Patents

Literature

698 results about "Optical coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An optical coating is one or more thin layers of material deposited on an optical component such as a lens or mirror, which alters the way in which the optic reflects and transmits light. One type of optical coating is an antireflection coating, which reduces unwanted reflections from surfaces, and is commonly used on spectacle and photographic lenses. Another type is the high-reflector coating which can be used to produce mirrors which reflect greater than 99.99% of the light which falls on them. More complex optical coatings exhibit high reflection over some range of wavelengths, and anti-reflection over another range, allowing the production of dichroic thin-film optical filters.

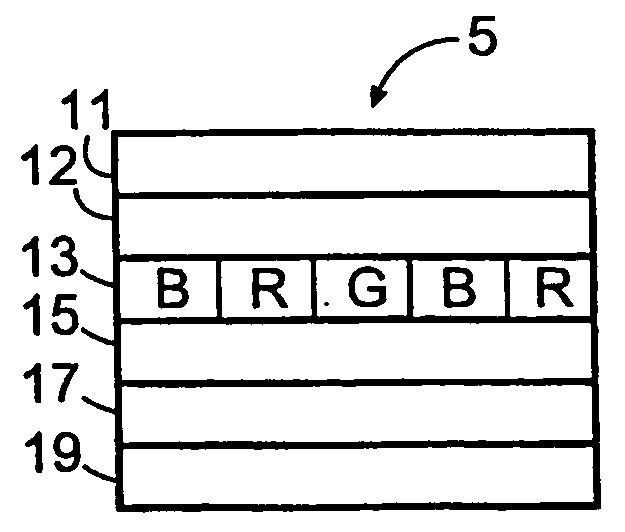

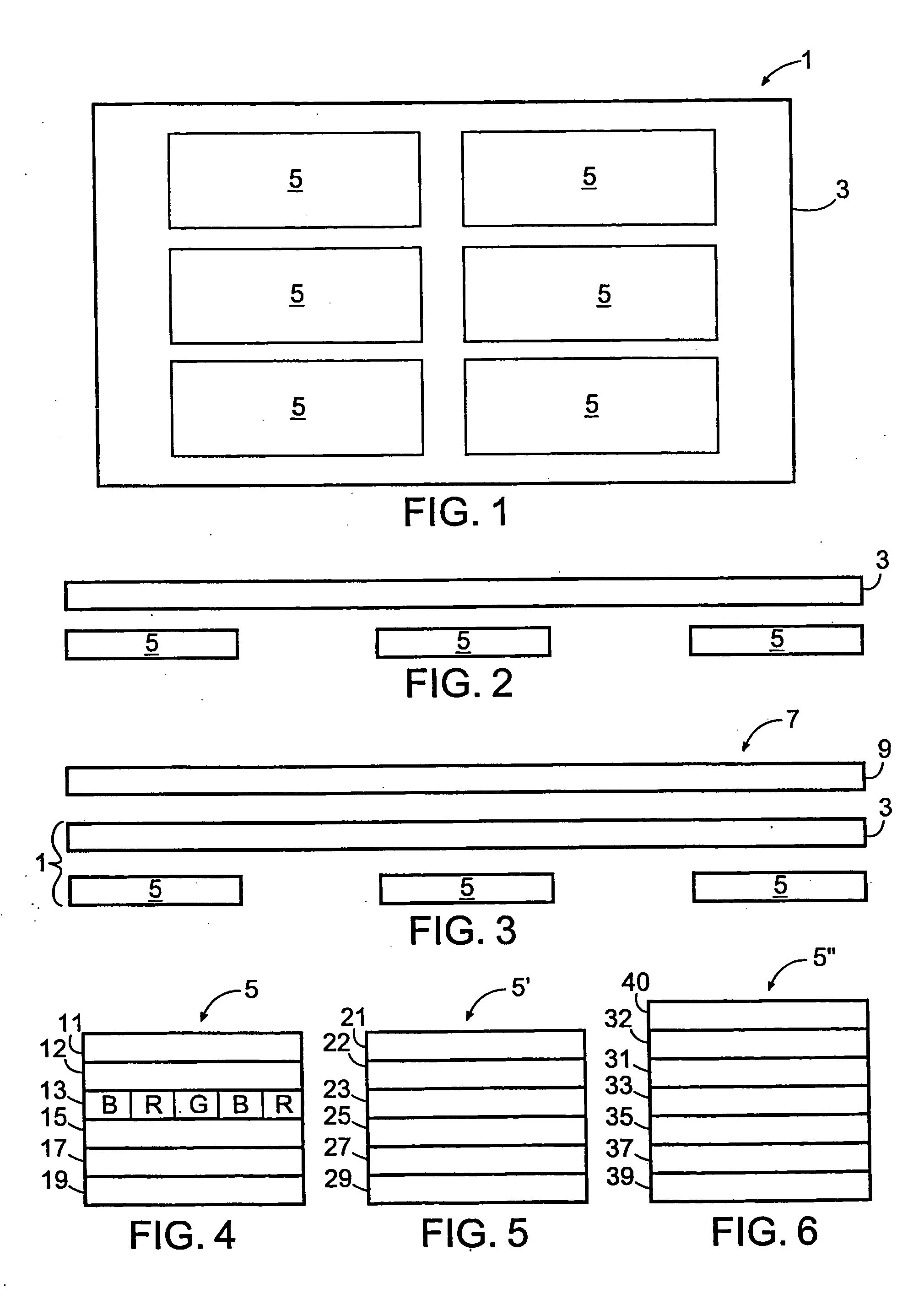

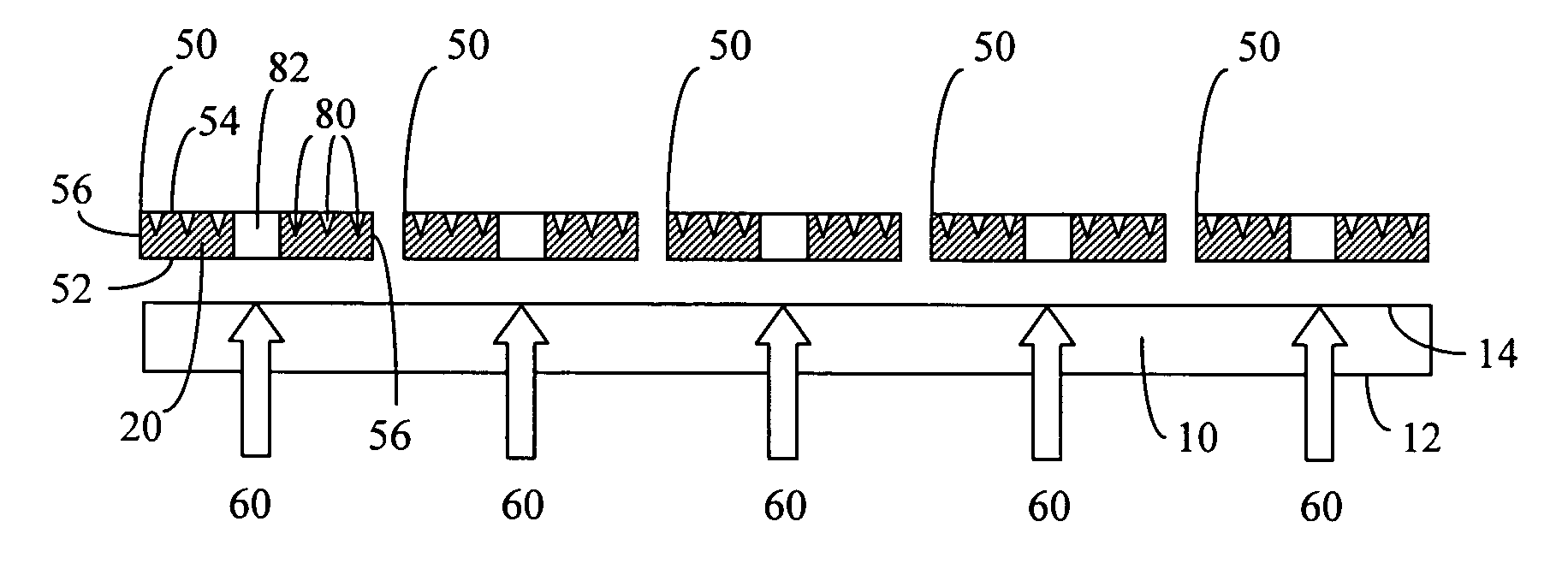

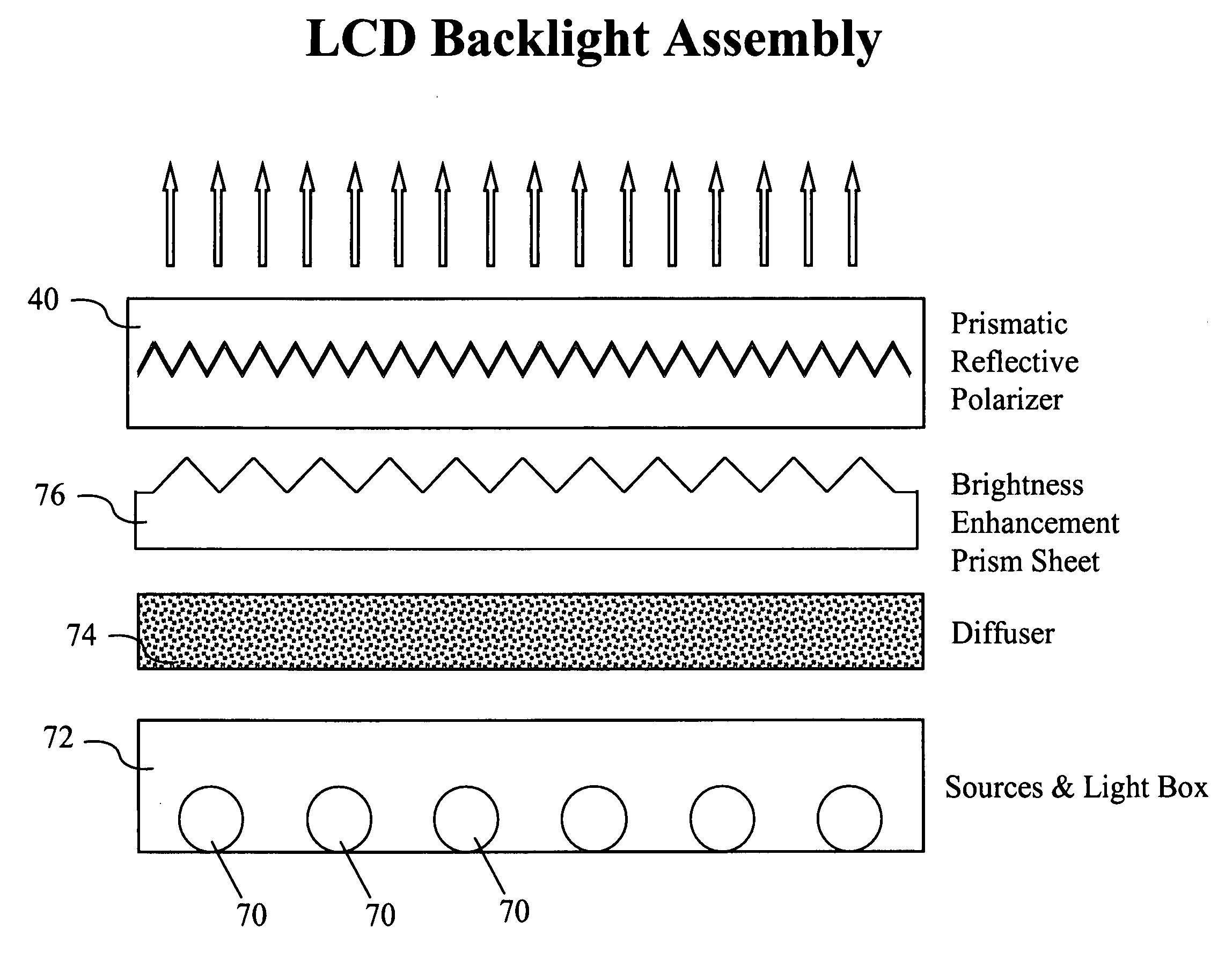

Organic light emitting diode (OLED) backlight

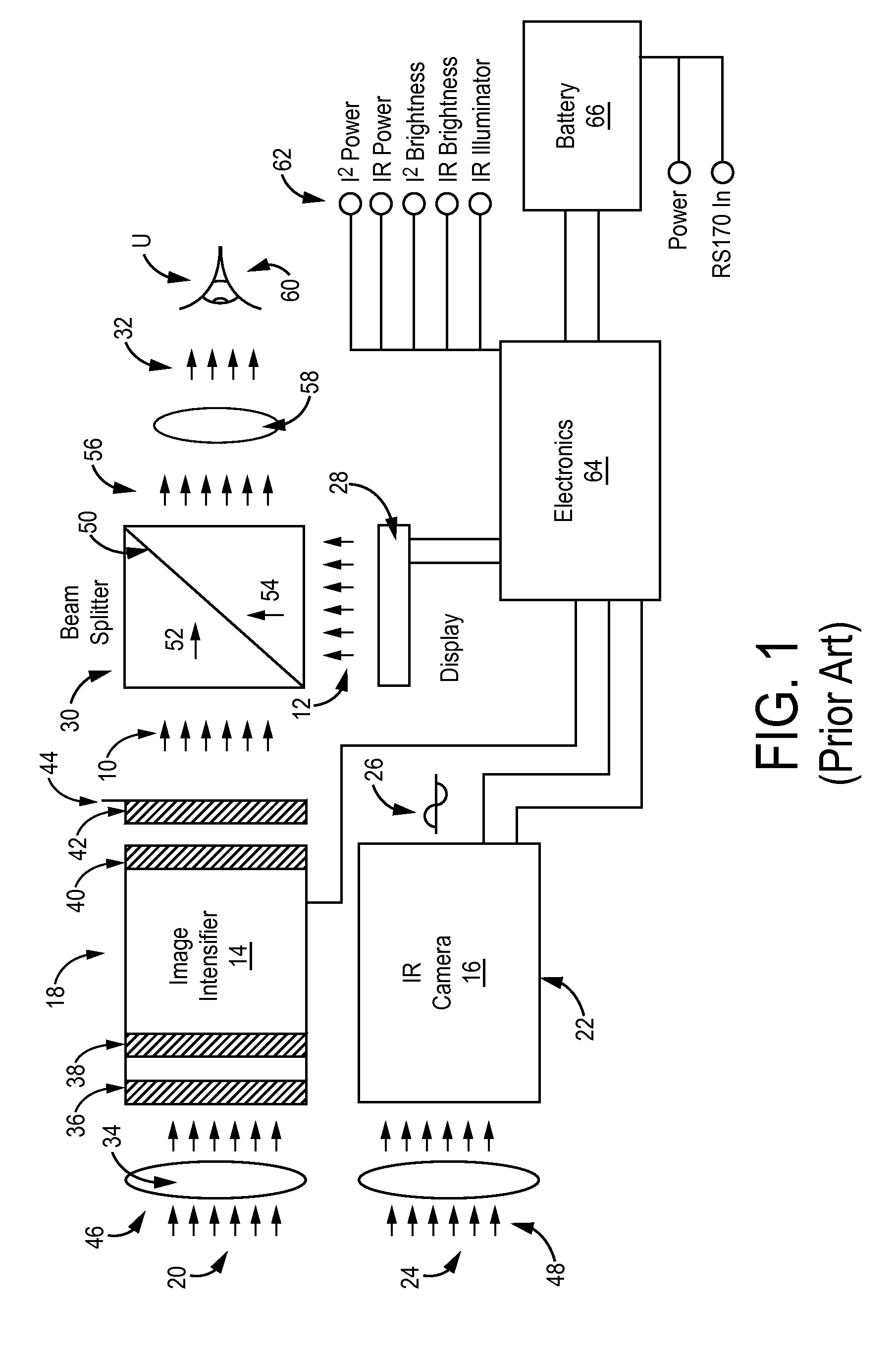

The present invention is directed to the use of a plurality of OLED displays and a diffuser to form a display backlight. Such a backlight can be used as an AMLCD backlight. The OLED displays can support NVIS compatibility by reducing current provided to red sub-pixels, and by limiting transmission of light beyond 630 nm, possibly by material selection or filtering using thin film optical coatings.

Owner:LITTON SYST INC

Improvements in and relating to displays

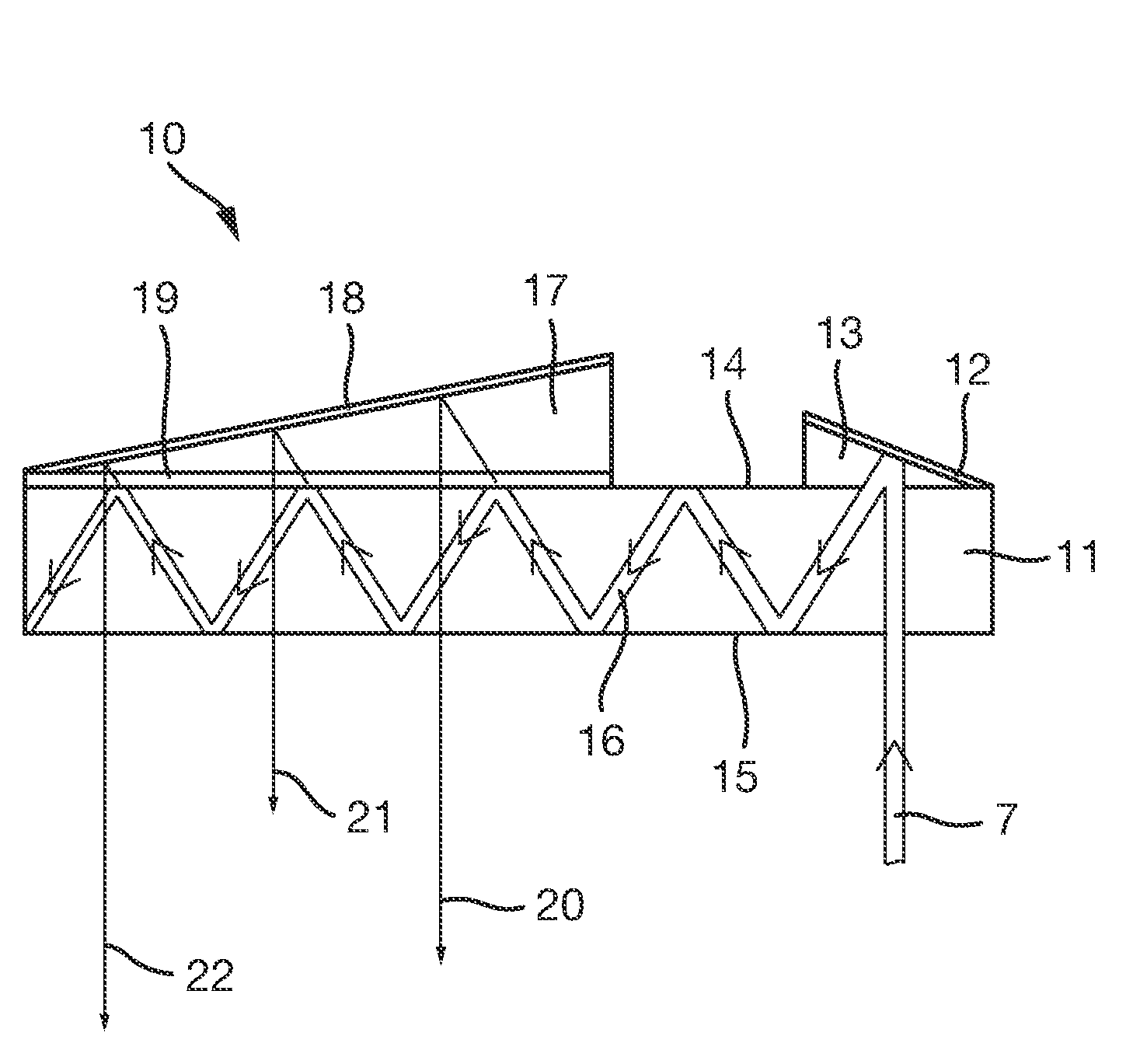

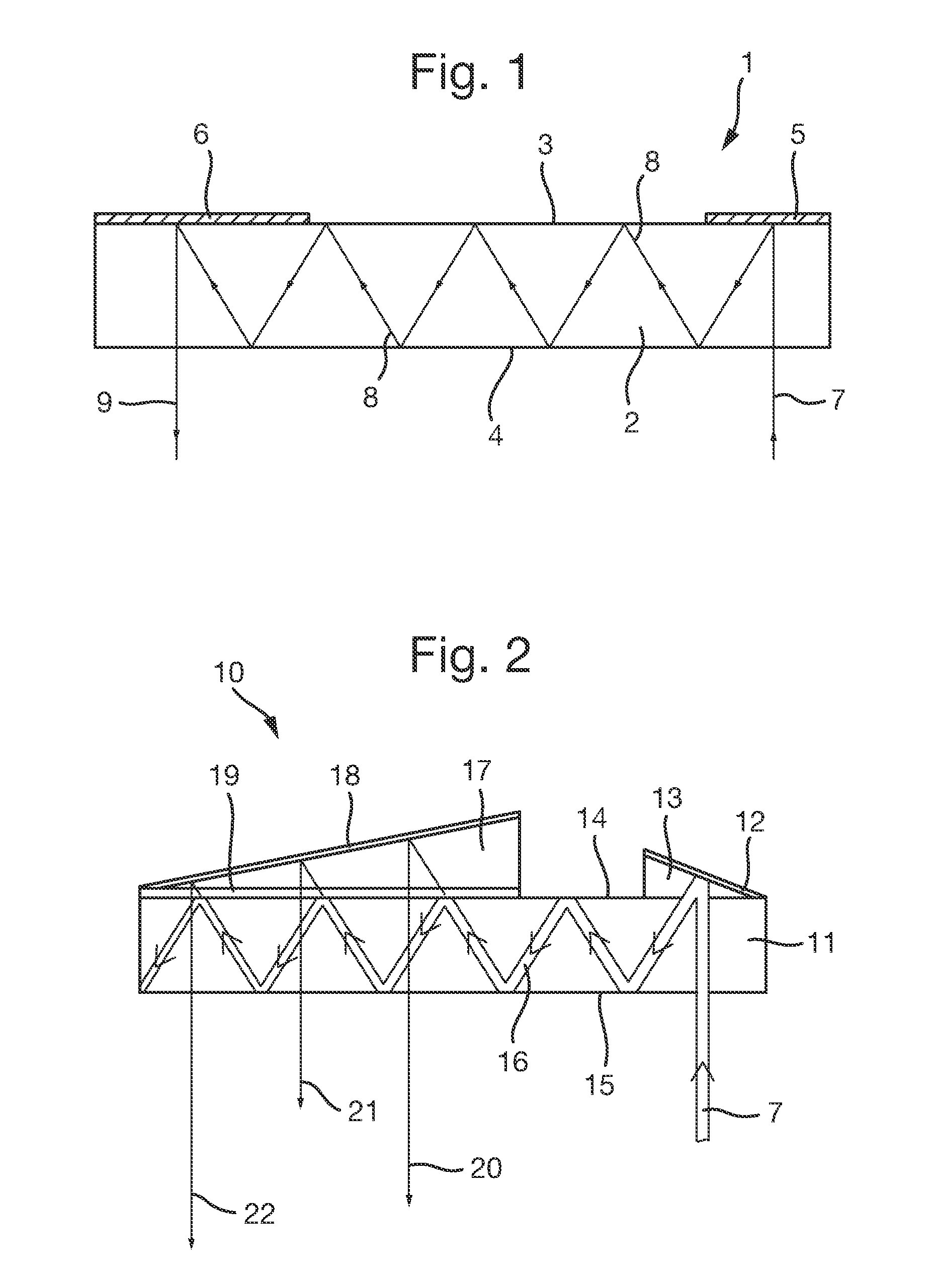

ActiveUS20160041387A1Small sizeFacilitate transmissionMechanical apparatusPolarising elementsOptical coatingDisplay device

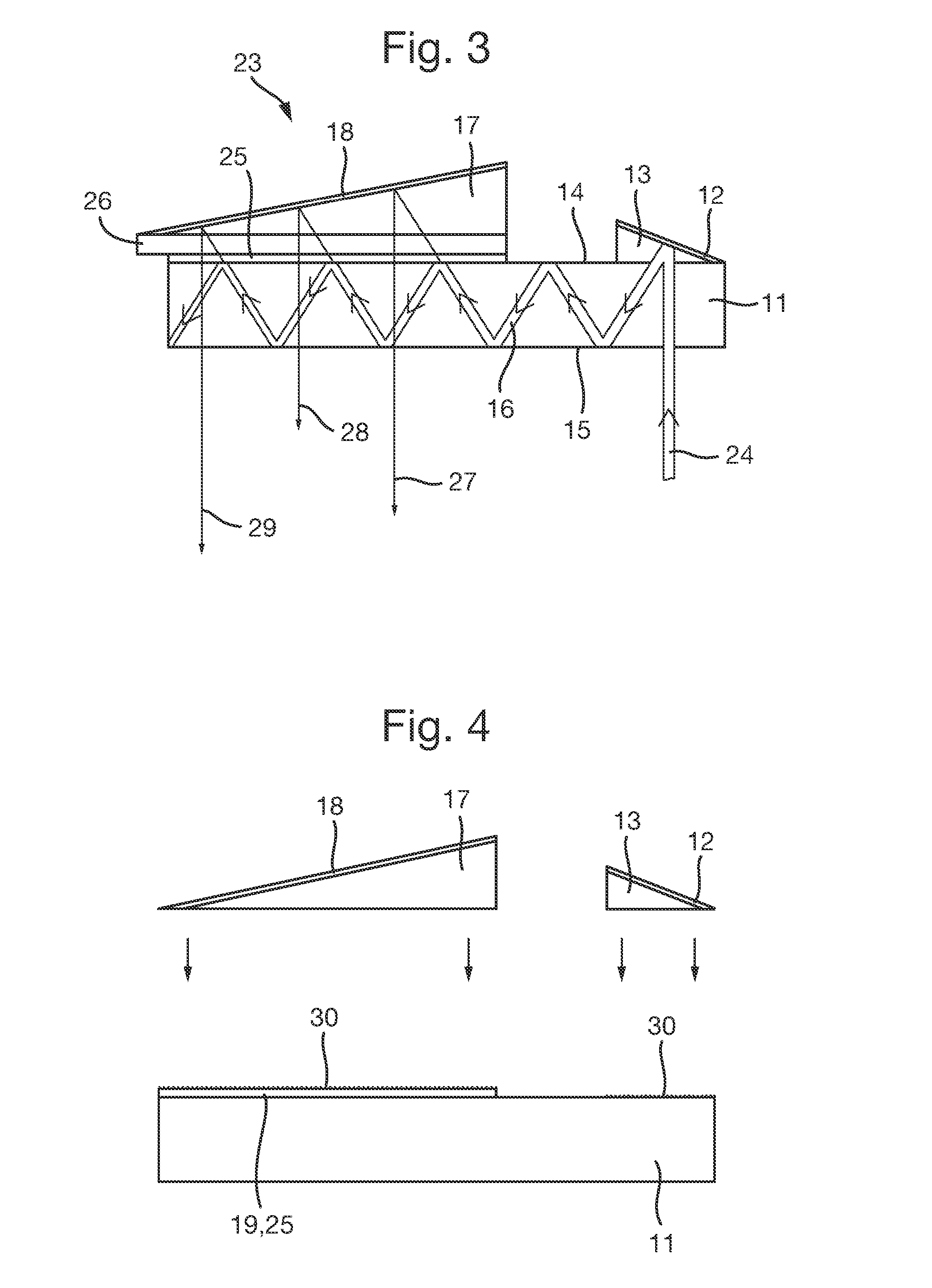

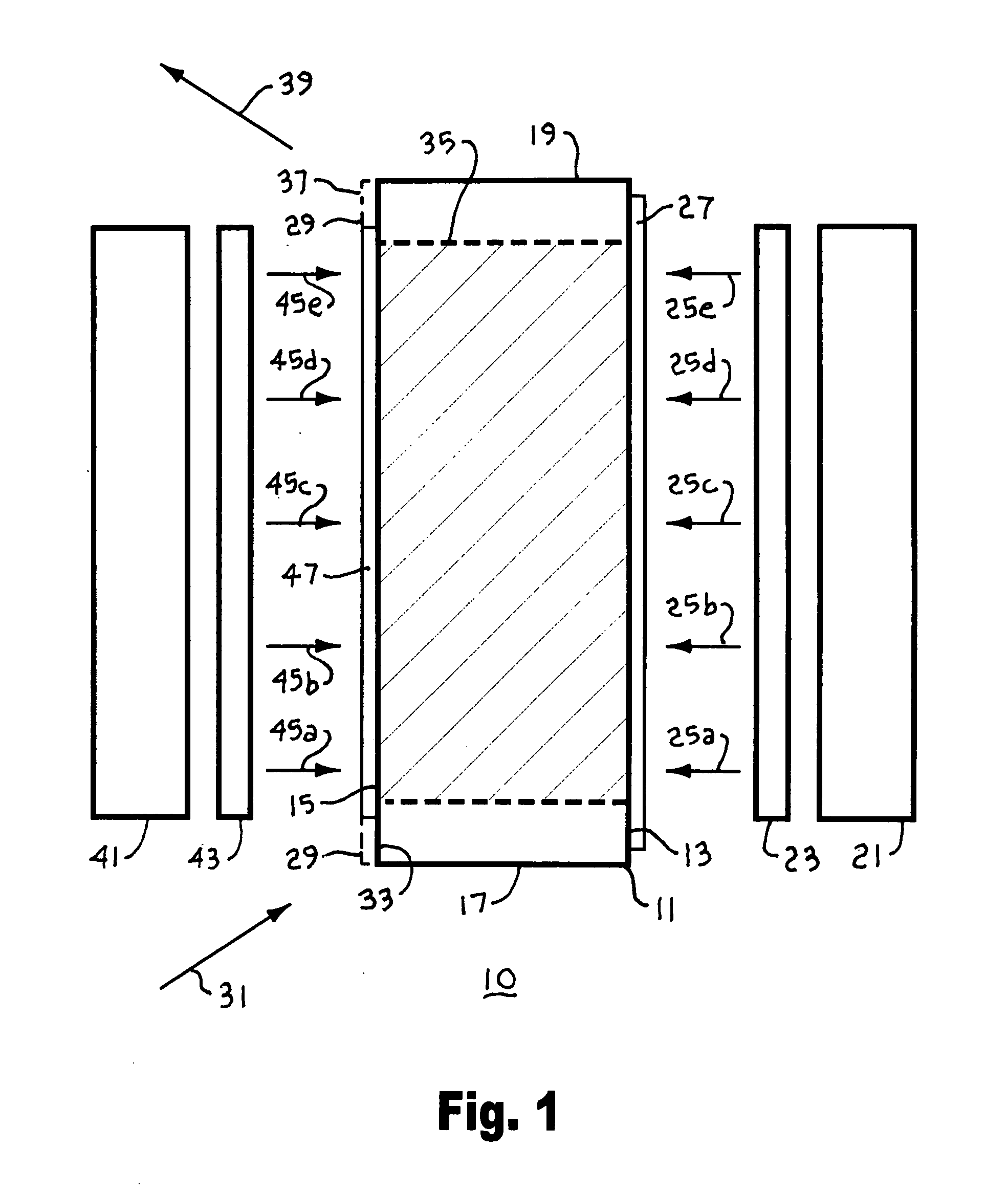

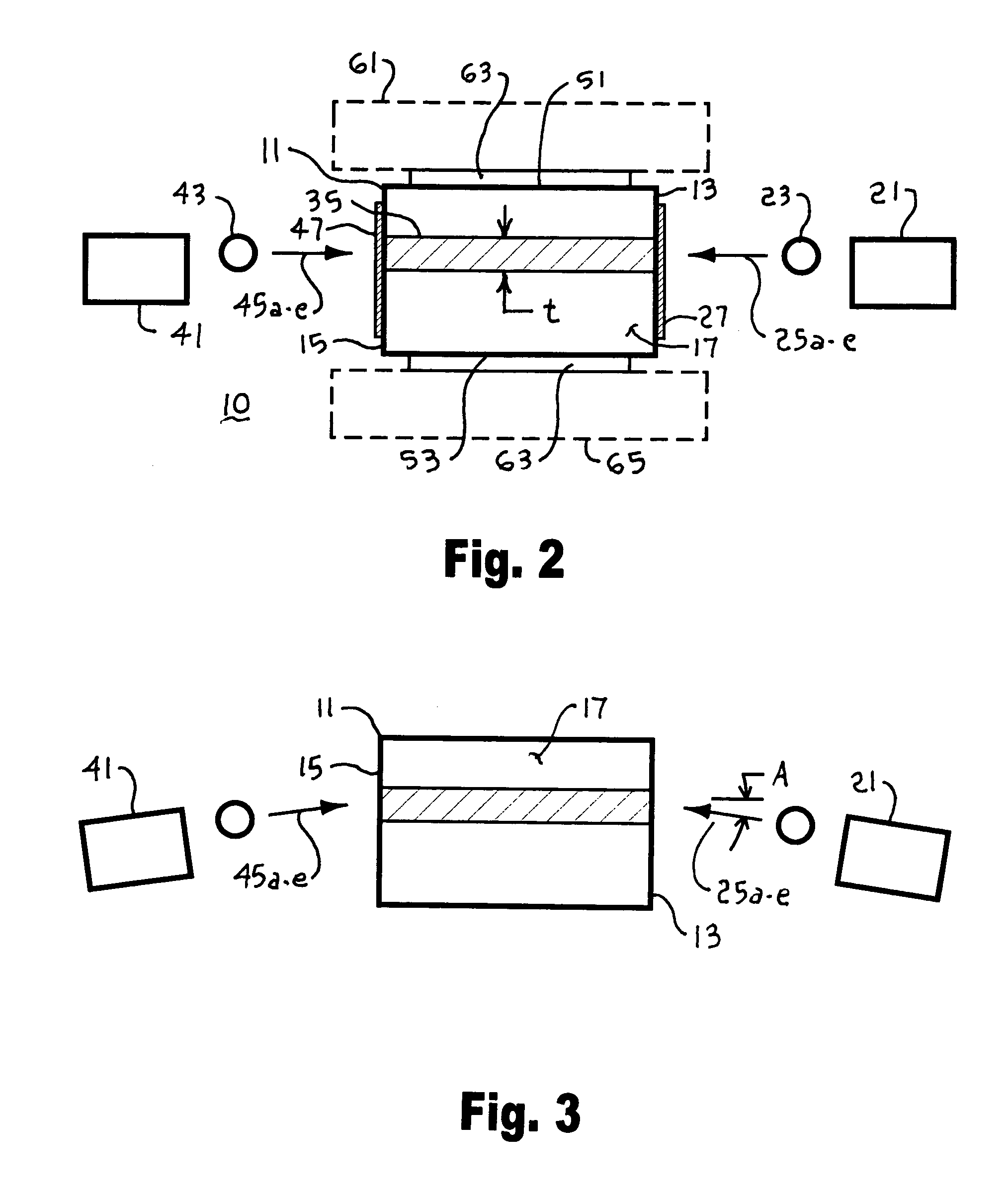

An optical component for a display apparatus comprises an optical waveguide part (11) arranged to guide light therealong between surface parts thereof by internal reflection, an input part (13) arranged to receive light and direct the received light into the optical waveguide part, and an output part comprising a partially transmissive angularly reflective optical coating (25) arranged upon a surface part of the optical waveguide part. The output part is optically coupled to the input part by the optical waveguide part to receive guided light and to transmit some but not all of said guided light out from the optical waveguide part. The angularly reflective optical coating extends along a dimension of the optical waveguide part to expand the guided light in said dimension along the output part by repeated partial transmission thereof for output.

Owner:BAE SYSTEMS PLC

High efficiency beam combiner coating

InactiveUS20150213754A1Minimize overlapStatic indicating devicesDiffusing elementsOptical coatingTransmittance

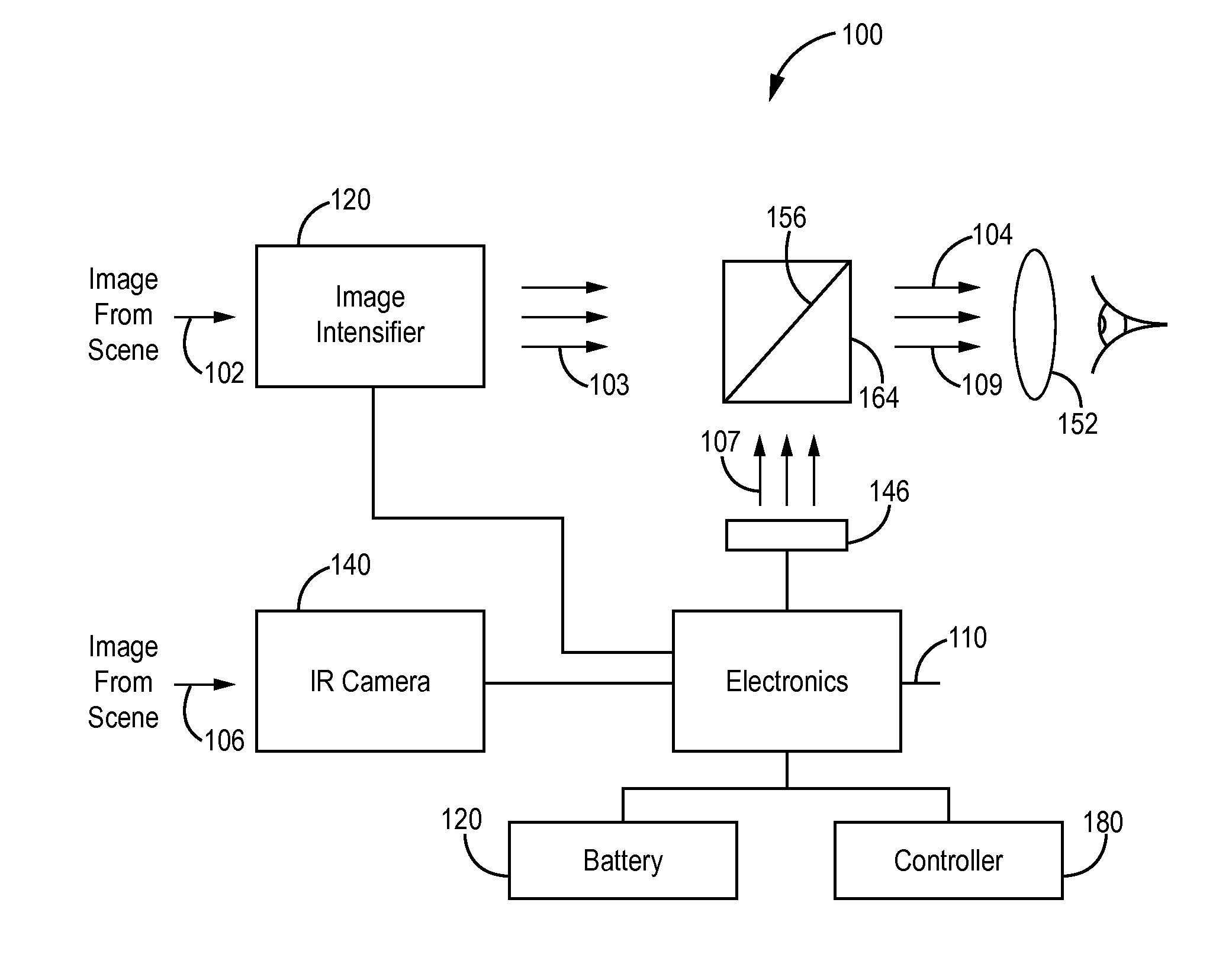

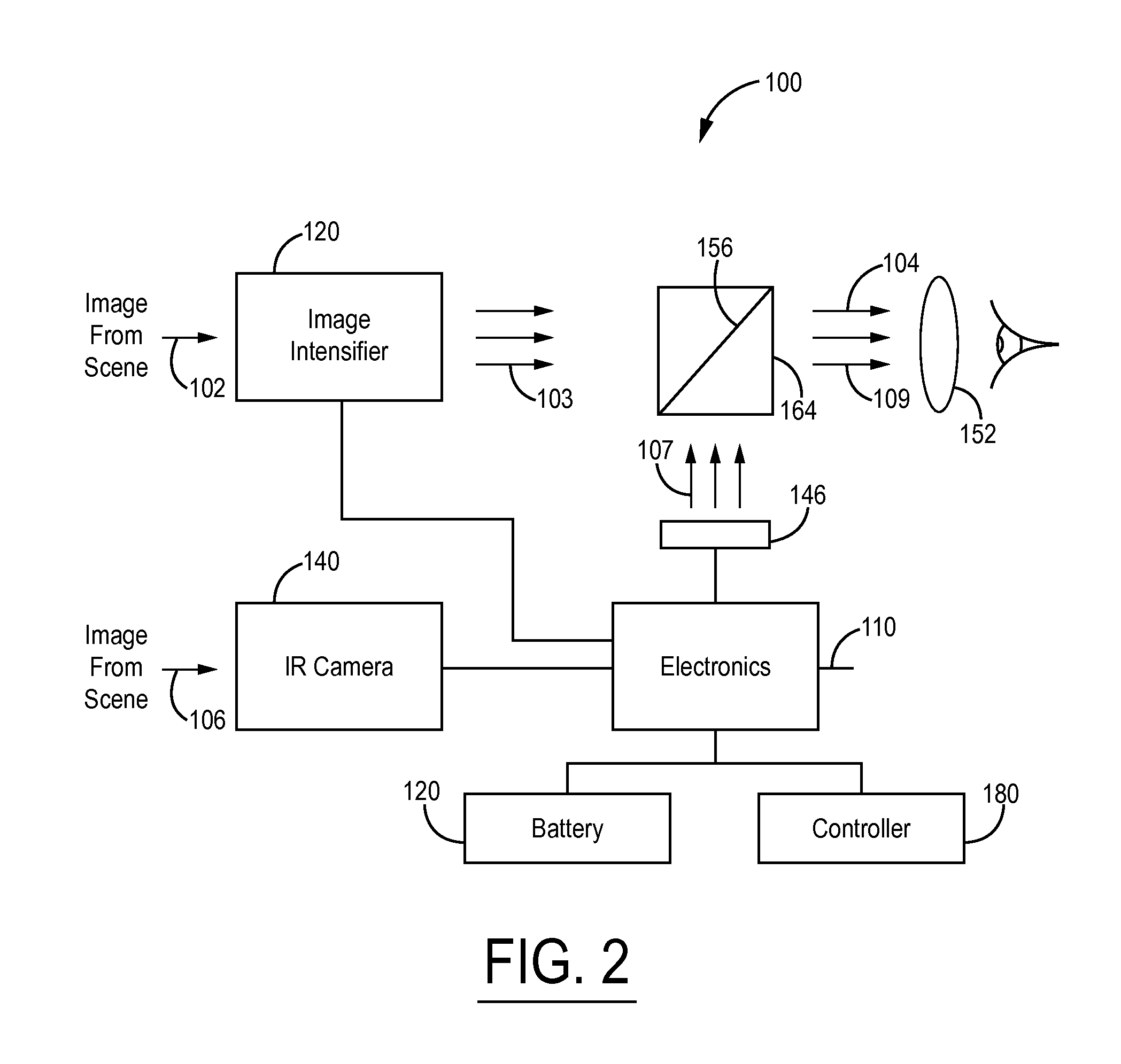

A system having an improved optical coating for use in beam combiner assemblies for an image fusion device using an organic light-emitting diode (OLED) display. The system combines multi-spectral images of a scene having superior reflection of the OLED display image while incorporating high transmission of the image fusion device while allowing low power requirements on the system.

Owner:EMAGIN CORP

Thin film solar cell

InactiveUS20080078444A1Good choiceImprovement factorPhotovoltaic energy generationSemiconductor devicesHigh energyUltraviolet

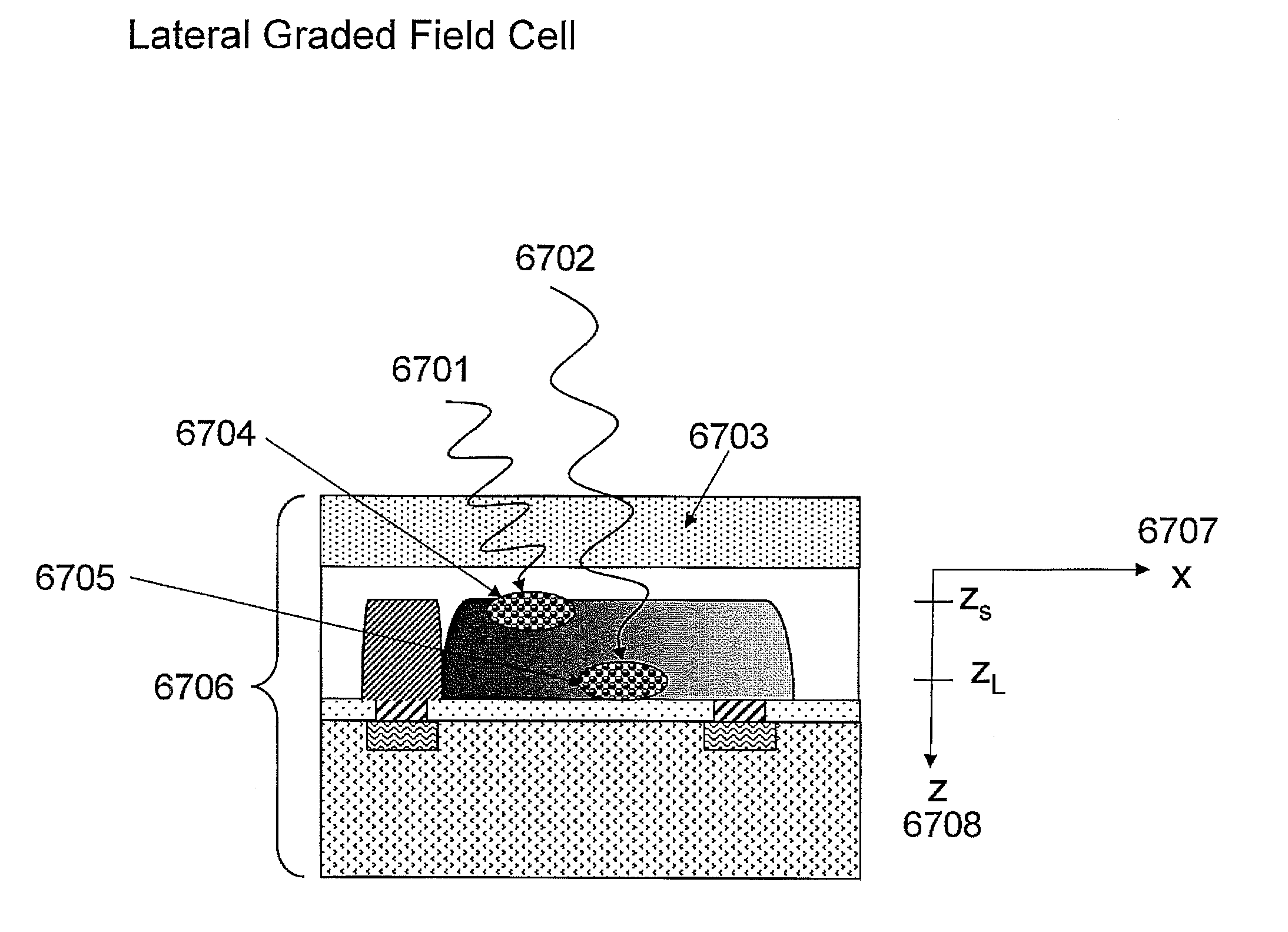

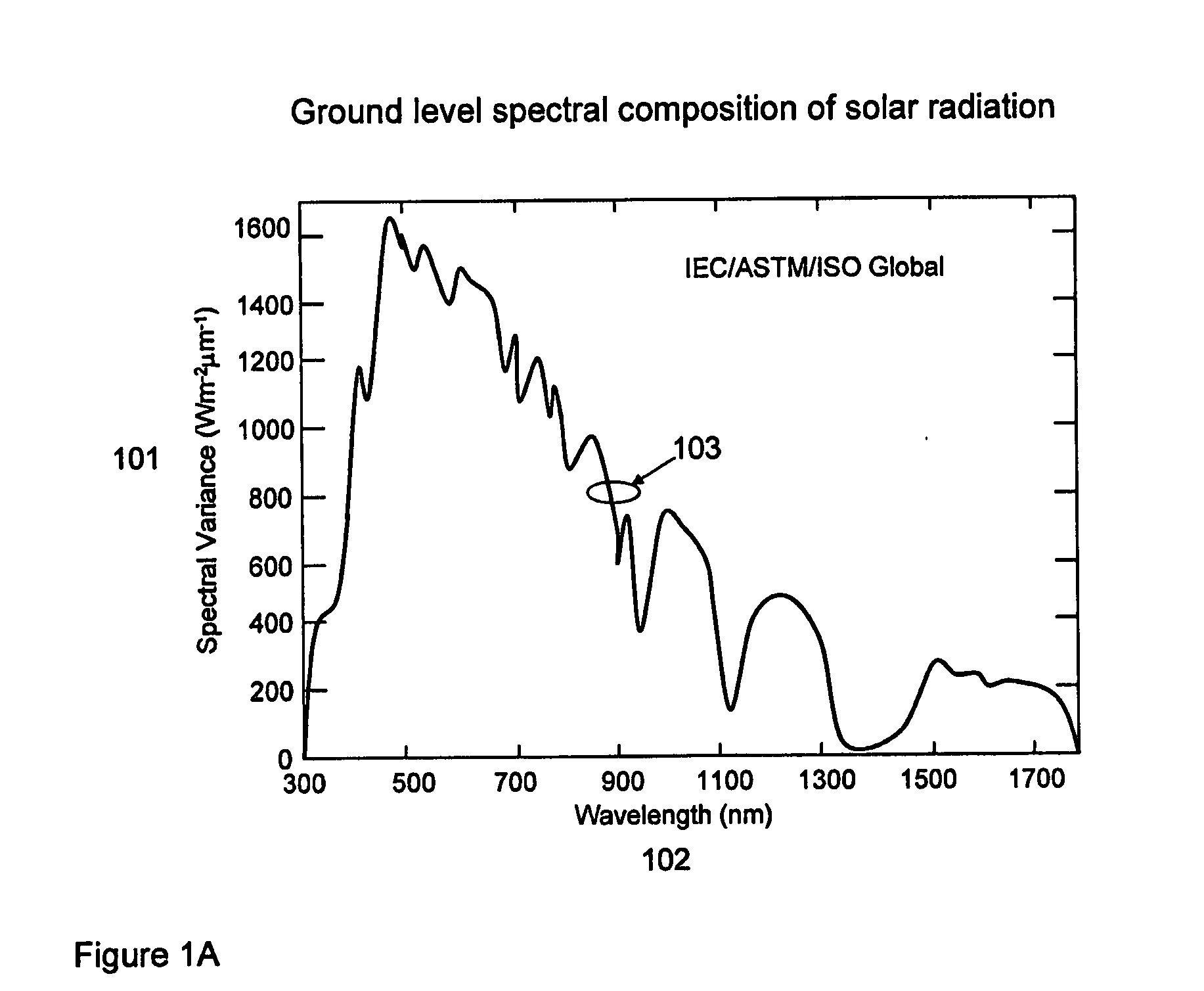

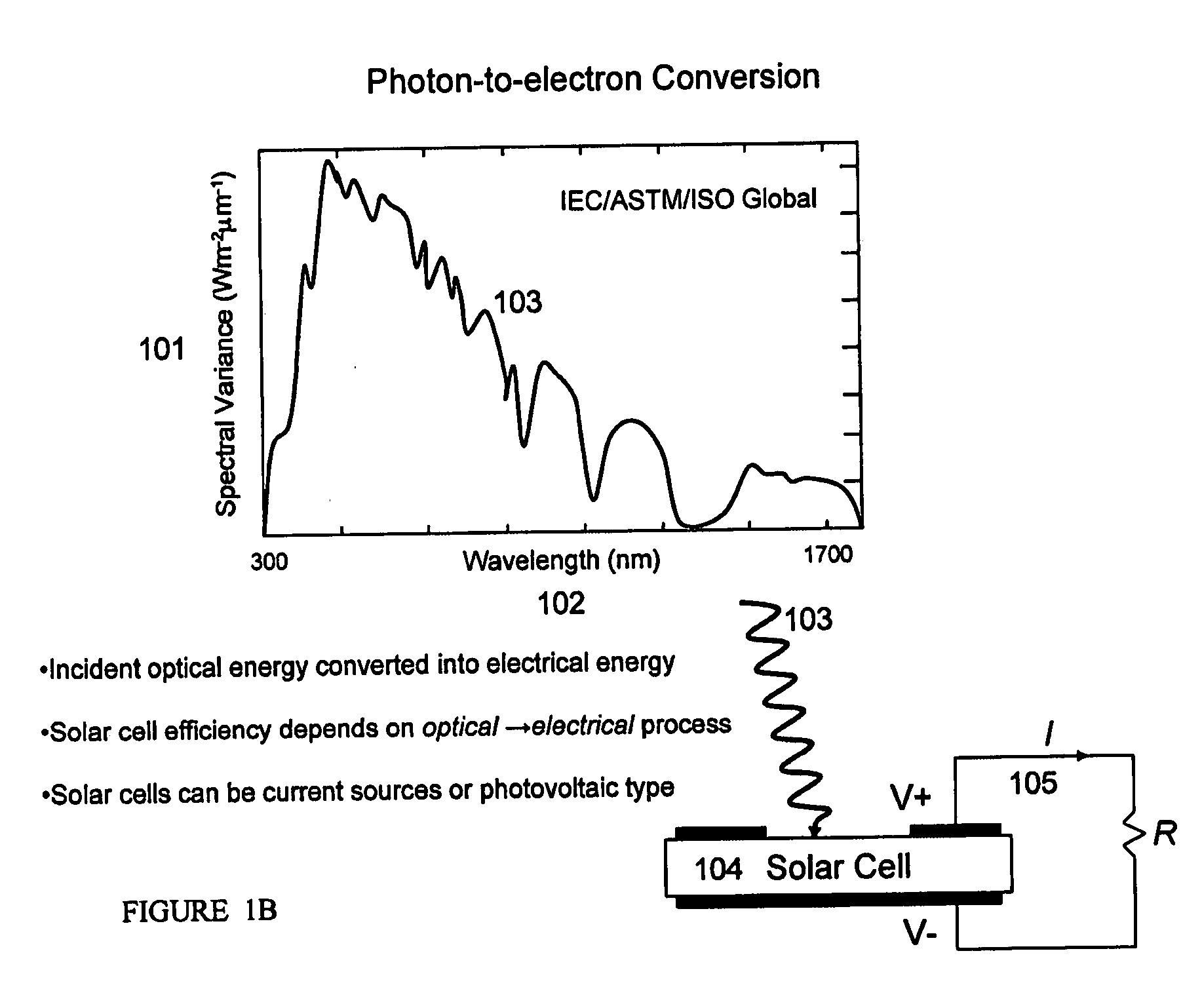

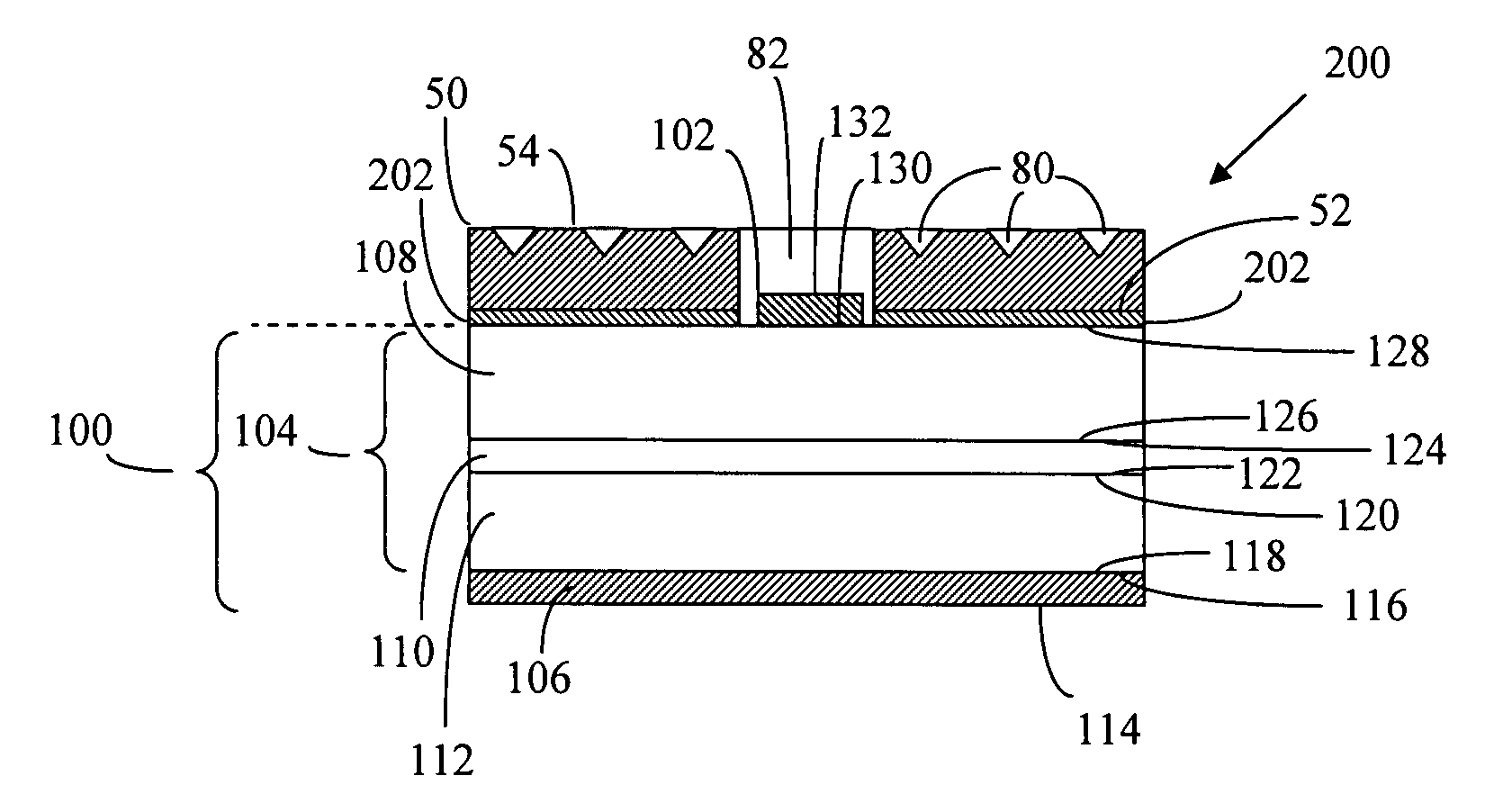

Optimal structures for high efficiency thin film silicon solar energy conversion devices and systems are disclosed. Thin film silicon active layer photoelectron conversion structures using ion implantation are disclosed. Thin film semiconductor devices optimized for exploiting the high energy and ultraviolet portion of the solar spectrum at the earths surface are also disclosed. Solar cell fabrication using high oxygen concentration single crystal silicon substrates formed using in preference the CZ method are used advantageously. Furthermore, the present invention discloses optical coatings for advantageous coupling of solar radiation into thin film solar cell devices via the use of rare-earth metal oxide (REOx), rare-earth metal oxynitride (REOxNy) and rare-earth metal oxy-phosphide (REOxPy) glasses and or crystalline material. The rare-earth metal is chosen from the group commonly known in the periodic table of elements as the lanthanide series.

Owner:IQE

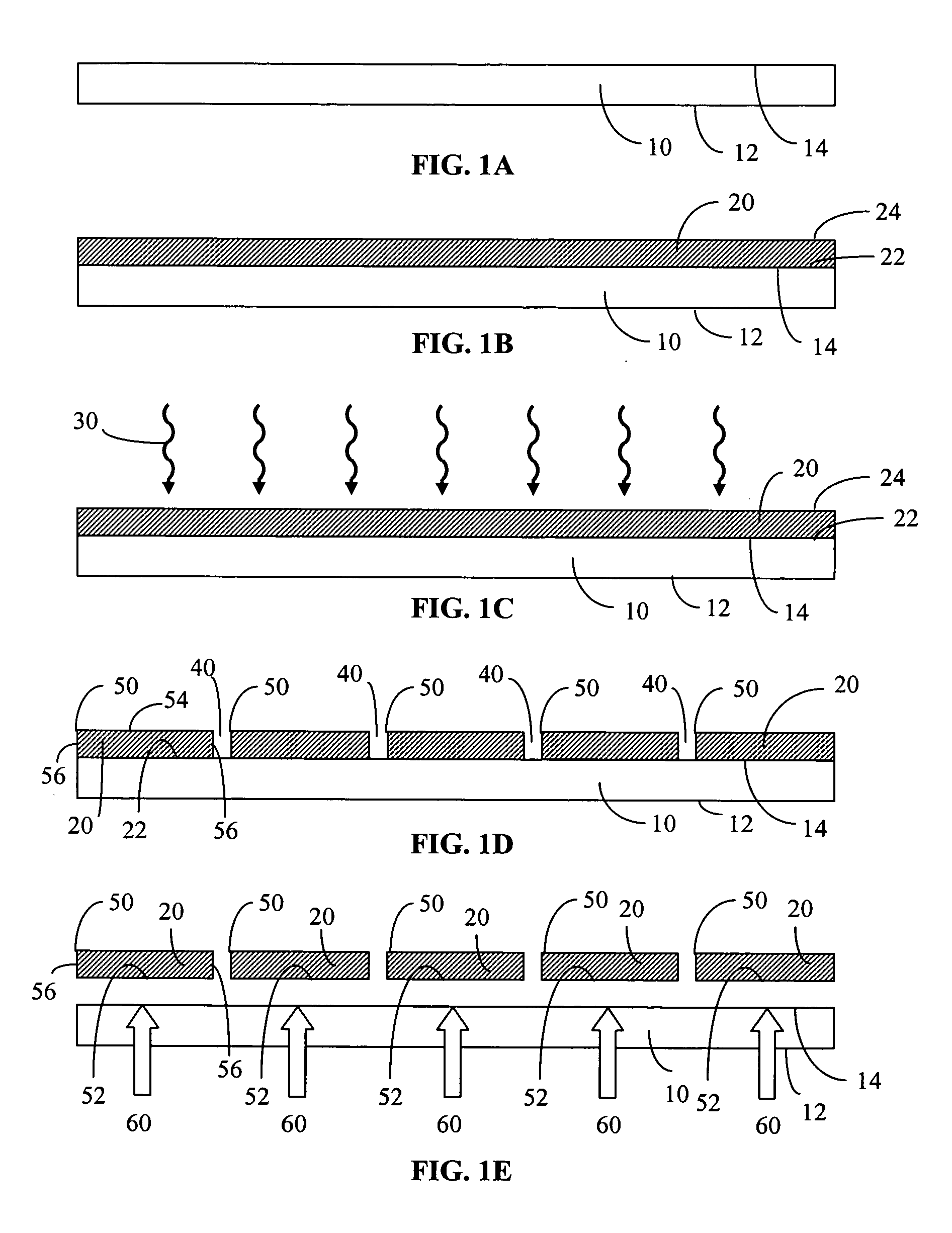

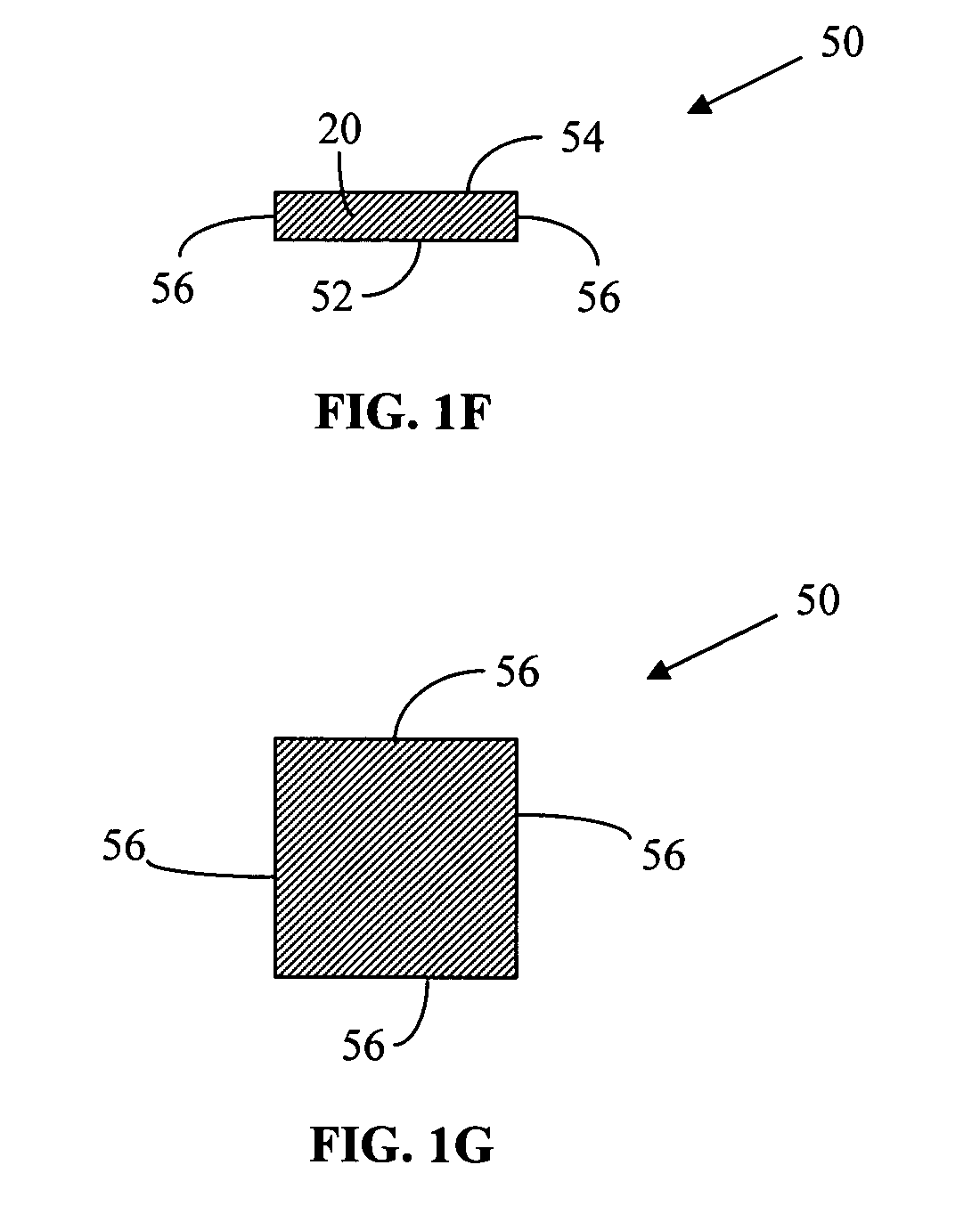

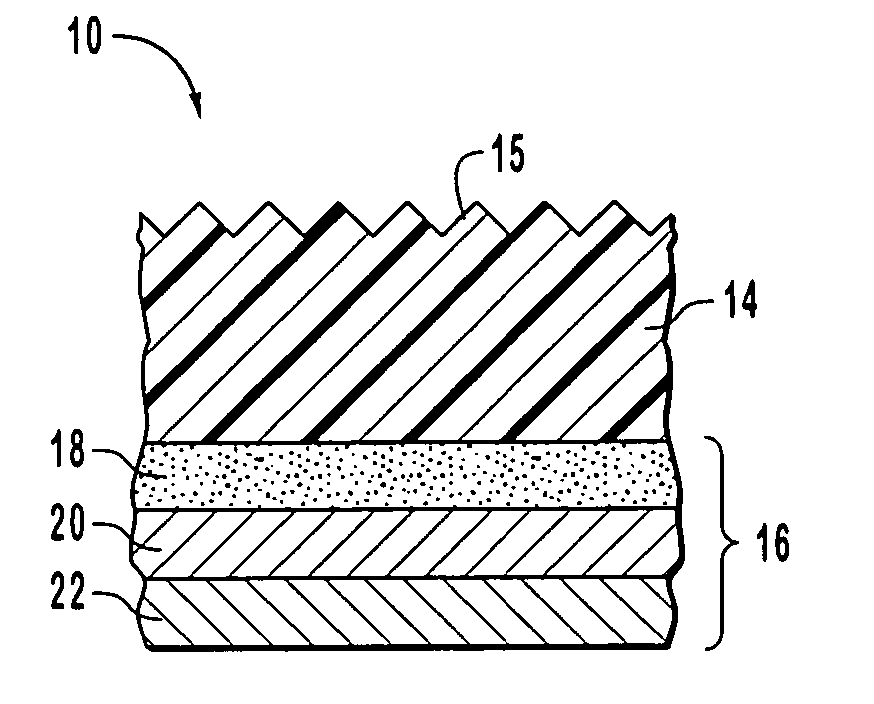

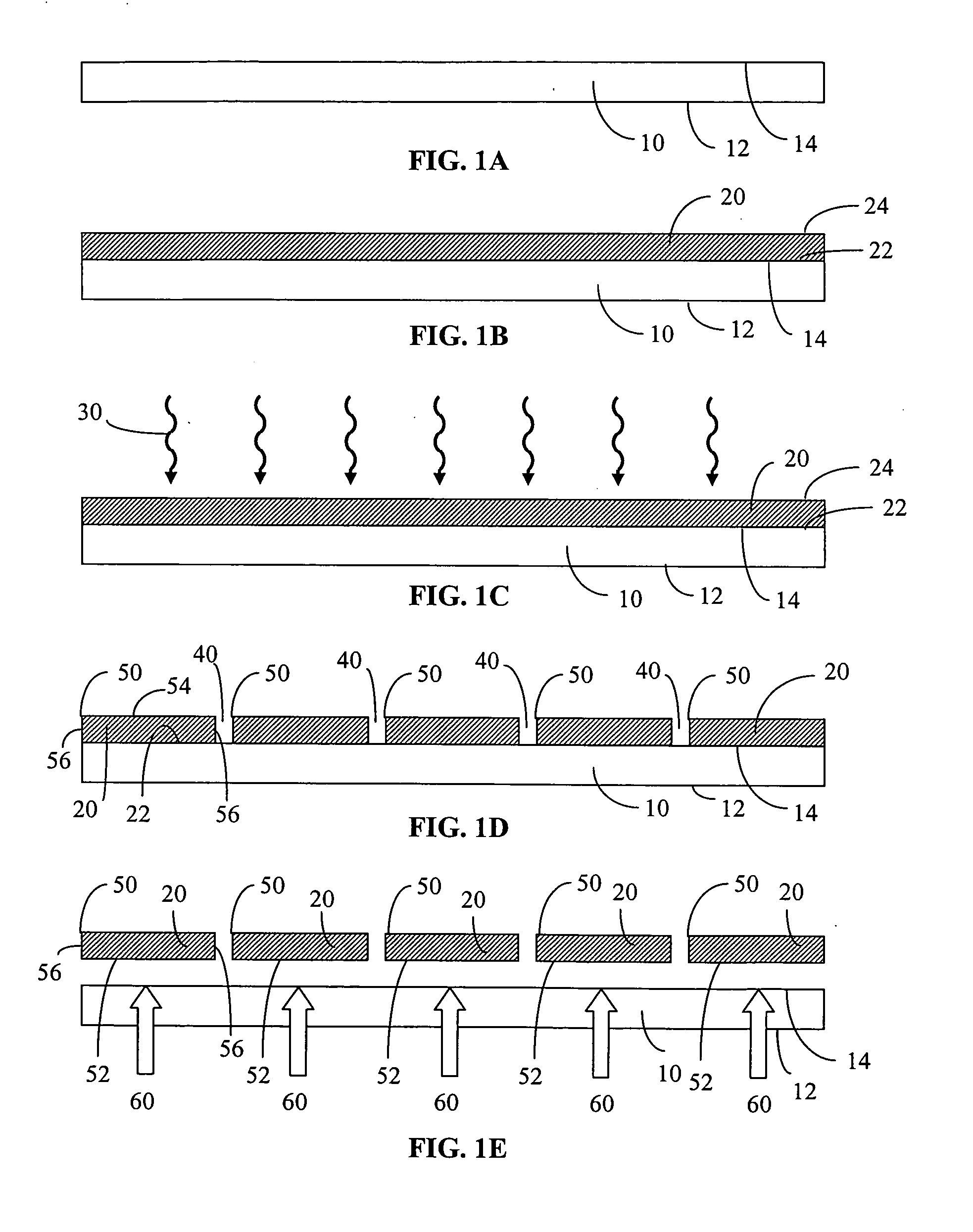

Wavelength conversion chip for use with light emitting diodes and method for making same

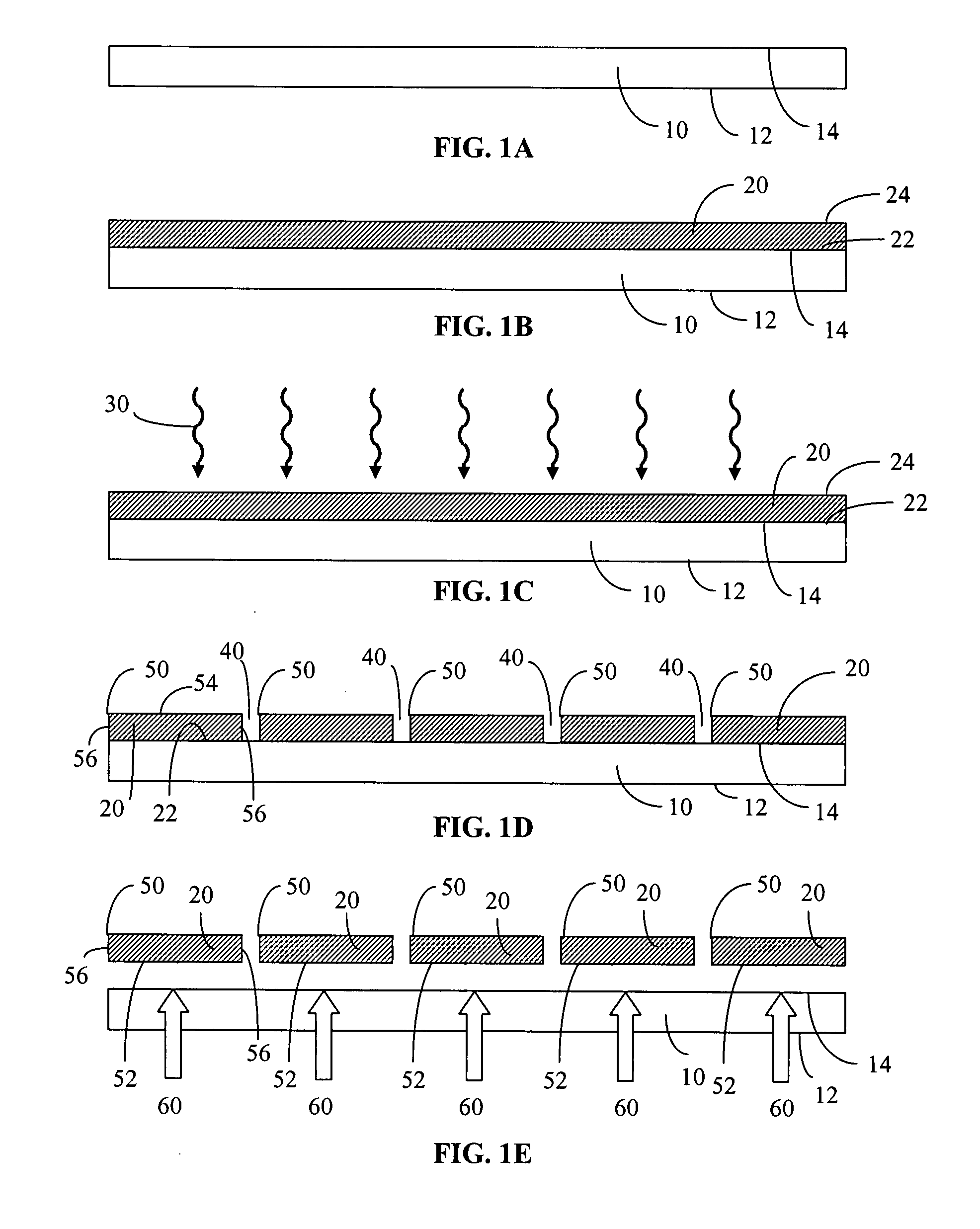

InactiveUS20080042153A1Improve conversion efficiencyShorten the counting processElectroluminescent light sourcesPhotometryOptical coatingElectrical connection

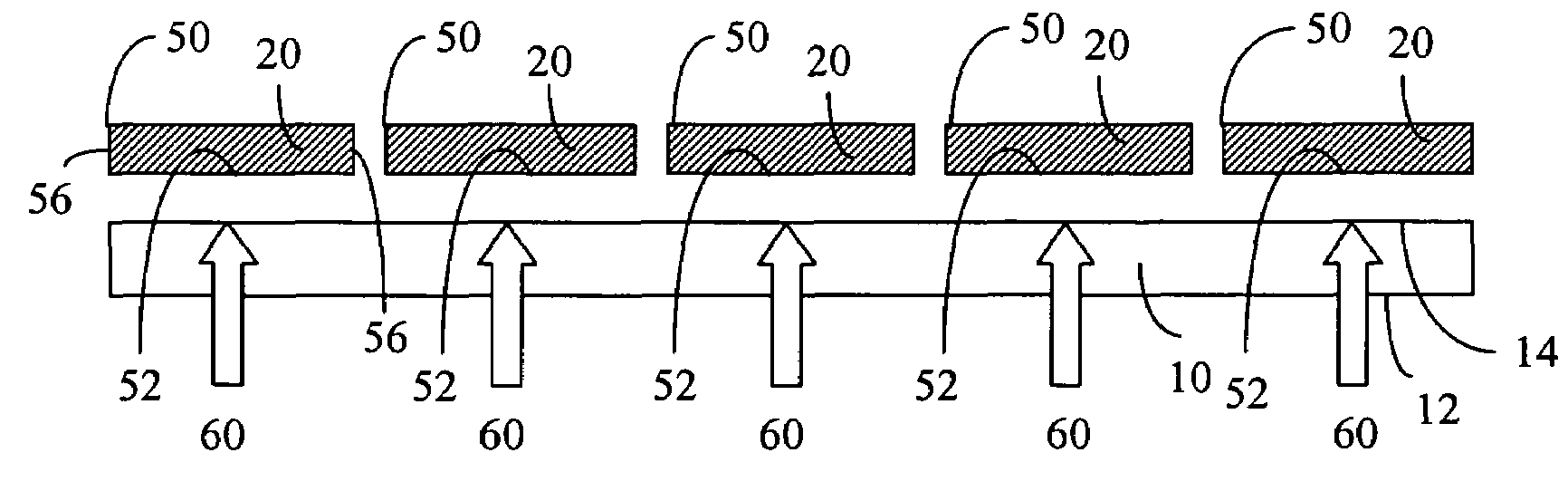

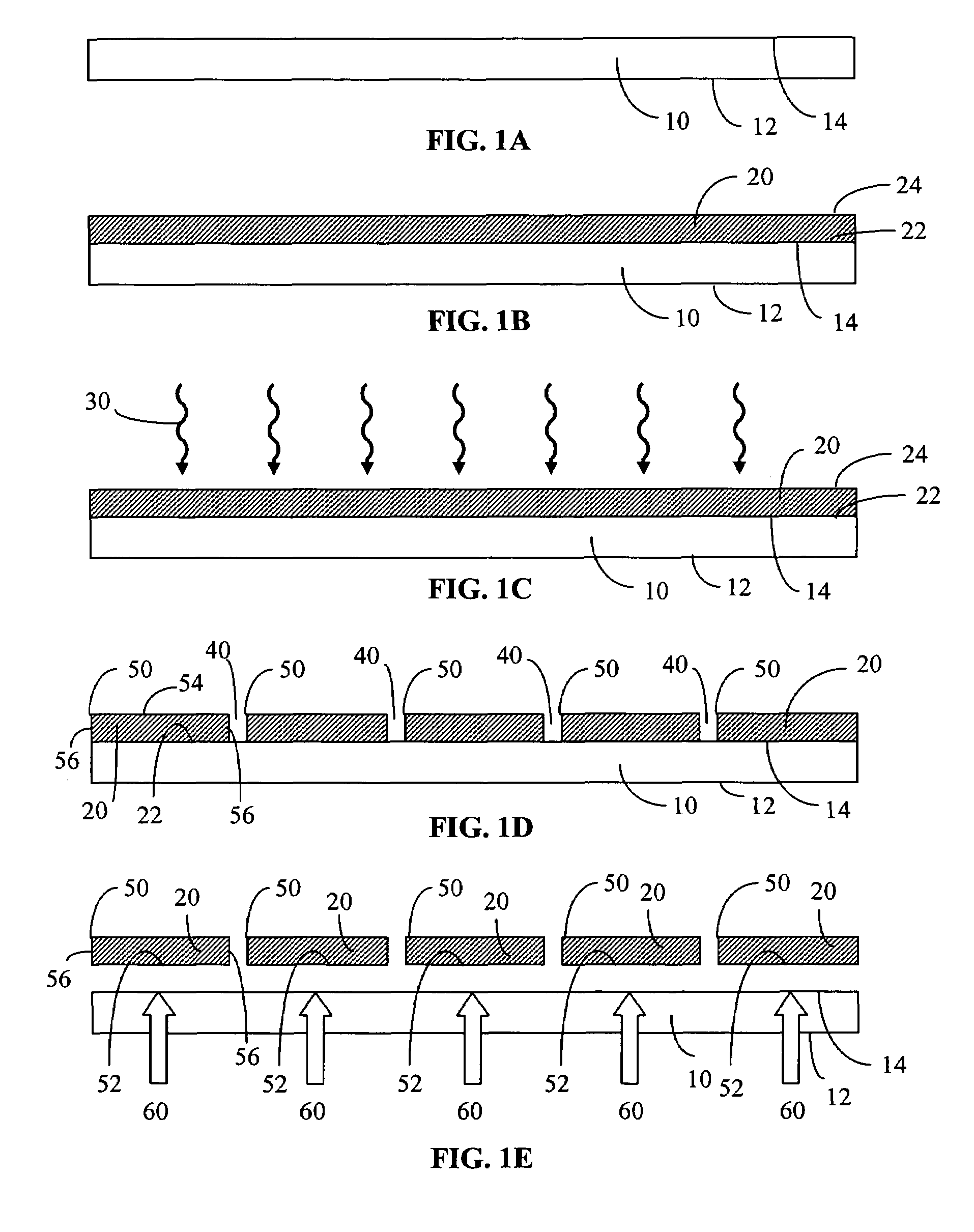

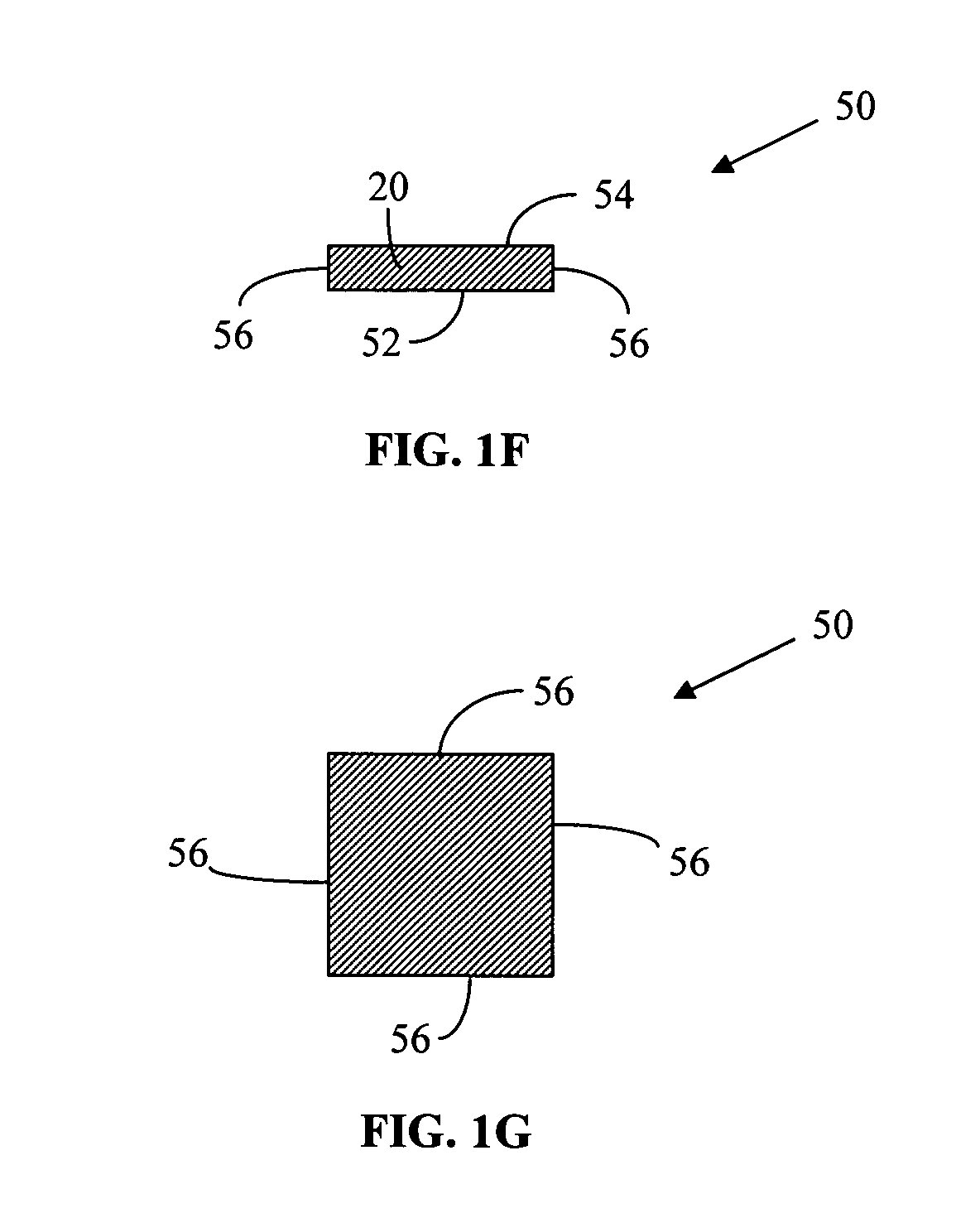

A wavelength conversion chip is formed by depositing a wavelength conversion material on a substrate to form a layer, removing the resulting wavelength conversion layer from the substrate and then segmenting the wavelength conversion layer into a plurality of wavelength conversion chips. The wavelength conversion material can be annealed by thermal annealing or radiation annealing to increase the wavelength conversion efficiency of the chips or to sinter the wavelength conversion material to form a ceramic material. Optical coatings, vias, light extraction elements, electrical connections or electrical bond pads can be fabricated on the wavelength conversion chips.

Owner:GOLDENEYE

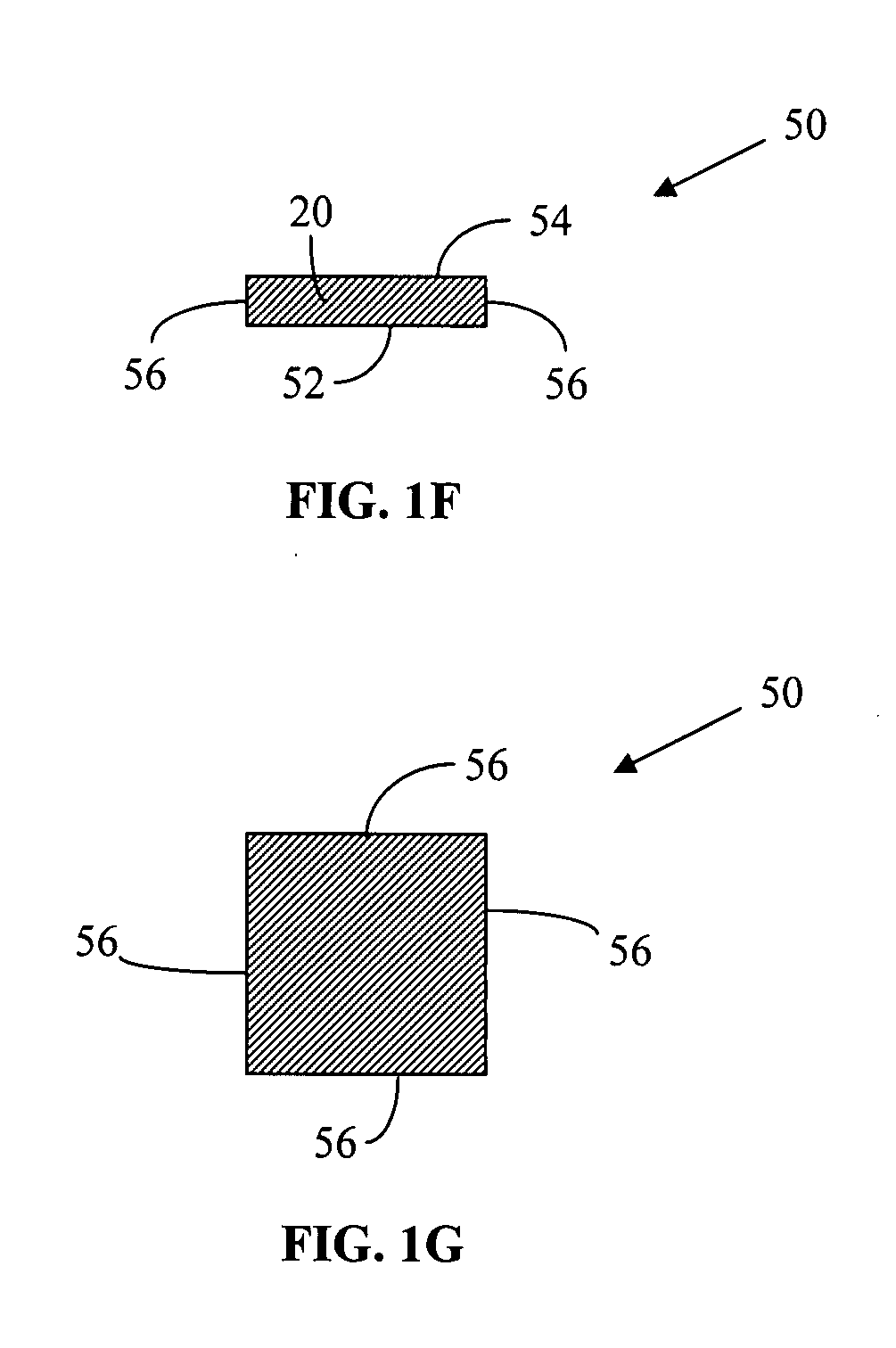

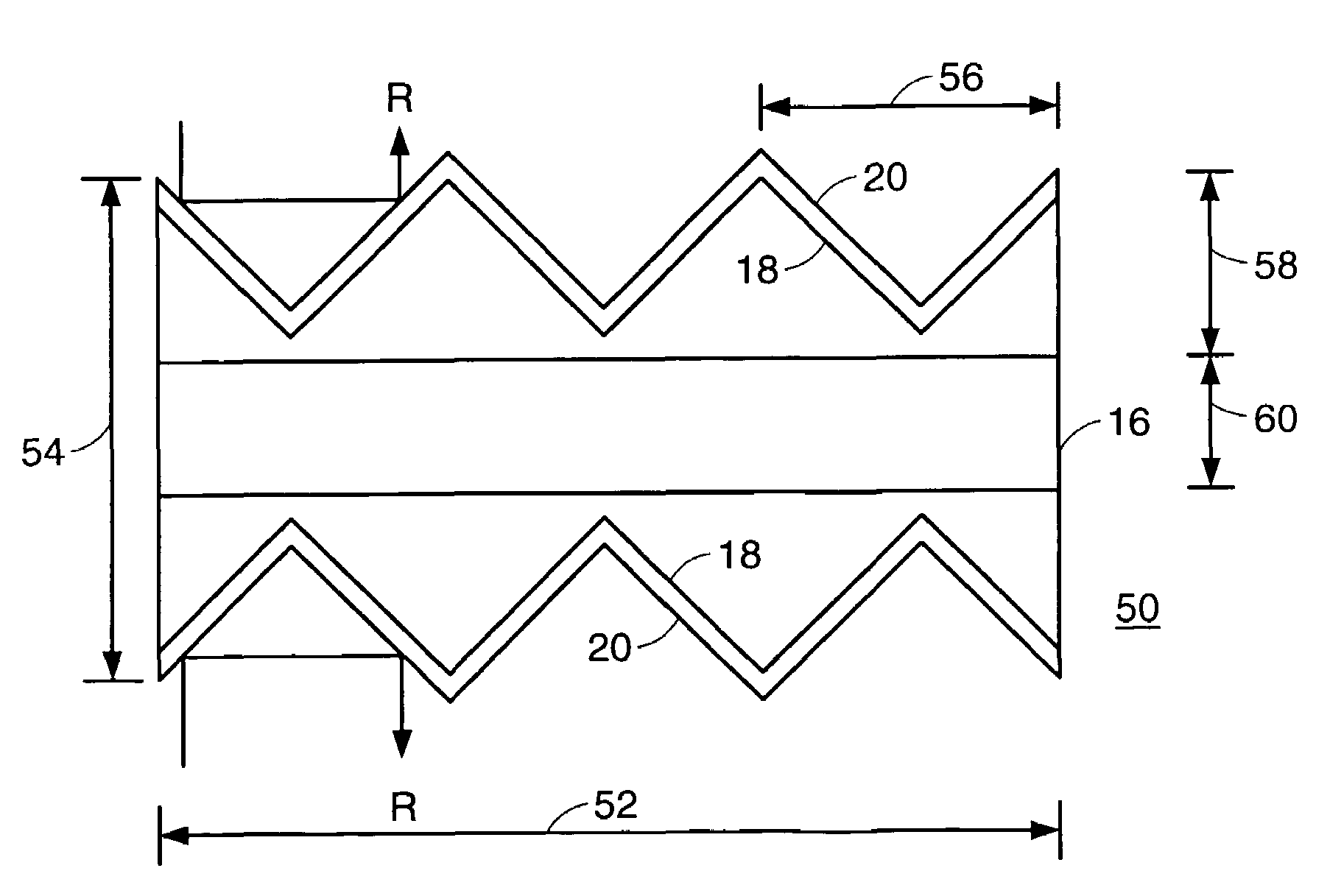

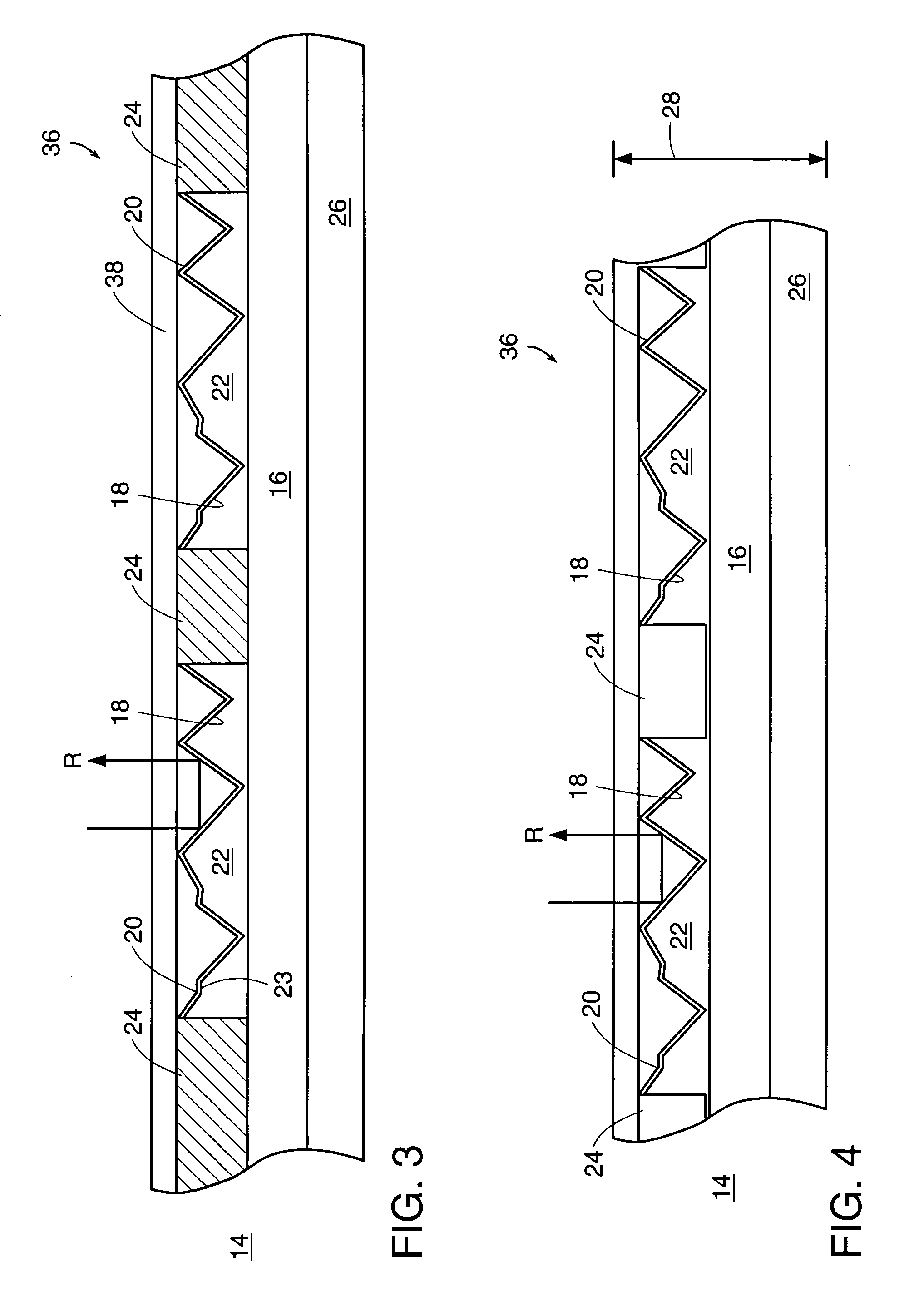

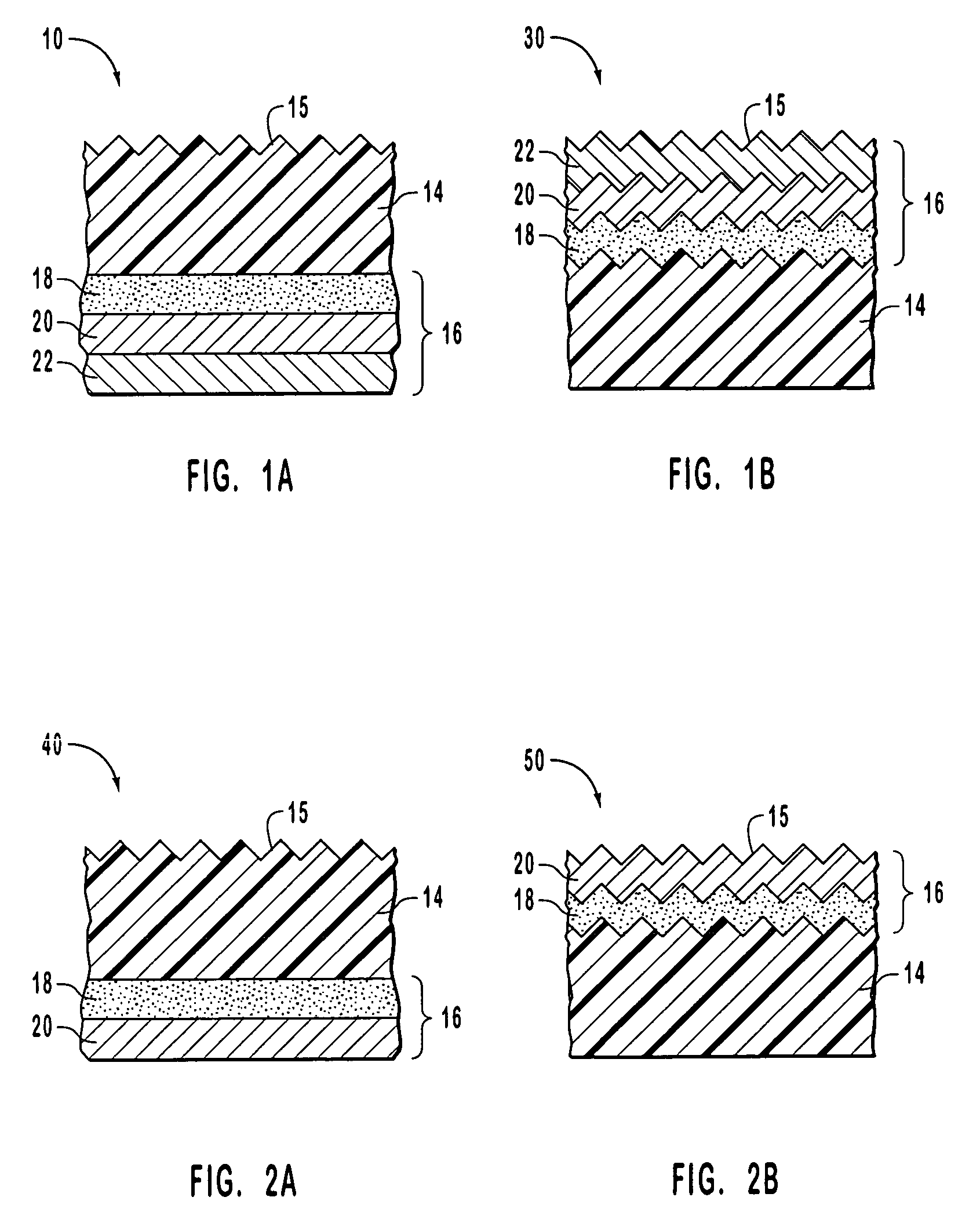

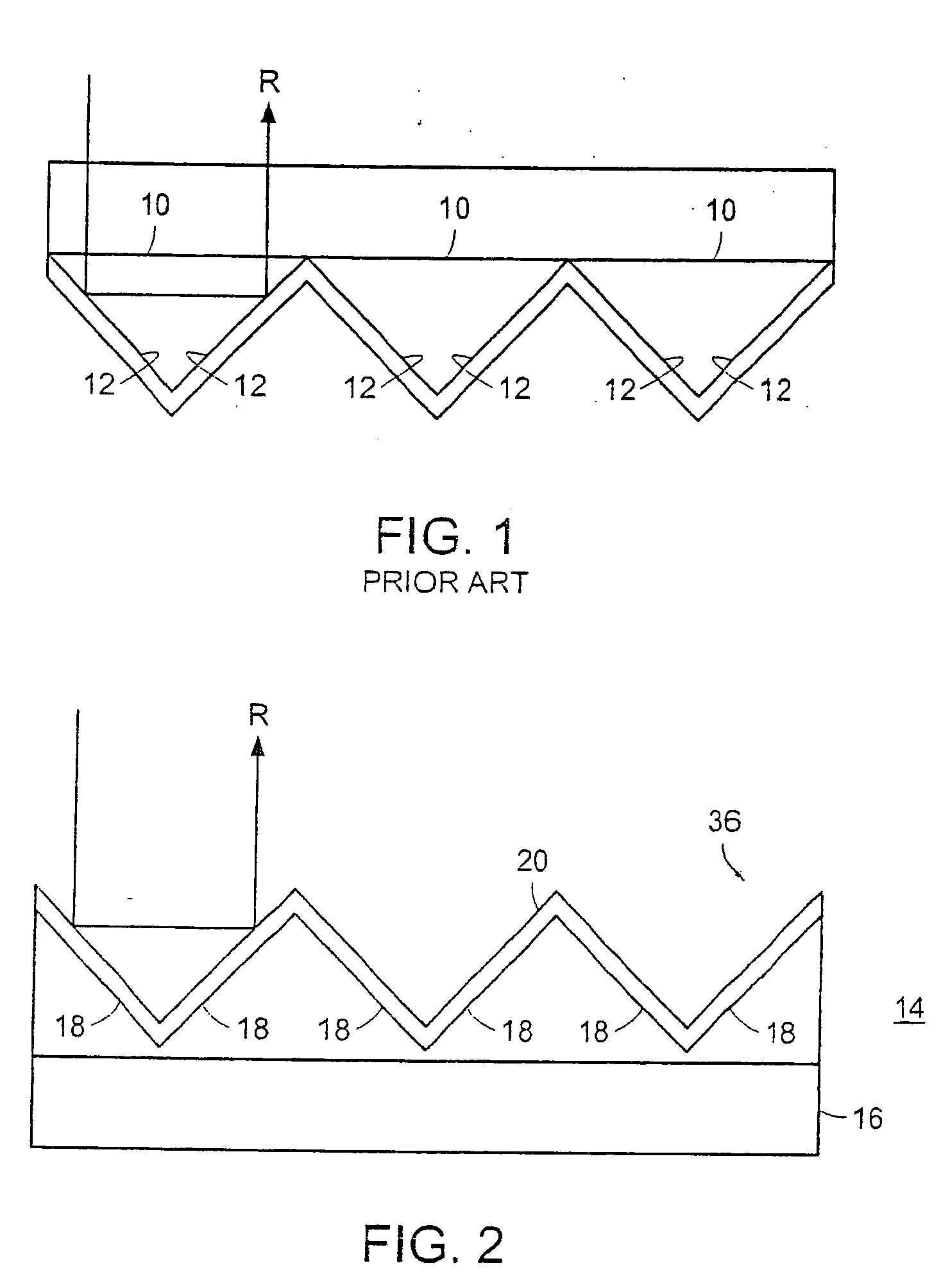

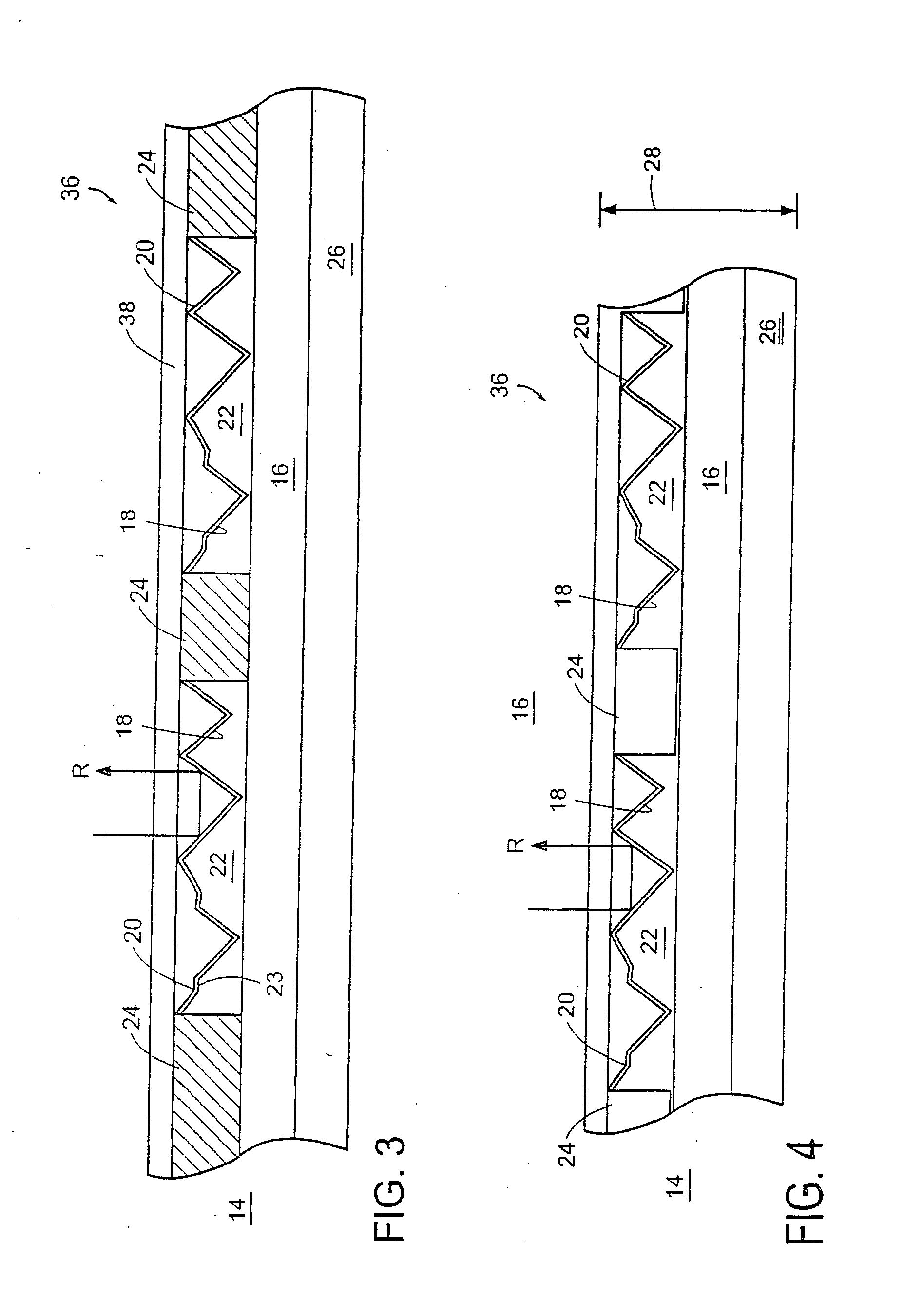

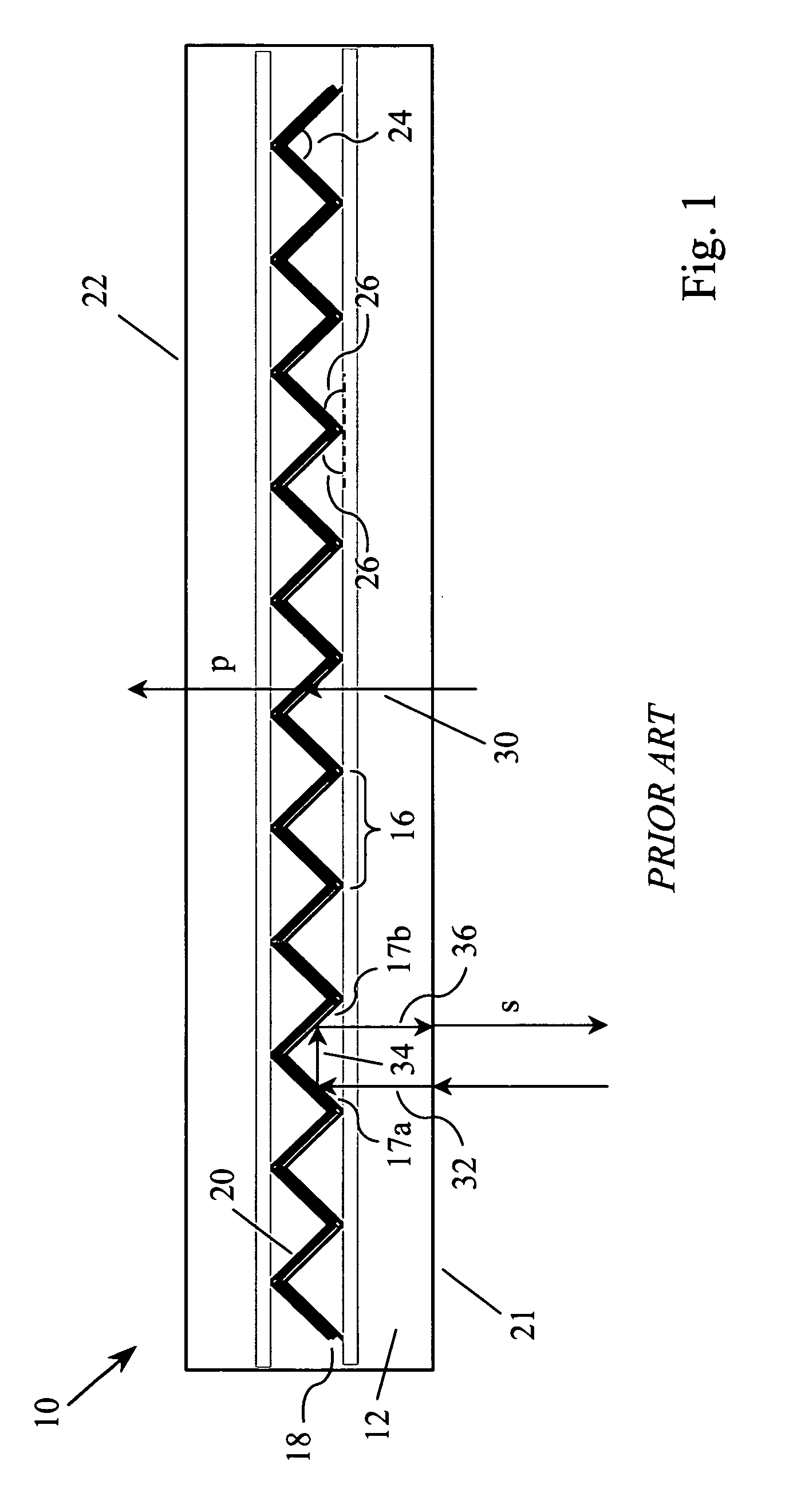

Durable, open-faced retroreflective prismatic construction

InactiveUS6967053B1Improve adhesionImprove the entrance angleReflex reflectorsThin material handlingOptical coatingPrism

Retroreflective sheeting and a method for making the same includes a plurality of open-faced cube-corner surfaces formed from a substantially rigid material to keep the cube-corner surfaces from flexing. An optical coating is formed on the surfaces, and a fill layer is attached to at least a portion of the optical coating. A plurality of voids form the open-faced cube-corner surfaces.

Owner:ORAFOL AMERICAS

Wavelength conversion chip for use in solid-state lighting and method for making same

InactiveUS20070221867A1Improve conversion efficiencyShorten the counting processElectroluminescent light sourcesPhotometrySmart lightingOptical coating

A wavelength conversion chip is formed by depositing a wavelength conversion material layer on a substrate, segmenting the wavelength conversion layer into a plurality of wavelength conversion chips, and then removing the wavelength conversion chips from the substrate. The wavelength conversion of the chips can be increased by thermal annealing or radiation annealing of the wavelength conversion material. Optical coatings or light extraction elements can be fabricated on the wavelength conversion layer.

Owner:GOLDENEYE

Security articles having diffractive surfaces and color shifting backgrounds

InactiveUS20040105963A1Increase the difficulty of counterfeitingOther printing matterDecorative surface effectsOptical diffractionColor shift

A security article includes a light transmissive substrate having a first surface and an opposing second surface, with the first surface having an embossed region with an optical diffraction pattern or a holographic image pattern. A color shifting optical coating is formed on the substrate such as on the opposing second surface, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. The security article can be used in a variety of applications and products to provide for enhanced security measures such as anticounterfeiting.

Owner:JDS UNIPHASE CORP

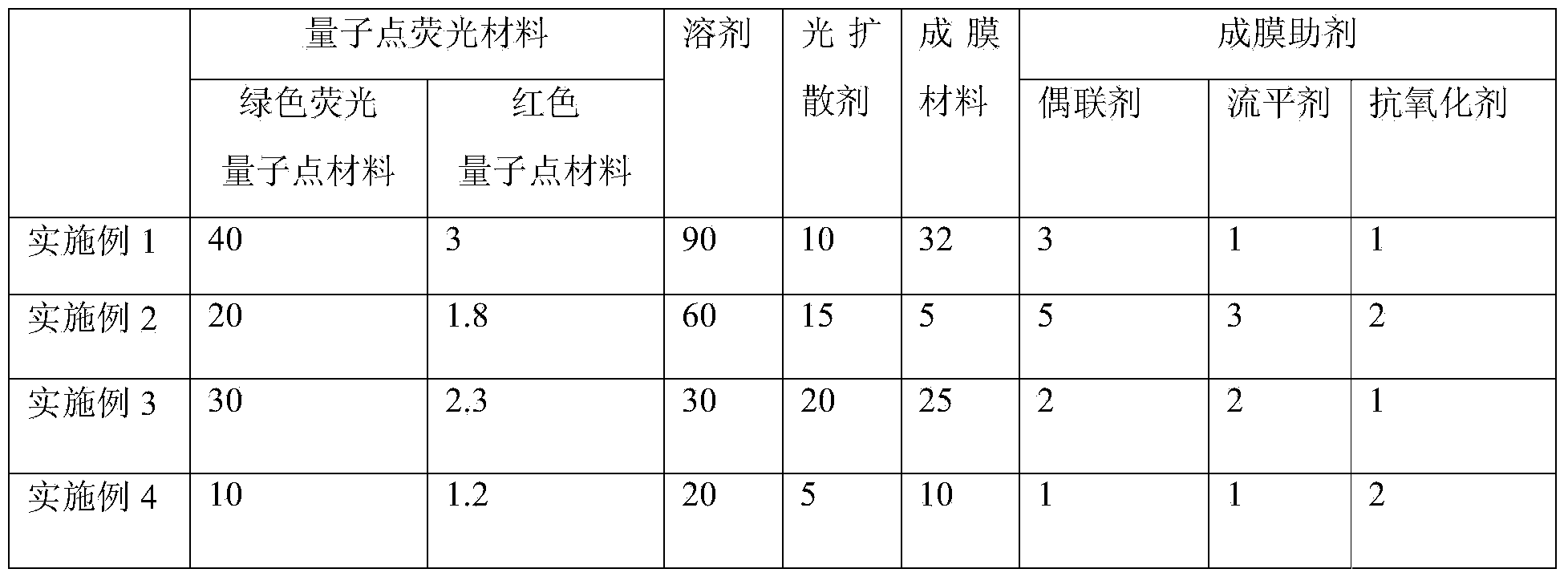

Optical coating composition, fluorescent optical membrane and preparation method thereof

InactiveCN103408984AImprove display color gamutDiffusing elementsLuminescent paintsOptical coatingQuantum dot

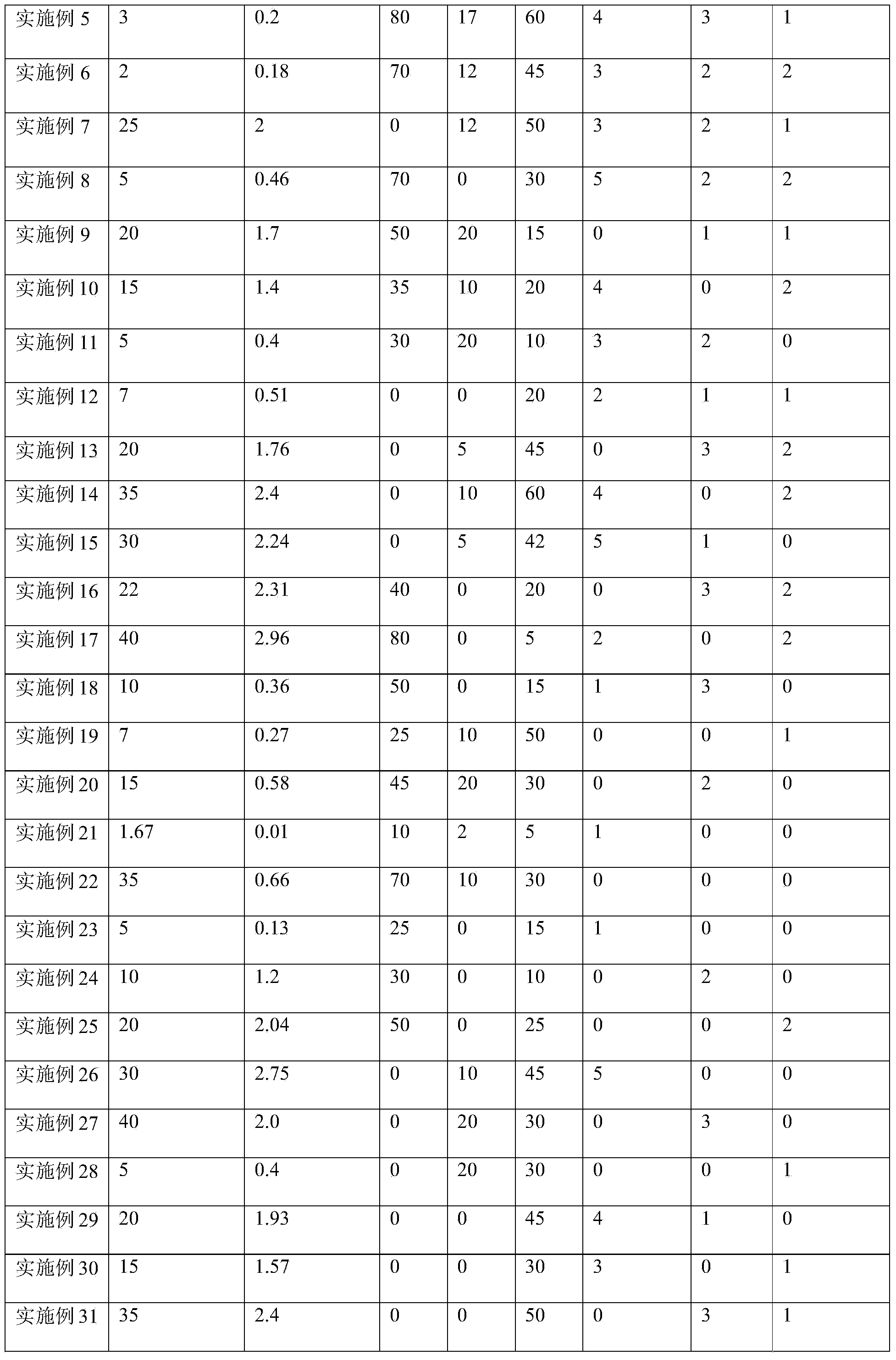

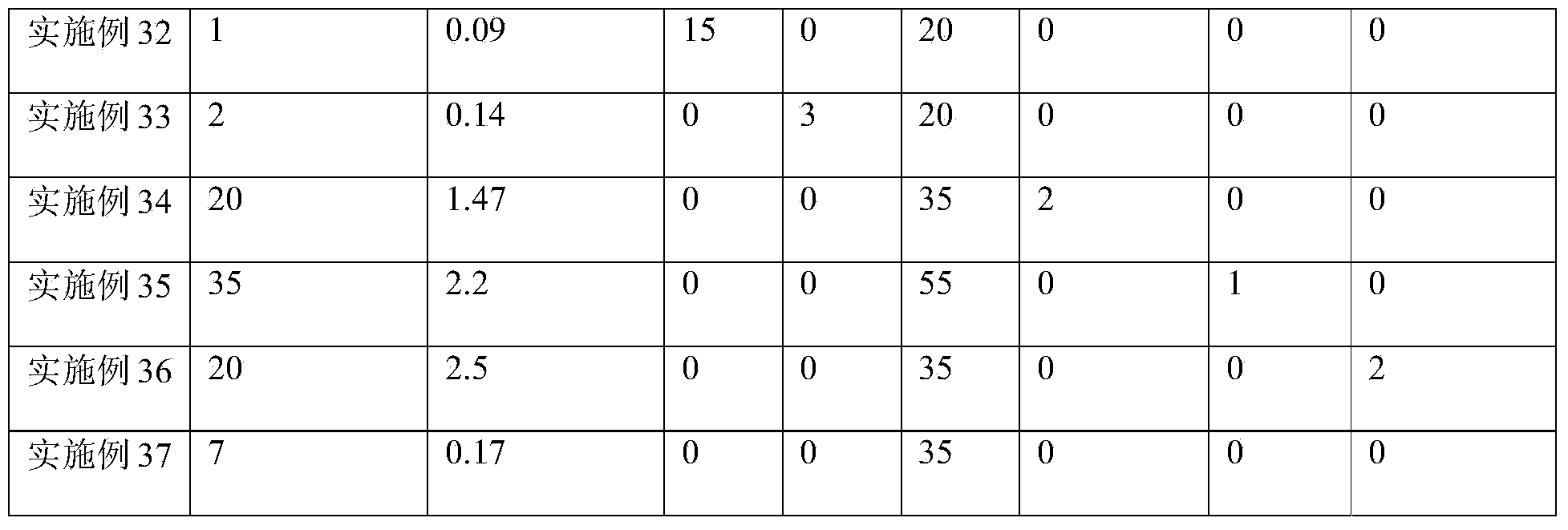

The invention provides an optical coating composition, a fluorescent optical membrane and a preparation method thereof. The optical coating composition comprises the following components in parts by weight: 0.01-3 parts of red fluorescence quantum dot material, 1-40 parts of green fluorescence quantum dot material, 0-90 parts of solvent, 0-20 parts of photodiffusion agent, 5-60 parts of film-forming material and 0-10 parts of film-forming assistant. The weight ratio of the red fluorescence quantum dot material to the green fluorescence quantum dot material is (1:100):(1:10). The optical coating composition provided by the invention can be applied on a transparent substrate or existing optical membrane surface to form a fluorescent optical membrane. The fluorescent optical membrane formed by the optical coating composition can achieve the effect of enhancing the displayable color range of the emergent light source.

Owner:GUANGDONG POLY OPTOELECTRONICS

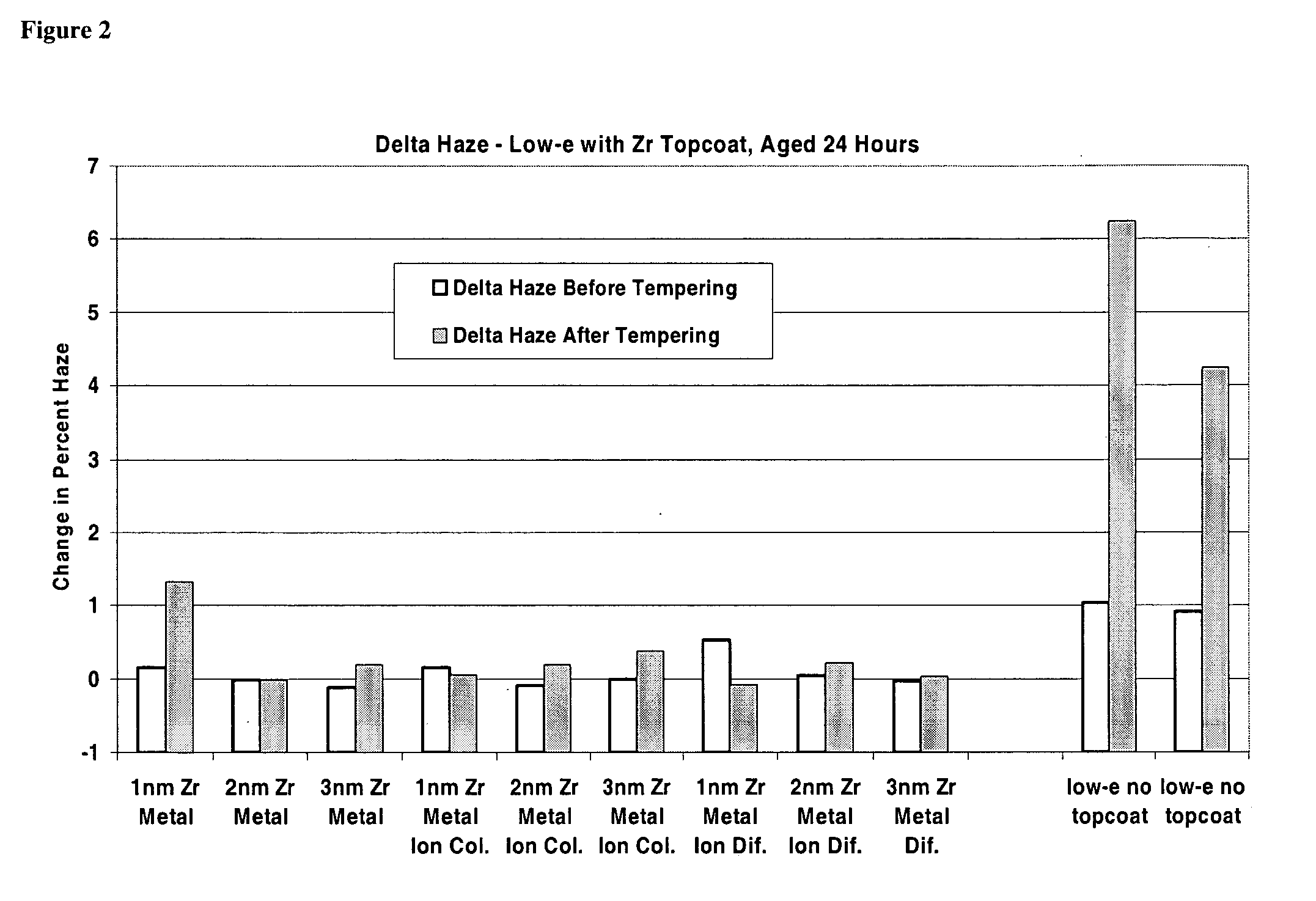

Air oxidizable scratch resistant protective layer for optical coatings

InactiveUS20060134436A1Reduce harmSolve the lack of durabilitySolid state diffusion coatingGlass/slag layered productsMetal alloyOptical coating

The present invention provides a scratch protecting layer comprising a metal, metal alloy, metal compound or an intermetallic layer deposited on an air contacting surface. The scratch protecting layer is typically from 1 to 3 nanometers thick and not optically absorbing after oxidation occurs. This layer is initially deposited in a primarily unoxidized or un-nitrided state. Full oxidation of the metal, metal alloy, metal compound or intermetallic layer occurs within several days after exposure to air. The scratch protection layer can be 2 to 5 nanometers thick if the layer is exposed to a plasma, electrical discharge or ion beam comprising a reactive gas such as oxygen or nitrogen.

Owner:AGC FLAT GLASS NORTH AMERICA INC

Polymeric optical substrate method of treatment

InactiveUS6156394AImprove adhesionHigh hardnessVacuum evaporation coatingSputtering coatingPretreatment methodOptical coating

A pretreatment method for use in manufacturing an improved optical component comprises (i) providing a polymeric optical substrate; and (ii) exposing the polymeric optical substrate to electromagnetic energy having a wavelength of about 30 nm to about 350 nm. The exposure of the polymeric optical substrate to the electromagnetic energy substantially improves adhesion between the substrate and an optical coating deposited onto the substrate following pretreatment. The invention addresses the significant need for coated plastic optics by providing a method to achieve reliable adhesion of optical coatings placed on polymeric optical substrates. Specifically, this invention enables improved adhesion for even highly curved or shaped parts which have been historically more difficult to coat. The pretreatment method is particularly useful for molded substrates such as molded polymethylmethacrylate.

Owner:JDS UNIPHASE CORP

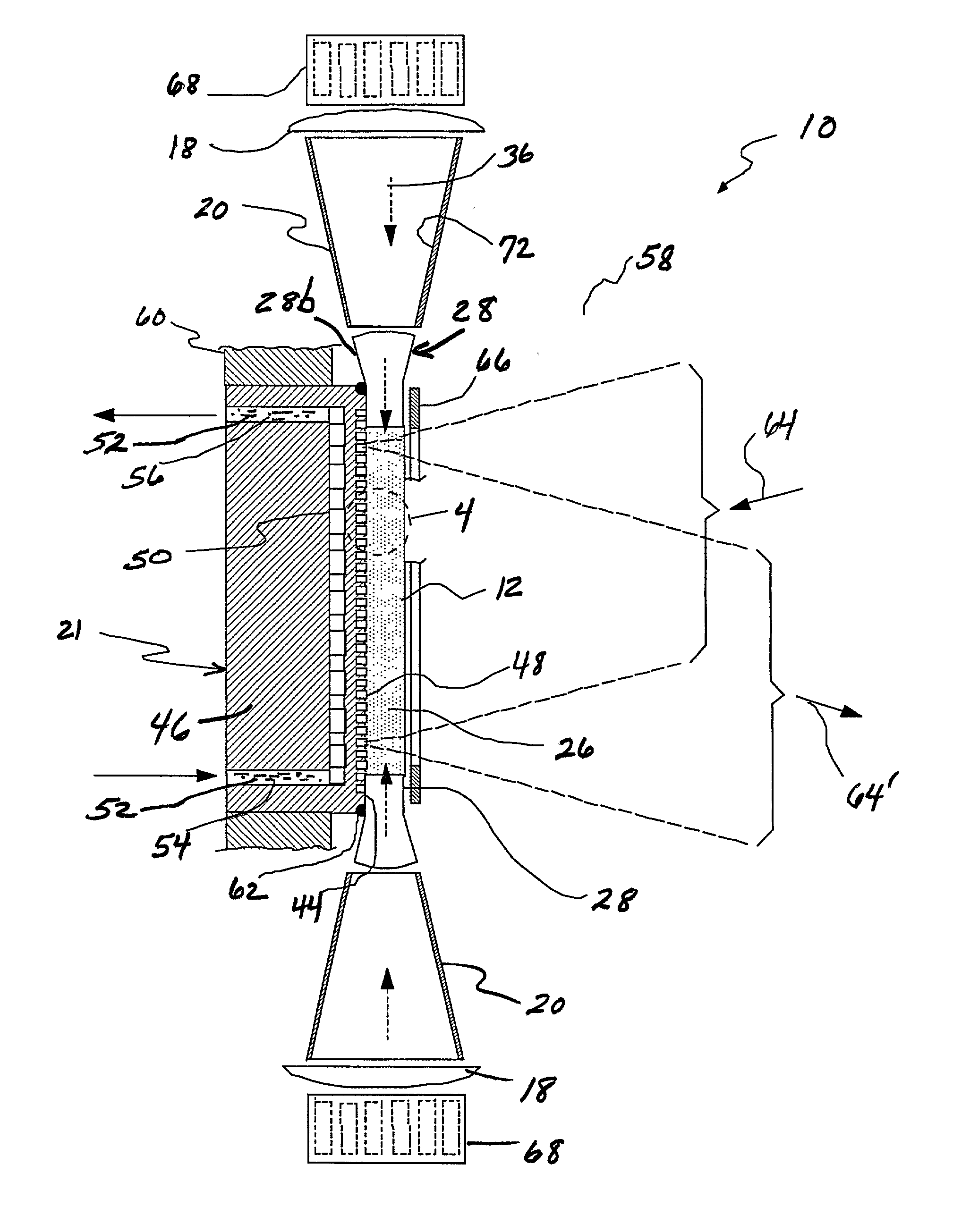

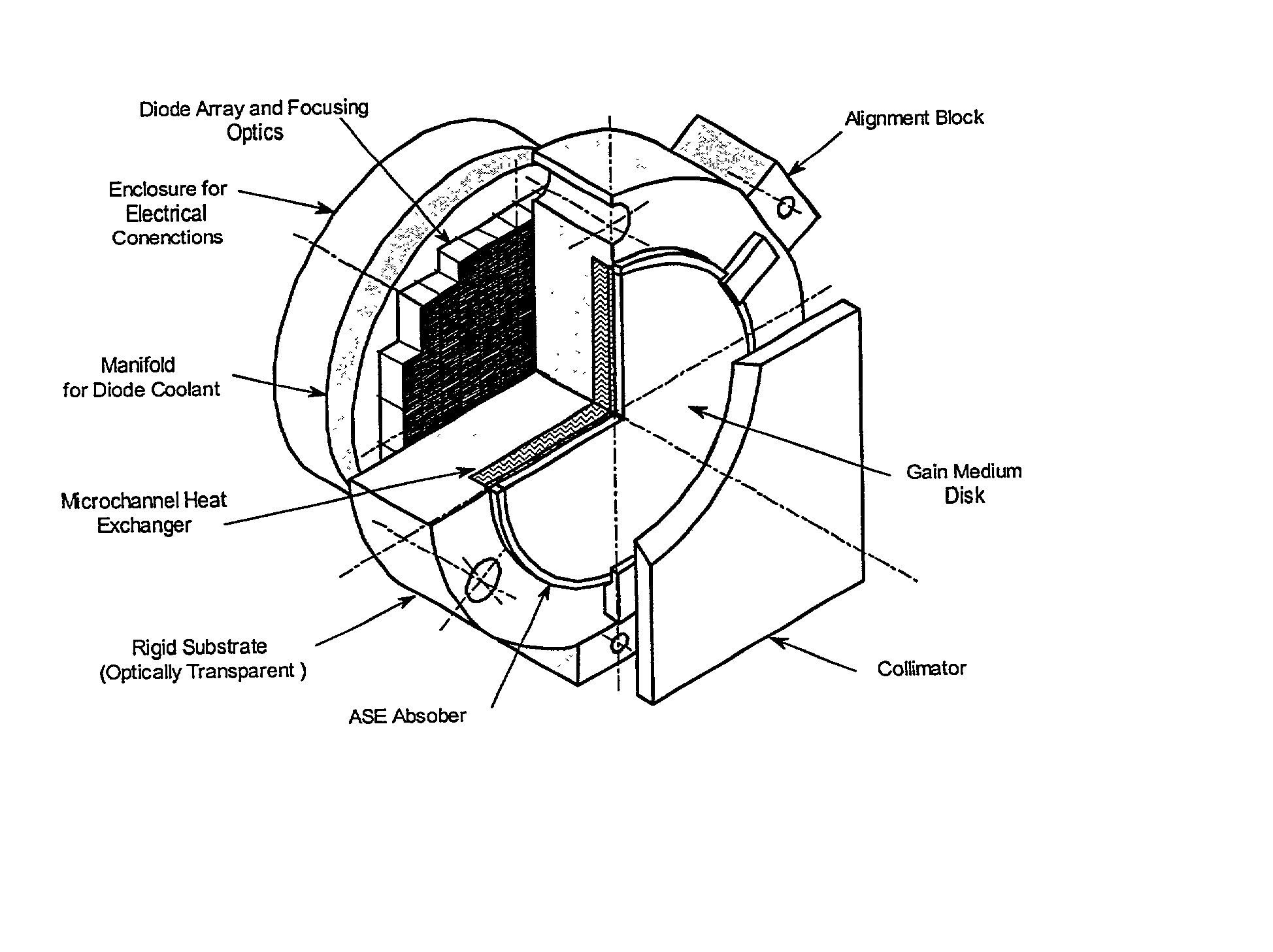

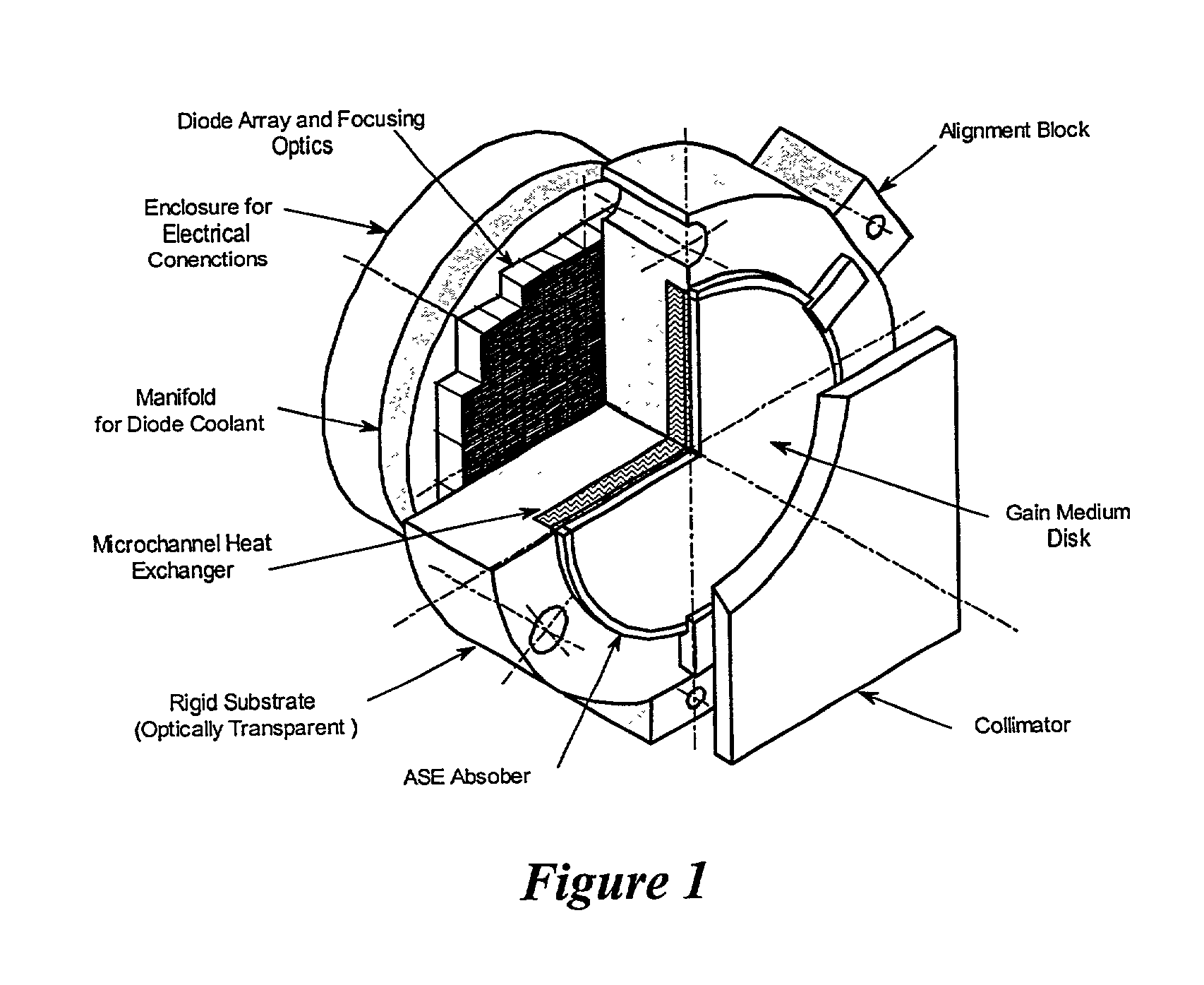

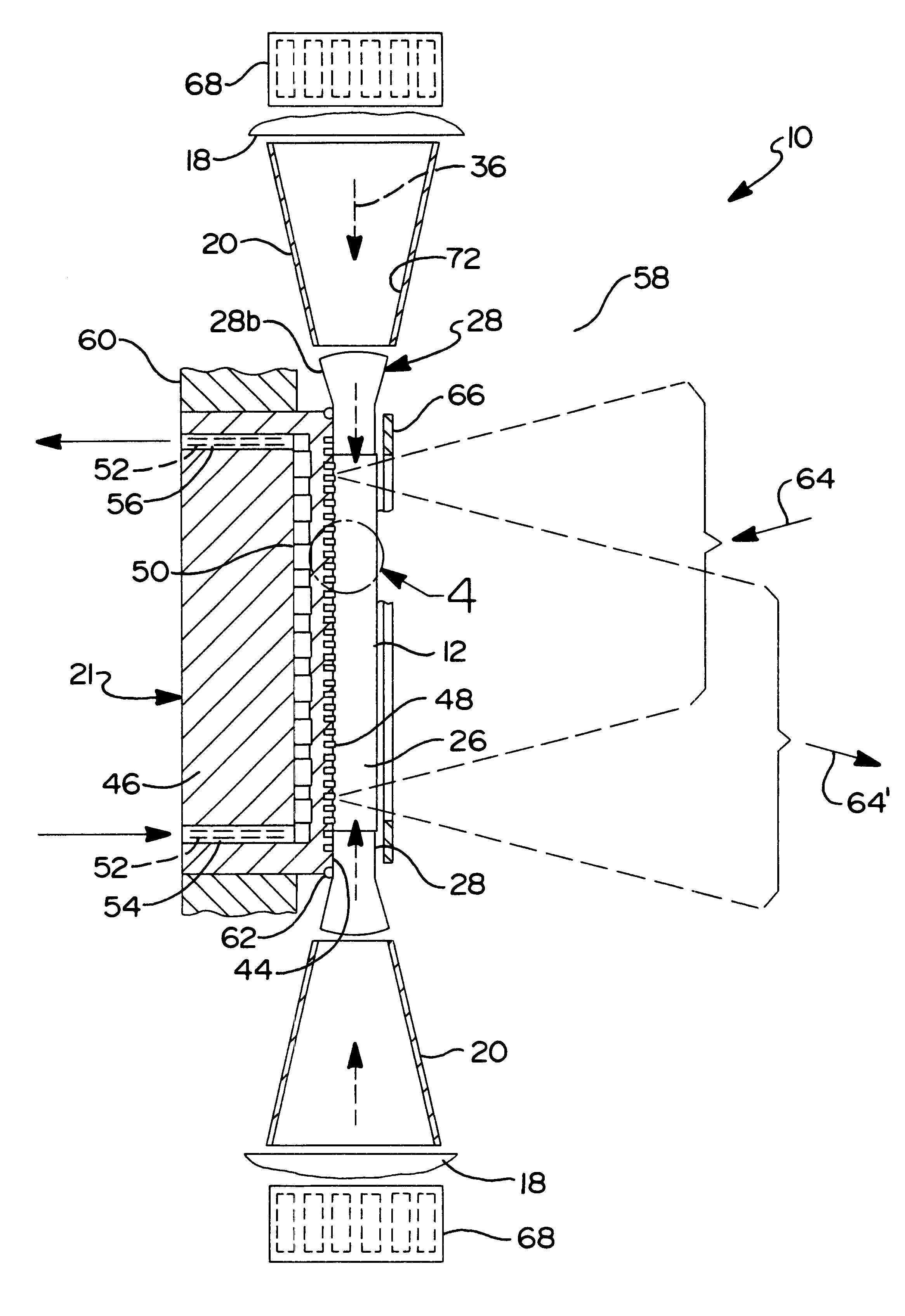

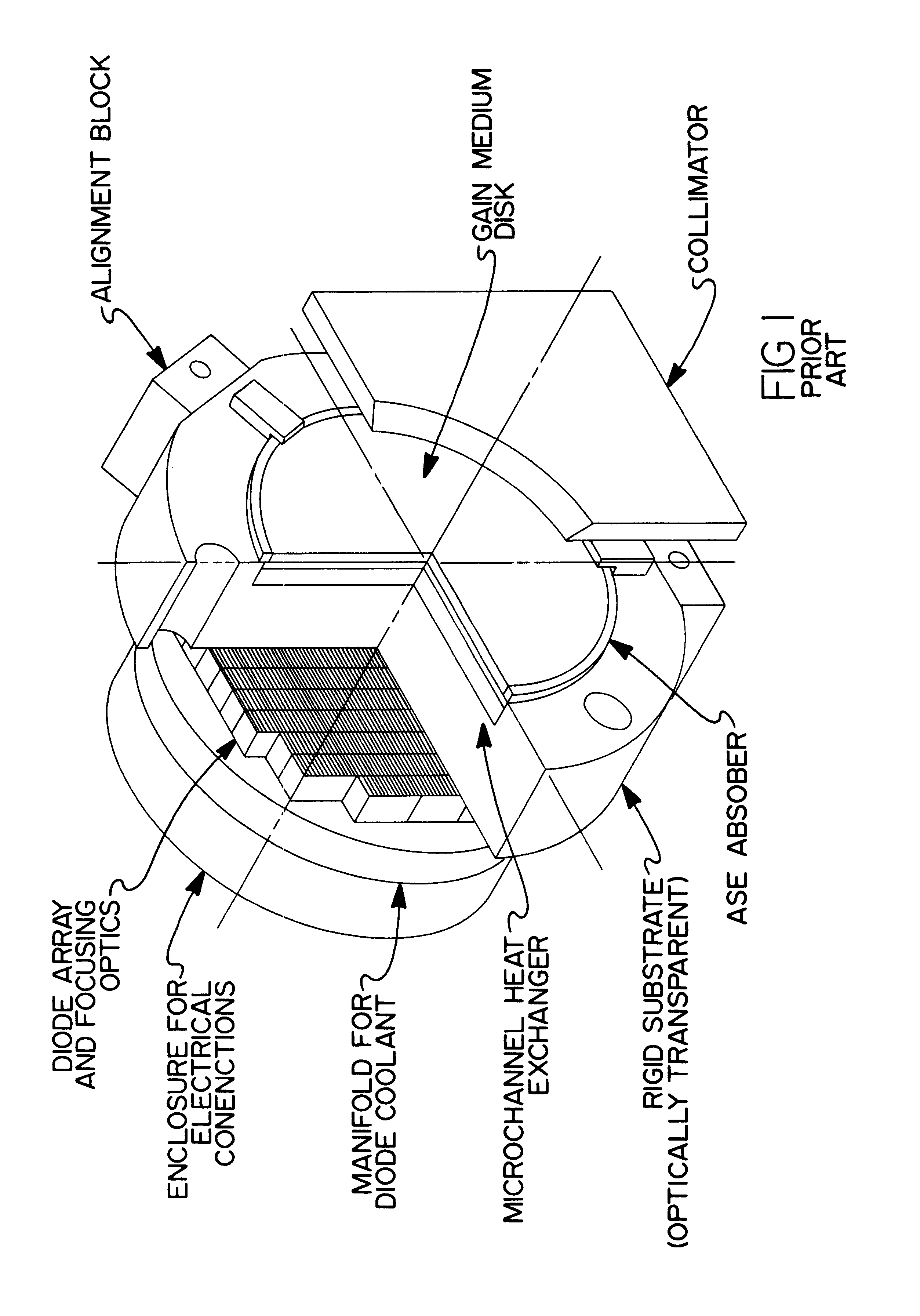

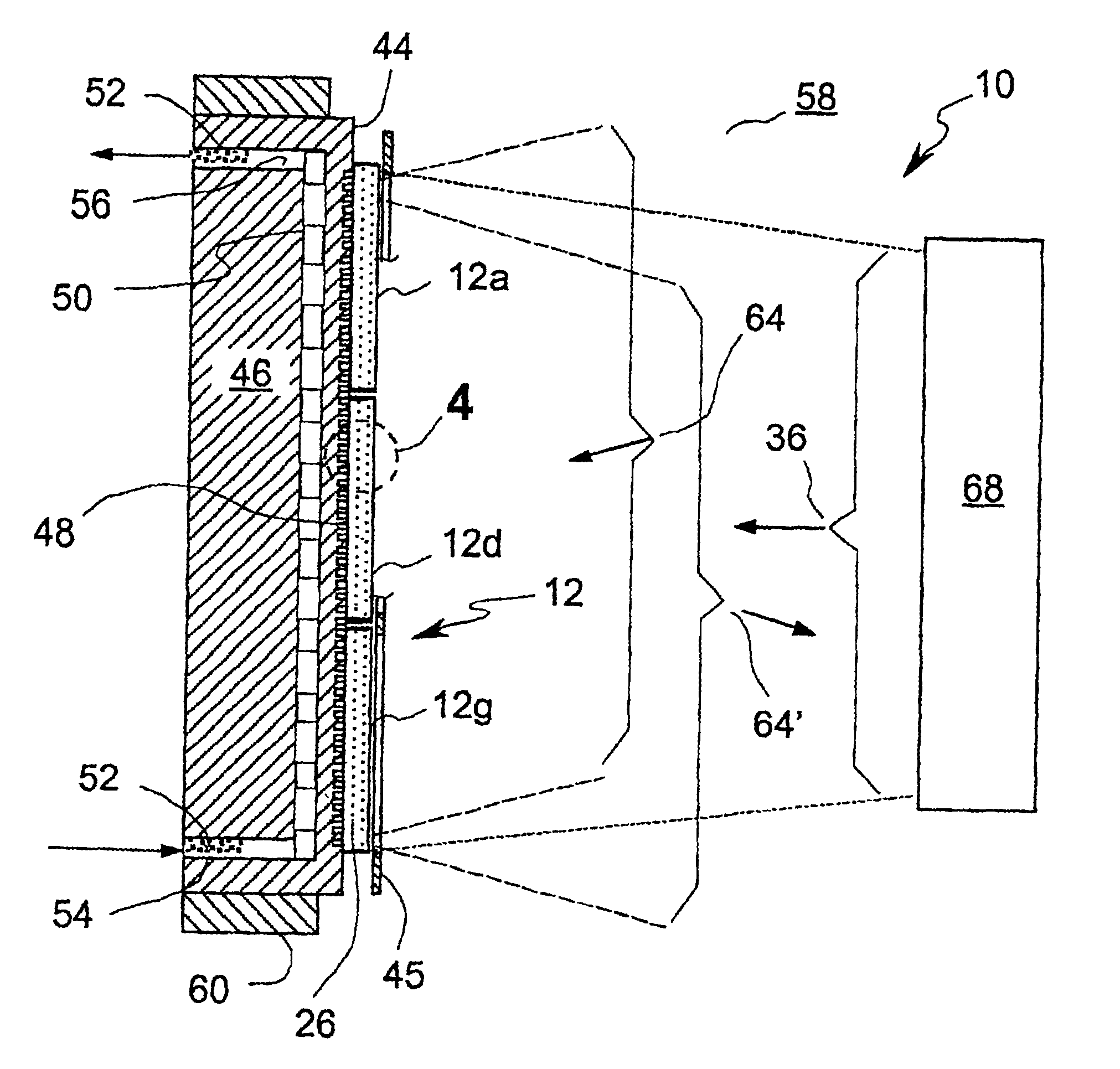

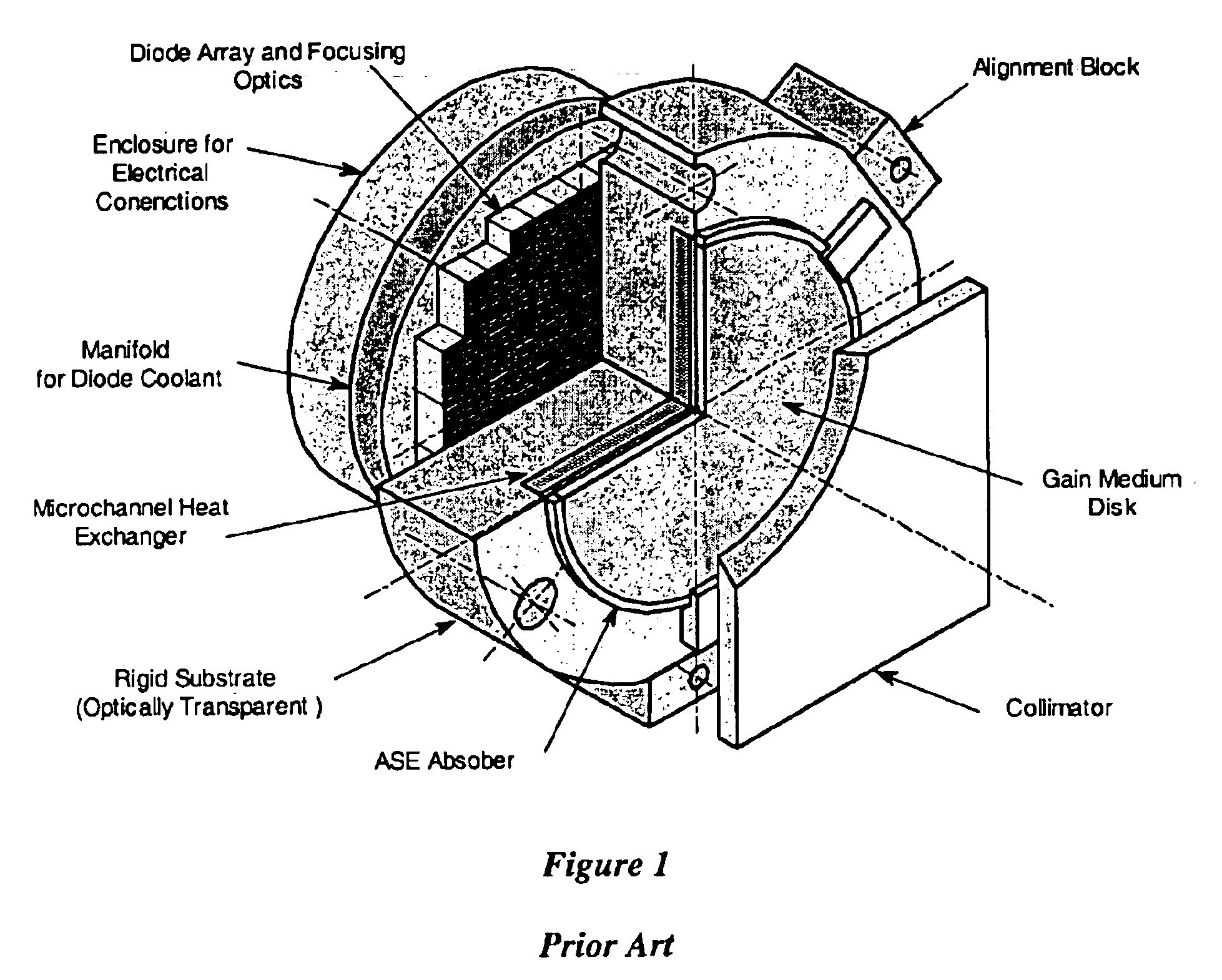

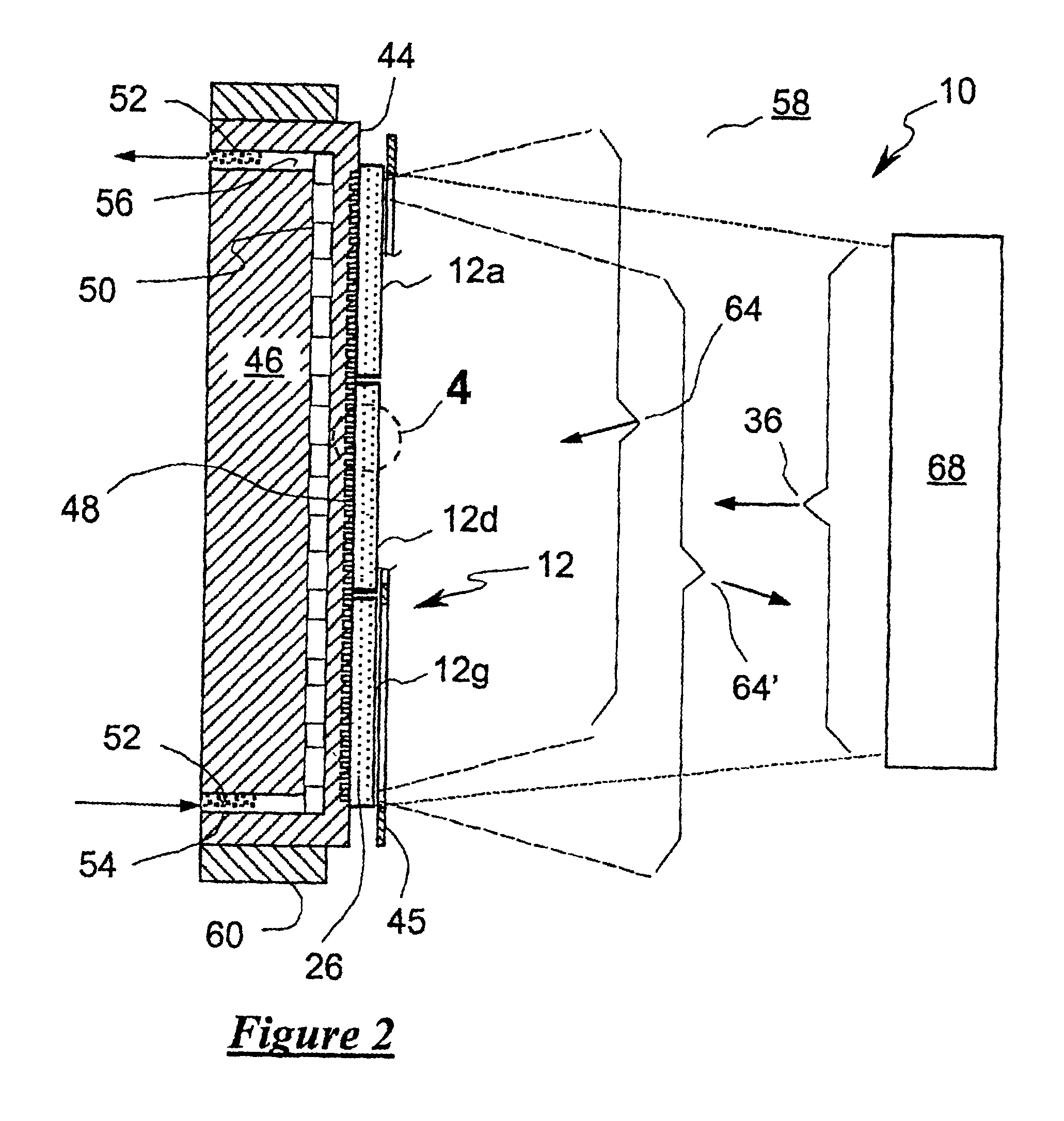

Side-pumped active mirror solid-state laser for high-average power

InactiveUS20020097769A1Active medium shape and constructionLaser cooling arrangementsSolid-state laser deviceOptical coating

Apparatus and method for achieving improved performance in a solid-state laser. The solid-state laser apparatus preferably uses a laser gain medium in the shape of a disk wherein optical pump radiation is injected into the peripheral edge of the disk. In the preferred embodiment the laser gain medium is provided with optical coatings for operation in the active mirror configuration. Furthermore, the laser gain medium is pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium. Sources of optical pump radiation are placed around the perimeter of the gain medium. Tapered ducts may be disposed between the sources and the gain medium for the purpose of concentrating optical pump radiation. With the proper choice of laser gain medium doping, pump source divergence and geometry, a uniform laser gain is achieved across large portions of the gain medium.

Owner:THE BOEING CO

Methods for forming security articles having diffractive surfaces and color shifting backgrounds

InactiveUS20040094850A1Increase the difficulty of counterfeitingOther printing matterOptical articlesOptical diffractionColor shift

A security article includes a light transmissive substrate having a first surface and an opposing second surface, with the first surface having an embossed region with an optical diffraction pattern or a holographic image pattern. A color shifting optical coating is formed on the substrate such as on the opposing second surface, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. The security article can be used in a variety of applications and products to provide for enhanced security measures such as anticounterfeiting.

Owner:JDS UNIPHASE CORP

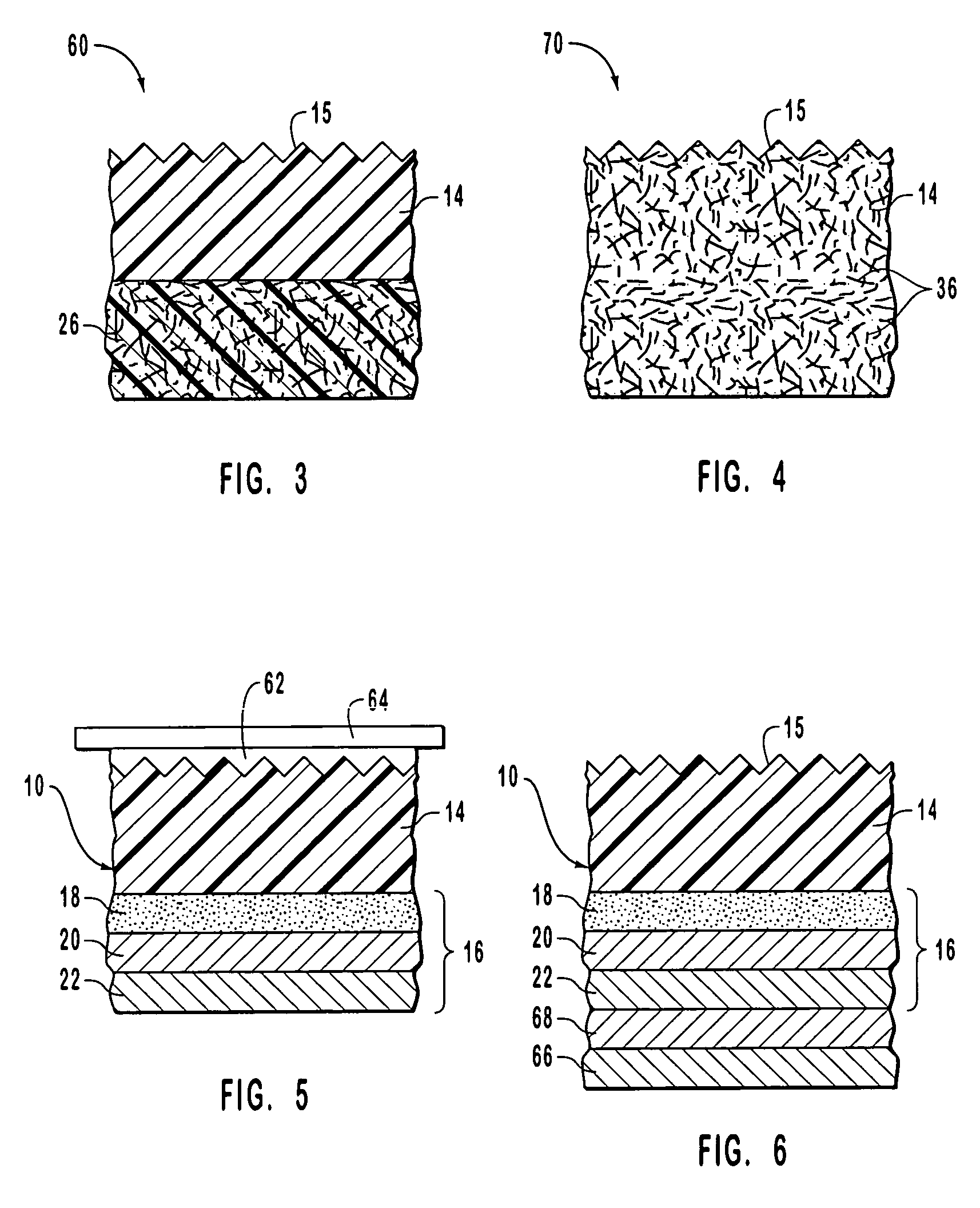

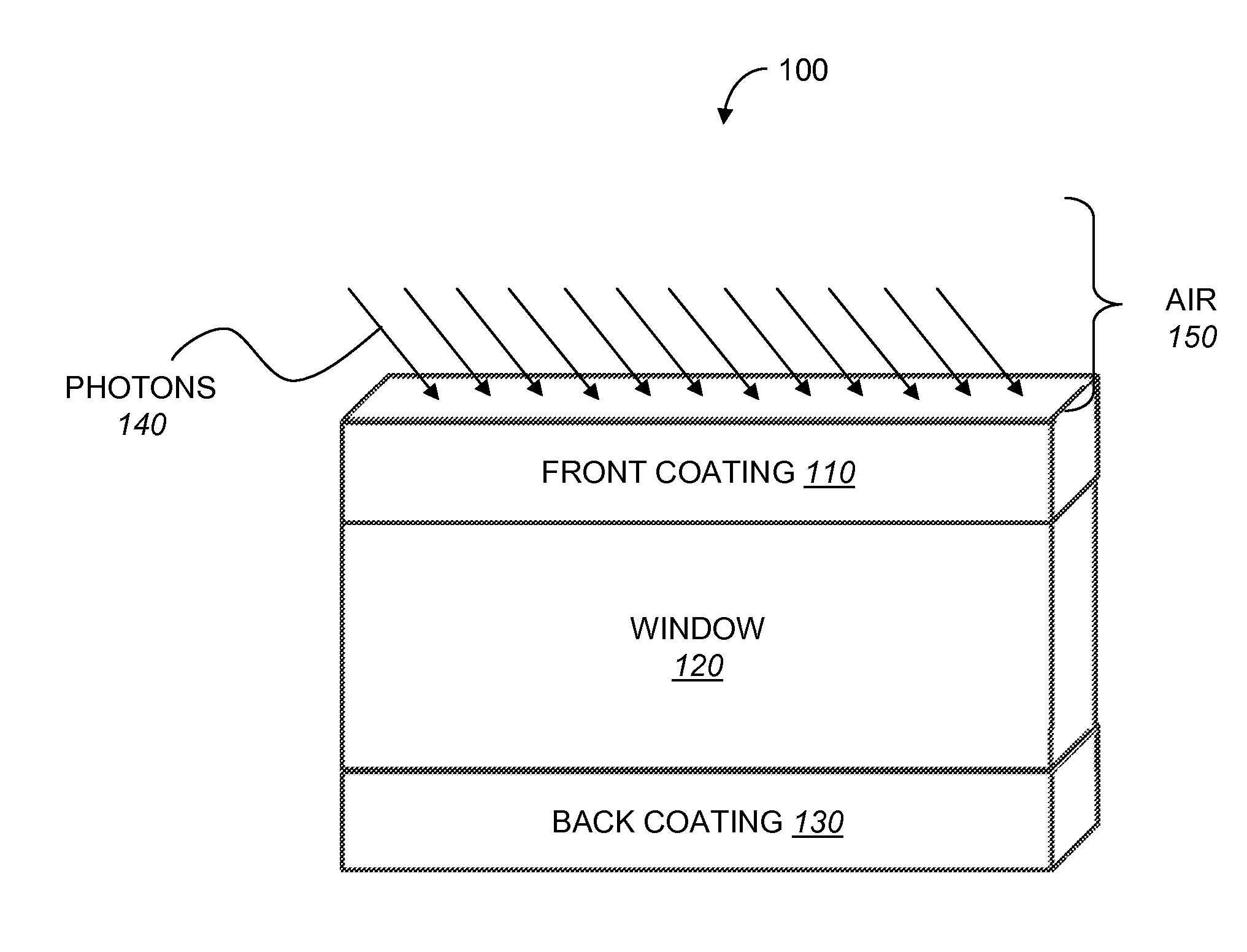

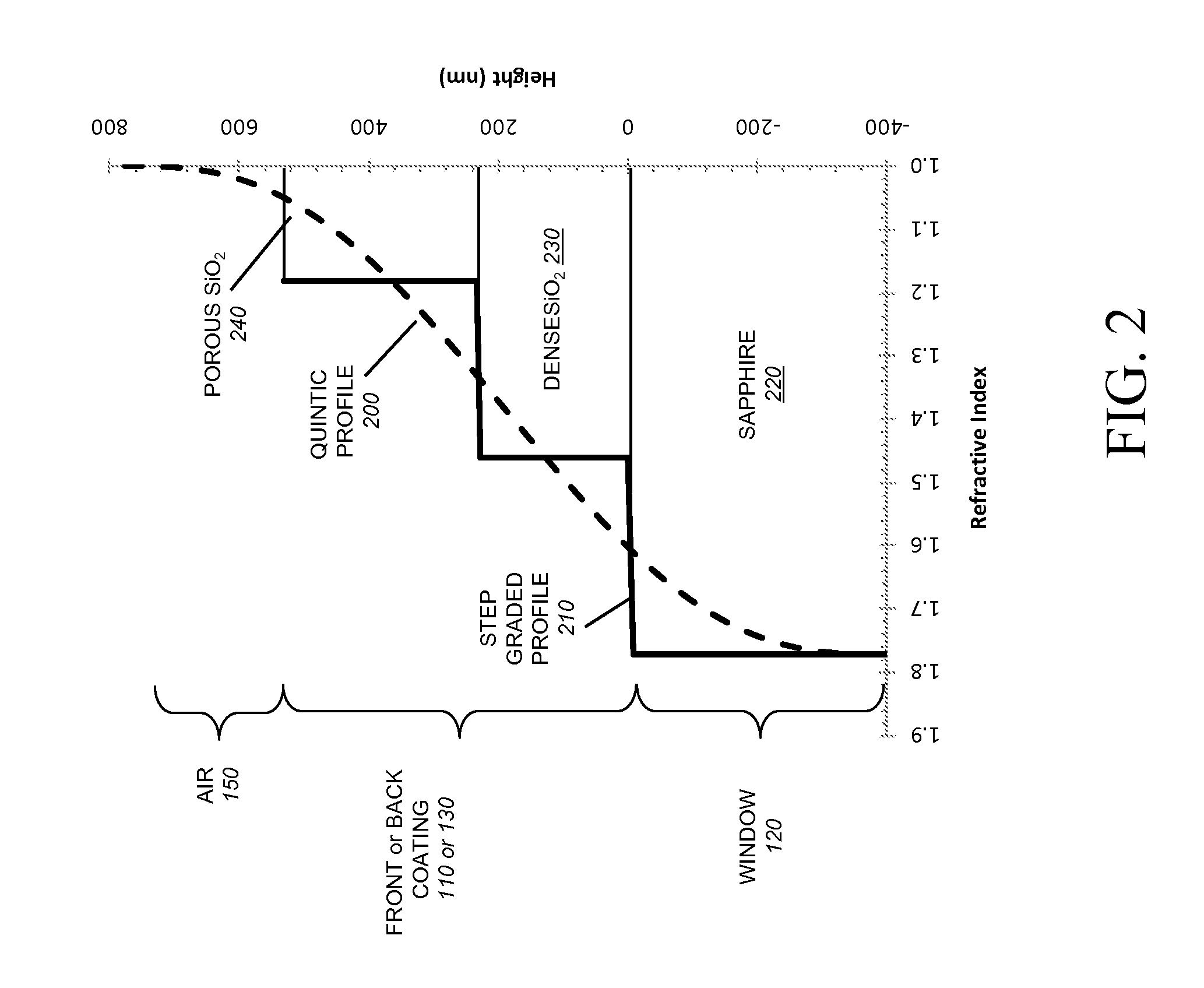

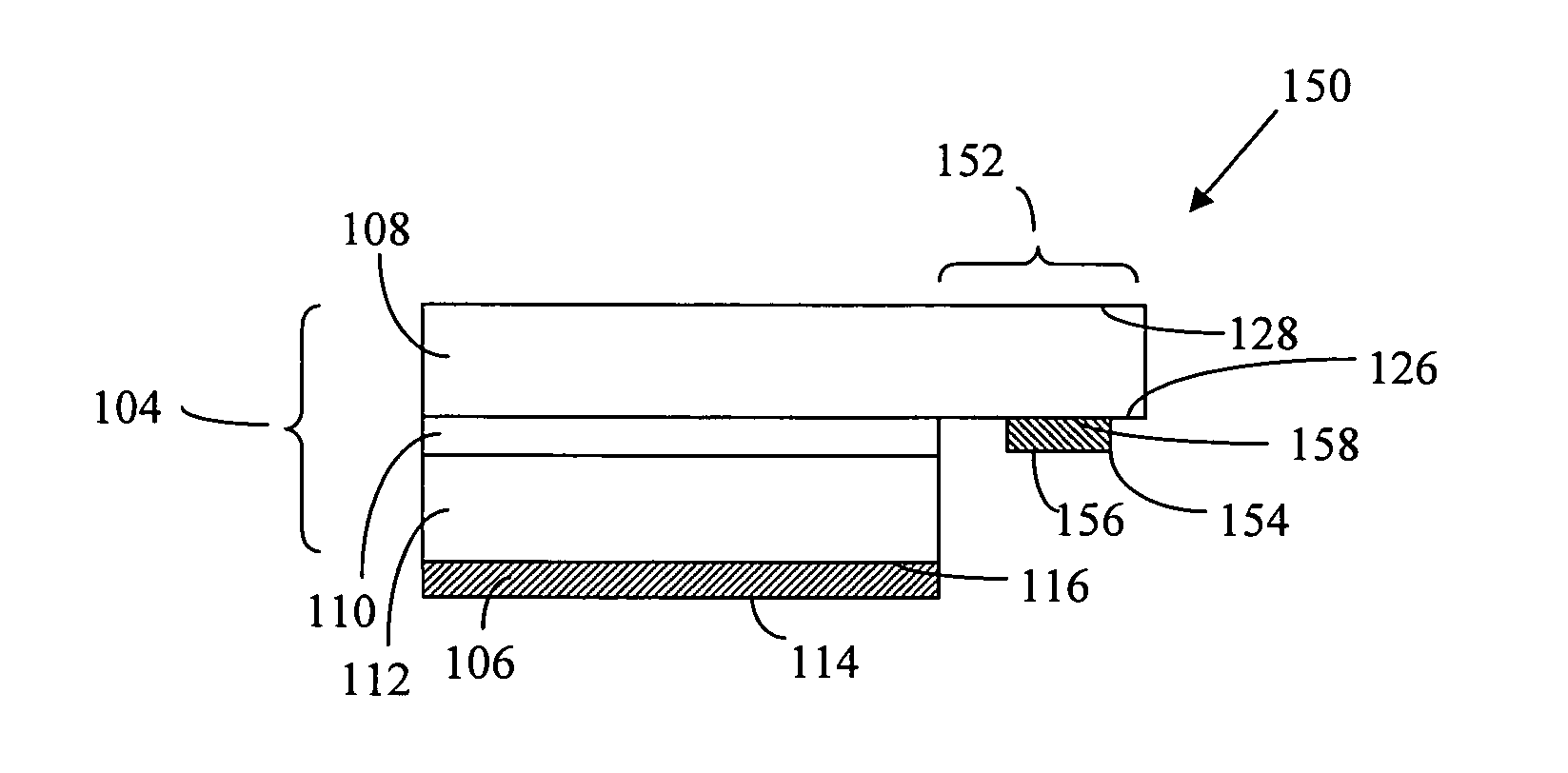

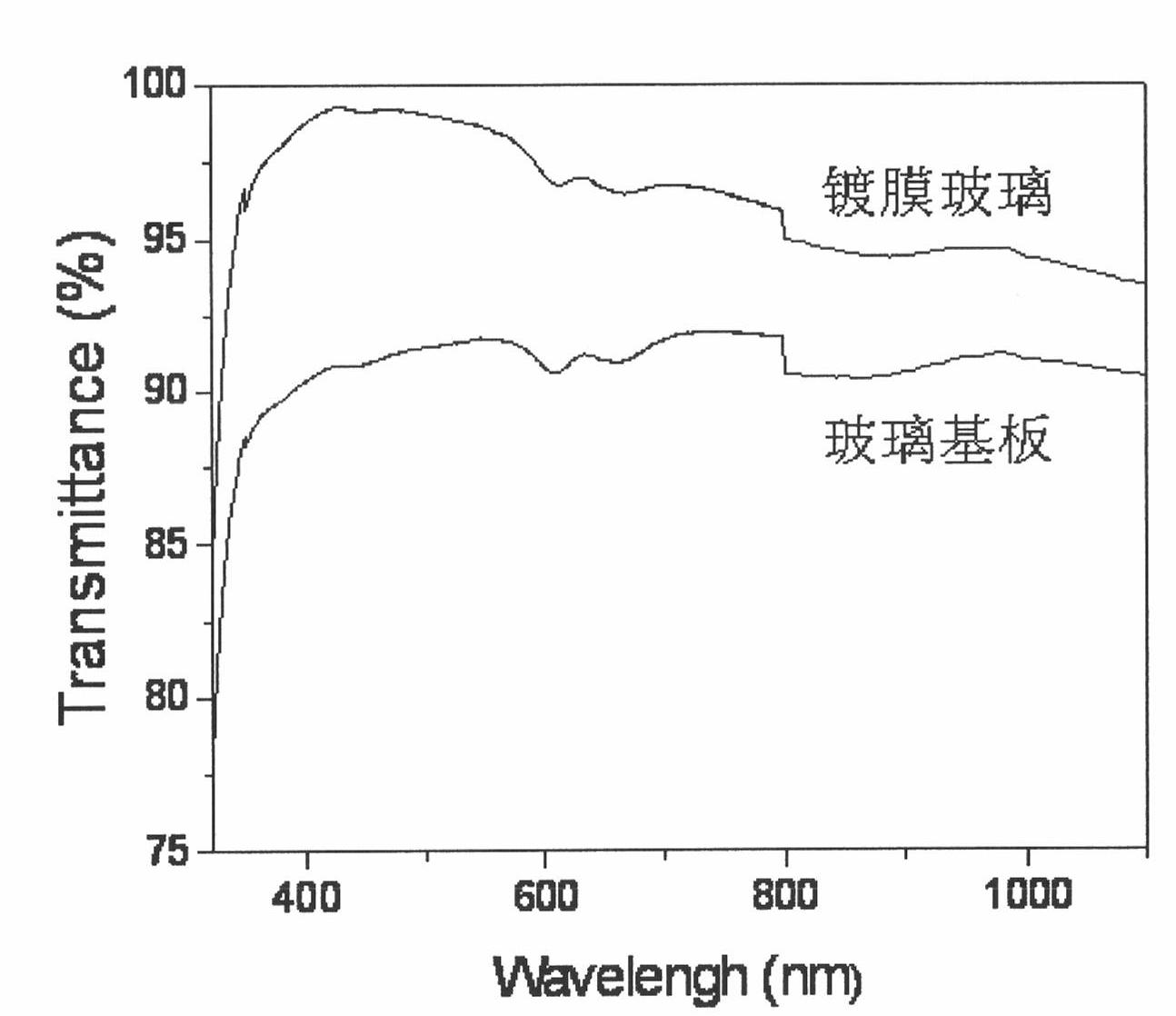

High transmittance optical windows and method of constructing the same

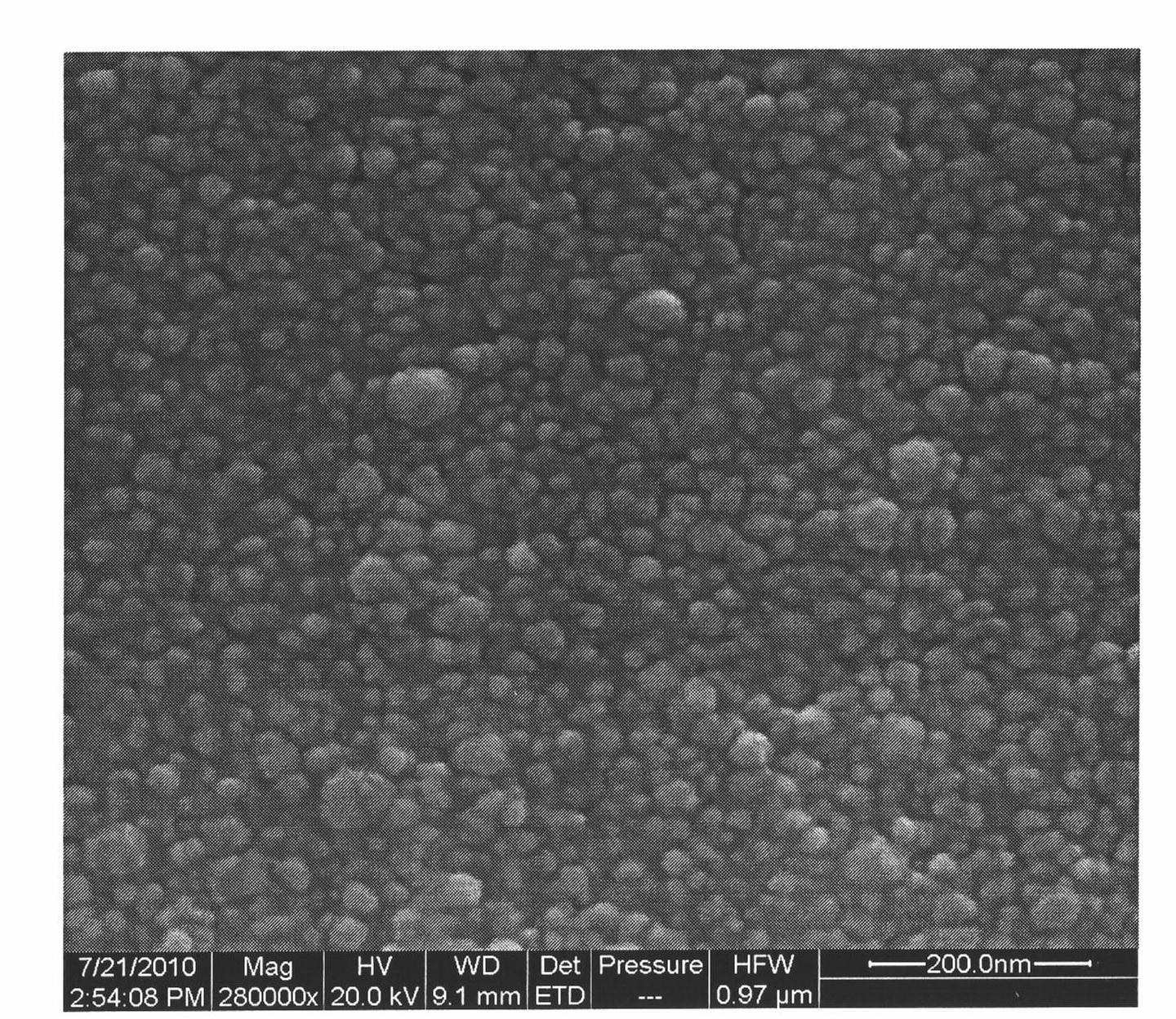

InactiveUS20110168261A1Avoid reflectionsHigh light transmittanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptical coatingMaterial synthesis

Designs for ultra-high, broadband transmittance through windows over a wide range of incident angles are disclosed. The improvements in transmittance result from coating the windows with a new class of materials consisting of porous nanorods. A high transmittance optical window comprises a transparent substrate coated on one or both sides with a multiple layer coating. Each multiple layer coating includes optical films with a refractive index intermediate between the refractive index of the transparent substrate and air. The optical coatings are applied using an oblique-angle deposition material synthesis technique. The coating can be performed by depositing porous SiO2 layers using oblique angle deposition. The high transmittance window coated with the multiple layer coating exhibits reduced reflectance and improved transmittance, as compared to an uncoated transparent substrate.

Owner:MAGNOLIA OPTICAL TECH +1

Wavelength conversion chip for use with light emitting diodes and method for making same

ActiveUS20120086028A1High lumens/gramEasy to installDischarge tube luminescnet screensElectroluminescent light sourcesOptical coatingElectrical connection

A wavelength conversion chip is formed by depositing a wavelength conversion material on a substrate to form a layer, removing the resulting wavelength conversion layer from the substrate and then segmenting the wavelength conversion layer into a plurality of wavelength conversion chips. The wavelength conversion material can be annealed by thermal annealing or radiation annealing to increase the wavelength conversion efficiency of the chips or to sinter the wavelength conversion material to form a ceramic material. Optical coatings, vias, light extraction elements, electrical connections or electrical bond pads can be fabricated on the wavelength conversion chips.

Owner:GOLDENEYE

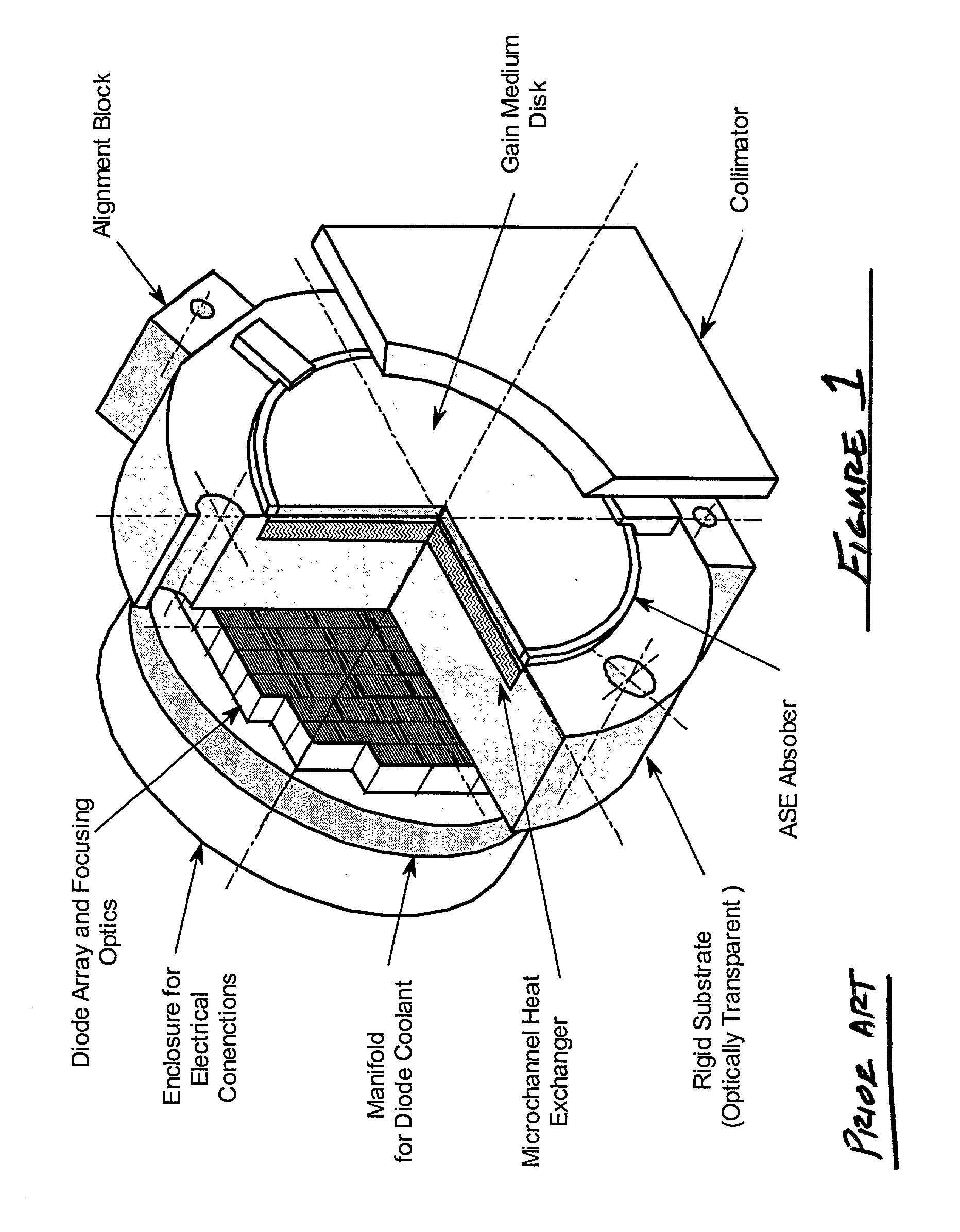

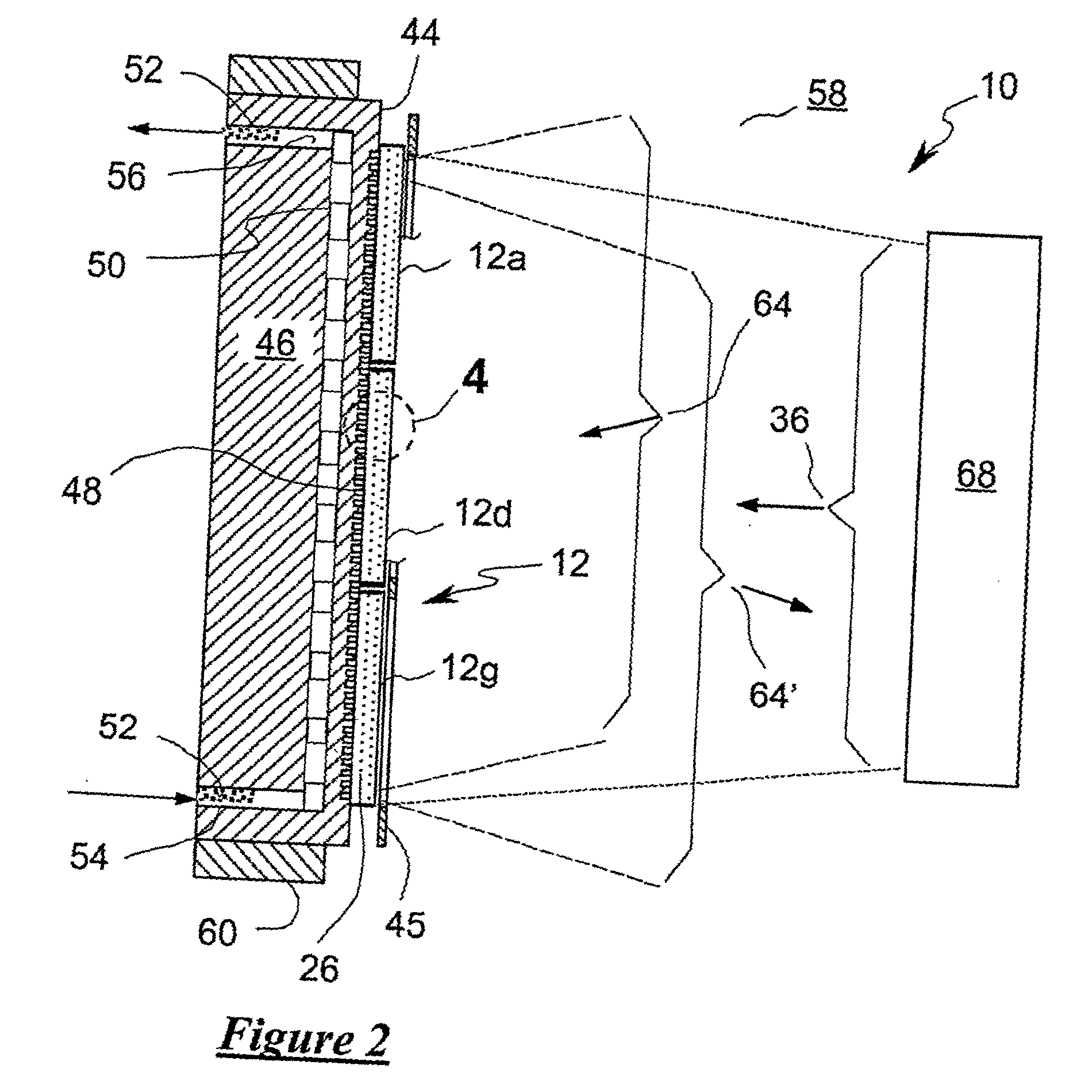

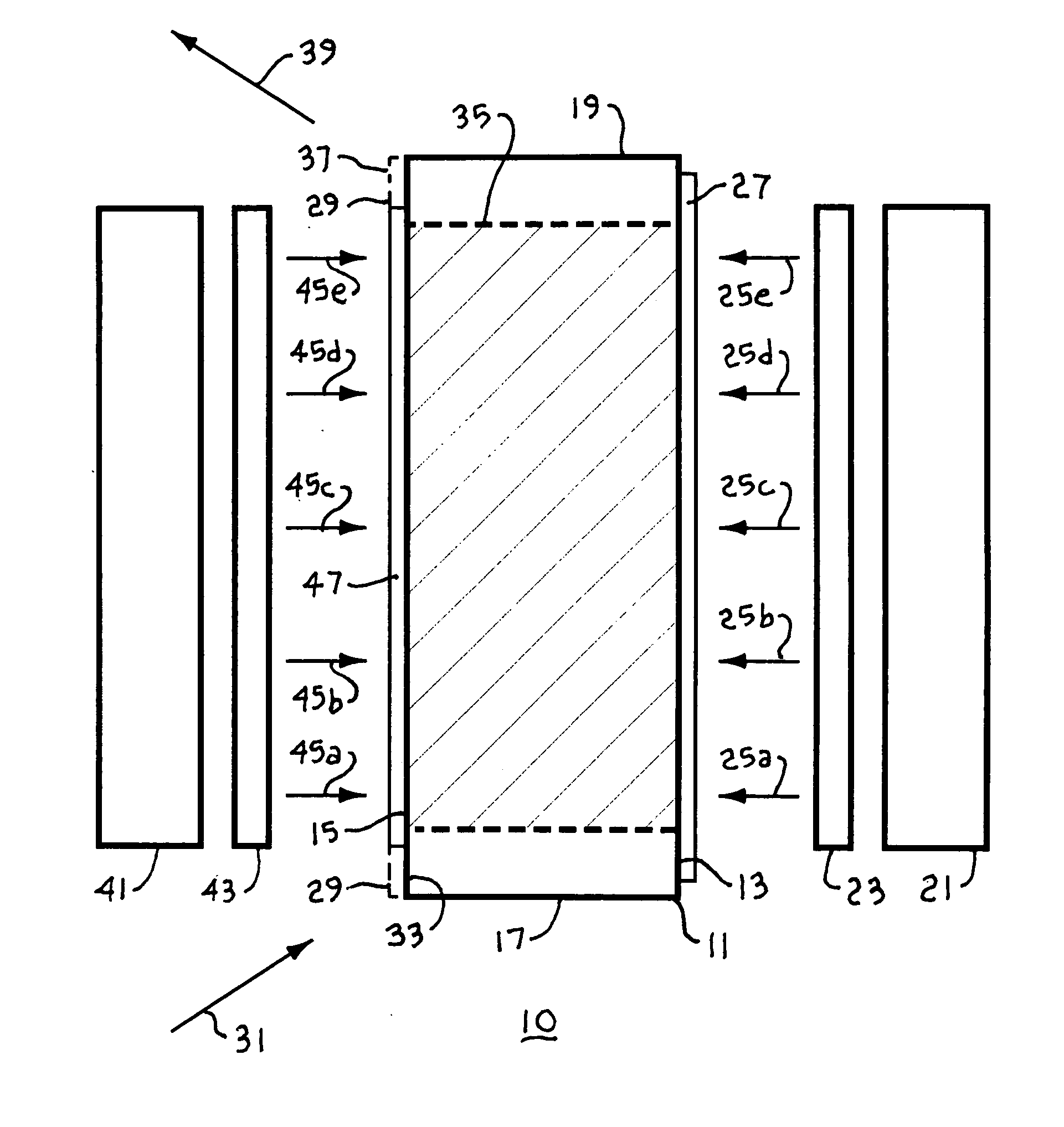

High-average power active mirror solid-state laser with multiple subapertures

InactiveUS20020110164A1Precise positioningRelieve pressureActive medium materialActive medium shape and constructionOptical coatingHydrostatic pressure

An apparatus and method for achieving ultrahigh-power output from a solid-state laser. The solid-state laser of the subject invention uses multiple disk-shaped laser gain media (subapertures) placed adjacent to each other to fill an optical aperture of an AMA module. In one preferred embodiment each of the laser gain media is provided with optical coatings for operation in the active mirror configuration. Furthermore, each of the laser gain media is hydrostatic pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium.

Owner:THE BOEING CO

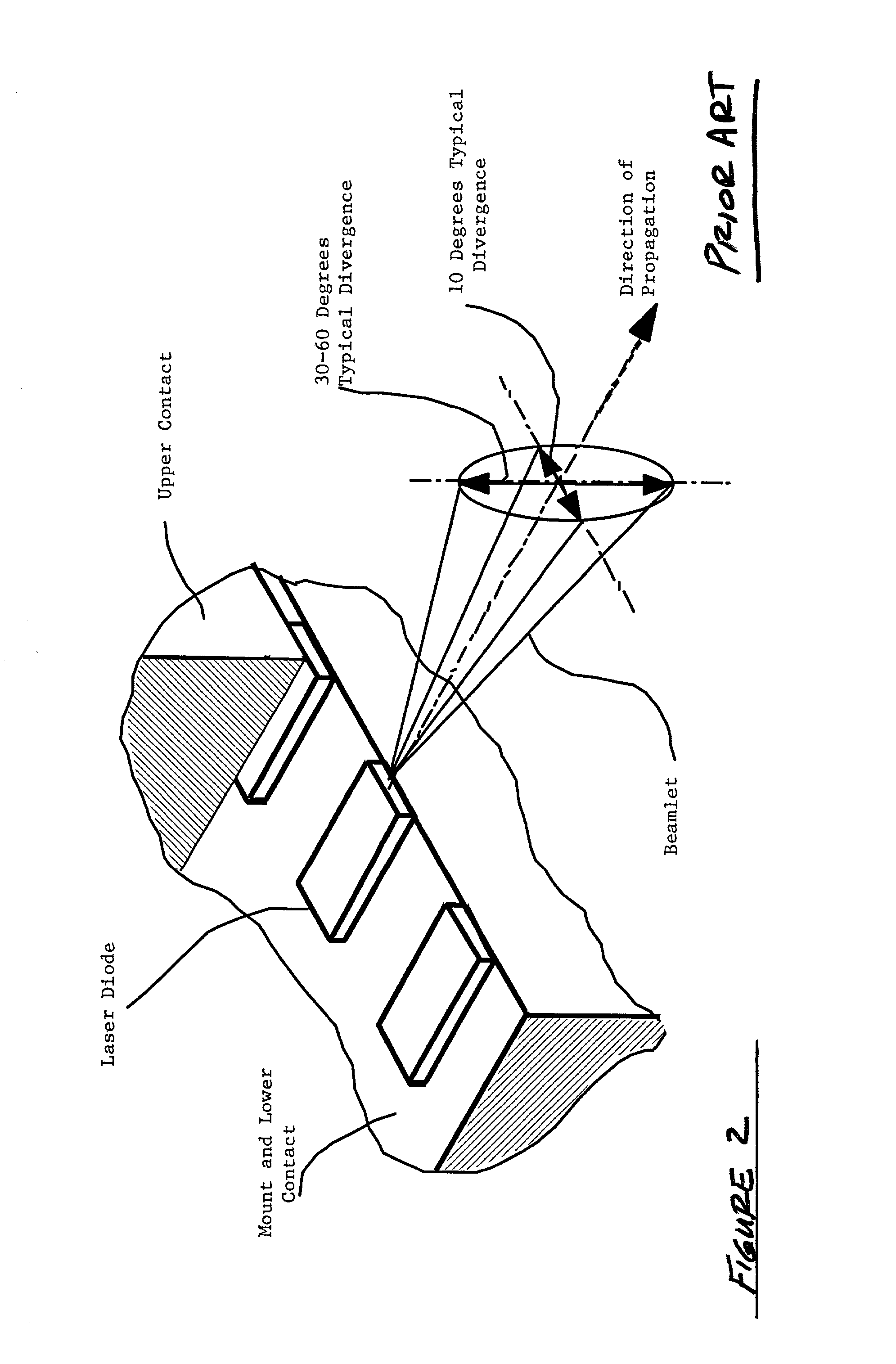

High-gain diode-pumped laser amplifier

InactiveUS20060114961A1Minimize parasitic amplified spontaneous emissionActive medium shape and constructionOptical devices for laserAudio power amplifierOptical coating

A laser amplifier includes a laser active slab with a source of pump power to amplify an input laser beam, the laser active slab including a block of laser active material having opposed lateral faces defining a wedge lateral dihedral angle, opposed longitudinal faces, and opposed parallel transverse faces, the wedge lateral dihedral angle specified to minimize parasitic amplified spontaneous emission. The source of pump power may be one or more laser diode bars and microlenses producing a gain sheet in the laser active slab. The lateral faces may include optical coatings highly transmitting at a wavelength of the pump power and highly reflecting at a lasing wavelength to provide a folded path for the input laser beam though the gain sheet. The laser amplifier may optionally include one or more external mirrors highly reflecting at the lasing wavelength positioned and oriented to provide one or more additional zig-zag passes through the gain sheet for the input laser beam and to provide a multi-pass-amplified laser beam.

Owner:MANNI JEFFREY G

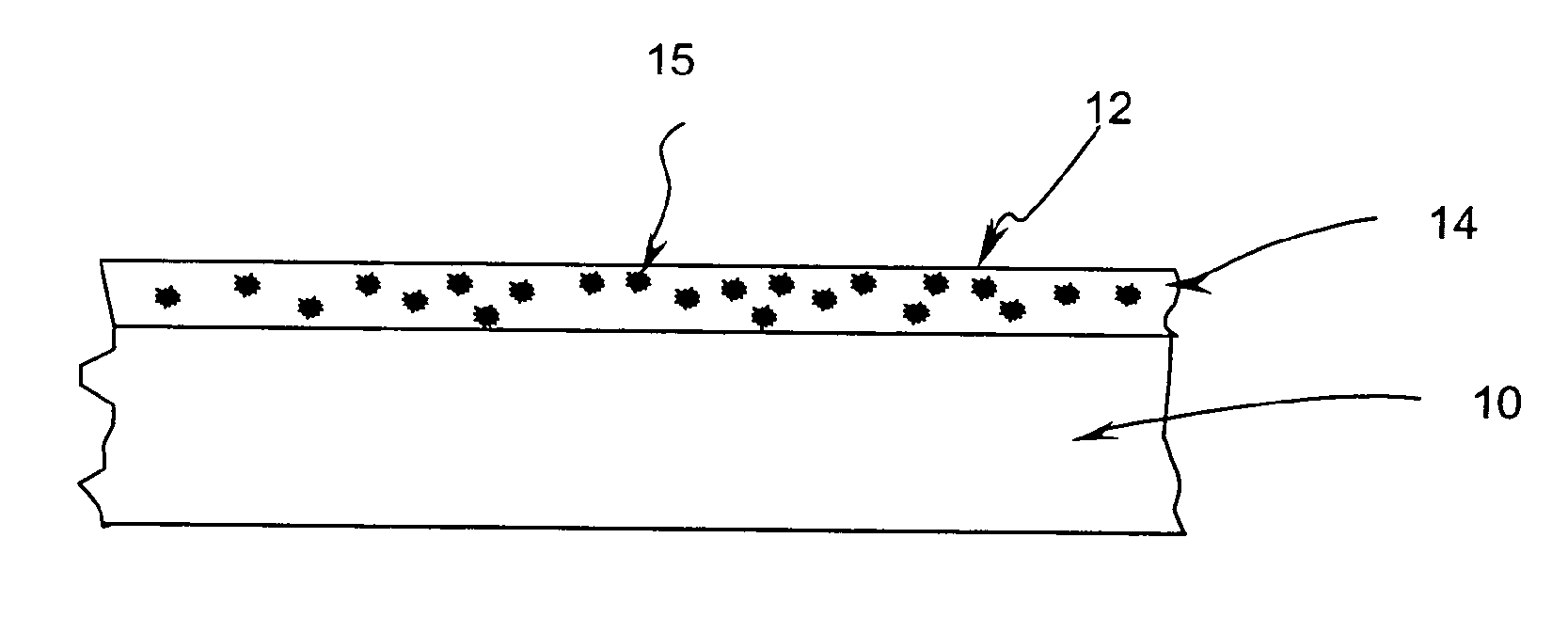

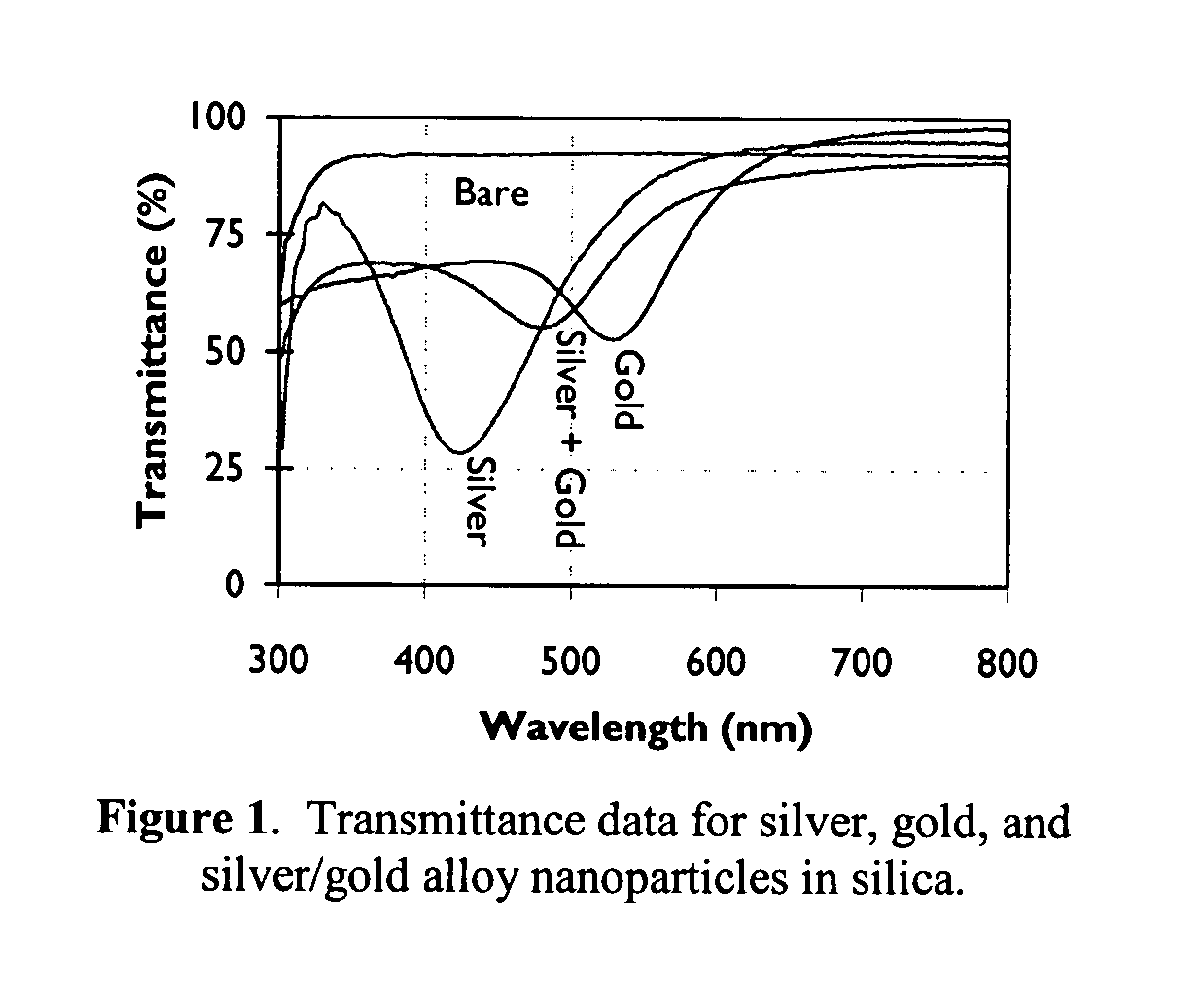

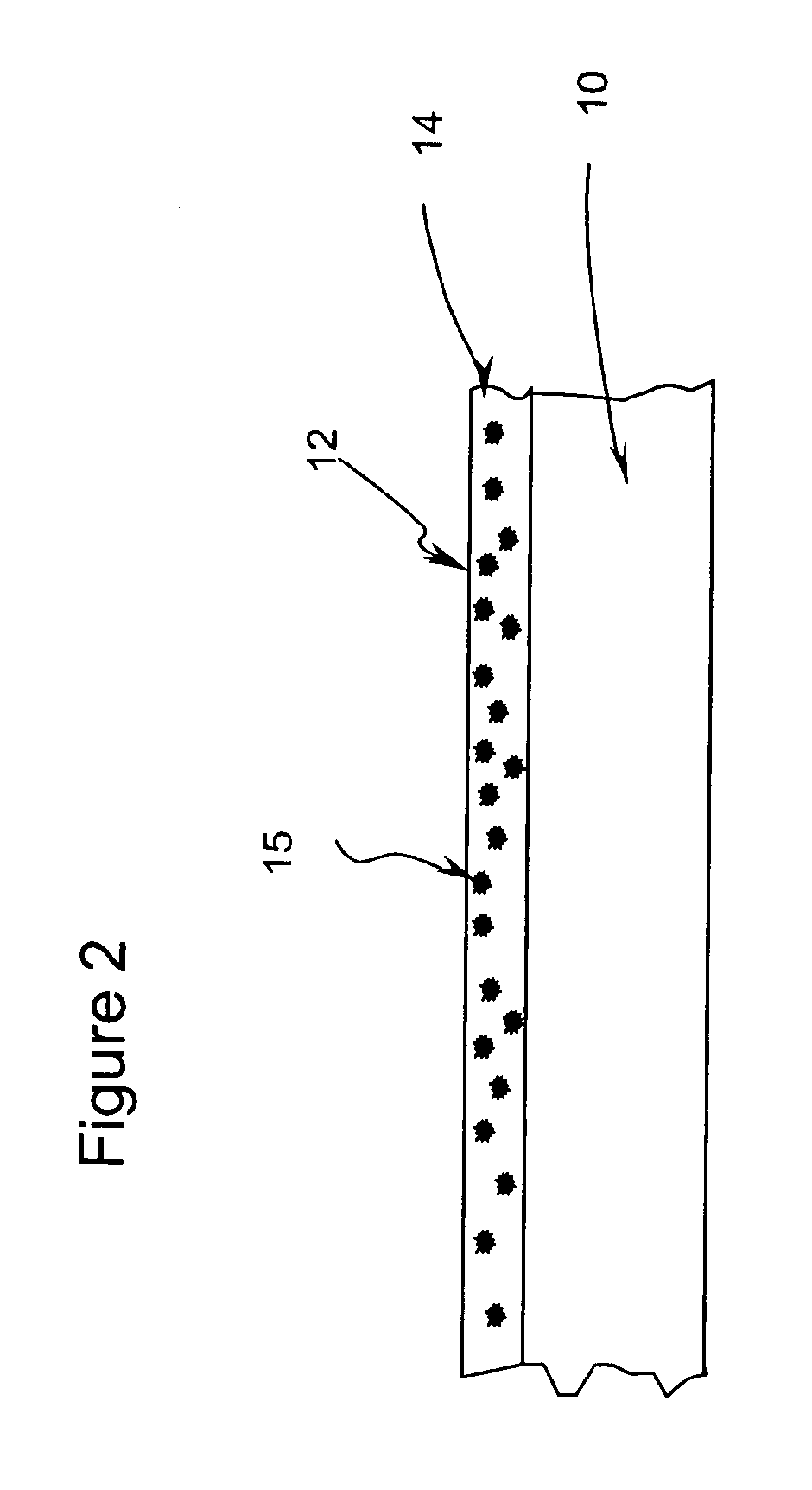

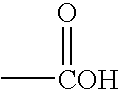

Optical coating

Optical coating materials comprise a transparent matrix material having dispersed nanoparticles comprising between 1 and 20 volume percent of the optical coating material. The coating materials are used to form optical coatings on substrates, such as glass / ceramic, polymer or metal, to alter the color or other optical properties. The nanoparticles are semiconductive material or elemental metals or elemental metal alloys that exhibit surface plasmon resonance.

Owner:POLLEY TODD A +4

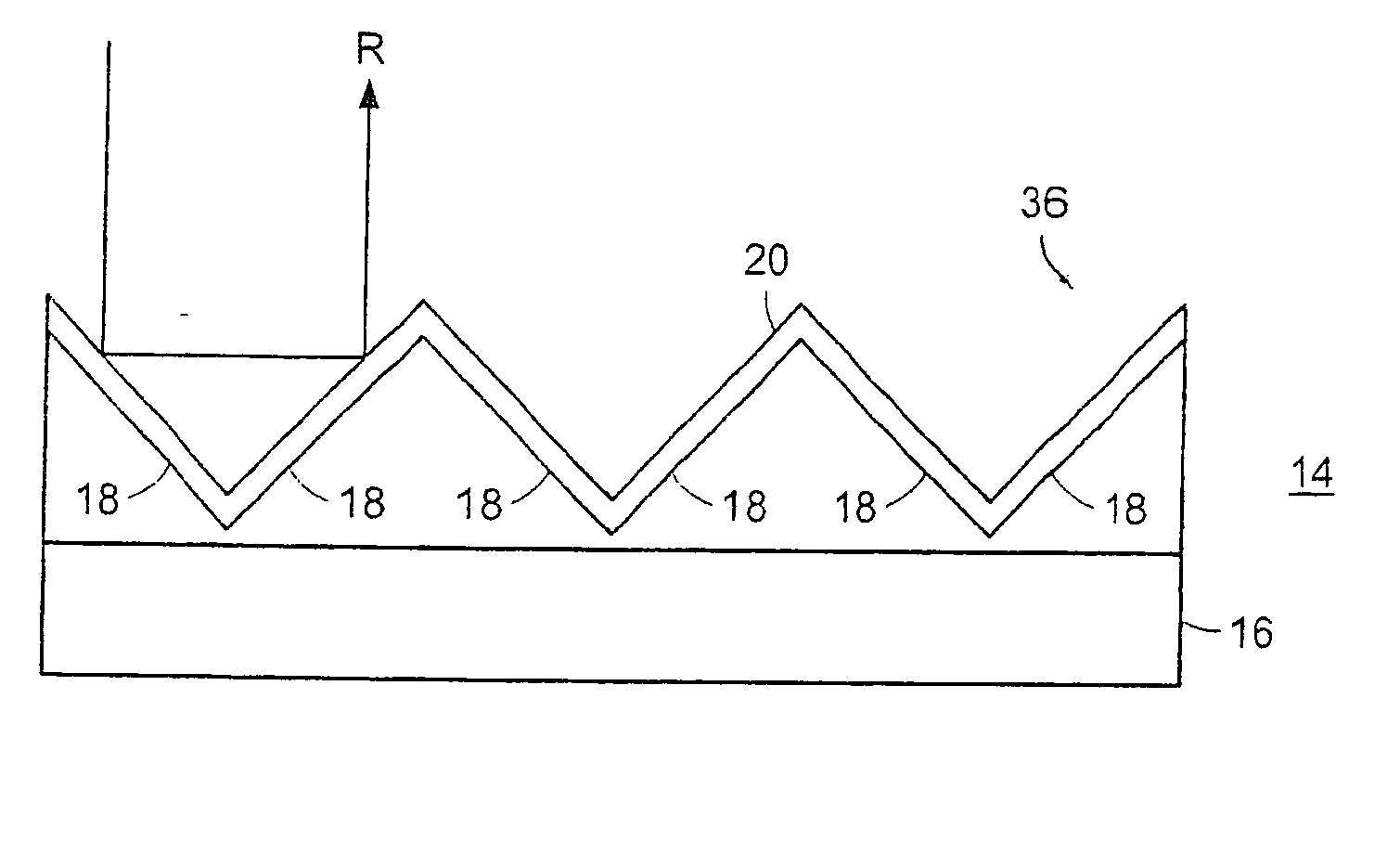

Durable, open-faced retroreflective prismatic construction

InactiveUS20050185279A1Improve adhesionImprove the entrance angleOptical elementsOptical coatingEngineering

Retroreflective sheeting and a method for making the same includes a plurality of open-faced cube-corner surfaces formed from a substantially rigid material to keep the cube-corner surfaces from flexing. A second plurality of open-faced cube-corner surfaces is formed from the substantially rigid material to keep the second plurality of open-faced cube-corner surfaces from flexing. The first and second open-faced cube-corner surfaces are configured to retroreflect light in opposite directions, that is, formed back-to-back in a particular embodiment. An optical coating can be formed on the surfaces. A plurality of voids forms the open-faced cube-corner surfaces. The retroreflective sheeting can be perforated in a particular embodiment.

Owner:REFLEXITE

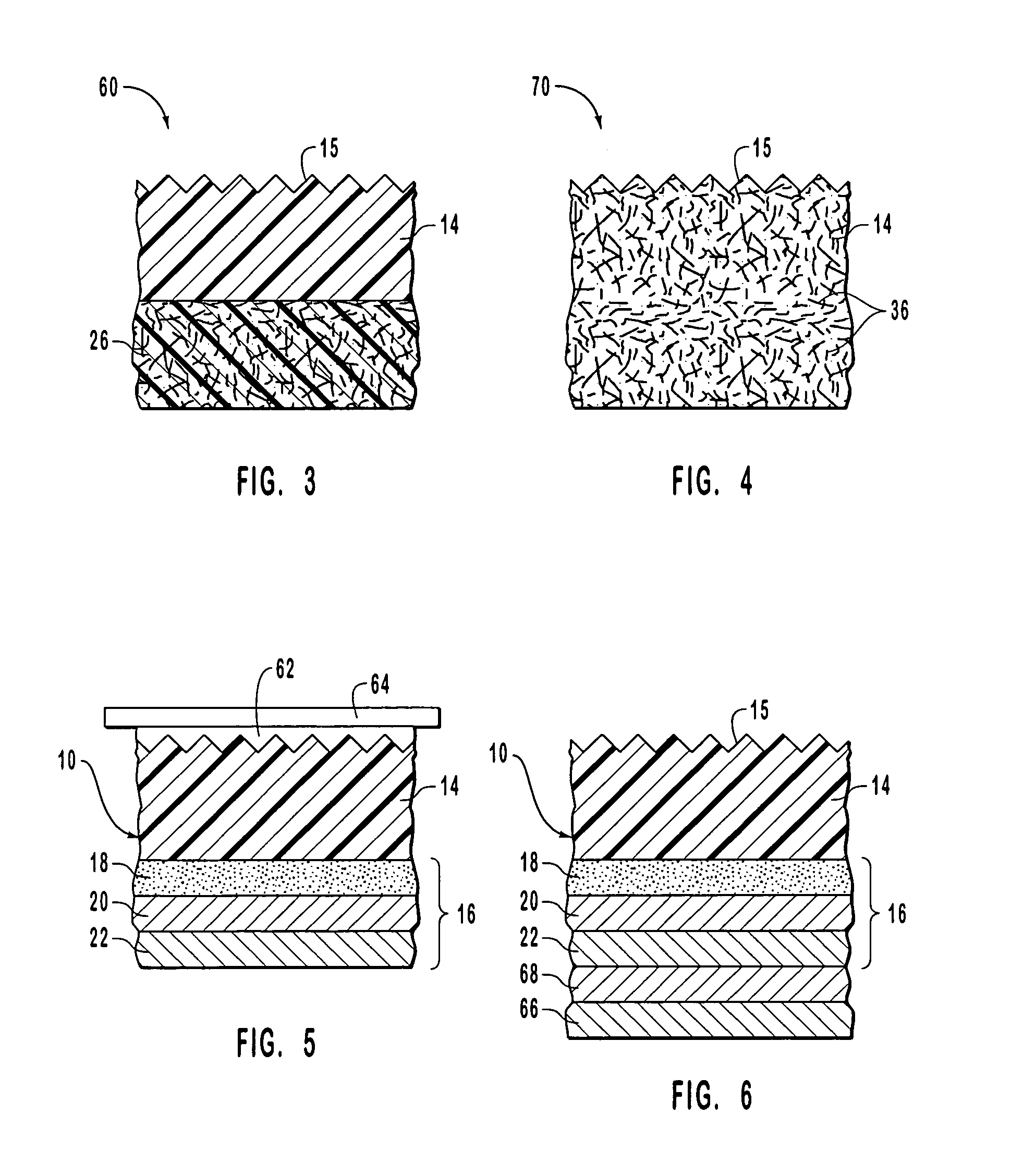

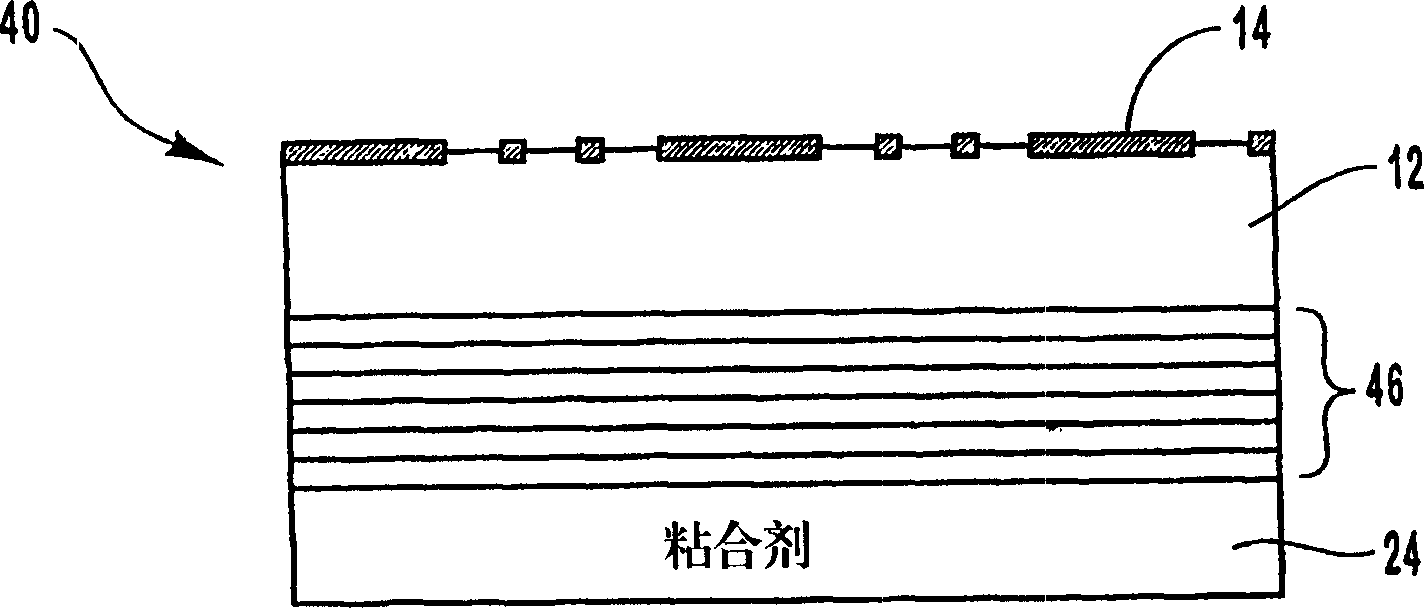

Sunlight readable display with reduced ambient specular reflection

The present technique relates to a method and apparatus for providing a display image that is readable under high ambient light conditions. The technique includes the use of an anti-glare surface with a significant surface texture. This surface will accommodate the deposition of an effective thin film anti-reflective optical coating. The technique provides a diffusive layer configured to diffuse light within the diffusive layer, and provides a bond between display layers to enhance performance of the display.

Owner:L 3 COMM CORP

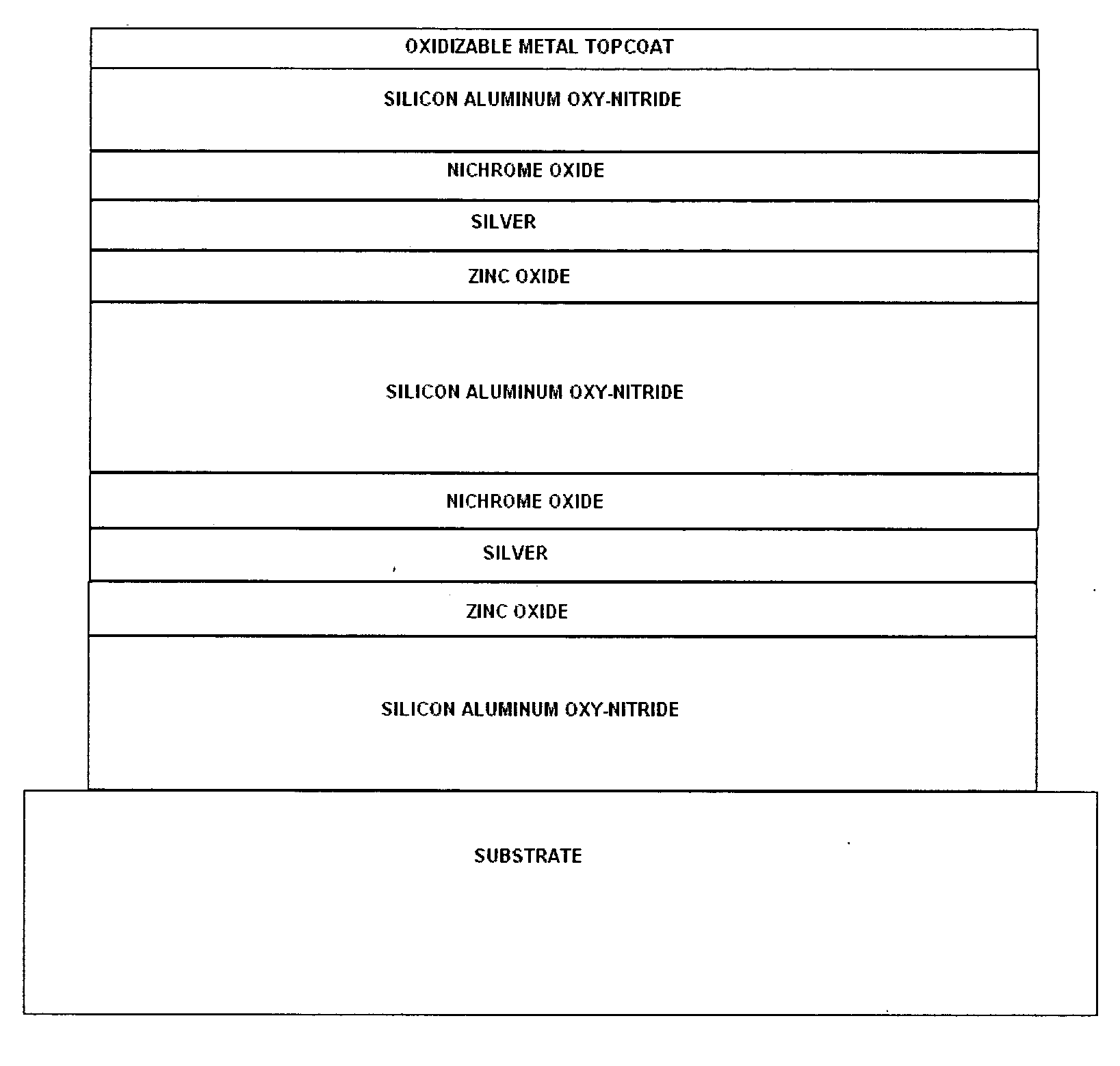

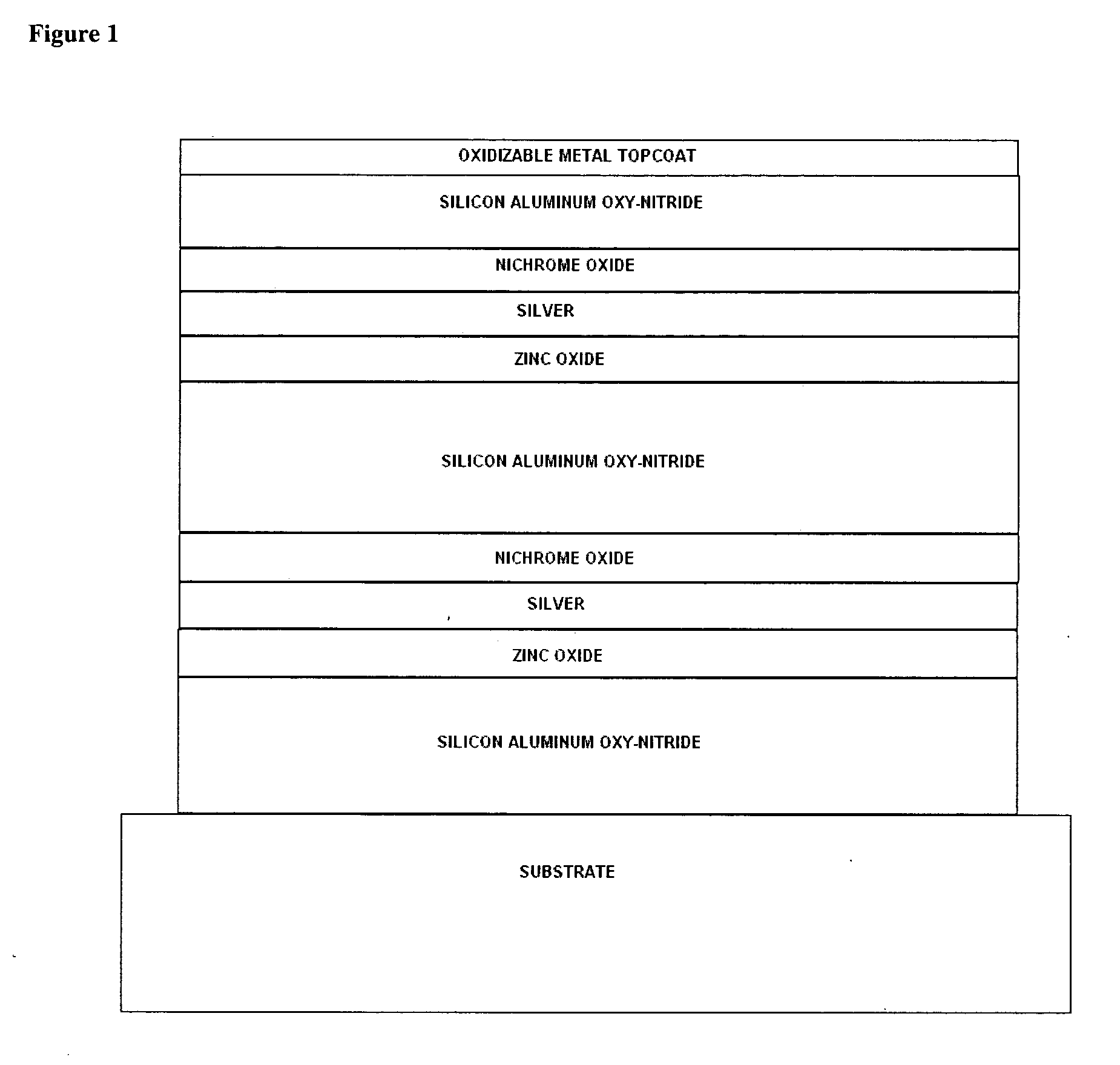

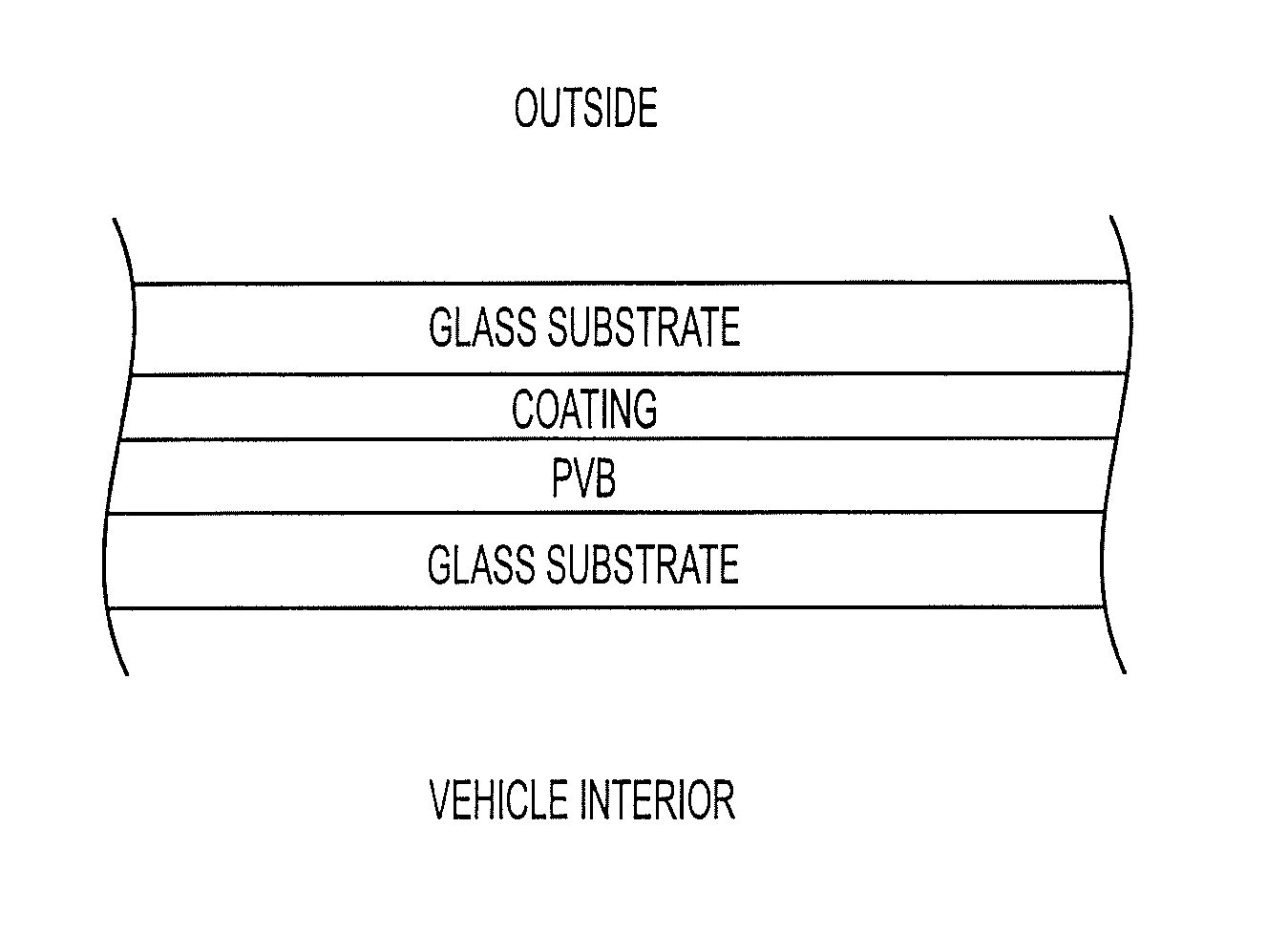

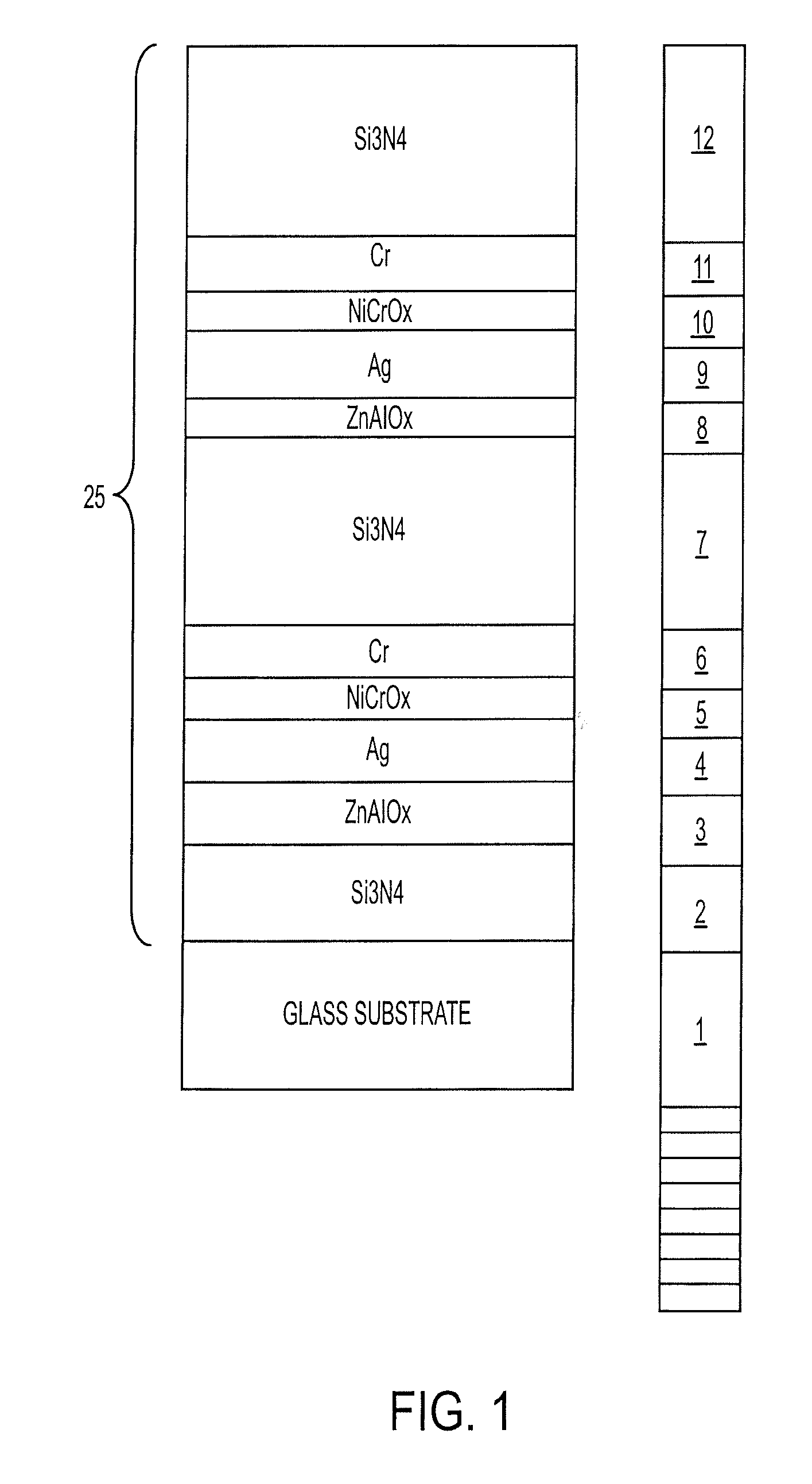

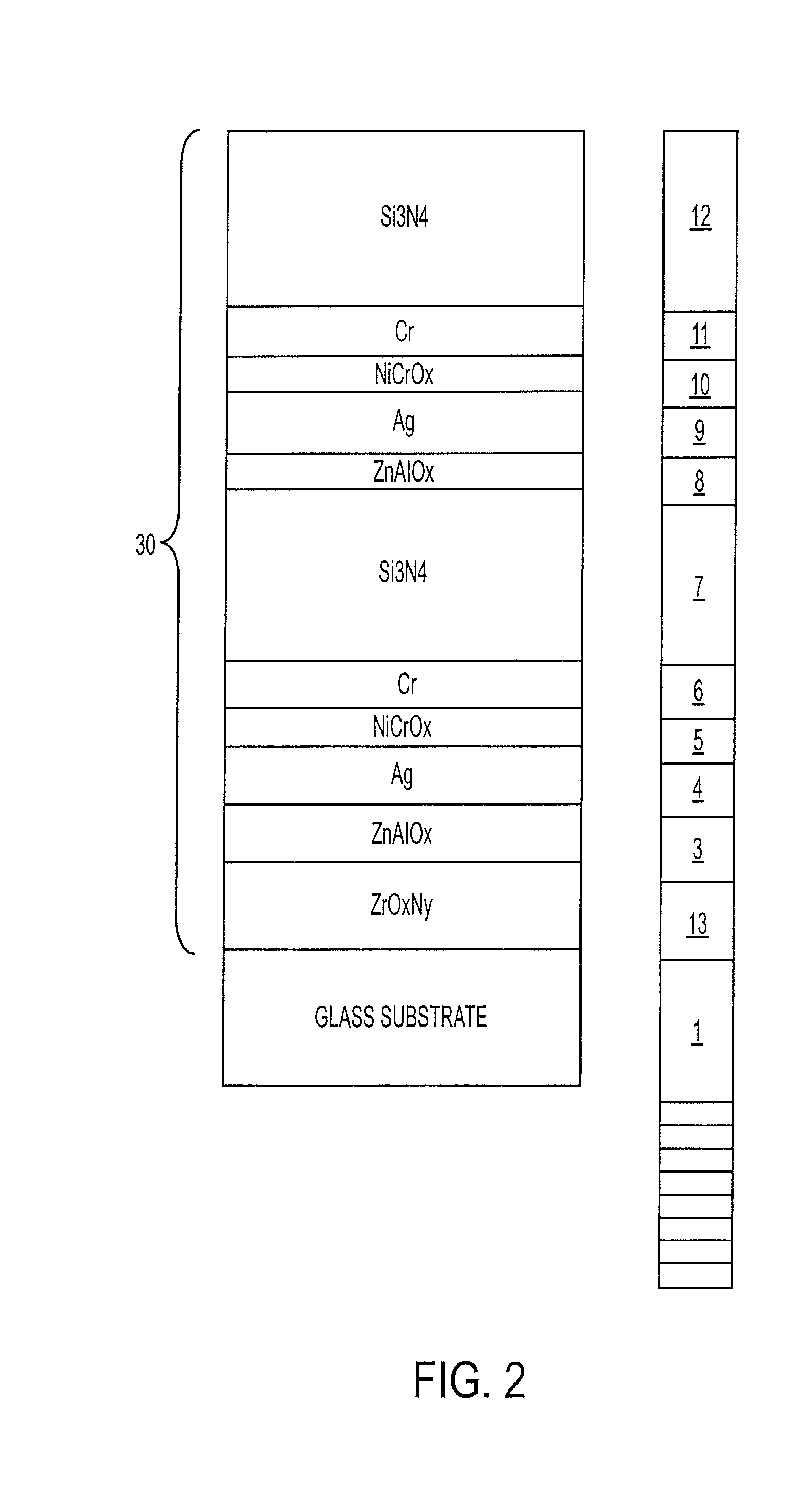

Optical coating with improved durability

ActiveUS20080138547A1Improve mechanical durabilityExcellent thermal durabilityLiquid surface applicatorsDoors/windowsOptical coatingOptoelectronics

The invention discloses optical coatings with improved durability, the coating comprising a durability enhancing layer, a nucleation layer and an infrared reflecting layer. The invention also discloses methods of making thin film layers having enhanced durability.

Owner:CARDINAL CG

Side-pumped active mirror solid-state laser for high-average power

InactiveUS6625193B2Active medium shape and constructionLaser cooling arrangementsOptoelectronicsPower apparatus

Apparatus and method for achieving improved performance in a solid-state laser. The solid-state laser apparatus preferably uses a laser gain medium in the shape of a disk wherein optical pump radiation is injected into the peripheral edge of the disk. In the preferred embodiment the laser gain medium is provided with optical coatings for operation in the active mirror configuration. Furthermore, the laser gain medium is pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium. Sources of optical pump radiation are placed around the perimeter of the gain medium. Tapered ducts may be disposed between the sources and the gain medium for the purpose of concentrating optical pump radiation. With the proper choice of laser gain medium doping, pump source divergence and geometry, a uniform laser gain is achieved across large portions of the gain medium.

Owner:THE BOEING CO

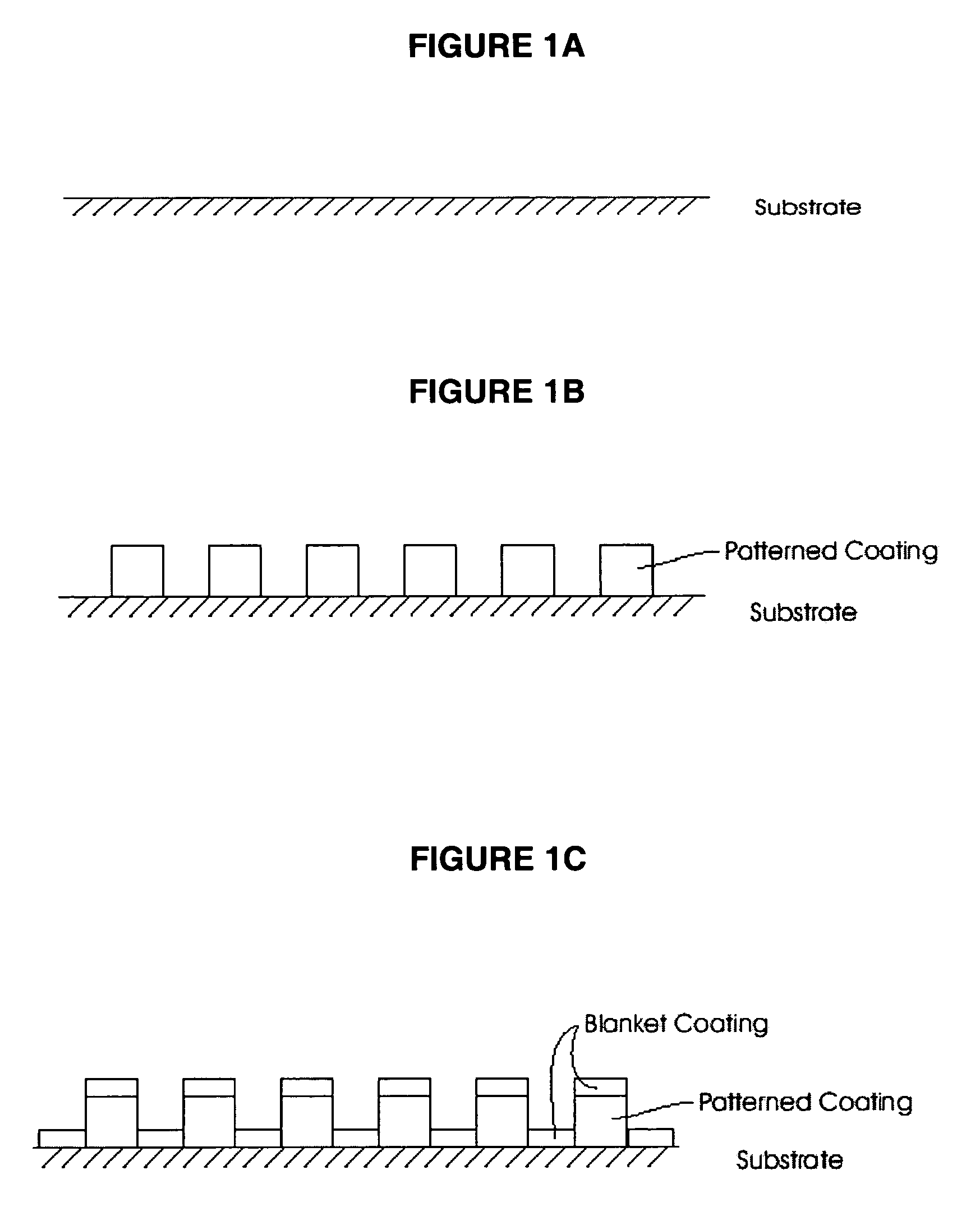

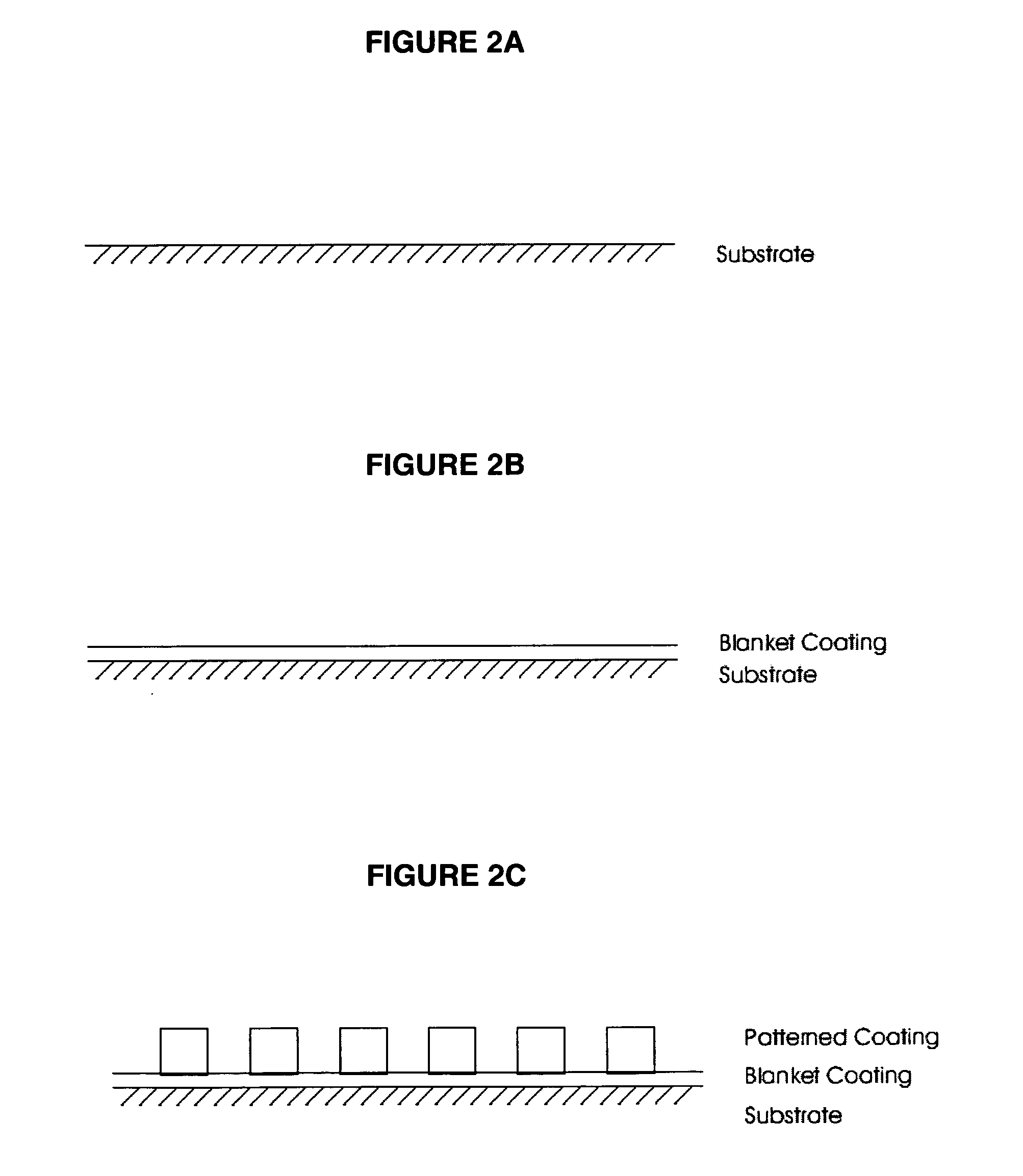

Patterned coated dichroic filter

Owner:OCEAN OPTICS

Wavelength conversion chip for use in solid-state lighting and method for making same

InactiveUS7285791B2Reduce impactEasy exitElectroluminescent light sourcesPhotometrySmart lightingOptical coating

A wavelength conversion chip is formed by depositing a wavelength conversion material layer on a substrate, segmenting the wavelength conversion layer into a plurality of wavelength conversion chips, and then removing the wavelength conversion chips from the substrate. The wavelength conversion of the chips can be increased by thermal annealing or radiation annealing of the wavelength conversion material. Optical coatings or light extraction elements can be fabricated on the wavelength conversion layer.

Owner:GOLDENEYE

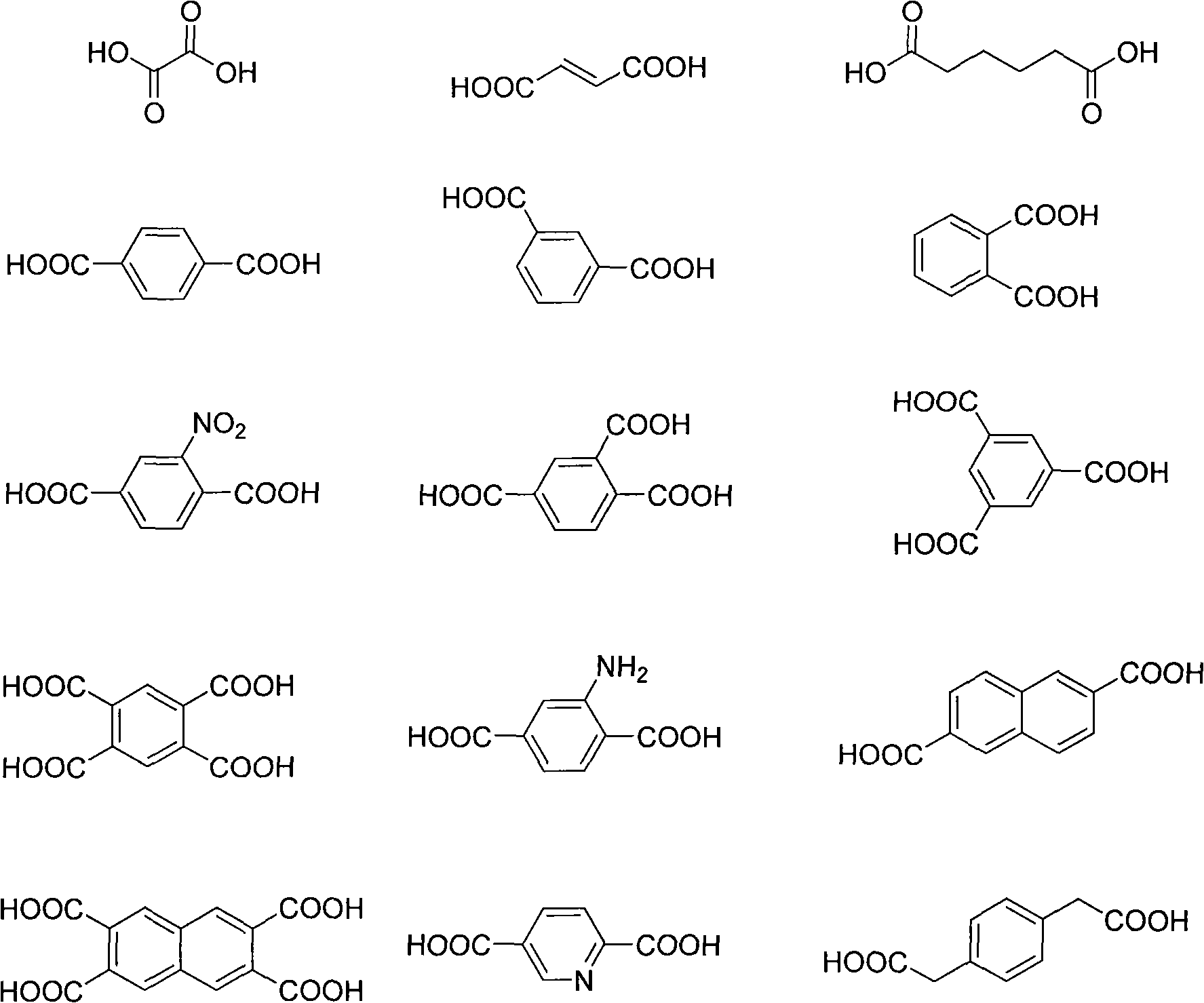

Preparation method of composite metal organic framework material colloidal solution and application thereof in optical coatings

InactiveCN102061112AImprove transmittanceImprove wear resistanceCoatingsOptical elementsWeather resistanceOptical coating

The invention discloses a preparation method of a composite metal organic framework material colloidal solution and application thereof in optical coatings. The composite material is formed by compounding silicon sol and a metal organic framework material colloidal solution, and then the composite material is coated on a substrate and cured at high temperature to obtain a film with an anti-reflection function. The film has high transmissivity, and the light transmissivity of the film is obviously improved within the sunlight spectrum, particularly in a visible light range, and moreover, the film has good wear resistance and weather resistance.

Owner:EAST CHINA NORMAL UNIV

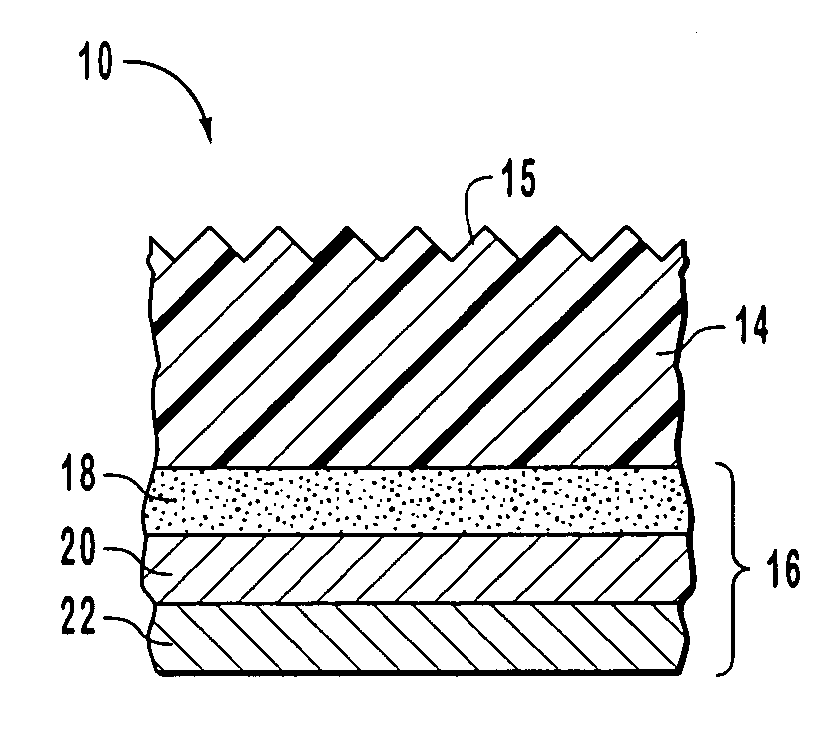

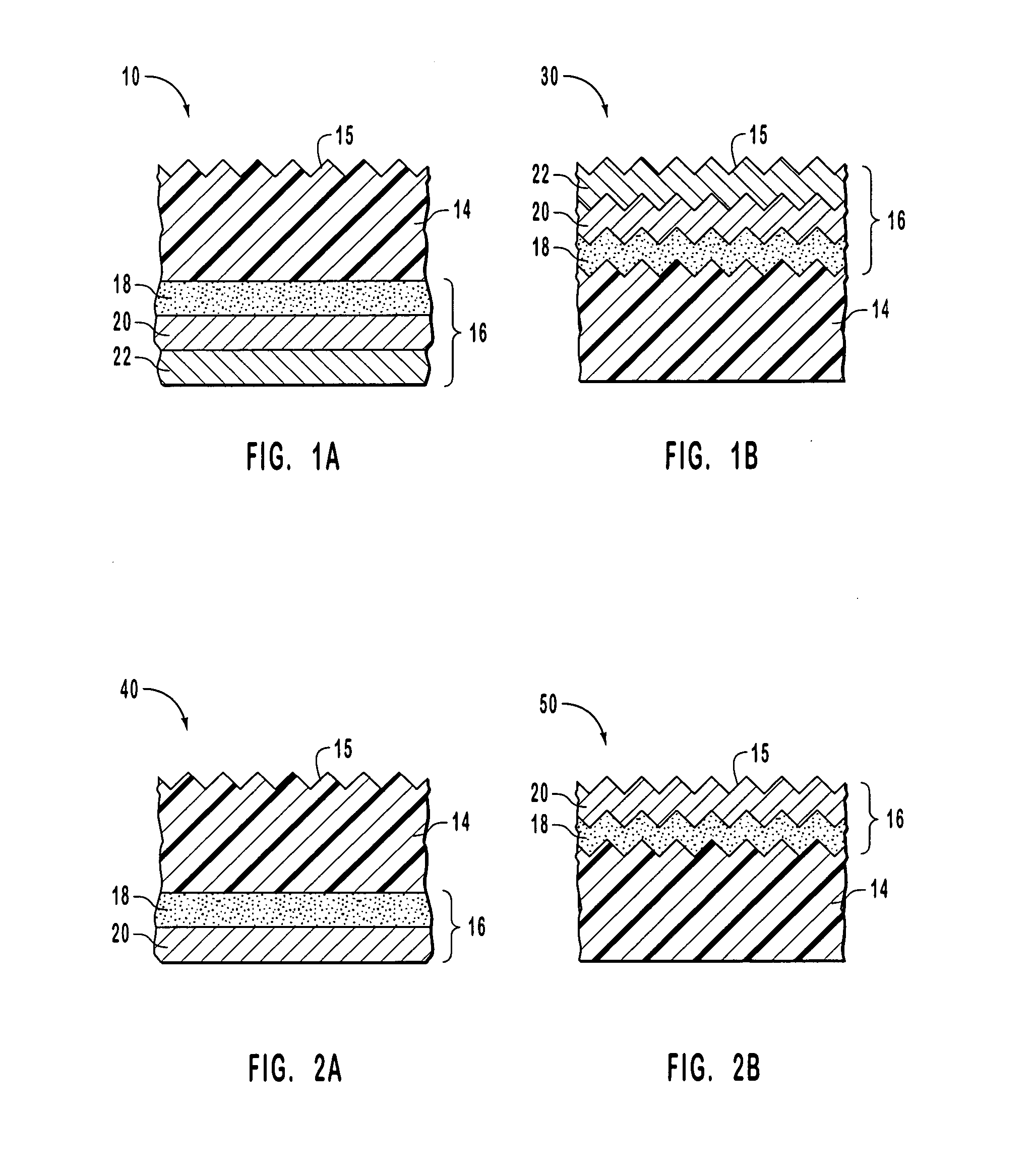

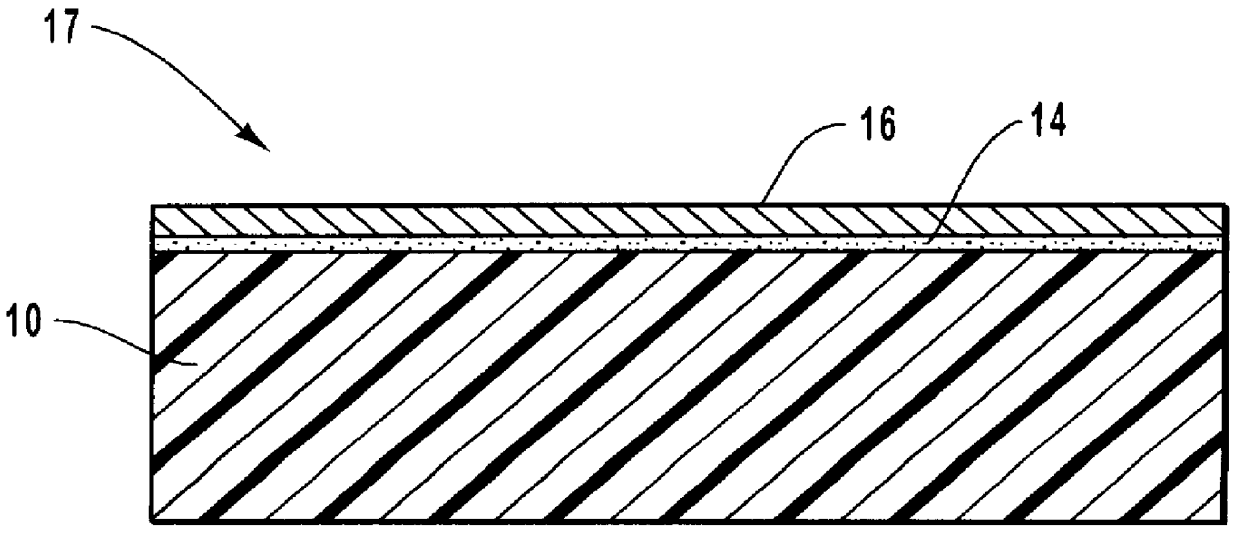

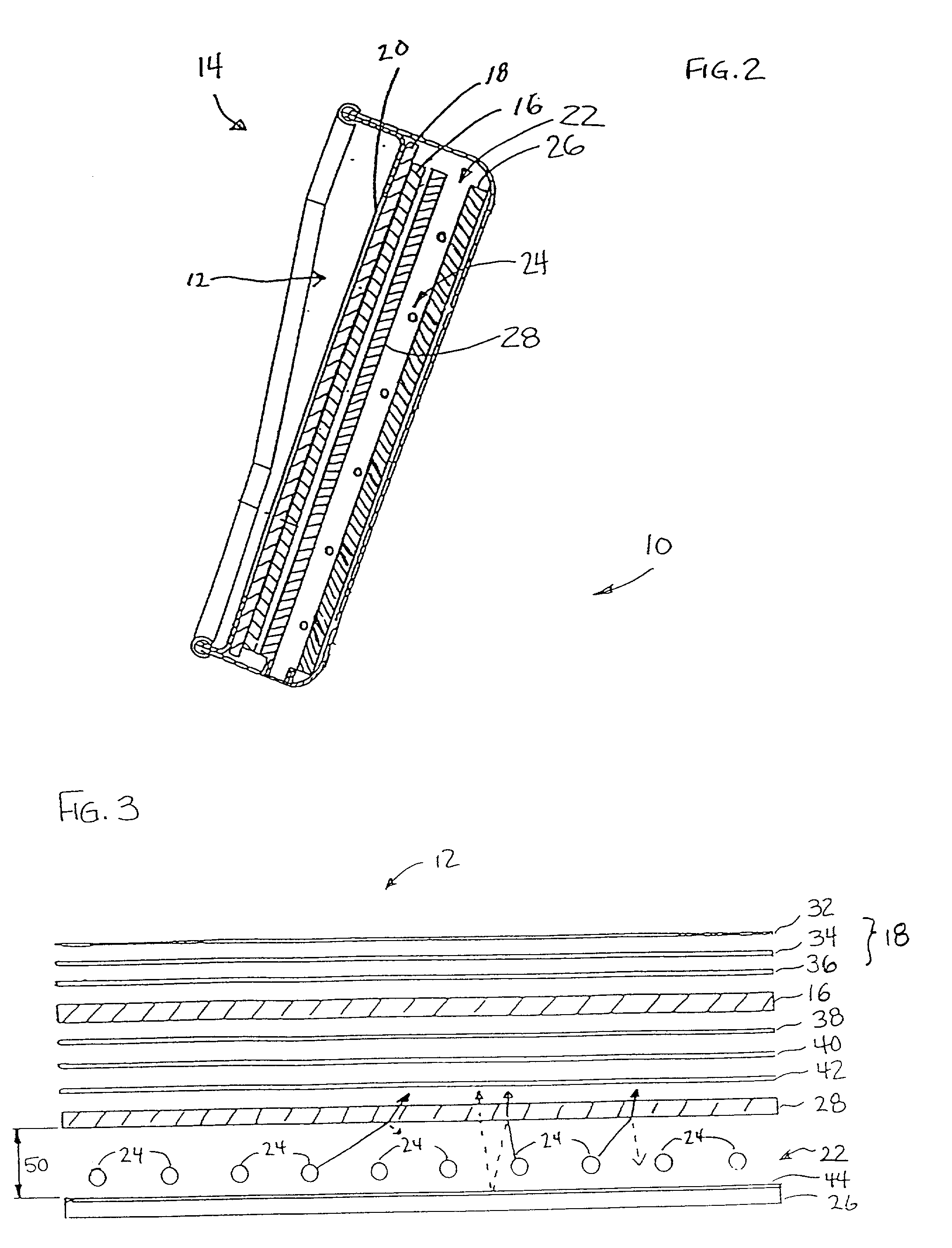

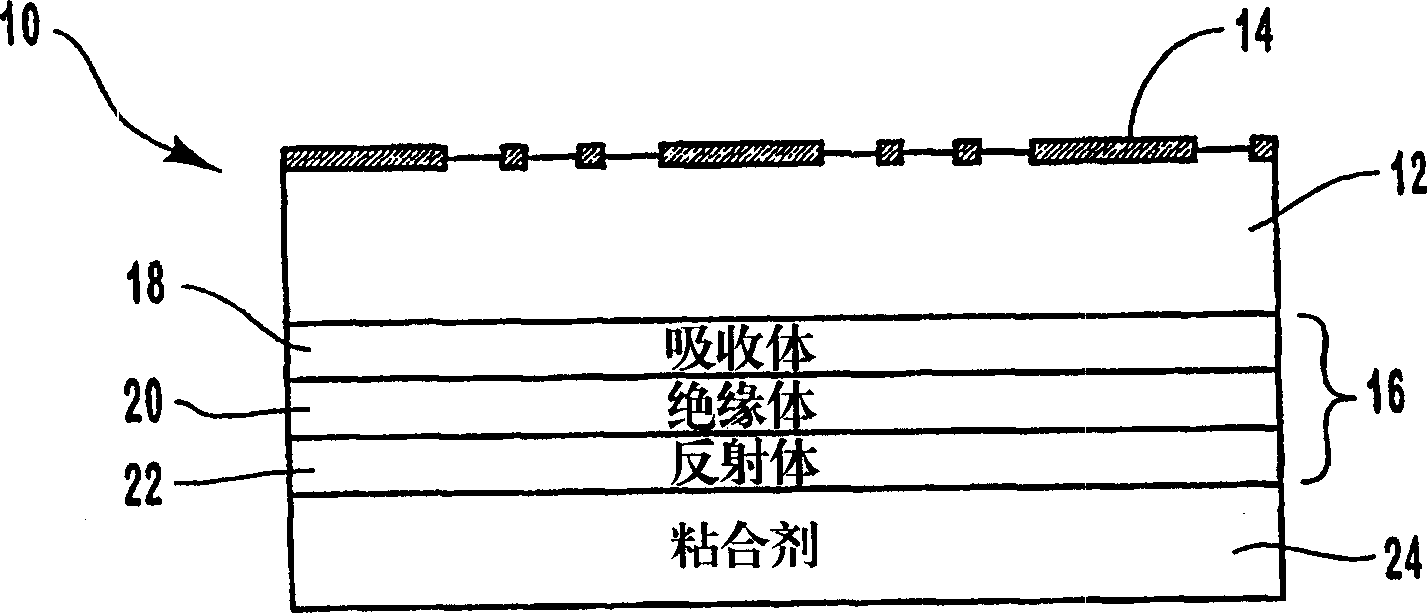

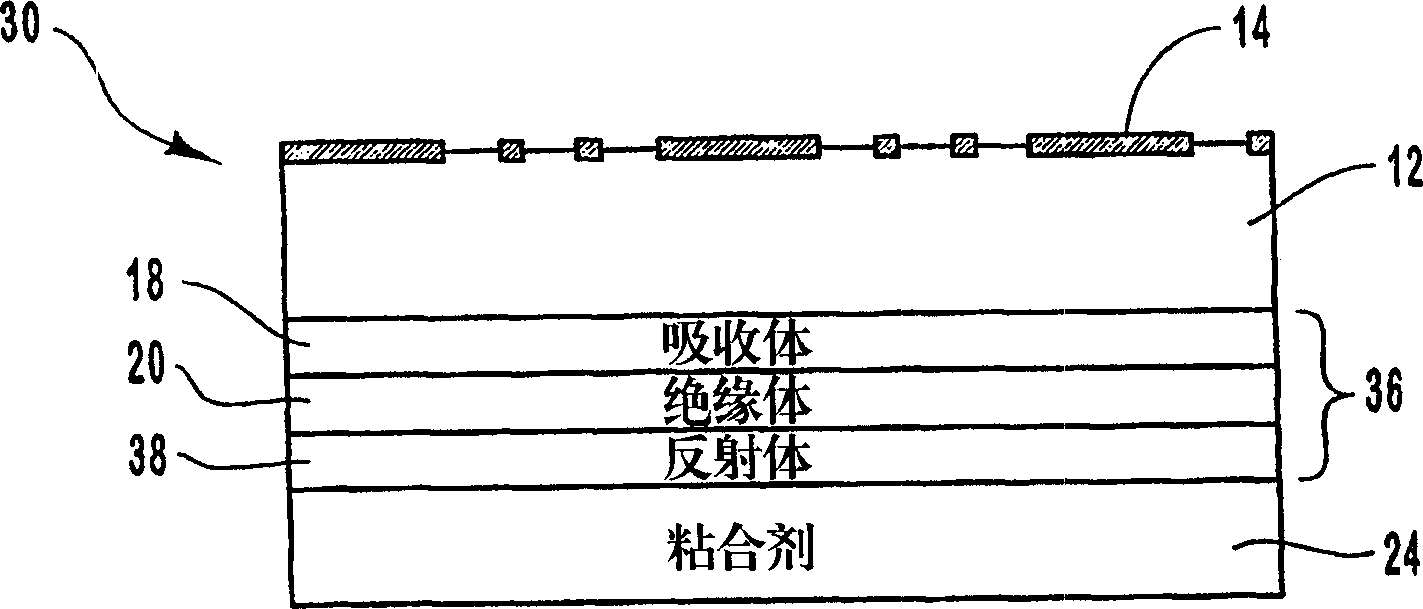

Uptically variable security devices

InactiveCN1423598AGood anti-counterfeiting measuresOther printing matterSynthetic resin layered productsHot stampingEngineering

A security article (10) includes a light transmissive substrate (12) having a first surface and an opposing second surface, with the first surface having an optical interference pattern (14) such as a holographic image pattern or an optical diffraction pattern thereon. A color shifting optical coating (16) is formed on the substrate such as on the interference pattern or on the opposing second surface of the substrate, with the optical coating providing an observable color shift as the angle of incident light or viewing angle changes. Various processes can be utilized to form the security article (10), such as vacuum coating processes, lamination, laser scribing, and laser imaging. The security article (10) can be affixed to a variety of objects through various attachment mechanisms, such as pressure sensitive adhesives or hot stamping processes, to provide for enhanced security measures such as anticounterfeiting.

Owner:光学涂层实验公司

High-average power active mirror solid-state laser with multiple subapertures

InactiveUS6810060B2Relieve pressureReduce thermal stressActive medium materialActive medium shape and constructionOptical coatingHydrostatic pressure

An apparatus and method for achieving ultrahigh-power output from a solid-state laser. The solid-state laser of the subject invention uses multiple disk-shaped laser gain media (subapertures) placed adjacent to each other to fill an optical aperture of an AMA module. In one preferred embodiment each of the laser gain media is provided with optical coatings for operation in the active mirror configuration. Furthermore, each of the laser gain media is hydrostatic pressure-clamped to a rigid, cooled substrate, which allows it to maintain a prescribed shape even when experiencing significant thermal load. A cooling medium can be provided to a heat exchanger internal to the substrate and / or flowed through the passages on the substrate surface, thereby directly cooling the laser gain medium.

Owner:THE BOEING CO

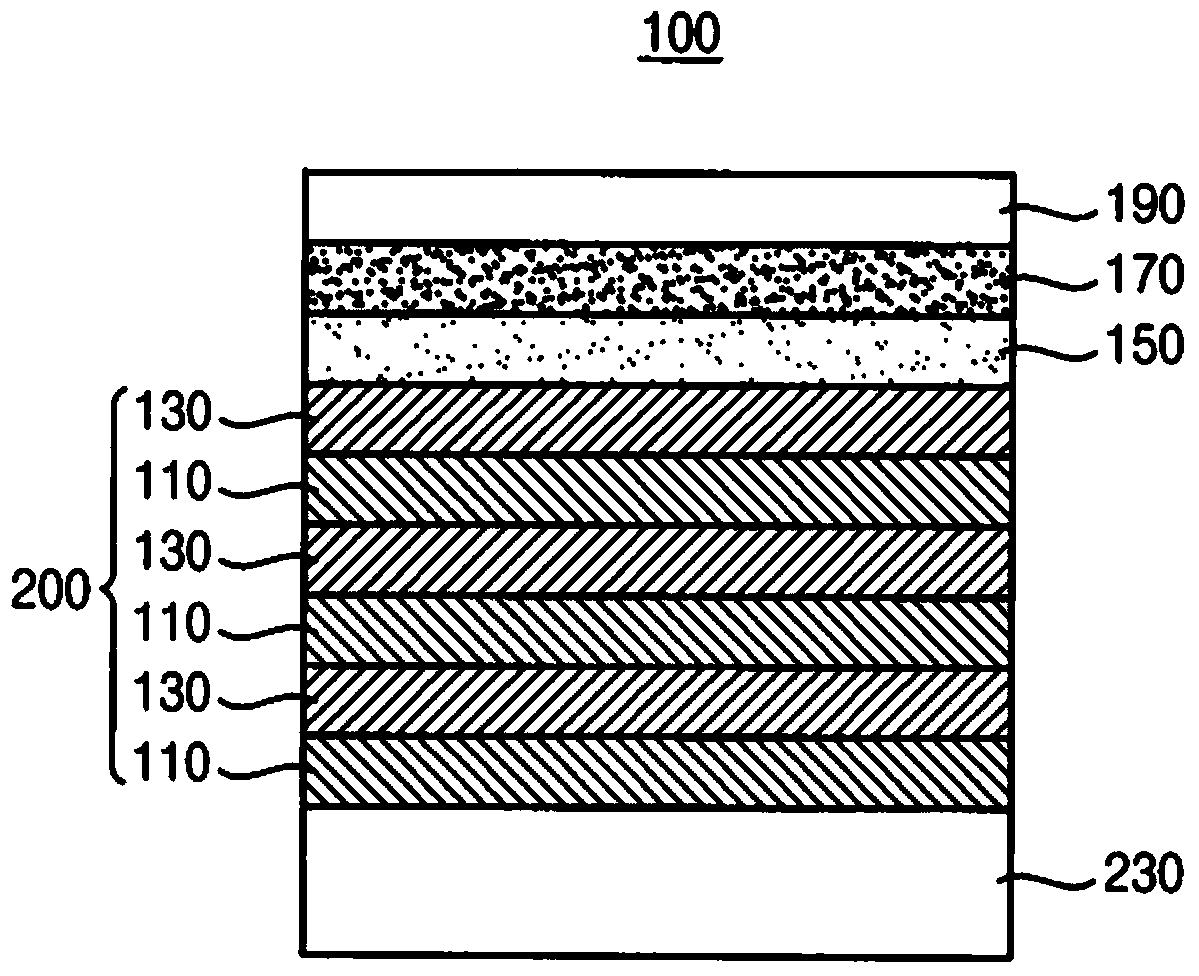

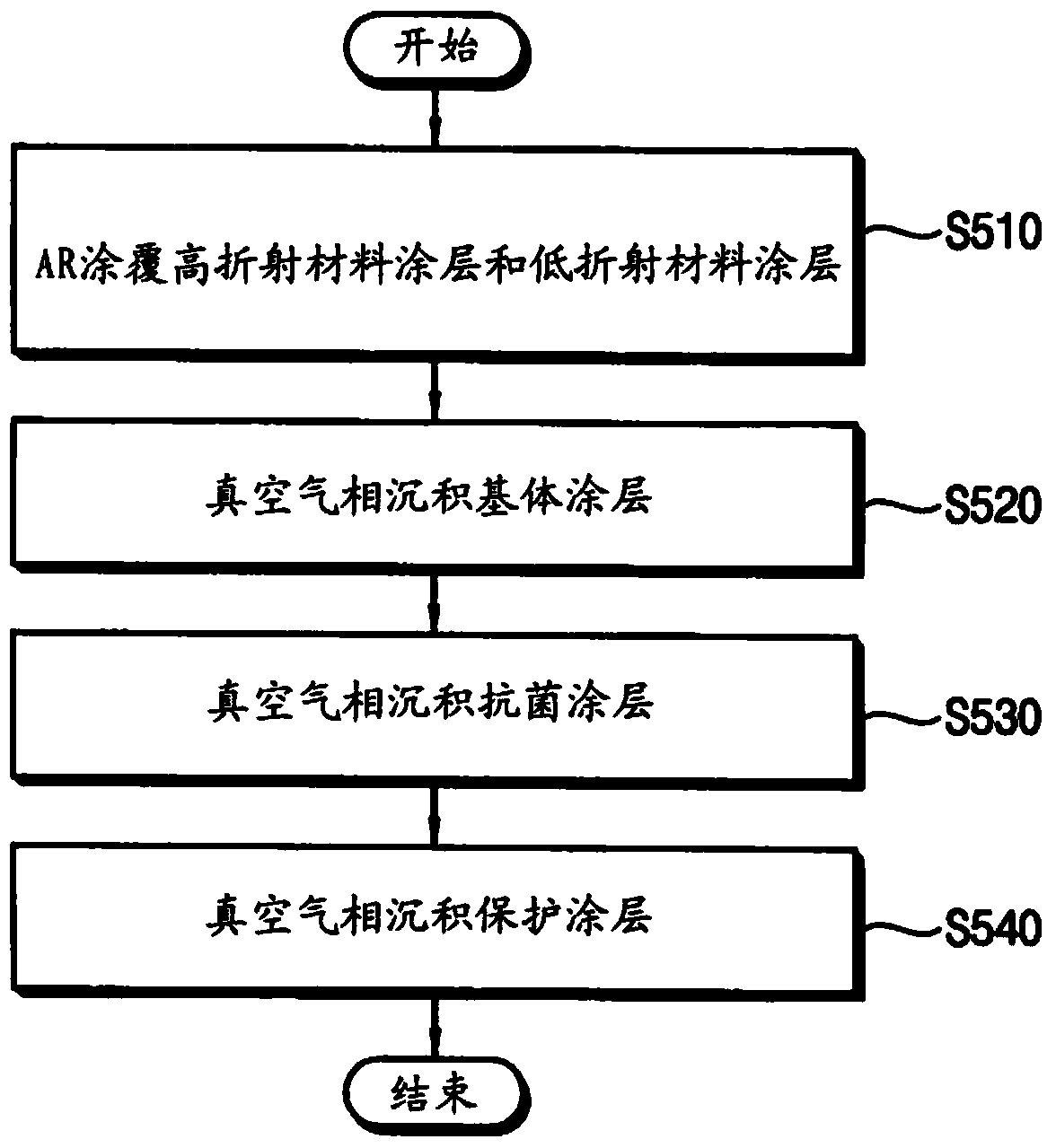

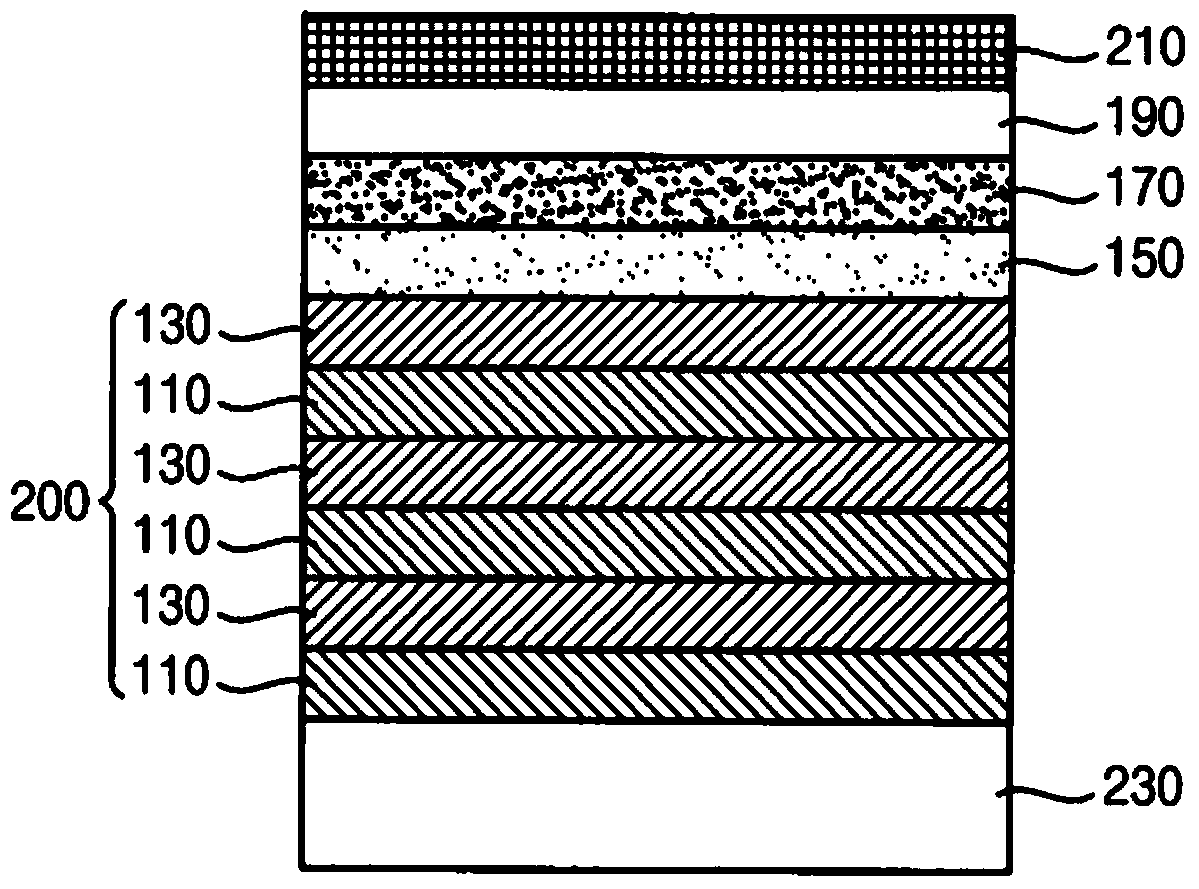

Multi-layer optical coating structure having an antibacterial coating layer

ActiveCN104339749ASynthetic resin layered productsVacuum evaporation coatingAnti-reflective coatingOptical coating

An optical coating structure includes a substrate, an anti-reflective coating layer, a base coating layer, an antibacterial coating layer, and a protective coating layer. The anti-reflective coating layer is disposed on the substrate. The anti-reflective coating layer covers the substrate. The base coating layer covers the anti-reflective coating layer. The antibacterial coating layer is disposed on the base coating layer, and the antibacterial coating layer is an interlayer. The protective coating layer covers the antibacterial coating layer. A super-hydrophobic coating layer or an anti-fingerprint coating layer may cover the protective coating layer.

Owner:SAMSUNG DISPLAY CO LTD +1

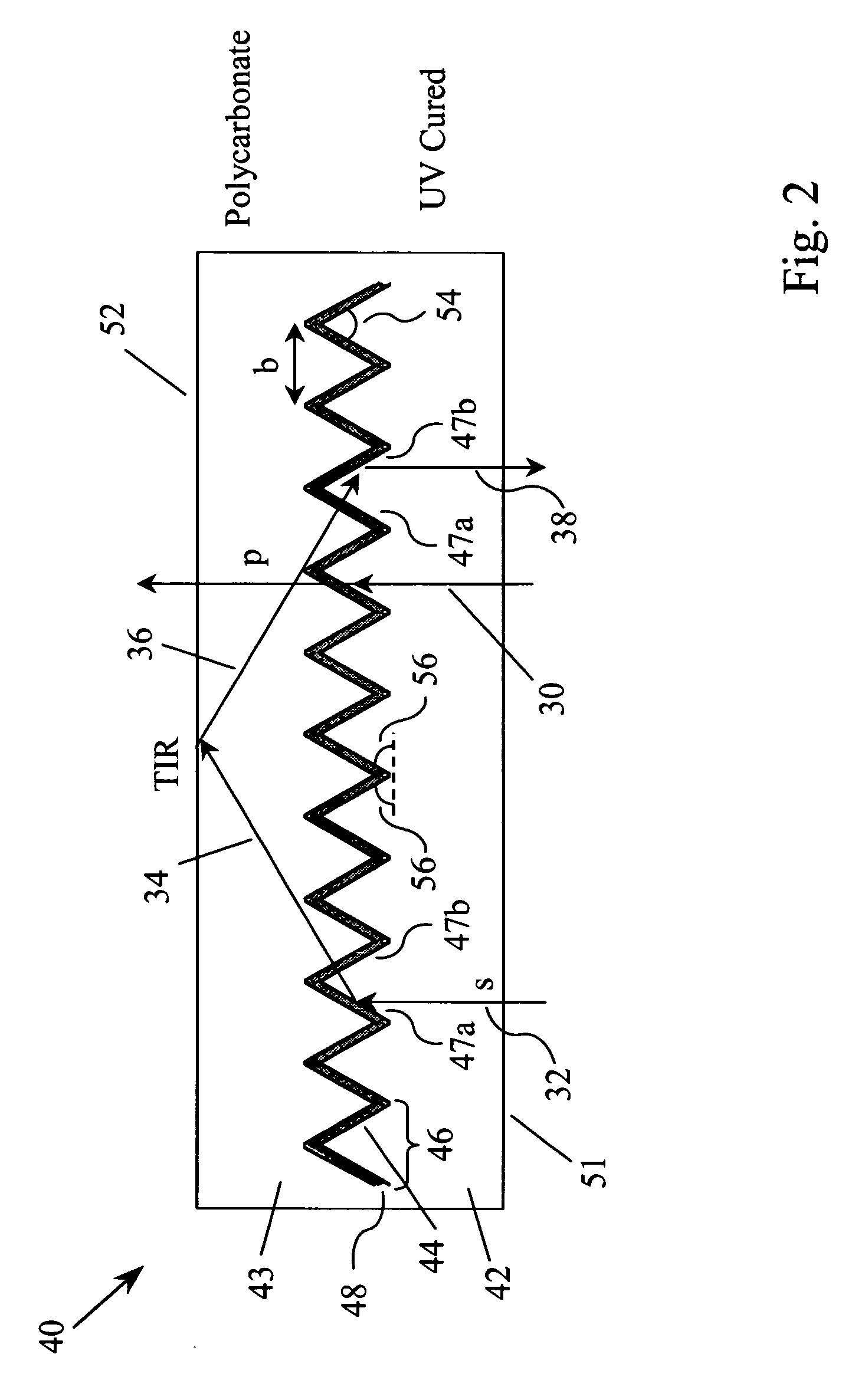

Reflective polarizer with polarization splitting microstructure

InactiveUS20070279554A1Large toleranceReduce manufacturing costPolarising elementsNon-linear opticsOptical coatingPolarizer

A reflective polarizer contains:(a) a light-entrance medium having a light-entrance surface and a microstructured surface with a series of prismatic structures, wherein first and second sidewalls of each prismatic structure have an inclination angle of more than 53 degrees with respect to the light-entrance surface;(b) a polarization-selective thin film optical coating on the series of prismatic structures, for transmitting a first polarization of light and reflecting a second polarization; and(c) a light-exit medium on the polarization-selective thin film optical coating that provides a smooth light-exit surface.

Owner:SKC HI TECH & MARKETING CO LTD CO REGISTRATION NO 161511 0225312

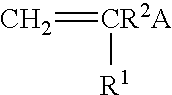

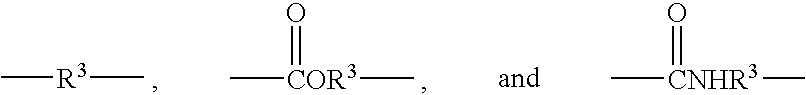

Reactive oligomers

InactiveUS7015286B2Easy to processImproved final mechanical propertyEster polymer adhesivesCoatingsPolymer scienceOligomer

The present invention provides melt-processible adhesive compositions prepared from a first oligomer containing reactive functional groups capable of reaction at effective rates (at normal processing temperatures) with a co-reactive second component oligomer possessing functionality that is complementary to that of the first oligomer. The compositions may be used as coatings, including hard surface coatings, clear coatings, powder coatings and pattern coatings; as adhesives, including pressure sensitive adhesives and hot melt adhesives; as sealants; as optical coatings; as blown microfibers (BMF); as high refractive index optical materials; as barrier films; in microreplication; as low adhesion backsizes, (LABs) and as release coatings.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com