Process for the continuous manufacture of sausages

a technology of manufacturing process and sausage, which is applied in the field of continuous manufacturing of sausage, can solve the problems of high cost of manufacturing technology, high amount of shaping requirements, and high cost, and achieve the effects of reducing the high cost of conventional methods, high cost, and high cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.

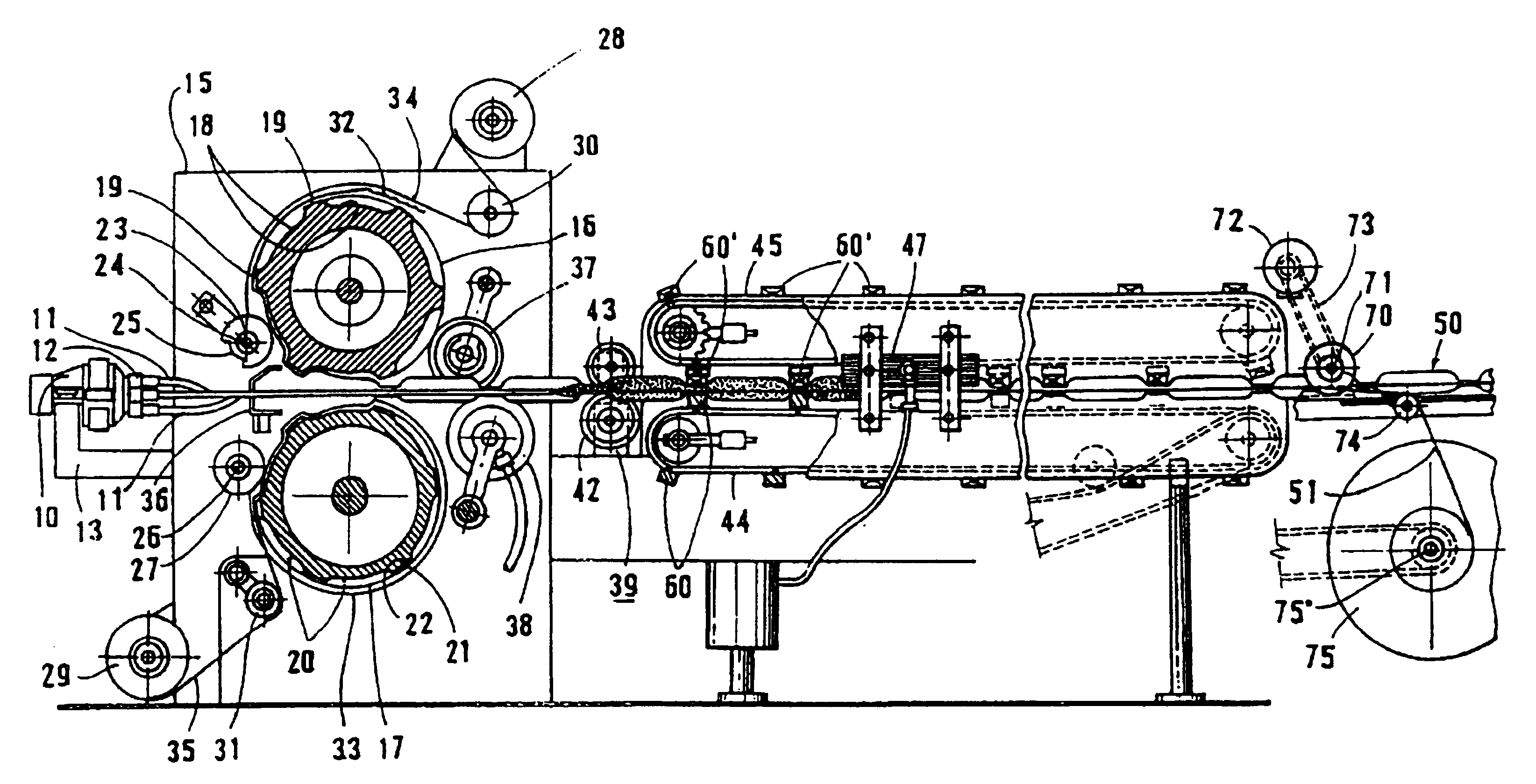

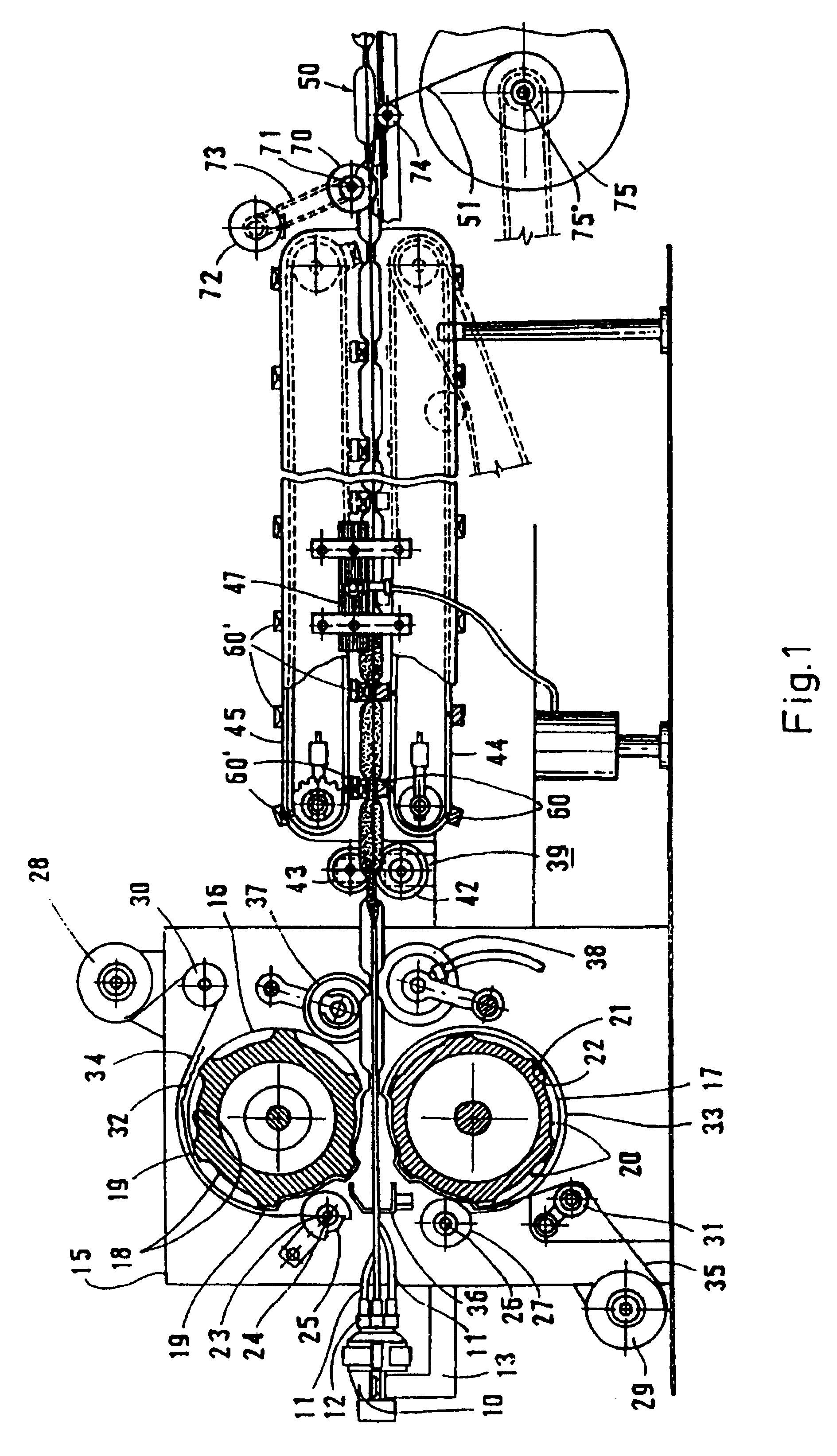

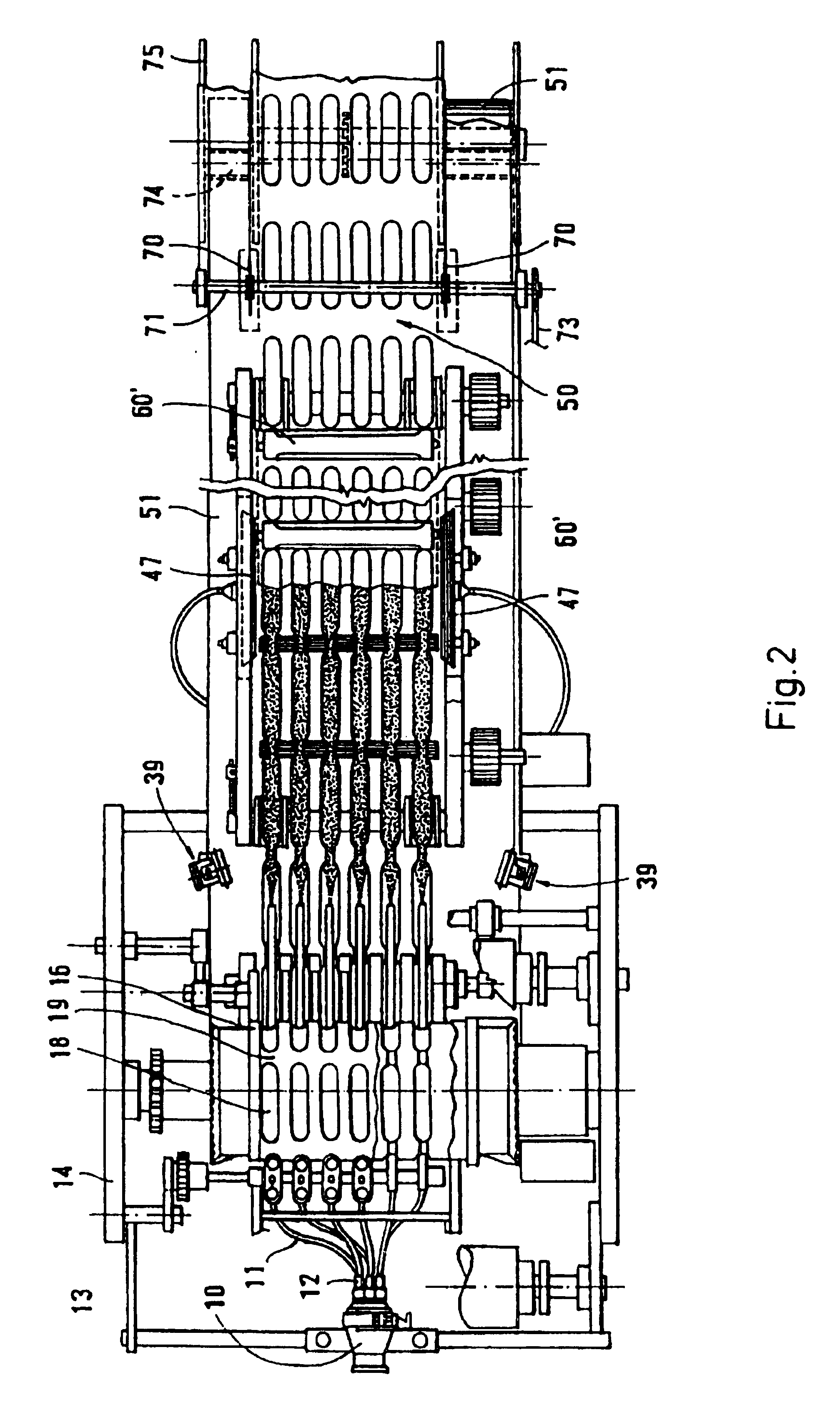

[0053]A substantially hollow head 10 wherein six nozzles 12 are provided, from which six tubes 11 project for distributing the product to be packed comprise the machine of the invention. Said head 10 is mounted on a cross member 13 rigidly connected to frame 14 of the machine, which comprises a pair of side brackets 15 between which a pair of shaping rollers, an upper roller 16 and a lower roller 17, are mounted. The upper shaping roller 16 at the cylindrical surface is provided with a plurality of channels 18, which being six, extend about six circumferences of the upper shaping roller 16 and are spaced by regions 19. Six channel 18 circumferences are provided on said upper shaper roller 16, matching with the distribution nozzles 12 in number.

[0054]Under the upper shaping roller 16 there is a second lower shaping roller 17, having the same features as the upper roller, i.e., having channels 20, which being six, extend about six circumferences of said roller 17 and are spaced by cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com