Patents

Literature

214 results about "Manual insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

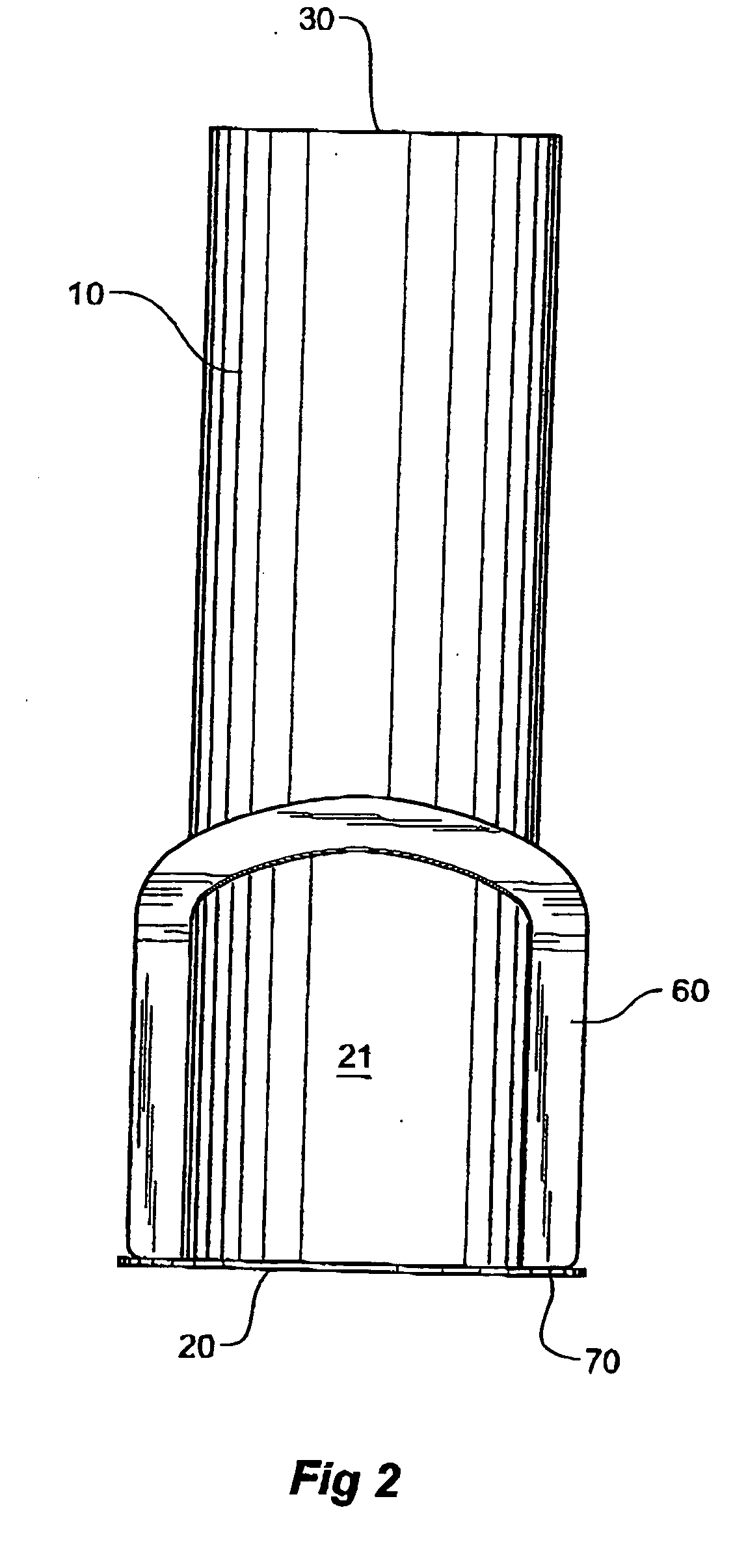

Automated pipetting system

InactiveUS6982063B2Good flexibilityImprove throughputChemical analysis using titrationWithdrawing sample devicesMechanical pipetteManual insertion

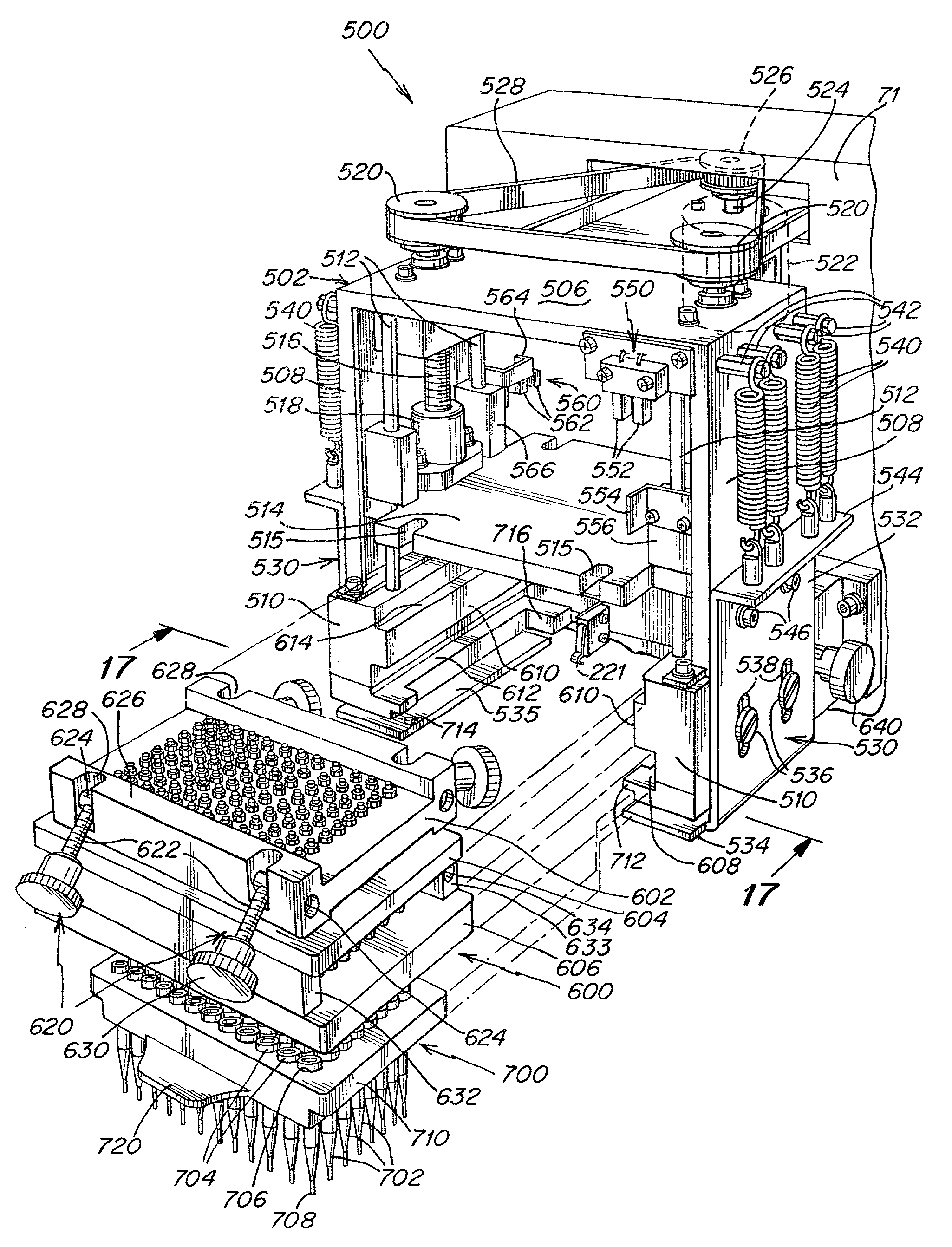

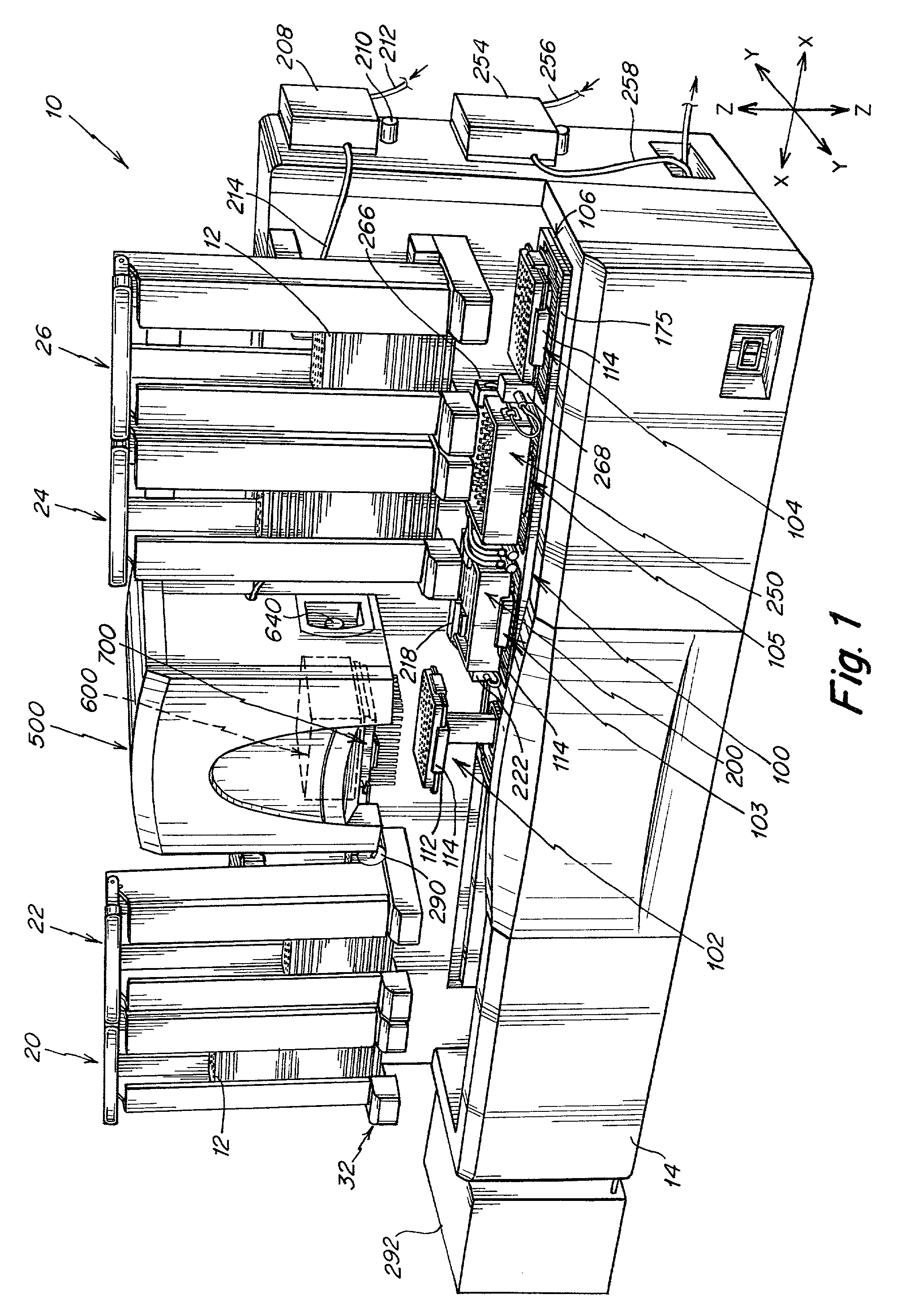

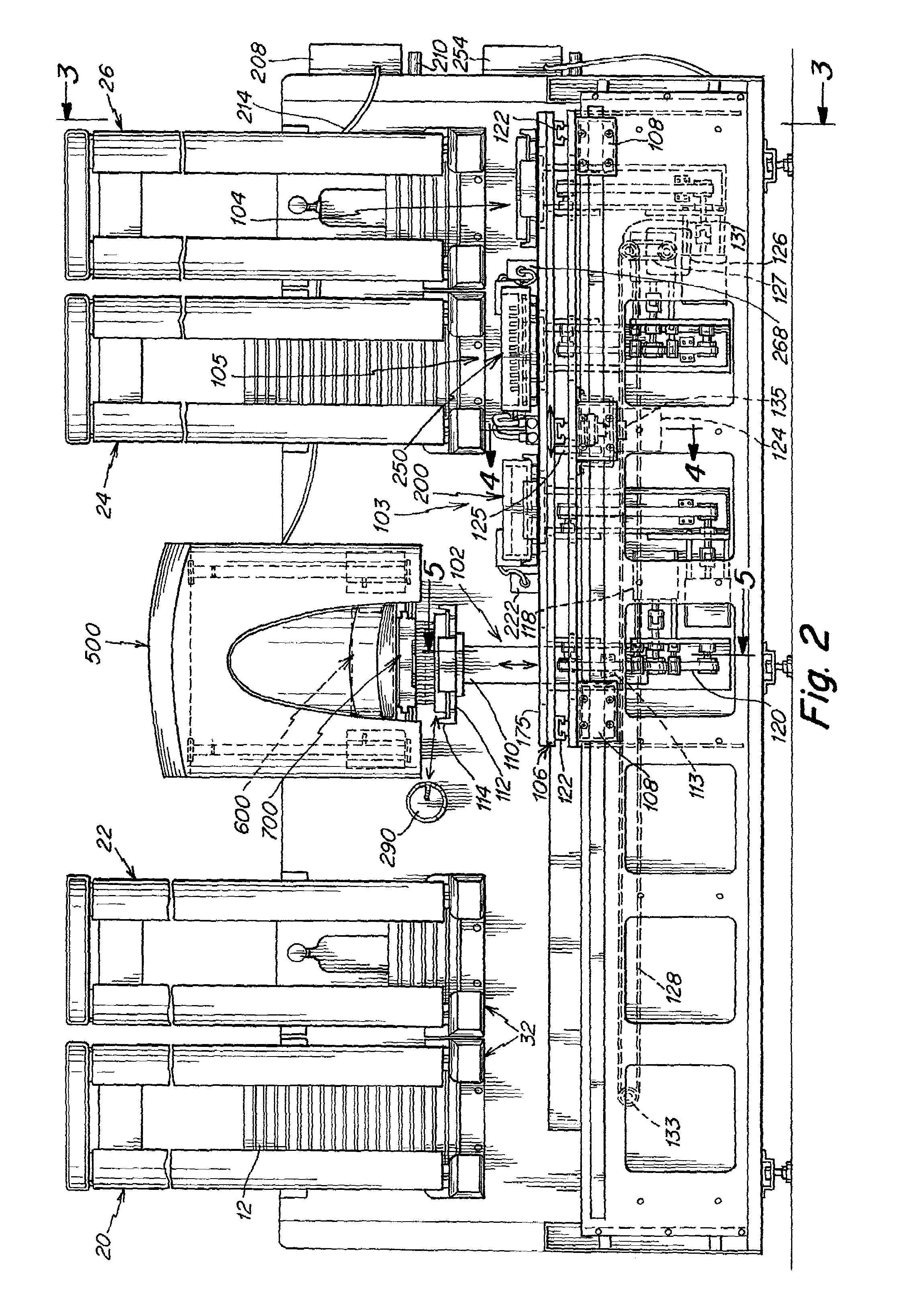

A highly automated, high volume multichannel pipetting system which transfers liquid from mother plates to daughter plates, or from a fill station to daughter plates. The mother plates are stacked in one set of stacker assemblies, while the empty daughter plates are stacked in another stacker assembly. A plate handling assembly which is capable of moving the plates in three orthogonal directions retrieves the plates from the stacker assemblies, carries them to the pipetting head, and returns them to other stacker assemblies. The pipetting head is removable for replacement or repair thereof, or for insertion of another head assembly having a different number of pipetting channels. The head slides into the housing on slideways, and is retained in place by manually operable, threaded knobs mounted on shafts. The stacker assemblies include a chimney which is removable from a base. The plates may be stacked in the chimney and then inserted on the base. The base includes solenoids whose arms are retractable to permit plates to be retrieved or replaced one at a time. The chimneys contain flaps which serve to retain the plates within the chimney if manually removed from the base. Doors in the stacker chimneys allow manual insertion and replacement of plates. Methods of operation of the pipetting system are also disclosed.

Owner:MATRIX TECH +1

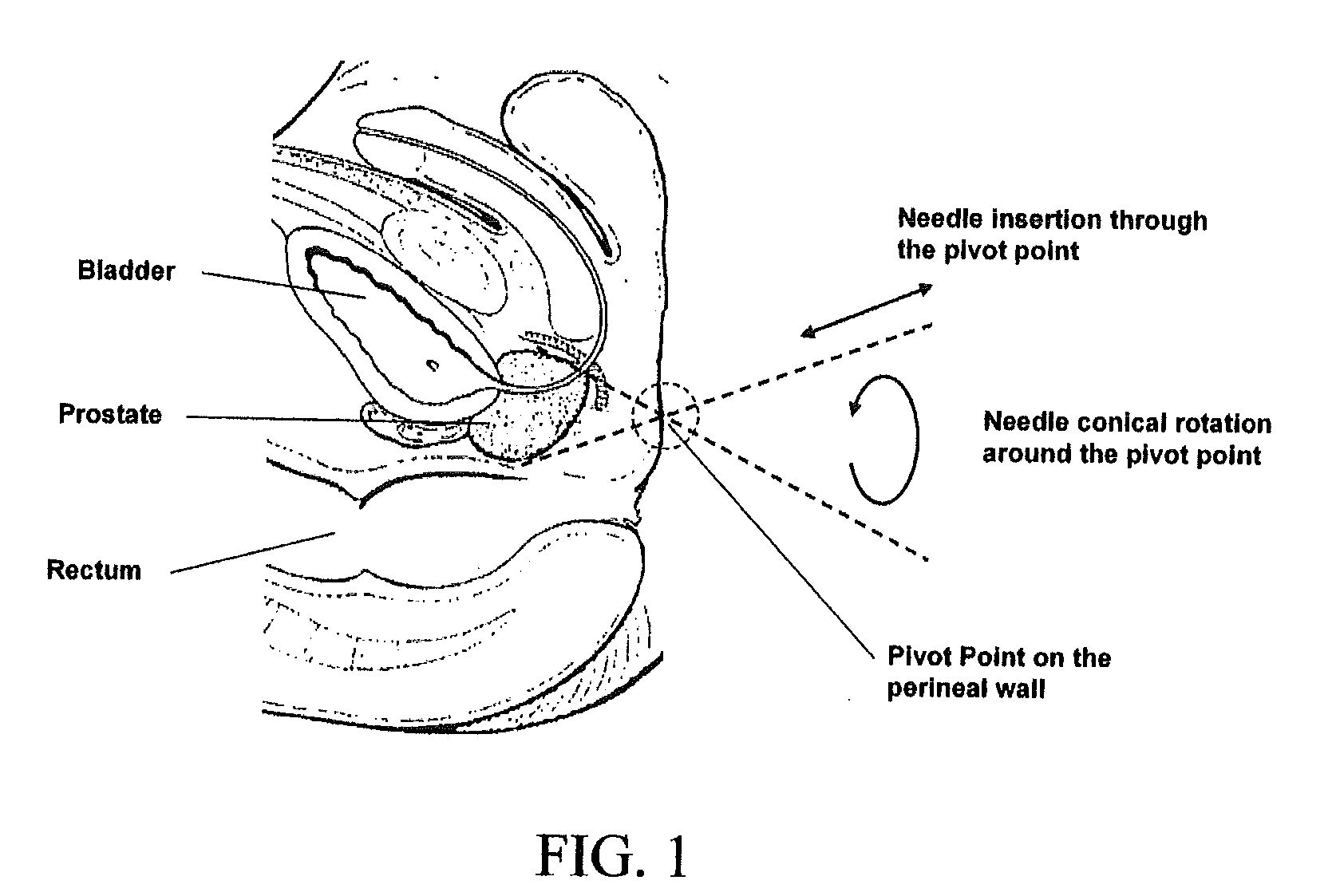

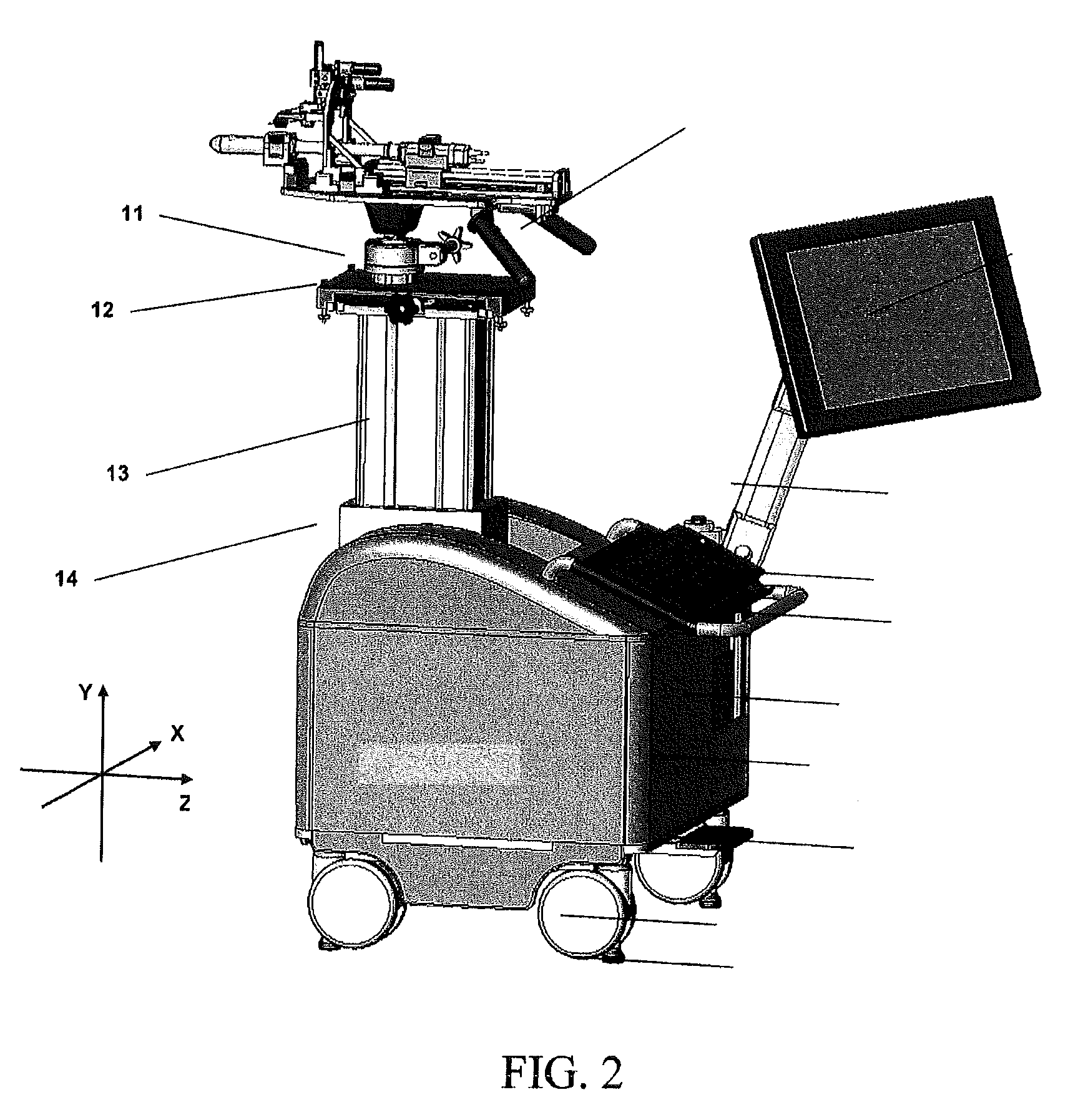

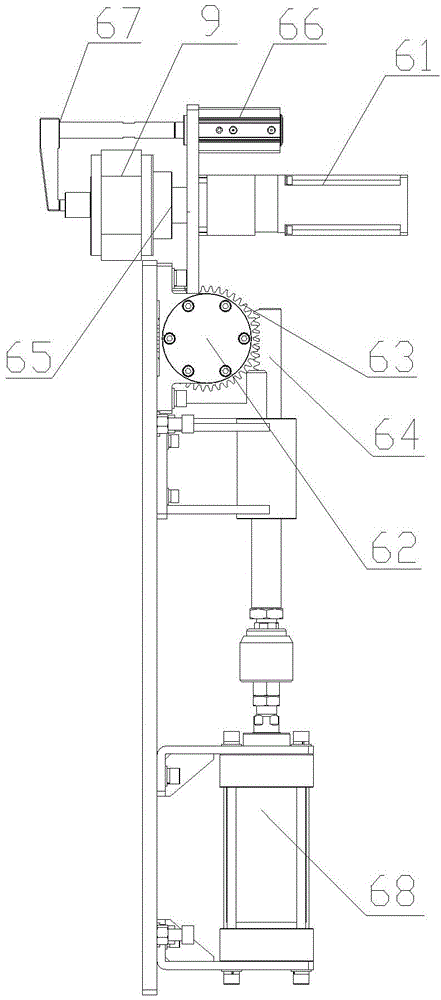

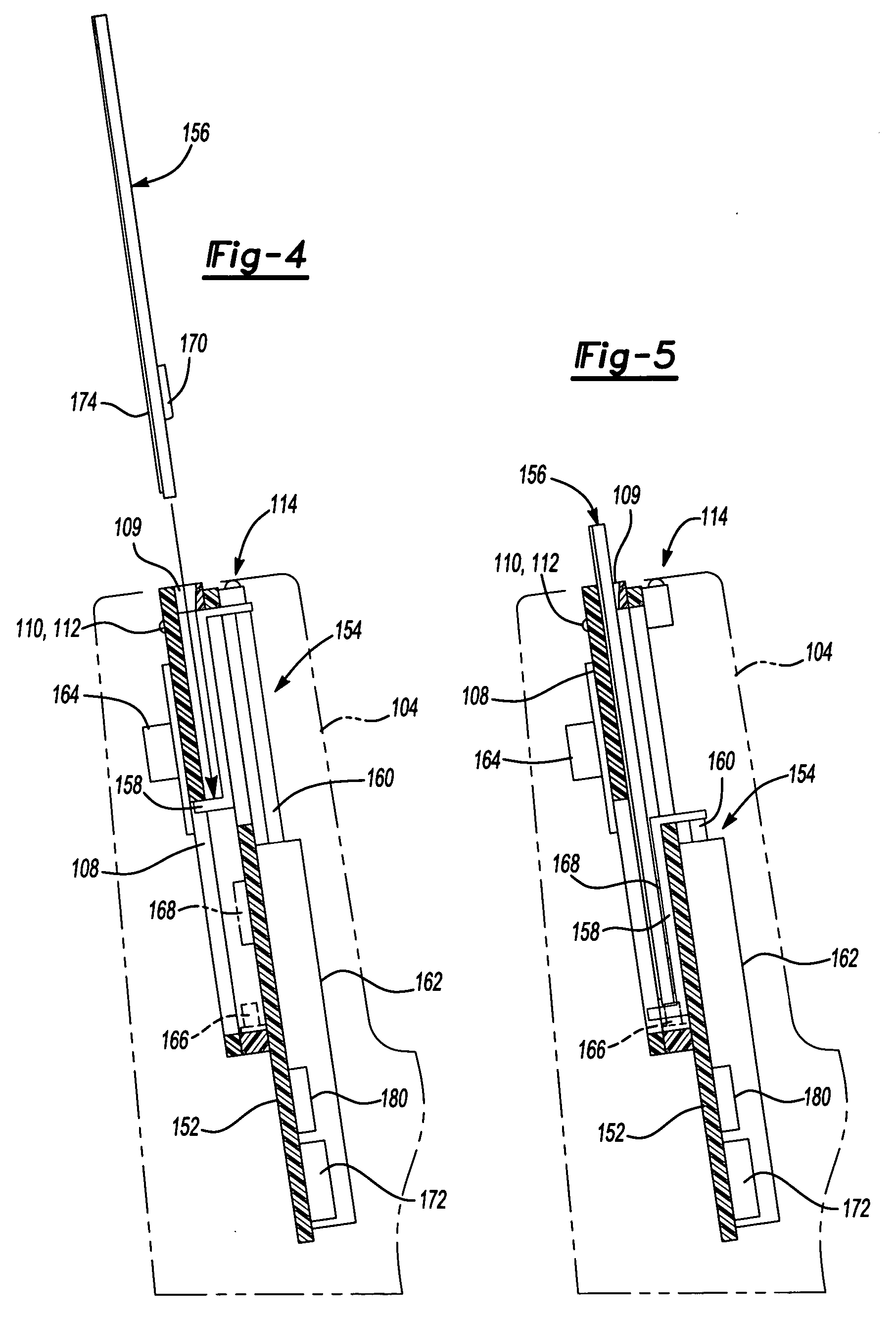

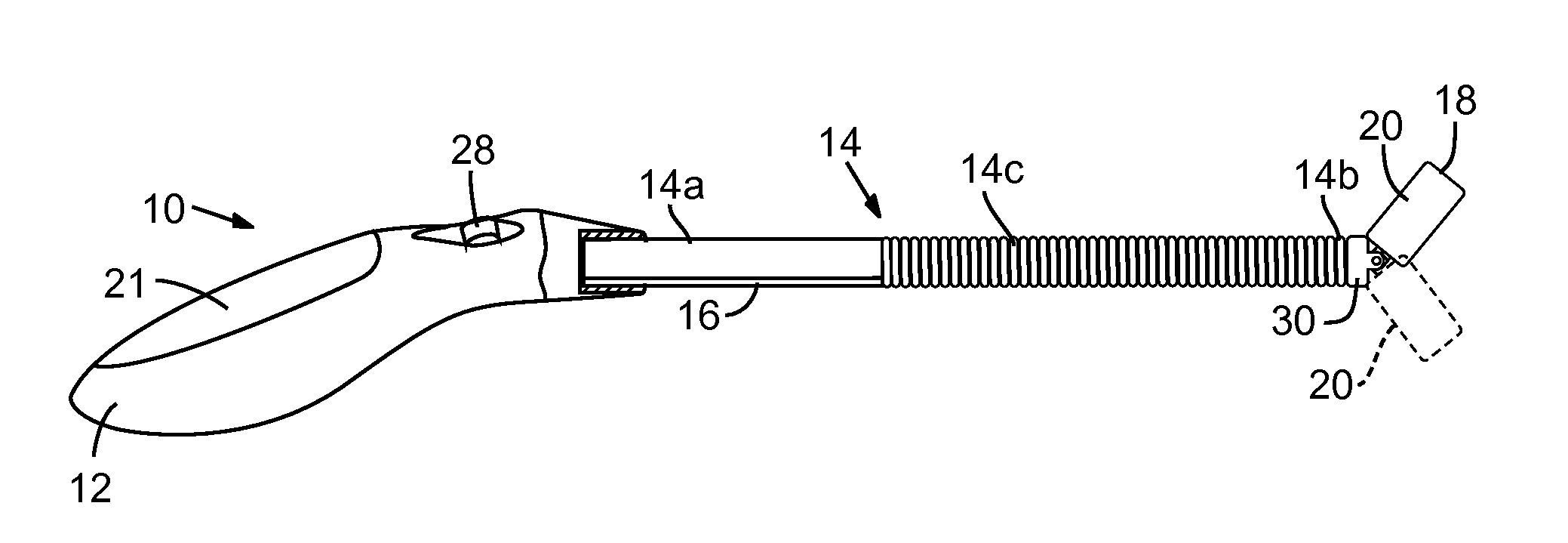

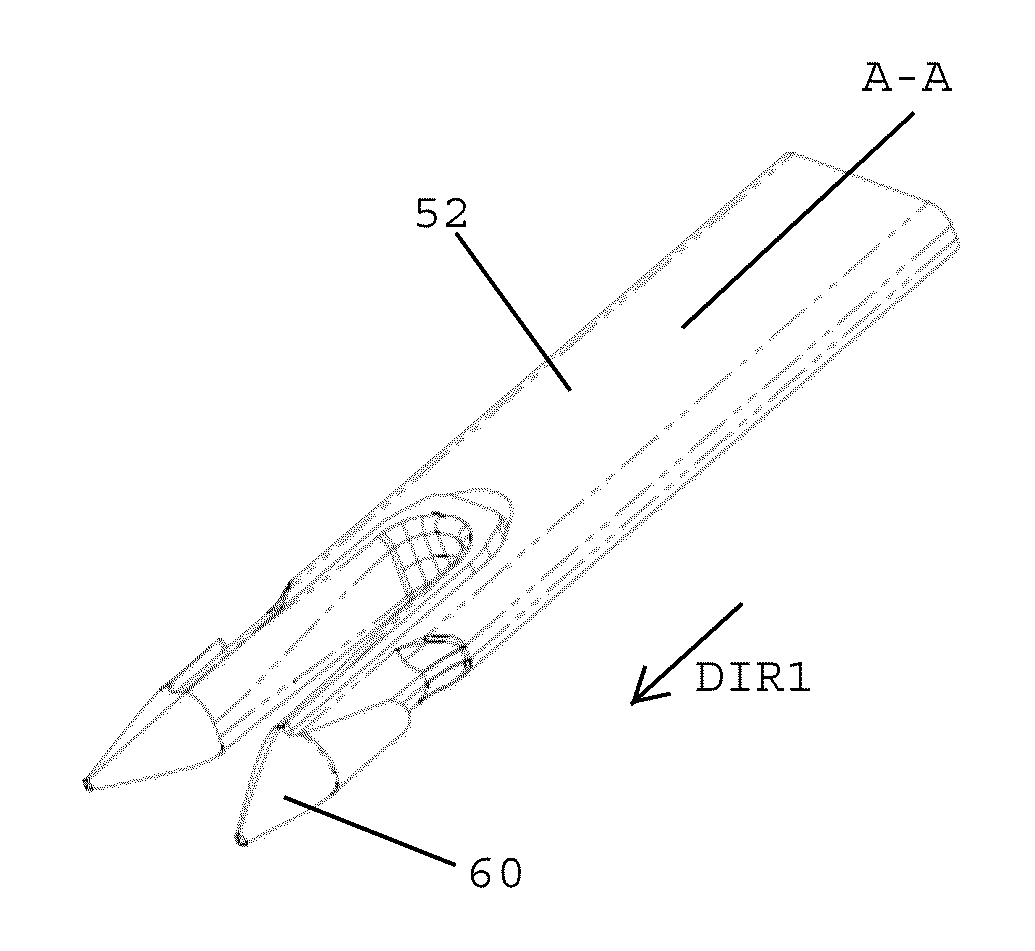

Apparatus and method for motorised placement of needle

InactiveUS20090030339A1Ultrasonic/sonic/infrasonic diagnosticsSurgical needlesUltrasound imagingManual insertion

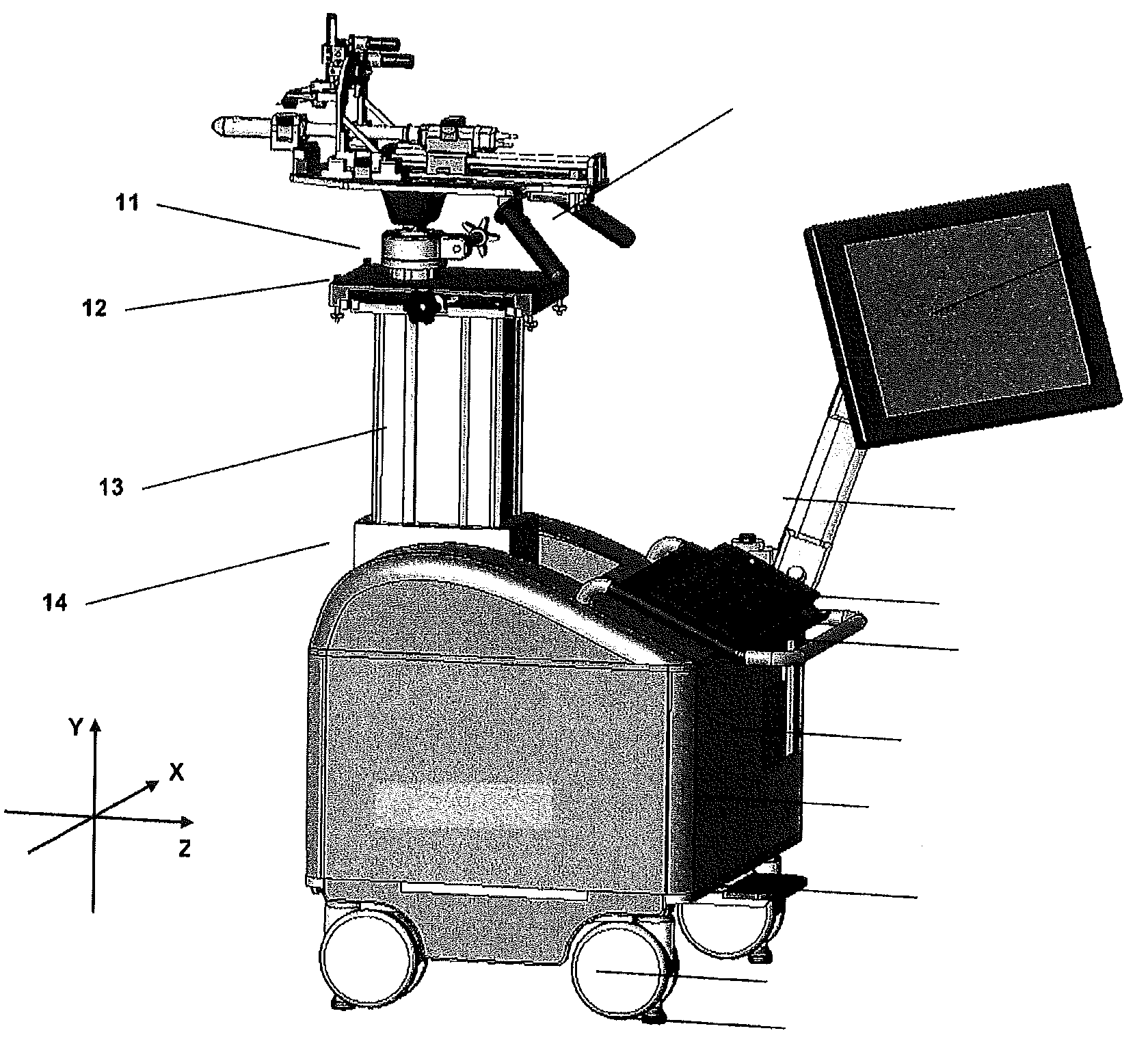

The present invention provides a method and apparatus to insert a needle through a predetermined trajectory and with a predetermined depth, in order to reach a target accurately within soft tissue, under ultrasound imaging guidance. The invention can be applied to carry out, for example, prostate biopsy, or prostate brachytherapy. The apparatus can guide a biopsy needle into defined sites in the prostate gland. A conical approach is used to reach the prostate through one or more pivot points on the perineal wall. The biopsy needle penetrates the patient's skin through the pivot point for multiple cores. The apparatus holds a needle sheath with two ball joints. The orientation of the needle sheath is controlled by locking the front ball joint at the pivot point, and moving the back ball joint on a virtual plane. The biopsy needle is inserted manually through the needle sheath. The depth of the insertion is controlled by the position of the stopper on the biopsy gun holder. Both the orientation and depth stopper are preferably driven by motors.

Owner:SINGAPORE HEALTH SERVICES PTE +1

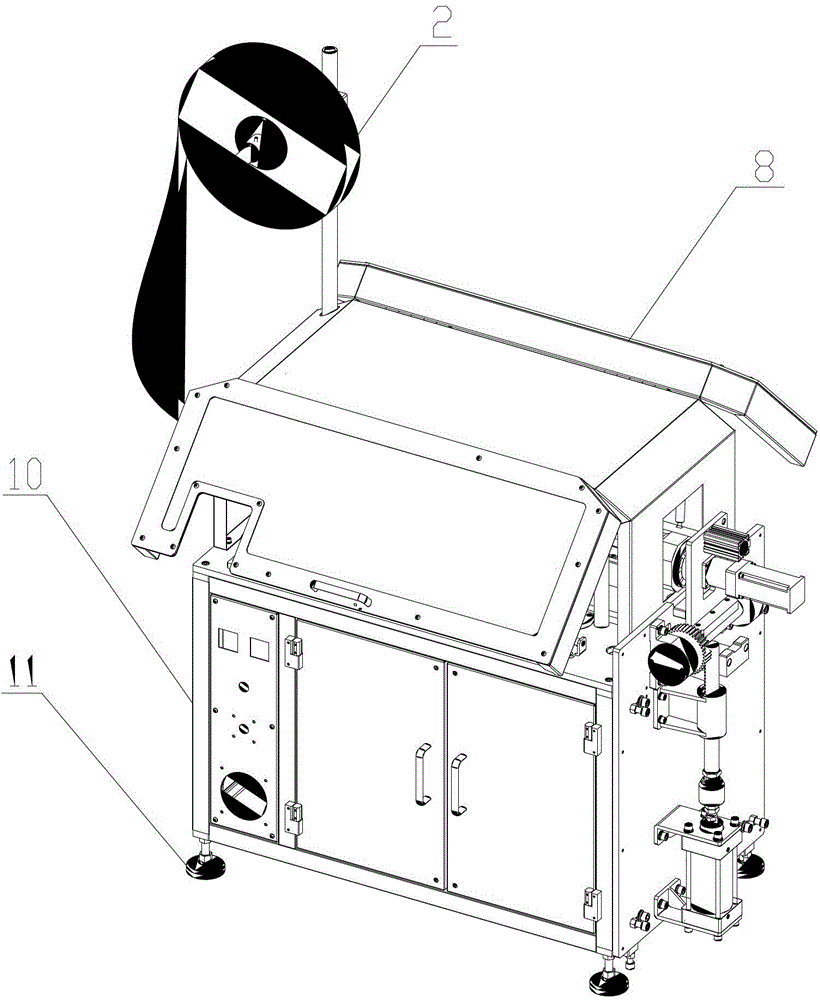

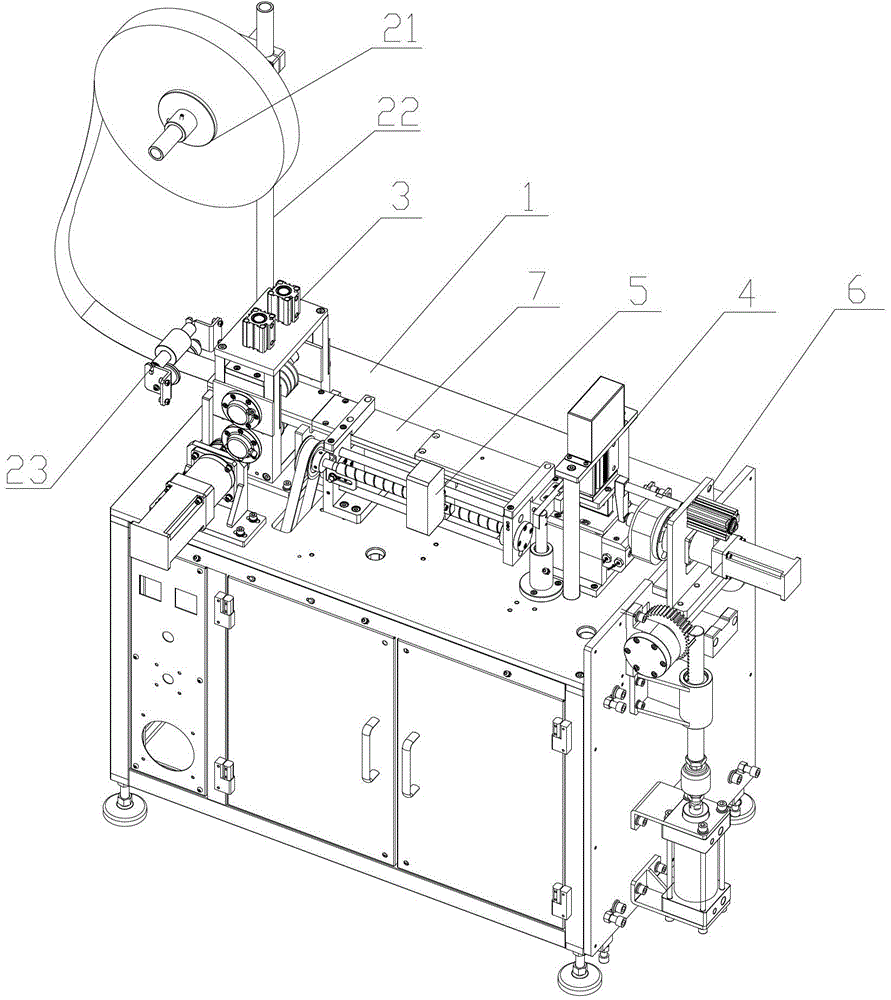

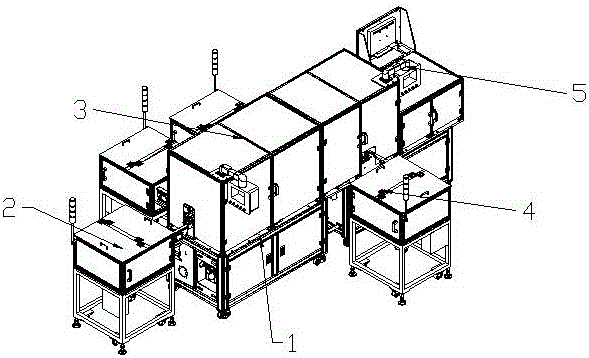

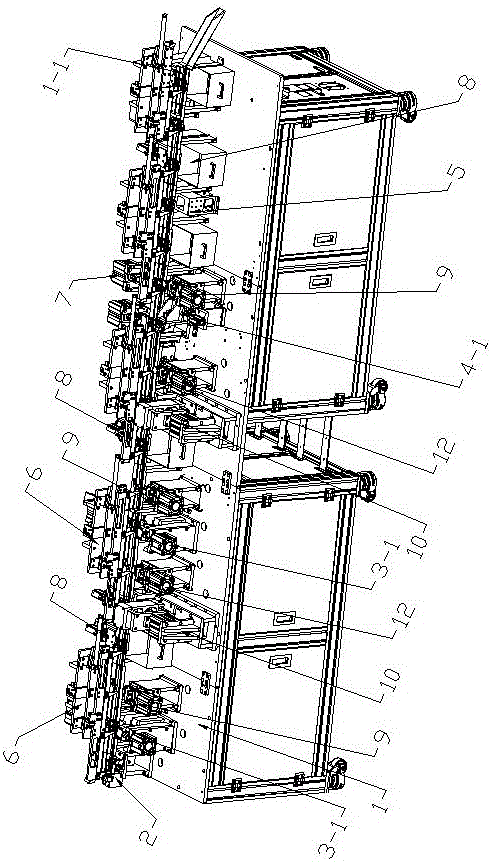

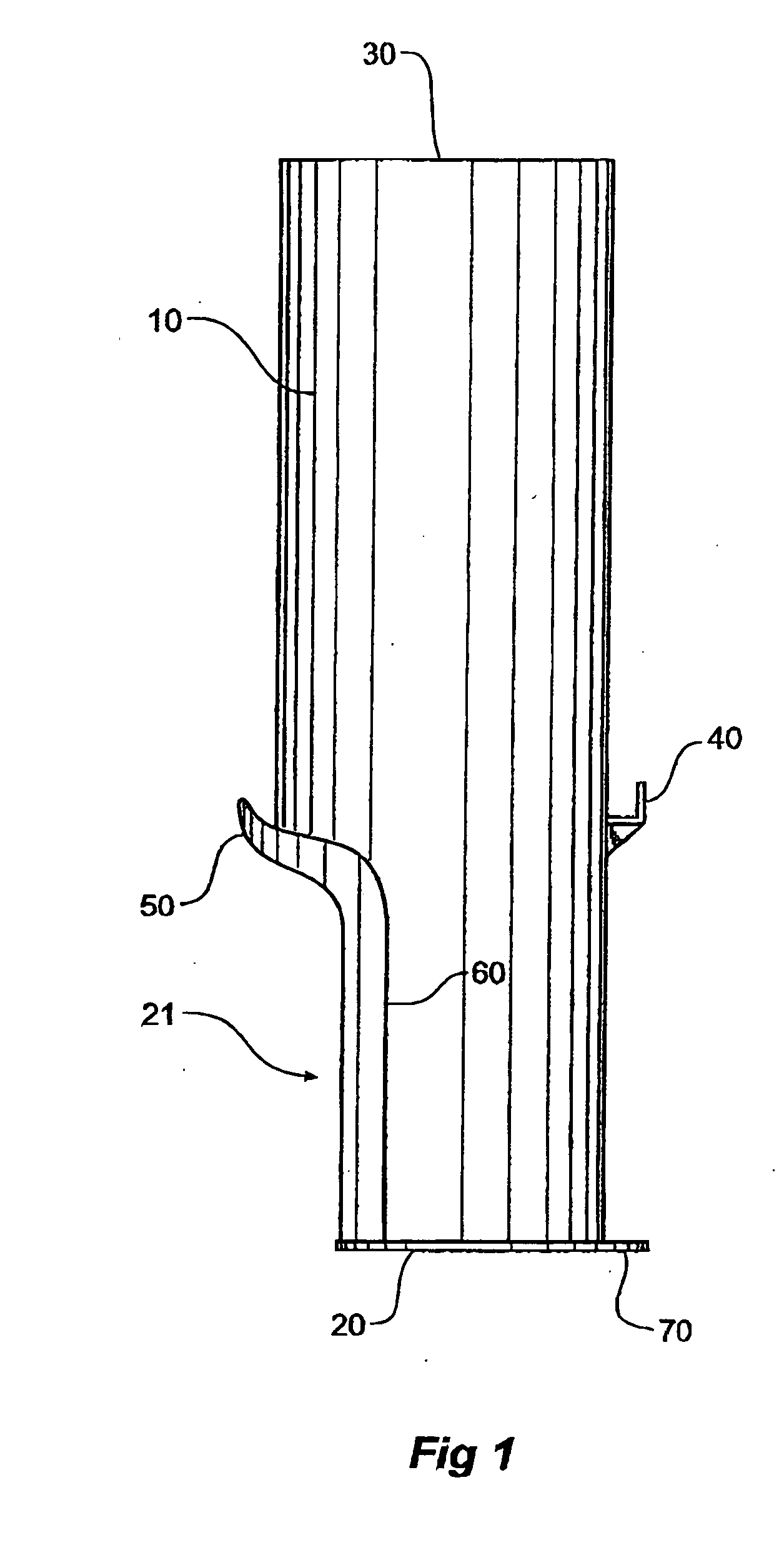

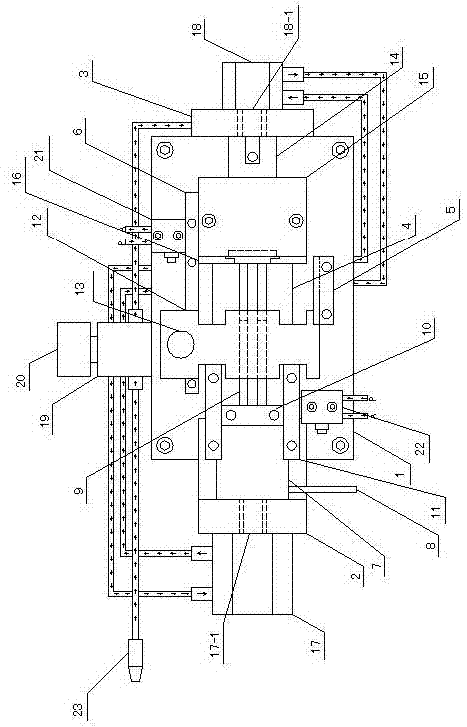

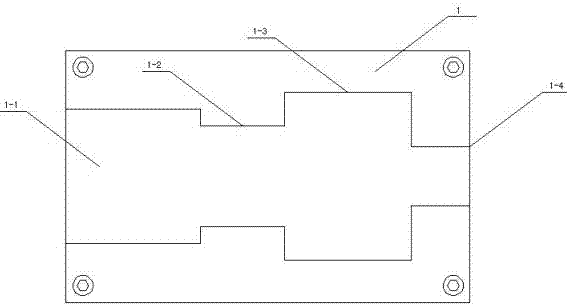

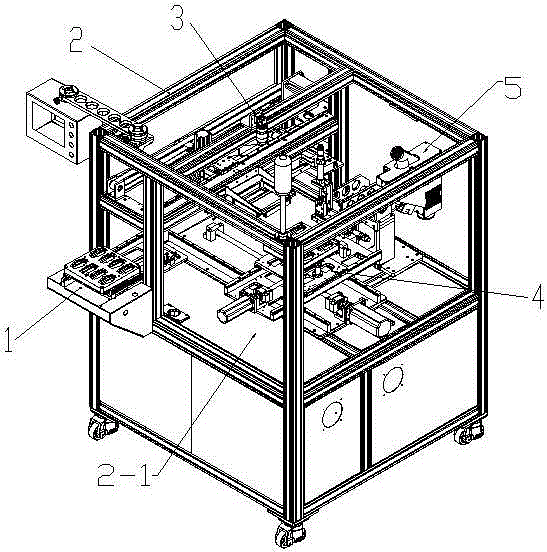

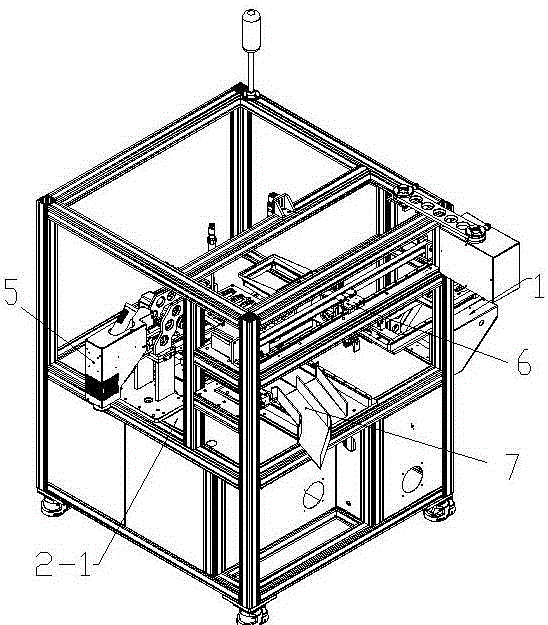

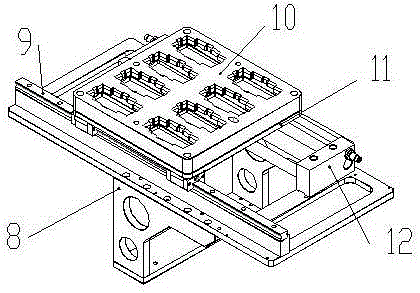

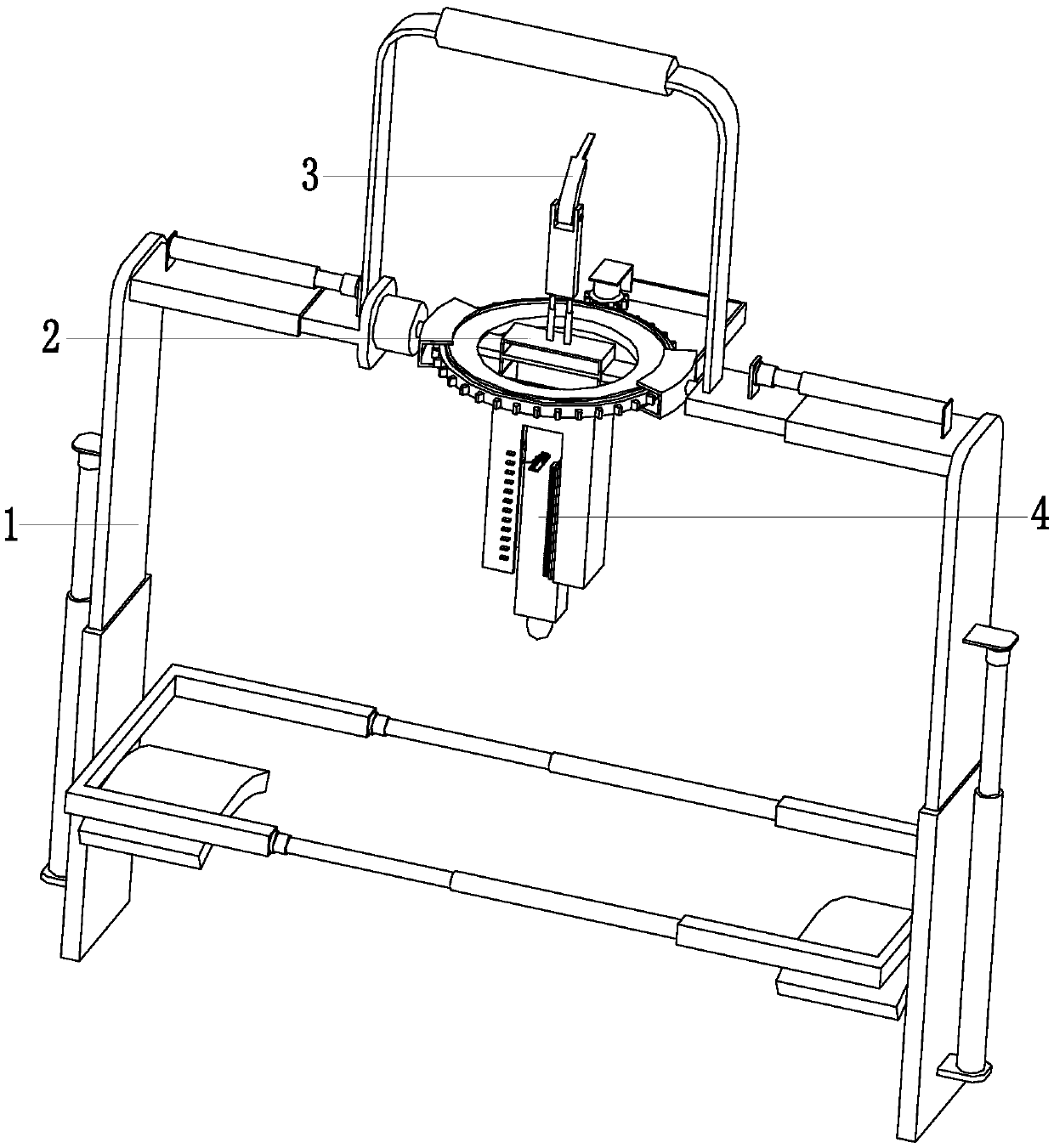

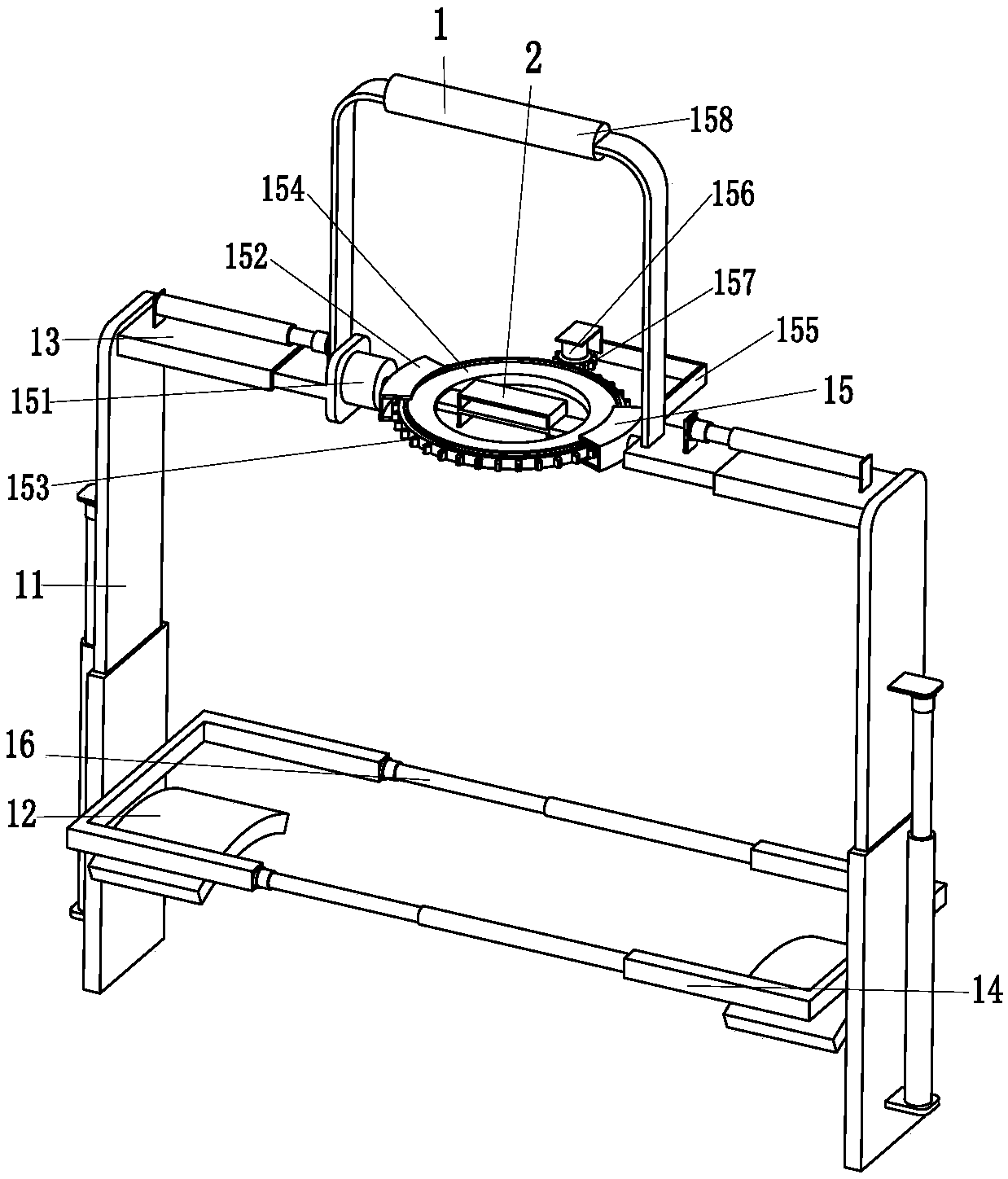

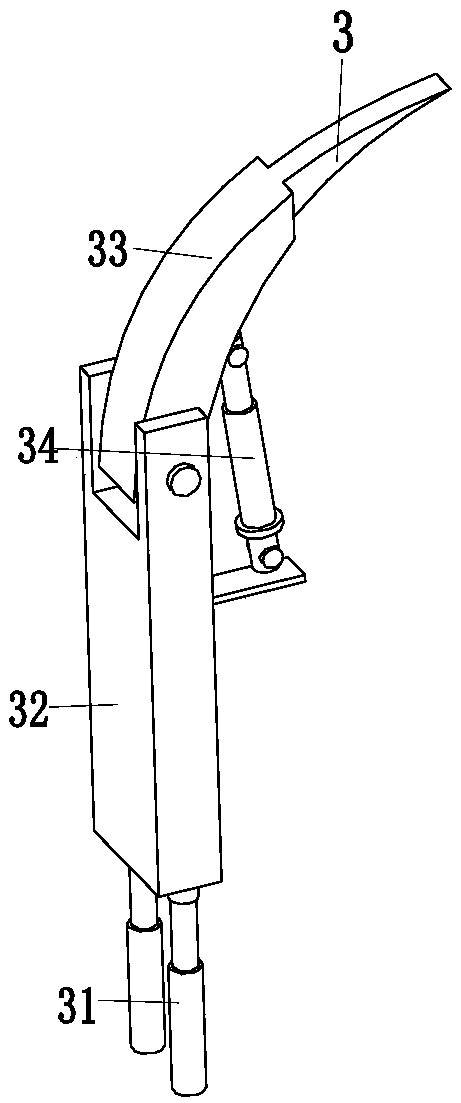

Insulation paper inserting machine for motor stator

InactiveCN103337935APrecise positioningEasy clampingApplying solid insulationManual insertionPulp and paper industry

The invention discloses an insulation paper inserting machine for a motor stator, which includes a working platform and a paper feeding device arranged on the working platform, wherein an indentation device and a cutting device are also mounted on the working platform; a paper guide slot is arranged between the indentation device and the cutting device; a paper pushing mechanism is matched with the cutting device; after the paper feeding device sends out a piece of insulation paper, the insulation paper passes through the indentation device, the paper guide slot and the cutting device sequentially, and then is pushed out of the cutting device by the paper pushing mechanism; the insulation paper finally enters the motor stator clamped on a stator clamping workbench on a side surface of the working platform; the stator clamping workbench is connected with the working platform via a rotating shaft, and can turn over around the rotating shaft. Through the manner, the insulation paper inserting machine for the motor stator not only has the insulation paper forming function, but also can push the clamped insulation paper into a groove of the motor stator, has efficient automatic performance, and puts an end to the low efficiency working manner of manual insertion.

Owner:NIDE MECHANICAL EQUIP

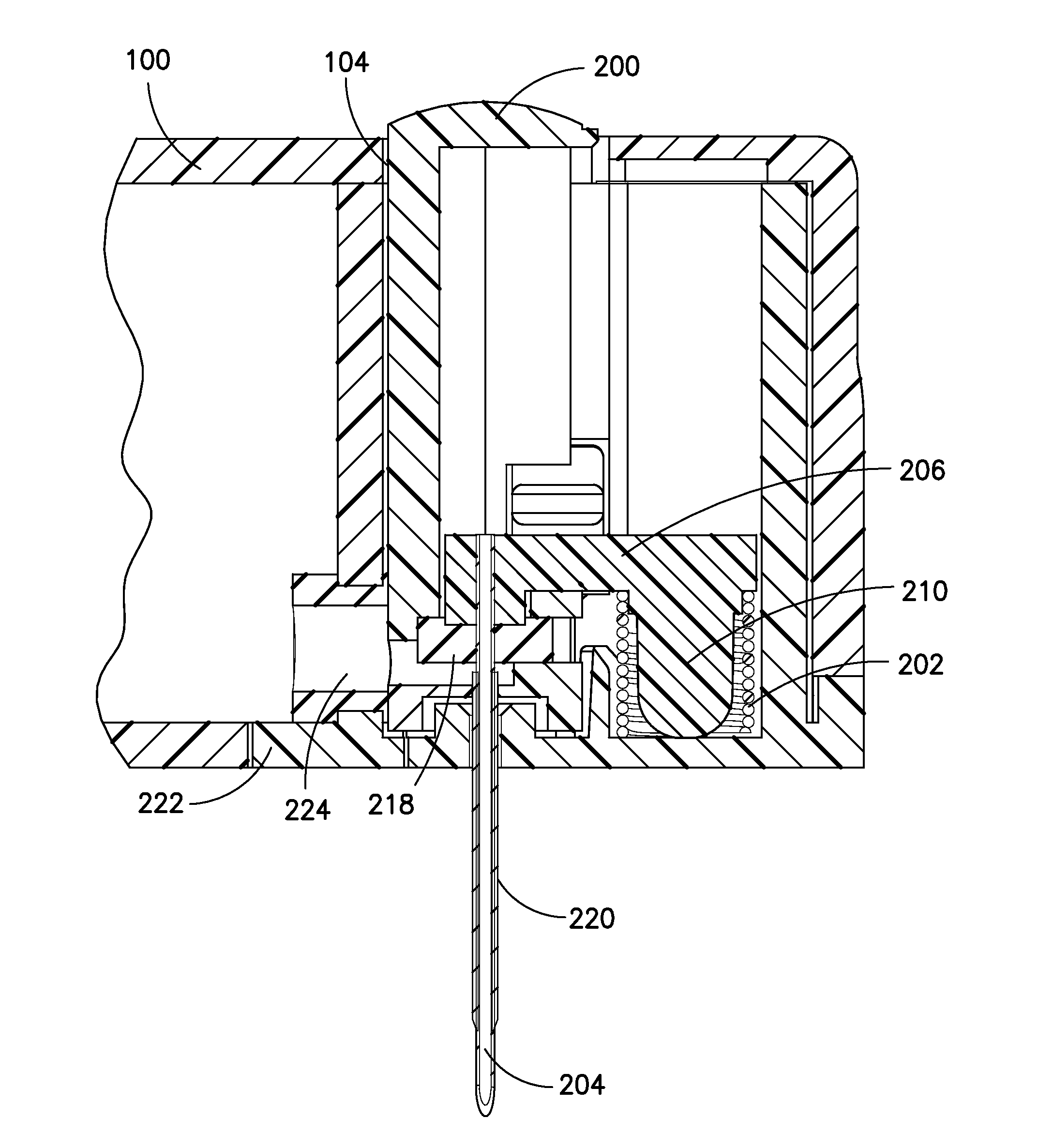

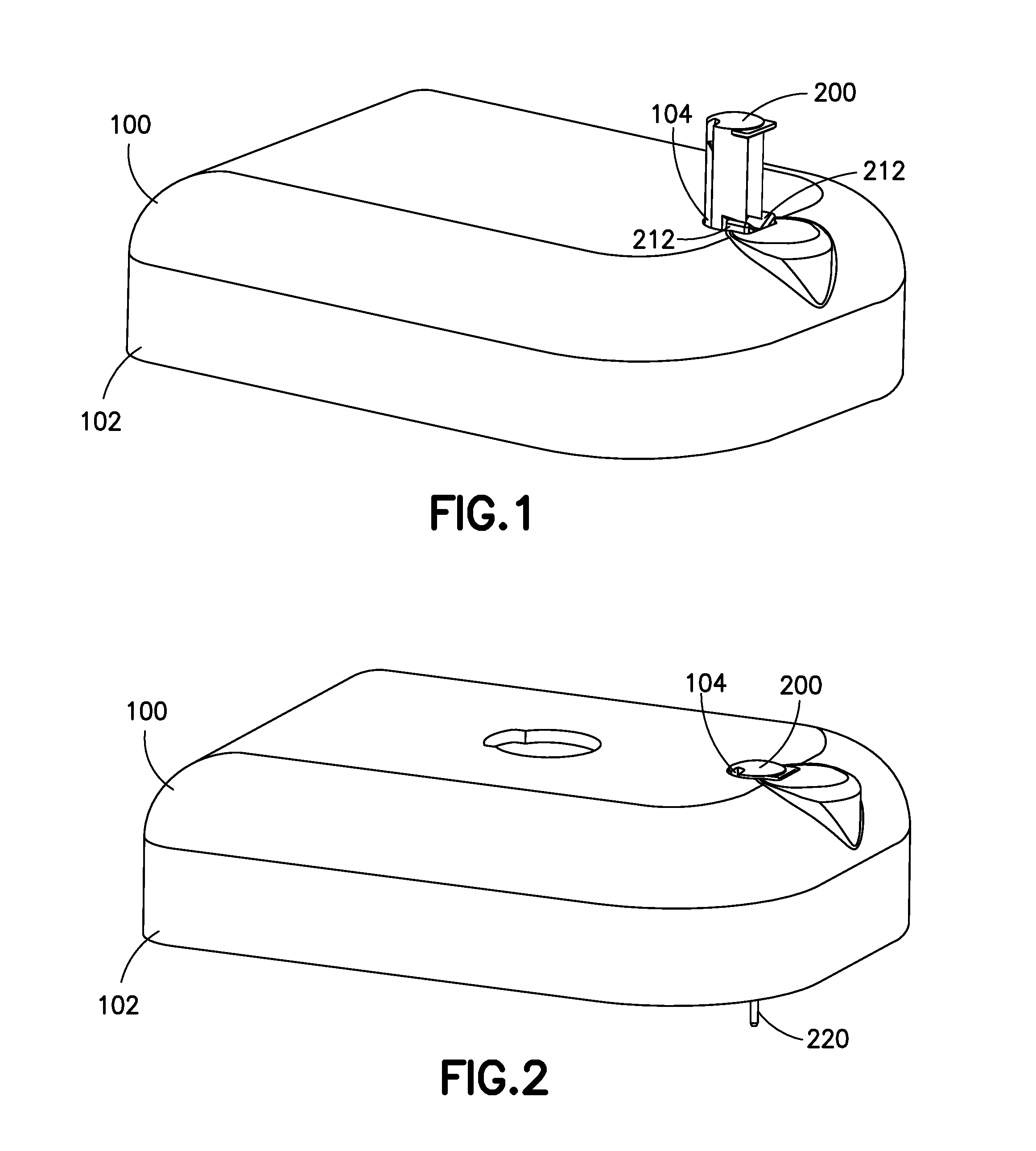

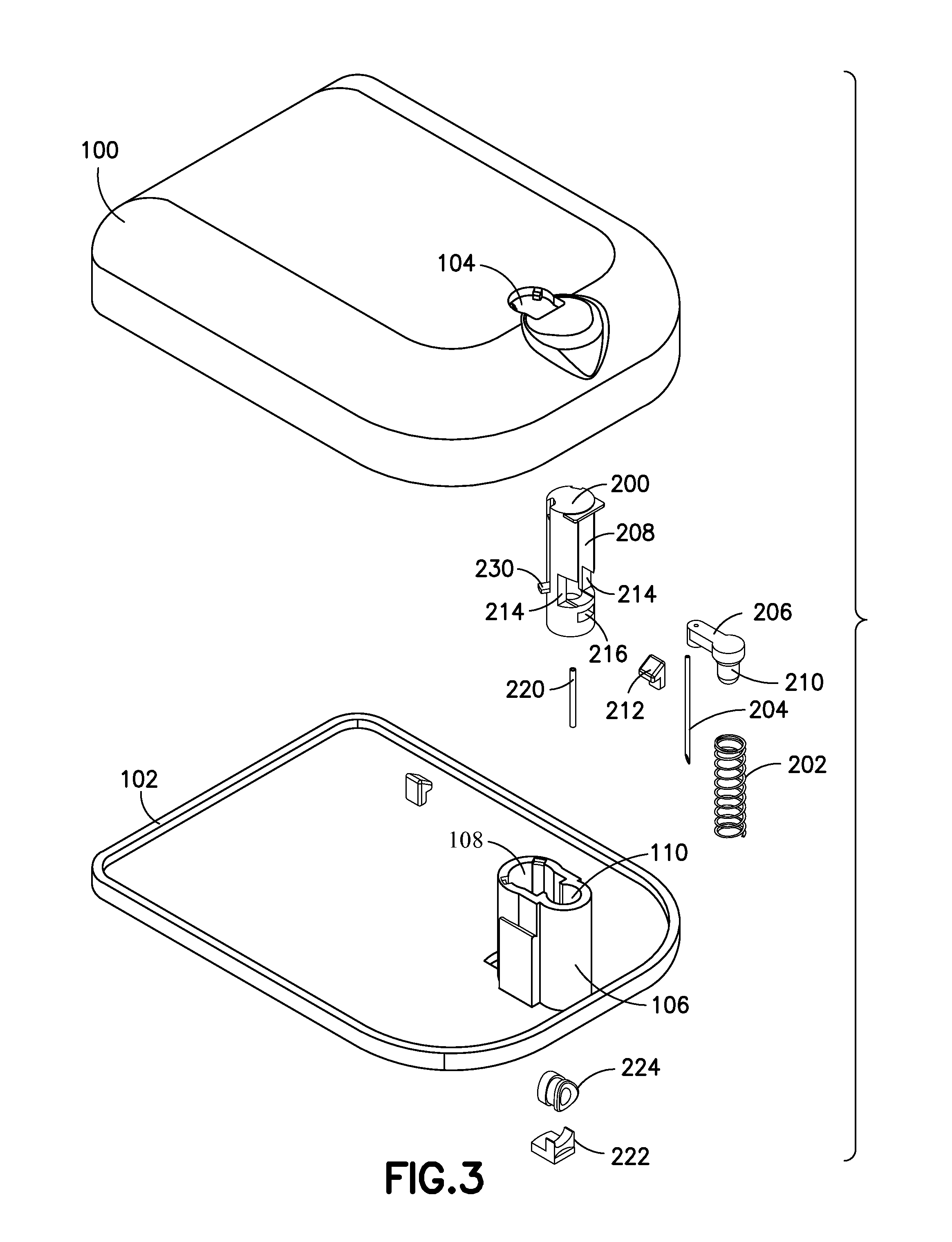

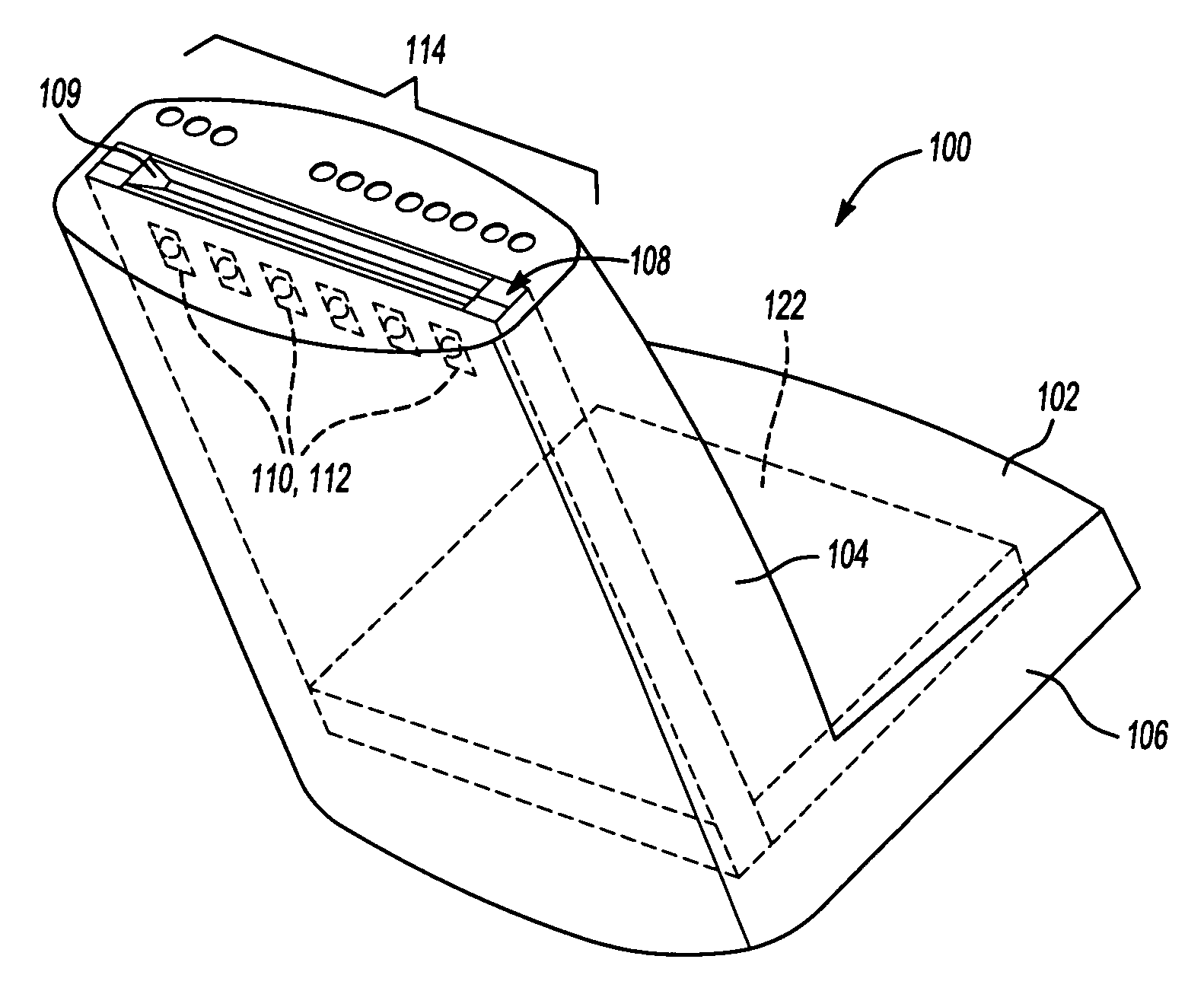

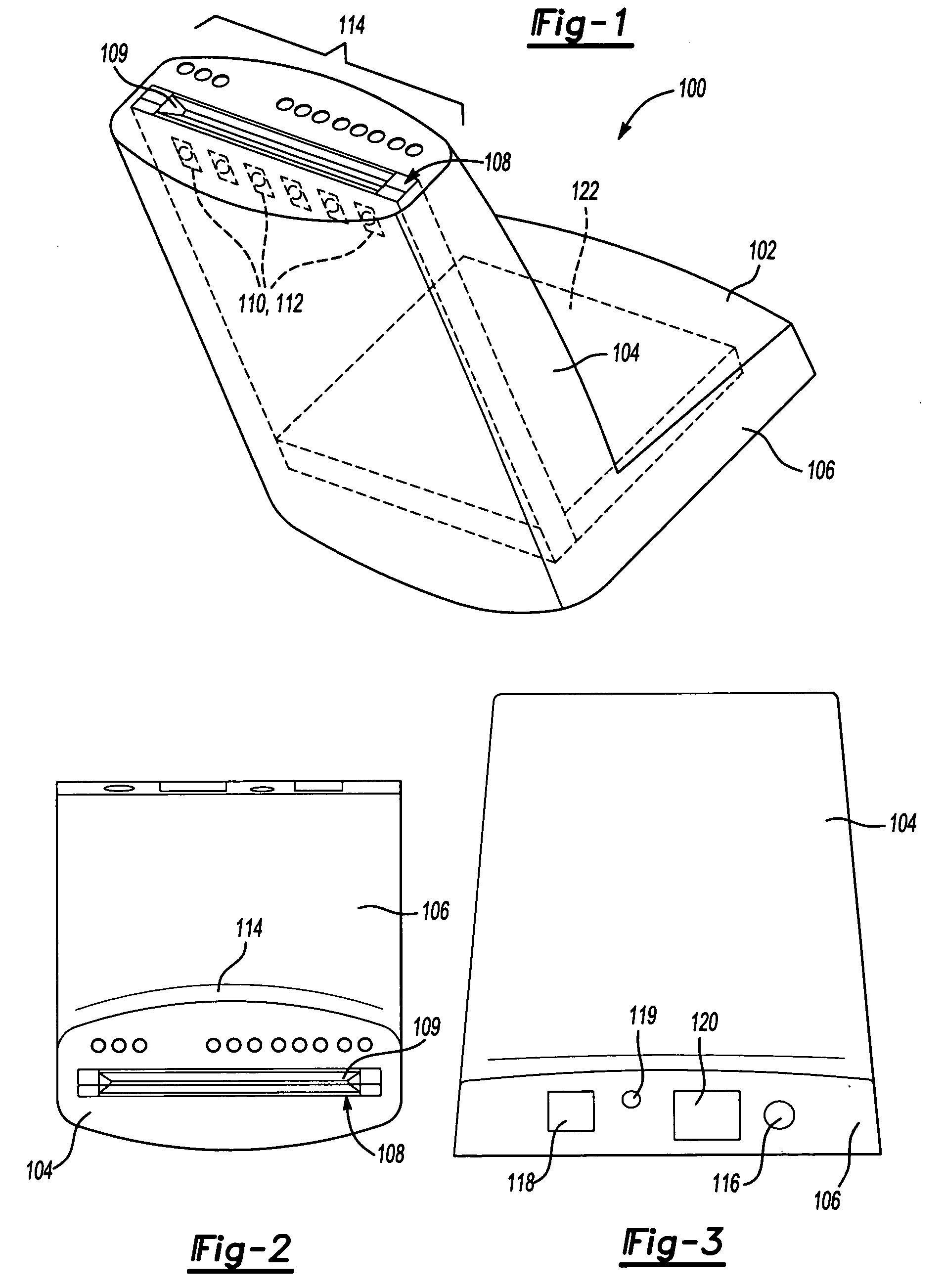

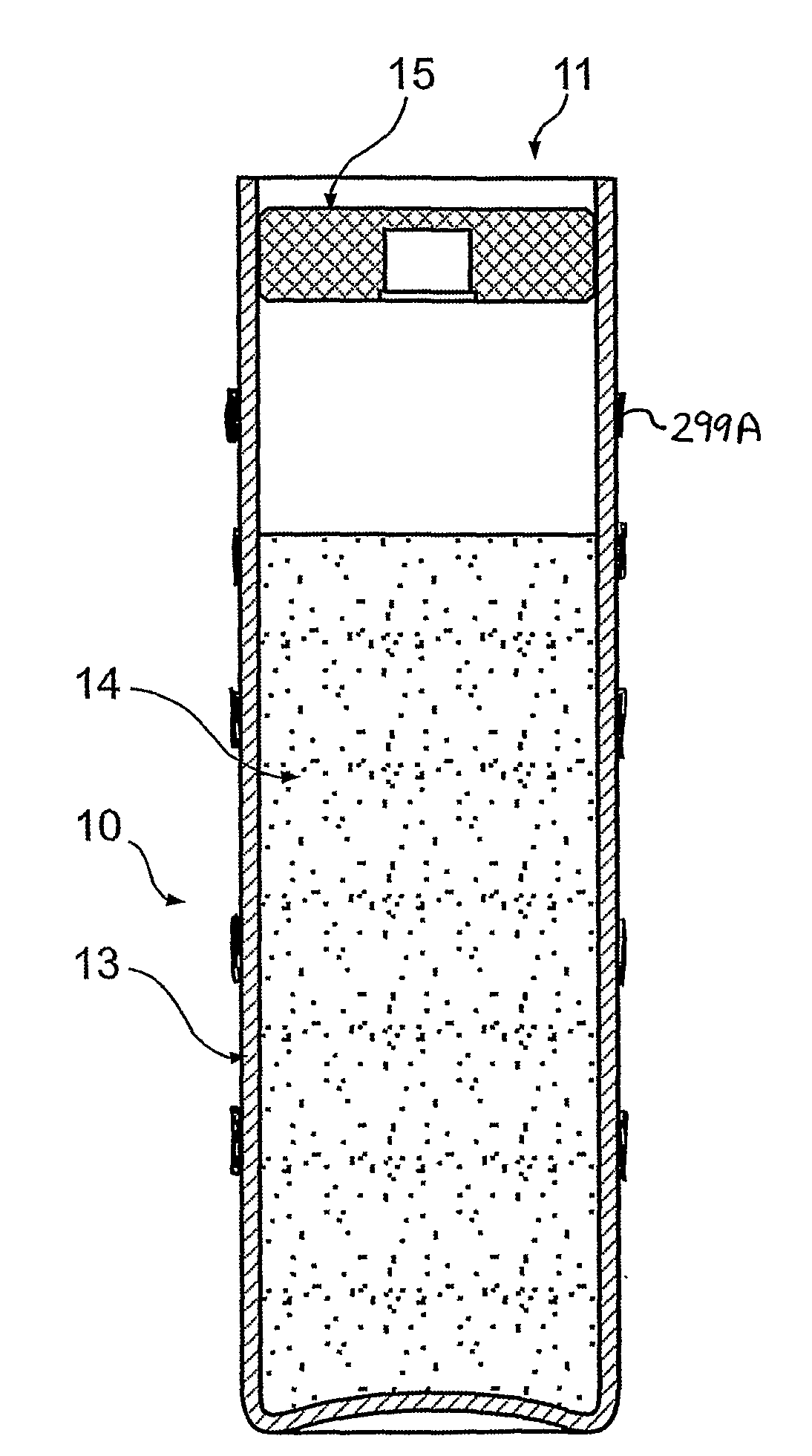

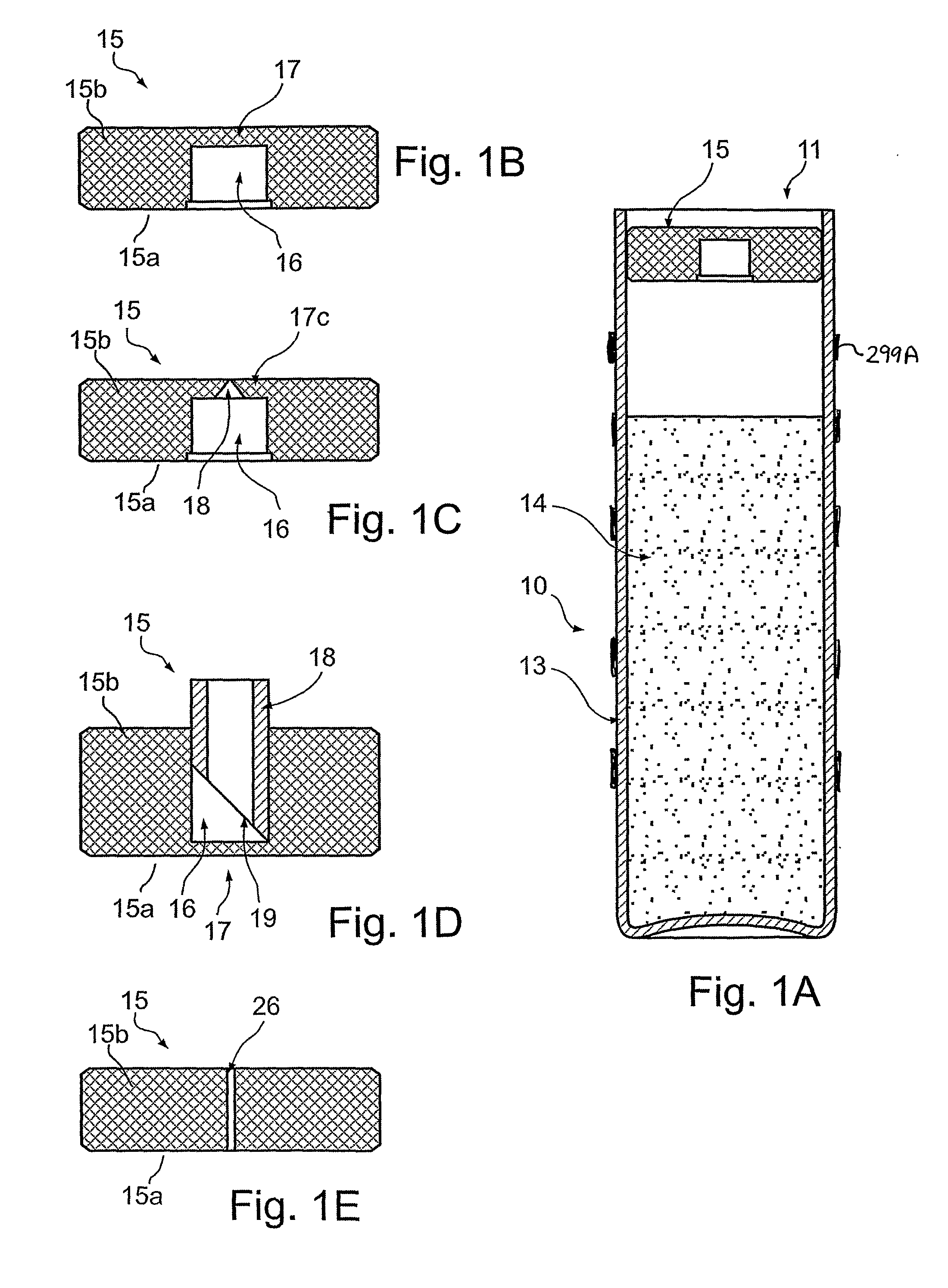

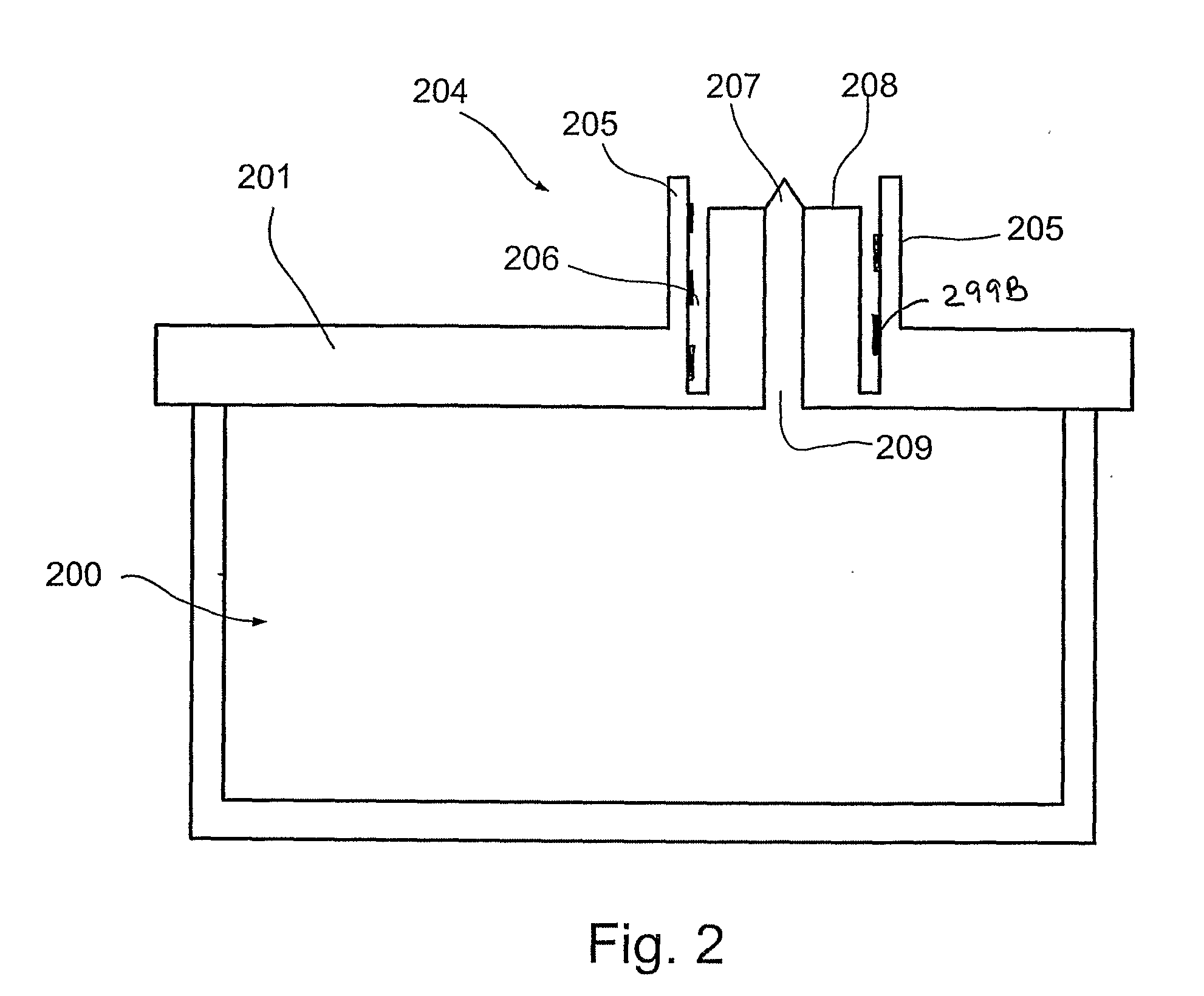

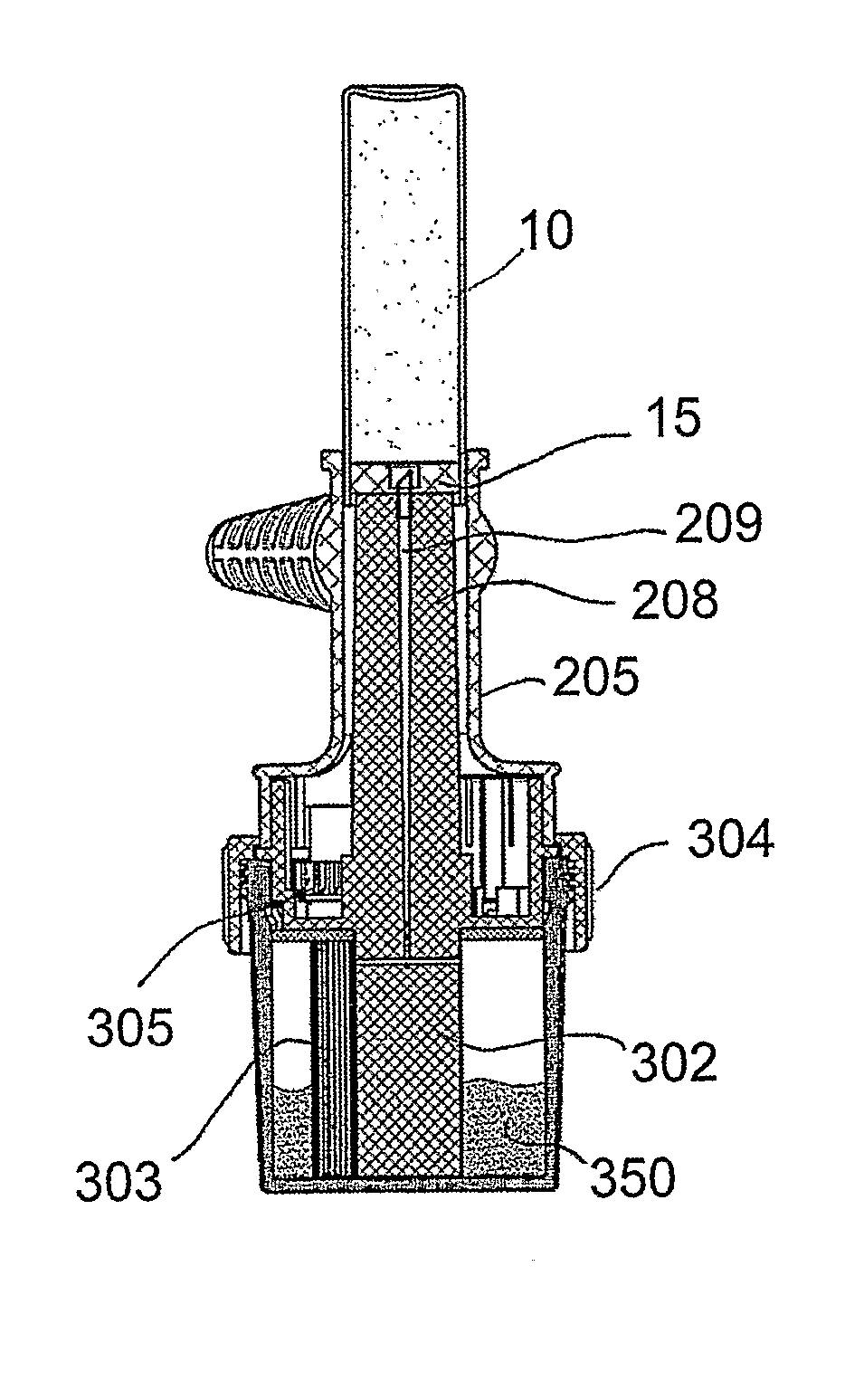

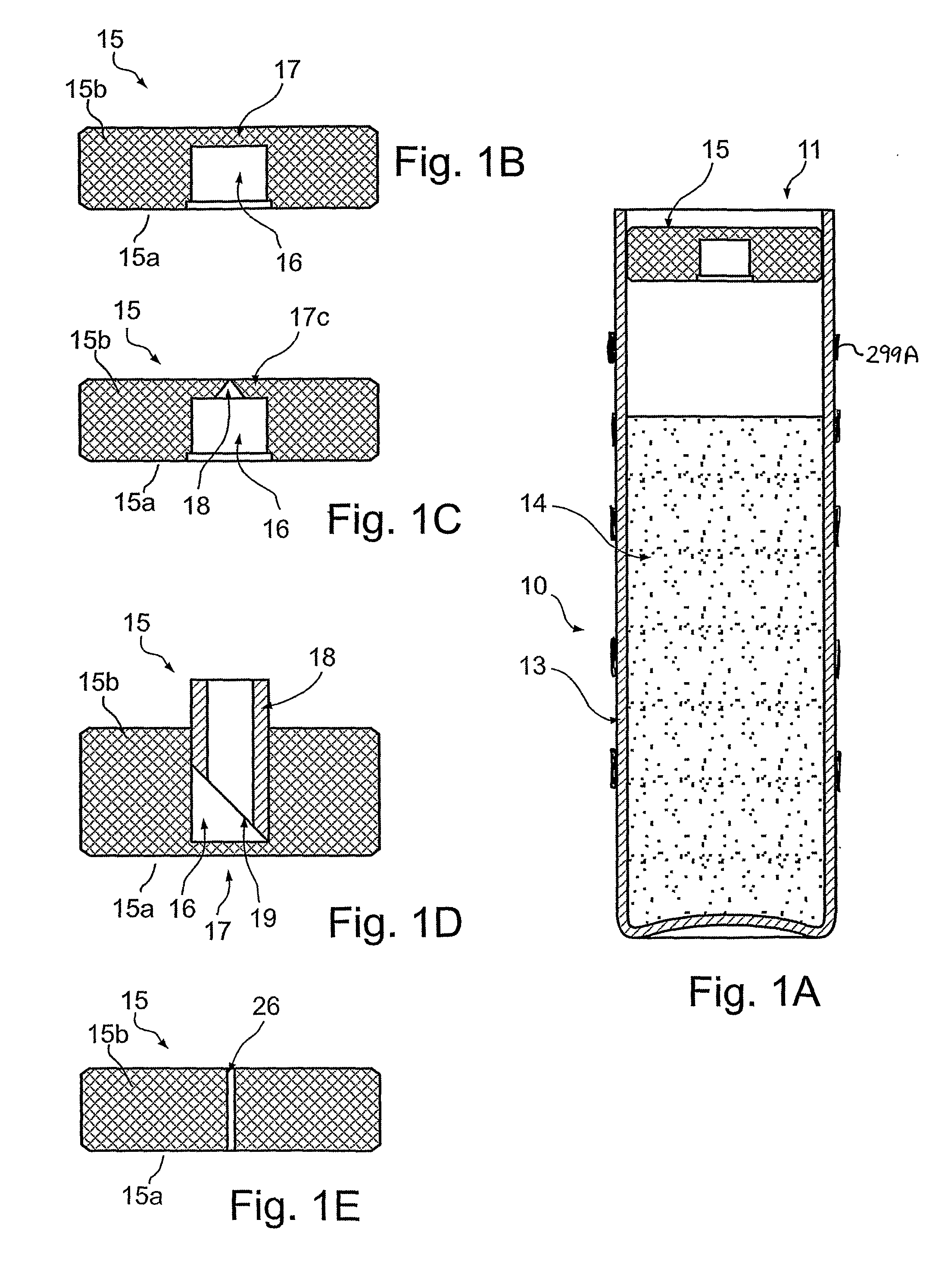

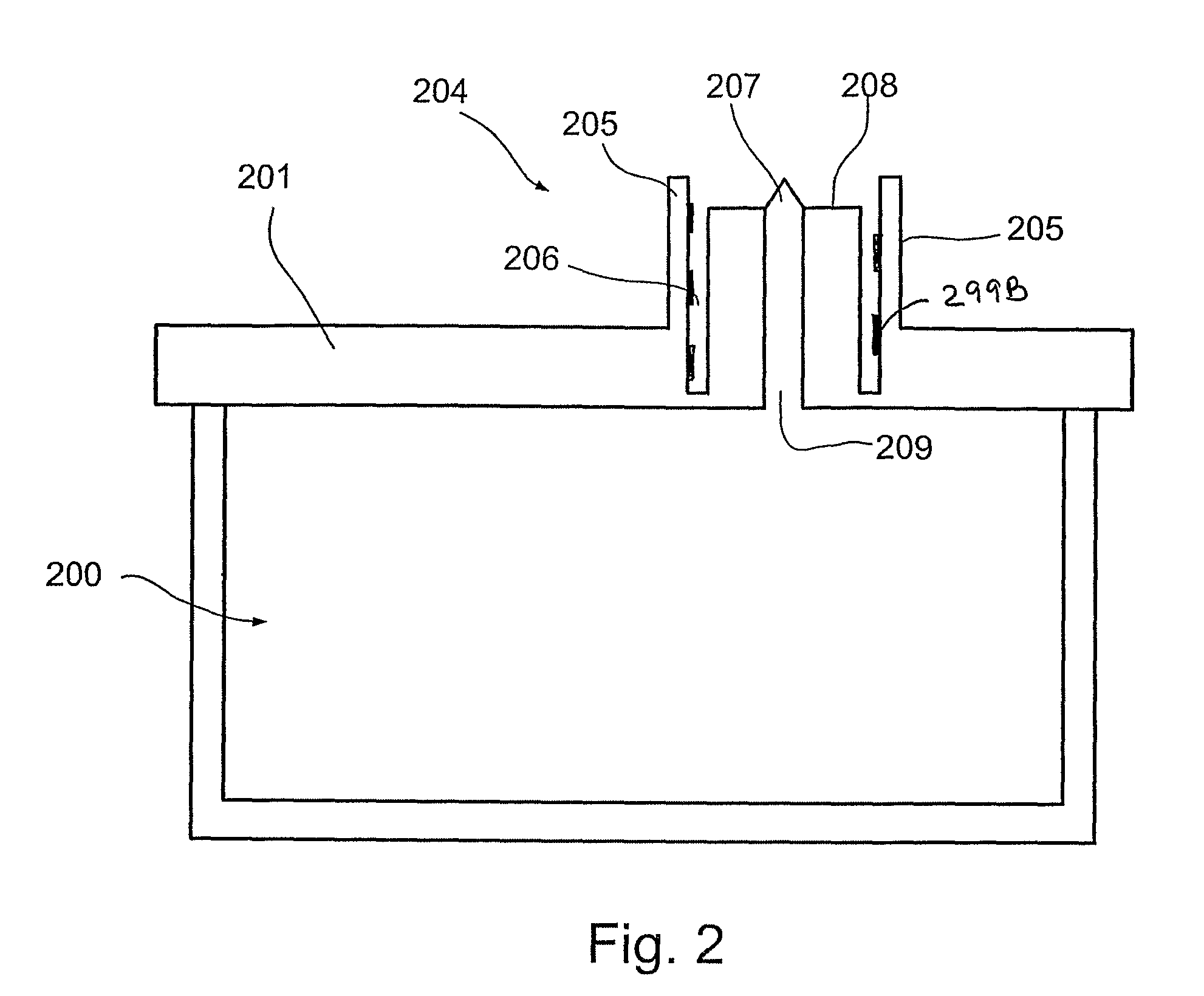

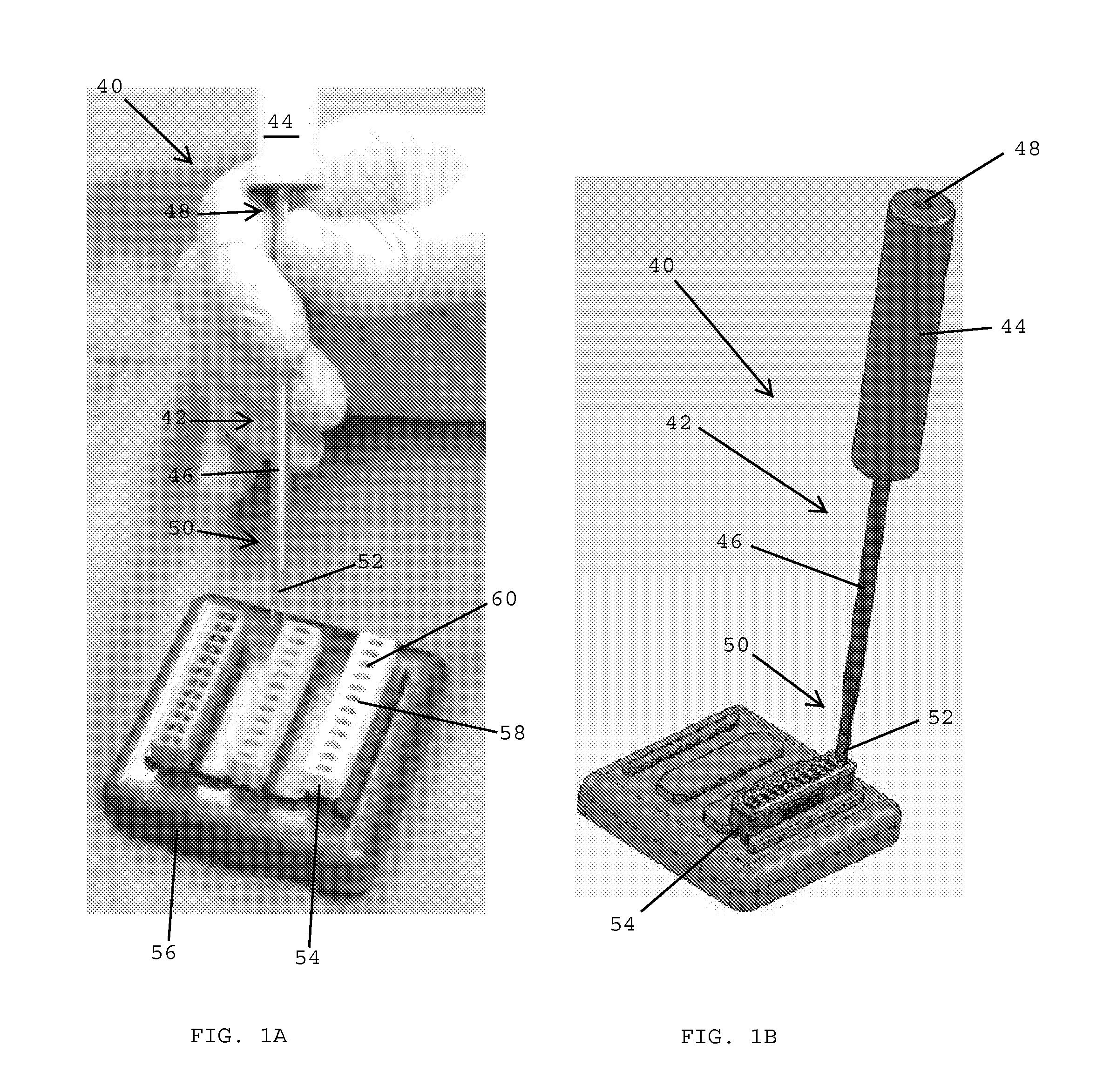

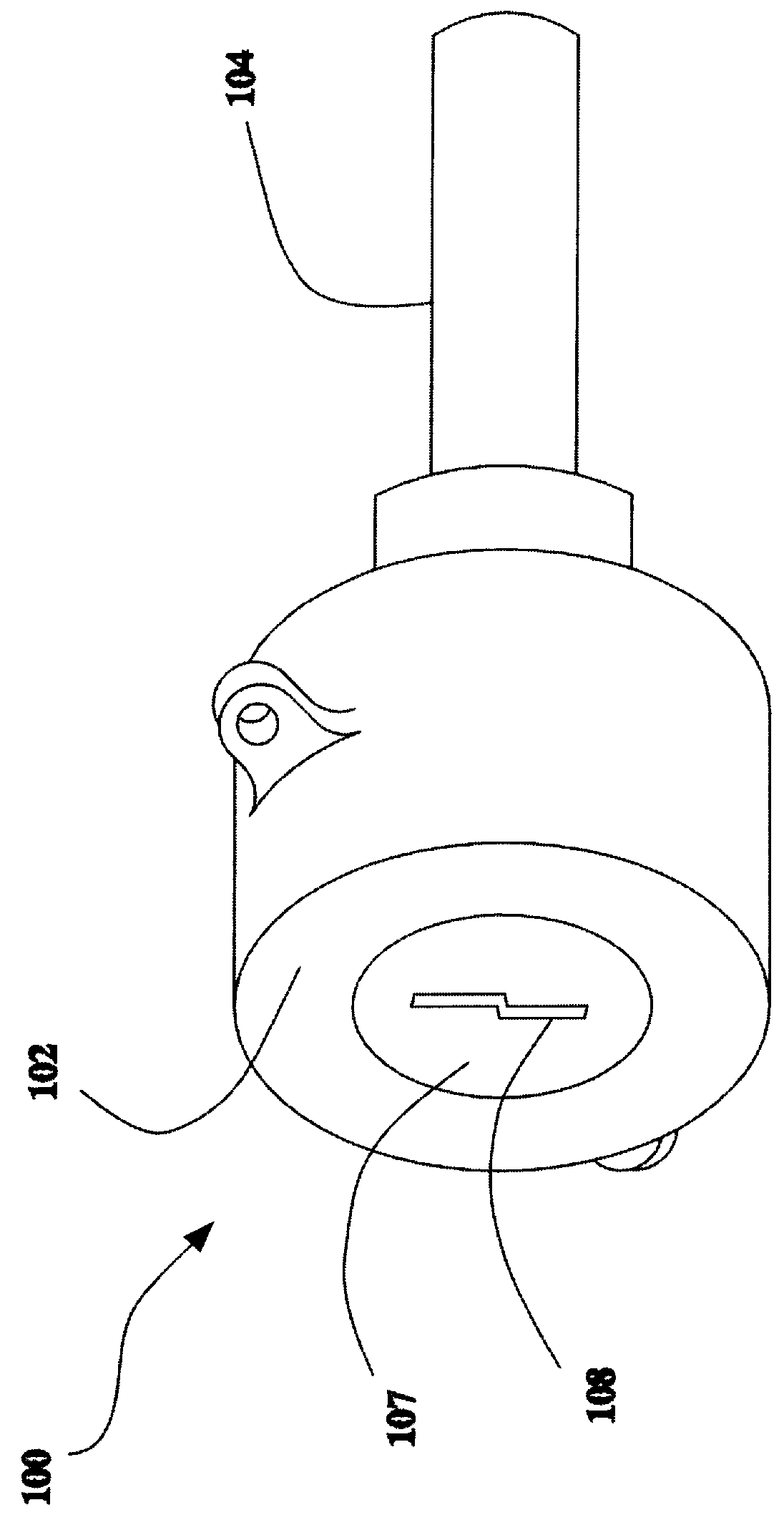

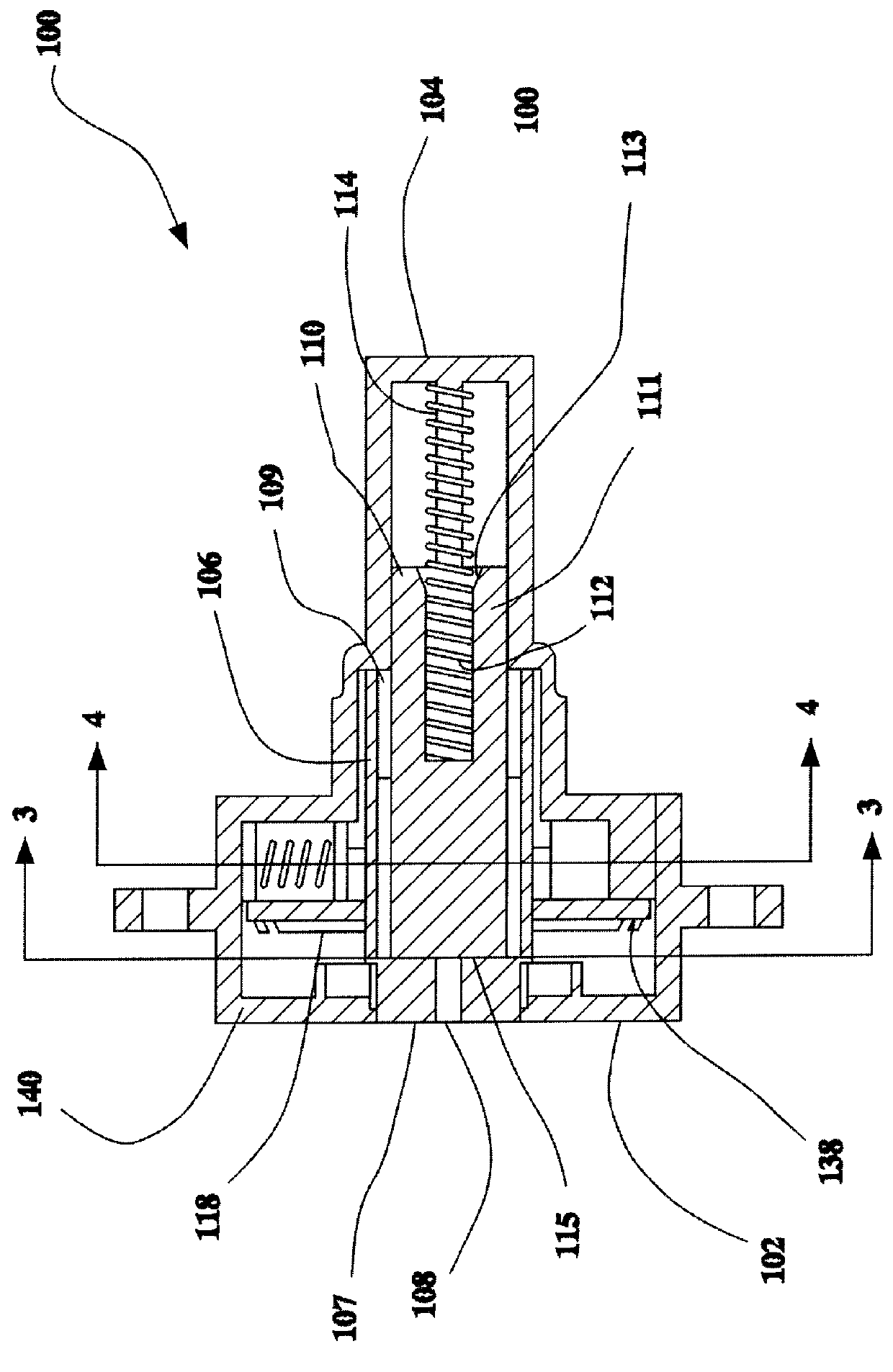

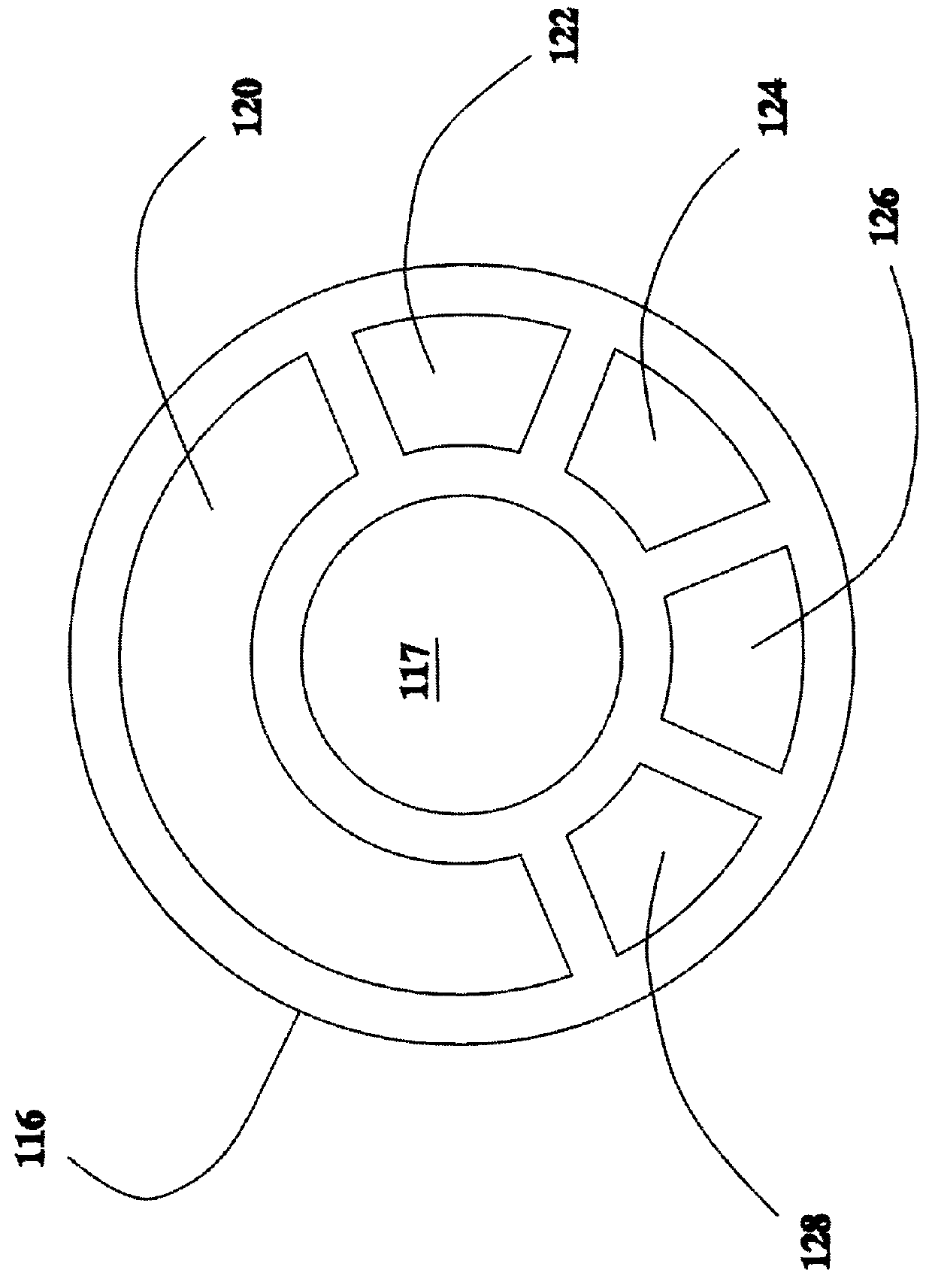

Catheter insertion mechanism for a patch pump

ActiveUS20170021137A1Easy to insertReduce in quantityGuide needlesMedical devicesSkin surfaceManual insertion

Manual insertion device has retraction spring (202) and hollow septum configuration (224) implemented using barrel-shaped guides (108, 110) and a guiding boss (210) in insertion device housing (106), and provides a fluid path through alignment of septum openings, side-port openings and catheter openings upon complete catheter insertion. Button (200) causes manual insertion of introducer needle (204) and catheter (220) of a first barrel (108) into a skin surface, and loading of retraction spring (202) disposed in an adjacent second barrel (110). Once introducer needle (204) and catheter (220) are fully inserted, the introducer needle hub (206) is released and automatically retracted by release of the retraction spring (202), leaving the catheter (220) in the user's body. Septums (218, 224) and side-port openings (216, 228) in the button (200) and introducer needle (204) are thus aligned, creating an uninterrupted fluid path between a reservoir or pump and catheter (220).

Owner:BECTON DICKINSON & CO

Treatment and prevention of systemic bacterial infections in plants using antimicrobial metal compositions

An embodiment of the invention is a treatment for the mitigation and prevention of systemic infection of plants using materials derived from bactericidal metals wherein one metal is silver. The candidate bactericidal metal is preferably introduced in metallic, nanocrystalline, salt form, chelated form, or otherwise coupled form. Metal atoms, ions, molecules, clusters, or particles in concentrations between 0.001 to 100,000 parts per million (ppm) may be employed, wherein the preferred concentration of silver is sufficient to suppress bacterial viability. The bactericidal principle is preferably introduced to the plant by injection, ballistic insertion, pneumatic insertion, mechanical insertion, manual insertion, root application, aerosolization or spray in order to effect the treatment and prevention of systemic plant infections by bacterial agents of disease or reduced productivity.

Owner:NEWMAN KAREL

Electronic card encoder

InactiveUS20050258244A1Reduce the possibilityCompact and inexpensive structureDigitally marking record carriersConveying record carriersManual insertionEngineering

A key card encoder incorporates a plunger that is pushed downward as the card is manually inserted into a slot in the encoder and a potentiometer whose value changes based on the plunger position to indicate the card's position at all times. As the card is inserted into the slot, a head encodes a magnetic strip on the card as the card is inserted into the slot, while the head verifies the code in the reverse direction as the card is withdrawn from the slot. The slot is illuminated in different colors and flashing patterns to guide the user through the encoding process and notify the user if there is an encoding error.

Owner:COMPIZED SECURITY SYST

Reusable hasp-locking mechanism

A locking mechanism for use on a hasp or other hardware of a door including a housing with an opening configured to receive the hasp, and a locking member that is removable from the locking mechanism during a normal unlocking operation. The locking member is insertable through at least a portion of the housing and the hasp into a locked position. The locking mechanism also includes a locking pin that is engageable with the locking member to lock the locking member in the locked position, and a spring biasing the locking pin in a first direction to lock the locking member. The locking member may have a first end and a second end, wherein the first end has a tapered surface. The tapered surface is engageable with the locking pin to push the locking pin in a second direction opposite the first direction so that the locking member may be manually inserted into the locked position. The locking member may be located predominantly within the housing when in the locked position. In one embodiment, the locking mechanism further includes a second spring, and the second spring biases the locking member along a longitudinal direction thereof when the locking member is in the locked position. The second spring may push the locking member out of the locked position when the locking pin is retracted. In one embodiment, the locking mechanism further includes an electro-mechanical device that retracts the locking pin to release the locking member from the locked position when actuated. The locking member may be manually inserted into the locked position.

Owner:TRANSGUARD INDS

Fluid Delivery System

ActiveUS20100065154A1Prevent undesired backwards movementFacilitates pushing the liquidCapsRotary stirring mixersManual insertionClosed chamber

A fluid delivery system for dispensing a liquid from a sealed container directly into a closed chamber comprises a container containing a liquid component of bone cement and plugged with a plug, and a closed chamber comprising a receiving port for receiving the sealed container, wherein the receiving port is configured to receive the liquid component in direct response to manual insertion of the sealed container through the receiving port using an open loop system.

Owner:DEPUY SYNTHES PROD INC

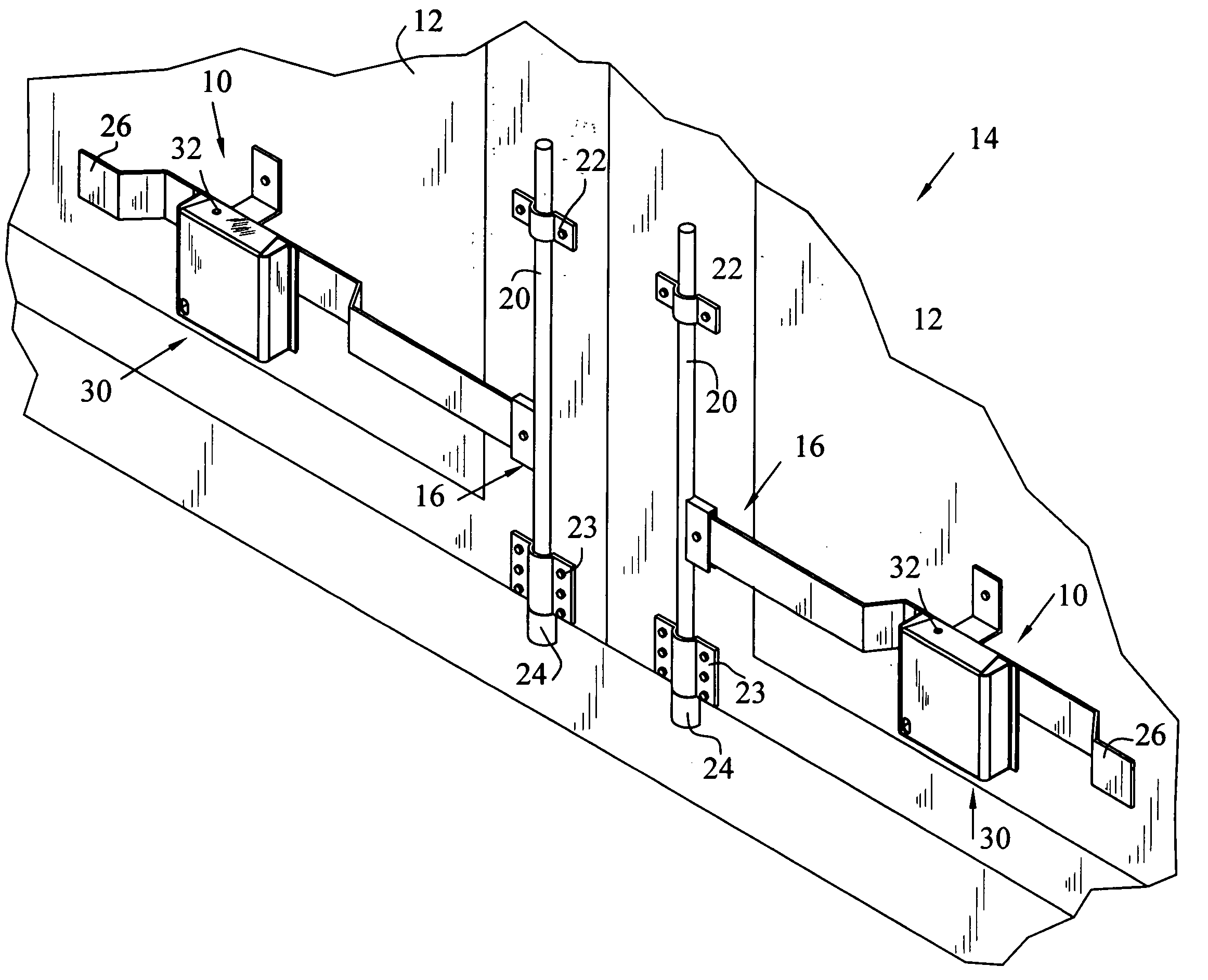

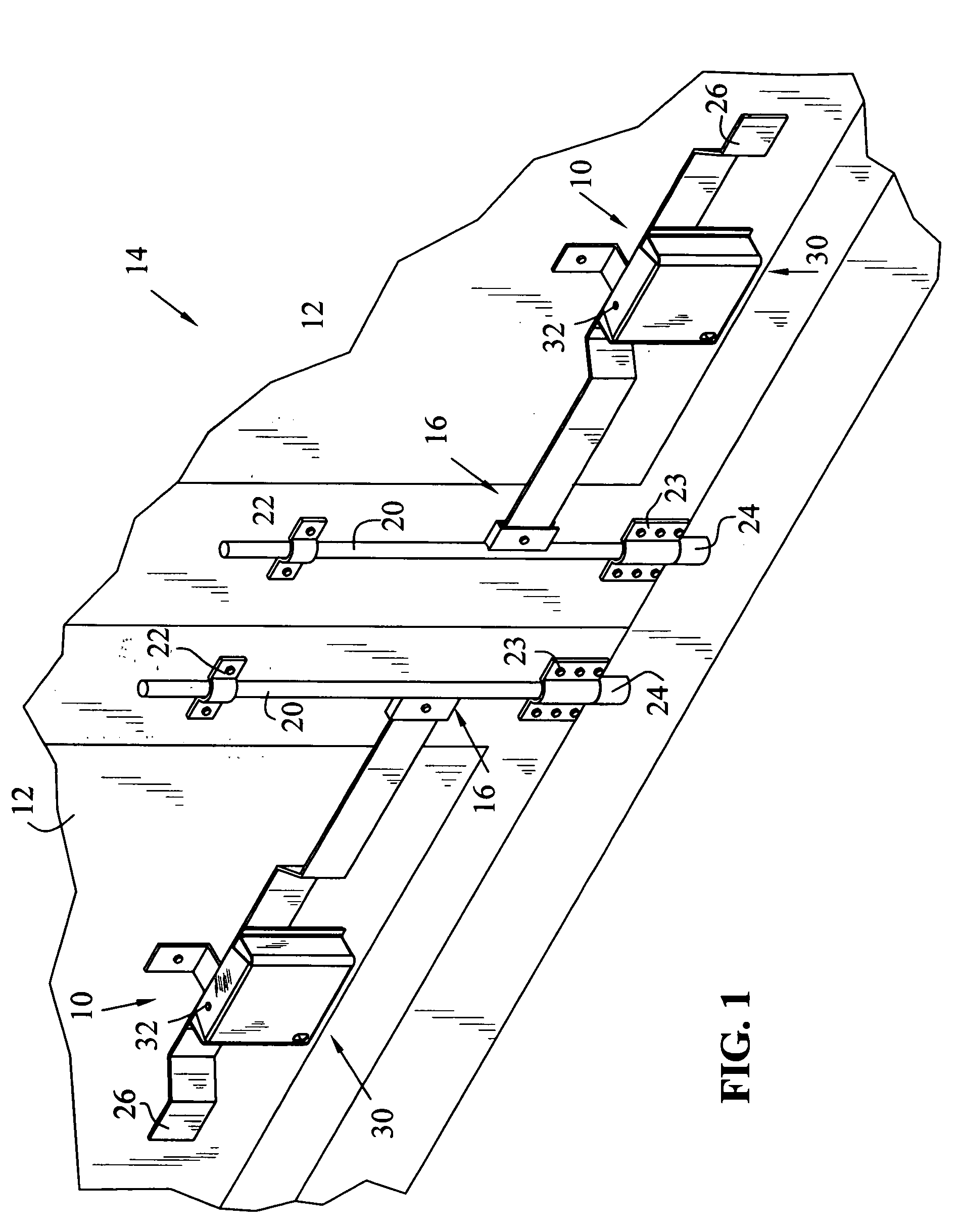

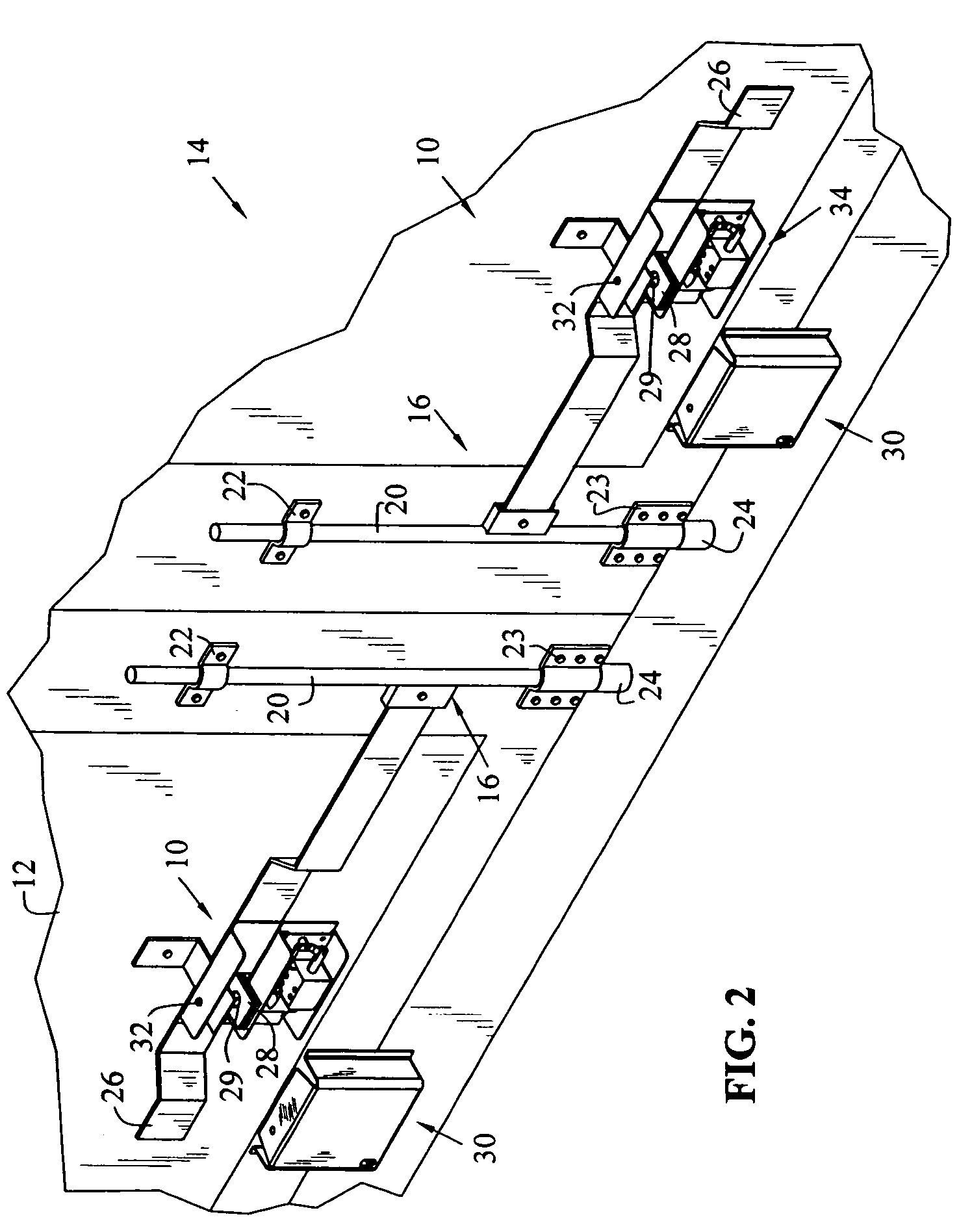

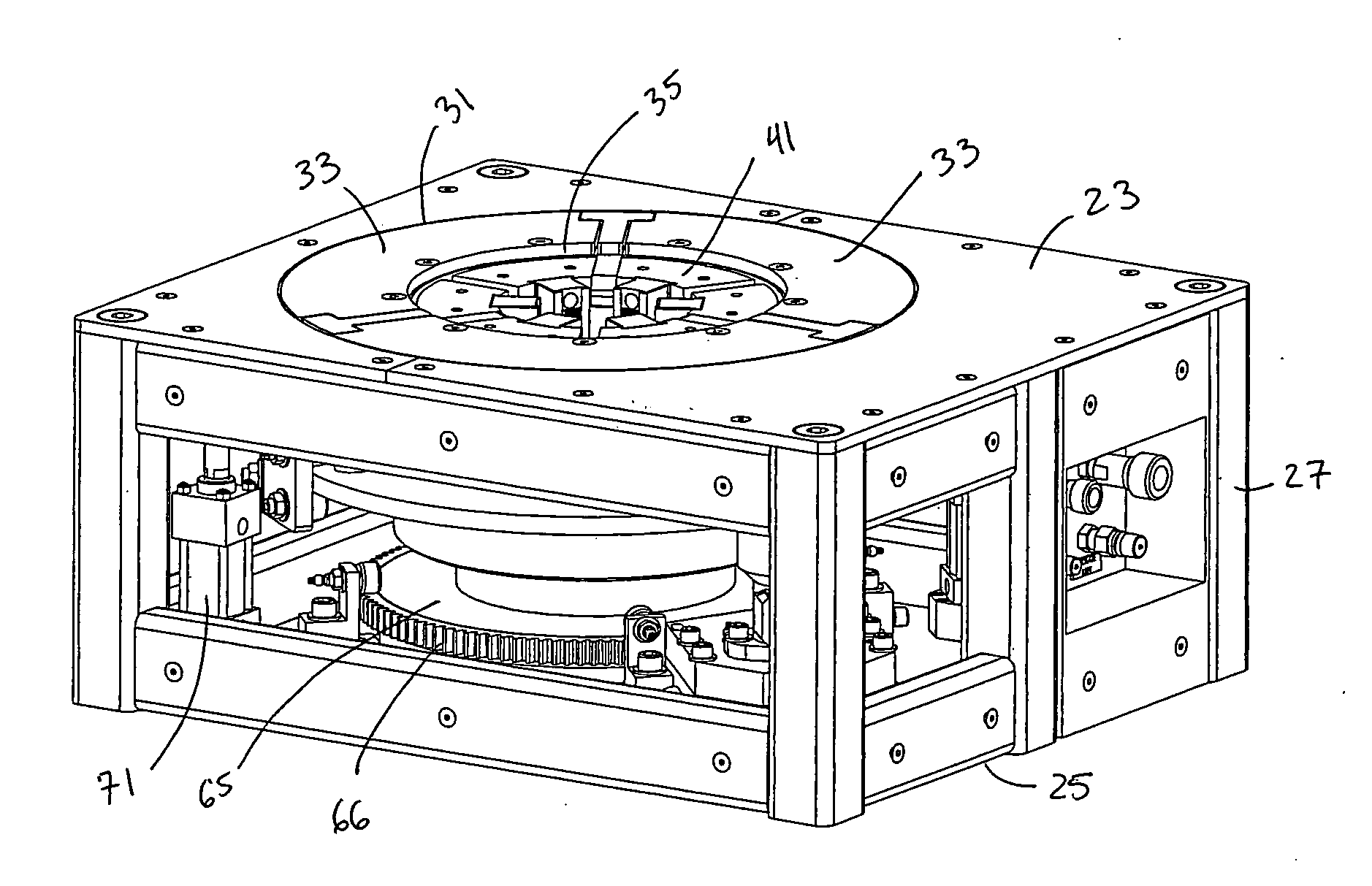

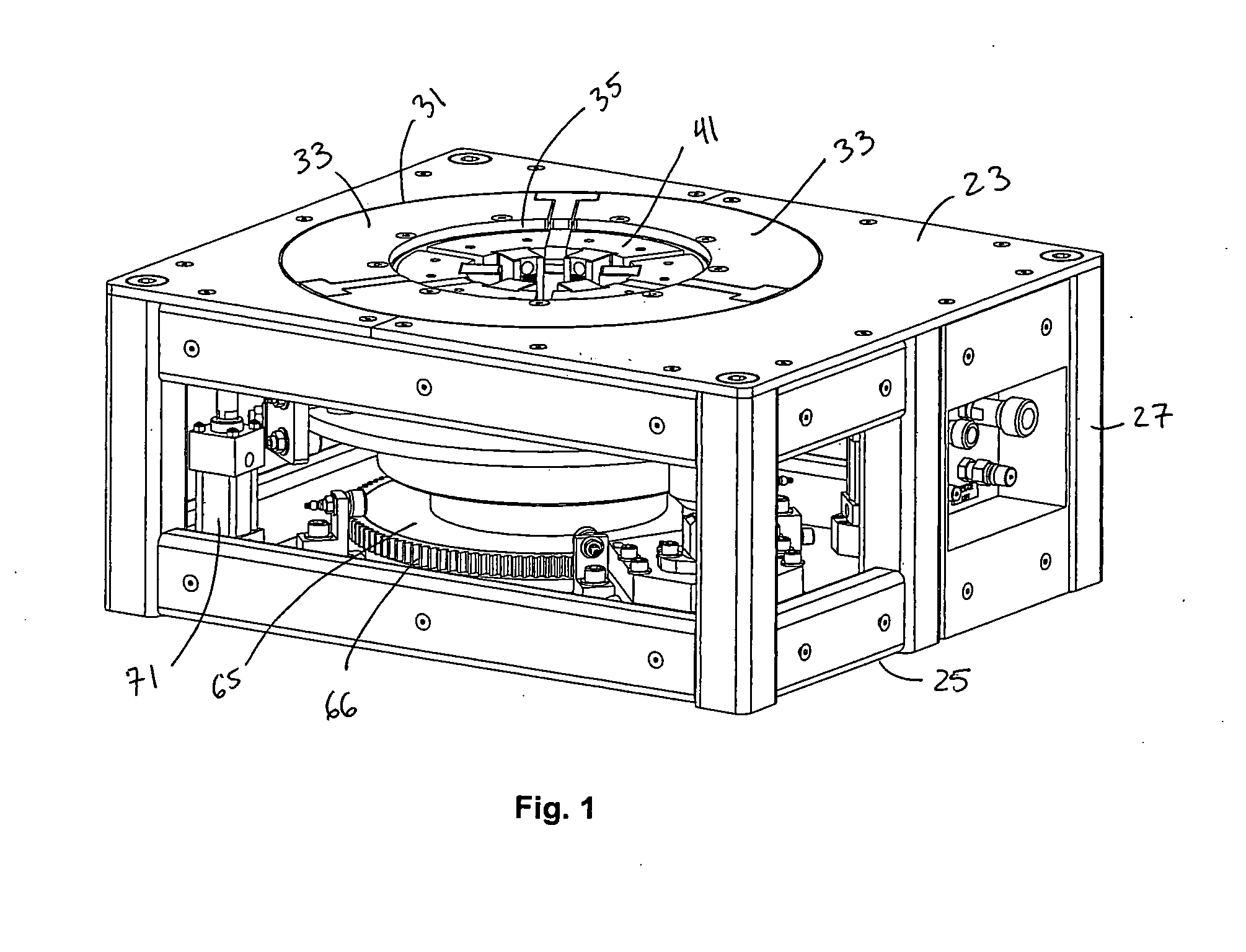

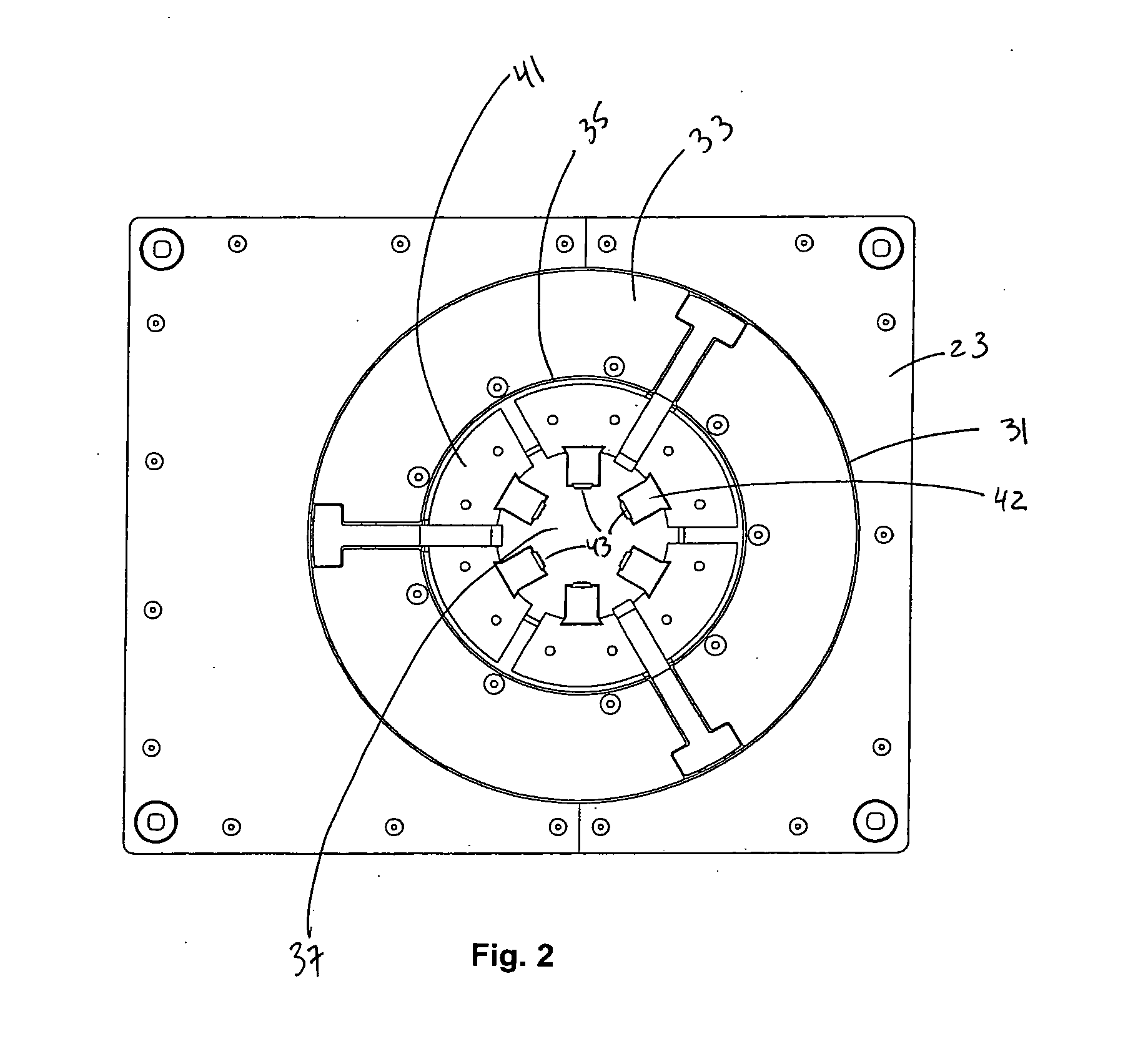

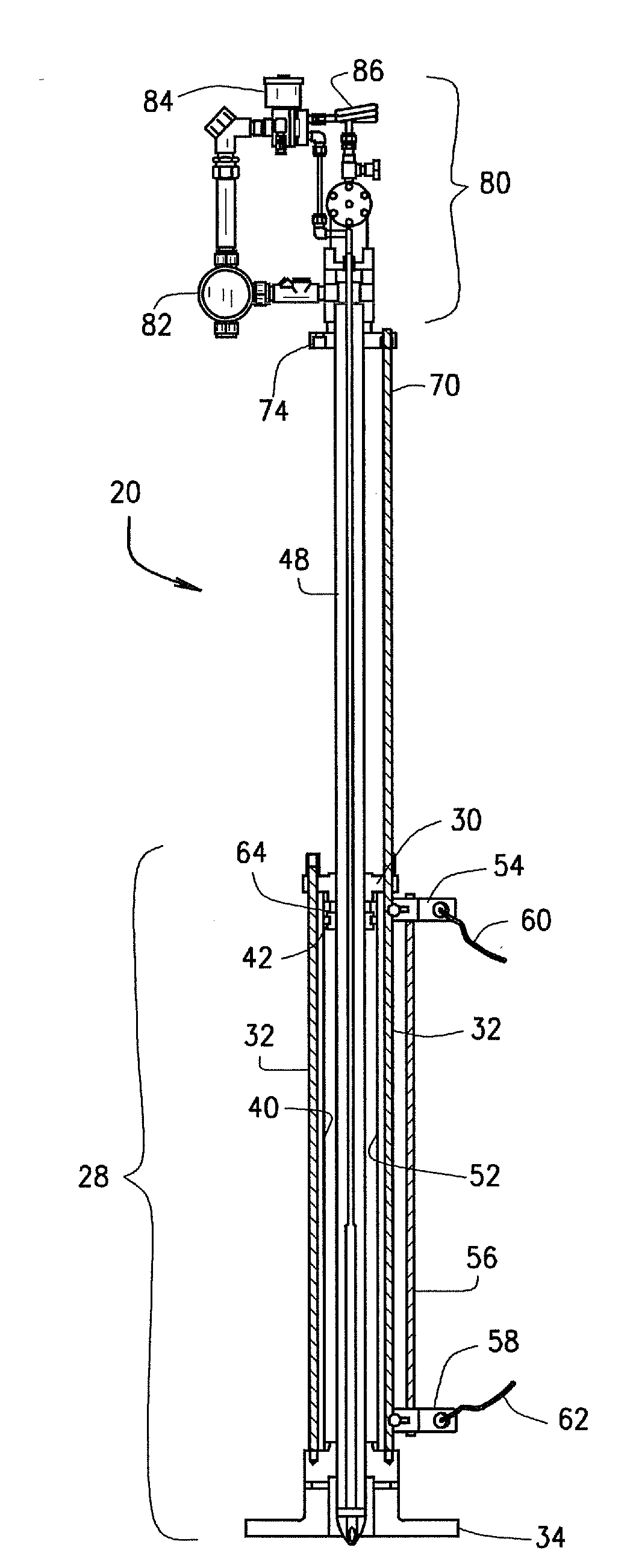

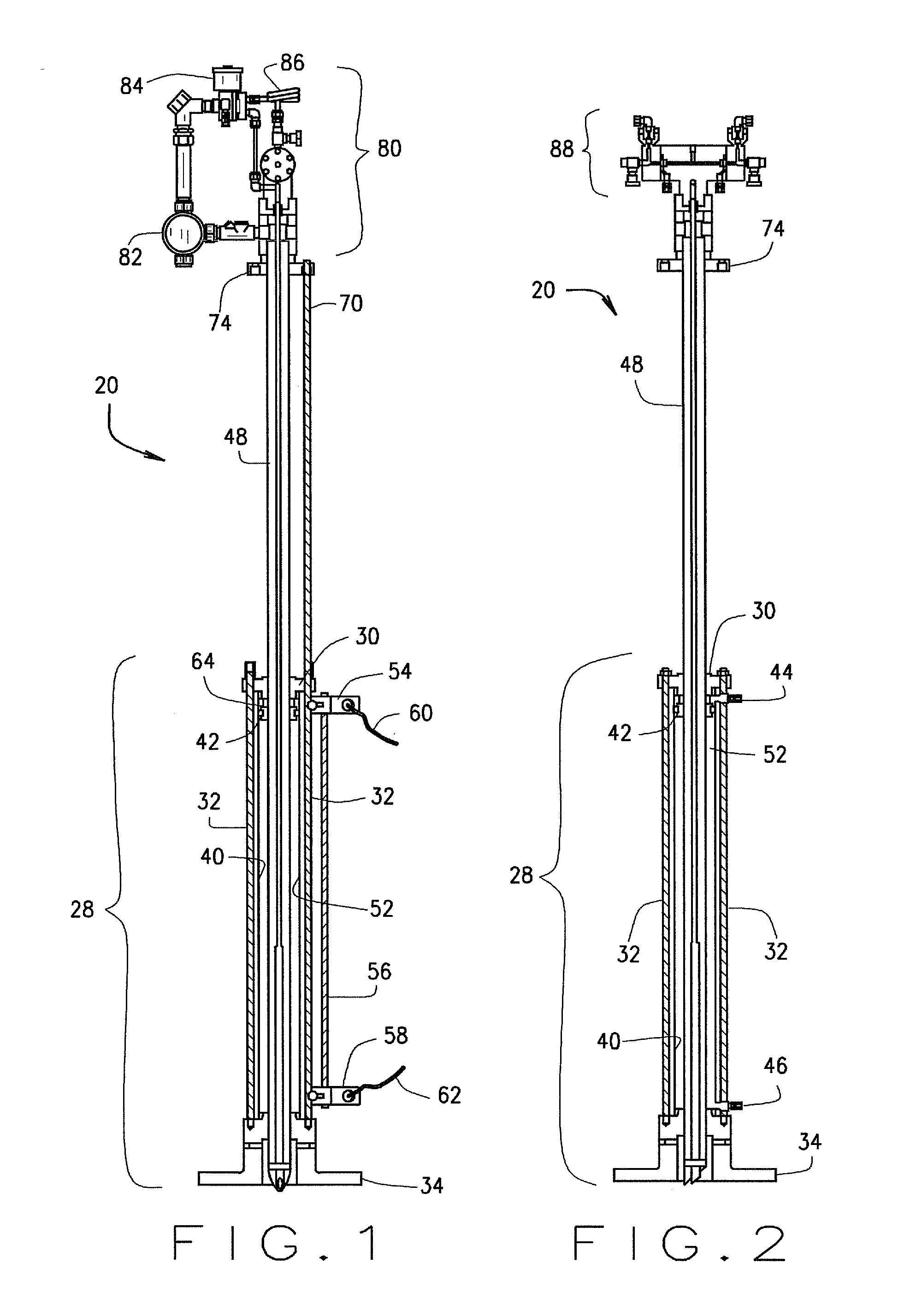

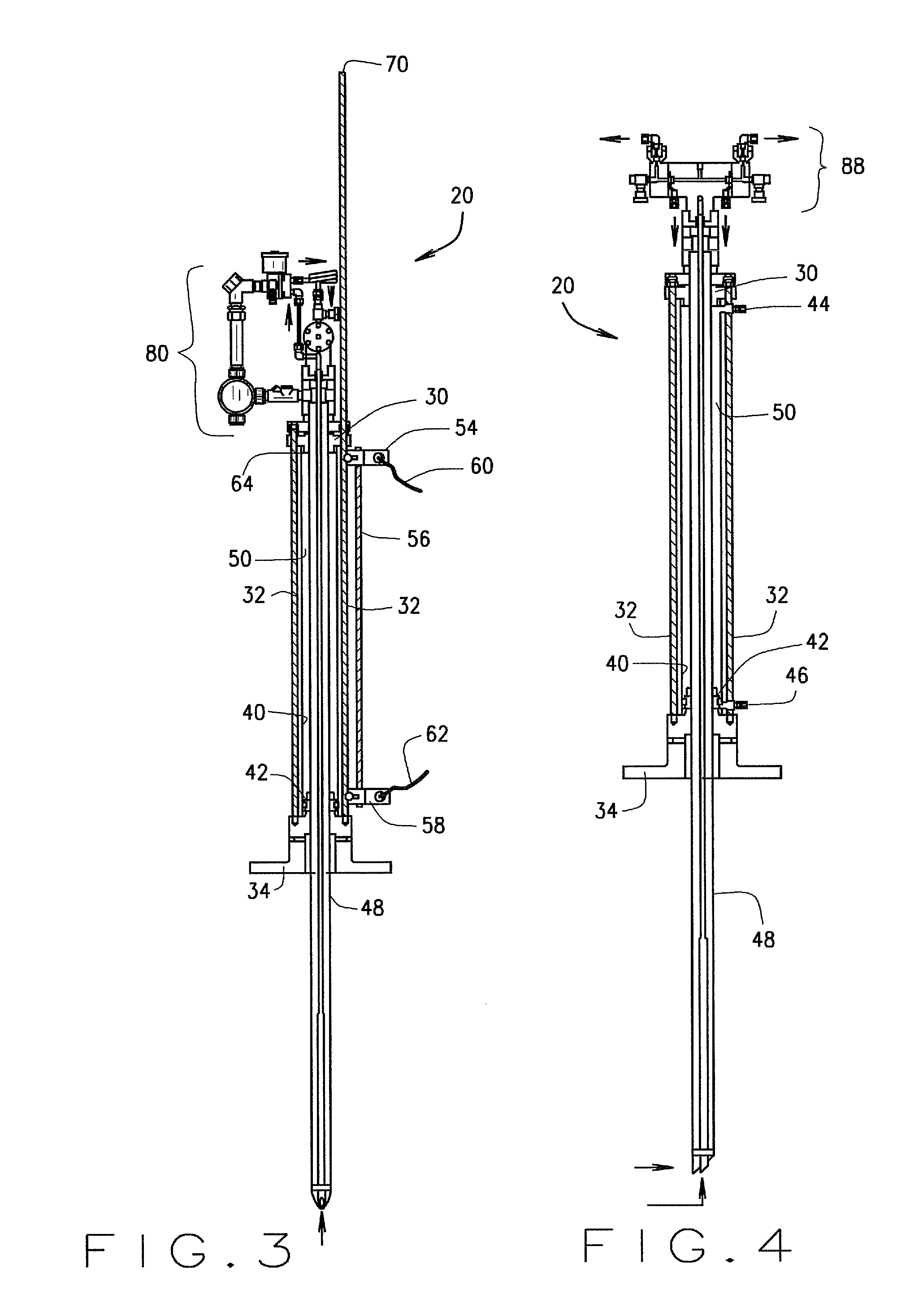

Mouse hole support unit with rotatable or stationary operation

InactiveUS20080202813A1Easy to set upConsiderable timeDrilling rodsConstructionsManual insertionDrill line

The present invention provides improved methods and apparatus for supporting and engaging drill pipe in a mouse hole that allows for multiple drill pipe sections to be attached together before being attached to an existing drill string. The present invention is designed to allow for engagement and disengagement of drill pipe sections of various diameters without the need for manually inserting or removing support shims or slips. Embodiments of the invention provide for rotation of the engaged drill pipe sections to assist in connection to another drill pipe section. These features allow for speedy set up and attachment of drill pipe sections during drilling operations. The support unit of the present invention is also portable, and may be retrofitted into an existing drill rig platform.

Owner:XTECH INDS

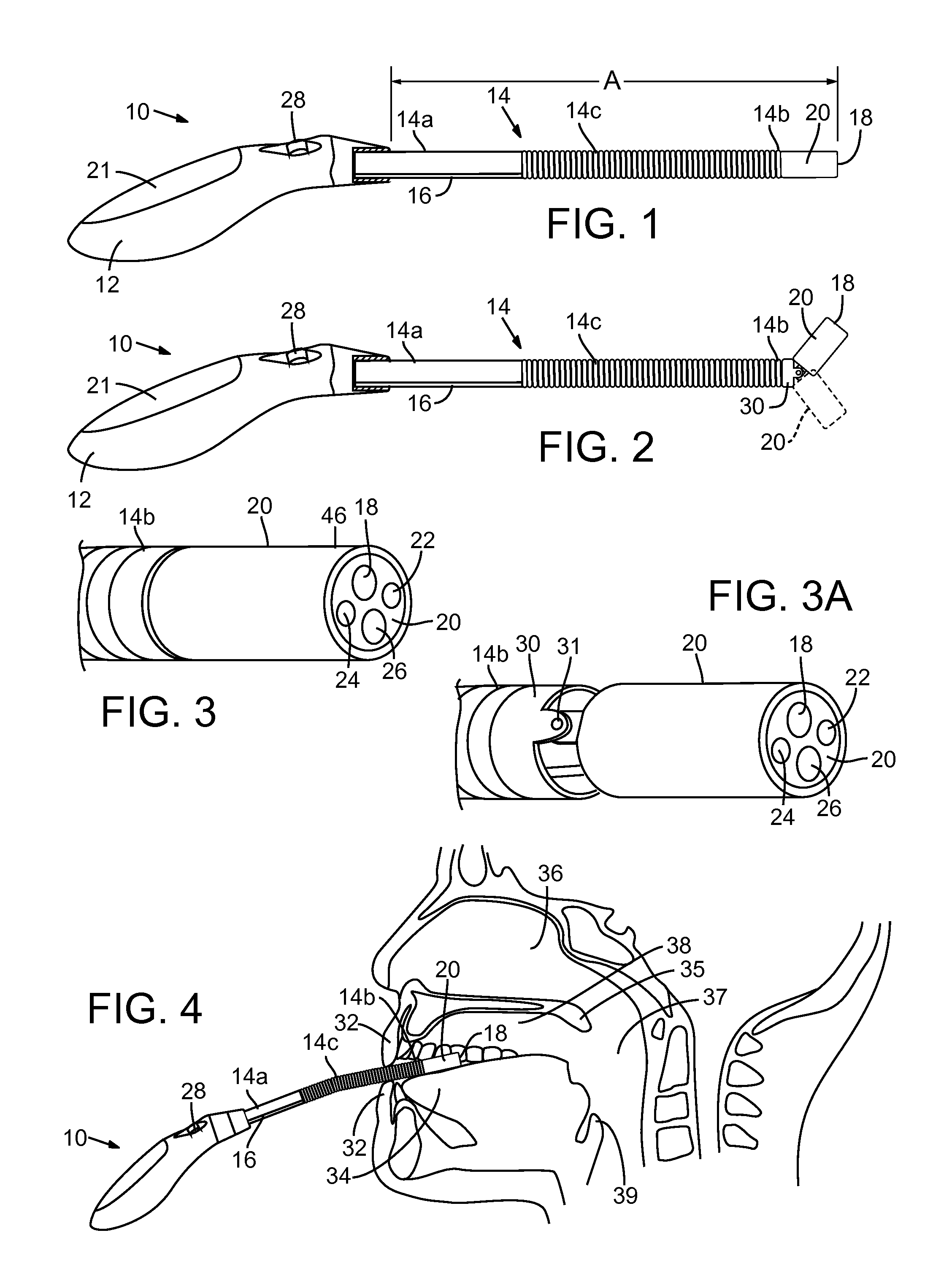

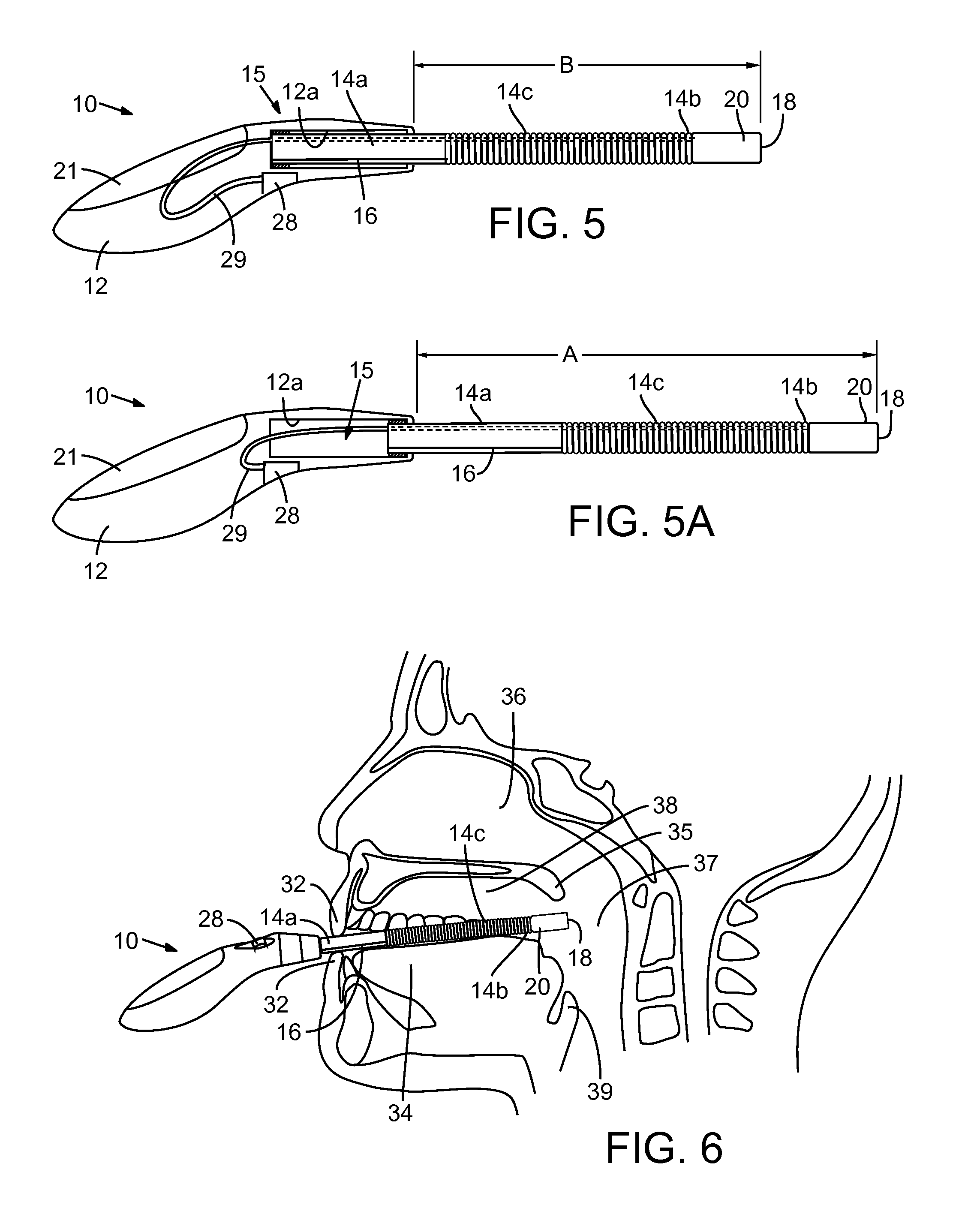

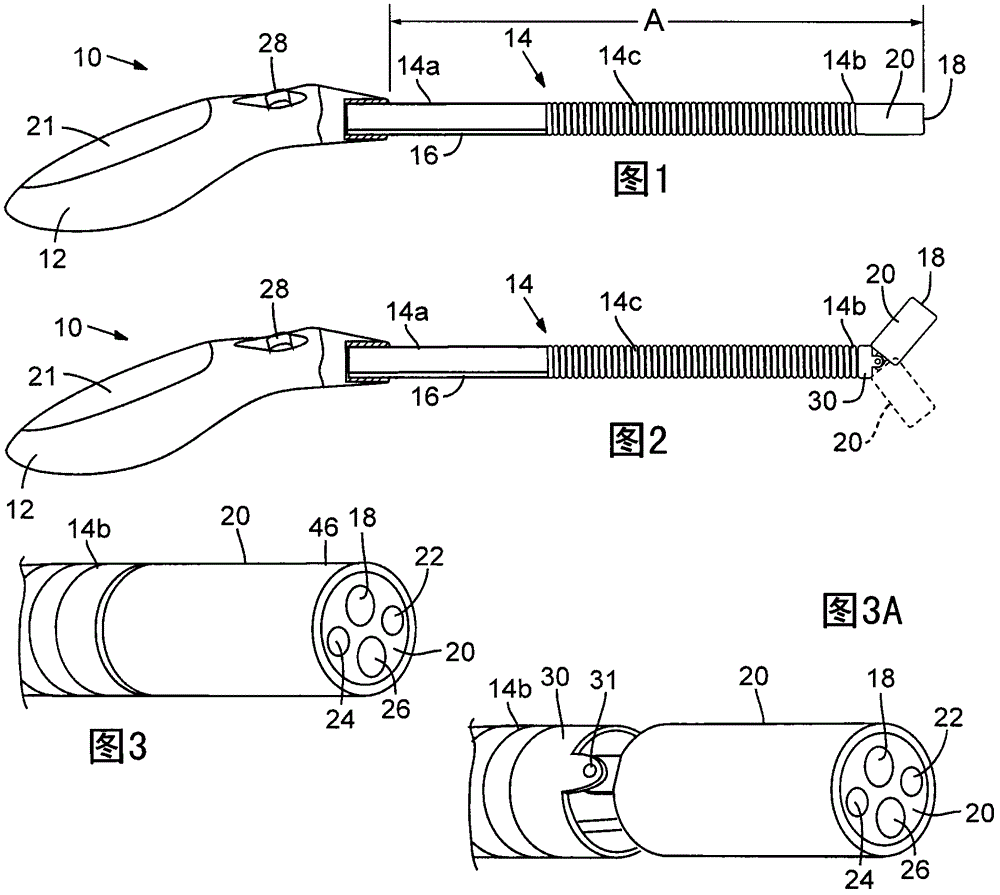

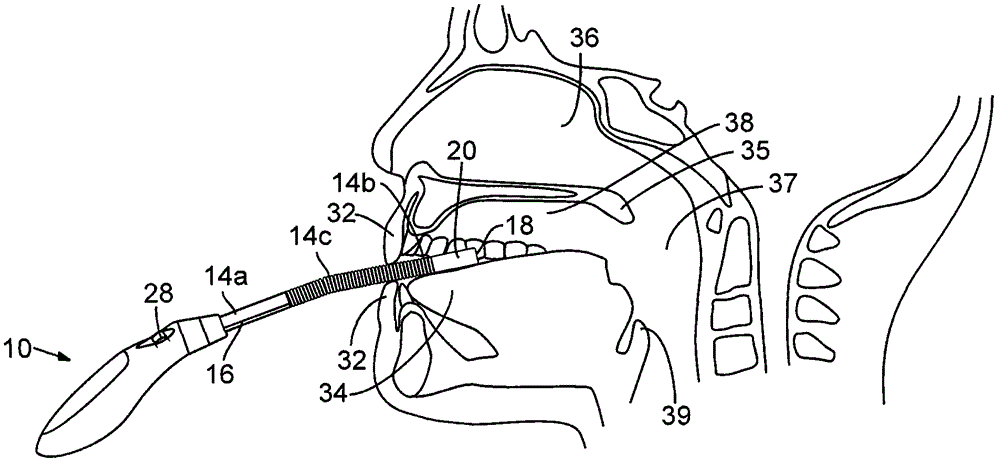

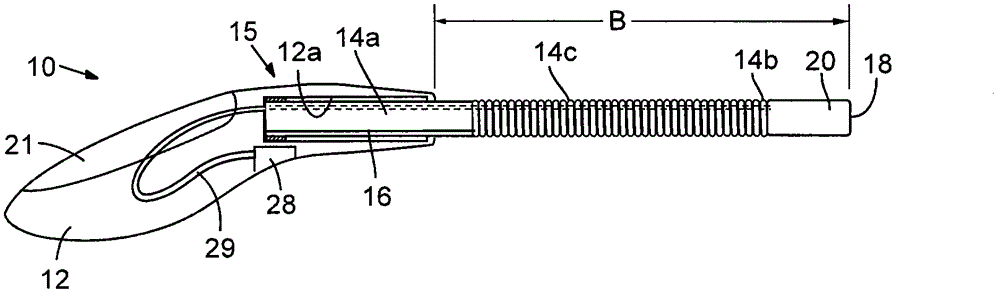

Oral scope system with image sensor and method for visual examination of oral cavity and upper airway

An oral scope instrument for facilitating visual examination and inspection of a person's oral cavity and upper airway includes an elongate, flexible arm having first and second ends, a temperature sensor connected to the flexible arm adjacent the first end, an image sensor mounted adjacent the second end, a processor in electrical communication with the image sensor and an image display device. An illumination unit located adjacent the second end provides illumination for the image sensor. A handle connected to the first end enables manual insertion of the flexible arm into the mouth along a portion of the top of the tongue to engage the temperature sensor therewith and position the image sensor for viewing and recording anatomical features of the oral cavity or the upper airway. The processor stores normal anatomical images and may transmit images of recorded anatomical features to the image display device.

Owner:QSCOPE

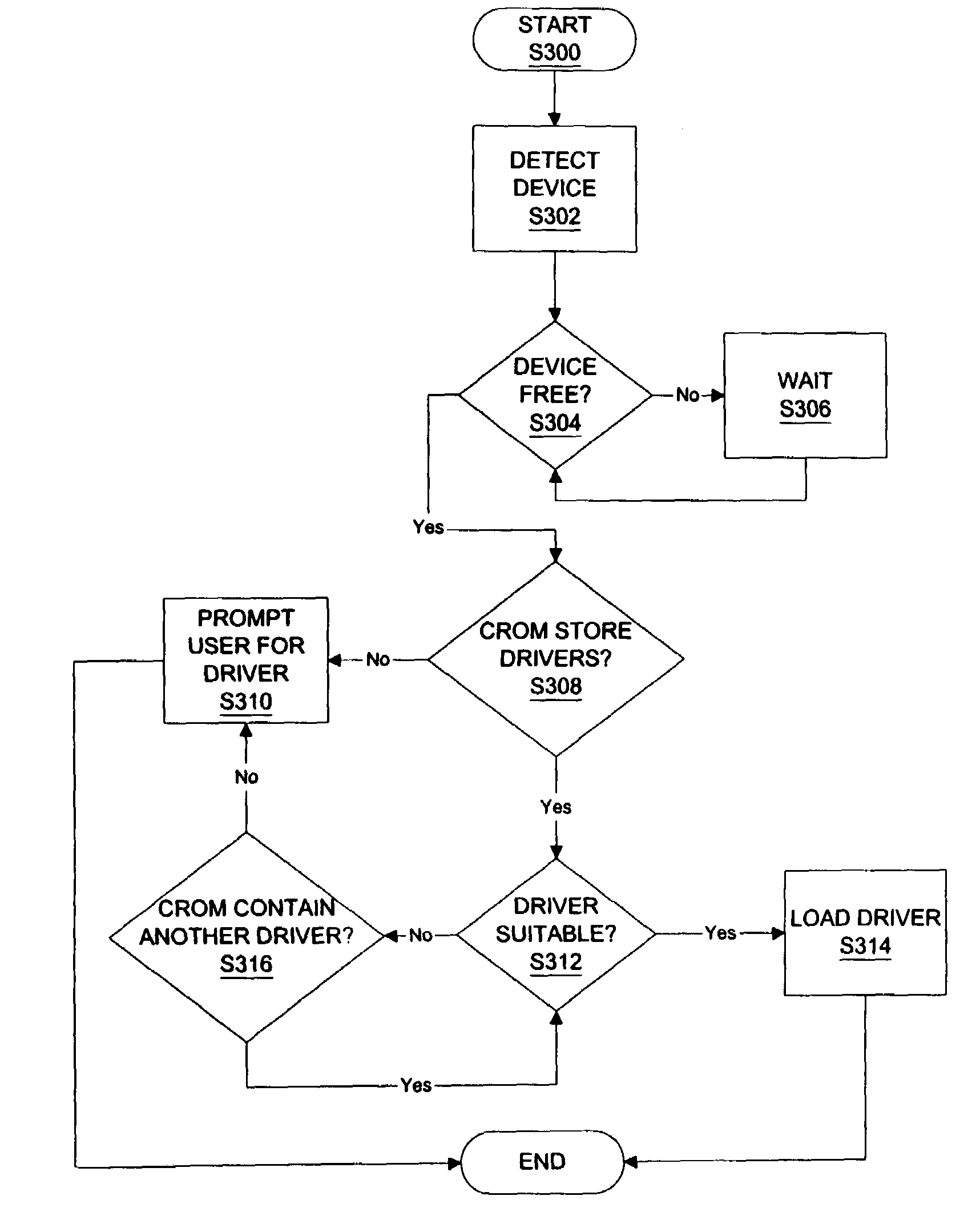

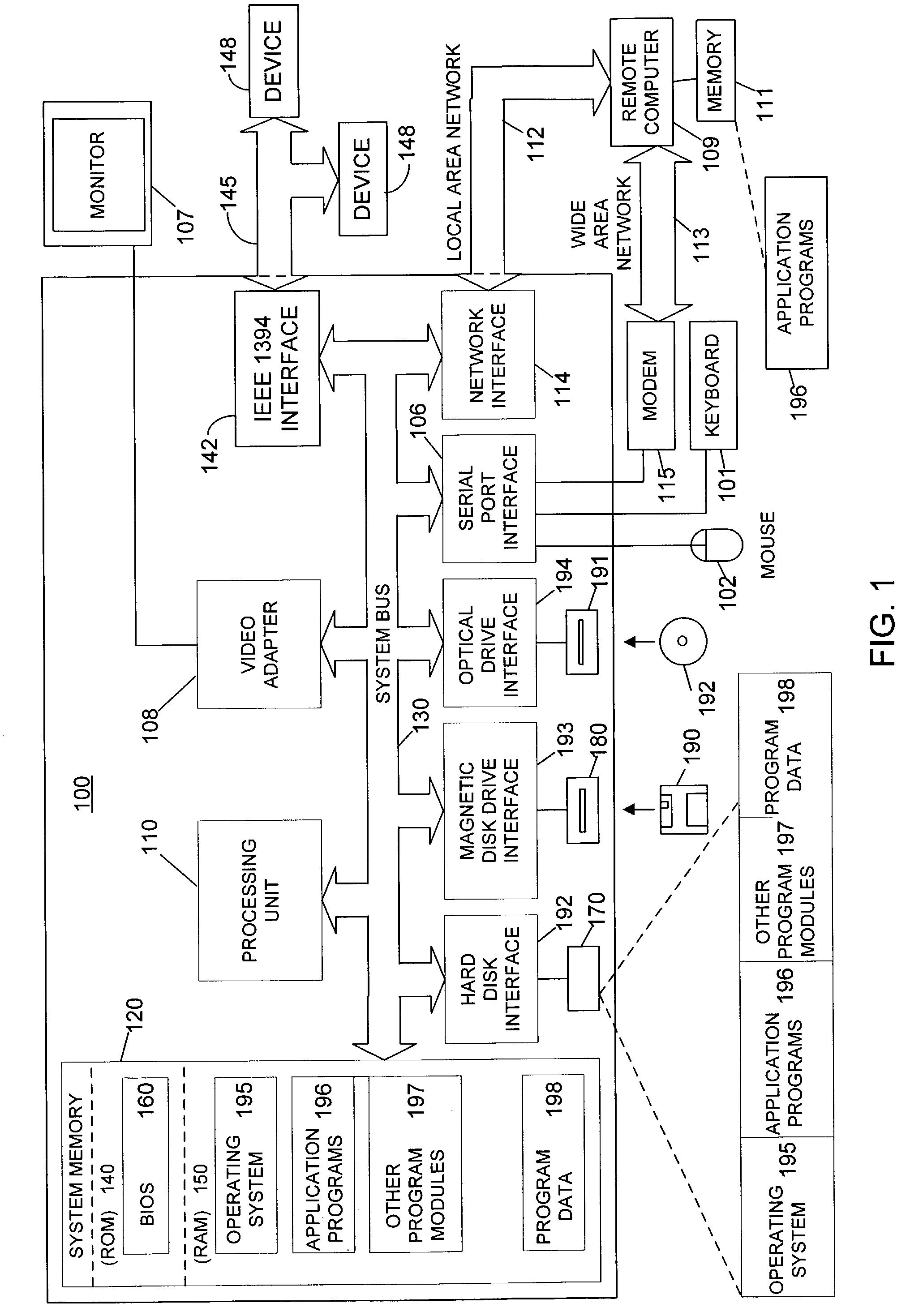

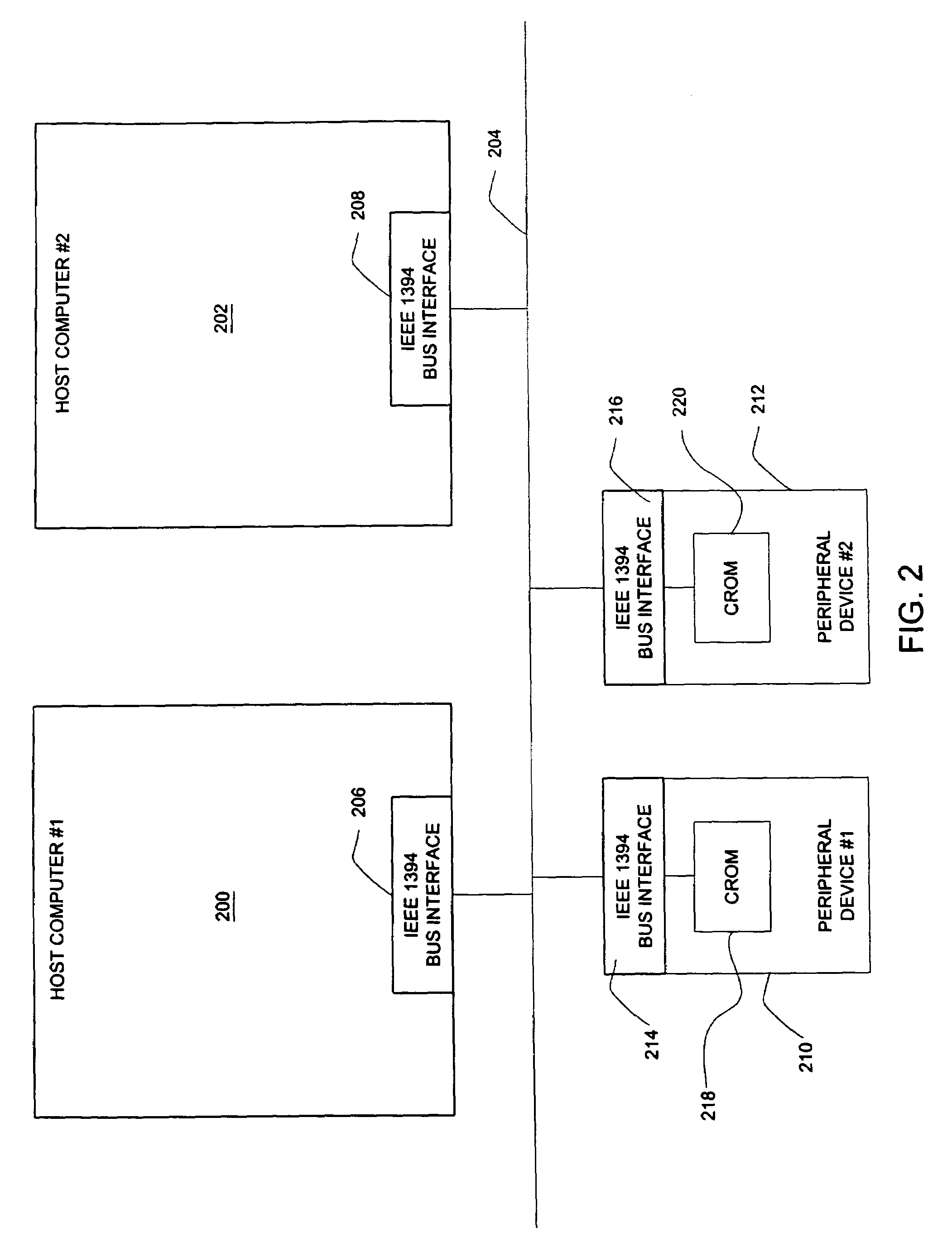

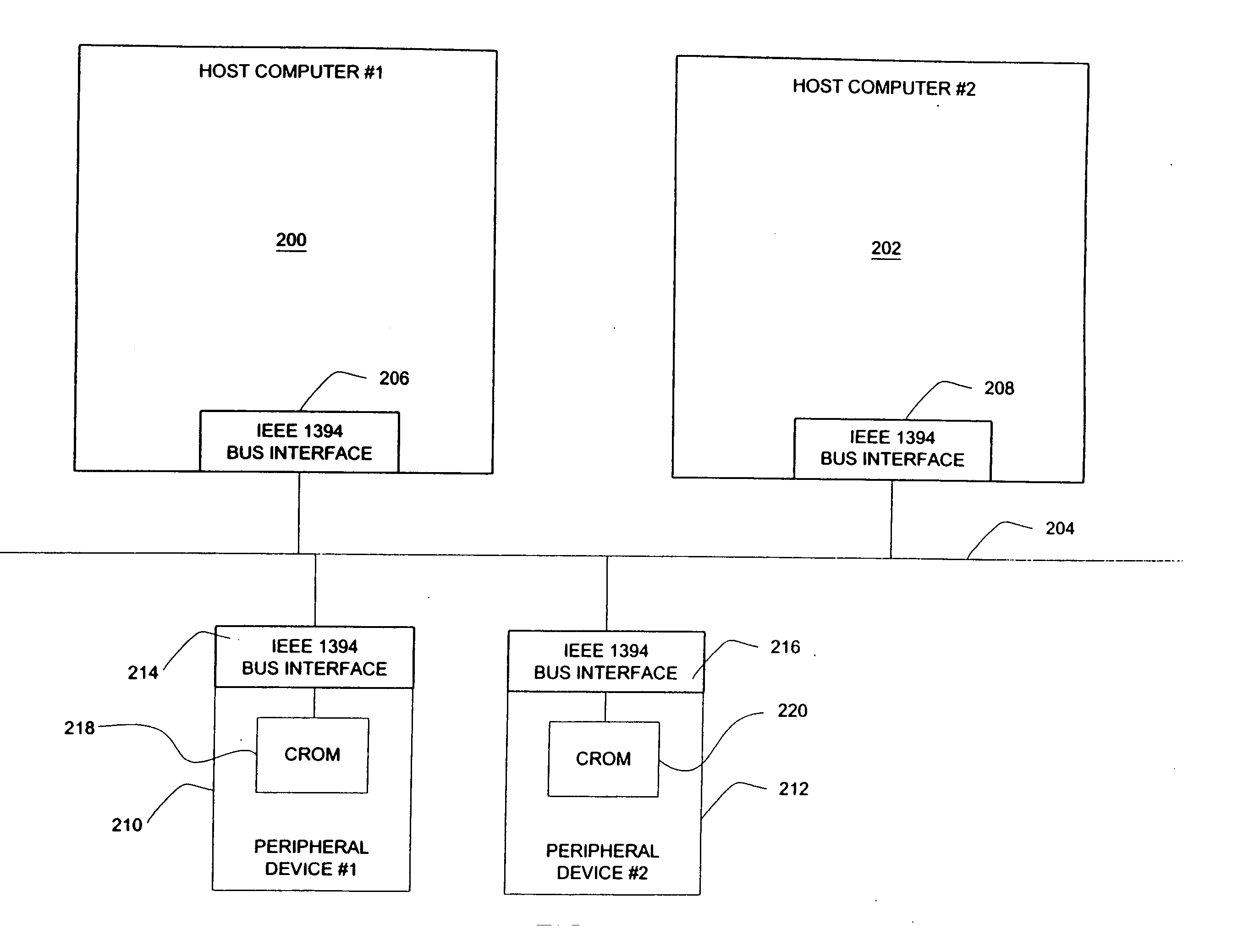

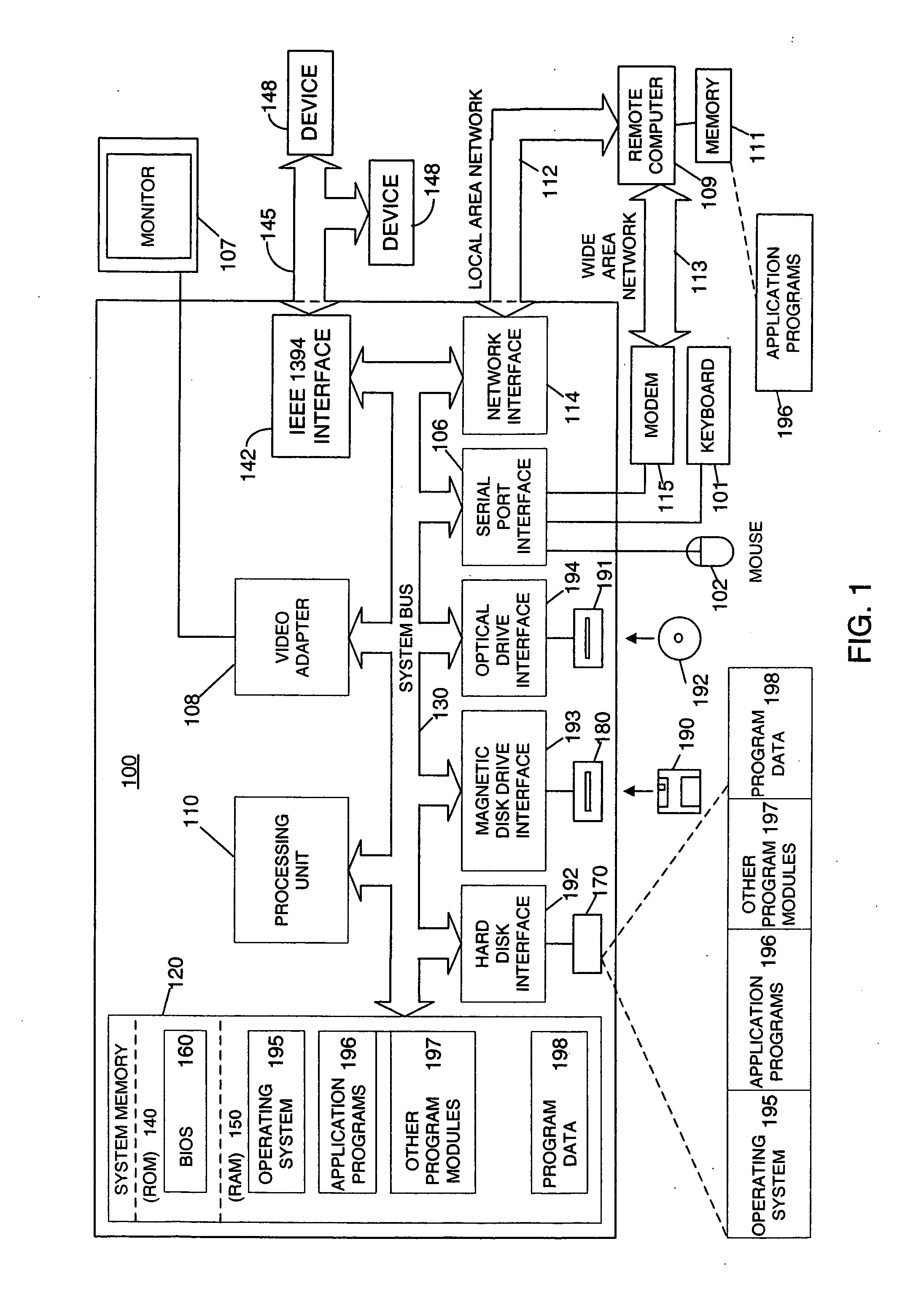

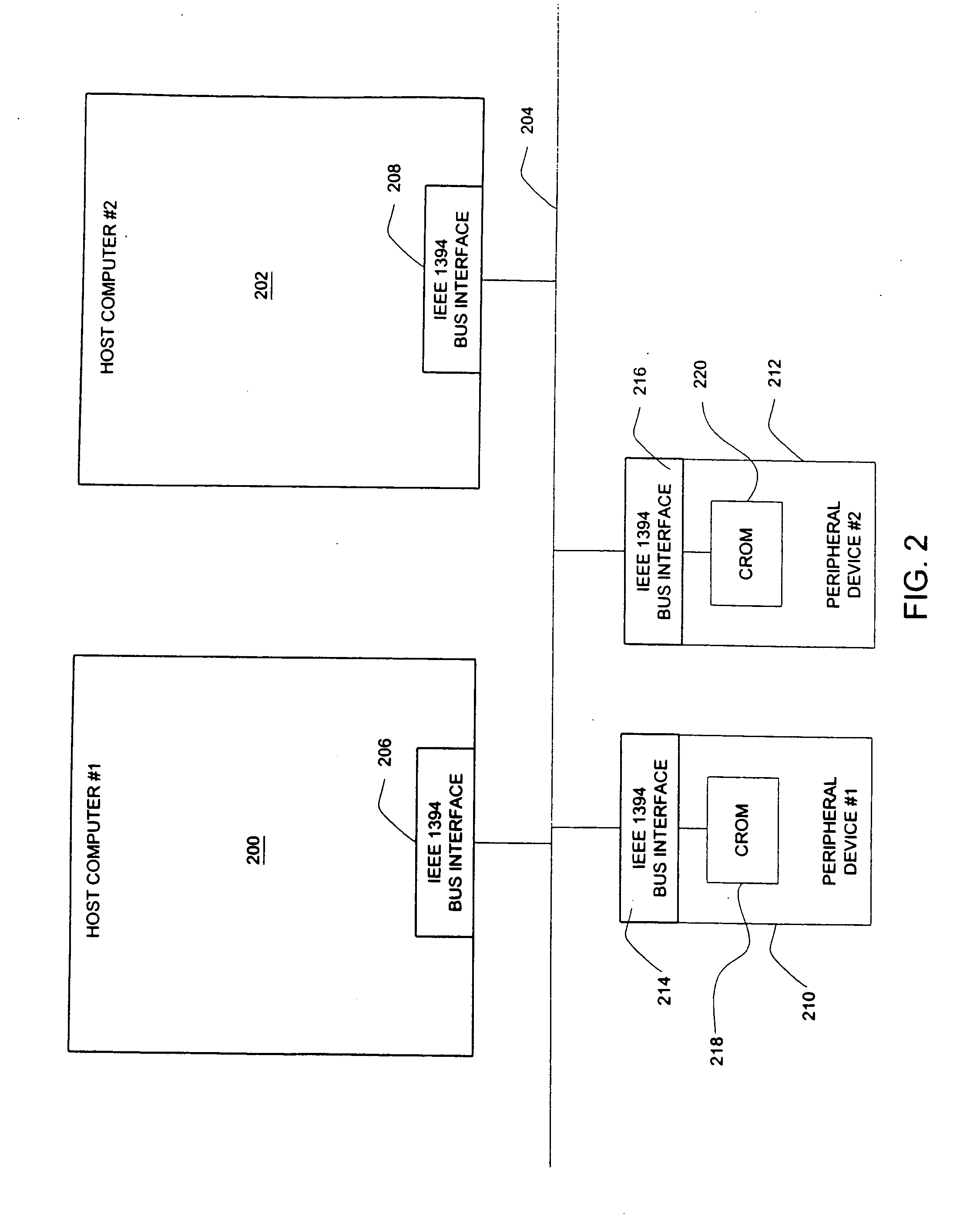

Device driver auto-load

InactiveUS7058563B1Program loading/initiatingSoftware simulation/interpretation/emulationOperational systemManual insertion

Methods and apparatus are provided for automatically loading drivers on computers for devices coupled to a communication medium such as an IEEE 1394 serial bus. Operating systems running on the computers detect when a device is connected to the communication medium. The operating systems then determine whether one of the drivers stored in memory on the device will enable the computers to utilize the device. The operating systems will then load the appropriate drivers for their respective computers and allow access to the device. If none of the drivers on the memory are suitable for a particular computer, then its operating system will prompt a user to manually insert a computer-readable medium containing the appropriate drivers. Thus, the present invention provides methods and apparatus for automatically loading device drivers.

Owner:MICROSOFT TECH LICENSING LLC

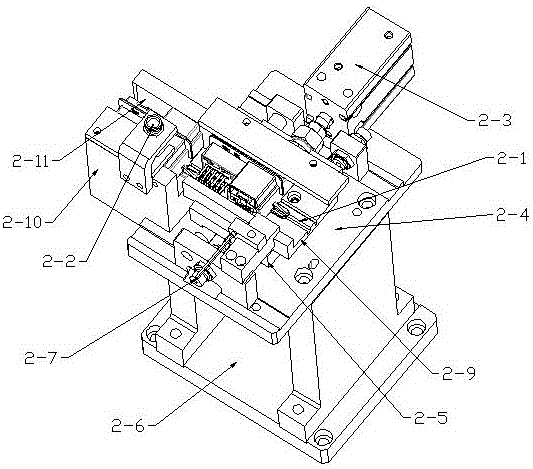

Automatic pin bender

InactiveCN105826794AFast feedingPrecise positioningVehicle connectorsContact member manufacturingDislocationManual insertion

The invention discloses an automatic pin bender comprising a workbench. A runner I is arranged on the workbench, a plurality of X-Y transplanting modules are mounted behind the runner I on the workbench, and the pusher dogs of the X-Y transplanting modules are parallel to the runner I. A sheath feeding dislocation module is mounted on the left of the runner I on the workbench, and a runner II of the sheath feeding dislocation module is in butt joint with the runner I. A round pin bending unit, a flaky pin bending unit and a CCD detection module are sequentially mounted on the right of the sheath feeding dislocation module on the workbench. Quick feeding and accurate positioning of sheathes, round pins and flaky pins and quick and stable inserting and bending of pins are realized, and the problem that manual insertion has the disadvantages of low efficiency, inconsistent insertion depth, irregular bending angle and error-proneness is solved. Through modular design, the automatic pin bender is applicable to assembly of different connectors, and can be effectively used in development of similar connector assembly equipment. The development cycle of new equipment can be greatly shortened.

Owner:HEBI HAICHANG SPECIAL EQUIP

Fluid delivery system

ActiveUS8950929B2Facilitates pushing the liquidPrevent undesired backwards movementCapsRotary stirring mixersManual insertionClosed chamber

A fluid delivery system for dispensing a liquid from a sealed container directly into a closed chamber comprises a container containing a liquid component of bone cement and plugged with a plug, and a closed chamber comprising a receiving port for receiving the sealed container, wherein the receiving port is configured to receive the liquid component in direct response to manual insertion of the sealed container through the receiving port using an open loop system.

Owner:DEPUY SYNTHES PROD INC

Applicator systems for surgical fasteners

An applicator system for surgical fasteners includes an insertion tool having a shaft with a proximal end, a distal end, and an insertion fork connected to the distal end of the shaft, and at least one cartridge containing a plurality of surgical fasteners used for securing an implant to tissue. The surgical fasteners are removed one at a time from the cartridge by engaging one of the surgical fasteners with the insertion fork and removing the engaged surgical fastener from the cartridge. The insertion fork with the loaded surgical fastener is manually inserted through an implant and into tissue for securing the implant to the tissue.

Owner:ETHICON INC

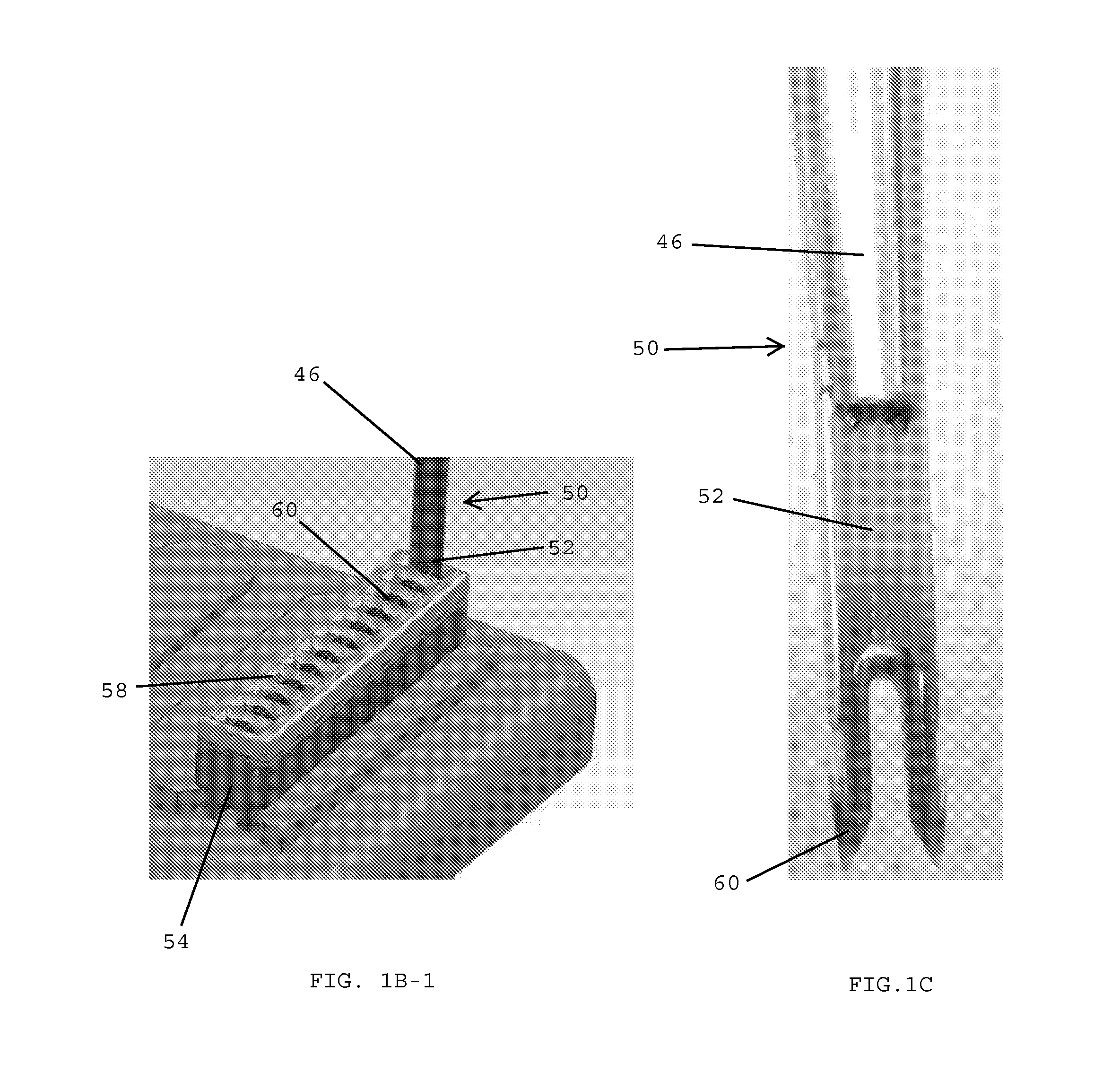

Net loader

InactiveUS20050048886A1Easy to manufactureEasy to cleanSkinless sausage makingSausage filling/stuffing machinesManual insertionEngineering

A device for filling tubular casings with edible material is disclosed. The device includes a tube upon which the casing can be shirred onto, a tube inlet, a tube outlet and tube support means. The support means allows the device to be supported for the manual insertion of edible material into the tube inlet and furthermore the manual forcing of this edible material through the tube and out of the tube outlet.

Owner:MERCTECH

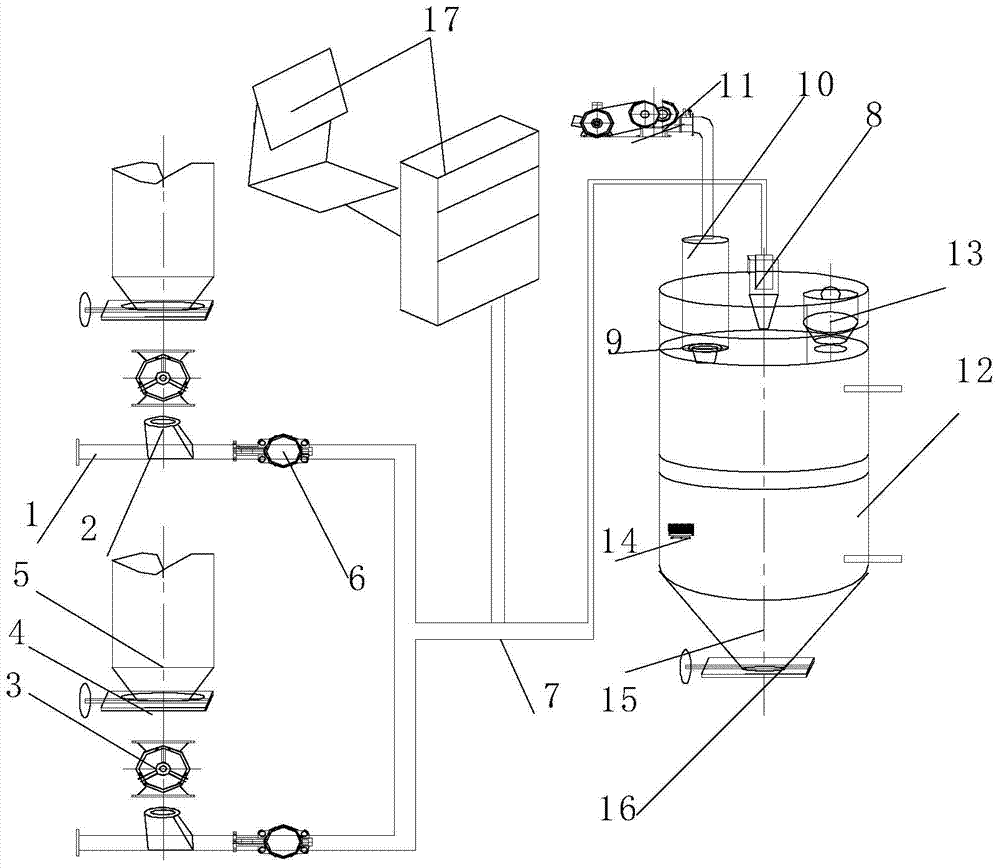

Pneumatic flour transmitting system

InactiveCN104512727AReduce maintenance rateLow failure rateBulk conveyorsControl systemControl engineering

The invention relates to a pneumatic flour transmitting system which is especially suitable for a negative-pressure pneumatic conveying system for flour. The pneumatic flour transmitting system comprises a flour and gas flow pipeline II, a gas-solid mixing accelerating room 2, an electronic unloading valve 3, a manual insertion plate valve 4, a hopper 5, a pneumatic reversing valve 6, a flour and gas flow conveying pipeline II 7, a cyclone dust collector 8, an air sealing machine 9, a pulse reverse-blowing bag type filter 10, a Roots blower 11, a material bin 12, a pressure release valve 13, a vibrating gas hammer 14, an activating hopper 15, a pneumatic insertion plate valve 16 and an electrical control system 17. The pneumatic flour transmitting system is characterized in that the Roots blower 11 is used for absorbing and transmitting rear-phase flour through negative pressure. The pneumatic flour transmitting system has the beneficial effects of relatively great system transmitting amount, and a simple transmitting system; the Roots blower is used for absorbing and transmitting through negative pressure, so that the maintenance rate and the fault rate are low, and the operation cost is low.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

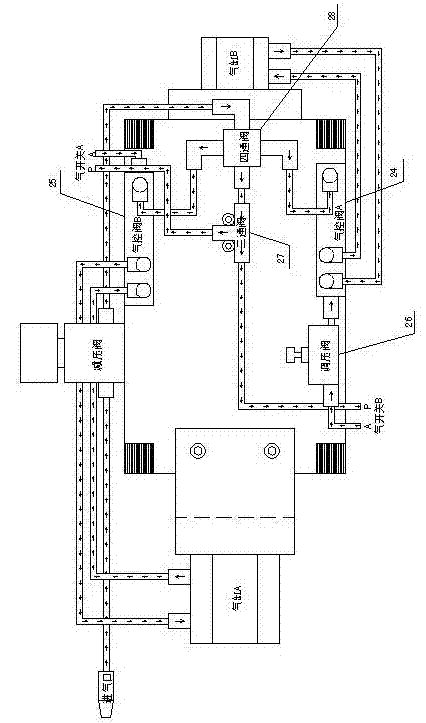

Pneumatic contact pin push bending machine

ActiveCN103035397AReduce labor intensityGuarantee safe and reliableContact member manufacturingContact member assembly/disassemblyTransformerFixed frame

The invention relates to a pneumatic contact pin push bending machine for production of a transformer. The pneumatic contact pin push bending machine comprises a working platform, two cylinders, a cylinder fixing plate, a thimble fixing plate, a slide fixing frame, a slide supporting frame, a thimble push plate, a push rod, a thimble plate, a thimble pressure plate, a thimble push plate slide block, a sliding cover plate, a switch rod, a curved needle push plate, a curved needle cover plate and a framework locating plate. By using compressed air as power, the cylinders are pushed to operate so that a guide needle is smoothly inserted into a framework guide needle position, and is bent by 100 DEG on the side surface of the framework, and therefore, the whole process of automatically bending a pin is realized during the production of the transformer. The pneumatic contact pin push bending machine has the advantages of high consistency and little errors when being used for processing products, thereby solving the problem that the appearance quality is influenced due to irregular radians on bending ends during manual insertion, reducing the labor intensity of operators, and increasing the production efficiency by about 10 times. Through regulating main parts of different specifications, the pneumatic contact pin push bending machine can adapt to various products and also be applicable to the insertion bending of guide needles of different sizes.

Owner:TIANJIN NEW VENTECH ELECTRONICS

Key operated rotary switch for disabling an automobile air bag supplemental restraint system

InactiveUS6122944AReduce stepsFree spinsBuilding locksPedestrian/occupant safety arrangementElectricityDetent

A key operated switch is provided for disabling an automobile air bag passive restraint system. The two or four position switch includes a housing, a rotor, a plurality of rotationally actuated electrical switch elements, a key ejecting mechanism, and a positive positioning detent. The switch assembly is arranged such that a transverse surface of the rotor defining a key slot is accessible through the housing. The key slot allows an operating key to be manually inserted into the rotor. In or order to insert the key, however, the therein, a certain minimum amount of force must be applied to the key sufficient to overcome the key ejecting mechanism. In the absence of such minimum insertion force, the key ejecting mechanism will act expel the key from the rotor. Once inserted into the rotor, the key may be manually rotated which causes corresponding rotation of the rotor. The rotation of the rotor in turn, actuates select electrical switch elements attached to the rotor, according to the angular position of the rotor. The electrical switch elements define a plurality of distinct switch states, each corresponding to a particular angular position of the rotor. Finally, the positive positioning detent forces the rotor to an angular position corresponding one of the distinct switch states defined by the electrical switch elements during those periods when no external torque is being applied to the rotor.

Owner:METHODE ELETRONICS INC

Unburned flare gas sample system

InactiveUS20100319468A1Reduce and prevent precipitationAccurate temperatureComponent separationWithdrawing sample devicesLine tubingManual insertion

A sample system withdraws a sample of unburned flare gas from a feed line and delivers a liquid free sample to a high pressure gas chromatograph for analysis. In one embodiment, the sample system may be fitted with an automatic insertion system. In other embodiments, the sample system may be static or have manual insertion. The sample system includes a liquid separator to separate liquids from the sample. In one embodiment, the sample system is housed in an insulated and heated cabinet to prevent condensation of liquids as the sample moves through the sample system.

Owner:WELKER ENG

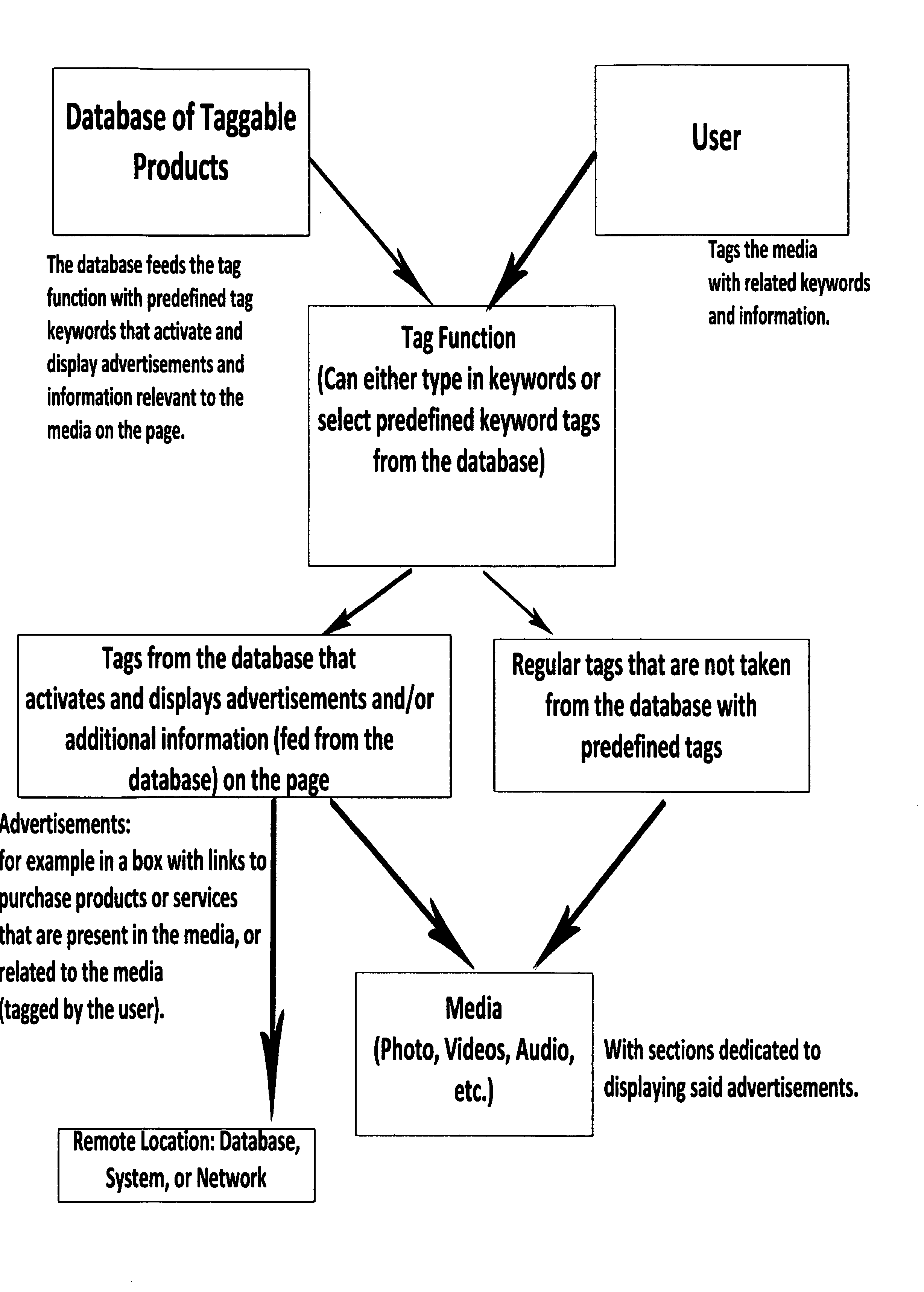

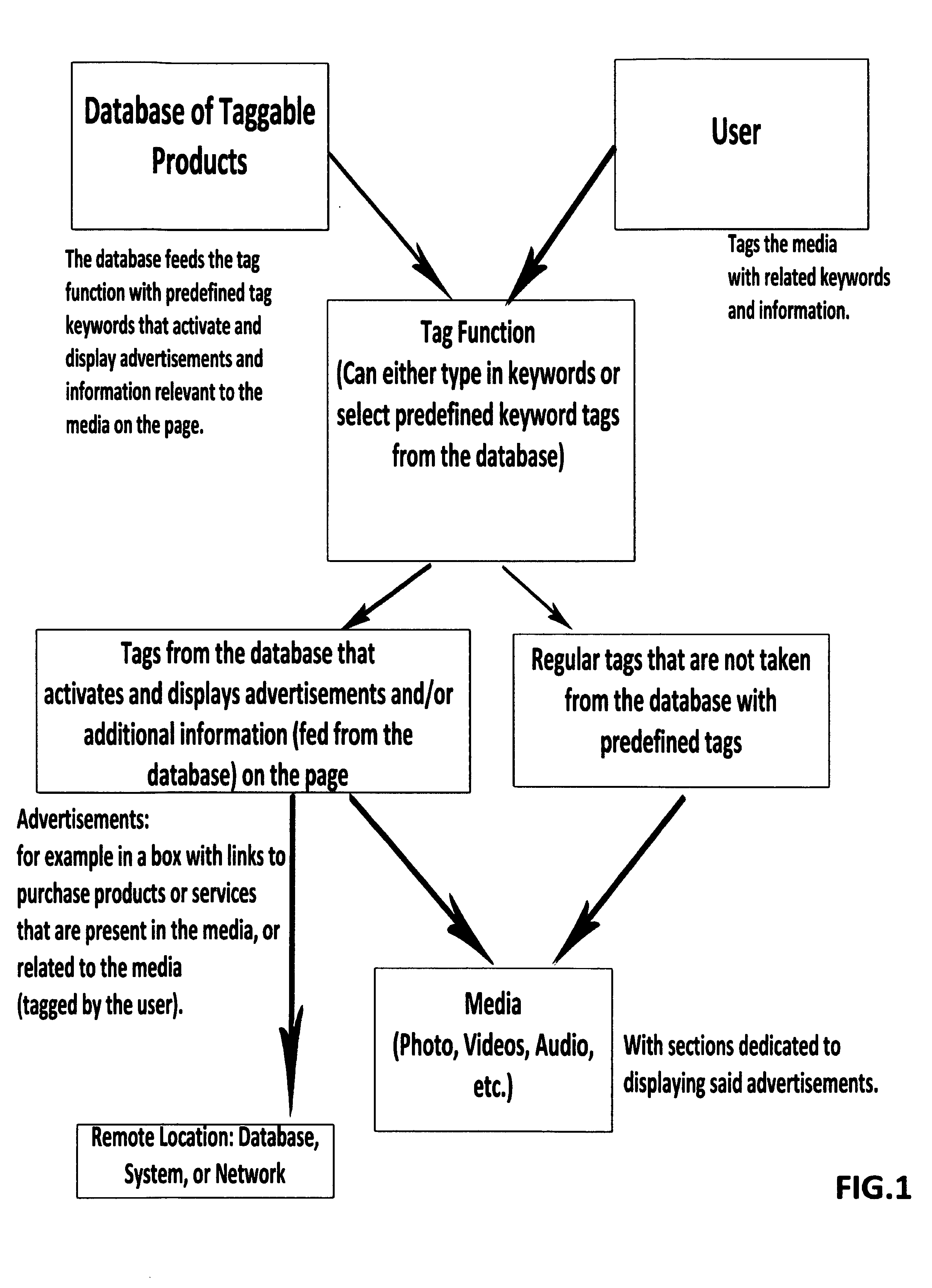

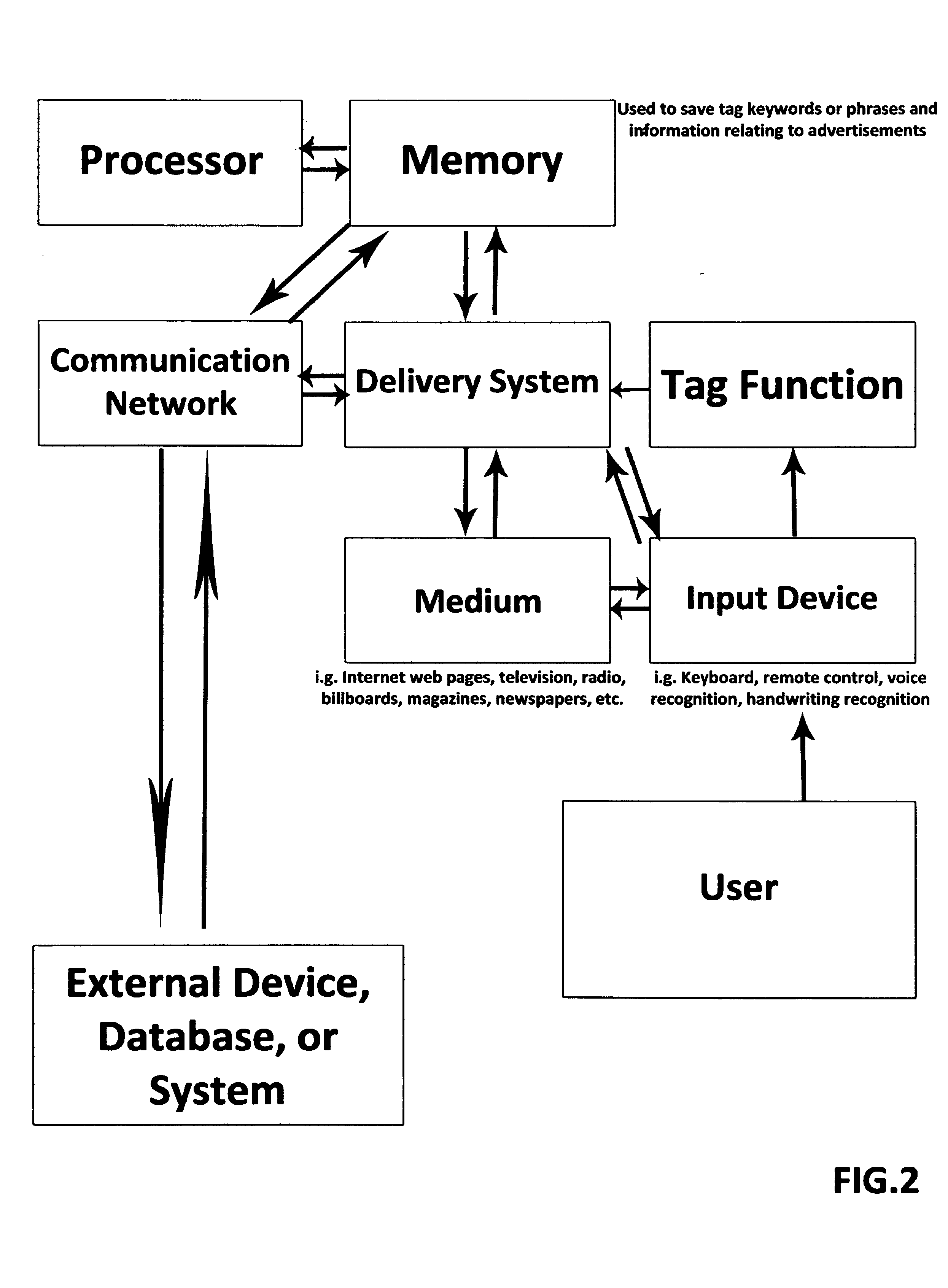

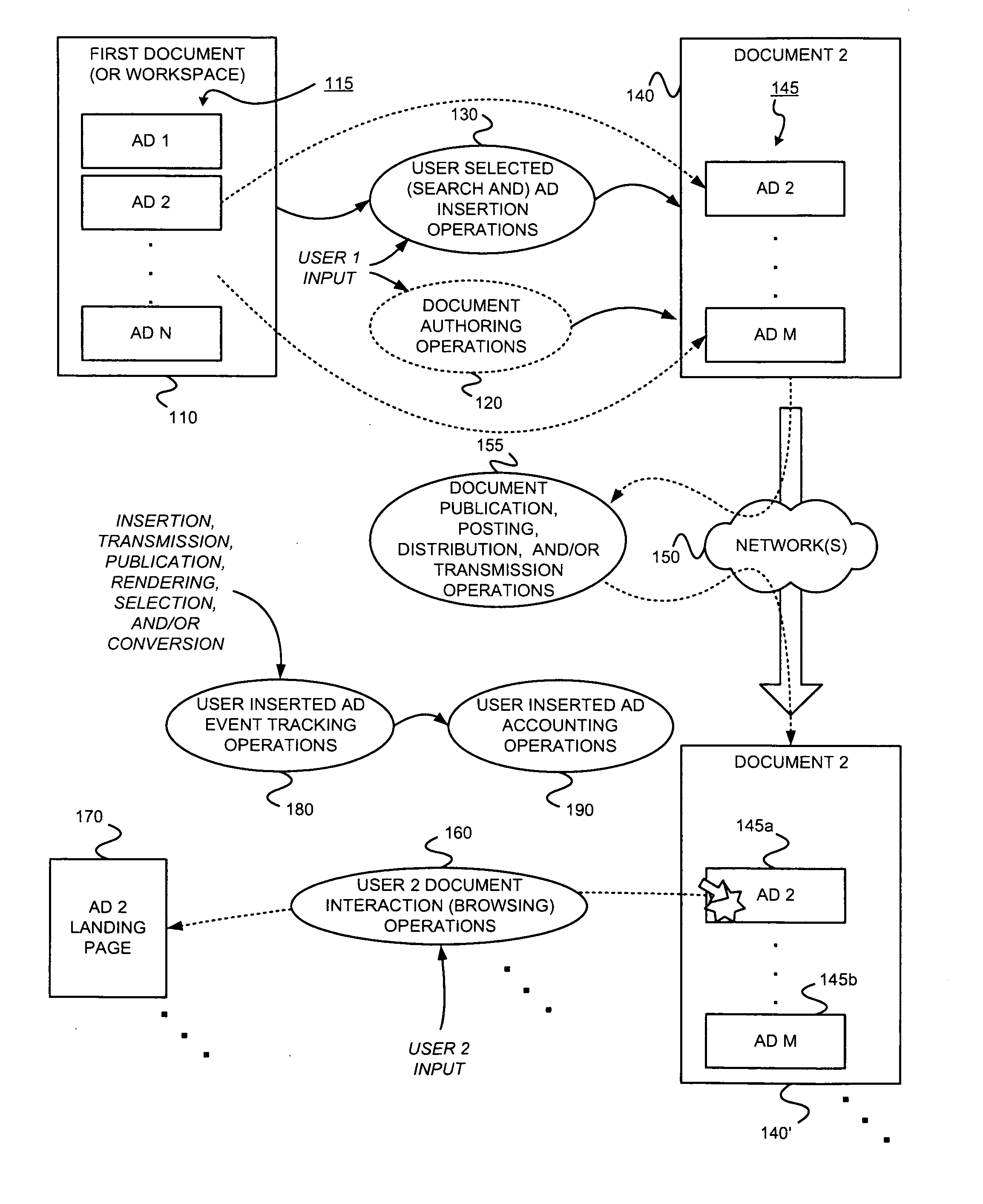

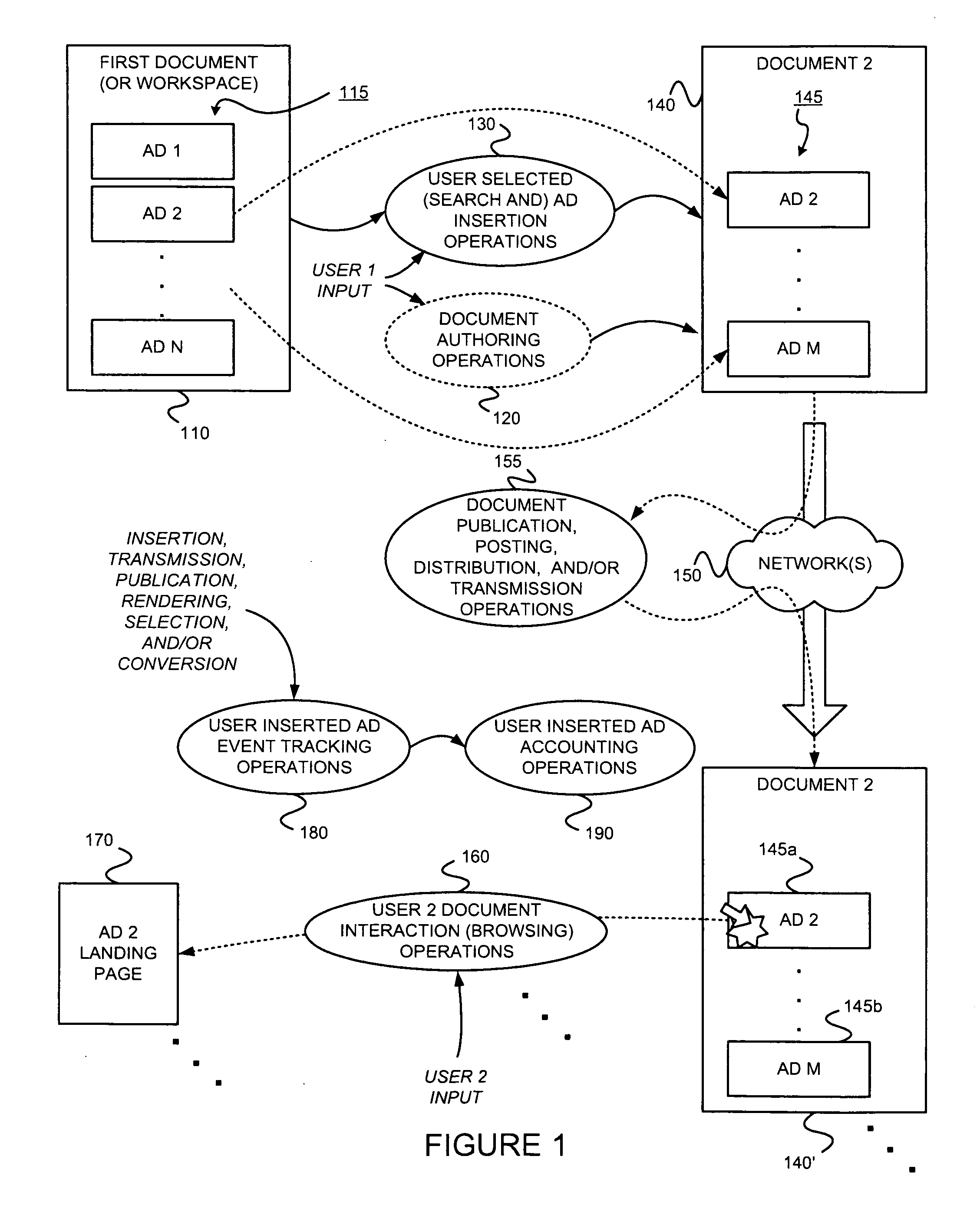

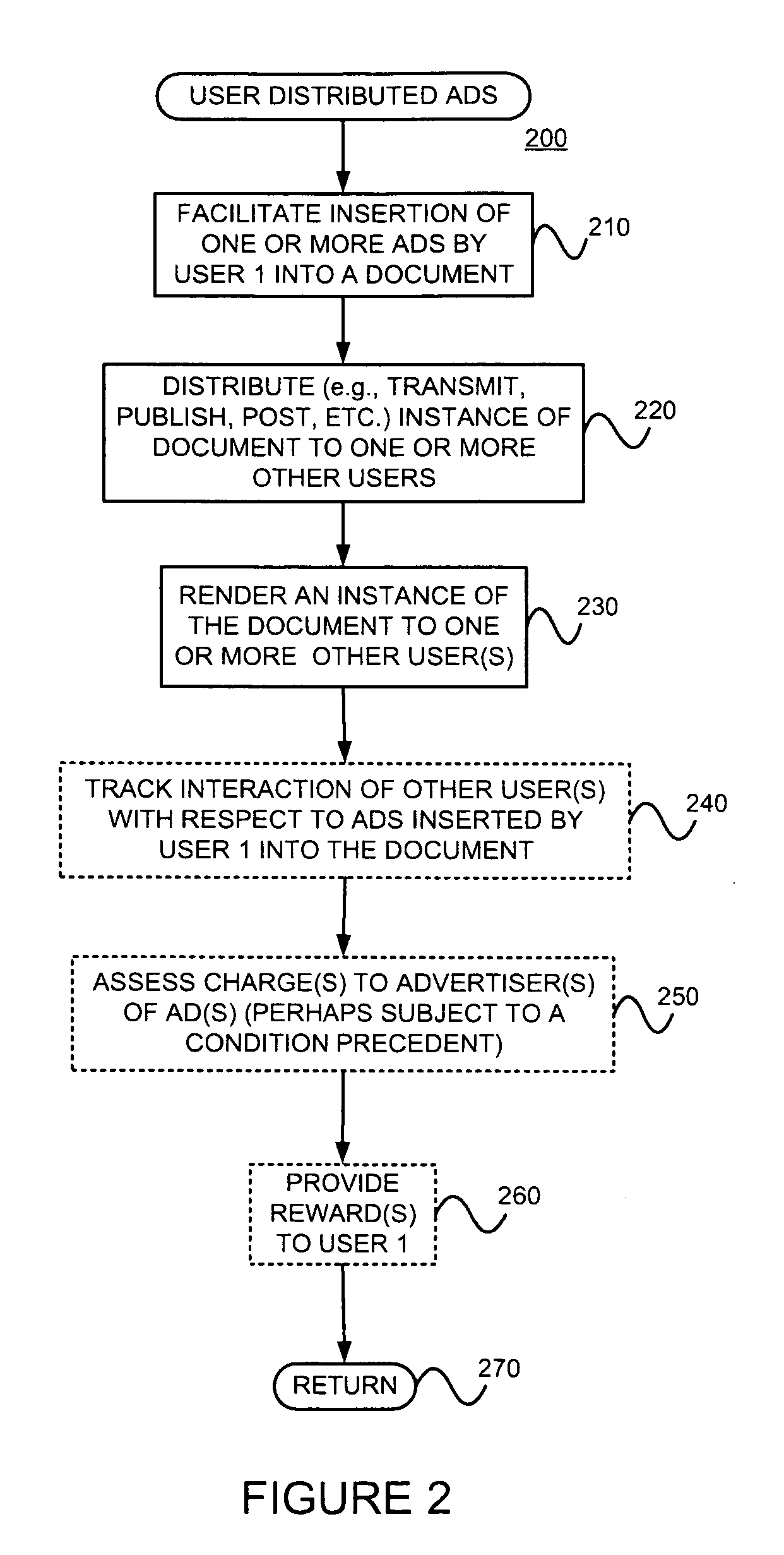

Determining one or more performance metrics related to ads enabled for manual insertion into a document for distribution, and/or using such performance metric or metrics

User distributed advertisements (UDA ads) facilitates insertion of manually selected ads into a document that is to be distributed (e.g., transmitted, published, and / or posted) such that the document is to be made available to other users. For example, manually selected ads can be inserted into an email to be sent to another user, a blog to be posted for viewing by other users, a message to be sent to another user, a message board entry to be posted for viewing by other users, a document published and made available to other users, etc. Hence, UDA ads provide a scaleable advertising platform that achieves at least some of the benefits of manual targeting. Charges might be assessed to the advertiser, perhaps subject to one or more conditions being met. Rewards might be provided to the user that inserts and / or distributes the UDA ad, perhaps subject to one or more conditions being met. Performance metrics of UDA ads might be determined and used for various purposes, such as later ad serving arbitrations. A user interface for advertisers to allow their ads to be UDA ad-enabled might be provided.

Owner:GOOGLE LLC

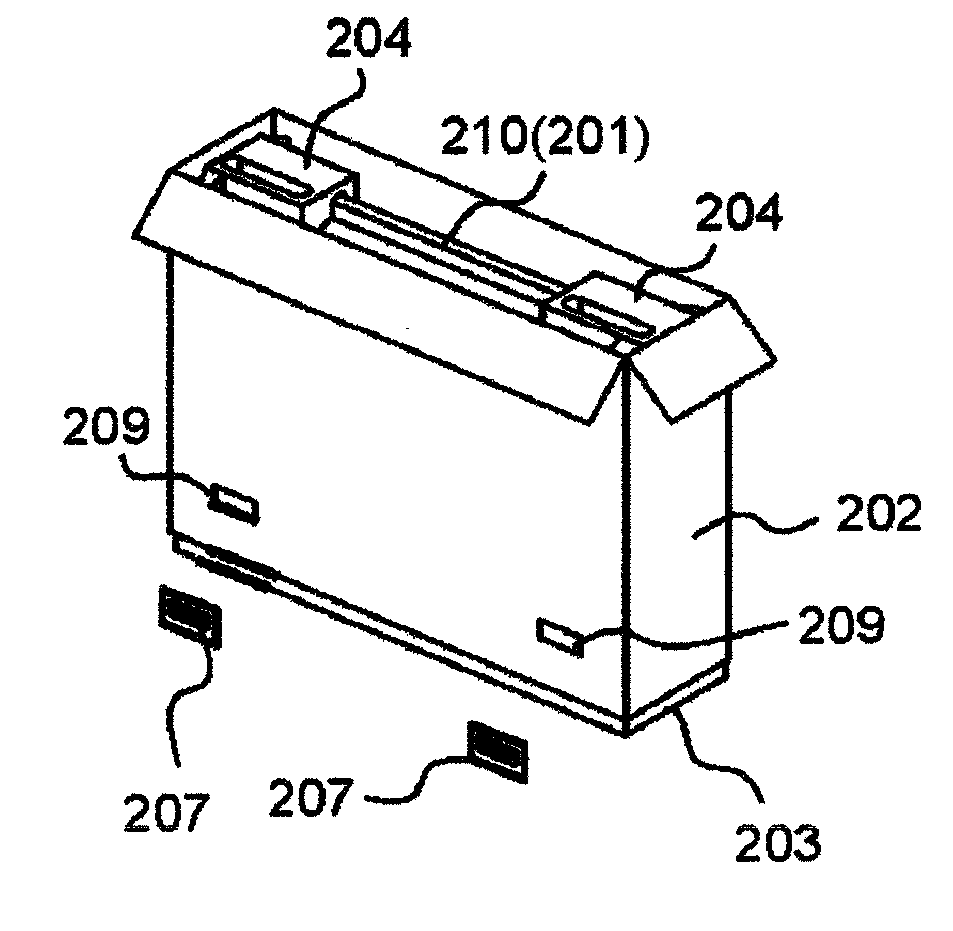

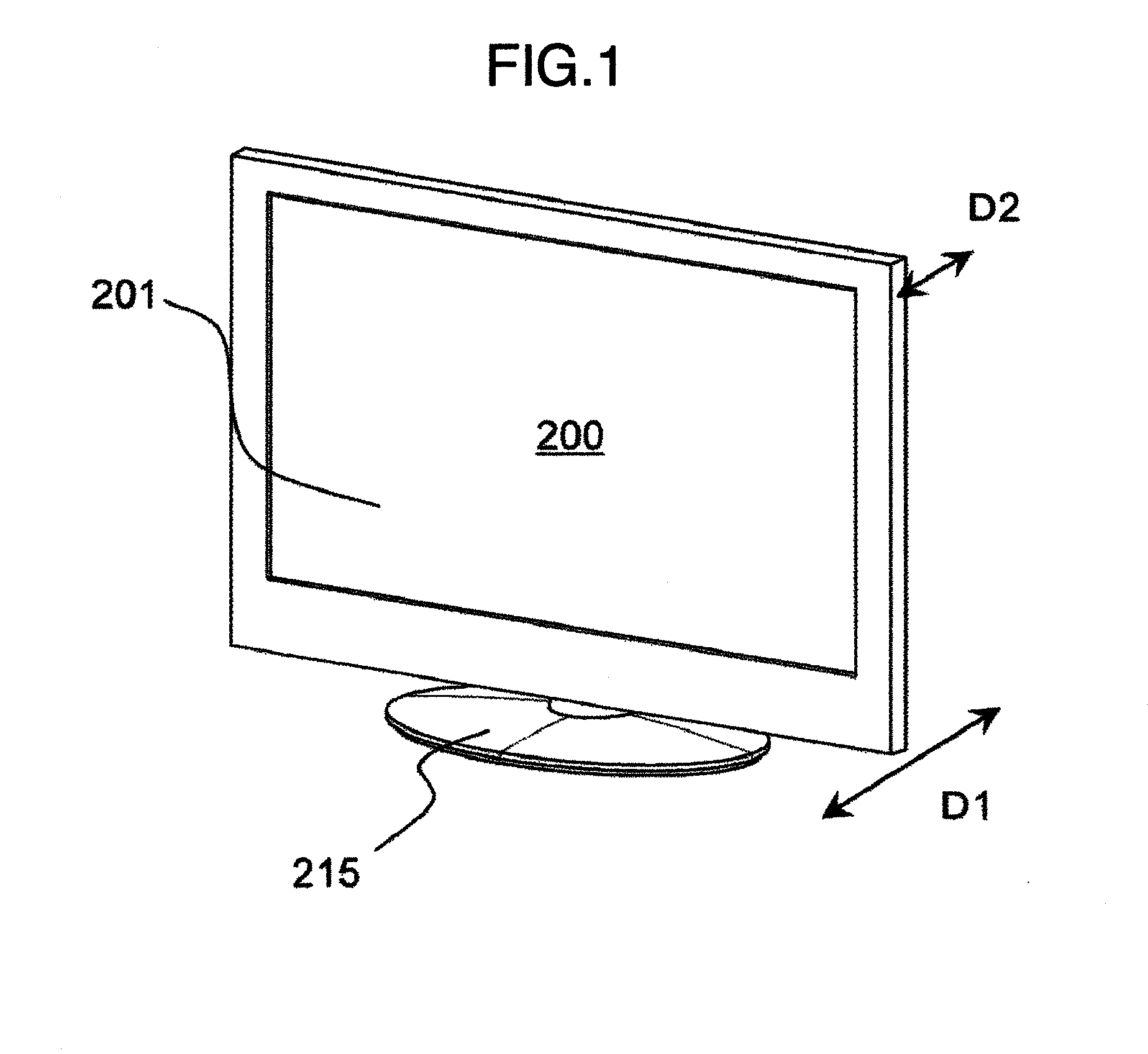

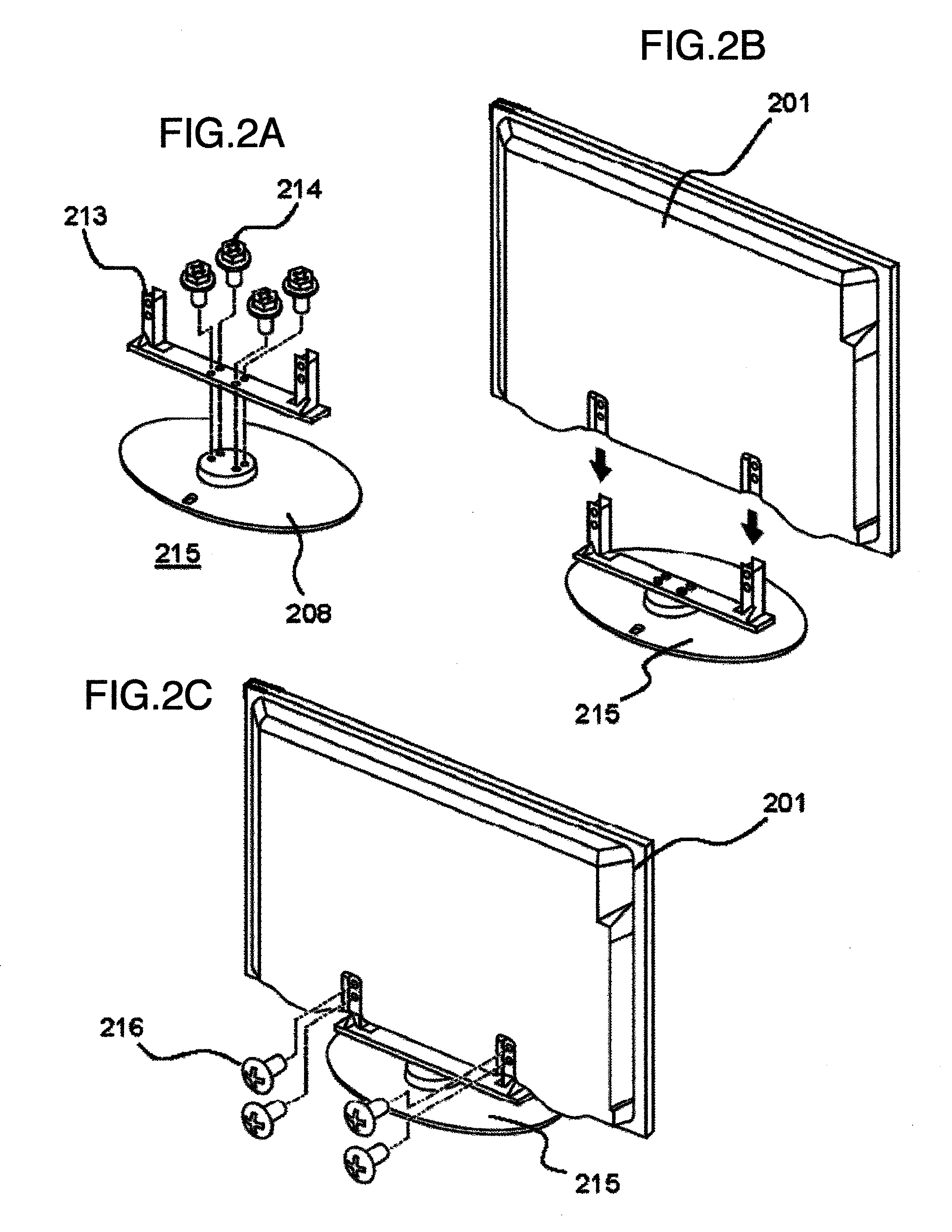

Package structure with a flat display unit packed therein and package structure for packing a flat display unit

ActiveUS20110210024A1Improve workabilityAvoid separationTelevision system detailsOther accessoriesCushioningDisplay device

There is provided a package structure for packing a flat display unit which improves workability in taking a flat display unit out of a packing box. A lower cushioning material which supports a display portion of the flat display unit from below has a manual insertion portion so that the display portion can be held at a portion close to a lifting person's body when the display portion is taken out of a lower part of the packing box. A reinforcing rib is provided on a front side of the lower cushioning material to prevent damage to the lower cushioning material due to a reduction in strength. To prevent the lower cushioning material from being taken out together with the display portion when the display portion is taken out, a recess is provided in the lower cushioning material so that the recess is caught on a bending portion in the lower part when the display portion is taken out.

Owner:MAXELL HLDG LTD

Device driver auto-load

InactiveUS20050097573A1Program loading/initiatingSoftware simulation/interpretation/emulationOperational systemManual insertion

Methods and apparatus are provided for automatically loading drivers on computers for devices coupled to a communication medium such as an IEEE 1394 serial bus. Operating systems running on the computers detect when a device is connected to the communication medium. The operating systems then determine whether one of the drivers stored in memory on the device will enable the computers to utilize the device. The operating systems will then load the appropriate drivers for their respective computers and allow access to the device. If none of the drivers on the memory are suitable for a particular computer, then its operating system will prompt a user to manually insert a computer-readable medium containing the appropriate drivers. Thus, the present invention provides methods and apparatus for automatically loading device drivers.

Owner:MICROSOFT TECH LICENSING LLC

Waterproof blind plug automatic insertion device

InactiveCN105196022AQuick clampingPrecise positioningVehicle componentsMetal working apparatusInsertion depthModular design

The invention discloses a waterproof blind plug automatic insertion device. The device comprises a plastic shell feeding module, a rack, a vision detection module, an X-Y movement module, a waterproof blind plug insertion module, a feeding and discharging module and an unloading module. The rack is provided with a worktable. The worktable is provided with the plastic shell feeding module, the X-Y movement module, the waterproof blind plug insertion module and the unloading module. The waterproof blind plug insertion module is arranged on one side of the X-Y movement module and is matched with the X-Y movement module. The feeding and discharging module is arranged above the portion, between the plastic shell feeding module and the unloading module, of the worktable. A bottom plate of the feeding and discharging module is perpendicular to an X-axis bottom plate of the X-Y movement module. The vision detection module is arranged at the top end of the rack. By means of the device, a plastic shell is quickly clamped, positioning is precise, a waterproof blind plug is quickly and stably inserted, and the problems that manual insertion efficiency is low, the insertion depths are not consistent, and faults are likely to occur are solved. By means of the modular design, the modules are quickly replaced, the waterproof blind plug automatic insertion device can be applicable to different waterproof blind plugs and plastic shells, and the application range of equipment is widened.

Owner:HEBI HAICHANG SPECIAL EQUIP

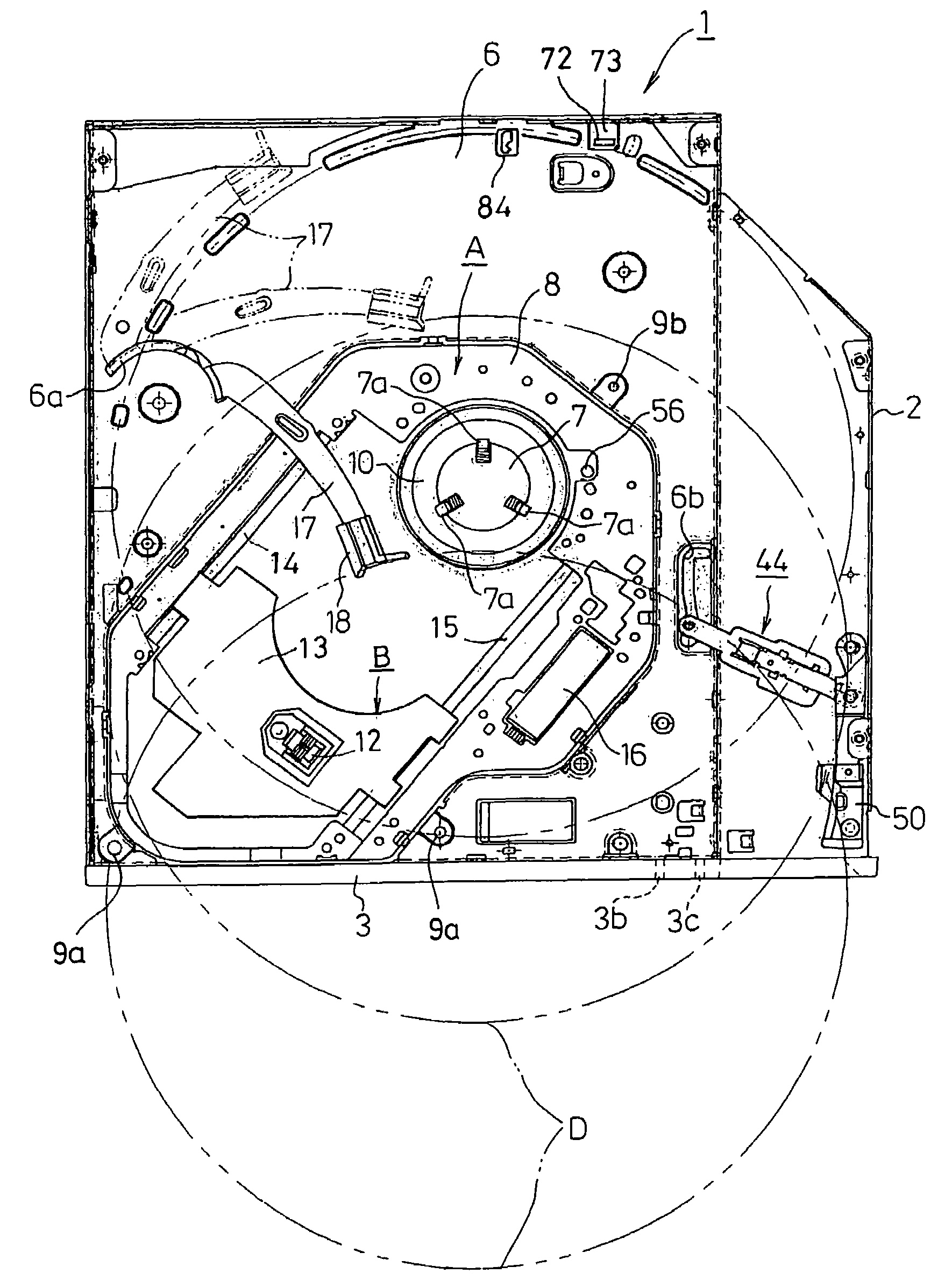

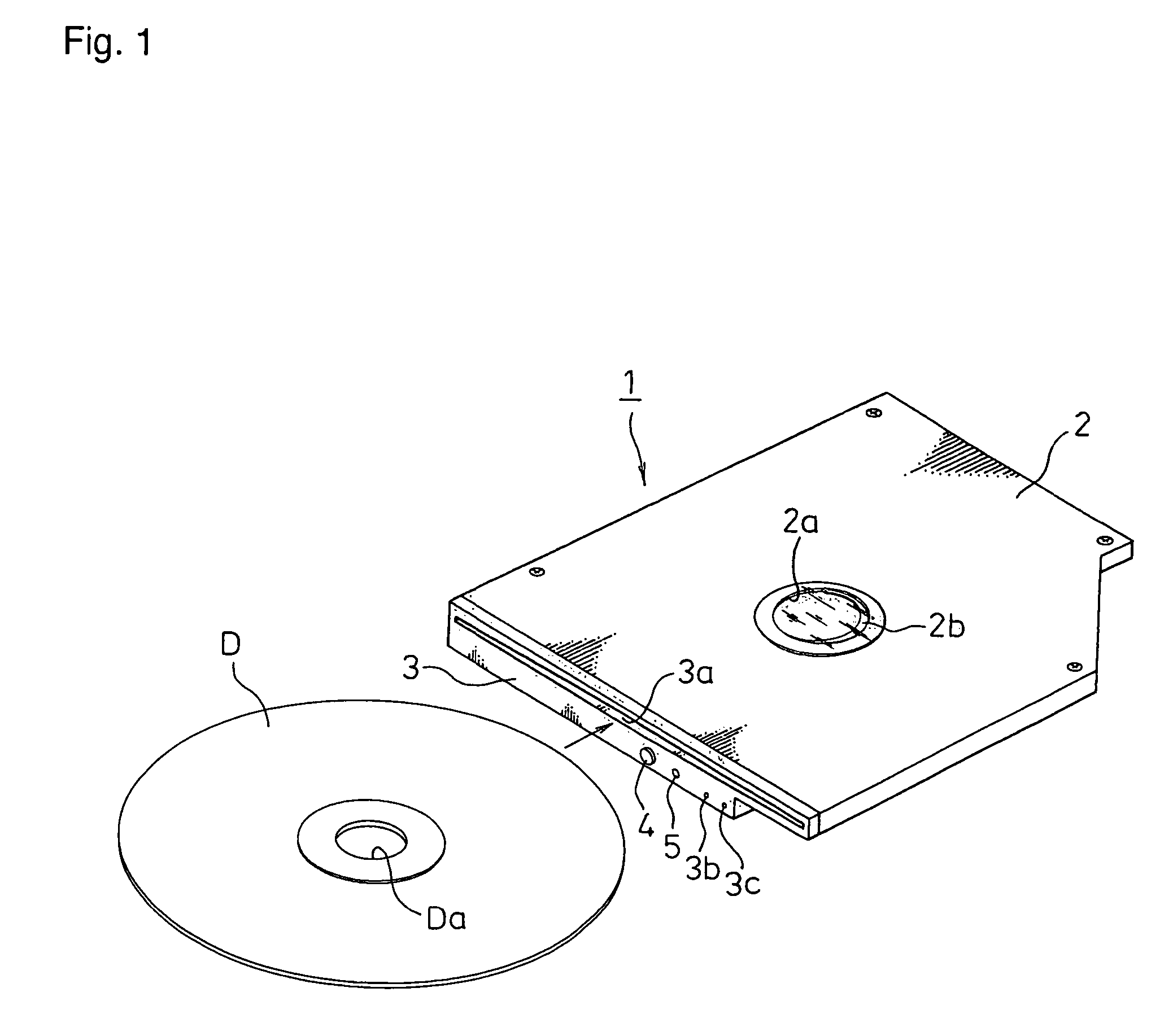

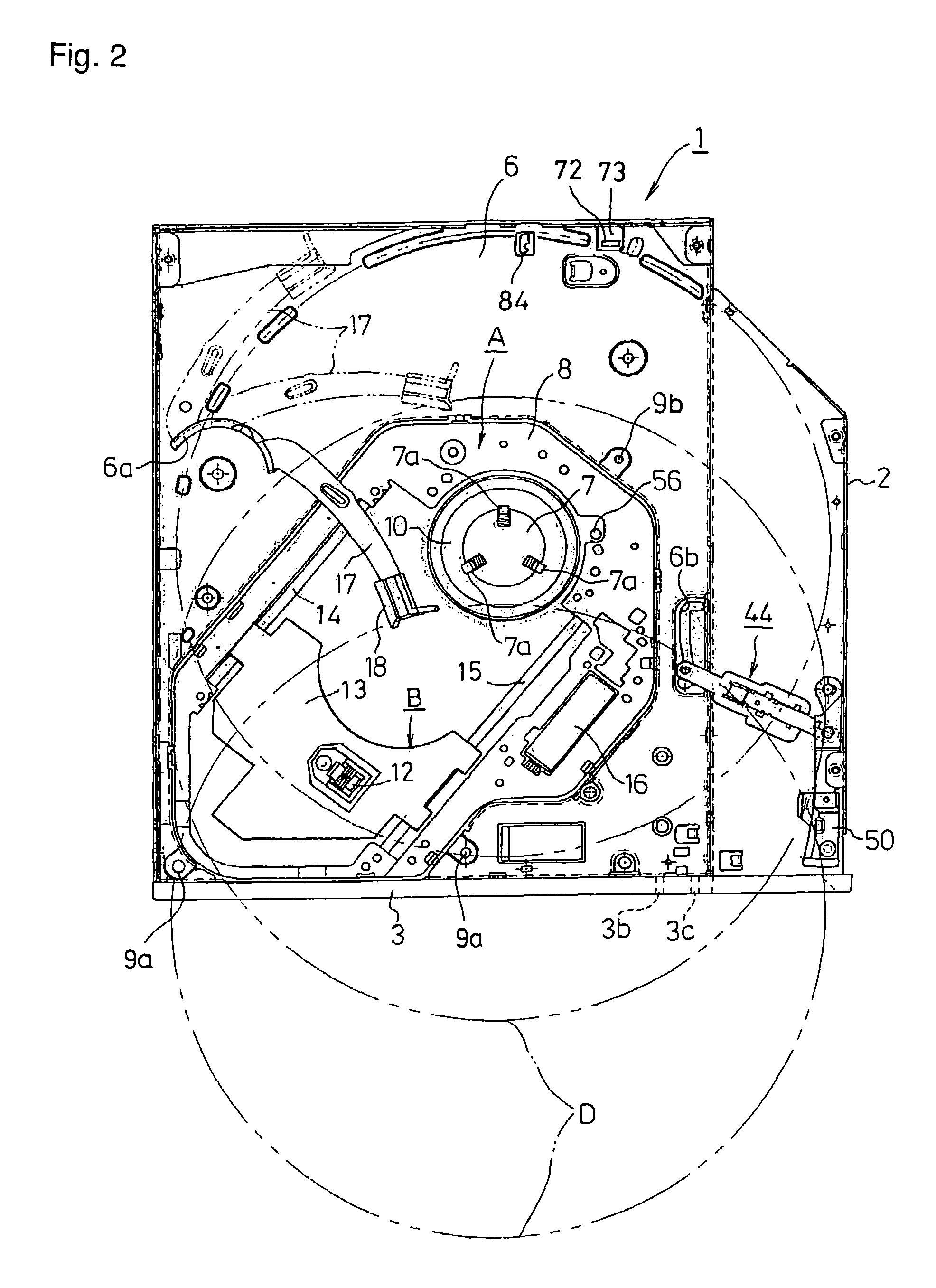

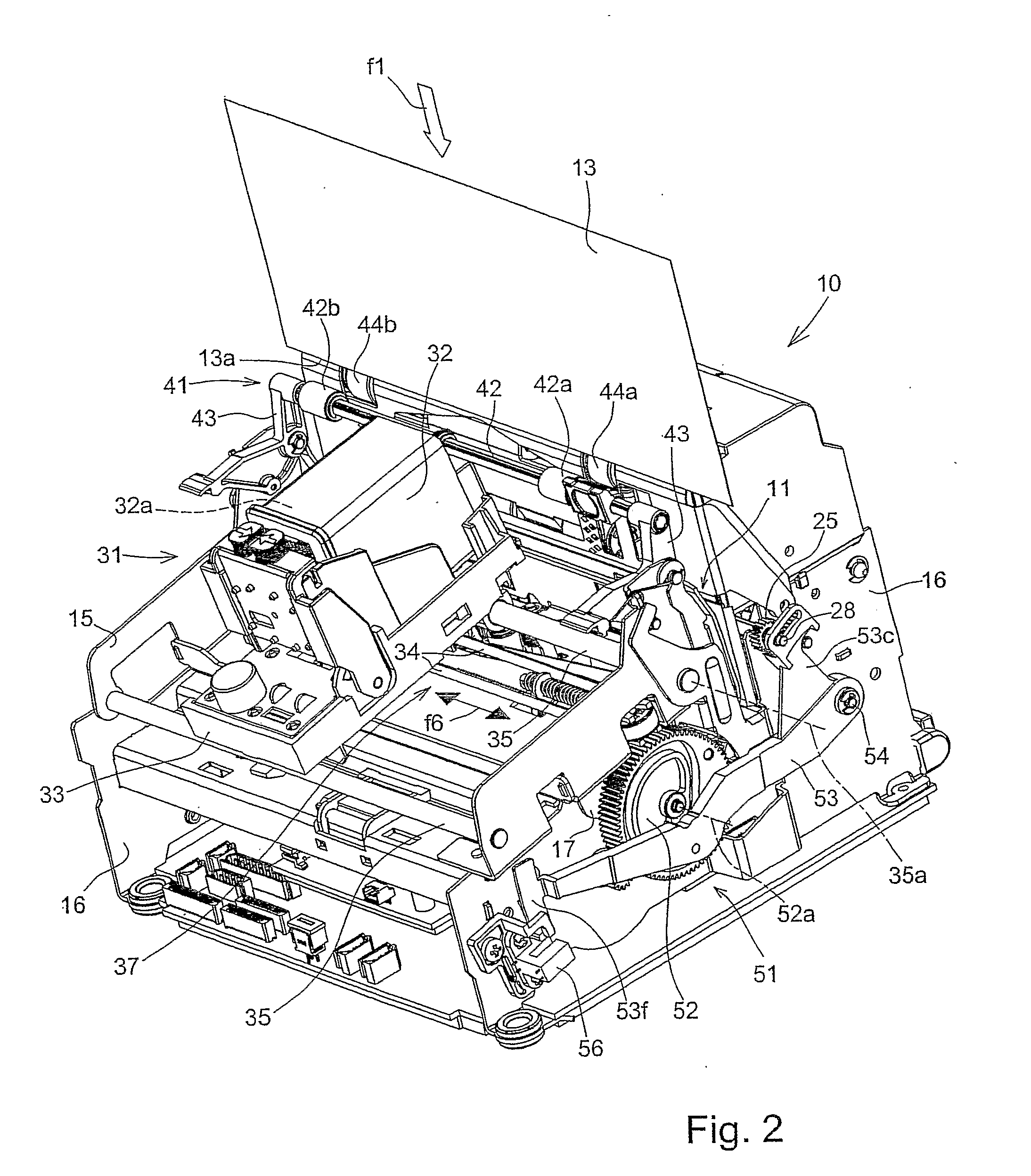

Disc loading mechanism for disc recording and/or reproducing device

InactiveUS7576946B2Evenly loadedNot to cause sense of incompatibilityRecord information storageOptical recording/reproducingTime lagManual insertion

In the loading of a disc in a slot-in type of disc apparatus, time lag occurs at the time of shift from an operation that manually inserts the disc to an operation that automatically swallows the disc. In order to solve this problem, a switch for detecting the position of a disc at the beginning of insertion thereof and a switch for detecting a position where the loading of the disc has been completed are provided respectively. The modification of control is made so that the disc support arm is driven with a weak electric power from the beginning of the insertion of the disc, and an error caused by time-out is further detected. If the error has been detected, the disc is ejected.

Owner:TEAC CORP

Automotive tyre pattern depth detector

InactiveCN109556501AAccurate readingImprove measurement efficiencyMechanical depth measurementsMaximum depthManual insertion

The invention relates to an automotive tyre pattern depth detector comprising a clamping adjusting device, a bracket, a small broken stone scratching device and a detecting device. The bracket is installed at the middle part of the clamping adjusting device; the small broken stone scratching device is installed at the upper end of the bracket; and the detecting device is installed at the lower endof the bracket. At present, when existing tyre pattern depth detection is carried out, the worker uses a pattern wear scaleplate to carry out measurement; the offset is caused easily when no verticalinsertion or sufficient insertion at the maximum depth is performed in a manual insertion mode; only on-site measurement by the worker is required and the read and measured data have low accuracy; and when the scaleplate is inserted, the small broken stones clamped in the pattern may affect the measurement accuracy, so that the detection efficiency is low. However, with the automotive tyre pattern depth detector, problems can be solved; the tyre pattern depth can be measured accurately; sufficient vertical insertion of different tyre patterns is realized; and a detection rod is fixed after depth detection, so that the worker can read the number conveniently after taking the rod and reading is carried out accurately.

Owner:陕西迈拓克能源科技有限公司

Oral scope system with image sensor and method for visual examination of oral cavity and upper airway

Owner:QSCOPE

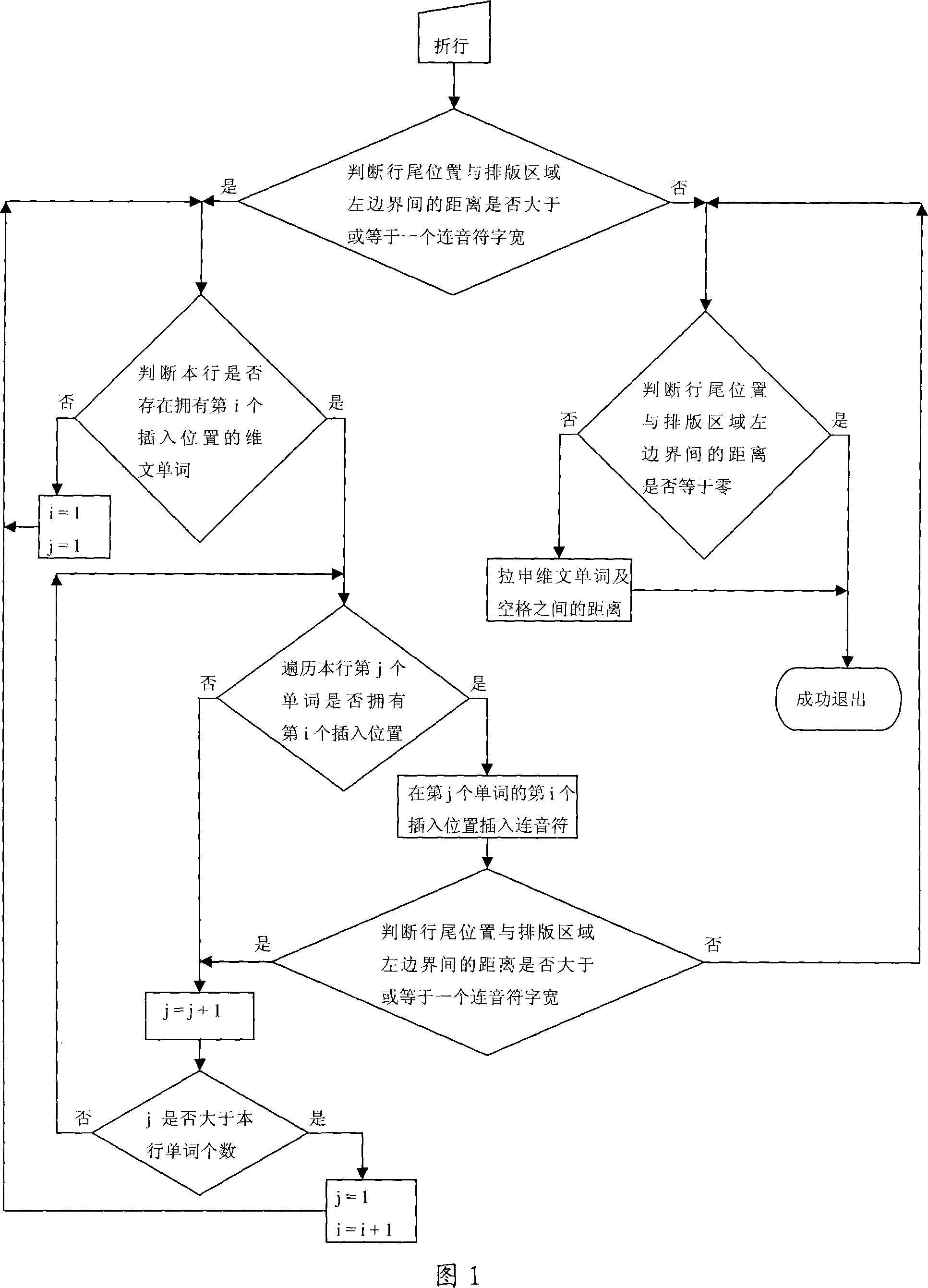

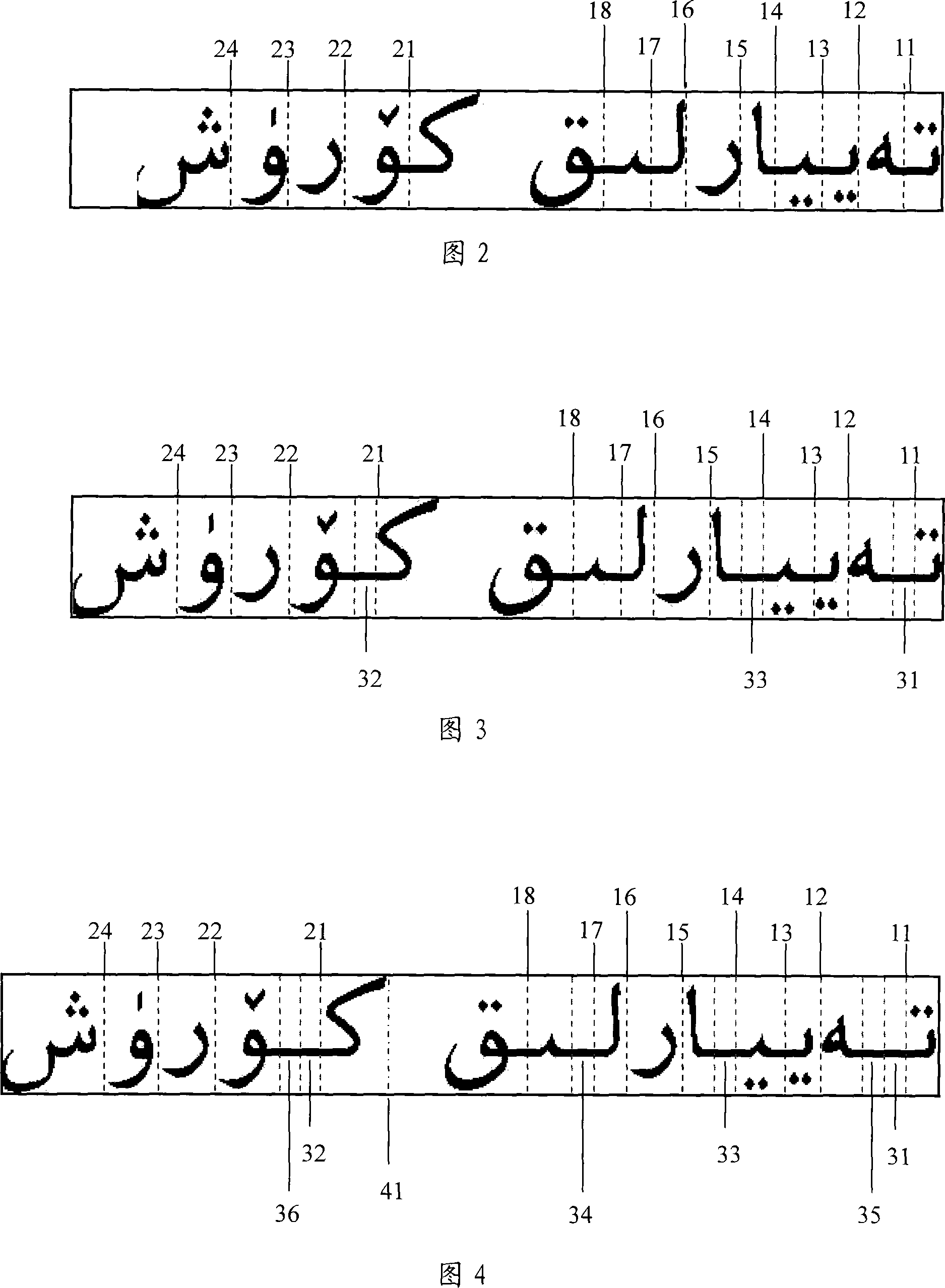

Method for automatic adding slur control line format filling in uigur type-setting

InactiveCN101021841AAvoid manual adjustmentsImprove typesetting efficiencyNatural language data processingSpecial data processing applicationsControl lineManual insertion

The invention relates to a method for automatically adding slur to control lines to be filled up. Victoria typesetting starts from right to left (that is reverse grid), and lines are generally required to be full. In existing technology, Victoria text typesetting needs to manually add notes at the appropriate location to keep a full trip, which seriously affects the efficiency. The method in the invention can use intelligent computer program to calculate the correct locations of peacekeeping text and insert the notes automatically to the appropriate locations.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +2

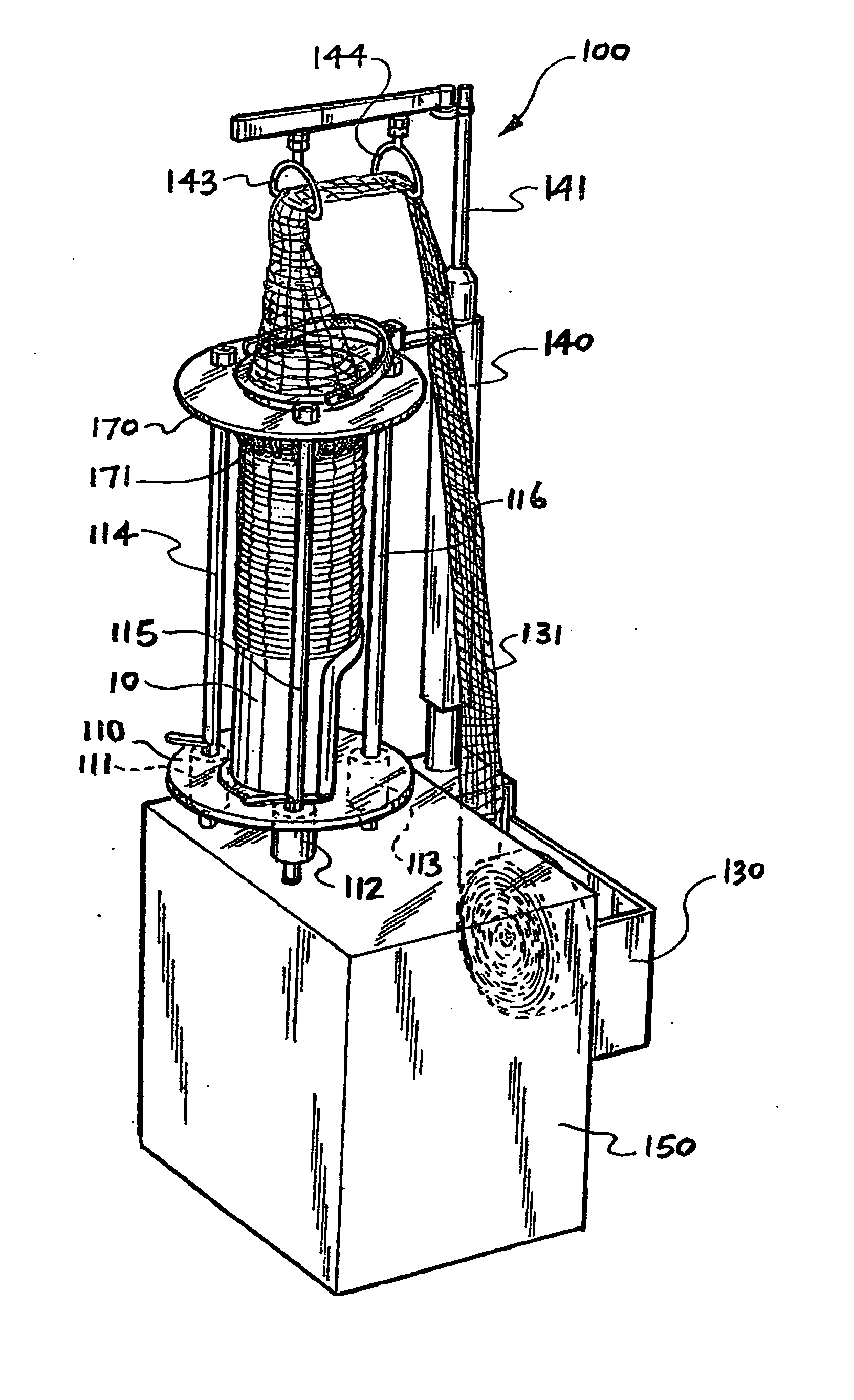

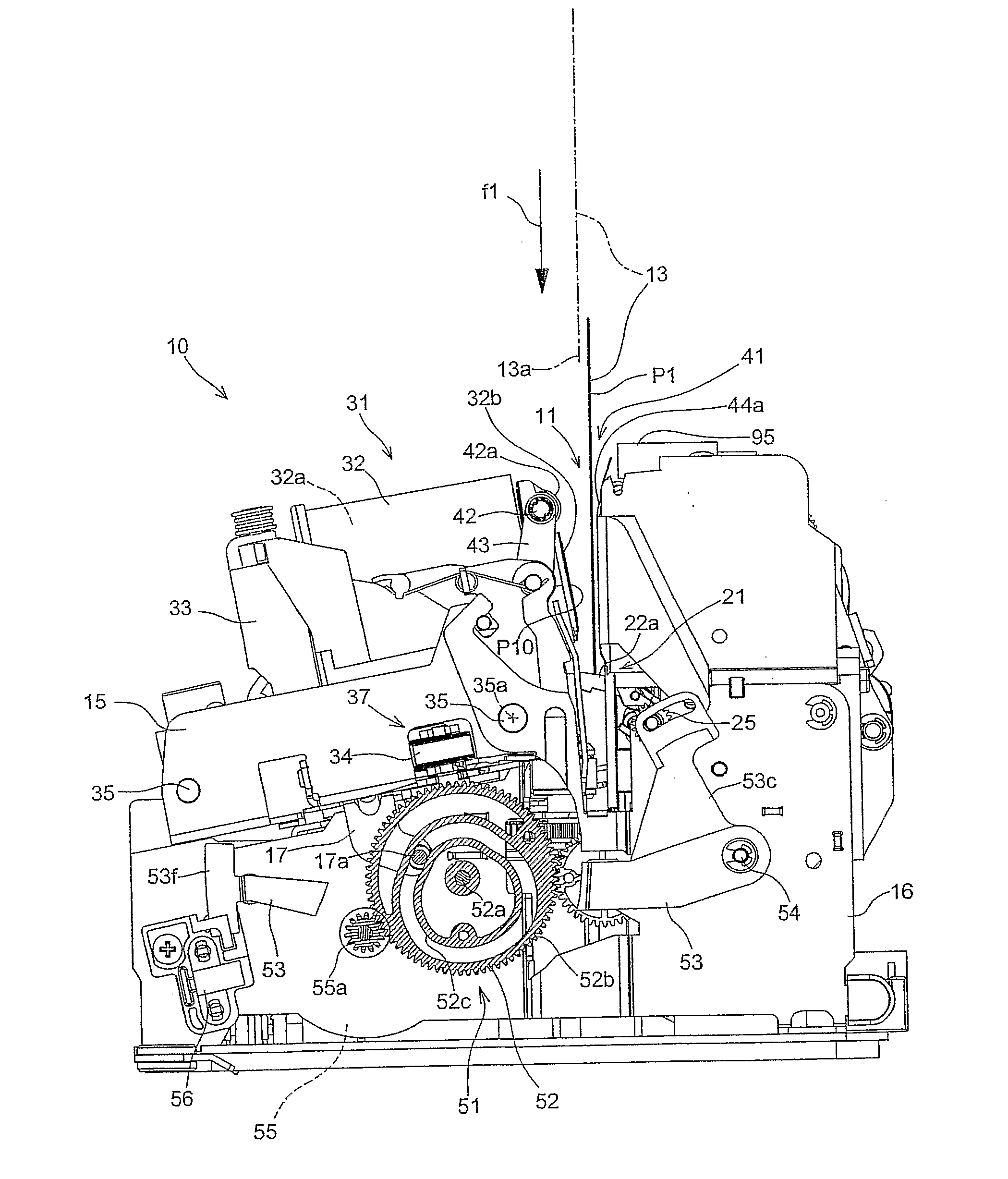

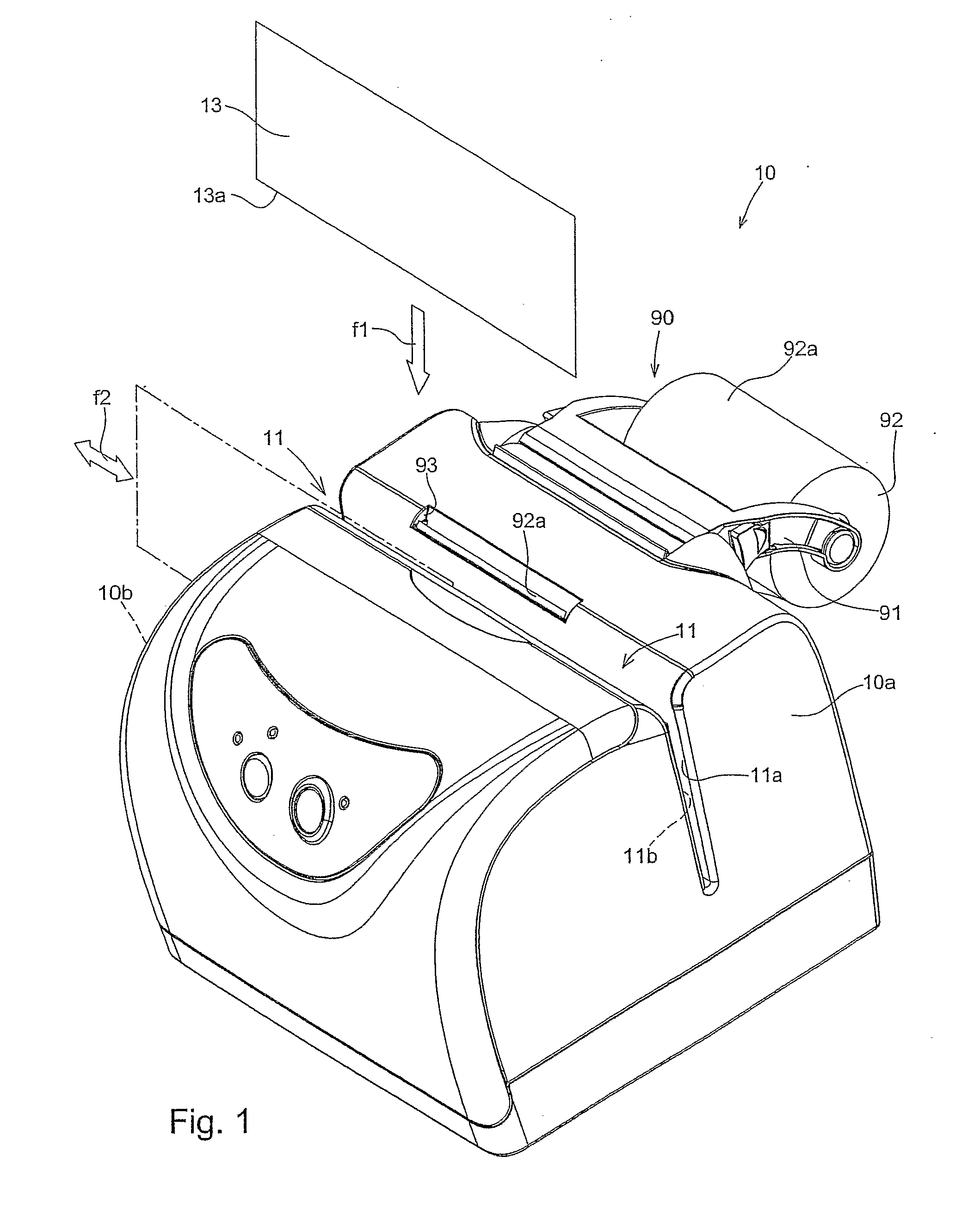

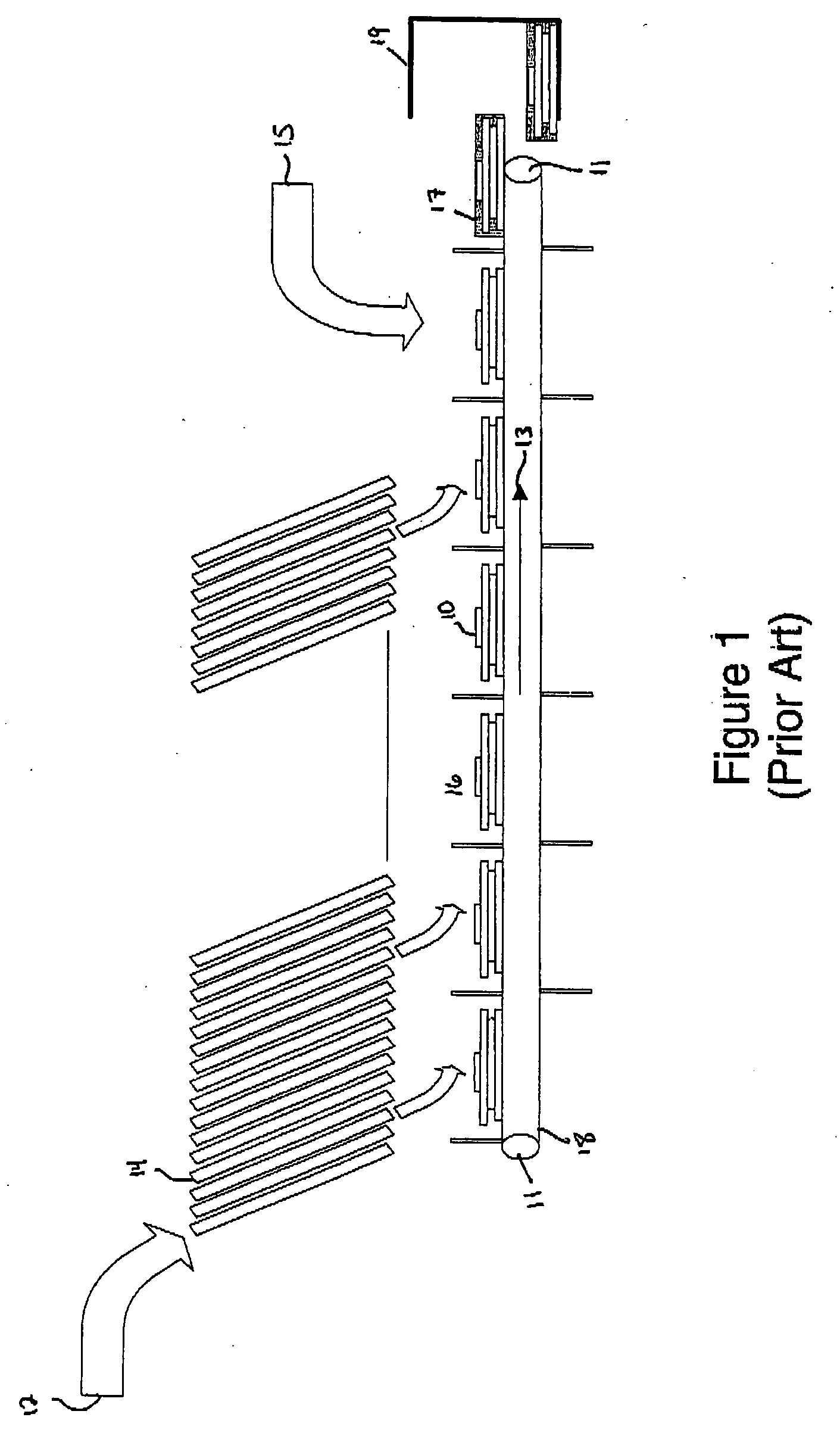

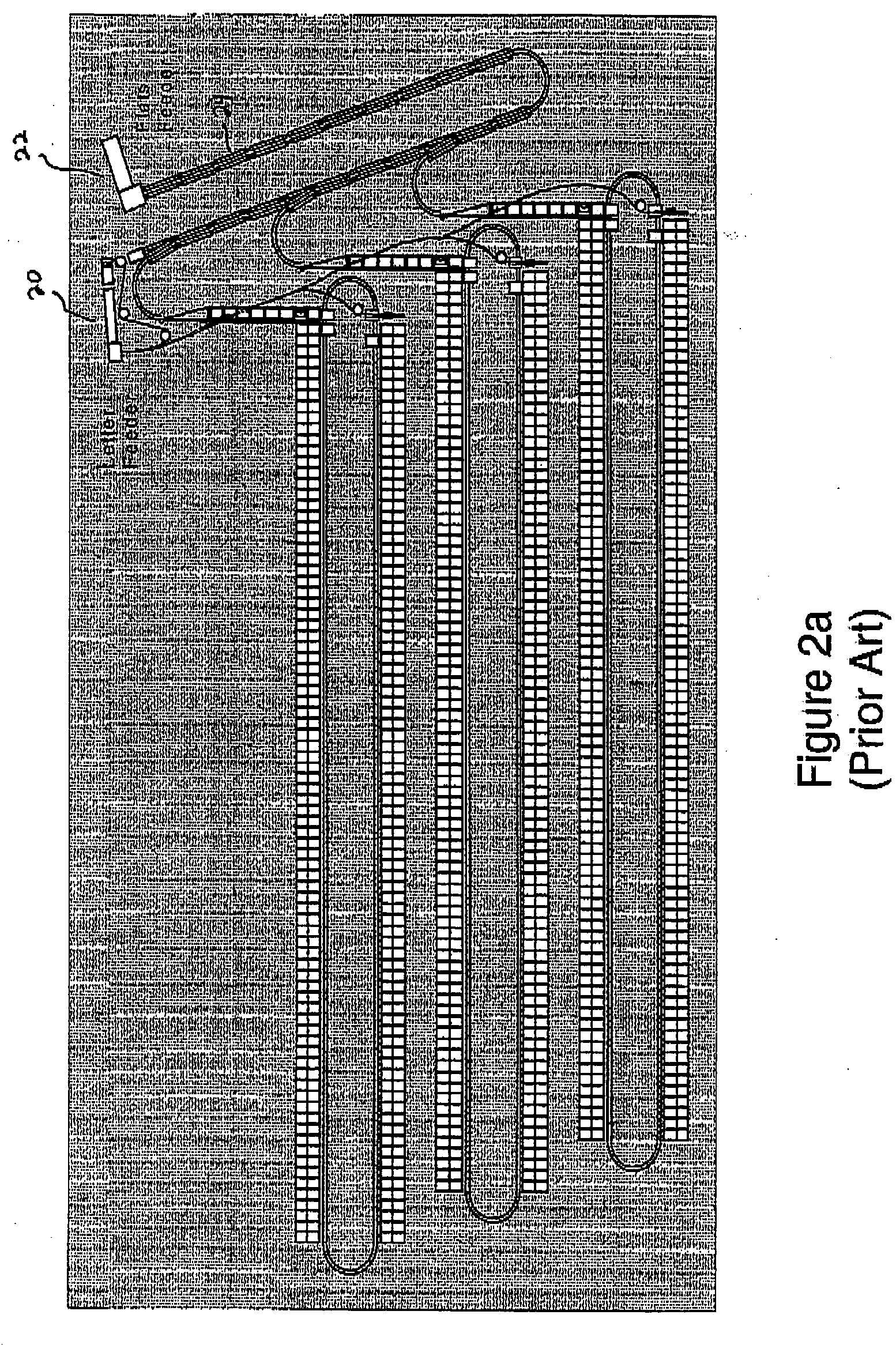

Apparatus For Processing Sheets Inserted Sertically, In Particular An Automatic Validating Machine For Documents, Such As Cheques

An apparatus ( 10 ) suitable to process sheets ( 13 ), in particular comprised of an validating machine ( 10 ) for the validation of documents ( 13 ) such as cheques or similar documents, comprising a vertical guide ( 11 ), and a pair of arms ( 22 a , 22 b) suitable to hold and support a cheque ( 13 ) along a respective lower edge ( 13 a) in a first hold position (Pi), when the cheque ( 13 ) is inserted into the vertical guide ( 11 ), wherein in response to the presence and alignment of the cheque ( 13 ) in said first position (Pi), two pairs of rotating rollers ( 42 a , 42 b , 44 a , 44 b) automatically engage the cheque ( 13 ) from opposite sides, the arms ( 22 a , 22 b) are moved out of contact with the lower edge ( 13 a) of the cheque ( 13 ), in order to free the feeding path of the cheque towards the interior of the validating machine, and the cheque is also fed vertically, in a downward direction, by means of the two pairs of rollers from the said first position (P 1 ) to a second processing position (P 2 ) in the validation zone for being validated. The cheque ( 13 ) inserted into the validating machine ( 10 ) can also be moved in a horizontal direction, for example, in order to perform the detection of data recorded on the cheque ( 13 ) by means of a magnetic detection unit ( 76 ). The validating machine ( 10 ) permits easy and practical manual insertion of the document to be validated from above, in a vertical direction, still at the same time ensuring correct and safe alignment of said document in the vertical guide, whereupon it activates and controls in a completely automatic manner the related validation cycle.

Owner:TELECOM ITALIA SPA

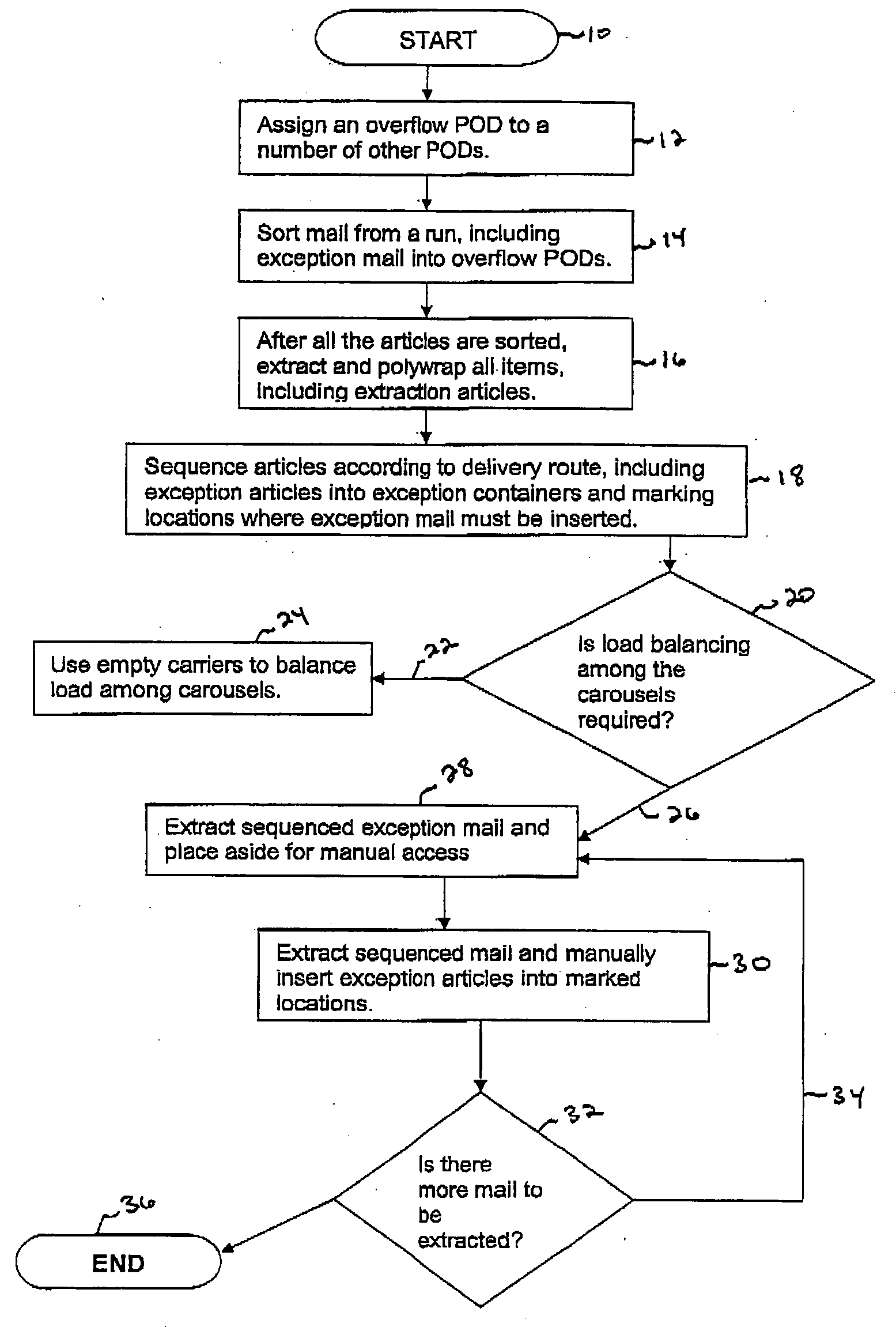

Exception mail handling

The present invention relates to article handling and sorting and in particular to a system and method for handling and sorting both regular and exception articles. Regular articles are ones which fit into an article bin assigned to the article's destination address. Exception articles are ones which no longer fit due to volume concerns. In operation, a first sort of the article batch is performed into bins or PODs assigned to regular and exception articles. The exception articles are extracted, polywrapped and sorted a second time in sequence of delivery. The exception articles are also sorted in sequence of delivery. Markers are inserted into the regular article stack to indicated where an exception article should have gone. After the second sort, the articles are again extracted, exception articles first. Related regular articles are then extracted and the exception articles are manually inserted where marked. Because the exception articles are in sequence order, they will also be in the order of the markings, making manual insertion sequential and therefore easier. The present invention also includes a system for performing the above.

Owner:SIEMENS AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com