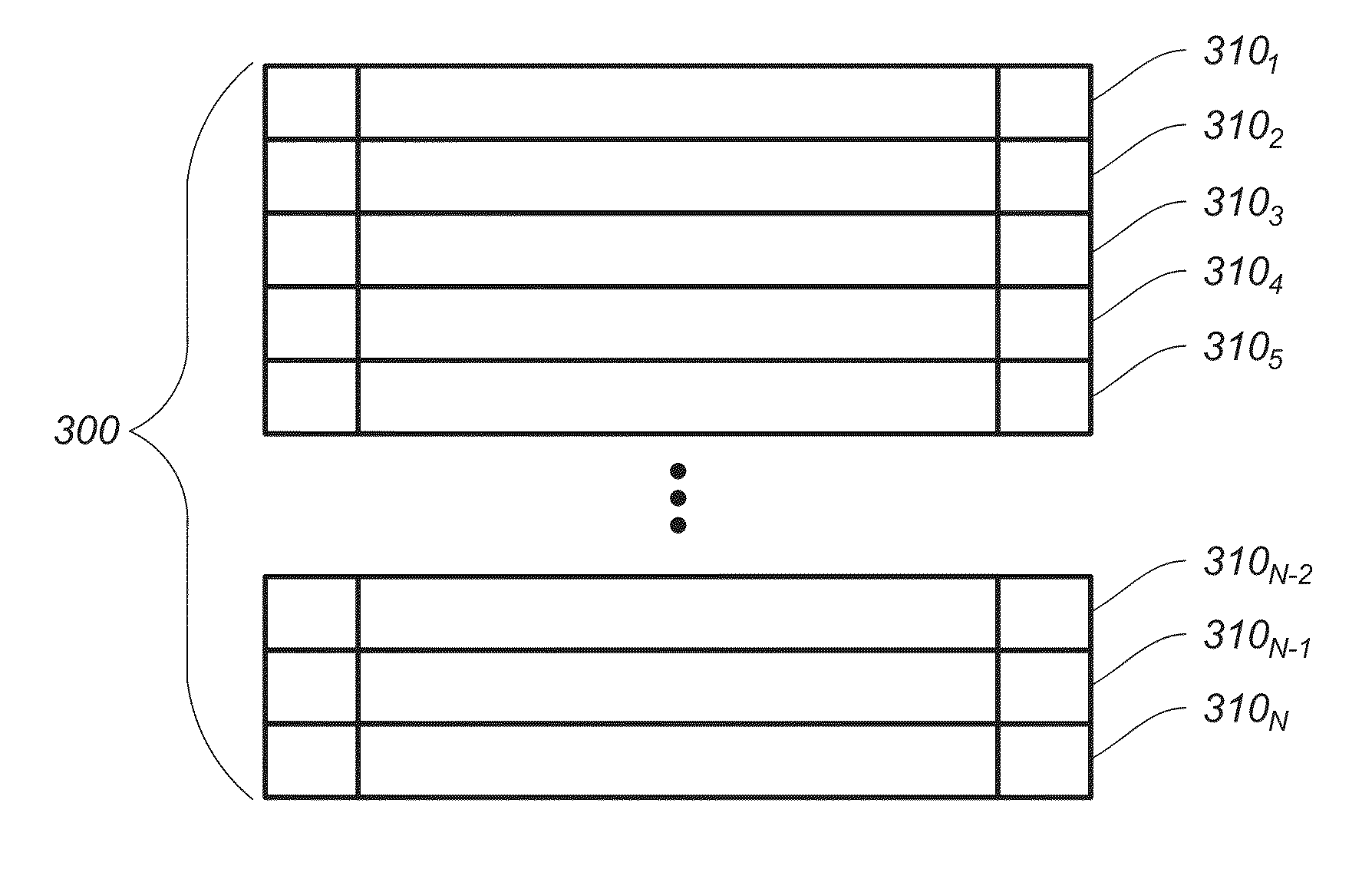

Patents

Literature

226results about How to "Achieve benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

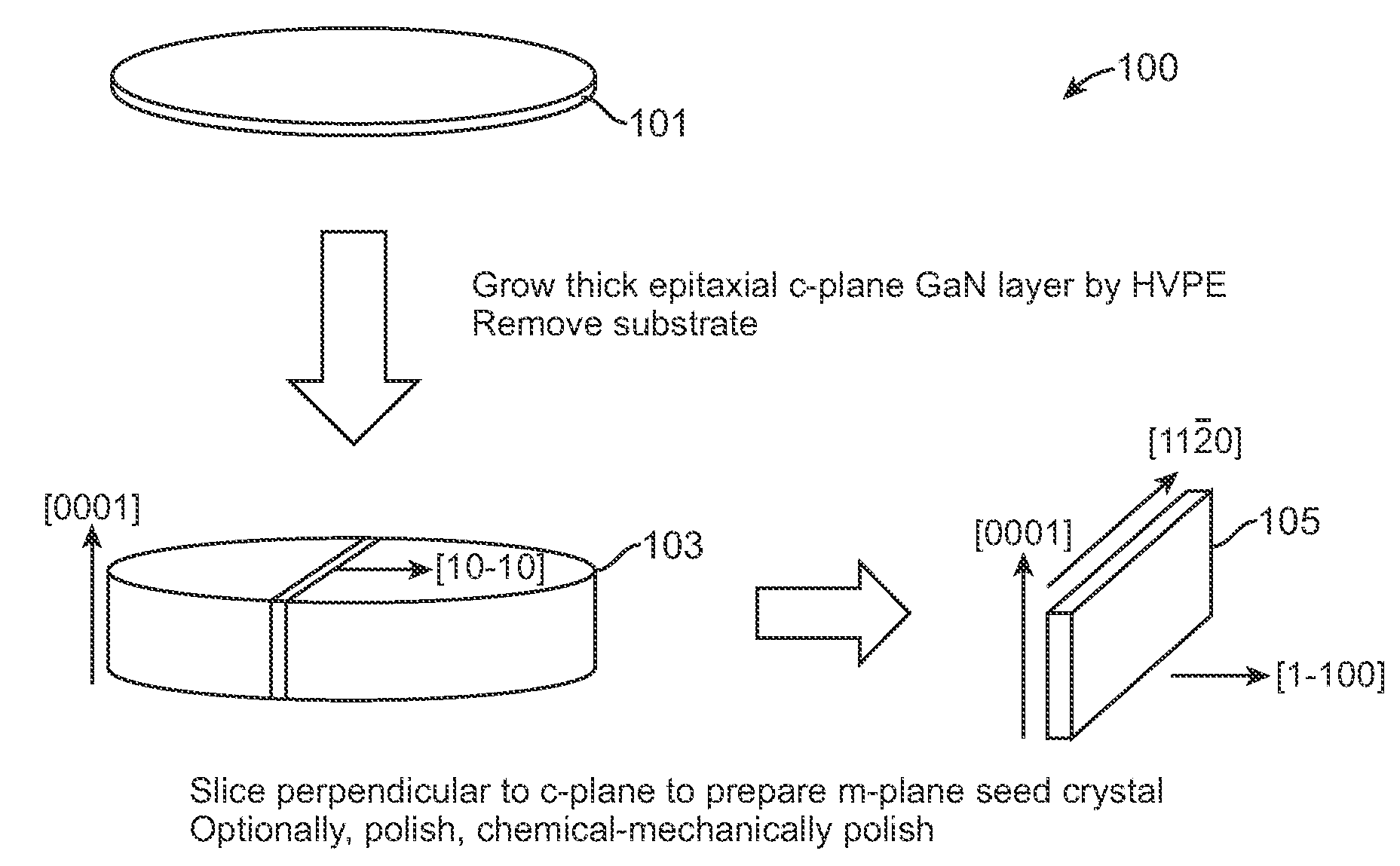

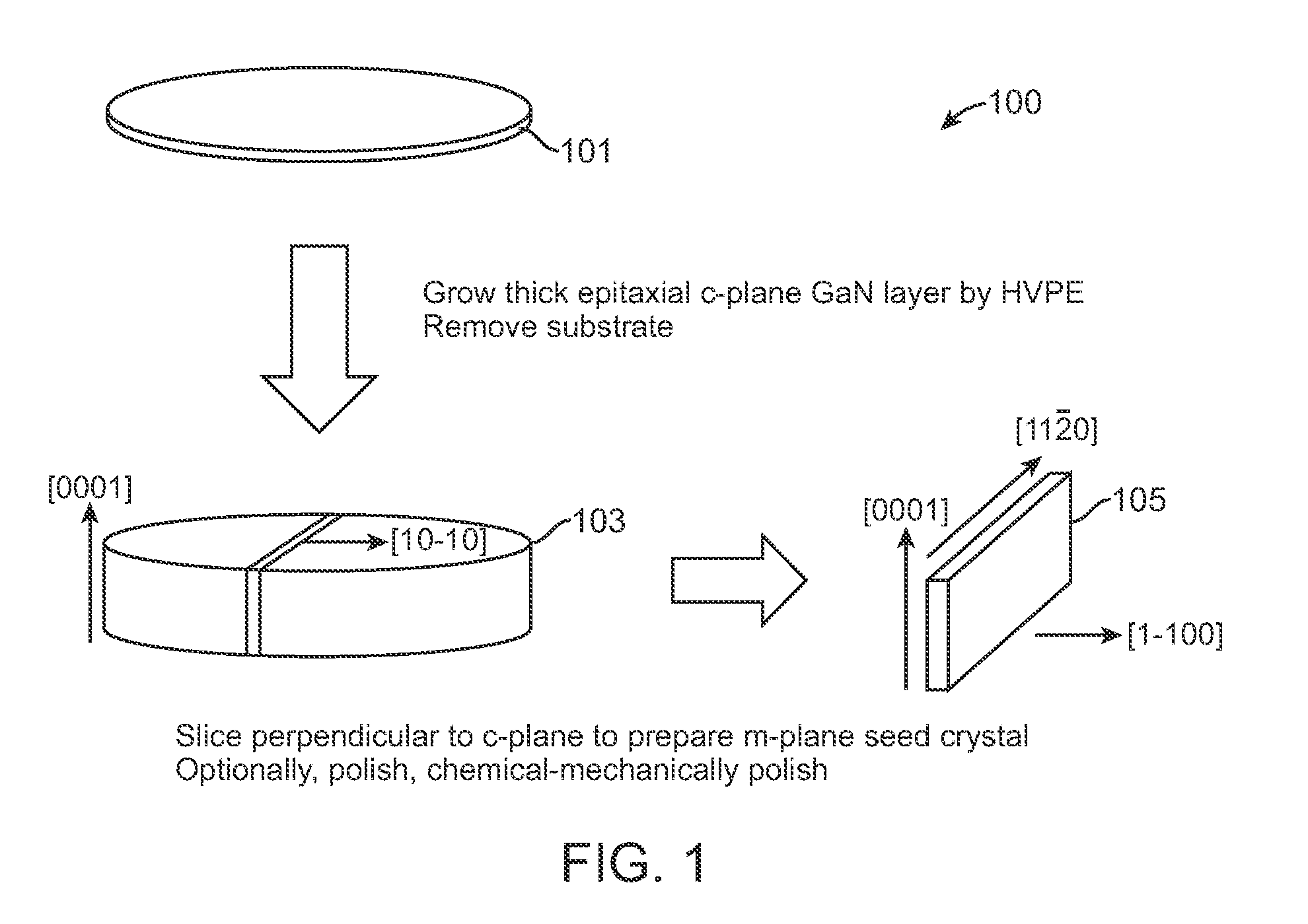

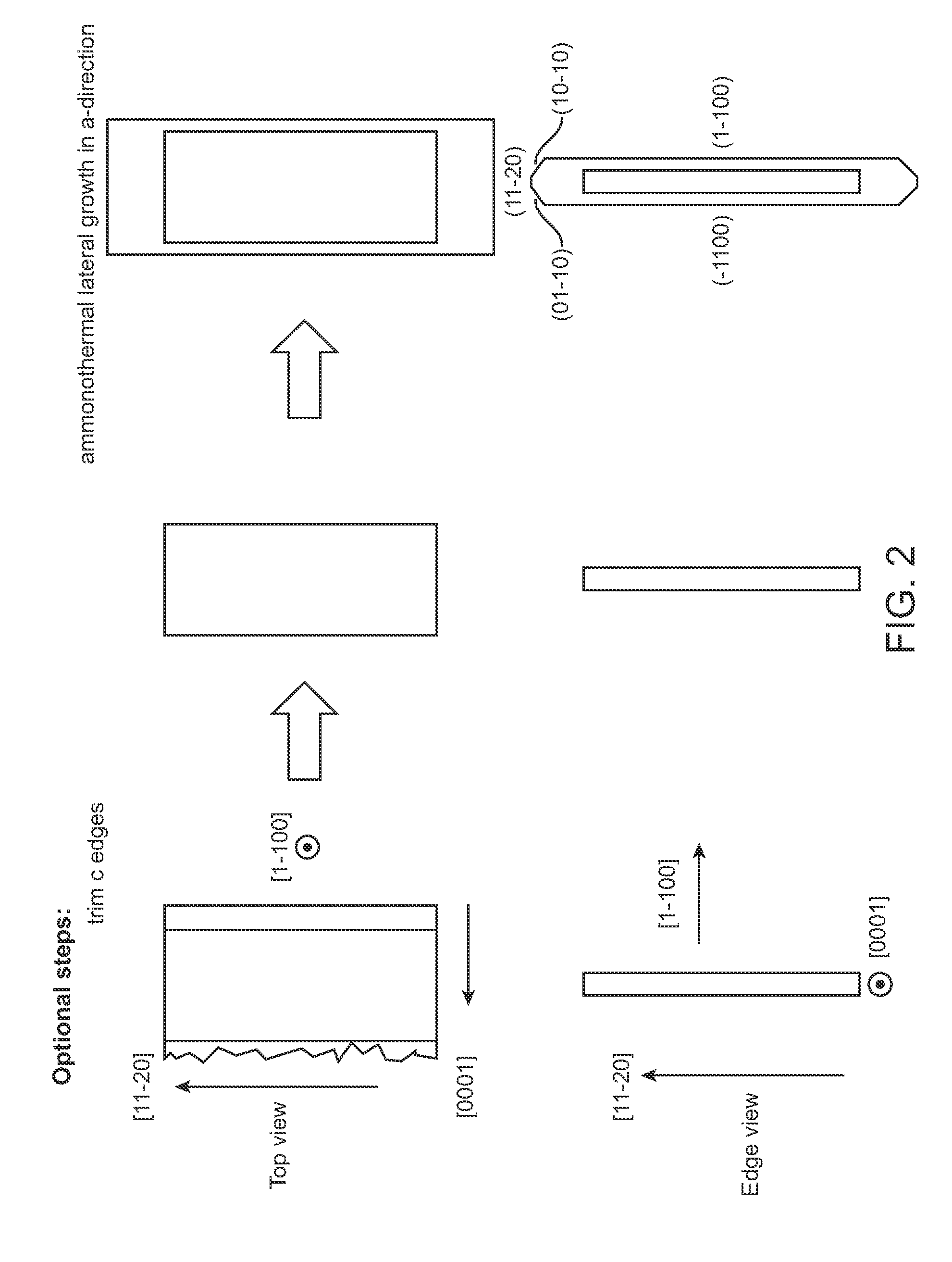

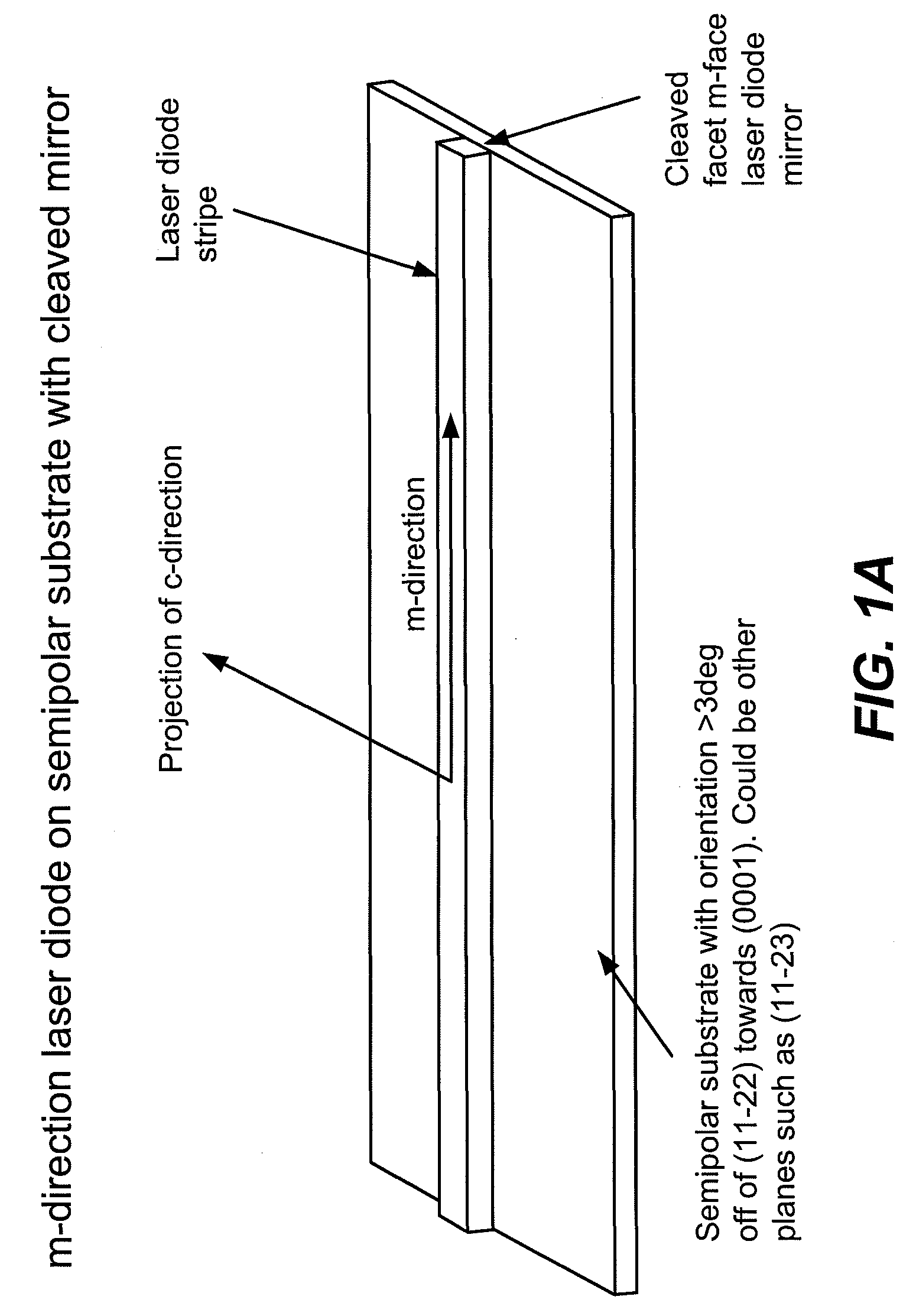

High quality large area bulk non-polar or semipolar gallium based substrates and methods

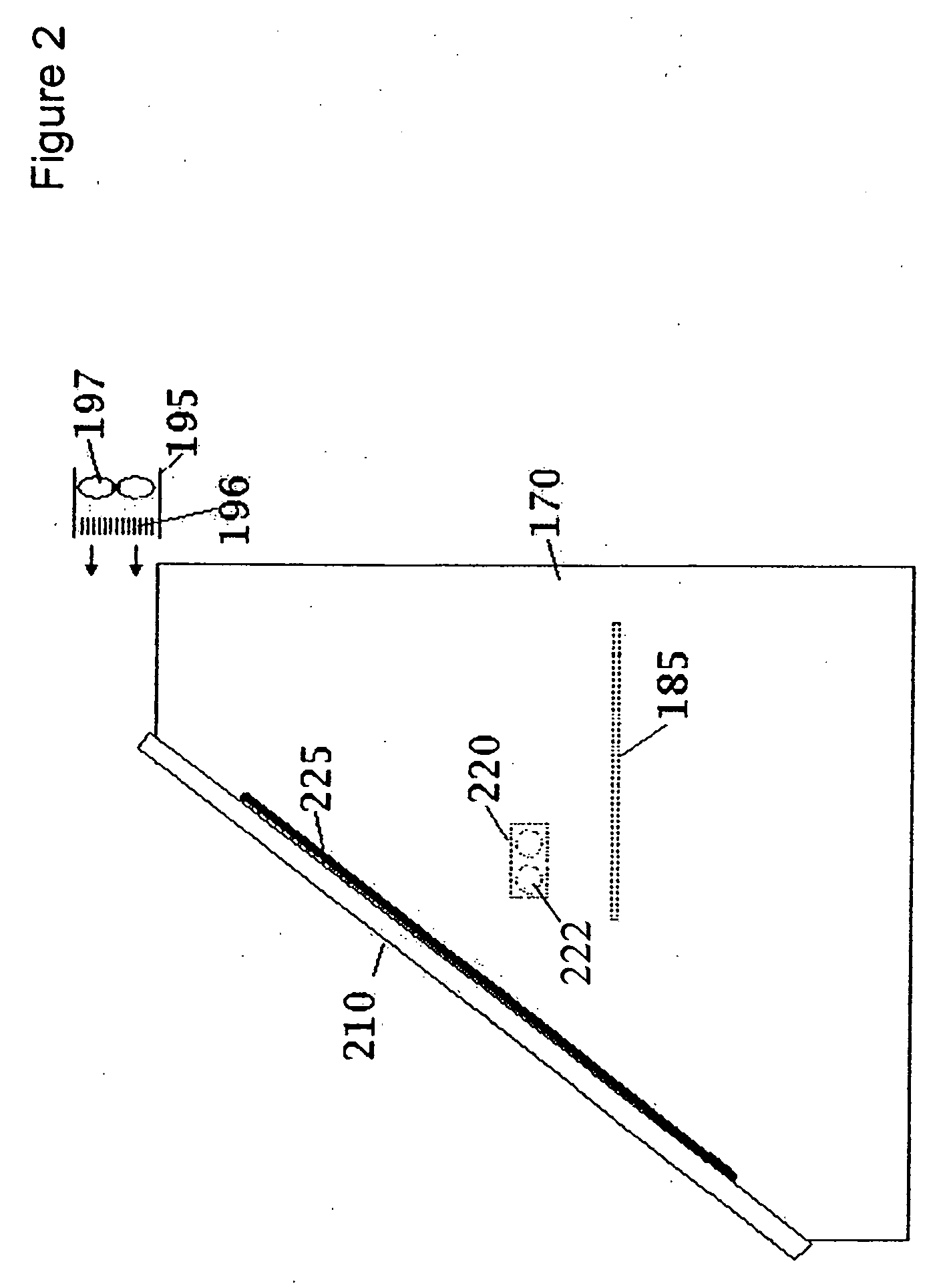

InactiveUS20100003492A1Great area of substrateCost-effective manufacturingPolycrystalline material growthConductive materialPhotodetectorSolar cell

A large area nitride crystal, comprising gallium and nitrogen, with a non-polar or semi-polar large-area face, is disclosed, along with a method for making. The crystal is useful as a substrate for a light emitting diode, a laser diode, a transistor, a photodetector, a solar cell, or for photoelectrochemical water splitting for hydrogen generation.

Owner:SORAA

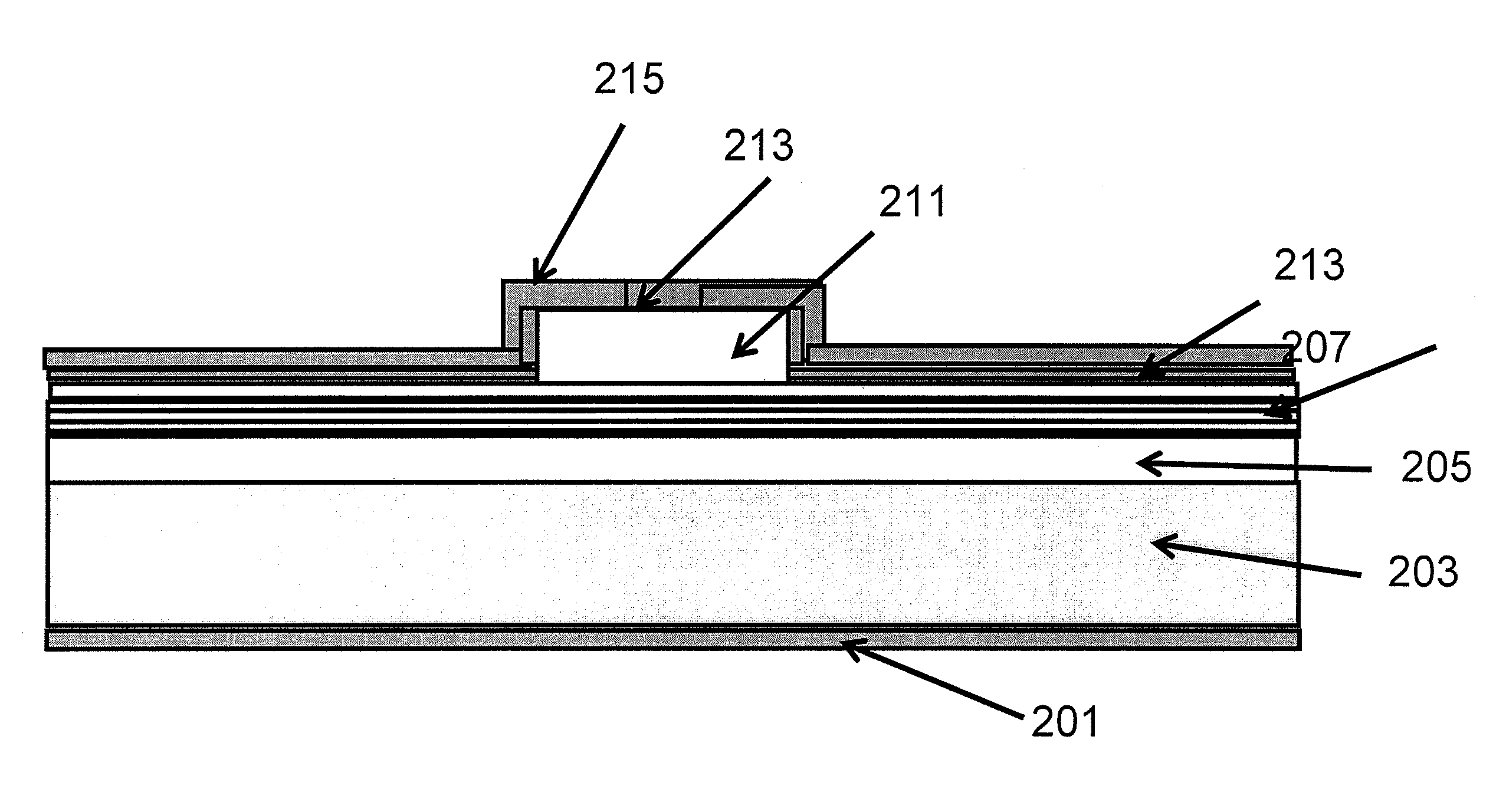

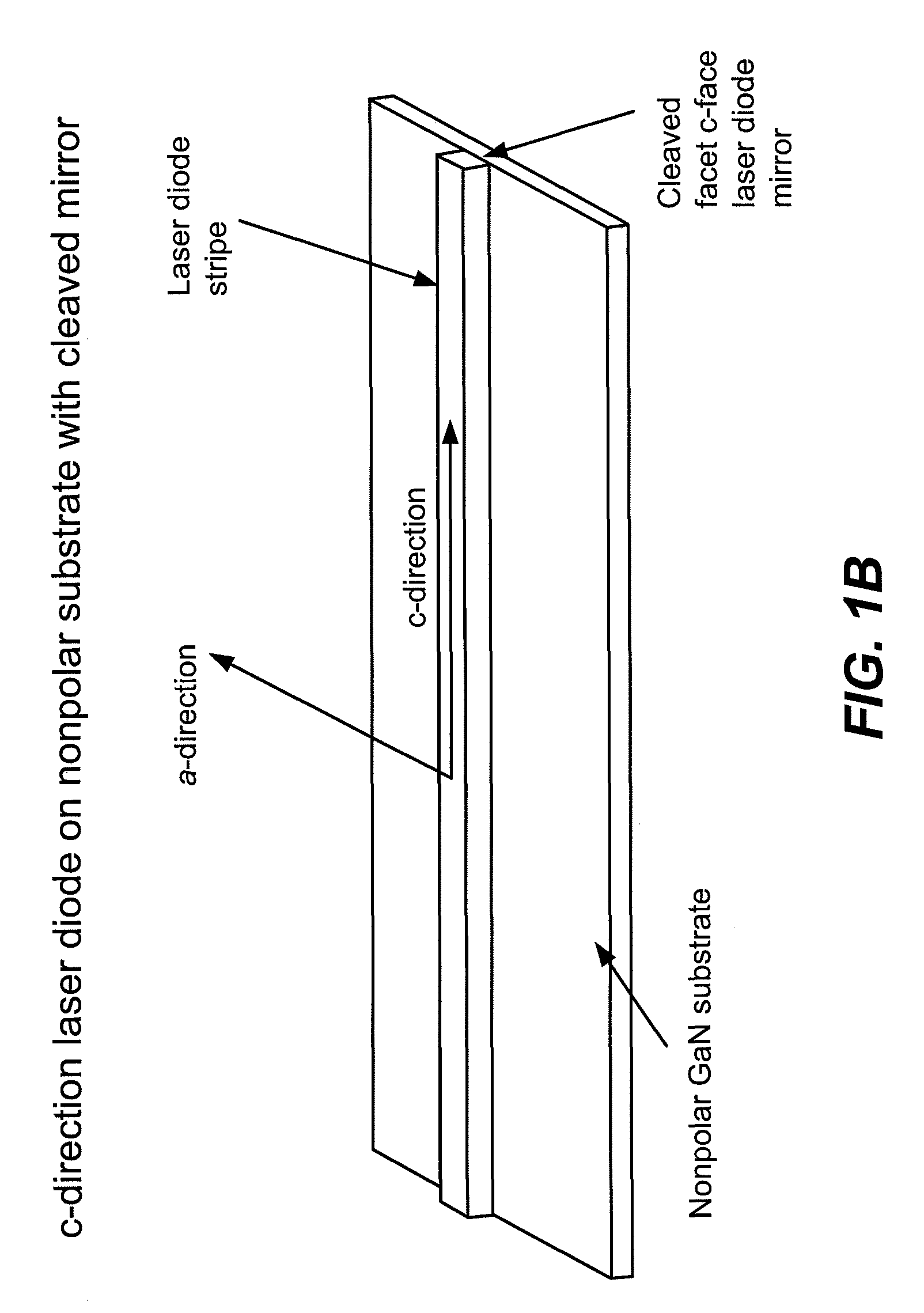

Optical device structure using GaN substrates and growth structures for laser applications of emissions of 500 nm and greater

ActiveUS8126024B1Simple and cost-effectiveAchieve benefitsLaser detailsNanoopticsLength waveLight emission

Owner:KYOCERA SLD LASER INC

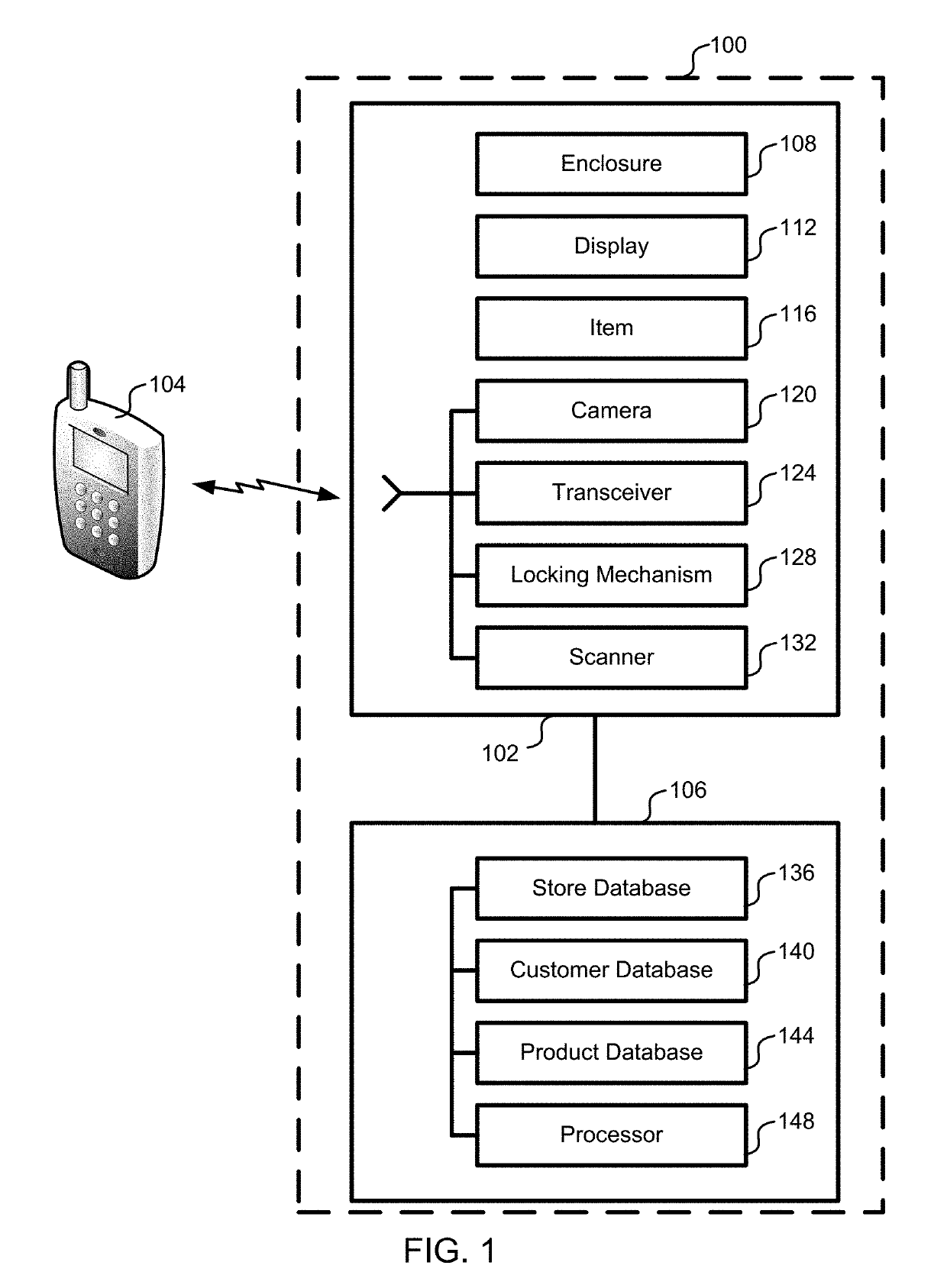

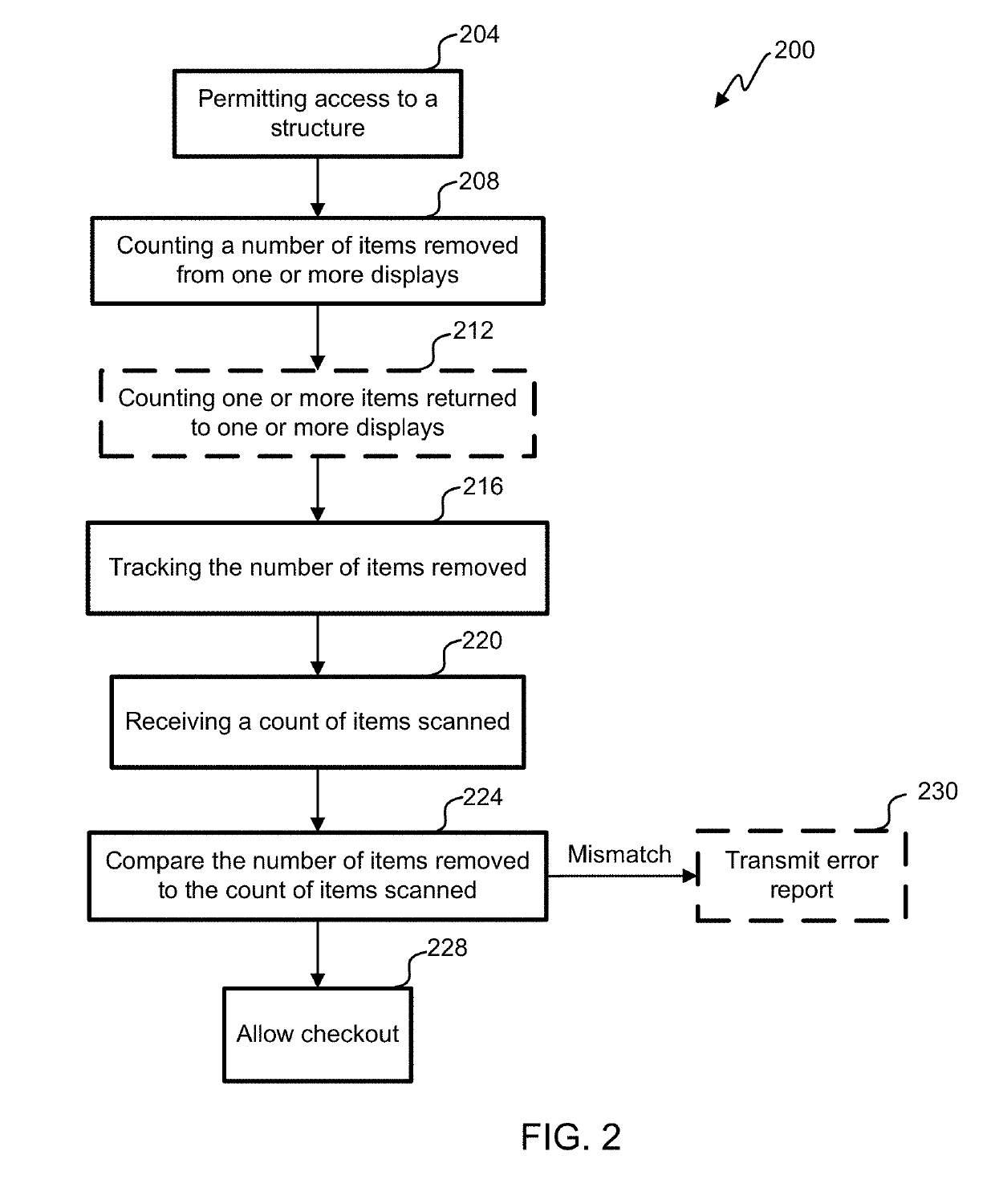

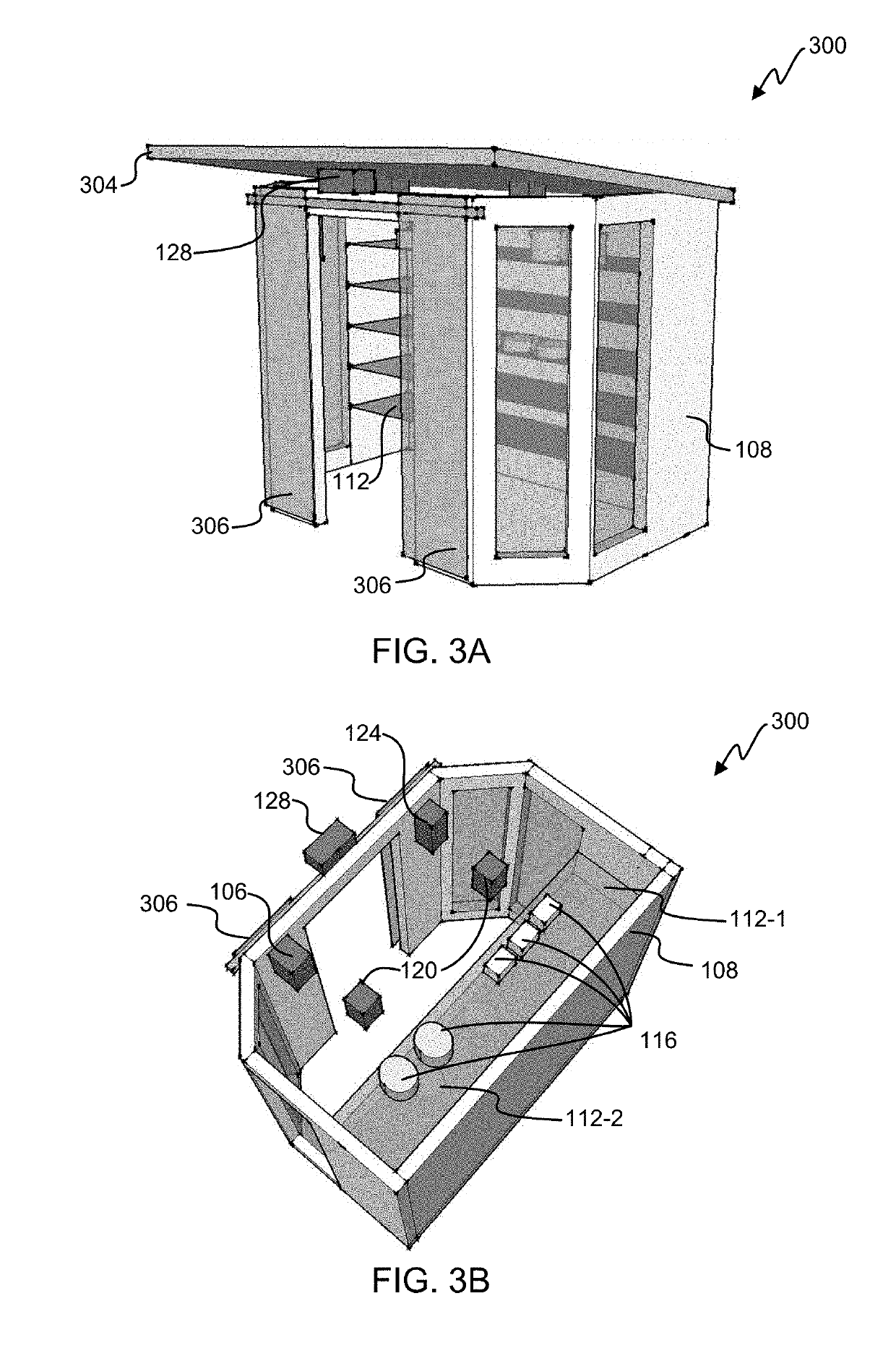

Registry verification for a mechanized store using radio frequency tags

ActiveUS20190147709A1Reduce shop liftingReduce theftCash registersPayment architectureRadio frequencyComputer science

Registry verification is used in a mechanized store. A camera is used to count a first number of items taken by a user. Radio frequency tags are used to determine a second number of items. The first number of items is compared to the second number of items to reduce a likelihood of errors.

Owner:STANDARD COGNITION CORP

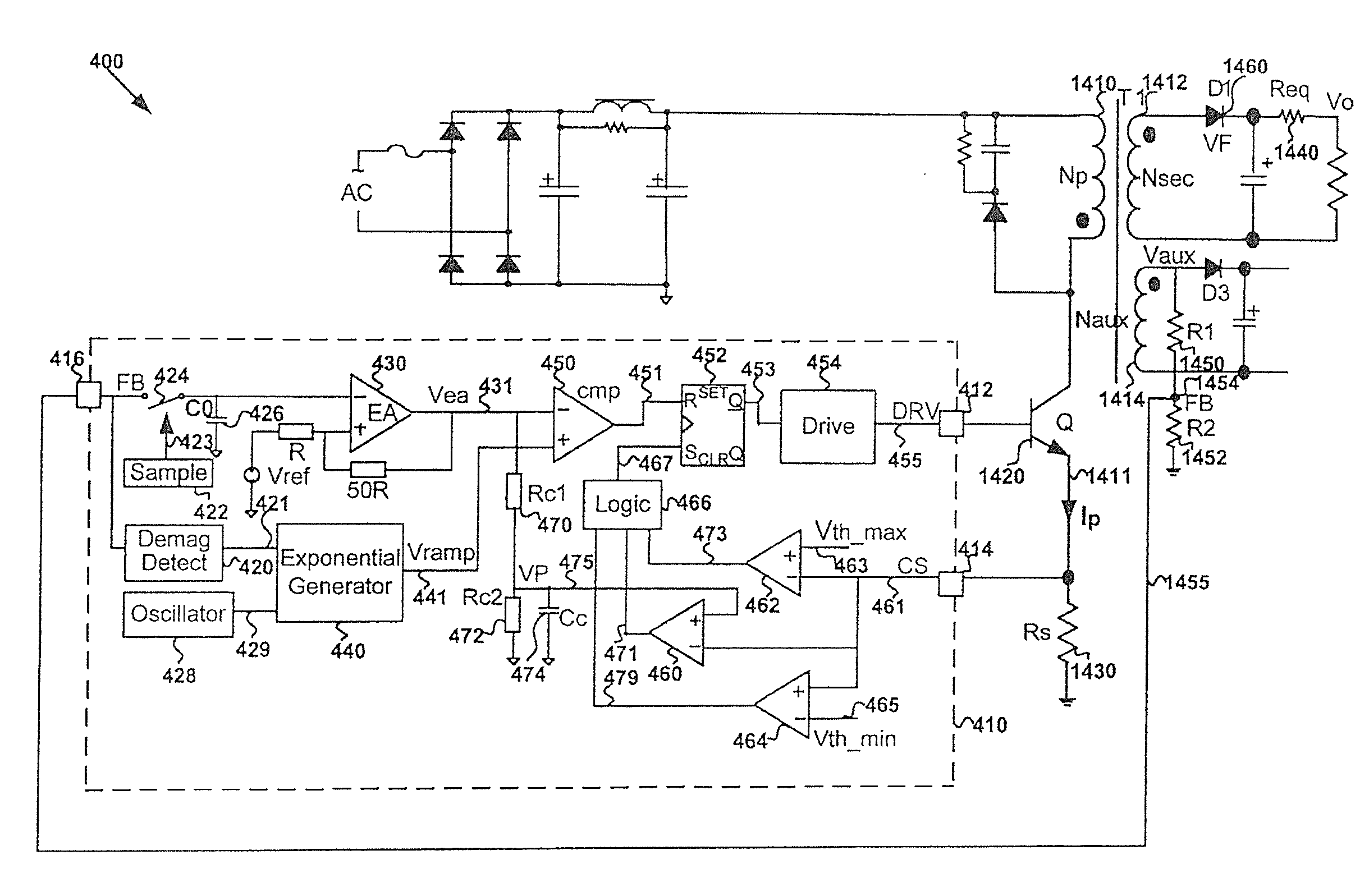

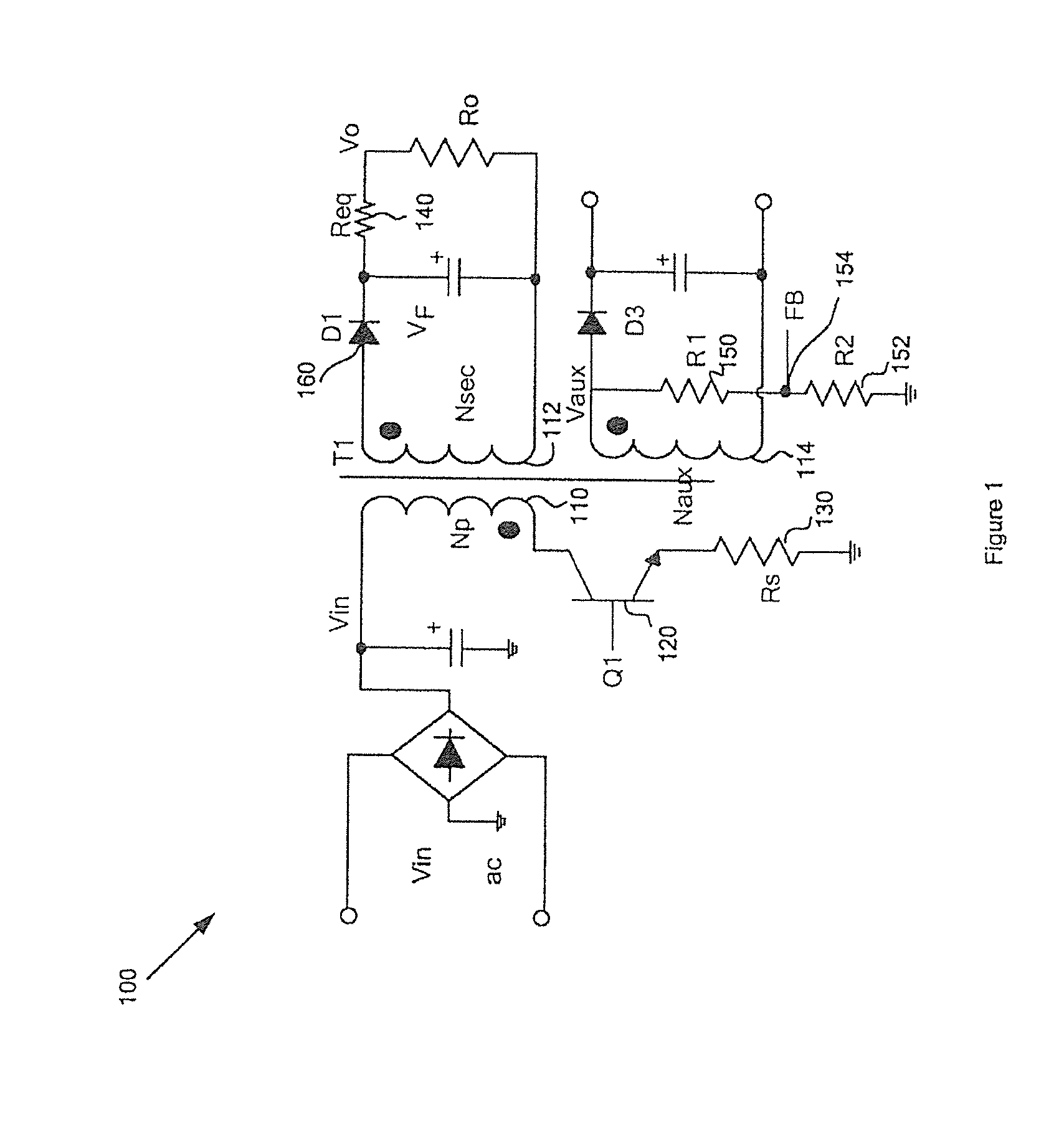

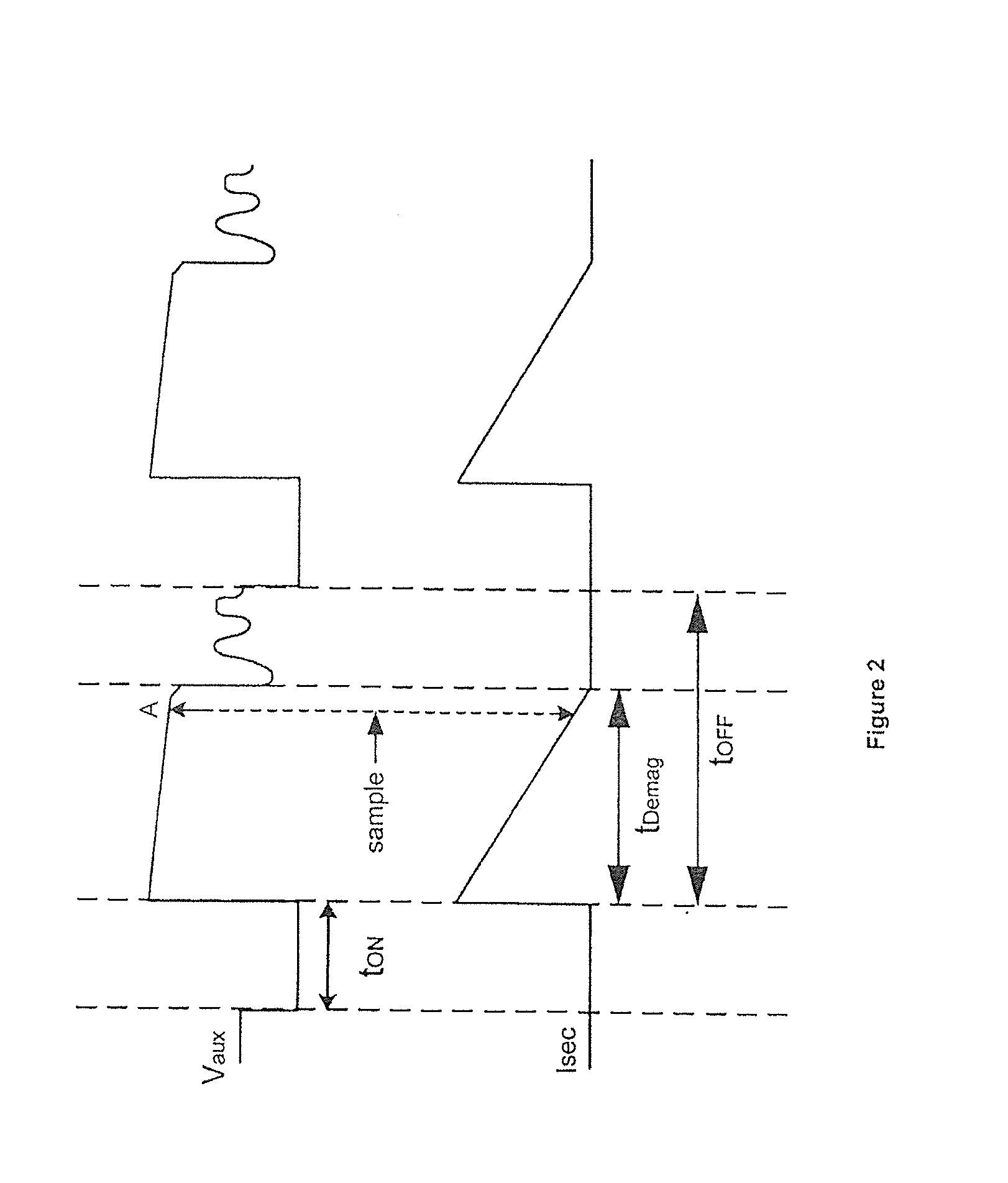

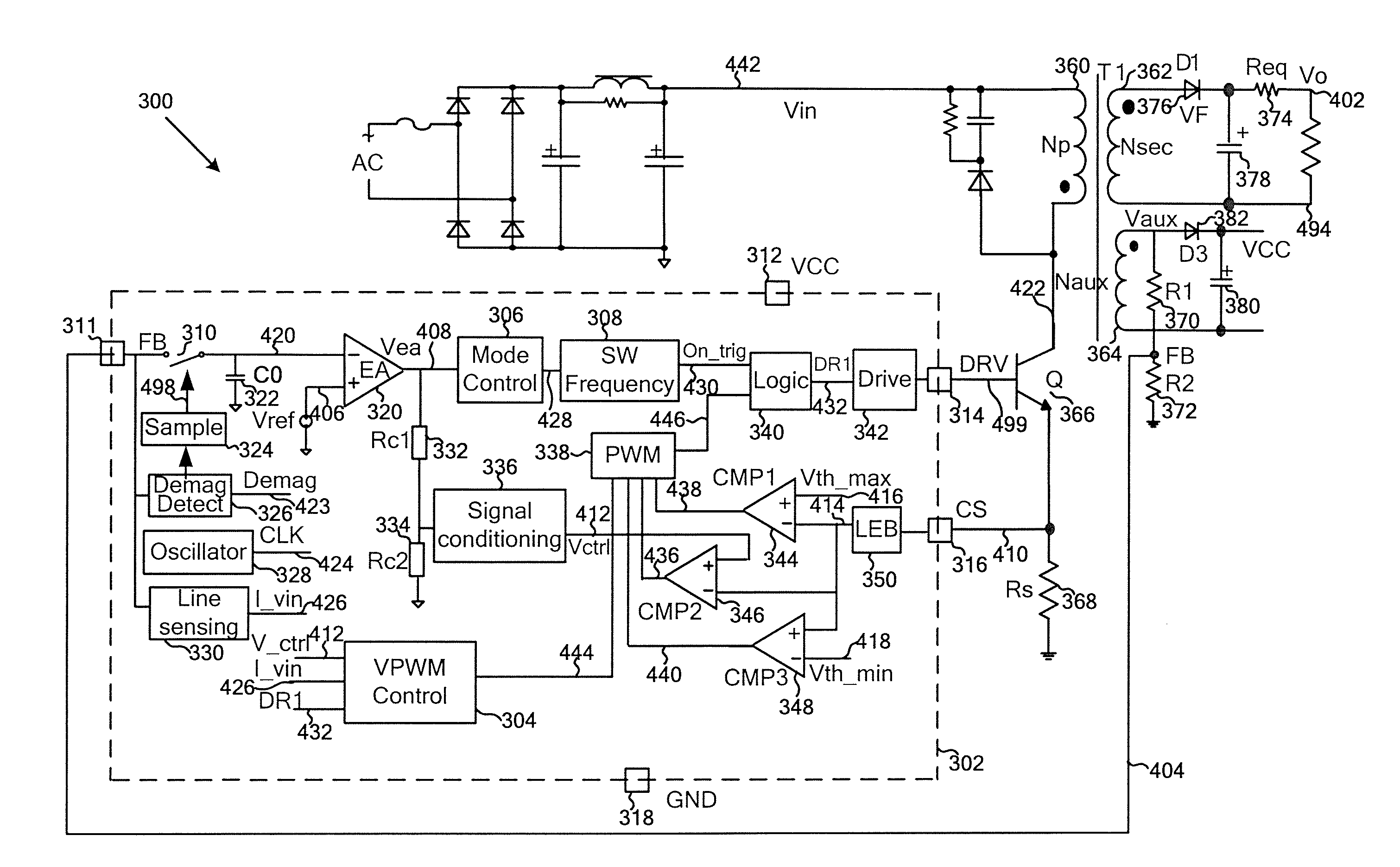

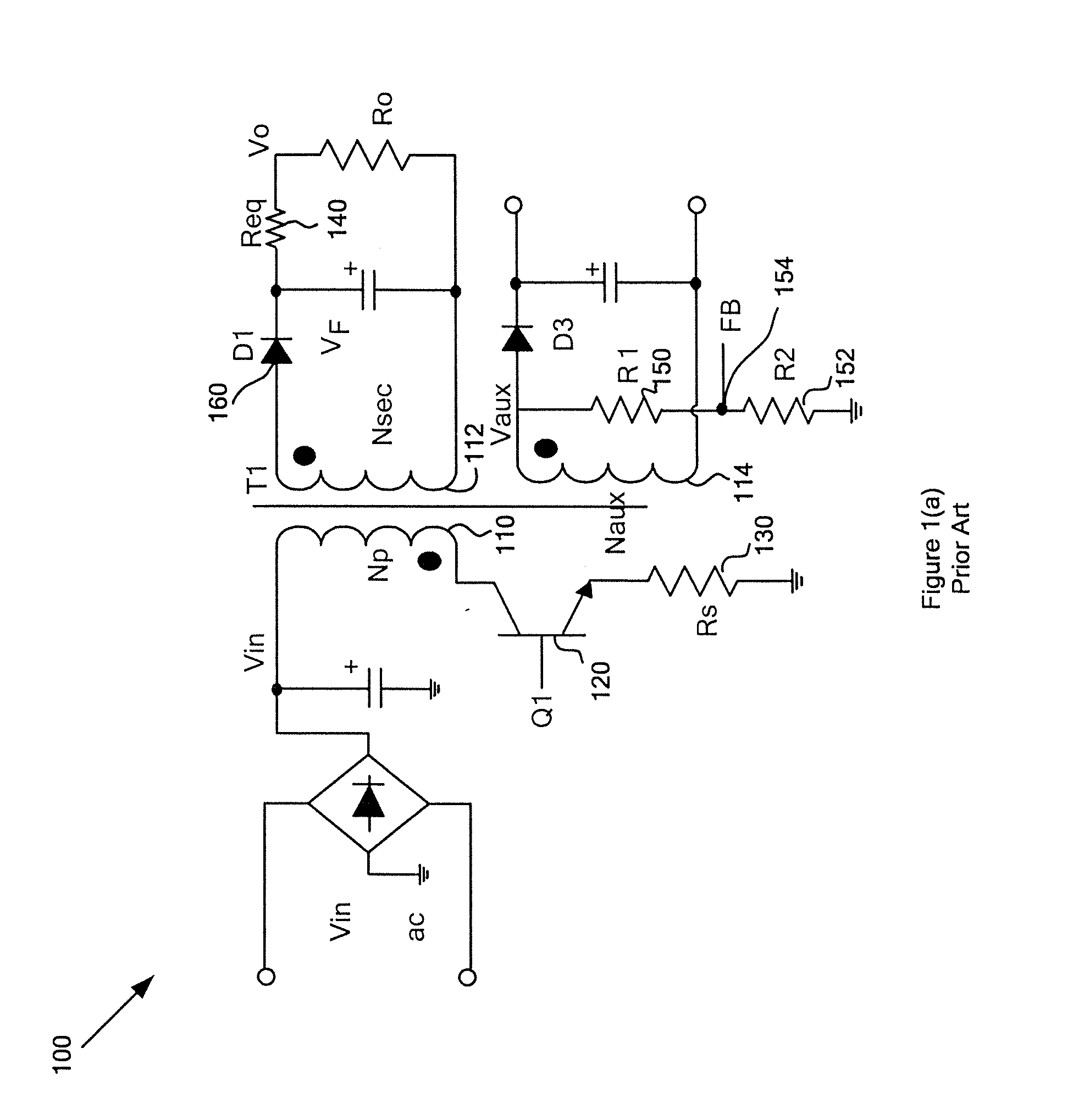

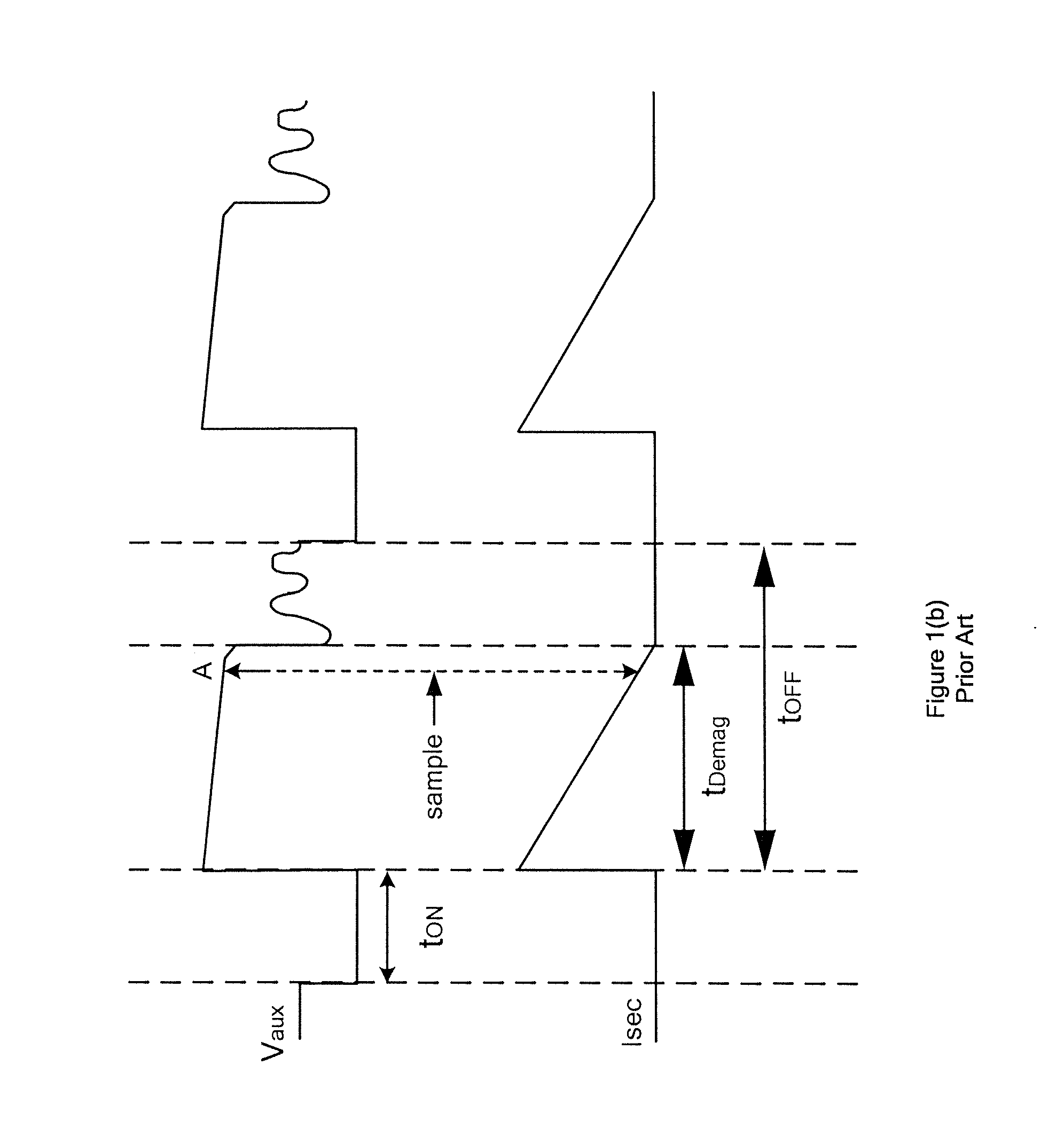

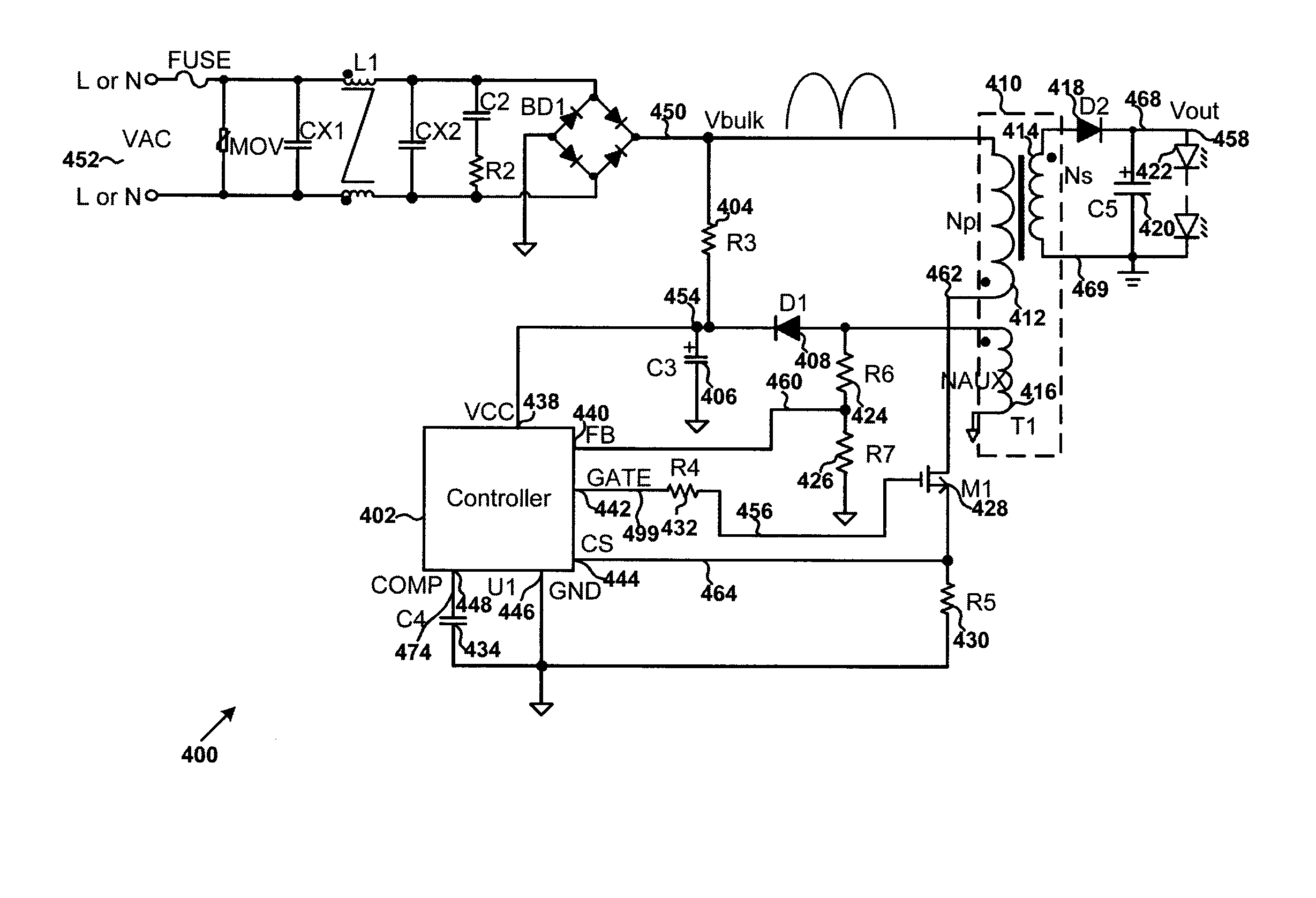

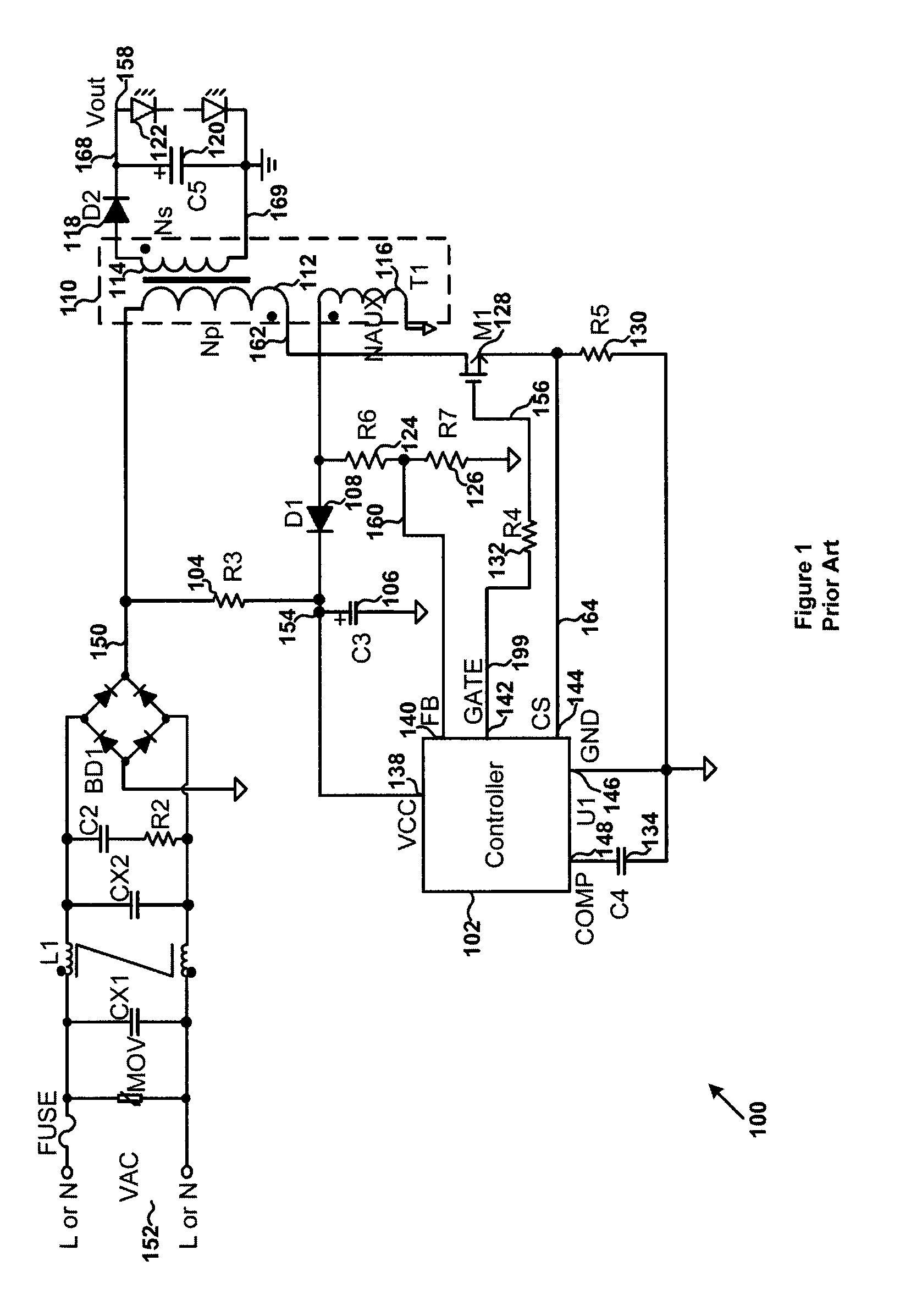

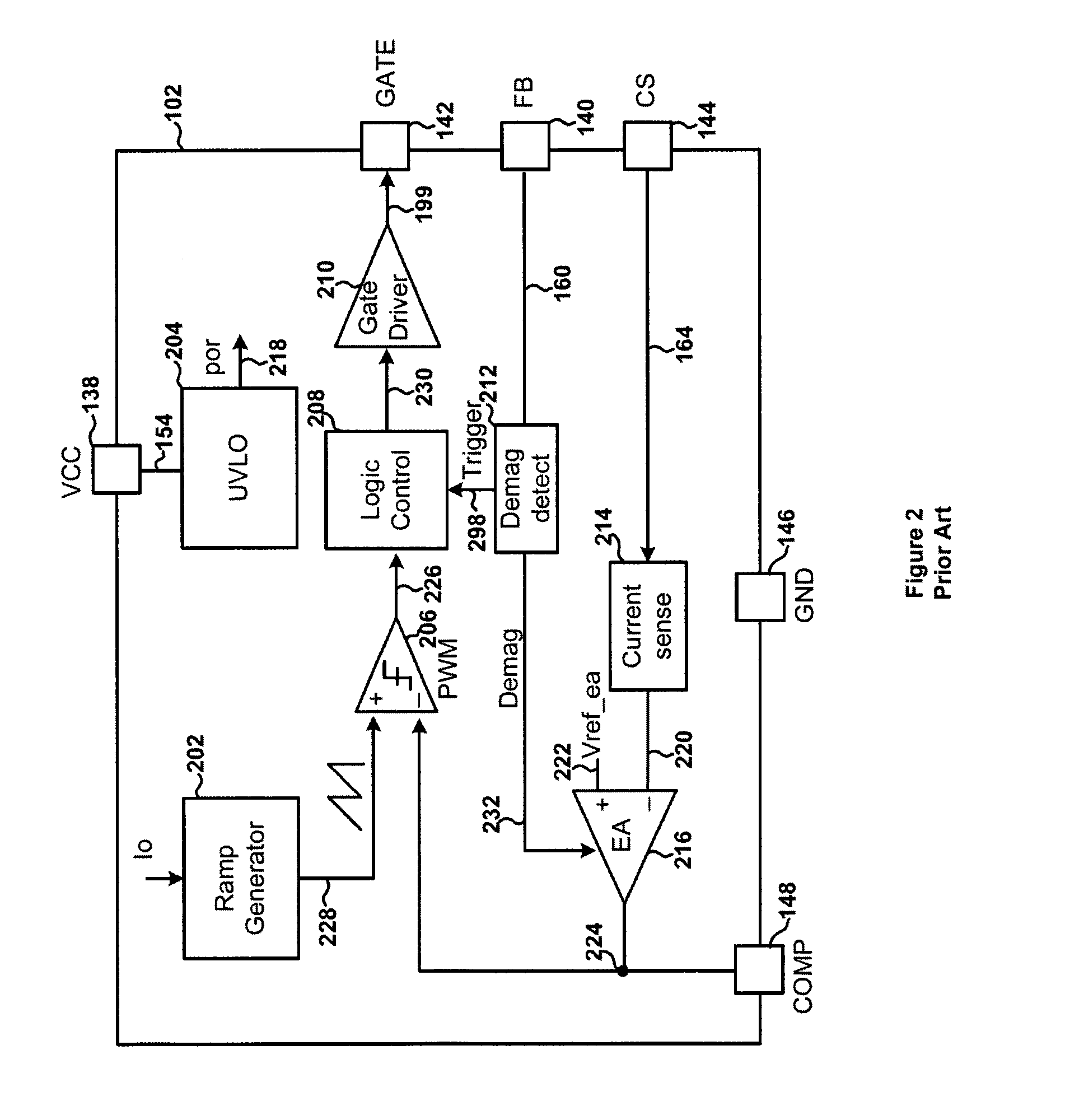

Systems and methods for flyback power converters with switching frequency and peak current adjustments based on changes in feedback signals

ActiveUS20130033905A1Increase frequencyIncreasing magnitudeEfficient power electronics conversionDc-dc conversionPeak currentEngineering

System and method for regulating a power converter. The system includes a first comparator configured to receive a first input signal and a second input signal and generate a first comparison signal based on at least information associated with the first input signal and the second input signal, a pulse-width-modulation generator configured to receive at least the first comparison signal and generate a modulation signal based on at least information associated with the first comparison signal, a driver component configured to receive the modulation signal and output a drive signal to a switch to adjust a primary current flowing through a primary winding of the power converter, and a voltage-change-rate detection component configured to sample the feedback signal to generate a first sampled signal for a first modulation period and to sample the feedback signal to generate a second sampled signal for a second modulation period.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

Systems and methods for peak current adjustments in power conversion systems

ActiveUS20140160809A1Reducing pulse widthAchieve benefitsEfficient power electronics conversionDc-dc conversionEngineeringPeak value

System and method for regulating an output of a power conversion system. An example system controller includes a signal generator and a modulation and drive component. The signal generator is configured to receive at least a first signal indicating a magnitude of an input voltage received by a primary winding of a power conversion system and receive a second signal indicating a magnitude of a primary current flowing through the primary winding, and generate a third signal. The modulation and drive component is configured to receive at least the third signal, generate a drive signal based on at least information associated with the third signal, and output the drive signal to a switch to affect the primary current.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

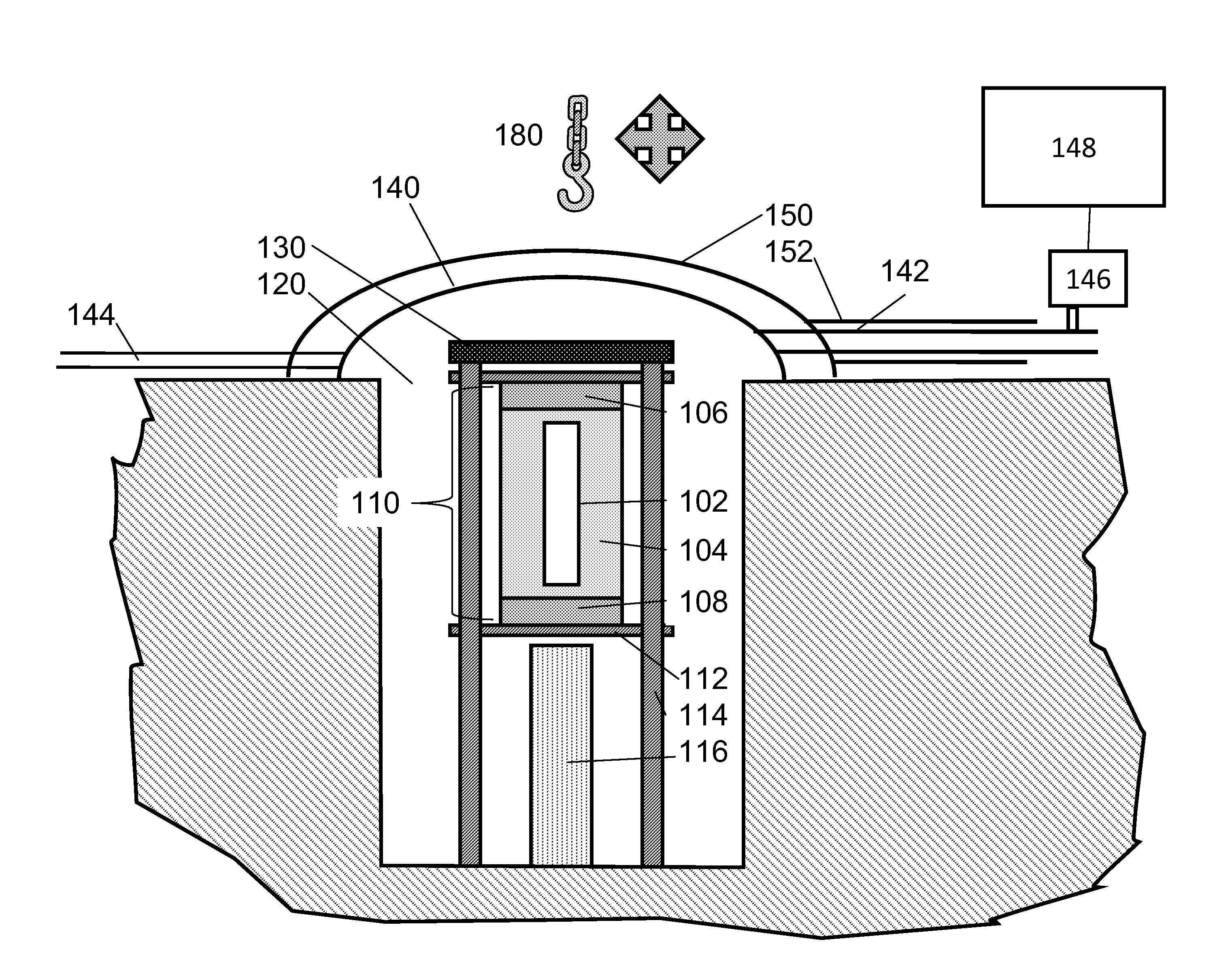

Plant and method for large-scale ammonothermal manufacturing of gallium nitride boules

InactiveUS20110100291A1Simple and cost-effective to manufactureSafe and cost-effectivePolycrystalline material growthFrom normal temperature solutionsNuclear engineeringGallium nitride

A method of operating a high pressure system for growth of gallium nitride containing materials. The method comprises providing a high pressure apparatus comprising a growth region and feedstock region. The high pressure reactor comprises a high pressure enclosure and is configured within a primary containment structure. The method includes operating an exhaust system coupled to the primary containment structure. The exhaust system is configured to remove ammonia gas derived from at least 0.3 liters of ammonia liquid.

Owner:SORAA

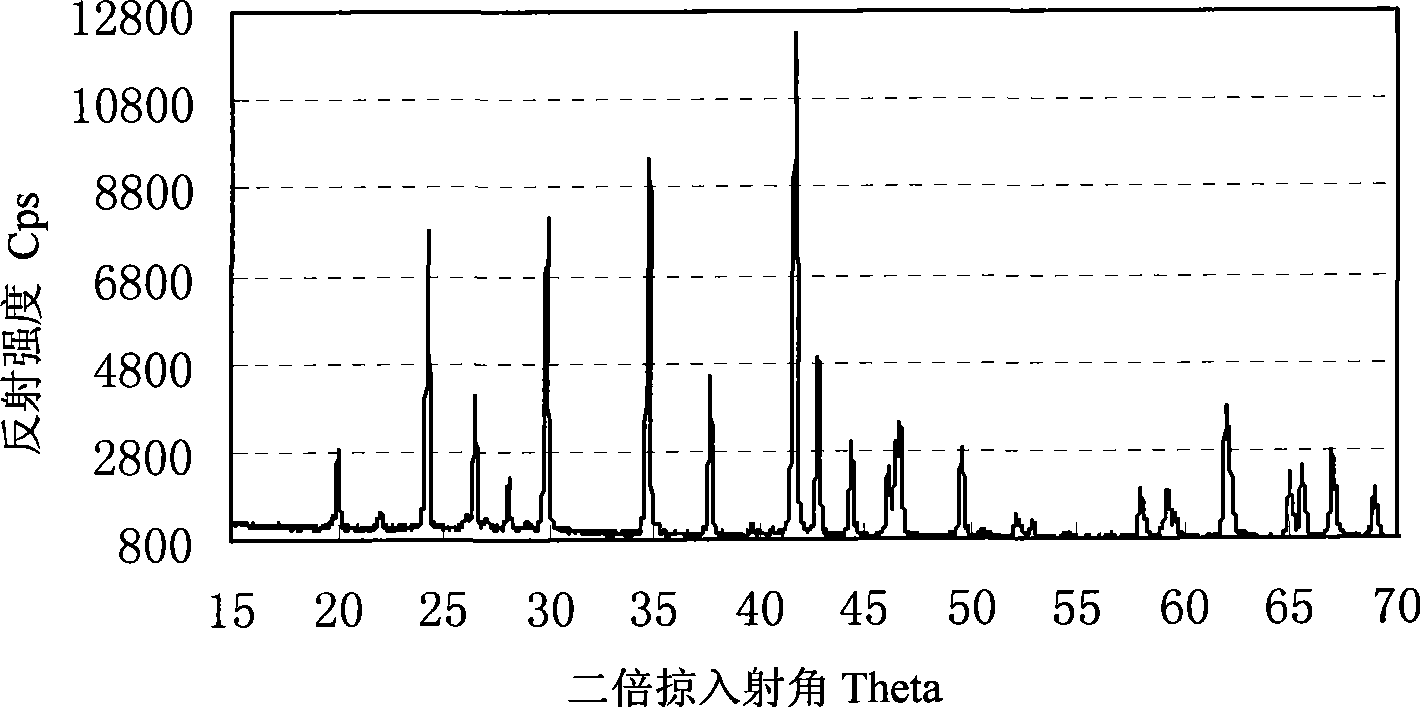

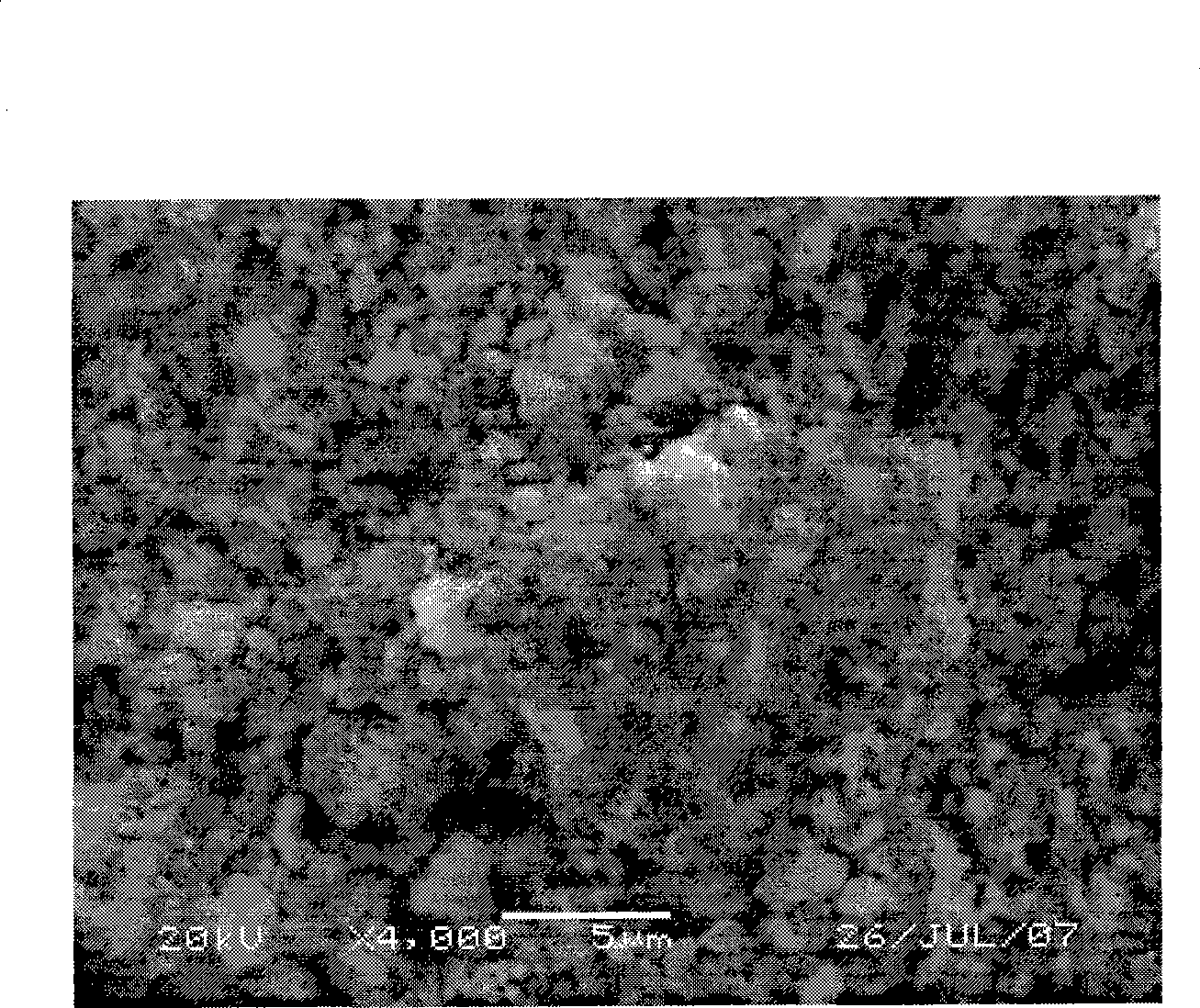

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

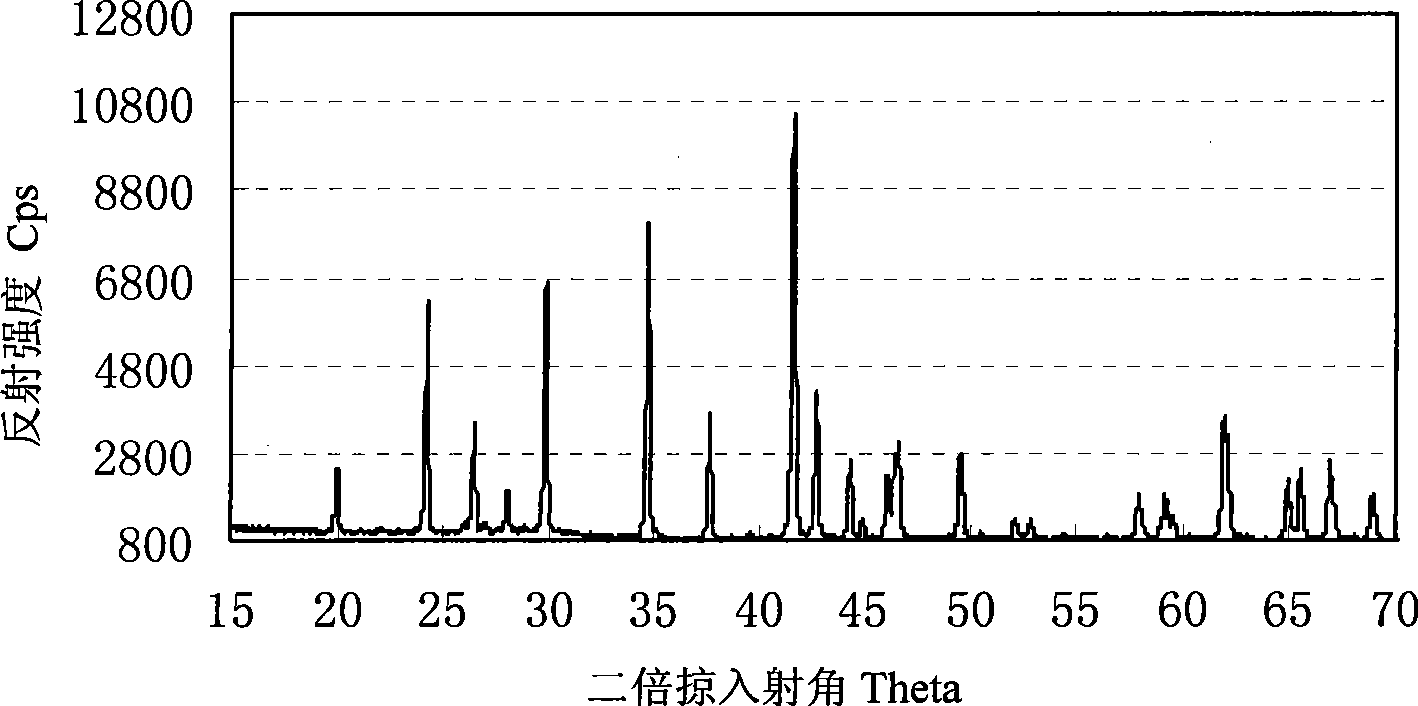

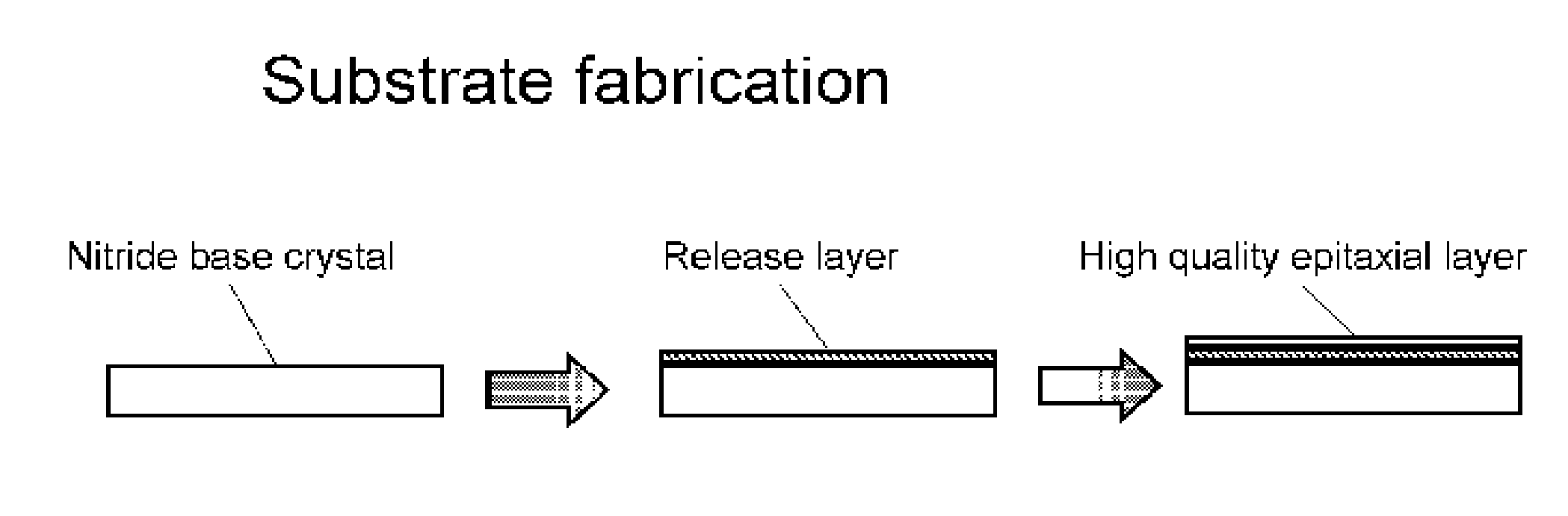

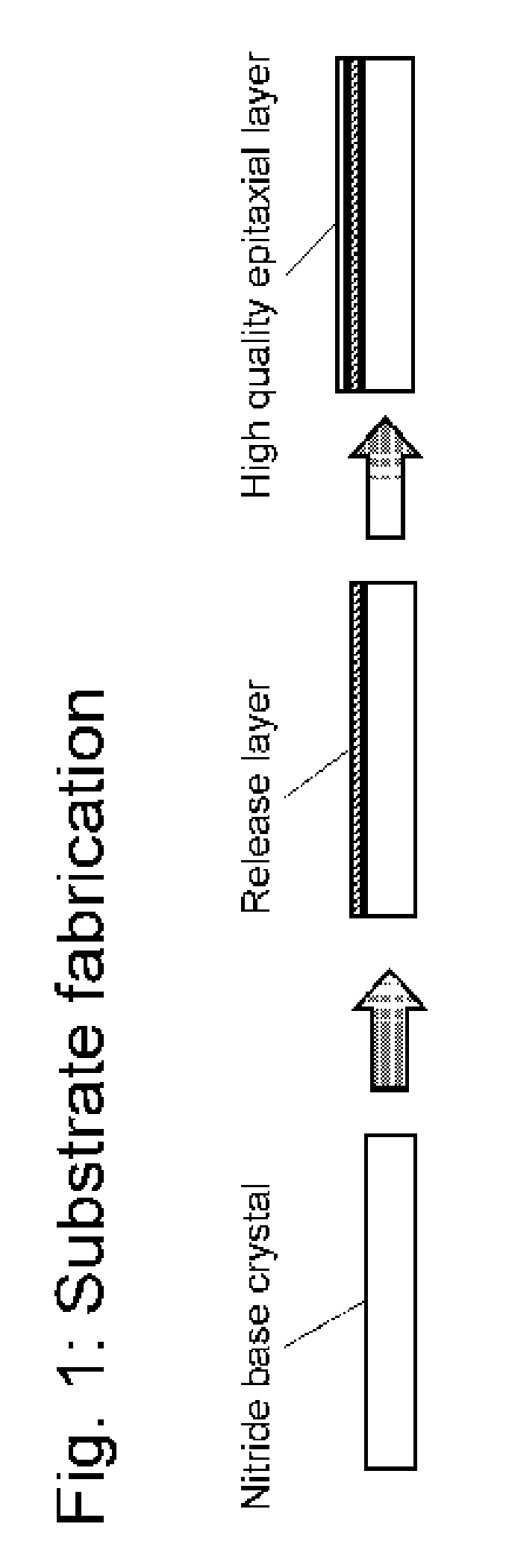

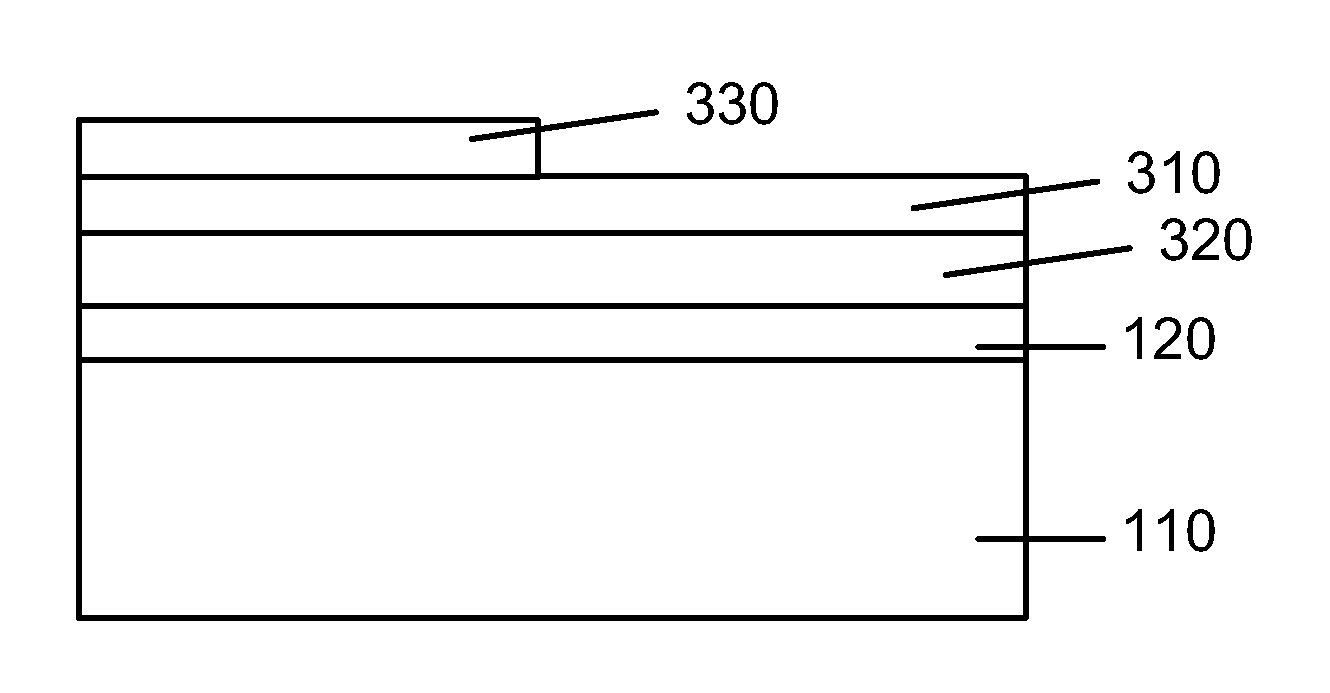

Nitride crystal with removable surface layer and methods of manufacture

ActiveUS20100219505A1Simple and cost-effectiveAchieve benefitsPolycrystalline material growthFrom normal temperature solutionsPhotodetectorSolar cell

A nitride crystal or wafer with a removable surface layer comprises a high quality nitride base crystal, a release layer, and a high quality epitaxial layer. The release layer has a large optical absorption coefficient at wavelengths where the base crystal is substantially transparent and may be etched under conditions where the nitride base crystal and the high quality epitaxial layer are not. The high quality epitaxial layer may be removed from the nitride base crystal by laser liftoff or by chemical etching after deposition of at least one epitaxial device layer. The nitride crystal with a removable surface layer is useful as a substrate for a light emitting diode, a laser diode, a transistor, a photodetector, a solar cell, or for photoelectrochemical water splitting for hydrogen generation.

Owner:SLT TECH

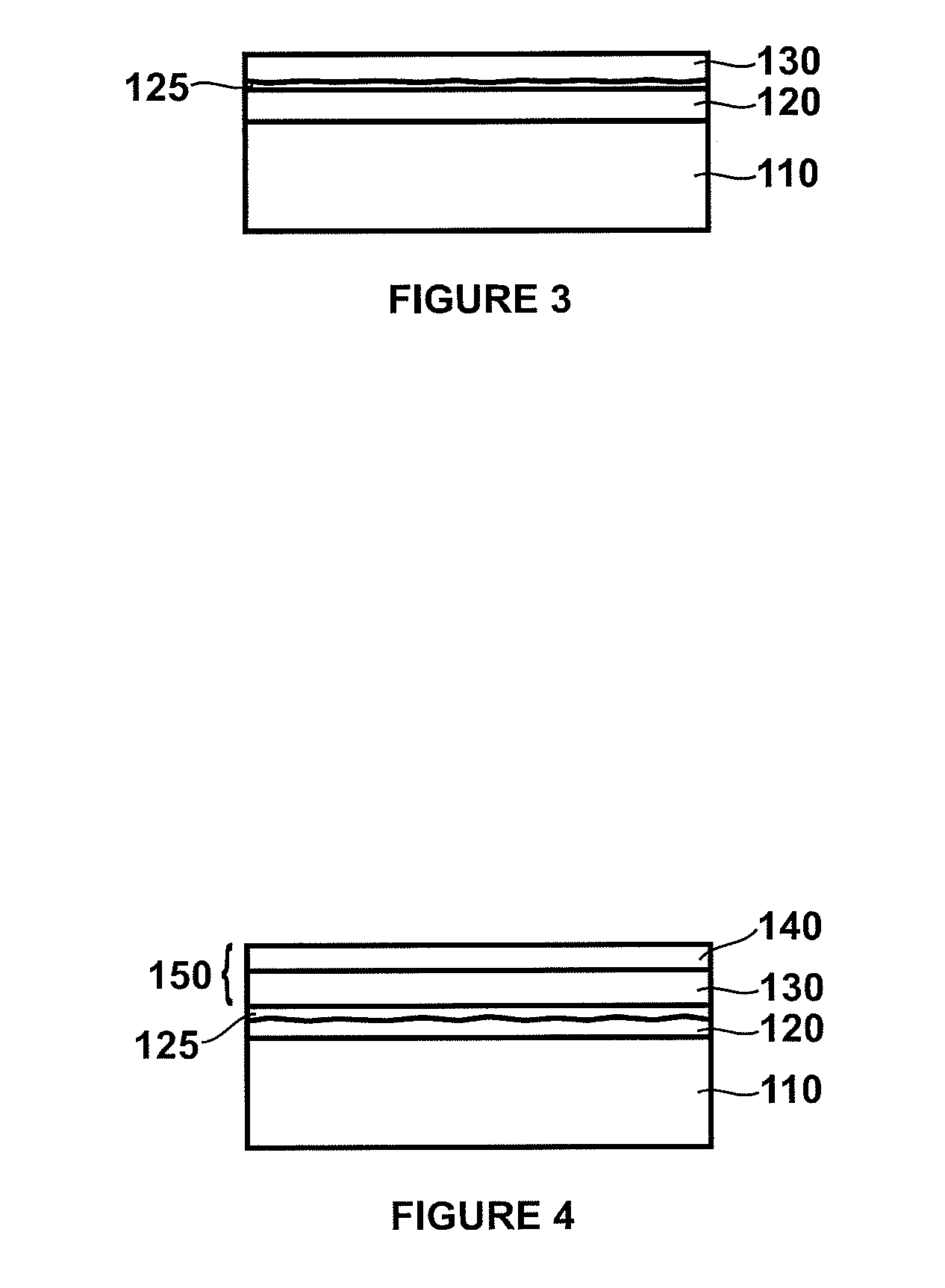

Method and structure for adhesion of absorber material for thin film photovoltaic cell

InactiveUS20100081230A1Toxic reductionImprove bindingSemiconductor/solid-state device manufacturingPhotovoltaic energy generationIndiumSulfur

A method for forming a thin film photovoltaic device includes providing a transparent substrate comprising a surface region and forming a first electrode layer overlying the surface region. The method further includes forming a thin layer of copper gallium material overlying the first electrode layer to act as an intermediary adhesive layer to facilitate attachment to the first electrode layer. Additionally, the method includes forming a copper layer overlying the thin layer and forming an indium layer overlying the copper layer to form a multilayered structure and subjecting the multilayered structure to thermal treatment process with sulfur bearing species to form a copper indium disulfide alloy material. The copper indium disulfide alloy material comprises a copper:indium atomic ratio of about 1.2:1 to about 3.0:1 overlying a copper gallium disulfide material converted from the thin layer. Furthermore, the method includes forming a window layer overlying the copper indium disulfide alloy material.

Owner:CM MFG

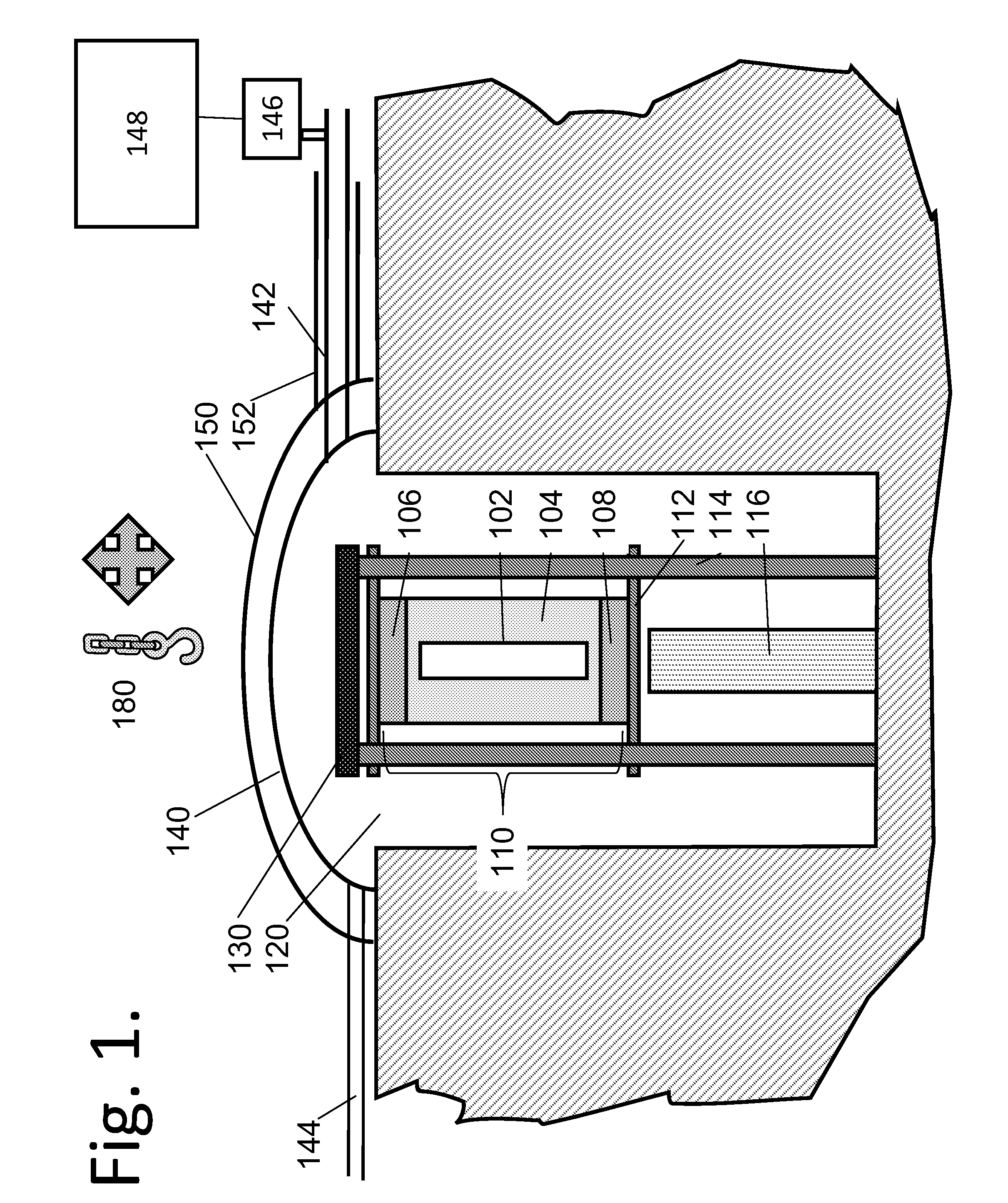

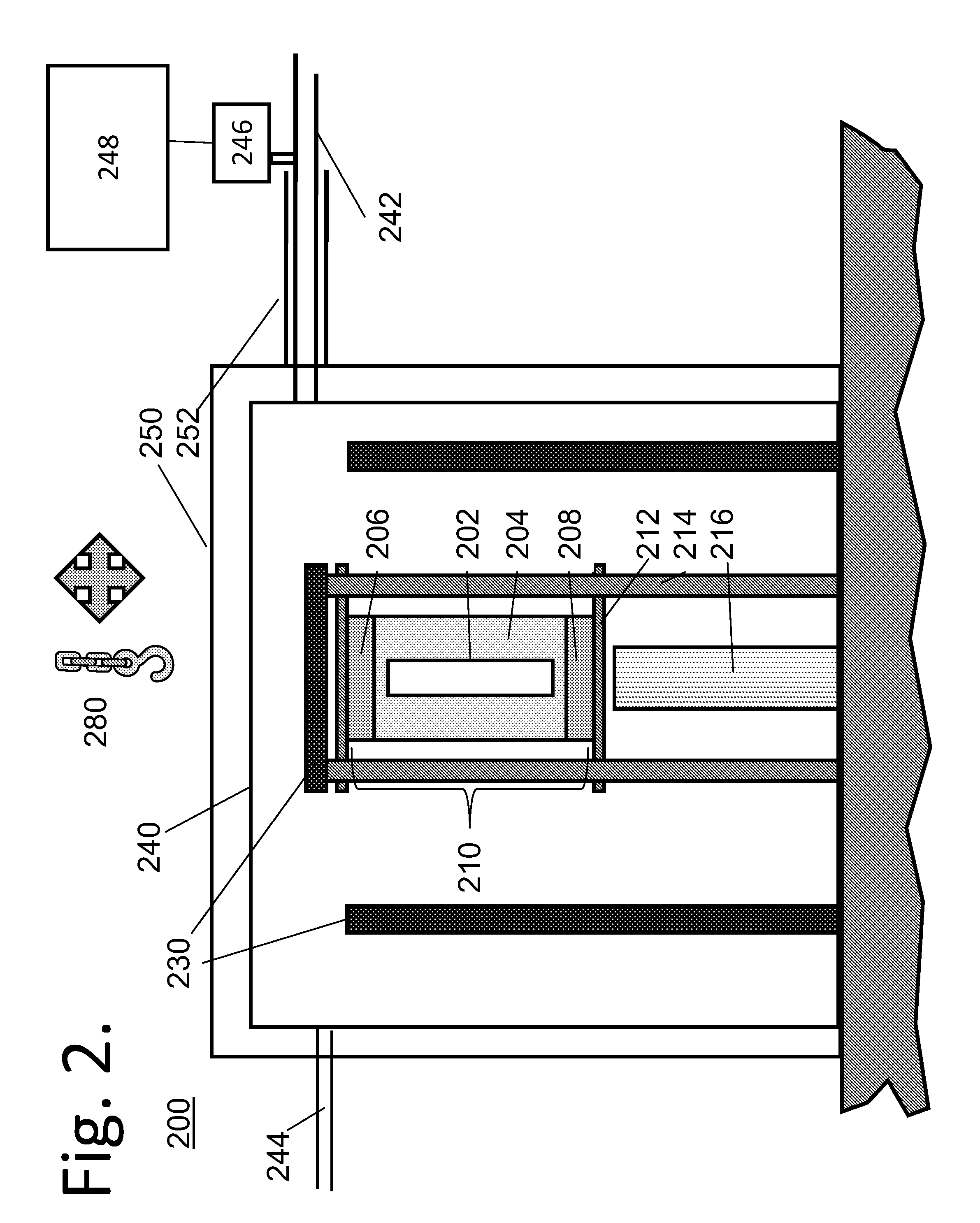

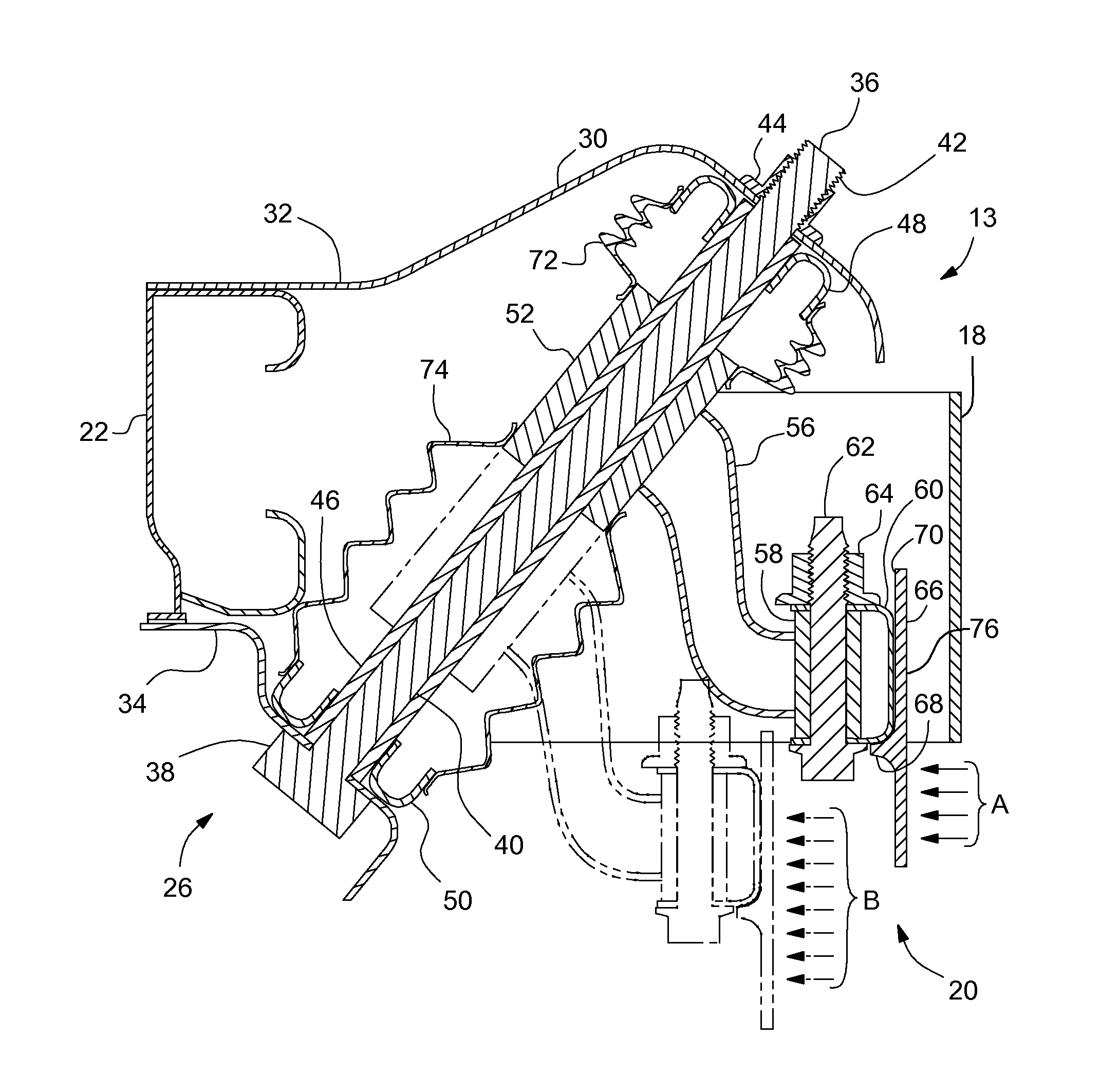

Heater device and method for high pressure processing of crystalline materials

InactiveUS20090320745A1ThinnerEasy to usePolycrystalline material growthFrom melt solutionsCost effectivenessMetallurgy

An improved heater for processing materials or growing crystals in supercritical fluids is provided. In a specific embodiment, the heater is scalable up to very large volumes and is cost effective. In conjunction with suitable high pressure apparatus, the heater is capable of processing materials at pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SORAA

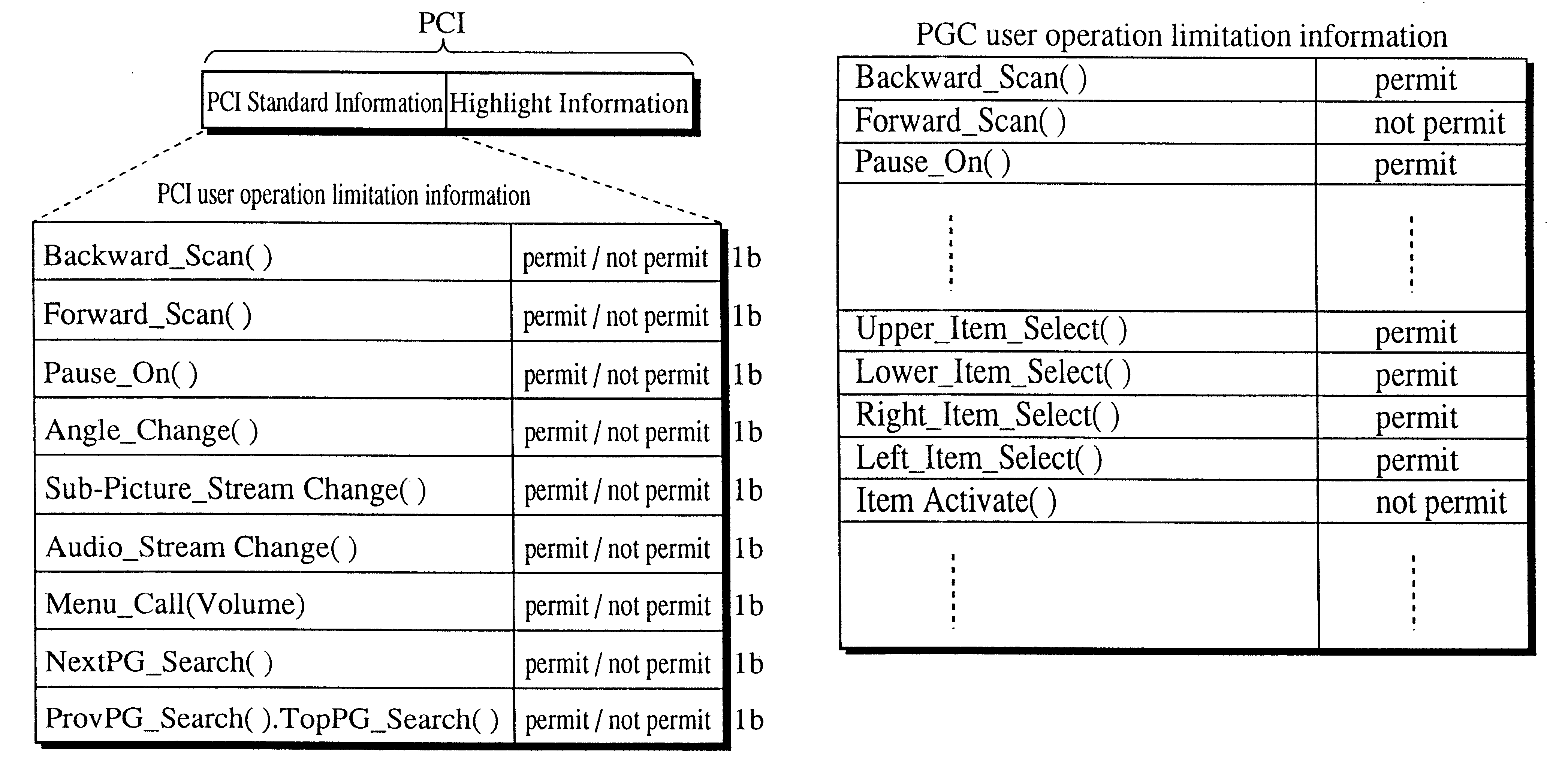

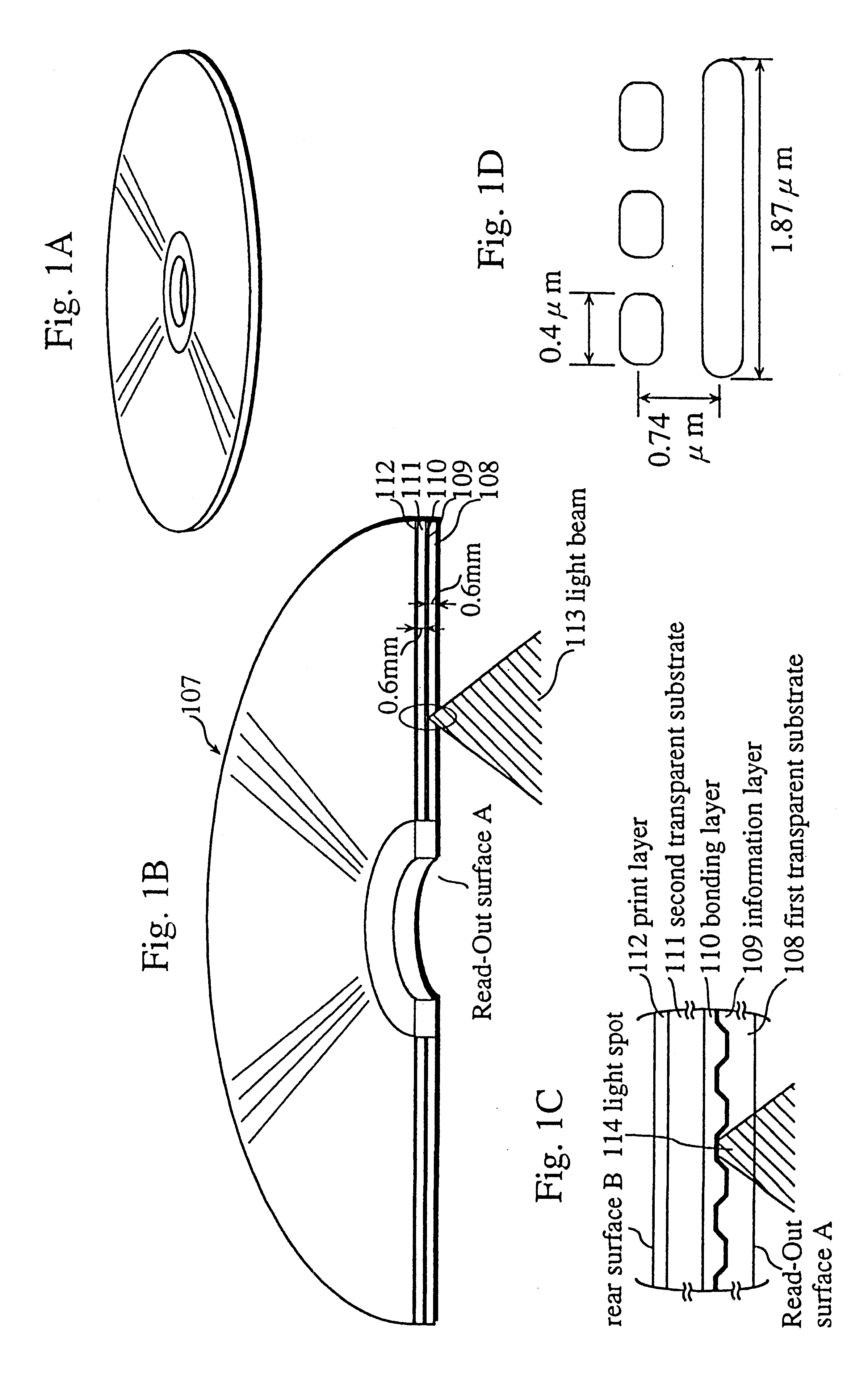

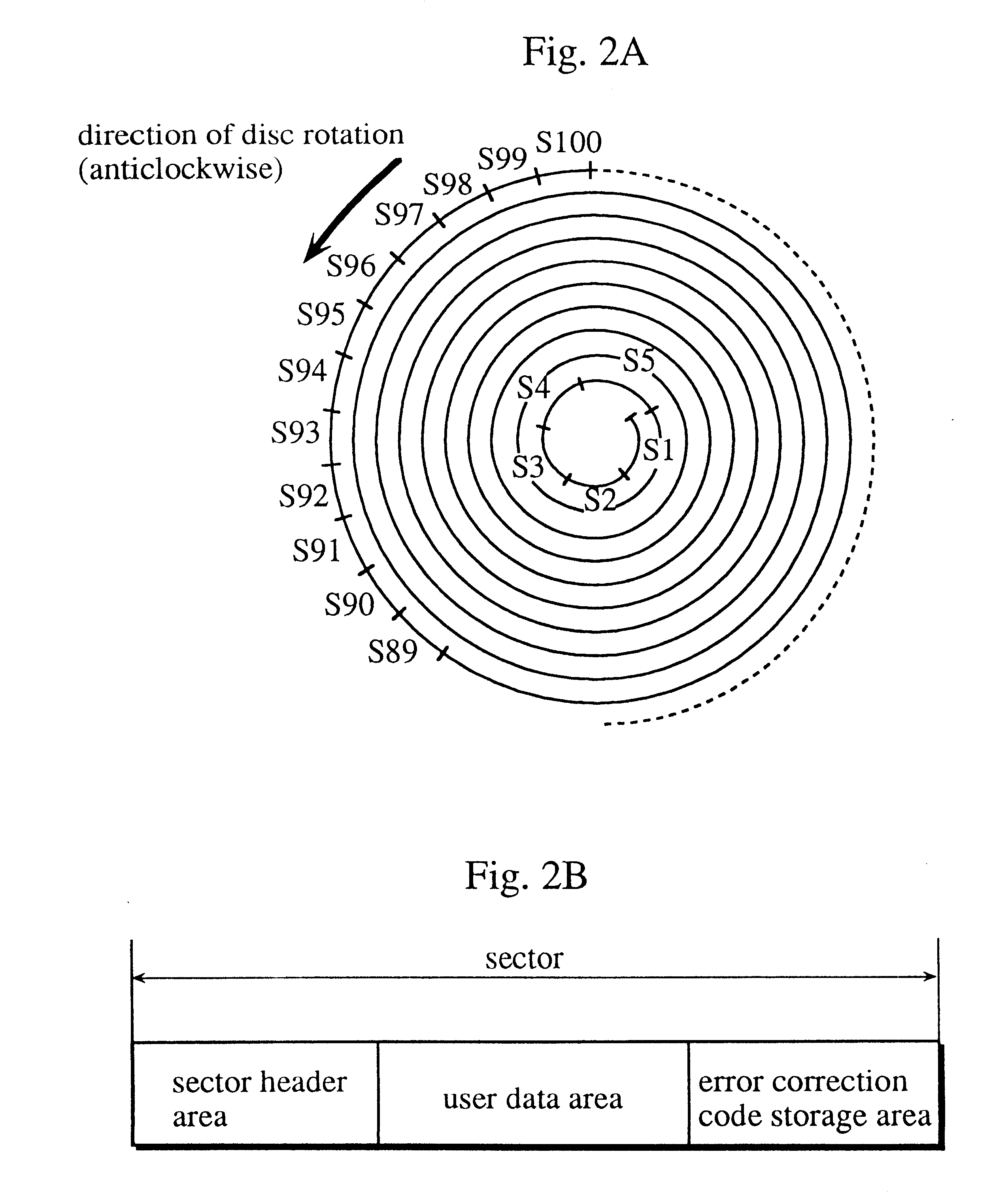

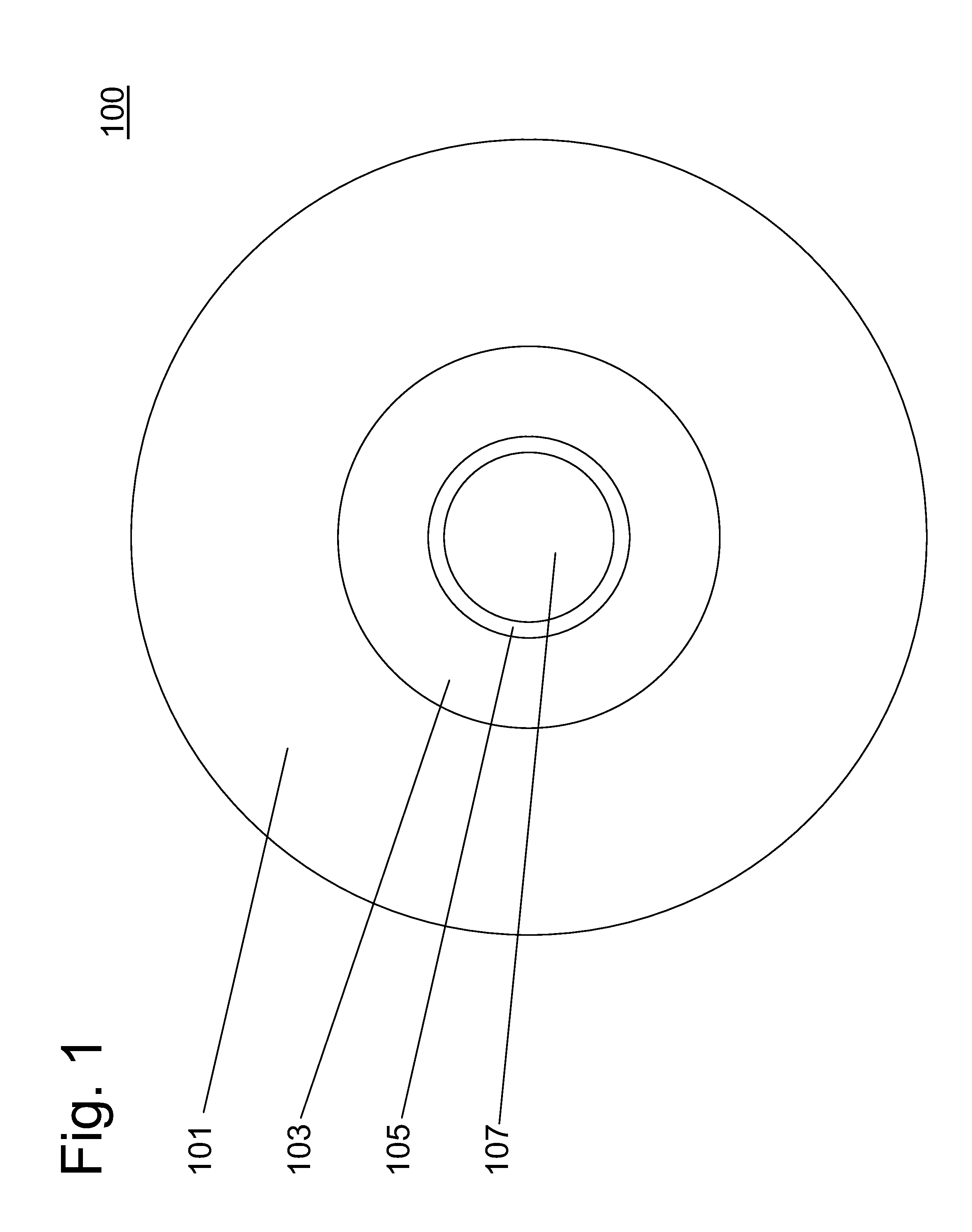

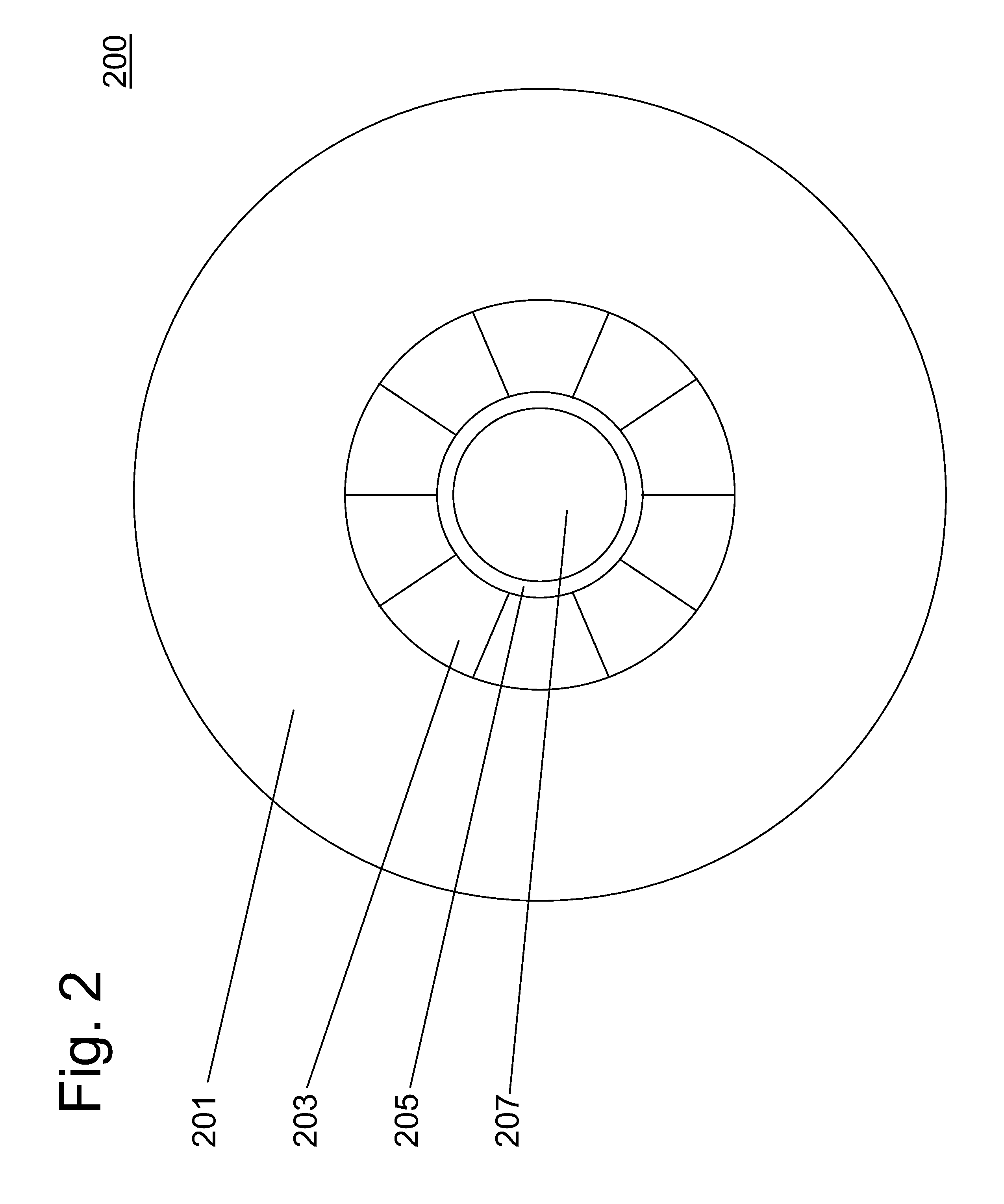

Optical disc for coordinating the use of special reproduction functions and a reproduction device for the optical disc

InactiveUS6553179B1Preventing executionDamage the interactive nature of a titleTelevision system detailsRecord information storageComputer hardwareReproduction function

A multimedia optical disc includes a lot of blocks each of which stores moving picture data, audio data, sub-picture data, and control information. Each piece of moving picture data, audio data, sub-picture data, and control information in the same block has the same reproduction time limit. Each piece of control information includes a mask flag indicating whether to mask a key interrupt requesting a special reproduction such as fast forward, the key interrupt being generated by the user by pressing a key on a remote controller and the like. The mask flag is effective for the key interrupt generated during the reproduction time limit stored in the control information.

Owner:PANASONIC CORP

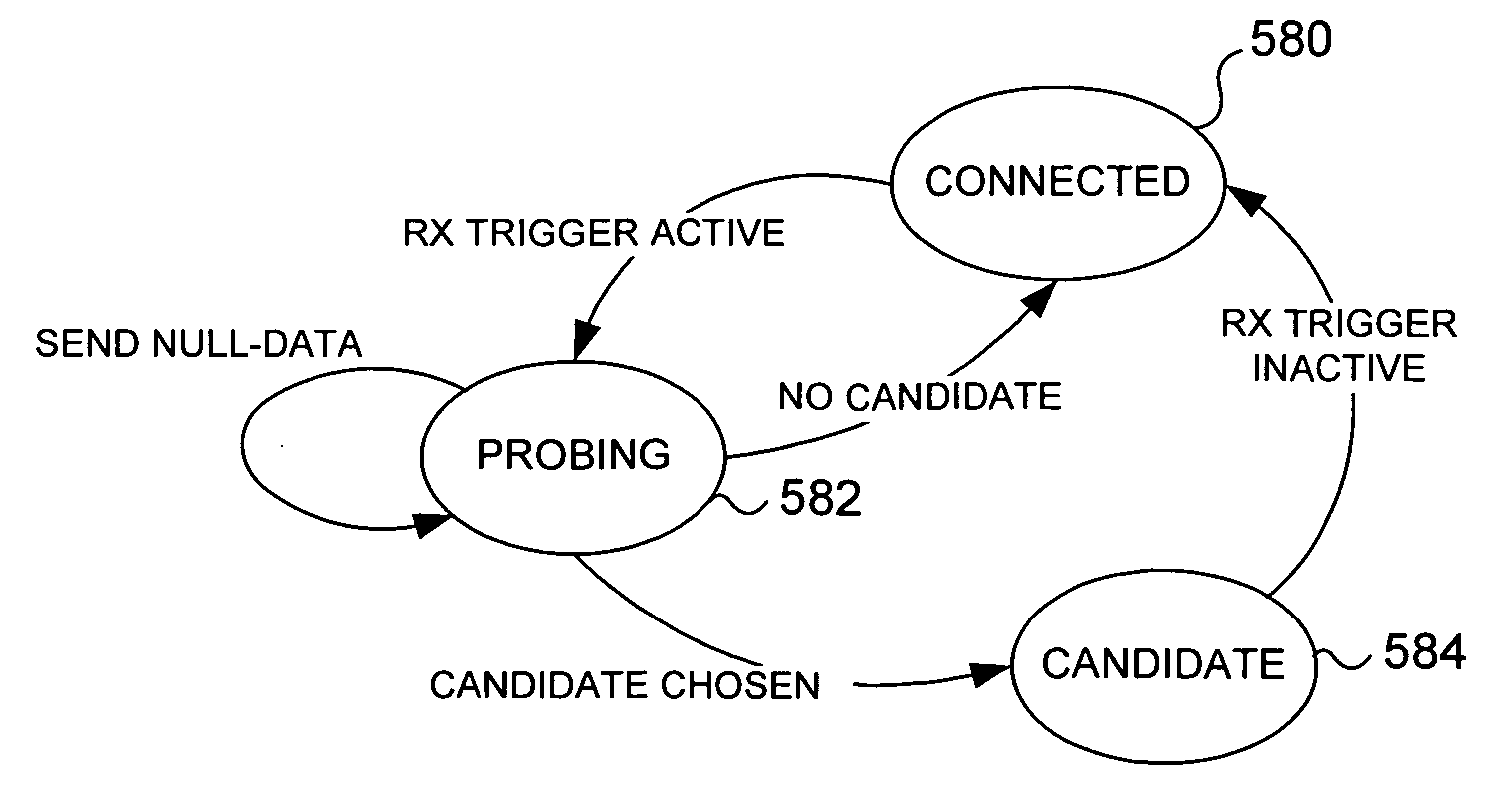

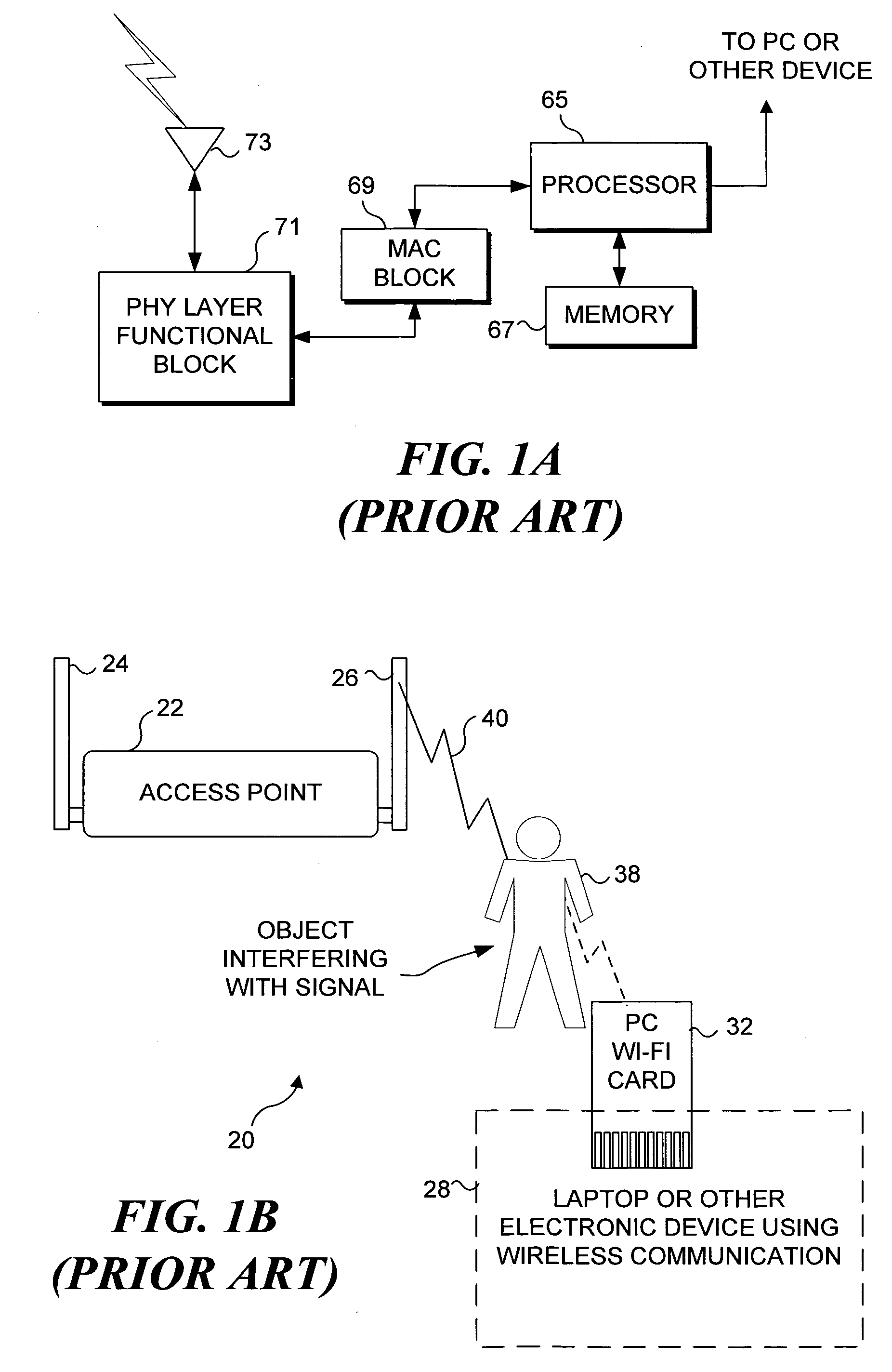

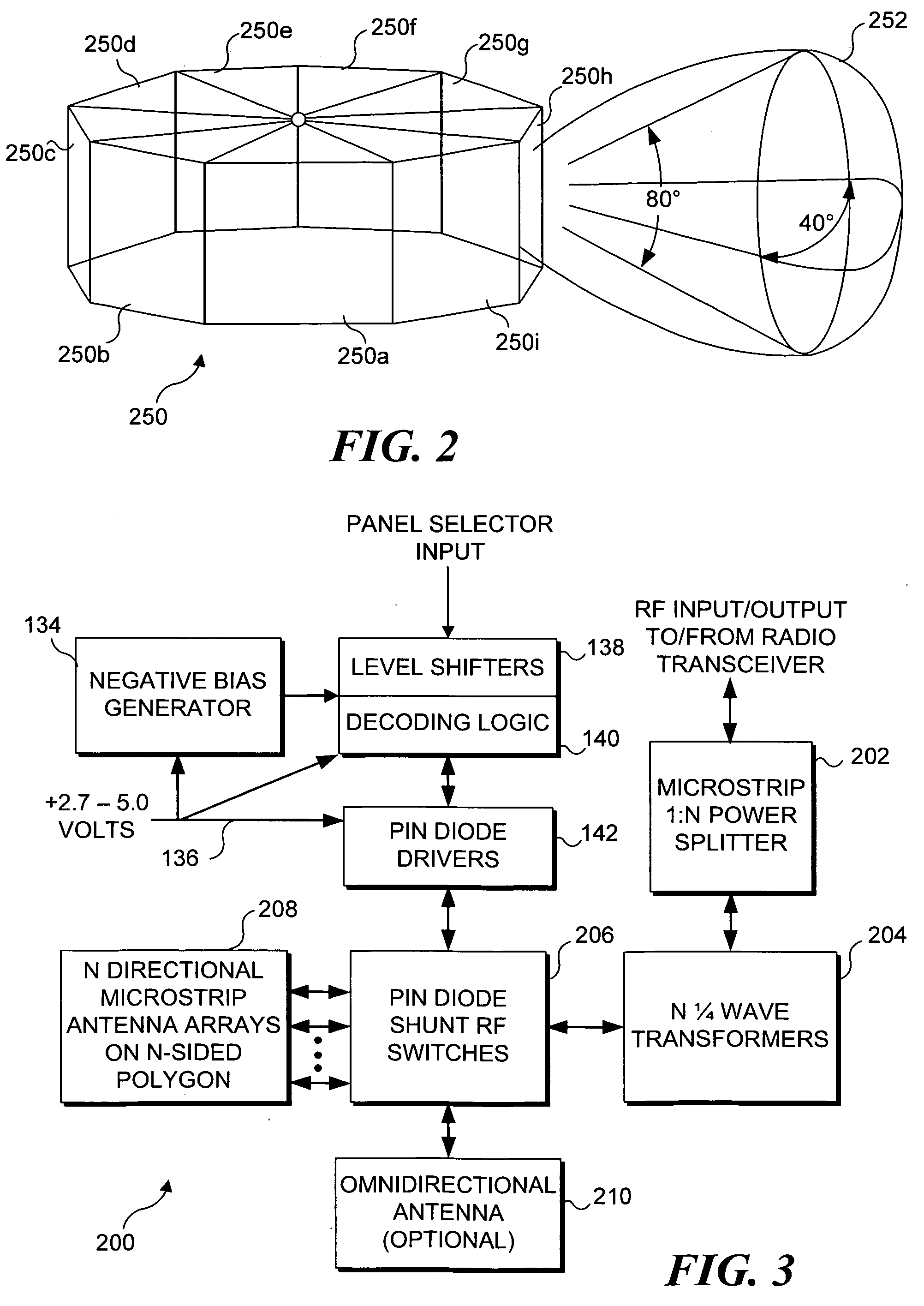

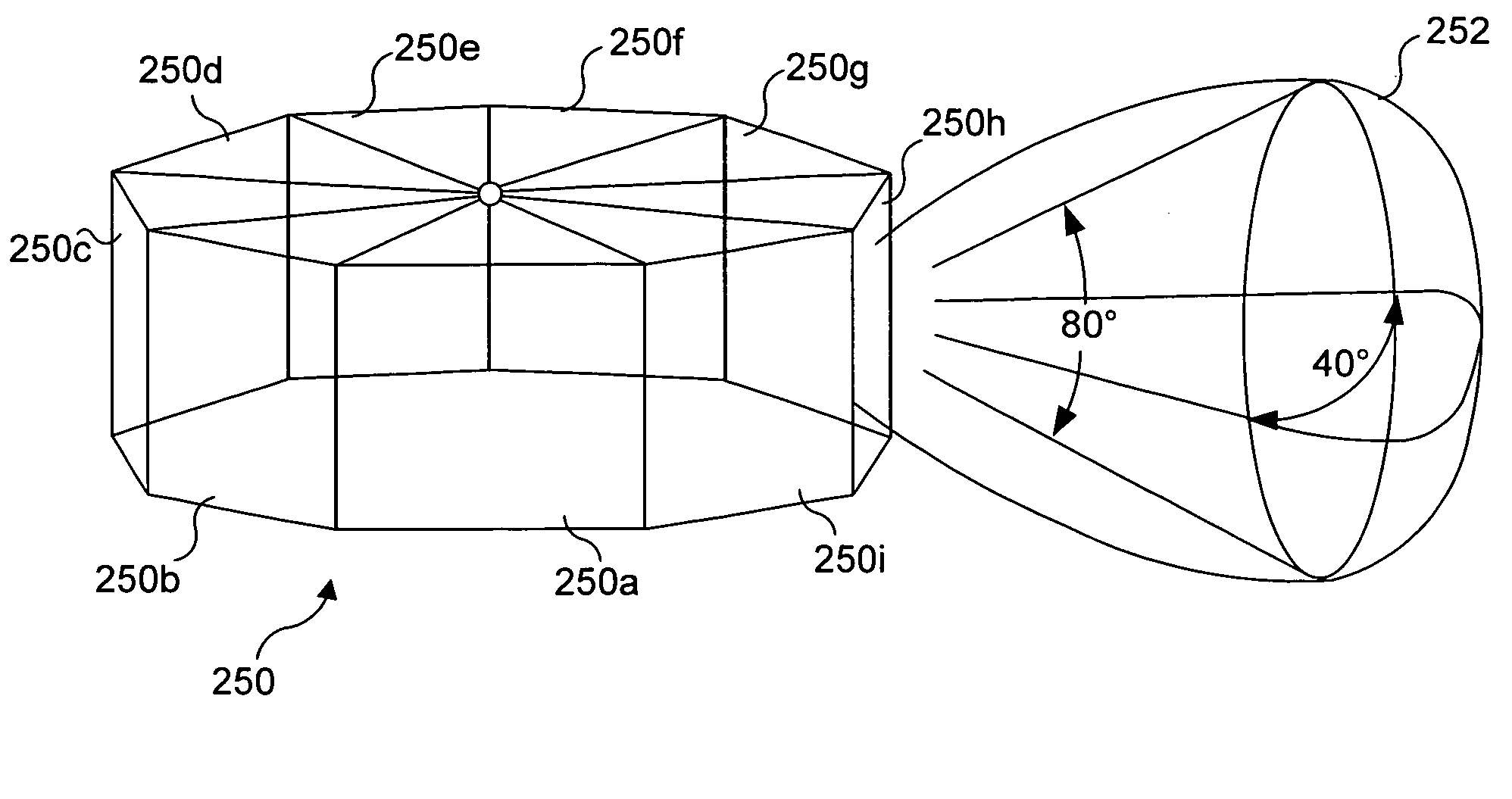

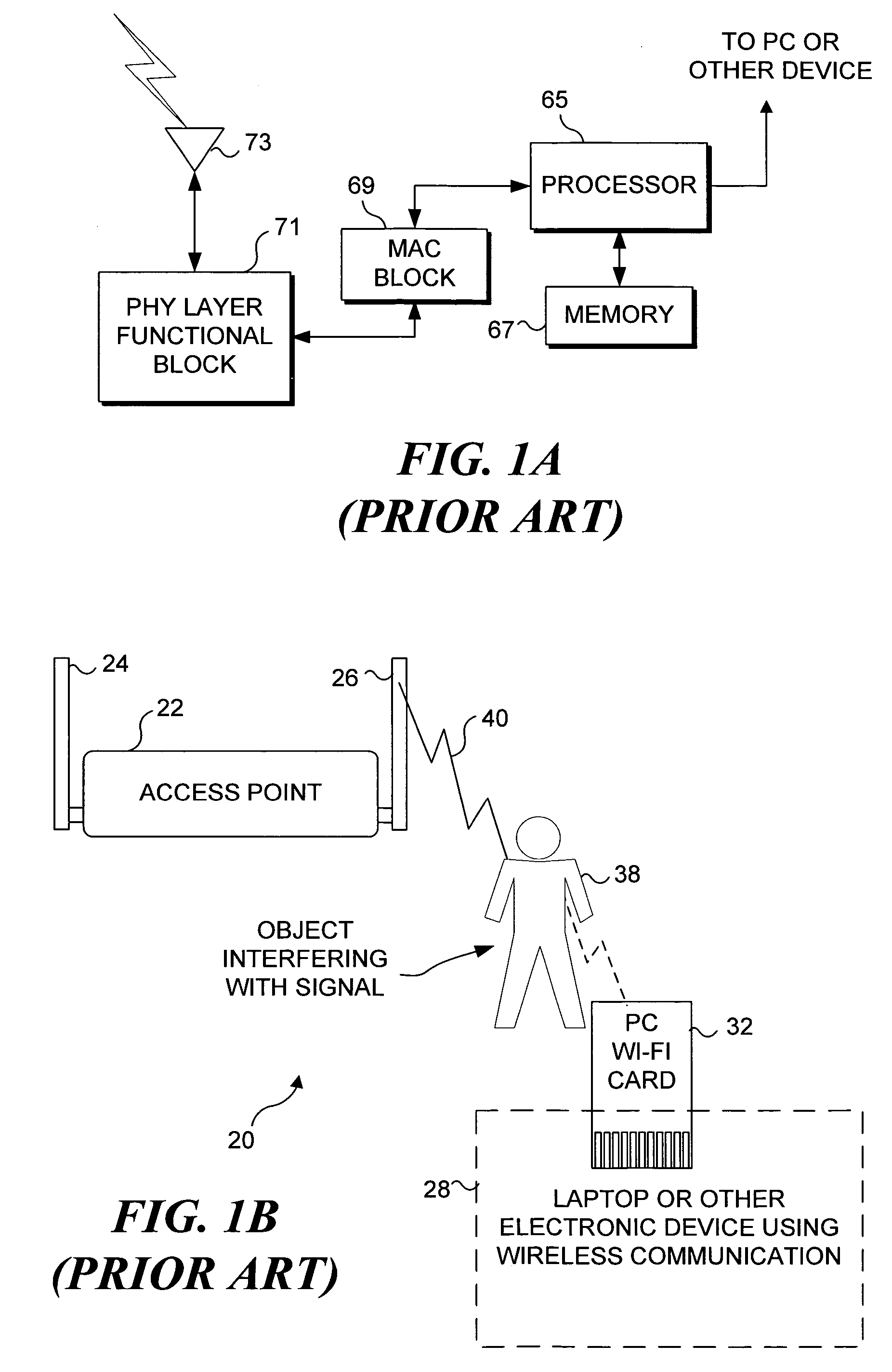

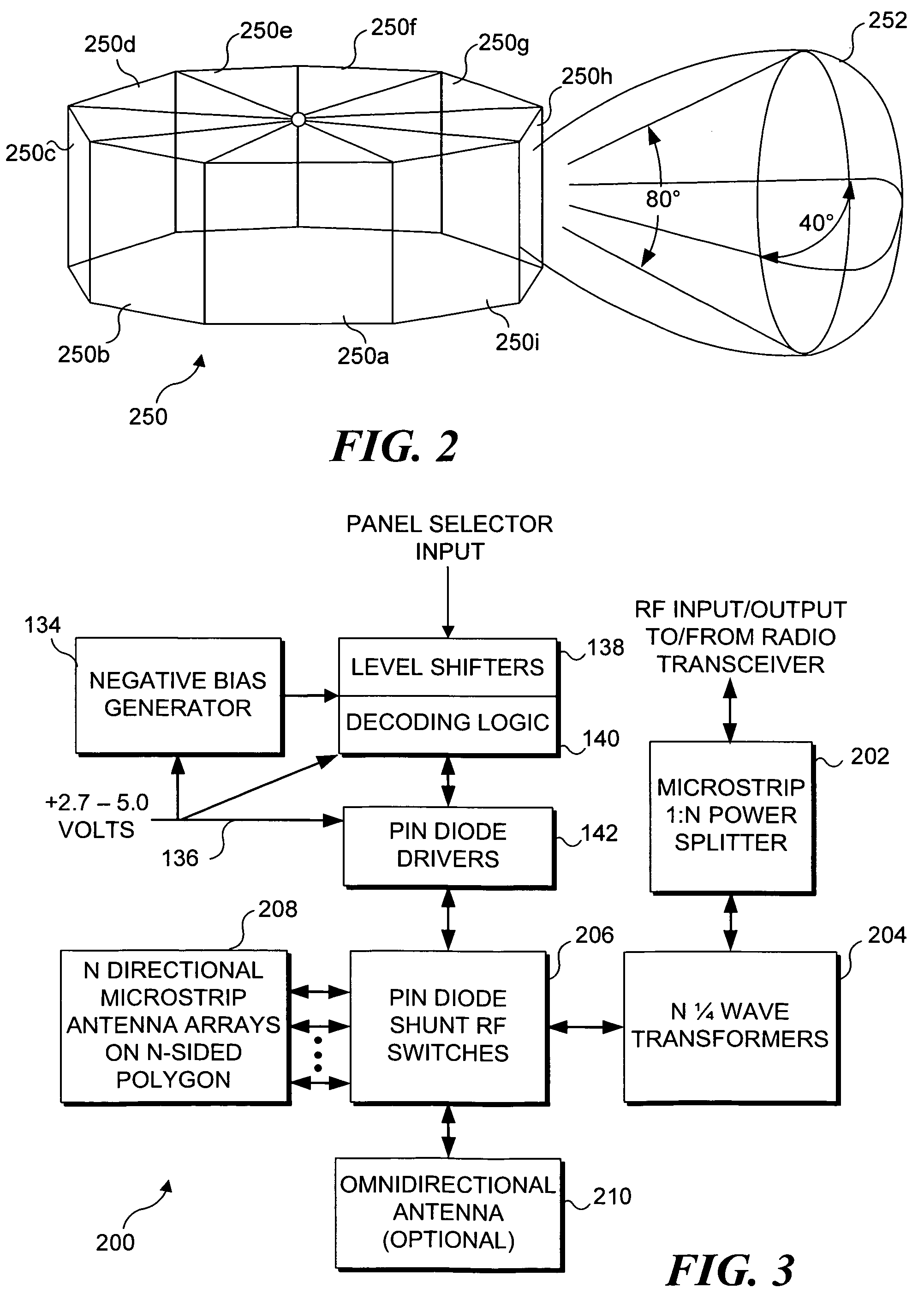

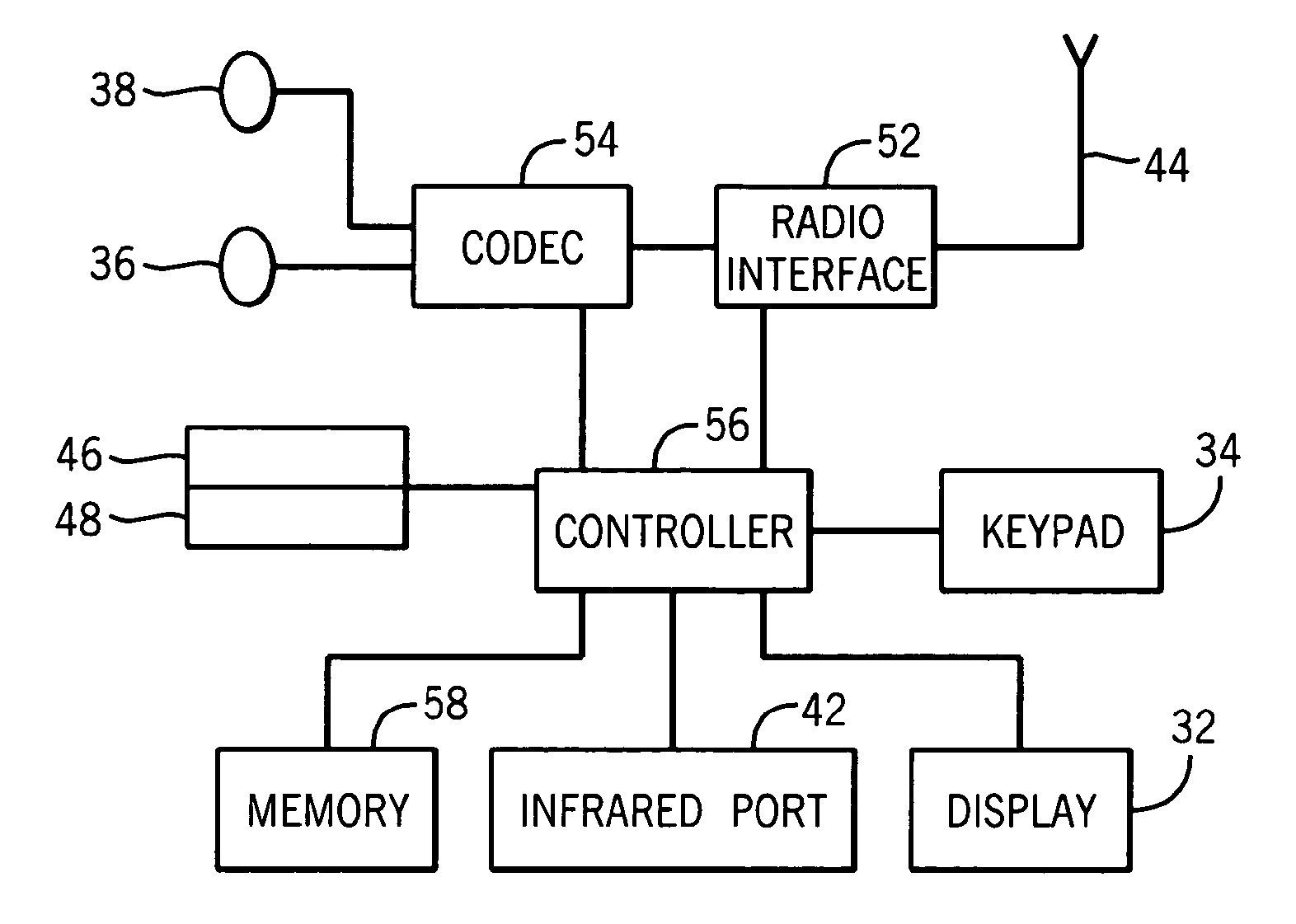

Control of a multi-sectored antenna system to improve channel efficiency

InactiveUS20060171357A1Increase data rateAchieve benefitsAntenna supports/mountingsSubstation equipmentOmnidirectional antennaSignal quality

A wireless device is coupled to a multi-sector antenna that includes a plurality of different sectors, any of which can be activated to transmit and receive in a desired direction specific to that sector. Optionally, an omnidirectional antenna is included for initially establishing a wireless connection with another wireless device, such as an access point. A parameter indicative of signal quality, such as throughput or received signal strength indication (RSSI) is determined by polling with each antenna sector to establish a prioritized candidate list. If a receive Trigger becomes active in response to a parameter falling below a threshold level, a new candidate sector is selected from the current list based upon a next-best signal quality. The directionality of the multi-sector antenna provides a substantially higher data rate compared to that of the conventional omnidirectional antenna.

Owner:MICROSOFT TECH LICENSING LLC

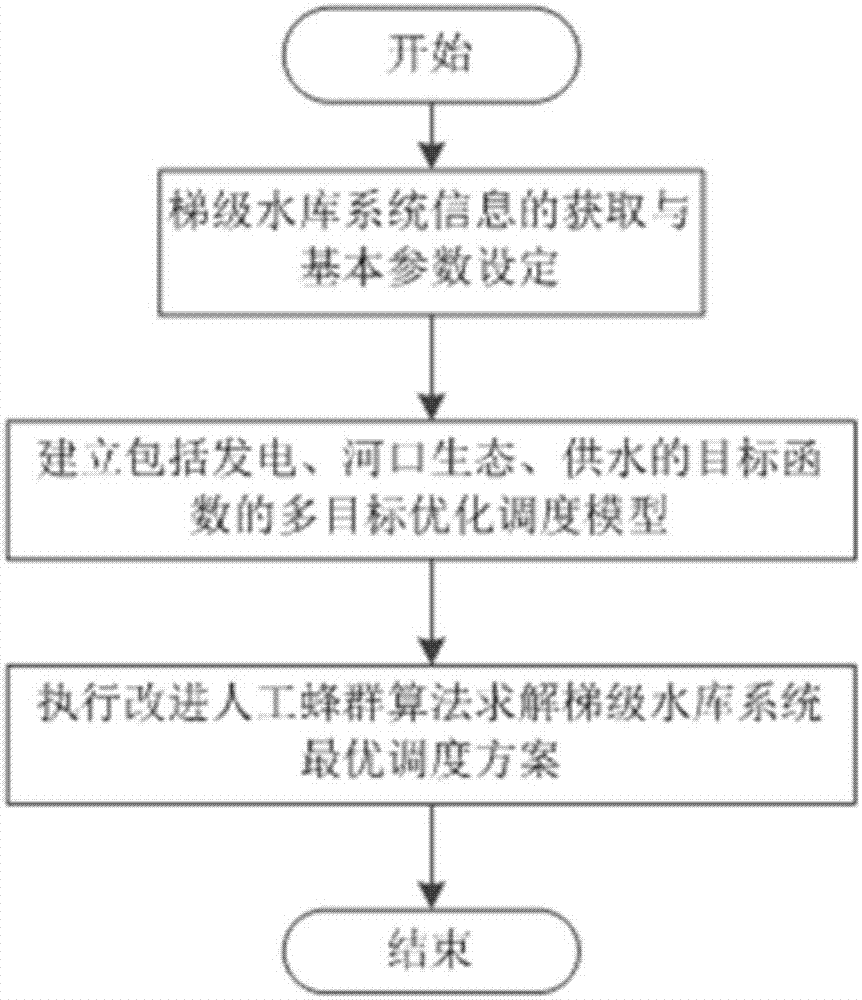

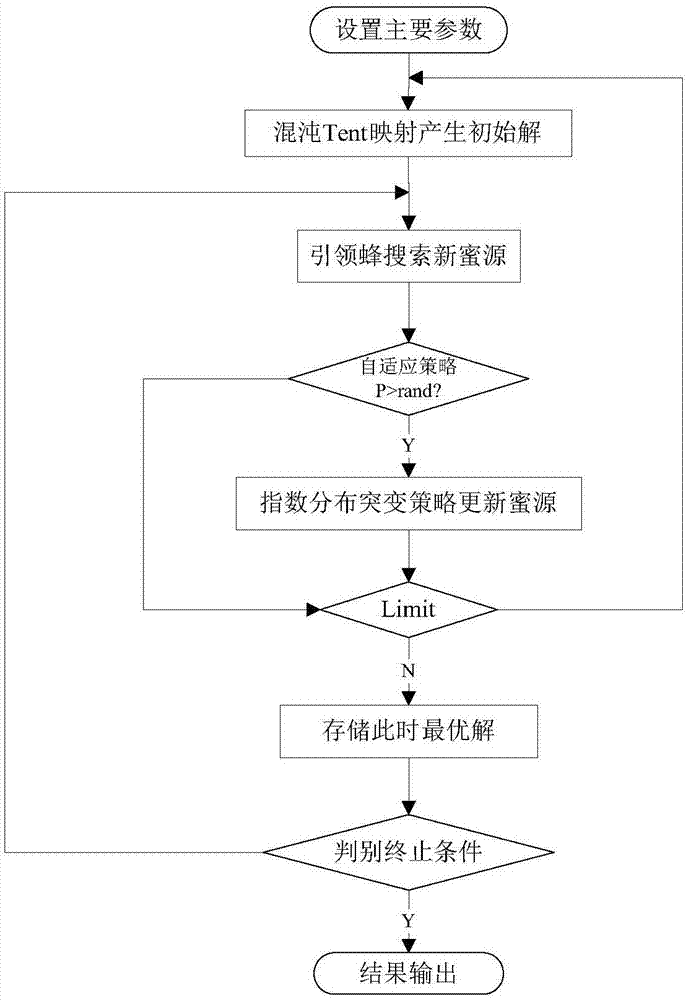

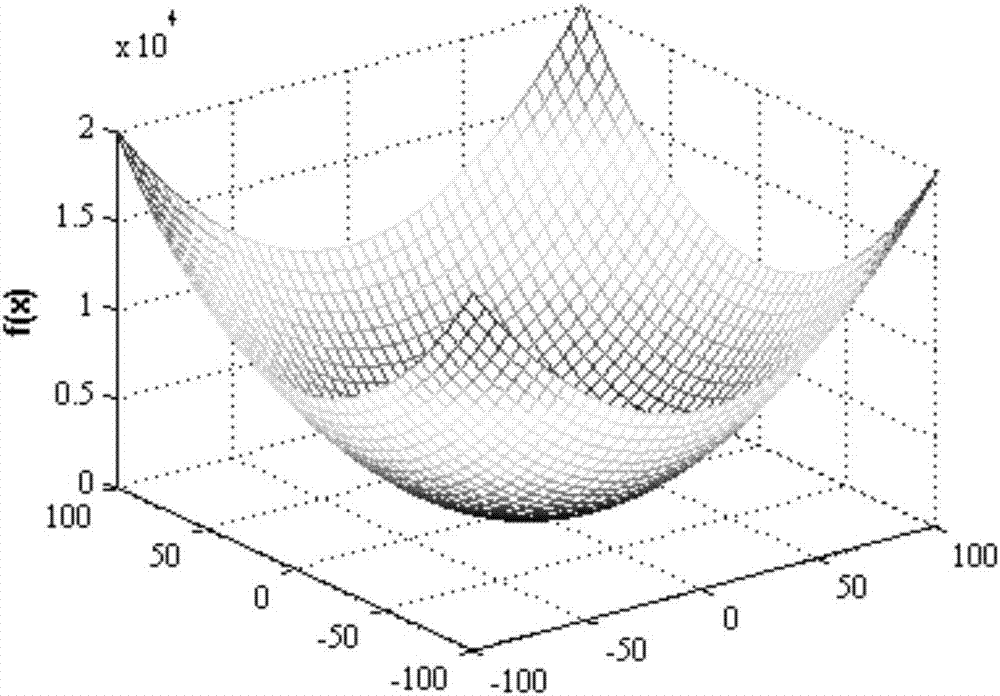

Cascade reservoir multi-objective optimization scheduling method based on improved artificial bee colony algorithm

ActiveCN106951985AAchieve benefitsAchieve improvementForecastingArtificial lifeOptimal schedulingGlobal optimization

The invention discloses a cascade reservoir multi-objective optimization scheduling method based on an improved artificial bee colony algorithm. The method comprises the following steps that s11, the basic information data of a cascade reservoir system are acquired; s12, a multi-objective scheduling model including power generation, estuarine ecology and water supply is established according to the information of the reservoir system; and s13, the optimal scheduling scheme of the cascade reservoir system is solved by performing the improved artificial bee colony algorithm. Global optimization of the reservoir scheduling problem can be realized so that the calculation efficiency and accuracy can be enhanced, and a new approach can be provided for solving the multi-objective optimization scheduling problem of the cascade reservoir system.

Owner:HOHAI UNIV

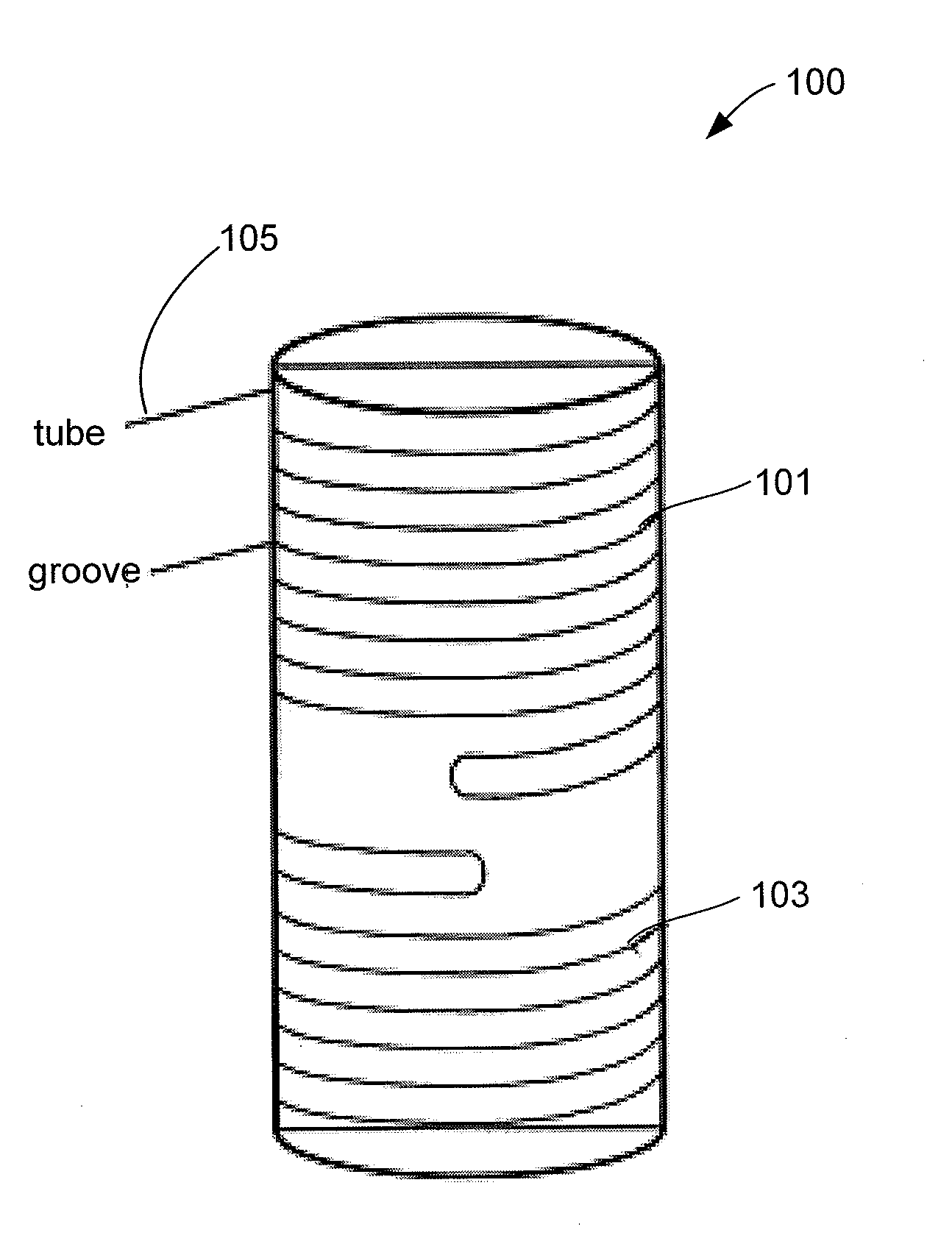

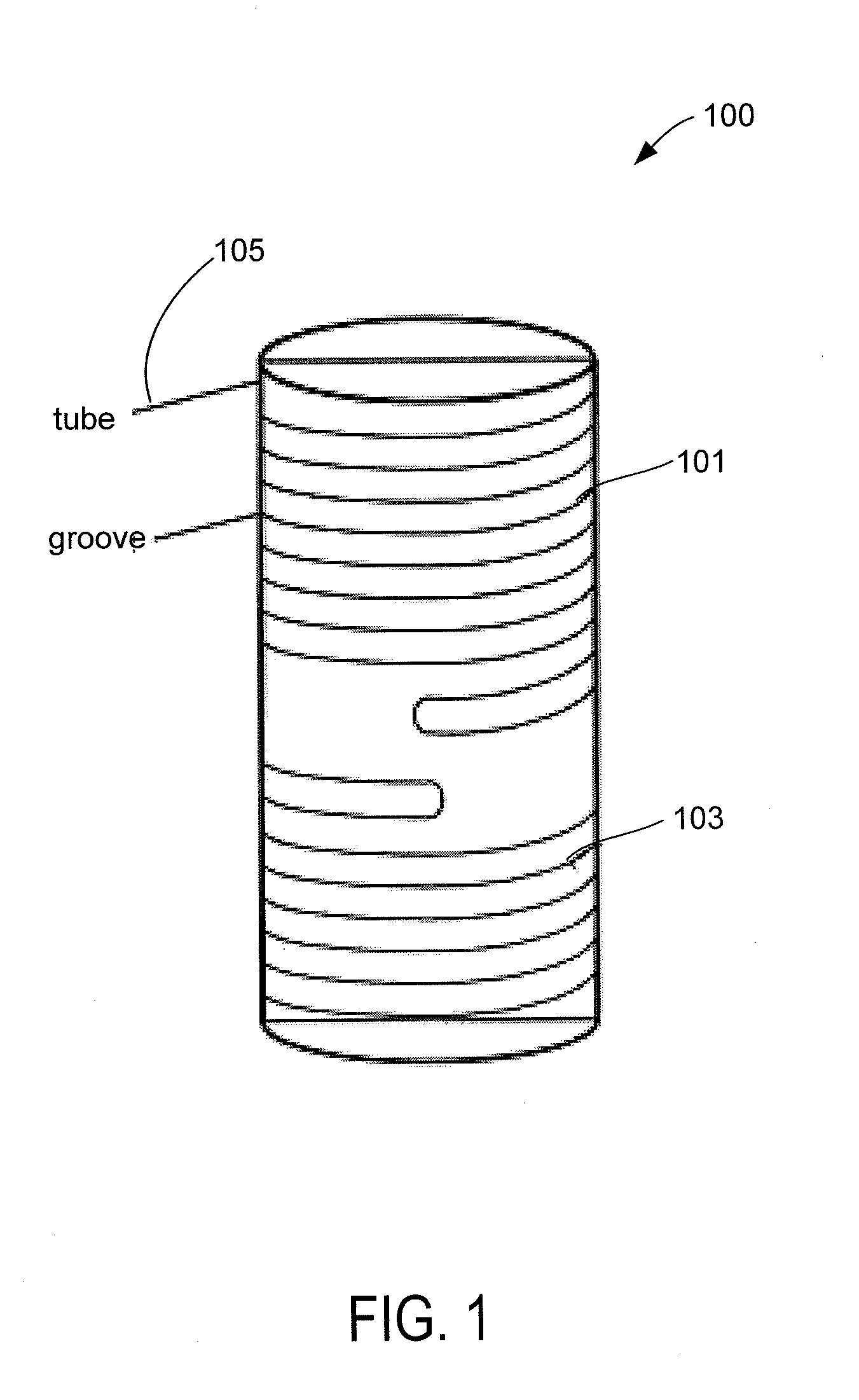

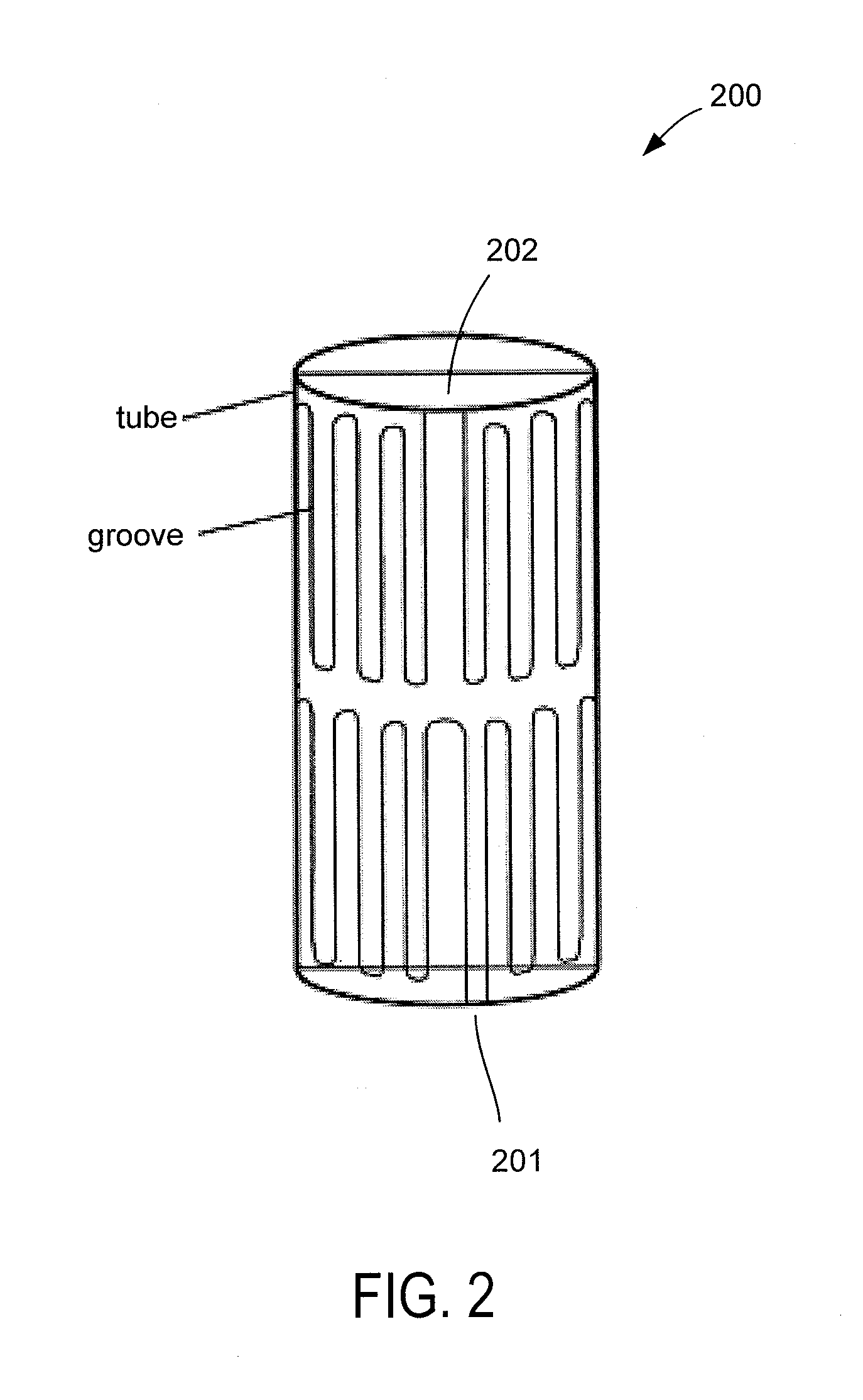

High Pressure Apparatus with Stackable Rings

InactiveUS20120137966A1Cost-effectiveSimple and cost-effective to manufactureAfter-treatment apparatusPolycrystalline material growthControl systemPower control system

A high pressure apparatus and related methods for processing supercritical fluids is described. The apparatus includes a capsule, a heater, at least one ceramic ring with one or more scribe marks and / or cracks present. The apparatus optionally has a metal sleeve containing each ceramic ring. The apparatus also has a high-strength enclosure, end flanges with associated insulation, and a power control system. The apparatus is capable of accessing pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:ELMHURST RES +1

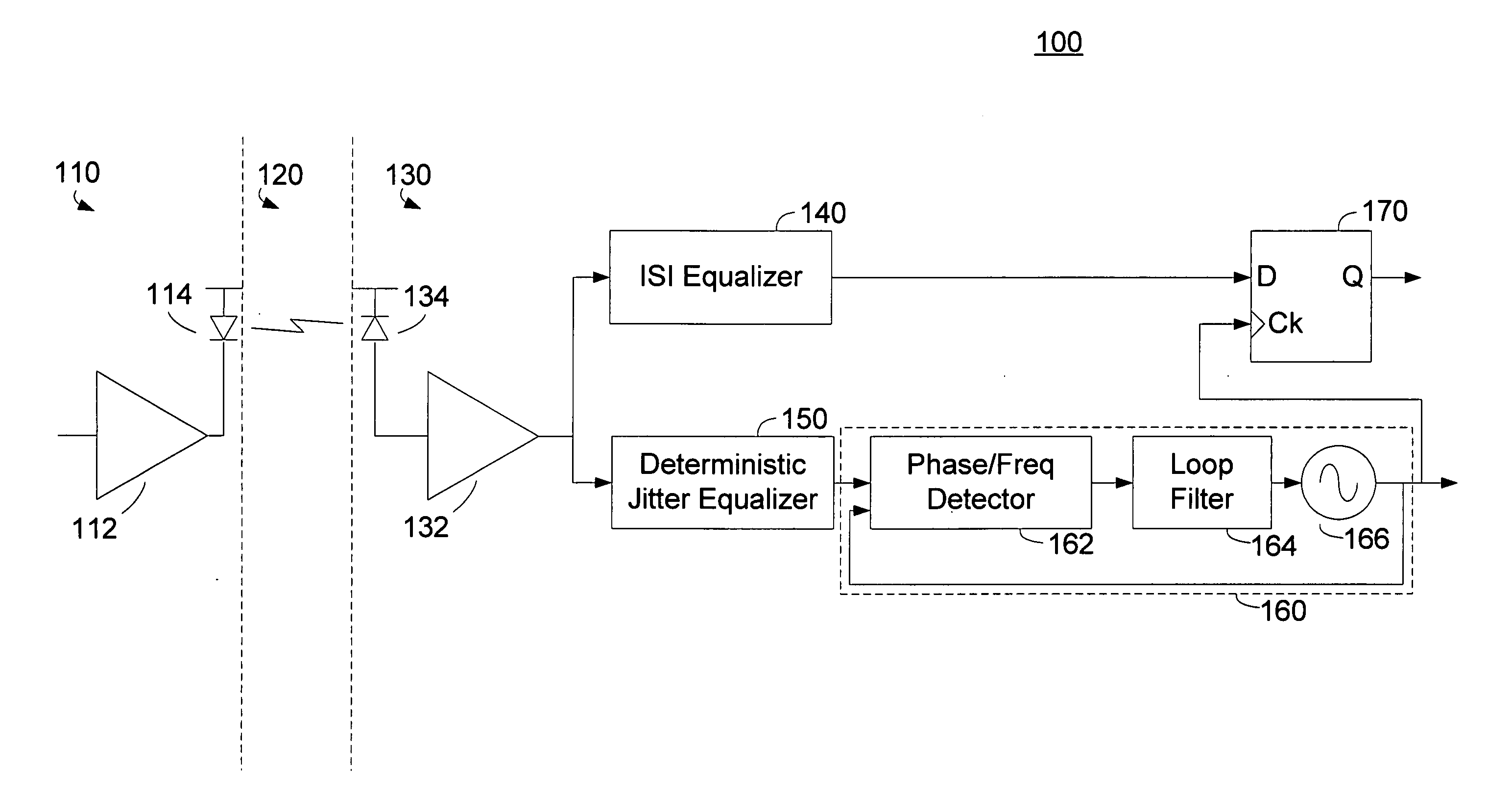

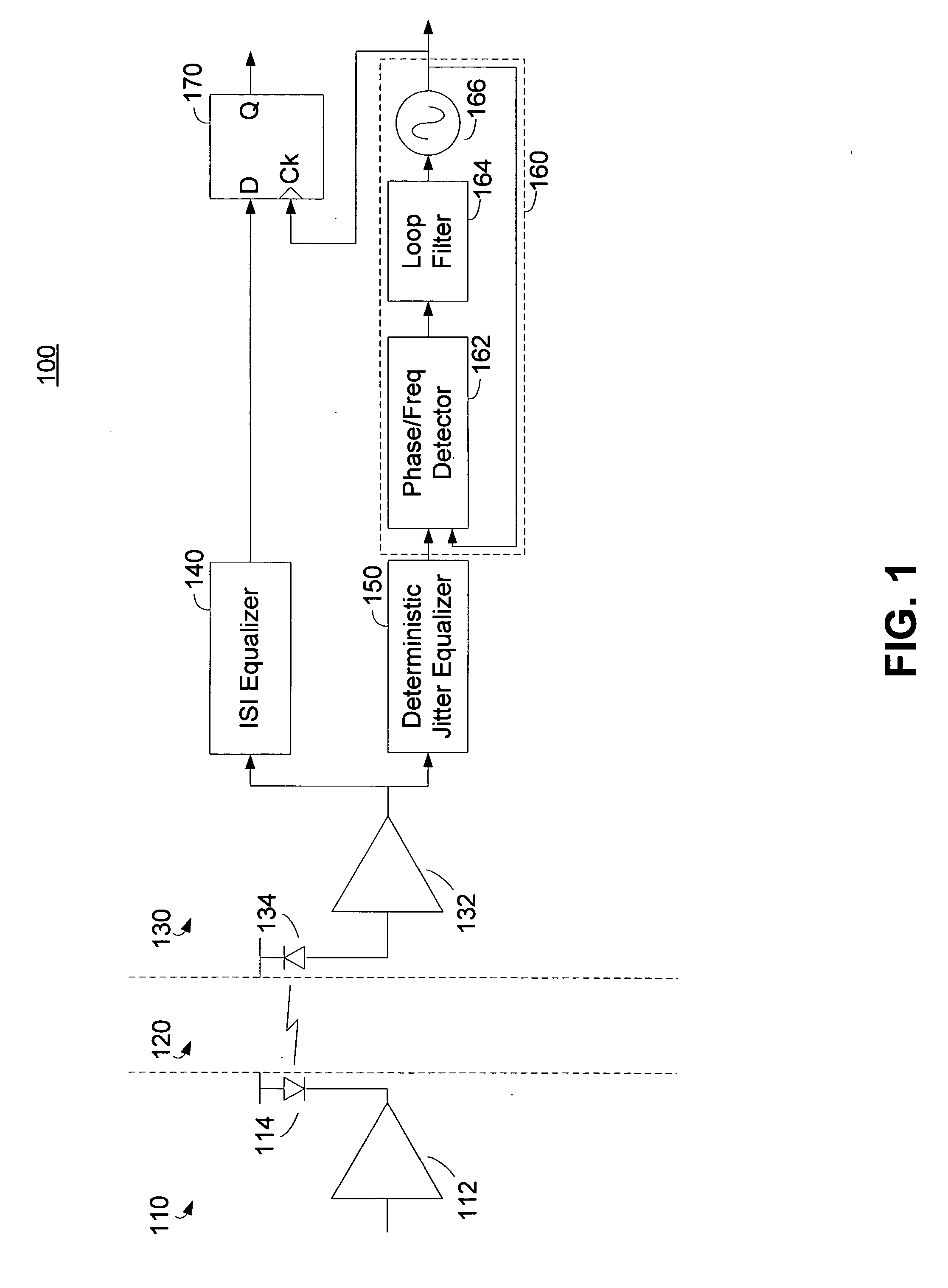

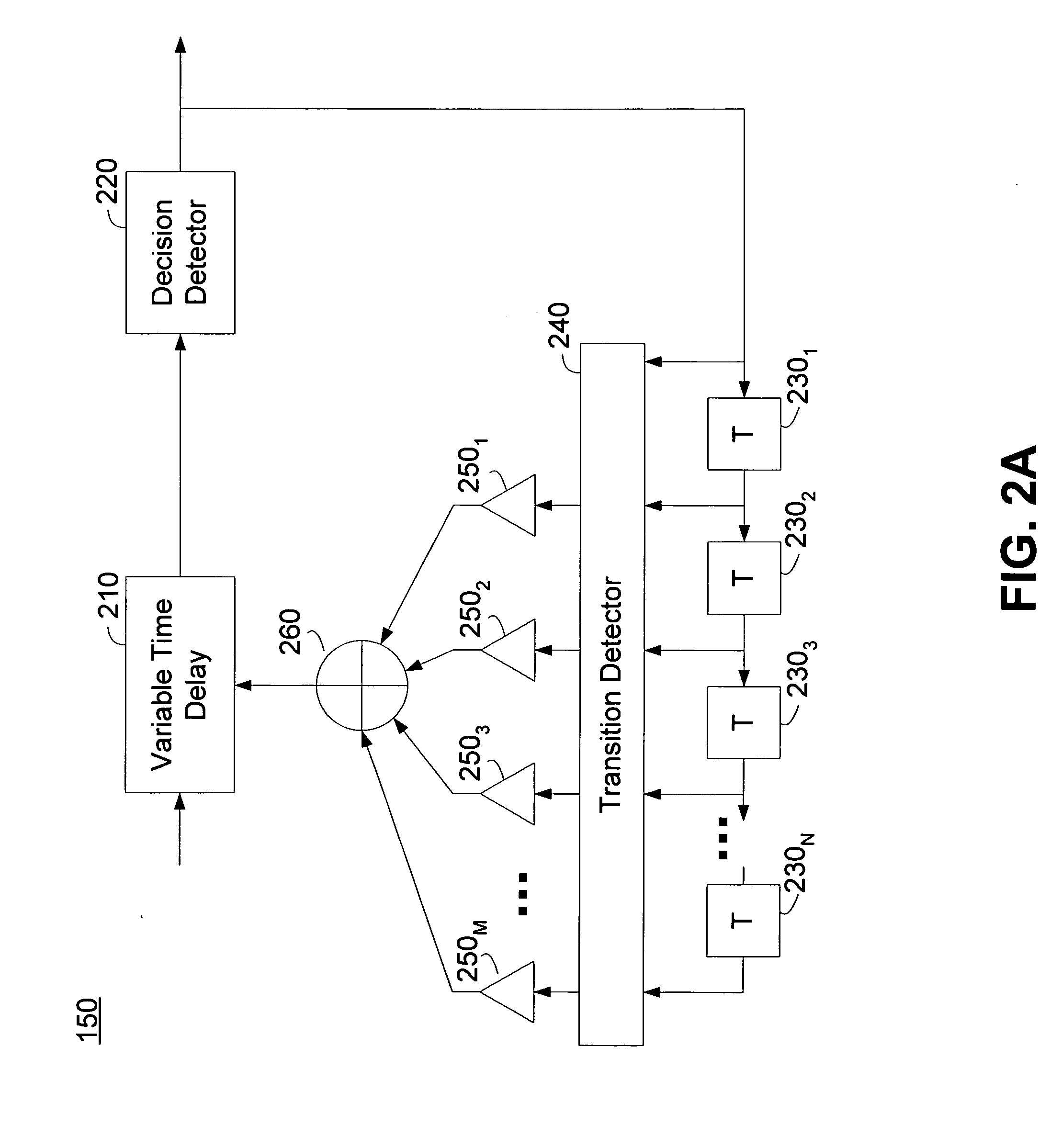

Deterministic jitter equalizer

ActiveUS20050152488A1Easy to implementImprove phase noiseMultiple-port networksError detection/prevention using signal quality detectorData streamDuty cycle distortion

An equalizer for serial data communications can be configured to compensate for the effects of deterministic jitter. The equalizer can be configured to compensate a received serial data stream for the effects of data-dependent jitter as well as duty cycle distortion jitter. The equalizer can be configured to determine the value of one or more previously received symbols and compare them to a recovered symbol. The equalizer can adjust a variable delay positioned in the serial data path to introduce a delay into the data path that is based in part on the received data stream. The equalizer can be configured to vary the delay when any of the one or more previously received symbols is different from the recovered symbol, and can be configured to maintain a constant delay if the one or more previously received symbols is the same as the recovered symbol.

Owner:CALIFORNIA INST OF TECH

Comprehensive utilization method of aluminum ash

ActiveCN105347361AHarmlessAvoid pollutionAmmonium salt preparationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAtmospheric dustAluminum industry

The invention belongs to the technical field of comprehensive utilization of waste resources from the aluminum industry and specifically discloses a comprehensive utilization method of aluminum ash. According to the comprehensive utilization method of aluminum ash, metallic aluminium is extracted from aluminum ash through an ore grinding method; the aluminum ash obtained after aluminium extraction undergoes catalytic deamination; the aluminum ash obtained after deamination is mixed with alkali and granulation forming is then carried out; and the granulation product is sintered and the sintered product is finally dissolved out. By the above method, useful components in the aluminum ash can be recovered to the maximum; ammonia gas which has been ignored for a long time is effectively recovered; components such as aluminium oxide, villiaumite and the like are recovered and utilized to the maximum; pollution of aluminum ash processing to the environment is avoided; atmospheric dust pollution is avoided; atmospheric pollution is also avoided due to ammonia gas recovery; pollution of aluminum ash stacking to underground water and soil is avoided due to extraction and recovery of fluoride salt; and environmental safety during the treating process is guaranteed.

Owner:湖南绿脉环保科技股份有限公司

Control of a multi-sectored antenna system to improve channel efficiency

InactiveUS7359362B2Increase data rateAchieve benefitsAntenna supports/mountingsSubstation equipmentOmnidirectional antennaSignal quality

Owner:MICROSOFT TECH LICENSING LLC

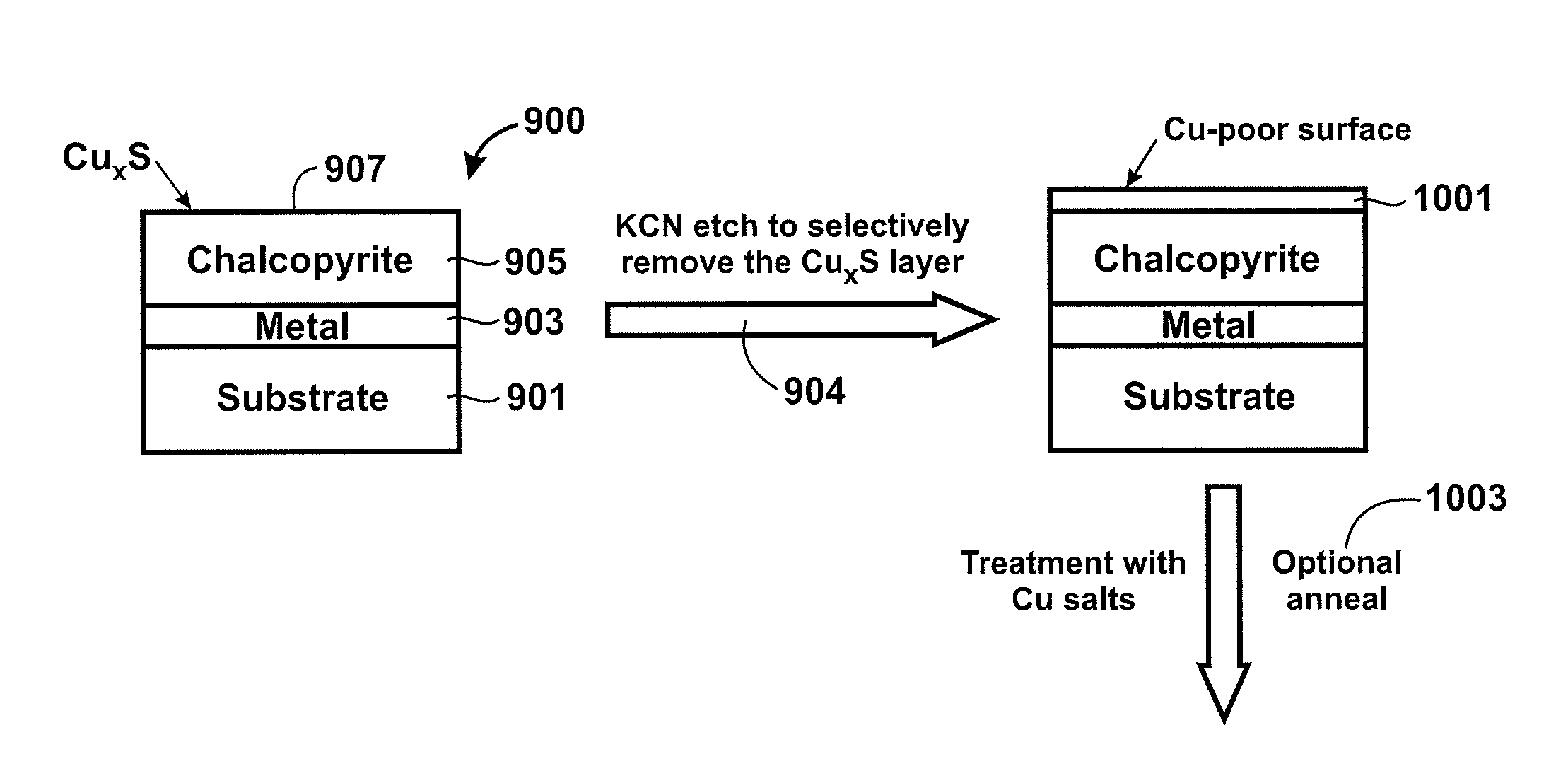

Bulk copper species treatment of thin film photovoltaic cell and manufacturing method

ActiveUS8008111B1Toxic reductionAchieve benefitsFinal product manufactureSemiconductor/solid-state device manufacturingIndiumSulfur

A method for forming a thin film photovoltaic device. The method includes providing a transparent substrate comprising a surface region. A first electrode layer is formed overlying the surface region. A copper layer is formed overlying the first electrode layer and an indium layer is formed overlying the copper layer to form a multi-layered structure. The method subject at least the multi-layered structure to a thermal treatment process in an environment containing a sulfur bearing species to form a bulk copper indium disulfide material. The bulk copper indium disulfide material includes one or more portions of copper indium disulfide material characterized by a copper-to-indium atomic ratio of less than about 0.95:1 and a copper poor surface comprising a copper to indium atomic ratio of less than about 0.95:1. The method subjects the copper poor surface and one or more portions of the bulk copper indium disulfide material to copper species to convert the copper poor surface from an n-type characteristic to a p-type characteristic and to convert any of the one or more portions of the bulk copper indium disulfide material having the copper-to-indium atomic ratio of less than about 0.95:1 from a p-type characteristic to an n-type characteristic. A window layer is formed overlying the copper indium disulfide material.

Owner:CM MFG

System and method for utilizing a sip events framework to deliver syndication feeds

InactiveUS20060253567A1Good serviceReduce processing requirementsDigital computer detailsTransmissionFeed consumptionClient-side

A system and method for applying a SIP events framework in order to deliver syndication feeds. The invention includes a feed delivery server and a feed consumption client. The feed consumption client uses a SIP SUBSCRIBE method to subscribe to the feed. Once the feed consumption client has subscribed to the feed, the feed delivery server starts delivering new feed items using a SIP NOTIFY method whenever new information becomes available, providing a PUSH mechanism where new material is provided to the client when available.

Owner:NOKIA CORP

Calcium Hydroxyapatite Based Sulfonate Grease Compositions and Method of Manufacture

An overbased calcium sulfonate grease composition comprising a reduced amount of overbased calcium sulfonate, calcium hydroxyapatite, base oil, one or more converting agents, and one or more complexing acids if a complex grease is desired. The calcium sulfonate grease composition improves thickener yield and expected high temperature utility as demonstrated by dropping point. A method of making the composition comprising the steps of mixing the calcium sulfonate and base oil, adding the calcium carbonate either before or after conversion, adding one or more converting agents, and adding one or more complexing acids. All or a portion of one or more of the complexing acids may be added with or prior to the one or more converting agents.

Owner:NCH CORP

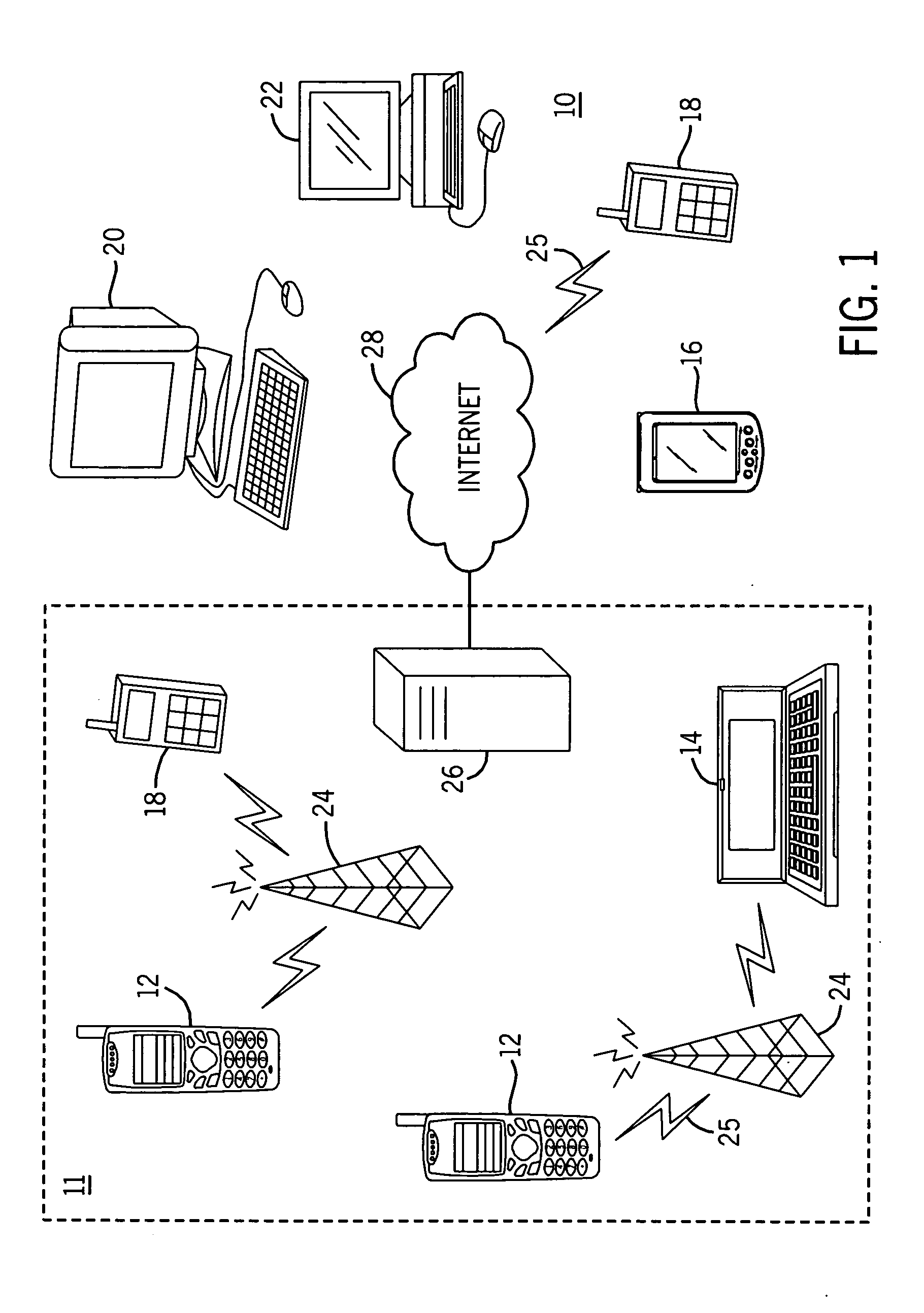

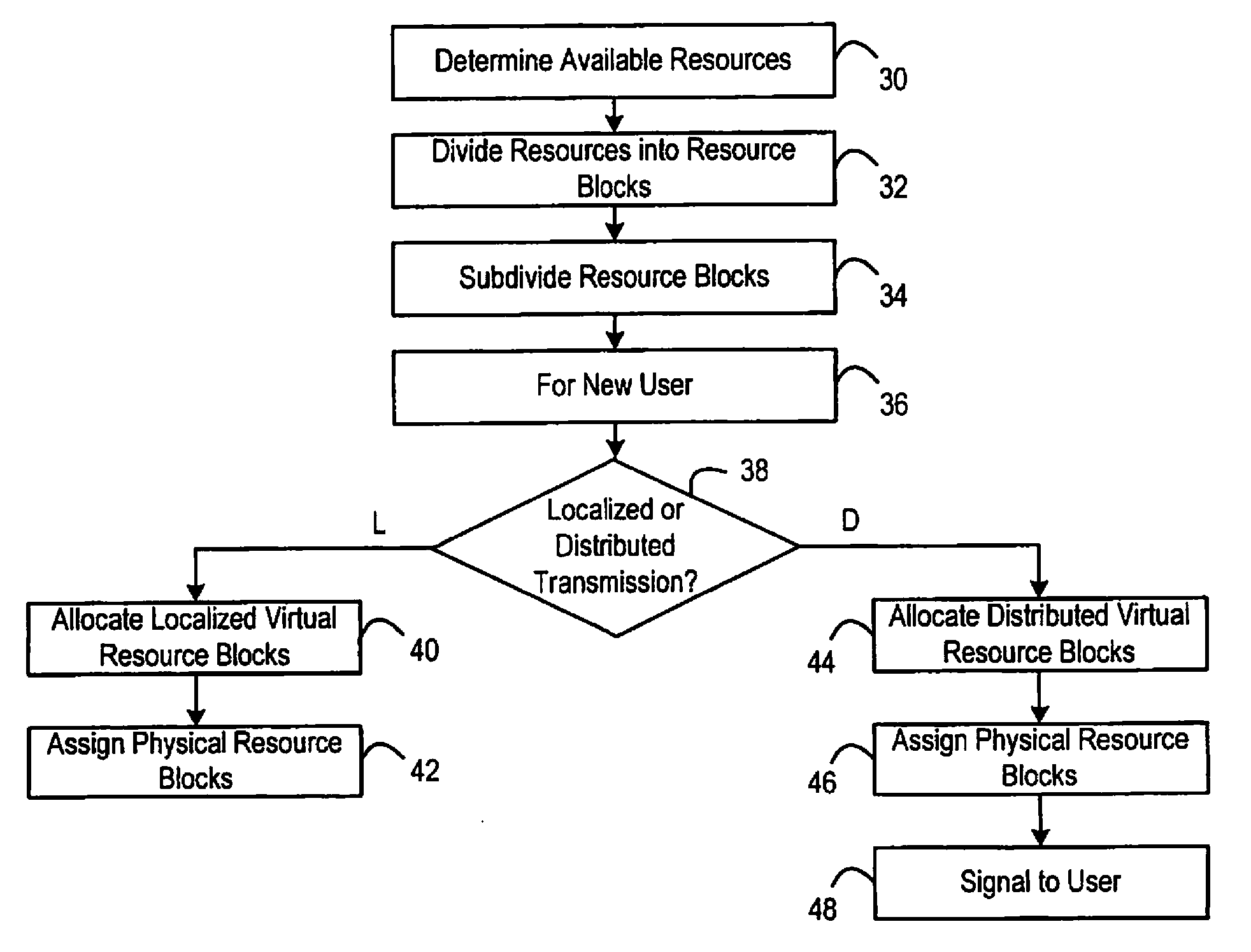

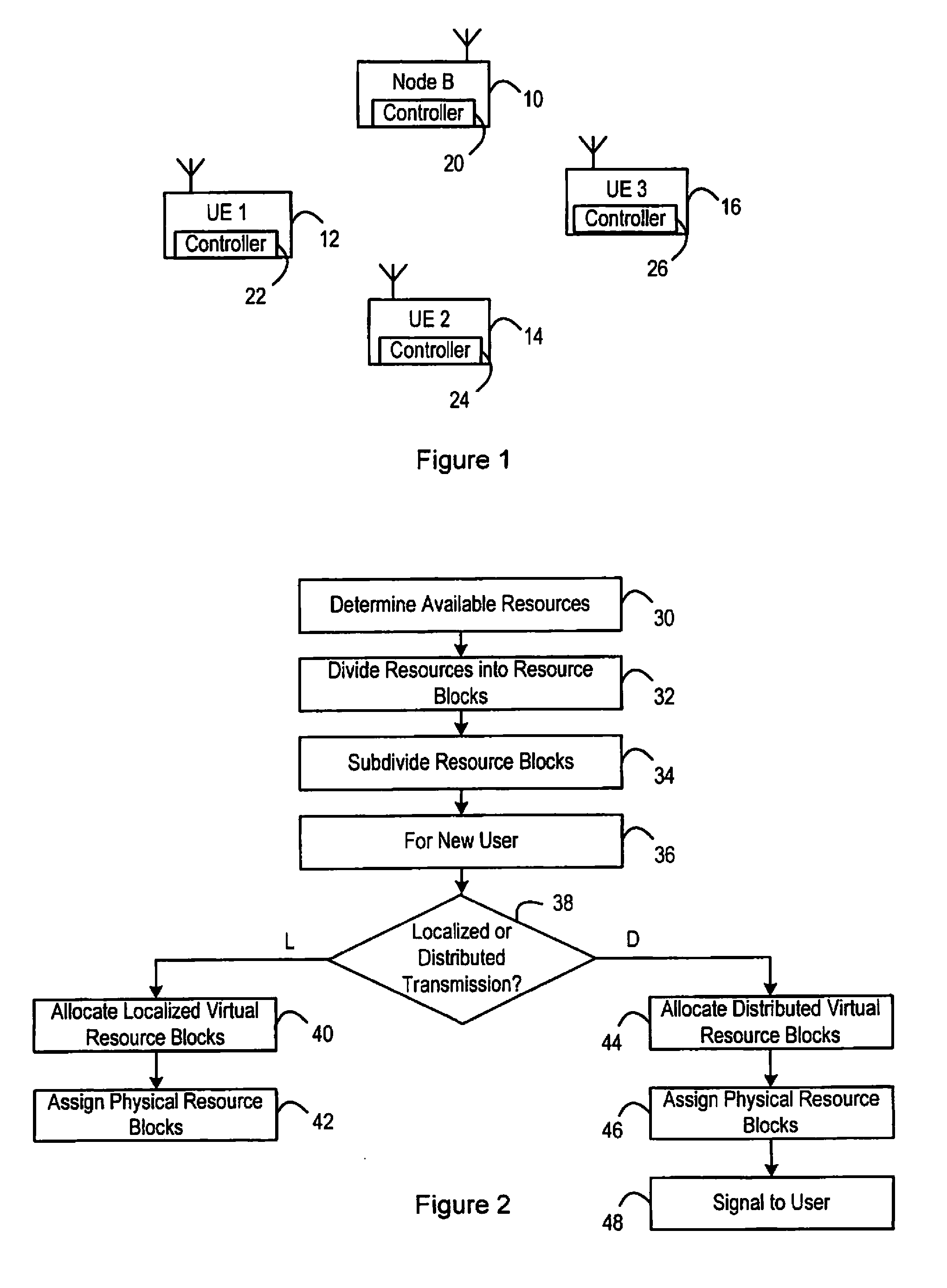

Localized and distributed transmission

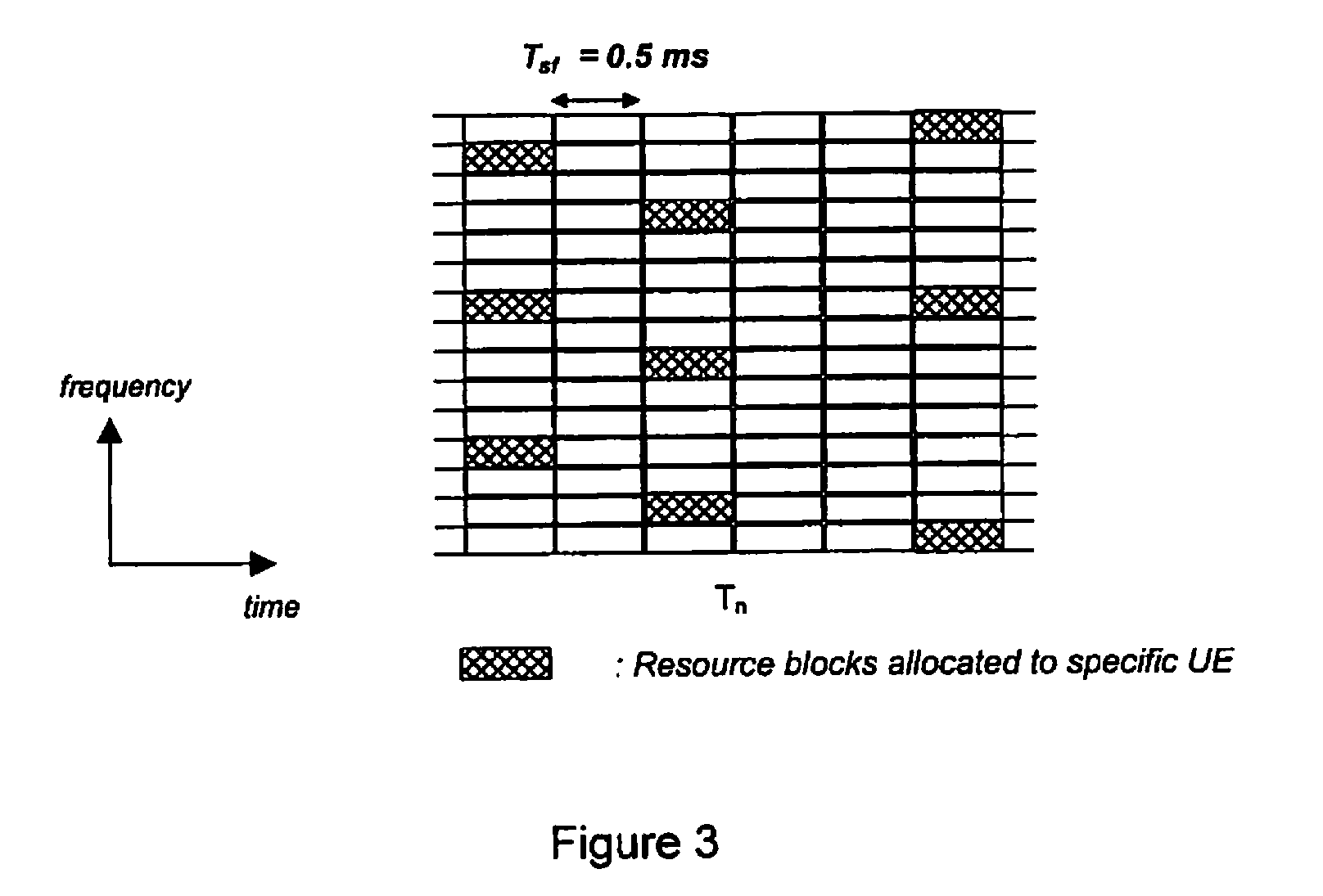

InactiveUS20110065468A1Efficient use ofSmall payloadSpatial transmit diversityTransmission path divisionTime segmentResource block

The available transmission resources on a downlink-shared channel are divided into resource blocks, each resource block comprising a predetermined number of sub-carriers during a predetermined time period. The resource blocks are subdivided into localized resource blocks and distributed resource blocks. A user requiring sufficient resources can be allocated a plurality of said localized resource blocks. A user who would require only a small number of said localized resource blocks can instead be allocated subunits of a plurality of said distributed resource blocks.

Owner:TELEFON AB LM ERICSSON (PUBL)

Integrated heat-supply and energy-saving system

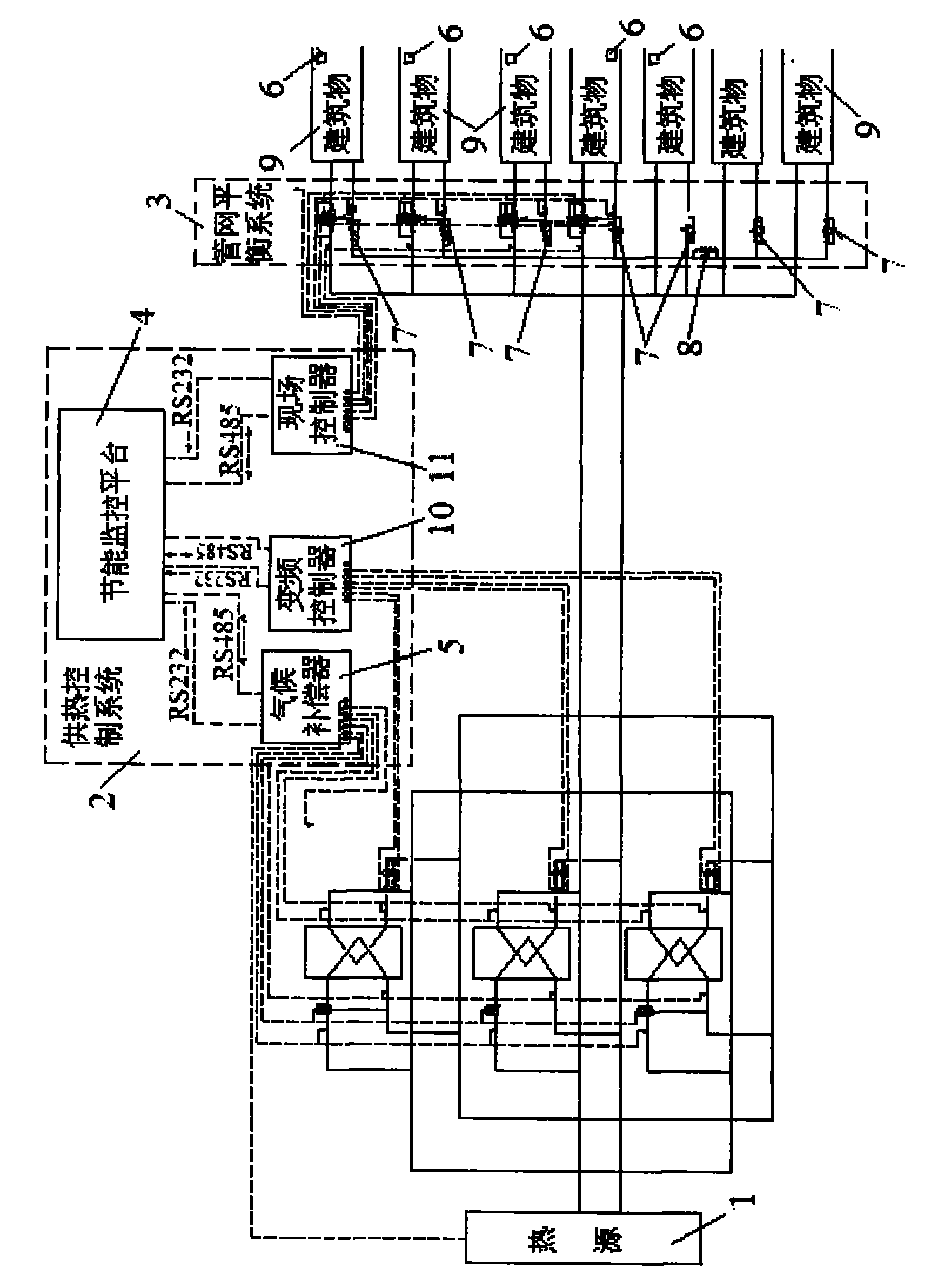

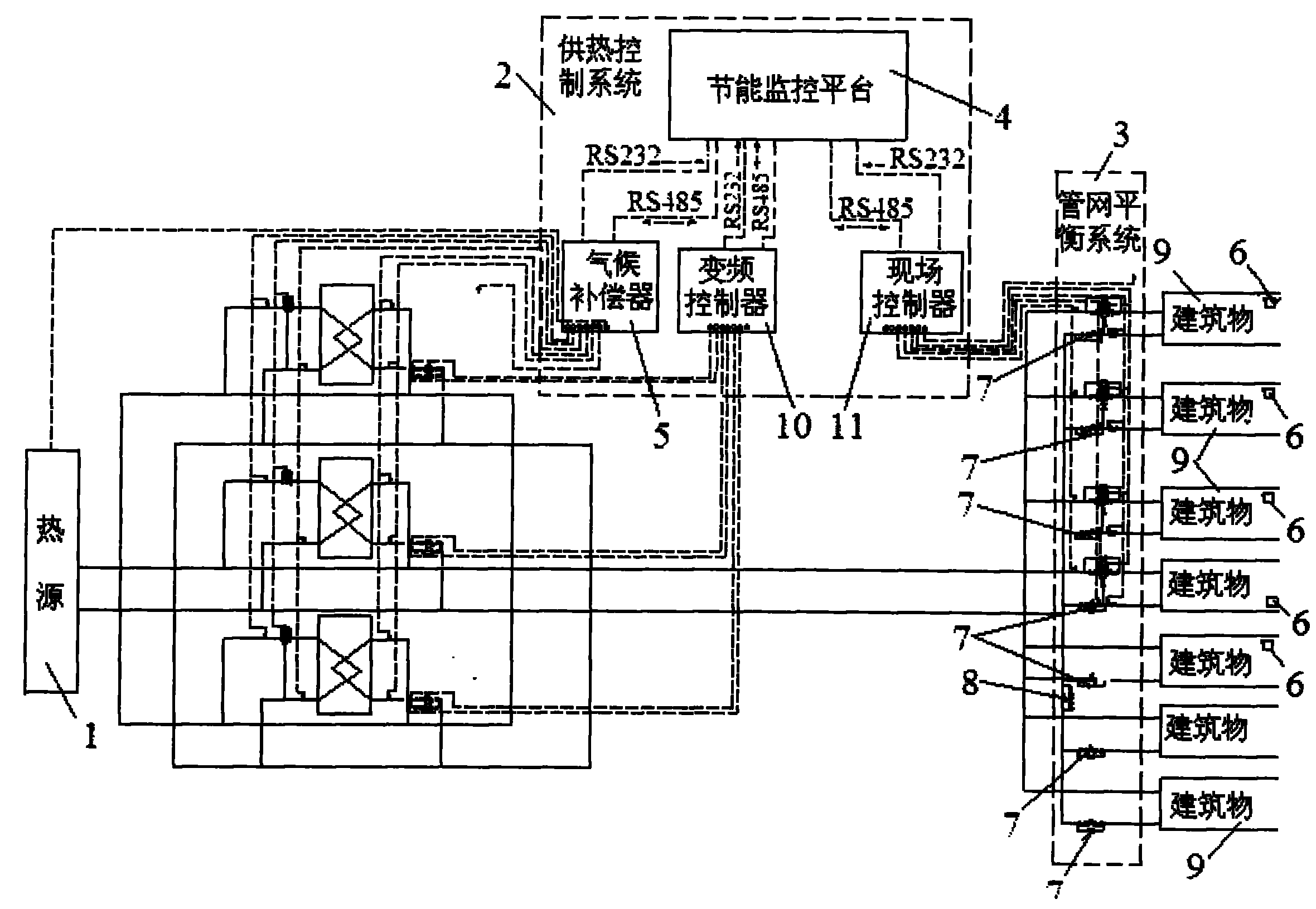

InactiveCN101886831AImprove heating efficiencyLow costLighting and heating apparatusEnergy efficient heating/coolingAnti freezingControl system

The invention relates to an integrated heat-supply and energy-saving system comprising a heat source, a heat-supply pipe network, a heat-supply control system, a pipe network balancing system and a waste heat recovering system, wherein the heat source is used for generating heat; the heat-supply control system is used for detecting indoor temperature to provide temperature parameters for weather compensation, monitoring the indoor temperature of users on line in real time and regulating the on / off of a relevant boiler, a circulating pump, an air conditioner, a ground source heat pump and a valve according to outdoor temperature and the indoor temperature of the users to control the heat-supply quantities of the heat users with different heat-supply properties, thereby realizing the automatic switching of anti-freezing running and heat supply; the pipe network balancing system is used for controlling each branch pipe to run by the set flow according to the branch pipe flows preset in one step, thereby improving the water pressure of the pipe network; and the waste heat recovering system is used for recovering energy for secondary application to reduce the heat loss of the heat-supply system. The integrated heat-supply and energy-saving system can automatically and intelligently control heat supply according to the heat-supply properties of the heat users, improve heat-supply quality, fully recycle waste heat at the tail end of the pipe network and carry out real-time on-line monitoring to the temperature of the pipe network.

Owner:西安特瑞斯热能技术有限公司

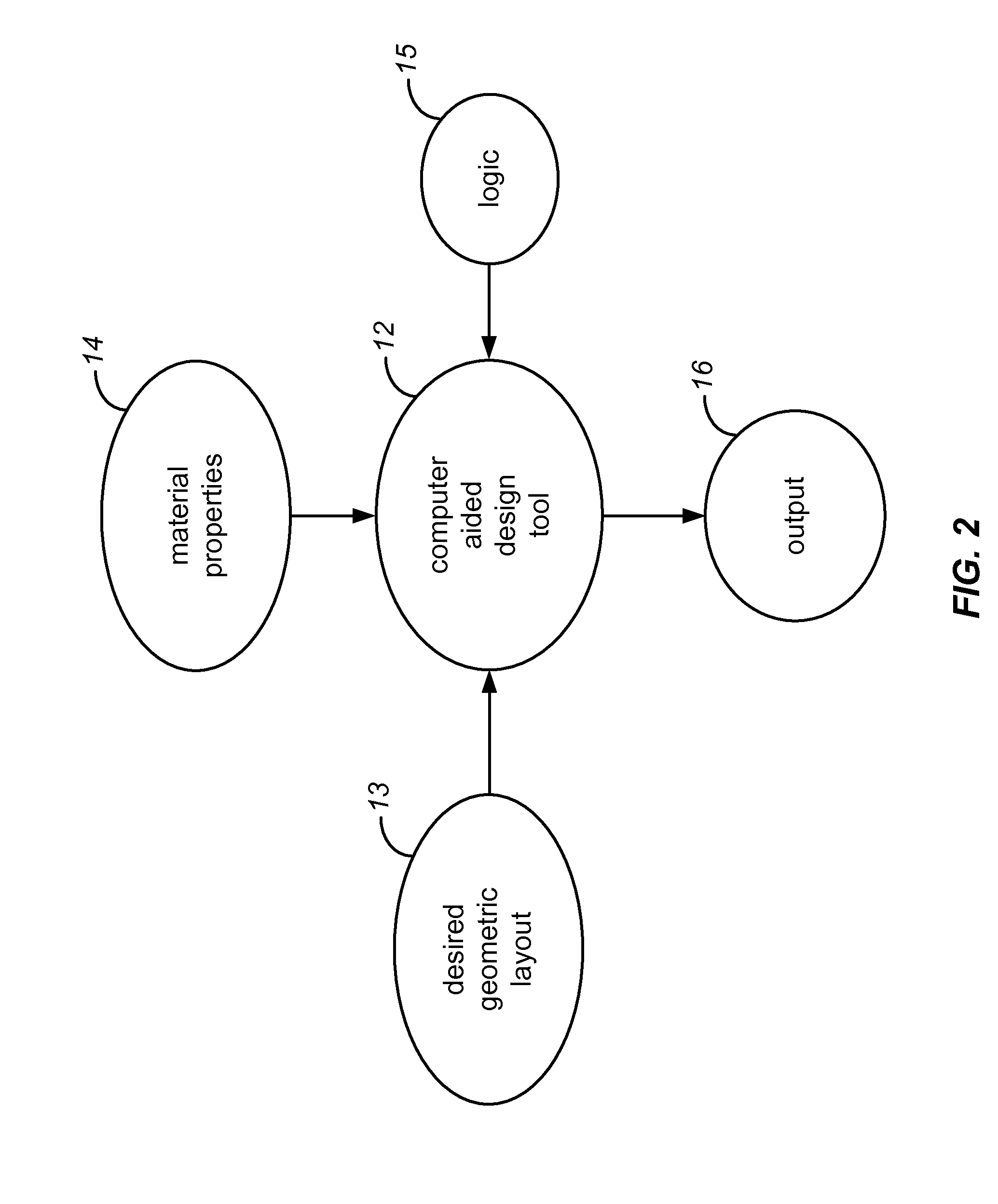

Computational method for design and manufacture of electrochemical systems

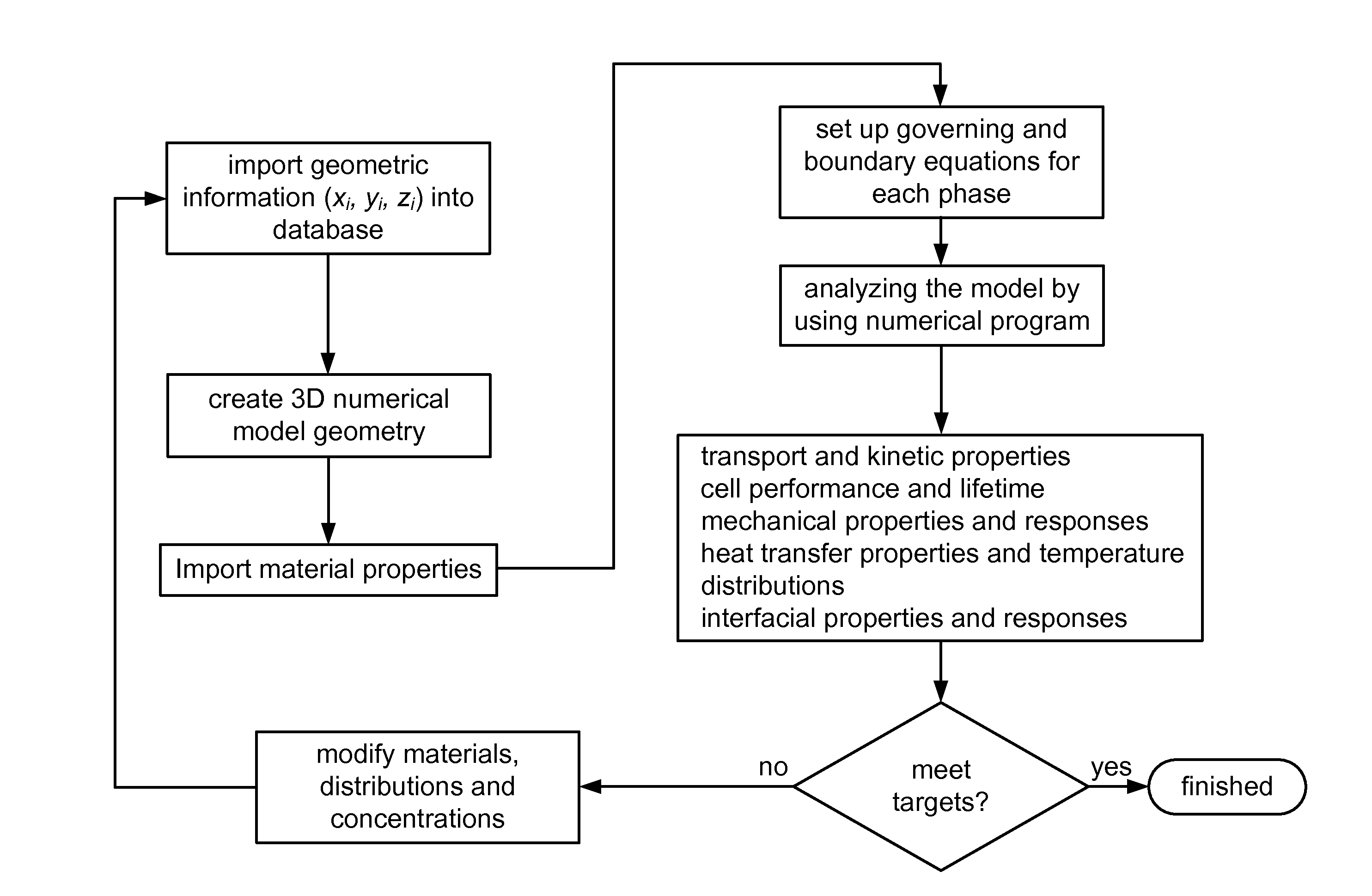

ActiveUS20090326696A1Maintain good propertiesEliminate errorsFuel cells groupingFinal product manufactureMulti materialEngineering

A method for manufacturing an electrochemical cell. The method includes generating spatial information including an anode geometry, a cathode geometry, a separator geometry, and one or more current collector geometries. The method also includes storing the spatial information including the anode geometry, the cathode geometry, the separator geometry, and the one or more current collector geometries into a database structure. In a specific embodiment, the method includes selecting one or more material properties from a plurality of materials and using the one or more material properties with the spatial information in a simulation program. The method includes outputting one or more performance parameters from the simulation program.

Owner:SAKTI3

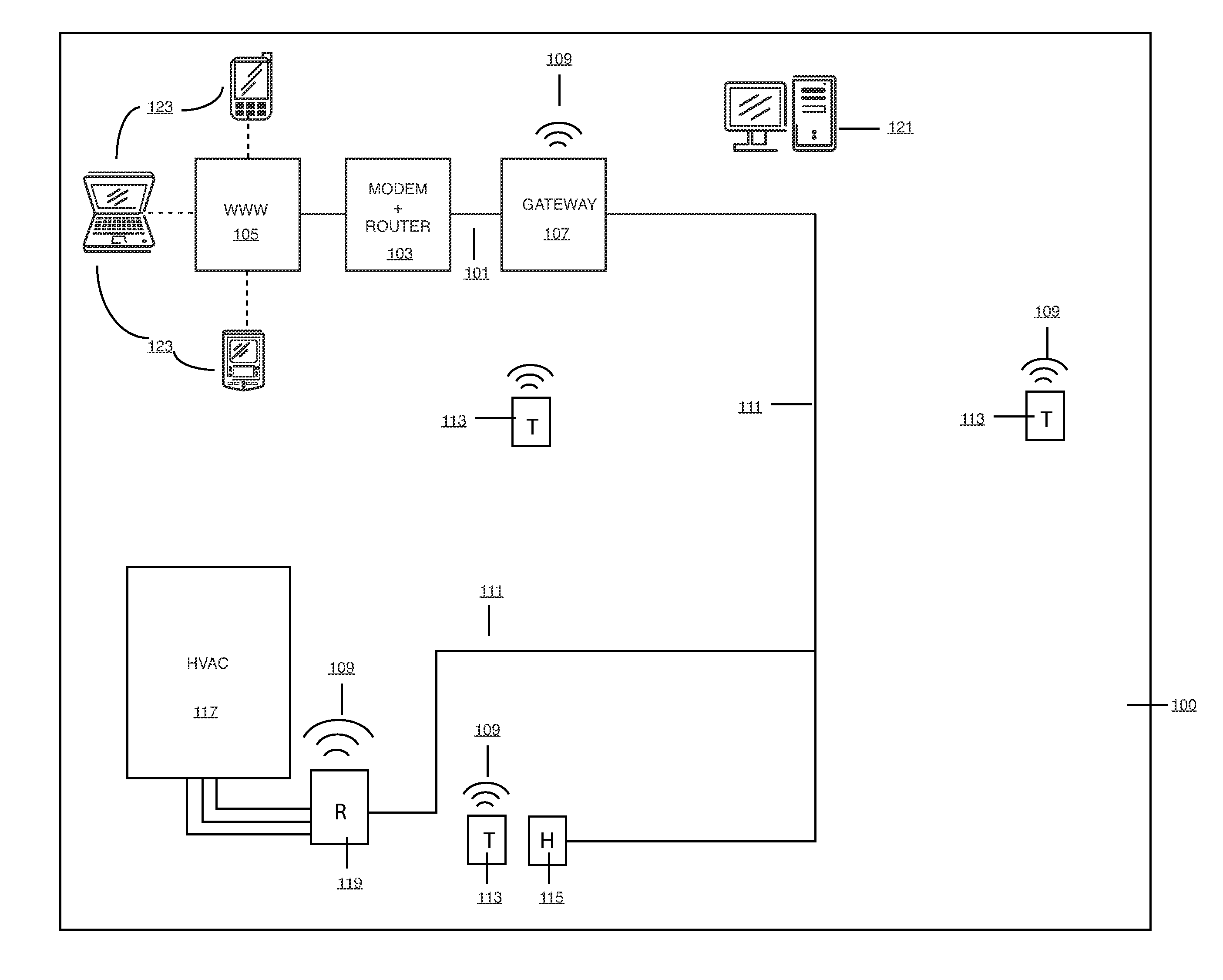

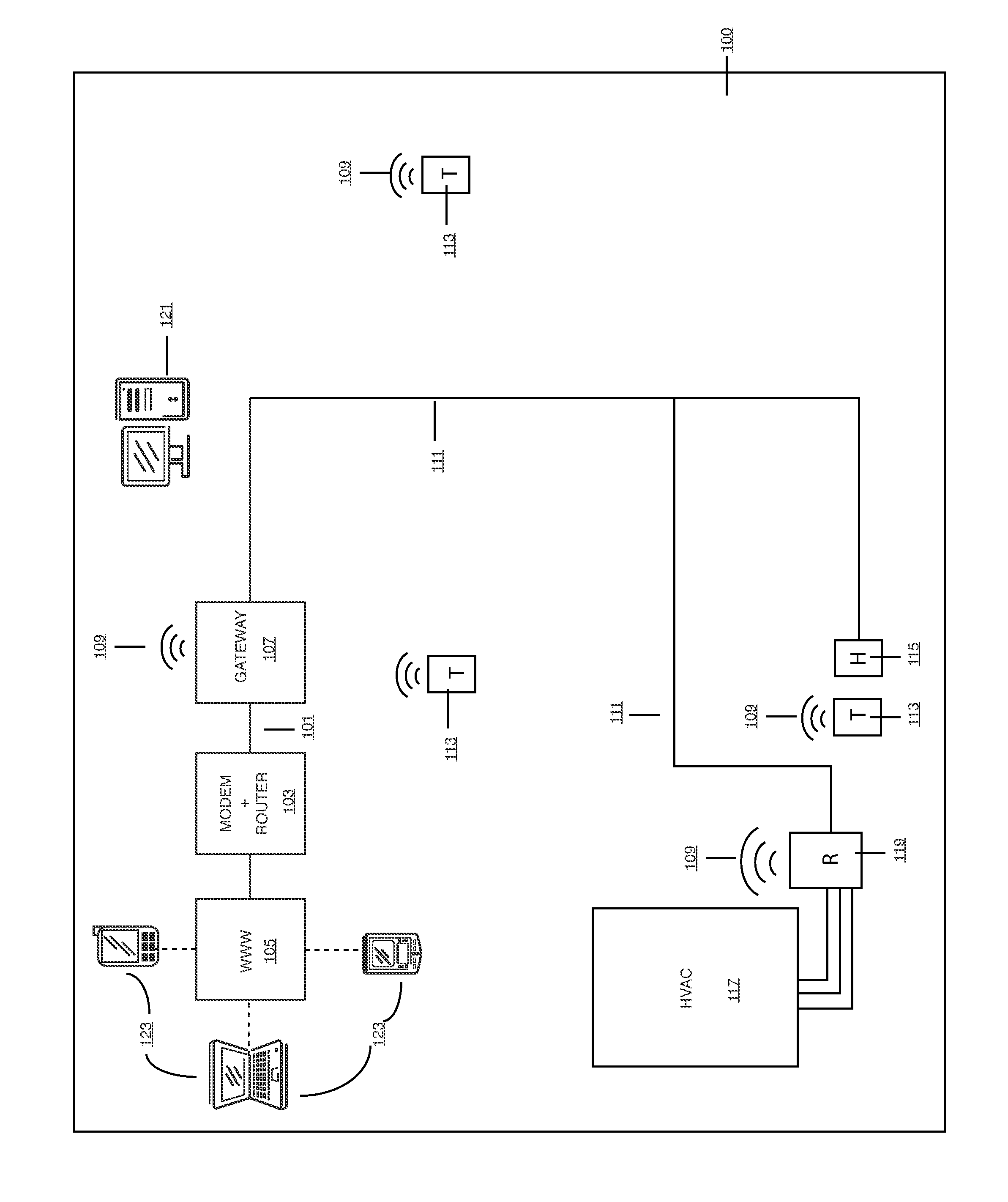

System for using a plurality of remote sensing devices for energy management

InactiveUS20110054700A1Simple wayBroaden applicationSampled-variable control systemsMechanical apparatusStructure of Management InformationEngineering

A system for energy management using a plurality or remote sensor devices. The system includes a plurality of sensor device spatially disposed in one or more regions of a building structure. The sensor device comprises a sensor element coupled to a transmitter device, which can be selected from a format including Zigbee, Zwave, 6-LoWPAN, Ultra-Low-Power WiFi, RFID, Bluetooth, or others. The system also has a gateway apparatus.

Owner:JETLUN CORP

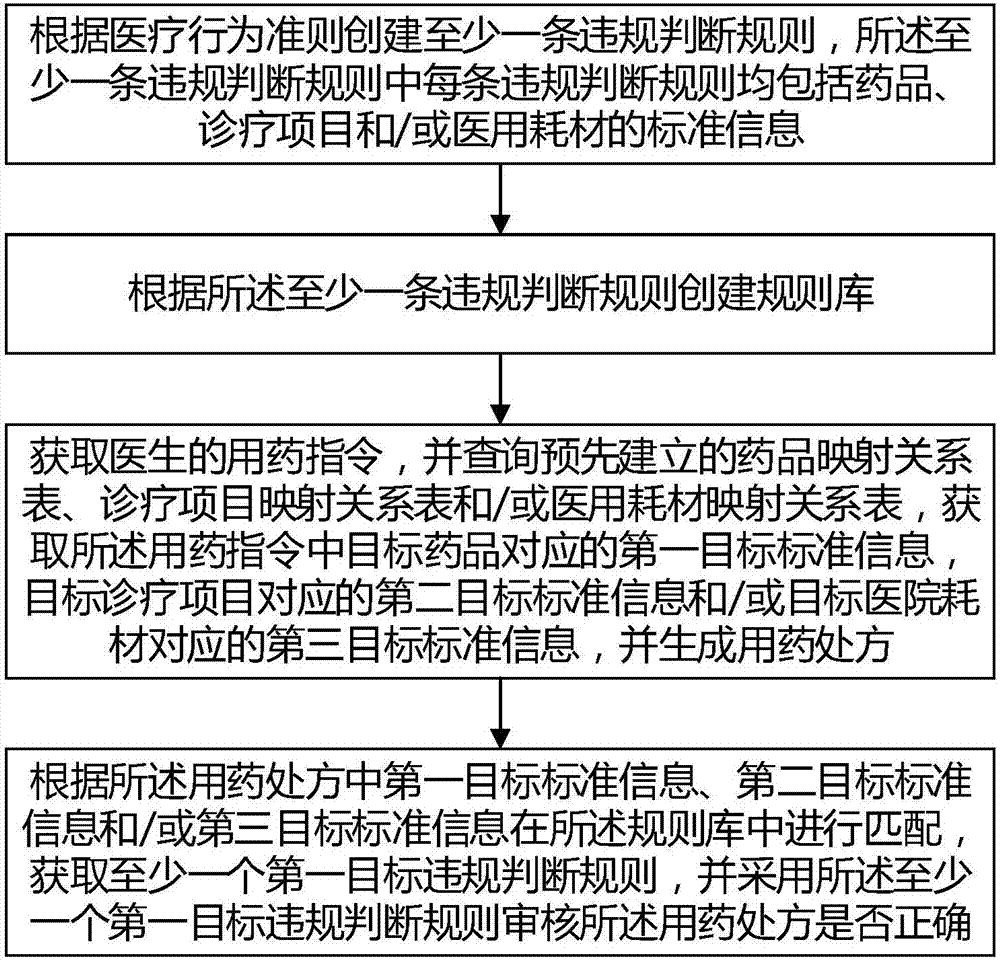

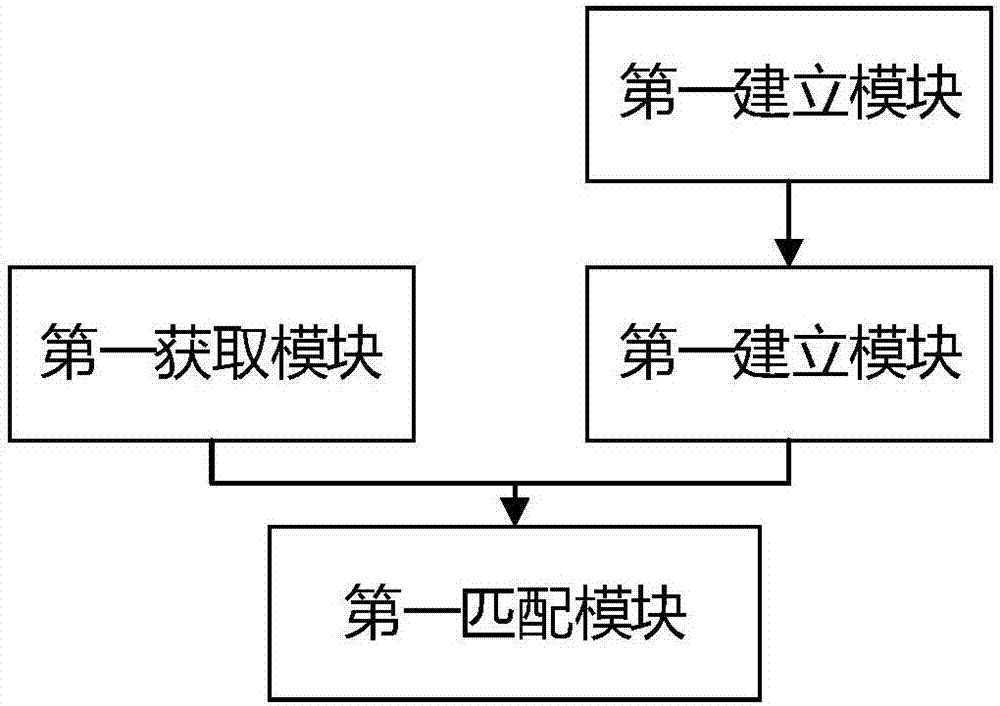

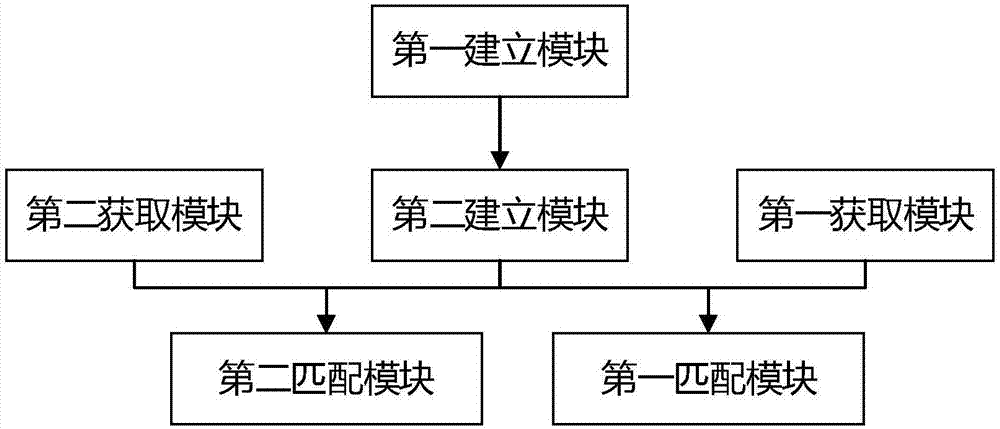

Medical insurance intelligent audit method and system

InactiveCN107451401AImprove service qualityAchieve benefitsSpecial data processing applicationsOver diagnosisSocial benefits

The present invention relates to a medical insurance intelligent audit method. The method comprises the following steps: creating a rule base according to at least one violation determination rule; obtaining a medication instruction of a doctor, querying a drug product mapping relationship table, a medical treatment project mapping relationship table and / or a medical supplies mapping relationship table, and generating the prescription for medication; and matching in the rule base according to standard information in the prescription for medication, obtaining at least one target violation determination rule, and using the target violation determination rule to audit whether the prescription for the medication is correct. According to the technical scheme of the present invention, the effect of the medical intelligent audit monitoring can be improved, the phenomena of over-diagnosis and treatment, indiscriminate use of drugs, arbitrary charges, and the like can be avoided, service quality of hospitals can be improved, a harmonious relationship between doctors and patients can be improved, and a win-win situation for the economic and social benefits of the hospitals can be achieved.

Owner:武汉金豆医疗数据科技有限公司

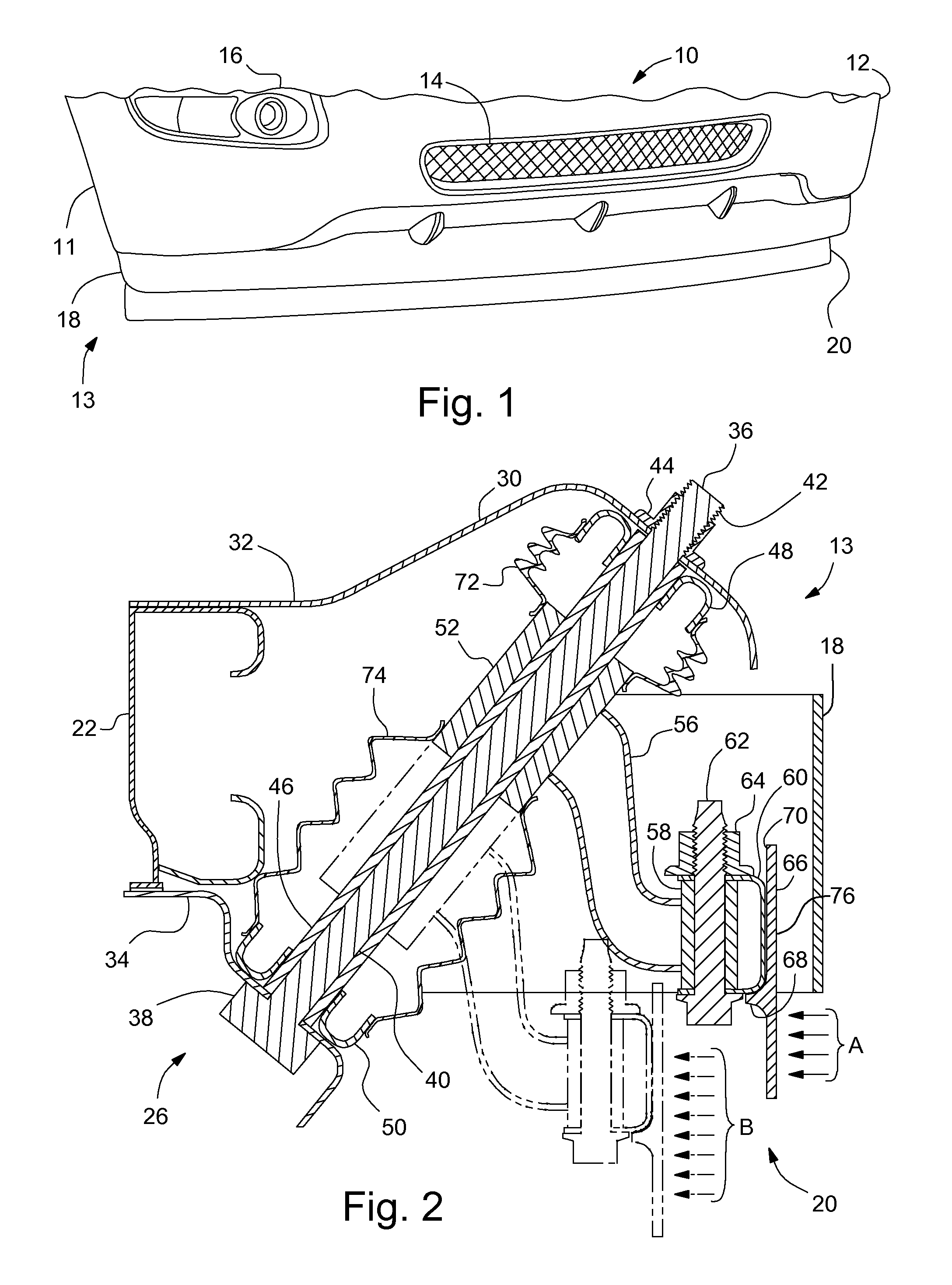

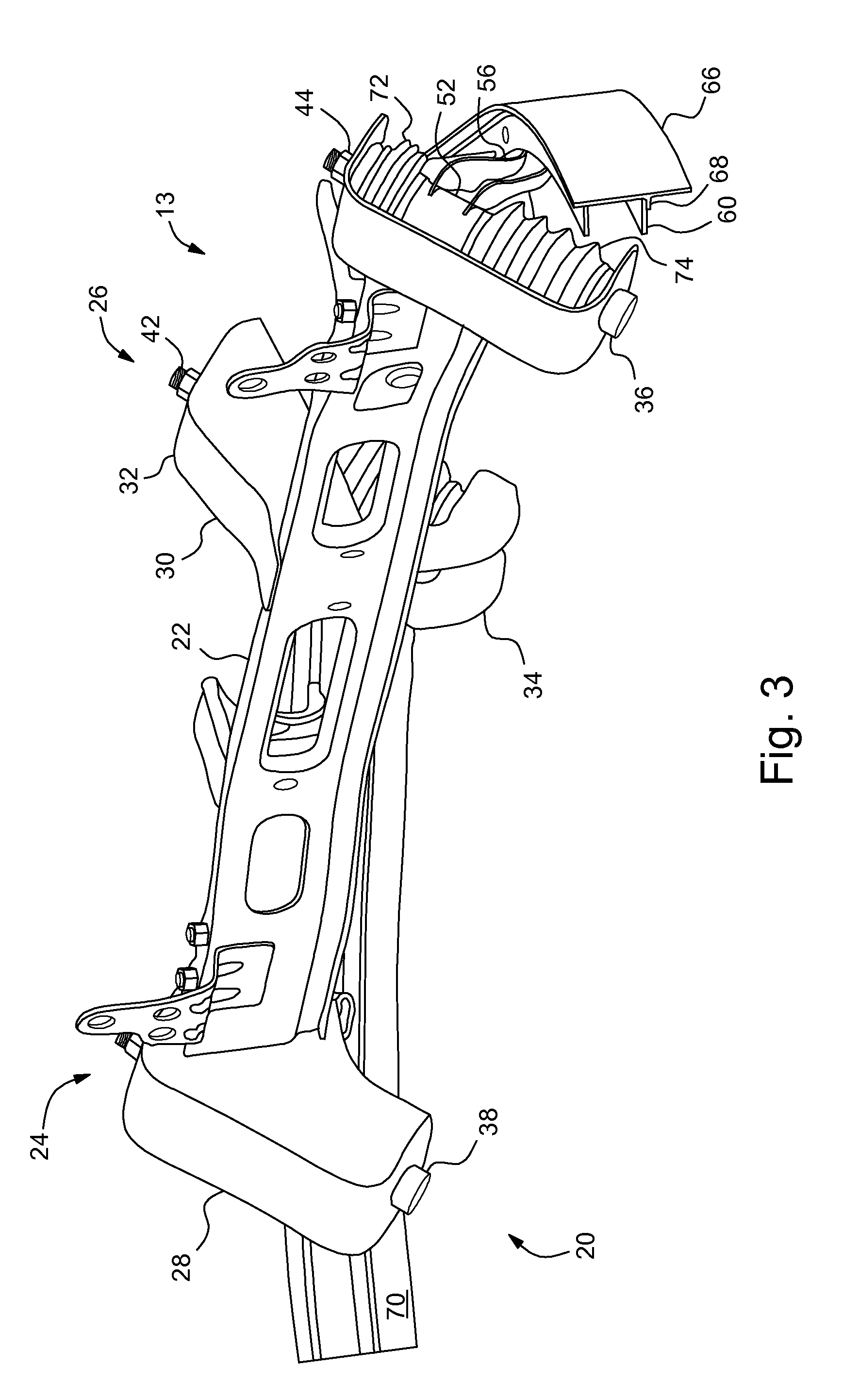

Passively deployable air dam for a vehicle

ActiveUS8186746B2Shorten the deployment cycleImprove fuel economyVehicle seatsWindowsBiological activationForward speed

An air dam assembly mounted under a front end of a vehicle includes a passively deployable air dam assembly. The passively deployable air dam assembly includes a passively deployable air dam having a front surface at least partially exposed to ram air when the vehicle is traveling in a forward direction, and a passive deployment assembly including at least one spring biasing the passively deployable air dam into a retracted position, with the passive deployment assembly engaging the passively deployable air dam to allow the passively deployable air dam to move, against the bias of the spring, from the retracted position to a deployed position closer to ground under the vehicle when a forward speed of the vehicle reaches or exceeds a predetermined activation speed.

Owner:GM GLOBAL TECH OPERATIONS LLC

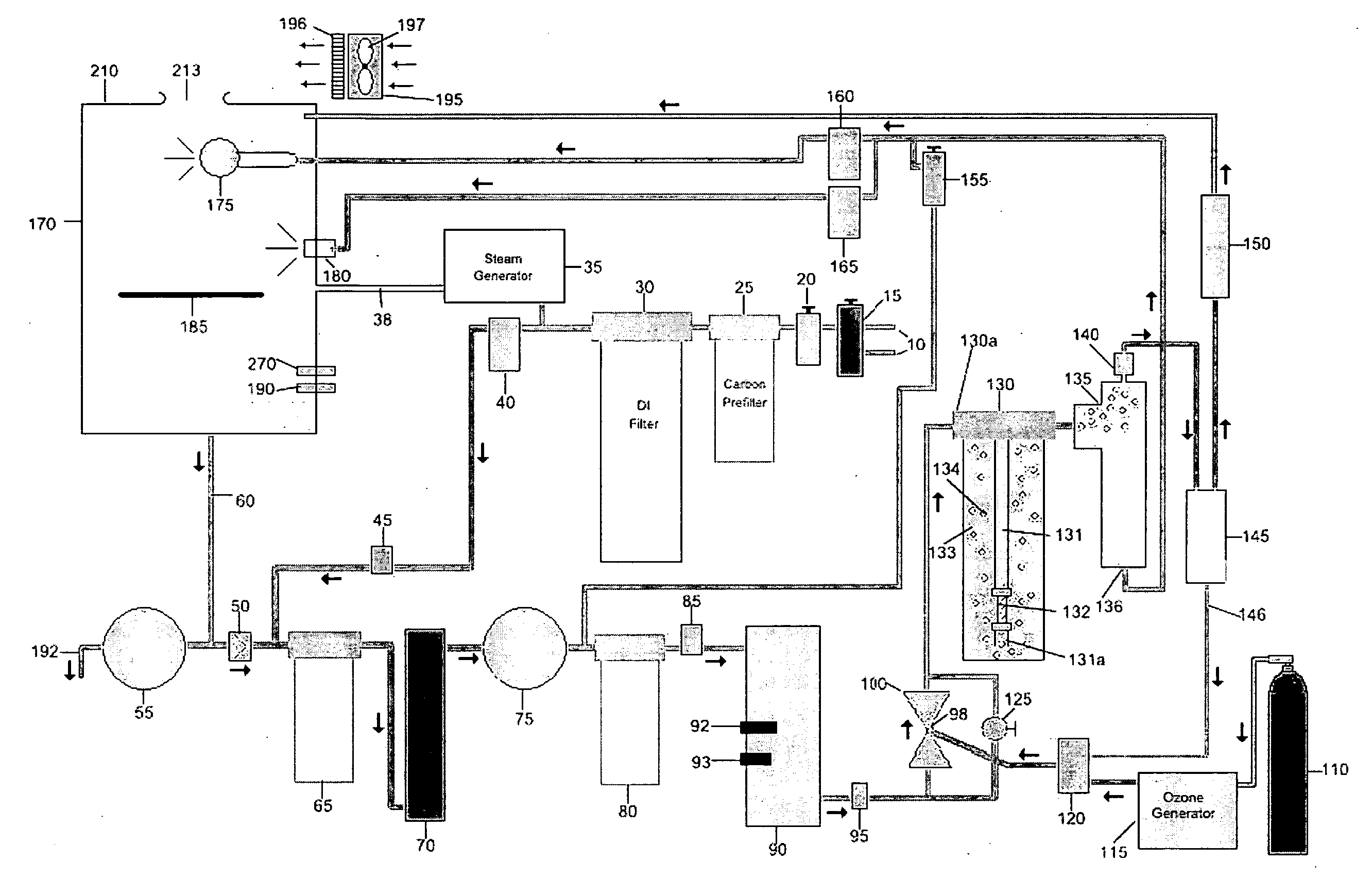

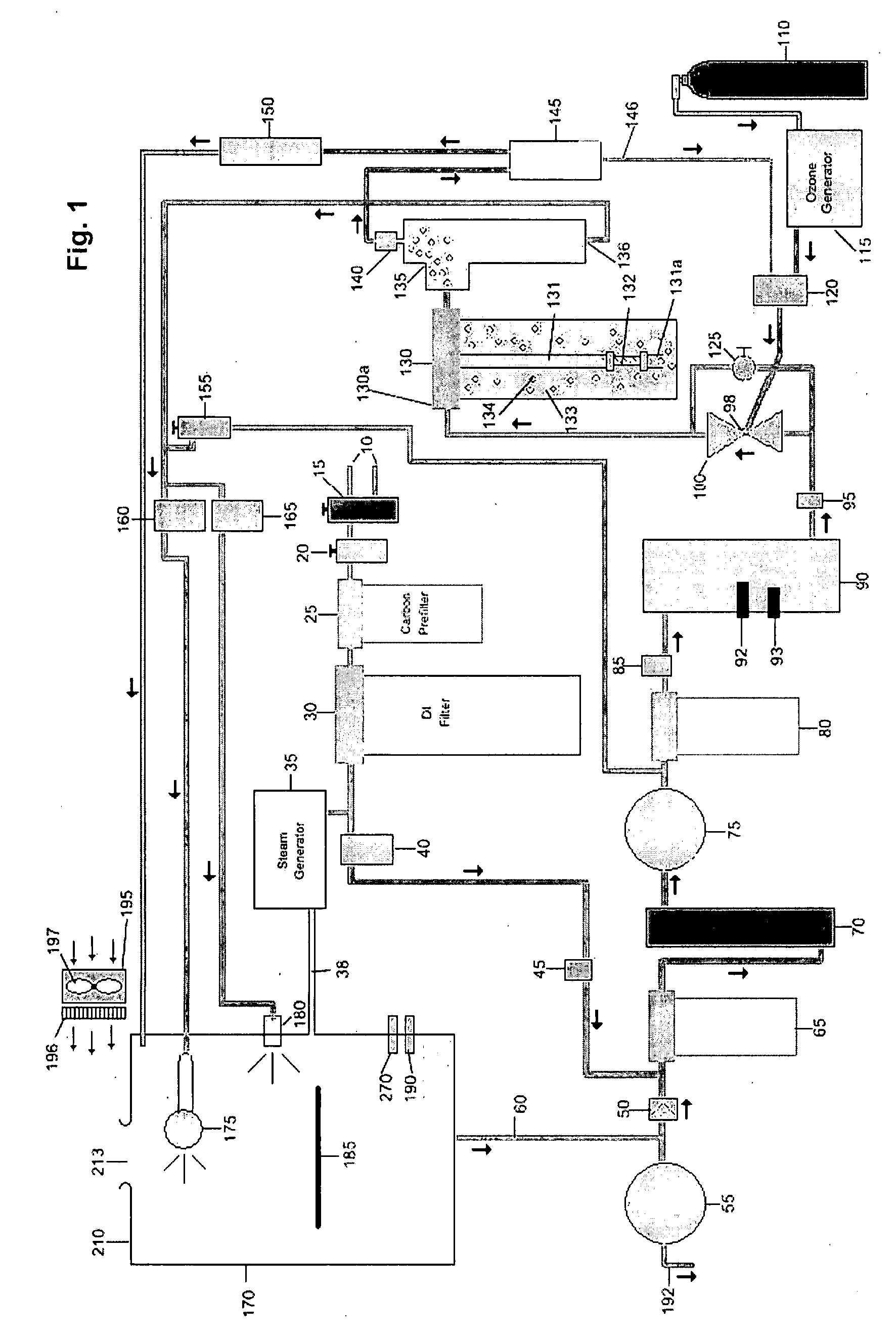

Aerobic spa system

An aerobic spa system comprising a water source providing water, an ozone source providing ozone, an ozone introduction mechanism adapted to introduce at least some of the ozone into the water, an ozone saturation mechanism adapted to cause at least some of the ozone to be dissolved into the water, a substantially enclosed chamber receiving water containing dissolved ozone; and a user at least partially disposed inside the chamber who comes into contact with the water containing dissolved ozone.

Owner:AEROBIC WATER WORKS

Systems and Methods for Output Current Regulation in Power Conversion Systems

ActiveUS20160336864A1Achieve benefitsEfficient power electronics conversionElectroluminescent light sourcesCurrent regulationSwitching cycle

Systems and methods are provided for regulating power conversion systems. A system controller includes: a first controller terminal configured to receive a first signal related to an input signal for a primary winding of a power conversation system; and a second controller terminal configured to output a drive signal to a switch to affect a current flowing through the primary winding, the drive signal being associated with a switching period including an on-time period and an off-time period. The switch is closed (e.g., being turned on) in response to the drive signal during the on-time period. The switch is opened (e.g., being turned off) in response to the drive signal during the off-time period. A duty cycle is equal to a duration of the on-time period divided by a duration of the switching period. The system controller is configured to keep a multiplication product of the duty cycle and the duration of the on-time period approximately constant.

Owner:ON BRIGHT ELECTRONICS SHANGHAI

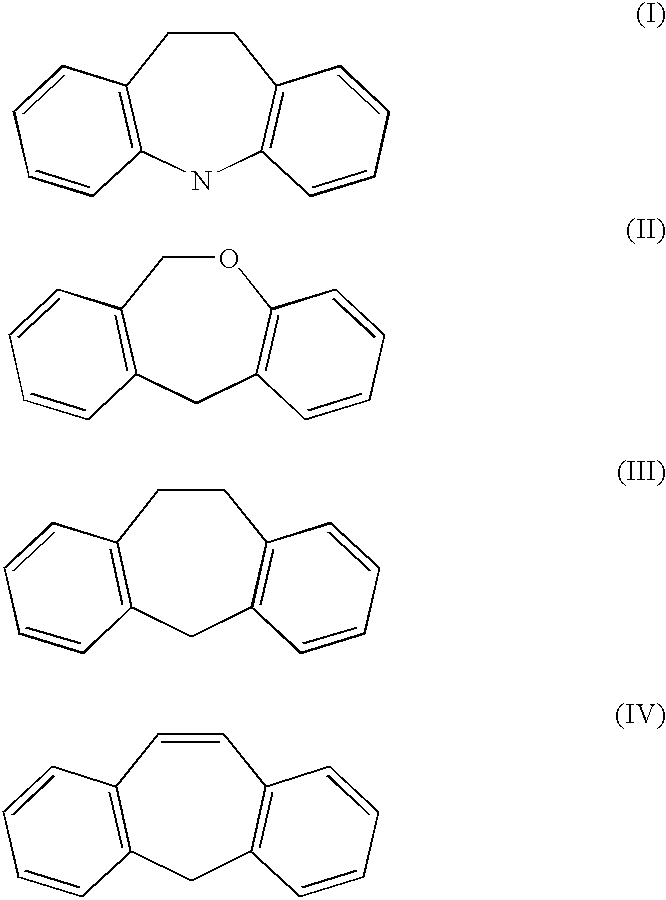

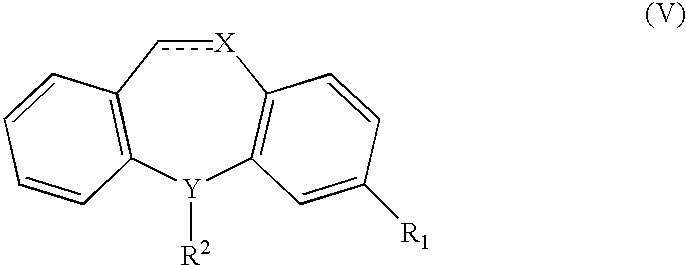

Methods of treating fibromyalgia

InactiveUS20030130353A1Achieve benefitsEffective amount for useBiocideNervous disorderAdrenergicNorepinephrine reuptake

The present invention provides a method of treating fibromyalgia syndrome (FMS), chronic fatigue syndrome (CFS), and pain in an animal subject. The method generally involves administering a therapeutically effective amount of a dual serotonin norepinephrine reuptake inhibitor compound or a pharmaceutically acceptable salt thereof, wherein said dual serotonin norepinephrine reuptake inhibitor compound is characterized by a non-tricyclic structure and an equal or greater inhibition of norepinephrine reuptake than serotonin reuptake. In particular, the use of milnacipran to treat FMS, CFS, and pain is disclosed.

Owner:FOREST LAB HLDG LTD

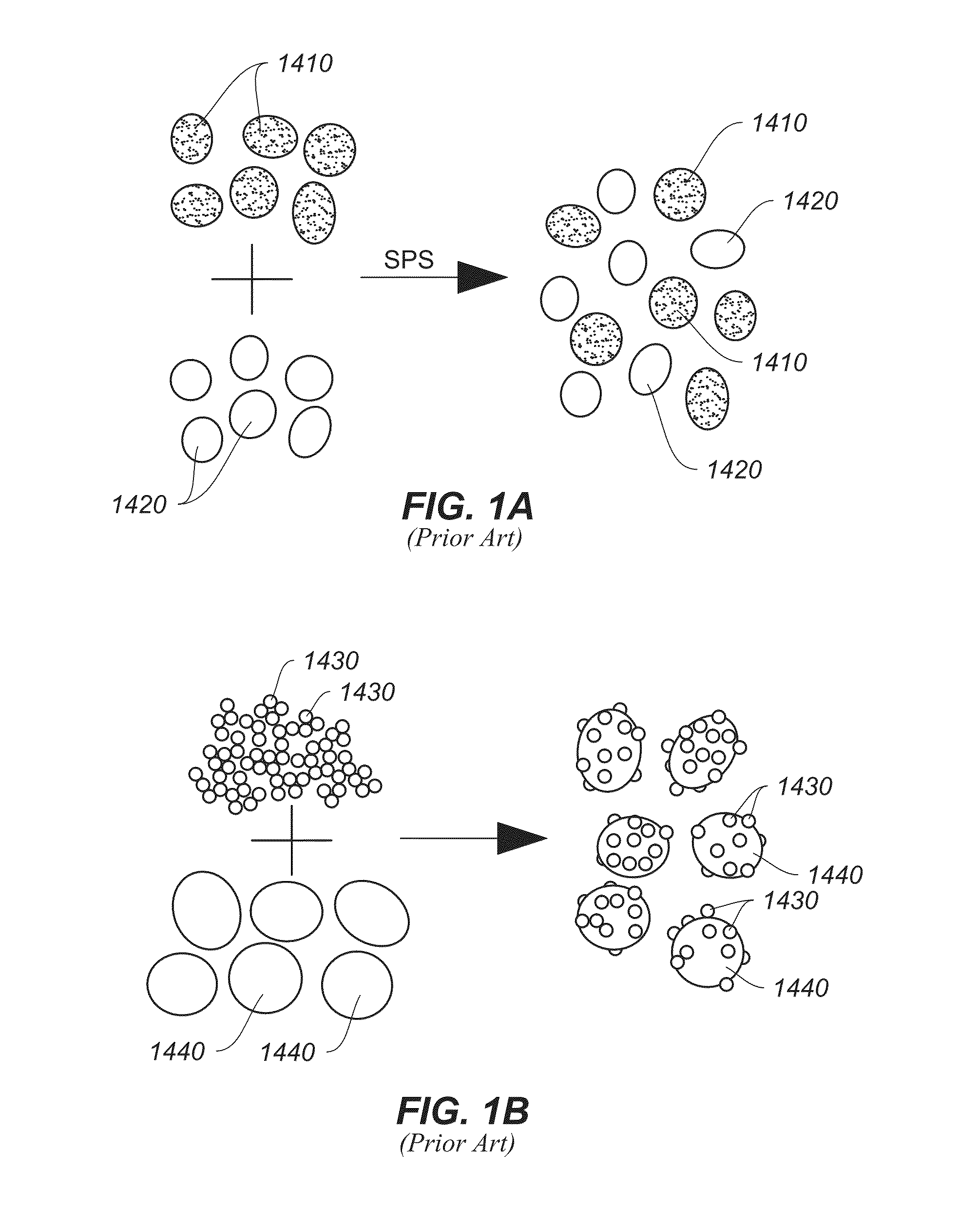

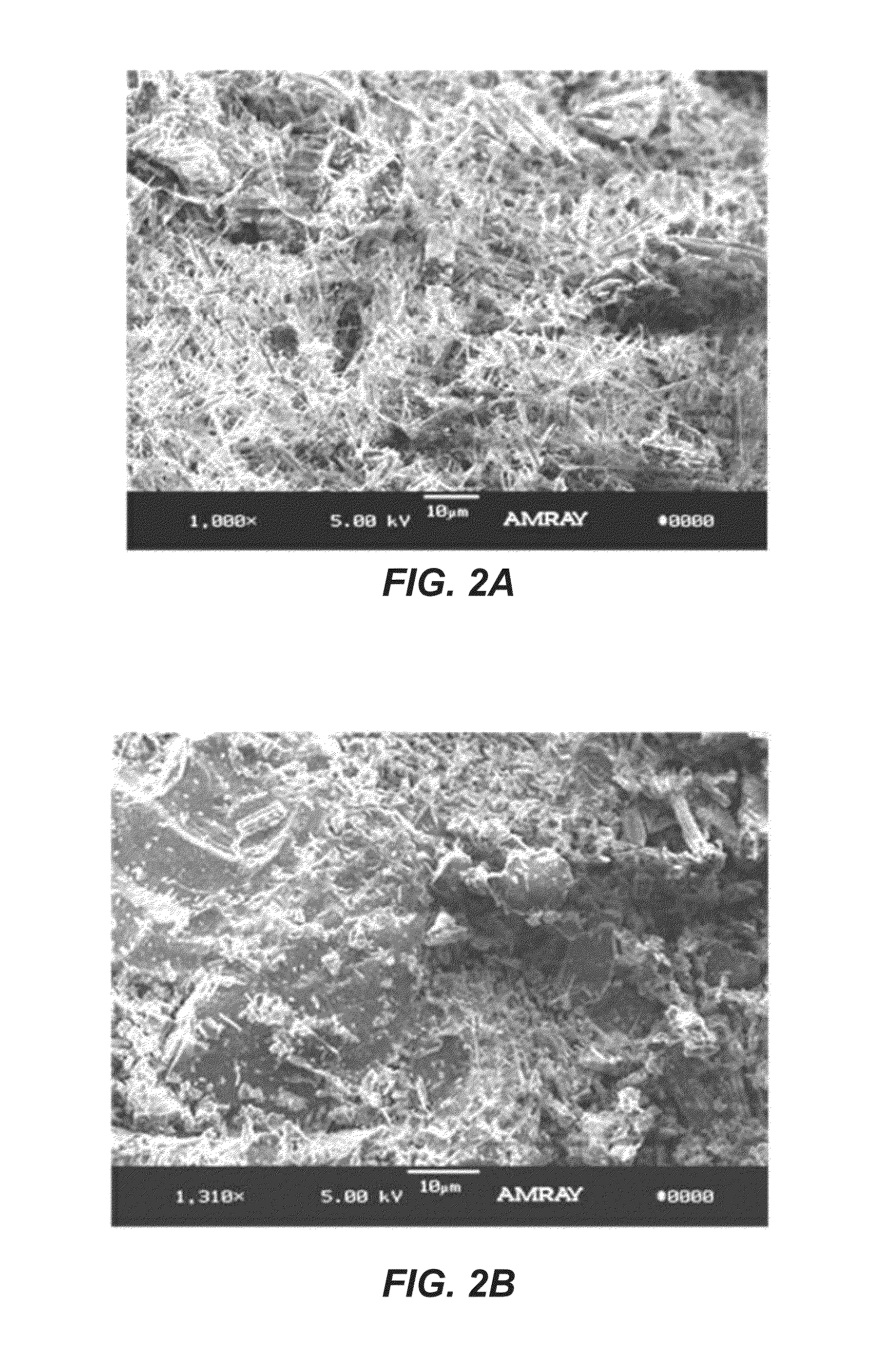

Bulk-size nanostructured materials and methods for making the same by sintering nanowires

InactiveUS20140116491A1Achieve benefitsMaterial nanotechnologySpecific nanostructure formationNanowireNanostructured materials

Thermoelectric solid material and method thereof. The thermoelectric solid material includes a plurality of nanowires. Each nanowire of the plurality of nanowires corresponds to an aspect ratio (e.g., a ratio of a length of a nanowire to a diameter of the nanowire) equal to or larger than 10, and each nanowire of the plurality of nanowires is chemically bonded to one or more other nanowires at at least two locations of the each nanowire.

Owner:ALPHABET ENERGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com