Continuous polar plate slitter machine and use method thereof

A slitting machine and pole plate technology, which is applied in the direction of shearing device, cutter for shearing machine, shearing machine control device, etc., can solve the problem that continuous pole plates cannot be produced by cutting plates of different specifications, and continuous pole plates cannot be introduced. Plate automatic production line, unable to guarantee the accuracy of continuous plate, etc., to achieve the effect of reducing cost investment, no bending deformation, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

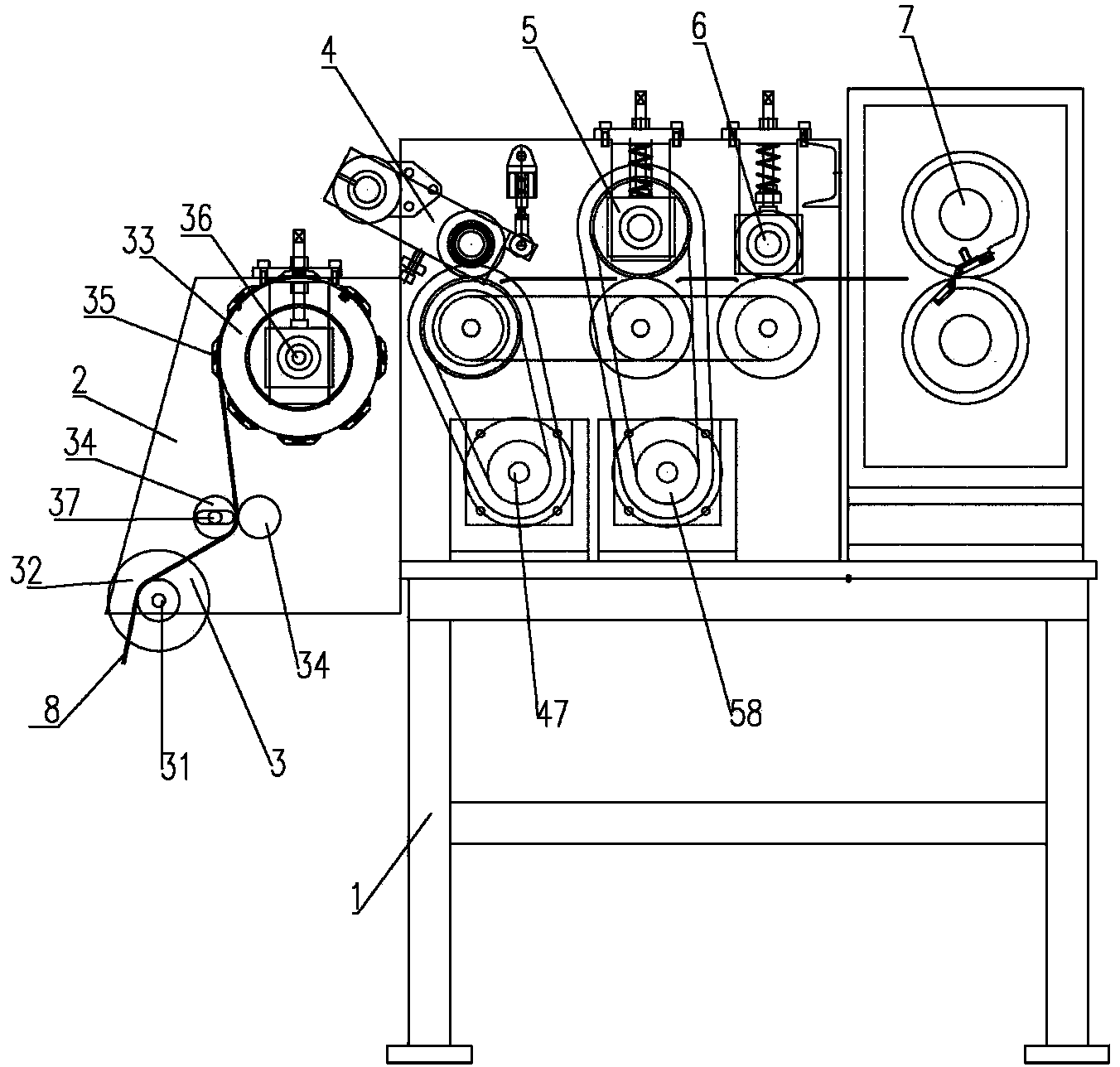

[0036] Such as image 3 As shown, a kind of continuous pole plate cutting machine that the present invention proposes, comprises: frame 1, two frames 2 that are respectively fixed on two opposite sides on frame 1, the material guide that is installed between two frames 2 successively Leading mechanism 3, front conveying roller mechanism 4, slitting mechanism 5, rear conveying roller mechanism 6, crosscutting mechanism 7 are used to control slitting mechanism 5 and crosscutting mechanism respectively connected with slitting mechanism 5 and crosscutting mechanism 7 7 servos.

[0037] Such as Figure 4As shown, the servo system includes: a speed measuring device and a detection switch device located between the front conveying roller mechanism 4 and the slitting mechanism 5, and a servo controller connected to the speed measurement device and the detection switch device. The speed measurement device can be a speed sensor. The speed measuring device detects the conveying speed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com