Patents

Literature

61results about How to "Realize consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

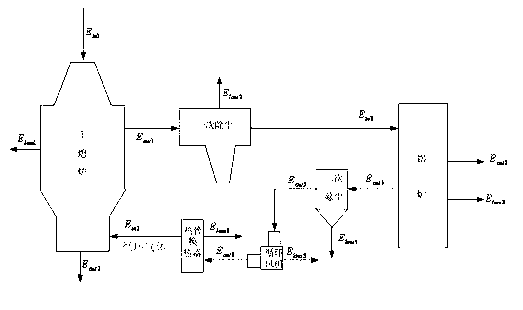

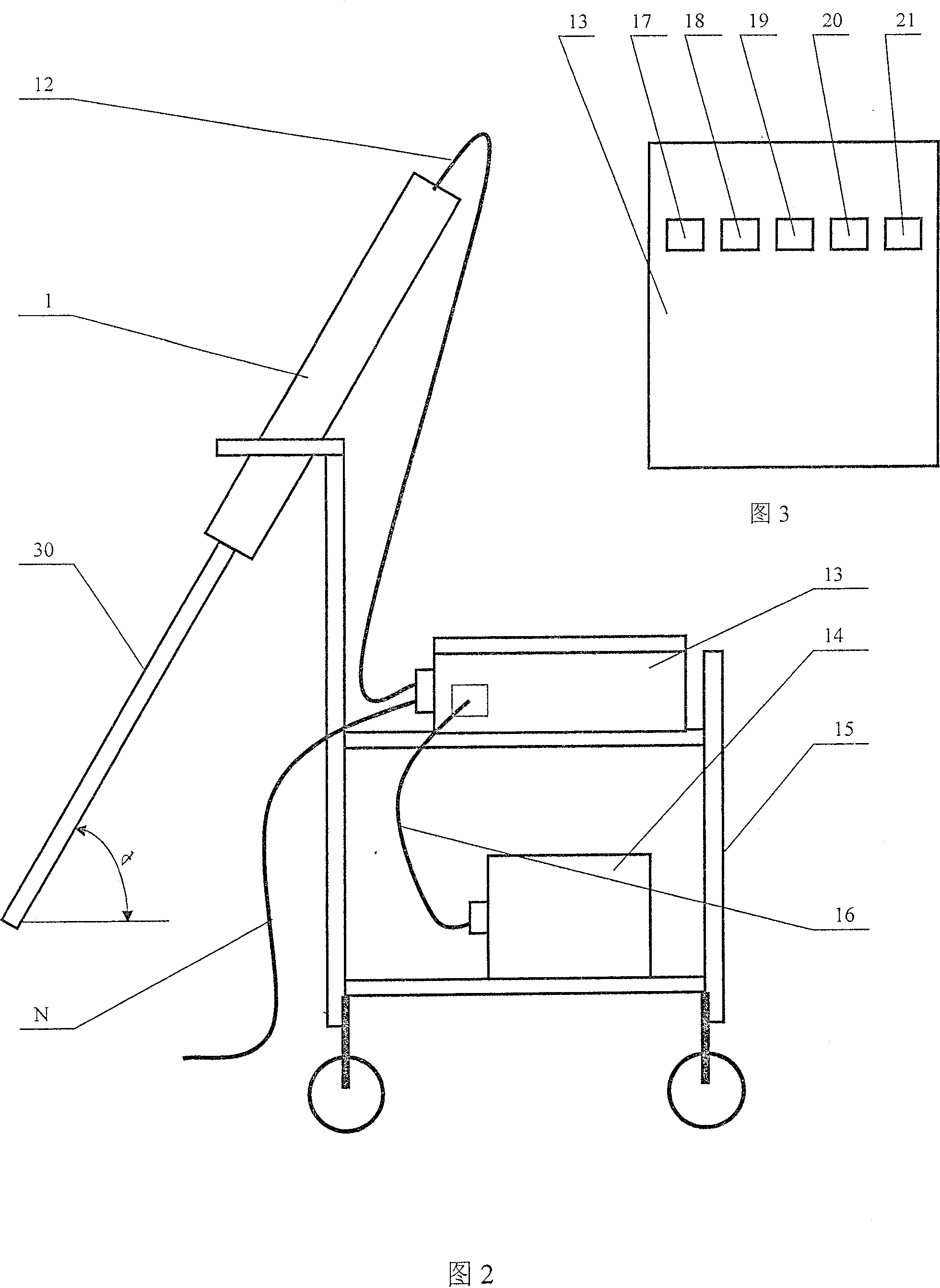

Integrated heat-supply and energy-saving system

InactiveCN101886831AImprove heating efficiencyLow costLighting and heating apparatusEnergy efficient heating/coolingAnti freezingControl system

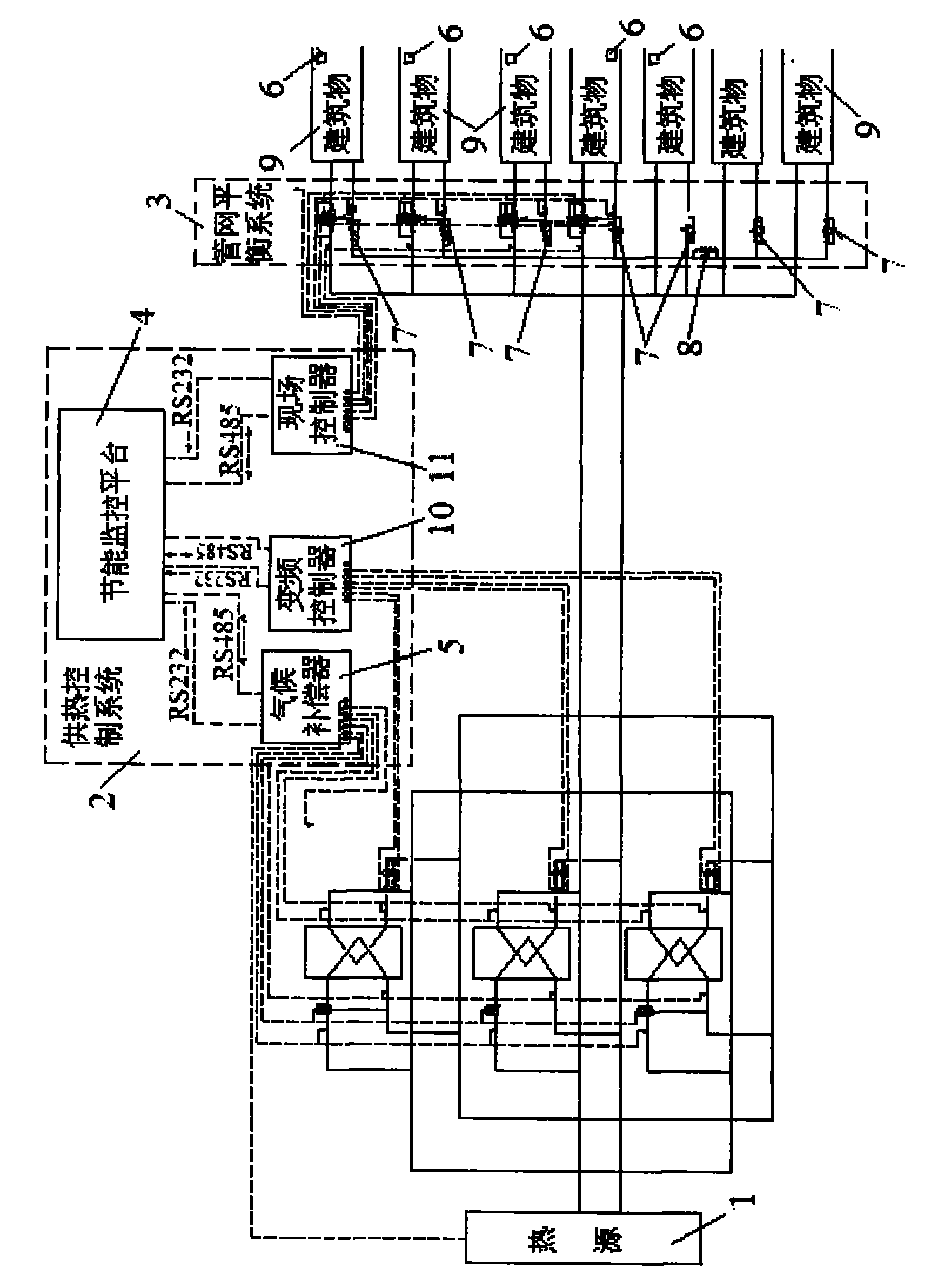

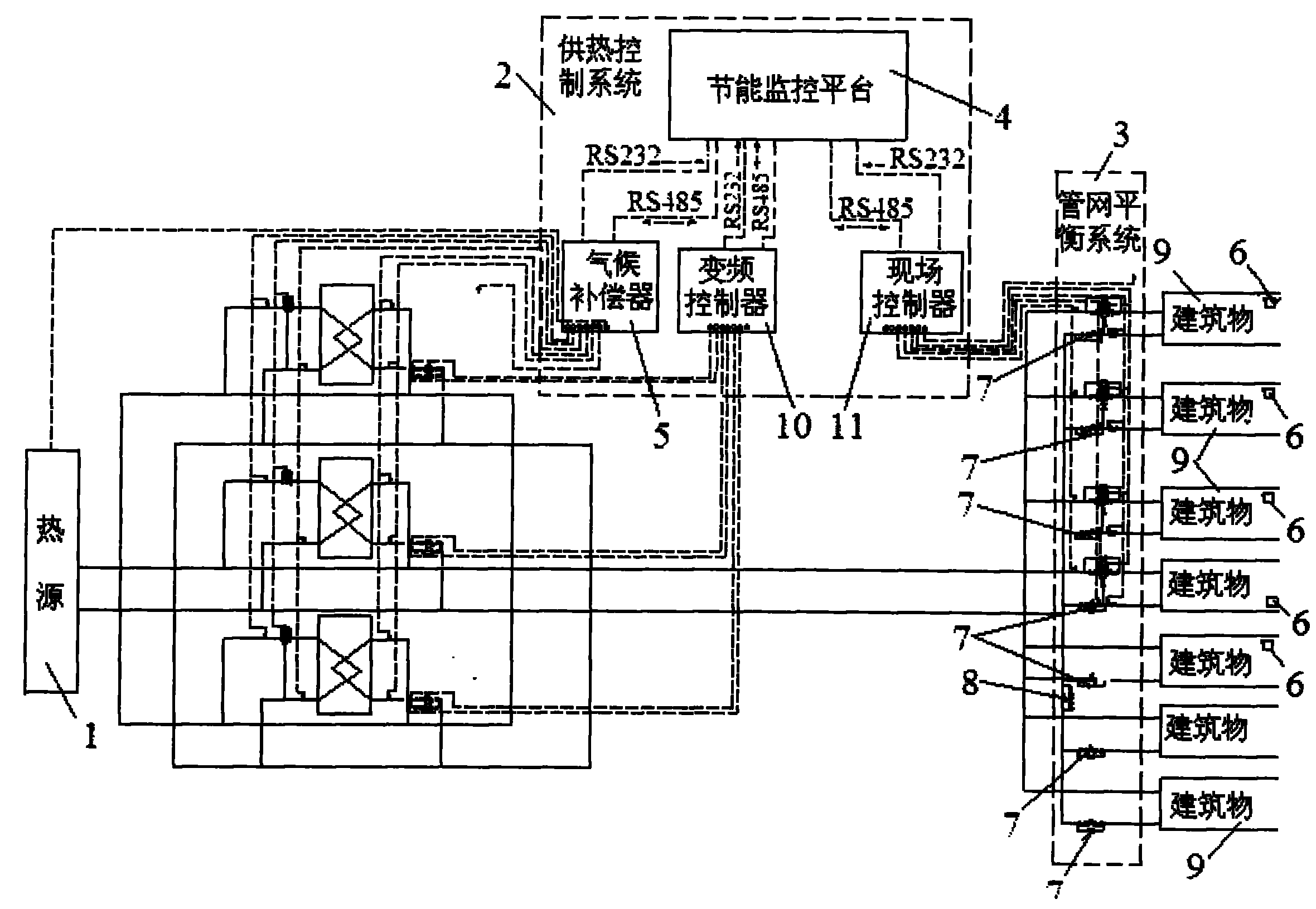

The invention relates to an integrated heat-supply and energy-saving system comprising a heat source, a heat-supply pipe network, a heat-supply control system, a pipe network balancing system and a waste heat recovering system, wherein the heat source is used for generating heat; the heat-supply control system is used for detecting indoor temperature to provide temperature parameters for weather compensation, monitoring the indoor temperature of users on line in real time and regulating the on / off of a relevant boiler, a circulating pump, an air conditioner, a ground source heat pump and a valve according to outdoor temperature and the indoor temperature of the users to control the heat-supply quantities of the heat users with different heat-supply properties, thereby realizing the automatic switching of anti-freezing running and heat supply; the pipe network balancing system is used for controlling each branch pipe to run by the set flow according to the branch pipe flows preset in one step, thereby improving the water pressure of the pipe network; and the waste heat recovering system is used for recovering energy for secondary application to reduce the heat loss of the heat-supply system. The integrated heat-supply and energy-saving system can automatically and intelligently control heat supply according to the heat-supply properties of the heat users, improve heat-supply quality, fully recycle waste heat at the tail end of the pipe network and carry out real-time on-line monitoring to the temperature of the pipe network.

Owner:西安特瑞斯热能技术有限公司

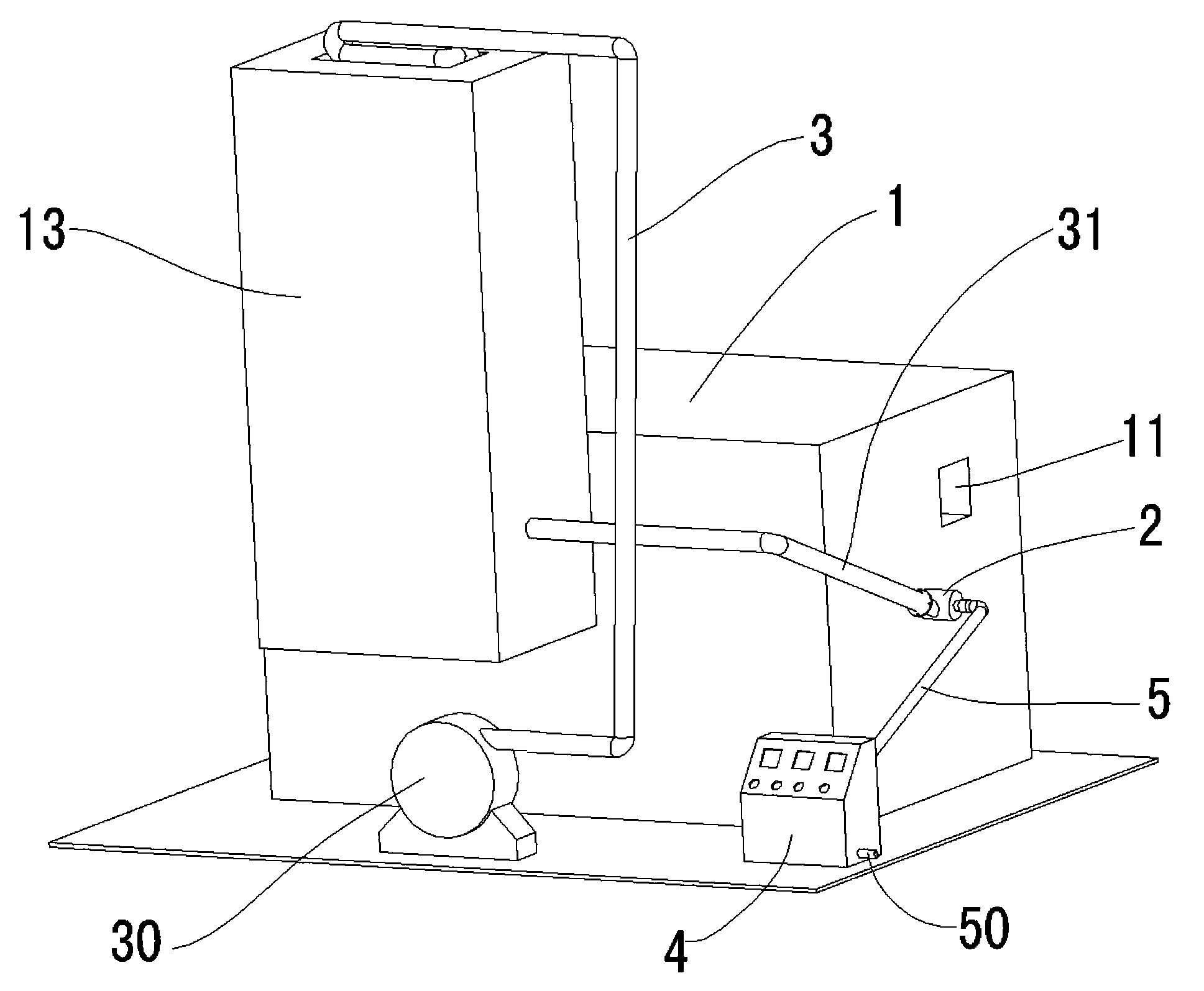

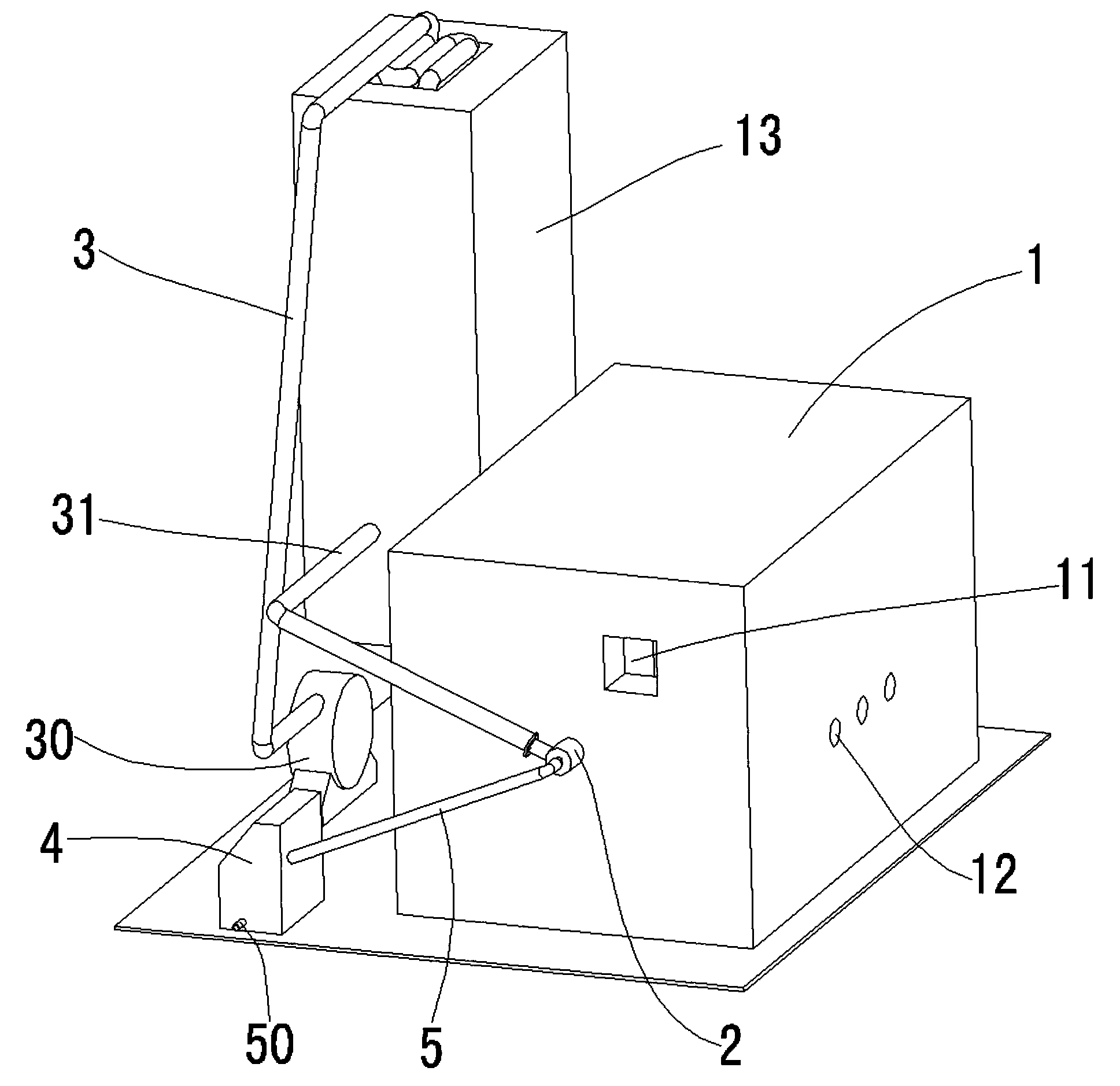

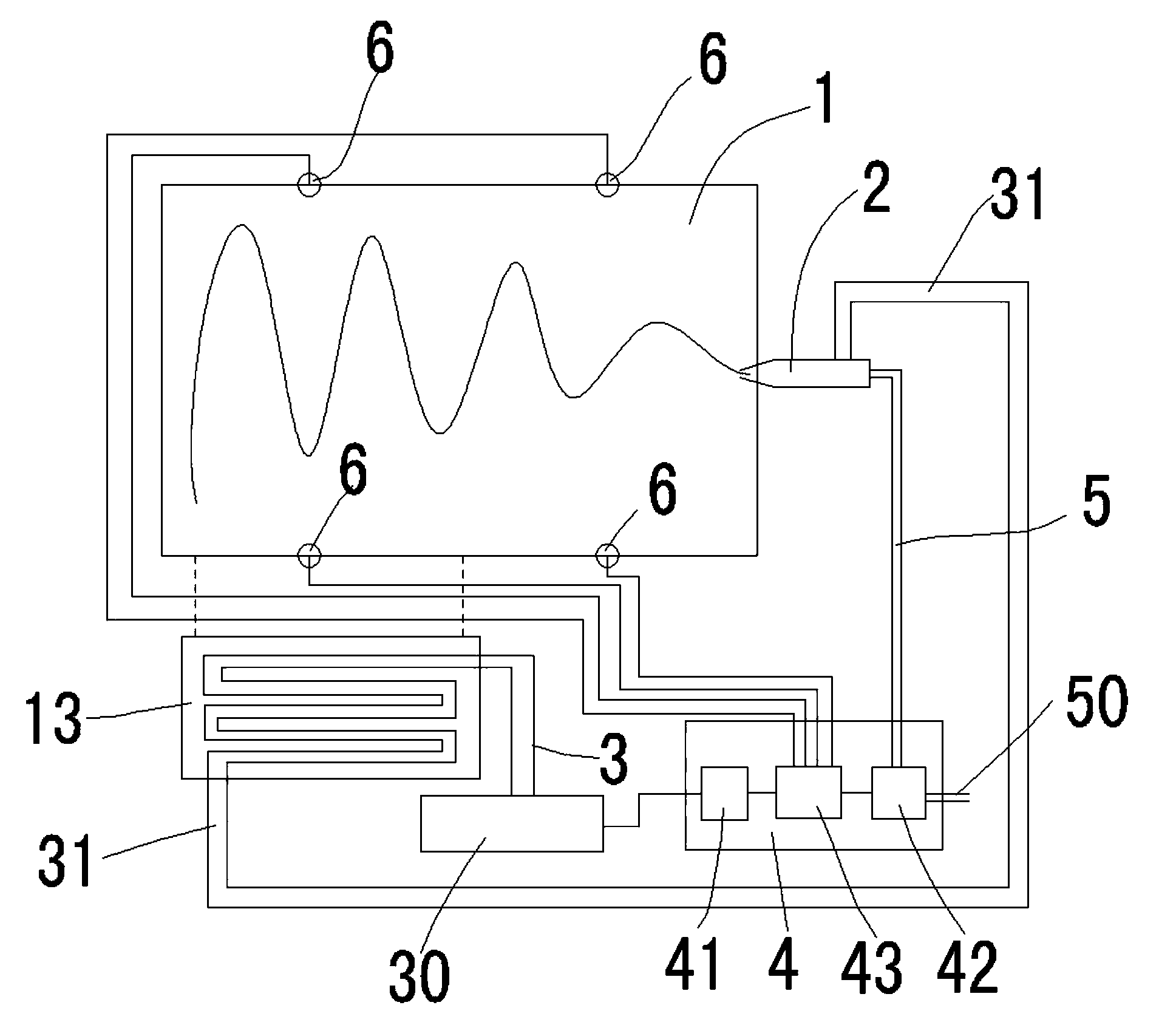

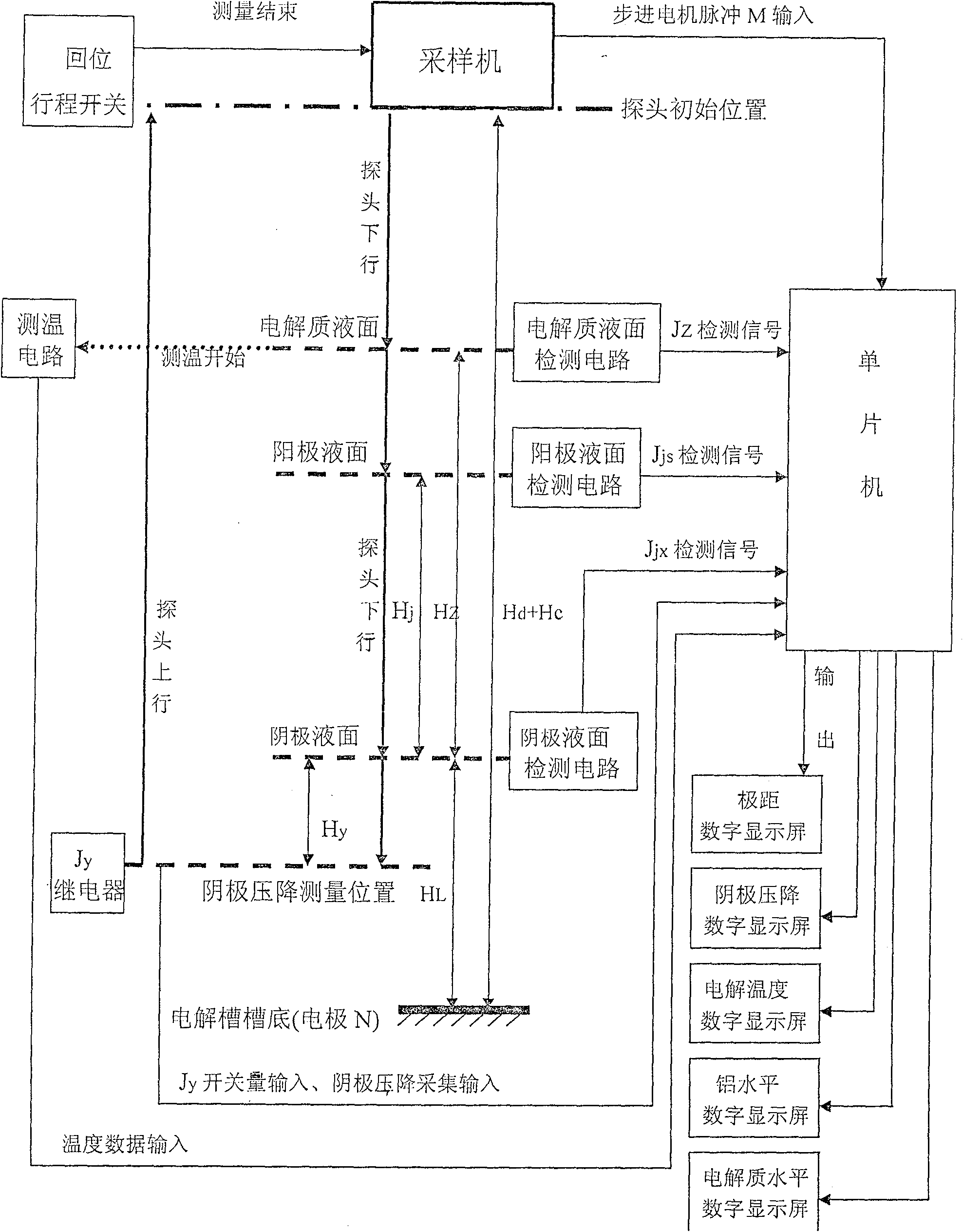

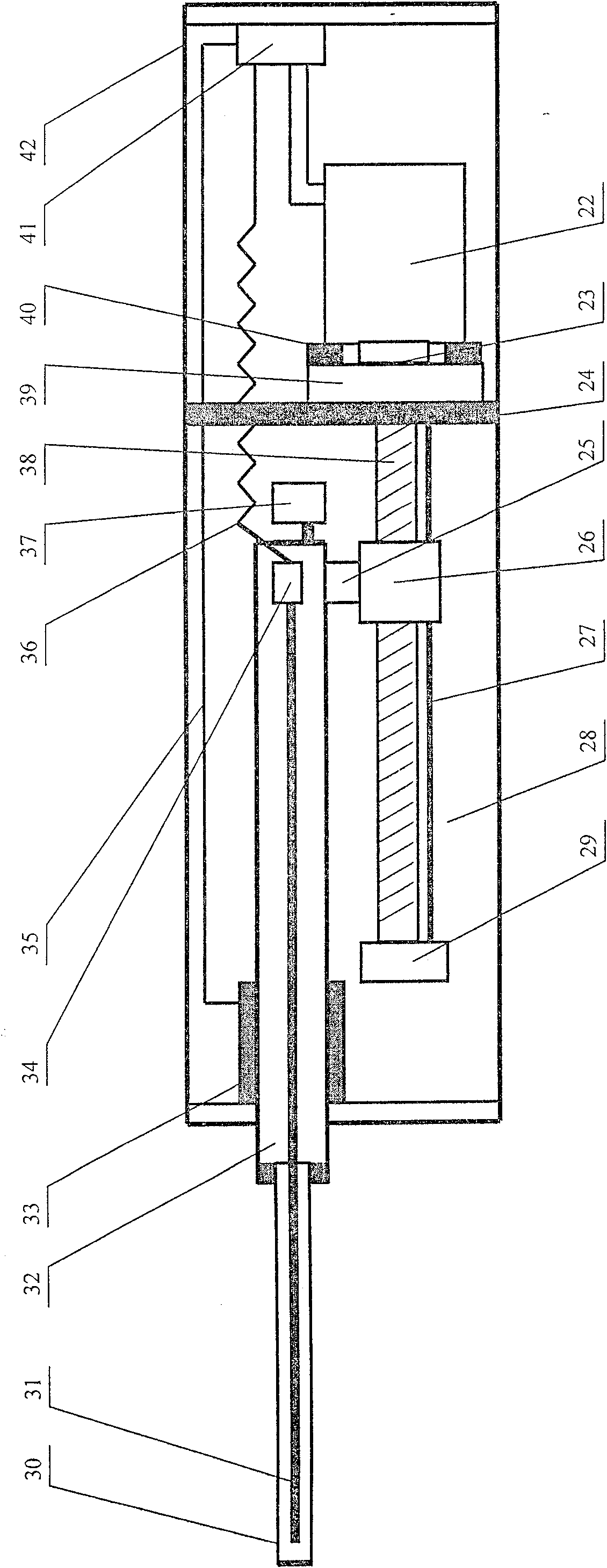

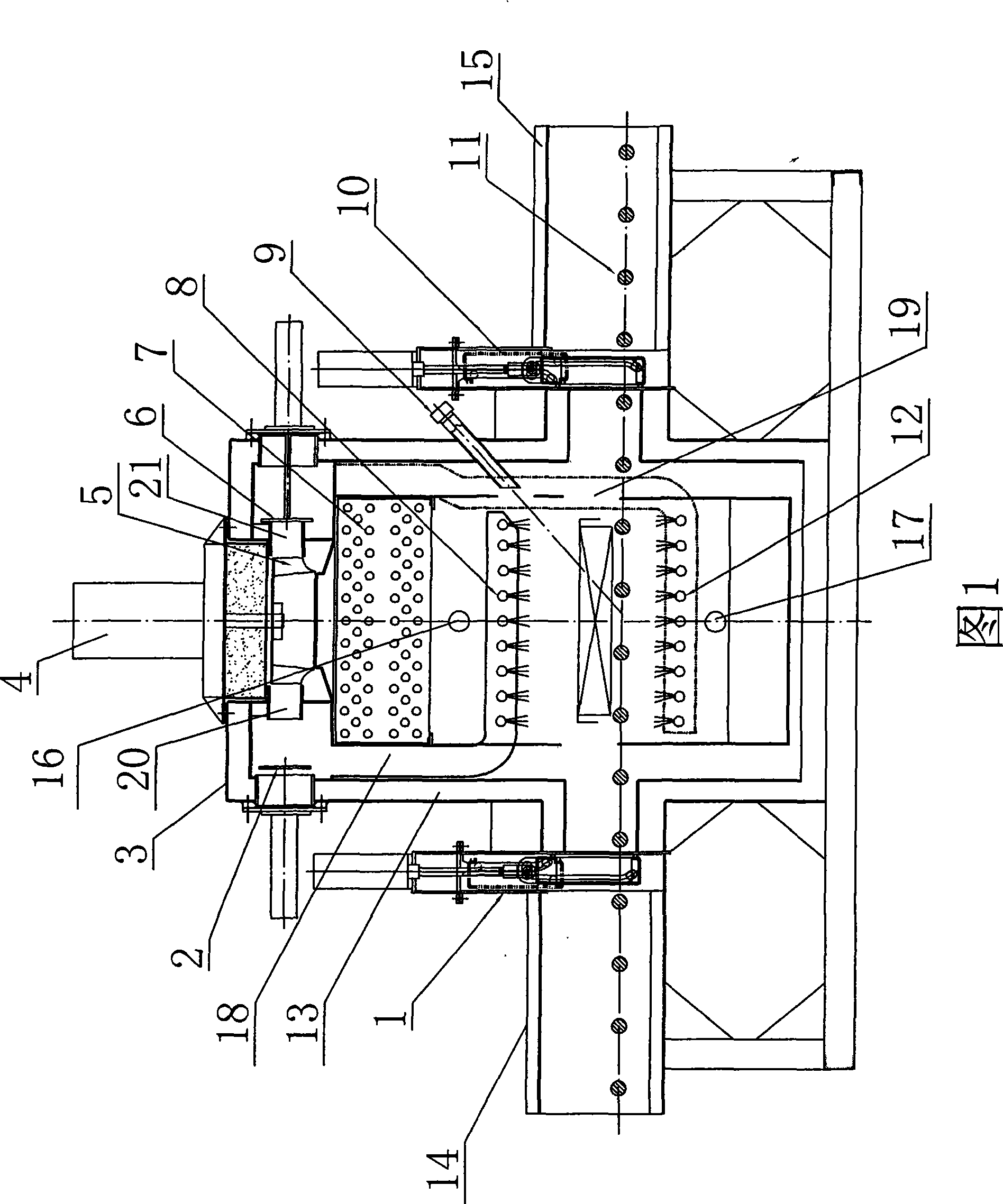

Prebaked aluminum electrolytic tank parameter measuring method and its device

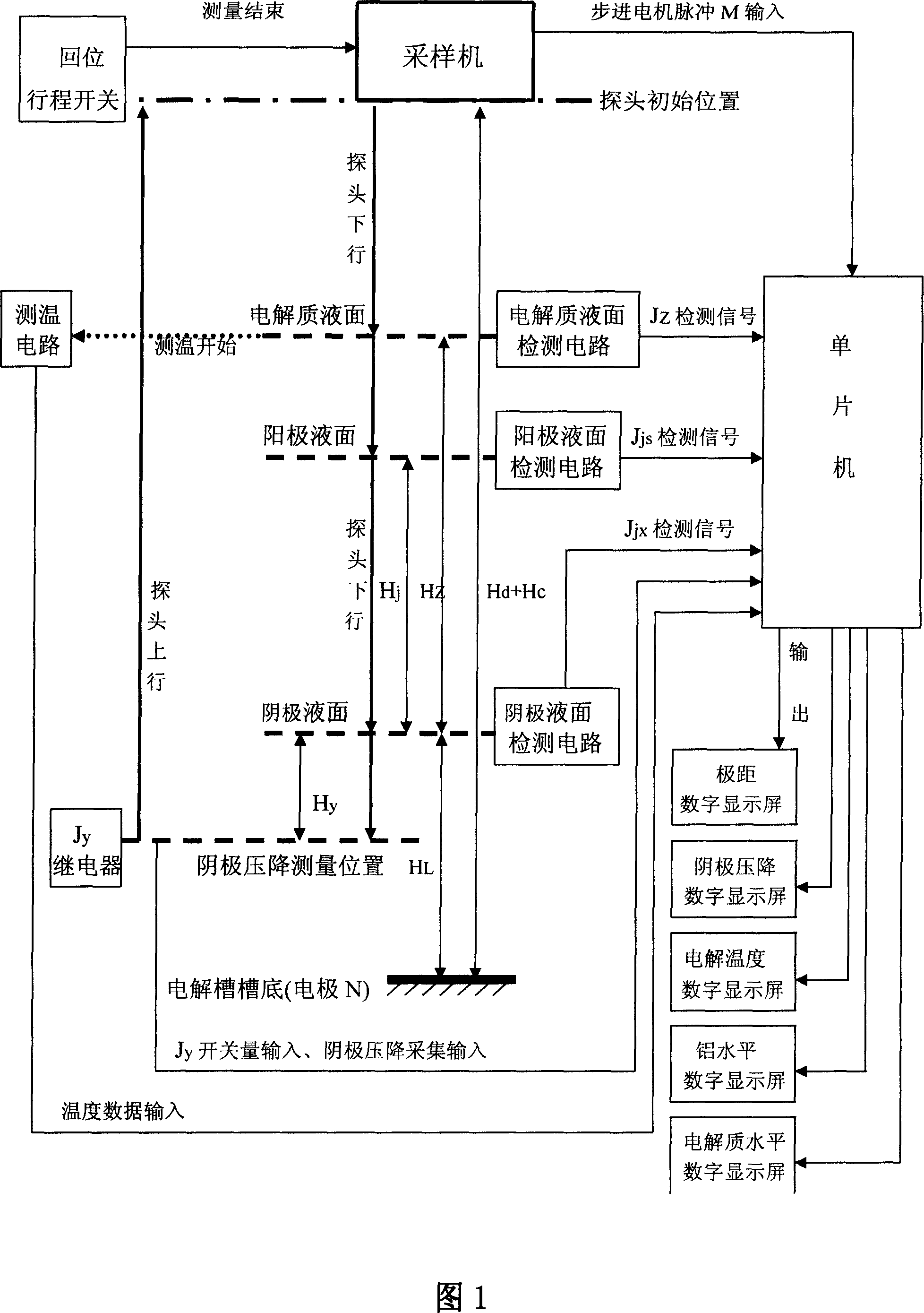

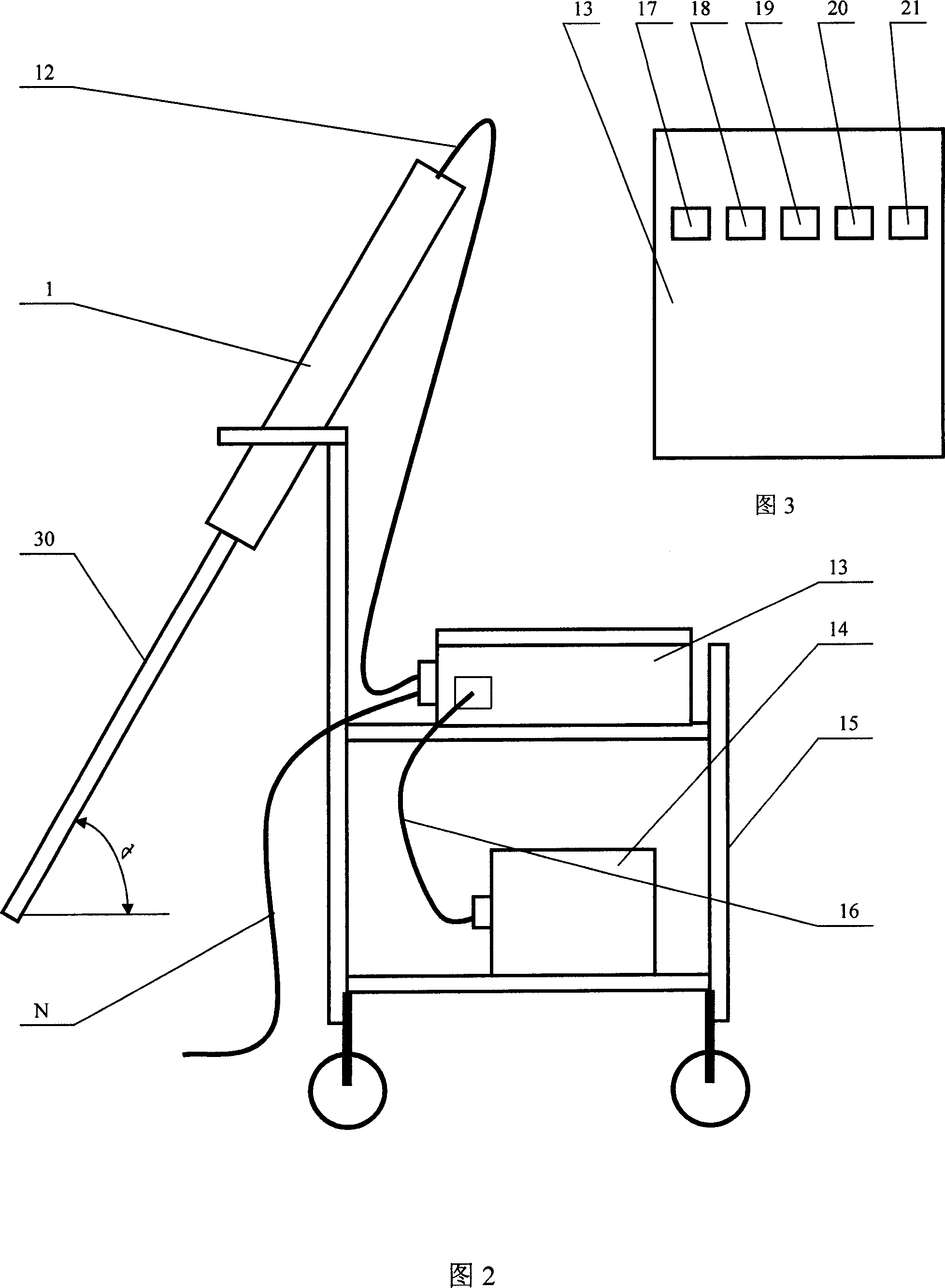

The invention discloses a method for measuring technological parameter for prebaked cell for aluminum-reduction, comprising following steps: inserting measuring probe driven by stepper motor into electrolyser, the impulse frequency of rotation rate for stepper motor continuously input into monolithic machine for counting and storing; checking electrolyte liquid surface, anode liquid surface and cathode liquid surface by relative checking circuit according to voltage change feature of different layer in aluminum cell solution, inputting relative measuring signal into monolithic machine; monolithic machine counting out polar distance, aluminum concentration and electrolyte concentration according to set mathematical model; the measured voltage is cathode voltage when the down vertical distance of measuring probe in aluminium liquid is 60- 100 mm; the polar distance, aluminum concentration, electrolyte concentration and electrolytic temperature are input into display screen by monolithic machine for real time display; the over travel-limit switch resetting measuring probe. The measuring device mainly comprises sampling machine and controlling tank; controlling tank is equipped with polarization layer measuring circuit and spacing measuring cathode pressure differential circuit; and sampling machine comprises data collecting device and operation power device.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Bayer process red mud processing method

The invention discloses a treatment method of Bayer method red mud, comprising the following steps: (a) the red mud is sorted by a beneficiation method and divided into three parts, namely, rough sand, fine sand and soil mortar; (b) milling grinding and settling separation are carried out to the rough sand in the step (a) to obtain rough sand one and tailing ore slurry one; (c) after the rough sand one in the step (b) and the fine sand in the step (a) are mixed, magnetic separation is carried out to obtain iron powder and quartz powder; (d) the iron powder obtained in the step (c) is refined and sorted by a magnetic separator to obtain fine iron powder F and fine iron powder P; and (e) the soil mortar in step (a) is pulse magnetic separated to obtain tailing ore slurry and fine iron powder PI. The method can reduce 35-40 percent of red mud discharge, the iron element effective utilization rate can reach more than 70 percent, and the monomer quartz extraction yield can reach 80 percent. The method optimizes the production flow of alumina by using a combination method, reduces the red mud discharge, protects the environment, reduces the production cost of alumina and improves the alumina production capacity.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

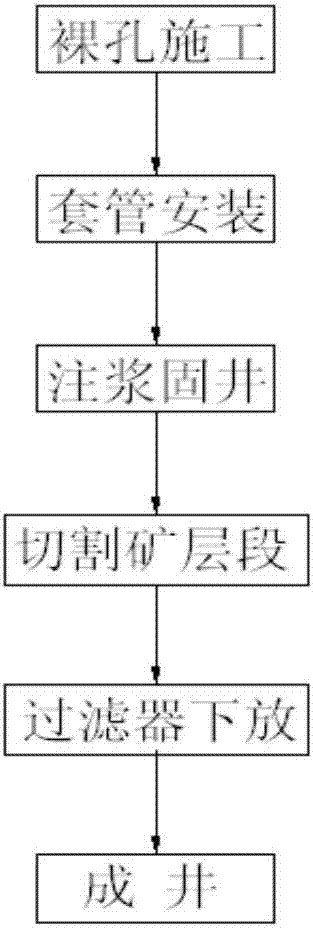

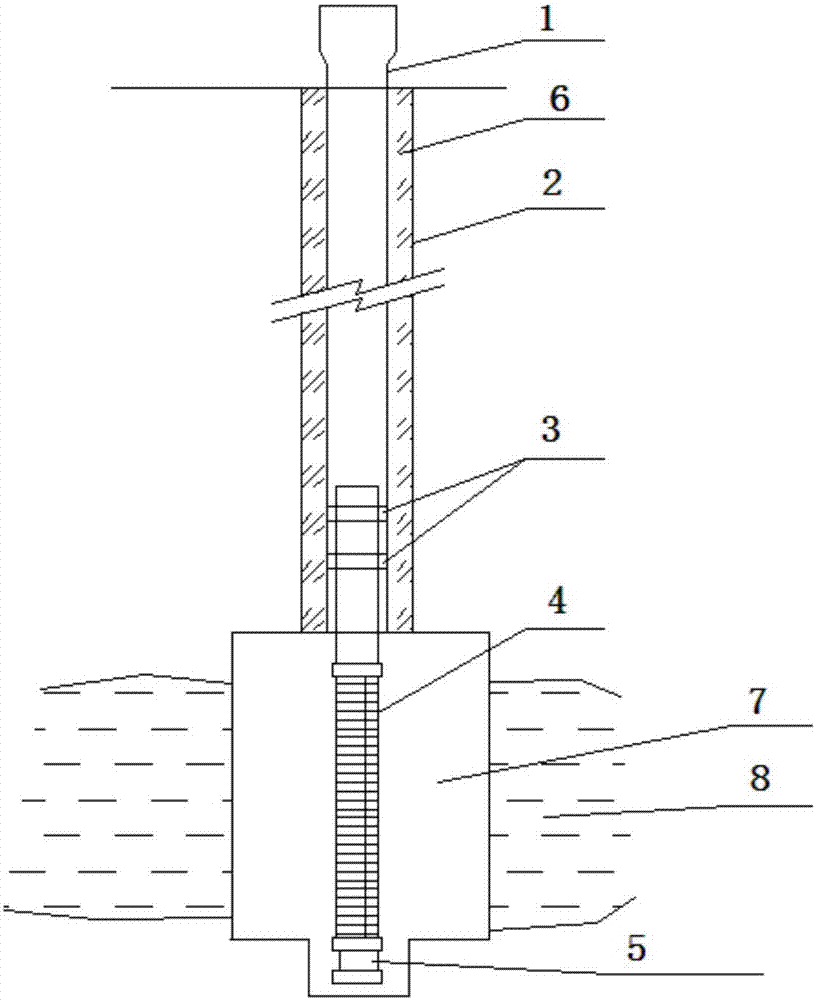

Construction method for novel drilling structure for in-situ leaching of uranium

ActiveCN107366505AAchieve quality improvementAchieve efficiencyFluid removalFlushingState of artWell cementing

The invention provides a construction method for a novel drilling structure for in-situ leaching of uranium. The construction method comprises the following steps of: (a), drilling open holes until 5-10m of the upper part of an ore bed, and replacing a drill bit to drill to designed depth; (b) replacing mud in holes with thin mud, performing comprehensive detection on a well, determining the position of the ore bed, determining length of a well tube, determining the positions and the length of filters, and using a roller bit to expand to required design, thereby obtaining the open holes; (c), after expanding is ended, using a thin mud pump to flush the open holes in a circulating mode, and sequentially introducing configured sleeves into the open holes in sequence; (d), injecting common silicate cement paste into outside-sleeve ring-shaped space from the bottoms of the sleeves to seal the holes, thereby completing grouting and well-cementing operation; (e), performing cement grouting and well-cementing for 16-18 hours, and cutting an ore-bed section, thereby forming an ore-bed cutting section; and (f), putting the filters into the sleeves until the ore-bed section after cutting is completed. The construction method solves the defects in the prior art, and realizes upgrading, efficiency-increasing and consumption-reducing of drilling construction.

Owner:中核通辽铀业有限责任公司

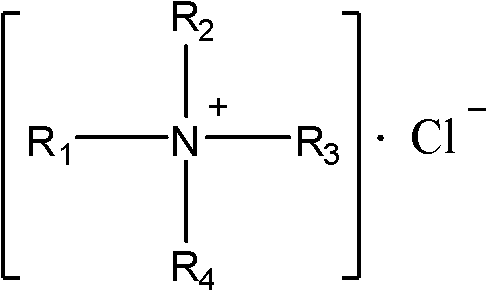

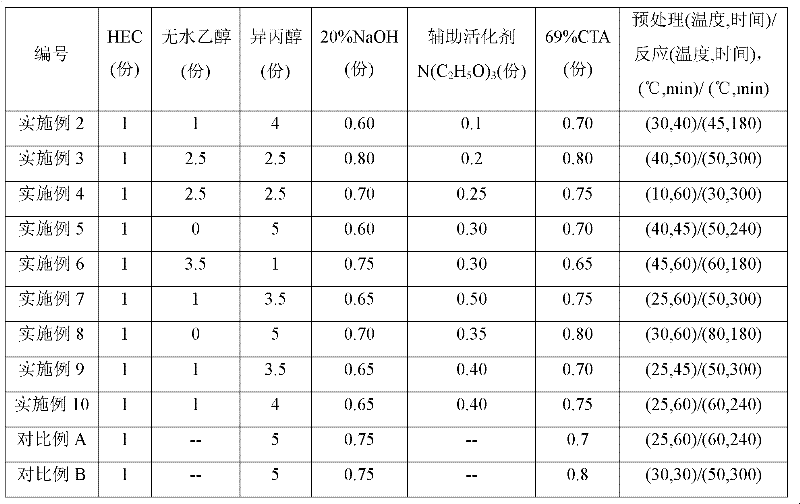

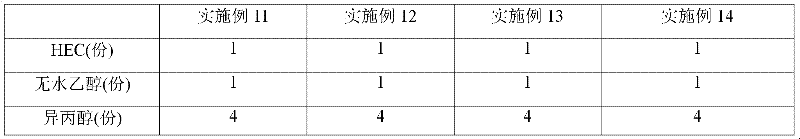

Preparation method of cationic hydroxyethyl cellulose ether

The invention discloses a preparation method of cationic hydroxyethyl cellulose ether. The method comprises the following steps: adding 1 part of hydroxyethyl cellulose, 0.6-0.8 part of 20-35wt% sodium hydroxide solution and 0-0.5 part of amine alkali coactivator in a mixed solution composed of 0-5 parts of absolute alcohol and 0-5 parts of isopropanol and stirring at 10-45 DEG C for 20-60 minutes to obtain liquid A; stirring the liquid A while controlling the temperature to 30-80 DEG C, adding 0.6-1.4 parts of cationic etherifying agent to react for 3-5h to obtain liquid B; cooling the liquid B to 25-35 DEG C, adjusting the pH value, filtering, extracting and drying to obtain the cationic hydroxyethyl cellulose ether. The cationic substitution degree of the method is 0.30-0.50, the cationic reaction efficiency is 42%-75%, the technological process does not require other intermediate links, the production cost is reduced and energy saving and emission reduction are realized in the production process.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Technique for extracting titanium slag form red mud

ActiveCN101054628AReduce production linksReduce manufacturing costRecycling and recovery technologiesProcess efficiency improvementRed mudAtmospheric temperature

A technical handling method of cuprum wires cross relates to the annealing process of cuprum wires cross and comprises the following steps: putting cuprum wires cross into a annealing furnace, pumping air in the furnace to form negative-pressure in the furnace, filling the furnace with carbon dioxide protective gas; performing a heating treatment of two stages under pressure, performing a gas releasing decompression processing between stages, then cooling-down slowly in the furnace for 0.3-1 hour, and opening the furnace to cool-down naturally to atmospheric temperature. Therefore, electrical soft wires cross through such annealing treatment has brightening surfaces and excellent finish, without greasy dirt or other soils; exhibits uniform flexibility and strong antioxidant ability, and can be stored for a long time.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

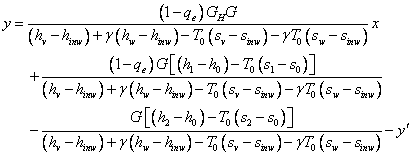

Method for measuring dry-quenching burning loss rate based on exergy balance

InactiveCN102759542AReduce manufacturing costSimple calculationMaterial heat developmentCokeIndustrial engineering

The invention discloses a method for measuring a dry-quenching burning loss rate based on an exergy balance. The method comprises the following steps of: establishing an exergy balance model for a dry-quenching burning system after analyzing a dry quenching process, operating situations and related factors for affecting the dry-quenching burning loss rate; and obtaining a relationship between the dry-quenching burning loss rate and a steam yield through the analysis of the exergy balance model. According to the method disclosed by the invention, the dry-quenching burning loss rate can be simply, conveniently, effectively and quickly calculated out by using the relationship; and besides, the method has important meanings for reducing the dry quenching production cost and improving the dry quenching yield and efficiency.

Owner:CHANGSHA CHANGZHI ELECTRICAL

Dry-type air cleaner

InactiveCN104121119AHigh filtration precisionExtended service lifeMachines/enginesAir cleaners for fuelEngineeringCentrifugal force

The invention relates to a dry-type air cleaner which comprises a maintenance warner, a front blocking cover, an air intake cap sub-assembly, vane rings, a main filter element, a safety filter element, a shell, a dust accumulation plate cover, a rear cover, a pull rod sub-assembly, a dust removal bag, a sealing ring and an air outlet pipe, wherein the dust accumulation plate cover is arranged between the right end of the main filter element and the rear cover. The dry-type air cleaner is reasonable in structure. Dust setting to the bottom of the rear cover under the action of centrifugal force of the vane rings cannot be absorbed back to the surfaces of the filter elements any more through the negative pressure effect generated by an engine. The dry-type air cleaner has the advantages of being high in filter precision, long in service life, long in maintenance period, low in maintenance cost and the like, thereby saving materials, reducing consumption, prolonging the service life of the engine and being capable of being widely used for being matched with heavy-duty cars.

Owner:蚌埠国威滤清器有限公司

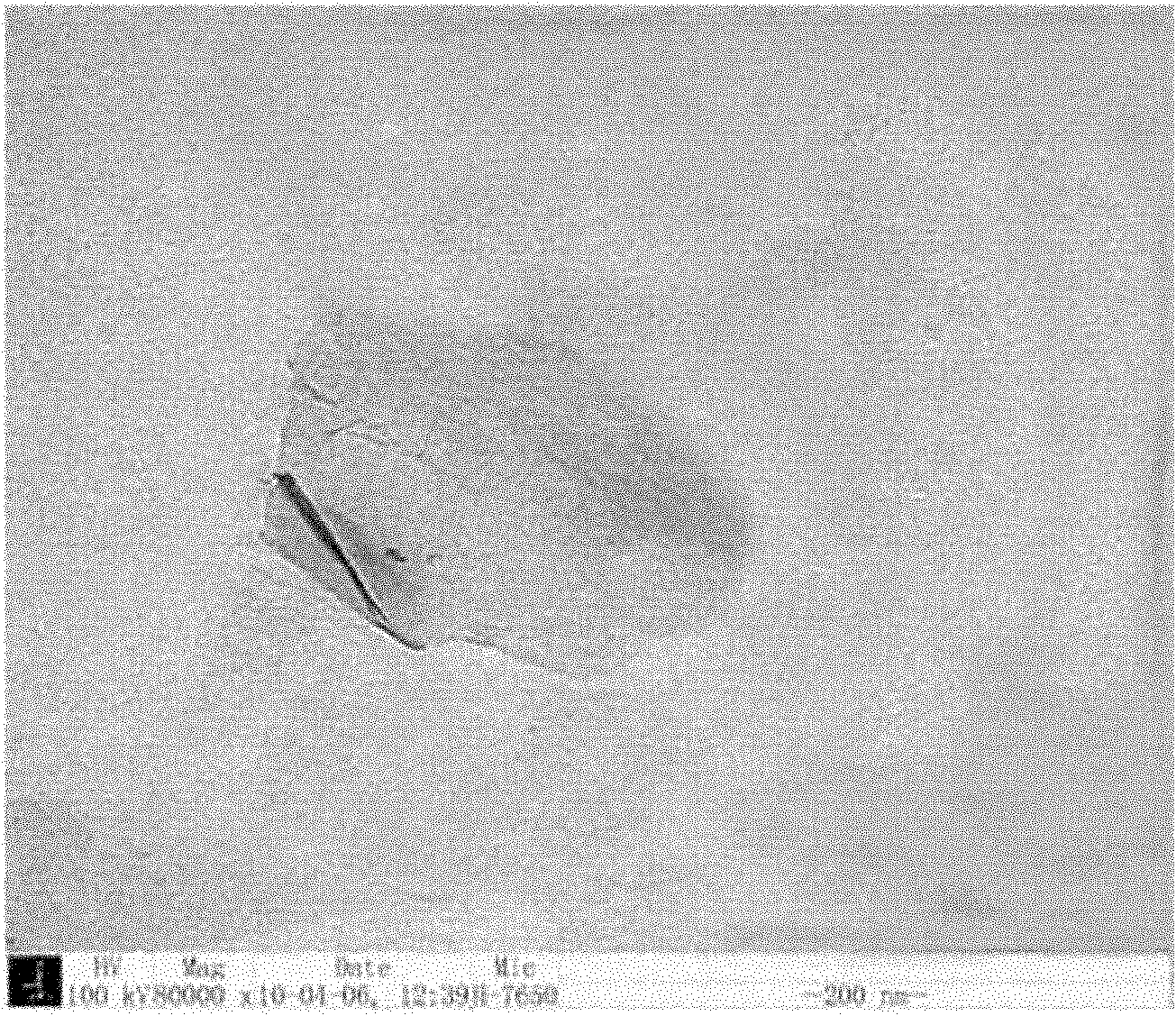

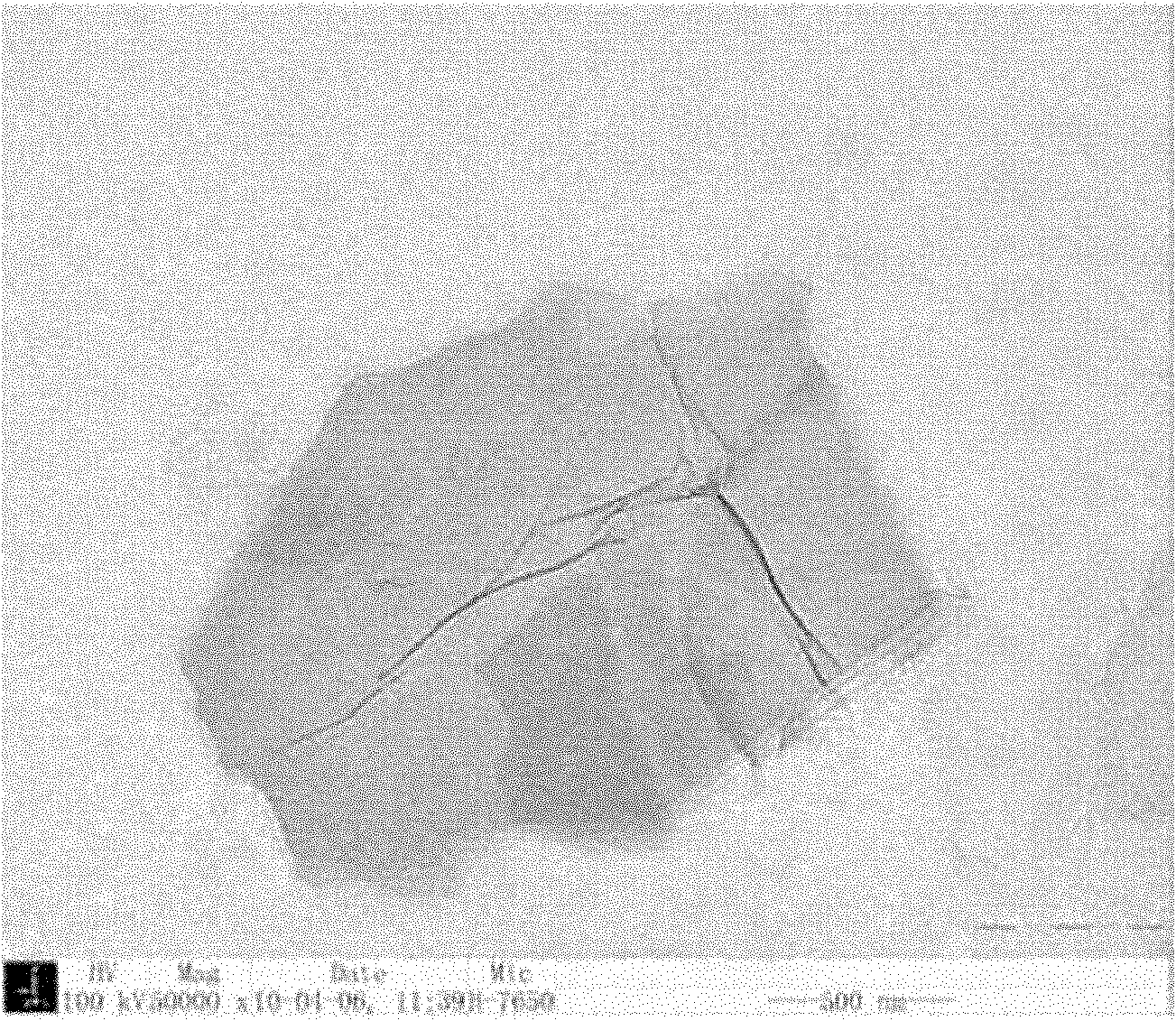

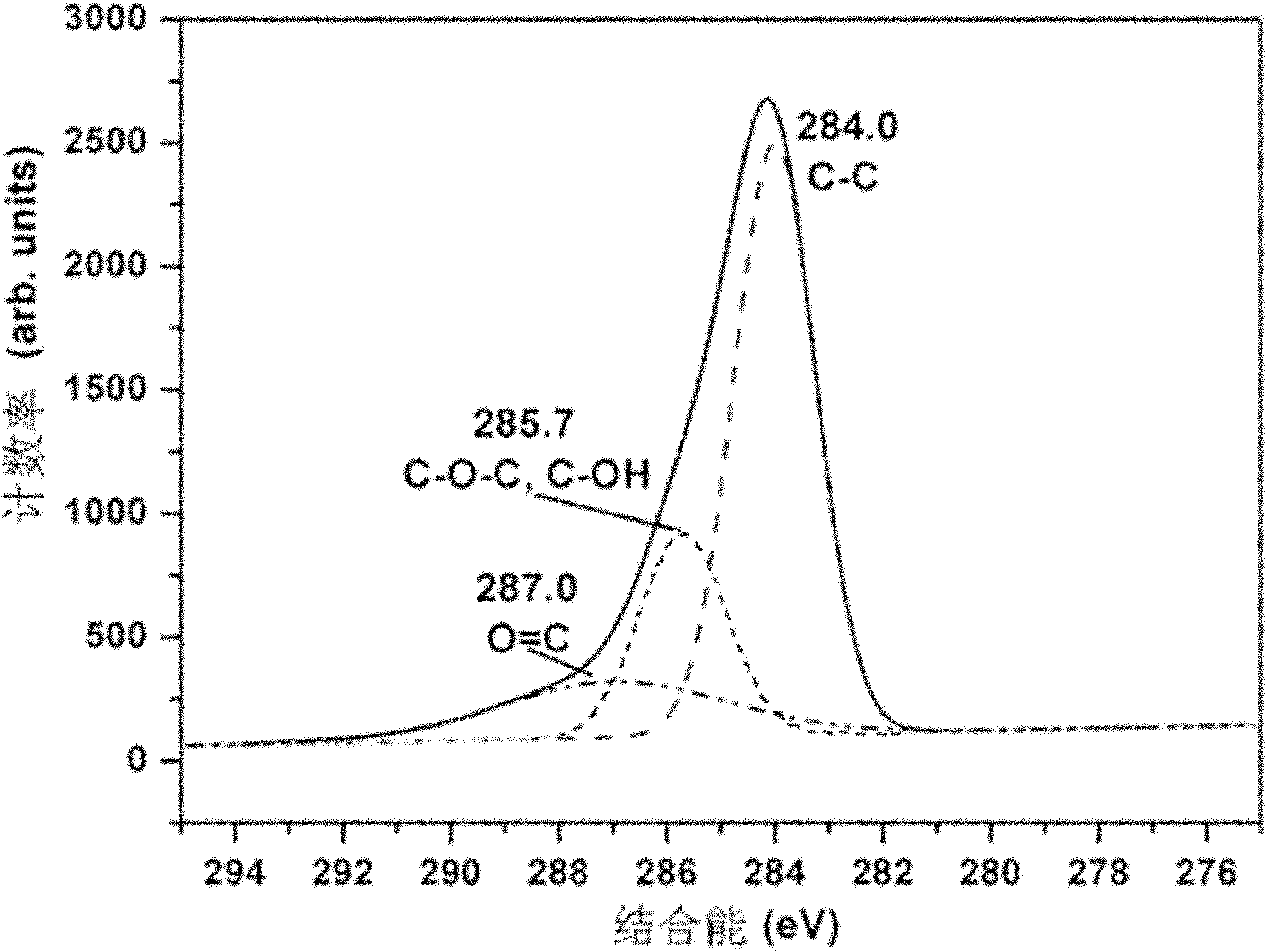

Method for preparing graphite oxide/macromolecular water-based cold rolling lubricating additive

InactiveCN102041139AStrong combinationImprove wear reduction performanceAdditivesDimethyl formamideEmulsion

The invention discloses a method for preparing a graphite oxide / macromolecular water-based cold rolling lubricating additive, and relates to a method for preparing a graphite oxide-based lubricating additive. The method solves the problems that the conventional cold rolling liquid has short service life, is easy to settle and break emulsion and has poor lubricating performance, poor anti-rust level, high viscosity and high residual carbon quantity and residual iron quantity. The method comprises the following steps of: adding graphite oxide into mixed solution of thionyl chloride and methylbenzene, performing reflux reaction to obtain graphite acetyl chloride, then adding the graphite acetyl chloride and water-soluble macromolecules into N,N-dimethyl formamide to react, drying the reaction system, dispersing the dried product into water, then adding ethanol to obtain sediment, and drying the sediment. The molecular structure of the water-based cold rolling lubricating additive has flexible polymer molecular chains, so the anti-friction performance of the lubricating additive is improved; the lubricating additive forms stable solution in water, and the solution has low viscosity, is not easy to settle and has long service life; and the lubricating additive has good anti-rust level and low residual carbon quantity and residual iron quantity. Through the water-based cold rolling lubricating additive, the friction spot diameter of the base liquid is reduced by 26.2 percent.

Owner:HARBIN INST OF TECH

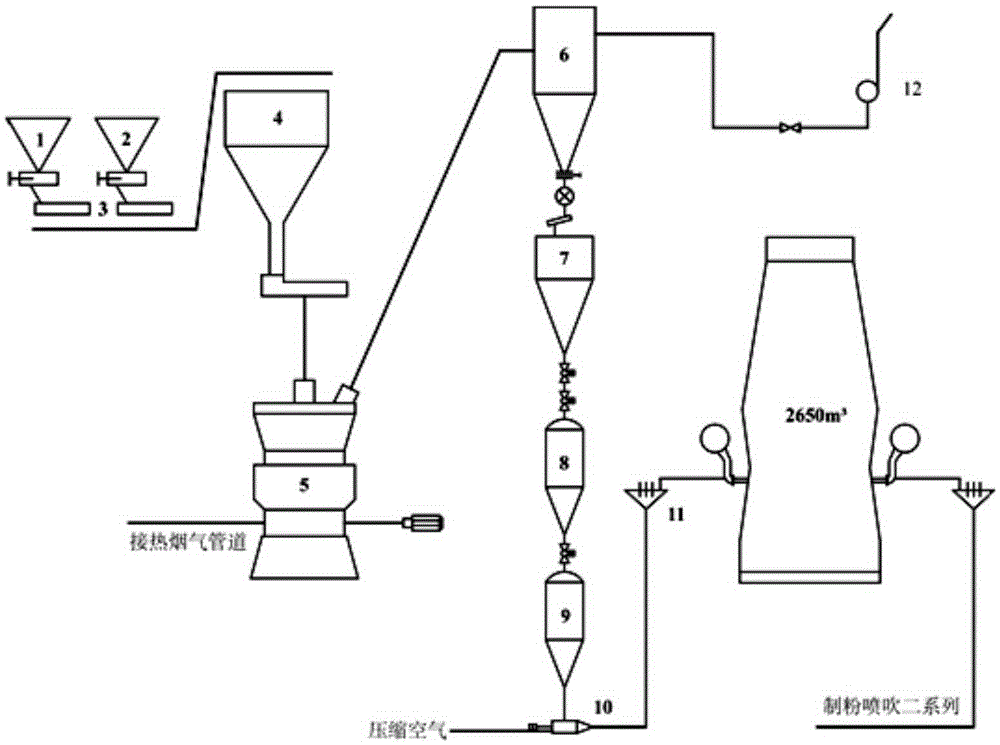

Method for achieving furnace protection through tuyere titanium injection with utilization of blast furnace coal injection system

The invention provides a method for achieving furnace protection through tuyere titanium injection with utilization of a blast furnace coal injection system. Prepared titanium fine powder with the main components being TiO2 and iron fine powder and the particle size being smaller than or equal to -200 meshes is hoisted and conveyed to a coal distribution bin. The titanium fine powder is added onto a coal feeding belt in batches through a coal feeder at the bin bottom of the coal distribution bin and enters a coal grinding system together with raw coal powder through a coal mill raw coal bin. The titanium fine powder and the raw coal powder enter a coal powder bin after mixed evenly in the coal grinding system. The evenly mixed titanium fine powder and raw coal powder entering the coal powder bin are together injected into a blast furnace through a tuyere by a blast furnace injection system. According to the method, additional equipment is not needed, the titanium fine powder and the coal powder can be mixed evenly through an existing power making coal injection system of the blast furnace, the titanium fine powder is injected into the blast furnace along with the coal powder through the tuyere of the blast furnace by a coal injection gun pertinently and safely in time according to the titanium load requirement needed by furnace protection of the blast furnace, and the furnace protection purpose is achieved.

Owner:金康 +1

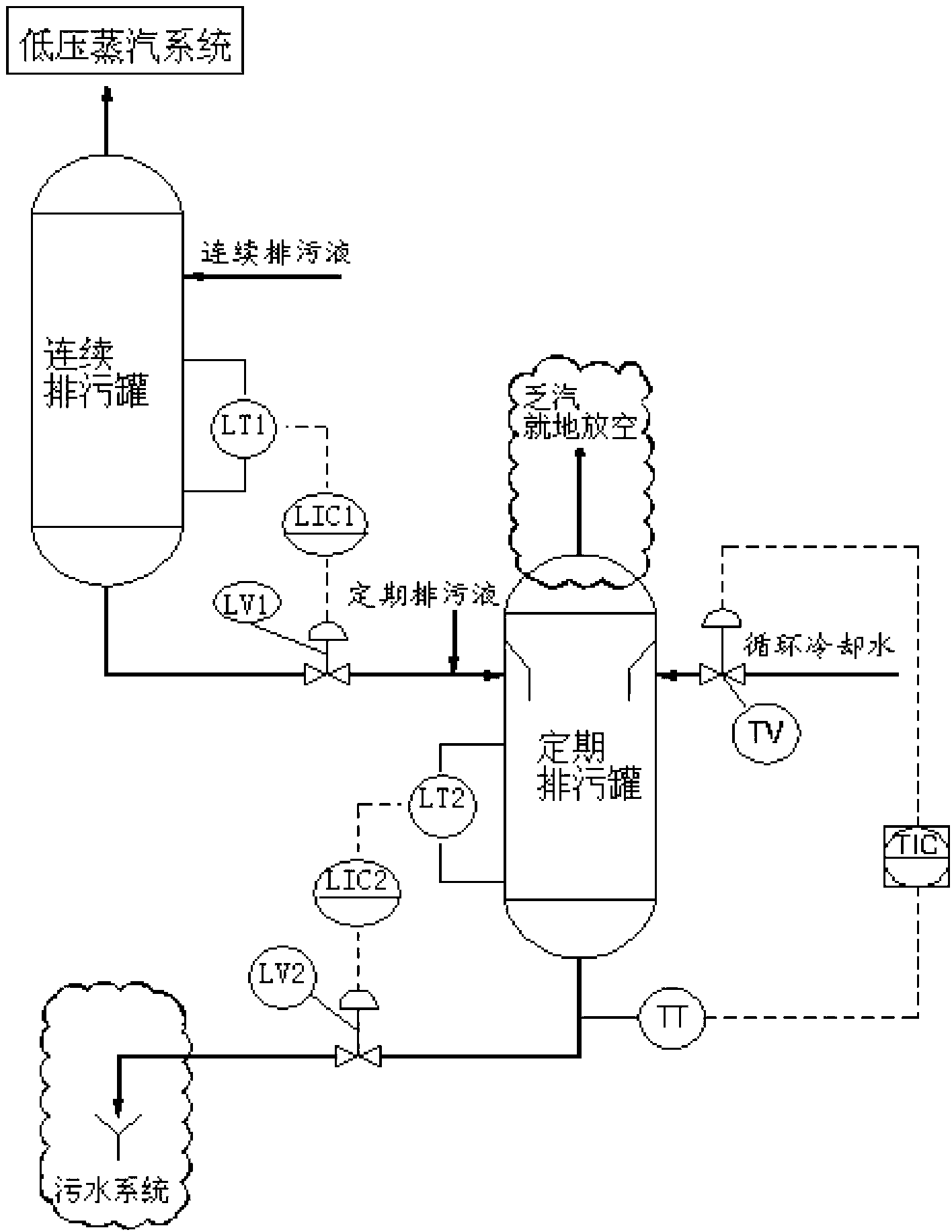

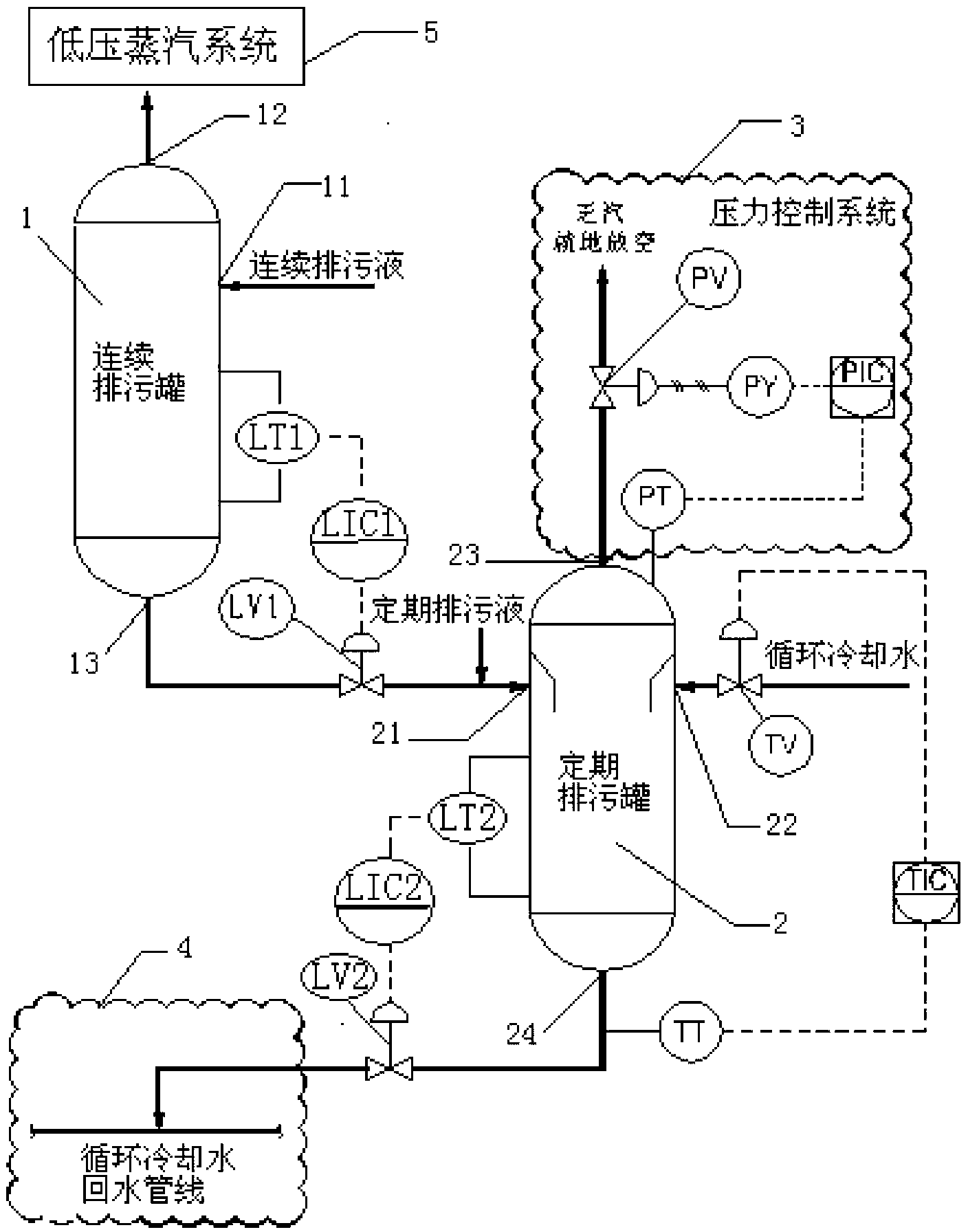

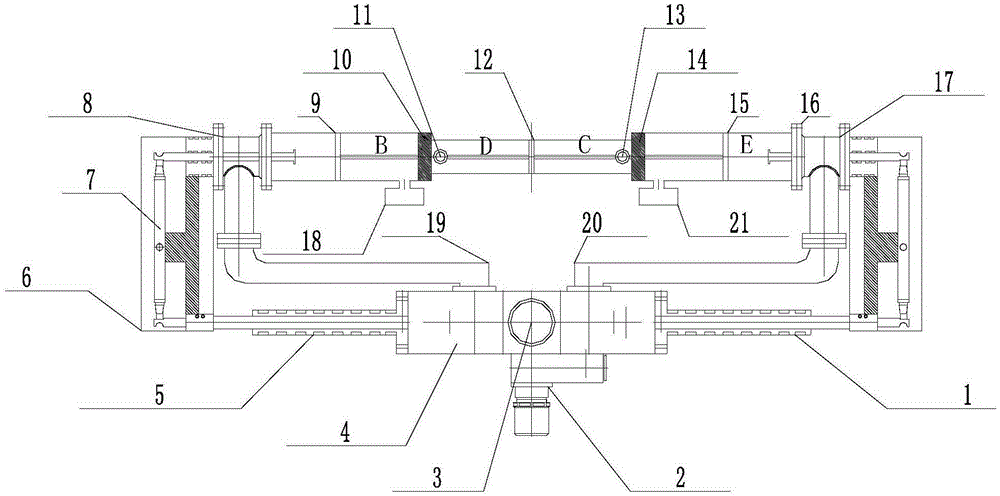

Boiler blow down system

ActiveCN103307591AReduce wasteIncrease the amount of condensateBoiler cleaning apparatusBoiler blowdownControl system

The invention relates to a boiler blow down system which comprises a continuous blow down tank, a periodic blow down tank, a pressure control system and a recirculated cooling water return pipeline, wherein as for the continuous blow down tank, a tangential input port is used for inputting continuous blow down liquid, an output port at the top is used for outputting low-pressure steam, and an output port at the bottom is used for outputting bottom condensate into the periodic blow down tank; as for the periodic blow down tank, a first tangential input port is used for inputting the bottom condensate and the periodic blow down liquid of the continuous blow down tank, a second tangential input port is used for inputting recirculated cooling water, the output port at the top is used for discharging the low-pressure exhaust steam into atmosphere through the pressure control system, and the output port at the bottom is used for discharging tank bottom condensed water into the recirculated cooling water return pipeline; the pressure control system is arranged at the top of the periodic blow down tank and used for controlling the operating pressure of the periodic blow down tank and discharging low-pressure exhaust steam; and the recirculated cooling water return pipeline is arranged at the bottom of the periodic blow down tank and used for recovering tank bottom condensed water of the periodic blow down tank. The boiler blow down system can reasonably recycle the periodic blow down condensed water, which reduces water resource waste and boosts corporate profitability.

Owner:BEIJING PETROCHEM ENG

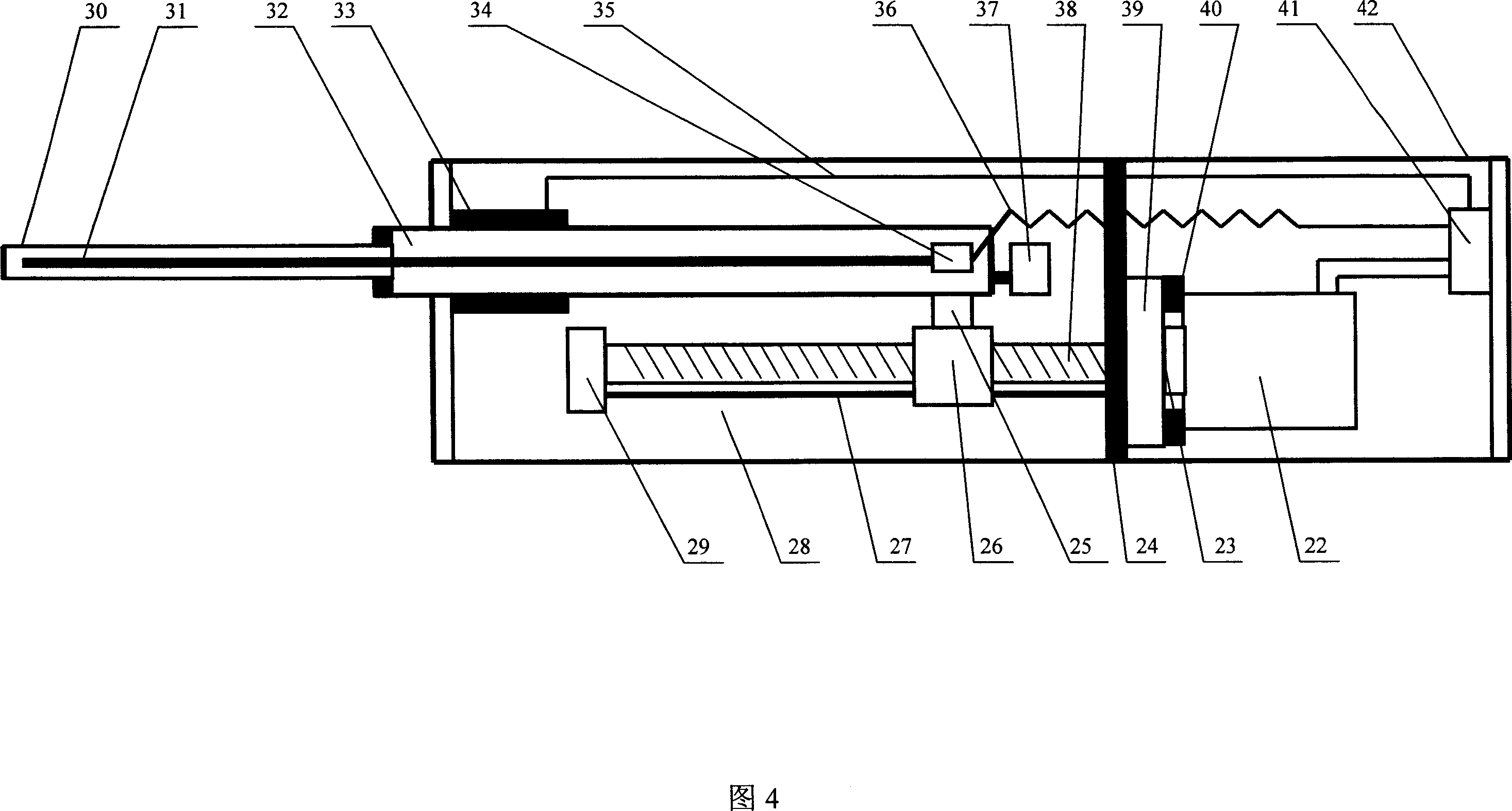

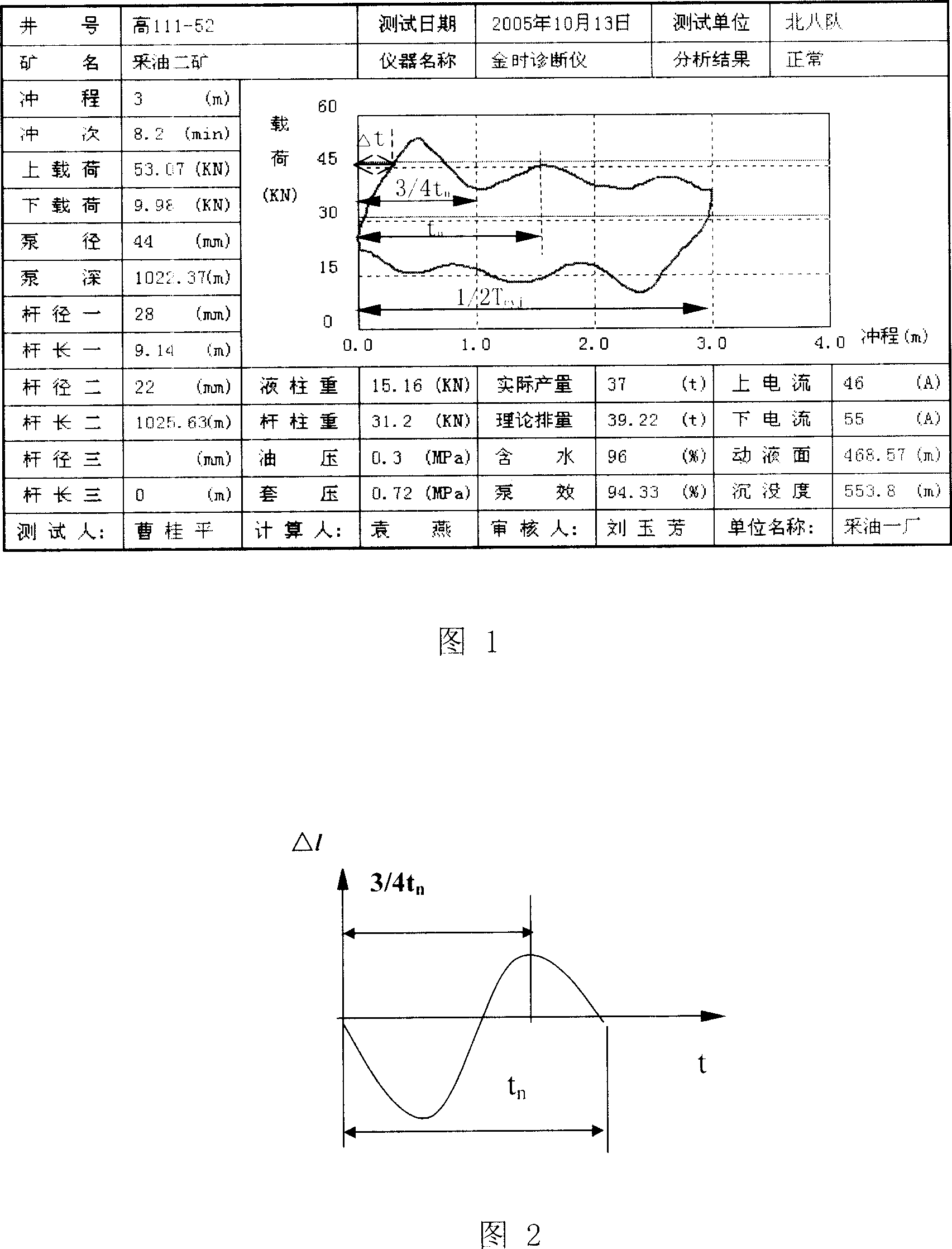

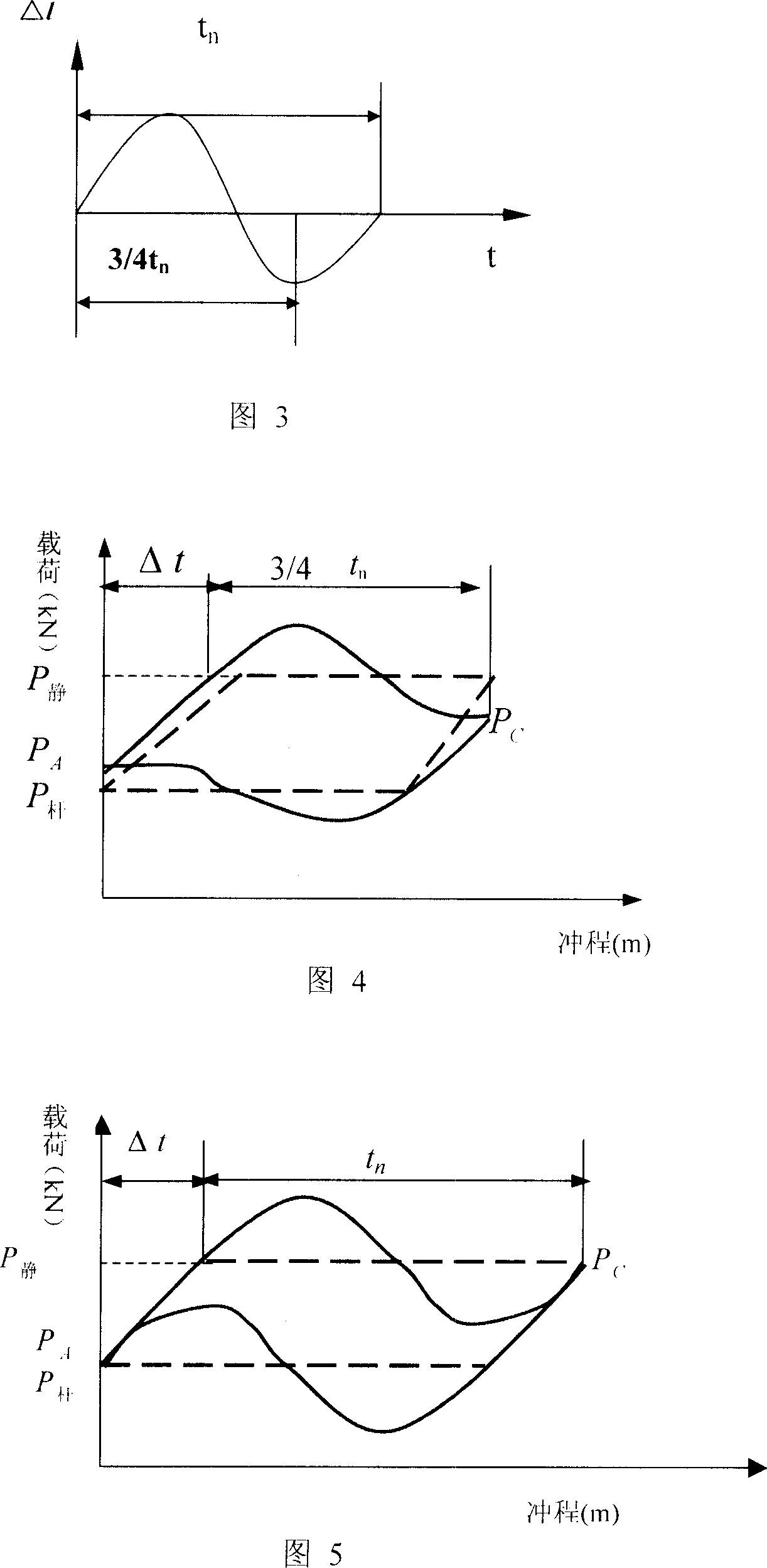

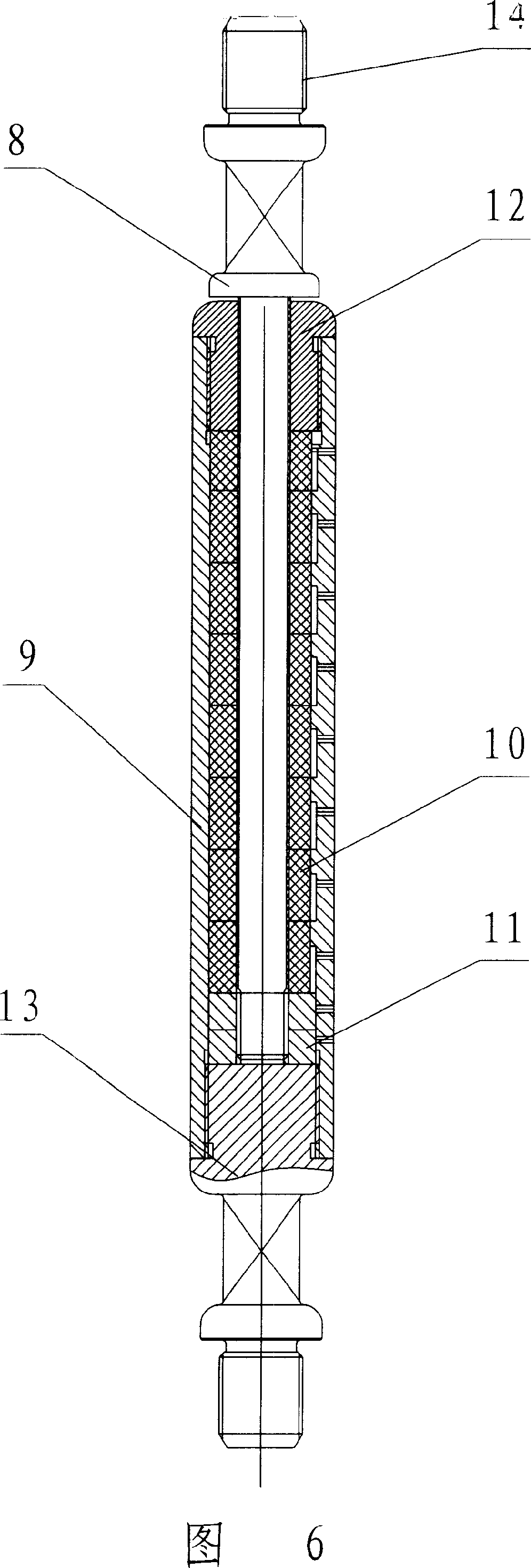

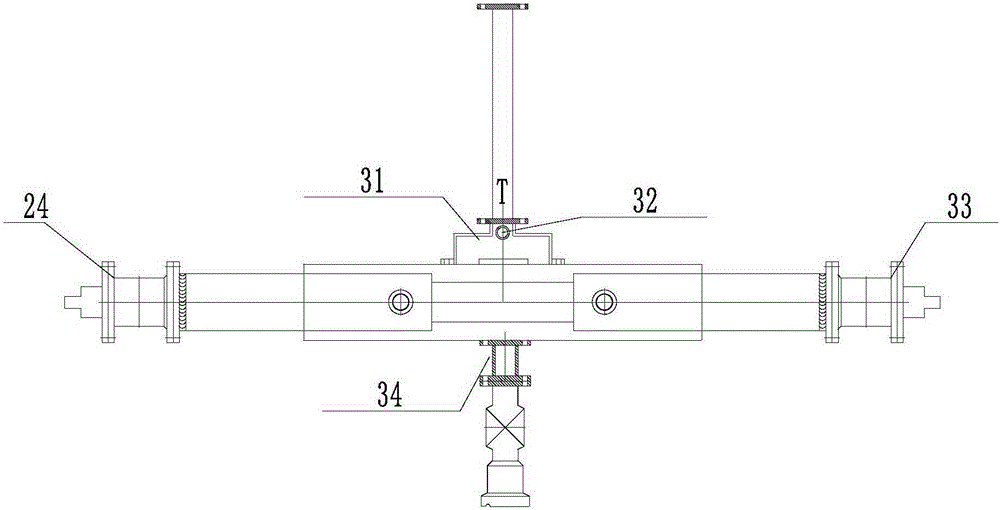

Method for lowing energy-consumption and increasing output by changing elasticity modulus of pumping rod and special apparatus

InactiveCN101012741ARealize energy savingRealize consumption reductionDrilling rodsFluid removalElastic componentDecreased energy

The invention relates to a method, which makes use of modifying the elastic modulus of sucker rod to decrease energy consumption and improve the output and is applied in the oil field manual lifting area. It mainly aims at lower rod pump efficiency and system efficiency of prior pumping well, bigger energy consumption transferred to ground pumping unit by the pumping rod in the rod pumping system and bigger influence to underground pump efficiency. It is characterized in that a sucker rod buffer made of elastic components is used to change the elastic modulus of sucker rod so that the natural frequency of sucker rod satisfies the formula (1) and then it can add the over-stroke to the utmost extent, improve the output, save energy and decrease consumption.

Owner:DAQING OILFIELD CO LTD

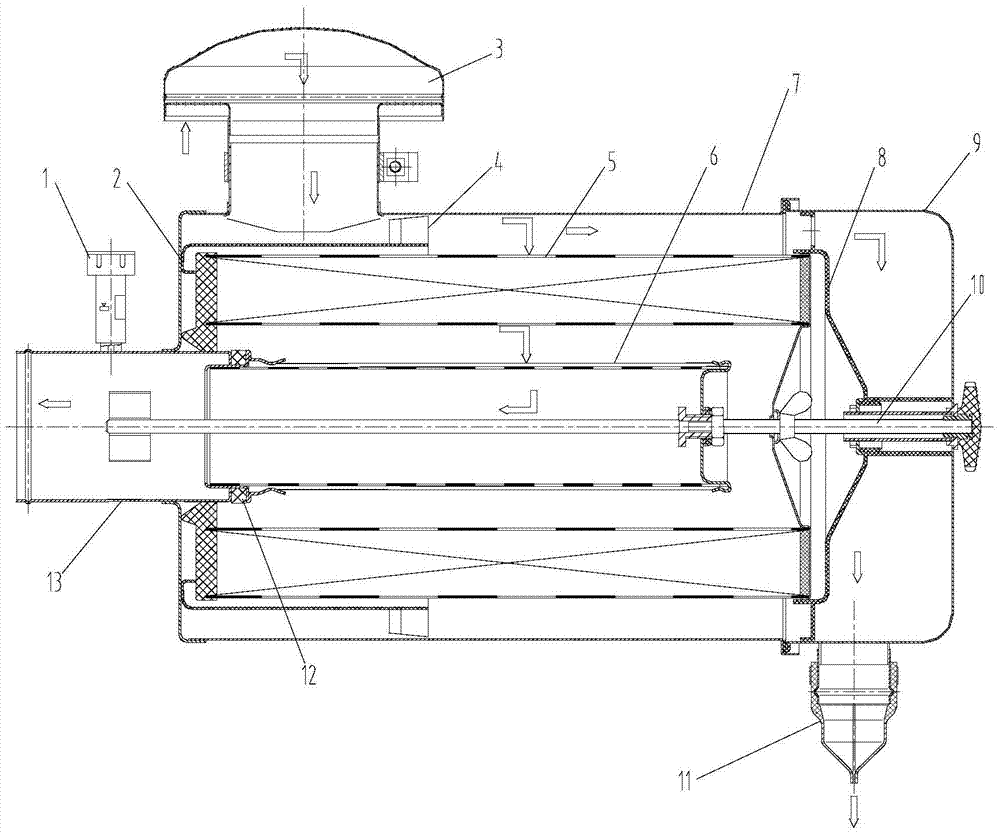

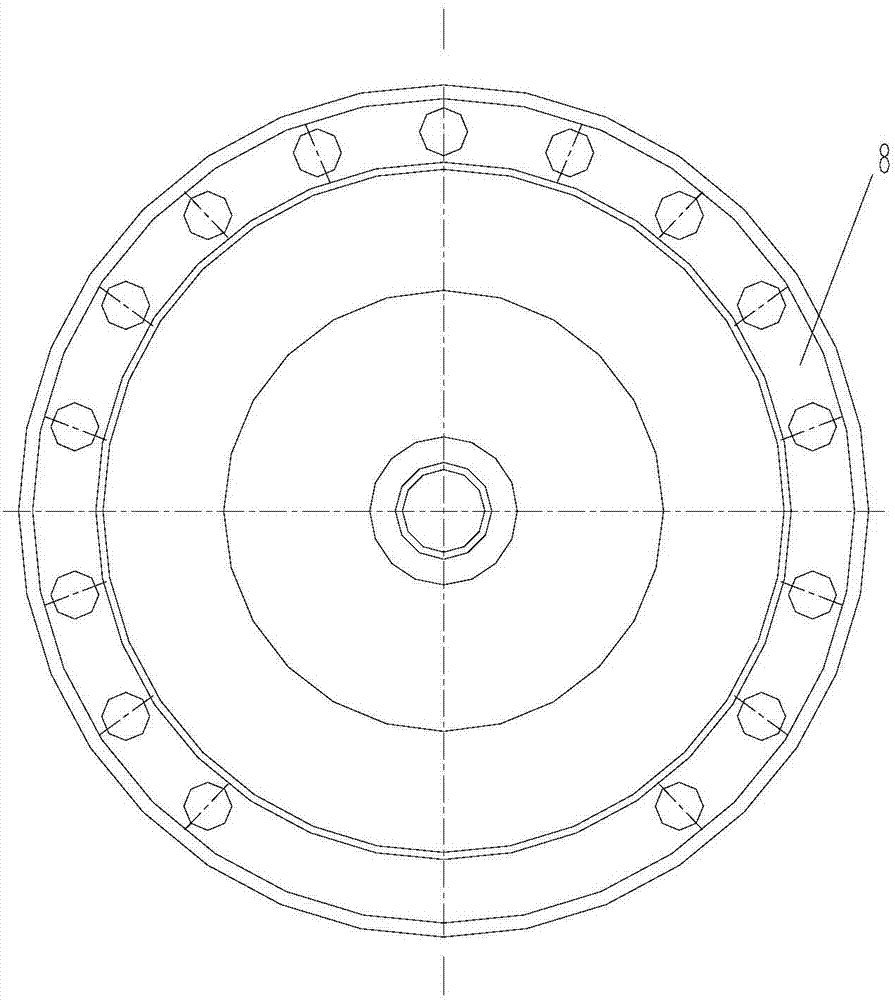

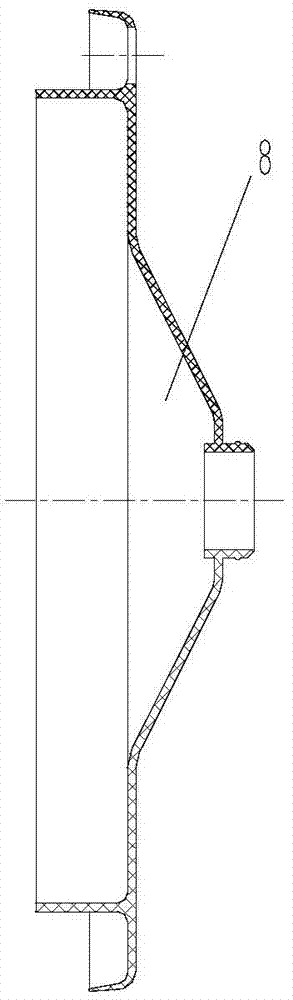

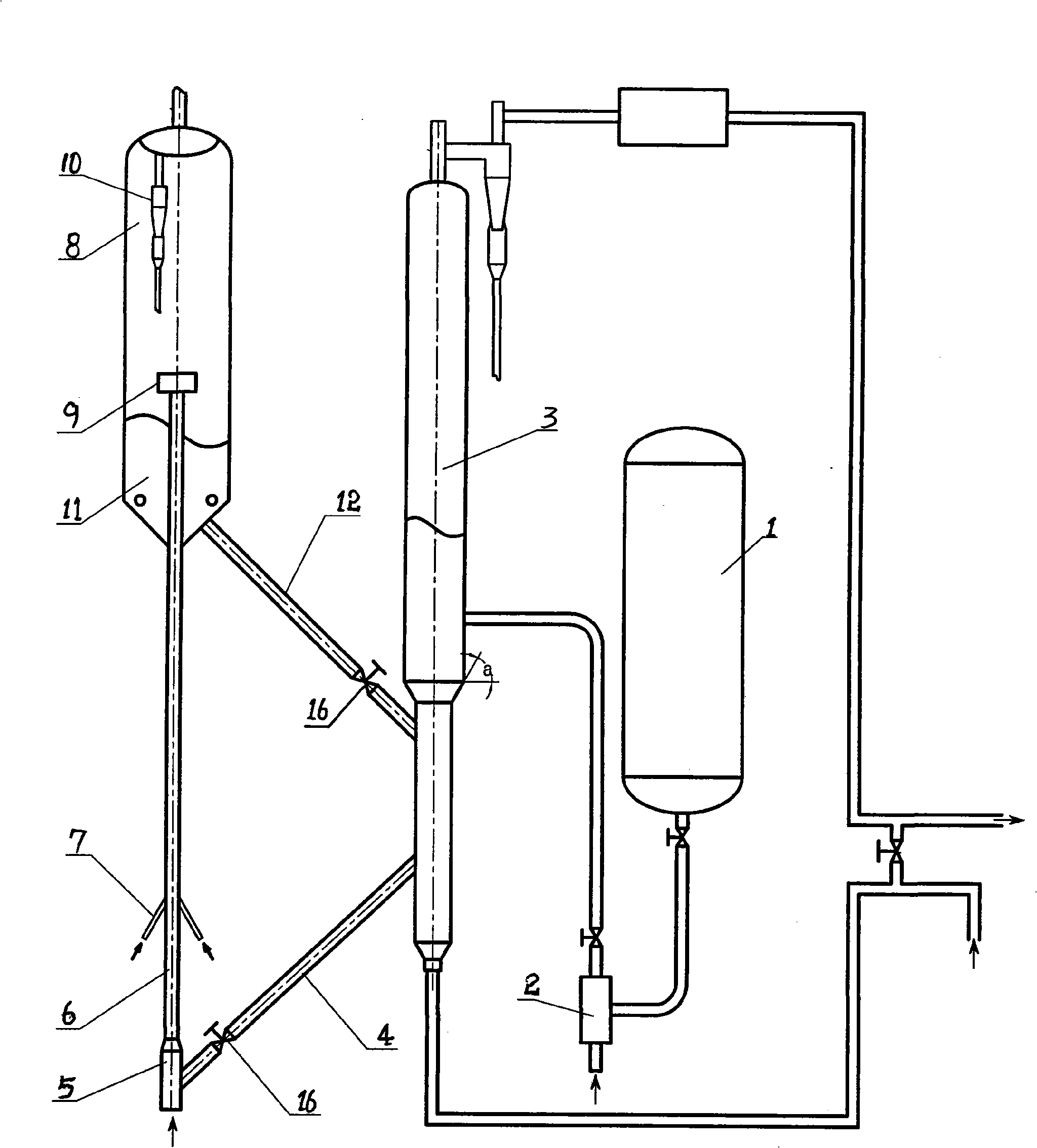

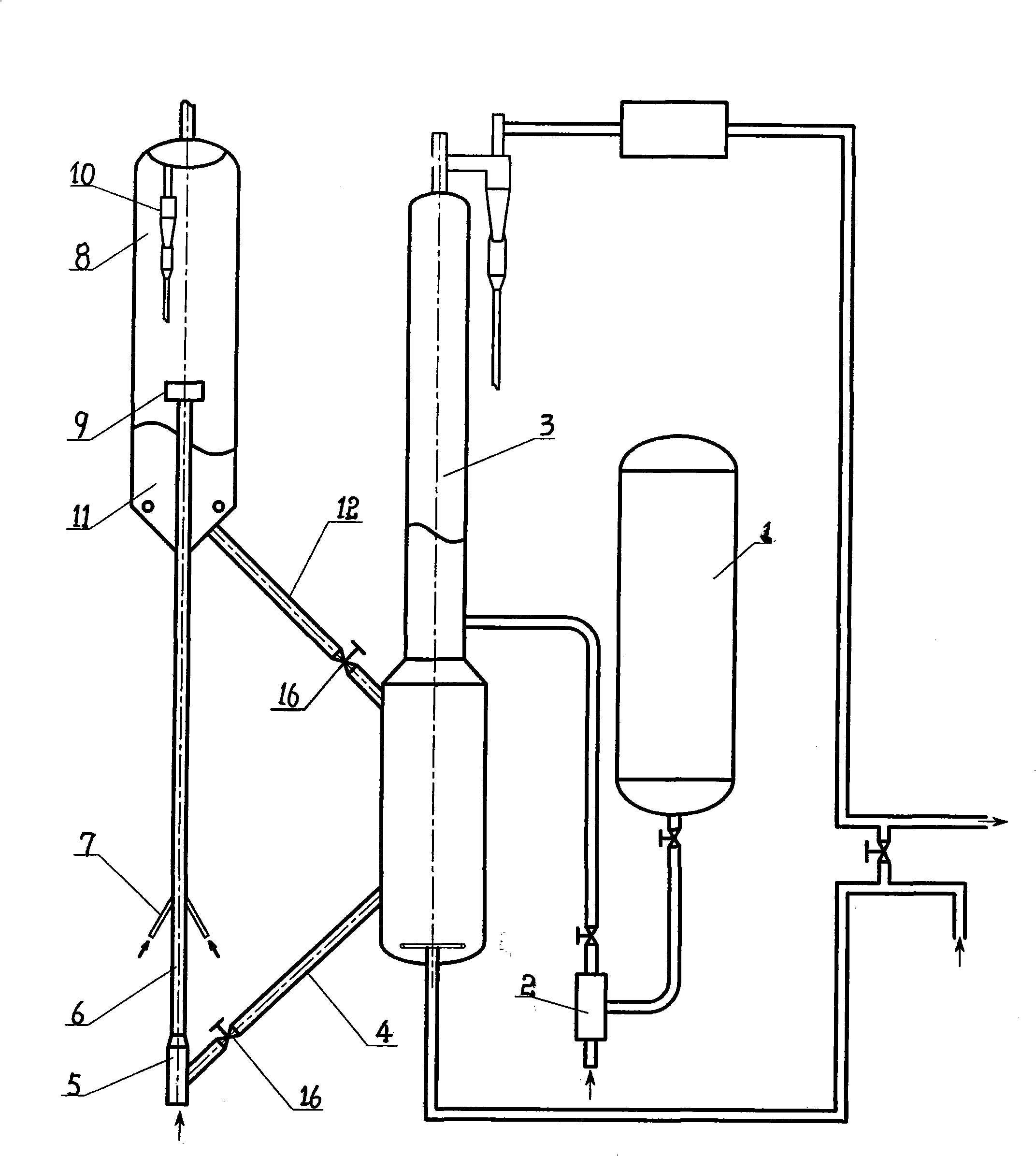

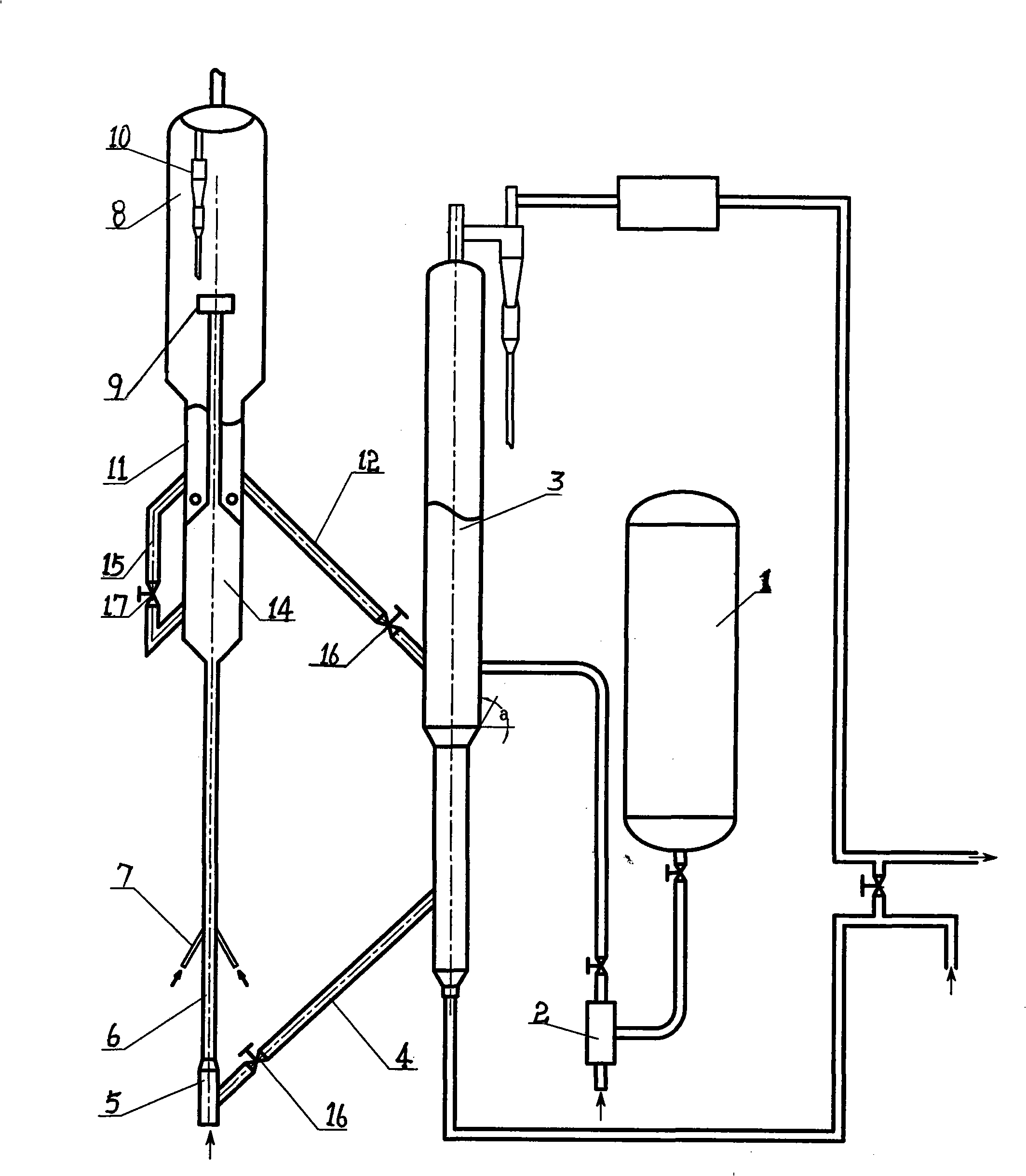

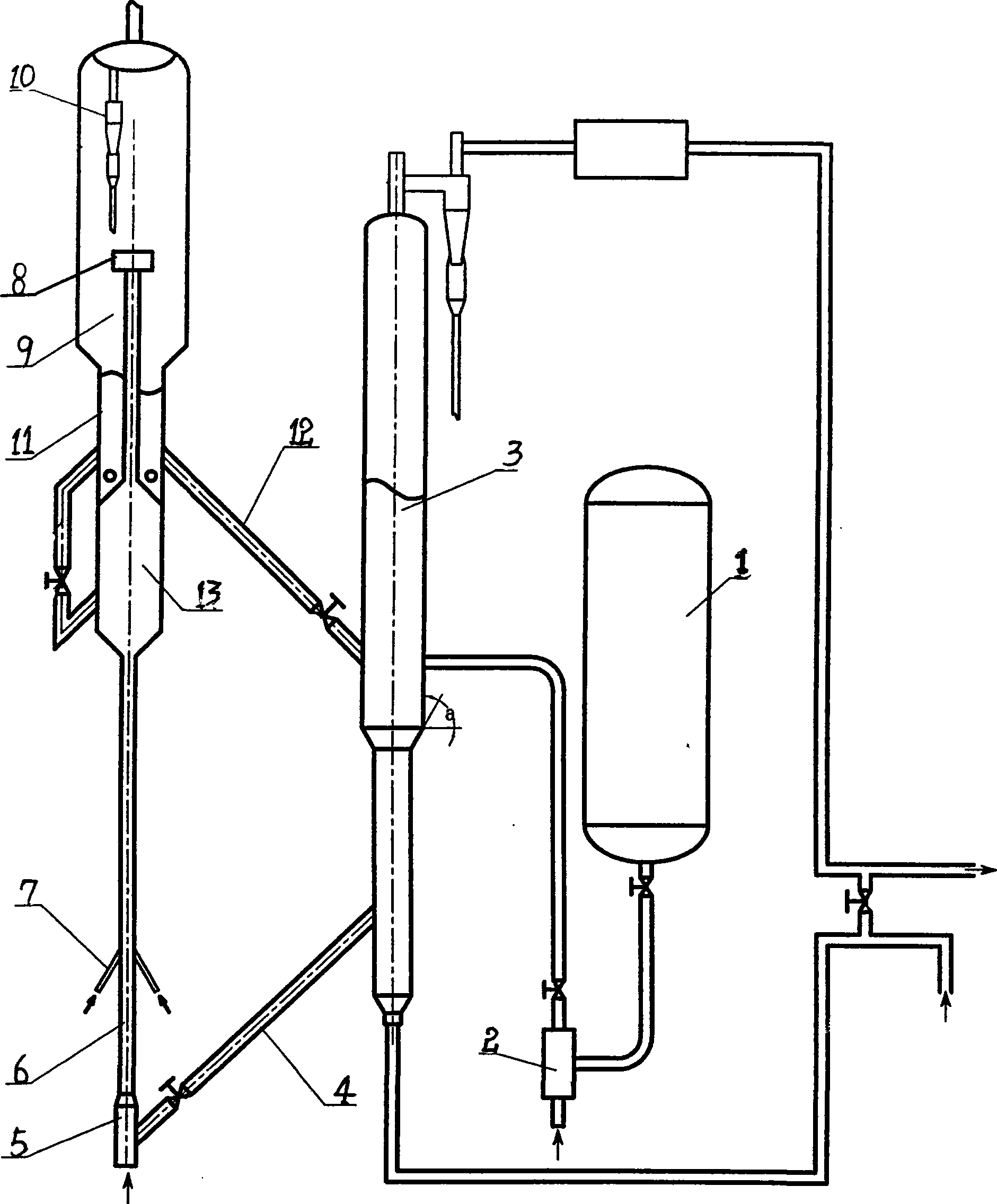

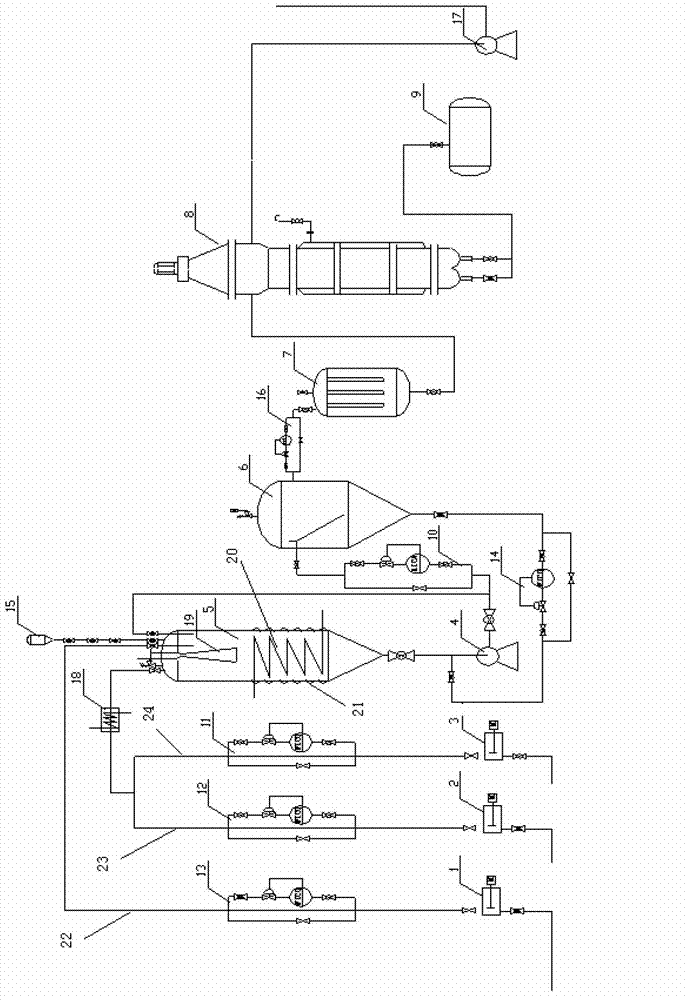

Equipment for preparing carbon disulfide with circulating fluidized bed

The invention relates to an apparatus for producing a compound containing carbon and sulfur, in particular to an apparatus for preparing carbon bisulfide with a circulating fluidized bed. The apparatus solves the disadvantages of the existing carbon bisulfide production process and equipment and comprises a storage hopper, a feeder and a fluidized bed furnace, a hot carbon pipeline is arranged under the fluidized bed furnace, the other end of the hot carbon pipeline is communicated with a pre-raiser, the upper part of the pre-raiser is connected with a riser which is provided with a nozzle, the upper end of the riser extends into a settler, the end of the riser is provided with a quick separation device, the internal top part of the settler is provided with a cyclone separator, the internal lower part of the settler is provided with a stripping section, and the lower part of the stripping section is provided with a cold carbon pipeline. By adopting the pre-raiser, the riser and the fluidized bed coating, the apparatus of the invention improves the contact efficiency of reactants; the sulfur can be a liquid state, the temperature is lower, the apparatus is simple; the arrangement of the stripping section can reduce pollution, and improve product yield; the apparatus has the advantages of simple structure, low cost, easy production, and is beneficial to realizing the continuous and automatic production and environmental protection treatment in course of production.

Owner:孔庆然

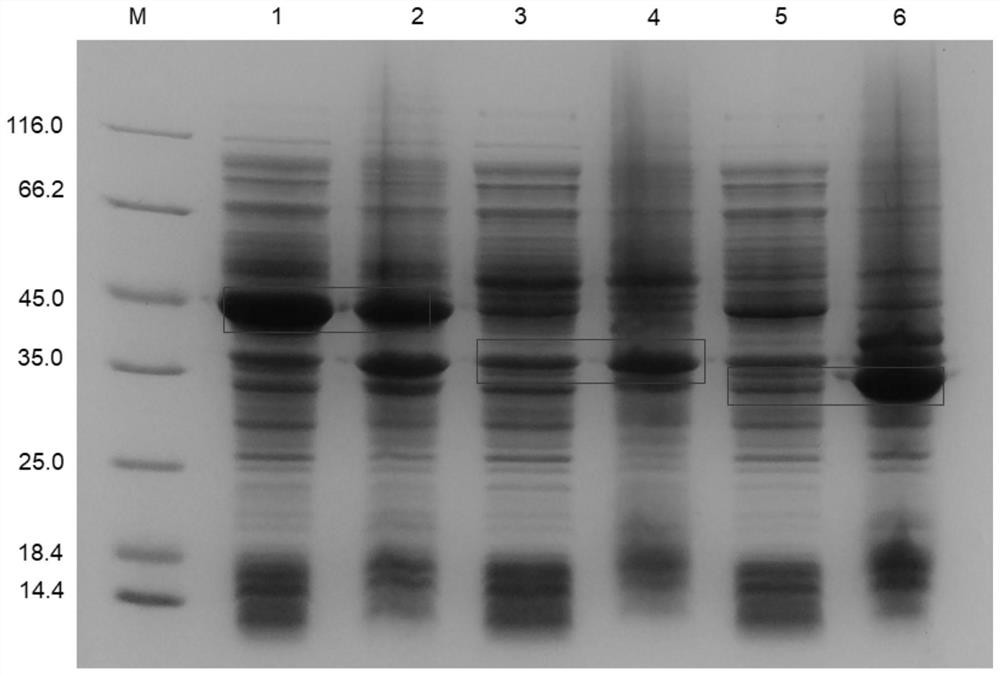

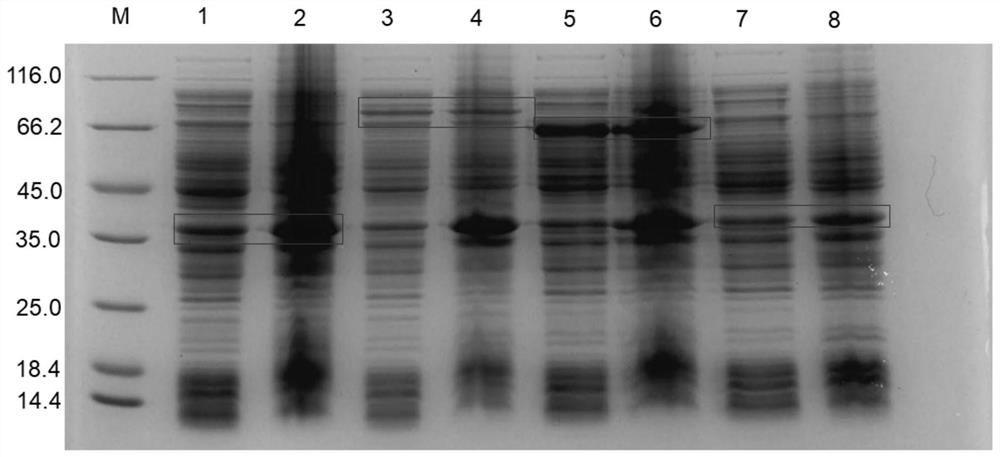

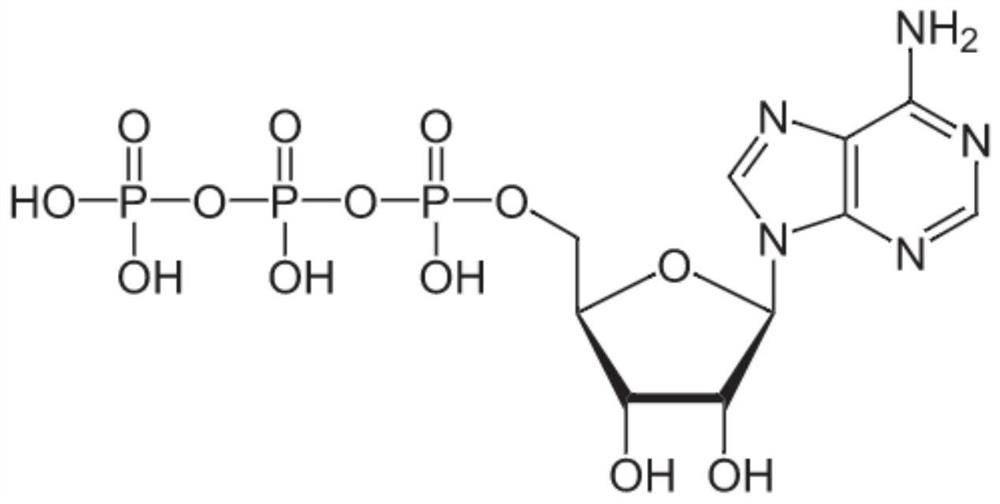

Method for preparing cyclic adenosine monophosphate by adenylate cyclase

PendingCN112063670AImprove stabilityExtended half-lifePhosphorus-oxygen lyasesFermentationCyclaseAdenosine

The invention discloses a method for preparing cyclic adenosine monophosphate by adenylate cyclase. The method comprises the following steps that the adenylate cyclase serves as a catalyst, adenosinetriphosphate serves as a substrate, and in the presence of Mg <2+>, a reaction solution containing the cyclic adenosine monophosphate is obtained. According to the adenylate cyclase, an amino acid sequence as shown in SEQ ID NO.14 is provided, the stability is good, the half-life period is long at medium and low temperatures, ATP can be efficiently catalyzed to generate cAMP in one step at mediumtemperature, a substrate conversion rate reaches 90 % or above, the advantages of simple industry, mild conditions, short period, few by-products and the like are achieved, the clean and pollution-free effects are achieved, and the energy conservation, consumption reduction and emission reduction in the cAMP production process can be realized.

Owner:杭州美亚药业股份有限公司

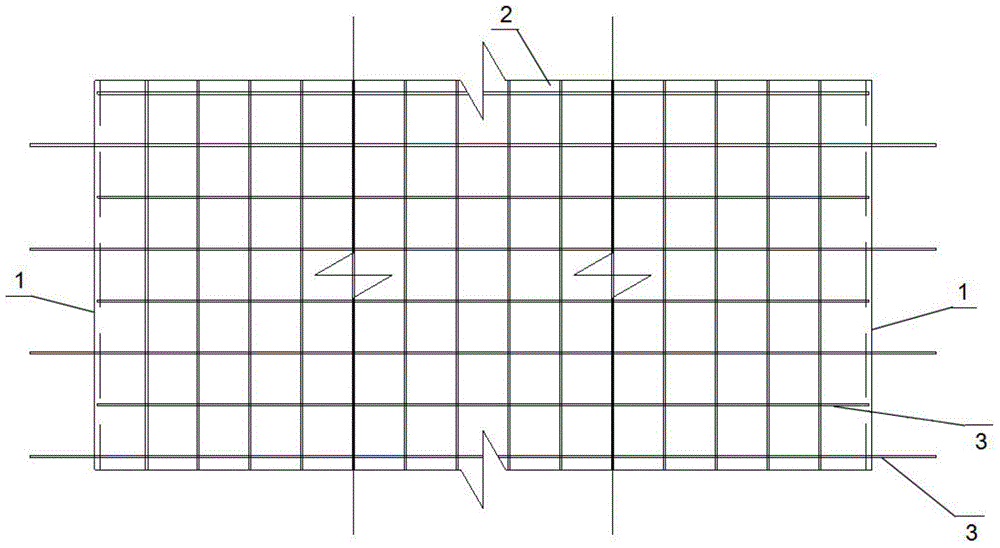

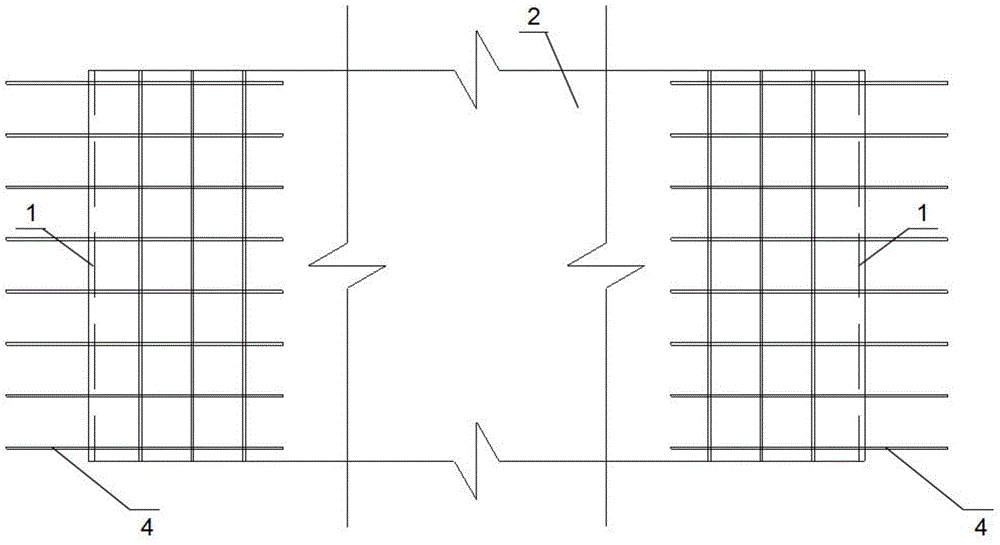

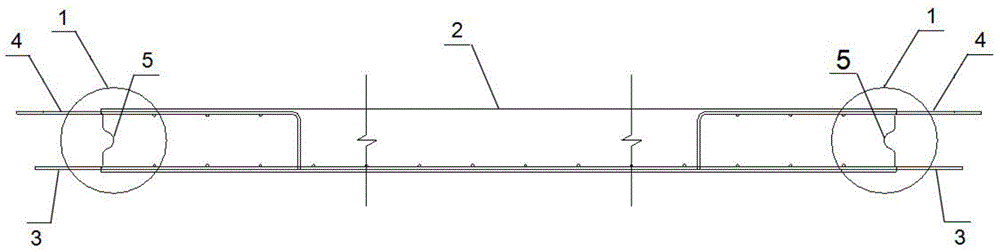

Assembled integrated type prefabricated concrete floor slab and connection method thereof

The invention relates to an assembled integrated type prefabricated concrete floor slab and a connection method thereof, and belongs to the field of buildings. A prefabricated concrete floor slab body or a plurality of prefabricated concrete floor slab bodies are connected into the assembled integrated type prefabricated concrete floor slab through nodes on a support and assembling nodes; the prefabricated concrete floor slab bodies comprise a prefabricated concrete floor slab body of which the two ends are floor slab support ends, a prefabricated concrete floor slab body of which one end is a floor slab support end and the other end is a floor slab assembling end for two prefabricated concrete floor slab bodies, and a prefabricated concrete floor slab body of which the two ends are floor slab assembling ends for the two prefabricated concrete floor slab bodies. Compared with the prior art, the assembled integrated type prefabricated concrete floor slab has the advantages that the quality and the reliability of the concrete floor slab are obviously improved; meanwhile, the assembled integrated type prefabricated concrete floor slab is conveniently and quickly produced, easy to transport and hoist and simple and convenient in design and meets a modular system; during construction and mounting, the costs of all relevant processes of engineering construction can be reduced, so that high quality, high efficiency and low consumption of engineering construction are realized.

Owner:孟凡林

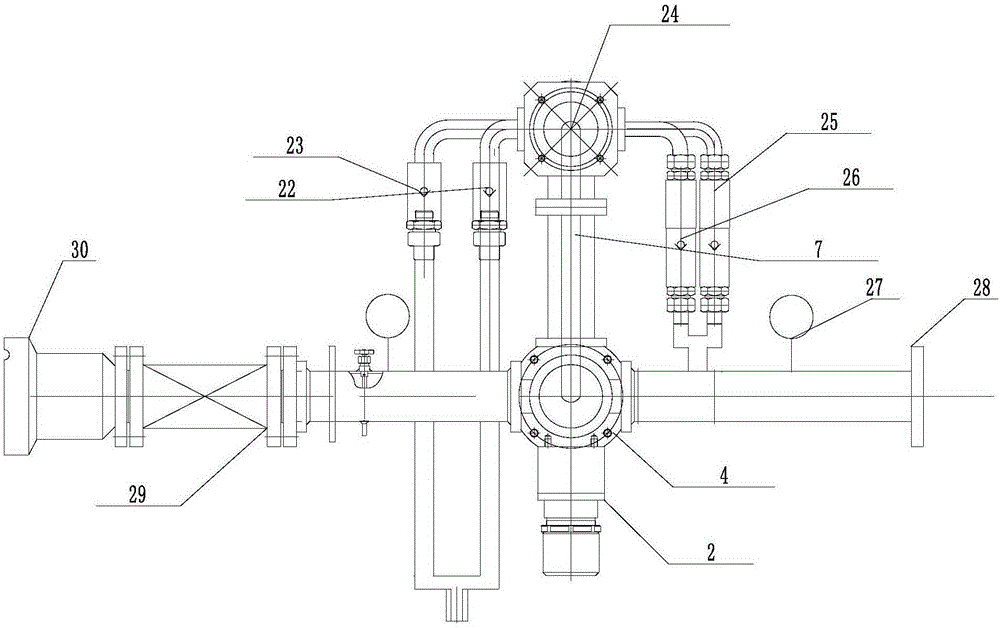

Self-controlled oil well casing gas recycling device

ActiveCN105178919AAchieve production management goalsAvoid pollutionFluid removalConnection typeHydraulic cylinder

The invention discloses a self-controlled oil well casing gas recycling device. A liquid feeding tee joint and a stroke push rod sealer are respectively connected to the front end and the rear end of a series-connection type piston pull rod hydraulic cylinder; a push rod reversing rocker arm rack is connected between the stroke push rod sealer and a reversing valve left end and right end reversing push rod sealer; liquid feeding and draining manifolds (A and B) are arranged at the lower end of the hydraulic cylinder; upper portions of two gas feeding one-way valves are connected with a gas feeding hole of the hydraulic cylinder; lower portions of the two gas feeding one-way valves are connected with a casing gate of a wellhead Christmas tree; upper portions of two gas discharging one-way valves are connected with a gas discharging hole of the hydraulic cylinder; lower portions of the two gas discharging one-way valves are connected with a liquid draining tee manifold connected to a T port of a reversing valve; a liquid feeding one-way valve of a liquid inlet of a P port of the reversing valve is connected with a production liquid draining gate of the wellhead Christmas tree; and the liquid draining tee manifold at the position of a liquid draining manifold of the T port of the reversing valve is connected with a production main line. Problems that oil well casing gas builds the pressure for a long time, an oil well working fluid level is reduced, capacity is reduced, and gas locking is caused are solved.

Owner:檀长江

Process for preparing carbon disulphide by using circulating fluid bed

The invention relates to a production method for a compound comprising carbon and sulfur, in particular to the technology for preparing carbon bisulfide by a circulating fluid bed, which aims at solving the problems of high energy consumption, discontinuous production process, serious environment pollution and the like in the existing production technology. The method comprises the following steps: carbonic solid substances are sent to a fluidized bed furnace, the heated carbonic solid substances are then sent to a pre-raiser, a lift pipe and a fluidized bed layer and contact and react with sulfur, a quick separation device and a settler are used for separating the gaseous carbon bisulfide out, and the rest unreacted carbonic solid substances fall in a stripping section under the settler, and return to the fluidized bed furnace to be heated after the entrained carbon bisulfide gas is stripped by inert gases. The method has the advantages of greatly improving the contact efficiency of the reactant, requiring lower temperature owing to liquid sulfur, having simple device, simple structure and low construction cost, reducing pollution and improving product yield thanks to the arrangement of the stripping section, which is beneficial to the realization of continuous and automatic production and the environmental protection treatment in the production process.

Owner:孔庆然

Furnace calcification desulphurization mineral powder material

InactiveCN102453584AIncrease contact areaImprove adsorption capacitySolid fuelsParticulatesCalcification

The invention relates to a furnace calcification desulphurization mineral powder material, comprising the following components in percentage by weight: 10-40 parts of alkaline tuff, 5-10 parts of bluestone, 10-25 parts of horse tartar, 15-35 parts of limestone and 10-30 parts of silica. Crushed alkaline tuff, bluestone, horse tartar, limestone and silica are weighed and prepared according above weight percentages. All the raw materials are crushed and dried, the mixture is ground into 50-150 meshes in a ball grinding mill, and no particulate mineral material less than 50 meshes exist, and thus the product is obtained. The alkaline tuff is utilized, and based on adsorbability, hydroscopicity and expansibility of the alkaline tuff, contact area with SO2 gas and adsorption capacity to SO2 gas in a desulphurizing process are improved, and desulphurization degree can reach 97%.

Owner:QUJING HUSN CHEM RAW MATERIALS PLANT

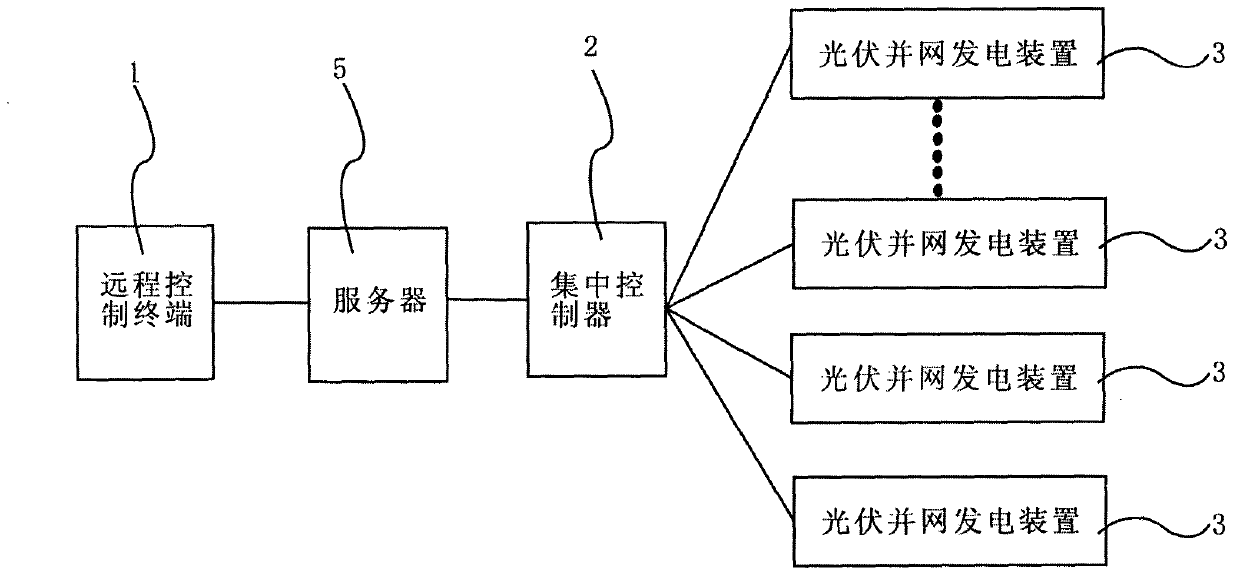

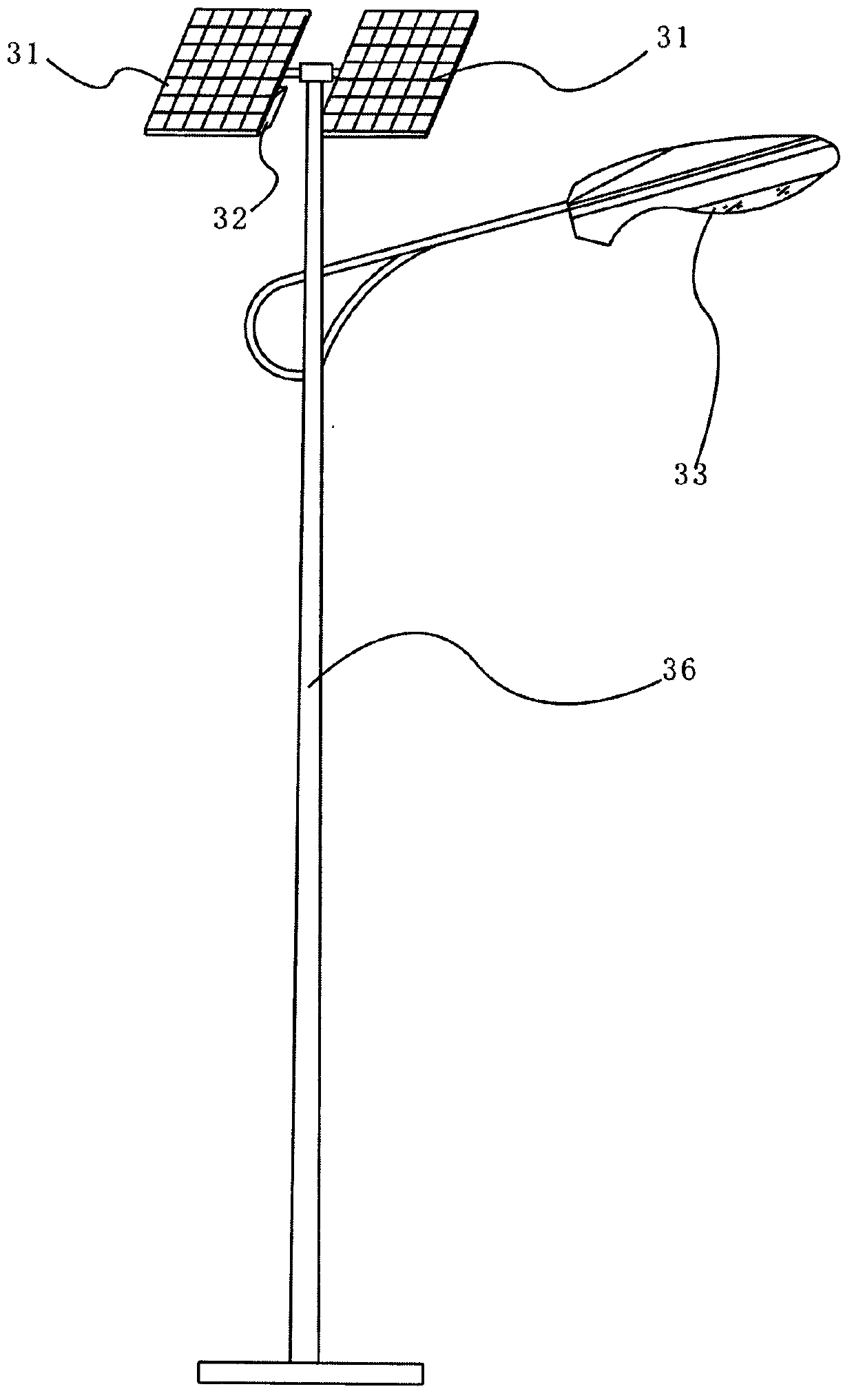

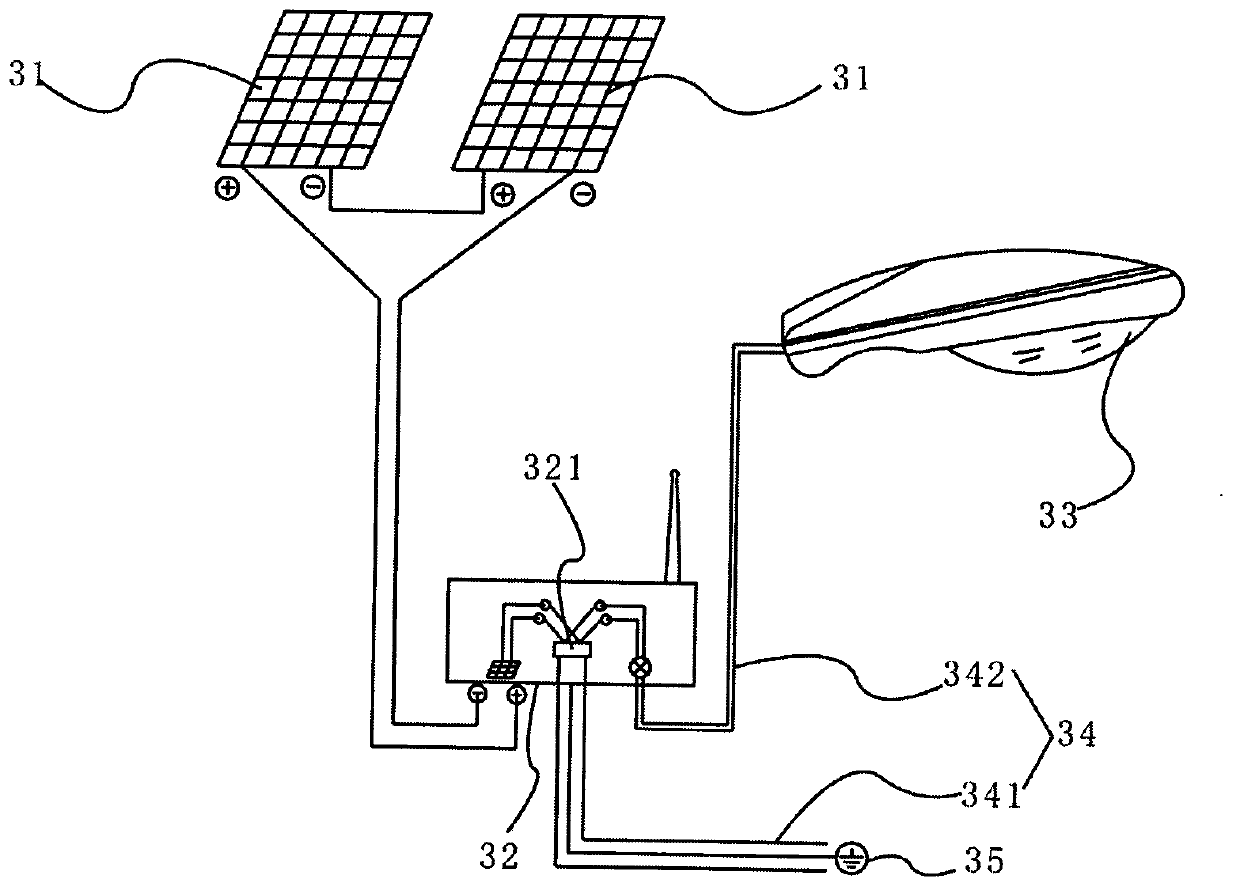

Solar grid-connected control system capable of being monitored from remote used for street lamp

InactiveCN103631215ARealize real-time monitoringRealize monitoringSingle network parallel feeding arrangementsPhotovoltaic energy generationSolar cellAlternating current

The invention discloses a solar grid-connected control system capable of being monitored from remote used for street lamps. The system comprises a remote control terminal, a server, an integrated controller, and a plurality of grid-connected photovoltaic power generation devices. The integrated controller is connected with the server in a communication manner. The remote control terminal is connected with the server in a communication manner. The integrated controller is connected with the plurality of grid-connected photovoltaic power generation devices in a communication manner. Each grid-connected photovoltaic power generation device comprises solar cell panels, a grid-connected inverter, a lighting fitting, a transmission and distribution line, a power grid, and a lamp-post. The grid-connected inverter is integrated with a communication control function. The system monitors and manages the grid-connected photovoltaic power generation devices through remote control. In daytime, the grid-connected inverter converts direct current provided by the solar cell panels to stable alternating current, and generates power for the power grid through the transmission and distribution line. At night, electricity in the power grid is transmitted to the lighting fittings through the transmission and distribution line, realizing an illumination function of the lighting fittings.

Owner:黄涛

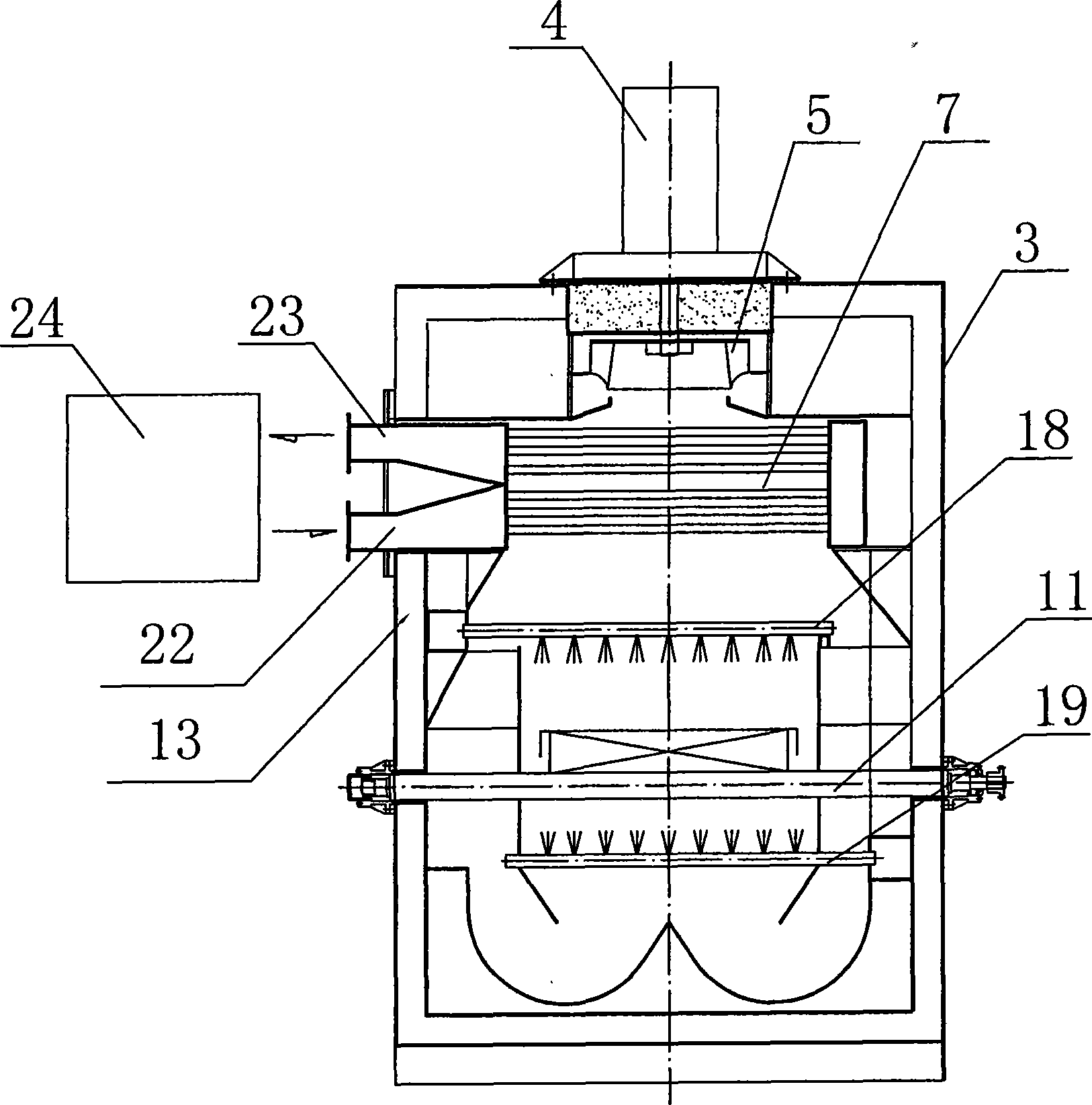

Energy-saving gas glass melting furnace

InactiveCN103922561ASimplify the preprocessing processImprove fuel efficiencyGlass furnace apparatusExhaust gasGlass melting

The invention relates to a glass melting furnace and provides an energy-saving gas glass melting furnace. The glass melting furnace is provided with a furnace body, wherein a gas burner is at least arranged at one end of the furnace body; at least one tail gas passage is formed in the sidewall of the furnace body; a combustion-supporting air preheating tube is spirally arranged inside the tail gas passage; combustion-supporting air is introduced into the combustion-supporting air preheating tube through a draught fan with a variable frequency regulation function, preheated in the tail gas passage and then sent to the gas burner; gas is regulated by an intelligent gas valve, then sent to the gas burner, mixed with the high-temperature combustion-supporting air according to a proportion, injected into the melting furnace and fully and completely combusted; an intelligent controller is arranged for intelligently regulating the intelligent gas valve and a variable frequency controller according to a temperature value and a set temperature value sent from a temperature sensor arranged in the furnace body so as to regulate the flow rate and ratio of the combustion-supporting air to the gas, so that the gas is combusted fully and completely and the temperature in the furnace in uniform so as to improve the quality of liquid melt. By adopting the scheme, energy conservation, consumption reduction, no pollution and high yield are realized.

Owner:佘万强

Prebaked aluminum electrolytic tank parameter measuring method and its device

The invention discloses a method for measuring technological parameter for prebaked cell for aluminum-reduction, comprising following steps: inserting measuring probe driven by stepper motor into electrolyser, the impulse frequency of rotation rate for stepper motor continuously input into monolithic machine for counting and storing; checking electrolyte liquid surface, anode liquid surface and cathode liquid surface by relative checking circuit according to voltage change feature of different layer in aluminum cell solution, inputting relative measuring signal into monolithic machine; monolithic machine counting out polar distance, aluminum concentration and electrolyte concentration according to set mathematical model; the measured voltage is cathode voltage when the down vertical distance of measuring probe in aluminium liquid is 60- 100 mm; the polar distance, aluminum concentration, electrolyte concentration and electrolytic temperature are input into display screen by monolithic machine for real time display; the over travel-limit switch resetting measuring probe. The measuring device mainly comprises sampling machine and controlling tank; controlling tank is equipped with polarization layer measuring circuit and spacing measuring cathode pressure differential circuit; and sampling machine comprises data collecting device and operation power device.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

Production process of anti-aging agent

ActiveCN103204778AReduce consumptionHigh activityPreparation by reductive alkylationAlcoholMethyl isobutyl ketone

The invention relates to a production method of anti-ageing agent N-(1,3-dimehtyl butyl)-N'-phenyl p-phenylenediamine. Ketoamine is adopted for condensing and catalyzing hydrogenation catalyst, so that the amount that the methylisobutyl ketone is converted into alcohol is greatly reducered, and the ketoamine proportion is lowered to 1.05 from 3.5 in the original process, and therefore, the consumption of ketone is lowered, aftertreatment load is lowered and energy consumption is lowered. Besides, a gas-liquid-solid three-phase mixer can be used for greatly improving the mass transfer effect, so that the hydrogenation reaction is easier to implement, and therefore, the device utilization efficiency is improved and the device investment is reduced.

Owner:SHANDONG SUNSINE CHEM

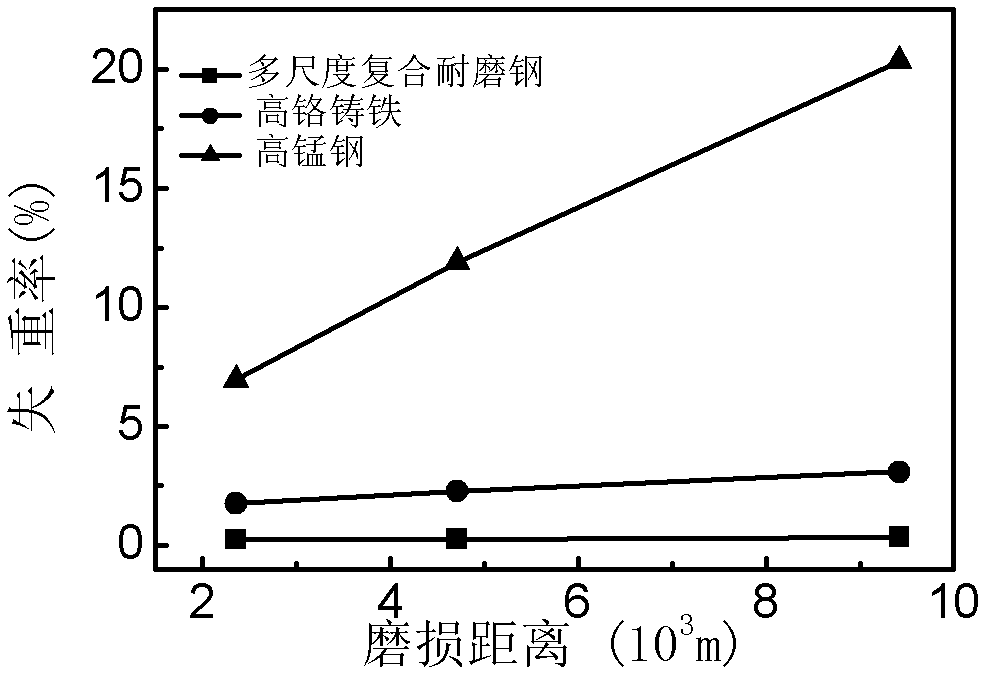

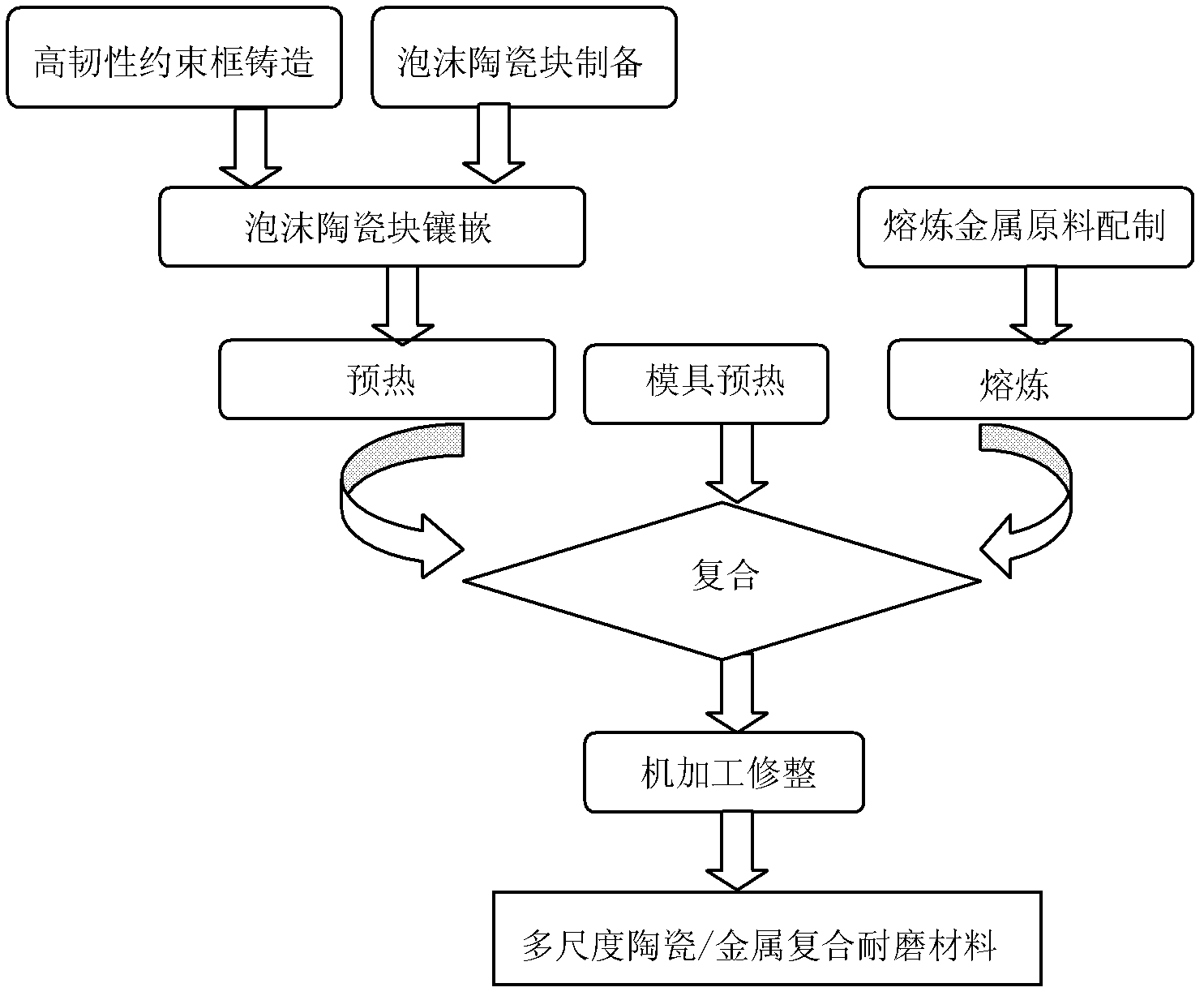

Multi-scale ceramic/metal composite abrasion-resistant material and preparation method thereof

ActiveCN102357652BSave resourcesRealize energy savingGearingCylindersComposite constructionSocial benefits

The invention relates to a preparation technology of a high-performance and abrasion-resistant material, in particular to a multi-scale ceramic / metal composite abrasion-resistant material and a preparation method thereof. The resource-saving high-performance and abrasion-resistant material is obtained by using a high-performance foamed ceramic / metal double continuous phase composite material as an abrasion-resistant matrix, using a high-toughness metal as a constraint framework and using a casting method. The abrasion-resistant material has multi-scale composite structural characteristics, the abrasion-resistant unit is compounded in micron and millimeter scales, and the abrasion-resistant unit and the constraint framework are compounded in a centimeter scale. The structure can well realize reasonable matching of high abrasion resistance and high strength and toughness of the material, the abrasion resistance and the impact toughness of the material are respectively over 7 times and 10 times those of high-chromium cast iron, and meanwhile, scarce alloy elements (Cr, Ni, Mo and the like) are not used. The material is applied to large engineering equipment of crushing, excavating, transporting and the like, is excellent in abrasion resistance, low in cost and convenient to use, greatly prolongs the service life, greatly improves the production efficiency, and has good social benefit and economic benefit.

Owner:LIAONING ZHUOYI NEW MATERIAL

Production method of polyaluminum chloride without heating

ActiveCN102275965ALess investmentLow investment costAluminium chloridesLiquid productAluminium chloride

The invention discloses a heating-free production method of polyaluminum chloride. The heating-free production method comprises the following steps of: firstly, diluting a raw material, i.e. hydrochloric acid, into a needed concentration, then adding bauxite under the condition of continuous stirring, adding a proper amount of calcium aluminate powder till the temperature of a reaction liquid rises to 84-87 DEG C, then automatically raising the temperature to 95-105 DEG C for reaction through heat release, observing the concentration of the reaction liquid after the reaction is ended, diluting the concentration of the reaction liquid to a needed concentration, then adding calcium aluminate powder for polymerization reaction, adjusting the concentration of the reaction liquid to a needed concentration after the reaction is ended, and obtaining a liquid product, i.e. the polyaluminum chloride. According to the heating-free production method of the polyaluminum chloride, steam heating isnot needed, thus heating equipment is omitted, and hydraulic acid steam generated in the reaction process is recycled through an absorbing device. Therefore, the heating-free production method disclosed by the invention has the advantages of being low in investment cost, saving energy, reducing consumption and emission, being beneficial to environmental friendliness and having obvious economic benefits and social benefits.

Owner:周松玉

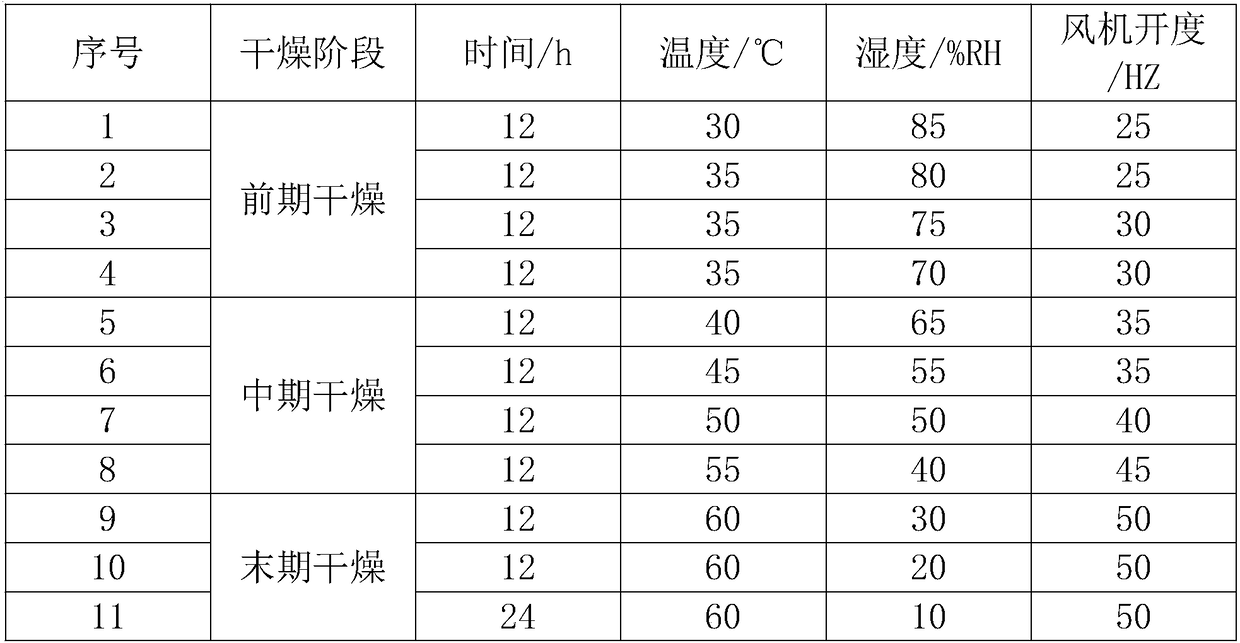

Rapid production technology of SCR (Selective Catalytic Reduction) denitrification catalyst

InactiveCN108212144AShorten the timeAchieve upgradeDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPre treatmentPre cooling

Owner:安徽弘昇环境工程科技有限公司

Sealing rapid cooling chamber

The invention relates to a sealed fast cooling chamber which mainly comprises a fast cooling chamber shell, a front door of the fast cooling chamber, a back door of the fast cooling chamber, a fan and fan blades. The fast cooling chamber shell, the front door of the fast cooling chamber and the back door of the fast cooling chamber form a sealed body, an upper blow-off nozzle and a lower blow-off nozzle which can be controllably opened and closed are arranged inside the inner cavity of the fast cooling chamber shell, the upper blow-off nozzle and the lower blow-off nozzle are oppositely arranged; the fan is arranged on the fast cooling chamber shell, an air inlet pipe is arranged under the air inlet of the fan blades, a cold-heat exchanger is arranged between the air inlet of the fan blades and the air inlet pipe, and air circulation is formed between the air inlet pipe and the air outlet pipe; the air outlet of the fan blades is respectively communicated with an upper air outlet pipe and a lower air outlet pipe, the upper blow-off nozzle is communicated with the upper air outlet pipe by an upper blow-off pipe, and the lower blow-off nozzle is communicated with the lower air outlet pipe by a lower blow-off pipe. The sealed fast cooling chamber has the advantages of providing a protective atmosphere fast cooling chamber with a novel sealed structure, solving the problem of uneven cooling, ensuring stable and reliable quality of the bright isothermal normalizing, and realizing the purposes of saving materials and reducing energy consumption.

Owner:HANGZHOU JINZHOU TECH CO INC

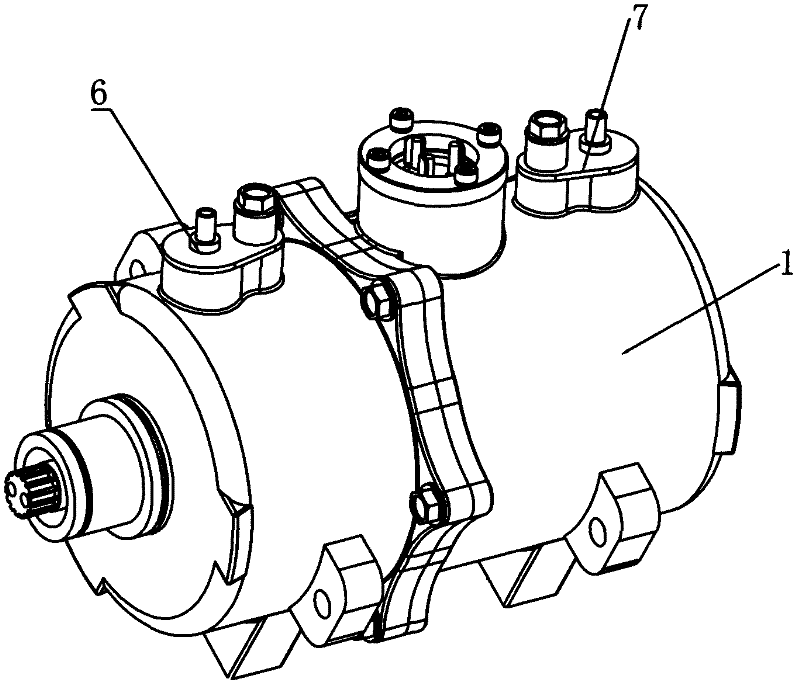

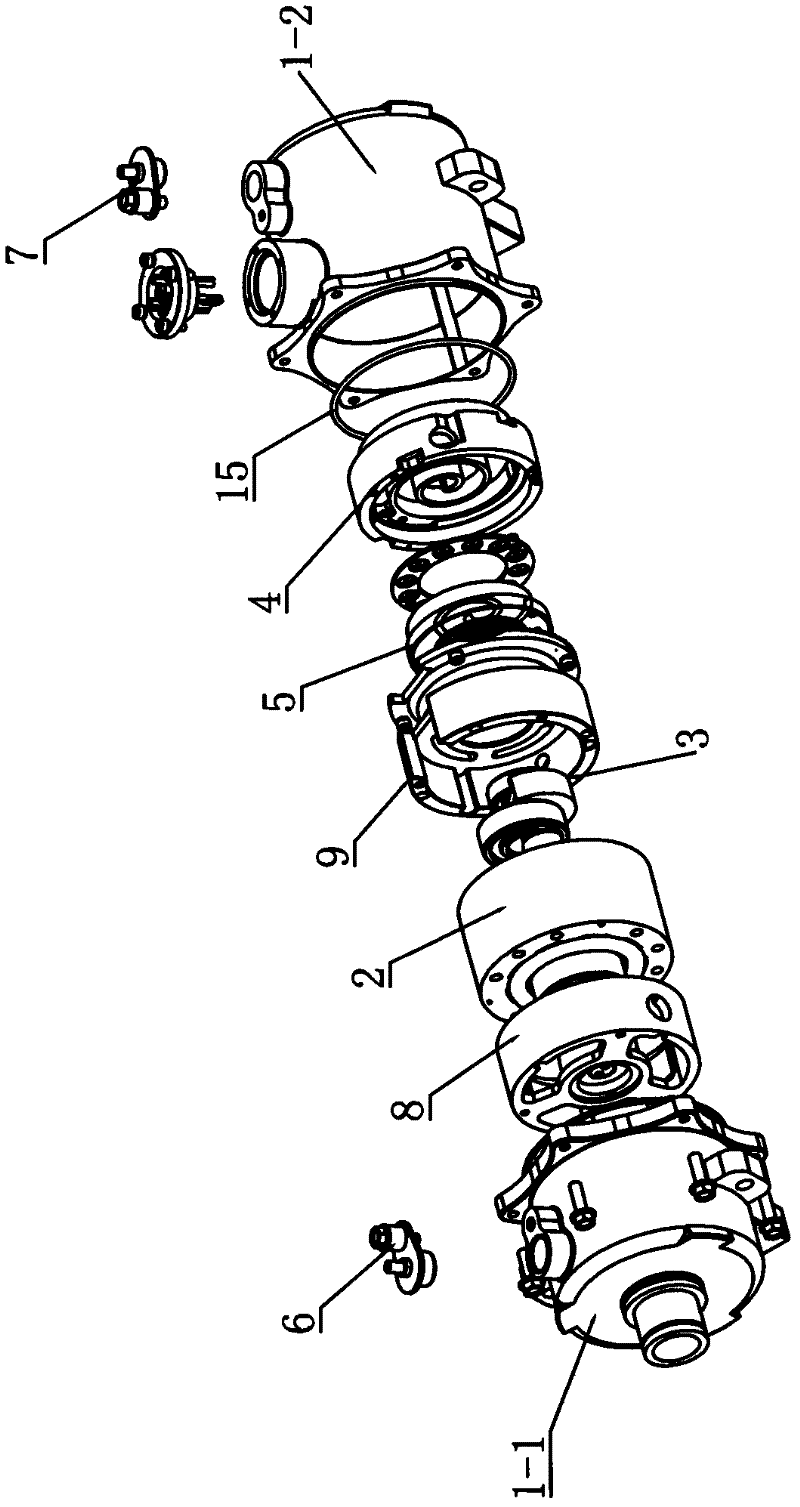

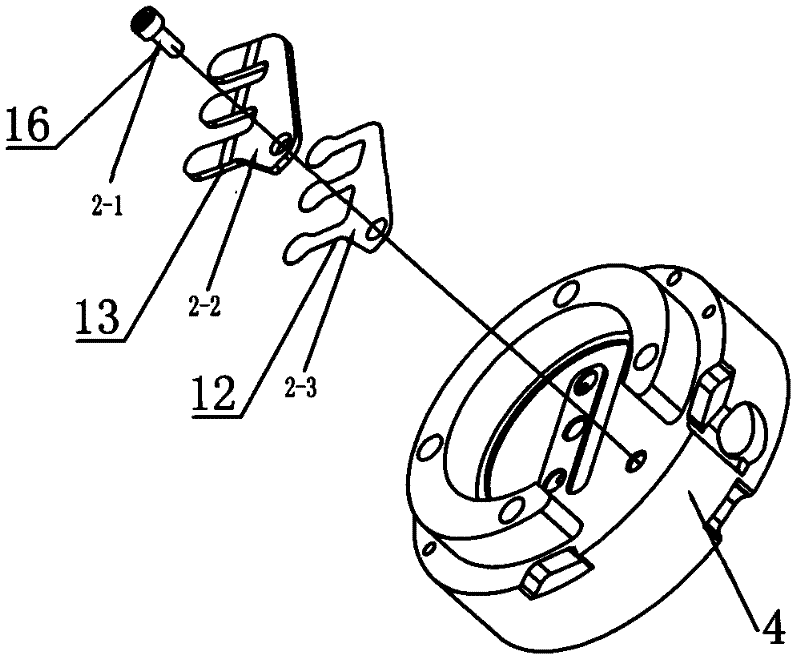

Vortex compressor with balancing and energy saving device

InactiveCN102367798ARealize the function of variable pressure and variable displacementRealize consumption reductionRotary piston pumpsRotary piston liquid enginesElectric machineSimulation

The invention discloses a balancing and energy saving device of a vortex compressor. The balancing and energy saving device comprises a static vortex disc and a moving vortex disk, wherein the static vortex disk and the moving vortex disk are arranged inside a casing, driven by a motor and respectively provided with vortex teeth which are meshed with each other; and the vortex teeth divide the interiors of the moving vortex disk and the static vortex disk into a plurality of compression chambers of which the volumes change along with the motion of the vortex teeth. The balancing and energy saving device is characterized in that more than two exhaust holes with different apertures and a valve assembly are arranged on the static vortex disk, the exhaust holes are communicated with the compression chambers, and the valve assembly comprises valve plates corresponding to the exhaust holes and travel limiters. According to the invention, the discharge capacity can be regulated in real time, the pressure and the discharge capacity can be changed according to system energy requirements so as to achieve the functions of consumption reduction and energy saving to the maximal extent.

Owner:FOSHAN GUANGSHUN ELECTRICAL EQUIP +1

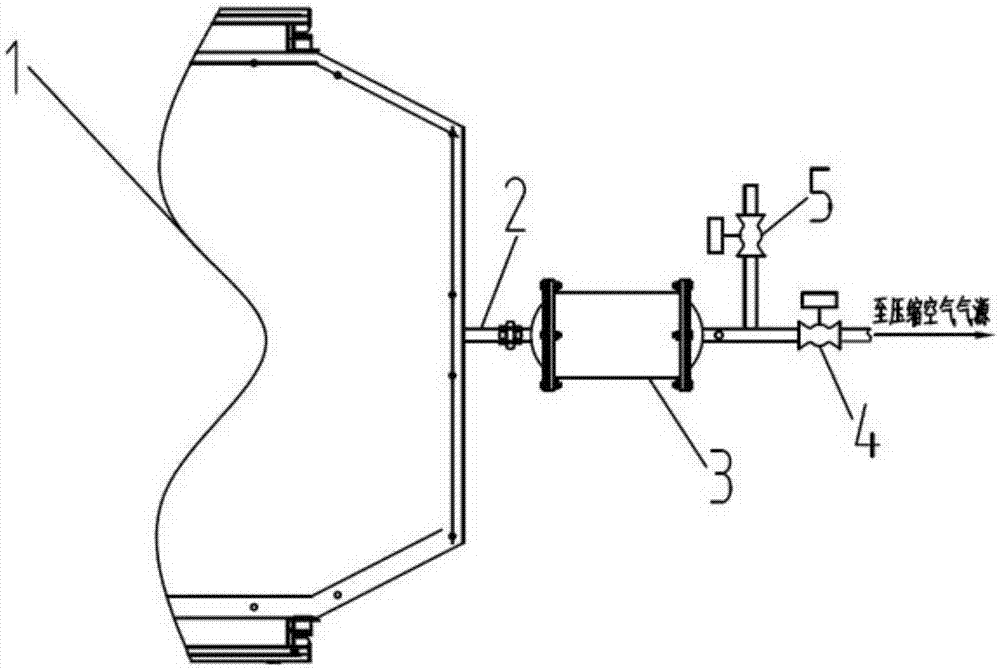

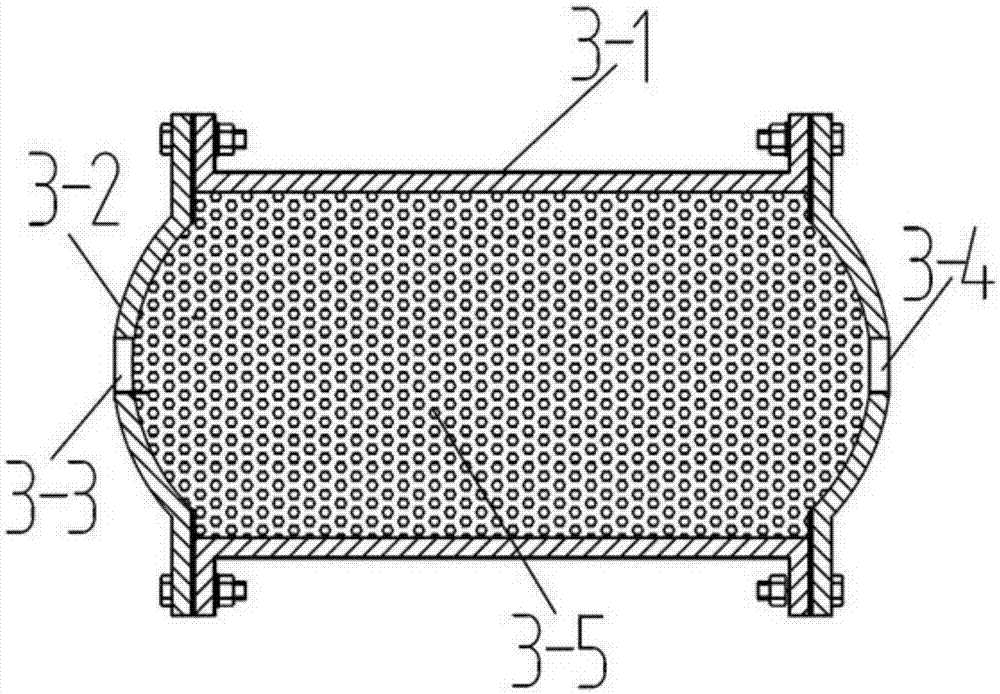

Energy-saving environment-friendly low-pressure die-casting machine heat-preserving furnace

The invention discloses an energy-saving environment-friendly low-pressure die-casting machine heat-preserving furnace. The die-casting machine heat-preserving furnace is provided with a furnace body air inlet / outlet hole, wherein the furnace body air inlet / outlet hole communicates with a regenerative chamber, a compressed air switch valve and a compressed air source in sequence through a pipeline; the furnace body air inlet / outlet hole also communicates with the regenerative chamber, an exhaust valve and the atmosphere in sequence through the pipeline; the regenerative chamber comprises a closed housing; a regenerator is arranged in the closed housing; and the closed housing is provided with a hot-end connection hole communicating with the furnace body air inlet / outlet hole, a hole communicating with the compressed air switch valve and a hole communicating with the exhaust valve. The die-casting machine heat-preserving furnace has the characteristics of energy conservation, emission reduction, consumption reduction and the like.

Owner:保定安保能冶金设备有限公司

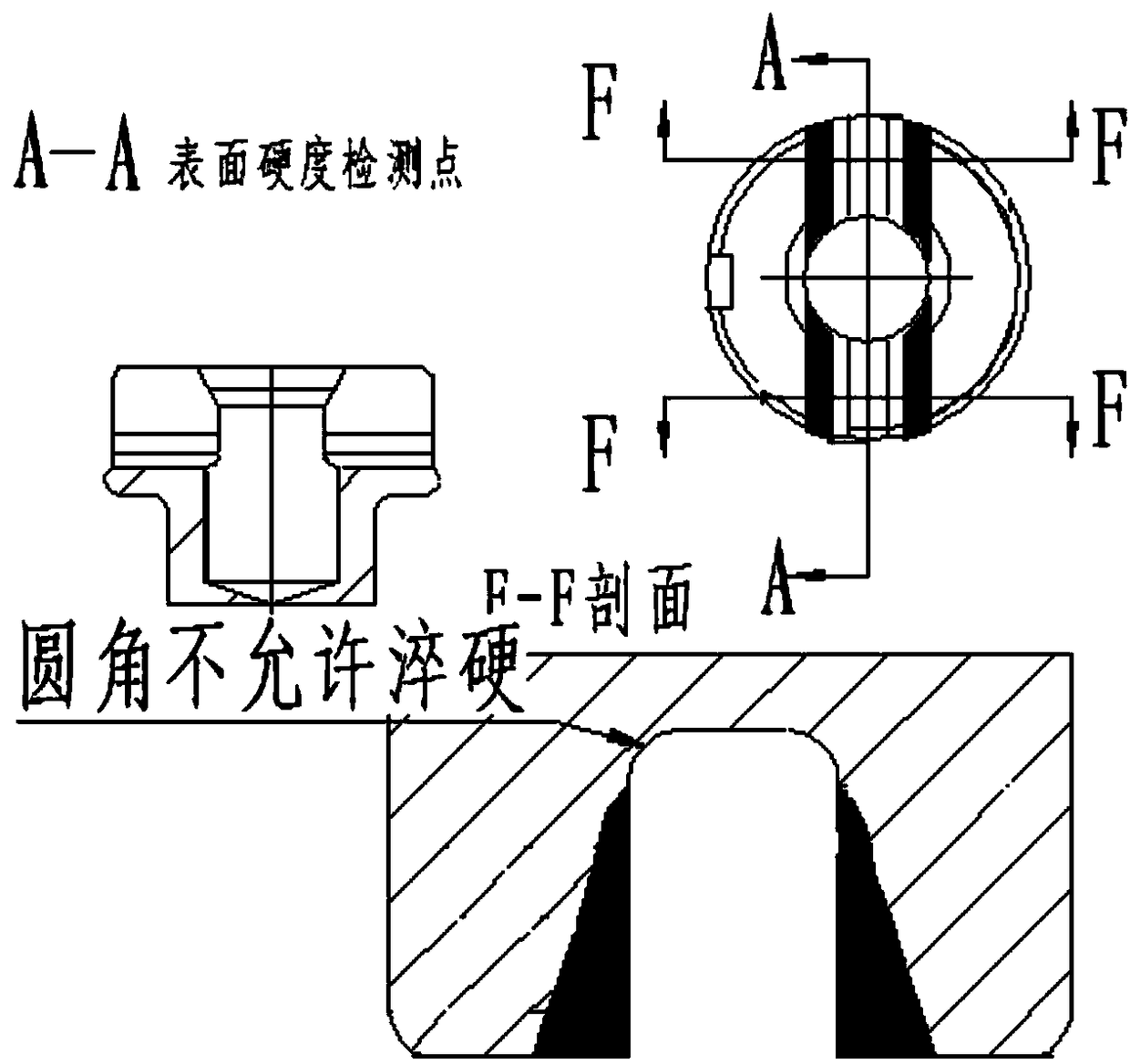

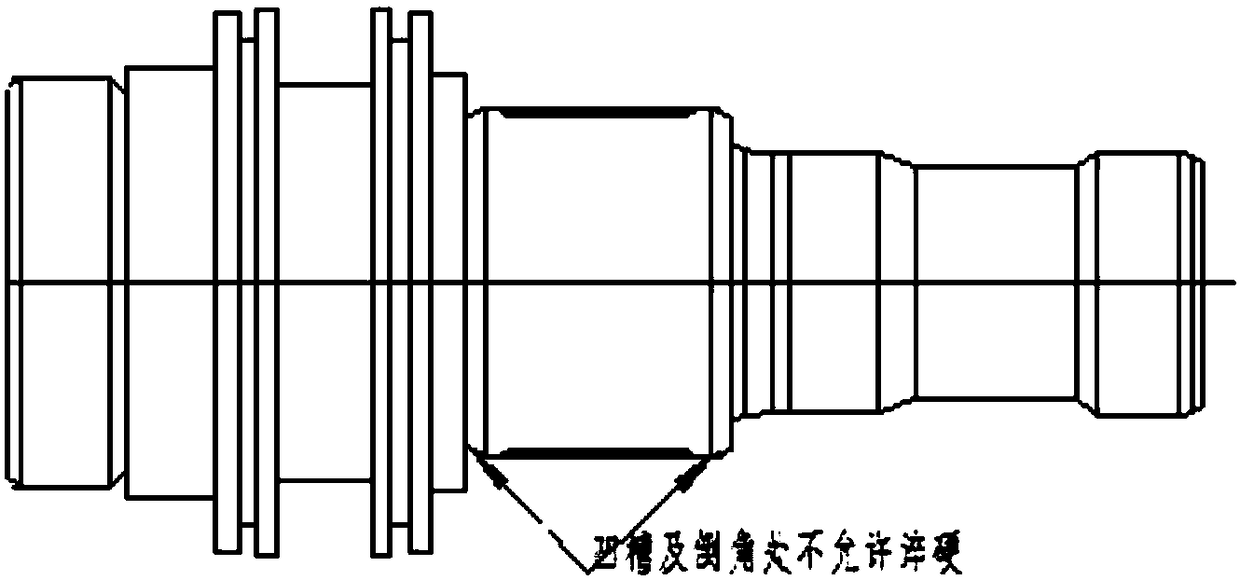

Induction heat treatment method for camshaft end piece

InactiveCN108823390AIncrease stiffnessIncrease shock loadIncreasing energy efficiencyFurnace typesEngineeringInduction hardening

The invention discloses an induction heat treatment method for a camshaft end piece. An induction heating apparatus with a magnetic field concentrating device is adopted to inductively quench and temper the notch and the outer circle of the camshaft end piece. The method includes the following steps: sleeving the induction coil of the induction heating device outside the notch and the outer circleof the camshaft end piece, performing heating under a certain direct-current voltage and a direct current, cooling the end piece by a quenching medium, keeping the temperature at a certain value to carry out tempering, and performing air cooling. The induction heat treatment method for the camshaft end piece improves the overall rigidity of the camshaft, reduces friction, makes the camshaft end piece withstand a high valve impact load, reduces the heat treatment energy consumption by 30%, makes the surface hardness and the hardened layer depth meet technical requirements of the product, and achieves the purposes of energy saving, emission reduction and consumption reduction.

Owner:上海上大热处理有限公司

Natural gas modular acquisition intelligent management platform

PendingCN113689123ARealize digital intelligent managementIncrease work intensityOffice automationResourcesData acquisitionProcess engineering

The invention discloses a natural gas modular acquisition intelligent management platform, which comprises a management system, a data acquisition module, a data transmission module and a production digital intelligent management application module, and the production digital intelligent management application module, the data acquisition module, the data transmission module and the management system are sequentially connected. Through the platform, comprehensive perception, safety strict control and decision optimization of the natural gas exploratory well pilot production process are realized, comprehensive deepening application of a new digital-intelligent management mode of natural gas pilot production work is promoted, digital-intelligent management of the oil and gas production process is realized, business mode reconstruction and production management transformation are driven, industrial upgrading and value increasing are realized, resources can be optimized, the production cost can be reduced, the production safety can be guaranteed, the management and control capability can be improved, monitoring can be enhanced, fine production can be realized, intelligent management can be realized, and high-quality development can be promoted.

Owner:北京大漠石油工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com