Patents

Literature

271results about "Shearing control devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional pipe cutter

The invention is concerned with a kind of three-dimensional machine to cut pipe, relating to machine rack, holding equipment, fixing seat for drill. The drill connects with the fixing seat in moving, and the holding equipment sets on the machine rack in sliding. The drill connects on the first running axis extending to the axis of X and the machine rack has guiding rail extending along the level direction and the holding equipment set on this guiding rail in sliding. The machine rack has the second running axis extending along the axis of Y that being upright to axis of X and the drill seat connects with the second running axis in sliding. There is the first lock equipment between the drill fixing equipment and machine rack, and the holding equipment relates to the sliding seat connecting with guiding rail and worktable on the sliding seat moving around the axis of Z, and the sliding seat and worktable can match and slide with each other and there is the second lock equipment between the sliding seat and worktable. The three-dimensional relationship between the drill and pipe piece to cut the pipe piece from multi-angle, and the adjustment is easy to cut the strange shape of pipe piece or cut for many times.

Owner:庄添财

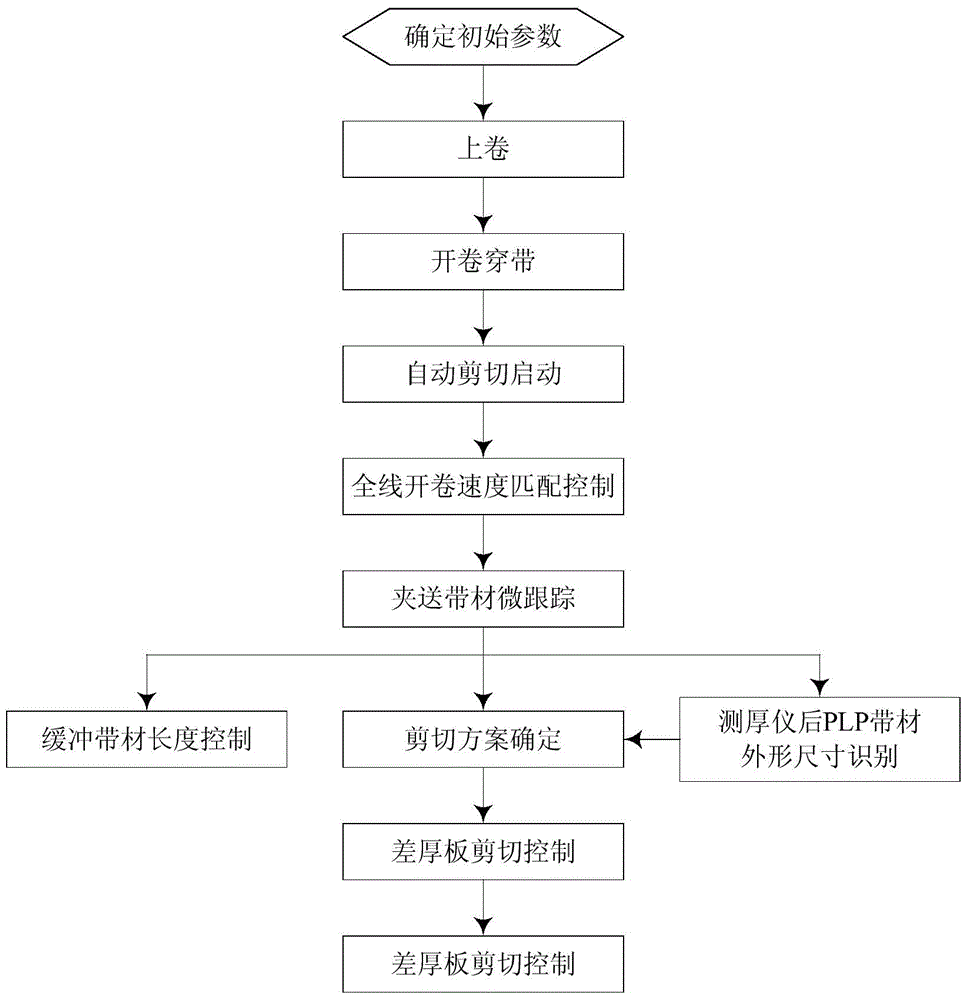

Differential thickness plate size-determined shearing manufacture method

ActiveCN104551538ALow length accuracyShearing machinesShearing control devicesComputer control systemThick plate

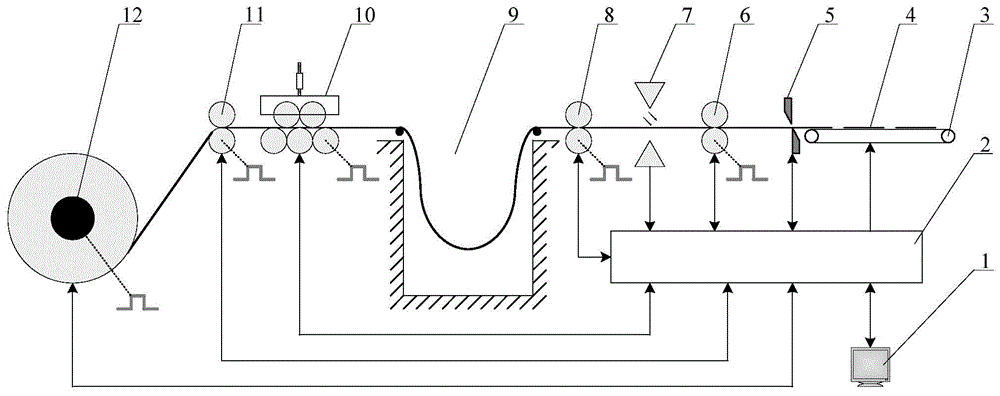

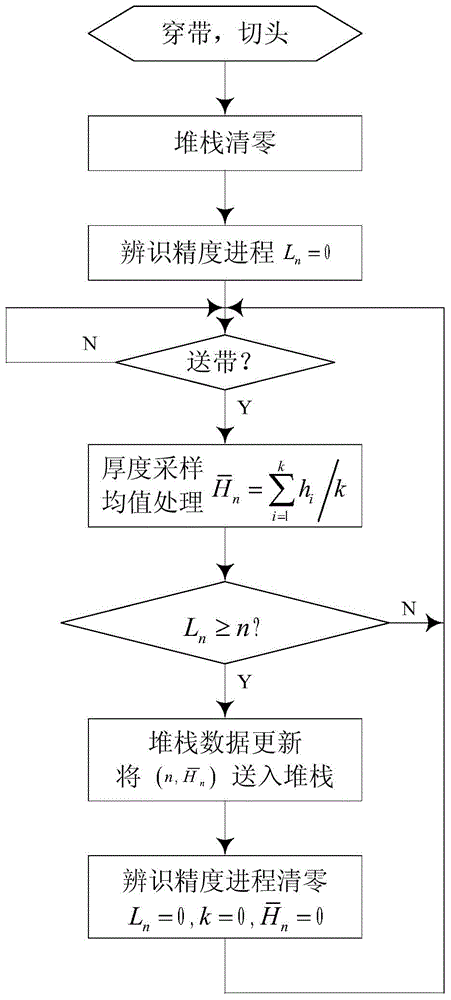

The invention belongs to the technical field of rolling; a target differential thickness plate is obtained by highly-accurate size-determined shearing of rolled stripe materials with thickness changed regularly. A method includes determining primary differential thickness plate shearing parameters; uncoiling the stripe materials with thickness changed regularly through an uncoiling machine, allowing the head of the stripe material to penetrate equipment, allowing clamping and conveying rollers to press the stripe materials sequentially, allowing the uncoiling machine to provide micro tension, allowing a hydraulic shear to shear the head of the stripe materials, and completing the stripe penetration; starting automatic shear control, allowing a control system to recognize the shape and size of the stripe materials with thickness changed regularly automatically, determining the shearing scheme according to the size of the target differential thickness plate, tracking the stripe material conveying length accurately, and completing shearing; allowing the shore differential thickness plate to convey to downstream procedures through a conveying belt after shearing for detection, sorting and packaging. A device comprises the uncoiling machine, clamping and conveying rollers before correction, a correction machine, a shear stripe material buffering pit, clamping rollers of front of a thickness measurement instrument, the thickness measurement instrument, the clamping and conveying rollers before shearing and the hydraulic shear. The clamping and conveying rollers and the uncoiling machine are provided with high-speed pulse encoders; the codes of the high-speed pulse encoders enter the computer control system with signals of the thickness measurement instrument.

Owner:苏州东宝海星金属材料科技有限公司

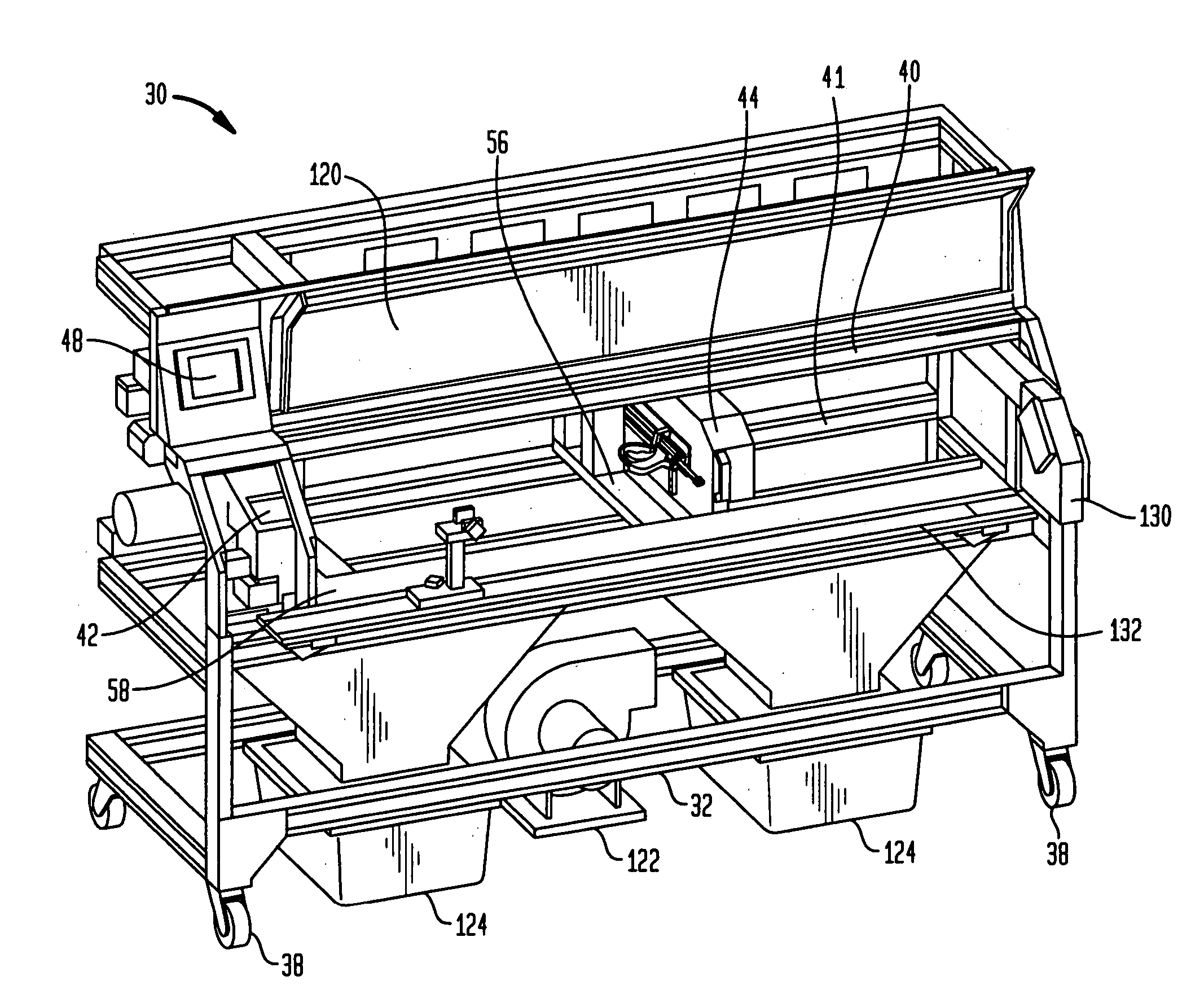

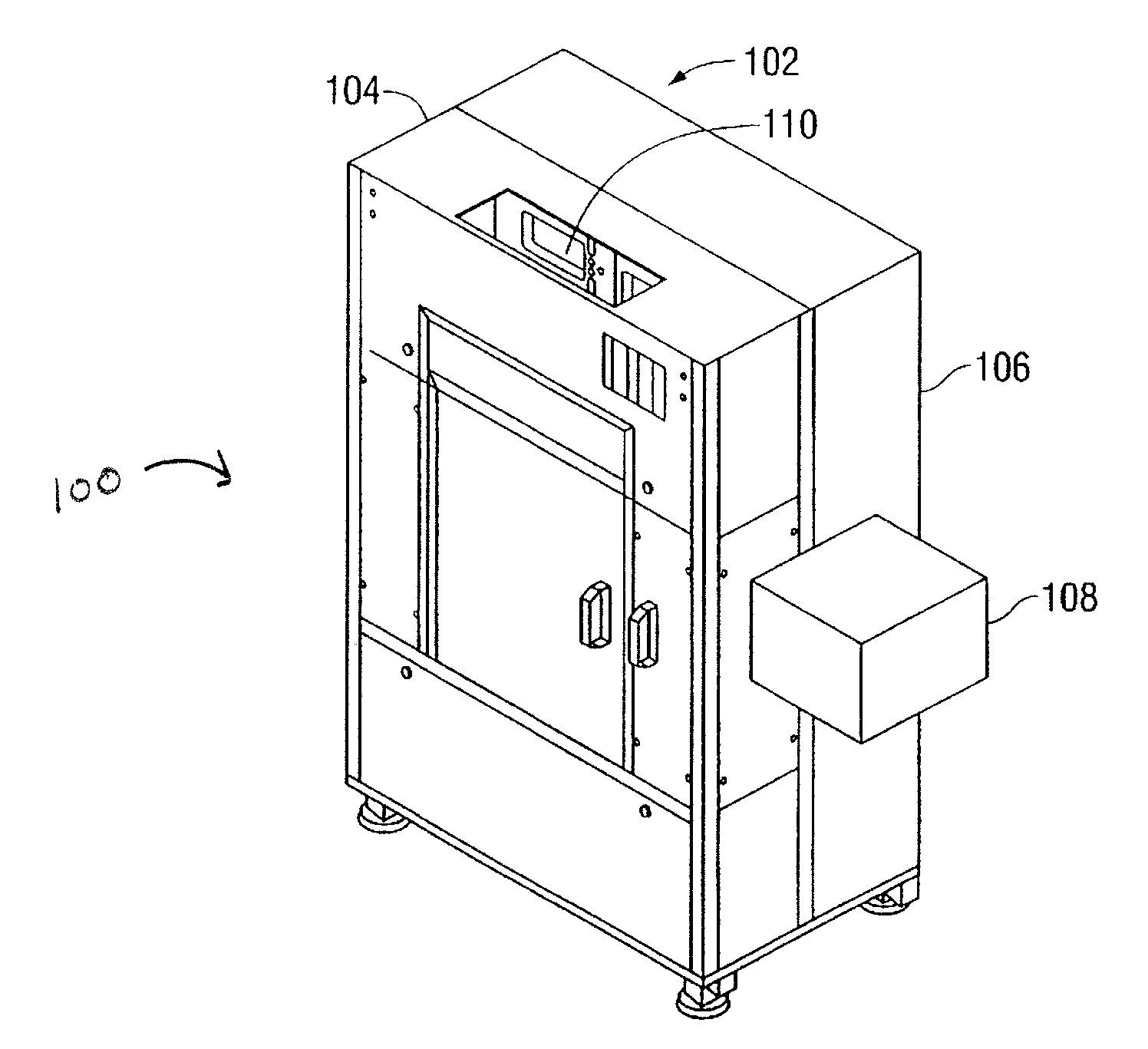

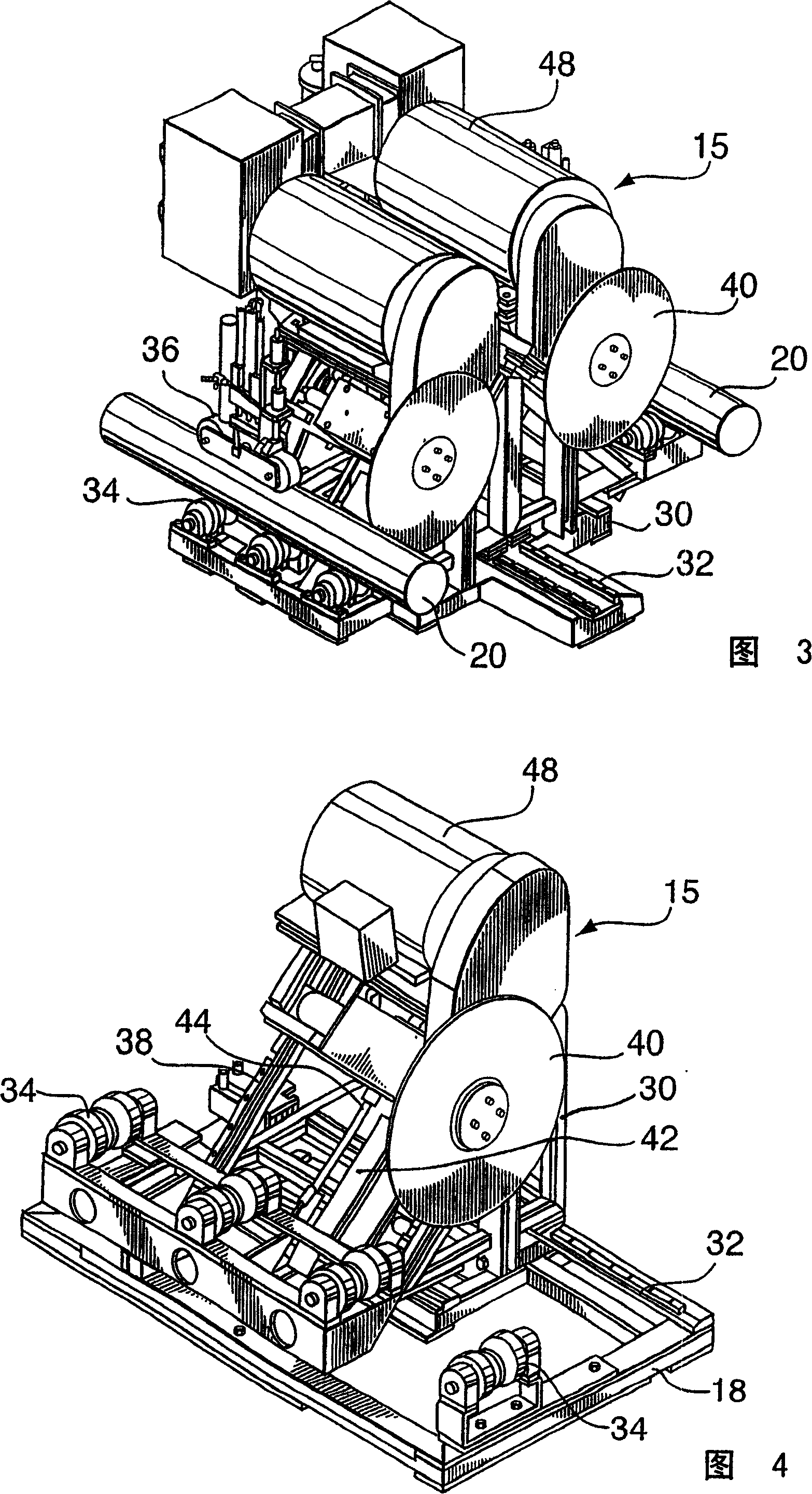

Window covering cutting apparatus and methods

InactiveUS20060065086A1Amount being removedMetal sawing devicesDoor/window protective devicesCombined useEngineering

A cutdown machine and method are disclosed. The cutdown apparatus preferably includes a pair of cutting assemblies for simultaneously cutting the ends of a window covering. Additionally, a calculation apparatus and method for use in conjunction with the cutdown machine are also disclosed. The calculation apparatus may be a stand alone unit, or preferably integrated into the cutdown machine. The calculation apparatus preferably calculates and automatically positions a stop element in the cutdown machine, in connection with desired end window covering dimensions and related stock window covering sizes.

Owner:SPRINGS WINDOW FASHIONS LP

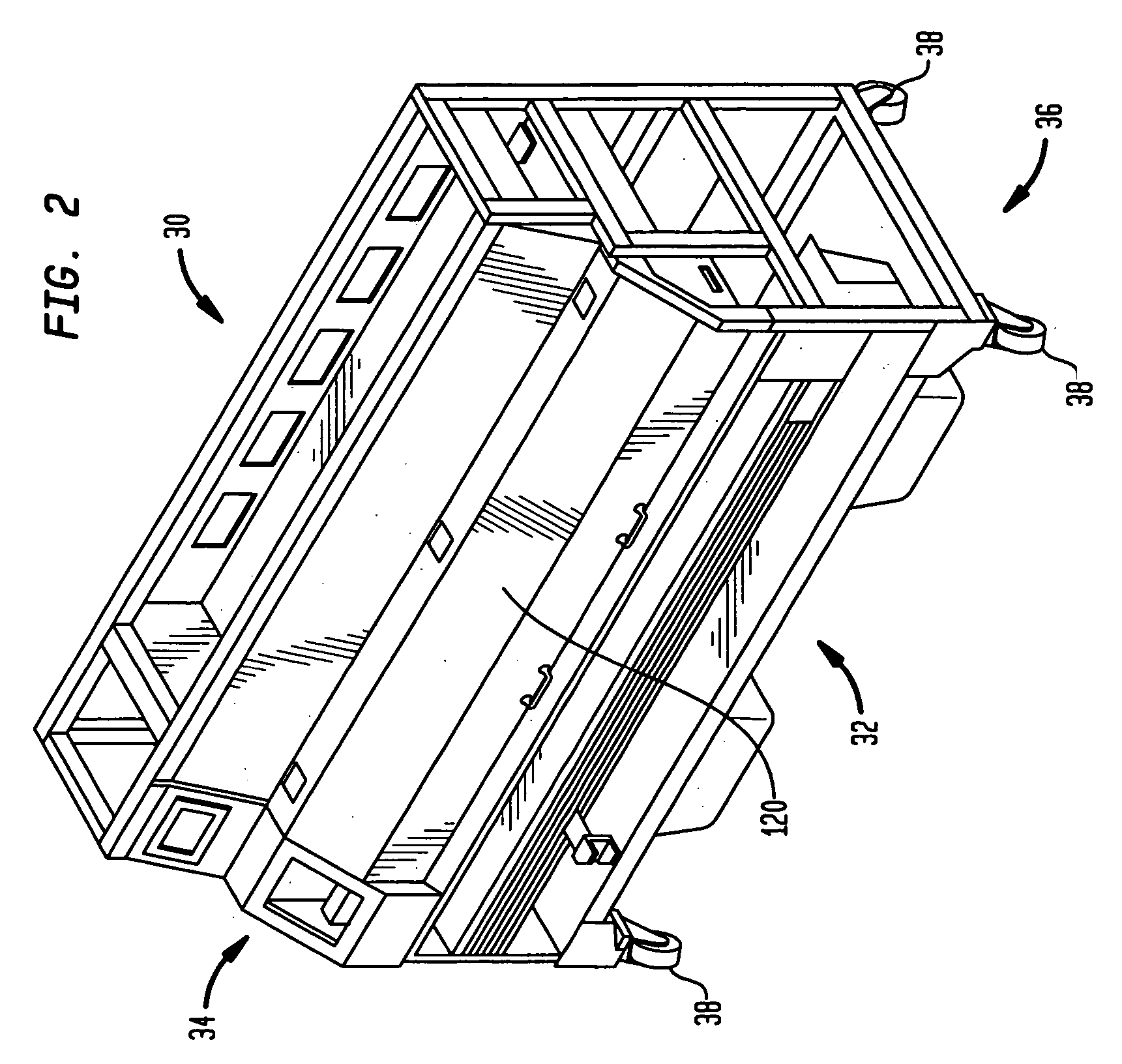

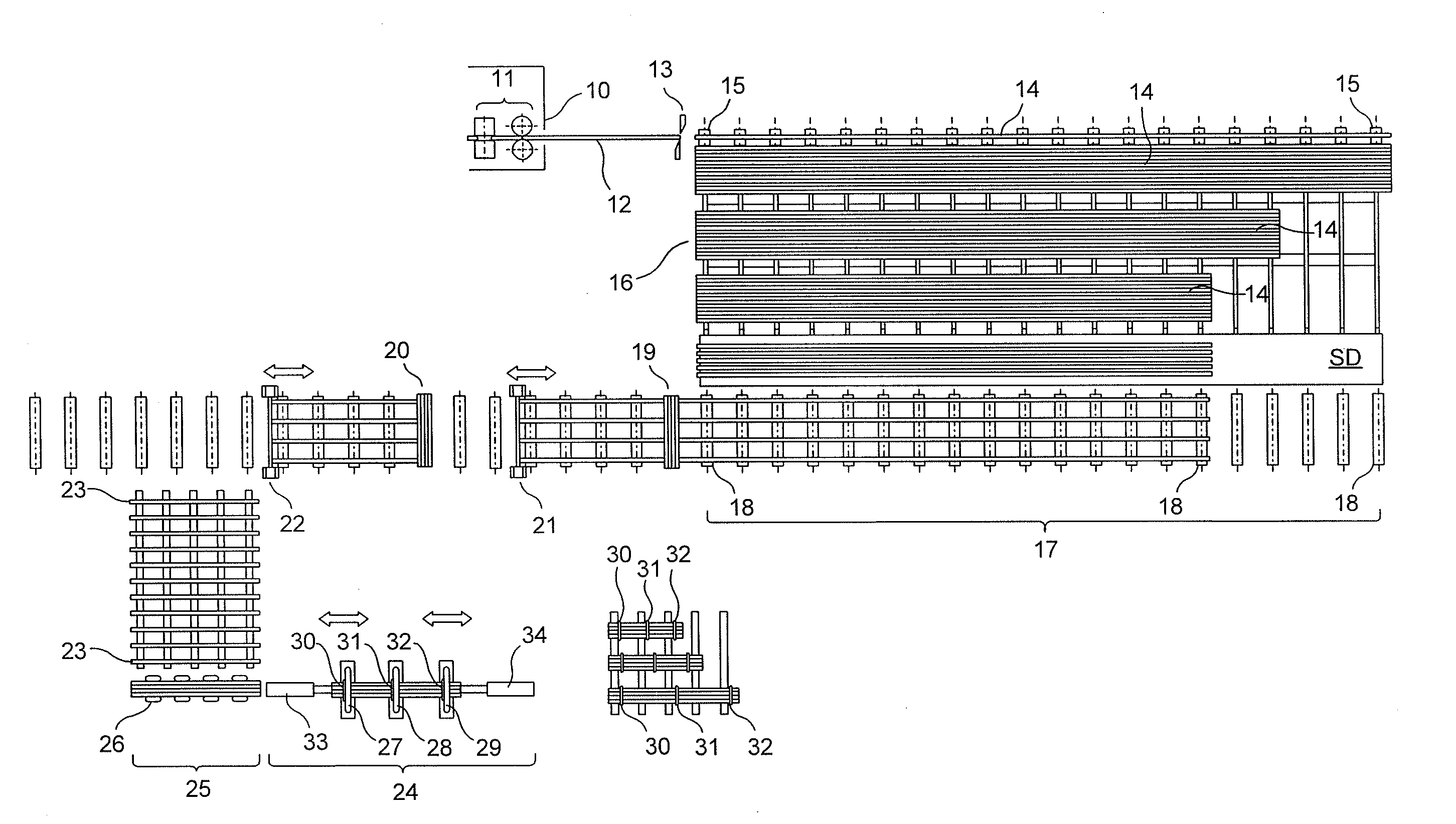

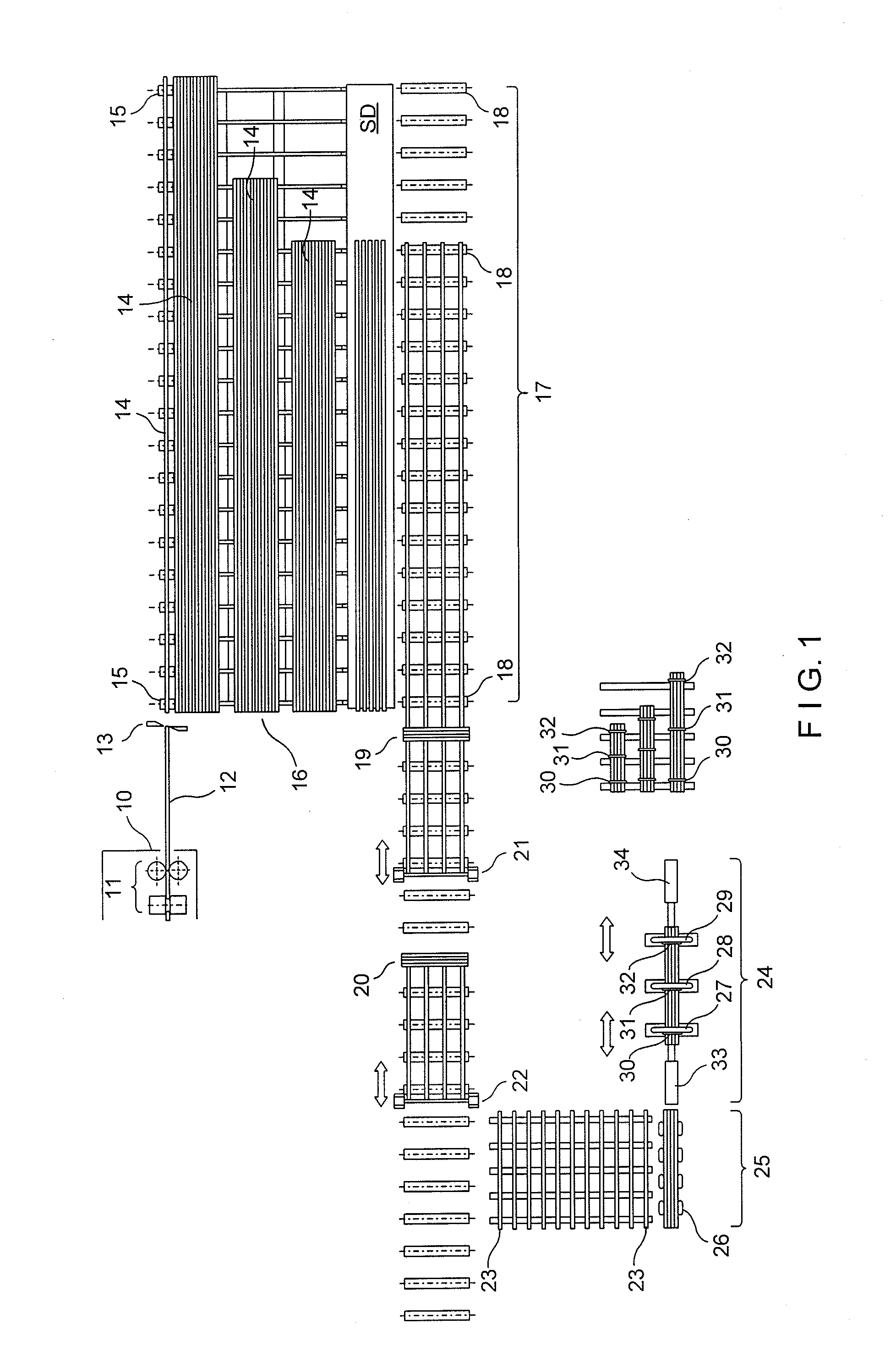

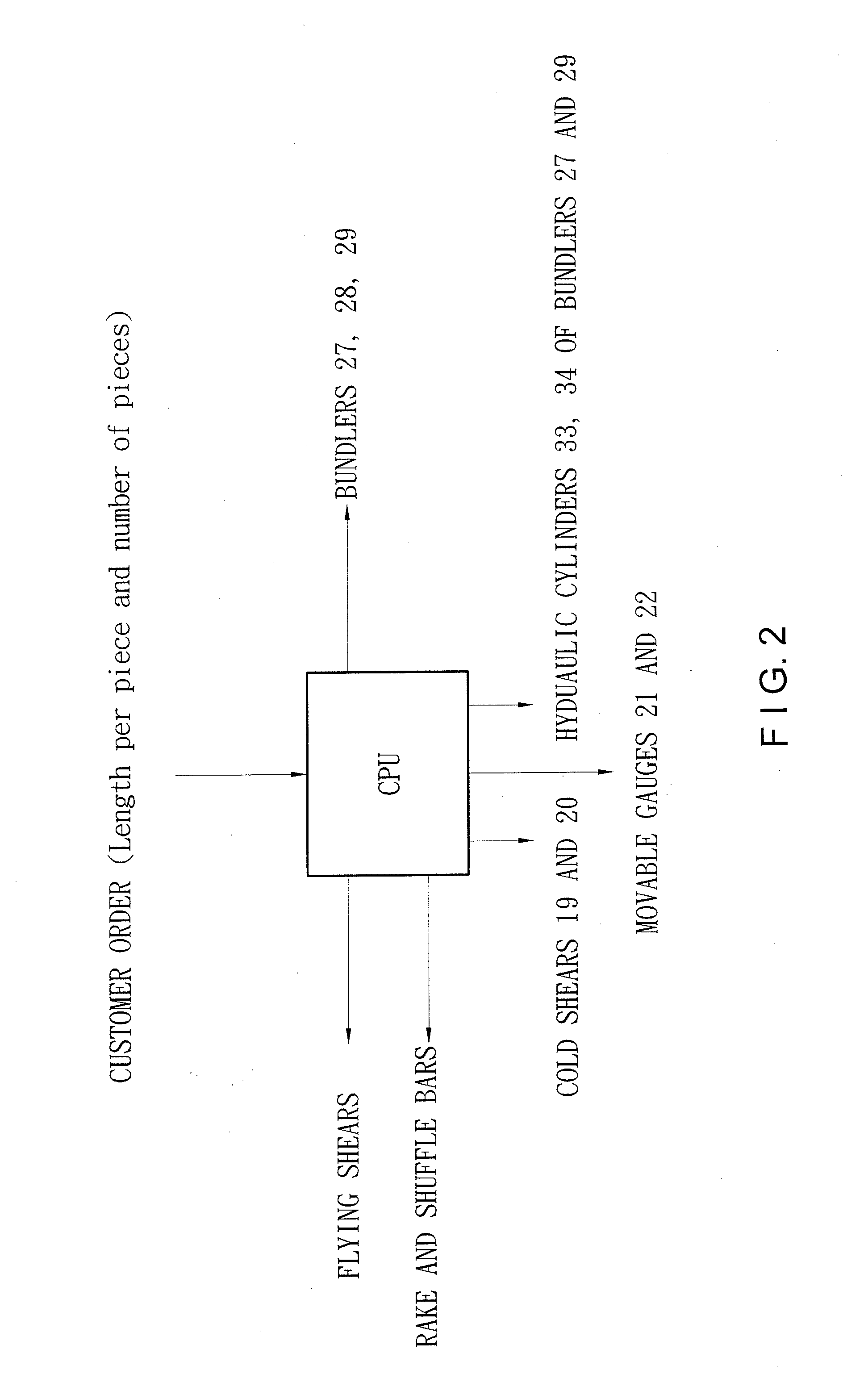

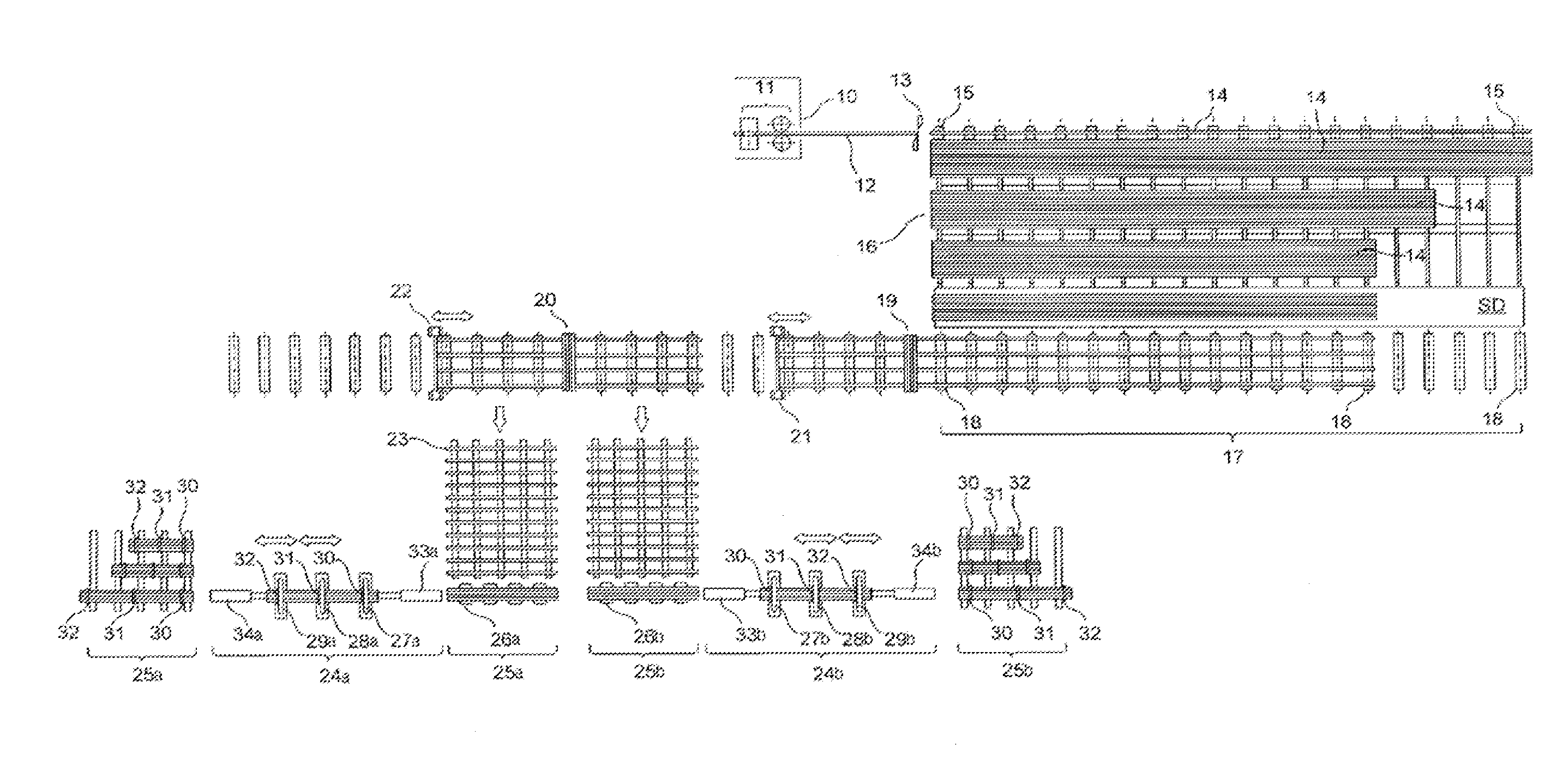

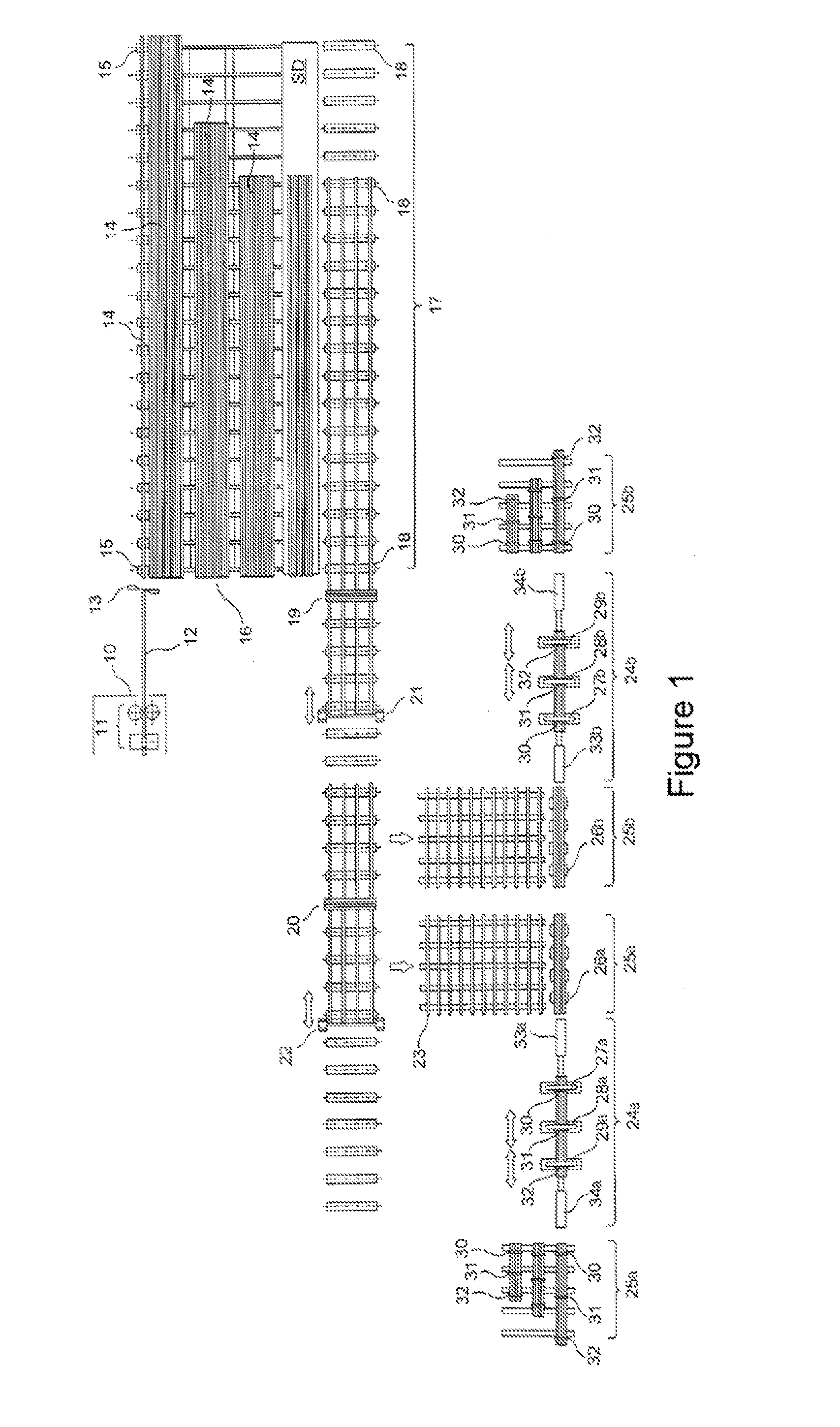

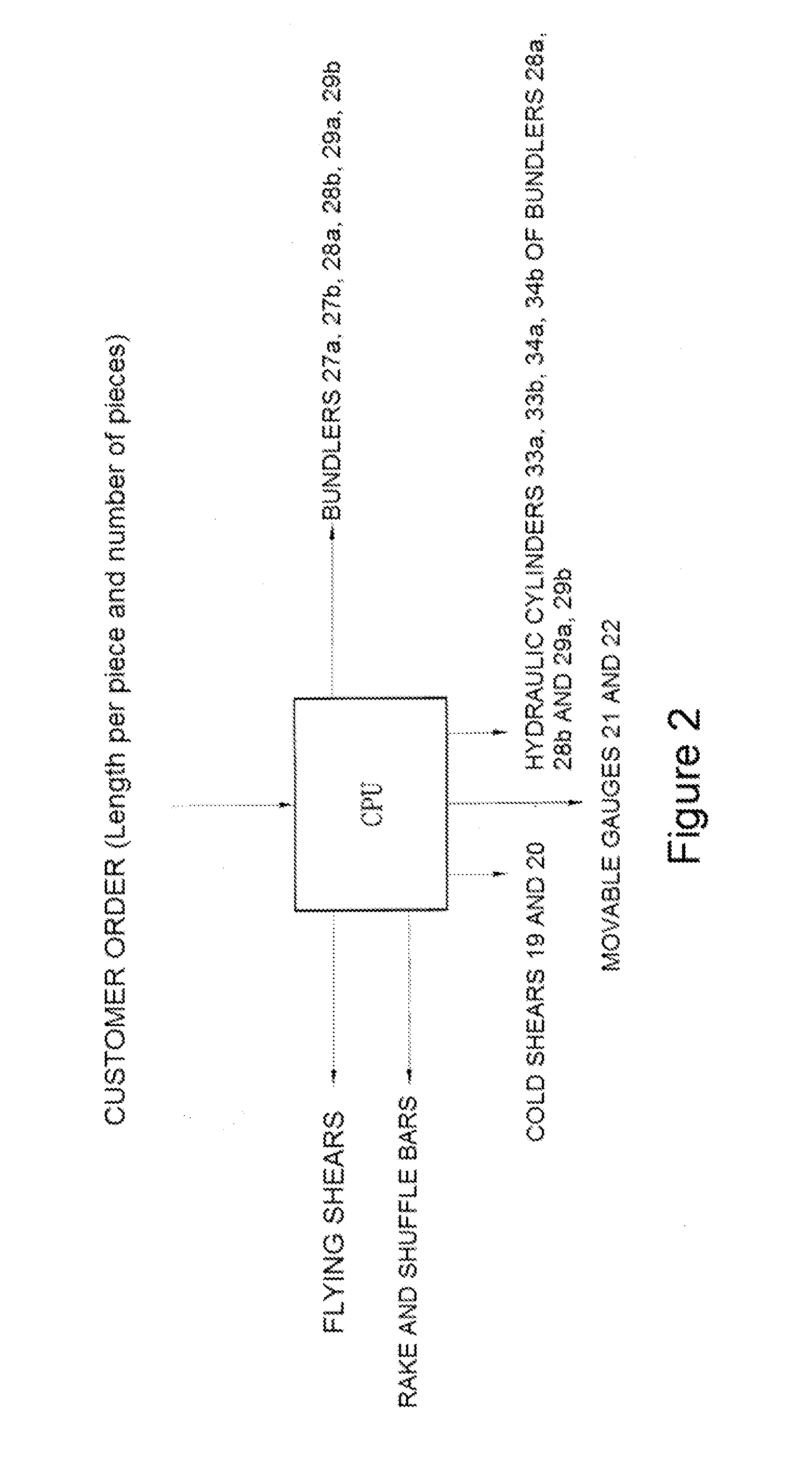

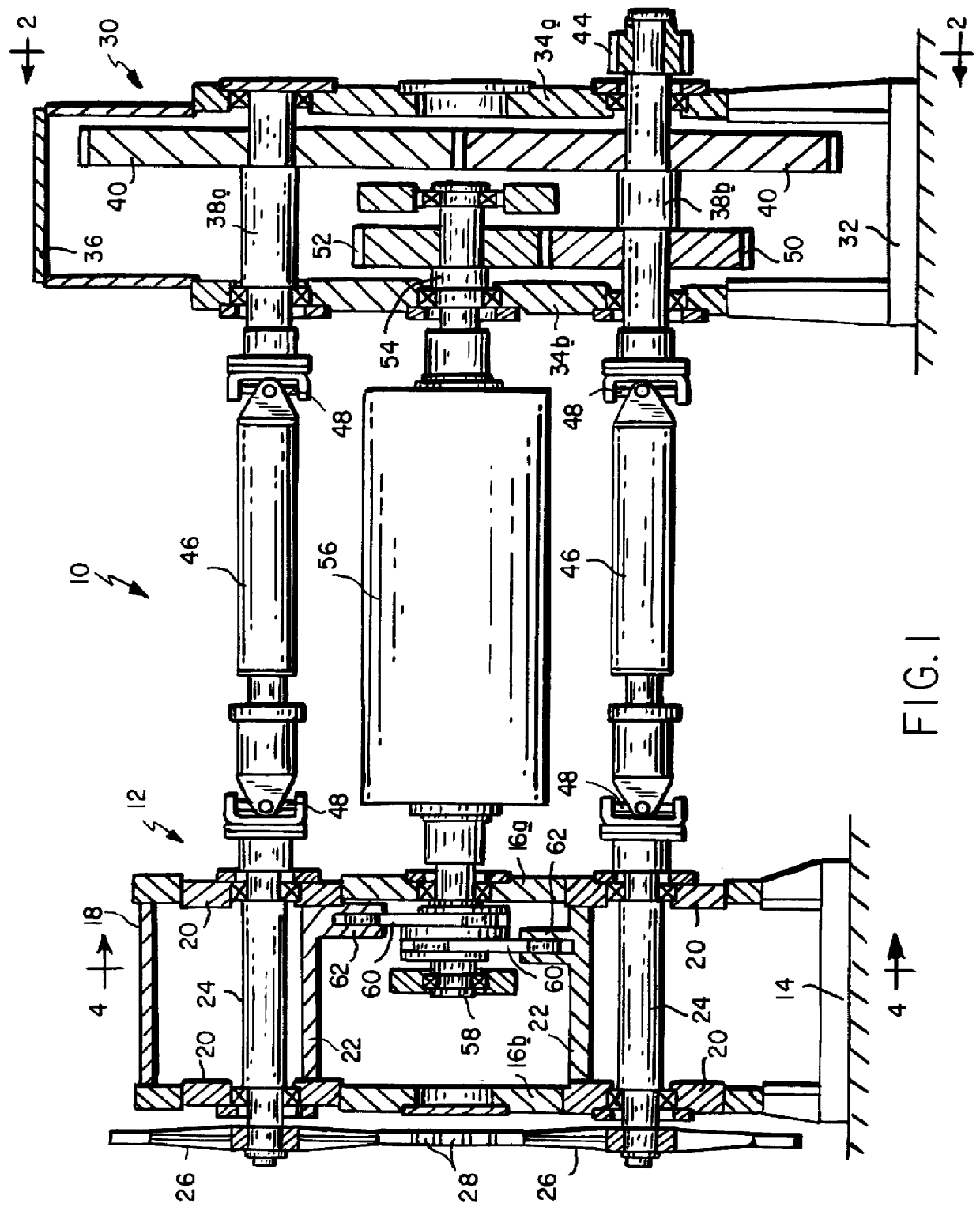

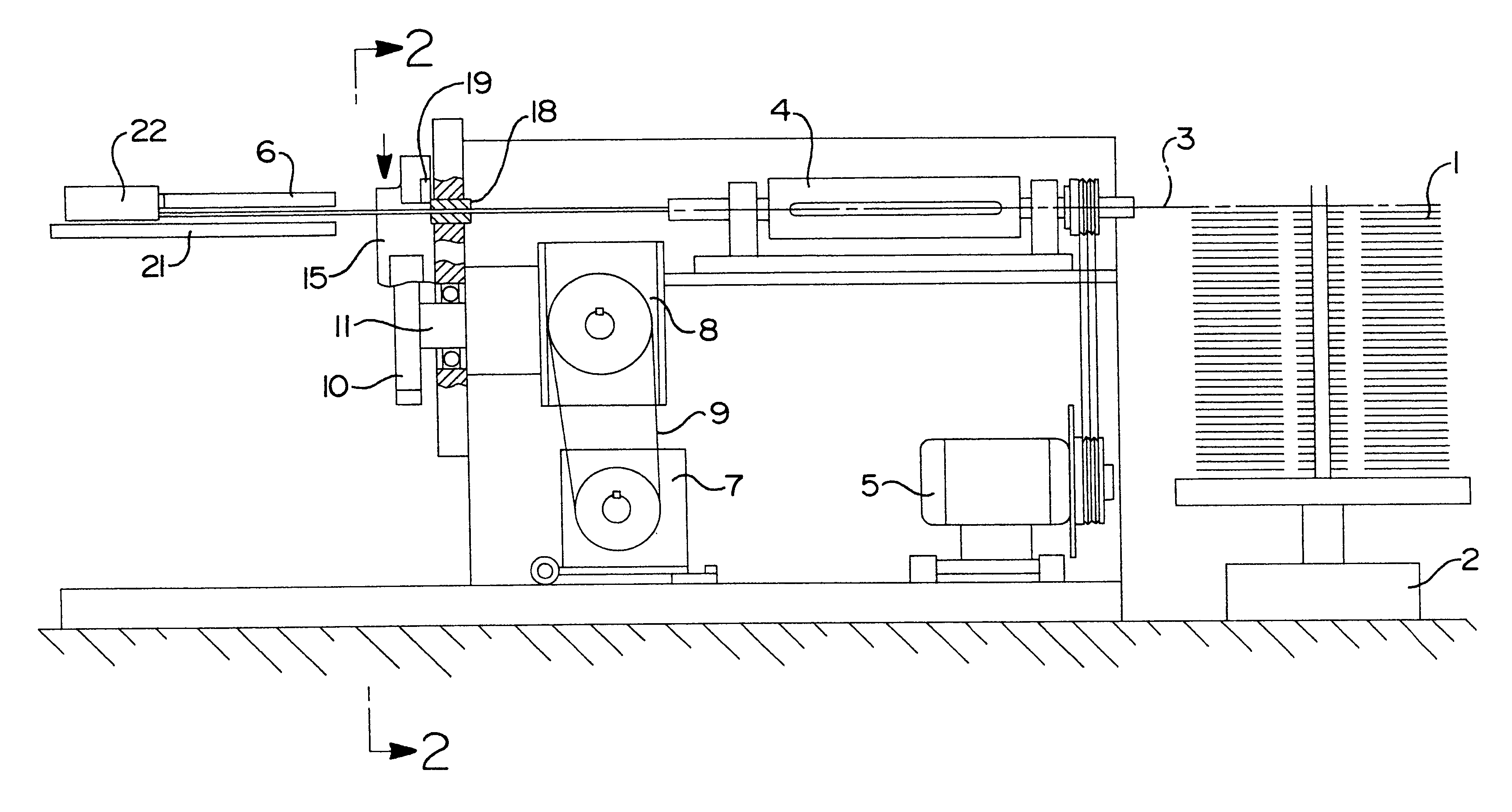

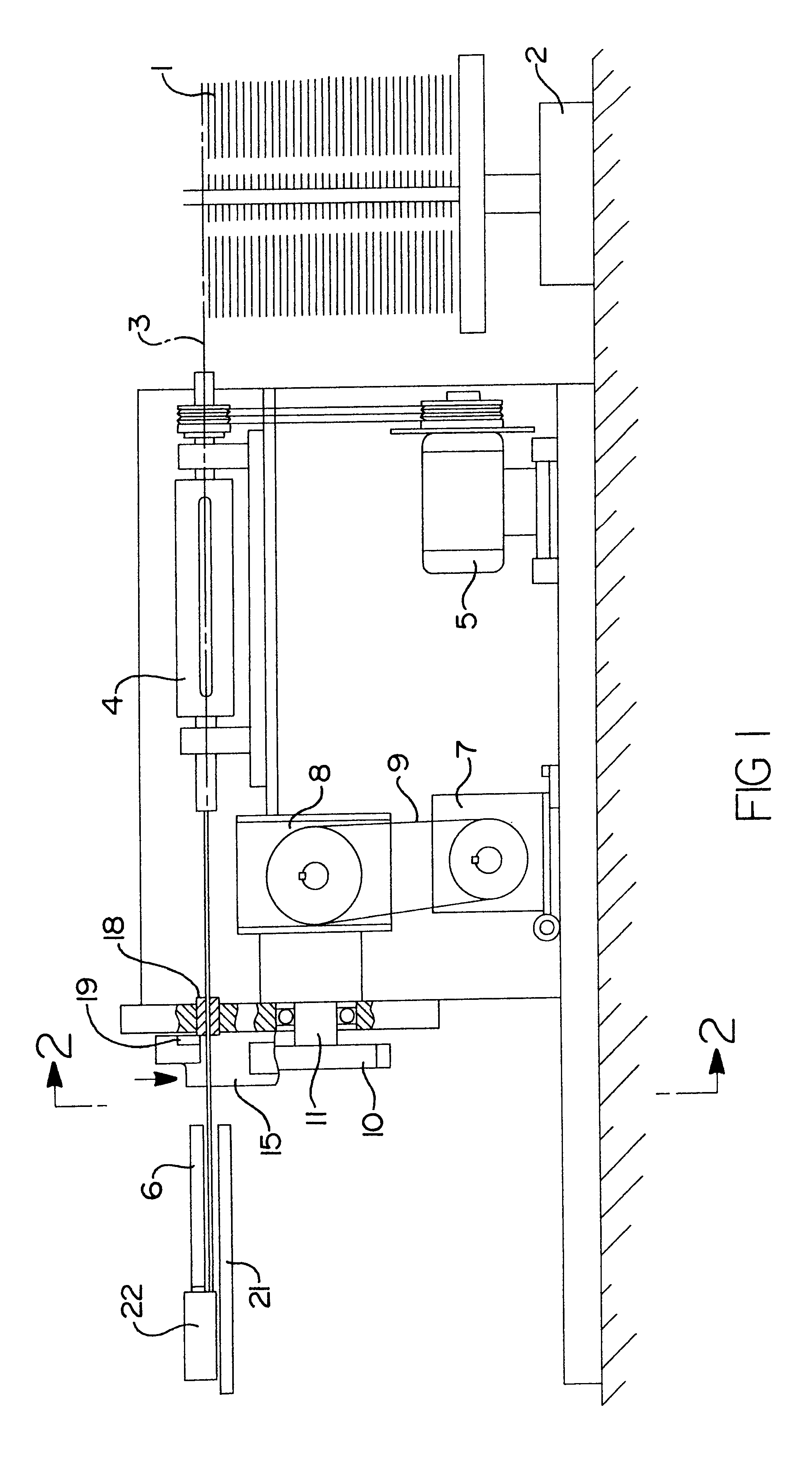

Method and apparatus for producing cut to length bars in a steel mill

A method and apparatus for producing steel bars that are cut to length in response to a customer order. The method includes producing a continuous length of steel bar from a rolling mill, cutting the continuous length of steel bar into successive segments, each representing a multiple of the length of the bar of the customer order, cutting the segments in in-line cold shears first into two times the length of the bar of the customer order and then in half into lengths equal to the length of the bar of the customer order while maintaining the production of the continuous length of steel bar produced by the rolling mill, and bundling the bars of the length of the customer order for discharge from the mill.

Owner:PONG DAVID TENG

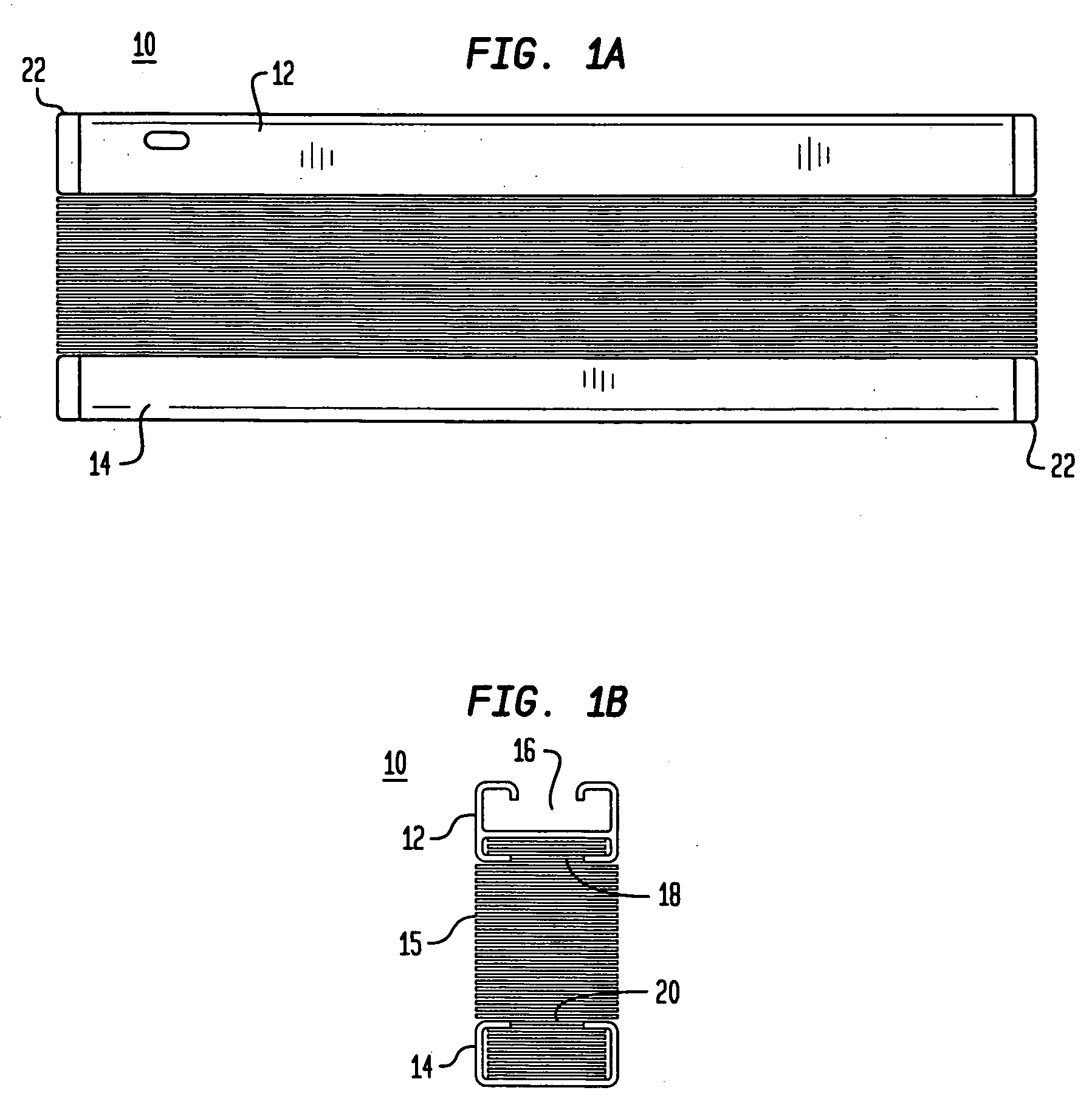

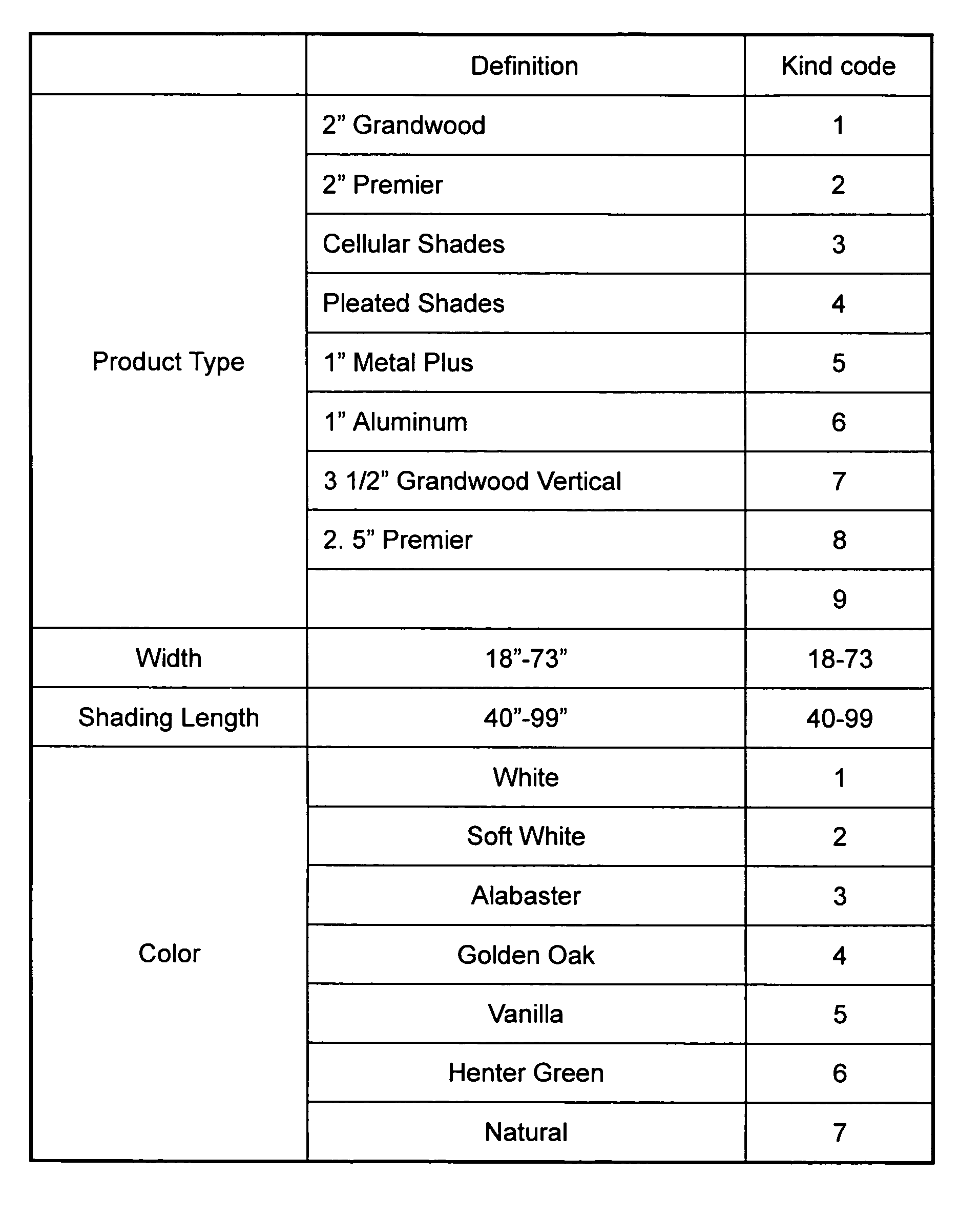

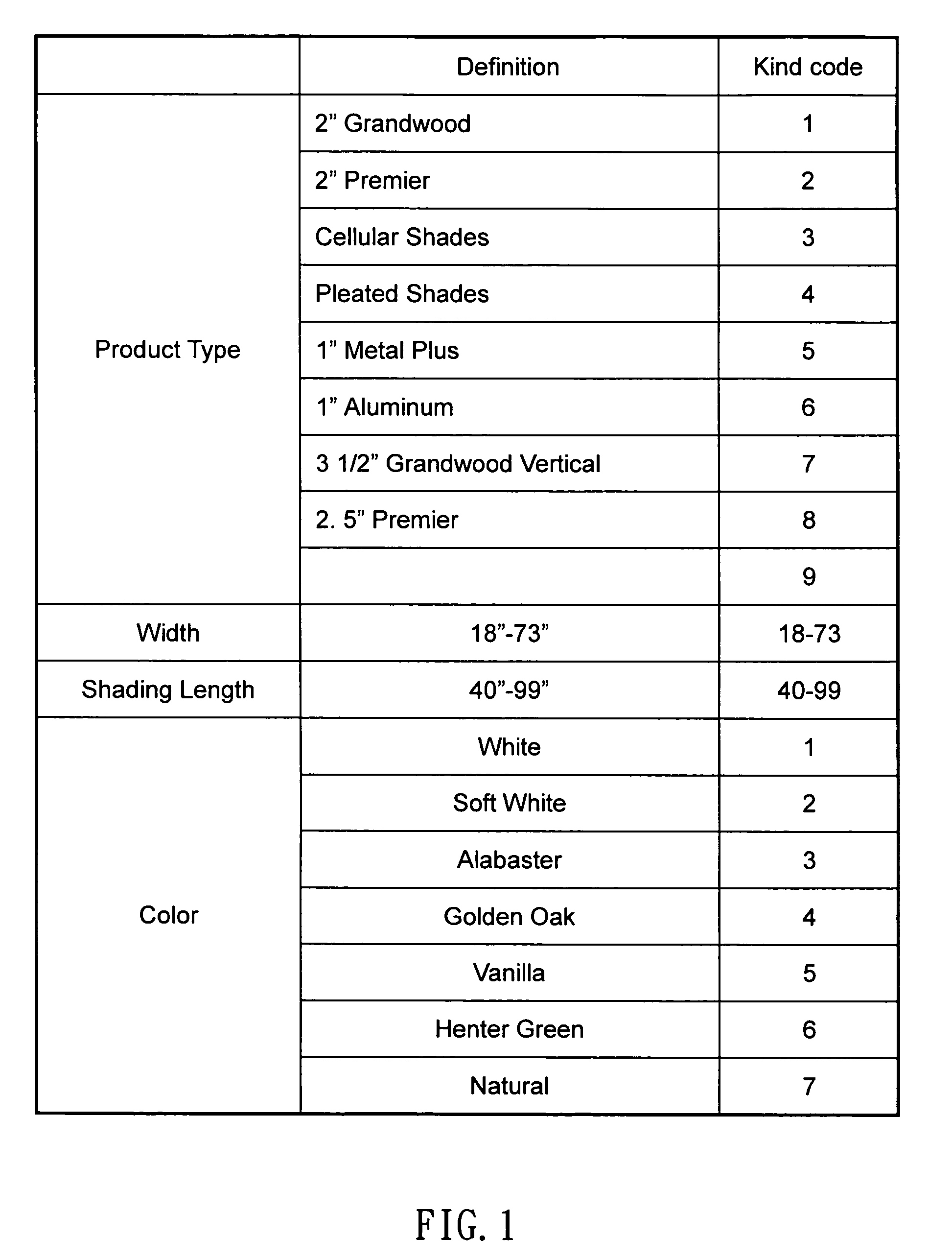

Method and machine for cutting window blind

InactiveUS7118028B2Reduction procedureEasy to operateMetal sawing devicesMetal sawing accessoriesComputer hardwareAutomatic control

A method for cutting a window blind by using a cutting machine includes the step of (a) displaying data of the window blind on a display by reading a barcode provided at the window blind; (b) inputting the size of a window that is to be installed with the window blind and an installation mode of the window blind by selection, and then calculating and displaying on the display a size to be cut based on the data of the window blind and the size of the window and the installation mode selected; and (c) automatically controlling a positioning mechanism of the cutting machine to move to a predetermined position corresponding to the calculated size to be cut by a processor for stopping the window blind in a cutting position, and then controlling a cutting unit of the cutting machine to cut the window blind by the processor.

Owner:NIEN MADE ENTERPRISE CO LTD +1

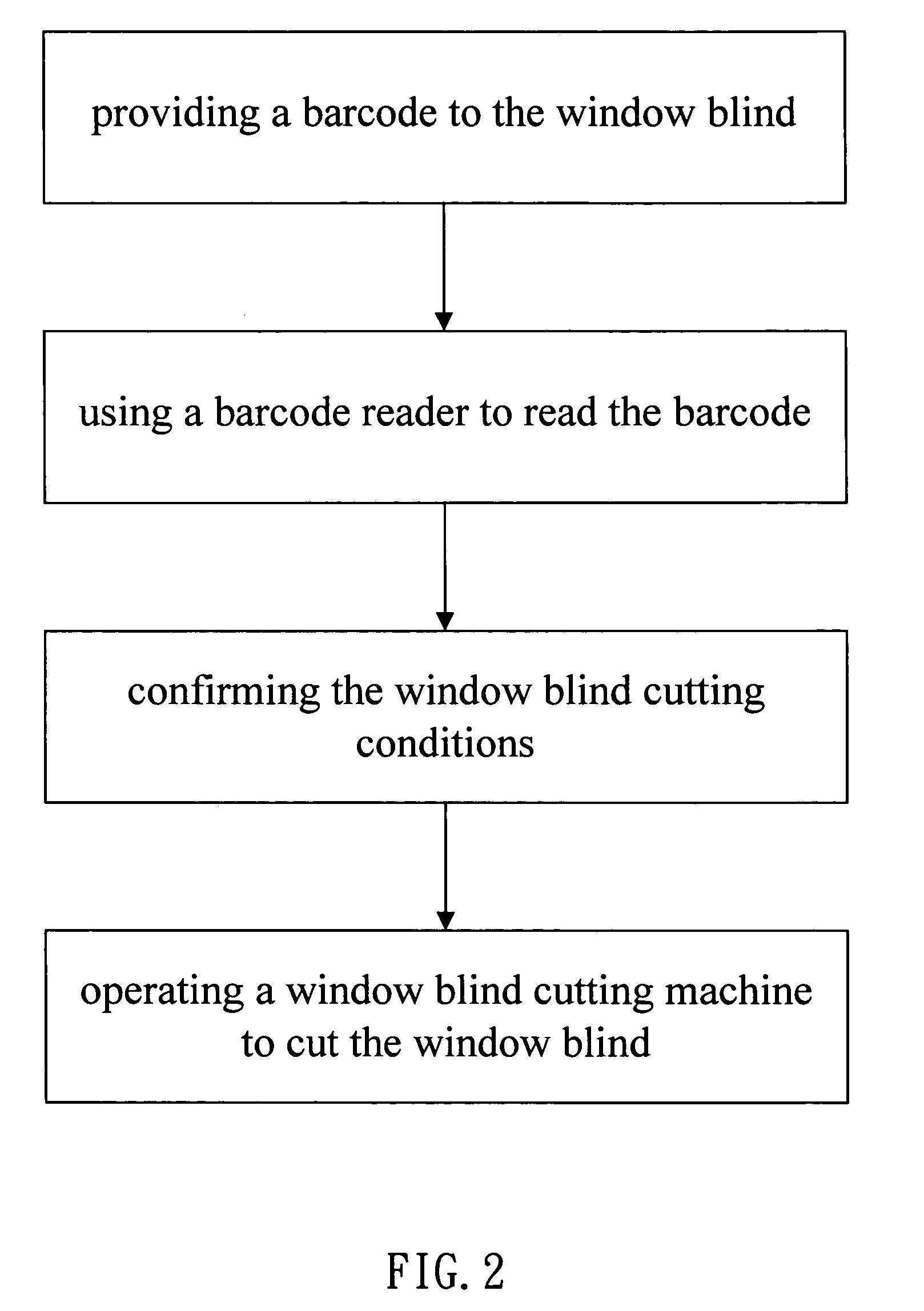

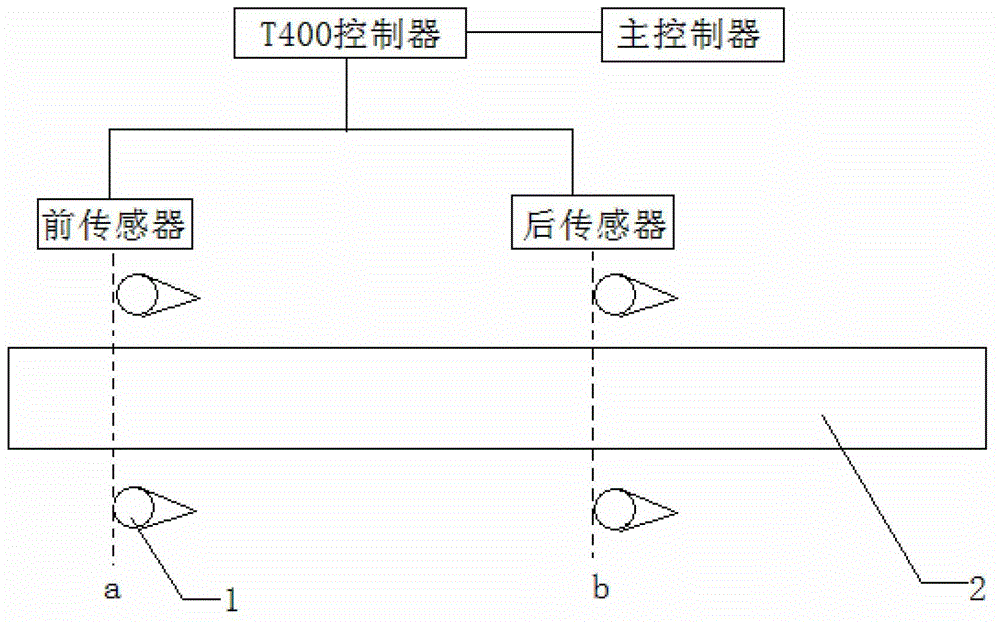

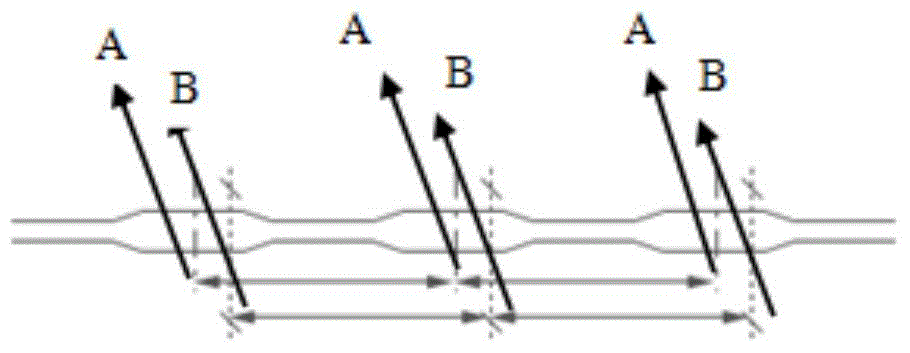

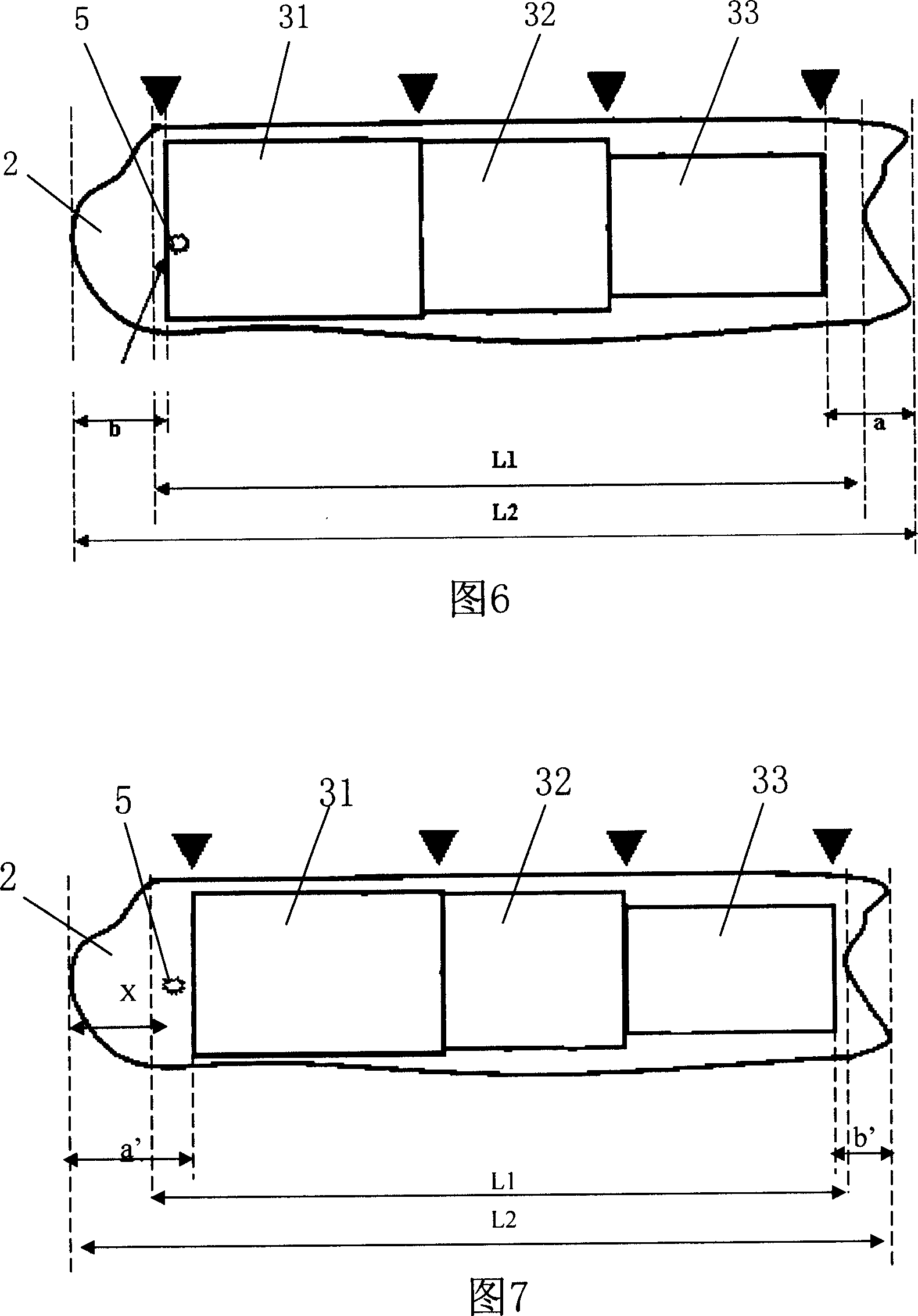

Method for controlling shearing length of multi-length flying shear

The invention discloses a method for controlling shearing length of a multi-length flying shear, which comprises the following steps: (1) after a rolled piece passes by a heating furnace delivery table, the weight Gn of the rolled piece is obtained; (2) a T400 controller records time Tw of the rolled piece passing through the head part and the tail part of the multi-length flying shear, and records time Tn of the whole rolled piece passing through the multi-length flying shear, so that the rolled piece length is computed through the formula: Ln=Tn*Lw / Tw; (3) after next rolled piece passes through the heating furnace delivery table, the weight Gm of the rolled piece is obtained, so that the length of the rolled piece is calculated through the formula: Lm=Gn*Ln / Gm; (4) the number of shearing times of the multi-length flying shear can be calculated through the formula: Lm tail=Lm-Sigma Lc, wherein when the Lm tail is zero or a negative value, x-1 is the number of shearing times; (5) the final specified length sheared by the multi-length flying shear can be calculated through the formula: Lz=Lm / x-1, and the rolled piece is sheared after the specified length is updated. In addition, the invention further discloses a device for controlling the shearing length of the multi-length flying shear. The method has the function of eliminating 'short tail' and avoiding steel heaping, the cold bed mounting fault is reduced, the production pace is guaranteed, and the potential safety hazard is reduced.

Owner:江苏联峰实业有限公司

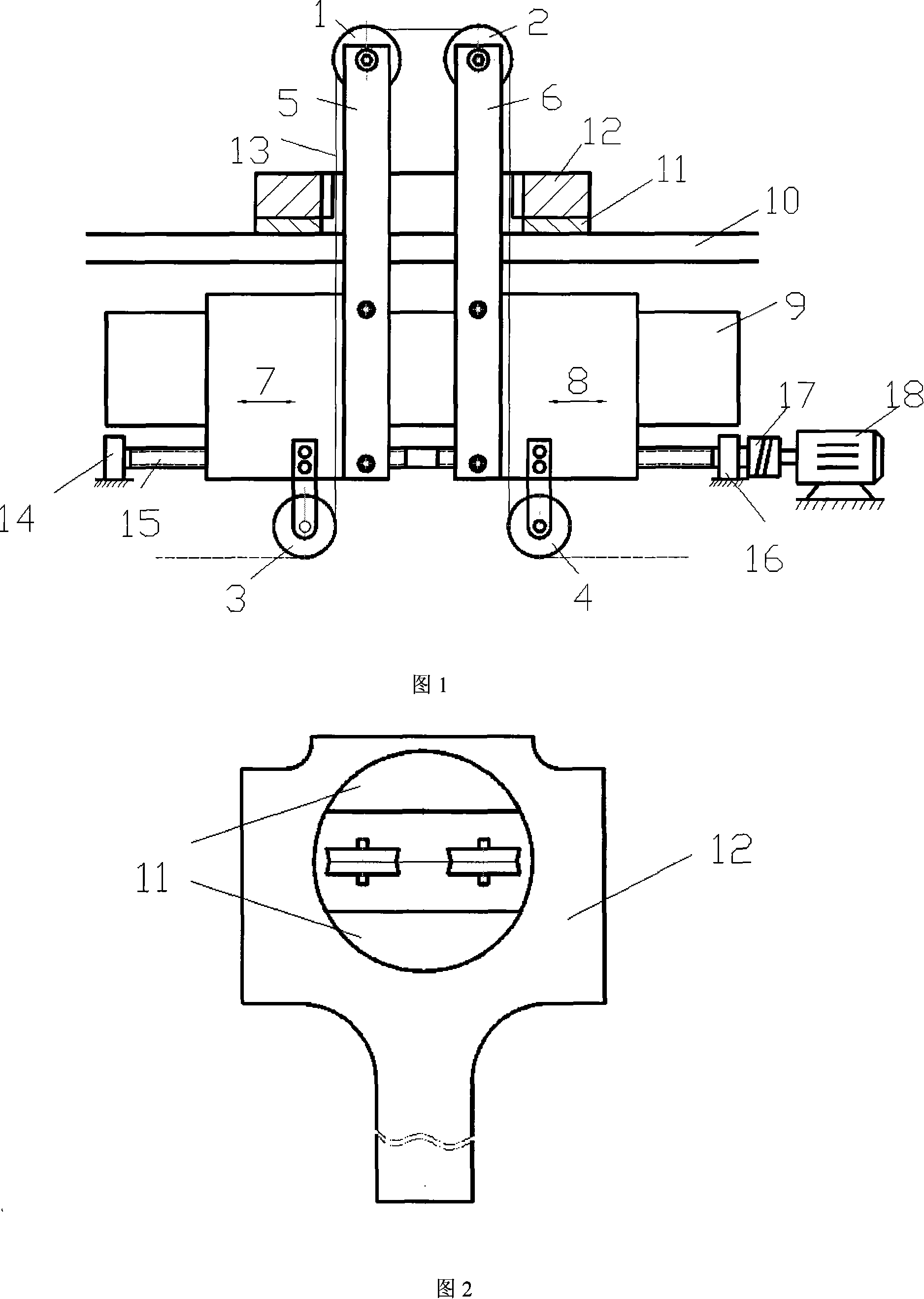

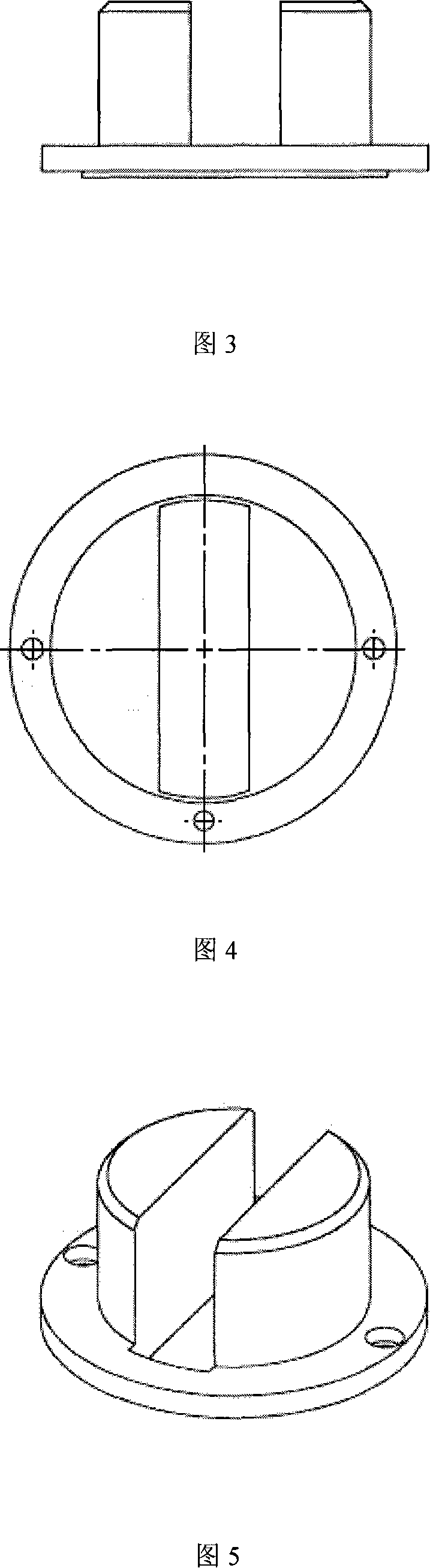

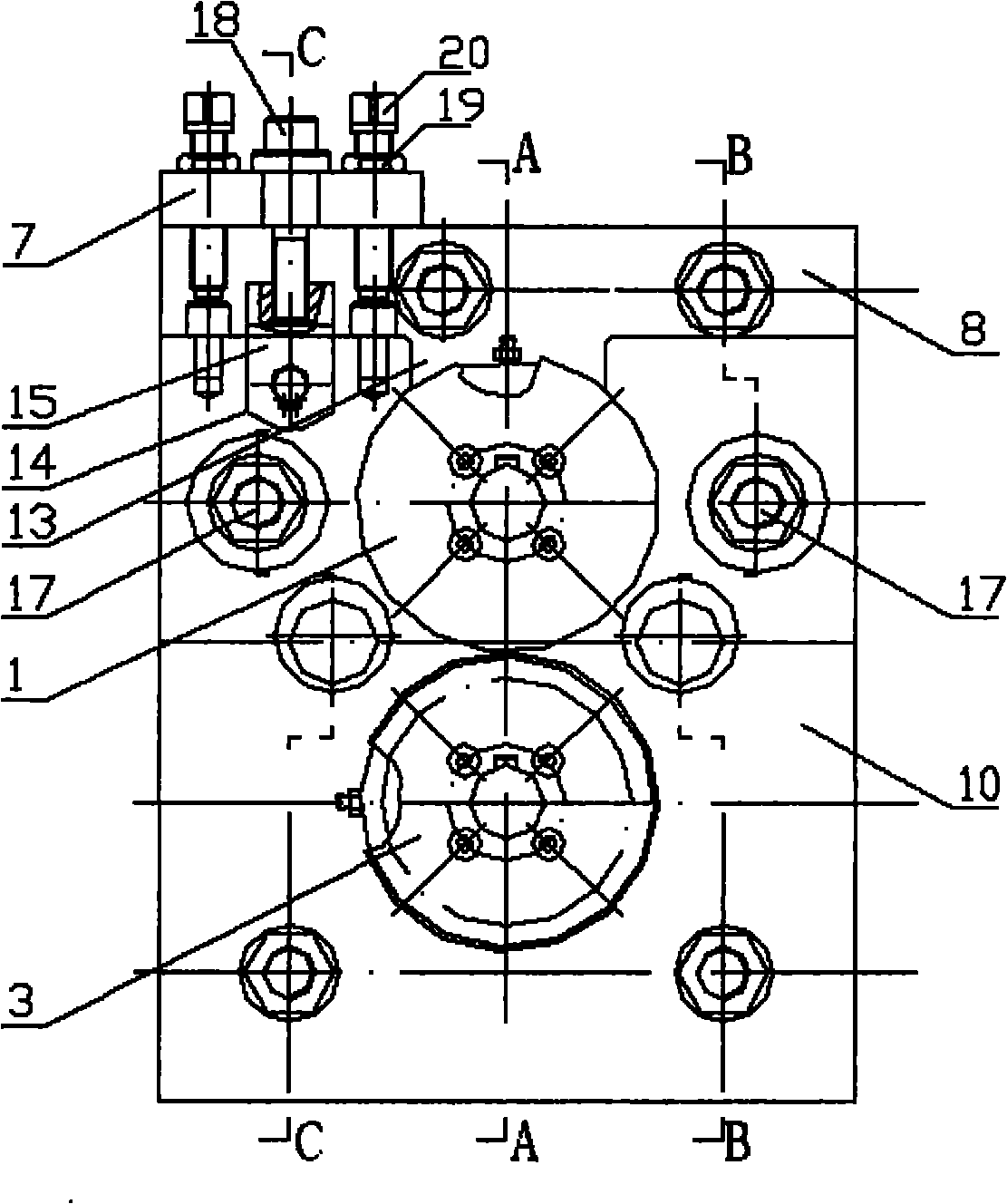

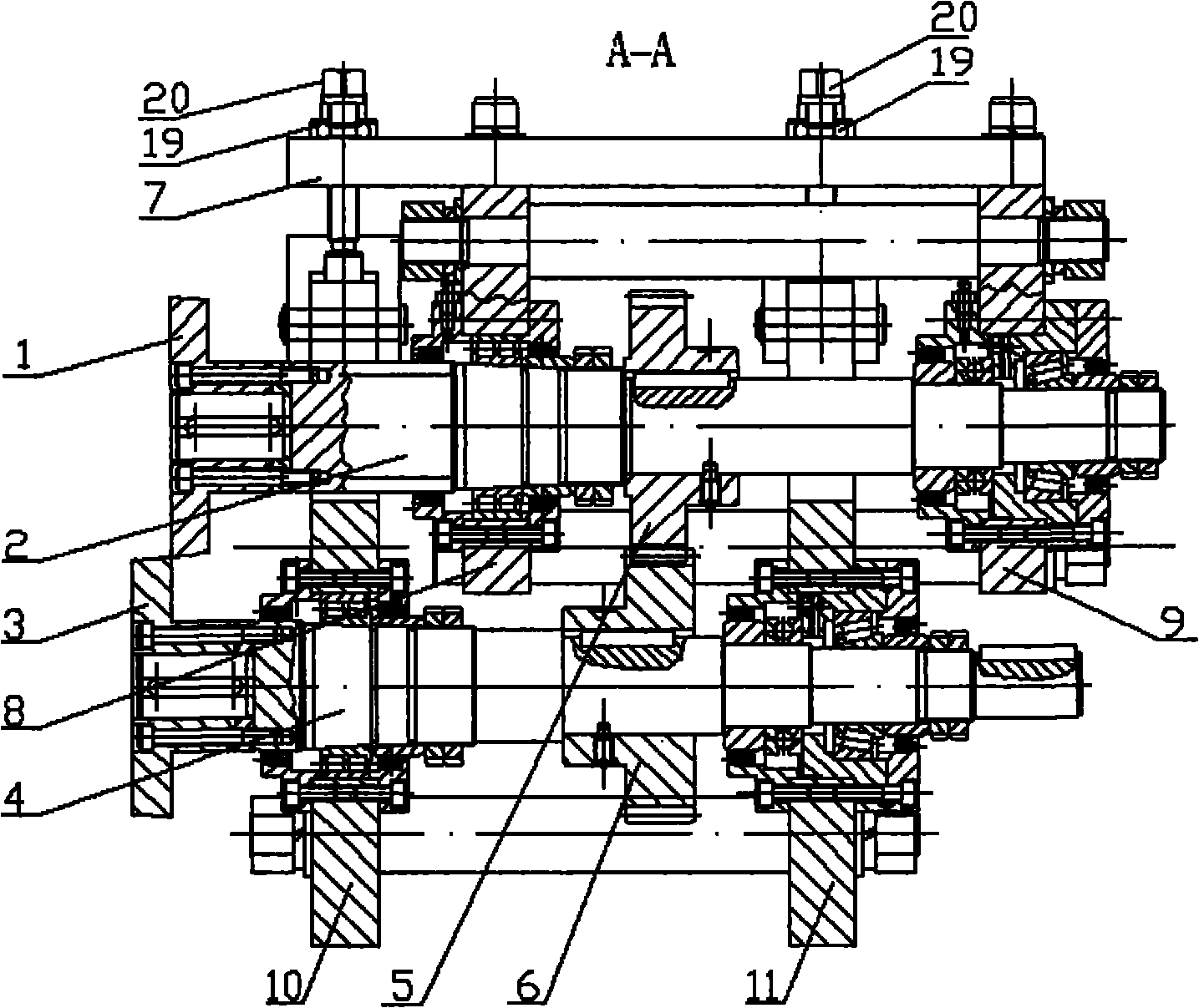

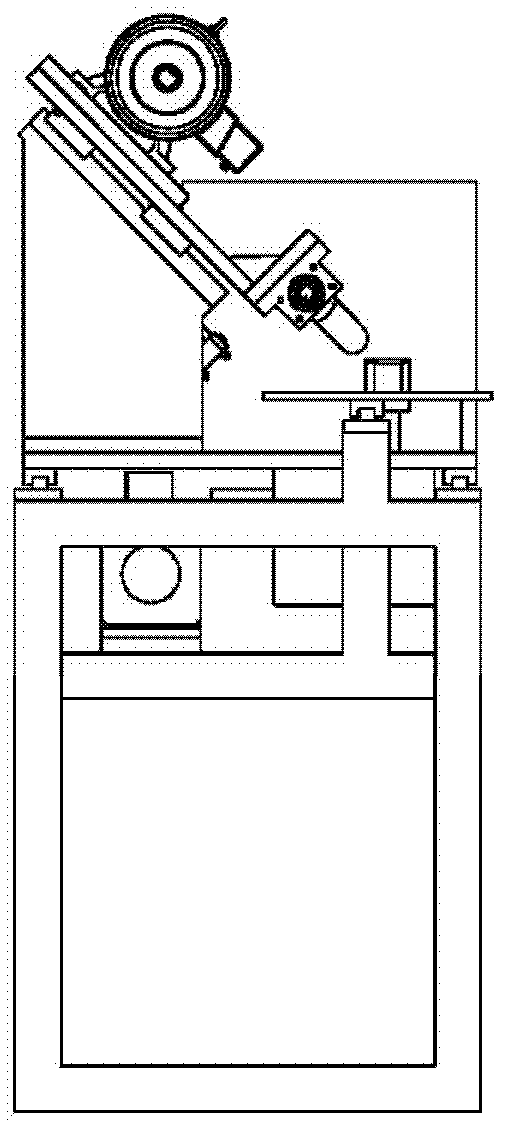

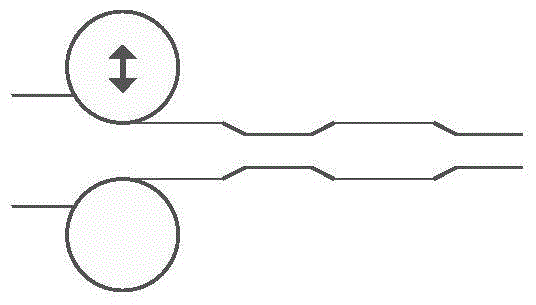

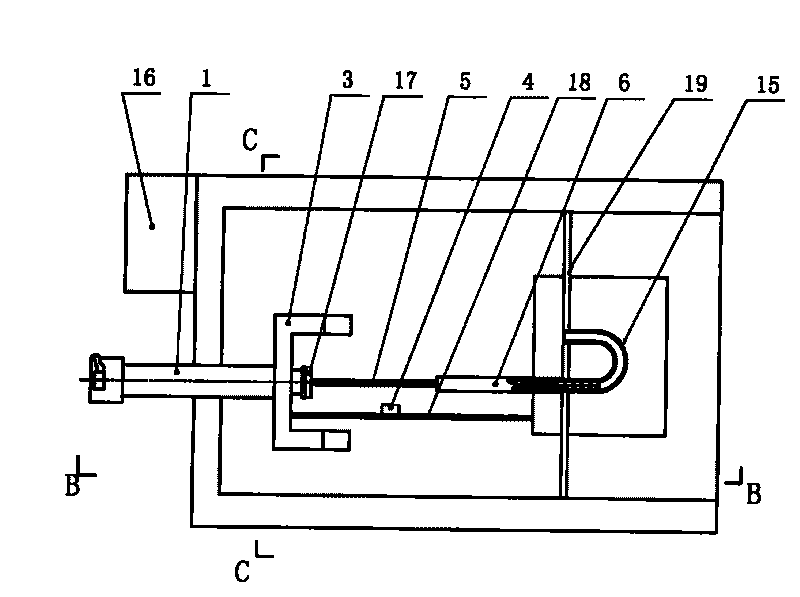

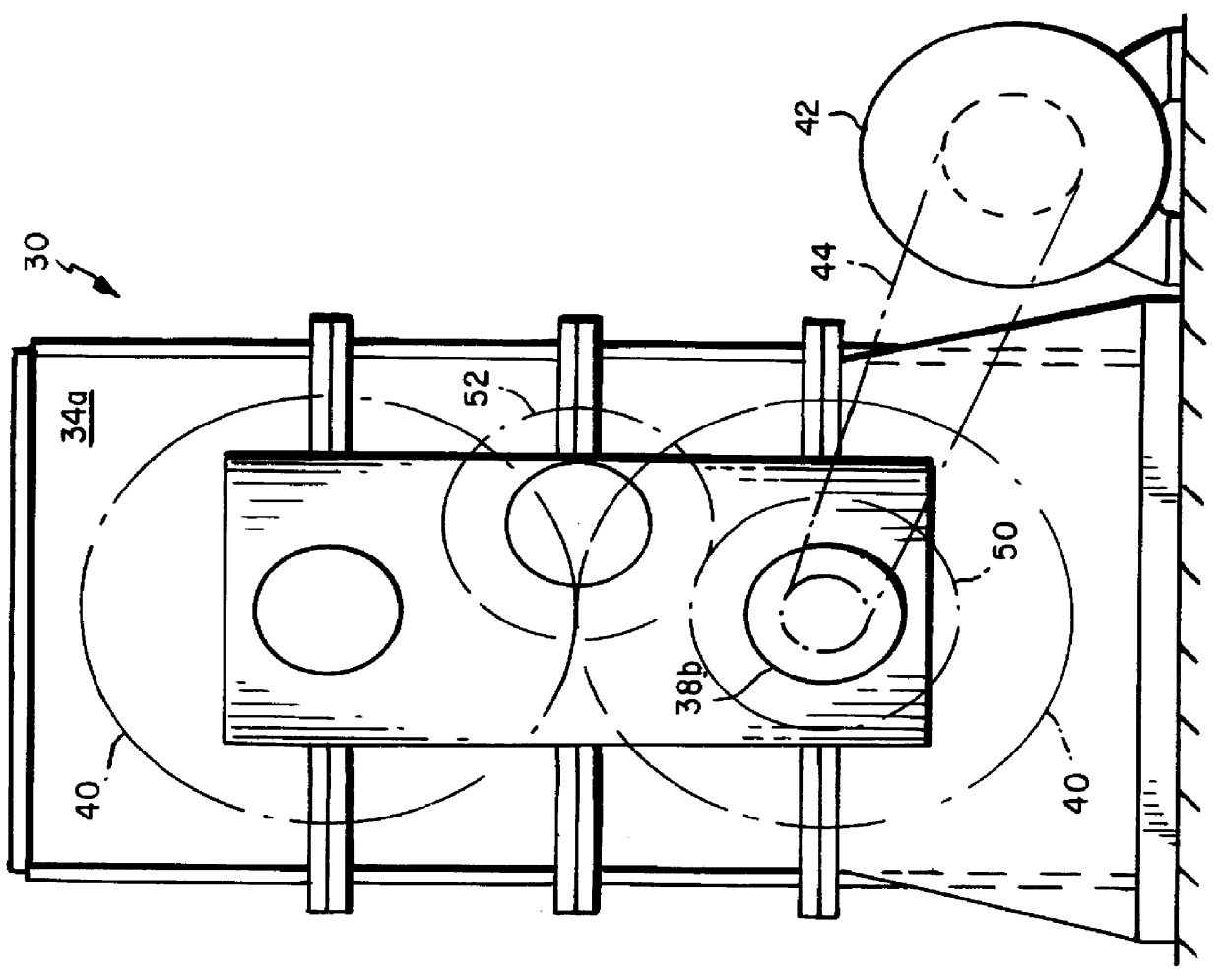

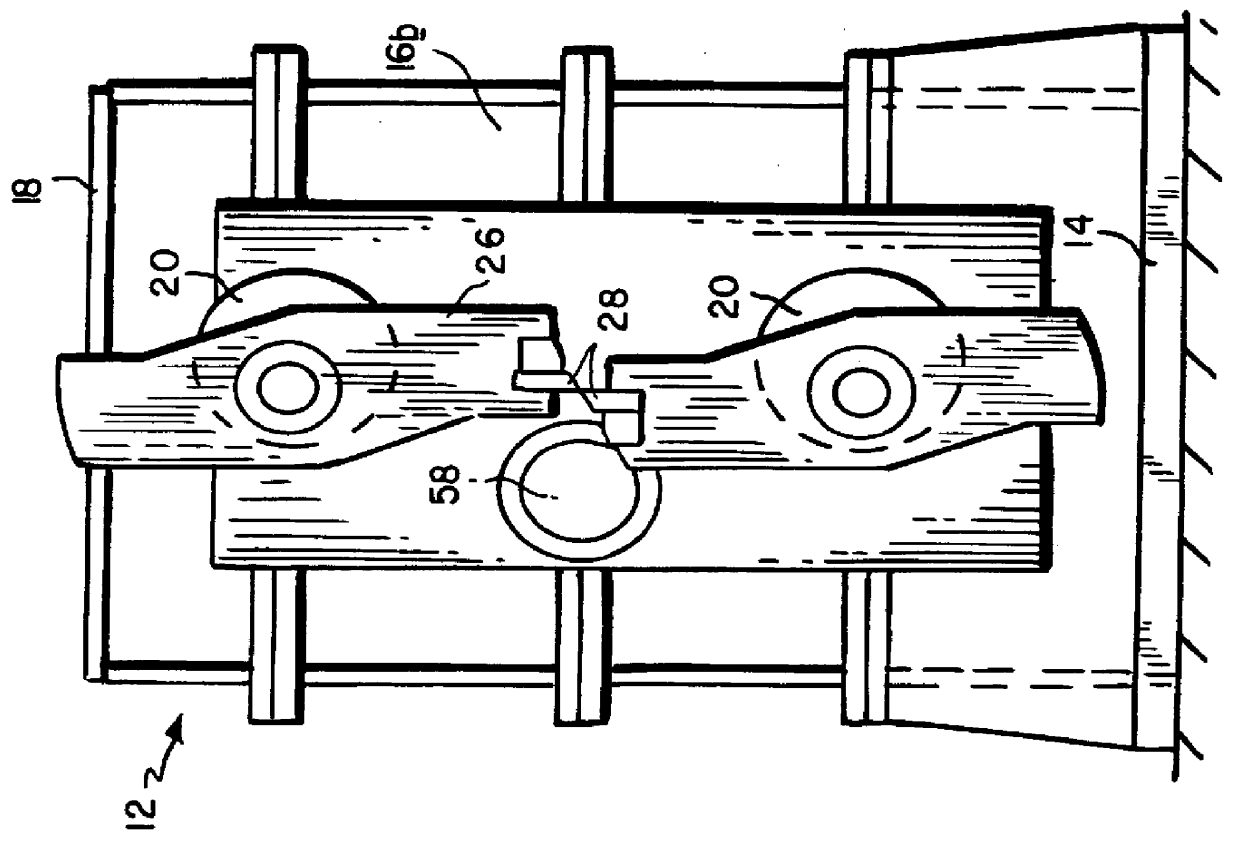

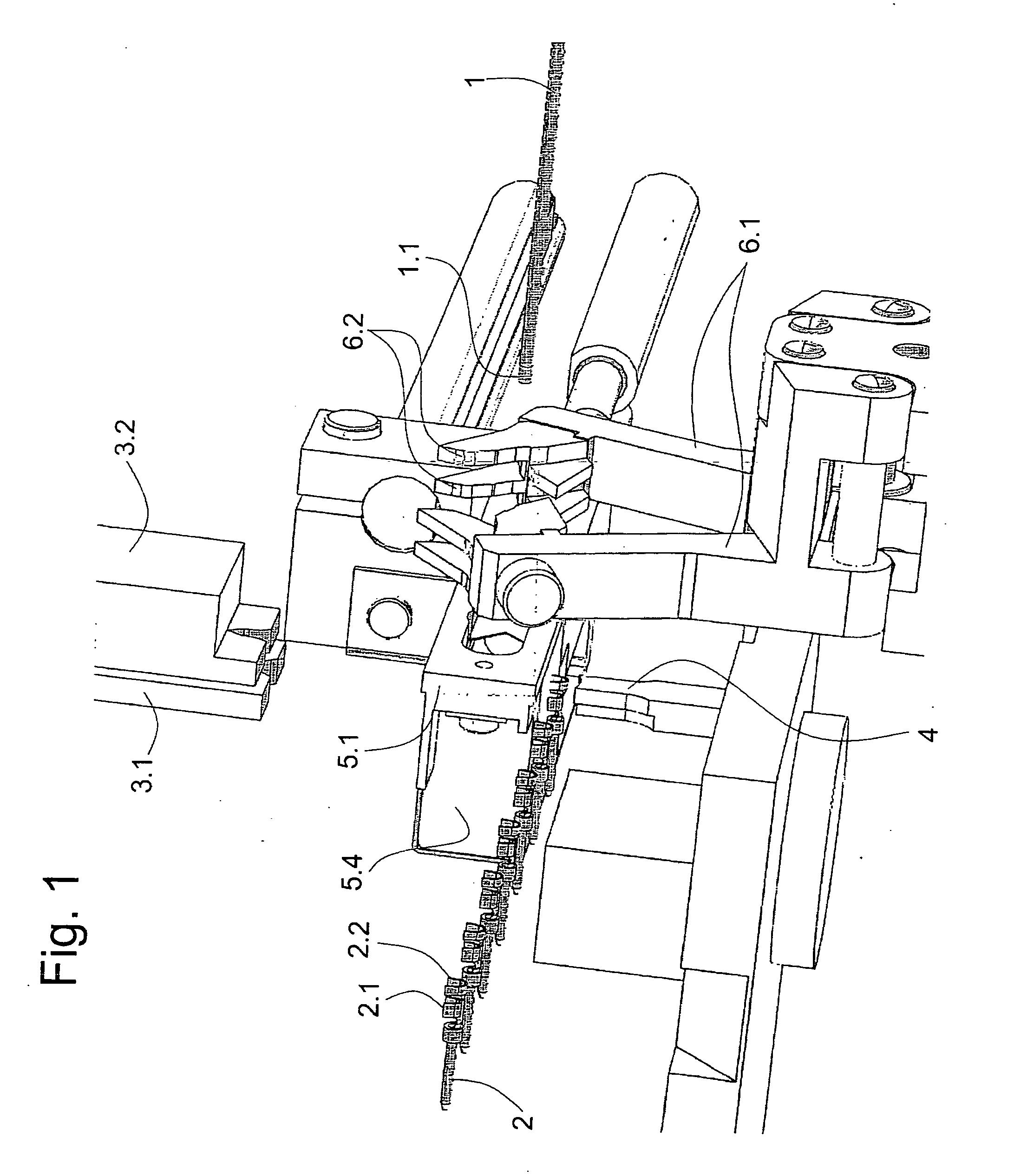

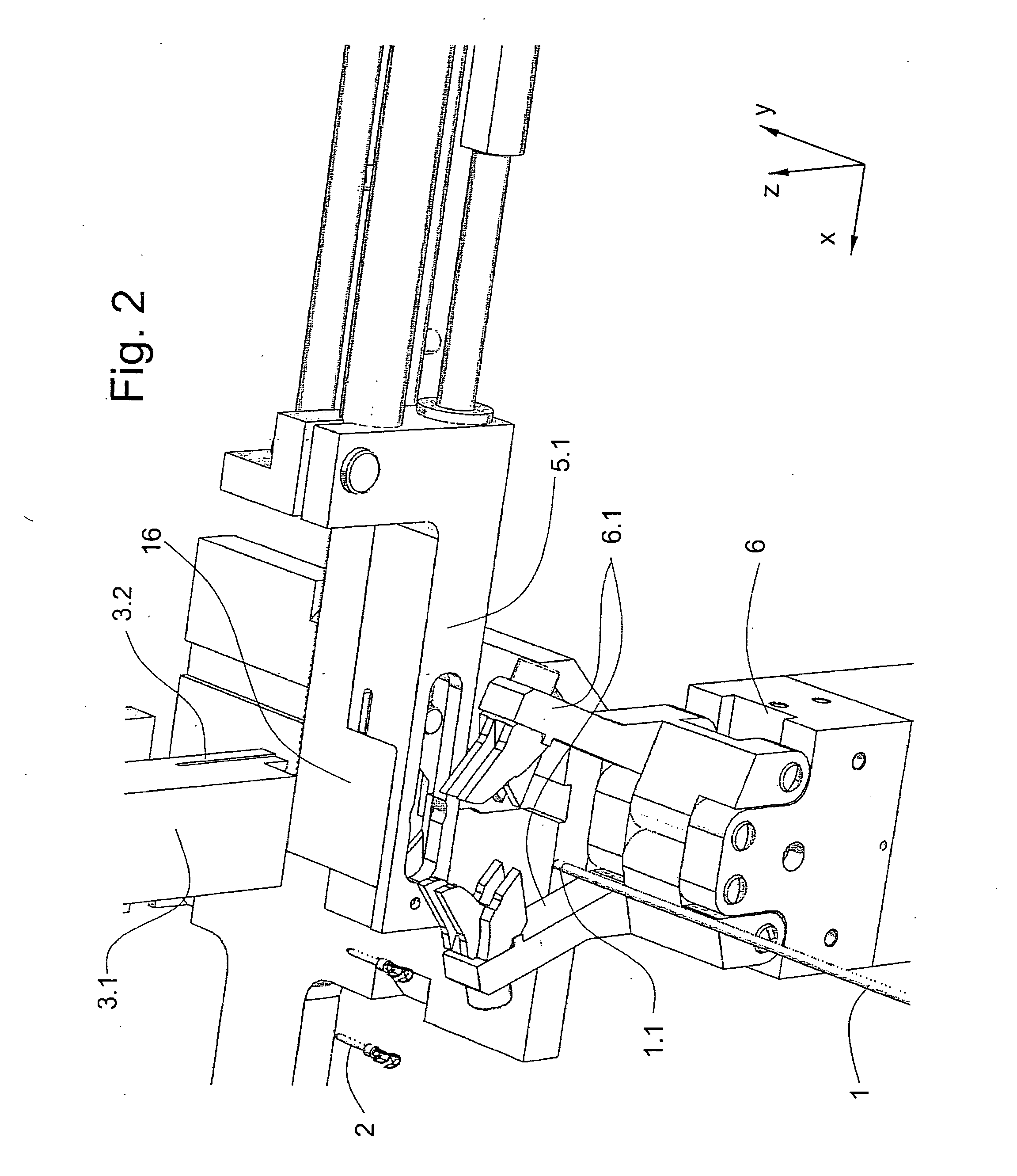

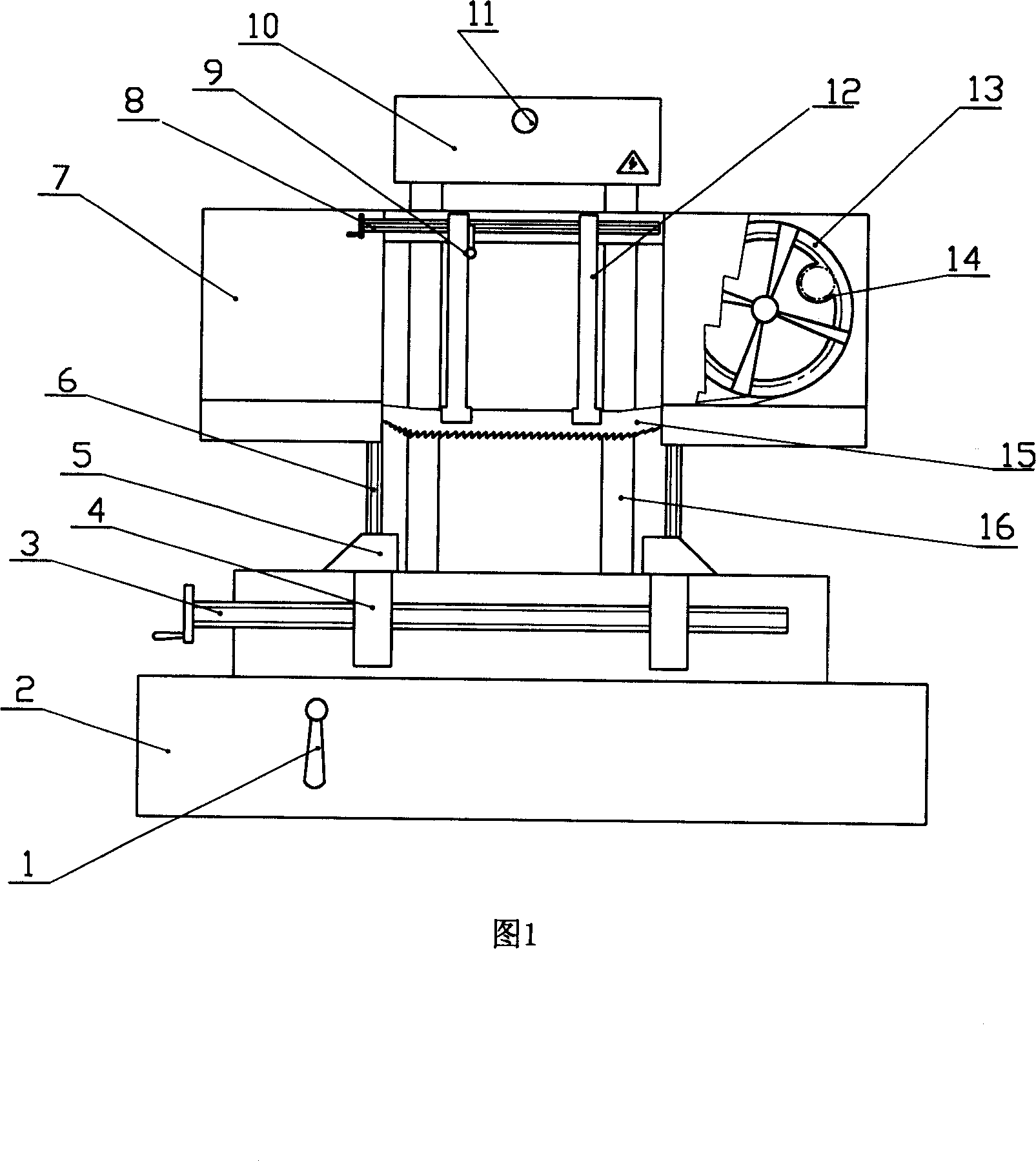

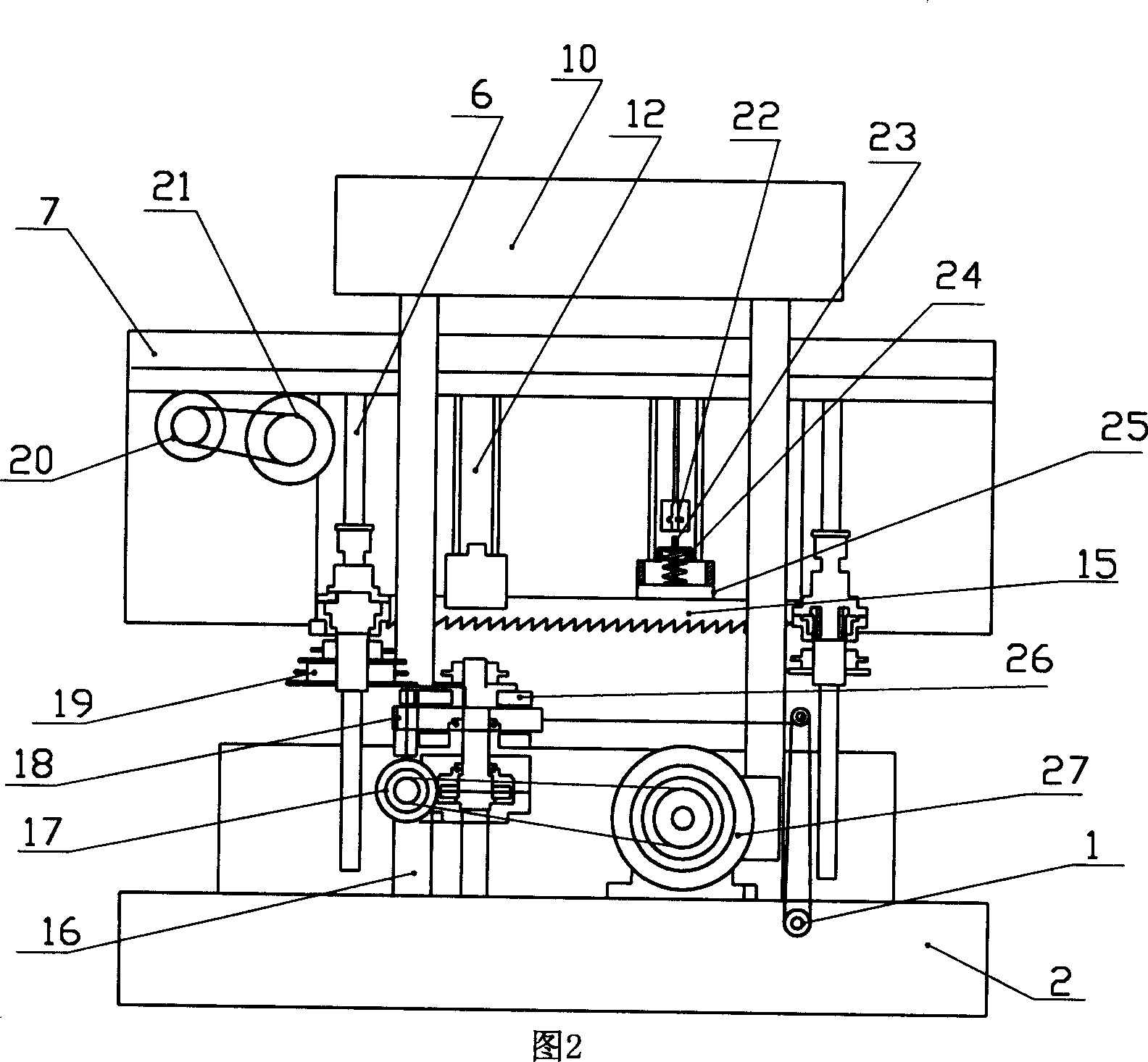

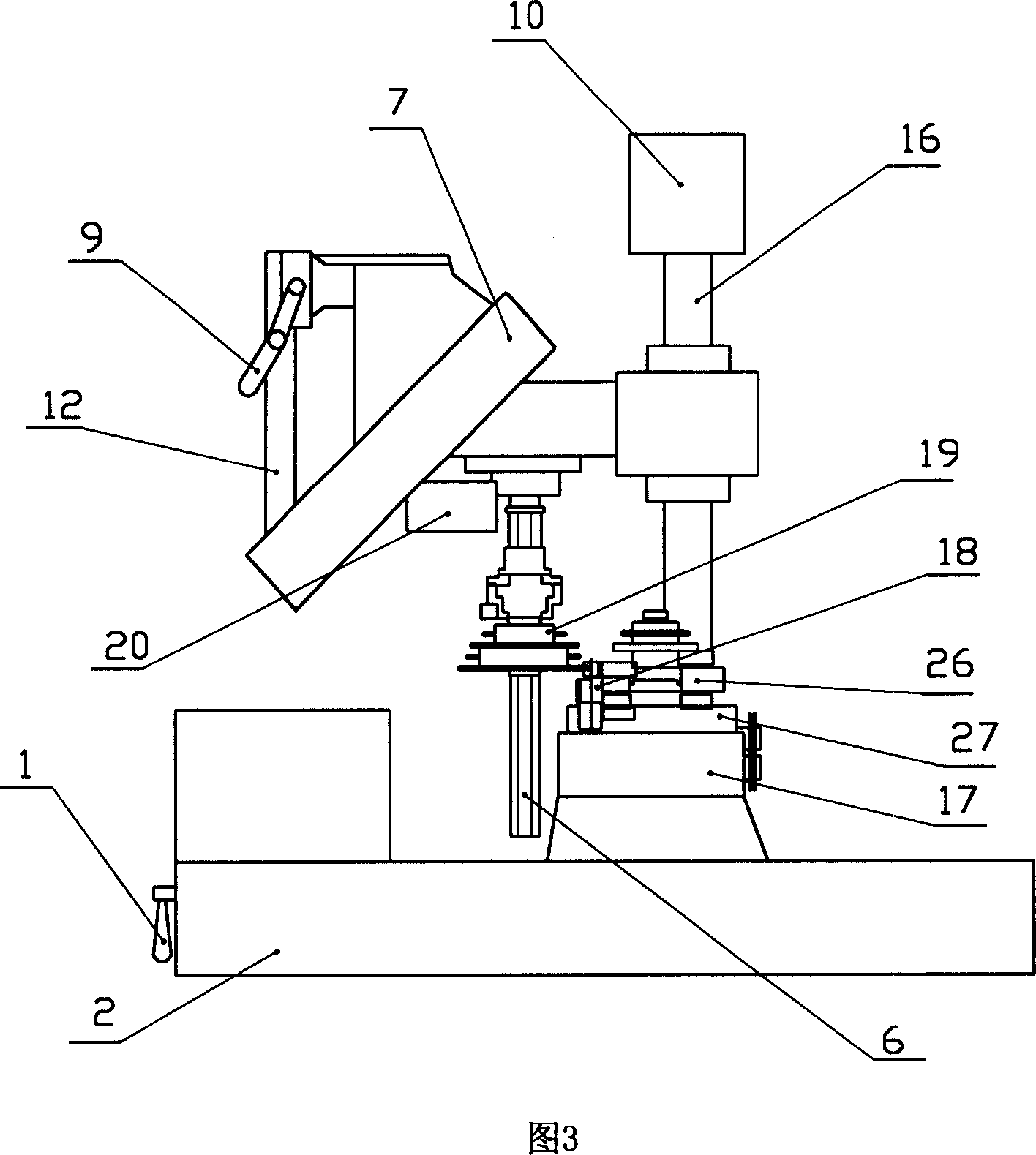

Cracking connecting-rod initial stress trough two-way processing device

InactiveCN101125379AReduce processing timeReduce idle travel timeShearing machinesShearing control devicesEngineeringMachining time

The present invention discloses a dual-way machining device of the cracking connecting rod initial stress slot. One of the proposals of the present invention is that a left and a right supporting rods which are respectively provided with at least one idler pulley and pass in from one end of inner hole of the work piece and extend out from the other end; a machining thread passes from the idler pulley arranged on the left slide block to the idler pulleys arranged on the left and right supporting rods where the thread turns 180 degree and reachs the idle pulley arranged on the right slide block, conducted by the pulleys the machining thread forms two sections of working parts, i.e. a left section and a right section axially paralleling with the surface shaft of the inner hole, namely, the machining thread section between the idler pulleys and the machining thread section between the idler pulleys; the slide block are separate from each other, while the two working sections of the machining thread are also separated and close to the surface of the inner hole of the work piece; the worktable is provided with a positioning pin, and the work piece is fixed on the positioning pin by the inner hole of the work piece. Adopting a dual-way cutting device, the present invention can synchronously cut the two cracking stress slots at the symmetric positions of the surface of the inner hole, shortening the machining time; moreover, the present invention has low cost and low maintenance fare.

Owner:GUANGDONG UNIV OF TECH

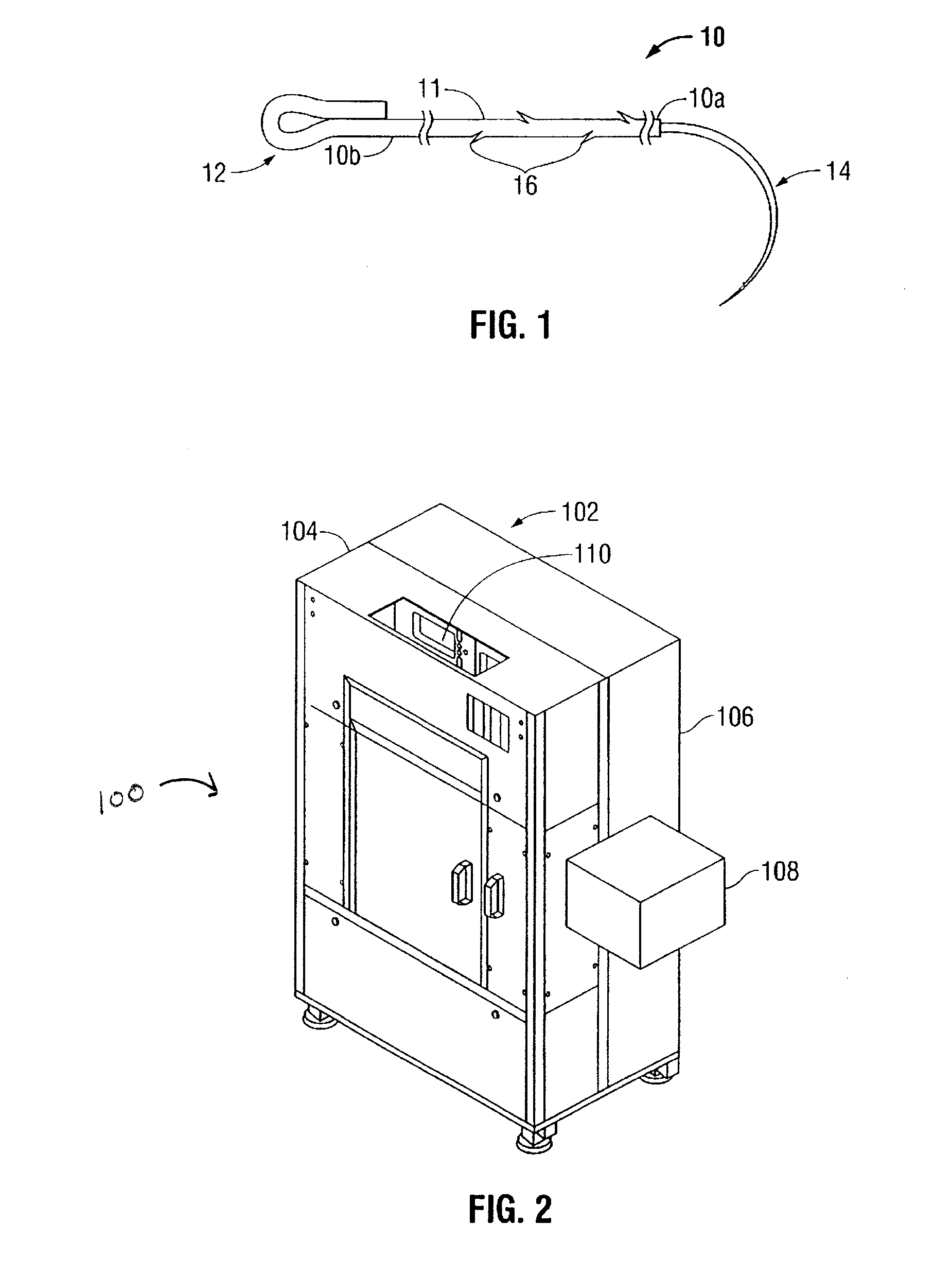

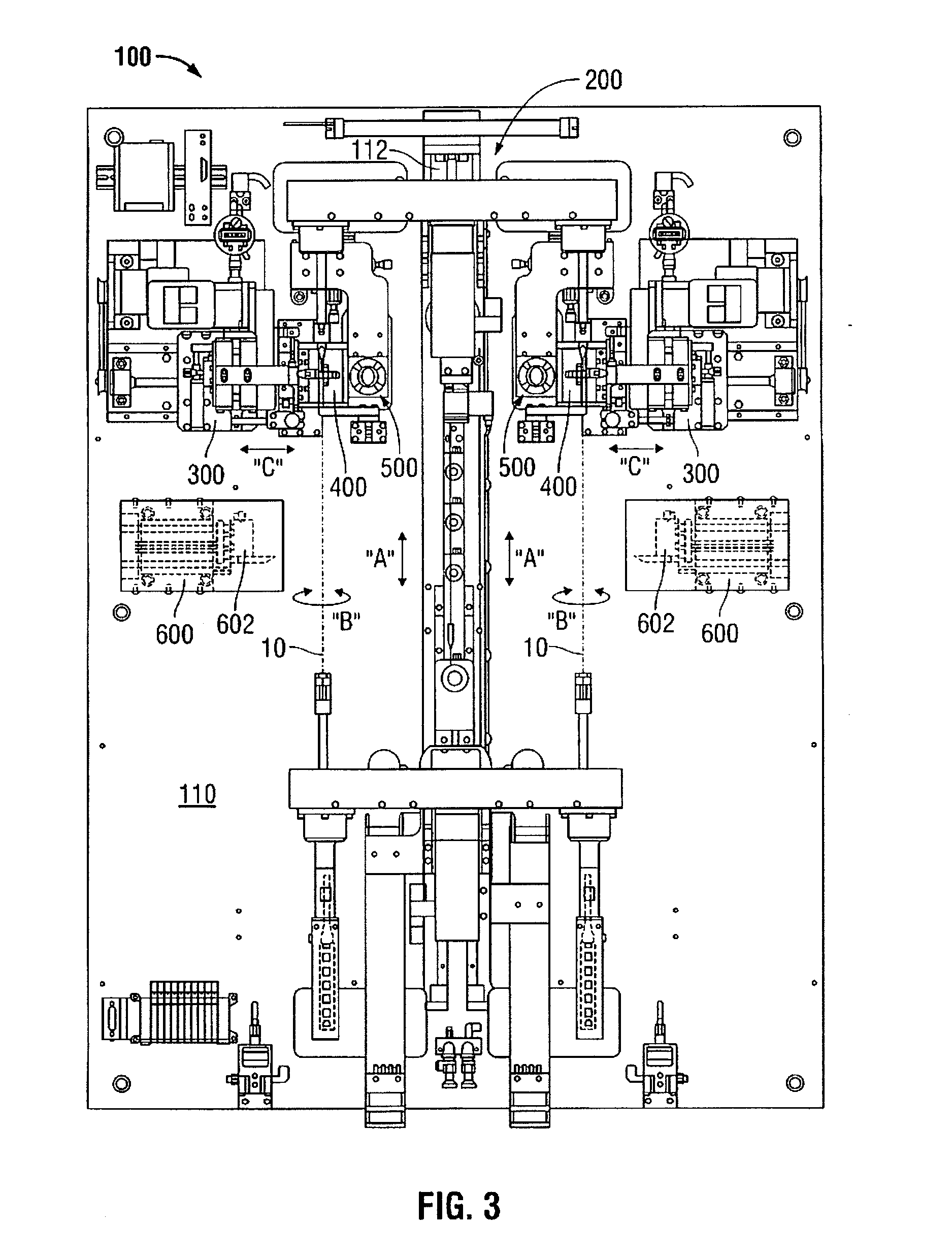

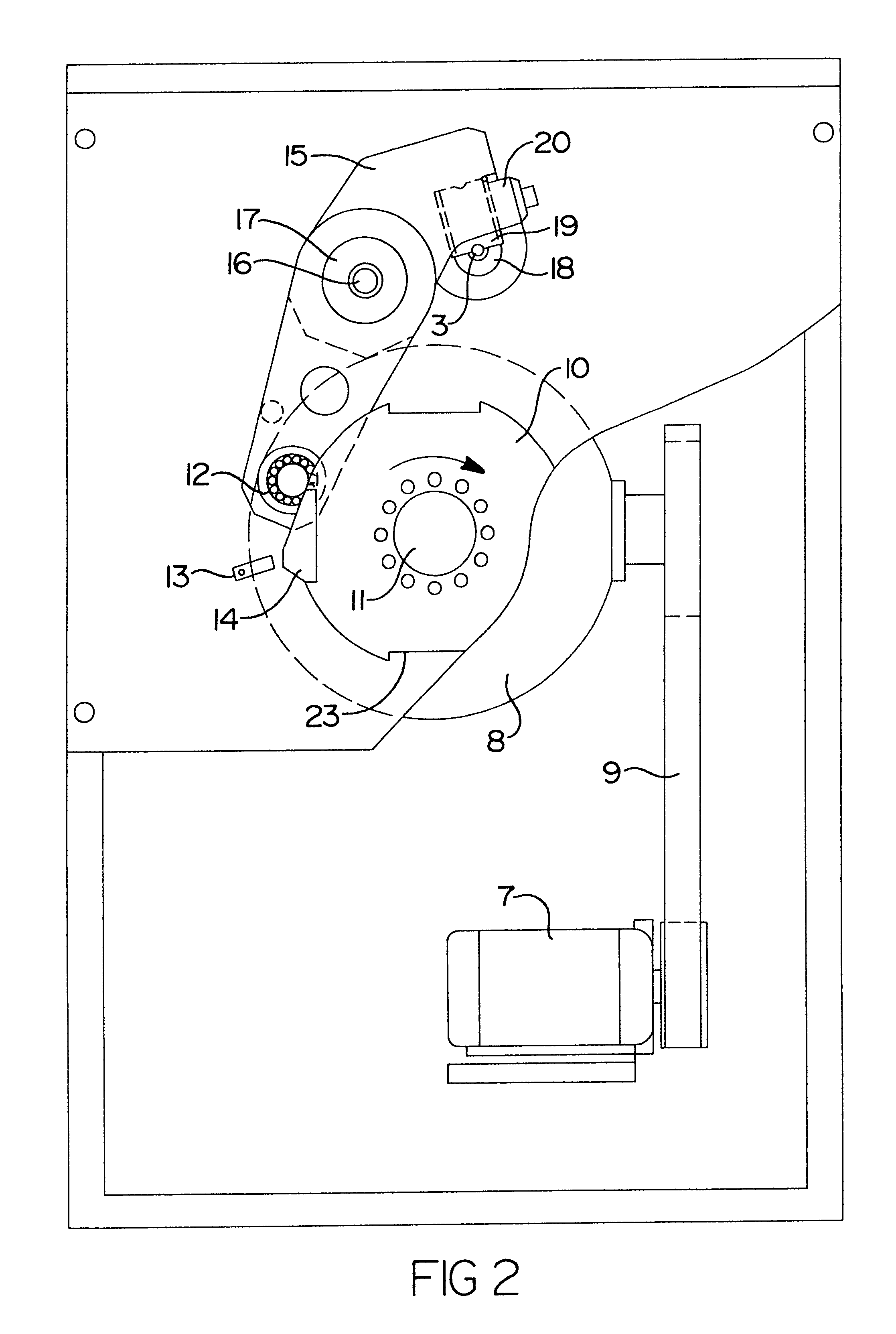

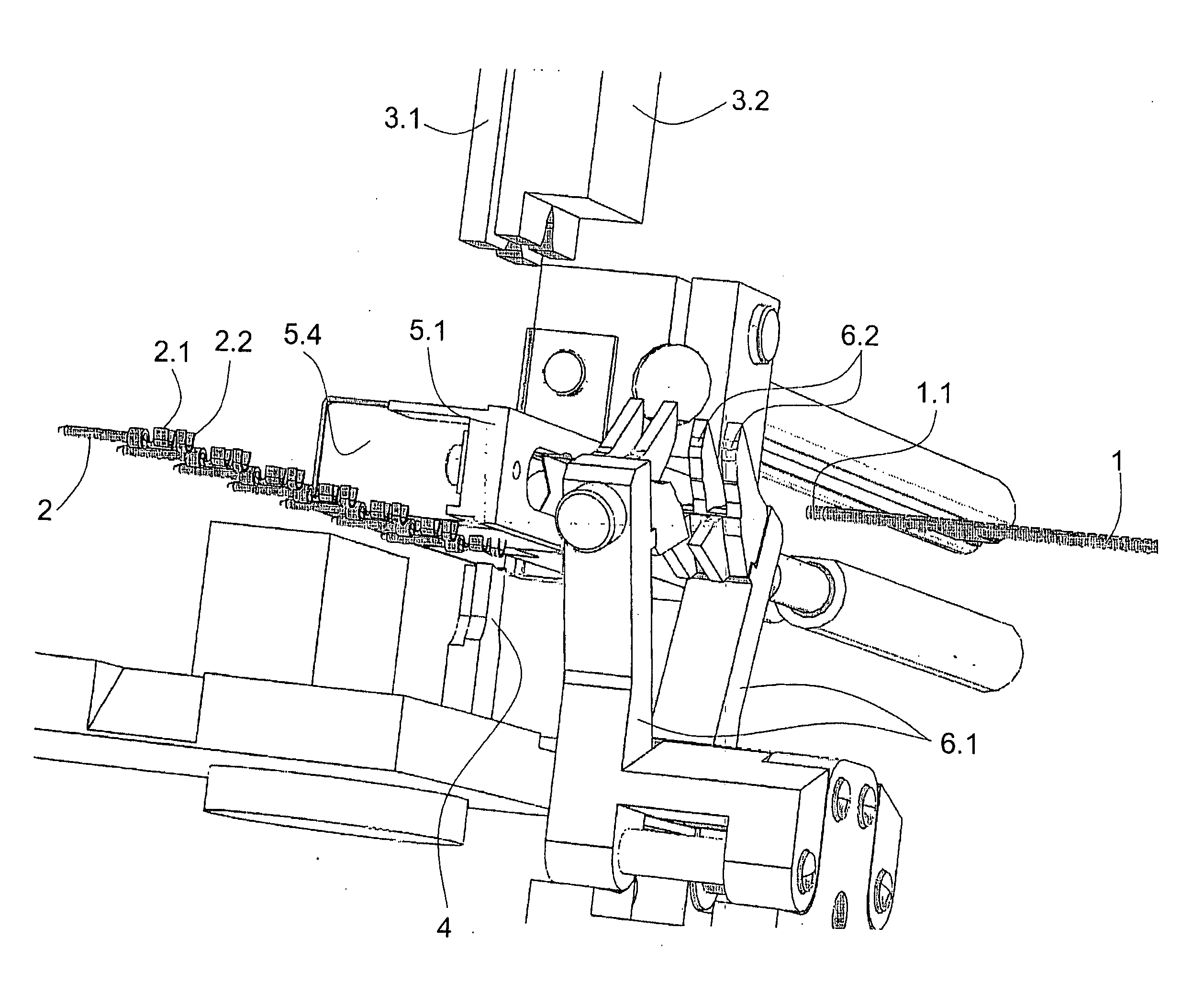

System and Method for Forming Barbs on a Suture

A station for cutting a barb suture is provided. The barb cutting station includes a suture transport assembly for supporting a first suture, a first knife assembly for forming barbs on the first suture, and a first clamp and position assembly for approximating the at least first suture towards the at least first knife assembly. The barb cutting station may further include at least a first suture cutting mechanism configured for severing the at least first suture when a defect is detected. The station may also include at least a first visual inspection assembly configured for detecting defective barbs.

Owner:TYCO HEALTHCARE GRP LP

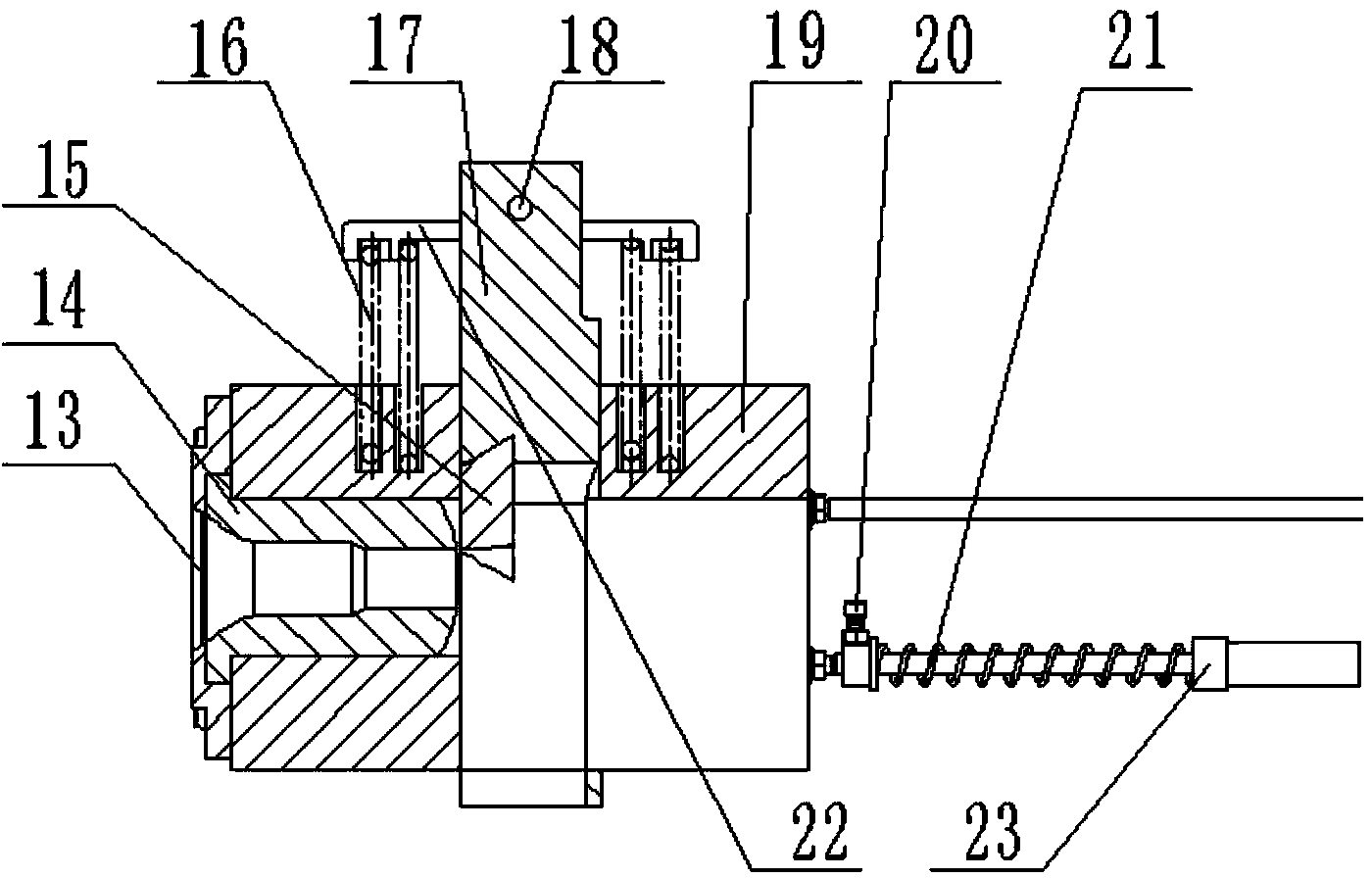

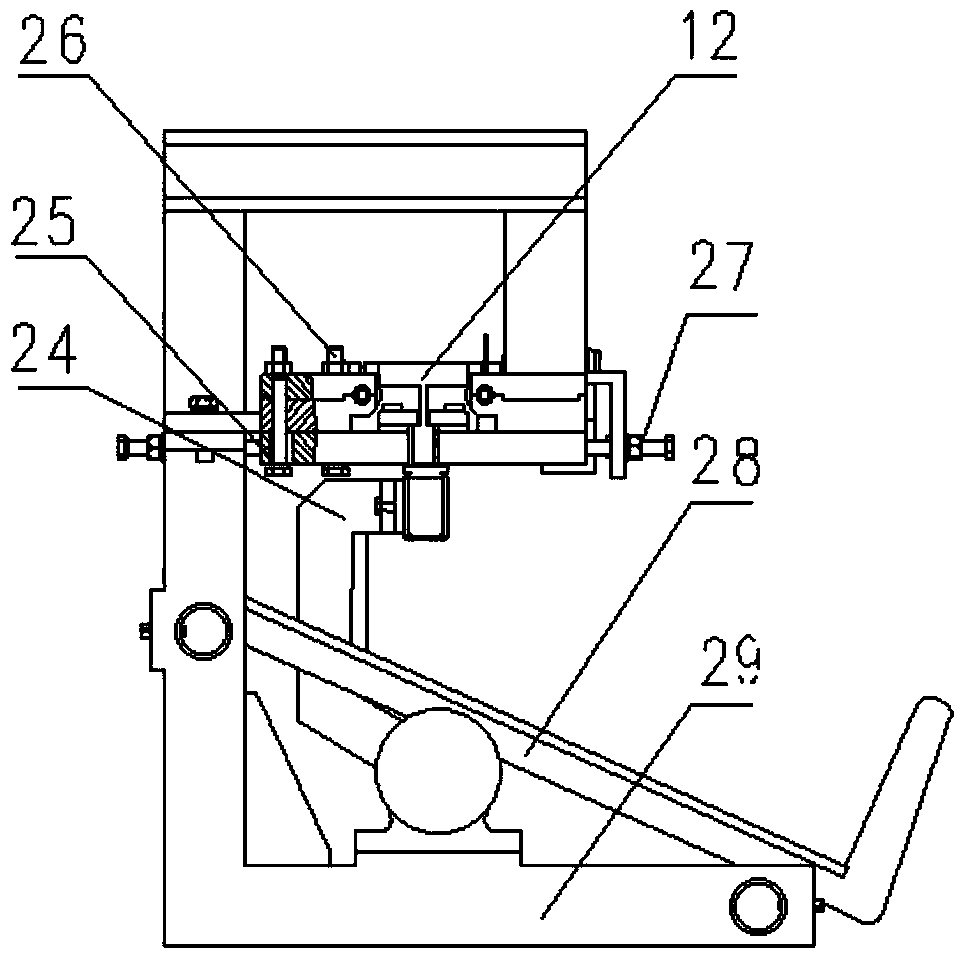

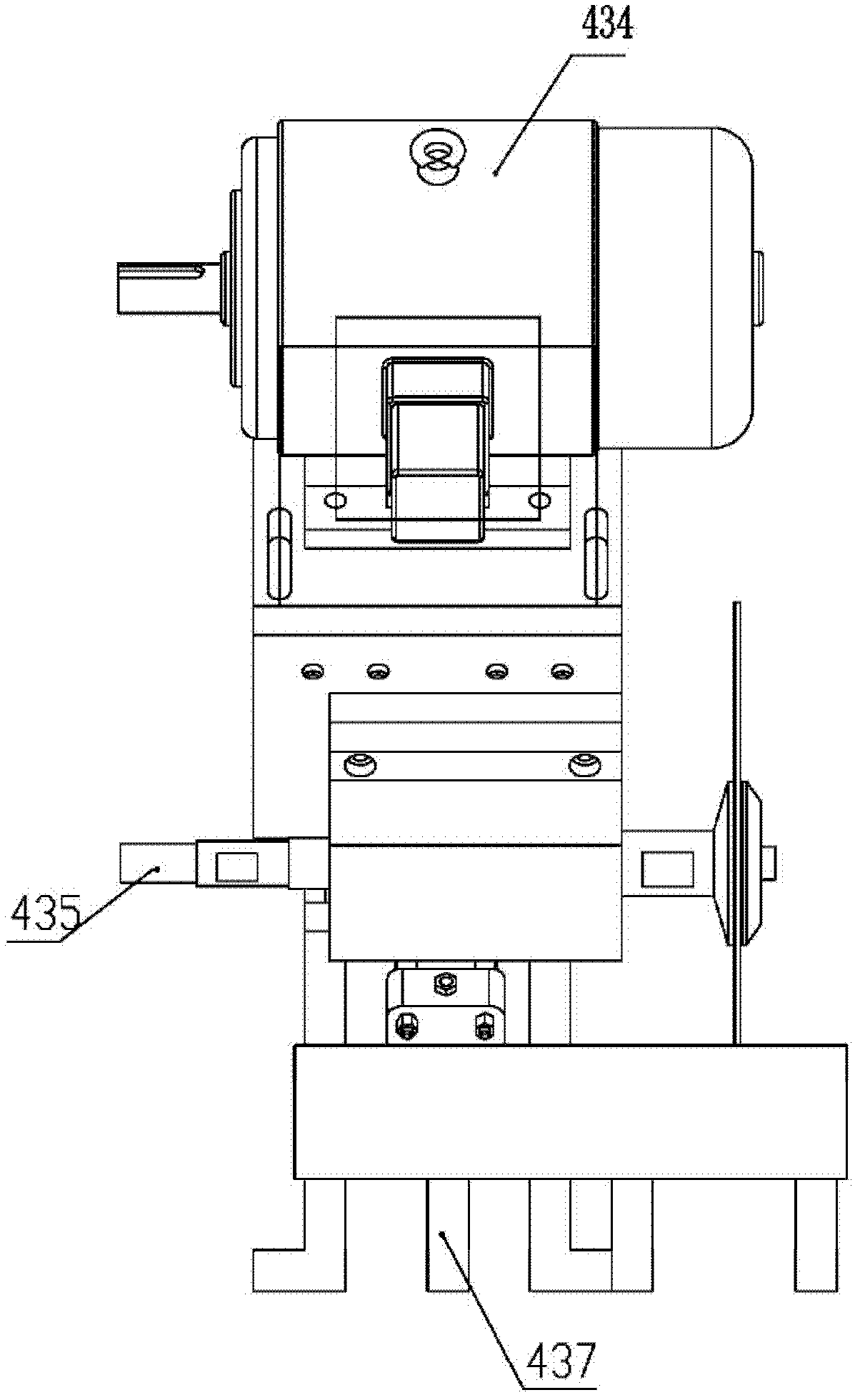

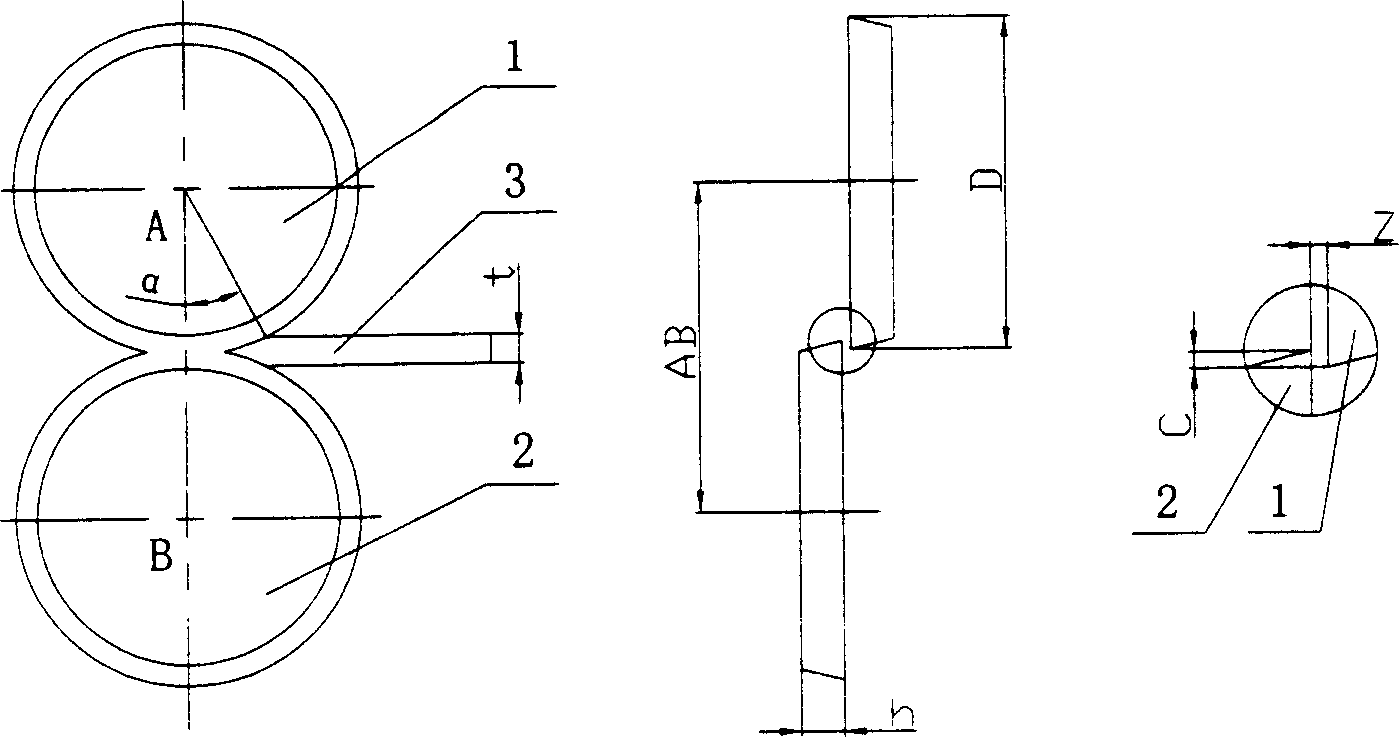

Device and method for adjusting gap of shear of disc shearing machine

InactiveCN101780562AStable structureFlexible and convenient operationShearing machinesShearing control devicesCircular discGear wheel

The invention discloses a device for adjusting a gap of a shear of a disc shearing machine, which comprises an upper shear shank with an upper shear shaft and a lower shear shank with a lower shear shaft, wherein a transmission gear I is mounted on the upper shear shaft, a transmission gear II is mounted on the lower shear shaft, the transmission gear I is meshed with the transmission gear II, the upper shear shank and the lower shear shank are connected through a first positioning pull rod and a second positioning pull rod, two adjusting devices I are mounted on the two positioning pull rod, and the adjusting devices II are mounted on the upper shear shank. The invention further discloses a method for adjusting the gap of the shear of the disc shearing machine, which comprises the steps of moving the upper shear shank along the first positioning pull rod and the second positioning pull rod for adjusting the lateral gap between an upper shear and a lower shear and / or rotating the upper shear shank around the first positioning pull rod for adjusting the overlap of the upper shear and the lower shear. The structure of the adjusting device is simple, and the operation of the adjusting method is convenient and flexible, thereby being applicable to requirements of plates with different thicknesses, realizing high shearing precision and having no need of using special tools or detaching parts.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

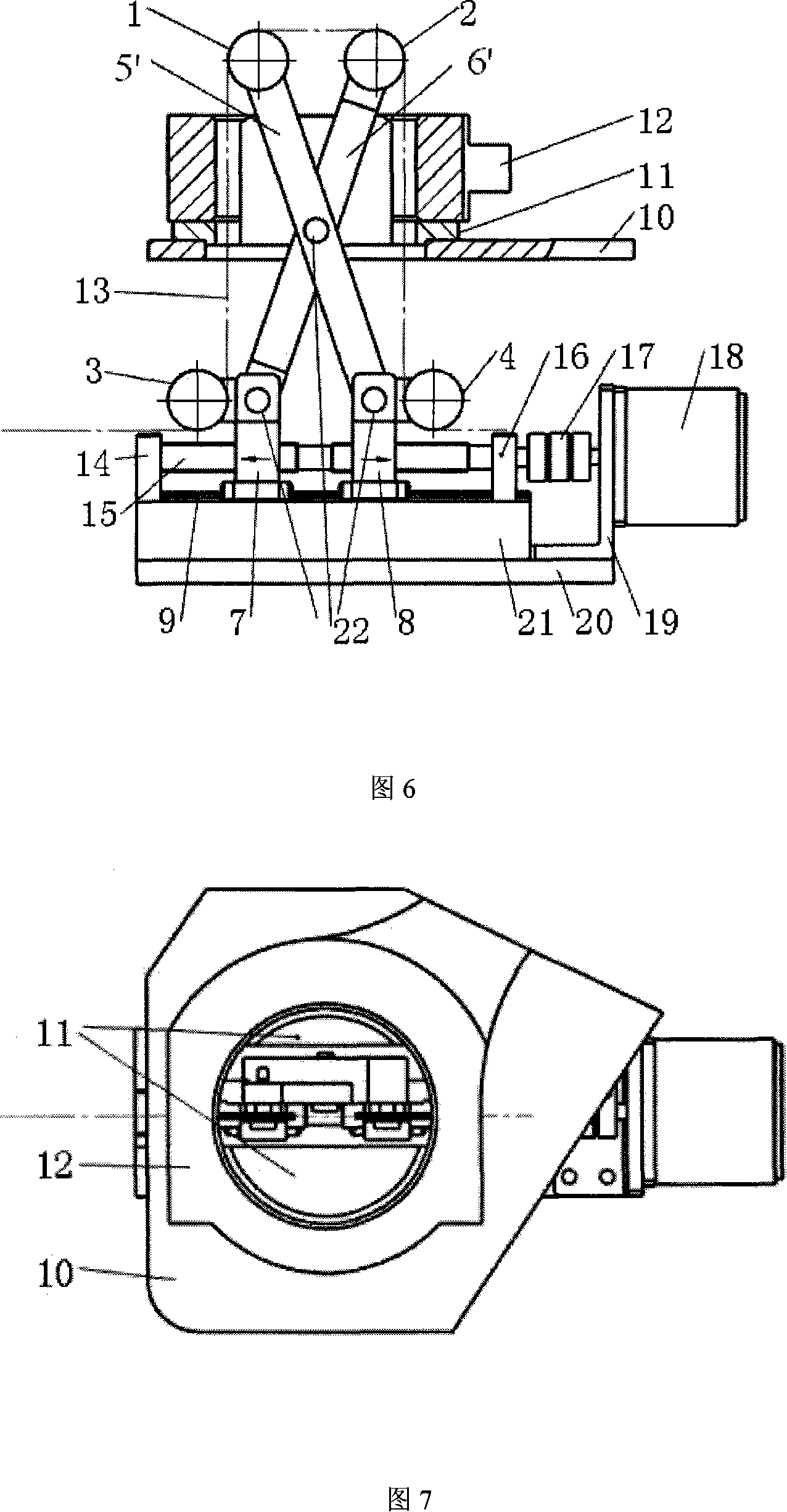

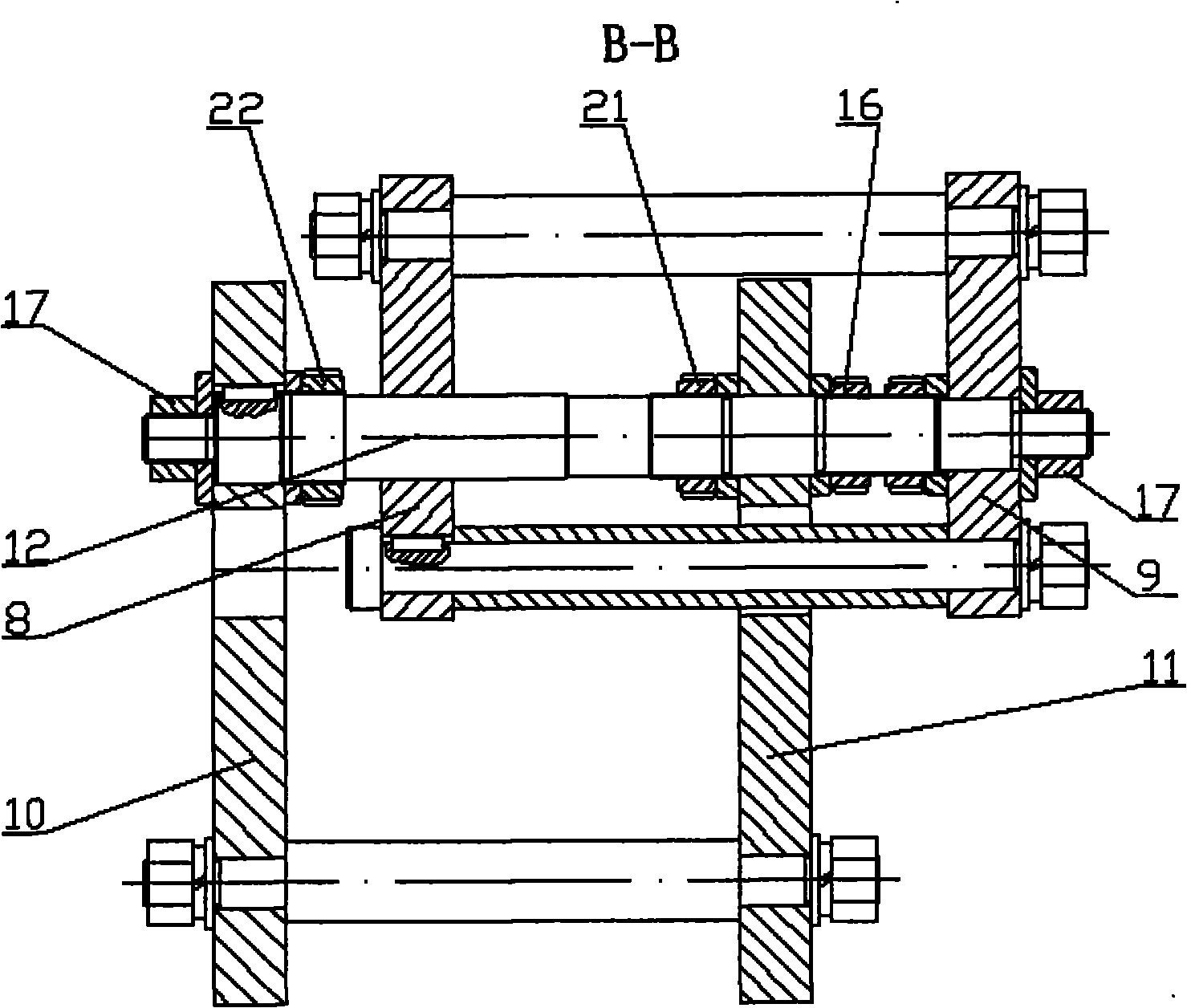

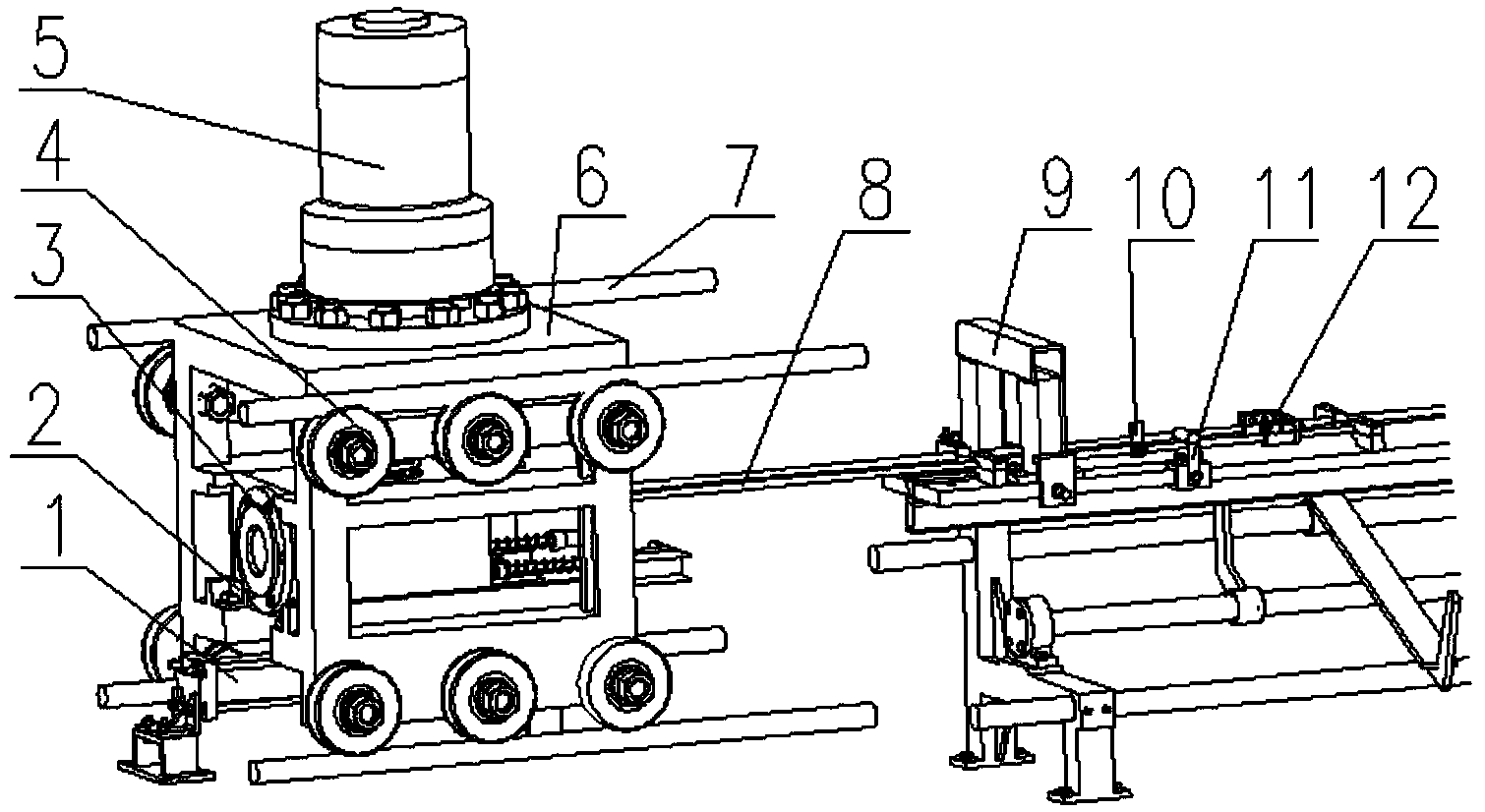

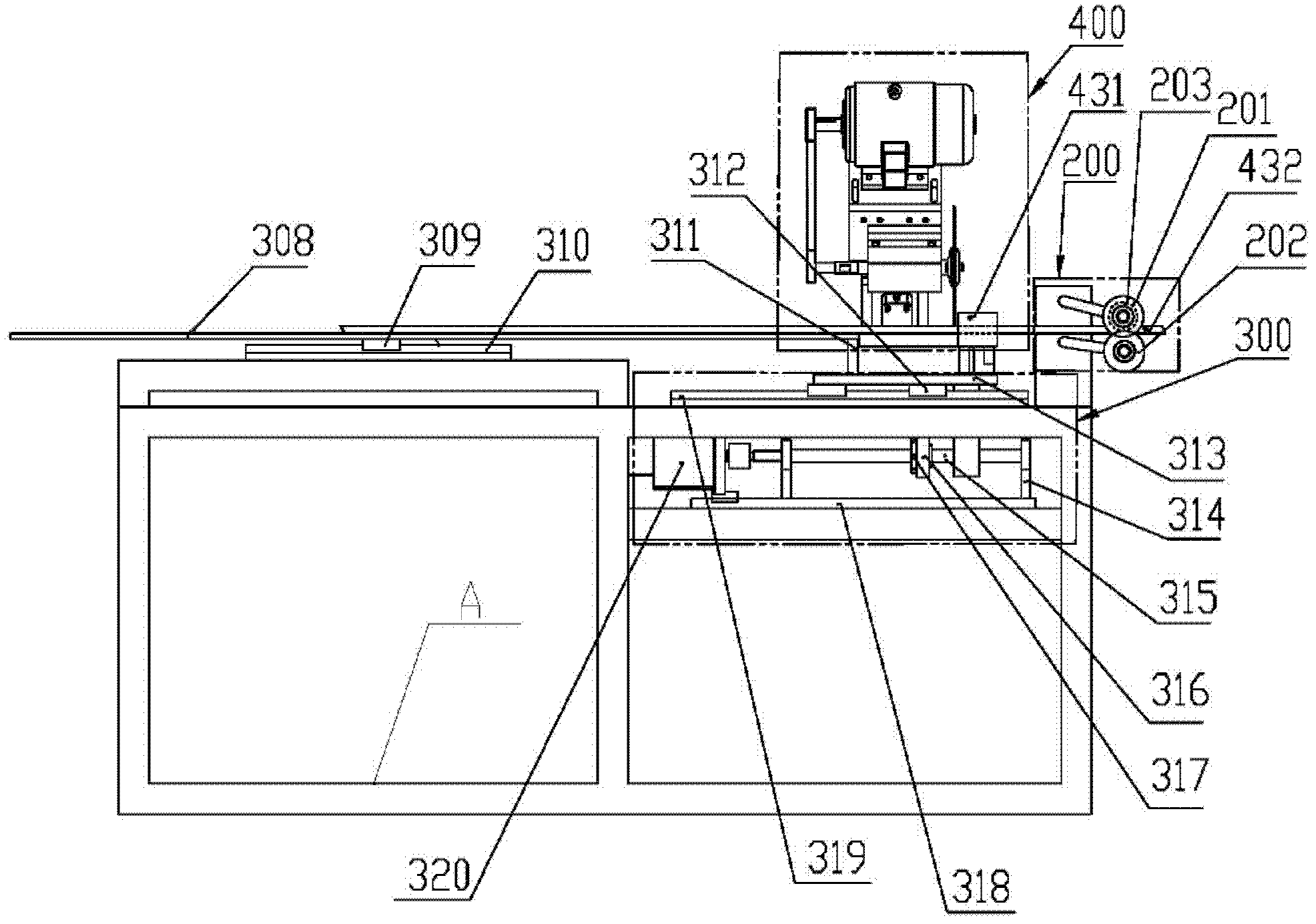

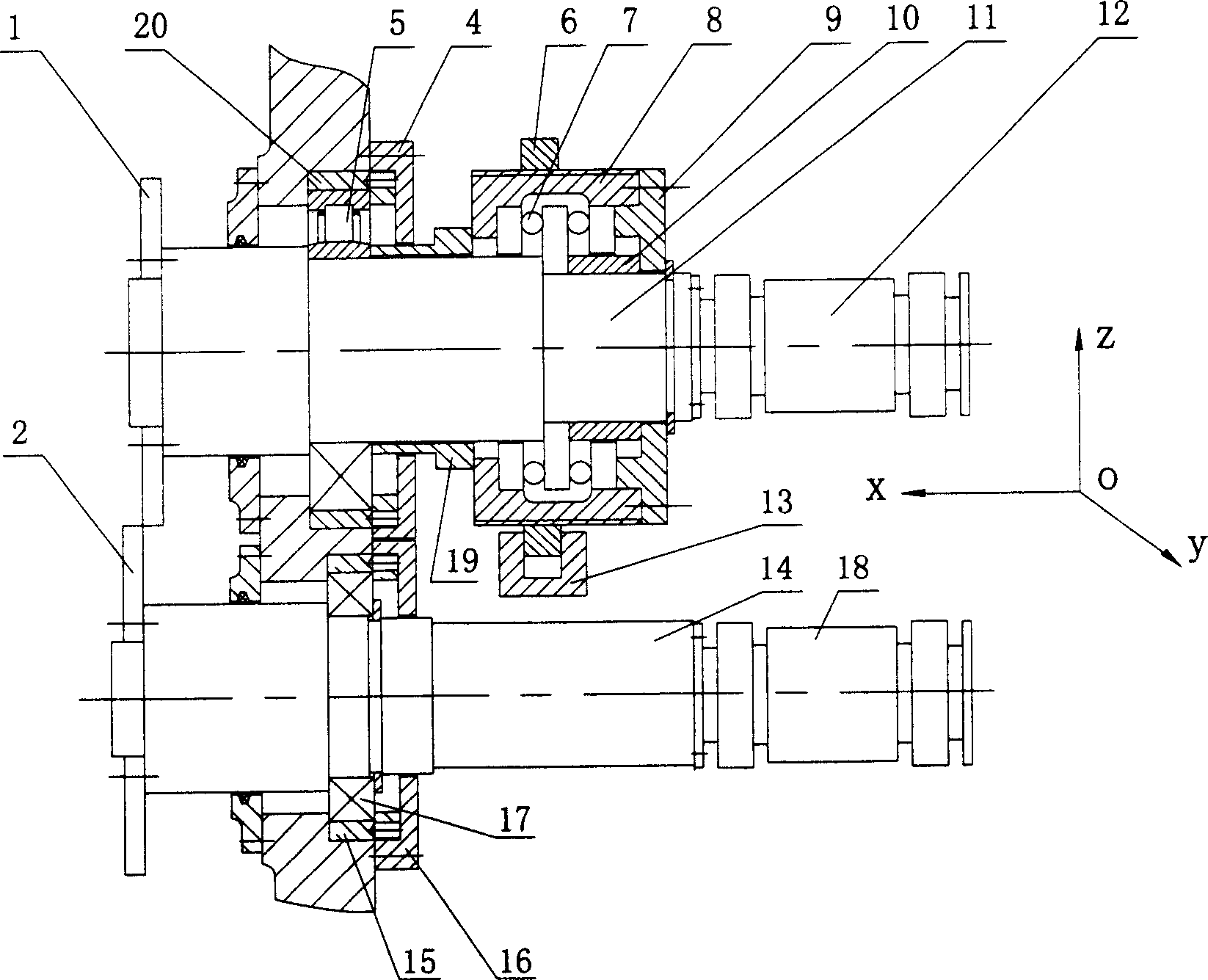

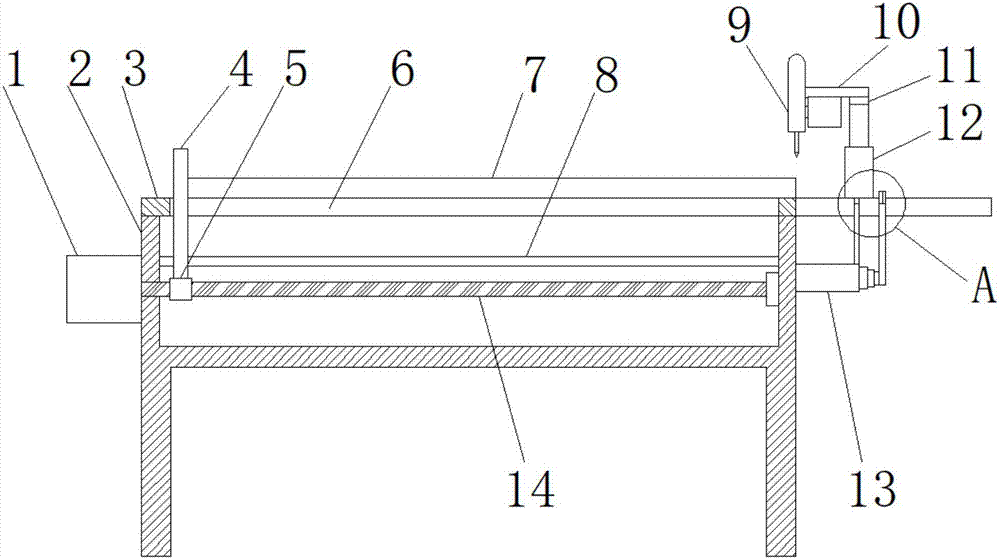

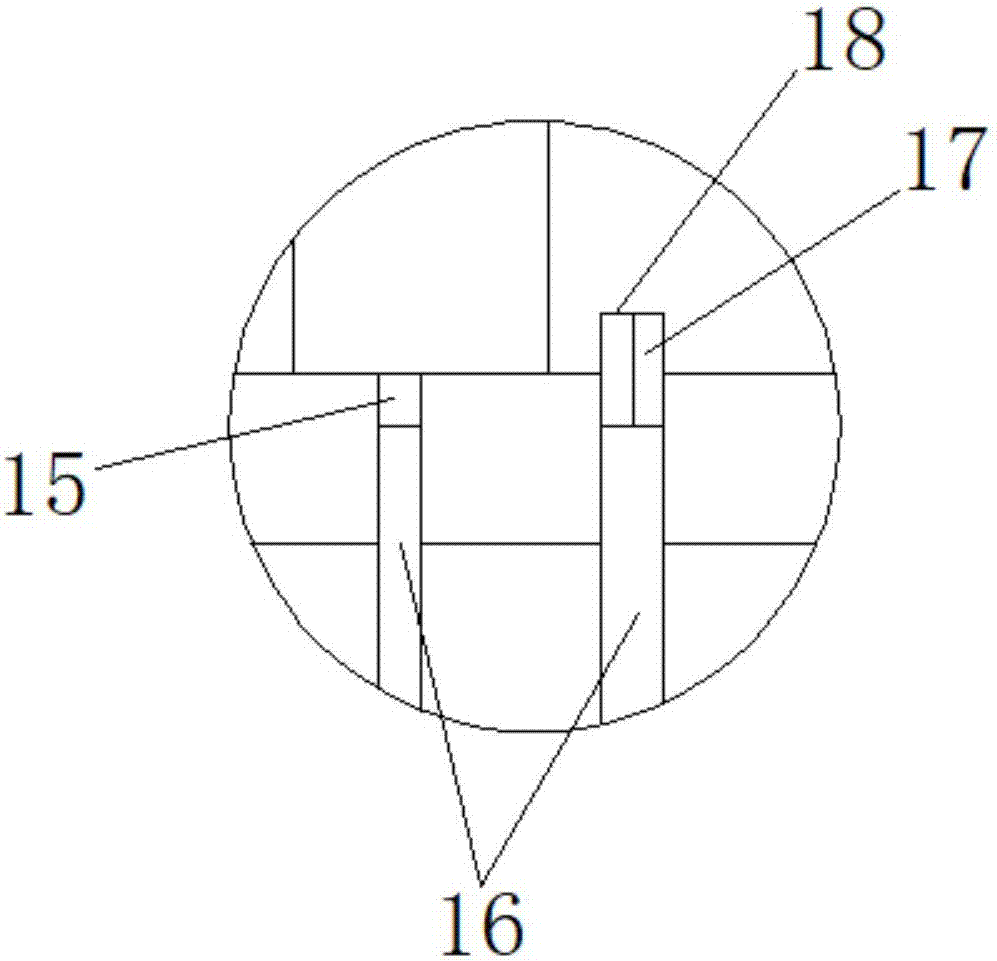

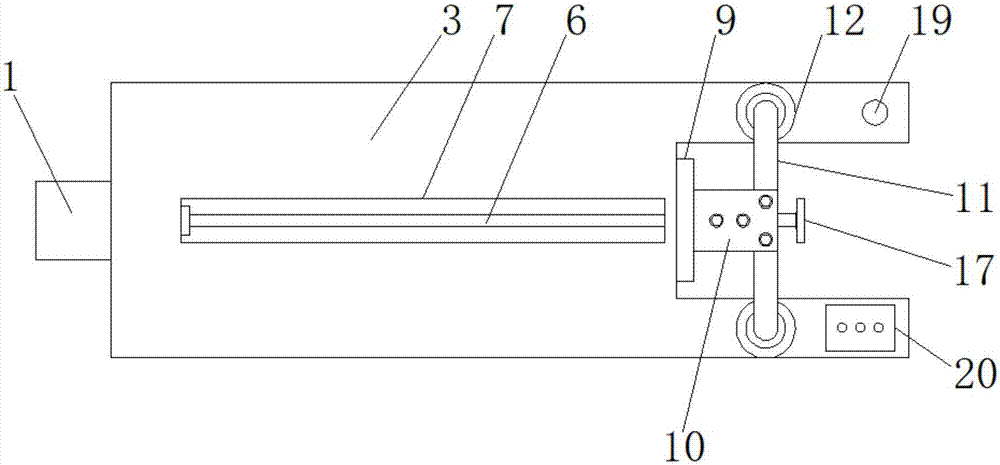

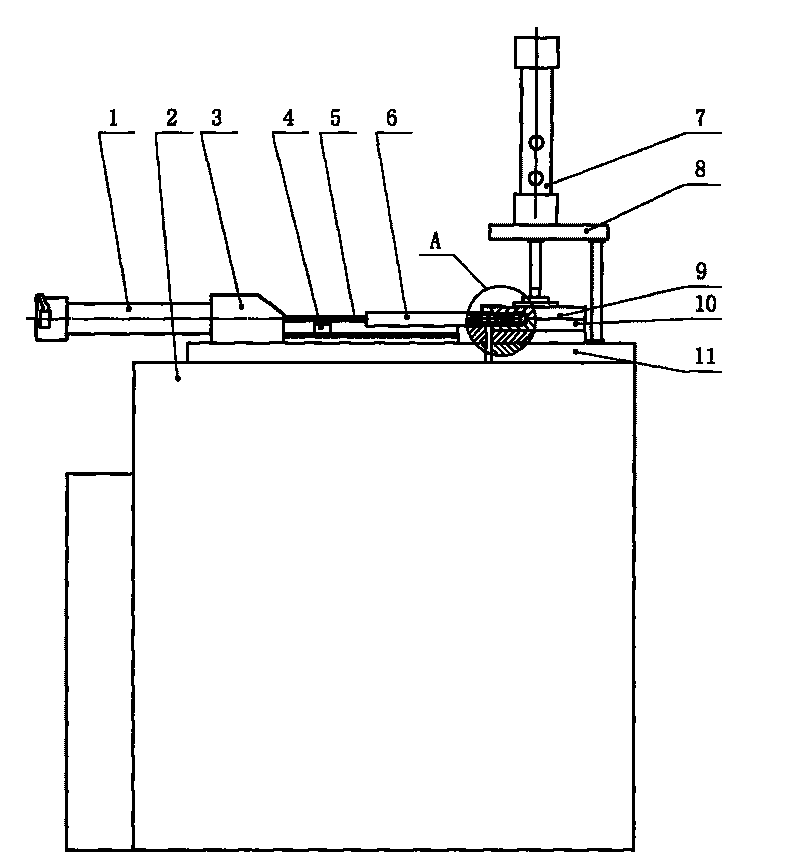

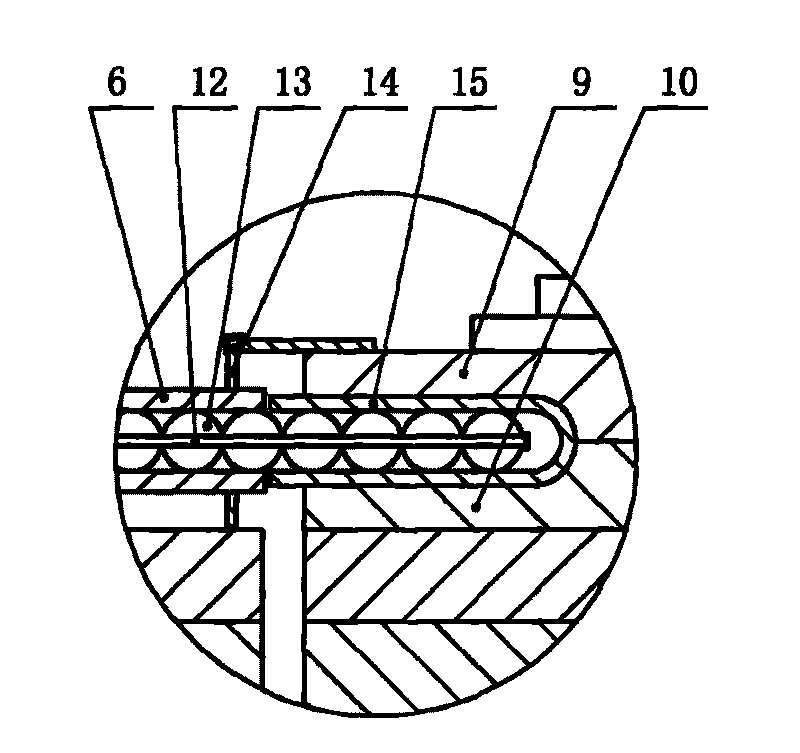

On-line servo cutting-to-length device for large-diameter PC steel bars

InactiveCN103801756AAddressed issue where length values were affected by control system response delaysImprove cutting accuracyStock shearing machinesShearing control devicesVehicle frameSteel bar

Provided is an on-line servo cutting-to-length device for large-diameter PC steel bars. According to the on-line servo cutting-to-length device for the large-diameter PC steel bars, two rows of guide wheels of a trolley frame are arranged between upper cylindrical guide rails and lower cylindrical guide rails, the front end of the trolley frame is connected with a servo air cylinder, a shearing mechanism is arranged in the middle of the trolley frame, one end of a tie bar is connected with the rear end of a square knife platform, and penetrates through a locating part of a fixed length baffle, the other end of the tie bar is located by a clamping part arranged on wide guide rails, a vertical plate in the middle of a T-shaped connecting plate of the fixed length baffle is arranged in a gap between the two wide guide rails, a touch panel is arranged on the portion, in front of the fixed length baffle, of the tie bar, a photoelectric switch is arranged on the portion, in front of the fixed length baffle, of one wide guide rail, an upper horizontal rod corresponding to the gap between the two wide guide rails is connected with the upper end of two identical crank arms through a horizontal revolute pair, the lower ends of the two crank arms are connected with a lower horizontal rod, and the two ends of the lower horizontal rod are arranged in bearing blocks of two material bearing frames respectively. According to the on-line servo cutting-to-length device for the large-diameter PC steel bars, operation is easy, production efficiency is high, and the quality of cross sections of the PC steel bars and the accuracy of the fixed length of the sheared bars are effectively improved.

Owner:YANSHAN UNIV

High-precision cutting machine

ActiveCN102350543AEasy to controlImprove flatnessMetal sawing devicesShearing control devicesProgrammable logic controllerControl system

The invention discloses a high-precision cutting machine, comprising a feeding device, a feeding speed detecting device, a material cutting device, a cutting device drive mechanism and a discharging device, wherein the feeding speed detecting device is used for acquiring the running speed data of a material and transmitting the running speed data to a main control system; and the main control system is used for controlling the cutting device to synchronously advance at the speed identical to the running speed of the material along a direction consistent to the advancing direction of the material while controlling the cutting device to perform cutting. In the cutting machine disclosed by the invention, an encoder is used for acquiring the running speed of the material and sending out pulse signals, a PLC (Programmable Logic Controller) is used for extracting the pulse signals of the encoder and performing accumulation operation on the pulse signals, when an accumulated value reaches a set value inside the PLC, a cutting length for the material is indicated to be reached, and the PLC sends out a cutting instruction, so that a cutting position during each cutting is accurately controlled; in addition, a cutting tool advances synchronously with the material during cutting, so that the cutting position does not change relatively, and the precision of the cutting length can reach + / -0.5mm.

Owner:ZHEJIANG XINGYU AUTO PARTS CO LTD

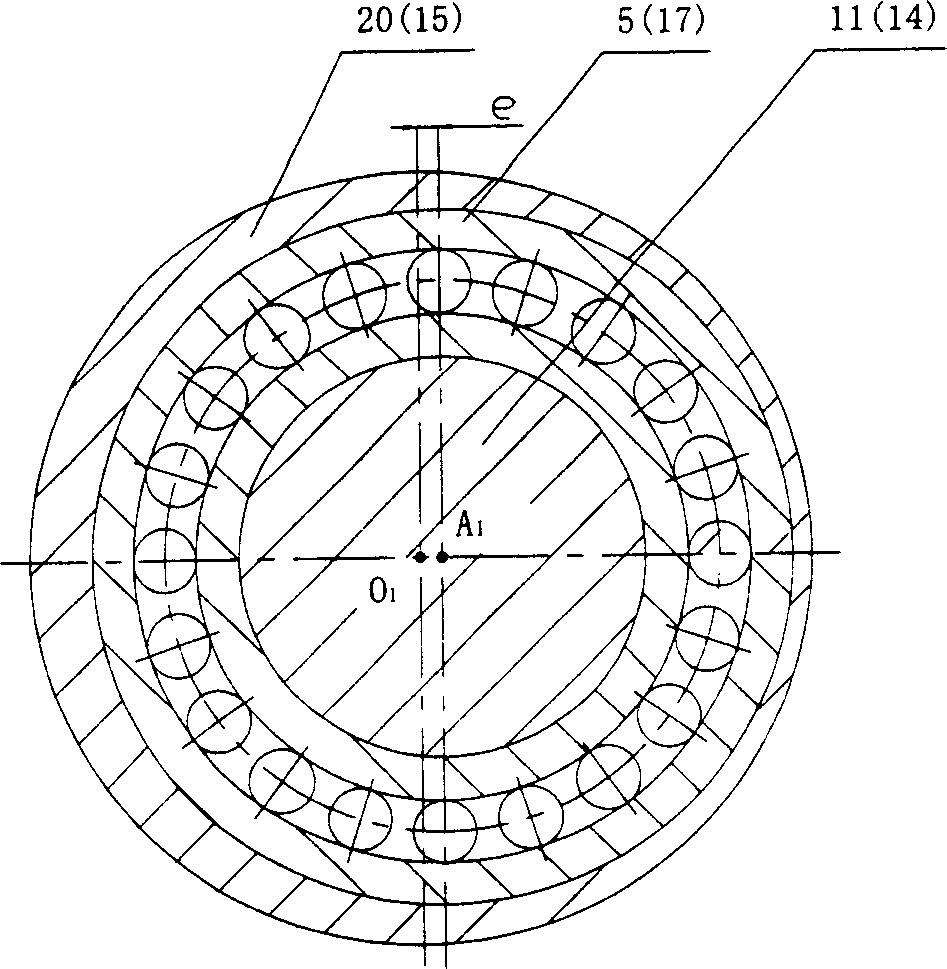

Apparatus and method for adjusting shears gap for circle shearing machine

InactiveCN1850408AEasy to adjustAdjust steplessShearing machinesShearing control devicesCircular discEngineering

The present invention discloses a device for regulating shears gap of disk shearing machine. It is characterized by that on two shear shafts respectively are connected an eccentric cover mechanism for regulating shear radial gap, in which on one shear shaft is connected a screw mechanism for regulating shears axial gap. Besides, said invention also provides the concrete steps of its regulation method.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

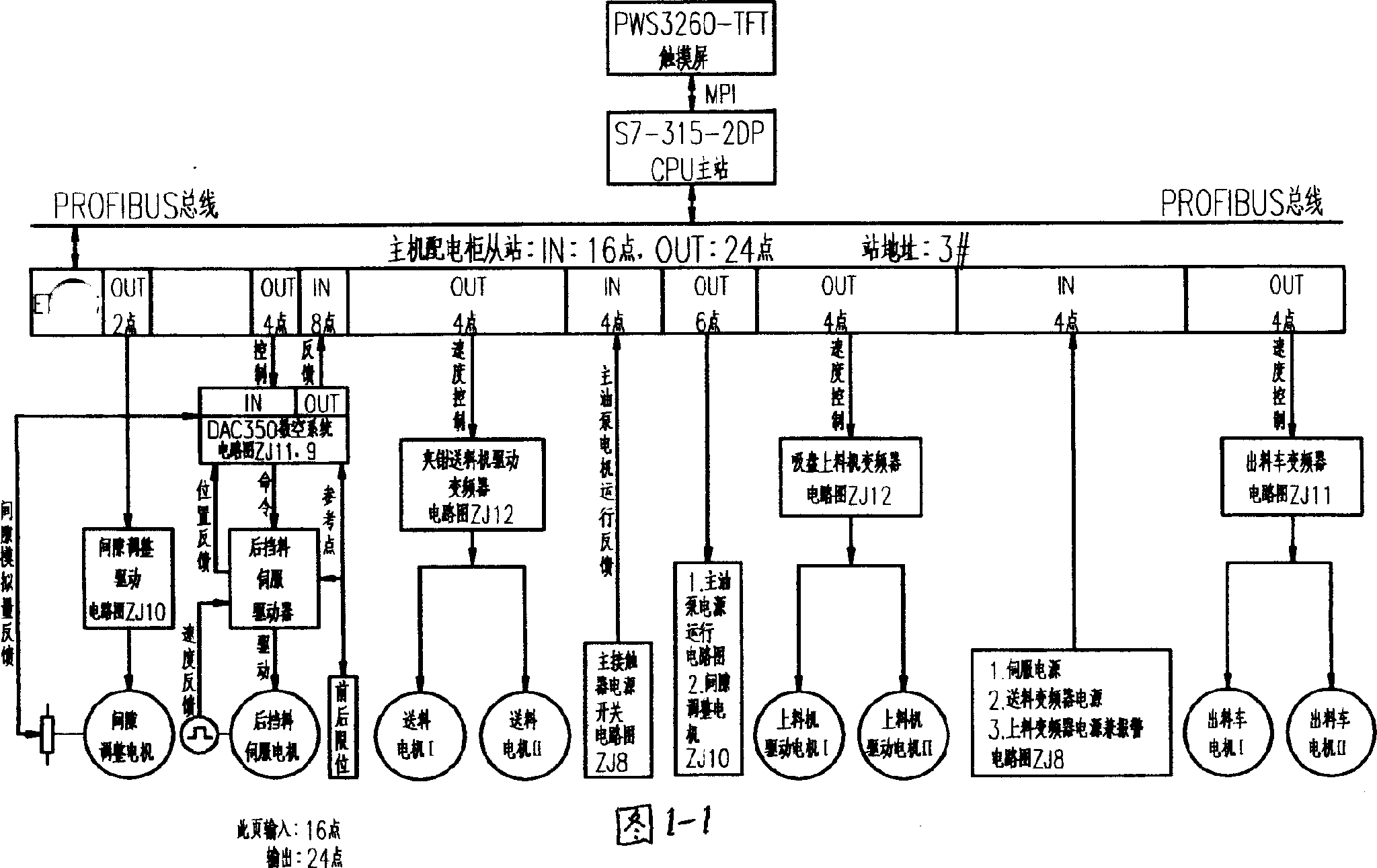

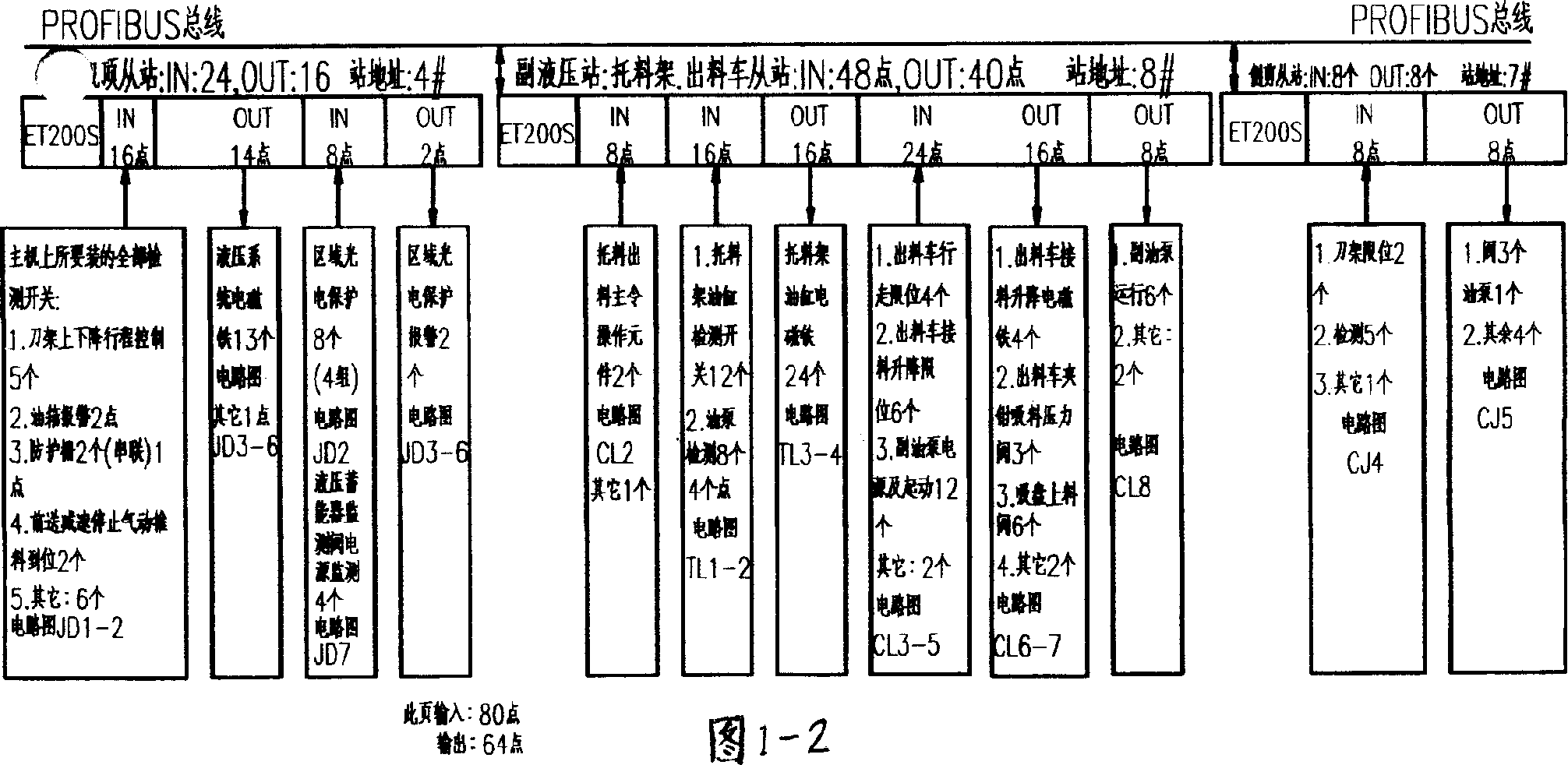

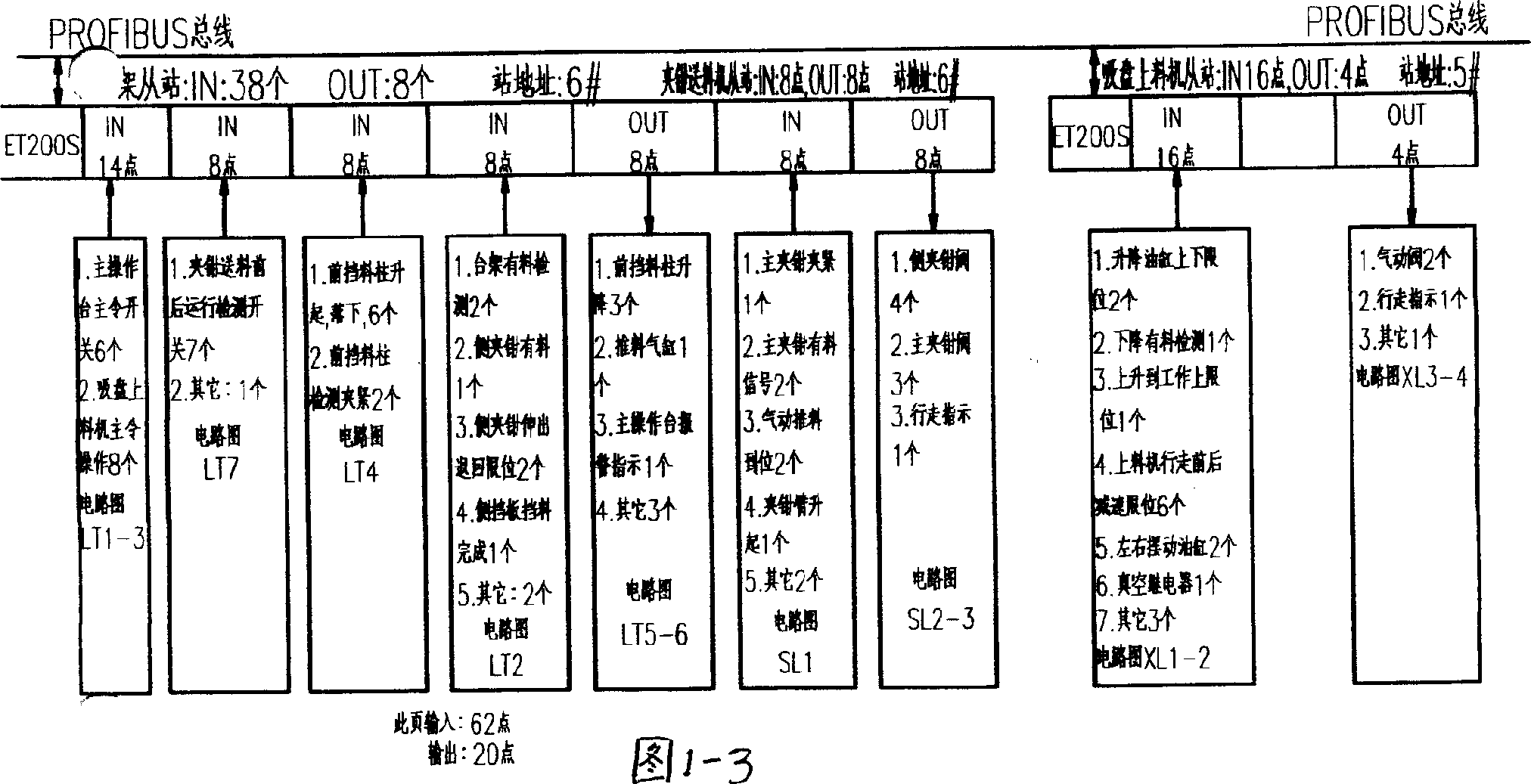

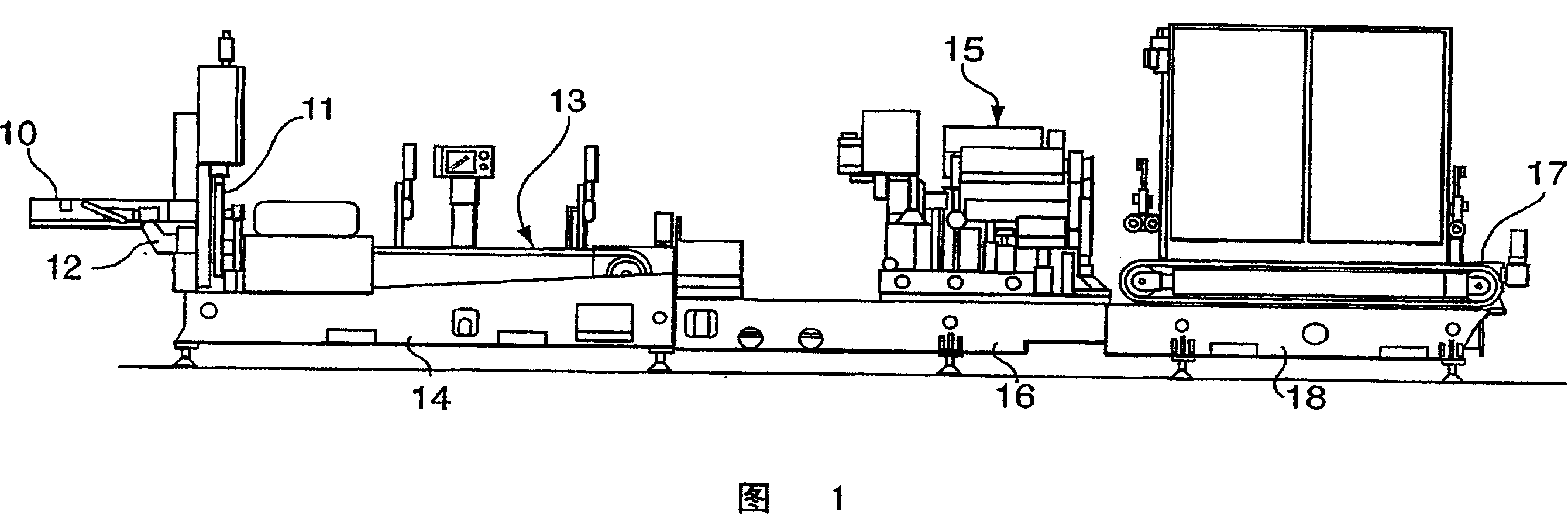

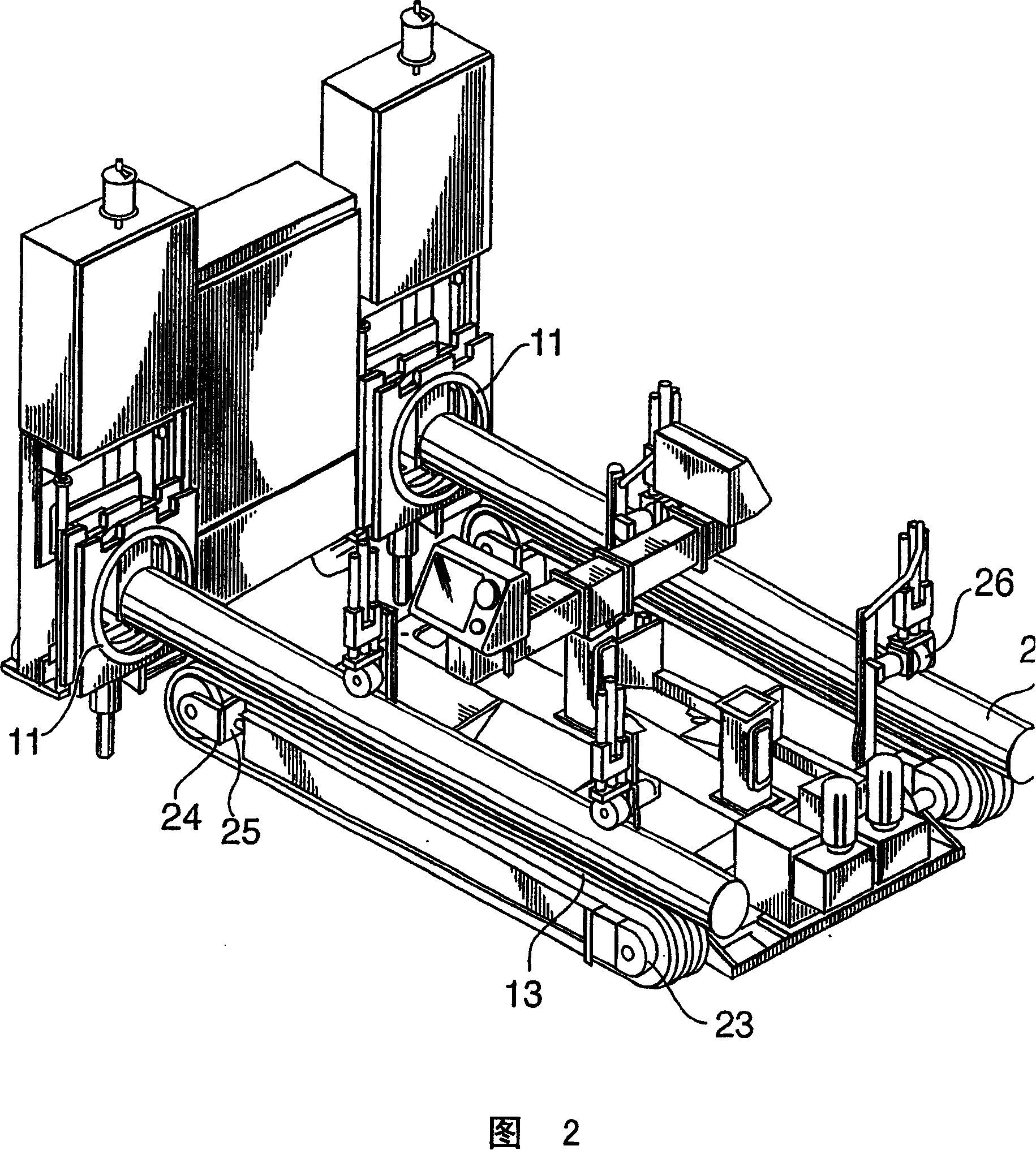

Fully-automatic plate-cutting apparatus

InactiveCN101024254AFully automaticFriendly man-machine interfaceShearing machinesTotal factory controlFrequency changerHuman–machine interface

The invention relates to full automatic sheet material shearing mechanism. It is formed by eights sets of machine tools and measurement control systems. The latter is DAC-350 numerical control system, combines with Siemens PLC and Profibus-DP bussing technique, touch screen human-machine interface, bus transducer hanging connecting control, position transducer hanging connecting control to realize full automatic unmanned operation. It has friend human-machine interface, self-diagnosis function, operation guiding, and real time operation help function.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

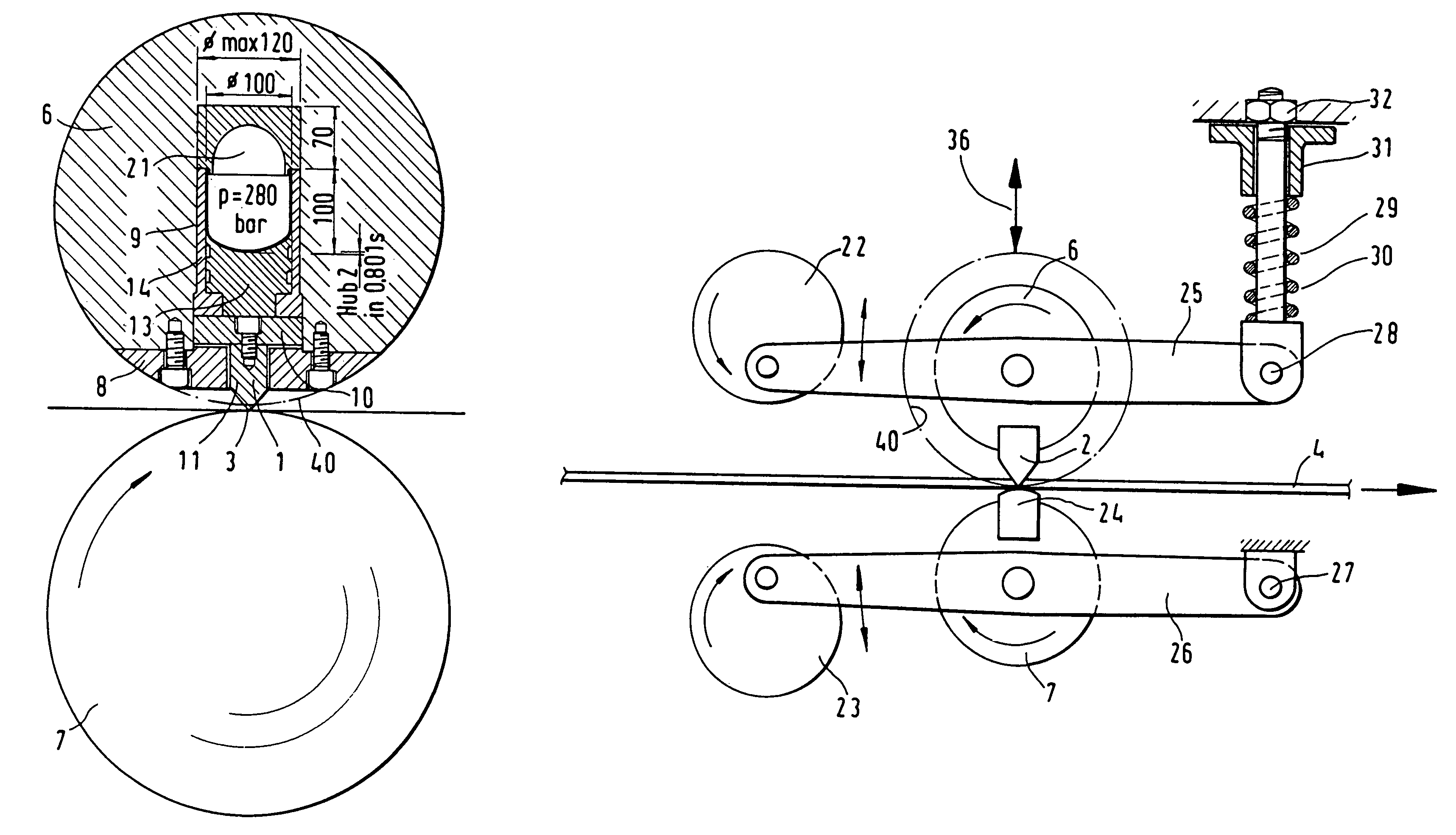

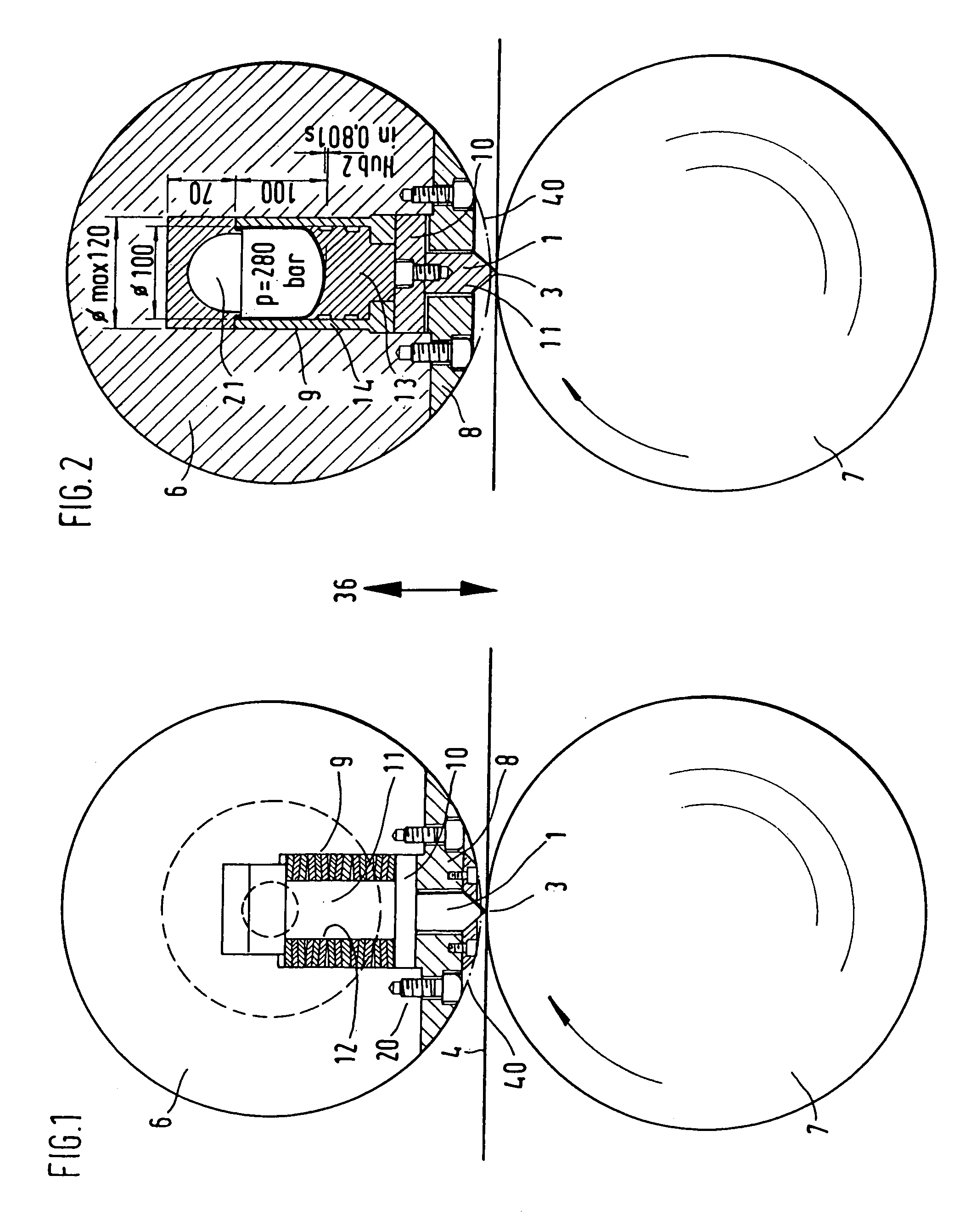

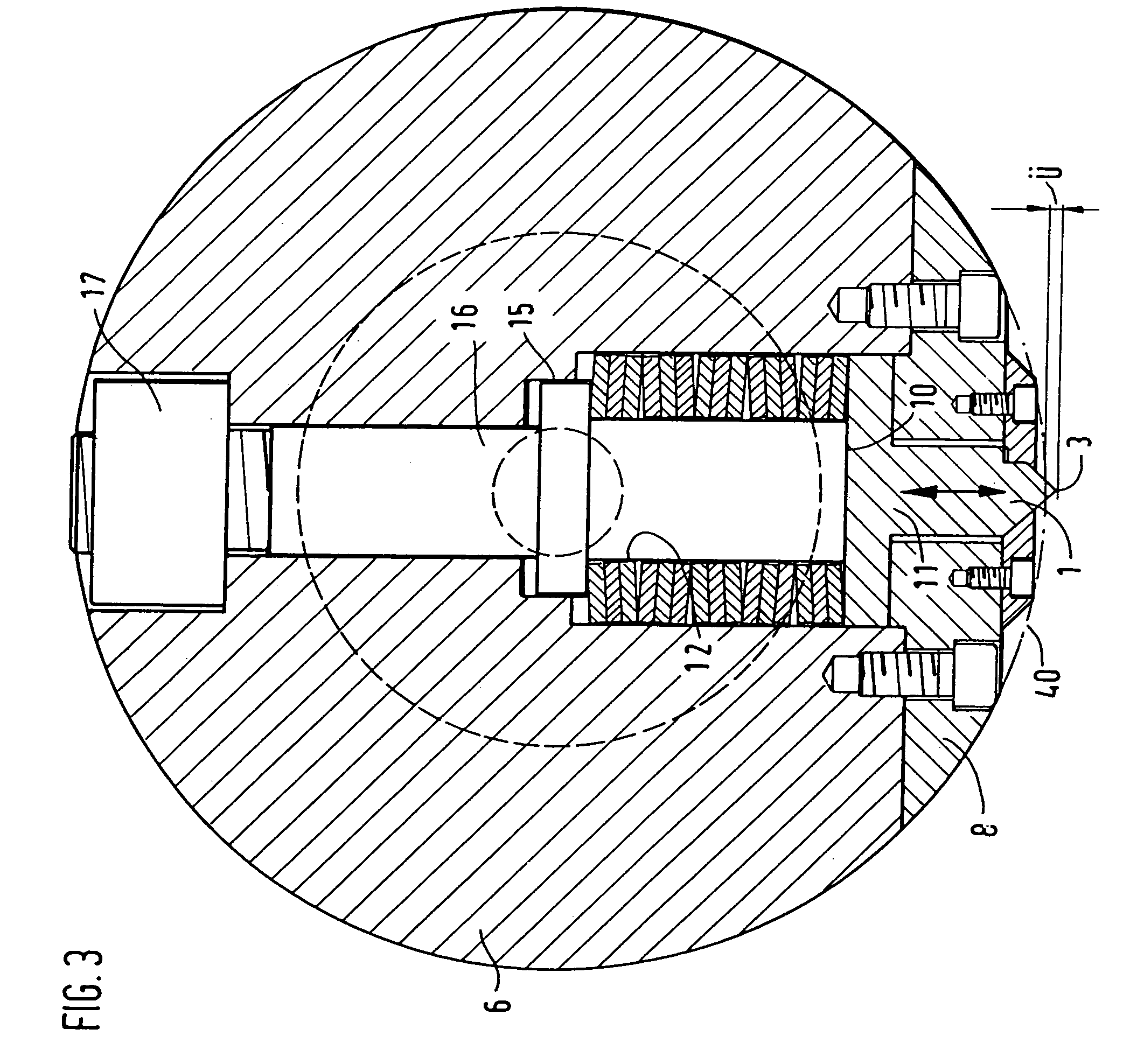

High-speed shear for transversely cutting rolled strip

InactiveUS7107891B2Avoid OverloadingSafely avoidedStock shearing machinesMetal working apparatusChiselEngineering

A high-speed shear with a knife, particularly a chisel-type knife with a knife edge, arranged on at least one of two oppositely arranged drums, wherein the knife can be accelerated to the feeding speed of the rolled strip and the drums can be adjusted relative to each other for carrying out a cut. At least one drive unit provided for the drums serves to accelerate the drums to the speed of the rolled strip to be cut and at least one of the drums may be provided with a separately controllable adjusting device. The chisel-type knife of the knife drum is mounted so as to protrude from the cutting circle towards the anvil or the surface portion of the second drum acting as an anvil and to mount the chisel-type knife of the knife drum so as to be resiliently supported against a predetermined restoring force.

Owner:SMS SCHLOEMANN SIEMAG AG

Cutting device for machining

InactiveCN107398588AImprove cutting efficiencyMeasurement/indication equipmentsMetal working apparatusSwitch boxPulp and paper industry

The invention discloses a cutting device for mechanical processing, which comprises a frame and a working table. The output shaft of the screw motor, the screw is screwed with a slider, the slider is welded and fixed with a push plate, one end of the work surface is fixedly connected with the bottom end of the electric telescopic rod, and the electric telescopic rod The top of the top is fixedly connected with a fixed rod by a bolt, and the fixed rod is connected with a fixed plate by a screw, and the cutting machine body is installed on the fixed plate by a screw, and a measuring rod is installed on the frame directly below the cutting machine body. An indicator light and a switch box are also installed on the worktable. In the invention, a single person can complete the fixed-length measuring and cutting work, which improves the cutting efficiency.

Owner:安陆市昌明粮食机械股份有限公司

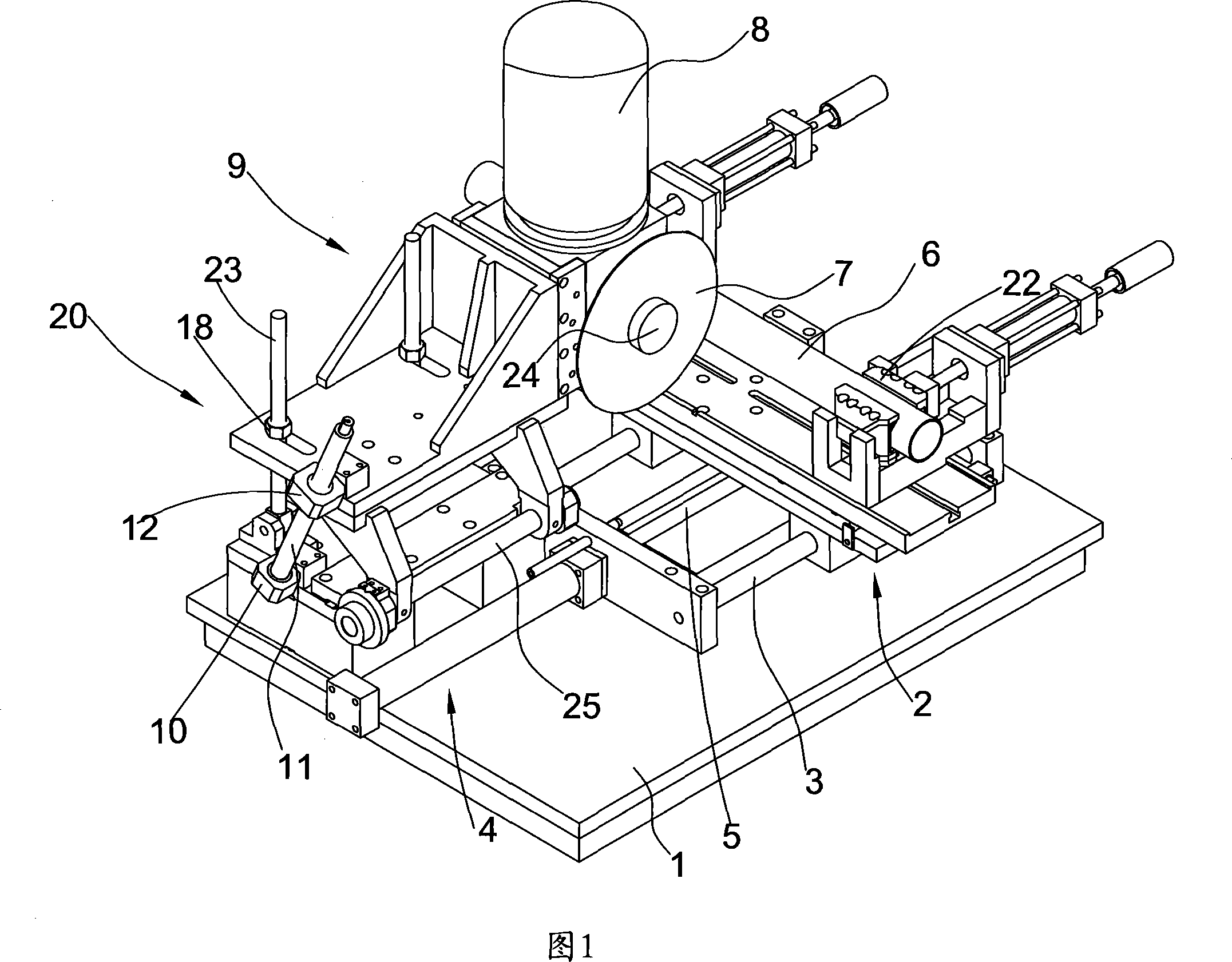

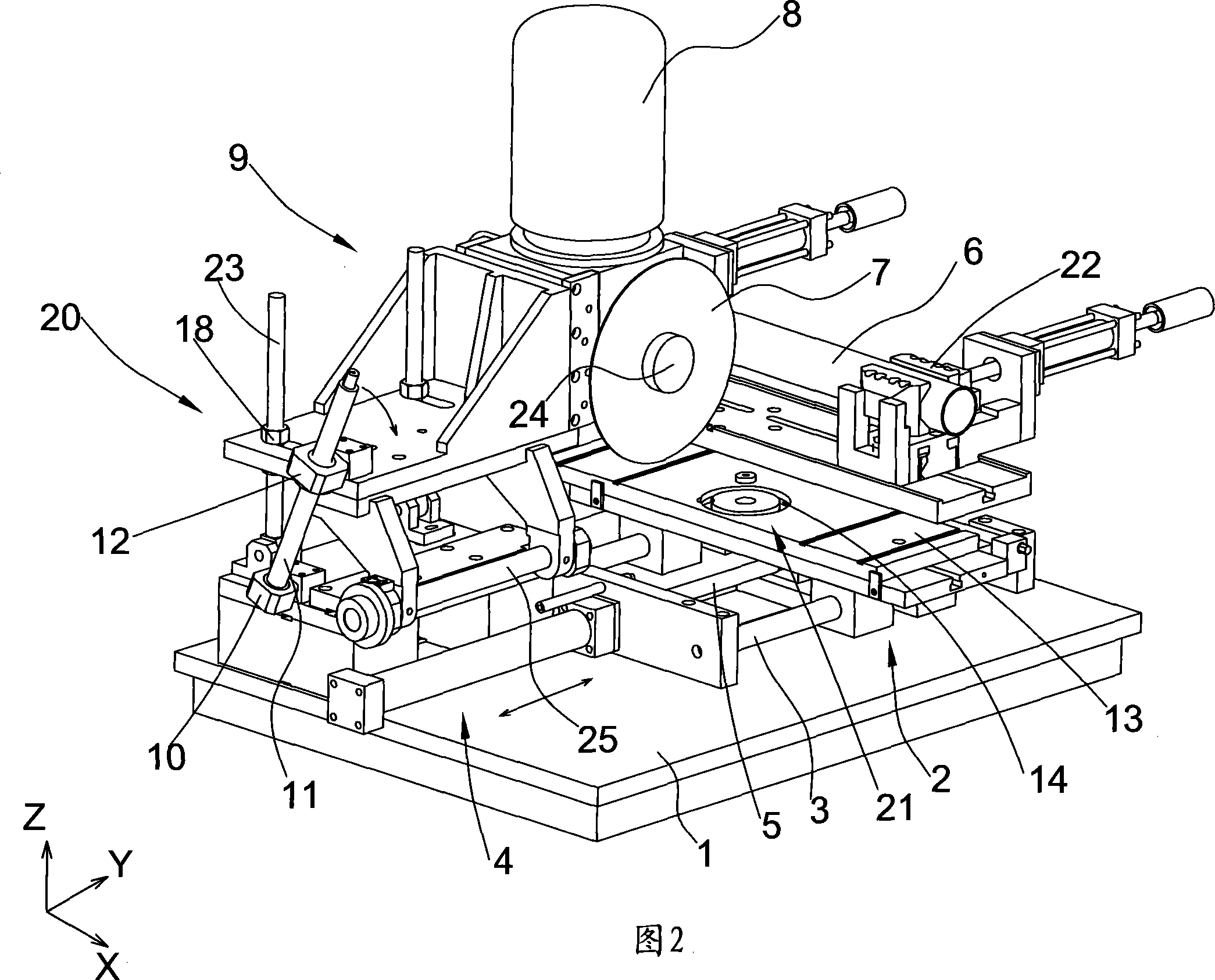

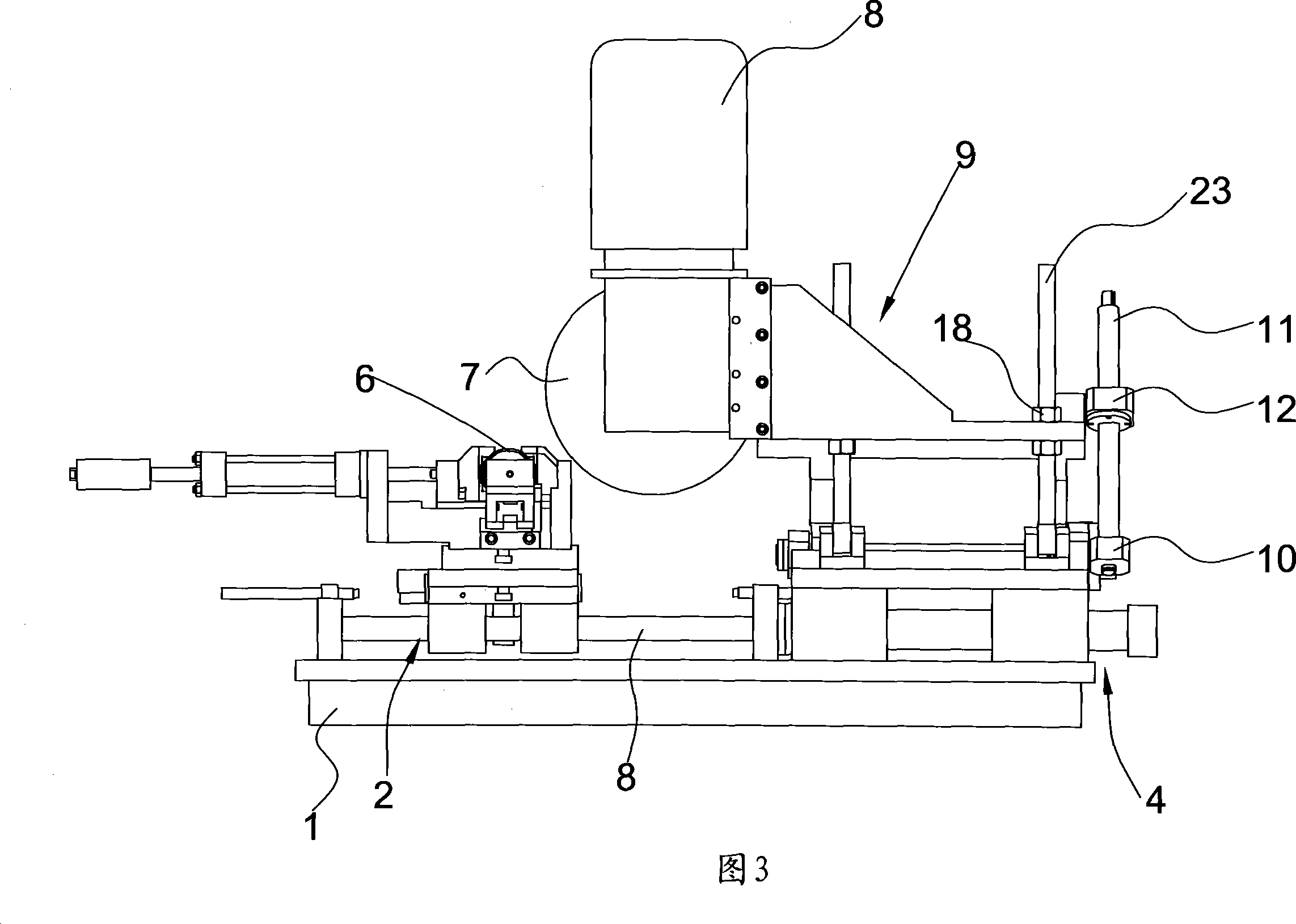

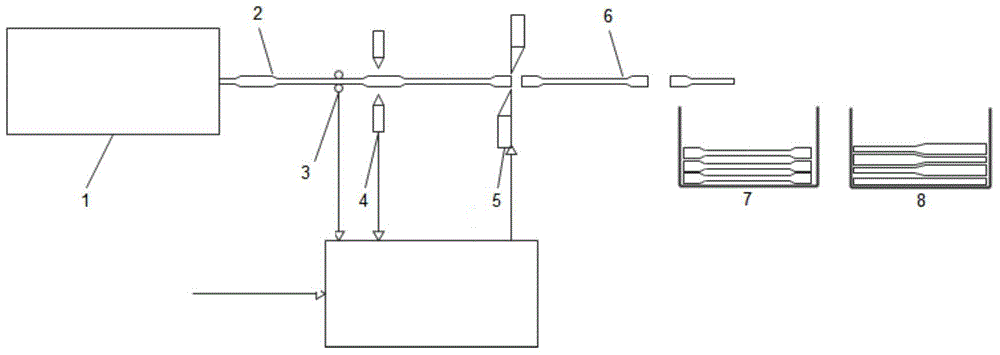

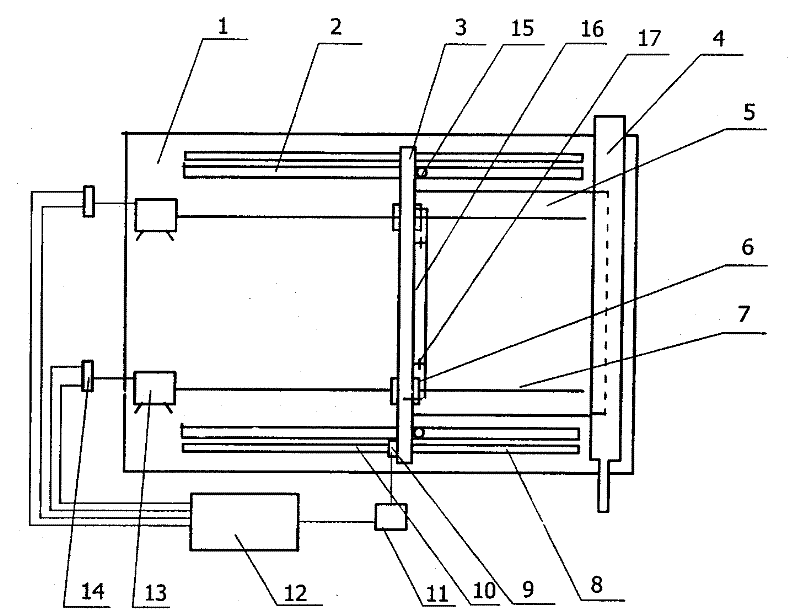

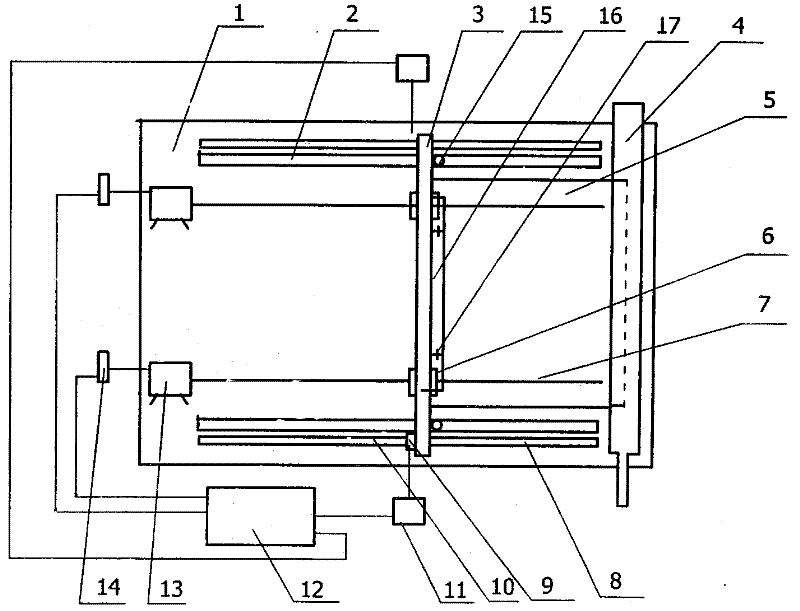

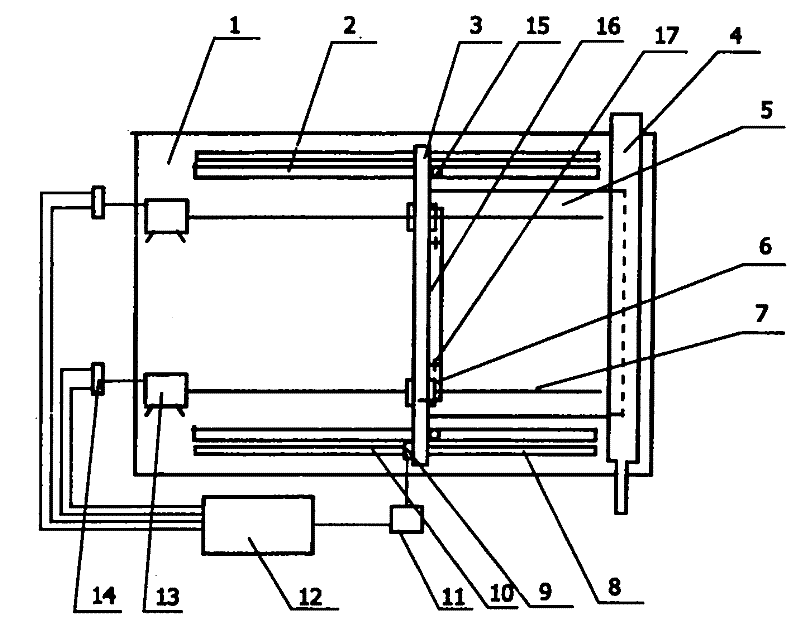

Automatic shearing device for cold-rolled variable-thickness plates and shearing method based on automatic shearing device

ActiveCN106270718AEfficient and precise cuttingMeasurement/indication equipmentsShearing machinesVariable thicknessEngineering

The invention discloses an automatic shearing method for variable-thickness plates by means of an automatic shearing device for the cold-rolled variable-thickness plates. The automatic shearing method comprises the following steps that a thickness tester is arranged in front of a shear, a length tester is arranged in front of the thickness tester, and a control device recognizes the profiles of strips passing through the thickness tester and judges the positions of the strips at the shear according to length tracking data and measured thickness values, and compares the profiles with set profiles of the continuously-variable-thickness plates at the same time so as to determine the action time of the shear; and meanwhile, the control device further judges whether the profiles of sheared-off plates are qualified or not, so that whether the sheared-off plates are stacked into a finished product stack or a waste stack is determined. The automatic shearing method for the variable-thickness plates has the beneficial effect that the rolls of continuously-variable-thickness incoming materials can be efficiently and accurately sheared into the continuously-variable-thickness plates which can be directly used by users.

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic equal-diameter elbow roundness shaping and cutting all-in-one machine

InactiveCN101722418AAvoid breakingGood plastic effectMetal sawing devicesOther manufacturing equipments/toolsSteel ballEngineering

The invention relates to an automatic equal-diameter elbow roundness shaping and cutting all-in-one machine which comprises a main body, a worktable, an upper die plate, a lower die plate and a pressing die cylinder, wherein the worktable is horizontally and fixedly provided with a cylinder in the position corresponding to a port of an equal-diameter semicircular curved furrow composed of the upper die plate and the lower die plate; the tail end of the push rod of the cylinder is fixedly provided with a steel ball string threaded by a steel wire; and the worktable is fixedly provided with a guiding cylinder in which the steel ball string slides; an elevating sawtooth disk is longitudinally arranged in the main body; the lengthwise position of the sawtooth disk corresponds to the port of the equal-diameter semicircular curved furrow composed of the upper die plate and the lower die plate of the worktable; and the worktable is provided with a cutting passage corresponding to the position of the sawtooth disk. The invention has high automation level, integrates the roundness shaping with the end processing allowance cutting, has the advantages of short consumed time for shaping and processing, high working efficiency, high working accuracy, good product quality, conforms to the requirement for product shape roundness, and is suitable for industrial mass production of horn instrument equal-diameter elbows.

Owner:TIANJIN JINBAO MUSICAL INSTR

Blanking line using slitter as feeder

A blanking line including an uncoiler, a first feeder, a slitter, and a shear. A coil of metal is carried by the uncoiler. The first feeder removes the material from the coil and typically includes a leveler for leveling the metal. The metal is fed from the leveler into a looping pit that is located between the leveler and slitter. The slitter feeds and slits the material a predetermined distance and is driven with servo motors. The looping pit acts as an accumulator allowing the metal to hang so the slitter can move metal intermittently into a shear while the leveler runs at a constant rate. The shear cuts the material to a predetermined length corresponding with the distance that the material is fed by the slitter. A measuring wheel may be included to measure the distance that the material is moved by the slitter.

Owner:BRANER USA

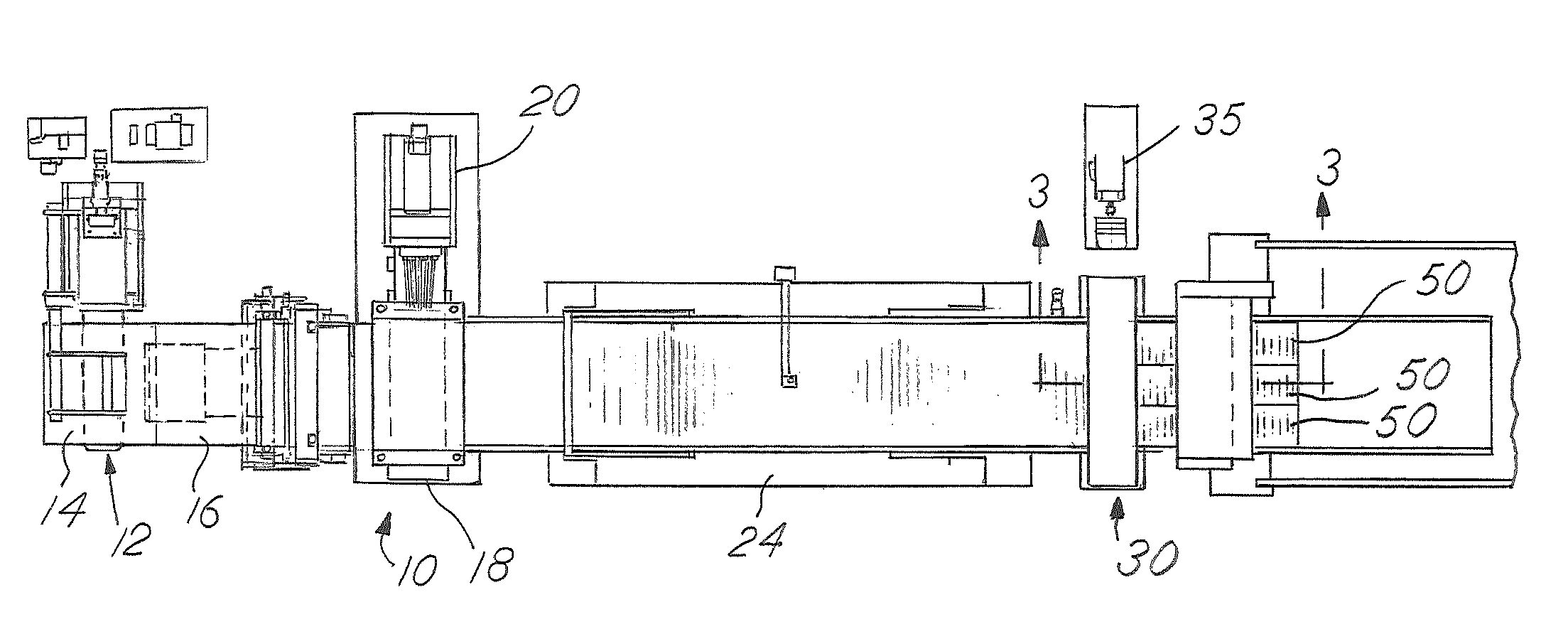

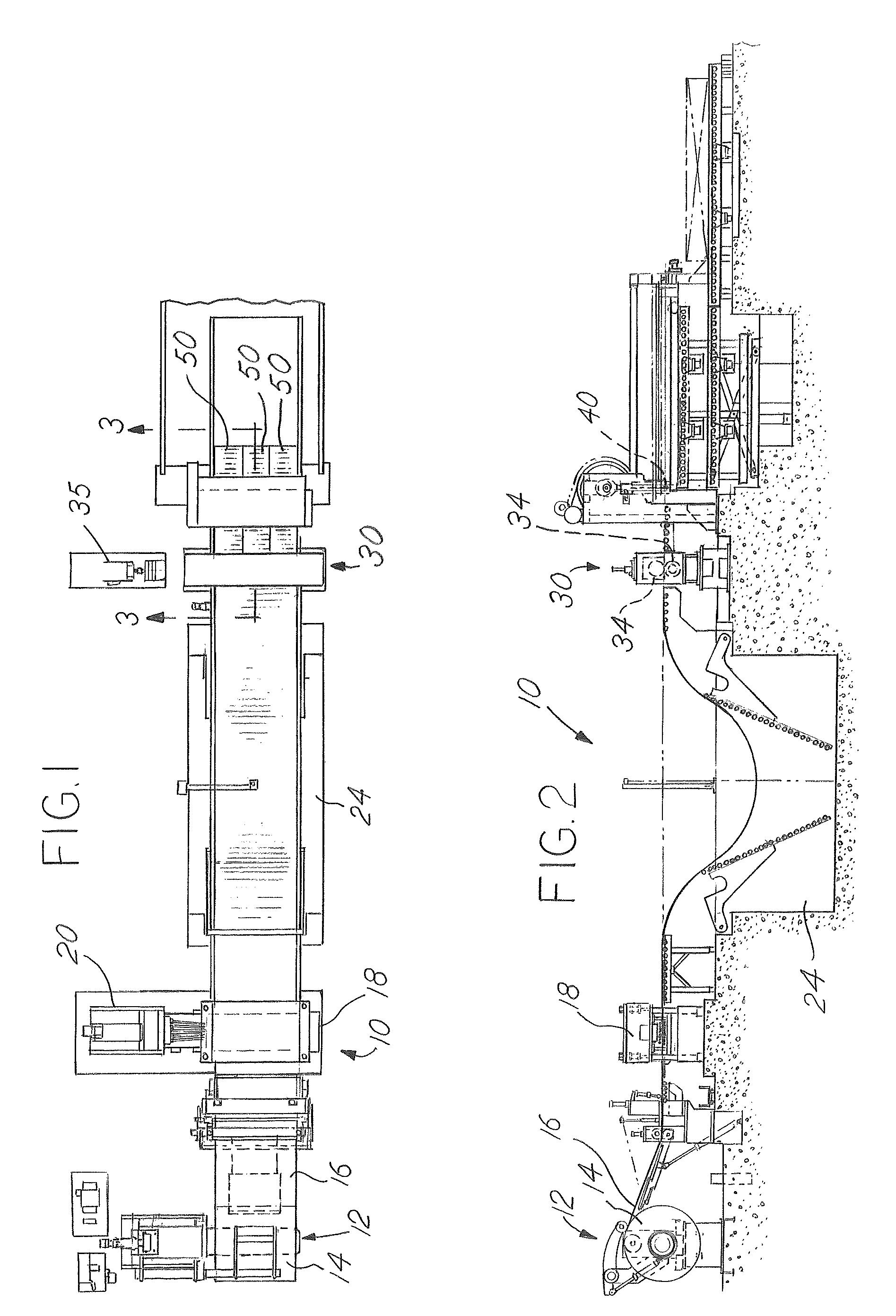

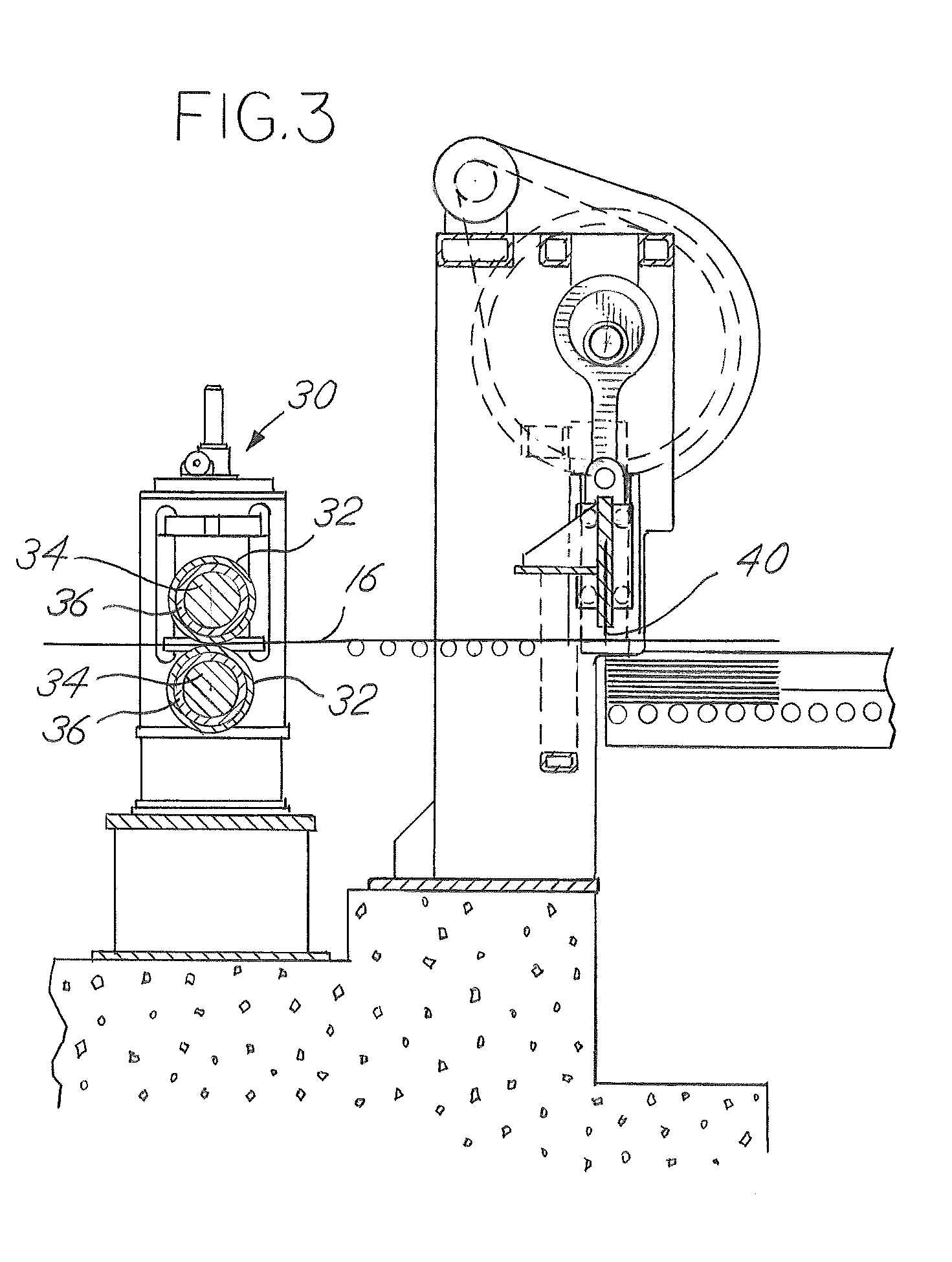

Method and Apparatus for Producing Cut to Length Bars in a Steel Mill

ActiveUS20130086870A1Increase ratingsRapid productionBinding material applicationShearing control devicesEngineeringRebar

A method of producing steel bars that are cut to length in response to a customer order. The method includes producing a continuous length of steel bar from a rolling mill, cutting said continuous length of steel bar into lengths equal to the length of the bar of the customer order while maintaining the production of the continuous length of steel bar produced by the rolling mill, and bundling bars of the length of the customer order for discharge from the mill using one of two bundling stations arranged to receive and bundle cut bars.

Owner:PONG DAVID TENG

High speed trimming shear

A high speed rod trimming shear includes a pair of eccentrically bored sleeves mounted for rotation about parallel first axes. Carrier shafts are supported in the bores of the eccentric sleeves for rotation about second axes parallel to the first axes and located on opposite sides of the rod path. The carrier shafts have blade holders with attached cutting blades. A primary drive rotates the carrier shafts continuously, and an adjustment mechanism rotatably oscillates the eccentric sleeves to adjust the distance between the carrier shafts between a first setting at which the cutting blades rotate out of contact with the rod, and a second setting at which the cutting blades coact during rotation to sever the product.

Owner:MORGAN CONSTR CO

Wire straightening and cut-off machine and process

A wire straightening and cut-off process and machine which feeds, straightens, and cuts wire, and which uses a servomotor in dual mode. In a continuous mode, short wire parts are cut at a high cut-off rate. In an intermittent mode, long wire parts are cut wherein each cut is triggered by a signal.

Owner:WIESENFELD YAIR

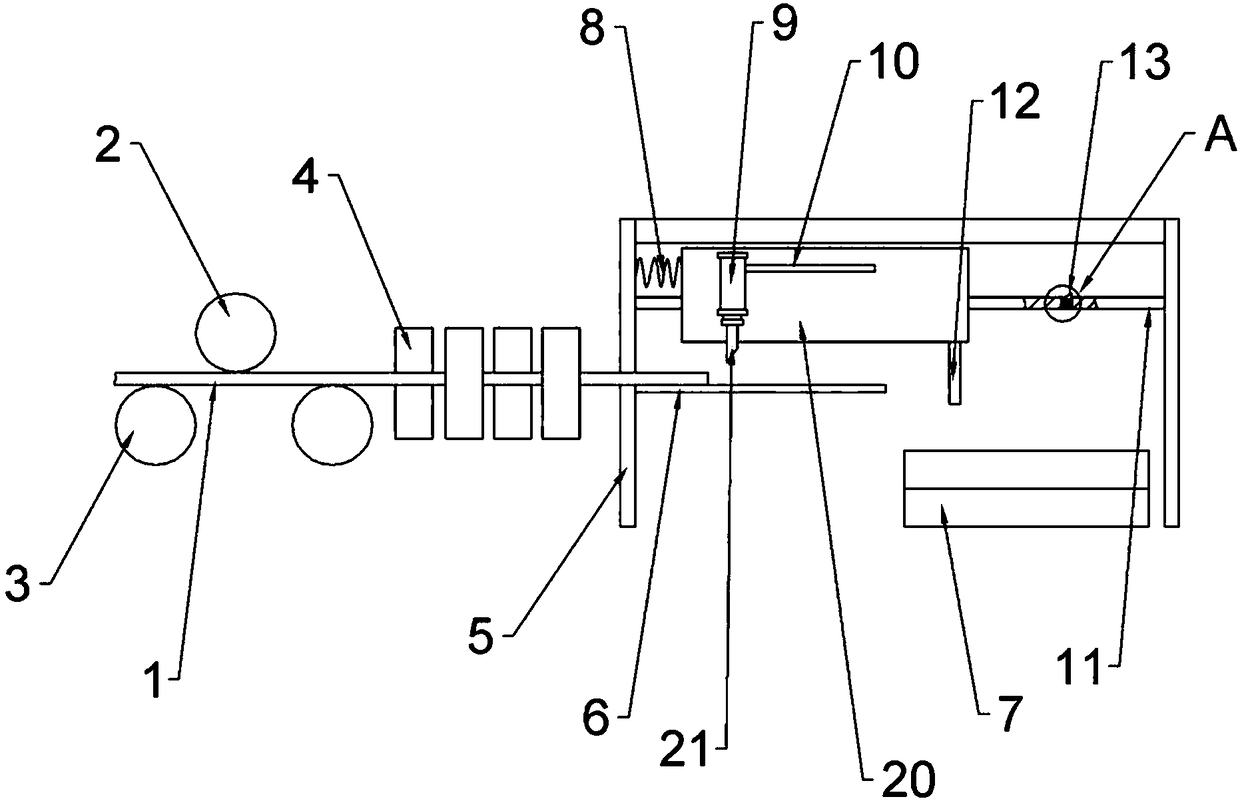

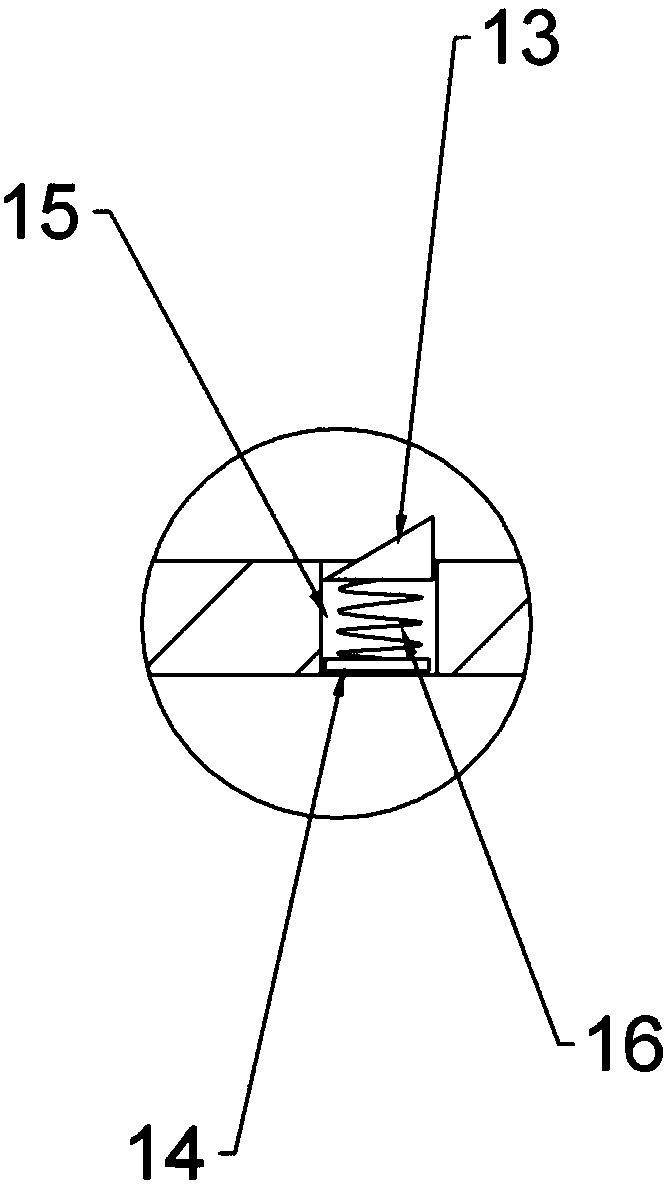

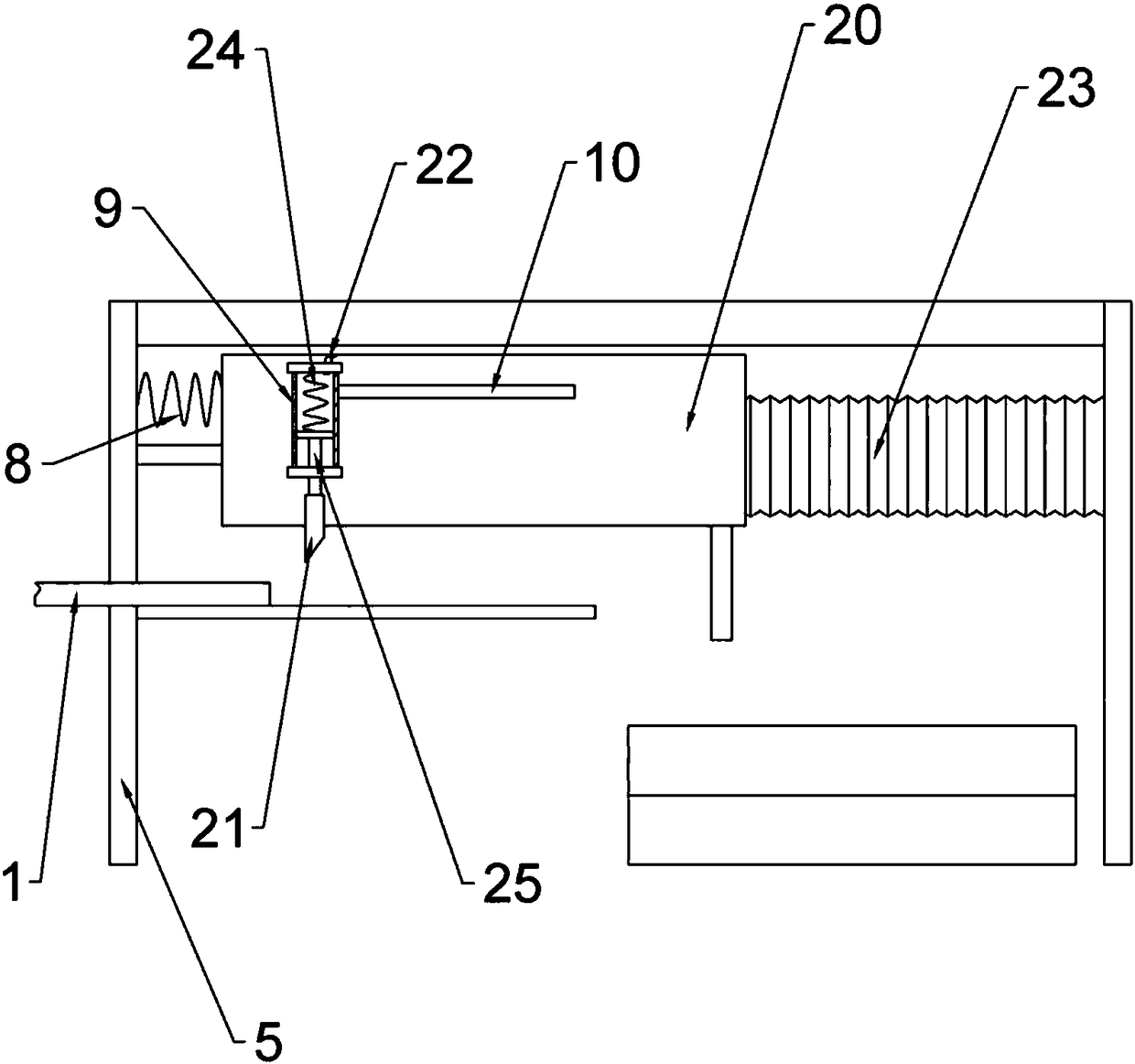

Fixed-length cutting device for tubular part

ActiveCN108480751AEasy to cutRealize continuous cuttingTube shearing machinesMetal working apparatusMotor vehicle partEngineering

The invention belongs to the field of machining devices of automobile parts and particularly discloses a fixed-length cutting device for a tubular part. The fixed-length cutting device for the tubularpart comprises a rack, a cutter and a long pipe conveying mechanism for conveying a long pipe. The long pipe conveying mechanism is located on one side of the rack, the cutter is arranged on the rack, and the fixed-length cutting device for the tubular part further comprises an elastic part. The rack is provided with a sliding rail, the sliding rail is in sliding connection with a sliding seat, abaffle capable of abutting against the long pipe is arranged on the sliding seat, the baffle is perpendicular to the sliding rail, an air cylinder is arranged on the sliding seat and connected with apiston rod, and the piston rod is fixedly connected with the cutter which is parallel to the baffle. One end of the elastic part is connected with the sliding seat, and the other end of the elastic part is fixedly connected with the rack. The rack is provided with a control part capable of controlling the piston rod of the air cylinder to stretch out, and the sliding seat can trigger the controlpart. The device can achieve fixed-length cutting of the tubular part and ensures that all parts have the same length.

Owner:宁波鑫神泽汽车零部件有限公司

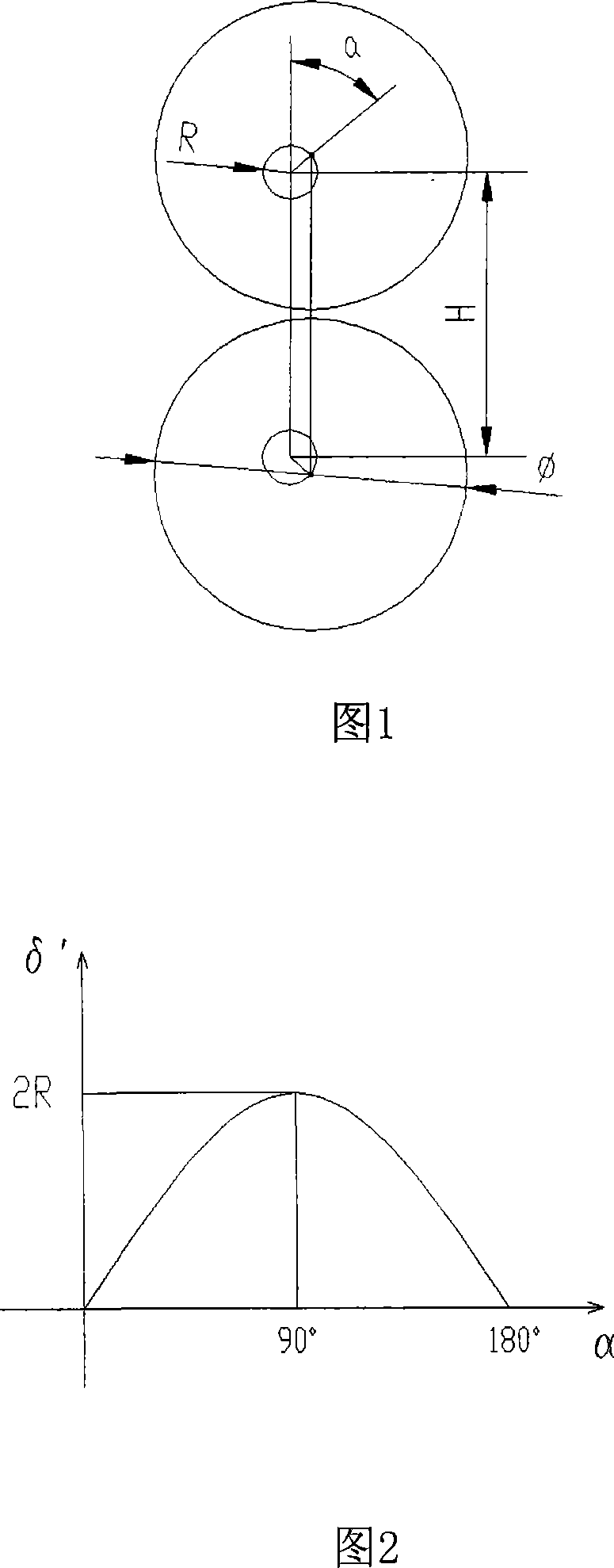

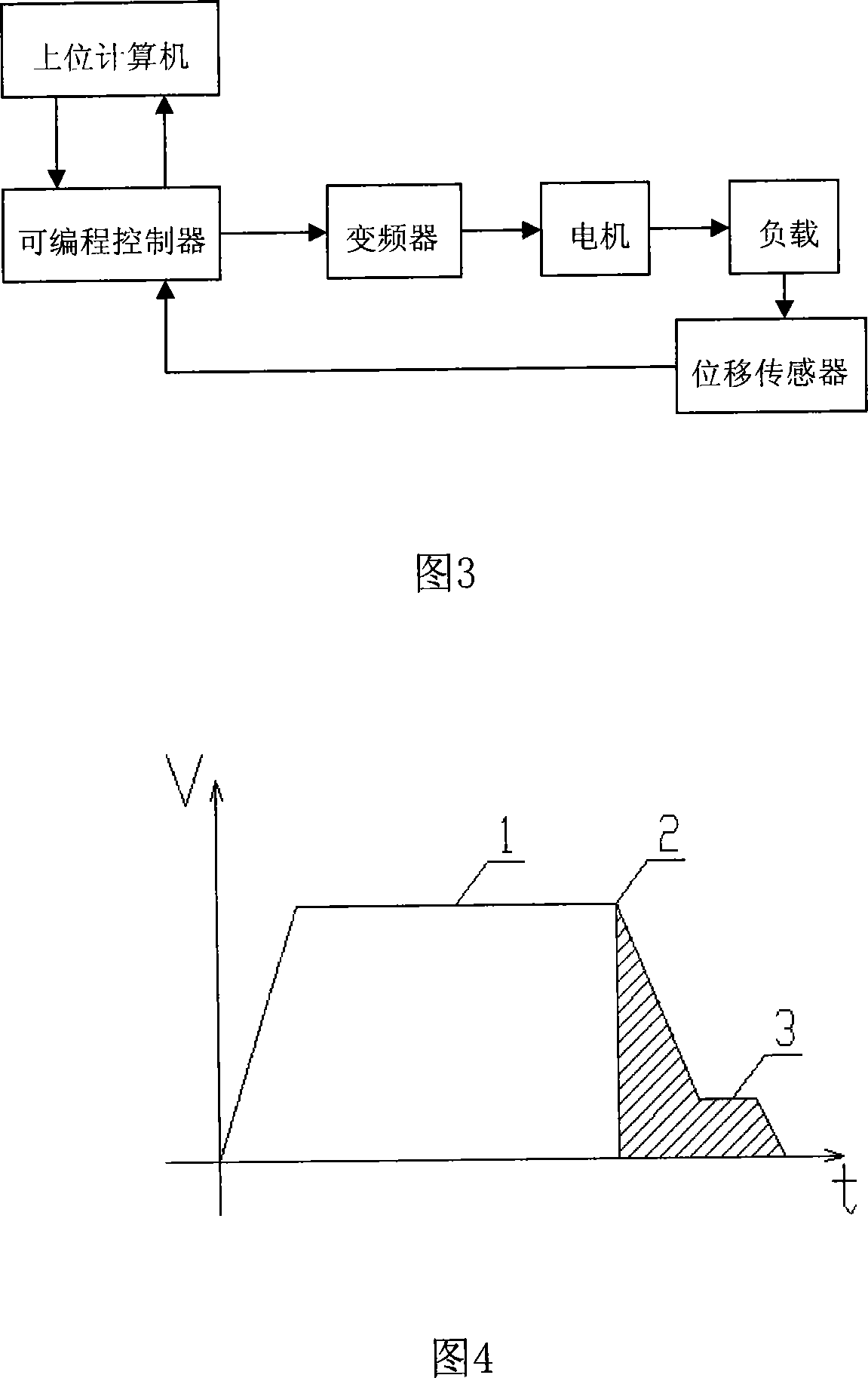

Disc shear cutter head overlap amount regulation control method

InactiveCN101145038AProgramme control in sequence/logic controllersShearing control devicesCircular discFrequency changer

The present invention relates to an adjusting and control method for device in a plate-strip shear line, in particular to an adjusting and control method for the overlapping value of the disk-shaped scissors plate; the present invention uses the frequency conversion and viable speed control system to achieve the control of the overlapping value of the disk-shaped scissors plate; and by the present invention, the absolute value of the difference value between the target value of the overlapping value and the measuring overlapping value of a displacement sensor can be compared with the ahead value L of the motor at the beginning of speeding down; through using the rotating speed of the control motor of the frequency convertor, the absolute value of the difference value between the target value and real overlapping value can be controlled to be equal to or less than 0.02mm. The adjusting and control method for the overlapping value of the disk-shaped scissors plate is time-saving, and has high control accuracy.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Apparatus and method for horizontal casting and cutting of metal billets

InactiveCN101124057AHigh speedTempo syncMetal sawing devicesMetal working apparatusHigh frequency vibrationMolten metal

The invention relates to an apparatus for continuous casting of metal billets comprising a horizontal casting mould having and inlet end and an outlet end. It includes a feed trough for feeding molten metal to the mould inlet end and a horizontal conveyor for receiving a cast billet from the mould outlet end. A moveable cutting saw is operable to move synchronously with the conveyor for cutting a continuous billet into lengths while supported on the conveyor. The billet is resiliently supported and the saw mechanism is isolated so as to minimize transmission of low and high frequency vibrations from the cutting and conveying operations to the mould.

Owner:NOVELIS INC

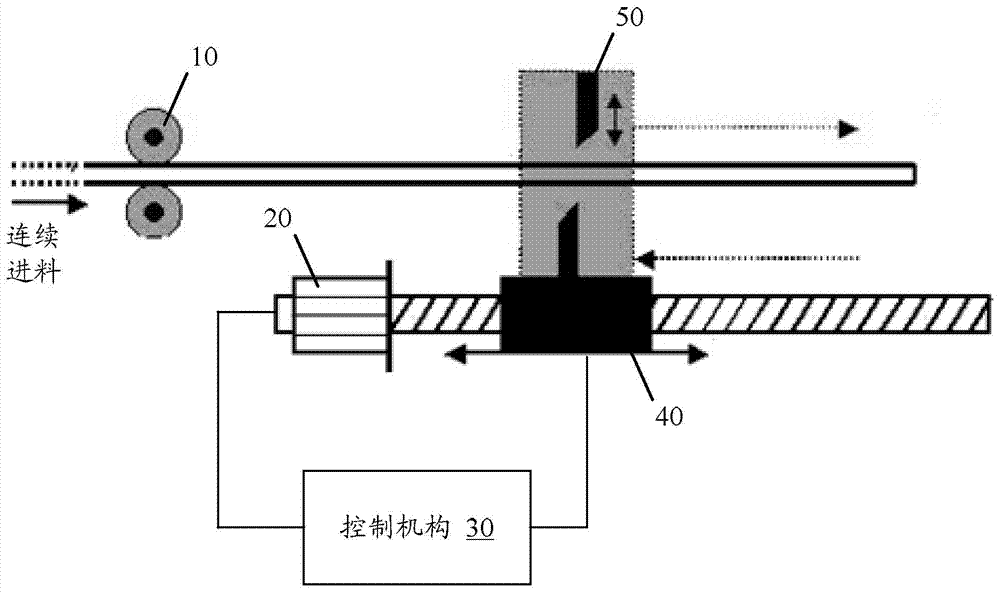

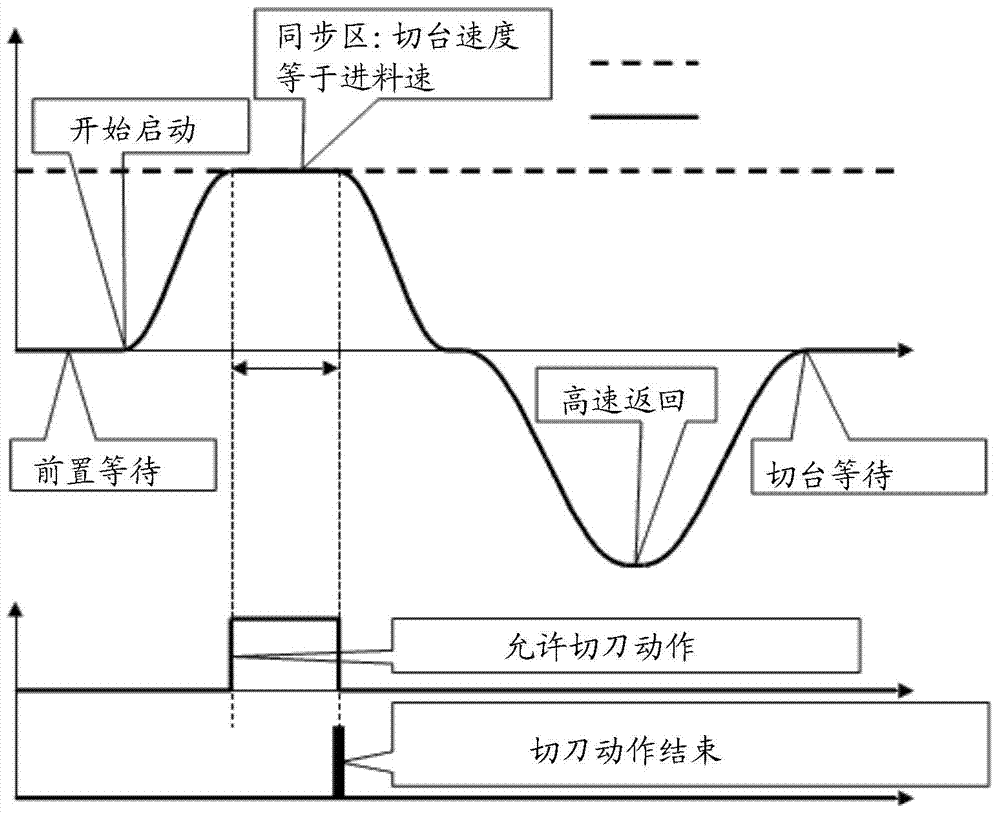

High-speed synchronization flying shear flying punching system

InactiveCN104708104AGuaranteed adjustabilityEnsure consistencyStock shearing machinesShearing control devicesProduction linePunching

The invention discloses a high-speed synchronization flying shear flying punching system. The system overcomes the defect that at present, a keel off-line punching production mode is low in efficiency and comprises a measuring mechanism, a tracking mechanism, a control mechanism, a sawing / cutting table and a punching mechanism. The measuring mechanism is arranged to measure the feeding speed and the feeding length of a keel, and the tracking mechanism is arranged to start the sawing / cutting table to begin to accelerate when the feeding length, measured by the measuring mechanism, of the keel reaches a starting position of the preset length, sends a synchronization signal to the control mechanism when the moving speed of the sawing / cutting table is the same as the feeding speed, and controls the sawing / cutting table to slow down according to a cut finish signal; the control mechanism is arranged to generate a cutting signal and send the cutting signal to the sawing / cutting table according to the synchronization signal; the sawing / cutting table is arranged to control a cutter mechanism to execute the cutting motion according to a cutting signal, and send the cutting finish signal to the tracking mechanism after the cutting motion execution is completed; and the punching mechanism punches the keel in the keel feeding process. According to the system, punching work can be directly carried out on a production line, and the production efficiency is improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Device for processing a wire

ActiveUS20050087055A1Optimization mechanismLess adjustment workShaping safety devicesSolid-state devicesElectrical conductorEngineering

A wire processing unit has a crimp head moved in a “z” direction by an eccentric drive and a crimping tool arranged on the crimp head moves with it. The crimp head also moves a pin connected to a lowering unit that has a C-shaped bracket on which the gripper unit is arranged. When a crimping punch moves, the gripper unit is moved with it, and the wire-end held by a gripper pair is inserted into an upwardly-open conductor crimp and an insulation crimp respectively. A cutting head of a cutting unit cuts off the leading wire-end, removes the insulation, and separates contacts with defective crimp fastening from the wire-end.

Owner:KOMAX HOLDING

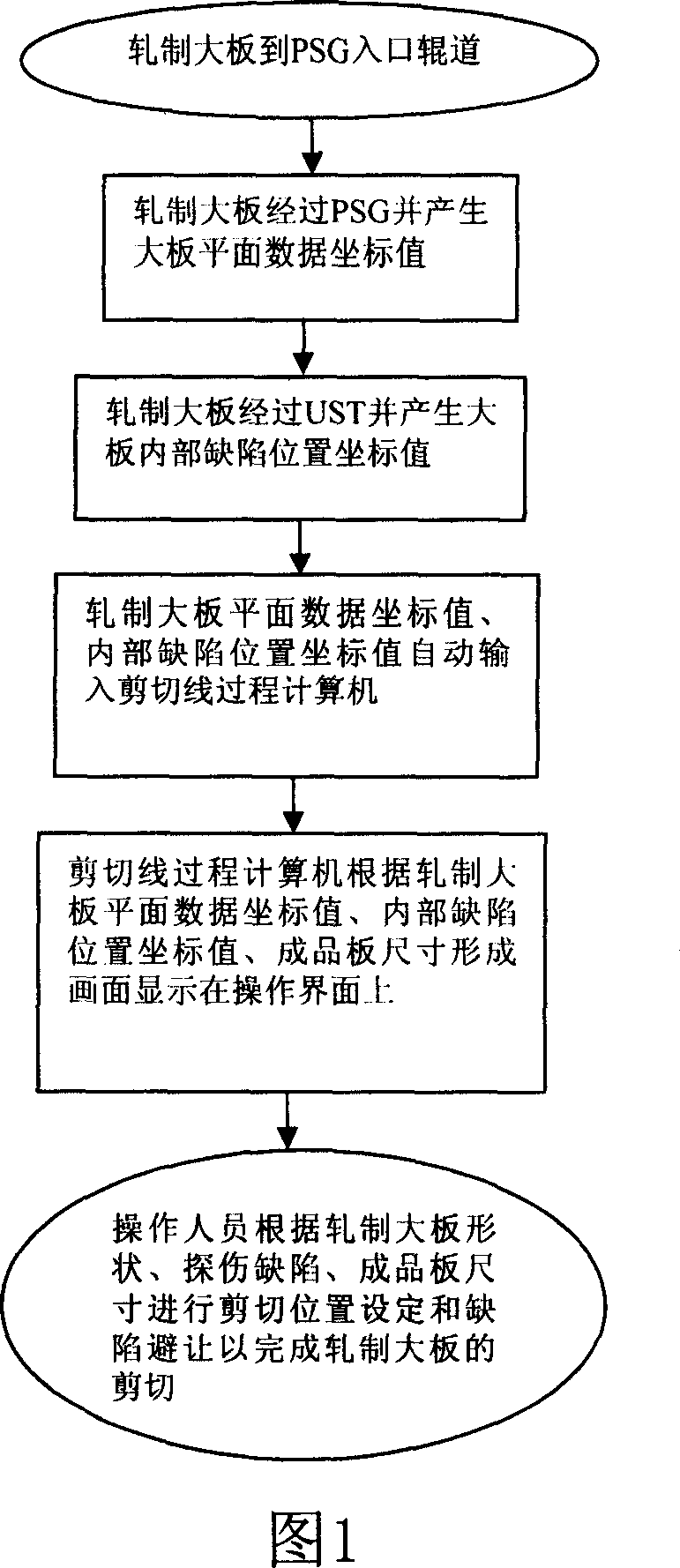

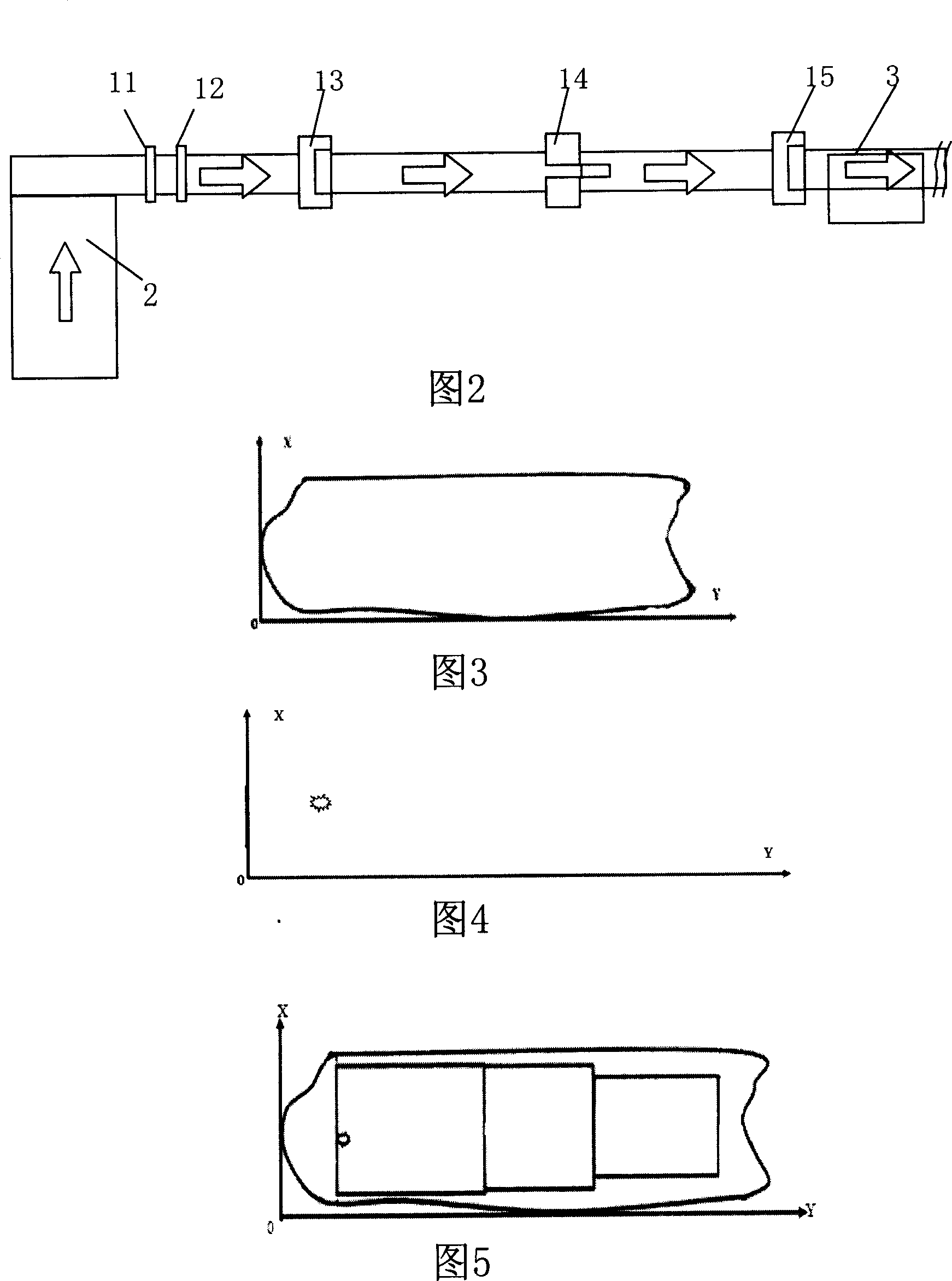

On-line optimizing shearing method of roller milling large plate

ActiveCN101097441AExtension of timeIncrease productionElectric programme controlShearing control devicesShear lineEngineering

The invention discloses a on-line optimizing cutting method of rolling board, it uses flat surface detecting device and on-line ultrasonic detection equipment to roll shape of big board and detect inner defect before snip head, and using cutting line course computer to transform detected shape data of rolling big board and inner defect data to image and displayed on operation interface and setting cutting position and defect avoiding to accomplish cutting of big board. The on-line optimizing cutting method resolves effectively problem that rolling big board with defects on head and trail needs manpower detection or finished board possesses defect of head and trail, it fits for continuous operation, and increasing cutting production capability and steel lumber ratio.

Owner:BAOSHAN IRON & STEEL CO LTD

A CNC cutting machine

InactiveCN102294514AGuaranteed machining dimensional accuracyRealize cutting automatic positioningMeasurement/indication equipmentsShearing control devicesNumerical controlConverters

The present invention relates to a cutting device, in particular to a numerically controlled board cutting machine, which provides a numerically controlled board cutting machine capable of ensuring cutting dimension accuracy instead of manual positioning to ensure cutting accuracy. A cutting knife is arranged longitudinally at one end of the guide rail, and a grating ruler includes a grating strip, a grating sensor and a grating control converter. A moving positioning rod is arranged longitudinally across the two guide rails, and the lower part of the moving positioning rod is fixed to the nut on the ball screw. One end of the ball screw is connected to the shaft of the servo motor, and the servo motor is electrically connected to the servo controller. On the outside of the double guide rails, at least one grating bar is arranged parallel to the guide rails. The grating sensor realizes the automatic positioning of cutting, that is, realizes the numerical control of measurement, high-precision numerical control, reduces mechanical transmission errors, improves automation, reduces scrap rate, improves work efficiency, and reduces and reduces labor costs.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

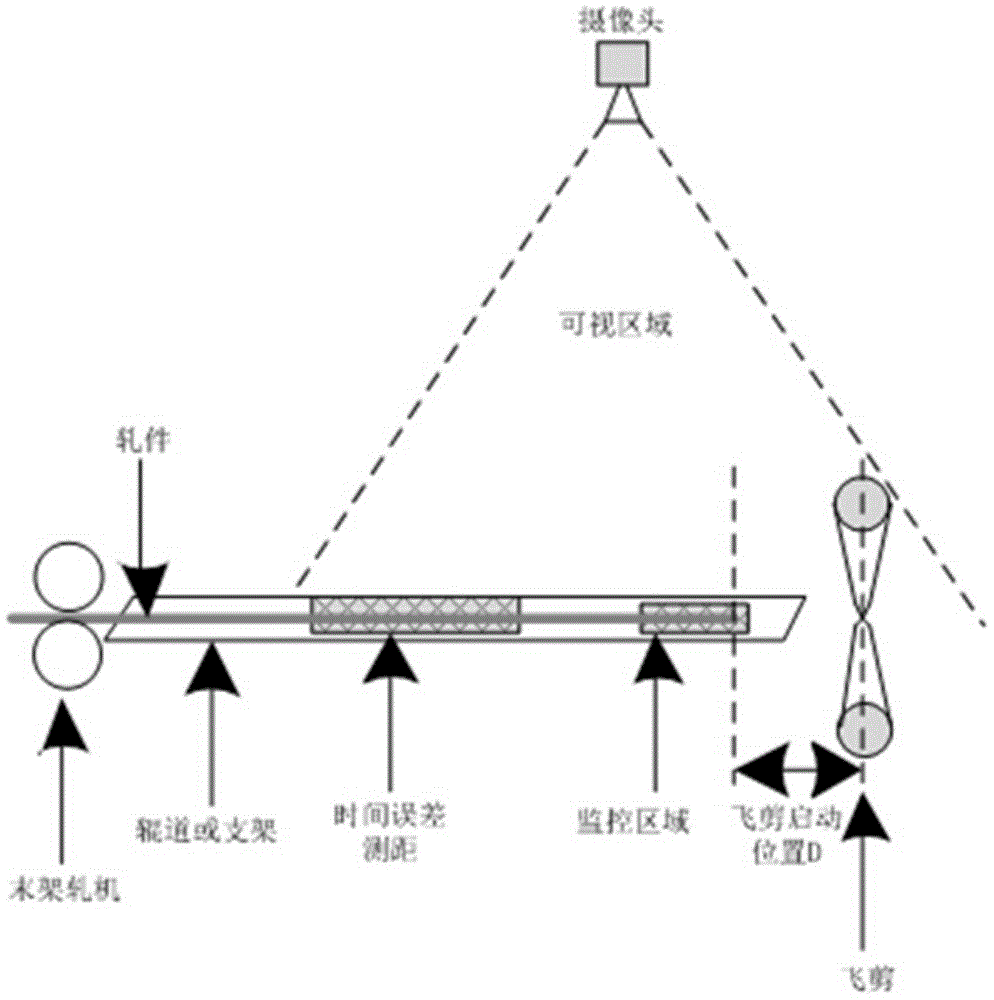

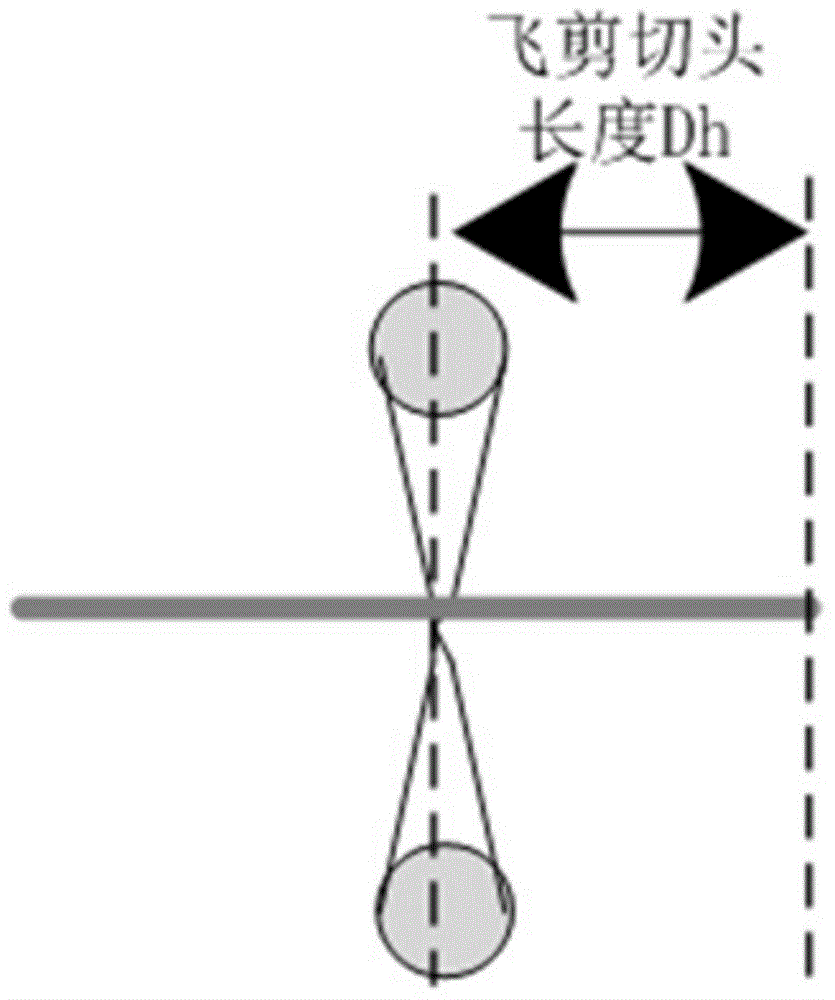

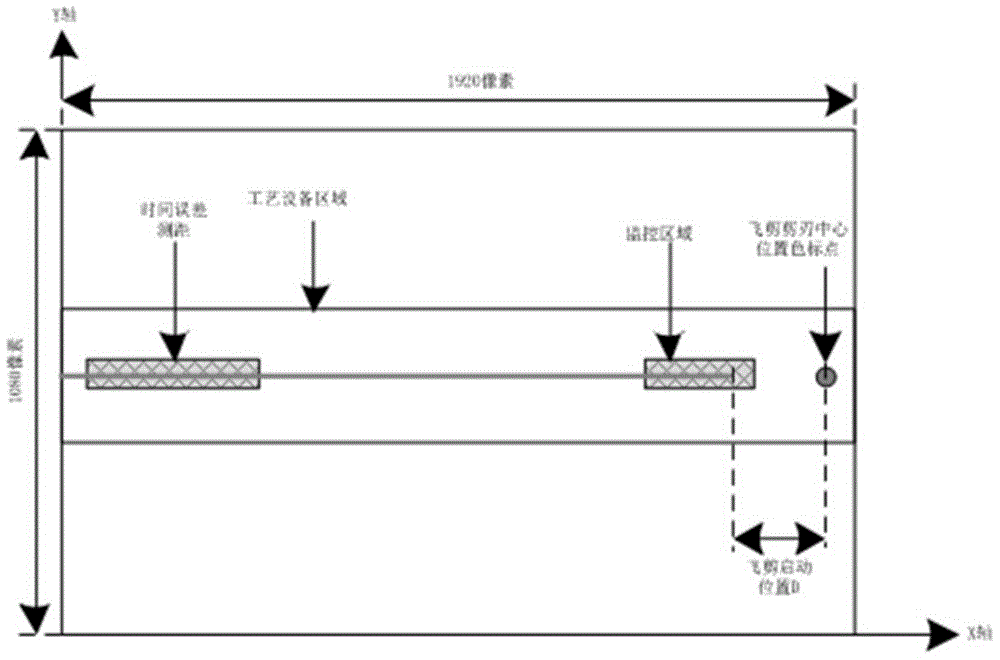

Flying shear control system and control method based on machine vision

ActiveCN105171115AAvoid cumbersomeAvoid irregularitiesStock shearing machinesShearing control devicesMachine visionControl system

The invention provides a flying shear control system and control method based on machine vision. The controls system comprises a controller, flying shears, a camera, a rolling mill and a rolled piece located on a roller bed of the rolling mill. The camera is arranged between the flying shears and the rolling mill, and is located above the position perpendicular to the roller bed. The controller receives information from the camera. The controller controls and triggers the motion of the flying shears. The flying shears are located within the image range of the camera. The center line between the flying shears and the roller bed is aligned to the center line of an image of the camera. The color of a shear edge center line of the flying shears is different from surrounding background colors. The industrial high-speed camera is used for accurately measuring the position of the rolled piece and triggering the flying shears to be started, and the trouble and unregularity of a method that errors in the prior art can only be compensated by repeatedly testing and correcting factors are avoided. Control precision is improved, the flying shear control system and control method can automatically adapt to steel types of any specification and any piece rolling speed, and the parameters do not need to be tested or corrected.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

Full mechanical band saw machine tool

InactiveCN101100009AEasy to operateMetal sawing devicesShearing control devicesDrive wheelGear wheel

The all mechanical band saw machine includes one pedestal, one guide upright, one arc frame, one driving wheel, one driven wheel, one band saw and one control cabinet, as well as one power switch, travel switches, one sawing motor, one elevating motor, one operating handle and other parts. The present invention has the advantages of simple operation with the handle, and no need of hydraulic oil.

Owner:孟广启

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com