Patents

Literature

67results about "Skinless sausage making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

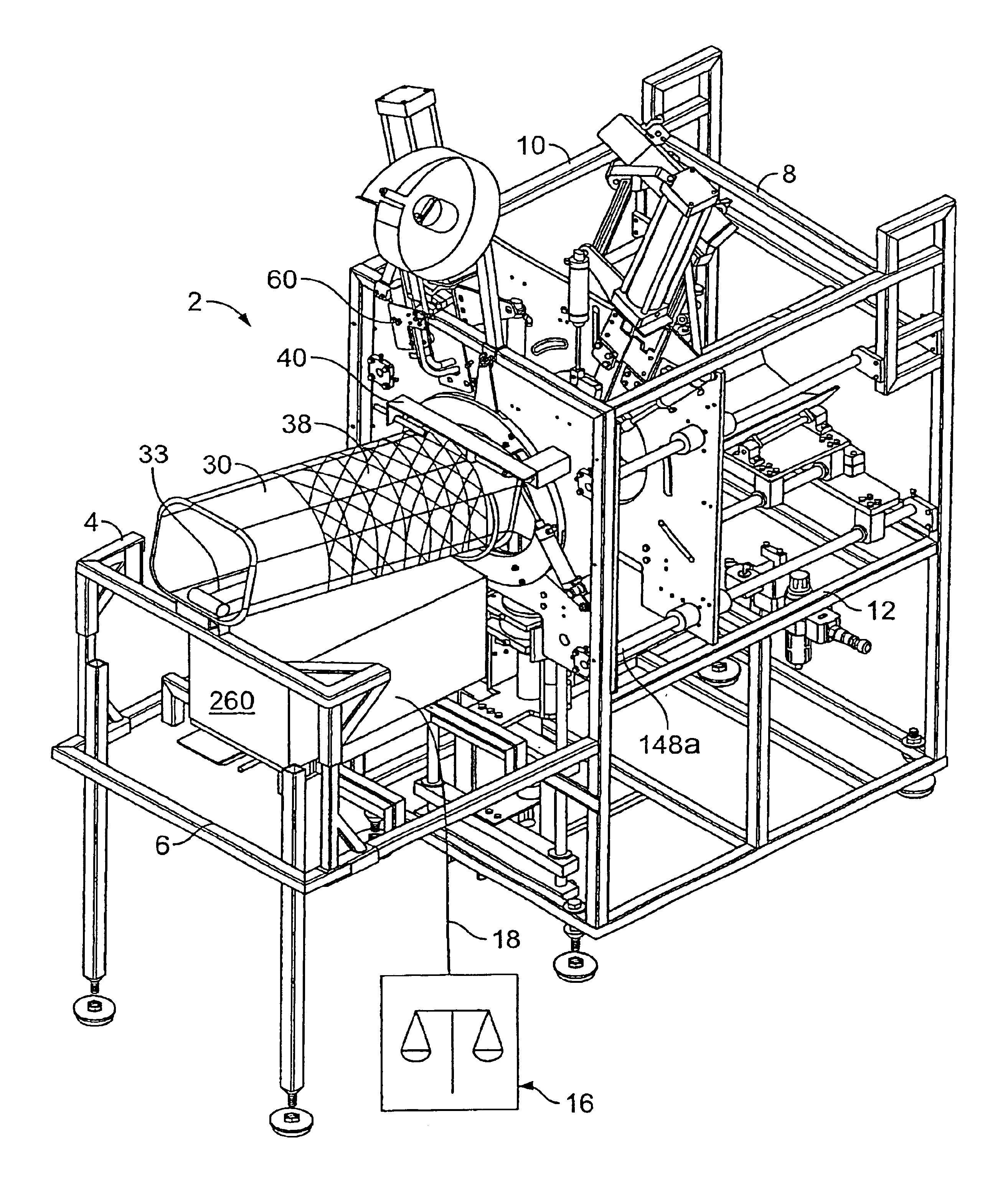

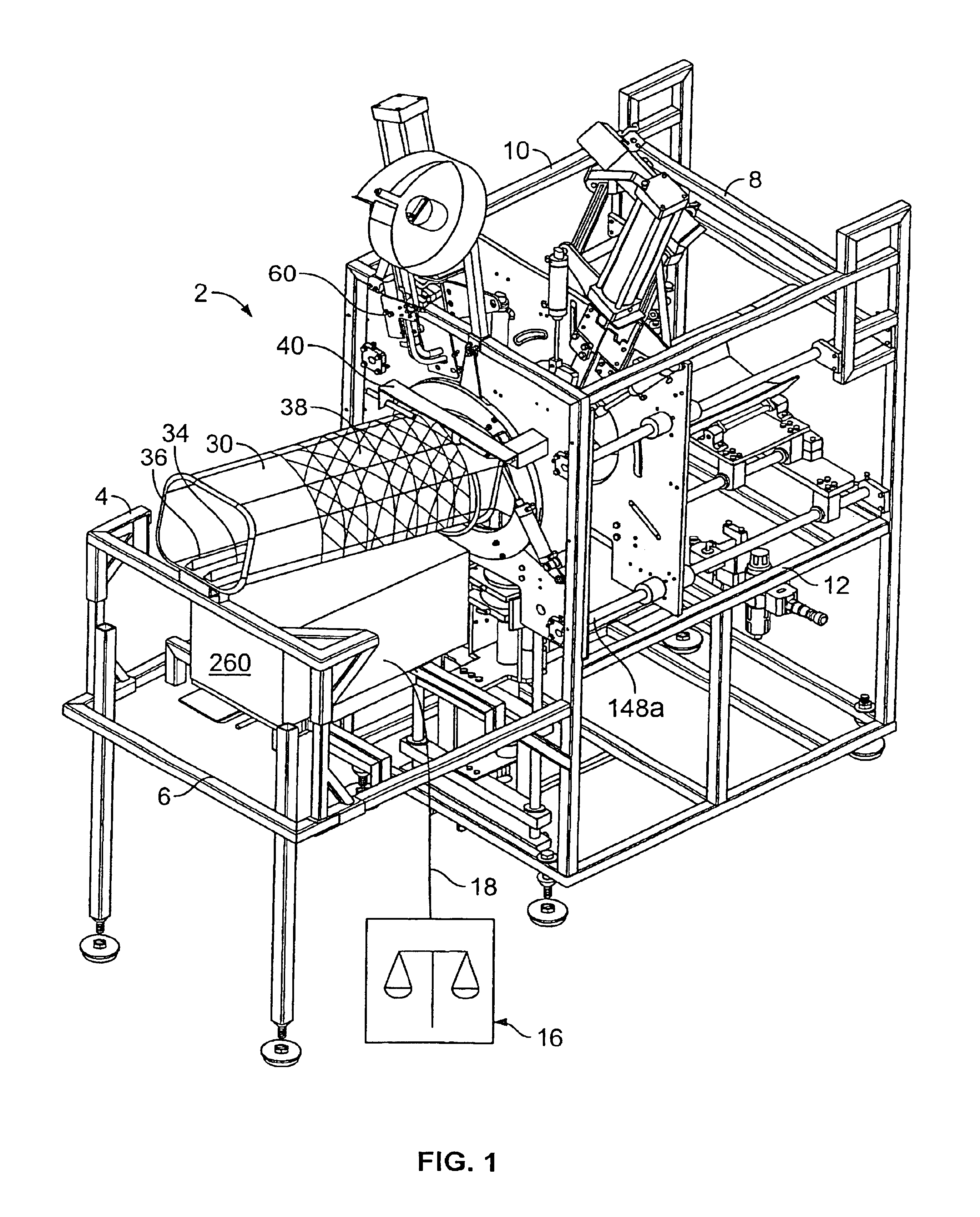

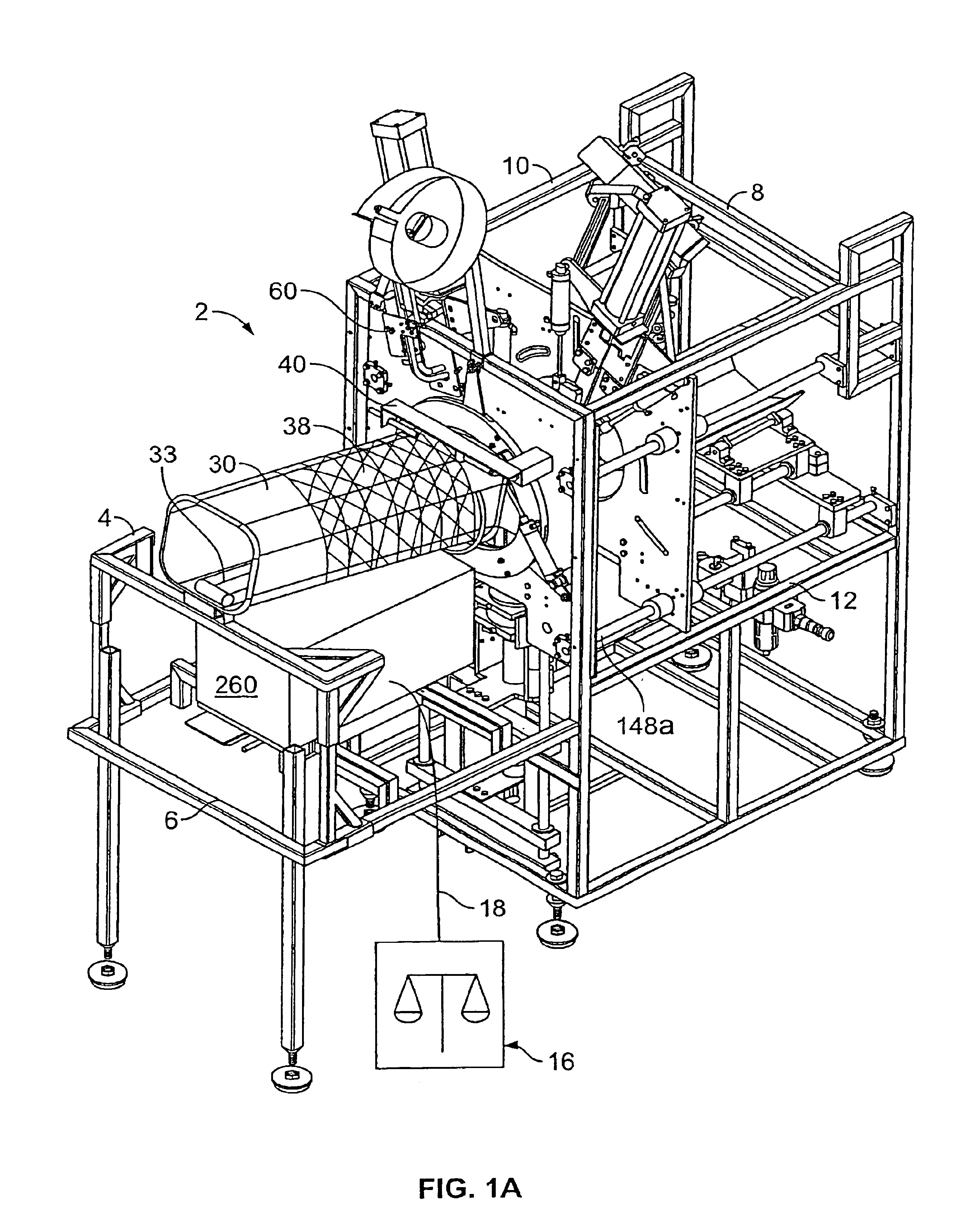

Apparatus for enclosing material in a net

InactiveUS6883297B2Uniform appearanceLighten the taskAffixing tagsSkinless sausage makingEngineeringMechanical engineering

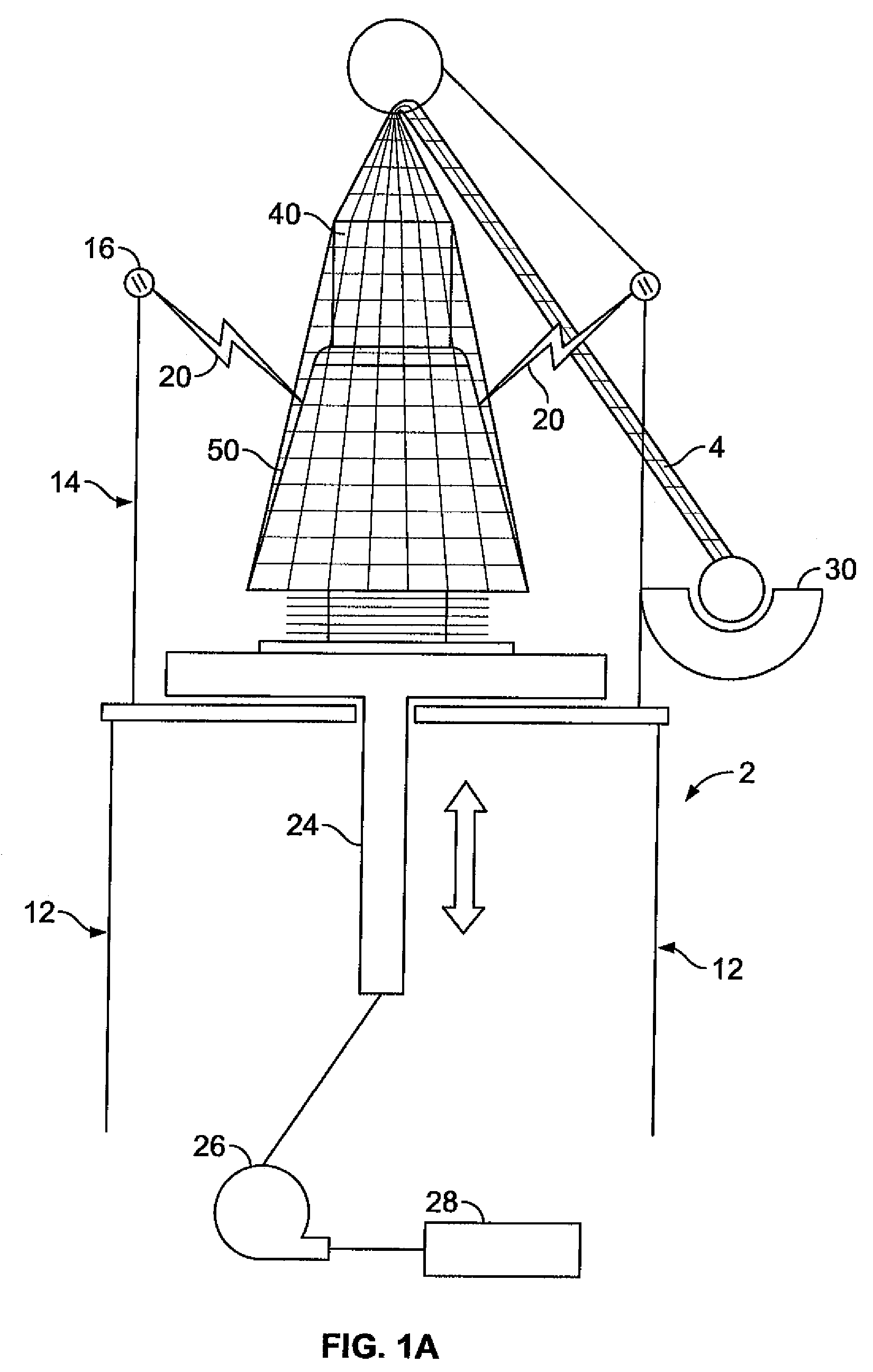

An apparatus and method of enclosing material in a net and supplying a handle for ease of carrying the netted material, comprising clippers, irises, and a handle maker. A conveyor carries the material to a pair of irises. The irises gather the netting around the material, the first clipper cuts and closes the netting, and the handle maker forms a loop out of the severed netting. The second clipper attaches the loop back to the netting to form a handle. A scale can be used to weigh the material and a printer can create a label, with the weight or whatever other information is desired, for attachment to the netting.

Owner:POLY CLIP SYST

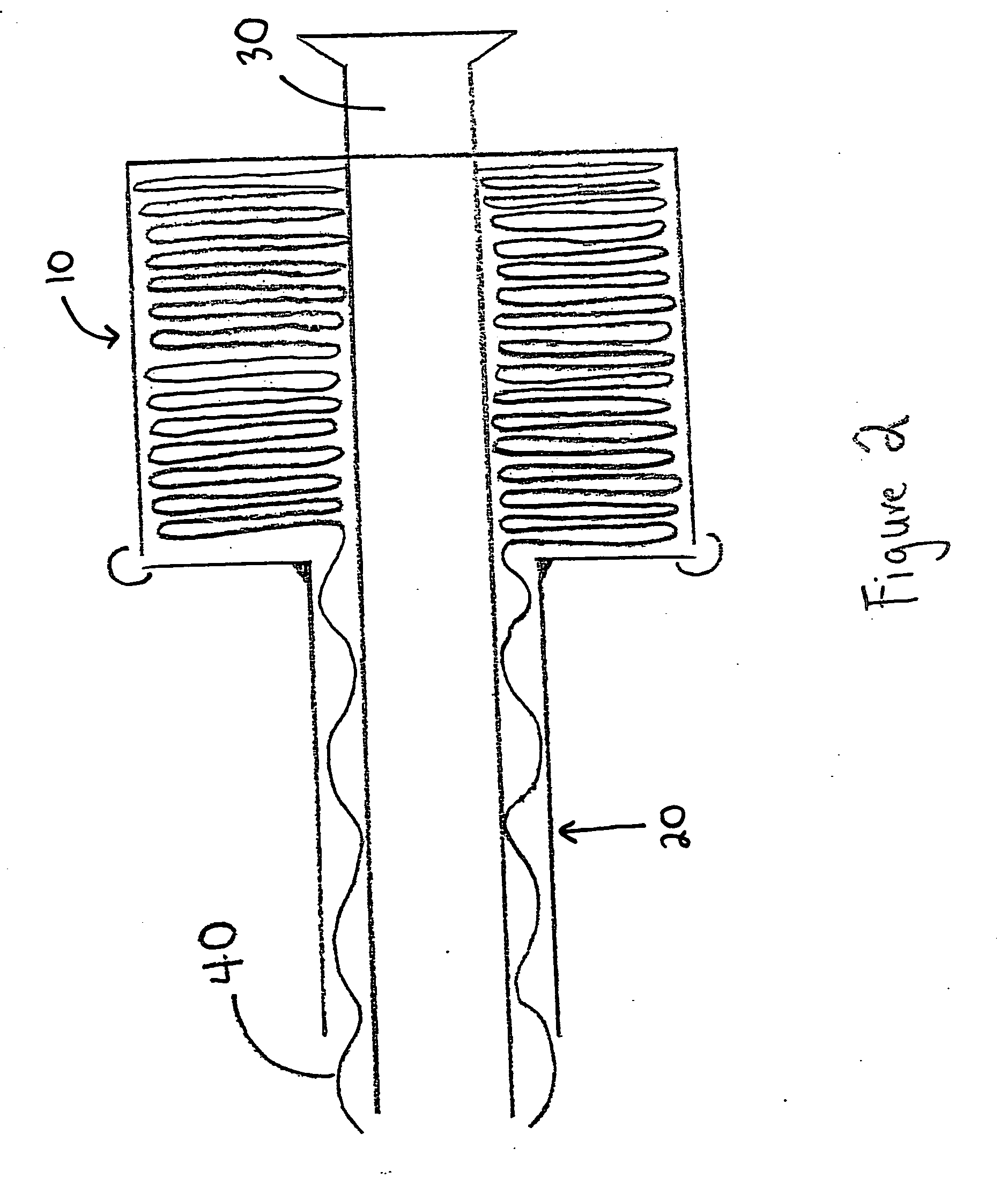

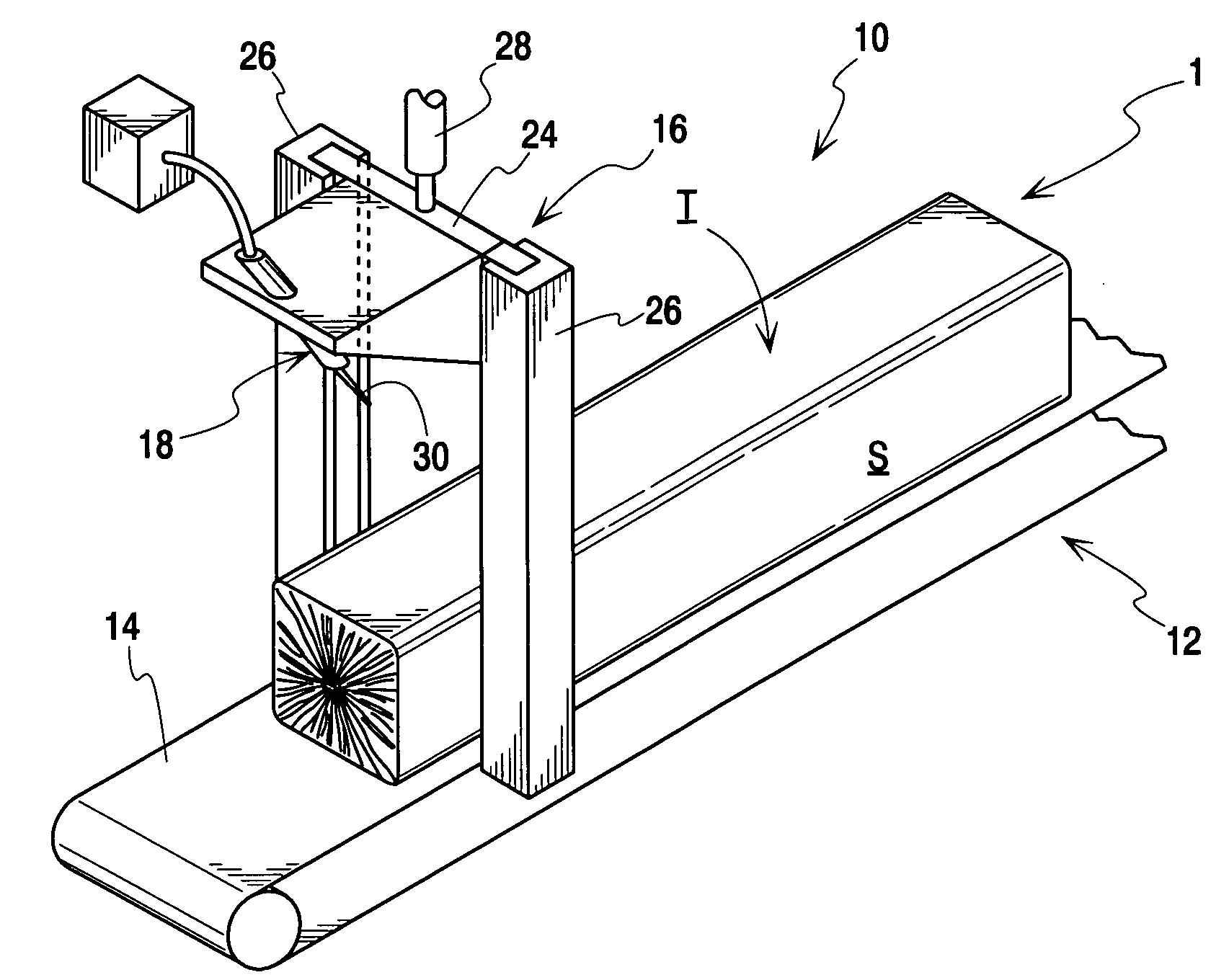

Skinless sausage or frankfurter manufacturing method and apparatus utilizing reusable deformable support

InactiveUS6326039B1Reduce manufacturing costLow costDough treatmentConfectioneryEngineeringConveyor belt

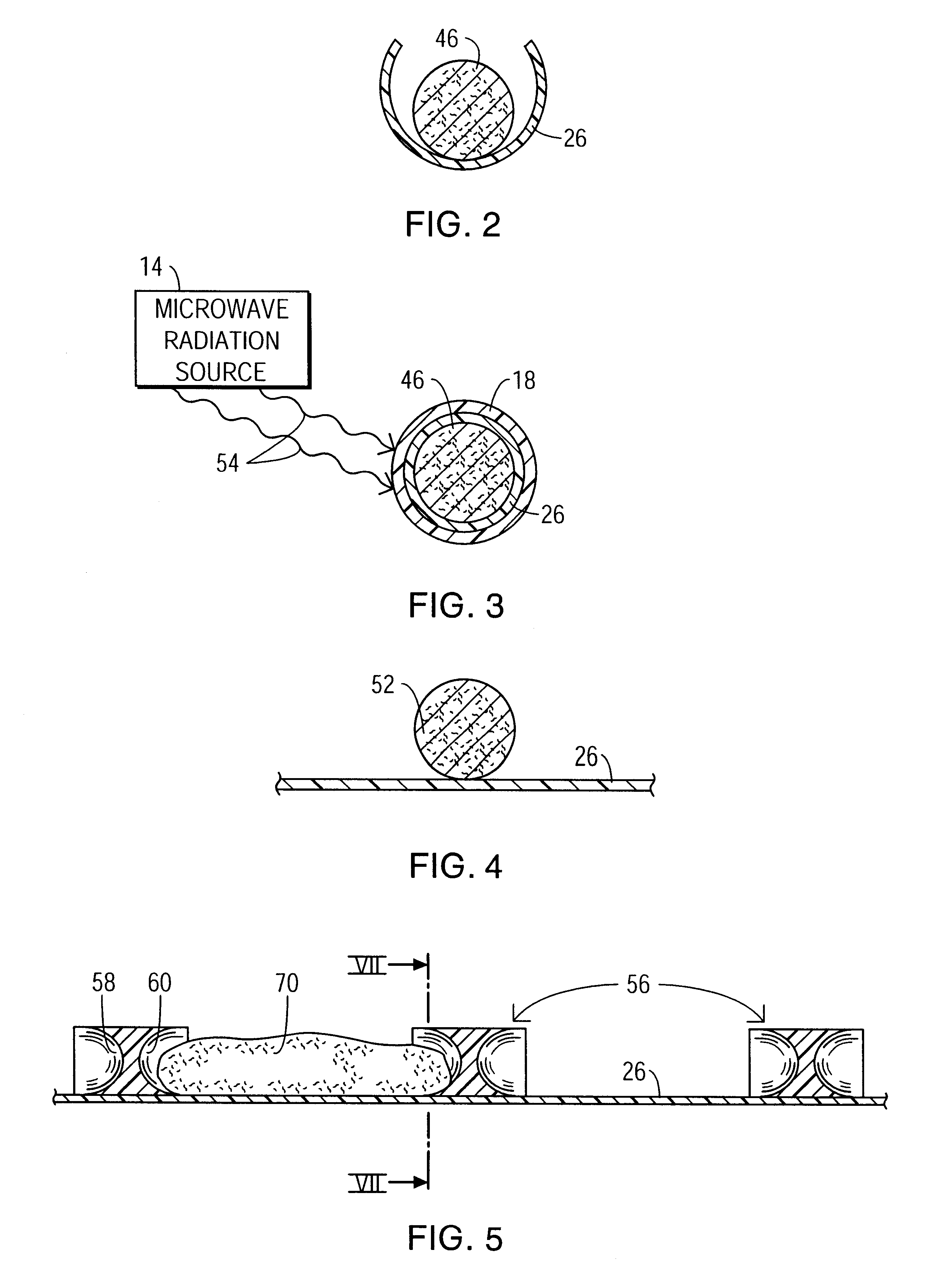

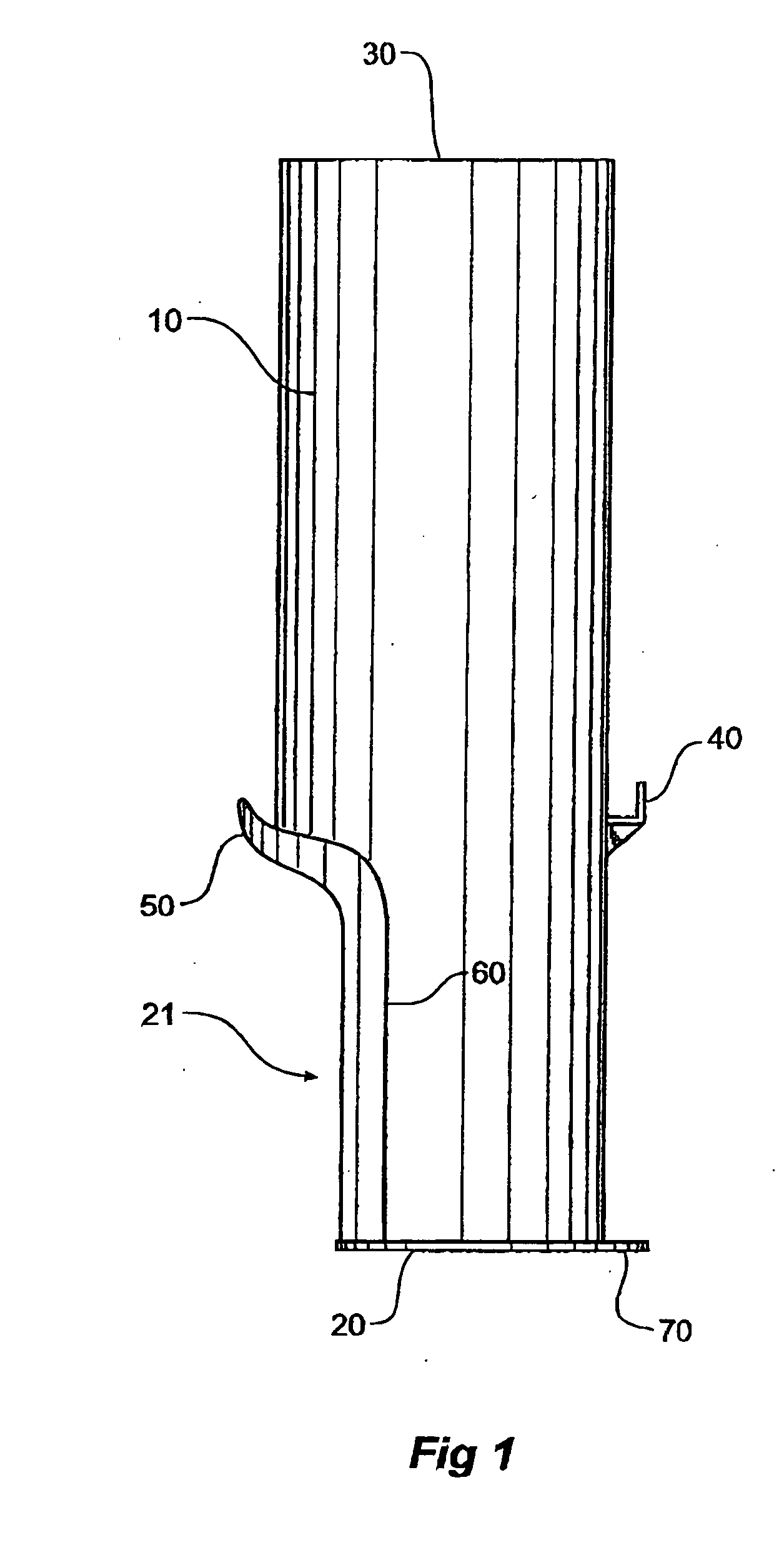

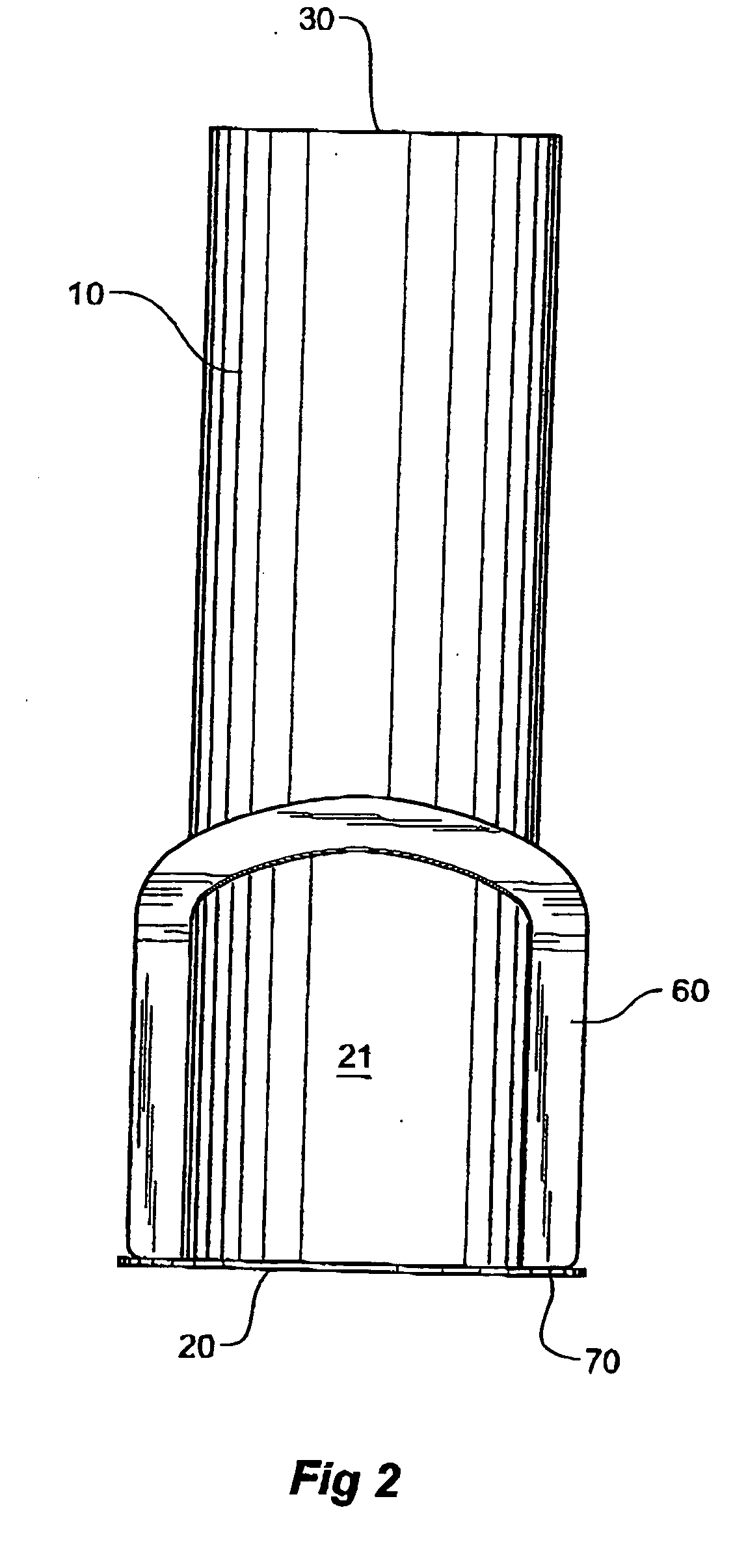

In a method for the manufacture of frankfurters, hot dogs and other skinless sausage products, a meat emulsion is extruded onto a flexible conveyor belt which is then conveyed through a tube whose internal diameter is equal to the desired diameter of the sausage product plus twice the thickness of the conveyor belt. In a camming type process, the conveyor belt is caused, upon its entry into the tube, to temporarily form a cylinder containing the meat emulsion. The temporary belt cylinder together with the surrounded meat emulsion extrudate is then conveyed through an ultrasonic waveform generator to cook an outer layer of the meat emulsion. The outer layer may be part of the meat emulsion or a thermoset gelling material deposited on the extruded meat emulsion. At the exit end of the tube, the conveyor belt naturally opens under internal stresses from its cylindrical shape to a flattened belt. The at least partially cooked sausage is then removed from the belt for further processing or packaging. The conveyor belt acts as a temporary skin to hold the meat emulsion during its ultrasonic processing.

Owner:MISONIX INC

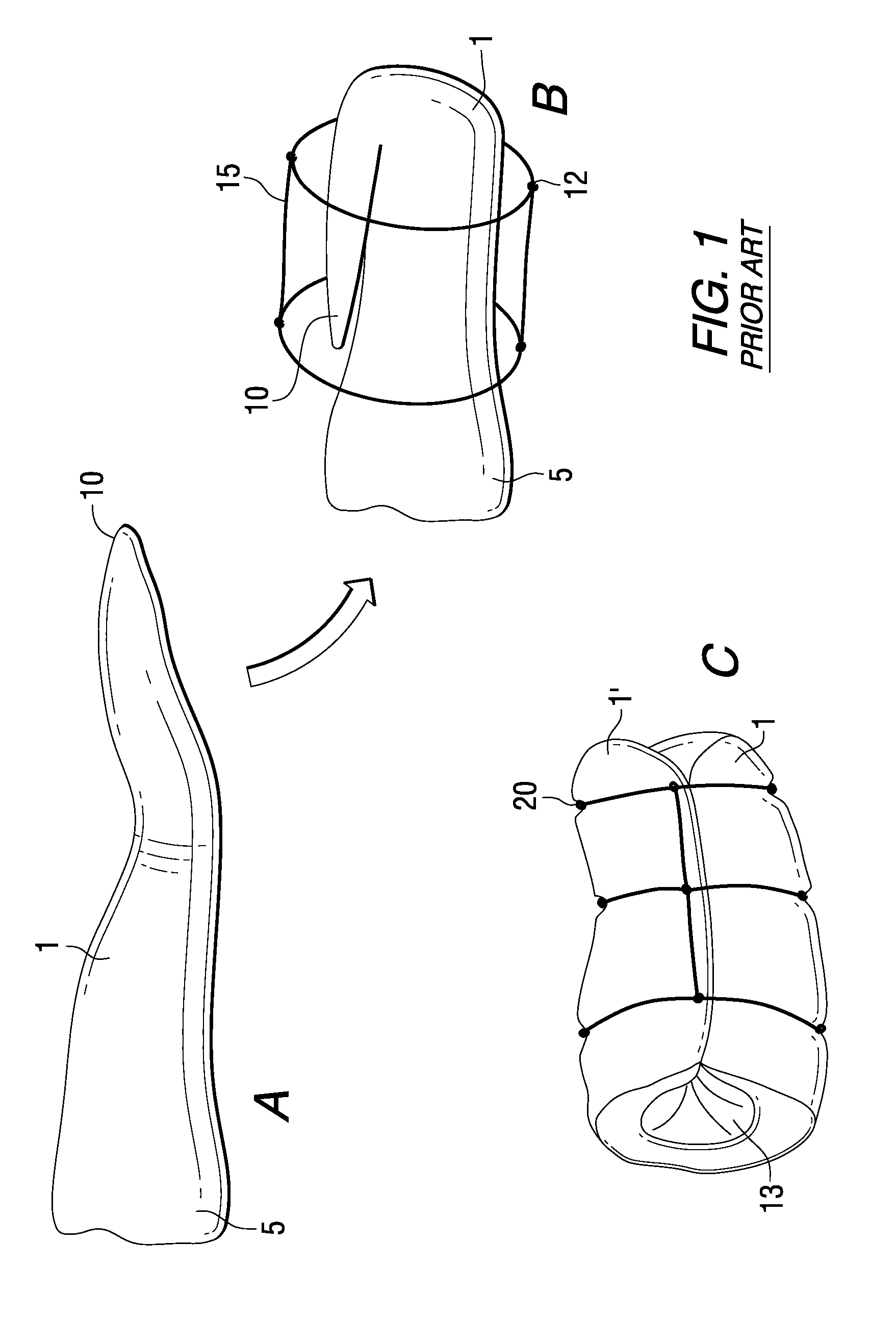

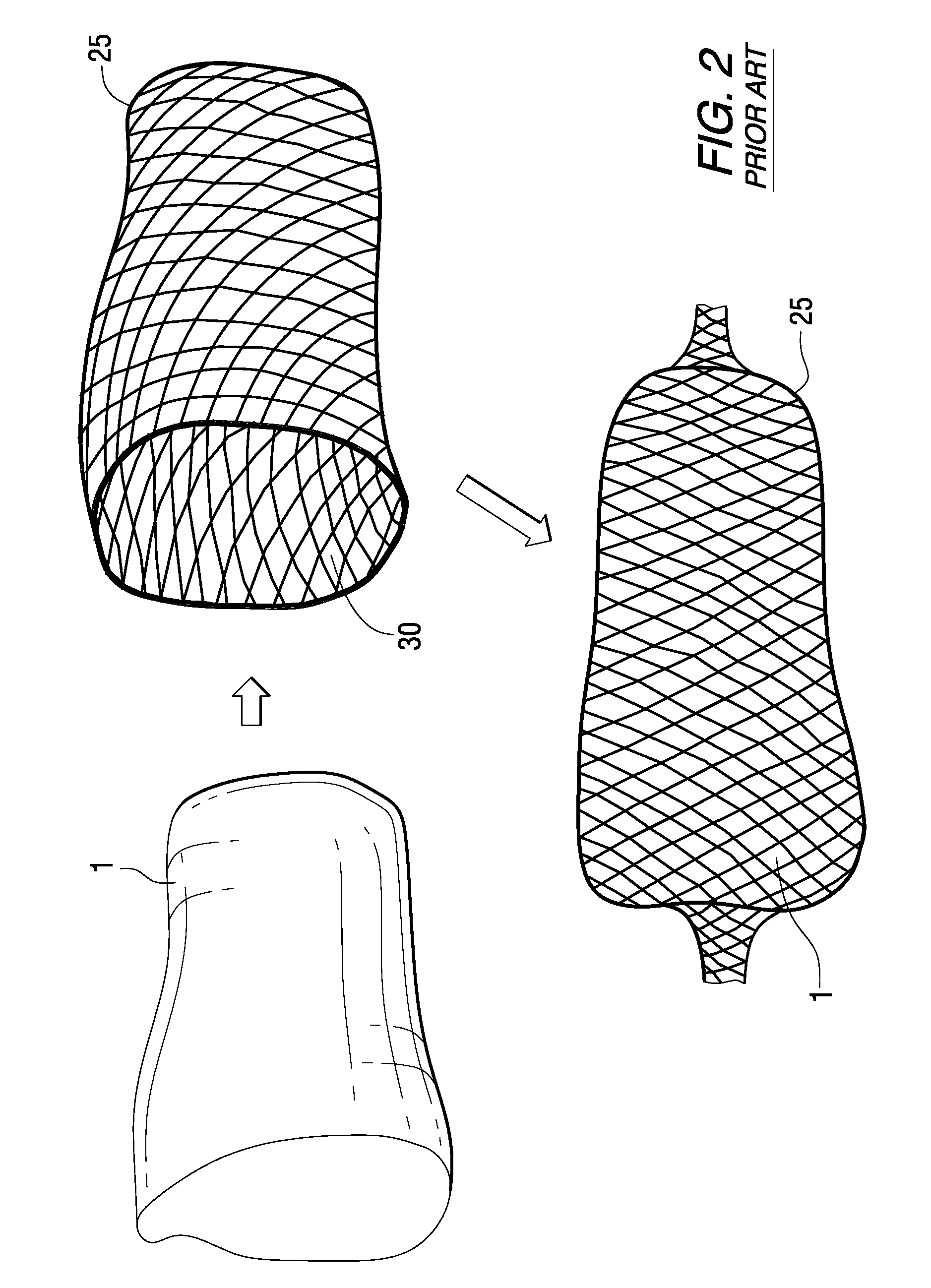

Apparatus and method to net food products in shirred tubular casing

An apparatus and method to net shirred tubular casing, in order to create a highly-dimpled foot product. A filling horn, shir housing, and removable netting tube allow for the extrusion of food products into an edible tubular collagen film, which itself expands into a netting of a smaller diameter than that of the film. As the food product under pressure expands against the tubular film, it presses through the spaces in the netting to created a dimpled appearance. After the food product has been further processed, the netting is removed, leaving a highly-dimpled appearance.

Owner:POLY CLIP SYST

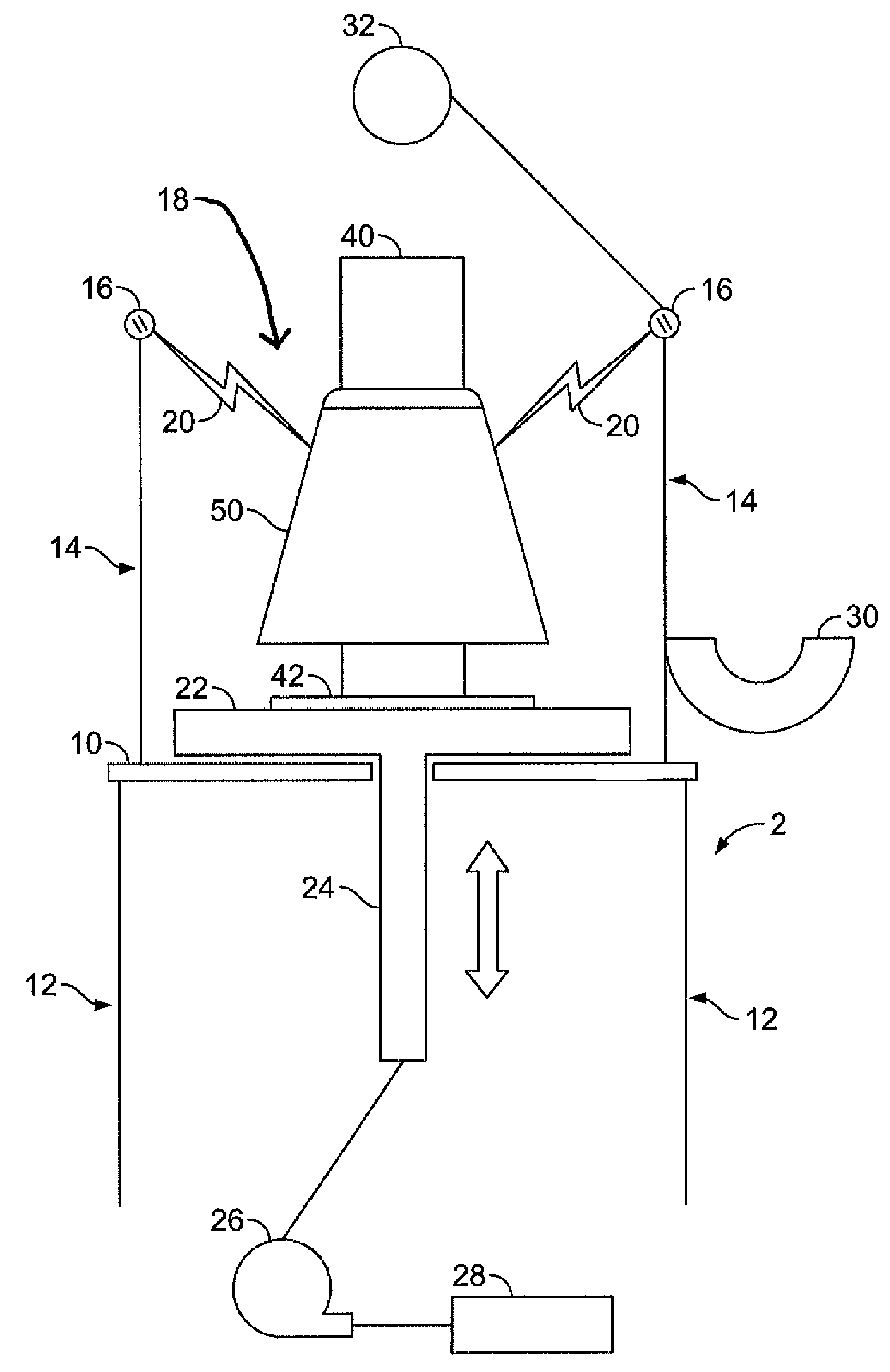

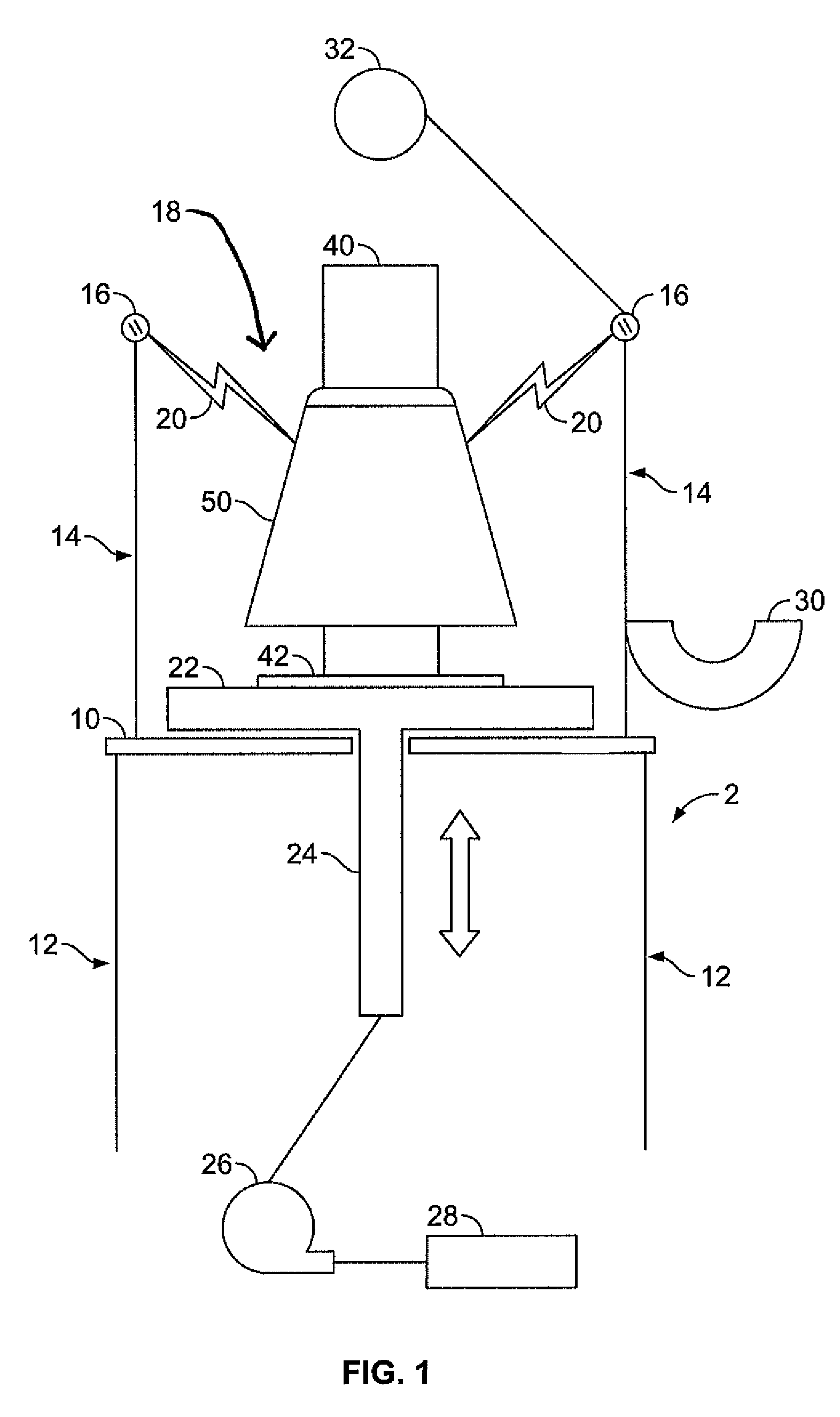

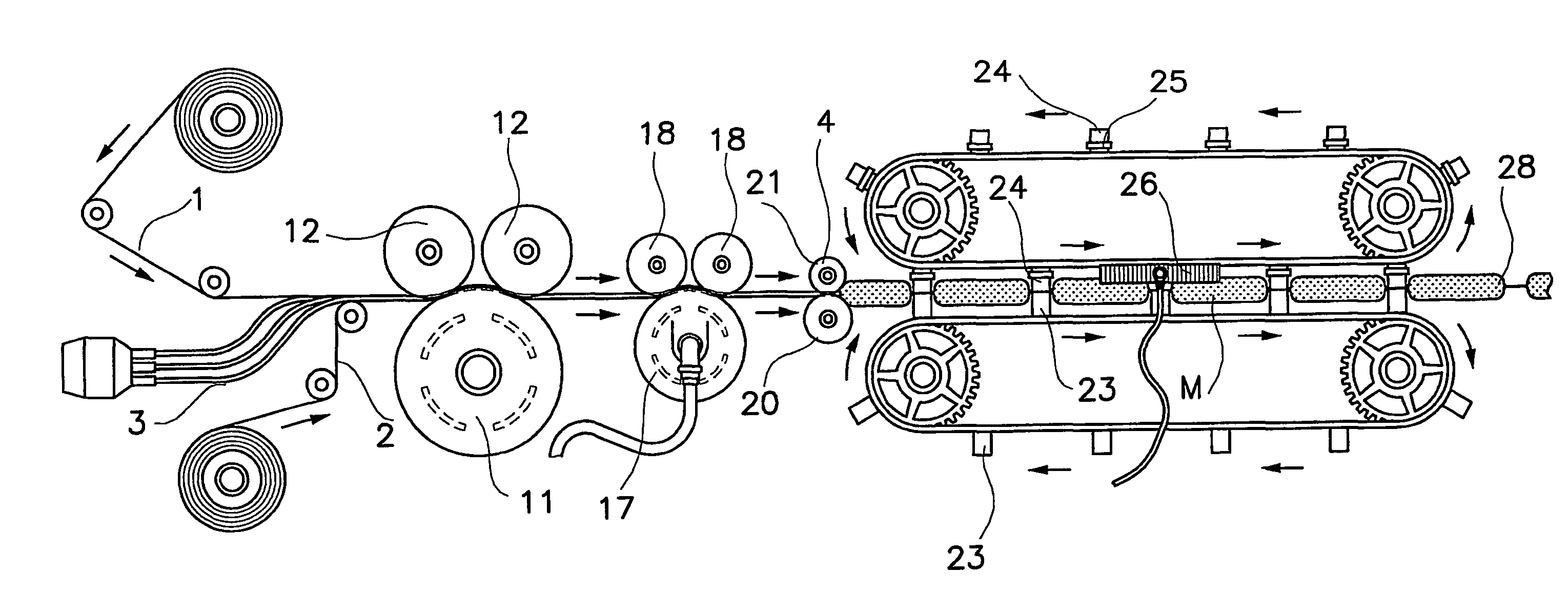

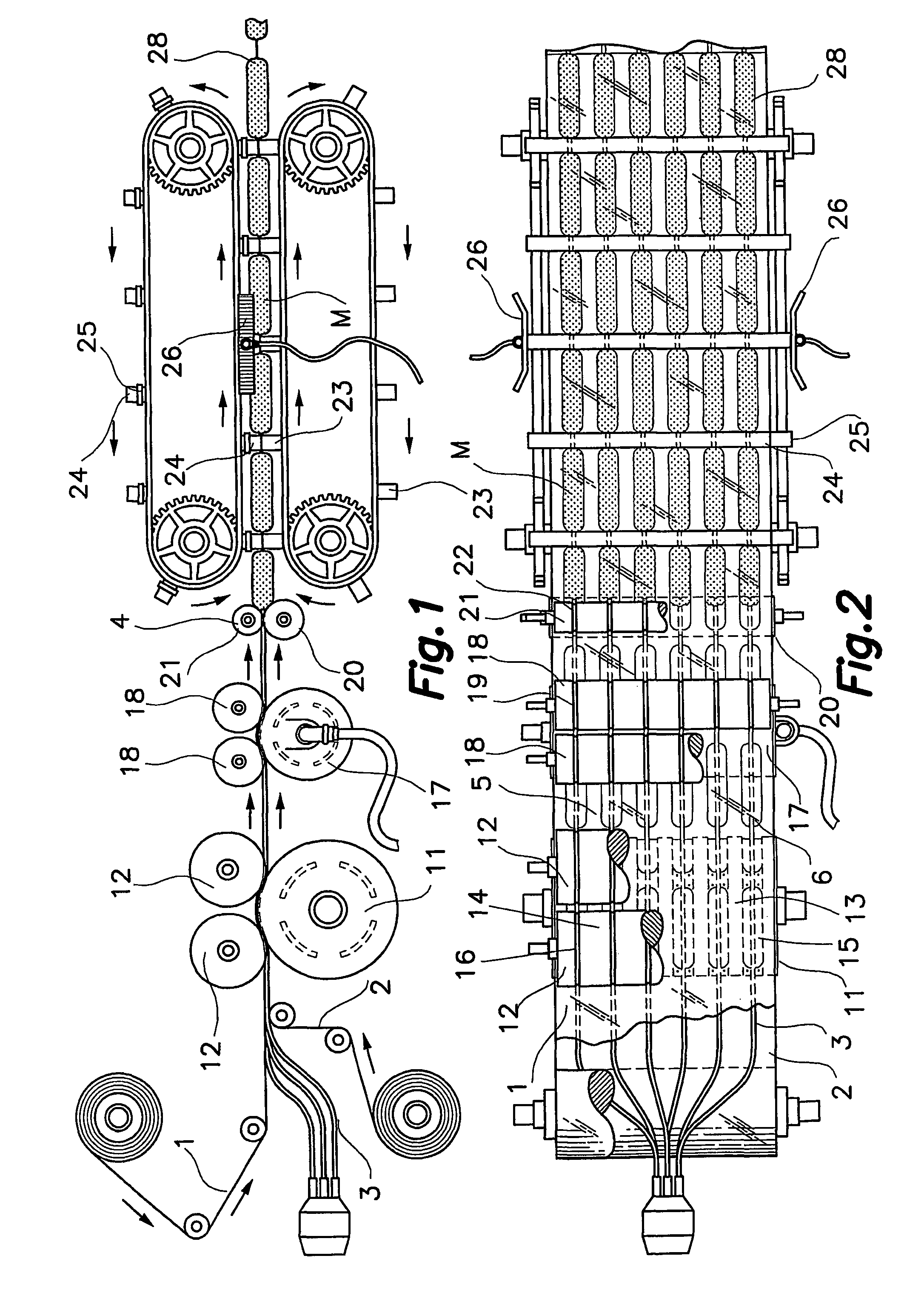

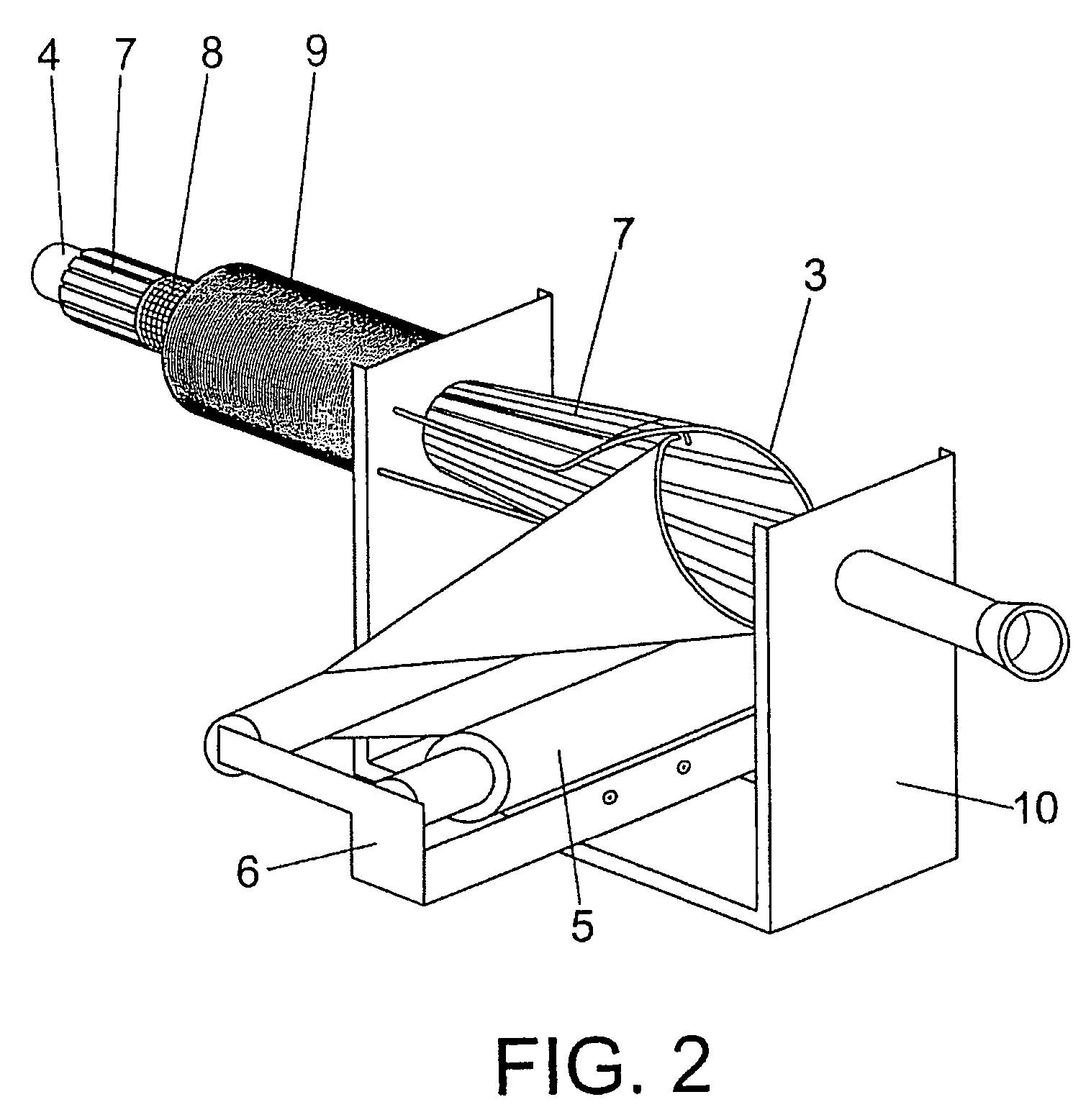

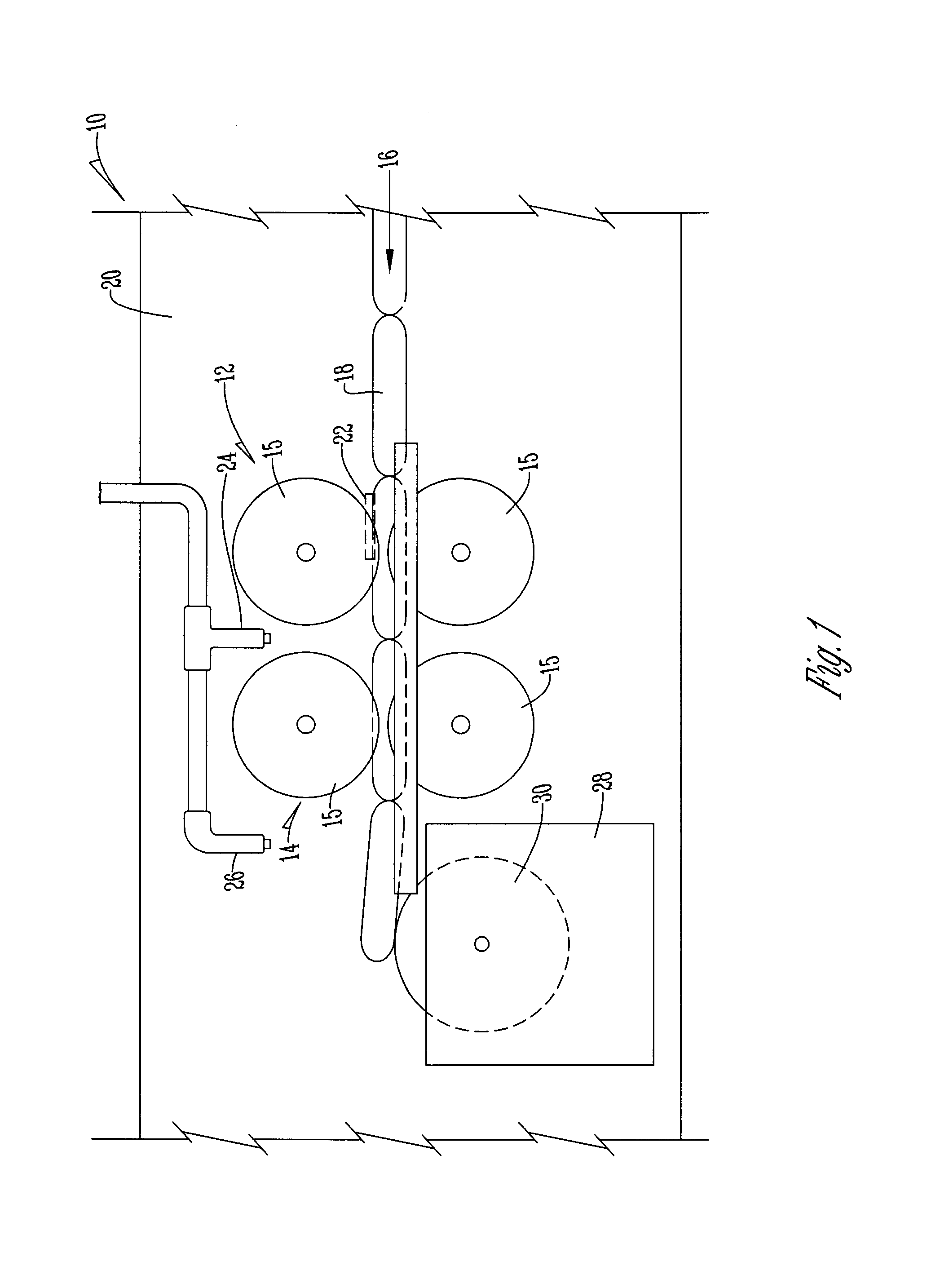

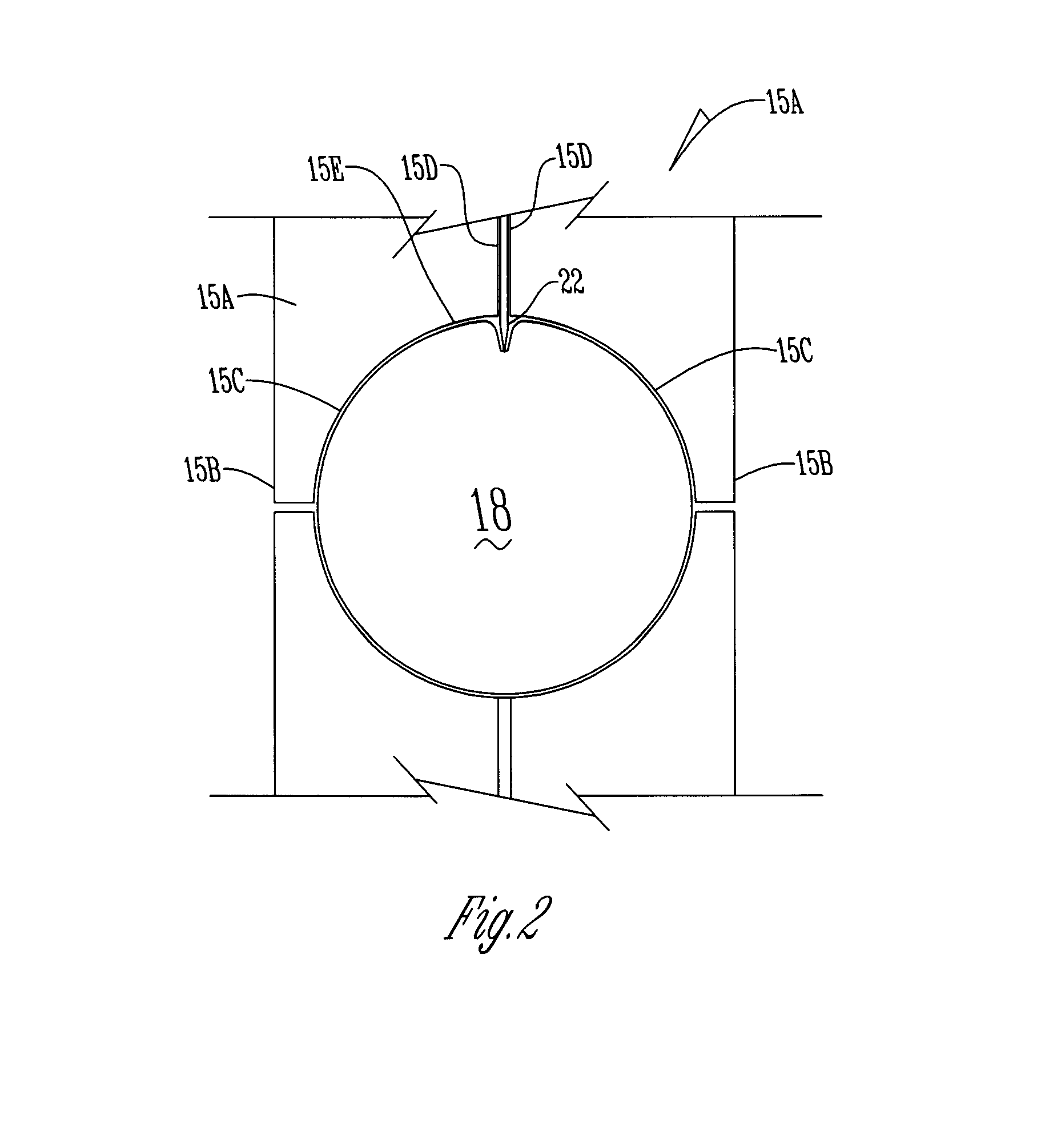

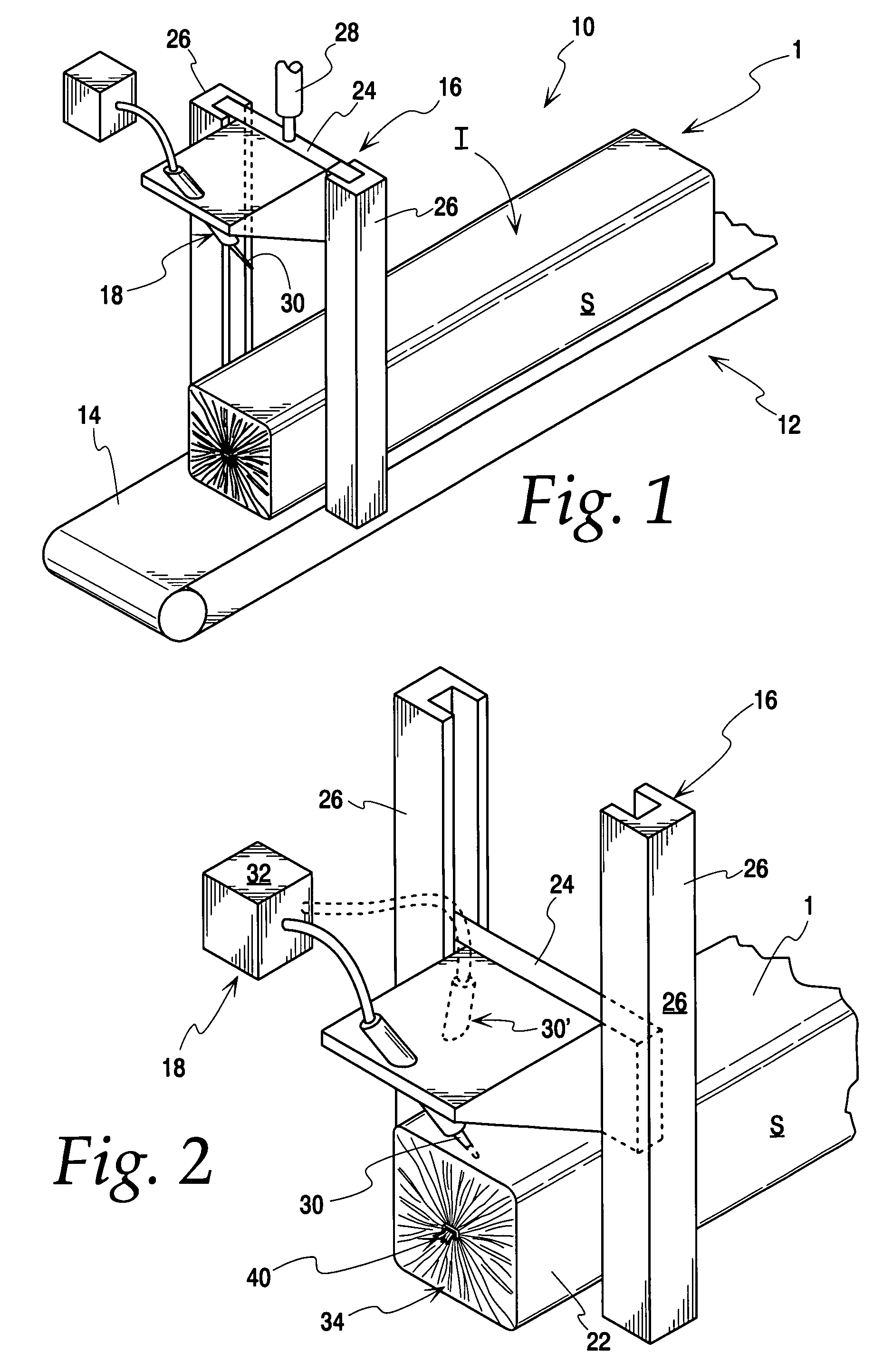

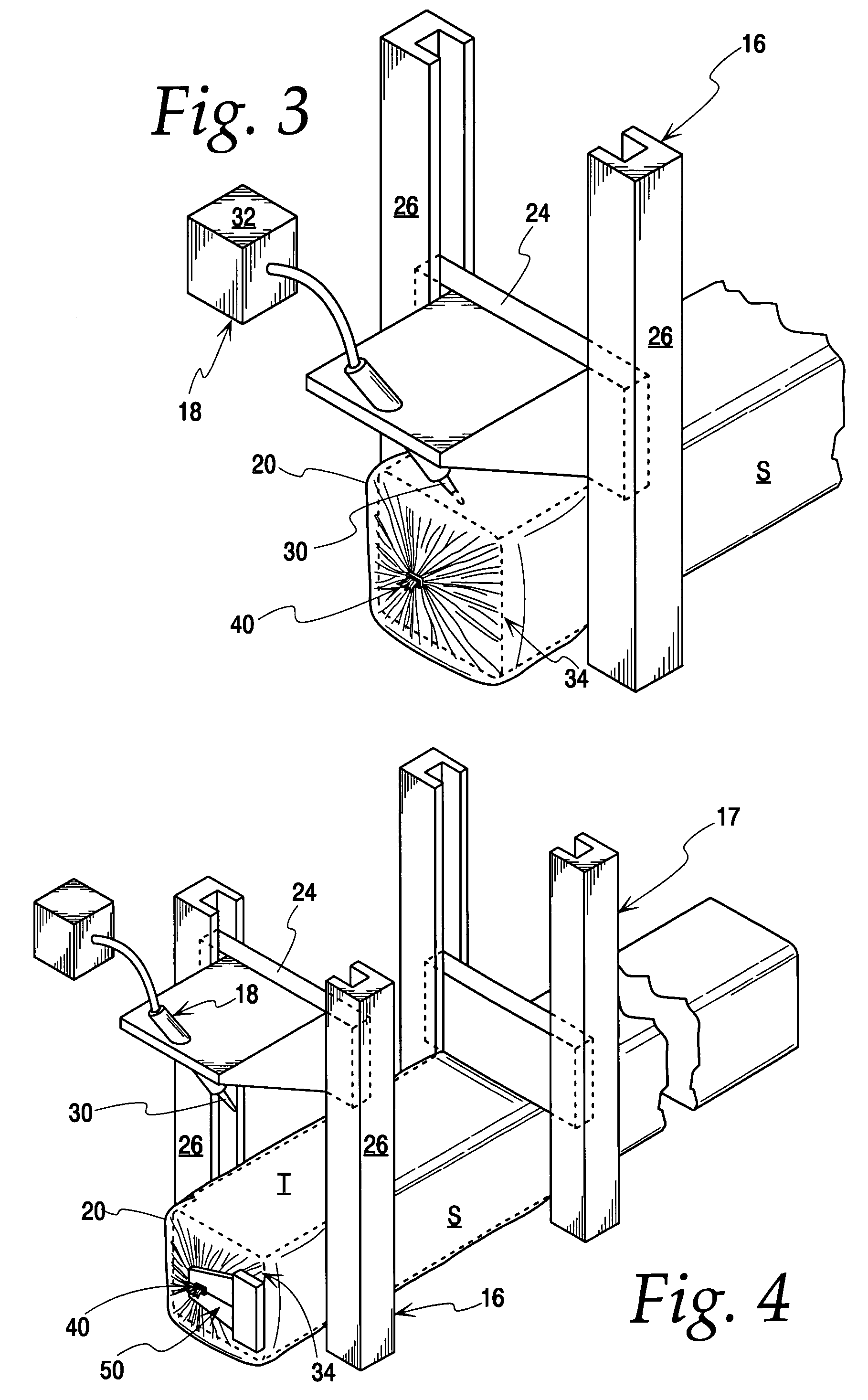

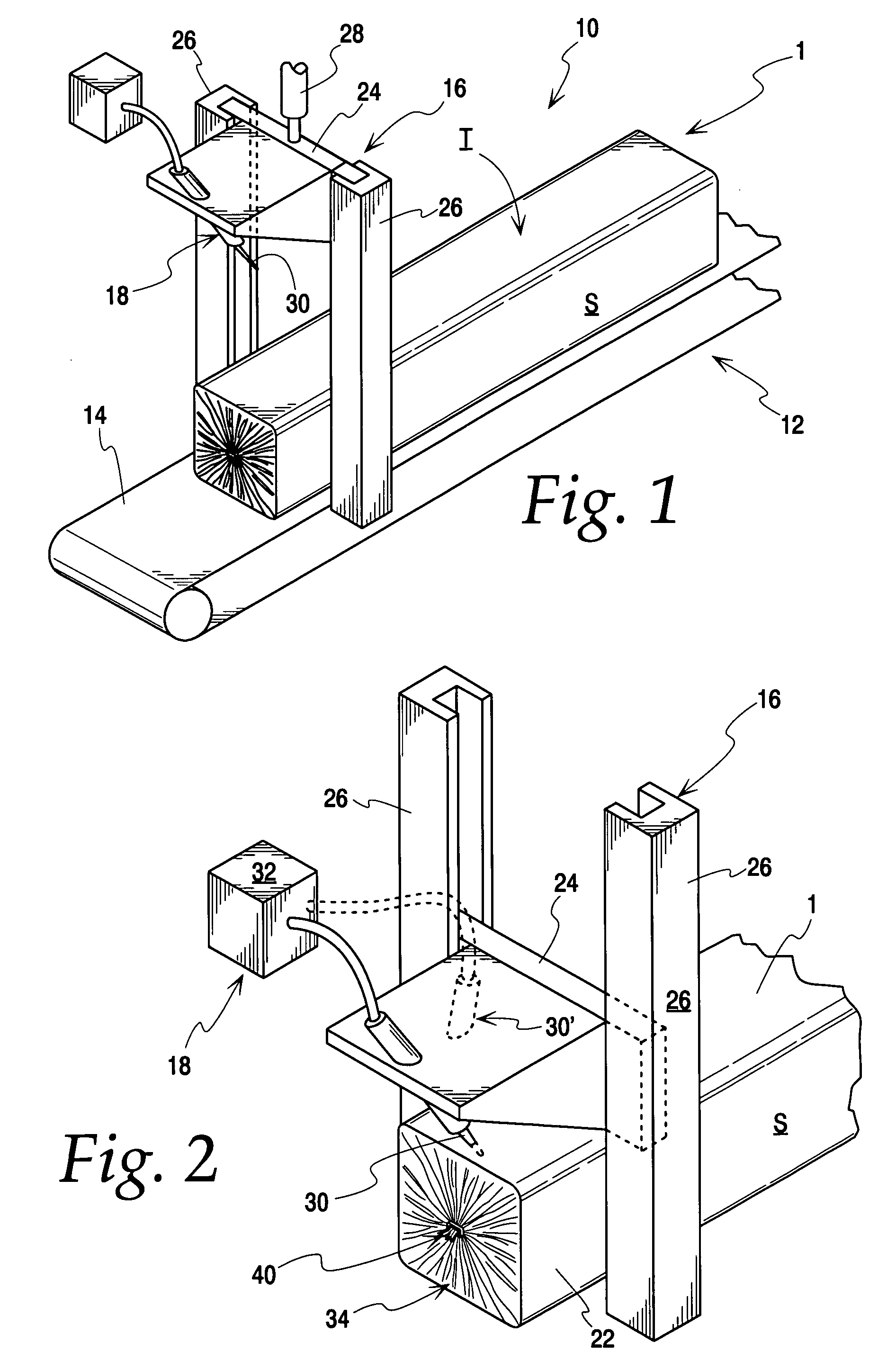

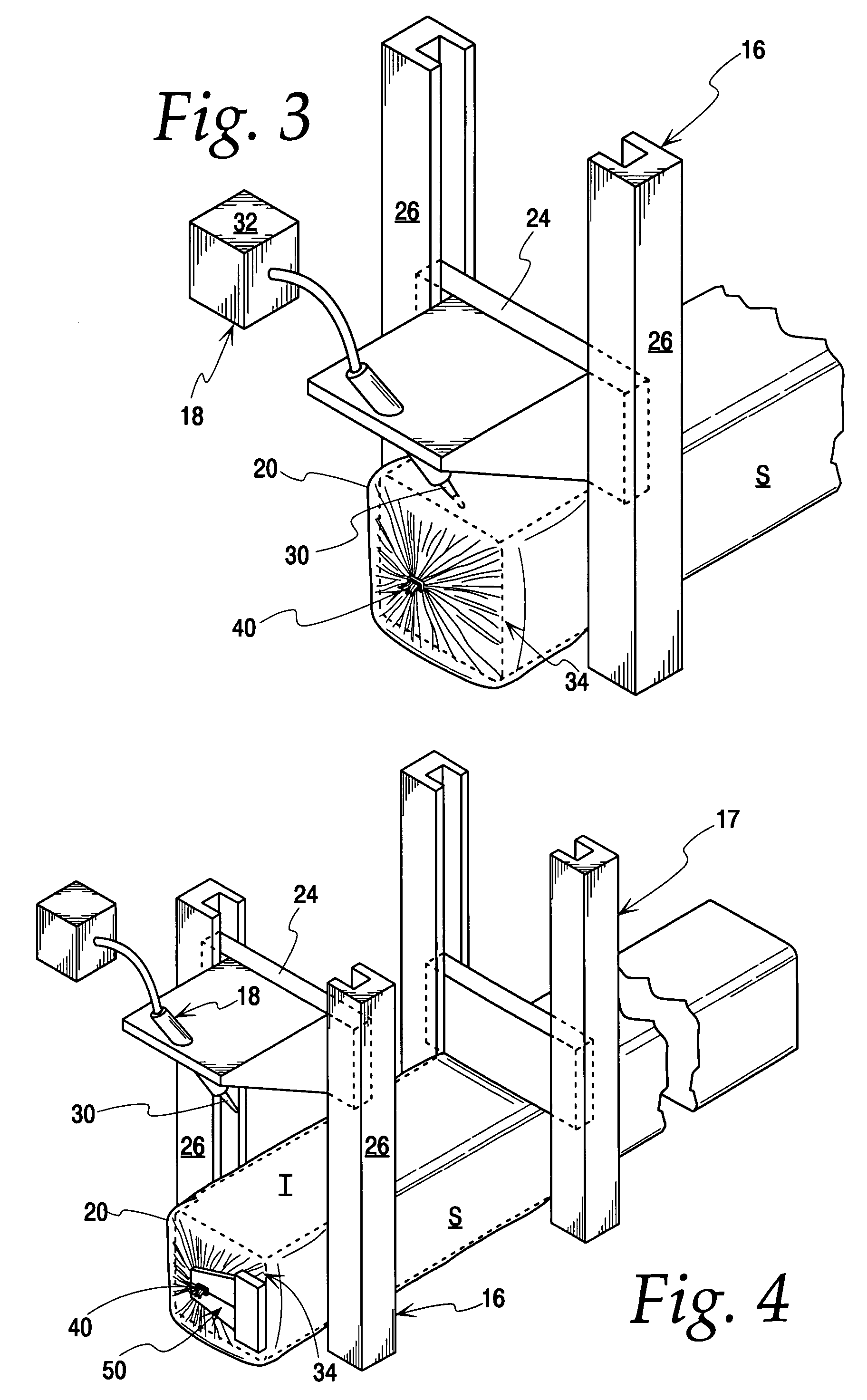

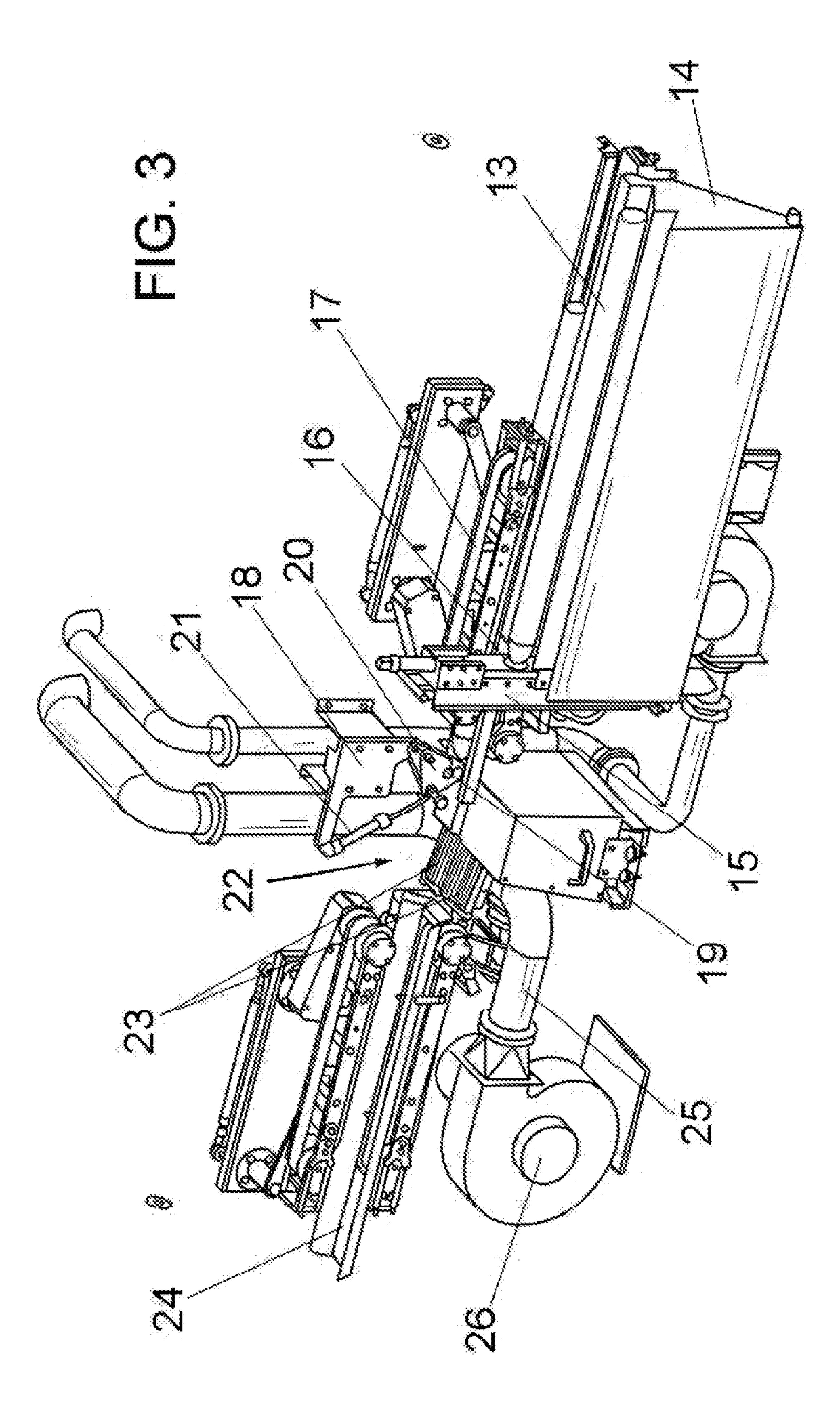

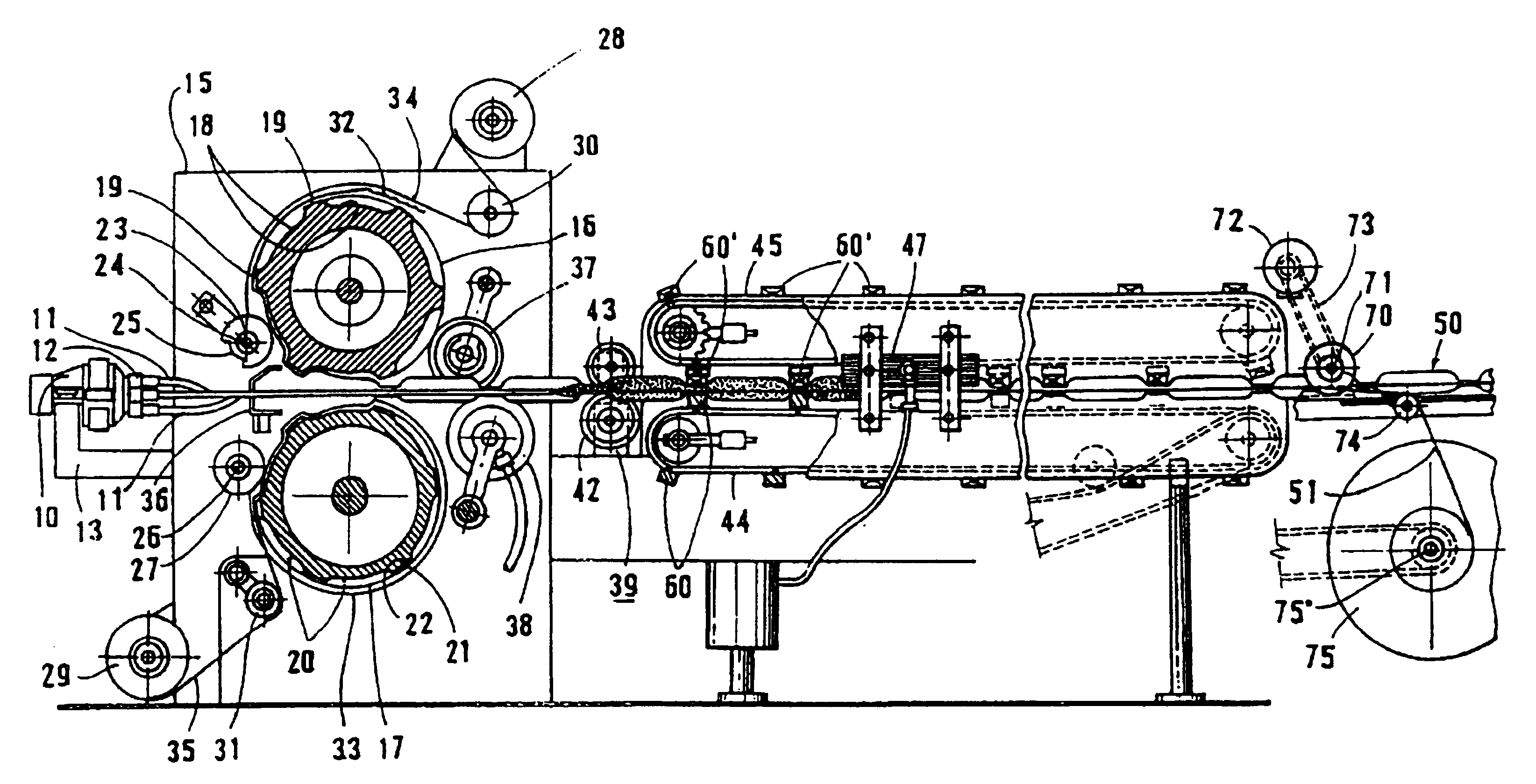

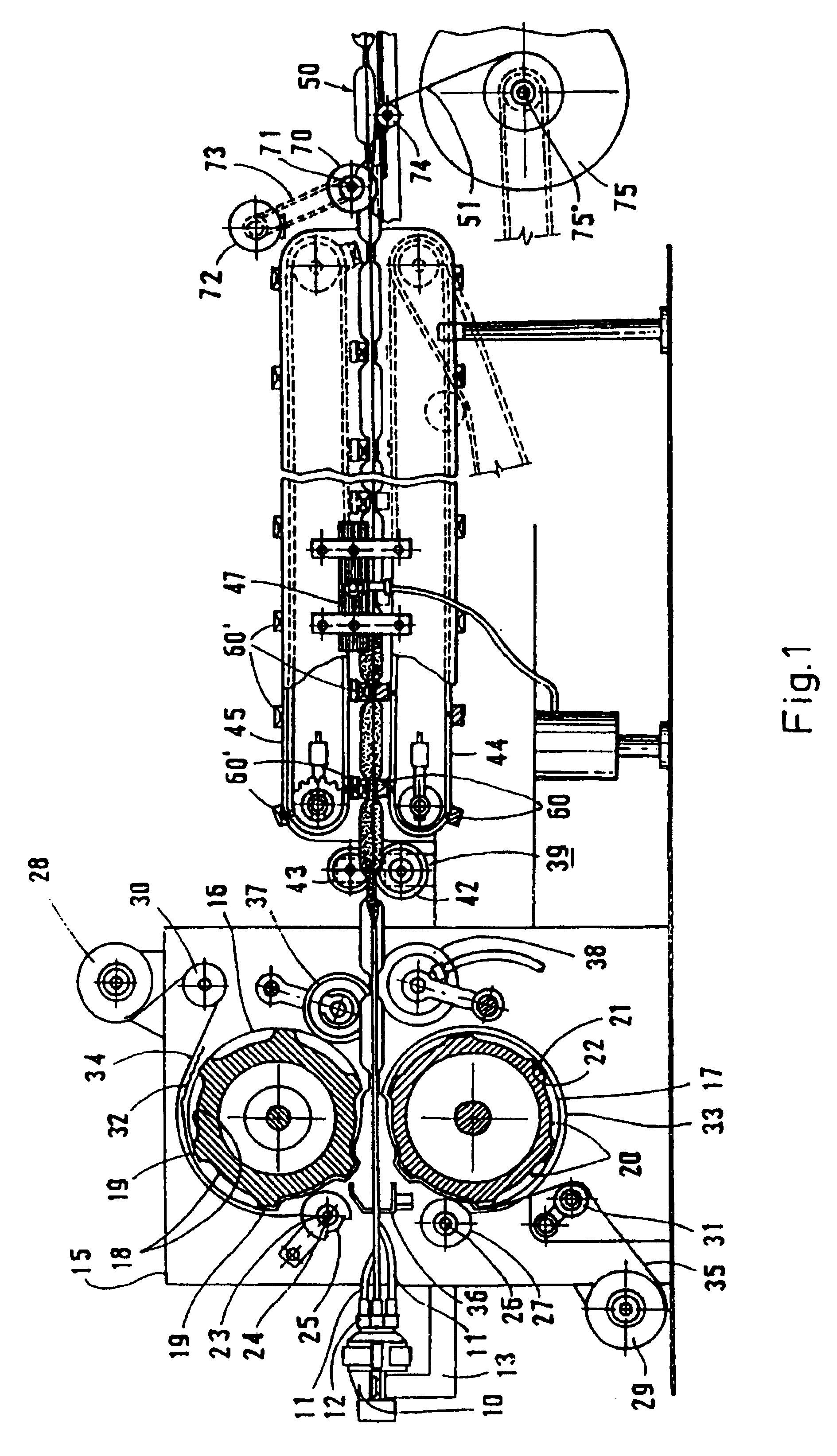

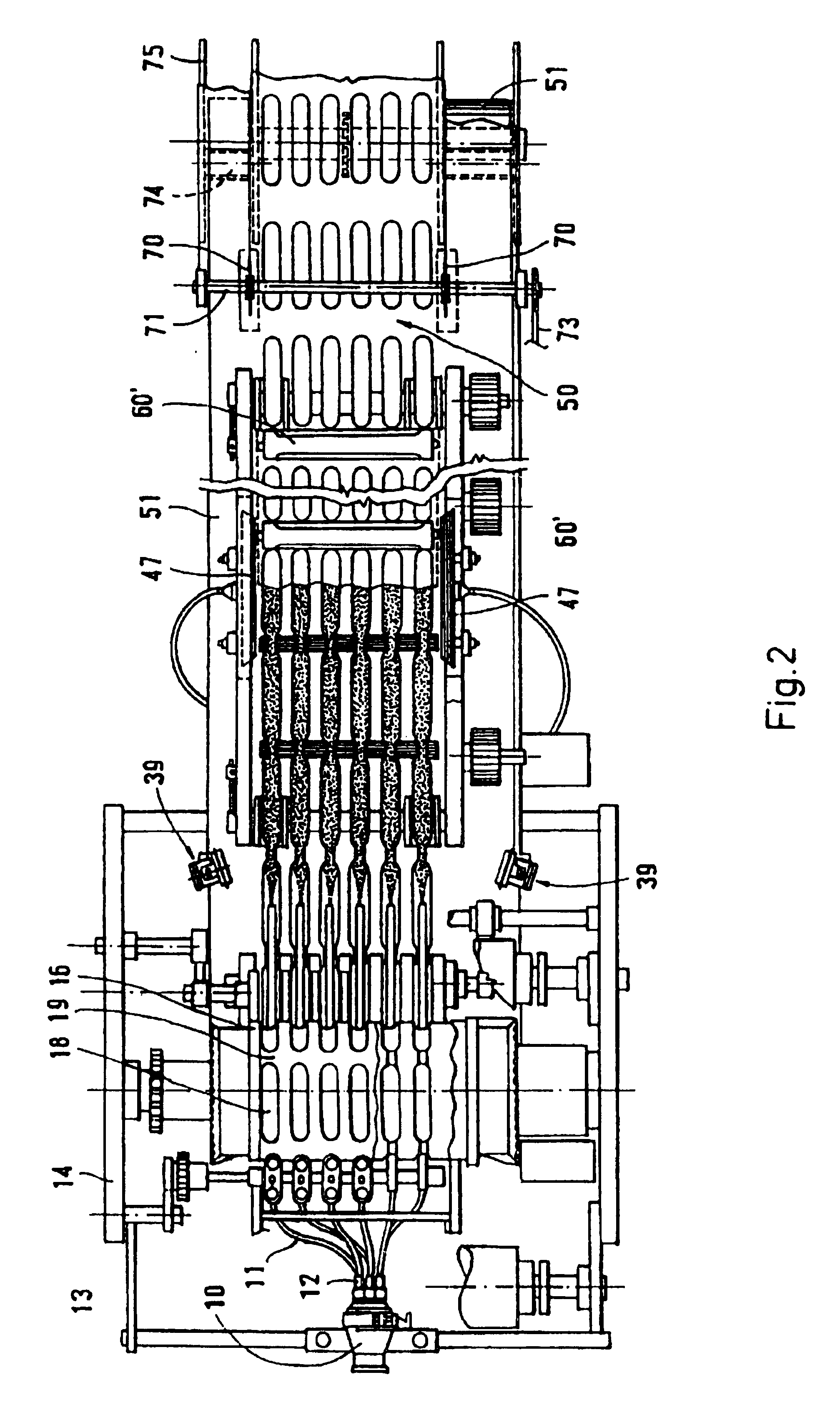

Process for the continuous manufacture of sausages

InactiveUS6135869ASkinless sausage makingPackaging under special atmospheric conditionsSynthetic resinGastric tube feeding

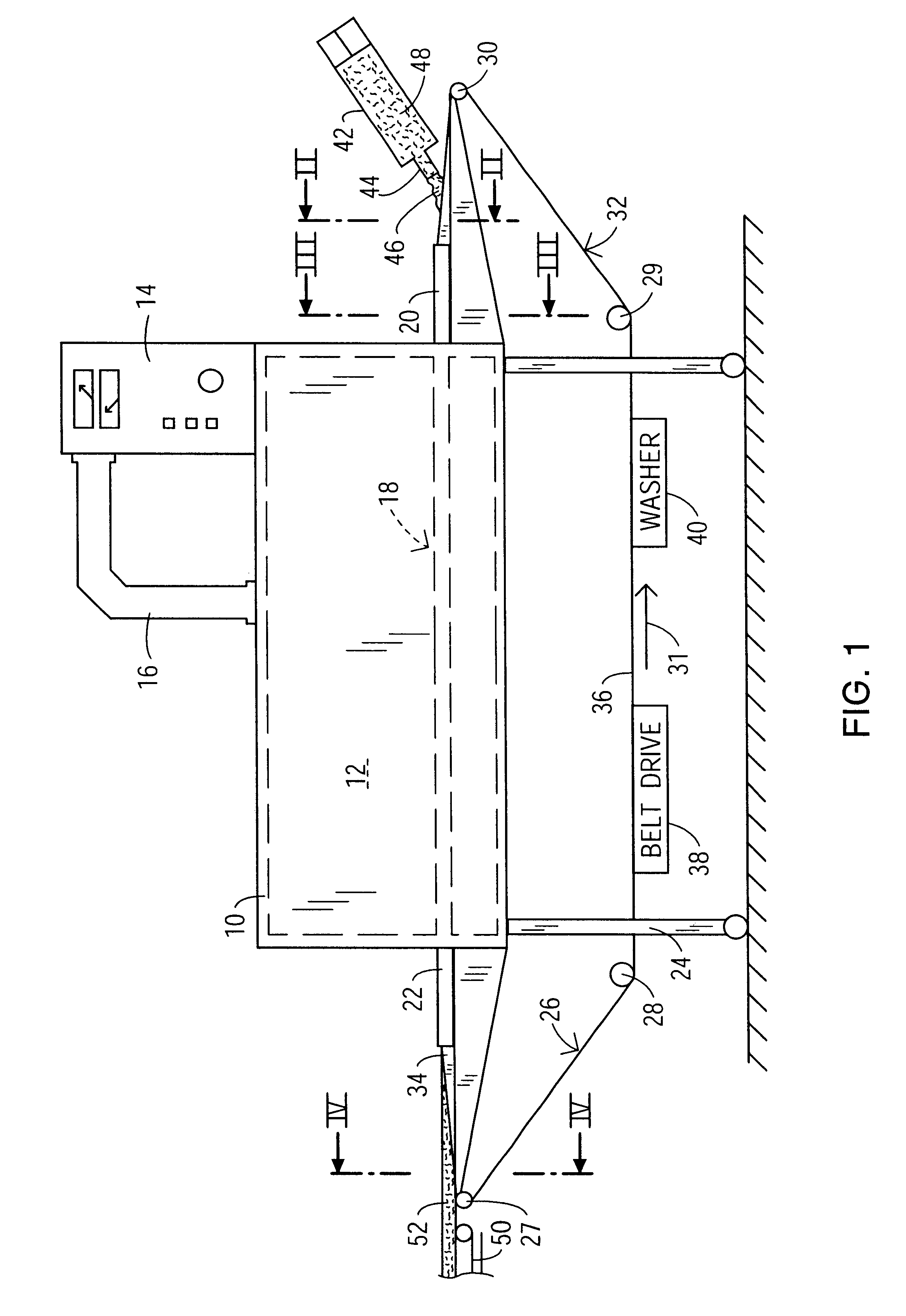

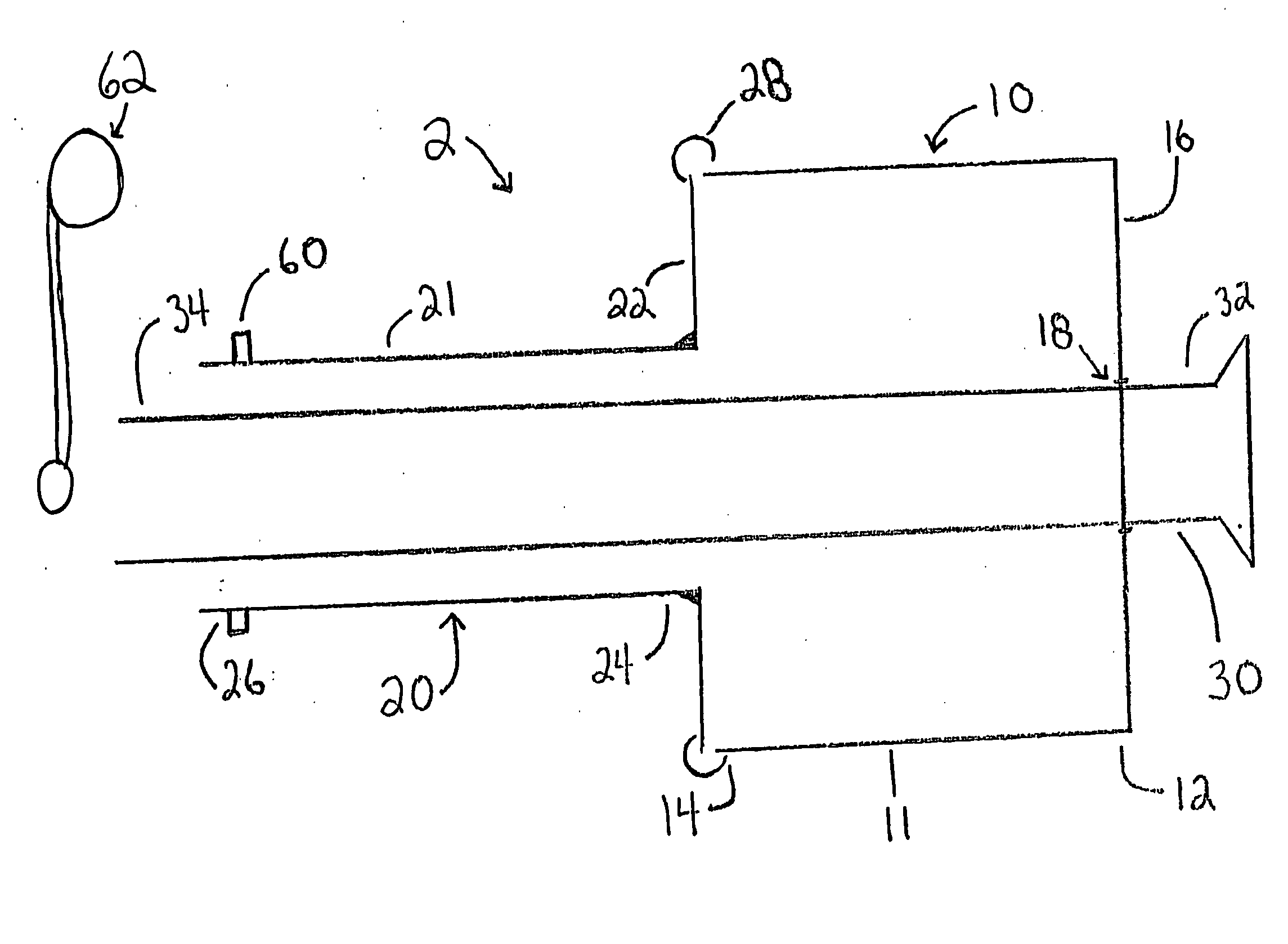

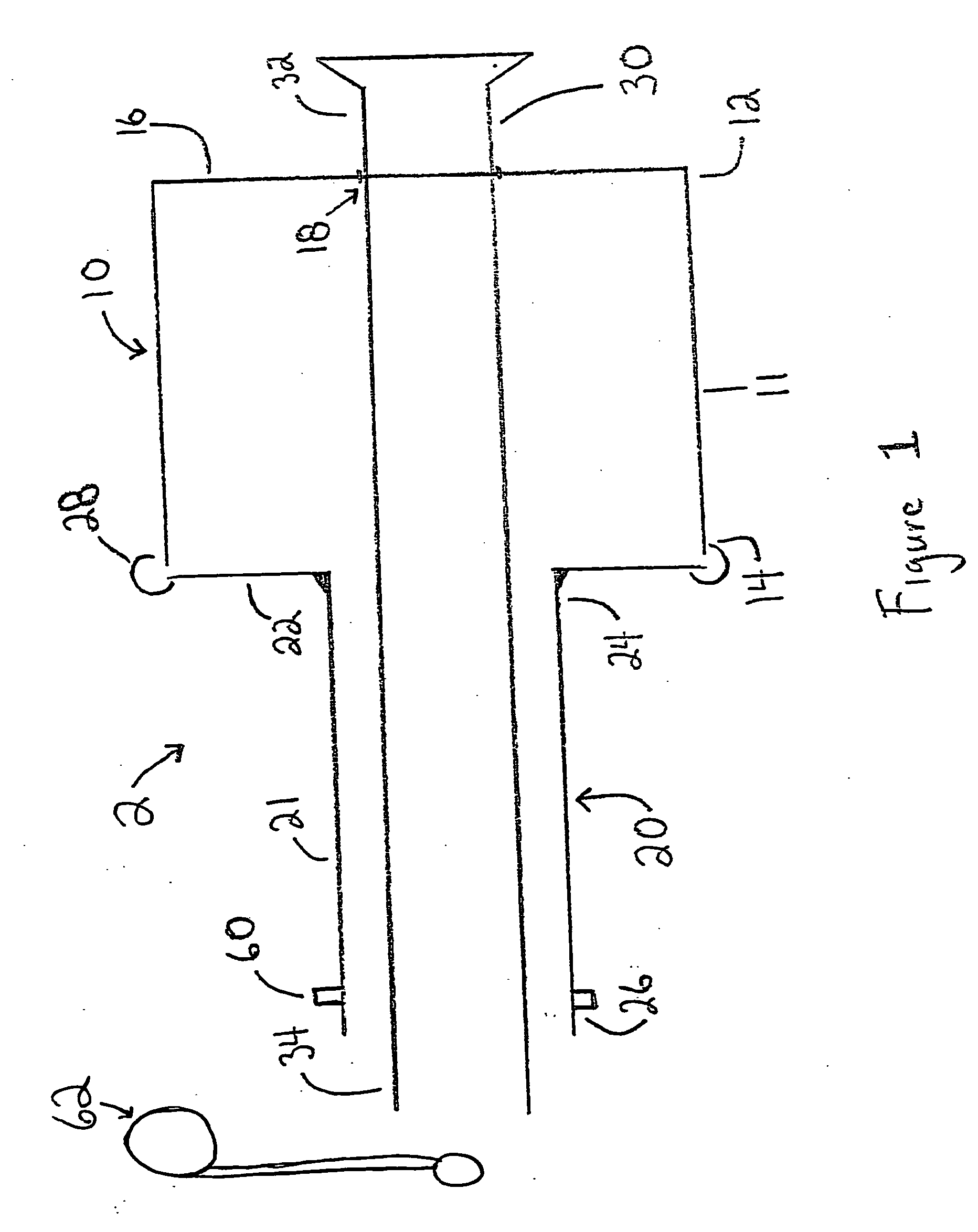

A process and apparatus for the continuous manufacture of food products such as sausages is provided which eliminates the need for intermediate stuffing of the food product into casings which are discarded prior to final packaging. The preferred apparatus of the invention includes first and second heated rollers (16, 17) each presenting a plurality of elongated, axially aligned channels or recesses (18,20) which are circumferentially and axially spaced on the corresponding rollers (16, 17); in addition, the second roller (17) includes a series of elongated, continuous, tube-receiving openings (22) extending between each series of aligned recesses (20). Mechanisms (28, 29) are associated with the rollers (16, 17) in order to continuously feed elongated synthetic resin sheets (34, 35) into the nip between the rollers (16, 17). Rollers (24, 27) are provided for forcing portions of the sheets (34,35) into the recesses (18,20) and openings (22) prior to passage of the sheets (34,35) between the rollers (16, 17) where they are longitudinally heat sealed together to continuously form elongated, aligned food-receiving cavities (48). A plurality of feeding tubes (11) extend through the rollers (16, 17) and are located within the corresponding openings (22) and recesses (20) during rotation of the rollers (16, 17). The tubes (11) continuously direct the flowing food material into the cavities (48), the latter being transversely heat sealed via transverse sealing bars (60, 60') to form complete, enclosed food packages.

Owner:ANDERSON ADAM

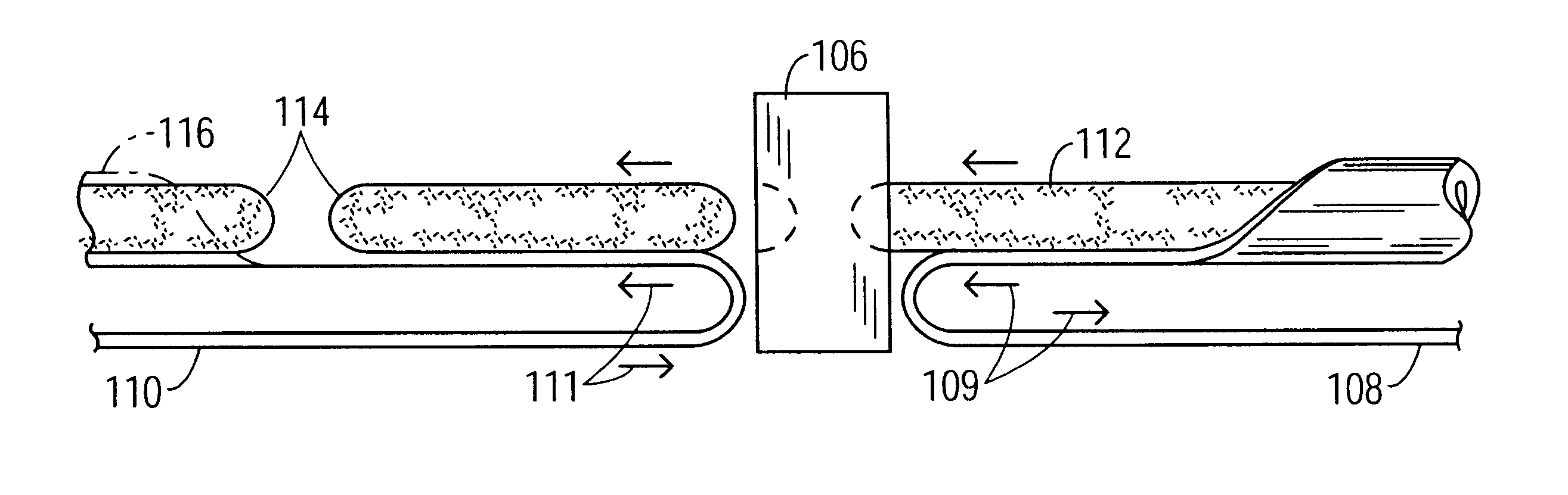

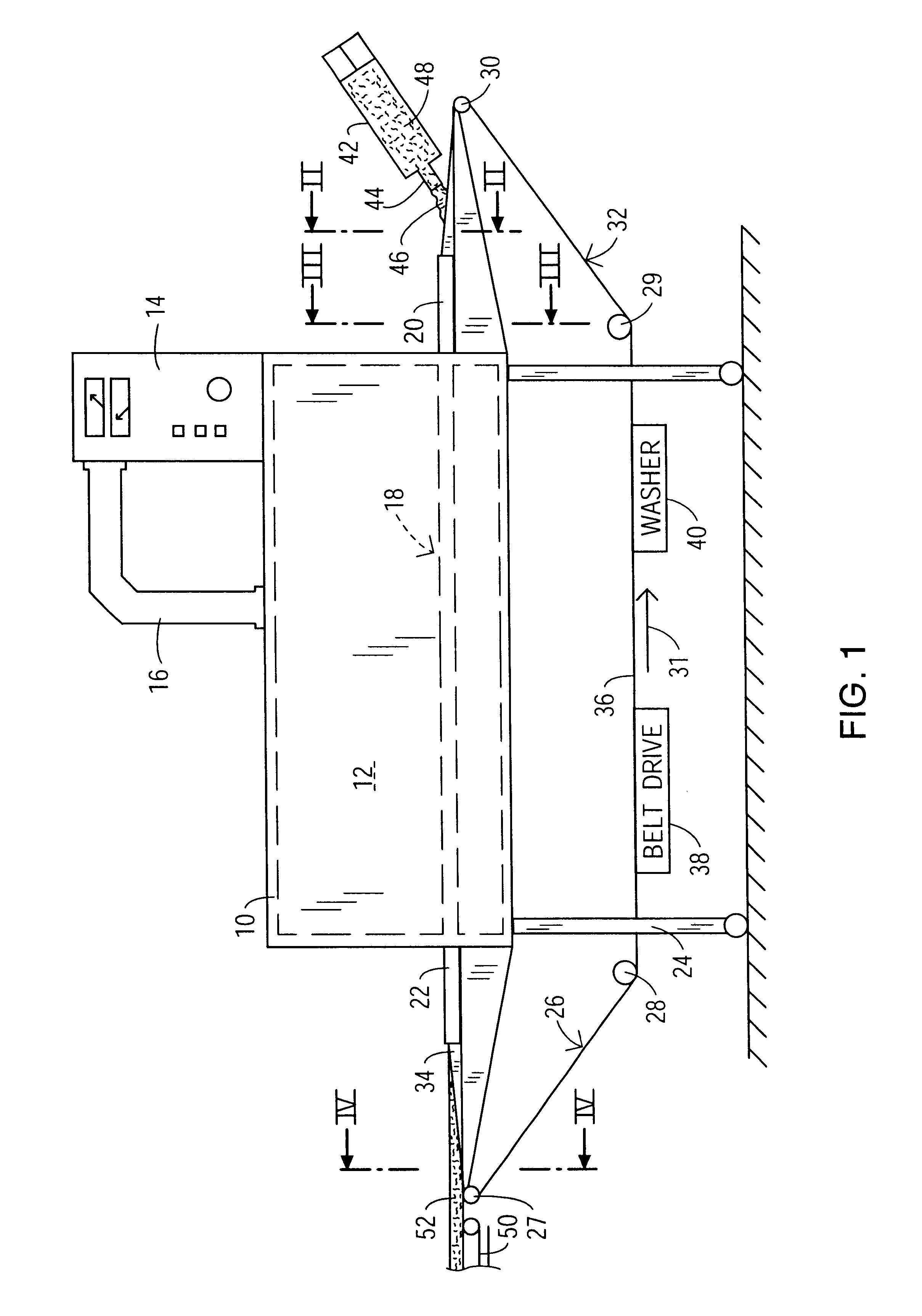

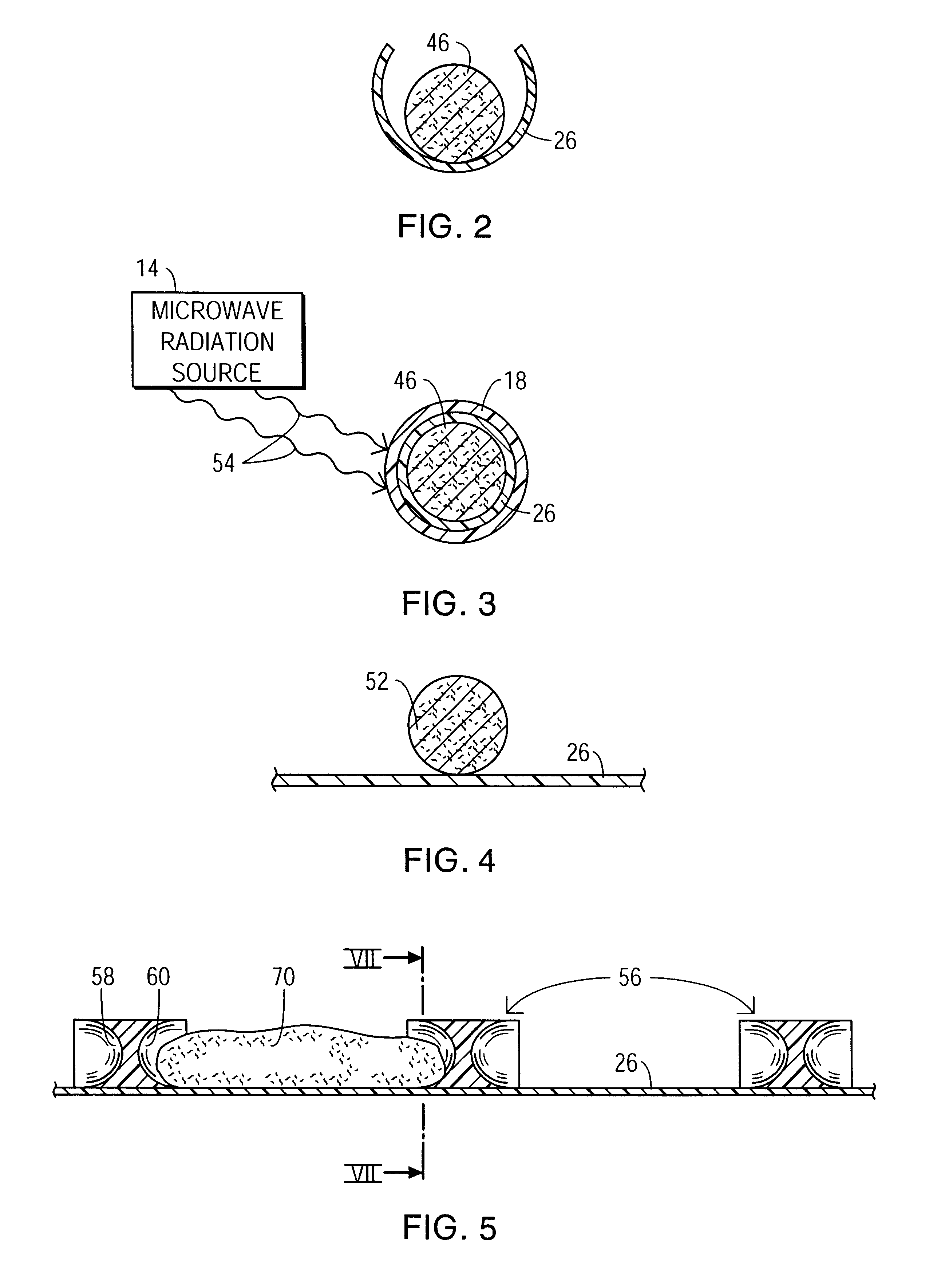

Manufacturing method and apparatus utilizing reusable deformable support

InactiveUS6322832B1Reduce manufacturing costLow costDough treatmentConfectioneryCanis lupus familiarisConveyor belt

In a method for the manufacture of frankfurters, hot dogs and other skinless sausage products, a meat emulsion is extruded onto a flexible conveyor belt which is then conveyed through an at least partially microwave-transparent tube whose internal diameter is equal to the desired diameter of the sausage product plus twice the thickness of the conveyor belt. In a camming type process, the conveyor belt is caused, upon its entry into the tube, to temporarily form a cylinder containing the meat emulsion. The temporary belt cylinder together with the surrounded meat emulsion extrudate is then conveyed through a microwave applicator to partially or thoroughly cook the meat emulsion. At the exit end of the tube, the conveyor belt naturally opens under internal stresses from its cylindrical shape to a flattened belt. The at least partially cooked sausage is then removed from the belt for further processing or packaging. The conveyor belt acts as a temporary skin to hold the meat emulsion during its microwave cooking.

Owner:MISONIX INC

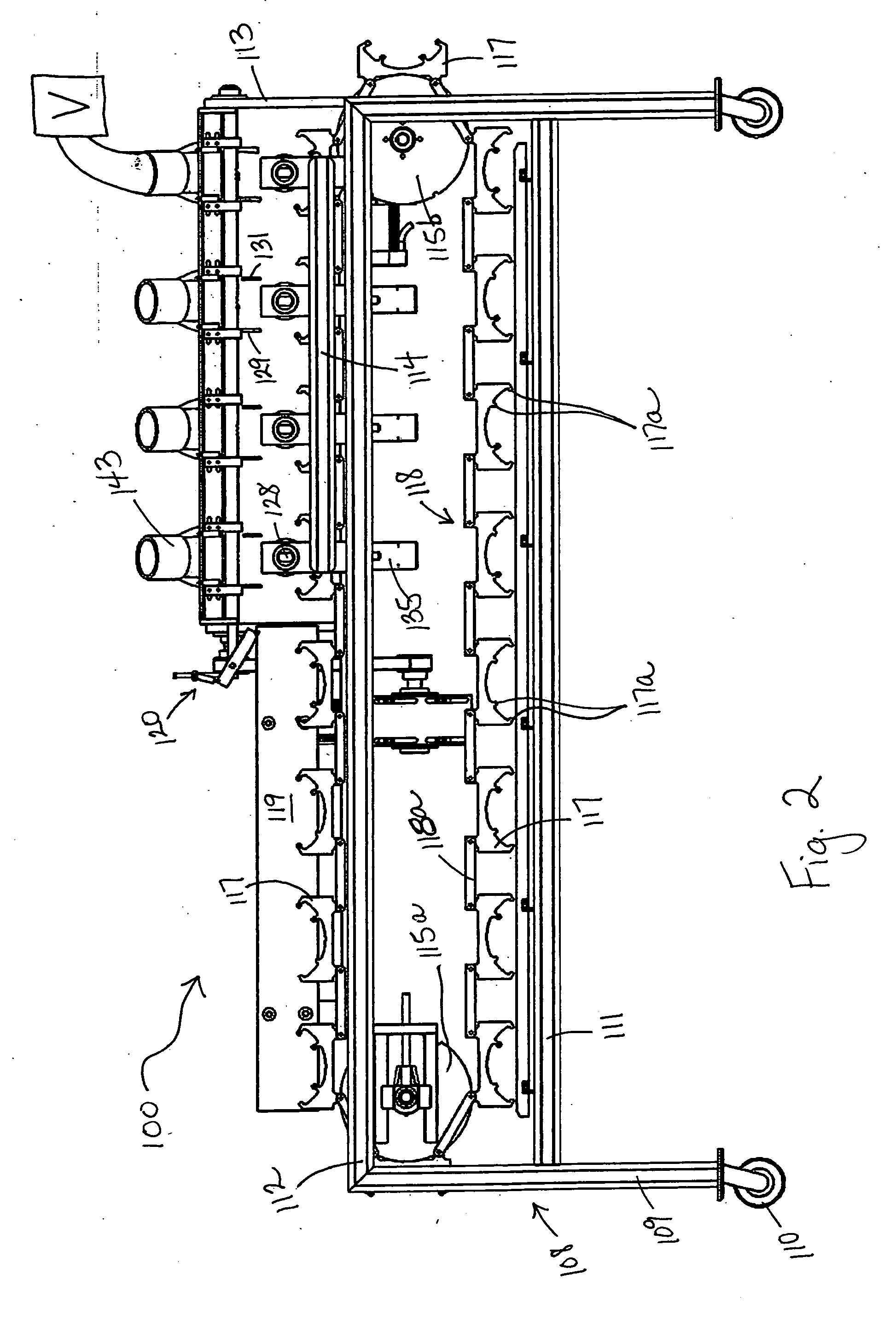

Continuous roll stock netting machine

Owner:POLY CLIP SYST

Continuous roll stock netting machine

Owner:POLY CLIP SYST

Net rucking apparatus and method

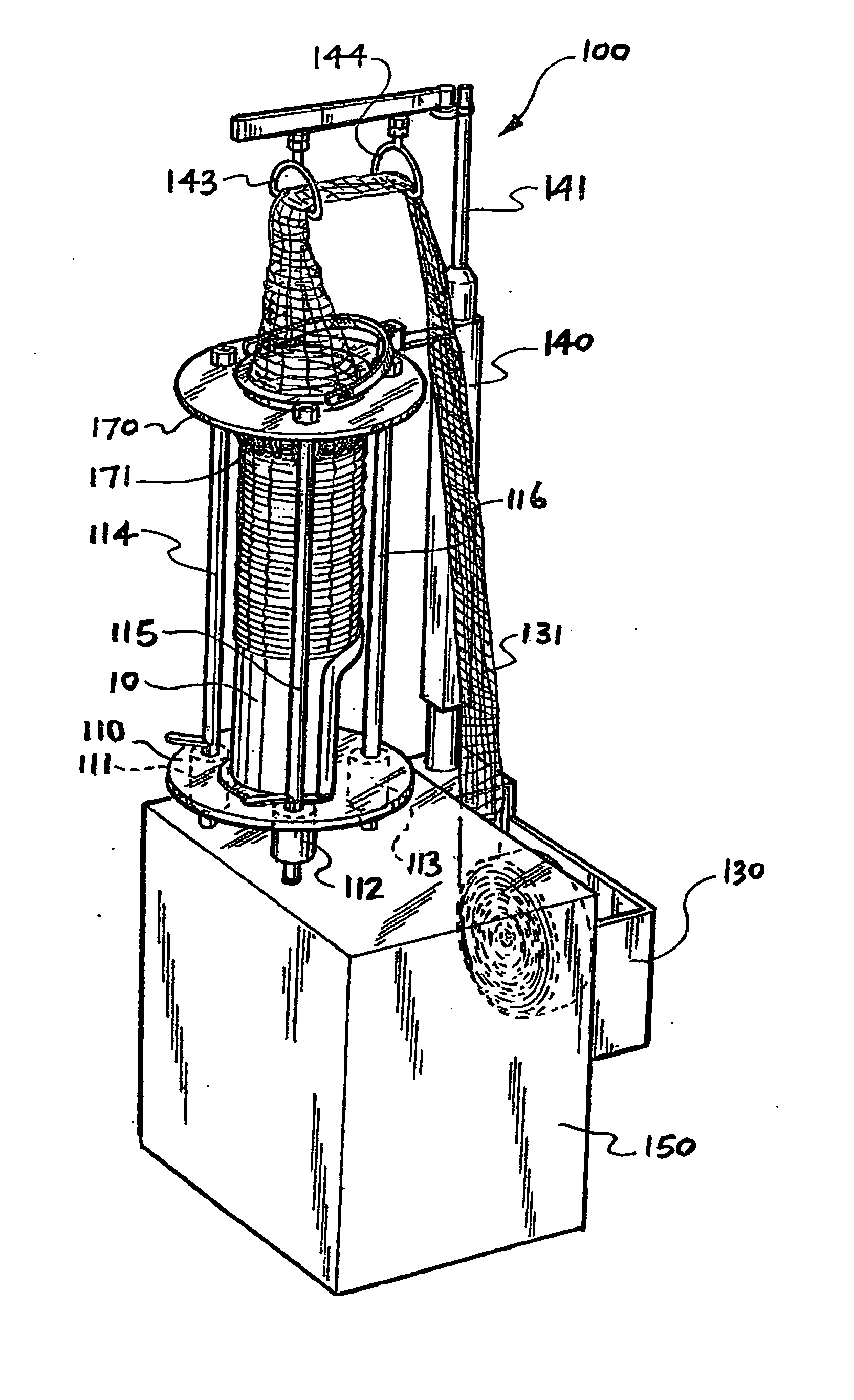

An apparatus and a method for rucking netting onto a tube are described. The apparatus, in a first embodiment, comprises a frame having an axis, a passage along the axis, means for reciprocating movement along the axis, a netting tube releasably attachable to the means for reciprocating movement, a second tube comprising a frustum having a bore, the second tube being slidable co-axially to the netting tube, an annular space defined by the second tube and the netting tube, and spring-loaded fingers attached to the frame and extending into the passage. In another embodiment, a method for rucking netting onto a tube comprises attaching a netting tube to a moveable platform, mounting a second tube axially over the netting tube, the second tube comprising a frustum having a bore therethrough, placing an end of a netting over the second tube, forming an annular space between the netting tube and the second tube, and moving the second tube reciprocatingly through spring-loaded fingers. The second tube is a frusto-conical shape, a frusto-pyramidal shape, or another frustum shape

Owner:PRETSITEK KORP

Net loader

InactiveUS20050048886A1Easy to manufactureEasy to cleanSkinless sausage makingSausage filling/stuffing machinesManual insertionEngineering

A device for filling tubular casings with edible material is disclosed. The device includes a tube upon which the casing can be shirred onto, a tube inlet, a tube outlet and tube support means. The support means allows the device to be supported for the manual insertion of edible material into the tube inlet and furthermore the manual forcing of this edible material through the tube and out of the tube outlet.

Owner:MERCTECH

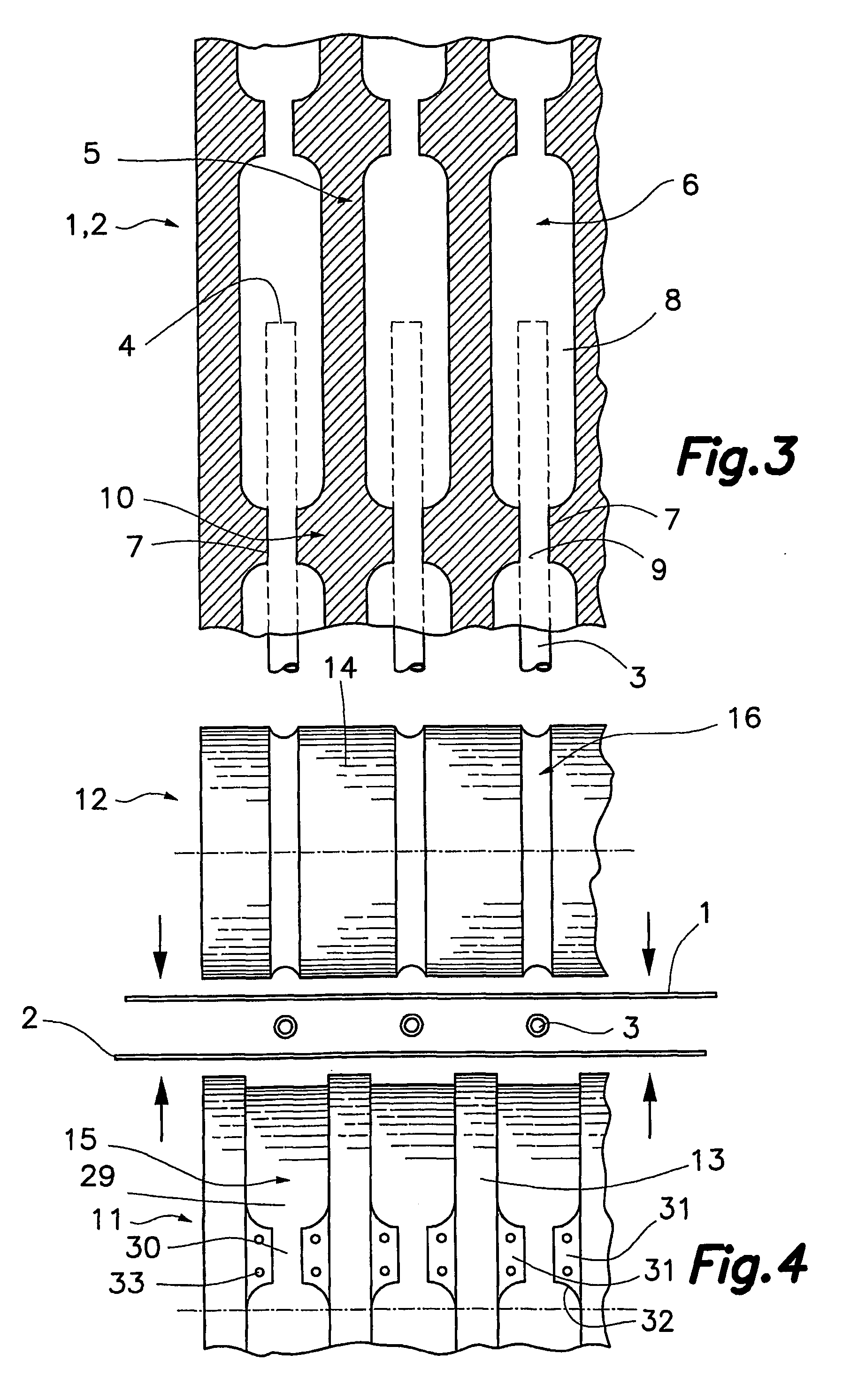

Process and machine for packing pasty, liquid or semiliquid products

InactiveUS7254929B1Accurate acquisitionSkinless sausage makingSausage casing manufactureLiquid productEngineering

Process and machine for packing pasty, liquid or semiliquid products comprising: nonstop feeding two sheets (1, 2) sandwiching ducts (3) ending in nozzles (4) feeding pasty, liquid or semiliquid products to be packed (M); nonstop longitudinally sealing the said sheets (1, 2) through longitudinal continuous beads (5) adjacent to the said continuous sleeves (6); forming through the said longitudinal sealing narrowings arranged at intervals longitudinally regular in the said sleeves (6) making possible the passage of the said ducts (3) and defining in the sleeves (6) long, wide lengths (8) and short narrow lengths (9); nonstop injecting with nozzles (4) material (M) within the said sleeves (6) which are inflated forming units (28) of material (M) with prior pressure closing of a narrow length (9) each sleeve advanced to each nozzle (4) while the sheets (1, 2) are moving forwards, and pressure closing and transversally sealing at regular intervals the said sleeves (6) filled with material (M).

Owner:SCHUTZ ALEJANDRO JAVIER +1

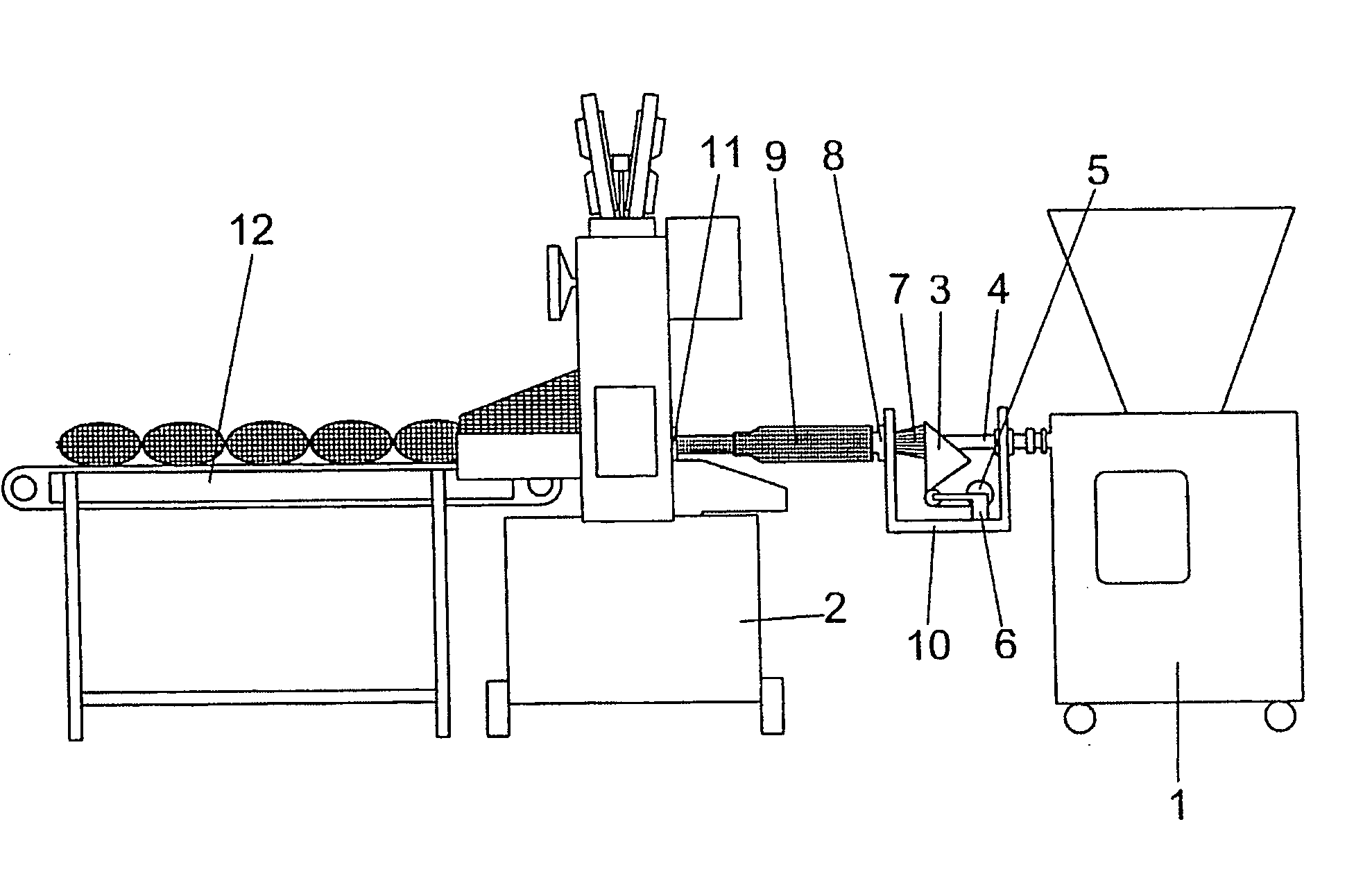

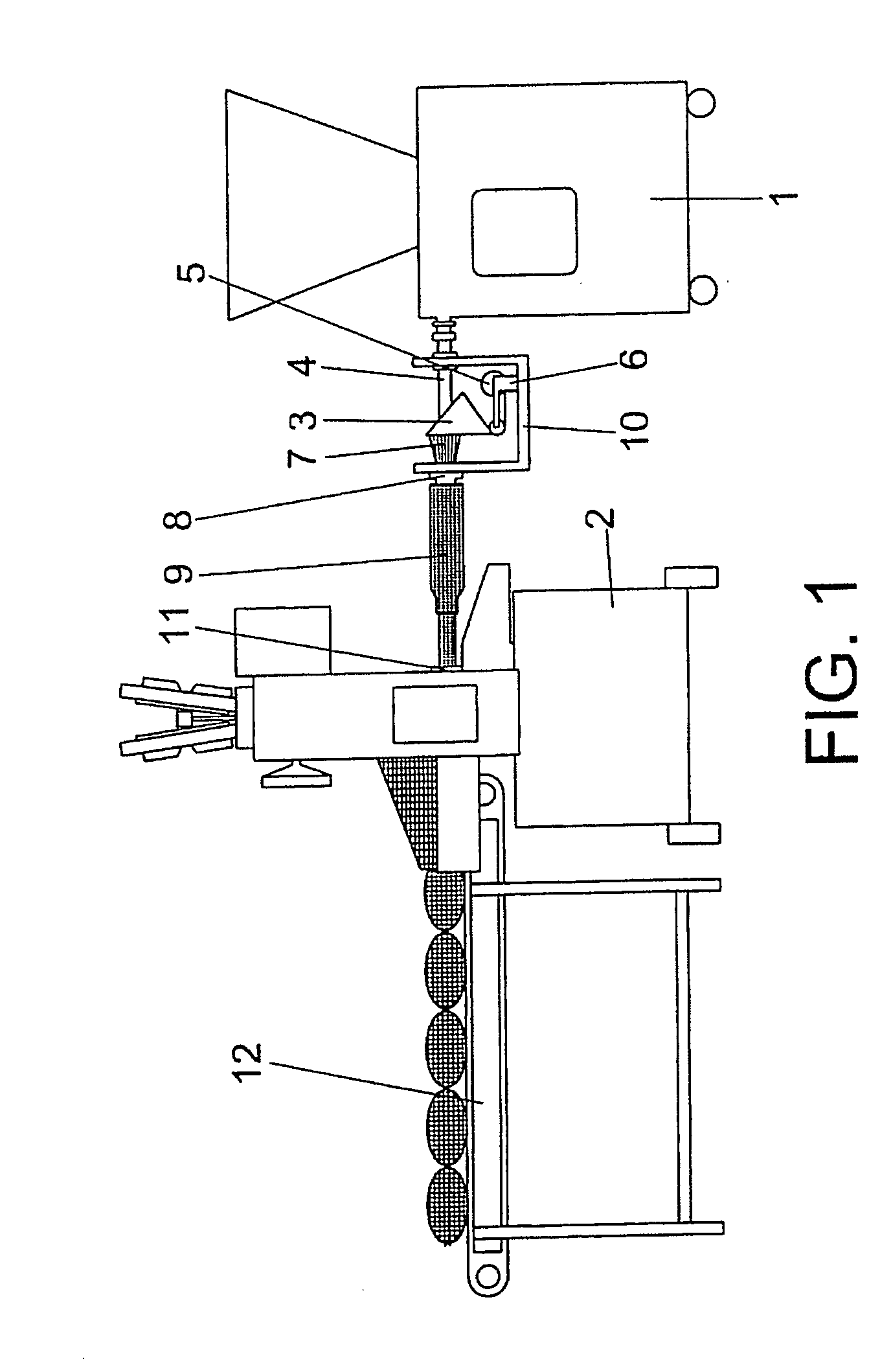

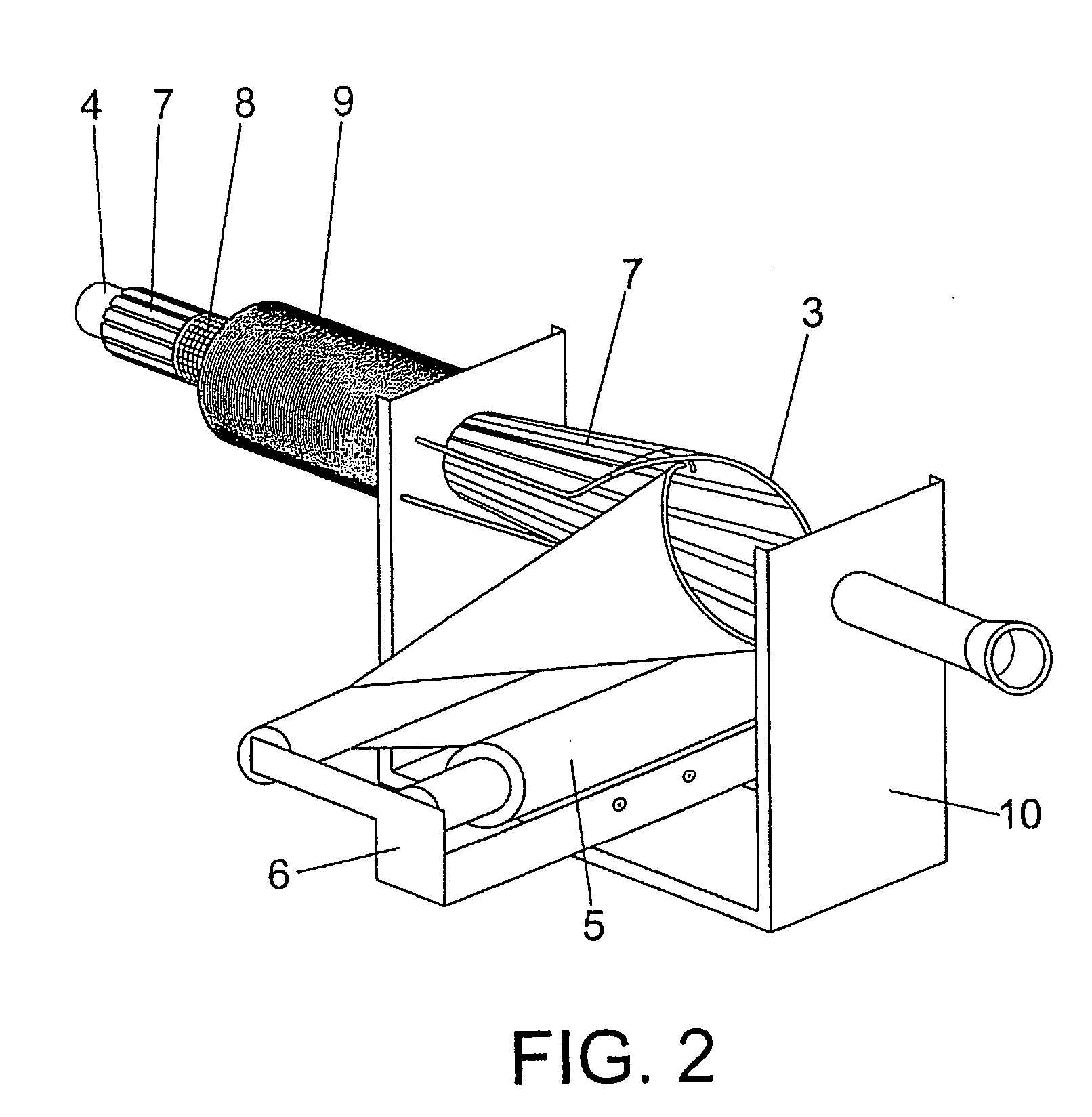

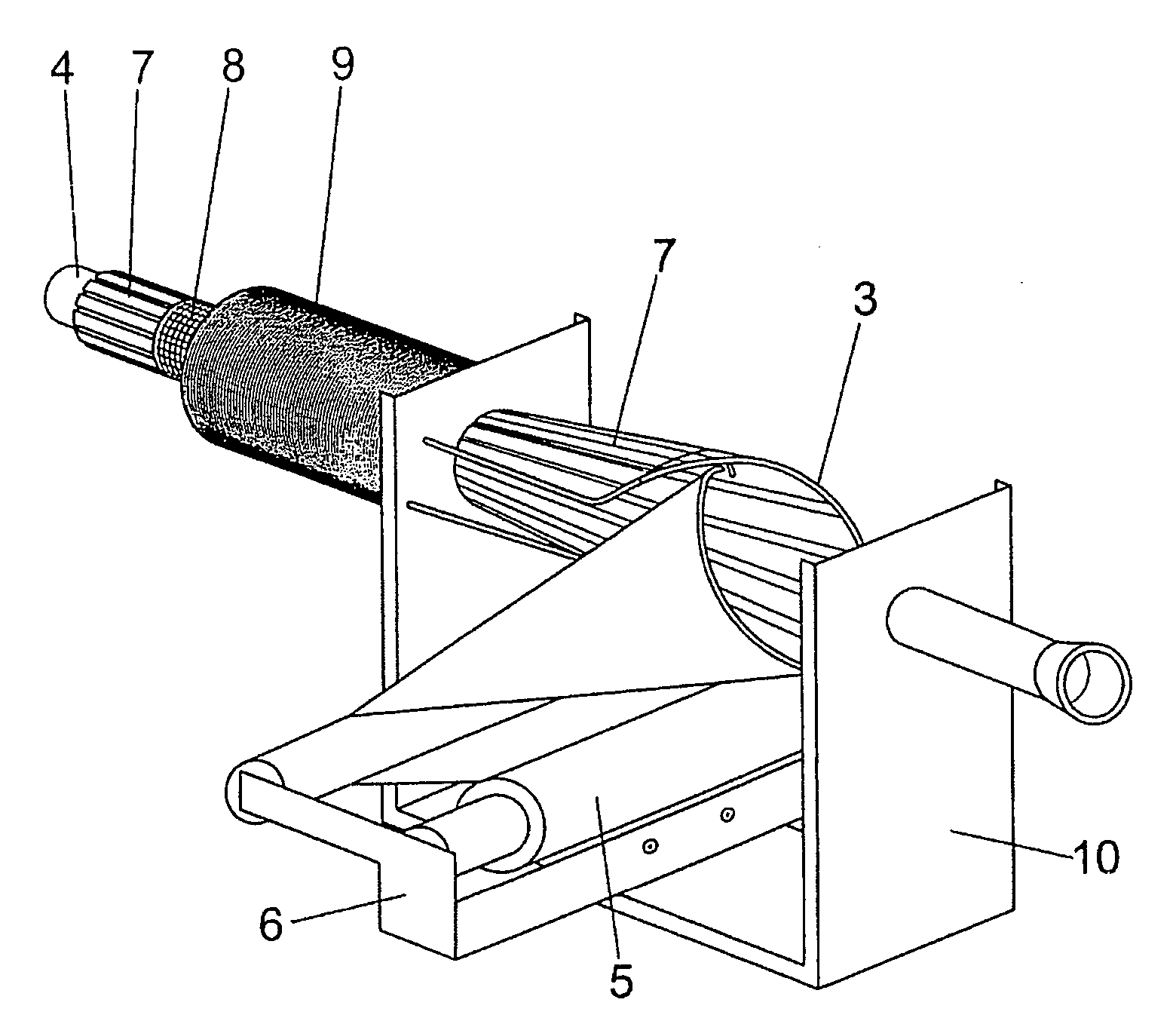

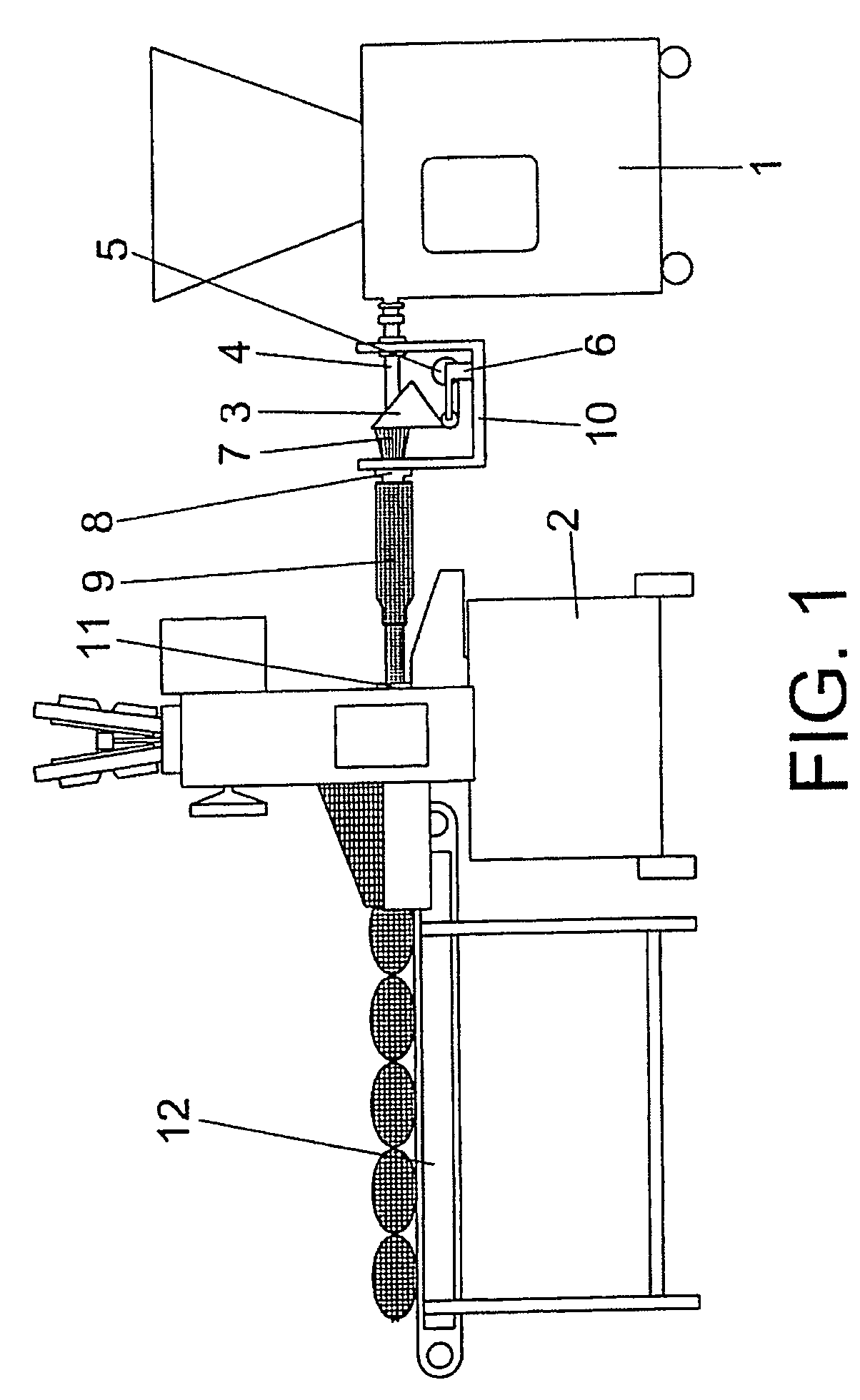

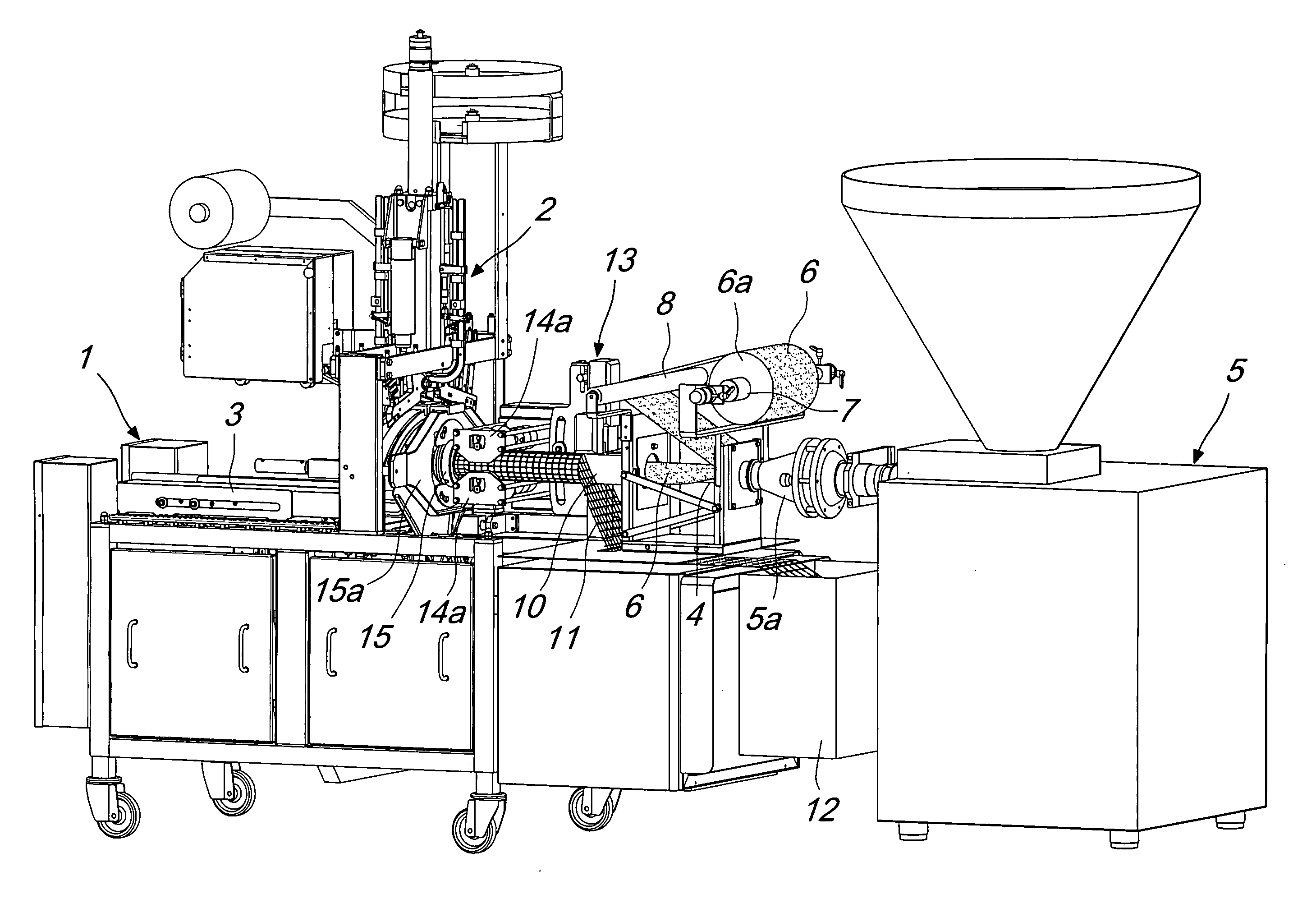

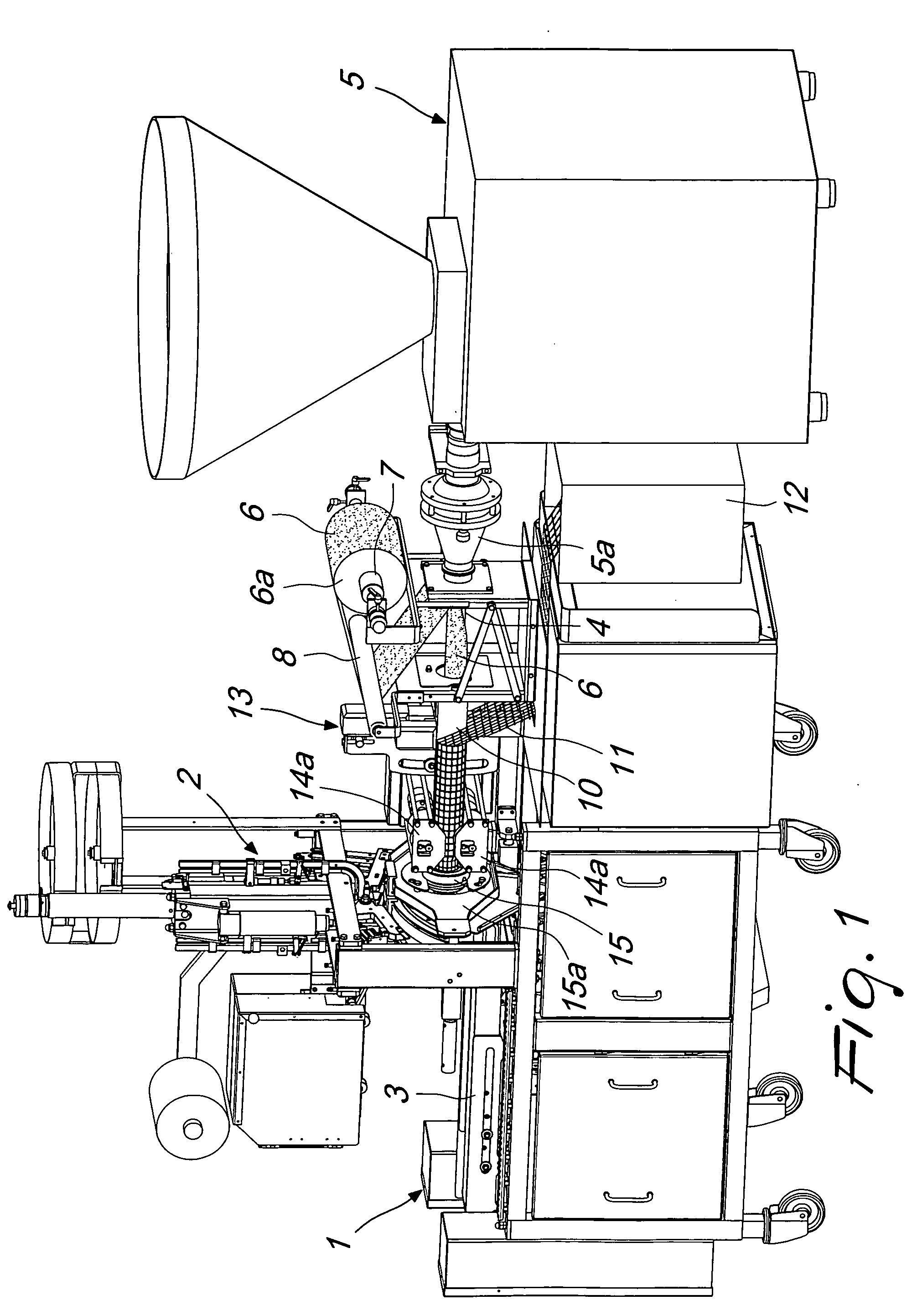

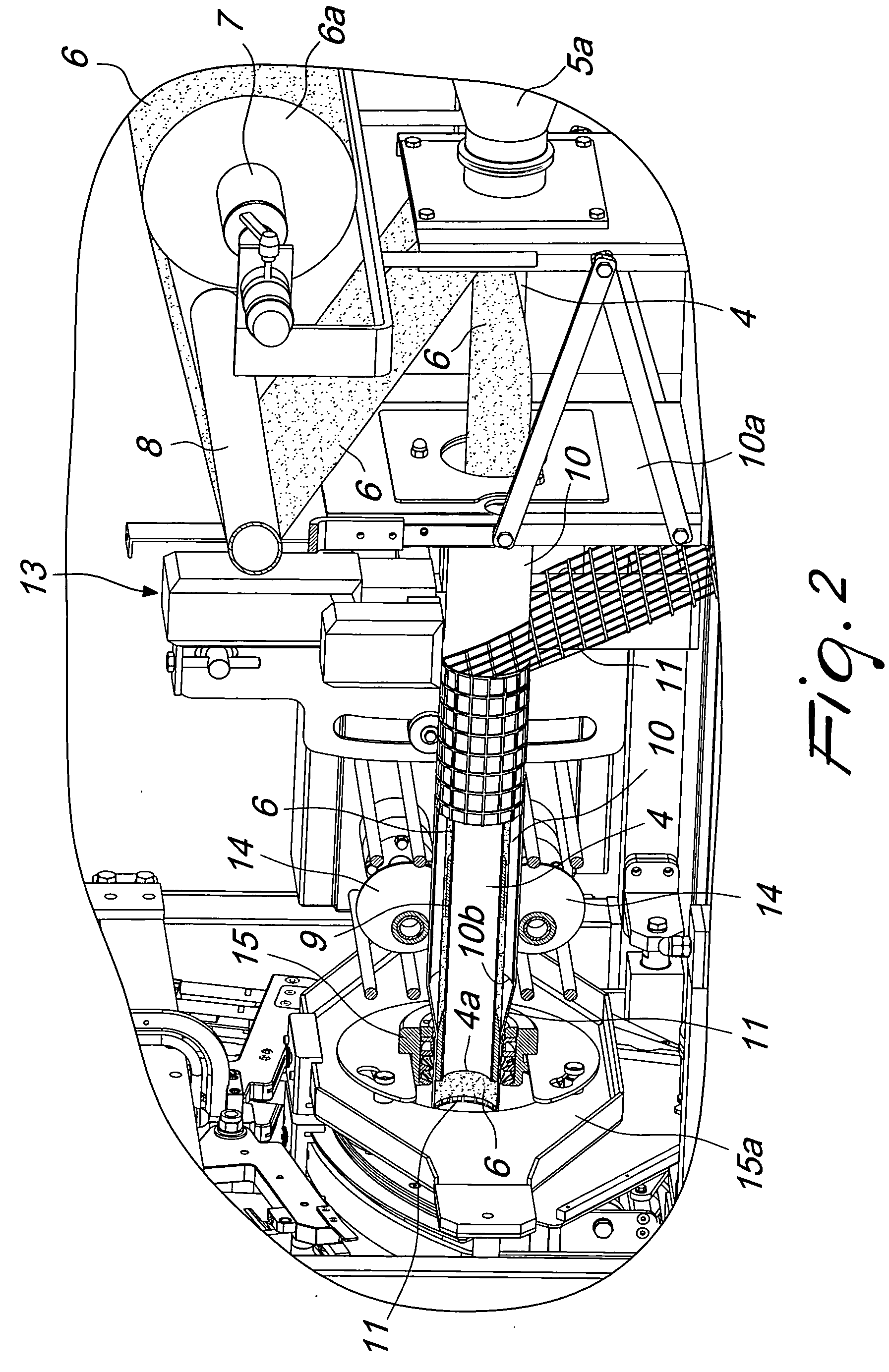

Method and apparatus for the automatic stuffing of meat products into a double casing comprising a sheet and a net

ActiveUS20050126403A1Increase speedImprove load effectMultilayer sausage casingsSkinless sausage makingAutomatic testingFood products

Based on a conventional installation including a stuffing-portioning machine (1) and a fast clipper (2), duly synchronised, between which is established a shaping device (3) that converts the film (5) meant to wrap food products that is supplied in the form of a coil into a tubular element that can be coupled to the stuffing tube (3), on which is coaxially mounted a second tube (8) bearing an external casing (9) based on a tubular net, the invention consists of using tubes (4) and (8) with a small diameter, much smaller than that of the finished product, so that the film (5) is adapted to the tube (4) after the former is profusely folded longitudinally, while the small diameter of the tube (8) allows the multilayer shirring of the tubular net (9), using the pressure provided by the pumping system of the stuffing machine (1) to achieve the radial expansion of the film (5) and the tubular net (9) to obtain the final diameter of the finished product, which will vary according to the speed with which it is separated from the double clipper (2) carried by a conveyor belt (12) with an adjustable speed.

Owner:VISCOFAN

Method and apparatus for the automatic stuffing of meat products into a double casing comprising a sheet and a net

ActiveUS7494405B2Increase speedImprove load effectMultilayer sausage casingsSkinless sausage makingEngineeringAutomatic testing

Owner:VISCOFAN

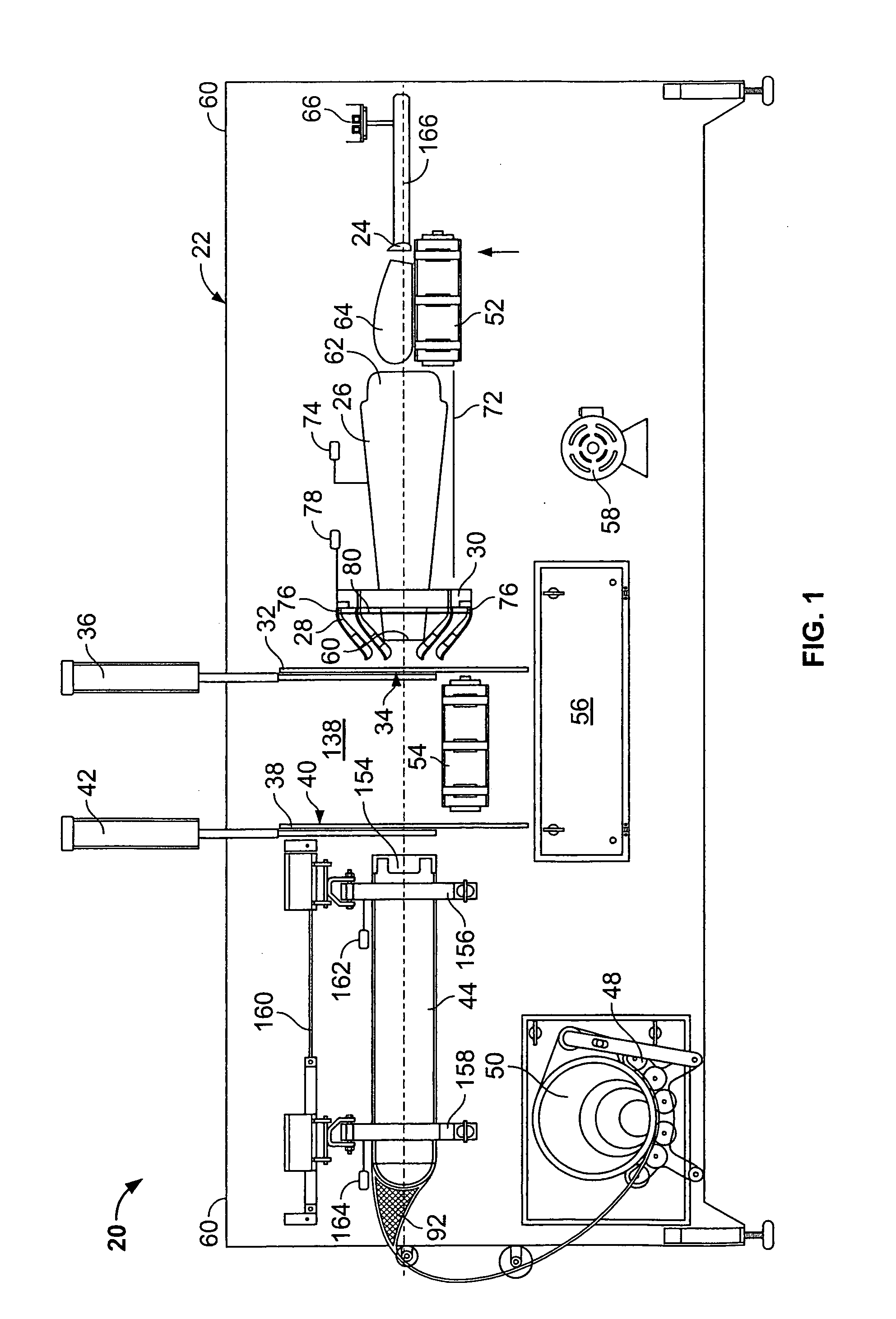

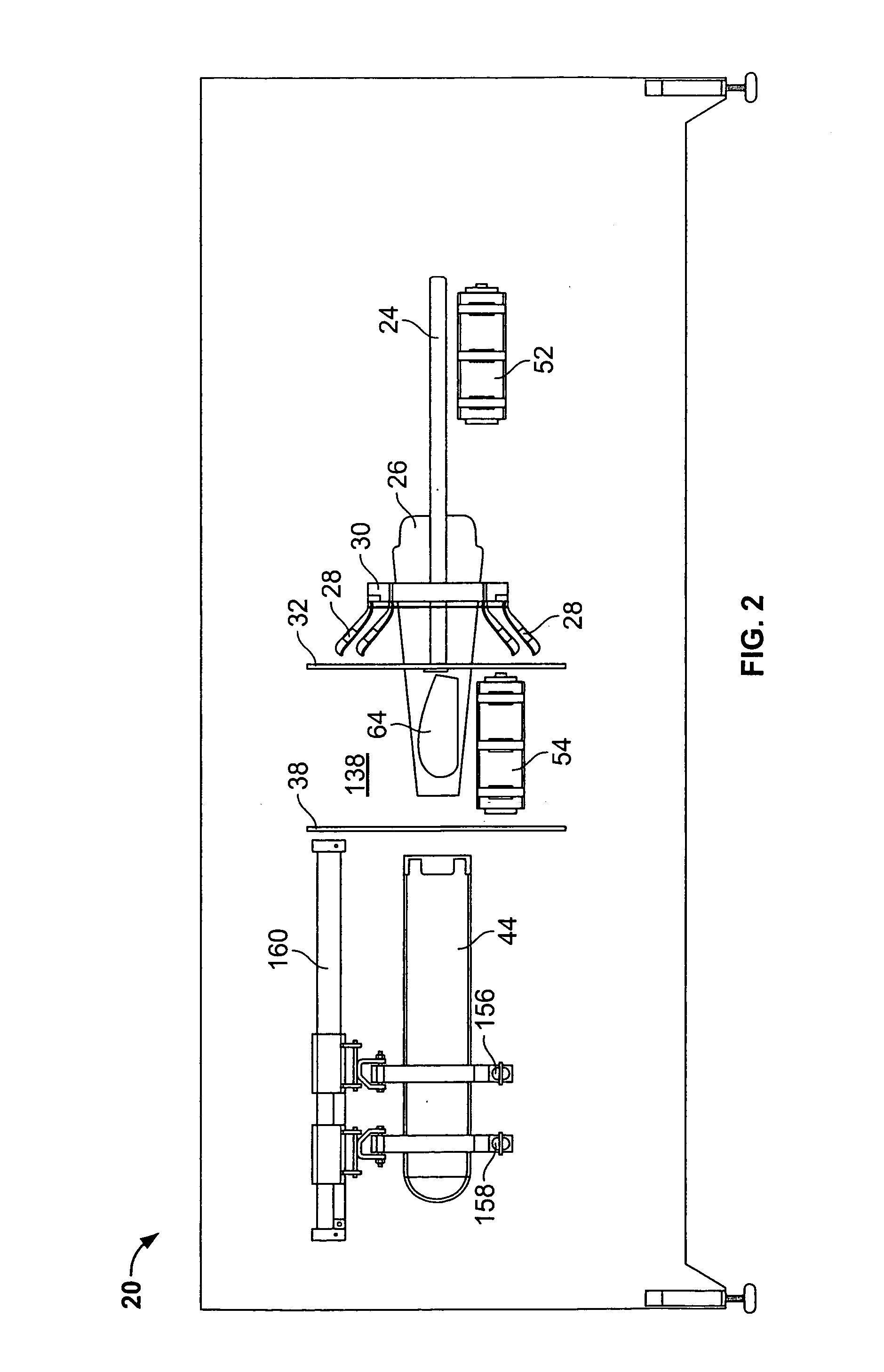

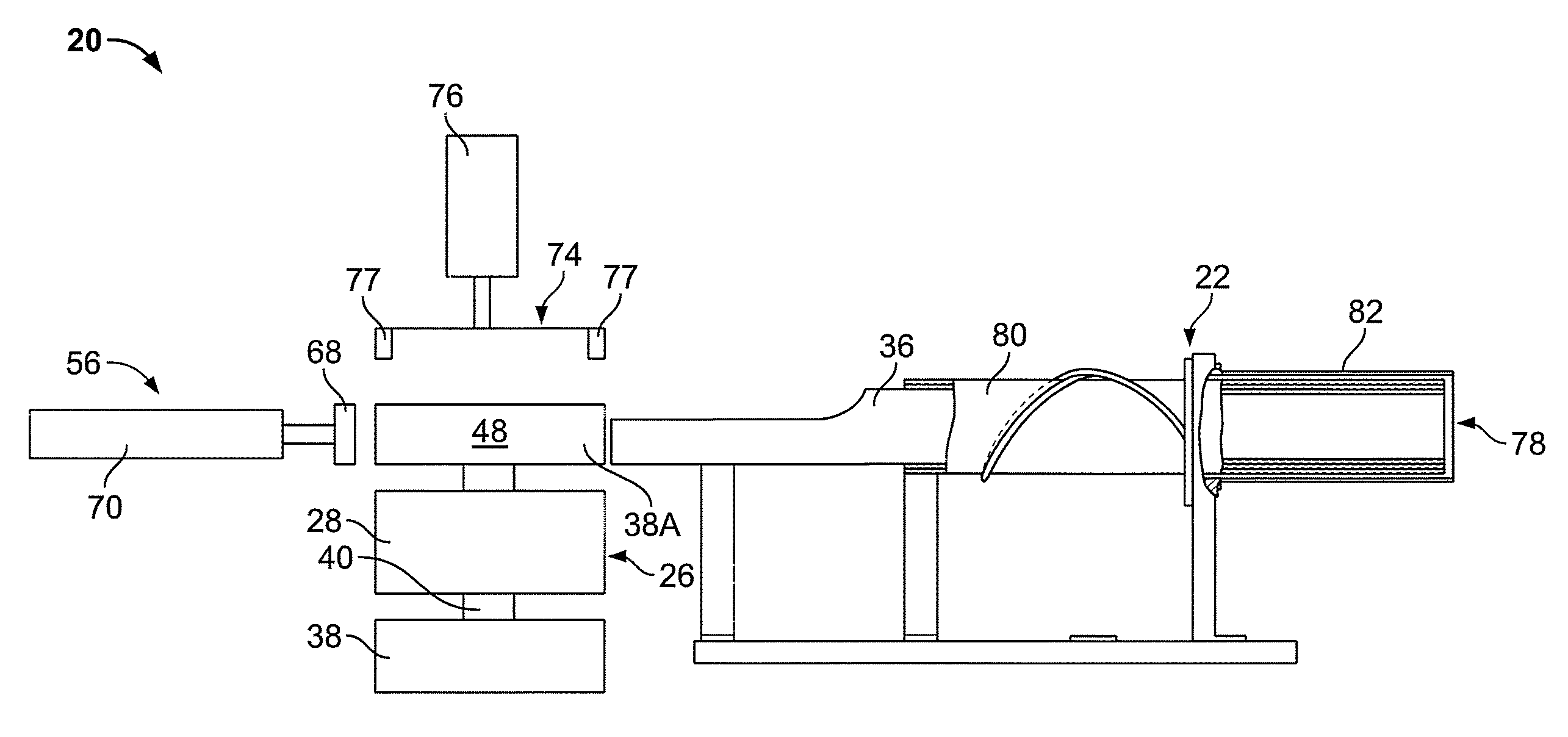

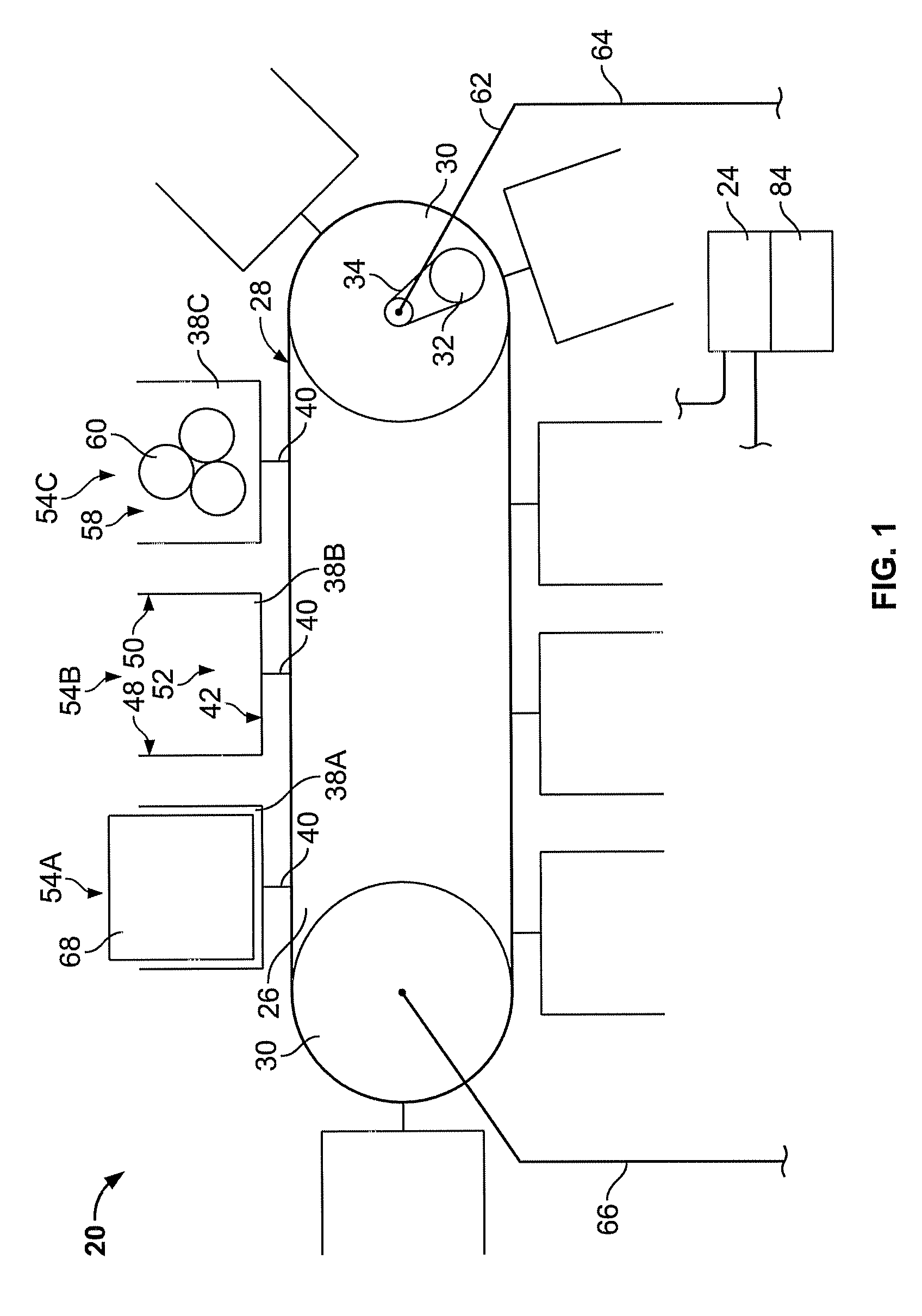

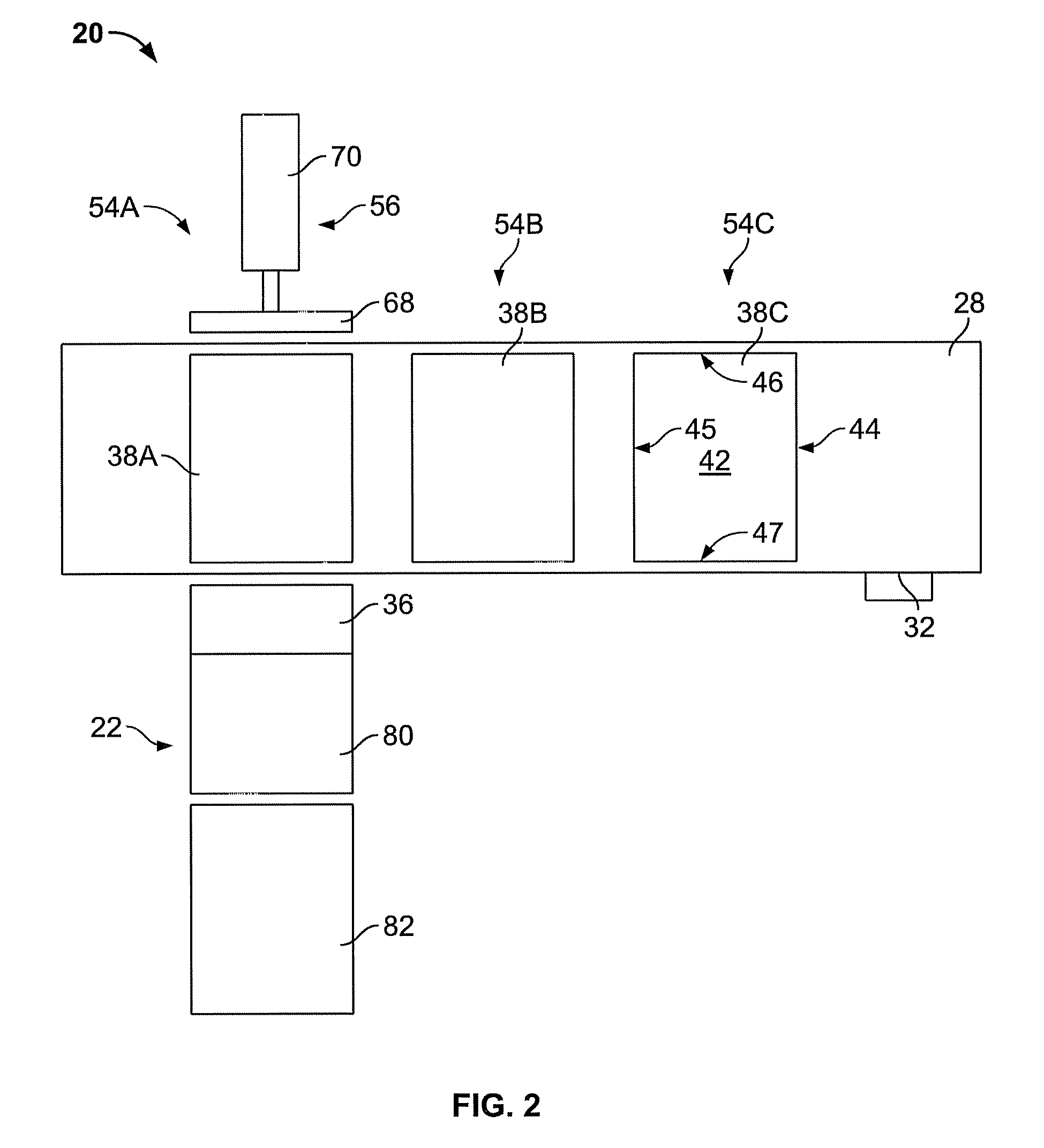

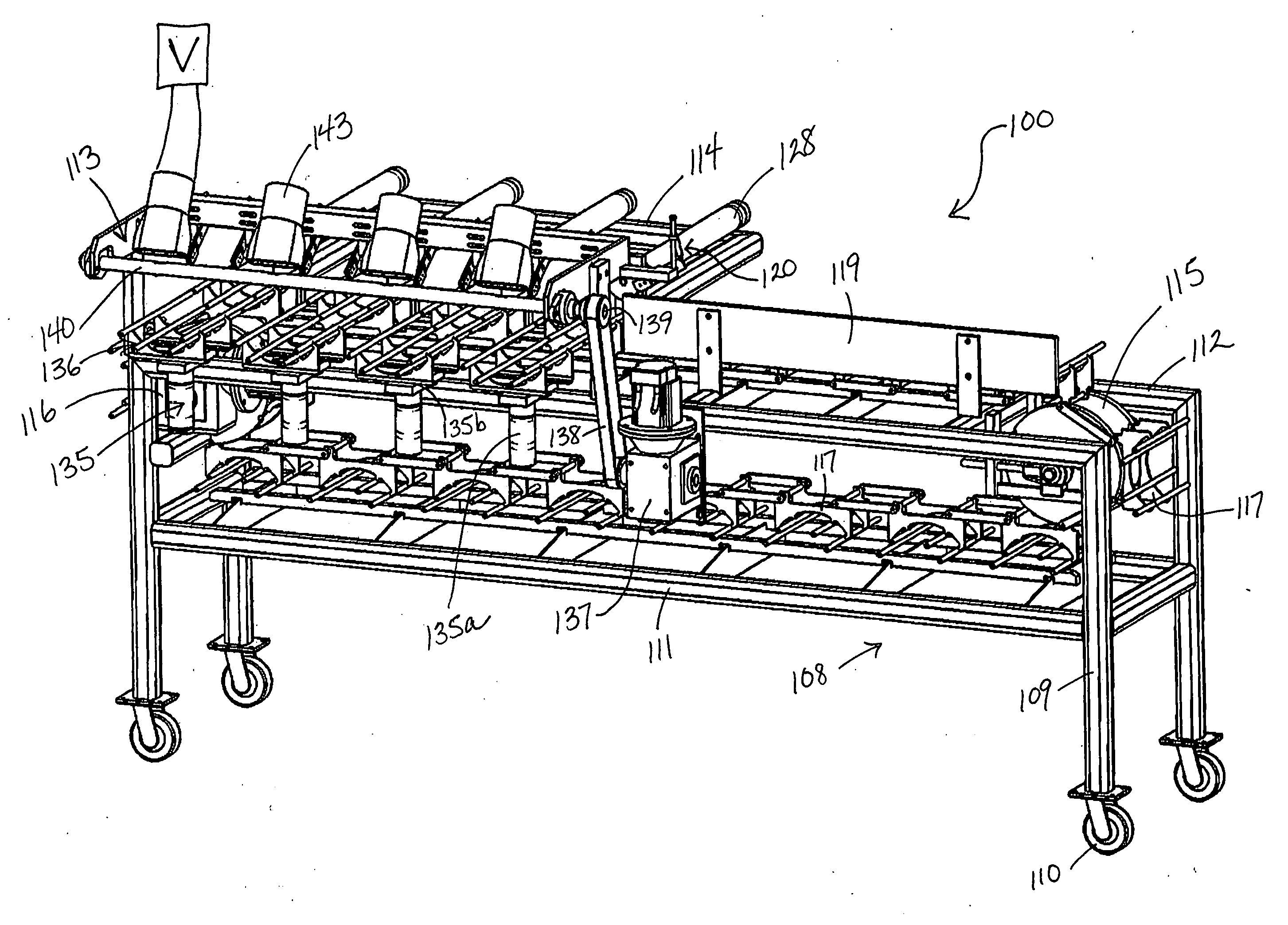

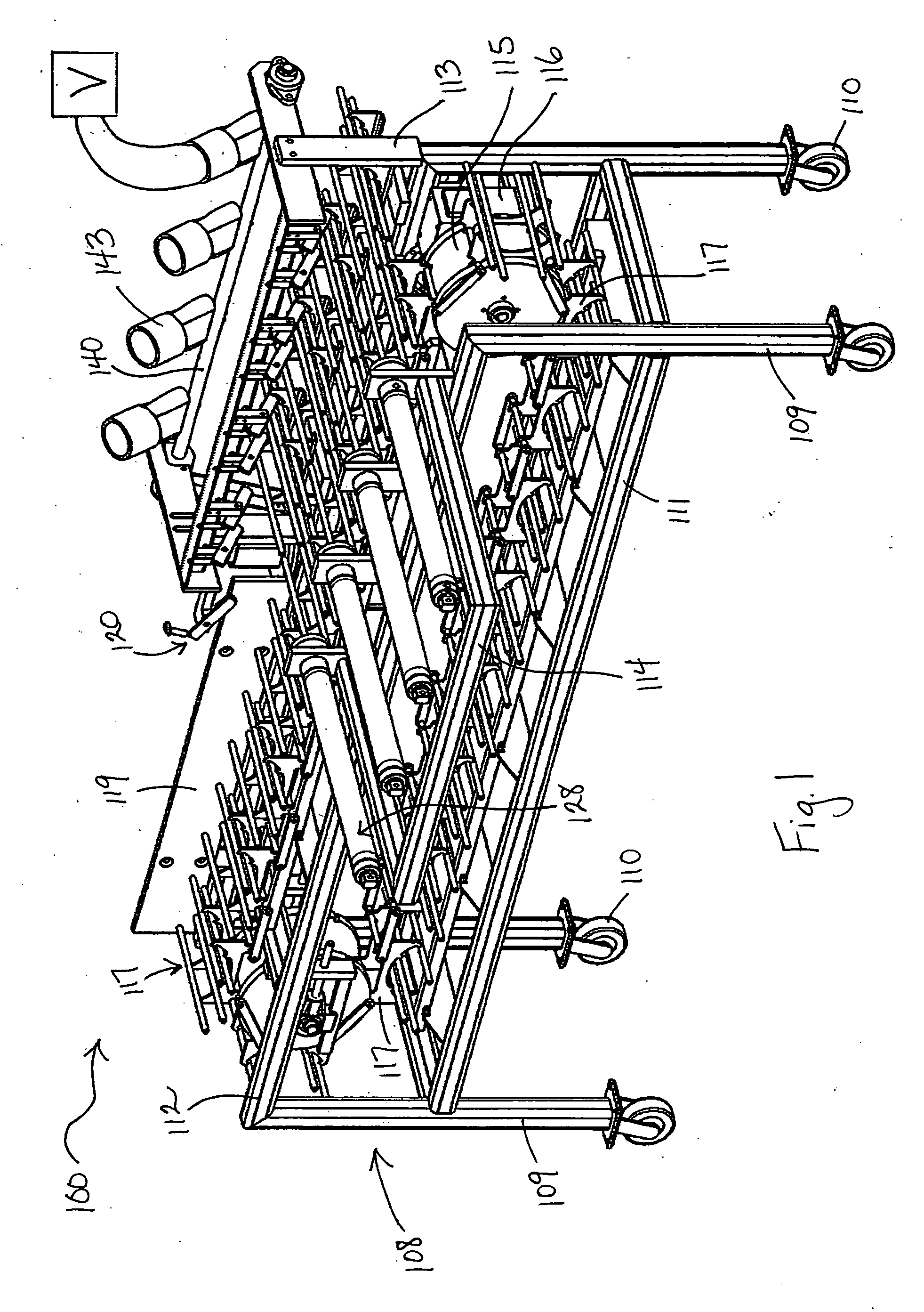

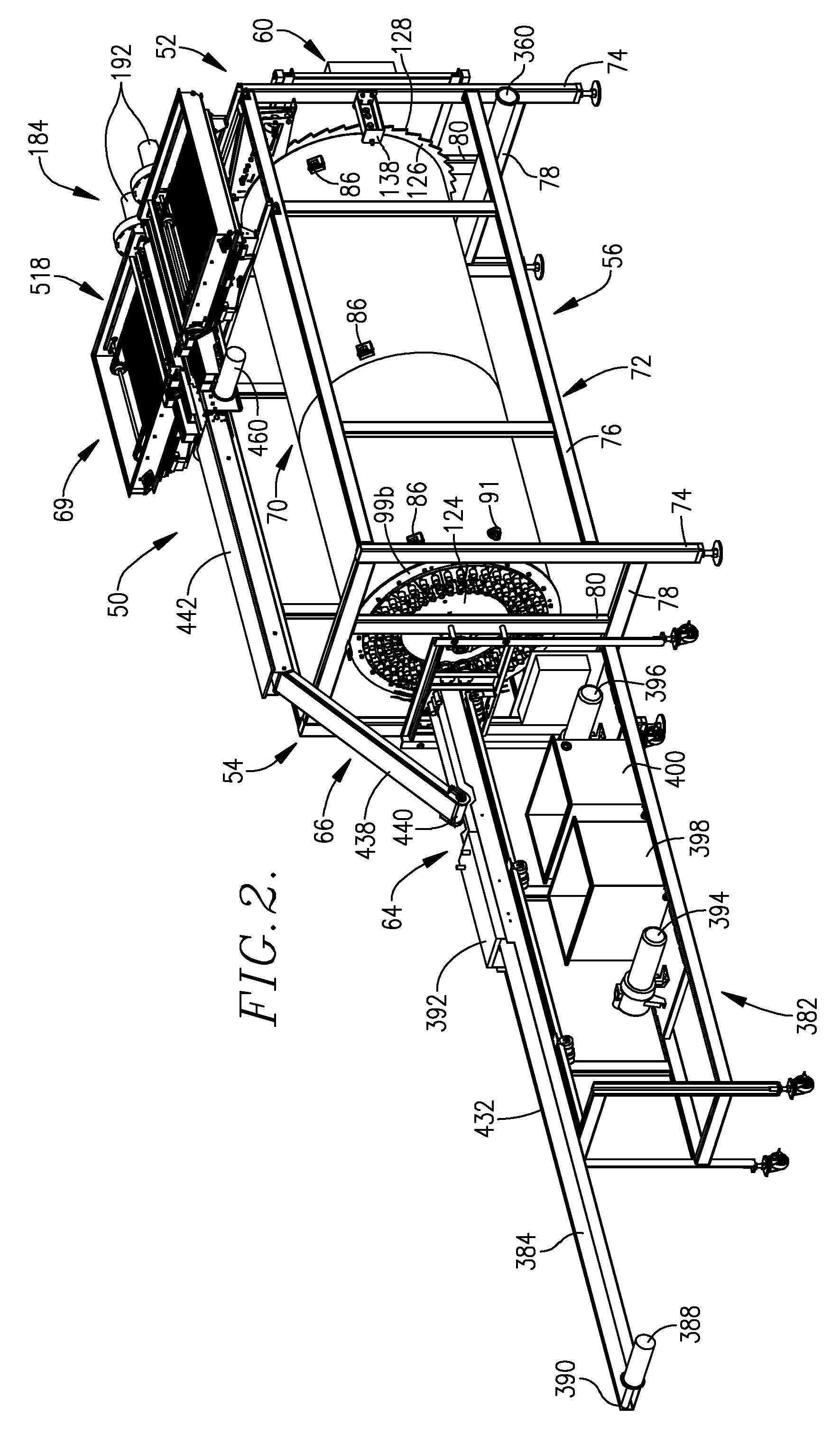

Breech loader

An apparatus for automatically delivering placed and oriented pieces of meat to a netter for wrapping and netting is described, in which the placement and orientation of the meat pieces remains unchanged from initial placement until final wrapping and netting. The apparatus is a conveyor having a series of compartments in which the meat is placed and oriented. The conveyor is situated below the level of the breech of the feed tube to the netter, so that a compartment carried on said conveyor will be precisely aligned with the opening to the feed tube. A ram pushes the meat pieces out of the compartment and into the feed tube, without changing the placement or orientation of the meat pieces relative to each other. The netter wraps the meat pieces in a collagen film and encases the wrapped meat in a net for further processing.

Owner:POLY CLIP SYST

Apparatus for cutting elongated meat

InactiveUS20100151780A1Skinless sausage makingMeat processing plantsEngineeringMechanical engineering

An apparatus for cutting elongated meat includes a frame that has a longitudinal axis and a motor proximate the frame. At least two generally circular blades are rotatably mounted to the frame each about a respective blade axis. Each blade axis is generally perpendicular to the longitudinal axis. The blades axes are positioned generally on an imaginary plane generally perpendicular to the longitudinal axis. The blades are rotated by the motor and cut the elongated meat when the elongated meat is placed generally collinear with the longitudinal axis and contacts the blades.

Owner:BATTLE EDWARD

Peeling System And Peeling Machine For Peeling A Strand Of Food Product

InactiveUS20140331870A1Aid removalFood preservationSkinless sausage makingEngineeringMechanical engineering

A peeling system and device that eliminates the need for a steam tube and / or air blasts by moving the position of a cutter blade or the use of a pincher wheel.

Owner:MAREL MEAT PROCESSING

Method and apparatus for removing a stockinette

One aspect of the invention includes an automated method of removing a stockinette from meat having an end, sides, and a length. The stockinette enveloped meat is conveyed in a first direction as the stockinette is cut proximate the end of the meat with a first knife. The stockinette enveloped meat is then conveyed in a second direction as the stockinette is cut proximate the sides of the meat with a second knife and a third knife. The cuts made by the second knife and the third knife intersect with the cut made by the first knife. The cuts in the stockinette create a flap in the stockinette between the cuts. The flap is engaged and peeled away from the meat, and the meat is removed from the stockinette.

Owner:HORMEL FOODS

Machine for preparing encased cured meats

InactiveUS20090011694A1Reduce downtimeEasy peeling operationSkinless sausage makingCelluloseEngineering

A machine for preparing encased cured meats, comprising a first tube for conveying the product to a clipping head, the tube being adapted to be wrapped by a cellulose sheet designed to contain the cured meats and drawn continuously from a reel, and a second tube, which is arranged coaxially and externally to the first tube and is designed to be wrapped by a gauged wrapper and is provided with means for drawing the wrapper so that it is superimposed on the cellulose sheet at a braking device arranged upstream of the clipping head.

Owner:INOX MECCANICA

Automated extraction of casing clips from cooked meat products

A method apparatus for removing a casing, particularly a casing with a clip end embedded in the product, is disclosed where the clipped end is clamped and gas is injected into this end to blow out the clip and casing end while the clamped portion prevents the entire casing from being inflated. The air or gas, such as HEPA filtered air, is injected into the product with a needle, for instance, to balloon out the casing in the clamped area to free the previously embedded clip. The clip is then gripped, certain cuts are made in the casing, and the casing is pulled from the product. An injector such as a needle is inserted into the end portion of the product and pressurized gas, such as HEPA filtered air, is injected into the end portion. The injection of the gas causes the casing to balloon out from the product thereby freeing the previously embedded clip. The freed clip is then gripped while the casing is then cut for removal. The casing may be cut in a Y-shape with two cuts beginning approximately at two corners of one side of the square end and angled towards each other along a side of the product. The two cuts meet, and a third cut is made longitudinally along the length of the product beginning at the meeting point of the two angled cuts. The gripped clip and casing are pulled causing the casing to separate from the product along the cut lines.

Owner:KRAFT FOODS GRP BRANDS LLC

Automated extraction of casing clips from cooked meat products

InactiveUS20050100644A1Effect separationSkinless sausage makingBakery productsHEPAPulp and paper industry

A method apparatus for removing a casing, particularly a casing with a clip end embedded in the product, is disclosed where the clipped end is clamped and gas is injected into this end to blow out the clip and casing end while the clamped portion prevents the entire casing from being inflated. The air or gas, such as HEPA filtered air, is injected into the product with a needle, for instance, to balloon out the casing in the clamped area to free the previously embedded clip. The clip is then gripped, certain cuts are made in the casing, and the casing is pulled from the product. An injector such as a needle is inserted into the end portion of the product and pressurized gas, such as HEPA filtered air, is injected into the end portion. The injection of the gas causes the casing to balloon out from the product thereby freeing the previously embedded clip. The freed clip is then gripped while the casing is then cut for removal. The casing may be cut in a Y-shape with two cuts beginning approximately at two corners of one side of the square end and angled towards each other along a side of the product. The two cuts meet, and a third cut is made longitudinally along the length of the product beginning at the meeting point of the two angled cuts. The gripped clip and casing are pulled causing the casing to separate from the product along the cut lines.

Owner:KRAFT FOODS GRP BRANDS LLC

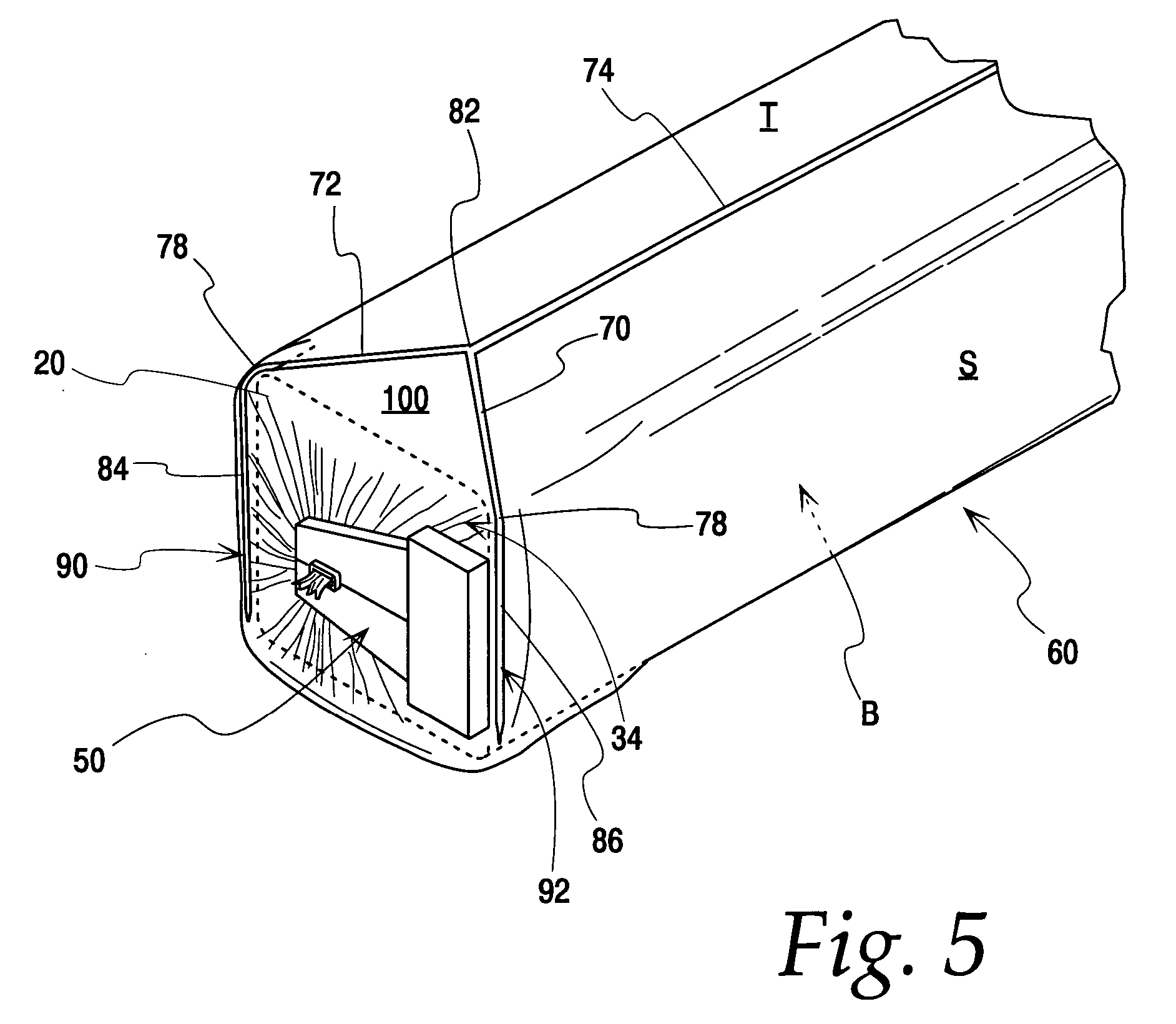

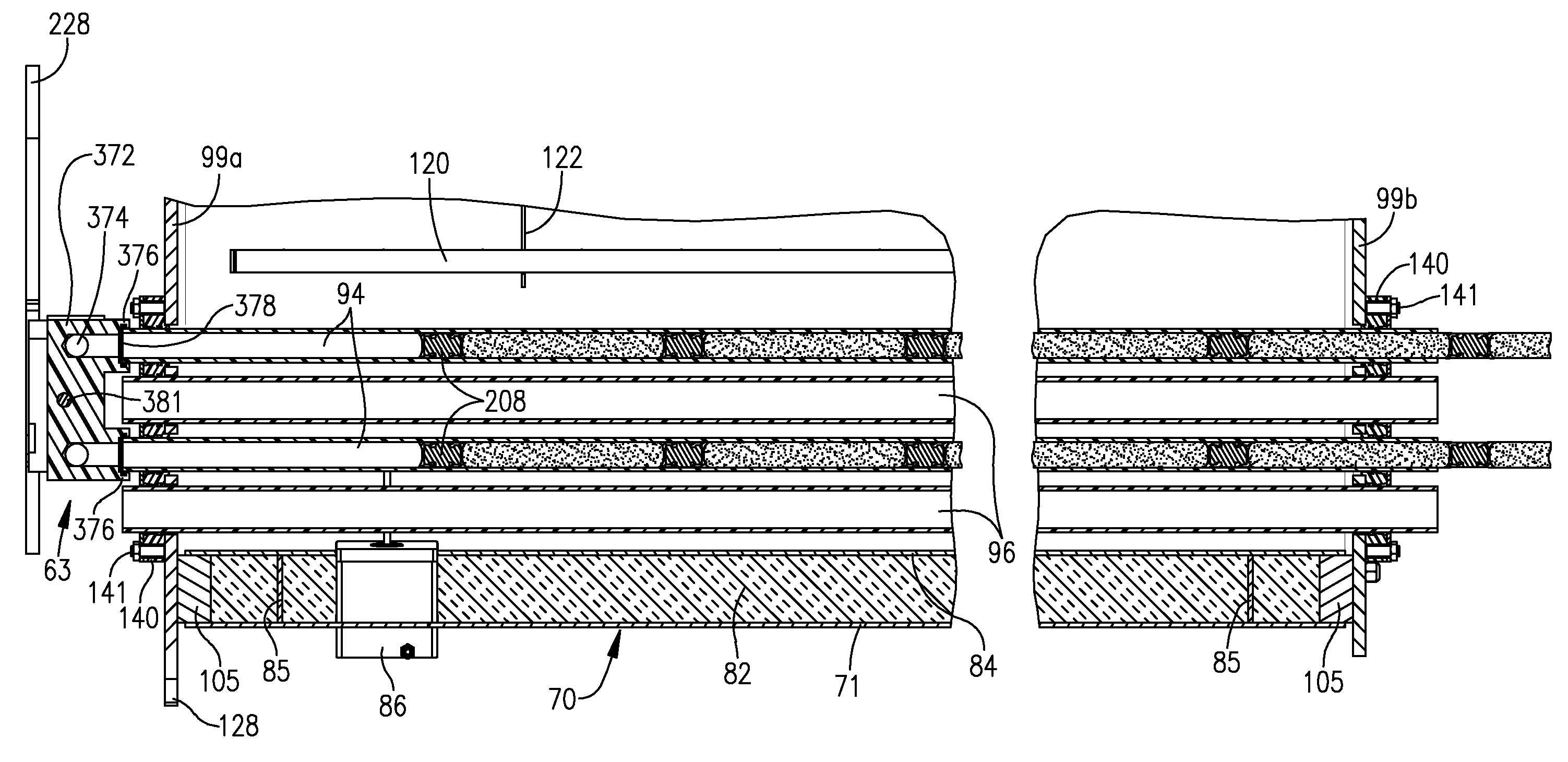

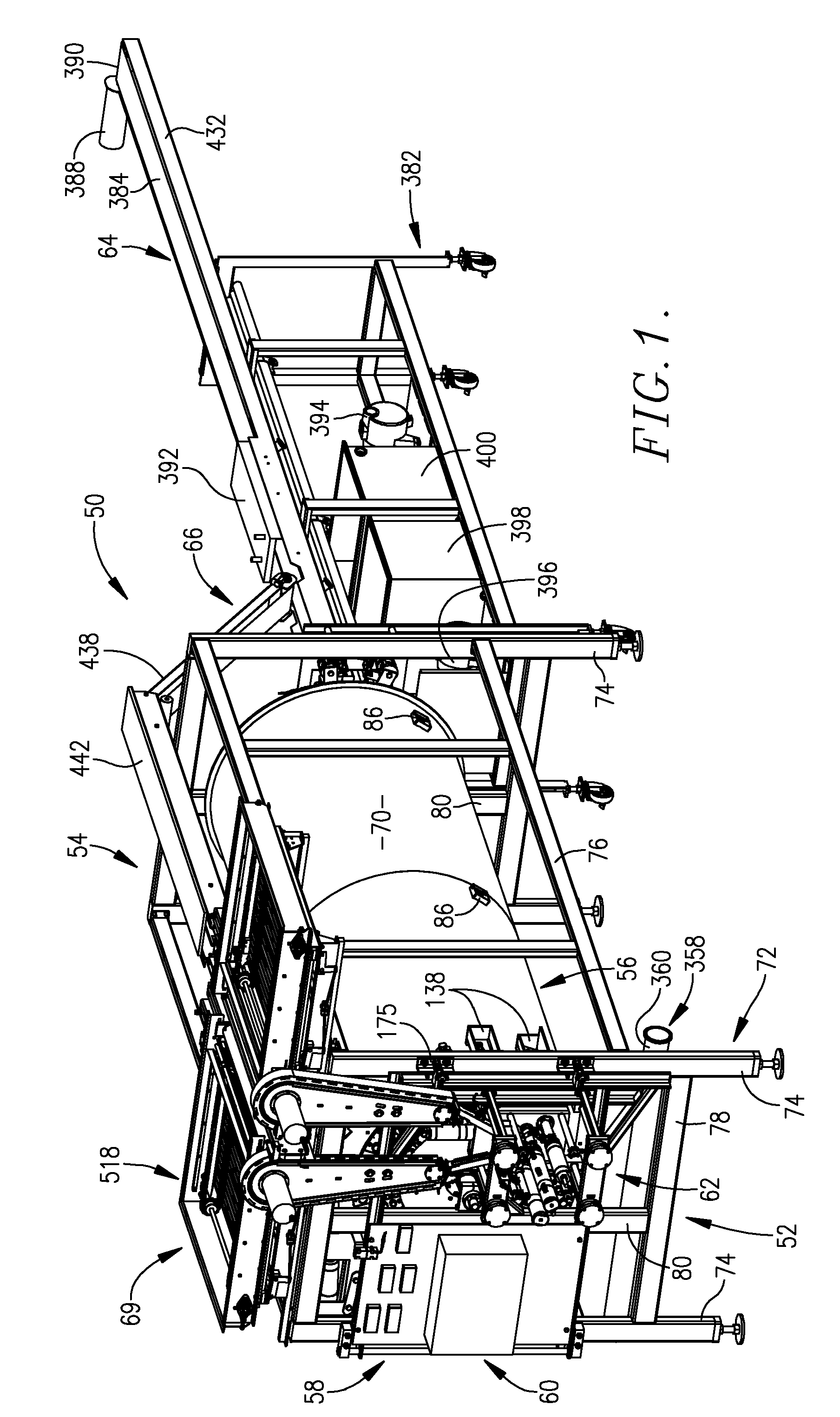

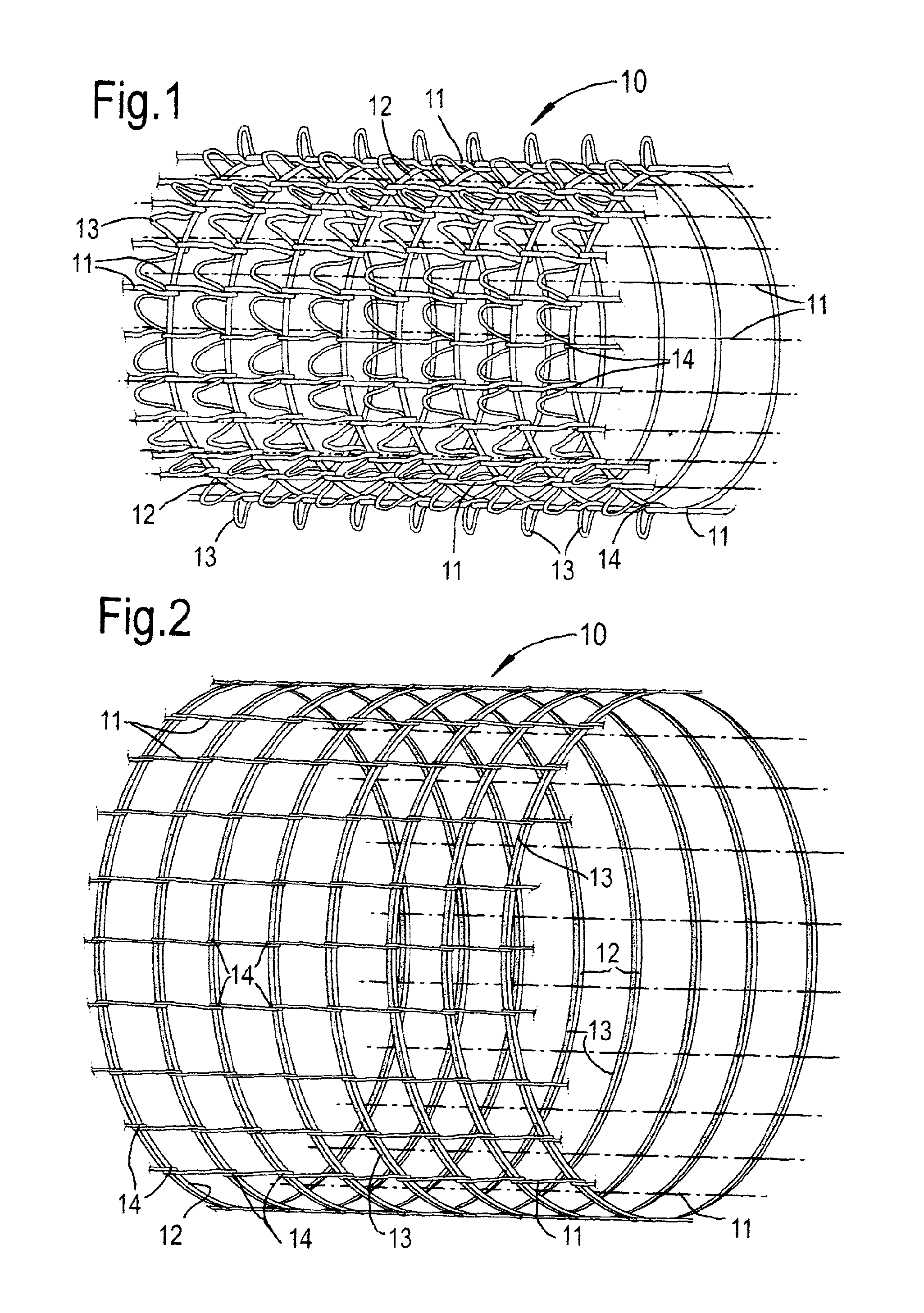

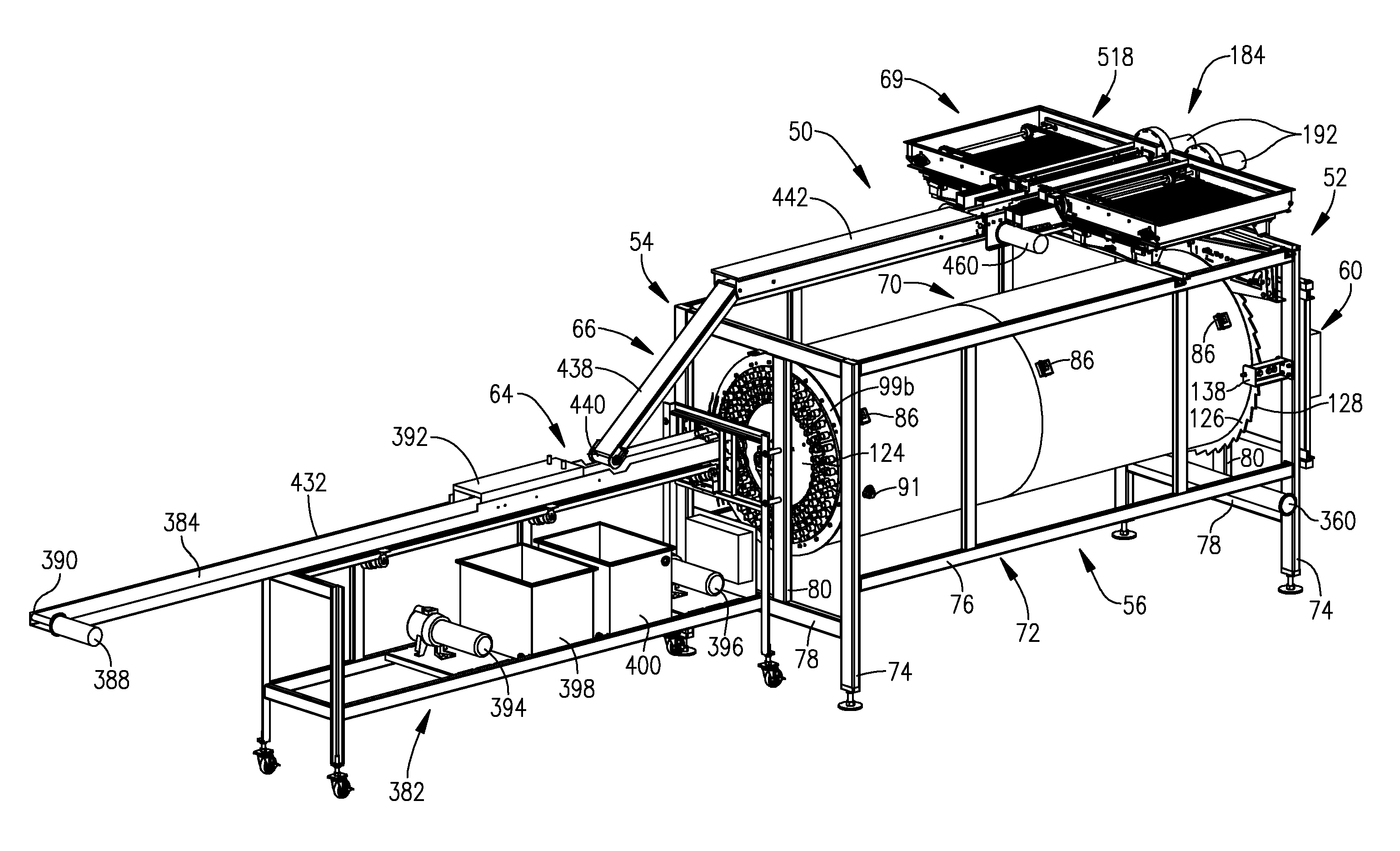

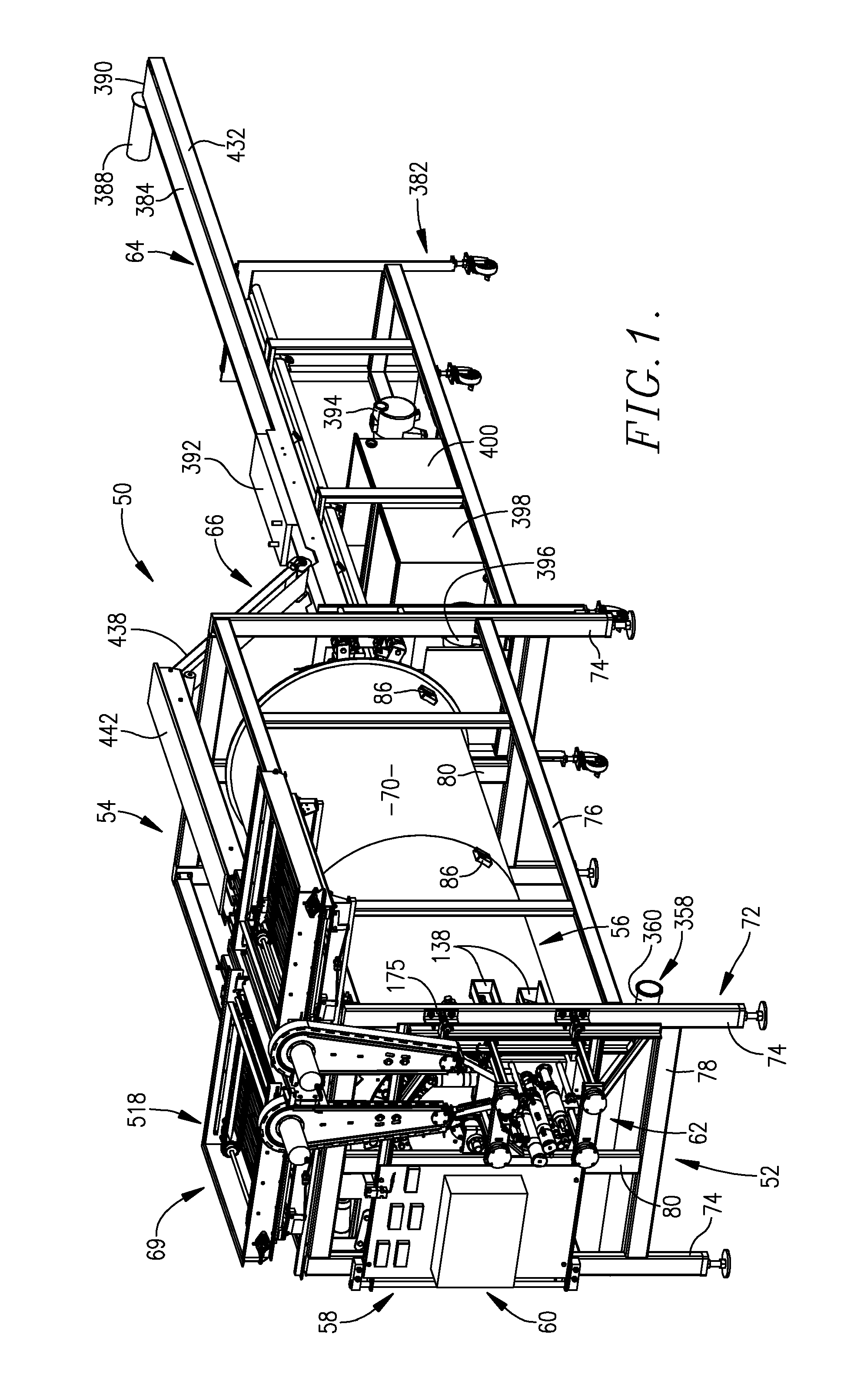

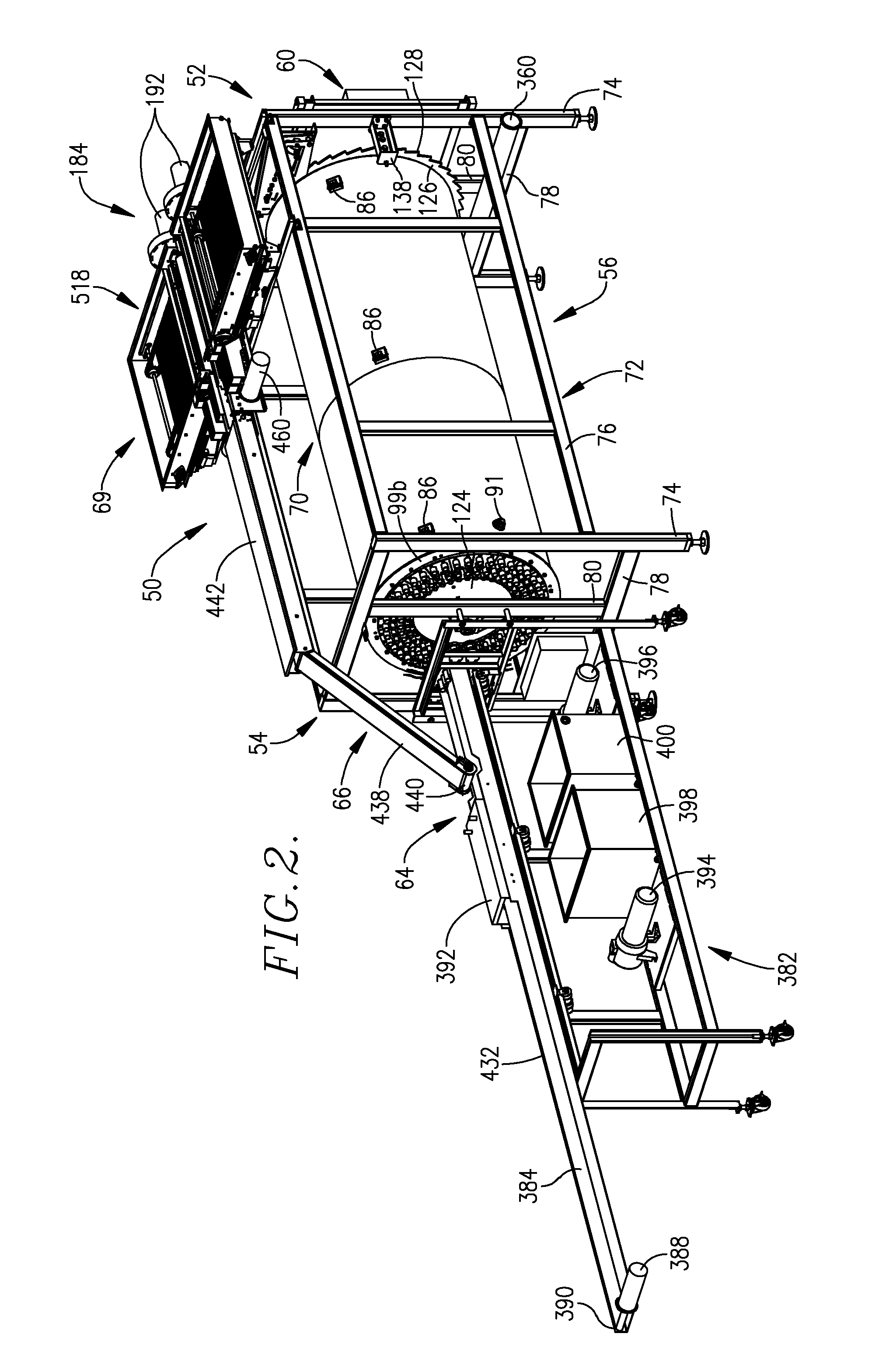

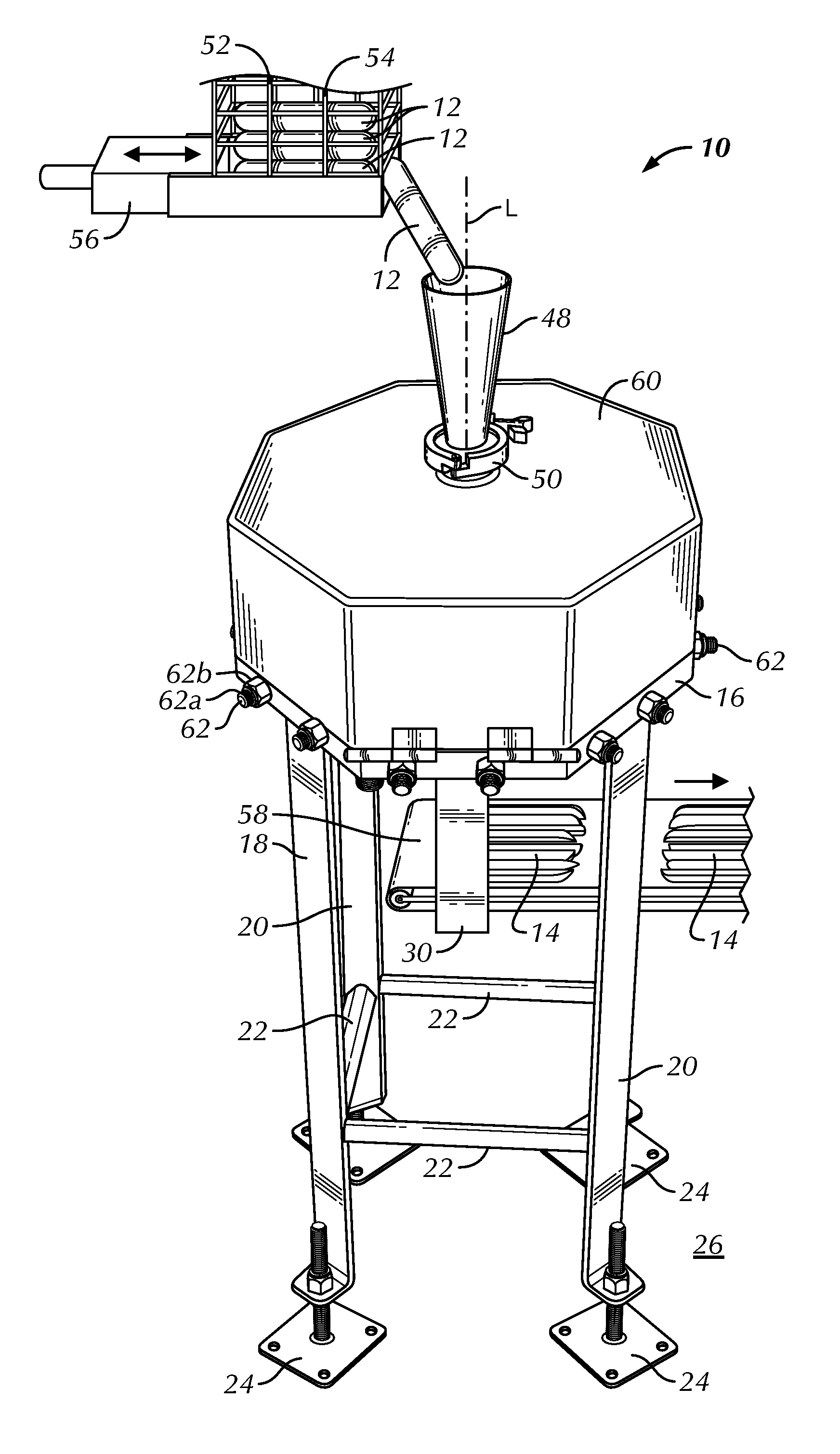

Method and apparatus for production of elongated meat products without casings

InactiveUS20100209570A1Eliminates costly expedientLow production costMeat/fish preservation by shapingConfectioneryVegetable oilEngineering

A system (50) is provided for the production of elongated comestible products such as hot dogs, without the use of traditional casings. The system (50) includes a circular pattern of arrays (92) of elongated, open-ended, extruded synthetic resin cooking tubes (92, 94) within a rotatable cylindrical heating drum or housing (70). The tube housing (70) and arrays (92) are incrementally rotated and at each stop position certain of the tubes (92, 94) are filled with portions of meat emulsion (590) and alternating plugs (208), while previously filled tubes (92, 94) containing cooked product are unloaded, and other unfilled tubes are internally coated with a lubricant (e.g., a mixture of lecithin and vegetable oil). Energy exchange media such as hot water and / or steam are used within the housing to continuously cook the emulsion portions within the tubes (92, 94) to the desired extent.

Owner:MARLEN INT

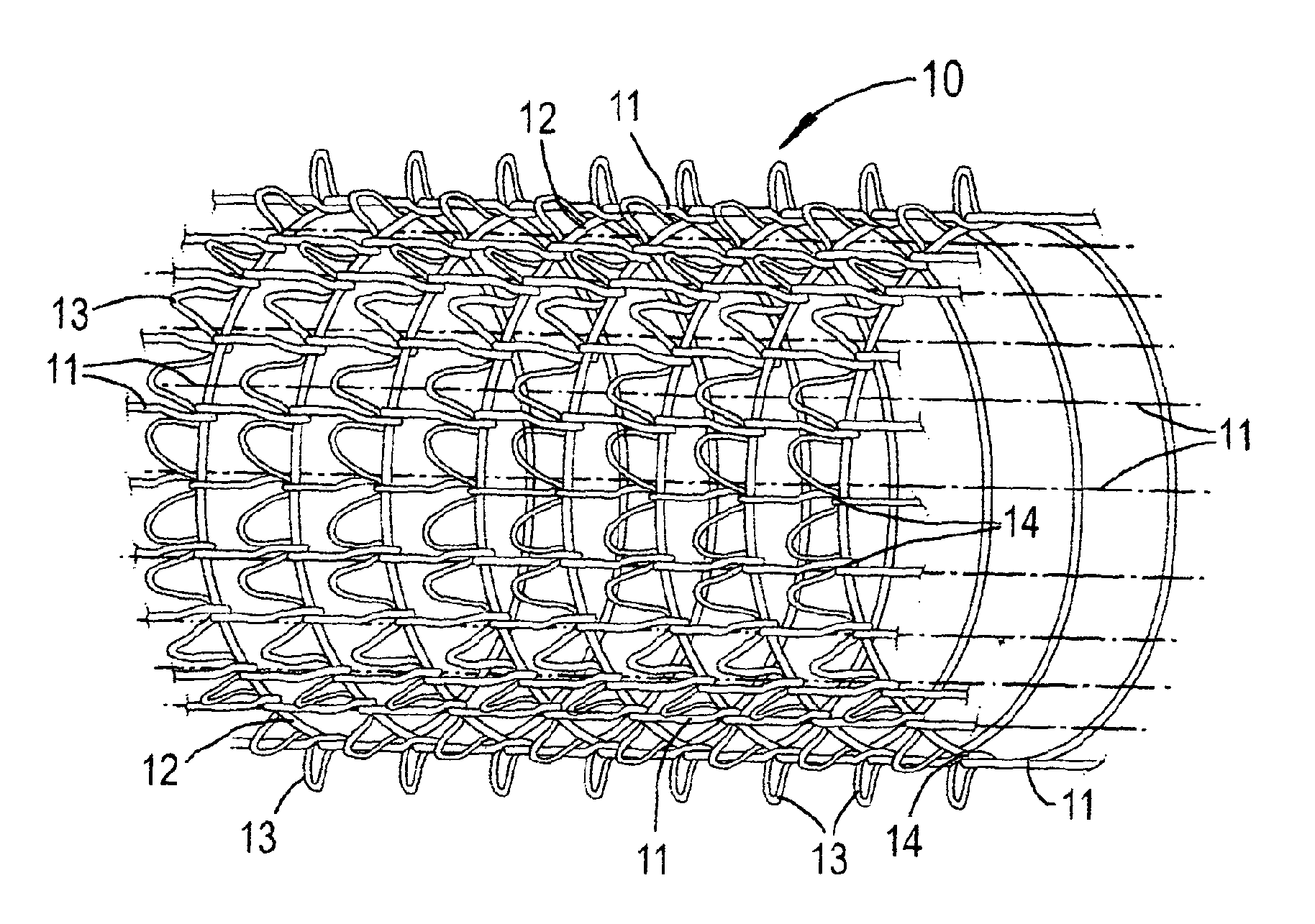

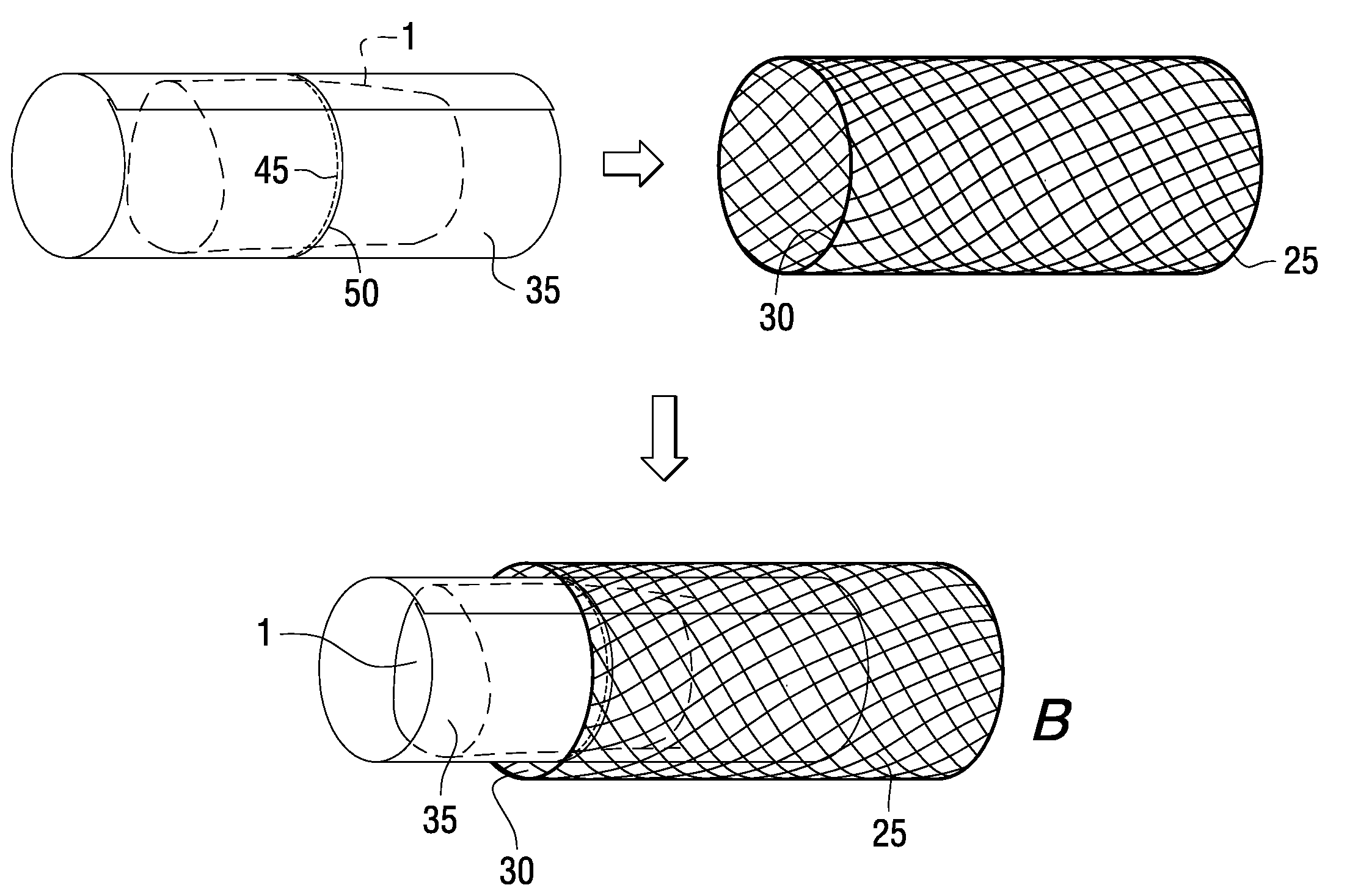

Tubular Elasticated Net with Inextensible Weft

Owner:TRUNATURE

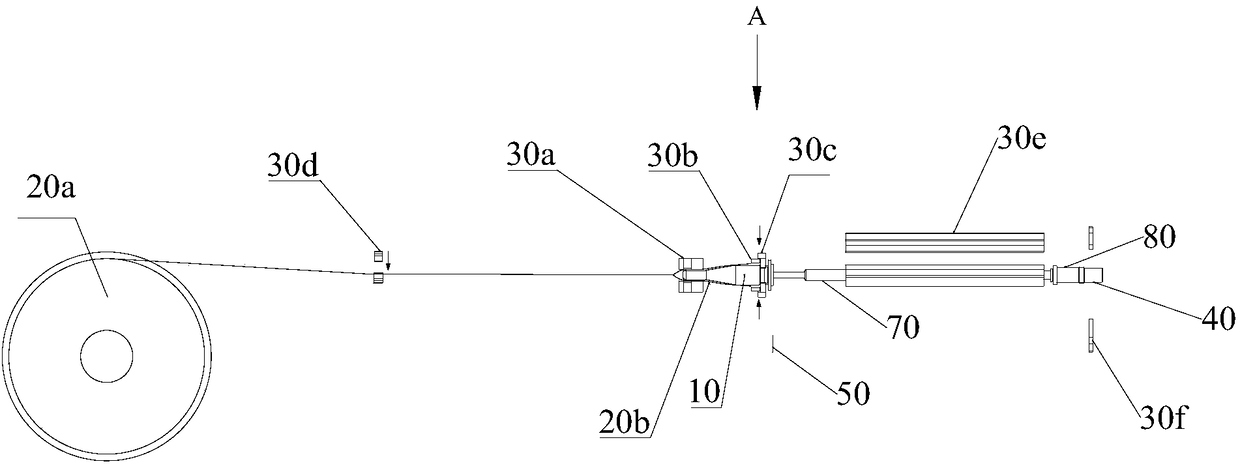

Packaging equipment, sleeving and shrinking machine and packaging method for performing continuous and automatic mesh sleeving of sausage casings

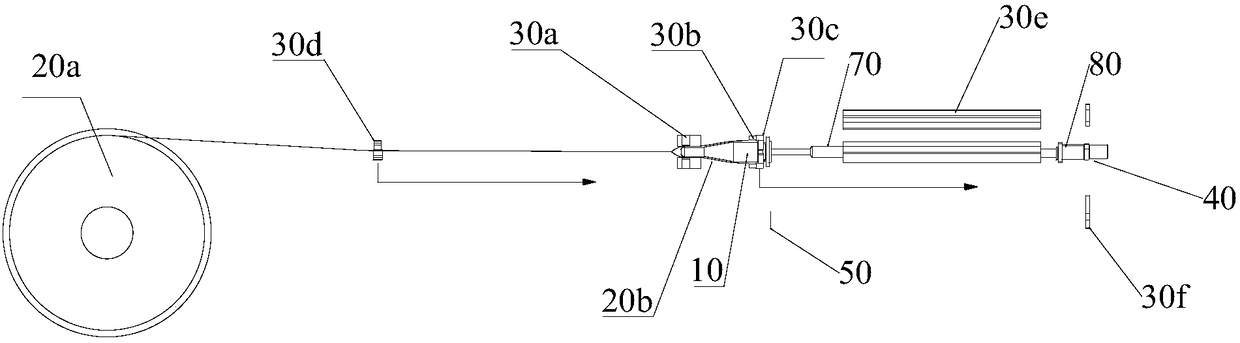

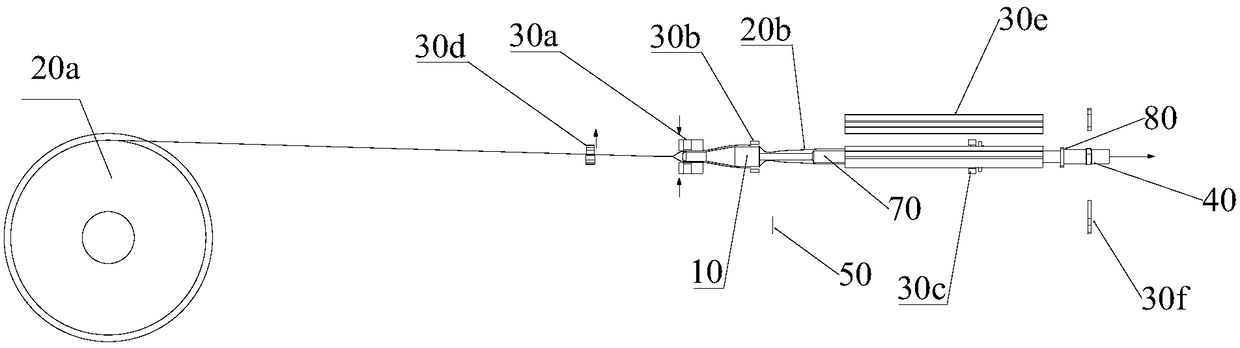

ActiveCN108477273ARealize fully automatic packagingSkinless sausage makingSausage casing manufactureReciprocating motionBiomedical engineering

The invention relates to packaging equipment, a sleeving and shrinking machine and a packaging method for performing continuous and automatic mesh sleeving of sausage casings. The packaging equipmentcomprises a shuttle (10), a first clamp hand (30a), a second clamp hand (30b), a third clamp hand (30c) and a fourth clamp hand (30d), wherein the shuttle (10) is used for sleeving mesh bags (20b); the first clamp hand (30a) can be opened or closed to release or fixedly clamp the shuttle (10); when closed, the second clamp hand (30b) can drive an open end of the mesh bag (20b) to perform reciprocating motion between a first position and a second position on the shuttle (10), and when opened, the second clamp hand (30b) can allow the mesh bag (20b) to move freely along a conveying direction ofthe mesh bag; the third clamp hand (30c) is used for clamping the open end of the mesh bag (20b) and dragging the mesh bag to sleeve a whole sleeved and shrunk sausage casing (70); and the fourth clamp hand (30d) is used for dragging the mesh bag (20b) to unwind the mesh bag (20b) from a mesh bag roll (20a), and the fourth clamp hand (30d) is designed in a form of capable of moving together with the third clamp hand (30c).

Owner:FOSHAN VEHICIAN LNTELLIGENT EQUIP CO LTD

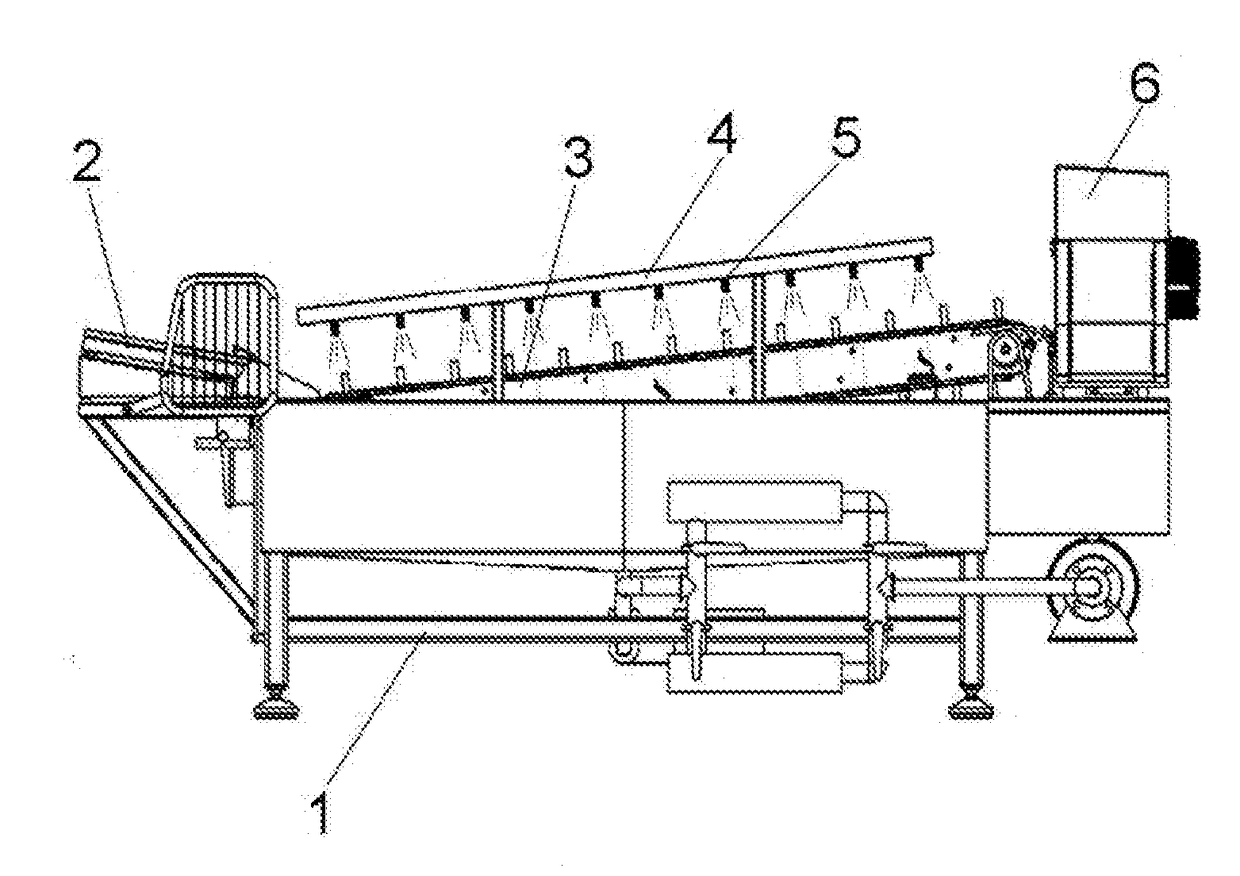

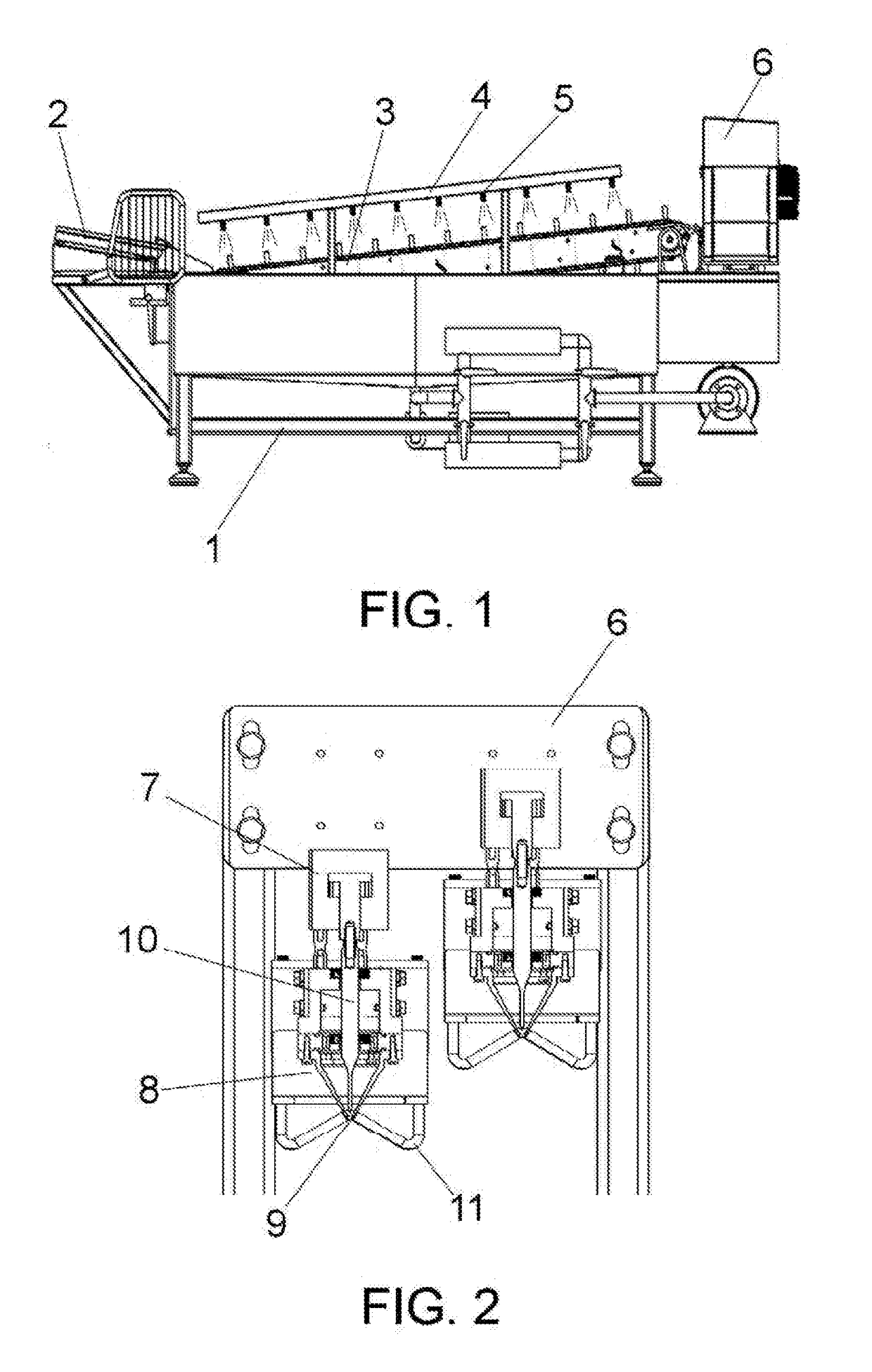

Device for automatic peeling sauges

The device consists of a supply area (2) through which a conveyor belt (3) is fed above which a moistening station (4) is arranged by means of which the skin of the sausage is softened in order for the sausage to then be perforated and injected in order for said internal air flow to cause the skin to detach from the meat in the corresponding gripping and blowing station (6). It is then subjected to transversal cutting with a guillotine mechanism (16) and then to longitudinal cutting (18) while the skins are removed underneath by means of a pair of toothed wheels (23), the clean product coming out by way of an outlet conveyor belt (24).

Owner:ARCTECNO APLICACIONES

Method and apparatus for production of elongated meat products without casings

InactiveUS20100209579A1Eliminates costly expedientLow production costMeat/fish preservation by shapingCooking vesselsVegetable oilEngineering

A system (50) is provided for the production of elongated comestible products such as hot dogs, without the use of traditional casings. The system (50) includes a circular pattern of arrays (92) of elongated, open-ended, extruded synthetic resin cooking tubes (92, 94) within a rotatable cylindrical heating drum or housing (70). The tube housing (70) and arrays (92) are incrementally rotated and at each stop position certain of the tubes (92, 94) are filled with portions of meat emulsion (590) and alternating plugs (208), while previously filled tubes (92, 94) containing cooked product are unloaded, and other unfilled tubes are internally coated with a lubricant (e.g., a mixture of lecithin and vegetable oil). Energy exchange media such as hot water and / or steam are used within the housing to continuously cook the emulsion portions within the tubes (92, 94) to the desired extent.

Owner:MARLEN INT

Process for the continuous manufacture of sausages

InactiveUSRE40029E1Reduce high costReduce the amount of solutionSkinless sausage makingSausage filling/stuffing machinesFood packagingSynthetic resin

A process and apparatus for the continuous manufacture of food products such as sausages is provided which eliminates the need for intermediate stuffing of the food product into casings which are discarded prior to final packaging. The preferred apparatus of the invention includes first and second heated rollers (16, 17) each presenting a plurality of elongated, axially aligned channels or recesses (18,20) which are circumferentially and axially spaced on the corresponding rollers (16, 17); in addition, the second roller (17) includes a series of elongated, continuous, tube-receiving openings (22) extending between each series of aligned openings (20). Mechanisms (28, 29) are associated with the rollers (16, 17) in order to continuously feed elongated synthetic resin sheets (34, 35) into the nip between the rollers (16, 17). Rollers (24, 27) are provided for forcing portions of the sheets (34,35) into the recesses (18,20) and openings (22) prior to passage of the sheets (34,35) between the rollers (16, 17) where they are longitudinally heat sealed together to continuously form elongated, aligned food-receiving cavities (48). A plurality of feeding tubes (11) extend through the rollers (16, 17) and are located within the corresponding openings (22) and recesses (20) during rotation of the rollers (16, 17). The tubes (11) continuously direct the flowing food material into the cavities (48), the latter being transversely heat sealed via transverse sealing bars (60, 60′) to form complete, enclosed food packages.

Owner:FRIGORIFICO SAN CARLOS +1

Apparatus for cutting elongated meat

An apparatus for cutting elongated meat includes a frame that has a longitudinal axis and a motor proximate the frame. At least two generally circular blades are rotatably mounted to the frame each about a respective blade axis. Each blade axis is generally perpendicular to the longitudinal axis. The blades axes are positioned generally on an imaginary plane generally perpendicular to the longitudinal axis. The blades are rotated by the motor and cut the elongated meat when the elongated meat is placed generally collinear with the longitudinal axis and contacts the blades.

Owner:BATTLE EDWARD

Imitation skinless sausages

ActiveCN107580452AProteins working-up by texturisingSkinless sausage makingPolymer scienceOrganic chemistry

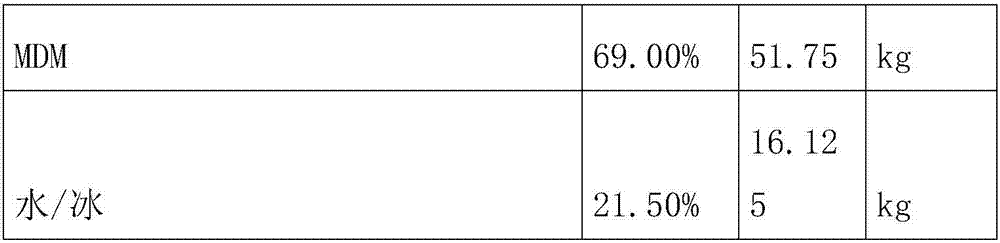

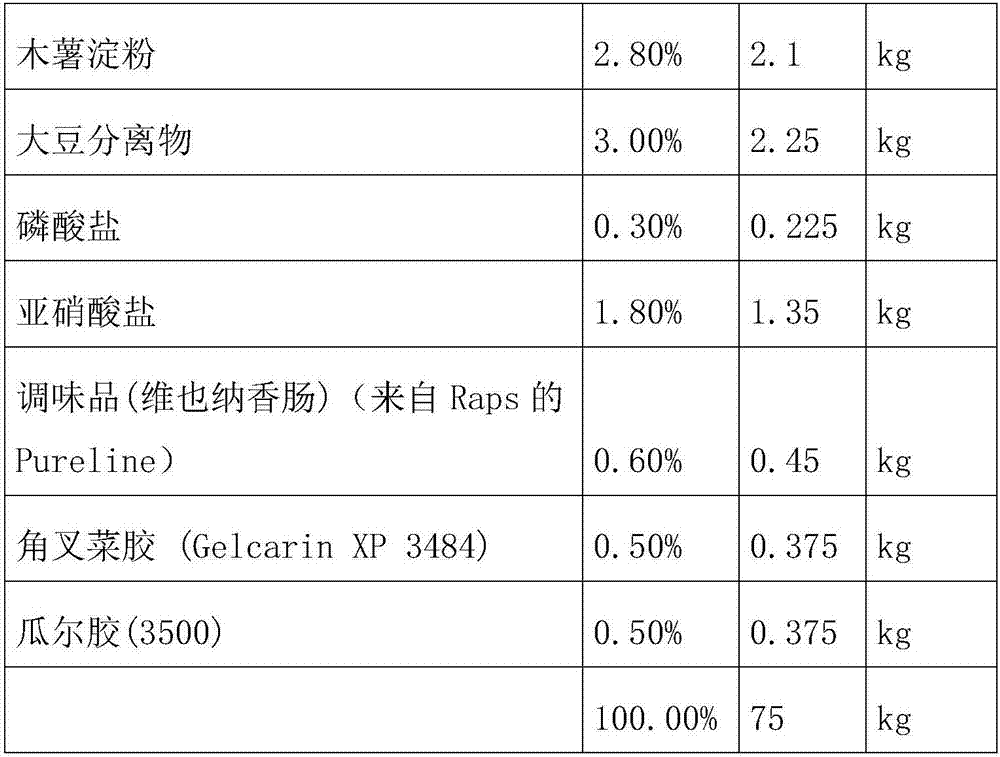

A fine emulsion sausage having an alginate coating having a thickness of 0.05 mm or less; said sausage substantially possessing the visible and organoleptic properties of a skinless sausage. Also, a method of manufacturing such sausages, which method comprises co-extruding a fine emulsion filling with a casing paste comprising alginate to form a coextruded product comprising 1.5% or less by weightof casing paste, based upon the total weight of the casing paste and filling; and contacting such coextruded product with a solution containing calcium ions, which solution has a pH below the pKa value of the alginate.

Owner:DUPONT NUTRITION USA INC

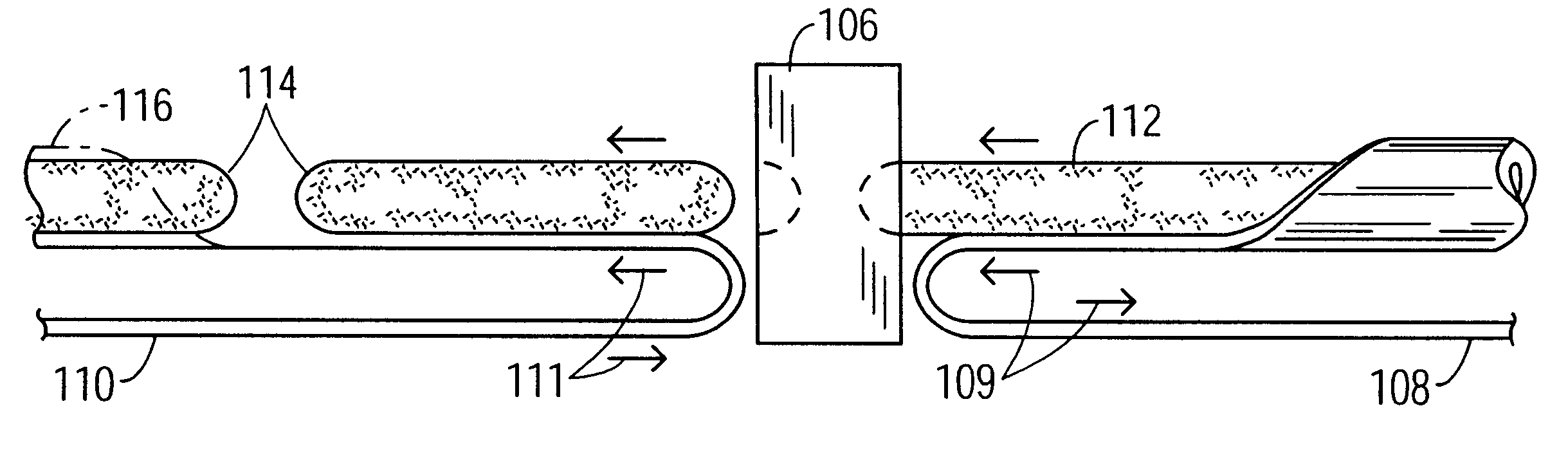

Method and apparatus for product packaging

InactiveUS20030208991A1Create efficientlyEfficient packagingPackaging meatSkinless sausage makingThermal energyMechanical engineering

A method and apparatus for packaging items, such as meat, non-meat products and non-food products, using ultrasound or heat is disclosed herein. In a preferred embodiment, a continuous thermoplastic tubular mesh material is used to package multiple meat products. The preferred packaging method does not use metal clips as in conventional packaging, and instead uses thermal energy, ultrasonic energy, or other types of energy to create seals in the packaging material itself. The method advantageously causes one seal to be formed between each pair of adjacently packaged products. This single seal can be cut in half thereby creating two seals, one seal for each adjacently packaged product.

Owner:CAD INDS

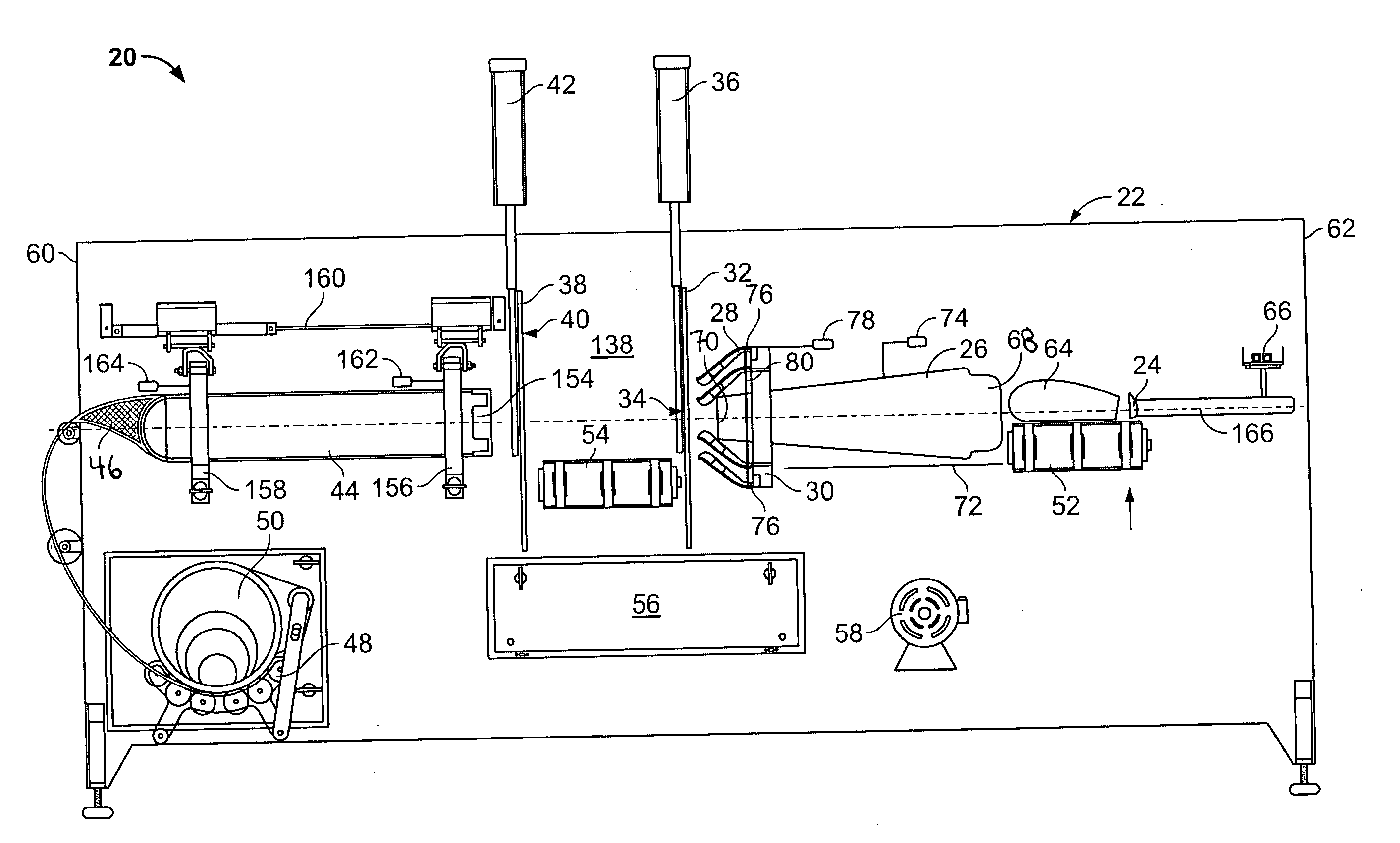

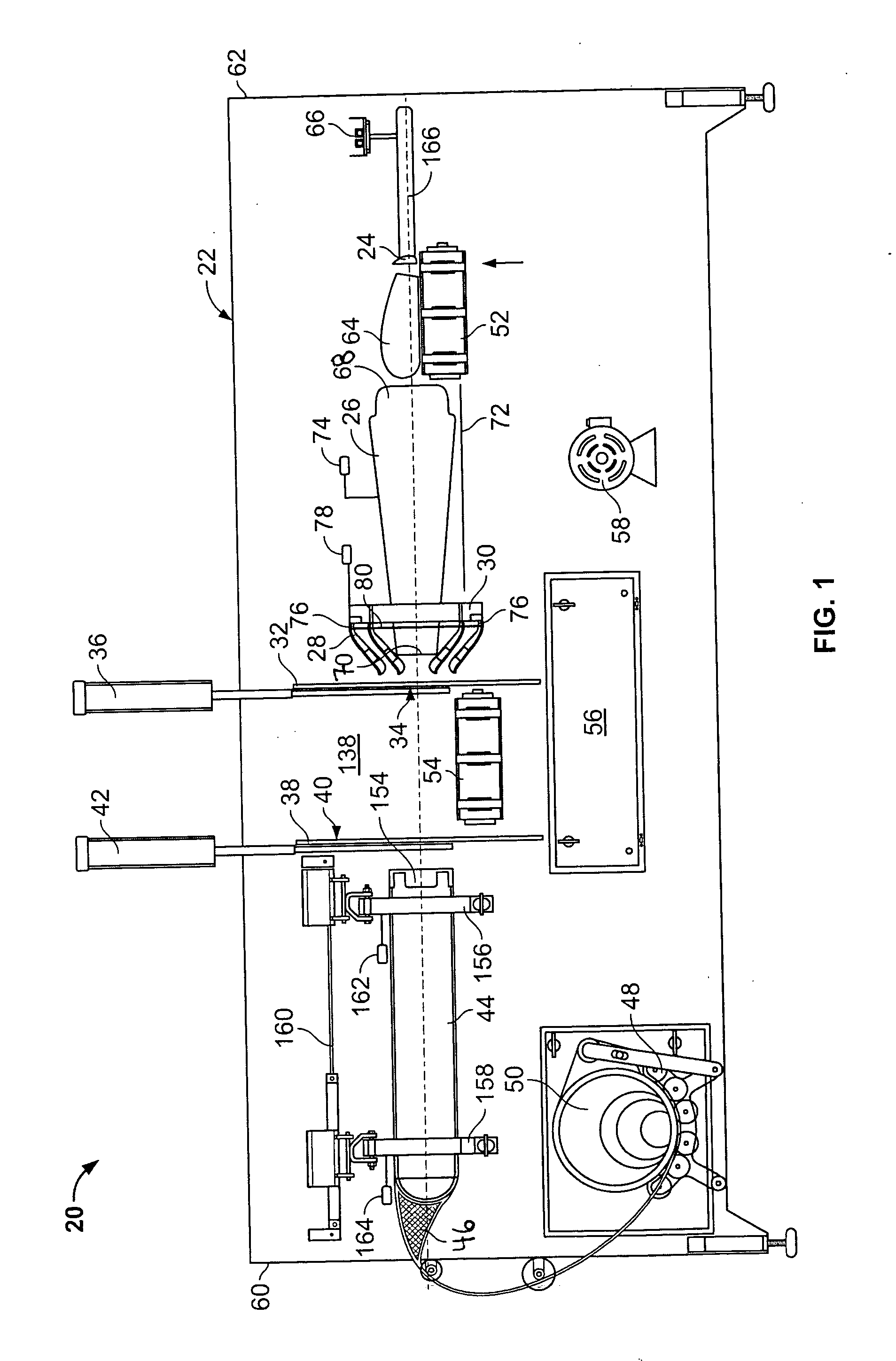

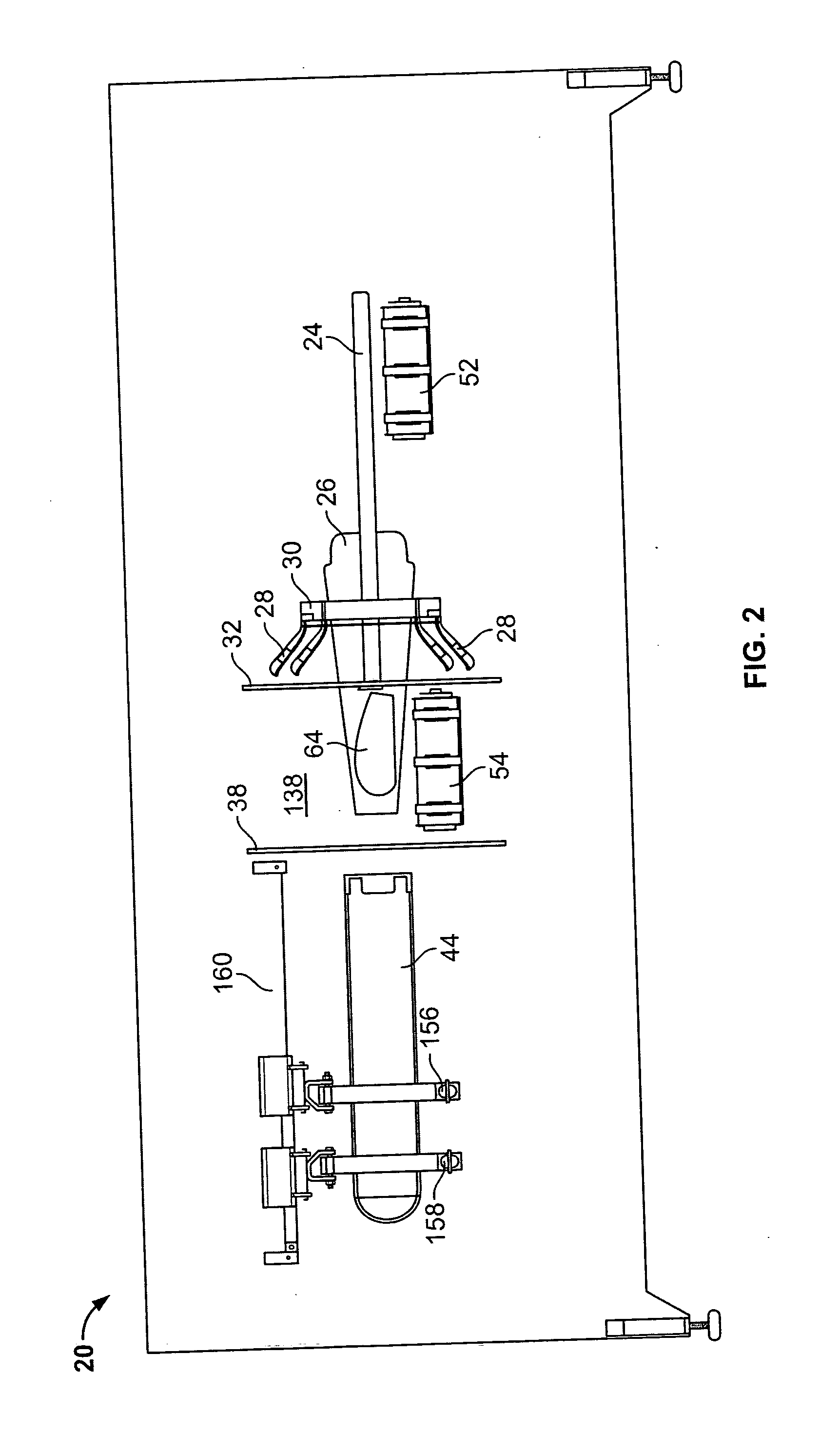

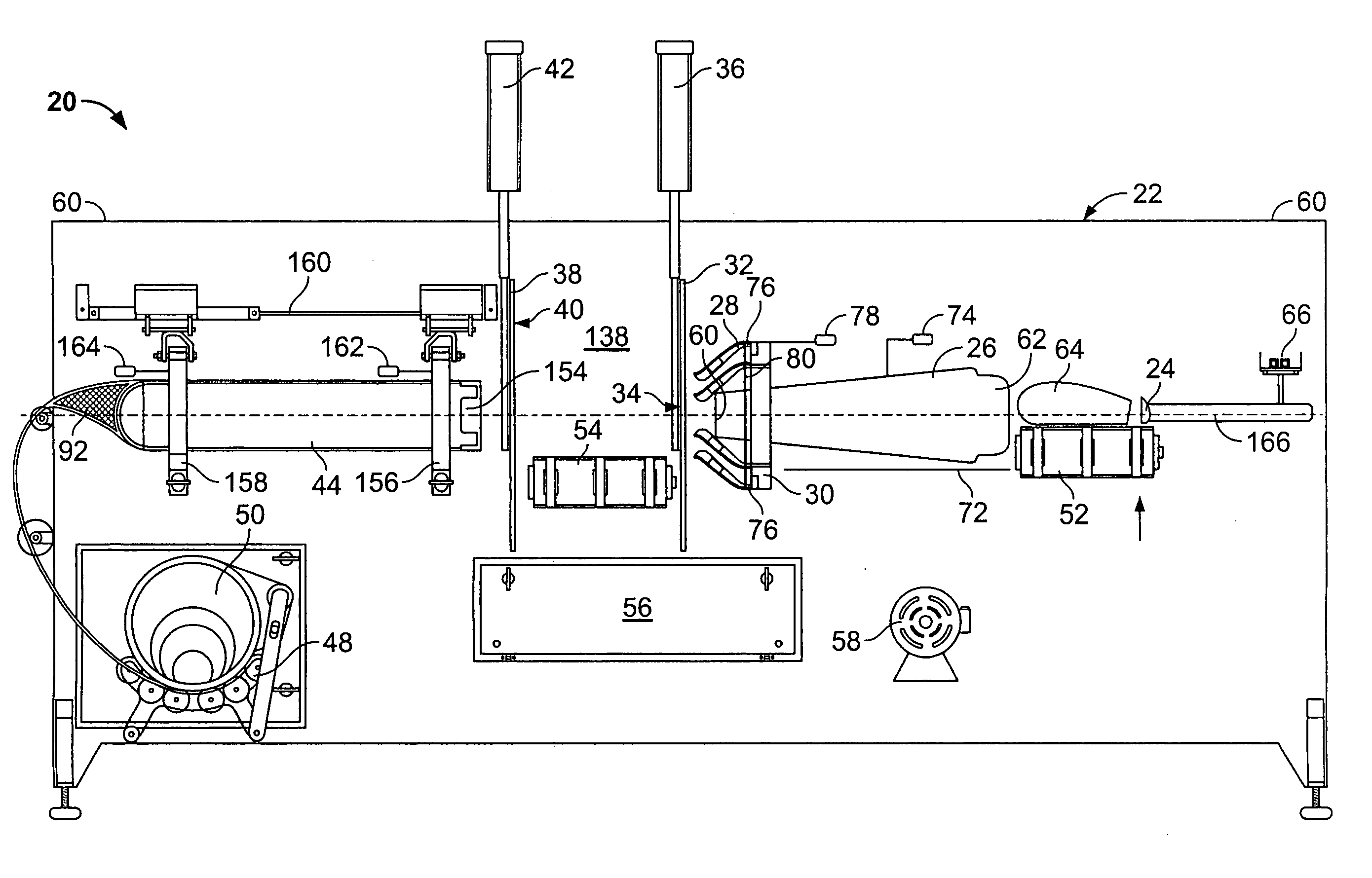

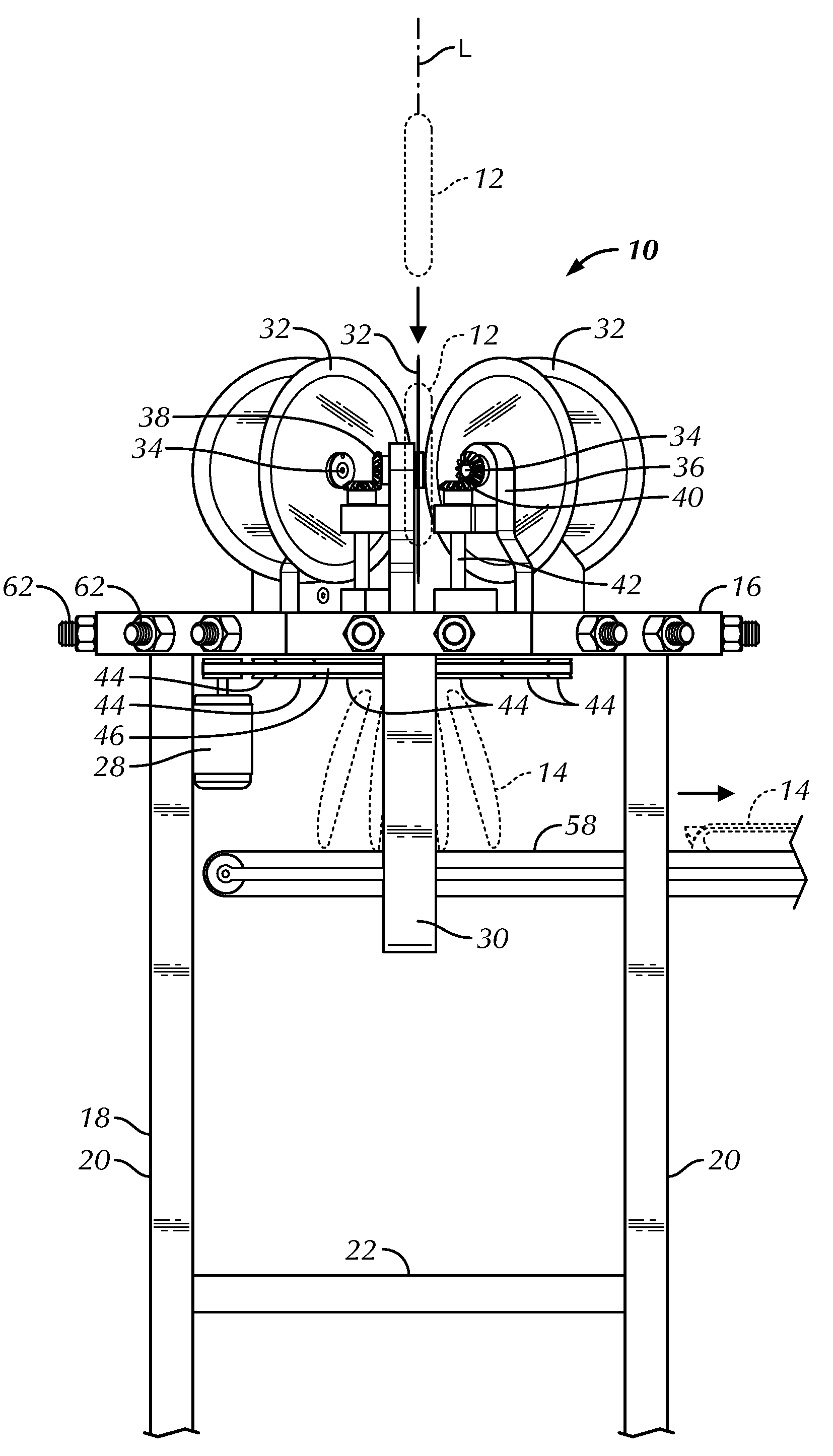

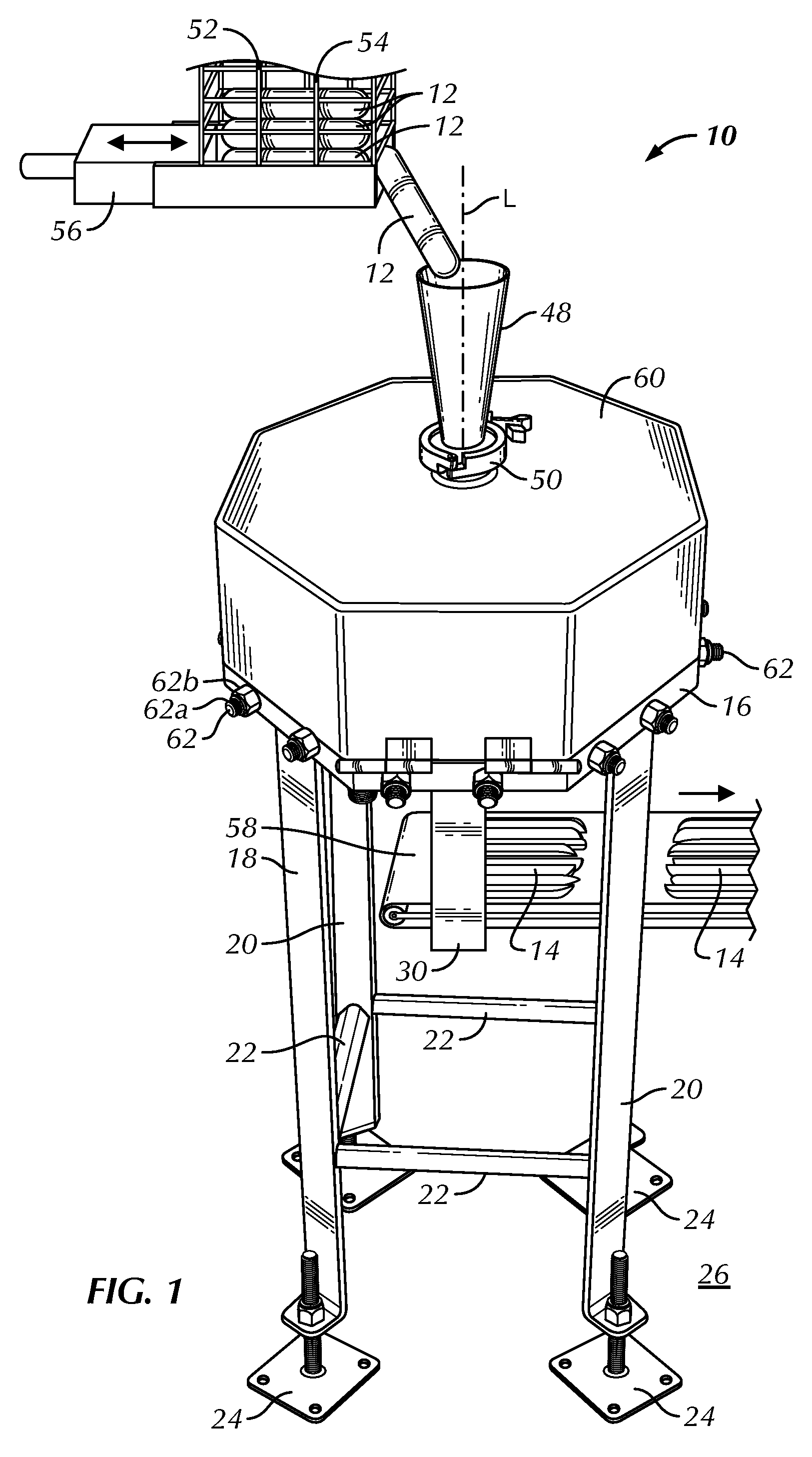

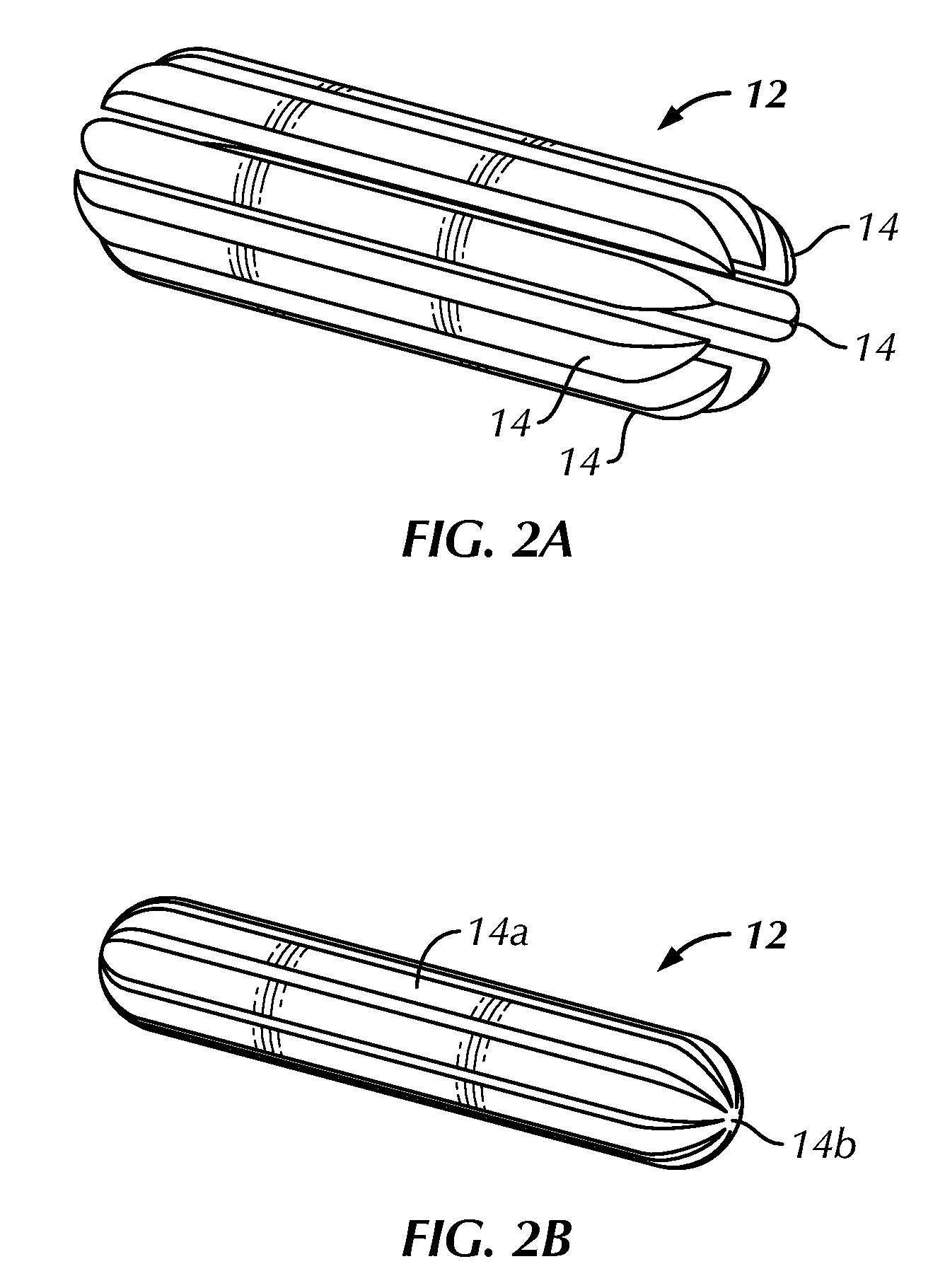

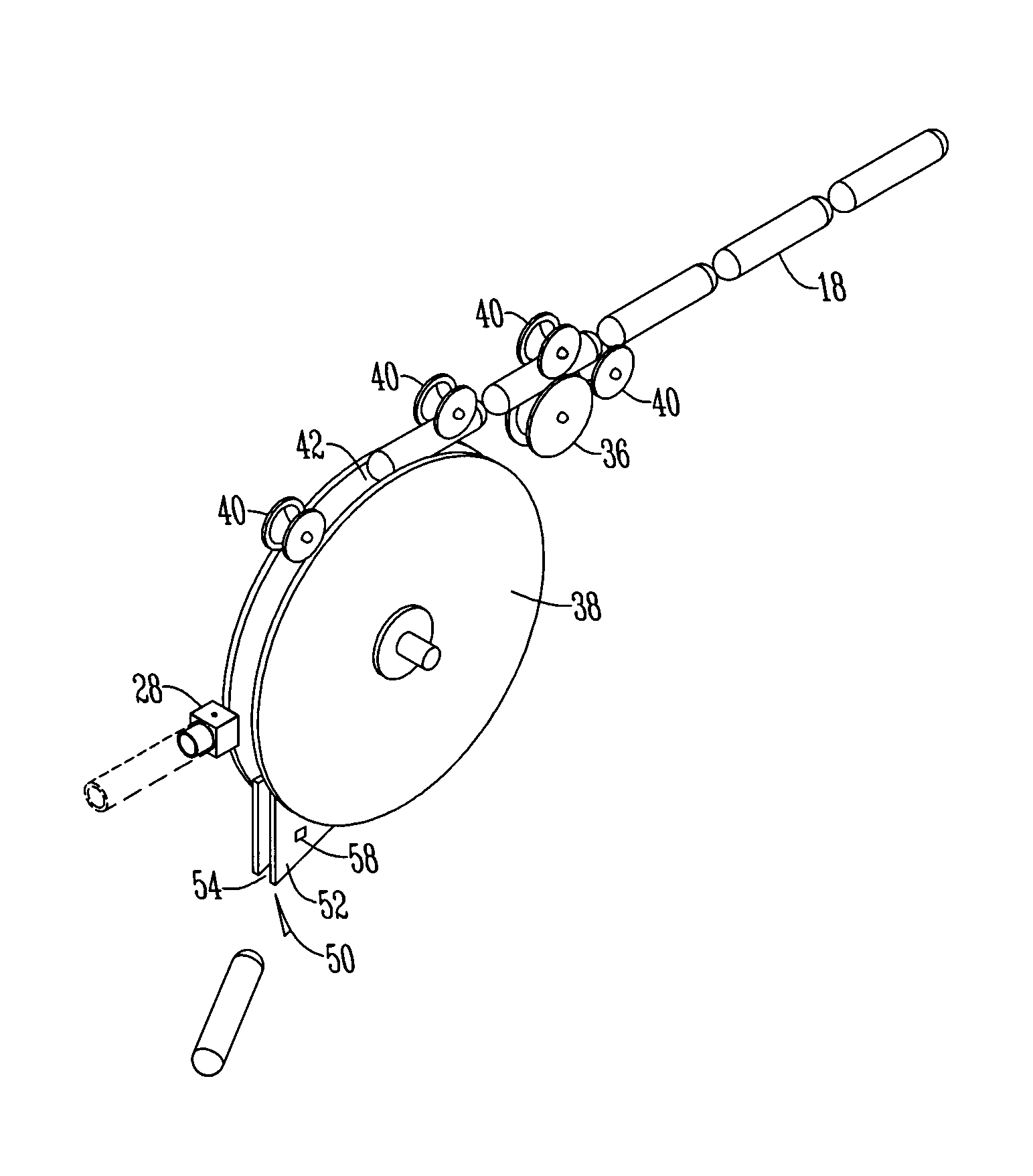

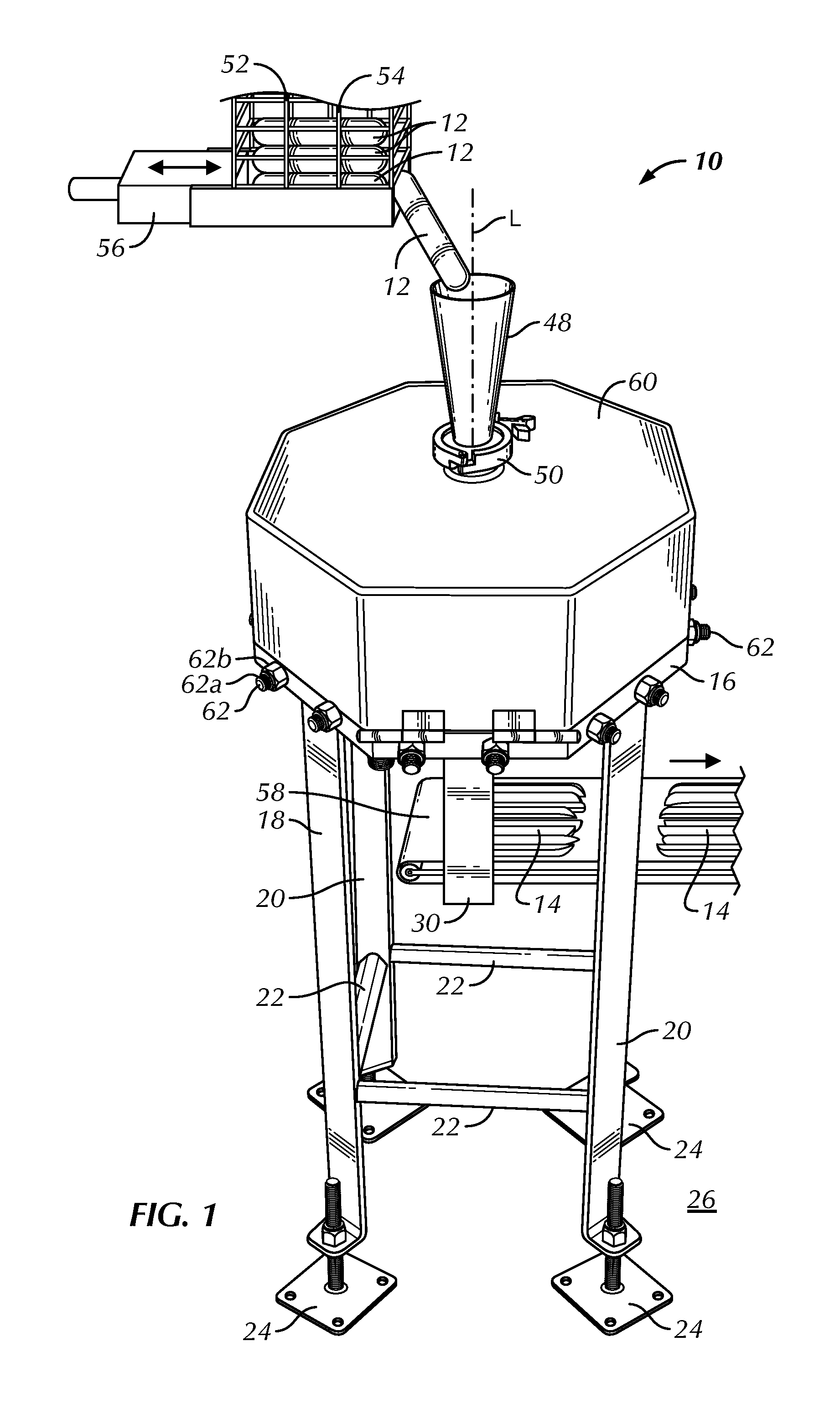

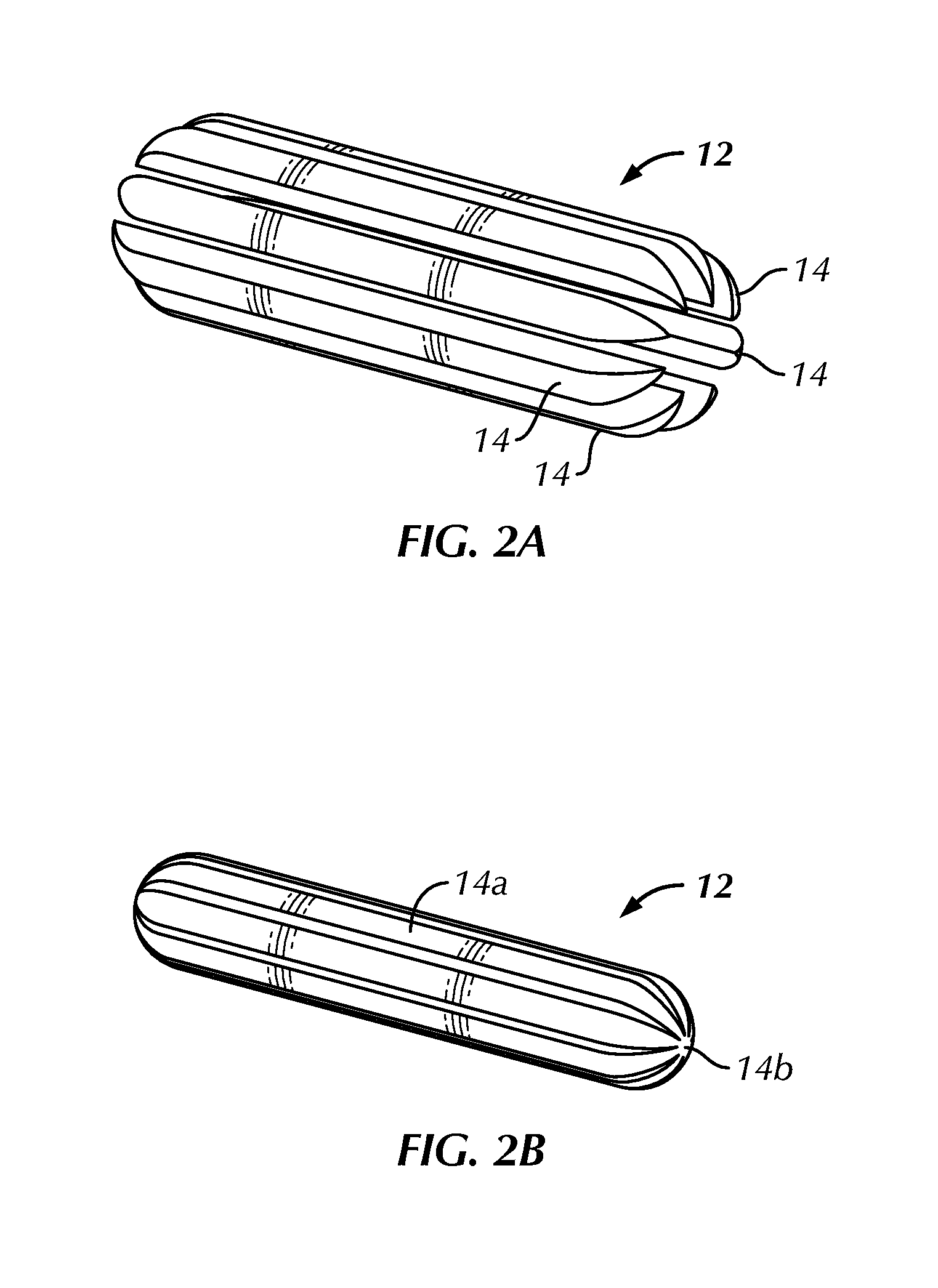

Breech loader

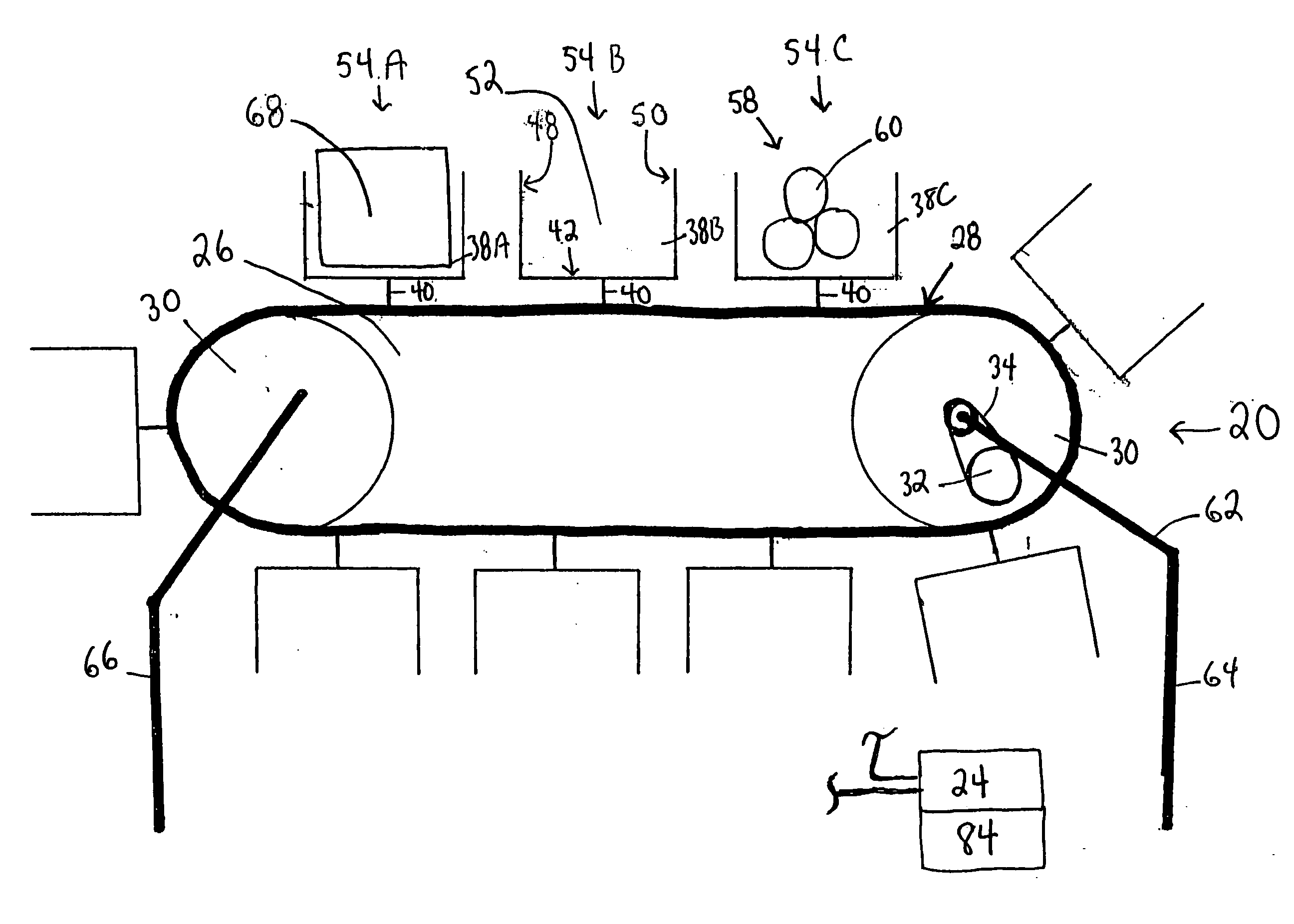

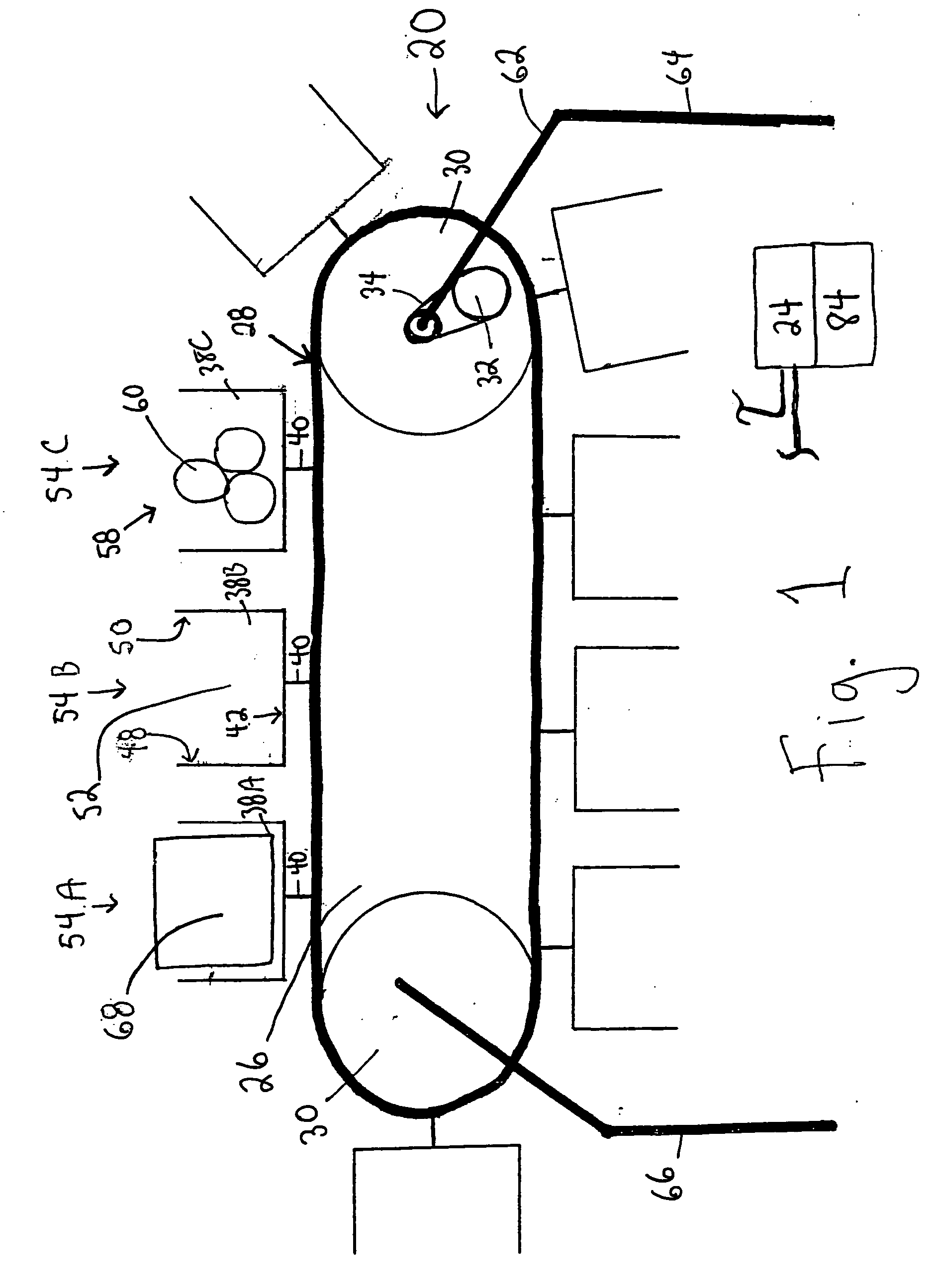

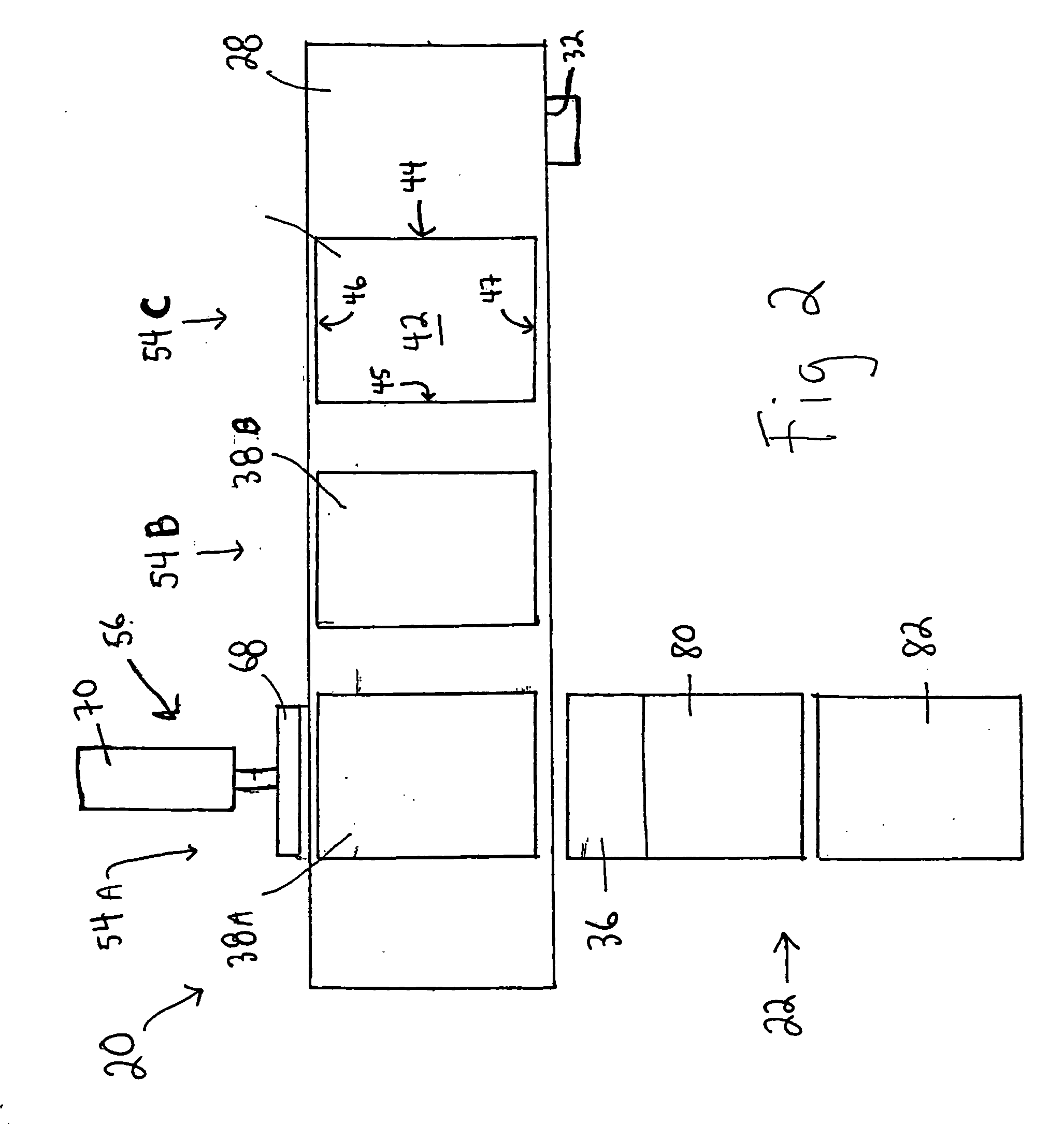

ActiveUS20060283155A1Packaging meatMeat packaging/handling/transportingEngineeringMechanical engineering

An apparatus for automatically delivering placed and oriented pieces of meat to a netter for wrapping and netting is described, in which the placement and orientation of the meat pieces remains unchanged from initial placement until final wrapping and netting. The apparatus is a conveyor having a series of compartments in which the meat is placed and oriented. The conveyor is situated below the level of the breech of the feed tube to the netter, so that a compartment carried on said conveyor will be precisely aligned with the opening to the feed tube. A ram pushes the meat pieces out of the compartment and into the feed tube, without changing the placement or orientation of the meat pieces relative to each other. The netter wraps the meat pieces in a collagen film and encases the wrapped meat in a net for further processing.

Owner:POLY CLIP SYST

Meat trussing system

InactiveUS20100239732A1Ready-for-oven doughsFruit and vegetables preservationEngineeringMaterial Perforation

A meat trussing system is provided which incorporates the use of an elastomeric net to receive and restrain meats and other food components, both unitary and combinations including independent meat and / or food elements. At least one flexible wrapper is provided into which the meat and / or food products are encased forming a cylindrical circumferential wrap having a low coefficient of friction with respect to the elastomeric net. The wrapper permits a relatively easy insertion of the wrapped food products into the elastomeric net. The wrapper is preferably provided with at least one perforation adapted to be circumferentially disposed near the midpoint of the food products within the elastomeric net. A method of use includes the deformation of the meat and / or food product. In order to sever the perforation which permits the relatively easy removal of the now separated wrapper portions from between the meat and / or food products and the elastomeric net.

Owner:JETNET CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com