High-heat-strength hot-work die steel and manufacturing method thereof

A technology of hot work die steel and its manufacturing method, which is applied in the fields of alloy steel and its manufacture, high thermal strength hot work die steel and its manufacture, and can solve problems such as restricting the development of the die casting industry and insufficient high temperature performance, so as to improve the heat strength Insufficient, excellent hardenability, good processability and reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

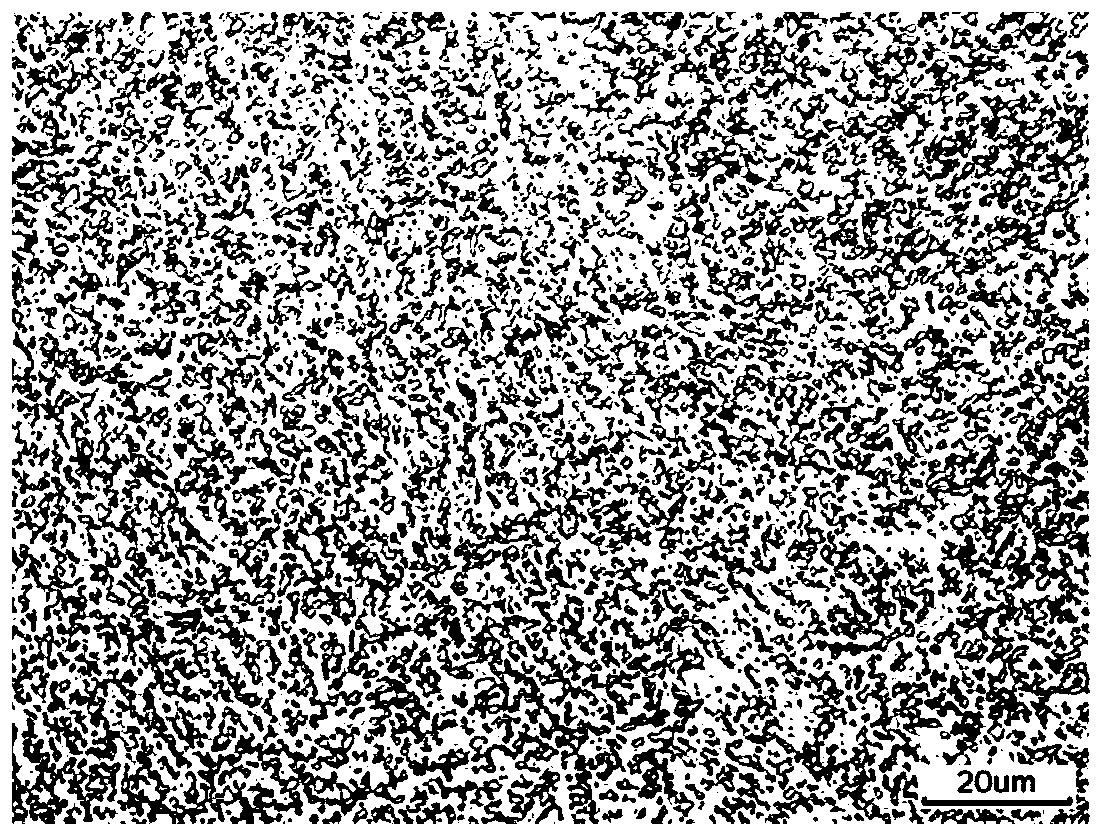

Embodiment 1

[0048] The steel of this embodiment has the following chemical composition in weight percent: carbon C: 0.44%, silicon Si: 0.30%, manganese Mn: 0.48%, chromium Cr: 4.52%, molybdenum Mo: 2.15%, vanadium V: 0.85%, Cobalt Co: 1.40%, Phosphorus P: 0.009%, Sulfur S: 0.002%, and the balance is iron Fe and unavoidable impurities.

[0049] In this embodiment, the manufacturing process and steps of hot work die steel are as follows:

[0050] Step 1. Electric furnace smelting: smelting in an electric furnace according to the above alloy element ratio, the melting temperature is greater than 1500°C, then vacuum degassing, then casting into electrode rods, and finally electroslag remelting into φ600mm electroslag ingots for future use.

[0051] Step 2. High-temperature diffusion annealing: heating the electroslag ingot to 1257° C. for 20 hours for high-temperature diffusion annealing, uniform structure, and elimination of alloy composition segregation and liquefied carbides.

[0052] Ste...

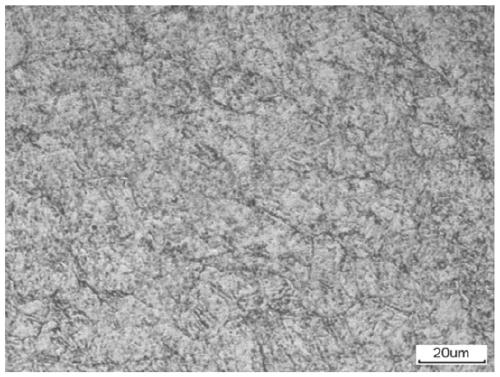

Embodiment 2

[0058] The steel of this embodiment has the following chemical composition in weight percent: carbon C: 0.41%, silicon Si: 0.10%, manganese Mn: 0.32%, chromium Cr: 4.95%, molybdenum Mo: 2.49%, vanadium V: 0.61%, Cobalt Co: 0.80%, Phosphorus P: 0.010%, Sulfur S: 0.002%, and the balance is iron Fe and unavoidable impurities.

[0059] The manufacturing method of steel is the same as embodiment 1.

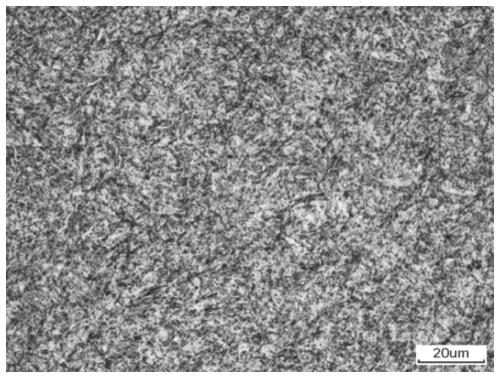

Embodiment 3

[0061] The steel of this embodiment has the following chemical composition in weight percent: carbon C: 0.42%, silicon Si: 0.20%, manganese Mn: 0.40%, chromium Cr: 4.85%, molybdenum Mo: 2.25%, vanadium V: 0.63%, Cobalt Co: 0.92%, phosphorus P: 0.010%, sulfur S: 0.002%, and the balance is iron Fe and unavoidable impurities.

[0062] The manufacturing method of steel is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quenching hardness | aaaaa | aaaaa |

| Tempering hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com