Uptically variable security devices

An optical coating and optical interference technology, applied in optics, optical components, diffraction gratings, etc., can solve problems such as difficult communication of images and difficult recall of images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Optical coatings consisting of color shifting flakes in a polymeric vehicle were formed by downdraw on a light transmissive substrate of PET film containing a holographic image. Pull-down media consists of two parts paint / catalyst and one part shifting flakes. The color shifting flakes used have the color shifting properties of green-to-magenta, blue-to-red and magenta-to-gold.

Embodiment 2

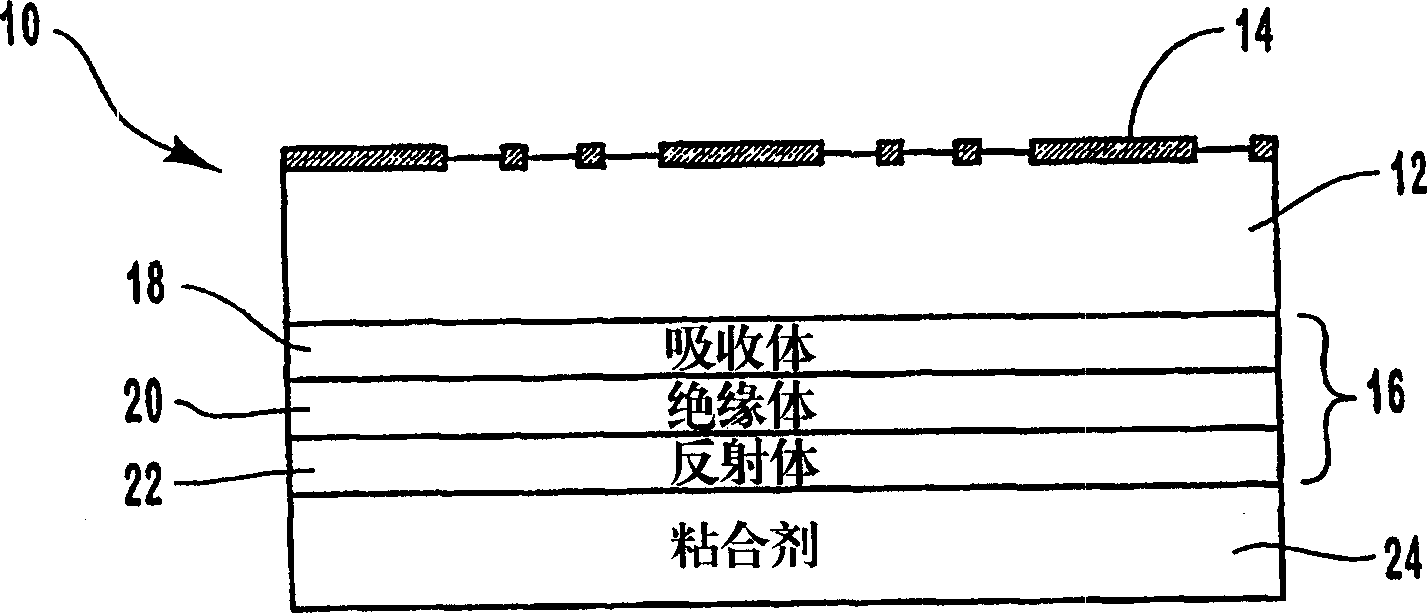

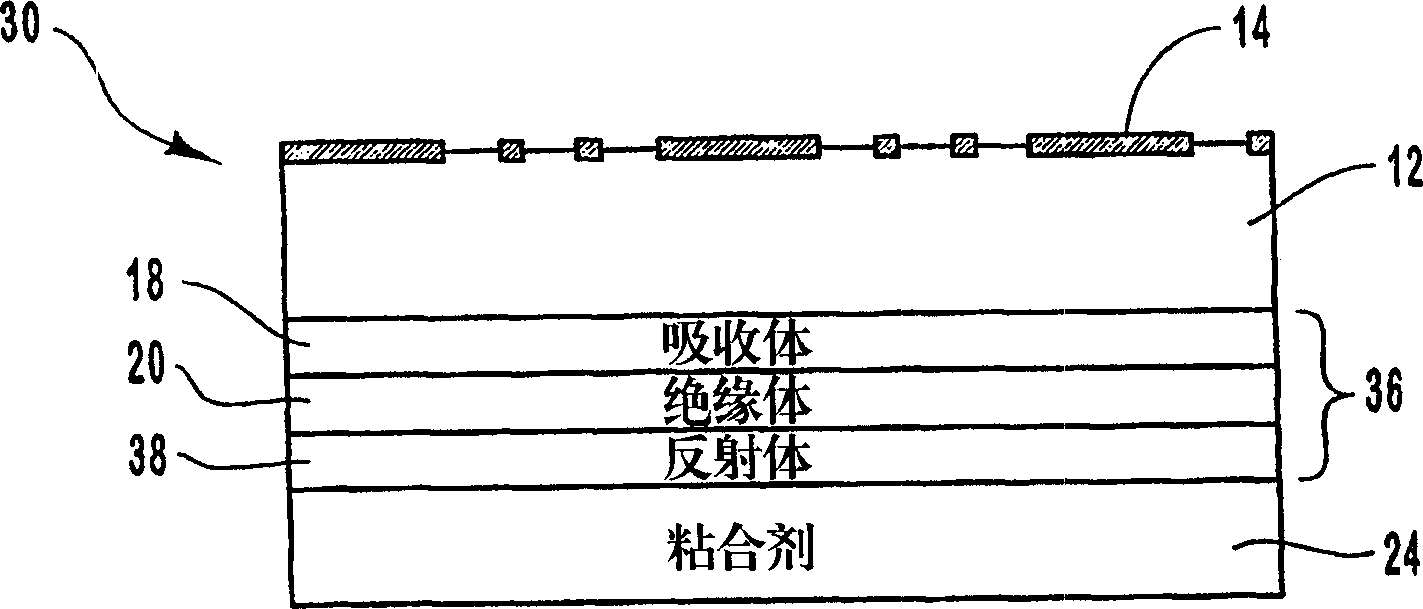

[0108] A color-shifting optical coating with a three-layer structure is formed on an embossed transparent film to produce anti-counterfeiting articles. An optical coating is formed on the plane of the transparent film opposite the embossed surface. The optical coating is formed by depositing an absorbing layer composed of chromium on the plane of the transparent film, depositing an insulating layer composed of magnesium fluoride on the absorbing layer, and depositing an aluminum reflective layer on the insulating layer.

[0109] Alternatively a layer of aluminum can be deposited such that it is substantially transparent. This also allows information printed on the item to be read through the optical coating. In addition, the reflective layer can be made of magnetic material. This magnetic feature in the color shifting composition, when incorporated into the holographic composition, can provide three separate security features to a security article.

[0110] The embossed fil...

Embodiment 3

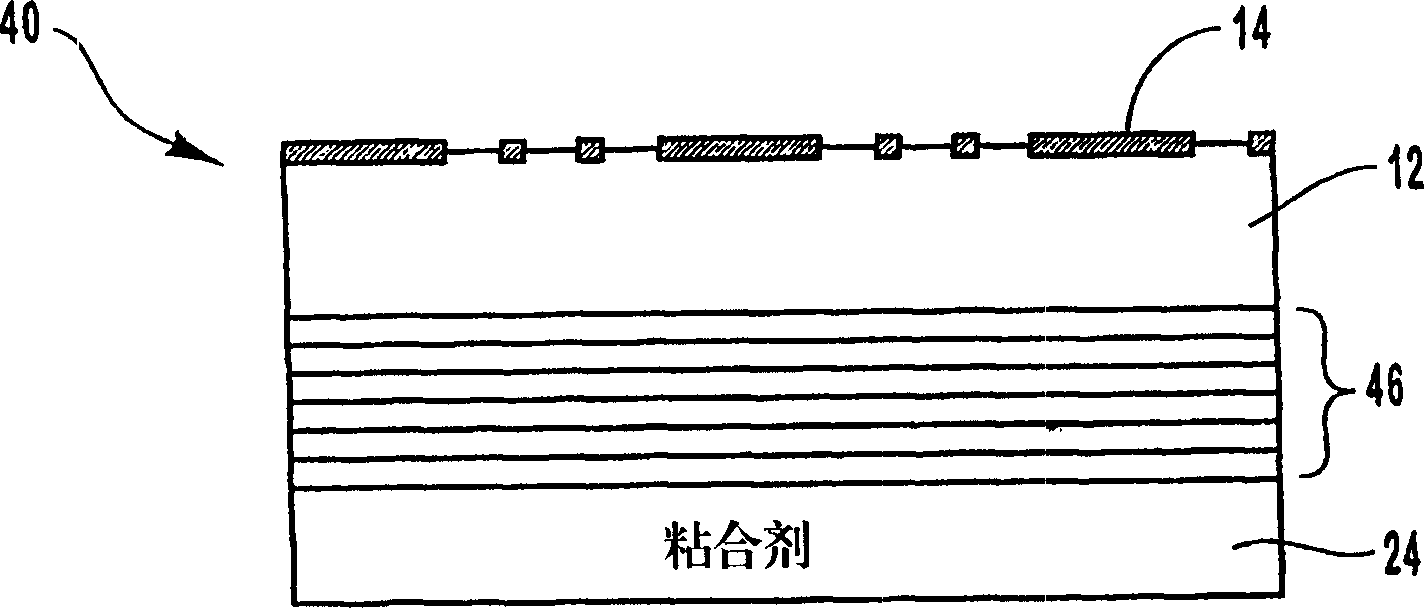

[0112] According to the present invention, a security article is produced by laminating a laser imaged optical coating to an embossed substrate. The anti-counterfeiting article consists of four main parts:

[0113] 1) laser ablated image, 2) laser ablated barcode or serial number, 3) multilayer color shifting film, and 4) holographic image.

[0114] Color shifting films were deposited on 1 mil thick clear polyester (PET) substrates in a vacuum roll coater. The film is formed by depositing an aluminum metal layer on the substrate, then depositing an insulating layer made of magnesium fluoride on the metal layer, and depositing an absorbing layer made of chromium on the insulating layer. The film was then laser ablated using a laser diode imaging system based on a Heidelberg Quickmaster printing system to provide a digital code. The imaging system uses a high-resolution diode array with a spot diameter of approximately 30 microns. After the digital information has been encode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com