Patents

Literature

323results about How to "Uniform density distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

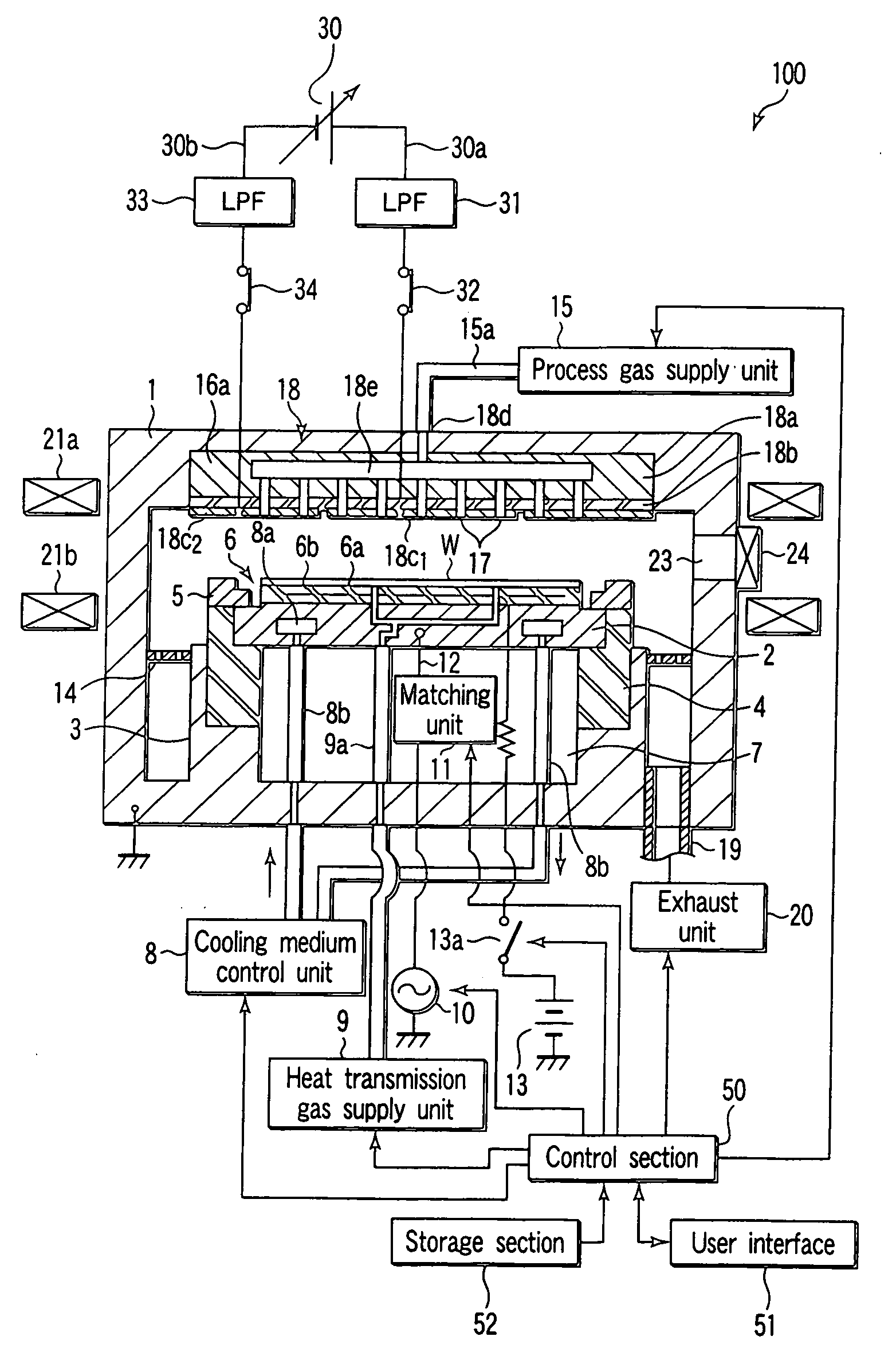

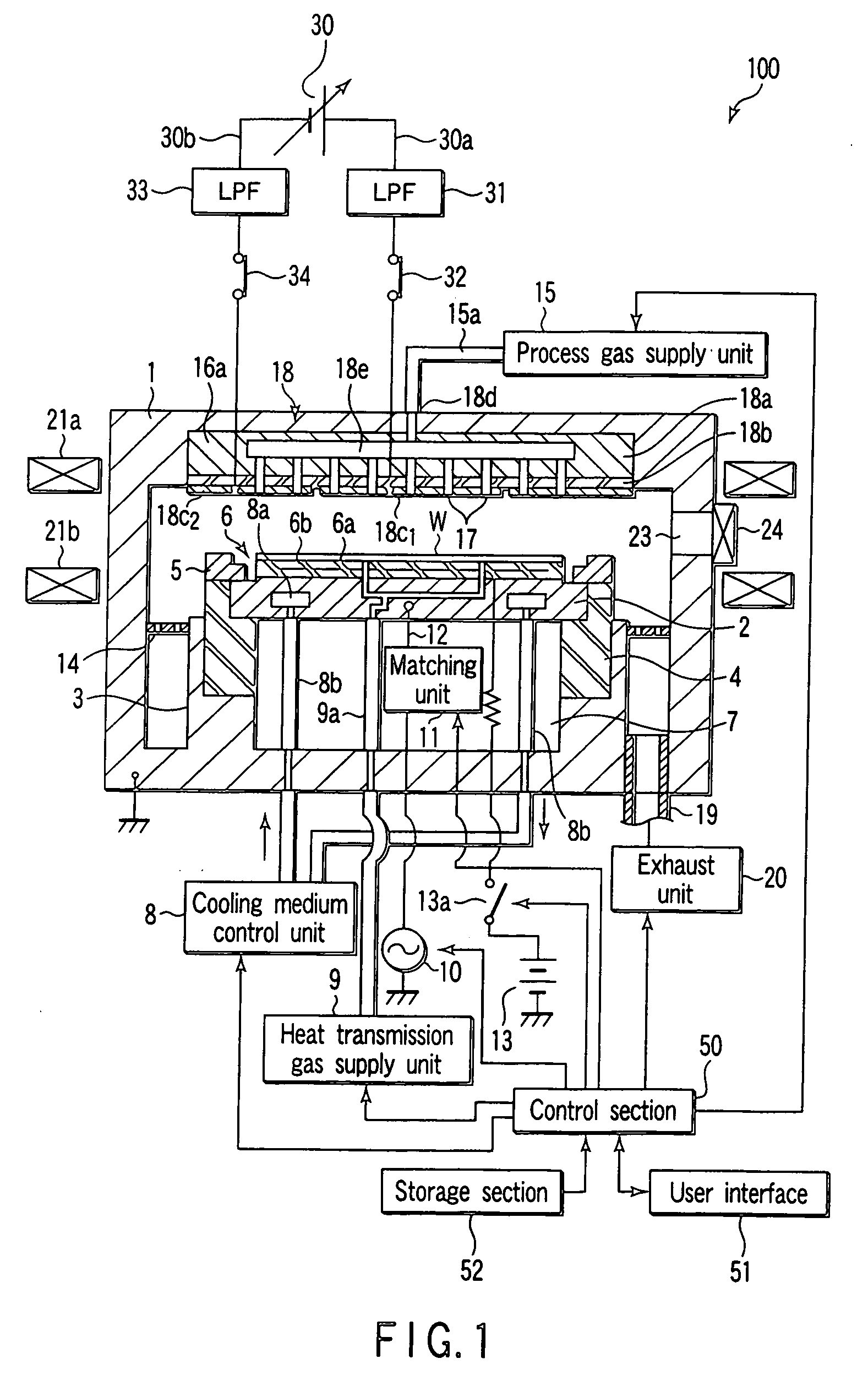

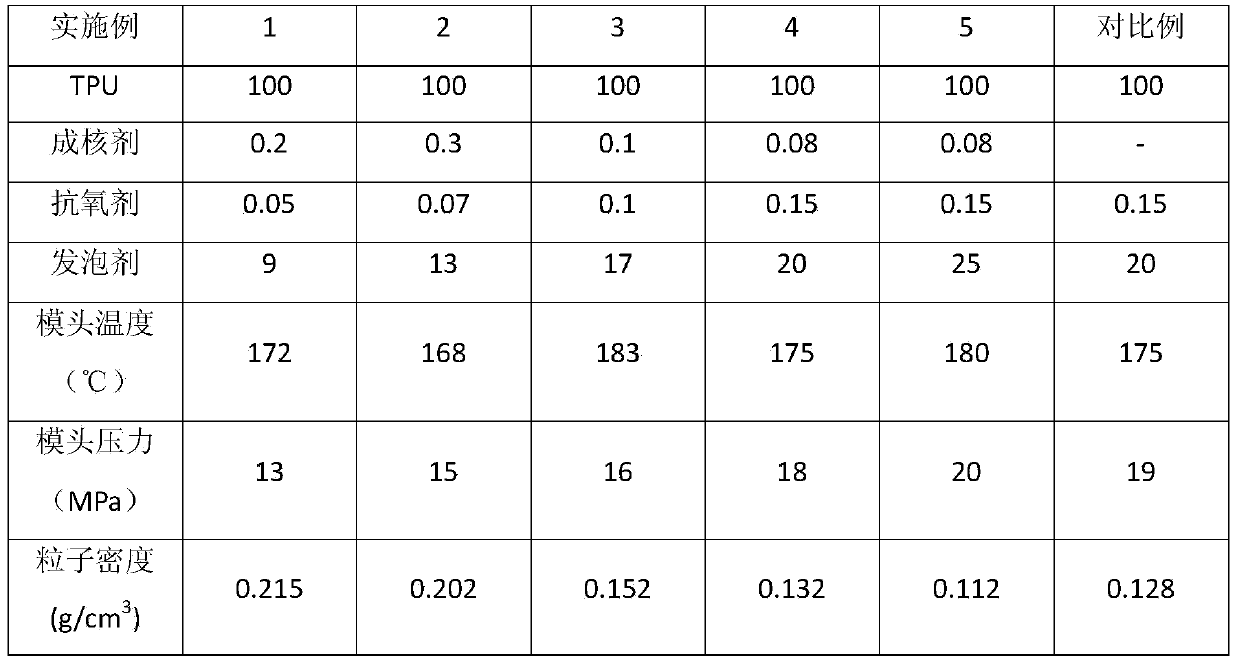

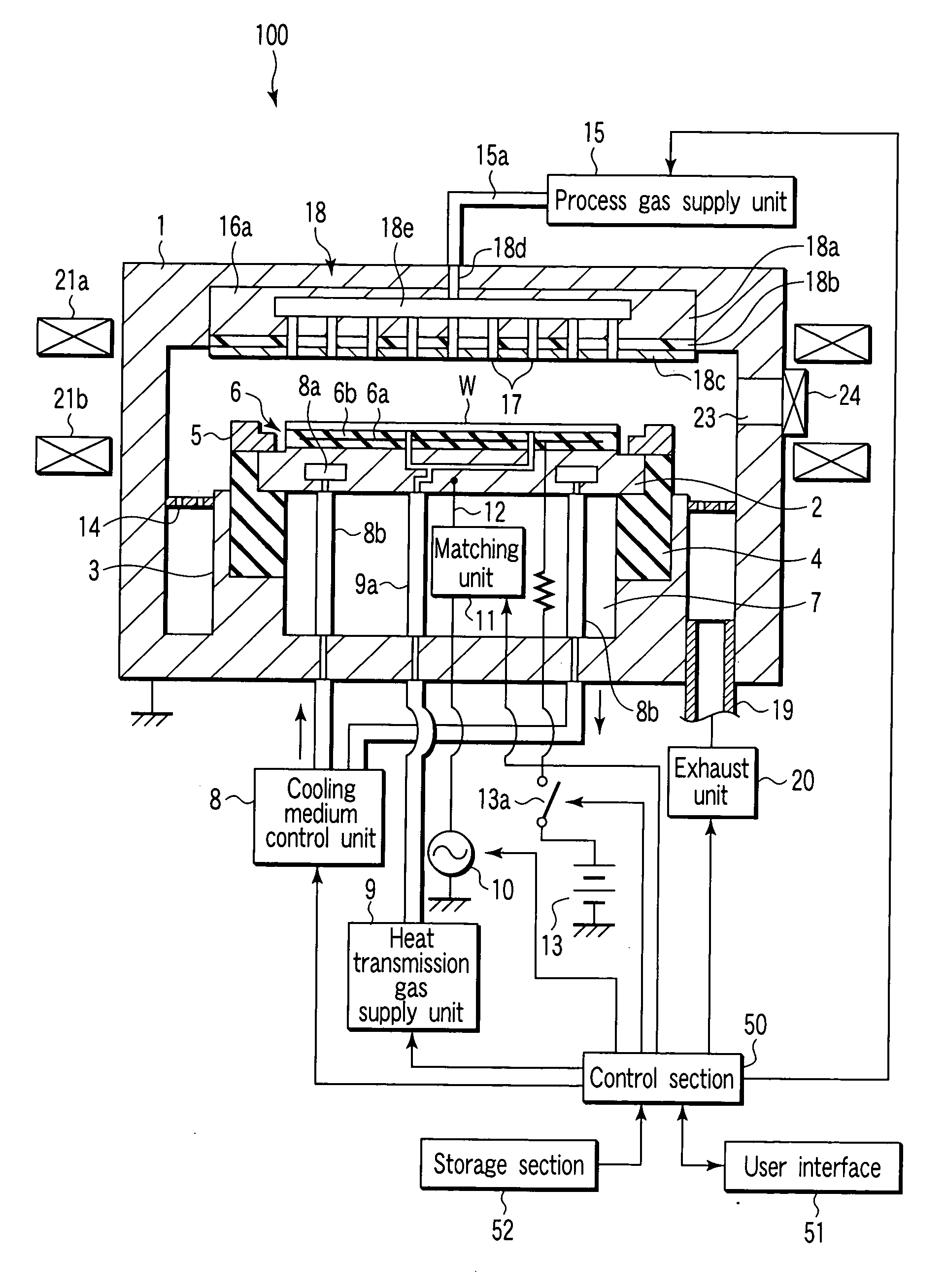

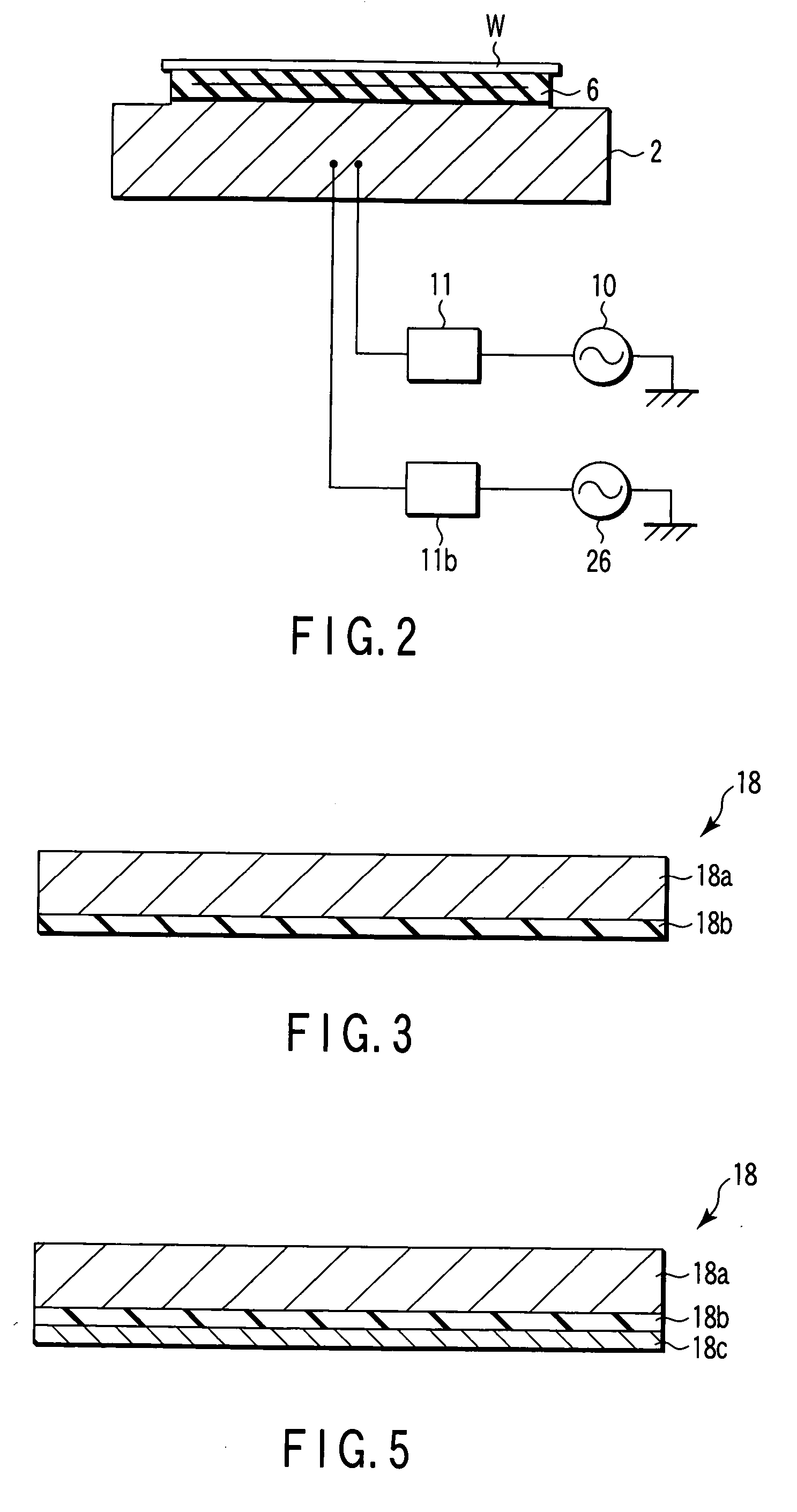

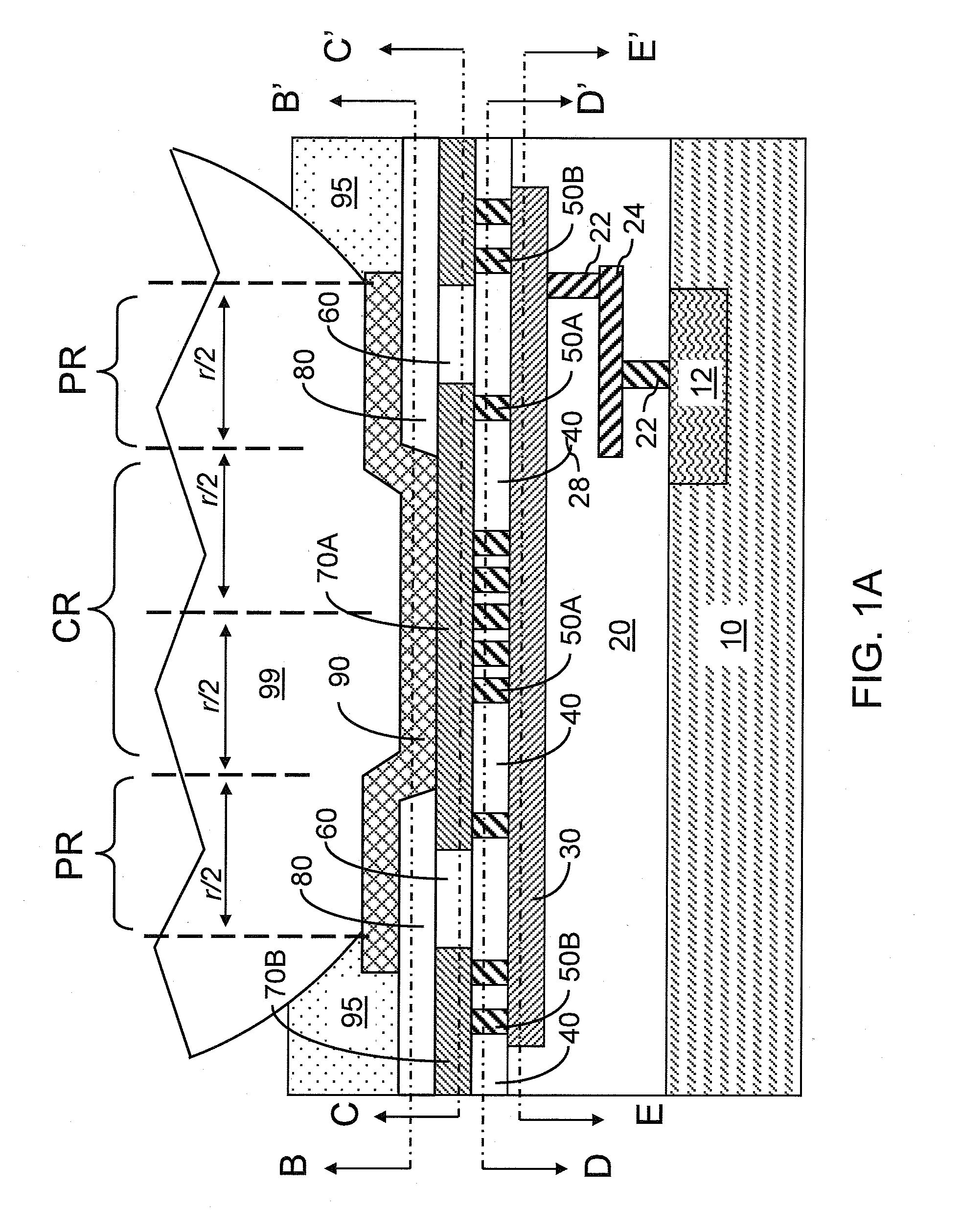

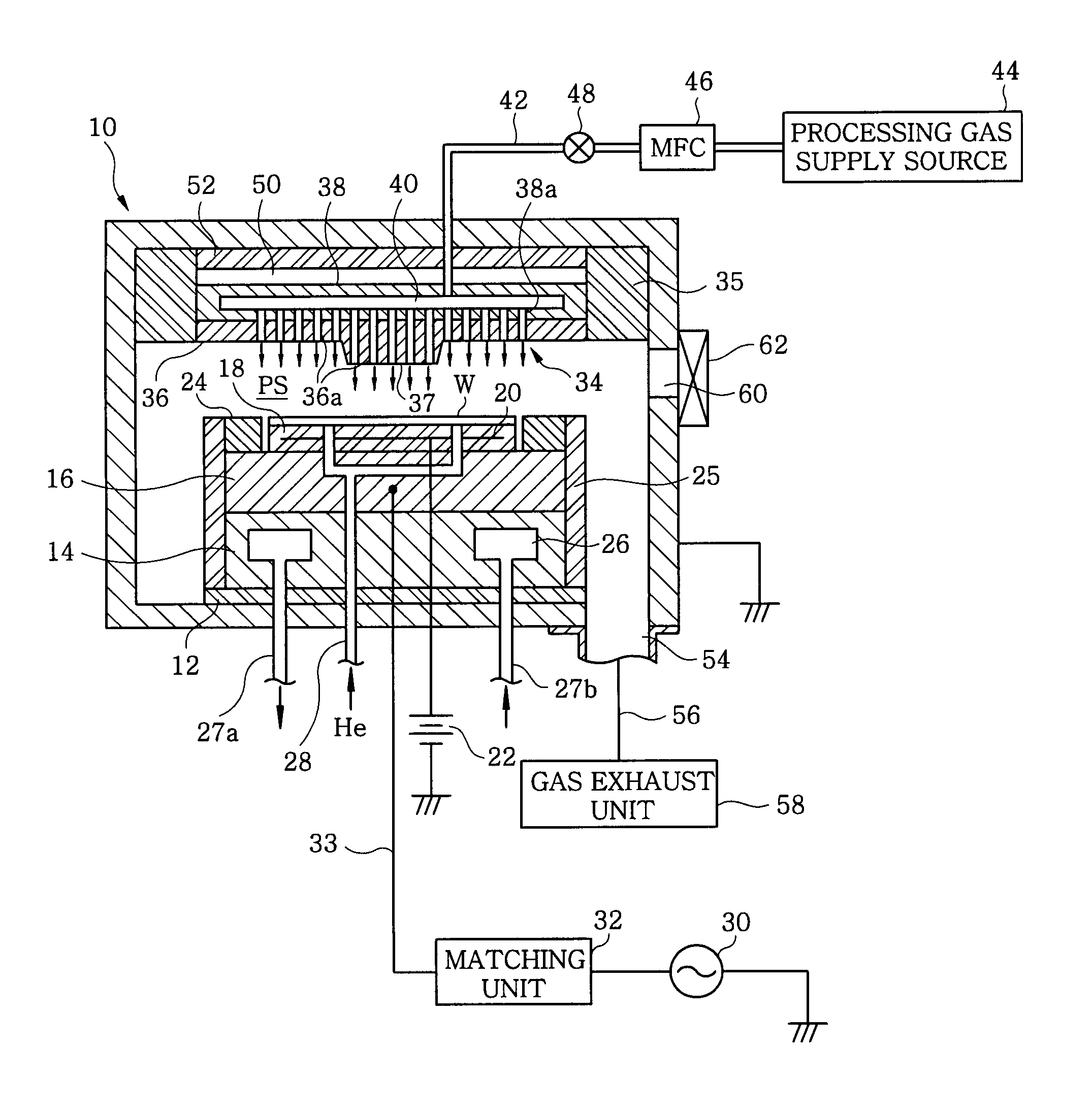

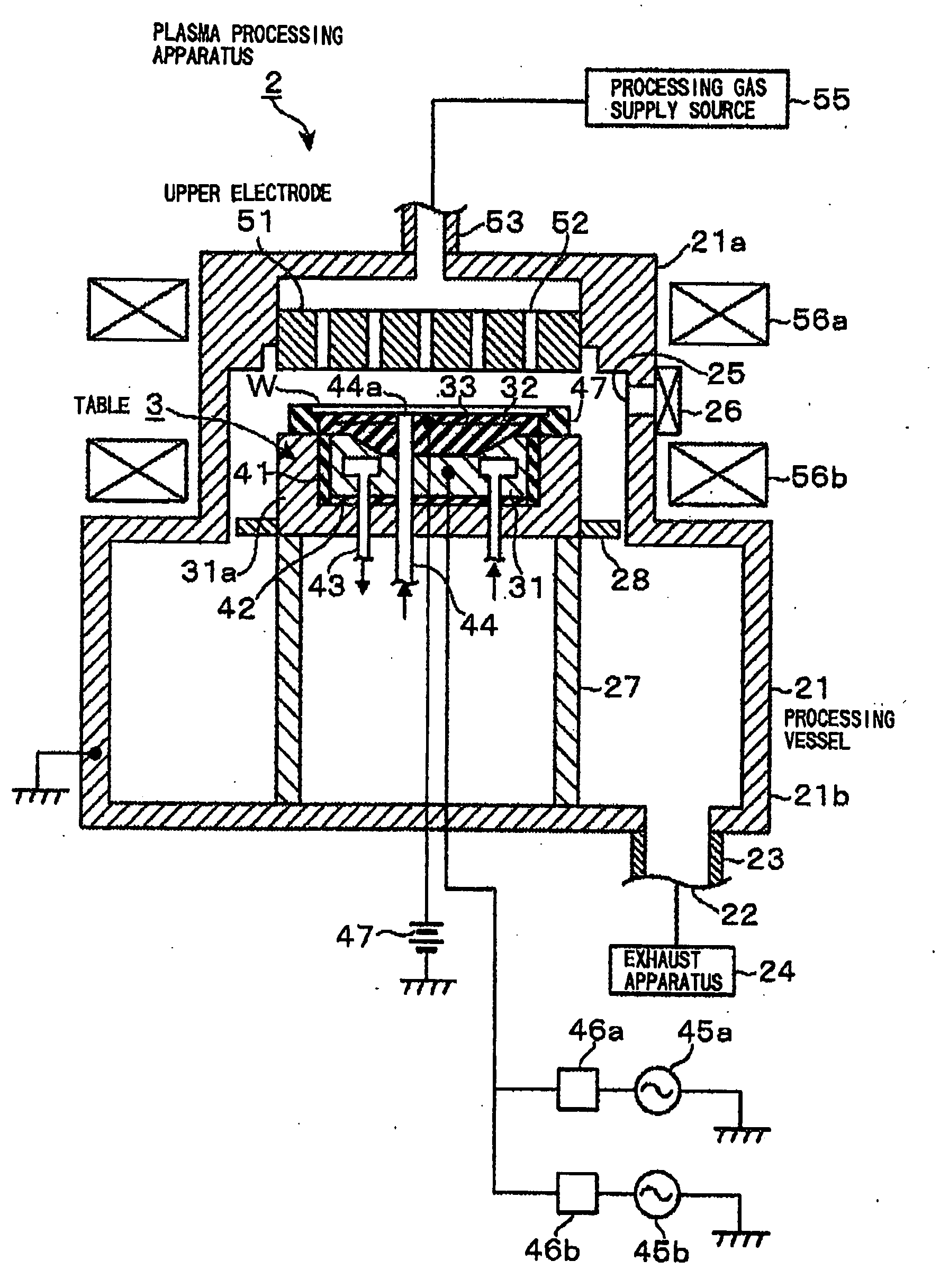

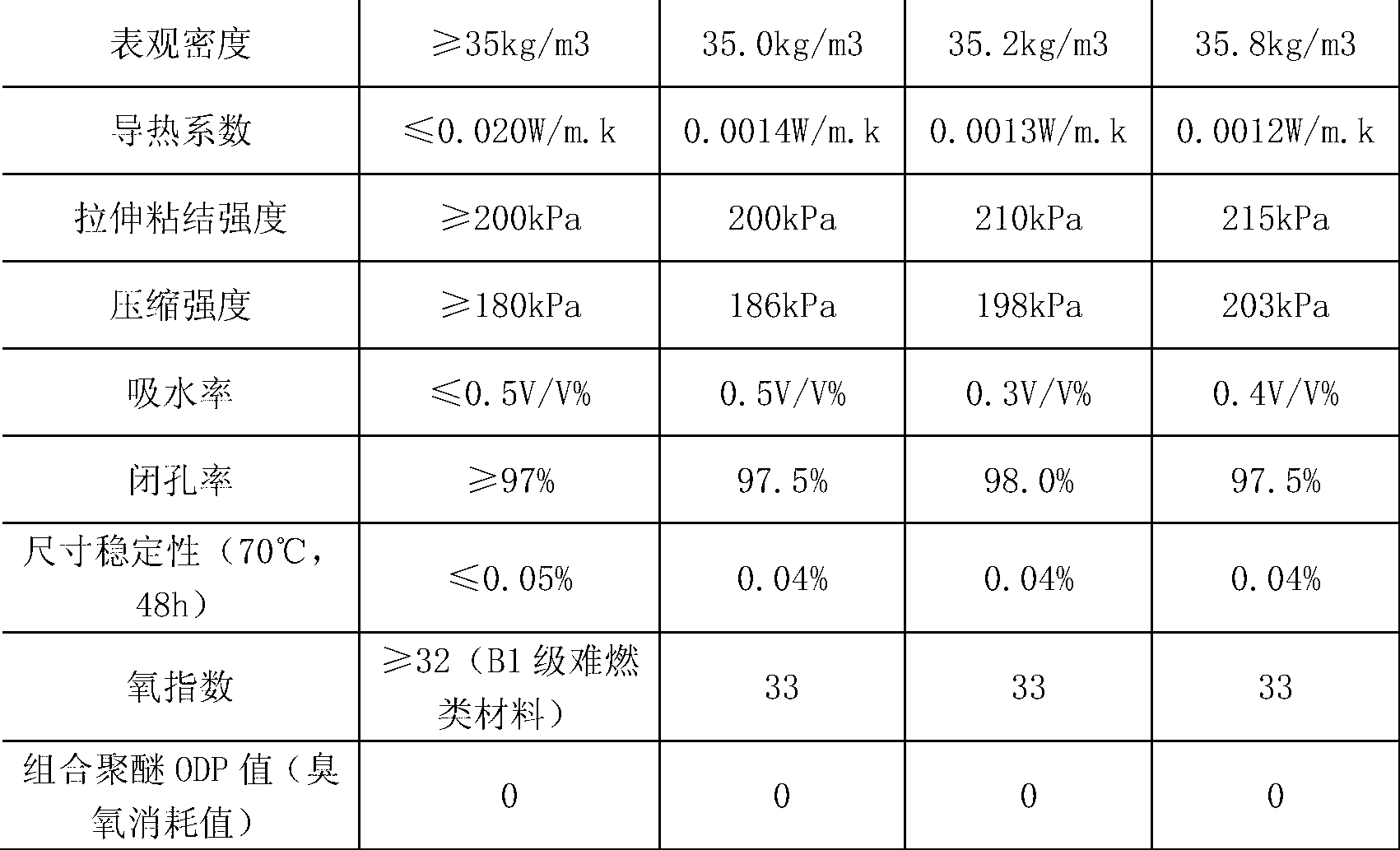

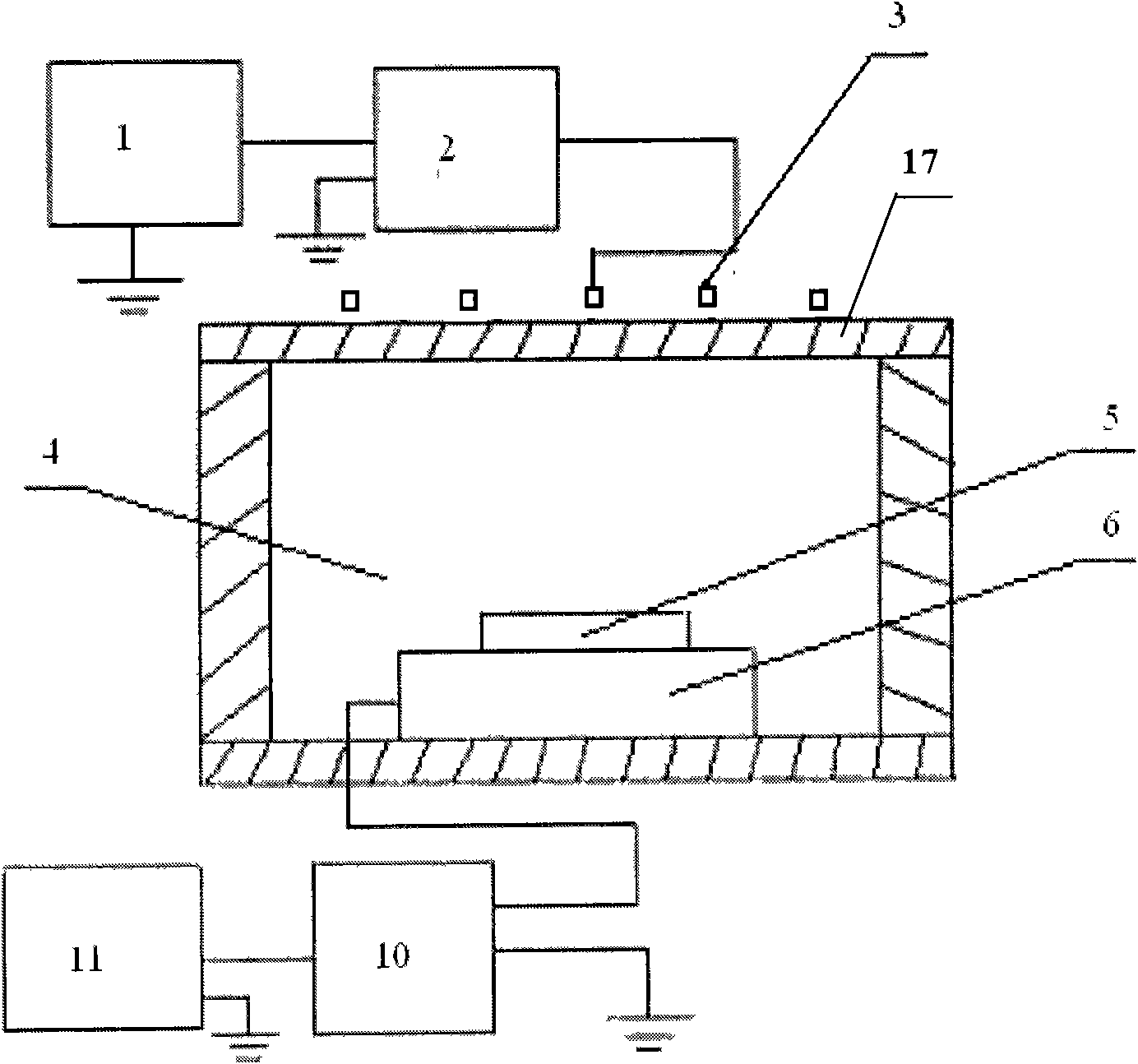

Capacitive coupling plasma processing apparatus

ActiveUS20060221540A1High planar uniformityPrevent charging damageElectric discharge tubesVacuum evaporation coatingCapacitanceCapacitive coupling

A capacitive coupling plasma processing apparatus includes a process chamber configured to have a vacuum atmosphere, and a process gas supply section configured to supply a process gas into the chamber. In the chamber, a first electrode and a second electrode are disposed opposite each other. The second electrode includes a plurality of conductive segments separated from each other and facing the first electrode. An RF power supply is configured to apply an RF power to the first electrode to form an RF electric field within a plasma generation region between the first and second electrodes, so as to turn the process gas into plasma by the RF electric field. A DC power supply is configured to apply a DC voltage to at least one of the segments of the second electrode.

Owner:TOKYO ELECTRON LTD

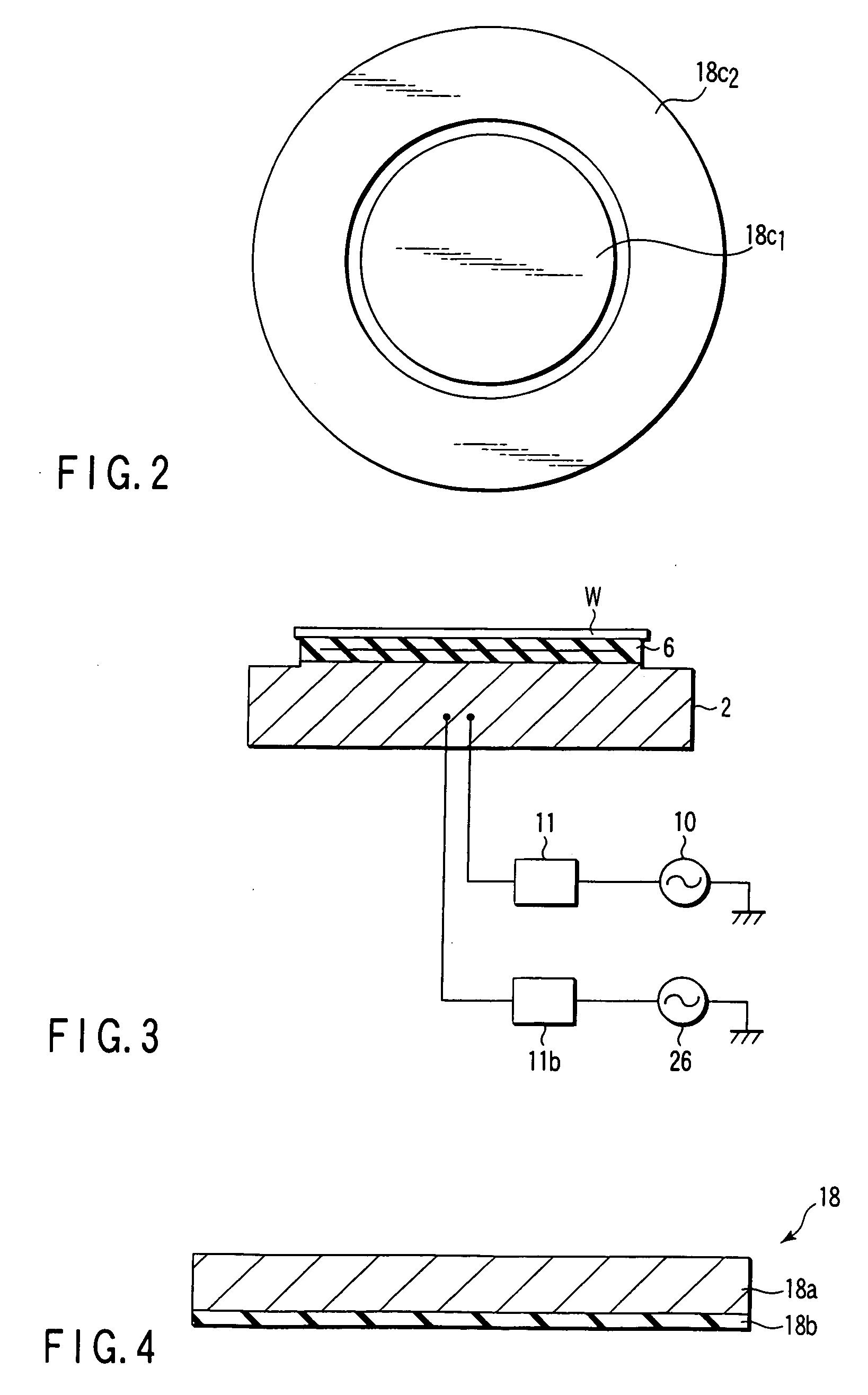

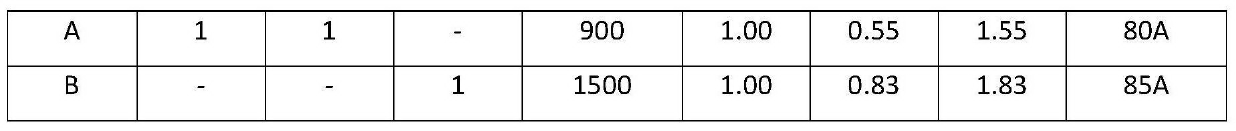

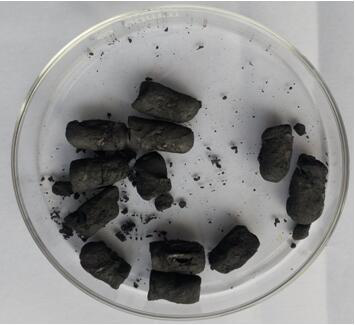

Extrusion foaming thermoplastic polyurethane elastomer bead and preparation method thereof

The invention discloses an extrusion foaming thermoplastic polyurethane elastomer bead. The extrusion foaming thermoplastic polyurethane elastomer bead comprises the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 0.01-0.5 parts of a foaming nucleating agent, and 0.01-0.2 parts of an antioxidant, wherein a foaming process adopts supercritical fluid with the addition amount of 1-40 parts. The invention also discloses a preparation method of the extrusion foaming thermoplastic polyurethane elastomer bead. The extrusion foaming thermoplastic polyurethane elastomer bead and the preparation method have the advantages that the foaming process does not cause environmental pollution; the obtained foaming material is stable in quality and high in foaming ratio; and the operation method in production is easy and suitable for continuous industrial production.

Owner:MIRACLL CHEM

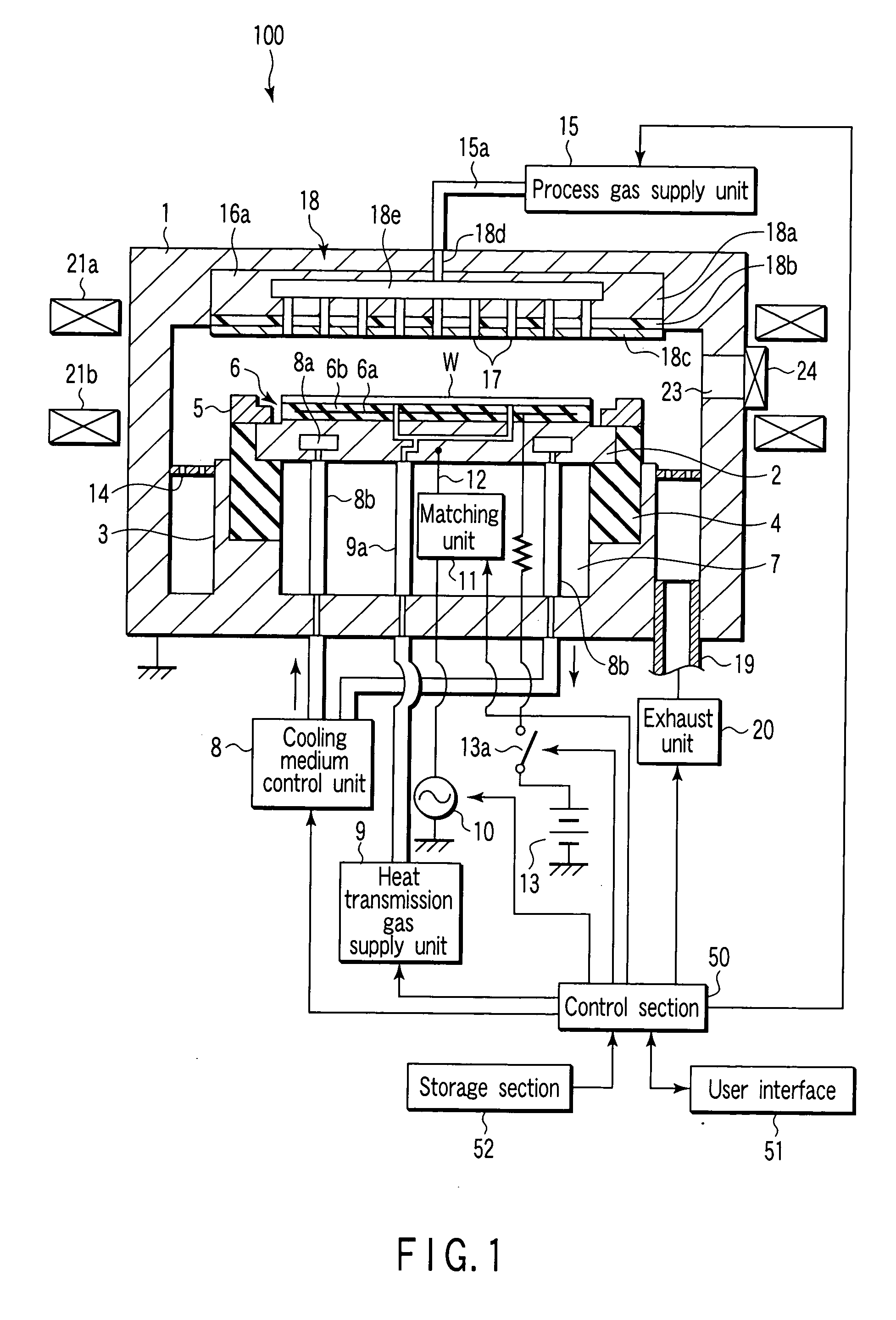

Extruded foaming thermoplastic polyurethane elastomer particles and preparation method thereof

The invention relates to extruded foaming thermoplastic polyurethane elastomer particles and a preparation method thereof. The particles comprise the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer, 0.01-0.5 part of foaming nucleating agent, and 0.01-0.2 part of antioxidant. The preparation method comprises steps of firstly, mixing the materials, then throwing the mixture into an extruder to prill to obtain a bead raw material suitable for foaming, finally, throwing the beads into a special extruder for foaming, and after foaming by an opening die, pelletizing underwater so as to prepare the particles. The thermoplastic polyurethane foaming particles are prepared through an extrusion method; by controlling the foaming technology conditions, the foaming particles are controllable in density and have uniform cell density; the whole production method is simple to operate, has no special limitation and requirement on the equipment, and is applicable to industrial continuous production.

Owner:MIRACLL CHEM

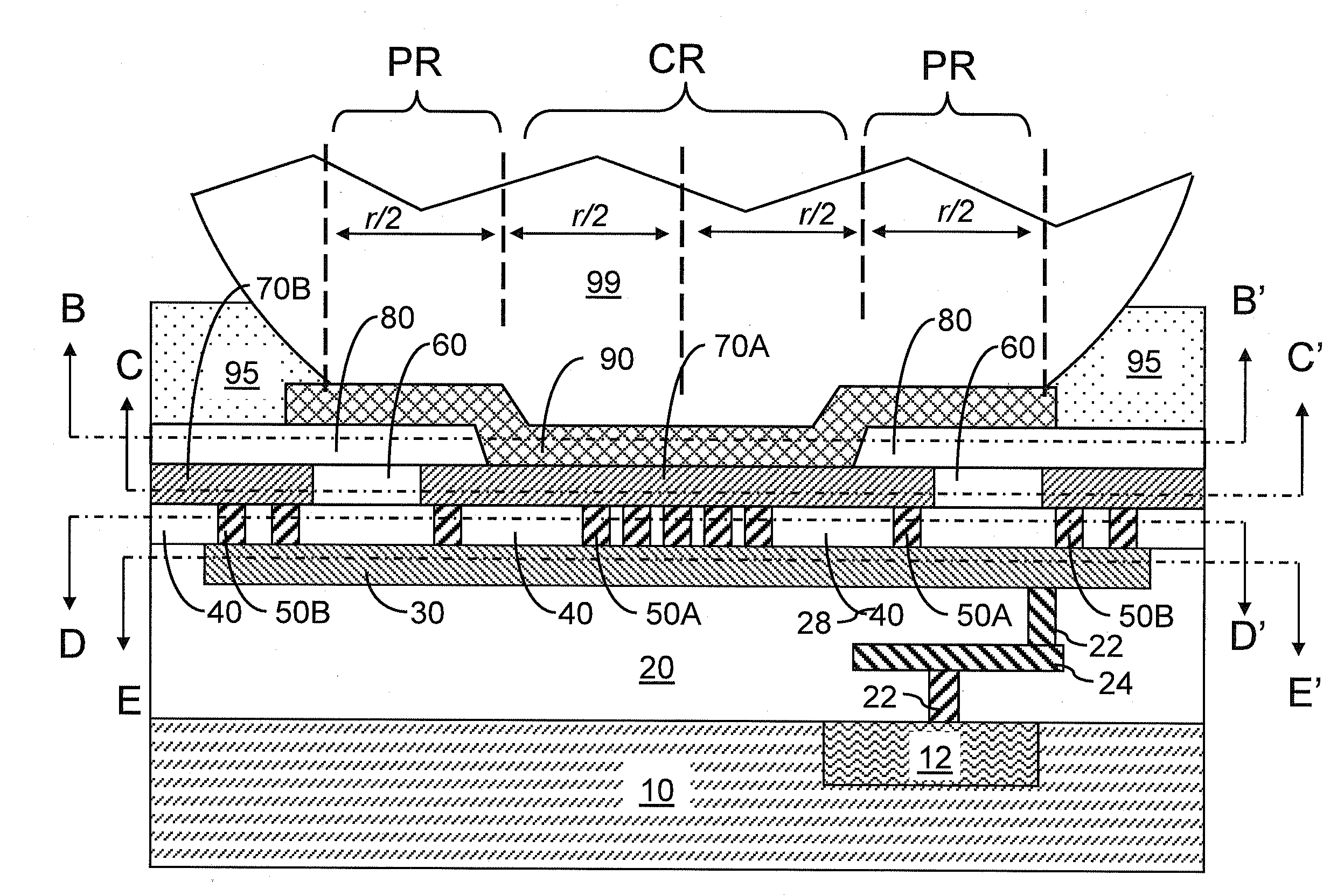

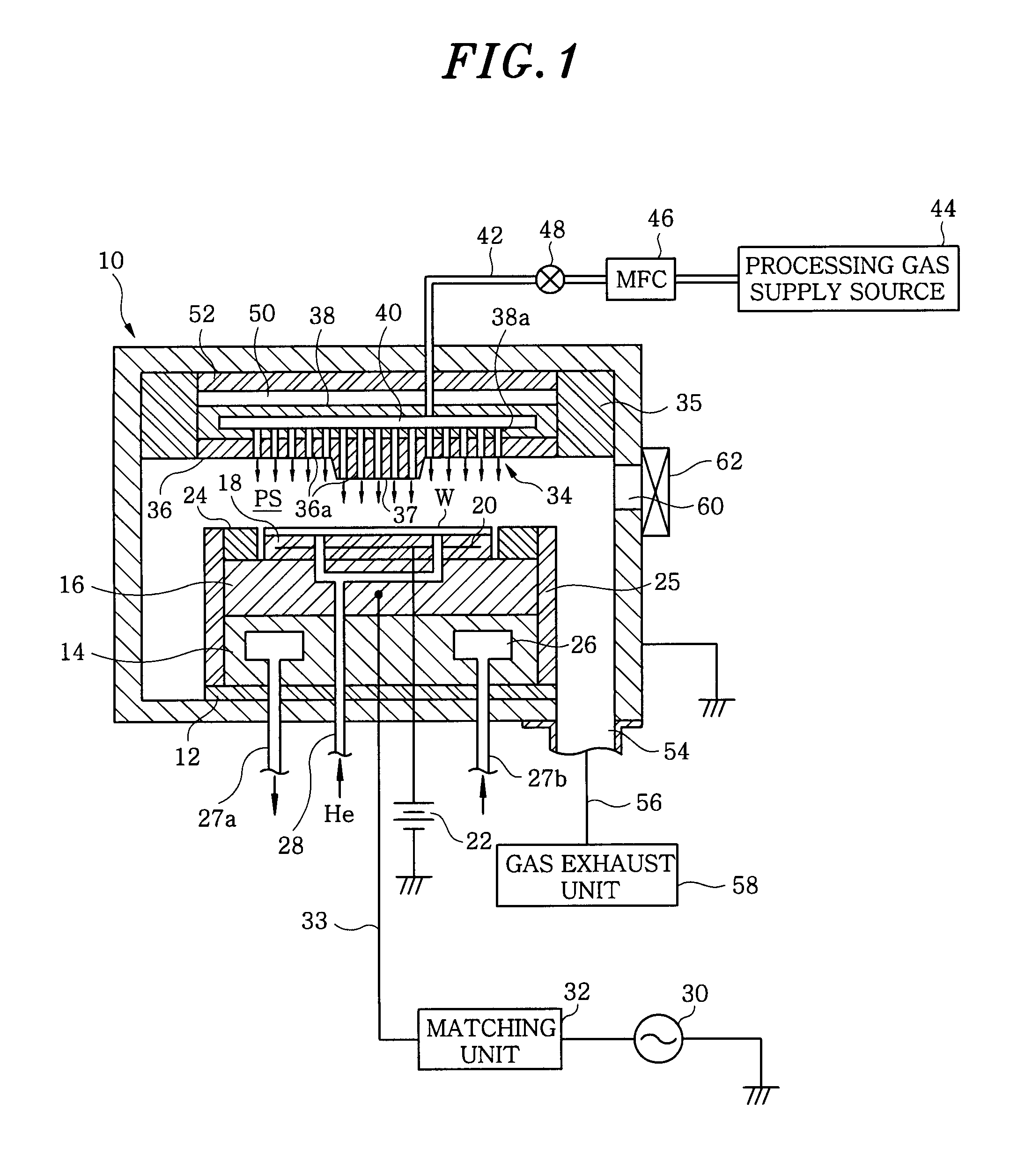

Capacitive coupling plasma processing apparatus

InactiveUS20060081337A1High planar uniformityPrevent charging damageCellsElectric discharge tubesCapacitanceTarget surface

A capacitive coupling plasma processing apparatus includes a process chamber configured to have a vacuum atmosphere, and a process gas supply section configured to supply a process gas into the chamber. In the chamber, a first electrode serving as a cathode electrode, and a second electrode grounded to serve as an anode electrode are disposed opposite each other. An RF power supply is disposed to supply an RF power to the first electrode to form an RF electric field within a plasma generation region between the first and second electrodes, so as to turn the process gas into plasma. The target substrate is supported by a support member between the first and second electrodes such that a process target surface thereof faces the second electrode. The second electrode includes a conductive counter surface facing the first electrode and exposed to the plasma generation region.

Owner:TOKYO ELECTRON LTD

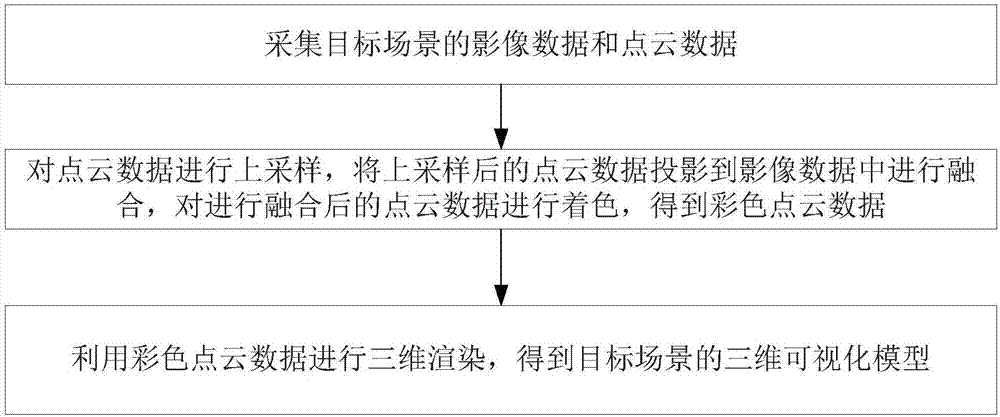

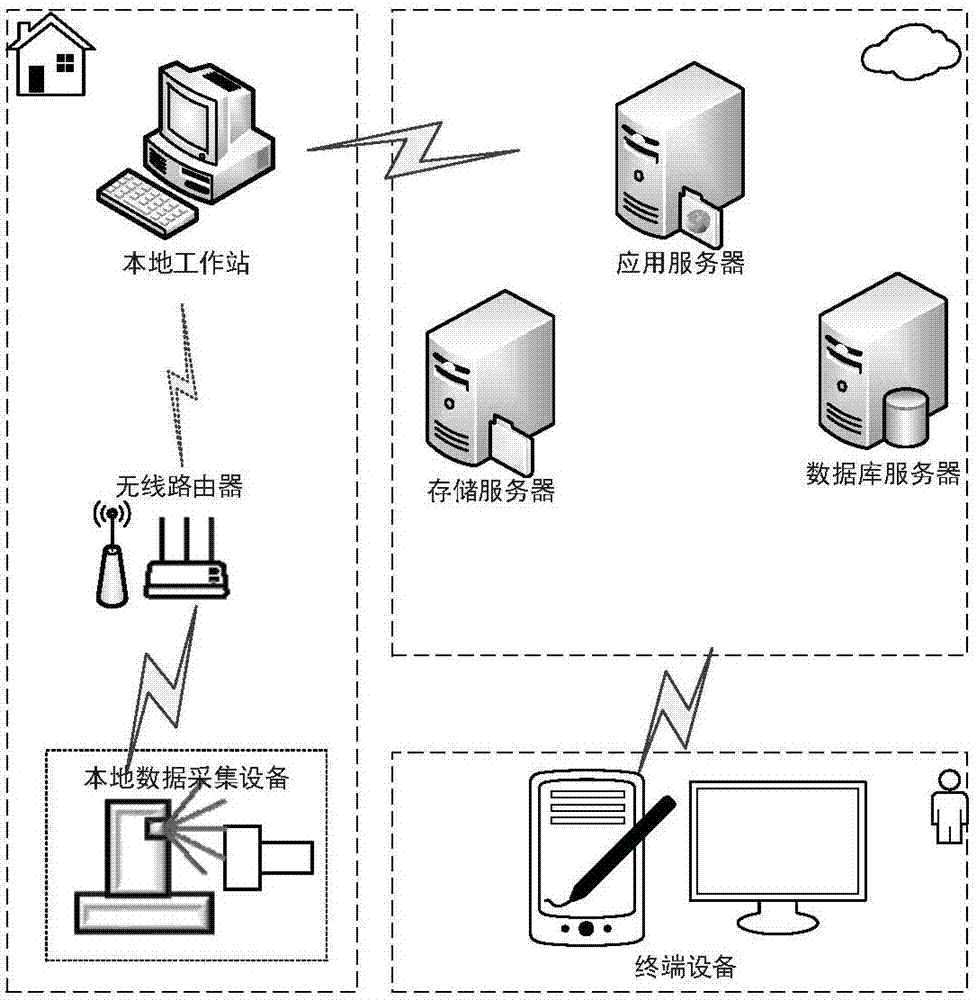

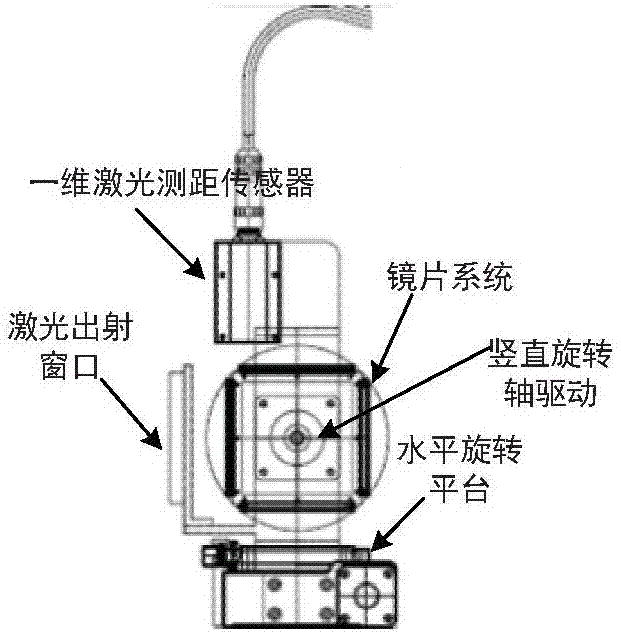

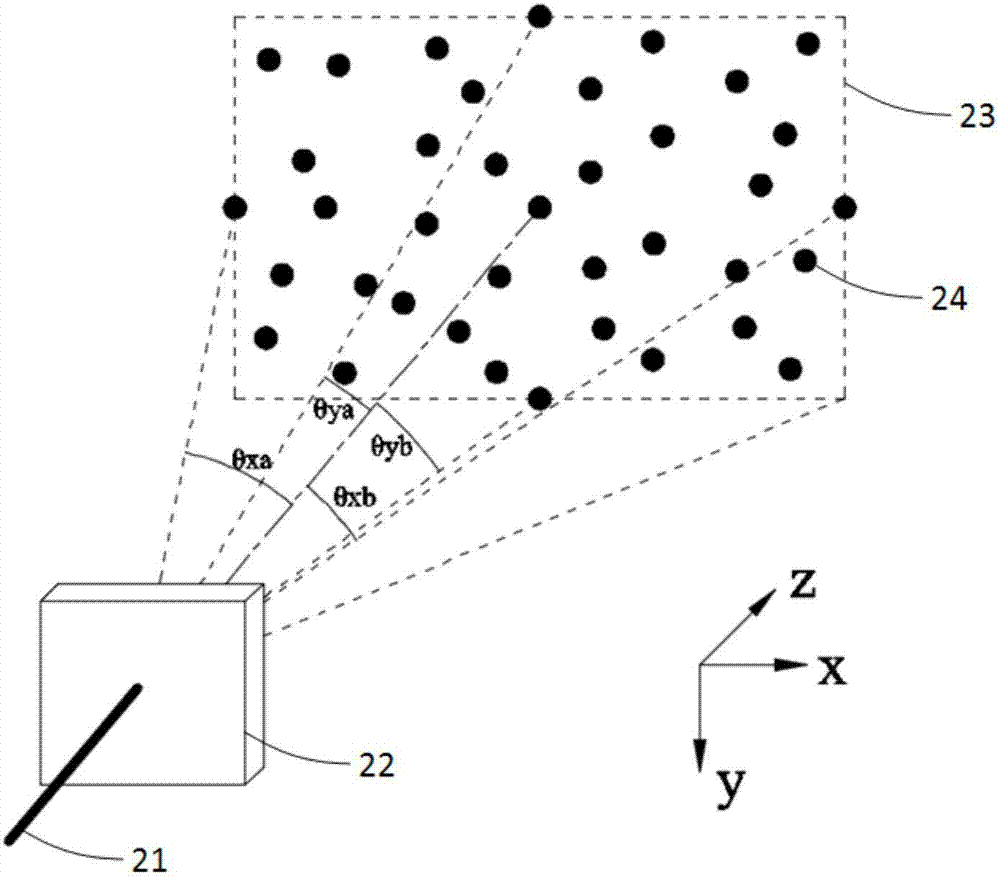

Three-dimensional visualization method based on point cloud and image data and system thereof

ActiveCN107194983AHigh resolutionIncrease profitImage enhancementImage analysisPoint cloudData acquisition

The invention discloses a three-dimensional visualization method based on point cloud and image data and a system thereof. The method comprises the following steps of collecting image data and point cloud data of a target scene; carrying out upsampling on the point cloud data, projecting the point cloud data after the upsampling to the image data so as to carry out fusion, coloring the fused point cloud data and acquiring the colorful point cloud data; and using the colorful point cloud data to carry out three-dimensional rendering and acquiring a three-dimensional visualization model of the target scene. In the invention, point-cloud three-dimensional visualization from data acquisition and fusion to final rendering display is realized, which is good for development of a laser point cloud technology; and accessibility and usability of the point cloud data to a common user are increased.

Owner:HUAZHONG UNIV OF SCI & TECH

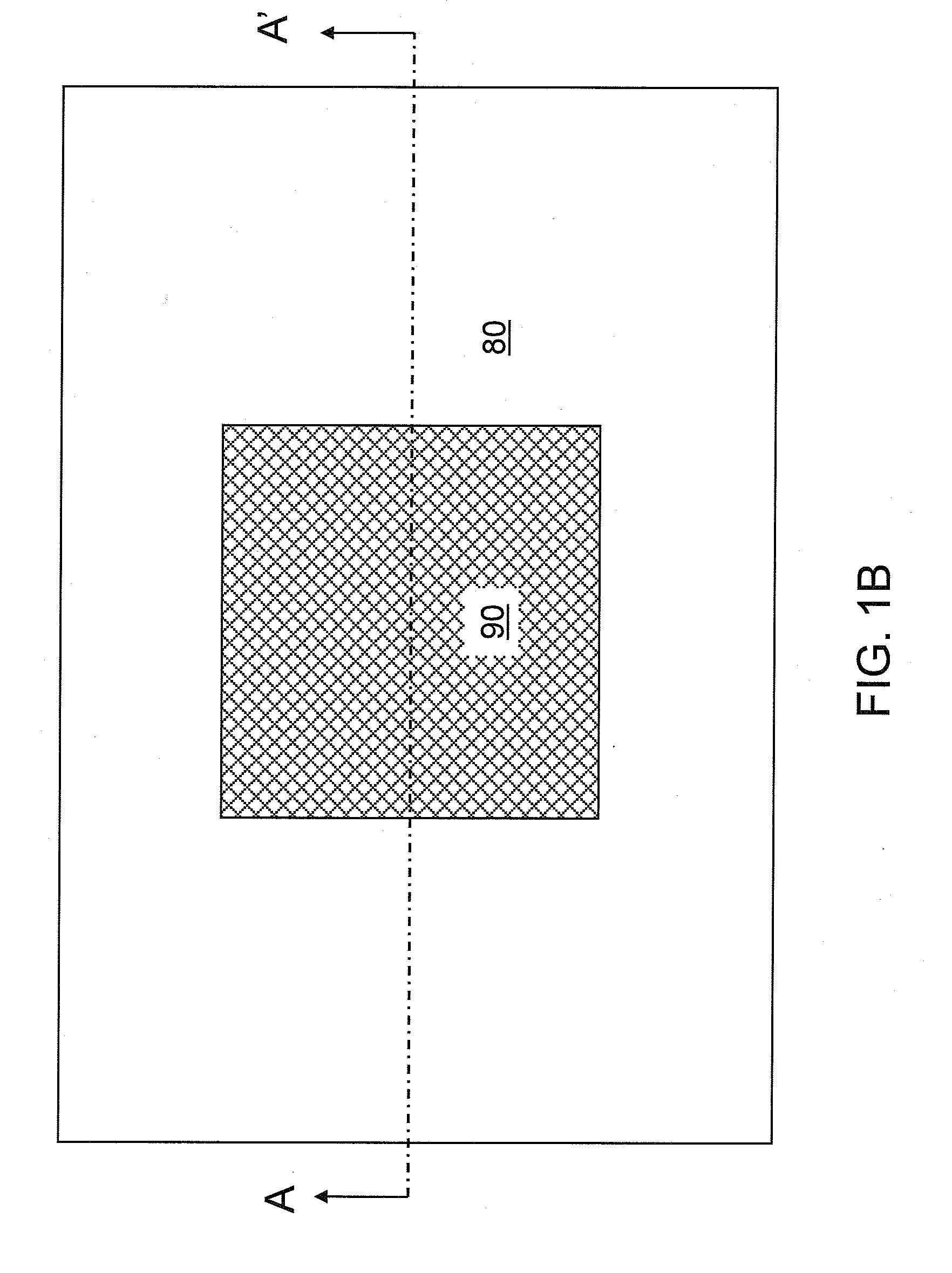

Metal wiring structures for uniform current density in c4 balls

ActiveUS20100263913A1Improve reliabilityFacilitates uniform current density distributionSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical connection

In one embodiment, a sub-pad assembly of metal structures is located directly underneath a metal pad. The sub-pad assembly includes an upper level metal line structure abutting the metal pad, a lower level metal line structure located underneath the upper level metal line structure, and a set of metal vias that provide electrical connection between the lower level metal line structure located underneath the upper level metal line structure. In another embodiment, the reliability of a C4 ball is enhanced by employing a metal pad structure having a set of integrated metal vias that are segmented and distributed to facilitate uniform current density distribution within the C4 ball. The area1 density of the cross-sectional area in the plurality of metal vias is higher at the center portion of the metal pad than at the peripheral portion of the planar portion of the metal pad.

Owner:GLOBALFOUNDRIES US INC

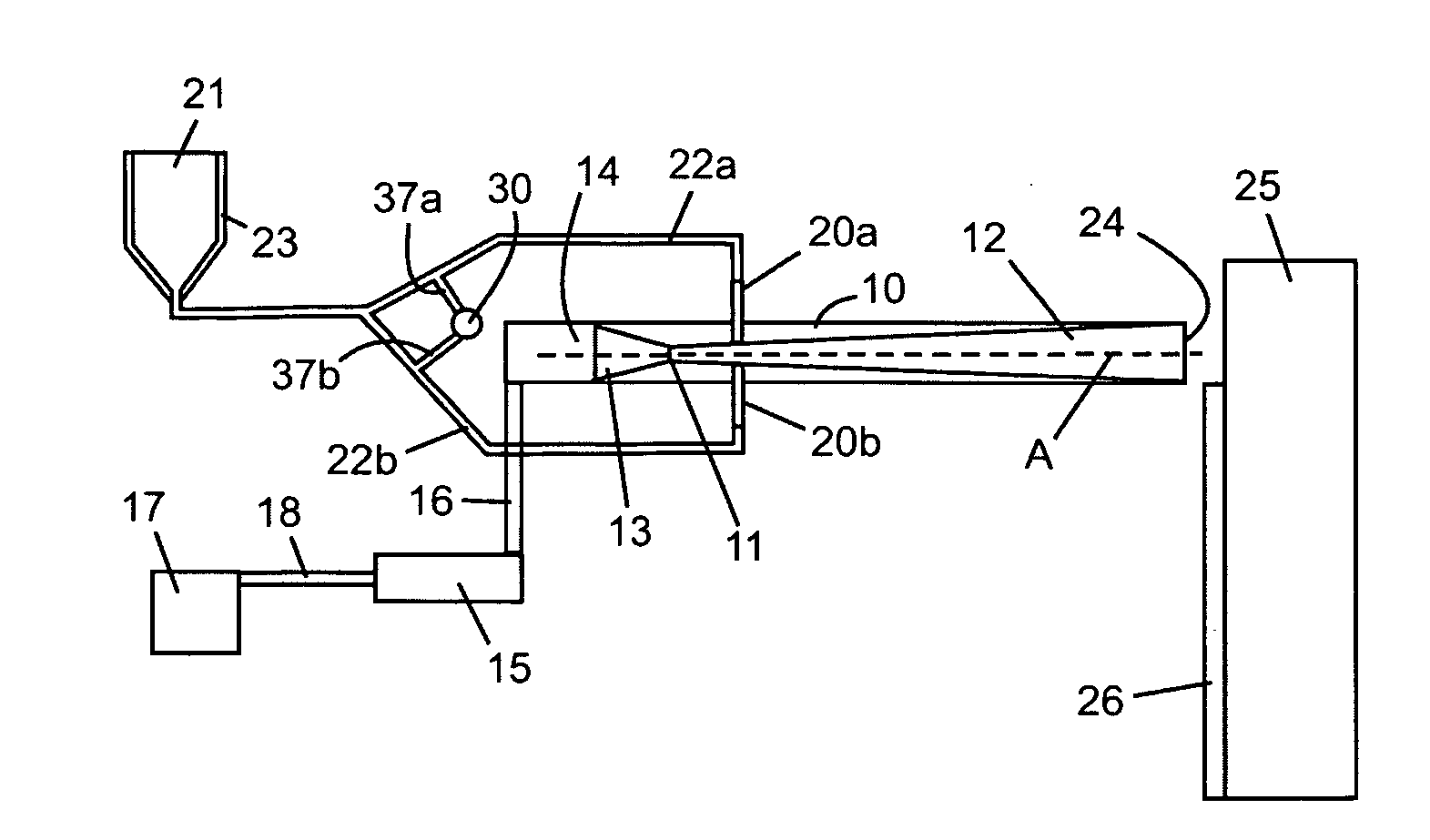

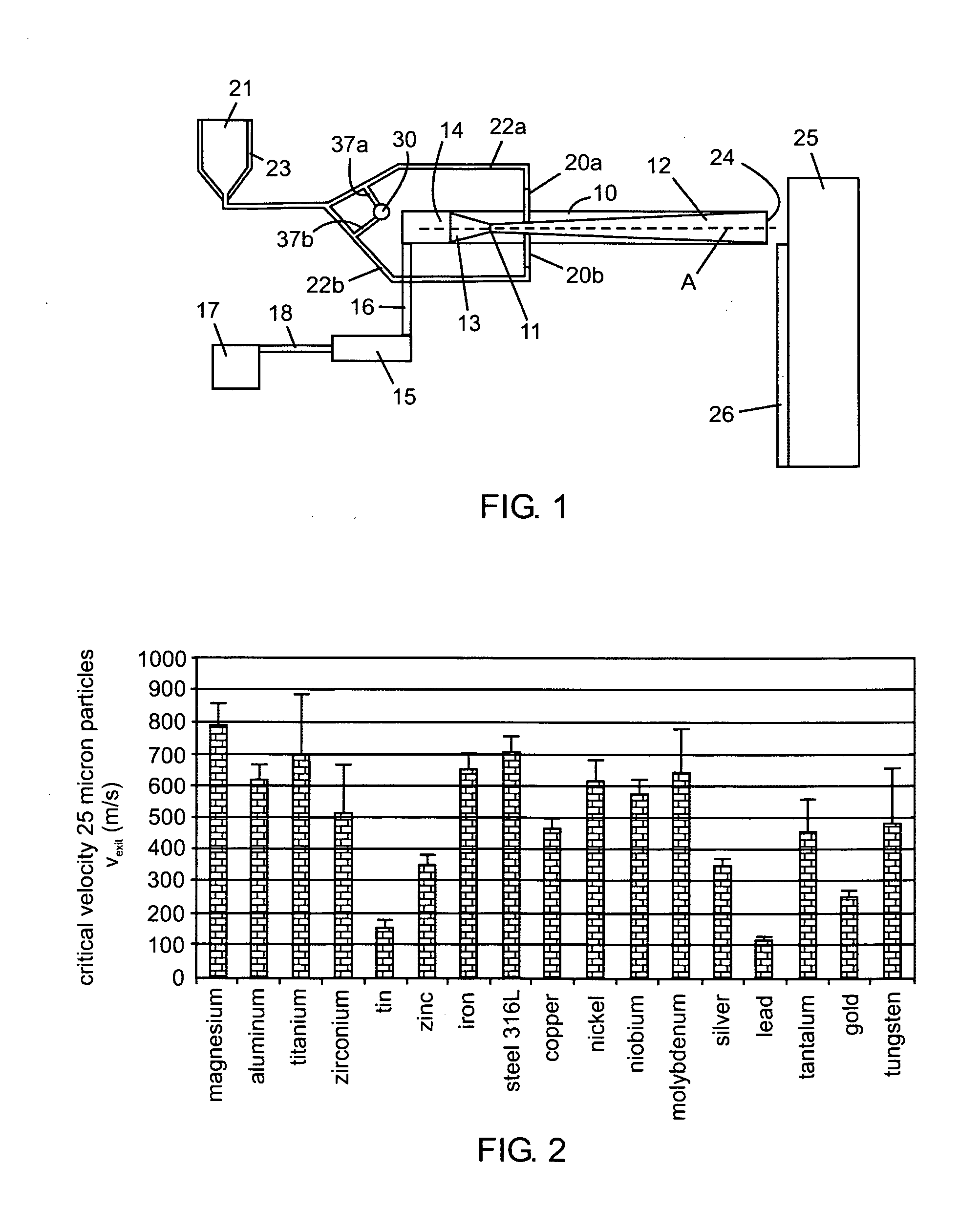

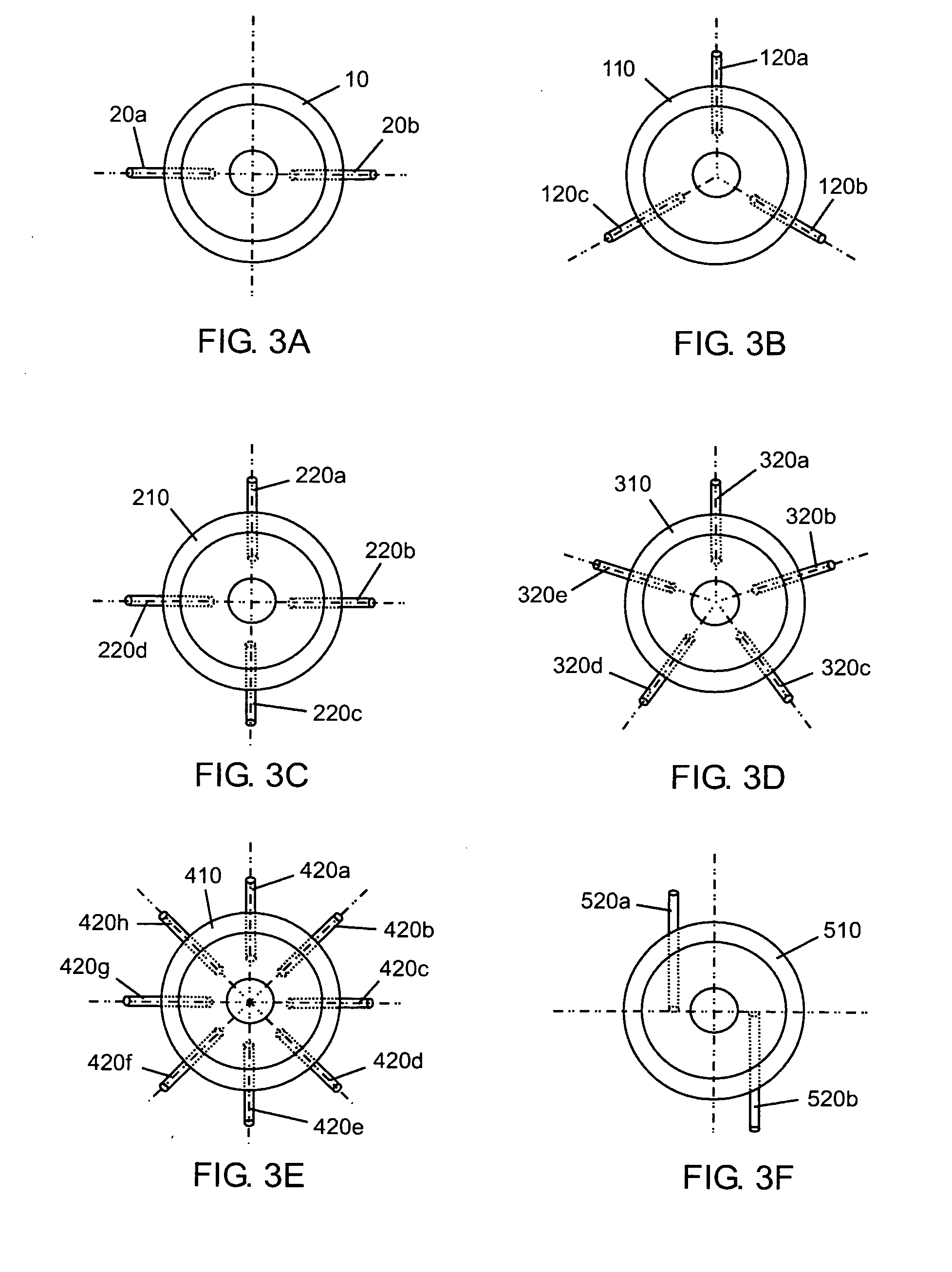

Cold gas dynamic spray apparatus, system and method

ActiveUS20100151124A1Large operating rangeEasy to clogLiquid surface applicatorsMolten spray coatingInjection pressureSpray nozzle

A system for cold gas dynamic spraying of particulate material has a de Laval nozzle and two or more radial particle inlets located between the throat and the outlet of the nozzle, the two or more particle inlets arranged symmetrically around a linear flow path of the nozzle. Blocking of the inlets is reduced by controlling pressure of particle carrier gas to provide a stable particulate material injection pressure before and during introduction of working gas into the nozzle, and / or by clearing the particle inlets of residual particles after a spraying process. Such a system and associated method combines benefits of both downstream and upstream cold gas spray systems. Further, a nozzle for spraying particulate material having a cross-sectional shape that is narrower in a middle section compared to edge sections provides coatings with superior cross-sectional profiles.

Owner:NAT RES COUNCIL OF CANADA

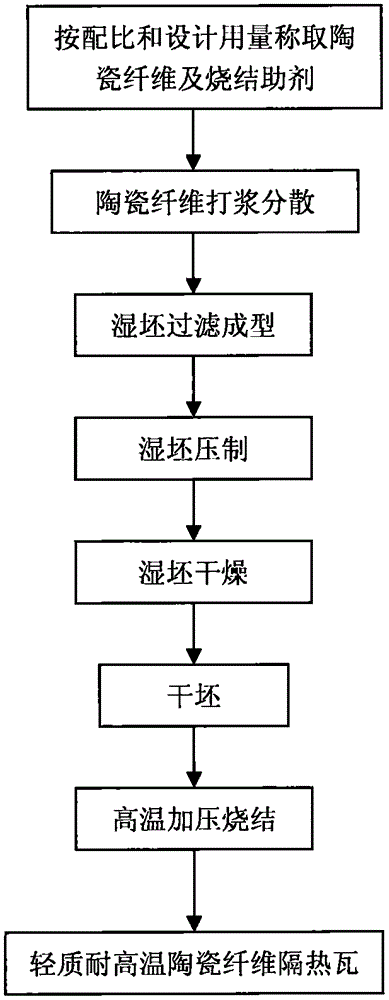

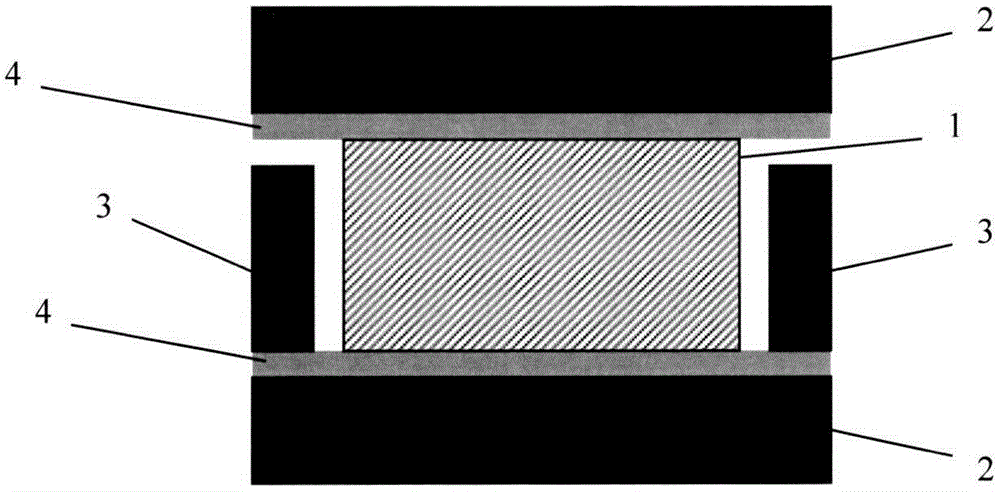

Light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and making method thereof

ActiveCN105272322AOvercome the problem of uneven distributionImprove mechanical propertiesRoom temperatureSlurry

The invention relates to a light-weight, high temperature-resistance and heat-insulation ceramic fiber tile and a making method thereof. The heat insulation tile comprises ceramic fibers and boron oxide, wherein the ceramic fibers comprise quartz fibers, alumina fibers and yttrium oxide stabilized zirconia fibers. The making method of the light-weight, high temperature-resistance and heat-insulation ceramic fiber tile comprises the following steps: preparing a sintering aid suspension, preparing a ceramic fiber slurry, carrying out wet green body molding, drying the obtained wet green body, and carrying out pressurization sintering. The heat insulation tile has good heat insulation effect and mechanical performances, has light weight and resists high temperature; the density is controllable between 0.10g / cm<3> and 0.90g / cm<3>; the lowest apparent heat conduction coefficient at room temperature reaches 0.033W / (m.K); the compressive strength at room temperature is greater than 3.0Mpa; and the long-time use temperature can reach 1350DEG C.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

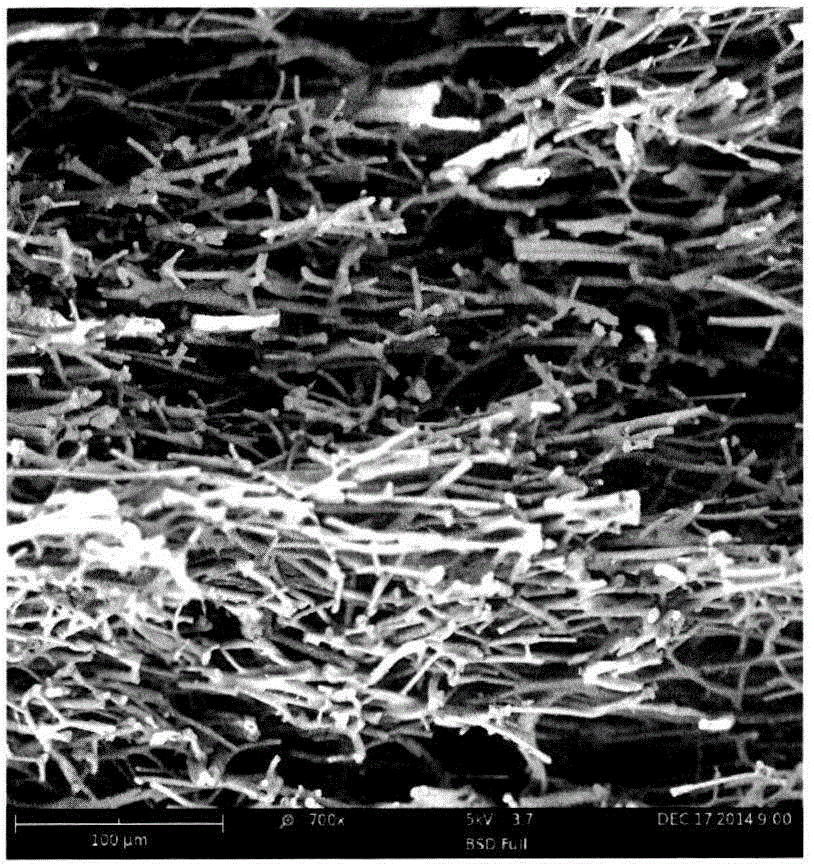

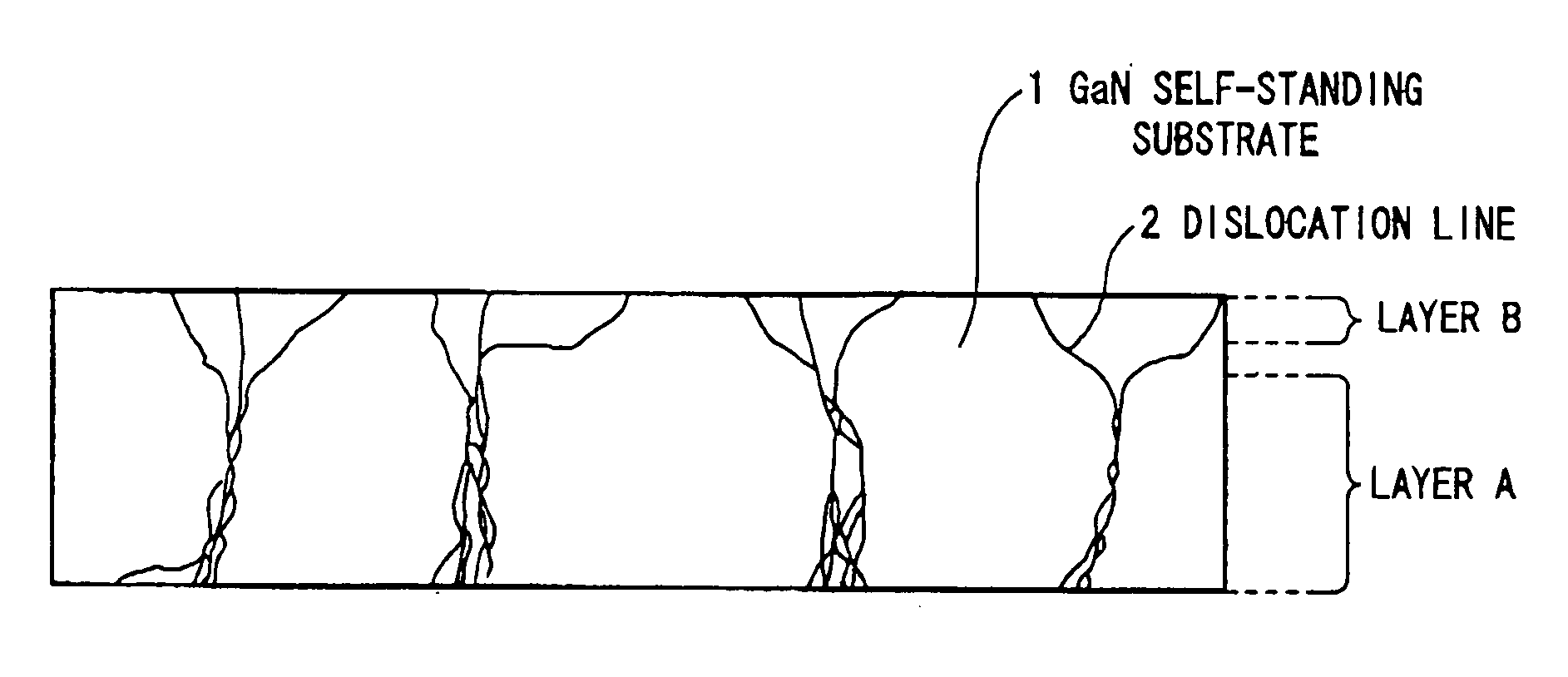

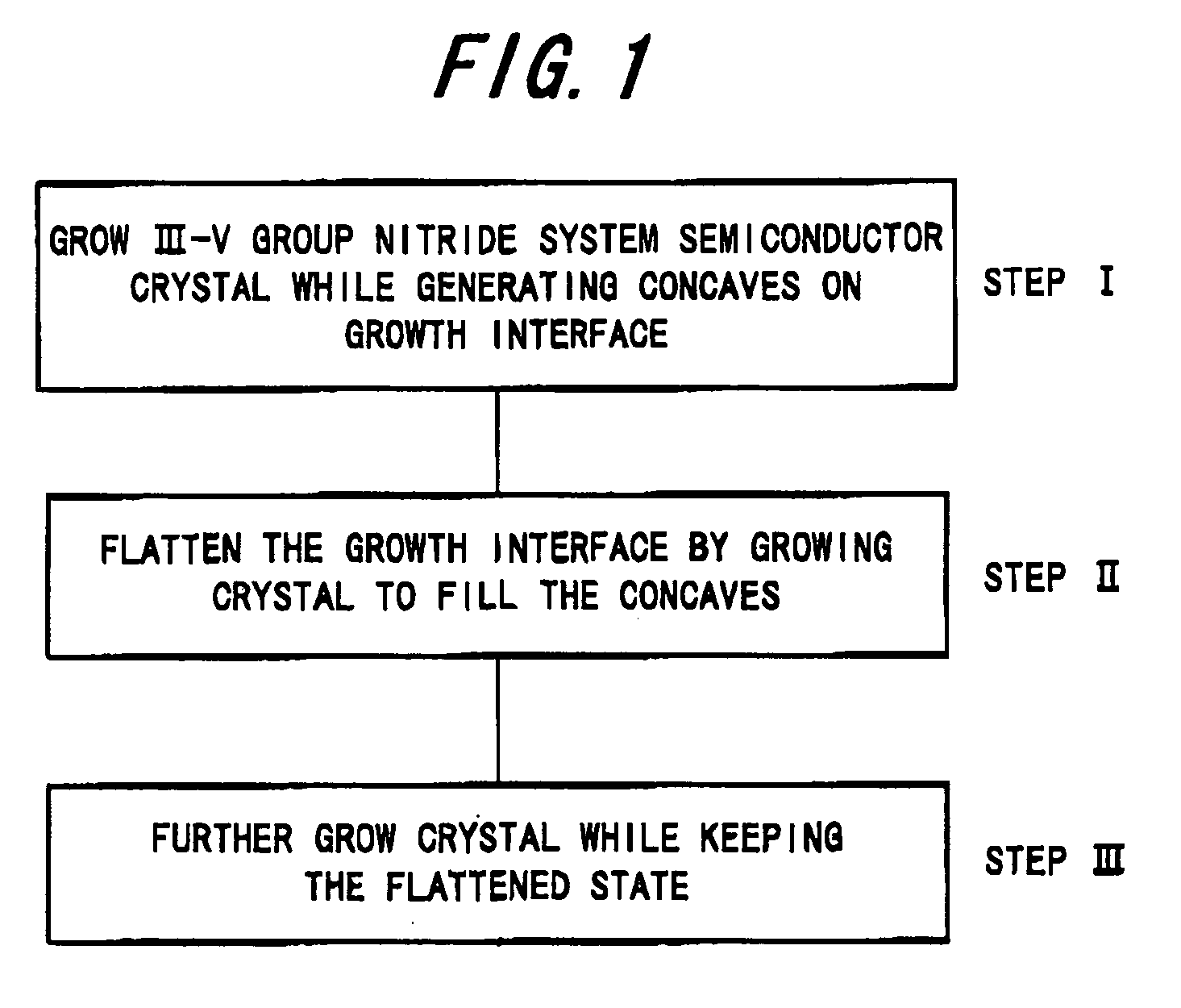

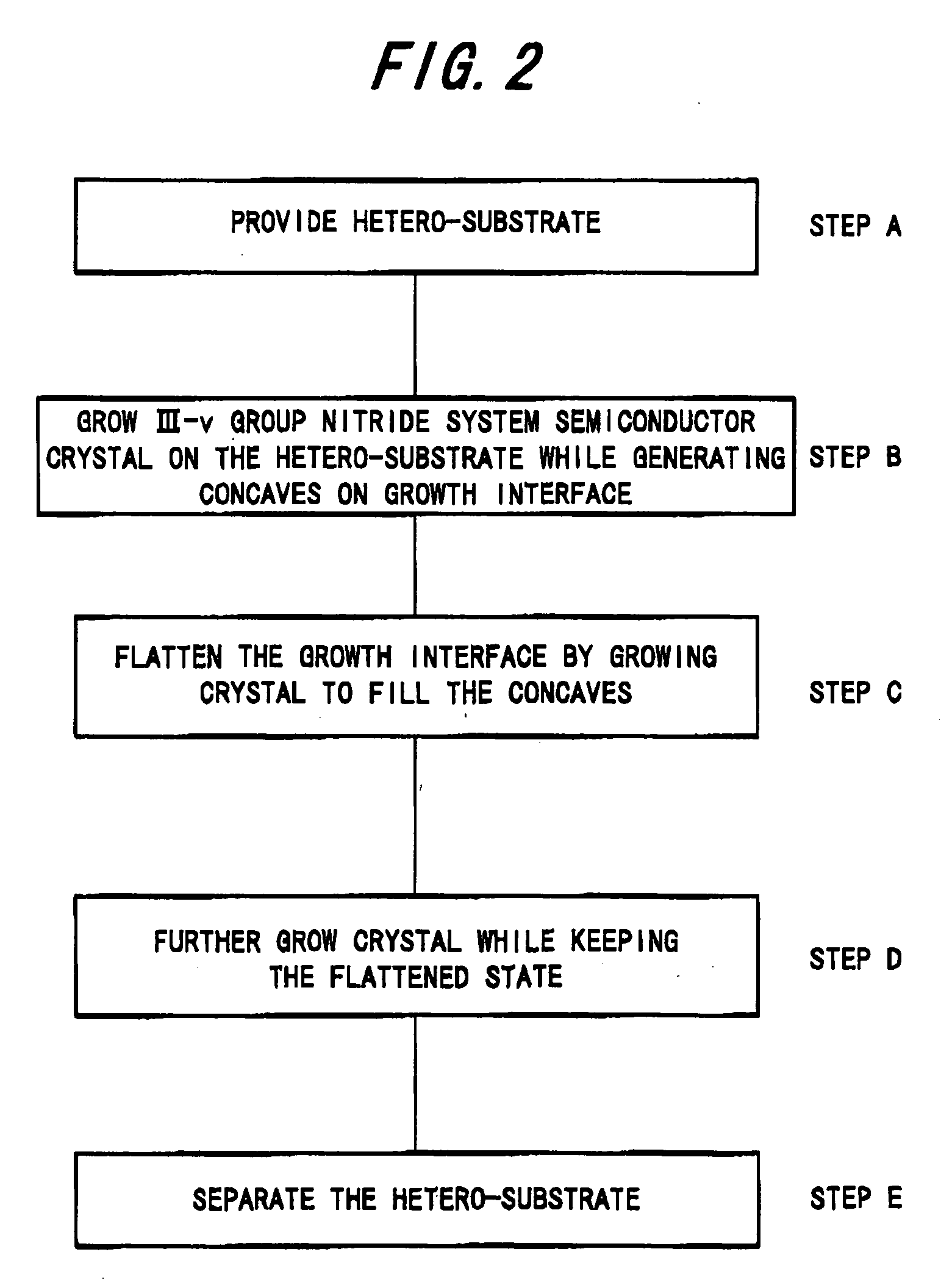

III-V group nitride system semiconductor self-standing substrate, method of making the same and III-V group nitride system semiconductor wafer

ActiveUS20060033119A1Improve crystal qualityLess distortionPolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingDensity distribution

A III-V group nitride system semiconductor self-standing substrate has: a first III-V group nitride system semiconductor crystal layer that has a region with dislocation lines gathered densely, the dislocation lines being gathered substantially perpendicular to a surface of the substrate, and a region with dislocation lines gathered thinly; and a second III-V group nitride system semiconductor crystal layer that is formed up to 10 μm from the surface of the substrate on the first III-V group nitride system semiconductor crystal layer and that has a dislocation density distribution that is substantially uniform.

Owner:SUMITOMO CHEM CO LTD

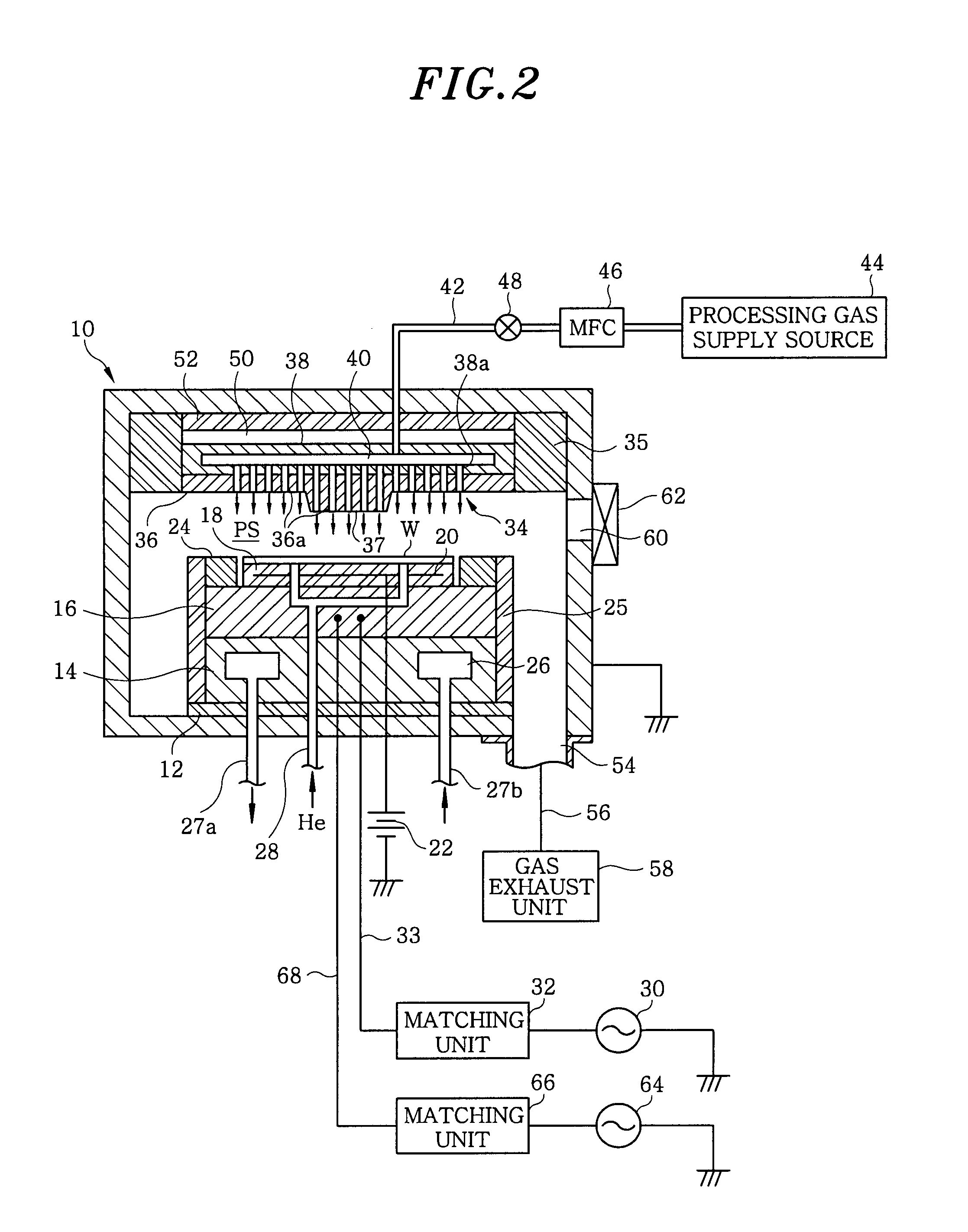

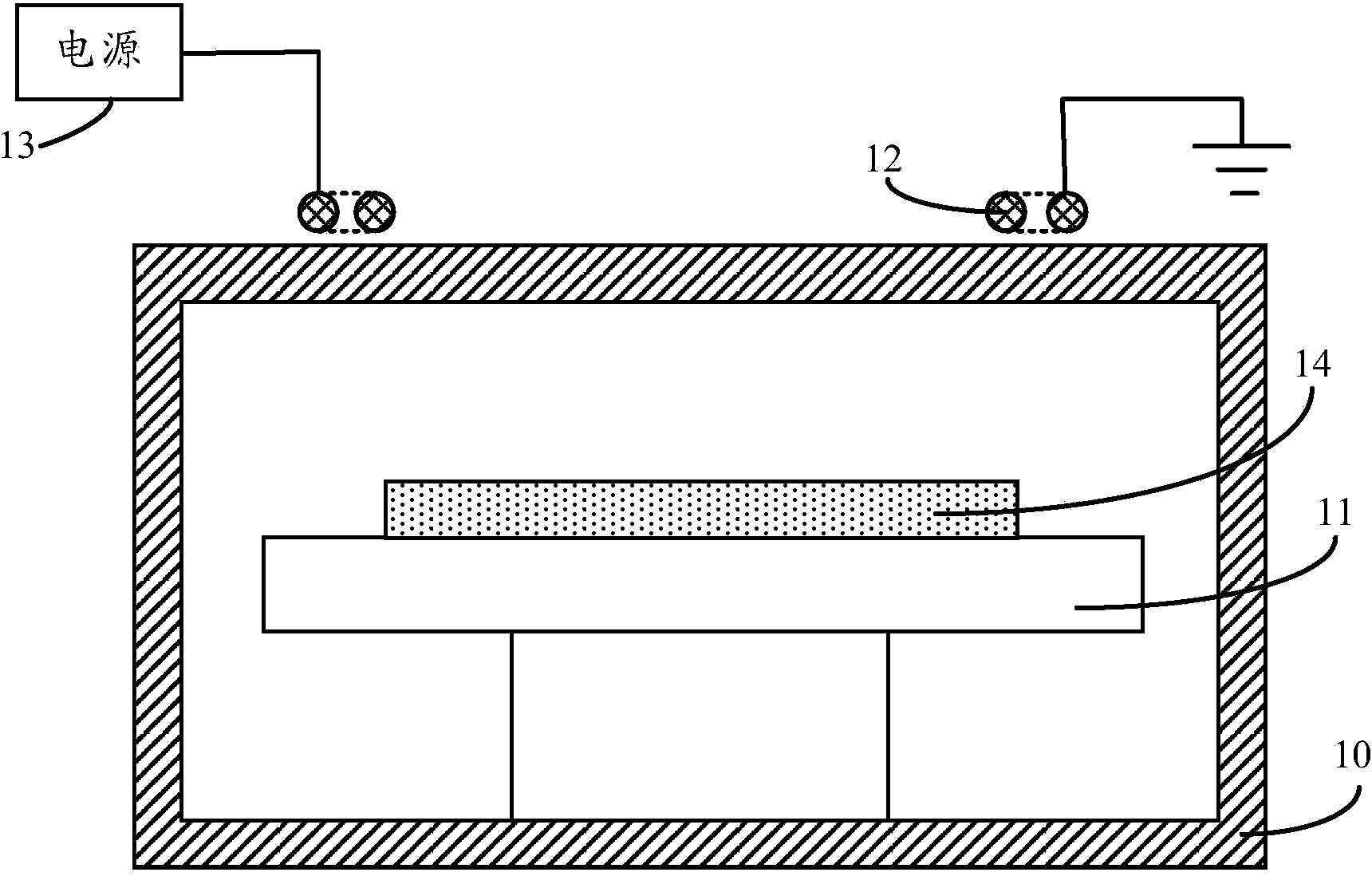

Plasma processing apparatus

InactiveUS20070227666A1Improving in-surface uniformityImprove surface uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyPlasma processing

A plasma processing apparatus includes a processing vessel capable of being vacuum evacuated; a first electrode installed in the processing vessel to be in a state electrically floating via an insulating member or a space; a second electrode disposed in the processing vessel to be in parallel to the first electrode with a specific interval, for supporting a target substrate thereon to face the first electrode; a processing gas supply unit for supplying a processing gas into a processing space between the first electrode, the second electrode and a sidewall of the processing vessel; and a first radio frequency power supply unit for applying a first radio frequency power to the second electrode to generate a plasma of the processing gas in the processing space. A protrusion projected toward the second electrode is formed at a central portion of the first electrode.

Owner:TOKYO ELECTRON LTD

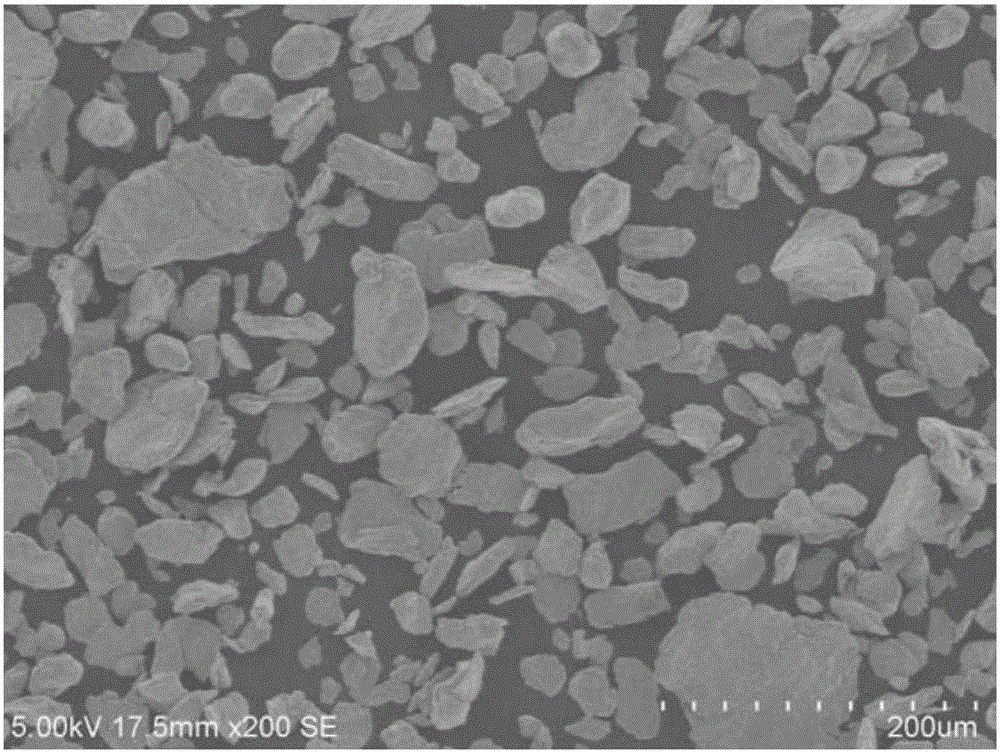

Preparation method of Fe-based metal soft magnetic powder core

ActiveCN105185560APowder moldingEasy to shapeInorganic material magnetismInductances/transformers/magnets manufactureEpoxyMaterials preparation

The invention relates to a preparation method of a Fe-based metal soft magnetic powder core, and belongs to the technical field of magnetic material preparation. The method comprises the following steps: with Fe-based flake-like metal soft magnetic powder as raw material powder, carrying out annealing treatment; carrying out passivation and insulated coating treatment on the annealed powder; carrying out drying treatment on the passivated and insulated powder; pressing the dried metal powder into a magnetic powder core blank, and adopting zinc stearate powder as a releasing agent; and carrying out annealing treatment on the molded magnetic powder core blank and spraying a layer of epoxy resin insulating paint on the surface of the magnetic powder core blank, so as to obtain the metal soft magnetic powder core. The density of the magnetic powder core prepared by the method is greatly improved; the density distribution is even; the magnetic powder core has relatively high compactness and good mechanical strength; and meanwhile, the magnetic powder core has relatively high magnetic conductivity and relatively low magnetic loss. In addition, the prepared magnetic powder core also has the characteristics of high magnetic conductivity, high quality factor and low loss.

Owner:有研增材技术有限公司

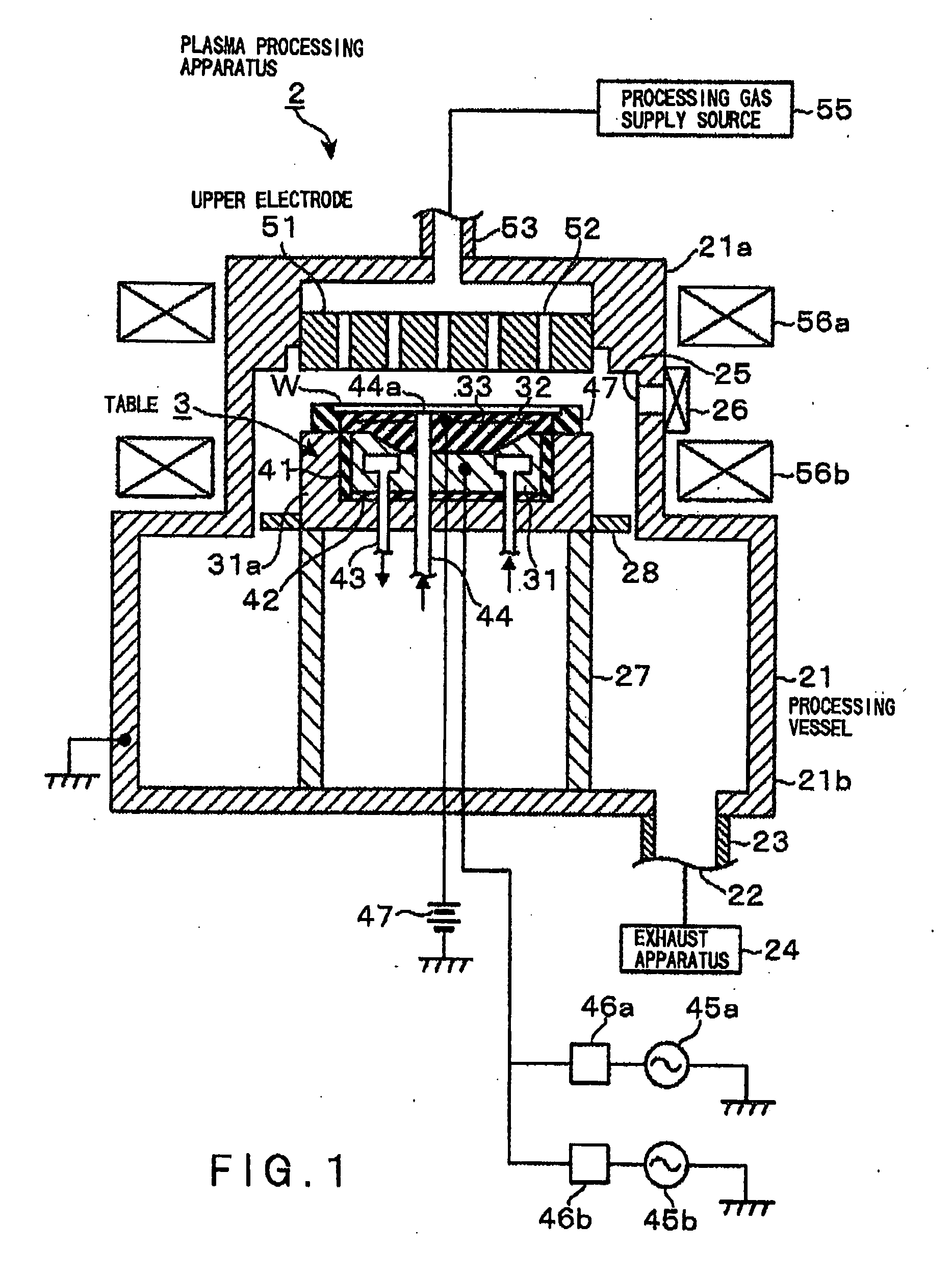

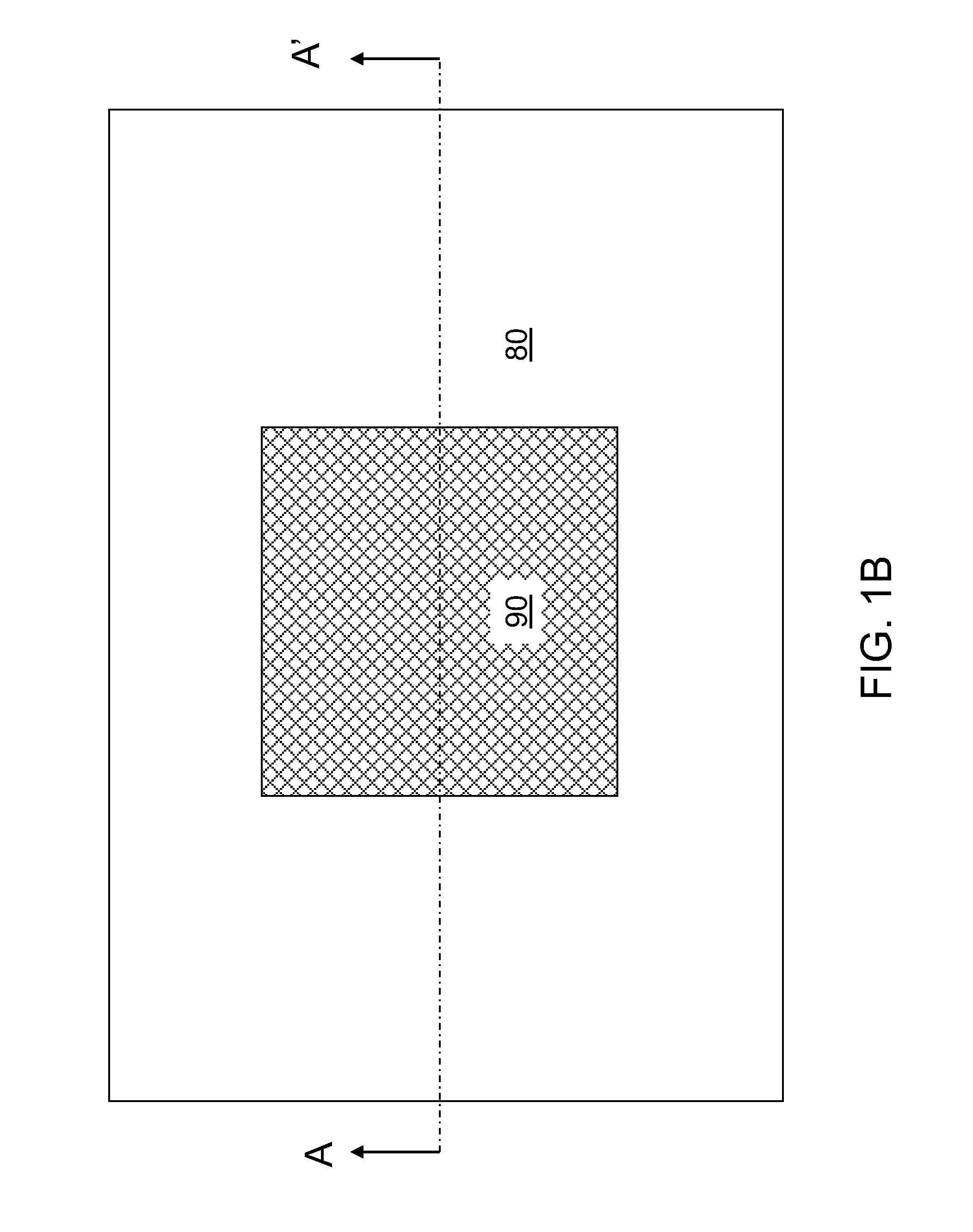

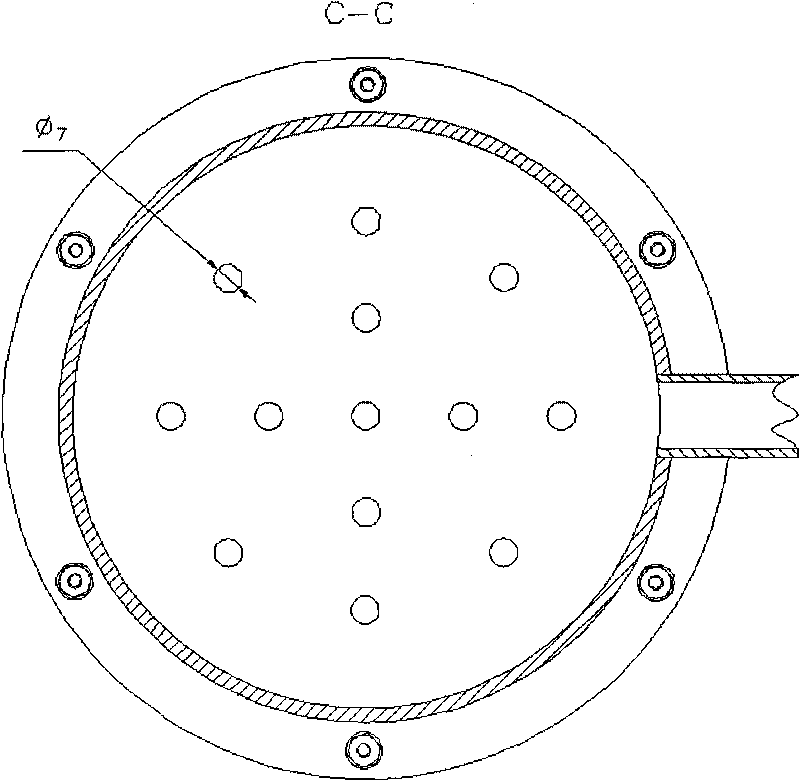

Table for plasma processing apparatus and plasma processing apparatus

InactiveUS20090101284A1Avoiding and suppressing damageUniform density distributionElectric discharge tubesSemiconductor/solid-state device manufacturingIn planeHigh frequency power

An object of the present invention is to suppress damage of an electrostatic chuck, by controlling stress exerted on each part of a table, which includes an electrically conductive material, i.e., an electrode for generating plasma, a dielectric layer for enhancing the in-plane uniformity of a plasma process, and an electrostatic chuck. The table for a plasma processing apparatus includes an electrically conductive member connected with a high frequency power source and adapted for plasma generation, for drawing ions present in the plasma, or for both thereof; a dielectric layer provided on a top face of the electrically conductive member, having a central portion and a peripheral portion that are different in thickness relative to each other, and adapted for providing uniformity of high frequency electric field intensity in a plane over the substrate to be processed; and an electrode film for an electrostatic chuck, provided in the dielectric layer and adapted for electrostatically chucking the substrate onto a top face of the dielectric layer. With such configuration, the stress exerted on the electrostatic chuck due to temperature change can be controlled.

Owner:TOKYO ELECTRON LTD

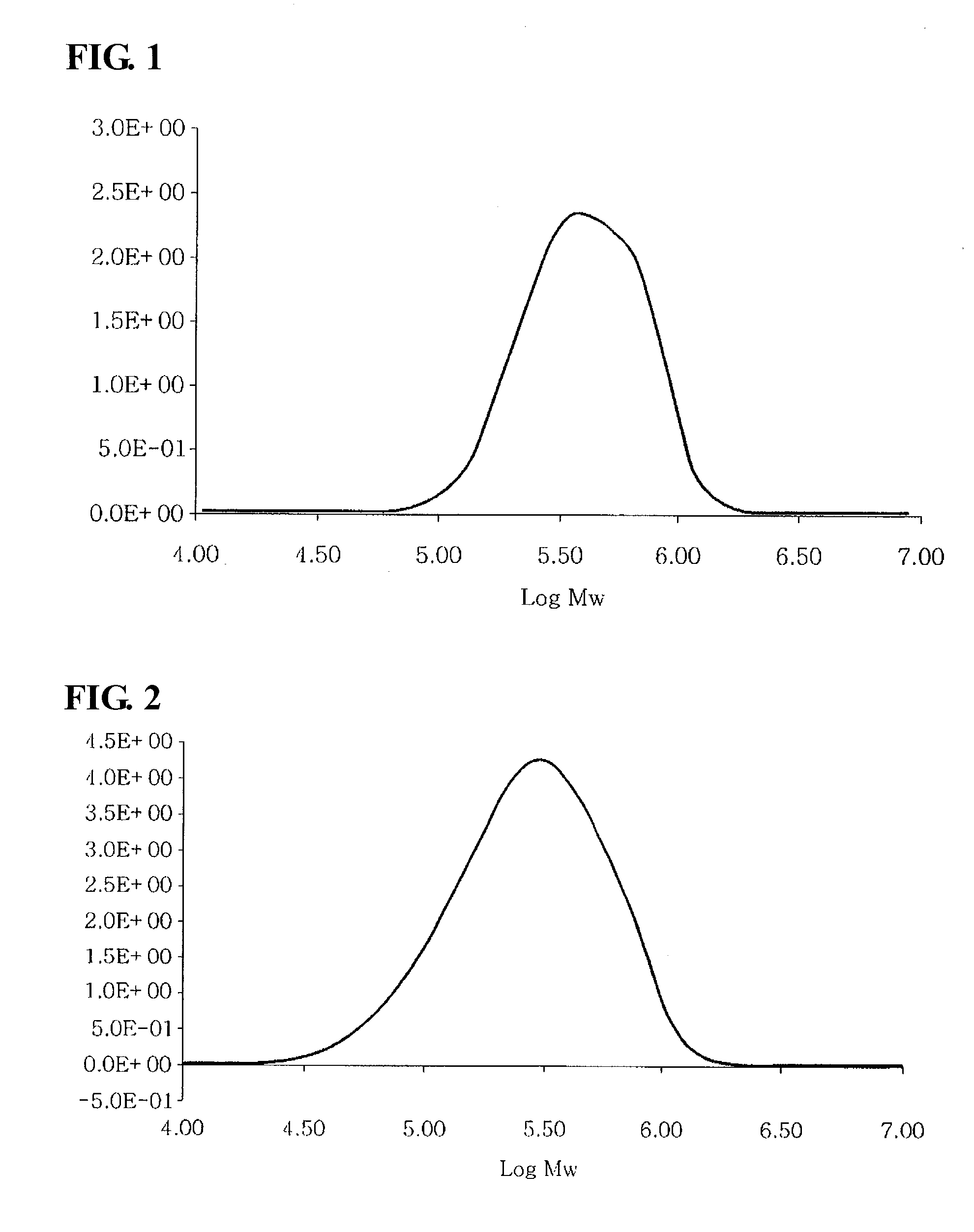

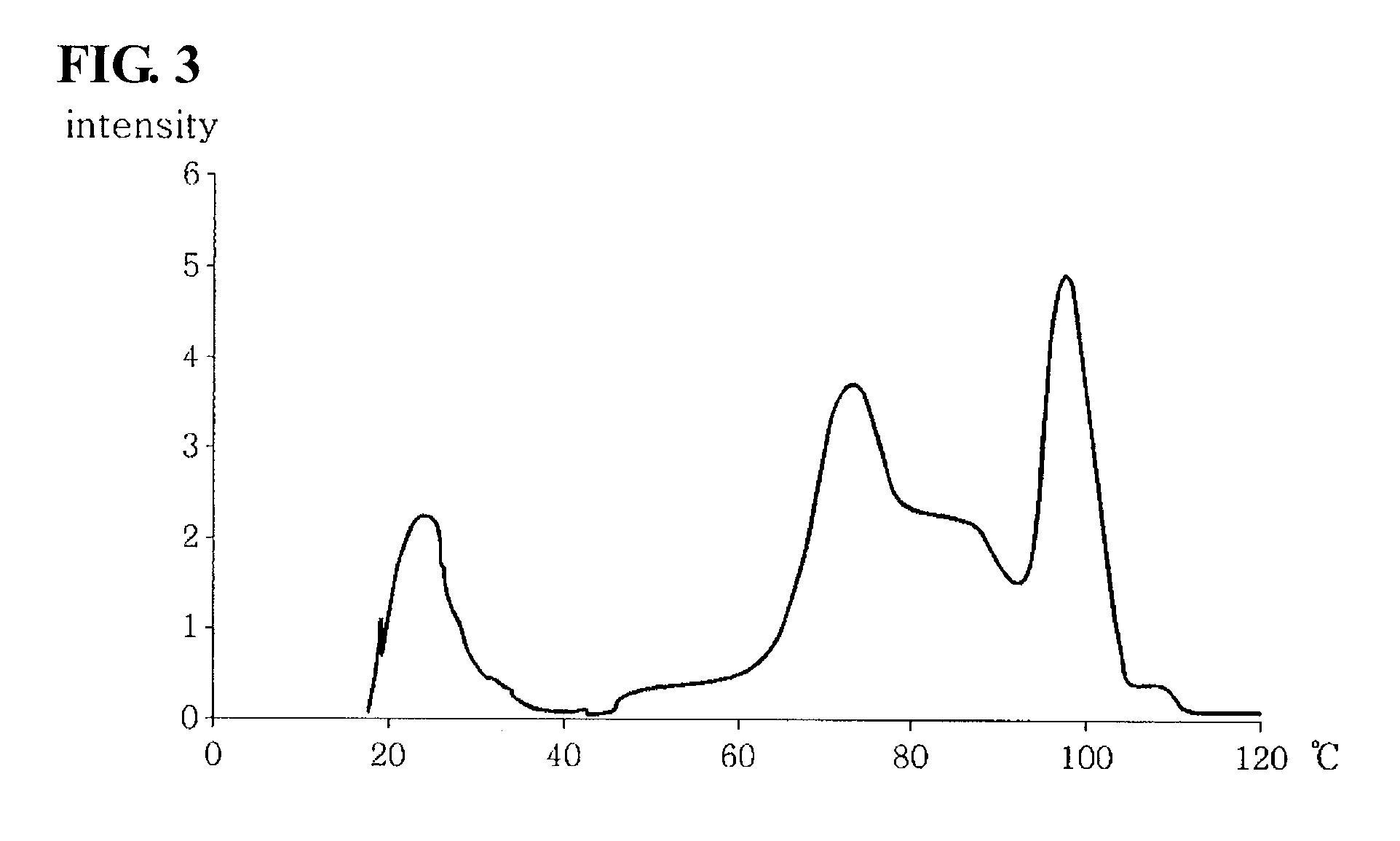

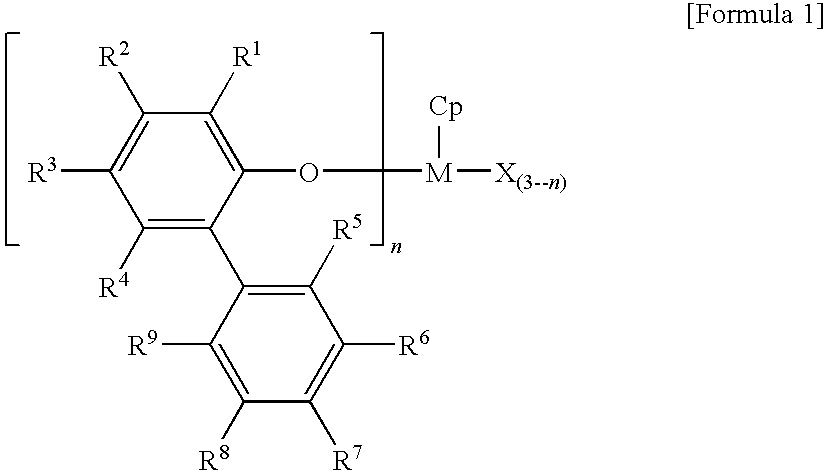

Ethylene copolymer having multiple pitch molecular weight distribution and the method of preparing the same

ActiveUS8076428B2Easy to processMaintain good propertiesThin material handlingMedium densityDensity distribution

Disclosed are an ethylene polymerization process, a catalyst for use in the process, a production method employing the catalyst, and a product produced thereby. More specifically, disclosed is a process of producing an ethylene copolymer from ethylene and an alpha-olefin comonomer, in which the produced ethylene copolymer has a multimodal molecular weight distribution and excellent processability and physical properties, and thus can increase the value and productivity of products, including pipes and films. Particularly, the produced ethylene copolymer has a trimodal or higher molecular weight distribution or density distribution, and thus, when it is a linear low-density copolymer, it has an excellent effect of improving the impact strength of films, and when it is a medium-density ethylene copolymer, it can be produced into pipes, which have slow crack growth rate and can be used even at high temperature.

Owner:SABIC NEXLENE CO PTE LTD

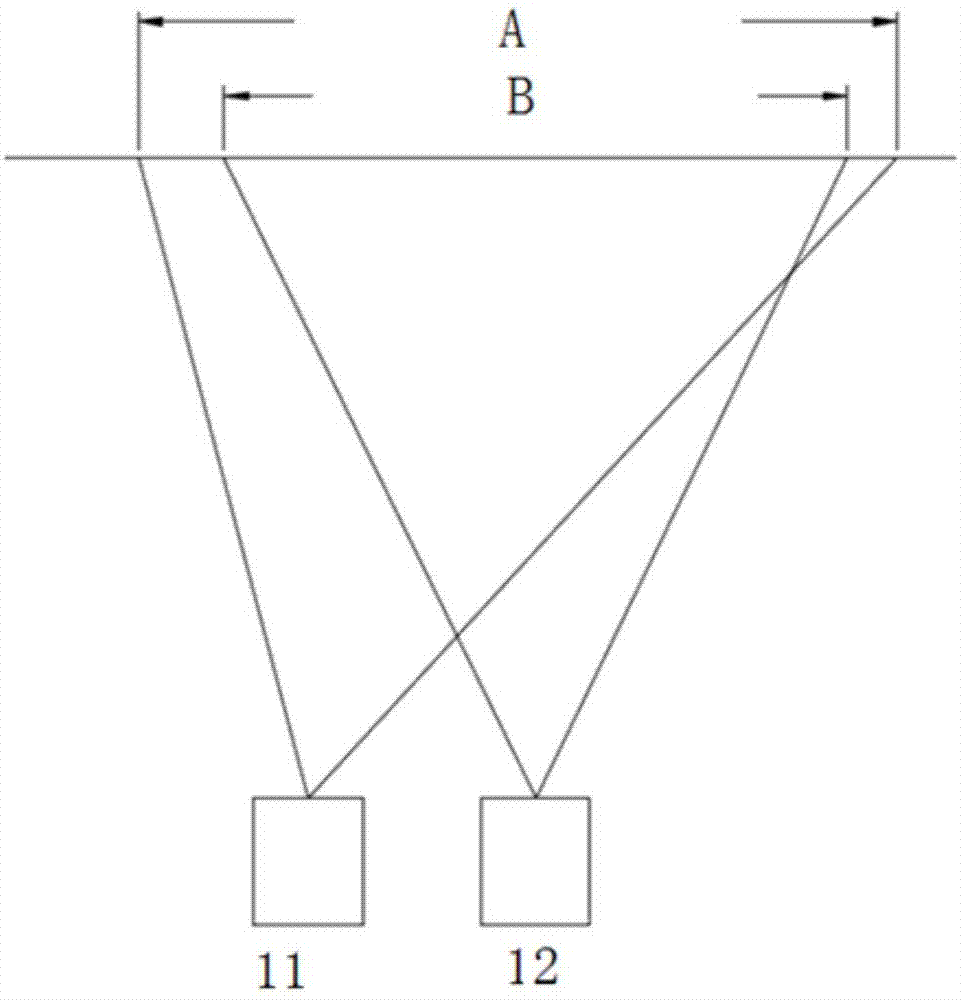

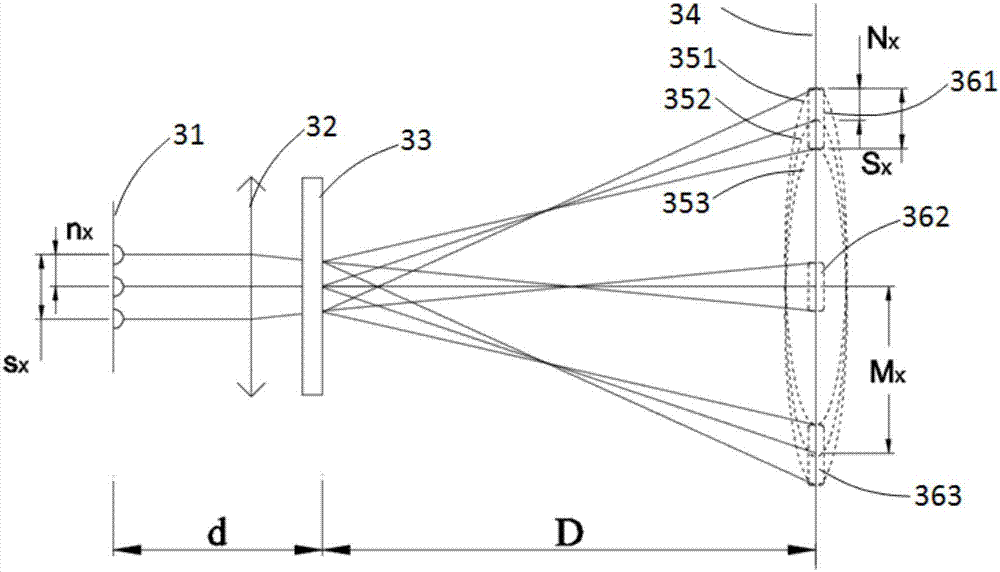

Diffractive optical element and preparation method

ActiveCN107450190AUniform density distributionSatisfies irrelevanceStereoscopic photographyOptical elementsDensity distributionLight beam

The present invention discloses a diffractive optical element used for a structural light projection module, and the structural light projection module comprises a light source; a plurality of sub-light sources which are arranged into a two dimensional array and are used for emitting the two dimensional patterned light beams consistent with the two dimensional array; the diffractive optical element used for receiving the two dimensional patterned light beams and generating multiple stages of diffractive light beams, wherein the diffractive optical element is configured to project the plurality of two dimensional patterned light beams which are not overlapped with each other, each two dimensional patterned light beam generates a copy pattern correspondingly, and the plurality of copy patterns which are not overlapped with each other form the density distribution uniform spot patterns. The present invention also discloses a method of using the diffractive optical element to prepare the structural light projection module. According to the present invention, by preparing the diffractive optical element for the structural light projection module, the density distribution uniform combined spot patterns can be projected on the condition of satisfying the irrelevance.

Owner:SHENZHEN ORBBEC CO LTD

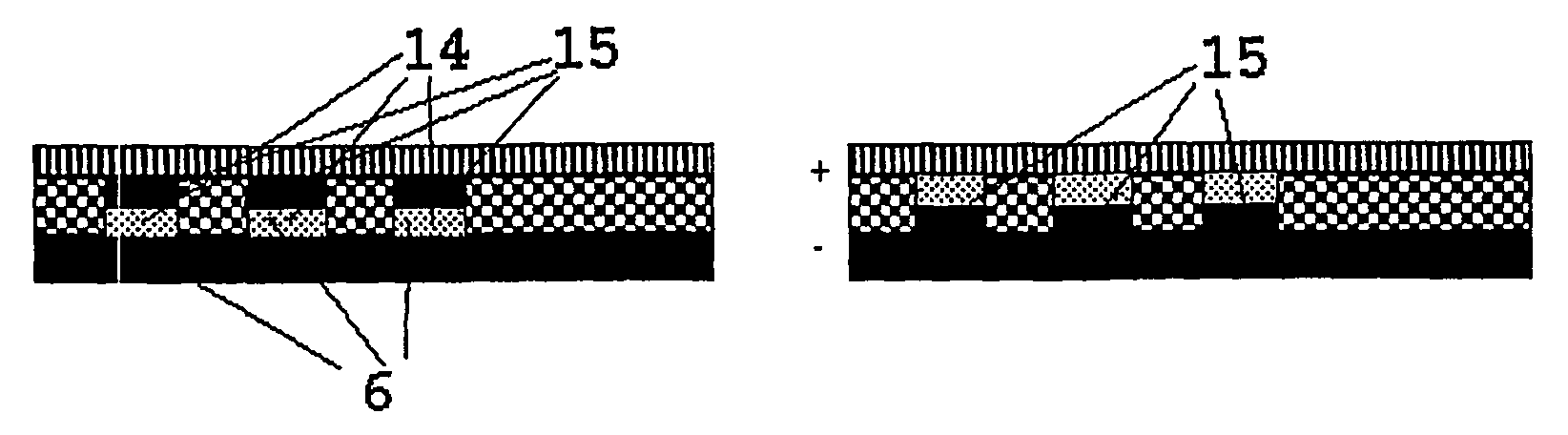

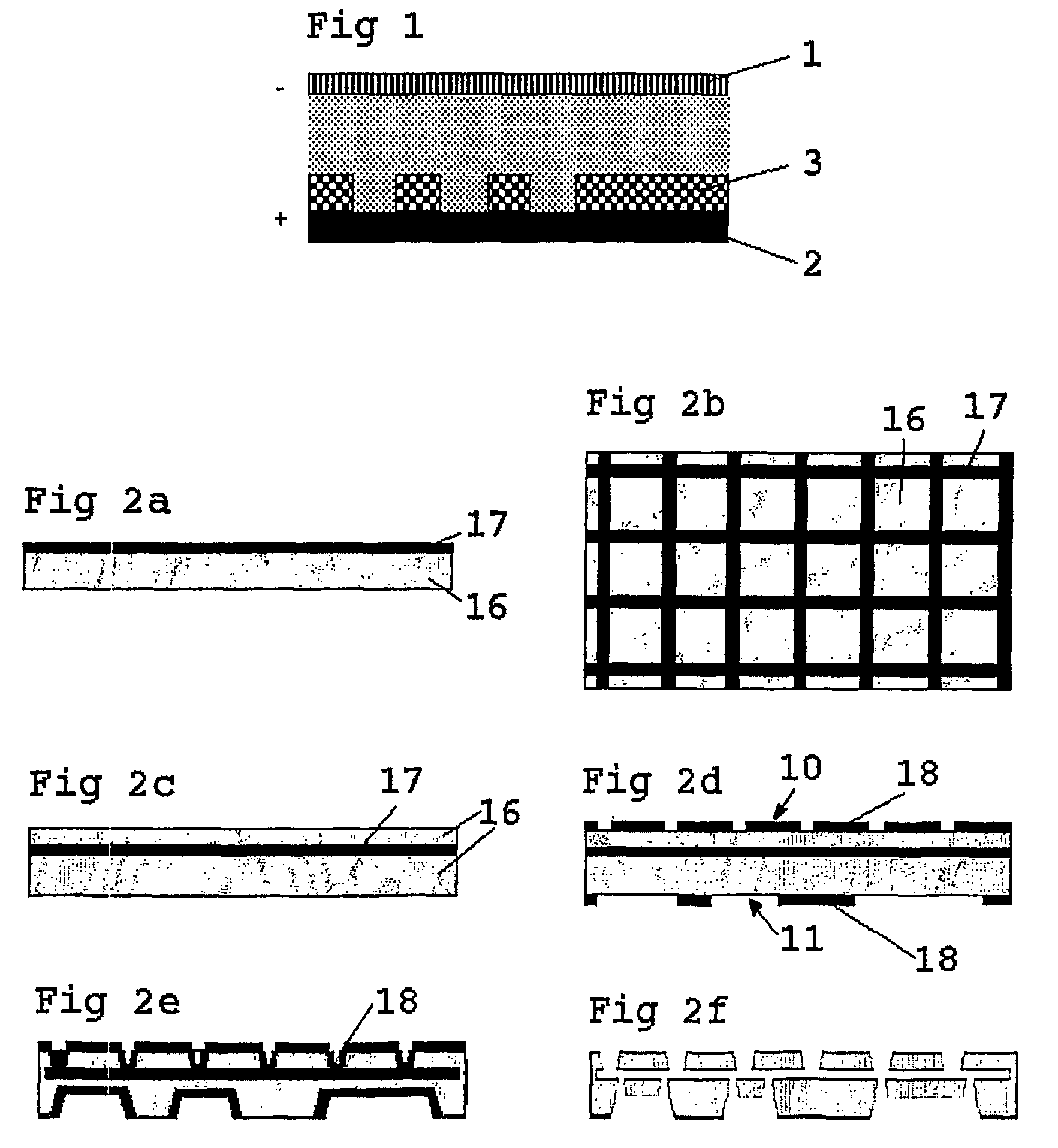

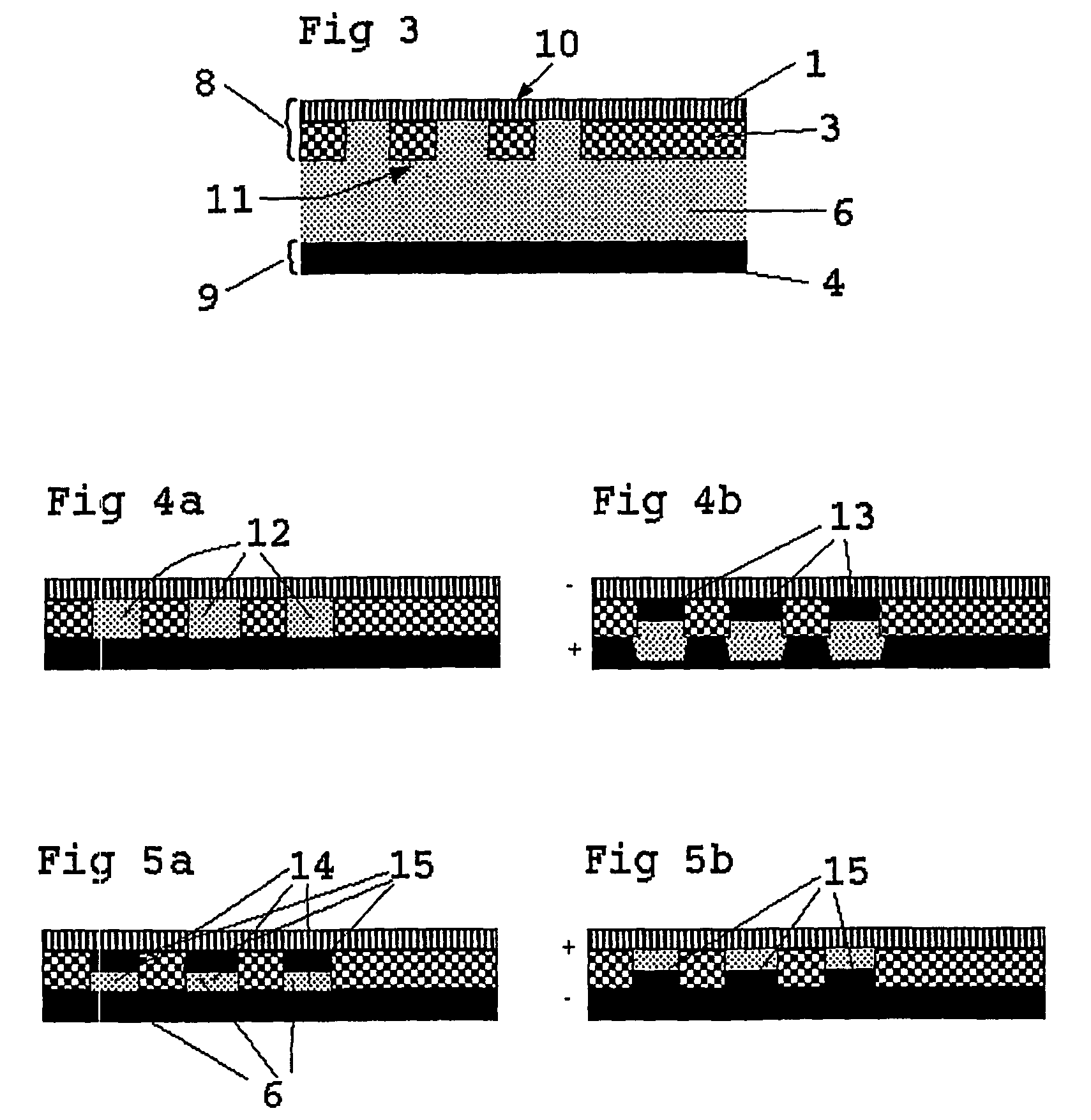

Method and electrode for defining and replicating structures in conducting materials

InactiveUS7790009B2Easy to manufactureHigh and well controlled anisotropic etch profileCellsNanoinformaticsEtchingReplication method

The present invention concerns an electrochemical pattern replication method, ECPR, and a construction of a conductive electrode for production of applications involving micro and nano structures. An etching or plating pattern, which is defined by a conductive electrode, a master electrode, is replicated on an electrically conductive material, a substrate. The master electrode is put in close contact with the substrate and the etching / plating pattern is directly transferred onto the substrate by using a contact etching / plating process. The contact etching / plating process is performed in local etching / plating cells, that are formed in closed or open cavities between the master electrode and the substrate.

Owner:REPLISAURUS GROUP

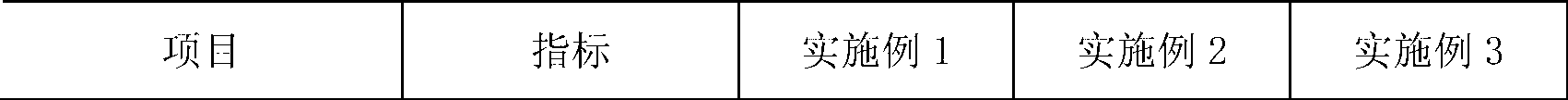

Polyurethane composite material for refrigeratory spray coating and preparation method thereof

InactiveCN102936329AGood compatibilityExtended storage timePolyurea/polyurethane coatingsPolyesterFoaming agent

The invention relates to a polyurethane composite material for refrigeratory spray coating and a preparation method thereof. The composite material is composed of a component A and a component B in a weight ratio of 1:(1-1.05), wherein the component A is composed of polyether glycol, polyester polyol, crosslinking agent, foam stabilizer, foaming agent, catalyst, flame retardant and other assistants; and the component B is polymethylene polyphenyl polyisocyanate. The preparation method comprises the following steps: sequentially adding the components in the component A into a reaction kettle, and thoroughly mixing for 0.5-1.5 hours at normal temperature; and evenly mixing the component A and the component B in a weight ratio of 1:(1-1.05) with a high-pressure spray coater, atomizing, foaming, and quickly forming and aging the foam to obtain the product. The foam provided by the invention has the advantages of low heat conductivity coefficient, excellent low-temperature dimensional stability, high strength, excellent flame retardancy (the fireproofing grade reaches Grade B1), favorable binding property with the substrate, uniform density distribution and smooth surface, and is especially suitable for refrigeratory spray coating construction.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

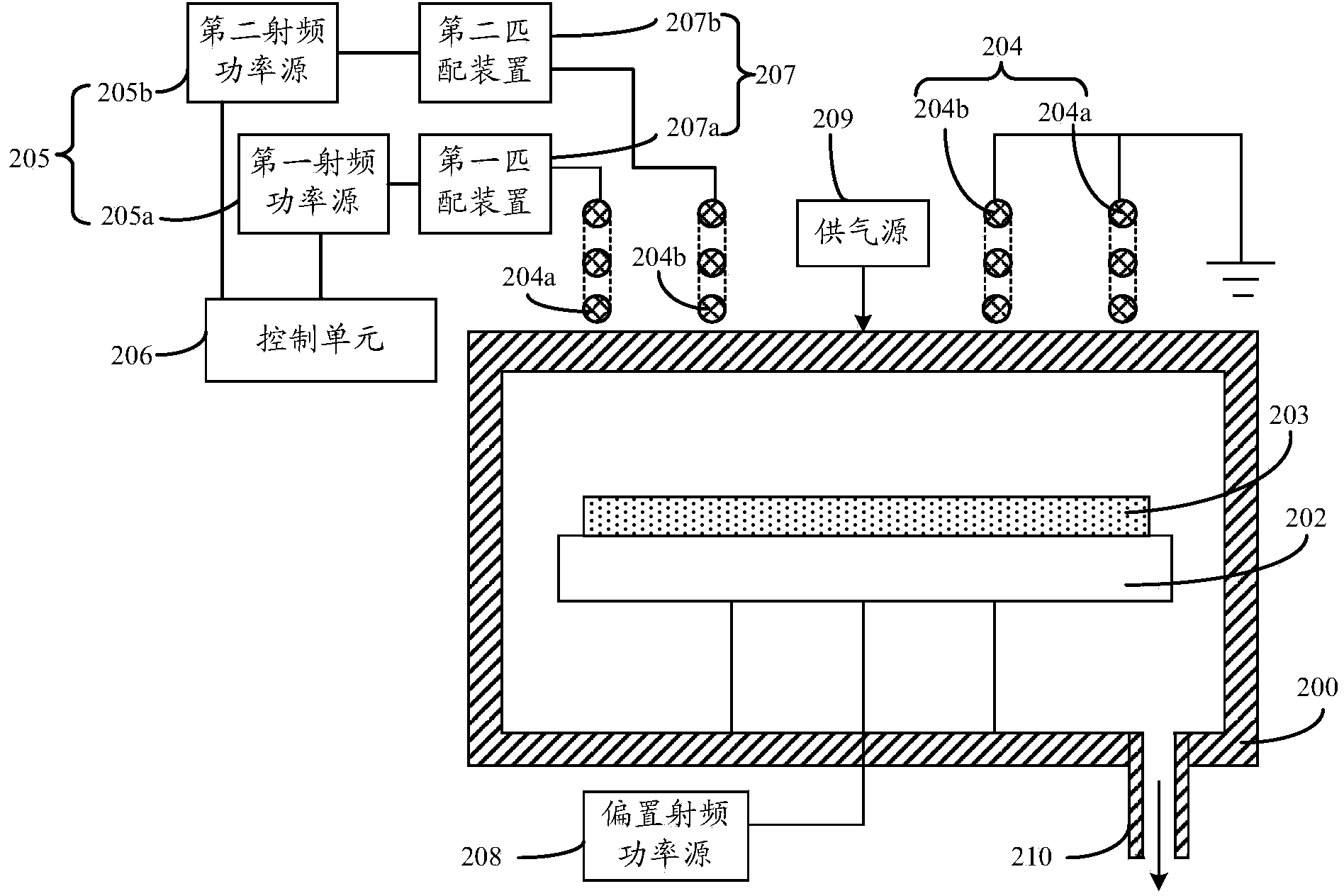

Plasma treatment device and plasma treatment method

ActiveCN103476196AUniform density distributionStable density distributionPlasma techniqueRadio frequency signalTherapeutic effect

Provided are a plasma treatment device and a plasma treatment method. The plasma treatment device comprises a plurality of concentrically-distributed inductive coupling coils arranged at the top of a reaction cavity and used for plasma treatment of gas in the reaction cavity, a plurality of radio-frequency power sources for respectively providing impulse type radio-frequency signals for the inductive coupling coils, and a control unit connected to the first radio-frequency power source and the second radio-frequency power source at least and used for controlling the impulse type radio-frequency signals formed by shifting of radio-frequency power output by the first radio-frequency power source and the second radio-frequency power source between the high-power output and the low-power output, wherein the inductive coupling coils are opposite to a wafer supporting table, the low-power output is larger than zero, and the control unit enables the impulse type radio-frequency power output by the first radio-frequency power source and the second radio-frequency power source to be independent and adjustable. The plasma distribution in the plasma treatment device is even, and the plasma treatment effect is good.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

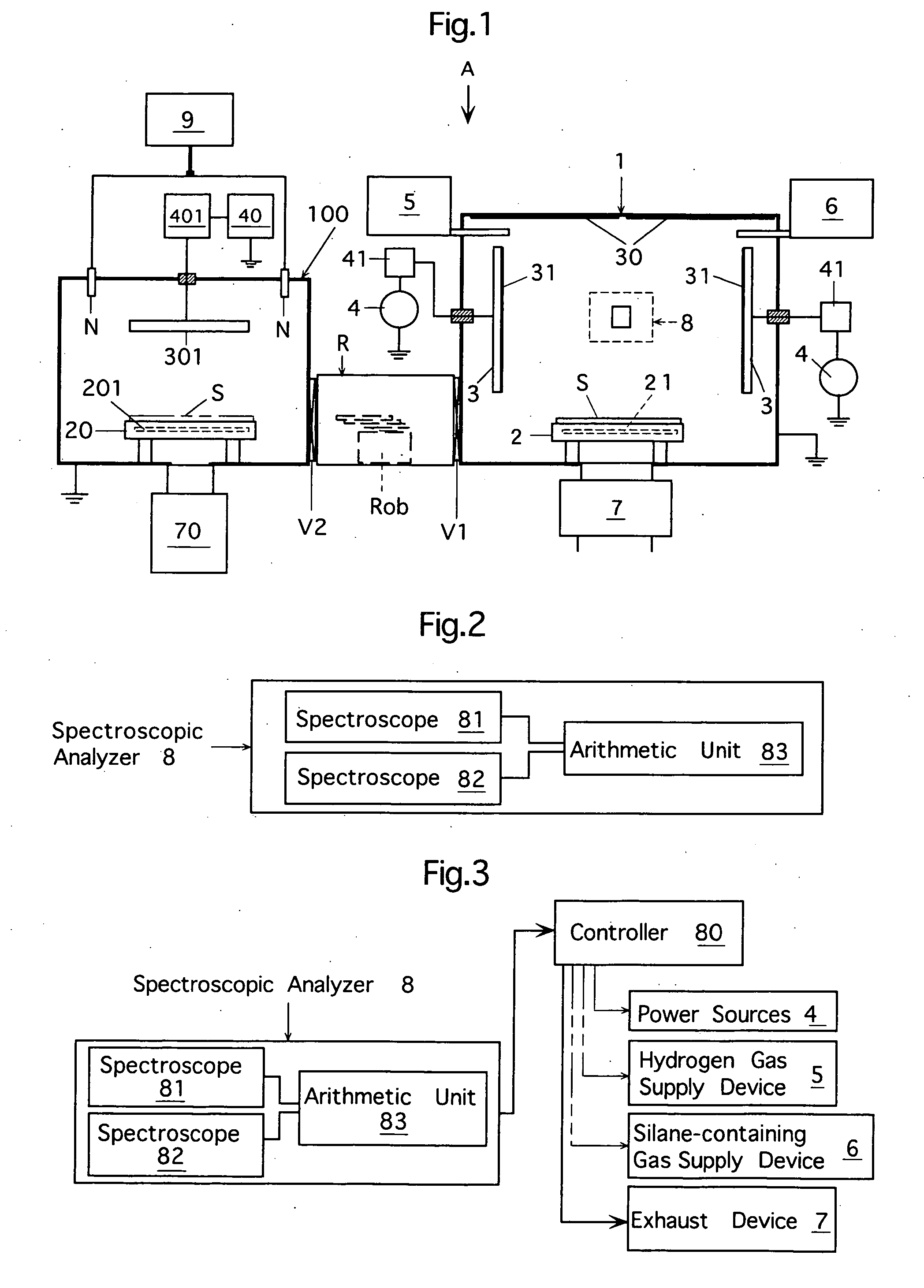

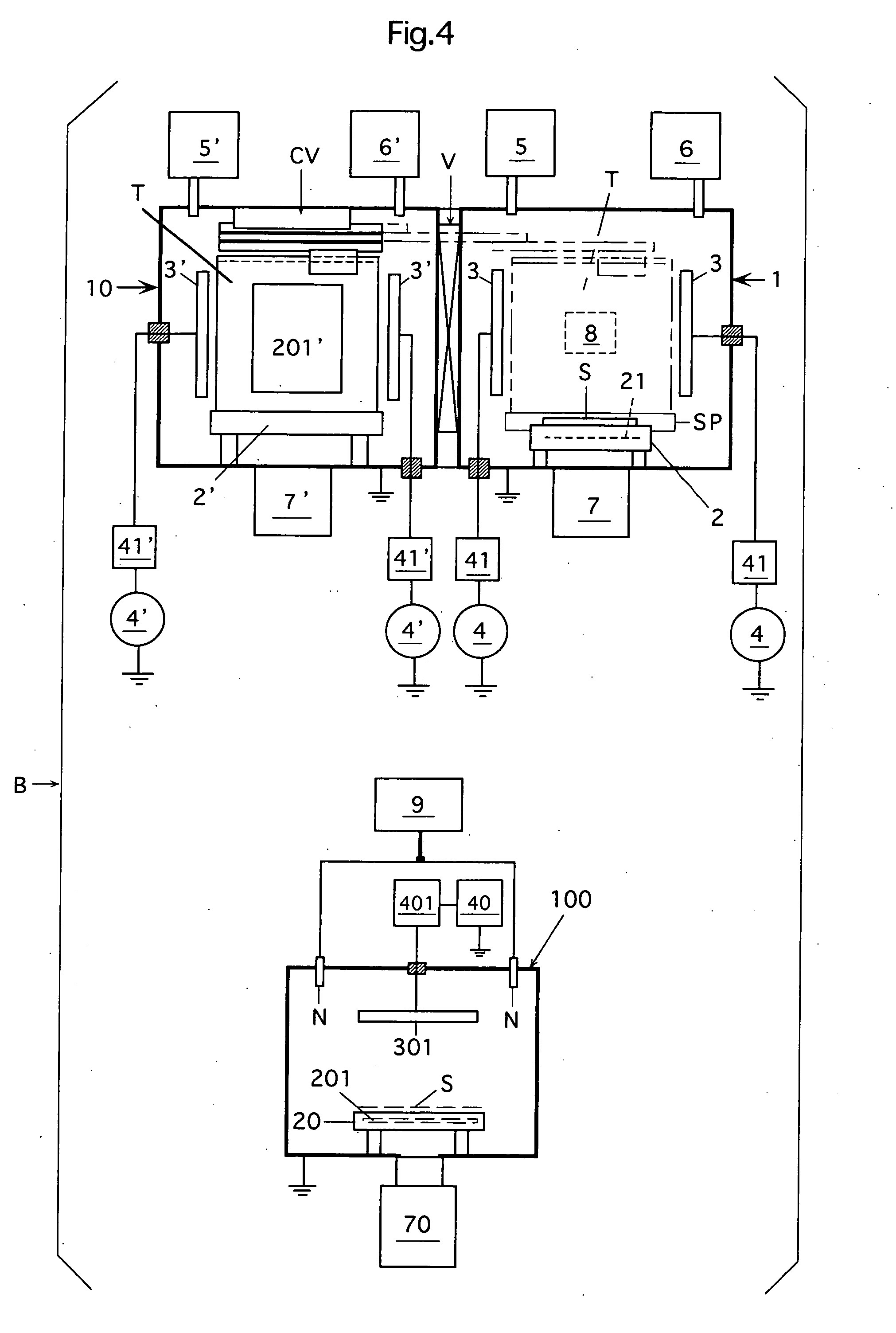

Silicon dot forming method and apparatus

InactiveUS20070158182A1Easy to getUniform particle sizeCellsRadiation applicationsSputteringHydrogen

A silicon sputter target is arranged in a silicon dot forming chamber, and a silicon dot formation target substrate is arranged in the chamber. Plasma is formed from a sputtering gas (typically a hydrogen gas) supplied into the chamber, and chemical sputtering is effected on the target with the plasma thus formed to form silicon dots on the substrate S. Optionally, with the plasma formed from a hydrogen gas and a silane-containing gas at a plasma emission intensity ratio (Si(288 nm) / Hβ) of 10.0 or lower, the silicon dots are formed on the substrate S. The silicon dots are terminally treated with the plasma derived from a terminally treating gas such as an oxygen gas.

Owner:NISSIN ELECTRIC CO LTD

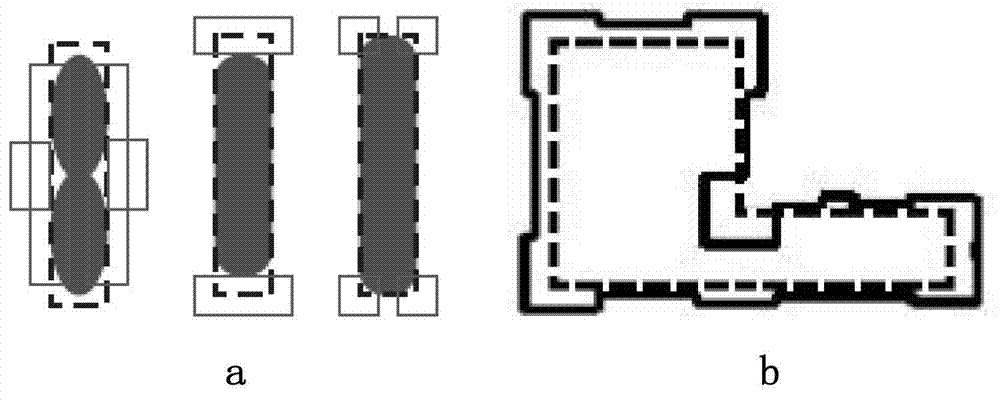

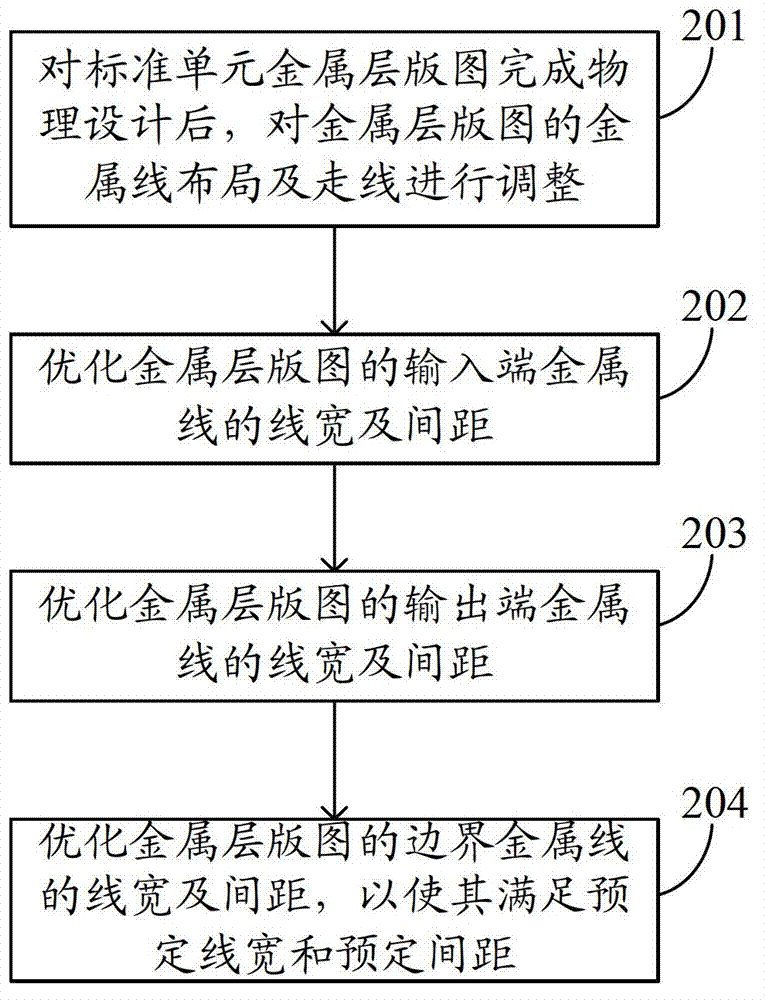

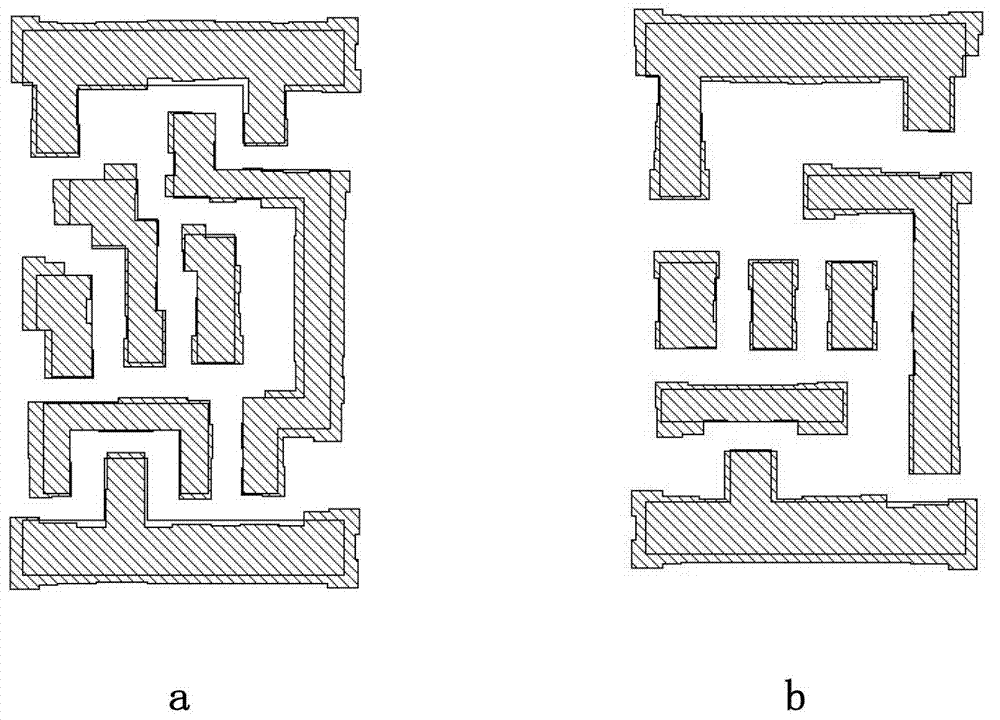

Optimizing design method of nanometer technical metal layer map

InactiveCN102855360AReduce cornersUniform density distributionSpecial data processing applicationsDensity distributionOptoelectronics

The embodiment of the invention provides an optimizing design method of a nanometer technical metal layer map. The method comprises the steps as follows: physically designing a standard unit metal layer map, and then adjusting the arrangement and direction of metal lines of the metal layer map; optimizing the width and spacing of the metal lines at the input end of the metal layer map; optimizing the width and spacing of the metal lines at the output end of the metal layer map; and optimizing the width and spacing of the metal lines at the boundary of the metal layer map, so as to meet the preset width and the preset spacing of the metal lines. With the adoption of the optimizing method provided by the embodiment of the invention, the turning in the metal layer map is reduced, and the metal layer map can be uniform in density distribution; the optics proximity correction and modification area required by the metal layer map can be optimized, the data volume in the optics proximity correction and modification and the modification time can be reduced, the manufacturability of a chip is improved, and the manufacturing cost of the chip is saved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

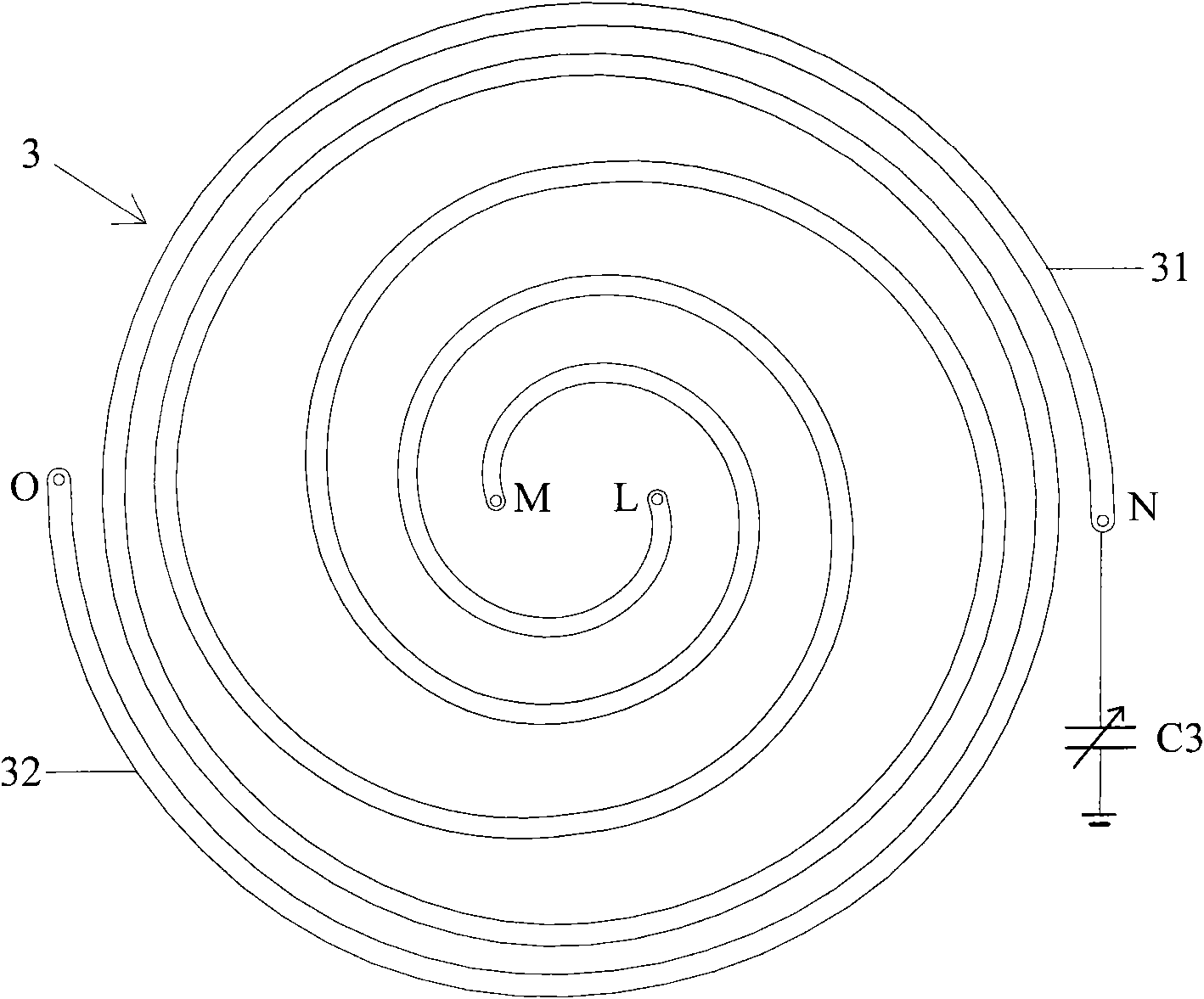

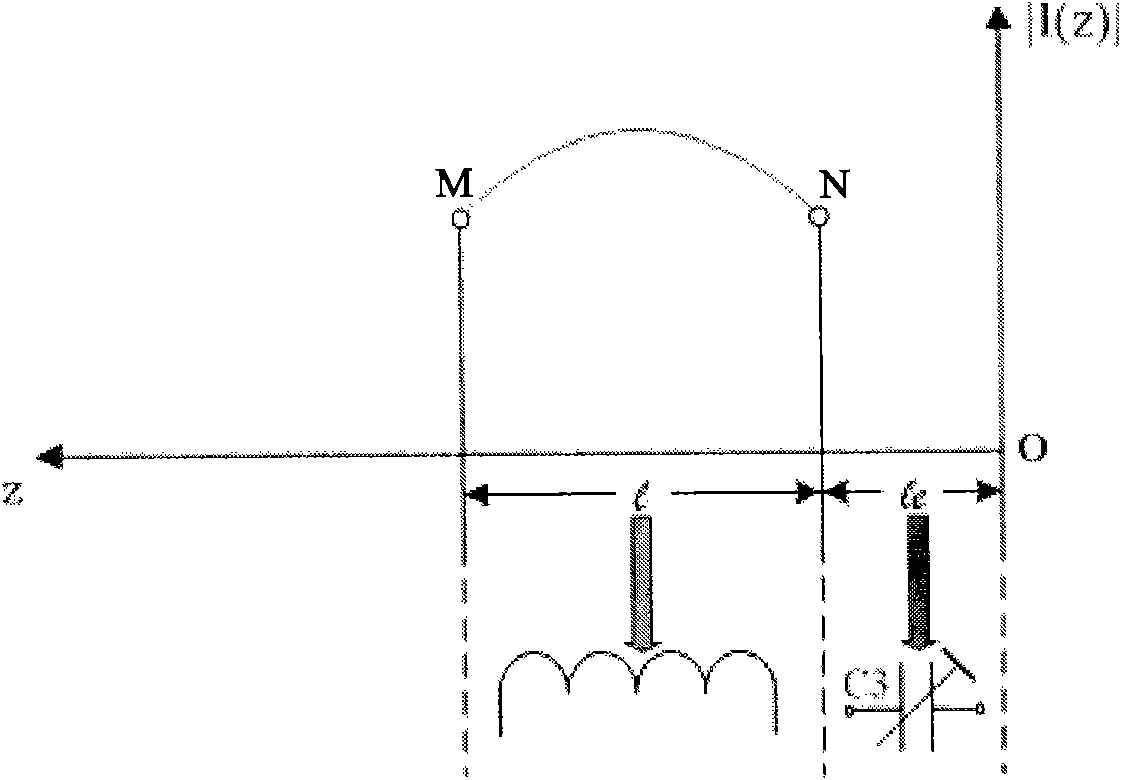

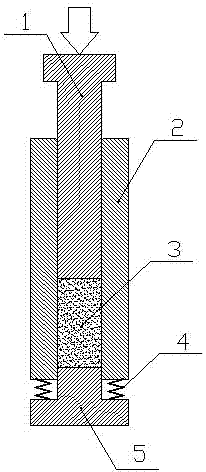

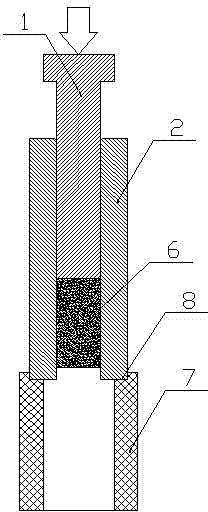

Inductive coupling coil and plasma processing device adopting same

ActiveCN101640091AReduce inductanceImprove absorption efficiencyTransformersSemiconductor/solid-state device manufacturingElectricityDensity distribution

The invention provides an inductive coupling coil. The coil comprises an even number of coil windings, wherein the coil windings are arranged in pairs; two coil windings in each pair of the coil windings have the same shape and are connected in parallel with each other, the input end of one coil winding is positioned in the center of the inductive coupling coil, while the output end is positionedon the edge of the inductive coupling coil and is connected in series with a reactance module; the input end of the other coil winding is positioned on the edge of the inductive coupling coil, while the output end is positioned in the center of the inductive coupling coil and is connected in series with the reactance module. Furthermore, the invention also provides a plasma processing device adopting the inductive coupling coil. The inductive coupling coil and the plasma processing device can easily realize conjugate match of impedance so as to improve the absorption efficiency of power, and ensure density distribution of generated plasma to be more evenly, so that manufacturing / processing results of a processed workpiece are more evenly.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Briquette coal sample making tool and method

InactiveCN102928272AUniform density distributionGuaranteed homogeneityPreparing sample for investigationEngineeringBriquette

The invention discloses a briquette coal sample making tool and method. The method comprises the following steps of: putting a wet coal powder between an upper pressing head and a lower pressing head in a coal pressing tube by using the briquette coal sample making tool which comprises the upper pressing head, the lower pressing head, a coal pressing tube spring and a sampling device; applying a load to the upper pressing head downwards by using a press machine; compacting the wet coal powder so as to form a coal sample and then stopping the applying of the load; and then unloading the spring and the lower pressing head; and pressing the upper pressing head downwards, so as to press the coal sample out of the coal pressing tube. According to the invention, technical defects in the traditional briquette coal sample making are solved; and the effective coal sample making tool and method are provided, so that the uniformity and making success rate of the briquette sample are increased.

Owner:HENAN POLYTECHNIC UNIV

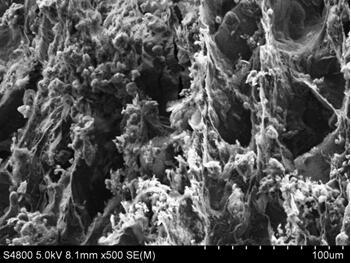

Method for preparing polyamidoxime/graphene nanobelt composite aerogel and method for separating and enriching uranium

InactiveCN111484644AHigh grafting rateUniform density distributionOther chemical processesCarbon compoundsHydroxylamineMultiwalled carbon

The invention discloses a method for preparing polyamidoxime / graphene nanobelt composite aerogel and separating and enriching uranium, which is characterized by comprising the following steps of: firstly, axially cutting a multiwalled carbon nanotube by using a potassium permanganate oxidation method to prepare a graphene oxide nanobelt; then adding into a mixed solution of acrylonitrile and ammonium persulfate which are fully mixed, and primarily preparing polyacrylonitrile / graphene nanobelt composite hydrogel by adopting a solvothermal polymerization method; and then converting cyano groupsinto amidoxime groups by virtue of a reaction between the cyano groups and hydroxylamine under an alkaline condition so as to obtain polyamidoxime / graphene nanoribbon composite hydrogel, and finally,carrying out low-temperature freeze drying so as to obtain the polyamidoxime / graphene nanoribbon composite aerogel. The prepared polyamidoxime / graphene nanobelt composite aerogel is high in grafting rate, uniform in density distribution, stable in structural performance and rich in special functional groups of uranium, the uranium can be effectively and selectively removed from different uranium-containing water bodies, the adsorbed aerogel can be rapidly separated and recycled from a solid-liquid system, and no pollution is caused to the environment.

Owner:EAST CHINA UNIV OF TECH

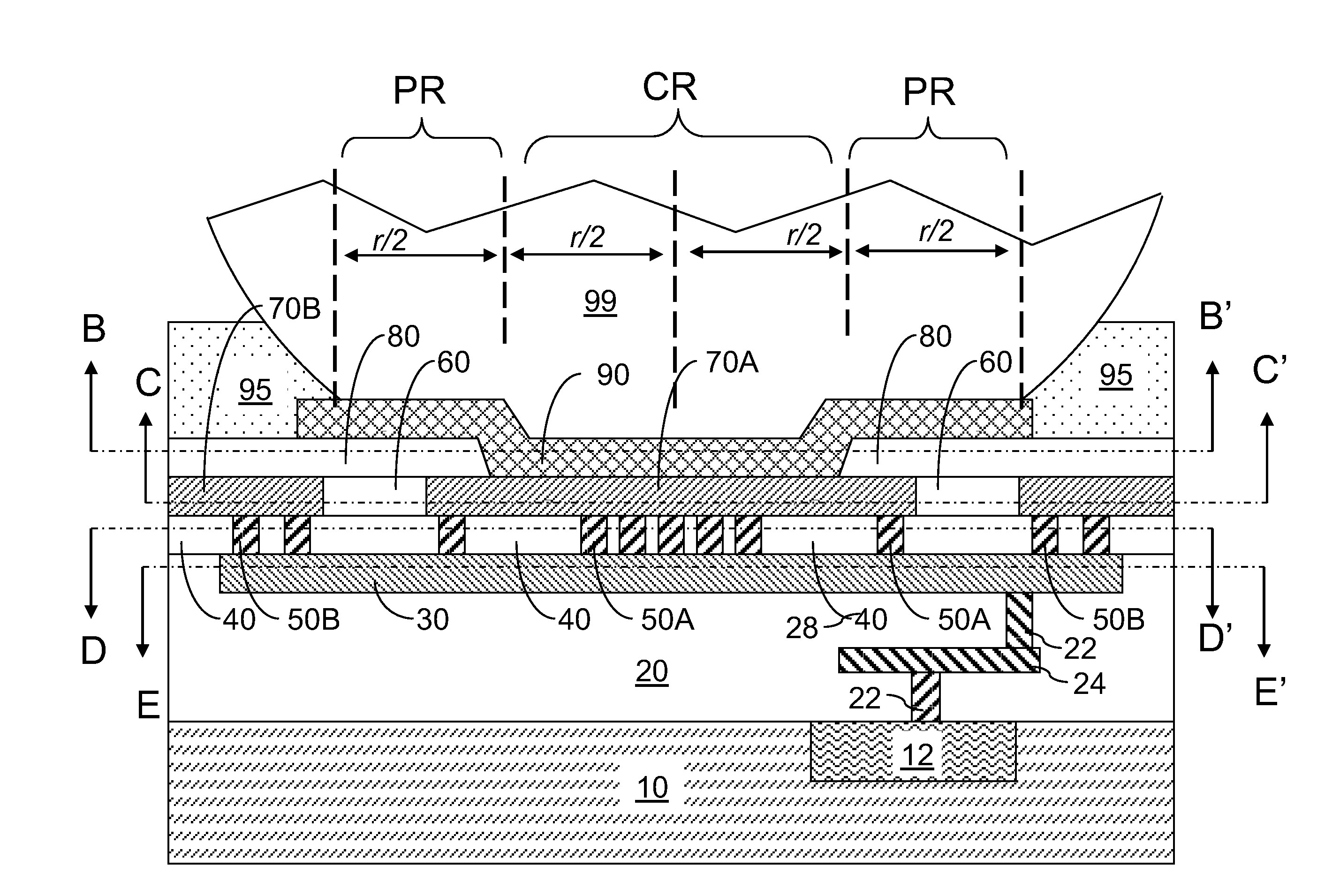

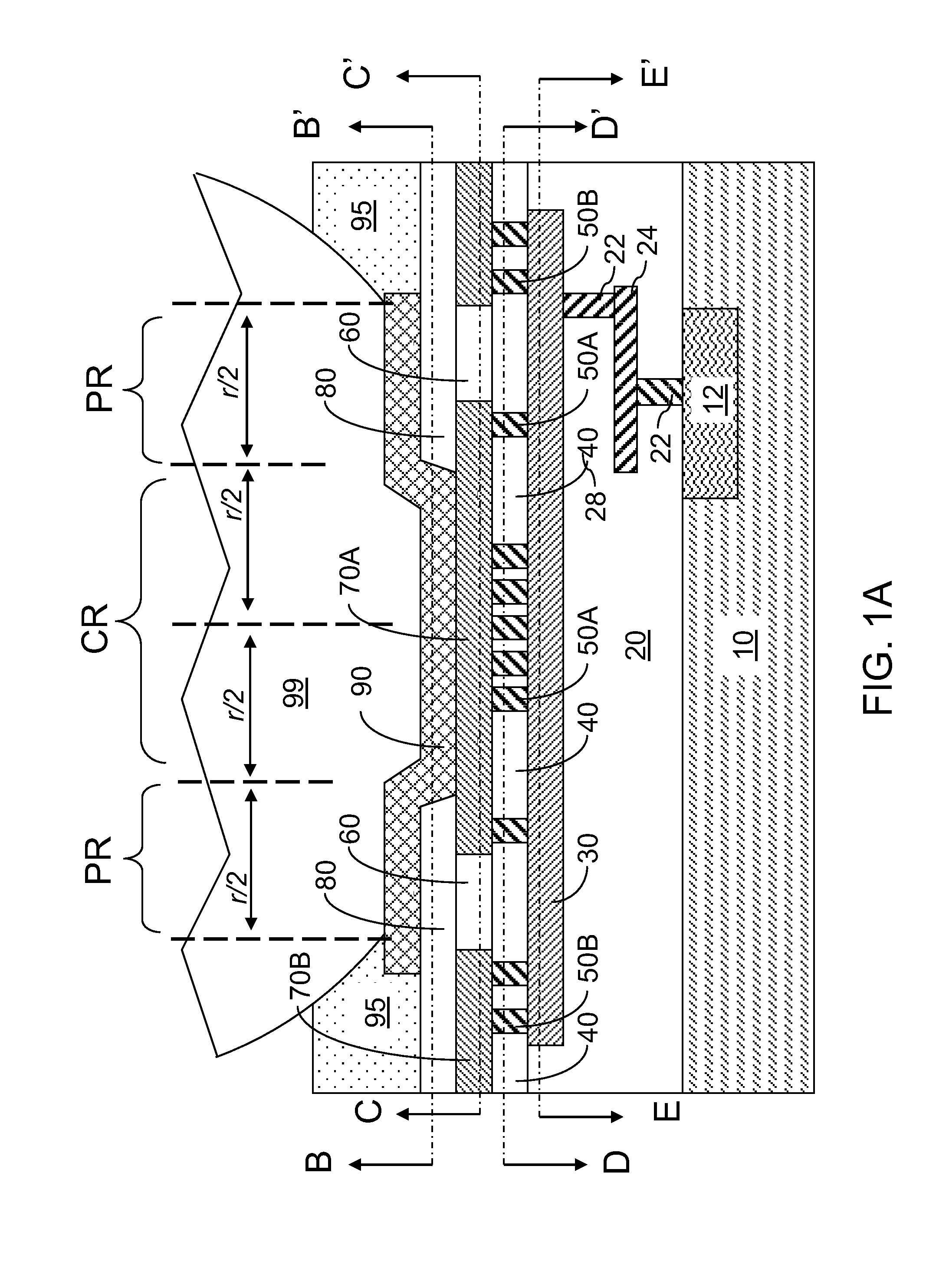

Metal wiring structures for uniform current density in c4 balls

ActiveUS20120080797A1Improve reliabilityFacilitates uniform current density distributionSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionMaterials science

In one embodiment, a sub-pad assembly of metal structures is located directly underneath a metal pad. The sub-pad assembly includes an upper level metal line structure abutting the metal pad, a lower level metal line structure located underneath the upper level metal line structure, and a set of metal vias that provide electrical connection between the lower level metal line structure located underneath the upper level metal line structure. In another embodiment, the reliability of a C4 ball is enhanced by employing a metal pad structure having a set of integrated metal vias that are segmented and distributed to facilitate uniform current density distribution within the C4 ball. The areal density of the cross-sectional area in the plurality of metal vias is higher at the center portion of the metal pad than at the peripheral portion of the planar portion of the metal pad.

Owner:GLOBALFOUNDRIES U S INC

Manufacturing method of recombined bamboo sliced veneer

ActiveCN103878854AAvoid crackingHigh strengthWood treatment detailsPressure impregnationMechanical engineeringIndustrial engineering

The invention relates to a manufacturing method of a recombined bamboo sliced veneer and aims to provide a simple-production and low-cost manufacturing method of the combined bamboo sliced veneer. Adopting bamboo splits to substitute for bamboo chips saves bamboo planning capacity and greatly improves bamboo utilization rate. The manufacturing method includes steps of 1) manufacturing the bamboo splits; 2) drying or carbonizing the bamboo splits; 3) impregnating and drying the bamboo splits; 4) shaping and processing the bamboo splits; 5) punching square timber of the bamboo splits; 6) dipping and conditioning the square timber of the bamboo splits; 7) softening the square timber of the bamboo splits; 8) slicing the square timber of the bamboo splits; 9) post processing.

Owner:ZHEJIANG FORESTRY UNIVERSITY

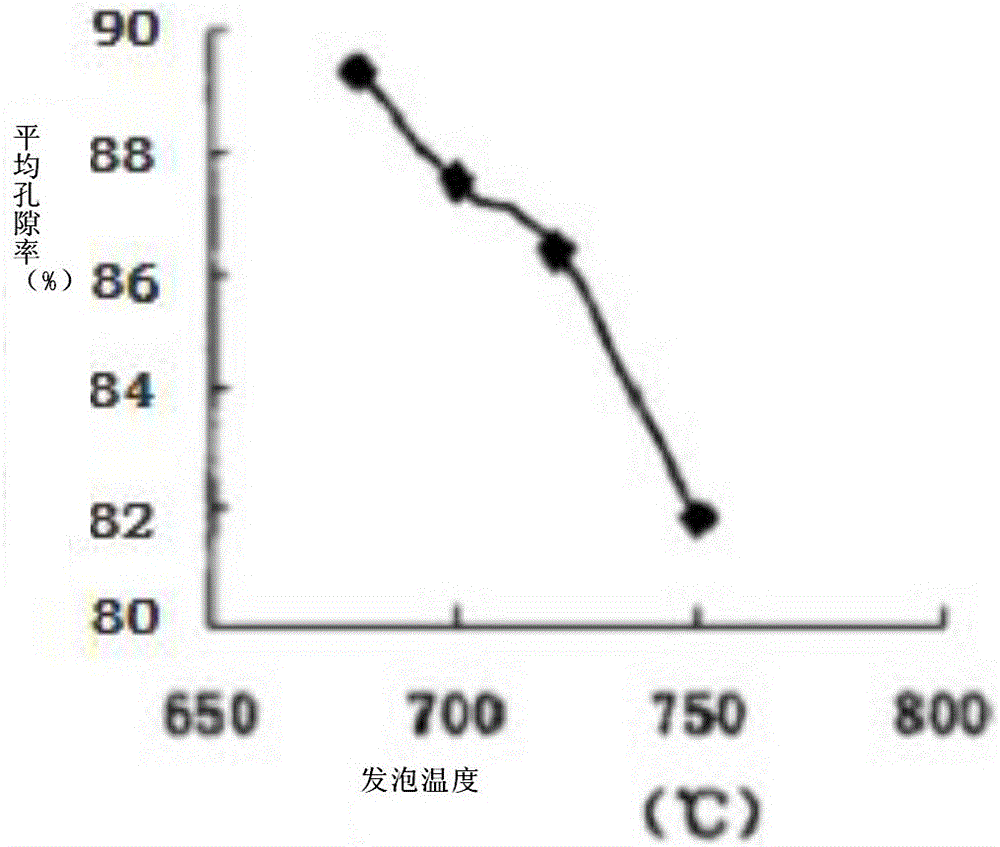

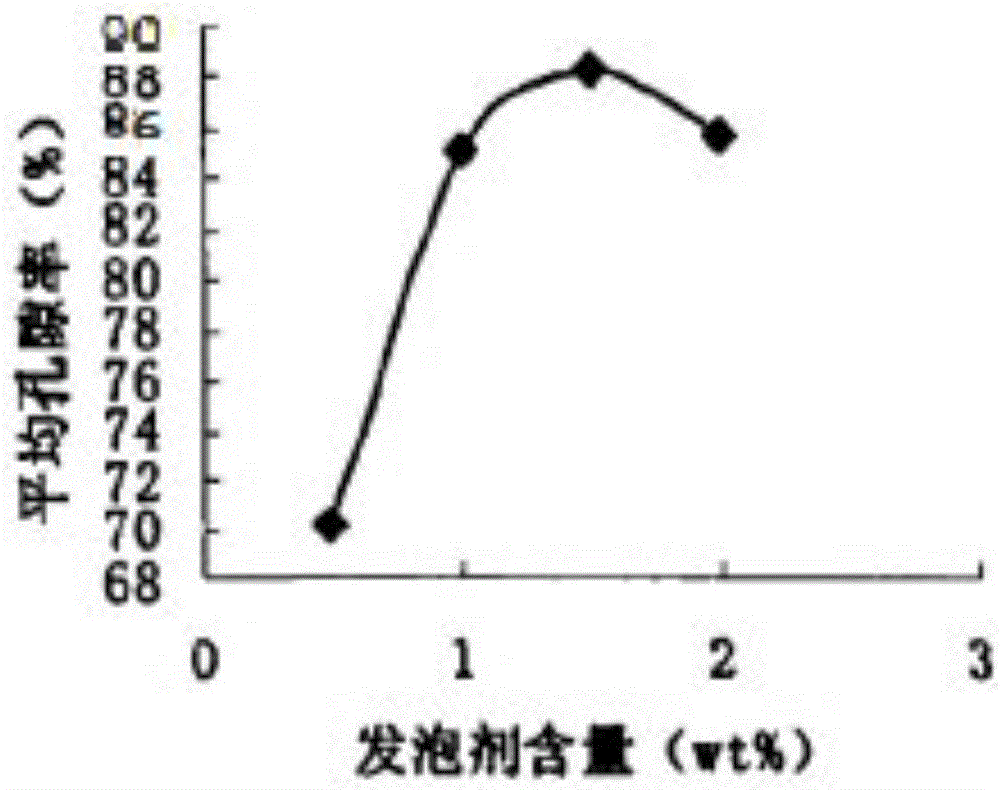

Rare earth high-strength foam aluminum prepared through melt foaming method and preparation process of rare earth high-strength foam aluminum

InactiveCN106435283ALow alloying temperatureEnergy-saving preparation methodZirconium hydrideCarbide silicon

The invention relates to a rare earth high-strength foam aluminum prepared through a melt foaming method. The rare earth high-strength foam aluminum is made of, by mass percentage, 85%-99.3% of aluminum powder or an aluminum ingot, 0.1%-2% of a rare earth additive, 0.3%-5% of a tackifier and 0.5%-6% of a blowing agent. The blowing agent is selected from one or more of particulate metal calcium, silicon carbide, alumina and ceramic particles. The blowing agent is selected from one or more of titanium hydride powder, lanthanum hydride powder and zirconium hydride powder. According to the rare earth high-strength foam aluminum, through holes and closed holes exist at the same time, and the pore size and density distribution are uniform; and the process has the beneficial effects of being low in production cost and facilitating large-scale production.

Owner:ZHONGAN SHUNXING BEIJING SAFETY TECH CO LTD

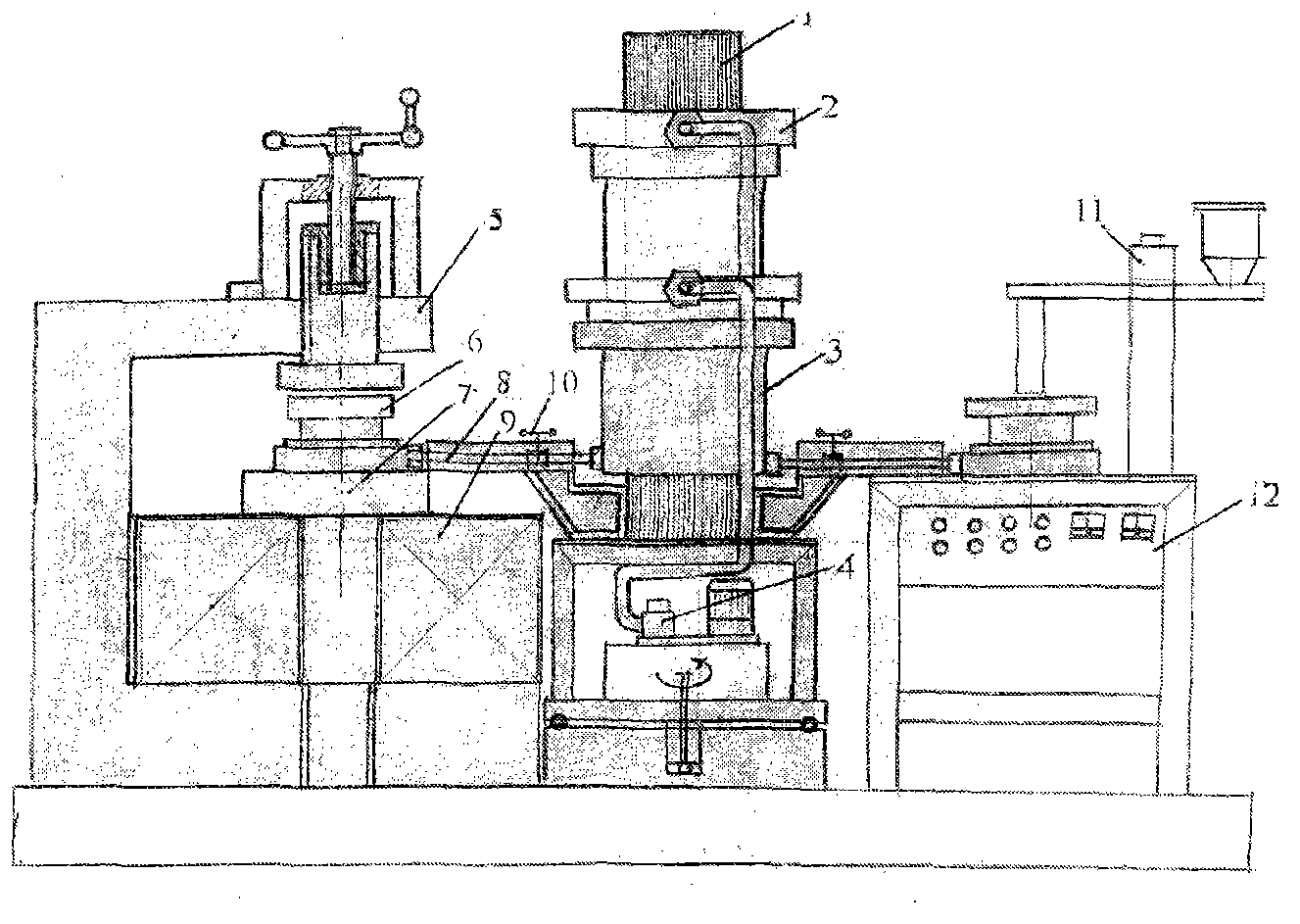

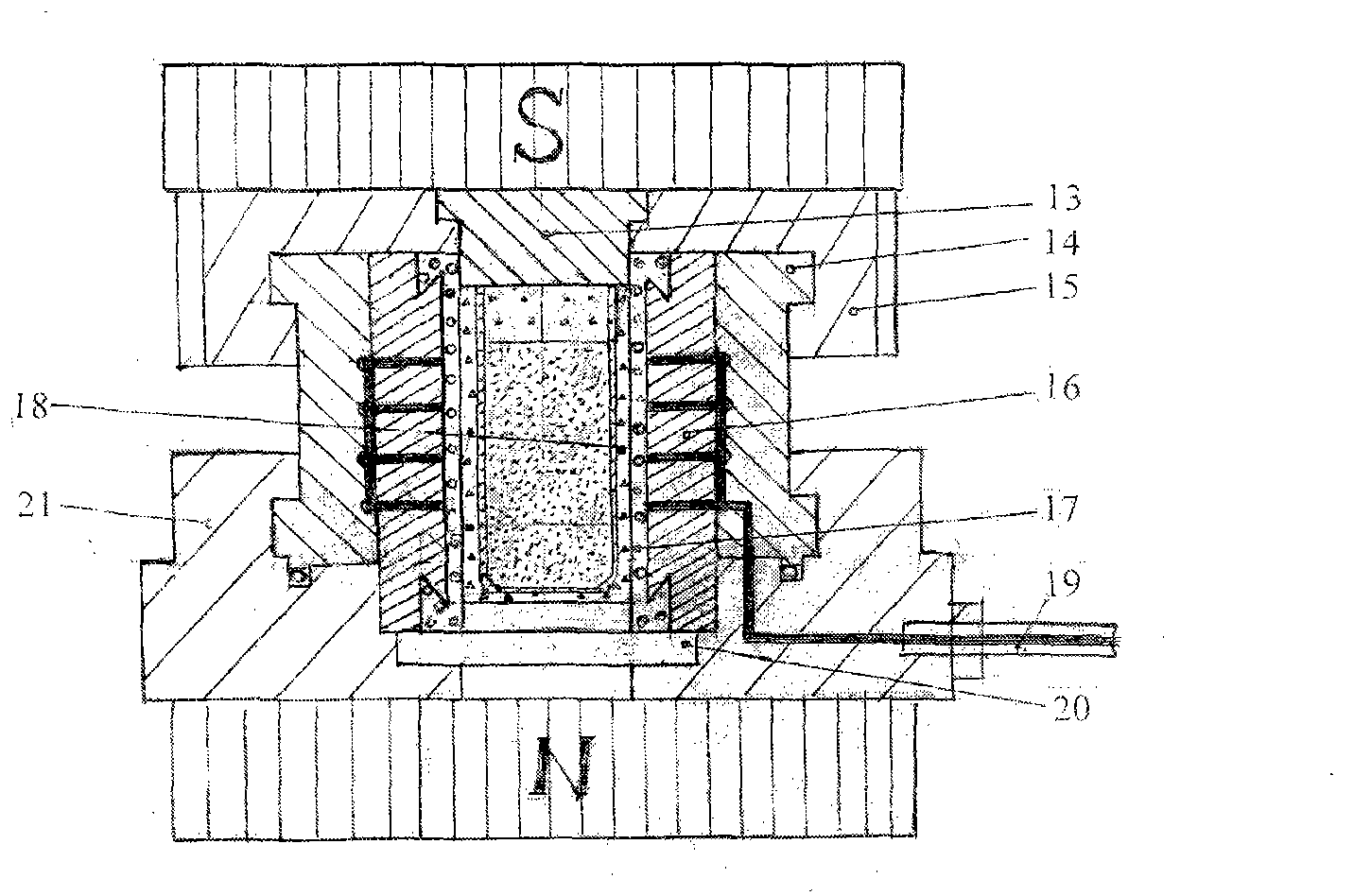

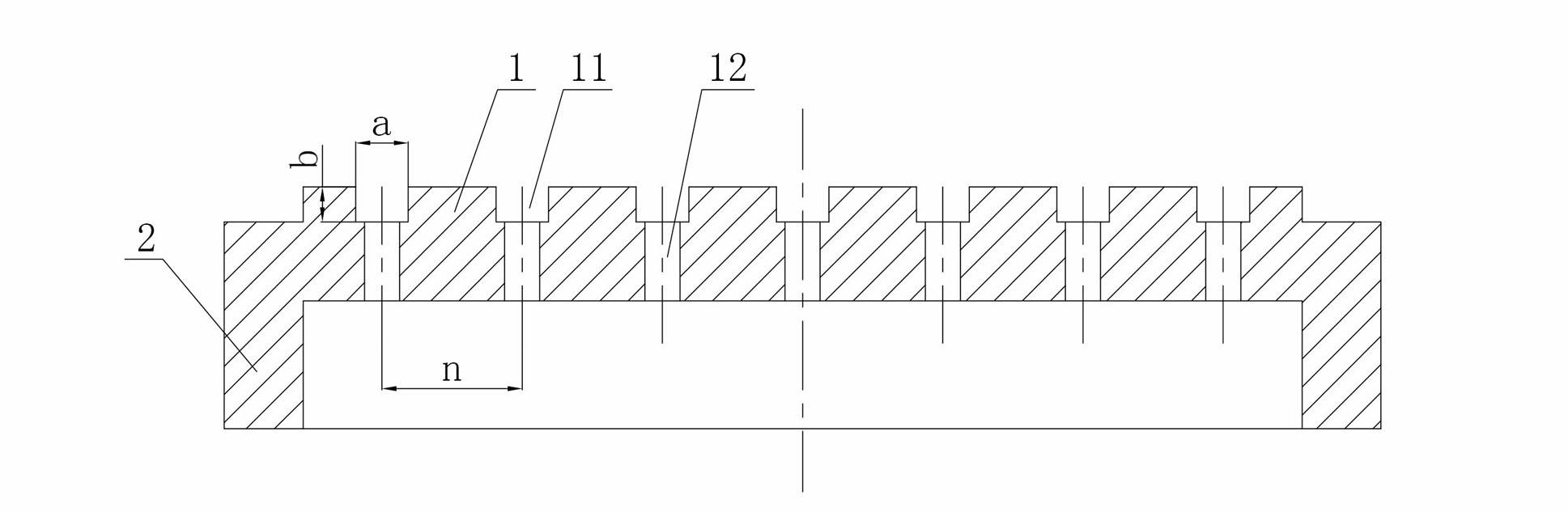

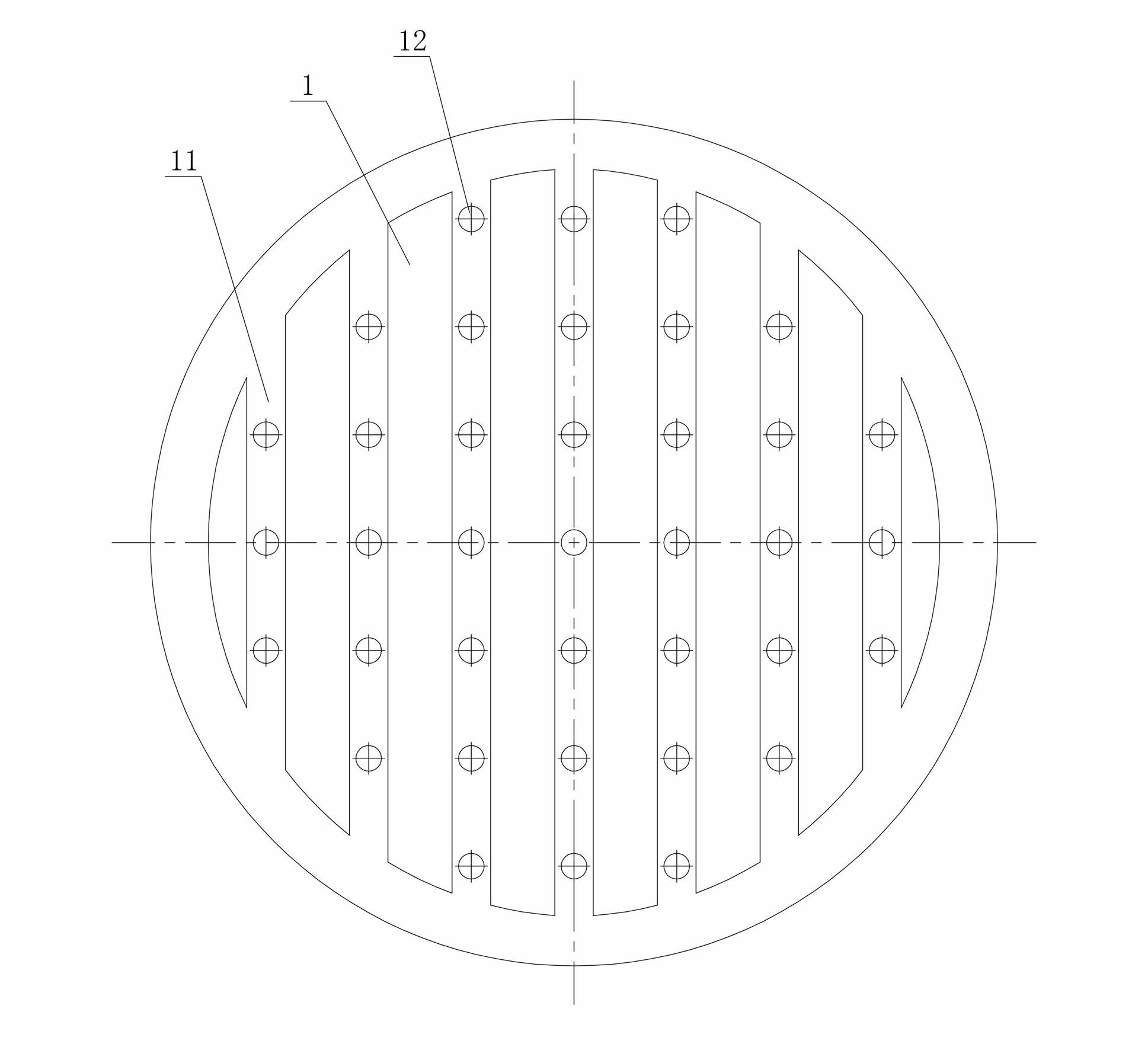

Technology and device for forming dry bag quick isostatic pressing in oriented magnetic fields

InactiveCN103878368AImprove automationIncrease the level of mechanizationInorganic material magnetismInductances/transformers/magnets manufactureResource utilizationMagnetic poles

The invention belongs to the field of technologies for manufacturing magnetic materials, and provides a technology and a device for forming dry bag quick isostatic pressing in oriented magnetic fields. The technology and the device have the advantages that an oriented magnetic field technology is ingeniously and organically combined with the technology and the device for forming dry bag isostatic pressing by the aid of a novel design concept, so that dry bag isostatic pressing can be formed in the oriented magnetic fields which have optional directions and optional magnetic field intensities by the aid of the novel technology and the novel device; orientation degrees of products can be obviously upgraded; two necessary working procedures in existing neodymium, iron and boron magnet production can be combined with each other to form one working procedure by the novel technology and the novel device, and the automation and mechanization levels are high; powder is not in contact with pressing blanks and oil in production procedures, and accordingly a latex sheath for binding the corresponding pressing blank can be omitted; the pressing blanks are quite uniform in density distribution and internal stress distribution; the pressing blanks can be machined, and original powder can be recycled; single-hole and multi-hole thin-walled pipes, sleeves and multi-magnetic-pole products which are heavy and are in complicated shapes or have large length-diameter (L / d) ratios can be produced by the aid of the technology and the device, the rare earth mineral resource utilization rate can be greatly increased, and the neodymium, iron and boron magnet industrial production level of China can be upgraded to the world leading level.

Owner:吴庆华 +2

Multipurpose boat for powder metallurgical sintering and multipurpose boat unit

The invention discloses a multipurpose boat for powder metallurgical sintering, which comprises a disk-shaped graphite boat body surrounded by a side wall and a base plate, wherein a plurality of grooves for accommodating the strip-shaped powder metallurgical sintering body are formed outside the base plate of the graphite boat body. The multipurpose boat for powder metallurgical sintering has the advantages of simple structure and wide application range, and is capable of reducing the handling cost of material. The invention further discloses a multipurpose boat unit which is made by overlapping more than two boats.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

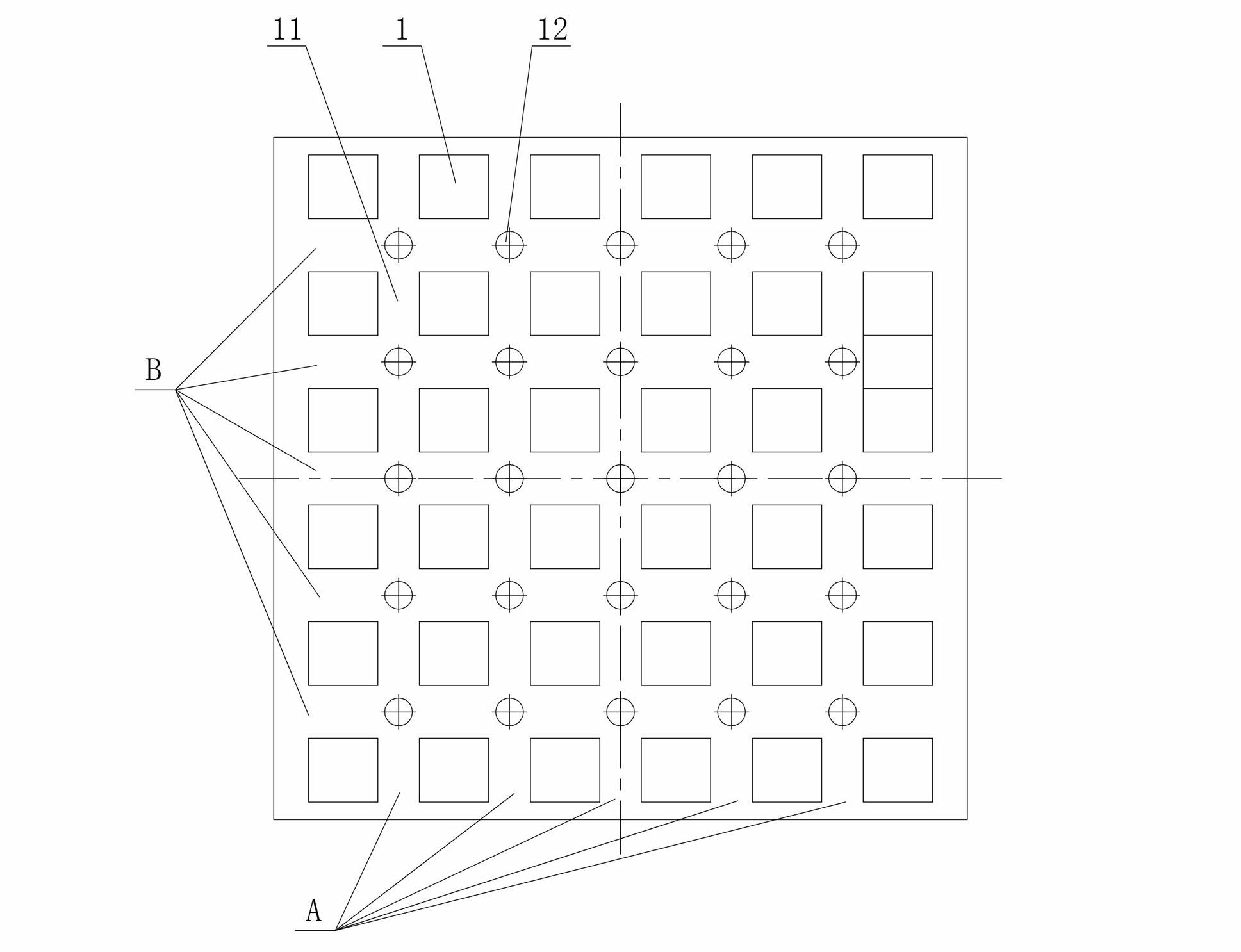

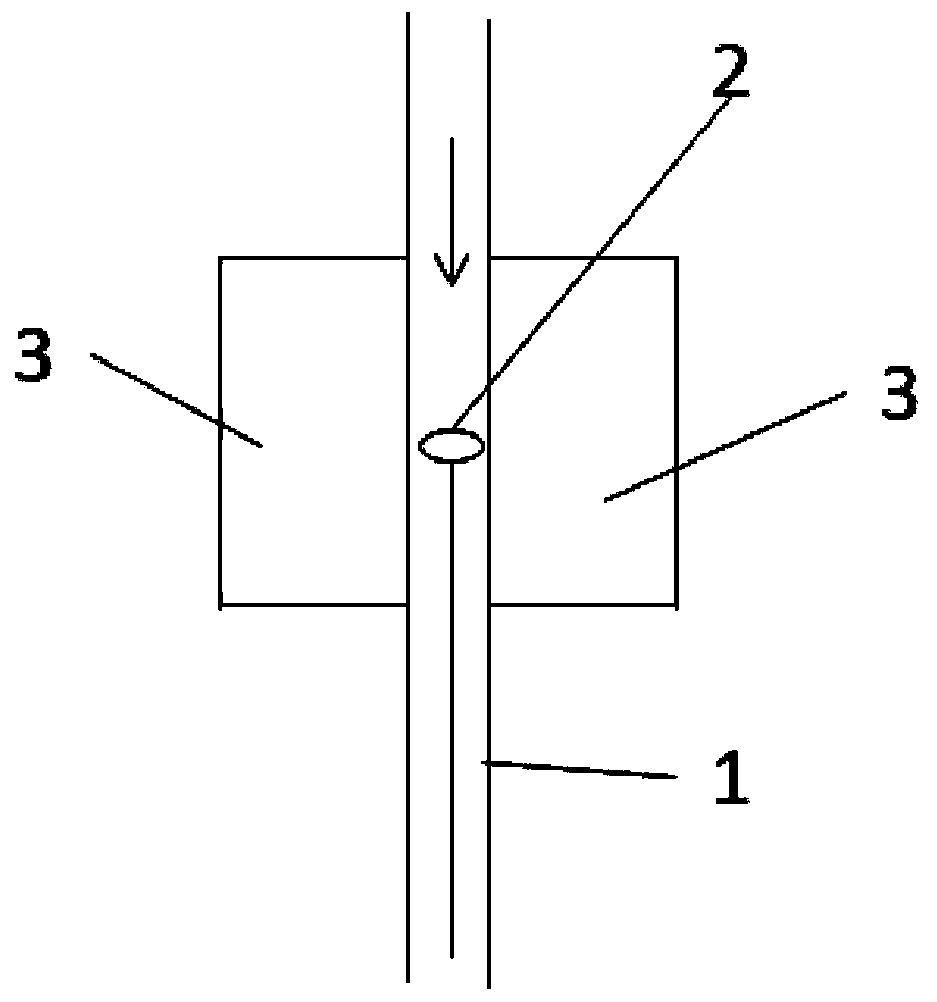

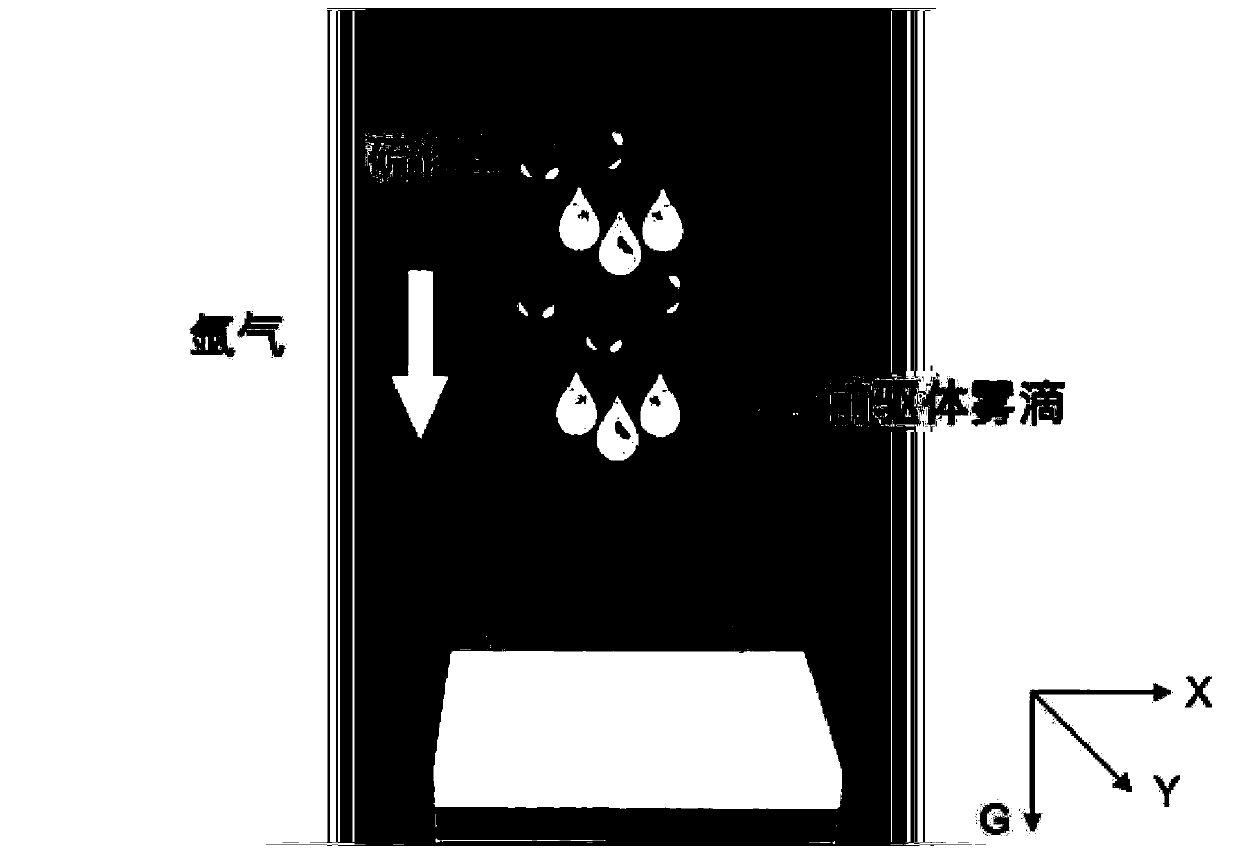

Two-dimensional material as well as preparation method, preparation device and application thereof

ActiveCN110205609AUniform shapeUniform density distributionChemical vapor deposition coatingDensity distributionGas phase

The invention relates to a two-dimensional material as well as a preparation method, a preparation device and application thereof. The preparation method utilizes a vertical chemical vapor depositionsystem, a gaseous precursor is reacted in the vertical direction through a substrate in a heating state, reacting is carried out, a two-dimensional material is formed on the surface of the substrate,and the surface of the substrate is perpendicular to the flowing direction of the gaseous precursor. According to the two-dimensional material, the two-dimensional material is grown by adopting a vertical chemical vapor deposition method compared with a traditional horizontal chemical vapor deposition method, the morphology, the thickness, the crystal domain size and the density distribution of the two-dimensional material on the substrate are more uniform, and the two-dimensional material has a better application prospect.

Owner:TSINGHUA BERKELEY SHENZHEN INST

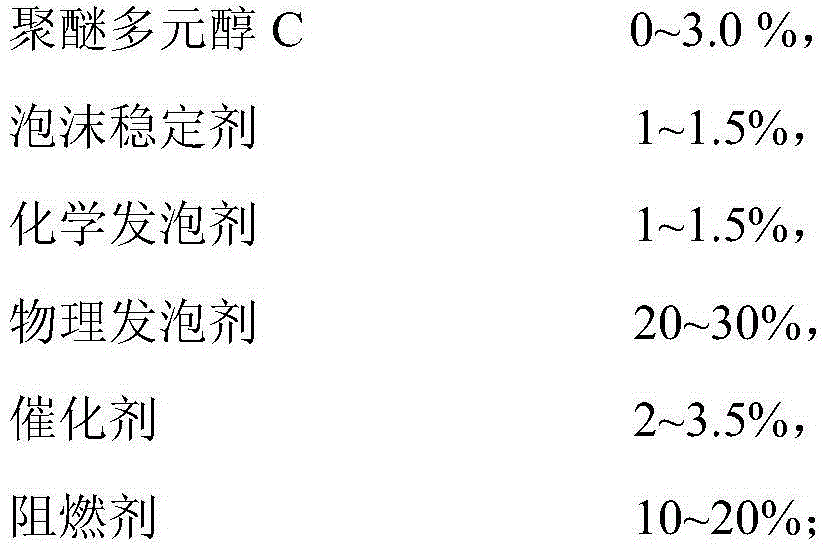

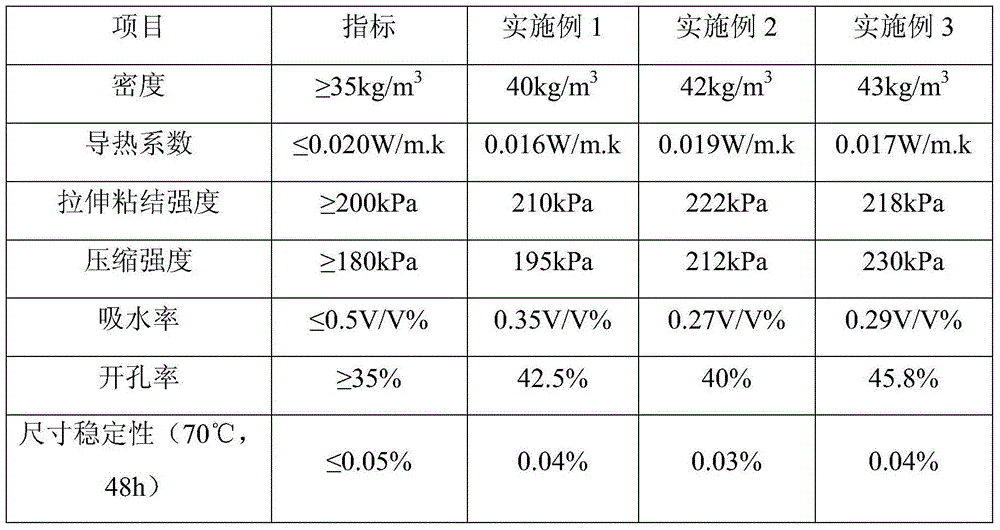

Premixed polyether polyol for polyurethane insulation board for electrothermic floor heating system and application method of premixed polyether polyol

The invention relates to premixed polyether polyol for a polyurethane insulation board for an electrothermic floor heating system and an application method of the premixed polyether polyol and belongs to the technical field of premixed polyether polyol. The premixed polyether polyol, which is disclosed by the invention, for the polyurethane insulation board for the electrothermic floor heating system consists of polyether polyol A, polyether polyol B, polyether polyol C, a foam stabilizer, a chemical foaming agent, a physical foaming agent, a catalyst and a flame retardant. The premixed polyether polyol, which is disclosed by the invention, for the polyurethane insulation board for the electrothermic floor heating system is wide in raw material source and is low in cost; the polyurethane insulation board prepared from the premixed polyether polyol has high low-temperature size stability, the heat conductivity coefficient of the polyurethane insulation board meets the use requirements, compression intensity is high and flame retardance is good; the invention also provides the application method of the premixed polyether polyol for the polyurethane insulation board for the electrothermic floor heating system; and the application method is simple in process and is high in production efficiency.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

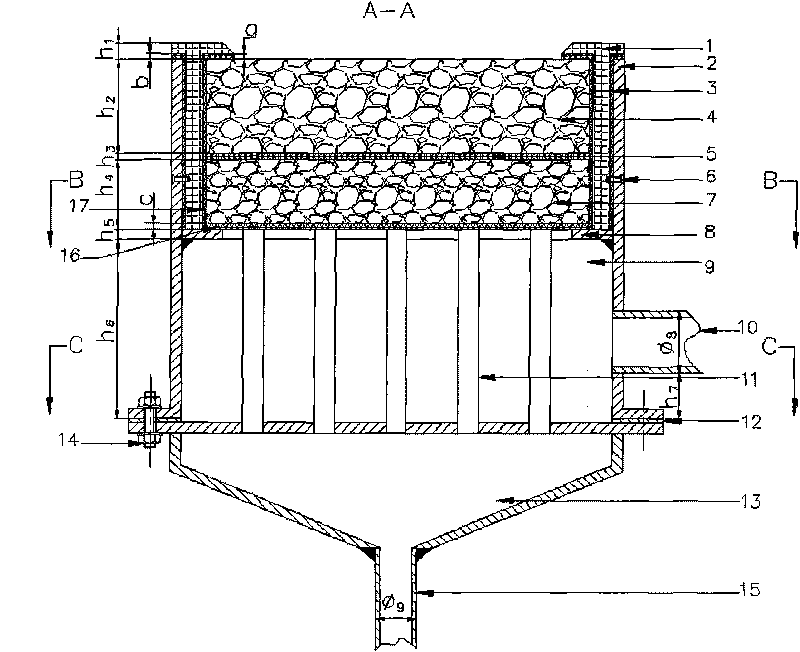

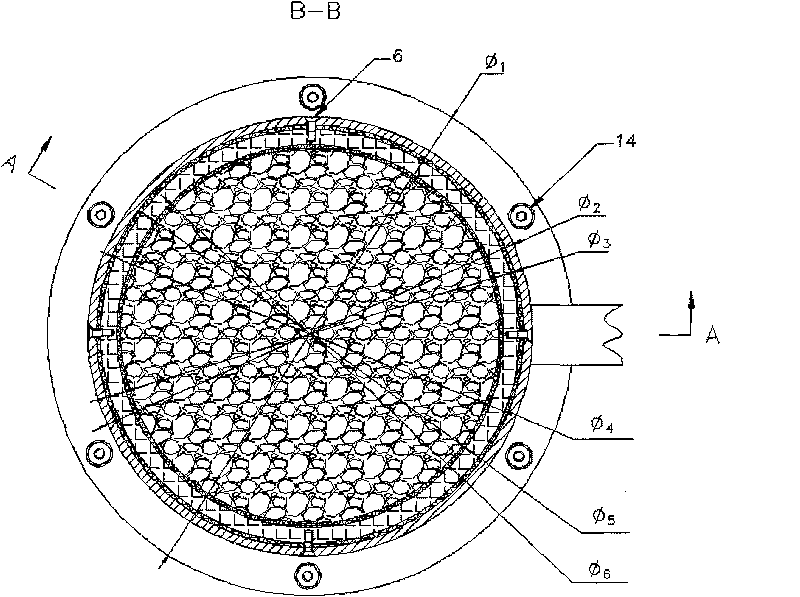

Diffusion type porous medium gas fuel combustor

InactiveCN101737778AUniform density distributionPrevent flashbackGaseous fuel burnerCombustorPorous medium

A diffusion type porous medium gas fuel combustor comprises a shell, an air duct and a fire-resistant casing pipe, the air duct is connected with the shell, the bottom end of the shell is connected with the top plate of a gas flow dividing tank, the shell is internally provided with the fire-resistant casing pipe, a tray and a gas flow dividing tube from top to bottom, the bottom end of the fire-resistant casing pipe is contacted with the tray, the tray is fixed on the shell or the gas flow dividing tube, the bottom end of the gas flow dividing tube is fixed on the top plate of the gas flow dividing tank, and the gas flow dividing tube and the gas flow dividing tank are communicated internally; the fire-resistant casing pipe is provided with macro porous medium, micro porous medium and lower layer metal fiber from top to bottom, and the lower layer metal fiber is connected with the tray and the gas flow dividing tube simultaneously. The inventive diffusion type porous medium gas fuel combustor can be used for efficiently avoiding tempering when combustion intensity is stronger, thus achieving the effects of protecting micro porous medium and saving energy.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com