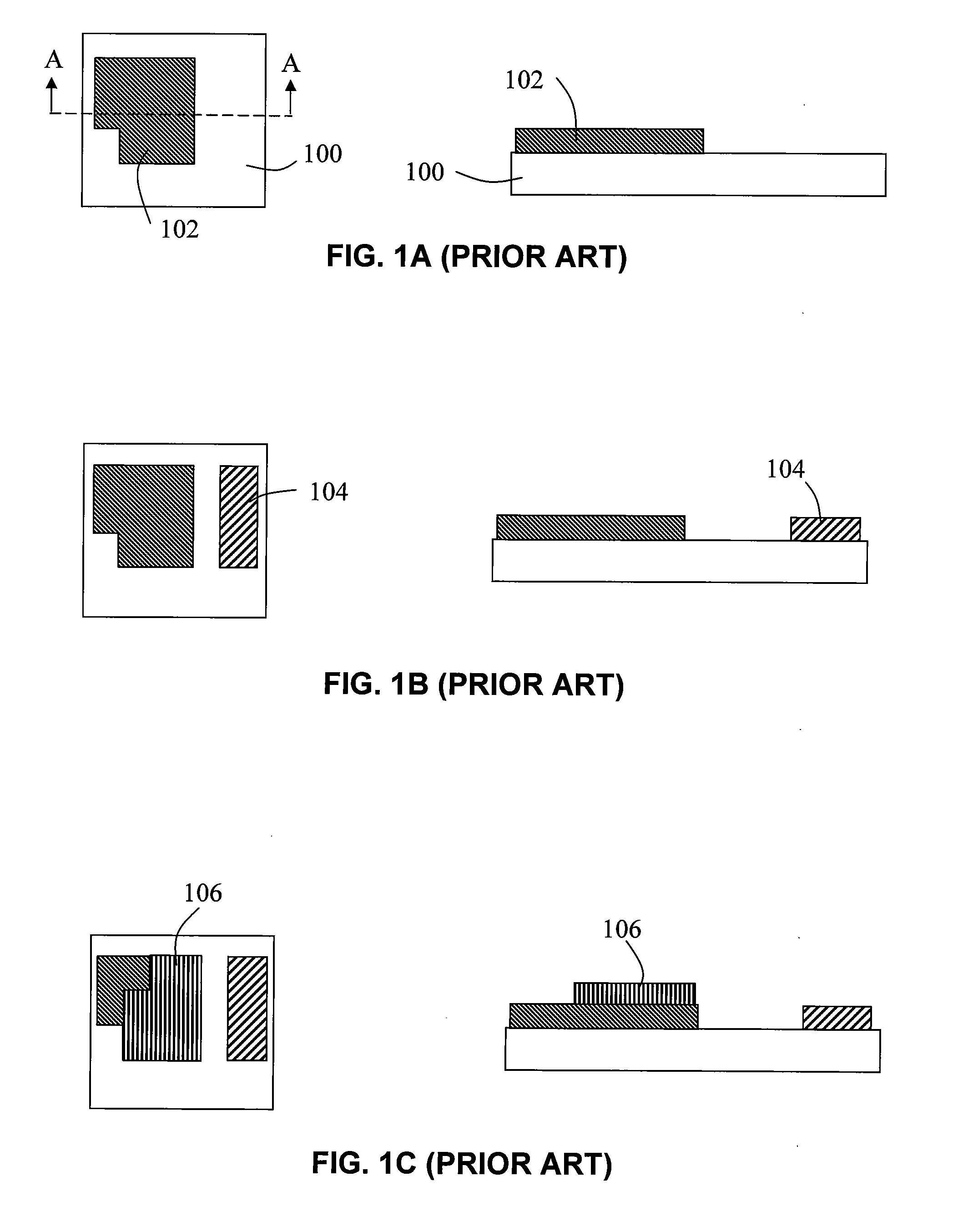

Method and Manufacturing Thin Film Photovoltaic Modules

A method for manufacturing a thin film photovoltaic module comprising series connected cells, the cells comprising a front contact, a back contact and a photovoltaically active region positioned between the front and back contacts, the series connected cell being formed by scribing a front contact layer, a photovoltaically active layer and a back contact layer on a substrate, the method comprising laser scribing at least one of the front contact layer, the photovoltaically active layer or the back contact layer to form laser scribes using a laser beam scanned rapidly over the layer.

Owner:BP CORP NORTH AMERICA INC

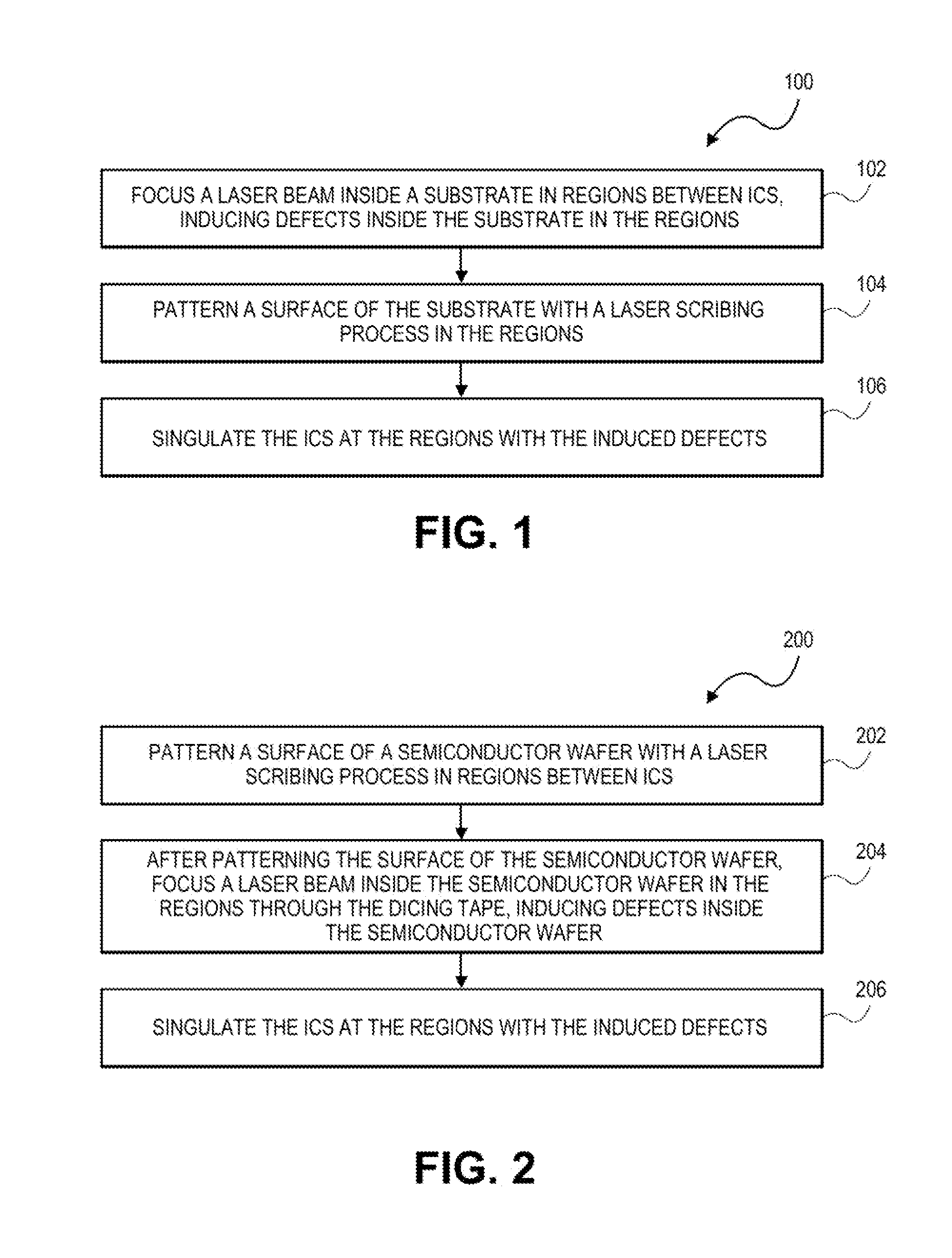

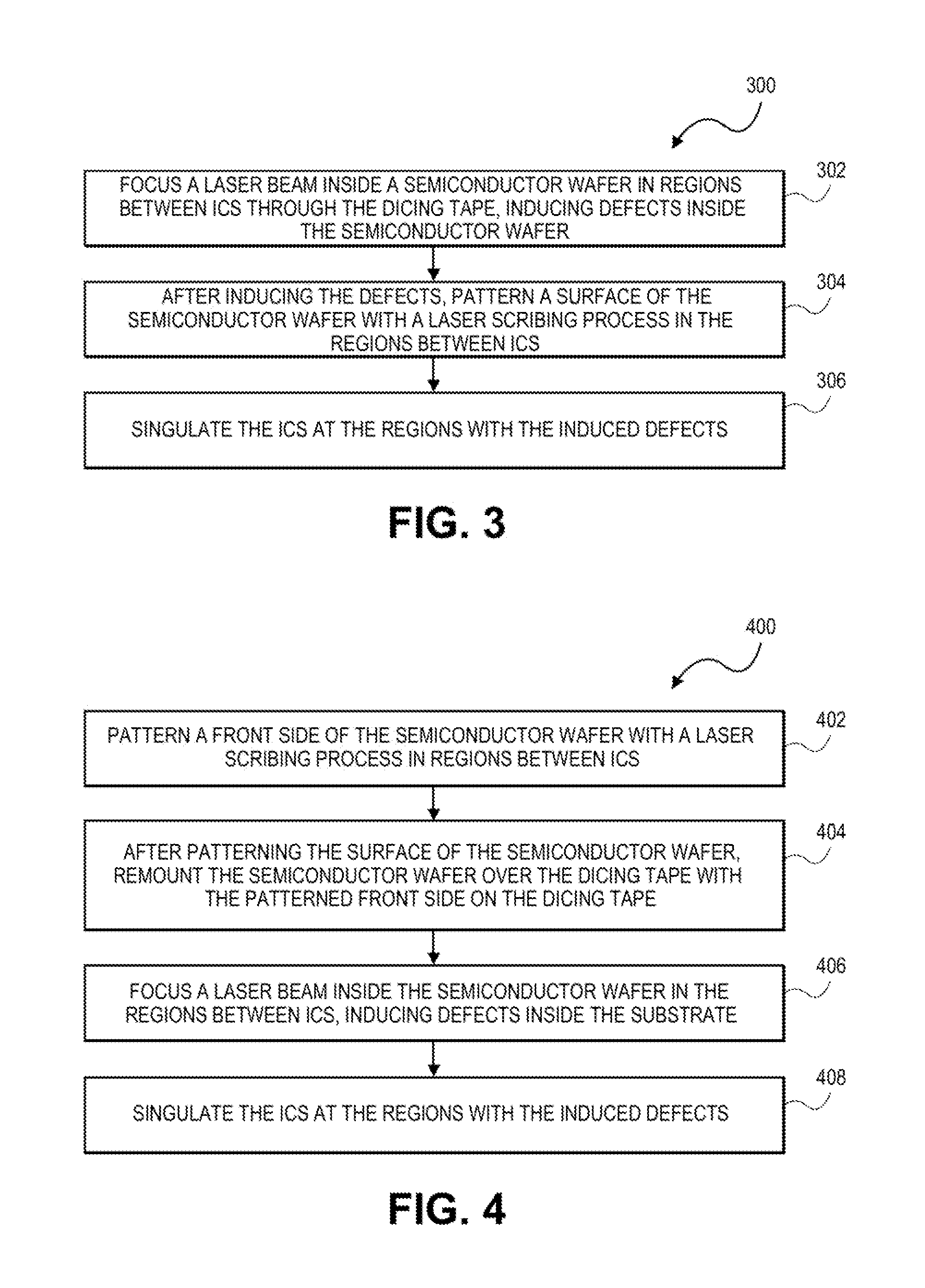

Method of die singulation using laser ablation and induction of internal defects with a laser

ActiveUS9165832B1Semiconductor/solid-state device detailsSolid-state devicesLaser scribingLaser beams

A method and system of hybrid laser dicing are described. In one embodiment, a method includes focusing a laser beam inside a substrate in regions between integrated circuits, inducing defects inside the substrate in the regions. The method involves patterning a surface of the substrate with a laser scribing process in the regions after inducing the defects in the substrate. The method further involves singulating the integrated circuits at the regions with the induced defects. In another embodiment, a system includes a first laser module configured to focus a laser beam inside a substrate in regions between integrated circuits, inducing defects inside the substrate in the regions. A second laser module is configured to pattern a surface of the substrate with a laser scribing process in the regions after inducing the defects. A tape extender is configured to stretch tape over which the substrate is mounted, singulating the integrated circuits.

Owner:APPLIED MATERIALS INC

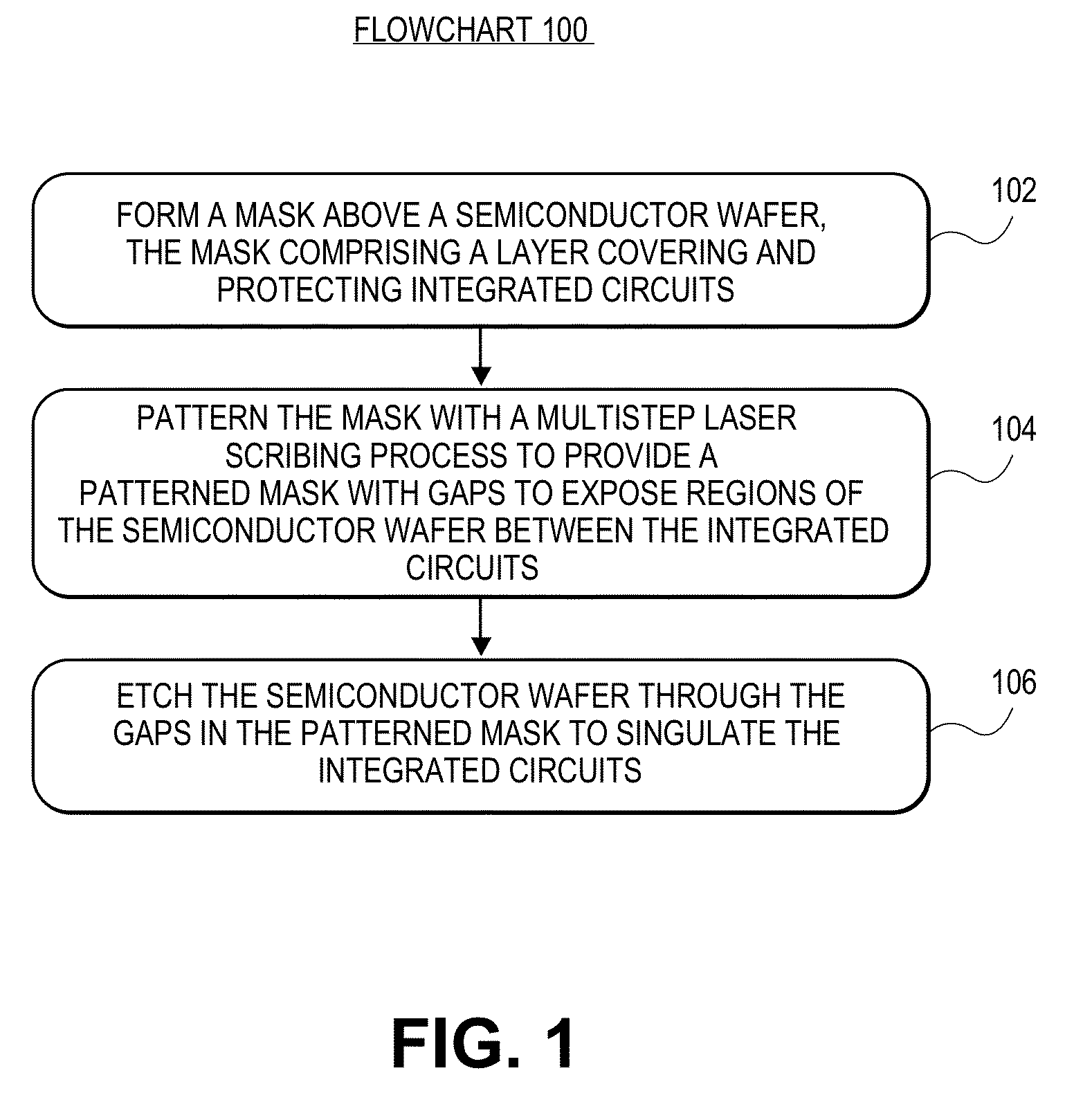

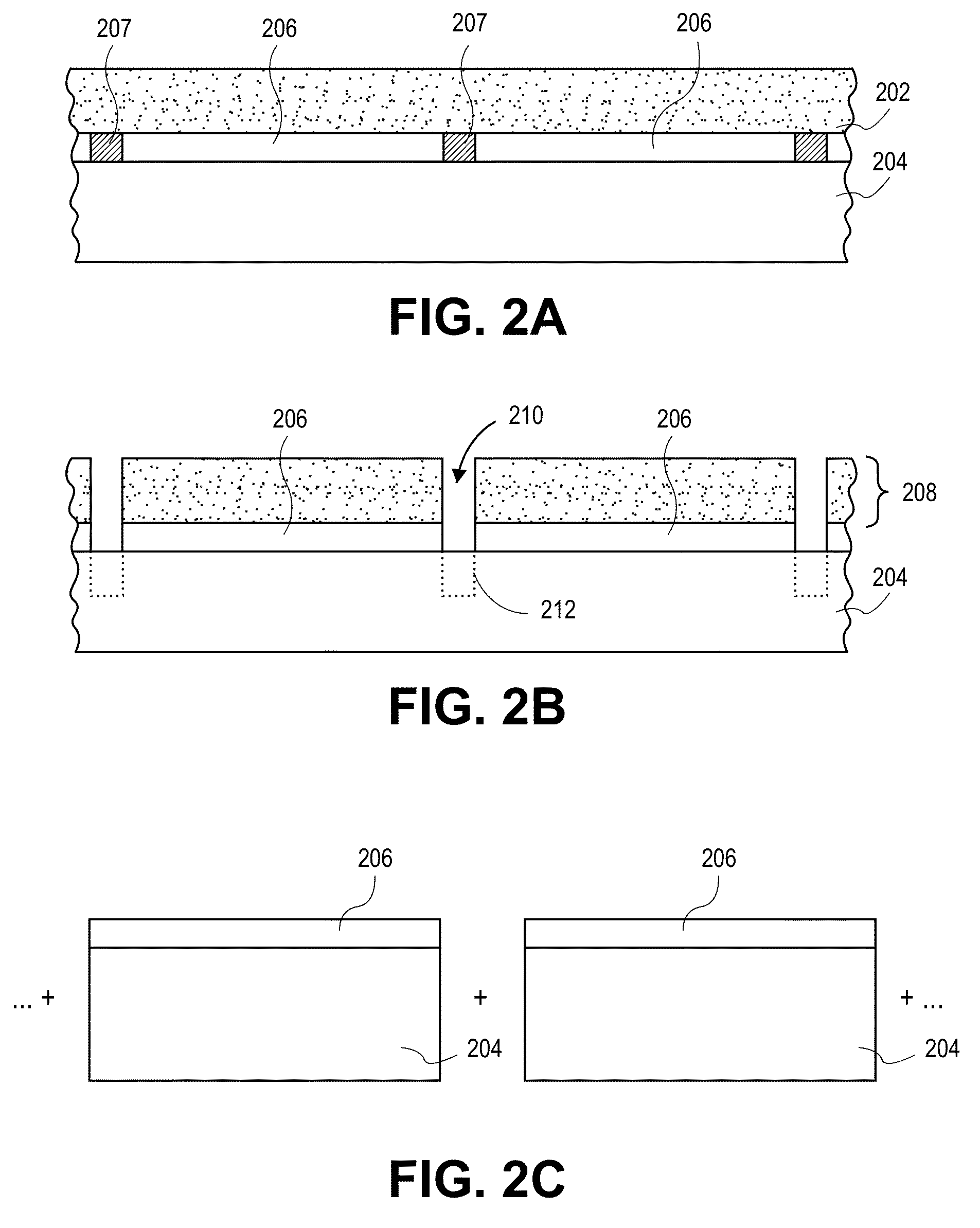

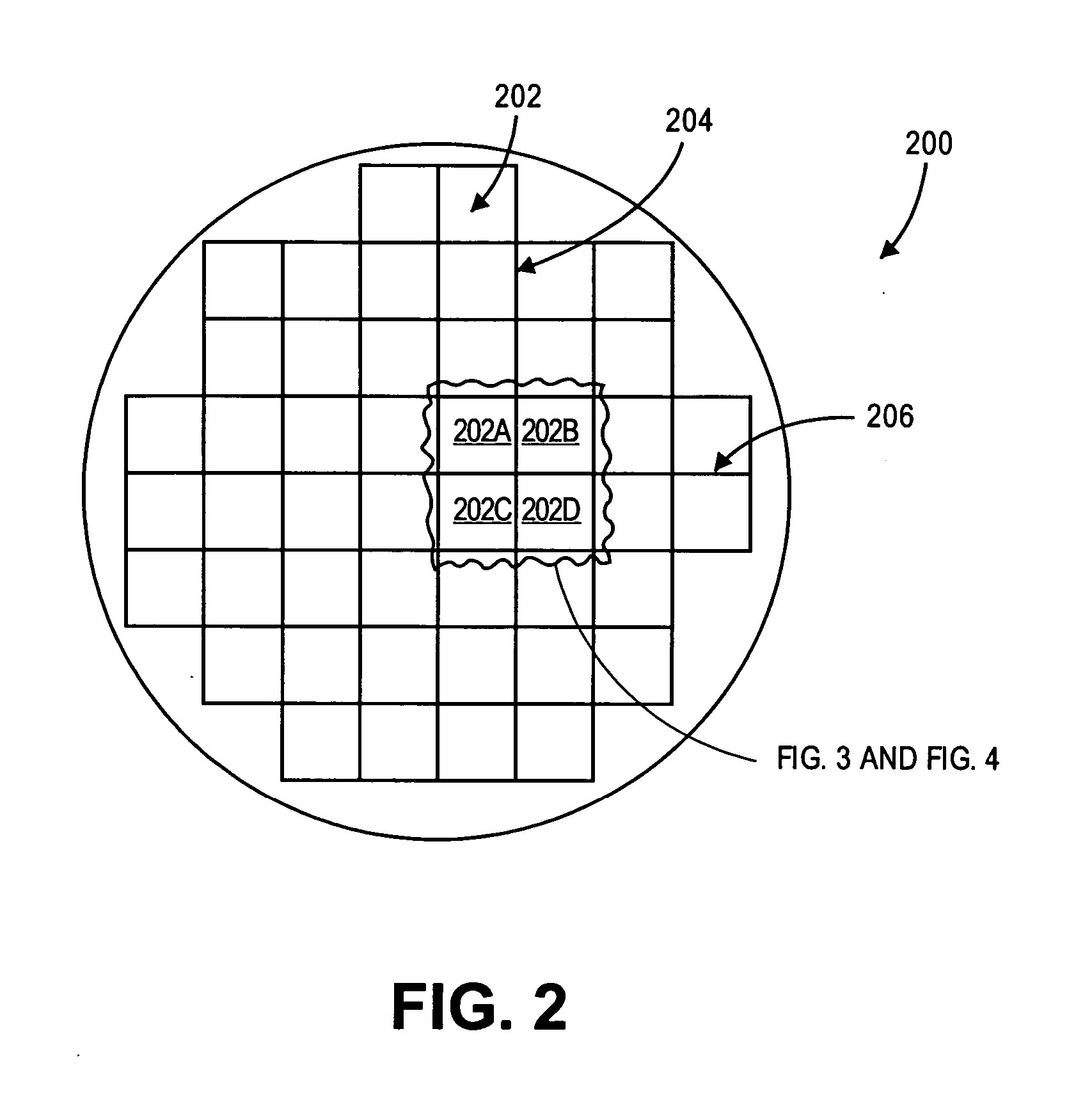

Wafer dicing using hybrid multi-step laser scribing process with plasma etch

ActiveUS20130267076A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesWafer dicingLaser scribing

Methods of dicing semiconductor wafers, each wafer having a plurality of integrated circuits, are described. A method includes forming a mask above the semiconductor wafer. The mask is composed of a layer covering and protecting the integrated circuits. The mask is patterned with a multi-step laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the semiconductor wafer between the integrated circuits. The semiconductor wafer is then etched through the gaps in the patterned mask to singulate the integrated circuits.

Owner:APPLIED MATERIALS INC

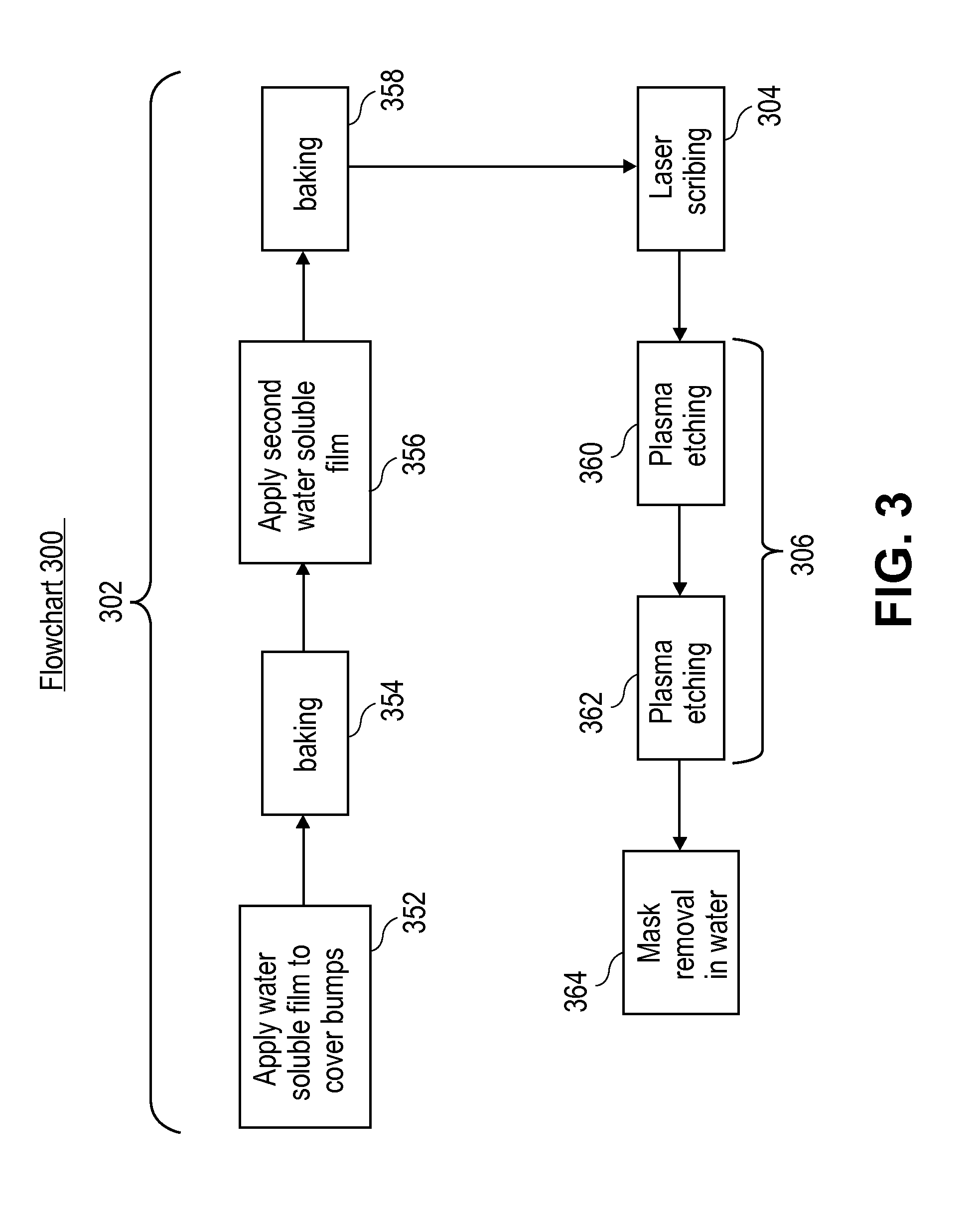

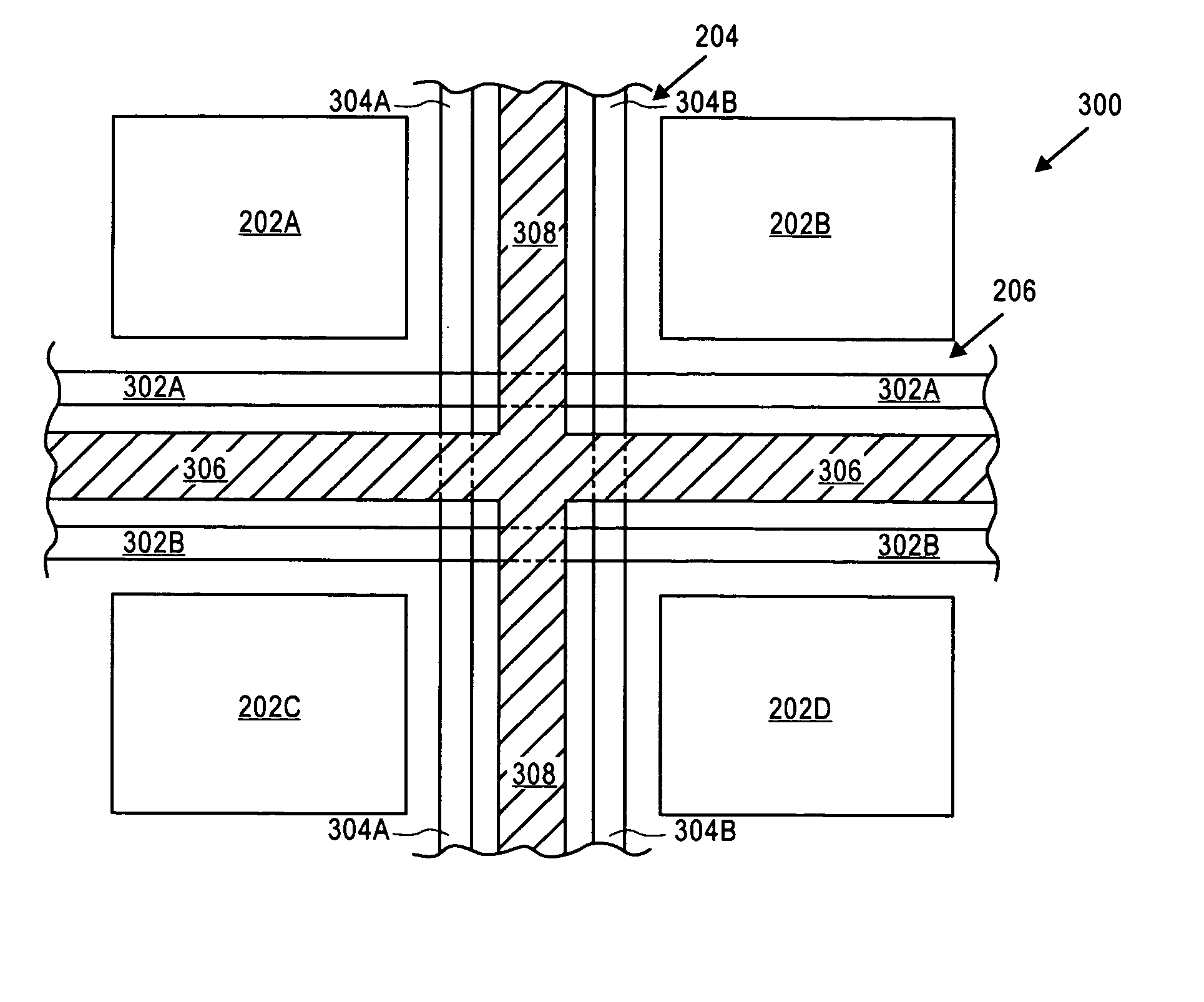

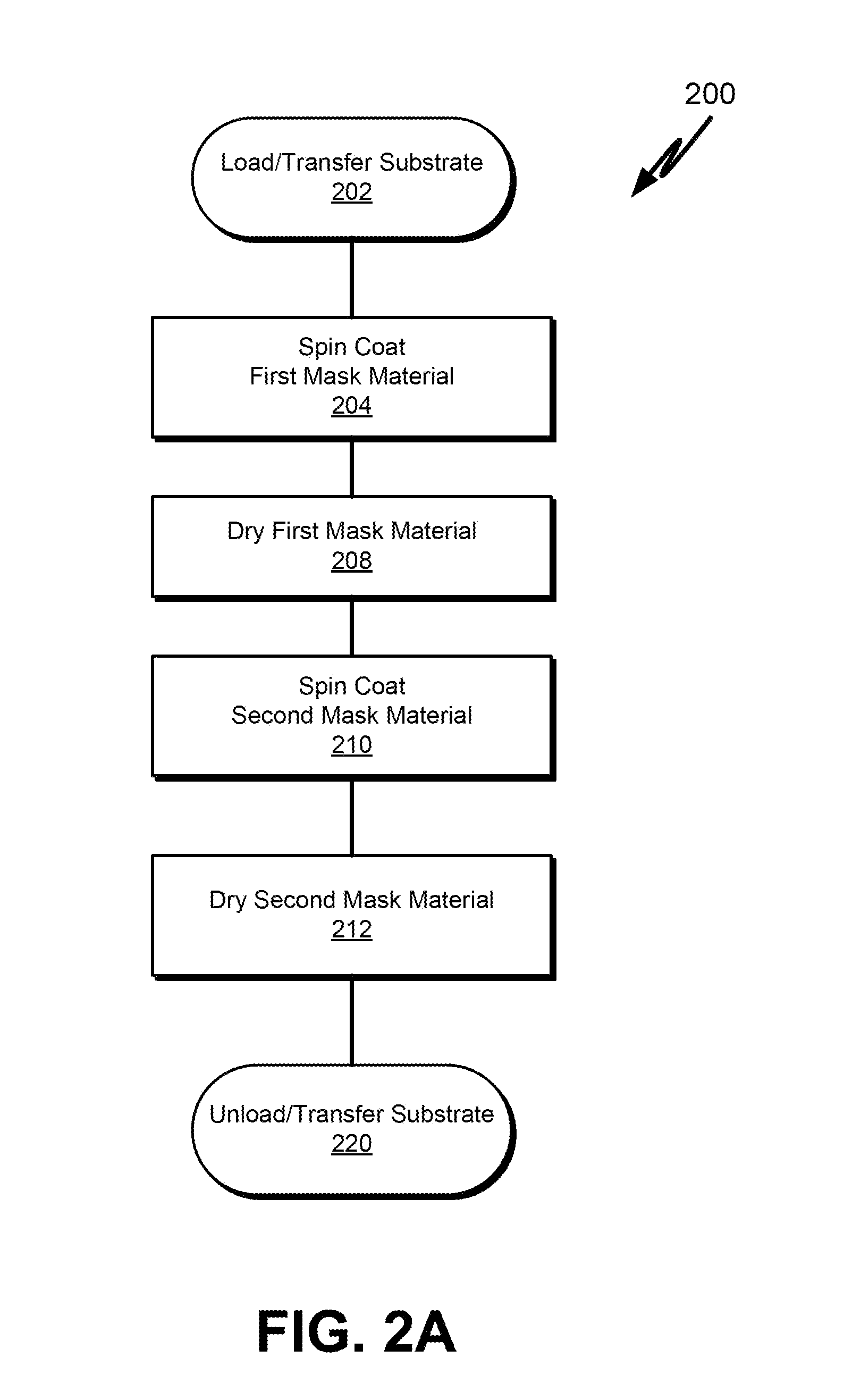

Method of coating water soluble mask for laser scribing and plasma etch

Methods of using a hybrid mask composed of a first water soluble film layer and a second water-soluble layer for wafer dicing using laser scribing and plasma etch described. In an example, a method of dicing a semiconductor wafer having a plurality of integrated circuits involves forming a hybrid mask above the semiconductor wafer. The hybrid mask is composed of a first water-soluble layer disposed on the integrated circuits, and a second water-soluble layer disposed on the first water-soluble layer. The method also involves patterning the hybrid mask with a laser scribing process to provide a patterned hybrid mask with gaps, exposing regions of the semiconductor wafer between the integrated circuits. The method also involves etching the semiconductor wafer through the gaps in the patterned hybrid mask to singulate the integrated circuits.

Owner:APPLIED MATERIALS INC

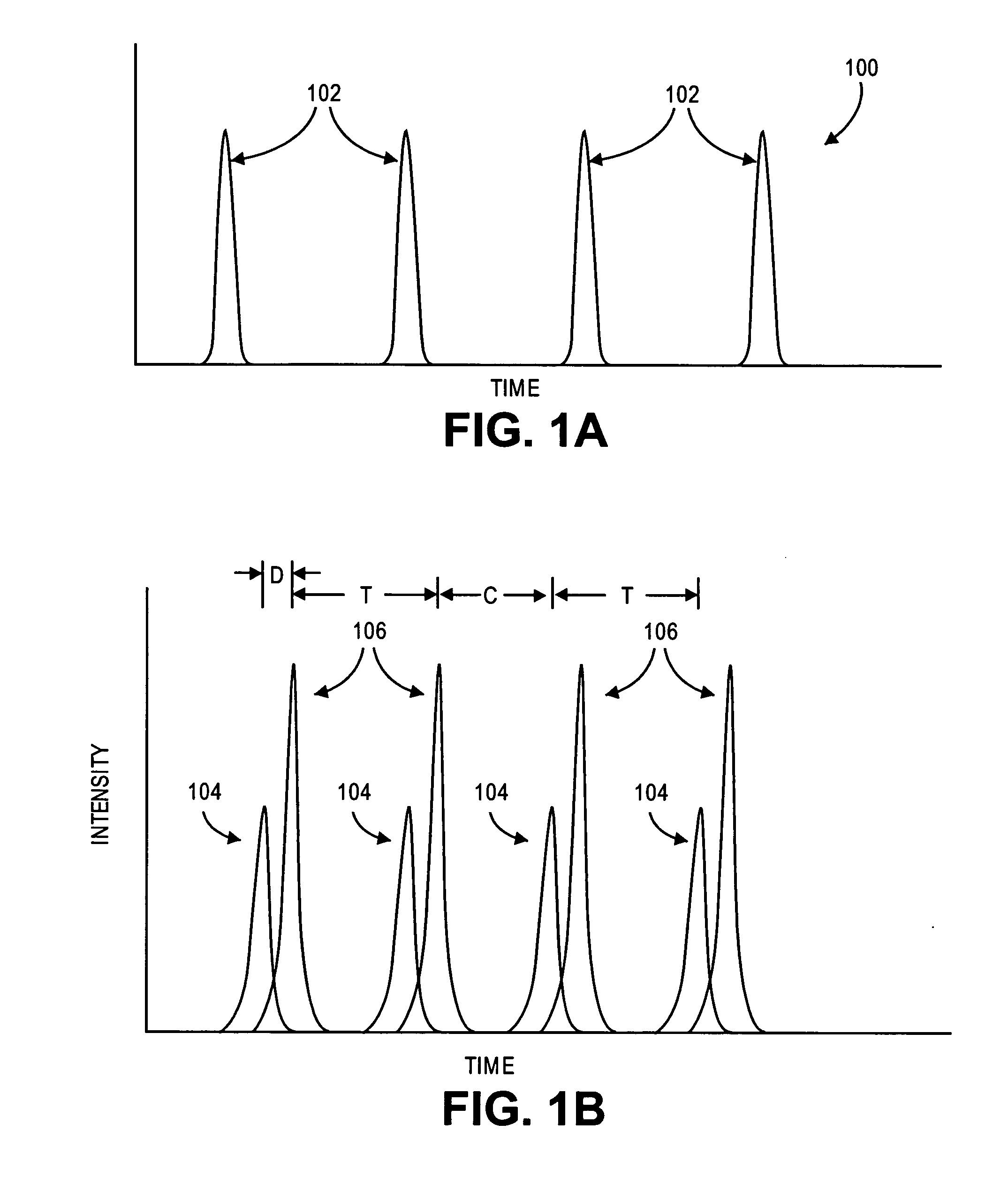

Dual pulsed beam laser micromachining method

InactiveUS20060249816A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsLaser scribing

Owner:INTEL CORP

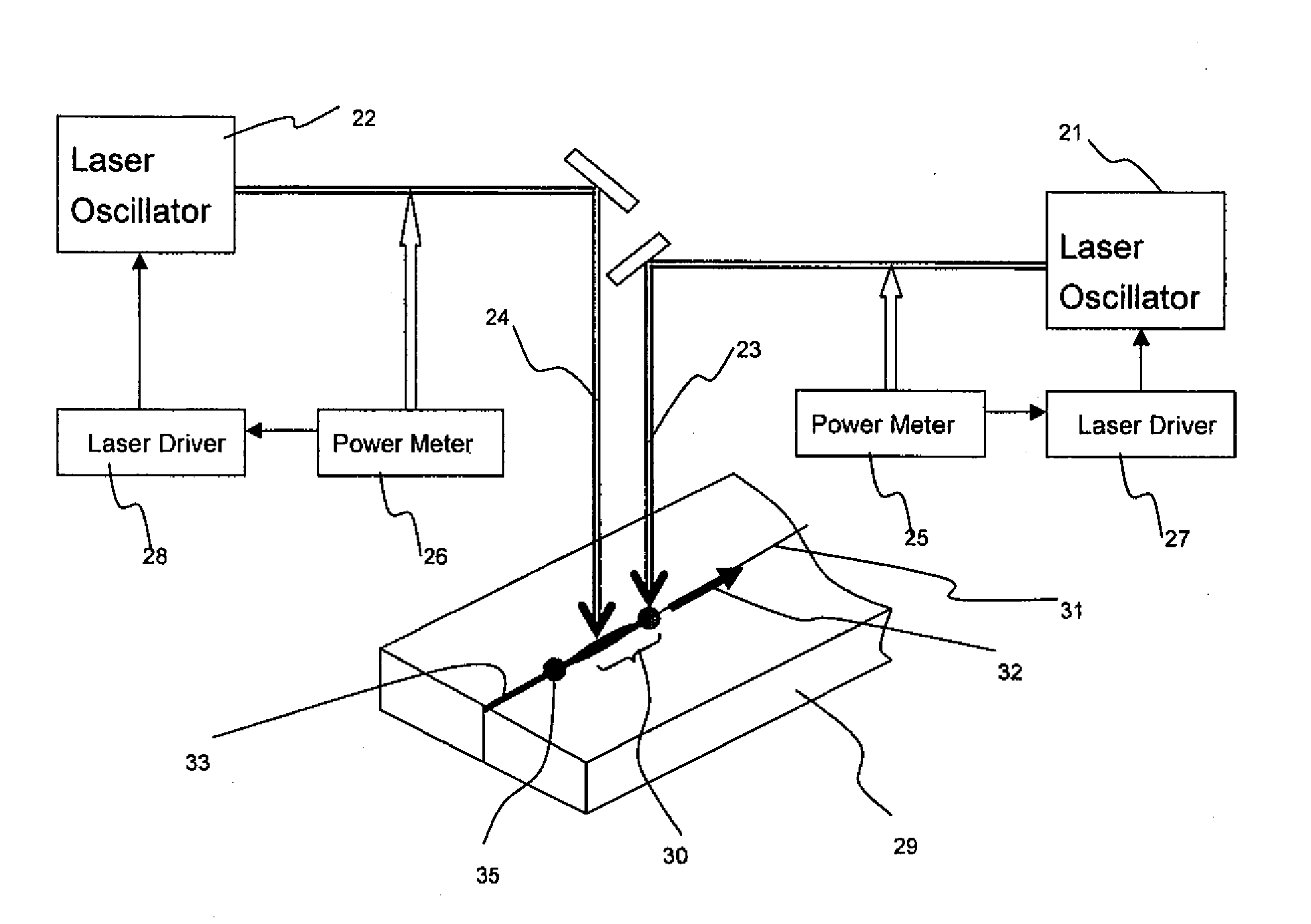

Laser micromachining method

InactiveUS20060091125A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesHigh energyLaser scribing

A method is described for laser scribing or dicing portions of a workpiece using multi-source laser systems. In one embodiment, a first laser uses multiphoton absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece. In an alternative embodiment, a first laser uses high energy single-photon absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece.

Owner:INTEL CORP

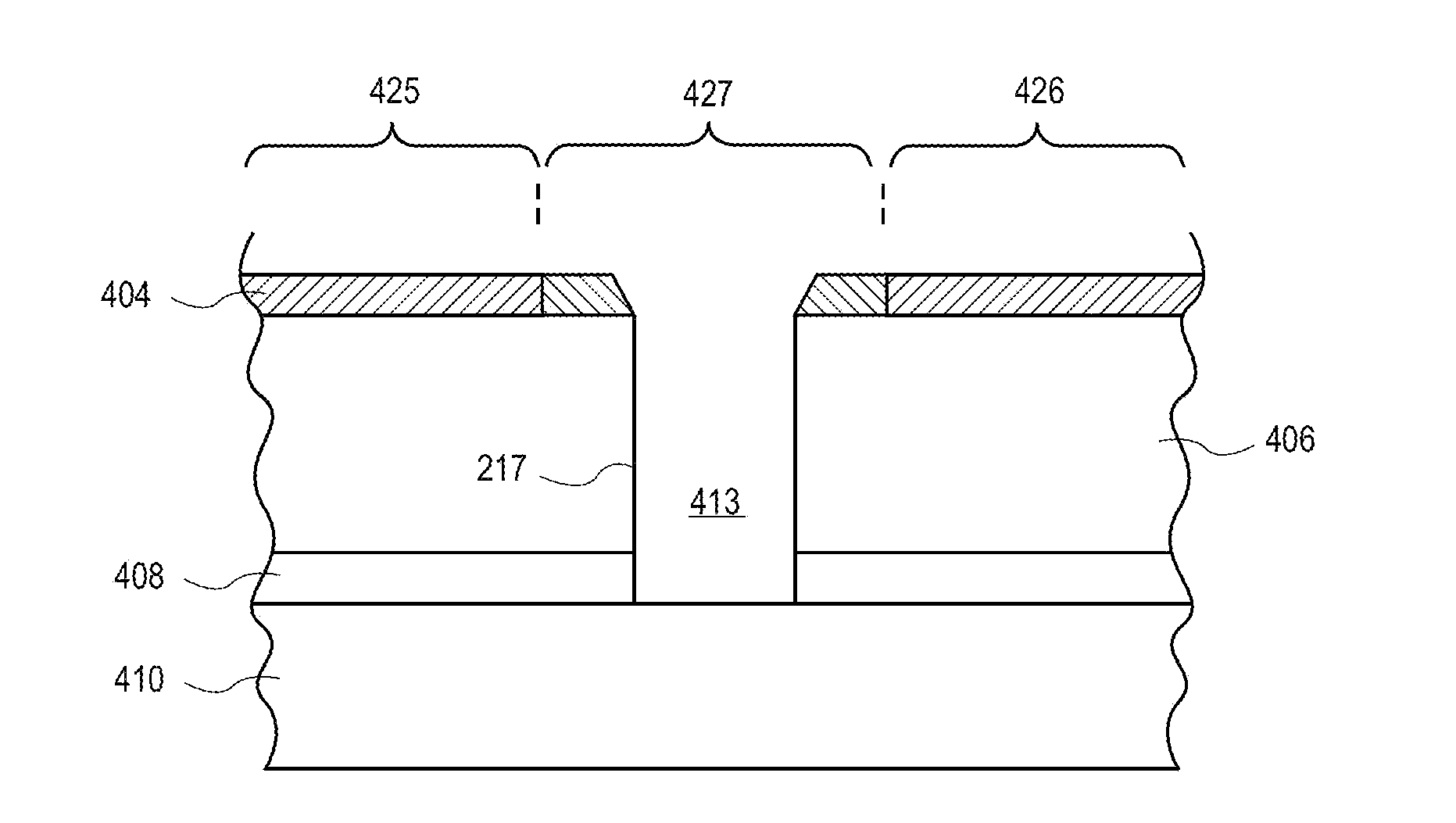

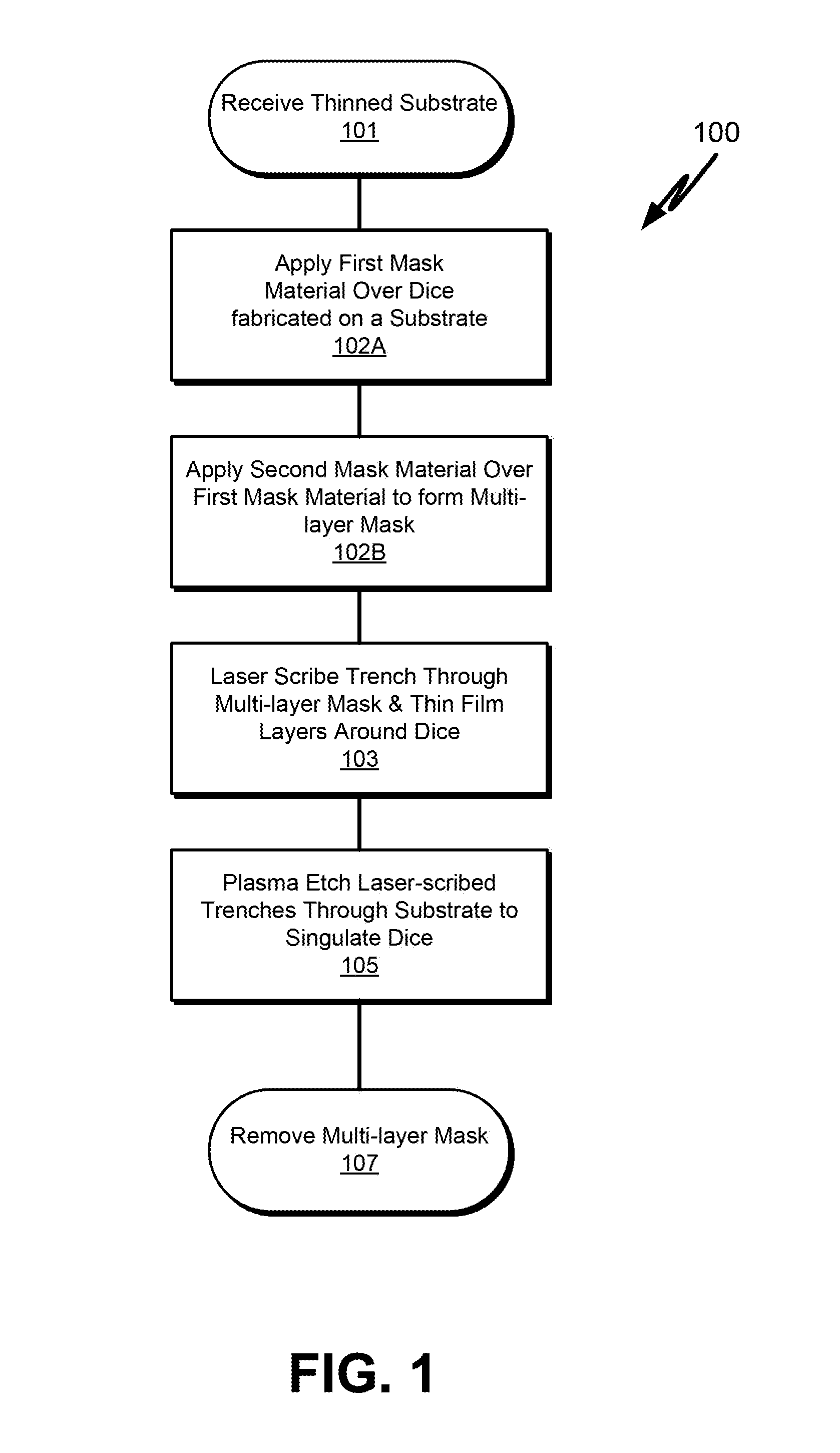

Multi-layer mask for substrate dicing by laser and plasma etch

ActiveUS20120322241A1Solid-state devicesSemiconductor/solid-state device manufacturingLaser scribingSemiconductor

Methods of dicing substrates having a plurality of ICs. A method includes forming a multi-layered mask comprising a first mask material layer soluble in a solvent over the semiconductor substrate and a second mask material layer, insoluble in the solvent, over the first mask material layer. The multi-layered mask is patterned with a laser scribing process to provide a patterned mask with gaps. The patterning exposes regions of the substrate between the ICs. The substrate is then plasma etched through the gaps in the patterned mask to singulate the IC with the second mask material layer protecting the first mask material layer for at least a portion of the plasma etch. The soluble material layer is dissolved subsequent to singulation to remove the multi-layered mask.

Owner:APPLIED MATERIALS INC

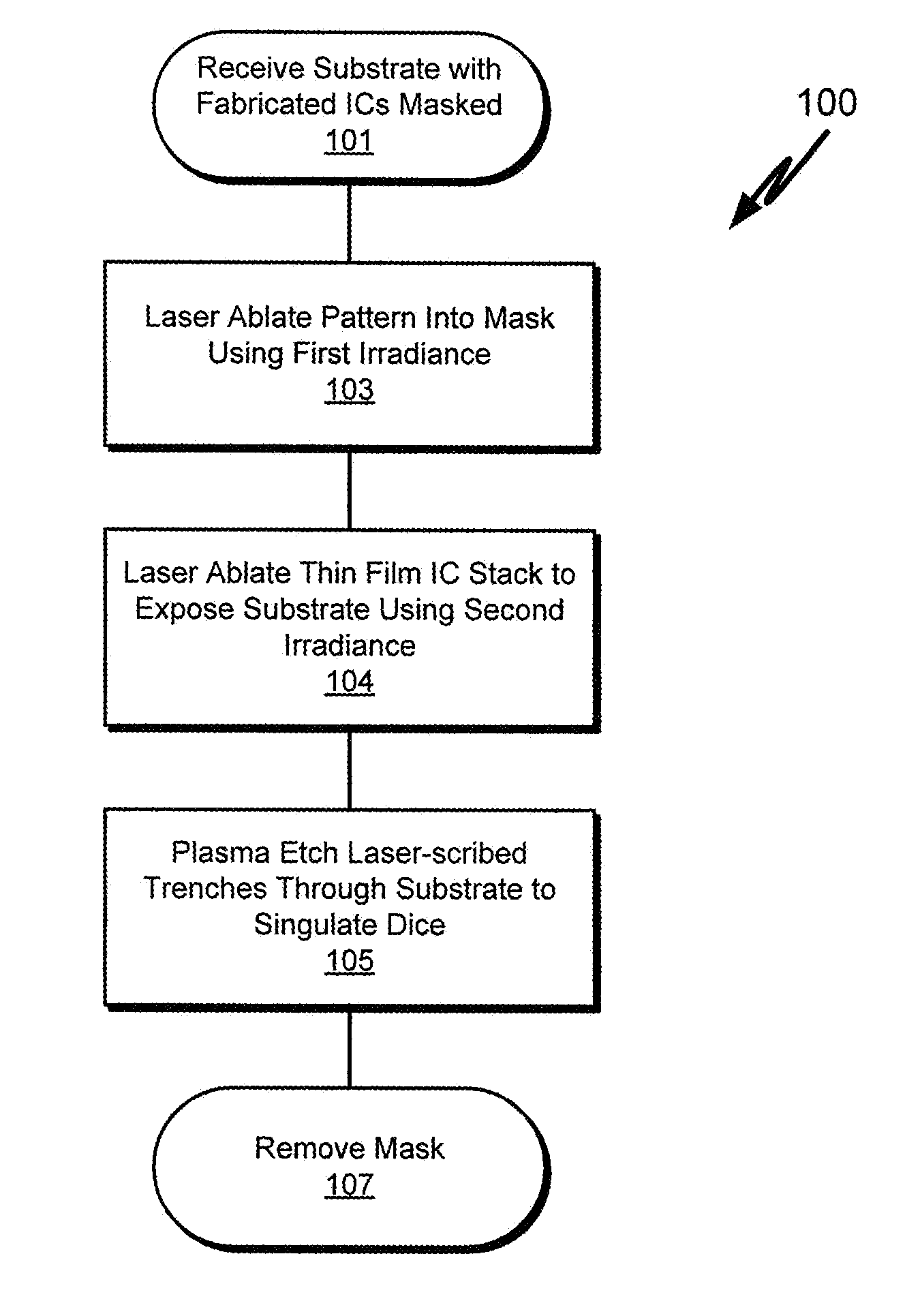

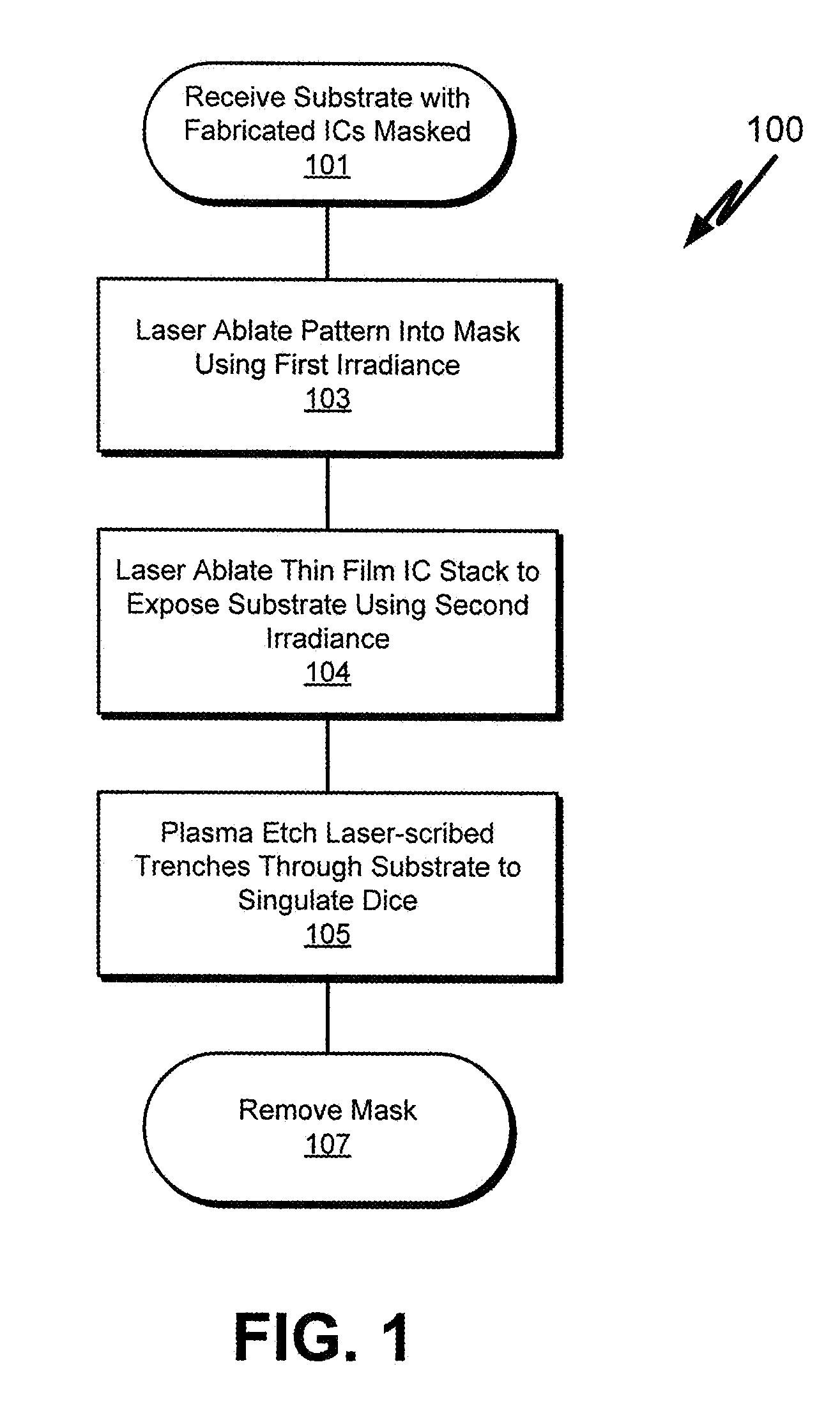

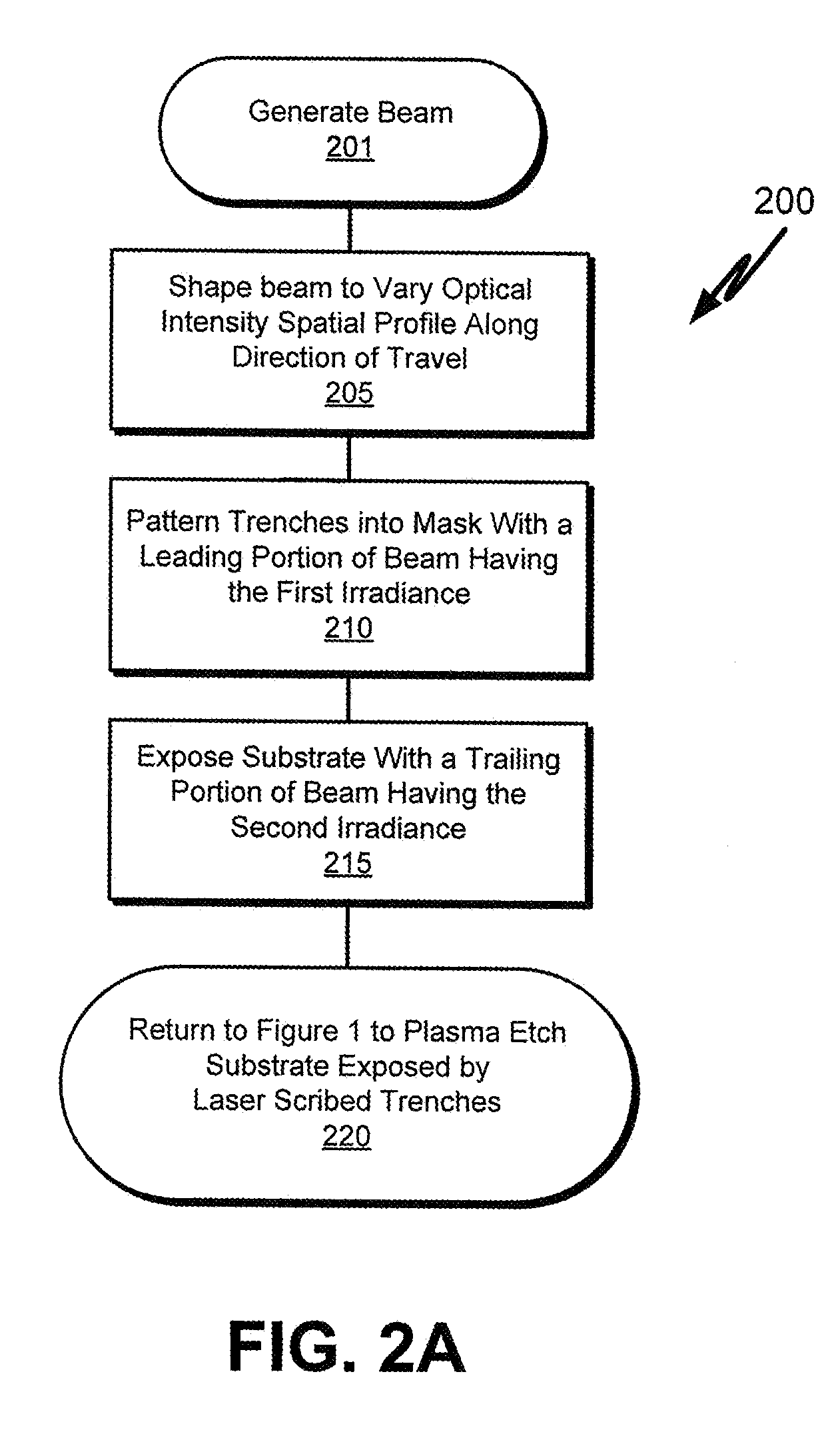

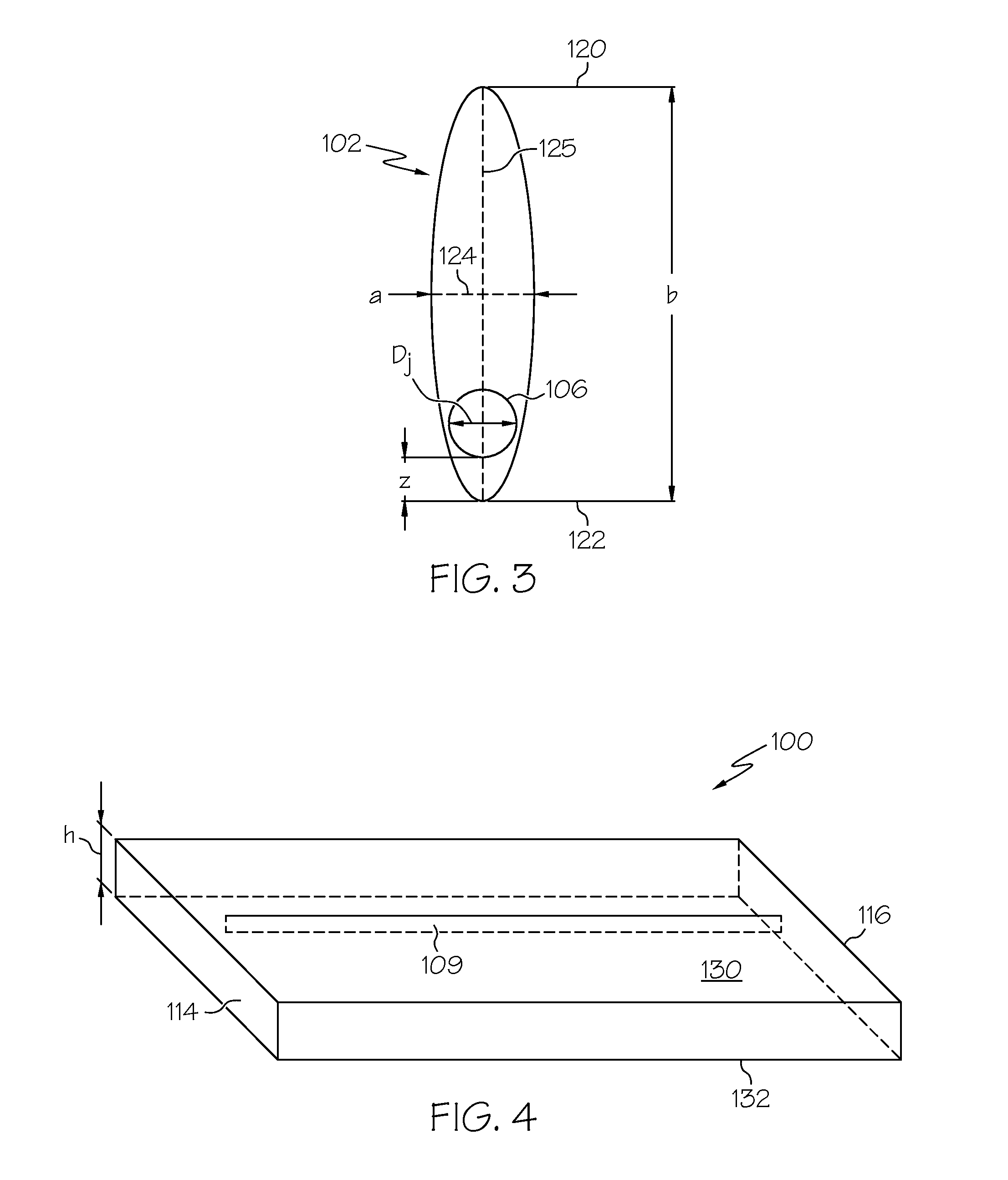

Multi-step and asymmetrically shaped laser beam scribing

ActiveUS20120322242A1Increase irradianceKerf width be reduced and increasedSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesBeam splitterOptoelectronics

Methods of dicing substrates by both laser scribing and plasma etching. A method includes laser ablating material layers, the ablating leading with a first irradiance and following with a second irradiance, lower than the first. Multiple passes of a beam adjusted to have different fluence level or multiple laser beams having various fluence levels may be utilized to ablate mask and IC layers to expose a substrate with the first fluence level and then clean off redeposited materials from the trench bottom with the second fluence level. A laser scribe apparatus employing a beam splitter may provide first and second beams of different fluence from a single laser.

Owner:APPLIED MATERIALS INC

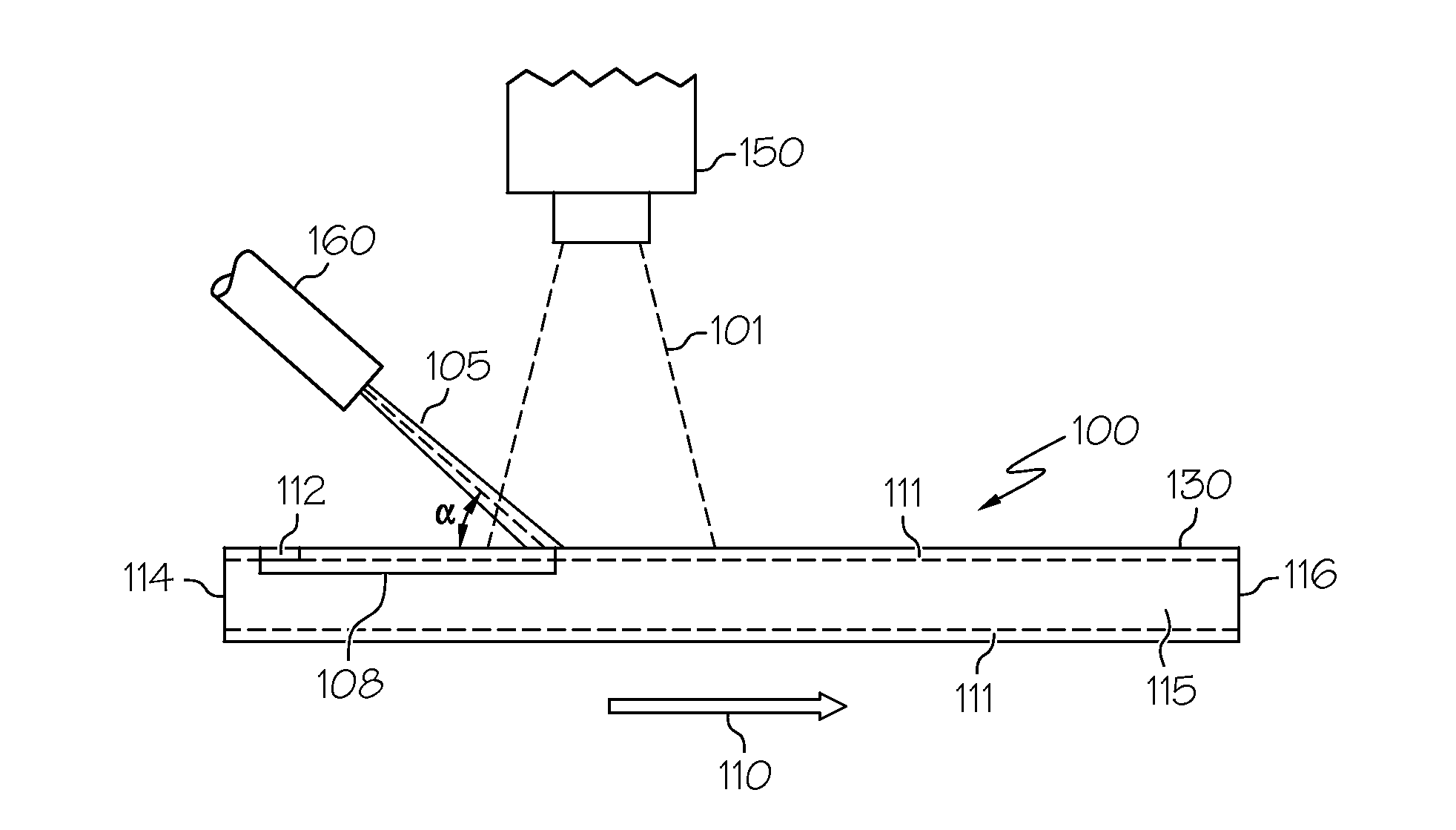

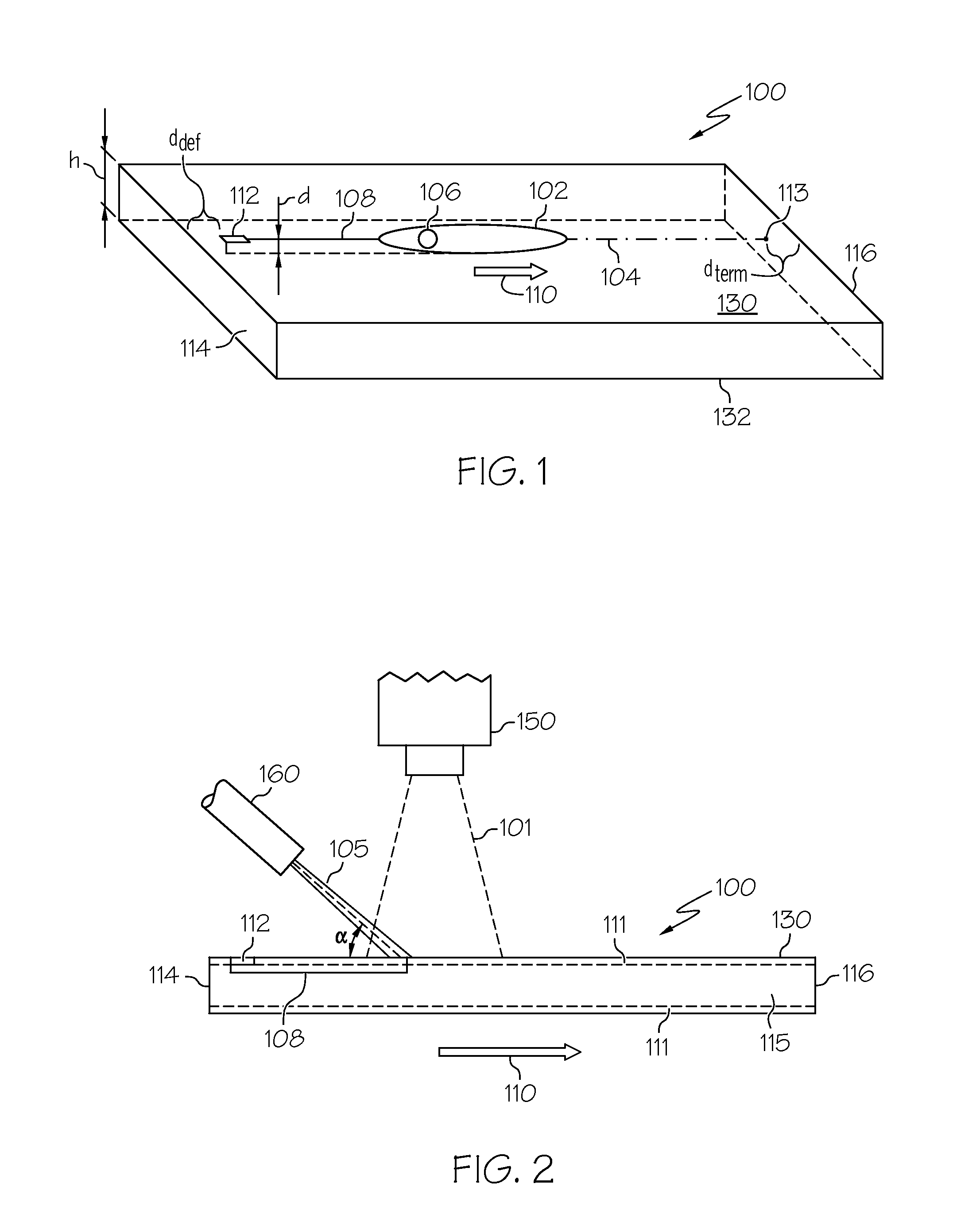

Methods for laser scribing and separating glass substrates

InactiveUS20110127242A1Avoid it happening againGlass severing apparatusLaser beam welding apparatusSurface layerOptoelectronics

A method of forming a scribe line in a glass substrate having a compressive surface layer and an inner tension layer includes forming a defect through the compressive surface layer that is offset from a first edge of the glass substrate. The defect extends through the compressive surface layer to partially expose the inner tension layer. A scribe line is generated through the compressive surface layer by translating the glass substrate with respect to a laser beam and a cooling jet. The scribe line is initiated at the defect and is terminated at a termination location along the scribe line that is offset from a second edge of the glass substrate.

Owner:CORNING INC

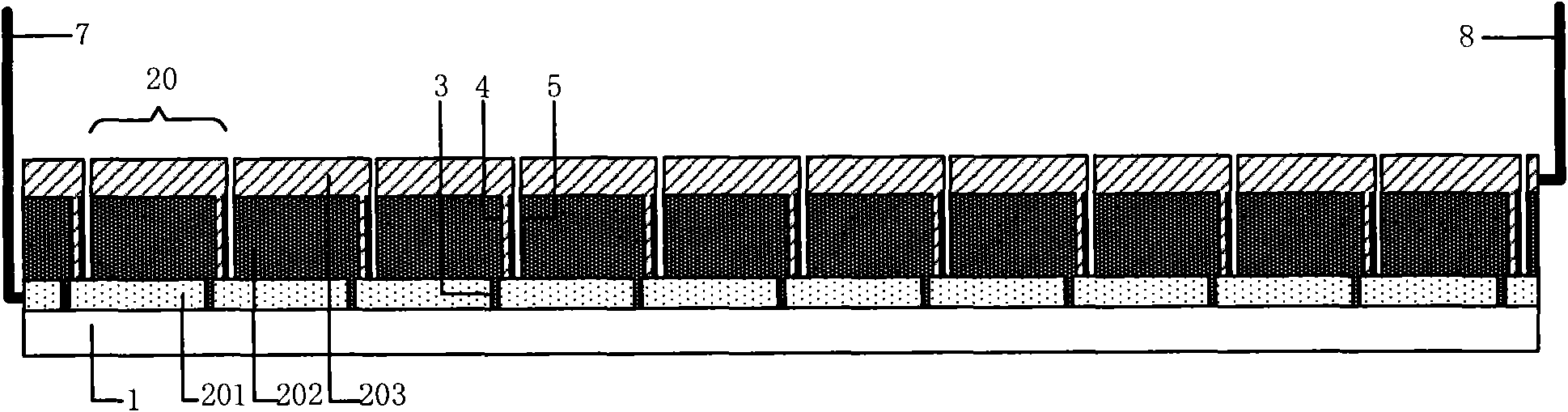

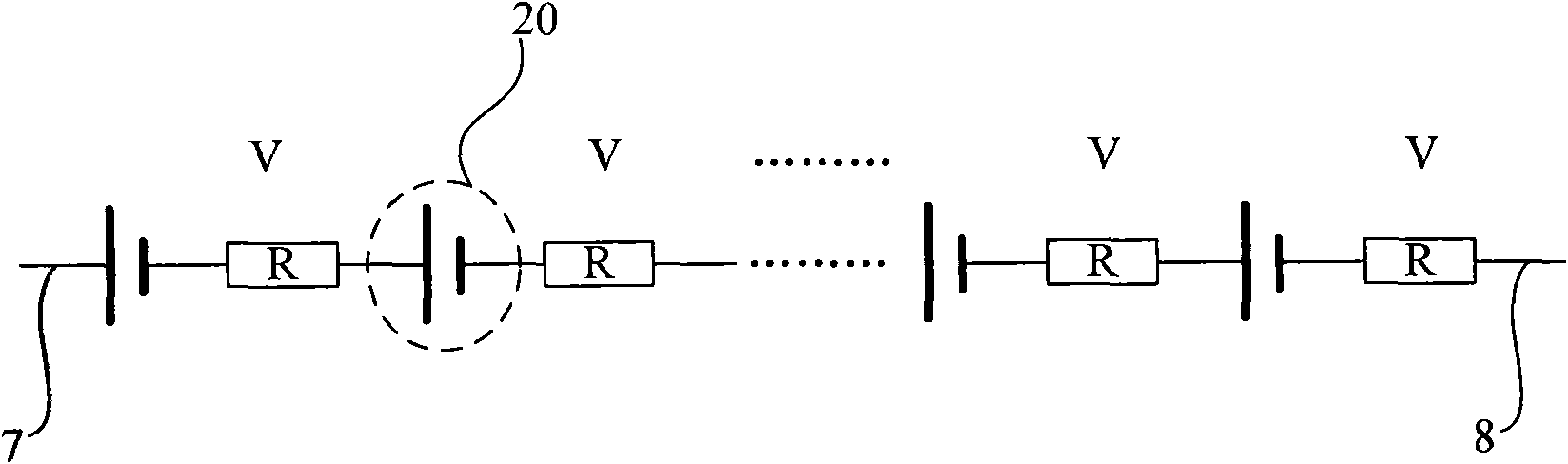

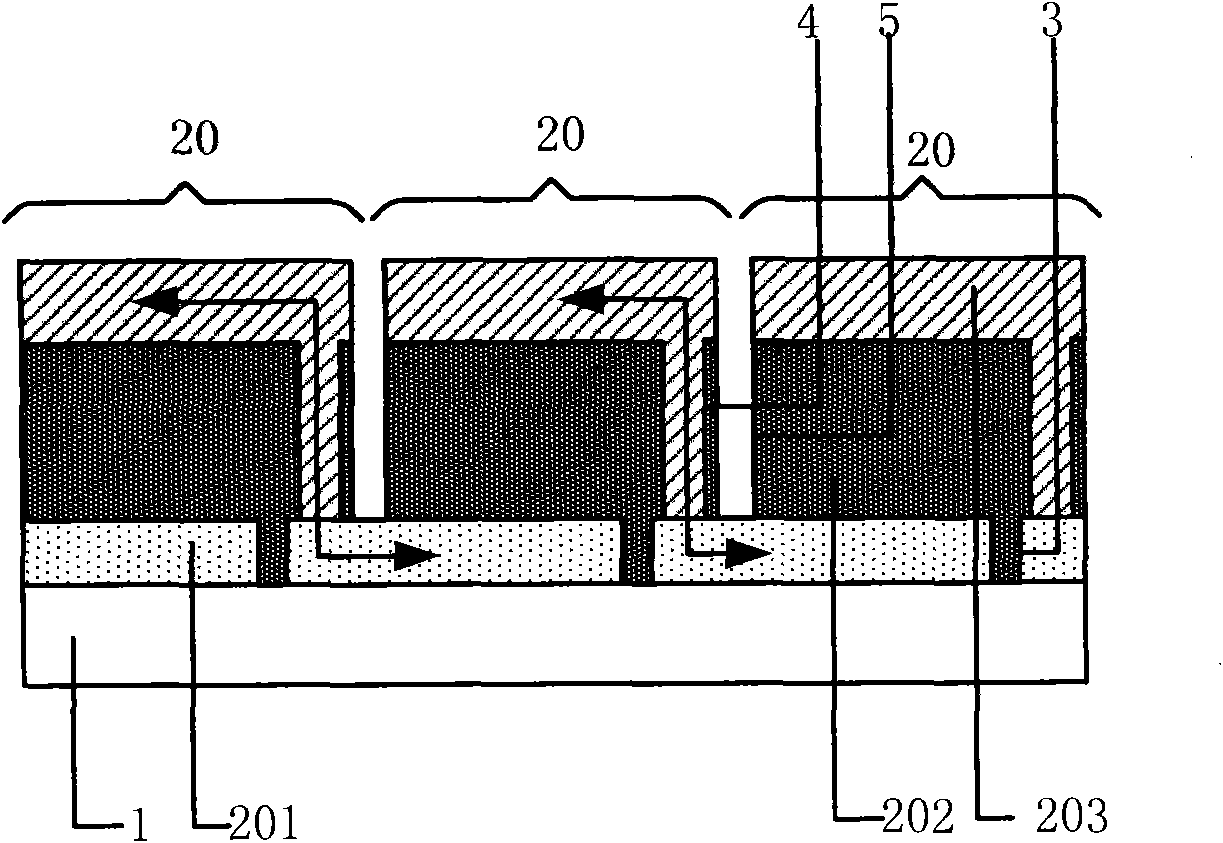

Solar battery assembly and preparation method thereof

ActiveCN102117815AEnsure safetyFinal product manufactureSemiconductor/solid-state device manufacturingPower flowElectrical battery

The invention relate to a solar battery assembly and a preparation method thereof. The solar battery assembly comprises a plurality of solar batteries and at least one fourth laser scribing, wherein each solar battery comprises a transparent conductive film, a solar battery layer and a metal back electrode which are sequentially overlapped, and the adjacent solar batteries are connected in serieswith each other through a laser scribing process; the fourth laser scribing penetrates through the metal back electrodes, the solar battery layers and the transparent conductive films, and the adjacent solar batteries are disconnected to form at least two independent battery units, wherein each battery unit comprises the solar batteries connected in series. The solar batteries assembly is dividedinto a plurality of independent battery units through the fourth laser scribing so that each battery unit comprises the specified number of solar batteries connected in series, therefore, the required working voltage and current can be obtained.

Owner:BOE TECH GRP CO LTD +1

Laser micromachining method

InactiveUS7169687B2Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesTwo-photon absorptionHigh energy

A method is described for laser scribing or dicing portions of a workpiece using multi-source laser systems. In one embodiment, a first laser uses multiphoton absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece. In an alternative embodiment, a first laser uses high energy single-photon absorption to lower the ablation threshold of portions of the workpiece prior to a second laser ablating the portions of the workpiece.

Owner:INTEL CORP

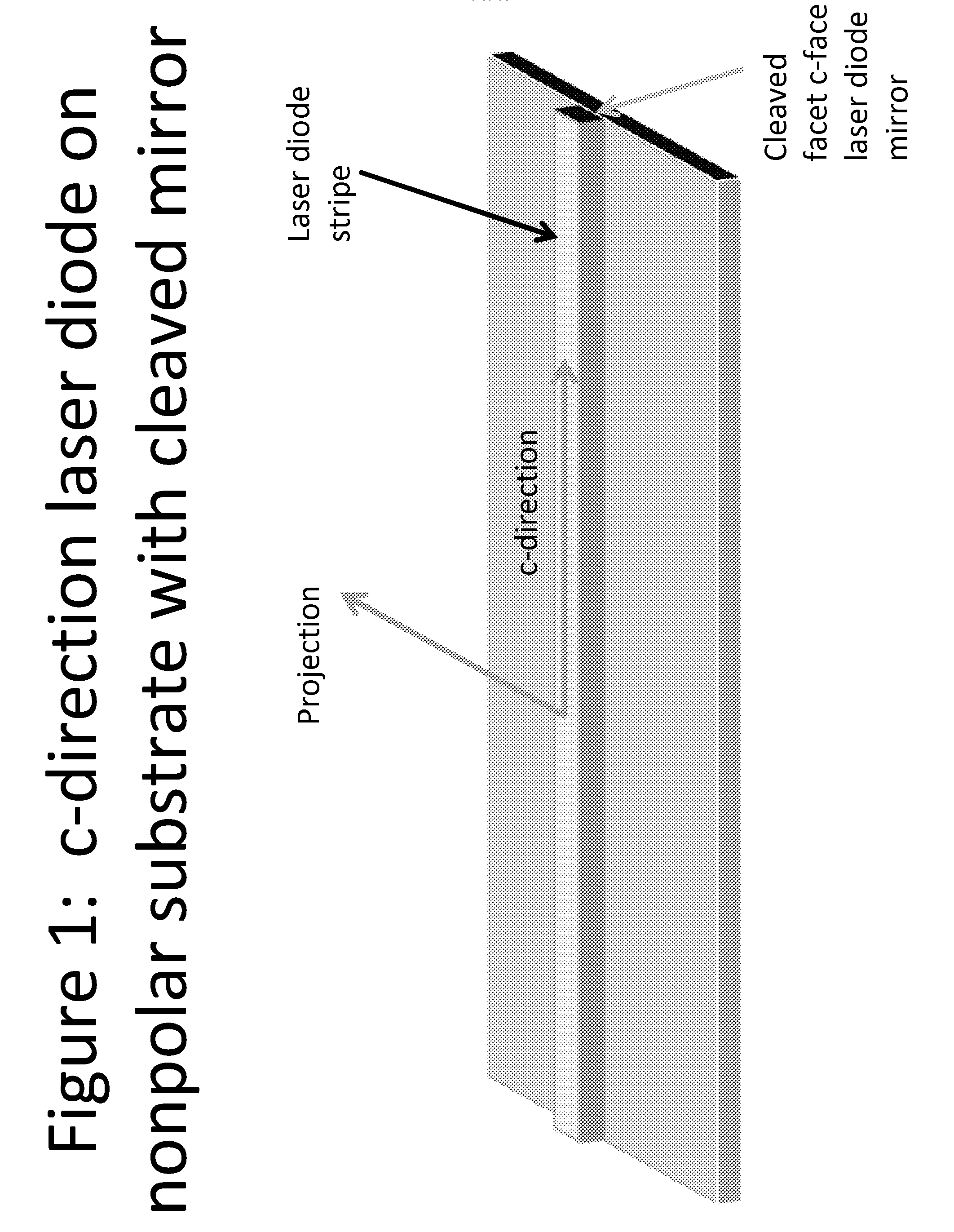

Thick laser-scribed GaN-on-sapphire optoelectronic devices

InactiveUS20050263854A1Semiconductor/solid-state device detailsSolid-state devicesWaferingTotal internal reflection

A sapphire wafer having a thickness greater than 125 microns and having devices disposed thereon is laser scribed to form a grid array pattern of laser scribe lines laser scribed into the sapphire wafer. The sapphire wafer is separated along the laser scribe lines to separate a plurality of device dice defined by the grid array pattern of laser scribe lines. Each device die includes (i) a device and (ii) a portion of the sapphire wafer having the thickness greater than 125 microns. In some embodiments, a GaN LED device die includes a GaN based LED device, and a sapphire substrate supporting the GaN based LED device. The sapphire substrate has: (i) a thickness greater than 125 microns effective for increased light extraction due to a lower critical angle for total internal reflection; and (ii) sides generated by laser scribing.

Owner:GELCORE LLC (US)

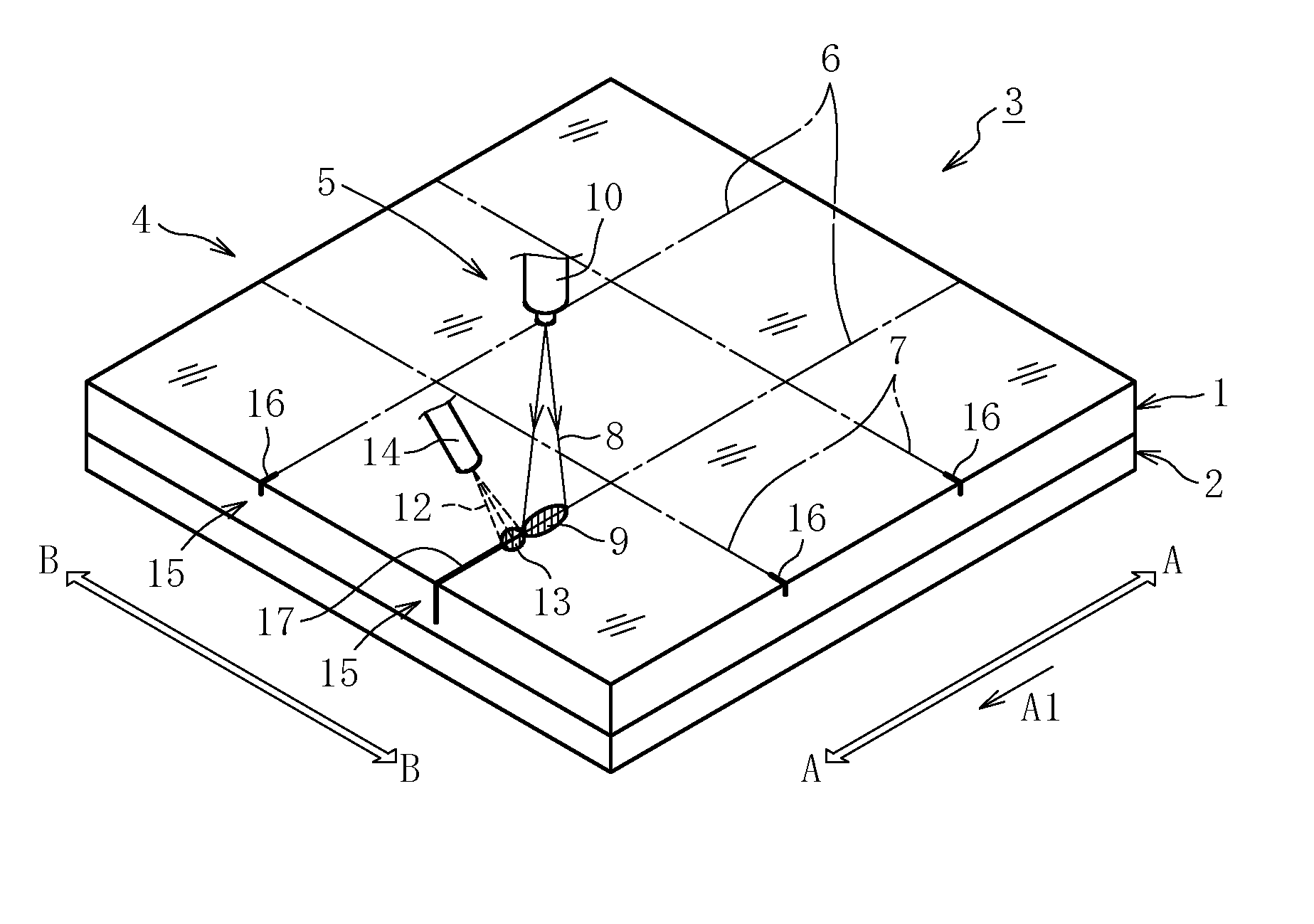

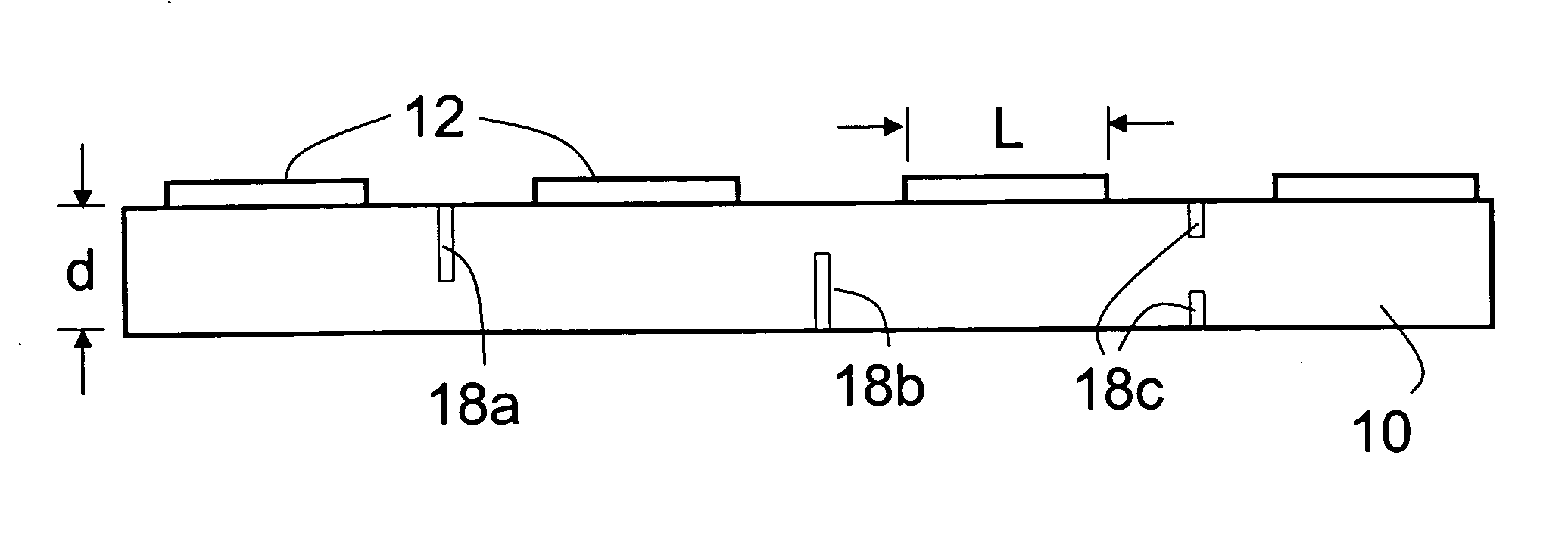

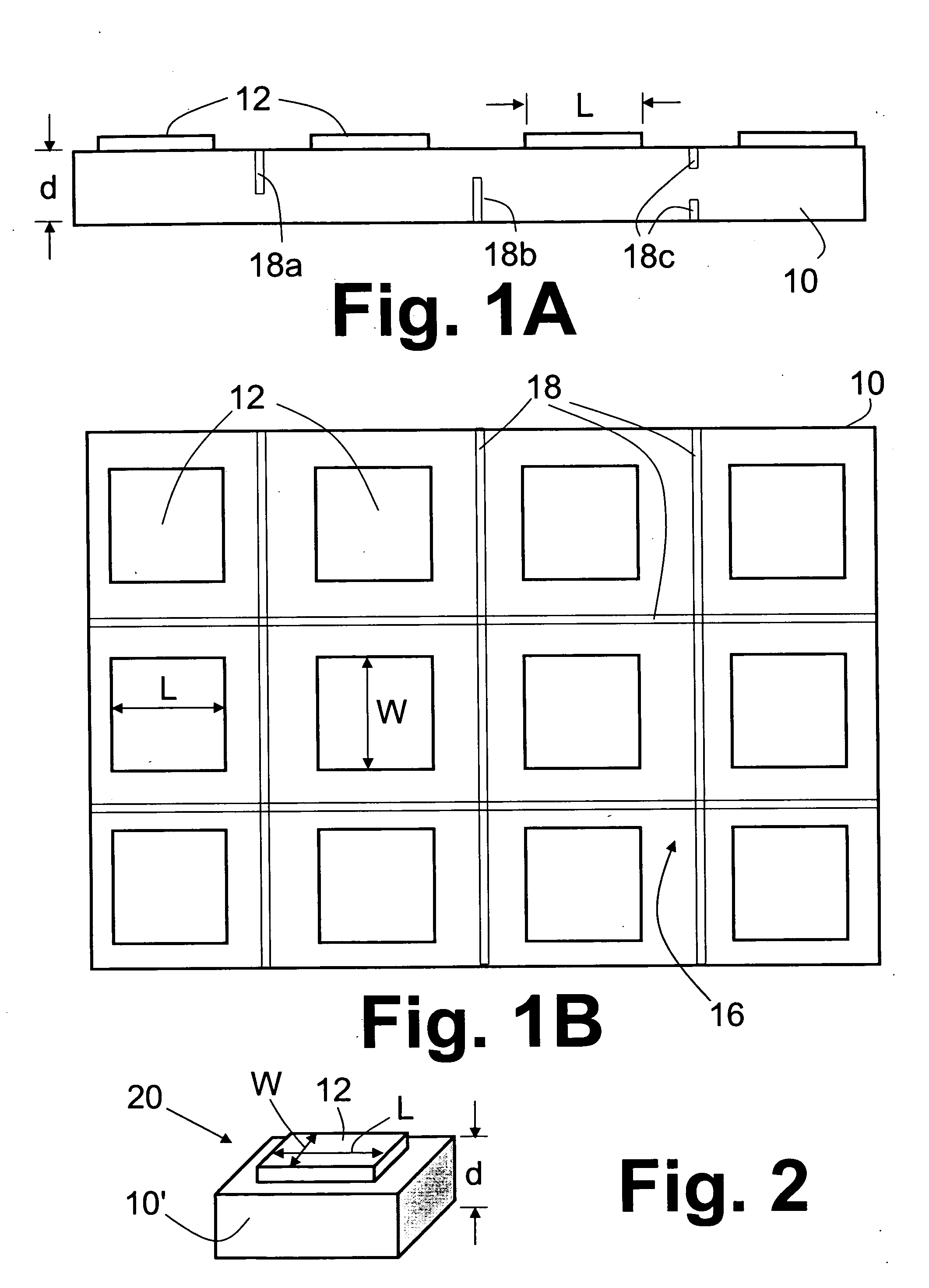

Process for laser scribing

InactiveUS20090188543A1Easy to controlEasy to implementPV power plantsLaser beam welding apparatusOptoelectronicsLaser scribing

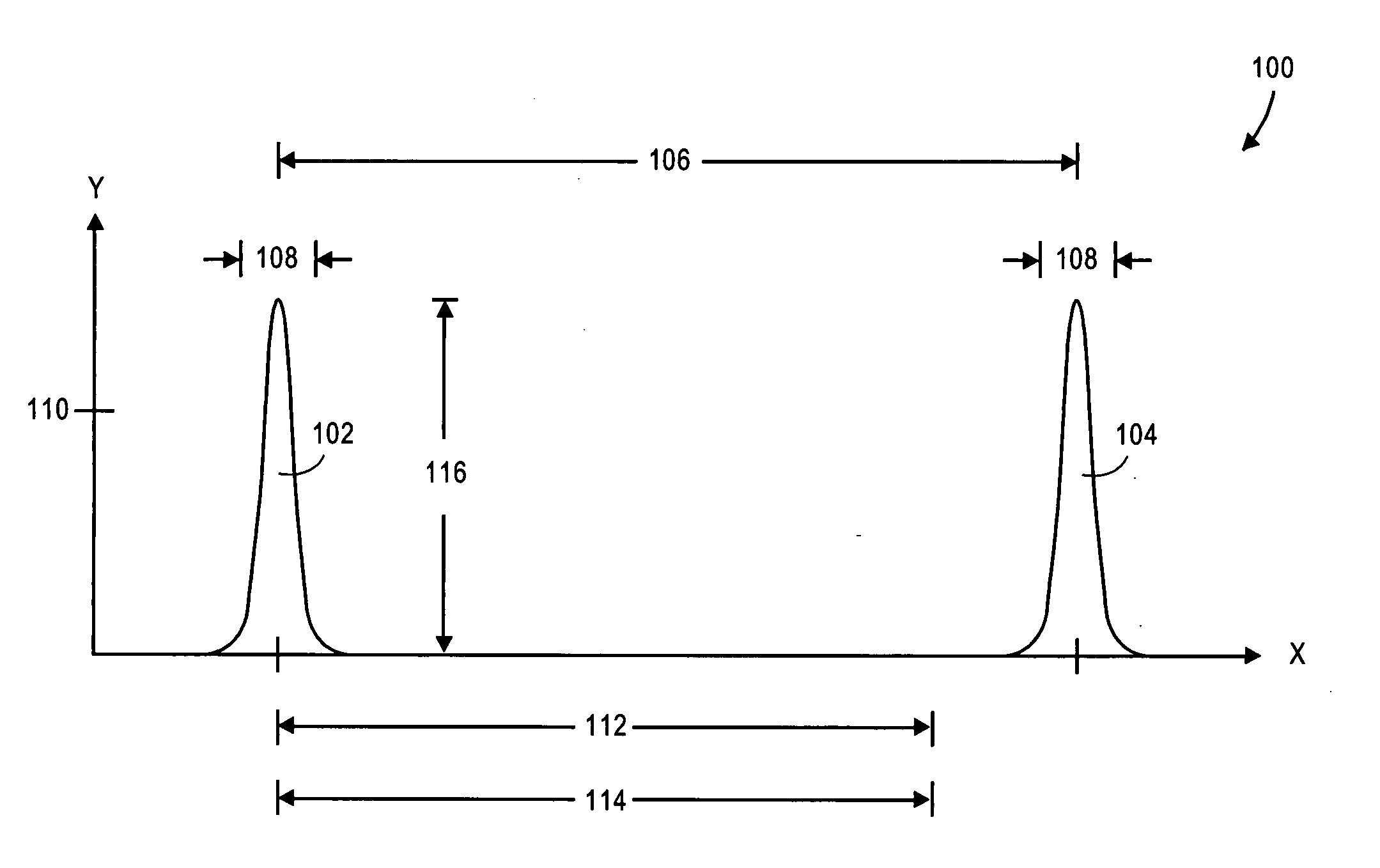

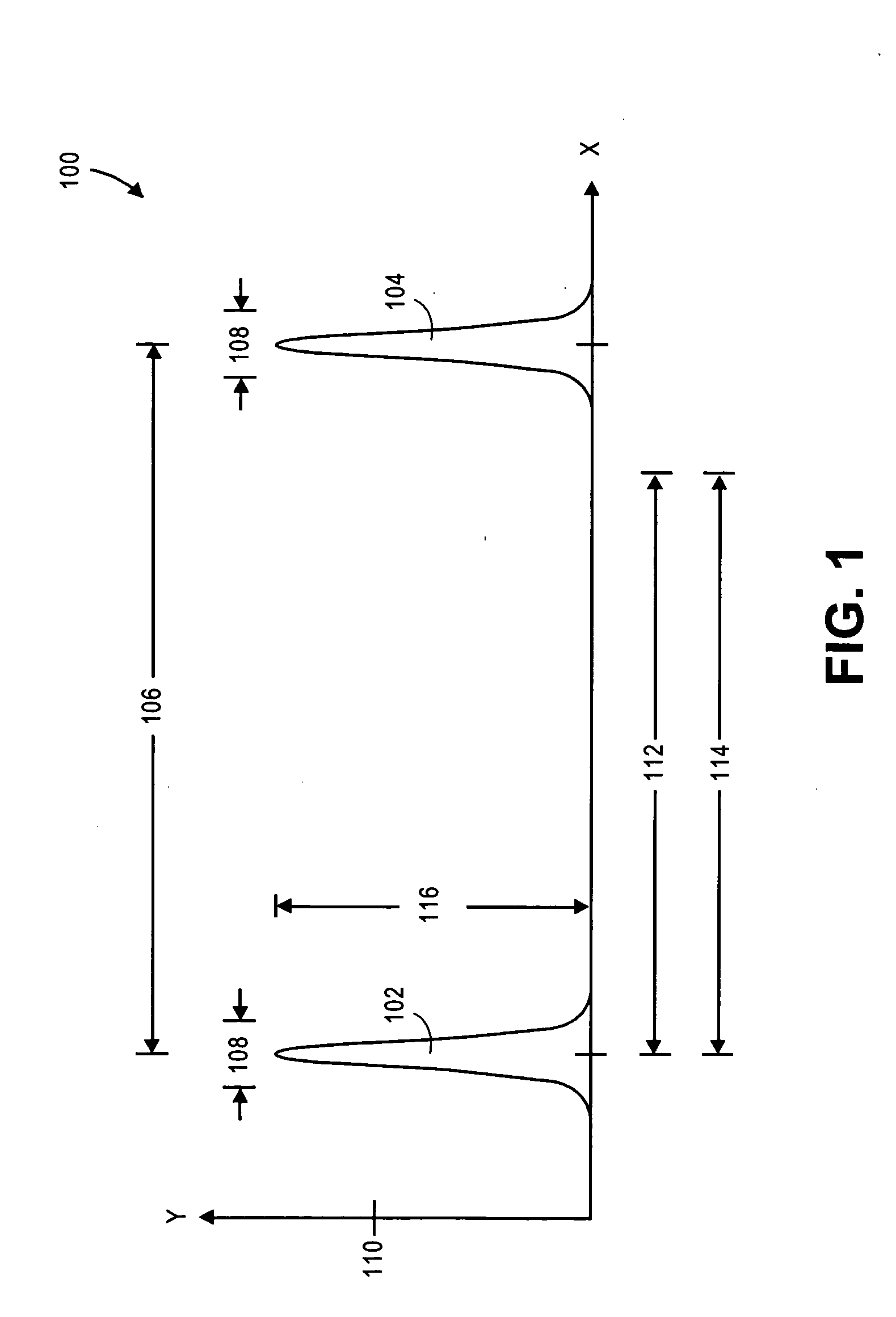

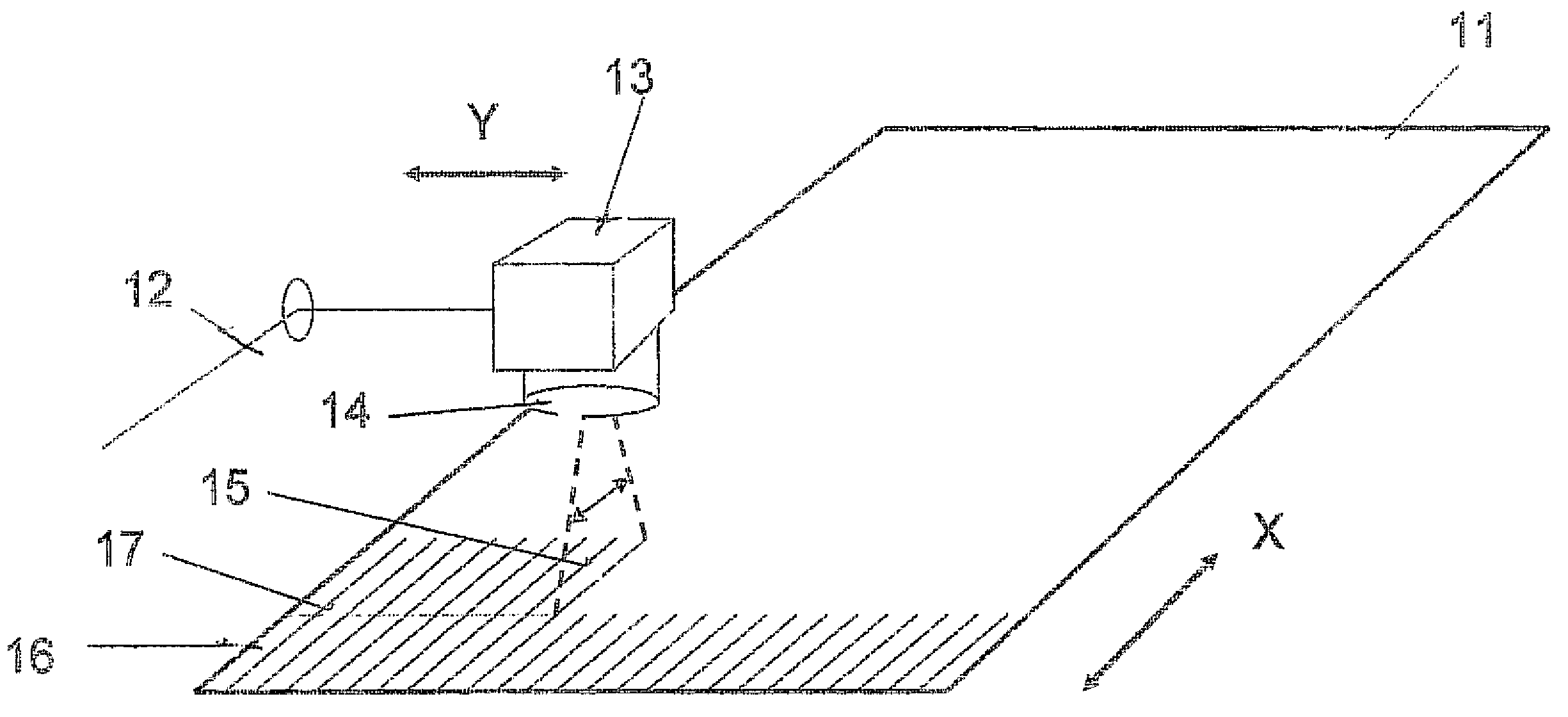

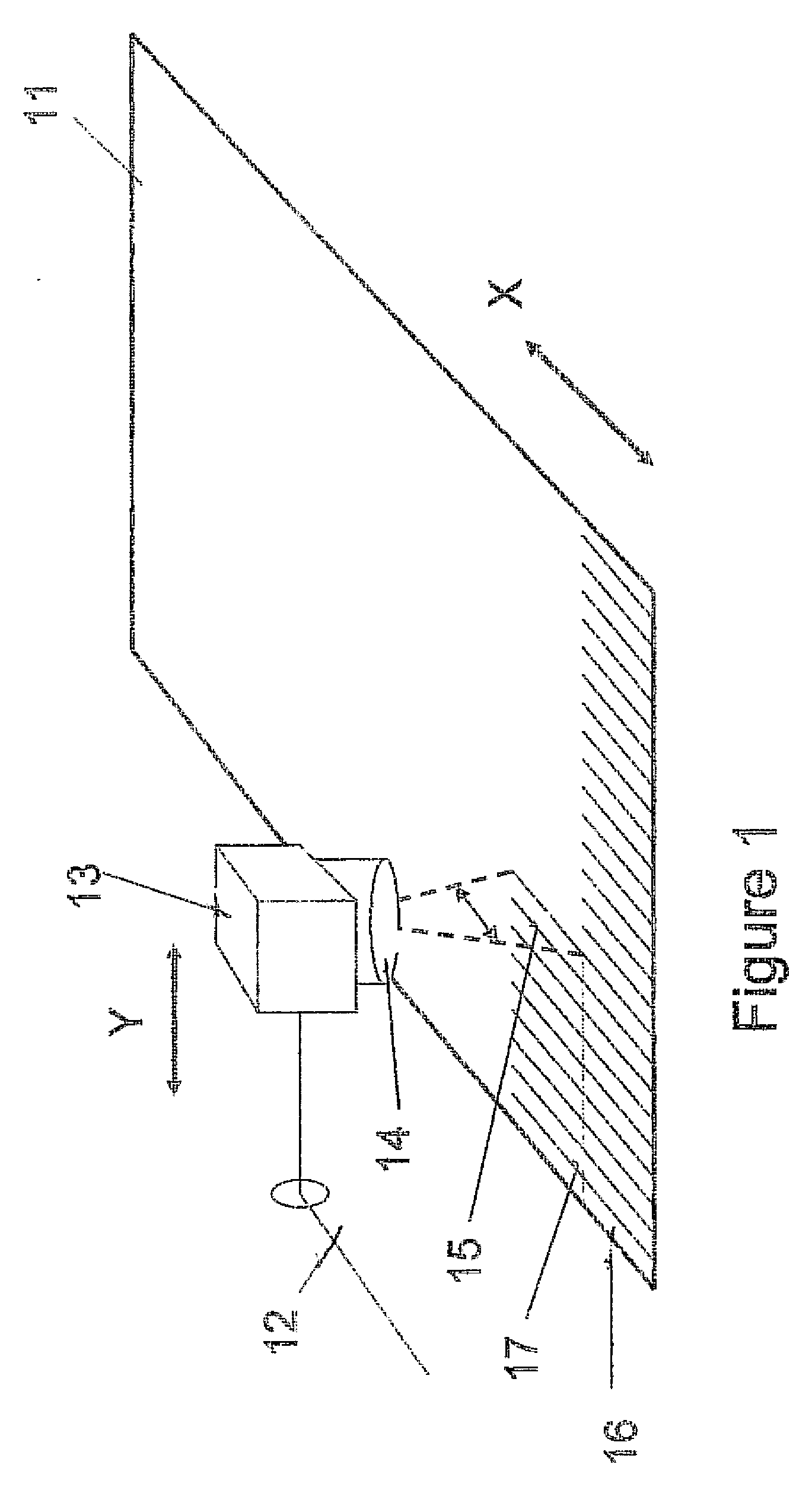

A method for accurately laser scribing lines on a panel utilising a laser beam scanner unit (13) including an optical system and a scanner lens. The unit (13) moves a laser beam (12) in a first direction (X), to scribe sections of lines (15) on the panel (11) that are a fraction of the total line length required and then moving the unit (13) continuously with respect to the panel (11) in a second direction (Y), perpendicular to the first direction (X), to form a band (16) of scribe lines. The scanner unit (13) is positioned so that the starting position of scribe lines in each band next to be processed overlap exactly the finishing position ends of scribe lines in the last band that has been processed so that all scribe lines interconnect. The method repeats the using and moving steps to form a plurality of parallel bands of scribe lines which cover the area of the panel.

Owner:OERLIKON SOLAR AG (TRUEBBACH)

Uptically variable security devices

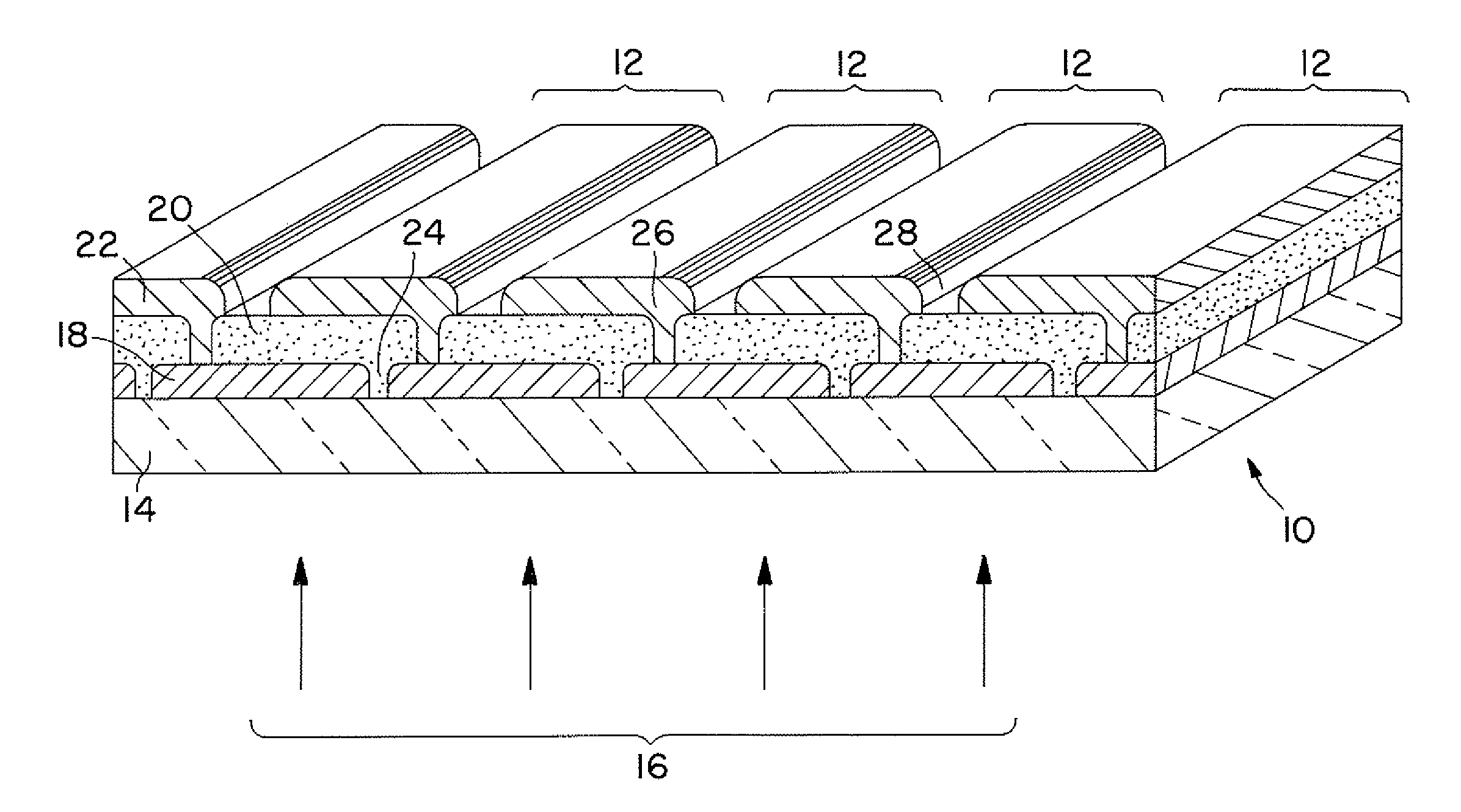

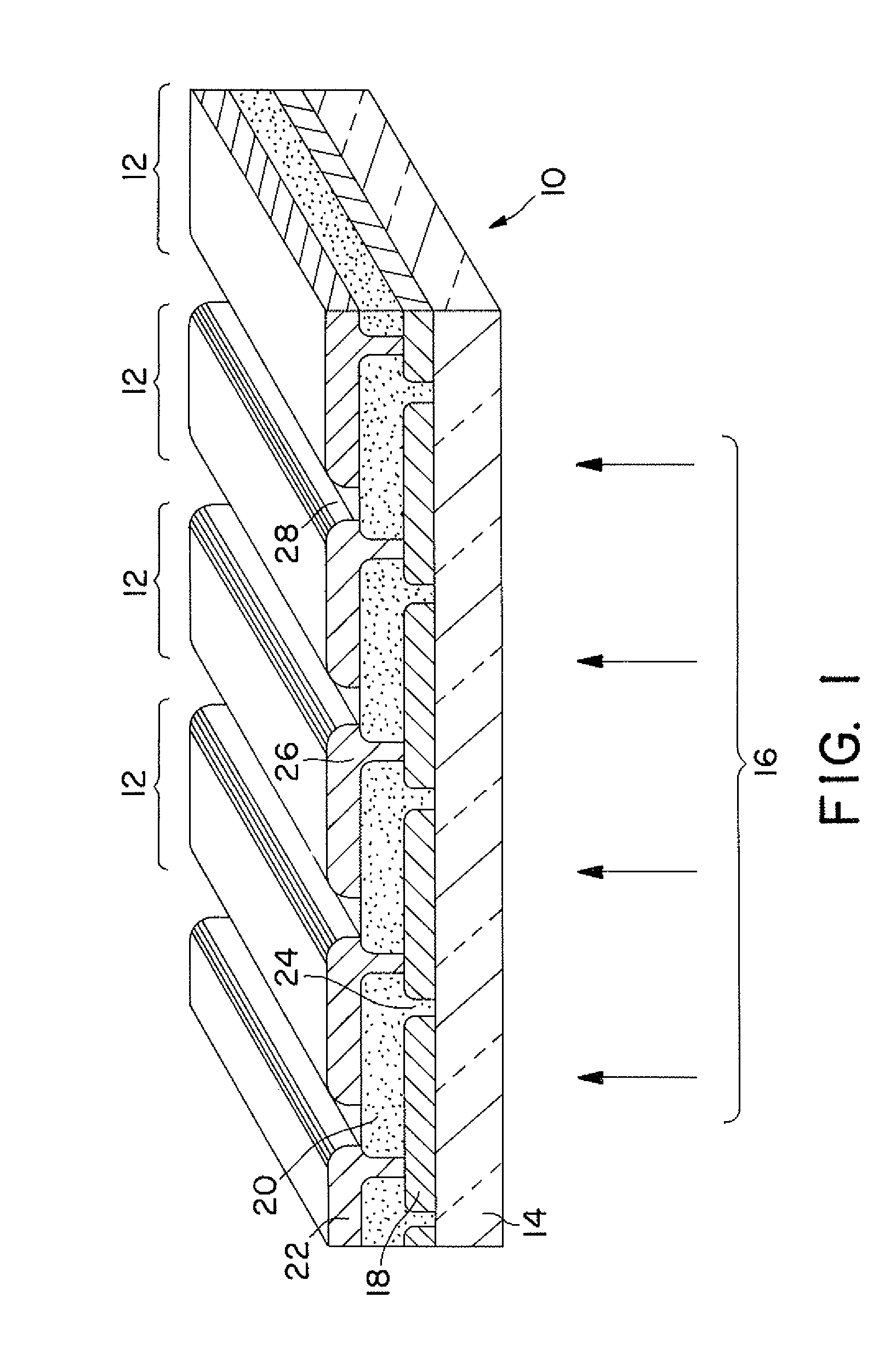

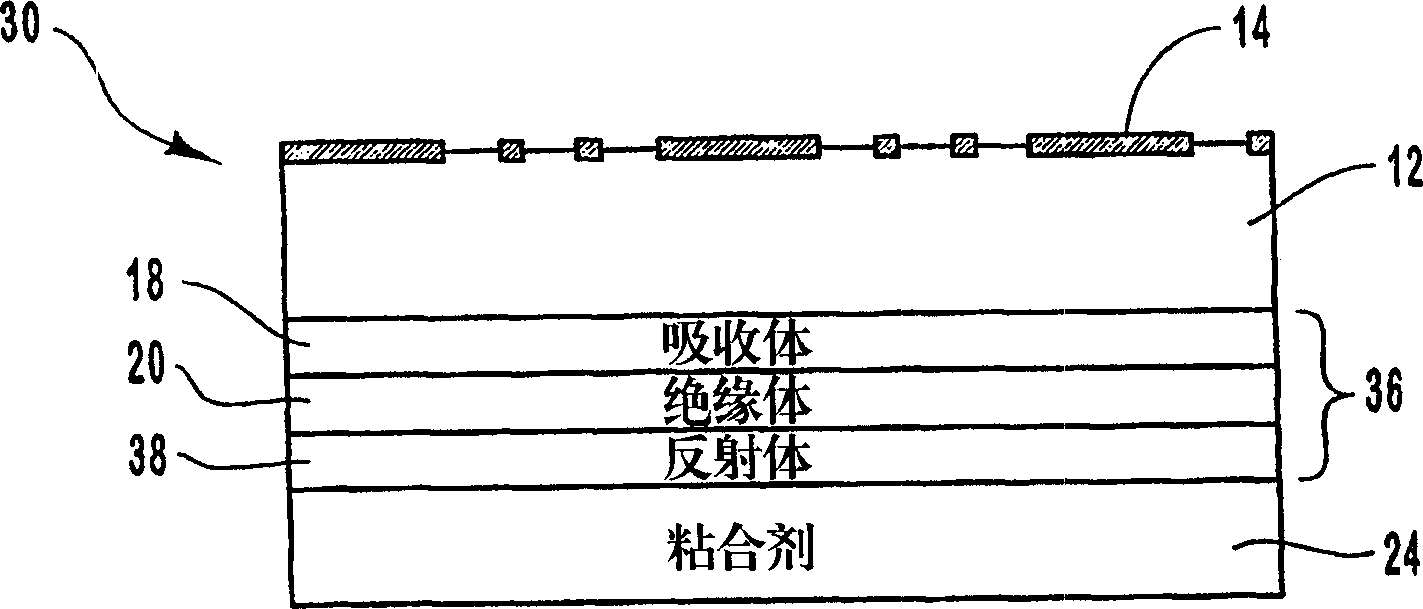

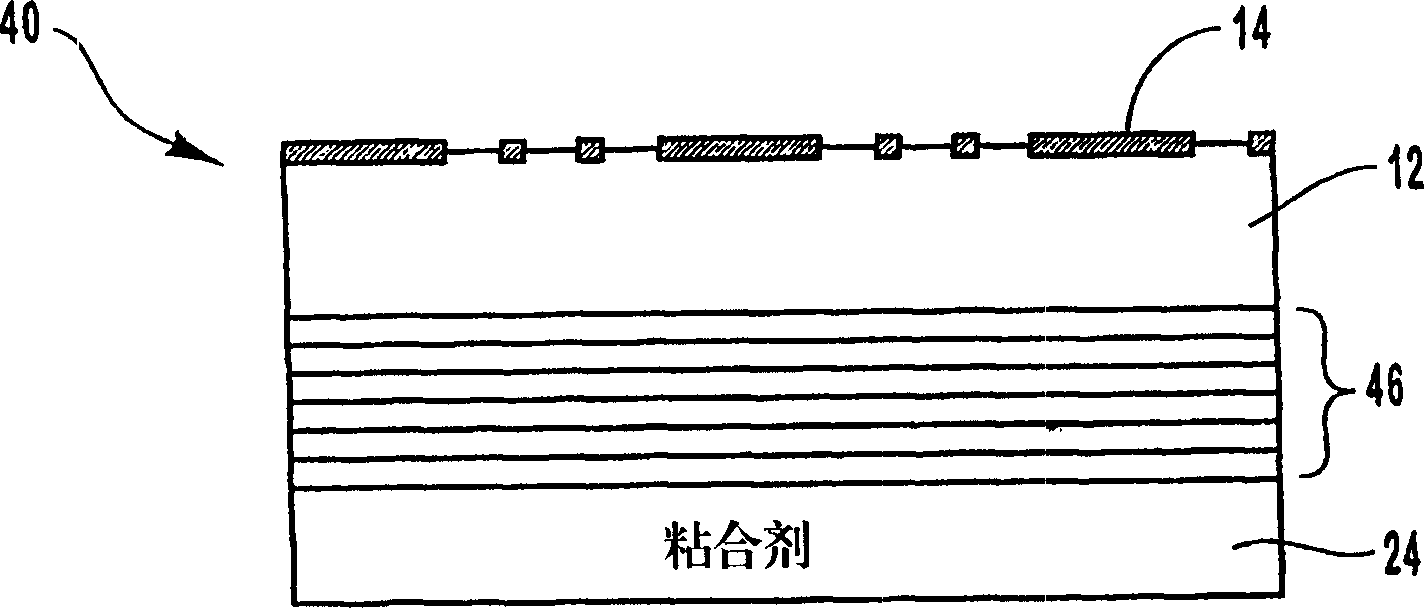

InactiveCN1423598AGood anti-counterfeiting measuresOther printing matterSynthetic resin layered productsHot stampingEngineering

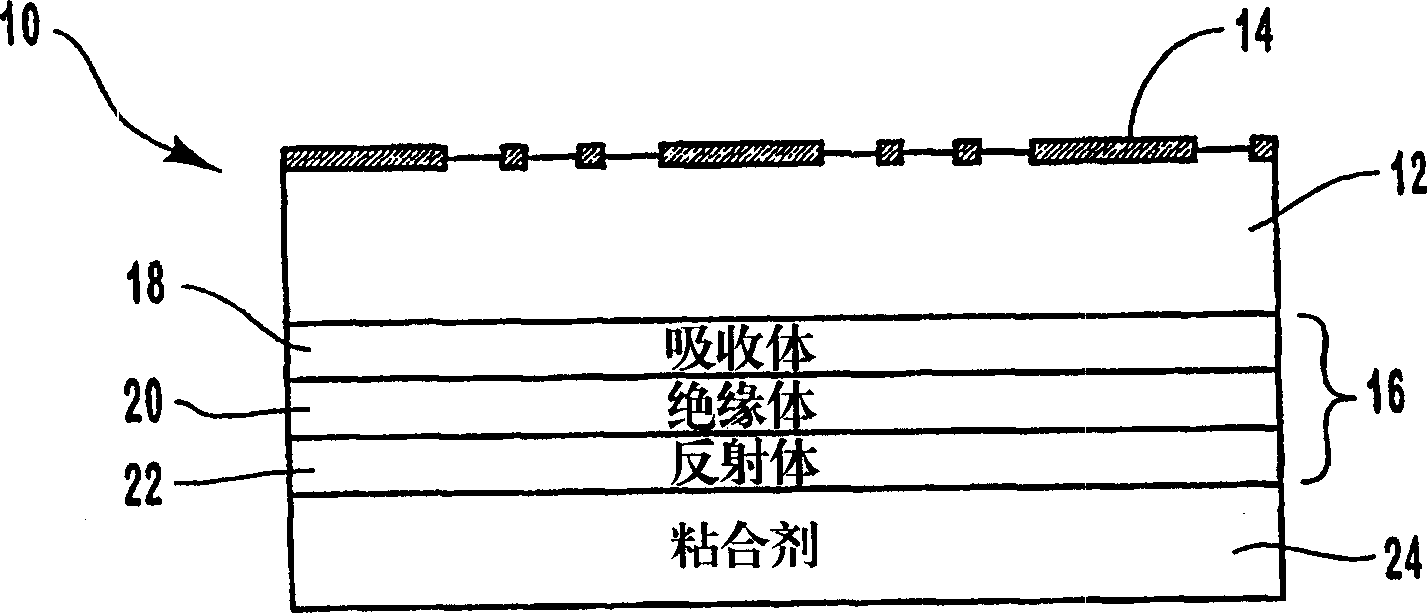

A security article (10) includes a light transmissive substrate (12) having a first surface and an opposing second surface, with the first surface having an optical interference pattern (14) such as a holographic image pattern or an optical diffraction pattern thereon. A color shifting optical coating (16) is formed on the substrate such as on the interference pattern or on the opposing second surface of the substrate, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. Various processes can be utilized to form the security article (10), such as vacuum coating processes, lamination, laser scribing, and laser imaging. The security article (10) can be affixed to a variety of objects through various attachment mechanisms, such as pressure sensitive adhesives or hot stamping processes, to provide for enhanced security measures such as anticounterfeiting.

Owner:光学涂层实验公司

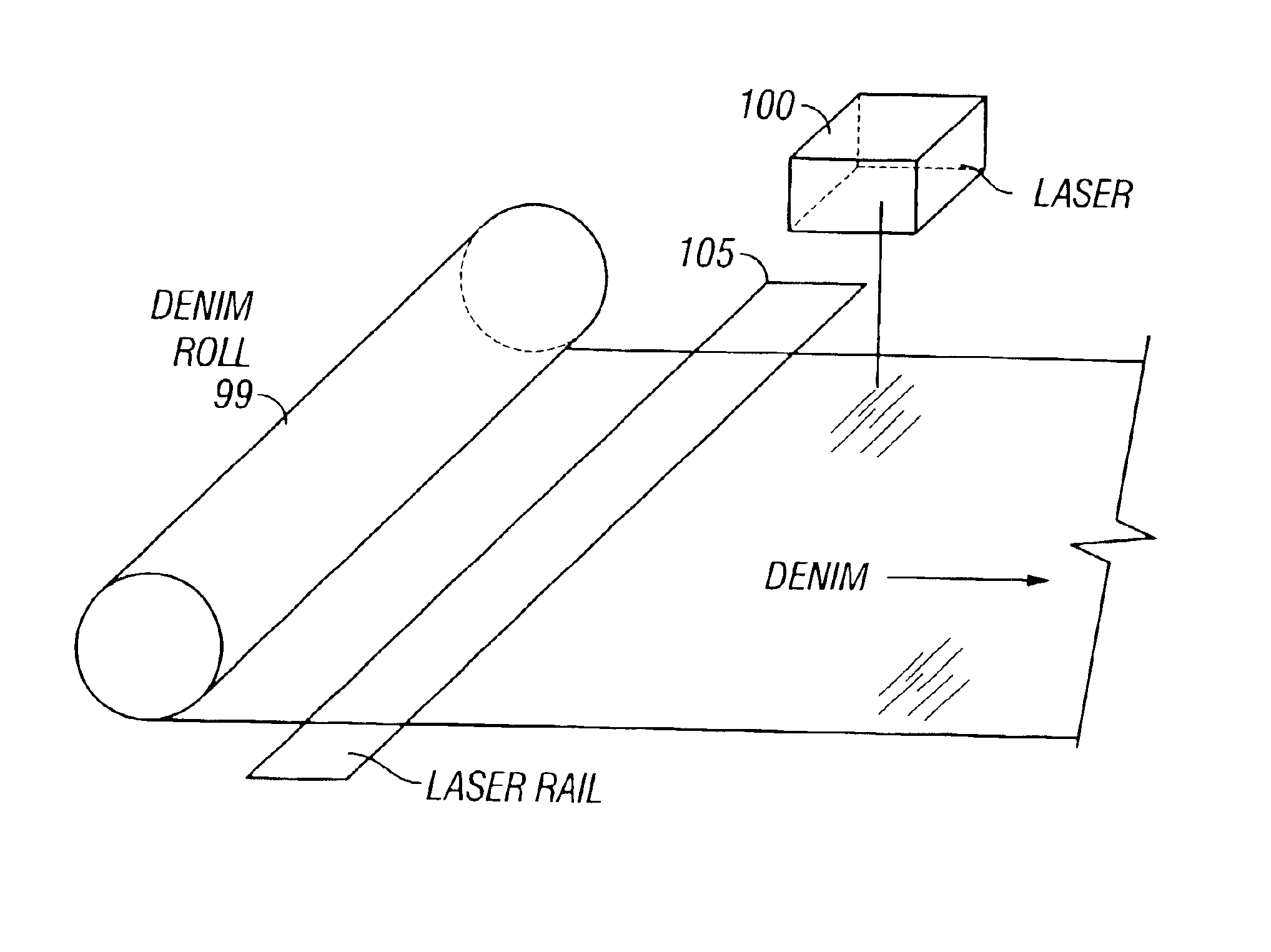

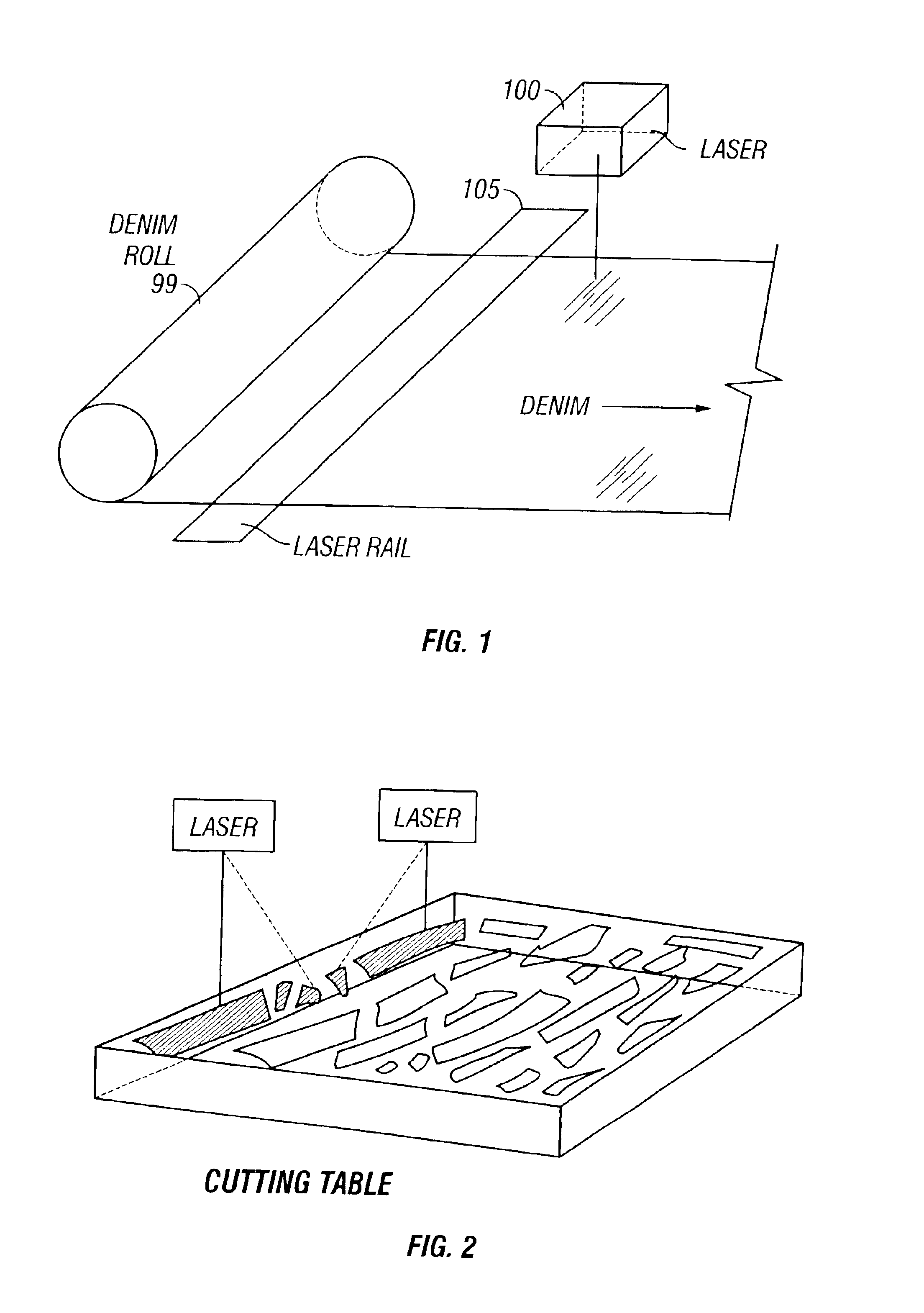

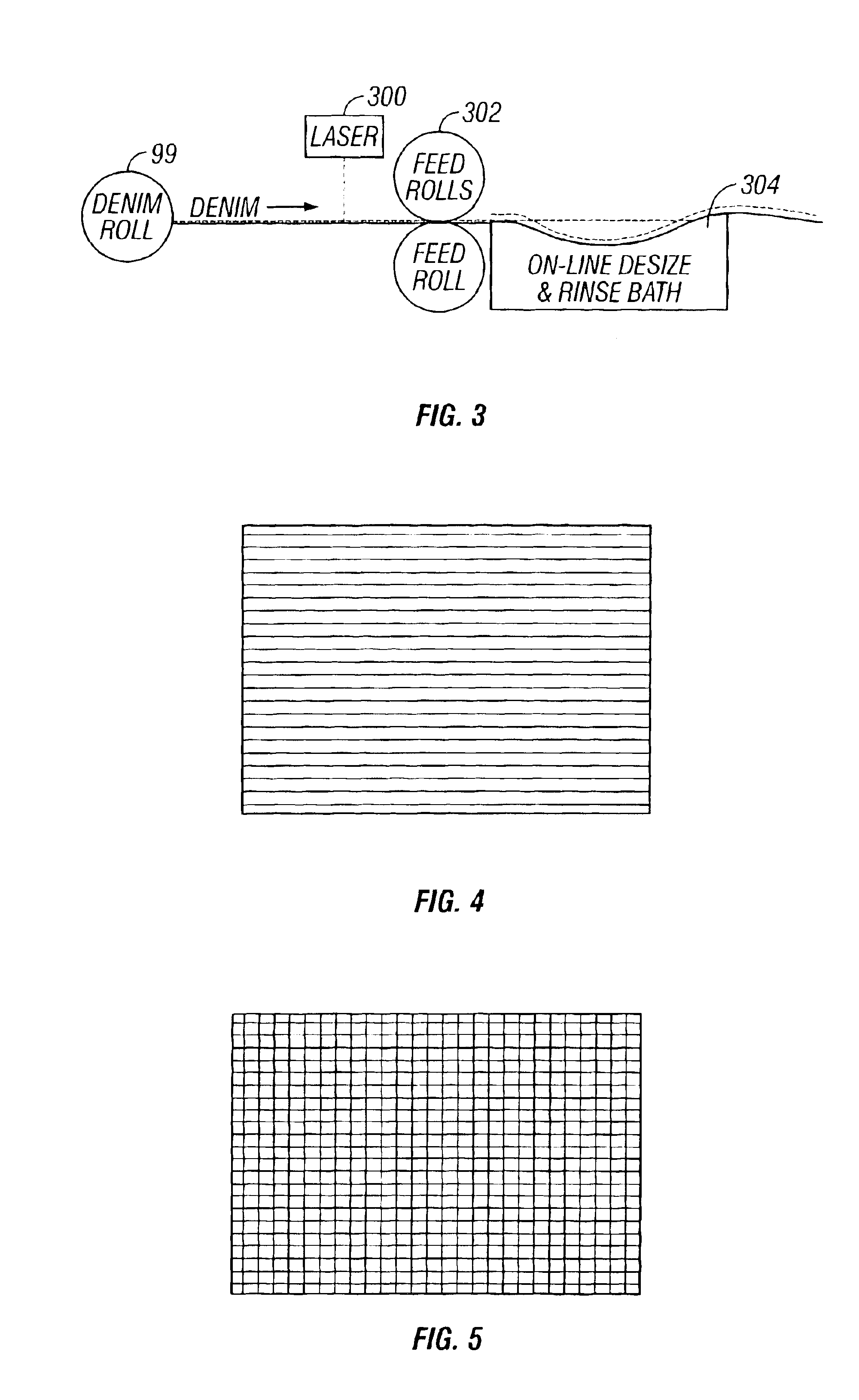

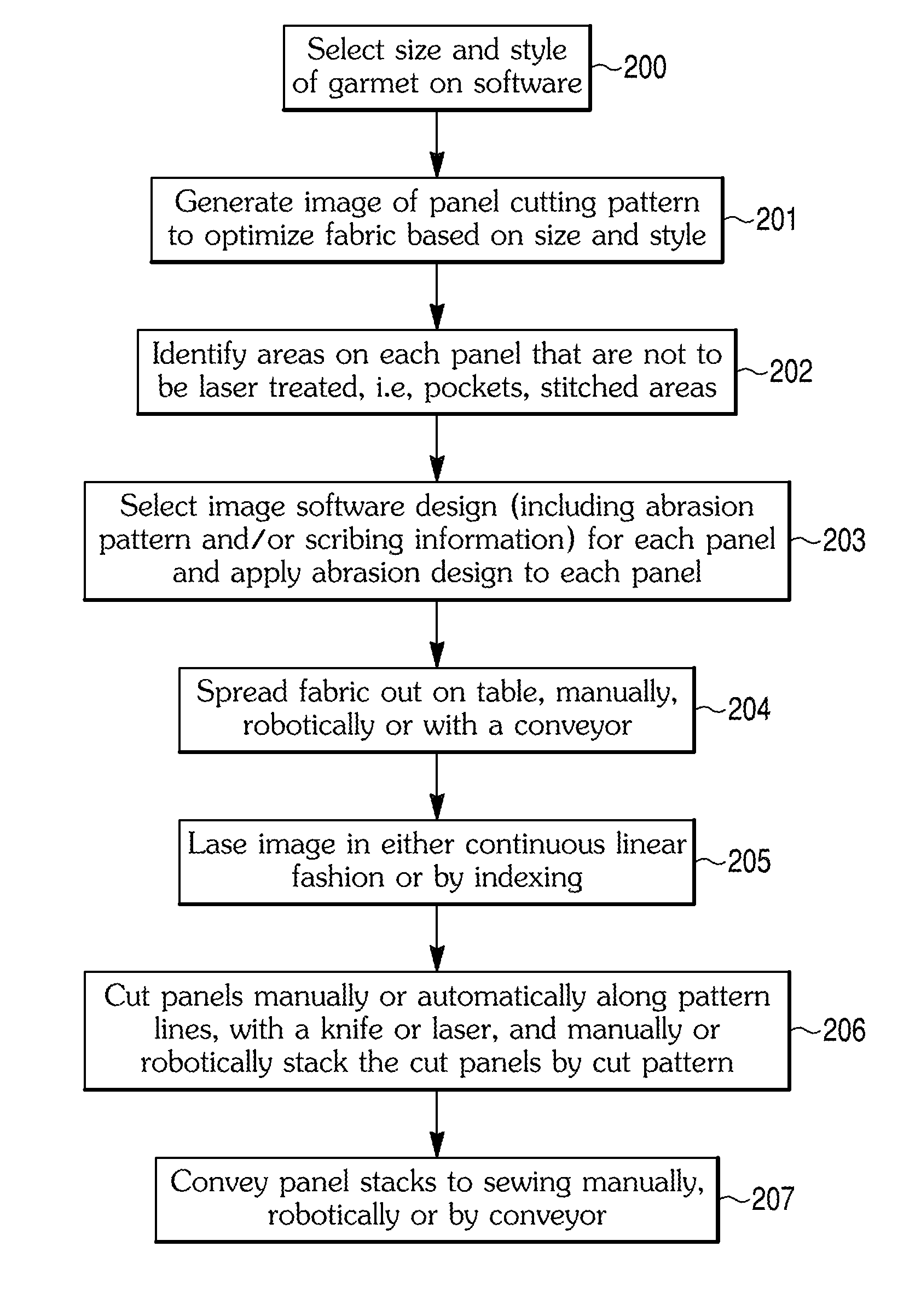

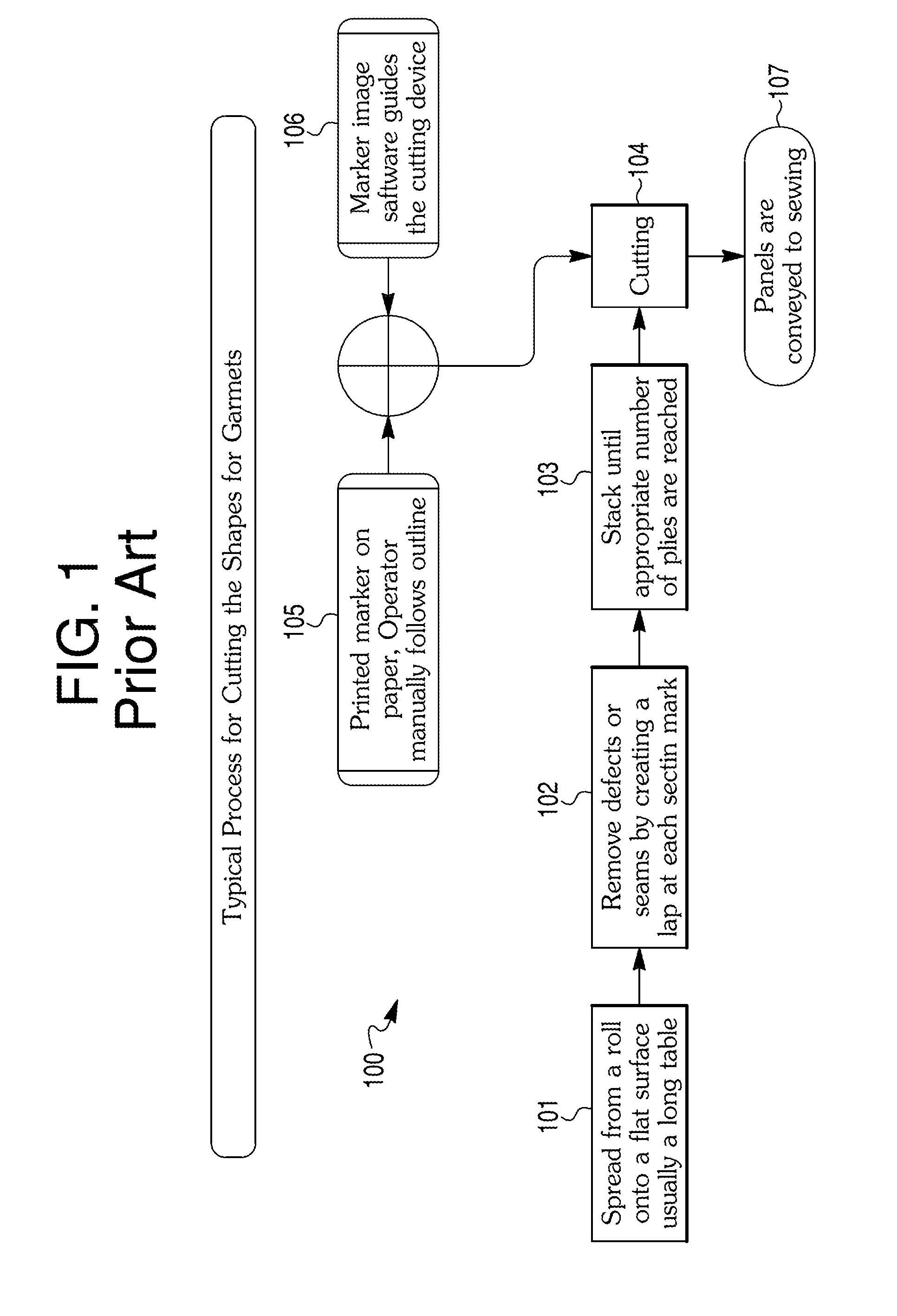

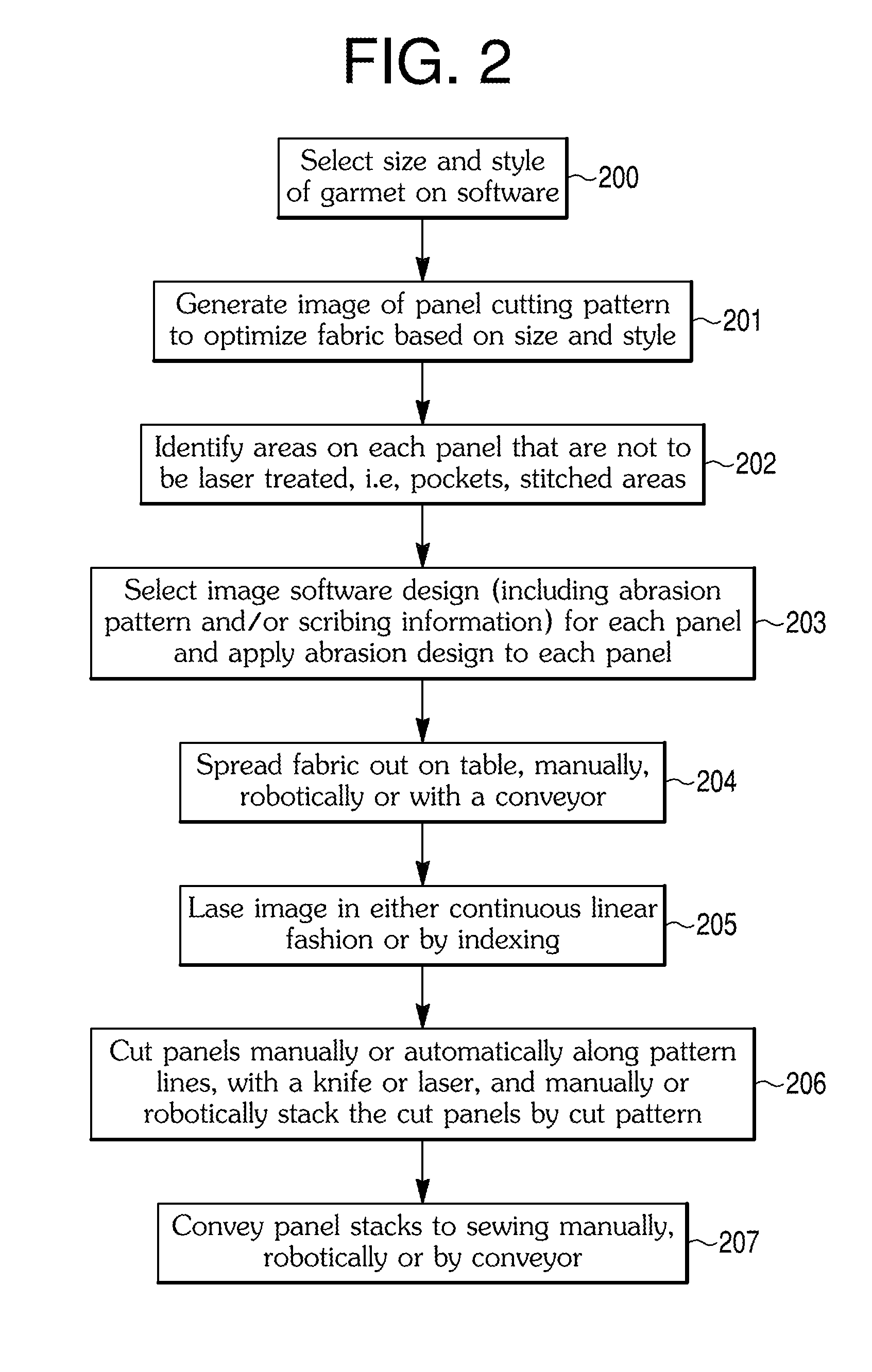

System and method of generating a pattern or image on fabric with linear laser irradiation, fabric made by said method, and products made with said fabric

A method of scribing abrasion aesthetics, patterns, images, serial numbers, ply markings and / or other information, such as sizing or care information, on fabric such as denim, before or during the fabric cutting process is provided. The method comprises loading the panel abrasion software, pattern marker software, and fabric scribing software; placing the fabric on a flat surface under at least one laser; laser scribing ply numbers, serial labels, fabric markers, and panel abrasions on the fabric; cutting the fabric into fabric lengths; spreading the pre-abraded and pre-marked fabric lengths on top of each other to create multiple plies in precise alignment; cutting shaped panels along the lines of the pattern marker with a conventional knife, laser, or other appropriate cutting tool; and stacking the abraded, labeled and shaped panels robotically or manually for sewing.

Owner:REVOLAZE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com