Integrated heat-supply and energy-saving system

A heat supply system and waste heat recovery system technology, applied in the field of heat energy utilization, can solve the problems of low degree of automation, low thermal efficiency, and lack of digital precise control system in the heating system, so as to achieve social benefits of increasing safety and stability and reducing emissions , Guarantee the effect of heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

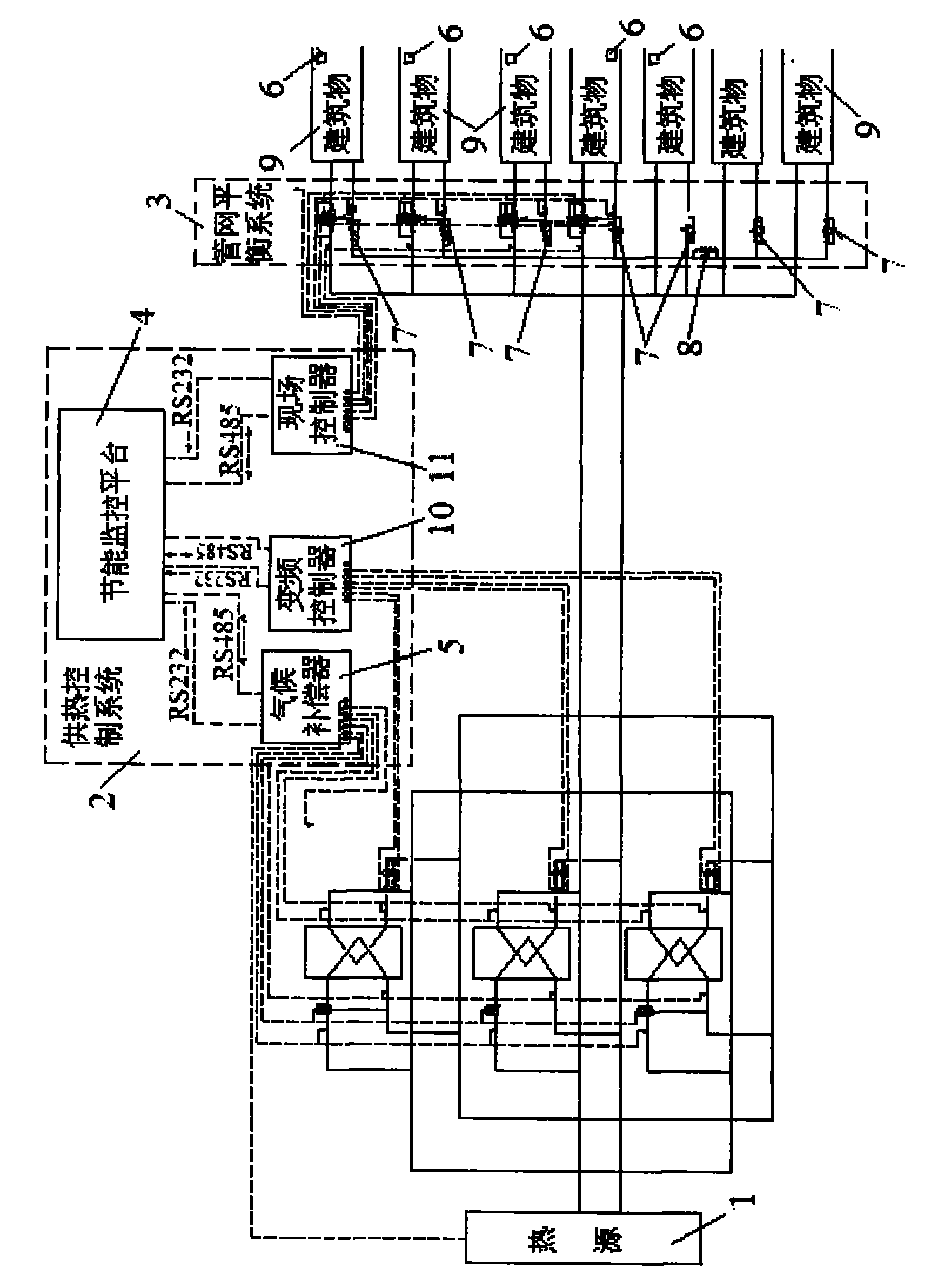

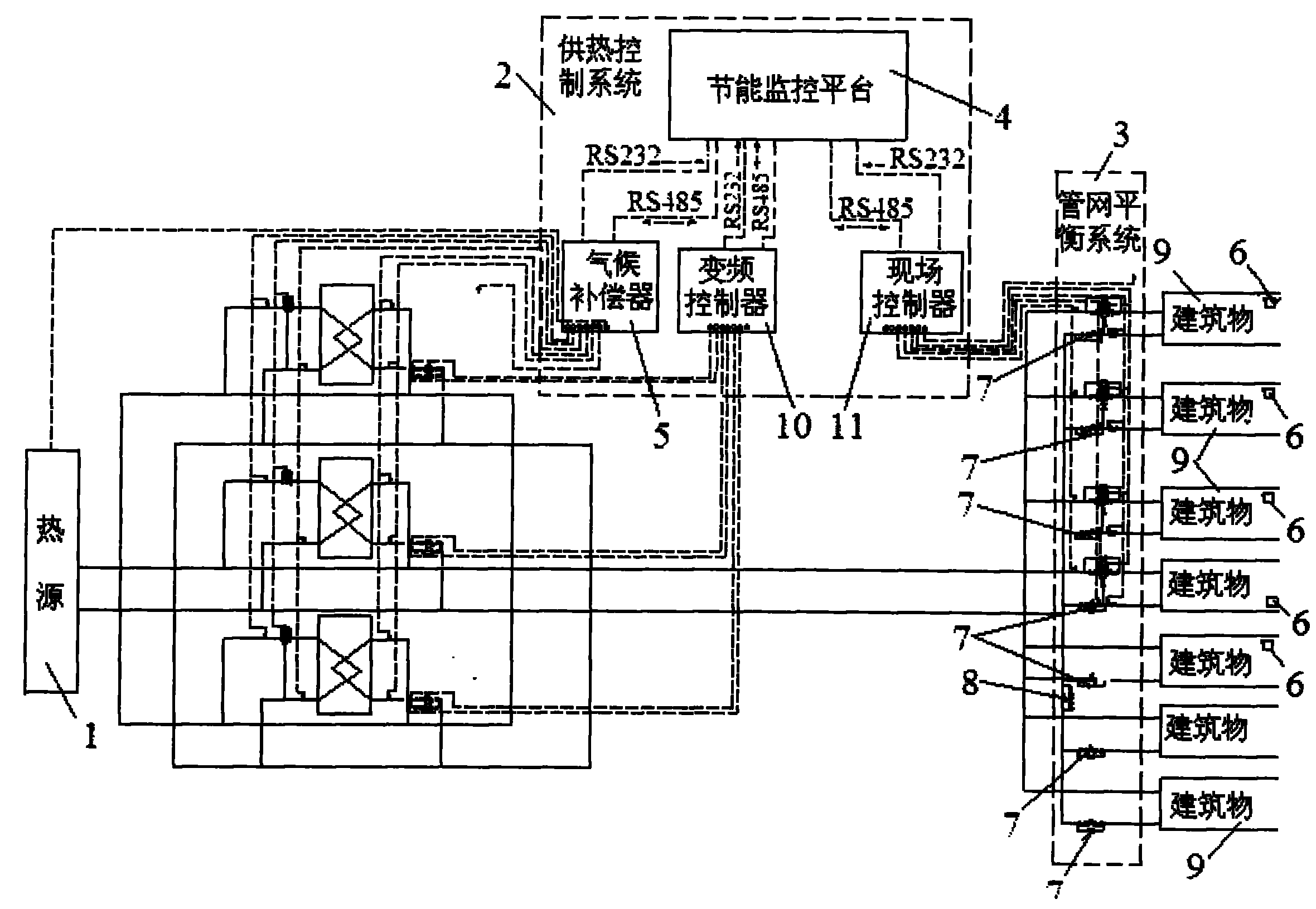

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The structure of the heat supply system of the present invention, as shown in the accompanying drawings, includes a heat source 1, and the heat source 1 communicates with the heat-using equipment in the building 9 through a heat supply pipe network. The heat supply system also includes a heat supply control system 2, a pipe network Balance system 3 and waste heat recovery system, heat supply control system 2 includes energy-saving monitoring platform 4, climate compensator 5, frequency conversion controller 10, field controller 11 and indoor temperature remote transmission collector 6, pipe network balance system 3 includes multiple Balancing valve 7 and multiple pipeline pumps 8 .

[0020] Heat source 1 is used to generate heat and send the generated heat into the heating pipe network;

[0021] Heat source 1 adopts environment-friend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com