Prebaked aluminum electrolytic tank parameter measuring method and its device

A technology of aluminum electrolytic cells and process parameters, which is applied in the field of measuring devices, can solve the problems of inability to measure the process parameters of pole distance and cathode voltage drop, increase labor intensity of workers, and reduce current efficiency, so as to improve measurement accuracy and reliability, Improve computer process control and improve the effect of current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

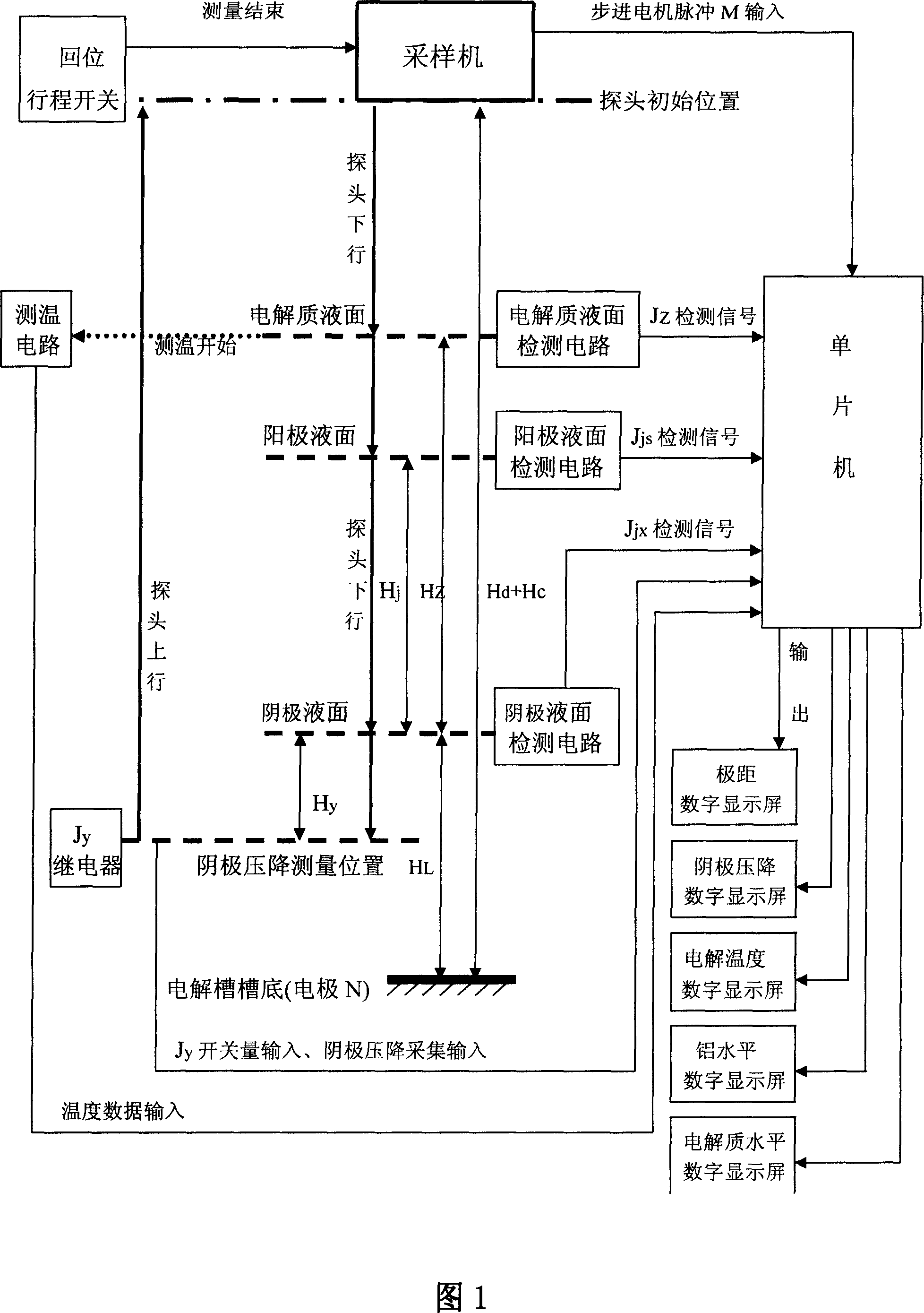

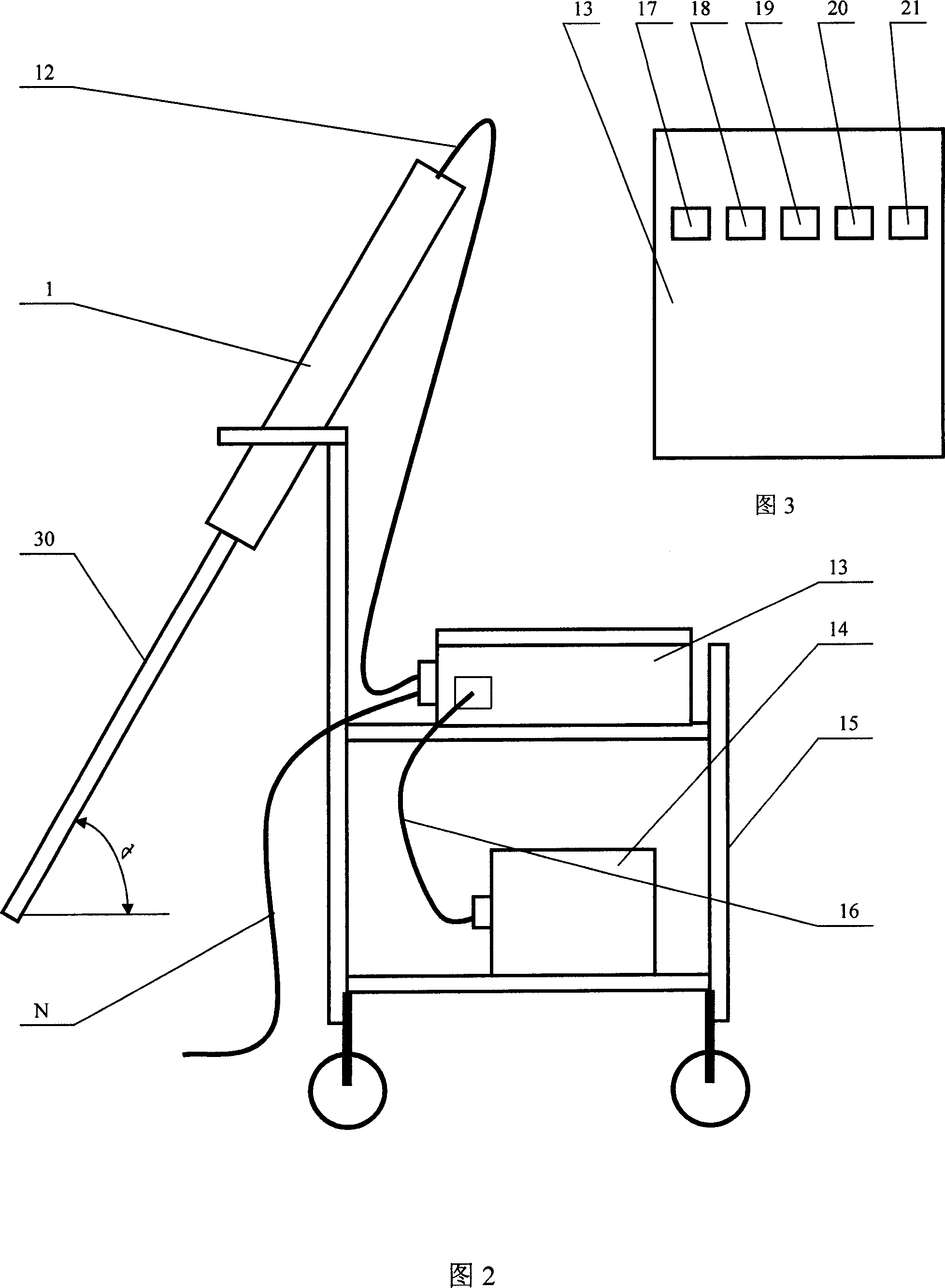

[0043] As shown in Figure 2: a device for measuring process parameters of a prebaked aluminum electrolytic cell, including a sampling machine 1, equipped with a polarization layer detection circuit, a fixed-distance measurement cathode voltage drop circuit, a single-chip microcomputer, an electrolyte liquid level detection circuit, and a reference electrode N and the control box 13 of the temperature measuring circuit; the communication line 12 connects the sampling machine 1 to the control box 13, and the reference electrode N is drawn from the control box 13 to connect with the cathode steel rod of the electrolytic cell; the measuring probe 30 is connected to the sampling machine 1 Extend to move in a straight line.

[0044] The measuring device is equipped with a UPS power supply 14, and the UPS power supply 14 supplies power to the control box 13 through the power line 16. The sampling machine 1, the control box 13, and the UPS power supply 14 inclined at an angle of α are ...

Embodiment 2

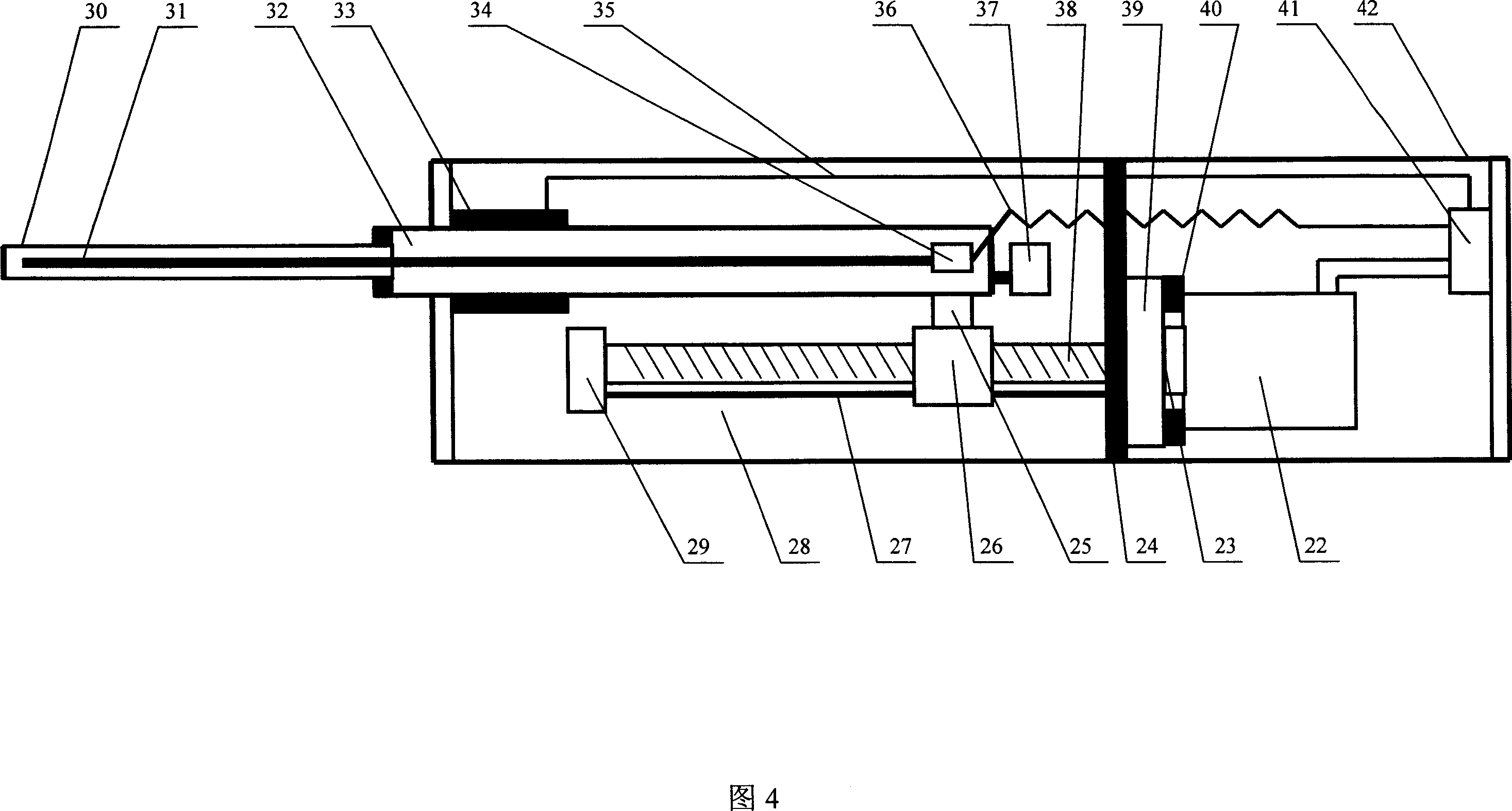

[0056] In Fig. 10: sampling machine 1 is made up of data acquisition device and running power device; Data acquisition device is made up of measuring probe 30, the armored thermocouple 31 that is positioned at measuring probe 30; The rack and pinion assembly of the lifting part is composed; the slideway 33 is fixed on the casing 42, the stepping motor 22 as the power source is fixed on the slideway 33, the output shaft of the stepping motor 22 is equipped with a gear 43, the measuring probe 30 and the rack 44 Fixedly connected, the gear 43 meshes with the rack 44 located in the slideway 33 for power transmission, the slideway 33 is the running track of the rack 44, and the rack 44 slides and runs linearly in the slideway 33; the measuring probe 30, the rack 44. The slideway 33 is connected, one end of the sampling wire 35 is electrically connected to the slideway 33, and the other end is connected to the terminal 41 fixedly installed on the casing 42 to form the measuring elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com