Extruding and grinding device for spray orifice of oil spray nozzle and extruding and grinding method for spray orifice of oil spray nozzle

A technology of extrusion grinding and oil injection nozzle, which is applied in the direction of grinding workpiece support, grinding/polishing equipment, metal processing equipment, etc., which can solve the problem of difficult to meet high-precision flow measurement, difficult to stabilize system pressure, high hydraulic oil requirements, etc. problems, to achieve the effect of facilitating daily production management, eliminating burrs, and improving process practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

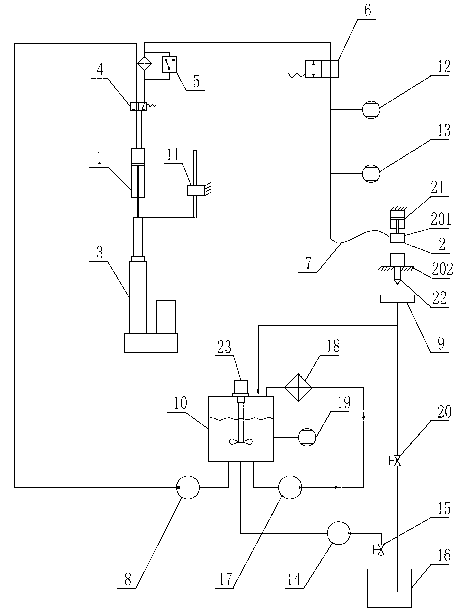

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] See figure 1 , the injector orifice extrusion grinding device of the present invention comprises an electric cylinder 3, the electric cylinder 3 is driven and connected with the abrasive cylinder 1, and the piston of the electric cylinder 3 drives the piston of the abrasive cylinder 1 to reciprocate, and the abrasive cylinder 1 is sequentially connected through pipelines. Reversing valve 4, filter 5, shut-off valve-6 and high-pressure hose 7, pressure sensor 12 and temperature sensor-13 are connected through pipelines between shut-off valve-6 and high-pressure hose 7, and high-pressure hose 7 is connected to the clamp 2. The clamp 2 includes a clamp pressure head 201 and a clamp base 202. The clamp pressure head 201 has a flow channel connected to the small hole of the processed part. The high-pressure hose 7 is connected to the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com