Device and method for adjusting gap of shear of disc shearing machine

A disc shearing and adjustment method technology, which is applied in the direction of shearing devices, shearing machine control devices, shearing machine equipment, etc., can solve the problem of difficult control of the precise adjustment of the overlap of scissors, inconvenient adjustment devices and methods, and radial dimensions Large and other problems, to achieve the effect of simple structure, convenient adjustment, high cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

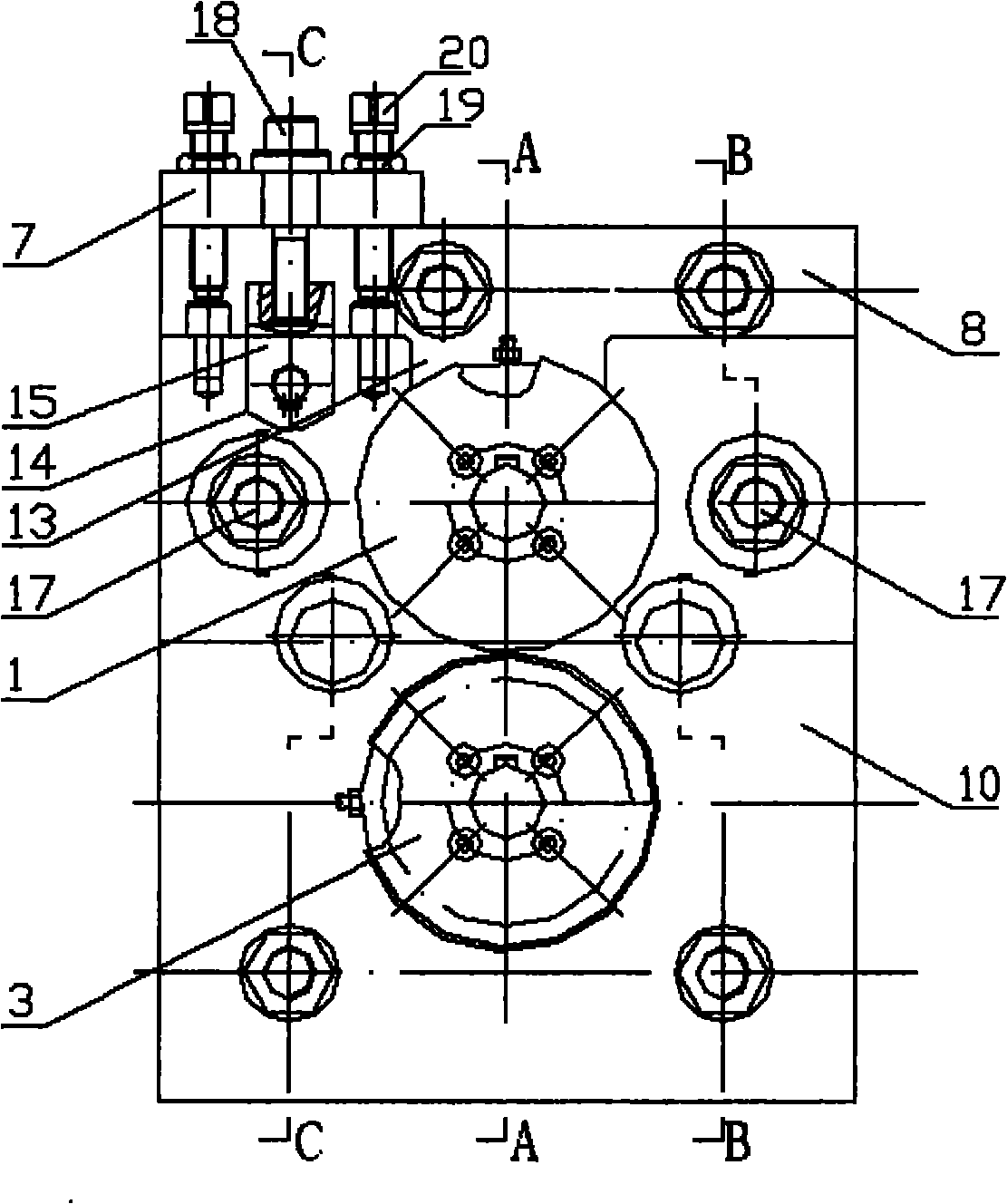

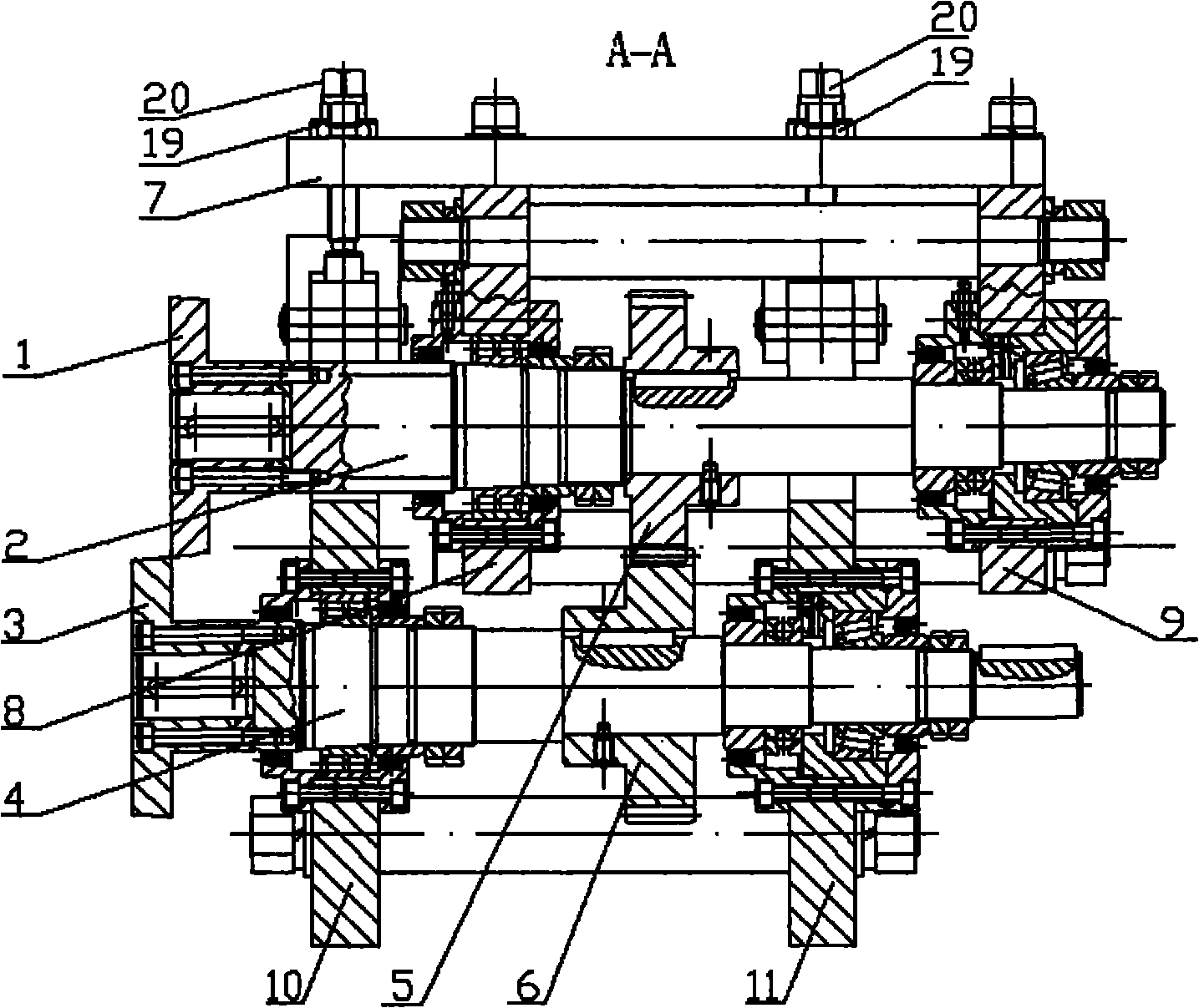

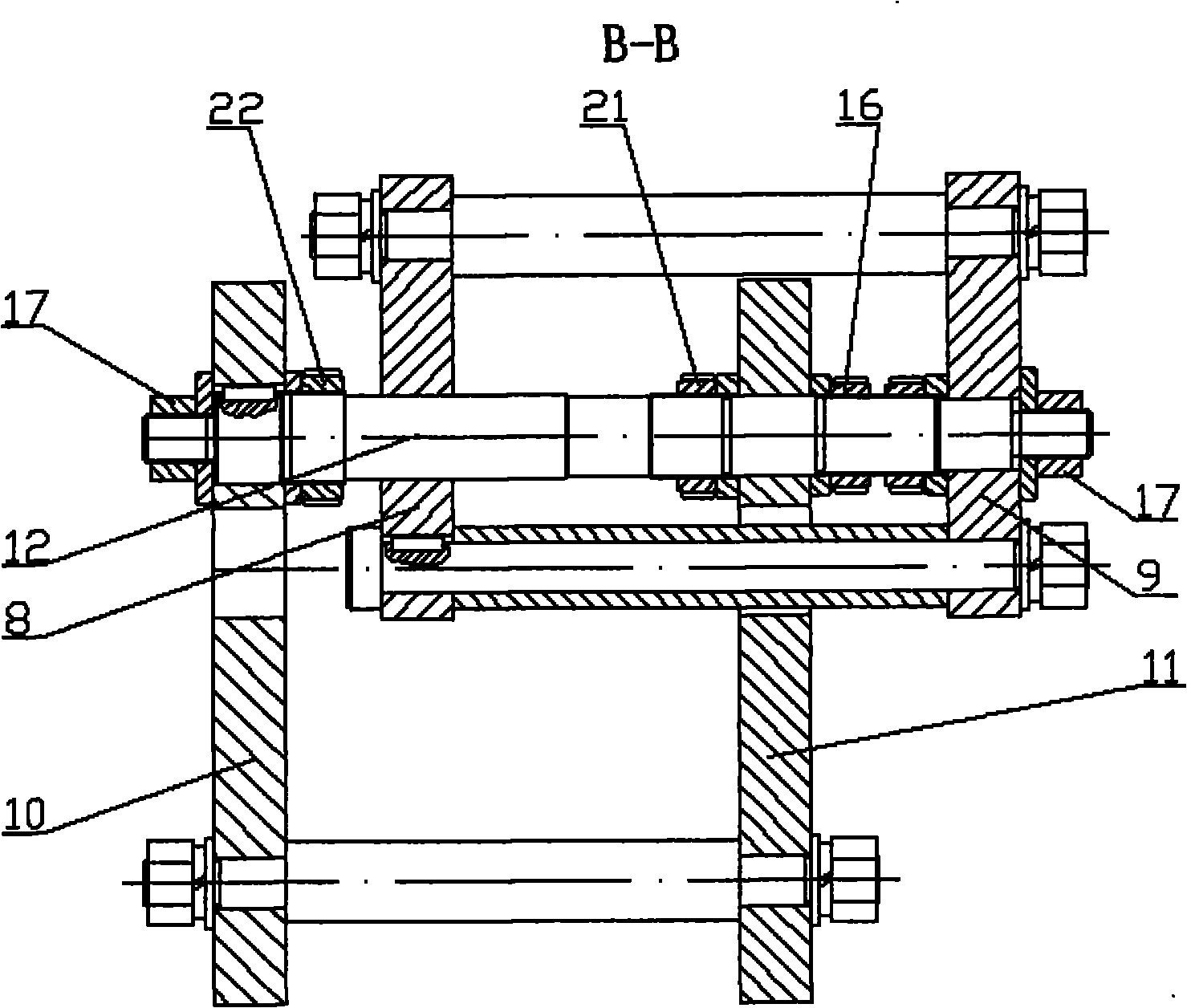

[0037] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] Such as Figure 7 As shown, when cutting the plate A, in order to improve the cutting accuracy, the gap between the upper scissors 1 and the lower scissors 3 depends on the thickness h of the plate to be sheared. Since the thickness h of the plate to be sheared is different, the relative positions of the upper scissors and the lower scissors 3 will also change accordingly. In order to ensure good cutting quality, the upper and lower scissors should be selected according to the thickness h of the plate to be sheared The overlapping amount S and the lateral gap δ of the upper and lower scissors. Figure 7 D is the diameter of the disc shear blade, h is the thickness of the plate to be sheared, α is the allowable bite angle, S is the overlapping amount of the upper and lower scissors, δ is the lateral clearance of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com