Patents

Literature

131results about How to "Improve flow coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

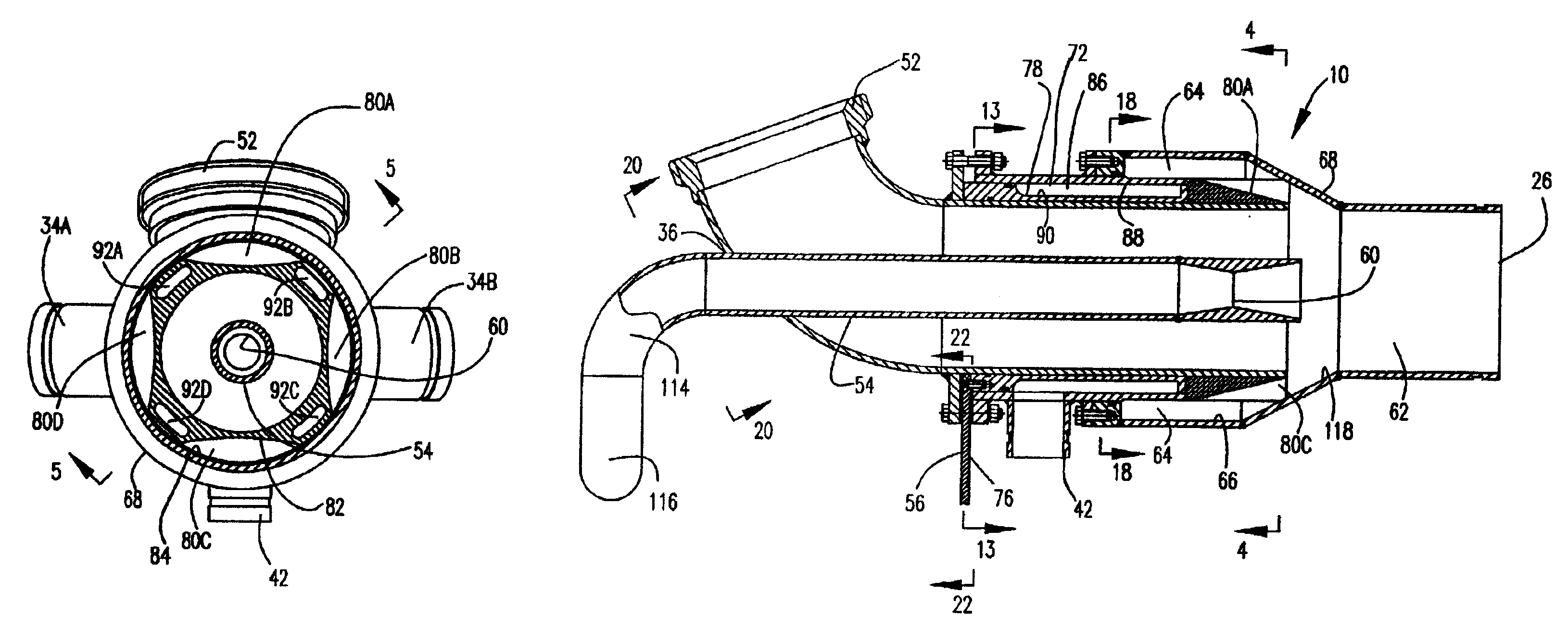

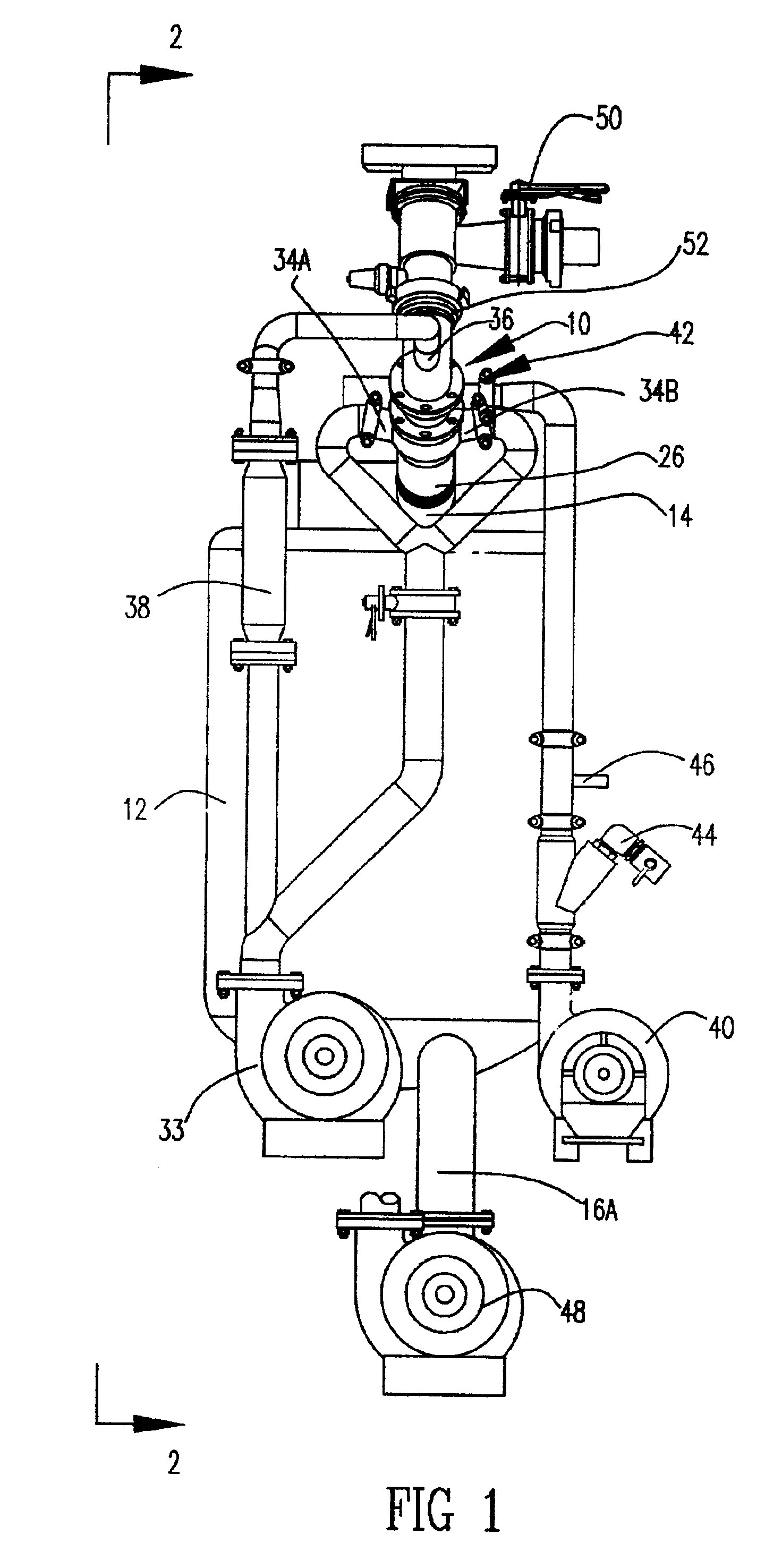

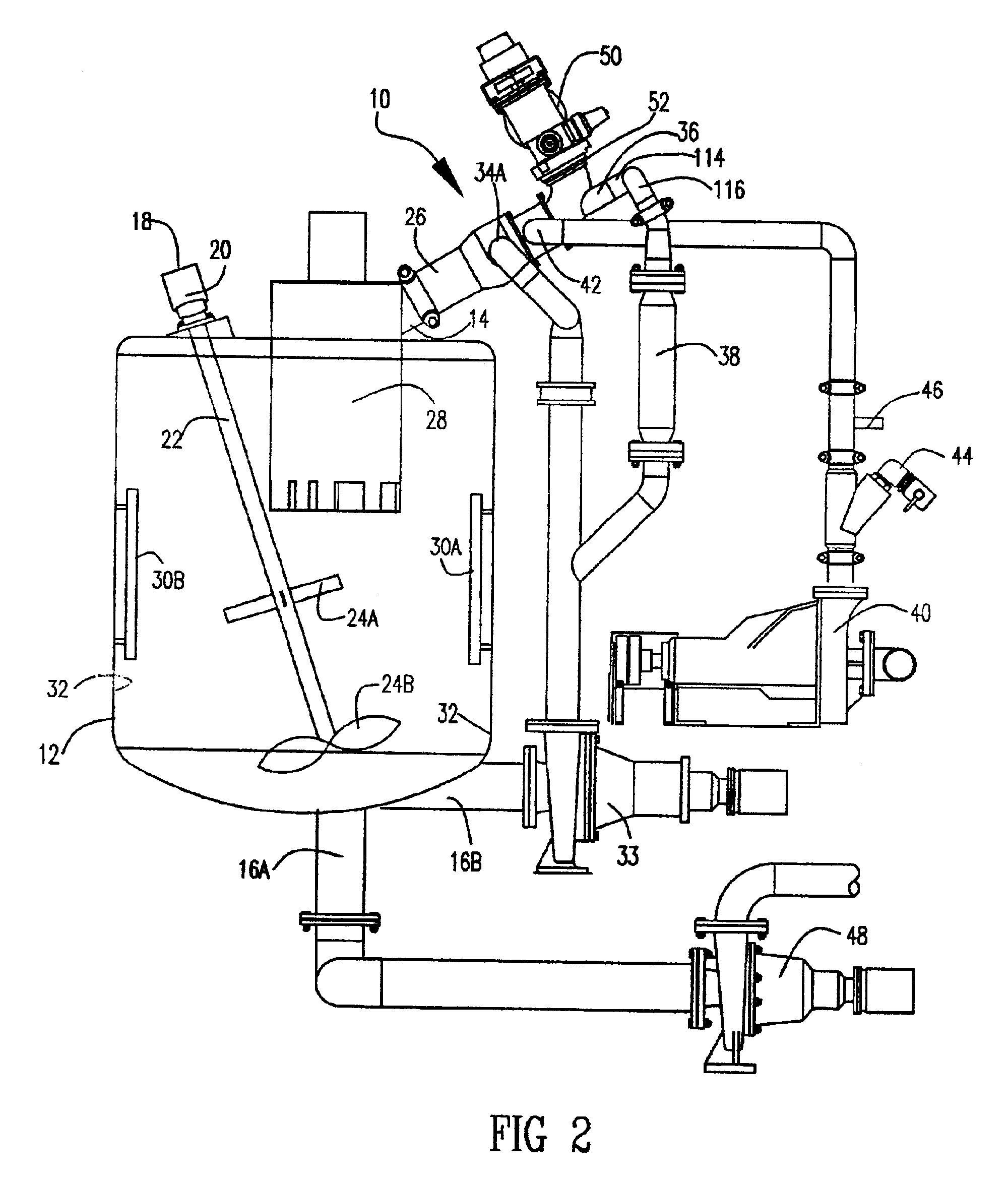

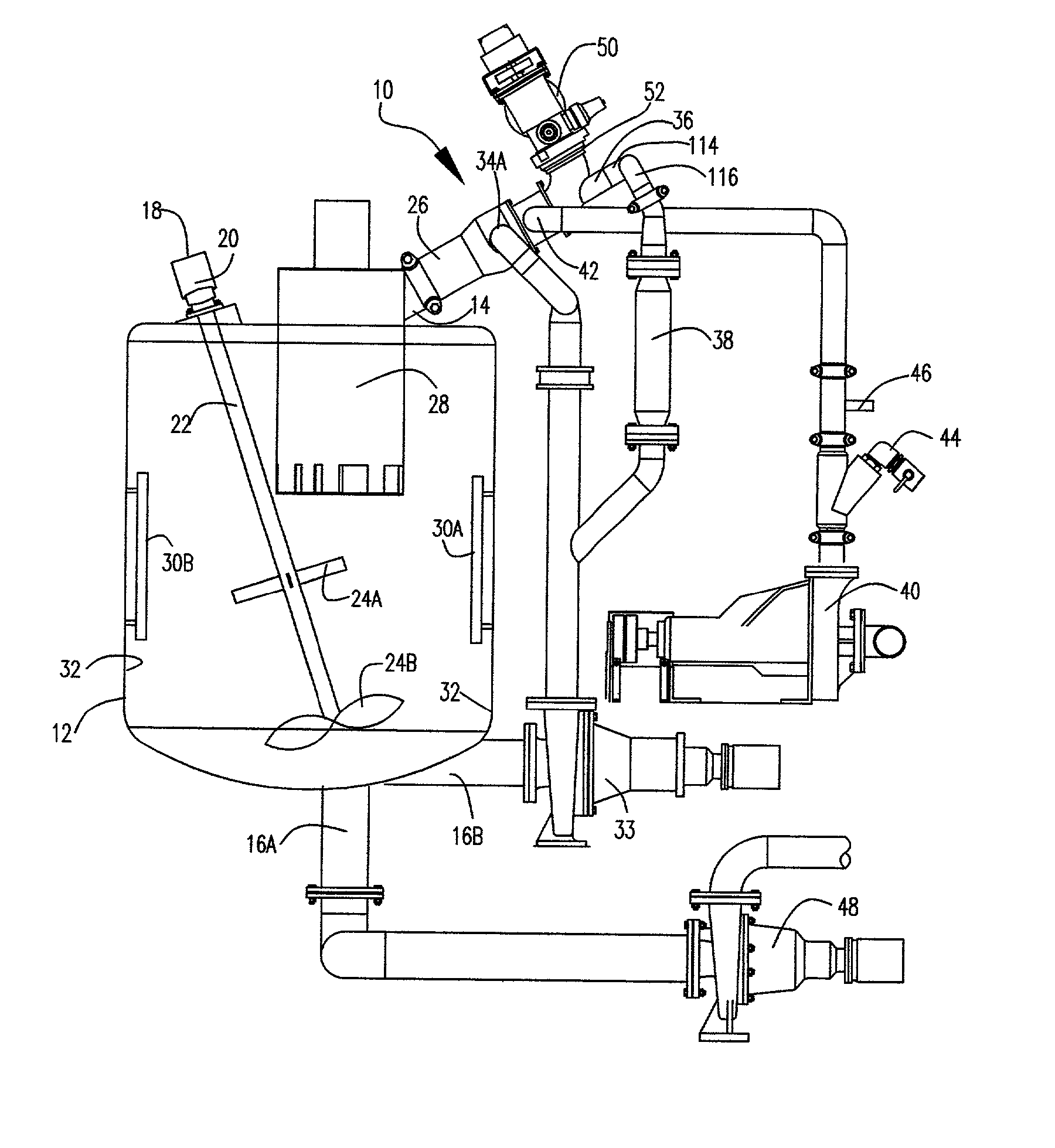

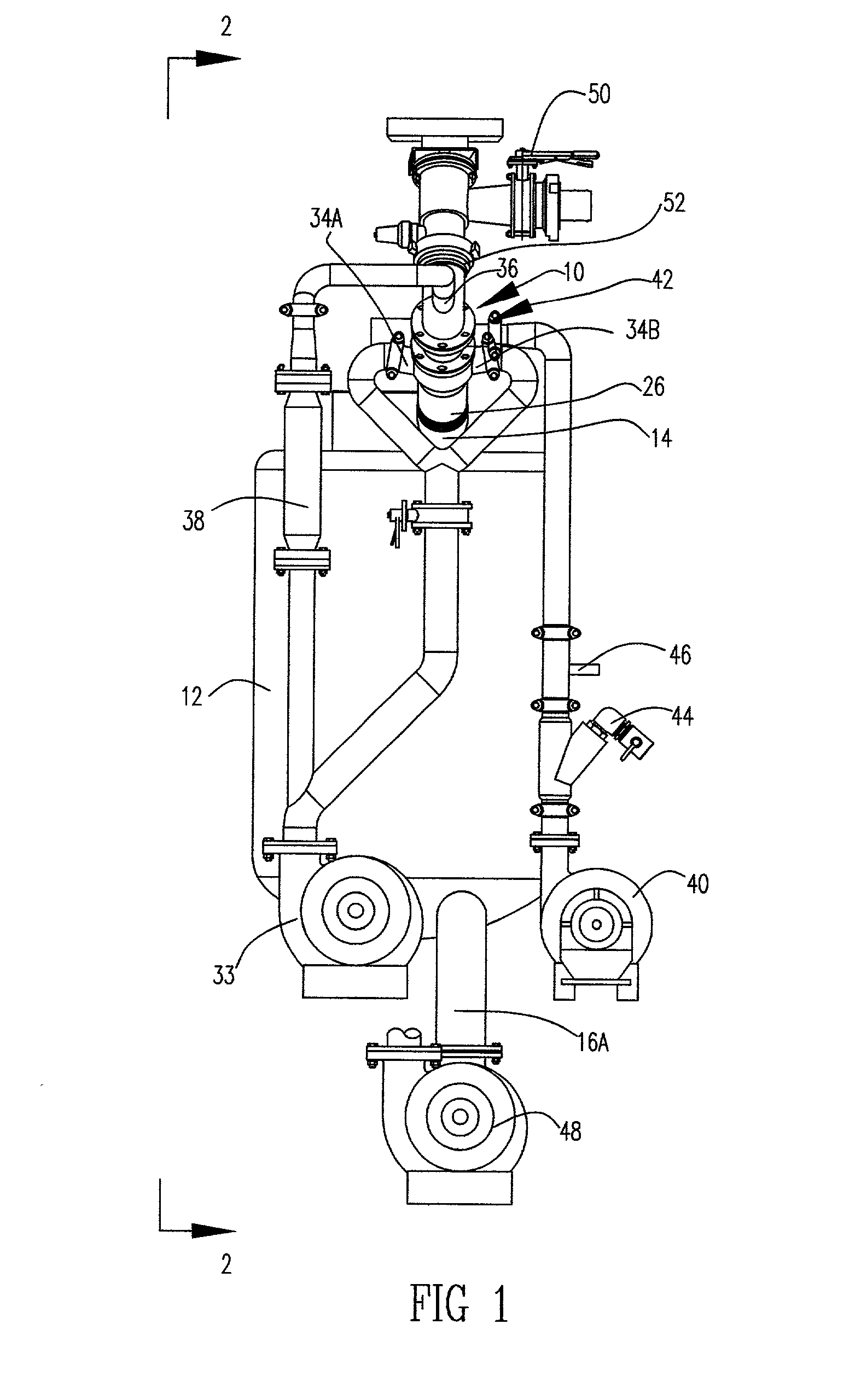

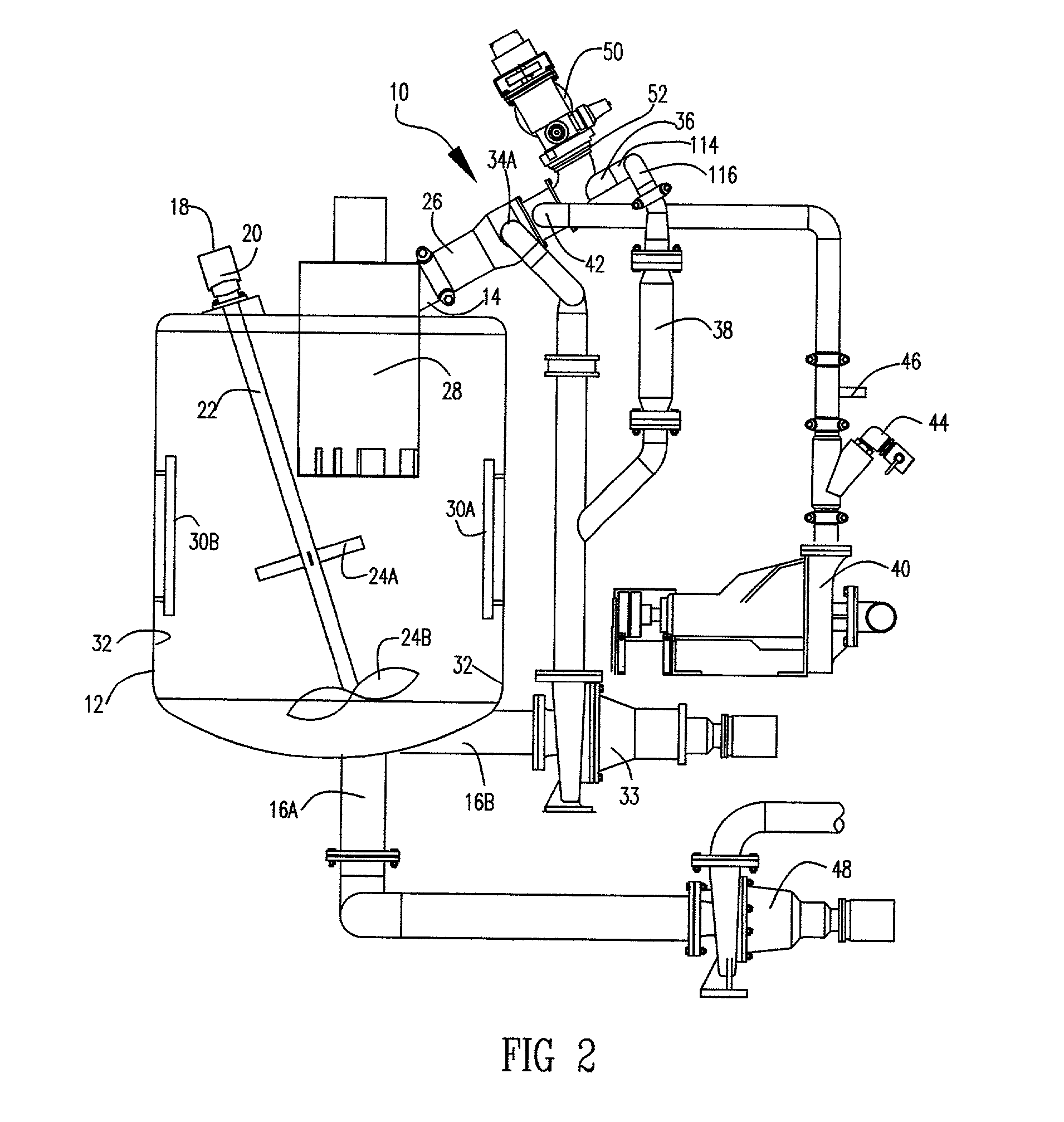

Cement mixing system for oil well cementing

InactiveUS6749330B2Improve flow coefficientReduction factorFlow mixersMixing operation control apparatusWell cementingMixed systems

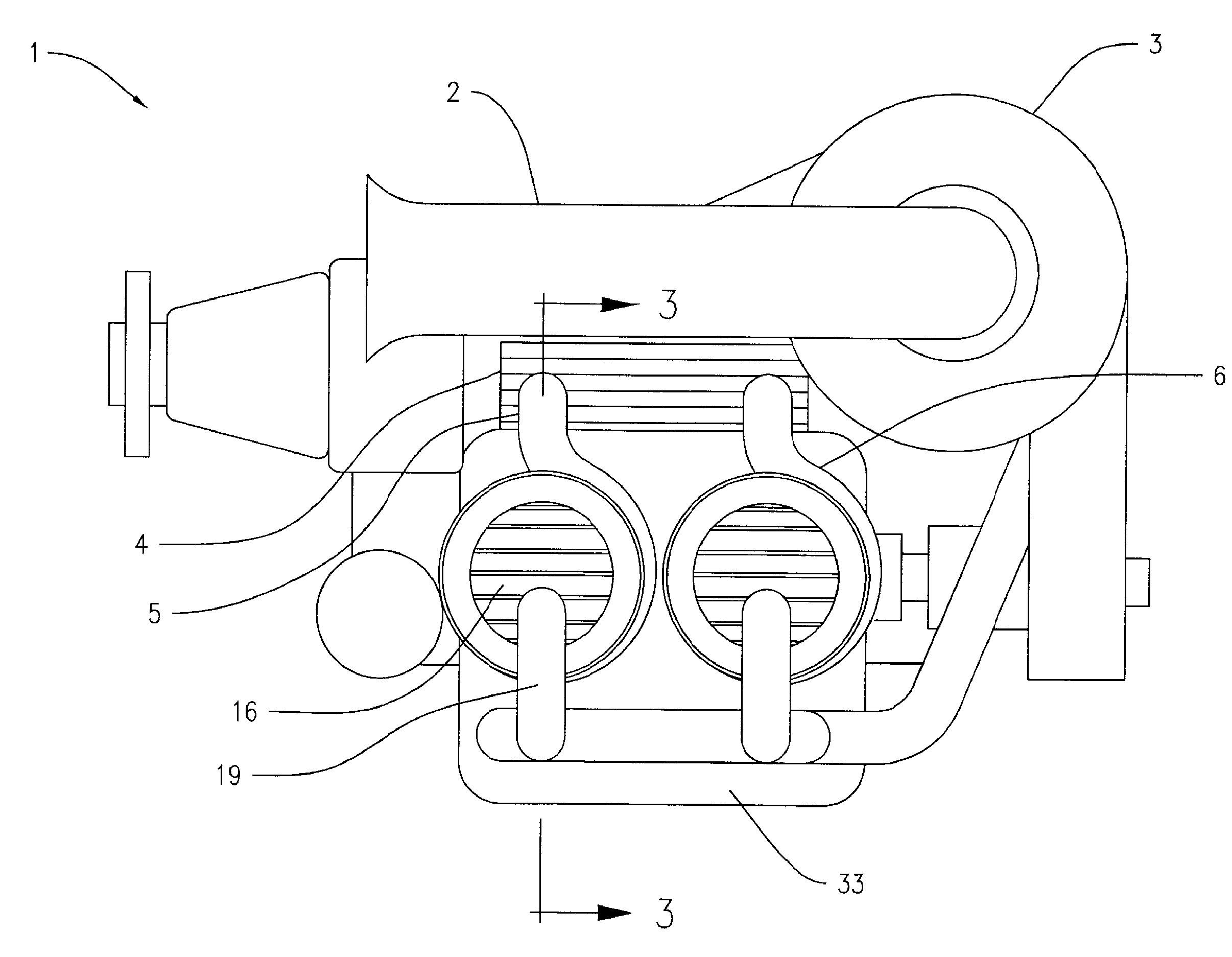

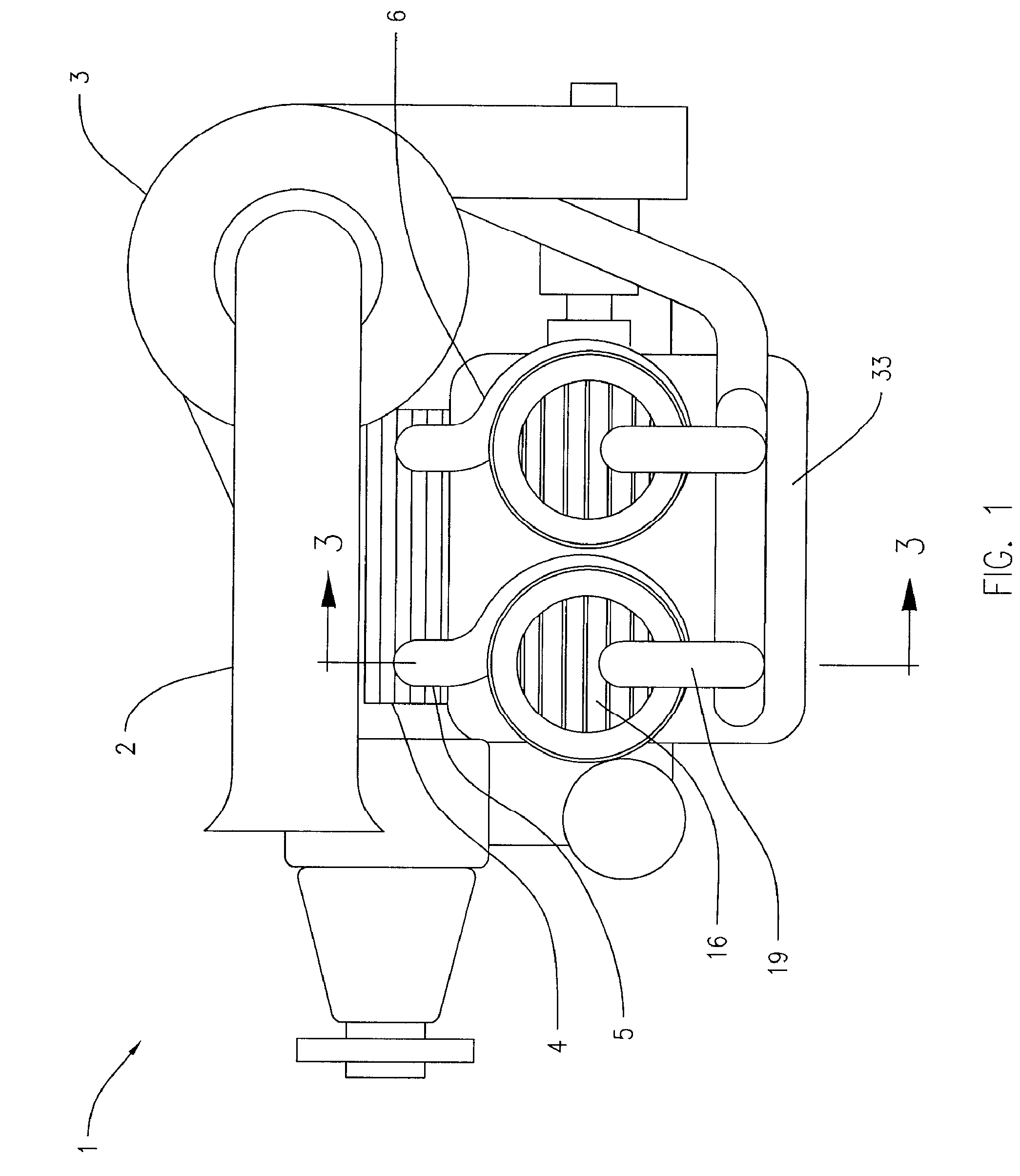

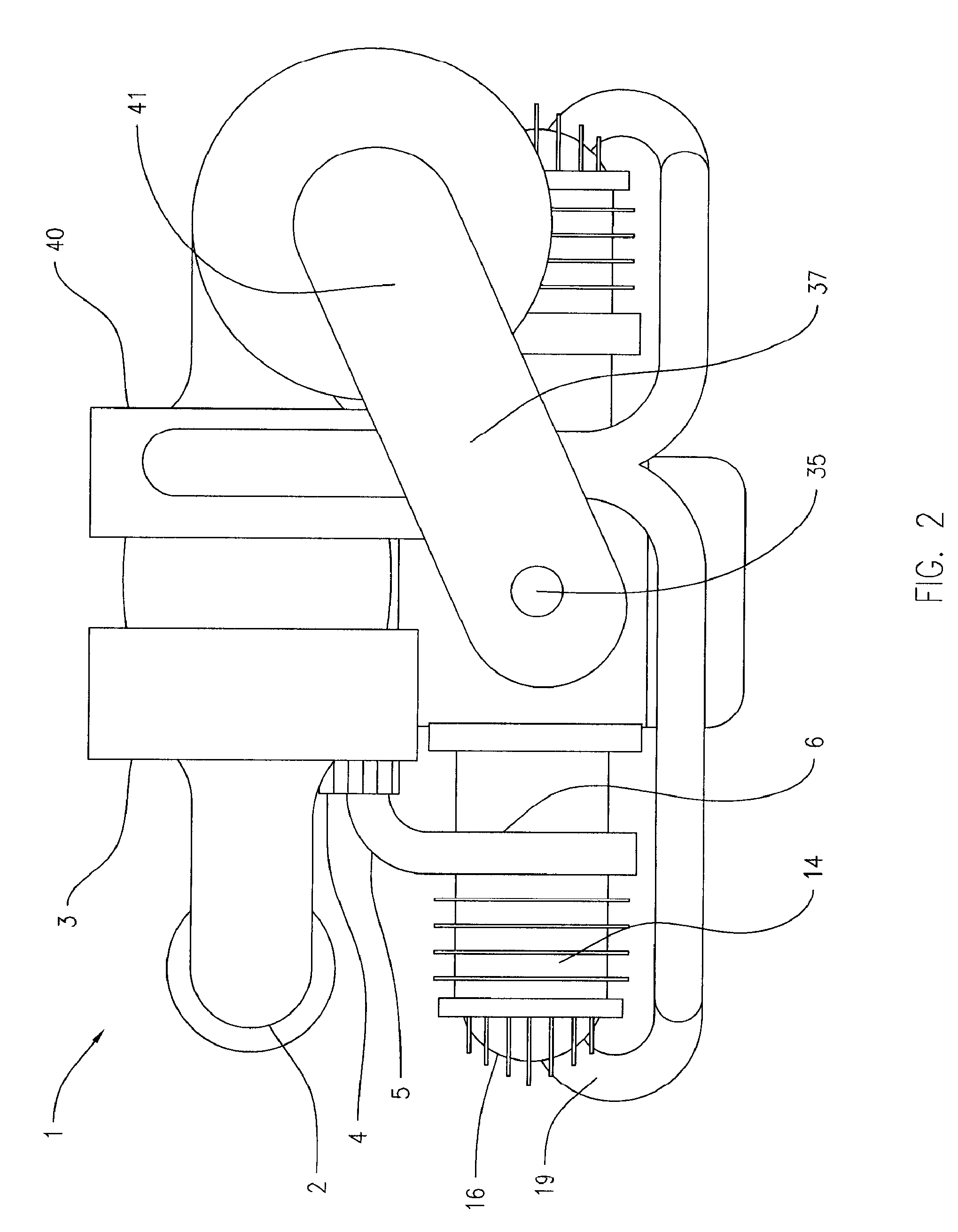

A powder mixing system and mixer for mixing cement used in cementing oil wells or other similar dry powder mixtures. The mixer is provided with a central recirculation jet and with annularly located alternating recirculation and mix water jets that discharge into the mixing chamber of the mixer in an overlapping fashion to effectively wet dry cement introduced into the mixing chamber. The mix water jets are formed from a set of slots provided both in a rotatable element and from another set of slots provided in a stationary portion so that when the rotatable element rotates, the size of mix water jets is adjusted. Two inlet elbows attach to the inlet of the central recirculation jet to cause the flow from the jet to rotate in a diverging pattern.

Owner:SERVA CORP

Cement mixing system for oil well cementing

InactiveUS20030081493A1Improve flow coefficientReduction factorFlow mixersMixing operation control apparatusWell cementingMixed systems

A powder mixing system and mixer for mixing cement used in cementing oil wells or other similar dry powder mixtures. The mixer is provided with a central recirculation jet and with annularly located alternating recirculation and mix water jets that discharge into the mixing chamber of the mixer in an overlapping fashion to effectively wet dry cement introduced into the mixing chamber. The mix water jets are formed from a set of slots provided both in a rotatable element and from another set of slots provided in a stationary portion so that when the rotatable element rotates, the size of mix water jets is adjusted. Two inlet elbows attach to the inlet of the central recirculation jet to cause the flow from the jet to rotate in a diverging pattern.

Owner:SERVA CORP

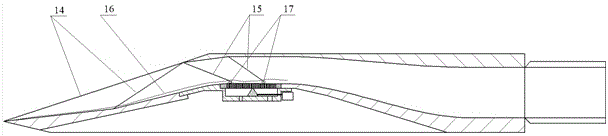

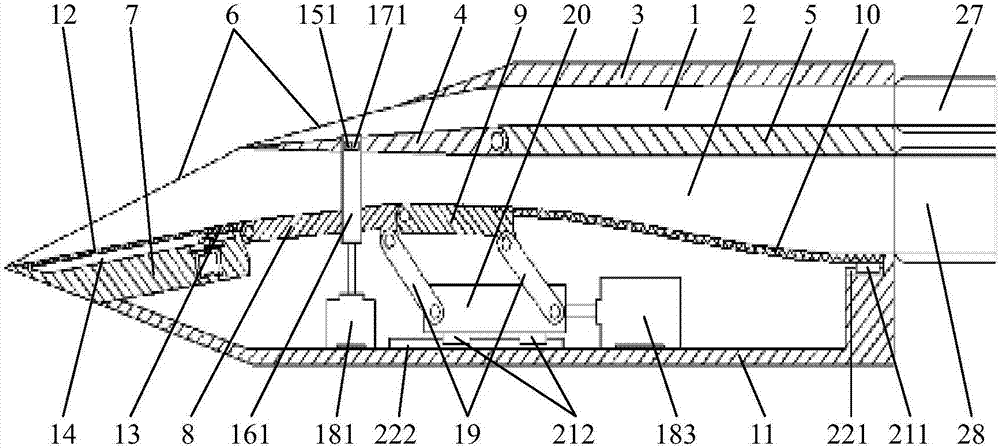

Aircraft supersonic air inlet channel with variable deflation system

ActiveCN103950543ASuppress interference phenomenonBroaden the scope of the work envelopePower plant air intake arrangementsShock waveInlet channel

The invention provides an aircraft supersonic air inlet channel with a variable deflation system. The aircraft supersonic air inlet channel with the variable deflation system comprises a supersonic front body compression surface, an air inlet channel lip cover, an air inlet channel side plate, an inner plate which extends inwards from the supersonic front body compression surface; a deflation chamber, a multi-seam or porous cover plate, a deflation chamber partition plate and flow limiting openings are arranged in the inner plate, wherein the multi-seam or porous cover plate covers the deflation chamber; the deflation chamber partition plate is positioned in the deflation chamber; the flow limiting openings are formed in the lower surface of the deflation chamber; the deflation chamber is partitioned into independent sub-chambers by the deflation chamber partition plate. The size of each sub-chamber, the number of the seams / pores of the multi-seam or porous cover plate corresponding to each sub-chamber and the opening and the closing of the flow limiting openings are adjusted by moving the deflation partition chamber according to the working Mach number and the attitude angle change of the supersonic air inlet channel, so that the deflation characteristics interfered by a lip cover shock wave / boundary layer are adjusted; therefore a good boundary layer control effect can be achieved in a wider work envelope range; the air emission amount is saved; a deflation flow channel in a certain area can even be closed when necessary.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

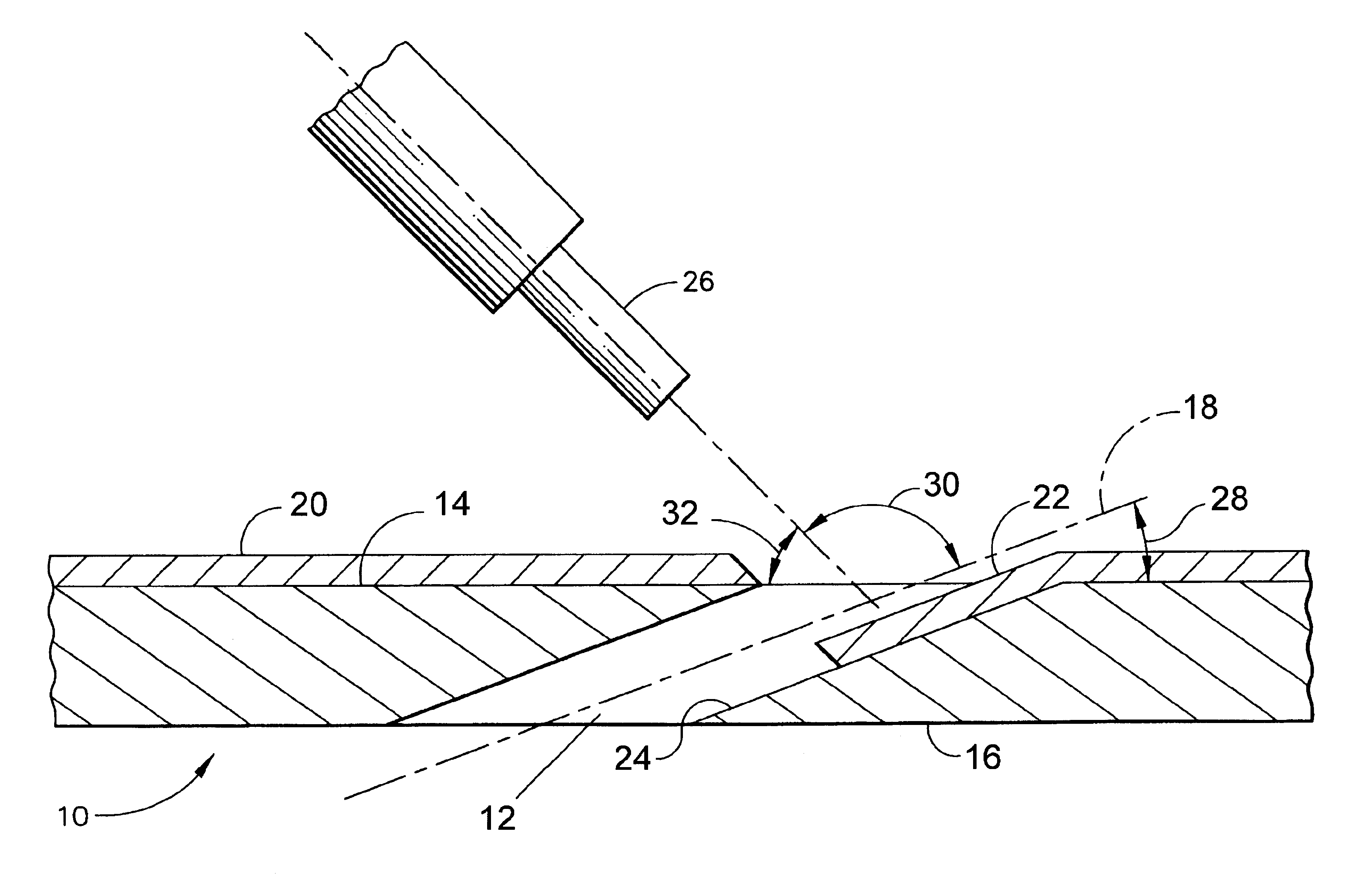

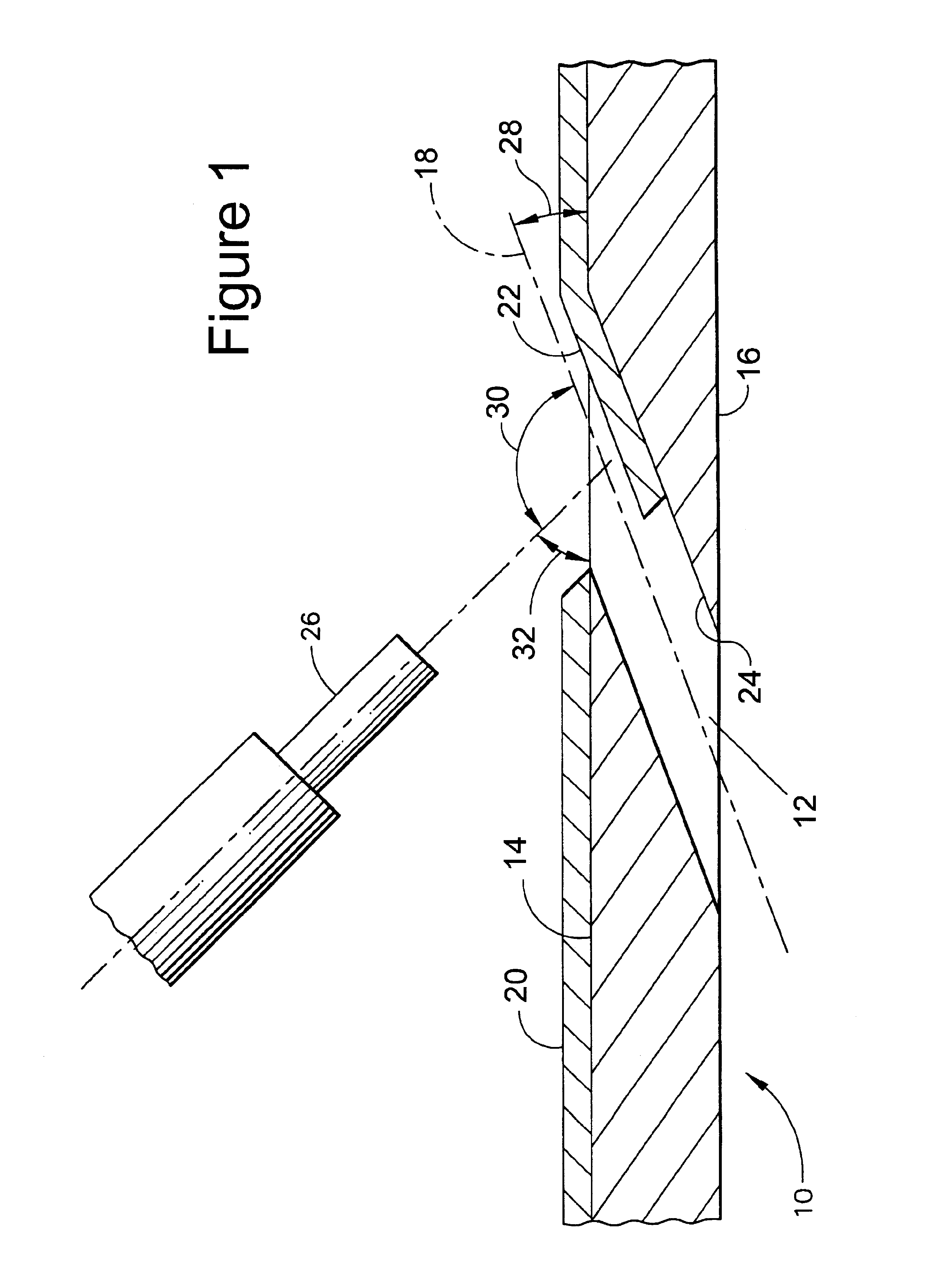

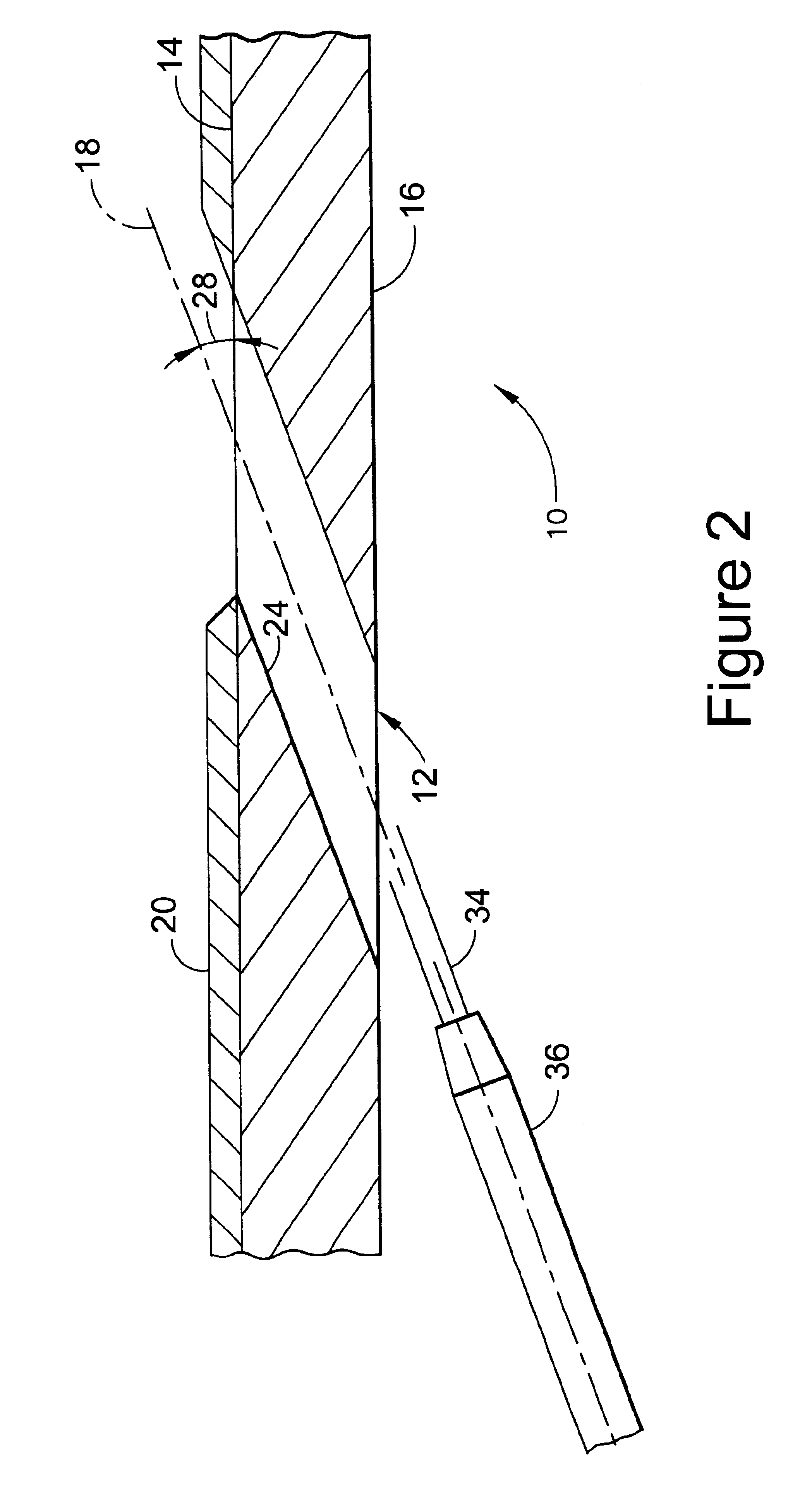

Coated component with through-hole having improved surface finish

InactiveUS6908657B2Increase discharge coefficientImprove surface characteristicMolten spray coatingEngine fuctionsGas turbinesCoated surface

A process of removing deposits from through-holes in a component, such as metallic bond coat and ceramic materials from cooling holes in an air-cooled gas turbine engine. The process is particularly effective in removing a TBC material deposited in a cooling hole of a component as a result of depositing a coating of the TBC material on a surface of the component, in which the deposit is removed from the cooling hole without damaging the cooling hole or the TBC coating surrounding the cooling hole on the coated surface of the component. A preferred feature is that the cooling hole, including the entrance to the hole at a surface of the component opposite the coated surface and the coating surrounding the exit of the hole at the coated surface, exhibits improved surface characteristics that increase the discharge coefficient of the cooling hole, as evidenced by an increase in the effective area of the cooling hole.

Owner:GENERAL ELECTRIC CO

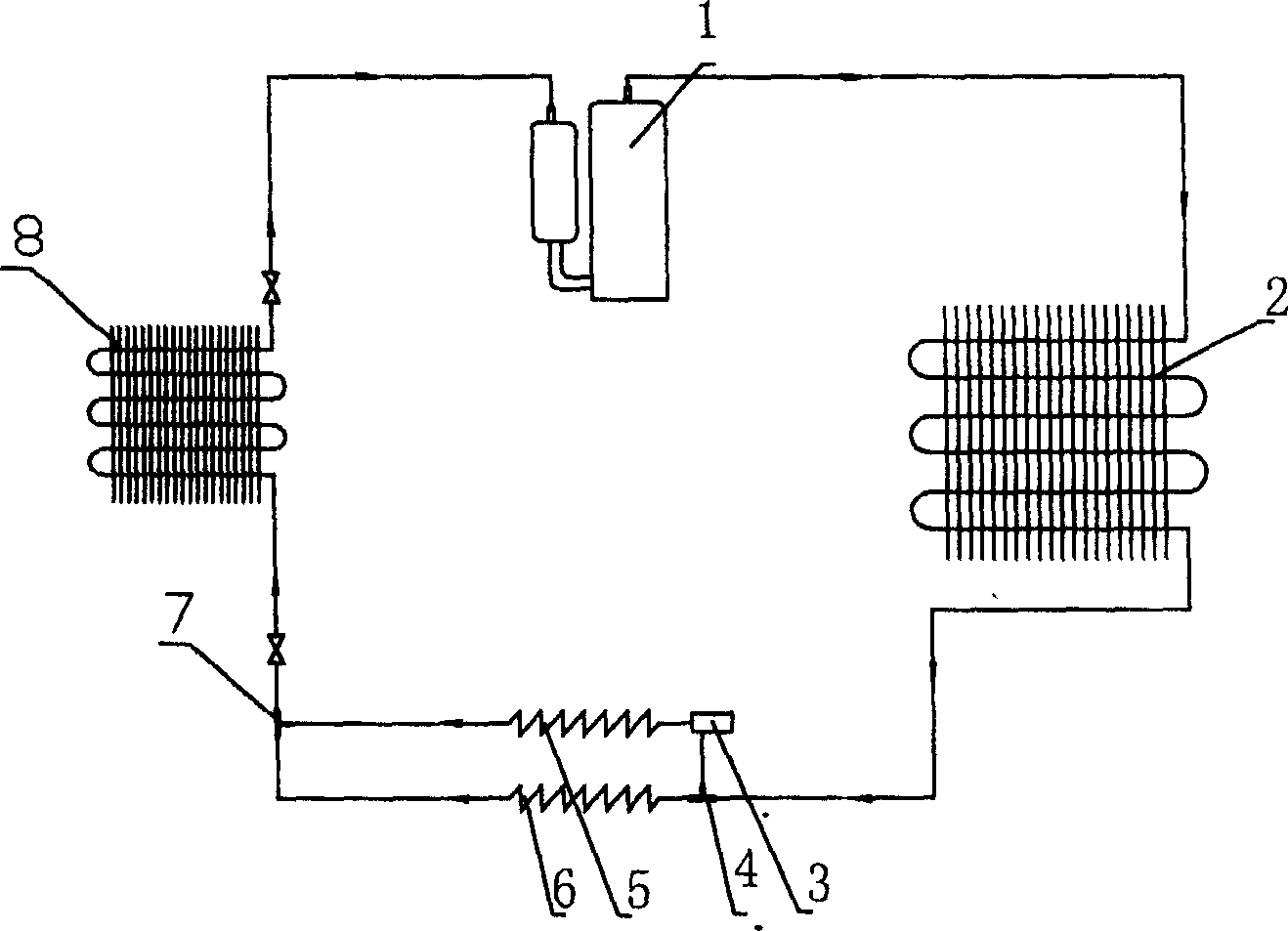

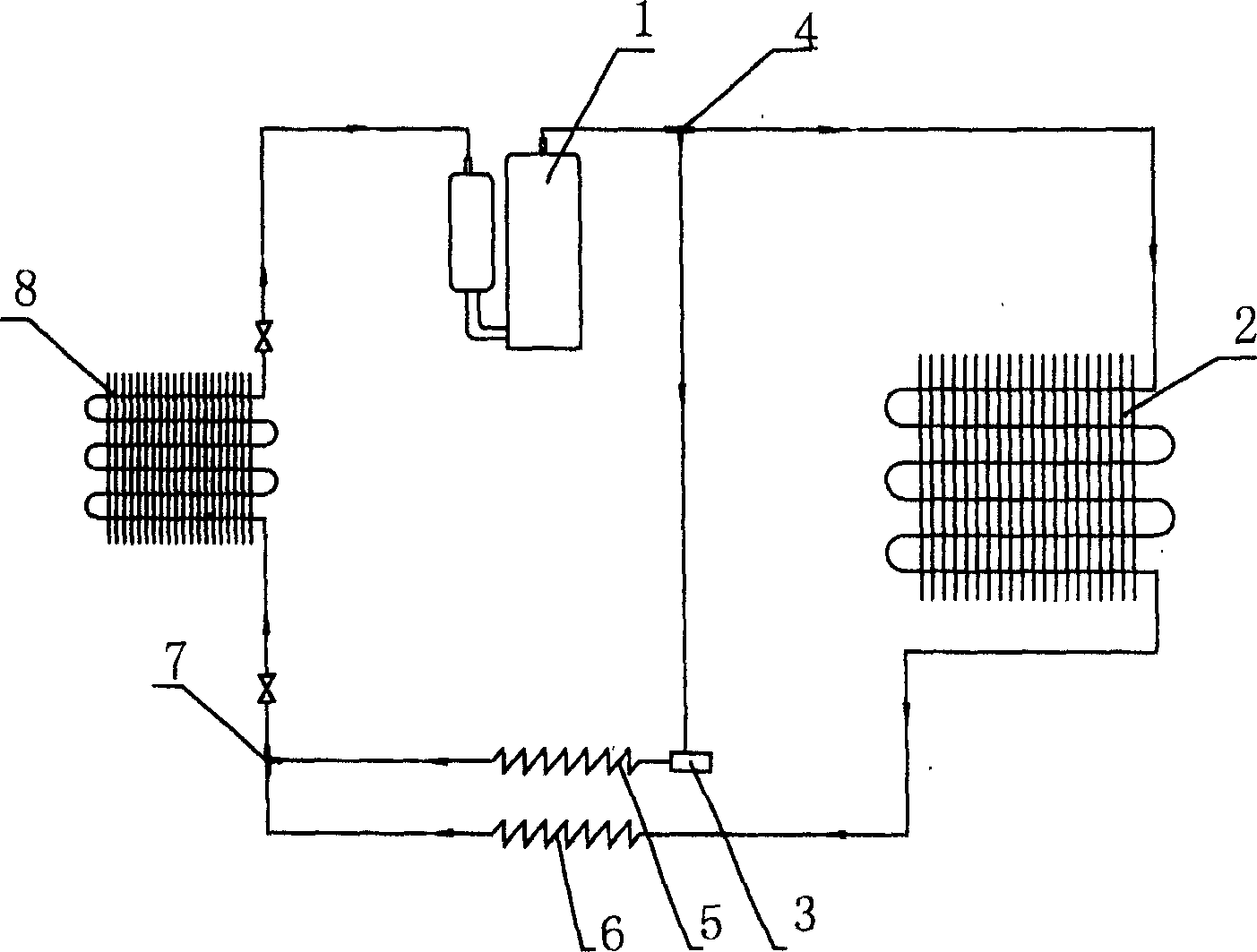

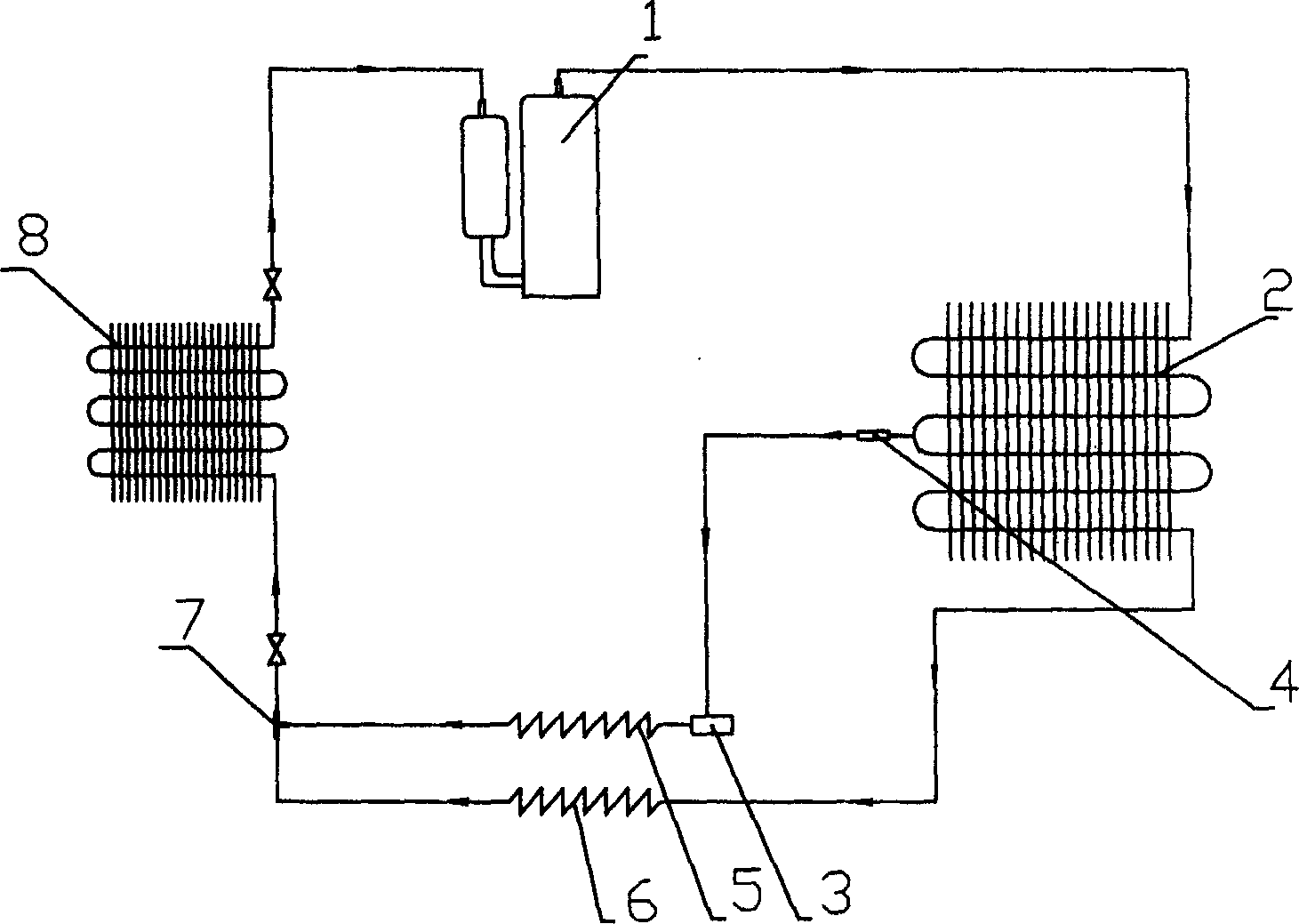

High temperature self-adaption separated air conditioners

InactiveCN1645016AImprove flow coefficientHigh trafficMechanical apparatusSpace heating and ventilation safety systemsDecreased pressureHigh pressure

A high temperature self-adapting air conditioner comprises a refrigerating circle which is composed by a compressor, a condenser, main capillary, an evaporator. The refrigerating circle is parallel connected by a subsidiary throttle sidecut which is composed by a filter, an unloading valve and subsidiary capillary. Due to the subsidiary throttle sidecut, upon the side condenser's pressure exceeds the safety limit, the unloading valve opens and the subsidiary sidecut got through; then the flux index of the capillary will be increased, refrigerant flux will be increased; then lower down the pressure of the condenser; then the compressor will be protected for a continuous running.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

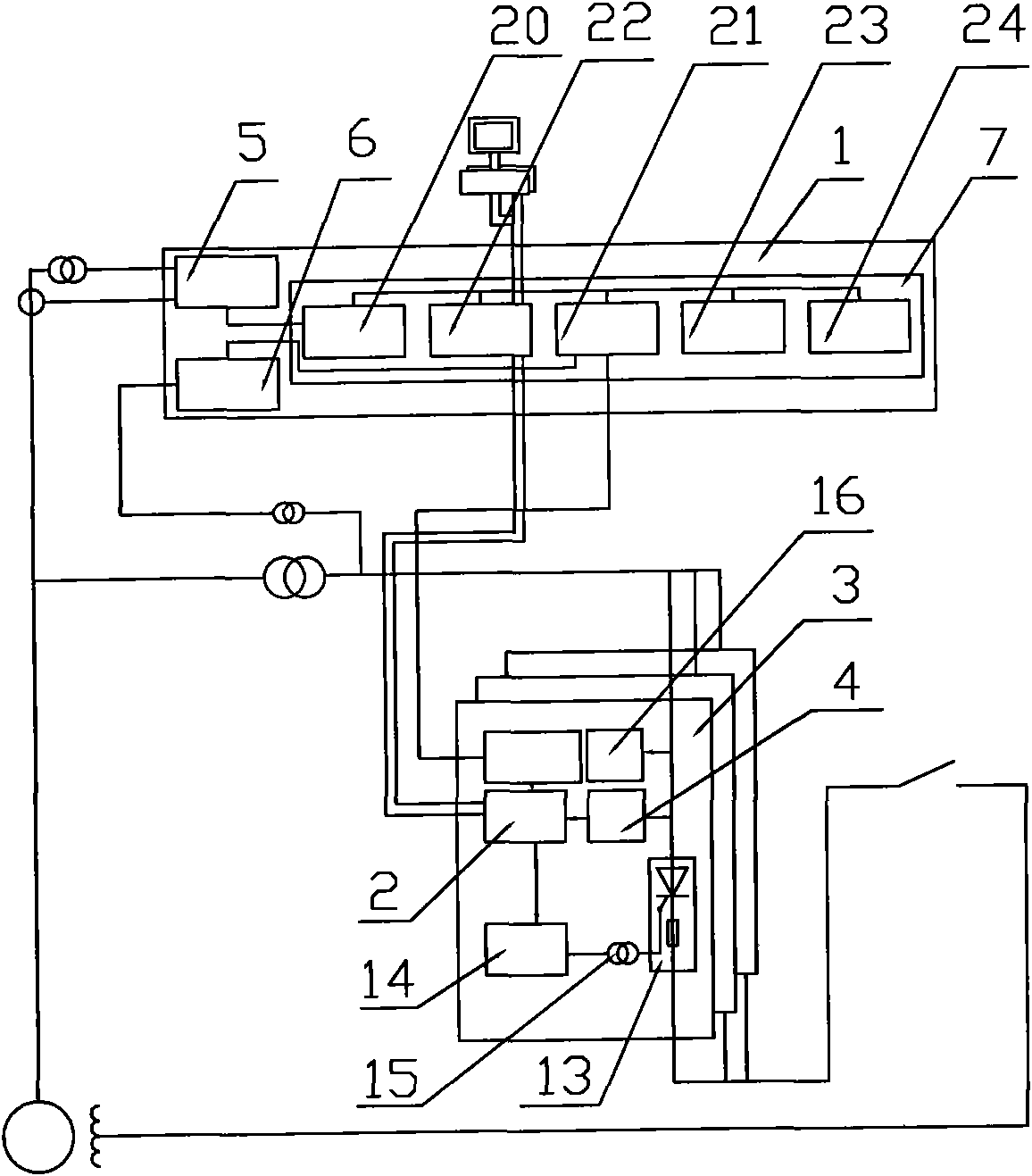

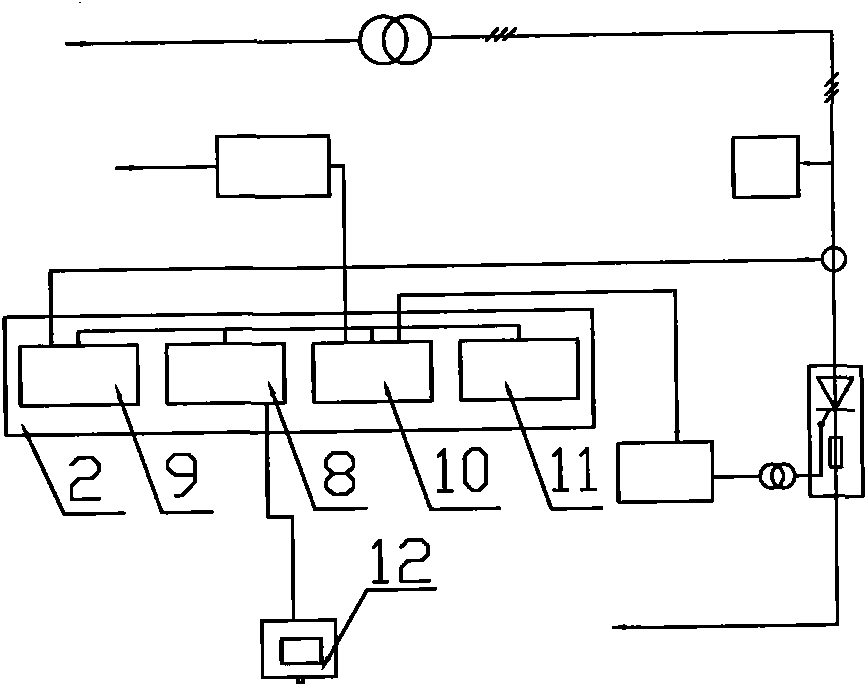

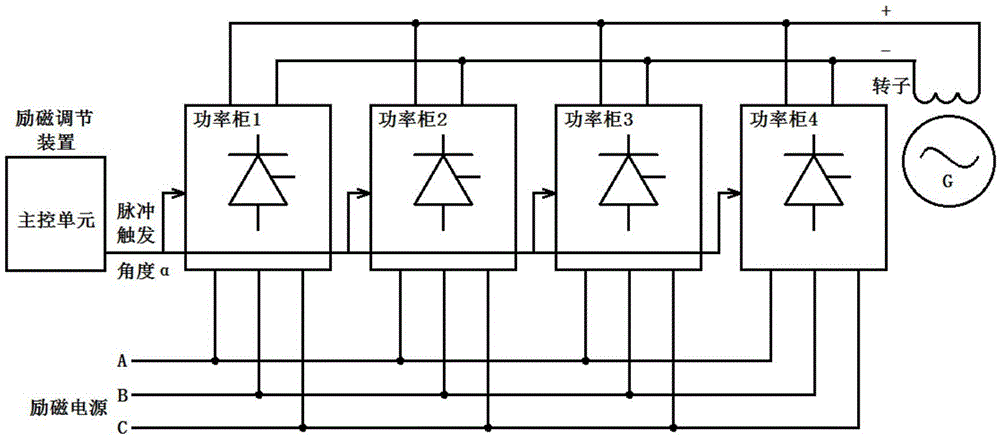

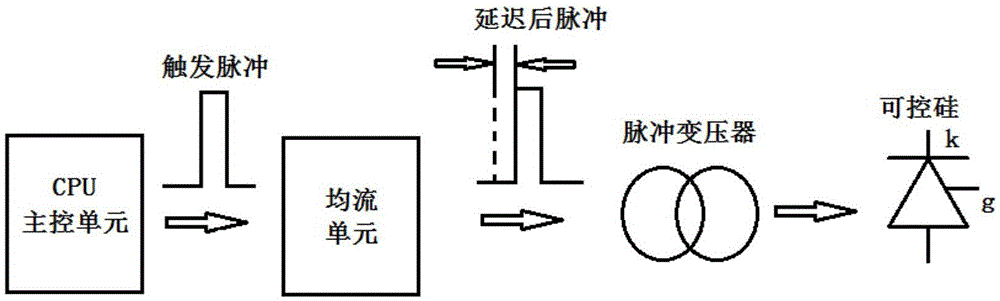

Thyristor rectifier bridge parallel operation full digital current homogenizing control device

ActiveCN101795084AHigh control precisionImprove real-time performanceAc-dc conversionTerminal voltageAnode voltage

The invention discloses a thyristor rectifier bridge parallel operation full digital current homogenizing control device, which comprises a regulator, a rectifier cabinet controller, thyristor rectifier bridges and a detection component. The regulator is a master controller; the rectifier cabinet controller is a slave controller; a terminal signal processing module regulates terminal voltage and current signals of a generator, so that the terminal voltage and current signals are suitable to be output to an analog-to-digital conversion module of a regulator controller; and a synchronization signal processing module regulates the anode voltage of the rectifier cabinet thyristor rectifier bridges, so the anode voltage is suitable to be output to a pulse formation module of the regulator controller to serve as a synchronization signal of the anode voltage of the thyristor rectifier bridges. Due to the adoption of digital closed loop control, full digital intelligent current homogenization for a plurality of parallel operation thyristor rectifier bridges under full-motion environment is realized by real-time sampling and control.

Owner:DONGFANG ELECTRIC MACHINERY +1

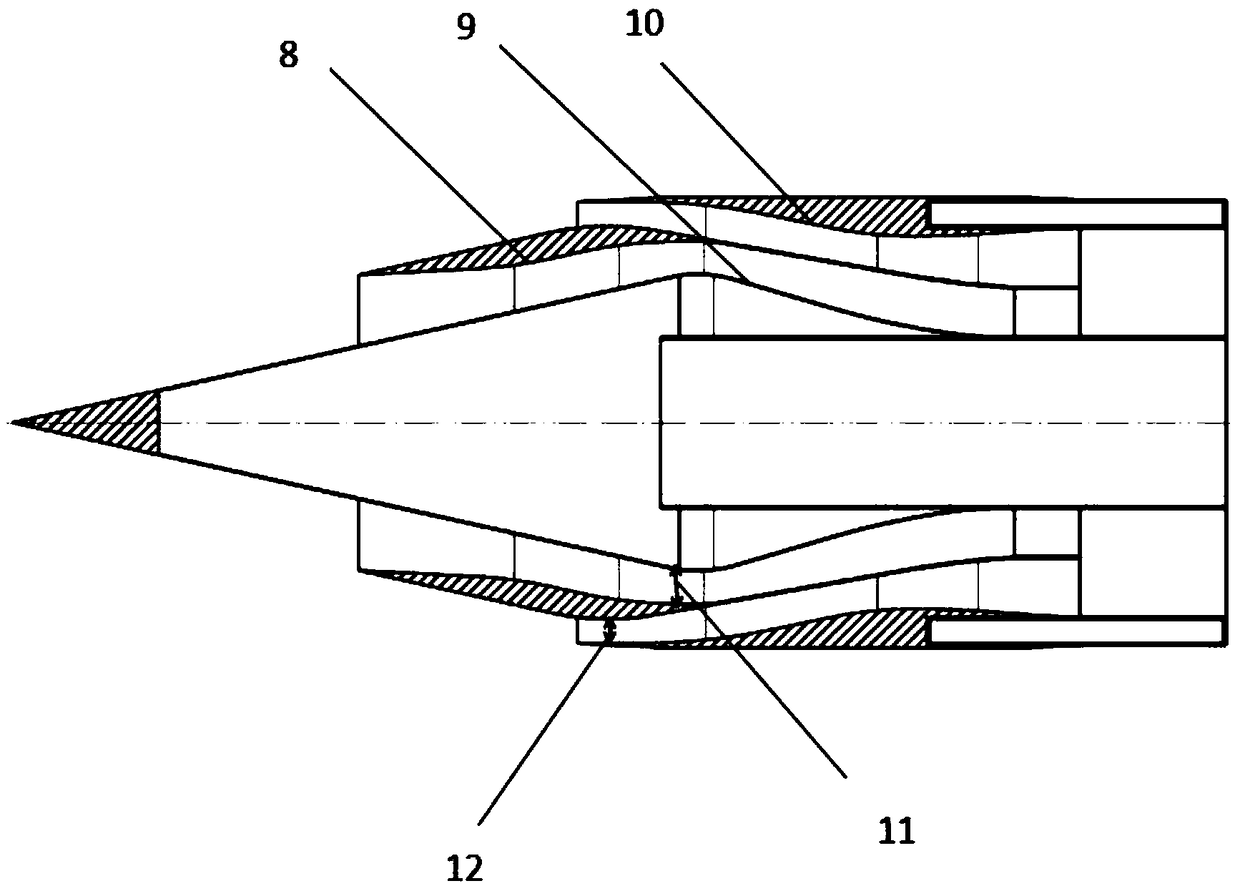

Pneumatic type/mechanical type combined adjustment mach number 0-7 stage combined engine air inlet

ActiveCN107448296AGuaranteed low Mach number starting performanceGuaranteed high Mach number compression performanceGas turbine plantsJet propulsion plantsShock waveWork performance

The invention discloses a pneumatic type / mechanical type combined adjustment mach number 0-7 stage combined engine air inlet. The pneumatic type / mechanical type combined adjustment mach number 0-7 stage combined engine air inlet is mainly composed of a high-speed channel, a low-speed channel, a mechanical type variable geometry assembly and a pneumatic type shock wave adjusting assembly. Under the low-speed mode, the mechanical type variable geometry assembly is adopted for adjusting the throat area and the internal shrinkage ratio of the air inlet, and the low mach number starting performance and the high mach number compression performance of the air inlet are guaranteed; and under the high-speed mode, the pneumatic type shock wave adjusting assembly is used for adjusting the precursor shock wave position, the precursor shock wave sealing state is kept, and the discharge coefficient and the working performance of the air inlet are obviously improved within the wide mach number scope. According to the pneumatic type / mechanical type combined adjustment scheme, the compression amount and the precursor shock wave position of the air inlet can be continuously adjusted, it is guaranteed that the combined engine air inlet can effectively work within the wide mach number scope, and the good pneumatic performance is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Two-Stroke Uniflow Turbo-Compound Internal Combustion Engine

InactiveUS20110030654A1Improve flow coefficientReduce areaInternal combustion piston enginesExhaust apparatusCombustionCylinder head

A reciprocating two-stroke uniflow internal combustion (IC) cylinder and multiple cylinder engine, the cylinder having a cylinder wall and a cylinder head, the cylinder head having an exhaust port, a fuel injector, and a spark means disposed through the cylinder head, a piston reciprocally mounted in the cylinder for movement alternately through compression and power strokes, and a scroll plenum extending unidirectional around the outside of the cylinder wall and having an inlet and a plurality of swirl ports disposed through the cylinder wall providing fluid communication from the scroll plenum into the cylinder chamber, wherein the plurality of swirl ports enter the cylinder chamber tangentially with respect to the axial centerline of the cylinder, and wherein the plurality of swirl ports are subject to opening and closing in response to movement of said piston.

Owner:TAYLOR PATENT HLDG CO LLC

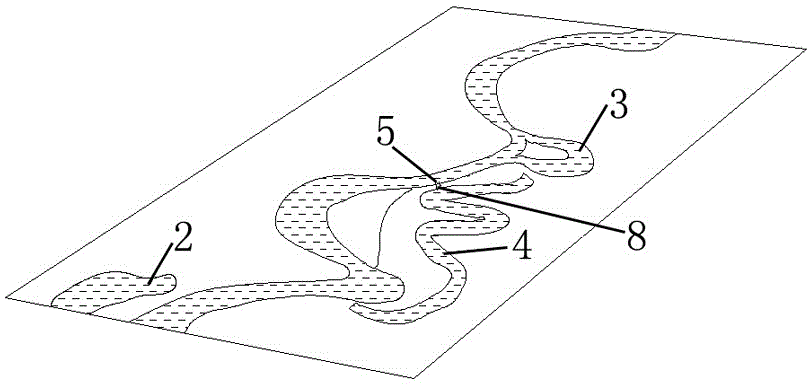

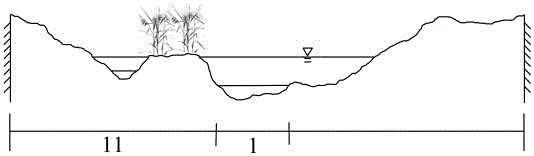

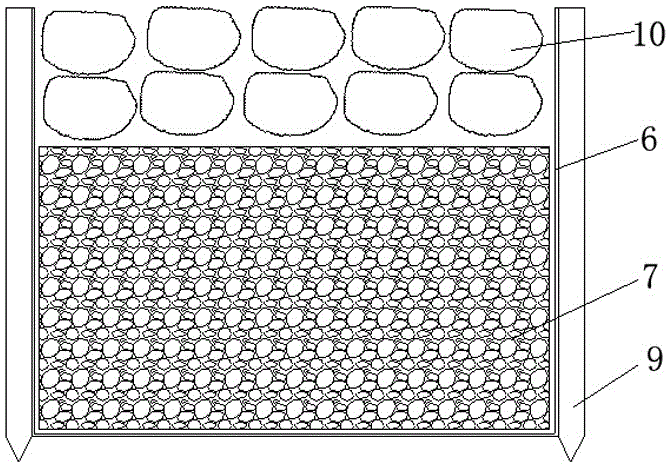

Constructing method for fish shelter under stress of high silt concentration flood

InactiveCN106049347AImprove flow coefficientSmooth flowWater resource protectionBarrages/weirsRiver waterFish habitat

The invention provides a constructing method for a fish shelter under the stress of high silt concentration flood. The constructing method comprises the following steps that a suitable river reach is selected according to the water area fish resource state, a flood plain tidal wetland system is artificially constructed by adopting an ecological engineering measure, and the flood plain wetland hydrologic connectivity is improved so that the stress of the high silt concentration flood on fish can be avoided, specifically, A, the fish which needs protecting and the required habitat condition of the target fish are determined; B, the site of a shelter is selected; and C, the shelter is constructed. According to the fish shelter constructing method under the stress of the high silt concentration flood, a natural river bend on one side of a river bed and a wide river channel of a wetland can serve as construction areas under the condition that flood drainage is not affected; the continuity of the river channel is restored by excavating an overflow weir; the complexity and the hydrologic condition diversity of the river channel are improved; the shelter for sheltering the fish and other aquatic animals from the high silt concentration flood is provided; conservation of the species of the aquatic animals in a river is facilitated; and the contradiction between river water silt regulation and fish habitat protection can be effectively relieved.

Owner:FRESHWATER FISHERIES RES INST OF SHANDONG PROVINCE

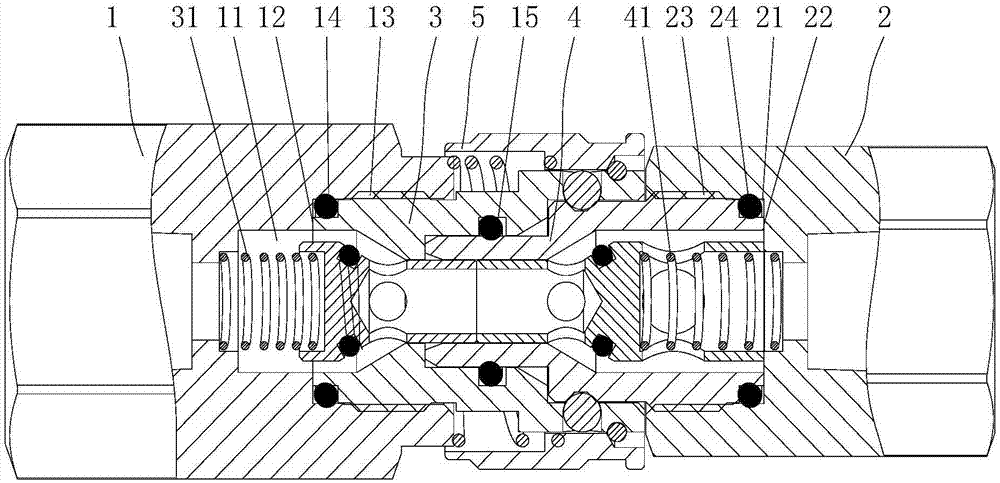

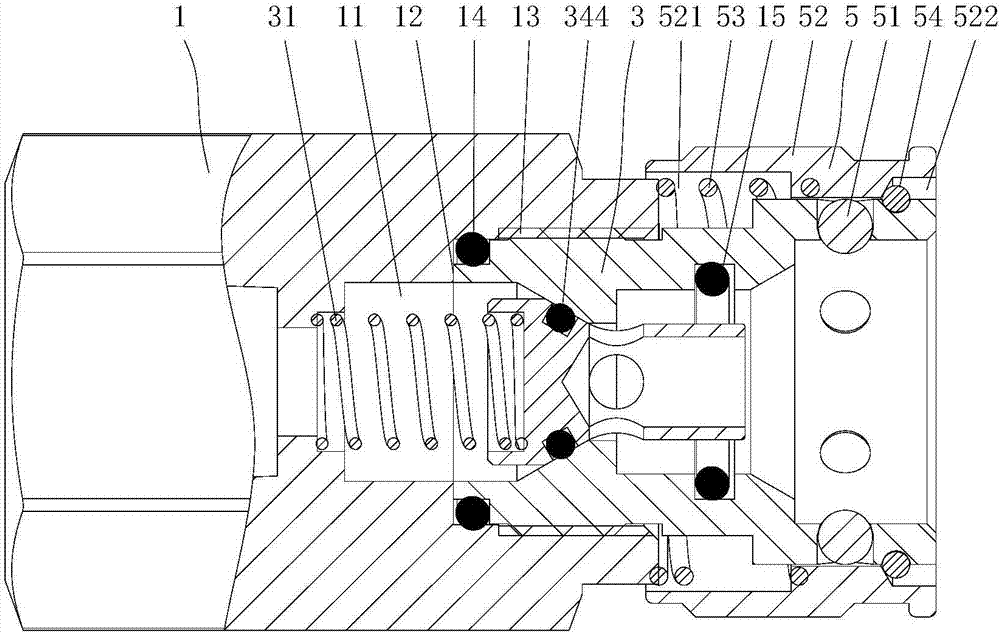

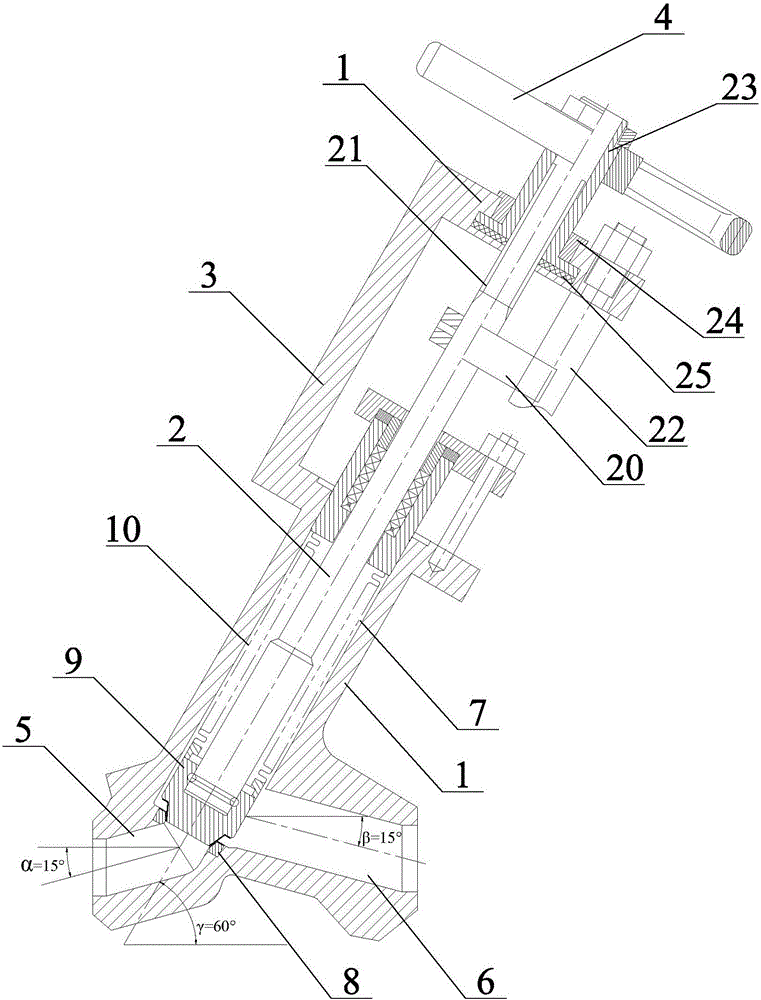

High-pressure pipeline rapid connector

The invention relates to a high-pressure pipeline rapid connector. The rapid connector comprises a first connector body and a second connector body which are provided with butt joint ends. The other ends of the first connector body and the second connector body are separately used for being connected with an upstream high-pressure pipeline and a downstream high-pressure pipeline. The butt joint ends of the first connector body and the second connector body are correspondingly provided with a first one-way valve and a second one-way valve which communicate with each other in an inserted mode. A first spring arranged on the first one-way valve is larger than a second spring arranged on the second one-way valve in elastic force. A fastening device used for controlling connecting on-off of the second one-way valve and the first one-way valve is arranged between the first one-way valve and the second one-way valve. When the first one-way valve and the second one-way valve are connected in an inserted mode, under the elastic force effect of the second spring, the second one-way valve is firstly opened and then pushes the first one-way valve to be opened and to communicate with the second one-way valve. The high-pressure pipeline rapid connector is reasonable in design, compact in structure, good in airtightness, easy and convenient to operate and rapid in connection, the flow area and flow of a flow channel after communication are stable, and a large flow coefficient is achieved.

Owner:FUJIAN WIDE PLUS PRECISION INSTR

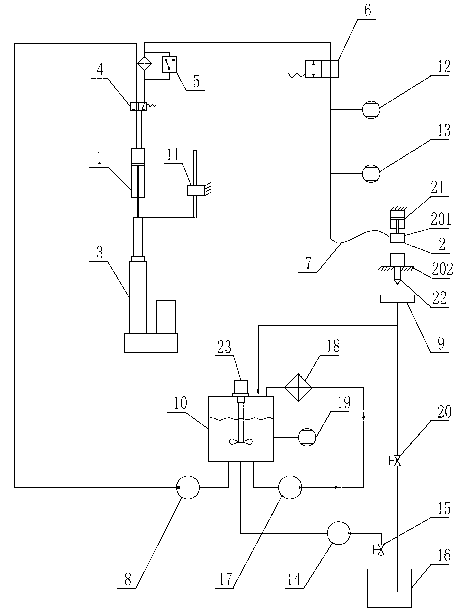

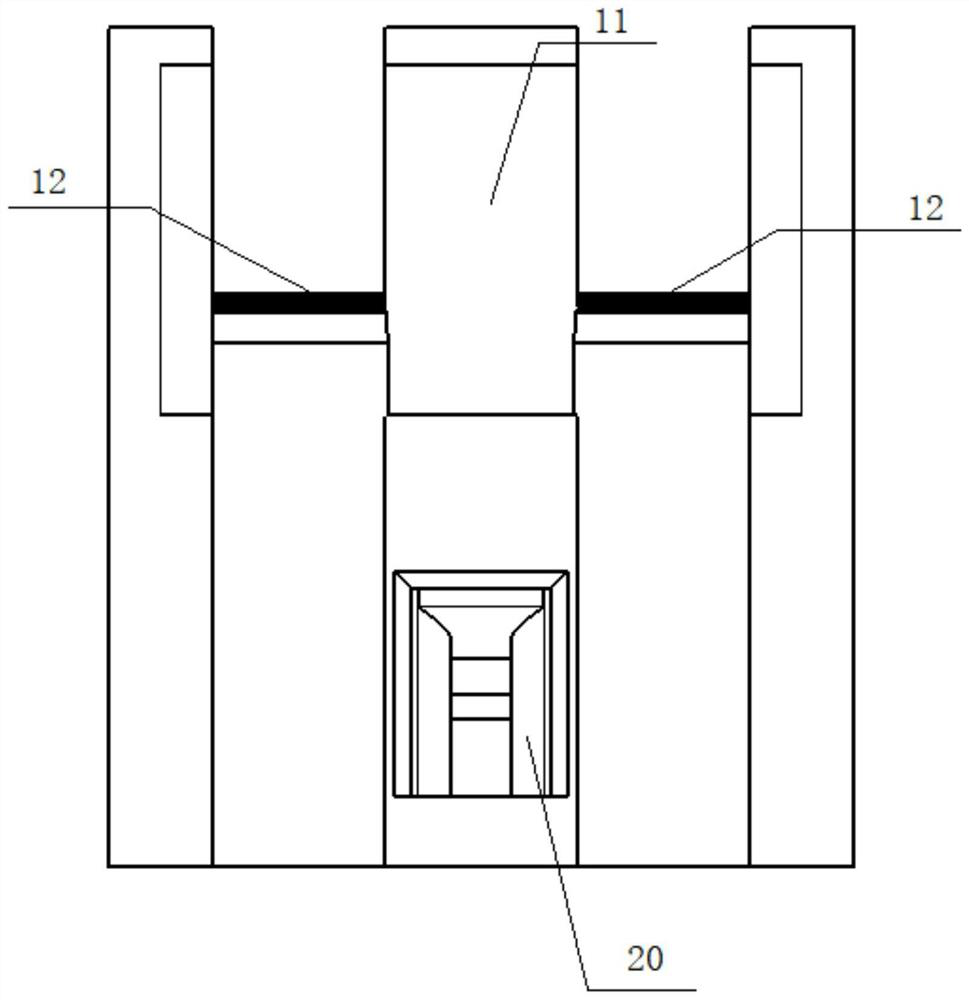

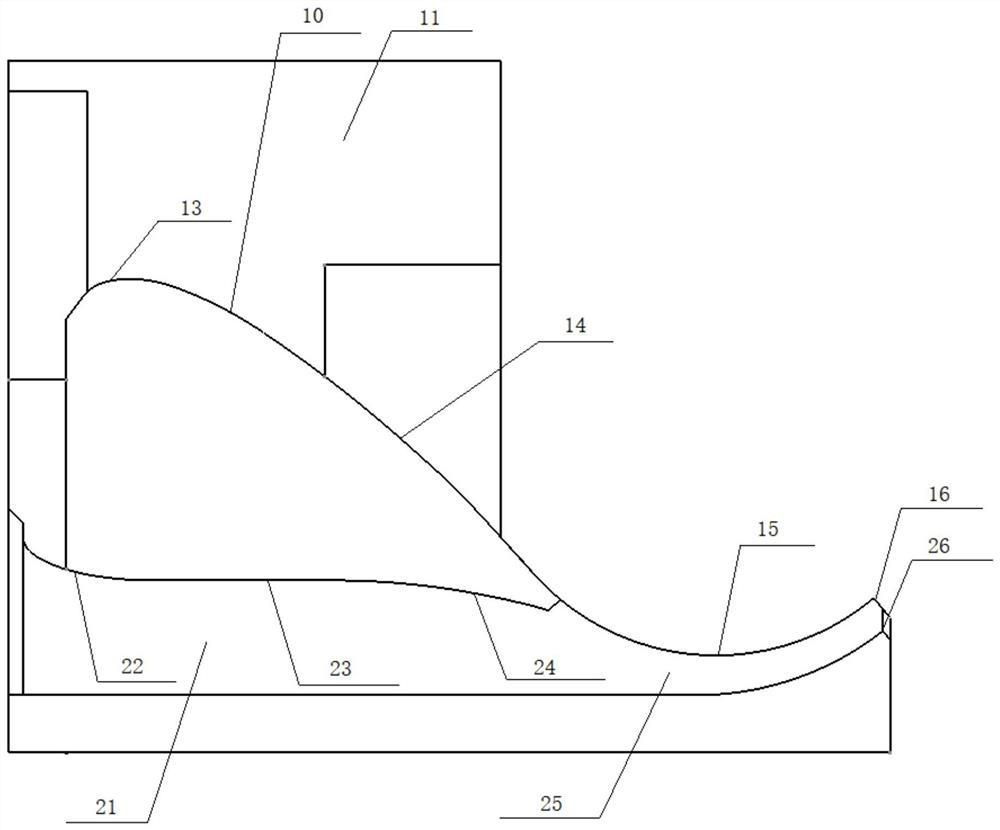

Extruding and grinding device for spray orifice of oil spray nozzle and extruding and grinding method for spray orifice of oil spray nozzle

ActiveCN102990506AImprove flow coefficientEasy maintenanceBurnishing machinesGrinding work supportsTemperature controlSpray nozzle

The invention provides an extruding and grinding device for a spray orifice of an oil spray nozzle and an extruding and grinding method for the spray orifice of the oil spray nozzle, belonging to the technical field of the precision machining of the spray orifice of the oil spray nozzle. The extruding and grinding device for the spray orifice of the oil spray nozzle provided by the invention comprises a grinding material filling pipeline, a grinding material processing pipeline, a grinding material emptying pipeline, a grinding material temperature control pipeline and an emergency emptying pipeline, wherein a detecting device is arranged on the grinding material processing pipeline for detecting the real-time grinding material flow of the spray orifice of the oil spray nozzle. The extruding and grinding method for the spray orifice of the oil spray nozzle provided by the invention mainly comprises the following steps of: grinding-detecting and comparing flow-grinding-detecting and comparing flow. The spray orifice of the oil spray nozzle is machined by means of extruding and grinding by a step-by-step approach method. According to the method, the real-time grinding material flow of the spray orifice is accurately detected and is compared step by step till the flow value reaches a set value, so that the grinding processing can be guaranteed to achieve the technological requirement. According to the invention, the filleted corner of the orifice, which accords with the technological requirement, can be formed, so that the fineness of the wall of the spray orifice can be improved, the flow coefficient of the oil spray nozzle can be improved, and the device is simple in structure and convenient to maintain.

Owner:CHINA FIRST AUTOMOBILE

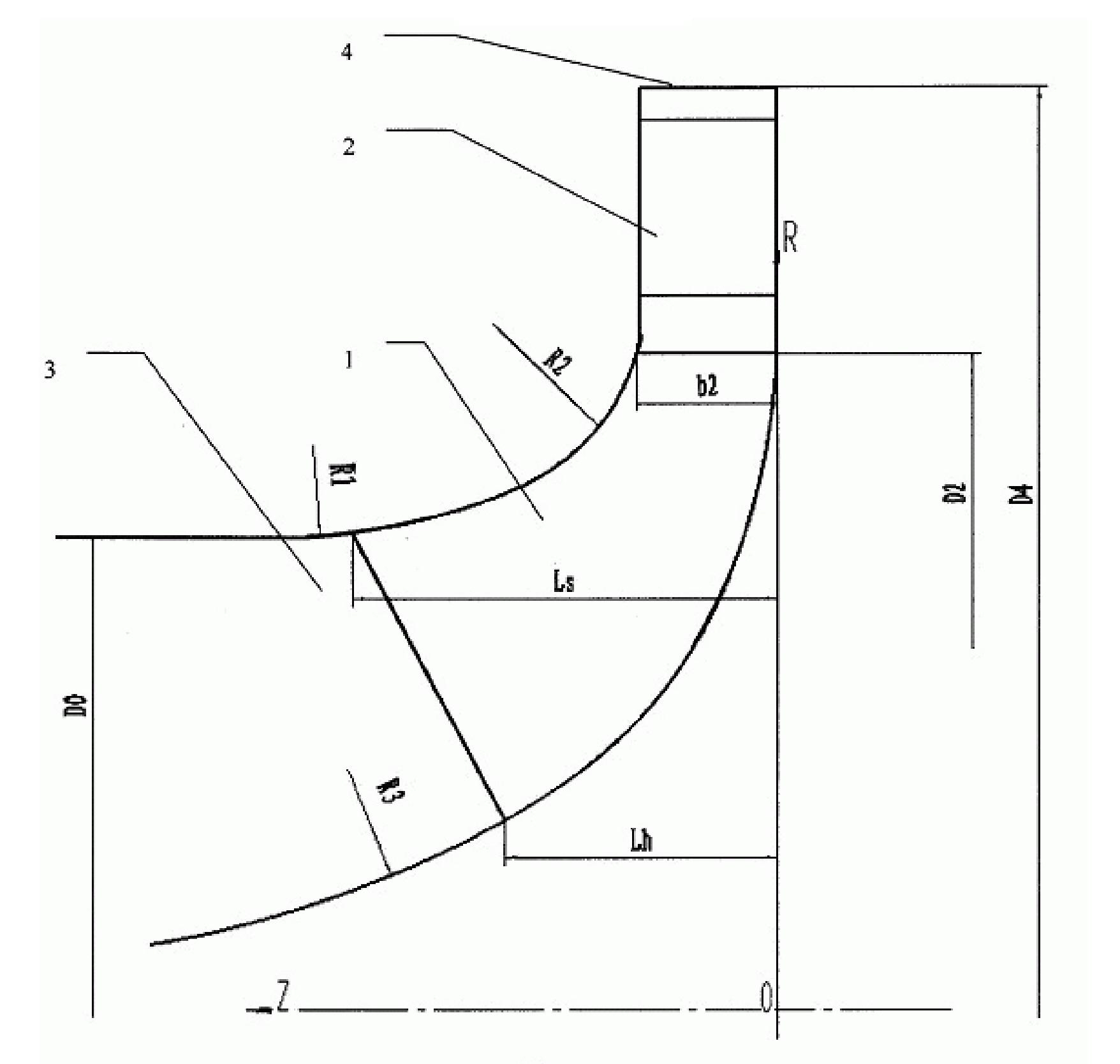

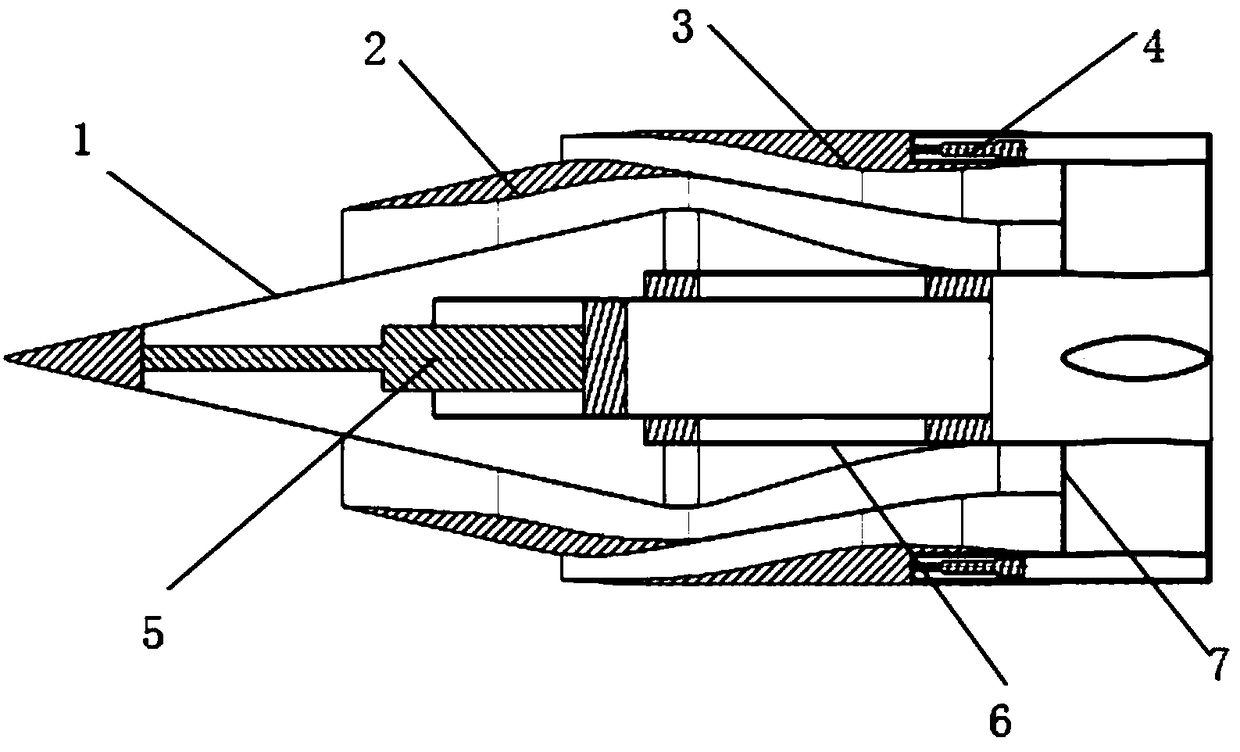

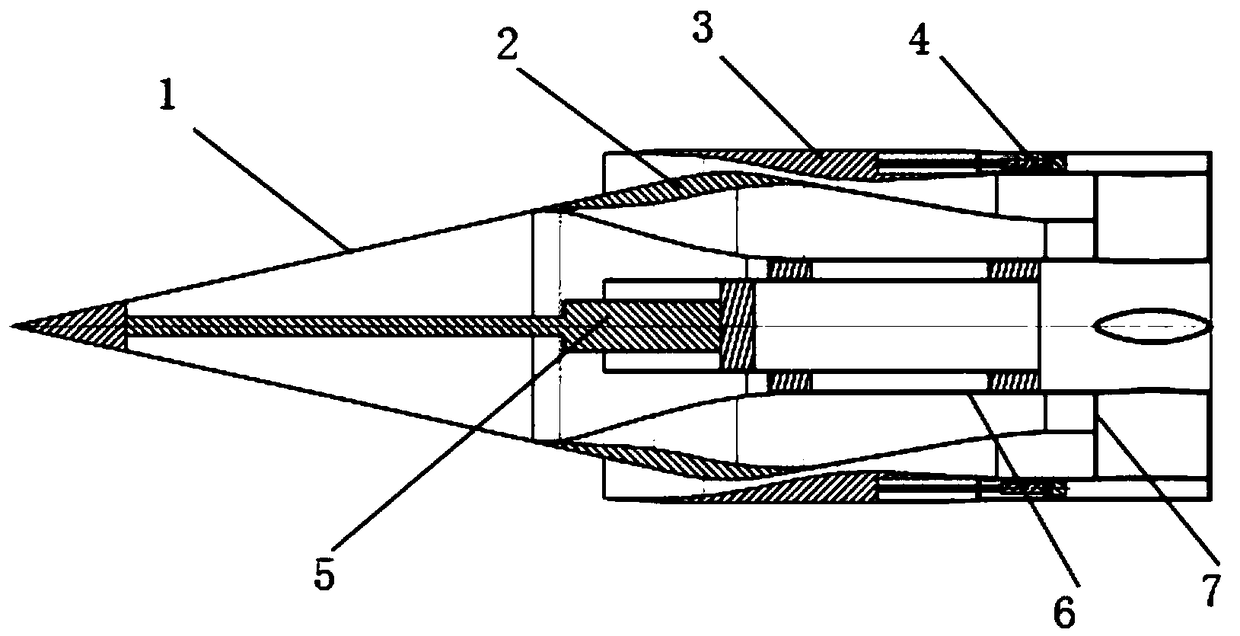

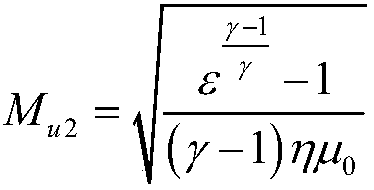

Recycle gas compressor module level and design method thereof

ActiveCN101776093ASmall sizeImprove flow coefficientPump componentsPumpsPolypropyleneCentrifugal compressor

The invention belongs to the centrifugal compressor module level, specifically to a recycle gas compressor module level and a design method thereof, suitable for the modeling design of the recycle gas compressor product for all of polyethylene and polypropylene units as well as the centrifugal compressor product for other units having similar parameters. The module level comprises a semi-open three-dimensional flow impeller and a vane diffuser; the modeling design of the centrifugal compressor performed according to the similar modeling theory can provide the module level for the similar modeling design of the recycle gas compressor for the polyethylene and polypropylene units of different sizes. The parameters of module level are as follows: the machine mach Mu2 is 0.5; the flow coefficient Phi1 is 0.152; the energy head coefficient T is 0.54; and the variable frequency Hpo1 is 0.82-0.84. The application of the large flow coefficient module level enables the recycle gas compressor for the polyethylene and polypropylene units and the centrifugal compressor for other units having similar parameters to avoid adopting a complicated double-sucking structure and to have higher operation efficiency and working condition range.

Owner:SHENYANG BLOWER WORKS GROUP CORP

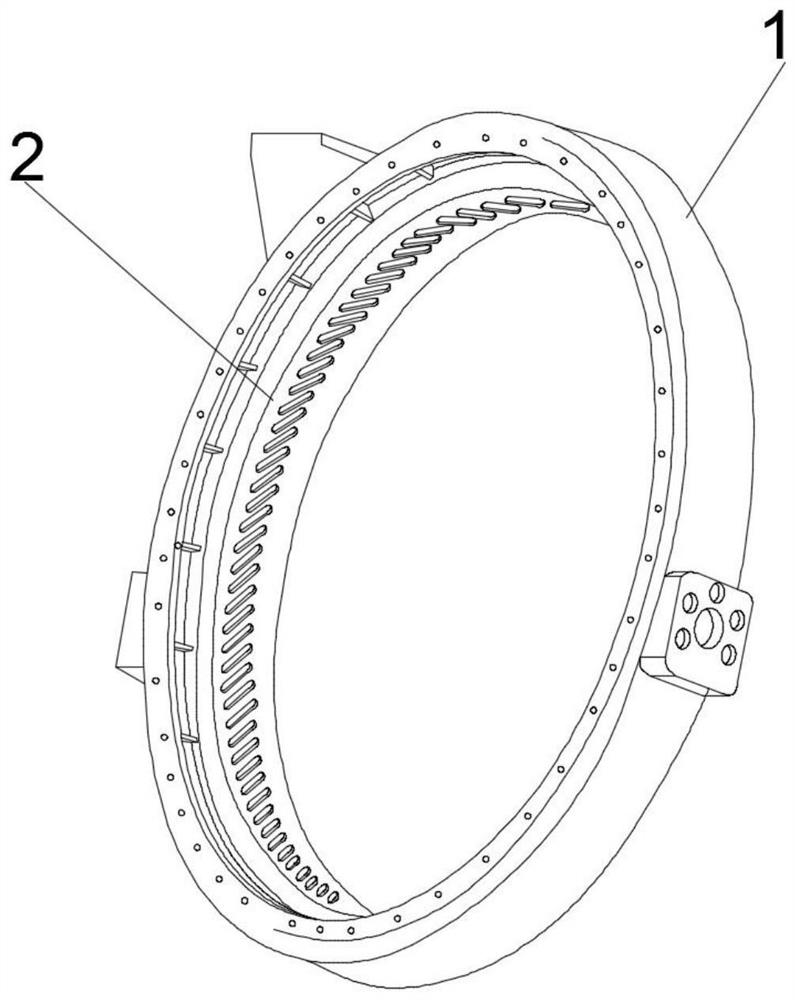

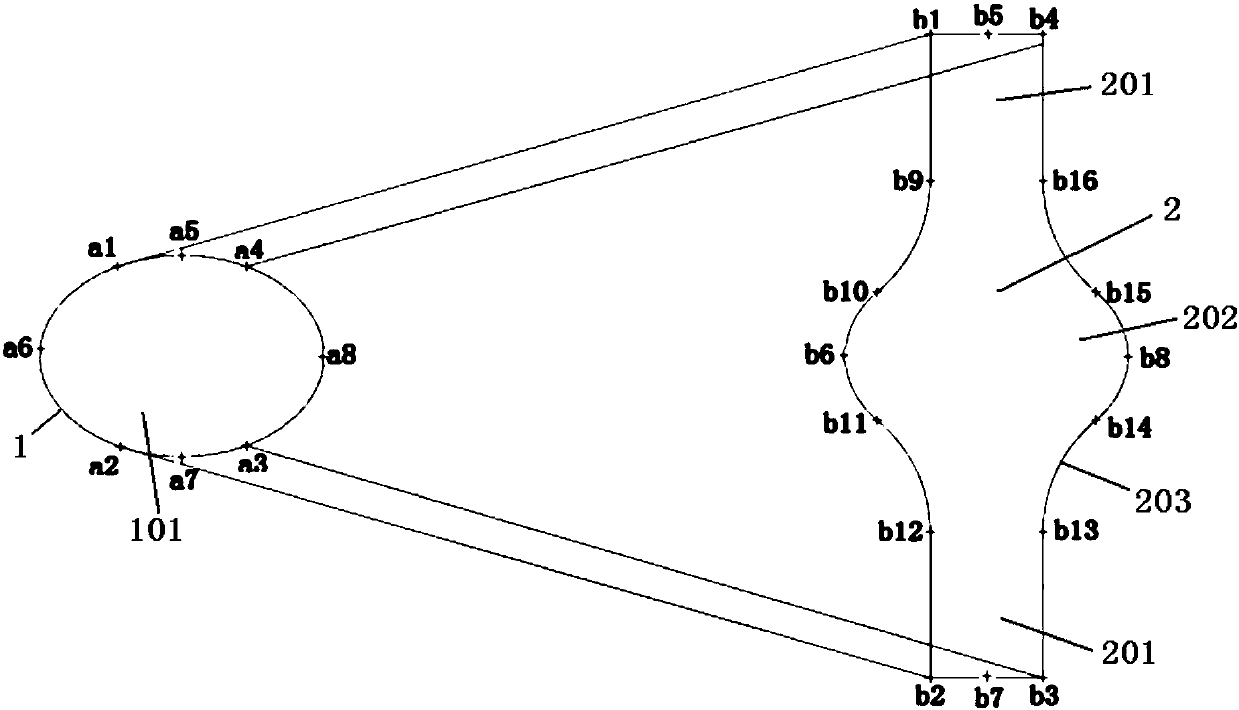

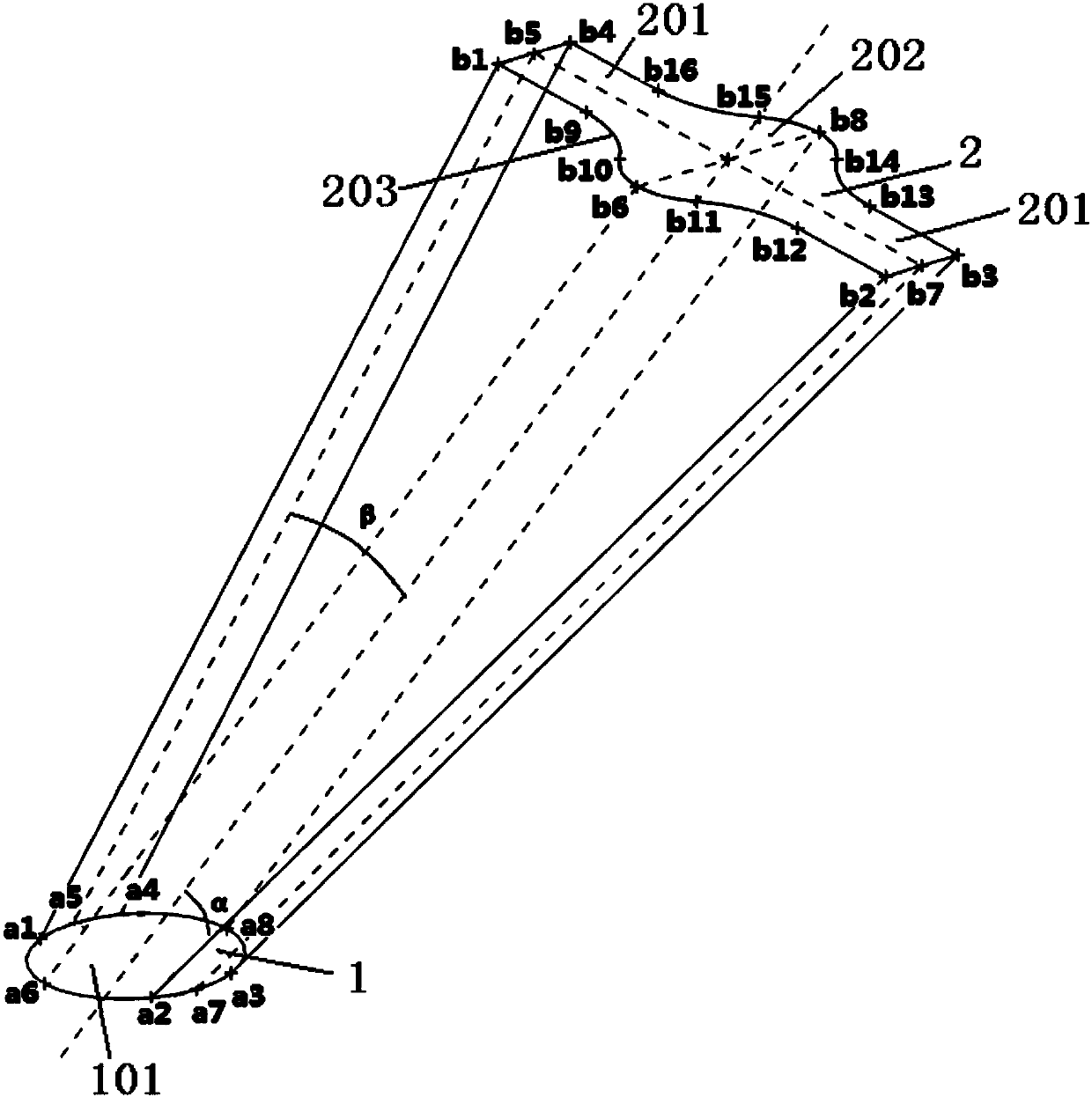

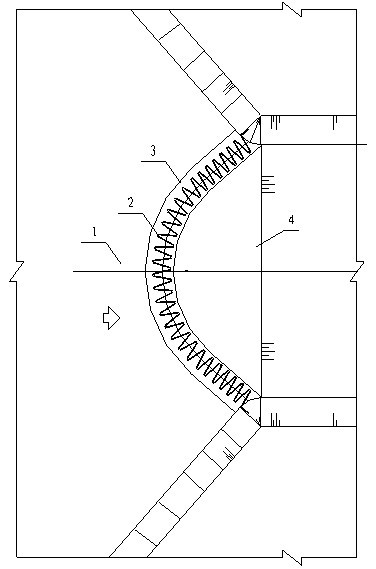

Axially symmetrical variable geometry bimodal air inlet channel adaptive to broad Mach number flight

ActiveCN109236472AImprove compression efficiencyAdequate flowGas turbine plantsJet propulsion plantsAerospace engineeringStreamflow

The invention discloses an axially symmetrical variable geometry bimodal air inlet channel adaptive to broad Mach number flight. The bimodal air inlet channel comprises a movable center cone, a flow deflector, a fairing and an actuation regulating system. In the working process of the air inlet channel, the actuation system drives the movable center cone and the fairing to translate front and backindependently along with variation of the Mach number of an incoming flow, the flow deflector is separated from the movable center cone at a low Mach working point, accordingly two air inlet passagesare formed, a throat channel area is widened, and the effect of increasing a flow coefficient in low Mach flight can be achieved; the movable center cone is seamlessly combined with the flow deflector in high Mach flight, a working mode of the air inlet channel turns to a one-channel working mode, at the moment, the throat channel area of the air inlet channel is shrunk, the internal compressionratio is increased, and the air compression requirement when the air inlet channel works at high Mach can be met while the flow requirement in high Mach flight is met.

Owner:BEIHANG UNIV

Crossing spray orifice type injection nozzle of internal combustion engine

InactiveCN101294533AIncreased turbulence intensityPromote atomizationFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention relates to a cross orifice typed injection nozzle for an internal-combustion engine and belongs to an oil injection device of a fuel system of the internal-combustion engine. The nozzle is a precision coupling formed by an injector valve body and an injector valve. The head of the injector valve body is provided with at least one cross sub-orifice and each cross orifice is formed by crossing and collecting of at least two sub-orifices. As the collection of fuel in the sub-orifices of the cross orifice can form intense disturbance, the turbulent kinetic energy is increased and the atomization is improved; as an outlet of the cross orifice is formed by the collection of the sub-orifices, the flow area of the outlet is less than the sum of the outlet areas of all the sub-orifices, the injection nozzle is characterized by improving discharge coefficient like an analogous V-shaped gradually shrinking orifice. In brief, the crossing of the sub-orifices increases the internal flow, improves the turbulent intensity, causes the cross orifice to improve atomization, improves the quality of the mixed gas and leads to rapid, sufficient and perfect combustion, thus being beneficial to the further improvement of the economic performance, discharging performance and kinetic performance of the motor.

Owner:DALIAN UNIV OF TECH

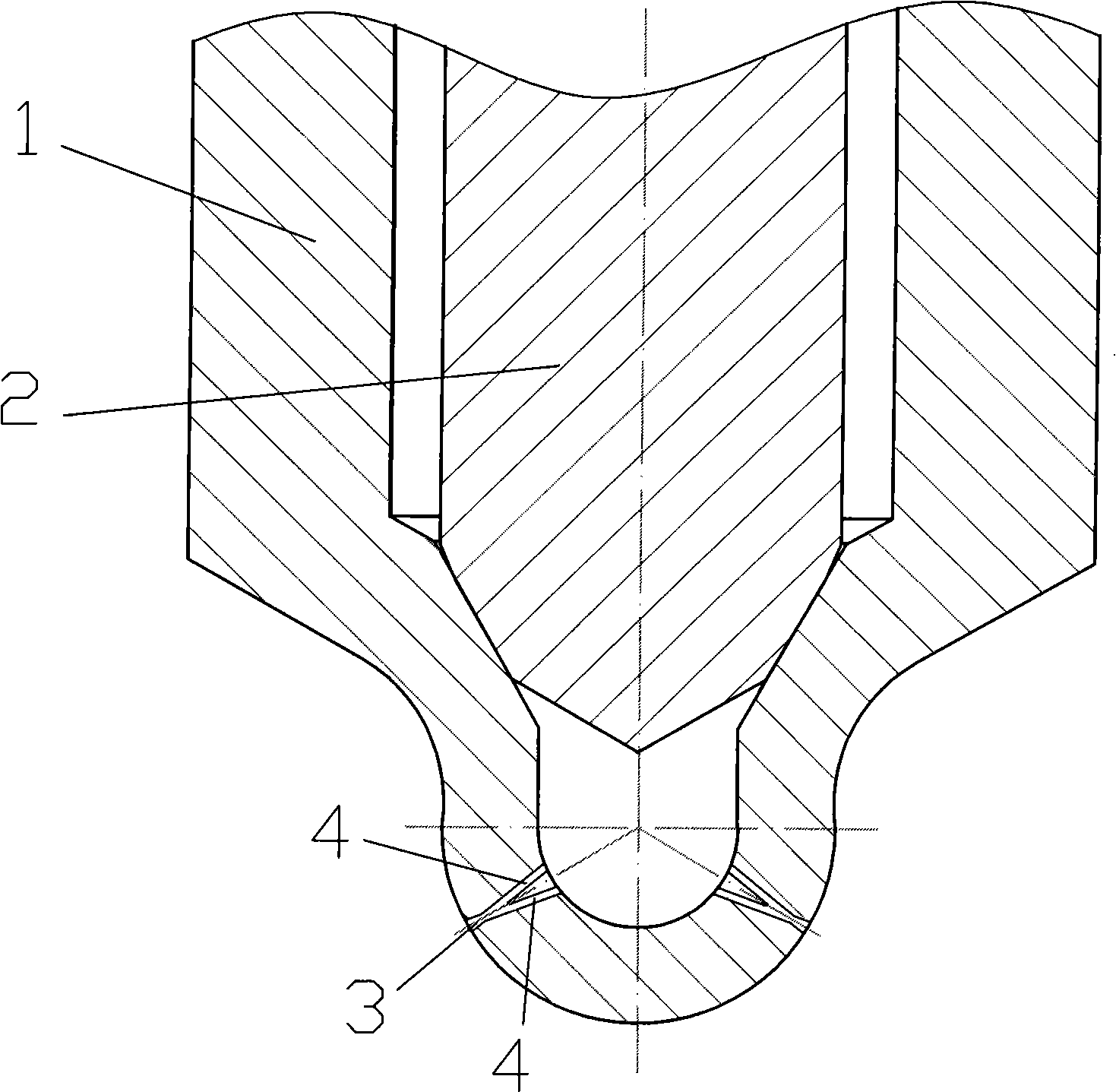

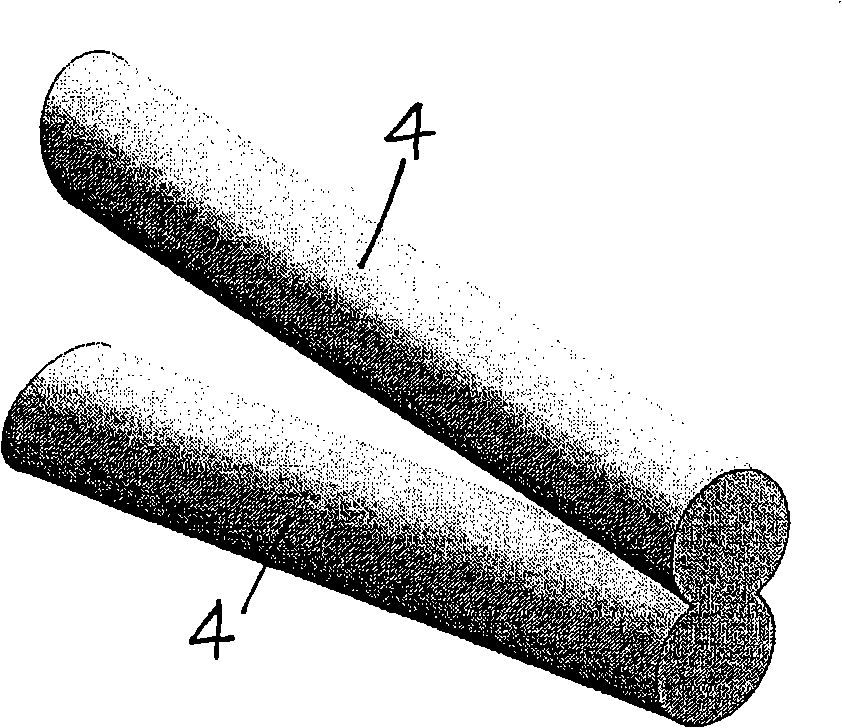

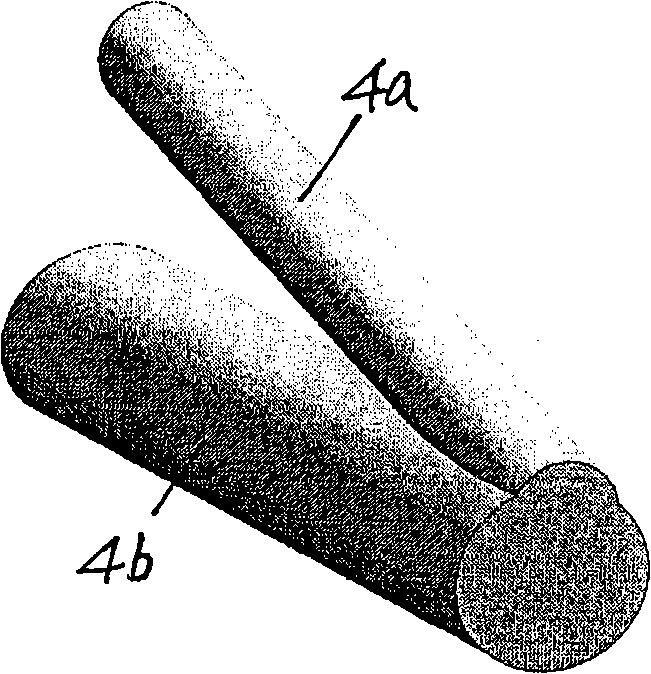

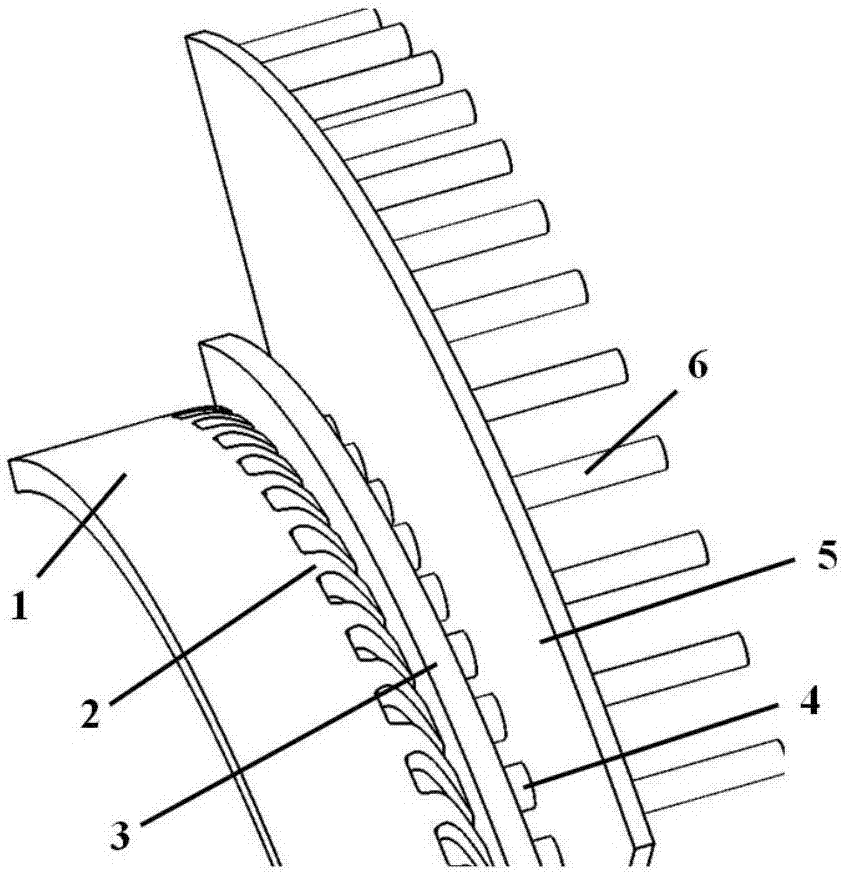

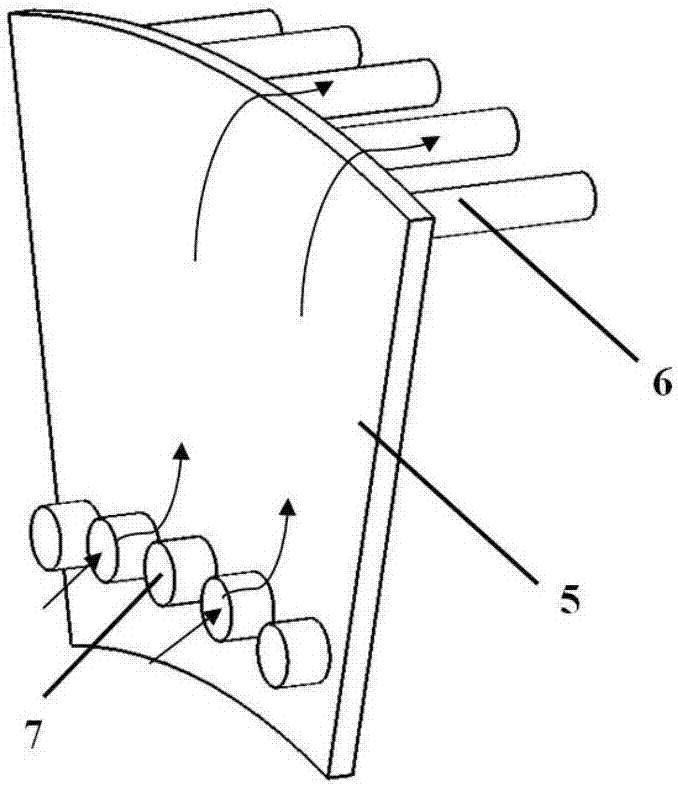

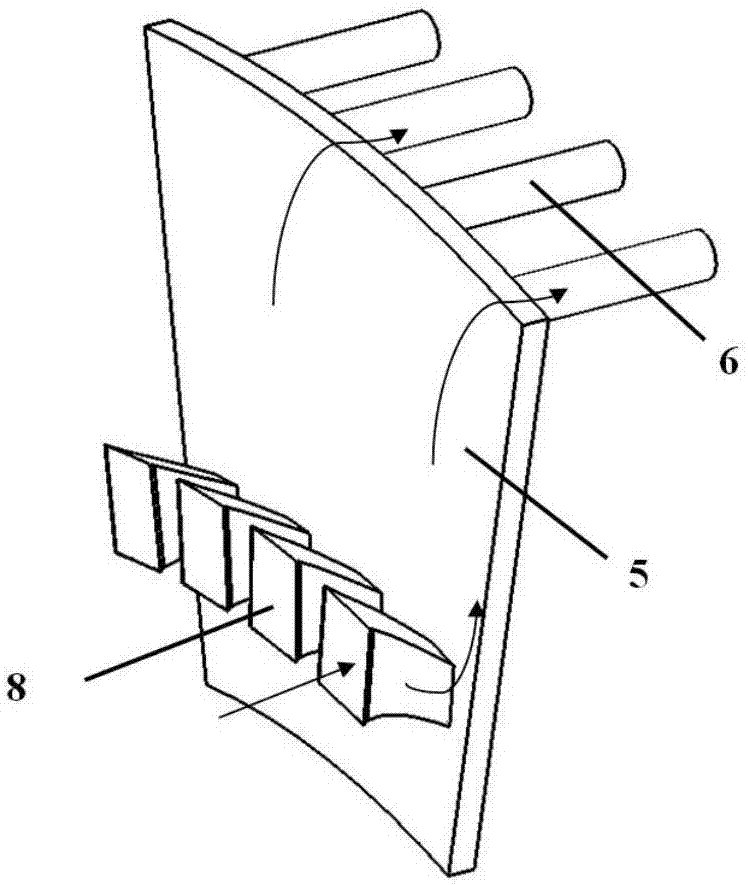

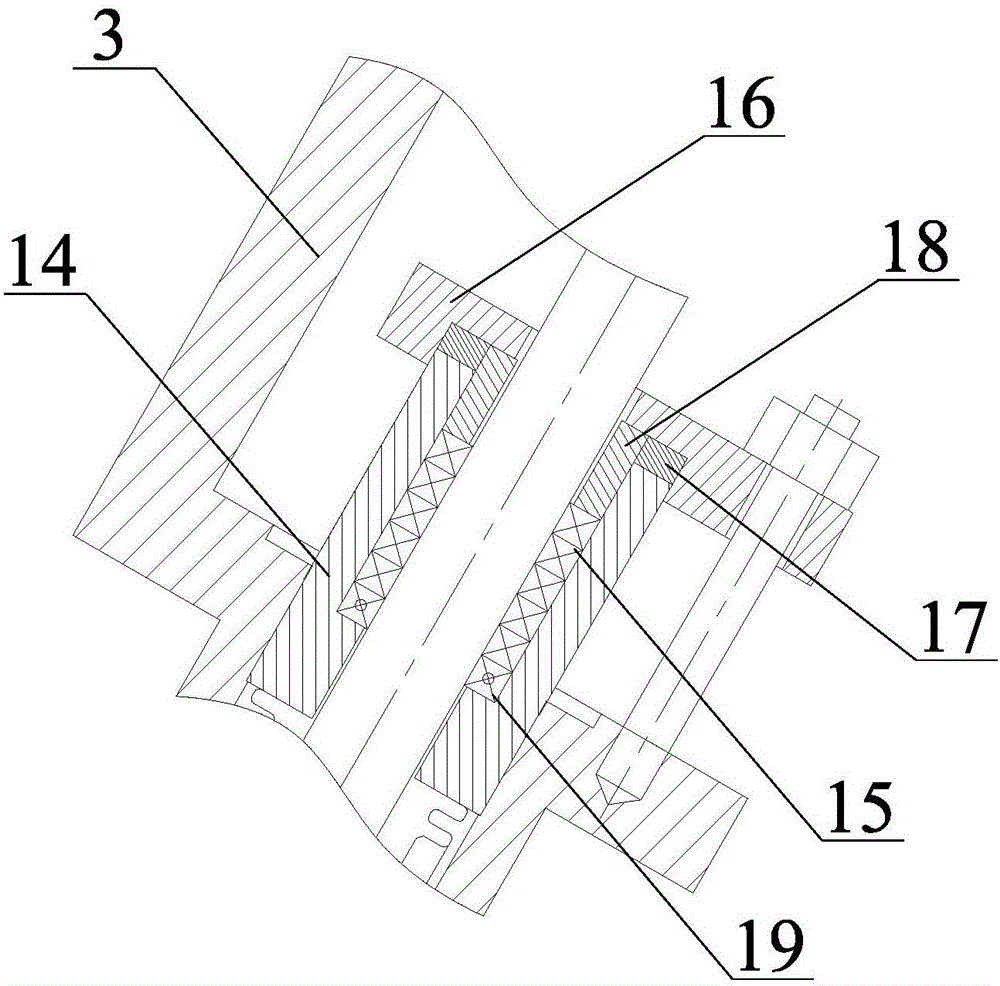

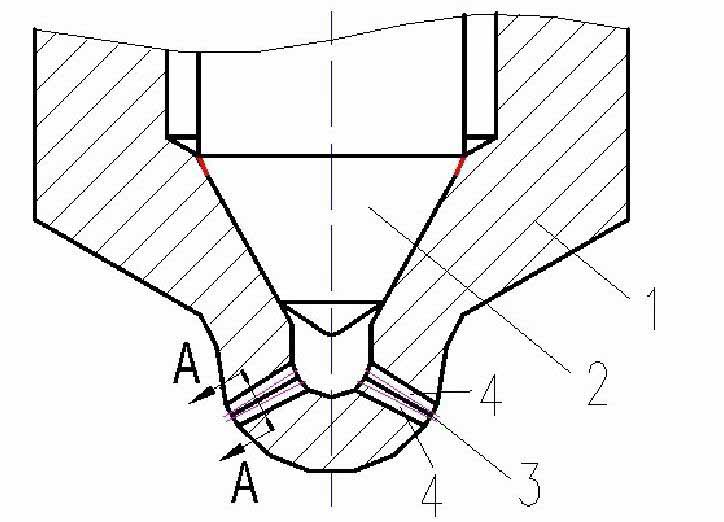

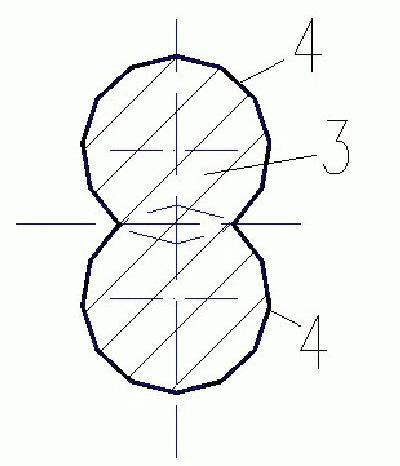

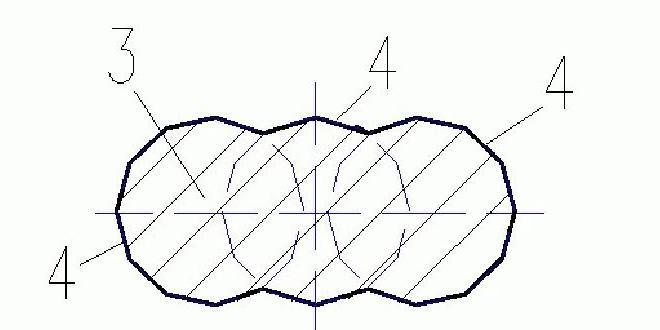

Blade profile receiving hole structure for prewhirl cooling system

InactiveCN107313860AReduce flow lossImprove flow coefficientTurbine/propulsion engine coolingEngineeringSuction surface

The invention discloses a blade profile receiving hole structure for a prewhirl cooling system. Each blade profile receiving hole is an inclined hole deflecting in the rotating direction of a rotary disc, a blade profile receiving hole runner is of a gradual contraction structure so that the effect that airflow is gradually accelerated in the axial flowing process. A blade profile receiving hole deflected profile comprises a self-designed blade profile force suction surface and a self-designed blade profile pressure surface and is used for ensuring the effect that the flowing loss of the airflow is the smallest when the airflow deflects along the blade profile receiving hole deflected profile. Each blade profile receiving hole has a blade profile receiving hole air inlet angle and a blade profile receiving hole air outlet angle which are determined by the nozzle outlet airflow rotating ratio and the receiving hole outlet target rotating ratio. The radial height, extending in the axial direction, of the blade profile receiving holes is gradually decreased. The acceleration characteristic of the blade profile receiving holes is ensured through blade profile receiving hole radial contraction curved surfaces on the two sides of the inlet section radial height and the outlet section radial height of the blade profile receiving holes. The flowing loss of the blade profile receiving holes and the flowing loss of air supply holes are decreased, so that the nozzle outlet rotating ratio is increased, the system temperature lowering seed is increased, and power consumption is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

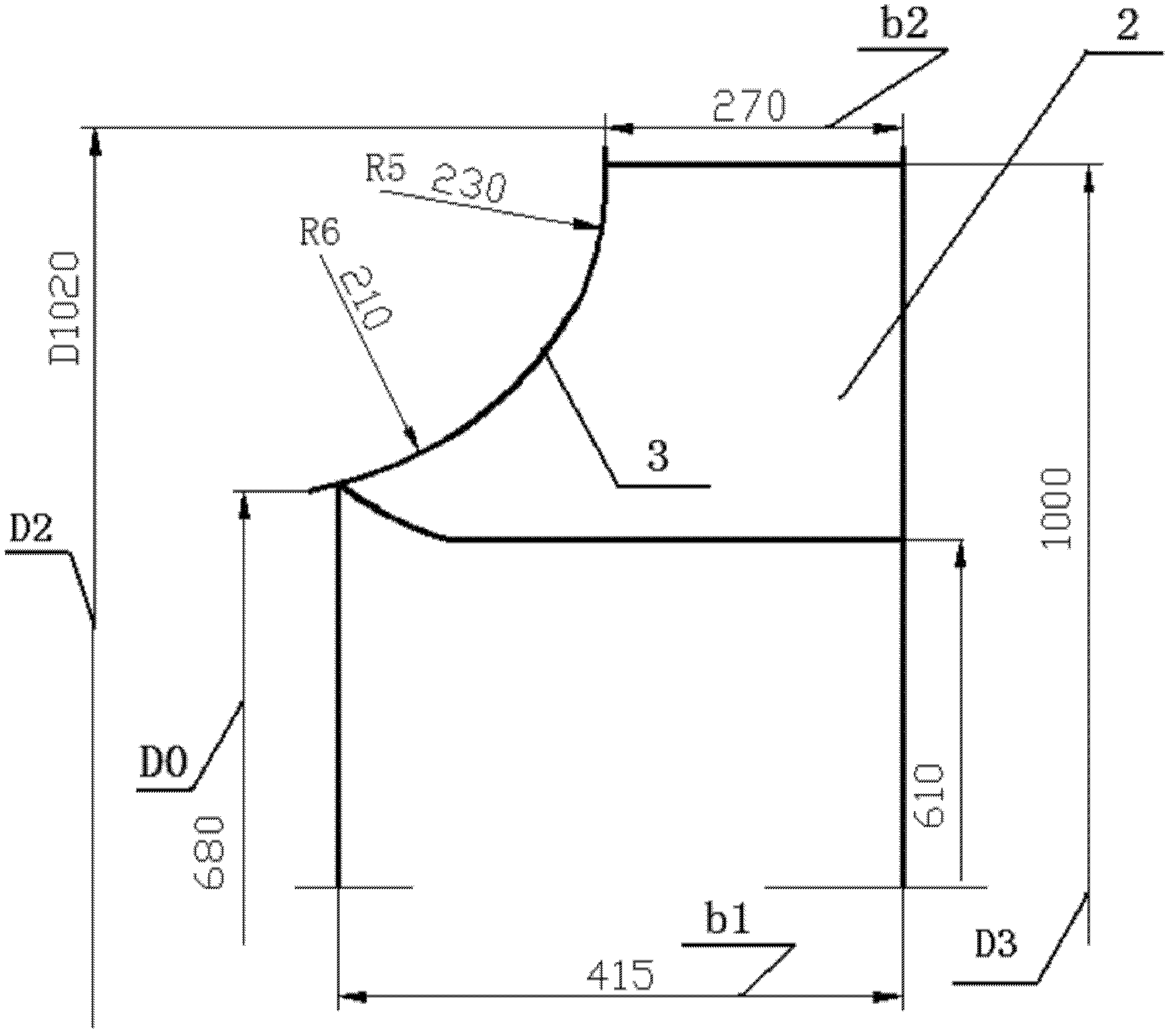

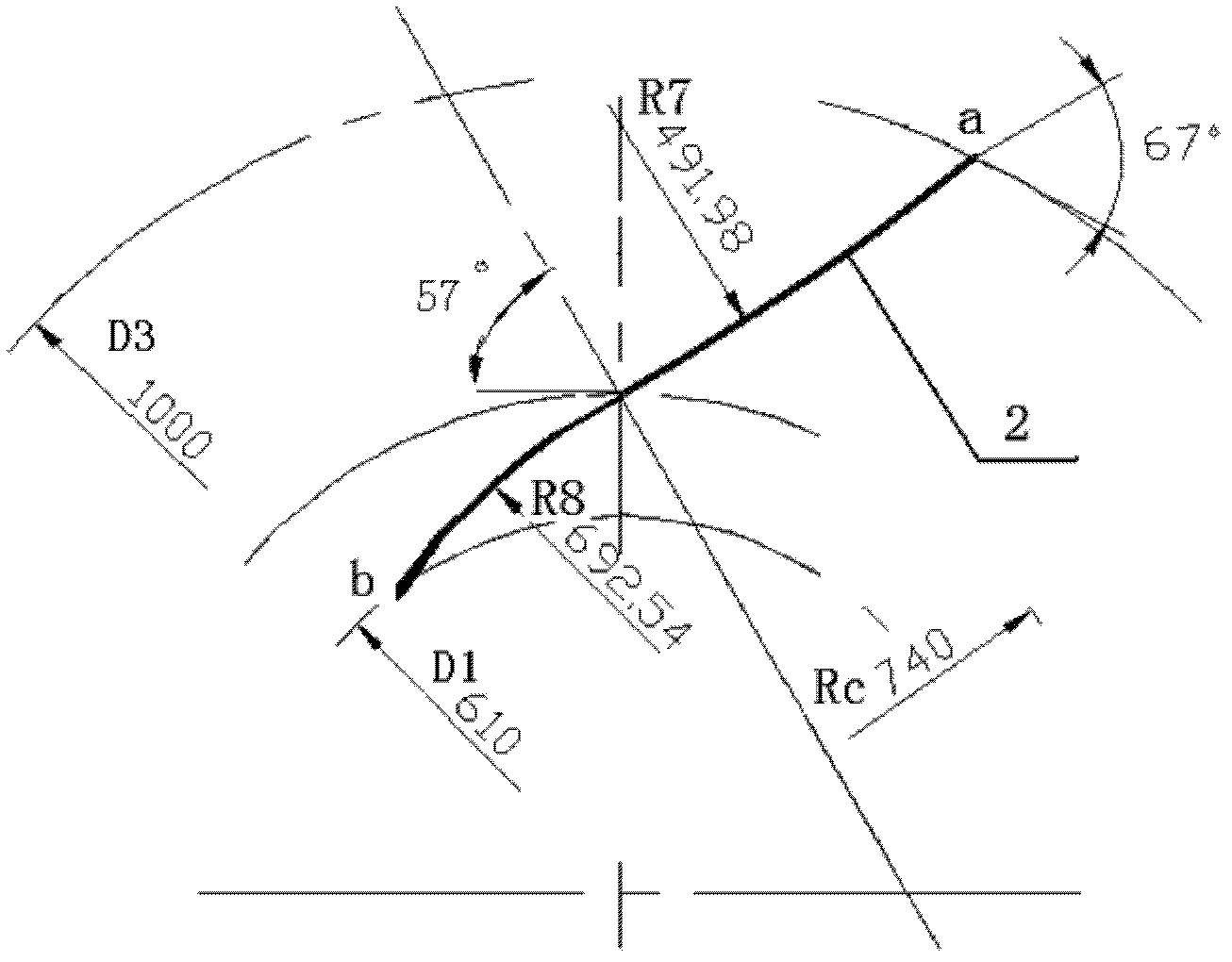

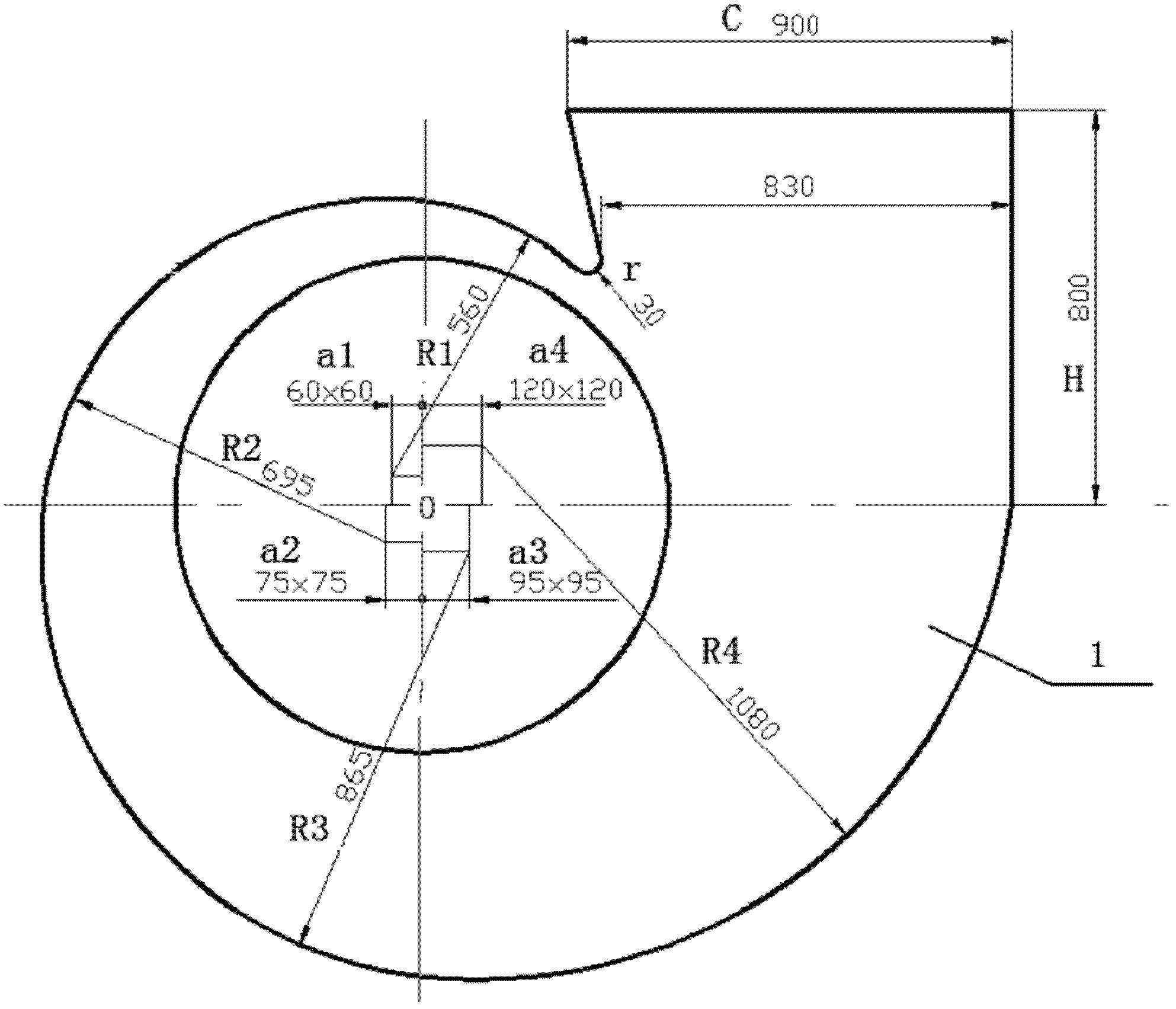

Centrifugal ventilator

ActiveCN102562660AHigh pressure coefficientImprove flow coefficientPump componentsPumpsImpellerEngineering

A centrifugal ventilator comprises a volute casing thereof and an impeller, wherein the impeller consists of a plurality of blades and is arranged in the volute casing of the centrifugal ventilator. The profile of each blade is in a two-dimensional double-arc structure, the two arcs bend to opposite directions and are connected smoothly at the position with the radius Rc ranging from 730mm to 750mm, the profile of a cap of the impeller is in double-arc transitional connection, the radiuses of the two arcs are respectively 230mm and 210mm, the outlet of the impeller has a rotary diffuser structure, and the circumferential profile of the volute casing is in smooth sectional eccentric arc connection. The flow coefficient of the centrifugal ventilator is 0.24, which is increased by 40% as compared with that of the L6-46 centrifugal ventilator and is increased by 90% as compared with that of Y5-58 centrifugal ventilator; the pressure coefficient is 1.234, which is increased by 40% as compared with that of a T4-79 centrifugal ventilator, and is increased by 11% as compared with that of the Y5-58 centrifugal ventilator; and the efficiency of the centrifugal ventilator is 86%, which is close to the highest efficiency point of a high-flow low-pressure high-efficiency ventilator, and is higher than the maximum efficiency value of a medium-flow high-pressure ventilator.

Owner:TIANJIN UNIV

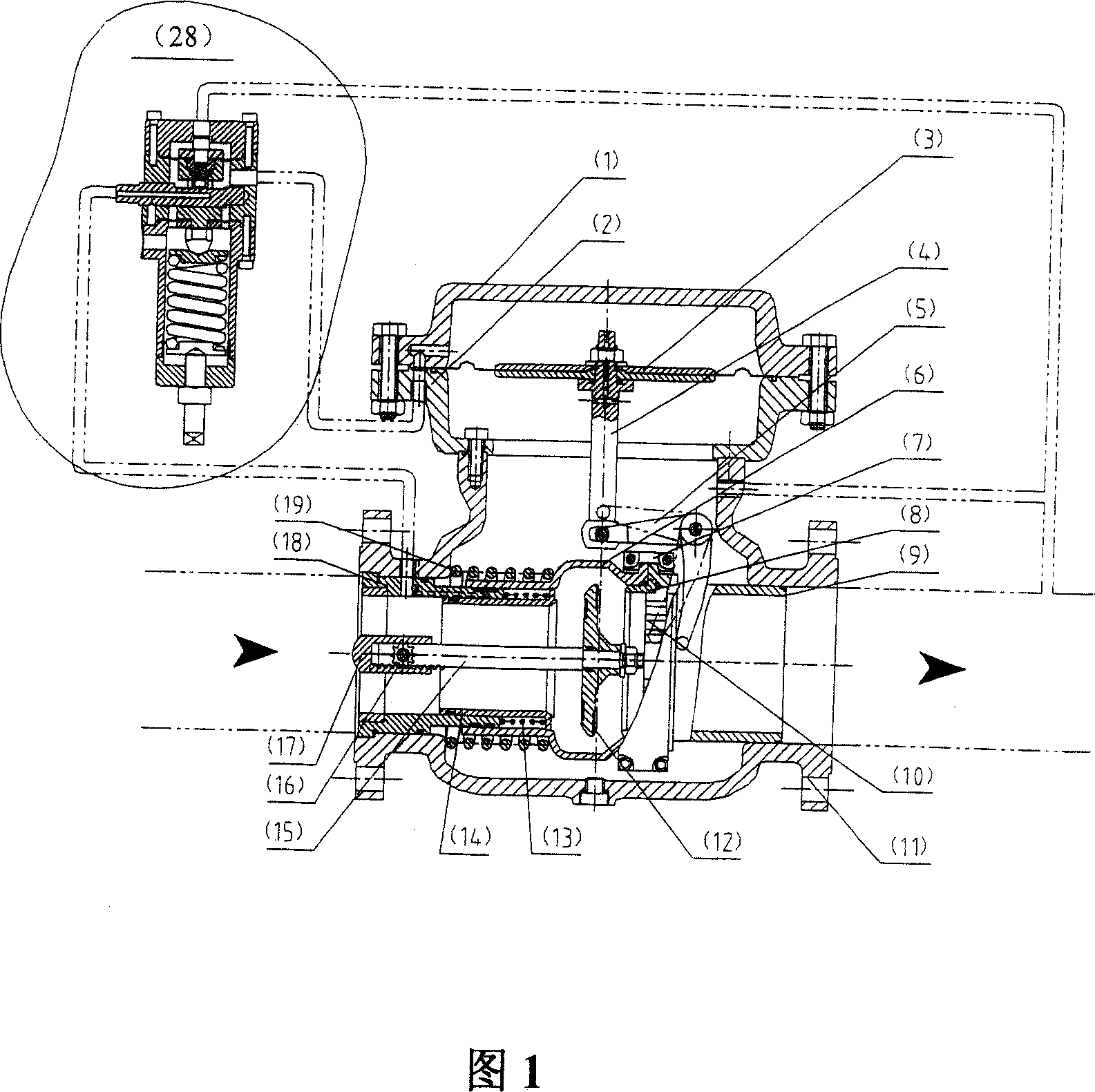

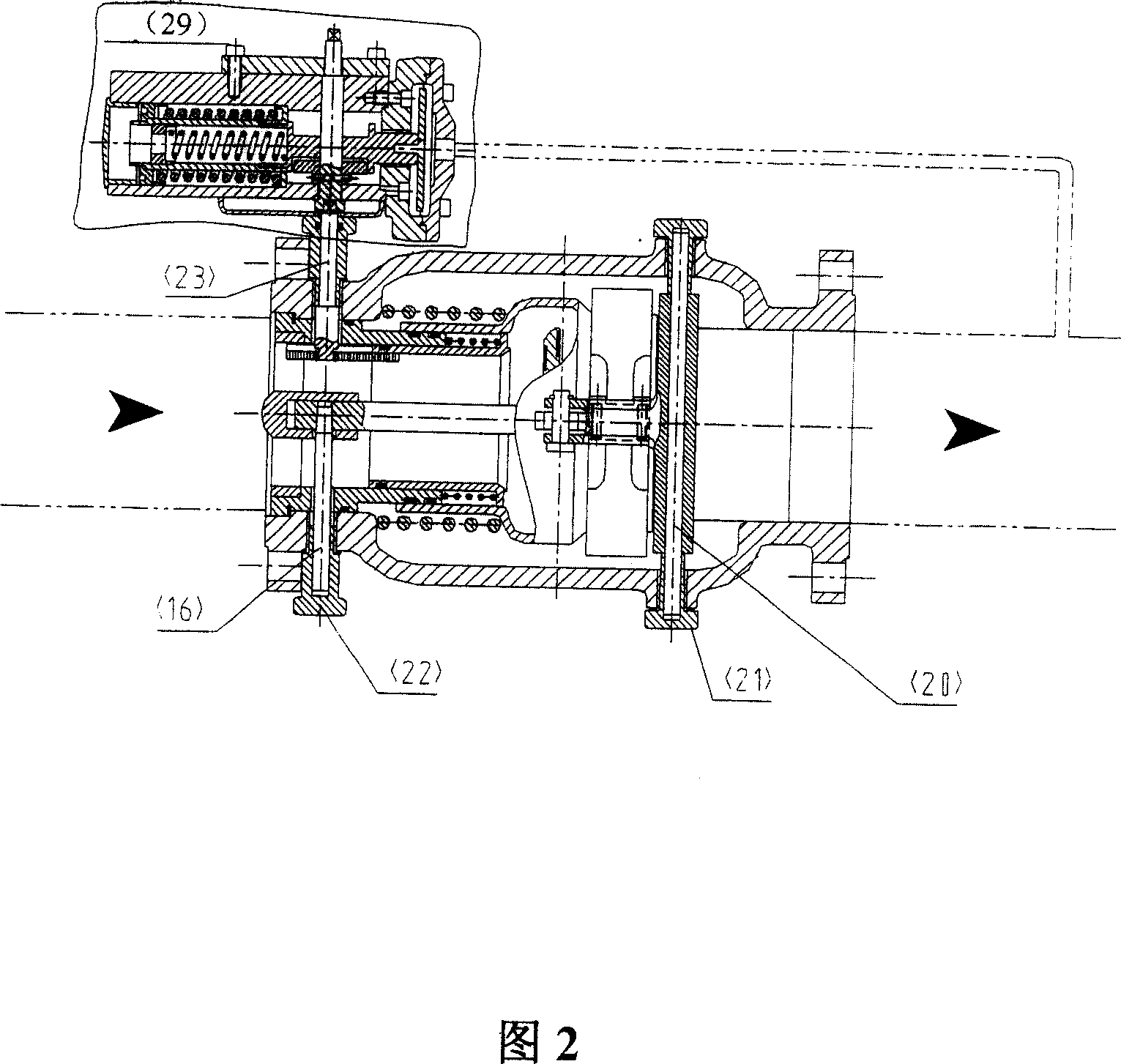

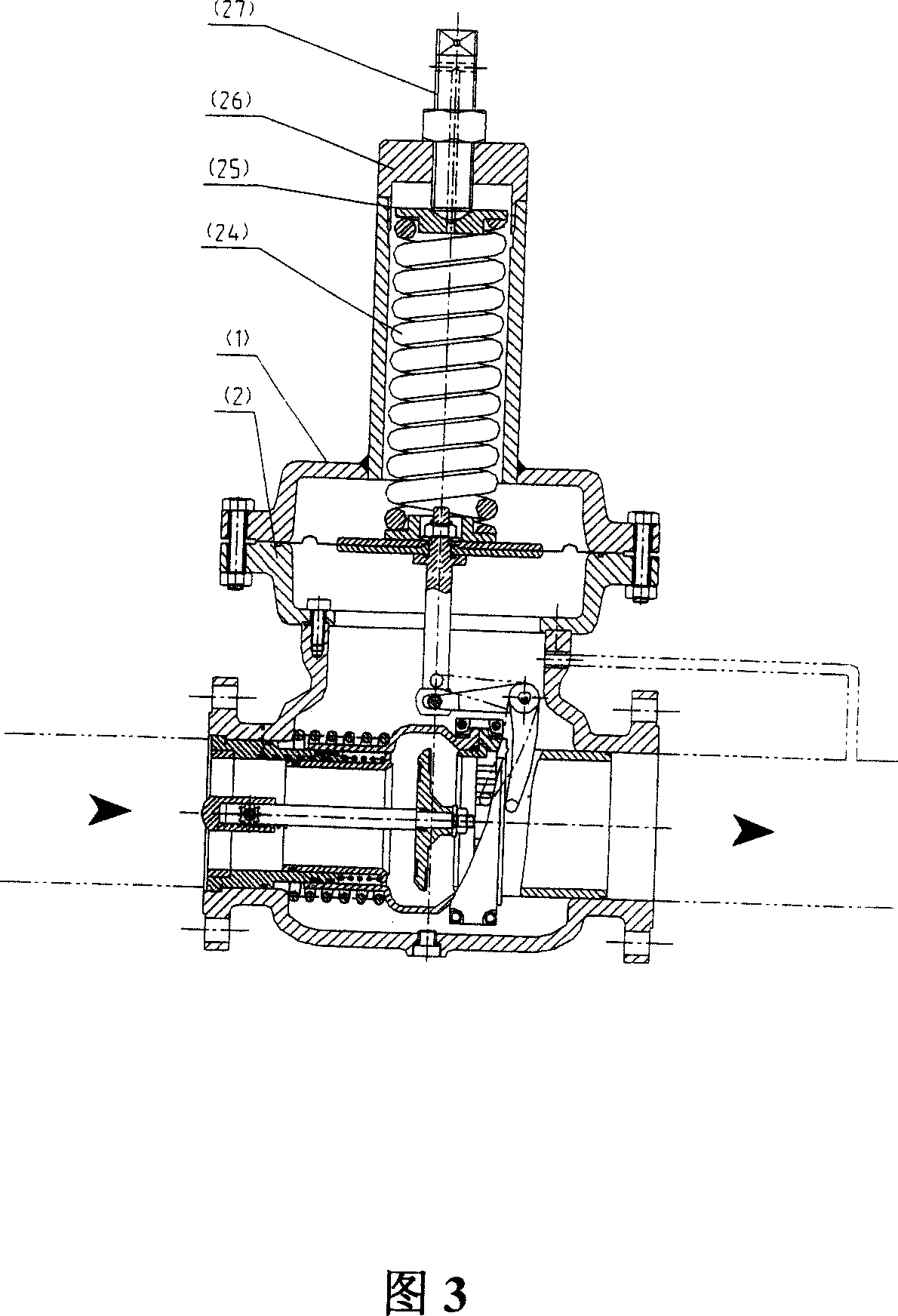

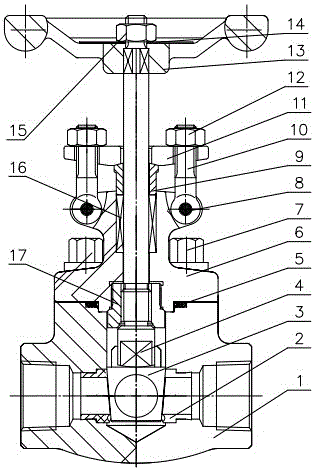

Top-loaded axial flow pressure regulator

InactiveCN101004227AImprove flow coefficientSmall flow resistanceEqualizing valvesSafety valvesPressure regulatorEngineering

The present invention relates to a top-mounted axial-flow pressure regulator. It mainly includes sheath component, valve jacket, pressure-regulating valve port, valve core, valve rod, pressure regulator valve body, valve port reset spring, cut-off valve controller and sealing element, in which the sheath component is separated from valve jacket, said sheath component is positioned in the top portion of pressure regulator valve body, the valve jacket is positioned in the pressure regulator valve body interior, sand valve jacket is divided into front valve jacket and rear valve jacket, the inlet end of pressure regulator valve body is equipped with a sleeve, in the pressure regulator valve body interior a cut-off valve port and a cut-off valve spring are set, the cut-off valve port is connected with cut-off valve controller; and the valve rod is locked by means of removable component extended to the exterior of pressure-regulator valve body.

Owner:SUZHOU ANLI GAS EQUIP CO LTD

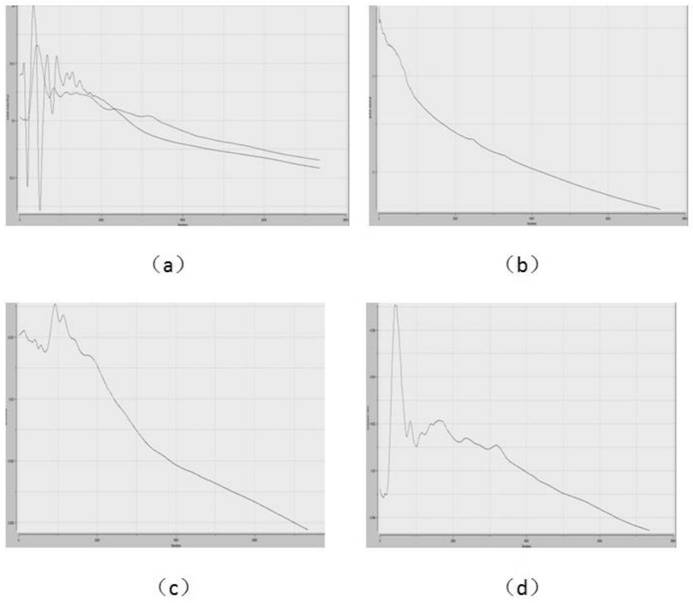

Gas turbine compressor casing anti-surge structure and surge margin evaluation method thereof

InactiveCN112160943AImprove flow statusReduce angle of attackPump componentsDesign optimisation/simulationEngineeringInlet flow

The invention discloses a gas turbine compressor casing anti-surge structure and a surge margin evaluation method thereof. The gas turbine compressor casing anti-surge structure comprises a compressorcasing, wherein a casing treatment section is arranged on the front portion of the compressor casing, the casing treatment section comprises an anti-flow-loss section inner cavity, an anti-flow-losssection inner ring is arranged on the inner side of the anti-flow-loss section inner cavity, an axial chute is formed in the anti-flow-loss section inner ring and communicates with a backflow cavity in the anti-flow-loss section inner cavity, and a radial baffle is arranged in the anti-flow-loss section inner cavity; the axial chute rotates by 90 degrees along the radius line of the circle where the axial chute is located, is parallel to the blade chord line of a rotor blade, and rotates by 45 degrees along the axis of the circle where the axial chute is located; by changing the structure of the axial chute, the air inlet amount and the air inlet flowing condition are changed; and meanwhile, an exhaust section is optimized, the axial speed is increased, the flow coefficient is increased, the flowing state with the too large top attack angle is improved, stability expansion is effectively carried out, and the beneficial effects of effectively reducing the increased air amount, reducingthe attack angle at the blade tip of a movable blade and reducing the flow of a stall point are achieved.

Owner:NAVAL UNIV OF ENG PLA

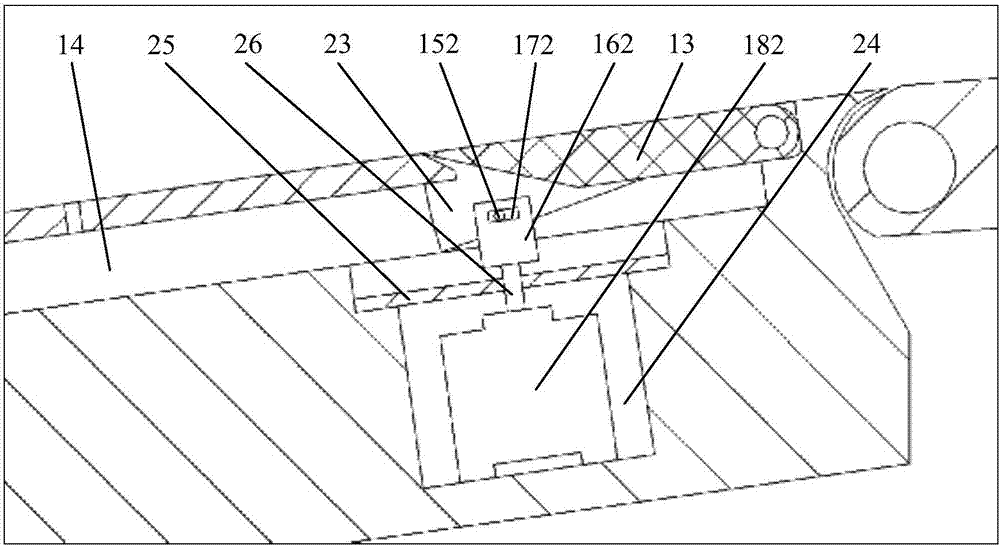

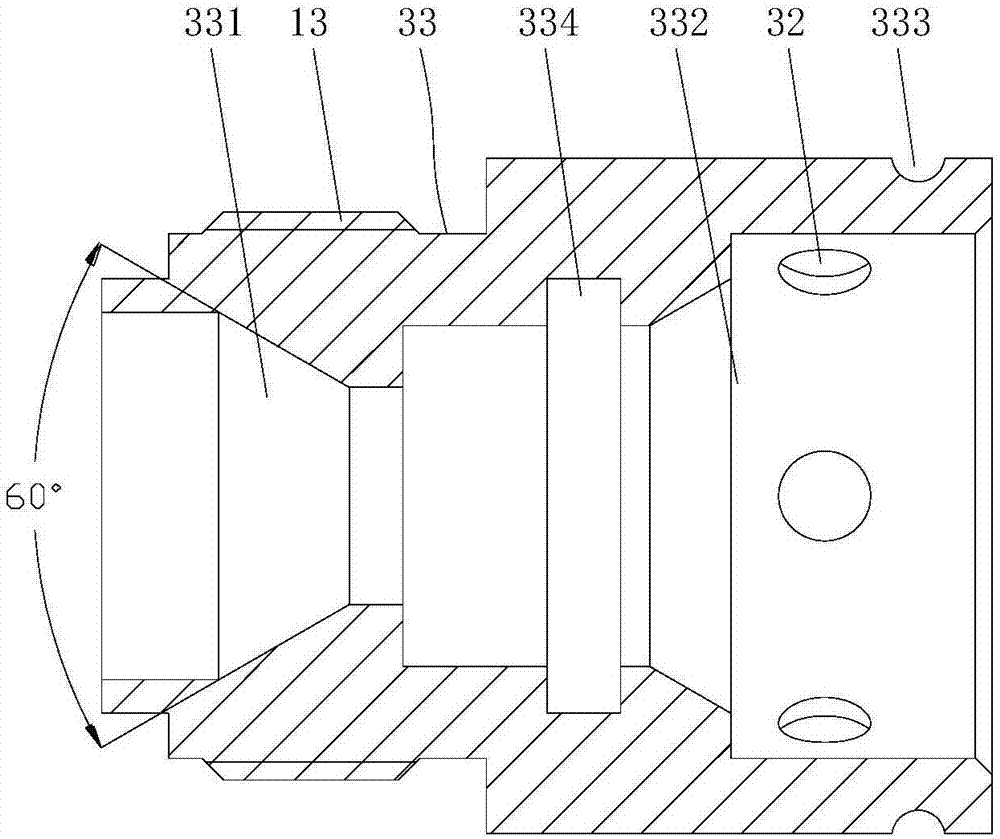

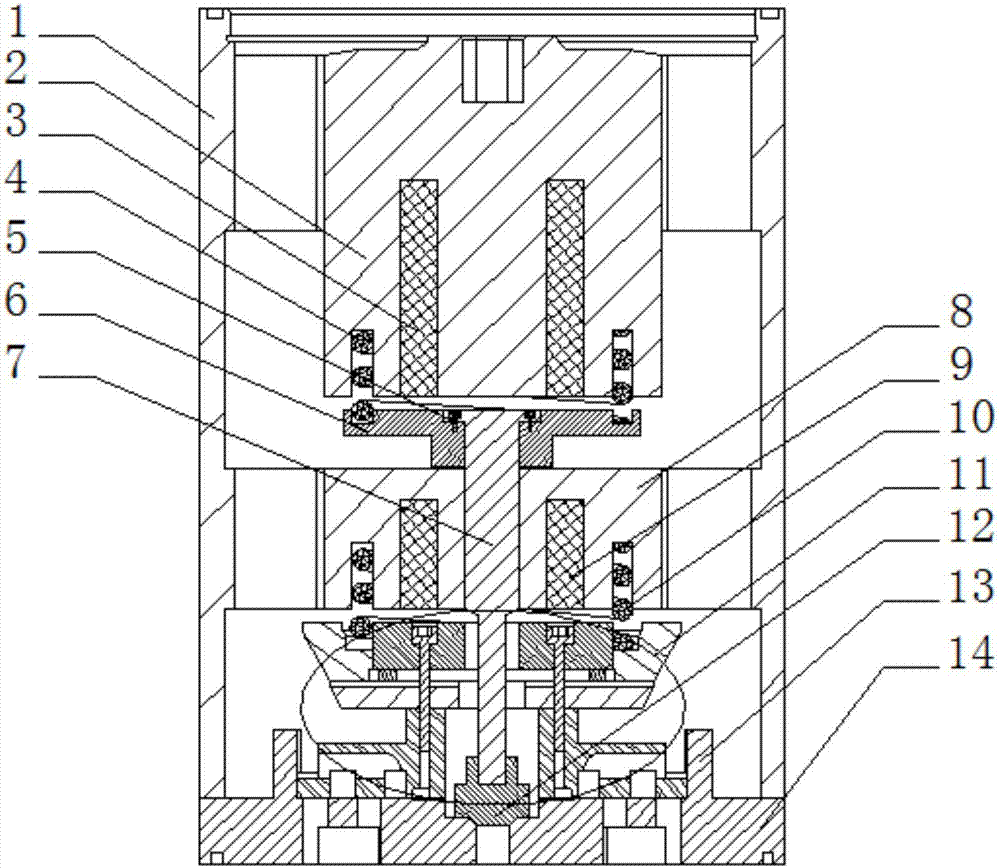

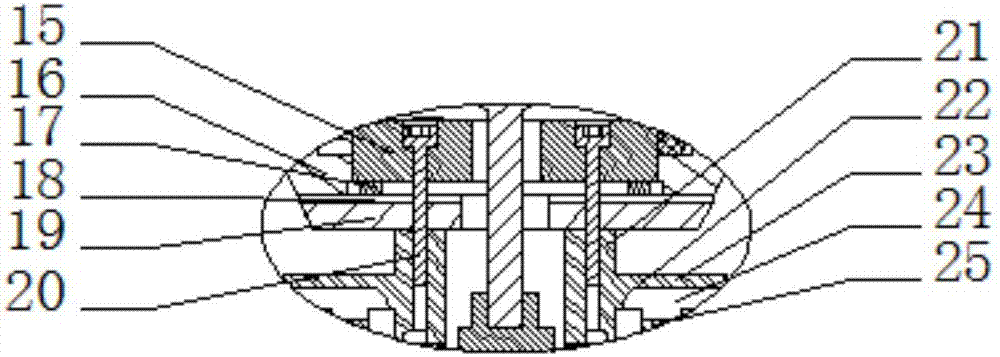

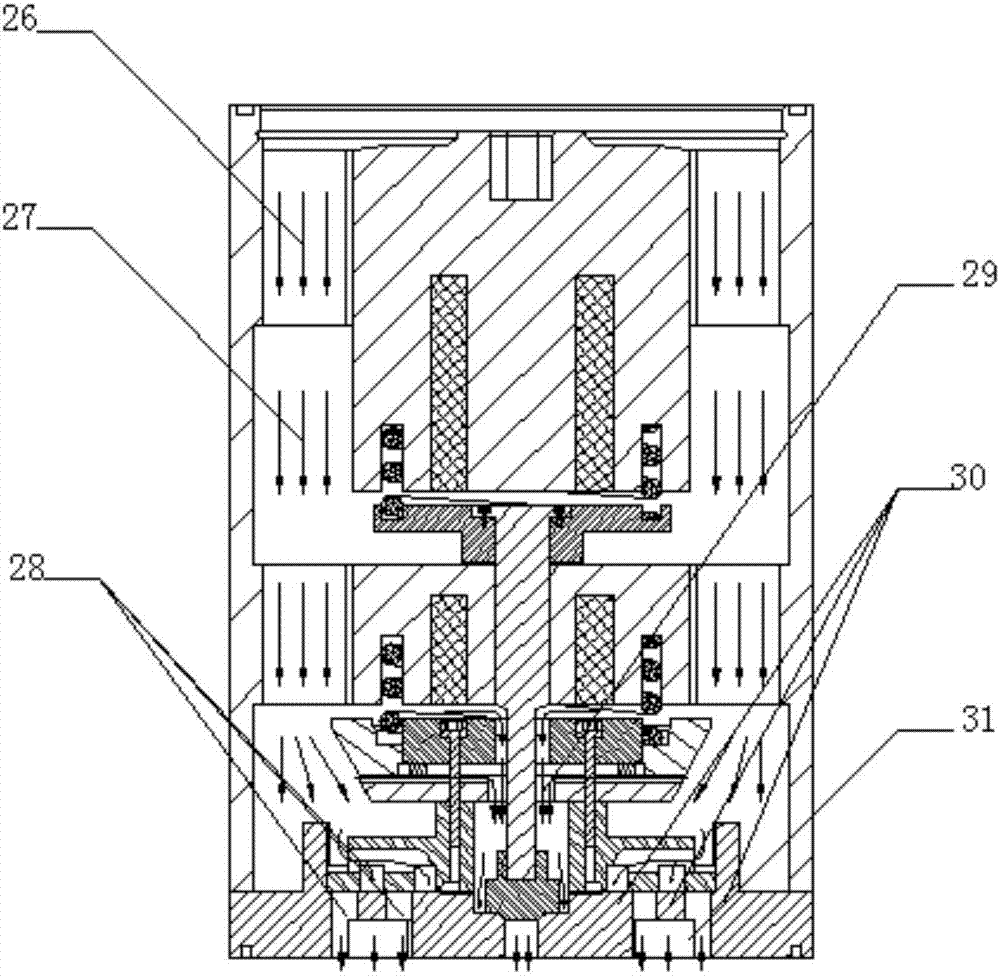

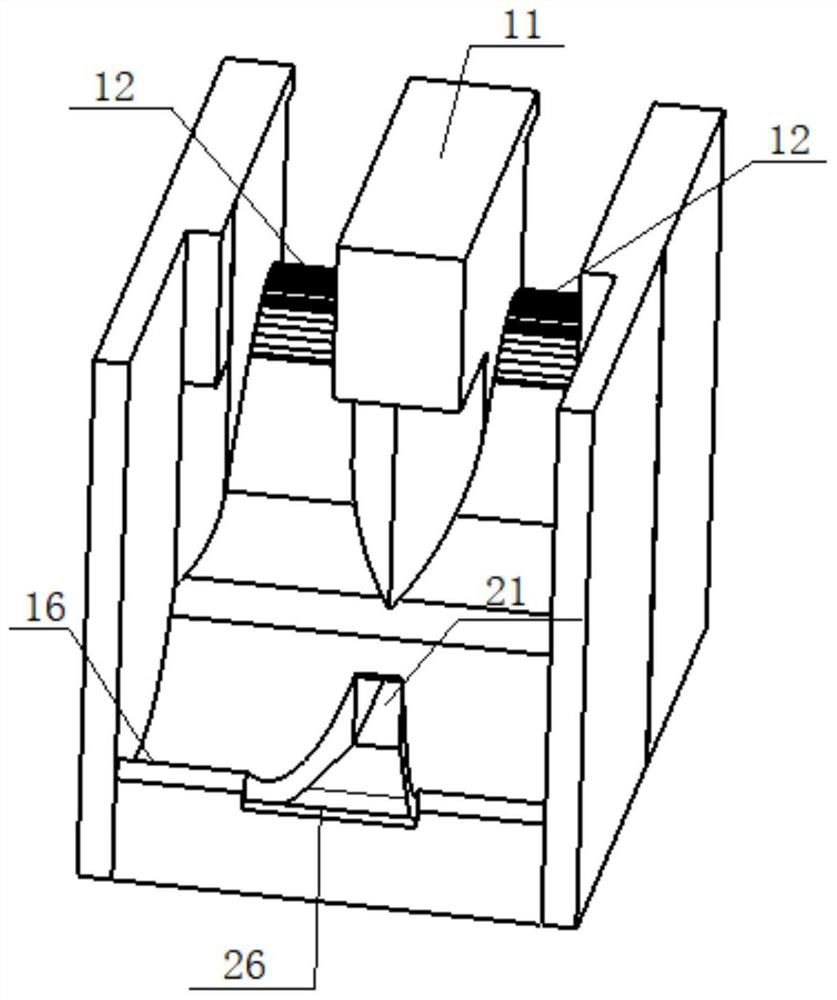

Fluid controller

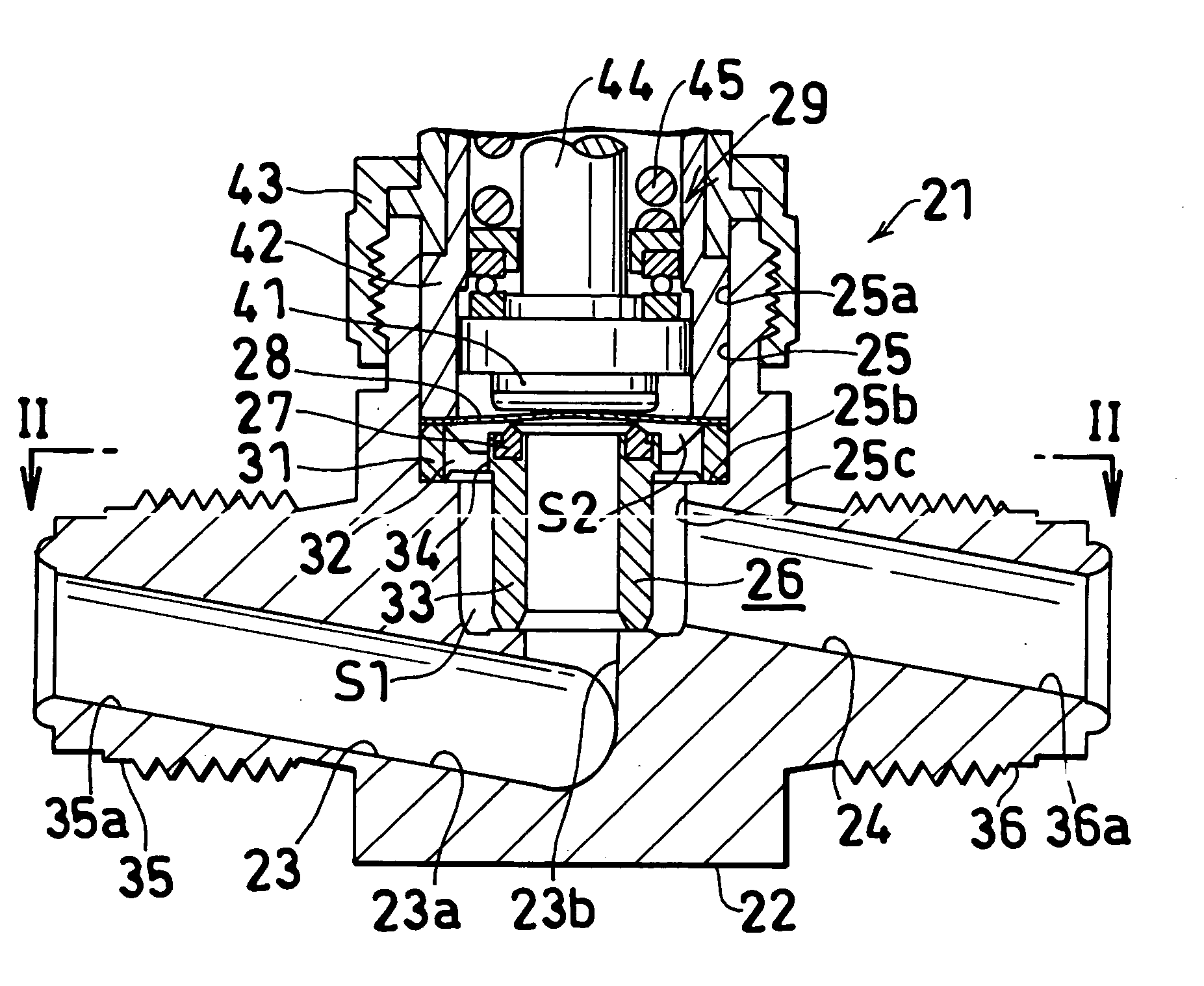

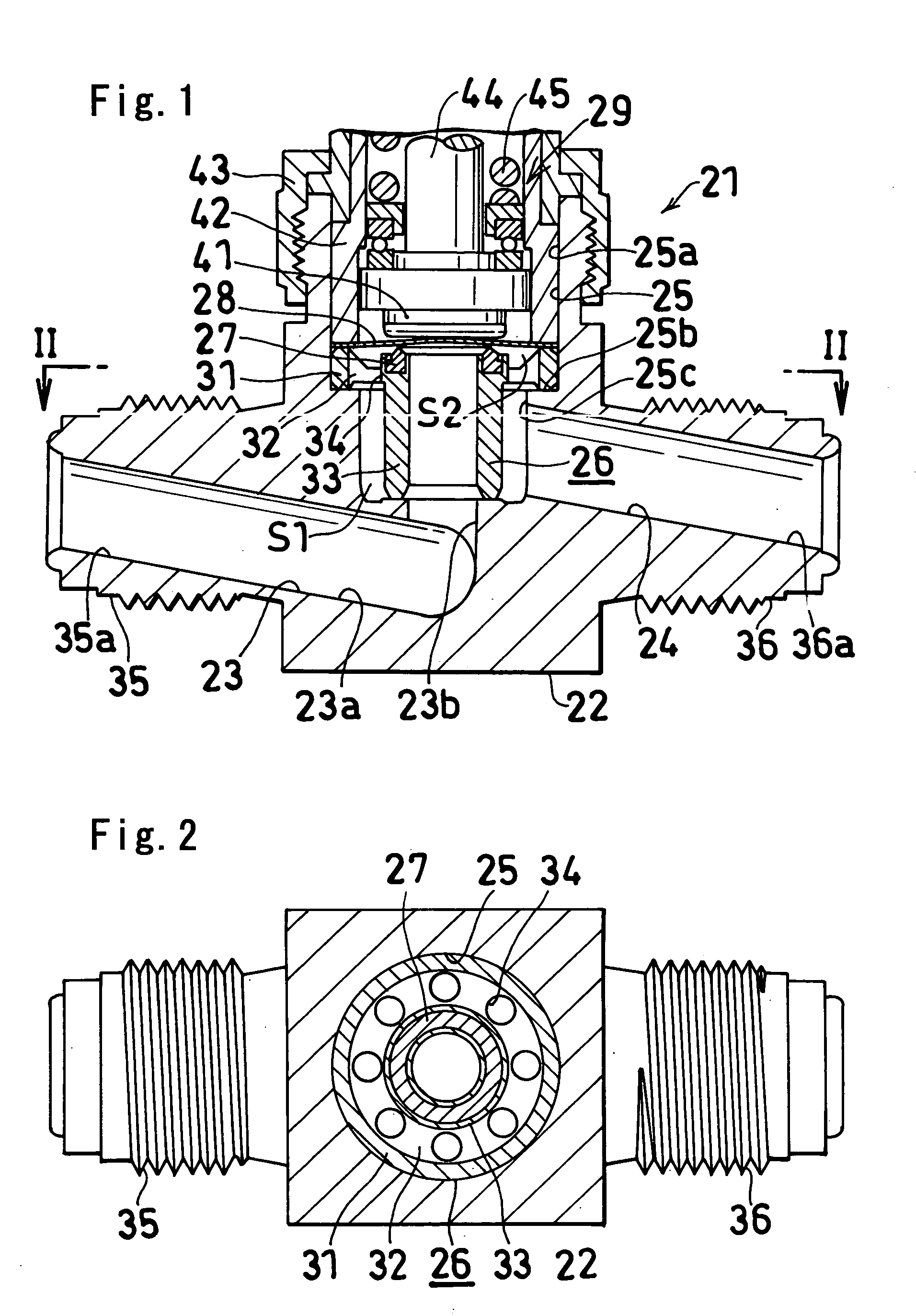

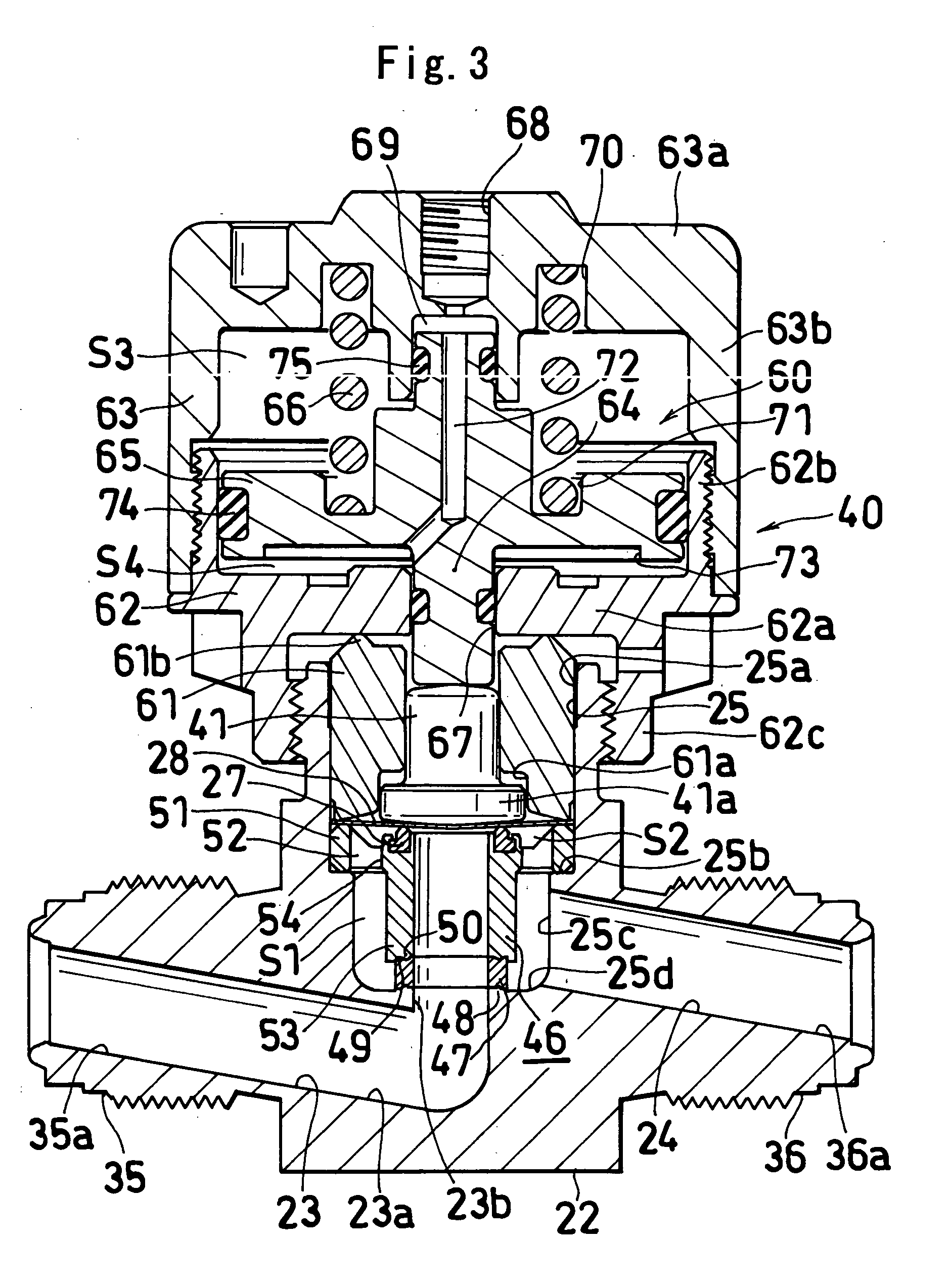

ActiveUS20060214130A1Improve flow coefficientDownsizingDiaphragm valvesEngine diaphragmsEngineeringMechanical engineering

A fluid controller, wherein the recessed port (25) of a body (22) is formed of larger diameter part (25a) near an opening and a small diameter part (25c) continued to the lower part of the large diameter part (25a) through a step part (25b). A flow passage forming disk (26) is fitted to the recessed portion (25). The fluid passage forming disk (26) comprises a large diameter cylindrical part (31) fitted to the large diameter part (25a) in the recessed portion, a connection part (32) supported by the step part (25b) in the recessed portion, and a small diameter cylindrical part (33) having an outer diameter smaller than the inner diameter of the small diameter part (25c) in the recessed portion and having a lower end supported by the bottom surface of the recessed portion (25). A plurality of through-holes (34) communicating an annular space (S1) on the outside of the small diameter cylindrical part with an annular space (S2) on the inside of the large diameter cylindrical part are formed at the connection part (32) of the flow passage forming disk. The fluid inflow passage (23) is led into the lower end of the small diameter cylindrical part (33) of the flow passage forming disk (26), and a fluid outflow passage (24) is led into the annular space (S1) on the outside of the small diameter cylindrical part.

Owner:FUJIKIN INC

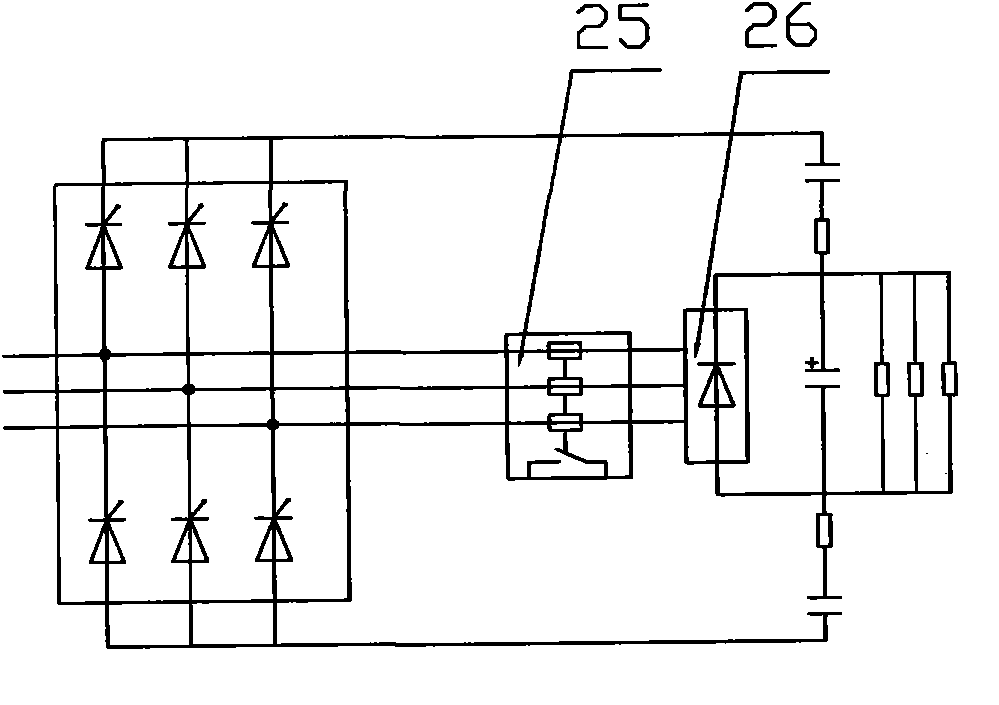

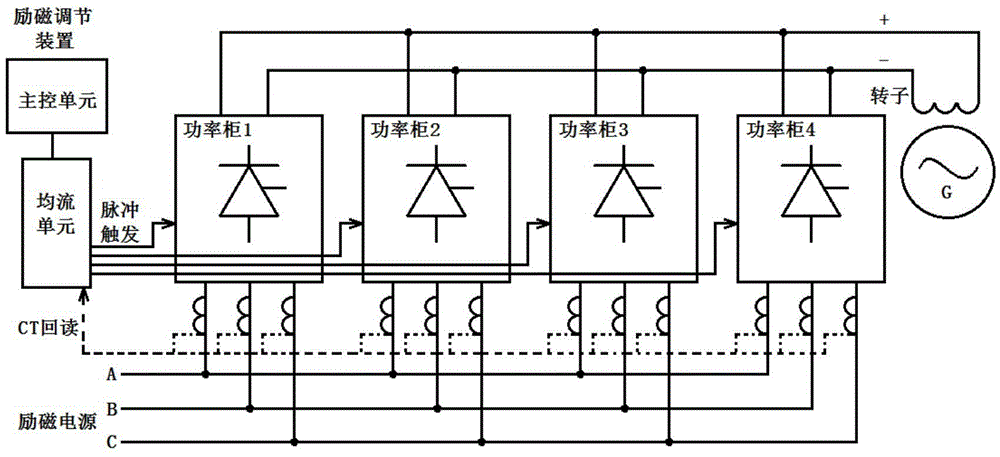

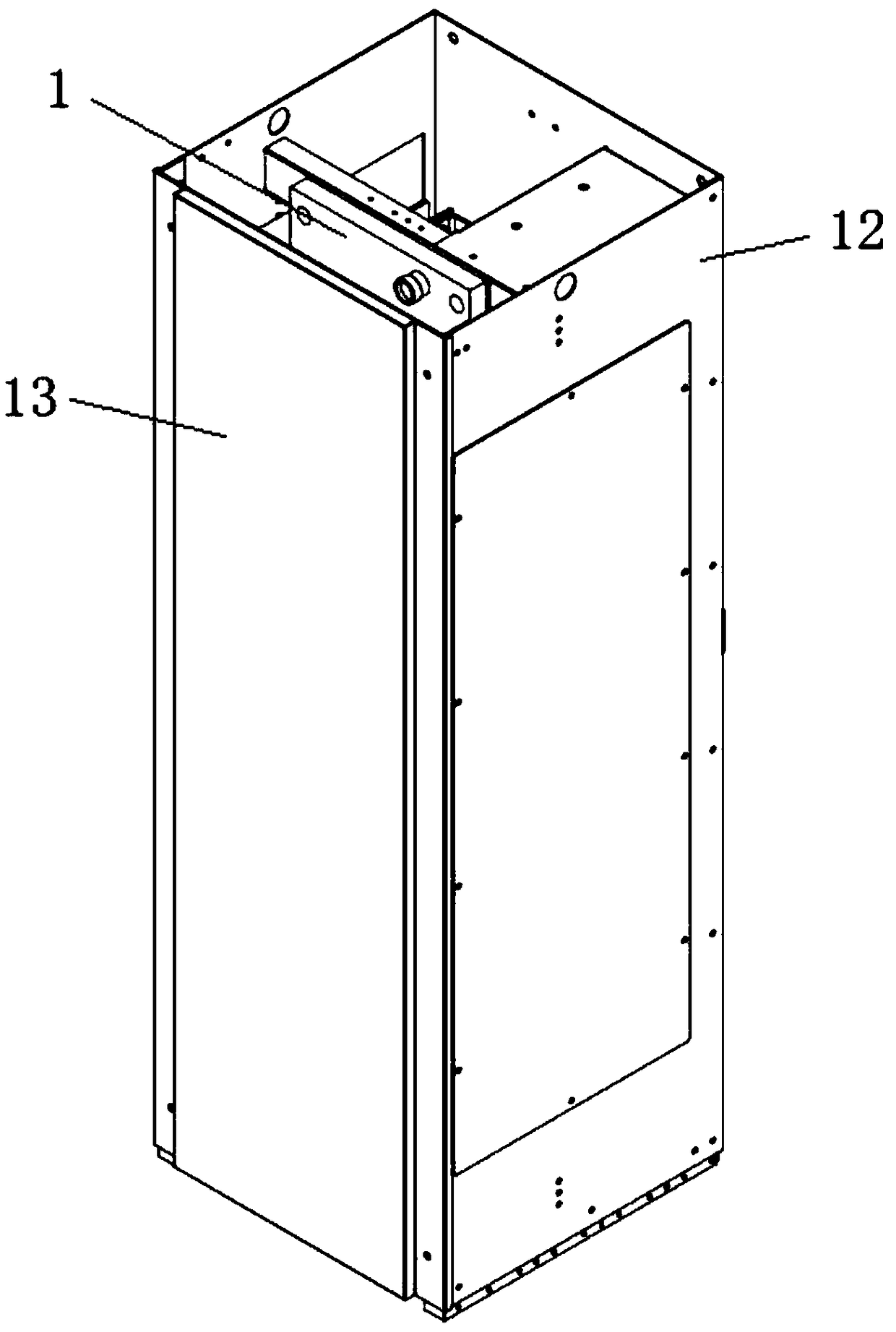

Centralized current sharing control method for excitation power cabinets

ActiveCN105553361AImprove flow coefficientAvoid damageGenerator control by field variationDistribution controlEngineering

The invention discloses a centralized current sharing control method for excitation power cabinets. The method is characterized by comprising power cabinets and a regulating device arranged in an excitation regulation cabinet, wherein the regulating device comprises a main control unit and a current sharing unit; a wire inlet side of an excitation source of each power cabinet is connected to a current transformer in series, and one current transformer is installed in each phase; and output ends of the current transformers are connected to the regulating device. The method has the following beneficial effects that equal distribution control of output current between the parallel running power cabinets is realized through the scheme, and except the regulating device with a current sharing function, the current transformers are only installed in the power cabinets; and furthermore, the method has good regulating performance, low cost and convenient transformation and can provide a solution for current sharing of the power cabinets, which is safe, reliable, lower in cost and easy to operate, for medium and large generator set excitation systems, the current sharing coefficient between the power cabinets is improved and the device damage and operation accidents caused by imbalanced output current are reduced.

Owner:GUODIAN NANJING AUTOMATION

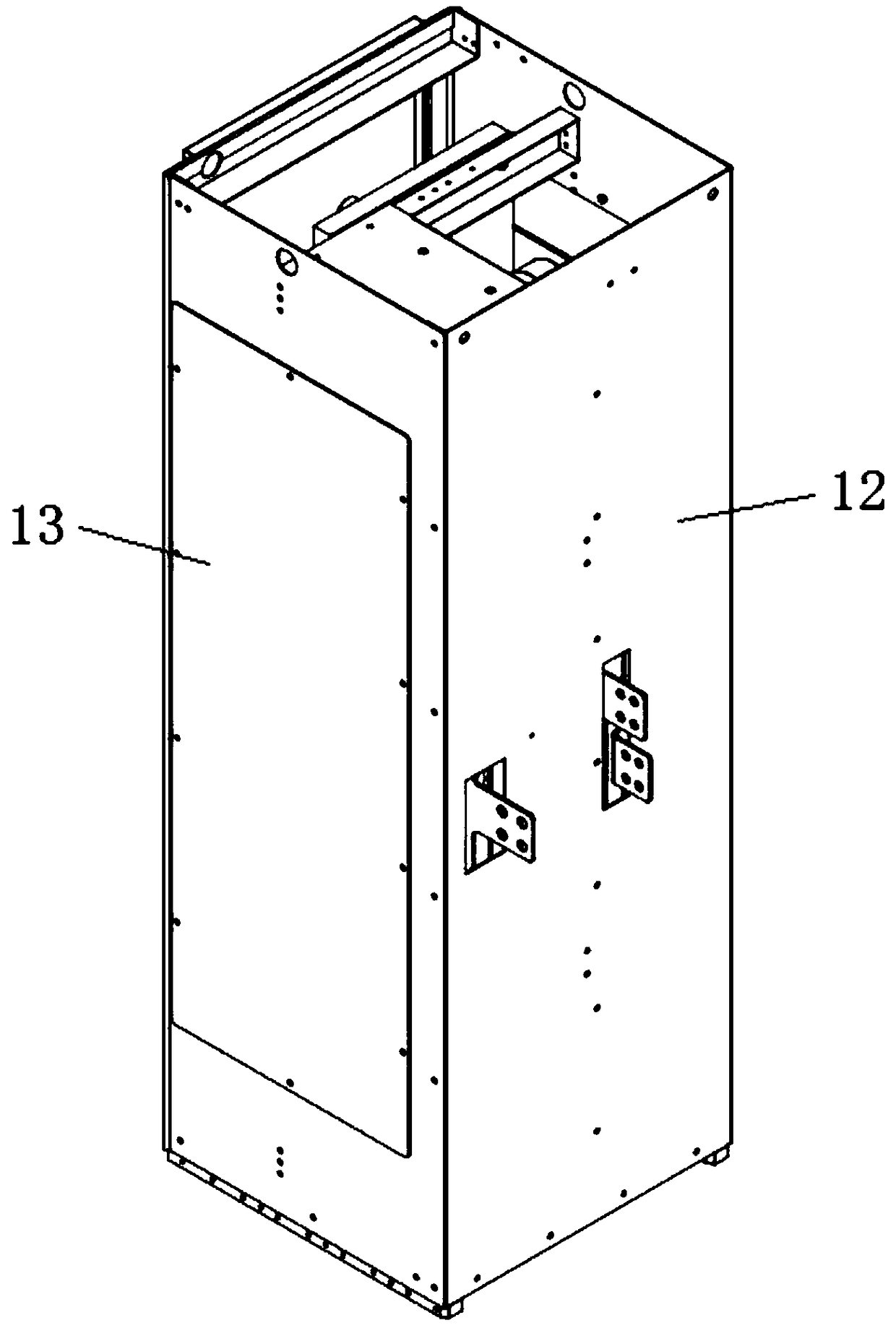

Large-capacity inverter module with high-current/high-voltage IGBT directly connected in parallel

PendingCN109510474AOptimization pathSmall sizeConversion constructional detailsCooling/ventilation/heating modificationsCapacitanceHigh voltage igbt

The invention discloses a large-capacity inverter module with high-current / high-voltage IGBTs directly connected in parallel. The large-capacity inverter module comprises a water-cooled plate, discrete IGBT devices, a laminated busbar, a first absorbing capacitor, a driving loop, an AC side convergence busbar, a current sensor, a DC side laminated busbar, a second absorbing capacitor, a DC side negative convergence busbar and a DC side positive convergence busbar, wherein the number of the discrete IGBT devices is six, and the six discrete IGBT devices are sequentially and evenly arranged on the water cooling plate from top to bottom. The large-capacity inverter module with the high-current / high-voltage IGBTs directly connected in parallel have the advantages that the calculation of current impedance of the branch circuits connected in parallel is precise, the consistency is guaranteed, a high current sharing coefficient is realized, the cable lengths of the devices of different phasesof the driving loop are identical, and the paths are separated and do not interfere with one another; and the large-capacity inverter module adopts a main loop layout design, makes full use of space,optimizes circuit paths, is high in power density, has small overall module size, is simple, is convenient to maintain and install, and has good electrical properties.

Owner:江苏同芯电气科技有限公司

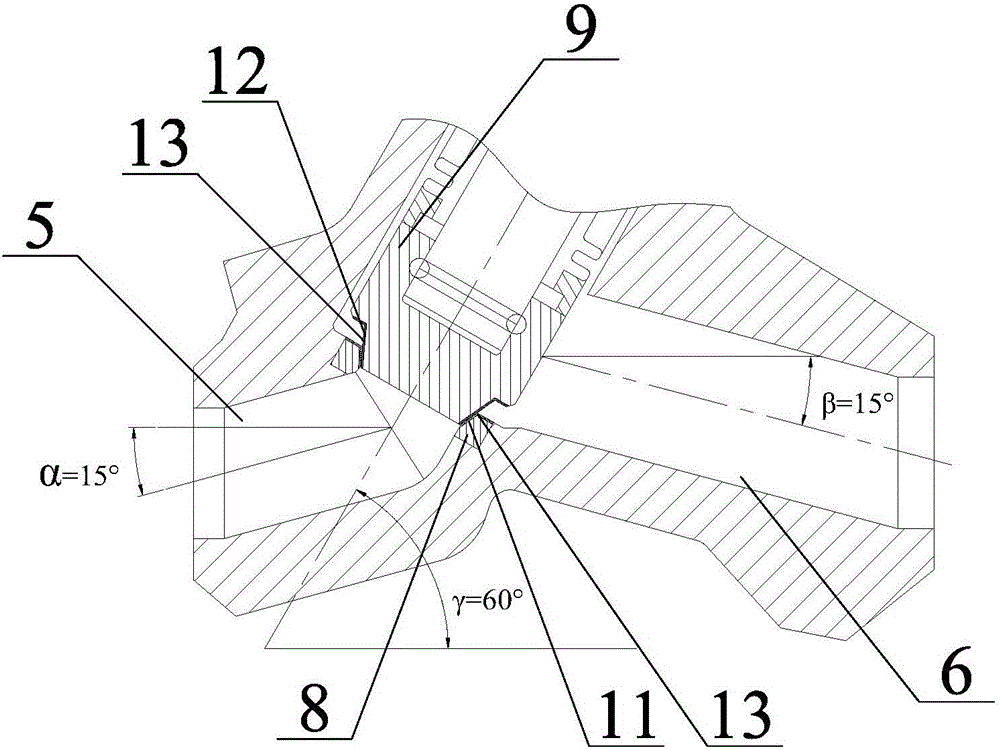

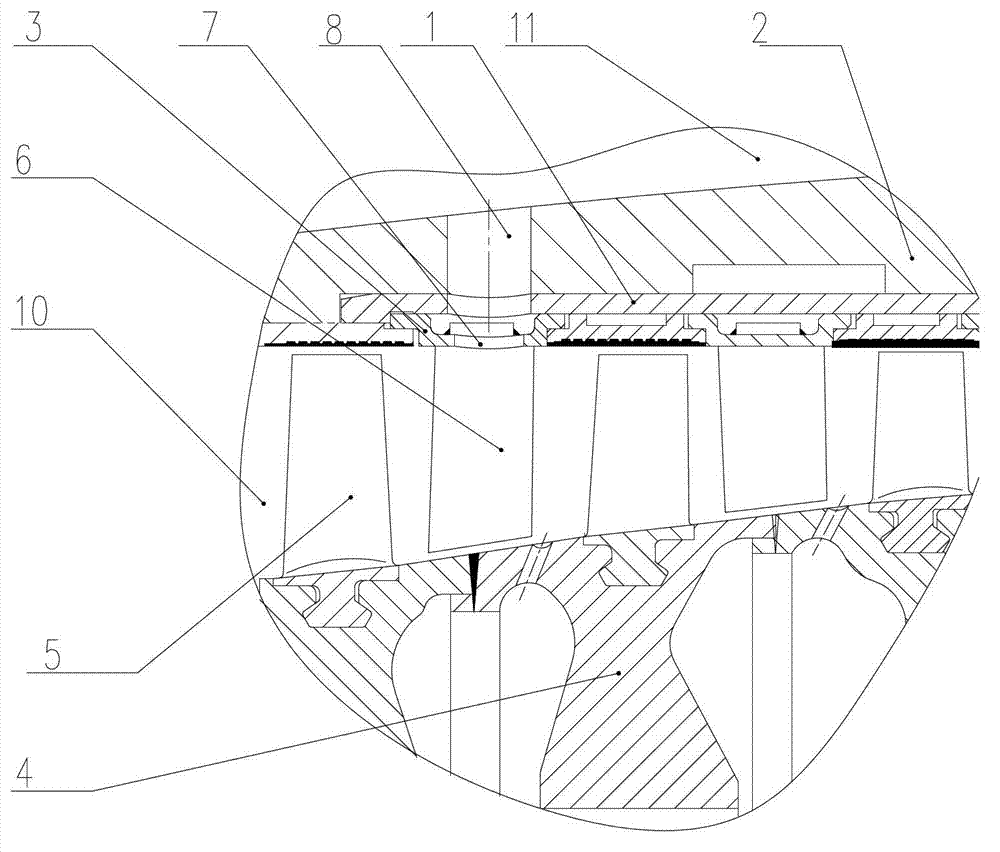

Novel photo-thermal power generation fused salt valve capable of avoiding residues

InactiveCN106051175AEasy maintenanceSimple structureSpindle sealingsLift valveInlet channelMolten salt

The invention discloses a novel photo-thermal power generation fused salt valve capable of avoiding residues. The novel photo-thermal power generation fused salt valve is a Y-shaped valve and comprises a valve body, a valve rod, a support, a hand wheel, a medium inlet channel and a medium outlet channel. The valve body and the support are integrally formed and integrally forged. A valve rod cavity is formed in the valve body, the valve rod extends into the valve rod cavity and is sleeved with a corrugated pipe in an embedded manner, and the corrugated pipe is located in the valve rod cavity. A packing box is arranged above the corrugated pipe, the valve rod is sleeved with the packing box in an embedded manner, a packing ring is placed in the packing box and is tightly pressed through a packing gland above the packing ring, and the packing gland is connected with the valve body through a bolt. The angle alpha formed between the medium inlet channel and the horizontal plane ranges from 10 degrees to 20 degrees, and the angle beta formed between the medium outlet channel and the horizontal plane ranges from 10 degrees to 20 degrees. The fused salt valve is simple in structure, good in sealing performance and convenient and rapid to operate; during work, no leakage happens, safety and reliability are achieved, and the service life is longer; and when a fused salt system stops operating, the situation that due to the fact that fused salt is left and solidified in the valve, the valve is blocked is avoided.

Owner:陈金环

Hard sealing lifting type brake plug valve and control method thereof

ActiveCN105065701AReduce frictionExtended service lifeOperating means/releasing devices for valvesSlide valveEngineeringHigh pressure

The invention relates to a hard sealing lifting type brake plug valve and a control method thereof. The hard sealing lifting type brake plug valve comprises a valve body, a valve seat, a valve plug, a valve rod, a gasket, a valve deck, studs, pins, a packing bushing, swing bolts, a packing pressing plate, swing bolts, a hand wheel, a hand wheel gasket, a nut, packing and a valve rod nut. The valve body and the valve deck are connected through the studs. The valve deck and the packing pressing plate are connected through the swing bolts. The valve rod is connected with the valve plug through a head flat-square part. A full-bore partial-rotation structure is adopted, the flow coefficient is large, and the opening and closing space is small. The metal-sealing, fireproof, anti-static and blowout prevention valve rod structure is adopted, and the hard sealing lifting type brake plug valve is suitable for high-temperature-resistant, high-pressure-resistant and strong-corrosion-resistant working conditions and is wide in application range. The packing structure can be replaced on line, and online maintenance is convenient. During operation, a sealing pair is disengaged, friction between opening and closing torque and the sealing pair is reduced, and the service life of the valve is prolonged.

Owner:浙江福瑞科流控机械有限公司

Coaxial dual-electromagnetic fuel gas injection valve with flowing sectional area adjustable

ActiveCN107091362AAvoid axial forceQuick responseOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringPressure balance

The invention aims at providing a coaxial dual-electromagnetic fuel gas injection valve with the flowing sectional area adjustable. The adjustable gas injection flow is achieved through a dual-valve-element dual-electromagnet control structure. The air inflowing and flow guiding process is achieved through a bypass structure and a flow guiding cavity structure; valve element control and gas way control are achieved through actuator control, and a gas injection function is achieved; through cooperation of an external guiding structure, an internal flow guiding cavity and a pressure balancing groove, the perpendicularity of a valve element is guaranteed, stable and reliable work of gas flow is achieved, and the high responding speed is achieved; through a mixed gas inflowing mode of combining direct gas inflowing of an axial main gas groove and gas inflowing of circumferential gas supplementing holes, high flow is achieved, the gas supplying efficiency of an engine is effectively improved, and meanwhile gas flow interference can be avoided, so that gas way stability is achieved; face sealing and high reliability of the fuel gas injection valve are achieved through multiple annular strip structures between the valve element and a valve base.

Owner:HARBIN ENG UNIV

Fuel nozzle

InactiveCN102235283AImprove economyImprove emission effectFuel injection apparatusMachines/enginesCombustionEngineering

The invention discloses a fuel nozzle, belonging to a fuel spraying device of an internal-combustion engine fuel system. The fuel nozzle is composed of a needle valve body and a needle valve, wherein the head of the needle valve body is provided with at least one combined spray orifice; each combined spray orifice is composed of at least two sub spray orifices; the cross sections of the sub spray orifices are tangent; and the central lines of the sub spray orifices can be parallel or can be in different planes. Because fuel in the combined orifices can have intense disturbance, turbulence kinetic energy is increased so as to improve atomization; and atomization throughout distance is regulated by changing the injection direction of each sub spray orifice so as to improve flow coefficient. By the arrangement of the spray orifices, internal turbulence intensity is improved, atomization is improved, the throughout distance can be regulated, the spatial distribution range of sprayed mist is expanded, the quality of mixed gas is improved, and the effect of quick, sufficient and complete combustion can be achieved, therefore the economic performance, the emission performance and the power performance of the engine can be further improved.

Owner:DALIAN UNIV OF TECH

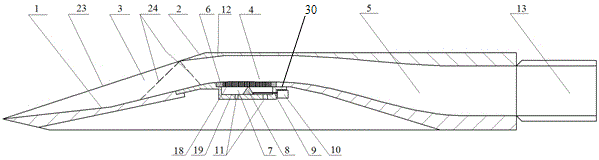

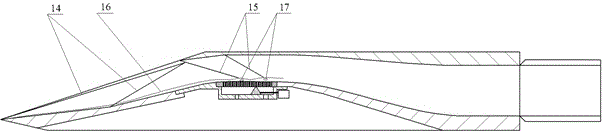

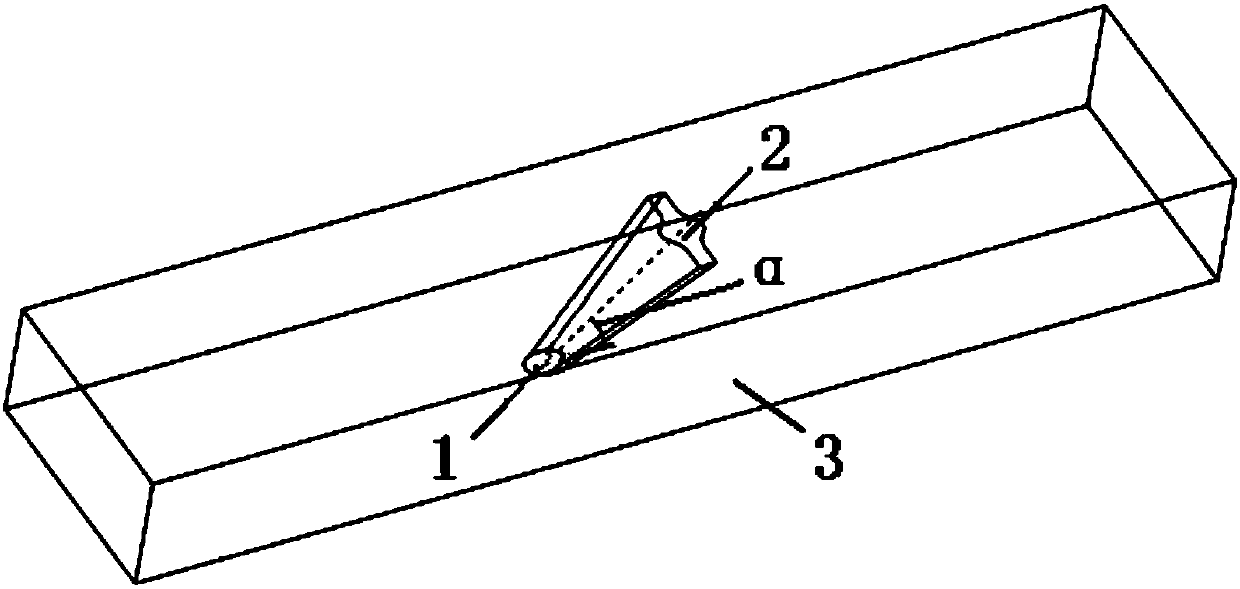

Wing-shaped film hole of hot end component of aeroengine and electrode

The invention discloses a wing-shaped film hole of a hot end component of an aeroengine and an electrode. The wing-shaped film hole of the hot end component of the aeroengine comprises a cold air inlet and a cold air outlet. A central hole shaft of the wing-shaped film hole inclines relative to the wall of the hot end component, and the included angle between the central hole shaft of the wing-shaped film hole and the hot end component is alpha. The span direction of the wing-shaped film hole is increased gradually from the cold air inlet to the cold air outlet, and the thickness of the wing-shaped film hole is decreased gradually from the cold air inlet to the cold air outlet, so that cold air flowing into the wing-shaped film hole from the cold air inlet gradually spreads towards the twosides and flows closely along the outer surface of the hot end component outside the cold air outlet after being sprayed out in a decelerated mode from the cold air outlet which becomes thinner gradually. On the one hand, the cold air can easy flow closely along the wall surface of the hot end component after being sprayed out from the cold air outlet; and on the other hand, the cold air is mixedinto high-temperature fuel gas at a low speed, the pneumatic mixing loss of the fuel gas and the cold air is reduced, and the pneumatic efficiency of turbine blades is improved. The wing-shaped filmhole of the hot end component of the aeroengine and the electrode are easy to manufacture and machine and high in efficiency.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

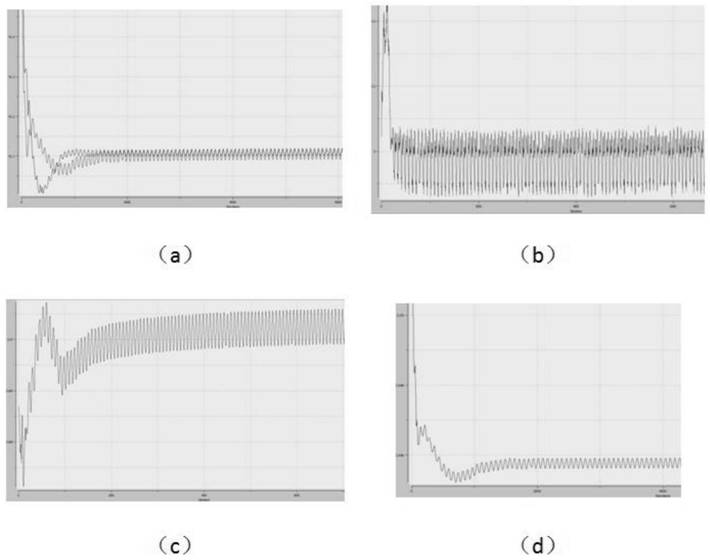

Surge-preventing structure for aero-engine compressor

ActiveCN103047193AIncrease pressure ratioImprove efficiencyPump componentsPumpsAero engineElectrical and Electronics engineering

The invention relates to a surge-preventing structure for an aero-engine compressor. A stator ring is mounted inside a compressor case, uniformly and peripherally distributed stator vanes are arranged on the stator ring, a compressor rotor is positioned inside the compressor case 1 and is provided with rotor vanes, a radial vent hole is reserved between each two stator vanes and at the peripheral position of the stator vanes on the stator ring, and vent holes with the diameter larger than that of each radial vent hole are reserved at the corresponding positions on an intermediate case and the compressor case. Speed loss and surge due to overlarge attack angles are eliminated; and flow condition is improved, thereby surge can be prevented effectively. The surge-preventing structure has the advantages that compressor characteristics can be improved, stable working range can be widened, and the surge-preventing structure can be used for preventing 'front-surge and rear-vortex' type surges and is convenient to process, low in size required accuracy, simple, low in cost and reduced in gas loss.

Owner:HARBIN DONGAN ENGINE GRP

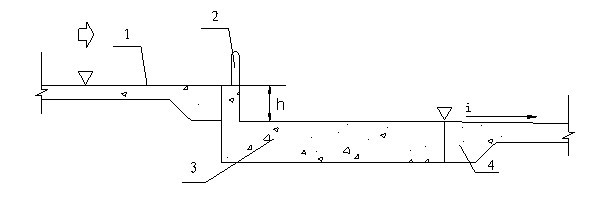

Flood discharge structure adopting bottom hole and surface hole combined flood discharge and energy dissipation

The invention provides a flood discharge structure adopting bottom hole and surface hole combined flood discharge and energy dissipation. The flood discharge structure comprises a surface hole and a bottom hole, wherein the surface hole and the bottom hole are formed in sequence from top to bottom in a vertical direction, the surface hole comprises a wide pier which is arranged in the middle and overflow surface holes which are formed in both sides of the wide pier, the bottom hole comprises a flood discharge bottom hole which is formed in the middle below the surface hole, and an outlet of the flood discharge bottom hole is located in a connected area of the two overflow surface holes. The overflow surface holes and the flood discharge bottom hole are formed in a combined mode from top tobottom in the vertical direction; when the discharge amount is small, only the bottom hole is opened so as to discharge water; and when the discharge capacity is large, the overflow surface holes andthe flood discharge bottom hole are opened at the same time so as to discharge flood, and the energy dissipation rate and the flow coefficient are increased. Water flow from the surface and bottom holes collides in the air, the nappe transversely diffuses, energy is dissipated, the impact strength on a stilling pool is reduced, and the digging depth can be correspondingly reduced; and additionally, the longitudinal length of the nappe is reduced, and the length of the stilling pool can be correspondingly reduced. Therefore, the flood discharge structure and the stilling pool are compact in arrangement and are convenient to manage, and the engineering investment is saved.

Owner:WUHAN UNIV

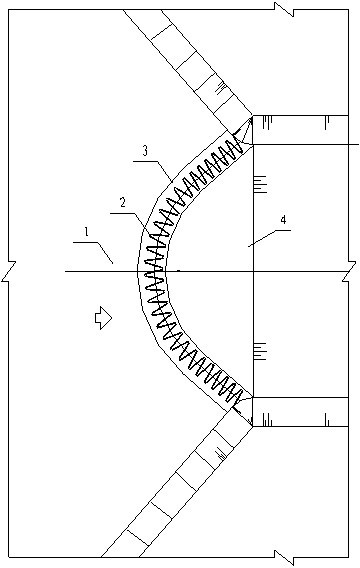

Arc-shaped labyrinth weir with downstream dropping slope chute

InactiveCN102587330ALower the elevationDelayed submerged flowBarrages/weirsClimate change adaptationWater flowEngineering

The invention relates to a labyrinth weir, in particular to an arc-shaped labyrinth weir with a downstream dropping slope chute. The arc-shaped labyrinth weir provided by the invention comprises an upstream approach channel, a labyrinth weir bottom plate and a labyrinth weir downstream chute connected in a water flow direction; the labyrinth weir bottom plate is an arc-shaped labyrinth weir; dams slantly extend out from two ends of the arc-shaped labyrinth weir in the water flow direction; and the dams at the two ends of the arc-shaped labyrinth weir are V-shaped. The arc-shaped labyrinth weir provided by the invention is characterized in that an arc-shaped labyrinth weir body is arranged on the top face of the labyrinth wire bottom plate and is folded in an arc shape from one end of the arc-shaped labyrinth weir bottom plate to the other end of the arc-shaped labyrinth weir bottom plate. With the adoption of the arc-shaped labyrinth weir provided by the invention, the disadvantage that the discharge capacity is reduced due to the submerged flow state at the downstream in the prior art is avoided.

Owner:POWERCHINA XIBEI ENG

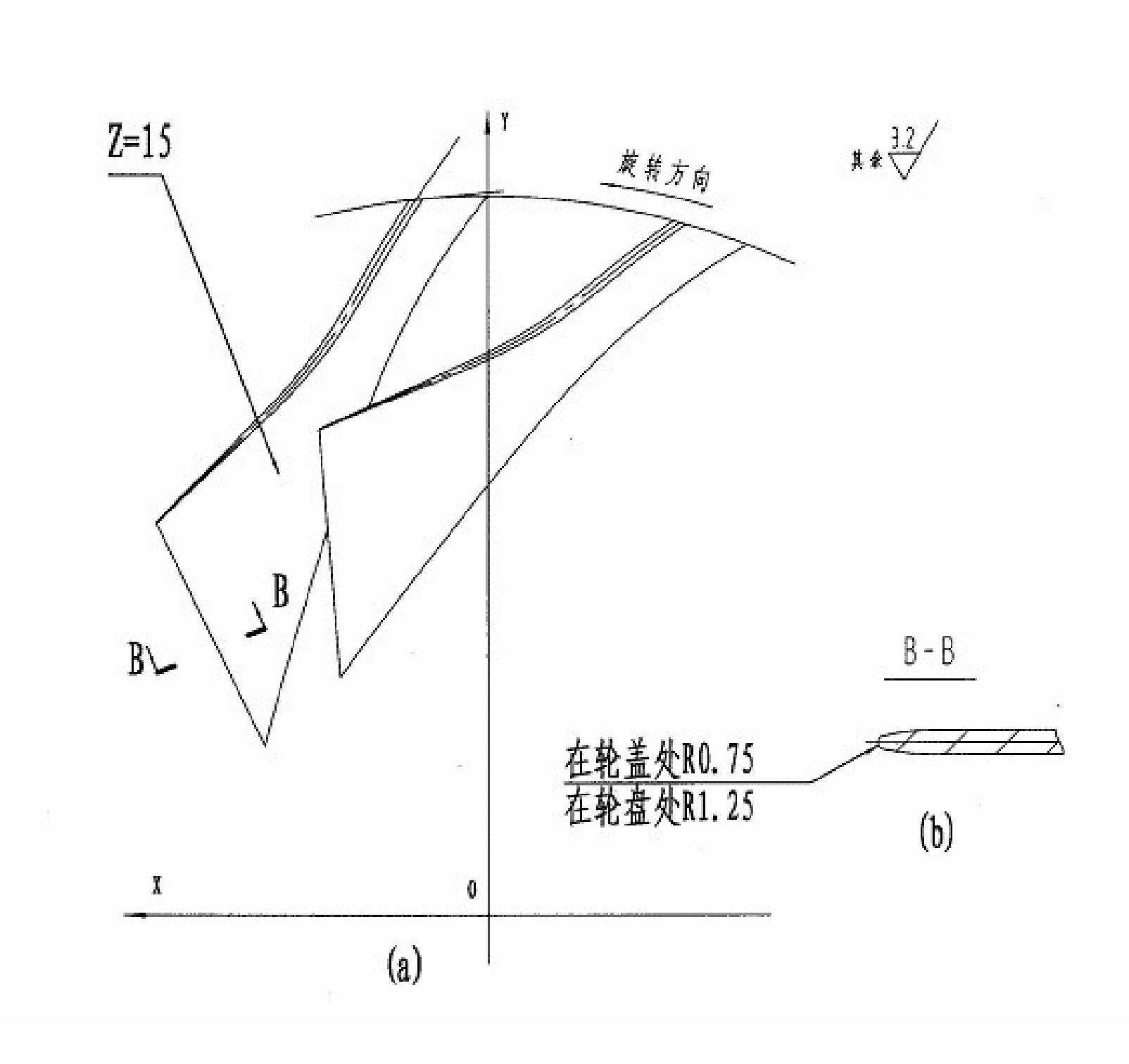

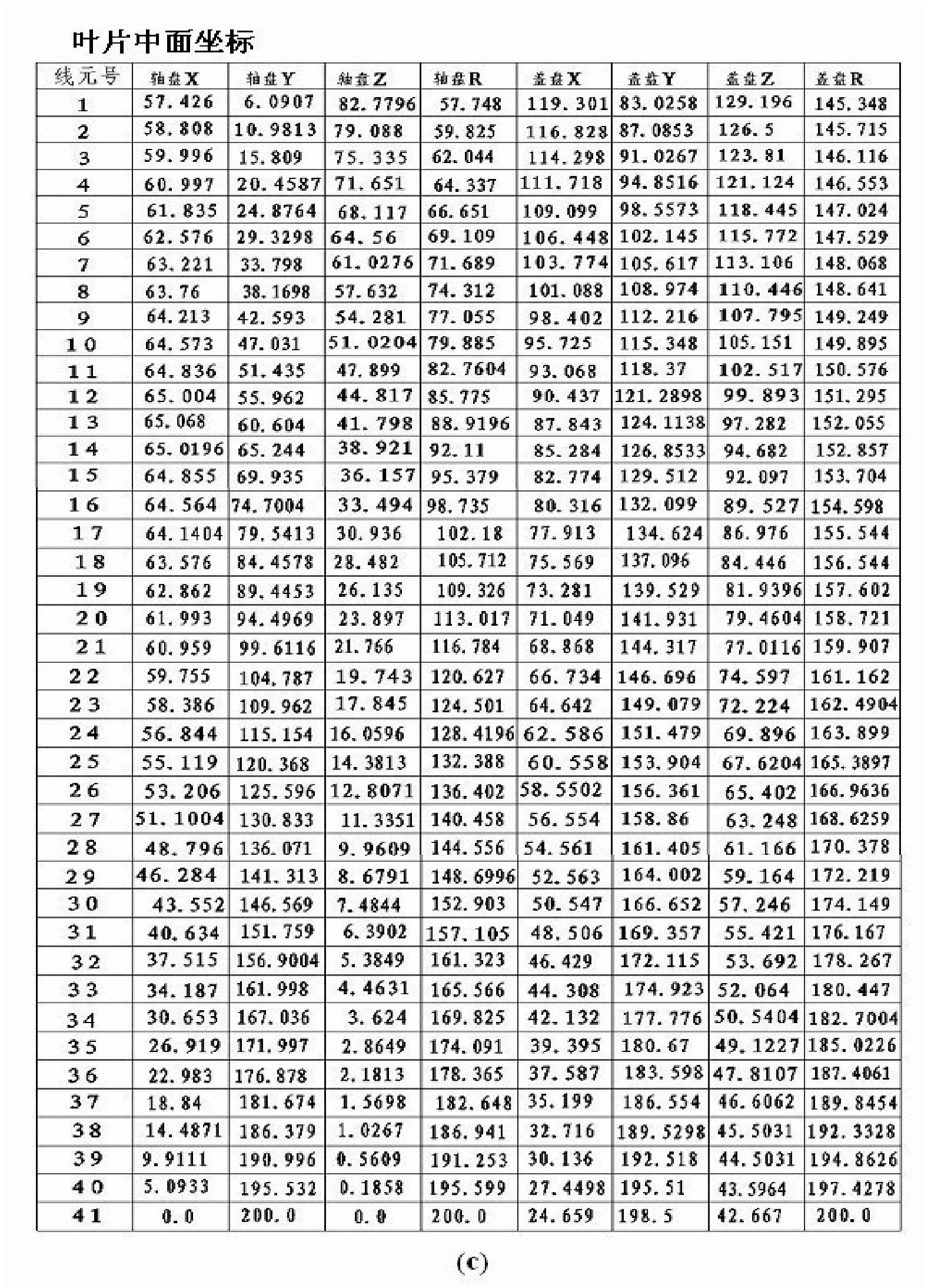

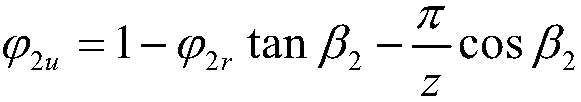

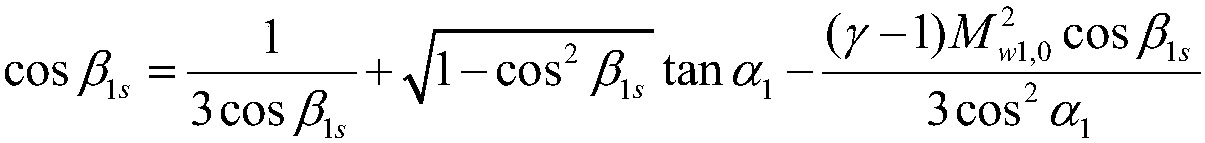

Method of calculating centrifugal impeller pre-swirl entry enthalpy rise coefficient based on maximum flow coefficient

ActiveCN108533525AHigh trafficImprove flow coefficientGeometric CADPump componentsImpellerEngineering

A method of calculating centrifugal impeller pre-swirl entry enthalpy rise coefficient based on maximum flow coefficient comprises: determining design requirements of a centrifugal impeller; giving acharacteristic constant of a fluid medium and a geometric constant of the centrifugal impeller; calculating outlet tangential speed ratio of the centrifugal impeller; setting initial enthalpy rise coefficient; calculating machine Mach number; setting initial relative Mach number of a centrifugal impeller inlet wheel cover; calculating relative axial flow angle of the centrifugal impeller inlet wheel cover; calculating relative Mach number of the centrifugal impeller inlet wheel cover; judging a relative error between the relative Mach number of the centrifugal impeller inlet wheel cover and aset initial relative Mach number of the centrifugal impeller inlet wheel cover is less than a set value; calculating a ratio of the diameter of the centrifugal impeller inlet wheel cover to the diameter of a centrifugal impeller outlet; calculating enthalpy rise coefficient; judging a relative error between the enthalpy rise coefficient and a set initial enthalpy rise coefficient is less than a set value. The method is capable of quickly and accurately calculating enthalpy rise coefficient of a high-flow centrifugal impeller under any pre-swirl entry angle; the centrifugal impeller manufactured has high flow and compact structure.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com