Patents

Literature

266results about How to "Prevent flashback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

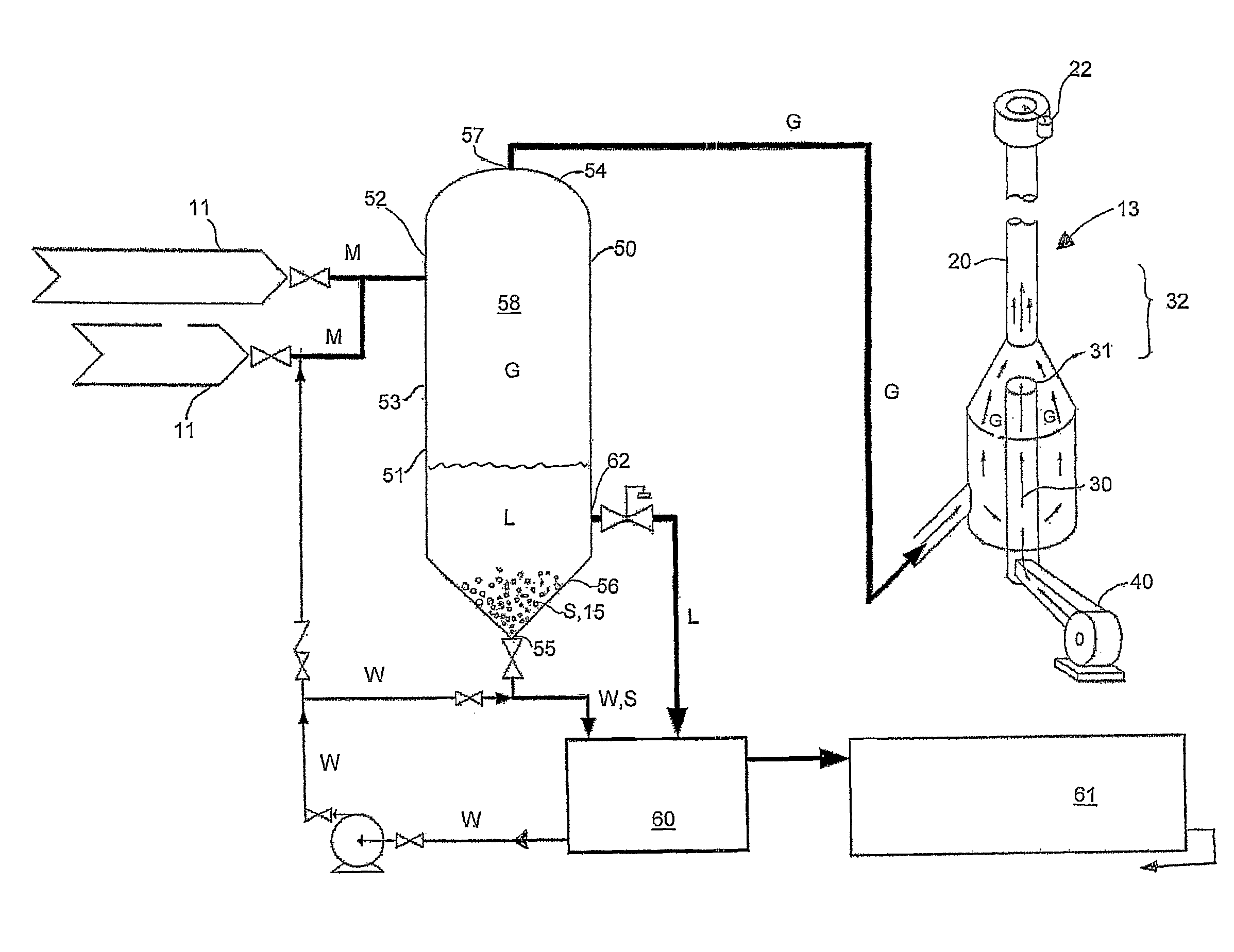

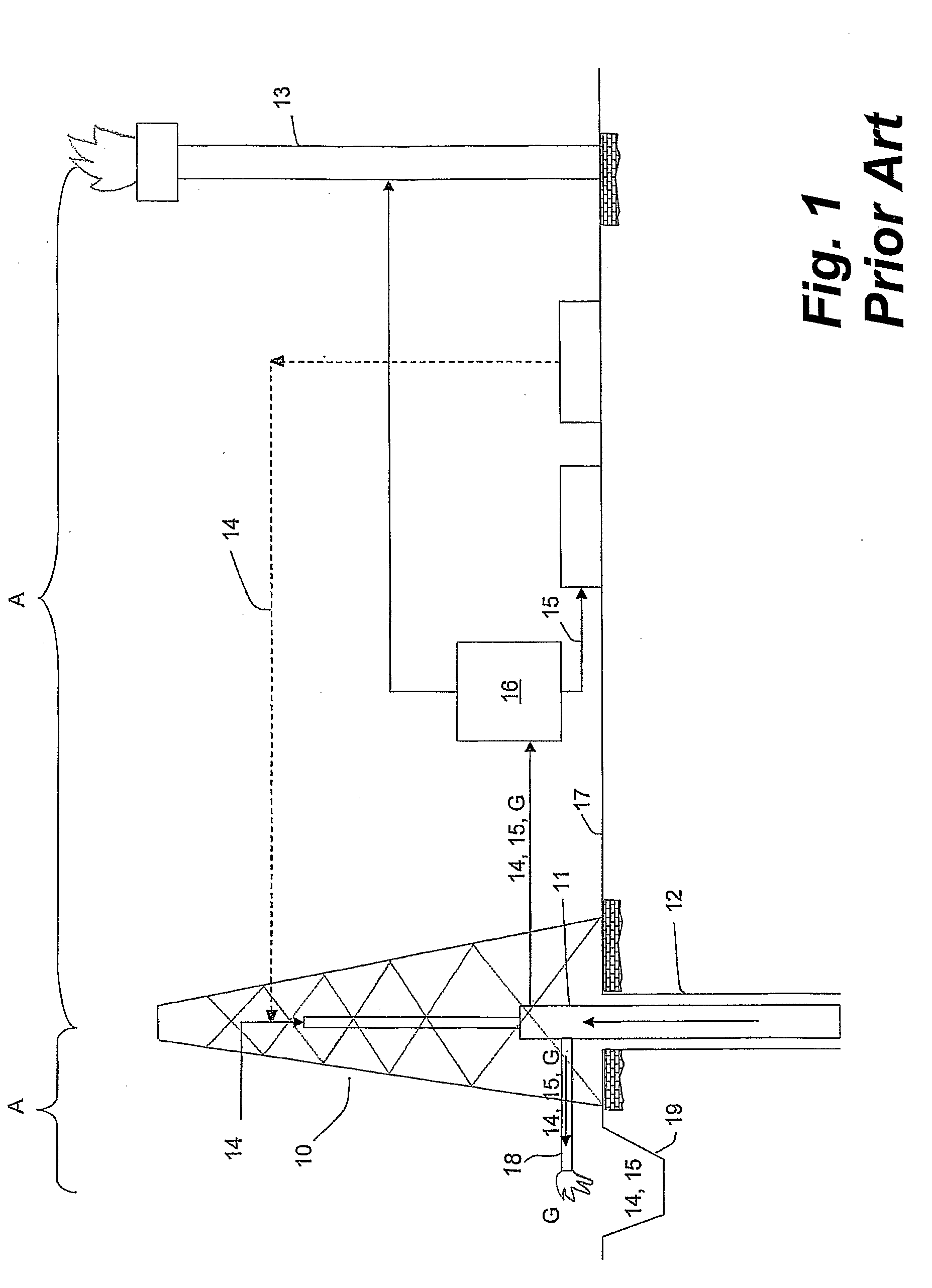

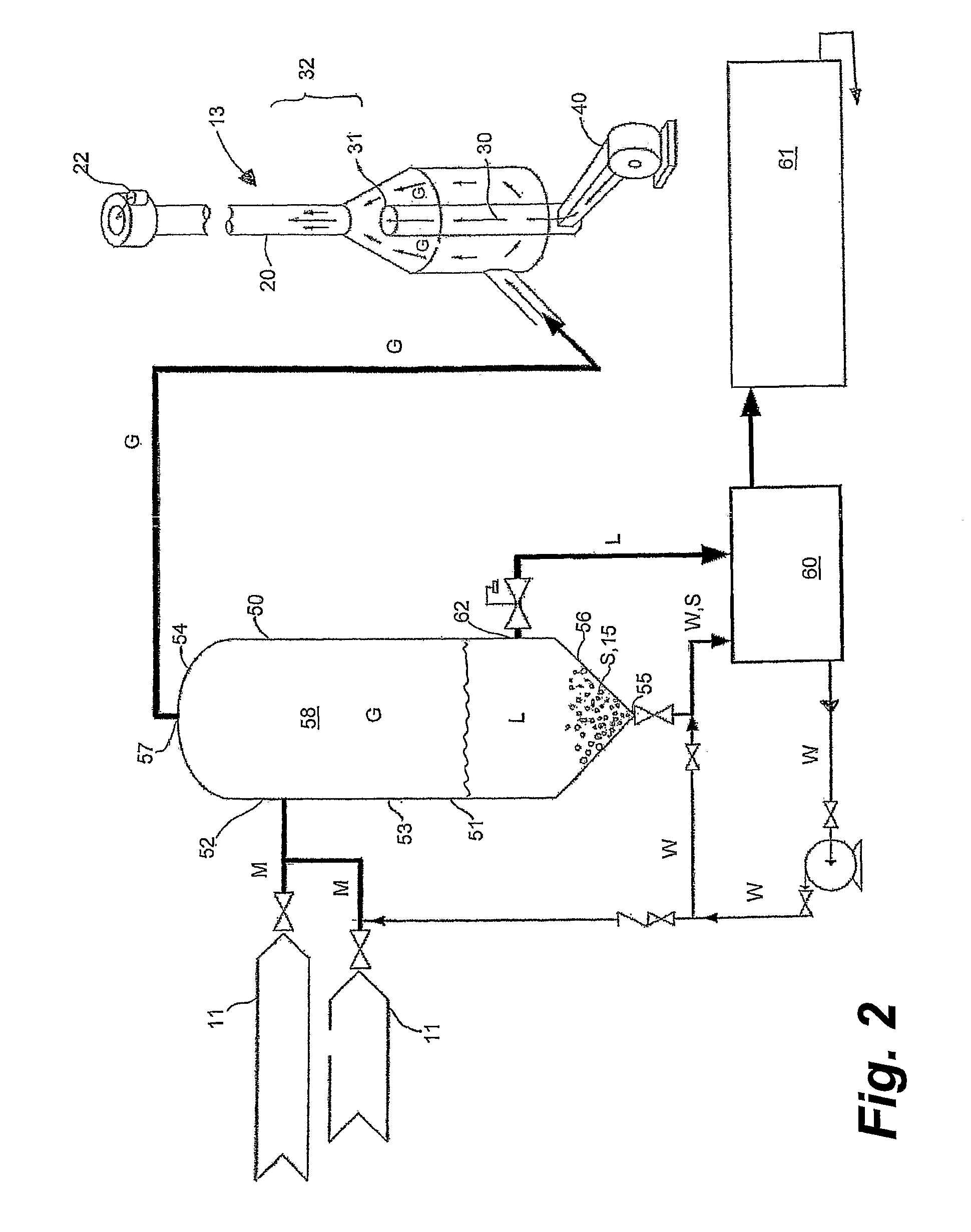

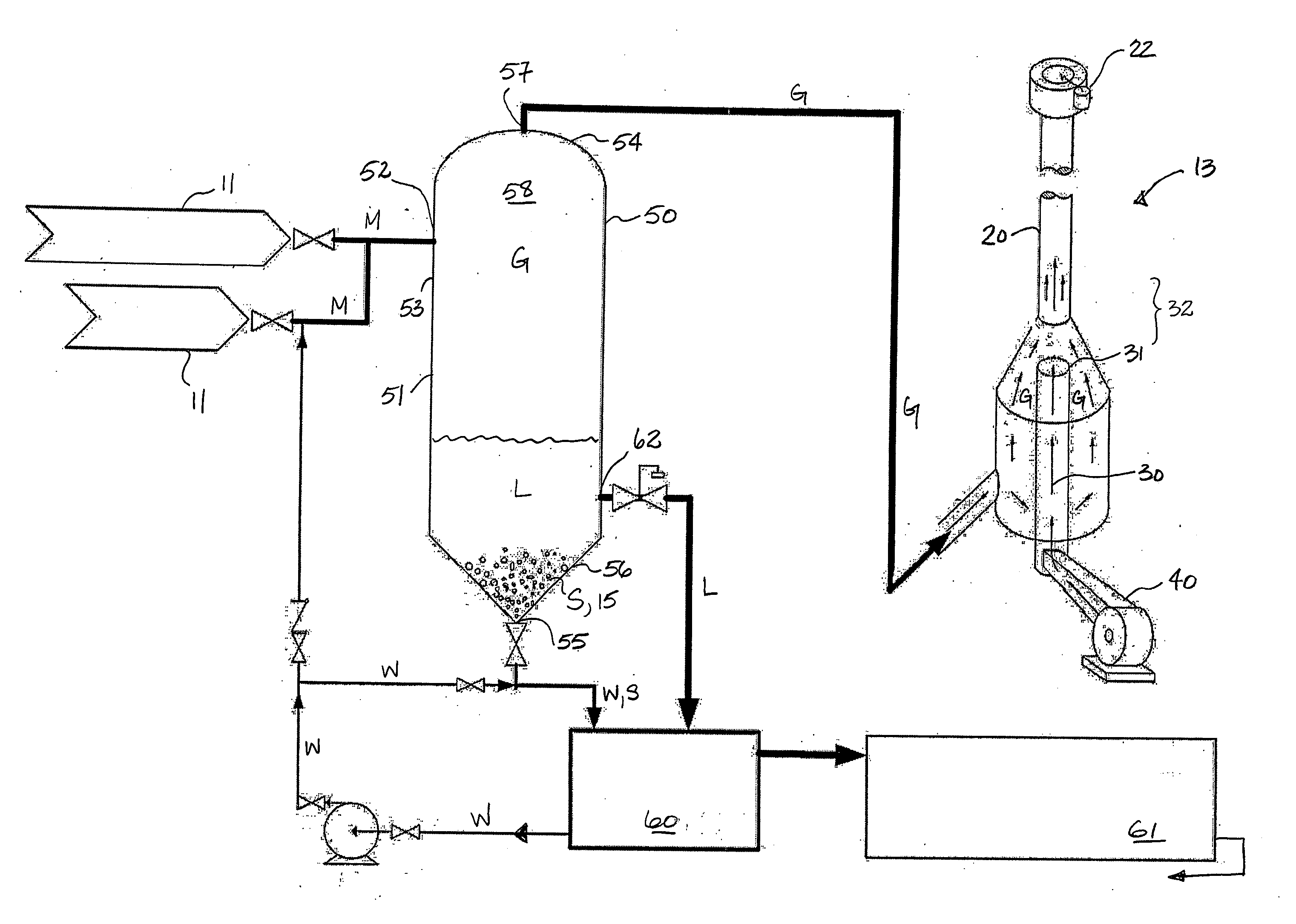

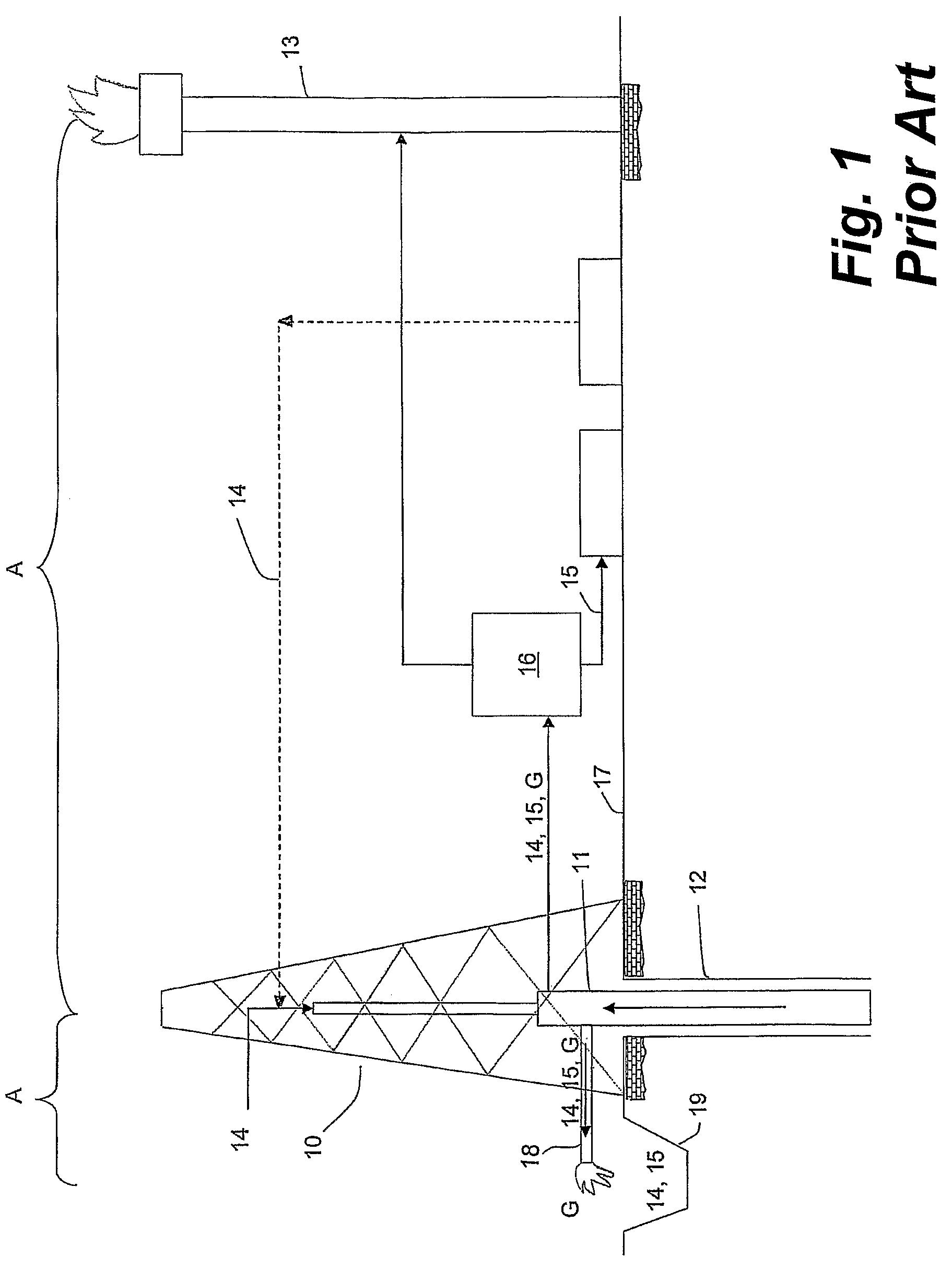

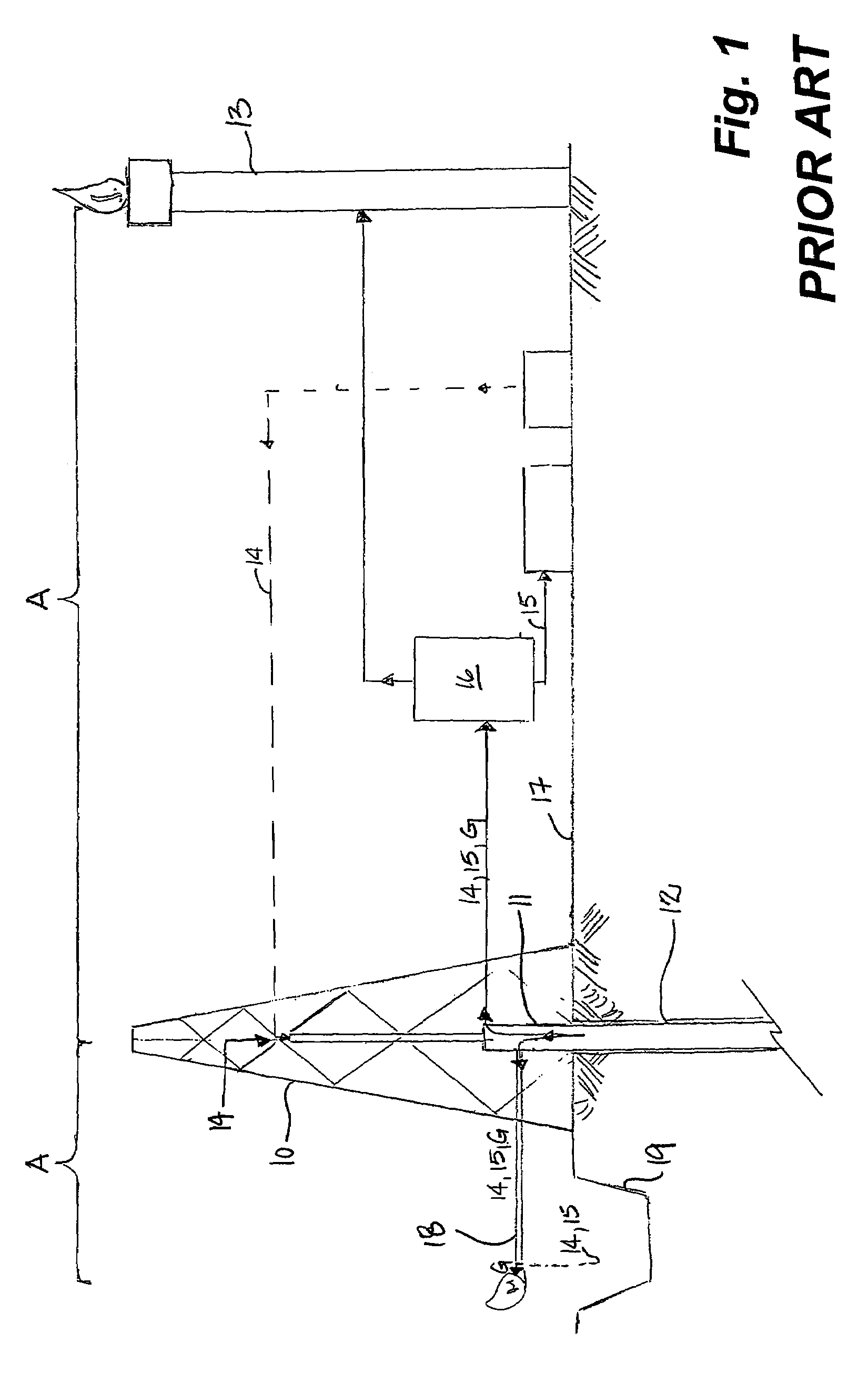

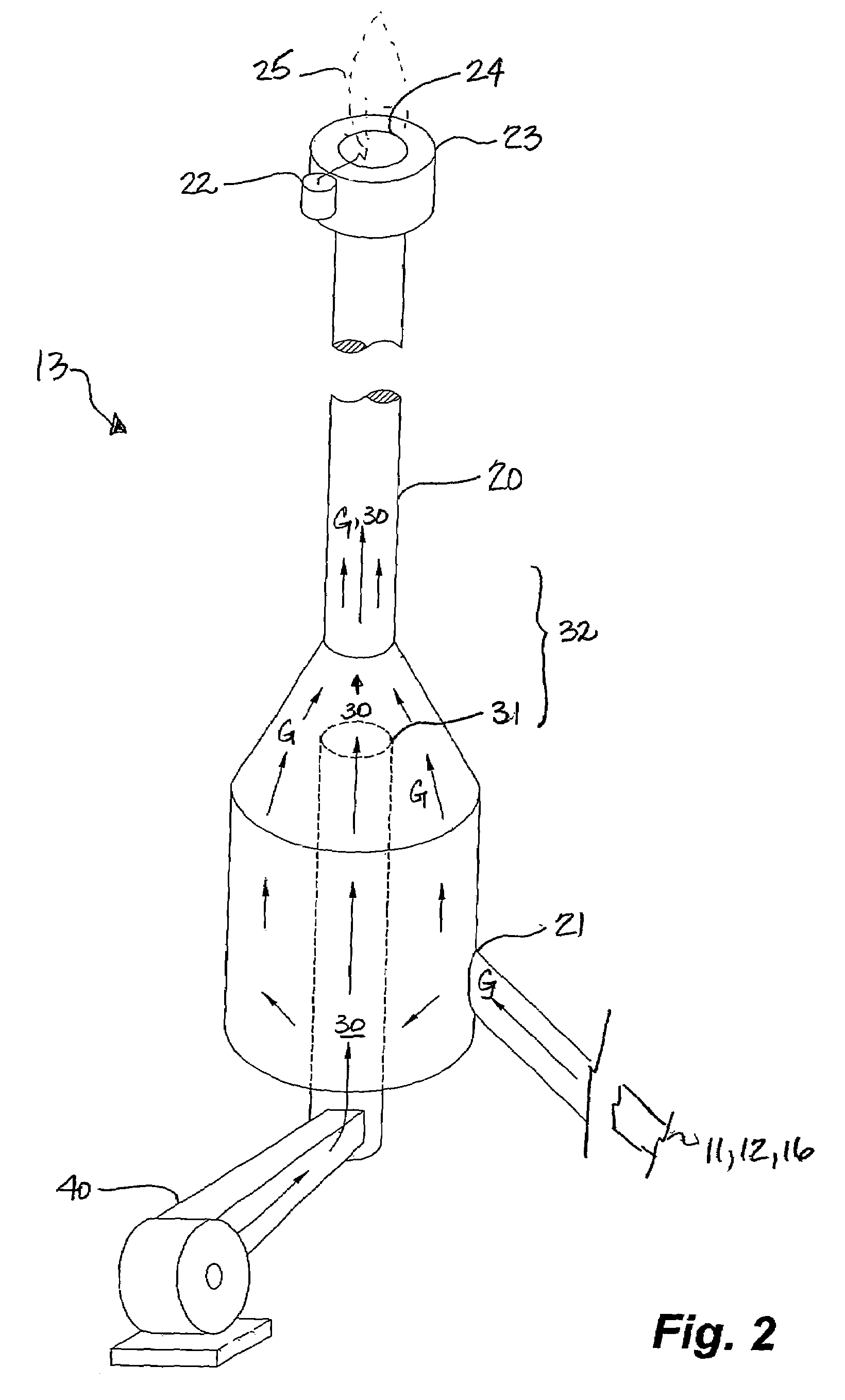

Separation Of Evolved Gases From Drilling Fluids In a Drilling Operation

InactiveUS20080190668A1Minimizes drilling interruptionAvoid evolutionDrilling rodsConstructionsDegasserWell drilling

A fluid handling system for drilling cuttings utilizes a constant and gravity managed liquid level between a substantially atmospheric separator and a shale shaker to maximize fluid residence time within the separator and ensure substantially all of the gas entrained in the cuttings is evolved and passed to a flare thus preventing evolution of the gas at the shale shaker. Solids from the separator are combined with liquid recirculation from and returning to the shale shaker. Optionally, a vacuum degasser is positioned between the separator and the shale shaker and separated gases are passed from the degasser to the flare. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas is intermittent and unpredictable.

Owner:SWARTOUT MATTHEW K

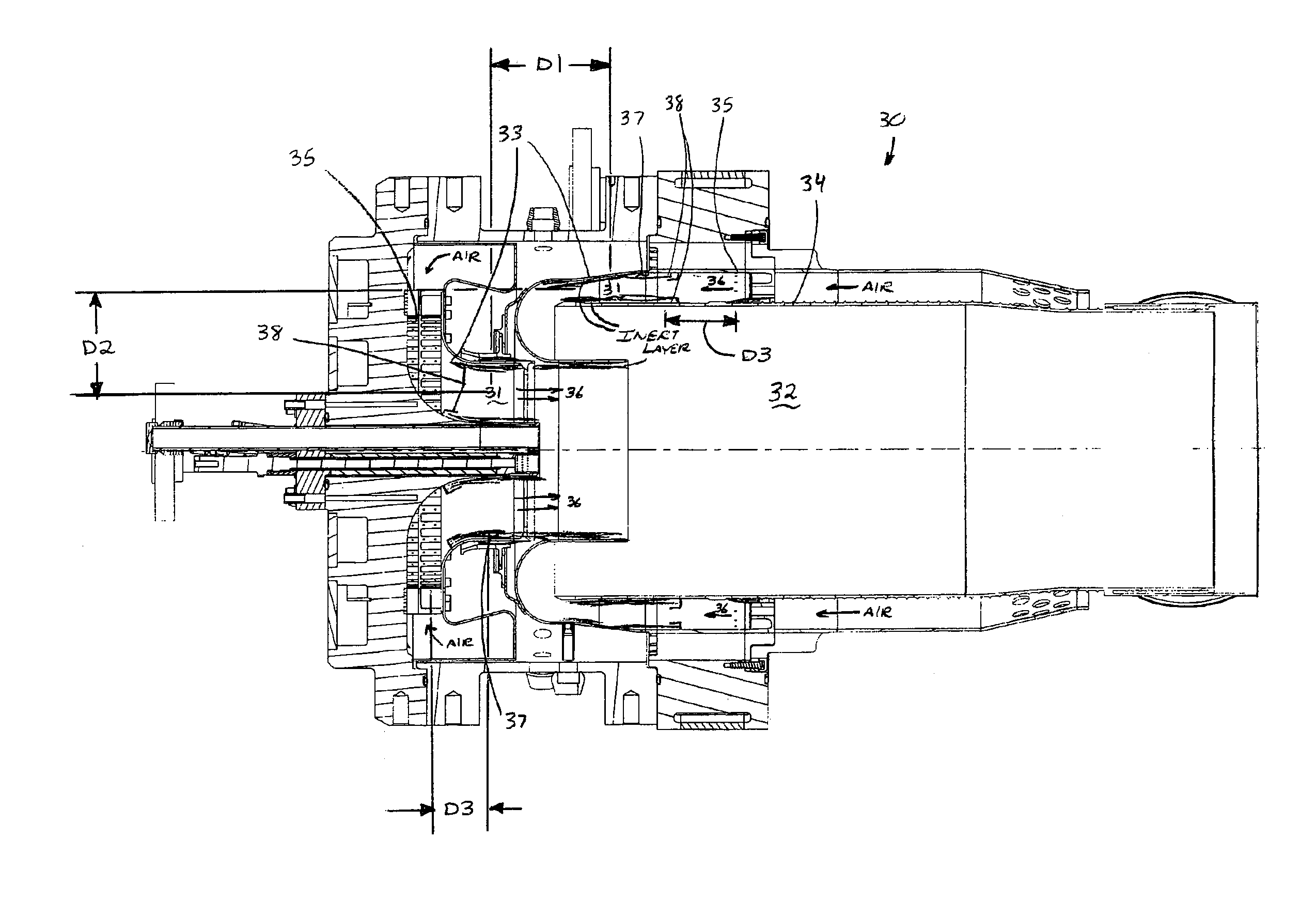

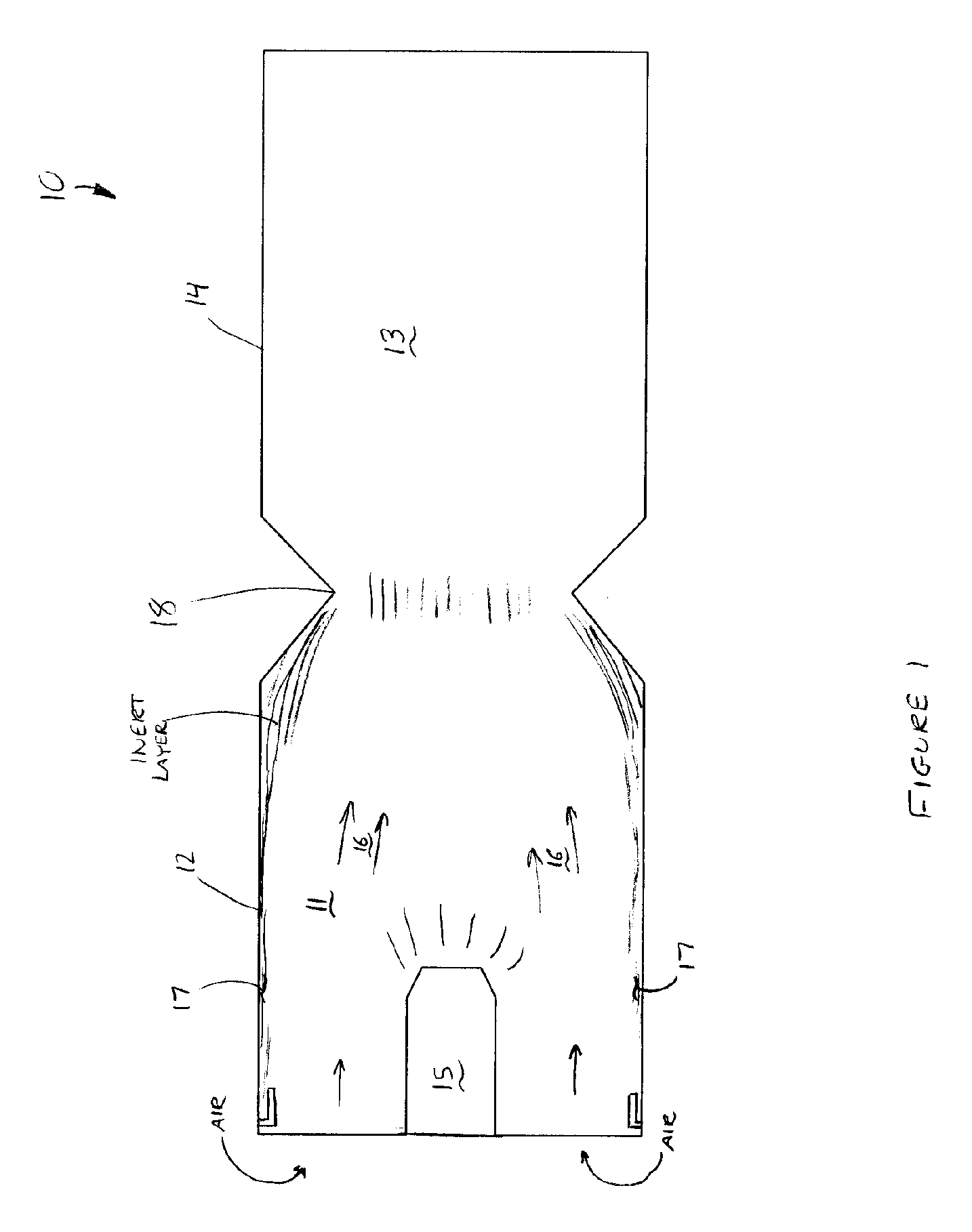

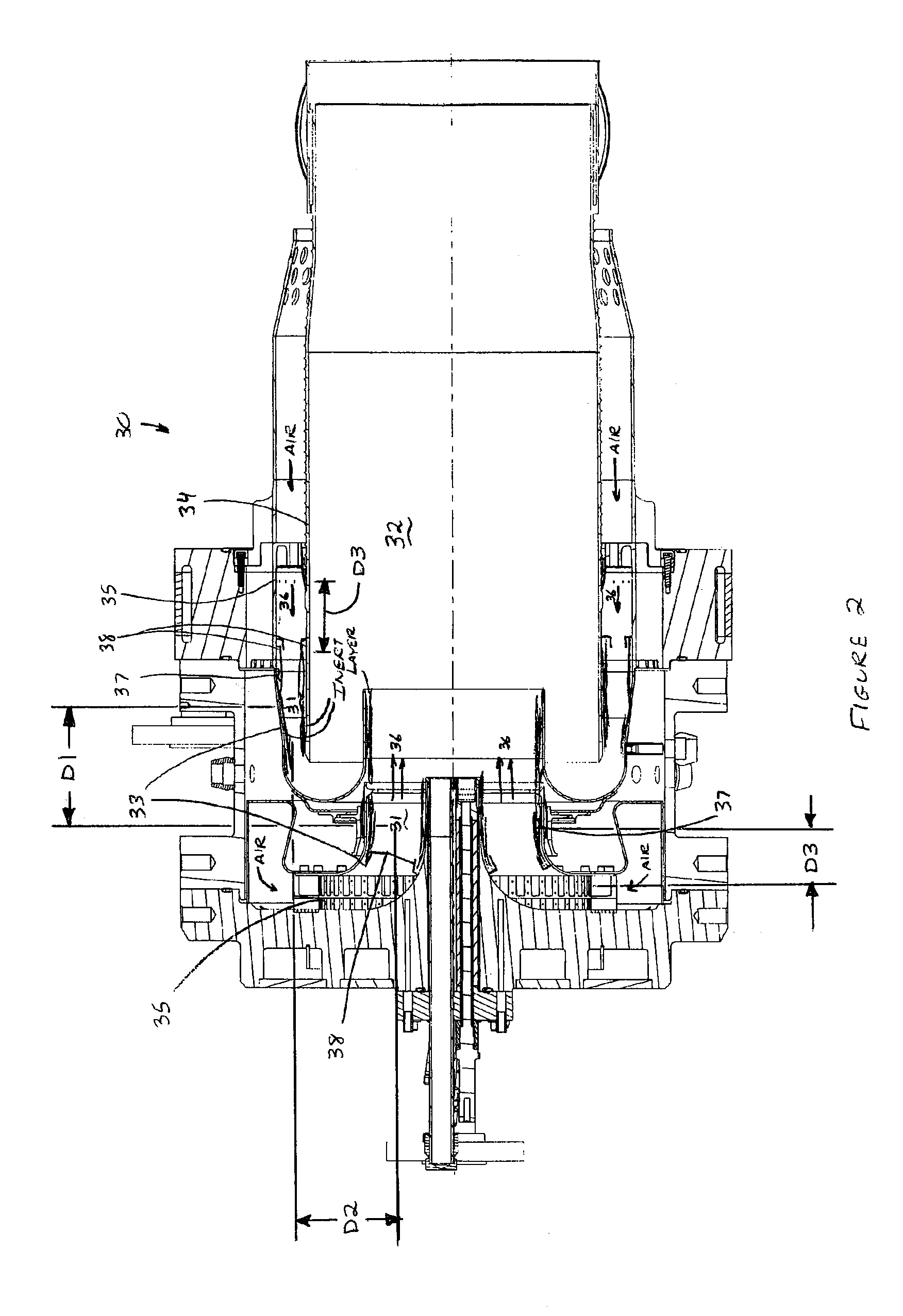

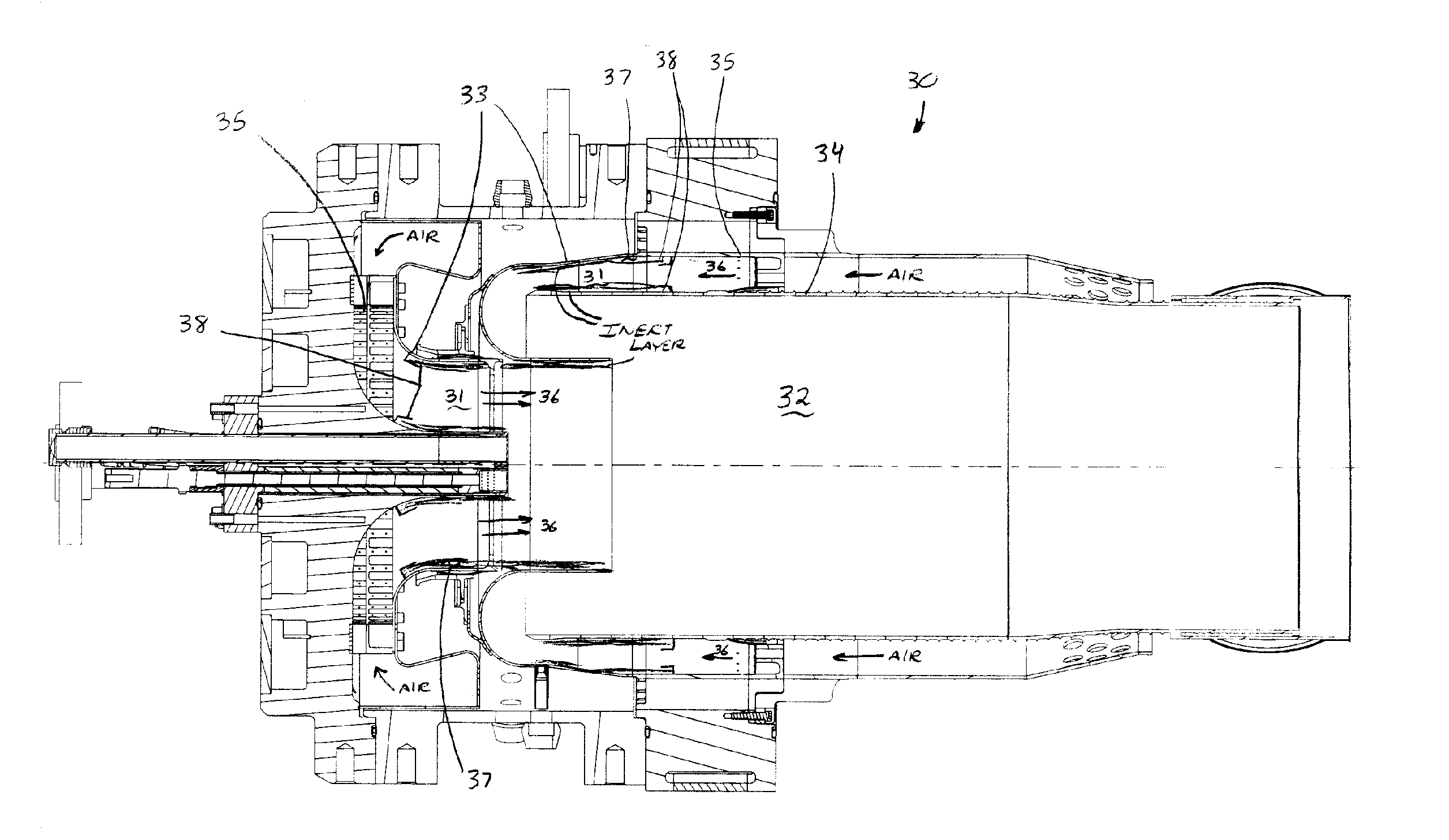

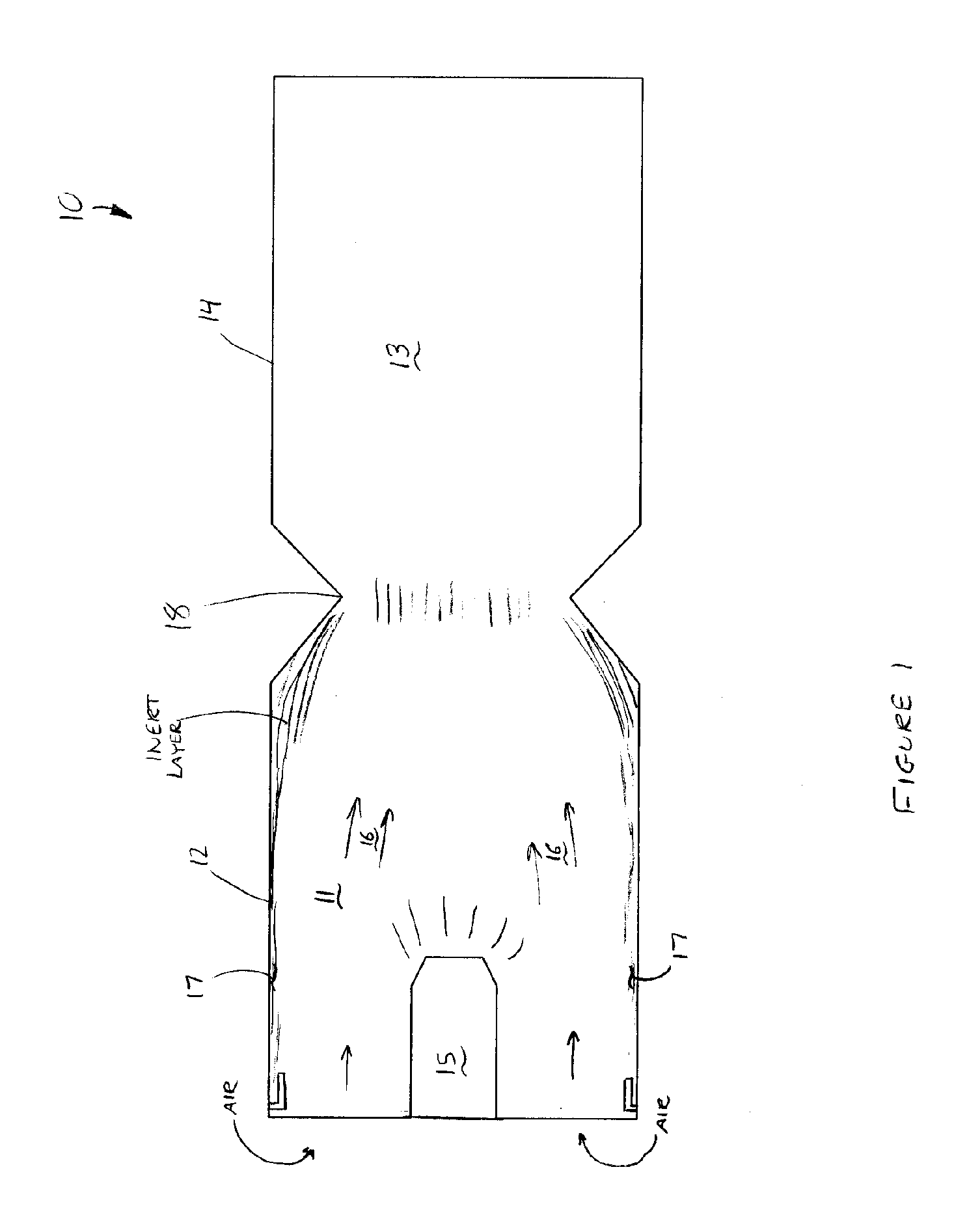

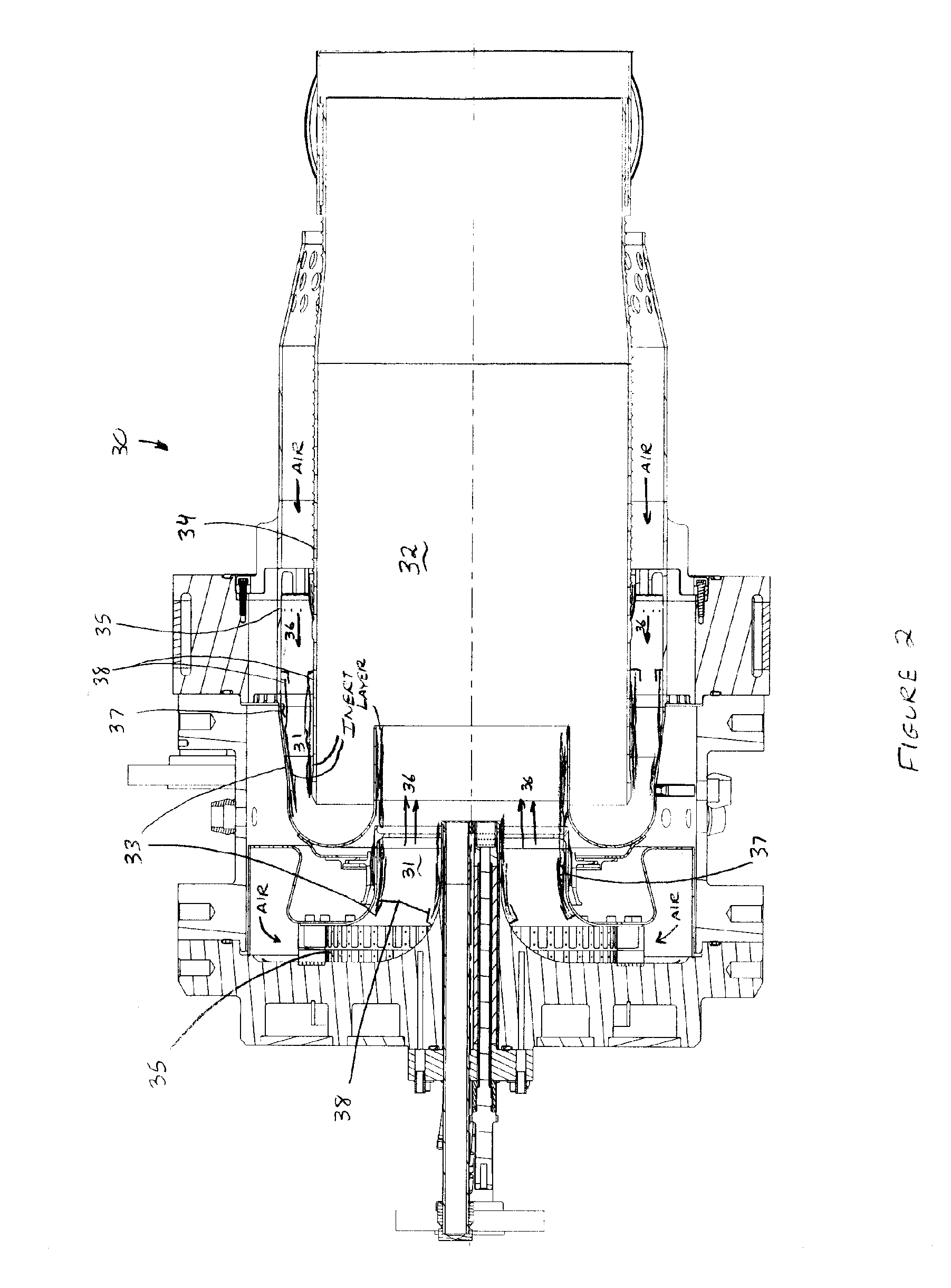

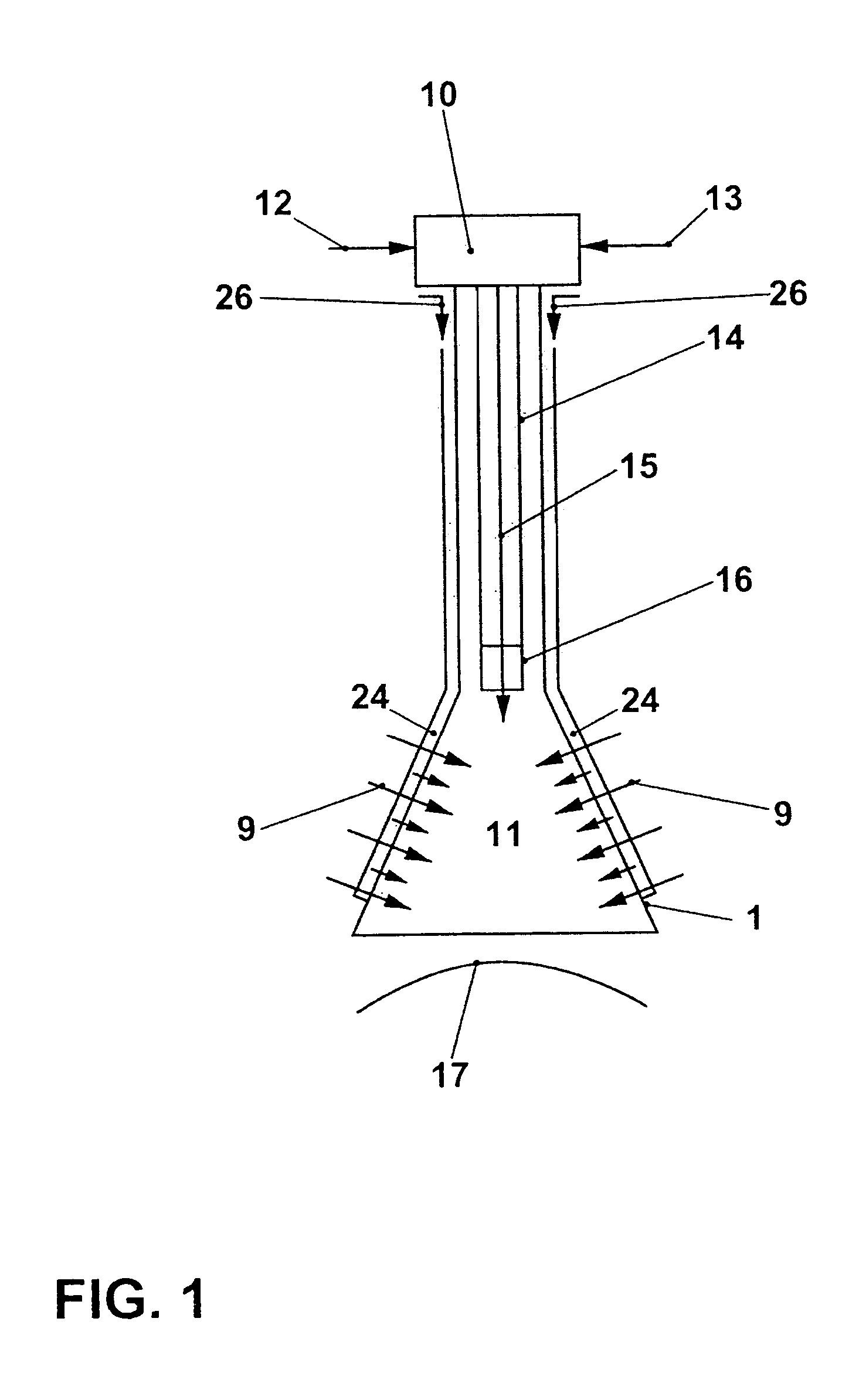

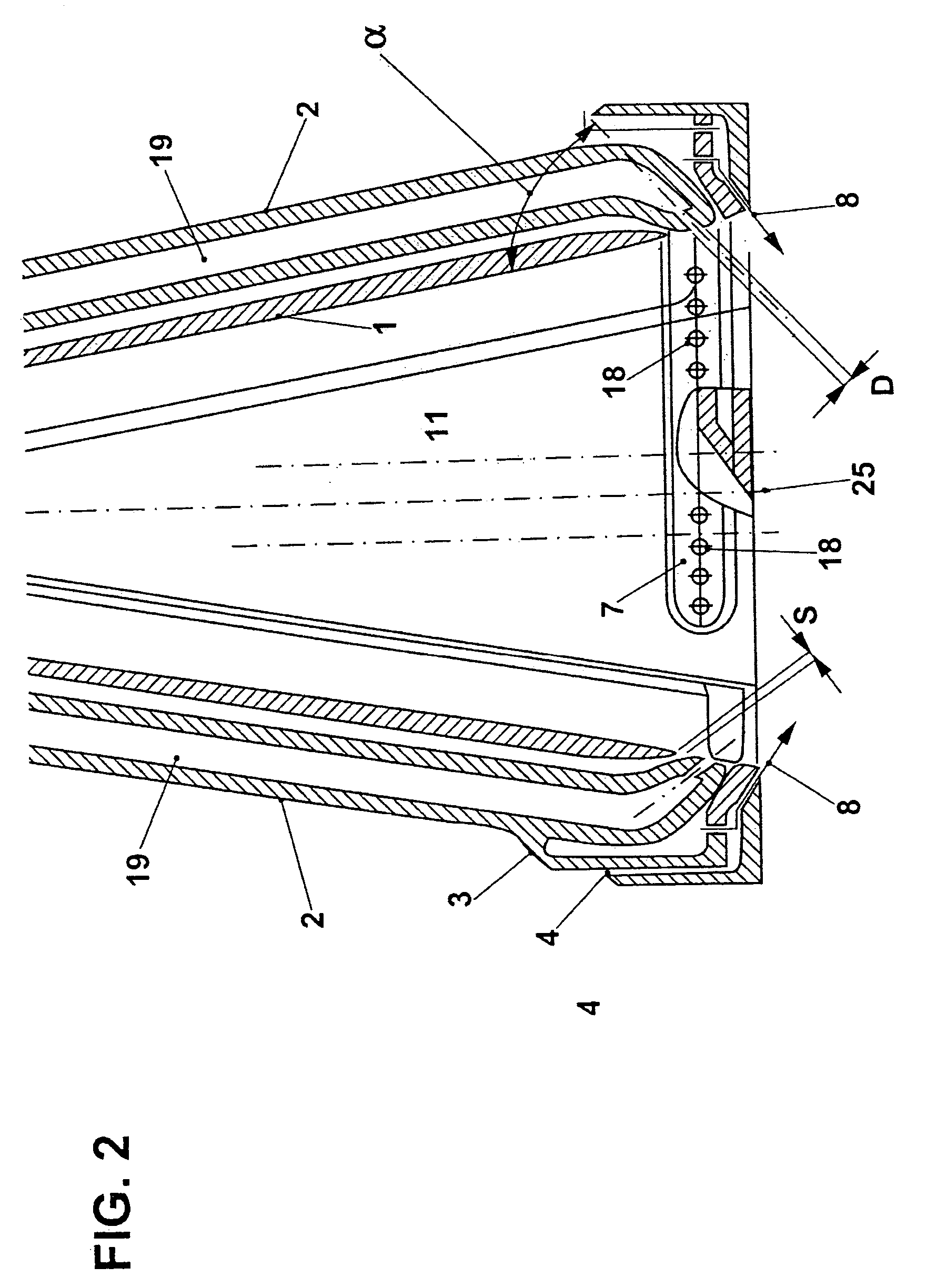

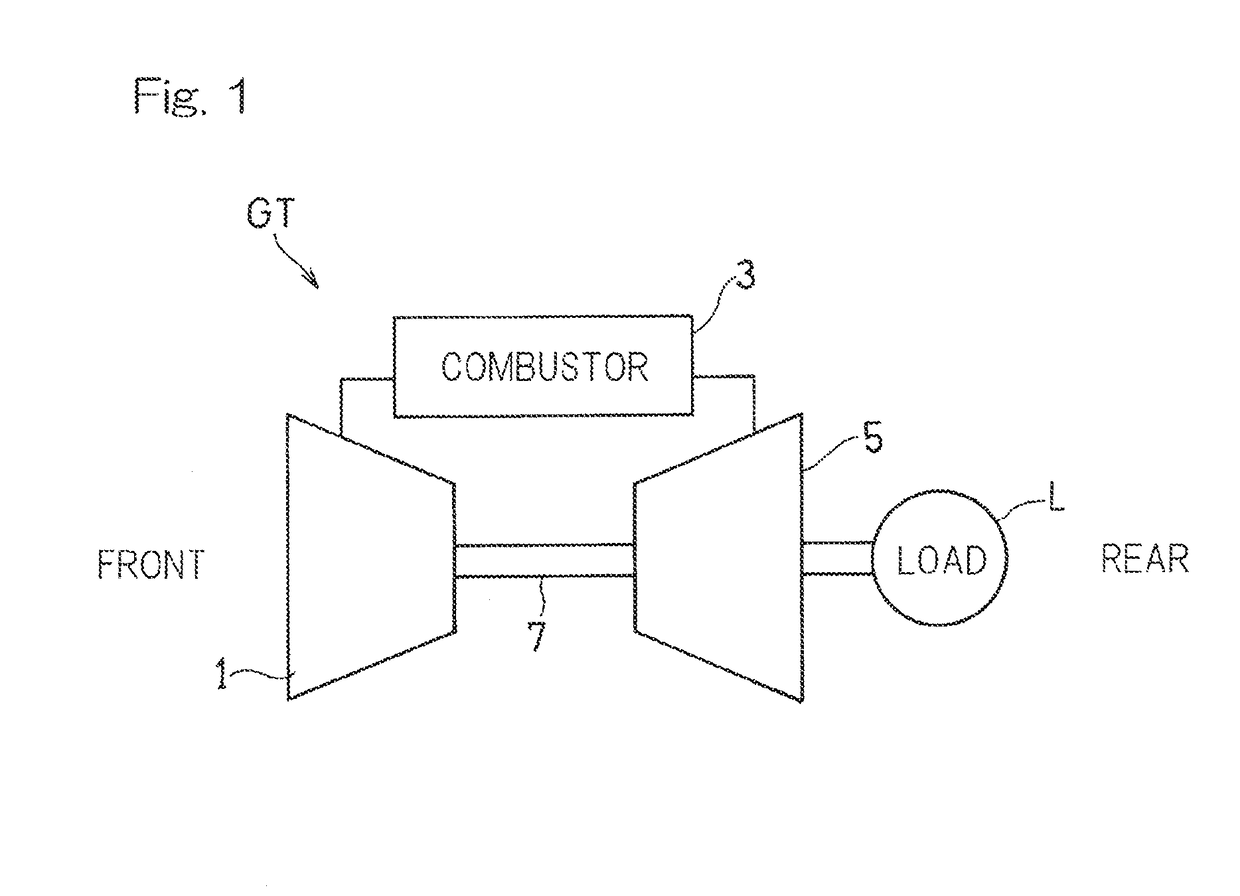

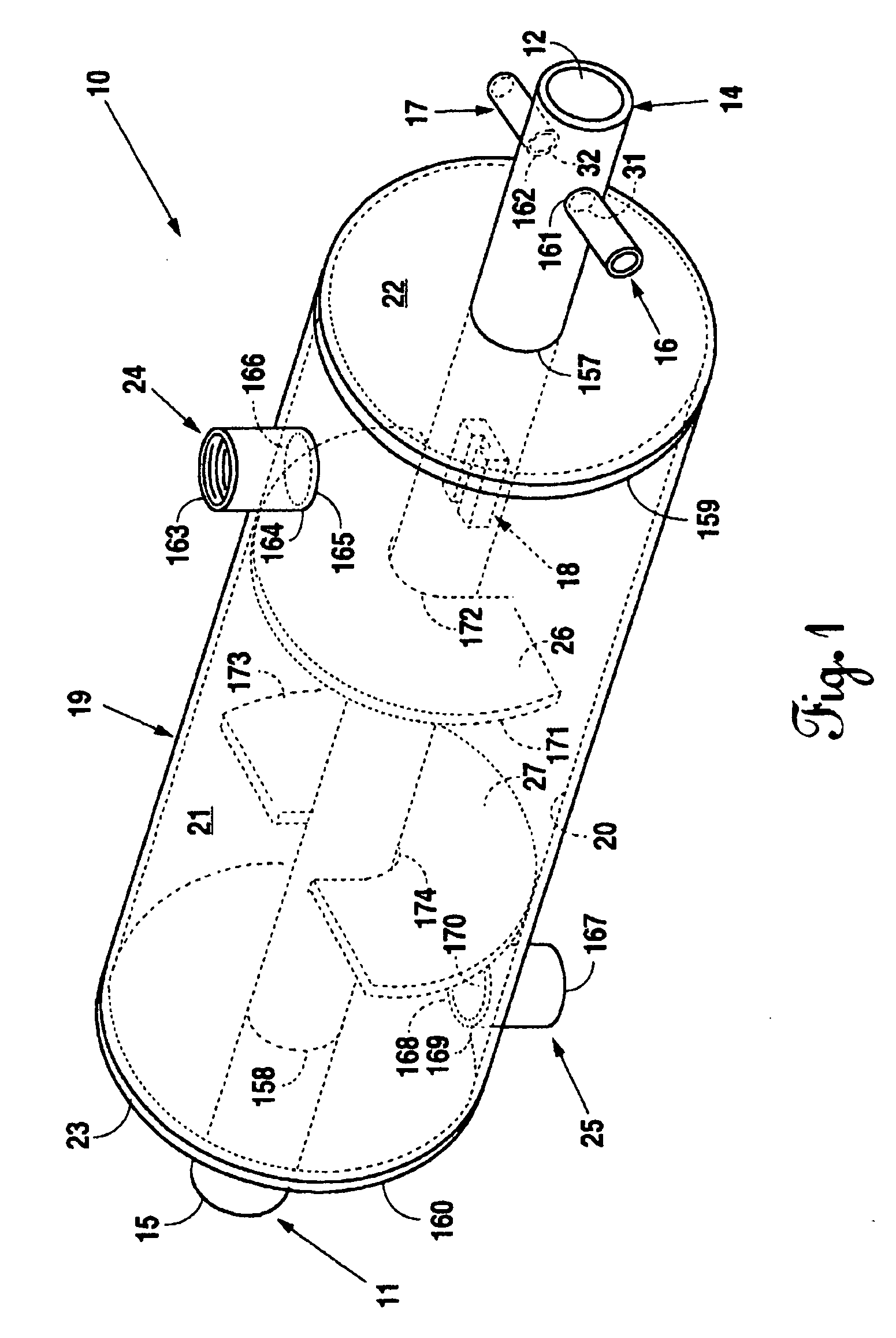

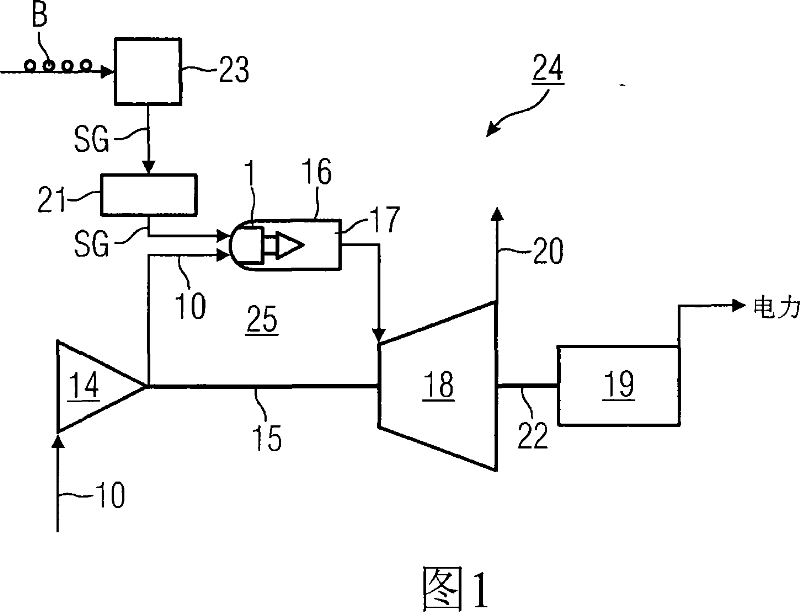

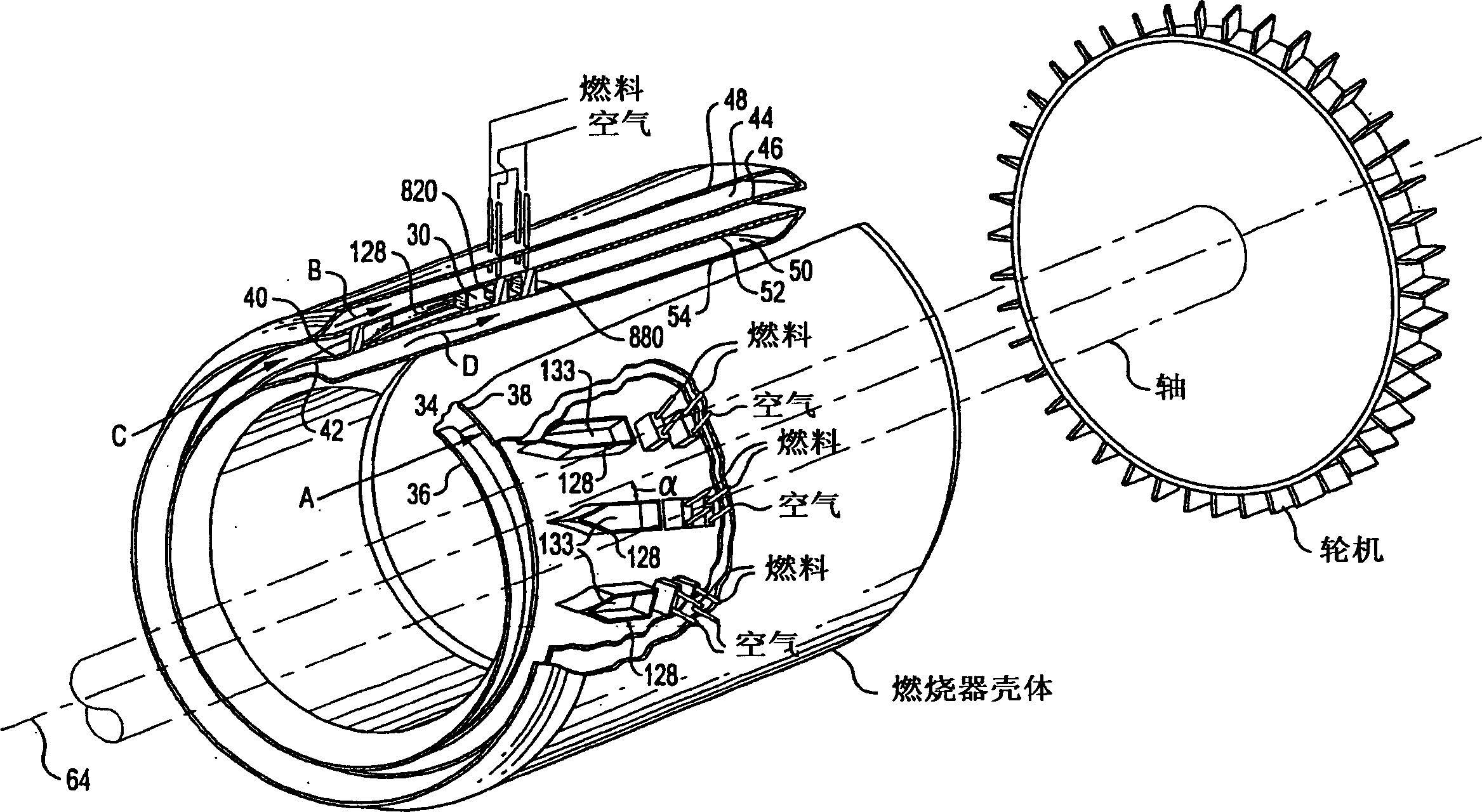

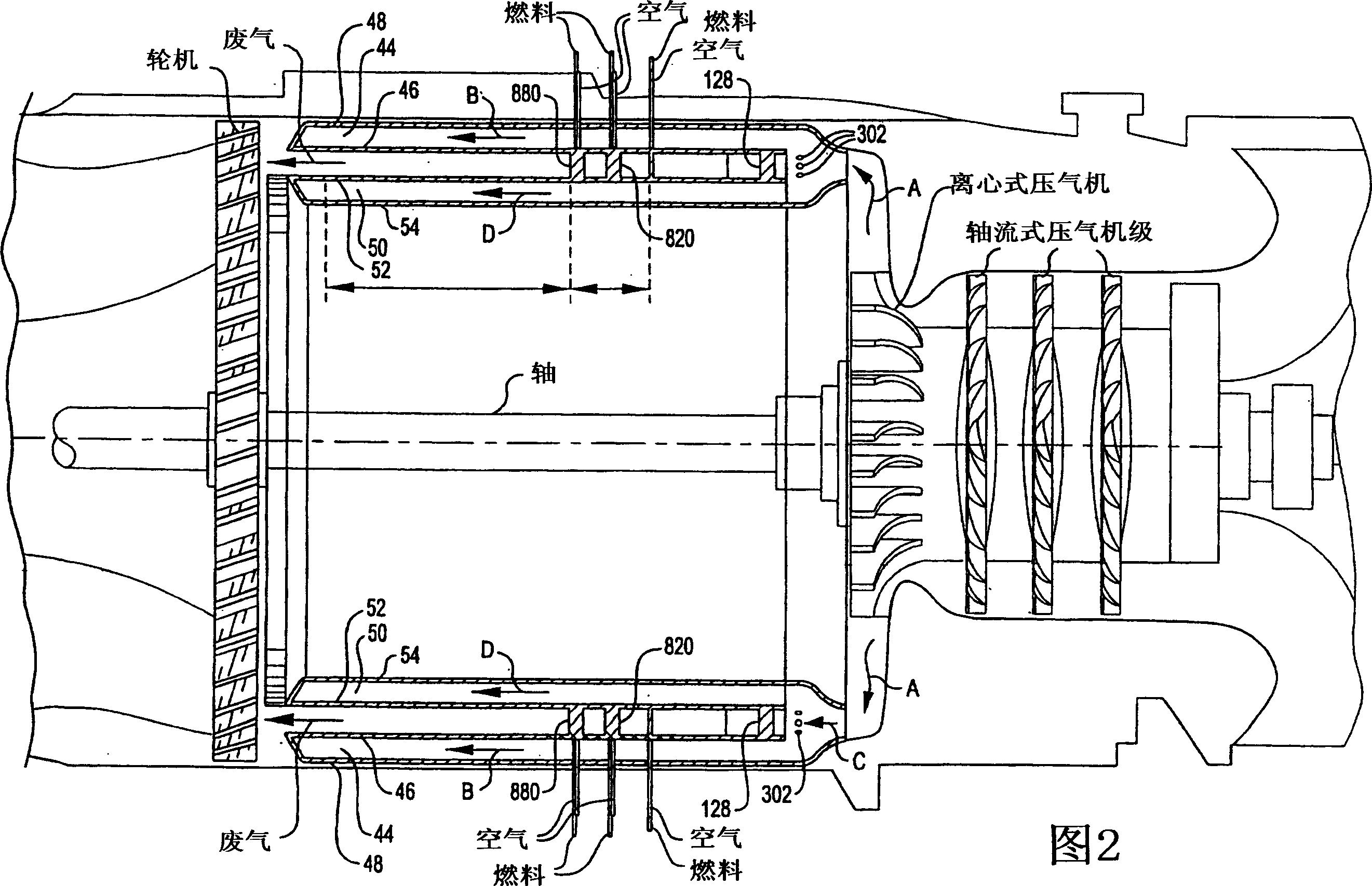

Flashback suppression system for a gas turbine combustor

ActiveUS7513115B2Small impactComprehensive performance is smallContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

A gas turbine combustor having improved flashback margin is disclosed. Multiple embodiments of the present invention are disclosed including combustors having a single premix chamber as well as multiple premix chambers. Flashback margin is increased for the combustor by incorporating a means for introducing an inert gas, such as nitrogen, into the premix chamber(s) at the region proximate the boundary layer to purge the boundary layer of combustible mixture, thereby ensuring that no combustion reaction occurs in the boundary layer.

Owner:H2 IP UK LTD

Flashback Suppression System for a Gas Turbine Combustor

ActiveUS20060260316A1Small impactComprehensive performance is smallContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A gas turbine combustor having improved flashback margin is disclosed. Multiple embodiments of the present invention are disclosed including combustors having a single premix chamber as well as multiple premix chambers. Flashback margin is increased for the combustor by incorporating a means for introducing an inert gas, such as nitrogen, into the premix chamber(s) at the region proximate the boundary layer to purge the boundary layer of combustible mixture, thereby ensuring that no combustion reaction occurs in the boundary layer.

Owner:H2 IP UK LTD

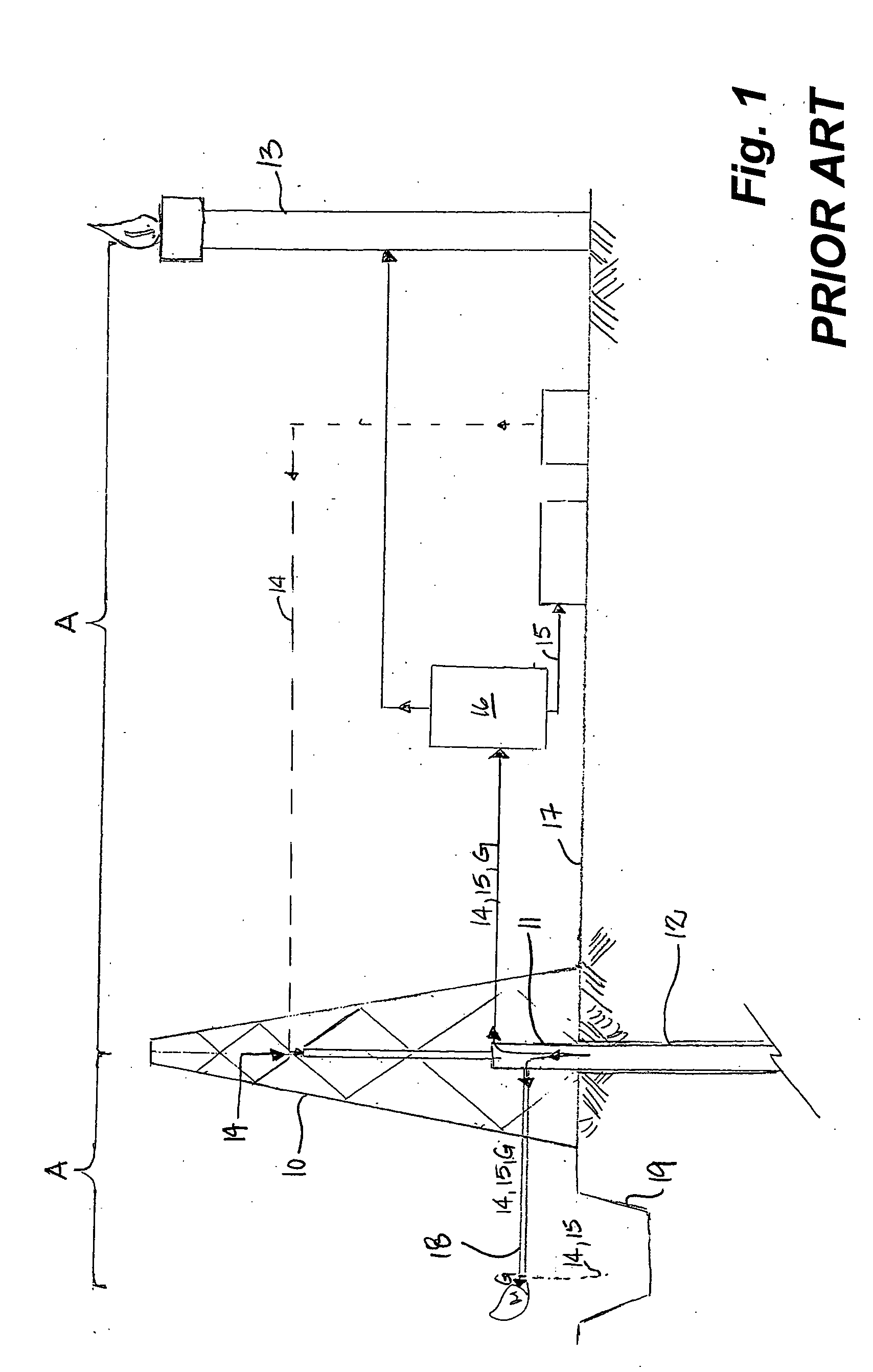

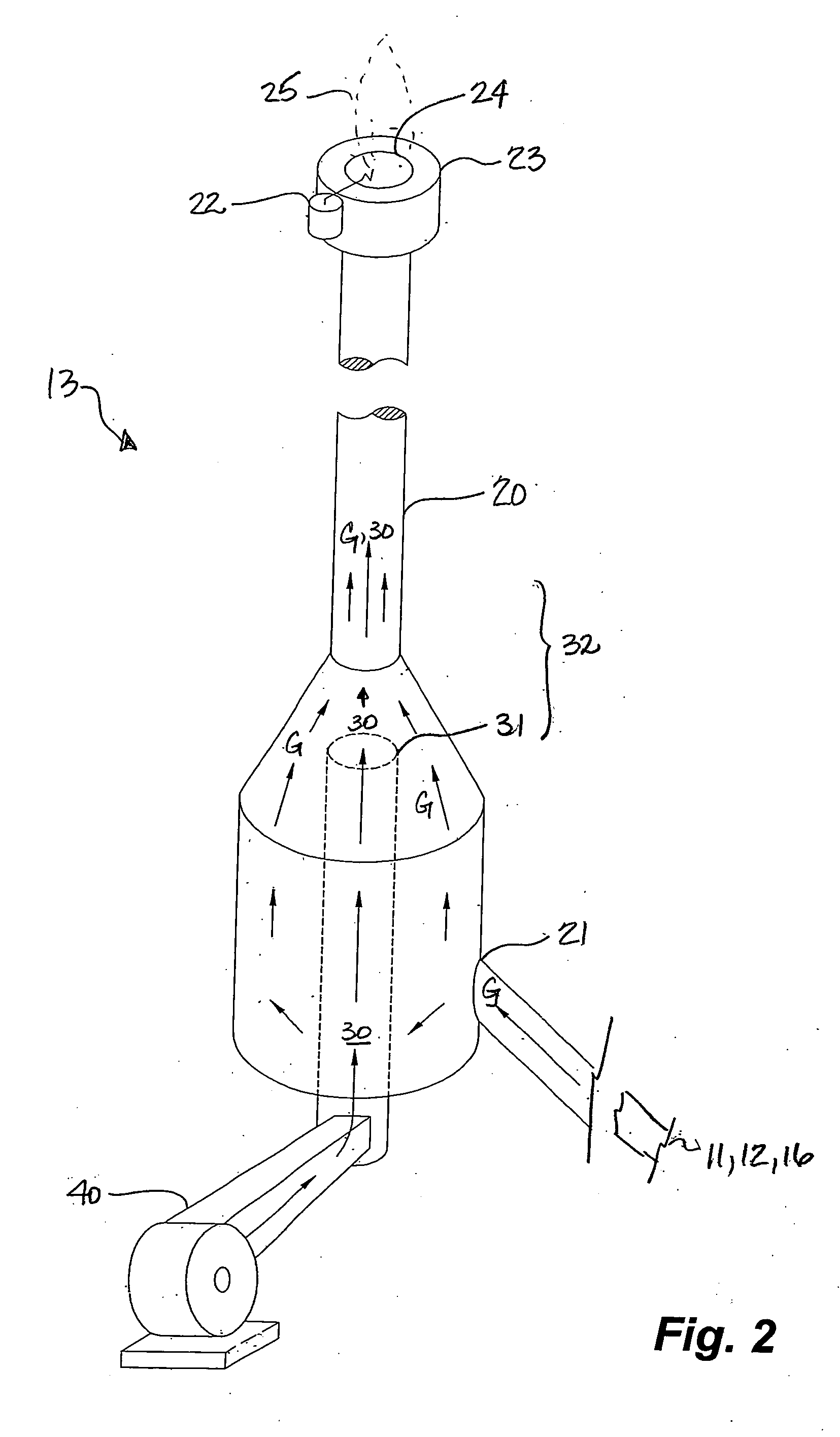

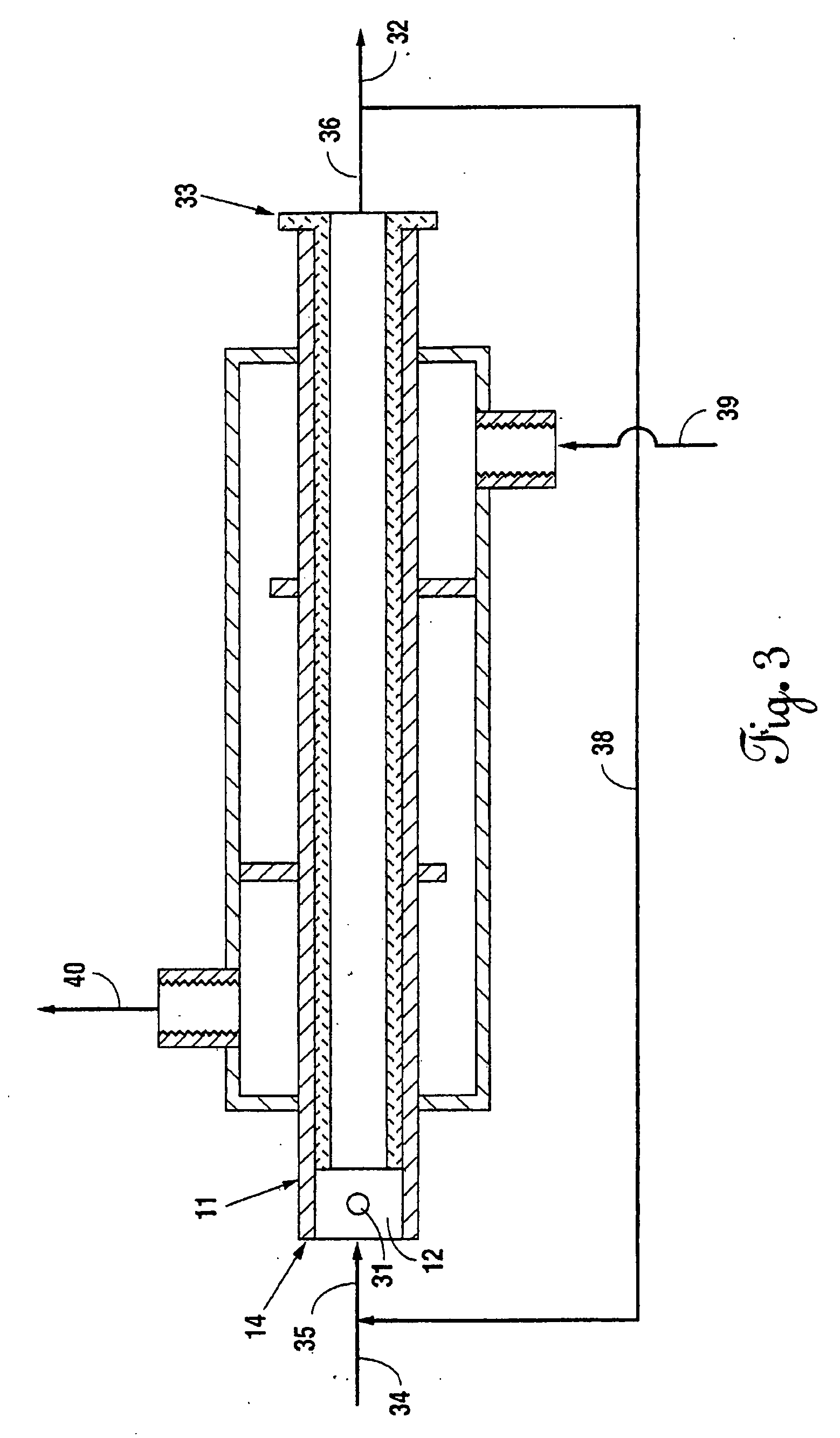

Continuous positive flow backflash prevention system

A method and system for the prevention of backflash from an ignition source in a flare stack to a separator or wellbore particularly during drilling and production. A continuous positive flow of air or exhaust gas is provided into the flow of gases from the wellbore or the separator to ensure that the velocity of the flow is always higher than the velocity at which the flame can propagate backwards into either the separator or the wellbore. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas from the wellbore is intermittent and unpredictable and can stop and start during connection and disconnection of the air used as the drilling fluid.

Owner:SWARTOUT MATT

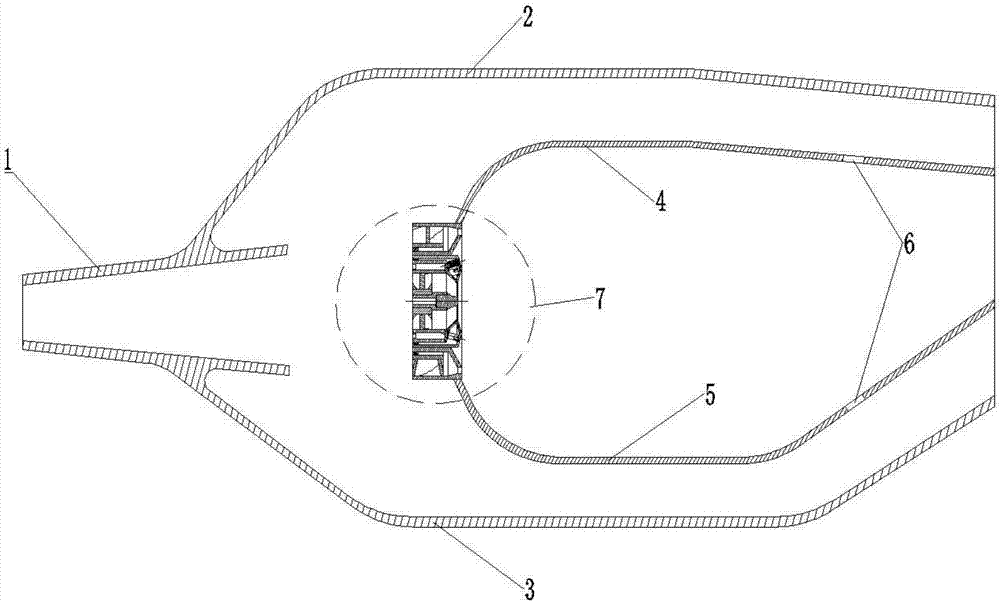

Lean oil direct injection and mixing low-pollution combustion chamber

ActiveCN107543201AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionGasoline direct injection

The invention relates to a lean oil direct injection and mixing low-pollution combustion chamber. The lean oil direct injection and mixing low-pollution combustion chamber is composed of a diffuser, acombustion chamber outer case, a combustion chamber inner case, a combustion chamber head, a flame tube outer wall and a flame tube inner wall, wherein combustion air all enters a flame tube from thecombustion chamber head; the combustion chamber head is divided into an on-duty grade and a main combustion grade through a grading and partitioning combustion strategy; the on-duty grade and the main combustion grade both adopt a direct injection and mixing combustion method, the phenomena of spontaneous combustion and tempering are effectively avoided, and the risk of occurrence of oscillationcombustion is lowered; the lean oil direct injection and mixing low-pollution combustion chamber only works in an on-duty grade mode under an idling rating state, the designed partial equivalence ratio is higher, and the work stability of the combustion chamber is guaranteed; and with the increase of the work state of the combustion chamber, the main combustion grade is opened gradually, the maincombustion grade and the on-duty grade work simultaneously under a large state, the designed combustion area average equivalence ratio is lower, the average temperature of the combustion area is effectively lowered, and therefore the generation quantity of pollutants is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

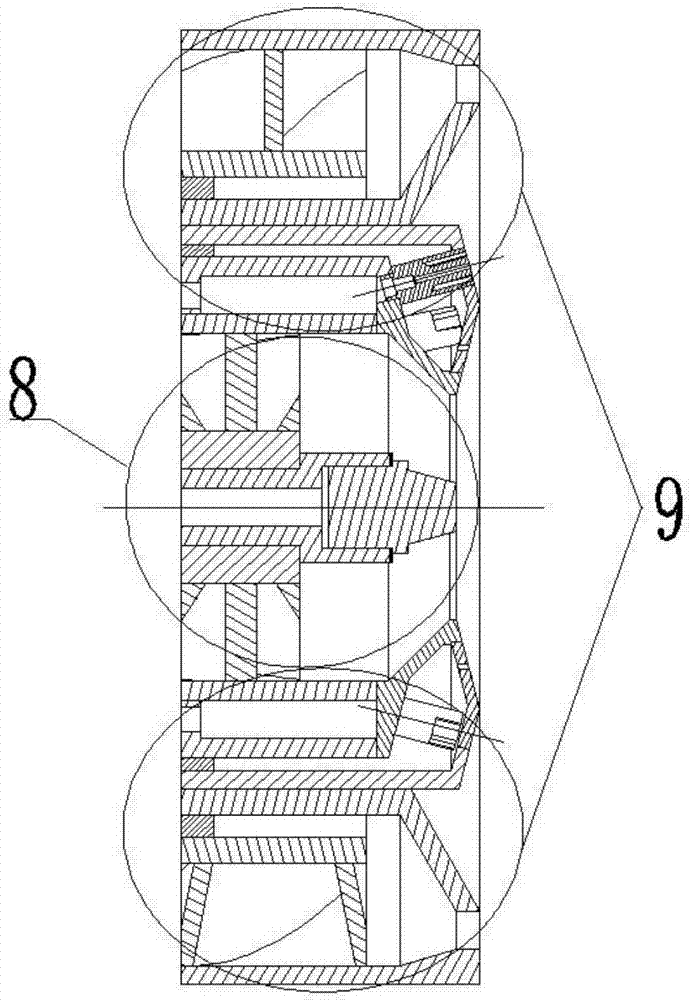

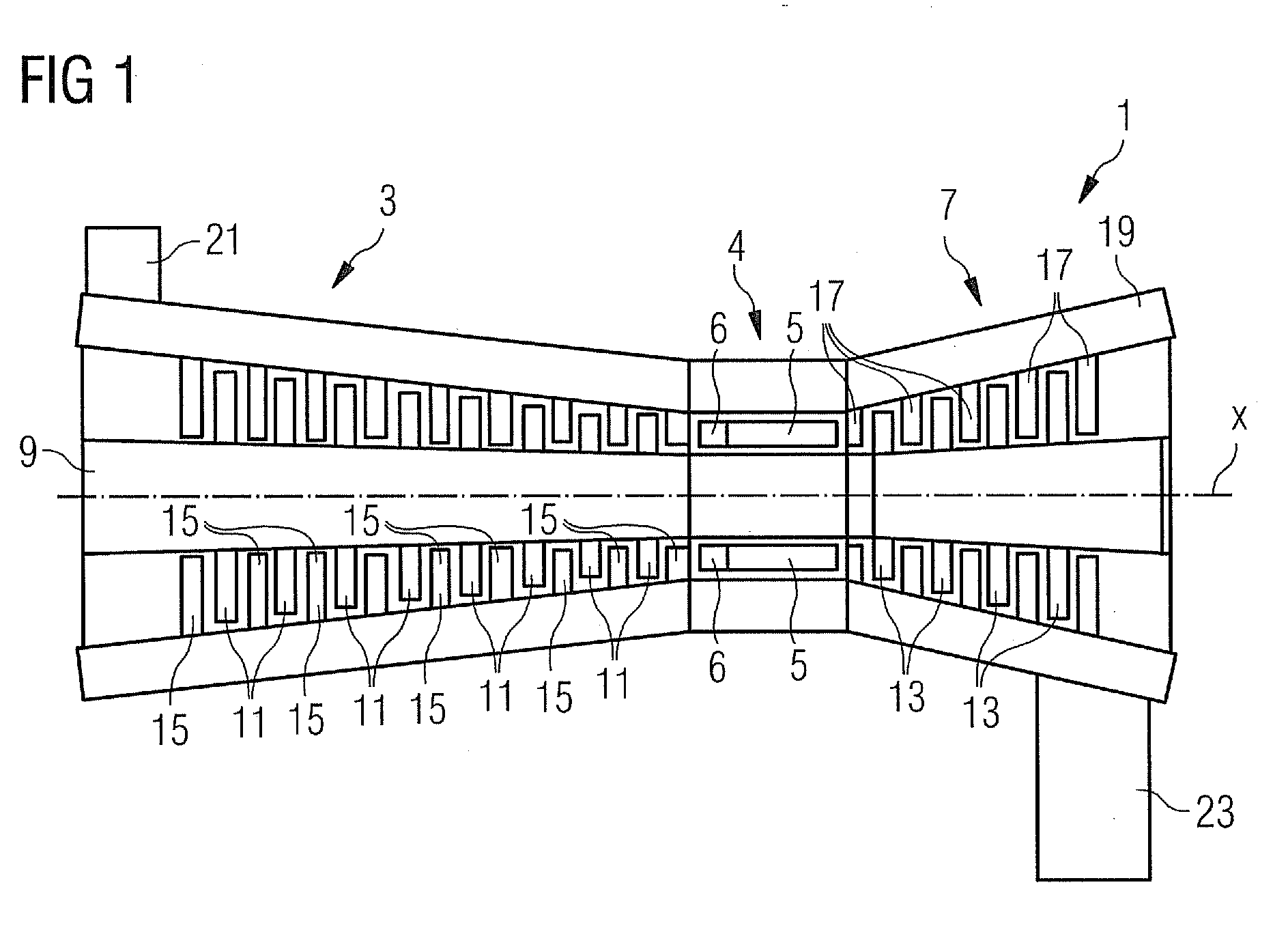

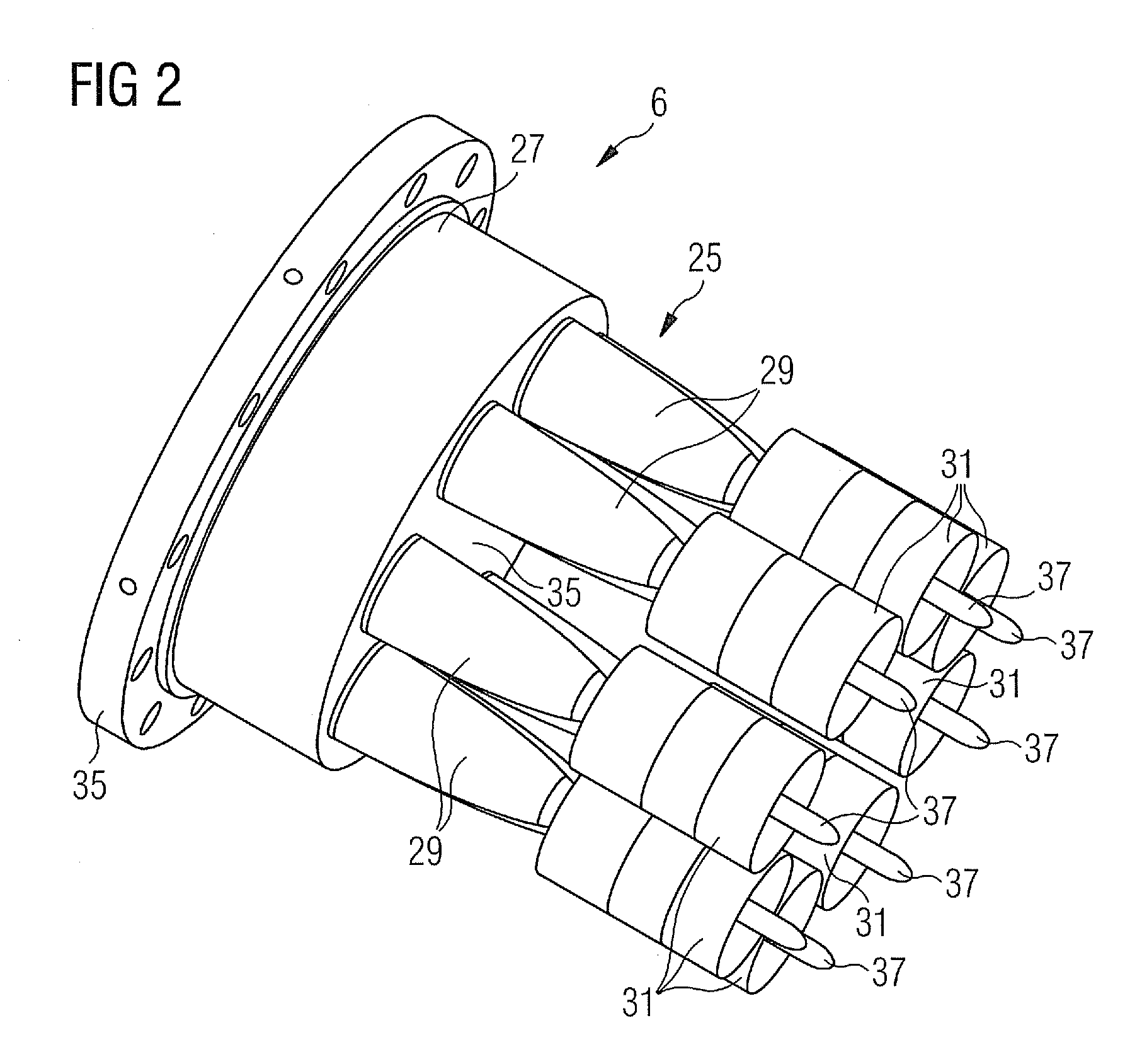

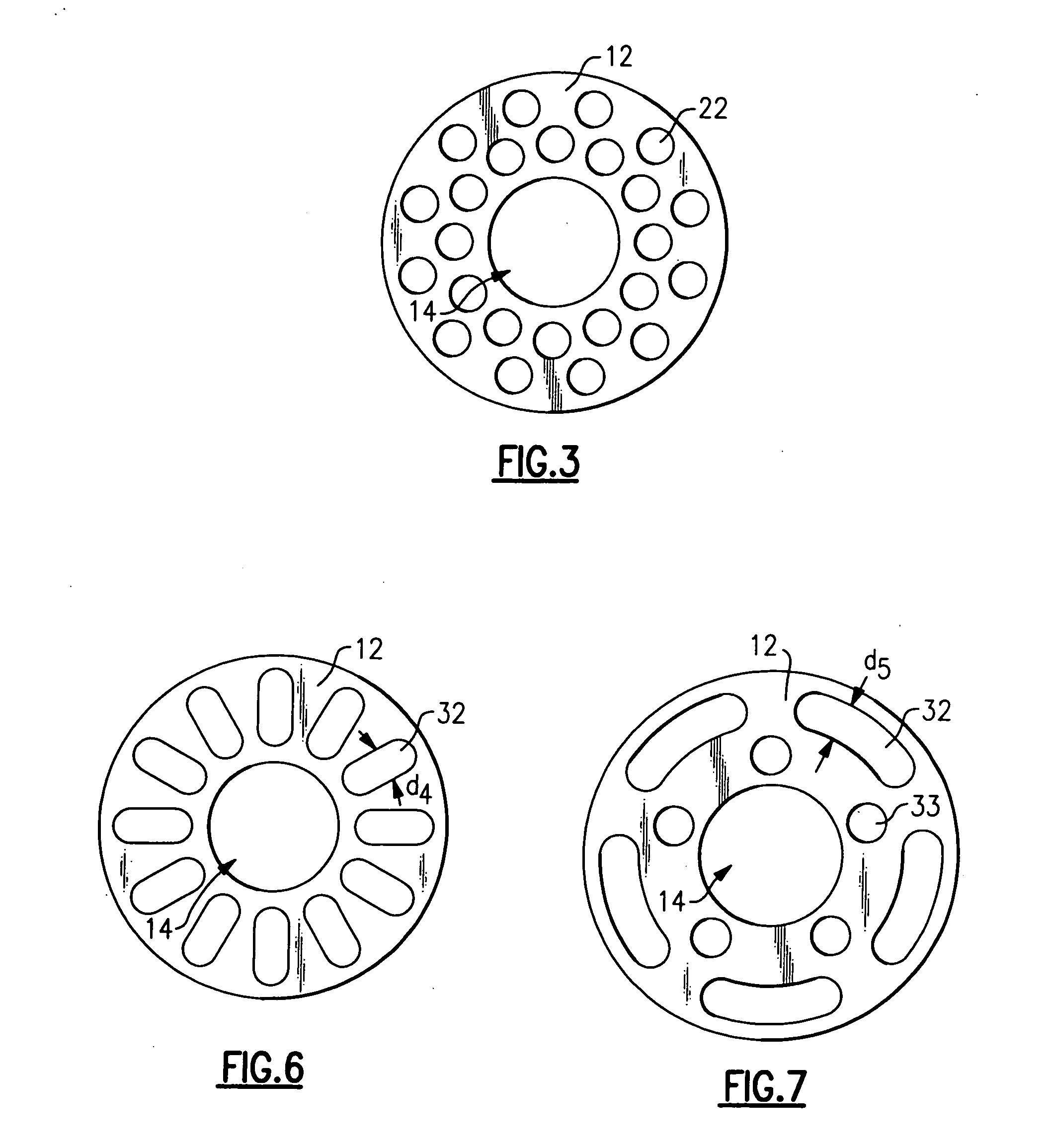

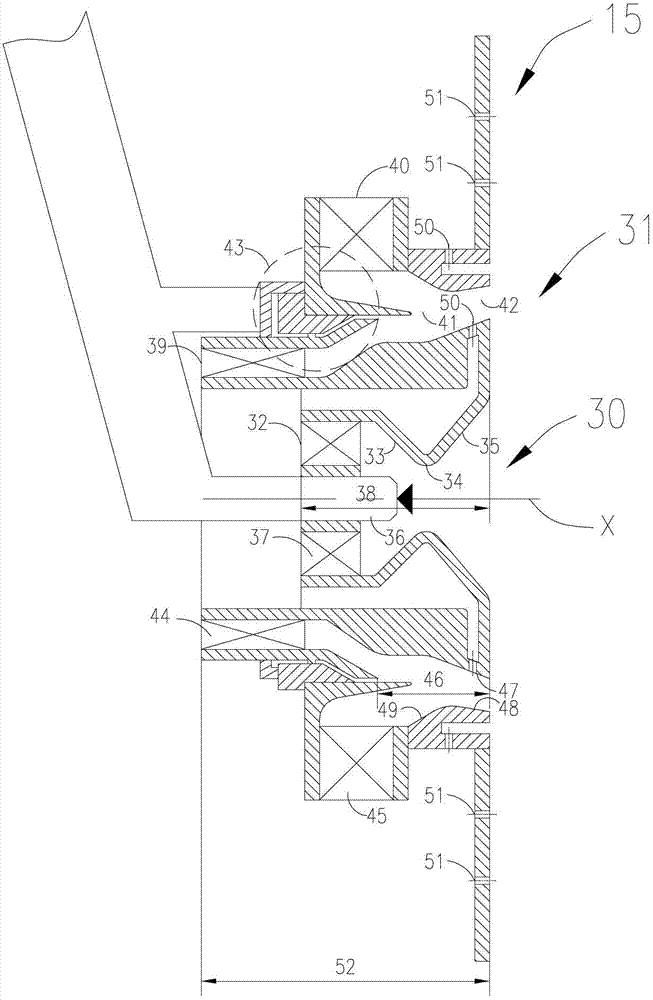

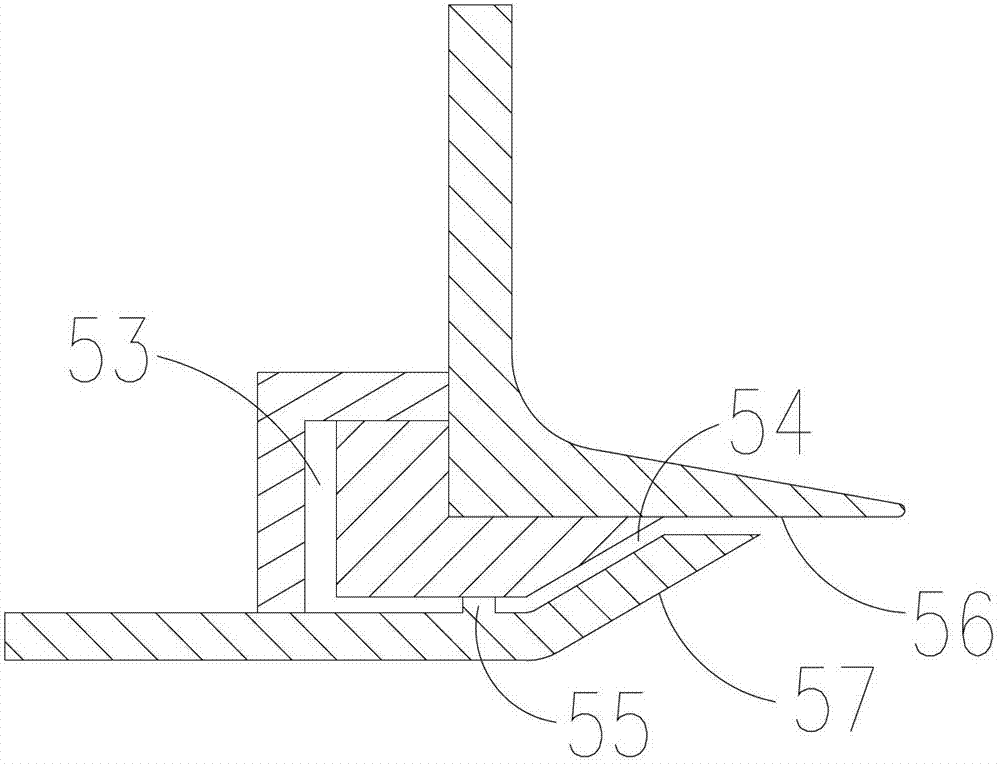

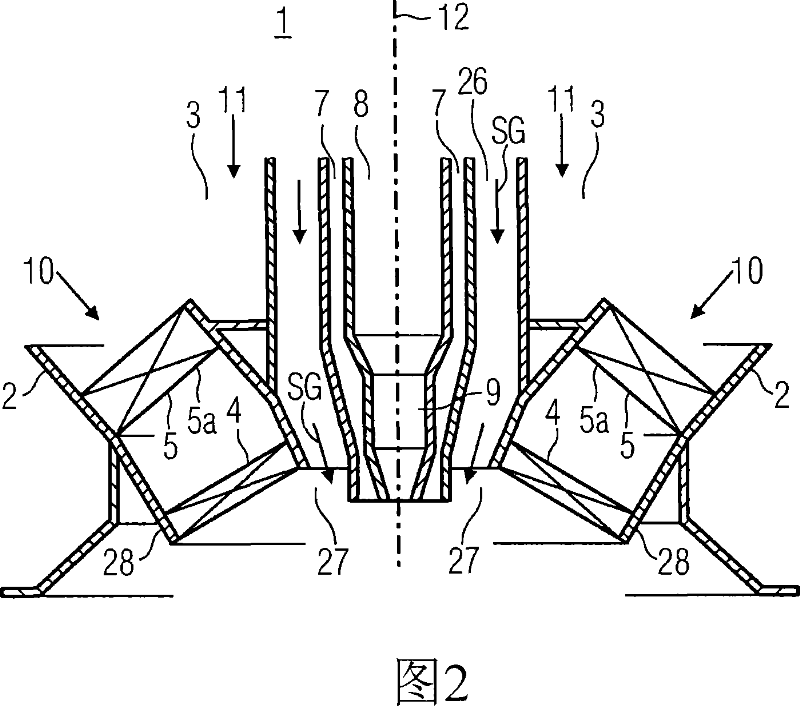

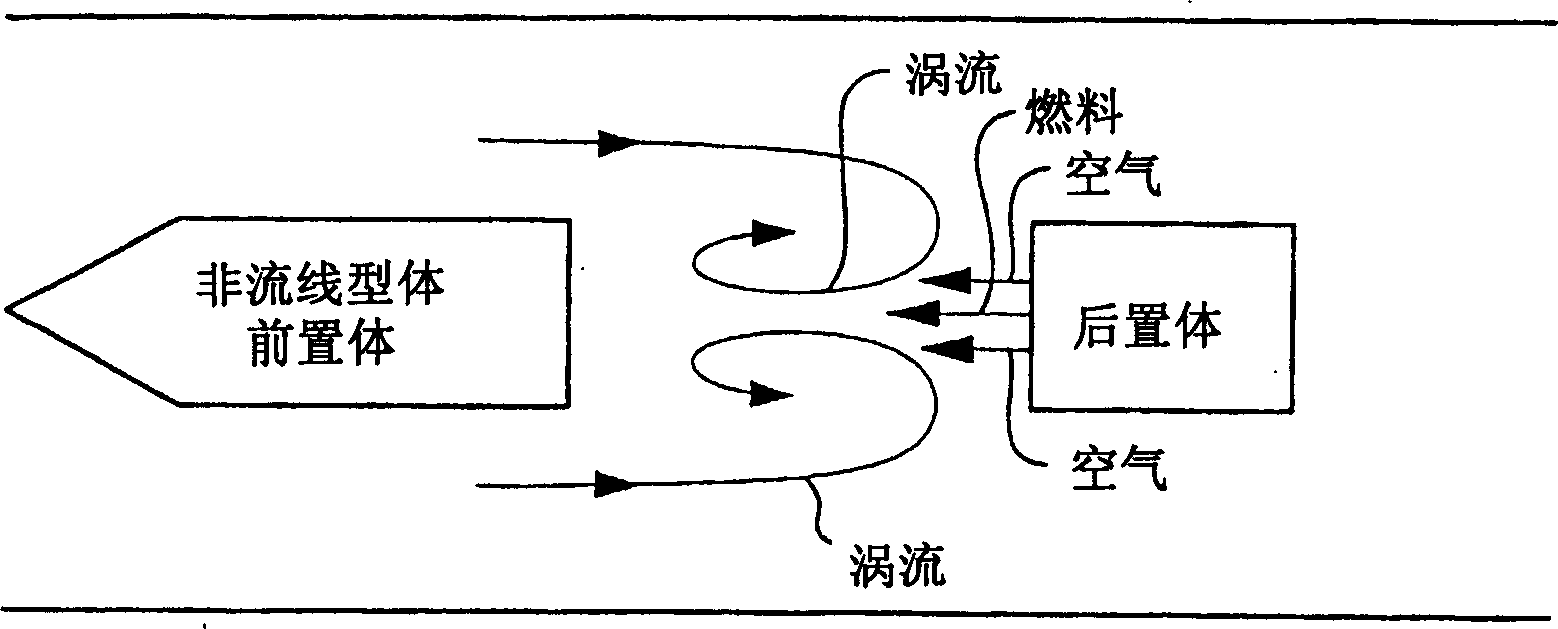

Swirl generator, method for preventing flashback in a burner having at least one swirl generator and burner

InactiveUS20100236252A1Prevent flashbackIncrease flow rateContinuous combustion chamberTurbine/propulsion fuel supply systemsEngineeringCombustor

A swirl generator, a method for preventing flashback in a burner with a swirl generator and a burner are provided. The swirl generator includes a central fuel distributor element, an outer wall enclosing the central fuel distributor element and bounding an axial flow channel for combustion air, swirl vanes extending in a radial direction to the outer wall and giving the flowing combustion air a tangential flow component, and a separating wall enclosing the central fuel distributor element and being positioned radially within the outer wall. The separating wall divides the flow channel into a radially inner channel segment and a radially outer channel segment. The radially inner channel segment allows the combustion air to pass without giving it a tangential flow component or while giving it a tangential flow component counter to the orientation of the tangential flow component in the radially outer channel segment.

Owner:SIEMENS AG

Inshot burner flame retainer

A flame retainer for an inshot burner has a plurality of secondary openings that take full advantage of the space available to limit their size in one dimension to prevent flashbacks but are sufficient in size to allow for the flow of sufficient primary air so as to prevent yellow tipping and soot formation. The slots are elongated in radially cross-sectional shape, and their widths are limited to a dimension of 0.13 inches. The width is also limited to dimensions equal to or greater than 0.09 inches so as to prevent the formation of soot.

Owner:CARRIER CORP

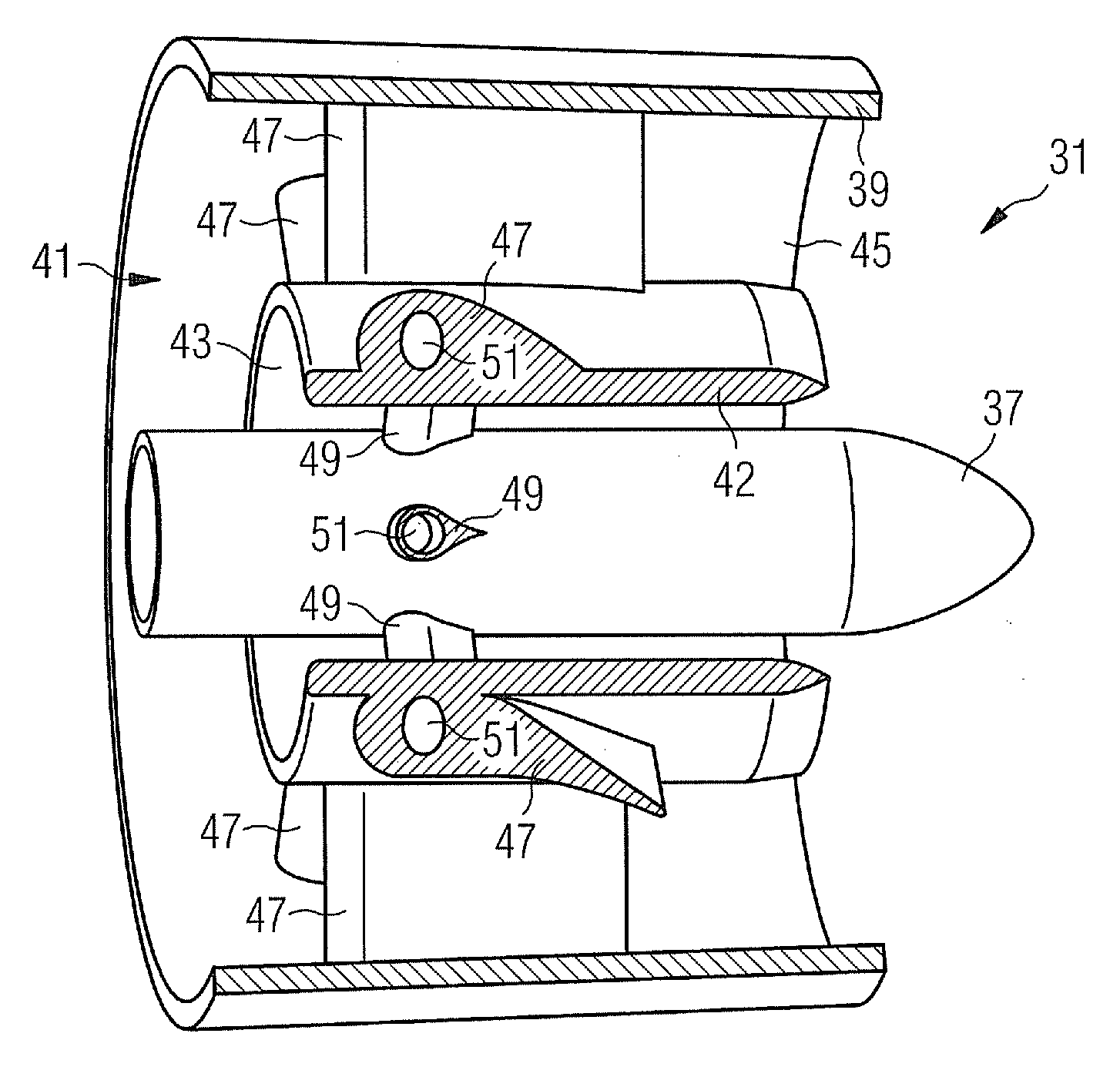

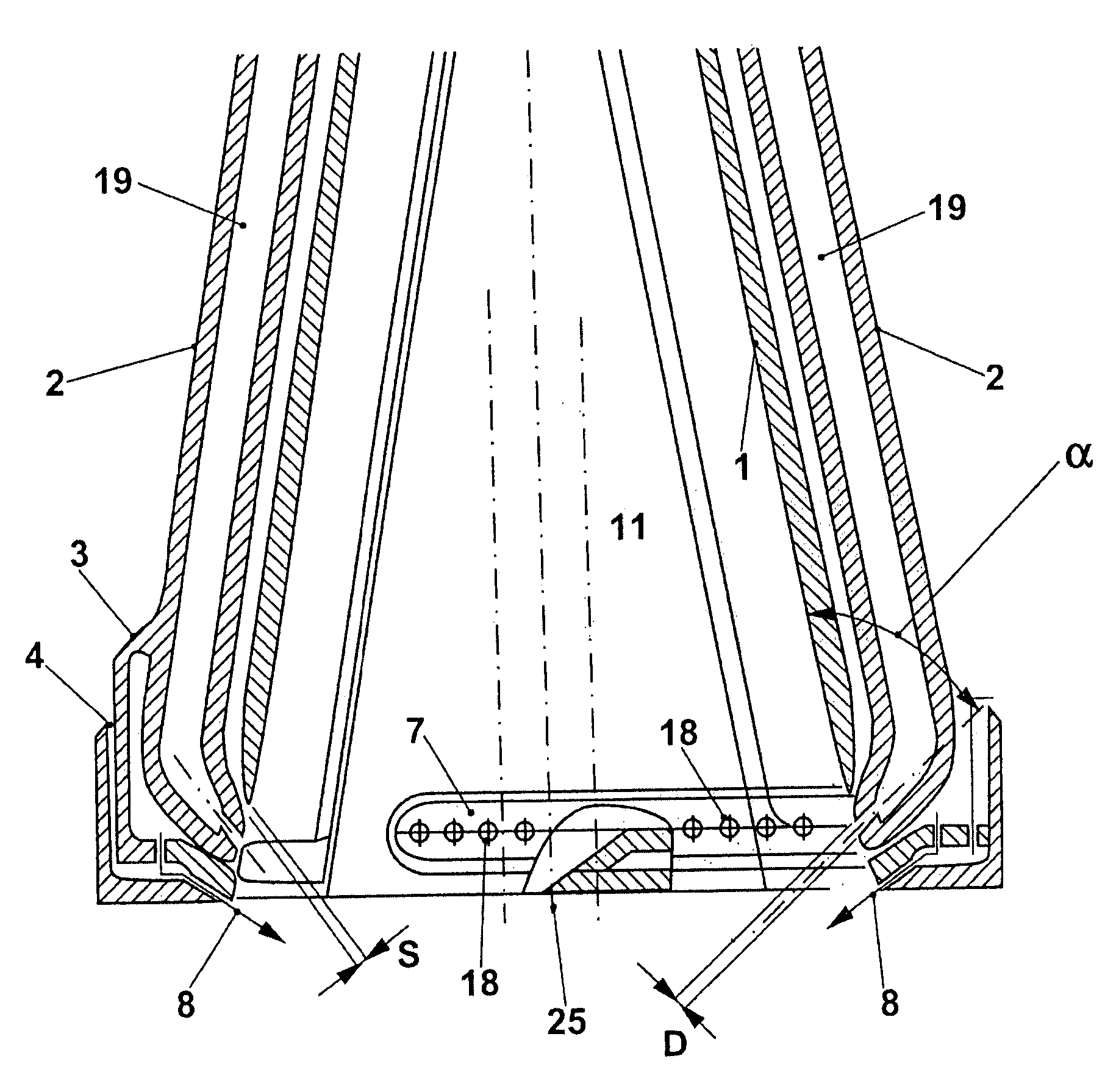

Burner for synthesis gas

InactiveUS7003957B2Further flexibilityOperational securityContinuous combustion chamberTurbine/propulsion fuel valvesAutomotive engineeringAirflow

The present invention relates to a burner, substantially comprising a swirl generator for a combustion air stream and means for introducing fuel into the combustion air stream, the swirl generator having combustion-air inlet openings for the combustion air stream that enters the burner, and the means for introducing fuel into the combustion air stream comprising one or more first fuel feeds having a group of first fuel outlet openings, arranged distributed around the burner axis at a combustion chamber-side end of the burner. The burner is distinguished by the fact that the one or more first fuel feeds having the group of first fuel outlet openings are mechanically decoupled from the swirl generator. The present burner allows reliable and safe use of synthesis gas in both dilute and undiluted form as fuel.

Owner:GENERAL ELECTRIC TECH GMBH

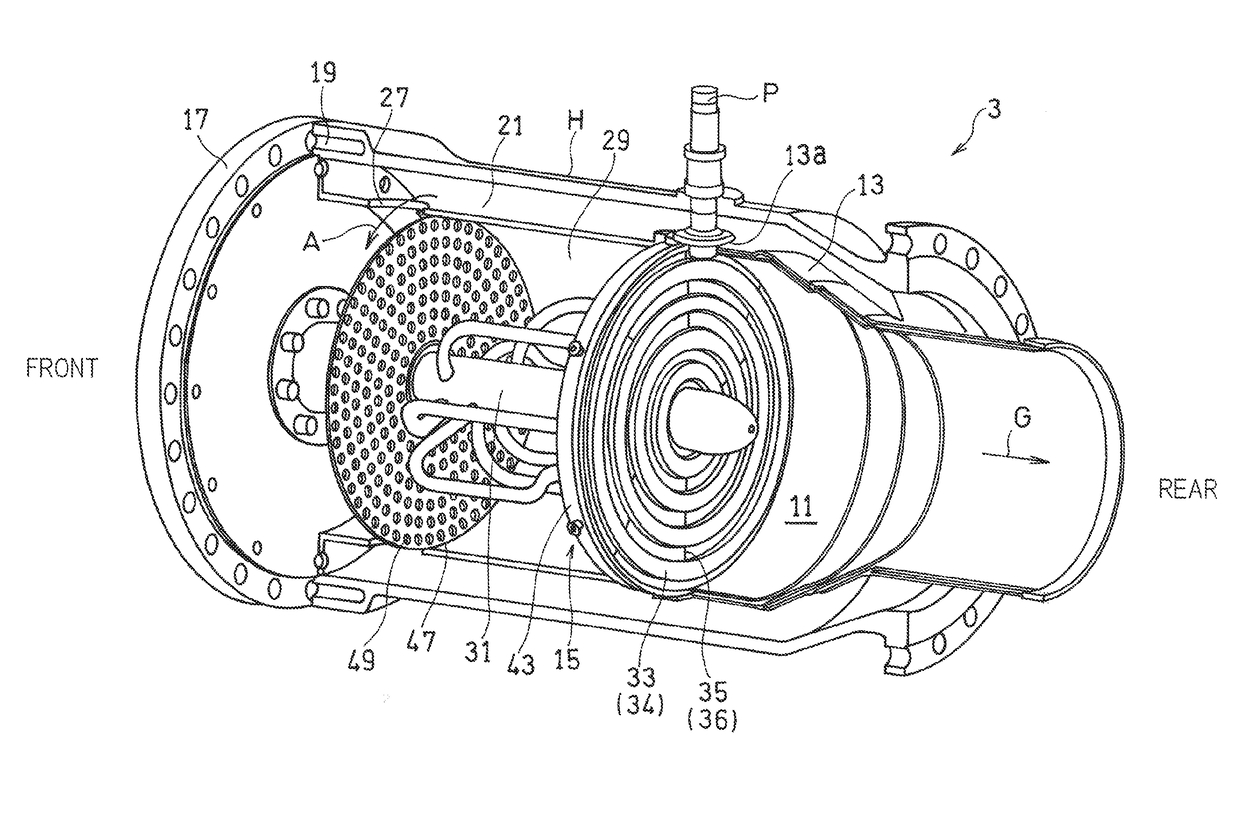

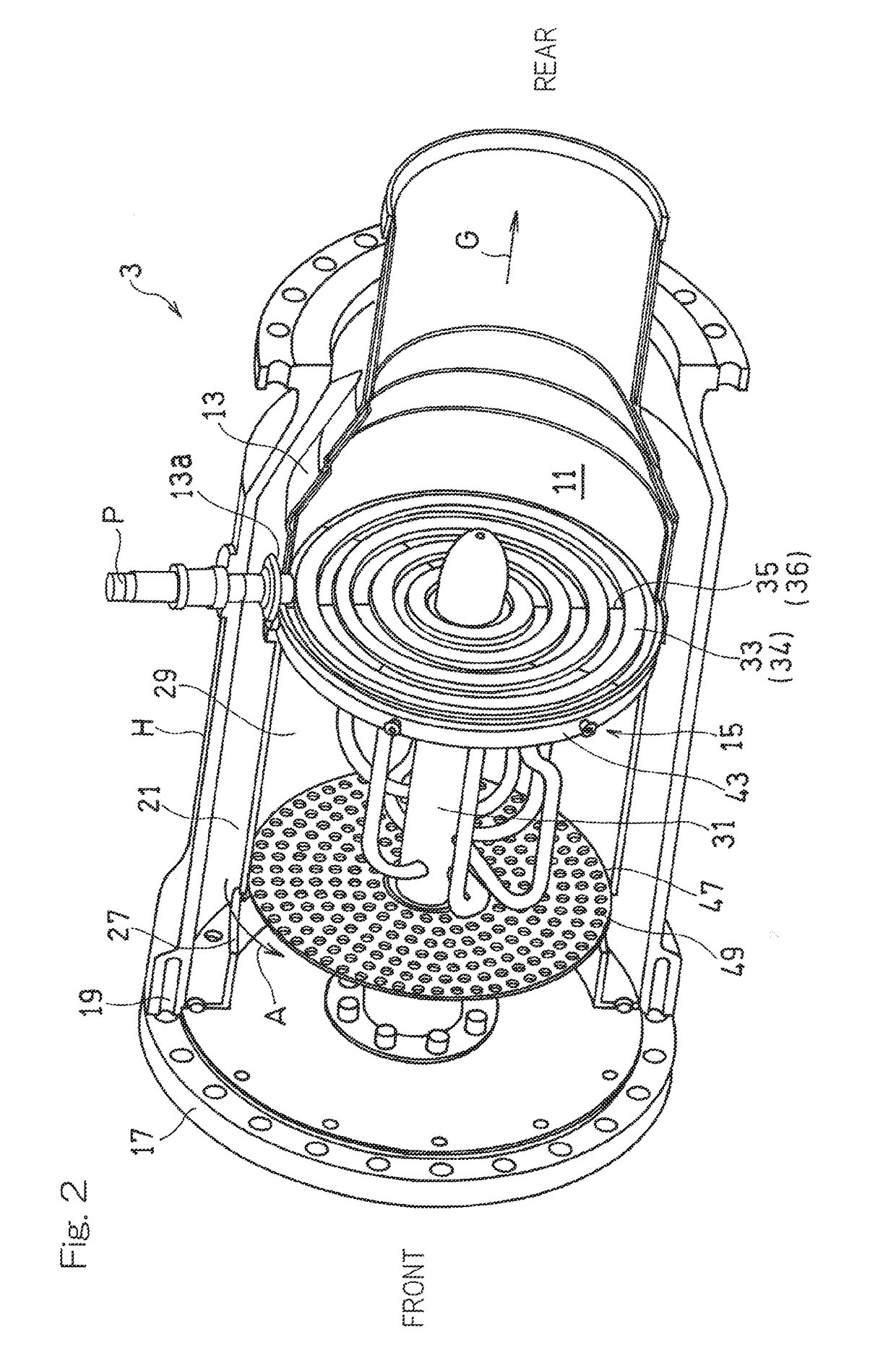

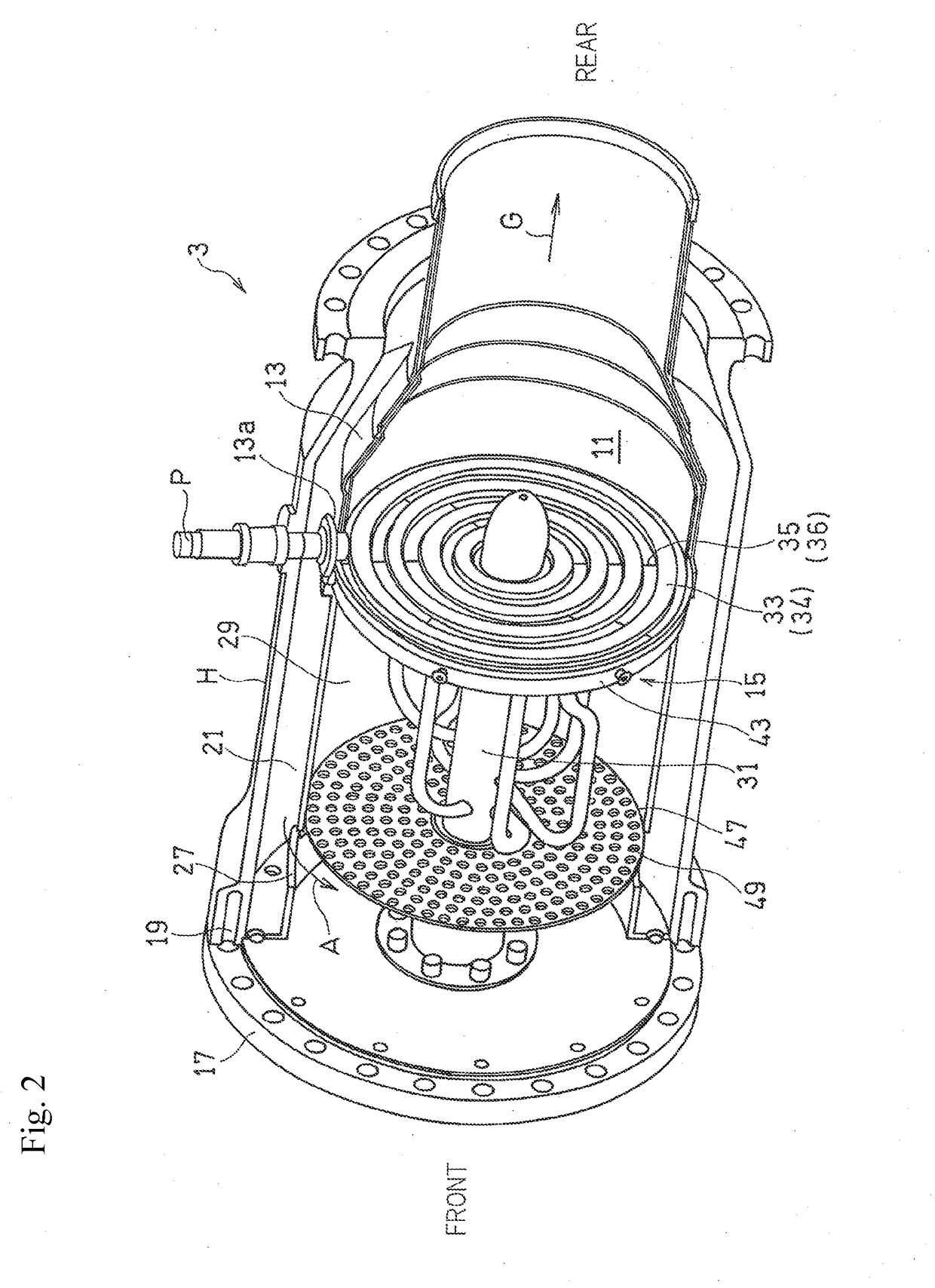

Combustion device for gas turbine engine

InactiveUS20170074521A1Reduce burnWell mixedBurnersBurner safety arrangementsCombustion chamberCombustor

A combustor includes: a combustion liner having a combustion chamber formed therein; a fuel injector mounted to a top portion of the combustion liner, and including a fuel injection member having a plurality of fuel injection annular portions and an air guide member including a plurality of combustion air annular portions that guide air for combustion; and a supplemental burner. The fuel injection annular portions and the combustion air annular portions are arranged concentrically and alternately. The fuel injector injects fuel and air into the combustion chamber. Each of the fuel injection annular portions includes a plurality of fuel injection holes that are open in a radial direction thereof, and each of the combustion air annular portions includes a plurality of air guide groove that are open in an axial direction thereof, and guide the air to the fuel jetted from the fuel injection holes.

Owner:KAWASAKI HEAVY IND LTD

Thermal disassociation of water

InactiveUS20070274905A1Prevent flashbackPrevent cessationOxygen/ozone/oxide/hydroxideHydrogen productionHydrogenWater vapor

An apparatus and method is provided for the ultra-high temperature cyclic thermal disassociation of water to produce usable hydrogen, oxygen, associated gases, and heat by igniting a previously-dissociated quantity of water and directing the resultant flame at a target material within a reactor whereupon the monatomic elements of the dissociated water recombine to water vapor, release energy, absorb the released energy, and re-dissociate, thereby producing a mostly monatomic mixture of dissociated water. Preferably, steam is produced in a heat exchanger arranged about the reactor and additionally provided to the reactor to undergo thermolytic disassociation.

Owner:WATER TO GAS

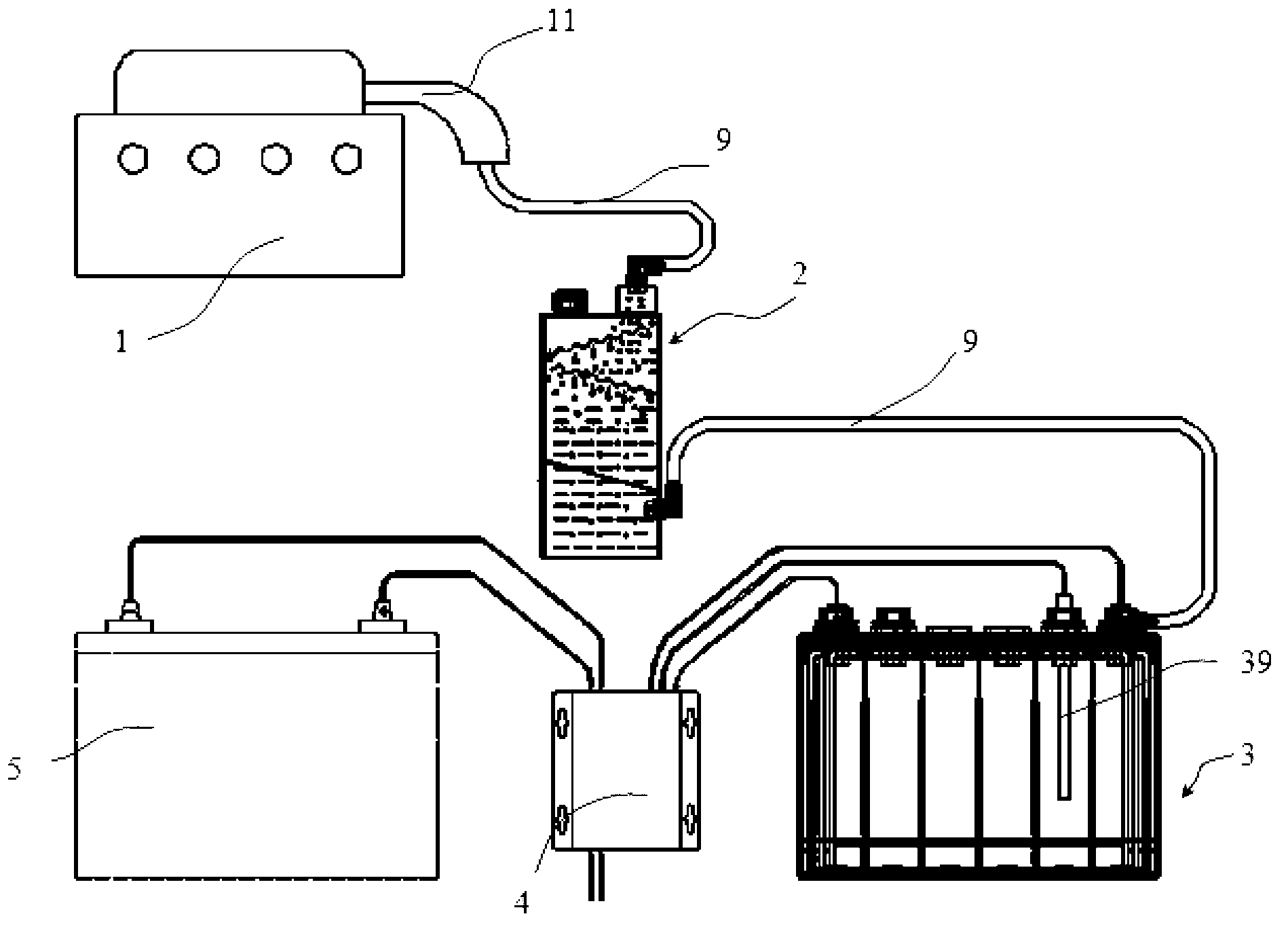

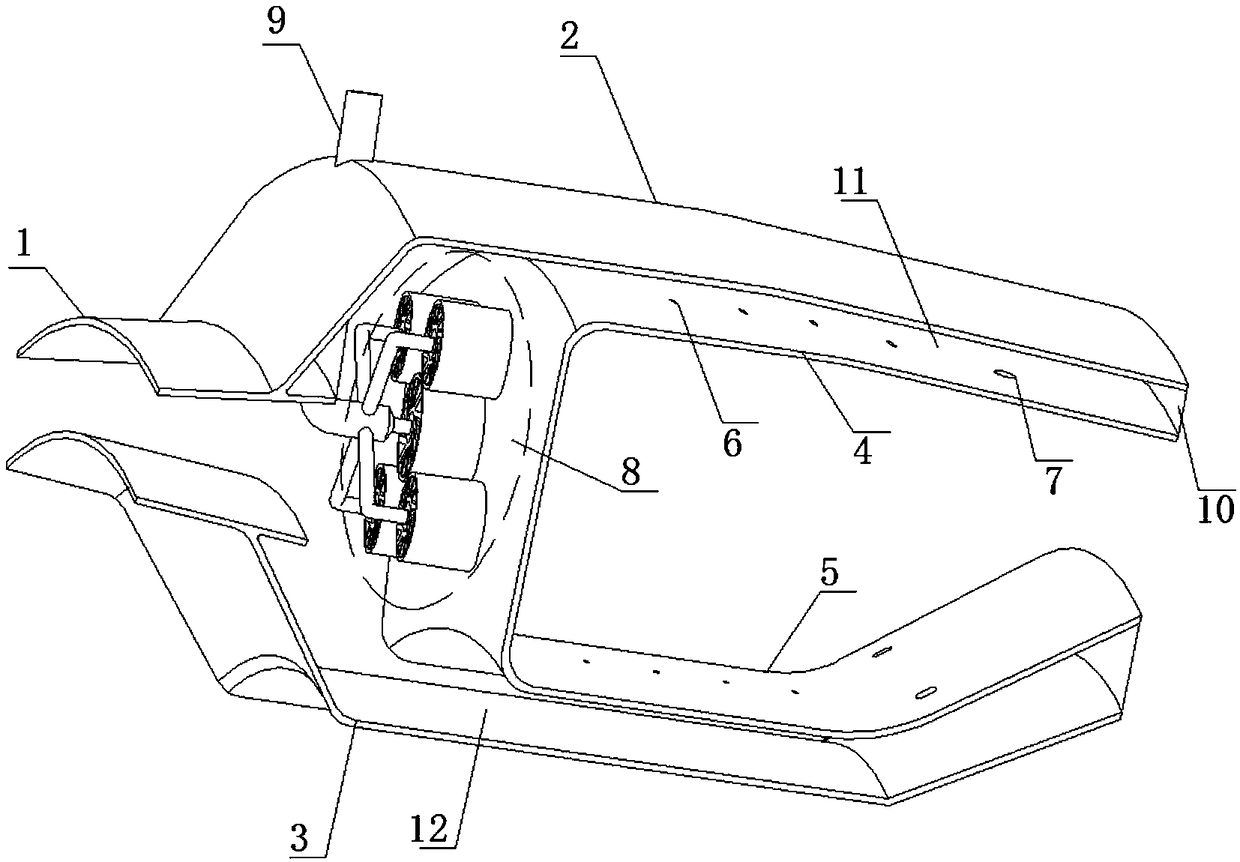

Oxy-hydrogen hybrid power device

ActiveCN103233830APrevent flashbackIncrease powerElectrolysis componentsInternal combustion piston enginesHydrogen purityElectricity

The invention relates to a power device for an automobile or a diesel engine, in particular to an oxy-hydrogen hybrid power device. The oxy-hydrogen hybrid power device comprises an engine provided with an oxy-hydrogen inlet branch tube, a container provided with an oxy-hydrogen inlet and an oxy-hydrogen outlet, filtrate contained in the container, a filter immersed into the filtrate and composed of an air-permeable plate, a water-splitting box composed of a positive electrolysis electrode, a negative electrolysis electrode and electrolyte contained in an electrolytic bath, an automatic controller electrically connected with the positive electrolysis electrode and the negative electrolysis electrode, and a vehicle-mounted storage battery electrically connected with the automatic controller. The oxy-hydrogen inlet is located under the liquid level of the filtrate, and the oxy-hydrogen outlet is located above the liquid level of the filtrate and is communicated with the oxy-hydrogen inlet branch tube. The water-splitting box is used for producing hydrogen and oxygen and is communicated with the oxy-hydrogen inlet. The automatic controller is used for controlling flows of produced hydrogen and oxygen. The oxy-hydrogen hybrid power device saves fuel oil, is environmental-friendly and can ensure the oxy-hydrogen purity and prevent an oxy-hydrogen tempering phenomenon.

Owner:SHANGHAI WONENG ENVIRONMENTAL PROTECTION TECH

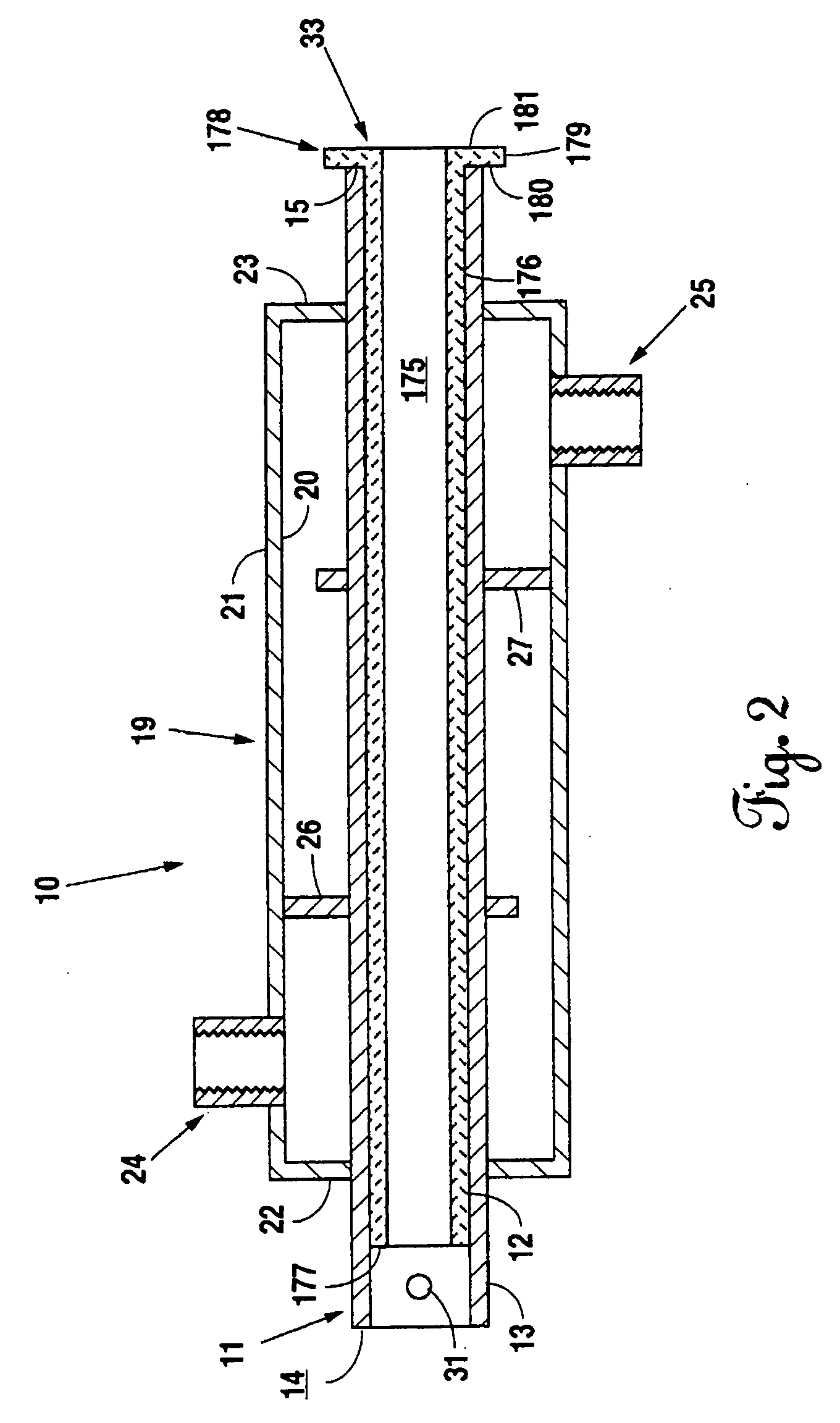

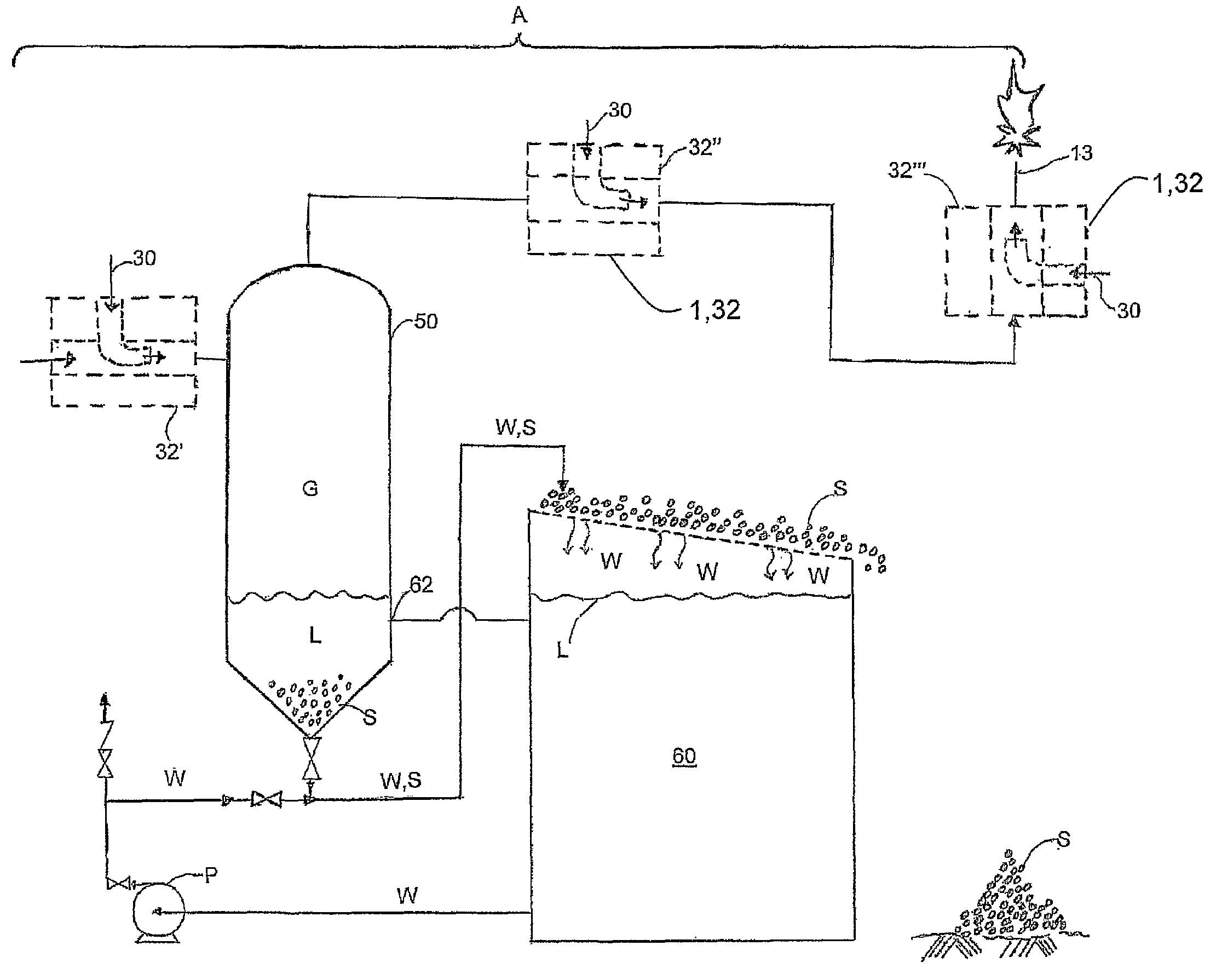

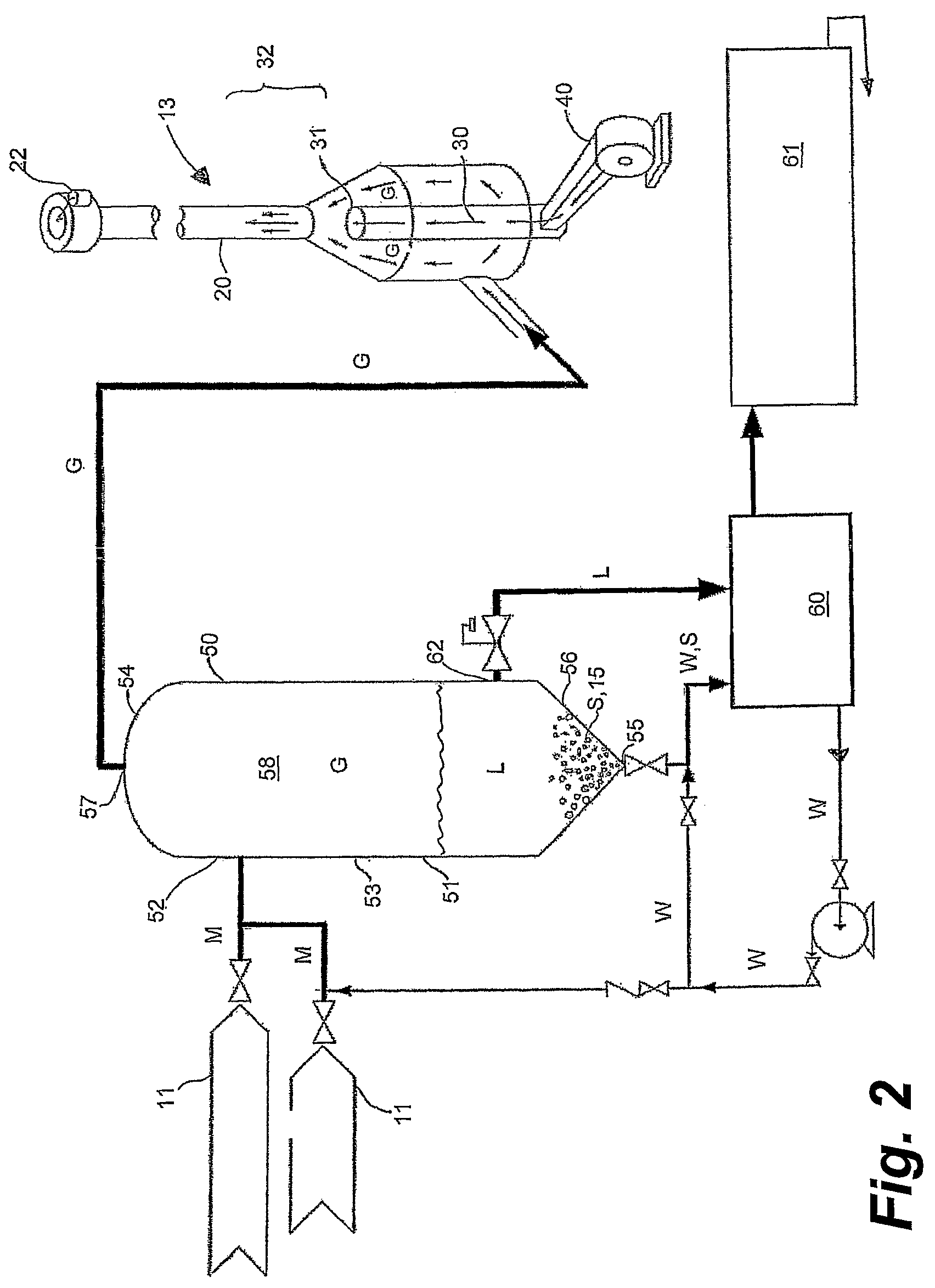

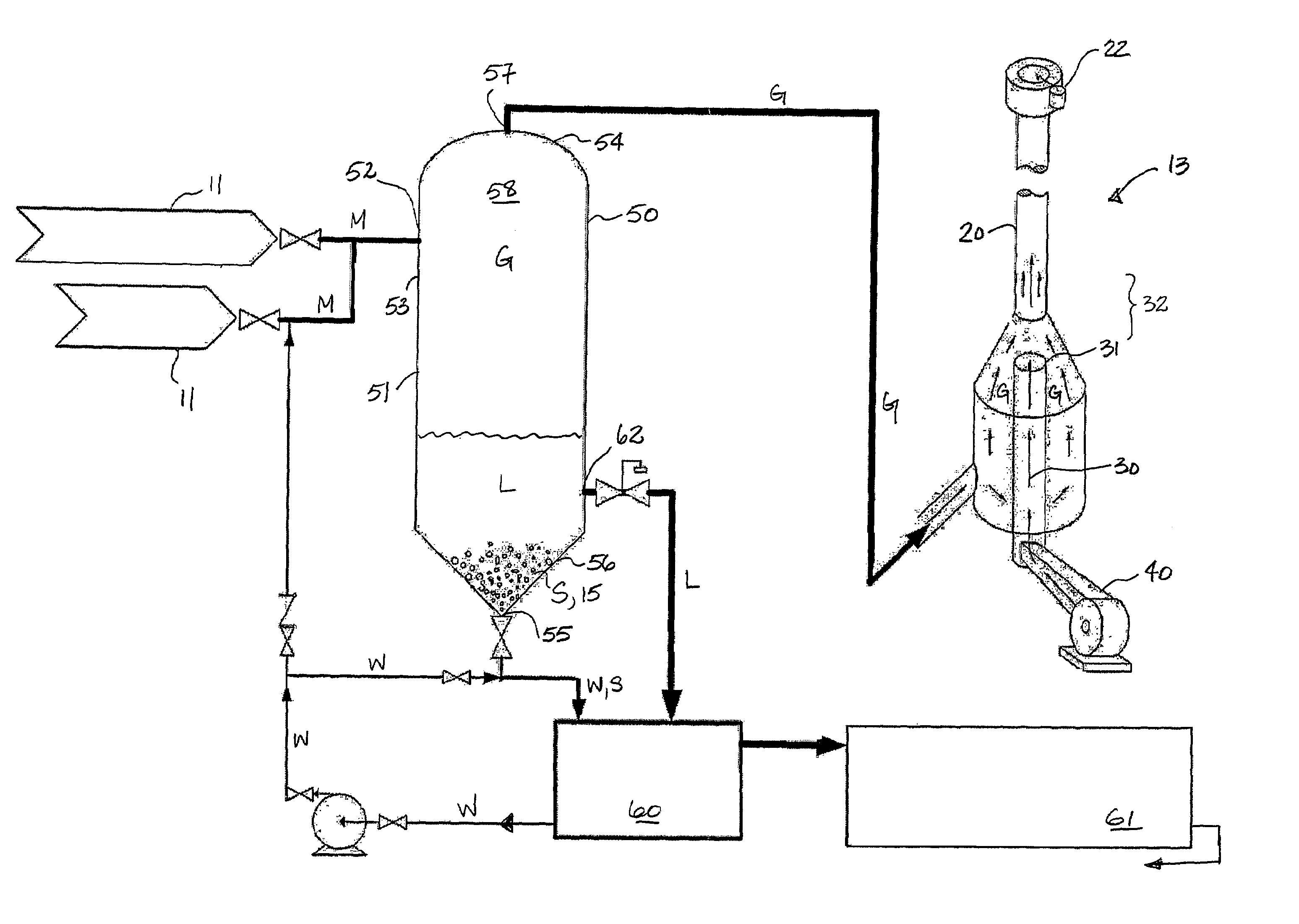

Separation of evolved gases from drilling fluids in a drilling operation

InactiveUS7575073B2Avoid evolutionSafely contained and controlledDrilling rodsConstructionsDegasserWell drilling

A fluid handling system for drilling cuttings utilizes a constant and gravity managed liquid level between a substantially atmospheric separator and a shale shaker to maximize fluid residence time within the separator and ensure substantially all of the gas entrained in the cuttings is evolved and passed to a flare thus preventing evolution of the gas at the shale shaker. Solids from the separator are combined with liquid recirculation from and returning to the shale shaker. Optionally, a vacuum degasser is positioned between the separator and the shale shaker and separated gases are passed from the degasser to the flare. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas is intermittent and unpredictable.

Owner:SWARTOUT MATTHEW K

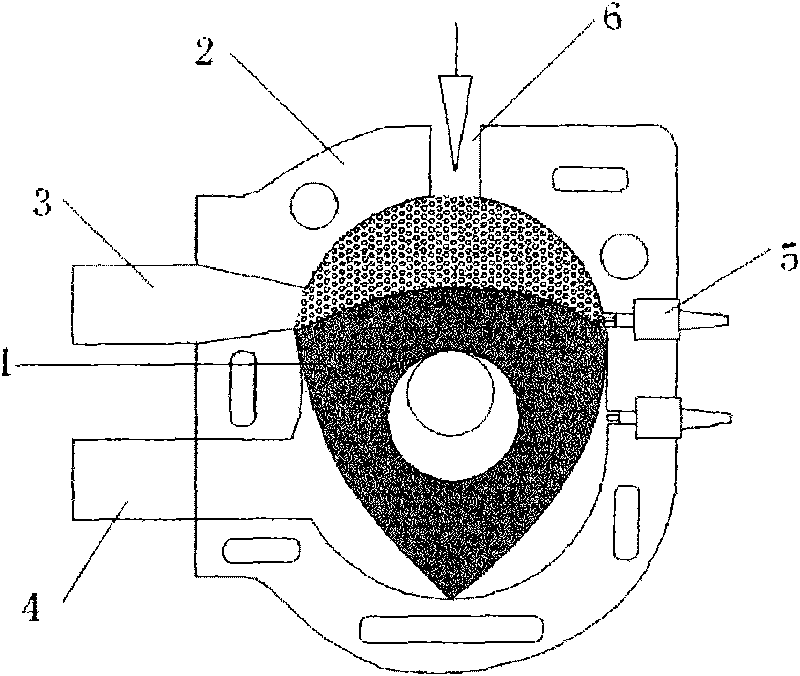

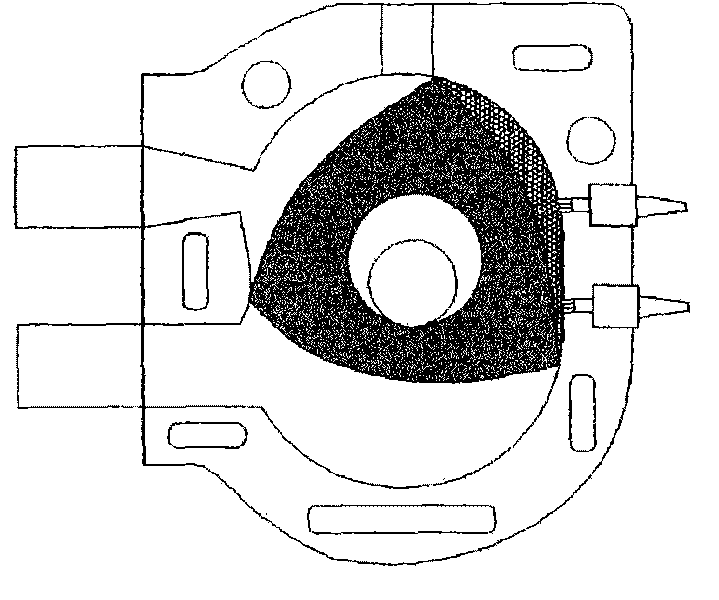

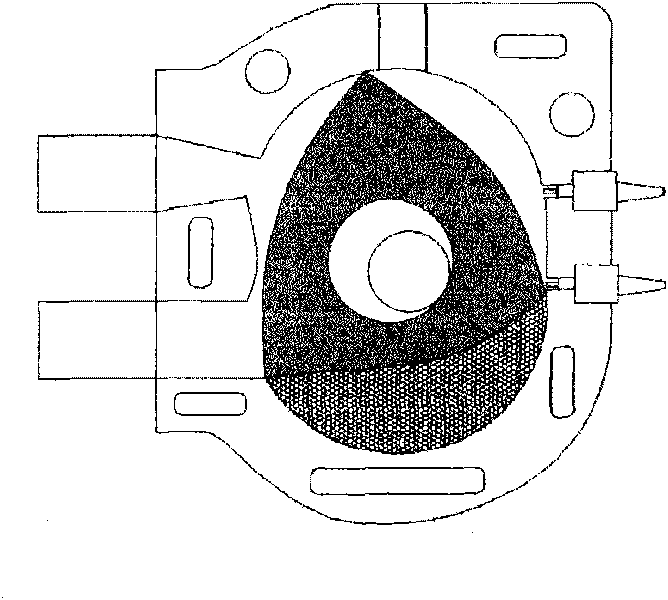

Application of hydrogen fuel and rotary engine thereof

InactiveCN101718221AUse technology to improveSolve backfire problemsInternal combustion piston enginesGaseous engine fuelsBack-fireRotary engine

The invention relates to application of hydrogen fuel and a rotary engine thereof; the hydrogen fuel can be effectively utilized and the problems of back fire, preignition and insufficient power of the hydrogen fuel engine; the technical proposal is that: the hydrogen fuel is used for the rotary engine, and the hydrogen fuel rotary engine is provided with a rotor and a shell, and an air inlet and an air outlet are arranged on the shell; the rotary engine is characterized in that: a hydrogen inlet is arranged on the shell.

Owner:CHERY AUTOMOBILE CO LTD

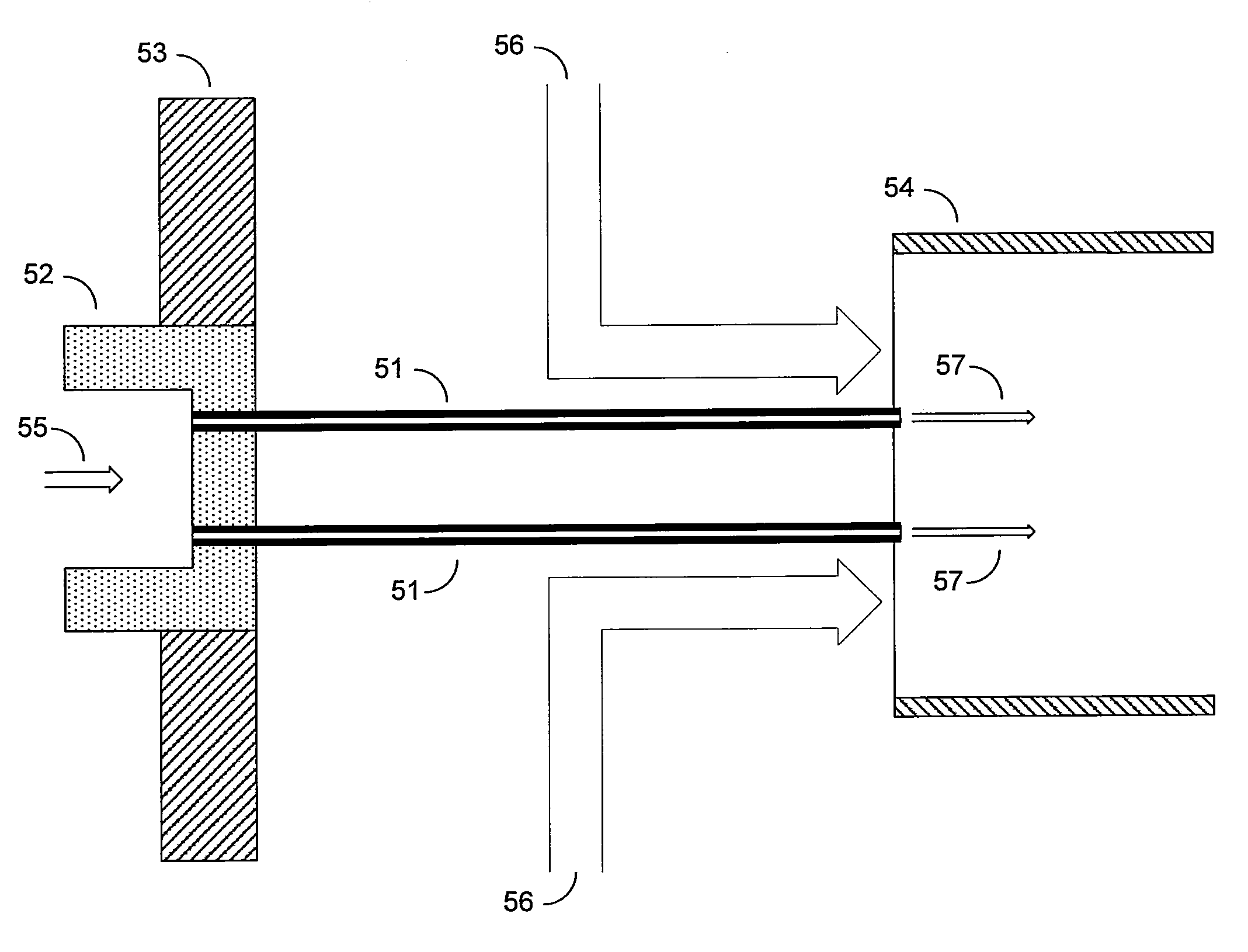

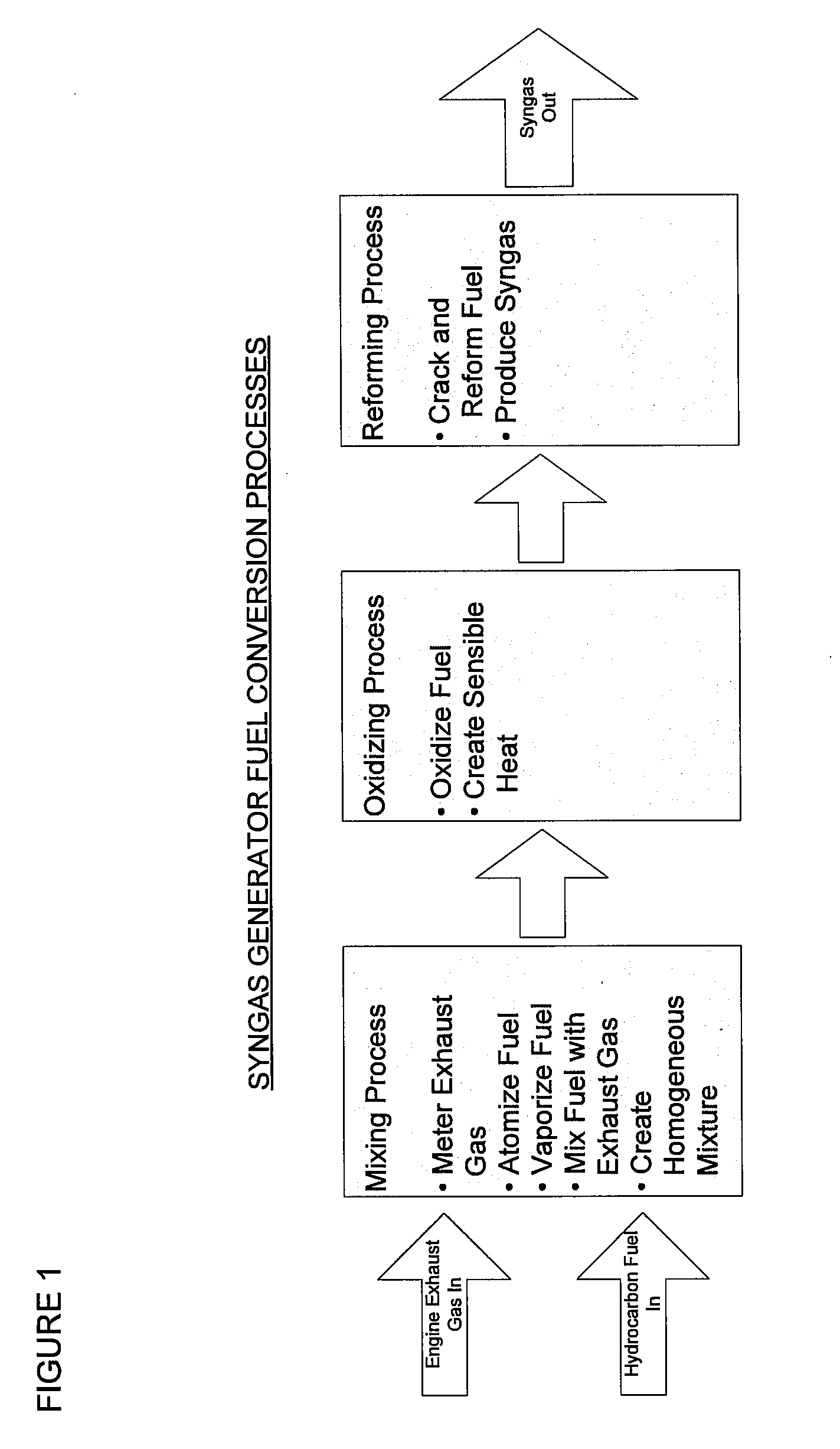

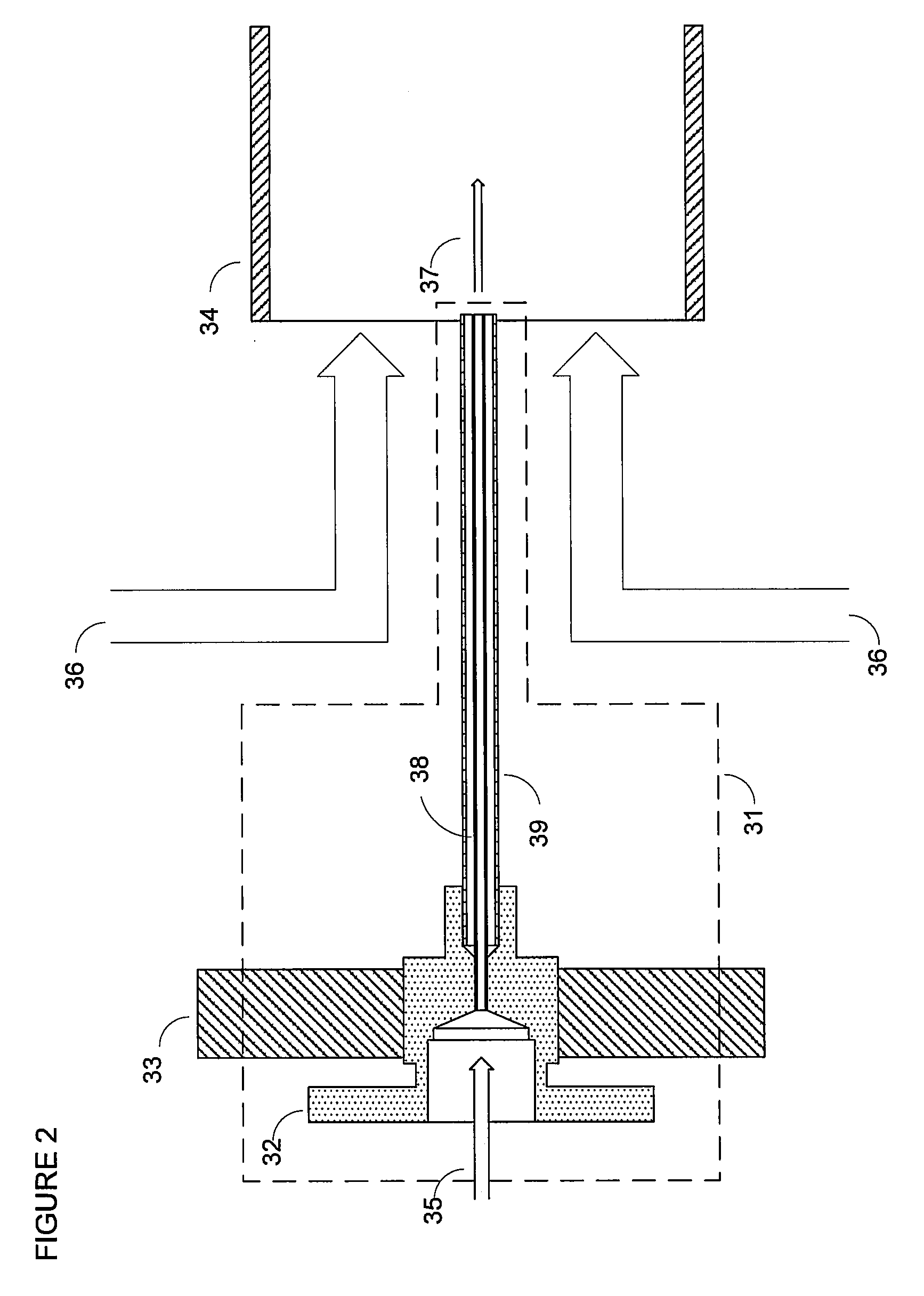

Fuel Processor, Components Thereof and Operating Methods Therefor

InactiveUS20080145297A1Prevent flashbackReduce boilingBurnersInternal combustion piston enginesSyngasExhaust gas

Fuel processors include at least one of a fuel introduction tube, a critical flow venturi and / or a heat exchanger along with other components. Such fuel processors are particularly suitable for use in engine system applications where a liquid fuel is introduced into an oxidant stream comprising hot engine exhaust gas, for downstream conversion in the fuel processor to produce a hydrogen-containing gas stream, such as a syngas stream.

Owner:WESTPORT POWER

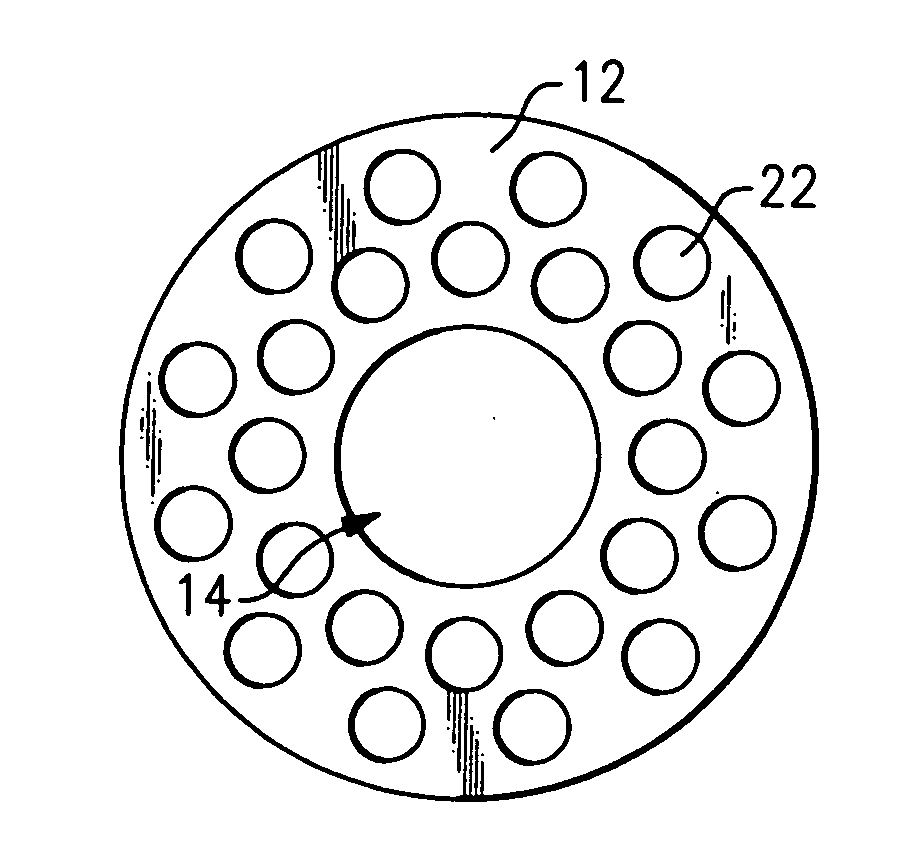

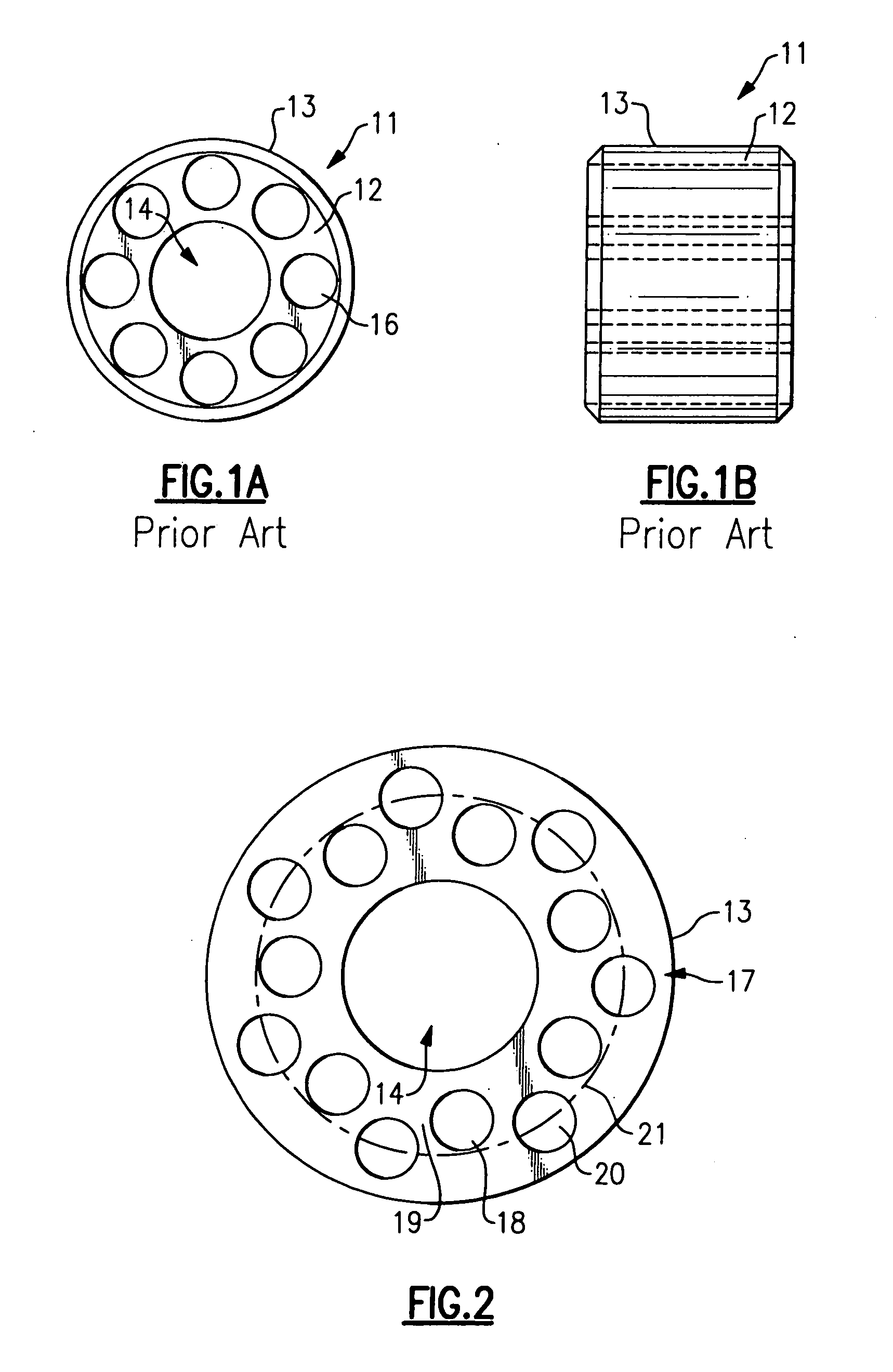

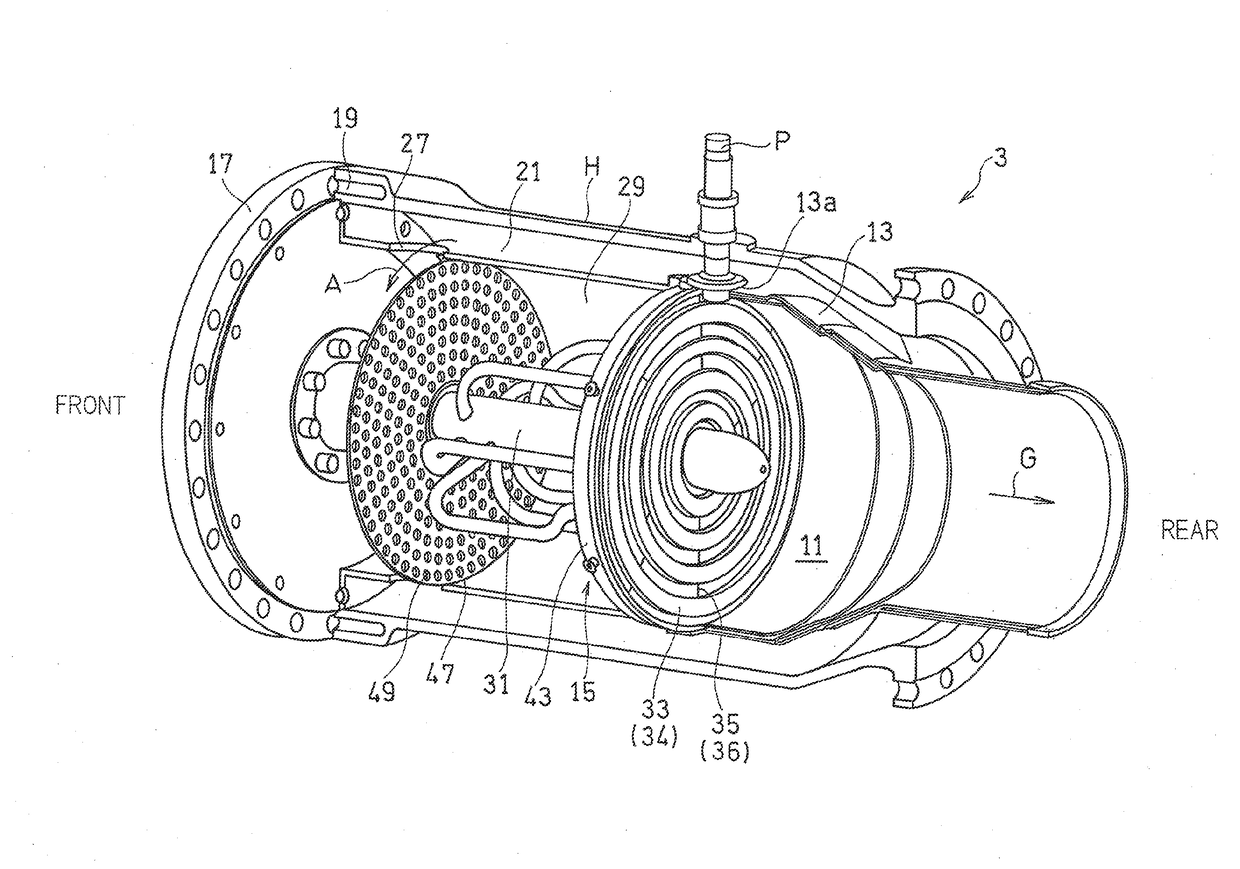

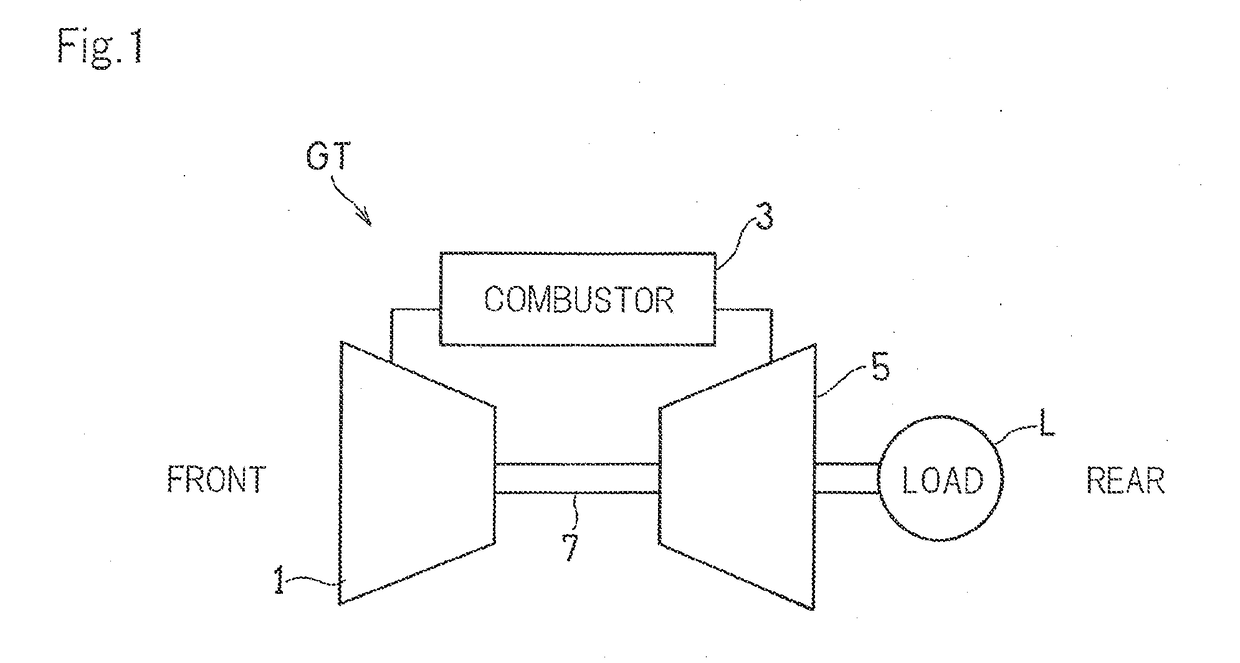

Combustor for gas turbine engine

ActiveUS20170082291A1Low NOx combustionStable combustionContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustorCombustion chamber

A combustor includes: a combustion liner having a combustion chamber formed therein; and a fuel injector mounted to a top portion of the combustion liner, and including a fuel injection member having a plurality of fuel injection annular portions and an air guide member including a plurality of combustion air annular portions that guide air for combustion. The fuel injection annular portions and the combustion air annular portions are arranged concentrically and alternately. The fuel injector injects fuel and air into the combustion chamber. Each of the fuel injection annular portions includes a plurality of fuel injection holes that are open in a radial direction thereof, and each of the combustion air annular portions includes a plurality of air guide grooves that are open in an axial direction thereof, and guide the air to the fuel jetted from the fuel injection holes.

Owner:KAWASAKI HEAVY IND LTD +1

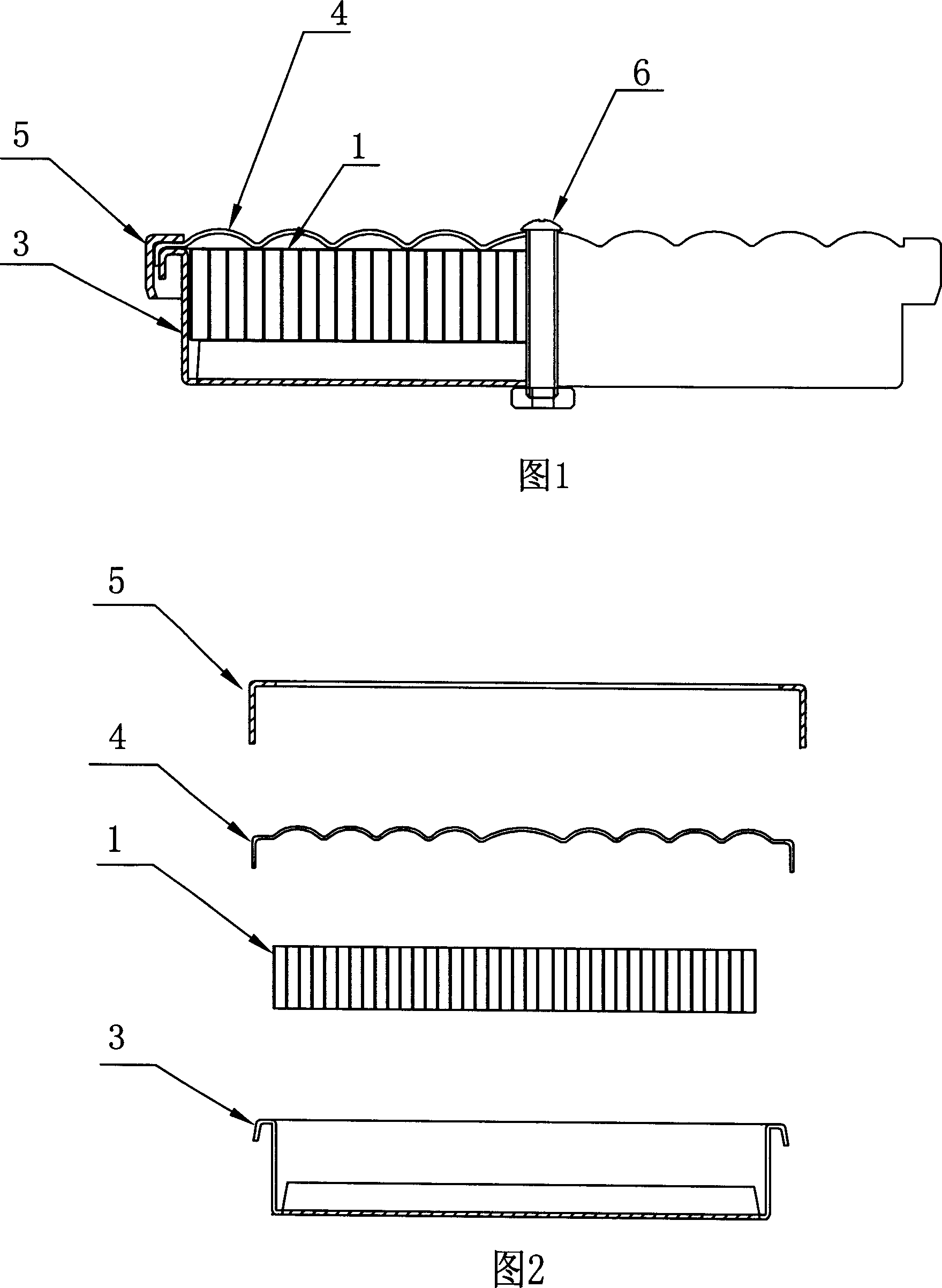

Combusting device composite heating element with infra red radiation function used on gas-fired boiler

InactiveCN101082428AImprove wind resistanceStable combustionDomestic stoves or rangesLighting and heating apparatusFiberCombustor

This invention provides a sort of complex heating unit having the function of infrared radiation of the burner that it is characterized in that simple technique, high standardization degree, no weathering, no breach, and blaze combustion stably and no backfire phenomenon happened in the gas stove. This complex heating unit consists ofthe double-tier material or the several double-tier material, There is the honeycomb body which can forbear the high temperature and the cauterization in the substrate, there is the wire reticulated body or the fibrin body which can forbear the high temperature and the cauterization in the super stratum. The wire reticulated body of the super stratum in this invention can stabilize the flow and prevent this phenomenon in that backfire. The wire reticulated body of the super stratum resists the wind greatly, burn much more steadily and its firepower is stronger, also this invention can obtain holistic slippage with the fitting surface contacts hermetically with the air drain of the burner, and can be use with no jointing.

Owner:罗添翼

Partial pre-mixing and pre-evaporation burning chamber with prefilm type nozzle

InactiveCN103047682AStable jobStable emissionsContinuous combustion chamberCombustion chamberEvaporation

The invention belongs to the field of aeroengines and mainly relates to a partial pre-mixing and pre-evaporation burning chamber with a prefilm type nozzle. The head of the burning chamber consists of an auxiliary burning level and a main burning level, wherein the auxiliary burning level comprises a primary axial swirler, a contraction section, a throat, an expansion section and an auxiliary oilway nozzle; and the main burning level comprises a primary axial swirler, a primary radial swirler, a pre-mixing section, a contraction throat and the prefilm type nozzle. The burning chamber at the head in the above structure adopts a DIPME (direct injection pre-mixing and pre-evaporation) mixed burning mode with central classification, when in small fire state, the auxiliary burning level adopts a rich oil direct injection burning mode, and when in large fire state, the auxiliary burning level adopts a lean oil direct injection burning mode, and the main burning level adopts a lean oil partial pre-mixing and pre-evaporation burning mode. In order to guaranteeing fuel oil atomization, the main burning level adopts the prefilm type nozzle. The head of the burning chamber can guarantee performance of the burning chamber, and pollutant discharge is greatly reduced.

Owner:CHINA GAS TURBINE ESTAB

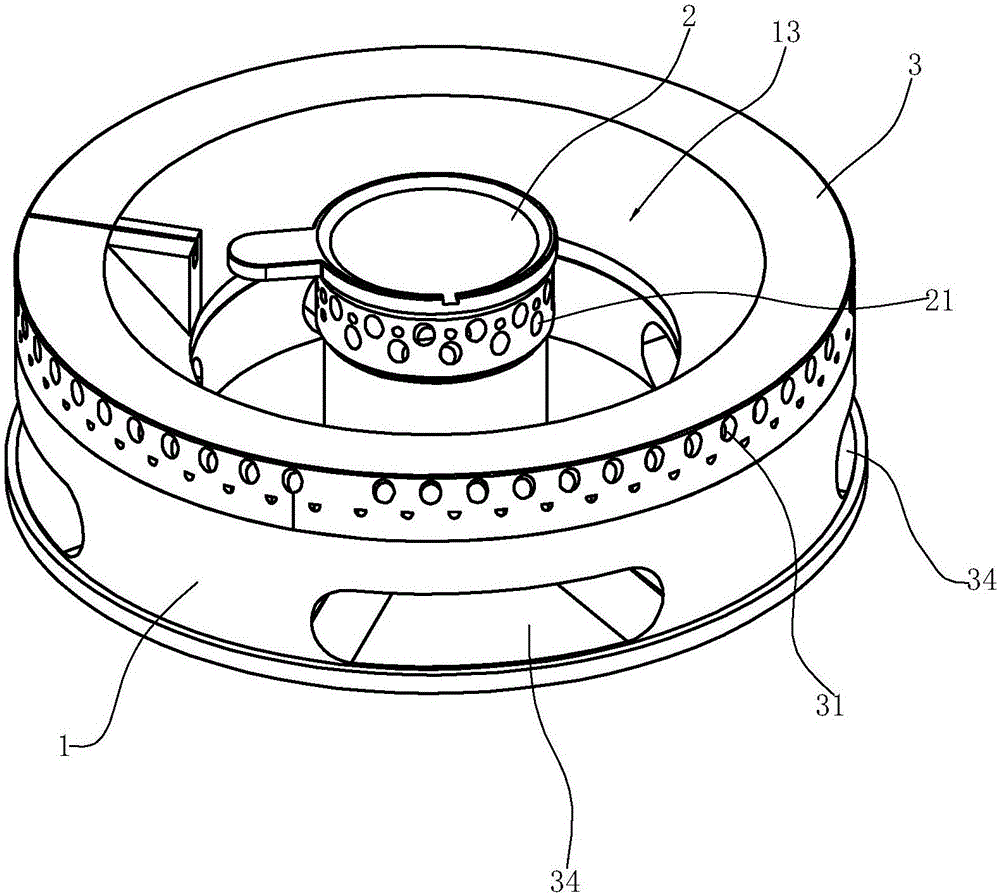

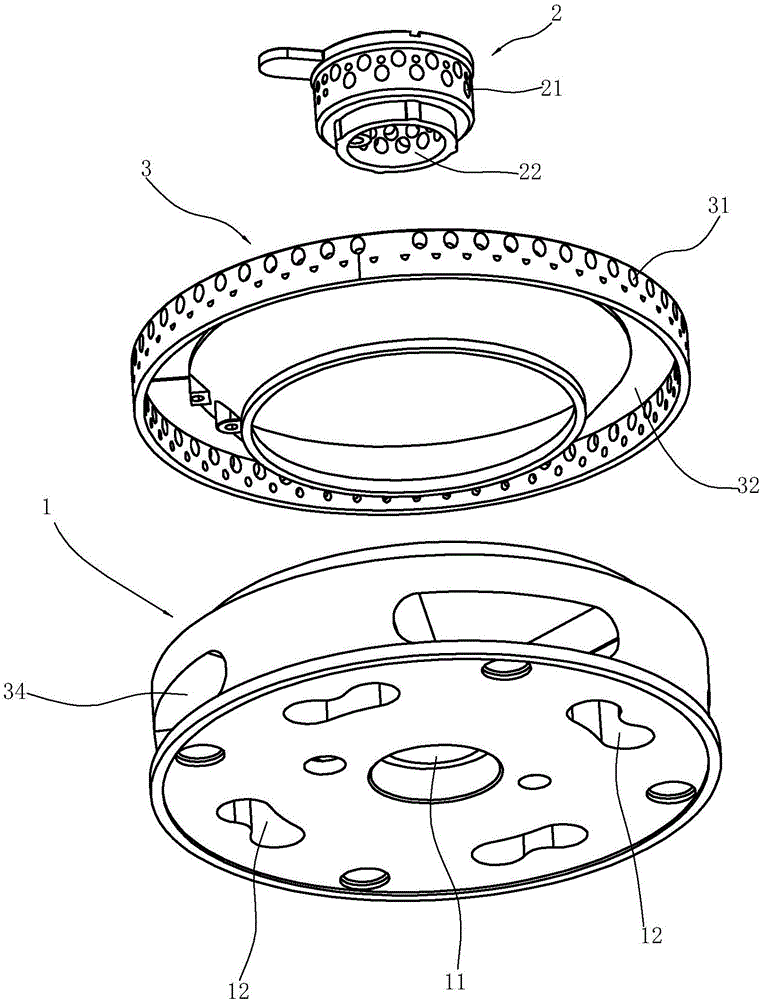

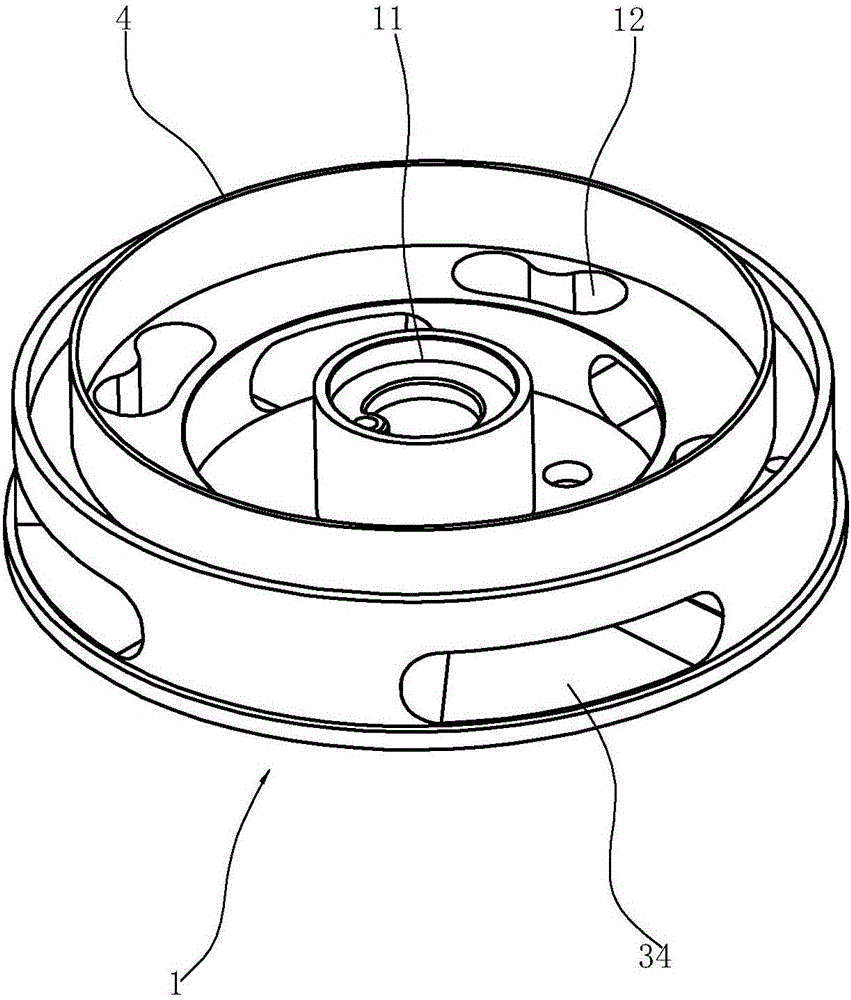

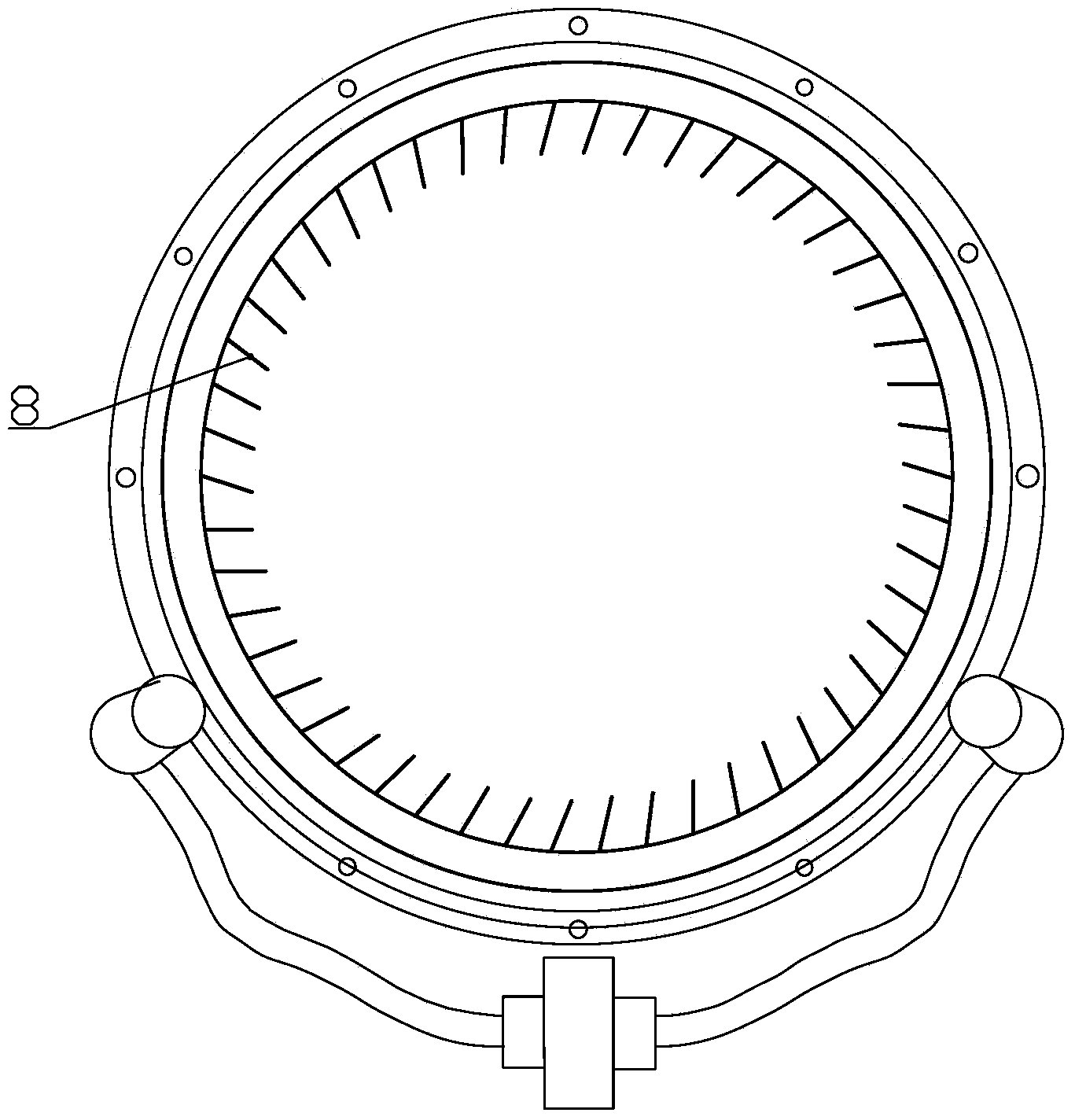

Combustor used for gas stove

The invention relates to a combustor used for a gas stove. The combustor comprises a pedestal as well as an inner ring fire cover and an outer ring fire cover which are connected on the pedestal, wherein the inner wall of the top surface of the inner ring fire cover and the ring-shaped peripheral wall of the inner ring fire cover form a central gas-mixing chamber; a plurality of inner ring fire holes which communicate with an outside central gas-mixing chamber are formed in the ring-shaped peripheral wall of the inner ring fire cover; the inner wall of the top surface of the outer ring fire cover and the ring-shaped peripheral wall of the outer ring fire cover form an outer ring gas-mixing chamber; a plurality of main fire holes are formed in the ring-shaped peripheral wall of the outer ring fire cover; and a central fuel gas channel which communicates with the central gas mixing chamber and an outer ring fuel gas channel which communicates with the outer ring gas-mixing chamber are arranged on the pedestal. The combustor is characterized in that a vertical ring-shaped partition is further arranged on the pedestal for partitioning the outer ring gas-mixing chamber into a gas mixing cavity at the inner side and a buffer cavity at the outer side; a gap for enabling the gas-mixing chamber to communicate with the buffer cavity is formed between the upper end edge of the baffle plate and the inner surface of the outer ring fire cover; and the outer ring fuel gas channel communicates with the gas mixing cavity.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Diffusion type porous medium gas fuel combustor

InactiveCN101737778AUniform density distributionPrevent flashbackGaseous fuel burnerCombustorPorous medium

A diffusion type porous medium gas fuel combustor comprises a shell, an air duct and a fire-resistant casing pipe, the air duct is connected with the shell, the bottom end of the shell is connected with the top plate of a gas flow dividing tank, the shell is internally provided with the fire-resistant casing pipe, a tray and a gas flow dividing tube from top to bottom, the bottom end of the fire-resistant casing pipe is contacted with the tray, the tray is fixed on the shell or the gas flow dividing tube, the bottom end of the gas flow dividing tube is fixed on the top plate of the gas flow dividing tank, and the gas flow dividing tube and the gas flow dividing tank are communicated internally; the fire-resistant casing pipe is provided with macro porous medium, micro porous medium and lower layer metal fiber from top to bottom, and the lower layer metal fiber is connected with the tray and the gas flow dividing tube simultaneously. The inventive diffusion type porous medium gas fuel combustor can be used for efficiently avoiding tempering when combustion intensity is stronger, thus achieving the effects of protecting micro porous medium and saving energy.

Owner:NORTHEASTERN UNIV

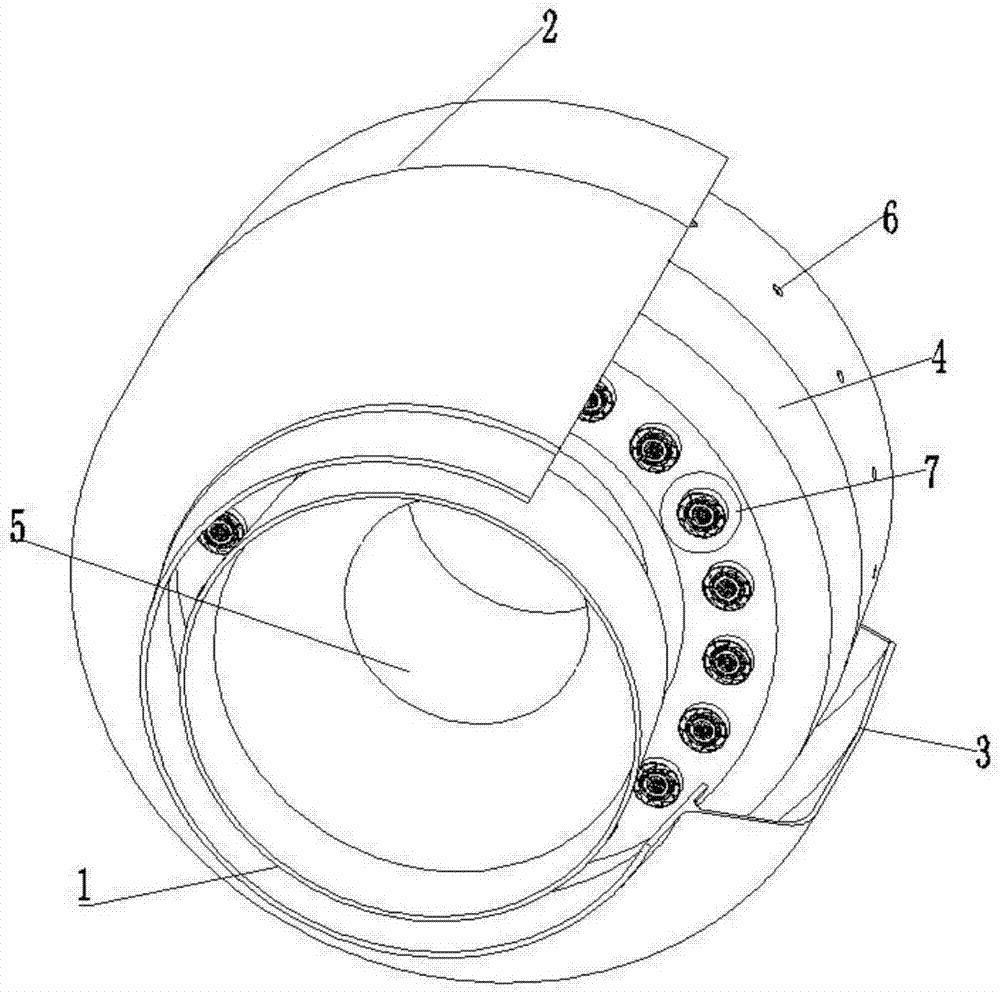

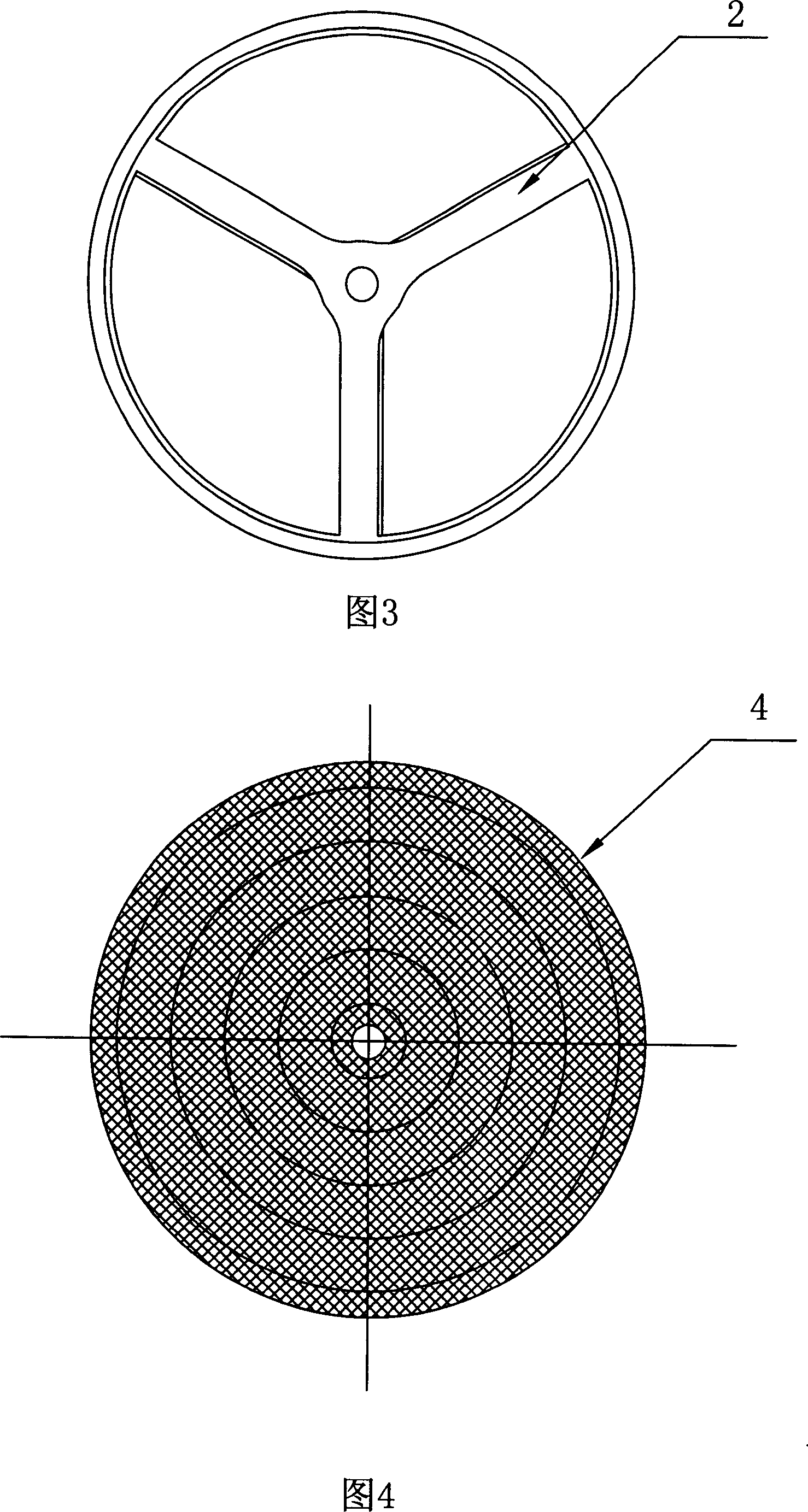

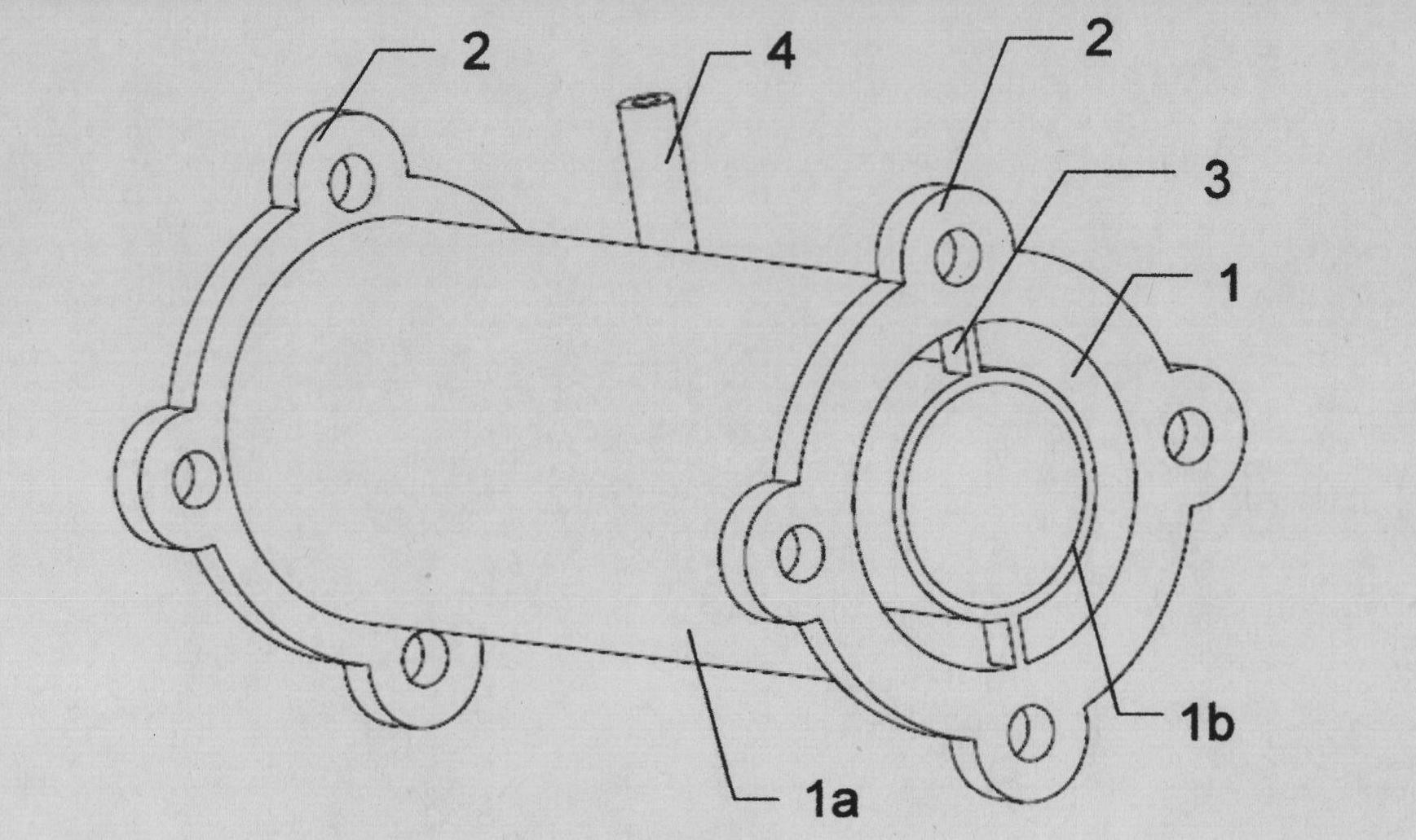

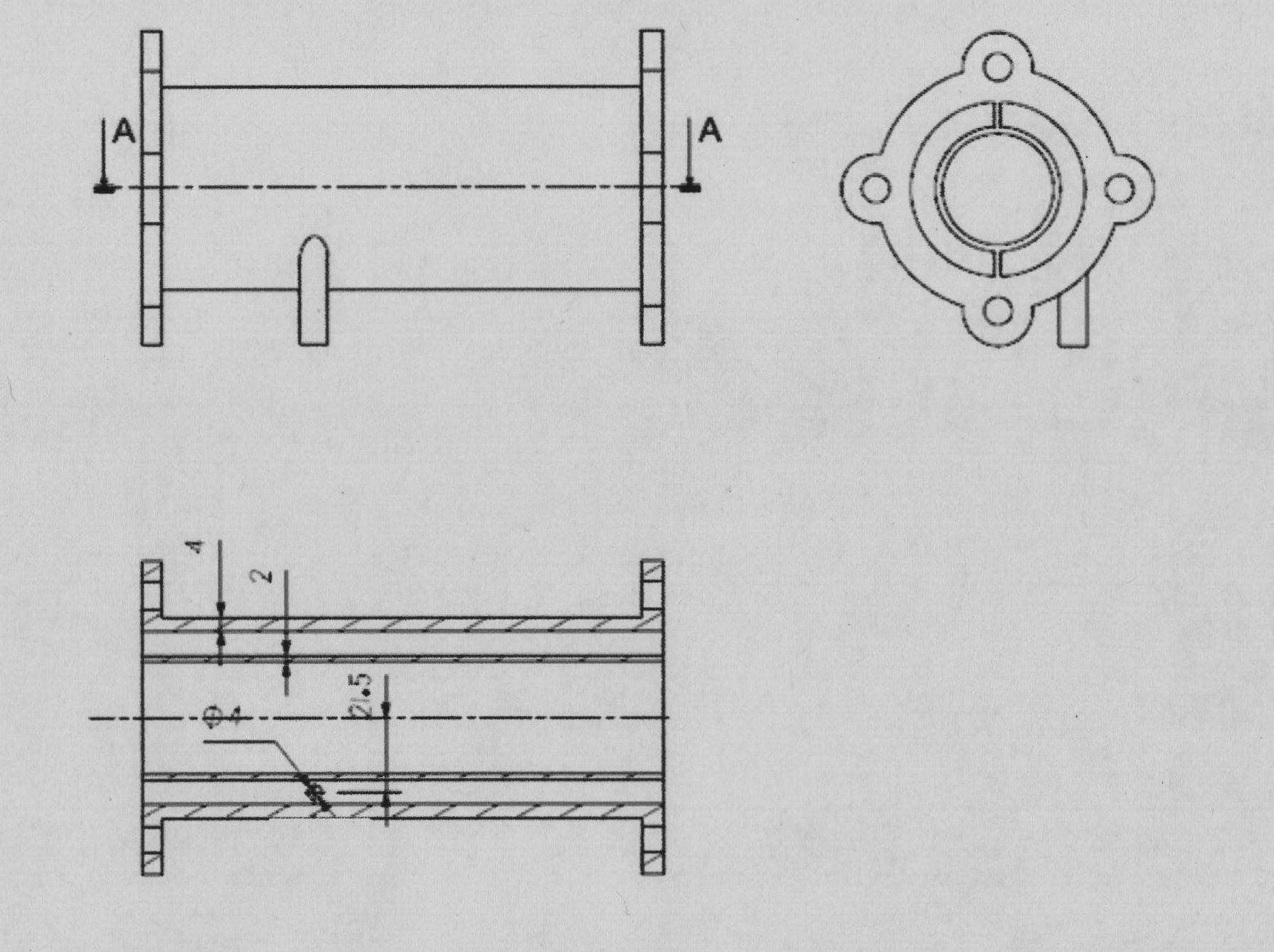

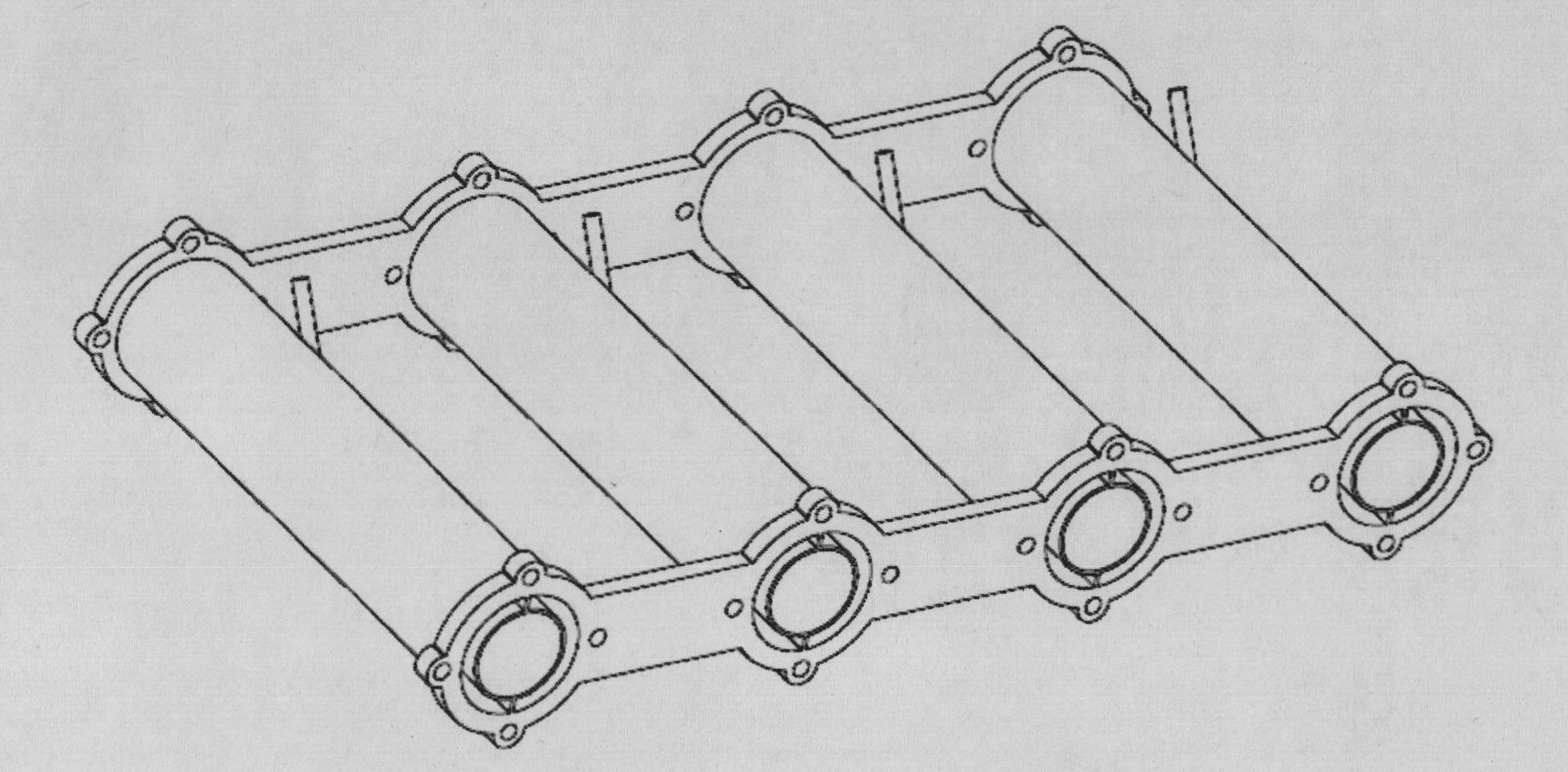

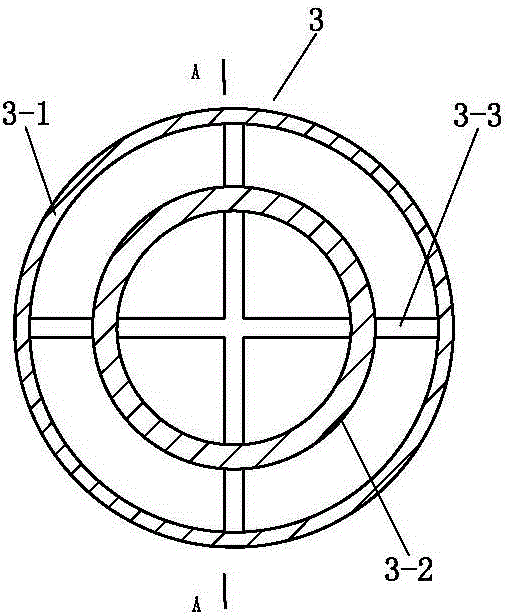

Flow guide sleeve type spiral mixed gas inlet device

InactiveCN102493899AImprove the phenomenon of serious decline in chargeReduce residual gas mixtureInternal combustion piston enginesFuel supply apparatusInlet channelEngineering

The invention relates to a flow guide sleeve type spiral mixed gas inlet device for a gas inlet channel jetting type gas fuel engine. The device comprises a flow guide sleeve 1 and flanges 2 arranged at two ends of the flow guide sleeve, wherein the flow guide sleeve 1 comprises an outer layer sleeve 1a, an inner layer sleeve 1b and a rib plate 3 connected between the outer layer sleeve 1a and the inner layer sleeve 1b; a jetting guide pipe 4 is arranged on the outer layer sleeve 1a; a gas fuel introduces fuel gas into an interlayer space between the inner layer sleeve 1b and the outer layer sleeve 1a through the jetting guide pipe so as to move around the outer wall of the inner layer sleeve in a spiral forwarding manner; and the fuel gas is fully mixed with air at a gas inlet channel on a cylinder cover. Due to the flow guide function of the device, the residual mixed gas amount in the gas inlet pipe is reduced; furthermore, the fuel gas and the air can be mixed at a place close to the gas inlet channel on the cylinder cover; and a tempering phenomenon is avoided effectively.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

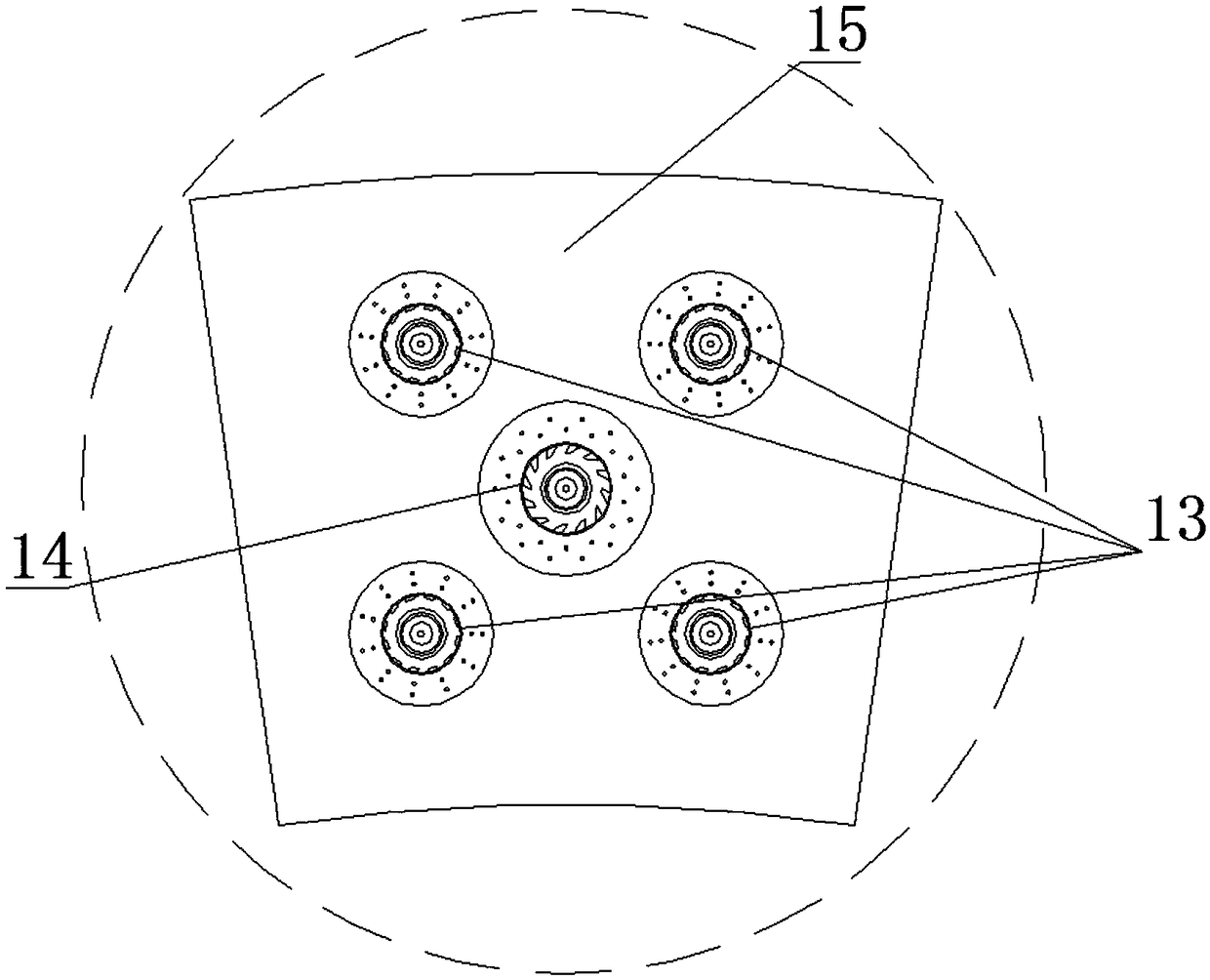

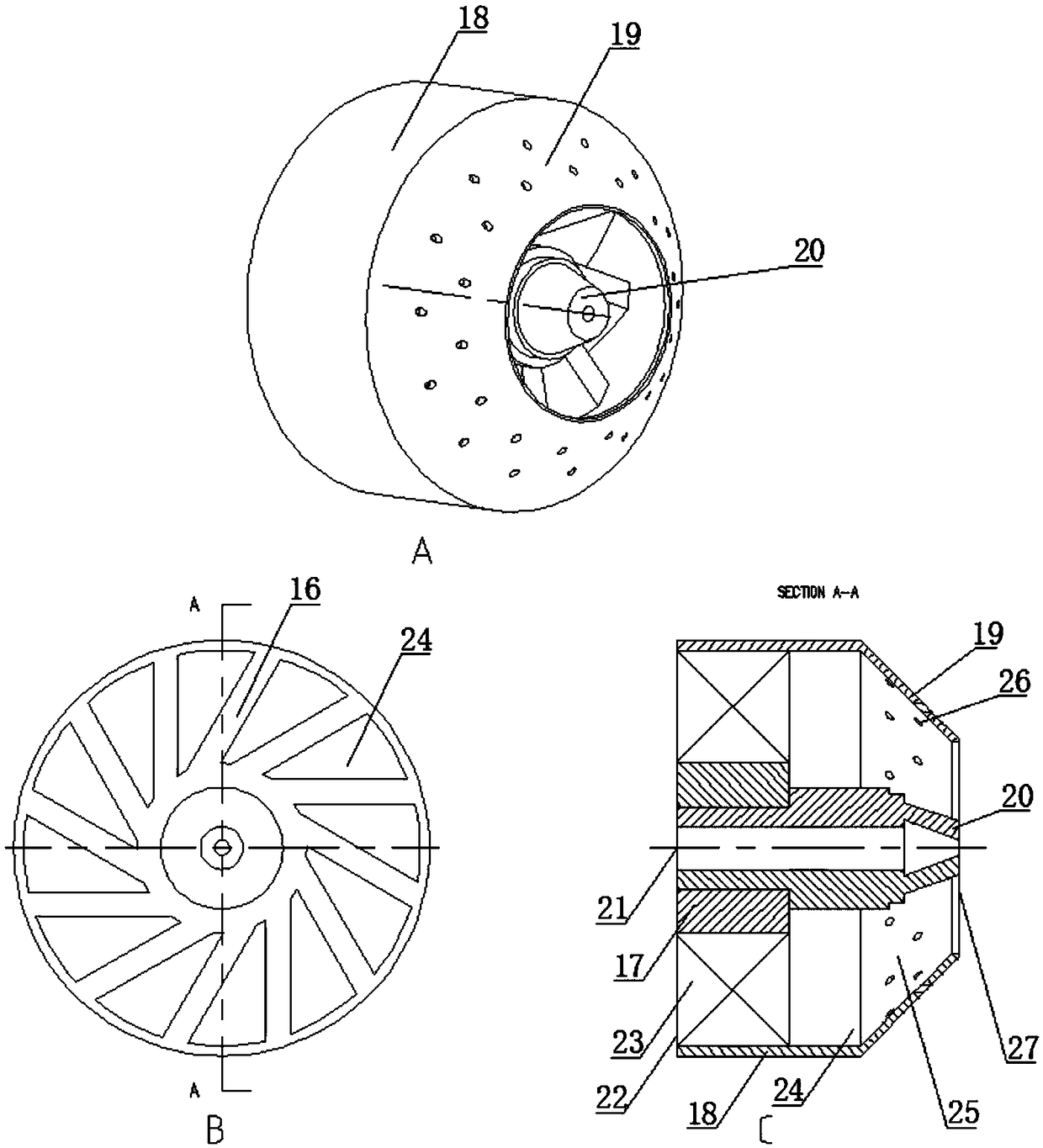

Multipoint unit direct jetting staged combustion chamber

InactiveCN108954388AGuarantee job stabilityReduce the temperatureContinuous combustion chamberSpontaneous combustionCyclone

The invention relates to a multipoint unit direct jetting staged combustion chamber. A head part of the combustion chamber is provided with an on-duty stage and a main combustion stage; the on-duty stage and the main combustion stage both adopt a direct mixed combustion manner, spontaneous combustion and fire return phenomena are effectively avoided, and the risk of vibration combustion is reduced; in the low-speed running state, only the on-duty stage works, the on-duty stage adopts strong cyclone design, the local equivalence ratio is relatively rich, the stable work of the combustion chamber is guaranteed, along with increase of the working state of the combustion chamber, the main combustion stage is gradually opened, the main combustion stage adopts weak cyclone design, and the fuel gas staying time is effectively shortened; and in the high state, the main combustion stage and the on-duty stage work at the same time, the designed combustion area average equivalence ratio is 0.4-1.2, the combustion area average temperature is effectively reduced, and the contaminant generating quantity is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

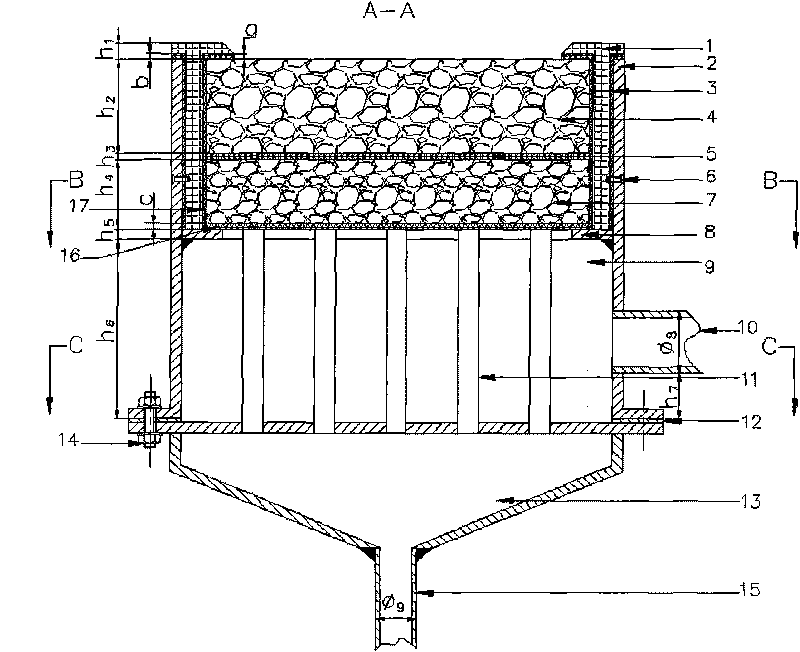

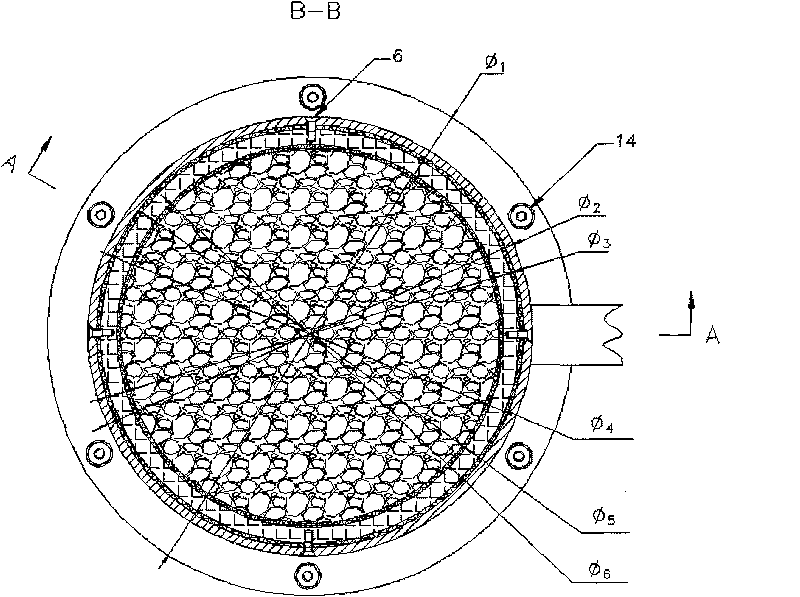

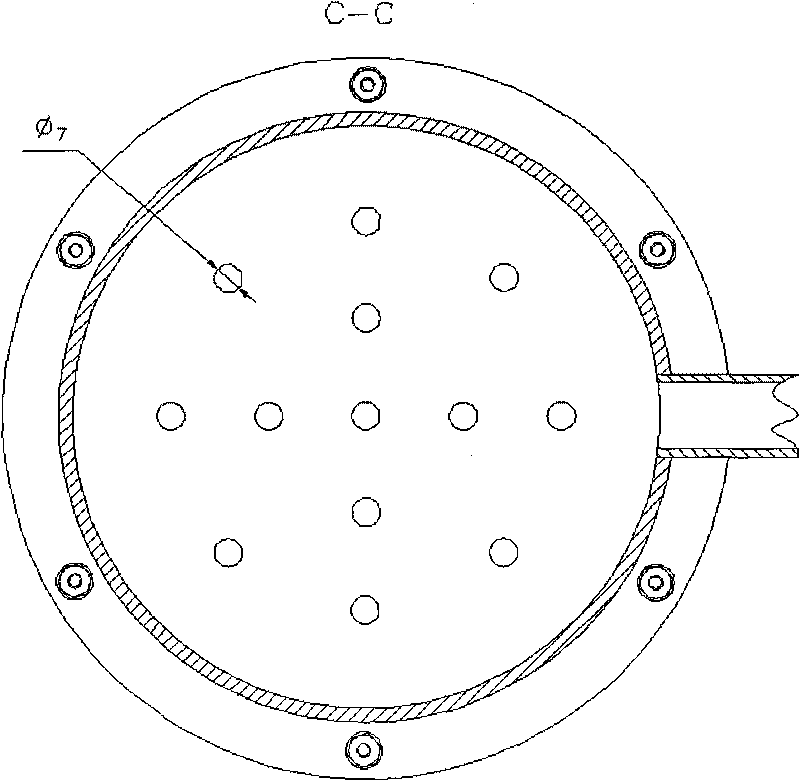

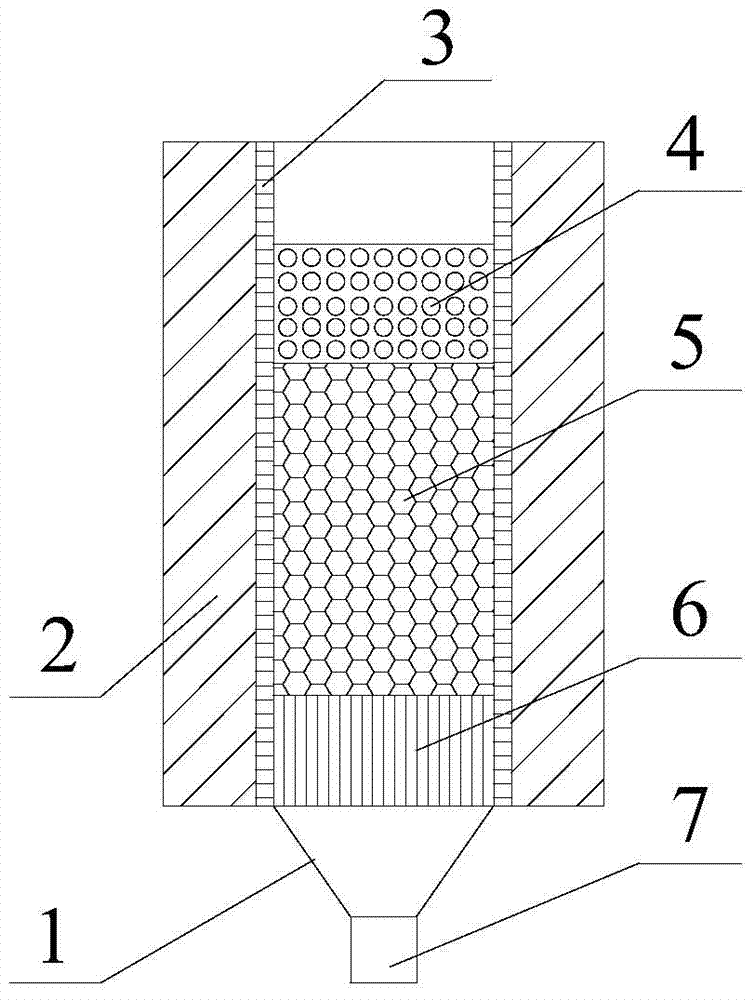

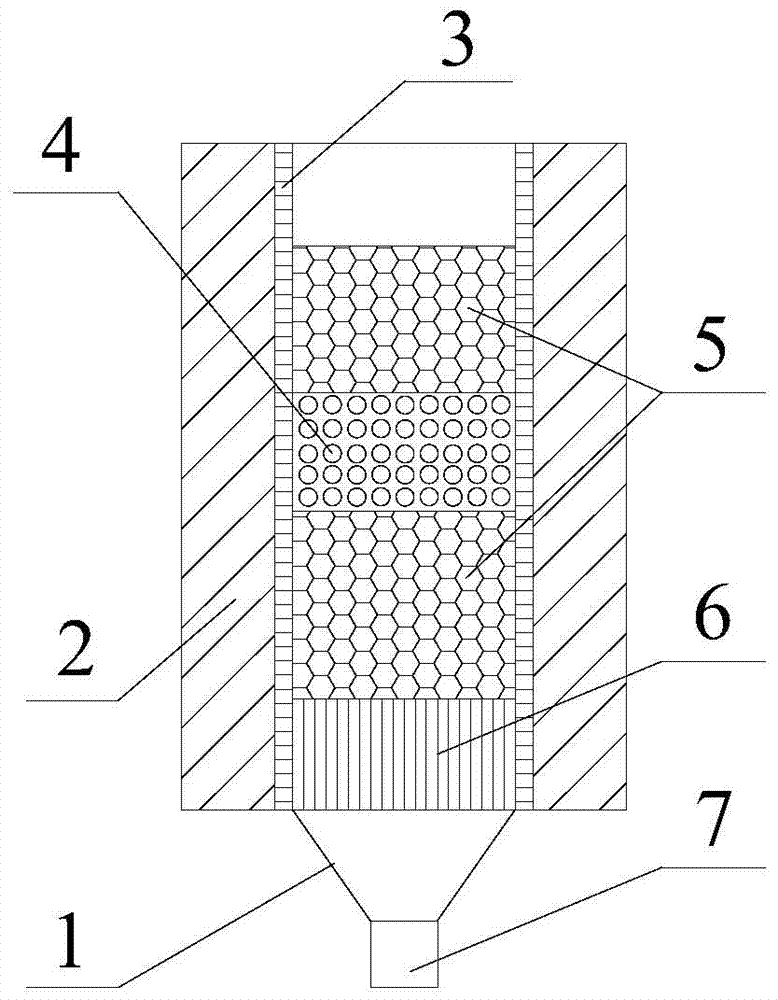

Porous medium burner with packed bed structure

InactiveCN104501162APromote exchangeBurn fullyIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorPorous medium

The invention provides a porous medium burner with a packed bed structure. The porous medium burner with the packed bed structure comprises an air inlet pipe, and a gradient type cylinder which is connected with the air inlet pipe; the upper end of the gradient type cylindrical is connected with an inner cylinder; the outer layer of the inner cylinder is wrapped with a heat preserving layer; a hole plate fills an area in the lower part of the inner layer of the inner cylinder; a setting porous medium is arranged above the hole plate; a packed bed medium is arranged above or in the middle part of the setting porous medium. The burner is applicable to positioning of heat exchange pipes of various shapes; the operation is convenient; the burning efficiency is high; the mounted hole plate is able to effectively prevent flame from burning back, and therefore, the safety of a device is improved.

Owner:CHINA UNIV OF MINING & TECH

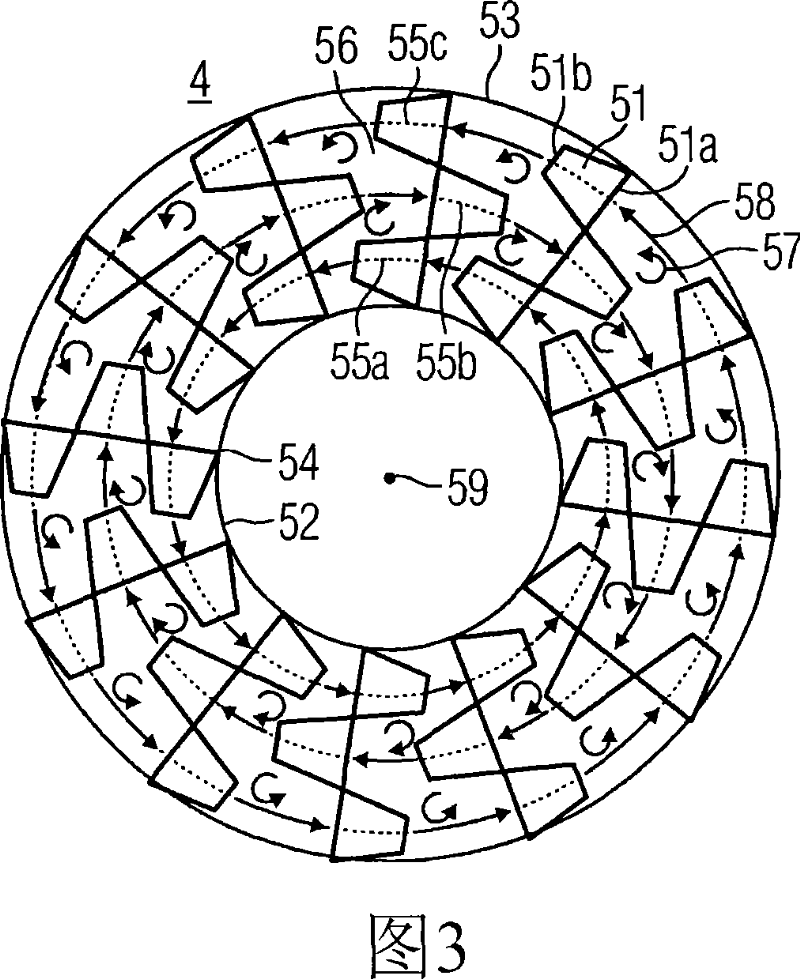

Burner for combustion of a low-calorific fuel gas and method for operating a burner

InactiveCN101040149AImprove spatial uniformityAvoid installationBurnersContinuous combustion chamberLow nitrogenProcess engineering

The invention relates to a burner (1), for the combustion of a low-calorific fuel gas (SG), with an air channel (2), running along a burner axis (12), for the introduction of combustion air (10) and a fuel gas channel (26), embodied for a high volumetric flow of low-calorific fuel gas (SG), whereby the fuel gas channel (26) and the air channel (2) open out into a mixing region (27). According to the invention, a low-nitrogen oxide synthesis gas operation of the burner (1) may be achieved, whereby a swirl element (4) is arranged in the air channel (2) for the generation of turbulent combustion air (10). The swirling element is provided in an opening region (28) directly adjacent to the flow of the mixing region (27). The invention further relates to a method of operation of a synthesis gas burner (1), whereby, directly before the mixing of the synthesis gas (SG) with the combustion air (10), the level of turbulence of the mass air flow is significantly increased on the microscopic level and a temporally and spatially homogenous mixing of the synthesis gas / air mixture is achieved.

Owner:SIEMENS AG

High-efficiency combined torch head

A high-efficiency combined torch head comprises a barrel, an ignition device, a vertical steam pipe, an annular steam pipe, quincunx steam spray nozzles, a burning stabilizing device and a jet flow sealer capable of forming rotary jet flow. The ignition device arranged at the gas outlet of the top of the barrel at least comprises an ignition gun and an incandescent lamp component, wherein the ignition gun and the incandescent lamp component are connected with a high-energy semiconductor nozzle. The quincunx steam spray nozzles are circumferentially arranged at a top outlet of the barrel and are communicated with the annular steam pipe, and the annular steam pipe is communicated with the vertical steam pipe. The burning stabilizing device is arranged on the upper portion of the barrel. The jet flow sealer is arranged at a lower inlet of the barrel, and a nitrogen gas purging pipe is communicated between the lower inlet of the barrel and the jet flow sealer. The high-efficiency combined torch head has functions of eliminating smoke, stabilizing burning, effectively preventing black smoke and tempering backfire and guaranteeing safety operation of equipment, and is simple in structure, universal, resistant to high temperature and corrosion, and long in service life.

Owner:JINAN TORCH CREATION ENERGY SCI & TECH

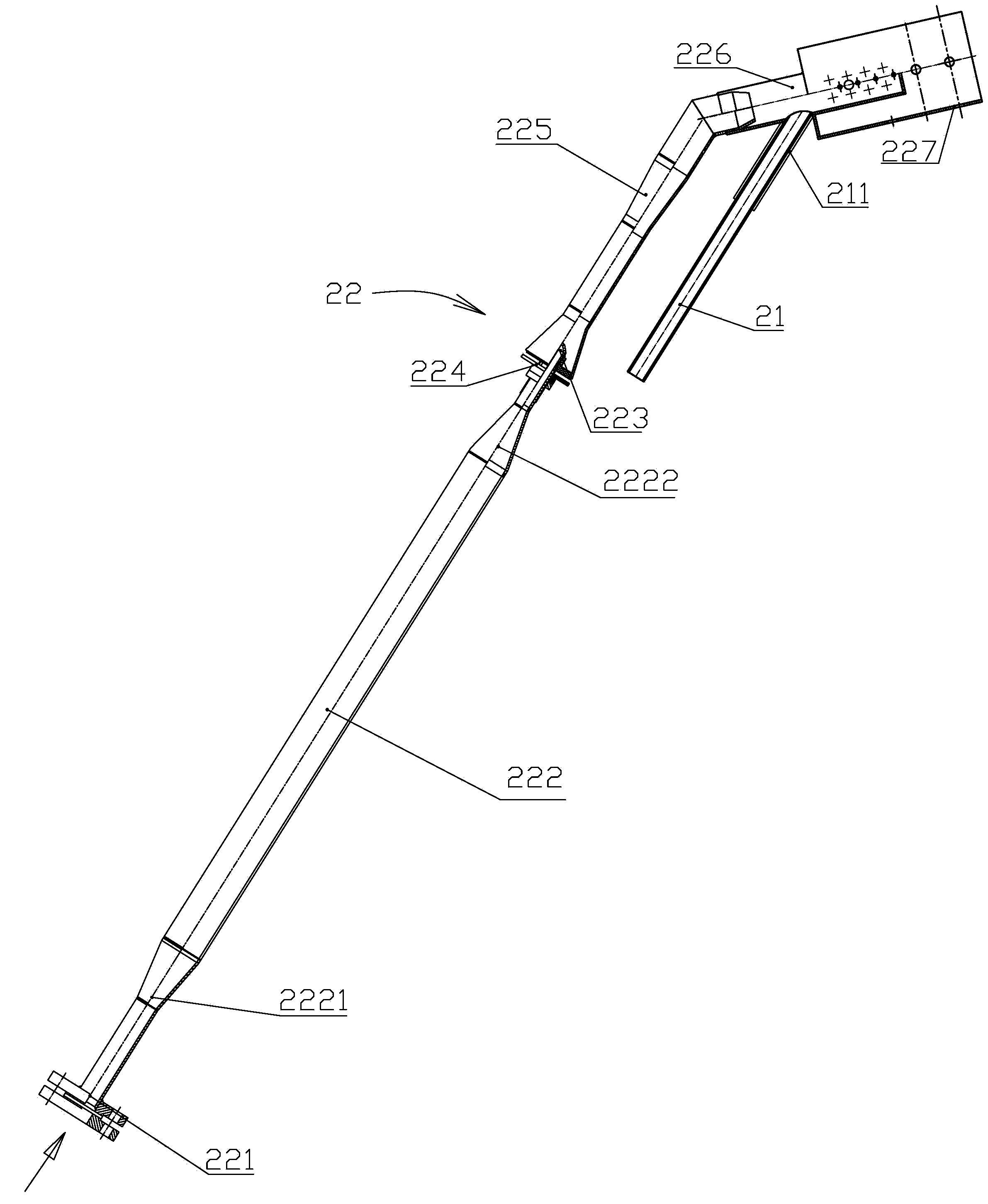

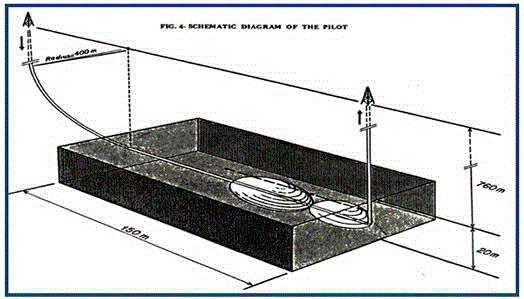

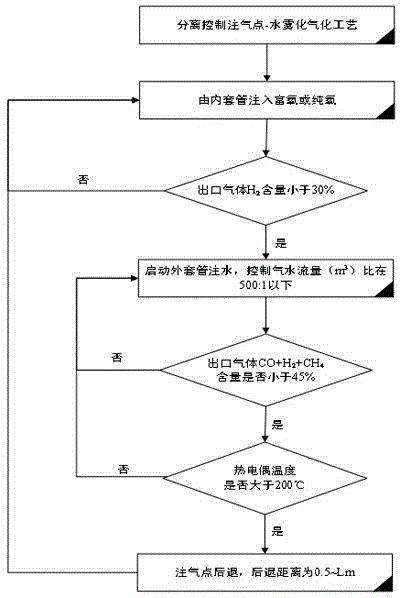

Underground fuel gasification method, gasifying agent delivery pipe and underground fuel gasification system

ActiveCN104895545AAchieve normalAchieve stabilizationConstructionsCoal gasificationWater vaporFuel gasification

The invention discloses an underground fuel gasification method, a gasifying agent delivery pipe and an underground fuel gasification system. The underground fuel gasification method comprises the steps of respectively and continuously delivering water and combustion-supporting gas to an underground fuel gasification reaction zone, atomizing the water delivered to the underground fuel gasification reaction zone by using pressure potential energy of water from the ground to the underground, mixing water vapor produced after atomization with the combustion-supporting gas delivered to the underground fuel gasification reaction zone to form mist gasifying agent, and producing fuel gas through gasification reaction between the mist gasifying agent and the underground fuel in the underground fuel gasification reaction zone by combustion and heating. The gasifying agent delivery pipe comprises a water delivery pipe and a gas delivery pipe. The underground fuel gasification system comprises an underground gasification furnace, the gasifying agent delivery pipe and an atomizing and mixing nozzle. The water and combustion-supporting gas can be mixed in the underground fuel gasification reaction zone to form the mist gasifying agent without using heat, the normalization and stabilization of the underground gasification process are realized, and the production cost is greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Continuous positive flow backflash prevention system

InactiveUS7156193B2Avoid problemsPrevent flashbackDrilling rodsConstructionsWell drillingEngineering

A method and system for the prevention of backflash from an ignition source in a flare stack to a separator or wellbore particularly during drilling and production. A continuous positive flow of air or exhaust gas is provided into the flow of gases from the wellbore or the separator to ensure that the velocity of the flow is always higher than the velocity at which the flame can propagate backwards into either the separator or the wellbore. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas from the wellbore is intermittent and unpredictable and can stop and start during connection and disconnection of the air used as the drilling fluid.

Owner:SWARTOUT MATT

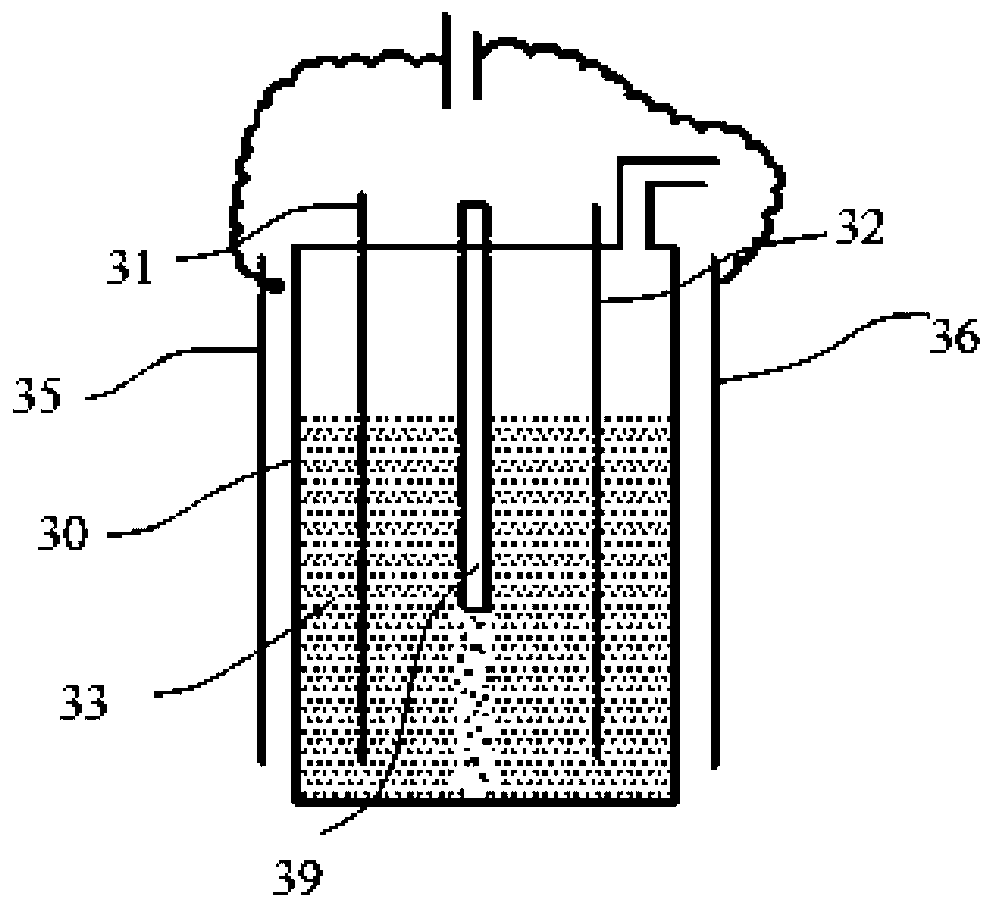

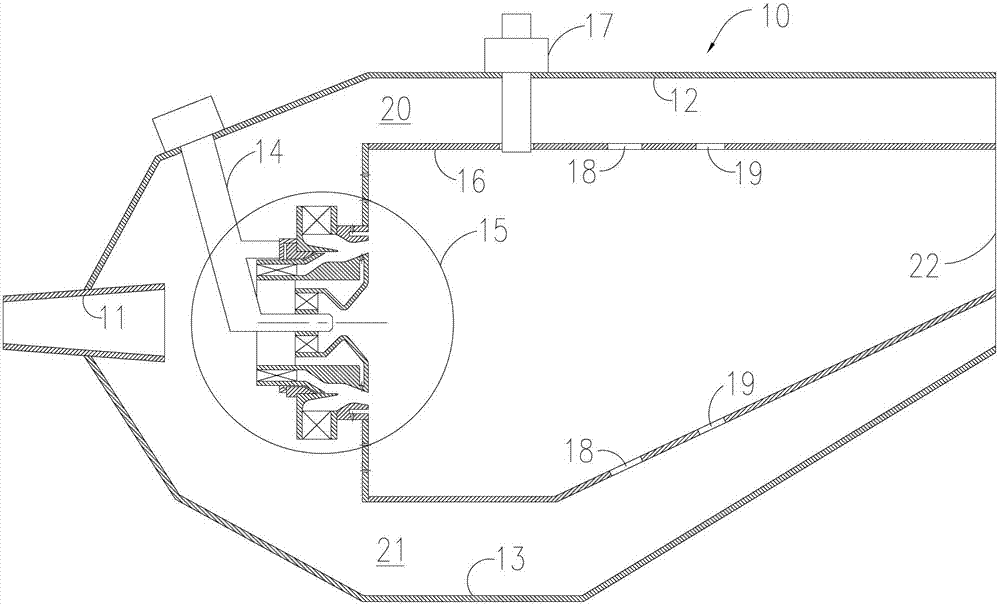

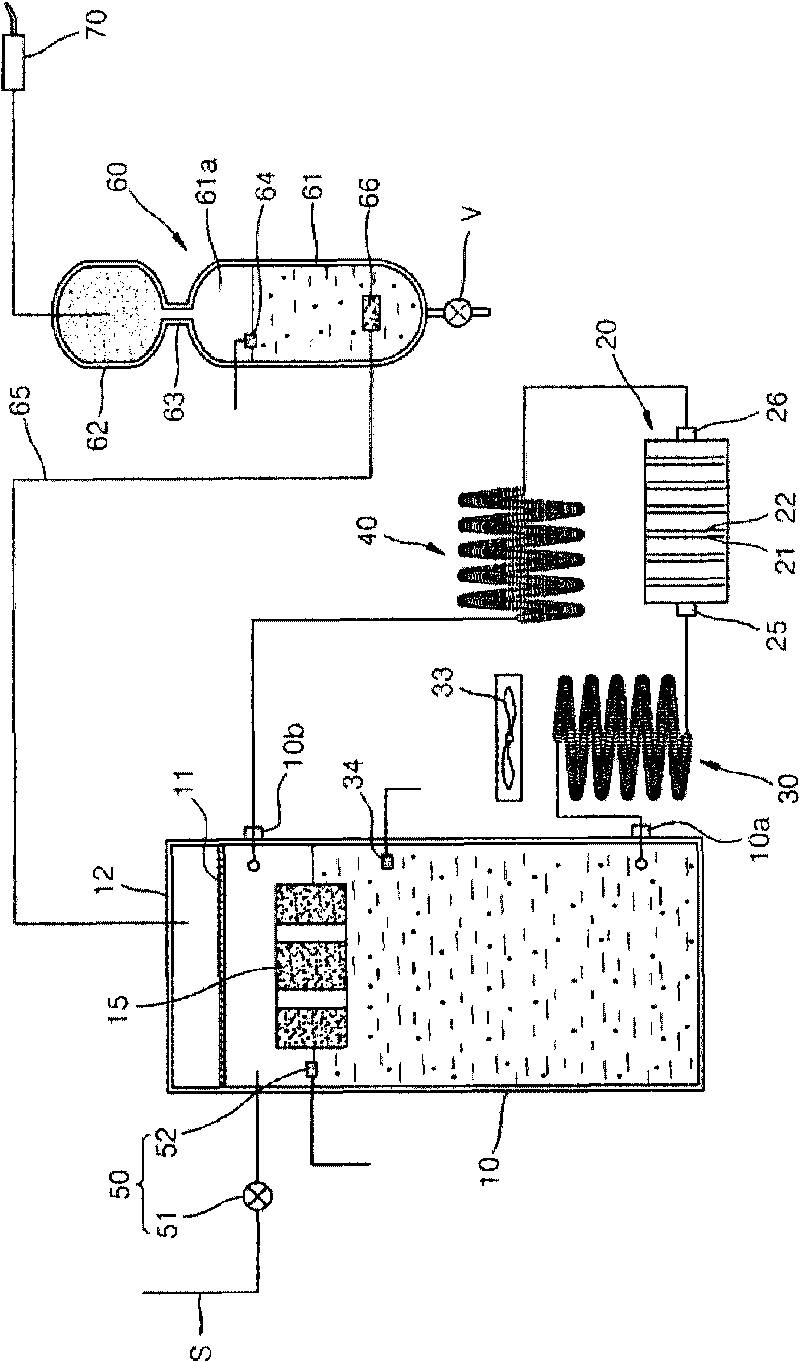

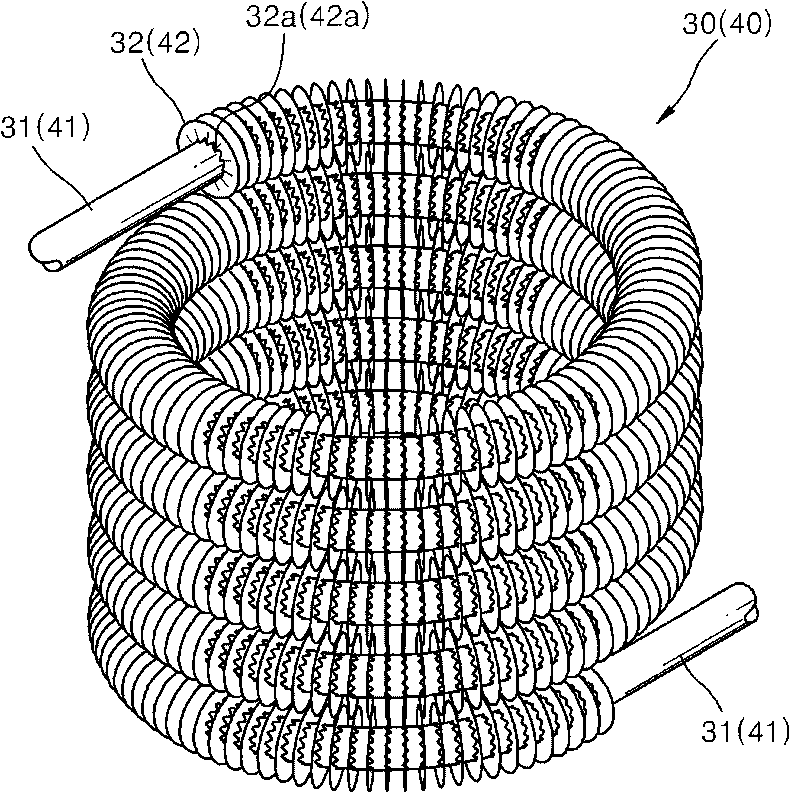

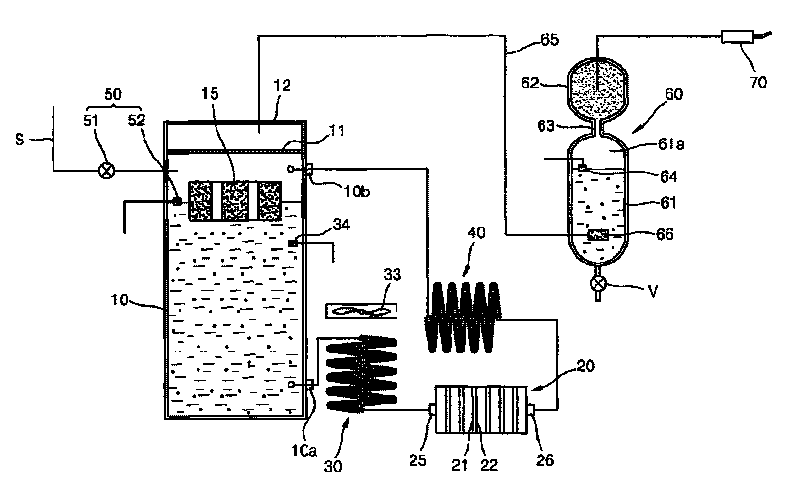

A hydrogen-oxygen generating system

InactiveCN101748420ATo achieve the purpose of heat dissipationSimple structureElectrolysis componentsDispersed particle filtrationHydrogenElectrolysis

A hydrogen-oxygen generating system includes a water capture-storage (10), where water is stored and hydrogen-oxygen mixed gas is captured, an electrolyte unit (20) including inflowing pipe (25) to inhale water, and out-flowing pipe (26) to exhale hydrogen-oxygen mixed gas and including a plurality of electrodes (21)(22) to electrolyze water, a first heat radiant pipe (30) radiating heat and supplying water to the electrolyte unit (20) from water capture-storage (10) and connected to a lower part of the water capture-storage (10) and a second heat radiant pipe (40) connected to the outflowing pipe (26) and an upper part of the water capture-storage (10) radiating heat as it provides hydrogen-oxygen mixed gas to the water capture-storage (10).

Owner:黄富成

Trapped vortex combustor

InactiveCN1784574AReduce "high temperature sectionOptimize volumeContinuous combustion chamberEngine manufactureLeading edgeCombustor

Cut-off vortex combustors for gas turbines. The annular burner housing has a plurality of inlet centerpieces arranged along the helical axis. The inlet centerbody includes a leading edge structure, opposing side walls, a pressurizable chamber, and a rear wall. The inlet center body cooperates with the adjacent structure and the rear body bluff body to define a shut-off swirl chamber combustor for mixing the inlet fluid and combustible fuel to form hot combustion gases. Mixing is enhanced by utilizing posts adjacent to the rear wall to create swirls in the fluid flow, and by injecting fuel and / or air in the opposite direction to the swirl created by the bulk fluid flow. The hot combustion gases are used in a turbine for kinetic energy extraction or in a heat exchange device for thermal energy recovery. High combustion efficiency can be obtained and the emission of nitrogen oxides and carbon monoxide is less than 10ppm.

Owner:DRESSER RAND CO

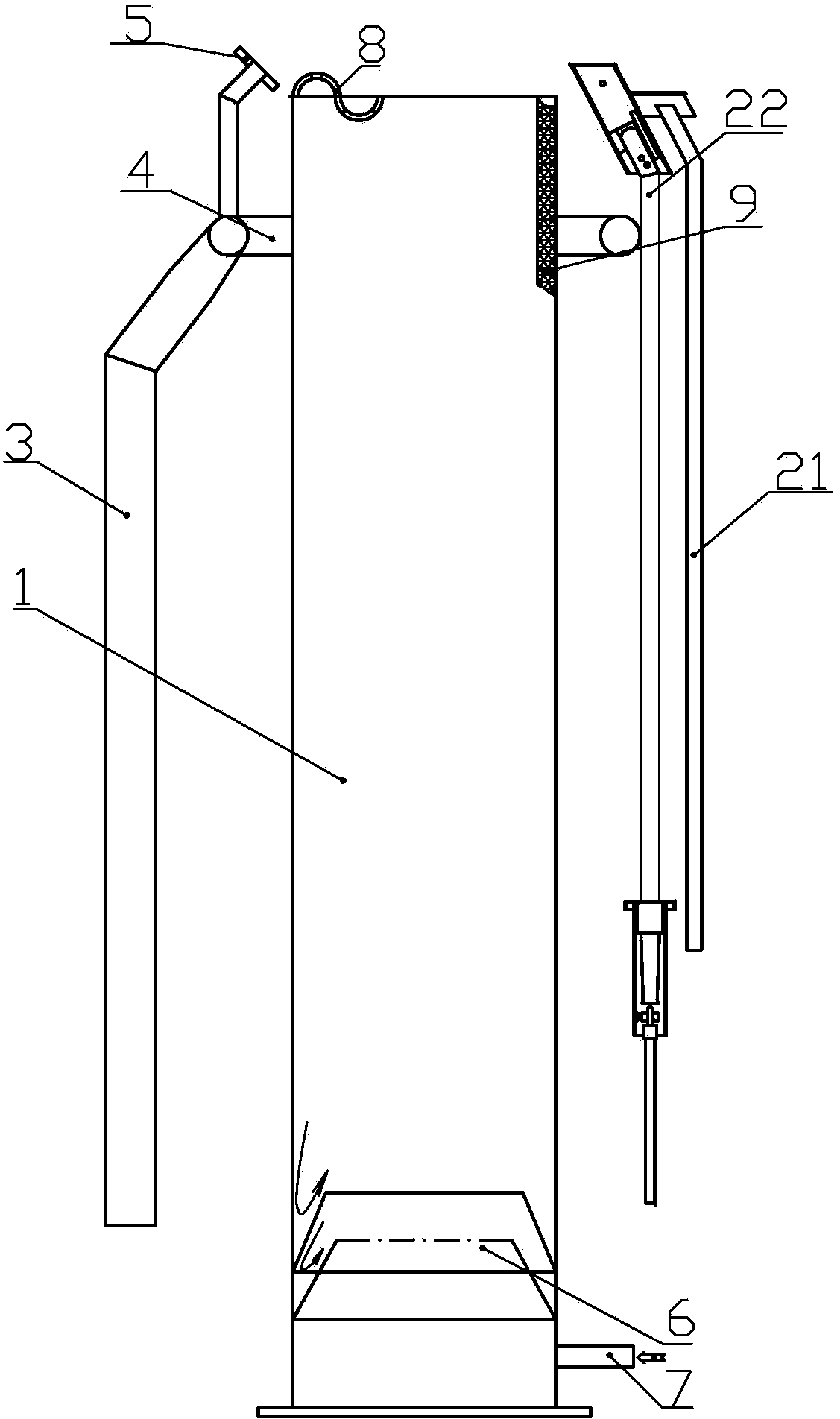

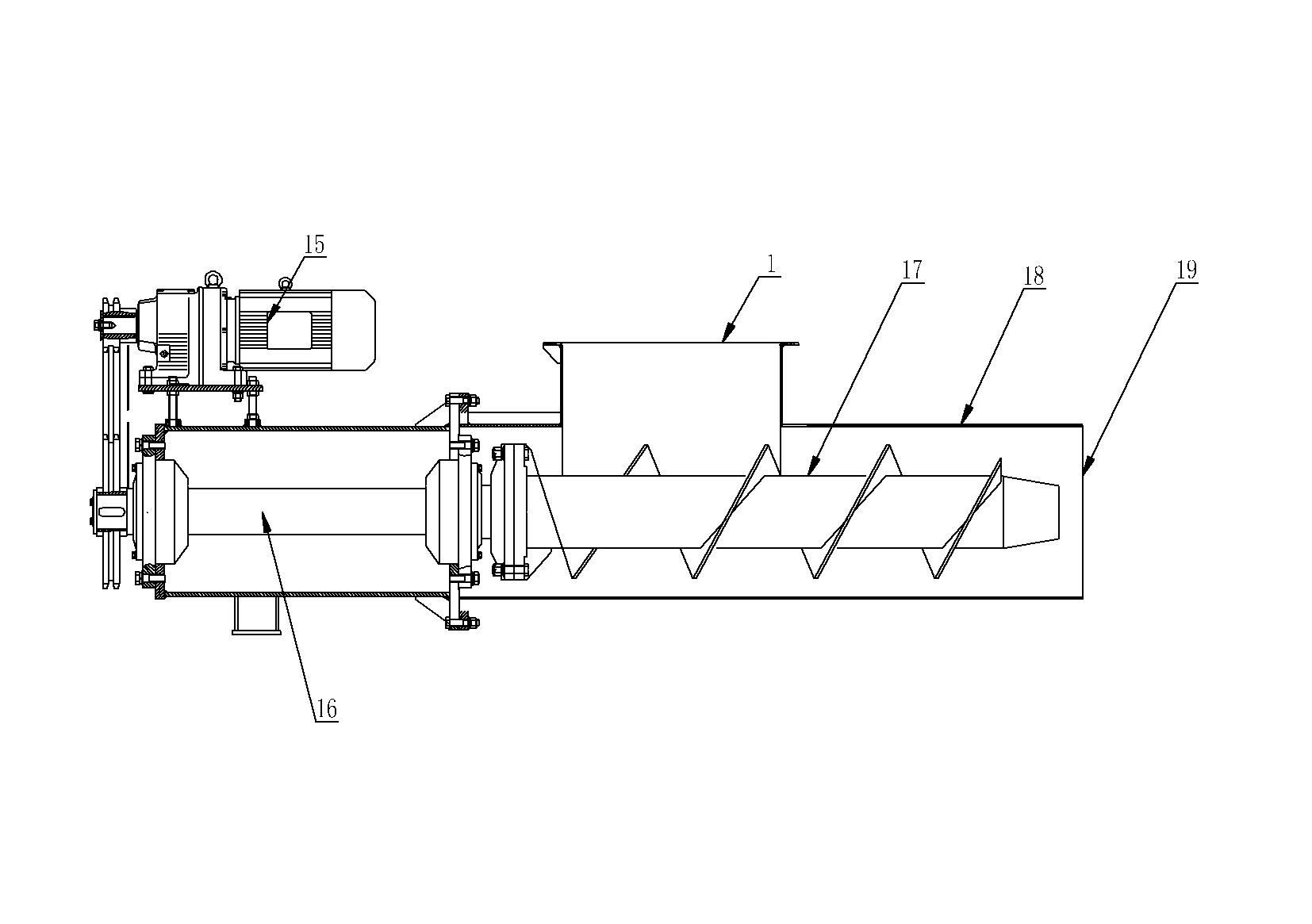

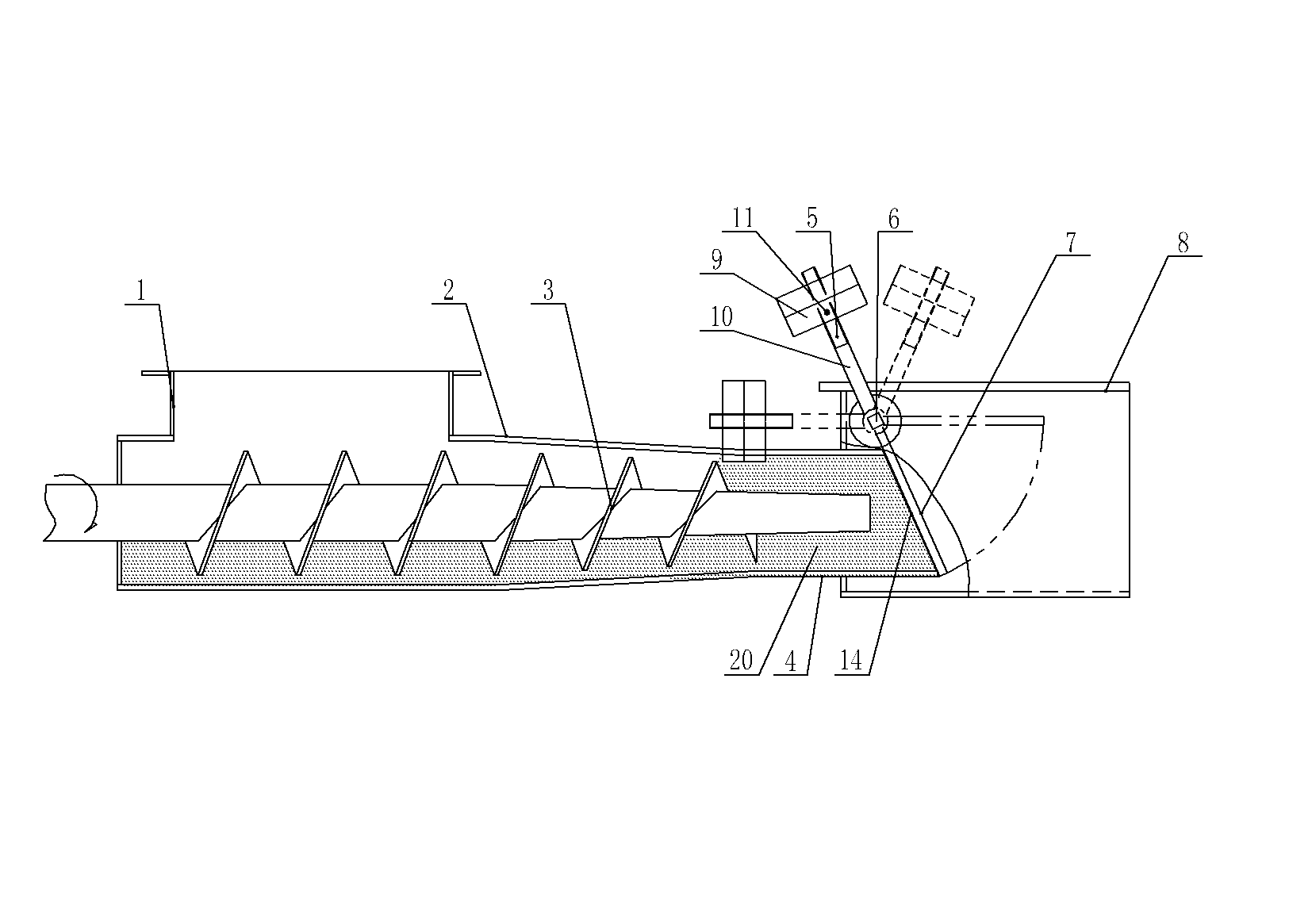

Improved screw feeder of raw biomass material incinerator

InactiveCN102644924APrevent flashbackPlay a sealing roleIncinerator apparatusLump/pulverulent fuel feeder/distributionBiomassEngineering

The invention relates to a feeding device of an incinerator, in particular to an improved screw feeder of a raw biomass material incinerator, which is capable of feeding continuously while preventing tempering effectively so as to guarantee safety in production. The improved screw feeder comprises a feeder casing and a screw shaft, wherein the feeder casing is provided with a feed inlet, a discharge outlet of the feeder casing is connected with a discharge hopper, and the screw shaft is driven by a drive device and penetrates through the feeder casing. The improved screw feeder is characterized in that a plugging section is arranged at the end of the discharge outlet of the feeder casing, a portion of the screw shaft located at the plugging section is provided with no screw blades, the discharge hopper is arranged above the discharge outlet and provided with a damper rotating shaft, and a damper is mounted at the discharge outlet through the damper rotating shaft which is further connected with a damping device.

Owner:WUXI XIDONG ENERGY TECH

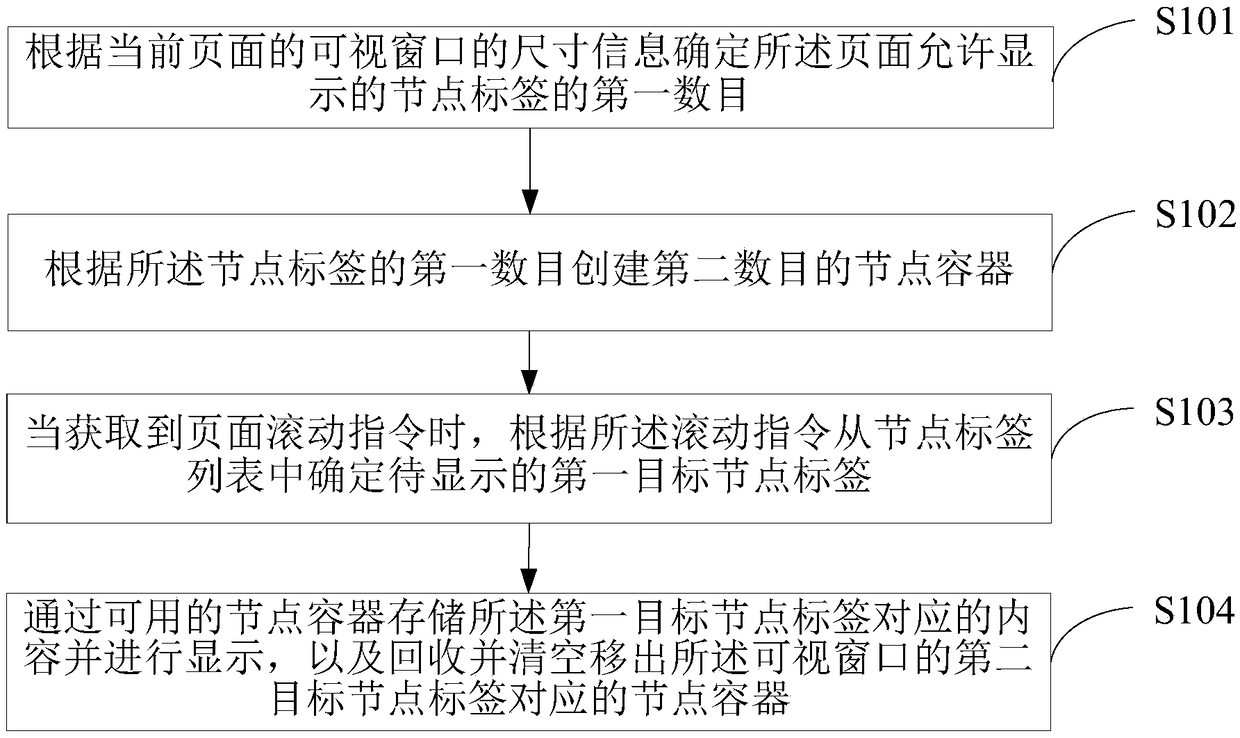

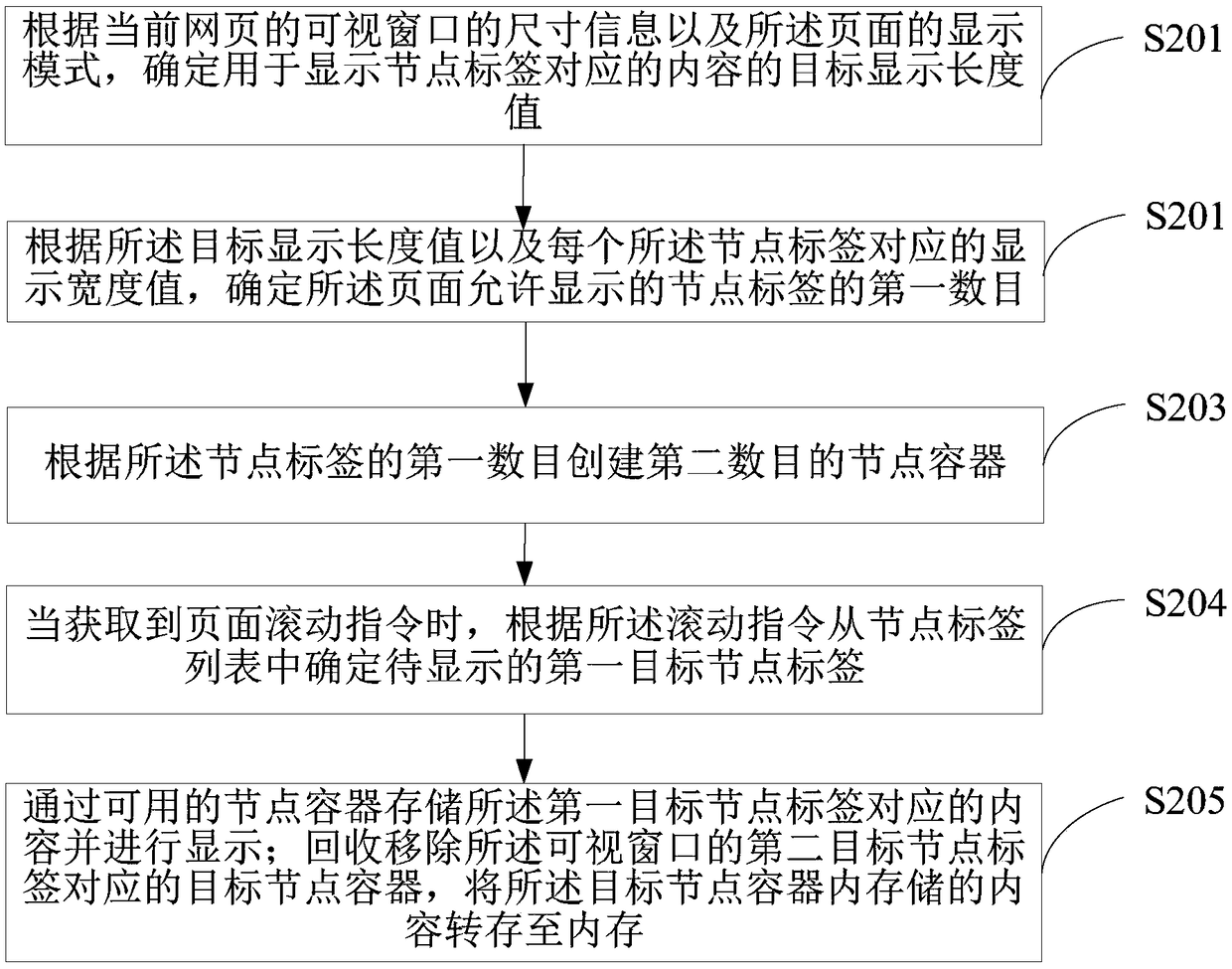

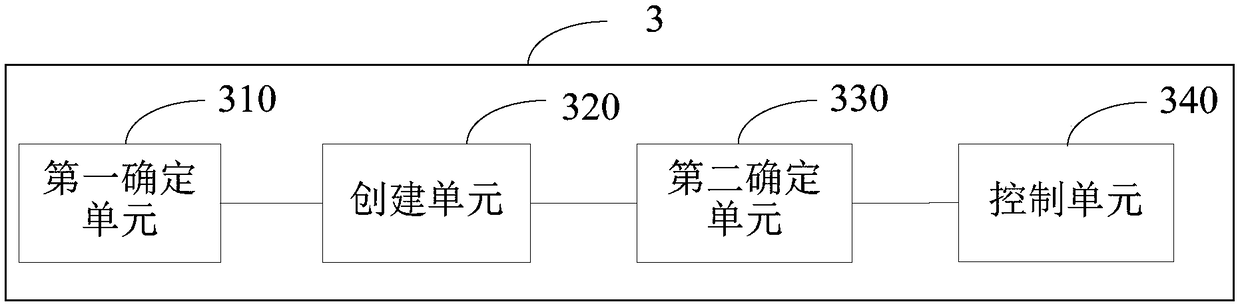

A method and terminal for displaying a page

The invention is applicable to the computer technical field, and provides a method and a terminal for displaying a page. The method comprises the following steps: determining a first number of node labels allowed to be displayed on the page according to the size information of a visual window of the current page; creating a second number of node containers according to the first number of node tags; the second number is greater than the first number; determining a first target node tag to be displayed from the node tag list according to the scrolling instruction when the page scrolling instruction is obtained; storing and displaying the contents corresponding to the first target node tag through an available node container; the node container corresponding to the second target node tag moved out of the visual window is recycled and emptied. The embodiment of the invention stores the content corresponding to the node label which is about to enter the visual window through the multiplexing node container, avoids the situation that new node information is continuously added to the list when the infinite information list is scrolled, and reduces the resource consumed by redrawing and rearranging the web page due to the increase of the node information.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com