Centrifugally cast TP310Cb/T11 bimetal composite tube blank and method for producing same

A bimetallic composite tube and centrifugal casting technology, which is applied in the field of tube billet casting, can solve problems such as large thermal resistance and affecting heat transfer efficiency, and achieve the effects of improving service life, reducing thermal resistance, and relieving interface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

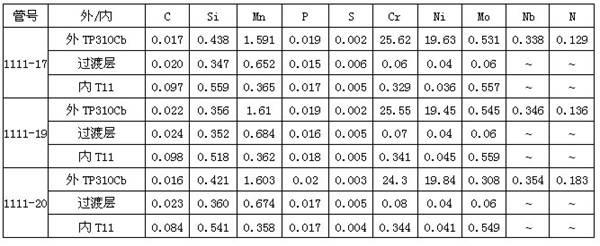

[0029] The present invention will be further described below through the processing of bimetal composite pipes of three pipe numbers.

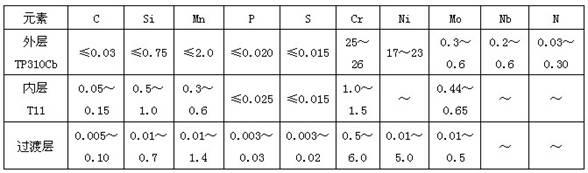

[0030] Firstly, detect the composition of the inner and outer layers of the TP310Cb / T11 extrusion (hot-rolled) raw material tube billet. The composition control requirements of the inner layer, outer layer and transition layer are shown in Table 1 (weight percentage).

[0031] Table 1 The composition control requirements of the inner and outer layers of the raw material tube blank and the transition layer

[0032]

[0033]Under the double protection of protective gas and mold slag, the outer layer of TP310Cb molten steel is poured first, and the solidification speed of the TP310Cb molten steel is controlled. After a certain interval, the transition layer is poured. When the transition layer is poured, the temperature of the inner surface of the outer layer is about 1250~ 1350°C. The molten steel of the transition layer adopts pure iron or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com