Briquette coal sample making tool and method

A technology for making tools and methods, applied in the preparation of test samples, etc., can solve the problems of different densities, changes in the physical and mechanical properties of coal samples, and reduce the overall homogeneity of coal samples, so as to achieve low cost and save sample preparation. time, ensuring the effect of homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

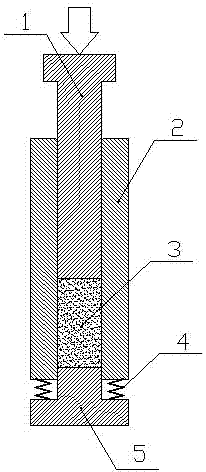

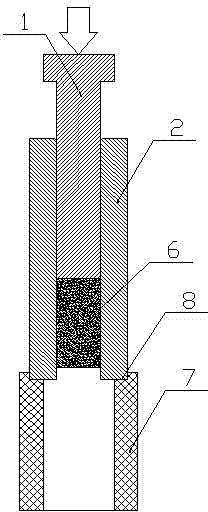

[0017] Depend on figure 1 with figure 2 The coal sample preparation tool shown includes upper and lower transparent coal pressing pipes 2 and an upper pressure for inserting into the top opening of the coal pressing pipe 2 and compacting the wet coal powder 3 in the coal pressing pipe 2 downwards. Head 1 and a "convex"-shaped pressing head 5.

[0018] The coal pressing pipe 2 is a steel pipe, and the upper pressing head 1 is composed of a pressing block at the top and a vertical plunger fixed on the lower side of the pressing block. Insert from the top port of the coal pressing pipe 2, the diameter of the plunger matches the inner diameter of the coal pressing pipe 2, the outer wall of the plunger fits the inner wall of the coal pressing pipe 2, and the upper pressure head 1 passes through the plunger and presses the coal The inner wall of the tube 2 is a sliding fit.

[0019] The protrusion of the lower pressing head 5 is inserted into the bottom opening of the coal press...

Embodiment 2

[0022] Such as figure 1 with figure 2 Shown briquette coal sample preparation method, comprises the steps:

[0023] (1) Take a certain quality of wet coal powder, weigh an appropriate amount of distilled water according to a certain ratio with an electronic balance and a measuring cup, mix the coal powder 3 and the distilled water evenly to become wet coal powder, and prepare for making briquette coal sample 6, Wet pulverized coal is the mixture of pulverized coal 3 and distilled water; Prepare the briquette coal sample making tool as described in embodiment 1 and install, and the installation process is as follows: spring 4 is enclosed within the raised outer ring of lower pressure head 5, and then The coal pressing pipe 2 is placed on the spring 4 and the lower pressure head 5, and an appropriate amount of wet coal powder is weighed with an electronic balance and placed in the coal pressing pipe 2 for making the coal sample 6, and is compacted with an iron bar; The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com