Patents

Literature

3324results about "Laser cooling arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

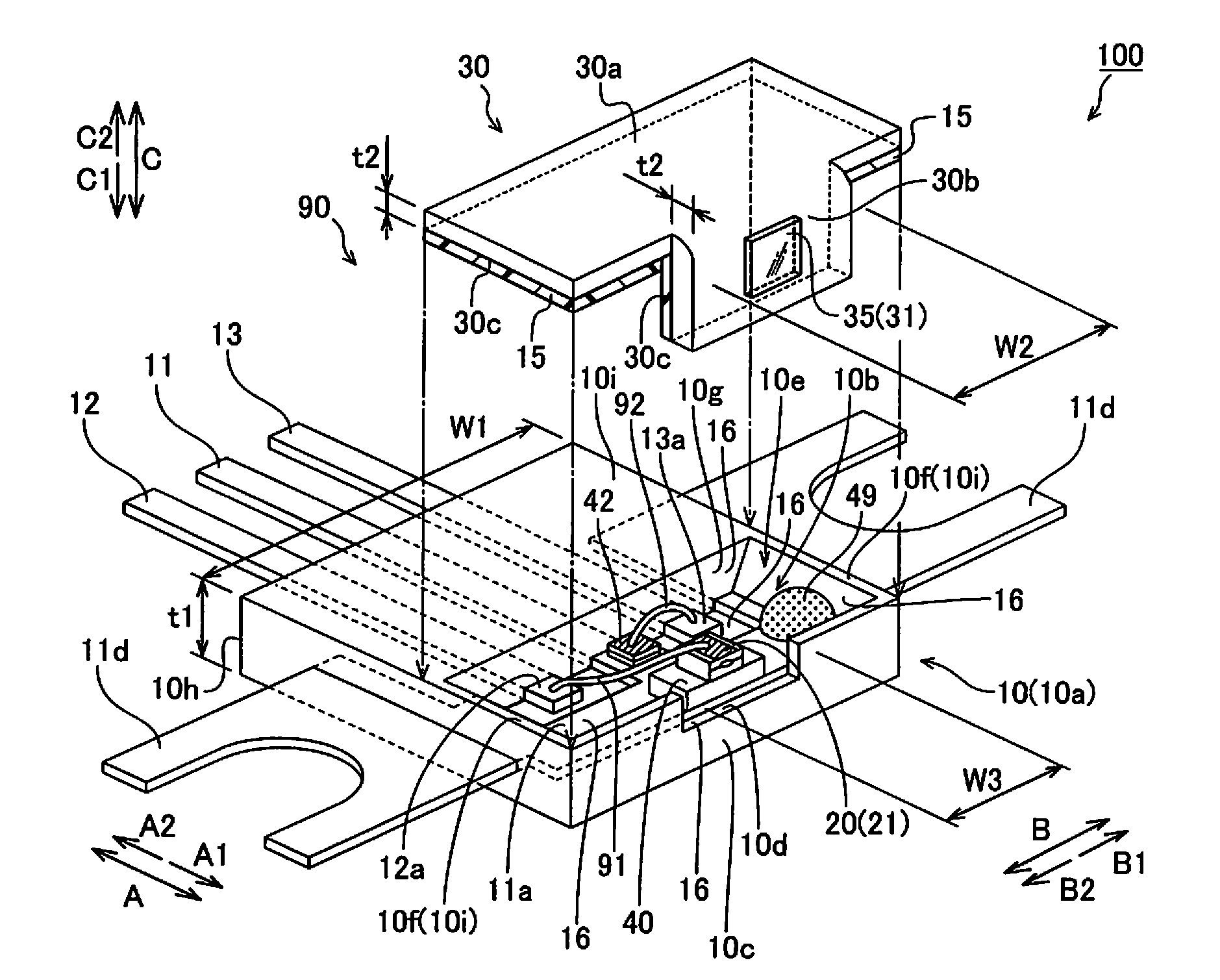

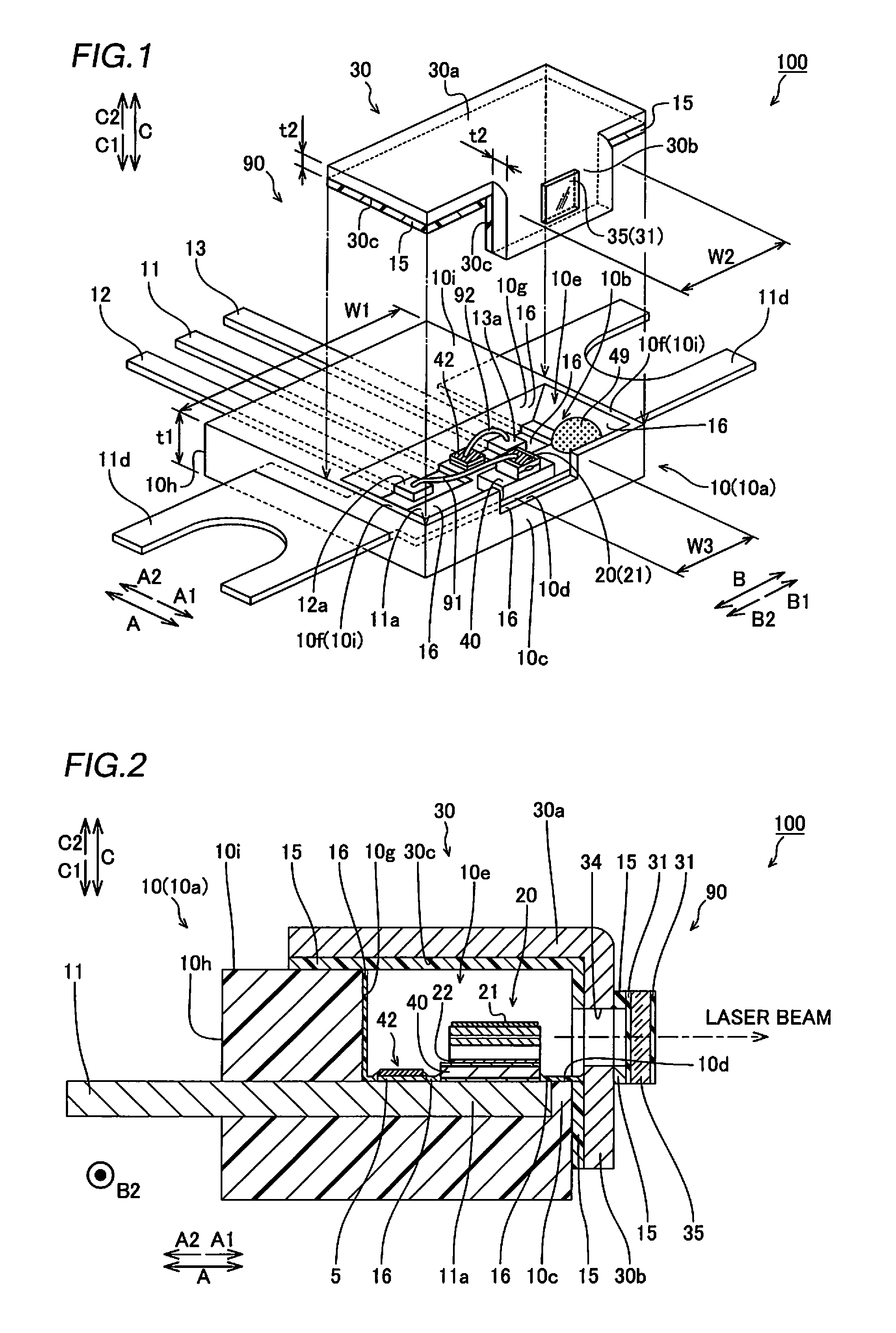

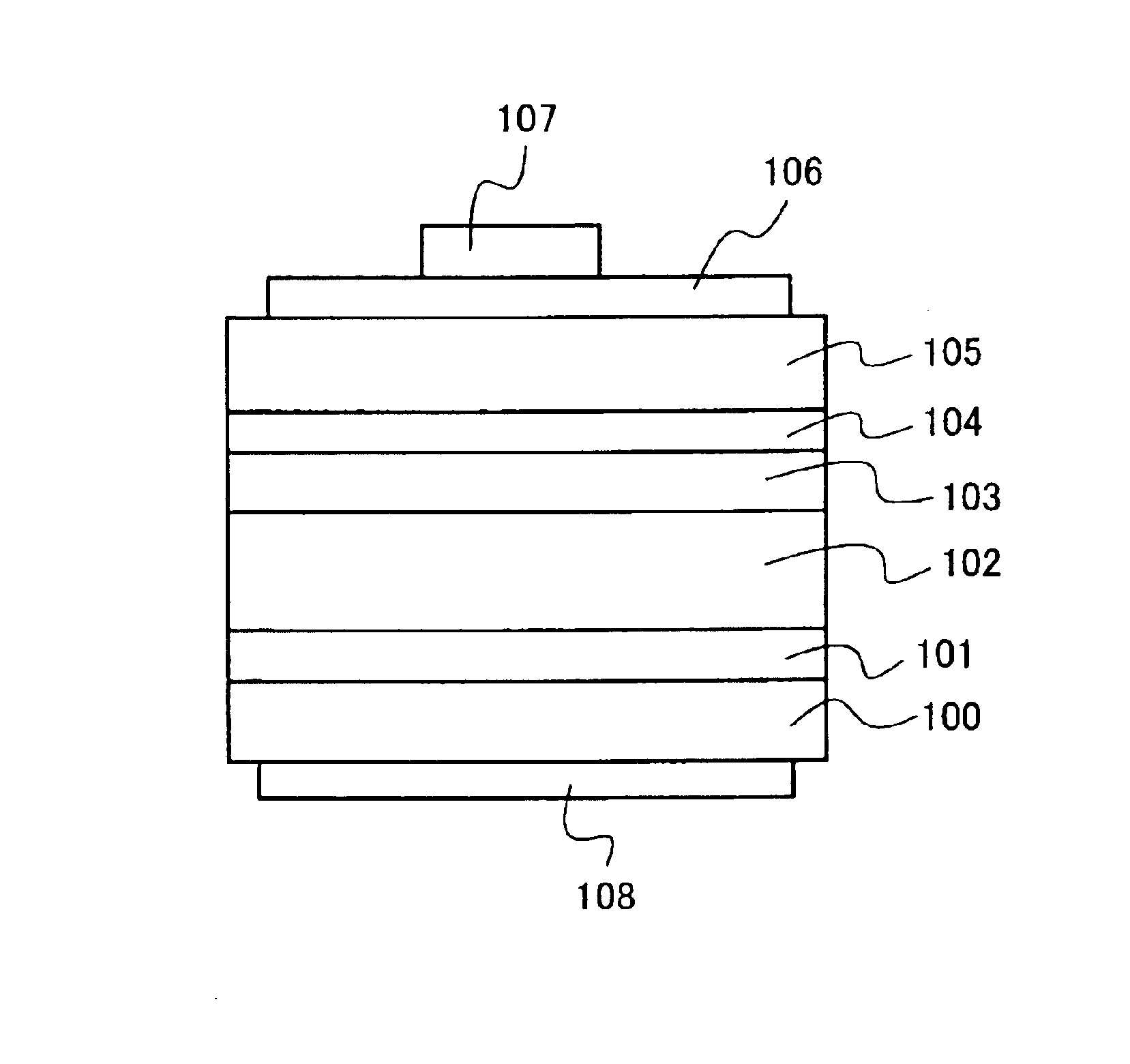

Semiconductor laser apparatus and optical apparatus

InactiveUS20120033695A1Improve sealingPromote absorptionSolid-state devicesSemiconductor lasersPolyvinyl alcoholSemiconductor chip

This semiconductor laser apparatus includes a package constituted by a plurality of members, having sealed space inside and a semiconductor laser chip arranged in the sealed space, while surfaces of the members located in the sealed space are covered with a covering agent made of an ethylene-polyvinyl alcohol copolymer.

Owner:SANYO ELECTRIC CO LTD

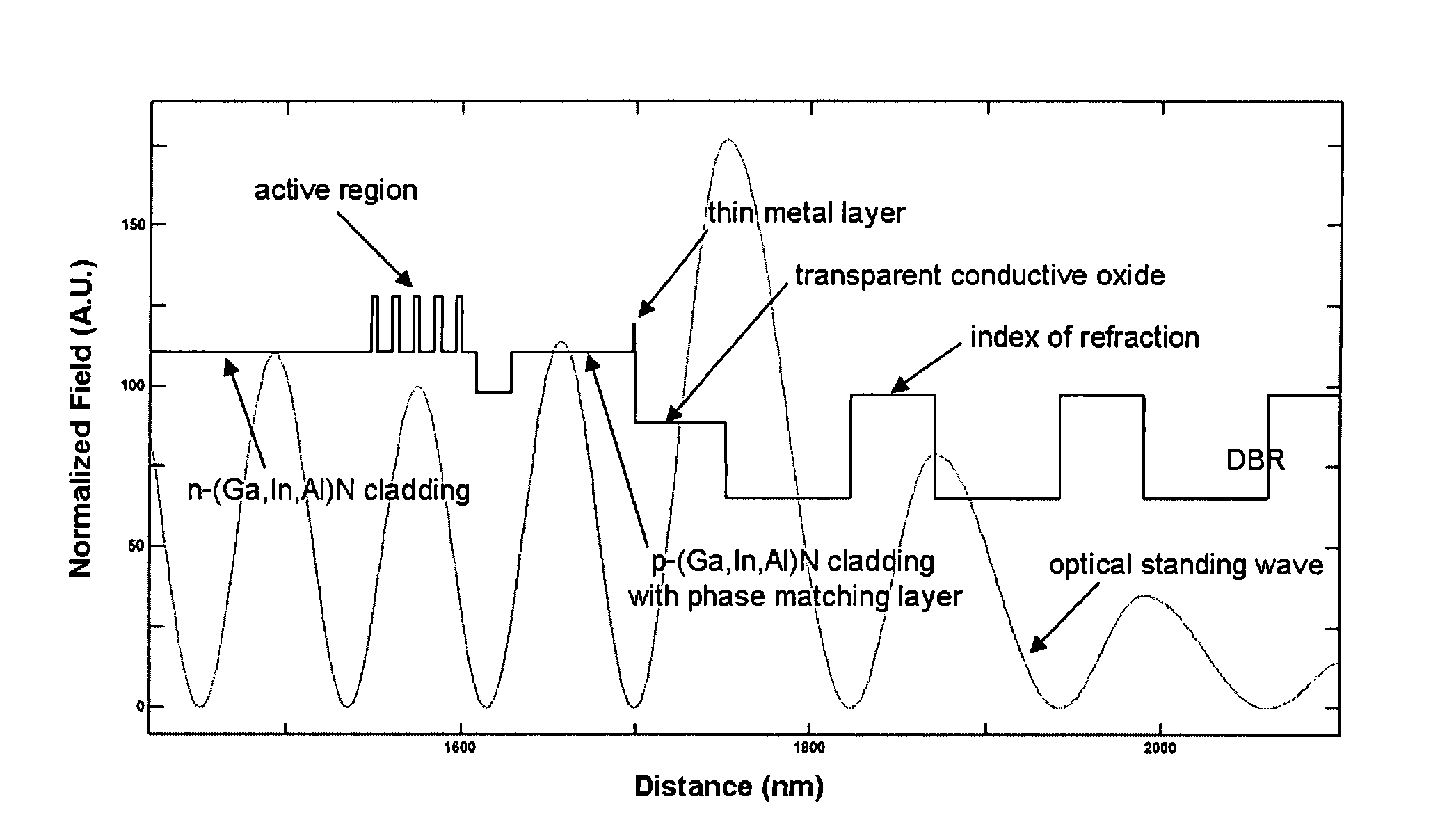

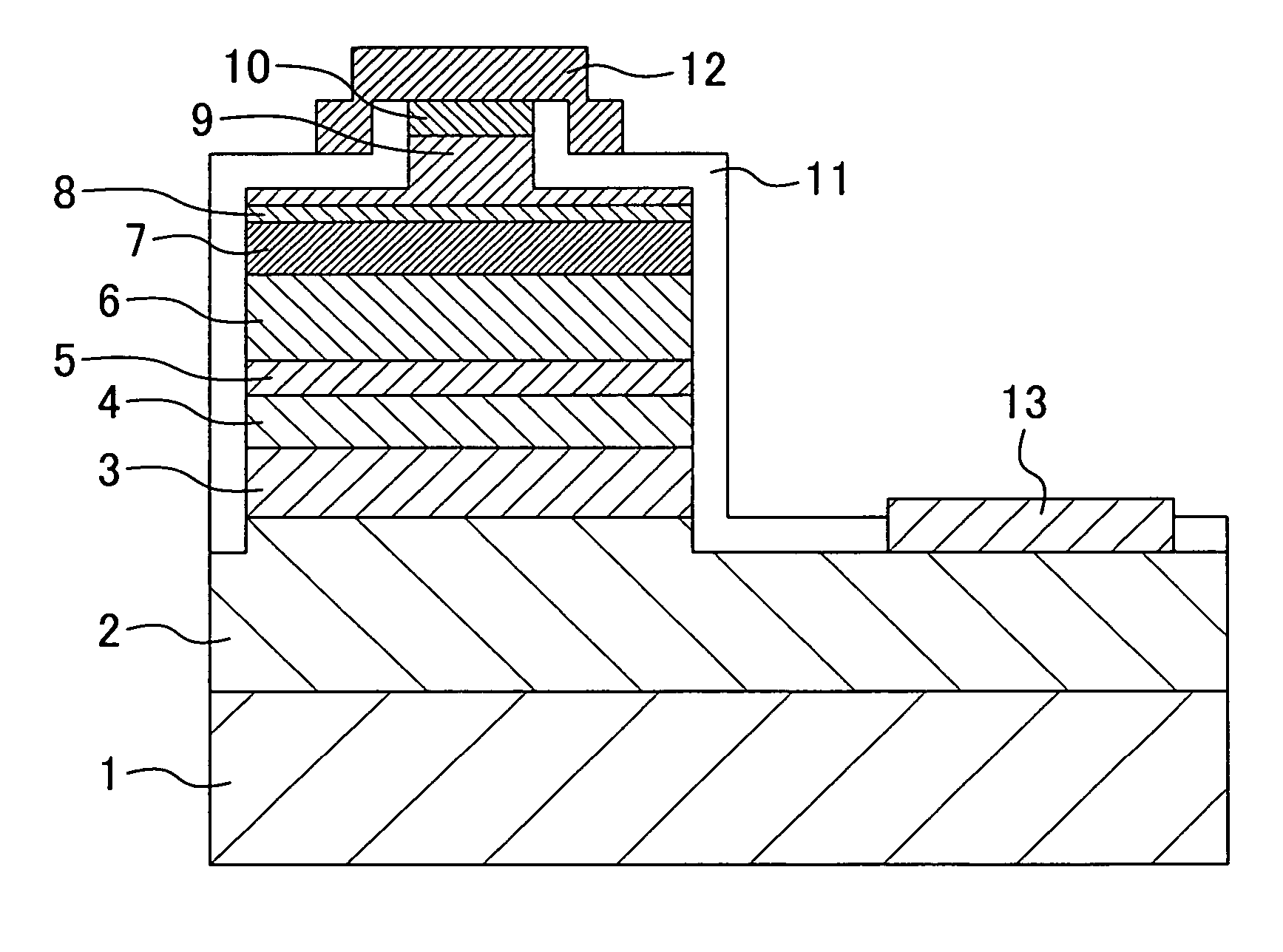

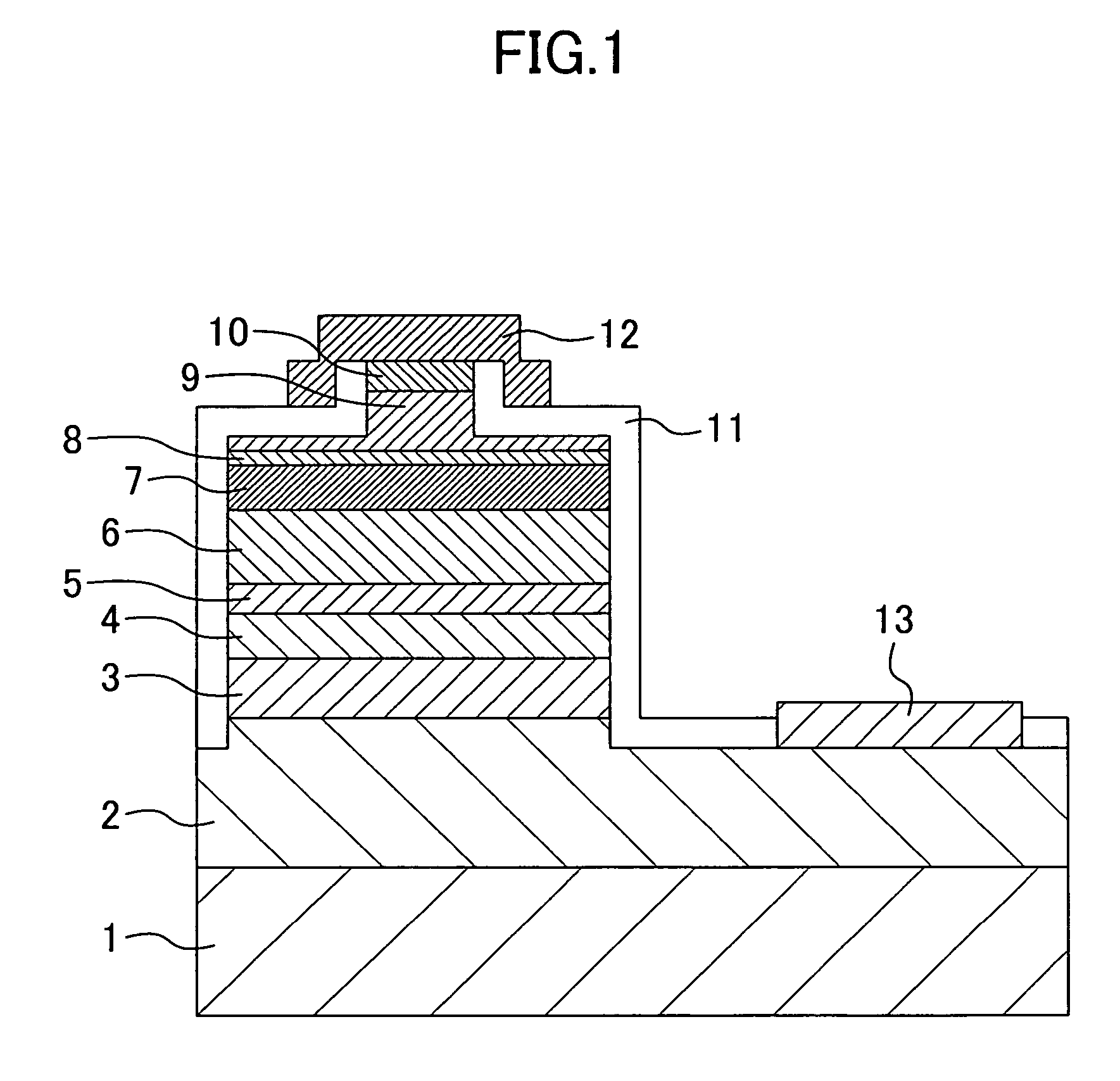

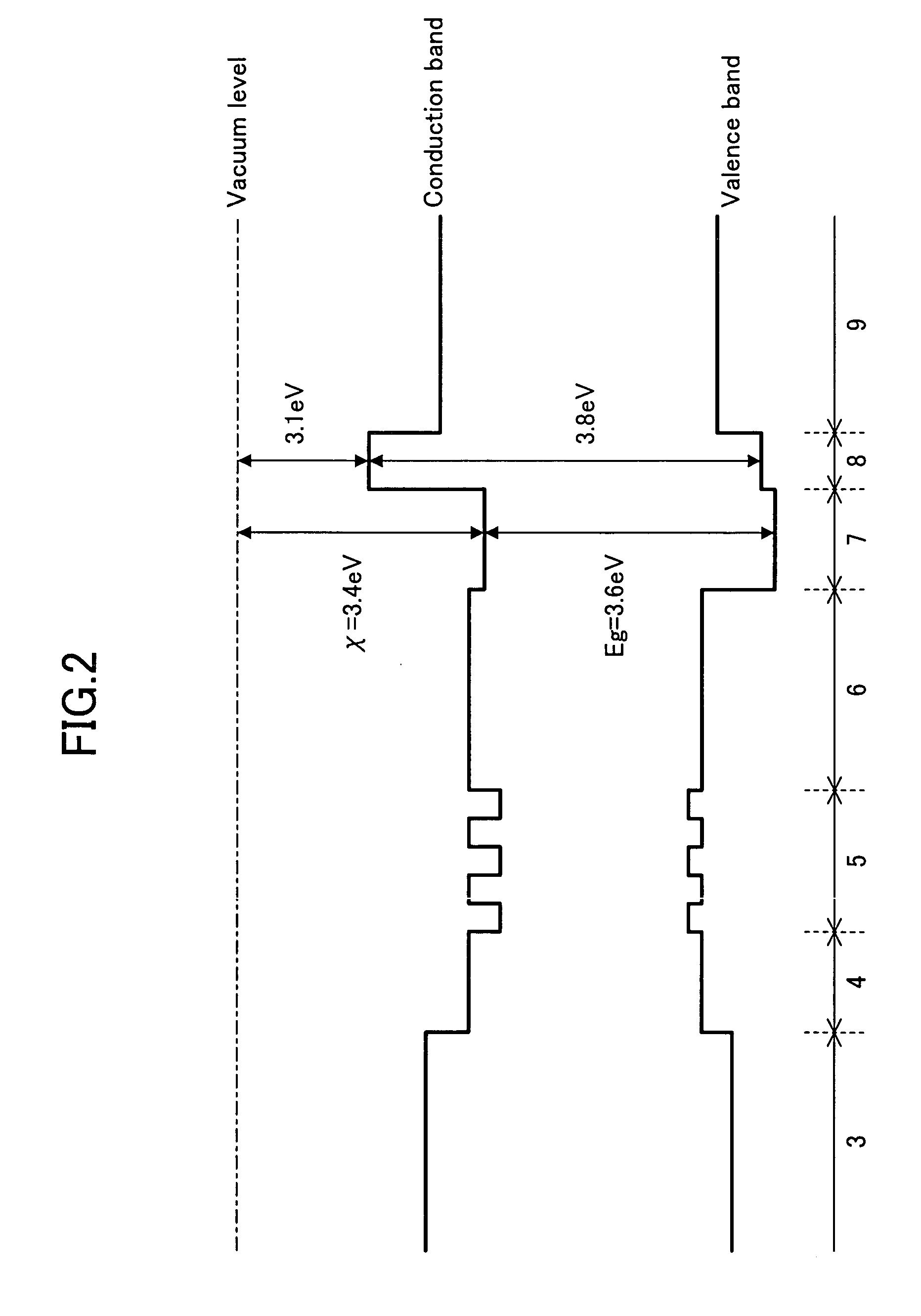

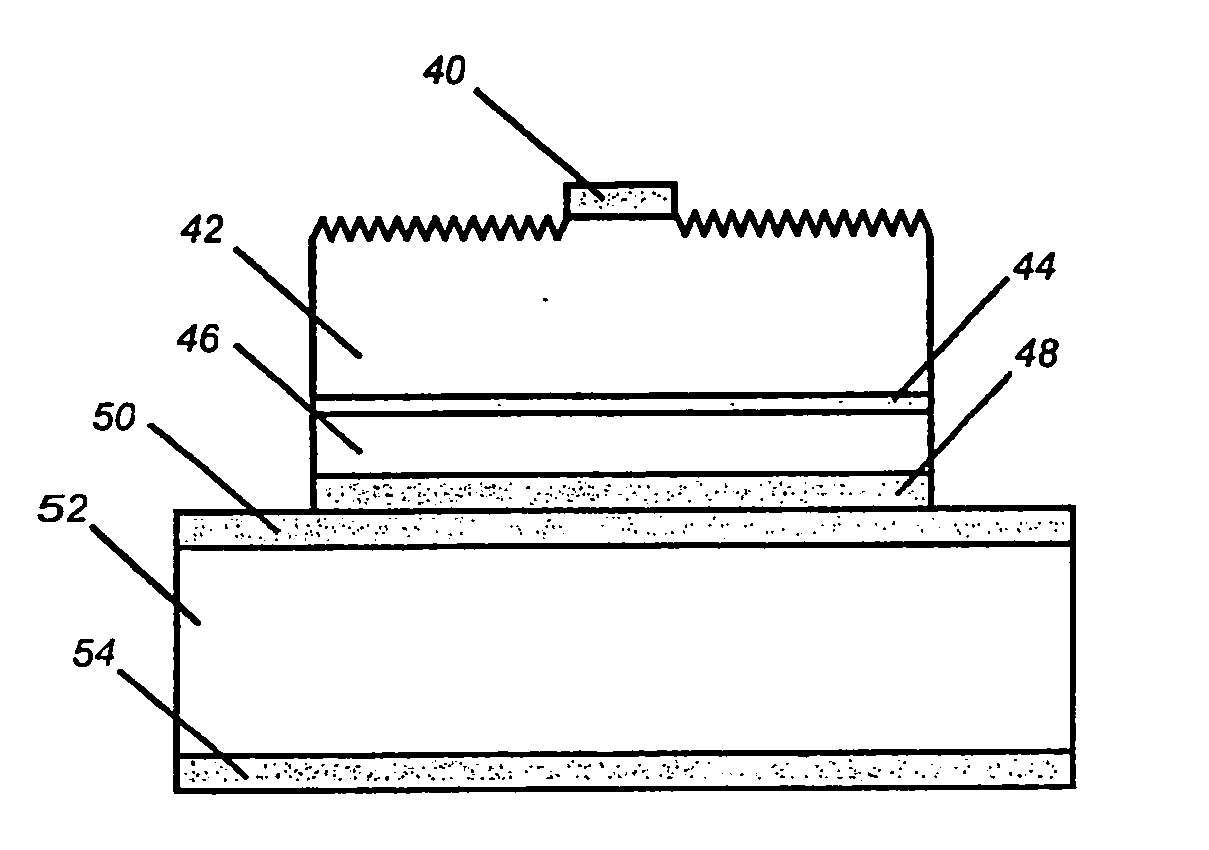

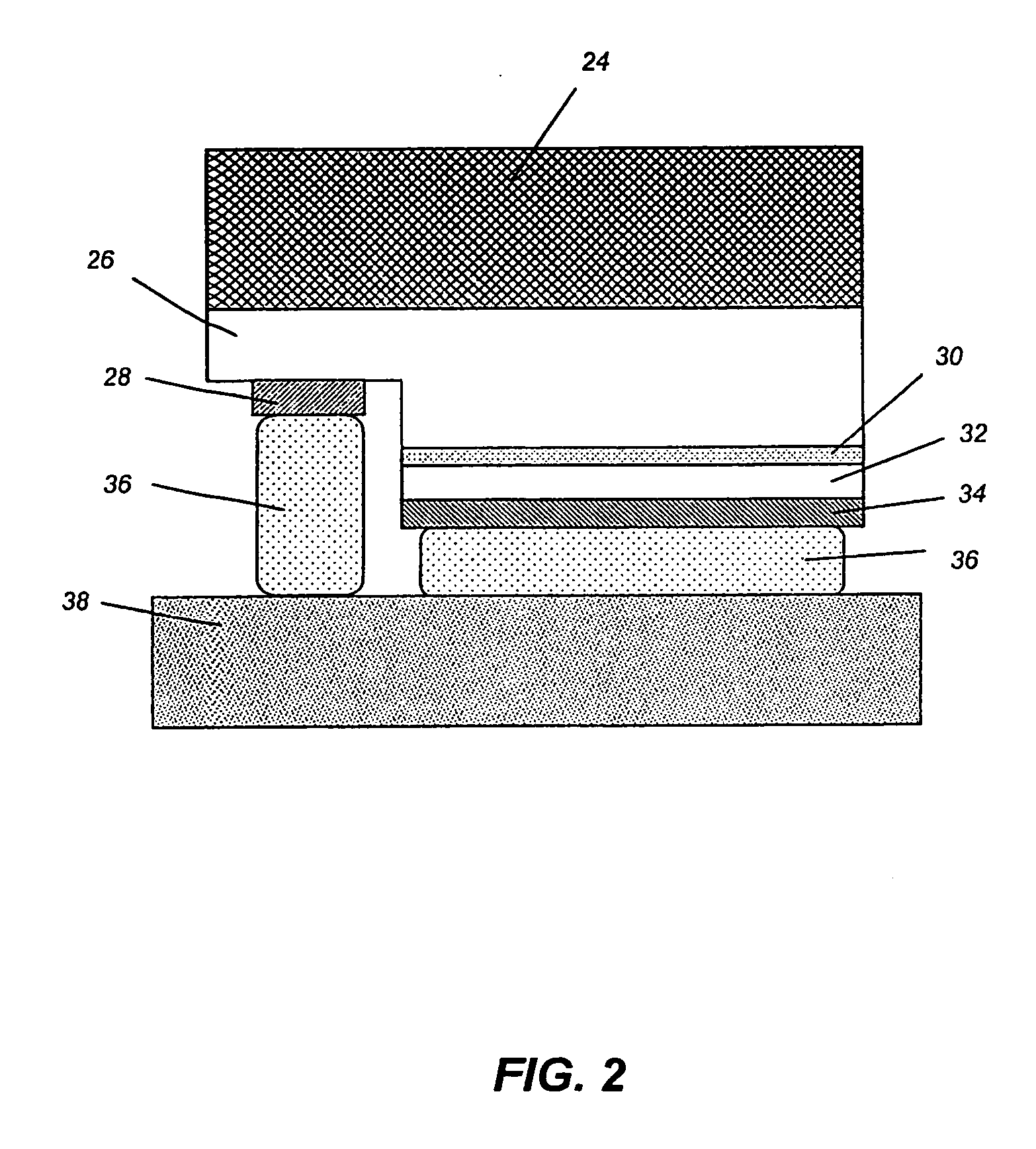

Electrically-pumped (Ga,In,Al)N vertical-cavity surface-emitting laser

InactiveUS20070280320A1Good ohmic contactOptical resonator shape and constructionSemiconductor lasersThin metalVertical-cavity surface-emitting laser

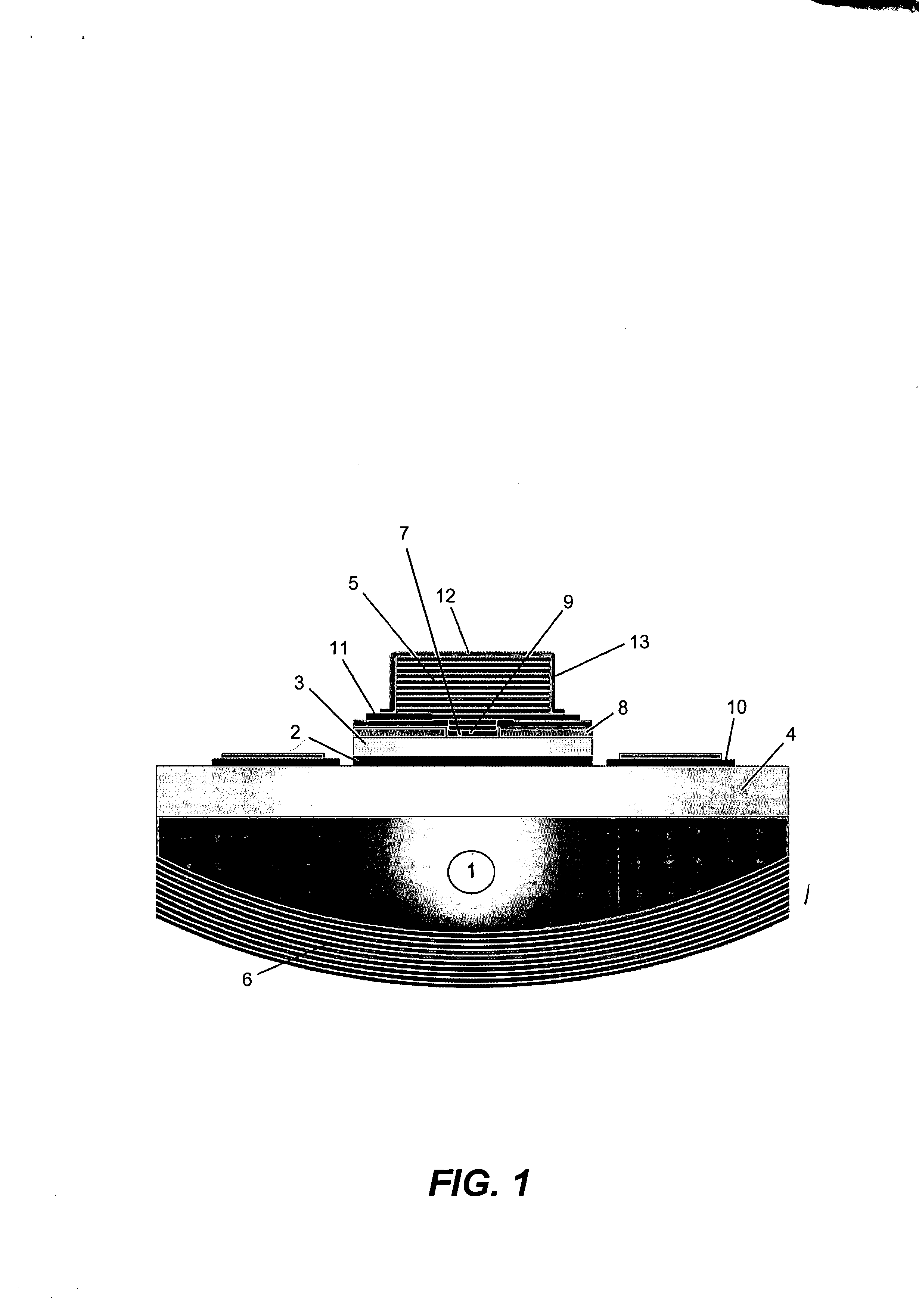

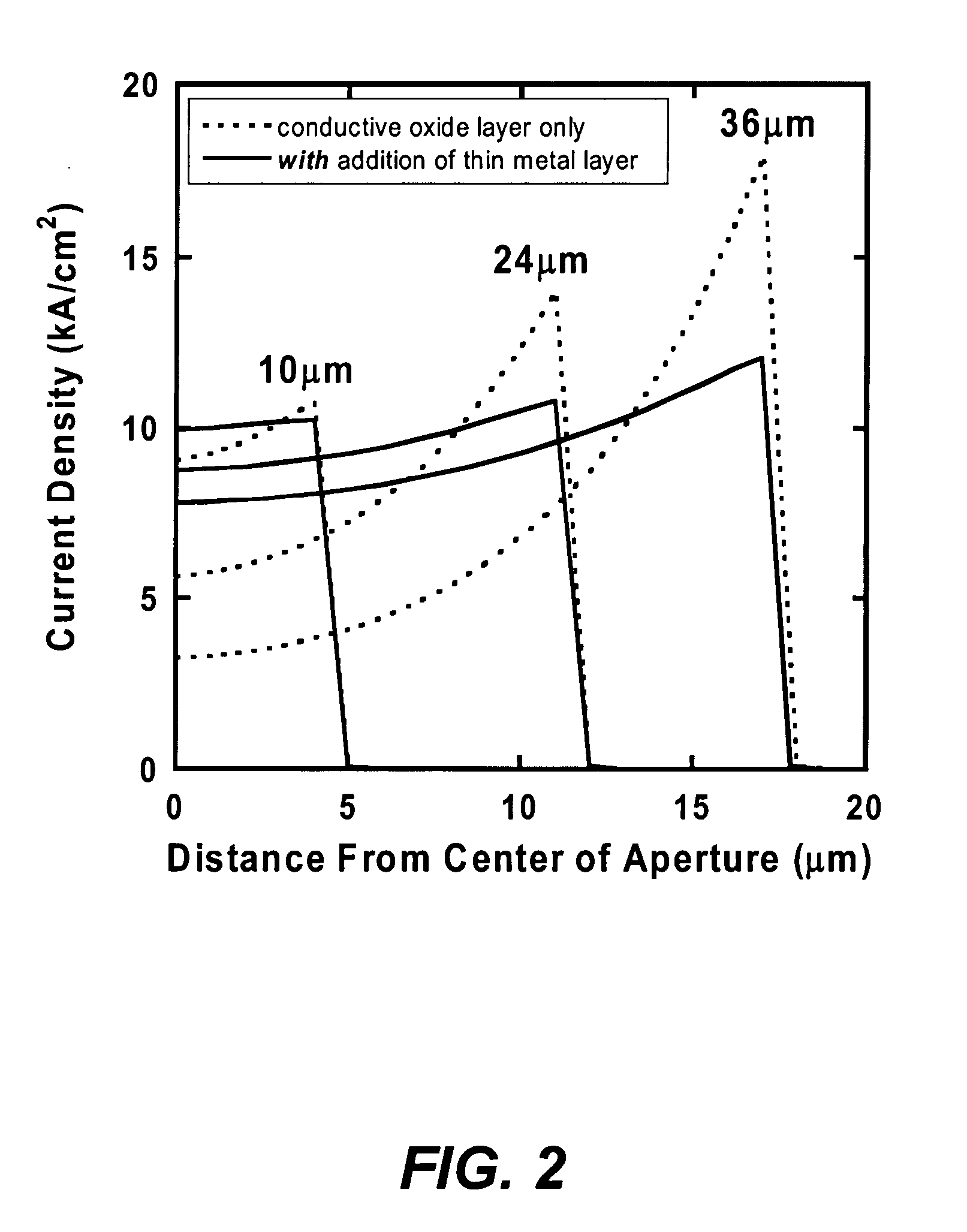

A vertical-cavity surface-emitting laser (VCSEL) comprising a low-loss thin metal contact and current spreading layer within the optical cavity that provides for improved ohmic contact and lateral current distribution, a substrate including a plano-concave optical cavity, a (Ga,In,Al)N multiple quantum well (MQW) active region contained within the optical cavity that generates light when injected by an electrical current, and an integrated micromirror fabricated onto the substrate that provides for optical mode control of the light generated by the active region. A relatively simple process is used to fabricate the VCSEL.

Owner:RGT UNIV OF CALIFORNIA

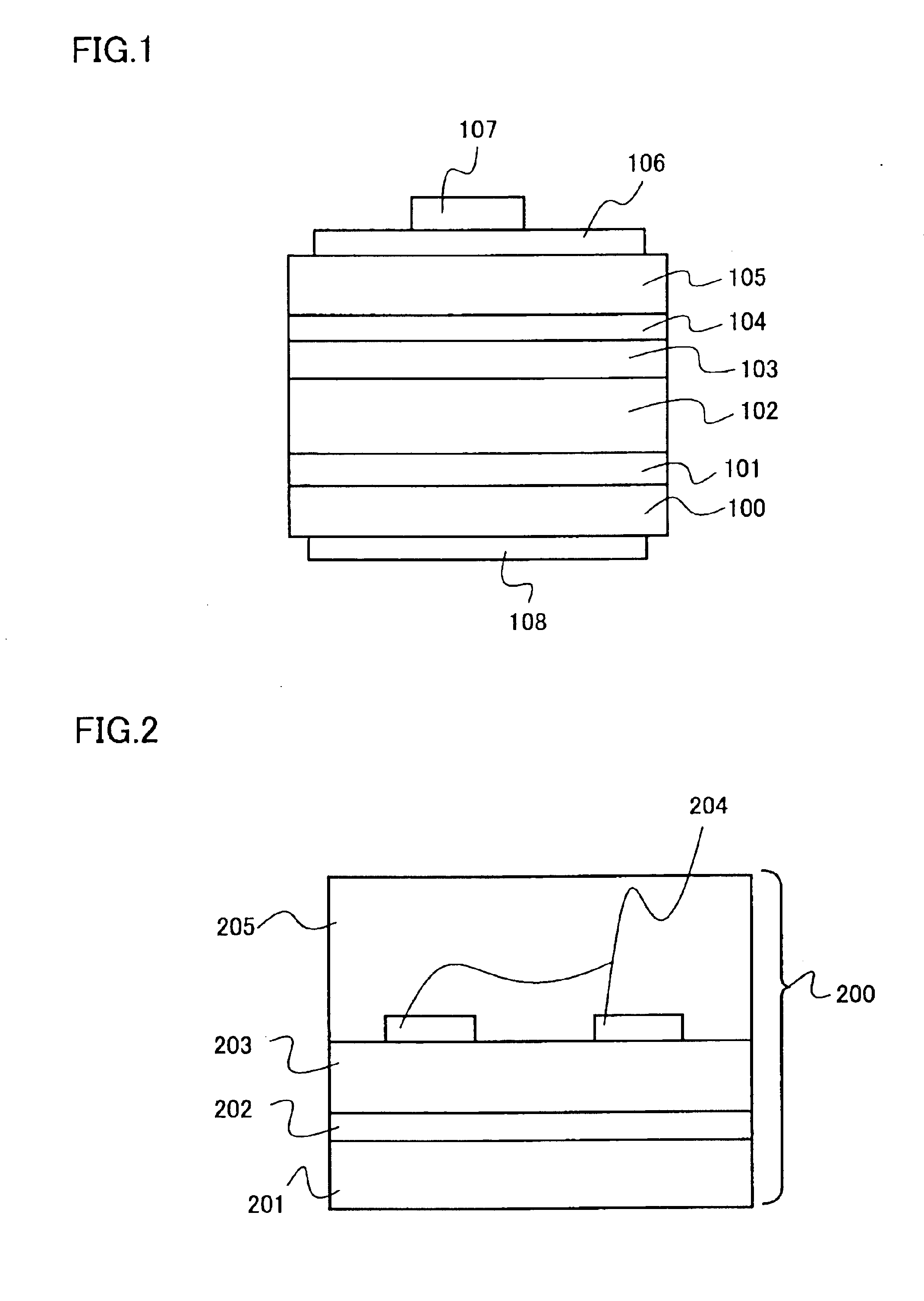

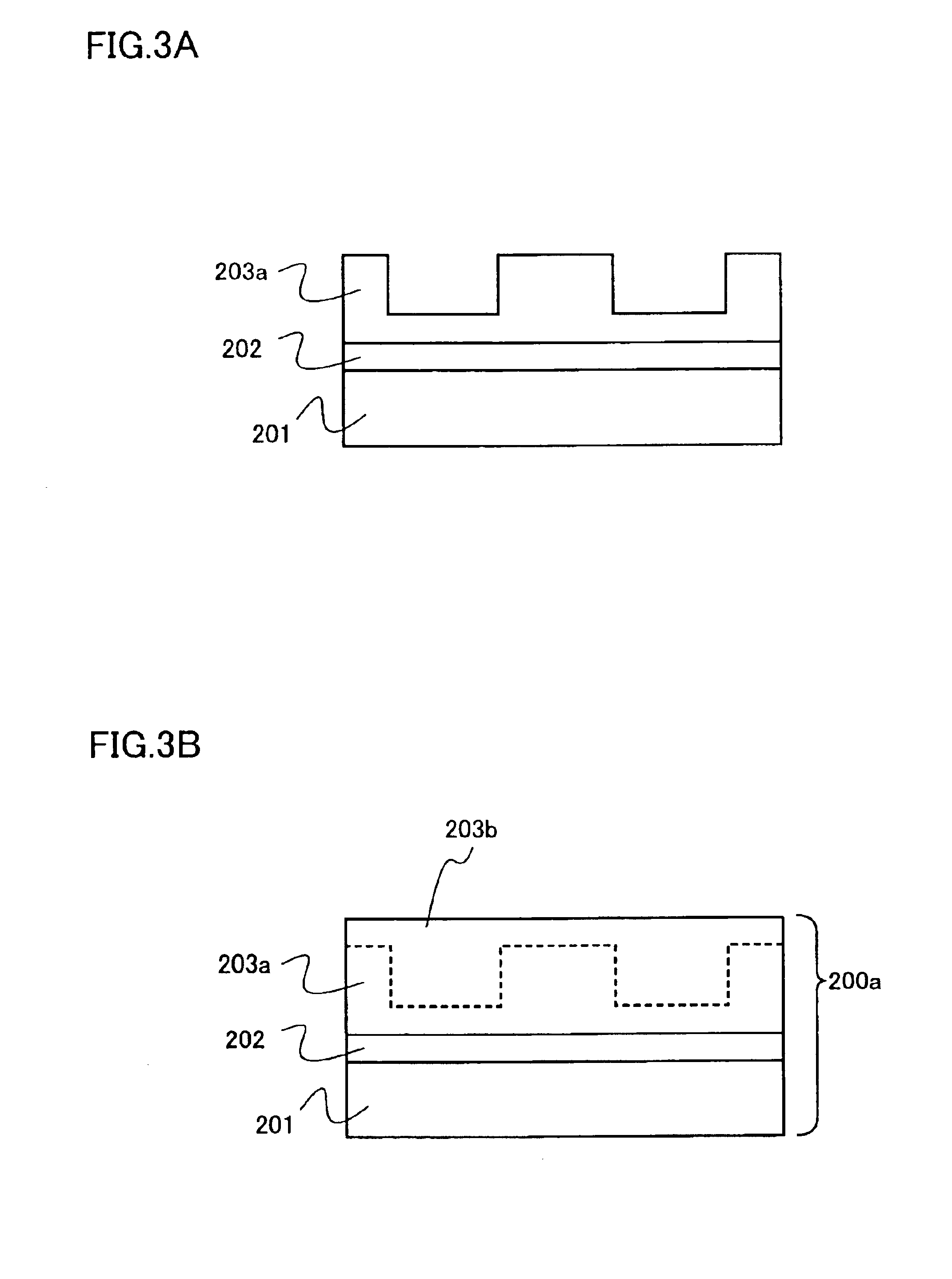

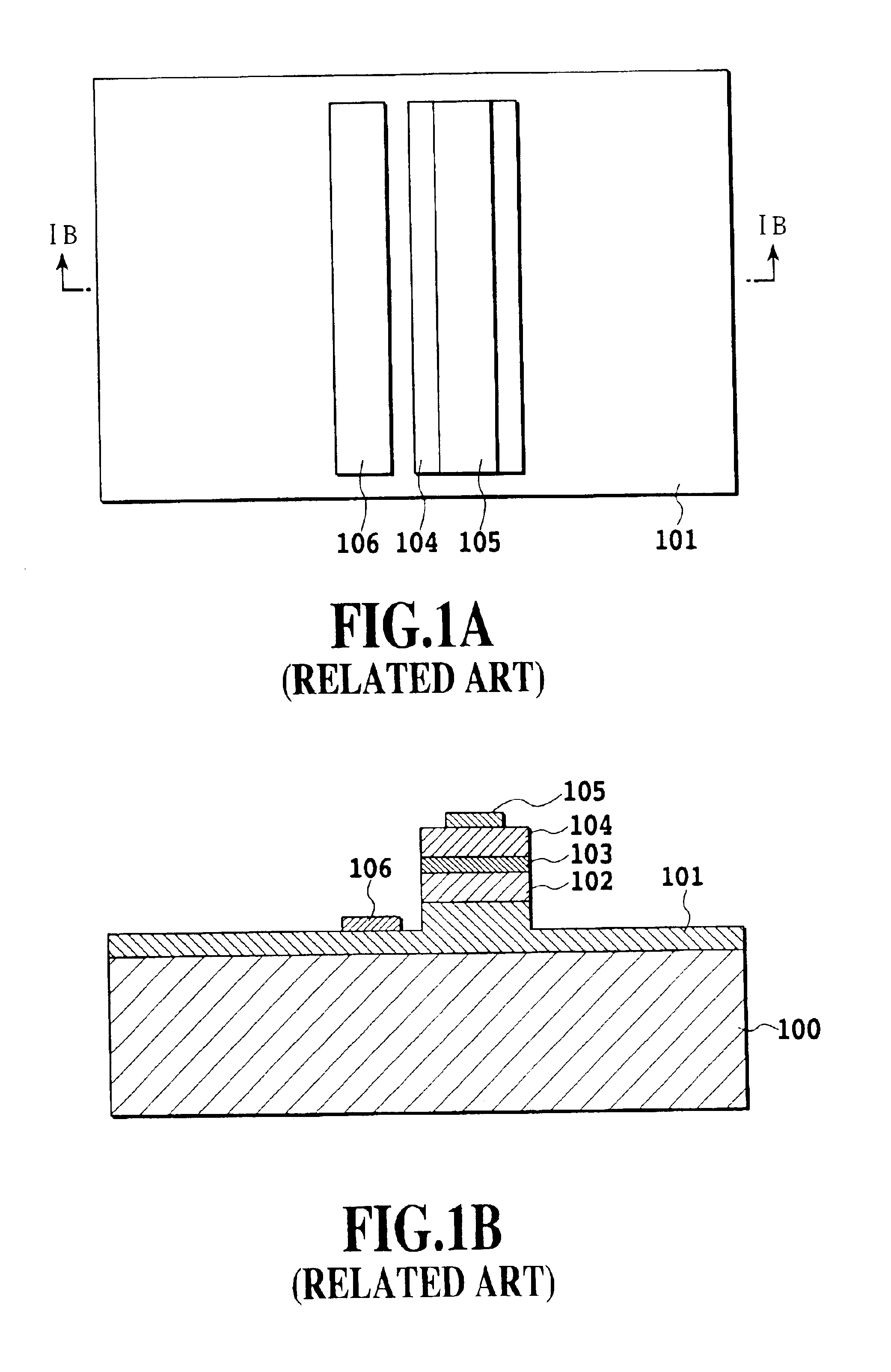

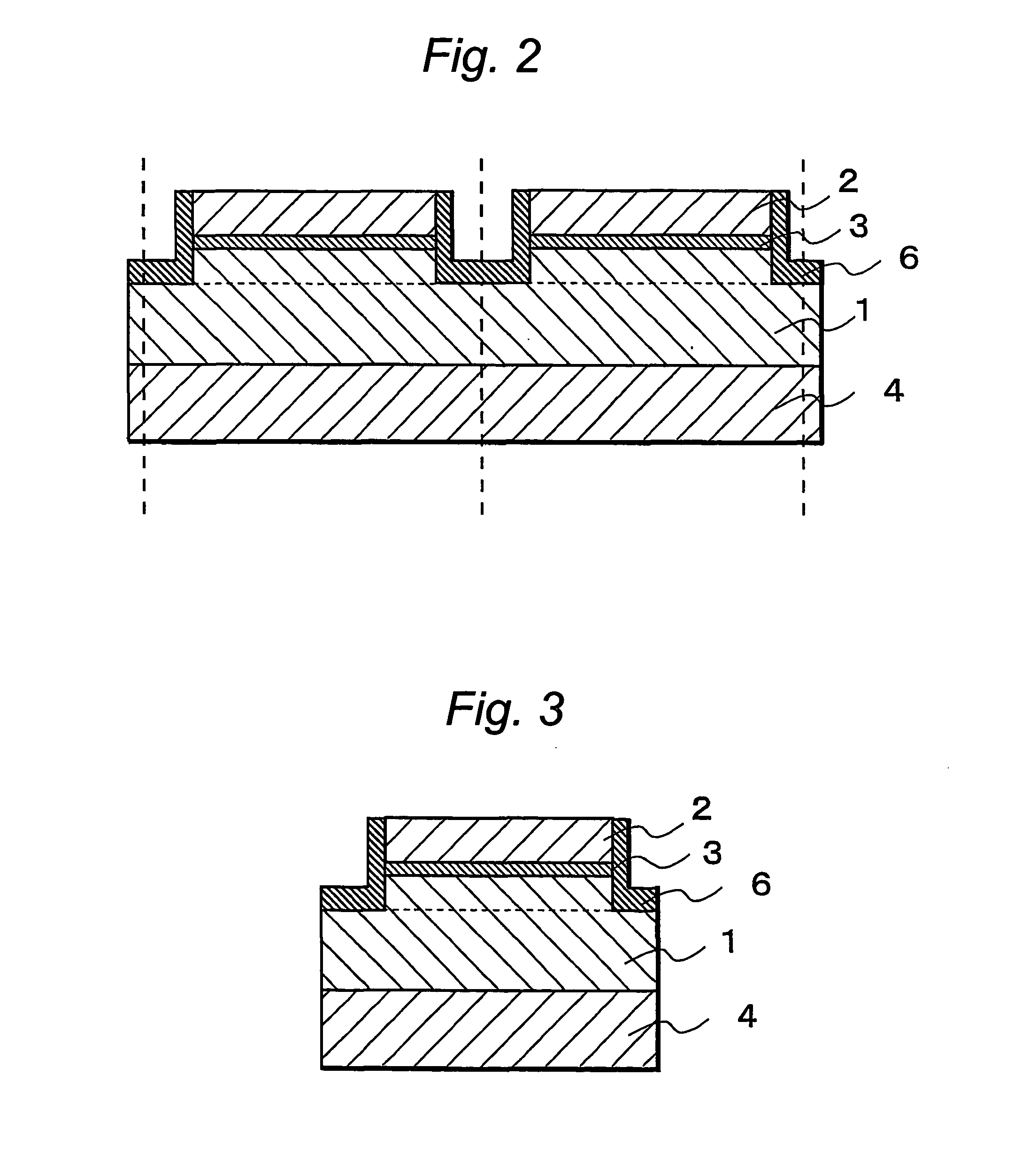

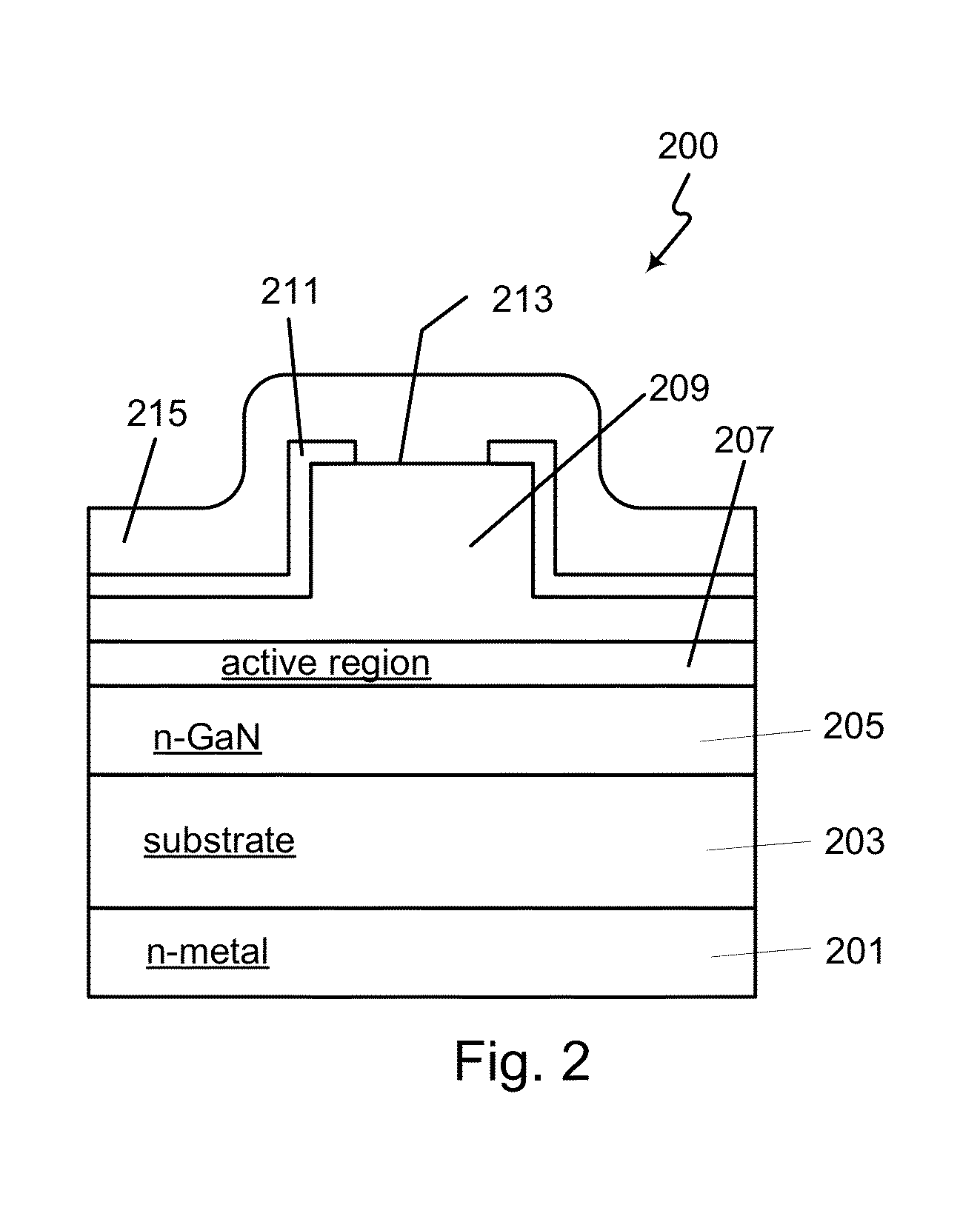

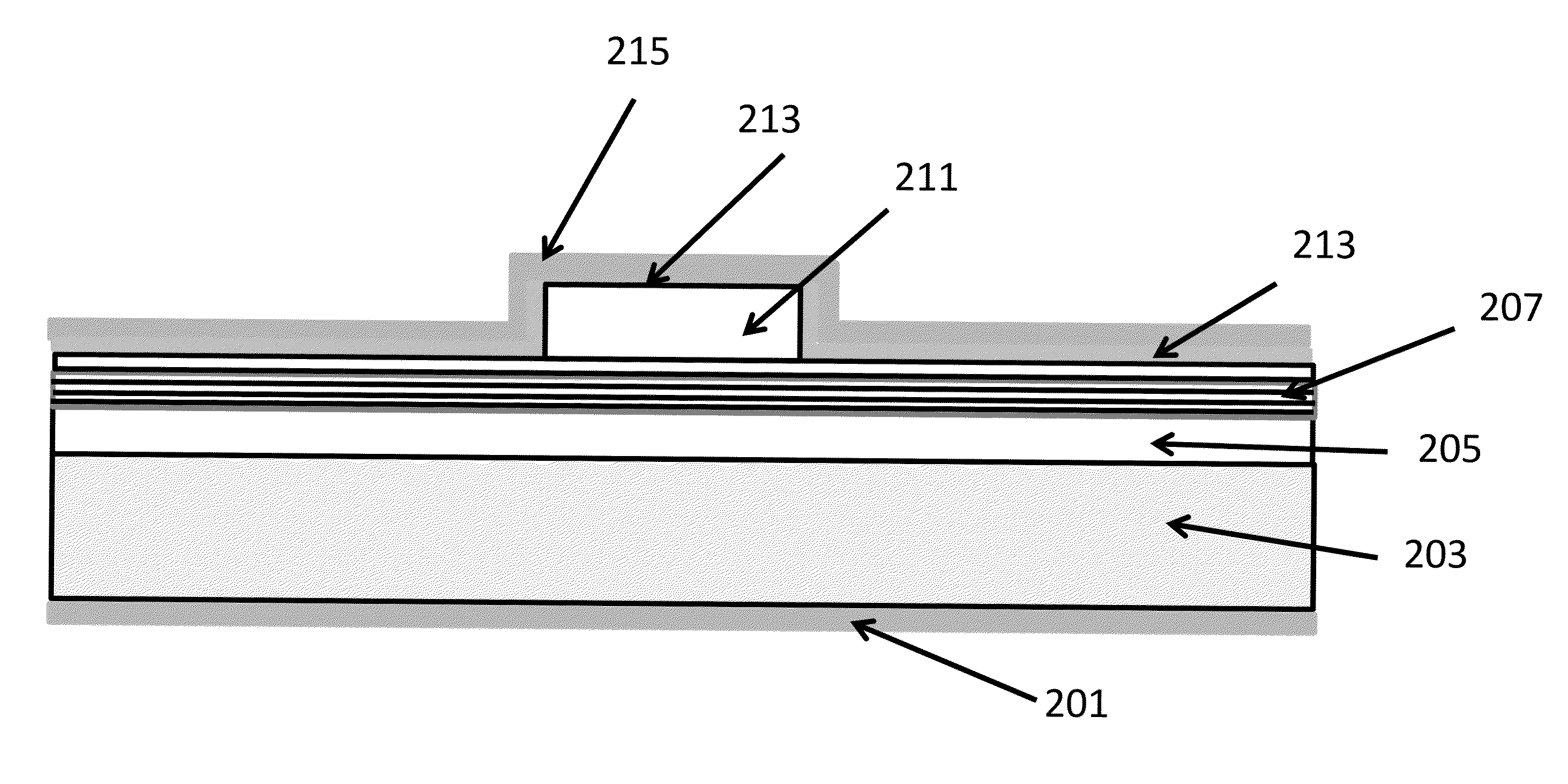

Nitride semiconductor laser device

InactiveUS20060078022A1Long lastingStable lateral modeOptical wave guidanceLaser active region structureContact layerTransverse mode

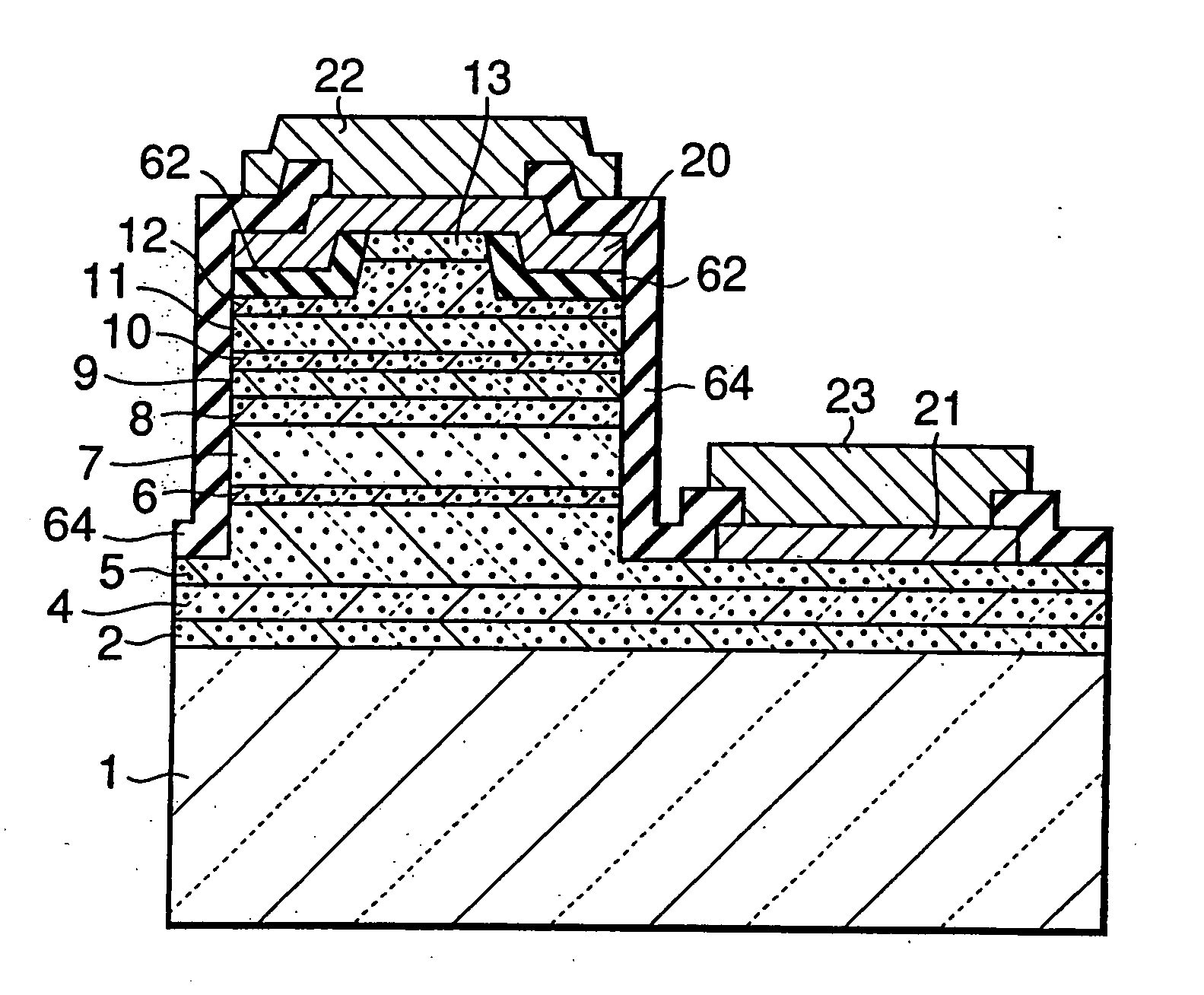

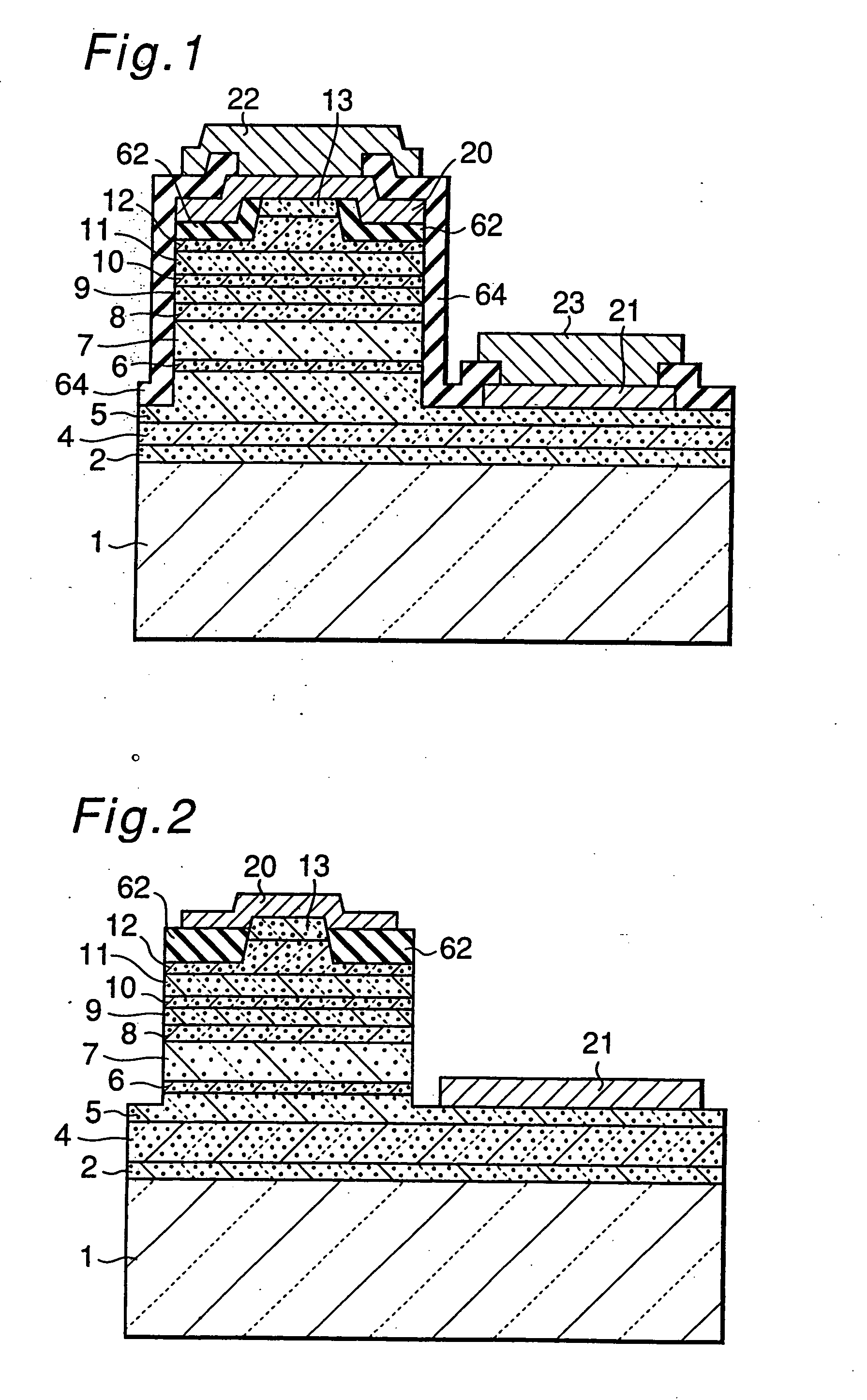

A nitride semiconductor laser device has an improved stability of the lateral mode under high output power and a longer lifetime, so that the device can be applied to write and read light sources for recording media with high capacity. The nitride semiconductor laser device includes an active layer, a p-side cladding layer, and a p-side contact layer laminated in turn. The device further includes a waveguide region of a stripe structure formed by etching from the p-side contact layer. The stripe width provided by etching is within the stripe range of 1 to 3 μm and the etching depth is below the thickness of the p-side cladding layer of 0.1 μm and above the active layer. Particularly, when a p-side optical waveguide layer includes a projection part of the stripe structure and a p-type nitride semiconductor layer on the projection part and the projection part of the p-side optical waveguide layer has a thickness of not more than 1 μm, an aspect ratio is improved in far field image. Moreover, the thickness of the p-side optical waveguide layer is greater than that of an n-side optical waveguide layer.

Owner:NICHIA CORP

Group III nitride semiconductor light emitting device

InactiveUS20070110112A1Increase fixed chargeEasy to overflowOptical wave guidanceSolid-state devicesElectron blocking layerActive layer

A group III nitride semiconductor light emitting device according to the present invention includes an immediate layer formed of AlxGa1-x-yInyN (0<x<1, 0<y<1, x+y<1) between an active layer and a cladding layer and an electron blocking layer formed of p-type group III nitride semiconductor having a smaller electron affinity than that of the intermediate layer so as to be in contact with the intermediate layer. The semiconductor light emitting layer may be a laser diode or a LED.

Owner:PANASONIC CORP

Nitride semiconductor light-emitting device and optical device including the same

InactiveUS6858882B2Solid-state devicesSemiconductor/solid-state device manufacturingQuantum wellLight emitting device

A nitride semiconductor light-emitting device includes an emission layer (103) formed on a substrate (100), and the emission layer includes a quantum well layer of GaN1-x−y−zAsxPySbz (0<x+y+z≦0.3) containing Al.

Owner:SHARP KK

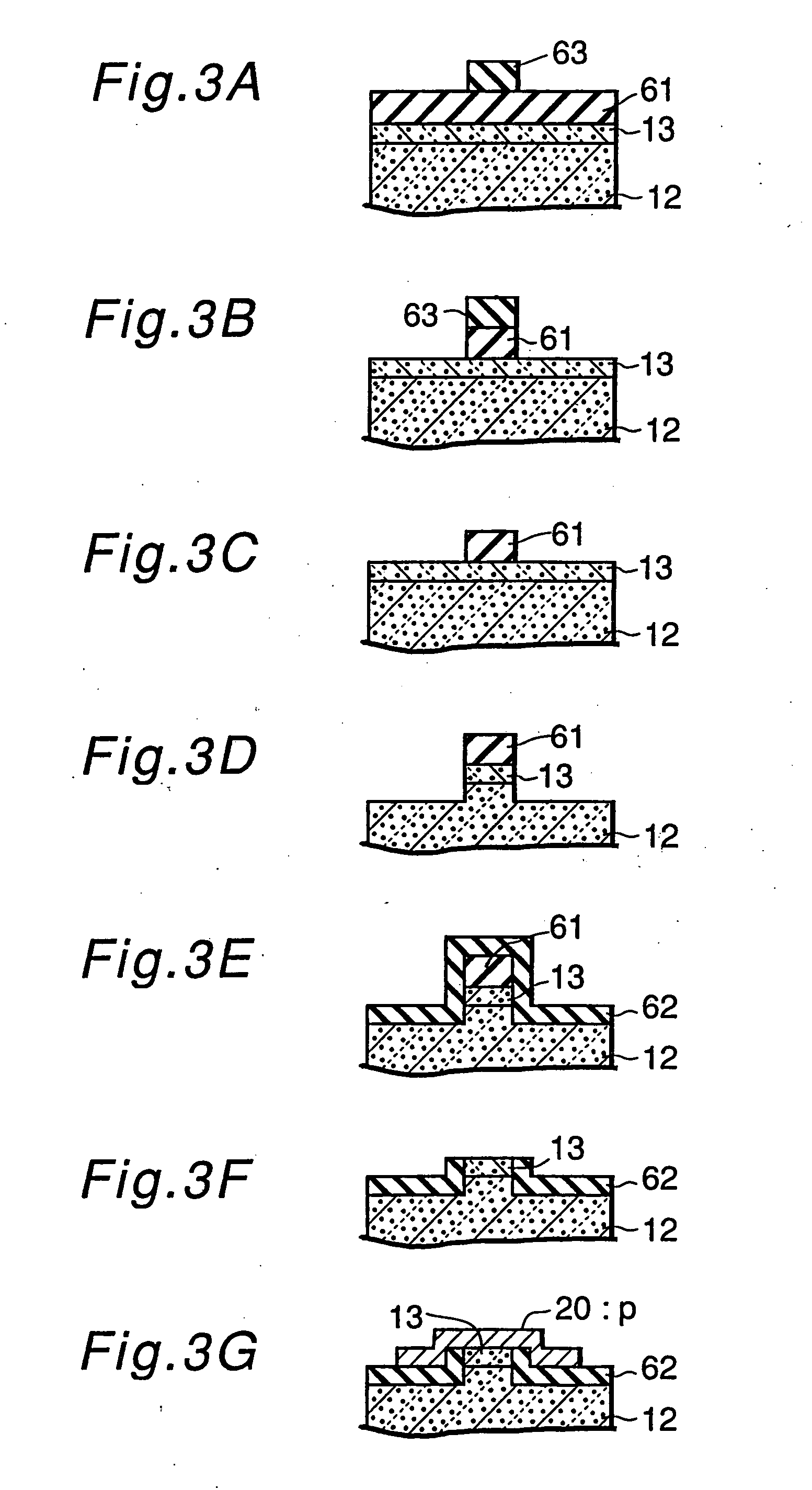

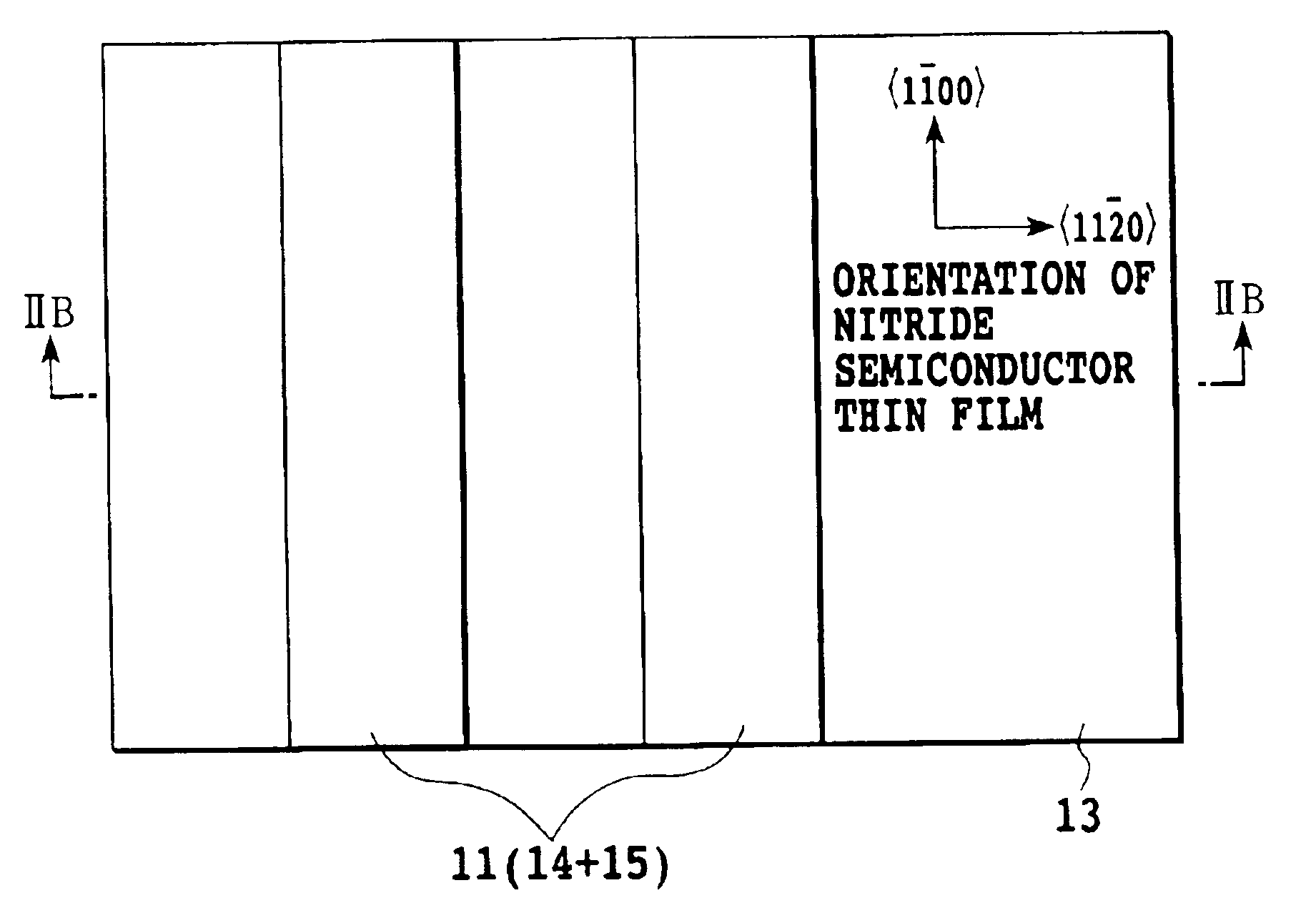

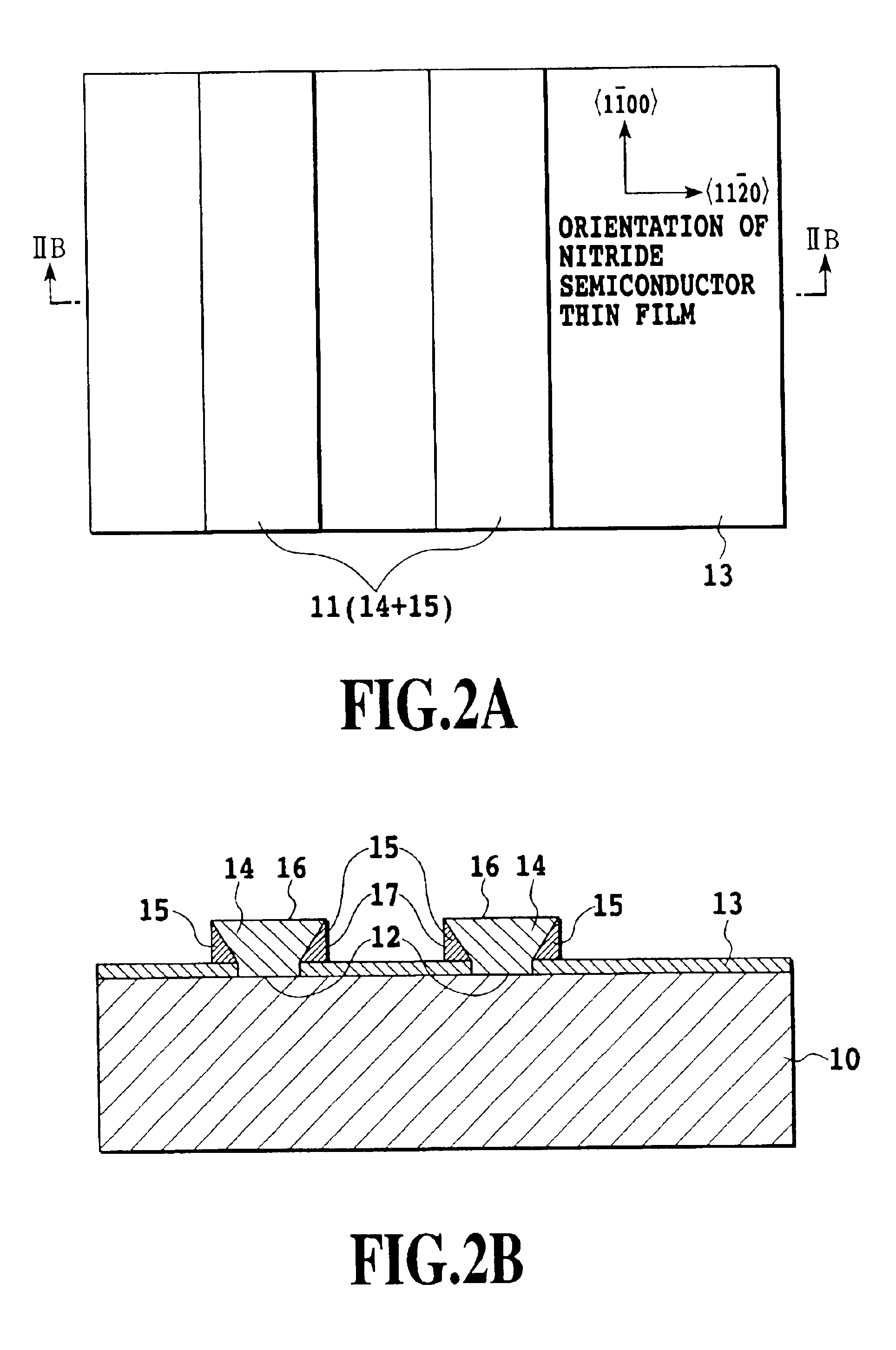

Thin film deposition method of nitride semiconductor and nitride semiconductor light emitting device

InactiveUS6920166B2Reduce adverse effectsSuppress loss of internal quantum efficiencyOptical wave guidanceSemiconductor/solid-state device manufacturingLight emitting deviceNitride semiconductors

A masking material 13, which includes stripe-like openings 12 parallel to the [1-100] direction of a nitride semiconductor thin film, is formed on a substrate. Nitride semiconductor thin films 11 doped with Mg are grown on the openings 12 by selective-area growth. The nitride semiconductor thin films 11 are composed of a portion 14 formed as a result of the growth in the direction perpendicular to a (0001) principal plane, and a portion 15 formed as a result of the growth of {11-2x} facets (x=0, 1, 2). The Mg concentration of the portion 15 is made lower than that of the portion 14.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

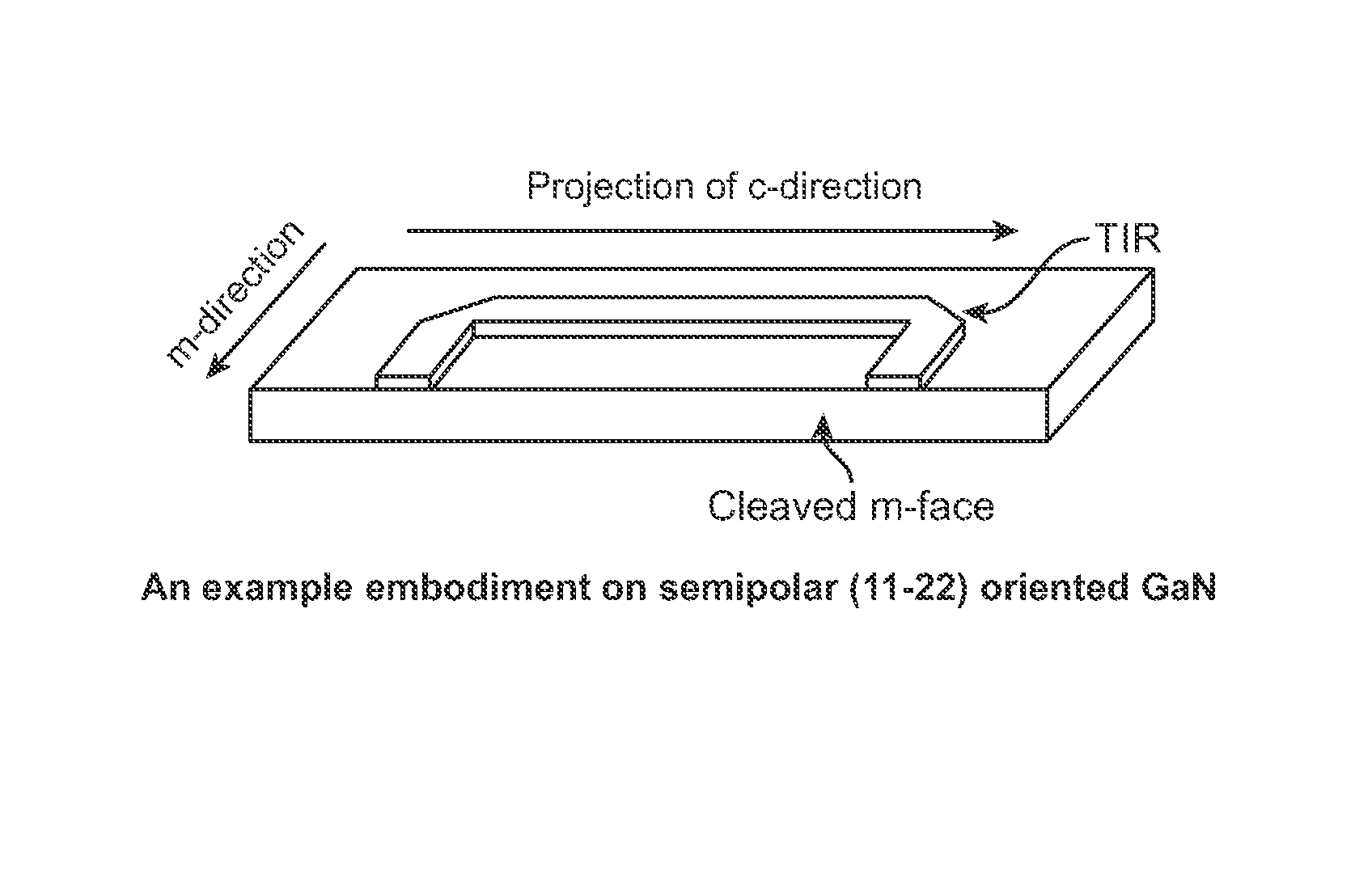

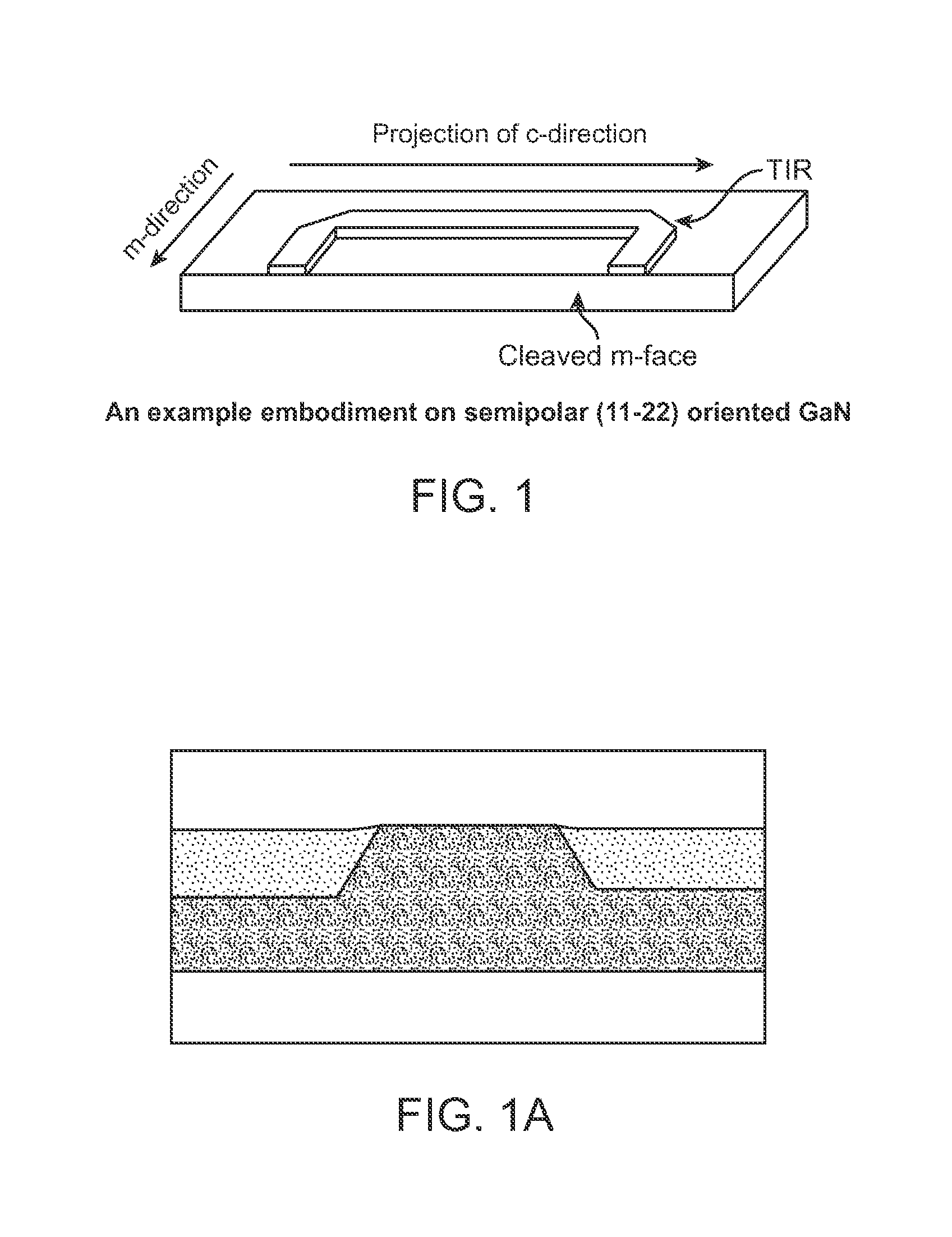

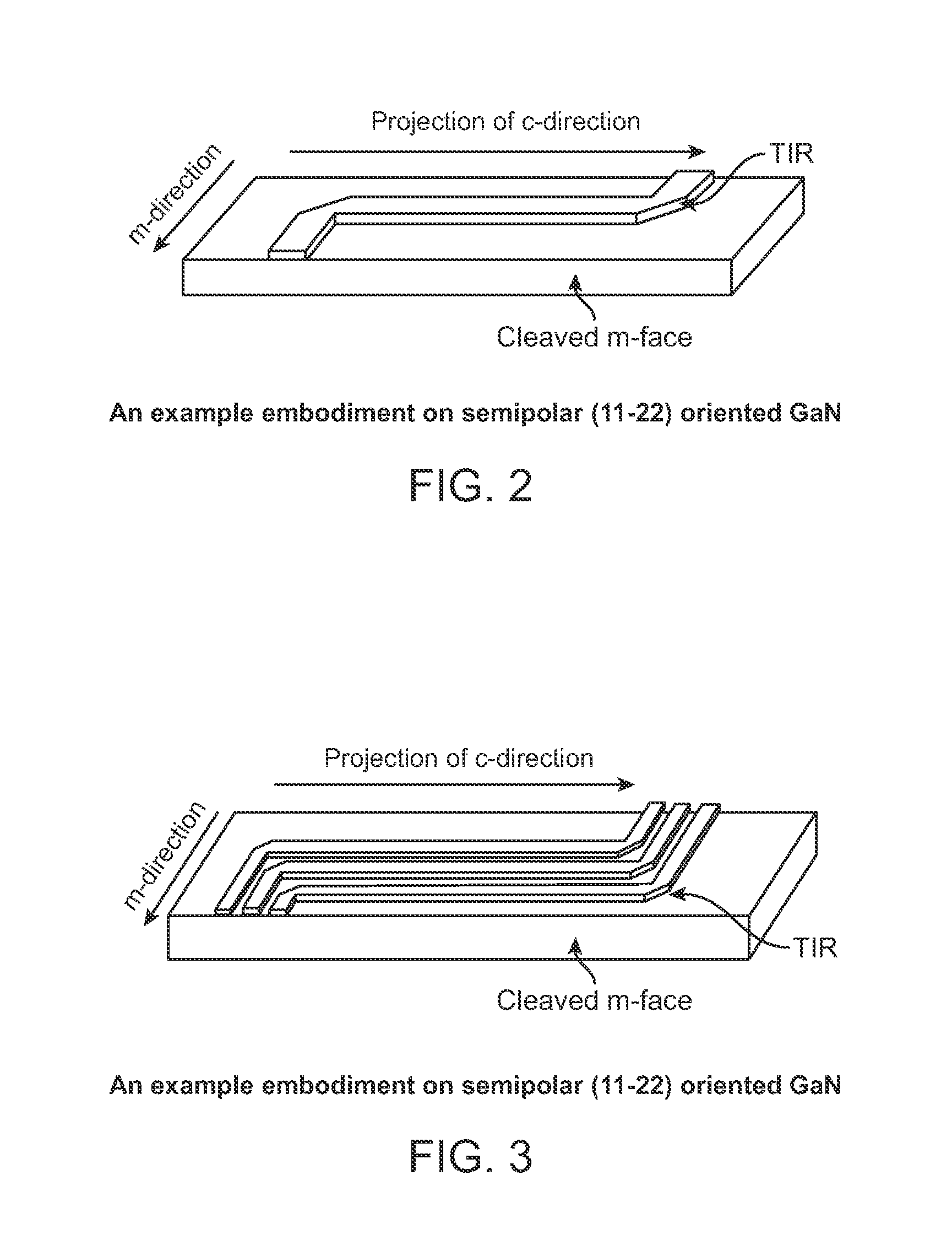

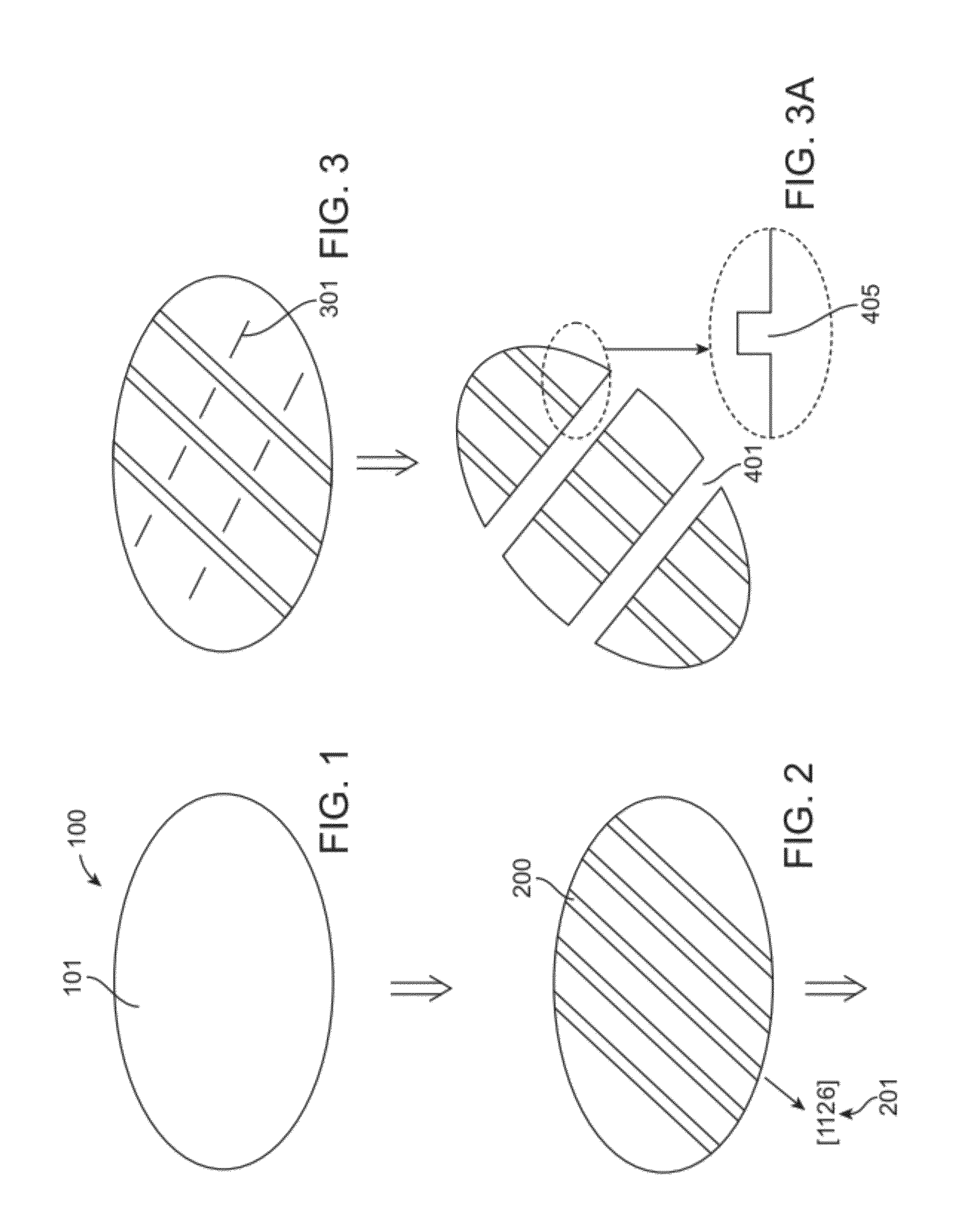

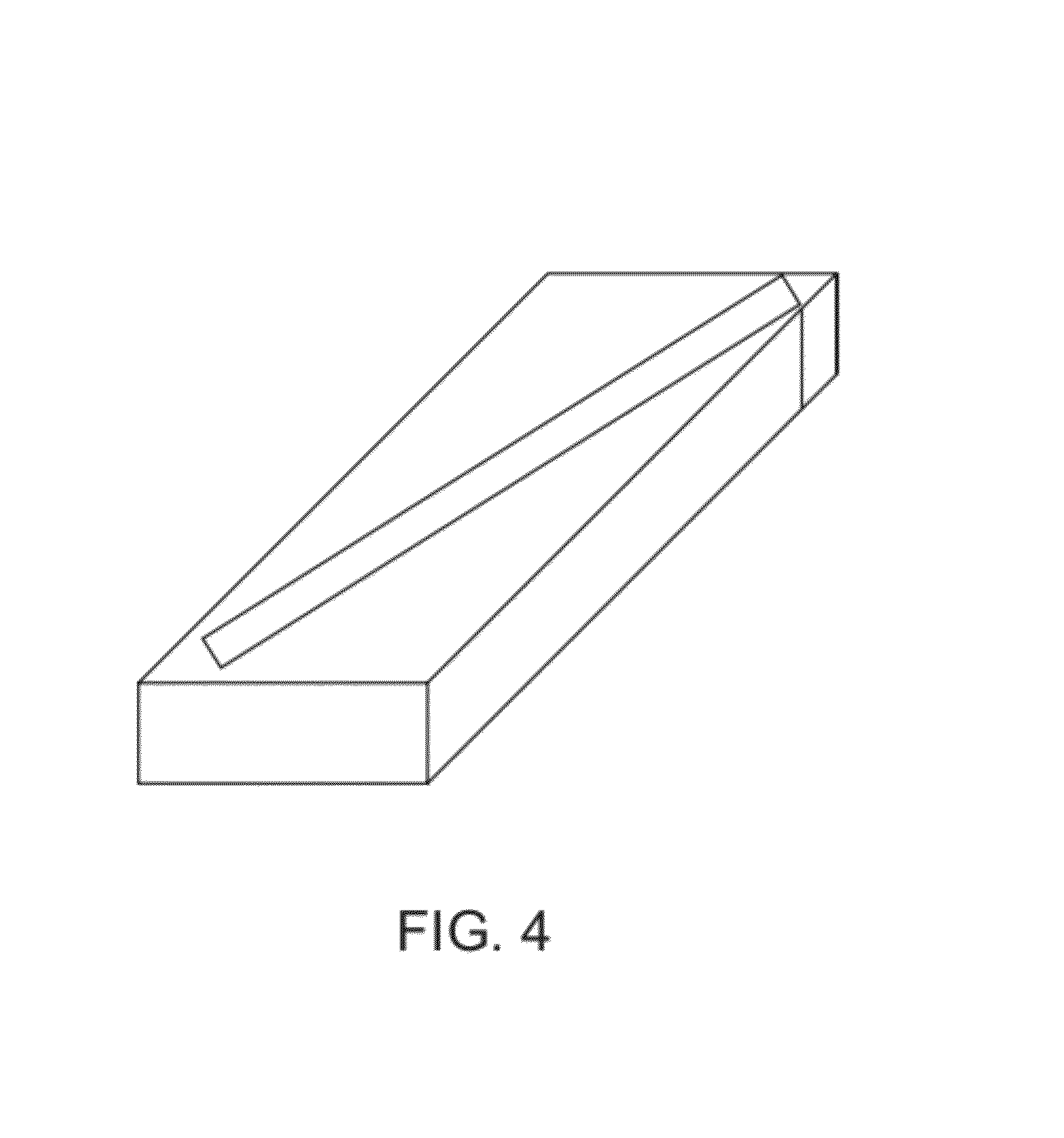

Integrated total internal reflectors for high-gain laser diodes with high quality cleaved facets on nonpolar/semipolar GaN substrates

ActiveUS8259769B1High yieldWell formedOptical wave guidanceOptical resonator shape and constructionTotal internal reflectionCrystal plane

A laser diode device operable at a one or more wavelength ranges. The device has a first waveguide provided on a non-polar or semipolar crystal plane of gallium containing material. In a specific embodiment, the first waveguide has a first gain characteristic and a first direction. In a specific embodiment, the first waveguide has a first end and a second end and a first length defined between the first end and the second end. The device has a second waveguide provided on a non-polar or semipolar crystal plane of gallium containing material. In a specific embodiment, the second waveguide has a second gain characteristic and a second direction. In a specific embodiment, the second waveguide has a first end, a second end, and a second length defined between the first end and the second end. In a specific embodiment, the second waveguide has the first end being coupled to the first end of the first waveguide. The second length is in a different direction from the second length. In a specific embodiment, the device has a cleaved region provided on the second end of the second waveguide, the cleaved region being perpendicular to the second direction of the second waveguide.

Owner:KAAI +1

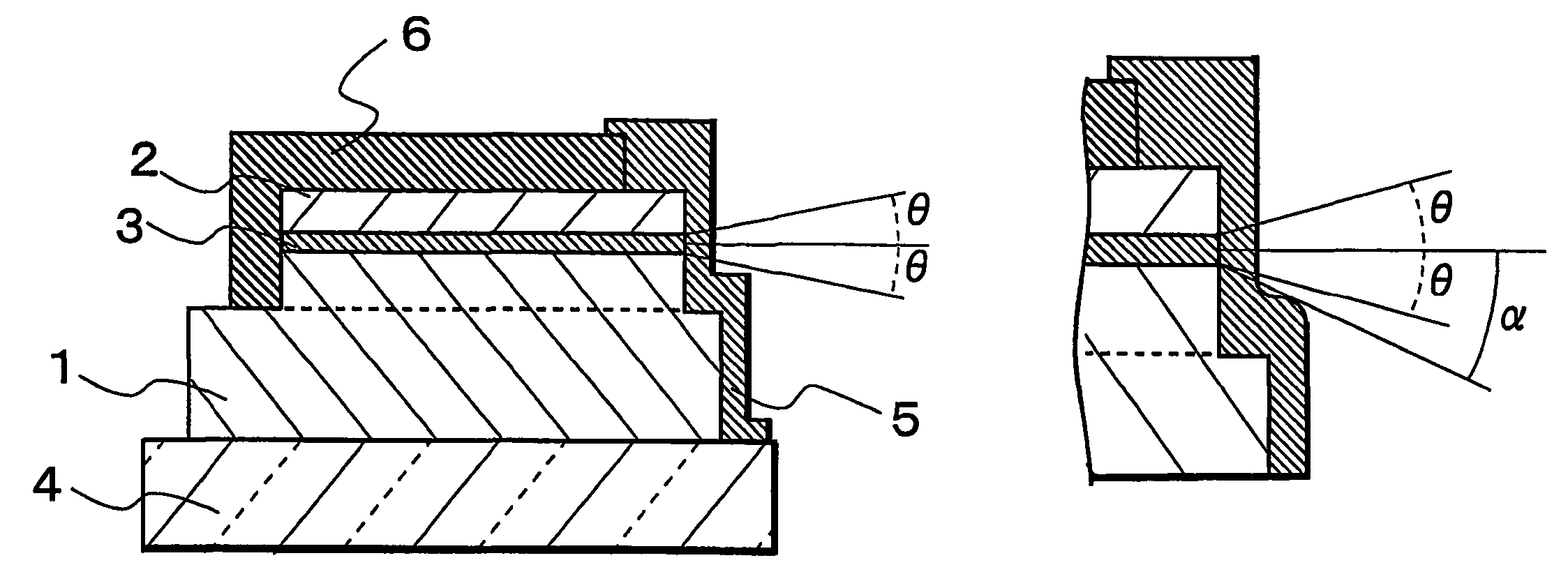

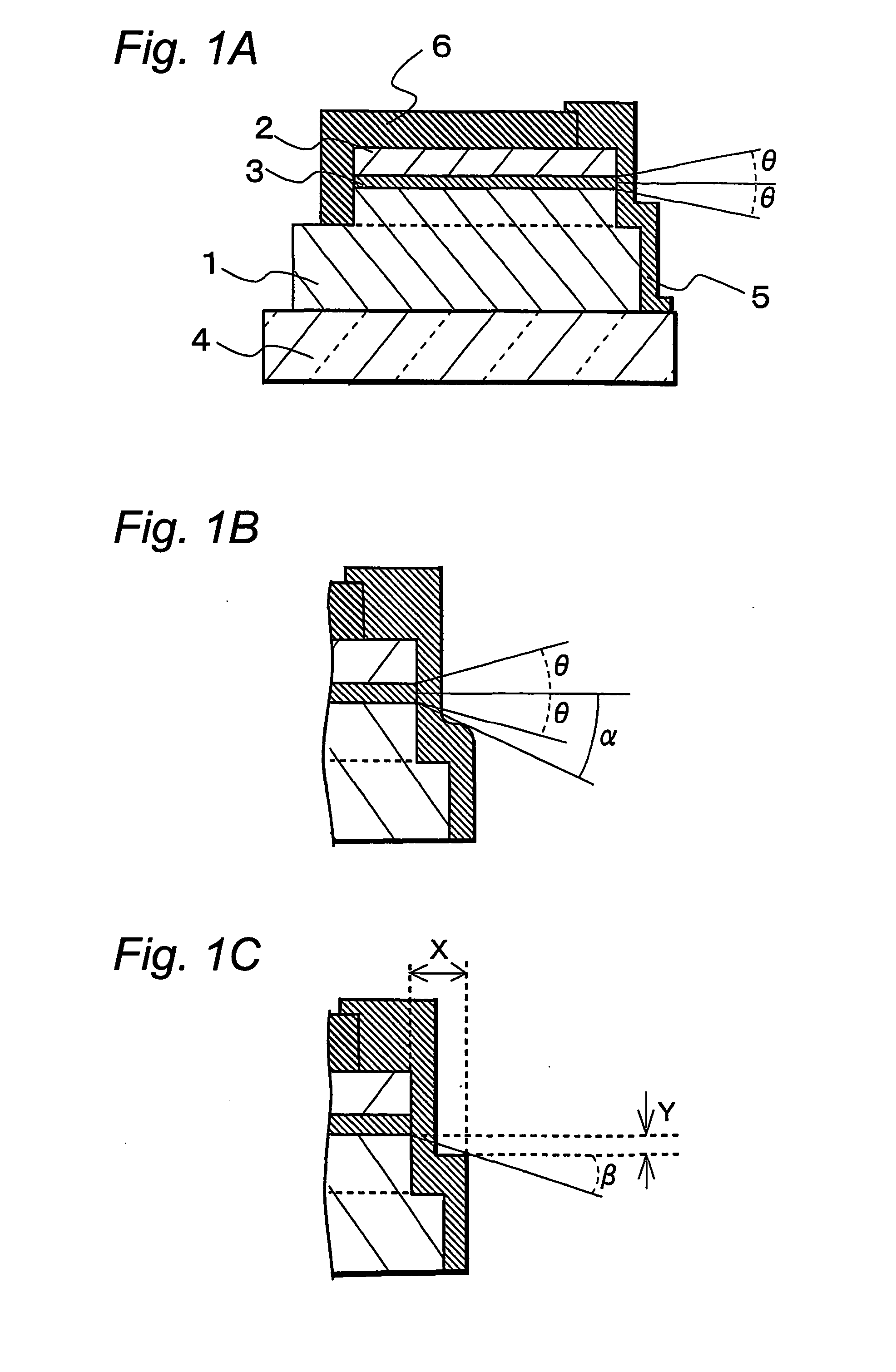

Semicondutor laser device and its manufacturing method

InactiveUS20040233950A1Efficient executionLaser optical resonator constructionSemiconductor laser structural detailsTectorial membraneSemiconductor package

A semiconductor laser device have, on a substrate, a semiconductor layer including an active layer sandwiched between an n-type layer and a p-type layer, the semiconductor layer having a sonator face formed by etching and a projection projecting out in an emission direction relatively to the resonator face, wherein a protective film is formed to extend from the resonator face to an end face of the projection, and, an emission critical angle, which is the largest angle at which light emitted from the resonator face can be radiated without being blocked by the projection and the protective film formed on the projection, is larger than an emission half-angle of an emission distribution in a vertical direction of a laser beam emitted from the resonator face.

Owner:NICHIA CORP

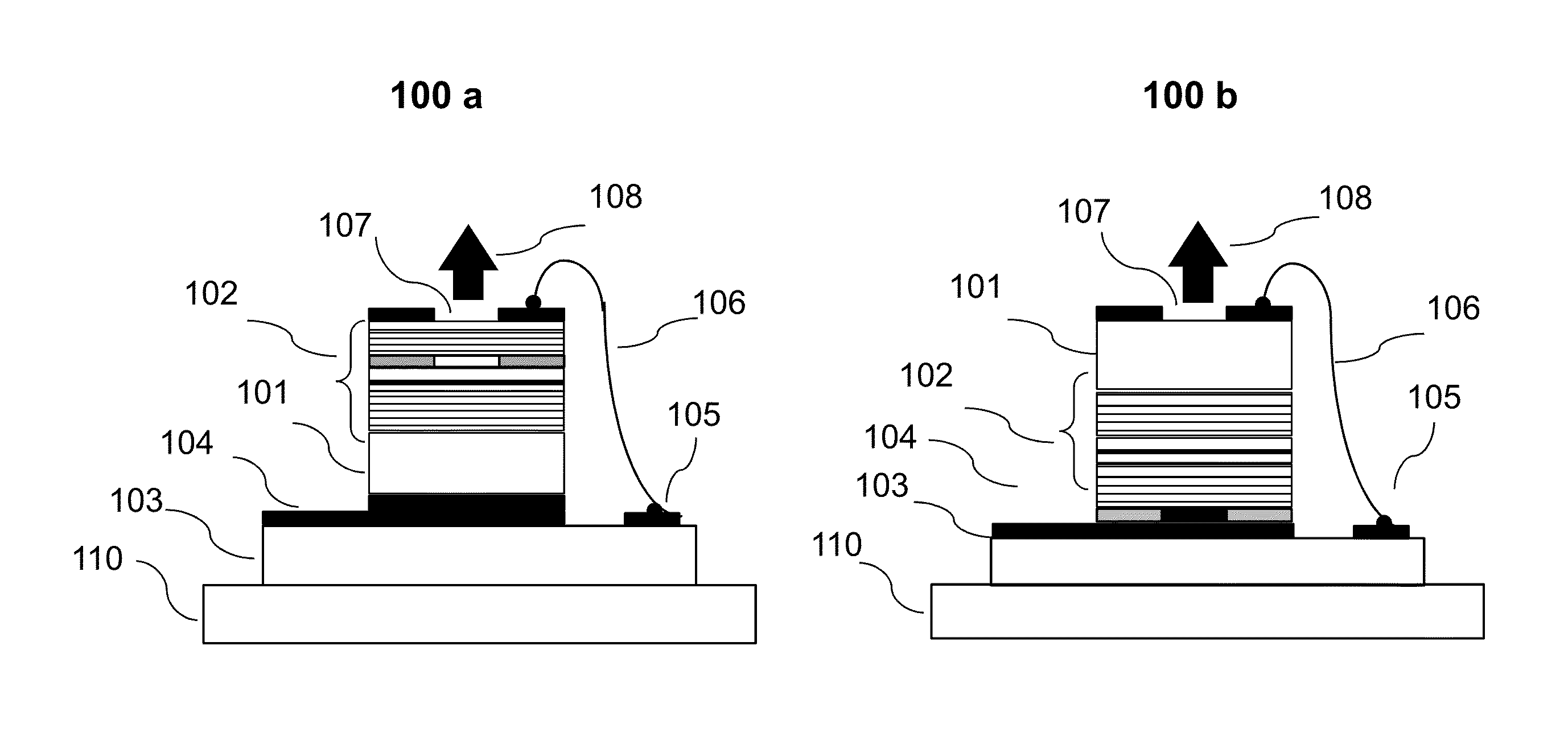

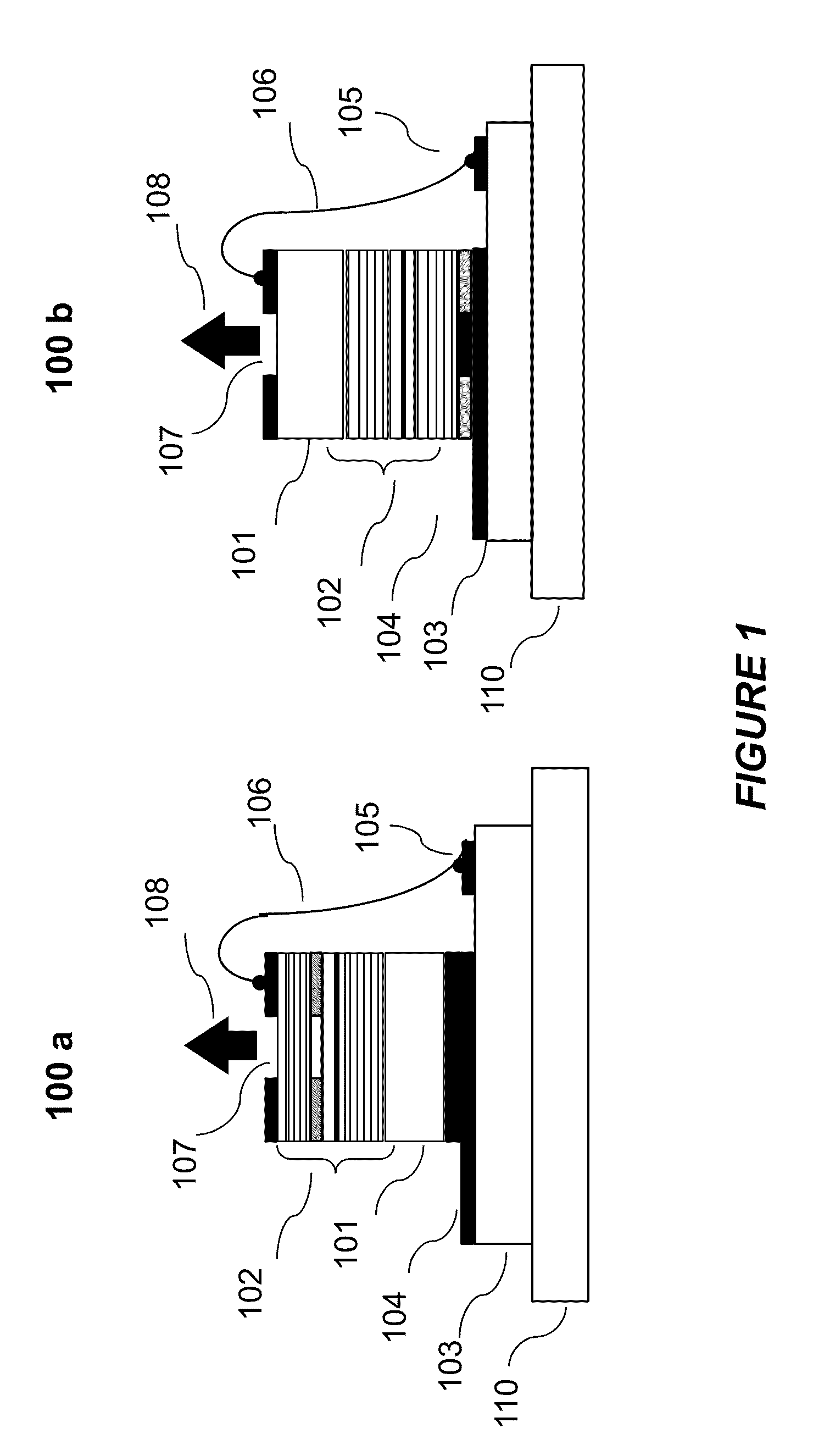

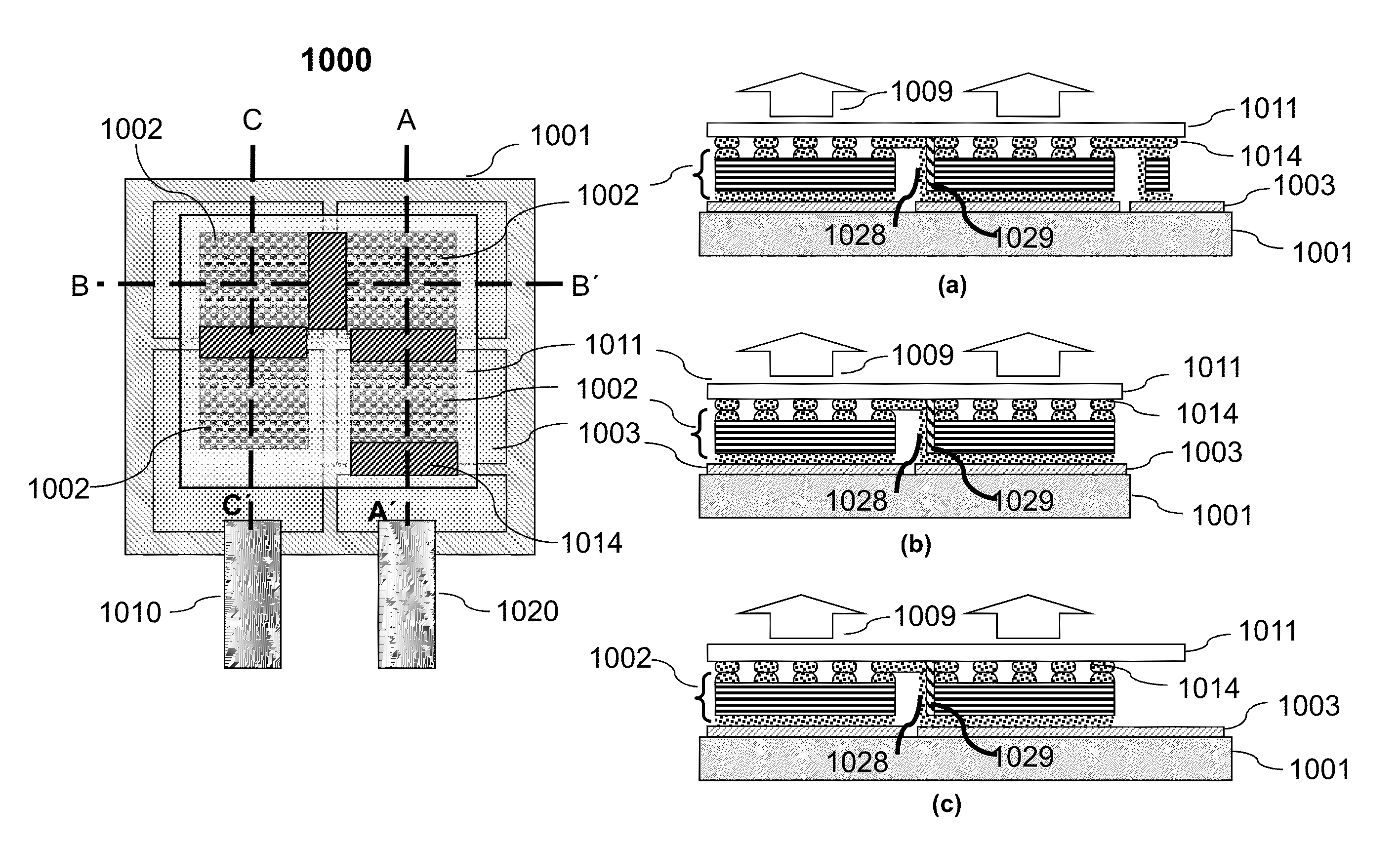

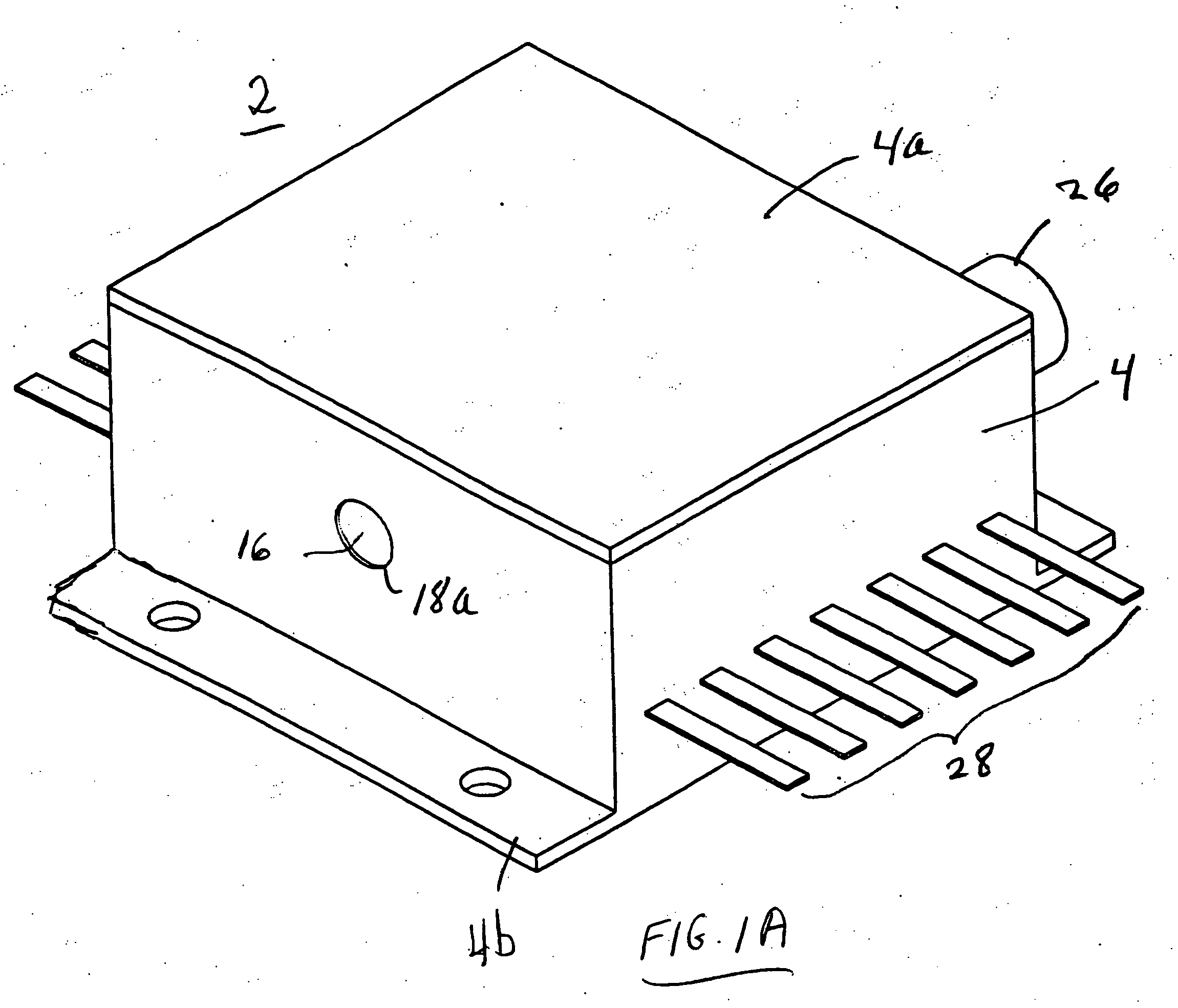

Laser Illuminator System

InactiveUS20130163627A1Improve thermal conductivityHeat dissipation fastSolid-state devicesSemiconductor lasersVertical-cavity surface-emitting laserLow inductance

An optical illuminator using Vertical Cavity Surface Emitting Laser (VCSEL) is disclosed. Optical modules configured using single VCSEL and VCSEL arrays bonded to a thermal submount to conduct heat away from the VCSEL array, are suited for high power and high speed operation. High speed optical modules are configured using single VCSEL or VCSEL arrays connected to a high speed electronic module on a common thermal submount or on a common Printed Circuit Board (PCB) platform including transmission lines. The electronic module provides low inductance current drive and control functions to operate the VCSEL and VCSEL array. VCSEL apertures are designed for a desired beam shape. Additional beam shaping elements are provided for VCSELs or VCSEL arrays, for desired output beam shapes and / or emission patterns. VCSEL arrays may be operated in continuous wave (CW) or pulse operation modes in a programmable fashion using a built-in or an external controller.

Owner:PRINCETON OPTRONICS

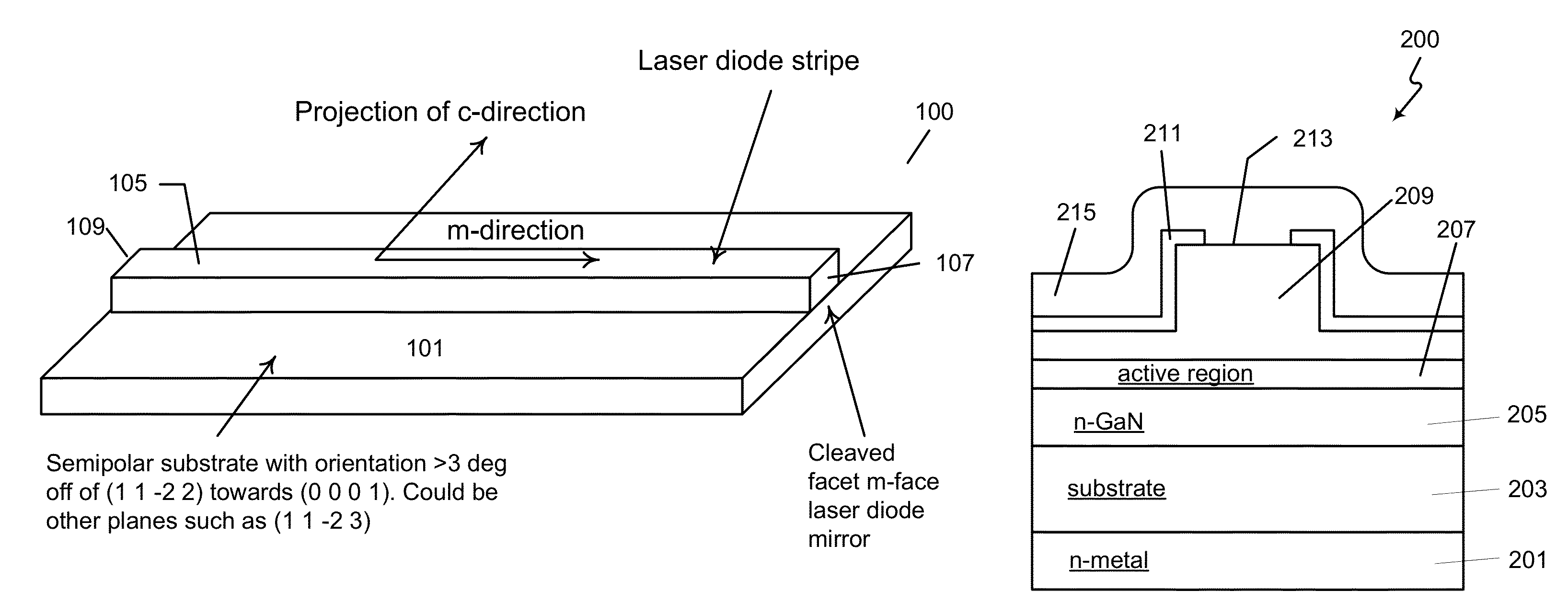

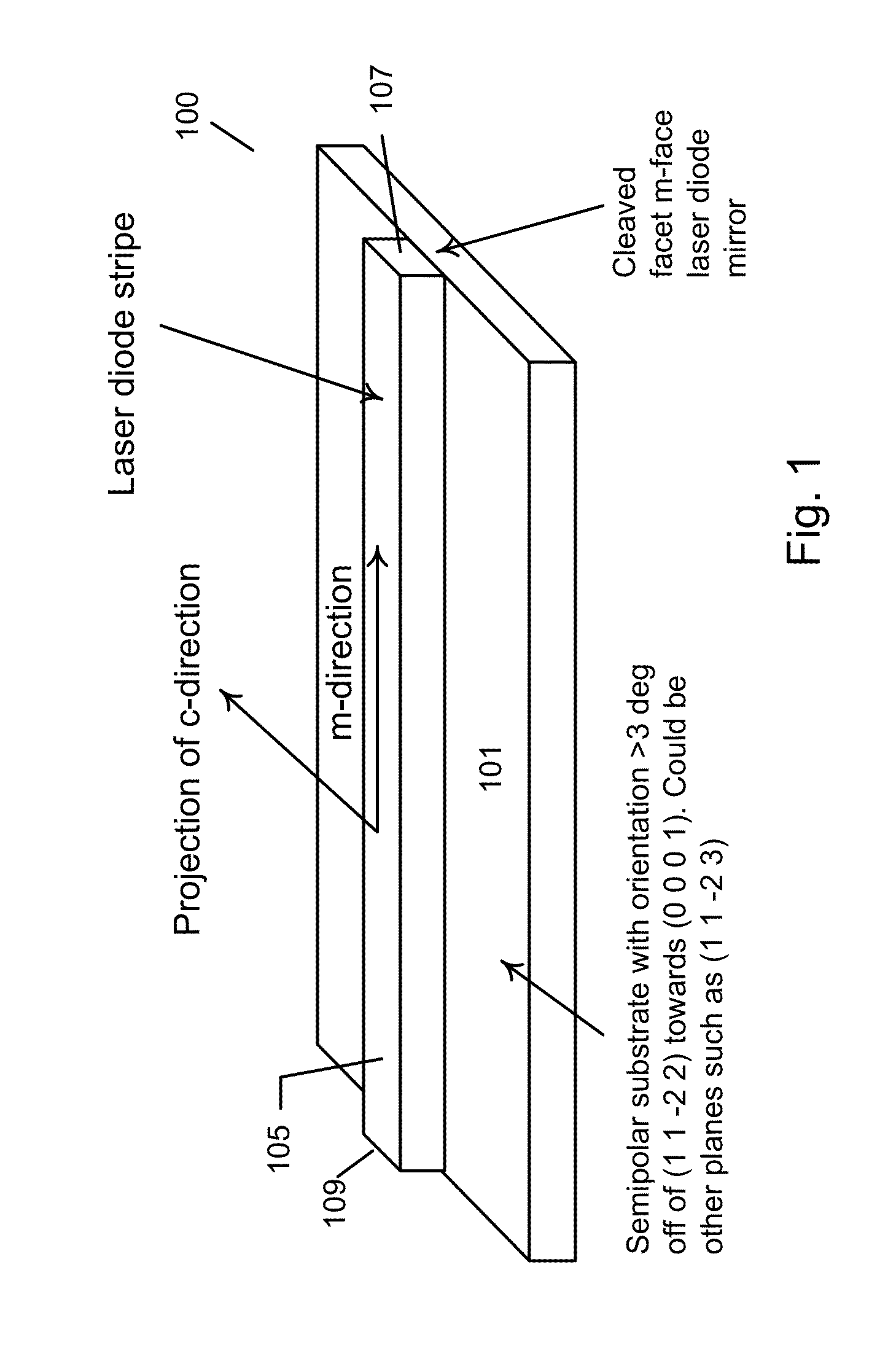

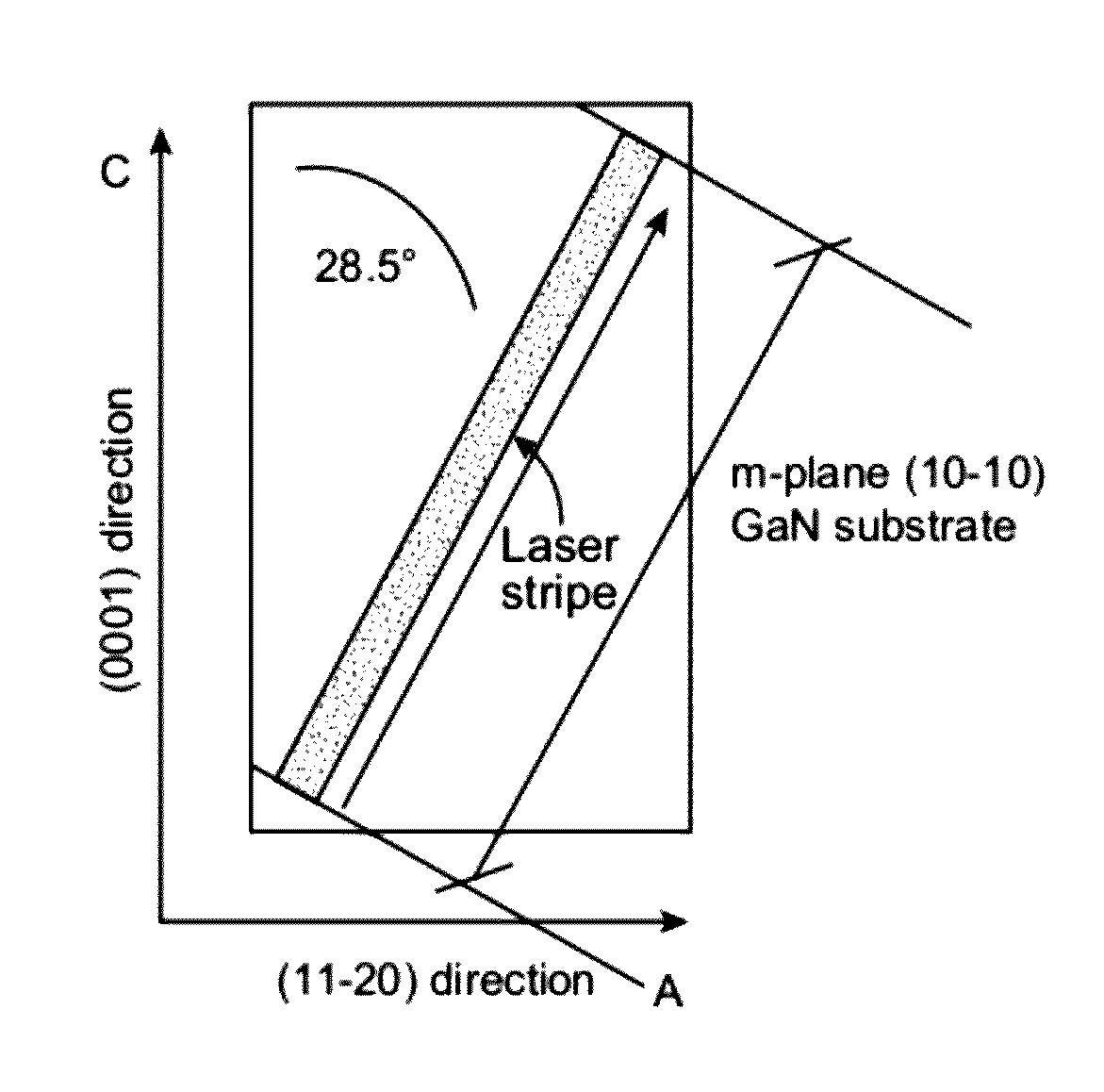

Optical device structure using miscut GaN substrates for laser applications

ActiveUS8422525B1Simple and cost-effectiveAchieve benefitsNanoopticsSemiconductor lasersLength waveGallium nitride

An optical device capable of emitting light having a wavelength ranging from about 490 to about 580 nanometers has a gallium nitride substrate with a semipolar crystalline surface region characterized by an orientation of greater than 3 degrees from (11-22) towards (0001) but less than about 50 degrees. A laser stripe formed on the substrate has a cavity orientation substantially parallel to the m-direction.

Owner:KYOCERA SLD LASER INC

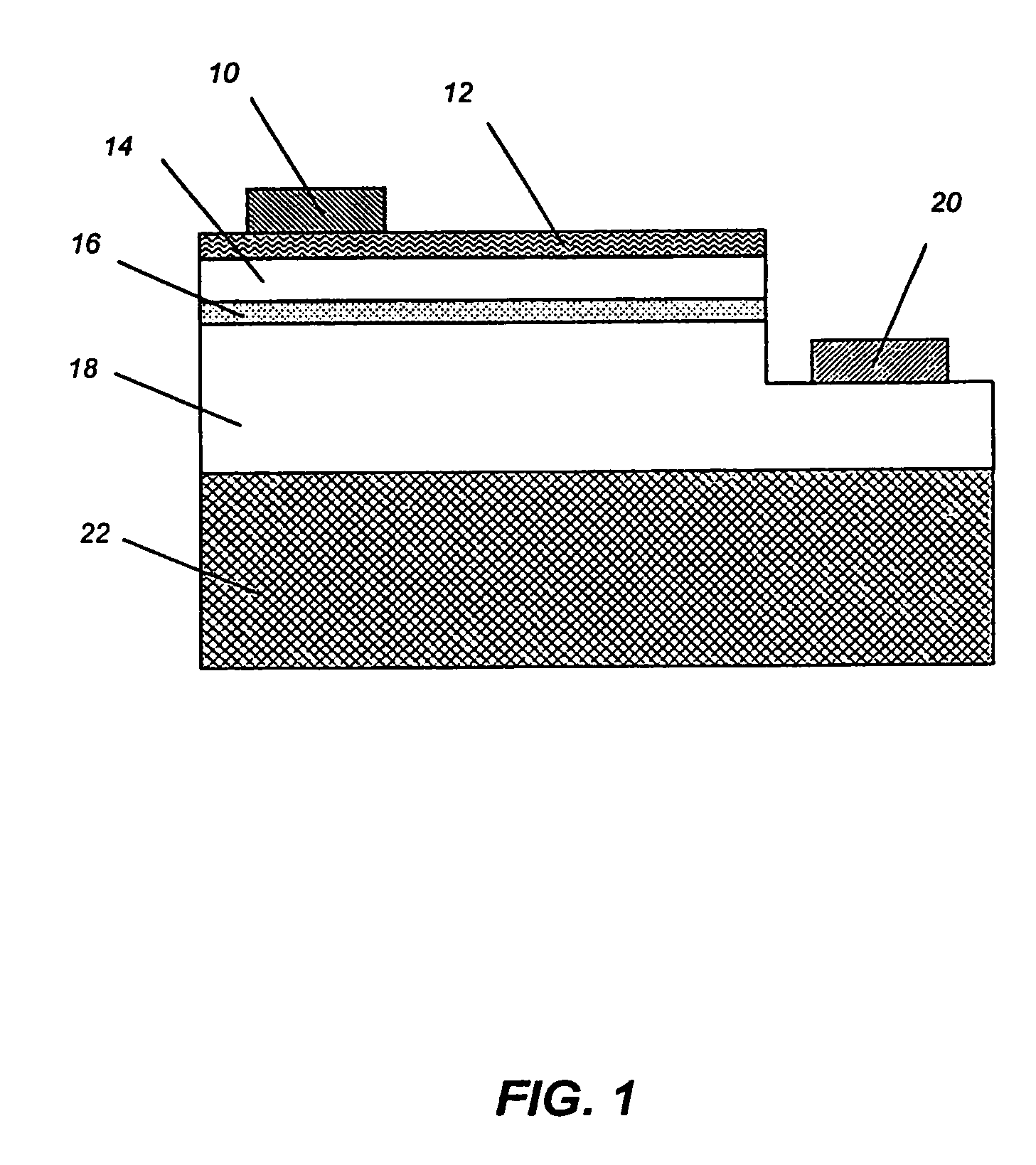

Highly efficient gallium nitride based light emitting diodes via surface roughening

ActiveUS20070121690A1Solid-state devicesSemiconductor/solid-state device manufacturingNitrogenLight reflection

A gallium nitride (GaN) based light emitting diode (LED), wherein light is extracted through a nitrogen face (N-face) (42) of the LED and a surface of the N-face (42) is roughened into one or more hexagonal shaped cones. The roughened surface reduces light reflections occurring repeatedly inside the LED, and thus extracts more light out of the LED. The surface of the N-face (42) is roughened by an anisotropic etching, which may comprise a dry etching or a photo-enhanced chemical (PEC) etching.

Owner:JAPAN SCI & TECH CORP

Solid state laser device using a selected crystal orientation in non-polar or semi-polar GaN containing materials and methods

ActiveUS8284810B1Facilitates parallel facetReduce surface roughnessNanoopticsSemiconductor lasersHigh current densitySolid-state laser device

An edge emitting solid state laser and method. The laser comprises at least one AlInGaN active layer on a bulk GaN substrate with a non-polar or semi-polar orientation. The edges of the laser comprise {1 1 −2 ±6} facets. The laser has high gain, low threshold currents, capability for extended operation at high current densities, and can be manufactured with improved yield. The laser is useful for optical data storage, projection displays, and as a source for general illumination.

Owner:KYOCERA SLD LASER INC

Surface plasmon devices

InactiveUS7010183B2Laser optical resonator constructionOptical resonator shape and constructionSoftware engineeringEngineering

A device including an input port configured to receive an input signal is described. The device also includes an output port and a structure, which structure includes a tunneling junction connected with the input port and the output port. The tunneling junction is configured in a way (i) which provides electrons in a particular energy state within the structure, (ii) which produces surface plasmons in response to the input signal, (iii) which causes the structure to act as a waveguide for directing at least a portion of the surface plasmons along a predetermined path toward the output port such that the surface plasmons so directed interact with the electrons in a particular way, and (iv) which produces at the output port an output signal resulting from the particular interaction between the electrons and the surface plasmons.

Owner:UNIV OF COLORADO THE REGENTS OF

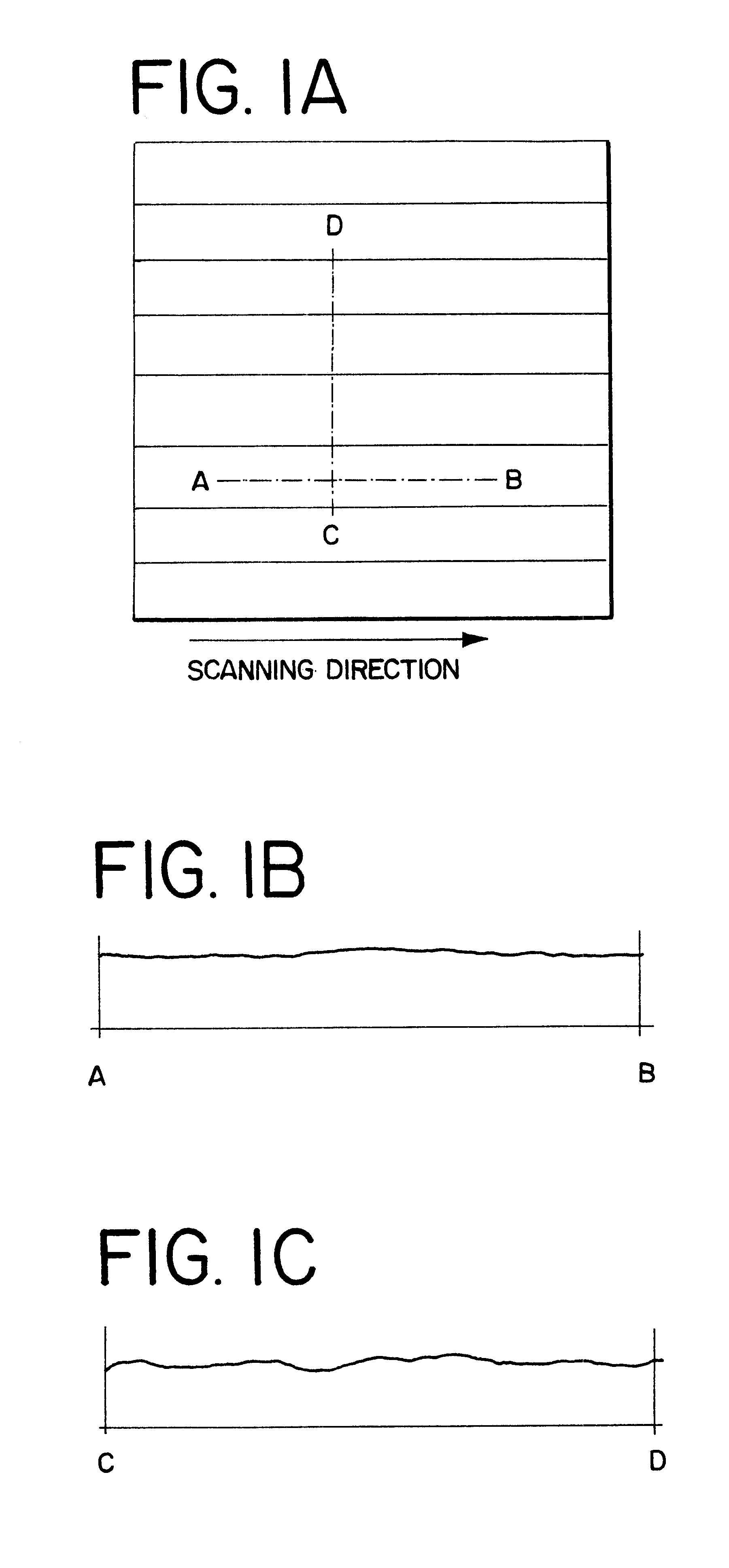

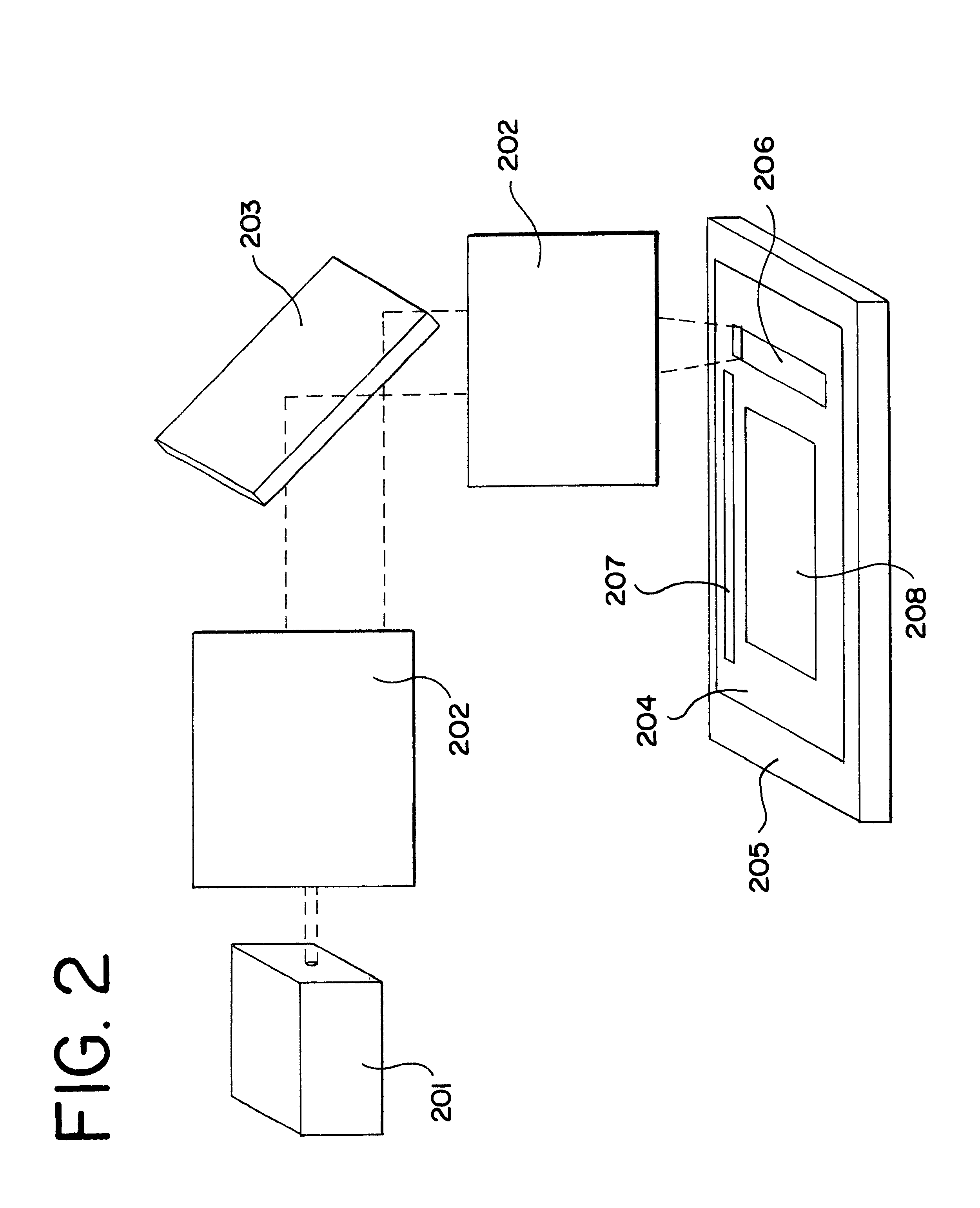

Laser irradiation method, laser irradiation apparatus, and semiconductor device

InactiveUS6535535B1Laser using scattering effectsSolid-state devicesContinuous lightLiquid-crystal display

An object of the present invention is obtaining a semiconductor film with uniform characteristics by improving irradiation variations of the semiconductor film. The irradiation variations are generated due to scanning while irradiating with a linear laser beam of the pulse emission. At a laser crystallization step of irradiating a semiconductor film with a laser light, a continuous light emission excimer laser emission device is used as a laser light source. For example, in a method of fabricating an active matrix type liquid crystal display device, a continuous light emission excimer laser beam is irradiated to a semiconductor film, which is processed to be a linear shape, while scanning in a vertical direction to the linear direction. Therefore, more uniform crystallization can be performed because irradiation marks can be avoided by a conventional pulse laser.

Owner:SEMICON ENERGY LAB CO LTD

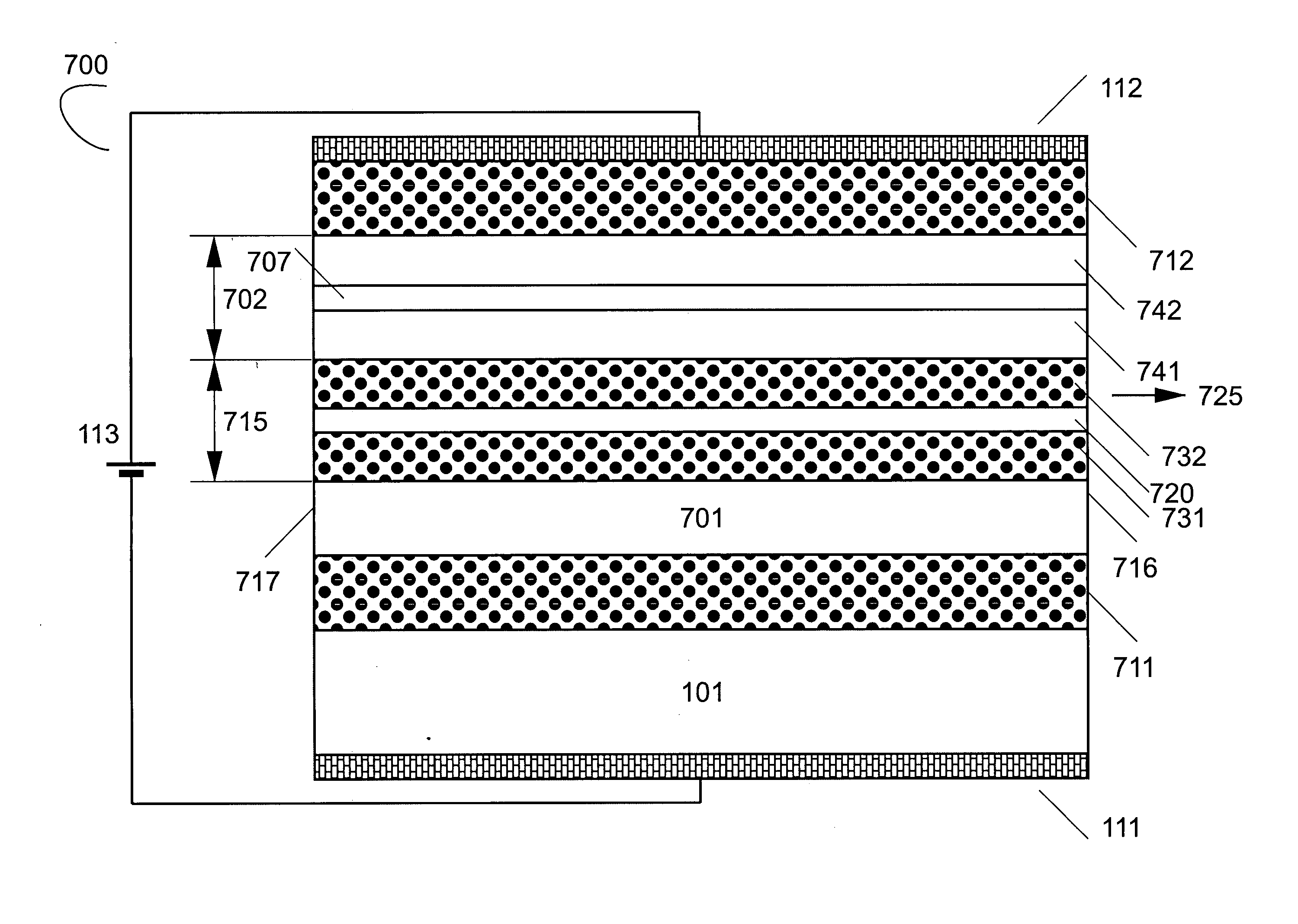

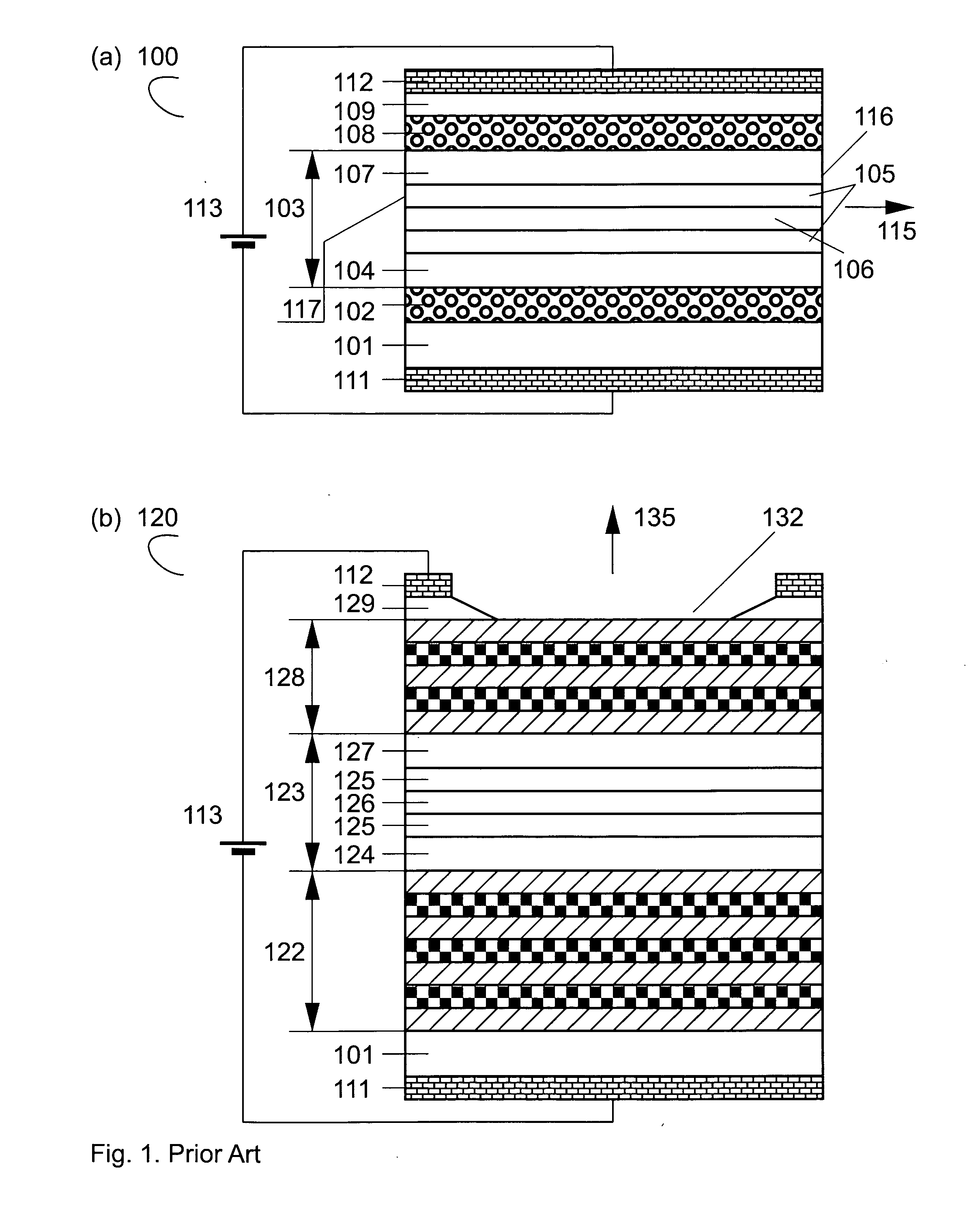

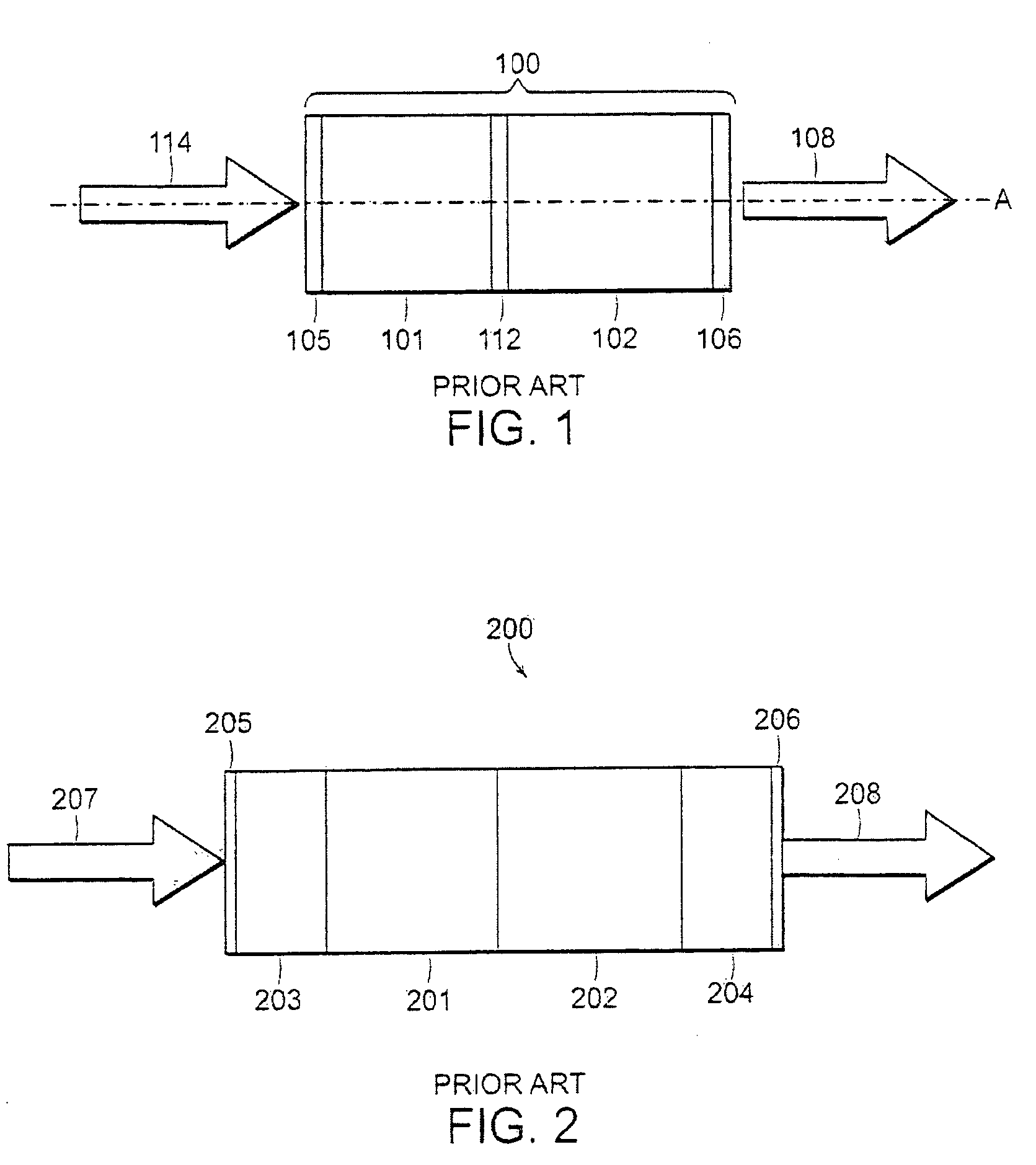

Optoelectronic device incorporating an interference filter

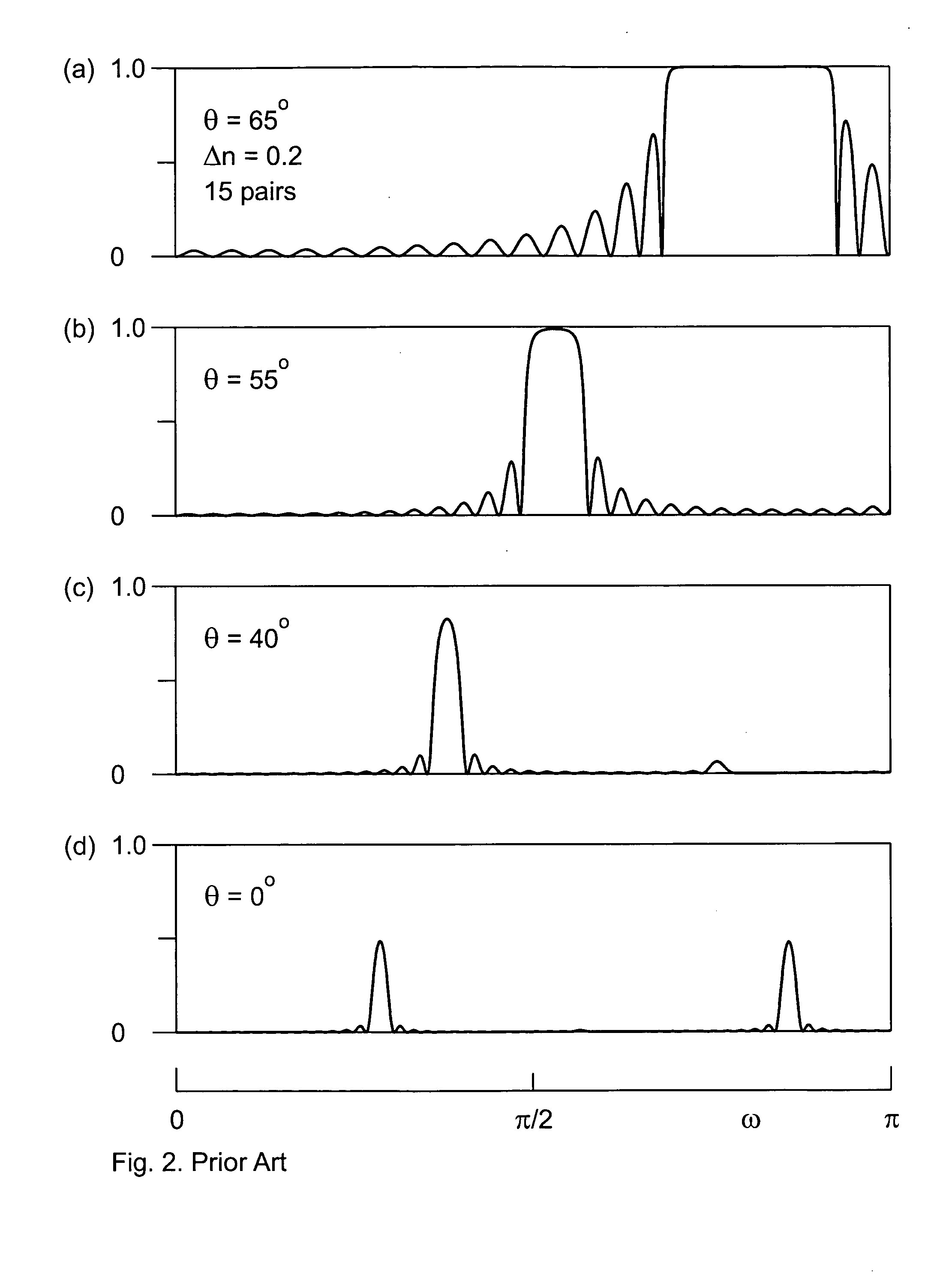

InactiveUS20050117623A1Optical wave guidanceLaser optical resonator constructionOptical cavityResonance

A novel class of optoelectronic devices incorporate an interference filter. The filter includes at least two optical cavities. Each of the cavities localizes al least one optical mode. The optical modes localized at two cavities are at resonance only at one or at a few discrete selective wavelengths. At resonance, the optical eigenmodes contain one mode having a zero intensity at a node position between the two cavities, where this position shifts as a function of the wavelength. A non-transparent element, which is preferably an absorbing element, a scatterer, or a reflector, is placed between two cavities. At a discrete selective wavelength, when the node of the optical mode matches with the non-transparent element, the filter is transparent for light. At other wavelengths, the filter is not transparent for light. This allows for the construction of various optoelectronic devices showing a strongly wavelength-selective operation.

Owner:INNOLUME

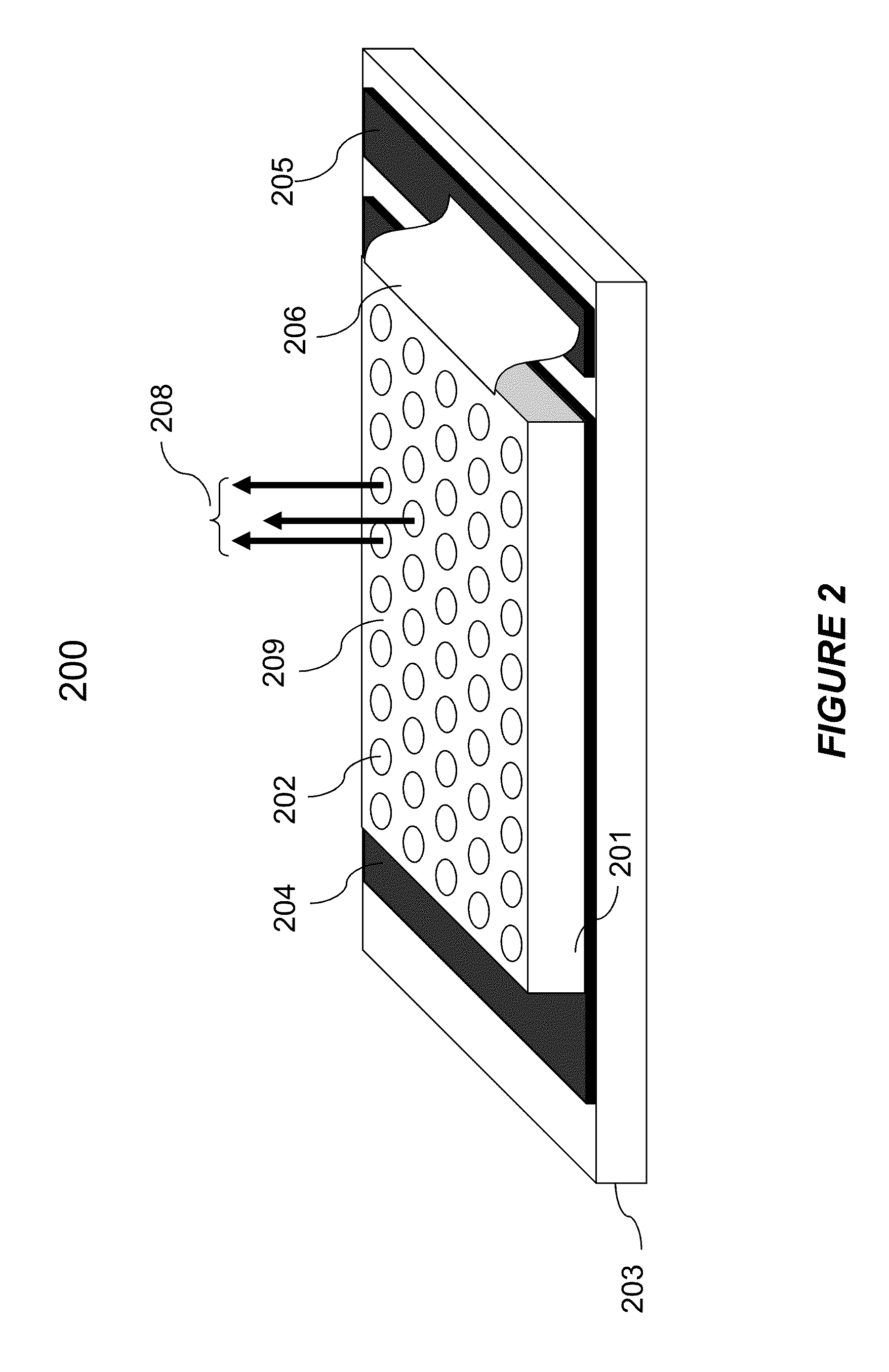

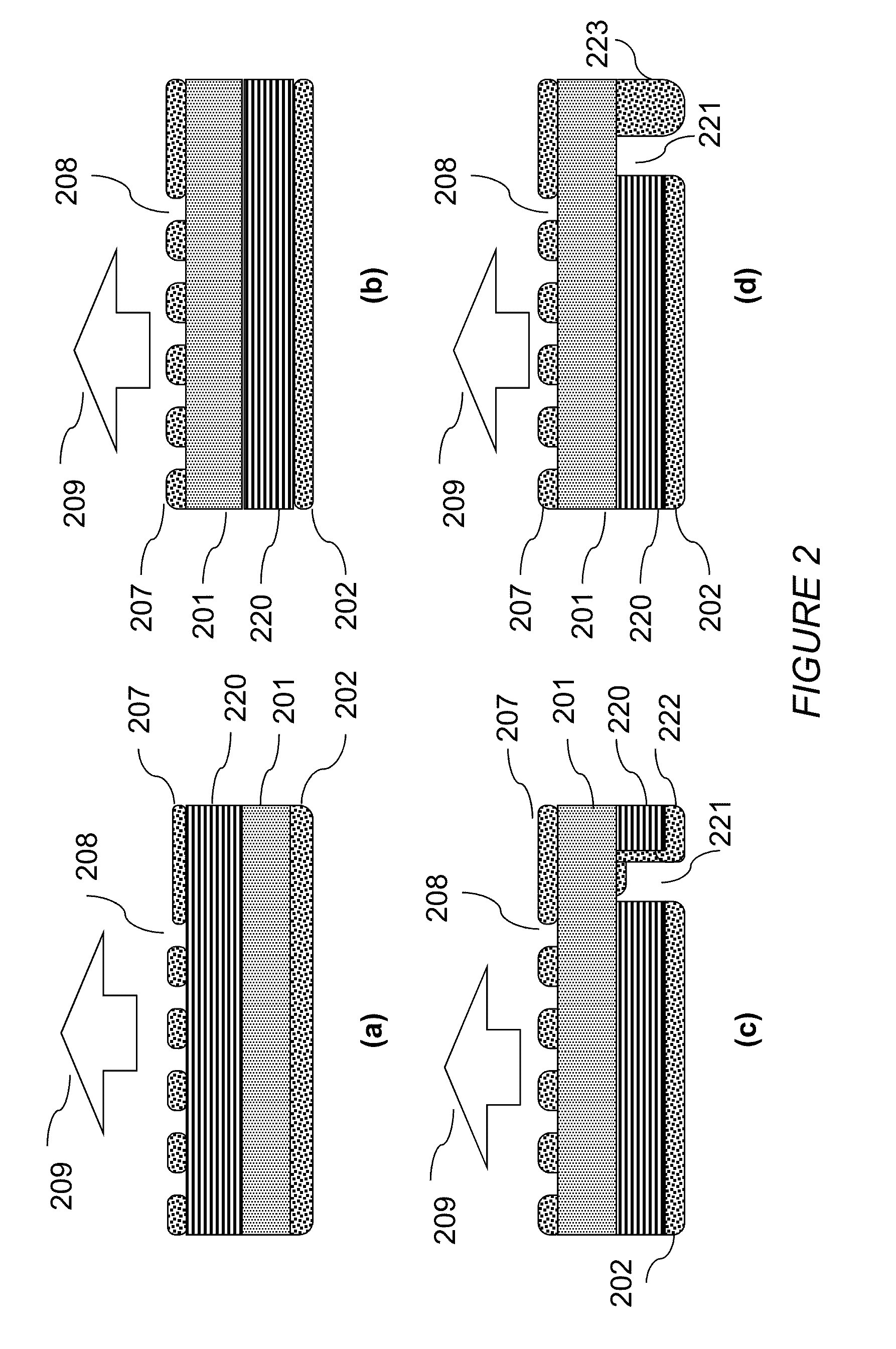

Optical illuminator

ActiveUS8675706B2Eliminate needIncrease the areaLighting heating/cooling arrangementsSolid-state devicesSurface mountingCurrent driver

Illuminator module comprising VCSEL arrays with planar electrical contacts, readily adaptable for surface mounting, is provided. Monolithic VCSEL arrays are configured in array patterns on two and three-dimensional surfaces. Illuminator modules are easily expandable by increasing the array size or by modularly arranging more arrays with or without a transparent substrate. Different shapes of illuminator modules may be configured by tiling array modules monolithically on a common substrate, or by tiling small modules. The surface mountable illuminator modules are easily assembled on a thermally conductive surface that may be air or liquid cooled for efficient heat dissipation. Array modules may be integrated with other electronic circuits such as current drivers, sensors, controllers, processors, etc. on a common platform, for example, a single or multiple layer printed circuit boards (PCB) to assemble illumination systems for different applications including a gesture recognition apparatus and a battery operated portable illuminator devices.

Owner:PRINCETON OPTRONICS

Method and system for providing bidirectional light sources with broad spectrum

ActiveUS8451876B1Simple and cost-effectiveCost-effectiveOptical wave guidanceLaser active region structureLength waveLight source

A system and method for providing laser diodes with broad spectrum is described. GaN-based laser diodes with broad or multi-peaked spectral output operating are obtained in various configurations by having a single laser diode device generating multiple-peak spectral outputs, operate in superluminescene mode, or by use of an RF source and / or a feedback signal. In some other embodiments, multi-peak outputs are achieved by having multiple laser devices output different lasers at different wavelengths.

Owner:KYOCERA SLD LASER INC

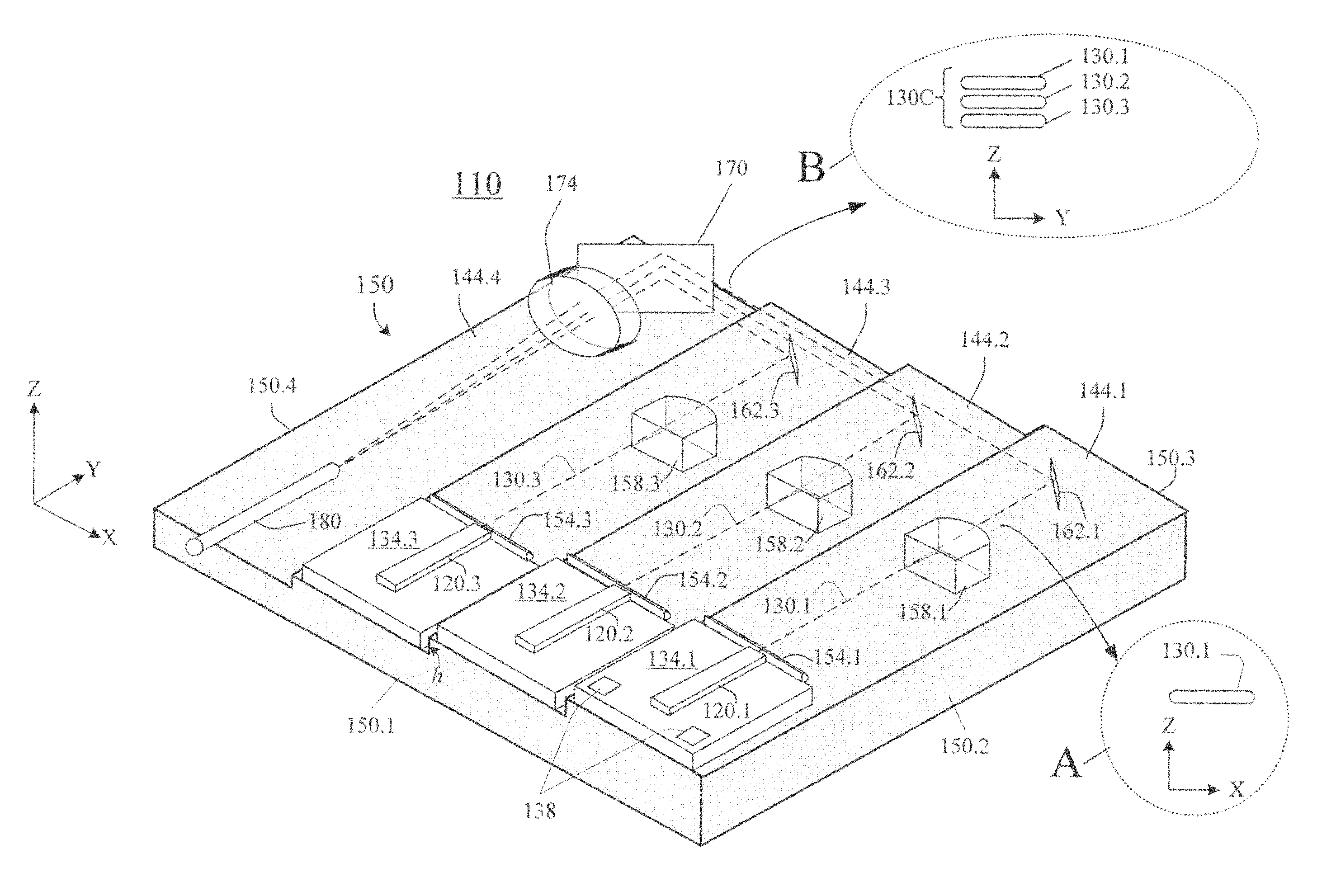

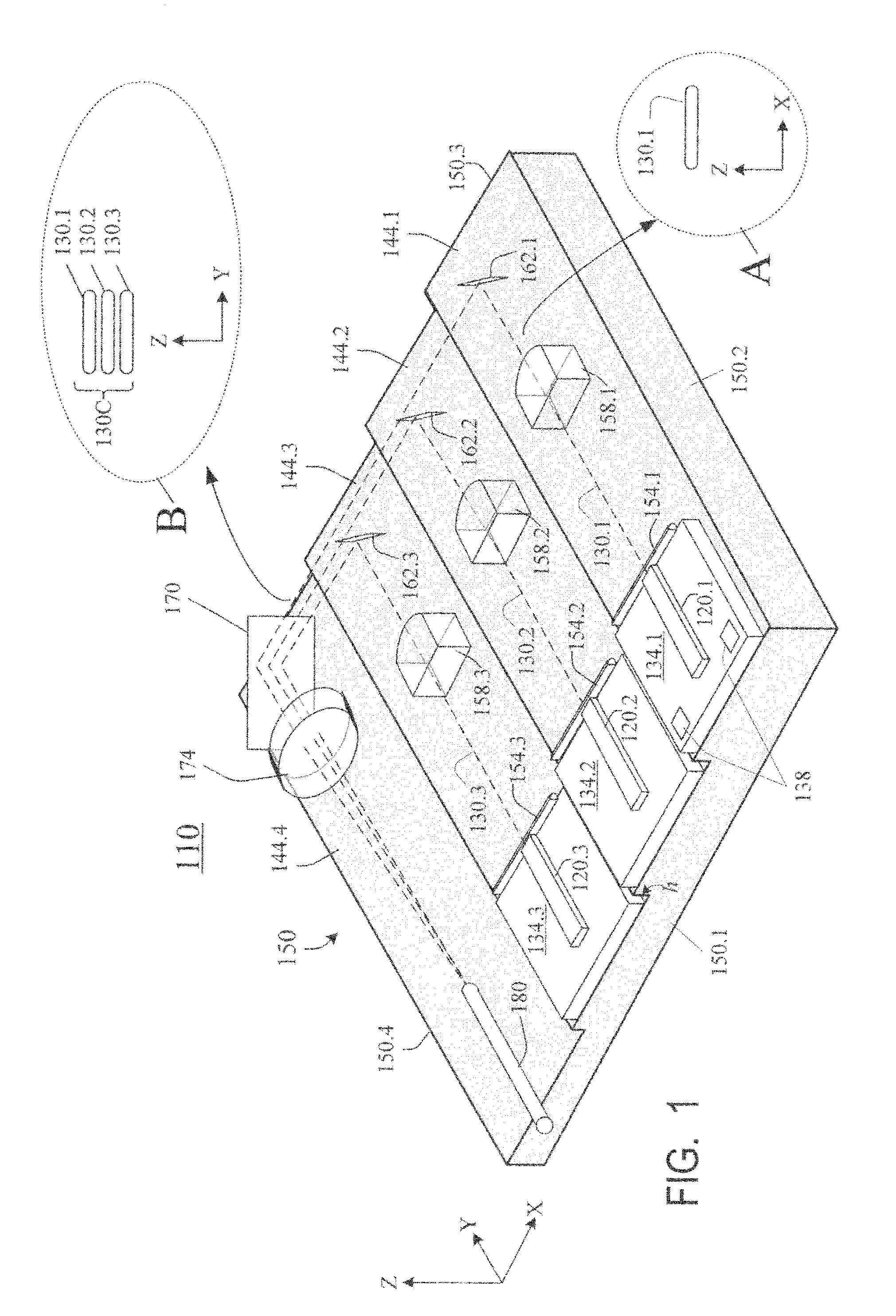

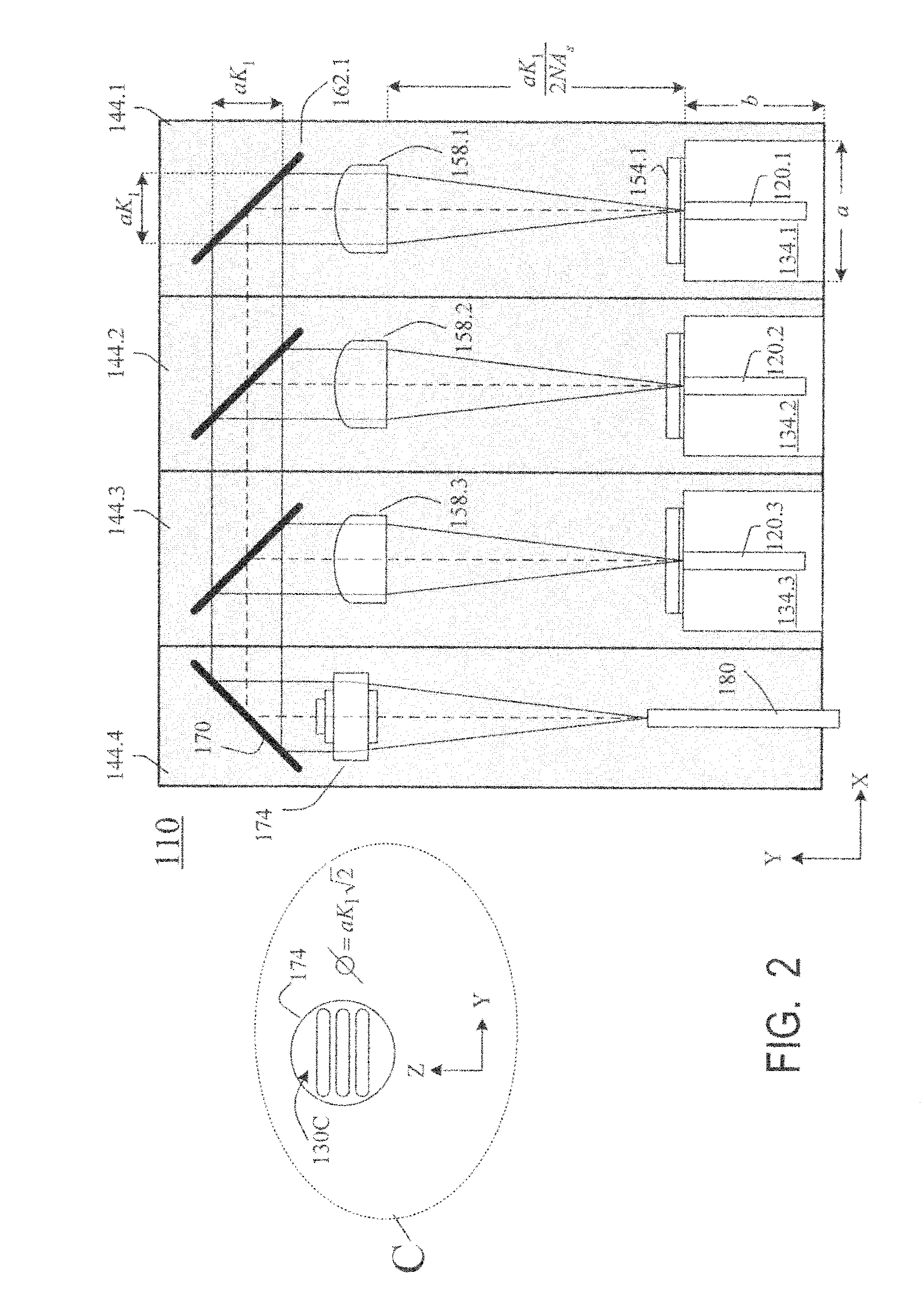

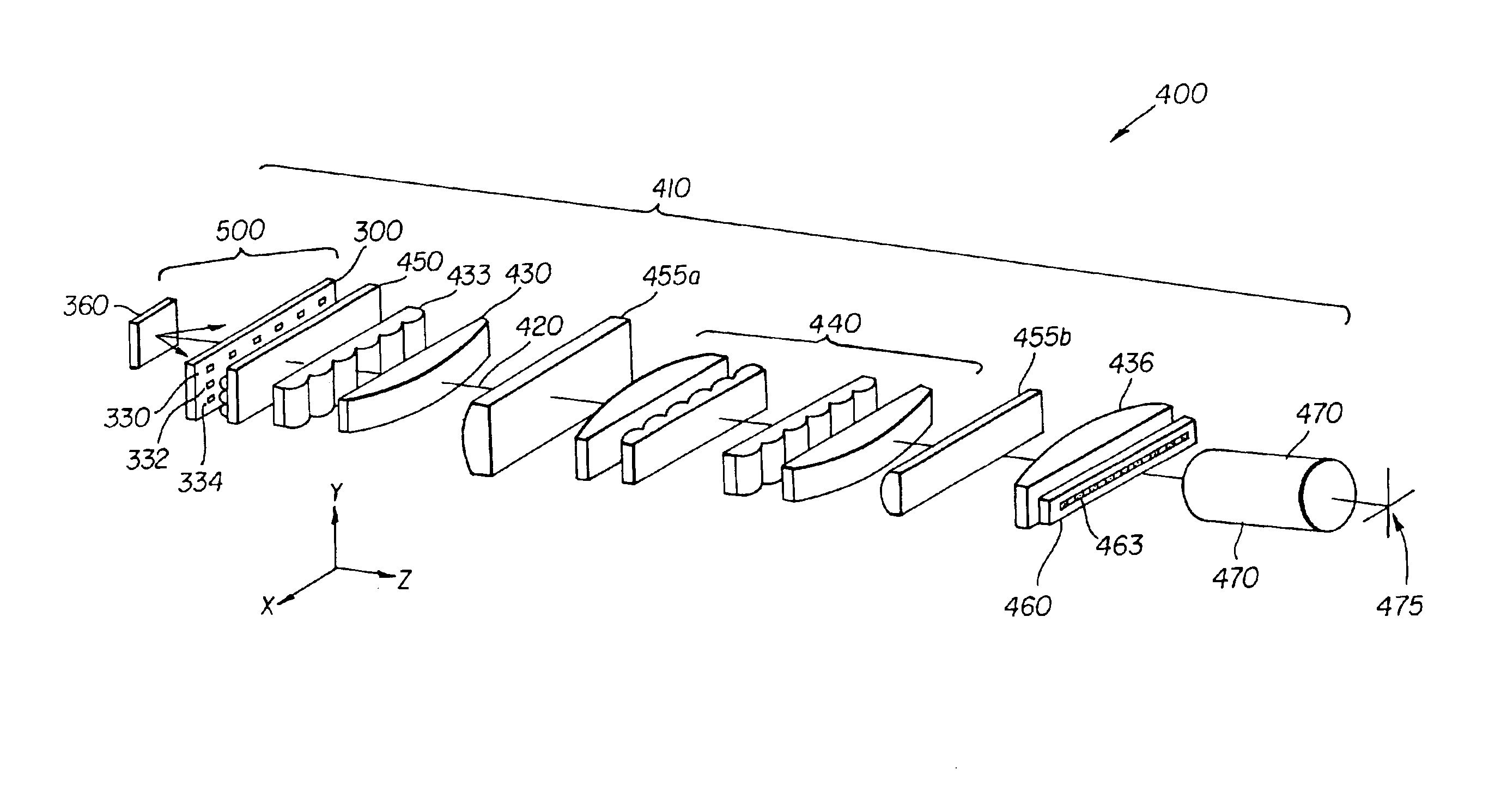

Laser diode assemblies

InactiveUS20090245315A1Reduce misalignmentReduce in quantitySemiconductor laser arrangementsSemiconductor laser optical deviceLight beamLaser beams

Laser diodes (120) emit laser beams along a vertical YZ plane at different distances from the YZ plane. The beams are collimated in their fast and slow axes, and are redirected by turning mirrors (162) to form a beam stack (130C) traveling along the XZ plane. The beam stack is turned by about 90°, then converged by a focusing lens (174) into an optical fiber (180). A compact assembly is thus provided. Each laser diode (120.i), its collimating optics (154.i, 158.i, i=1, 2, . . . ) and its turning mirror (162.i) are rigidly attached to a flat, heat-spreading surface (144.i) and thus remain aligned with each other in thermal cycling.

Owner:FAYBISHENKO VICTOR

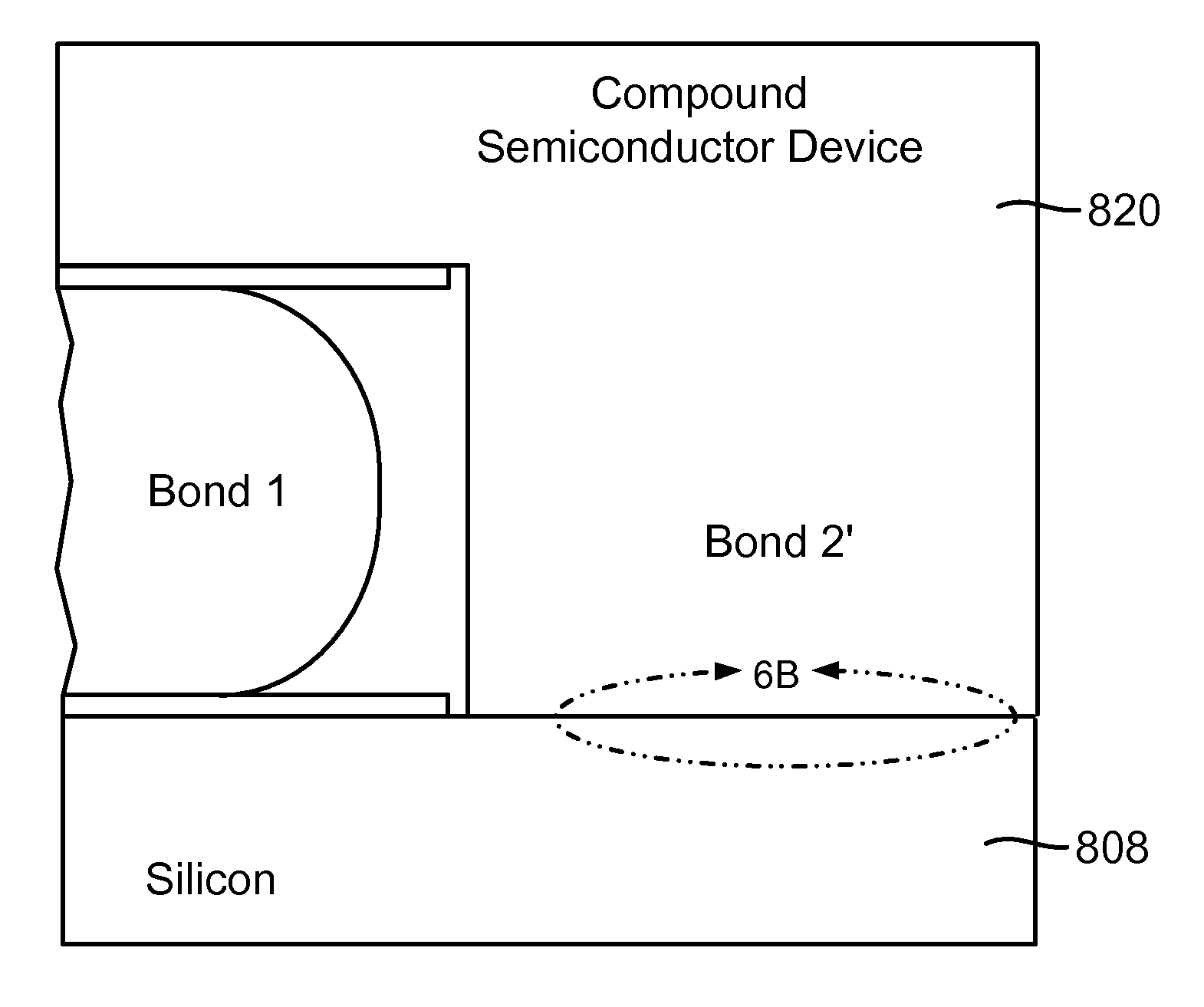

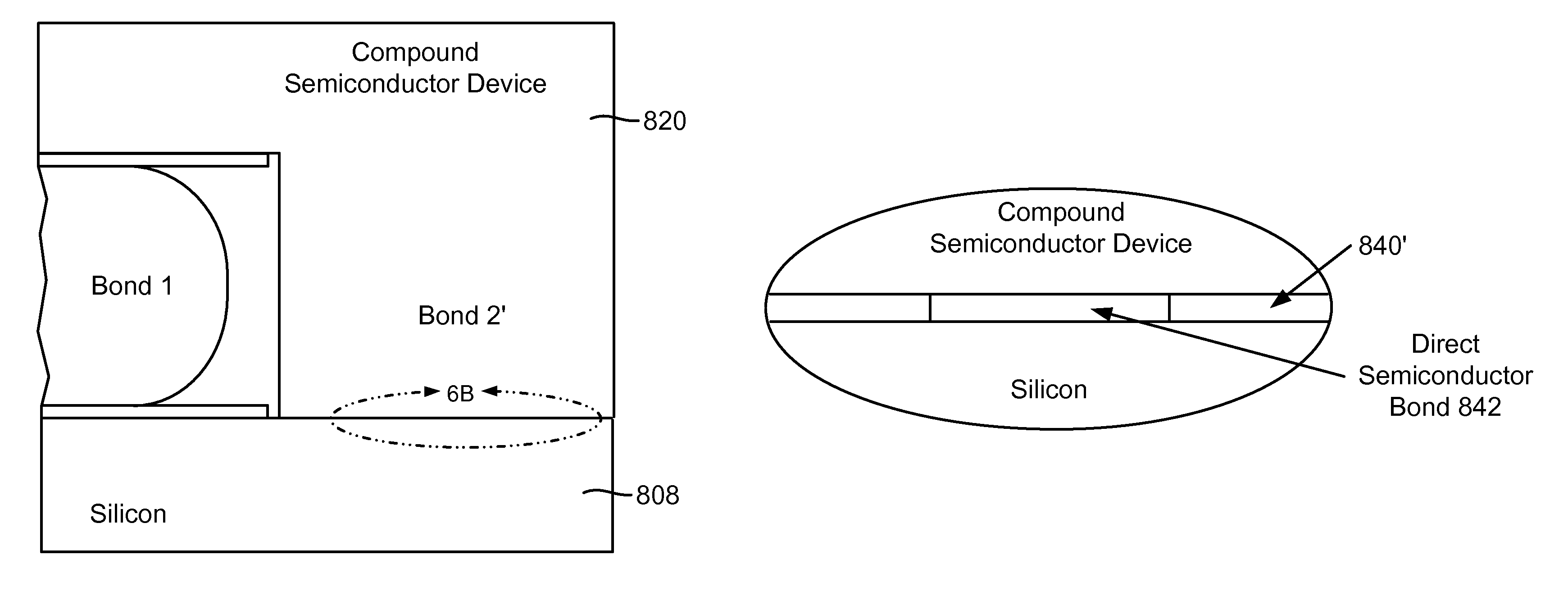

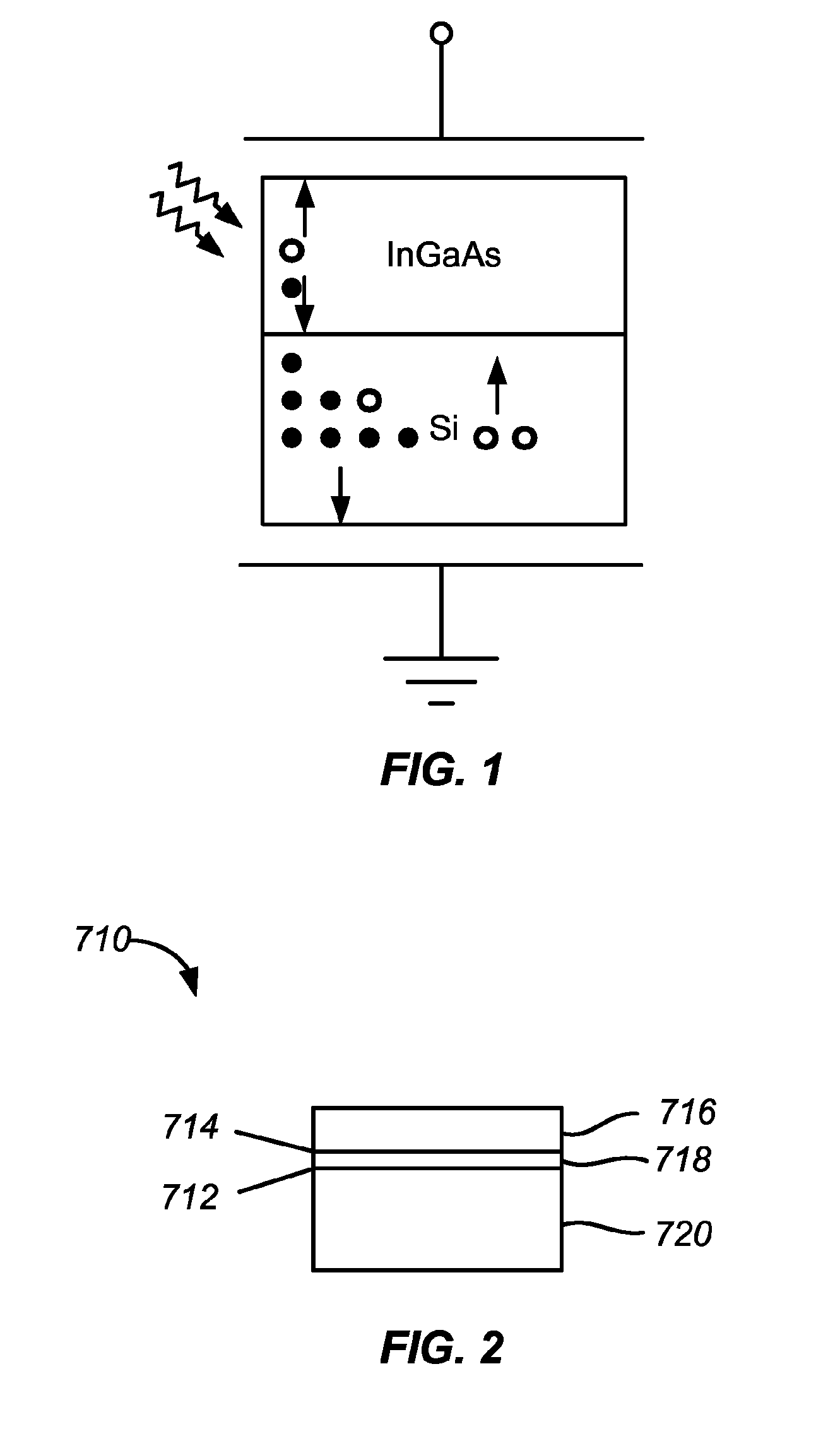

Method and system of heterogeneous substrate bonding for photonic integration

ActiveUS8630326B2Semiconductor/solid-state device detailsSolid-state devicesPhotonicsInterface layer

A hybrid integrated optical device includes a substrate comprising a silicon layer and a compound semiconductor device bonded to the silicon layer. The device also includes a bonding region disposed between the silicon layer and the compound semiconductor device. The bonding region includes a metal-semiconductor bond at a first portion of the bonding region. The metal-semiconductor bond includes a first pad bonded to the silicon layer, a bonding metal bonded to the first pad, and a second pad bonded to the bonding metal and the compound semiconductor device. The bonding region also includes an interface assisted bond at a second portion of the bonding region. The interface assisted bond includes an interface layer positioned between the silicon layer and the compound semiconductor device, wherein the interface assisted bond provides an ohmic contact between the silicon layer and the compound semiconductor device.

Owner:SKORPIOS TECH

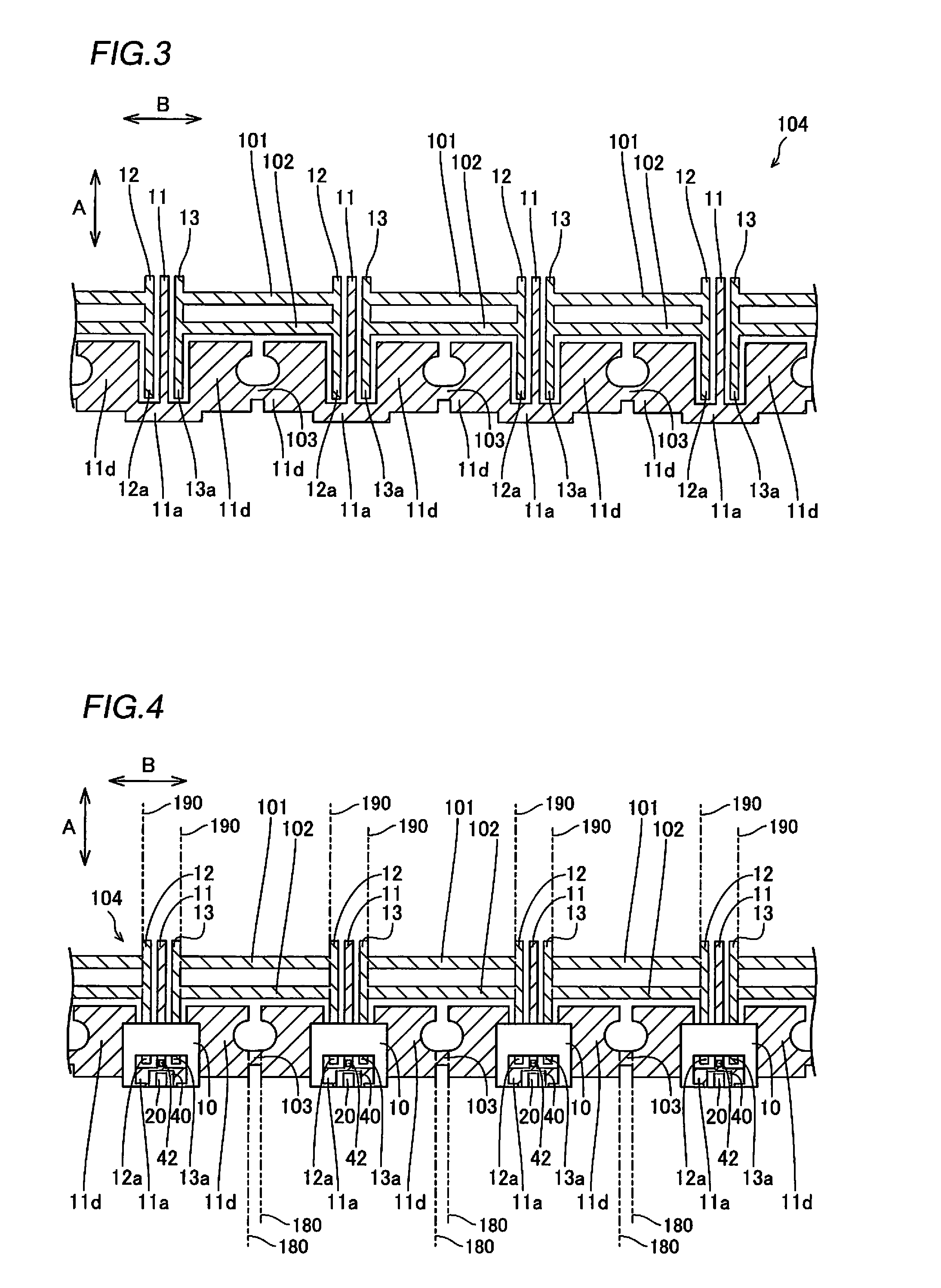

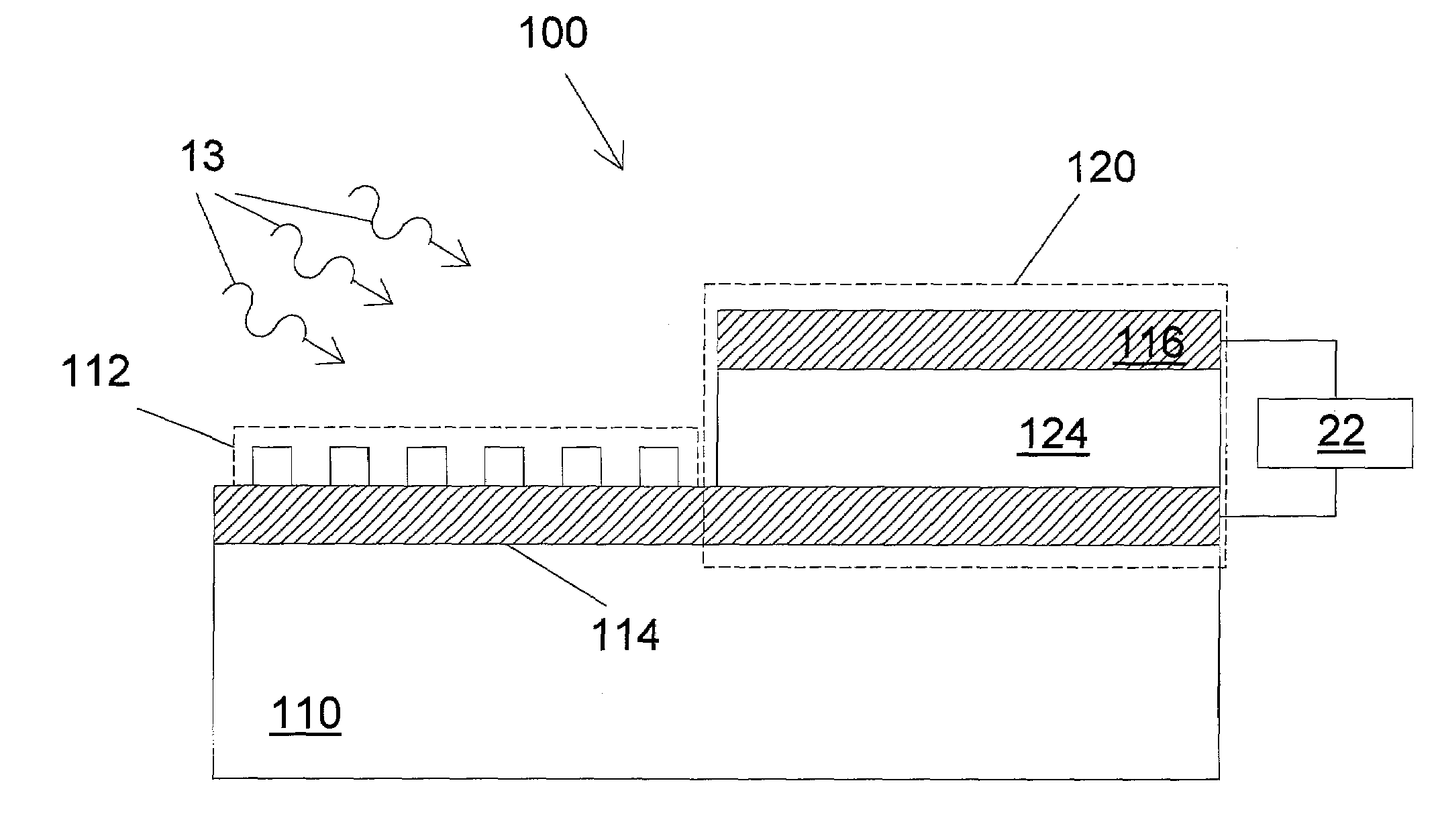

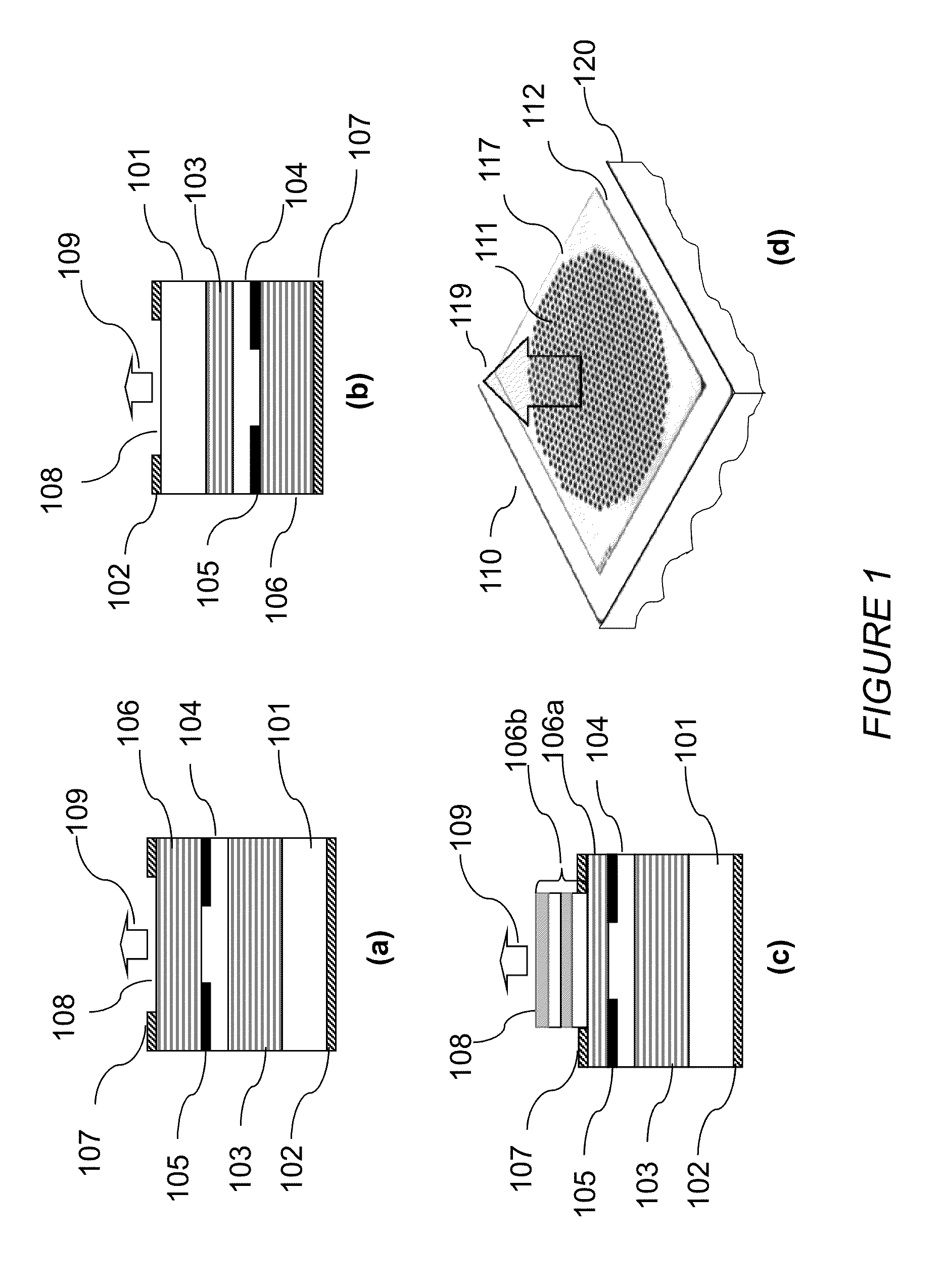

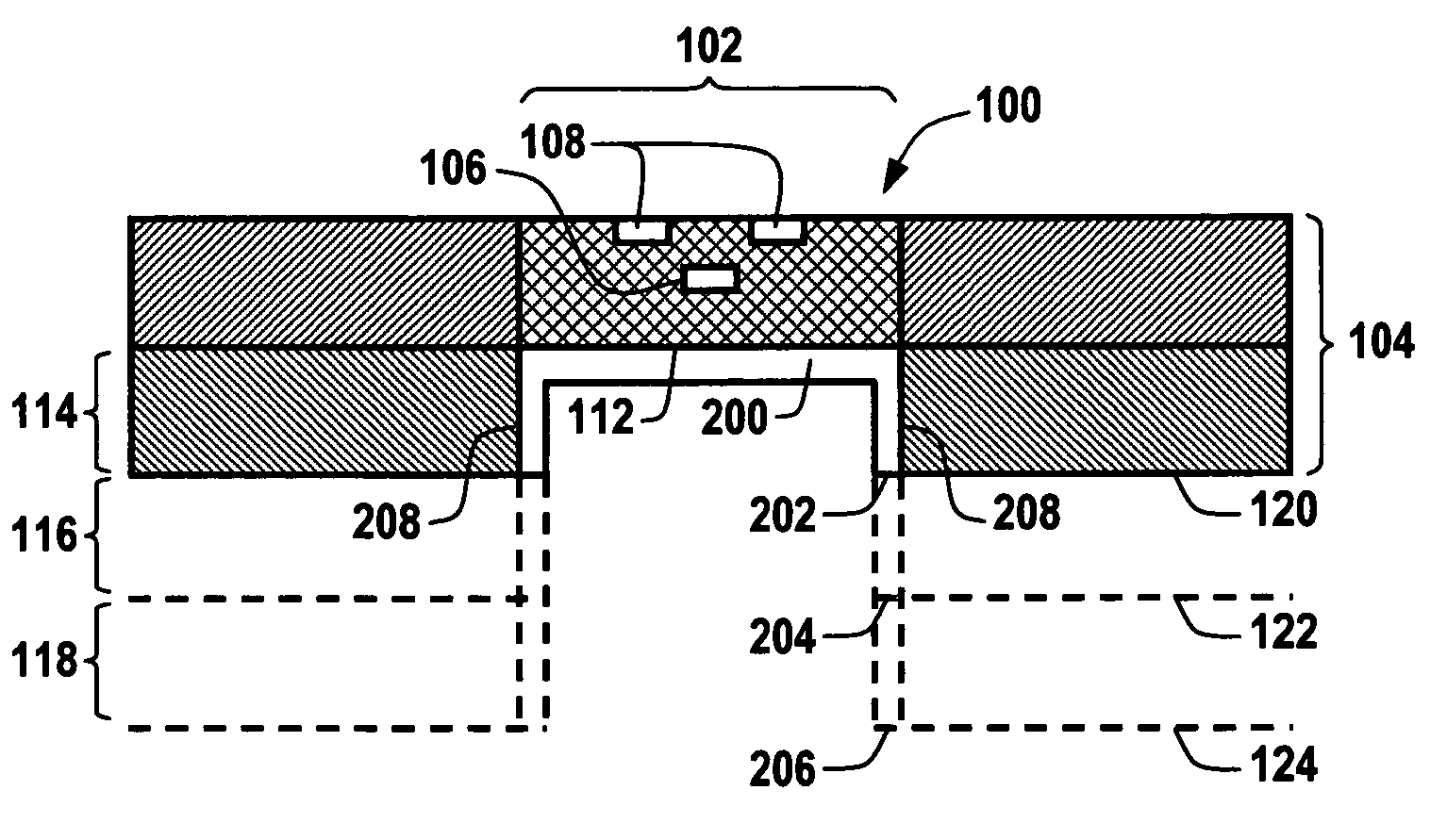

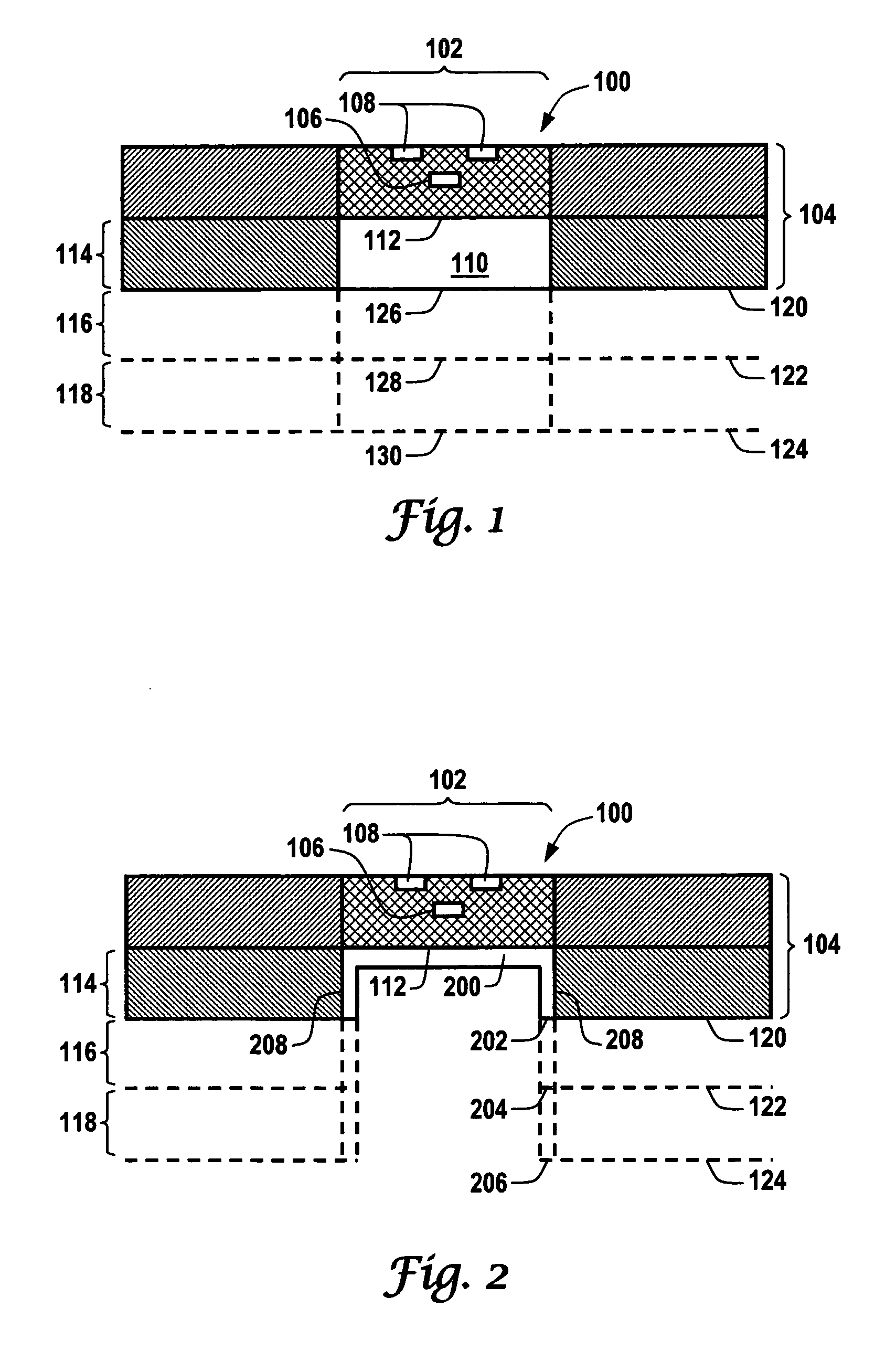

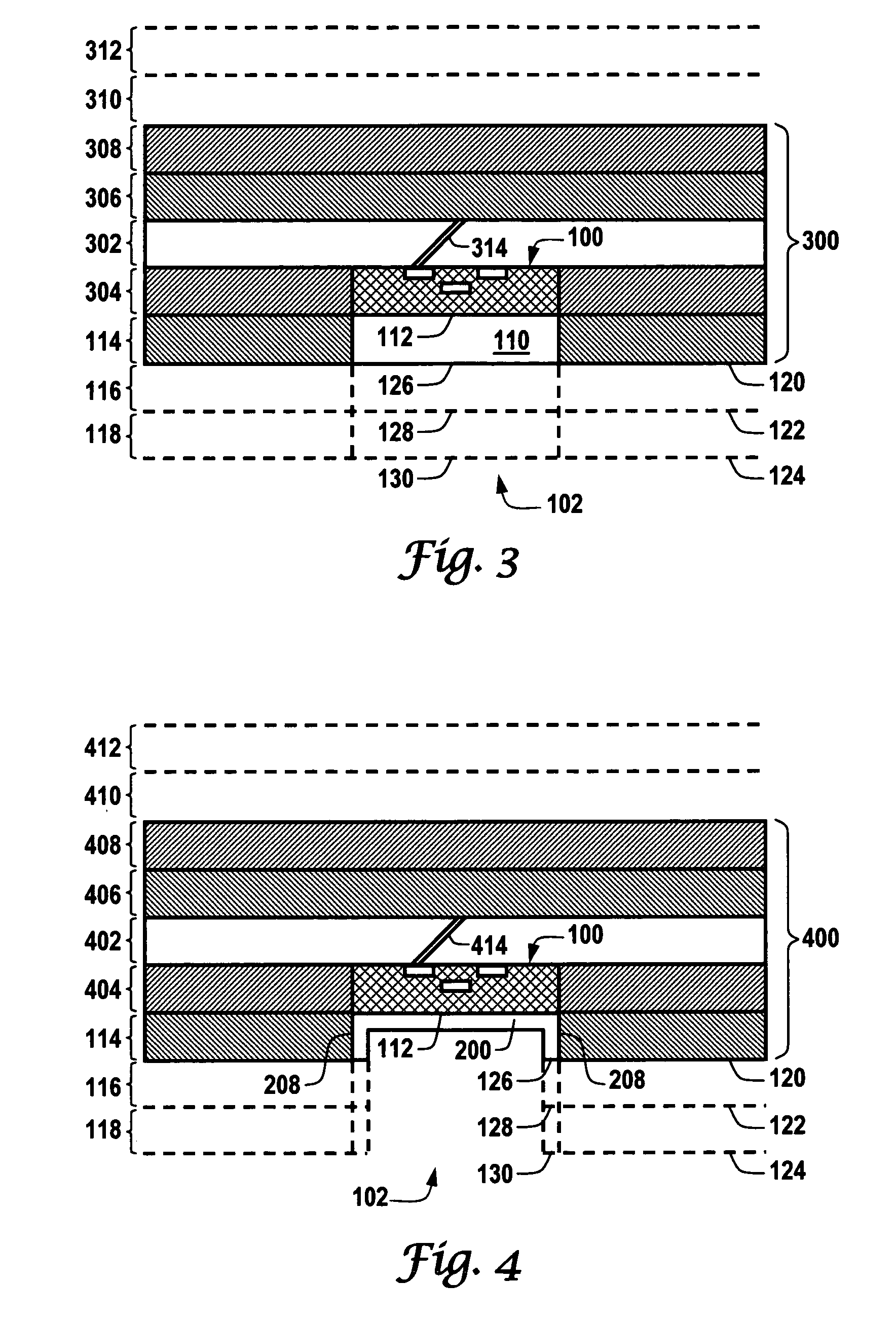

System, method and apparatus for improved electrical-to-optical transmitters disposed within printed circuit boards

InactiveUS20050046011A1Simple and reliable processAdded fabricationCircuit optical detailsSemiconductor/solid-state device detailsCommunications systemConductive materials

The present invention provides a system, method and apparatus for improved electrical-to-optical transmitters (100) disposed within printed circuit boards (104). The heat sink (110, 200) is a thermal conductive material disposed within a cavity (102) of the printed circuit board (104) and is thermally coupled to a bottom surface (112) of the electrical-to-optical transmitter (100). A portion of the thermal conductive material extends approximately to an outer surface (120, 122 or 124) of a layer (114, 116 or 118) of the printed circuit board (104). The printed circuit board may comprise a planarized signal communications system or an optoelectronic signal communications system. In addition, the present invention provides a method for fabricating the heat sink wherein the electrical-to-optical transmitter disposed within a cavity of the printed circuit board is fabricated. New methods for flexible waveguides and micro-mirror couplers are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

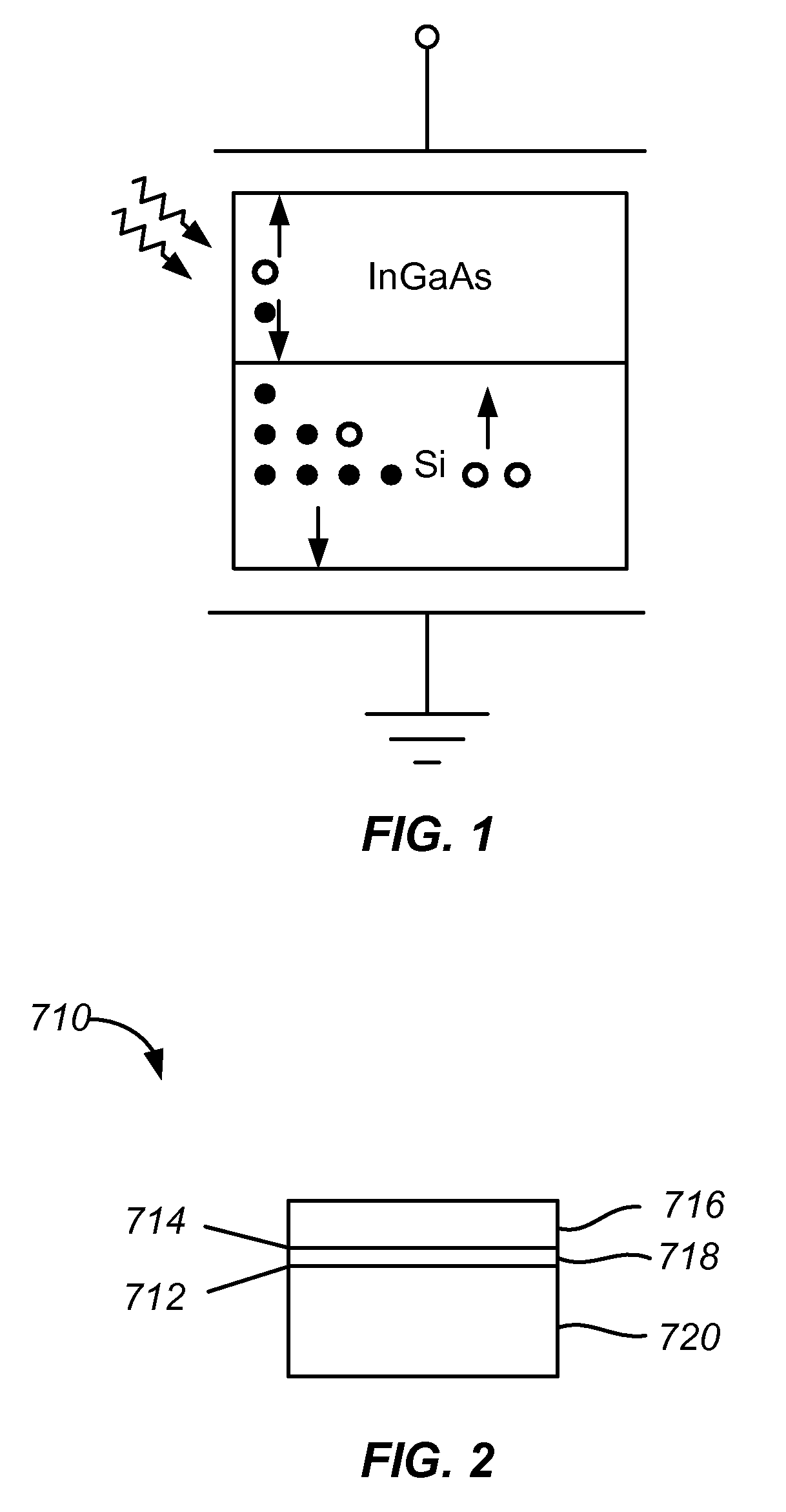

Method and system for heterogeneous substrate bonding of waveguide receivers

InactiveUS8611388B2Semiconductor/solid-state device detailsSolid-state devicesInterface layerWaveguide

A composite integrated optical device includes a substrate including a silicon layer and a waveguide disposed in the silicon layer. The composite integrated optical device also includes an optical detector bonded to the silicon layer and a bonding region disposed between the silicon layer and the optical detector. The bonding region includes a metal-assisted bond at a first portion of the bonding region. The metal-assisted bond includes an interface layer positioned between the silicon layer and the optical detector. The bonding region also includes a direct semiconductor-semiconductor bond at a second portion of the bonding region.

Owner:SKORPIOS TECH

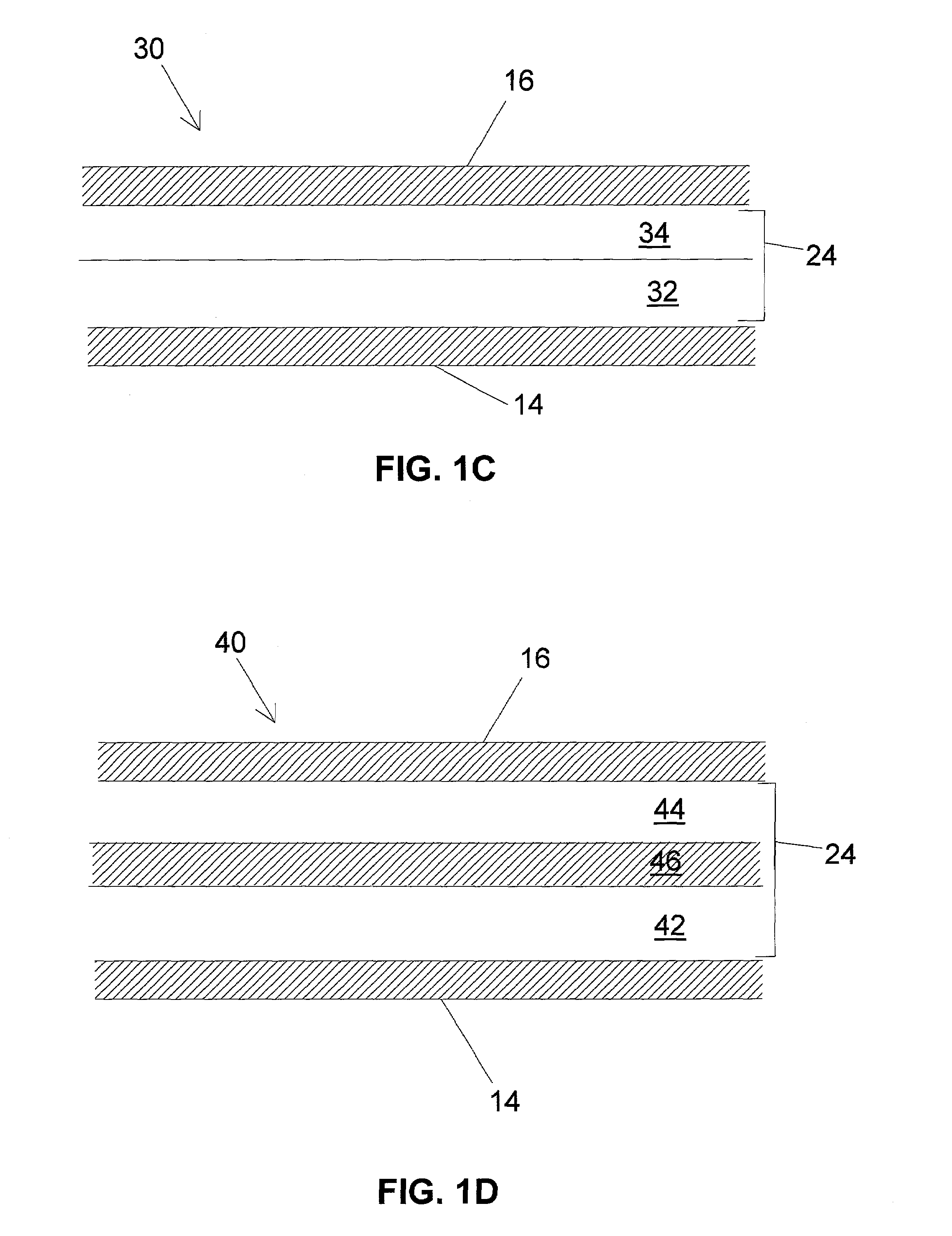

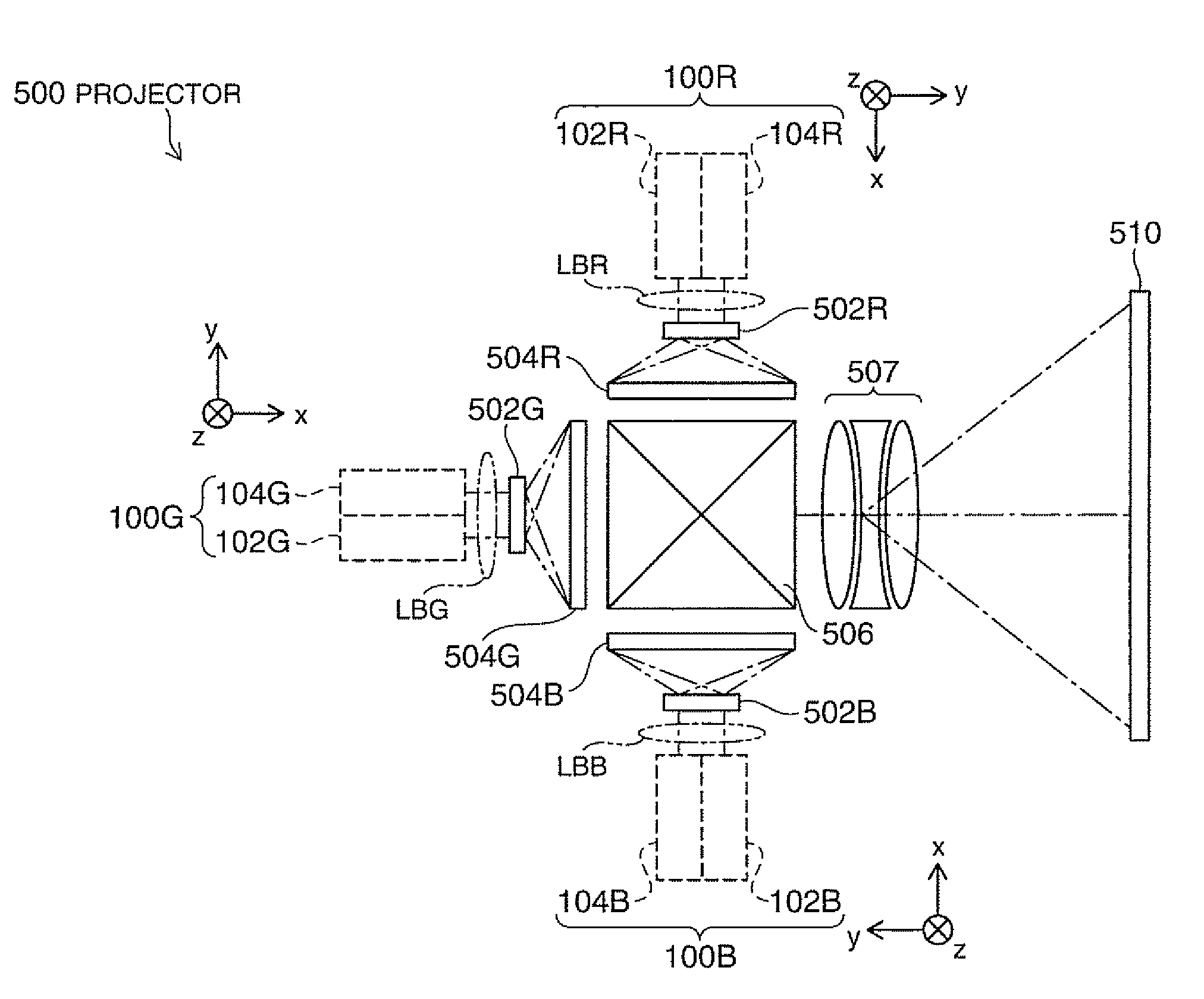

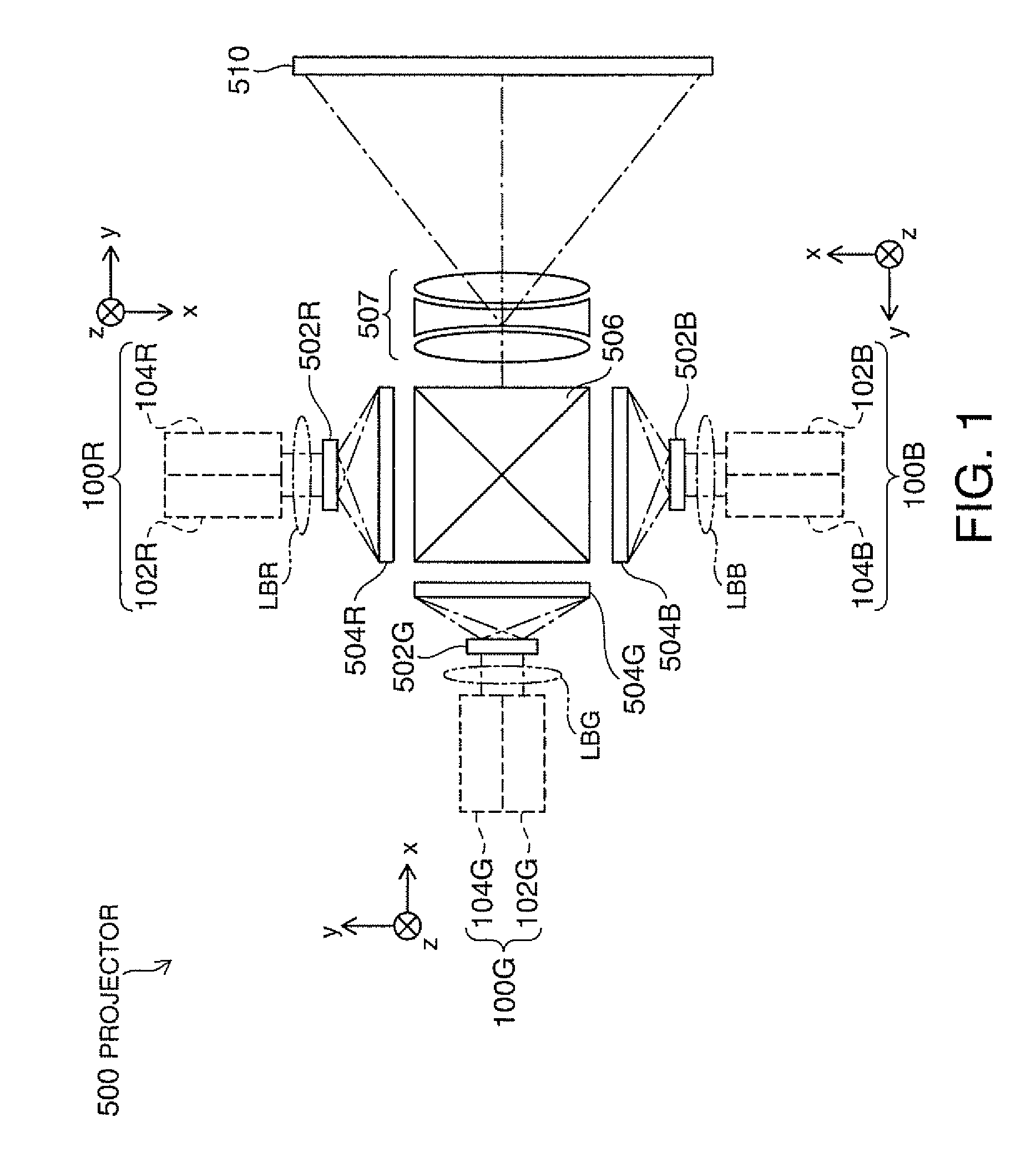

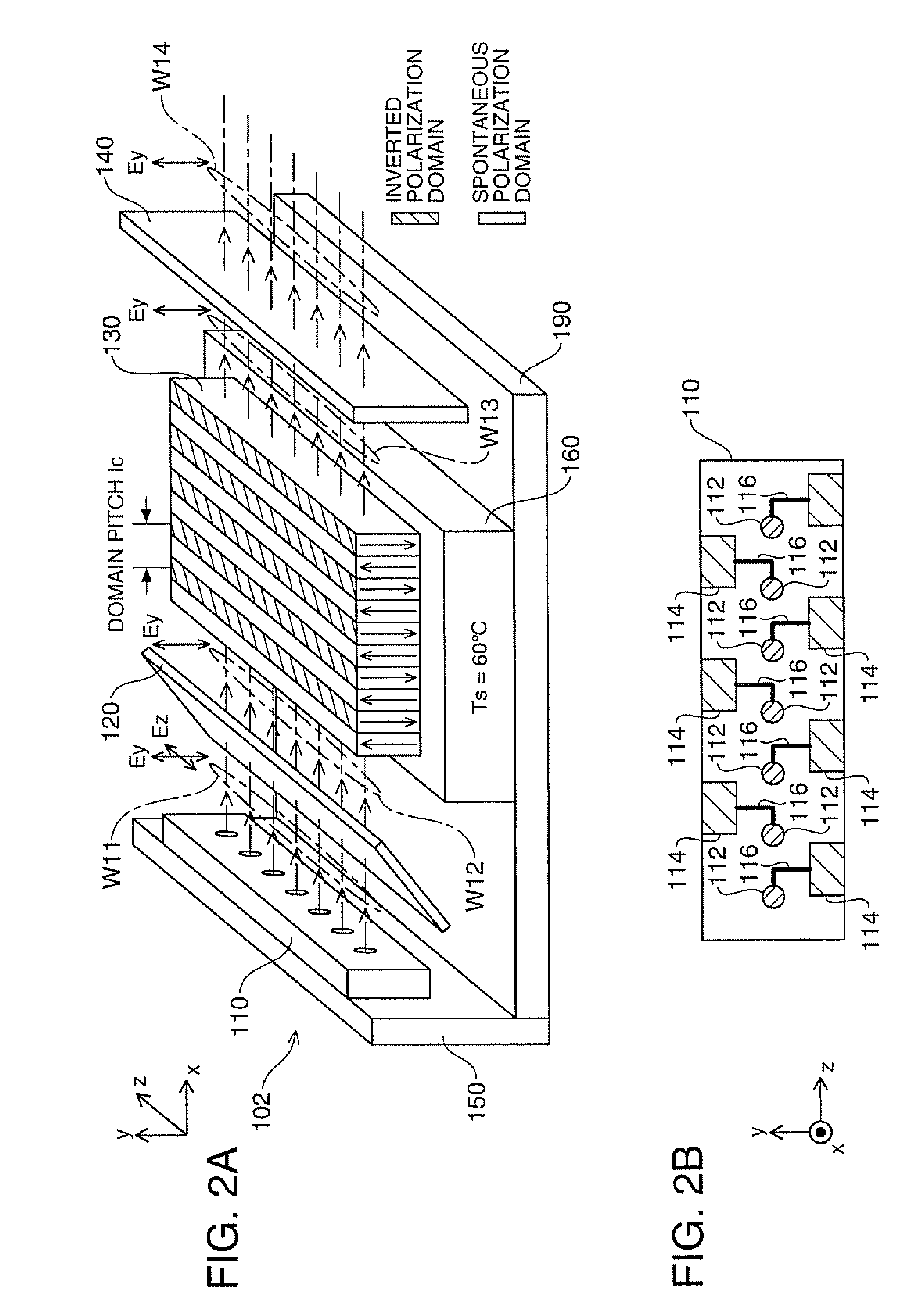

Laser light source apparatus, and monitoring apparatus and image display apparatus using the same

ActiveUS8126025B2Reduce coherenceLaser optical resonator constructionProjectorsLaser arrayLaser light

Owner:SEIKO EPSON CORP

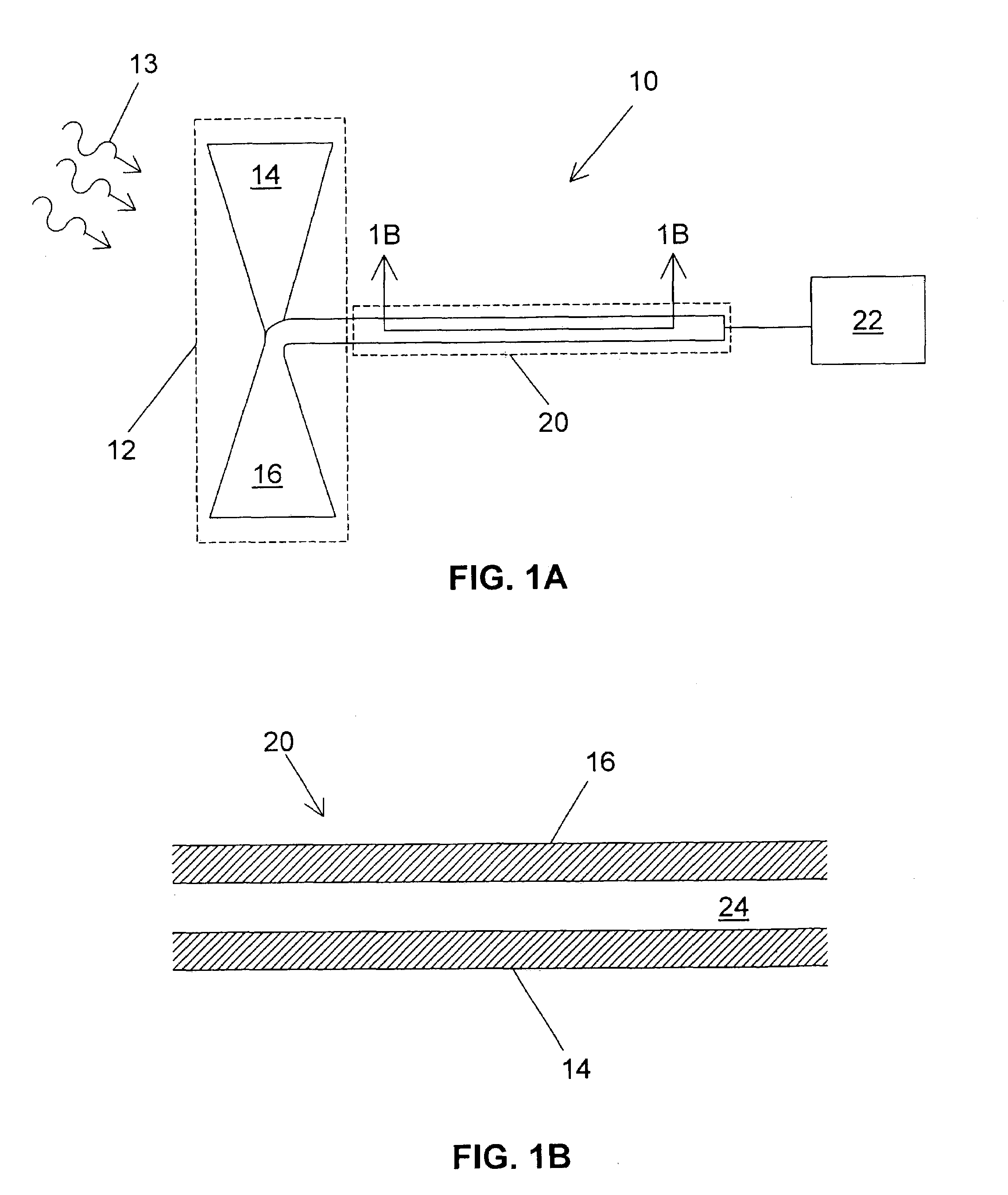

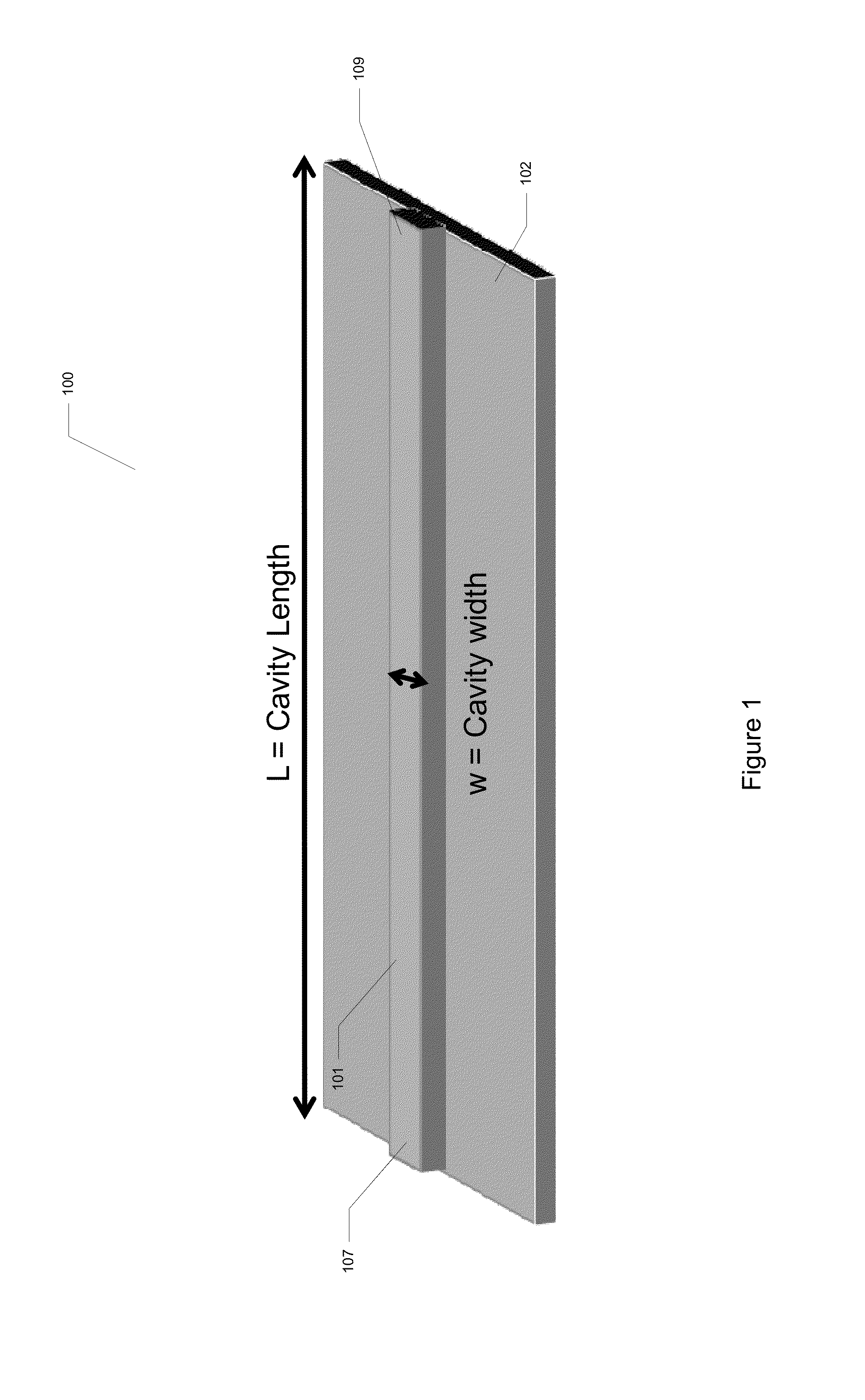

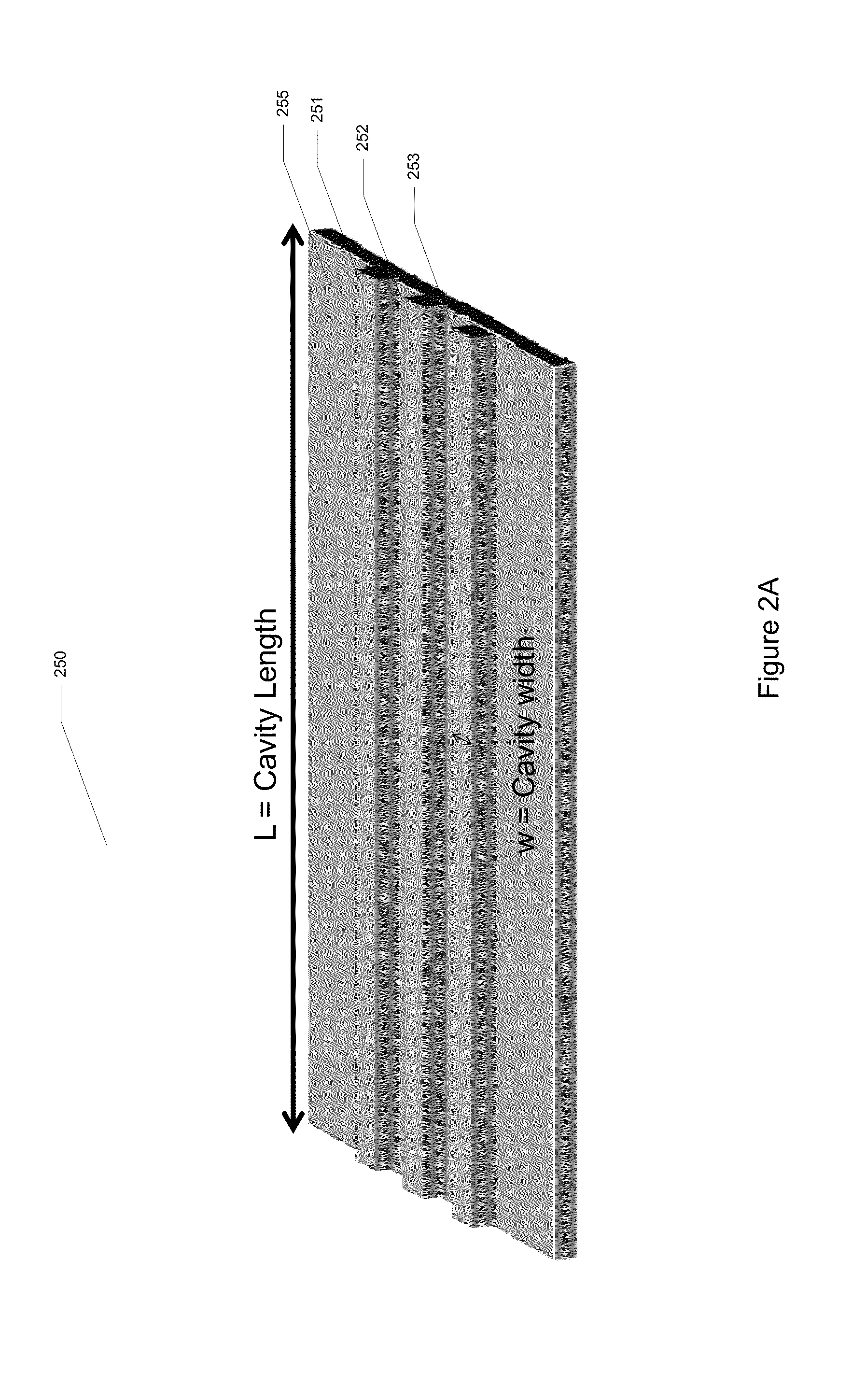

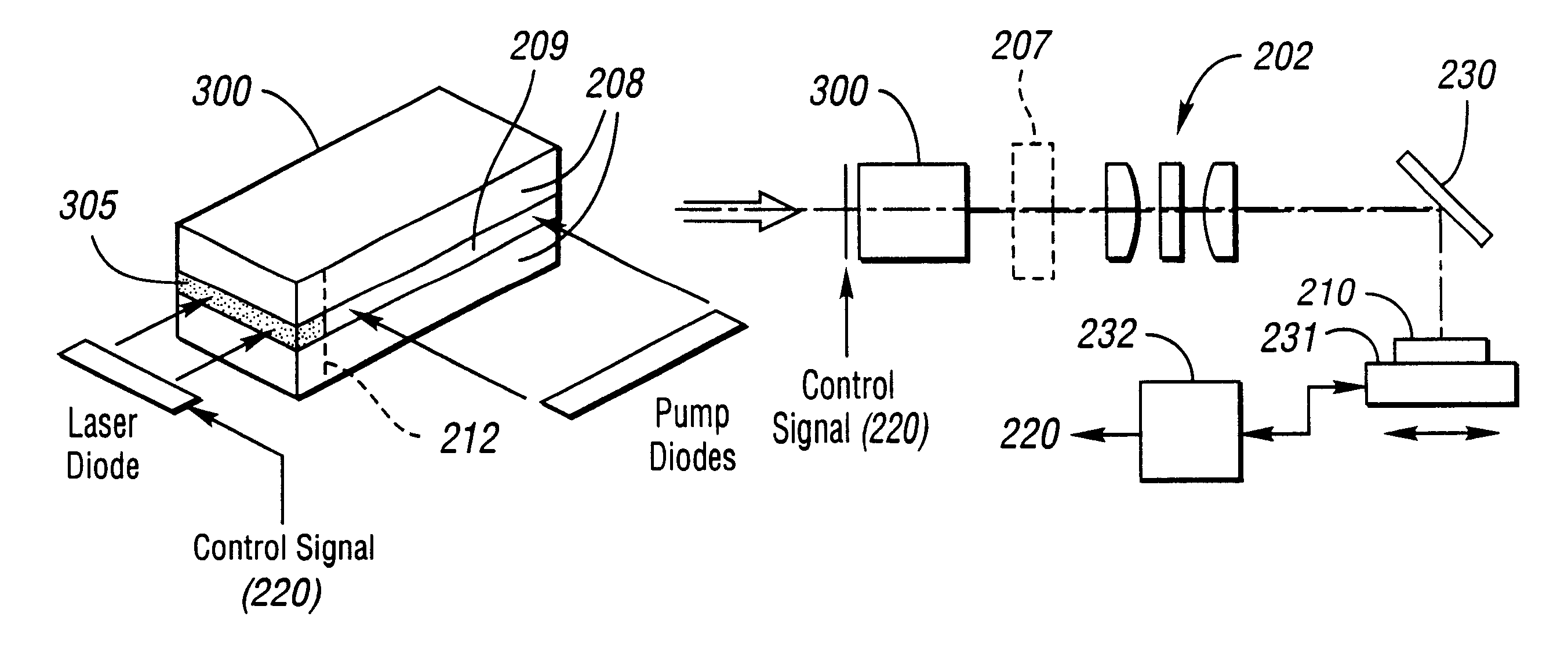

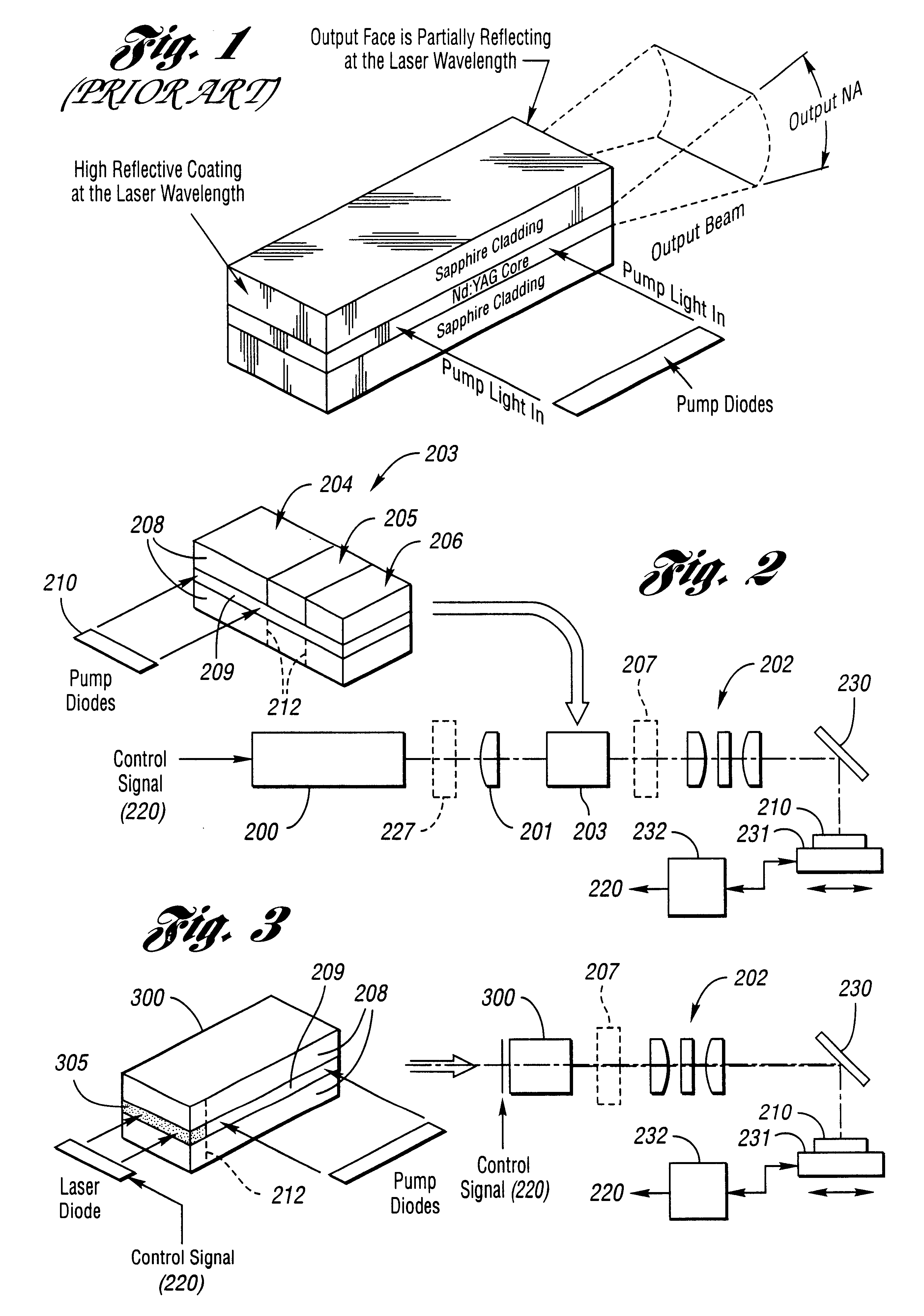

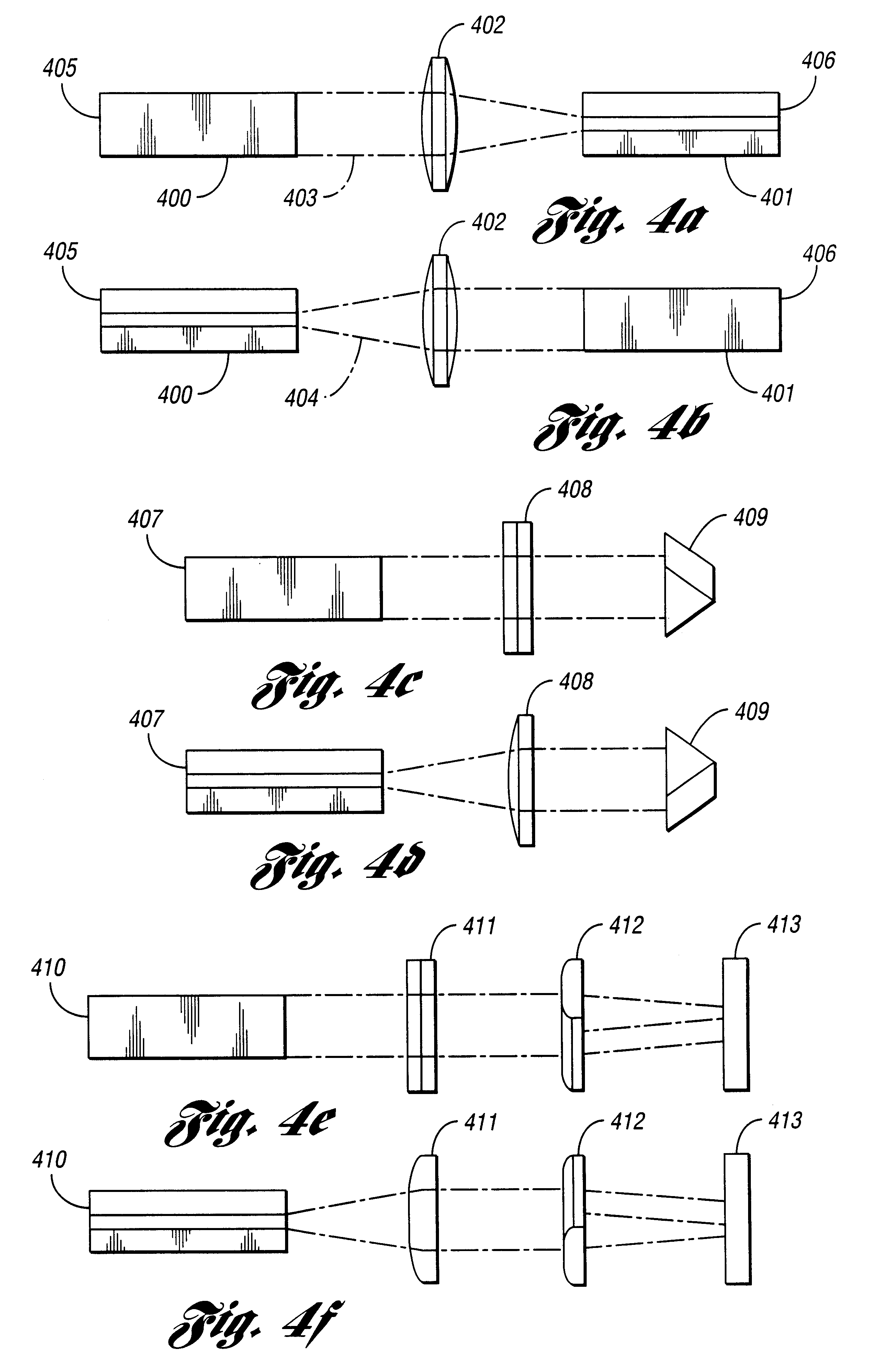

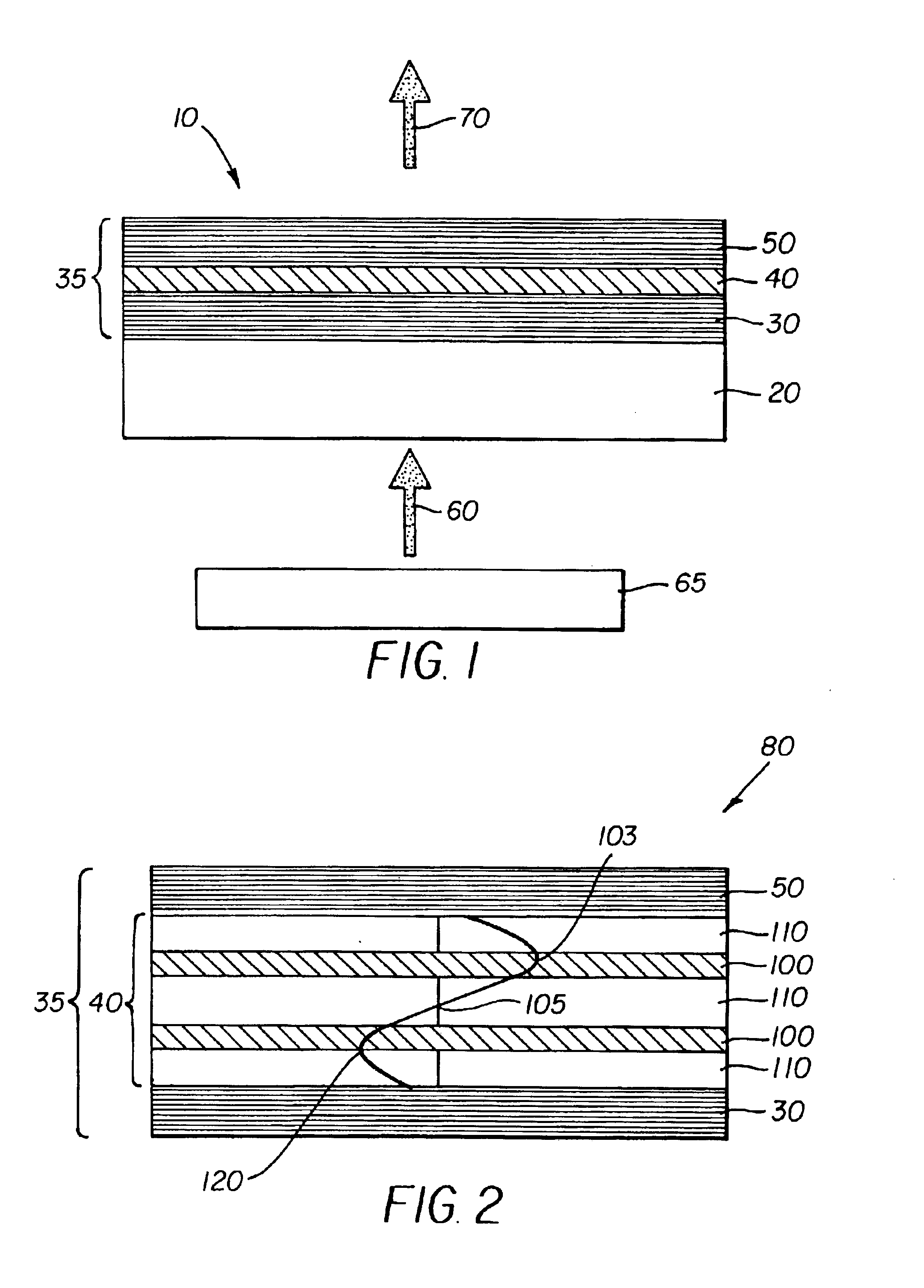

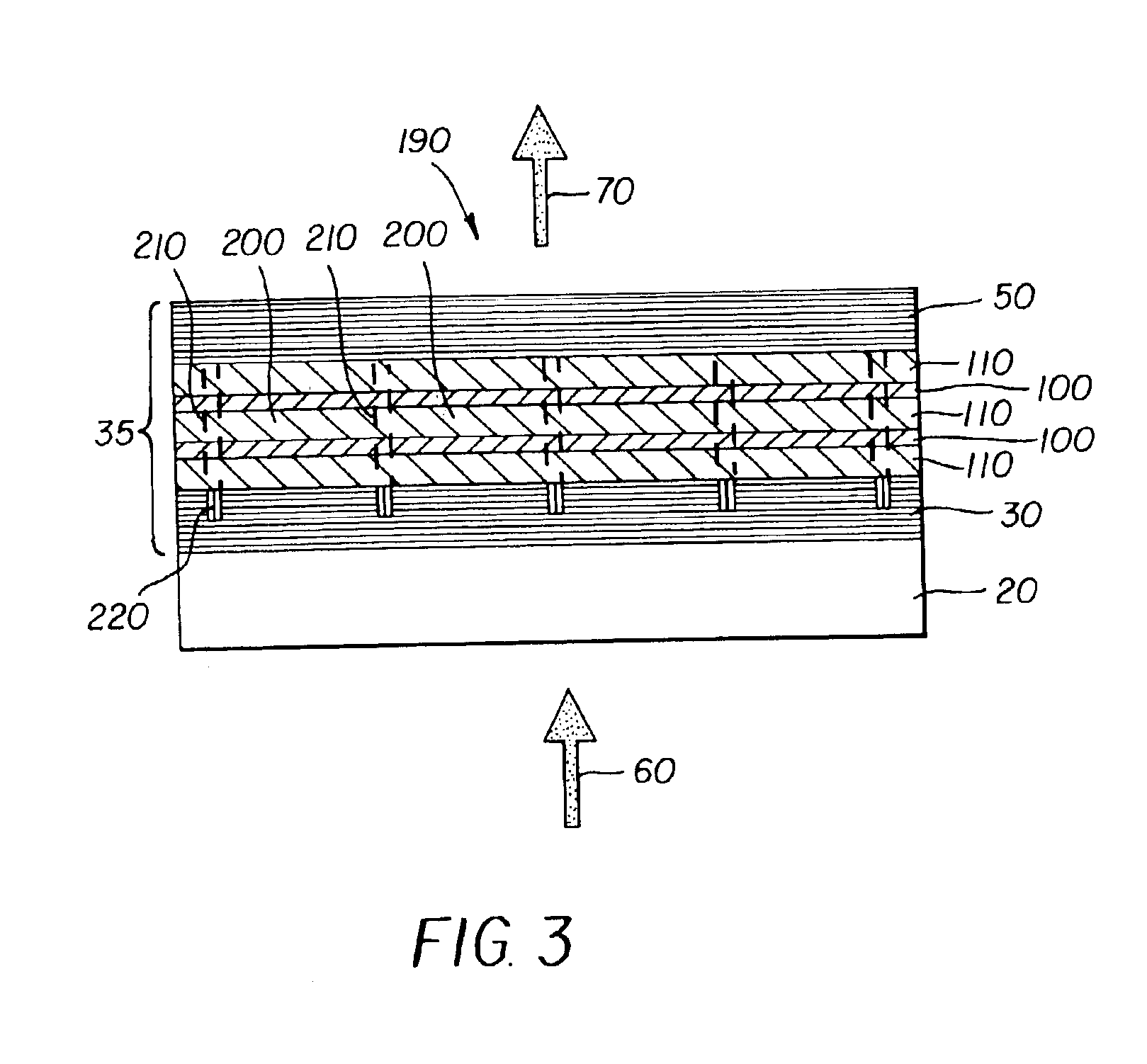

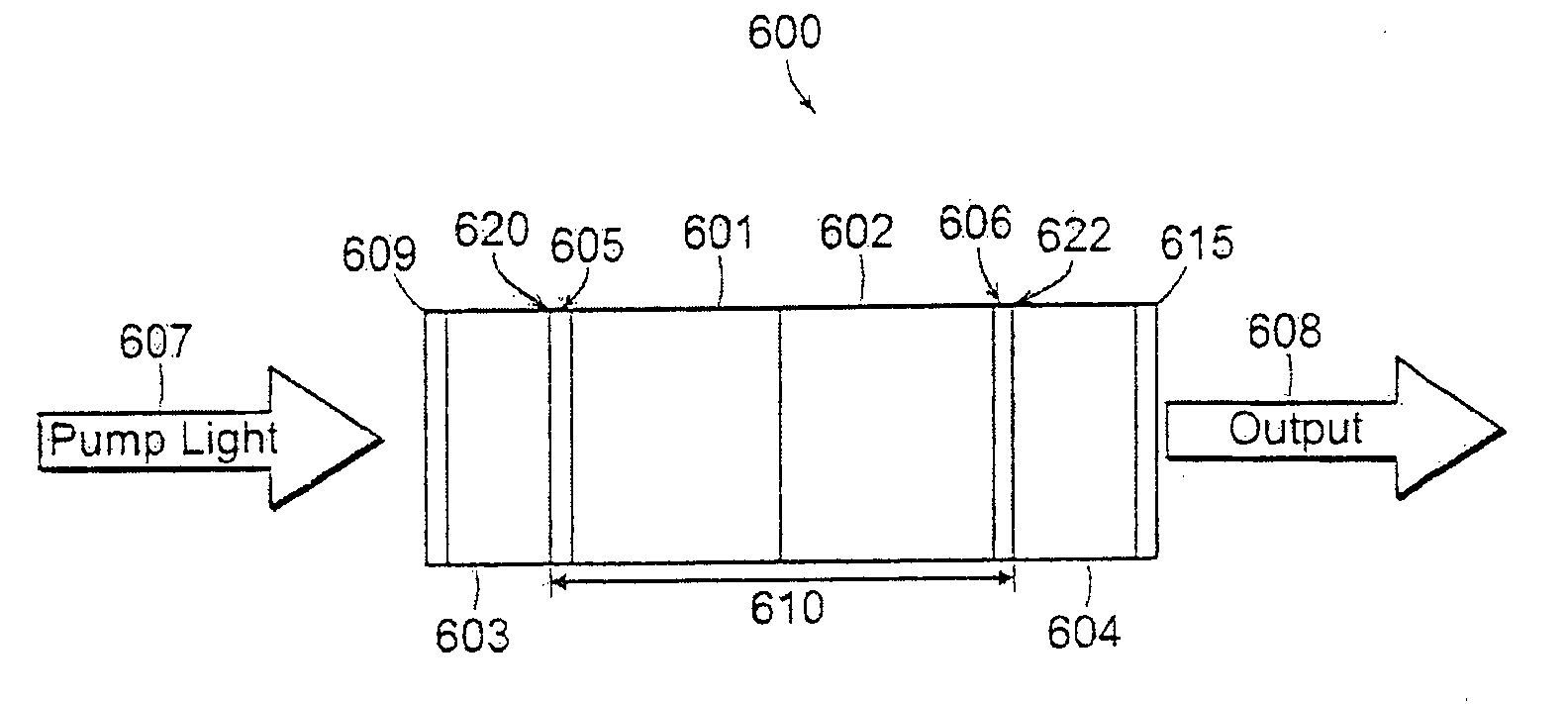

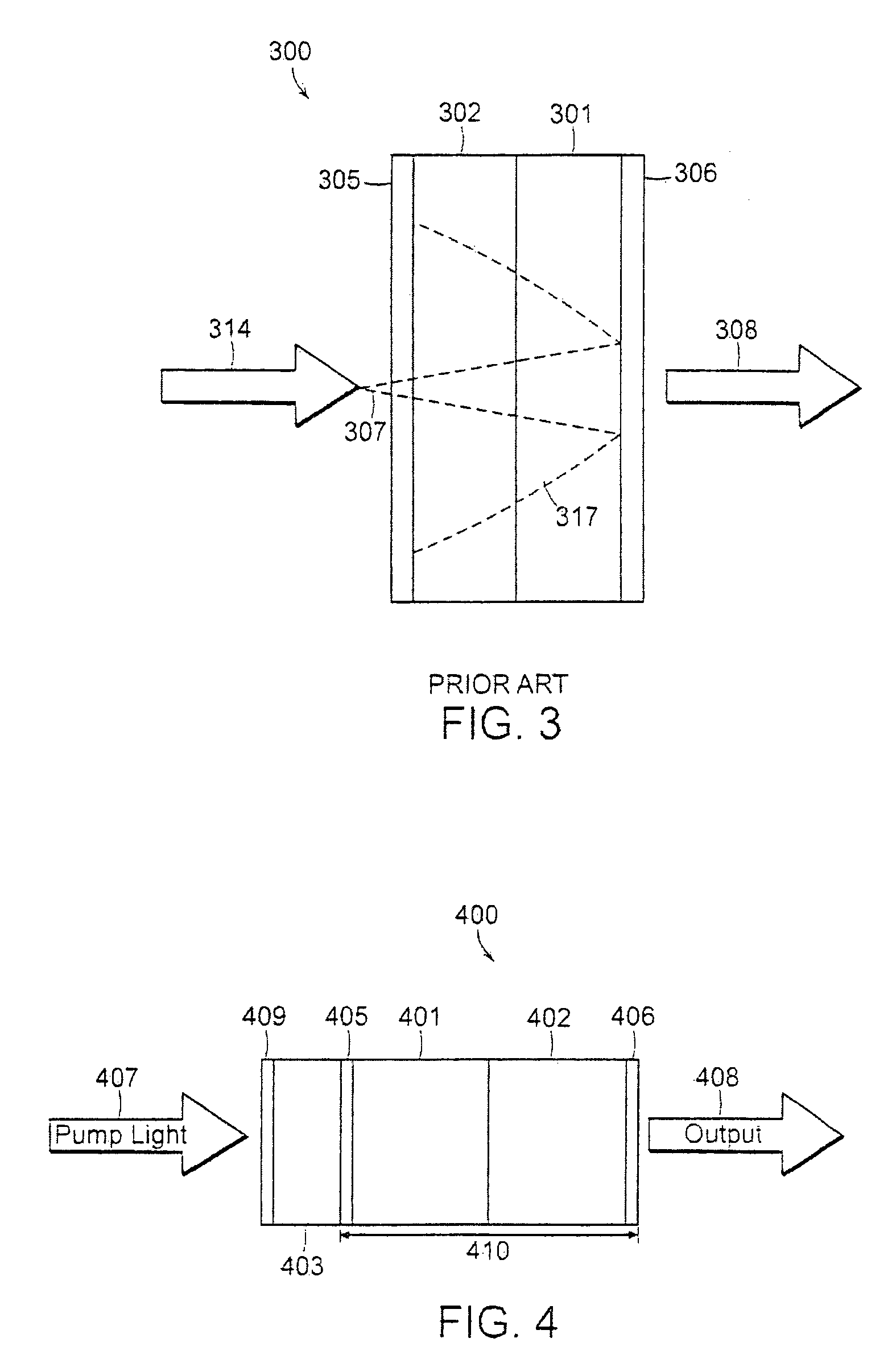

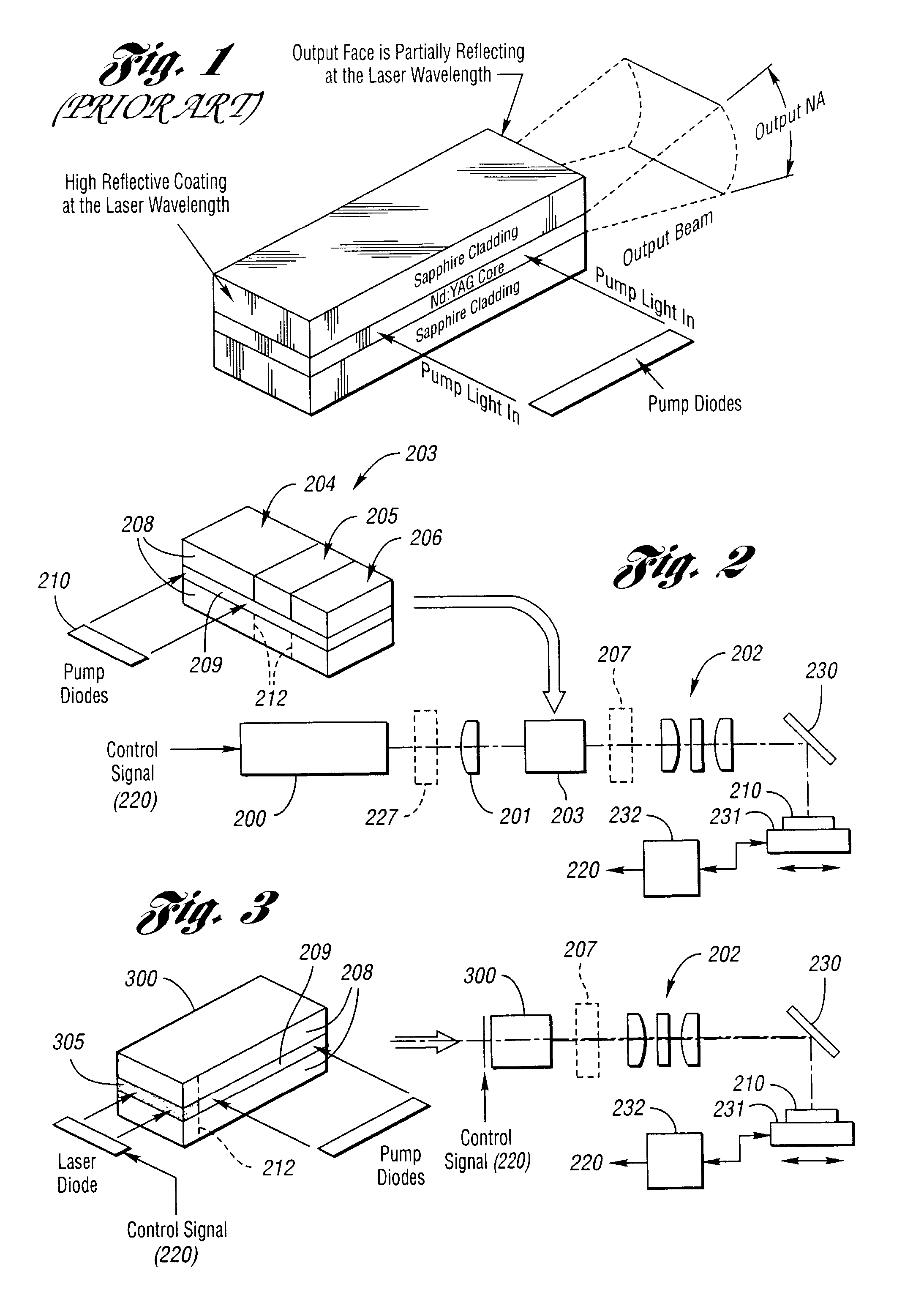

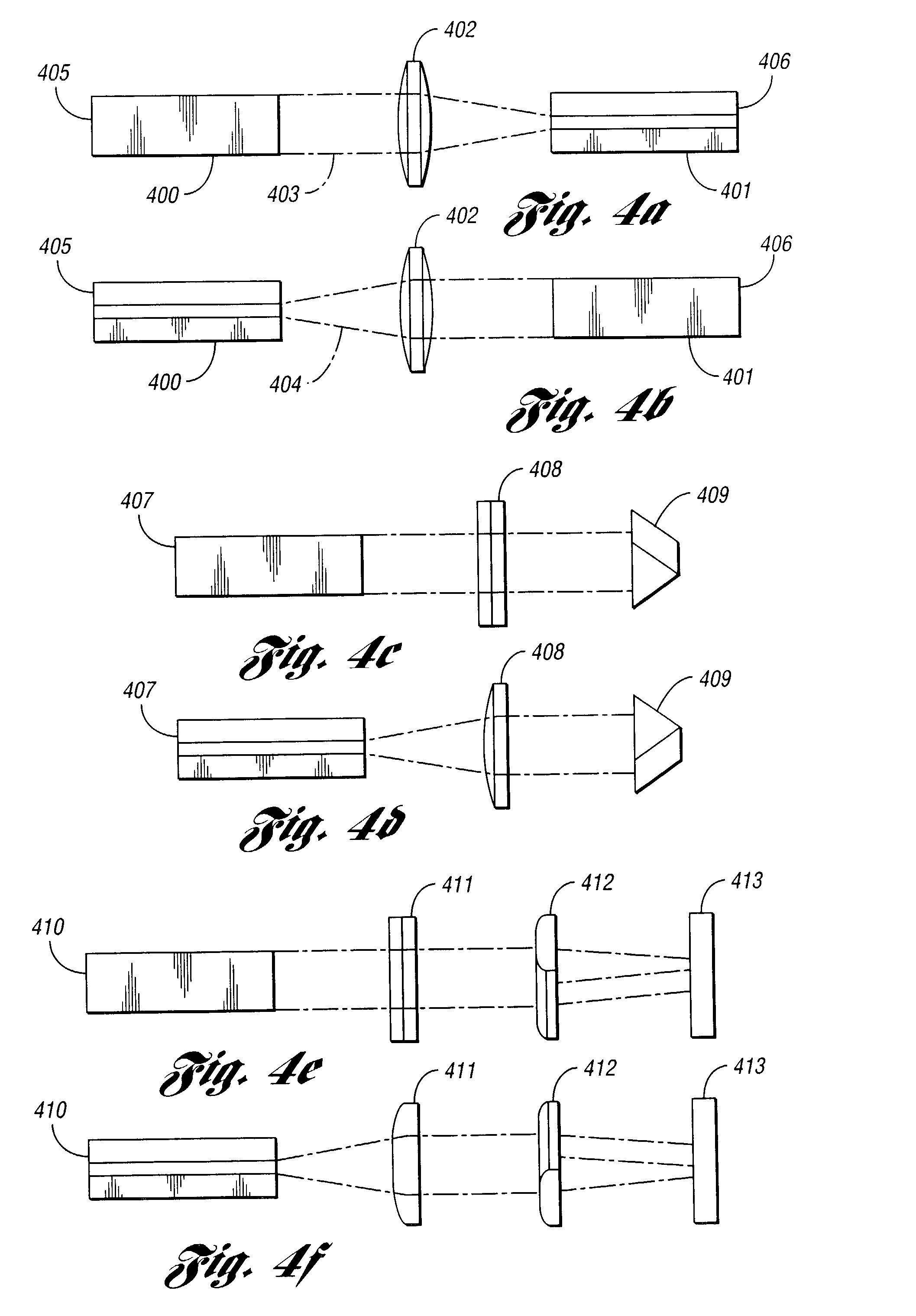

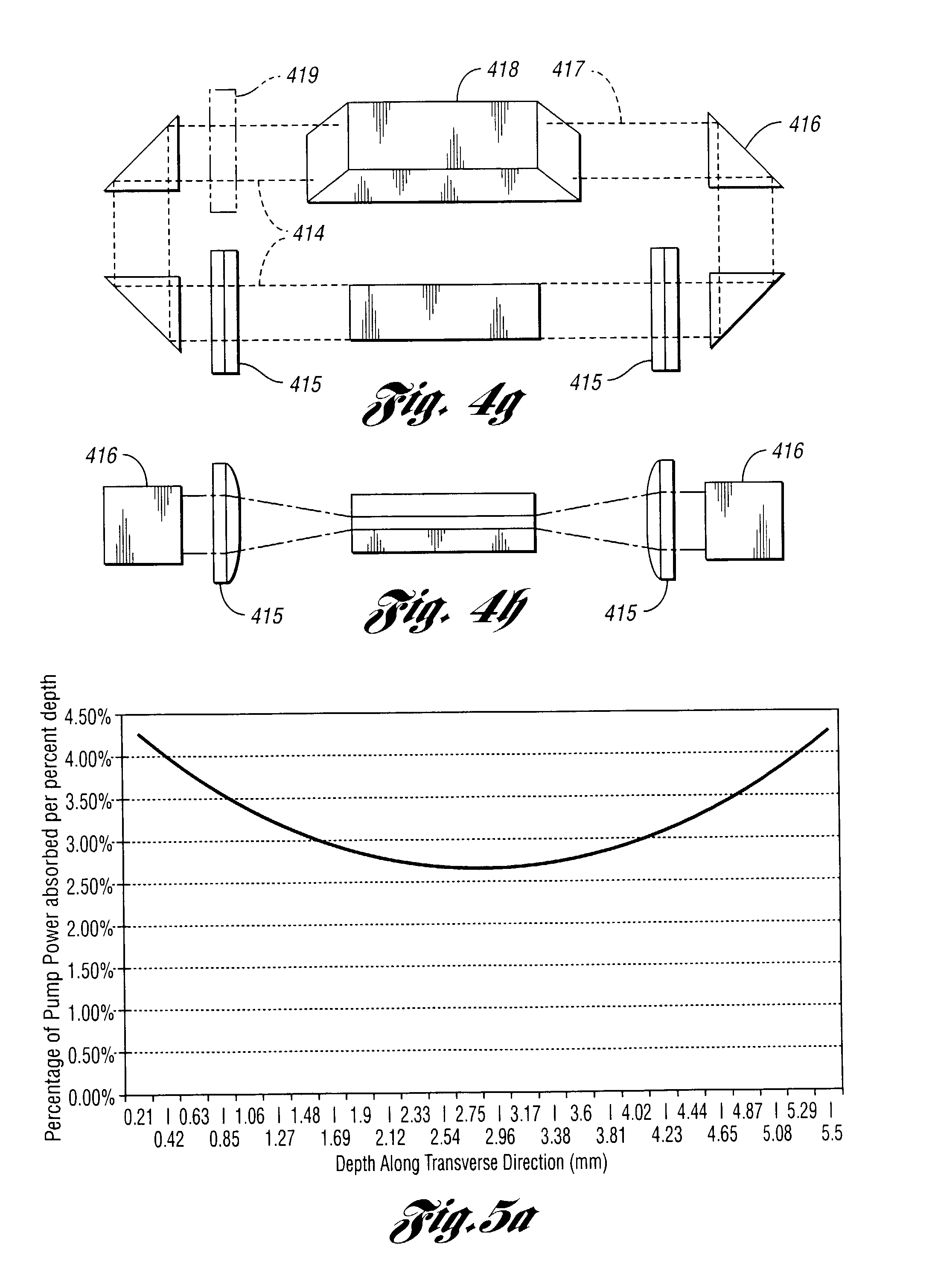

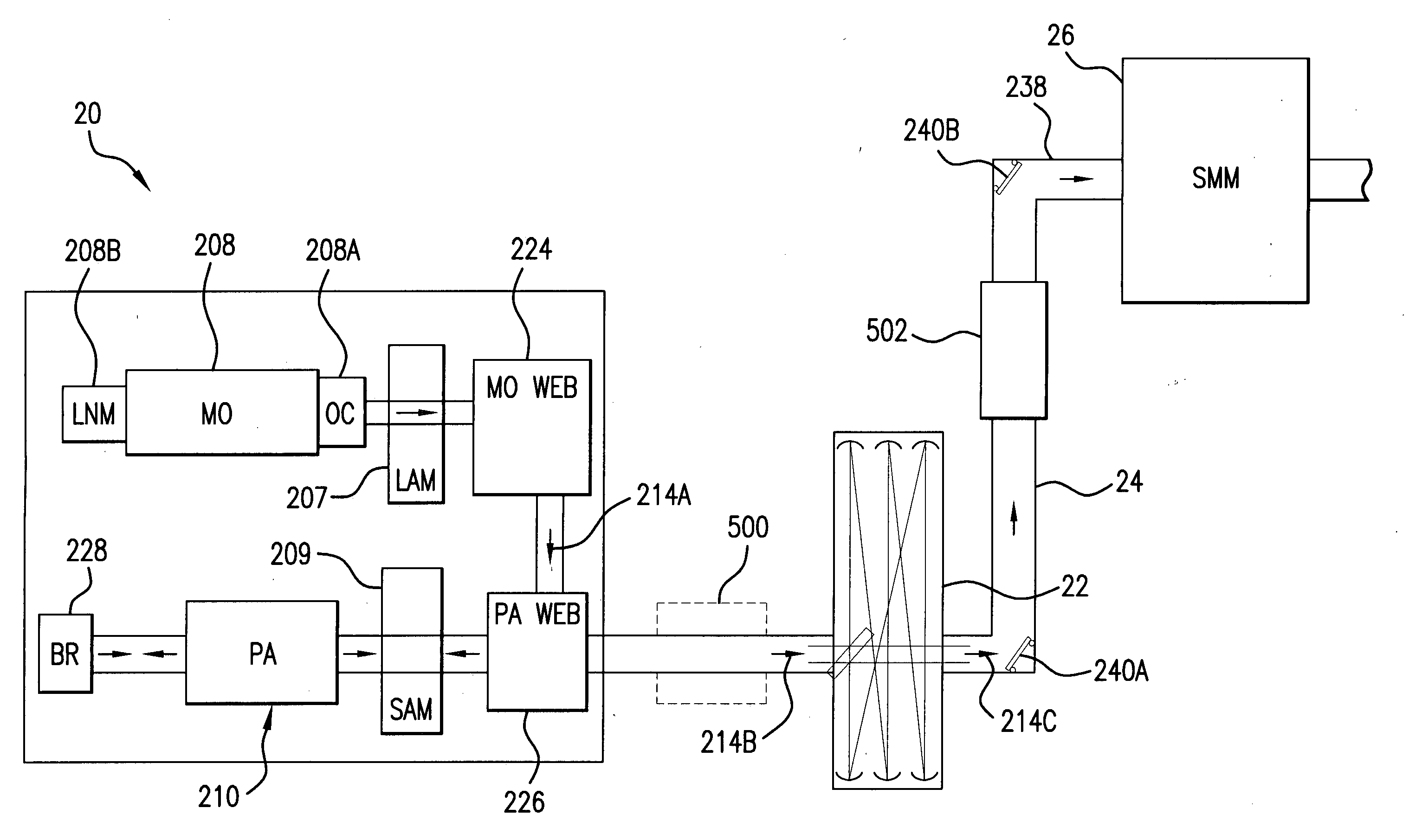

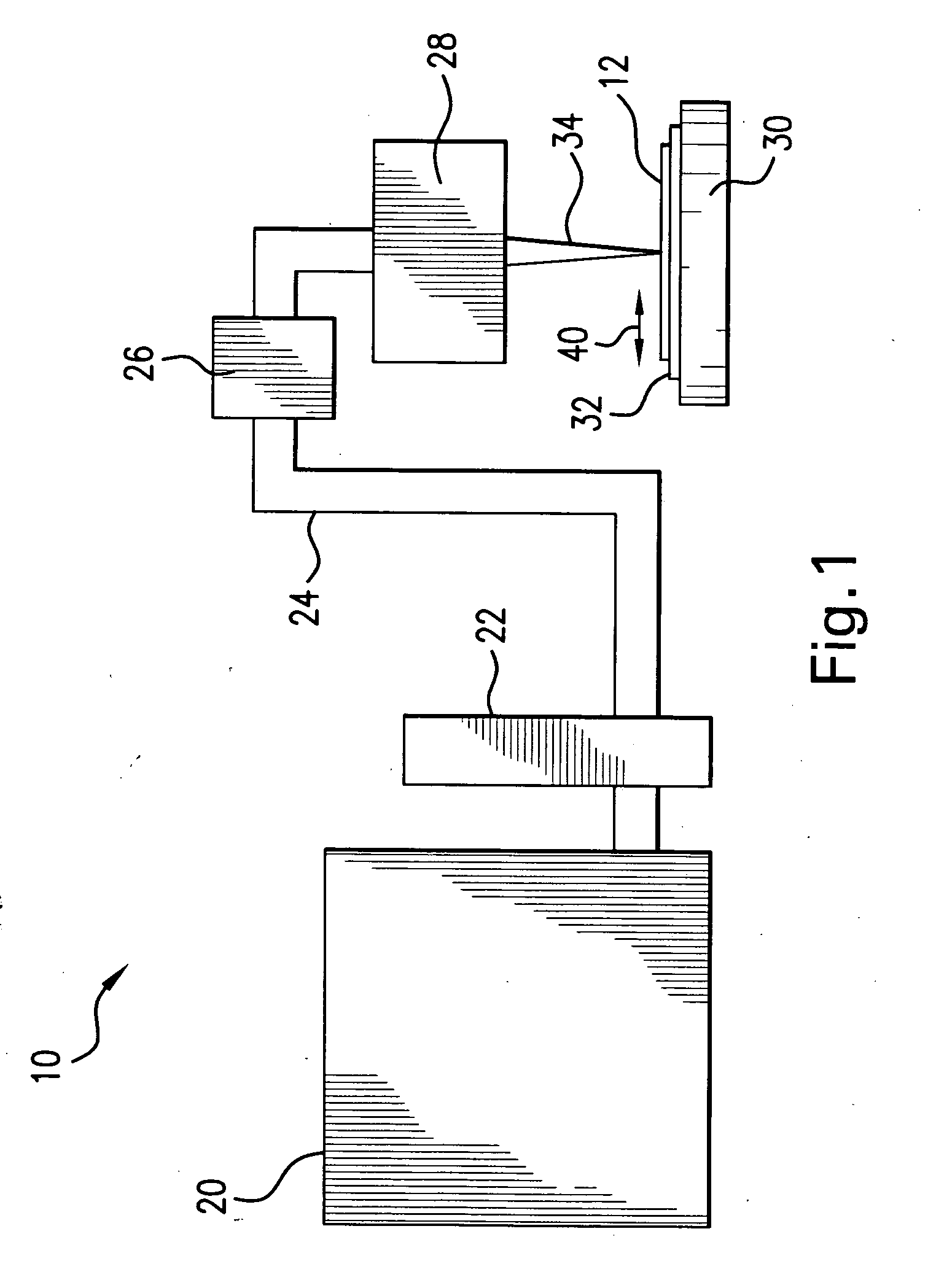

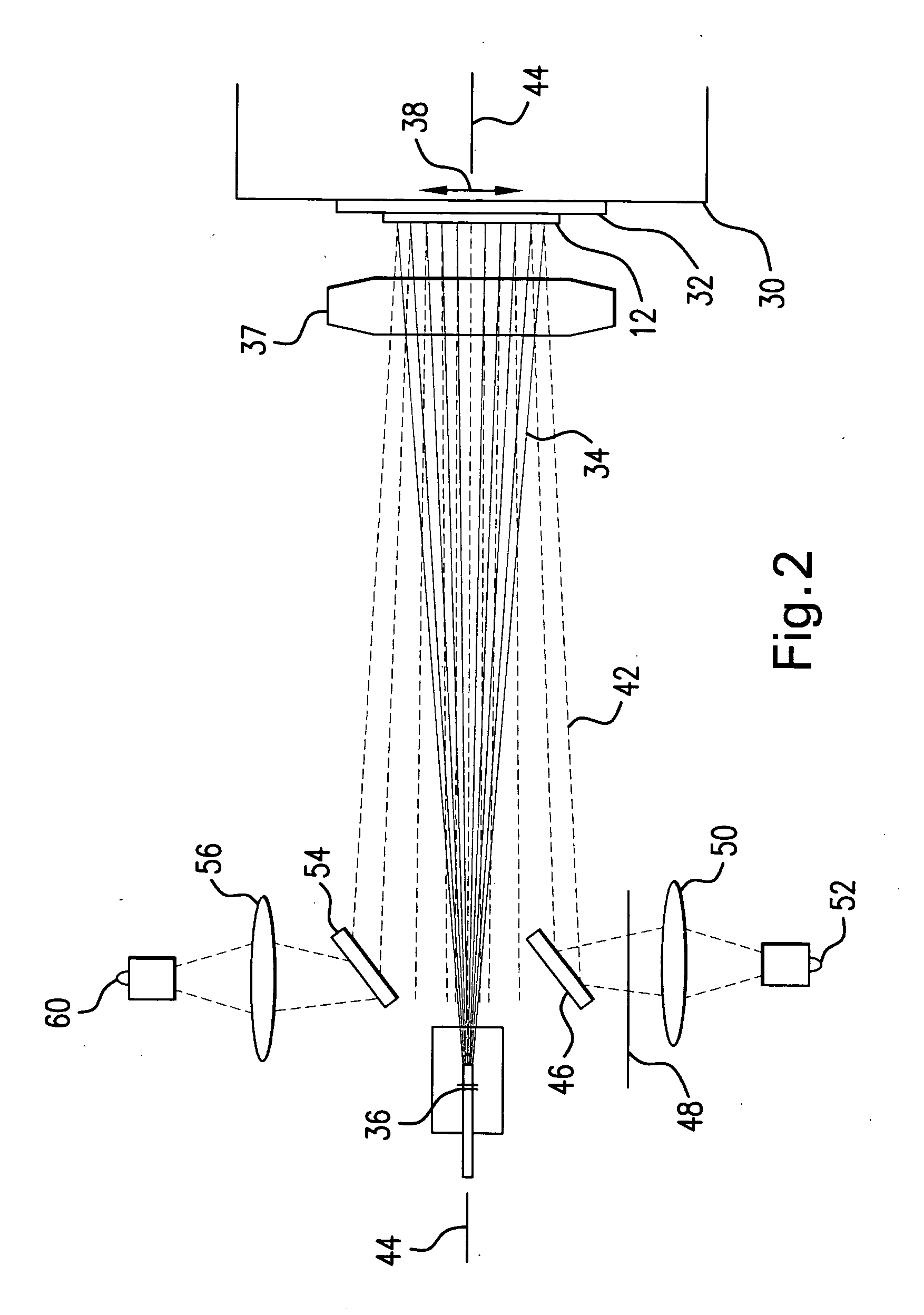

Laser based material processing methods and scalable architecture for material processing

InactiveUS6738396B2Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

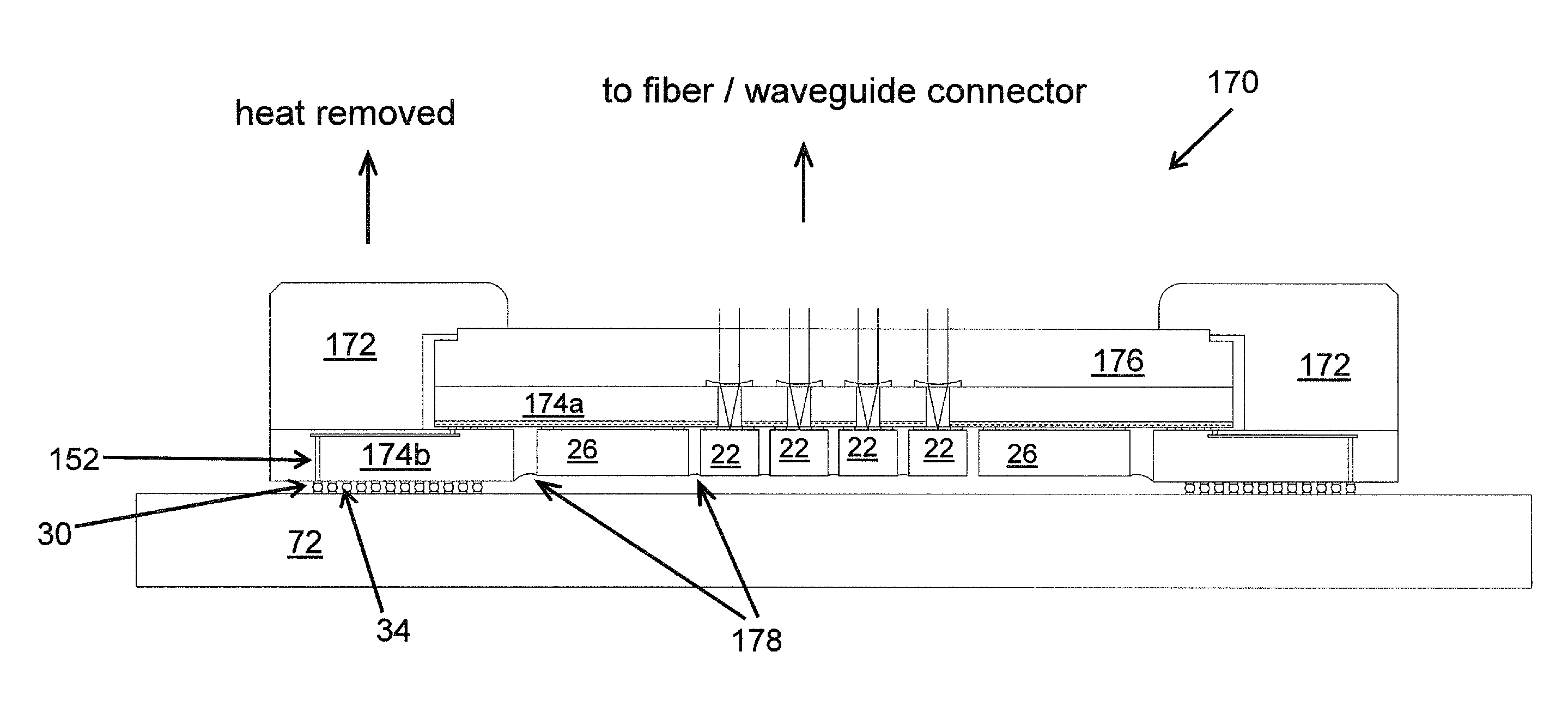

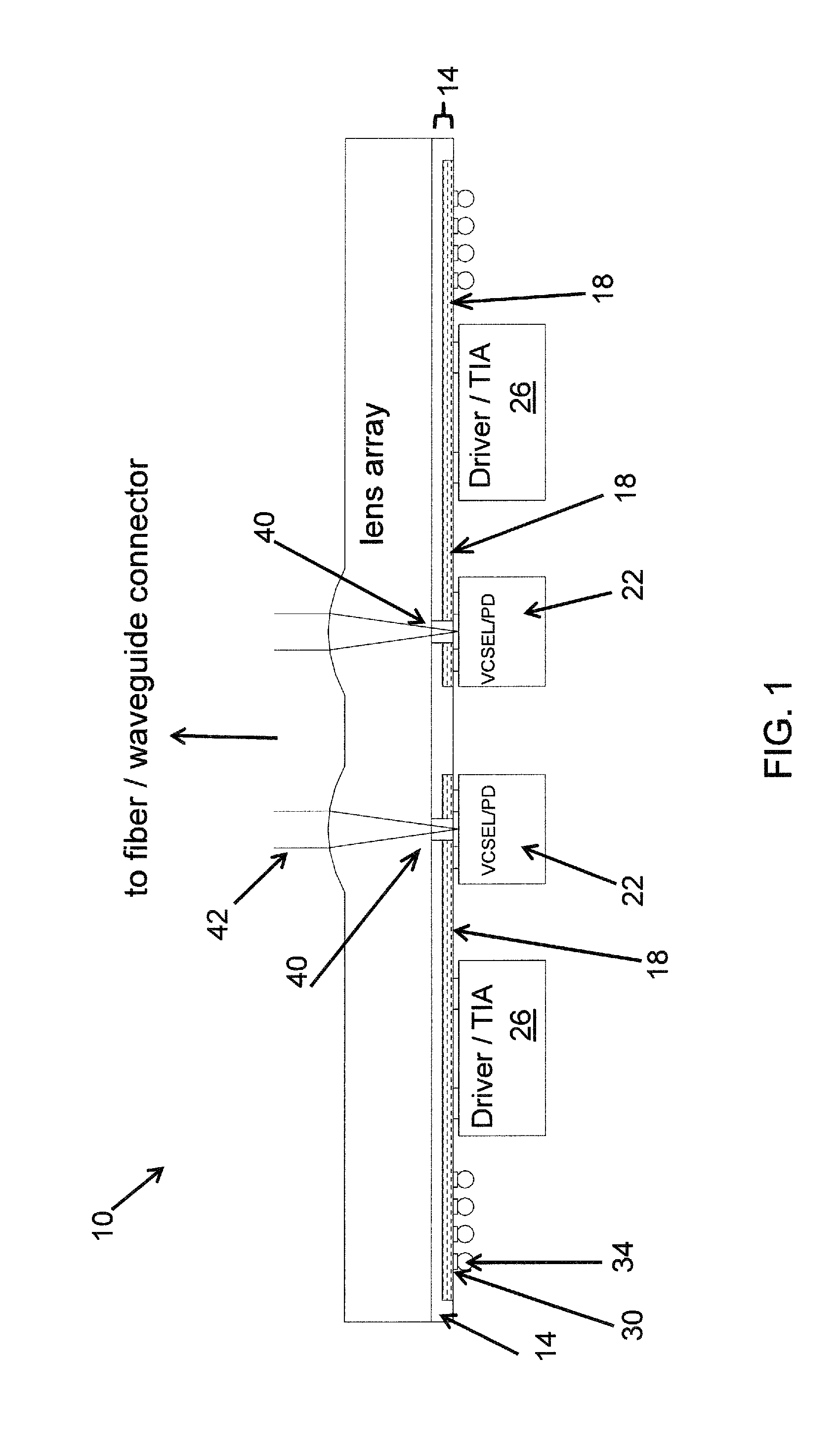

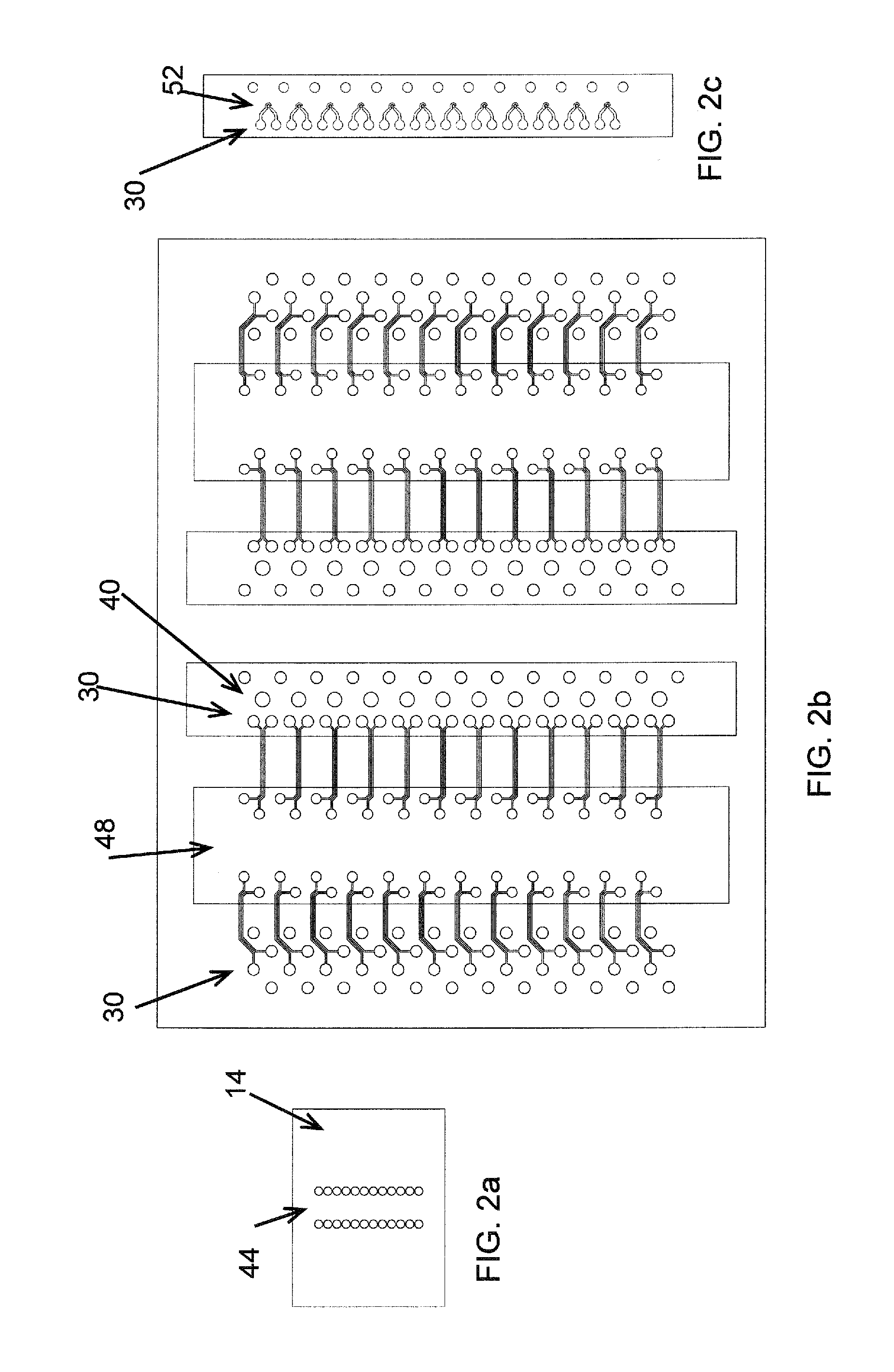

Silicon carrier optoelectronic packaging

ActiveUS20110044369A1Small sizeLow costLaser optical resonator constructionSemiconductor/solid-state device detailsOpto electronicOptical coupling

An optoelectronic (OE) package or system and method for fabrication is disclosed which includes a silicon layer with wiring. The silicon layer has an optical via for allowing light to pass therethrough. An optical coupling layer is bonded to the silicon layer, and the optical coupling layer includes a plurality of microlenses for focusing and or collimating the light through the optical via. A plurality of OE elements are coupled to the silicon layer and electrically communicating with the wiring. At least one of the OE elements positioned in optical alignment with the optical via for receiving the light. A carrier is interposed between electrical interconnect elements. The carrier is positioned between the wiring of the silicon layer and a circuit board and the carrier is electrically connecting first interconnect elements connected to the wiring of the silicon layer and second interconnect elements connected to the circuit board.

Owner:GLOBALFOUNDRIES US INC

Organic vertical cavity laser and imaging system

InactiveUS6947459B2Semiconductor laser arrangementsLaser active region structureLaser transmitterLaser light

Owner:EASTMAN KODAK CO

Q-switched microlaser apparatus and method for use

A monolithic passively Q switched microlaser includes an optically transparent heat conductive element bonded to a gain medium, which is in turn bonded to a saturable absorber, which may also be bonded to a second optically transparent heat conductive element. Only the gain medium and saturable absorber are disposed within the laser resonator.

Owner:KK TOPCON +1

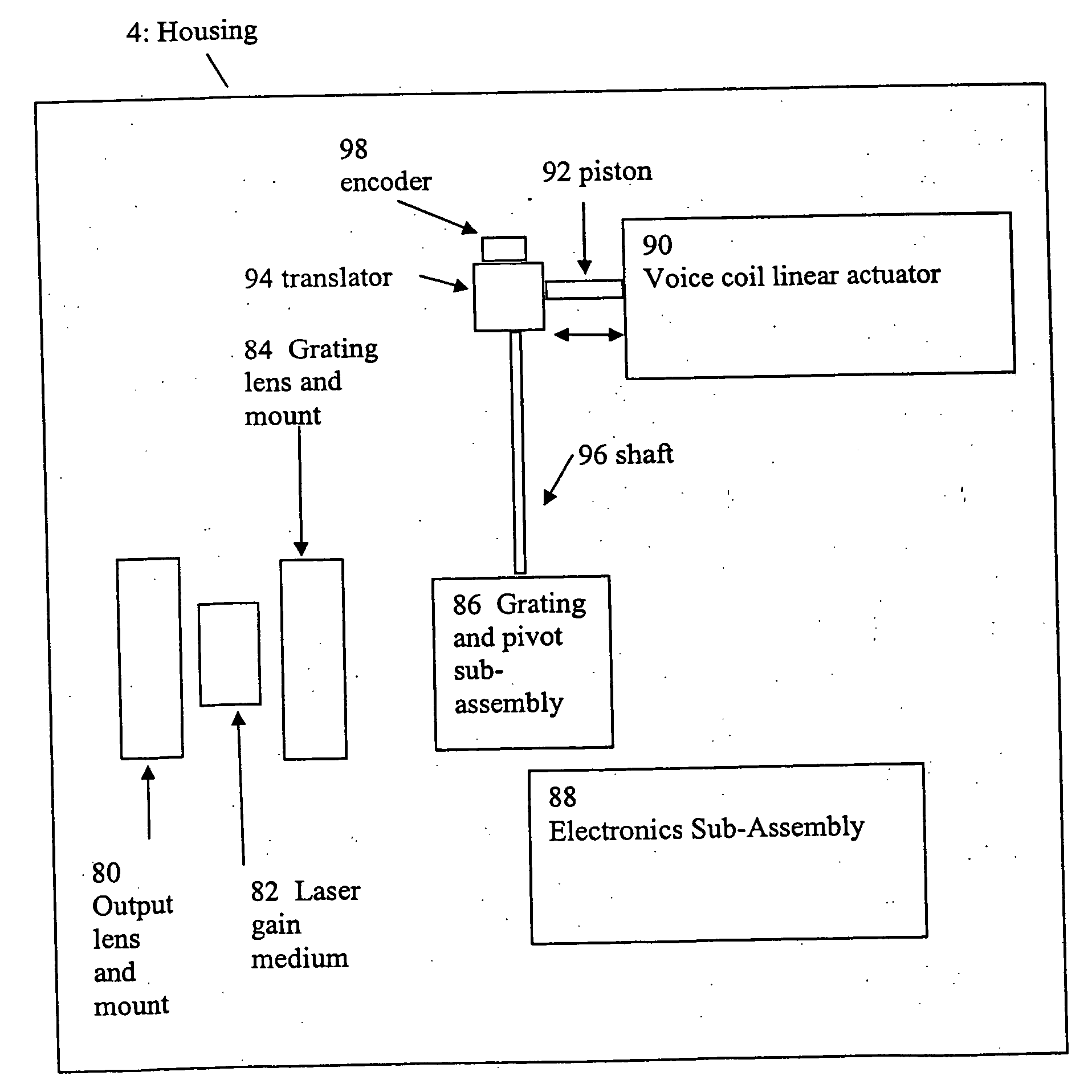

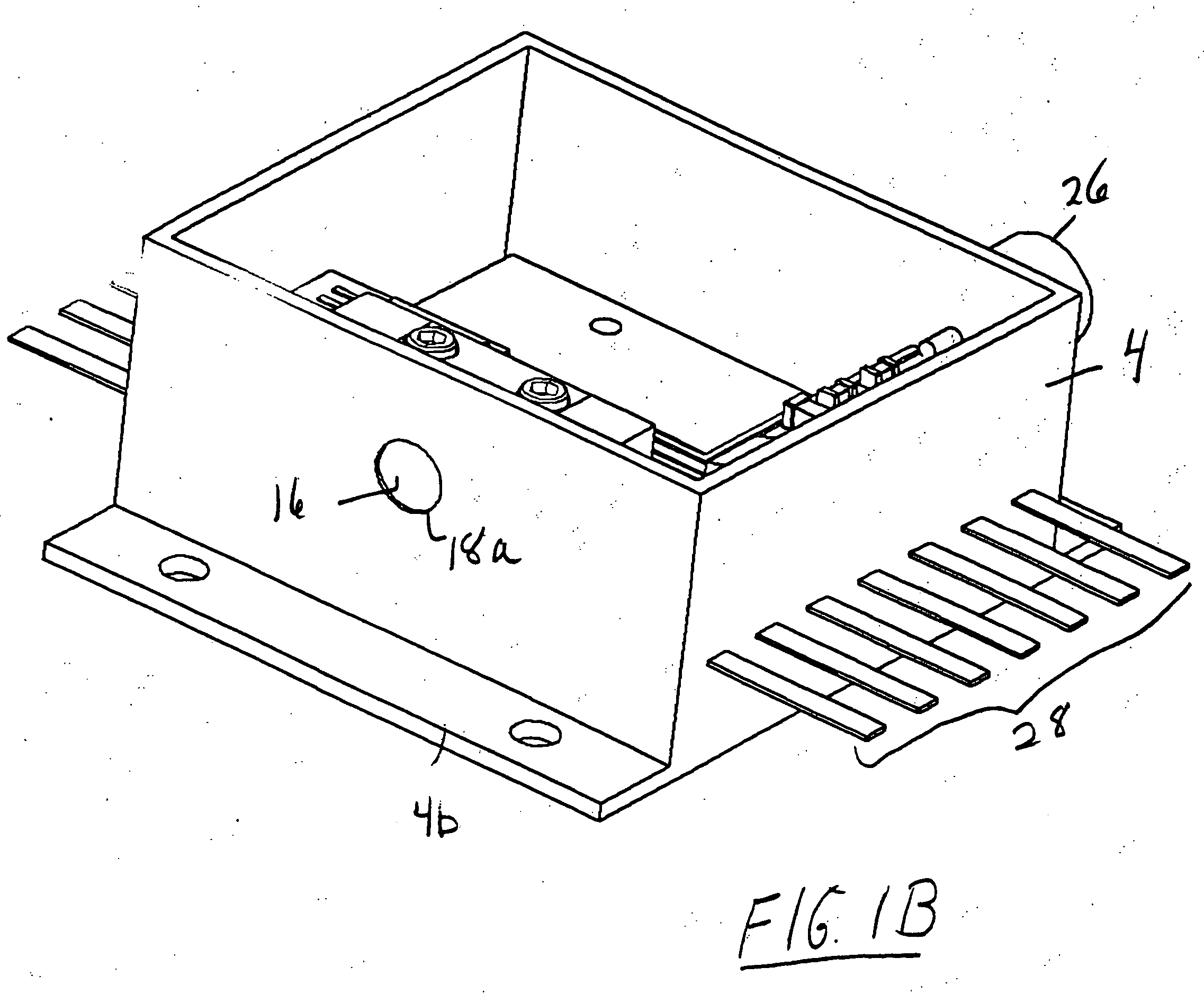

External cavity tunable compact mid-IR laser

ActiveUS20070030865A1Reduce usageImprove cooling effectLaser using scattering effectsOptical resonator shape and constructionThermoelectric coolingGrating

A compact mid-IR laser device utilizes an external cavity to tune the laser. The external cavity may employ a Littrow or Littman cavity arrangement. In the Littrow cavity arrangement, a filter, such as a grating, is rotated to provide wavelength gain medium selectivity. In the Littman cavity arrangement, a reflector is rotated to provide tuning. A quantum cascade laser gain medium provides mid-IR frequencies suitable for use in molecular detection by signature absorption spectra. The compact nature of the device is obtained owing to an efficient heat transfer structure, the use of a small diameter aspheric lens for both the output lens and the external cavity lens and a monolithic assembly structure to hold the optical elements in a fixed position relative to one another. The compact housing size may be approximately 20 cm×20 cm×20 cm or less. Efficient heat transfer is achieved using a thermoelectric cooler TEC combined with a high thermal conductivity heat spreader onto which the quantum cascade laser gain medium is thermally coupled. The heat spreader not only serves to dissipate heat and conduct same to the TEC, but also serves as an optical platform to secure the optical elements within the housing in a fixed relationship relative on one another. The small diameter aspheric output and external cavity lens each may have a diameter of 10 mm or less and each lens is positioned to provided a collimated beam output from the quantum cascade laser gain medium. The housing is hermetically sealed to provide a rugged, light weight portable MIR laser source.

Owner:DAYLIGHT SOLUTIONS

Laser based material processing methods and scalable architecture for material processing

InactiveUS20030160034A1Improve stabilityLaser using scattering effectsOptical resonator shape and constructionPower applicationNanosecond

Methods and systems for laser-based processing of materials are disclosed wherein a scalable laser architecture, based on planar waveguide technology, provides for pulsed laser micromachining applications while supporting higher average power applications like laser welding and cutting. Various embodiments relate to improvements in planar waveguide technology which provide for stable operation at high powers with a reduction in spurious outputs and thermal effects. At least one embodiment provides for micromachining with pulsewidths in the range of femtoseconds to nanoseconds. In another embodiment, 100W or greater average output power operation is provided for with a diode-pumped, planar waveguide architecture.

Owner:THE GSI GRP LLC

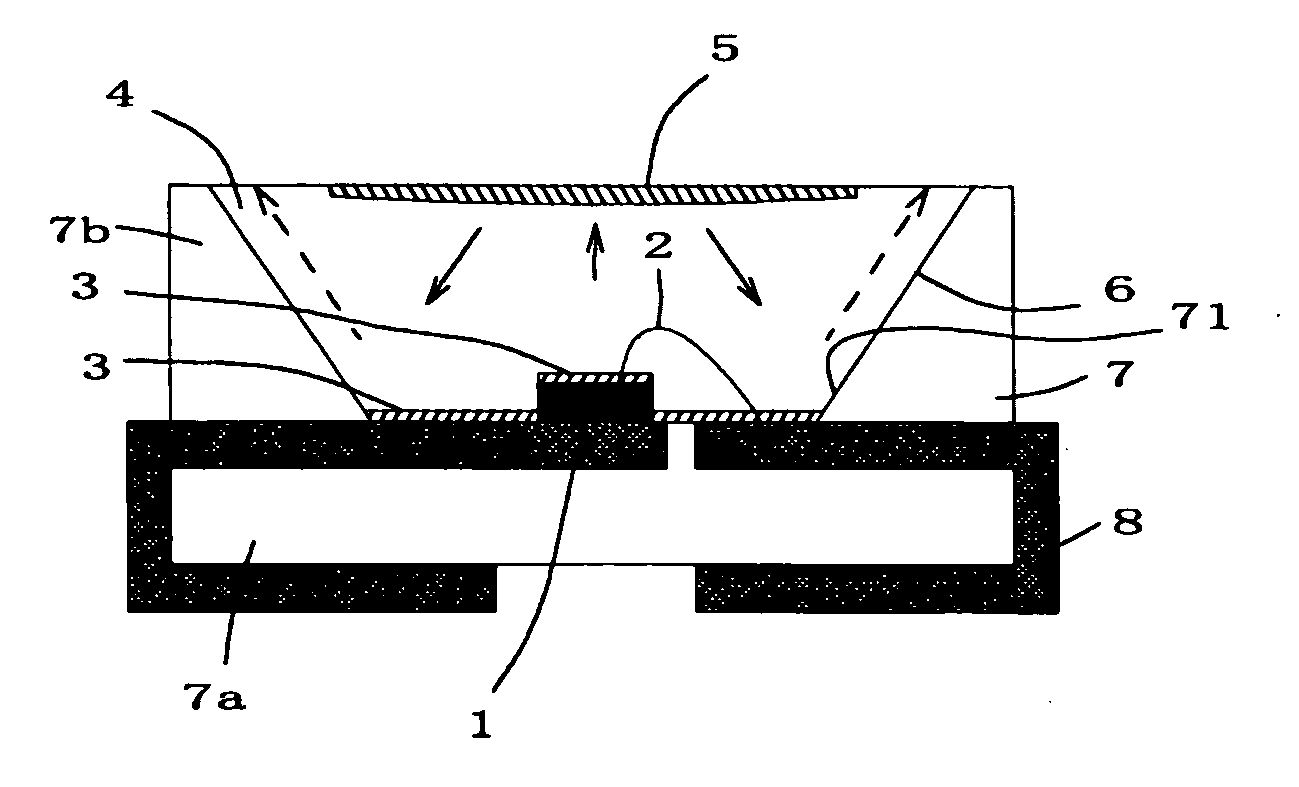

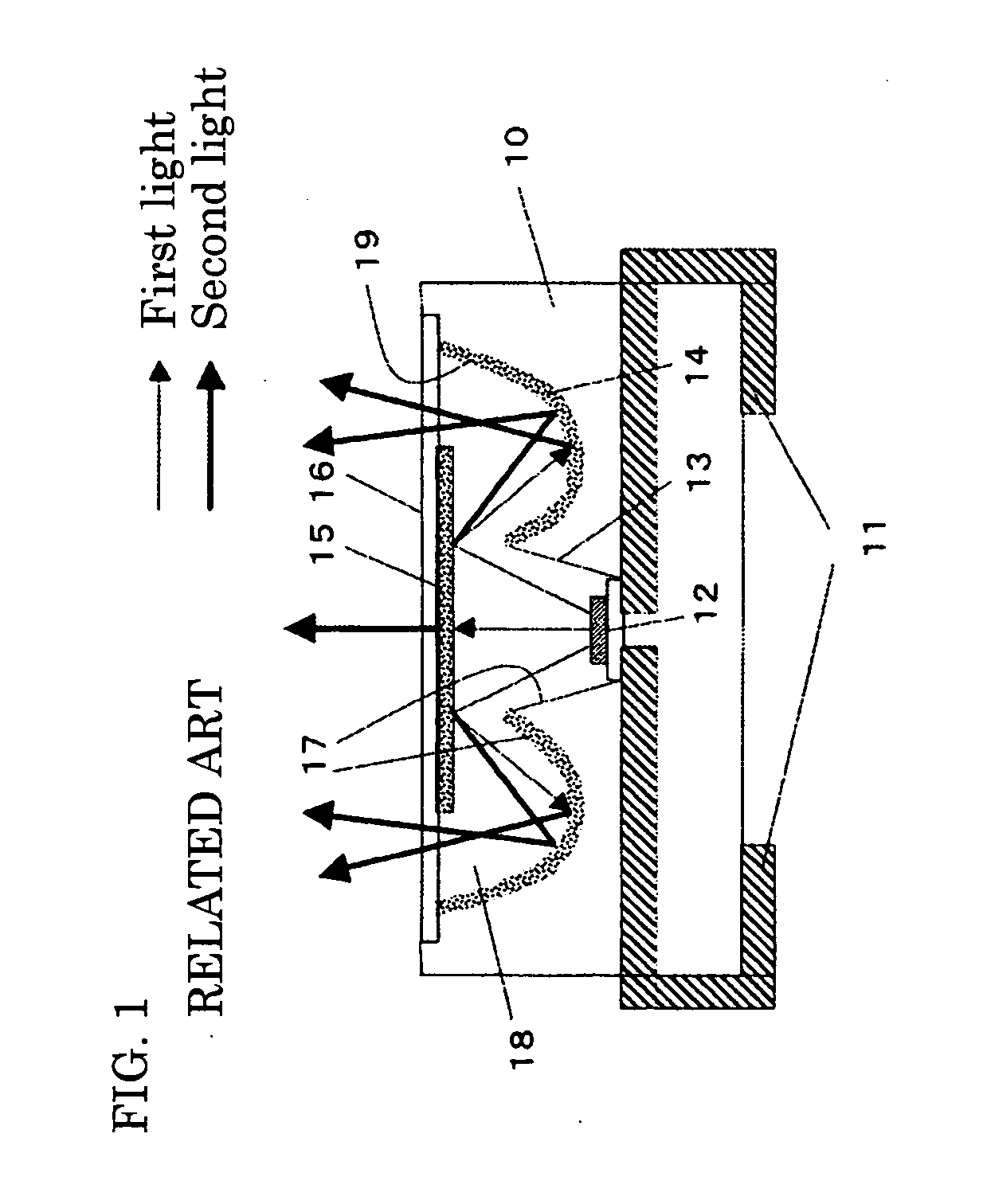

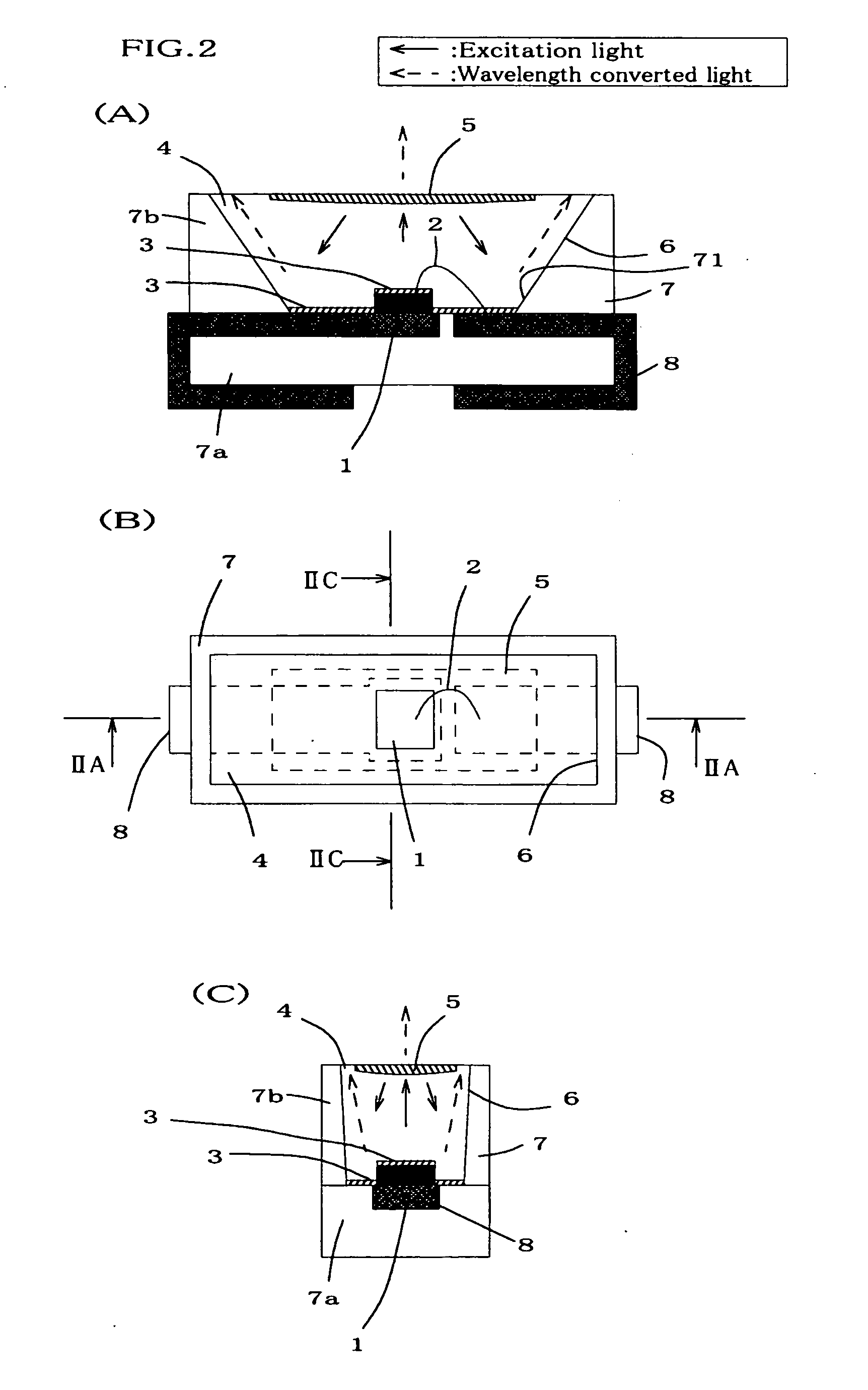

Semiconductor light-emitting apparatus having wavelength conversion portion and method of fabricating the same

ActiveUS20050139851A1Low profileGreat easeSolid-state devicesSemiconductor lasersDevice materialLength wave

A semiconductor light-emitting apparatus which has a simple structure can include a base having a concave portion having an upward opening, a semiconductor light-emitting device placed on the bottom of the concave portion, and a wavelength conversion portion for converting the wavelength of light emitted from the semiconductor light-emitting device. The wavelength conversion portion can include first and second wavelength conversion layers formed on the bottom of the concave portion and in the opening thereof at a distance above the device, respectively. A space defined by the base having the concave portion and the second wavelength conversion layer can be provided with a sealing portion containing a material for transmitting the light emitted from the semiconductor device and light that is emitted from the first and second wavelength conversion layers.

Owner:STANLEY ELECTRIC CO LTD

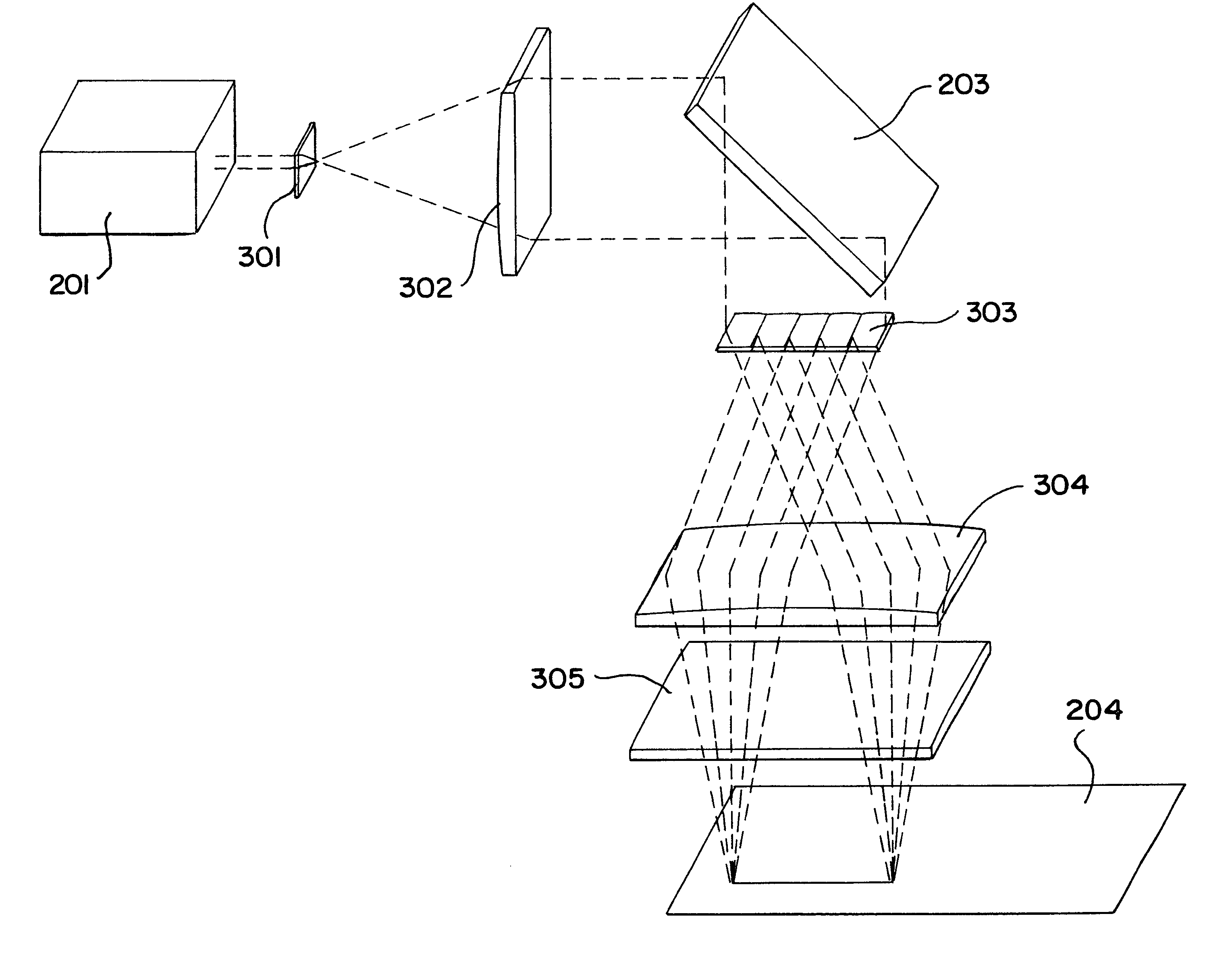

Systems and methods for implementing an interaction between a laser shaped as a line beam and a film deposited on a substrate

InactiveUS20050259709A1Maintain energy densityFrom solid stateBy zone-melting liquidsLaser crystallizationLight beam

A laser crystallization apparatus and method are disclosed for selectively melting a film such as amorphous silicon that is deposited on a substrate. The apparatus may comprise an optical system for producing stretched laser pulses for use in melting the film. In still another aspect of an embodiment of the present invention, a system and method are provided for stretching a laser pulse. In another aspect, a system is provided for maintaining a divergence of a pulsed laser beam (stretched or non-stretched) at a location along a beam path within a predetermined range. In another aspect, a system may be provided for maintaining the energy density at a film within a predetermined range during an interaction of the film with a shaped line beam.

Owner:CYMER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com