Patents

Literature

168results about How to "Eliminate burrs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

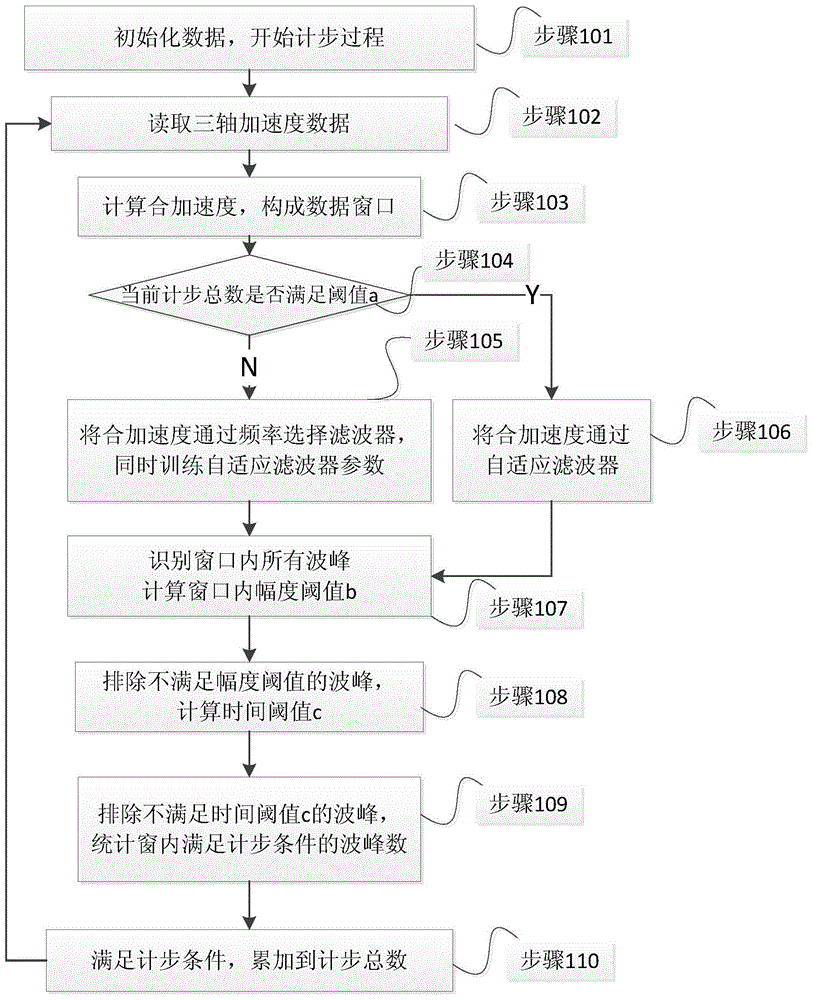

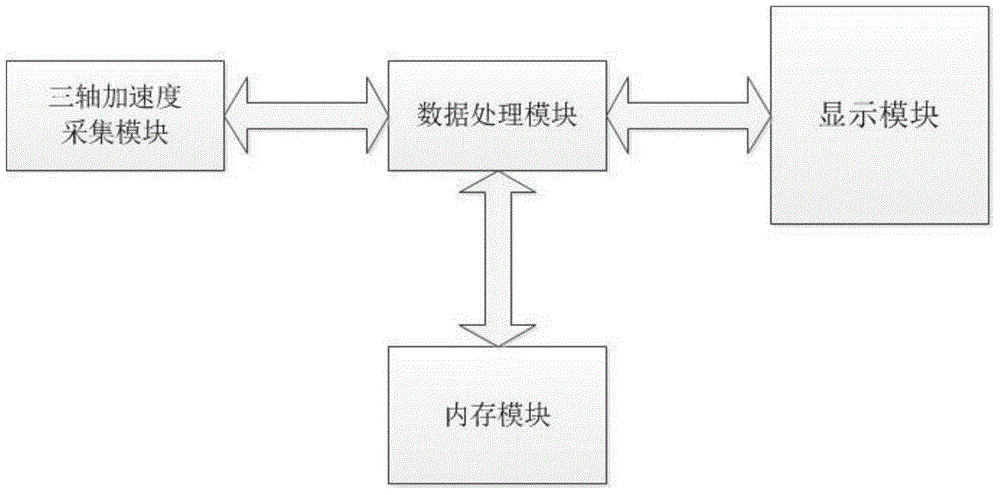

Step counting method

ActiveCN104406604AEliminate burrsAccurate step countingDistance measurementStep countingAdaptive filter

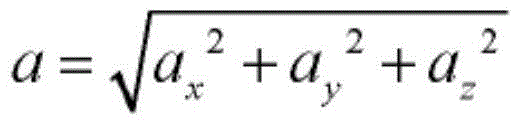

The invention provides a step counting method which comprises the following steps: 1), obtaining resultant acceleration data within a period of time according to a data window, wherein the data window continuously translates in the forward direction on a timer shaft; 2), using a self-adapting filter for filtering the resultant acceleration data in a current data window, wherein self-adaptation training is performed on the filter coefficient of the self-adapting filter according to the resultant acceleration data in the current data window; 3), performing step counting according to the filtered resultant acceleration data in the current data window. The step counting method can provides relatively accurate step counting results timely.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

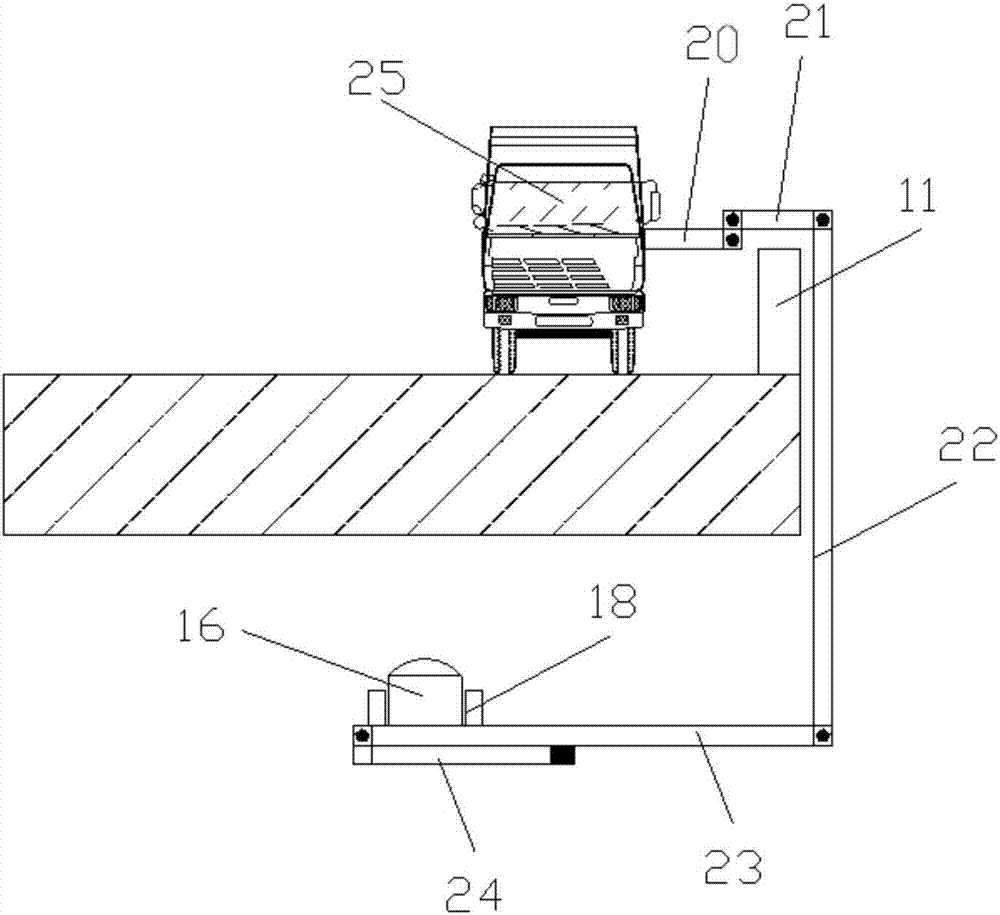

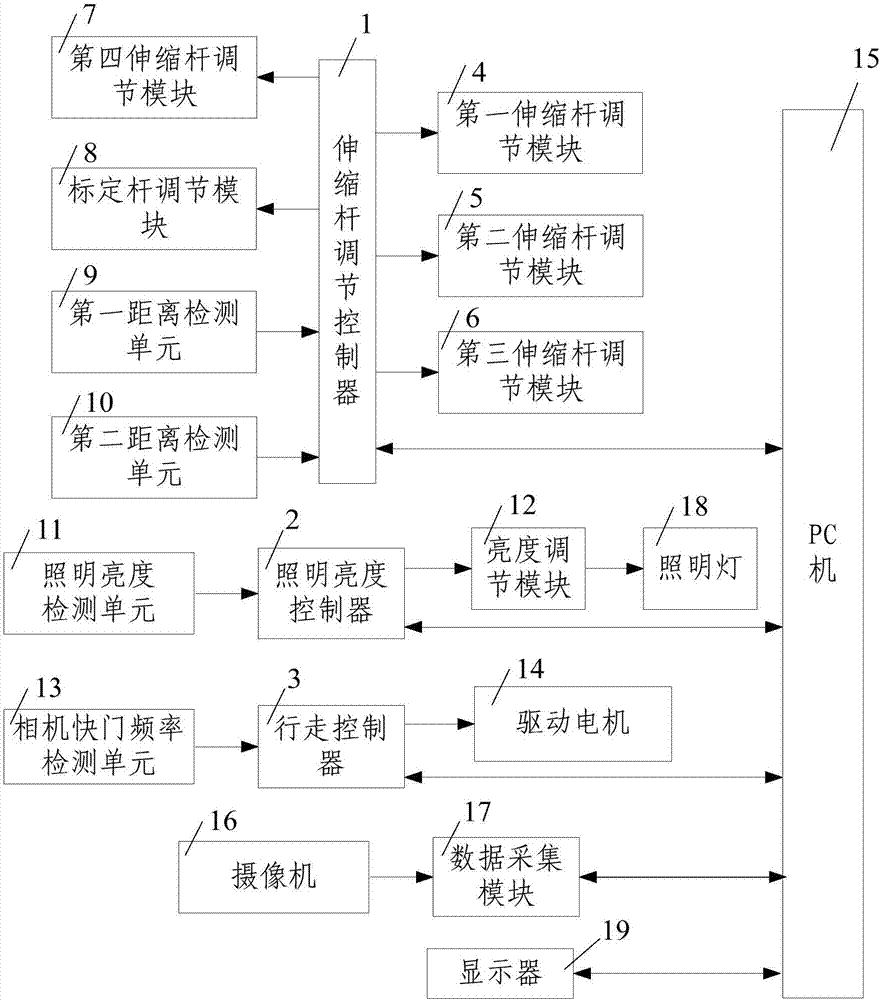

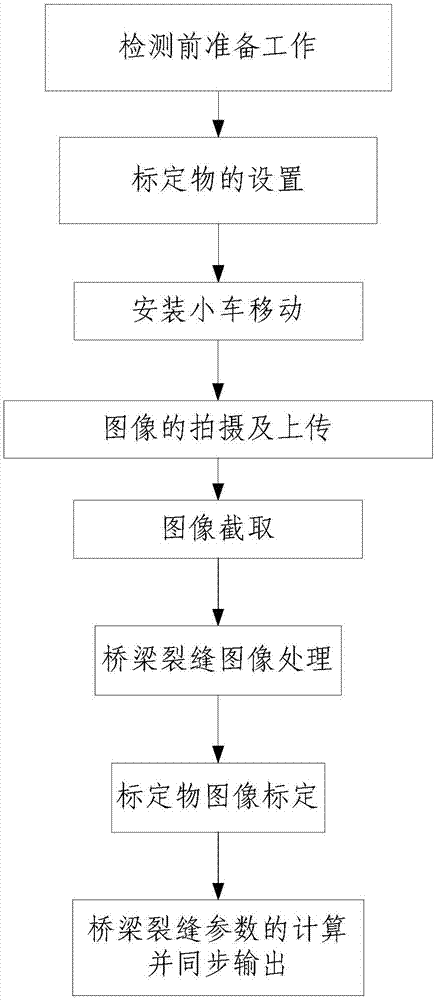

Bridge crack detection device and detection method

ActiveCN107064169ASimple structureReasonable designOptically investigating flaws/contaminationImaging processingImage calibration

The invention discloses a bridge crack detection device and detection method. The automatic bridge crack detection device comprises a control device, an installation car, a telescopic rod mechanism and a detection device, wherein the control device comprises a data processing device, a display, a walking controller, a camera shutter frequency detection unit, a telescopic rod adjusting device, a telescopic rod adjusting controller, a first distance detection unit, a second distance detection unit, an illuminating brightness detection unit, a brightness adjusting module and an illuminating brightness controller. The detection method comprises the steps of (1) preparatory work before detection; (2) shooting and uploading of an image; (3) image capturing; (4) bridge crack image processing; (5) calibration object image calibration; and (6) calculating and synchronous outputting of bridge crack parameters. The bridge crack detection device is simple in structure, reasonable in design, and convenient to use and operate, accurate and quick detection of the size of bridge cracks can be achieved, and the work efficiency of bridge crack detection and the reliability of detection data are improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

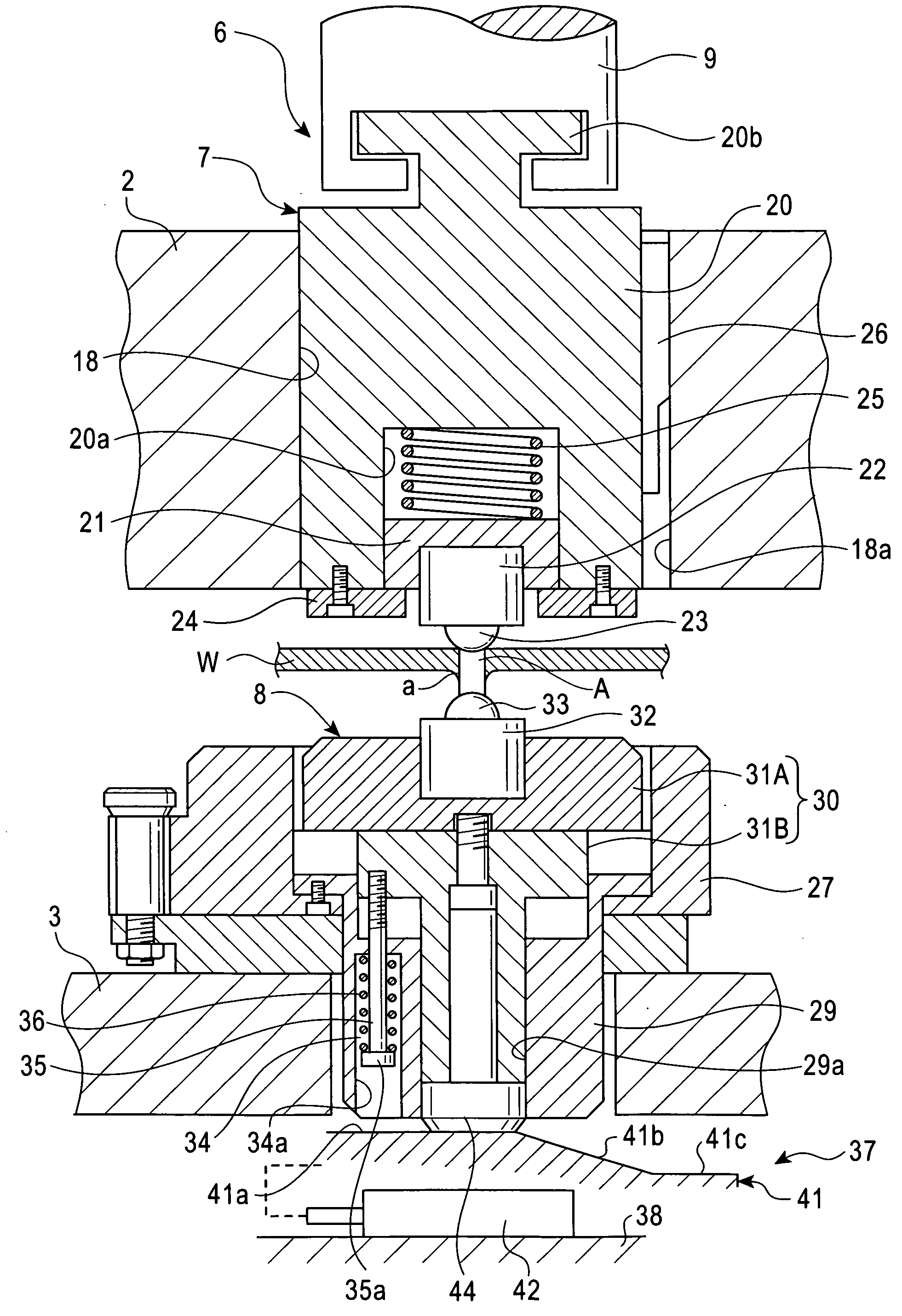

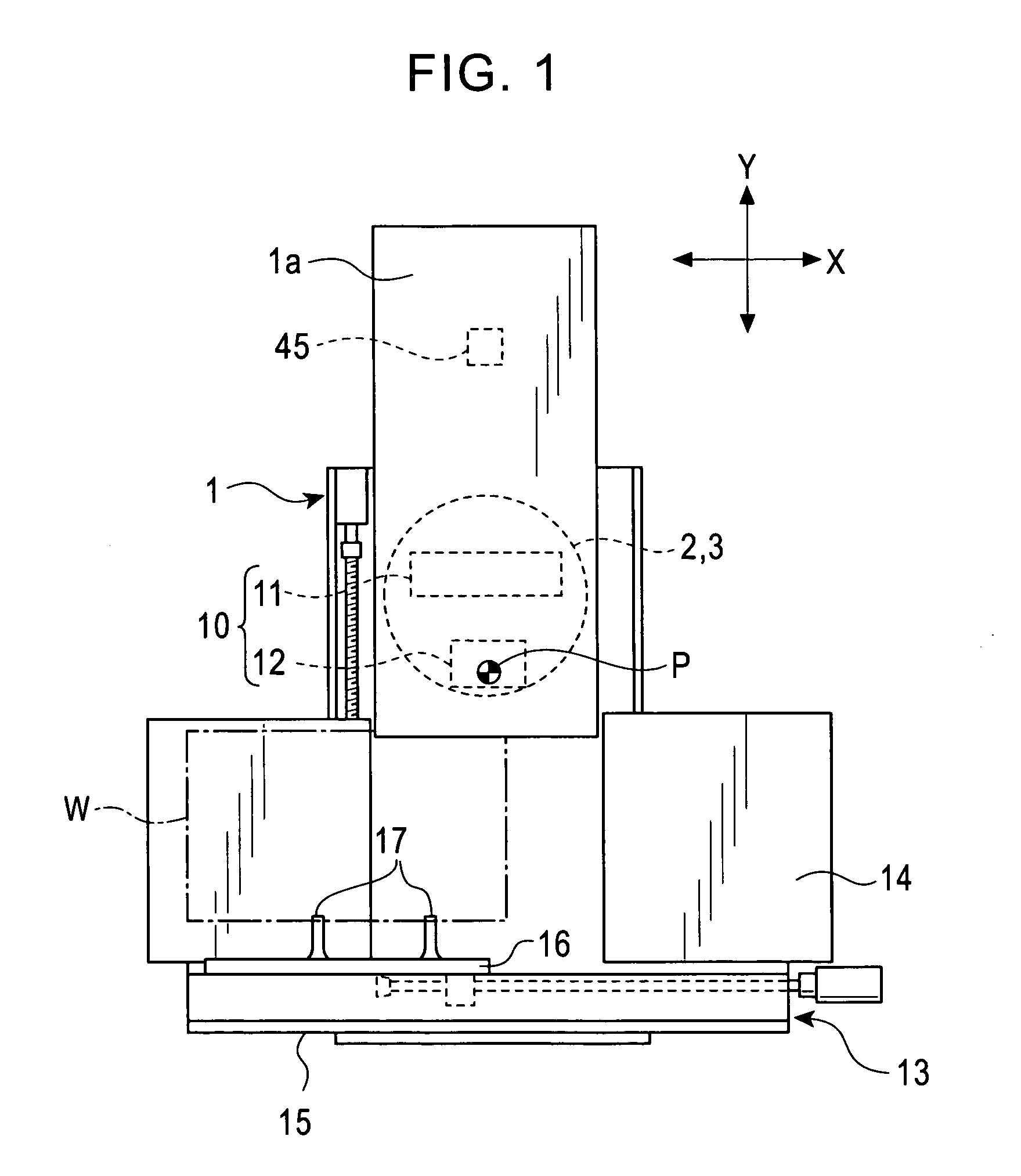

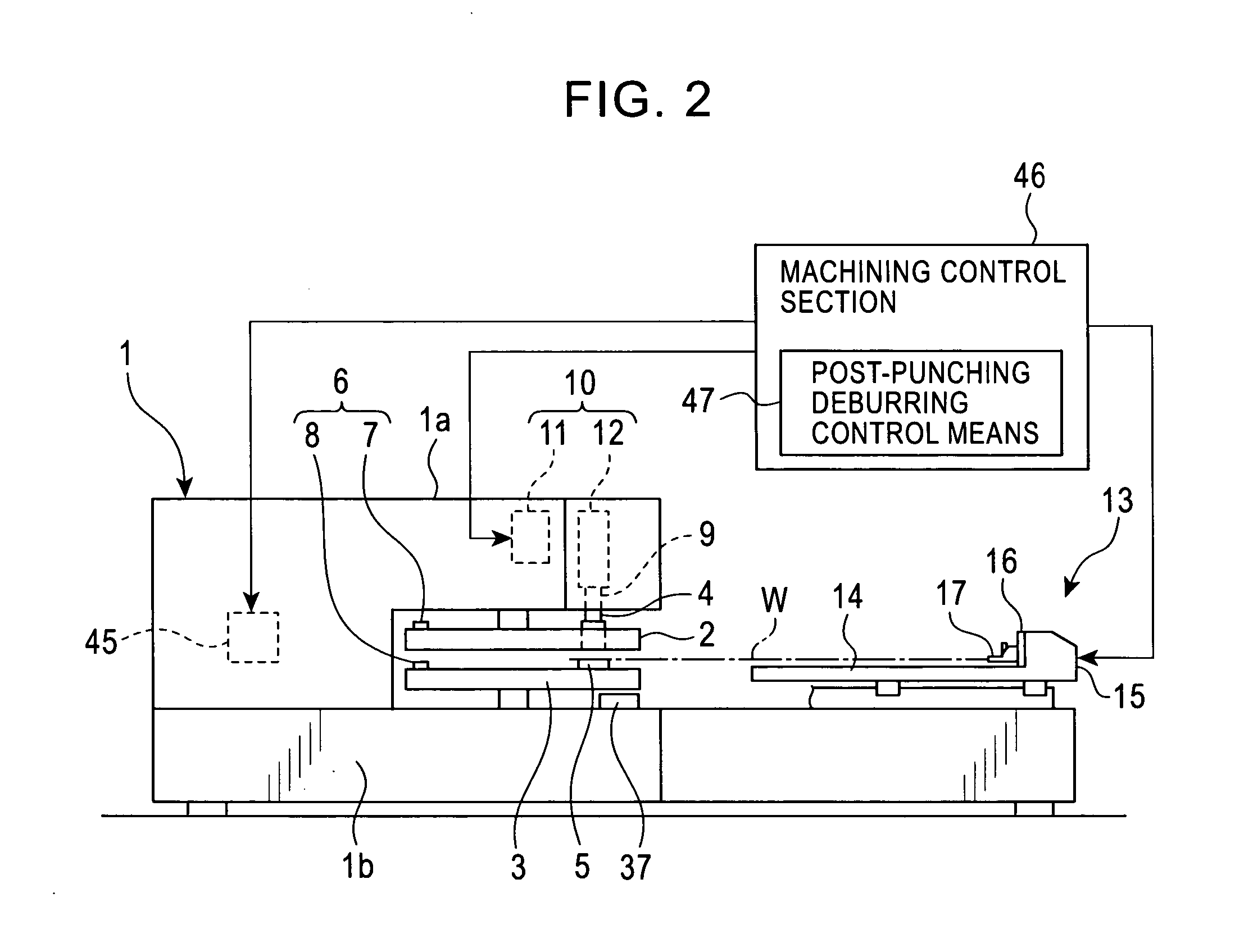

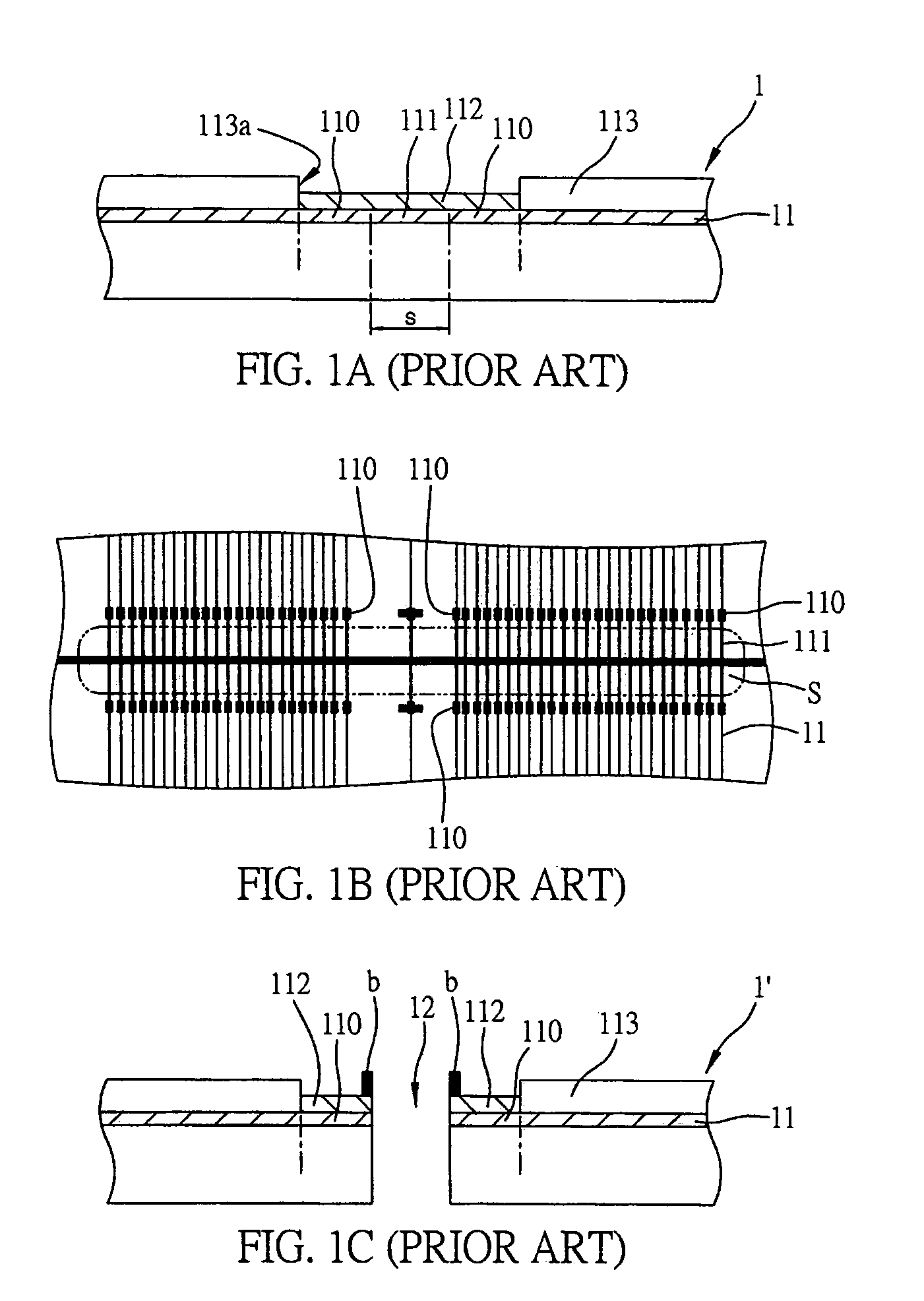

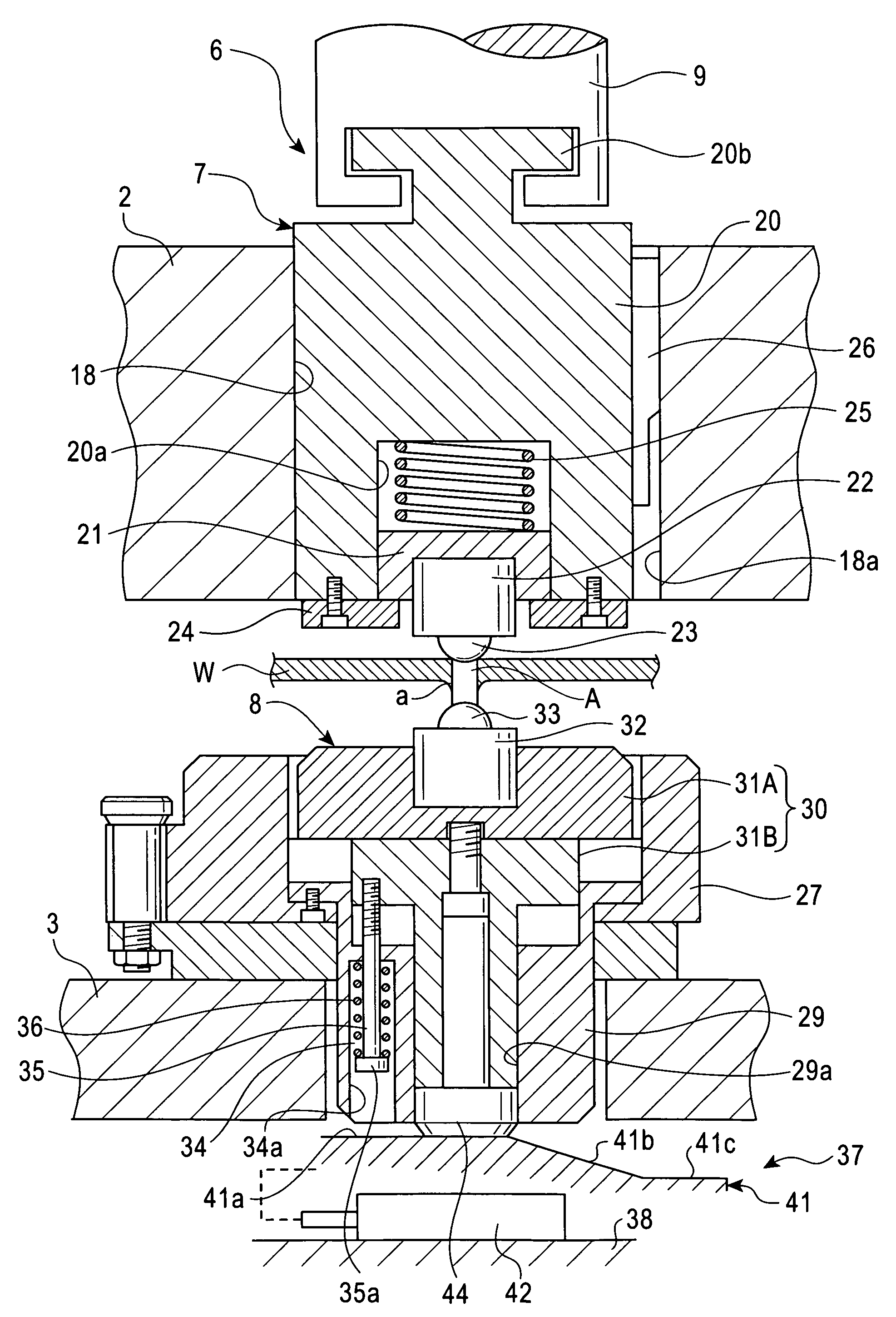

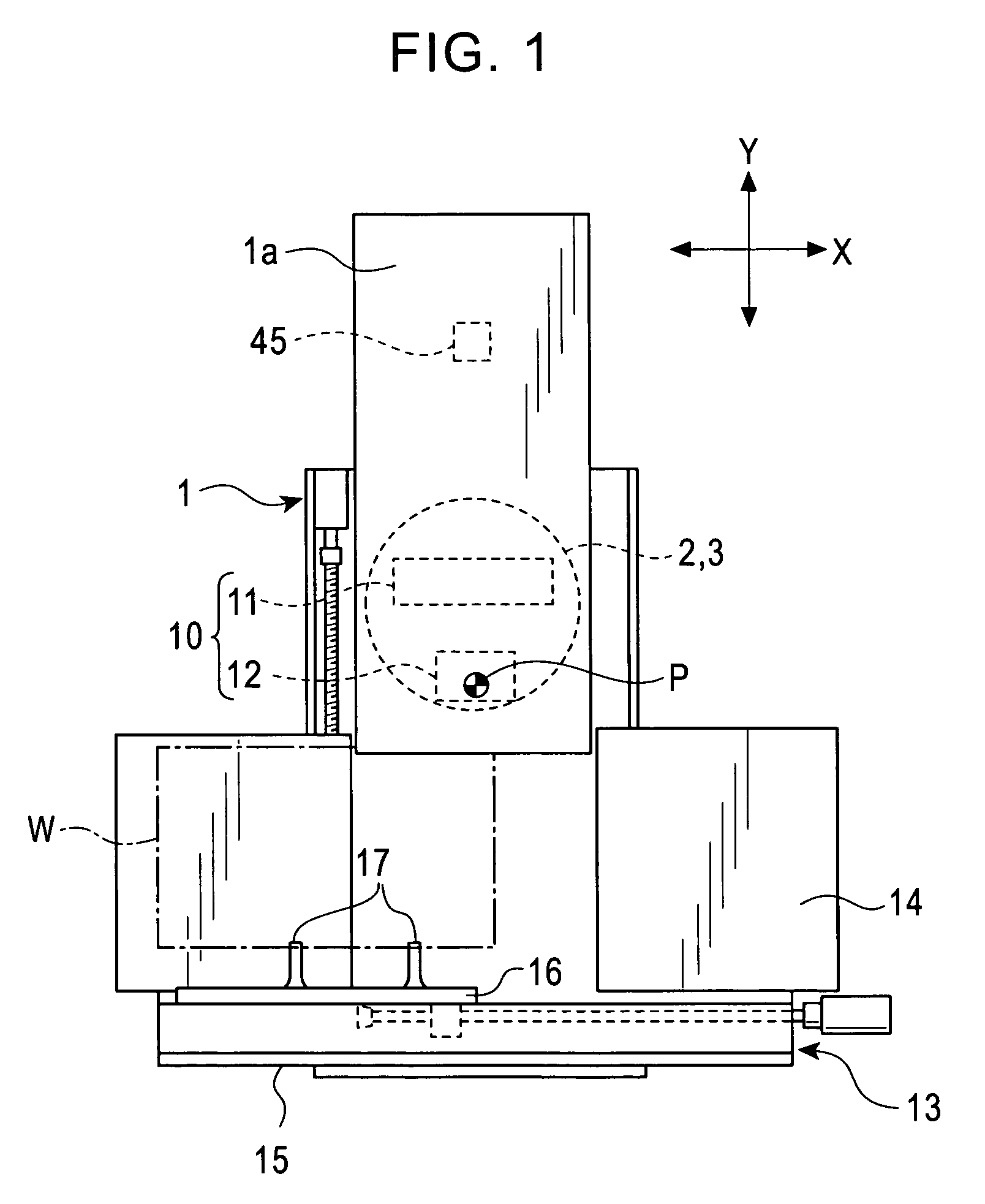

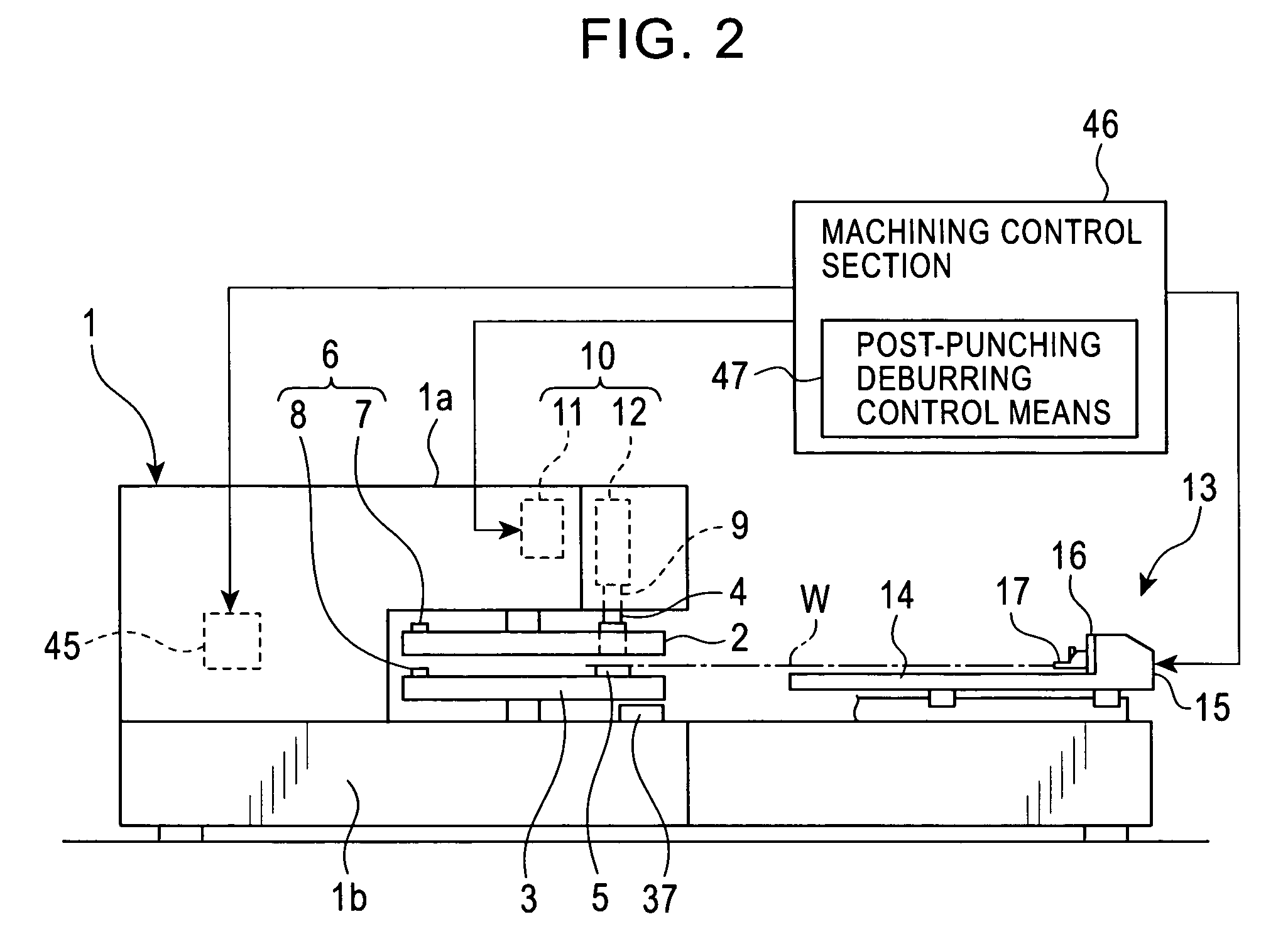

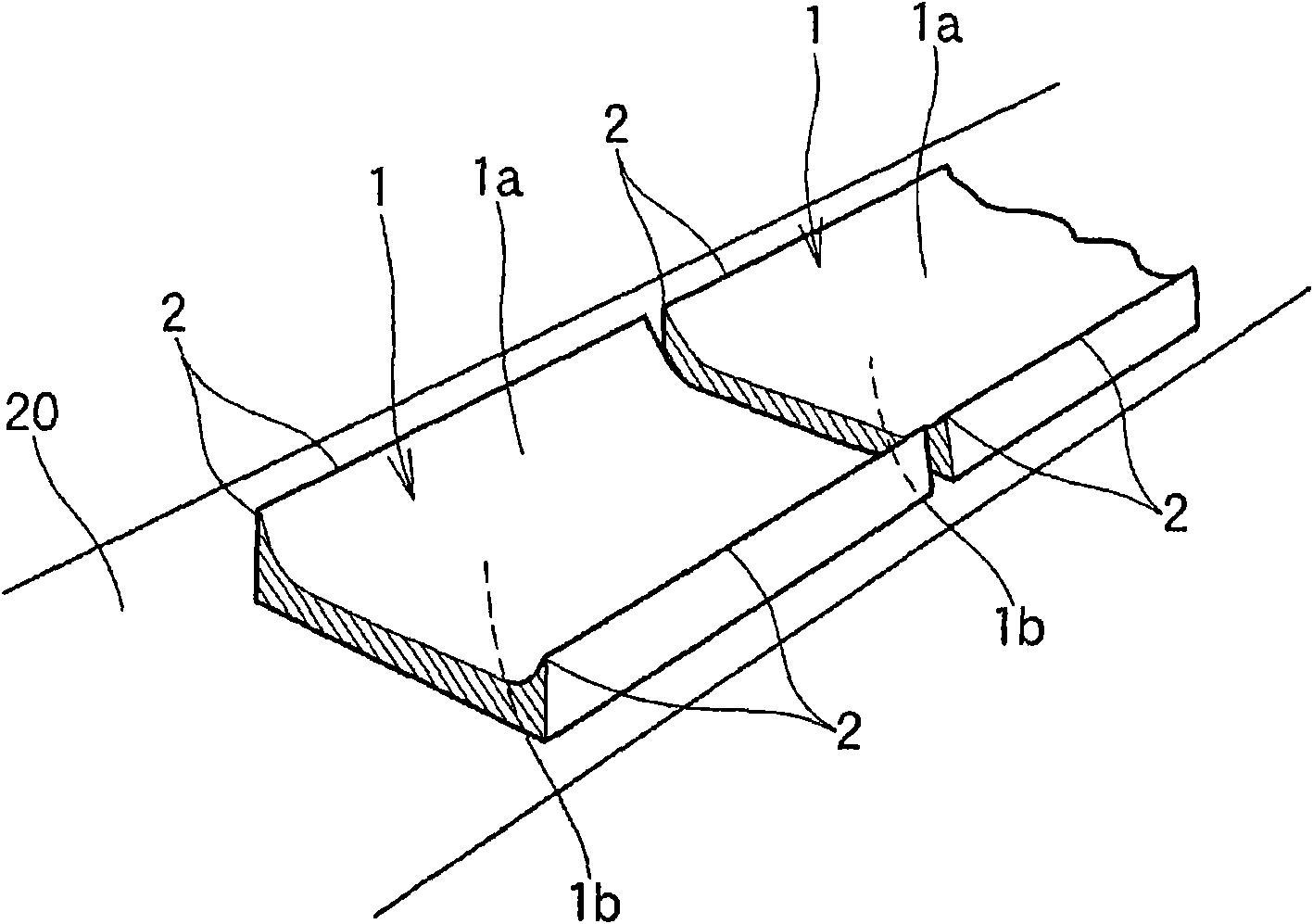

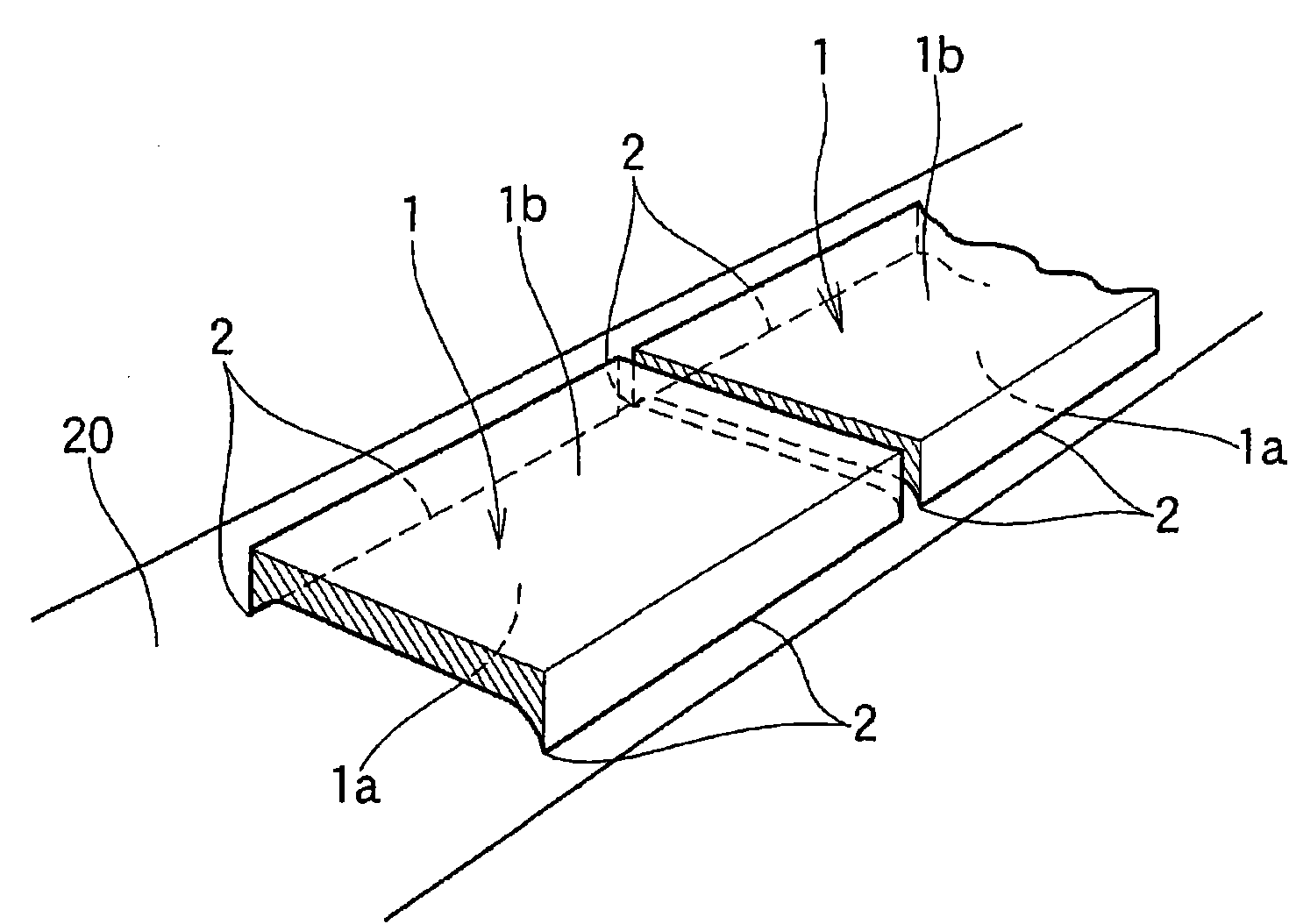

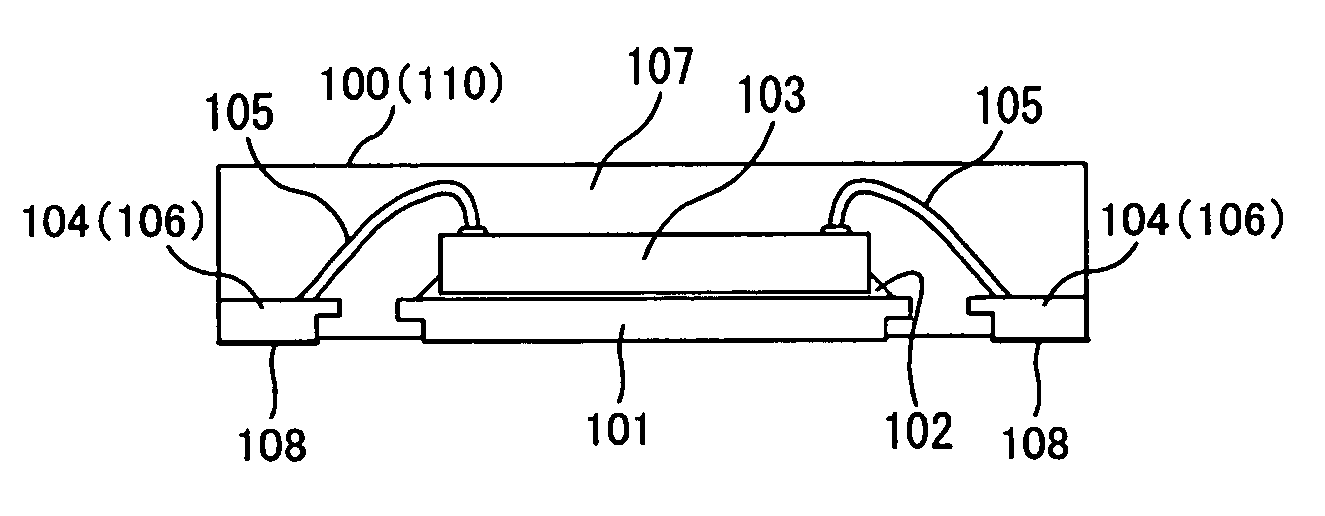

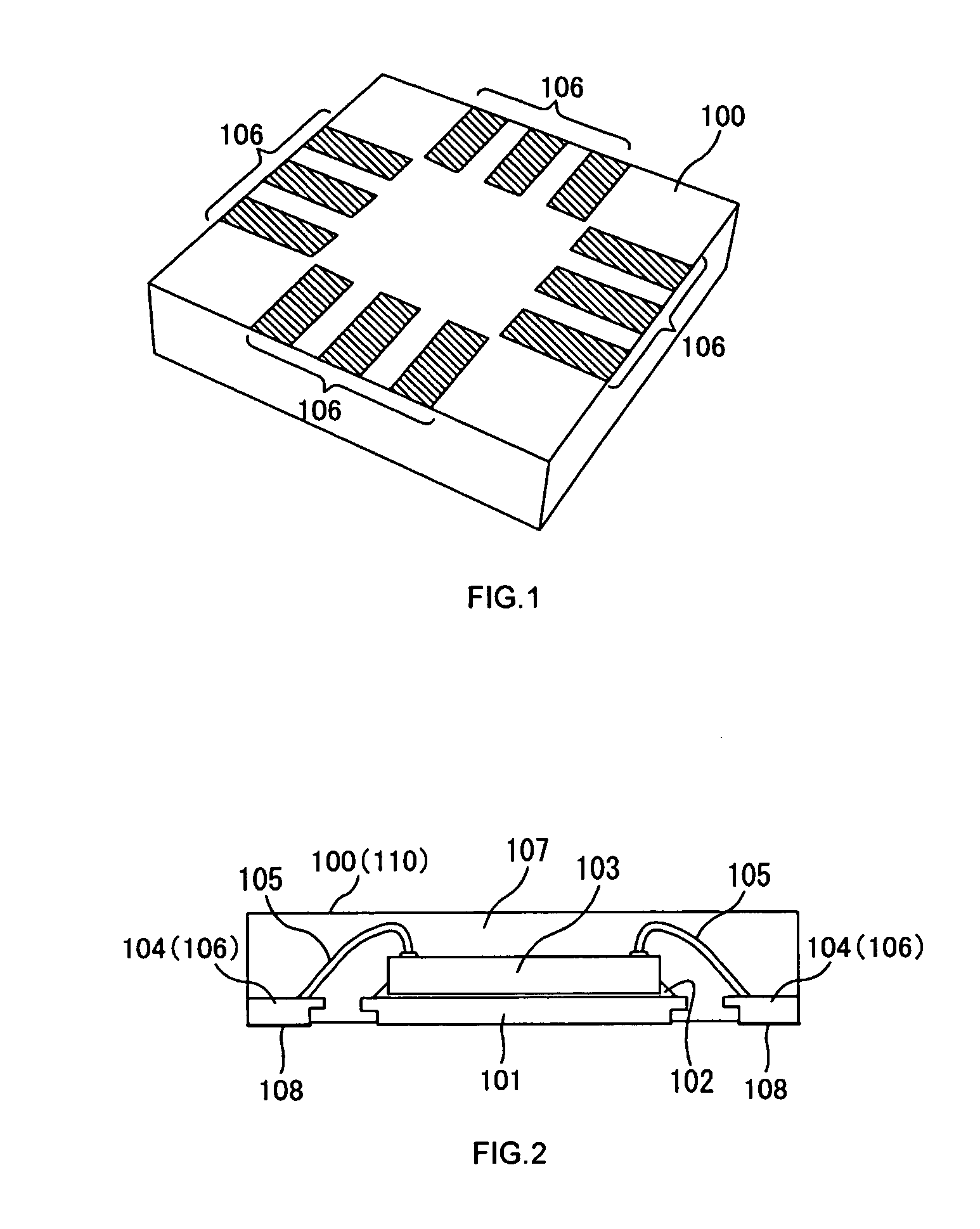

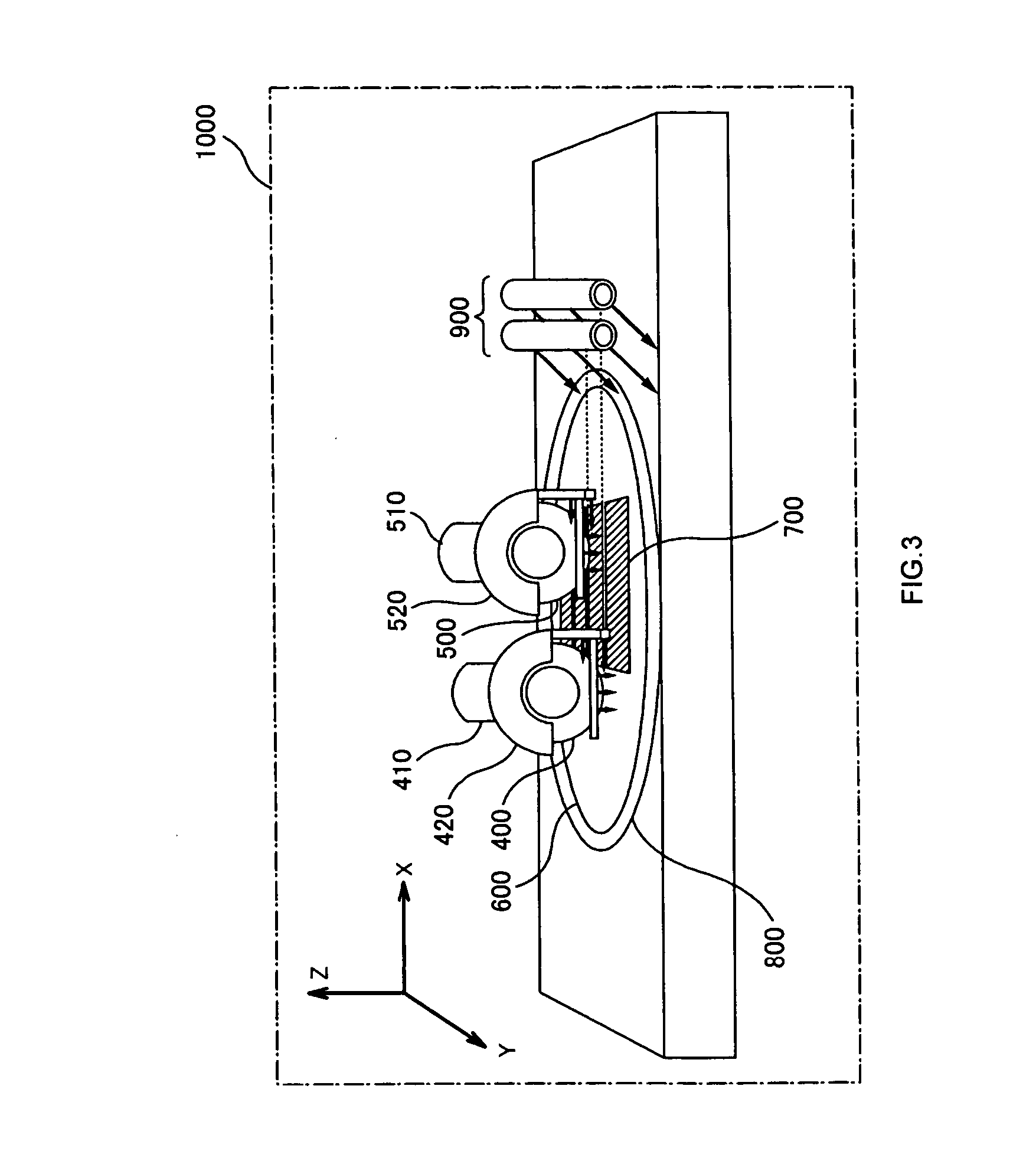

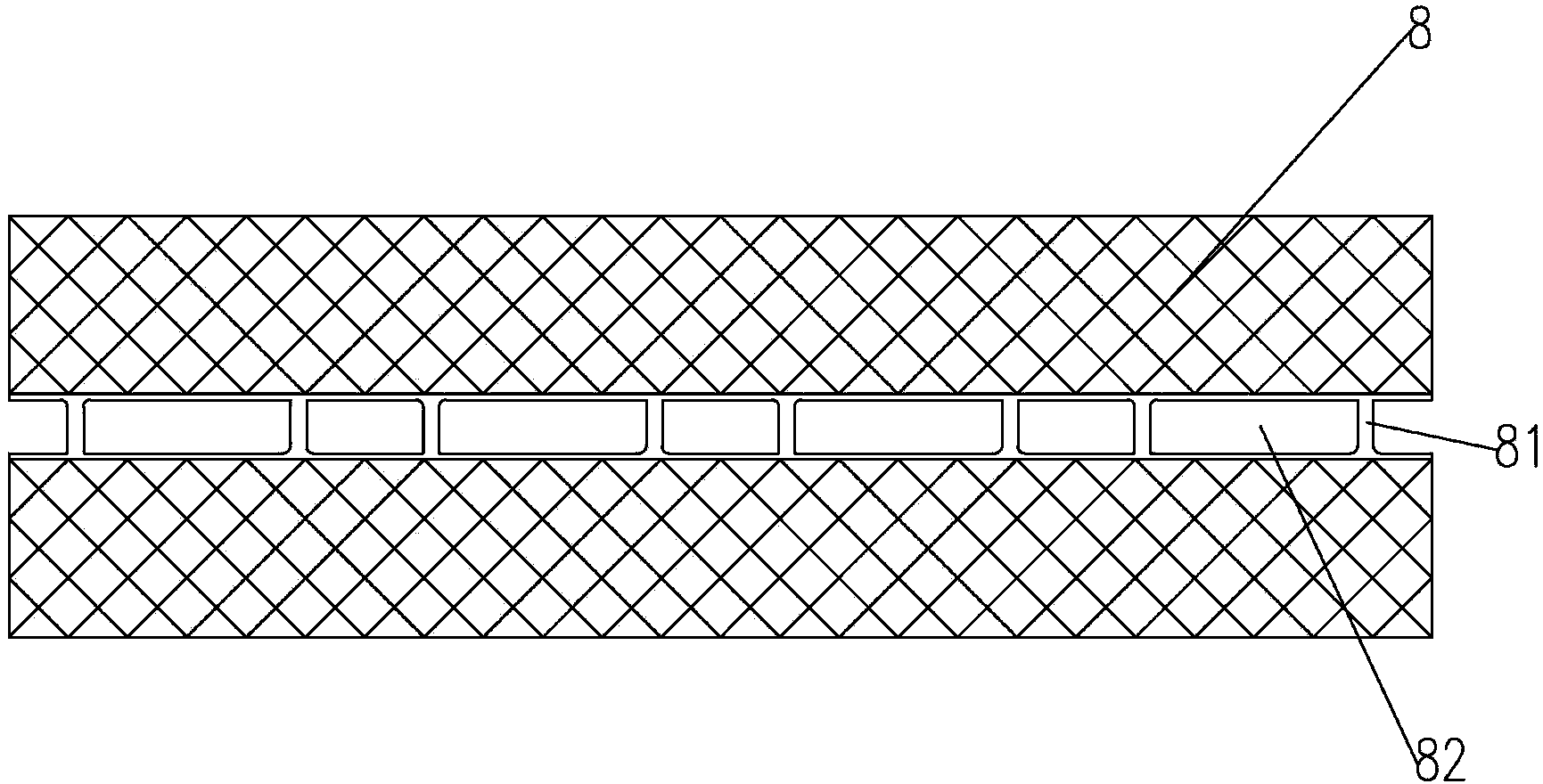

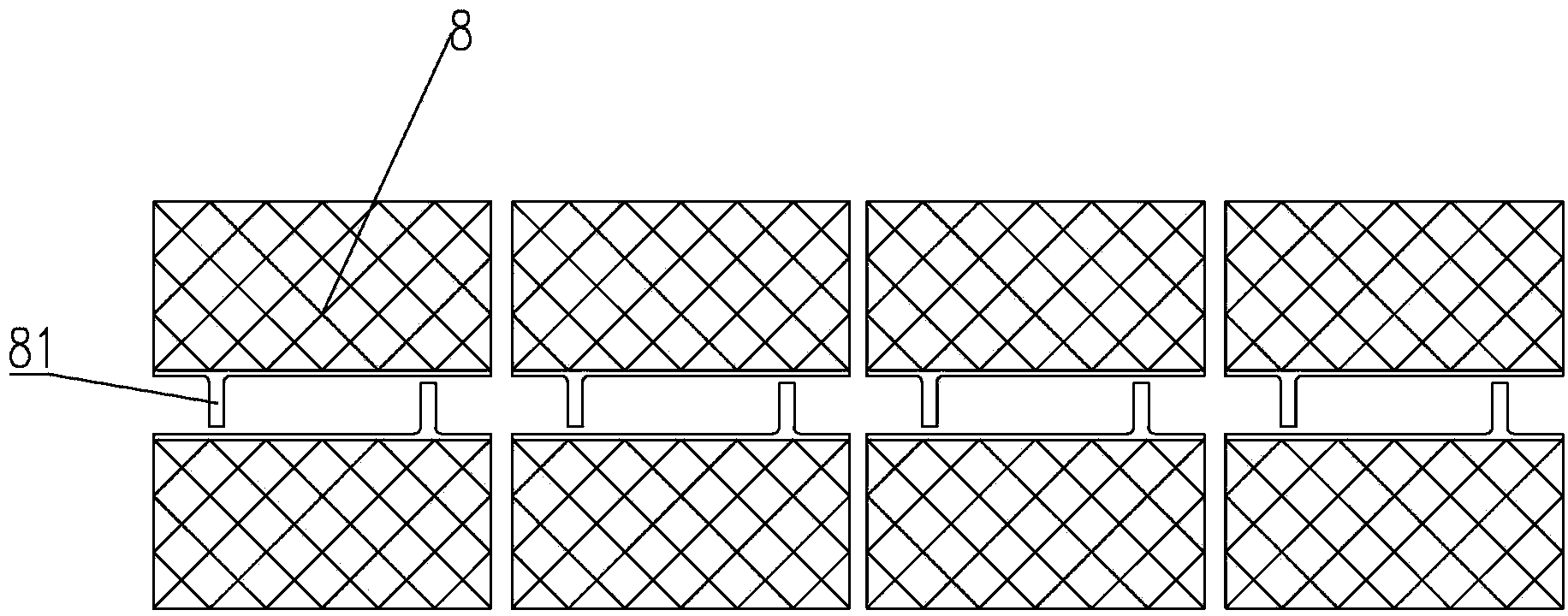

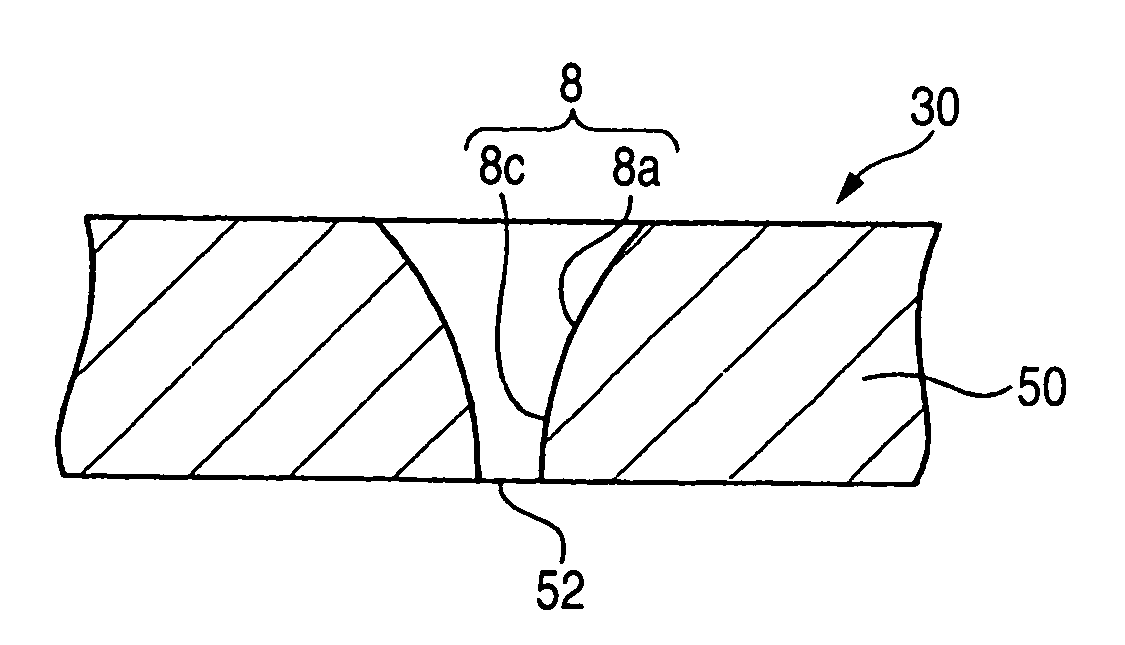

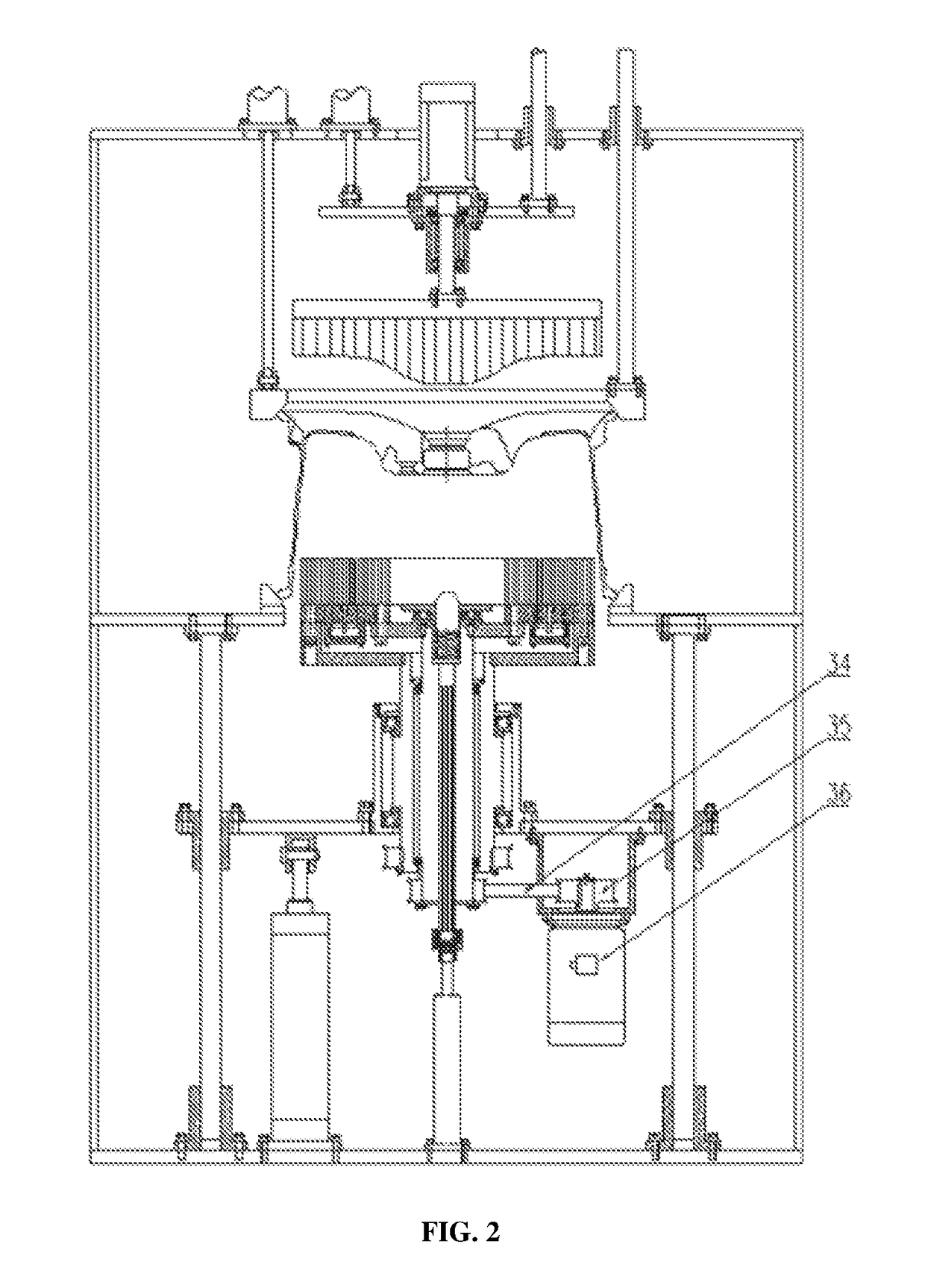

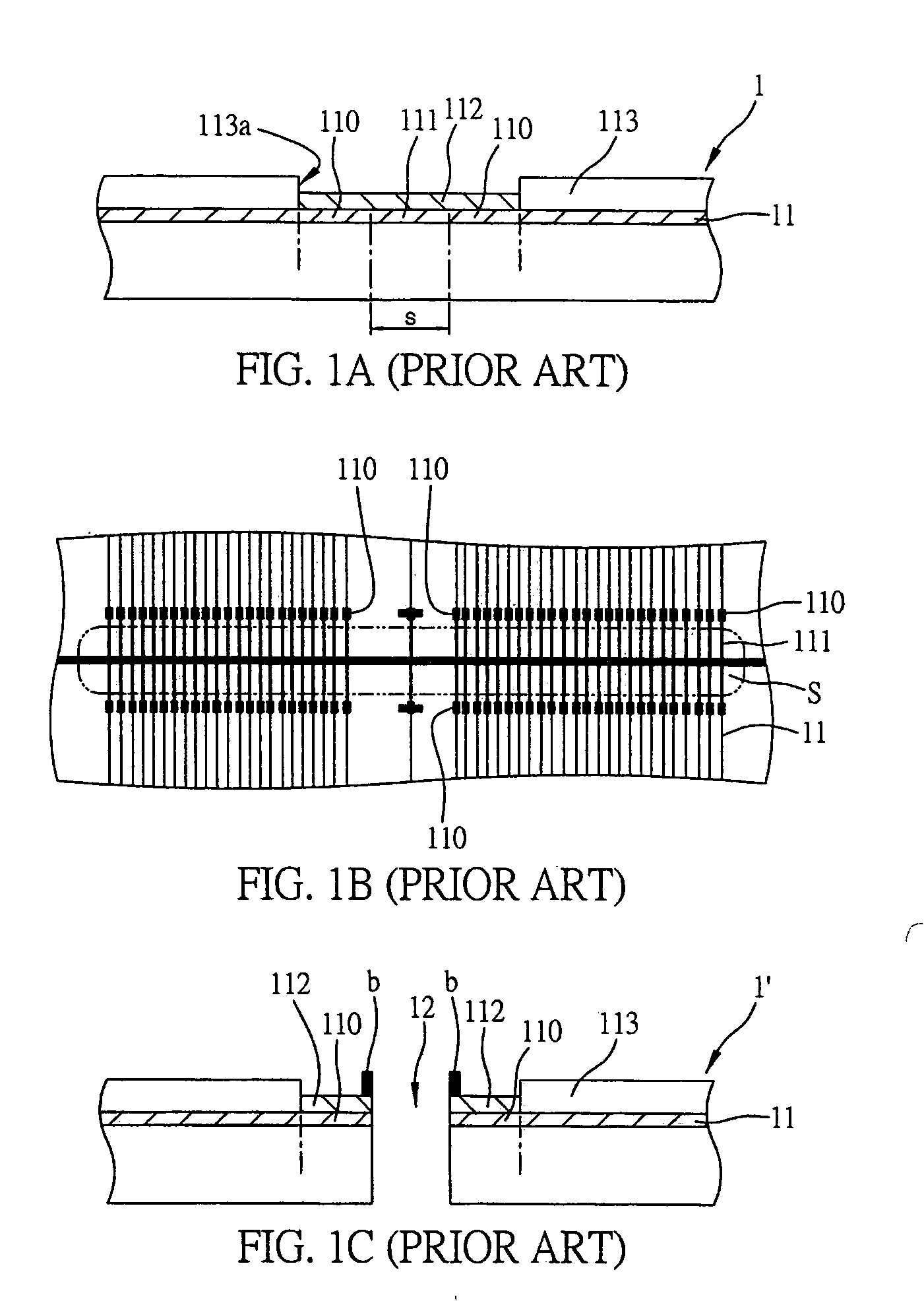

Deburring device, and deburring method for punch press, and punch press

ActiveUS20060042341A1Continuously and smoothly removeEliminate burrsBurnishing machinesPunch pressEngineering

The present invention provides a deburring device for a punch press which can remove burrs produced along a slot or a cut portion formed in a plate material by punching or cutting using a punch press so that the removal is carried out as a process with the same punch press. A deburring device 6 for a punch press has an upper tool 7 and a lower tool 8 arranged opposite each other. The upper and lower tools 7, 8 each have a ball holding member 22, 32, respectively, and a ball 23, 33, respectively, rotatably supported by the ball holding member and projecting from a surface of the ball holding member 22, 32 toward an opposite surface of the opposite ball holding member 32, 22. Each of the upper and lower balls 23, 33 has a diameter larger than the width of the slot A, in its portion projecting from the ball holding member 22, 32, respectively, the slot A being formed in the plate material W so as to extend across the plane. The plate material W moves with the vertical pair of balls 23, 33 partly fitted into the slot A and with the plate material W sandwiched between the upper and lower balls 23, 33 to continuously remove burrs (a) produced along a longitudinal direction of the slot A. The deburring device 6 continuously removes not only the burrs produced along the slot A but also those produced along a cut portion in the plate material W as described above.

Owner:MURATA MASCH LTD

Automatic turnover device for conveying forklift hub brake drum assembly

The invention relates to an automatic turnover device for conveying a forklift hub brake drum assembly. The automatic turnover device comprises a motor, a speed reducer, a rotating shaft and a clamping mechanism, two sides of the rotating shaft are arranged at the tops of two vertical support legs through bearings and bearing blocks respectively, the two support legs are positioned on two sides of a conveying mechanism respectively, the rotating shaft is parallel to a power plate chain on a power plate chain output rail, one end of the rotating shaft is connected with the speed reducer and the motor, the clamping mechanism is arranged on the rotating shaft and comprises a pair of clamping arms, each clamping arm comprises a cantilever plate, one end of each cantilever plate is fixedly connected with the rotating shaft, a thin-walled cylinder is arranged at the other end of each cantilever plate, a piston rod of each thin-walled cylinder is parallel to the rotating shaft, the outer end of the piston rod of each thin-walled cylinder is connected with a connecting plate, two clamp plates are arranged on each connecting plate in a splayed manner to form a pair, and two pairs of clamp plates on the pair of clamping arms are folded. Labor intensity is reduced, and product quality is improved.

Owner:ANHUI HELI CO LTD

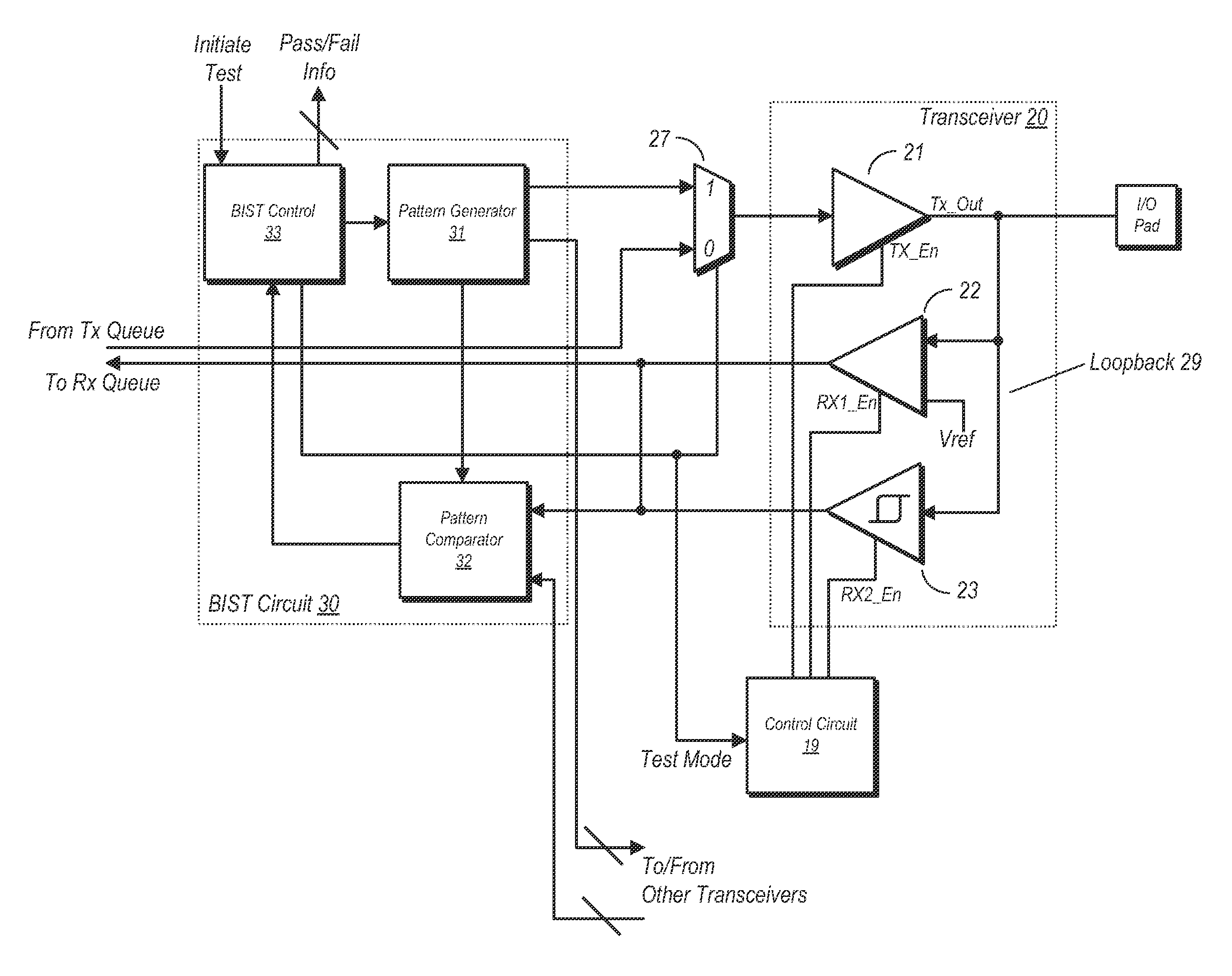

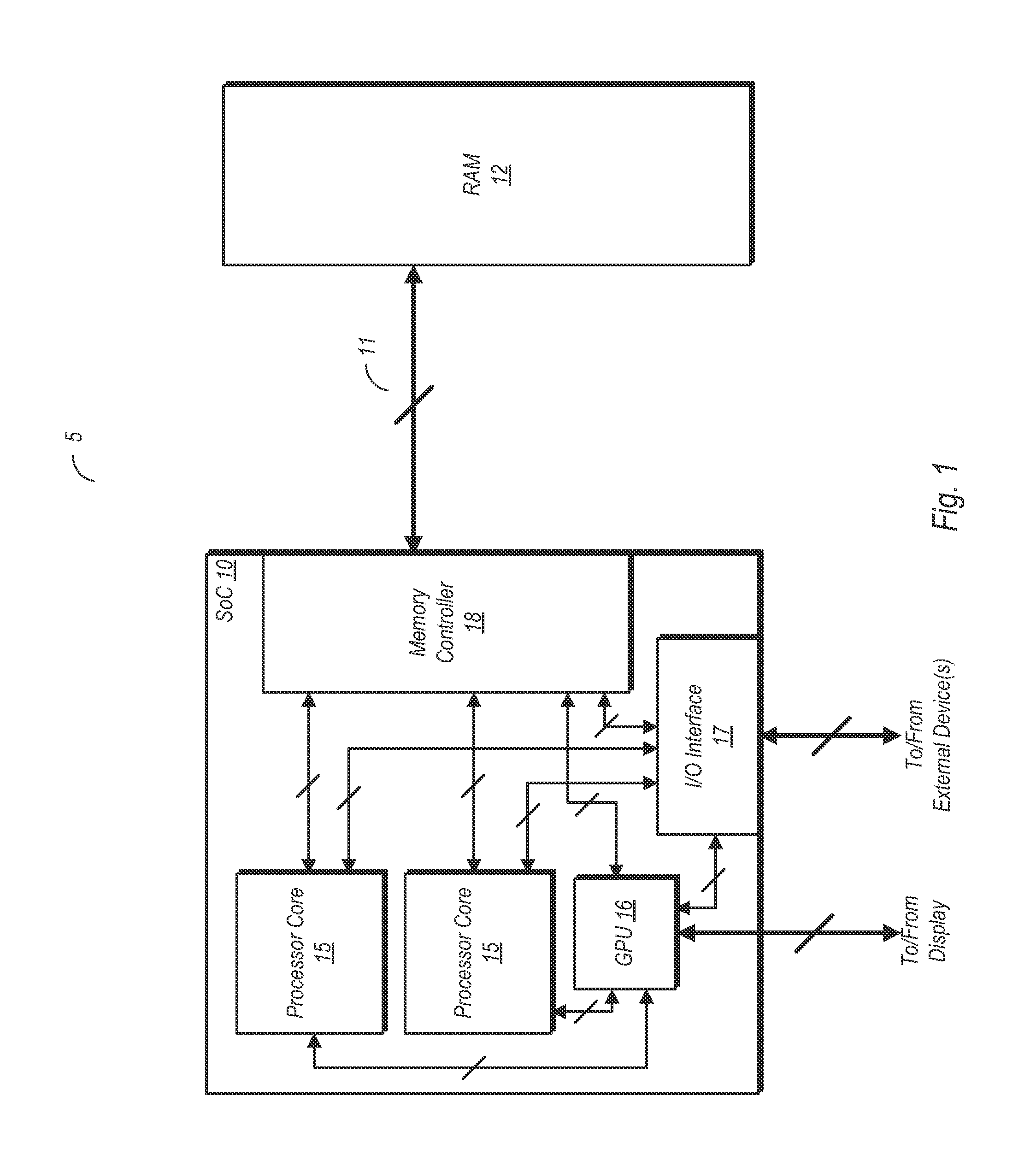

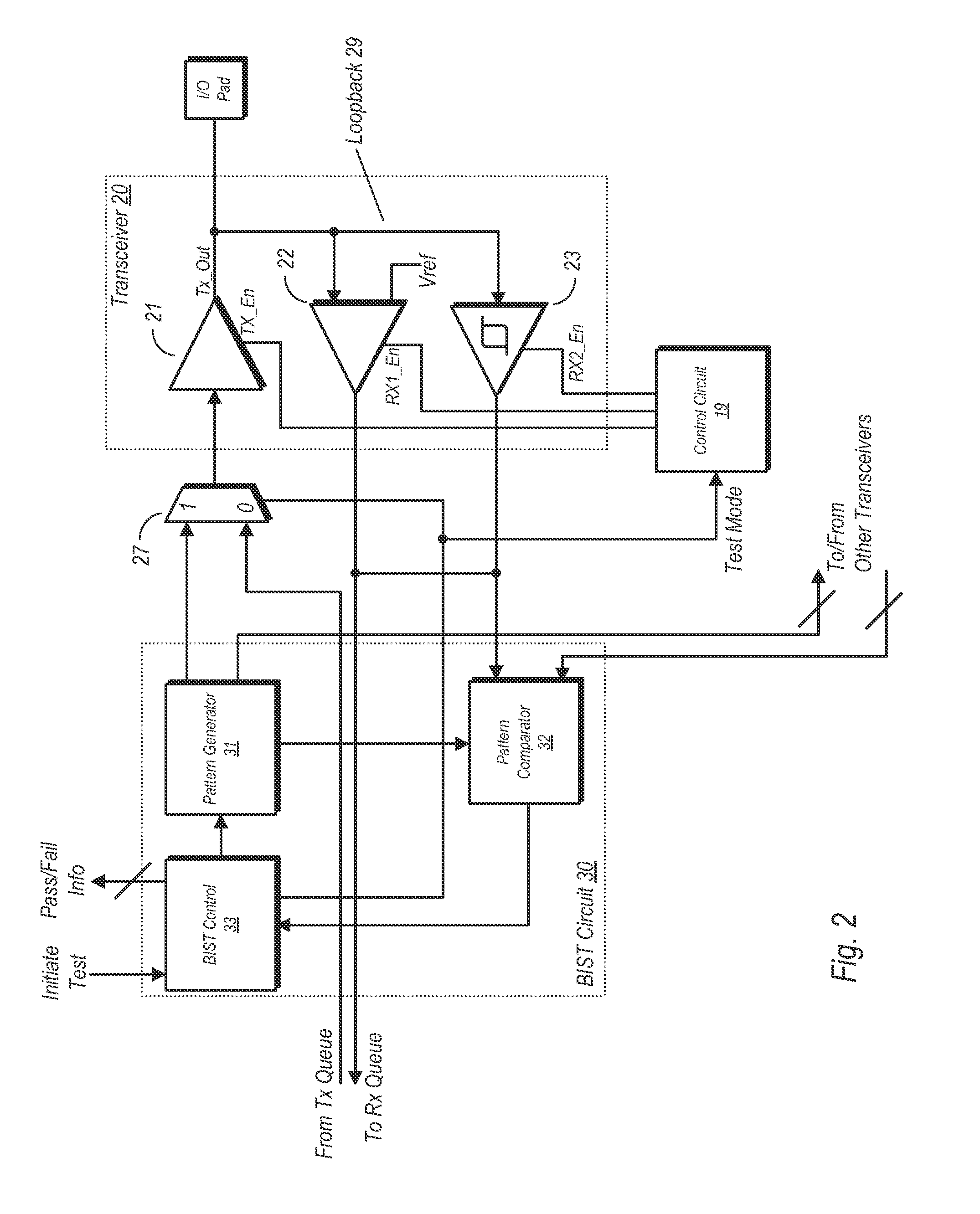

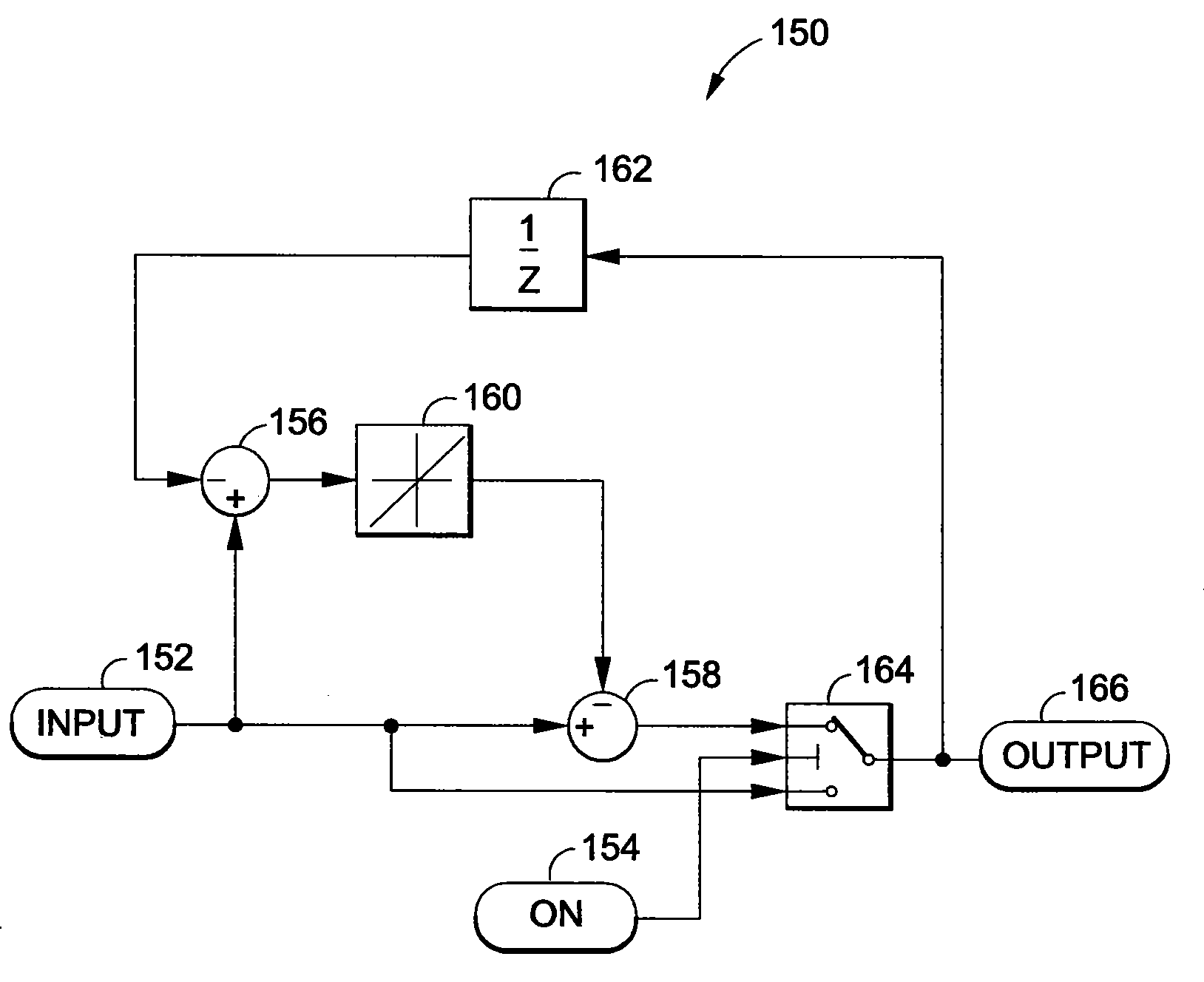

Noise Rejection for Built-In Self-Test with Loopback

InactiveUS20140019817A1Eliminate burrsElectronic circuit testingFunctional testingSchmitt triggerEngineering

A self-test loopback apparatus for an interface is disclosed. In one embodiment, a bidirectional interface of an integrated circuit includes a transmitter coupled to an external pin, a first receiver coupled to the external pin, and a second receiver coupled to the external pin. During operation in a test mode, the first receiver may be disabled. The transmitter may transmit test patterns generated by a built-in self-test (BIST) circuit, and compare those test patterns to patterns received by the second receiver. The second receiver may be implemented as a Schmitt trigger (wherein the first receiver may be a standard single-bit comparator). When operating in functional mode, the second receiver may be disabled.

Owner:APPLE INC

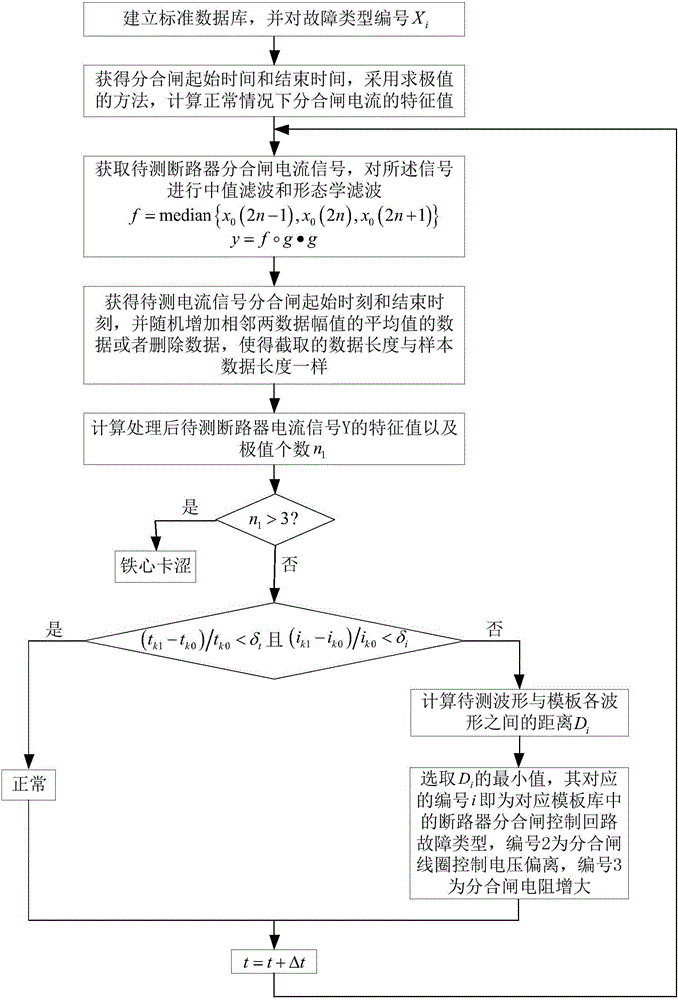

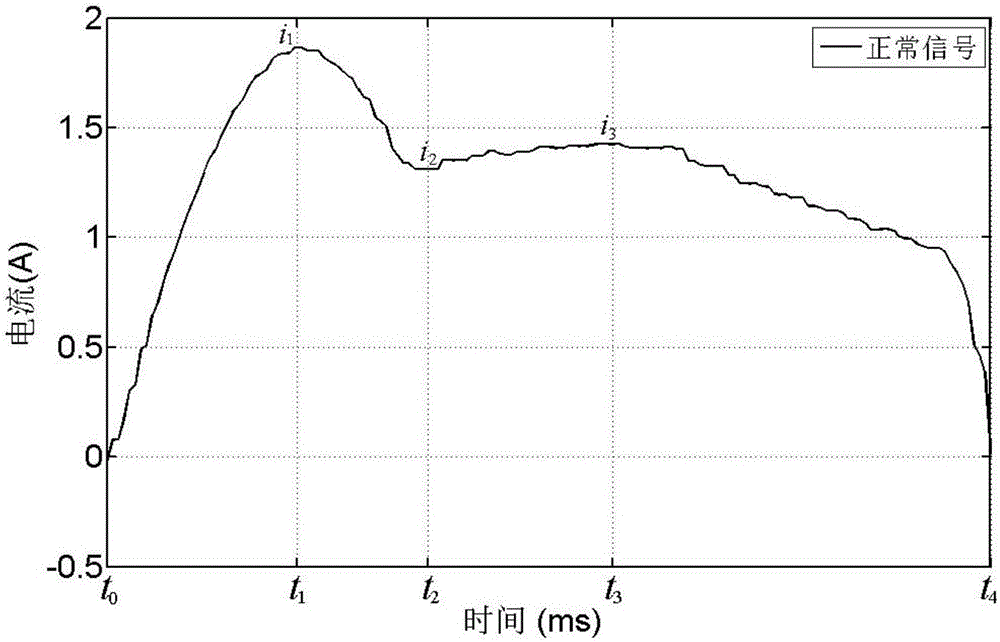

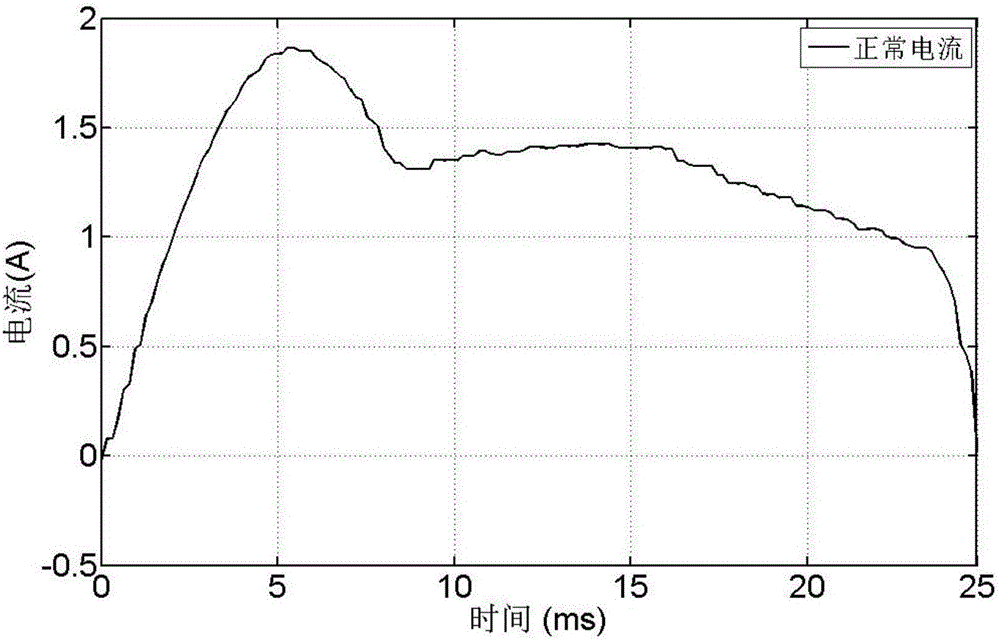

Circuit breaker breaking-closing control loop fault diagnosis method

InactiveCN105866669AMeet the requirements of online fault diagnosisEliminate burrsCharacter and pattern recognitionCircuit interrupters testingDiagnosis methodsElectrical current

The invention discloses a circuit breaker breaking-closing control loop fault diagnosis method. The method comprises steps as follows: 1) a sample database for storing actual fault waveforms is established, and fault types are numbered; 2) a characteristic value of a current signal of a breaking-closing coil is acquired under the fault-free condition; 3) a to-be-measured breaking-closing current signal is acquired and filtered; 4) the breaking-closing starting moment and the breaking-closing ending moment of the to-be-measured current signal are acquired, and part of data are randomly deleted or copied, so that the intercepted data length is equal to the length of sample data; 5) the characteristic value and the number of extreme values of the processed to-be-measured current signal are acquired; 6) whether the number of the extreme values is larger than 3 is judged, and whether a jam fault happens is determined; 7) the distance between the characteristic value of the to-be-measured signal and the characteristic value of a normal signal is compared, and whether the signal is a normal signal is determined; 8) the to-be-measured signal is compared with data in the actual fault sample database, and the fault type is determined by comparing the distance of the waveform of the to-be-measured signal and the waveform of the actual fault sample database. By means of the circuit breaker breaking-closing control loop fault diagnosis method, calculation is simple and convenient, and the reliability is high.

Owner:SOUTH CHINA UNIV OF TECH

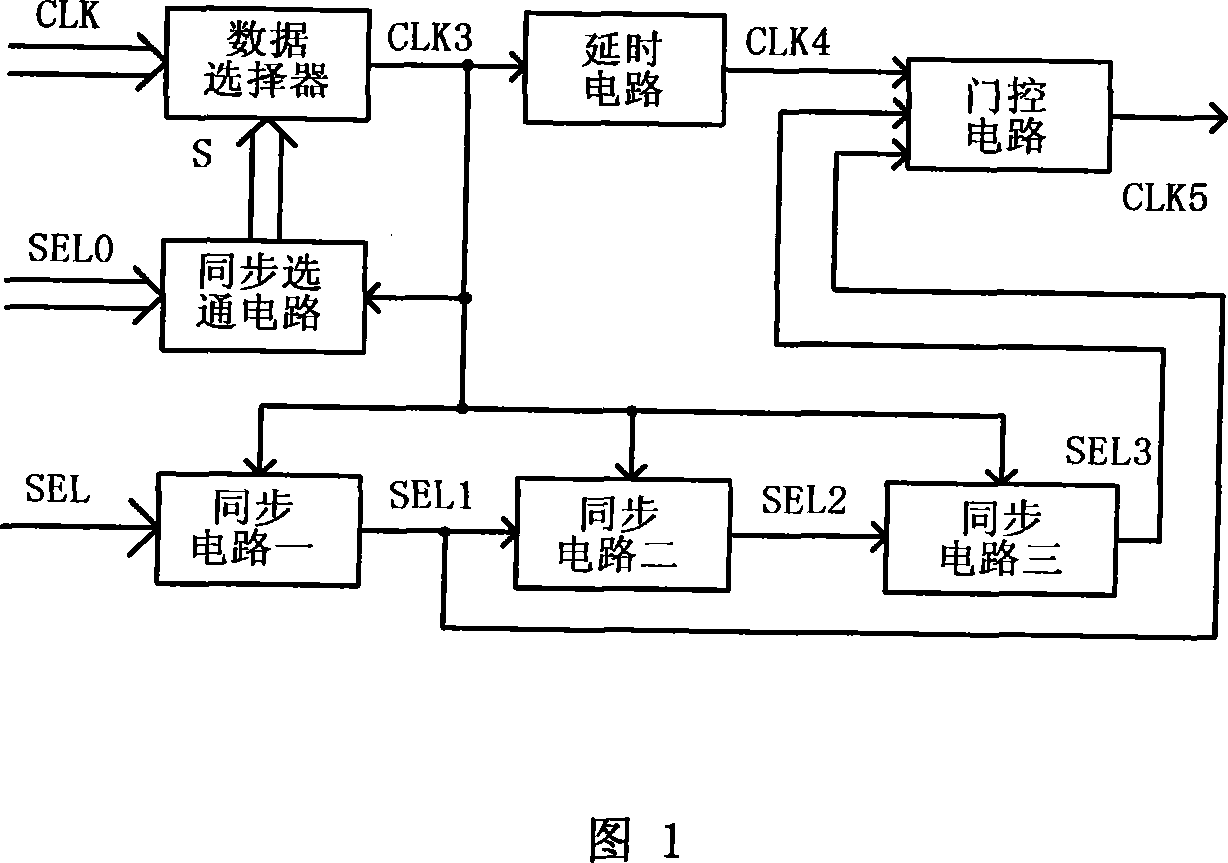

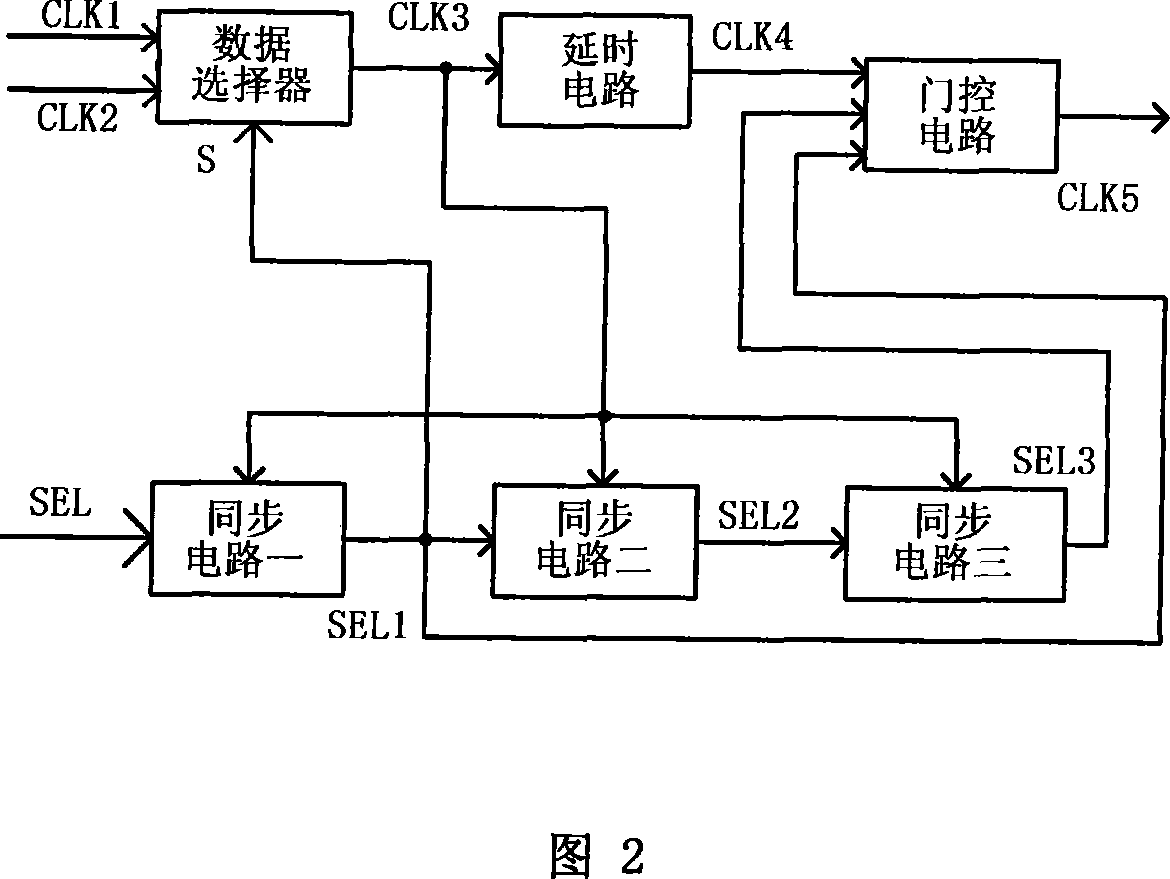

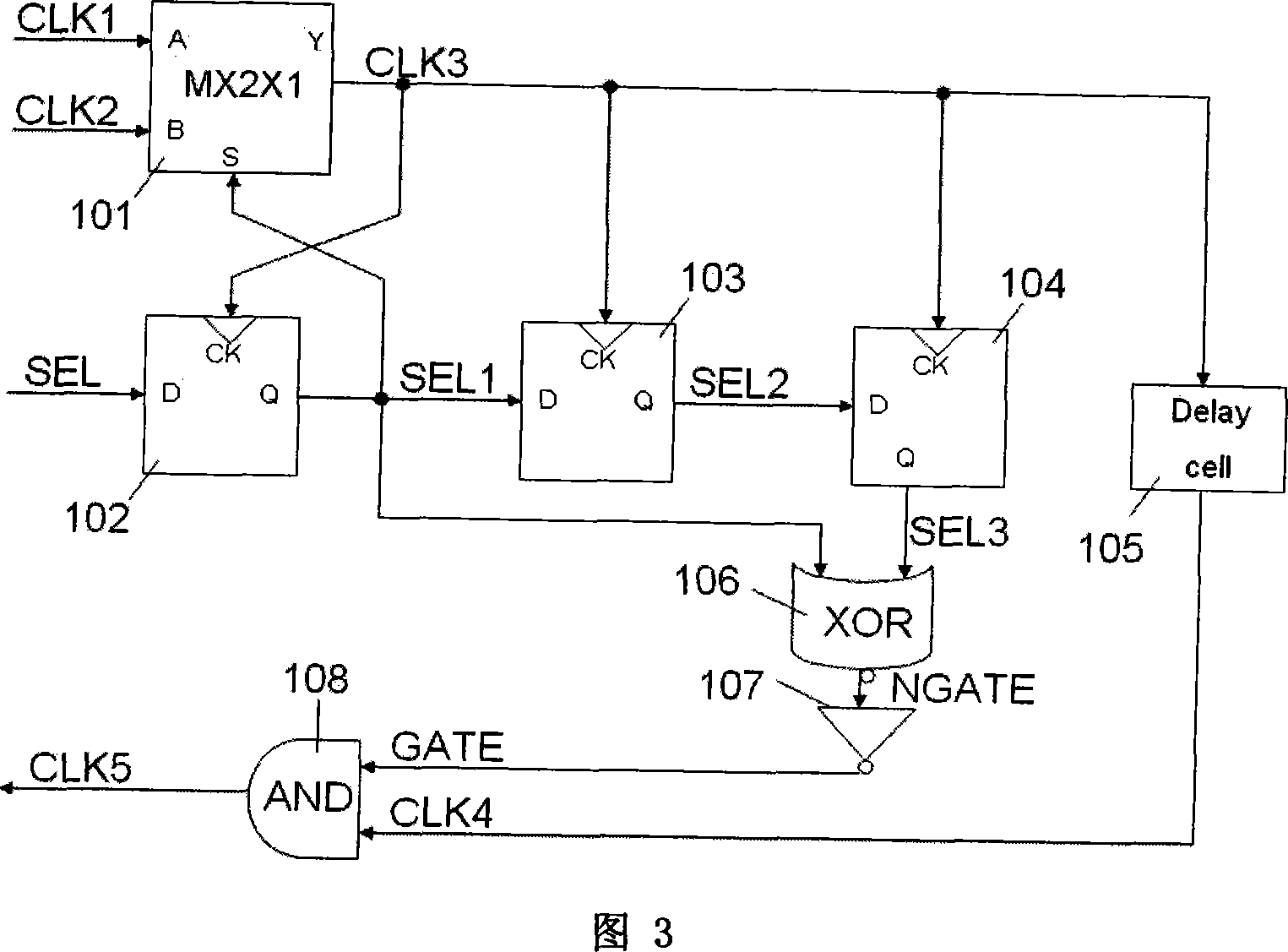

Clock switching circuit

ActiveCN101078944AEliminate burrsGenerating/distributing signalsPulse manipulationMultiplexerTime delays

The invention discloses a clock commutation circuit without burr, which is characterized by the following: comprising data selector, multistage three grades synchronous circuit, time delay circuit and gate controlling circuit; switching the imputing clock signal with the data selector; generating the clock signal with burr; synchronizing the three grades synchronous circuit and the outputting signal of the data selector; excluding the outputting signal of the first grade synchronous circuit and the third synchronous circuit in the gate controlling circuit; masking the burr of clock signal switching; delaying time for the clock signal with the time delay circuit; avoiding simultaneous roll-over of the clock signal edge and the electrical level of the synchronous circuit outputting; generating new burr. This invention can be used to the system with multipath clock signal.

Owner:SOUTHEAST UNIV

A burr judgement and elimination circuit

InactiveCN101267194AEliminate burrsEnsure safe workSingle output arrangementsPulse descriminationGlitch removalFeedback control

The present invention discloses a burr eliminating circuit which comprises a delay module which is used for detecting the width of the burr and a delay output module for eliminating the burr problem generated in specific condition. The delay module is connected with a feedback control circuit module. The delay module controls the feedback control circuit module to reset with an accelerated speed when the burr is detected and sets with an accelerated speed when the valid data is detected. The circuit of the invention totally satisfies the functions of determining and eliminating the burr and can expands the width of the valid narrow pulsewidth signal to a safe width for securing the safe operation.

Owner:CHIPHOMER TECH SHANGHAI

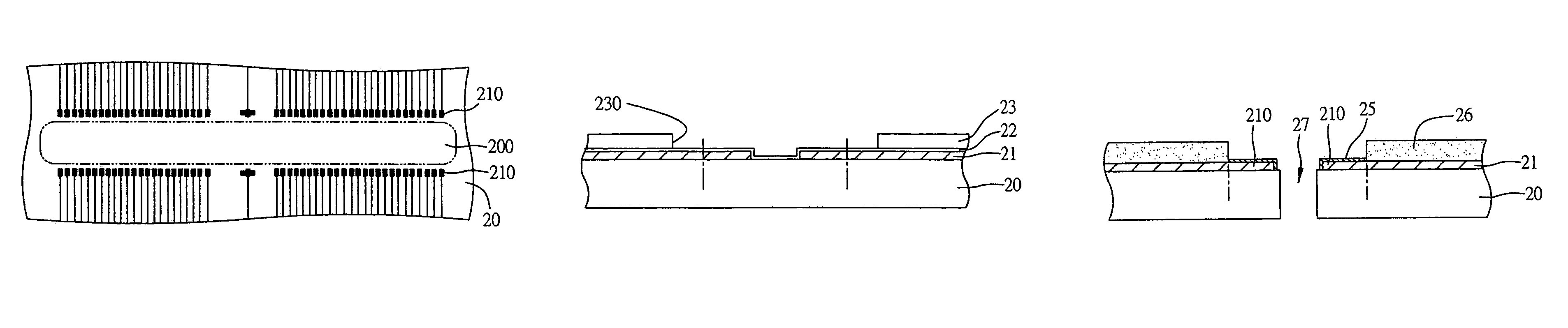

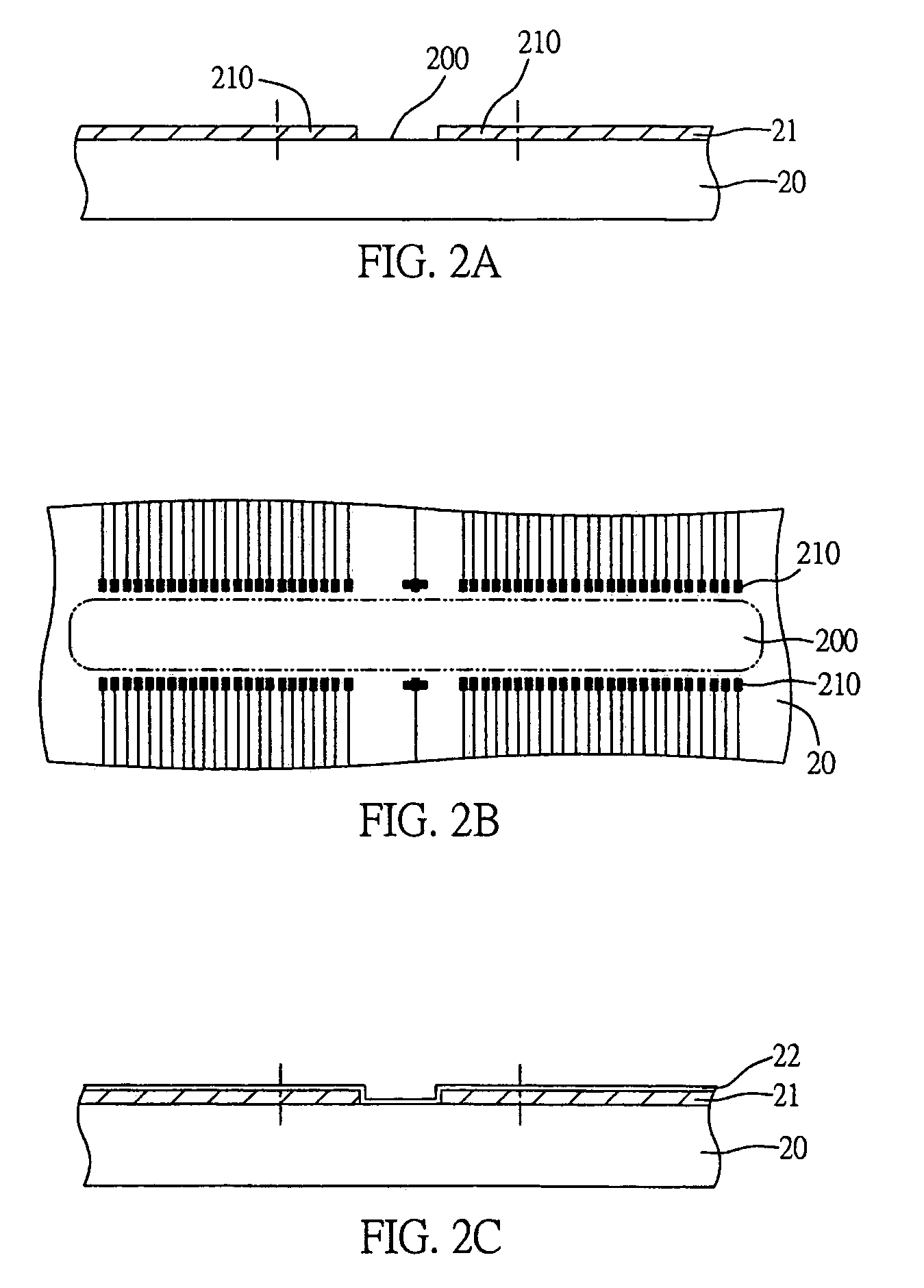

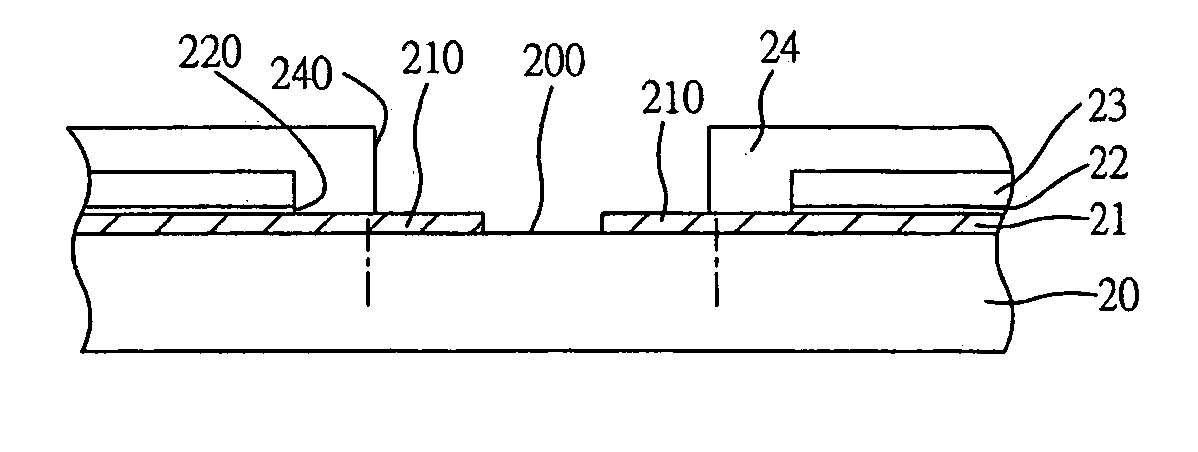

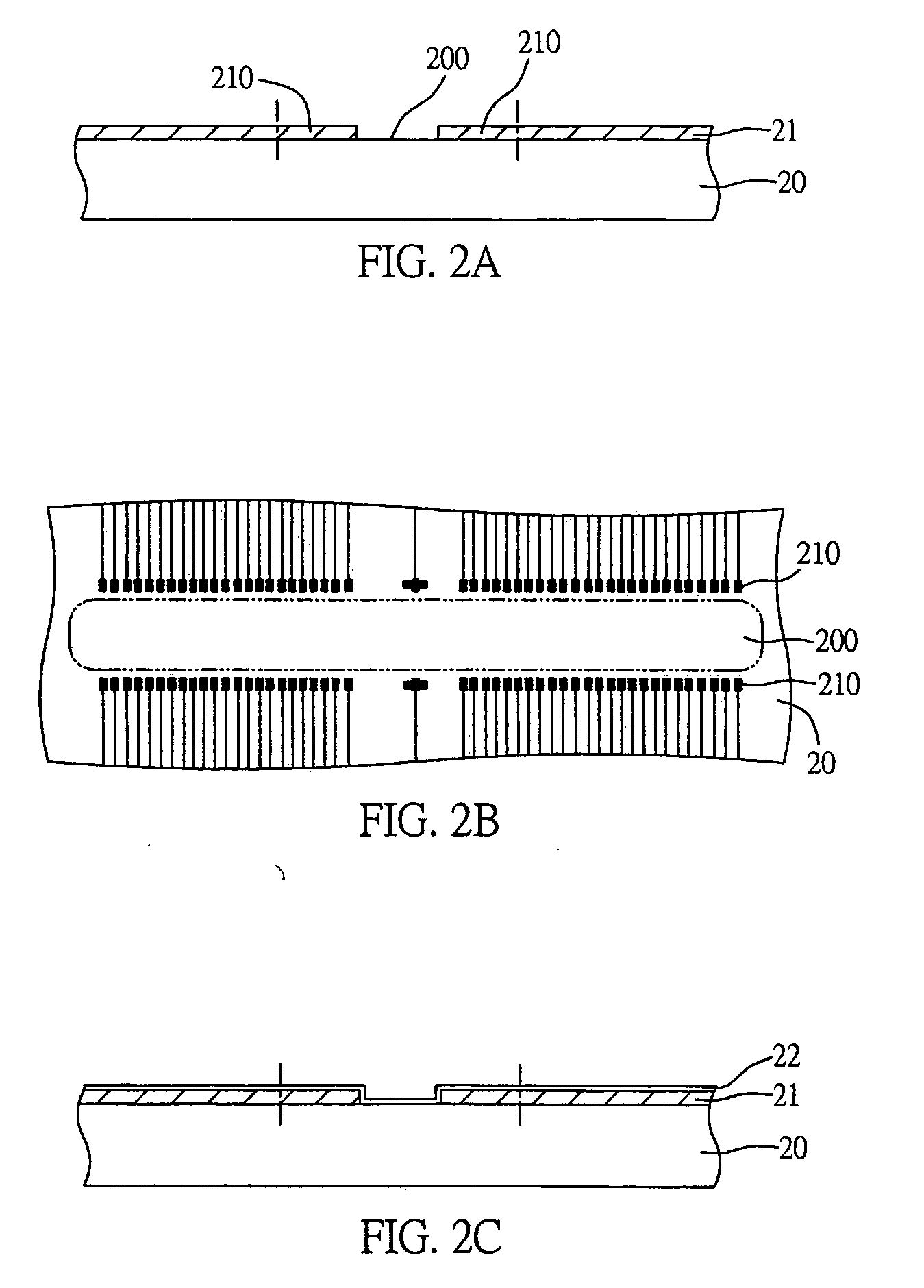

Method for manufacturing semiconductor package substrate

ActiveUS7399399B2Eliminate burrsIncrease productionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectroplating

A method for manufacturing a semiconductor package is proposed. A circuit board with a circuit layer on at least one surface thereof is provided. The circuit board has at least one free area, and the circuit layer has a plurality of electrically connecting pads distributed on the periphery of the free area. A metal protecting layer is plated on the electrically connecting pads by non-plating line. The free area is removed, to form a cavity penetrating the circuit board. The present invention prevents burrs which may otherwise form on the periphery of a cavity, to increase the yield and throughput.

Owner:PHONEIX PRECISION TECH

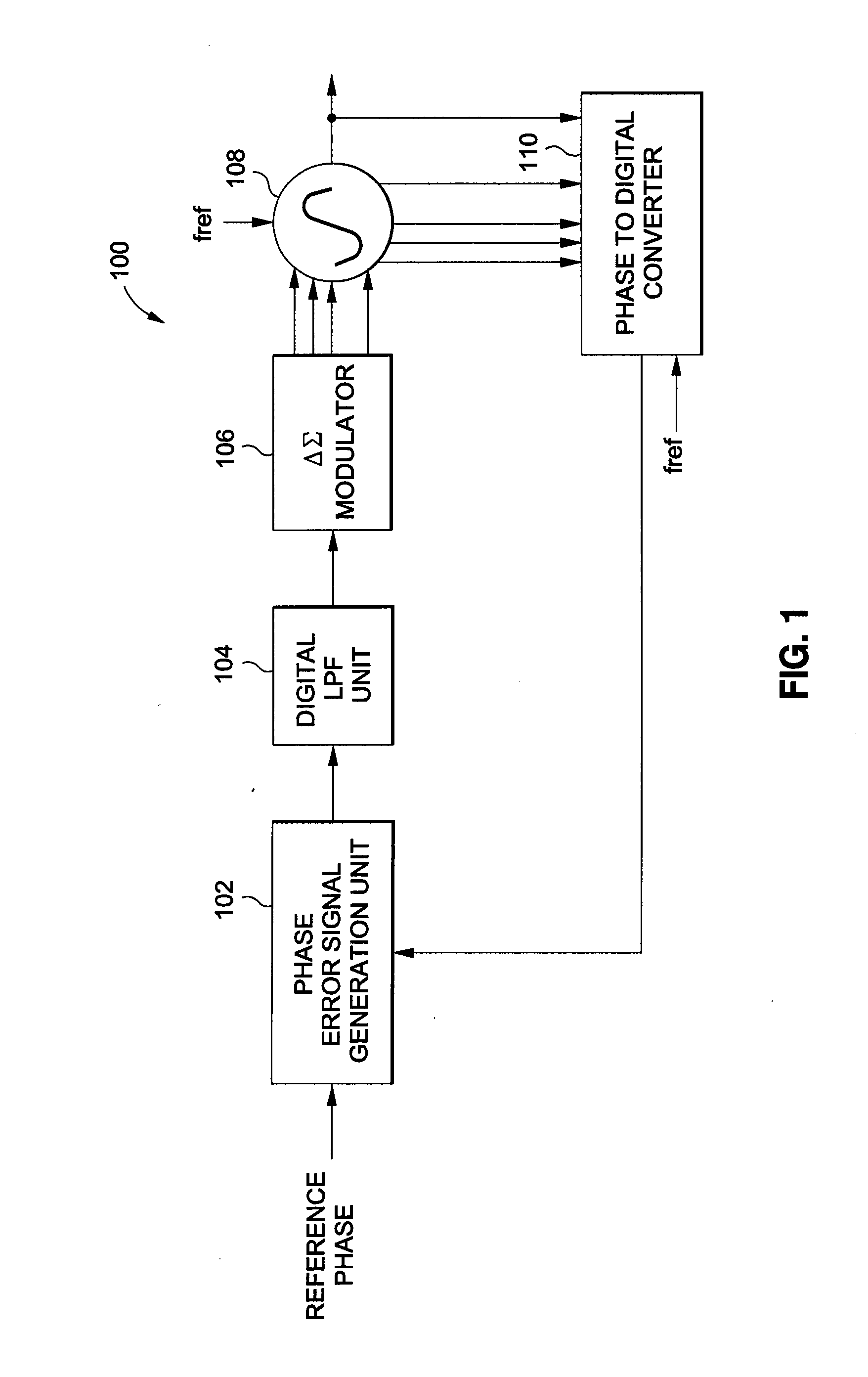

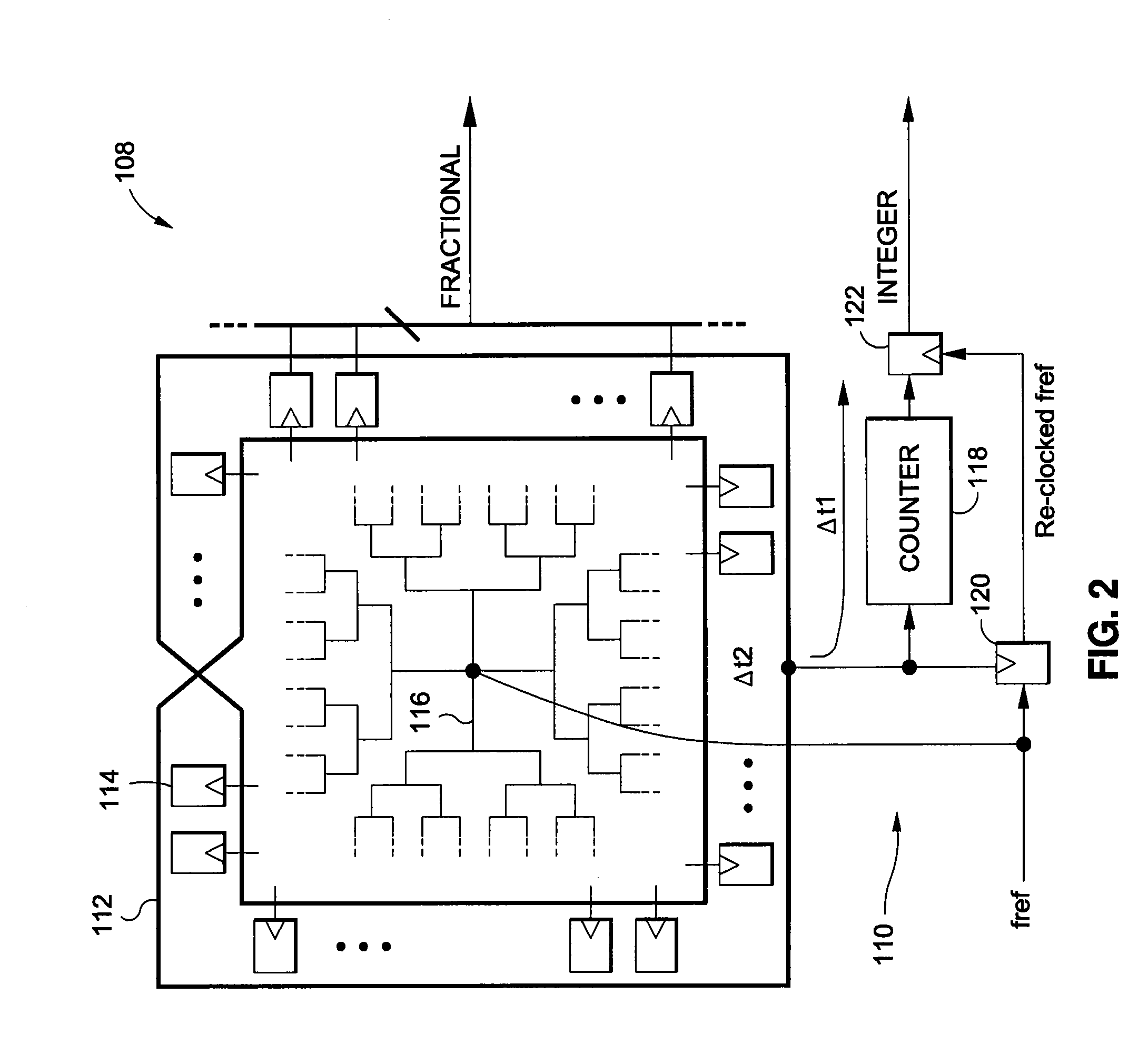

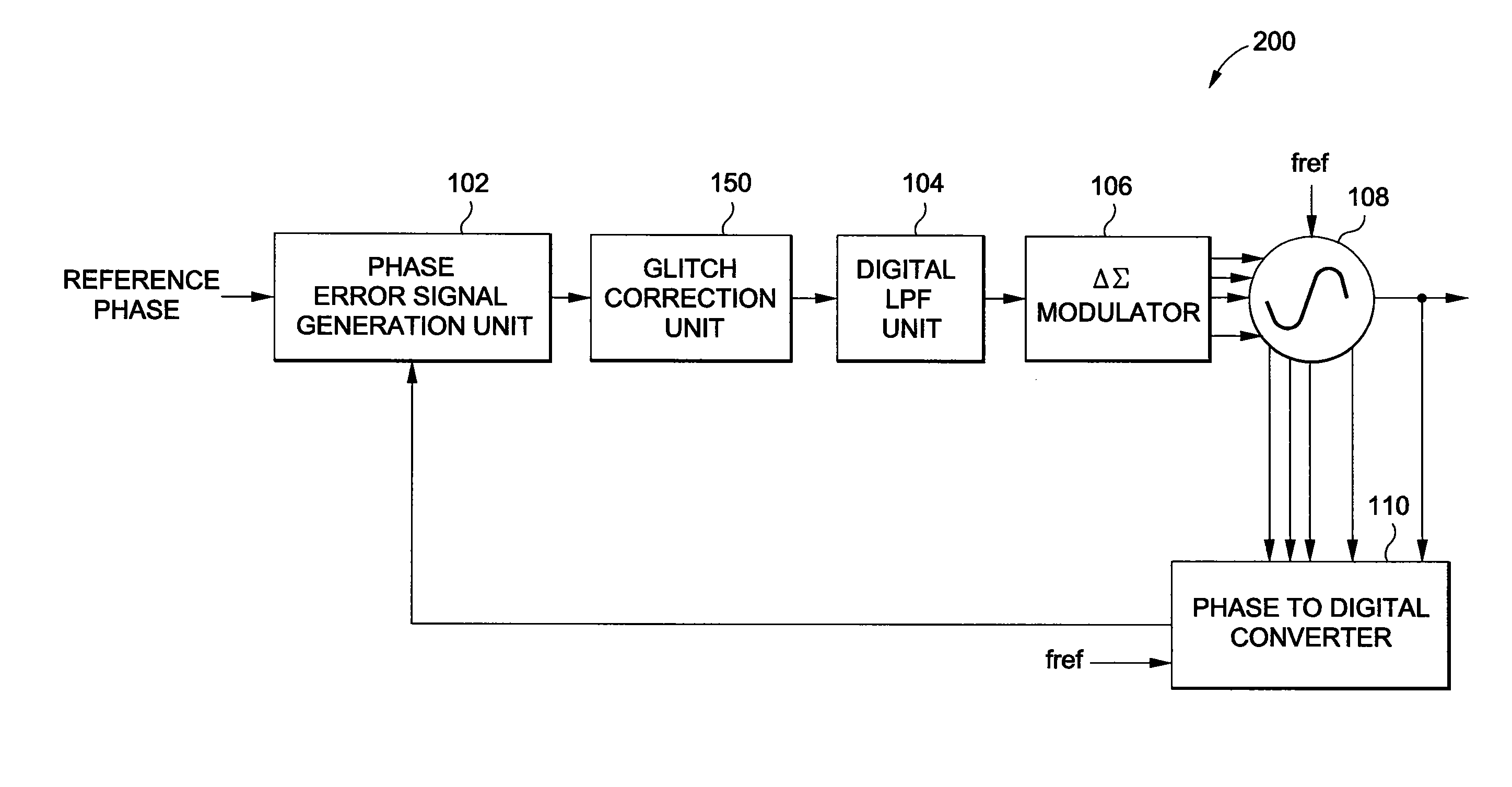

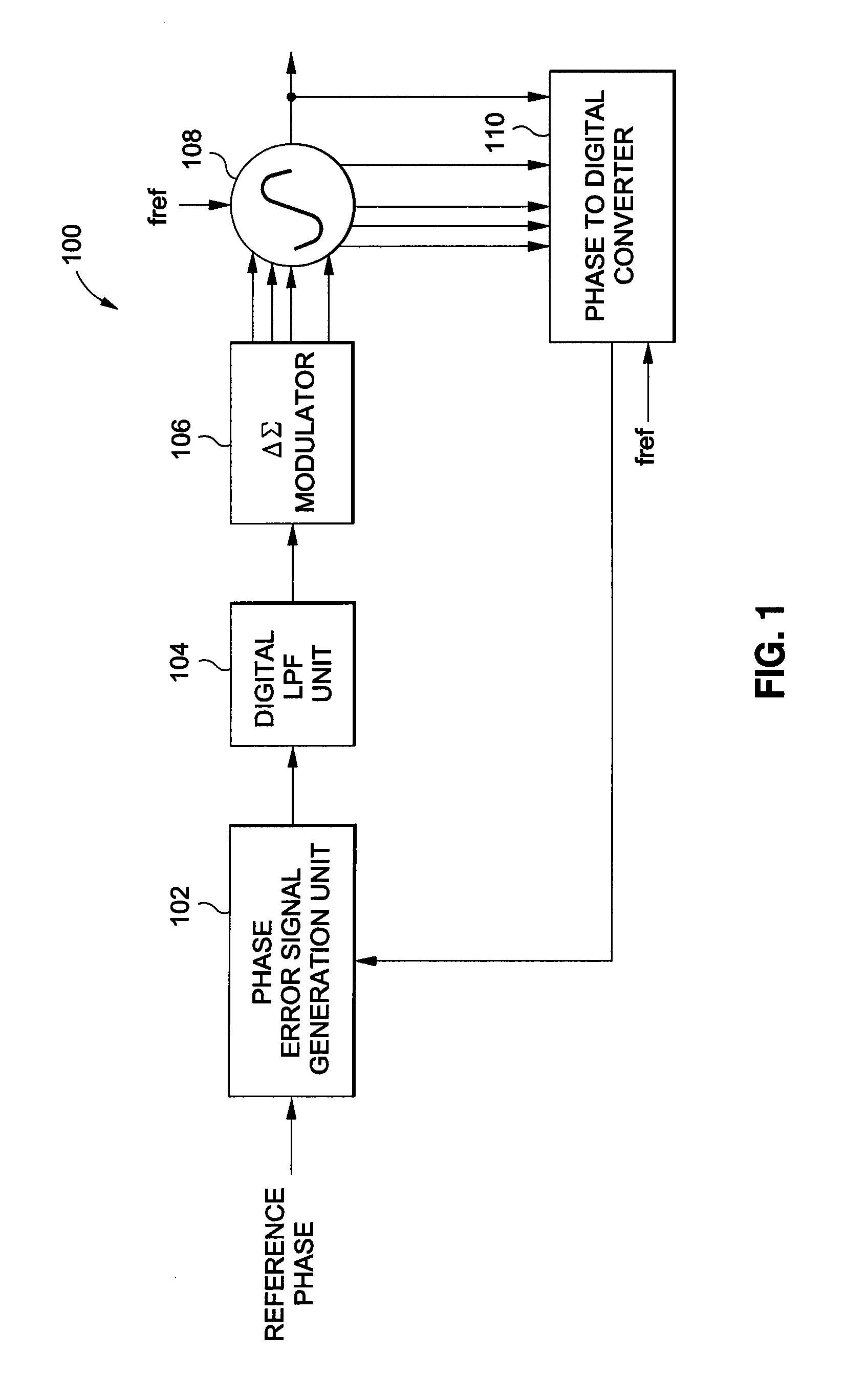

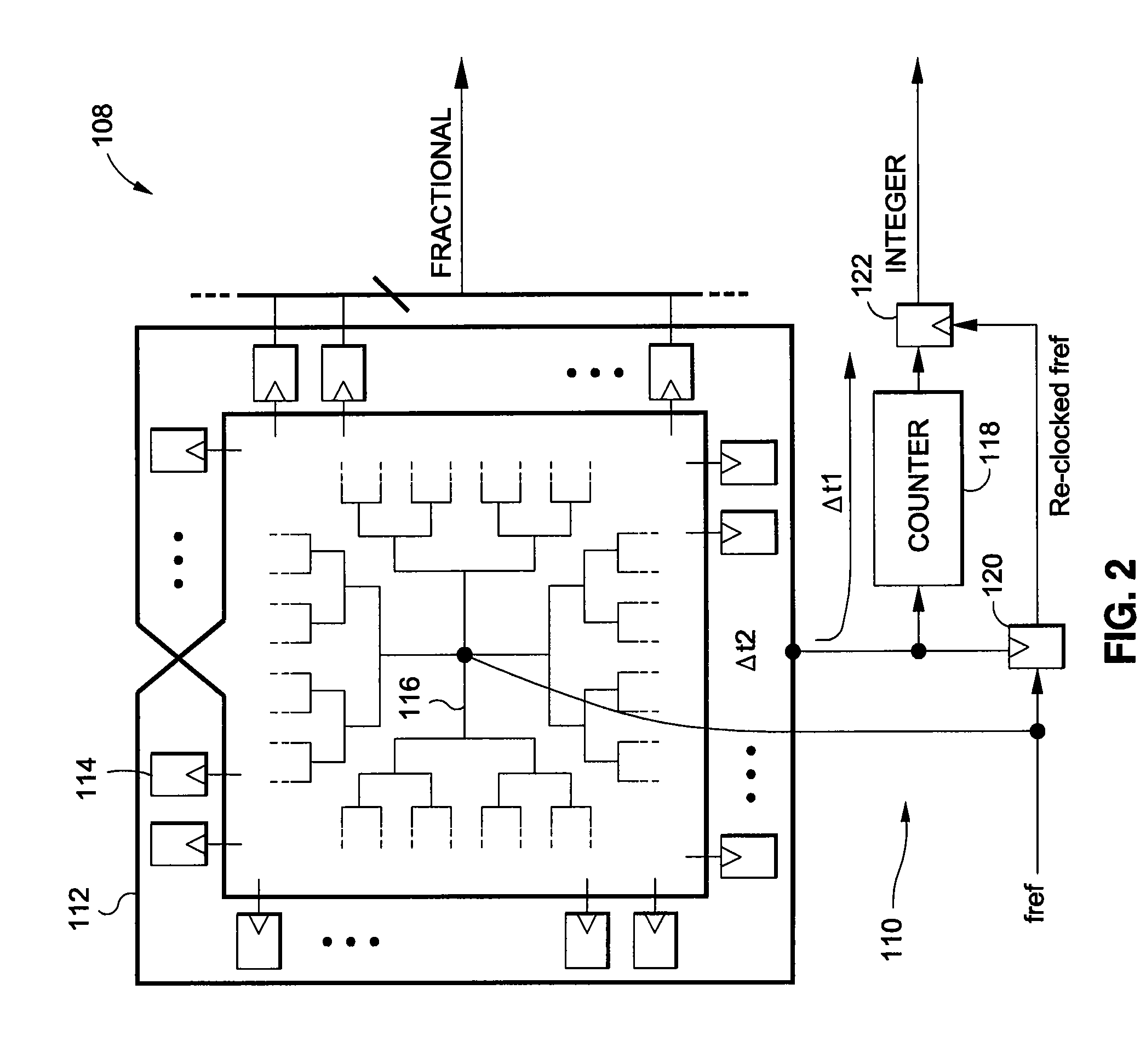

Method and system for a glitch correction in an all digital phase lock loop

InactiveUS20120013363A1Reduce in quantityImprove energy efficiencyPulse automatic controlDuration/width modulated pulse demodulationSignal correctionEngineering

The present invention relates to a method and system for glitch correction in an all digital phase lock loop. An all digital phase lock loop can include a phase error signal generation unit, a multi-phase oscillator, a glitch correction unit, and a phase to digital converter. The phase to digital converter receives a multi-phase signal from the multi-phase oscillator and generates a phase signal. The error signal generation unit receives the phase signal and a reference phase signal and generates a phase error signal, which is fed to the glitch correction unit. The glitch correction unit removes the glitches in the phase error signal by a portion of the phase error signal. The phase lock loop can also include a phase rotator and a calibration block. The calibration block instructs the phase rotator to rotate the multi-phase signal by the phase rotation which generates the minimum number of glitches.

Owner:PANASONIC CORP

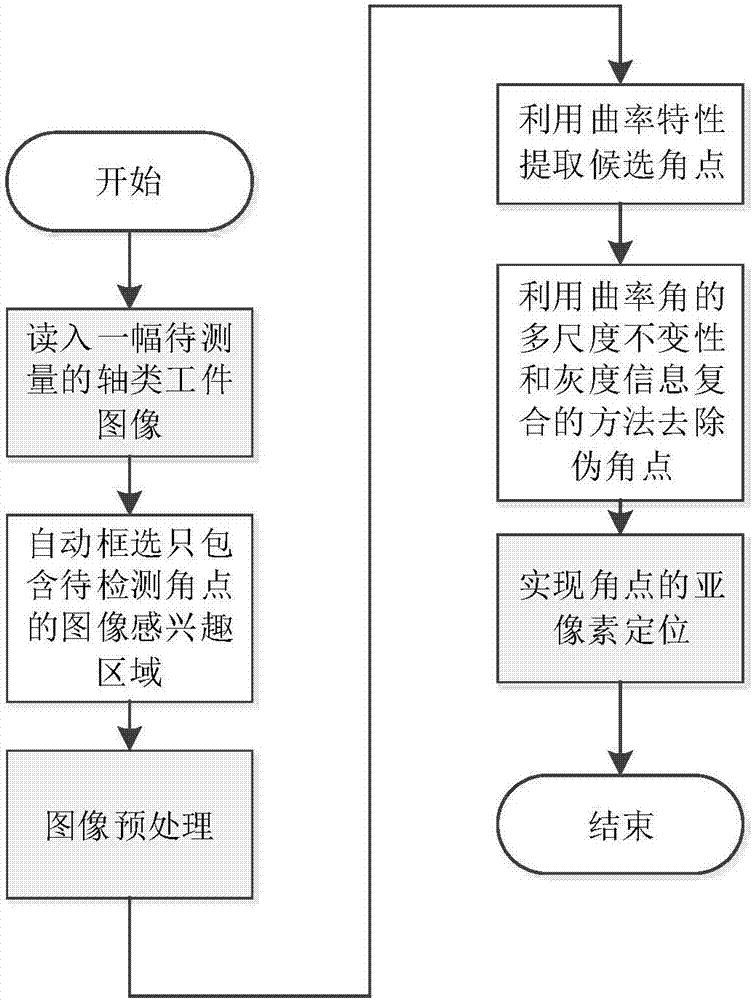

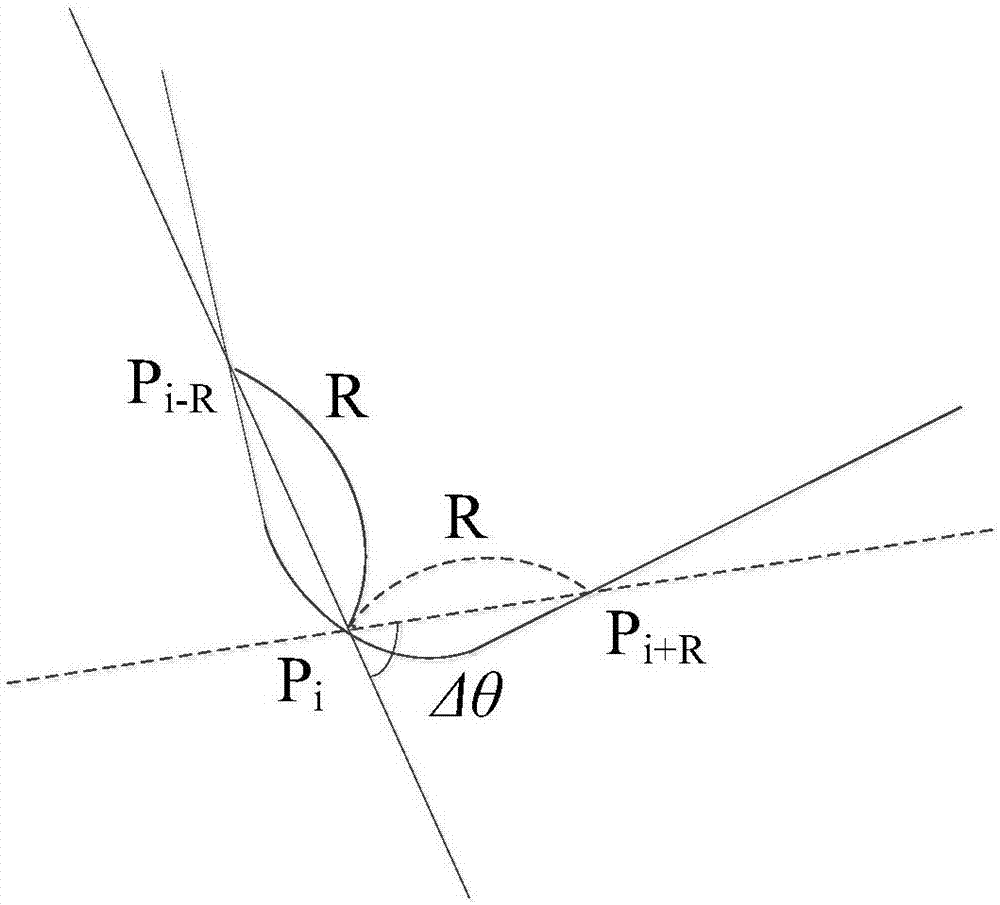

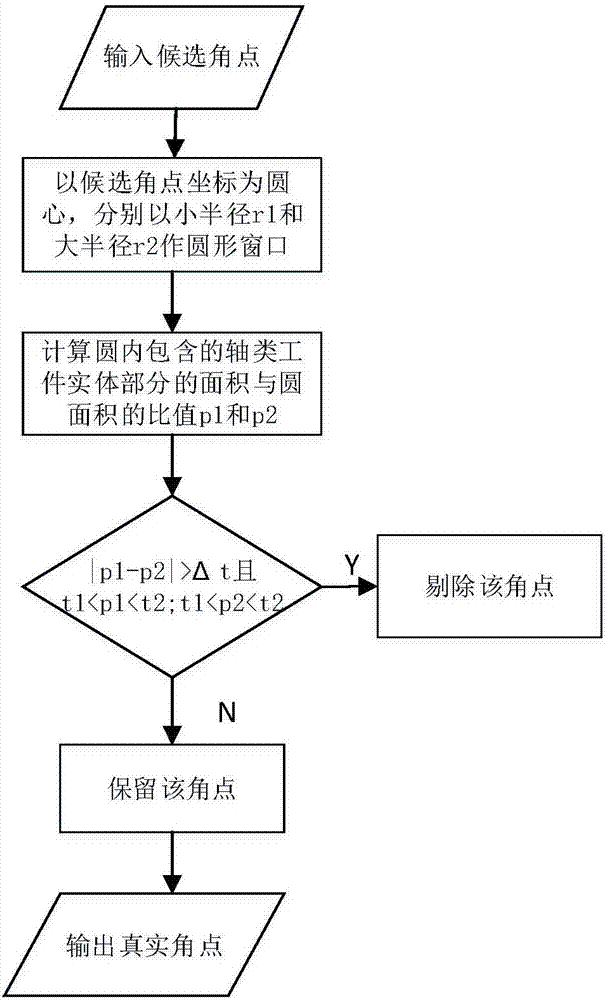

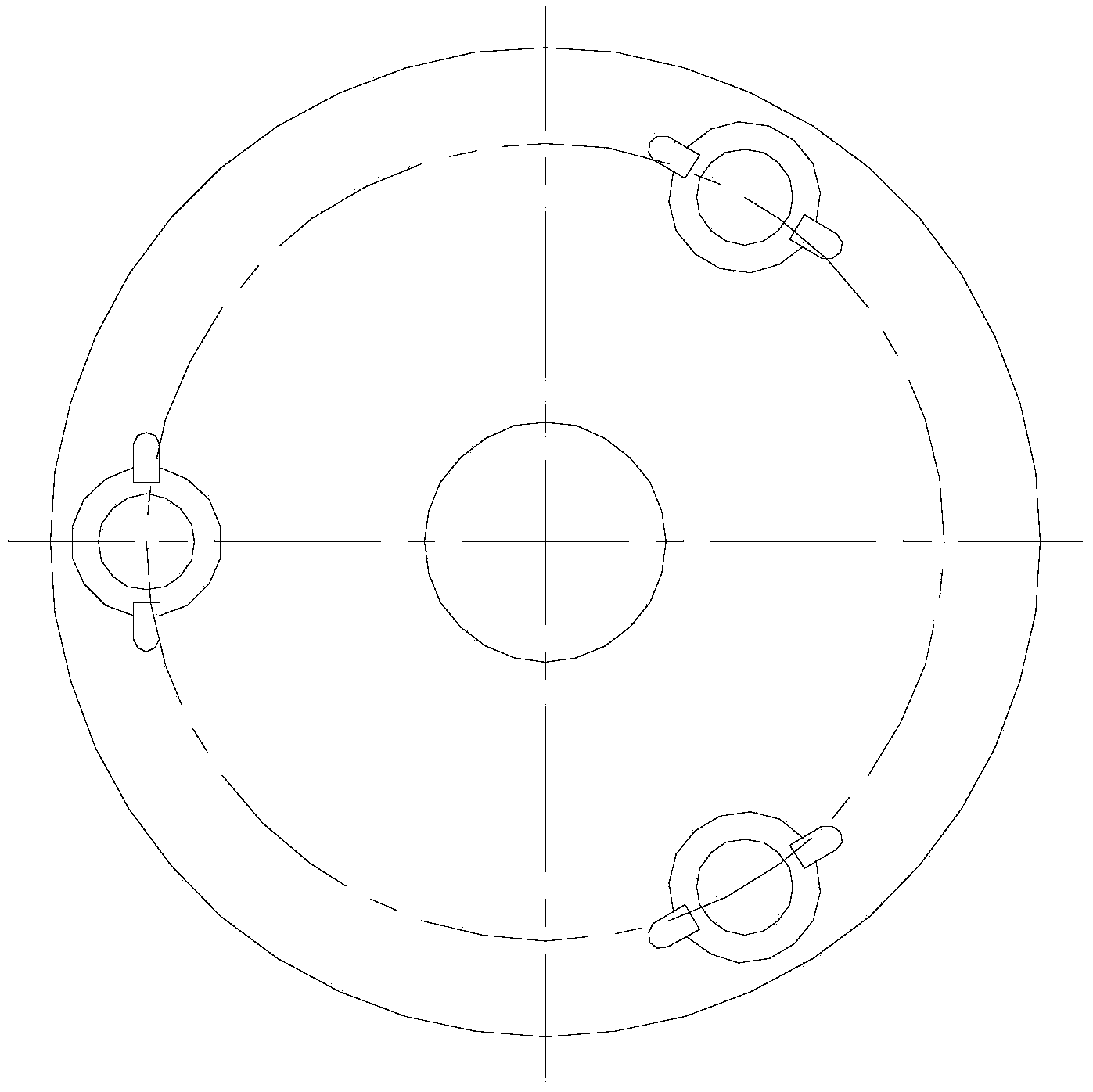

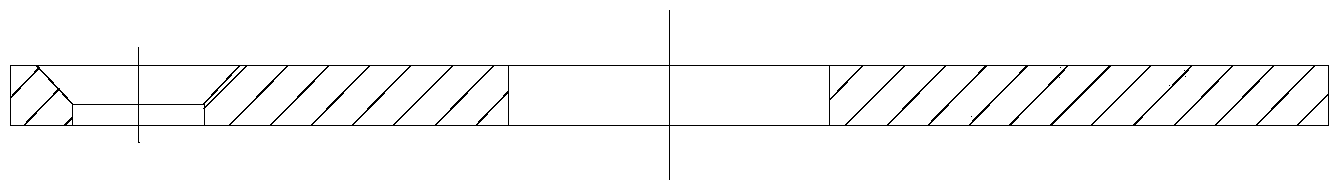

Composite sub-pixel angle point positioning method based on curvature and gray level

ActiveCN107341802AEasy extractionAddress reliabilityImage enhancementImage analysisTechnology researchScale invariance

The invention provides a composite sub-pixel angle point positioning method based on curvature and a gray level and relates to the machine vision precise measurement technology research field. According to the method, firstly image pre-processing on a frame selection interest area is carried out, and burr and oil stain of an original image are eliminated; candidate angle points are extracted through an angle point detection method based on curvature characteristics; multiple dimensioned invariance of an angle point curvature angle and the gray level information in a circular window taking an angle point as a circle center are utilized to eliminate pseudo angle points, and contour end points are considered; the angle point and the contour end points are connected to acquire two straight lines, the two straight lines are taken as reference, edge points of the original image are screened, a point set of the two straight lines of to-be-detected angle points is acquired, the least square method is utilized for fitting to acquire two straight lines, and the intersection point is the angle point. The method is advantaged in that a problem of reduction of angle point detection reliability and accuracy caused by attachment existing in shaft workpieces is solved, the acquired angle point is closer to an actual angle point, and precision reaches a sub-pixel level.

Owner:WUXI XINJIE ELECTRICAL

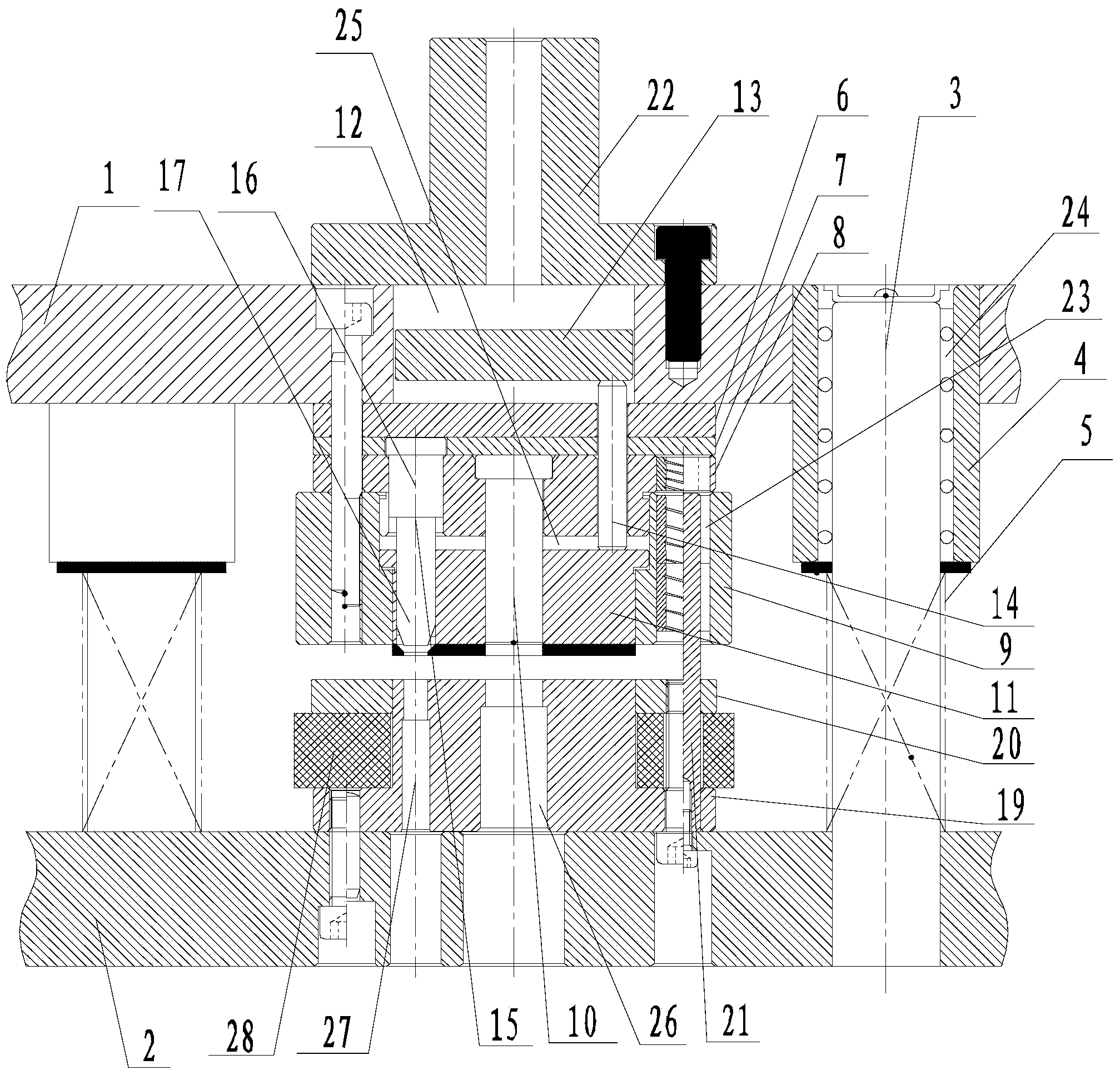

Die of overrunning clutch gland of motorcycle

InactiveCN103521615ASimple procedureIncrease productivityShaping toolsClutchElectrical and Electronics engineering

The invention relates to a die of an overrunning clutch gland of a motorcycle. The die comprises an upper die carrier and a lower die carrier, wherein the upper die carrier and the lower die carrier are connected through a die carrier guide post. The lower portion of the upper die carrier is fixedly connected with a first base plate, a second base plate, a male die fixing plate and a female die. A large male die is arranged in the middle of the male die fixing plate and perpendicularly connected with an upper stripper plate, a cavity is formed in the middle of the upper die carrier, a knockout plate is arranged in the cavity and connected with one end of a knockout rod, the other end of the knockout rod is connected with the upper stripper plate, three small male dies are further arranged on the male die fixing plate and provided with die ends and die heads, protruding parts are arranged on the outer walls of the die heads, the bottoms of the protruding parts on the two sides and the heads of the die heads form a stamping part which is of a countersunk screw shape, a female-and-male die and a lower stripper plate are fixed to the lower die carrier, the female die and the female-and-male die are connected through a stripper plate guide post, a stripper plate guide sleeve is arranged on the outer wall of the stripper plate guide post, and the top of the middle of the upper die carrier is connected with a die handle. According to the die, procedures are simplified, production efficiency is improved, burrs are removed, and roughness is improved.

Owner:JIANG SU NAN FANG BEARING CO LTD

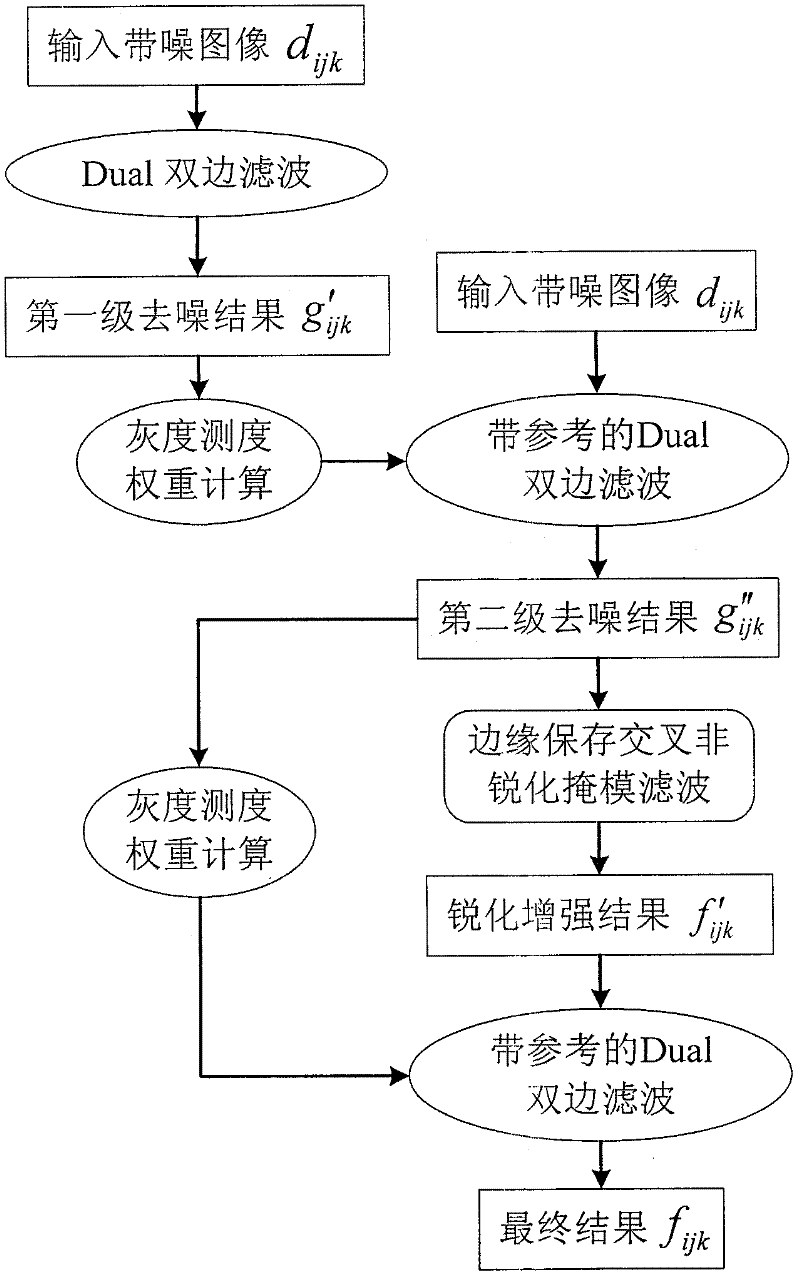

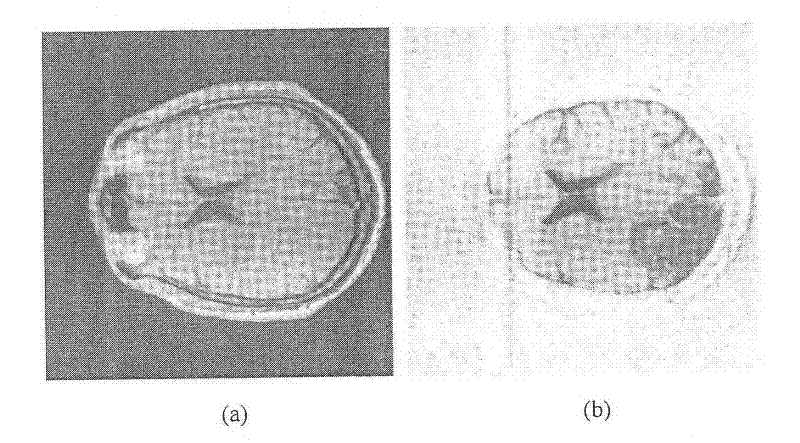

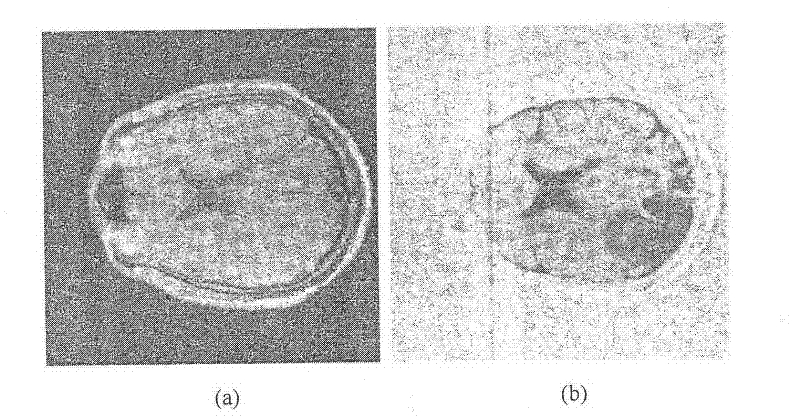

Denoising and sharpening method by aiming at multimode image

InactiveCN102521800AAchieving Noise SuppressionAchieve denoisingImage enhancementPattern recognitionReference image

The invention discloses a denoising and sharpening method by aiming at a multimode image, which comprises the following steps: 1, carrying out Dual bilateral filtering to an input noise multimode image group dijk to obtain a first level of denoised image group g'ijk; 2, taking the first level of denoised image group g'ijk as a reference image, and carrying out referenced Dual bilateral filtering to the original noise image group dijk to obtain a second level of denoised image group g''ijk; 3, carrying out edge-preservation cross unsharpened masking filtering to the second level of denoised image group g''ijk to obtain a sharpened and enhanced image group f'ijk; and 4, taking the g''ijk as a reference image, and carrying out referenced Dual bilateral filtering to the sharpened and enhanced image group f'ijk to obtain a final result fijk. According to the characteristic that information among component images in the multimode image group has certain relativity, the multimode image can be subjected to noise suppression and edge selectivity sharpening, and the subjective visual quality is improved.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

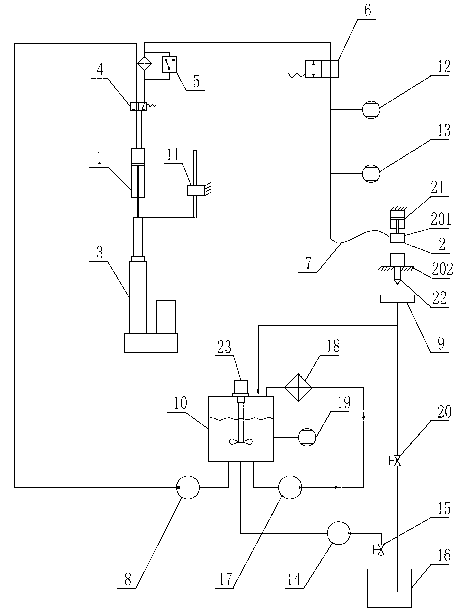

Extruding and grinding device for spray orifice of oil spray nozzle and extruding and grinding method for spray orifice of oil spray nozzle

ActiveCN102990506AImprove flow coefficientEasy maintenanceBurnishing machinesGrinding work supportsTemperature controlSpray nozzle

The invention provides an extruding and grinding device for a spray orifice of an oil spray nozzle and an extruding and grinding method for the spray orifice of the oil spray nozzle, belonging to the technical field of the precision machining of the spray orifice of the oil spray nozzle. The extruding and grinding device for the spray orifice of the oil spray nozzle provided by the invention comprises a grinding material filling pipeline, a grinding material processing pipeline, a grinding material emptying pipeline, a grinding material temperature control pipeline and an emergency emptying pipeline, wherein a detecting device is arranged on the grinding material processing pipeline for detecting the real-time grinding material flow of the spray orifice of the oil spray nozzle. The extruding and grinding method for the spray orifice of the oil spray nozzle provided by the invention mainly comprises the following steps of: grinding-detecting and comparing flow-grinding-detecting and comparing flow. The spray orifice of the oil spray nozzle is machined by means of extruding and grinding by a step-by-step approach method. According to the method, the real-time grinding material flow of the spray orifice is accurately detected and is compared step by step till the flow value reaches a set value, so that the grinding processing can be guaranteed to achieve the technological requirement. According to the invention, the filleted corner of the orifice, which accords with the technological requirement, can be formed, so that the fineness of the wall of the spray orifice can be improved, the flow coefficient of the oil spray nozzle can be improved, and the device is simple in structure and convenient to maintain.

Owner:CHINA FIRST AUTOMOBILE

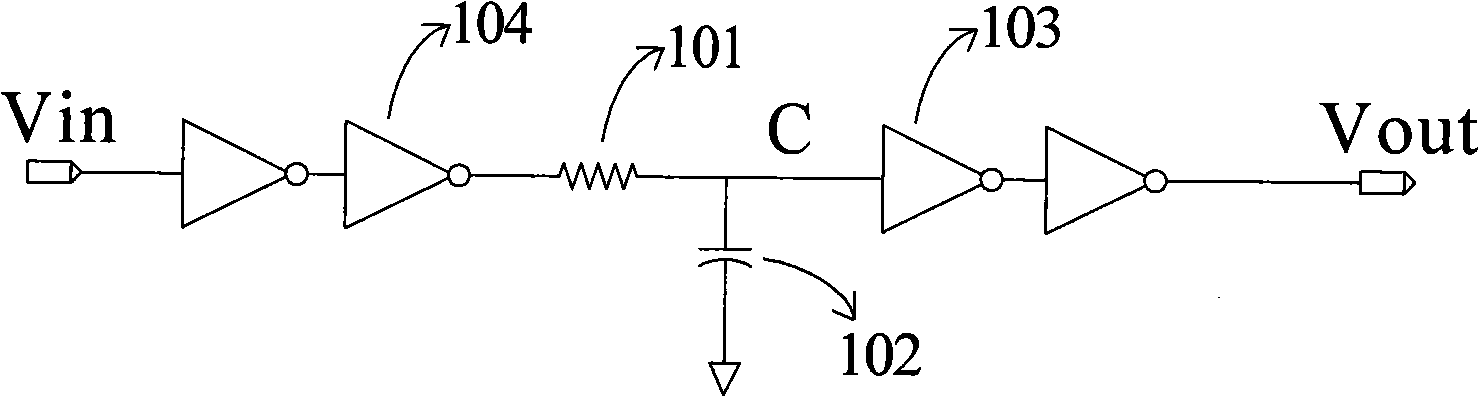

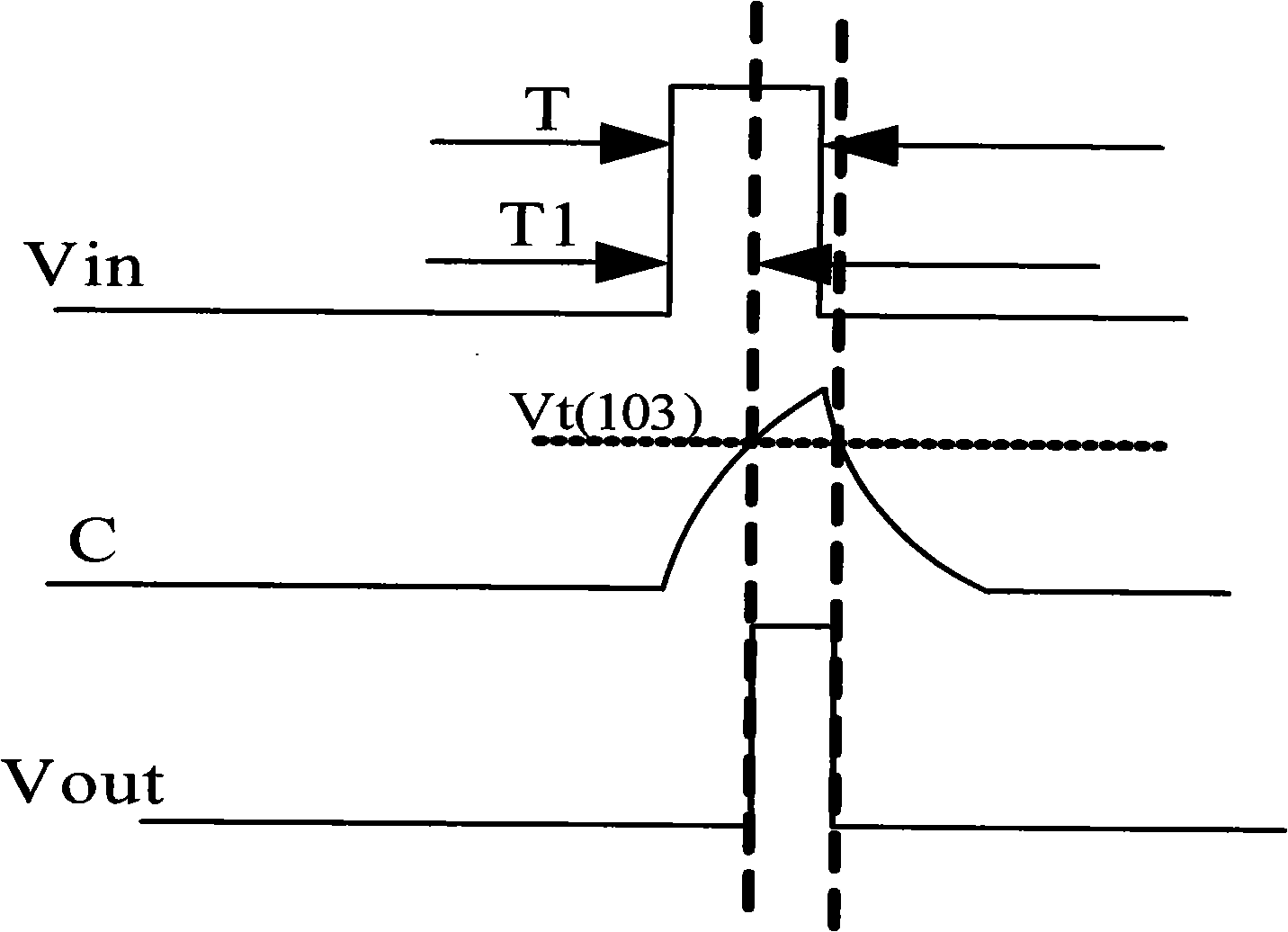

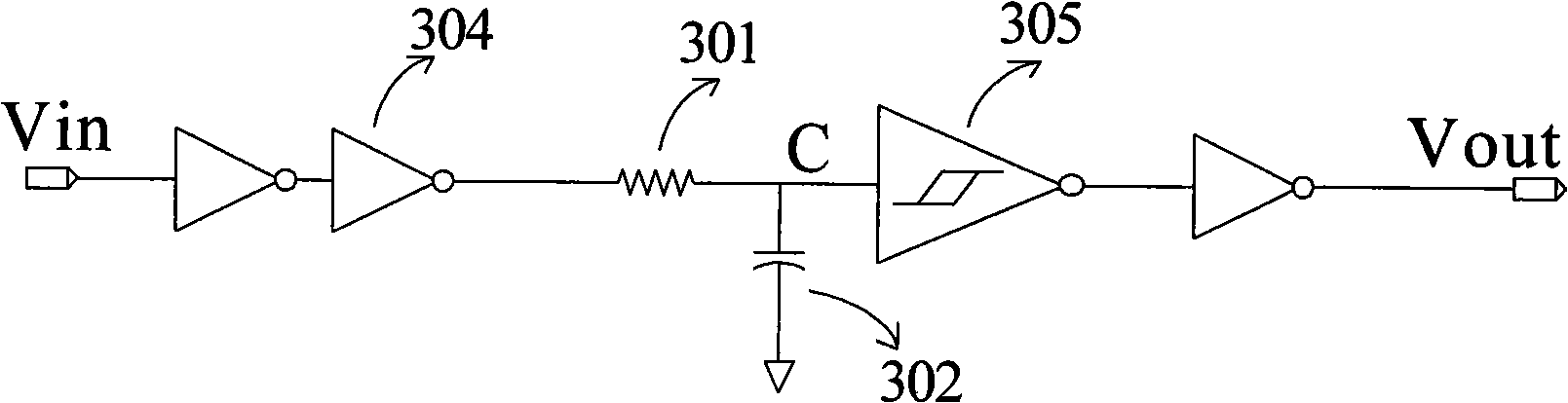

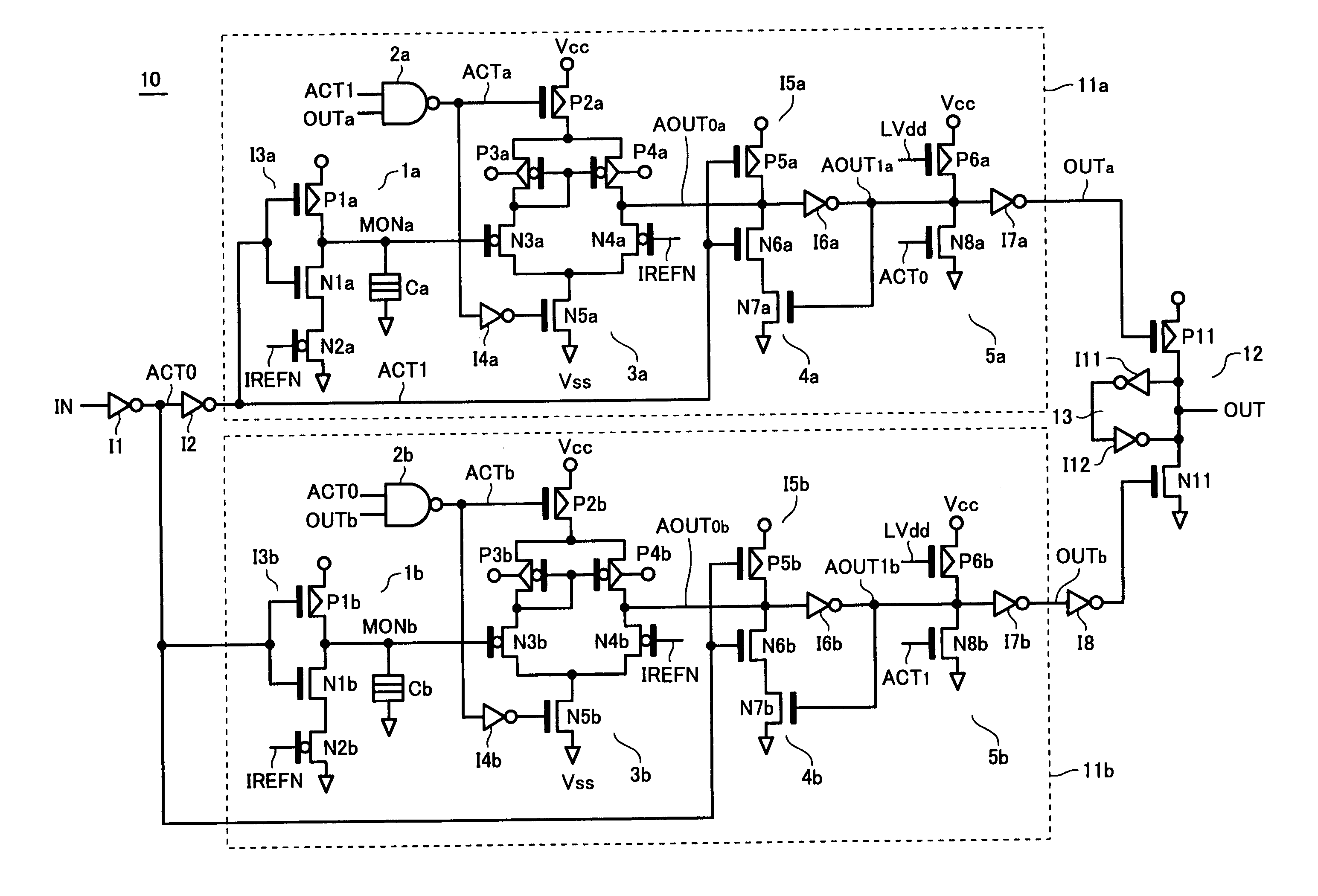

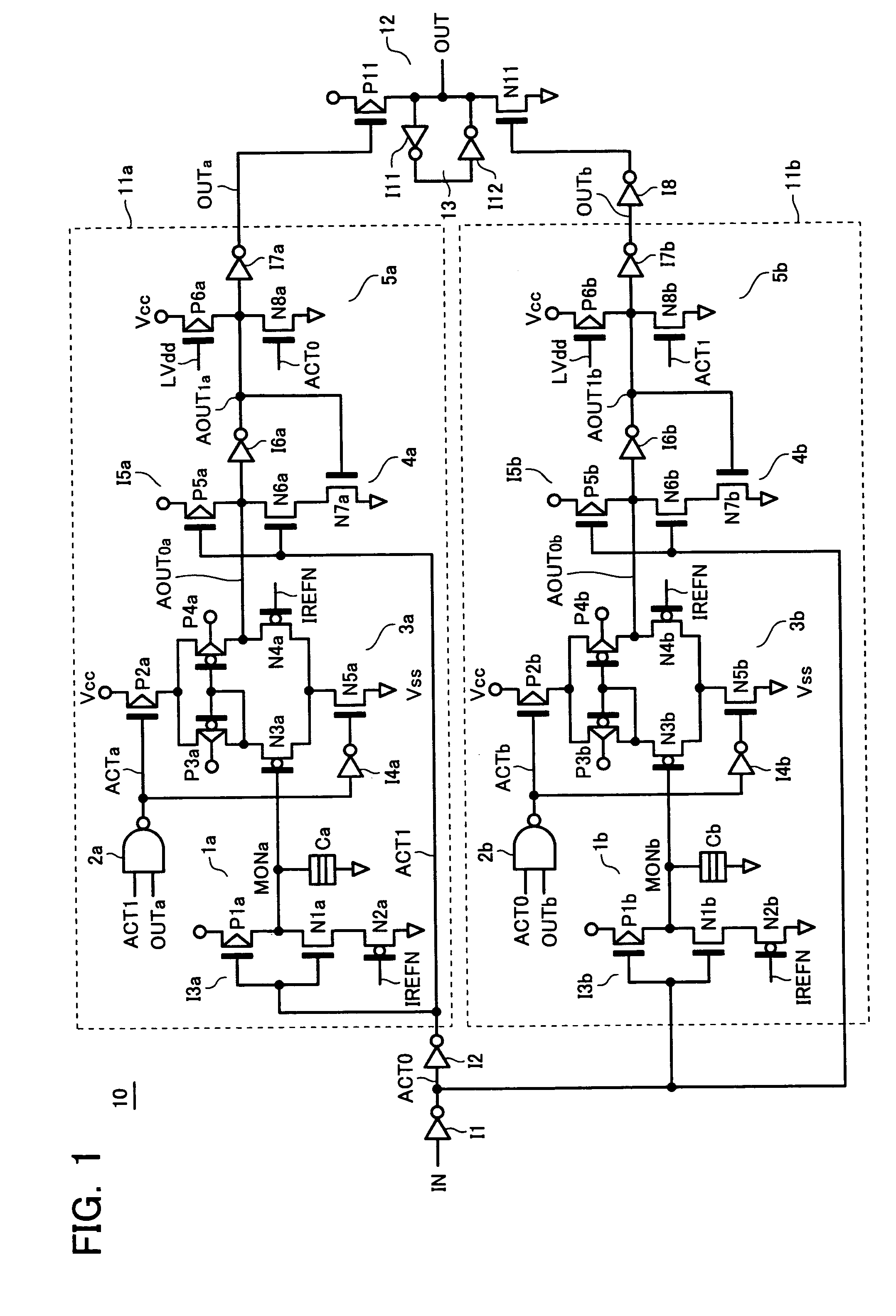

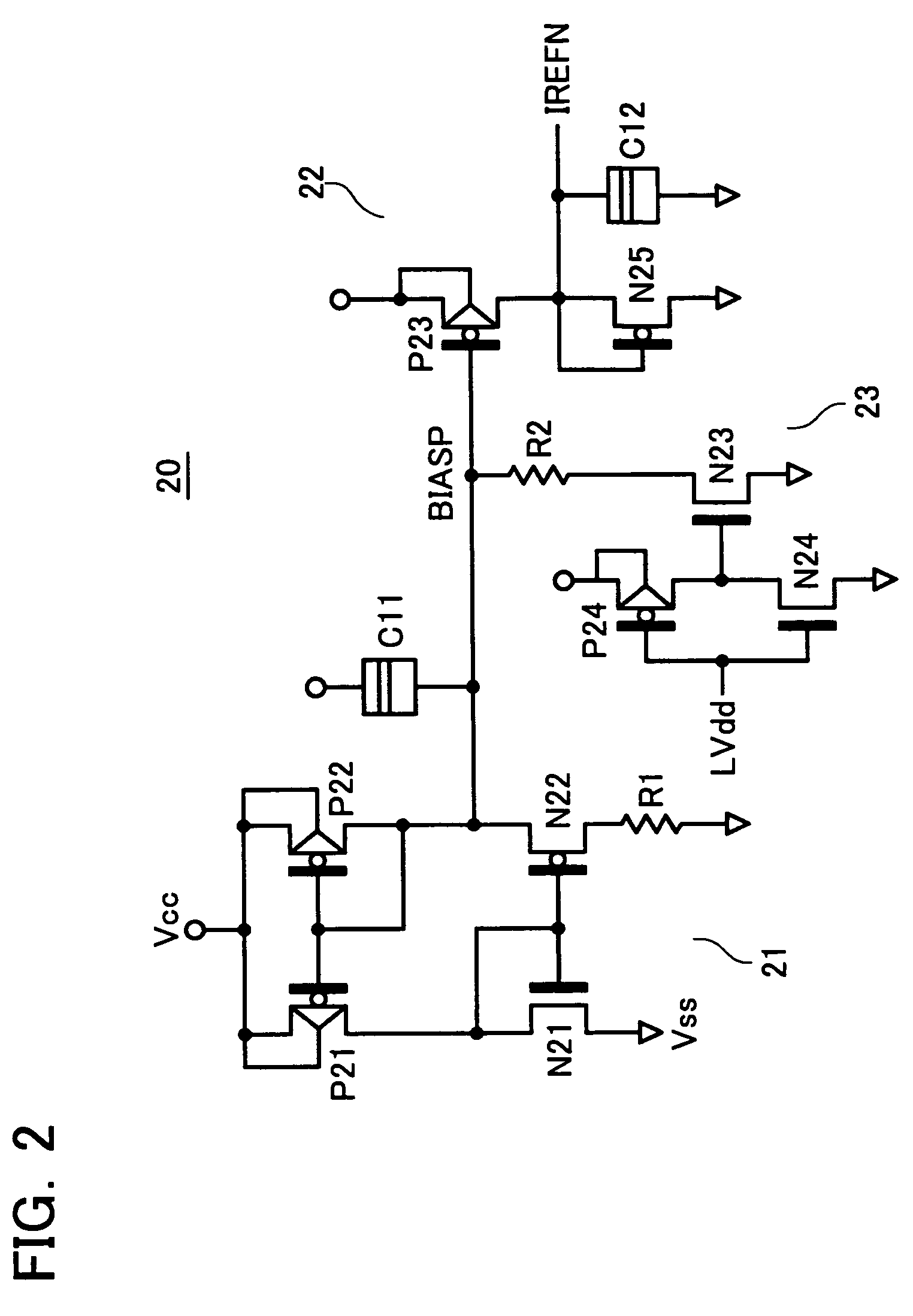

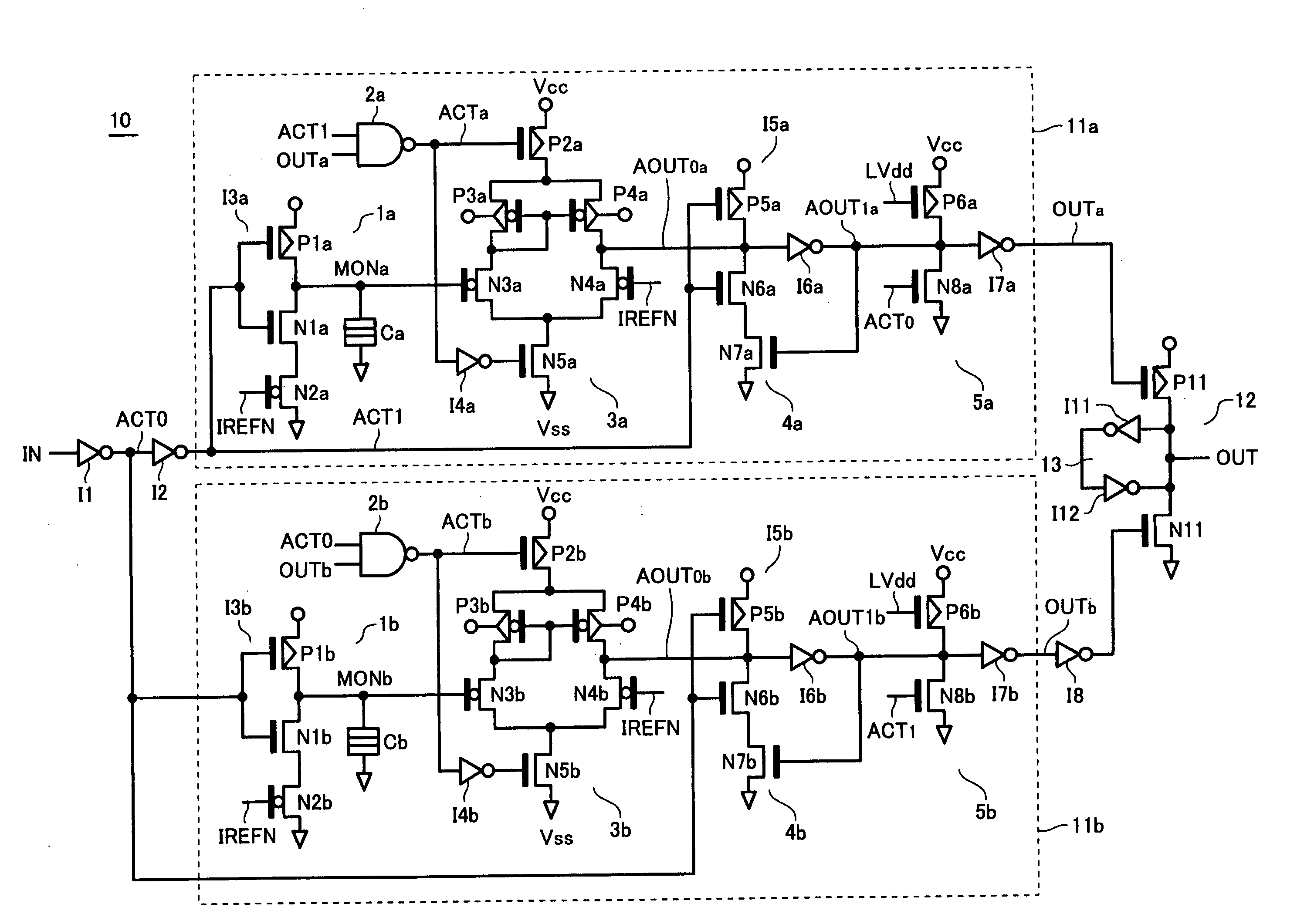

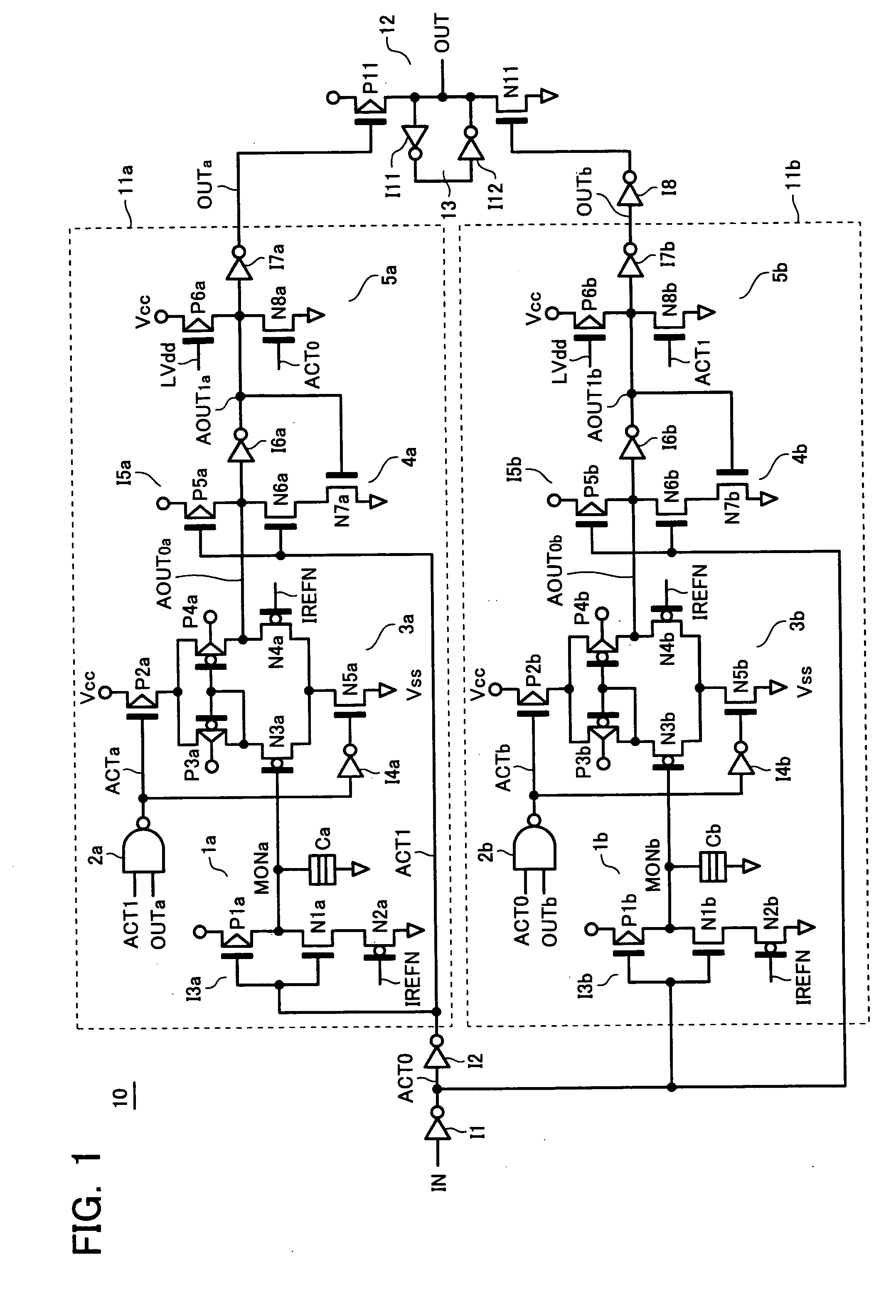

Semiconductor integrated circuit device with filter circuit

There is provided a semiconductor integrated circuit device with a filer circuit serving for eliminating a glitch contained in a logic signal supplied to the device, wherein the filter circuit includes: a first delay circuit activated within a certain period after each rising edge timing of input logic signals to delay the rising edge; a second delay circuit activated within a certain period after each falling edge timing of the input logic signals to delay the falling edge; and an output driver controlled by outputs of the first and second delay circuits to output delayed logic signals to an output node in response to the input logic signals.

Owner:KK TOSHIBA

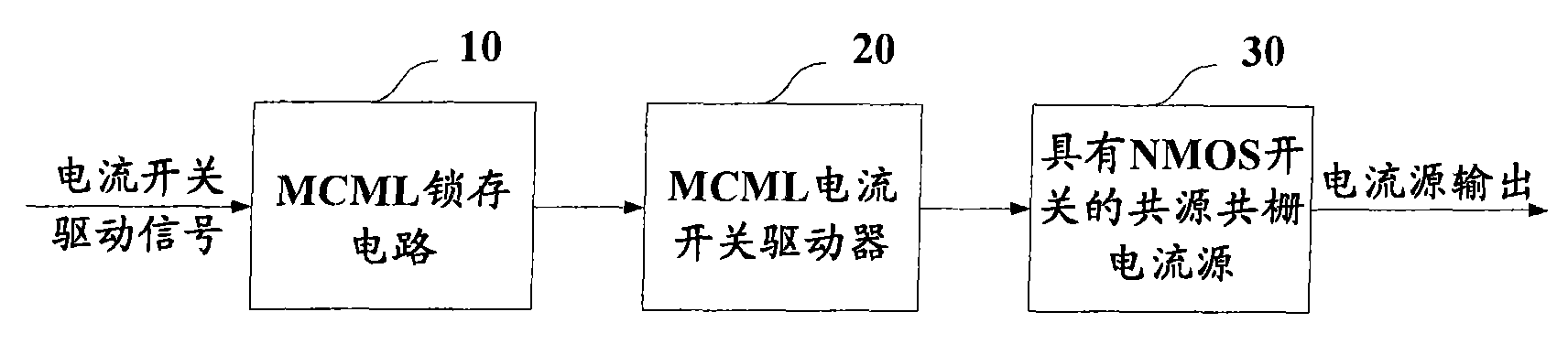

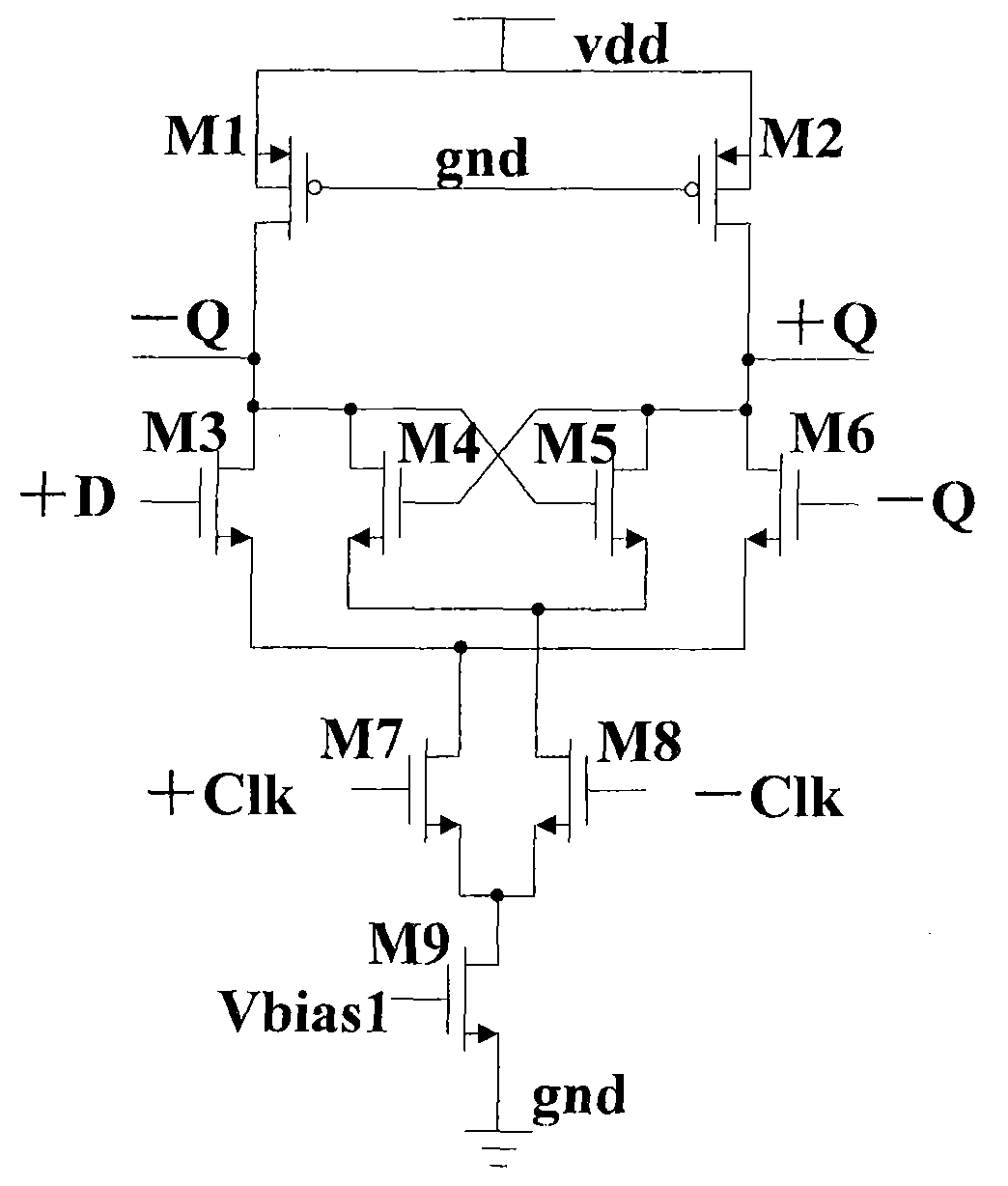

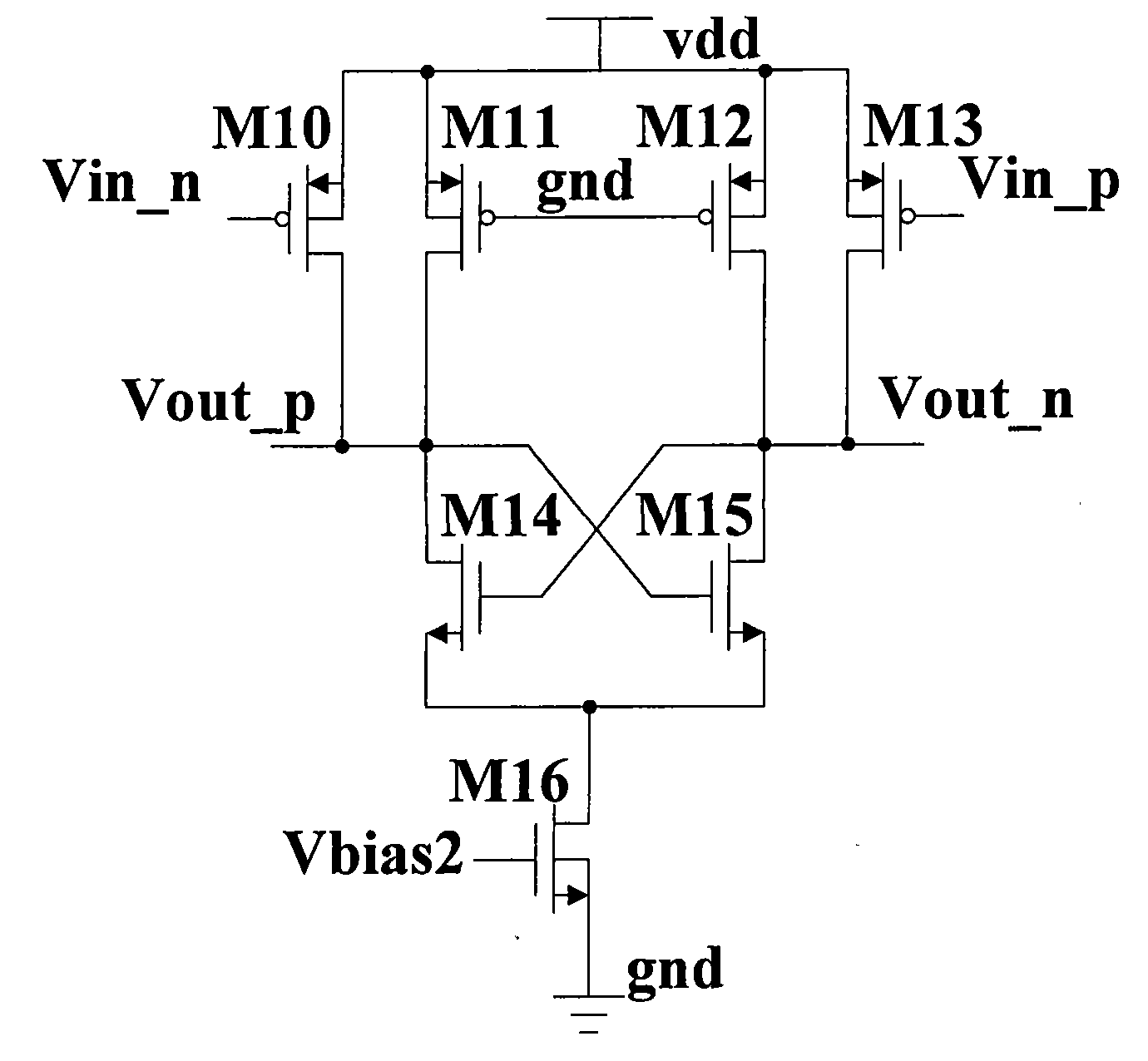

High-speed current switch driver based on MOS current-mode logic

ActiveCN101562449ASmall swingPrevent simultaneous shutdownLogic circuitsLow distortionCurrent switch

The invention provides a high-speed current switch driver based on MOS current-mode logic. The driver comprises: a MOS current-mode logic latch circuit for receiving current switch drive signals, and performing latching and amplitude limiting on the current switch drive signals so as to synchronize the current switch drive signals; a MOS current-mode logic current switch for receiving signals processed by the MOS current-mode logic latch circuit, generating current source drive signals with amplitude limited and adjusting crossing points of the current switch drive signals; and a common-source and common-gate current source with a NMOS switch for receiving the current switch drive signals processed by the MOS current-mode logic current switch and outputting low-distortion current signals, thus synchronizing the current switch drive signals and reducing feed-through effect.

Owner:陕西光电子先导院科技有限公司

Punch press and deburring device for the punch press

The present invention provides a deburring device for a punch press which can remove burrs produced along a slot or a cut portion formed in a plate material by punching or cutting using a punch press so that the removal is carried out as a process with the same punch press. A deburring device 6 for a punch press has an upper tool 7 and a lower tool 8 arranged opposite each other. The upper and lower tools 7, 8 each have a ball holding member 22, 32, respectively, and a ball 23, 33, respectively, rotatably supported by the ball holding member and projecting from a surface of the ball holding member 22, 32 toward an opposite surface of the opposite ball holding member 32, 22. Each of the upper and lower balls 23, 33 has a diameter larger than the width of the slot A, in its portion projecting from the ball holding member 22, 32, respectively, the slot A being formed in the plate material W so as to extend across the plane. The plate material W moves with the vertical pair of balls 23, 33 partly fitted into the slot A and with the plate material W sandwiched between the upper and lower balls 23, 33 to continuously remove burrs (a) produced along a longitudinal direction of the slot A. The deburring device 6 continuously removes not only the burrs produced along the slot A but also those produced along a cut portion in the plate material W as described above.

Owner:MURATA MASCH LTD

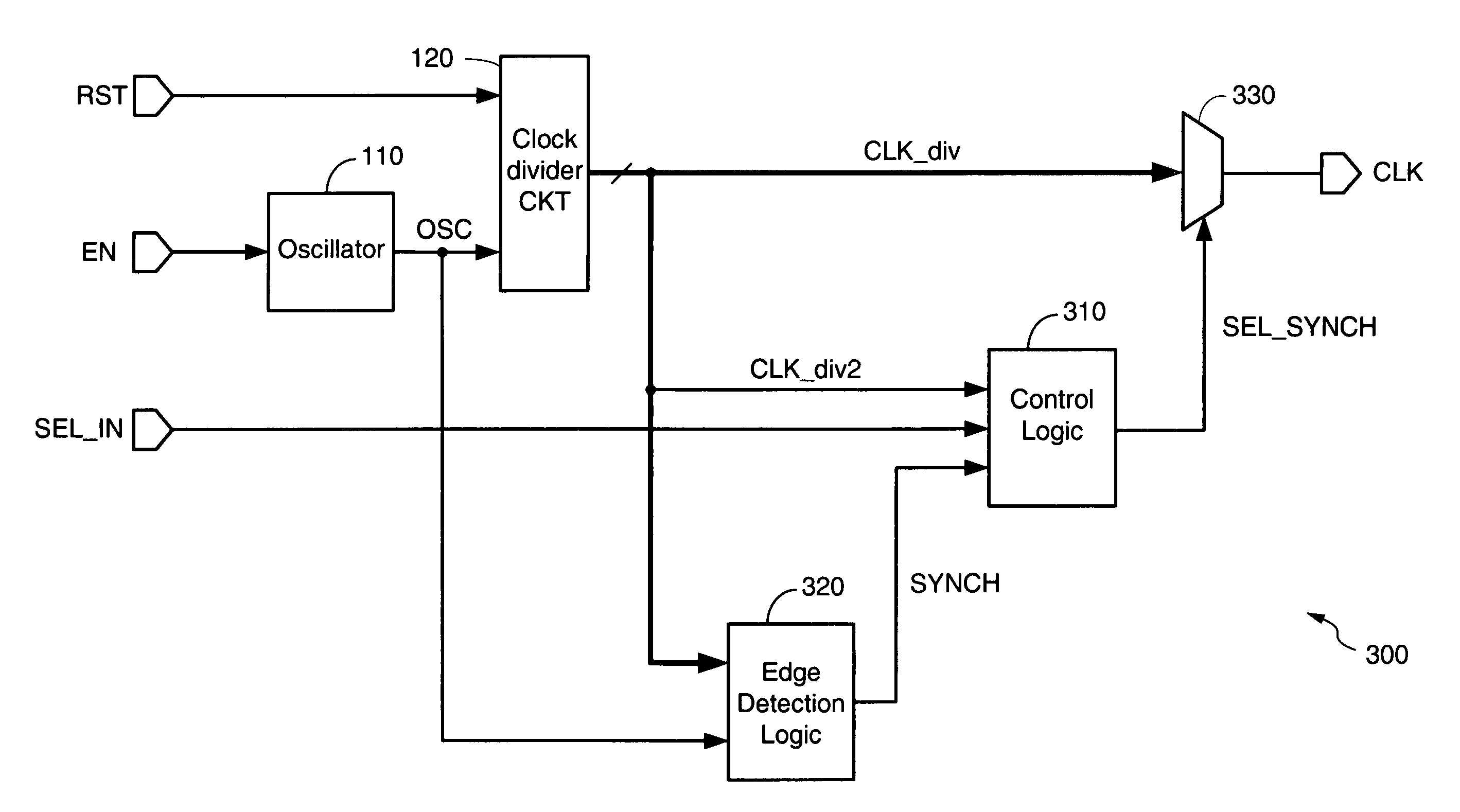

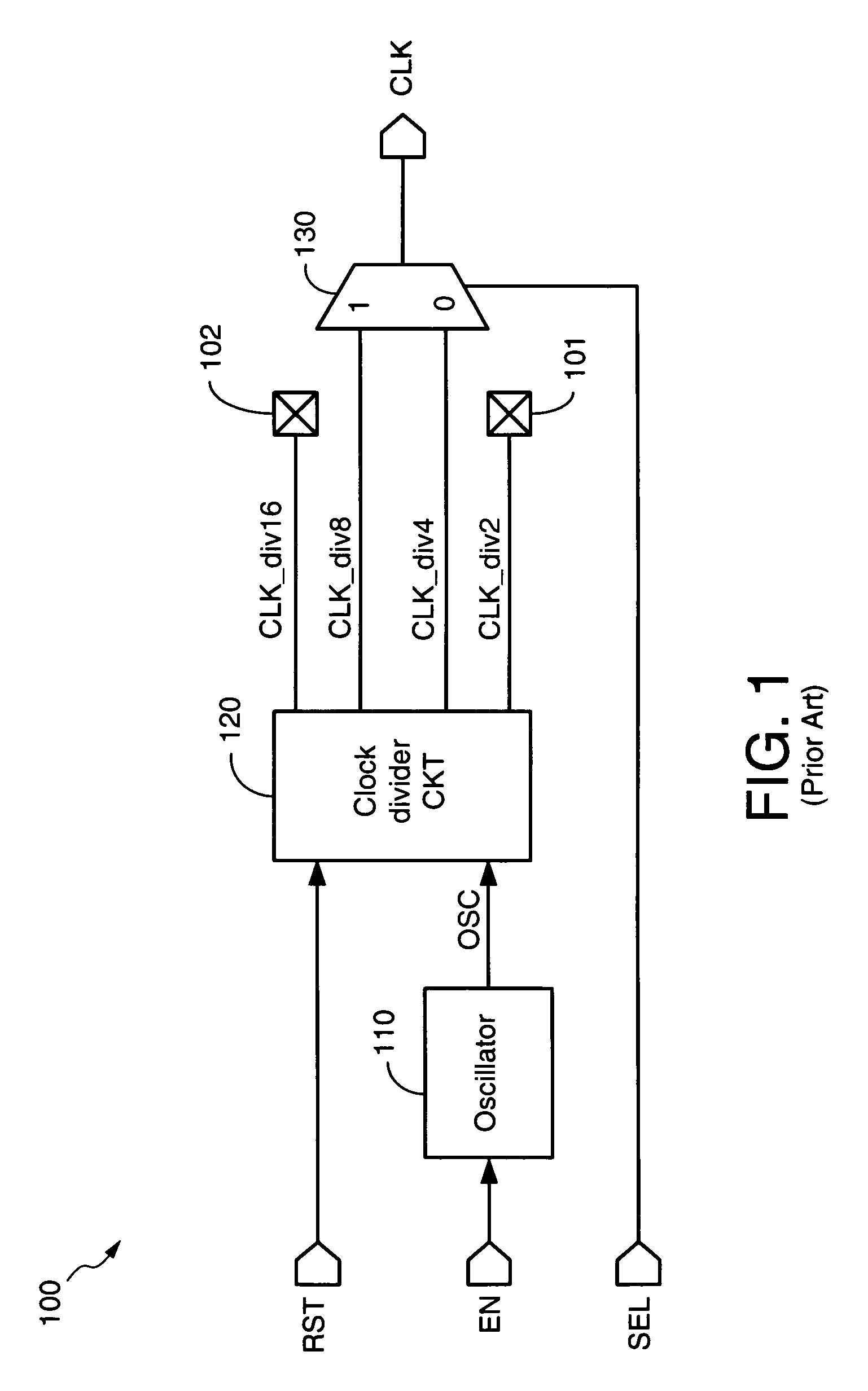

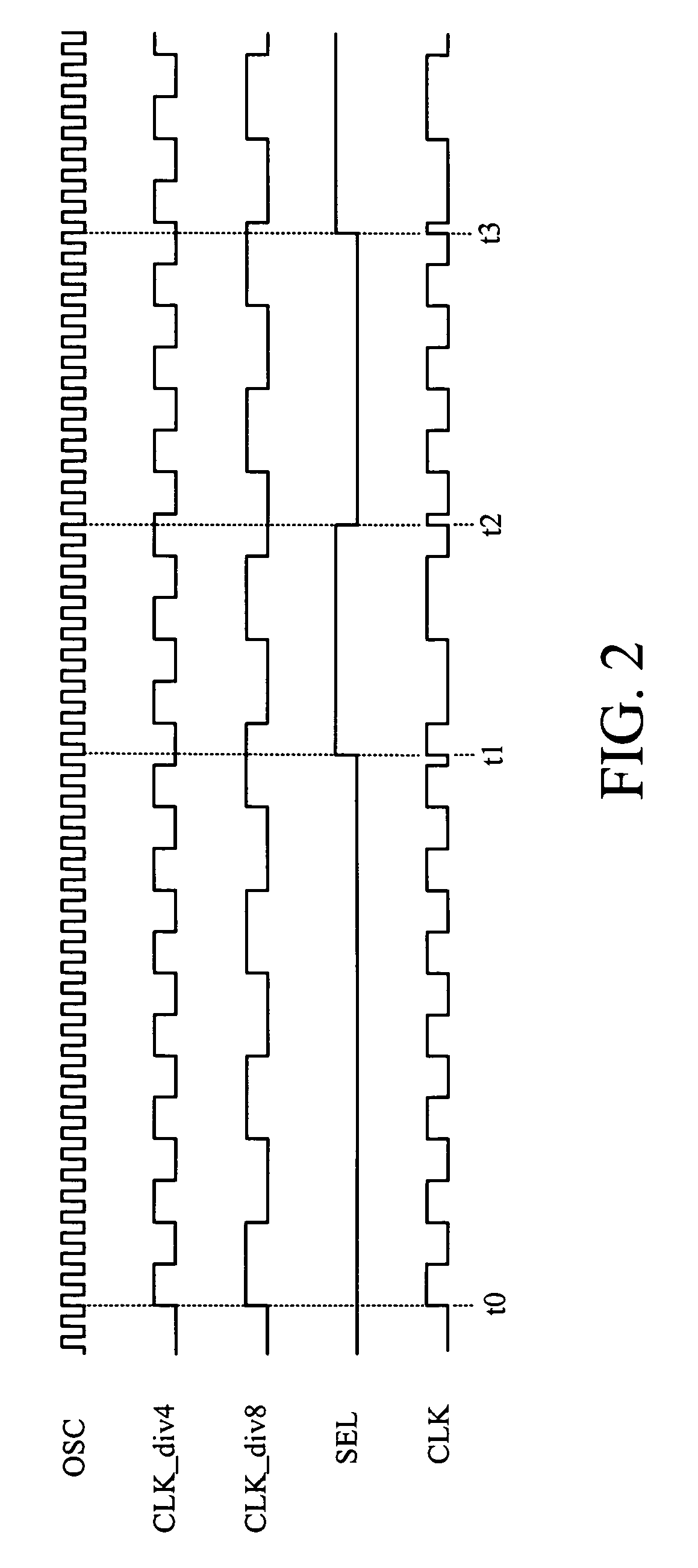

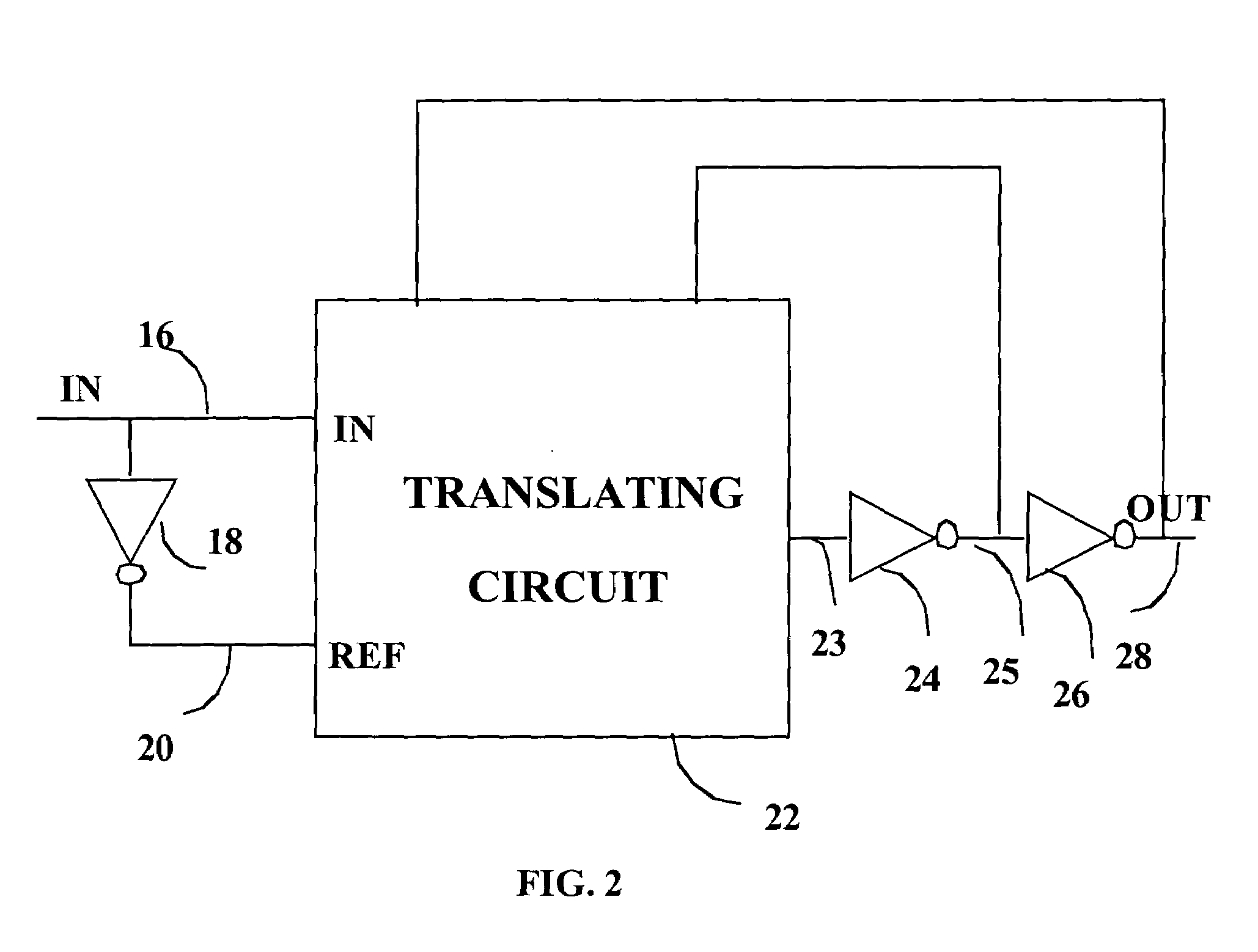

Glitchless clock selection circuit using phase detection switching

ActiveUS7071738B1Eliminate burrsPulse automatic controlElectronic switchingControl signalMultiplexer

A clock selection circuit includes an output multiplexer, control logic, and edge detection logic. The multiplexer includes inputs to receive multiple input clock signals, an output to generate the output clock signal, and a control terminal to receive a synchronized clock select signal. The control logic includes a first input to receive a clock select signal, a second input to receive a first control clock signal, a third input to receive a synchronization signal, and an output to selectively update the synchronized clock select signal with transitions in the clock select signal. The edge detection logic includes first inputs to receive the multiple input clock signals, a second input to receive a second control clock signal, and an output to generate the synchronization signal.

Owner:XILINX INC

Method and system for a glitch correction in an all digital phase lock loop

InactiveUS8222939B2Eliminate burrsReduce in quantityPulse automatic controlDuration/width modulated pulse demodulationSignal correctionMulti phase

The present invention relates to a method and system for glitch correction in an all digital phase lock loop. An all digital phase lock loop can include a phase error signal generation unit, a multi-phase oscillator, a glitch correction unit, and a phase to digital converter. The phase to digital converter receives a multi-phase signal from the multi-phase oscillator and generates a phase signal. The error signal generation unit receives the phase signal and a reference phase signal and generates a phase error signal, which is fed to the glitch correction unit. The glitch correction unit removes the glitches in the phase error signal by a portion of the phase error signal. The phase lock loop can also include a phase rotator and a calibration block. The calibration block instructs the phase rotator to rotate the multi-phase signal by the phase rotation which generates the minimum number of glitches.

Owner:PANASONIC CORP

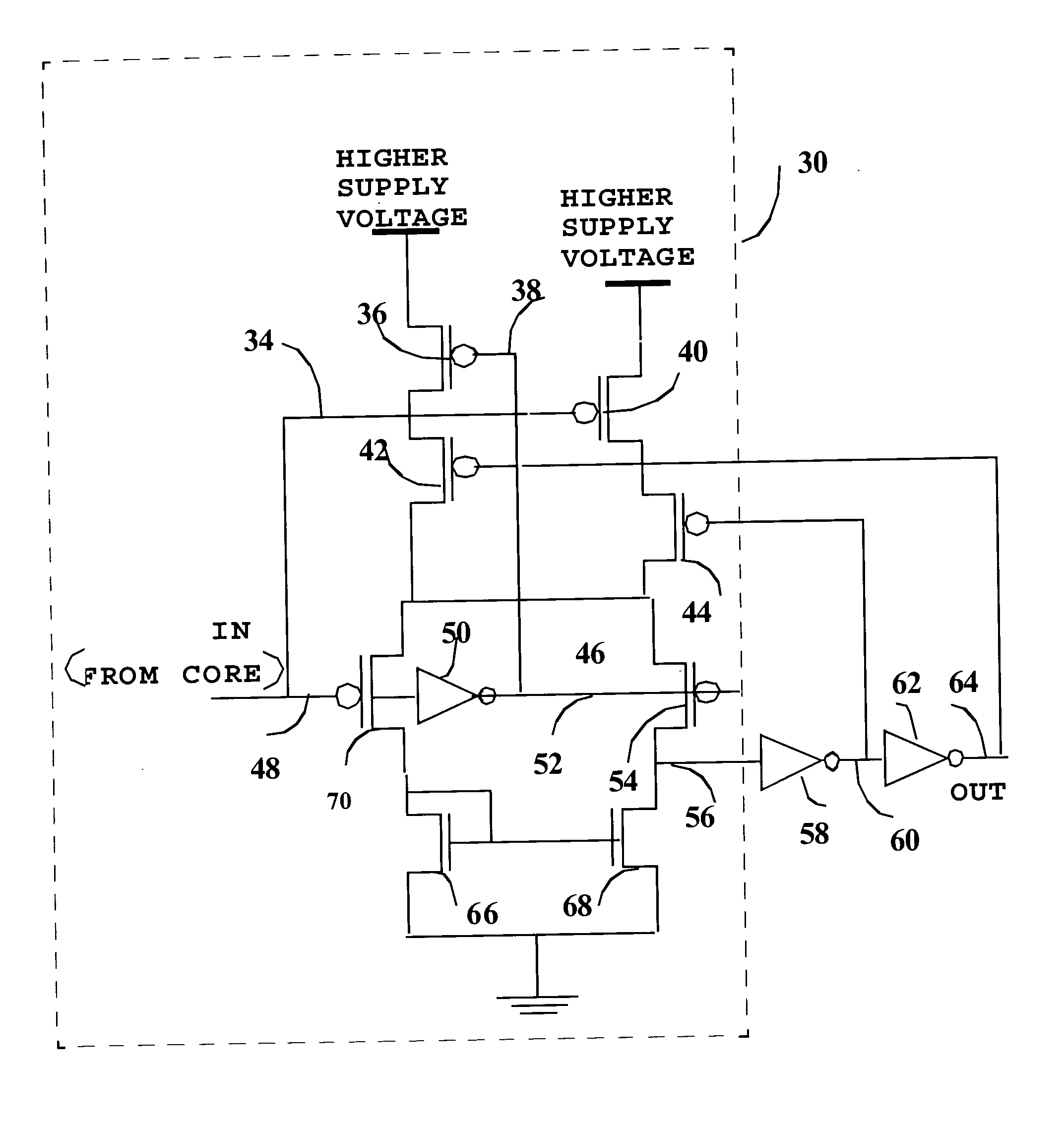

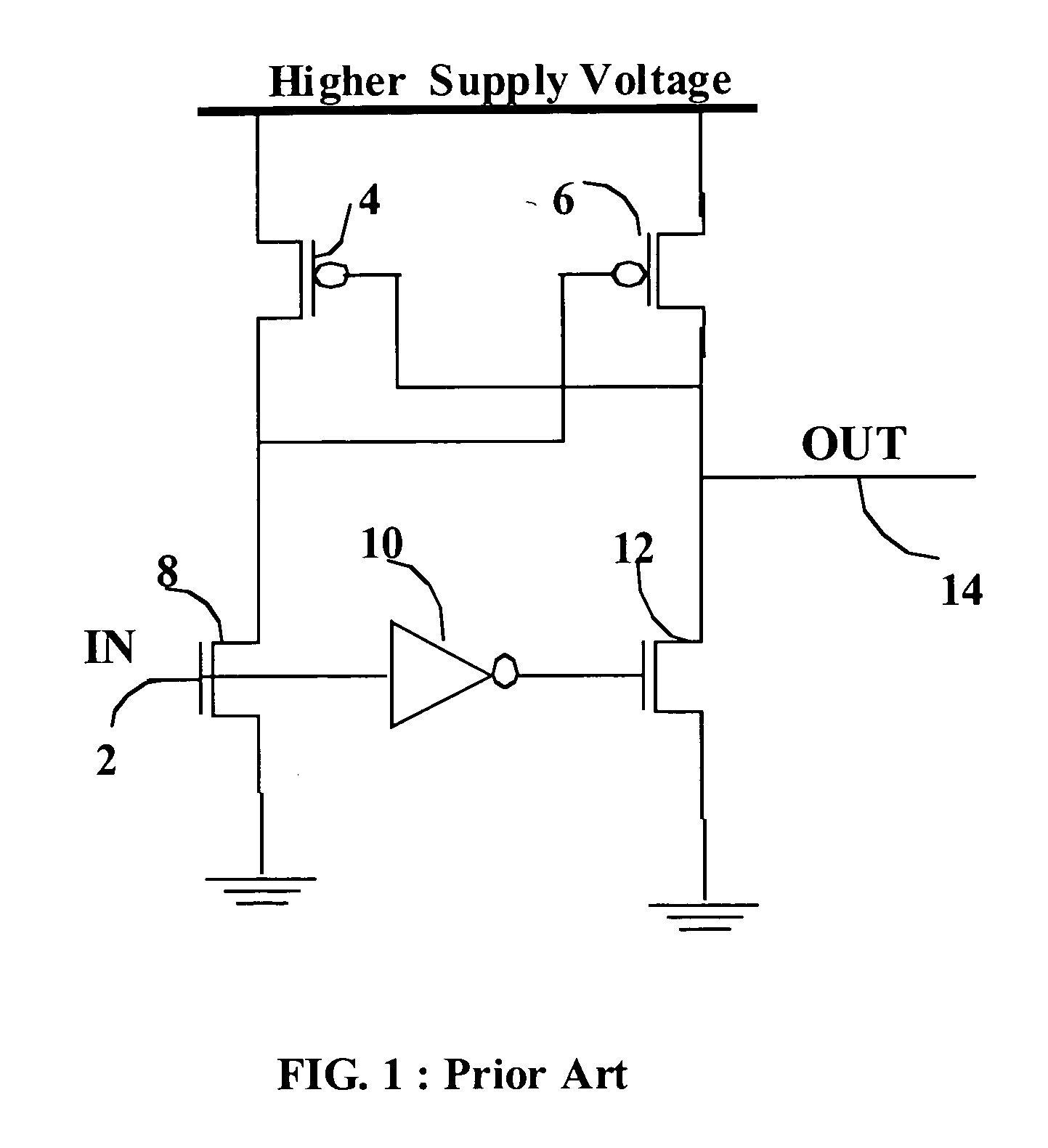

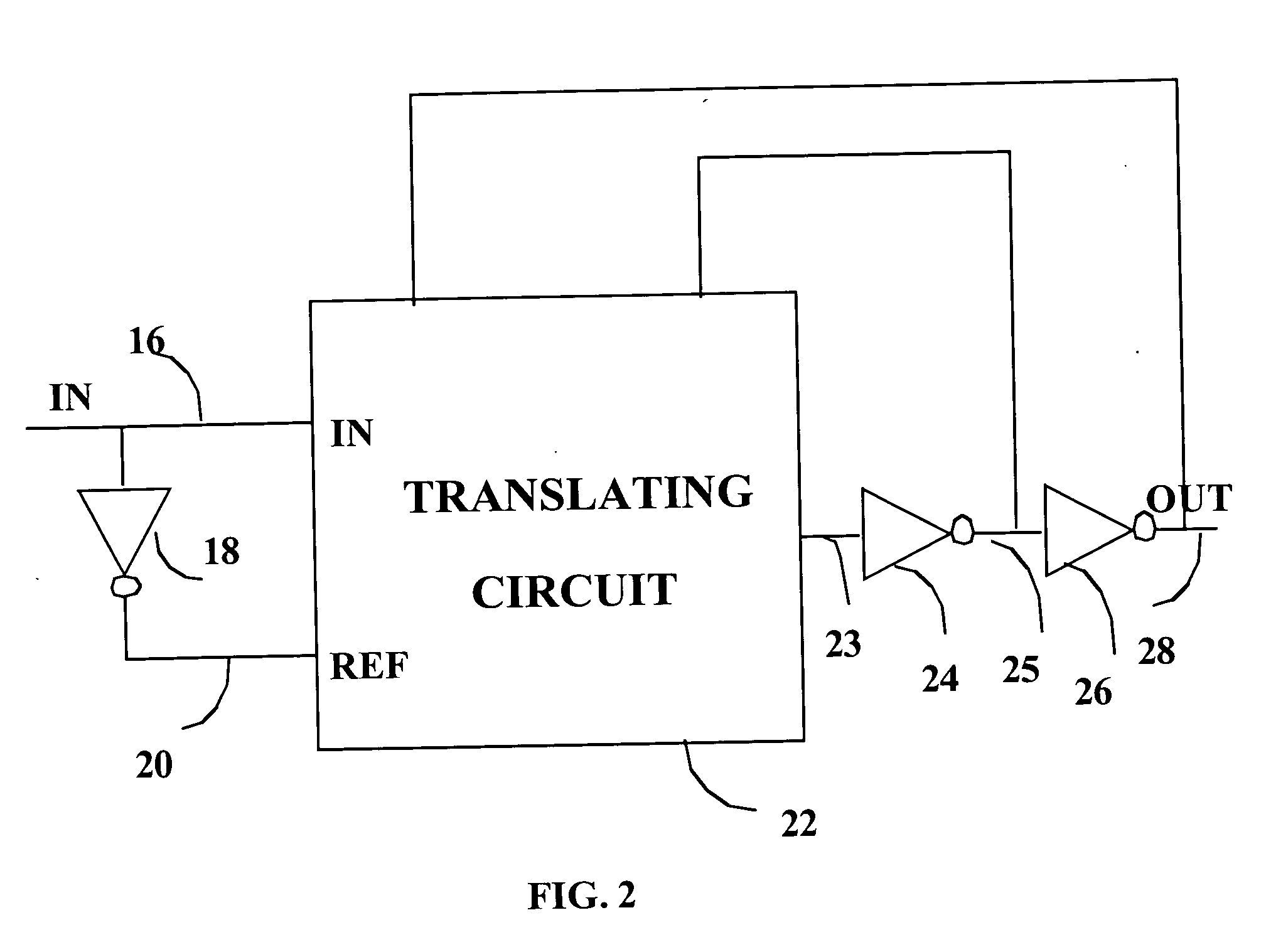

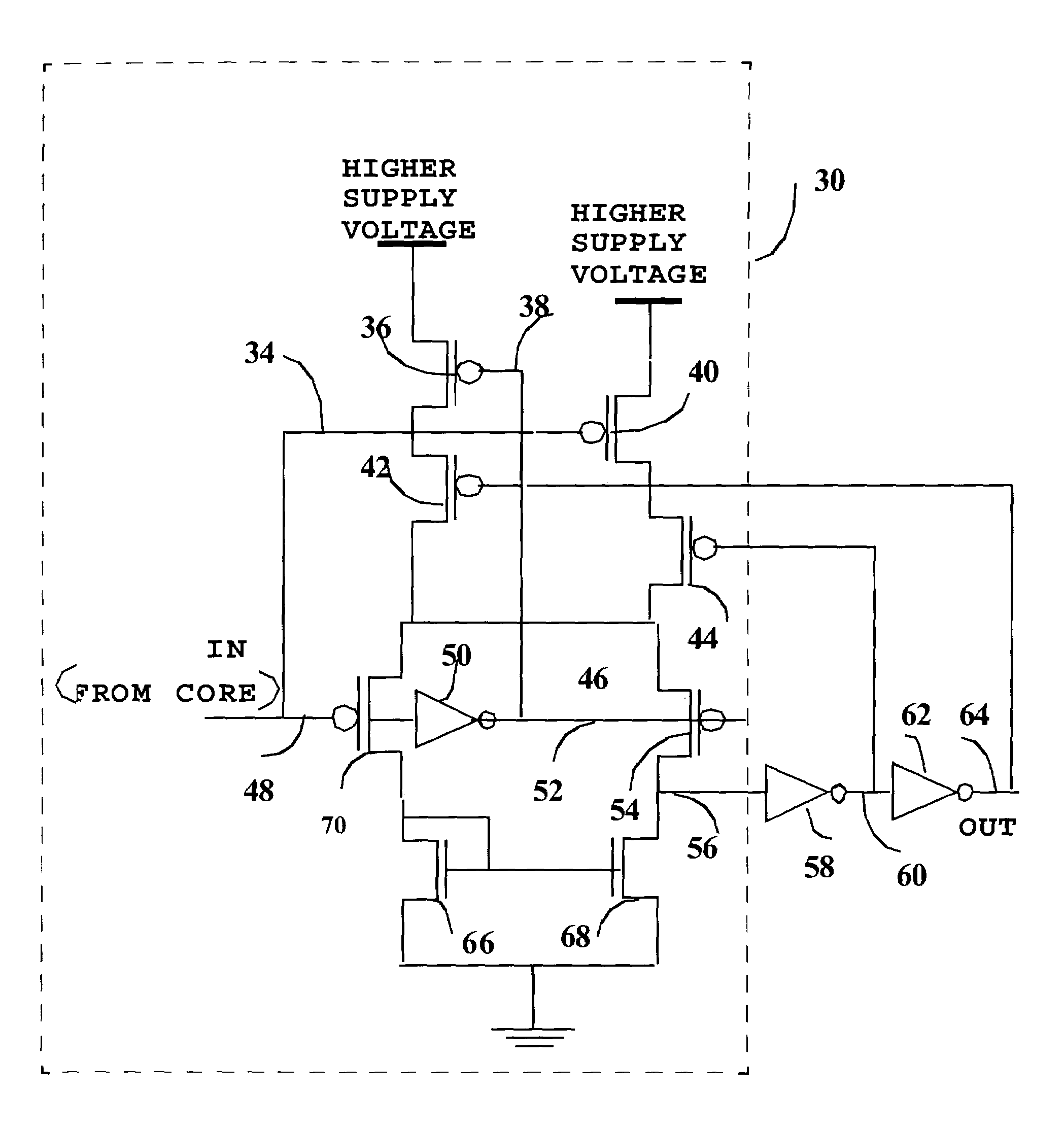

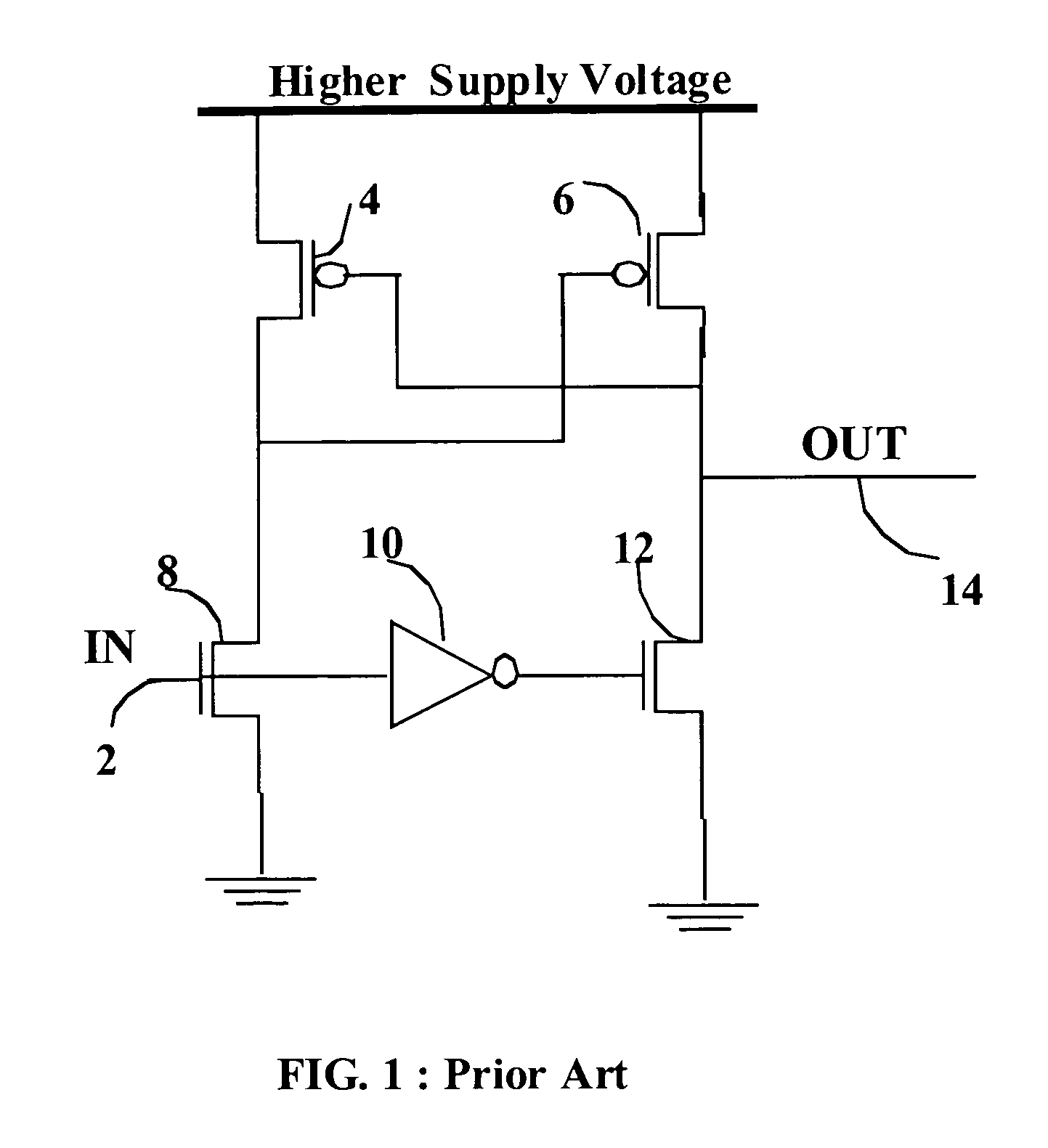

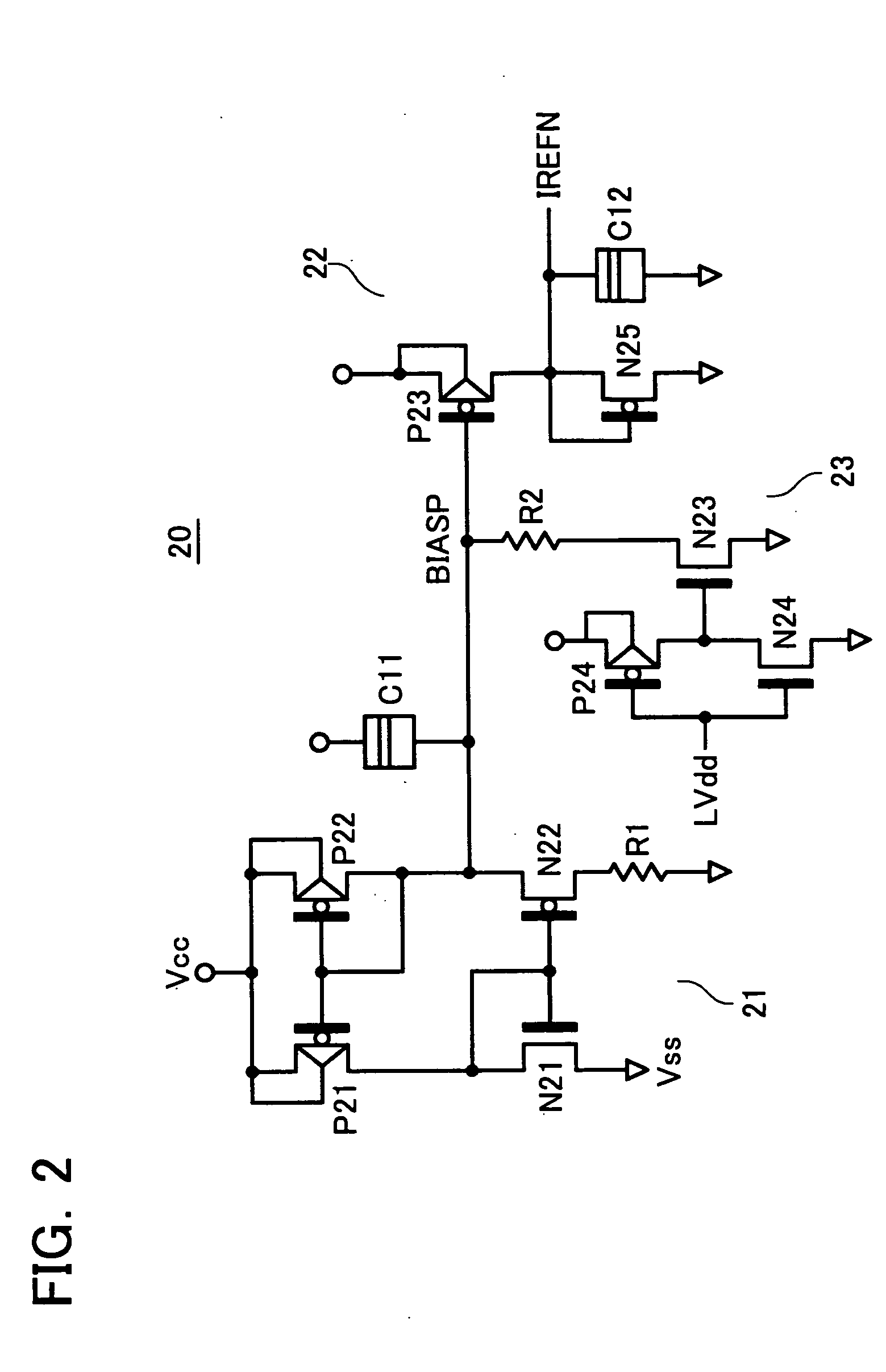

High speed voltage level translator

ActiveUS20050162209A1Reduce circuit areaMinimize power consumptionMultiple input and output pulse circuitsPulse automatic controlLow voltageEngineering

A high speed voltage level translator having minimum power dissipation and reduced area, specifically in the sub 0.1 micron domain, includes a transistorized arrangement to receive a low voltage input signal and to control current in the translated high level voltage signal. The translator further provides a differential amplifier arrangement for receiving the low level voltage input signal and provides feedback signals to the transistorized arrangement thereby outputting a high level voltage translated signal.

Owner:STMICROELECTRONICS PVT LTD

Method for making a flux cored wire

ActiveCN101804534AEliminate burrsArc welding apparatusWelding/cutting media/materialsSheet steelButt joint

the ends of strip steels are butt-jointed with each other in the longitudinal direction in order and are connected by welding, when such long strip steel raw material is used for continuously making a thin flux-cored wire, the burr generated due to the shearing of the steel plate and continuously existing at the end of the width direction of the strip steel along the whole longitudinal direction of the strip steel faces the upper part of the connecting strip steels, then the ends of strip steels are butt-jointed with each other in the longitudinal direction, and are connected by welding, no burr toward the outside of the thin flux-cored wire exists. By adopting the method, the circularity of the flux-cored wire can be ensured, in case of thin flux-cored wire, no bad influence on the supply of the extending-out welding wire in the welding construction for a welding machine is caused, and the supply is good.

Owner:KOBE STEEL LTD

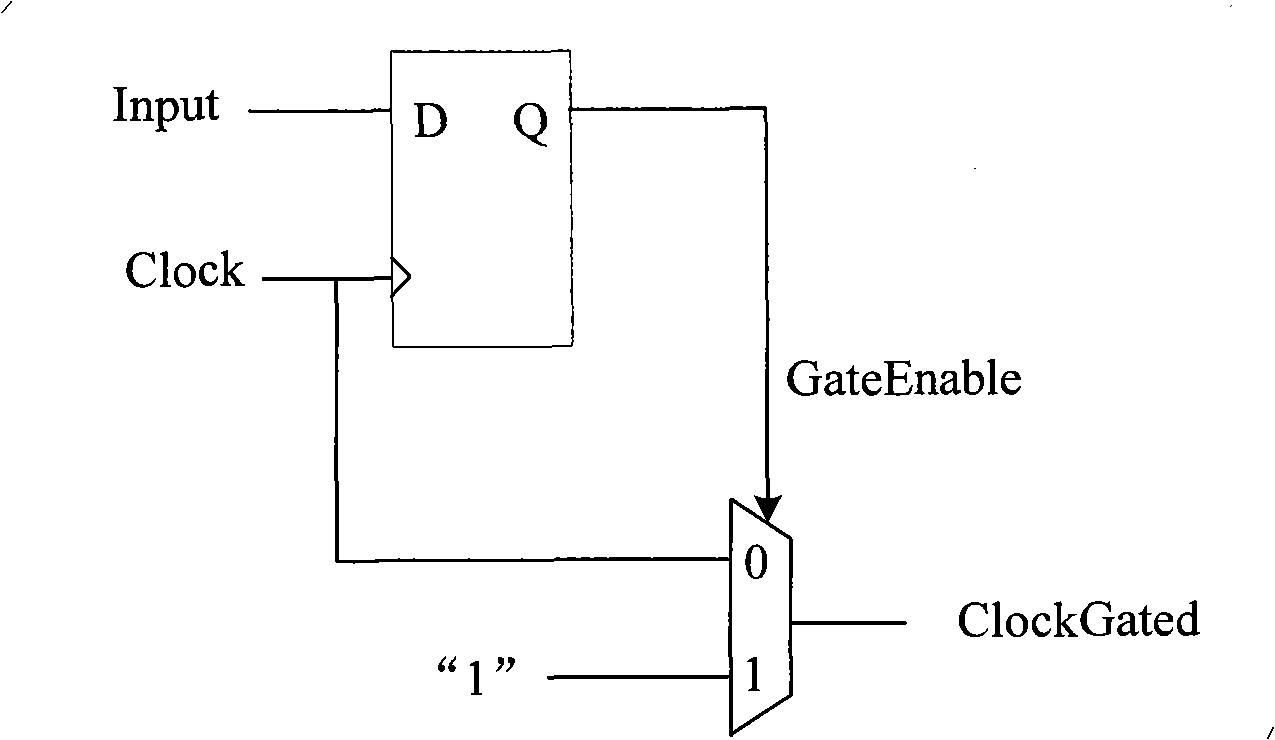

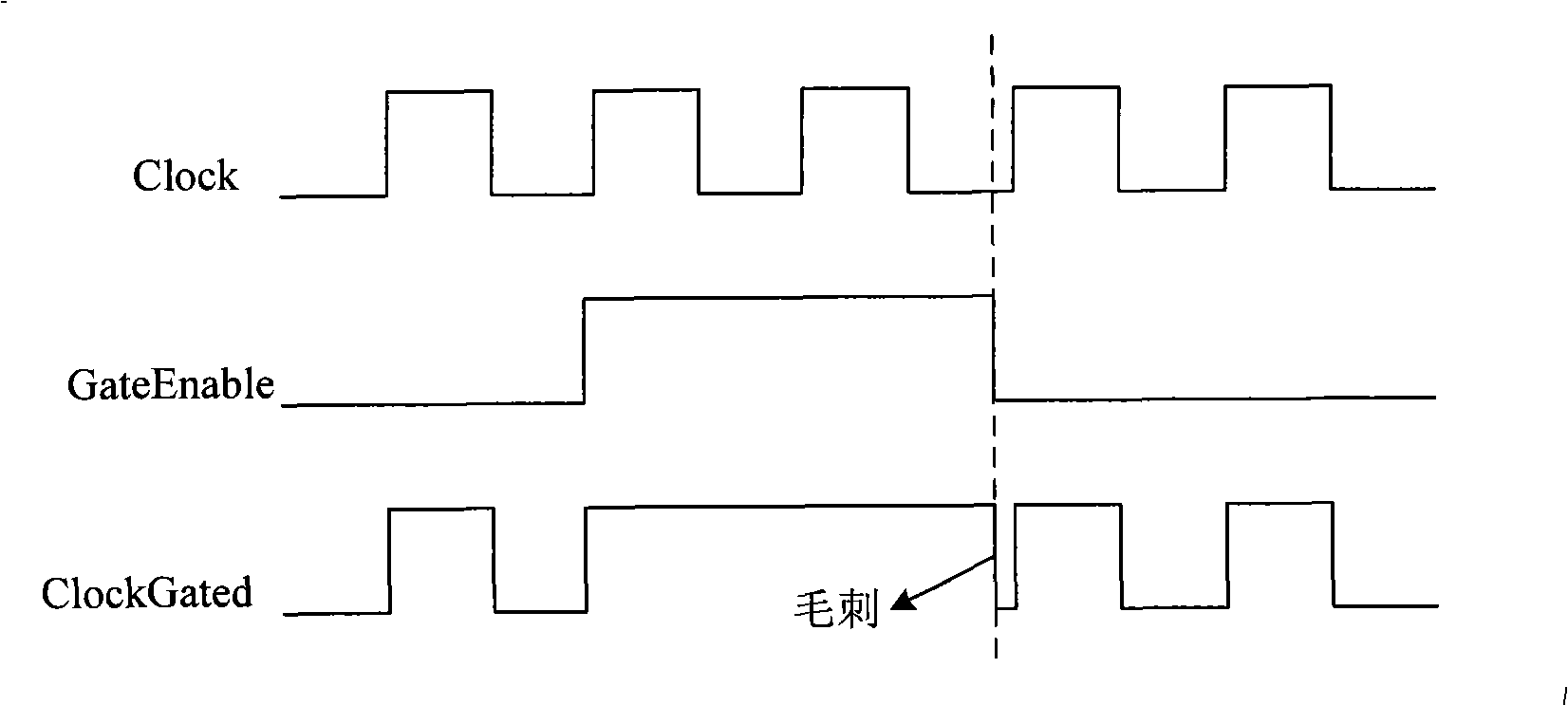

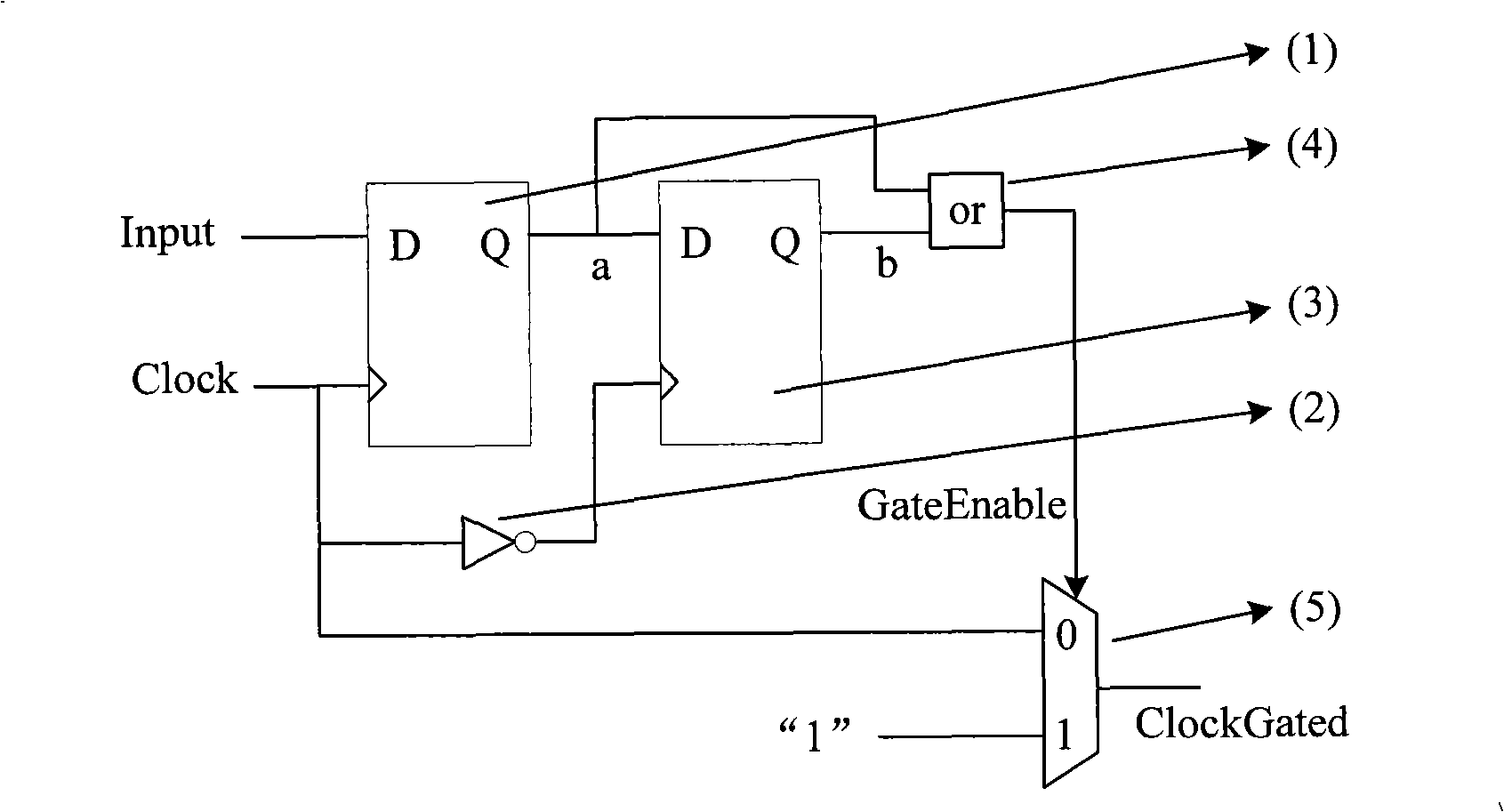

Circuit for preventing gating clock bur

InactiveCN101350612AImprove stabilityImprove reliabilityPulse manipulationLow-power electronicsGlitch

The present invention provides a circuit, which is used for preventing clock-gating glitches in the processing circuit of no-working clock in the design of low power consumption. The circuit adopts different clock edges to realize the clock switching control, effectively eliminates the potential competition in the clock switching process, and thus achieves the purpose of preventing the clock from generating the glitches in the gating process. No-working clock is generally applied in the design of low power consumption; the glitches appear in the switching process between the no-working clock and the novel provision of the clock; the circuit can be used for preventing the glitches in the switching process of clocks, and improving the stability and reliability of the circuit.

Owner:BEIJING CEC HUADA ELECTRONIC DESIGN CO LTD

Cutting method and method of manufacturing semiconductor device

ActiveUS20050012193A1Efficient removalEliminate burrsThyristorSemiconductor/solid-state device detailsRotational axisDevice material

A cutting method for separating individual semiconductor devices by cutting boundary portions in a group of semiconductor devices made up by arranging a plurality of semiconductor devices in which a ductile first layer and a second layer are stacked on a peripheral side thereof, the cutting method comprises a cutting step of cutting the first and second layers by moving a first rotary body from the boundary portions of the group of semiconductor devices in the direction in which the first and second layers are stacked; and a burr removal step of removing burrs from the first layer by moving a second rotary body, softer than the first rotary body and wider than the first rotary body in the direction of rotational axis, from the cut boundary portions of the group of semiconductor devices in the direction in which the first and second layers are stacked.

Owner:SEMICON COMPONENTS IND LLC

High speed voltage level translator

ActiveUS7199638B2Reduce circuit areaMinimize power consumptionMultiple input and output pulse circuitsPulse automatic controlLow voltageLevel converter

A high speed voltage level translator having minimum power dissipation and reduced area, specifically in the sub 0.1 micron domain, includes a transistorized arrangement to receive a low voltage input signal and to control current in the translated high level voltage signal. The translator further provides a differential amplifier arrangement for receiving the low level voltage input signal and provides feedback signals to the transistorized arrangement thereby outputting a high level voltage translated signal.

Owner:STMICROELECTRONICS PVT LTD

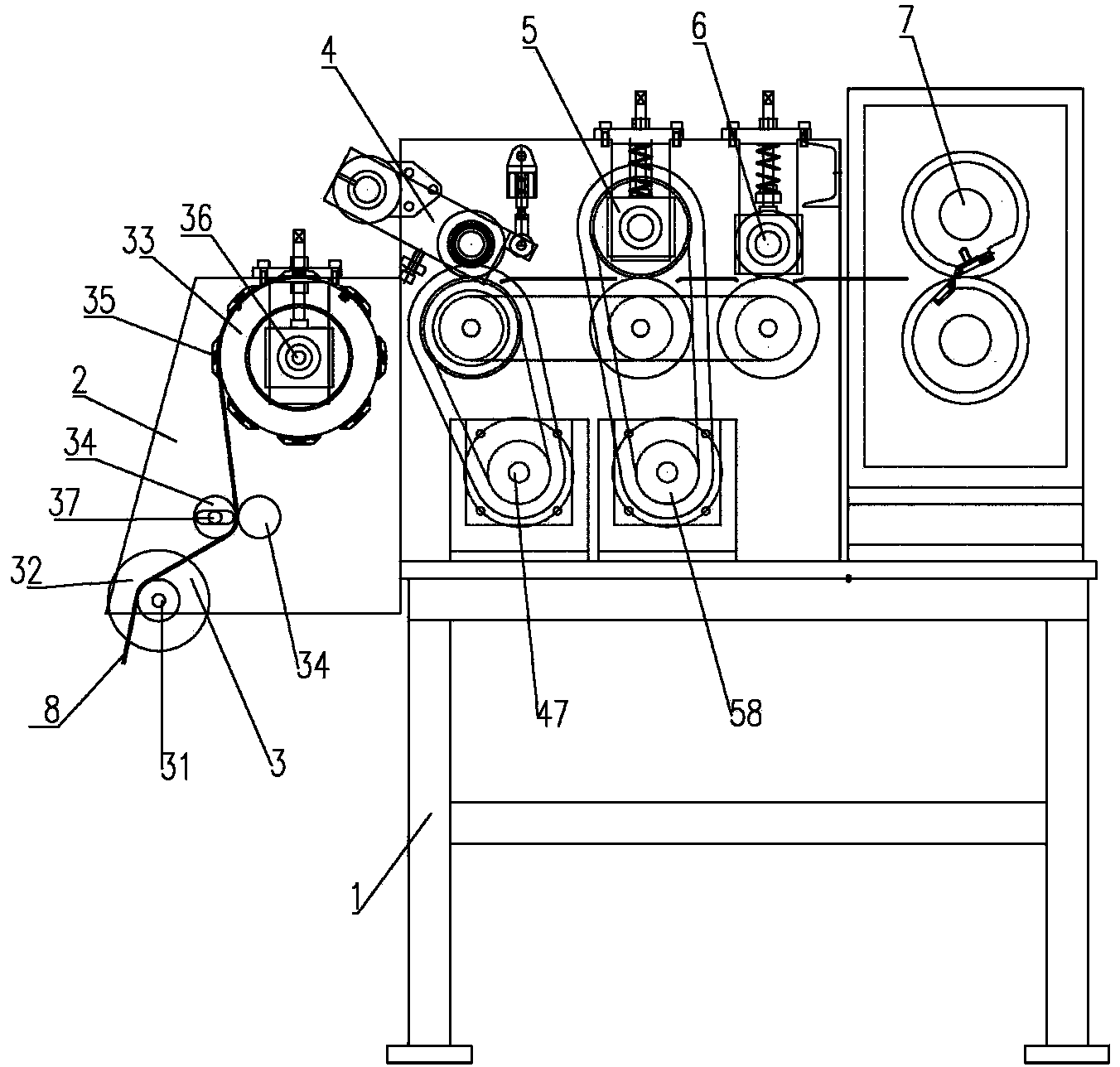

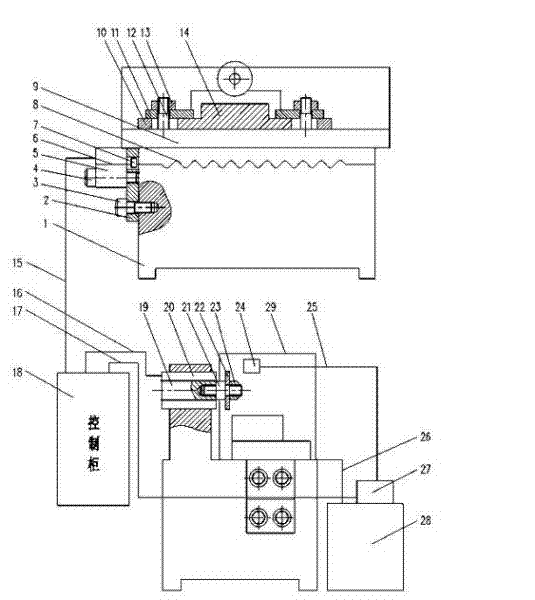

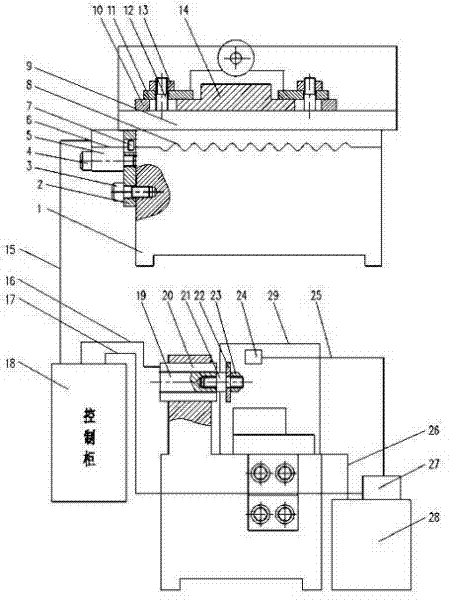

Continuous polar plate slitter machine and use method thereof

ActiveCN103962625AGuaranteed qualityGuaranteed cutting accuracyShearing machinesShearing control devicesMechanical engineeringAcceleration Unit

The invention discloses a continuous polar plate slitter machine which comprises a machine base, two machine frames, a material guide mechanism, a front conveying roller mechanism, a speed measuring device, a detection switch device, a longitudinal cutting mechanism, a rear conveying roller mechanism, a transverse cutting mechanism and a servo system, wherein the two machine frames are fixed to opposite sides of the machine base respectively, the material guide mechanism, the front conveying roller mechanism, the speed measuring device, the detection switch device, the longitudinal cutting mechanism, the rear conveying roller mechanism and the transverse cutting mechanism are sequentially arranged between the two machine frames, and the servo system is connected with the longitudinal cutting mechanism and the transverse cutting mechanism and is used for controlling the longitudinal cutting mechanism and the transverse cutting mechanism. The speed measuring device and the detection switch device feed back detected speed and lug position signals to the servo system. The servo system carries out compensation operation on the detected signals and preset parameters through a servo controller, and adjusts a slitter variable acceleration curve for compensation and modification. The invention further discloses a use method of the continuous polar plate slitter machine. The servo controller outputs corresponding execution instructions by changing input parameters, a slitter mechanism executes the variable acceleration curve and carries out compensation and modification according to the instructions, and accordingly the situation that continuous polar plates of different specifications are automatically switched for splitting is achieved.

Owner:SHENZHEN CENT POWER TECH

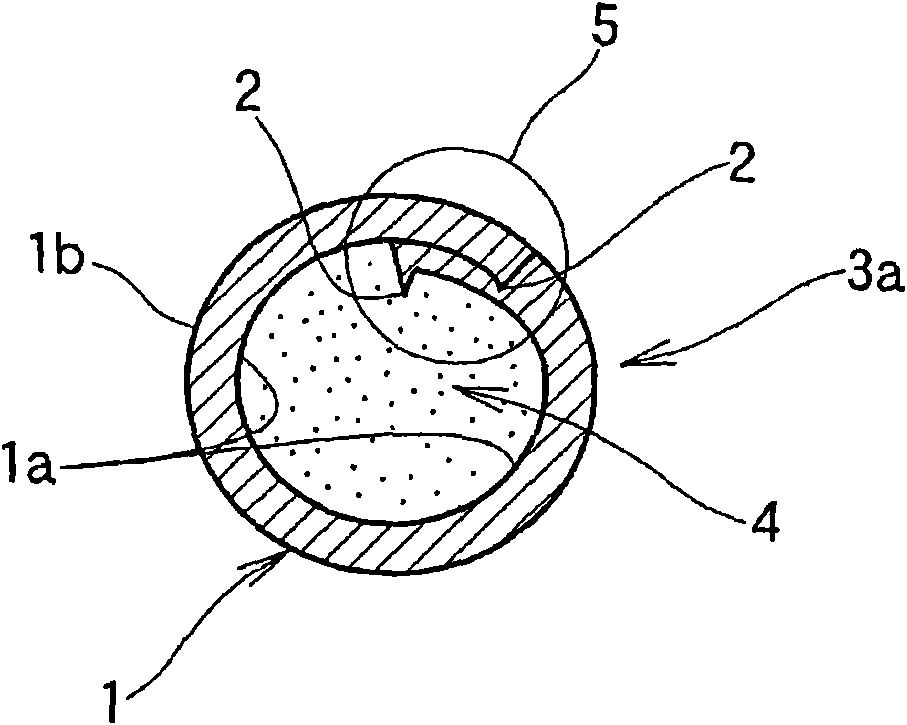

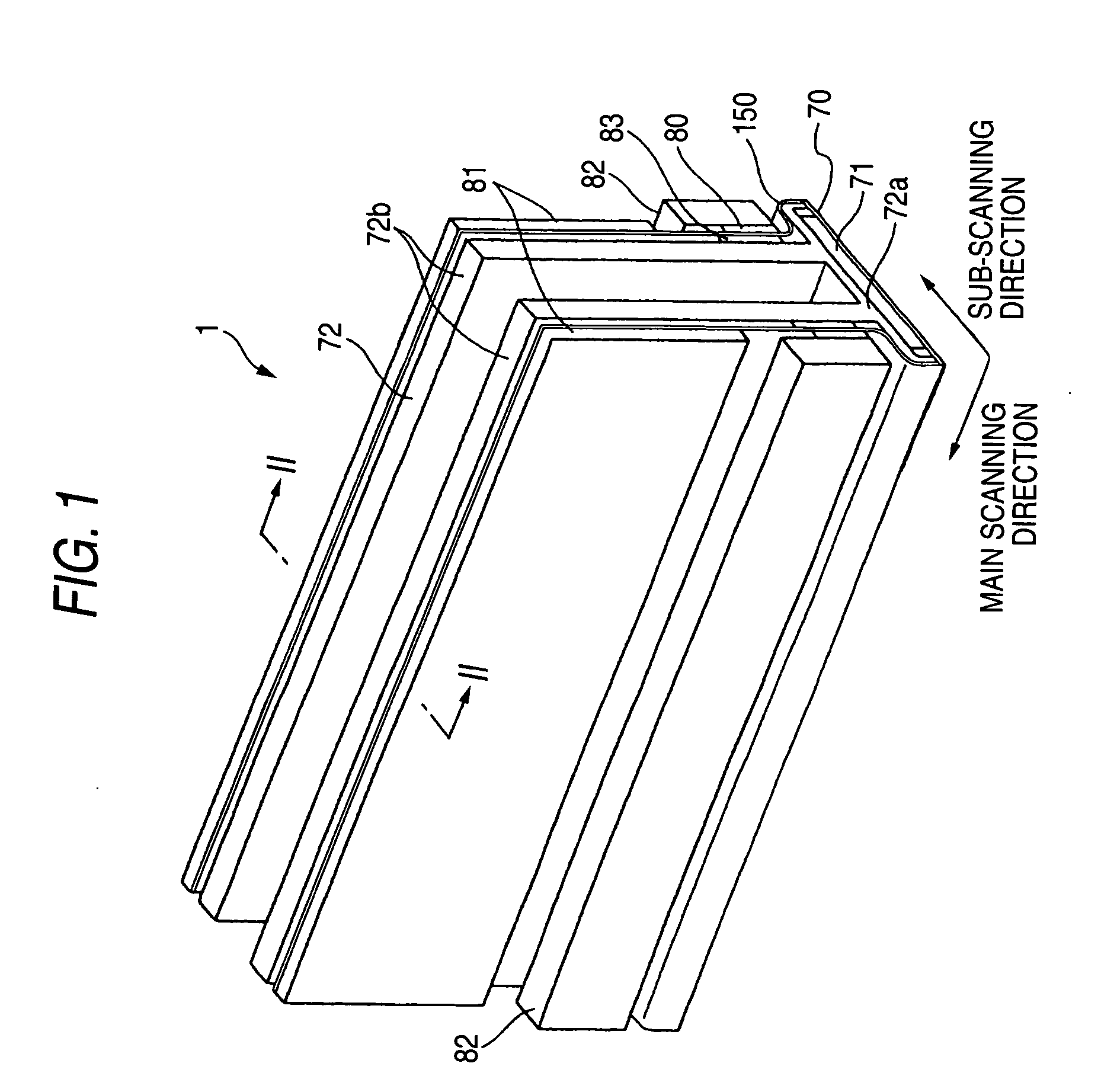

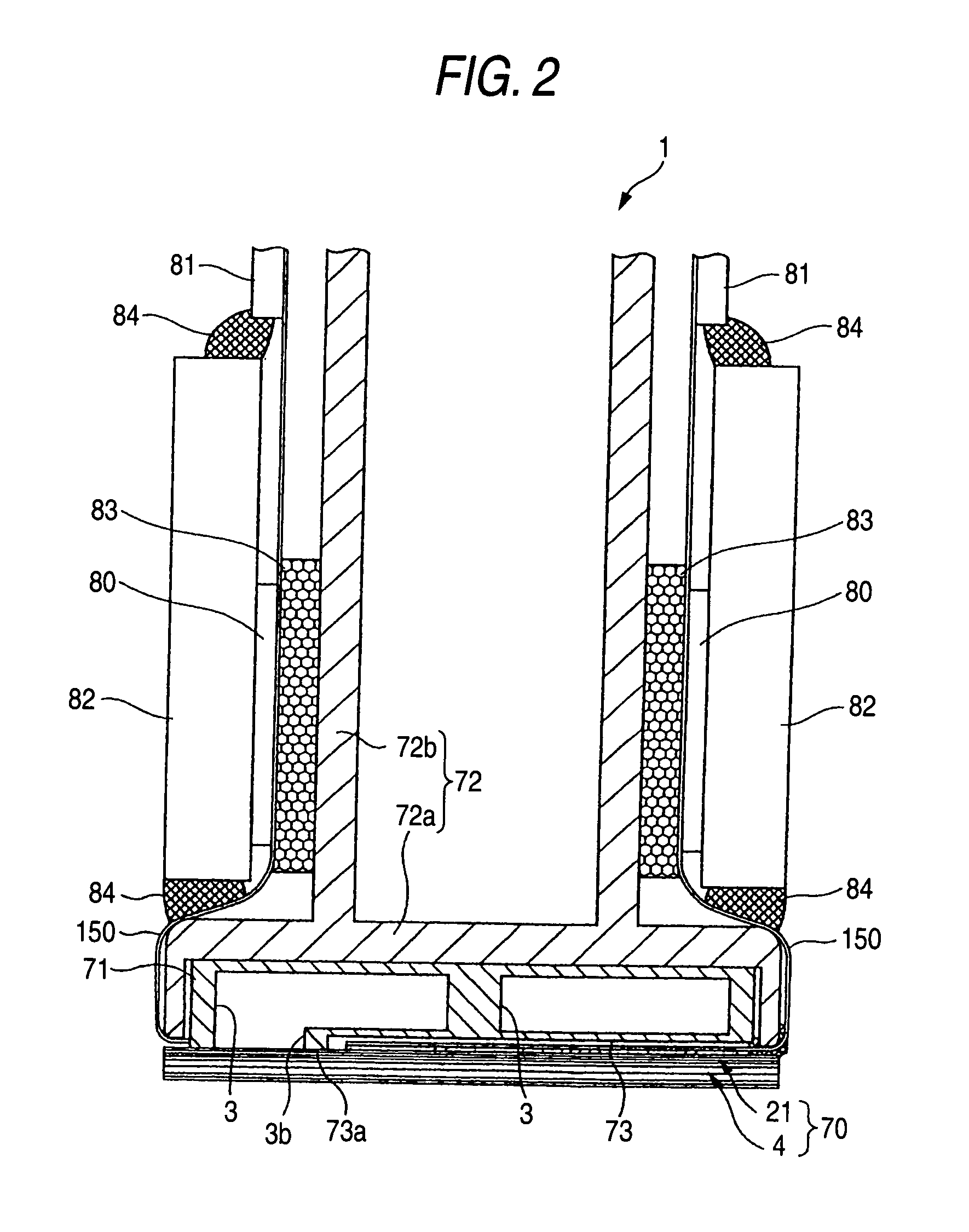

Method of producing nozzle plate and said nozzle plate

ActiveUS20050110835A1Improve impactImprove impact accuracyLiquid surface applicatorsWriting implementsCircular coneSurface shape

A nozzle plate includes a nozzle surface and a nozzle hole. The nozzle surface defines an ink ejection port. The nozzle hole includes a taper hole portion and a curved-surface hole portion. The taper hole portion has an inner surface of a truncated conical shape and has the smallest diameter at one end thereof. The curved-surface hole portion has an inner surface of a curved-surface shape. The inner diameter of the curved-surface hole portion gradually decreases as approaching from the one end of the taper hole portion to the ink ejection port.

Owner:BROTHER KOGYO KK

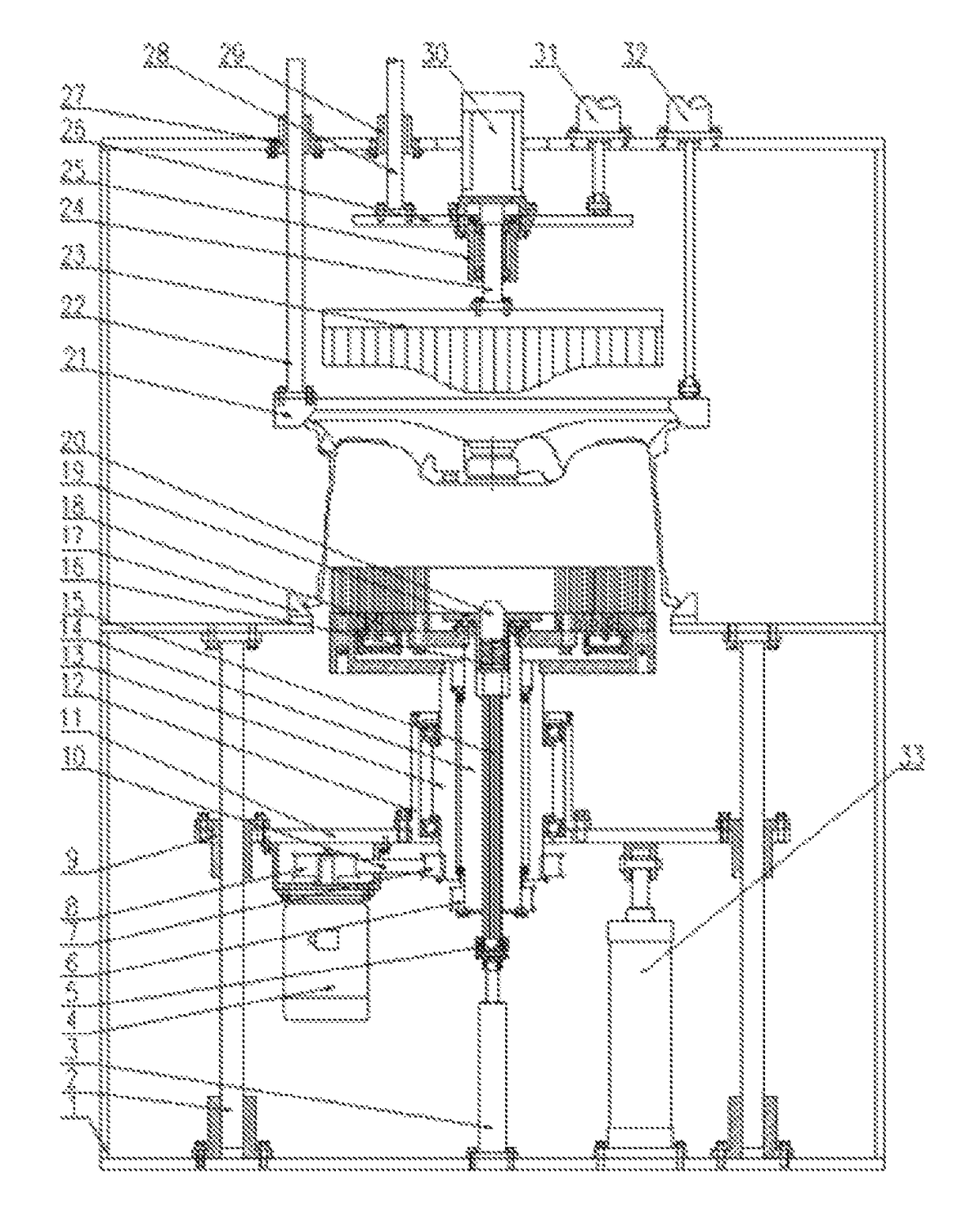

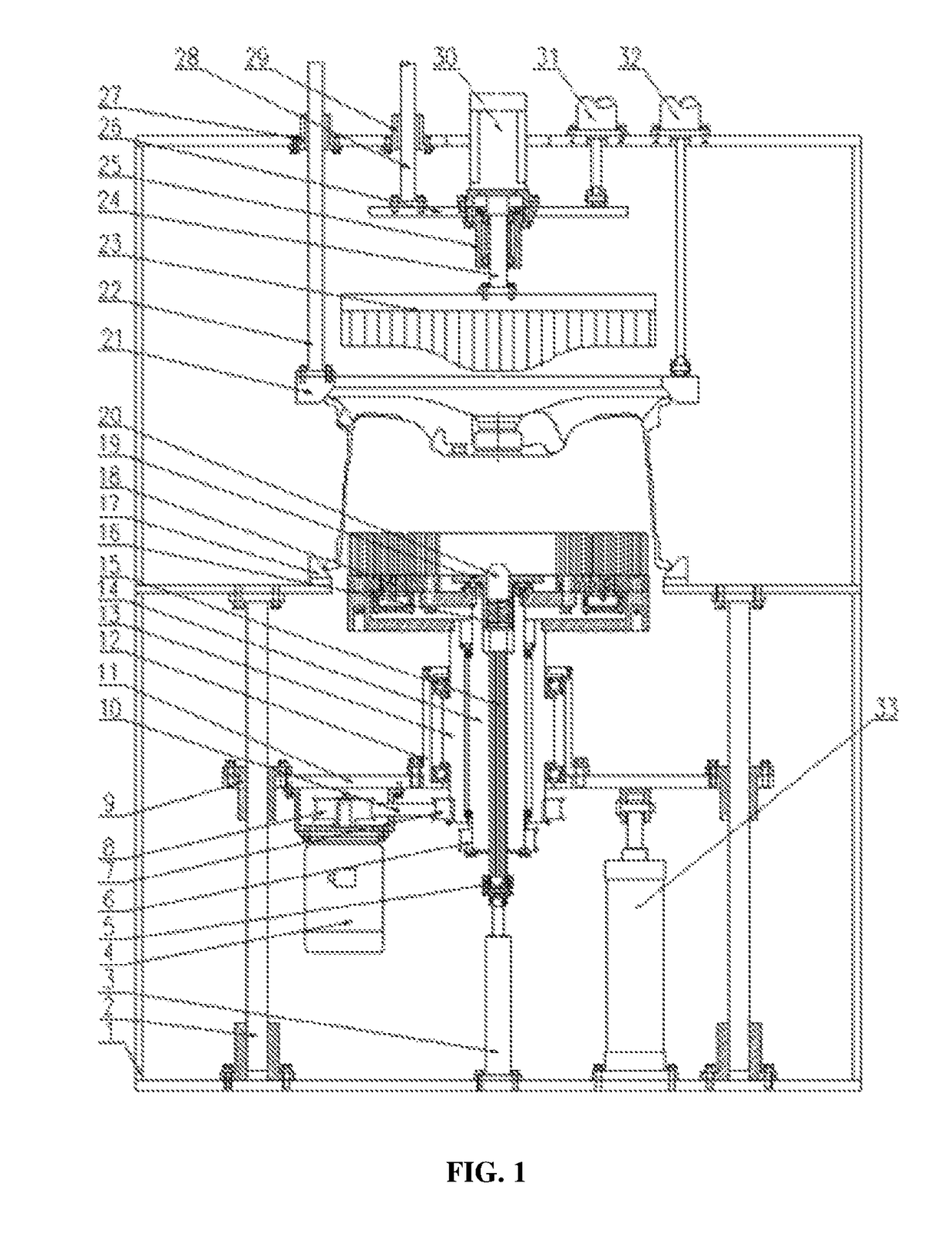

Processing device for directly grinding inclined groove and straight groove of plunger piston

The invention discloses a processing device for directly grinding an inclined groove and a straight groove of a plunger piston, which comprises a machine tool body and a cooling filter, wherein a work table, a transmission device, a grinding device and a control cabinet are arranged on the machine tool body, the cooling filter is arranged on the machine tool body and consists of a cooling spray head, a cooling pipe, a water collection pipe, a water pump and a cooling box, the grinding device comprises an electronic grinding head, a grinding rod is arranged on a main shaft of the electronic grinding head, a cubic boron nitride (CBN) grinding wheel is arranged on the grinding rod. The device can be more conveniently and accurately used for processing the inclined groove and the straight groove of the plunger piston, in the cutting process, the damage occurring in the grinding process is avoided through the cooling filter, the burrs are eliminated, the normal use of products in a diesel engine is ensured, and simultaneously, the production efficiency is improved.

Owner:NANTONG WIEDSON FUEL INJECTION EQUIP

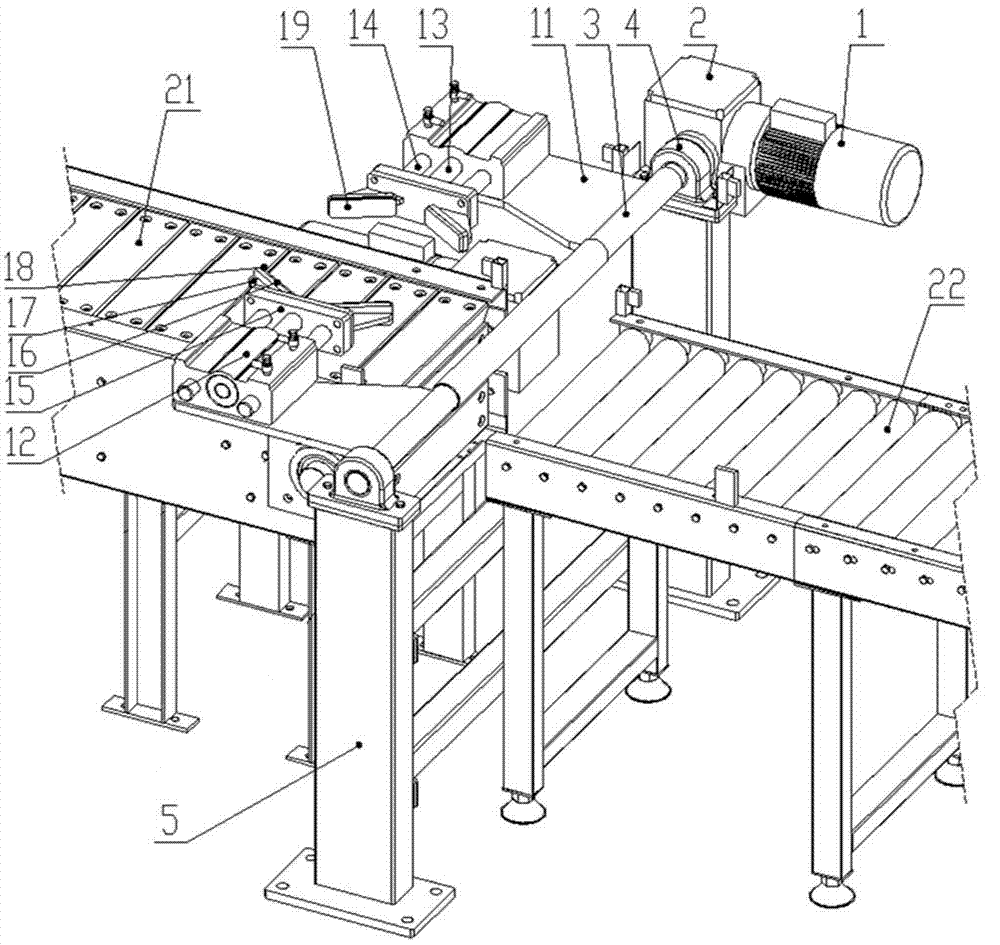

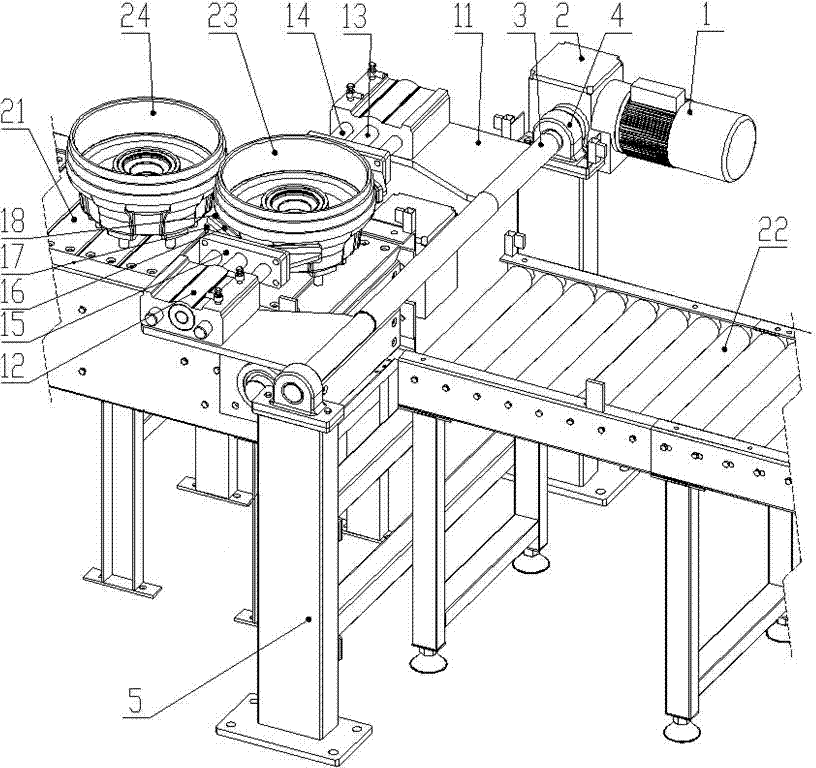

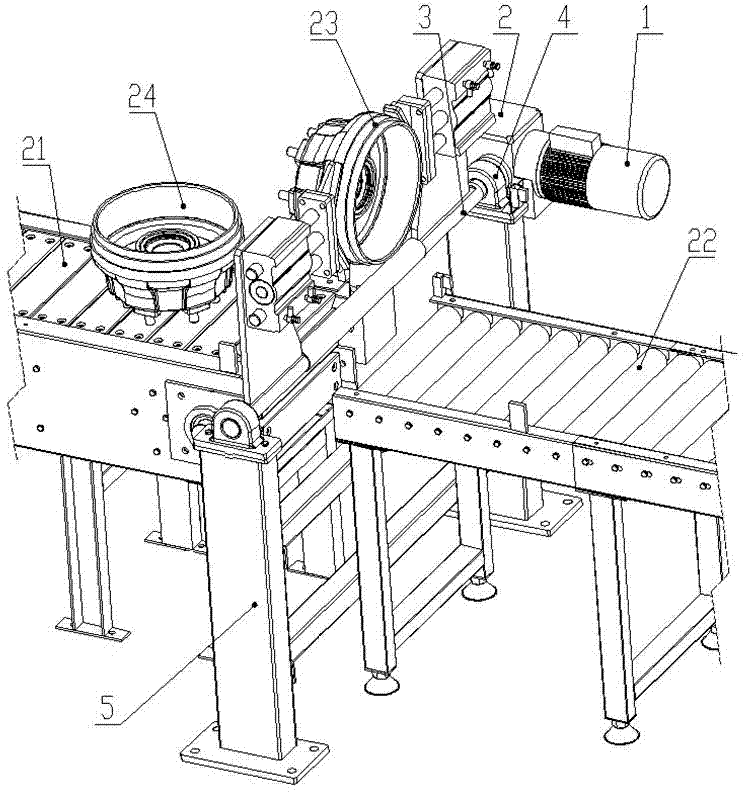

Wheel deburring device

ActiveUS10112282B2Eliminate burrsHigh degree of automationEdge grinding machinesPolishing machinesMotor driveGear wheel

A wheel deburring device. A second motor drives an upper brush to rotate, second cylinders enable the upper brush to fall through third posts, and burrs of a front surface can be removed when the upper brush is in contact with the front surface of a wheel; a first motor enables an outer ring and a first geared ring to rotate through a first belt; a third motor enables an inner ring and a second geared ring to rotate through a second belt, directions of rotation of the inner ring and the second geared ring are opposite to that of the outer ring, and brushes are driven to rotate through a gear; and fourth cylinders enable a lower brush to rise through first guide posts, and burrs of a back cavity of the wheel can be removed when the lower brush is in contact with that back cavity.

Owner:CITIC DICASTAL

Semiconductor integrated circuit device with filter circuit

There is provided a semiconductor integrated circuit device with a filer circuit serving for eliminating a glitch contained in a logic signal supplied to the device, wherein the filter circuit includes: a first delay circuit activated within a certain period after each rising edge timing of input logic signals to delay the rising edge; a second delay circuit activated within a certain period after each falling edge timing of the input logic signals to delay the falling edge; and an output driver controlled by outputs of the first and second delay circuits to output delayed logic signals to an output node in response to the input logic signals.

Owner:KK TOSHIBA

Method for manufacturing semiconductor package substrate

ActiveUS20070087473A1Eliminate burrsIncrease productionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A method for manufacturing a semiconductor package is proposed. A circuit board with a circuit layer on at least one surface thereof is provided. The circuit board has at least one free area, and the circuit layer has a plurality of electrically connecting pads distributed on the periphery of the free area. A metal protecting layer is plated on the electrically connecting pads by non-plating line. The free area is removed, to form a cavity penetrating the circuit board. The present invention prevents burrs which may otherwise form on the periphery of a cavity, to increase the yield and throughput.

Owner:PHONEIX PRECISION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com