Patents

Literature

266results about How to "Improve heat strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloy powder for laser cladding and preparation method of cladding layer

InactiveCN106086580AHigh bonding strengthEasy to diluteMetallic material coating processesHigh entropy alloysHardness

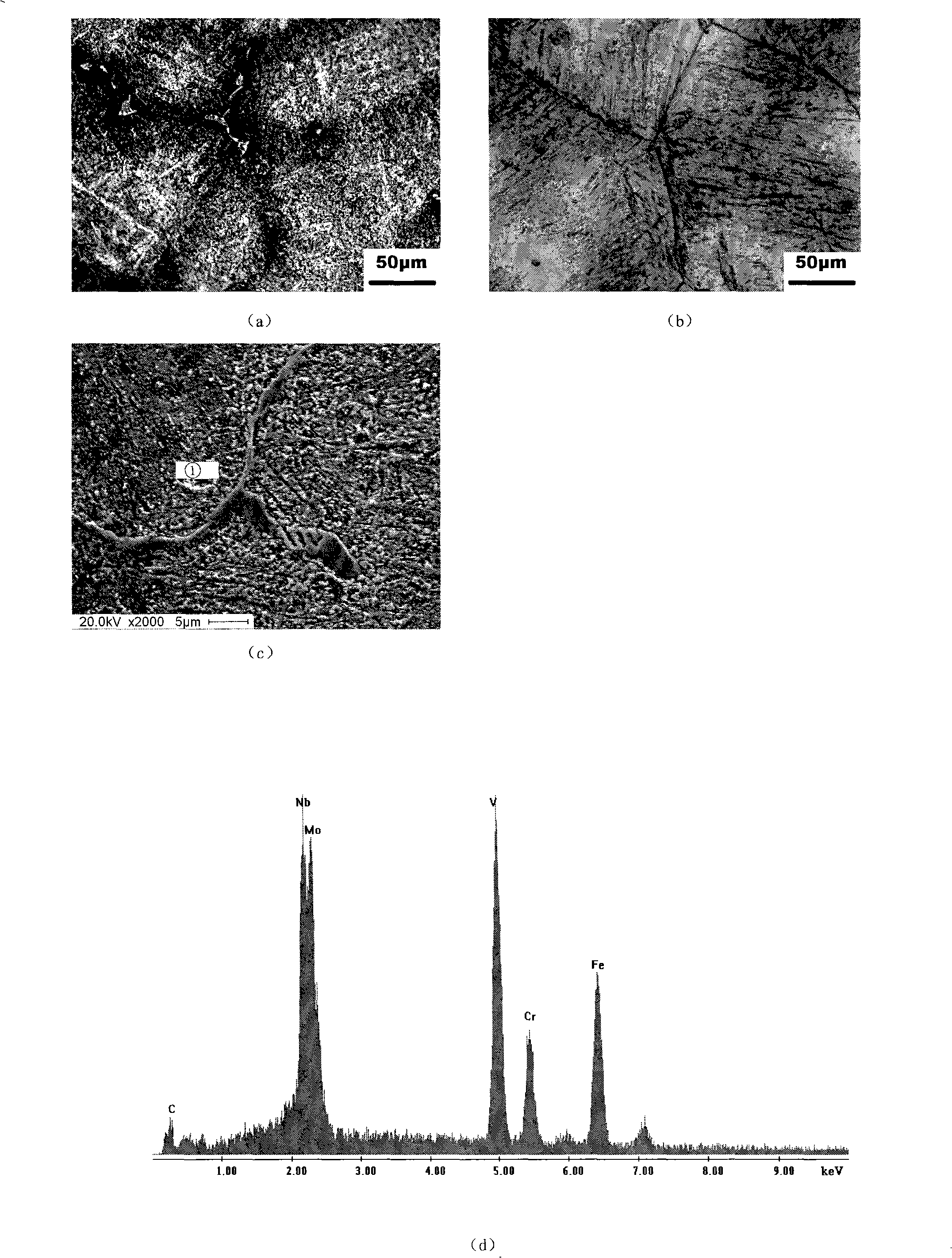

The invention discloses high-entropy alloy powder for laser cladding and a preparation method of a cladding layer. The high-entropy alloy powder comprises Ti, Zr, V, Nb, Ta and Mo. In addition, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo and W, high-entropy alloy powder which comprises Ti, Zr, V, Nb, Ta, Mo, W and Cr and the preparation method of the cladding layer of the high-entropy alloy powder for laser cladding are provided. The high-entropy alloy powder mainly comprises two characteristics, namely, the high-entropy effect and the cocktail effect, each kind of powder exerts respective advantages, and therefore the cladding layer with high hardness, high corrosion resistance, excellent tempering softening resisting performance and excellent structure performance is obtained. Metallurgical bonding is formed by an alloy layer and a matrix through laser cladding; the bonding strength of the cladding layer and the matrix is greatly improved, and the heating speed is high; metal of the cladding layer is not prone to being diluted by the matrix; little heat deformation is generated; and therefore the part rejection rate is low.

Owner:KUNMING UNIV OF SCI & TECH

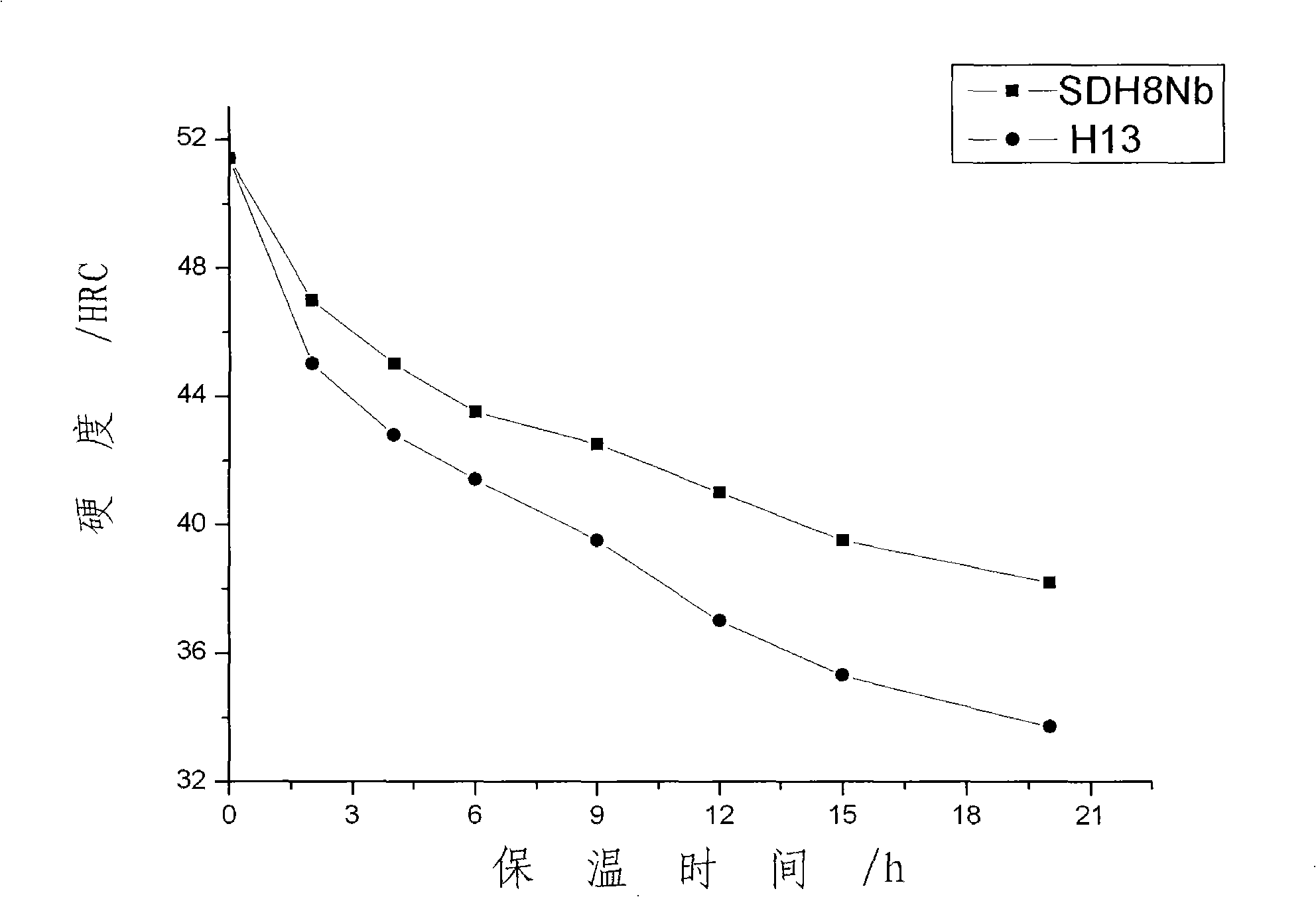

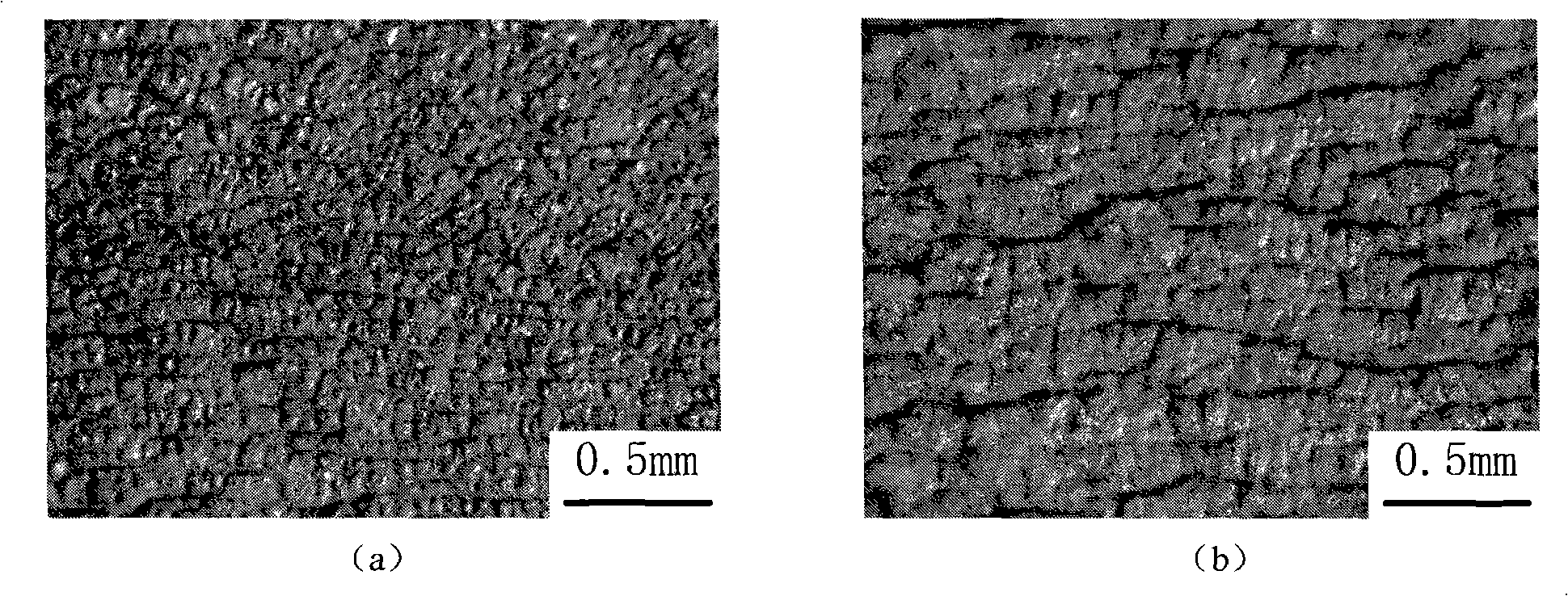

Niobium microalloyed high strength hot work die steel and preparation thereof

The invention relates to niobium microalloyed high-strength hot working die steel, belonging to the alloy steel manufacturing process technical field. The compositions by weight percentage of the steel are: 0.3 to 0.6 percent of C, 0.1 to 0.5 percent of Si, 0.1 to 0.5 percent of Mn, 4.0 to 6.5 percent of Cr, 1.0 to 3.5 percent of Mo, 0.4 to 1.4 percent of V, 0.02 to 0.10 percent of Nb, less than 0.03 percent of P, less than 0.03 percent of S, and the balance being Fe. The process for preparing the hot working die steel comprises the following steps of: batching, smelting, secondary refining and electroslag remelting; homogenizing the mixture for 5 to 10 hours at a temperature of between 1210 and 1300 DEG C, and forging, annealing, quenching and tempering the mixture; heating up the mixture to a temperature of between 1000 and 1100 DEG C for austenization, after performing 'step heating' at a temperature of 650 DEG C and at a temperature of 800 DEG C, then performing secondary tempering to the processed mixture, and finally acquiring the hot working die steel. The die steel has the advantages of good thermal resistance, good thermal stability and good thermal fatigue performance.

Owner:SHANGHAI UNIV

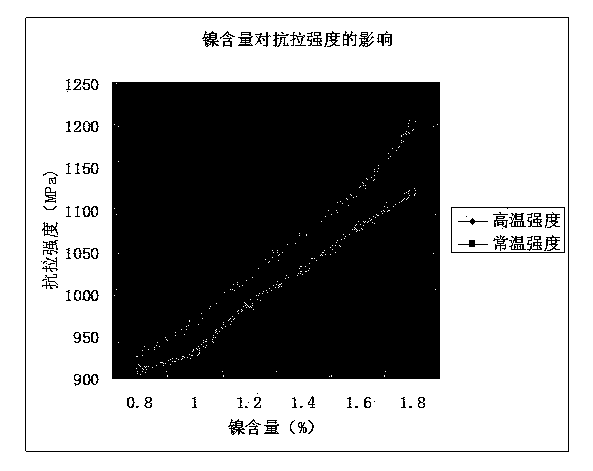

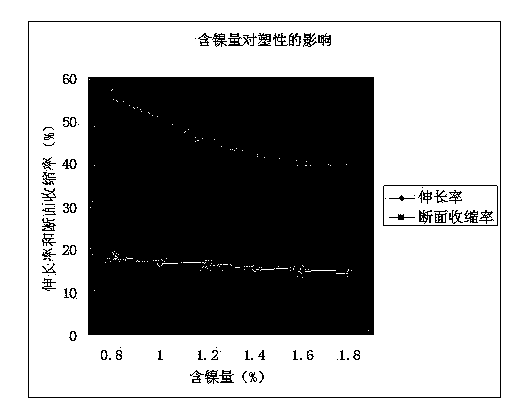

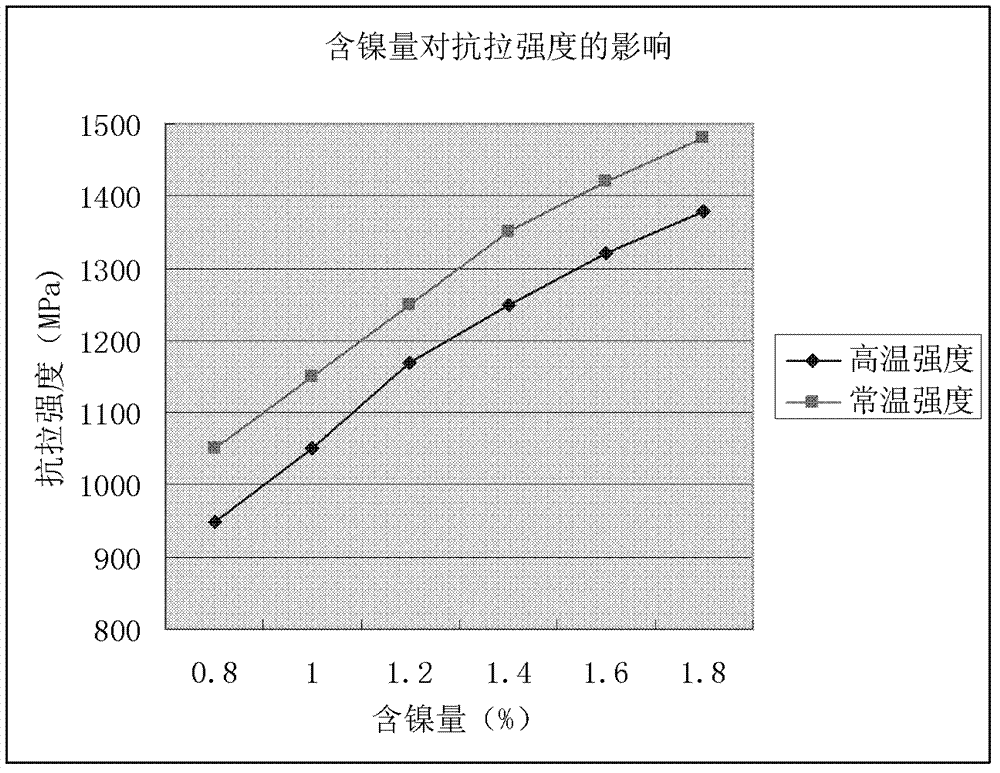

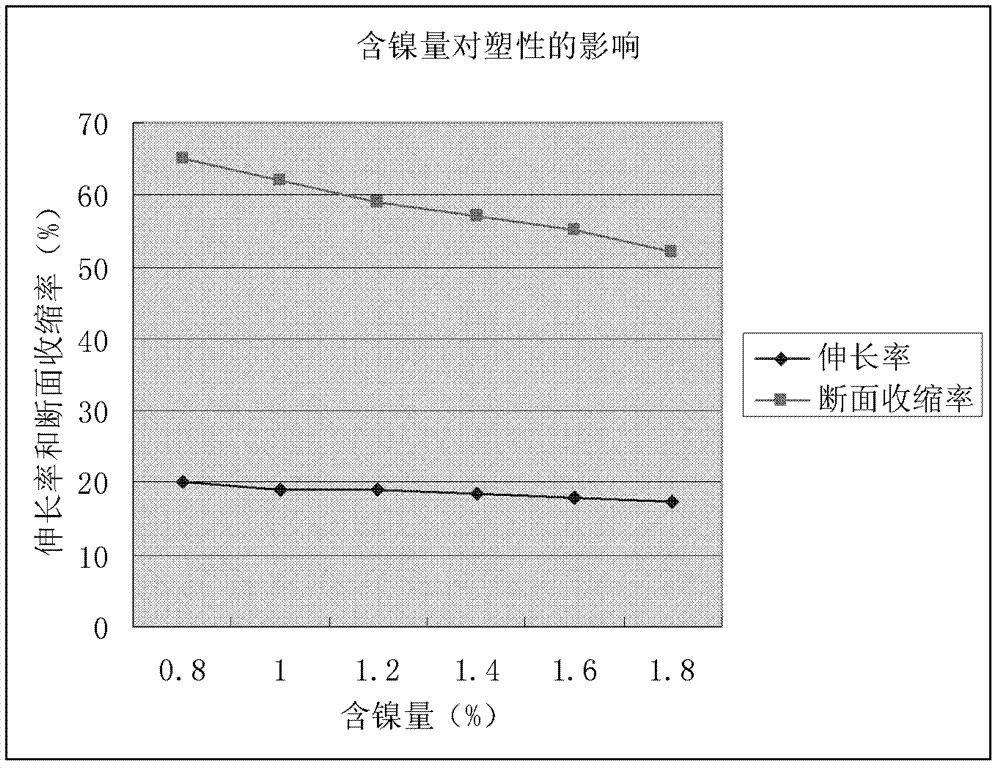

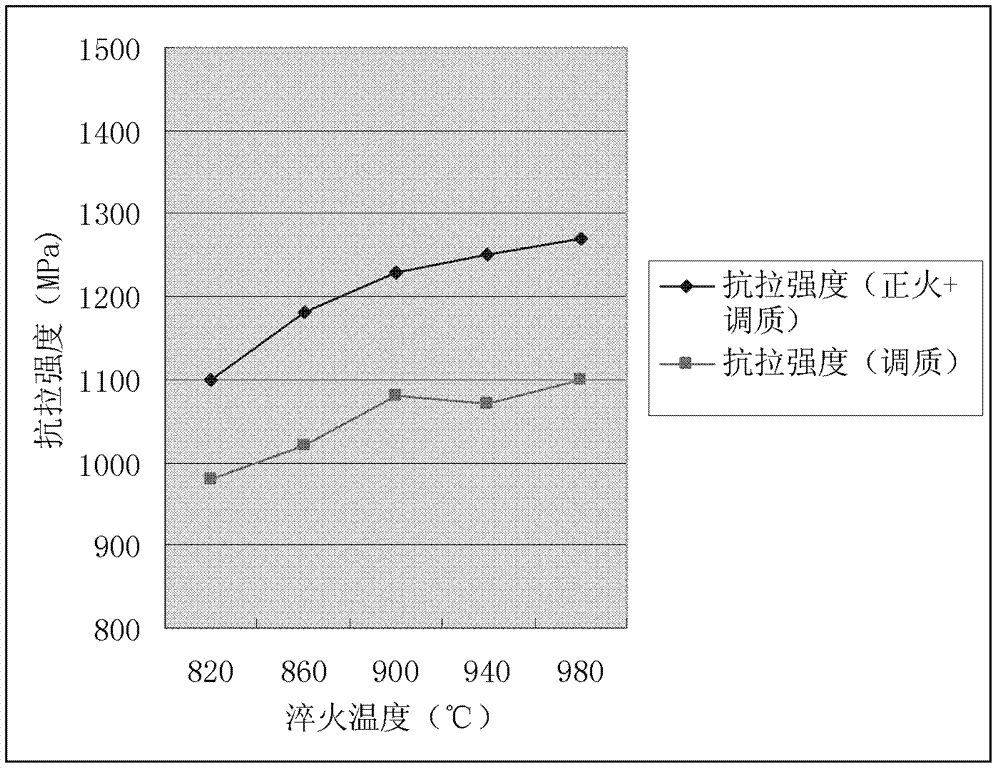

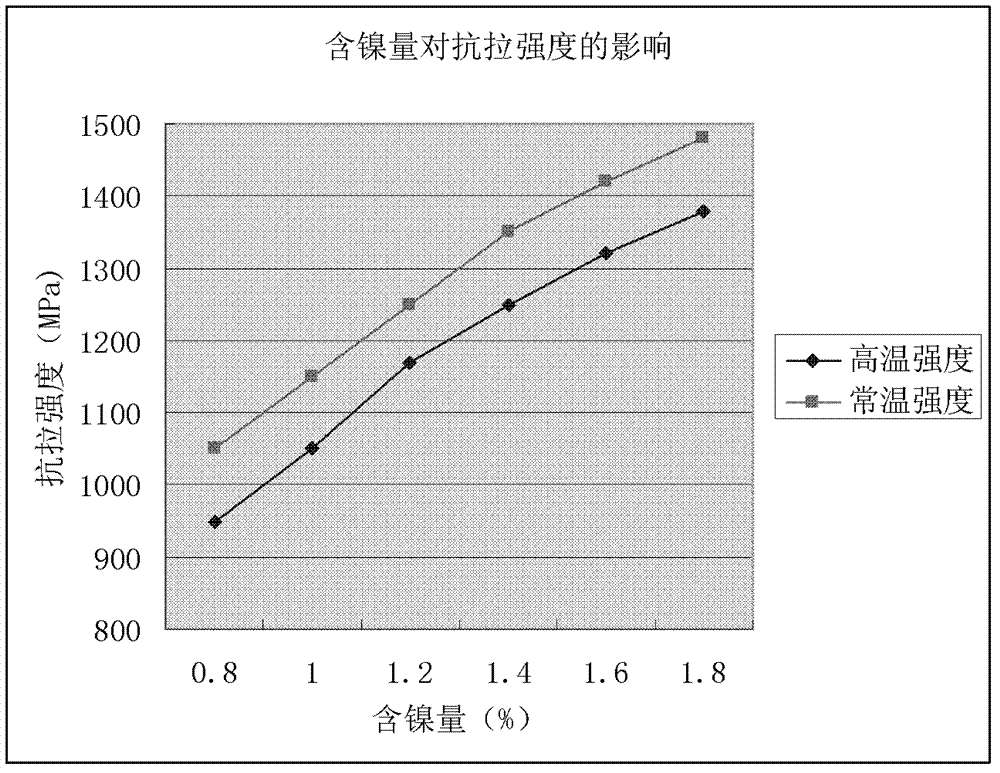

Alloy cast steel for high speed train brake disc, heat treatment method thereof and high speed train brake disc manufactured by the alloy cast steel

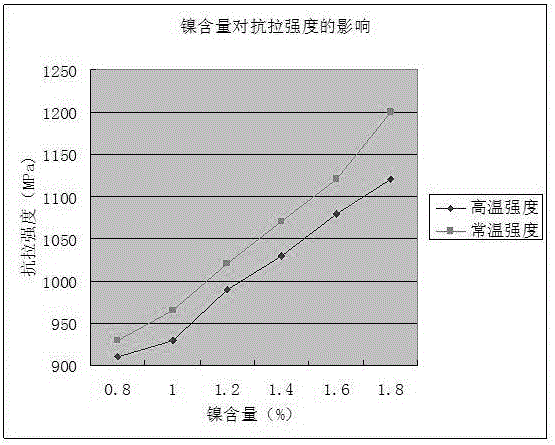

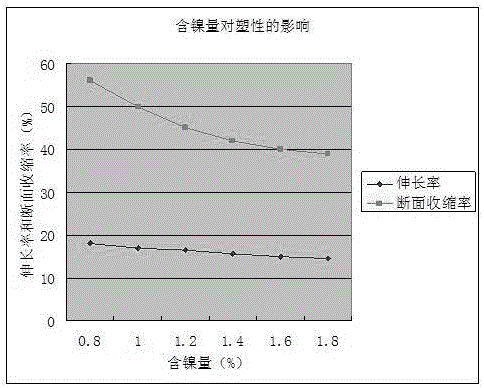

The invention discloses an alloy cast steel for a high speed train brake disc, a heat treatment method thereof and a high speed train brake disc manufactured by the alloy cast steel. The alloy cast steel is composed of the following components in percentage by weight: 0.18-0.26% of carbon, 0.16-0.50% of silicon, 0.55-1.40% of manganese, not larger than 0.03% of phosphorus, not larger than 0.03% of sulfur, 0.90-2.00% of chromium, 0.71-1.80% of nickel, 0.65-1.20% of molybdenum, 0.20-0.35% of vanadium, not larger than 0.30% of other components, smaller than 0.1% of tungsten and the balance of ferrum; and the heat treatment method comprises two steps of normalizing and tempering. The alloy cast steel disclosed by the invention has the beneficial effects that such alloy elements as manganese, nickel, chromium, molybdenum, vanadium, and the like, and such main components in the cast steel material as carbon, silicon and the like are reasonably mixed and are effectively thermally treated to refine the crystalline grain and improve the hardenability and heat resistant properties of the alloy cast steel material, and the normal temperature strength and the high temperature strength are greatly improved, so that the alloy cast steel material has excellent comprehensive mechanical properties. A brake disc manufactured by the alloy cast steel can meet the application requirements of high speed trains.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

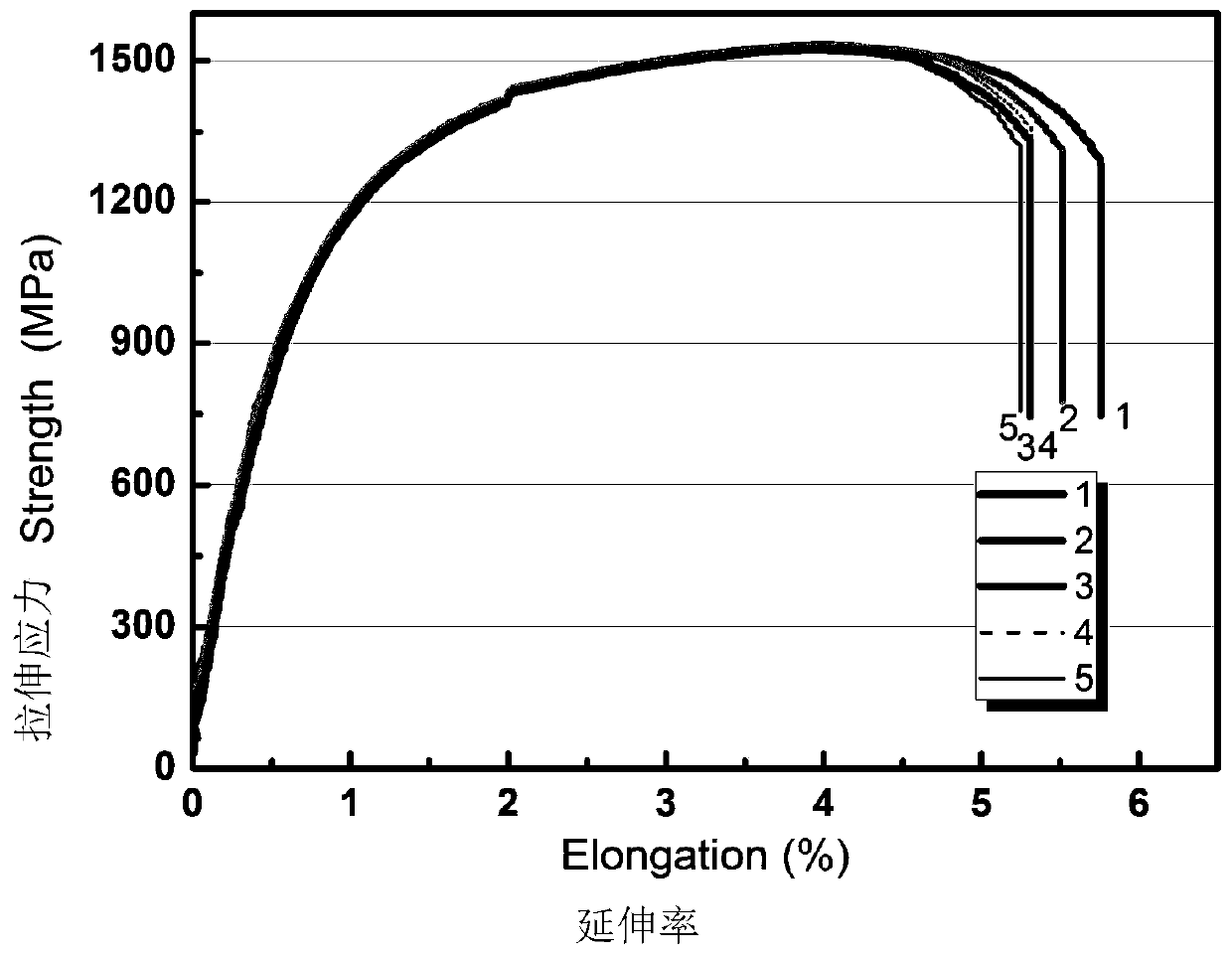

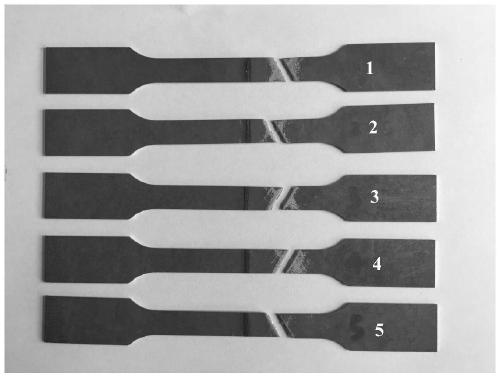

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heat-resisting steel flux-cored wire

InactiveCN101450425ASimple welding processImproved arc stabilityArc welding apparatusWelding/cutting media/materialsFerrochromeRutile

The invention discloses a flux cored wire for heat resistant steel. Flux cored powder of the flux cored wire is formed by mixing the following components by weight percentage: 21 to 23 percent of rutile, 1.5 to 2.5 percent of aedelforsite, 19 to 21 percent of silicon-manganese alloy, 8.5 to 10.5 percent of ferrous powder, 1.5 to 2.5 percent of nickel powder, 2.5 to 3.5 percent of cryolite, 7 to 9 percent of feldspar, 13 to 14 percent of ferrochrome, 6 to 7 percent of ferromolybdenum, 6 to 7 percent of mid-carbon ferromanganese, 2.5 to 4.5 percent of magnesite, 6 to 7.5 percent of quartz, 0.5 to 2 percent of fluorite, 1.5 to 3 percent of aluminum-magnesium alloy and 0.5 to 2 percent of ferrotitanium. During the welding, the flux cored wire not only uses CO2 to protect shielded welding, but also has the advantages of small splash, easy slag removal, stable electric arc burning, and spray transfer as a droplet transfer form.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

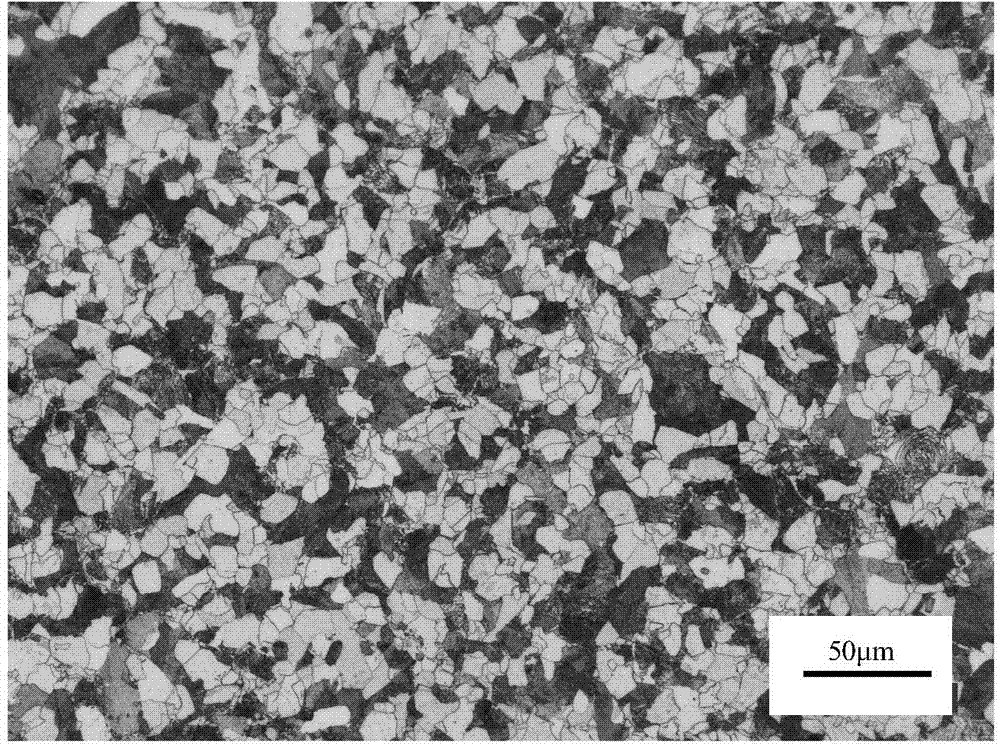

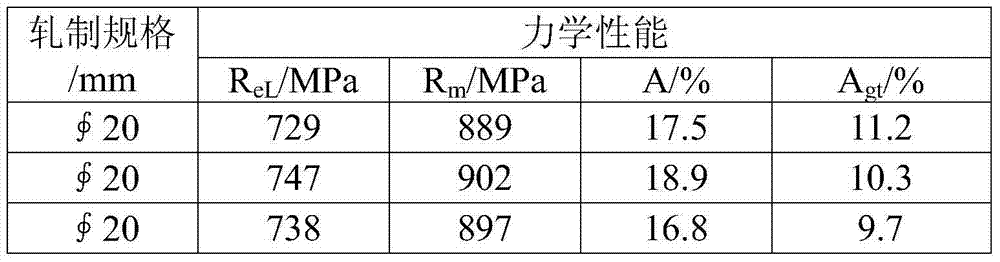

700MPa grade twisted steel and production method thereof

The invention provides a 700MPa grade twisted steel and a production method thereof. The twisted steel comprises the following basic components: 0.28-0.32% of C, 0.40-0.80% of Si, 1.20-1.60% of Mn, 0.18-0.24% of V, 0.02-0.06% of Nb, 0.02-0.10% of Ni, 200-300ppm of N, and the balance of Fe and inevitable impurities, and optionally comprises any one or more than two of 0.001-0.020% of Ti, 0.01-0.05% of Mo and 0.02%-0.10% of Cu. The twisted steel is produced by a process comprising smelting in a converter or an electric furnace, refining in an LF (Ladle Furnace), continuous casting and continuous rolling of billets and cooling by using a cooling bed. The twisted steel produced from the components by the method has the lower yield strength of greater than 700MPa and the percentage elongation after fracture of greater than 14%; the microscopic structure of the twisted steel comprises ferrites and pearlites.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

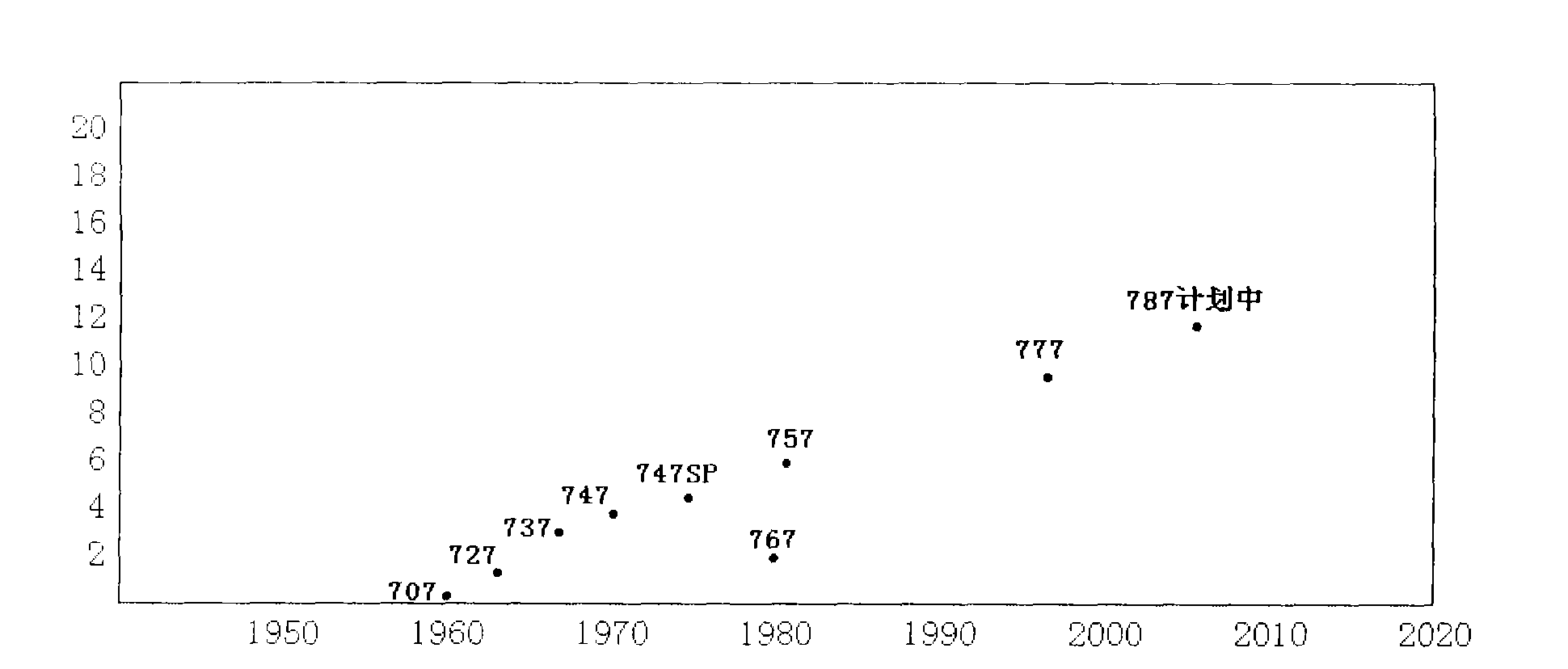

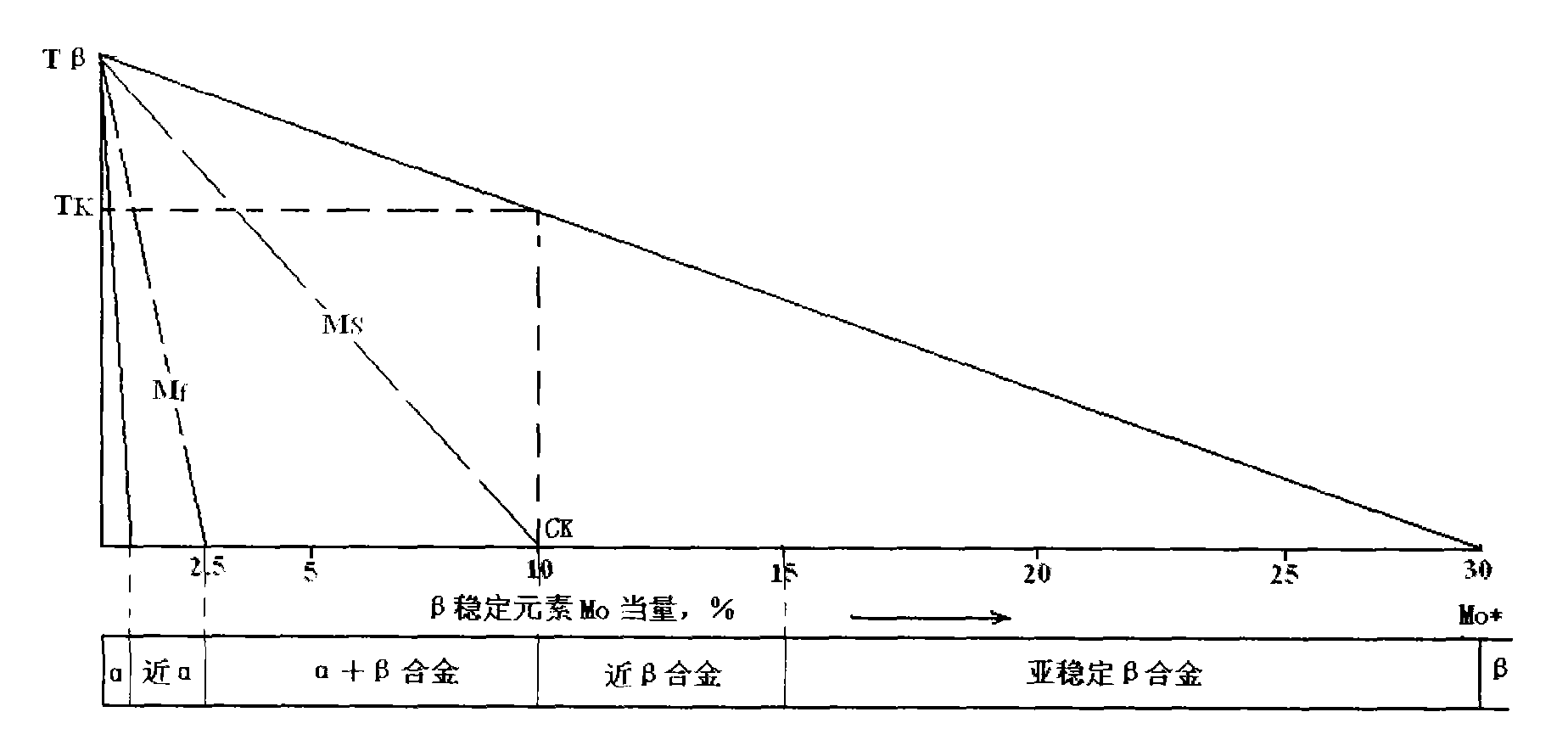

Ti alloy with high performance

The invention relates to a Ti alloy new material with high performance. The alloy has the chemical components by weight percent: 3-7 percent of Al, 1-6 percent of Mo, 0.5-6 percent of V, 1-4 percent of Sn, 1-4 percent of Zr, 0.5-3 percent of Cr, 0.5-3 percent of Nb, 0.01-0.3 percent of Si, and the balance of Ti. The high performance Ti alloy has favorable comprehensive performance, is in the leadin the worldwide and has the breakthrough points that the strength and the plasticity are kept at the highest level, the fracture toughness of the Ti alloy are greatly enhanced, the use performance ofTi alloy parts is improved, and the comprehensive performance of planes of the country is further improved.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND +1

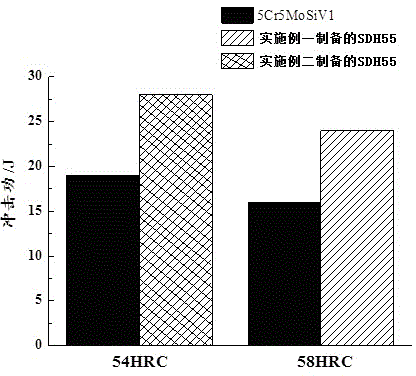

Alloy steel SDH55 for shield machine tools and production method thereof

The invention discloses alloy steel SDH55 for shield machine tools and a production method thereof. The alloy steel comprises, by weight, 0.4% to 0.55% of C, 0.10% to 0.40% of Si, 0.10% to 0.30% of Mn, 5.10% to 6.50% of Cr, 2.20% to 3.00% of Mo, 0.45% to 0.85% of V, the balance of Fe and unavoidable impurity elements, including not greater than 0.005% of S and not greater than 0.010% of P. The alloy steel high in wear resistance and high in toughness is made by means of matching, smelting, casting and electroslag remelting, by thermal feeding for high-temperature homogenous treatment after demolding, and by means of multidirectional forging, soft annealing and ultra-fining treatment; the problem that the current tools for shield machines are of short lives due to wear and failure and edges cracking caused by low toughness is solved; the alloy steel is of great significance to the development of the industry of special steels of shield machine tools.

Owner:SHANGHAI SHIJIN NEW MATERIAL TECH

High-performance hot stamping die steel and manufacturing process thereof

The invention relates to high-performance hot stamping die steel and a manufacturing process thereof. The high-performance hot stamping die steel comprises the following components of, in percentage by mass, 0.66% - 0.80% of C, 0.80% - 1.20% of Si, 0.20% - 0.50% of Mn, 5.00% - 6.50% of Cr, 1.50% - 2.00% of Mo, 0.40% - 0.80% of V, less than 0.015% of P, less than 0.015% of S and the balance Fe. Themanufacturing process of the die steel comprises the following steps of carrying out burdening, smelting, casting, electroslag remelting; carrying out high-temperature diffusion thermal treatment, multi-direction forging and hot machining and cooling control after forging; then carrying out secondary carbide refining thermal treatment and isothermal annealing treatment; and finally carrying out quenching and tempering thermal treatment. The high-performance hot stamping die steel and the manufacturing process thereof has the advantages that the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of the hot-work die steel are superior to the hardenability, the thermal stability, the wear resistance and the thermal fatigue performance of H13 steel,and the hot-work die steel can be machined into a large-scale hot stamping die with the single-piece weight reaching 5 tons or above, and the usability is good.

Owner:RUGAO HONGMAO HEAVY FORGING

Preparation process for high-strength high-conductivity micro copper wire

The invention discloses a preparation process for a high-strength high-conductivity micro copper wire. The preparation process comprises the following steps: S1, adding electrolytic copper into a smelting furnace, preserving heat and melting the electrolytic copper completely to obtain molten copper, introducing an inert gas, adding a composite refining agent, standing and slagging; S2, detecting that the molten copper comprises the following components in percentage by weight: 0.45 to 0.55 percent of Ti, 0.25 to 0.35 percent of Zr, 0.07 to 0.09 percent of Te, 0.07 to 0.09 percent of La, 0.03 to 0.05 percent of Y, 0.15 to 0.25 percent of Sn, less than or equal to 0.05 percent of Mg, and the balance of Cu; S3, enabling a crystallizer of a continuous casting machine to extend into the molten copper, and drawing upwards through a drawing roller mechanism to form an oxygen-free copper rod; S4, extruding the oxygen-free copper rod continuously and drawing repeatedly to obtain the high-strength high-conductivity micro copper wire. According to the copper wire which is prepared by the preparation process, the electric conductivity reaches over 95 percent IACS, and moreover, the tensile strength is also over 480 MPa.

Owner:安徽晋源铜业有限公司

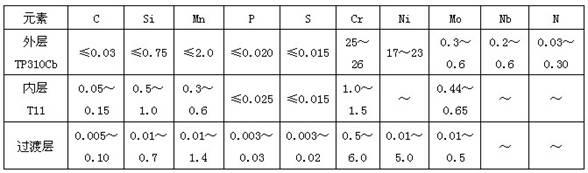

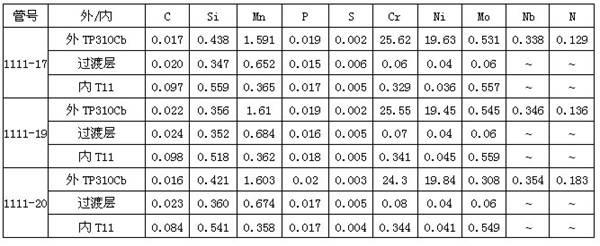

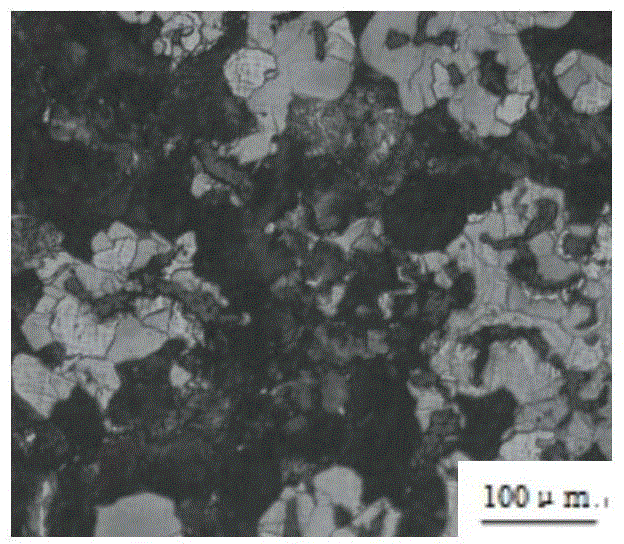

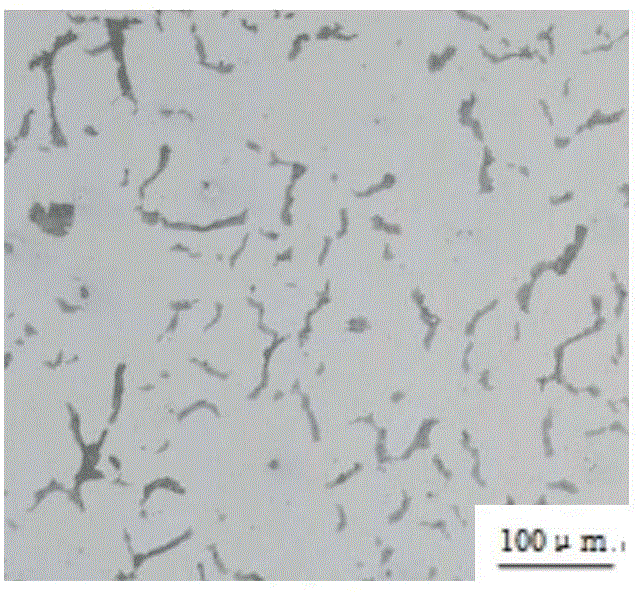

Centrifugally cast TP310Cb/T11 bimetal composite tube blank and method for producing same

InactiveCN102581250ABrittleAvoid ingredients that are out of toleranceStress concentrationHeat resistance

The invention discloses a centrifugally cast TP310Cb / T11 bimetal composite tube blank and a method for producing the same, which belong to the field of casting of tube blanks. The centrifugally cast TP301Cb / T11 bimetal composite tube blank comprises a tube blank inner layer, a tube blank outer layer and a tube blank transitional layer. The method includes controlling components of the inner layer, the outer layer and the transitional layer by means of controlling selection of a tube blank raw material at first; pouring the outer layer; then pouring the transitional layer; and finally pouring the inner layer. The transitional layer is fused with the outer layer, the inner layer is fused with the transitional layer, difference between the components of the outer layer and the components of the outer layer are relieved by the aid of the transitional layer, the purpose of completely fusing is achieved simultaneously, accordingly, interface stress between the inner layer and the outer layer is greatly relieved, stress concentration of interfaces of the inner layer and the outer layer is avoided, and the service life of the centrifugally cast TP310Cb / T11 bimetal composite tube blank is greatly prolonged. Simultaneously, conduction heat resistance of the inner layer and the outer layer is reduced by the aid of metallurgical fusion of the inner layer and the outer layer, and accordingly heat conduction efficiency of a bimetal tube is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

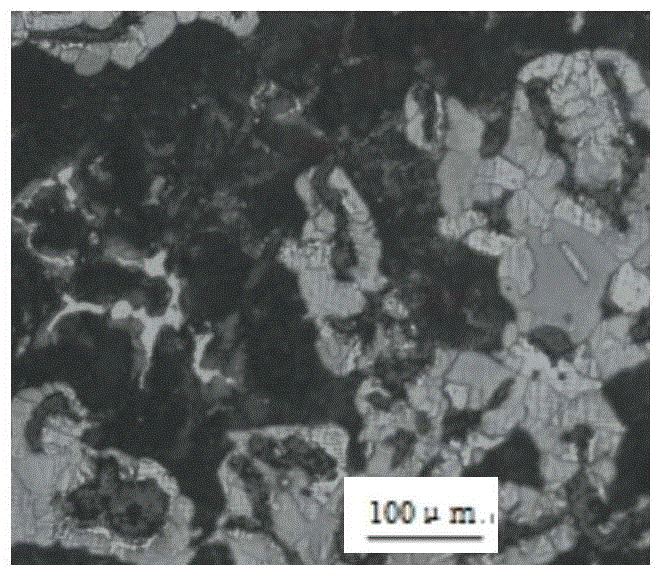

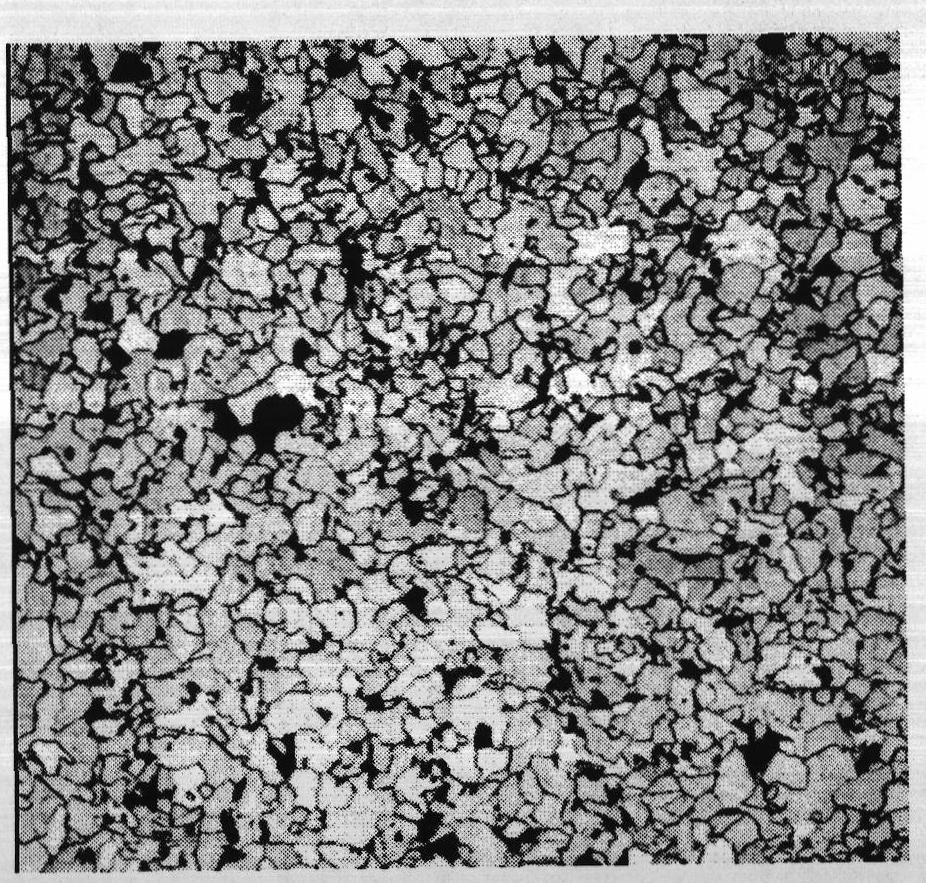

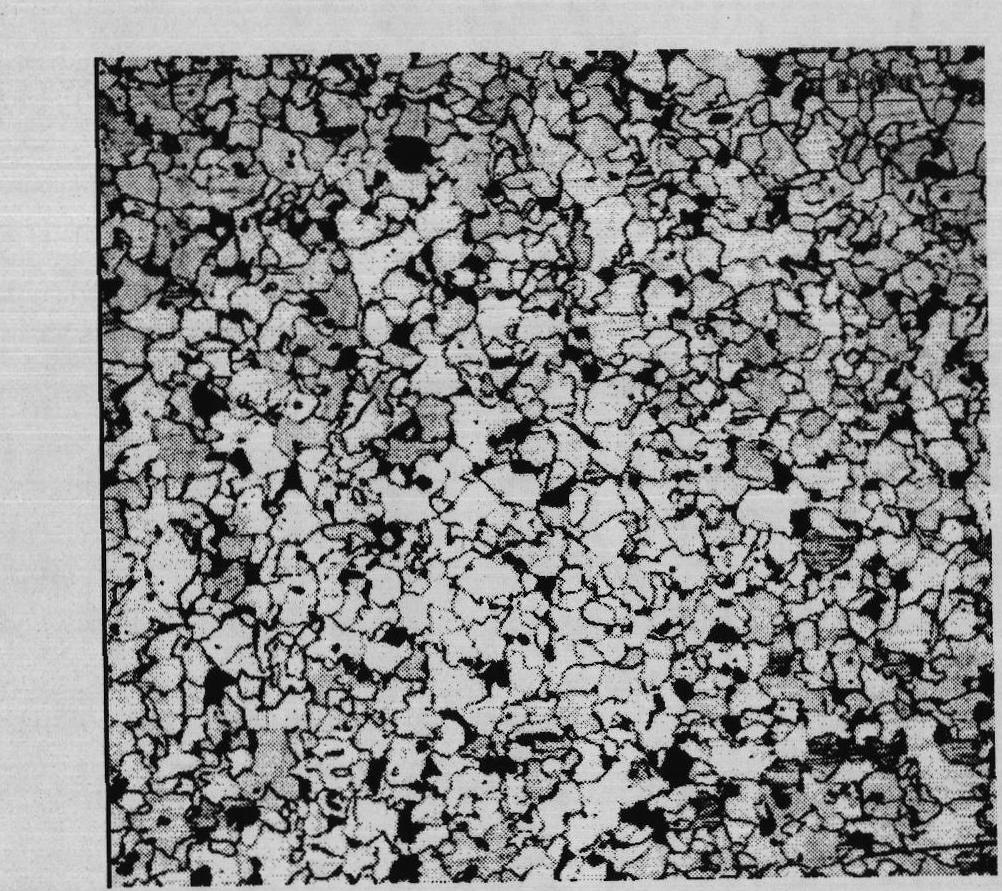

Alloy vermicular graphite cast iron for railway vehicle brake disc and smelting method of alloy vermicular graphite cast iron

The invention relates to alloy vermicular graphite cast iron for a railway vehicle brake disc and a smelting method of the alloy vermicular graphite cast iron. The vermicular graphite cast iron is composed of, by mass, 3.3%-3.5% of C, 2.3%-2.5% of Si, 0.4%-0.7% of Mn, 0.6%-1.0% of Cu, 0.2%-0.6% of Mo, 0.6%-1.0% of Ni, 0-0.07% of P, 0-0.02% of S and the balance Fe. The vermicular graphite rate of the vermicular graphite cast iron brake disc is higher than or equal to 75% and the pearlite content is 50% to 60%. According to the alloy vermicular graphite cast iron for the railway vehicle brake disc and the smelting method of the alloy vermicular graphite cast iron, the stress threshold value when a disc body is cracked and extended due to thermal stress concentration can be increased, and the mechanical property of the railway vehicle brake disc is improved.

Owner:CHANGZHOU LANGRUI CASTING +1

Alloy forged steel and its heat treatment method and use

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

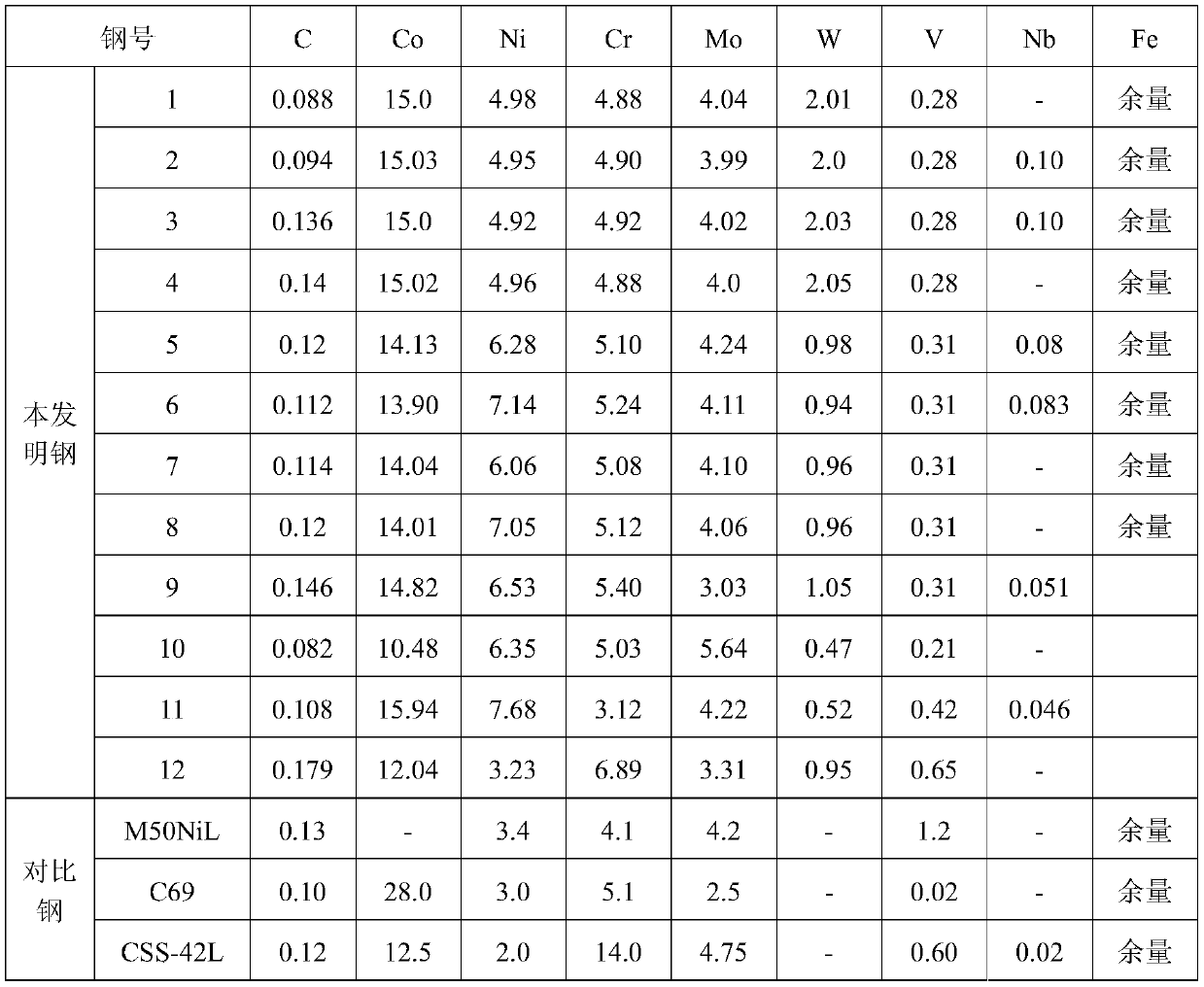

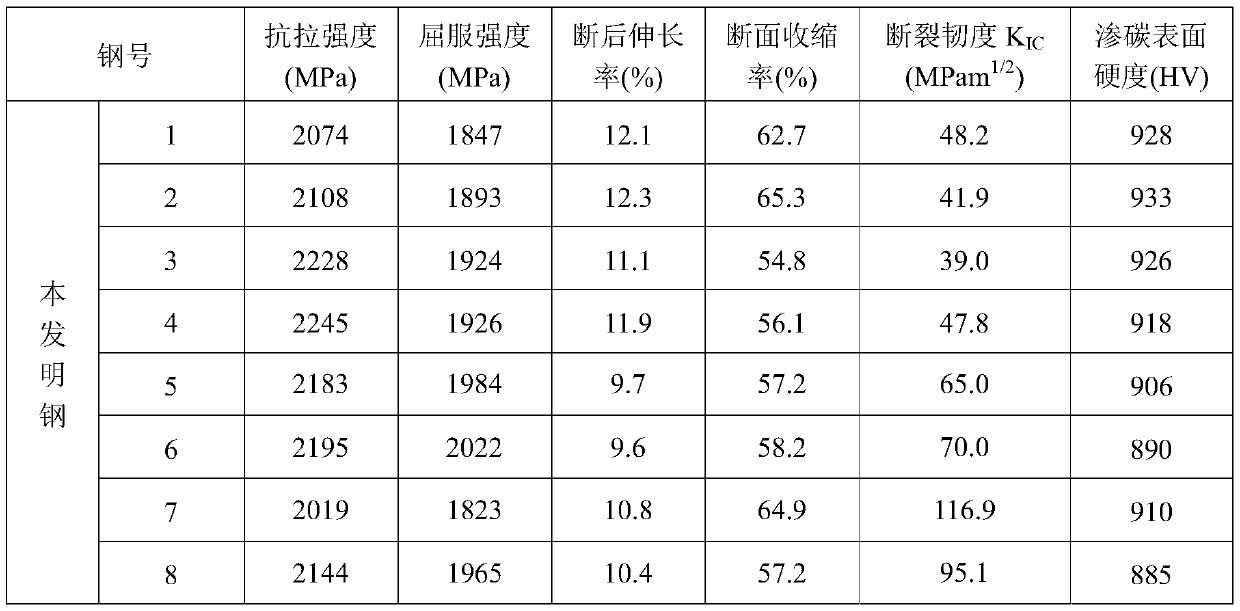

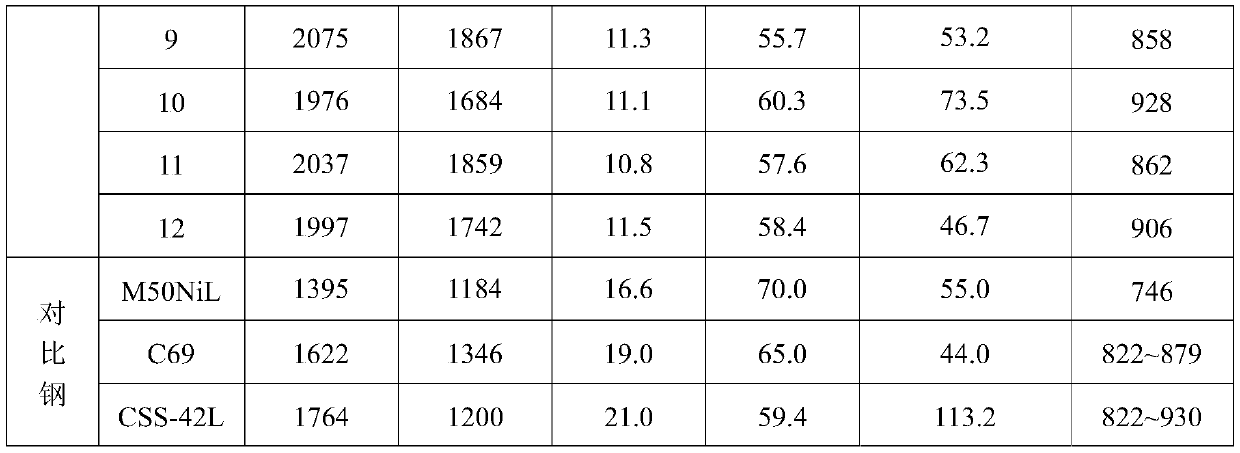

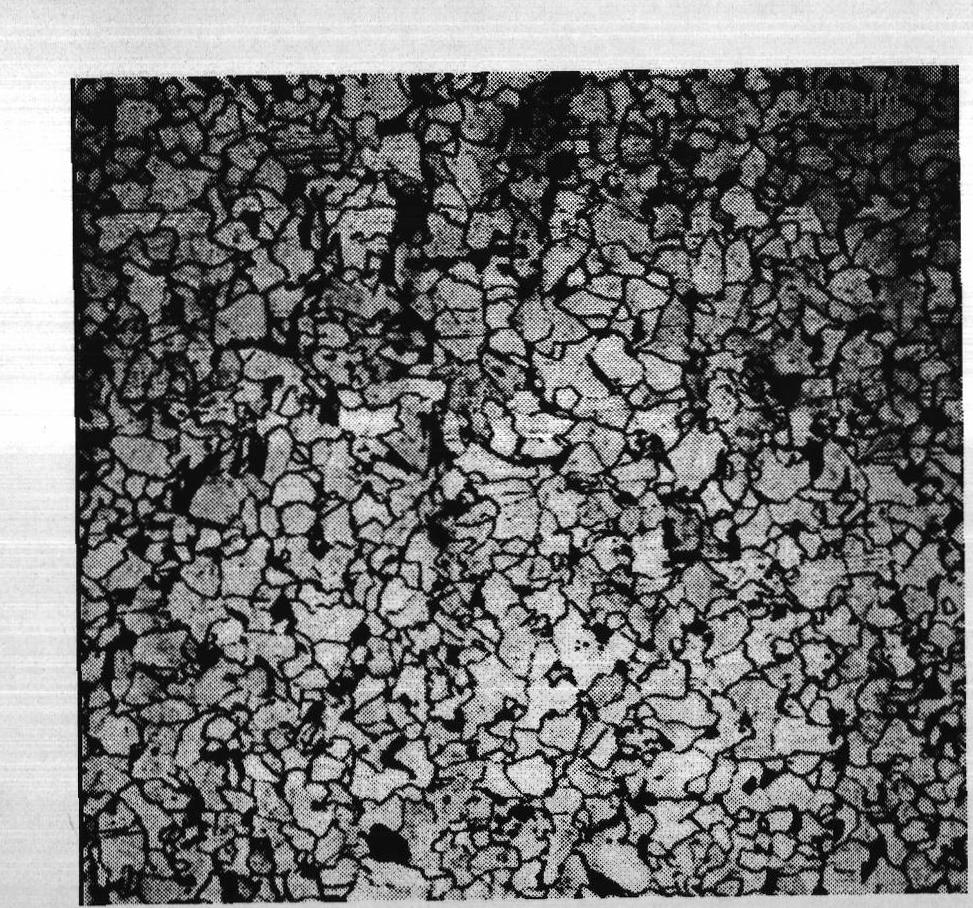

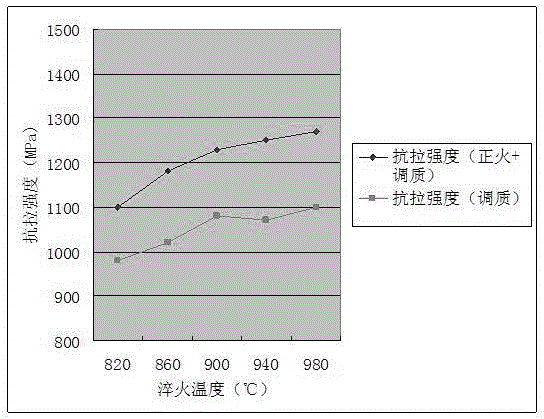

Ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and preparation method thereof

ActiveCN110423955AHigh tensile strengthImprove plasticitySolid state diffusion coatingCarburizingVacuum arc remelting

The invention belongs to the technical field of materials, and relates to an ultra-high-strength heat-resistant gear bearing steel with ultra-hardened surface layer and a preparation method thereof. The chemical composition of the steel comprises the following chemical components of, in percentage by mass, 0.08-0.18% of C, 10.0-16.0% of Co, 3.0-8.0% of Ni, 3.0-7.0% of Cr, 3.0-6.0% of Mo, 0.5-2.0%of W, 0.2-1.0% of V, 0-0.1% of Nb, and the balance Fe and impurity elements. According to the method, vacuum induction melting, vacuum induction melting and vacuum arc remelting or vacuum induction melting and electroslag remelting are adopted for smelting. Steel ingots are diffusion annealed and forged into steel products. Steel samples are subjected to preliminary heat treatment, carburization and final heat treatment, the tensile strength of the steel is not less than 1900 MP a, the yield strength is not less than 1600 MP a, and the carburized surface hardness is not less than 850 HV (equivalent to 66 HRC). The method has the advantages that compared with the prior art, the method has higher tensile strength, yield strength and relatively good plasticity, toughness and heat resistance,has excellent surface carburization super-hardening performance and fatigue performance, and achieves good matching of the core super-toughening and surface super-hardening.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Ultra-thick high temperature-resistant steel for pressure vessel and preparation method thereof

ActiveCN102094150AProportion design is reasonableIncrease productivityTemperature control deviceMetal rolling arrangementsChemical compositionMetallurgy

The invention relates to an ultra-thick high temperature-resistant steel for a pressure vessel and a preparation method thereof. After smelting and refining, the steel is subjected to continuous casting, hot rolling, normalizing and tempering. The steel comprises the following controlled chemical components in percentage by mass: 0.08-0.15% of C, 0.15-0.40% of Si, 0.40-0.70% of Mn, 0.90-1.20% of Cr, 0.15-0.30% of V, 0.25-0.35% of Mo, at most 0.025% of P, at most 0.010% of S and the balance of Fe and inevitable inclusions. The preparation method provided by the invention comprises the steps of smelting, heating, rough rolling, finish rolling, normalizing and tempering. The invention has the characteristics of appropriate design and proportion of the chemical components, simple manufacturing process, large thickness dimension (80mm), good heat resistance, stable product performance and the like.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Intermediate-carbon high-speed cutting saw blade matrix steel and production method thereof

The invention discloses an intermediate-carbon high-speed cutting saw blade matrix steel and a production method thereof. The steel comprises the following components in percentage by weight: 0.20-0.40% of C, 0.10-0.30% of Si, 0.45-0.63% of Mn, not more than 0.010% of P, not more than 0.005% of S, 0.008-0.020% of Ti, 0.80-1.20% of Cr, not more than 0.005% of N, 0.020-0.050% of Al, 0.10-0.20% of Ni, 0.030-0.050% of V and the balance of Fe and inevitable impurities, wherein Als / N is not less than 30%, Mn +Cr is 1.45-1.85. The production method comprises the following steps of: desulfurizing molten iron, smelting in a converter, carrying out vacuum treatment, casting continuously, hot-rolling continuously, cooling, coiling, leveling, quenching and tempering. Facts prove that the steel has pure steel quality, strong toughness, high wearing resistance and low cost at the same time. The production method of the steel is simple in process and stable in product property.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

ActiveCN111230301APromote homogenizationImprove hardenabilityArc welding apparatusWelding/cutting media/materialsHot stampingMetal alloy

Provided is a method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings. A steel plate to be welded comprises a base body and at least one coating on the surface of the base body. Each coating comprises an intermetallic compound alloy layer in contact with the base body and a metal alloy layer on the intermetallic compound alloy layer. Thecoatings do not need to be removed or thinned before welding or in the welding process; by presetting the welding gap and using a carbon manganese steel welding wire, a welding process and protectivegas for welding, after a welding component is subjected to hot stamping treatment, the tensile strength of a weld joint is greater than the tensile strength of a base material, the extension rate of the weld joint is greater than 4%, and the application requirement of the equal-strength welding components in the hot stamping field is met.

Owner:BAOSHAN IRON & STEEL CO LTD

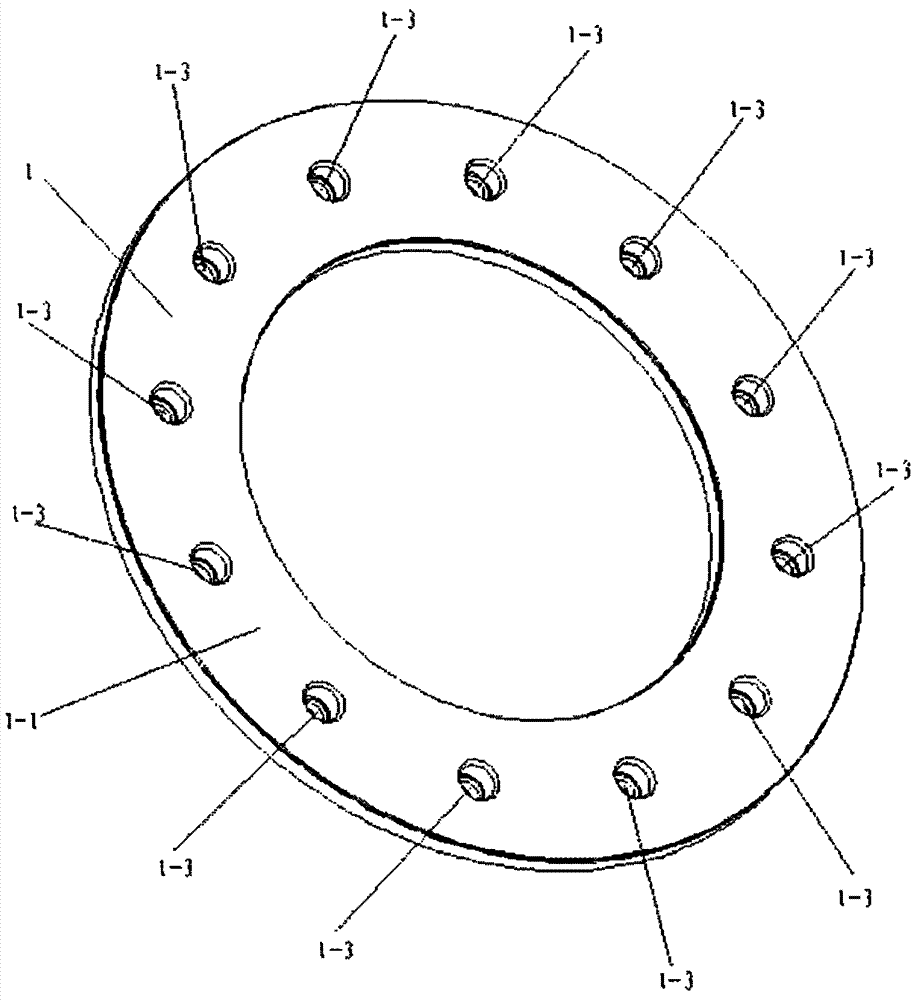

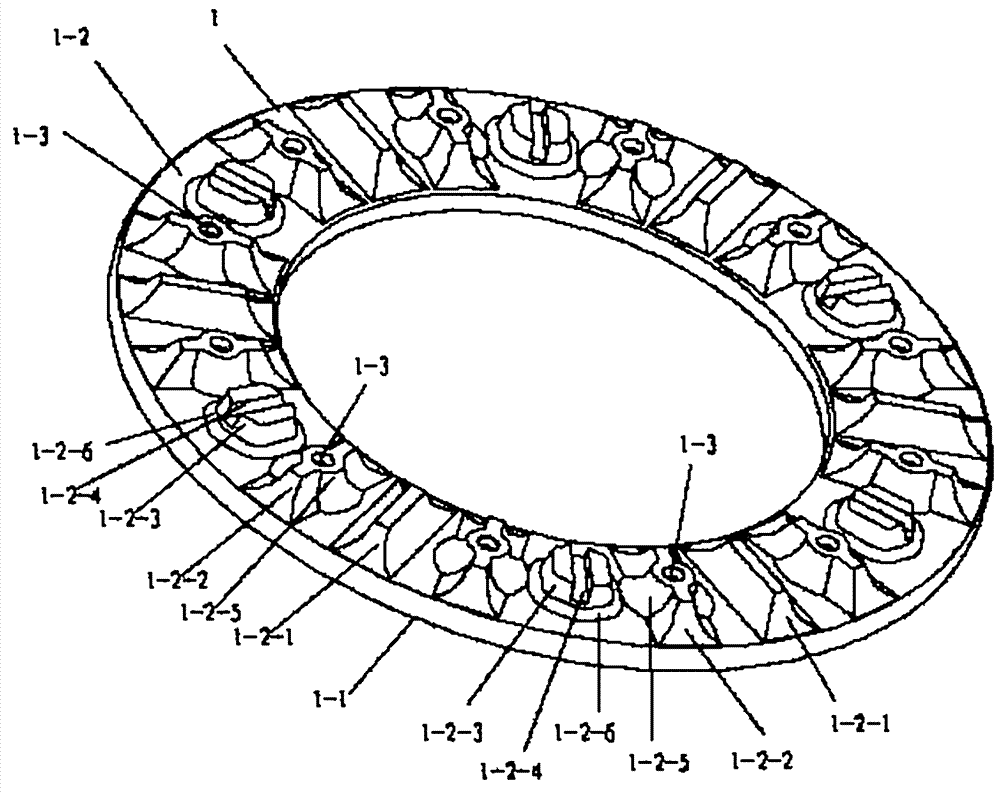

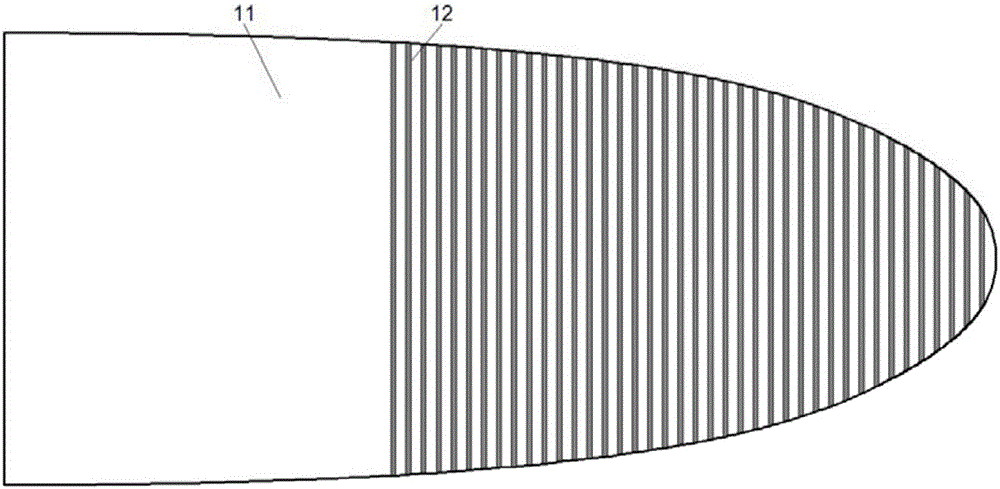

Brake disc of high-speed train

ActiveCN102900793ASpeed up circulationImprove cooling effectBraking discsEngineeringMechanical engineering

The invention discloses a brake disc of a high-speed train. The brake disc is provided with a disc body with a center hole. The disc body is provided with a friction surface and an inner side surface positioned on the back of the friction surface, a plurality of mounting holes are uniformly distributed on the disc body, a plurality of first radial platy radiating ribs, a plurality of second radial platy radiating ribs and a plurality of bosses are integrally forged on the inner side surface of the disc body, side surfaces of the first radial platy radiating ribs, side surfaces of the second radial platy radiating ribs and side surfaces of the bosses have draft angles, the mounting holes penetrate through the second radial platy radiating ribs, and radial keyways are arranged on the bosses. The brake disc is good in radiating effect, simple in forging forming and high in strength.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

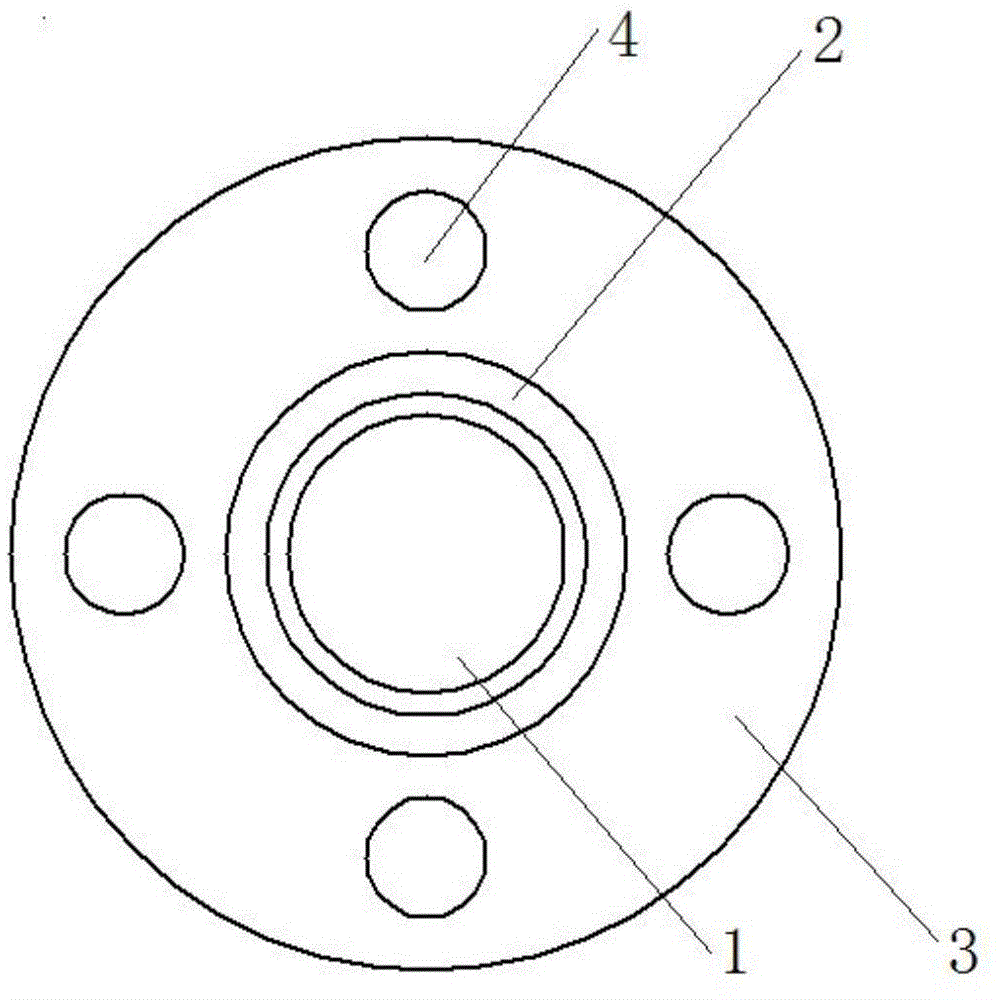

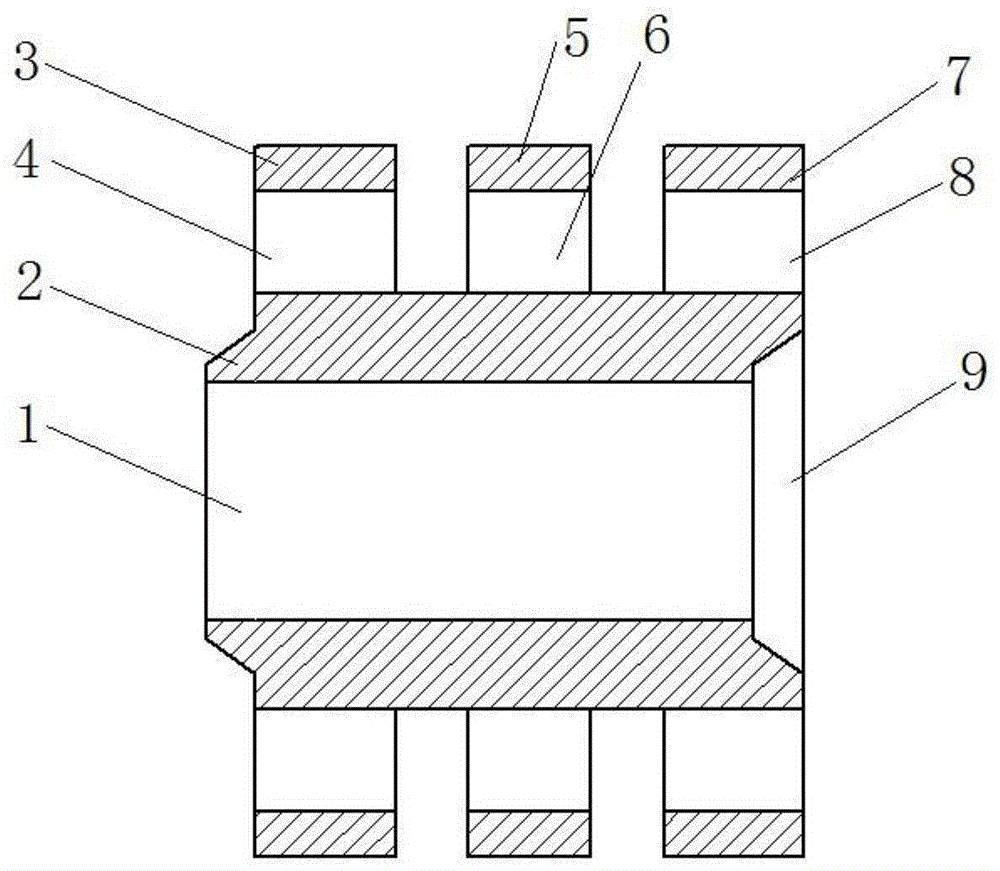

F304/F304L double-standard stainless steel flange and production process thereof

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

High-strength heat-resisting and cold-heading steel wire rod and production method thereof

The invention discloses a high-strength heat-resisting and cold-heading steel wire rod and a production method thereof. The high-strength heat-resisting and cold-heading steel wire rod is prepared from the following components in percentage by weight: 0.38 to 0.50 percent of C, 0.30 to 0.40 percent of Si, 0.75 to 1.00 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, 0.90 to 1.20 percent of Cr, 0.35 to 0.45 percent of Mo, 0.25 to 0.35 percent of V, less than or equal to 15 ppm of [O], less than or equal to 45 ppm of [N] and the balance of Fe and trace impurities. The wire rod is microalloyed by Cr-V-Mo, thus ensuring that elements are uniformly dispersed and the gas content is well controlled, and the wire rod can be high in heat resistance. The wire rod is high in strength and heat resistance; and no noble metals are added, so that the cost is lower. According to the production method, equipment and the investment are not needed to be added, so that the production cost is not increased; the conventional equipment and the conventional process are fully used; high-strength bolts prepared from the wire rod obtained according to the requirement of a downstream manufacturing enterprise on the resistance to high temperature stability can keep high strength and toughness indexes when working under a high temperature state of 600 DEG C; and the high-strength heat-resisting and cold-heading steel wire rod is high in resistance to high temperature stability, strength and heat resistance.

Owner:XINGTAI IRON & STEEL

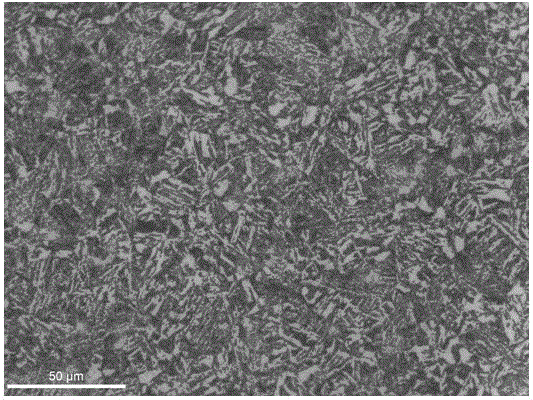

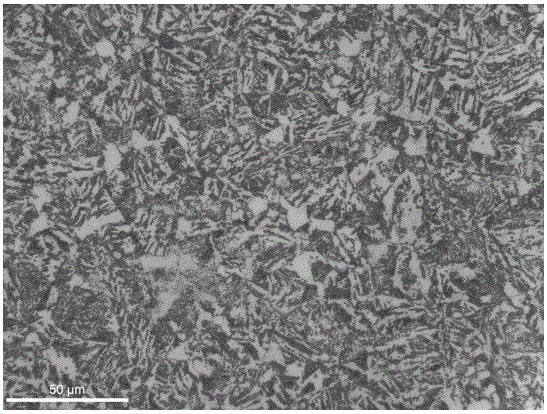

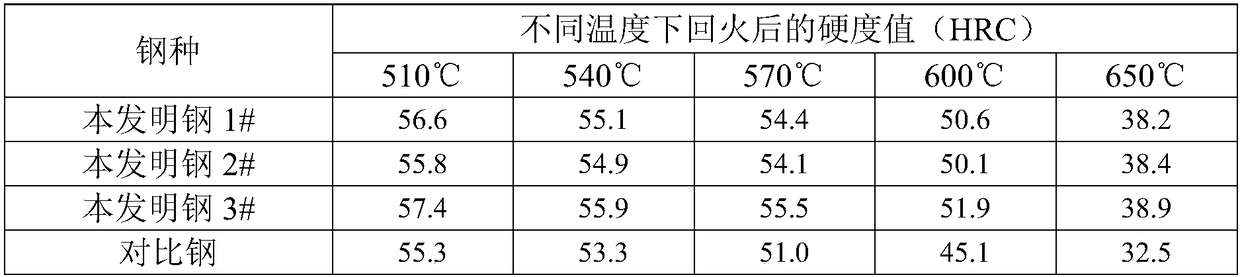

High-heat-resistance and high-impact-toughness hot-work die steel for hot forging and preparation method

ActiveCN108220815AImprove heat strengthImprove impact toughnessMetal-working apparatusRare-earth elementIsothermal annealing

The invention discloses high-heat-resistance and high-impact-toughness hot-work die steel for hot forging and a preparation method thereof, and belongs to the technical field of die steel. The die steel comprises the following chemical components, by weight ratio: 0.40-0.50% of C, 0.30-0.60% of Si, less than or equal to 0.006% of S, less than or equal to 0.01% of P, 0.60-0.9% of Mn, 1.80-2.80% ofMo, 3.00-3.80% of Cr , 0.40-0.60% of V, 0.80-1.40% of Ni, 0.3-0.6% of Al, 0.50-1.10% of Co, 0.002-0.008% of rare earth elements and the balance Fe and inevitable impurities. The preparation method comprises the steps that steel is subjected to smelting and ingot casting, after a prepared steel ingot is subjected to high-temperature diffusing heat treatment, multi-directional forging and hot working are carried out, controlled cooling after forging is carried out, microstructure homogenization is carried out, refining heat treatment is carried out, and isothermal annealing treatment is carriedout. The die steel has the advantages of being relatively high in heat resistance, impact toughness and hardenability and particularly suitable for manufacturing a hot-work die with high heat resistance and impact toughness and with the large cross section with the thickness of 400mm or larger.

Owner:CENT IRON & STEEL RES INST

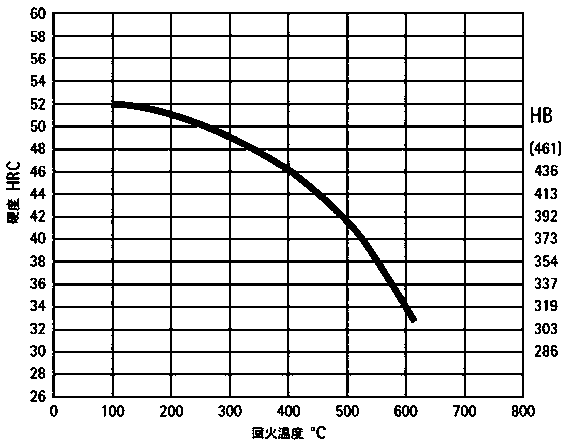

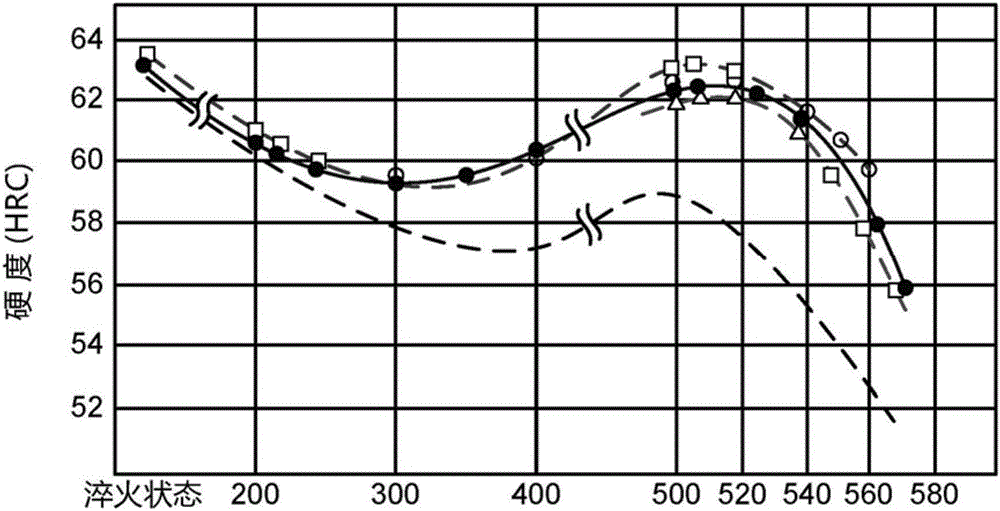

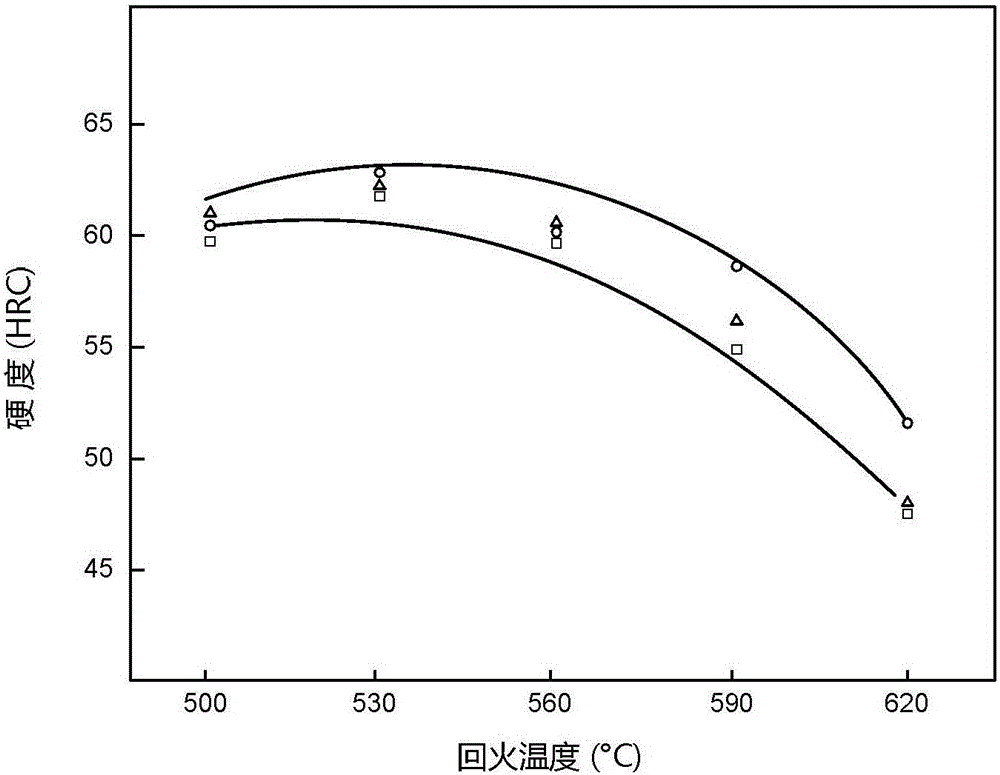

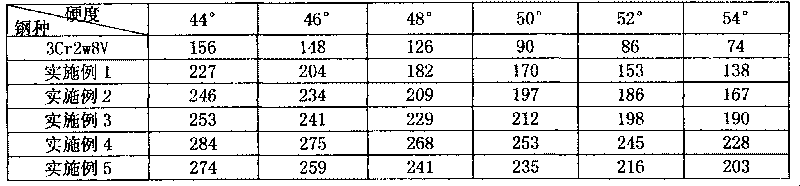

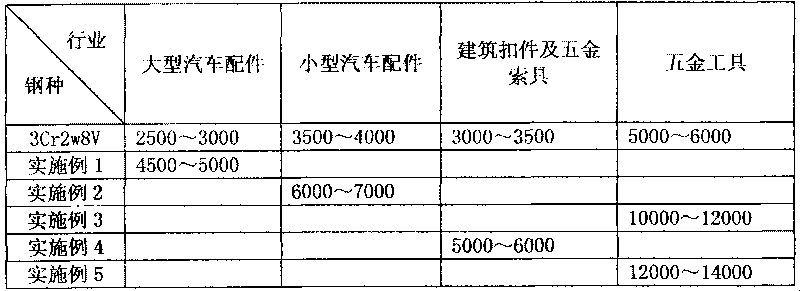

High-performance and high-speed-stamping cold work die steel and preparation method thereof

The invention relates to high-speed-stamping cold work die steel and a preparation method thereof. The high-speed-stamping cold work die steel is characterized by primarily comprising, by mass, 0.85%-0.95% of C, 0.80%-1.20% of Si, 0.30%-0.60% of Mn, 0.025% or less of P, 0.015% or less of S, 7.90%-8.40% of Cr, 1.40%-1.70% of Mo, 1.90%-2.20% of W, 2.20%-2.50% of V, 0.90%-1.20% of Al, 0.20% or less of Cu, 0.25% or less of Ni, and the balance Fe. By adding the alloy element, namely Al, the hardness, red hardness and the surface hardness and heat stability after nitriding of the steel are further improved; through addition of Mo, the hardenability, heat resistance, temper embrittlement resistance and temper softening resistance of the steel can be improved; and the high-speed-stamping cold work die steel has the remarkable beneficial effects of having high hardness, heat hardness and heat stability, meeting the development demand of modern industry, reducing consumption and increasing social benefits.

Owner:GUANGDONG STRONG METAL TECH

Copper alloy powder for additive manufacturing and preparation method and application thereof

ActiveCN110116202AMeet manufacturing and forming requirementsRaise the recrystallization temperatureAdditive manufacturing apparatusIncreasing energy efficiencyHeat resistanceGrain boundary

The invention discloses copper alloy powder for additive manufacturing and a preparation method and application thereof. The copper alloy powder is prepared from Cr powder, Zr powder and Cu powder according to the specific proportion, the eutectic temperature of the alloy is 1,072 DEG C, the maximum solid solubility of chromium in copper is 0.65% at the eutectic temperature, high temperature is generated when the 3D printing forming power is between 420 W and 500 W through a 3D printing forming technology, a second phase Cu5Zr and other polycompounds which are separated out in copper grains and on the grain boundaries of the copper grains are cooled to 150 DEG C or below along with the temperature in the printing process, the solid solubility is rapidly decreased along with lowering of thetemperature, and a Cr-particle phase is separated out. Through addition of chromium, the recrystallization temperature and the heat resistance of the alloy are obviously improved. Therefore, the Cu-Cr-Zr copper alloy powder can be better suitable for an additive manufacturing forming technology compared with a common copper alloy material, and the obtained material has the characteristics that the density is between 8.5 g / cm<3> and 8.9 g / cm<3>, the tensile strength is between 260 MPa and 330 MPa, the percentage elongation after fracture is between 18%-25%, and the yield strength is between 220 MPa and 270 MPa and meets the additive manufacturing forming requirements.

Owner:西安国宏天易智能科技有限公司

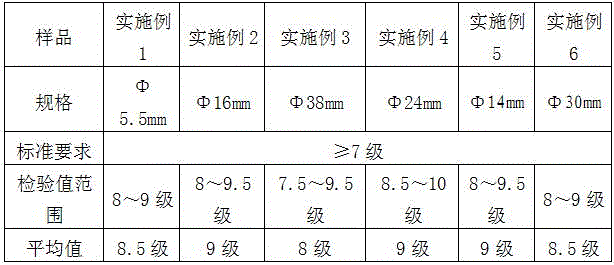

Alloy cast steel used for high-speed train brake disc and high-speed train brake disc manufactured through alloy cast steel

The invention discloses alloy cast steel used for a high-speed train brake disc and the high-speed train brake disc manufactured through the alloy cast steel. The alloy cast steel in the claim 1 comprises, by weight percent, 0.18%-0.26% of carbon, 0.30%-0.50% of silicon, 0.68%-1.40% of manganese, smaller than or equal to 0.025% of phosphorus, smaller than or equal to 0.013% of sulfur, 1.10%-1.82% of chromium, 0.90%-1.50% of nickel, 0.65%-1.02% of molybdenum, 0.22%-0.34% of vanadium, smaller than or equal to 0.30% of the sum of the content of other components and the balance iron, wherein tungsten is smaller than 0.1%. The alloy cast steel has the main beneficial effects that grains are refined through reasonable matching and heat treatment of alloy elements such as manganese, nickel, chromium, molybdenum and vanadium and main components such as carbon and silicon in a cast steel material, hardenability and the thermal strength performance of the alloy cast steel material are improved, the constant-temperature strength and the high-temperature strength are greatly improved, and the good comprehensive mechanical property is achieved. The brake disc manufactured through the alloy cast steel can completely meet the technical requirement for use of high-speed trains under the working condition.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

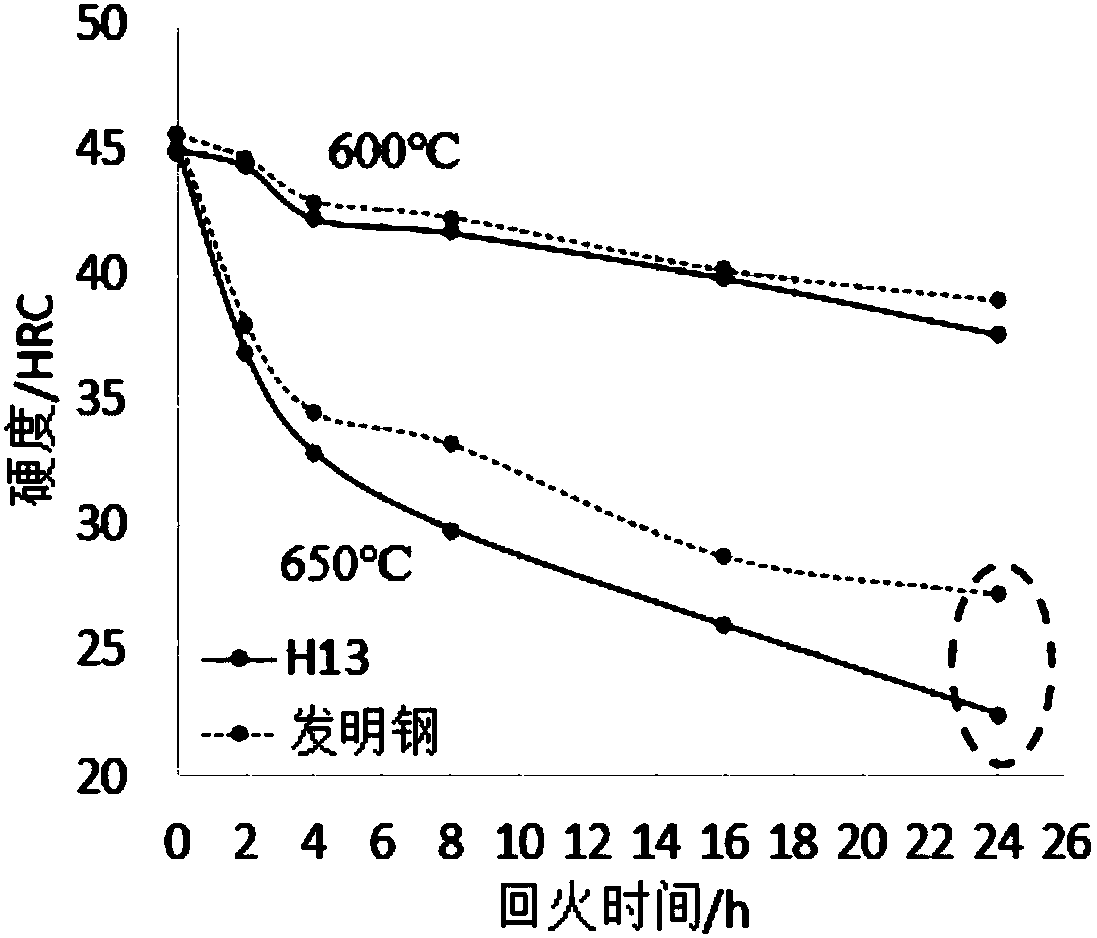

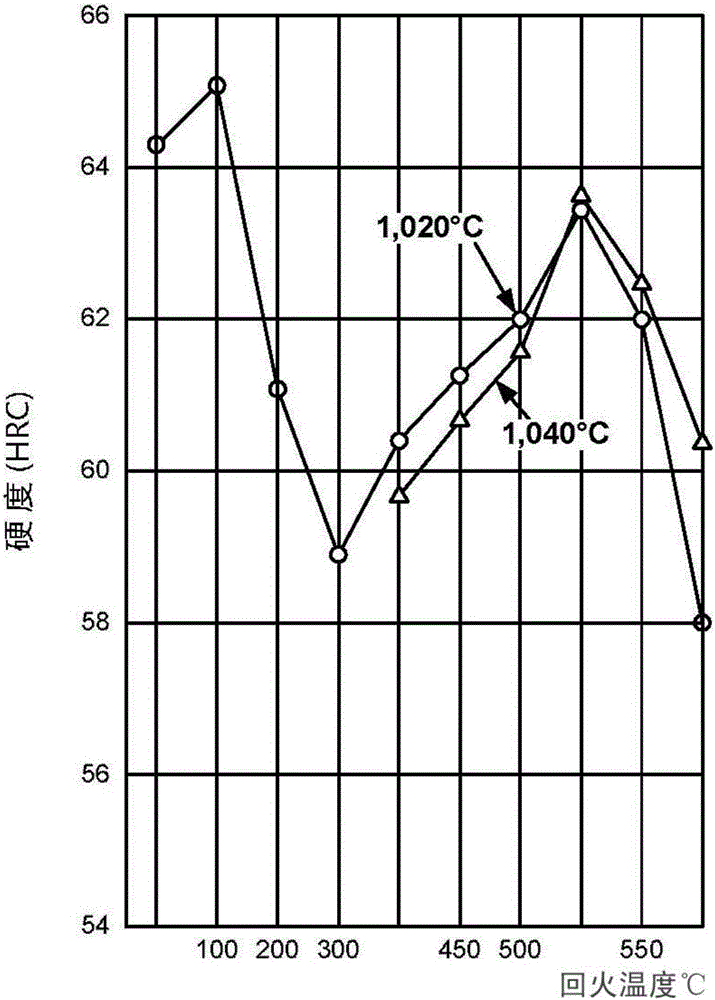

Hot die steel and tempering process thereof

The invention relates to hot die steel which comprises the following components in percentage by weight: 0.32-0.42 percent of carbon, 0.2-0.5 percent of silicon, 0.2-0.5 percent of manganese, 2.2-2.7 percent of chromium, 1.0-3.4 percent of molybdenum, 0.8-2.2 percent of tungsten, 0.4-0.6 percent of vanadium, 0.2-1.5 percent of cobalt and the balance of Fe. A tempering process of the hot die steel comprises the following steps of: firstly, tempering at 440-460 DEG C for 1-2 hours and then cooling to room temperature; then tempering at 520-560 DEG C for 1-2 hours and then cooling to room temperature; and finally, tempering at 520-560 DEG C for 1-2 hours and then cooling to room temperature. The hot die steel has the characteristics of high heat resistance and high toughness. The tempering process greatly reduces the fracture speed of materials and further improves the toughness of die materials.

Owner:ZHEJIANG ZHENGDA MOLD

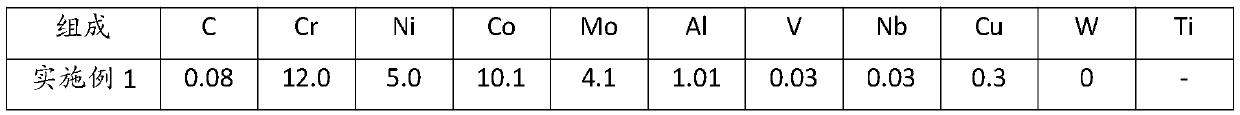

High-cobalt martensitic stainless steel and preparation method

The invention belongs to the technical field of alloys, and particularly relates to high-cobalt martensitic stainless steel and a preparation method thereof. The high-cobalt martensitic stainless steel is prepared from the following chemical components in percentage by mass: 0.03 to 0.15 percent of C, 11.0 to 13.0 percent of Cr, 3.0 to 6.0 percent of Ni, 8 to 14 percent of Co, 3.0 to 5.0 percent of Mo, 0.7 to 1.5 percent of Al, 0.01 to 0.3 percent of V, 0.01 to 0.03 percent of Nb, 0.1 to 0.3 percent of Cu, and the balance Fe. According to the high-cobalt martensitic stainless steel and the preparation method thereof provided by the invention, through a compound reinforcement means, under the condition of room temperature, the tensile strength of the high-cobalt martensitic stainless steelis larger than or equal to 2000MPa, and the yield strength of the high-cobalt martensitic stainless steel is larger than or equal to 1700MPa; and under the condition of high temperature being 500 DEGC, the tensile strength of the high-cobalt martensitic stainless steel is larger than or equal to 1500MPa, and the yield strength of the high-cobalt martensitic stainless steel is larger than or equalto 1280MPa

Owner:王俊乔

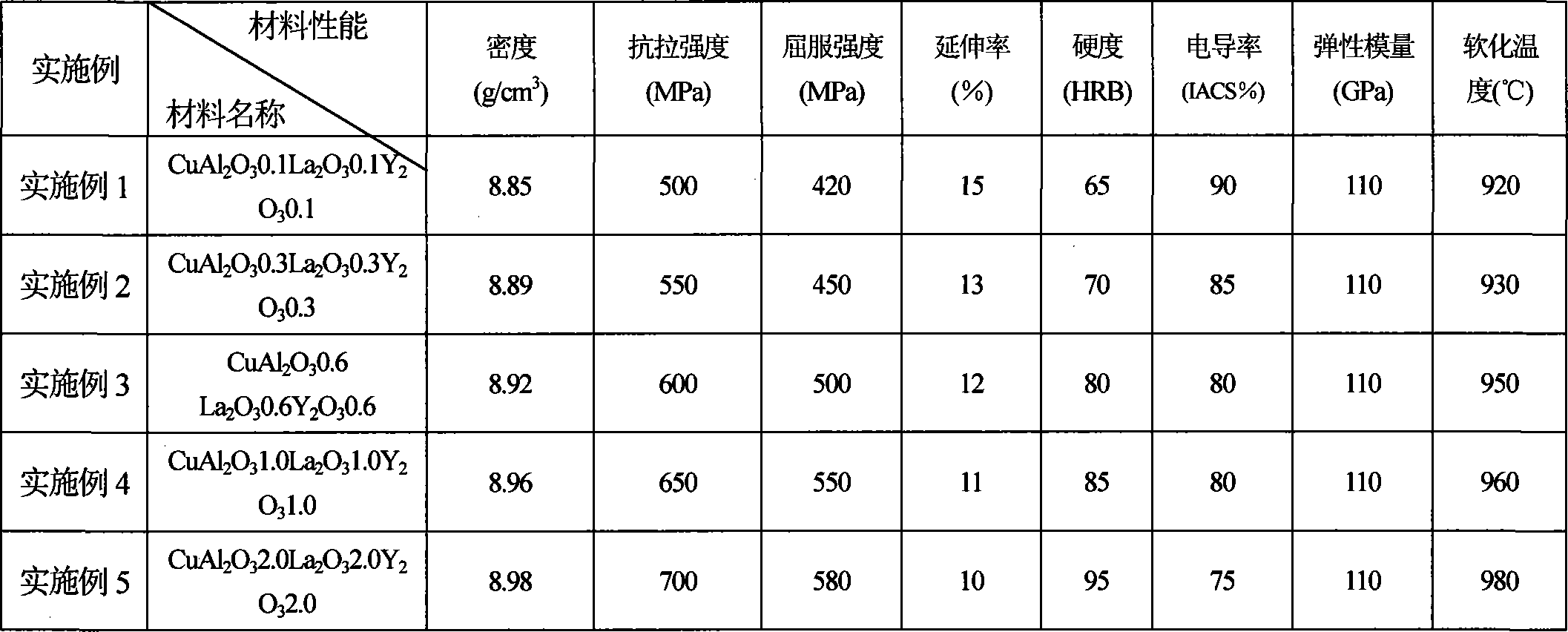

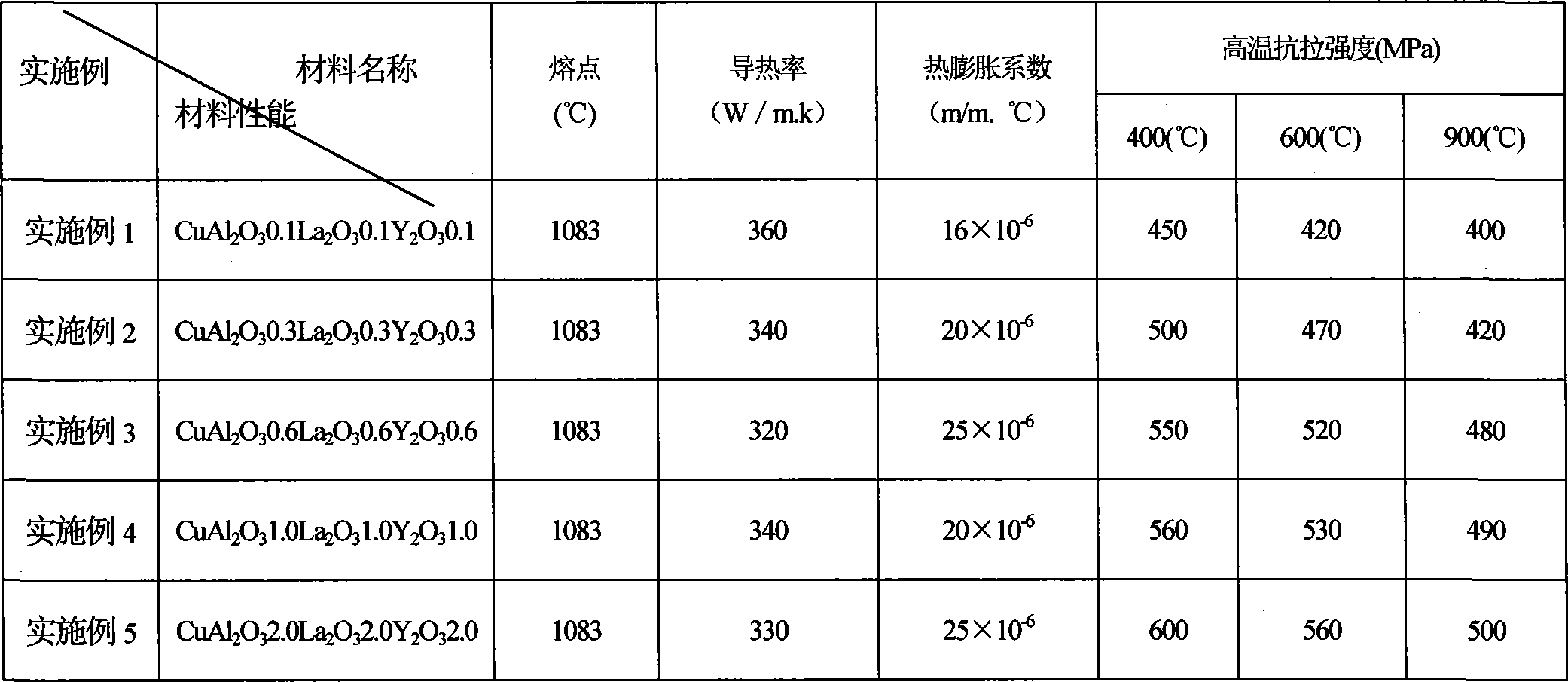

Multiphase oxide particles enhanced copper-base composite material and preparing method thereof

InactiveCN101168806AGood electrical and thermal conductivityImprove thermal stabilityChemical reactionCorrosion

The invention discloses a multi-phase oxide grain enforced copper-based compound material and the preparation method thereof. The weight percentage of components is Al2O3: 0.1 to 2.0, La2O3: 0.1 to 2.0, Y2O3: 0.1 to 2.0, and the surplus is Cu. The preparation method is realized by that alloy elements of Cu, Al, La, and Y are proportioned according to the alloy design component proportion, and the CuAlLaY alloy ingot blank is prepared through the vacuum spraying forming technology and the device; the insitu chemical reaction processing is performed to the copper alloy by controlling the oxygen partial pressure, to prepare CuAl2O3La2O3Y2O3 system compound material; the compound material is performed with the processing technologies of forging, extruding, rolling, drawing, and heat treatment, to be prepared into products of complex shapes of bar material, plate material, sheet material, silk material, profile shaped material or contact, to realize even coagulation, short flow and near forming and processing; the new material has high conduction and heat conduction property, thermal stability and heat strength, electric contact properties of abrasion resistance, corrosion resistance, arc burning resistance and melting welding resistance, and intensity and processing property are more excellent than the material prepared in the conventional fusion casting method and the powder metallurgy method, and the production cost is greatly reduced.

Owner:KUNMING INST OF PRECIOUS METALS +1

Super-strength aluminum alloy drill rod pipe body for super-deep well and manufacturing method for super-strength aluminum alloy drill rod pipe body

ActiveCN104404321ASimple ingredientsElements that increase heat resistanceAlloy substrateSolid solution

The invention discloses a super-strength aluminum alloy drill rod pipe body for a super-deep well and a manufacturing method for the super-strength aluminum alloy drill rod pipe body. The super-strength aluminum alloy drill rod pipe body comprises the following components in percentage by weight: 2.1 to 3.0 percent of Cu, 2.8 to 3.1 percent of Mg, 10.0 to 12.9 percent of Zn, 0.1 to 0.3 percent of Mn, 0.1 to 0.5 percent of Ni, 0.1 to 0.5 percent of Cr, 0.05 to 0.20 percent of Ti, 0.2 to 0.5 percent of Zr, 0.001 to 0.01 percent of B, 0.02 to 0.05 percent of Yb and the balance of Al and inevitable impurities. According to the super-strength aluminum alloy drill rod pipe body and the manufacturing method, heat treatment processes of multistage homogenization treatment, multistage solid solution treatment, aging and the like are adopted, segregation, heterogeneousness and the like in a substrate are greatly eliminated, and the melting-back of an un-melted eutectic phase in the aluminum alloy substrate is remarkably promoted, so that high strength is maintained, hot strength is improved, and the problems of insufficient strength, low surface hardness, insufficient hot strength and the like of the conventional aluminum alloy drill rod pipe body are solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-alloy steel pipe piercing plugand manufacturing method thereof

InactiveCN104988416AHigh temperature strengthImprove toughnessMandrelsSolid state diffusion coatingUltimate tensile strengthToughness

The invention discloses a high-alloy steel pipe piercing plug. The high-alloy steel pipe piercing plug comprises the following chemical elements in percentage by mass: 0.25-0.35% of C, 0.35-1.5% of Si, 0.35-1.0% of Mn, 1.0-3.0% of Cr, 2.0-3.0% of Mo, 1.0-2.0% of Ni, 1.5-2.5% of W, 0.2-1.0% of V, and the balance of Fe and inevitable impurities; the surface of the high-alloy steel pipe piercing plug has an oxide film; and the outer surface of the high-alloy steel pipe piercing plug has a screw way. The invention further discloses a manufacturing method of the piercing plug; and the manufacturing method comprises the step of: manufacturing of a plug blank; annealing; machining of the steel pipe piercing plug and machining of the screw way on the surface of the plug; and formation of the oxide film through the surface high-temperature oxidation treatment. The piercing plug is higher in high-temperature strength and better in toughness. The oxide film on the surface of the piercing plug is excellent in adhesive force.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com