Flow guide sleeve type spiral mixed gas inlet device

A diversion sleeve and helical mixing technology, which can be used in oil supply devices, charging systems, combustion air/combustion-air processing, etc., can solve problems such as low injection difficulty, weakening of engine air intake, and flashback.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

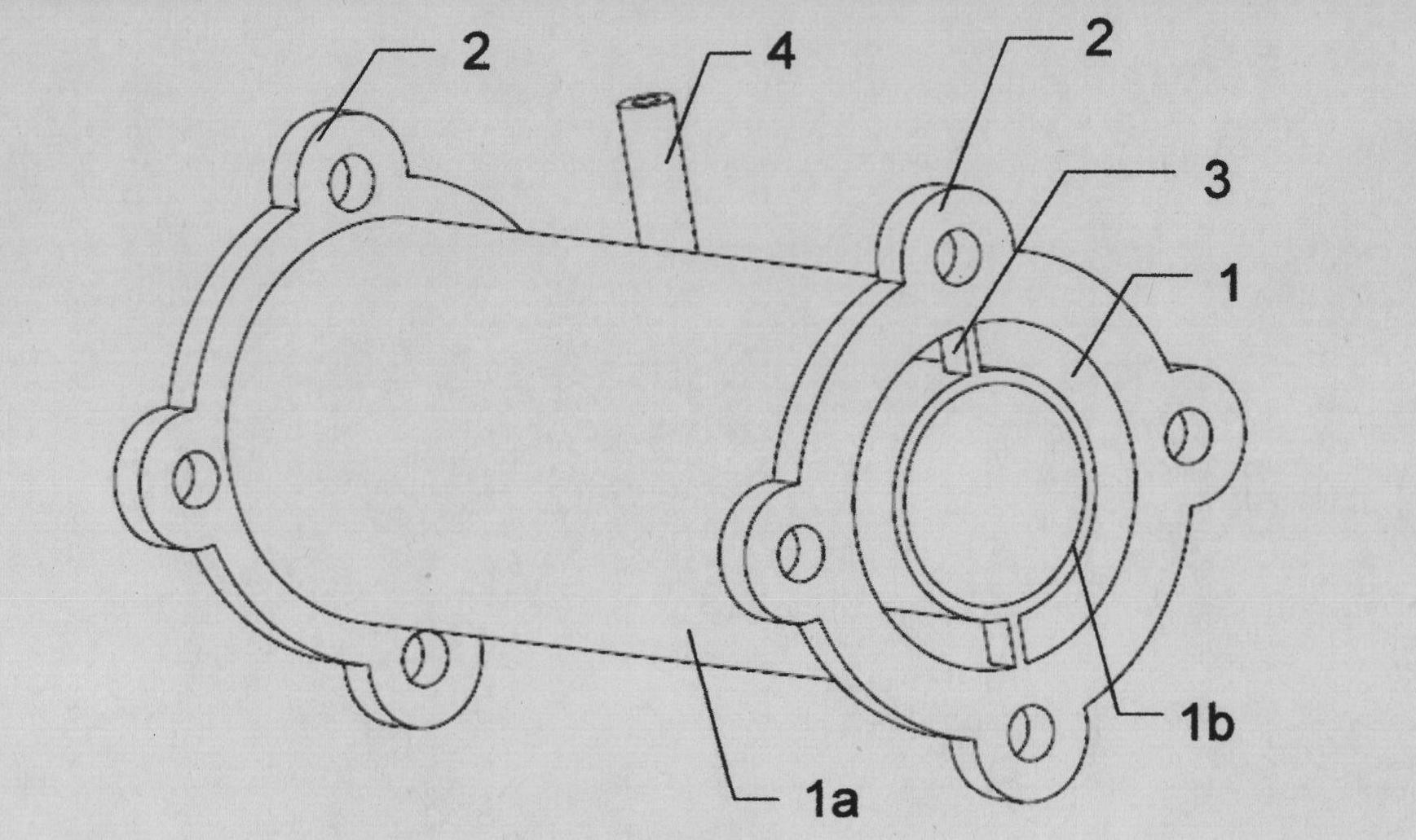

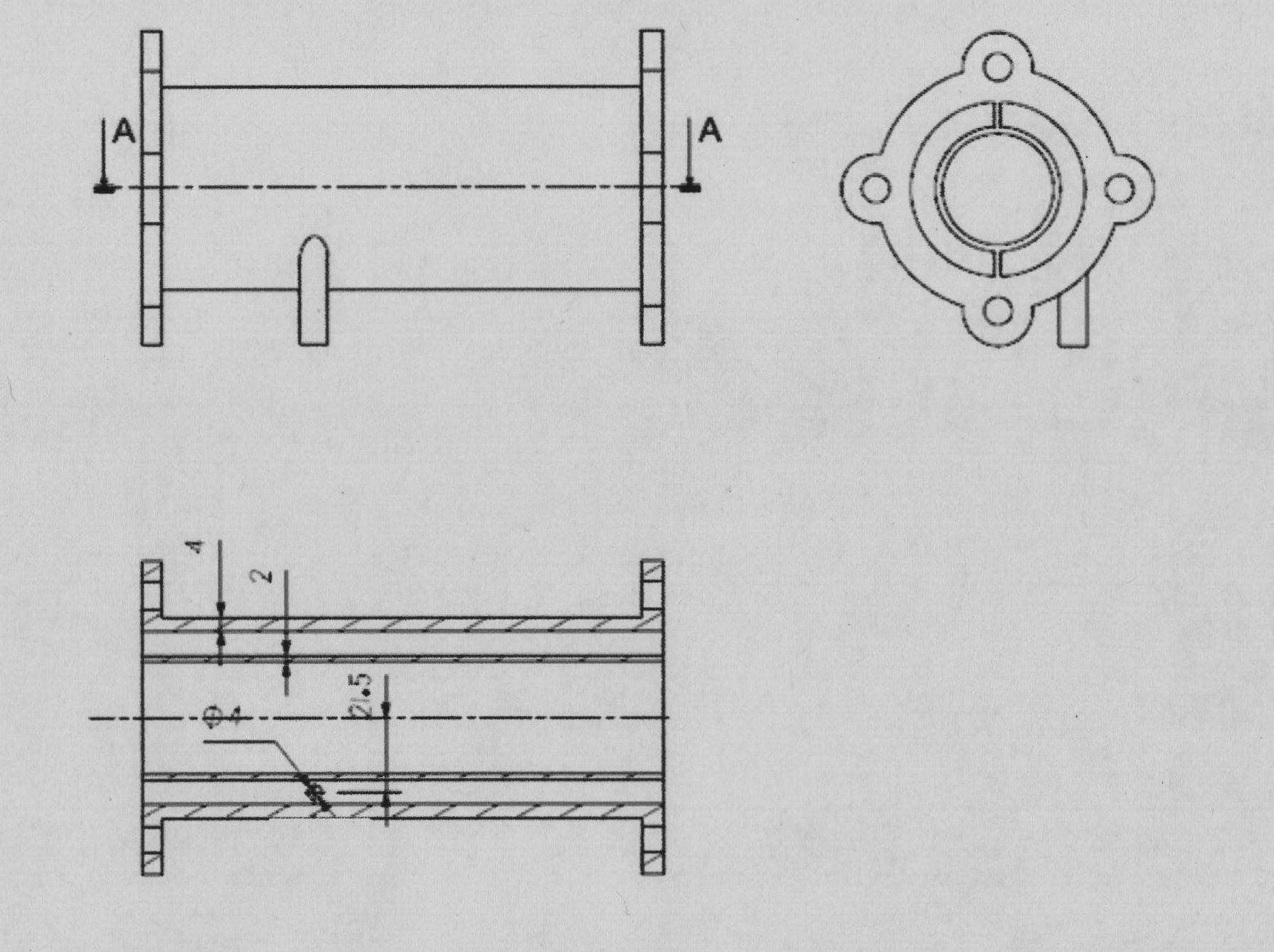

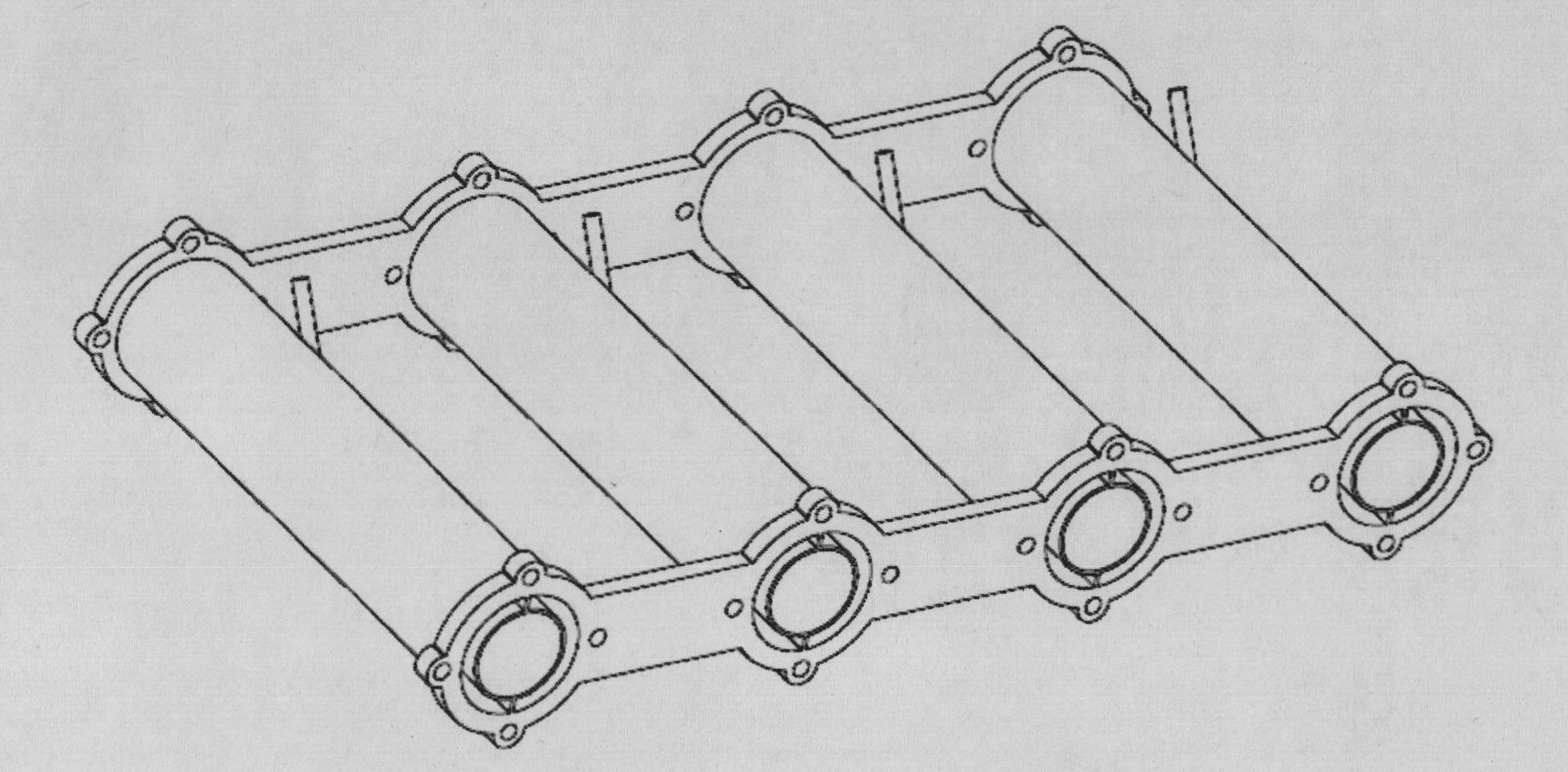

[0016] figure 1 , 2 A preferred embodiment based on the present invention is shown. The shown guide sleeve type spiral hybrid air intake device is used in a port injection type in-line four-cylinder hydrogen fuel engine, but is not limited to this engine. The guide sleeve type spiral hybrid air intake device includes a guide sleeve 1 and flanges 2 at both ends of the guide sleeve. The guide casing 1 includes an outer casing 1a and an inner casing 1b, and a rib 3 connected between the outer casing 1a and the inner casing 1b. An injection duct 4 is provided on the outer casing 1a. The gas fuel is introduced into the interlayer space between the inner casing and the outer casing through the injection duct to move spirally around the outer wall of the inner casing, and Fully mix with air at the cylinder head intake.

[0017] For a certain hydrogen engine, the total length of the draft tube is 150mm. The thickness of the outer casing is 4 to 5 mm, and the thickness of the inner casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com