Patents

Literature

30results about How to "Guaranteed machining dimensional accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

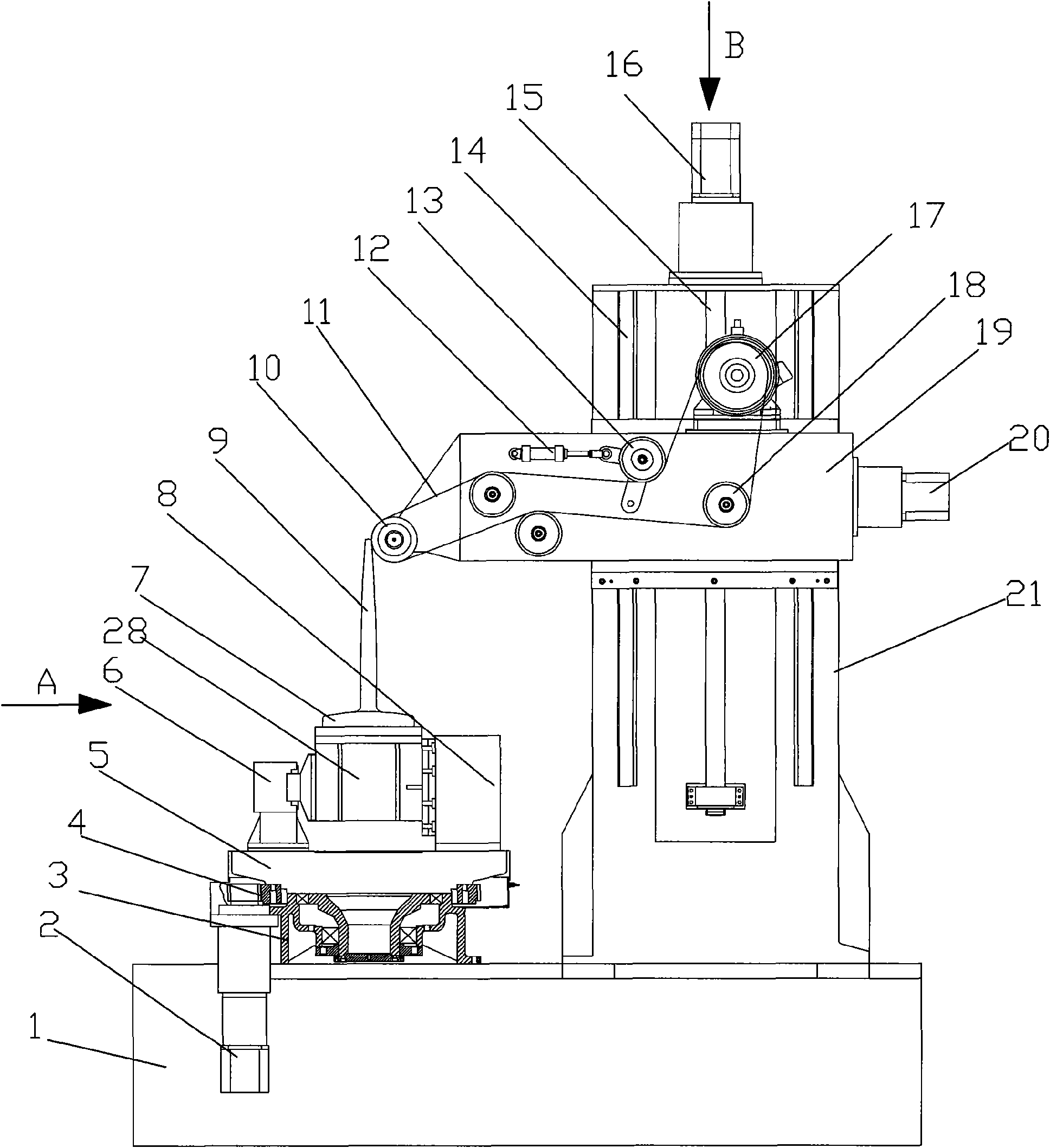

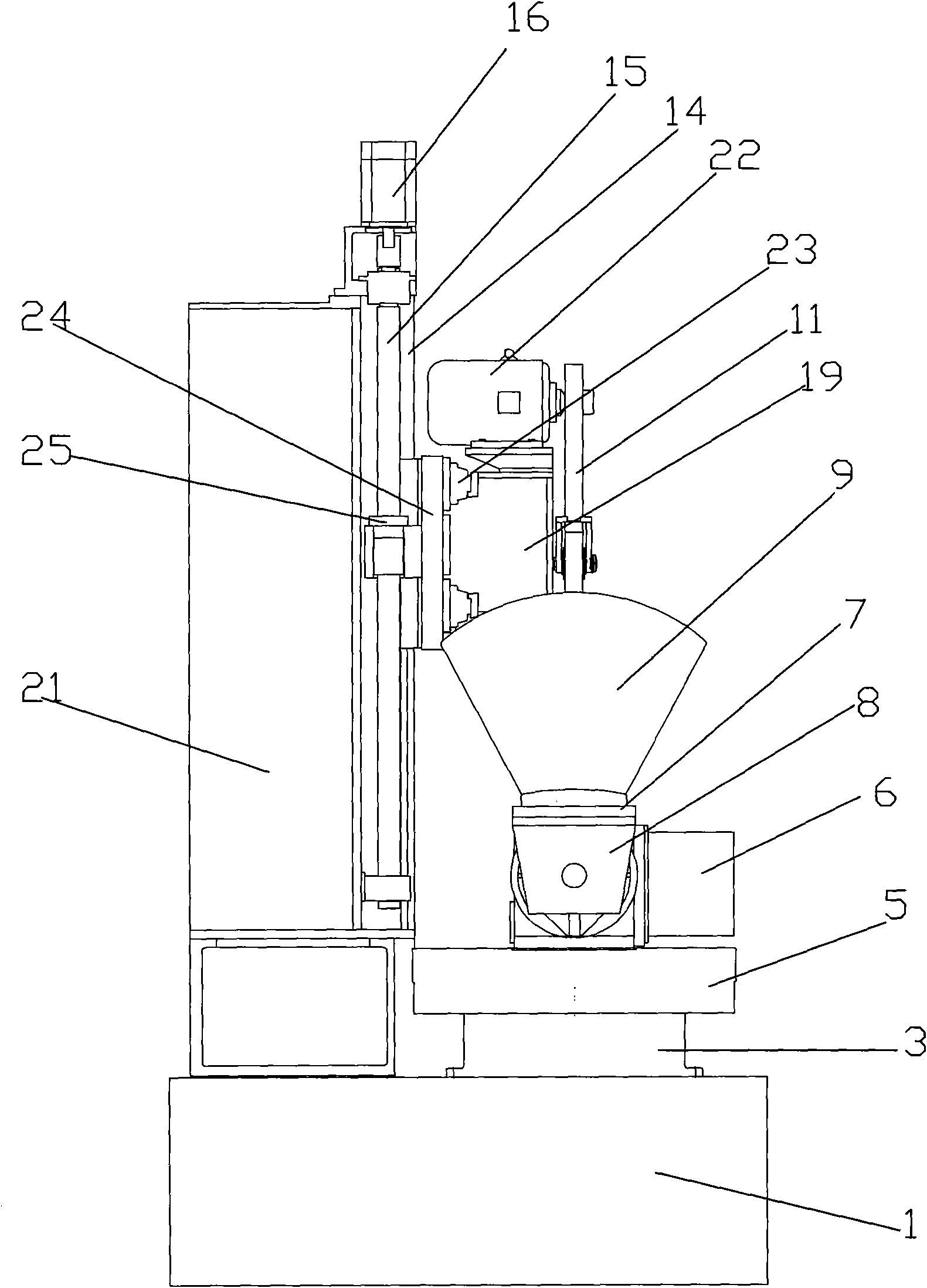

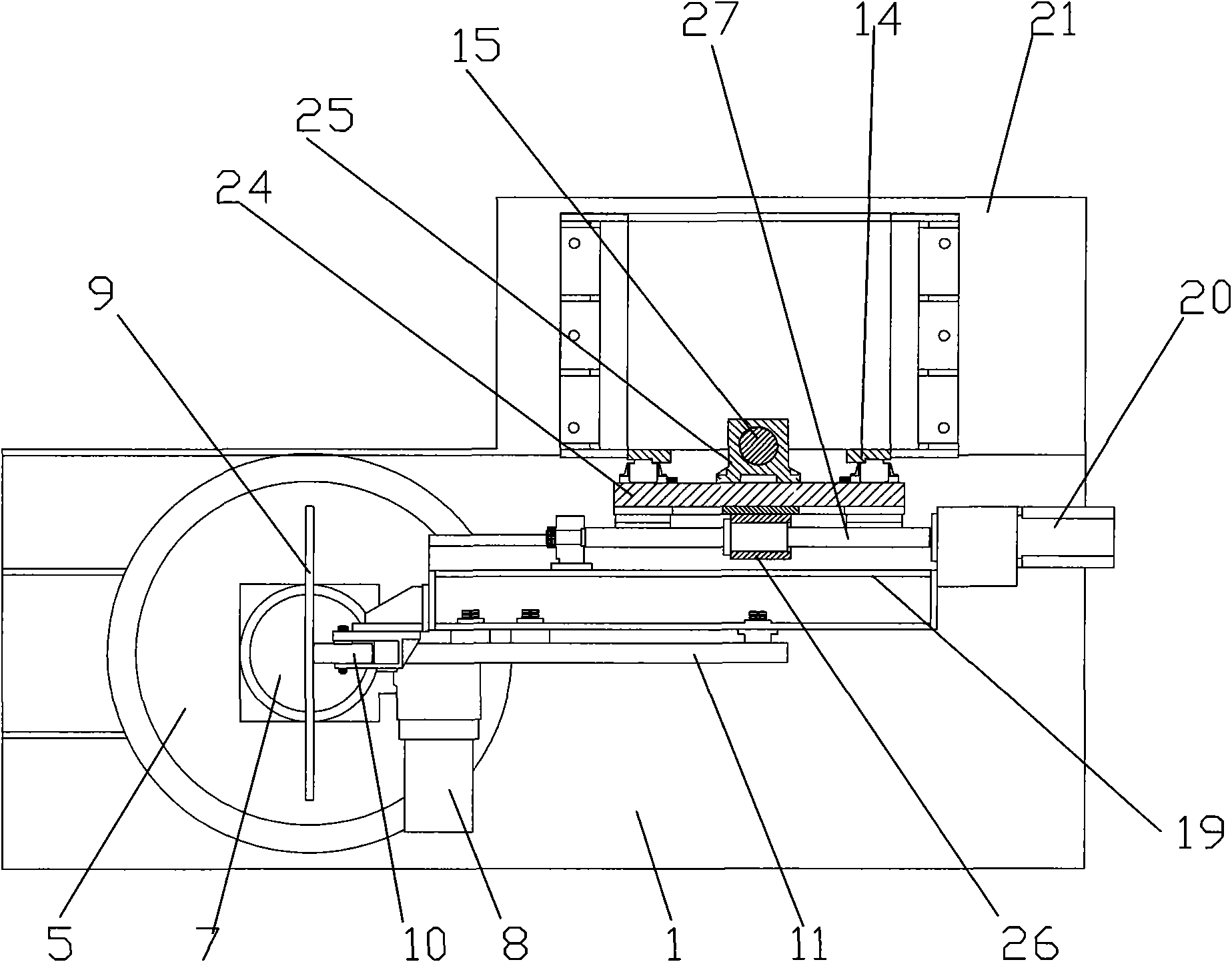

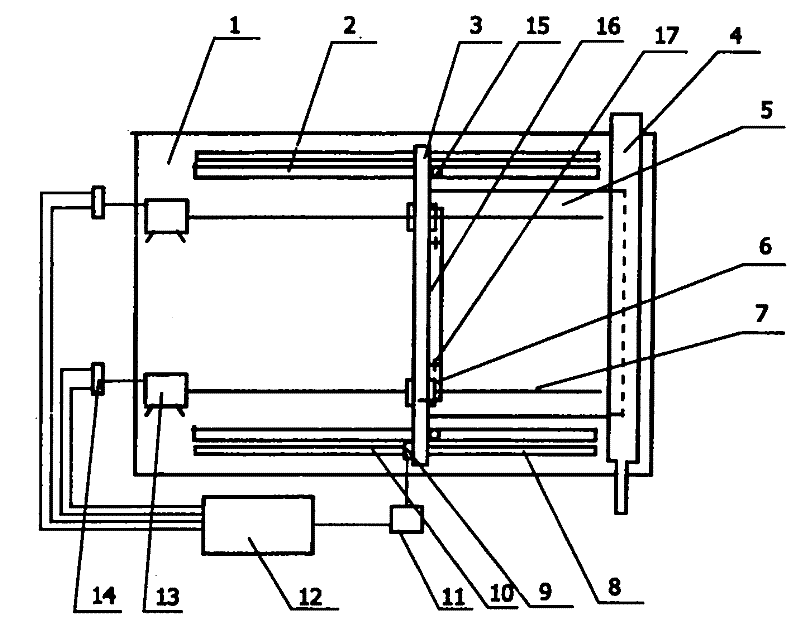

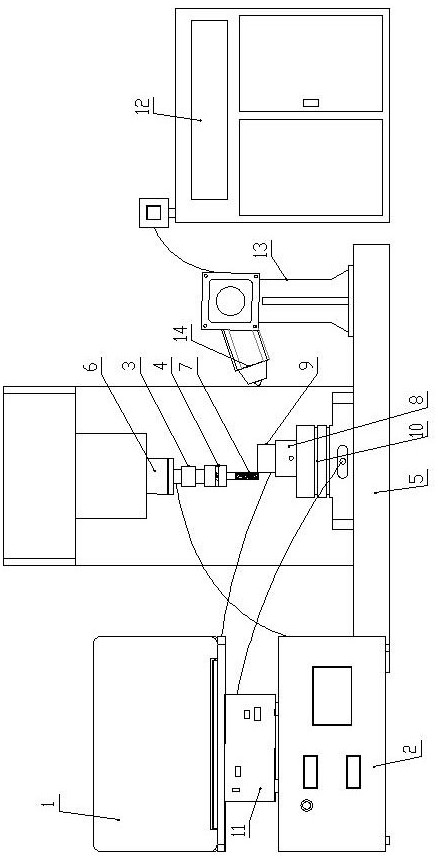

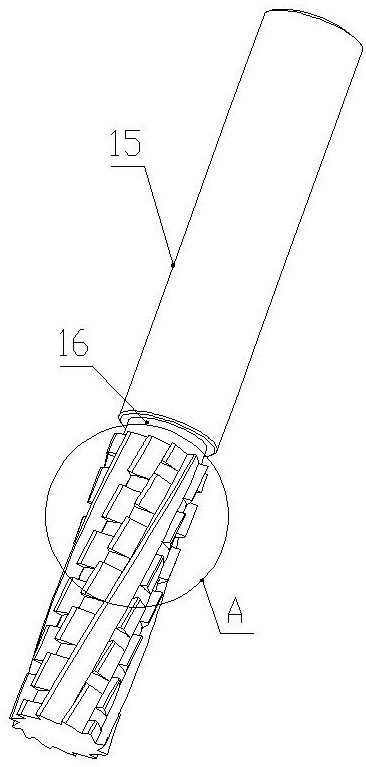

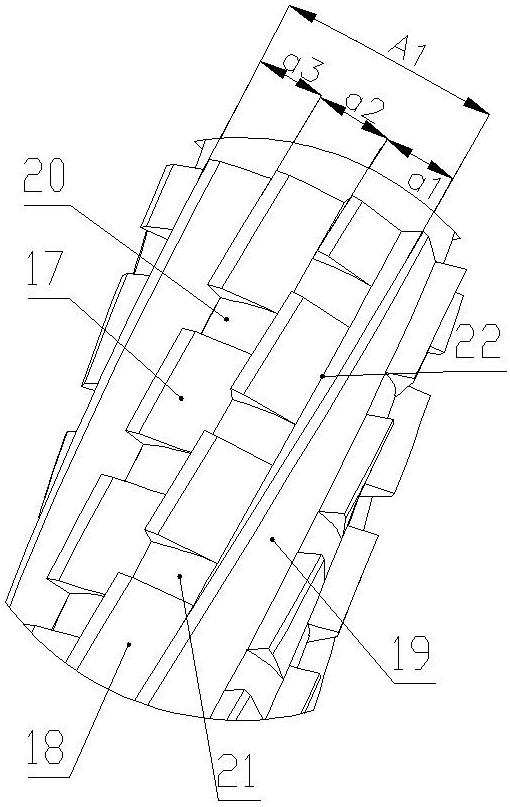

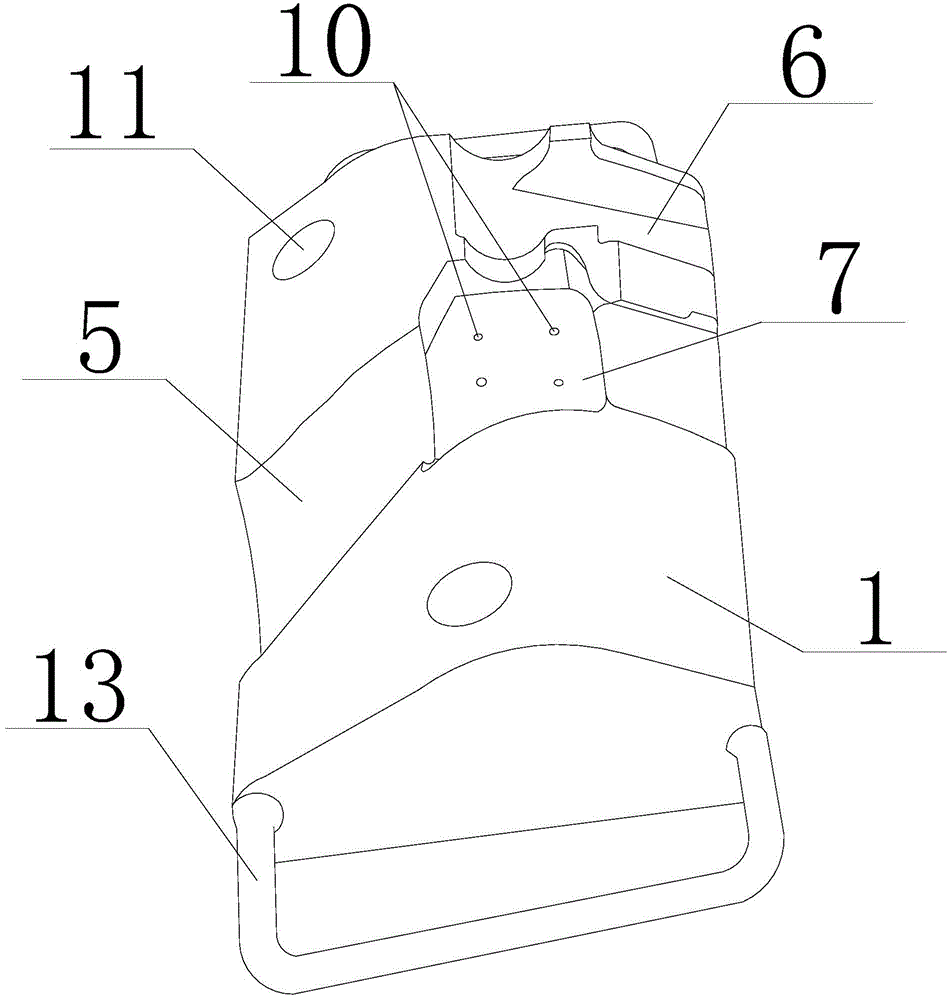

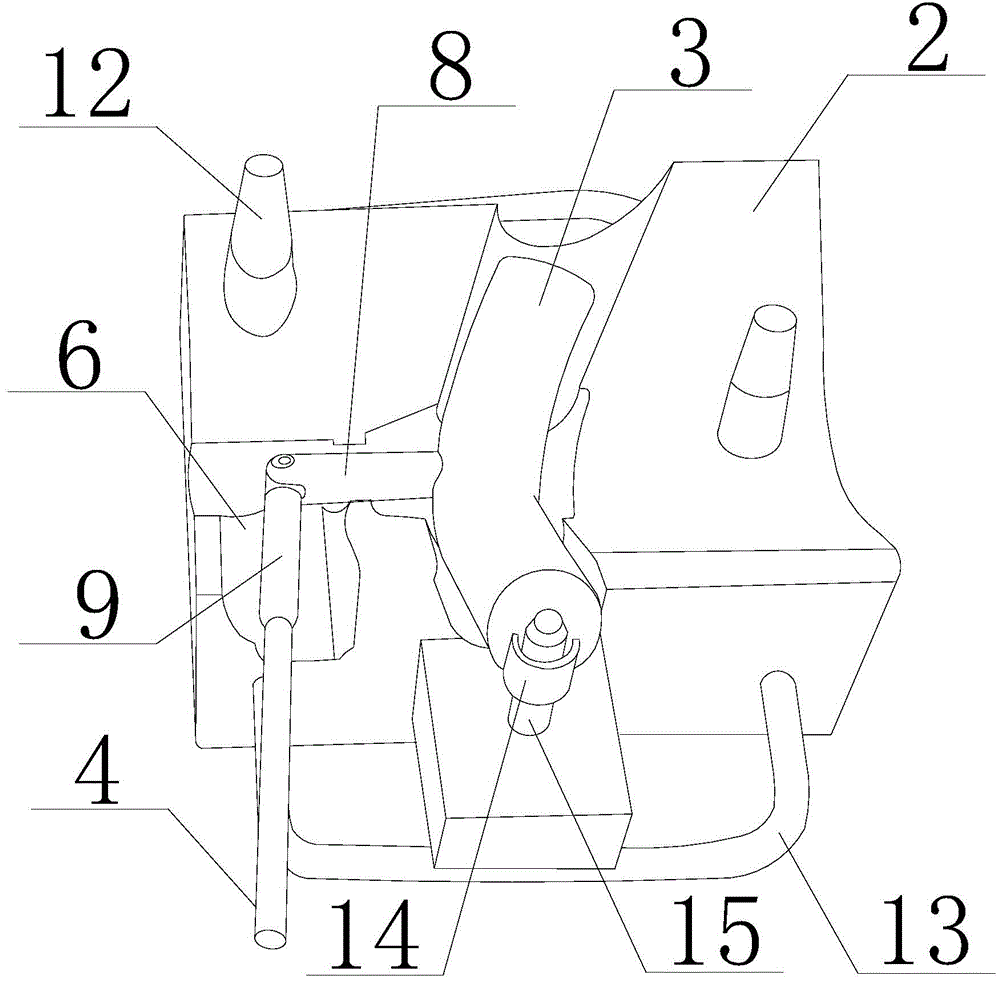

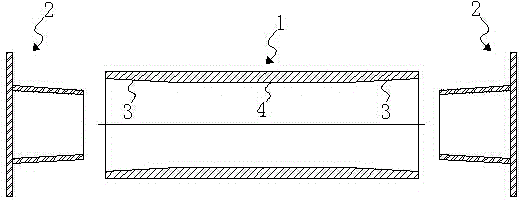

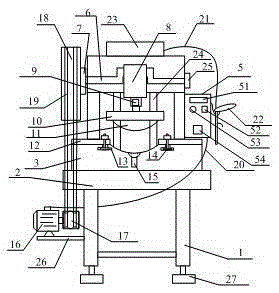

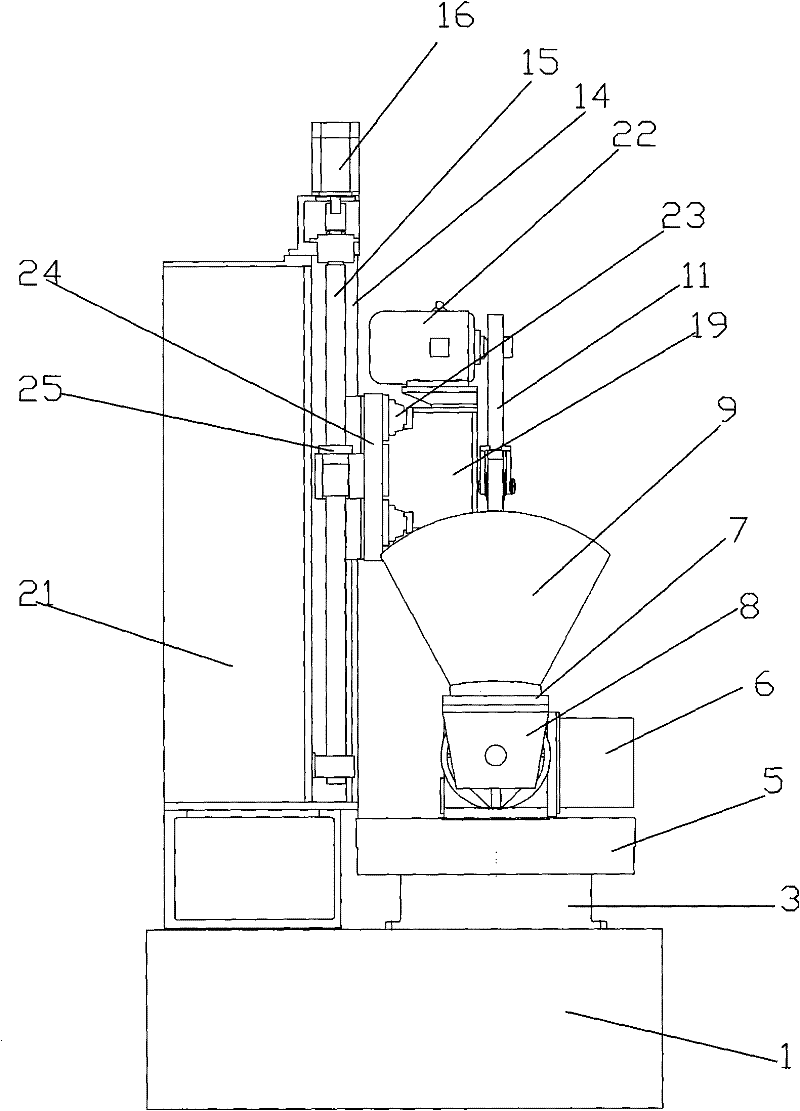

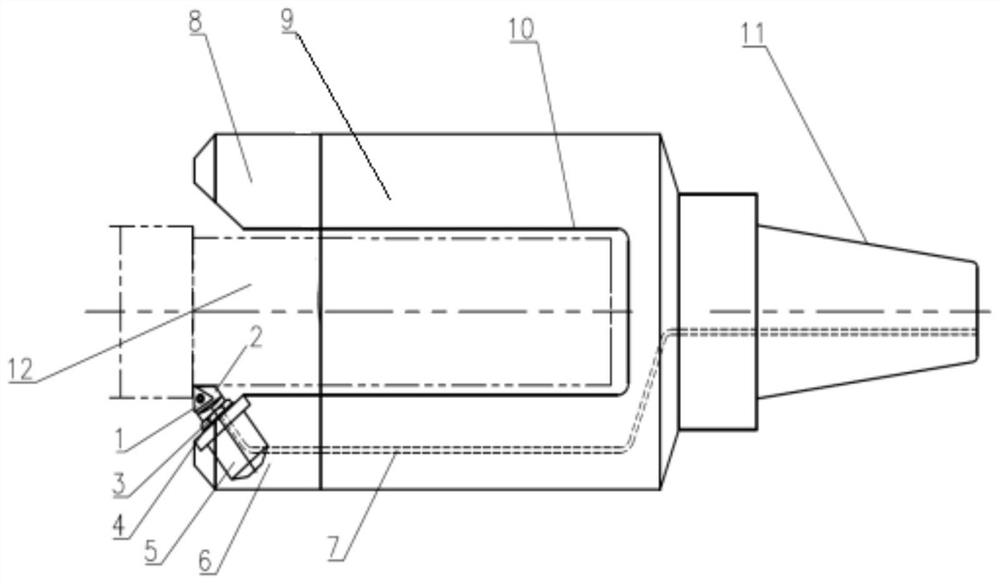

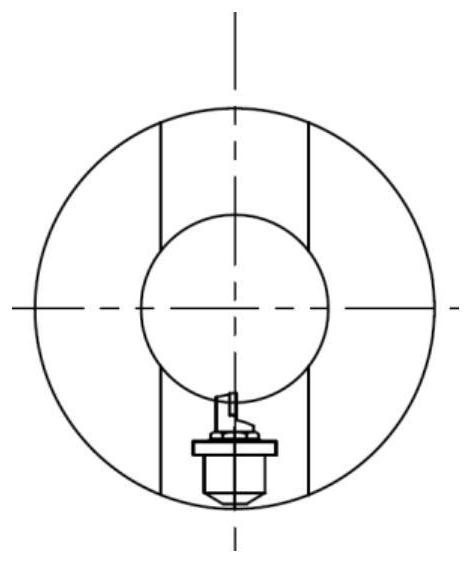

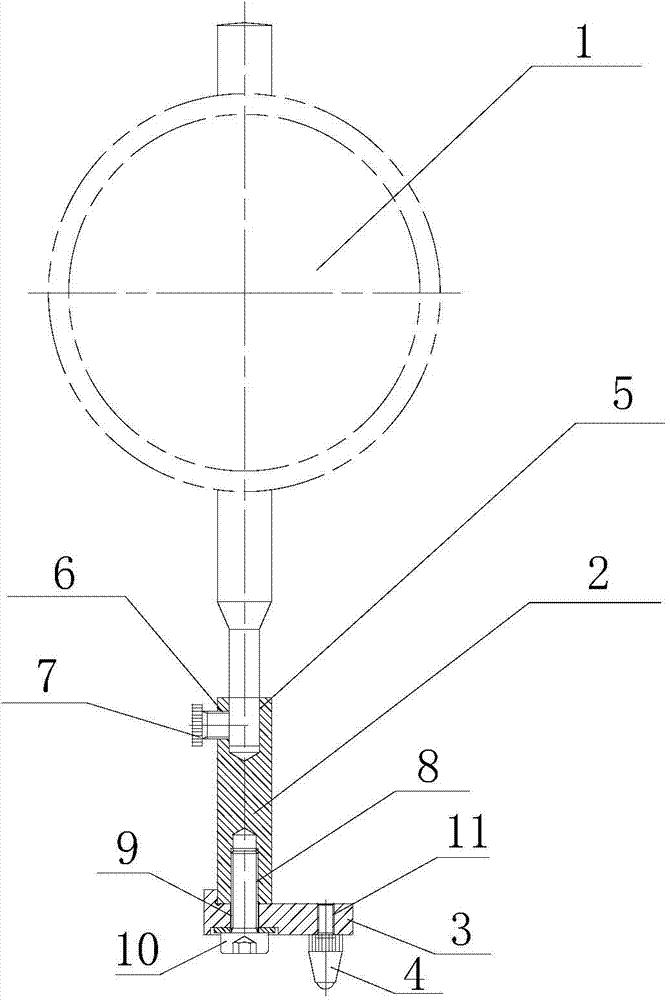

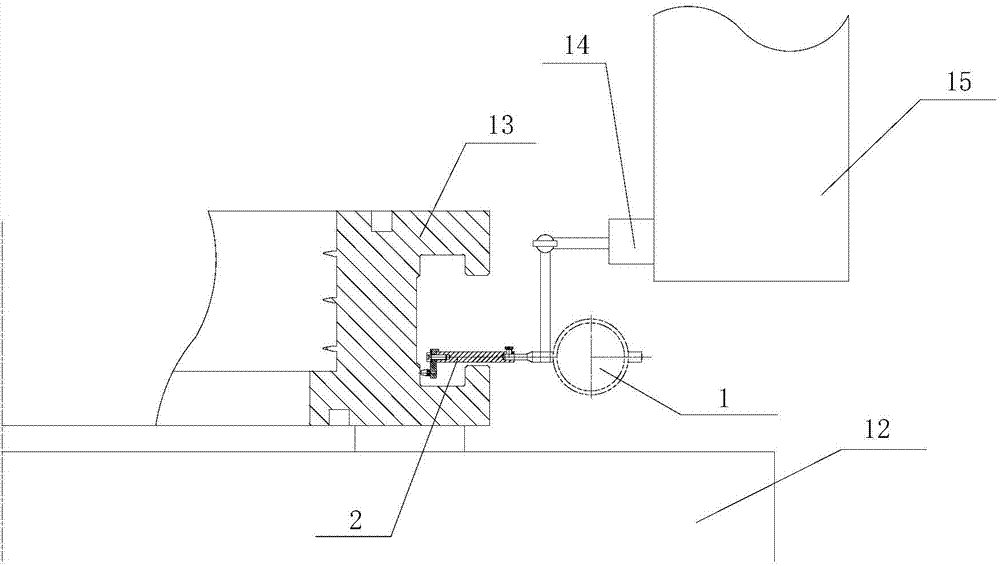

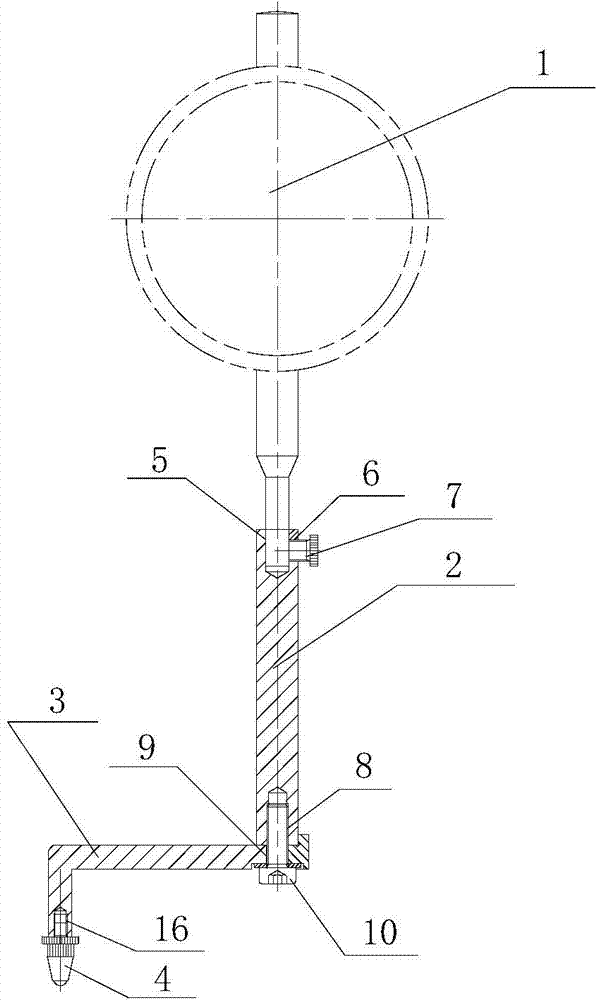

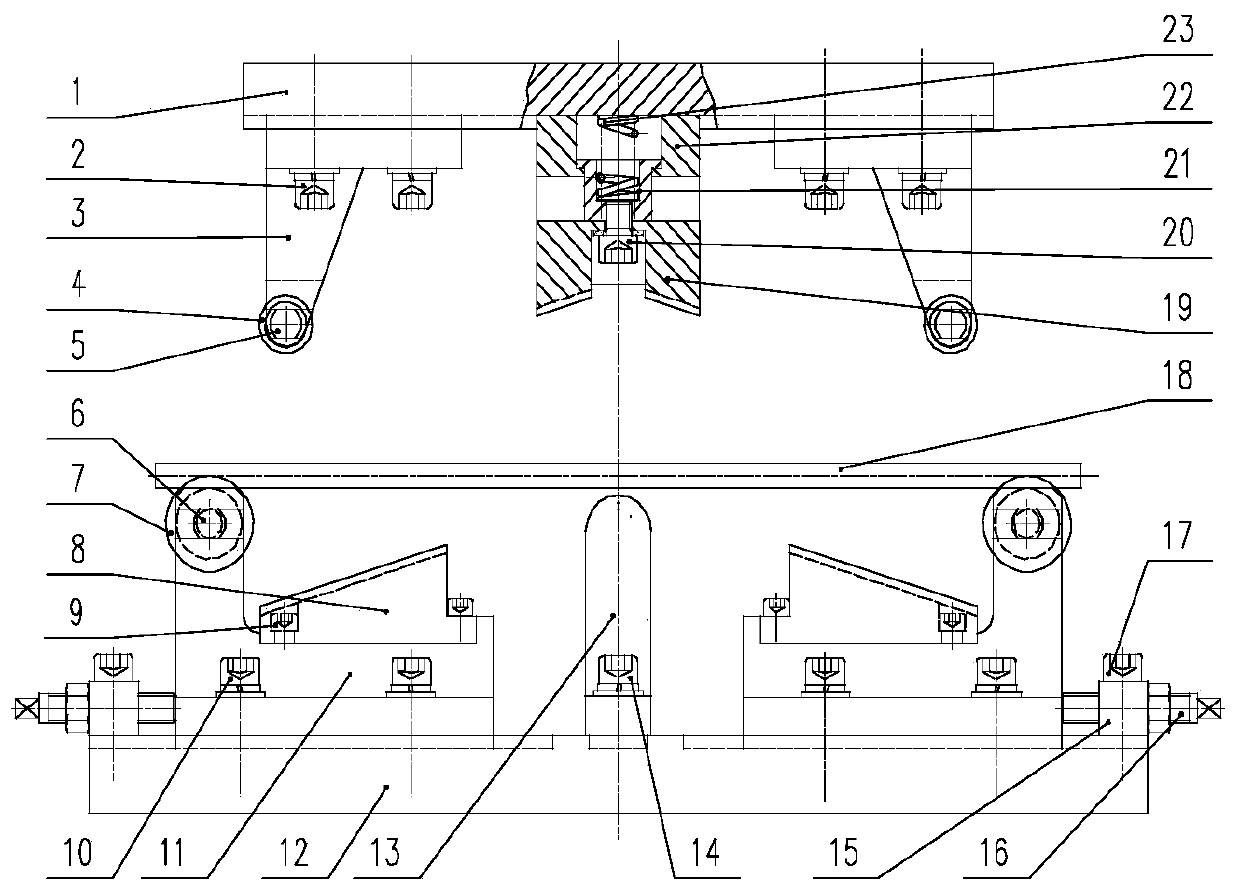

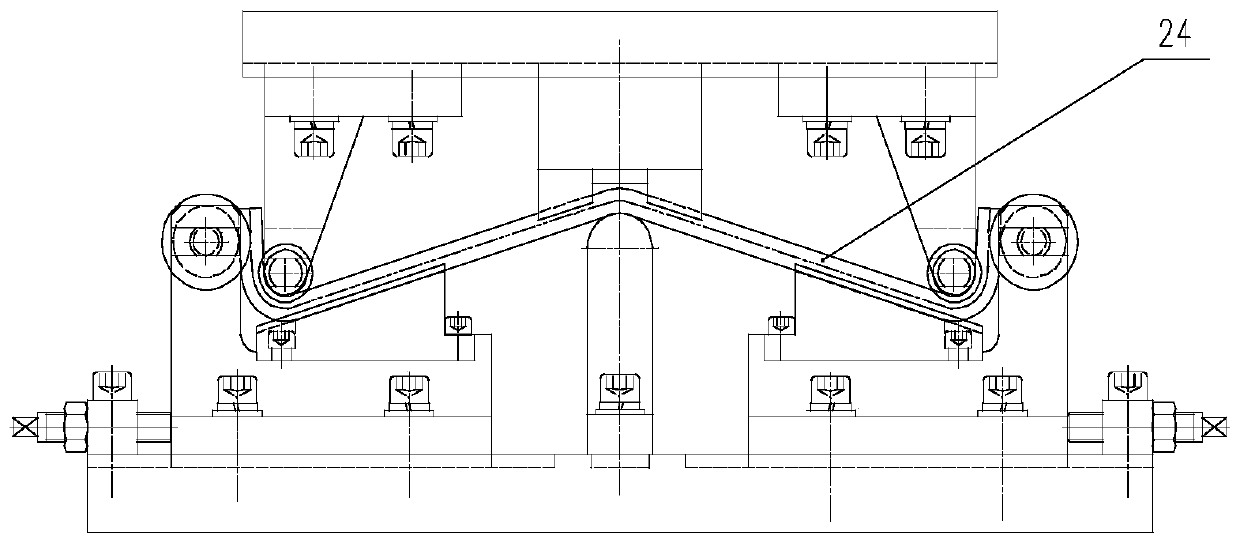

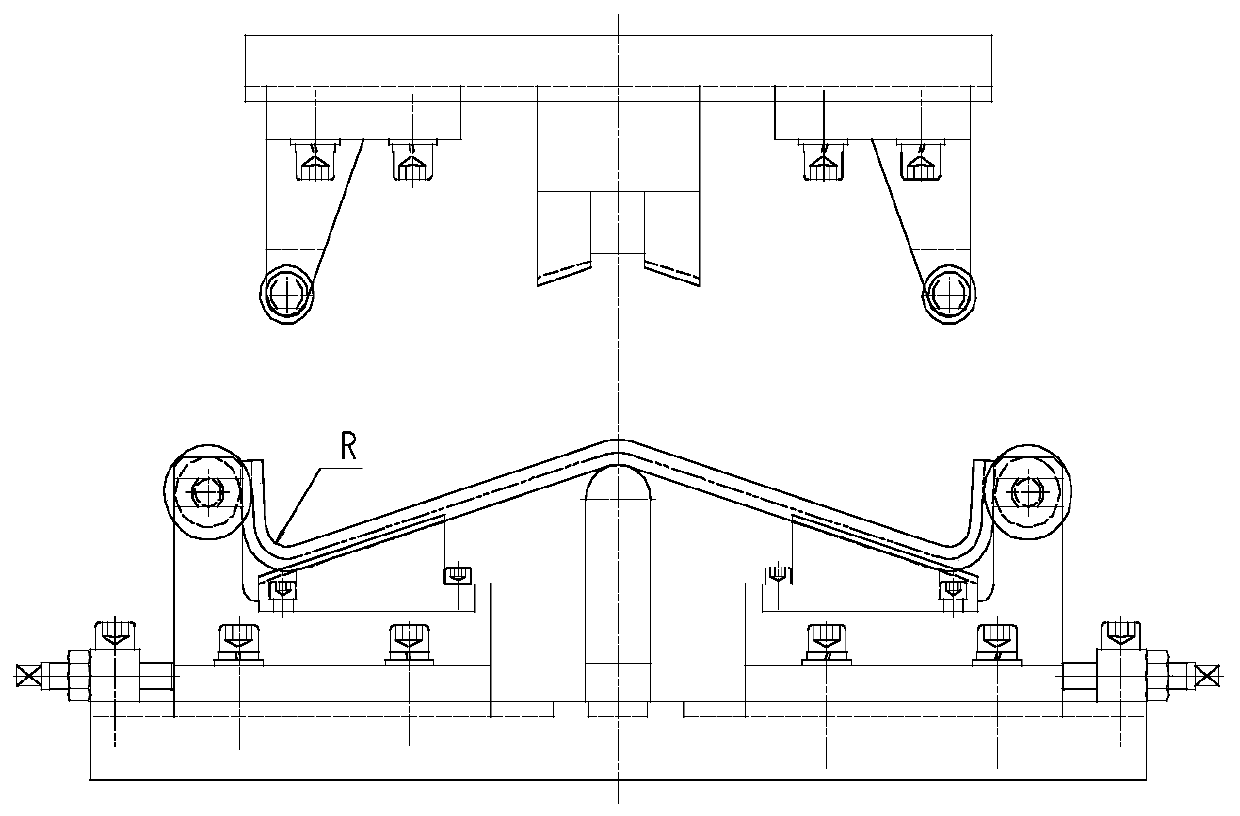

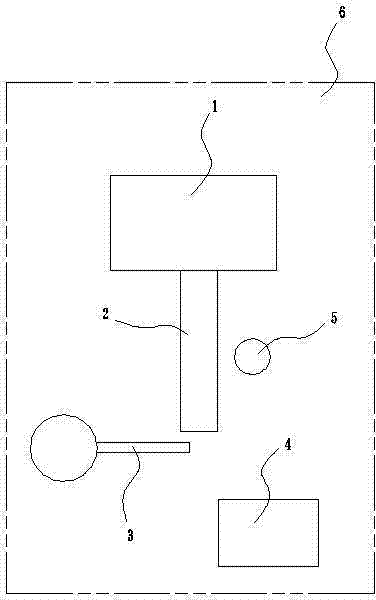

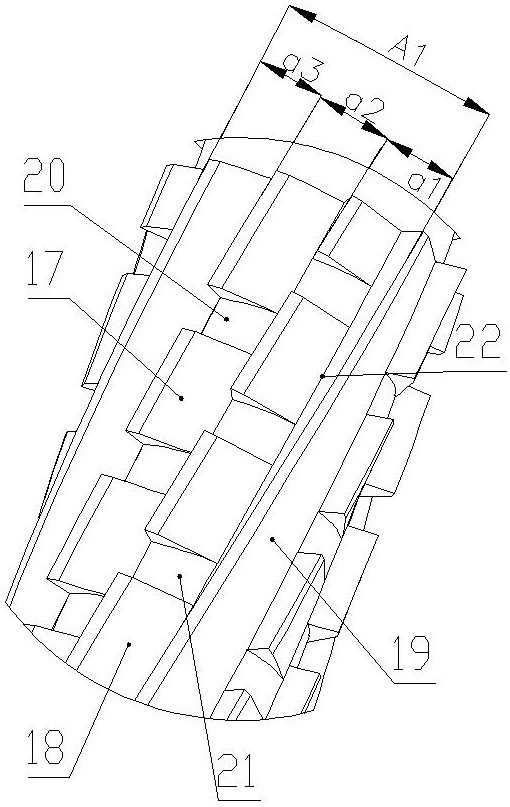

Coated abrasive grinder of propeller blade

InactiveCN101664897AGuaranteed rigidityGuaranteed machining dimensional accuracyBelt grinding machinesDrive wheelPropeller

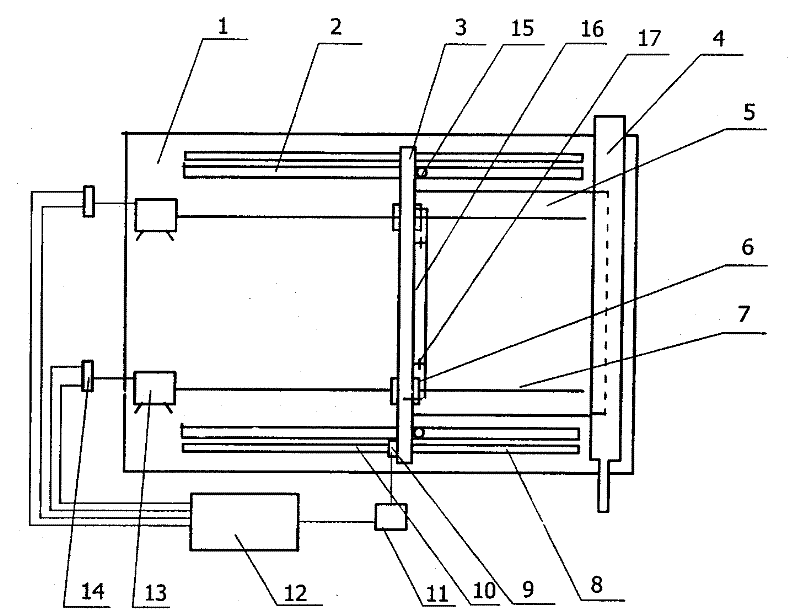

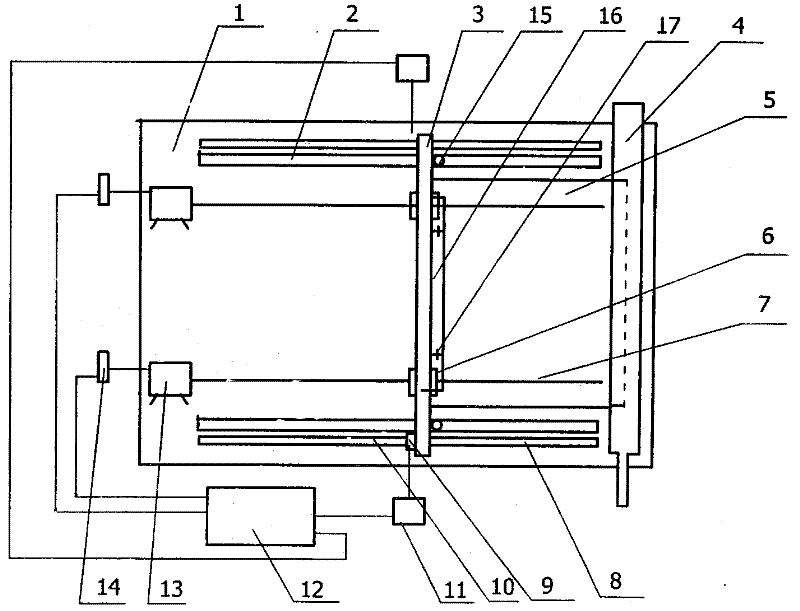

The invention discloses a coated abrasive grinder of a propeller blade, which comprises a grinder body, a grinding head mechanism, a grinding head feeding mechanism and a workpiece position adjustingmechaism, wherein the grinding head mechanism comprises an abrasive belt, a driving wheel, a contact wheel, a tensioning wheel and a grinding head drive motor; the grinding head feeding mechanism comprises an axial feed mechanism and radial feed mechanism relative to the workpiece; the coated abrasive grinder realizes combination of four degree of freedom of space by reasonable distribution of grinding head feeding and adjustment of the angle of the workpiece position as well as a shorter drive chain, guarantees the rigidity of the grinding head mechanism and a workpiece clamping mechanism, ensures the contact stabiltiy between the contact wheel and the workpice when the contact wheel rotates with a high speed, and improves work efficiency simultaneously when guaranteeing the process sizeprecision of a complex curve workpiece; and thickness is even in curve polishing, the quality of profiles is ensured, the qualificaiton rate of finished products is improved, the labor intensity of workers is reduced, and the management and production cost is decreased.

Owner:CHONGQING SAMHIDA GRINDING MACHINE

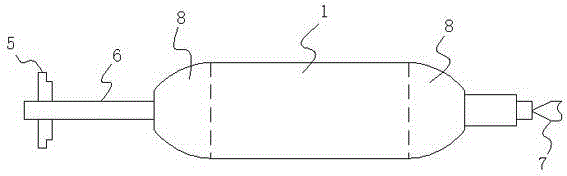

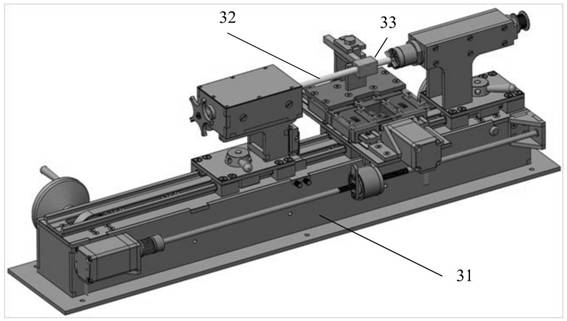

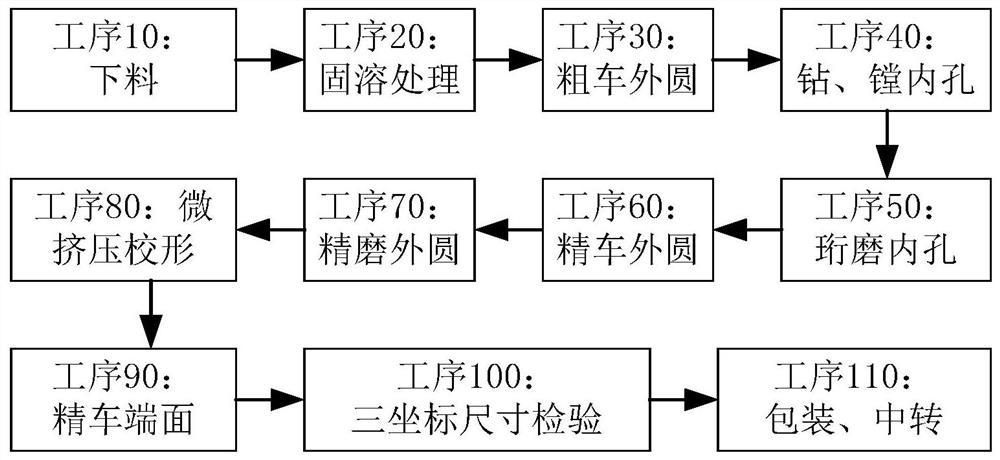

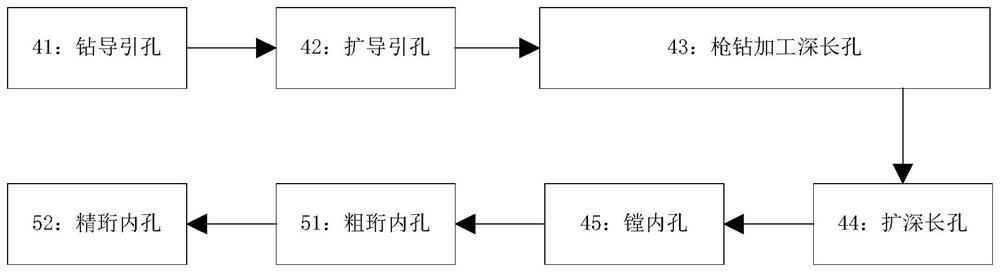

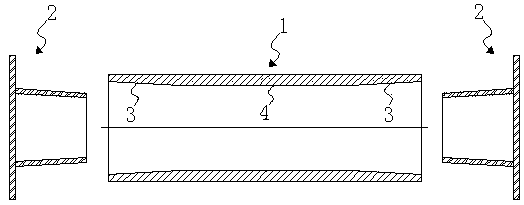

Thin-walled elongated pipe member whole precision processing method

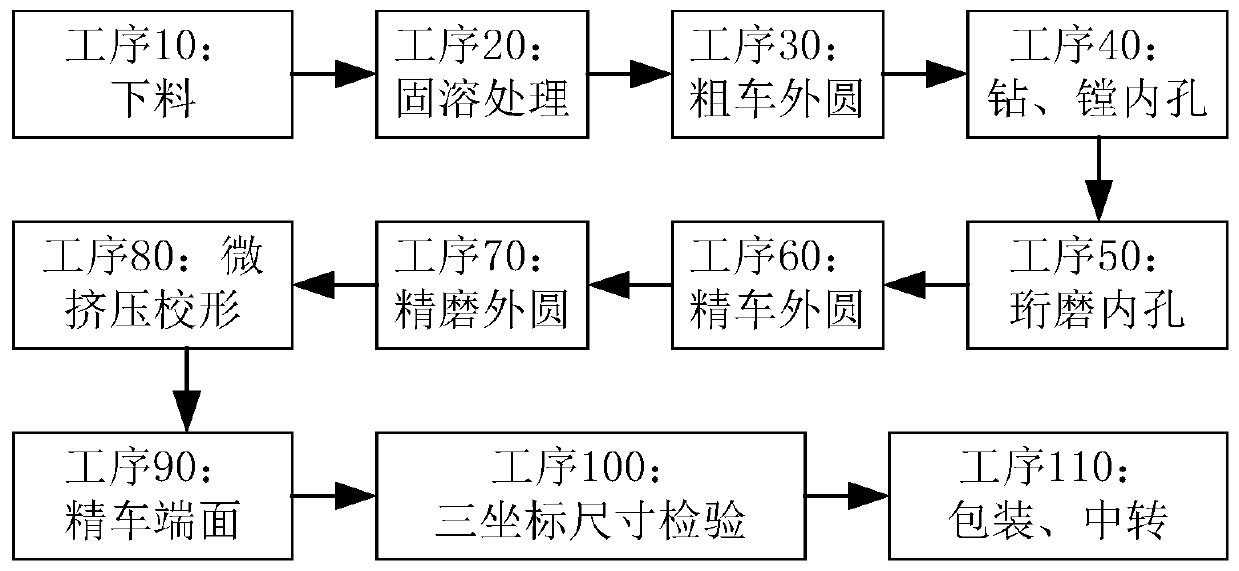

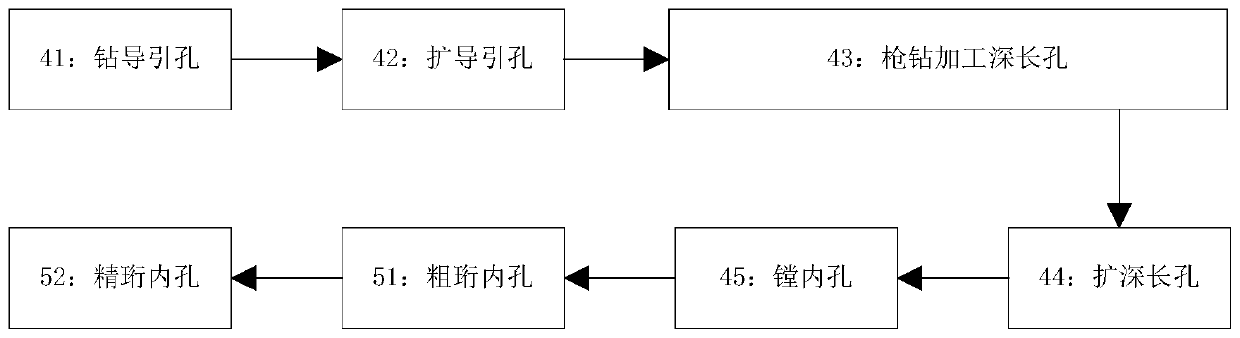

The invention provides a thin-walled elongated pipe member whole precision processing method. The thin-walled elongated pipe member whole precision processing method comprises the following steps of S1, blanking; S2, hot working; S3, rough turning of the end face and the outer circle; S4, drilling and boring of an inner hole; S5, honing of the inner hole; S6, semi-finish turning and finish turningof the outer circle; S7, fine grinding of the outer circle; S8, micro-extrusion correction; S9, finish turning of the end face; and S10, inspection and packaging. By means of the method, the whole precision machining of thin-walled elongated pipe members which are made of austenitic stainless steel materials, have the maximum length being 575 mm, have the minimum pipe diameter being 24 mm, have the maximum draw ratio being 24 and have the thinnest wall thickness being 0.3 mm can be achieved, and the inner hole and outer circle precision reaches the IT5 stage, the coaxiality reaches 0.025 mm,the straightness reaches 0.025mm, the surface roughness reaches Ra0.8, and the method is a high-efficiency, precise and low-cost thin-walled elongated pipe member processing method.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST +1

A CNC cutting machine

InactiveCN102294514AGuaranteed machining dimensional accuracyRealize cutting automatic positioningMeasurement/indication equipmentsShearing control devicesNumerical controlConverters

The present invention relates to a cutting device, in particular to a numerically controlled board cutting machine, which provides a numerically controlled board cutting machine capable of ensuring cutting dimension accuracy instead of manual positioning to ensure cutting accuracy. A cutting knife is arranged longitudinally at one end of the guide rail, and a grating ruler includes a grating strip, a grating sensor and a grating control converter. A moving positioning rod is arranged longitudinally across the two guide rails, and the lower part of the moving positioning rod is fixed to the nut on the ball screw. One end of the ball screw is connected to the shaft of the servo motor, and the servo motor is electrically connected to the servo controller. On the outside of the double guide rails, at least one grating bar is arranged parallel to the guide rails. The grating sensor realizes the automatic positioning of cutting, that is, realizes the numerical control of measurement, high-precision numerical control, reduces mechanical transmission errors, improves automation, reduces scrap rate, improves work efficiency, and reduces and reduces labor costs.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

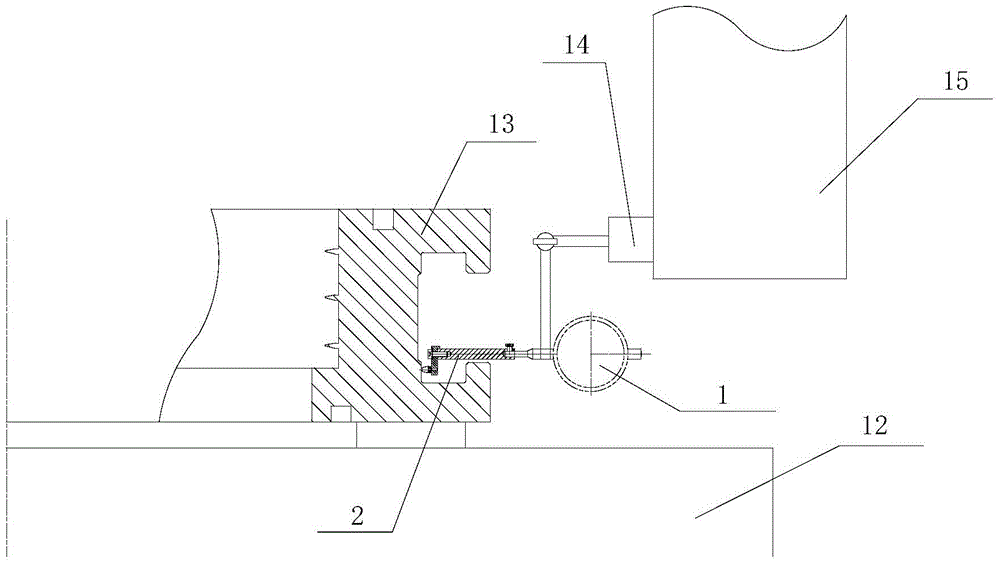

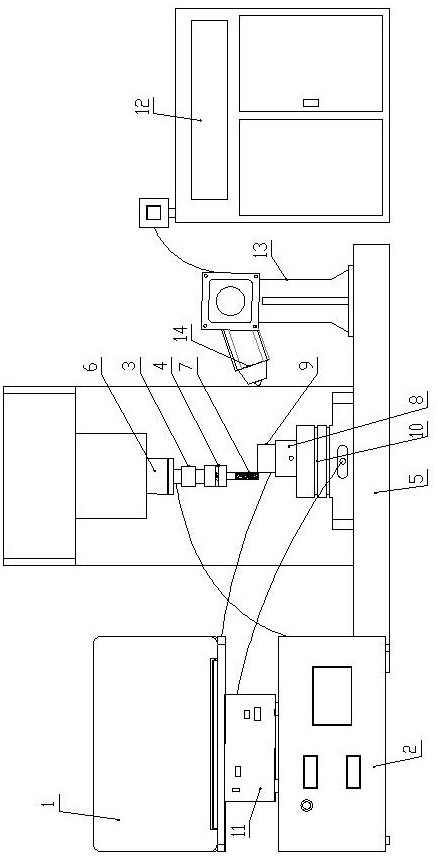

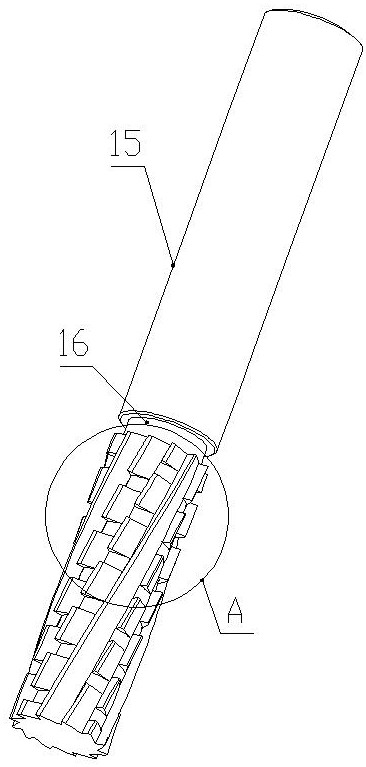

Ultrasonic vibration machining device and method for aluminum-based silicon carbide composite material

ActiveCN112548175AImprove quality and efficiencyImprove processing efficiencyMilling equipment detailsCarbide siliconMachine parts

The invention discloses an ultrasonic vibration machining device and method for an aluminum-based silicon carbide composite material. The ultrasonic vibration machining device comprises a computer, alaser auxiliary heating part, an ultrasonic vibration machining part, a machine tool workbench, a machine tool spindle and a micro-edge milling cutter, wherein the ultrasonic vibration machining partcomprises an ultrasonic generator, a transducer and an amplitude-change pole; the lower end of the machine tool spindle is connected with the transducer, the lower end of the transducer is connected with the amplitude-change pole, the upper end of the micro-edge milling cutter is clamped at the lower end of the amplitude-change pole, and the ultrasonic generator is connected with the transducer through a wire; a clamp holder is arranged on the machine tool workbench, a workpiece made of the aluminum-based silicon carbide composite material is clamped on the clamp holder, and the clamp holder is connected with a three-way dynamometer; and the laser auxiliary heating part is used for heating a to-be-machined part of the workpiece. In the milling operation process, chip removal can be accelerated, flutter of a cutter is eliminated, abrasive abrasion and adhesive abrasion are reduced, milling force and cutting heat are reduced, the machining size precision is guaranteed, the workpiece surface quality and the machining efficiency are improved, and the machining cost is saved.

Owner:HENAN POLYTECHNIC UNIV

Molding technology of bending connection pipe

The invention discloses a molding technology of a bending connection pipe; the bending connection pipe is manufactured by molding a bendable branch pipe mandril; after being molded in a way of vulcanization, the branch pipe mandril can be easily and conveniently pulled out from the bending connection pipe, so that the bending connection pipe can be manufactured into any needed size. According to the molding technology of the bending connection pipe, a connecting rubber die cavity is arranged at the connecting part of a main pipe and a branch pipe, and a vulcanized rubber material in the connecting rubber die cavity is used for closely wrapping the connecting part of the main pipe and the branch pipe, so that the integral bending connection pipe can be manufactured, the sealing property of the bending connection pipe is effectively improved, and the service life of the bending connection pipe is effectively prolonged.

Owner:SICHUAN FUXIANG TECH

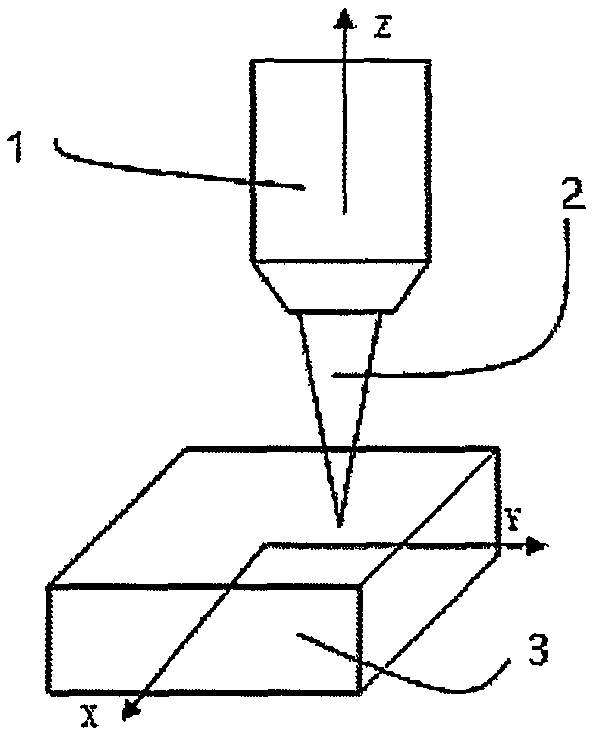

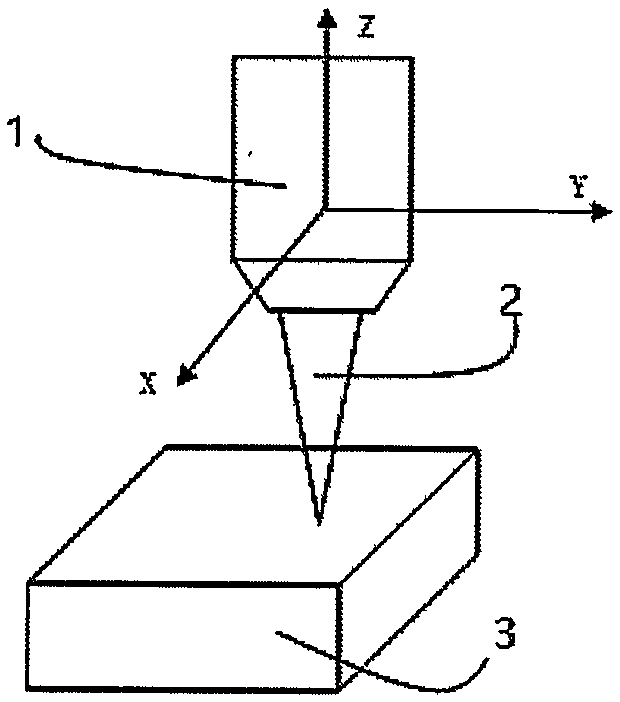

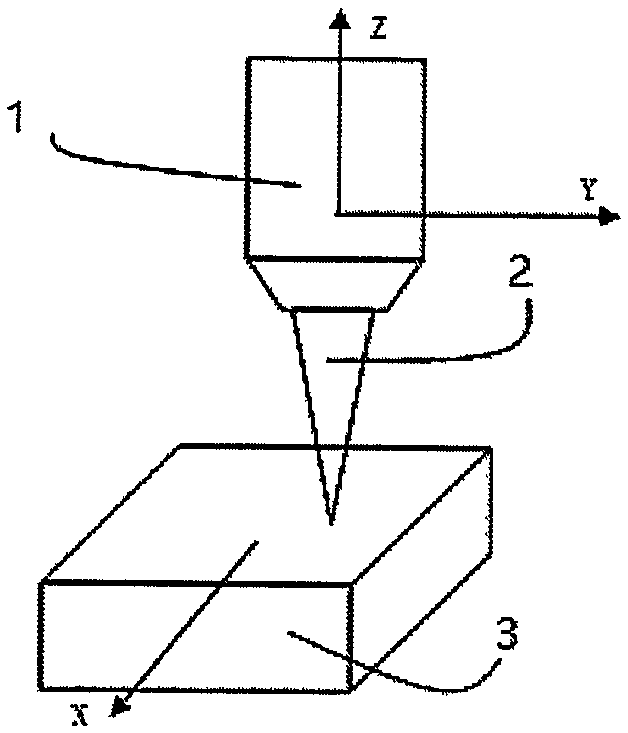

Multi-axis linkage ultrafast laser processing system

InactiveCN106853556ALow dispersionReduce reflection lossLaser beam welding apparatusEngineeringLinear motion

Disclosed is a multi-axis linkage ultrafast laser processing system. The system comprises an ultrafast laser generator, an optical module, a lens assembly, a machined part platform for bearing a machined part, and a linkage controller and a linkage driver for controlling the lens assembly or the machined part platform to move, wherein the lens assembly and / or the machined part platform perform linear motion along one of an X axis and / or a Y axis and / or a Z axis, and the lens assembly and / or the machined part platform can rotate around at least one of the X axis, the Y axis and the Z axis.

Owner:彭翔 +1

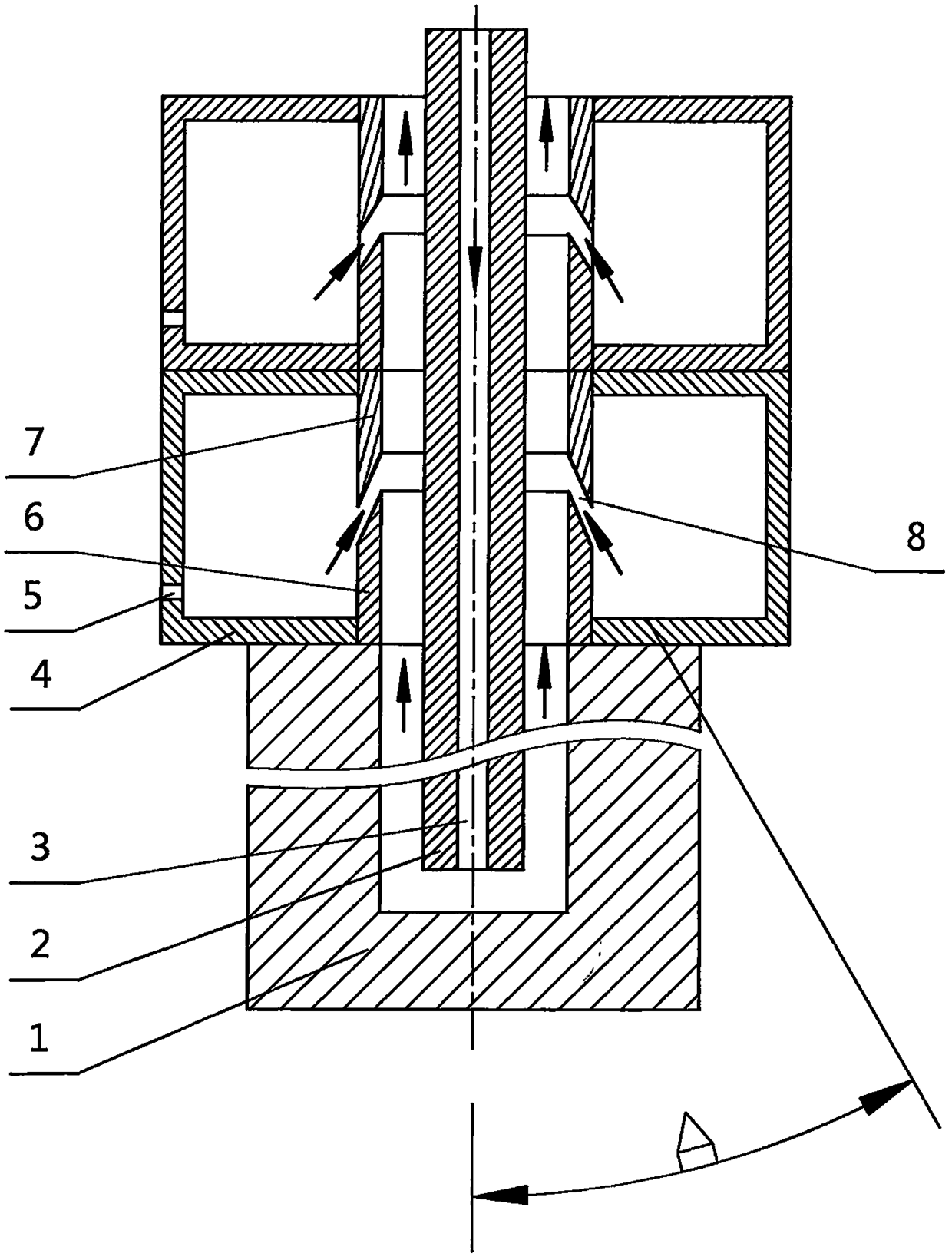

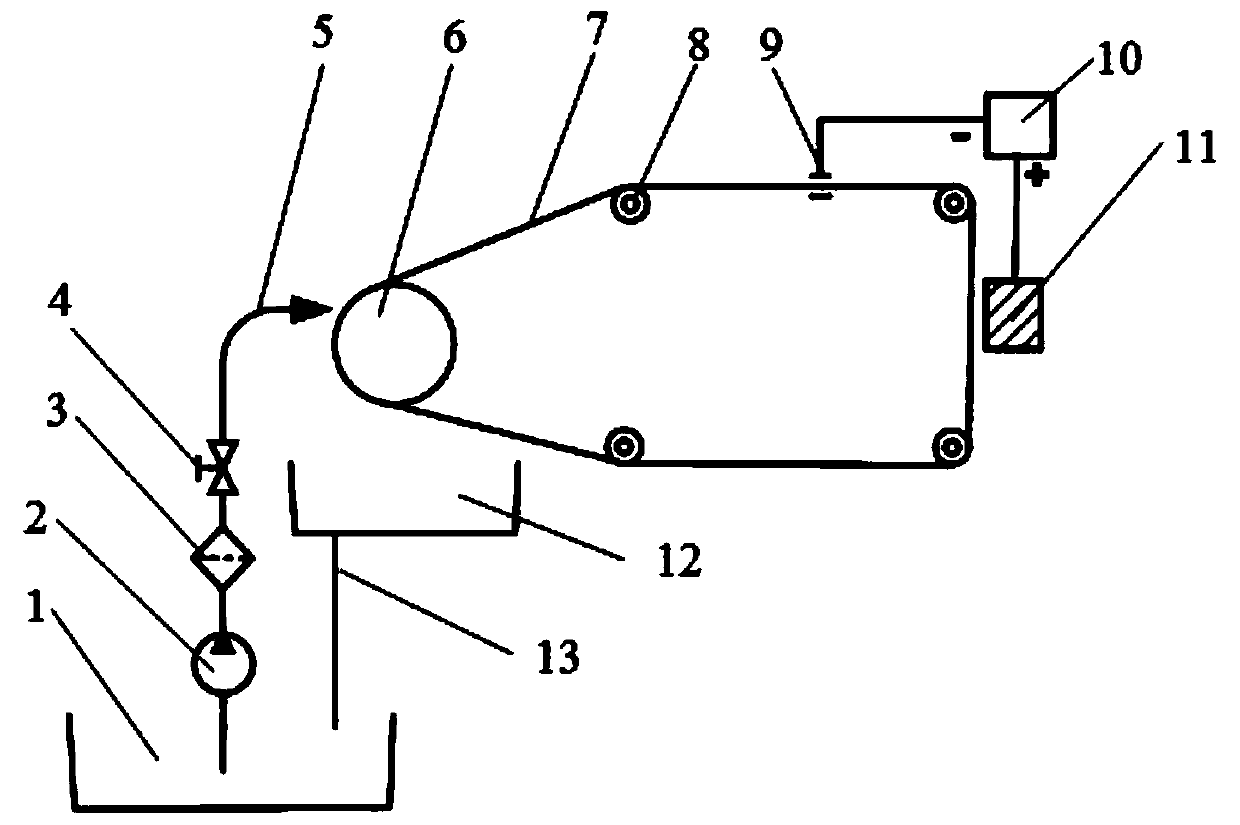

Discharging method for electric corrosion products for electric spark machining

ActiveCN109175551AGuaranteed stabilityGuaranteed machining dimensional accuracyElectricityAcute angle

The invention belongs to the technical field of special machining and particularly relates to a discharging method for electric corrosion products for electric spark machining, and the discharging method is used for discharging the electric corrosion products in the electric spark machining process of deep holes, deep grooves, narrow seams and other structures. The method relates to a hydraulic force discharging device, and the device is composed of a hydraulic force box, an outer cone body, an inner cone body and an annular gap. Liquid with pressure flows into the hydraulic force box and flows out of the annular gap; an included angle A formed between the annular gap and the axis of an electrode is an acute angle; and the hydraulic force discharging device can be in one set, two sets or aplurality of sets. The steps of the discharging method for the electric corrosion products includes that firstly, the electrode and the hydraulic force discharging device are machined; secondly, theelectrode, a workpiece and the hydraulic force discharging device are installed; and thirdly, electric spark discharging machining is performed, and the liquid with the pressure flows into and flows out of a discharging device for the electric corrosion products. Due to a method that flowing liquid is externally added, the electric corrosion products of the machining system are discharged in time,blocking is prevented, the size precision of machining and the shape and position precision are guaranteed, and the machining efficiency is improved.

Owner:ZHONGBEI UNIV

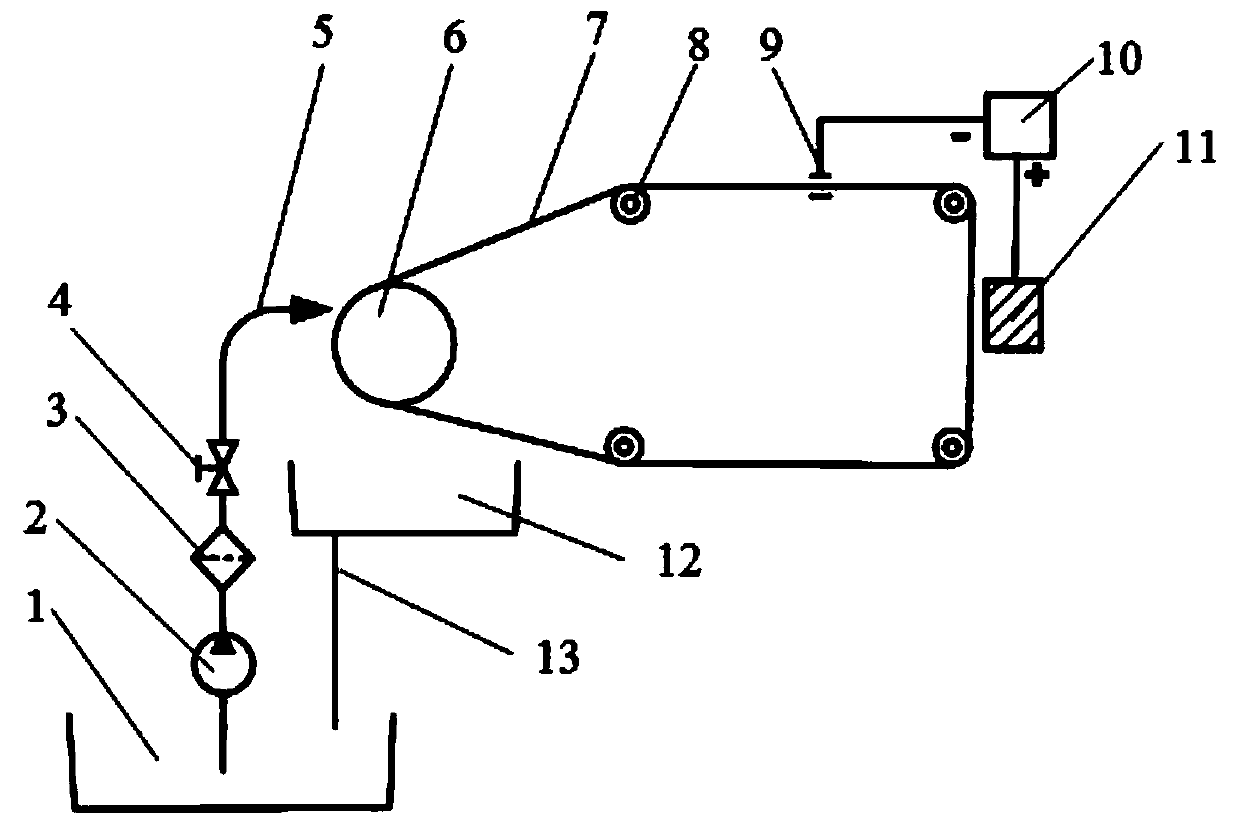

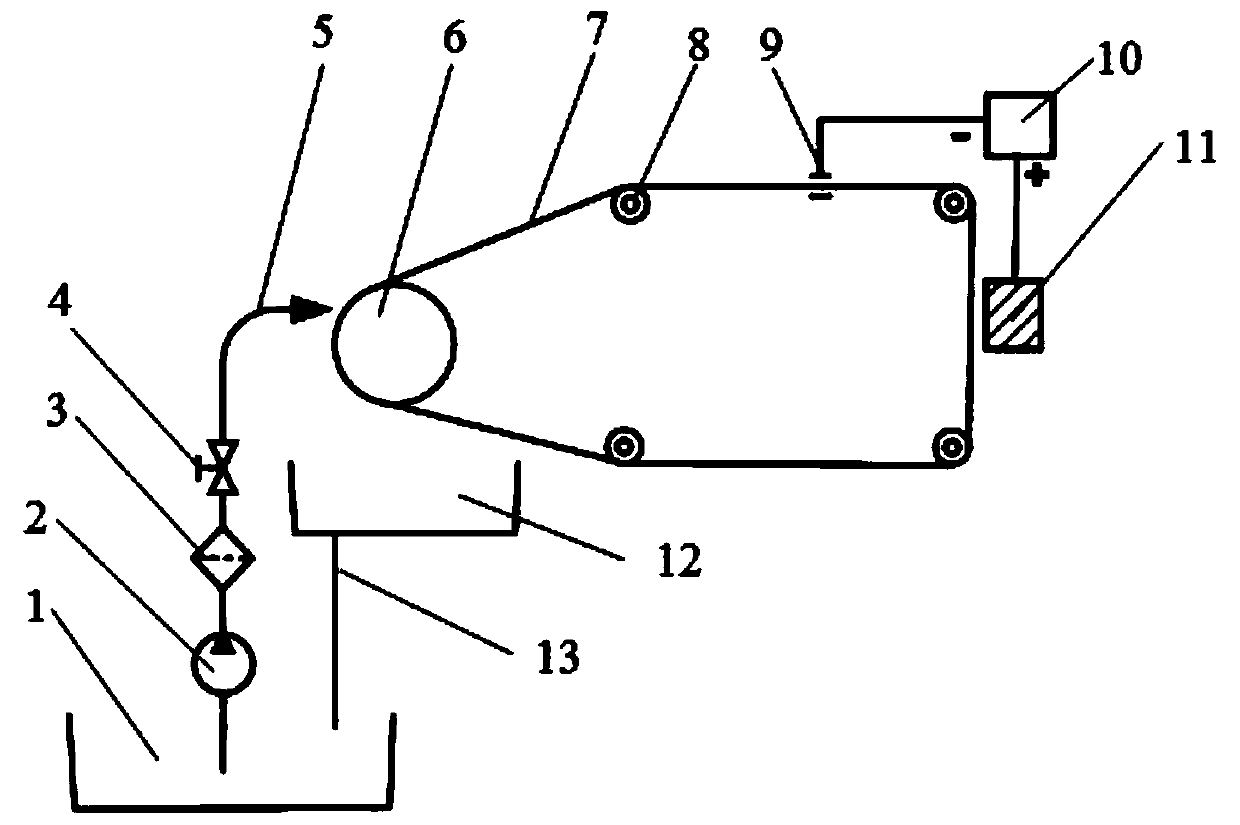

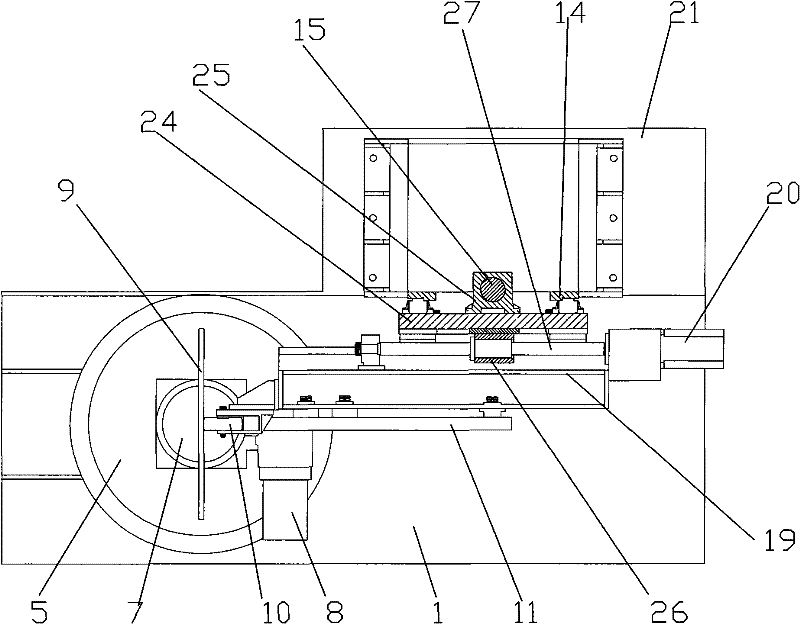

Electric spark wire cutting device and liquid amount control method between electrodes

ActiveCN110000437AGuaranteed machining dimensional accuracyEliminates back-and-forth cutting streaksElectrical-based machining electrodesElectric dischargeWire speed

The invention discloses an electric spark wire cutting device. The electric spark wire cutting device comprises a liquid supply system and a cutting system, wherein the liquid supply system is used for providing an inter-electrode working solution, and the cutting system is used for machining a workpiece by using an electric discharge wire; the cutting system comprises a lead barrel, a plurality of guide wheels and an electrode wire, wherein the electrode wire winds the wire barrel and the guide wheel and can be driven by the wire barrel to move between the guide wheel and a discharging gap; and the liquid supply system comprises a nozzle capable of spraying the working solution, and the nozzle sprays the working solution on the electrode wire of the wire barrel, so that the electrode wireis wrapped with the working solution, and the working liquid amount between the electrodes can be controlled by controlling the wire speed of the electrode wire; and the wire barrel drives the electrode wire to enter the electrode wire wrapped with the working solution into the discharging gap.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

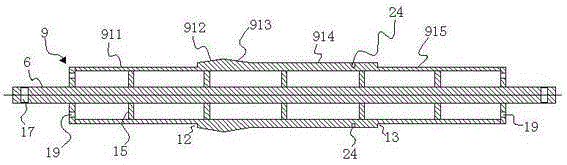

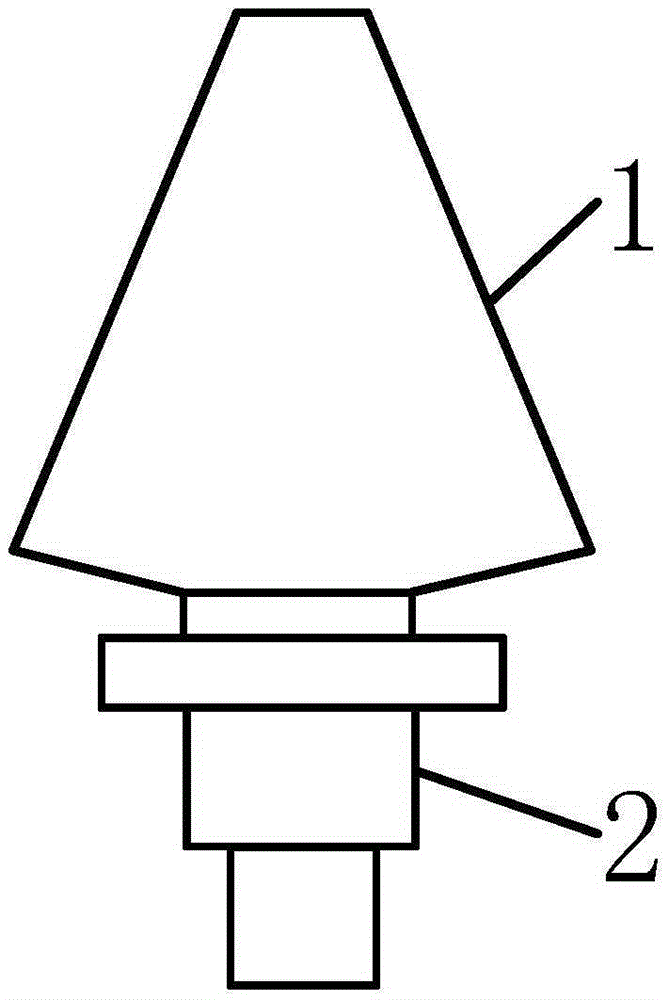

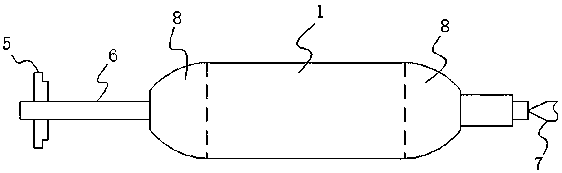

Multi-station winding mold for manufacturing intermediate pipe and manufacturing method for intermediate pipe

ActiveCN106182716AGuarantee processing qualityGuaranteed machining dimensional accuracyCircular coneMaterials science

The invention discloses a multi-station winding mold for manufacturing an intermediate pipe. The multi-station winding mold comprises a main mold cylinder with a spindle, two hollow auxiliary mold cylinders and one or more special-shaped circular rings. The main mold cylinder comprises a first main mold cylinder body, a first main mold circular truncated cone body, a second main mold circular truncated cone body, a second main mold cylinder body and a third main mold cylinder body. Each auxiliary mold cylinder comprises a hollow first auxiliary mold cylinder body, a hollow auxiliary mold circular truncated cone body, a hollow second auxiliary mold cylinder body, a circular-ring-shaped end cover and a hollow round pipe. Each special-shaped circular ring comprises a hollow first circular cone and a hollow second circular cone. During assembling, the one or more special-shaped circular rings are detachably installed on the second main mold cylinder body in a sleeving mode. The two auxiliary mold cylinder bodies are detachably installed at the two ends of the main mold cylinder correspondingly in a sleeving mode in the direction of the two ends of the main mold cylinder. The two ends of the spindle penetrate through end covers of the two auxiliary mold cylinder bodies and the round pipes correspondingly, the two ends of the spindle are exposed to the round pipes of the two auxiliary mold cylinder bodies, and thus a plurality of stations winding the intermediate pipe are formed. Through the multi-station winding mold, a plurality of intermediate pipes can be formed at one time, and thus the cost is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Machining method of tool moulding bed

InactiveCN111119502AEasy to makeImprove efficiencyBuilding material handlingManufacturing computing systemsDimensional precisionManufacturing engineering

The invention relates to a machining method of a tool moulding bed. The machining method of the tool moulding bed includes the following steps of positioning and paying off; determining the height ofa horizontal moulding bed; and determining supporting columns and upper plate assembling. The machining method of the tool moulding bed solves the problems that for a large rotating angle and large size twisting box type steel beam rotating stair, a moulding bed manufacturing technology is complex in calculating of positioning point calculates and large in moulding bed height, and danger is high,and the machining method of the tool moulding bed is provided. The machining method is simple in manufacturing, high in efficiency and capable of saving a moulding bed manufacturing material; the moulding bed is simple in structure, reasonable in layout and positioning, steady in acting force and capable of saving the moulding bed manufacturing material, the moulding bed can be repeatedly utilized, and cost is saved; the machining size precision of a spiral box type beam of the rotating stair using the moulding bed is effectively controlled, and operation of the rotating stair curve beam is achieved; and according to the arc height of the curved type beam, the height of each web support can be set on a joint, and it is guaranteed that splicing is free of sinking.

Owner:KOCEL STEEL STRUCTURE CO LTD

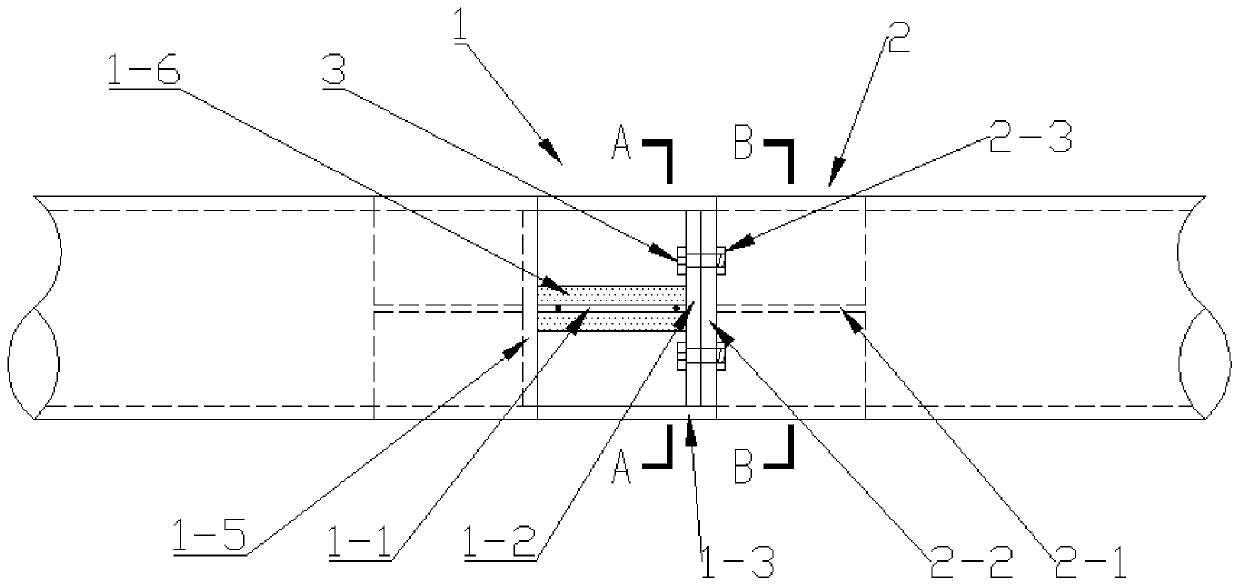

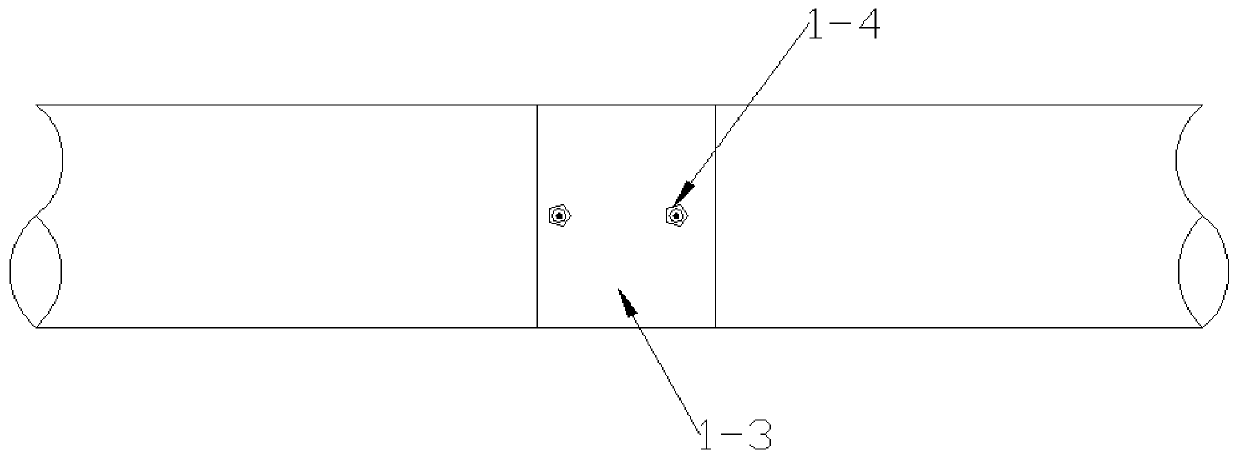

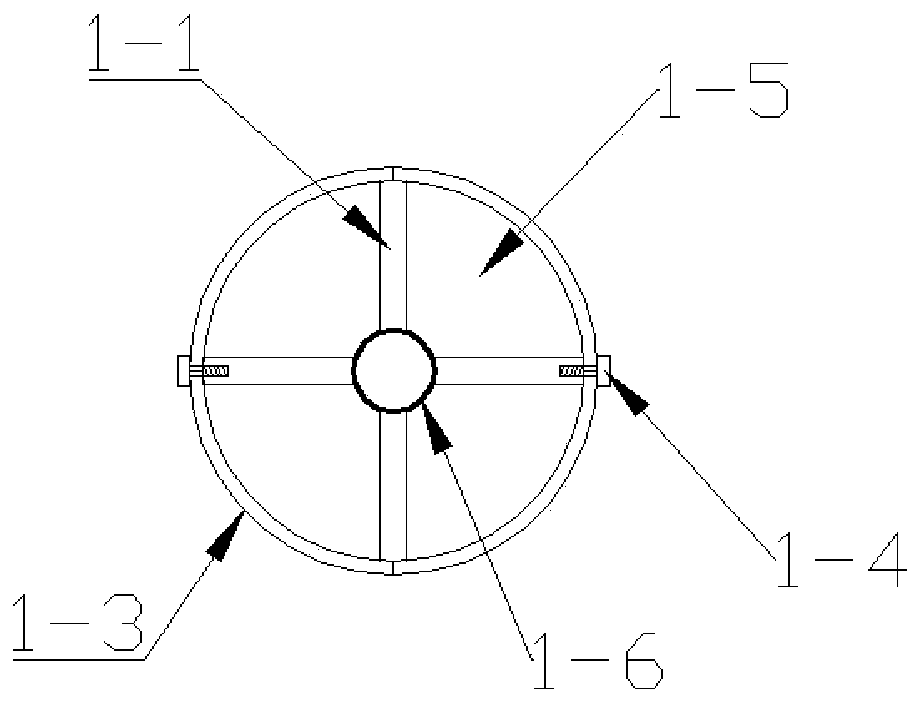

Tube assembly joint

PendingCN111288054AGuaranteed quality and accuracyGuaranteed machining dimensional accuracyRod connectionsIndustrial engineeringSteel tube

The invention relates to a tube assembly joint, and belongs to the technical field of tube connection. The tube assembly joint mainly solves the problems that a truss is large in integral cross section so as to be inconvenient to transport in actual engineering, and the on-site assembly of the assembly truss occupies a large space, the assembly welding workload is high, on-site welding conditionsof rod pieces are poor, and welding quality can not be guaranteed. According to the technical scheme, the tube assembly joint comprises a device I and a device II which are respectively arranged at the two ends of a butt-joint steel tube interface; stiffening grooves are formed in the two ends of the butt-joint steel tube interface; the device I comprises a cross stiffening plate I and a left connecting flange plate, and a sheath tube is arranged on the periphery of the portion, extending out of a left butt-joint steel tube, of the cross stiffening plate I; the device II comprises a cross stiffening plate II and a right connecting flange plate; and the left connecting flange plate of the device I is connected with the right connecting flange plate of the device II through a high-strength bolt. The tube assembly joint has the advantages of being novel in structure, convenient to install and the like.

Owner:科顿环境科学股份有限公司

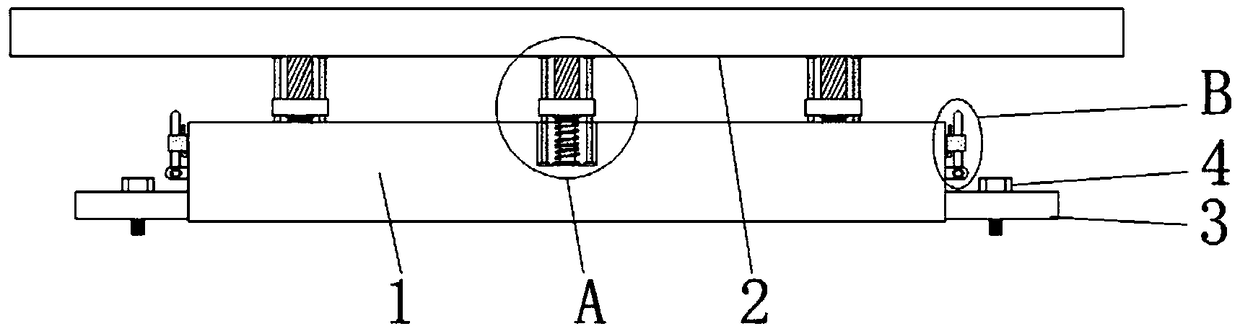

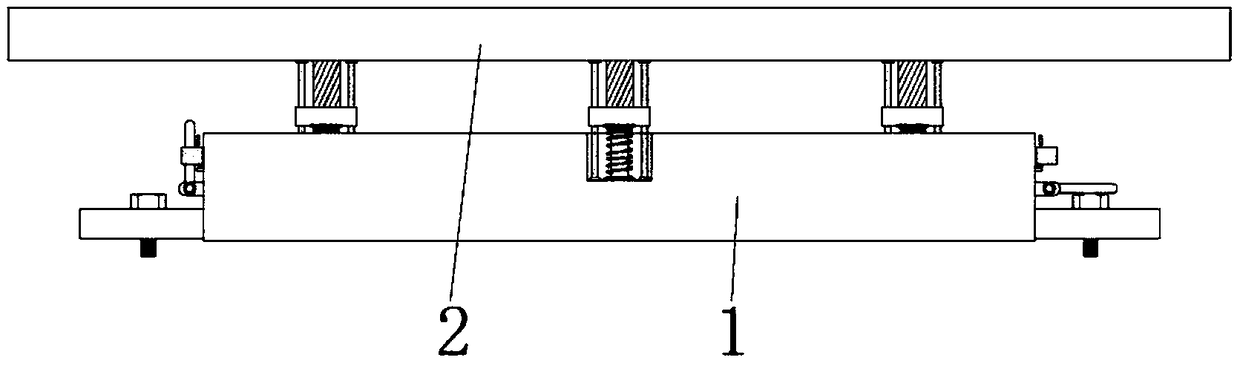

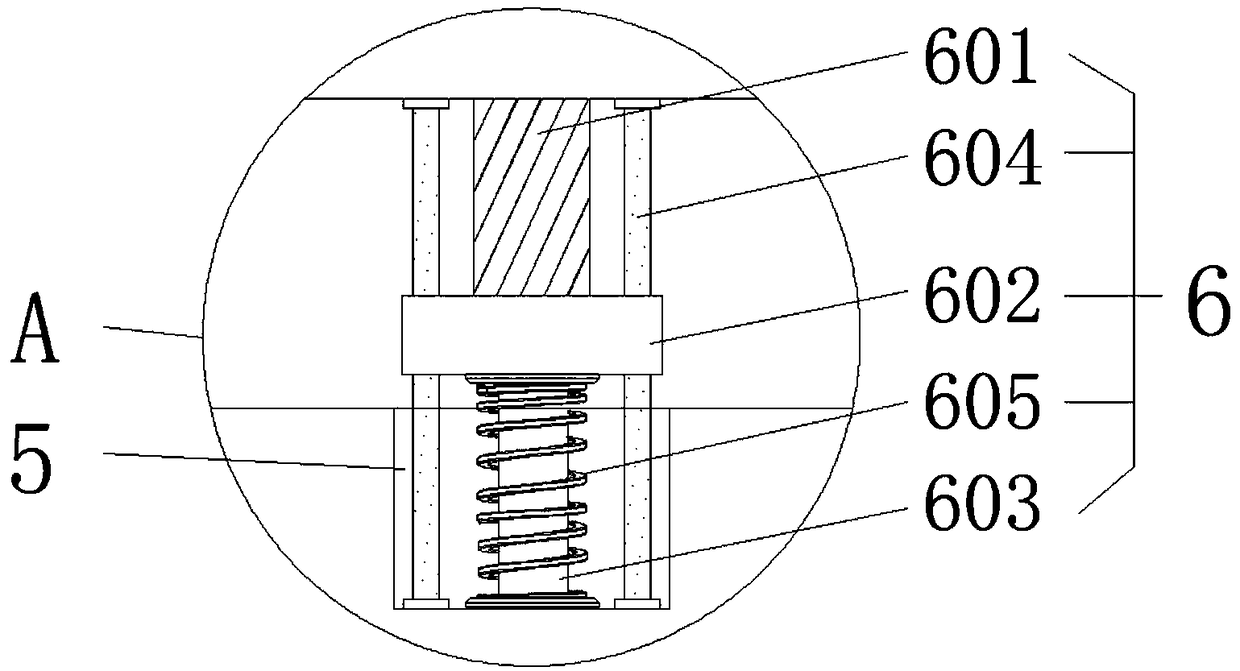

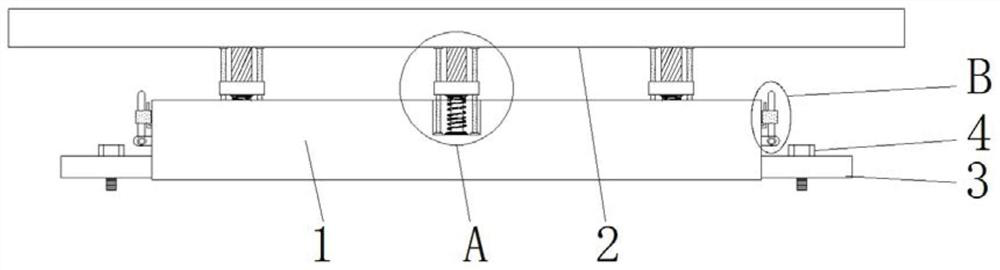

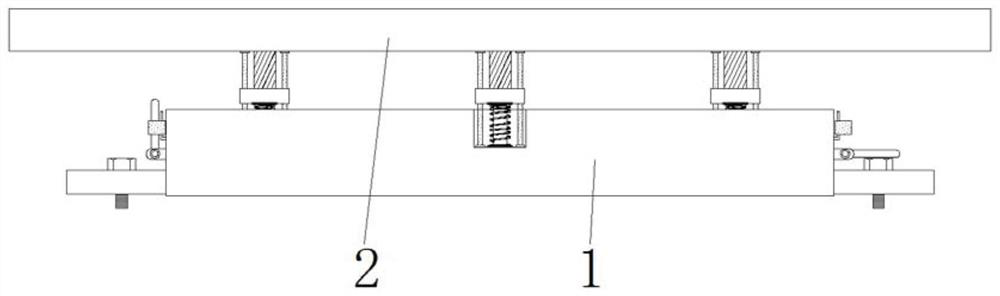

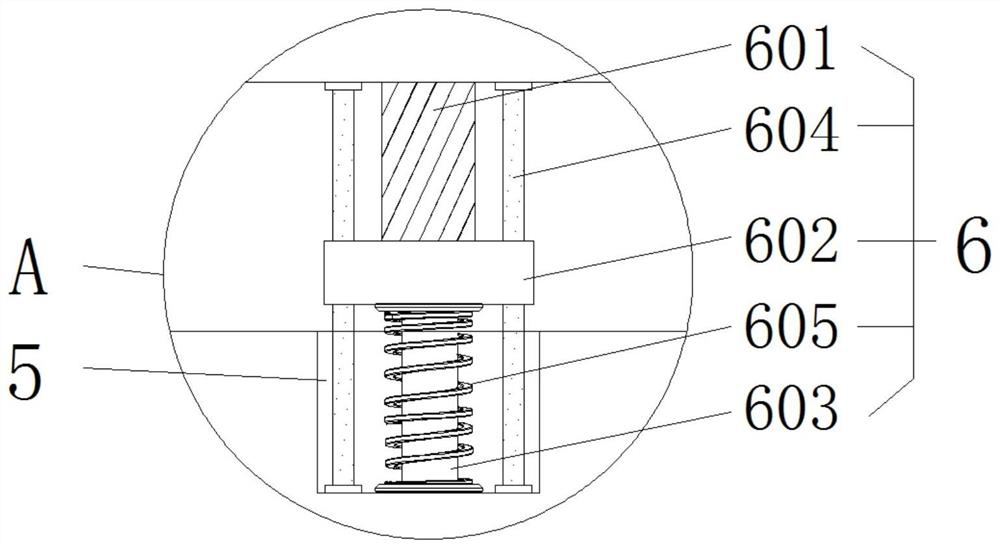

Mechanical base with functions of buffering and damping

ActiveCN109506085AWith shock absorbing functionHave a shock absorbing effectShock absorbersEngine bedsShock resistanceEngineering

The invention discloses a mechanical base with the functions of buffering and damping. The mechanical base comprises a base body, a mounting plate, a plurality of buffering devices uniformly arrangedbetween the base body and the mounting plate, and a locking device, wherein the buffering devices include slide canisters, slider rods, limit rods and springs; the upper ends of the slide canisters are fixed to the lower end surface of the base body; the lower portions of the slide canisters and the upper portions of the slide rods are in sliding connection; the lower ends of the slide rods are fixed to the mounting plate; the slide rods are sleeved with the springs that are compressed and arranged on the lower ends of the slide canisters; the upper ends and the lower ends of the limit rods are correspondingly fixed to the base body and the mounting plate; and the locking device includes pressing plates for pressing and fixing screws so that the screws can be prevented from loosing. According to the mechanical base, the problems that the capacities of buffering and shock resistance are poor, the deformation is prone to occurring, the screws are prone to looseness, and the processing dimensional accuracy is prone to decrease in the prior art are solved; the buffering and damping effects of the mechanical base are good; the base is not prone to deformation; the processing dimensionalaccuracy is high; and the phenomenon that the screws are prone to looseness during machining is avoided.

Owner:SUZHOU INST OF TRADE & COMMERCE

Intelligent special-shaped forming machine for air conditioner mesh enclosure production

The invention discloses an intelligent special-shaped forming machine for air conditioner mesh enclosure production. The intelligent special-shaped forming machine is characterized by comprising a base, a bed body, a workbench, damping padding iron, an intelligent control device, a crankshaft, a clutch, a connection rod, a pneumatic tightening switch, a hammer body, a special-shaped hammer head, a special-shaped die, a T-shaped groove, a fixing bolt, a drawing device, a motor, a motor belt wheel, a big belt wheel, a V-shaped belt, a cable, a pneumatic pipe, a pneumatic blow gun, an air pump, a guide rail, a brake and a motor support; and the bed body is arranged on the base, the damping padding iron is arranged below the base, and the workbench is arranged in front of the bed body. According to the intelligent special-shaped forming machine, through arrangement of the intelligent control device, the clutch, the brake, the special-shaped die, the special-shaped hammer head and the damping padding iron, the machining efficiency and the machining quality of an air conditioner mesh enclosure are facilitated, the intelligent degree is increased, the production cost is lowered, damping and noise reduction are achieved, the service life is prolonged, multiple purposes are achieved through one machine, and application and popularization are facilitated.

Owner:TIANJIN MALIGAISHA TECH

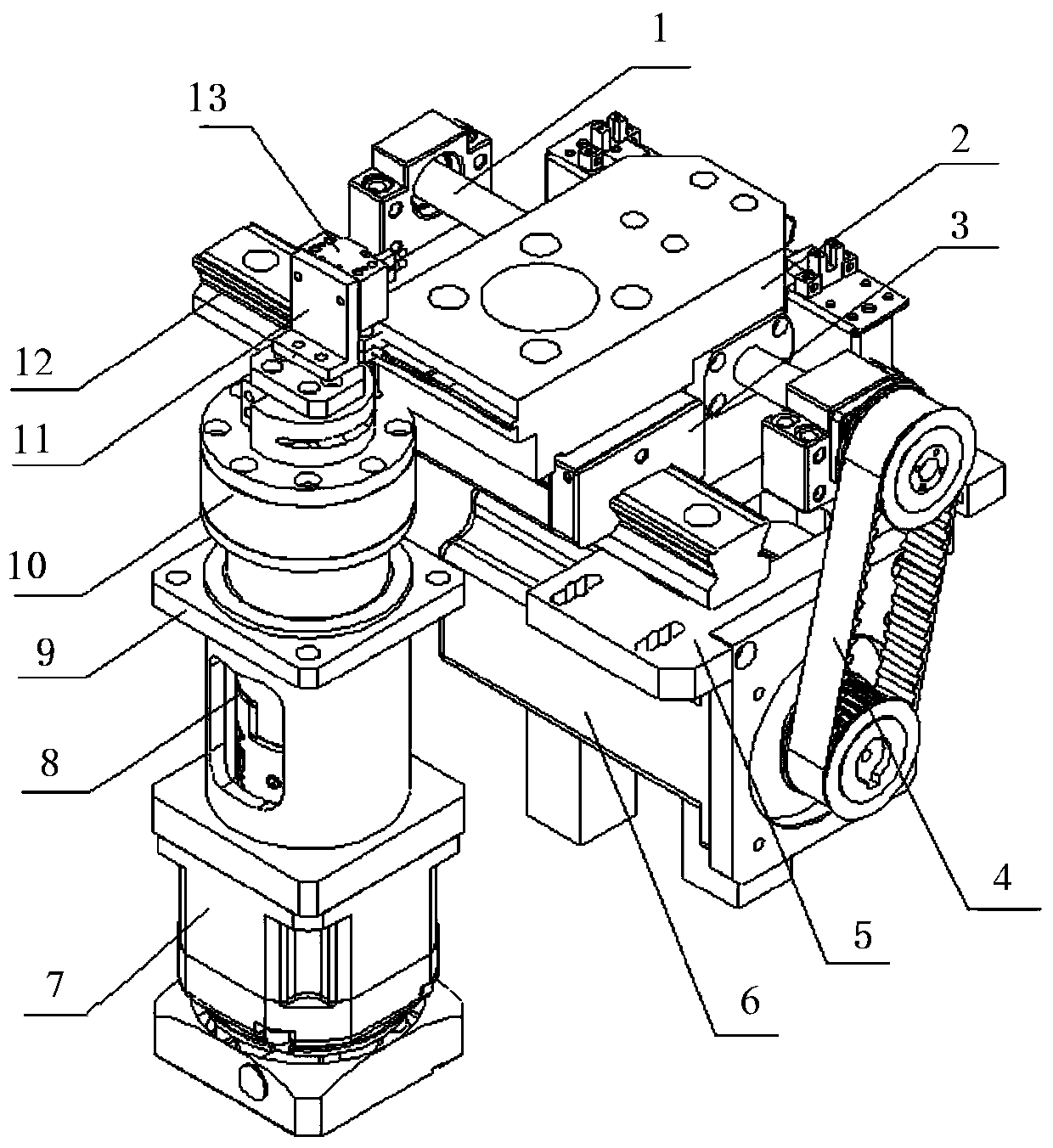

Coated abrasive grinder of propeller blade

InactiveCN101664897BGuaranteed rigidityGuaranteed machining dimensional accuracyBelt grinding machinesDrive wheelPropeller

The invention discloses a coated abrasive grinder of a propeller blade, which comprises a grinder body, a grinding head mechanism, a grinding head feeding mechanism and a workpiece position adjusting mechaism, wherein the grinding head mechanism comprises an abrasive belt, a driving wheel, a contact wheel, a tensioning wheel and a grinding head drive motor; the grinding head feeding mechanism comprises an axial feed mechanism and radial feed mechanism relative to the workpiece; the coated abrasive grinder realizes combination of four degree of freedom of space by reasonable distribution of grinding head feeding and adjustment of the angle of the workpiece position as well as a shorter drive chain, guarantees the rigidity of the grinding head mechanism and a workpiece clamping mechanism, ensures the contact stabiltiy between the contact wheel and the workpice when the contact wheel rotates with a high speed, and improves work efficiency simultaneously when guaranteeing the process sizeprecision of a complex curve workpiece; and thickness is even in curve polishing, the quality of profiles is ensured, the qualificaiton rate of finished products is improved, the labor intensity of workers is reduced, and the management and production cost is decreased.

Owner:CHONGQING SAMHIDA GRINDING MACHINE

A wire electric discharge cutting device and a method for controlling liquid volume between electrodes

ActiveCN110000437BGuaranteed machining dimensional accuracyEliminates back-and-forth cutting streaksElectrical-based machining electrodesElectric dischargeWire cutting

The invention discloses an electric spark wire cutting device. The electric spark wire cutting device comprises a liquid supply system and a cutting system, wherein the liquid supply system is used for providing an inter-electrode working solution, and the cutting system is used for machining a workpiece by using an electric discharge wire; the cutting system comprises a lead barrel, a plurality of guide wheels and an electrode wire, wherein the electrode wire winds the wire barrel and the guide wheel and can be driven by the wire barrel to move between the guide wheel and a discharging gap; and the liquid supply system comprises a nozzle capable of spraying the working solution, and the nozzle sprays the working solution on the electrode wire of the wire barrel, so that the electrode wireis wrapped with the working solution, and the working liquid amount between the electrodes can be controlled by controlling the wire speed of the electrode wire; and the wire barrel drives the electrode wire to enter the electrode wire wrapped with the working solution into the discharging gap.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

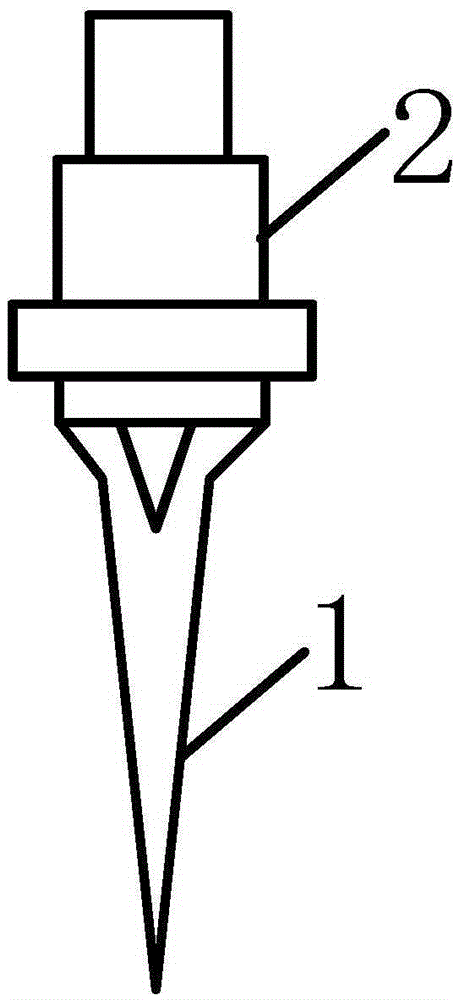

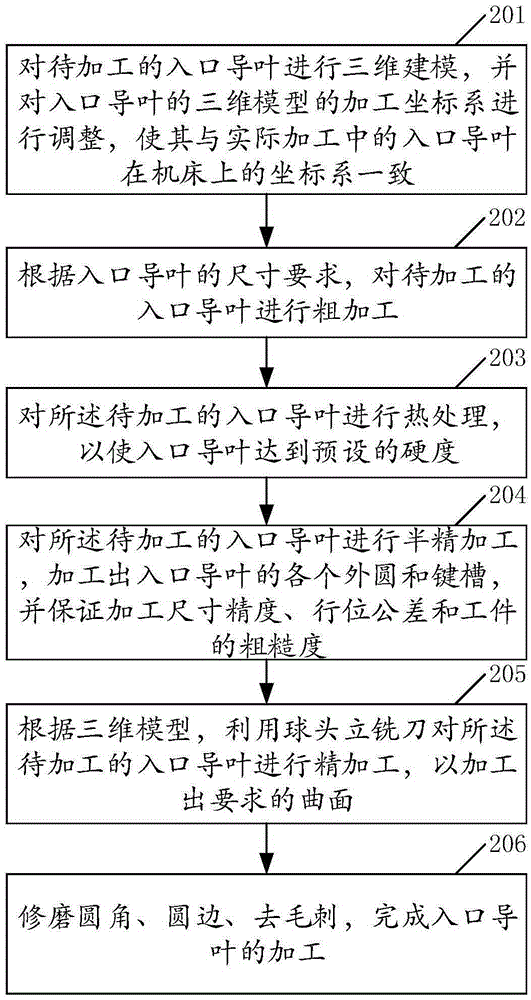

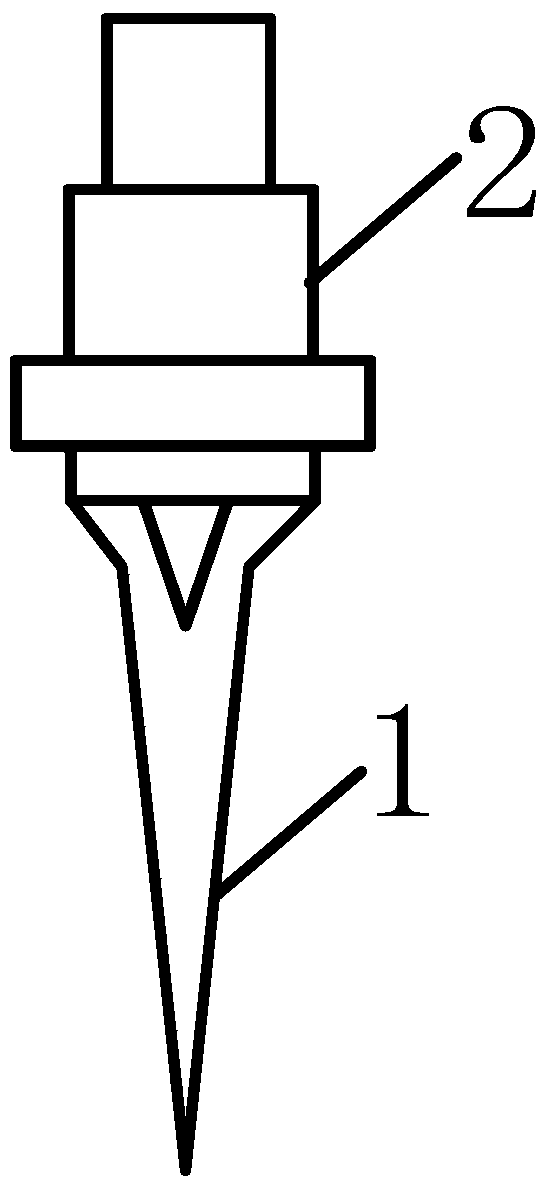

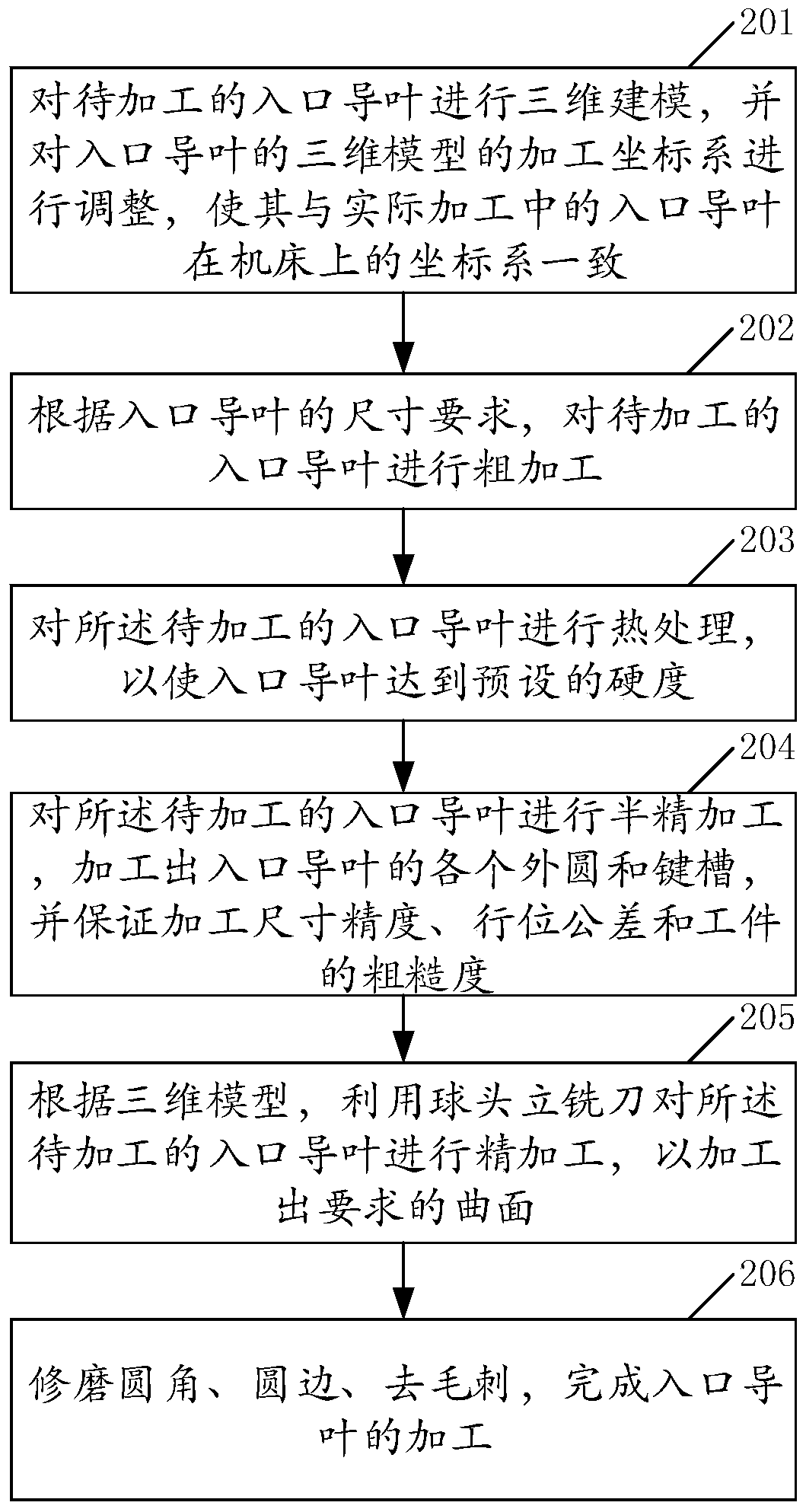

Machining method and device of compressor inlet guide blade

ActiveCN105382503ASolve the technological gap in processingGuaranteed roughnessOther manufacturing equipments/toolsDimensional modelingHardness

The invention relates to the field of machining, and discloses a machining method and a device of a compressor inlet guide blade. The three-dimensional modeling is performed for an inlet guide base to be machined, and a machining coordinate system of a three-dimensional model of the inlet guide blade is adjusted, so that the machining coordinate system is consistent with a coordinate system of the inlet guide blade on a machine tool in actual machining; according to the size requirements of the inlet guide blade, the inlet guide blade to be machined is roughly machined; the inlet guide blade to be machined is heated to reach a preset hardness; the inlet guide blade to be machined is semi finished; according to the three-dimensional model, the inlet guide blade to be machined is finished by using a ball end mill to machine a requested curved surface; and the machining of the inlet guide blade is finished through round angle and round edge polishing and deburring. The invention realizes a practical, efficient and precise machining method of the compressor inlet guide blade, and solves the technical blank of traditional inlet guide blade machining.

Owner:SHENYANG BLOWER GRP GEAR COMPRESSOR

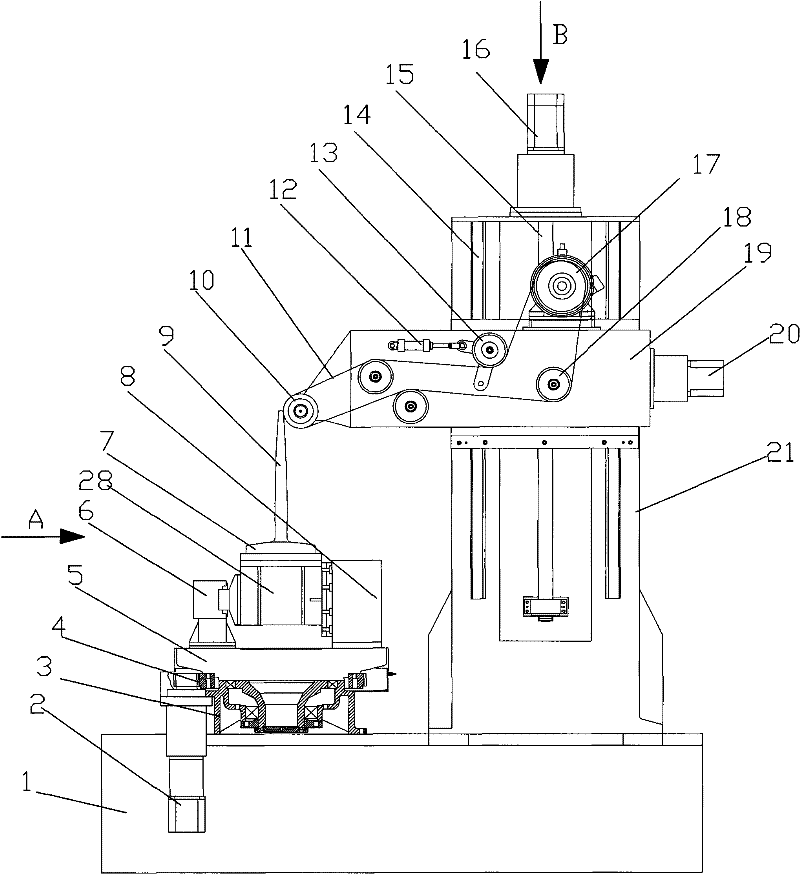

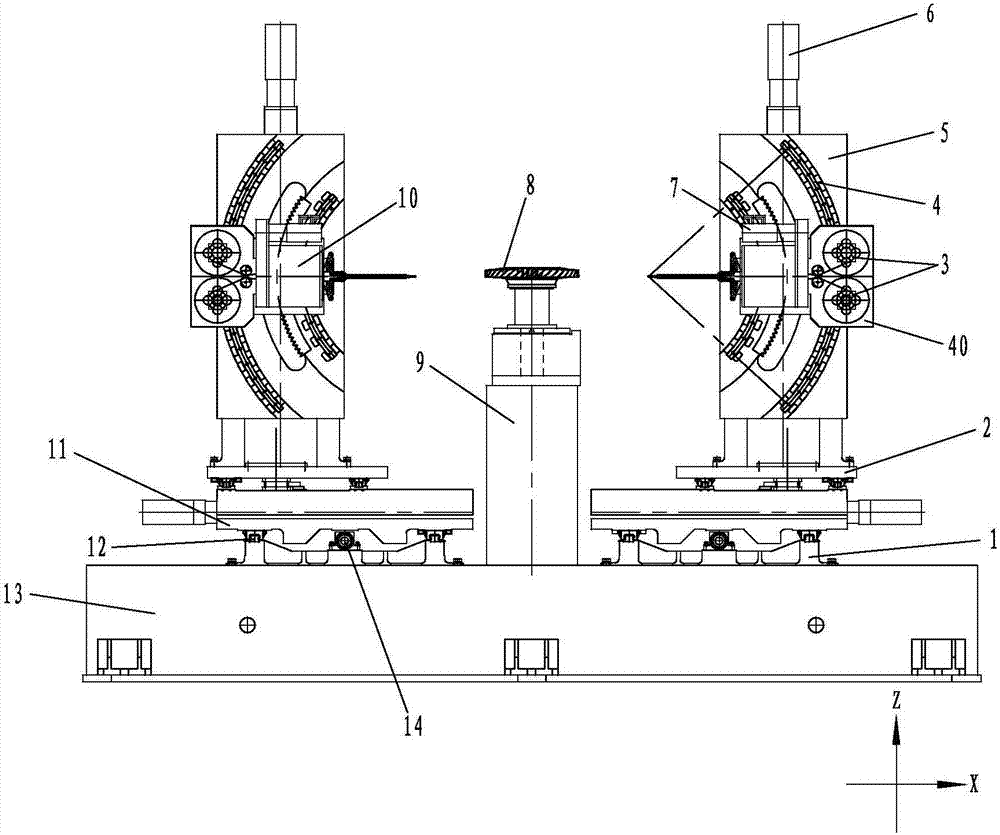

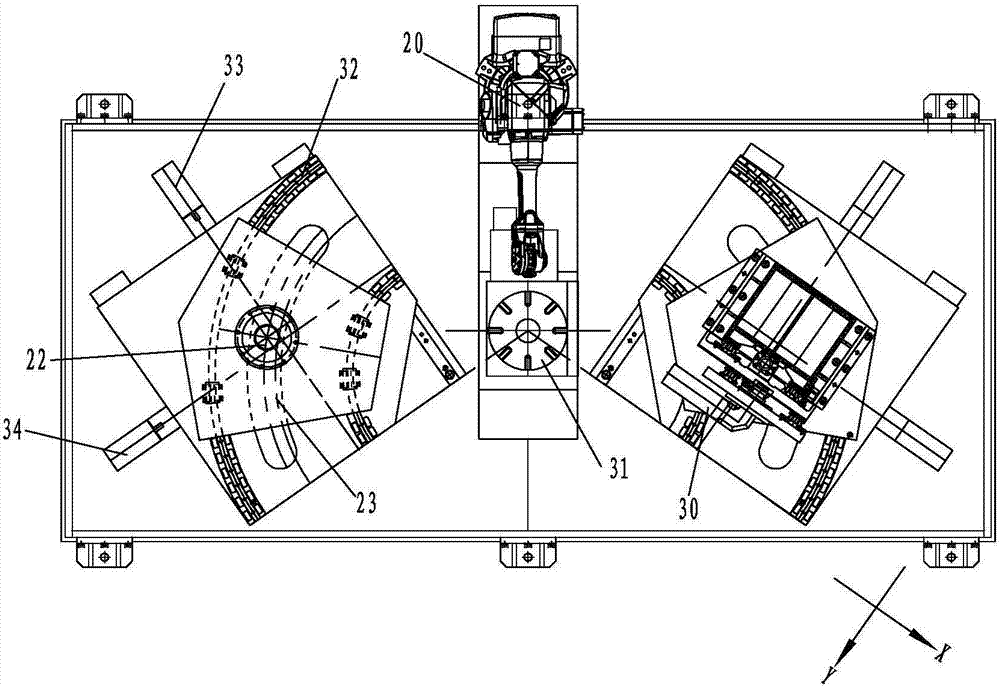

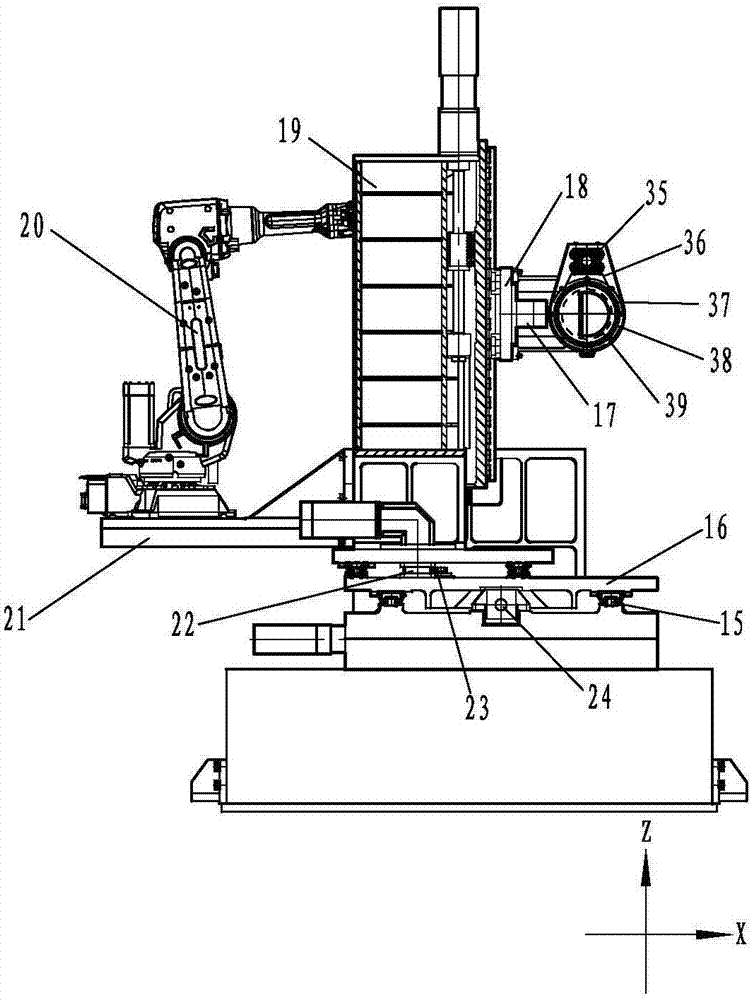

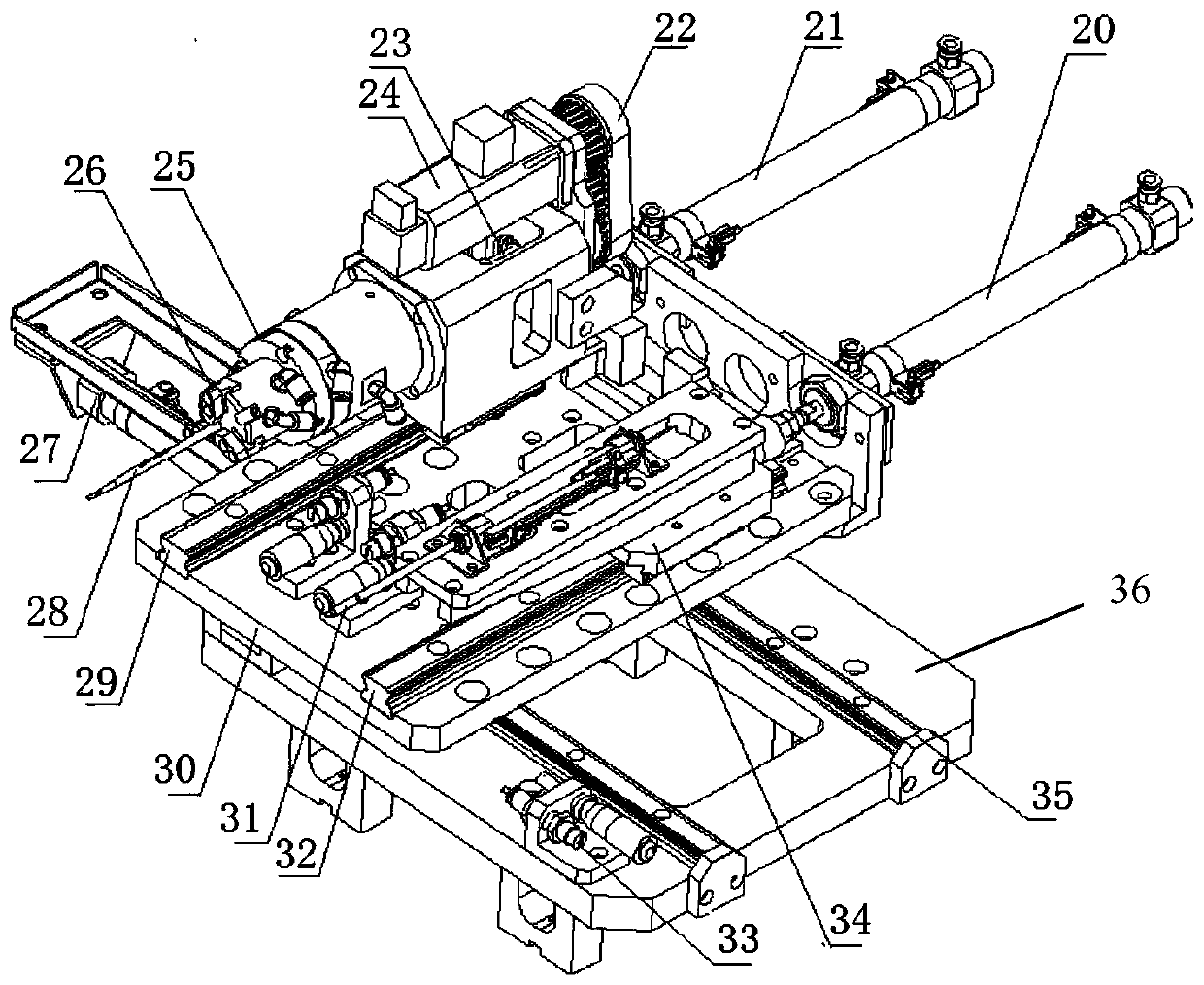

Abrasive belt grinding center suitable for full surface grinding and polishing of blisks

ActiveCN106112752BContact stabilityRealize free adjustmentBelt grinding machinesGrinding work supportsEngineeringMachining

An abrasive belt grinding center applicable to grinding and polishing of a whole profile of a blisk is provided, an X-axis feed mechanism, a Y-axis feed mechanism, a Z-axis feed mechanism, a B-axis rotation mechanism and a C-axis rotation mechanism constitute a grinding head feed mechanism, and a housing, a drum, a synchronous driven pulley, a synchronous belt, a synchronous driving pulley, and a grinding head rotation driving motor constitute a grinding head rotation mechanism. In the present application, two grinding heads are utilized to reasonably assign the machining angle and the feeding, and rough machining and fine machining can be both realized by one time of clamping, and the combination of six degrees of freedom in space is achieved by a short drive chain, and further the rigidities of a grinding head mechanism and a workpiece clamping mechanism are ensured. The combination of double grinding heads and a grinding robot can achieve grinding and polishing of the whole profile of the blisk. The contact wheel of the grinding head mechanism and the abrasive belt can go into a small clearance between blades of the blisk, thus can significantly improve the machining efficiency and reduce the management and production costs on the premise of ensuring the machining precision of a complex curved surface and the quality of the profile.

Owner:CHONGQING UNIV +1

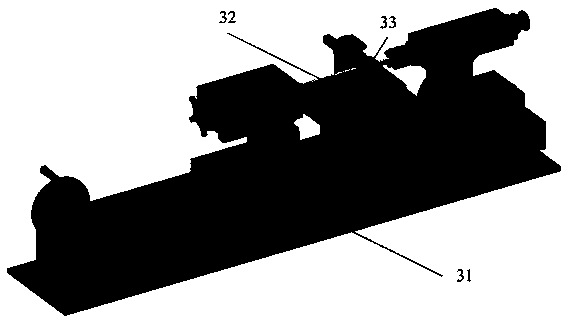

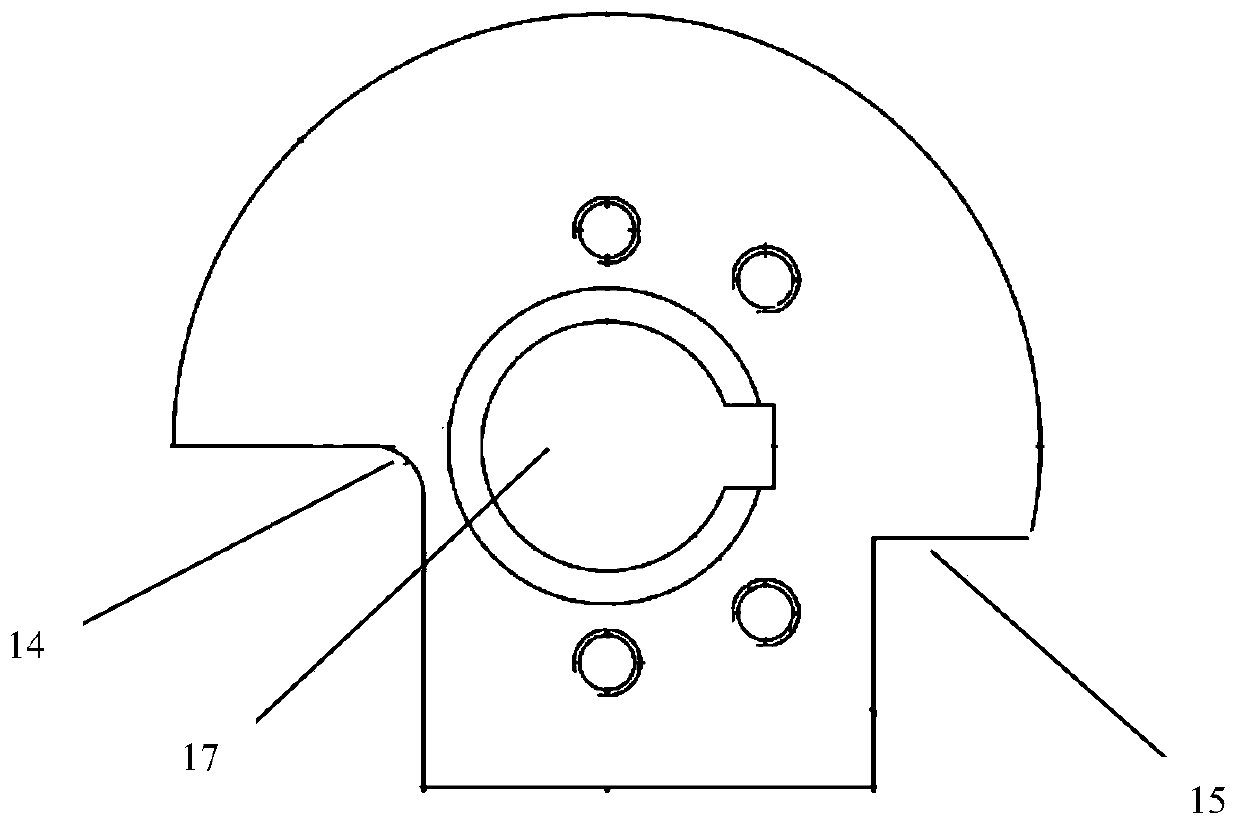

An inner cavity hook groove and plane detection centering device

ActiveCN103925860BNot easy to looseGuaranteed accuracyMechanical measuring arrangementsBiomedical engineering

Owner:NANJING TURBINE & ELECTRIC MASCH (GRP) CO LTD

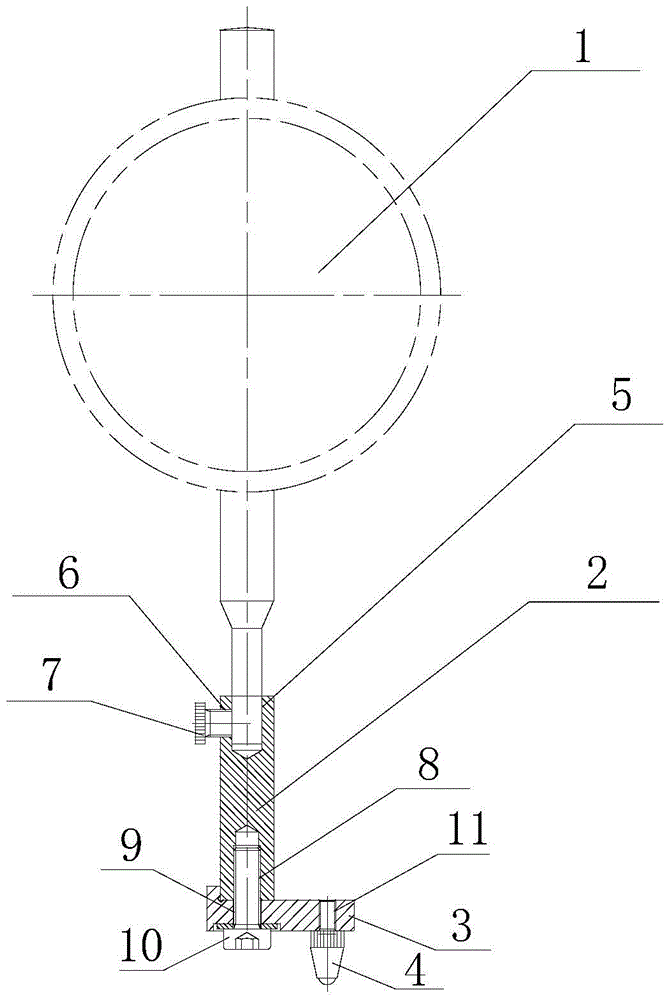

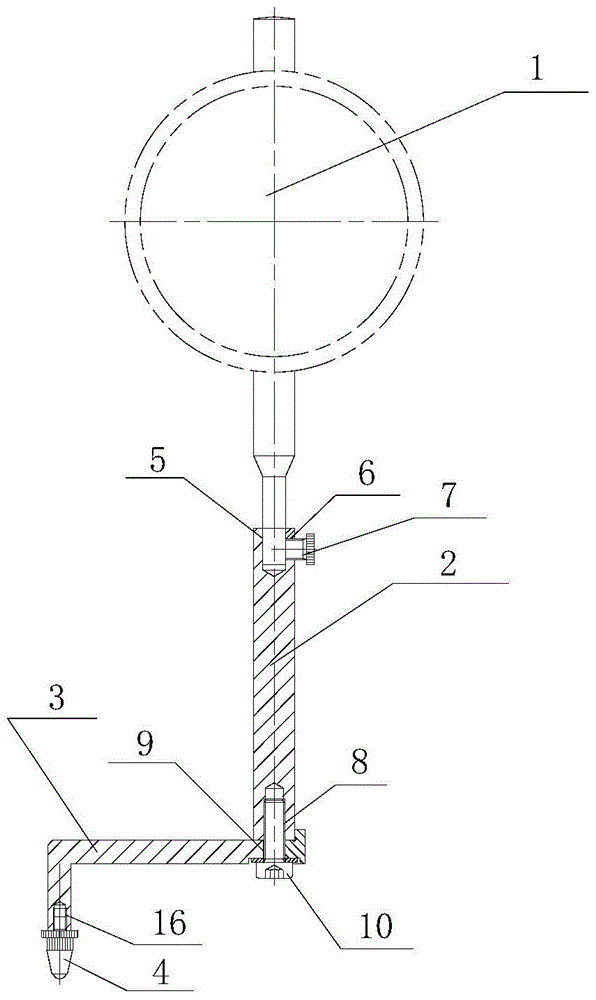

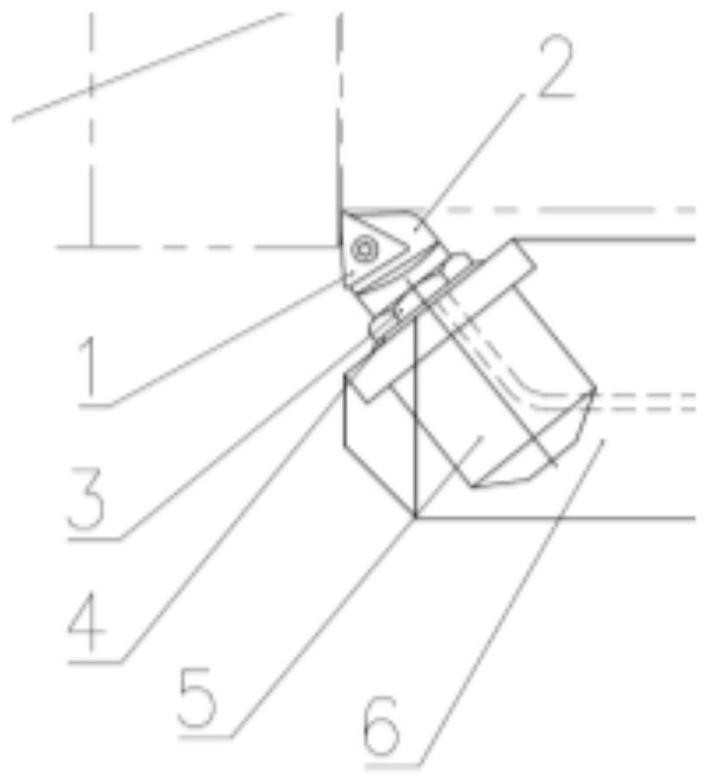

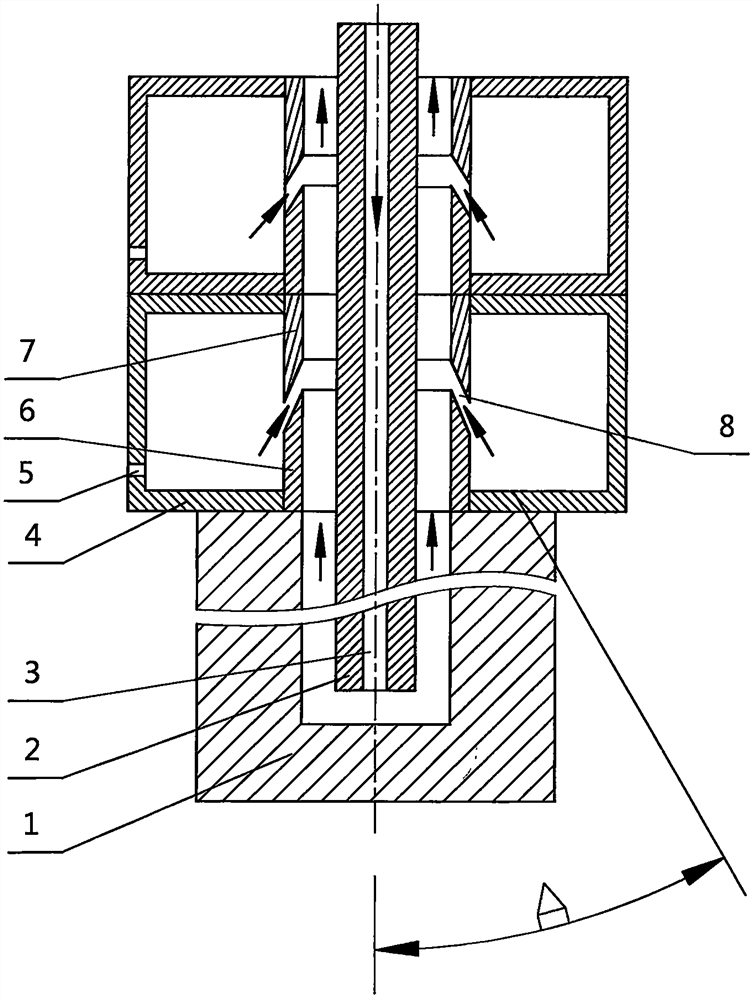

Boring-based cantilever shaft machining method for achieving large-size irregular appearances

PendingCN113547144AGuaranteed machining dimensional accuracyImprove clamping difficultiesBoring/drilling componentsMaintainance and safety accessoriesKnife bladesCantilever

The invention provides a boring-based cantilever shaft machining method for achieving large-size irregular appearances. Through cooperative use of a blade, a blade reinforcing plate, a diameter fine adjustment nut, a dial, a cutter body mounting mechanism, a machining arm, a cooling liquid channel, a balance arm, a rigid reinforcing ring, an avoiding hole and a cutter handle cone, a large-length-diameter-ratio cantilever shaft is precisely machined in a common machining center, the blade is cooled, the cutter rigidity is improved, workpiece vibration is restrained, the machining precision of parts of the type is improved, the cost is saved, and the machining efficiency is improved.

Owner:NANJING CHENGUANG GRP

A mechanical base with buffering and shock-absorbing functions

ActiveCN109506085BHave a shock absorbing effectGuaranteed accuracyShock absorbersEngine bedsMachiningDimensional precision

The invention discloses a mechanical base with buffering and shock-absorbing functions, which comprises a base, a mounting plate, several buffering devices evenly arranged between the base and the mounting plate, and an anti-loosening device; the buffering device includes a sliding cylinder, a sliding rod, Limit rod and spring, the upper end of the sliding cylinder is fixed on the lower end surface of the base, the lower part of the sliding cylinder is slidingly connected with the upper part of the sliding rod, the lower end of the sliding rod is fixedly installed on the mounting plate, and the spring sleeve installed at the lower end of the sliding cylinder is compressed Set on the sliding rod, the upper and lower ends of the limit rod are respectively fixedly connected to the base and the mounting plate; the anti-loosening device includes a pressing plate for pressing the fixing screw to prevent the screw from loosening, which solves the buffering and shock resistance existing in the prior art Poor, easily deformed, and the screws are easy to loosen, and the processing dimensional accuracy is easy to drop; the invention has a good buffering and shock absorption effect, reduces the deformation of the base, has high processing dimensional accuracy, and avoids easy loosening of the screws during processing The phenomenon.

Owner:SUZHOU INST OF TRADE & COMMERCE

A Whole Precision Machining Method for Thin-walled Slender Pipe Fittings

The invention provides a thin-walled slender pipe integral precision machining method, comprising the following steps: S1, blanking; S2, thermal processing; S3, rough turning end face and outer circle; S4, drilling and boring the inner hole; S5, honing the inner hole Hole; S6, semi-finished turning, finishing outer circle; S7, fine grinding outer circle; S8, micro-extrusion correction; S9, finish turning end face; S10, inspection and packaging. The invention can realize the overall precision machining of thin-walled elongated pipe fittings made of austenitic stainless steel, with a maximum length of 575mm, a minimum pipe diameter of 24mm, a maximum length-to-diameter ratio of 24, and a thinnest wall thickness of 0.3mm. The axiality reaches 0.025mm, the straightness reaches 0.025mm, and the surface roughness reaches Ra0.8. It is an efficient, precise and low-cost processing method for thin-walled slender pipe fittings.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST +1

Material returning and feeding forming mechanism for special-shaped parts and method thereof

PendingCN111151647AGuaranteed machining dimensional accuracyAvoid damage to partsMetal-working feeding devicesPositioning devicesDimensional precisionManufacturing engineering

The invention discloses a material returning and feeding forming mechanism for special-shaped parts. The material returning and feeding forming mechanism comprises a forming mechanism for carrying outroll extrusion forming on a blank workpiece according to a preset angle, and a double-station orientation / material returning mechanism for carrying out orientation, material returning and station conversion on the blank workpiece; and the operation end of the double-station orientation / material returning mechanism corresponds to the machining end of the forming mechanism, and the double-station orientation / material returning mechanism is used for conveying the grabbed blank workpiece into the forming mechanism and used for exiting the formed workpiece machined and formed in the forming mechanism. A grabbing station and a material returning station are switched on the double-station orientation / material returning mechanism, the grabbing station and the material returning station are matched with the forming mechanism, the feeding or material returning function is provided for the forming mechanism, the problem that the parts are damaged due to the fact that the parts are clamped many times is avoided, and the machining size precision of the parts is guaranteed.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

Inner cavity groove and plane detection centering device

ActiveCN103925860AImprove processing and inspection efficiencyAccurate detectionMechanical measuring arrangementsBiomedical engineeringEngineering

Owner:NANJING TURBINE & ELECTRIC MASCH (GRP) CO LTD

Discharge method of electro-corrosion products in EDM

ActiveCN109175551BGuaranteed stabilityGuaranteed machining dimensional accuracyAcute angleElectrical discharge machining

Owner:ZHONGBEI UNIV

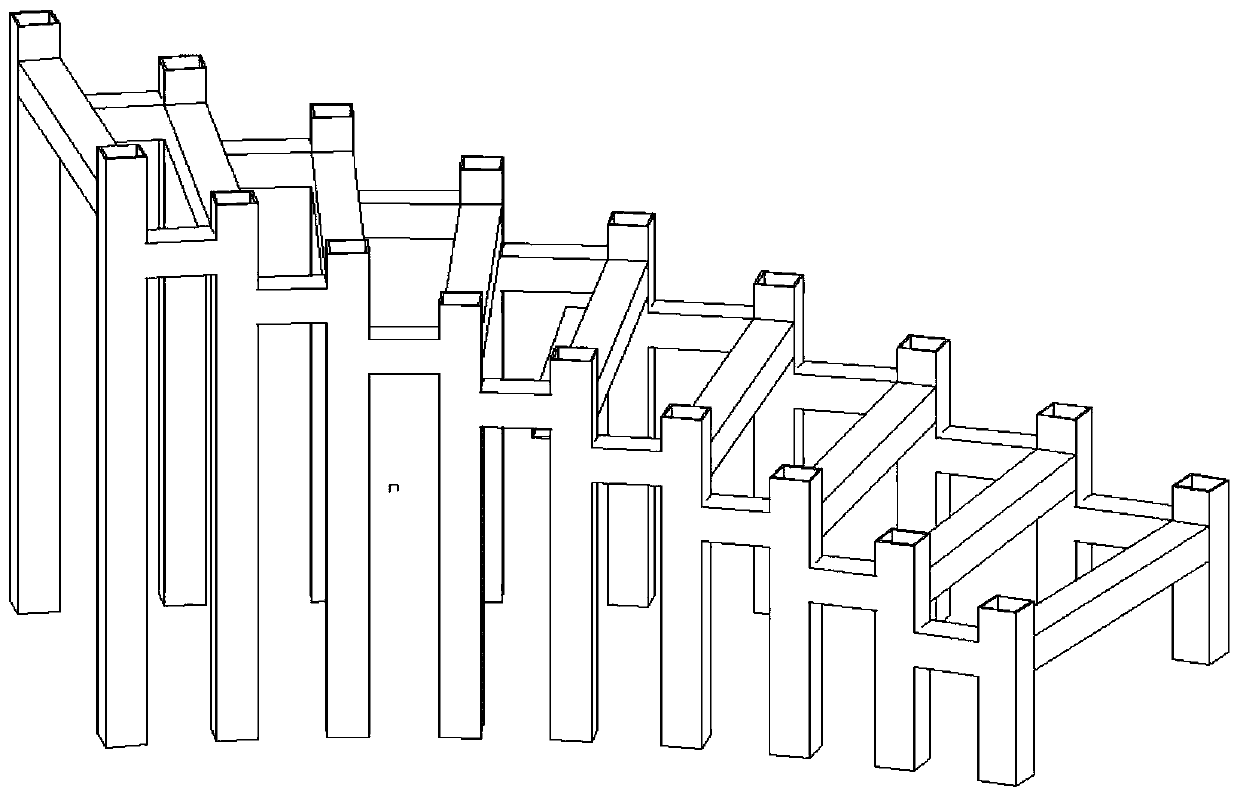

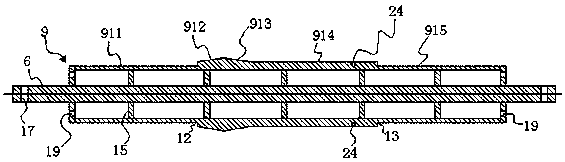

Primary-sequence forming tool and forming method for omega-shaped elastic strip production

PendingCN110496879AGuaranteed machining dimensional accuracyGuaranteed positioningShaping toolsEngineeringPrimary sequence

The invention discloses a primary-sequence forming tool and forming method for omega-shaped elastic strip production. The forming tool comprises an upper die plate and a lower die plate; a left upperdie, a right upper die and a middle upper die are arranged on the upper die plate, upper die rollers are arranged on the left upper die and the right upper die, and a middle upper die roller is arranged on the middle upper die; a left lower die holder, a right lower die holder and a middle lower die are arranged on the lower die plate, a material bearing wheel, a forming roller and a lower die cushion block are arranged on each of the left lower die holder and the right lower die holder, and a middle lower die roller is arranged on the middle lower die. According to the primary-sequence forming tool for an omega-shaped elastic strip, the middle part of the elastic strip is also primarily formed while the two limbs of the elastic strip are formed, and the positioning of the middle part of the elastic strip in the subsequent process is guaranteed; and the operation is simpler, and the positioning is more accurate; and the middle part of the elastic strip is primarily formed in the primary sequence and formed in the subsequent secondary sequence, the purpose of reducing thin-drawing of the middle part and the tail part of the elastic strip can be achieved, and the processing size precision of the omega-shaped elastic strip can be better guaranteed.

Owner:CHINA RAILWAY LONGCHANG MATERIALS

High-accuracy positioning device of cutter working platform of numerical control lathe under fast operation

InactiveCN102390018AShorten speedSolve the problem of poor positioningLarge fixed membersNumerical controlRapid processing

The invention discloses a high-accuracy positioning device of a cutter working platform of a numerical control lathe under fast operation. The front end part of the cutter working platform is provided with a contact rod with adjustable length; the left front side of the contact rod is provided with a mechanical type flow adjusting valve which is used for adjusting a hydraulic driving oil path of the cutter working platform and is adjustable in position, the right front side of the contact rod is provided with a limit switch with an adjustable position, and the right lower part of the contact rod is provided with a limiting block with an adjustable position; when a cutter is close to a material to be processed, the contact rod is contacted with the mechanical type flow adjusting valve, the hydraulic driving oil path is turned down by the mechanical type flow adjusting valve and the speed of the cutter working platform is slowed down; and when the stroke of the cutter working platform reaches a set value, the cutter working platform is contacted with the limiting block, the contact rod is contacted with the limit switch simultaneously, and the cutter working platform returns after finishing the forward action. According to the high-accuracy positioning device, the problem of poor positioning when the numerical control lathe is in fast processing can be solved, and the high-accuracy positioning of the numerical control lathe under fast operation is realized.

Owner:SHAOXING UNIVERSITY

A multi-station winding mold for manufacturing an intermediate pipe and a manufacturing method for the intermediate pipe

ActiveCN106182716BGuarantee processing qualityGuaranteed machining dimensional accuracyCircular coneMaterials science

The invention discloses a multi-station winding mold for manufacturing an intermediate pipe. The multi-station winding mold comprises a main mold cylinder with a spindle, two hollow auxiliary mold cylinders and one or more special-shaped circular rings. The main mold cylinder comprises a first main mold cylinder body, a first main mold circular truncated cone body, a second main mold circular truncated cone body, a second main mold cylinder body and a third main mold cylinder body. Each auxiliary mold cylinder comprises a hollow first auxiliary mold cylinder body, a hollow auxiliary mold circular truncated cone body, a hollow second auxiliary mold cylinder body, a circular-ring-shaped end cover and a hollow round pipe. Each special-shaped circular ring comprises a hollow first circular cone and a hollow second circular cone. During assembling, the one or more special-shaped circular rings are detachably installed on the second main mold cylinder body in a sleeving mode. The two auxiliary mold cylinder bodies are detachably installed at the two ends of the main mold cylinder correspondingly in a sleeving mode in the direction of the two ends of the main mold cylinder. The two ends of the spindle penetrate through end covers of the two auxiliary mold cylinder bodies and the round pipes correspondingly, the two ends of the spindle are exposed to the round pipes of the two auxiliary mold cylinder bodies, and thus a plurality of stations winding the intermediate pipe are formed. Through the multi-station winding mold, a plurality of intermediate pipes can be formed at one time, and thus the cost is reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

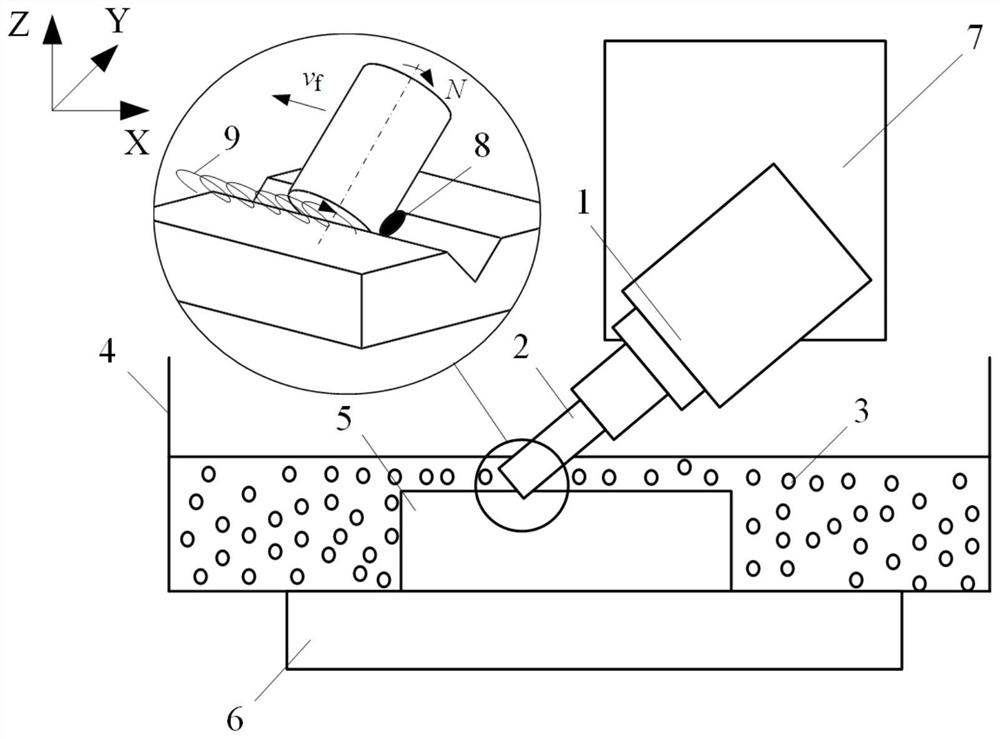

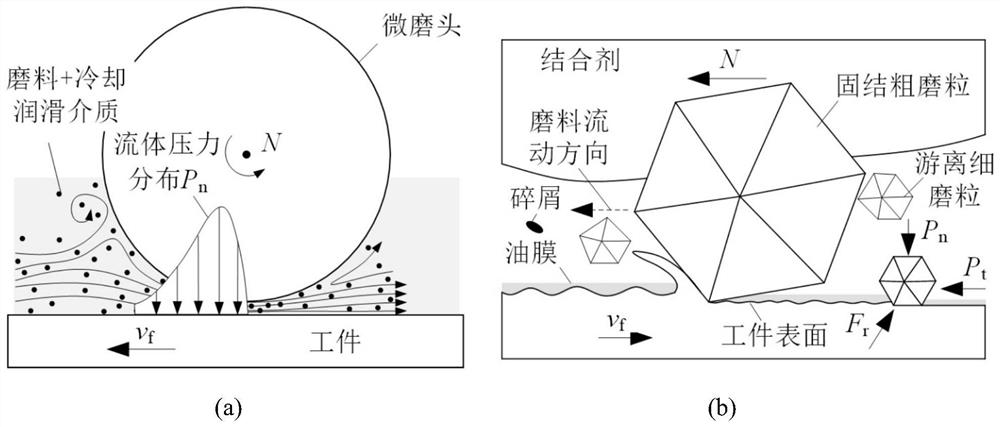

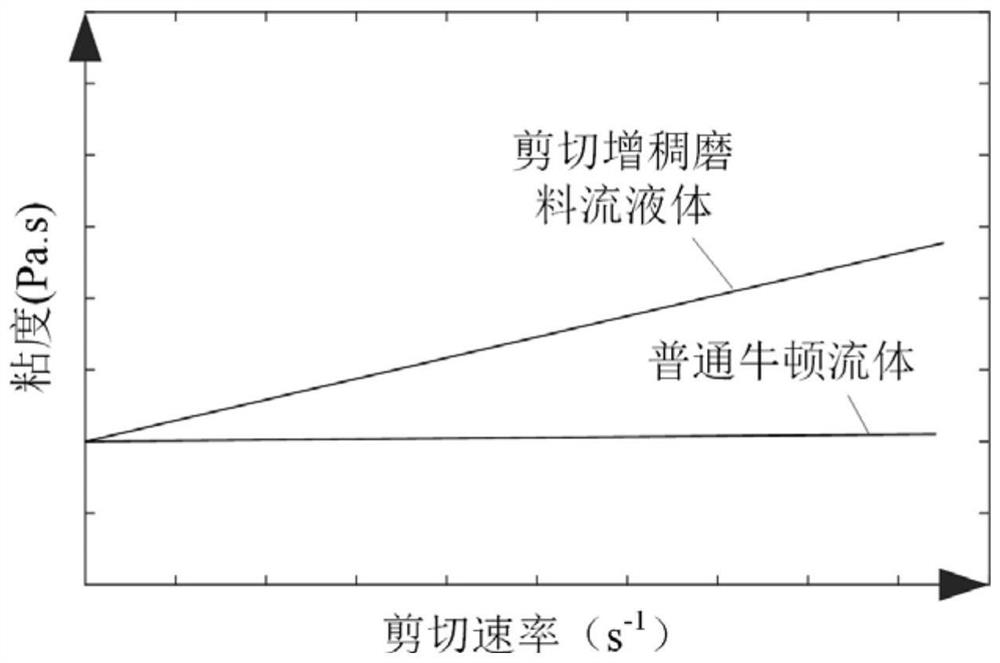

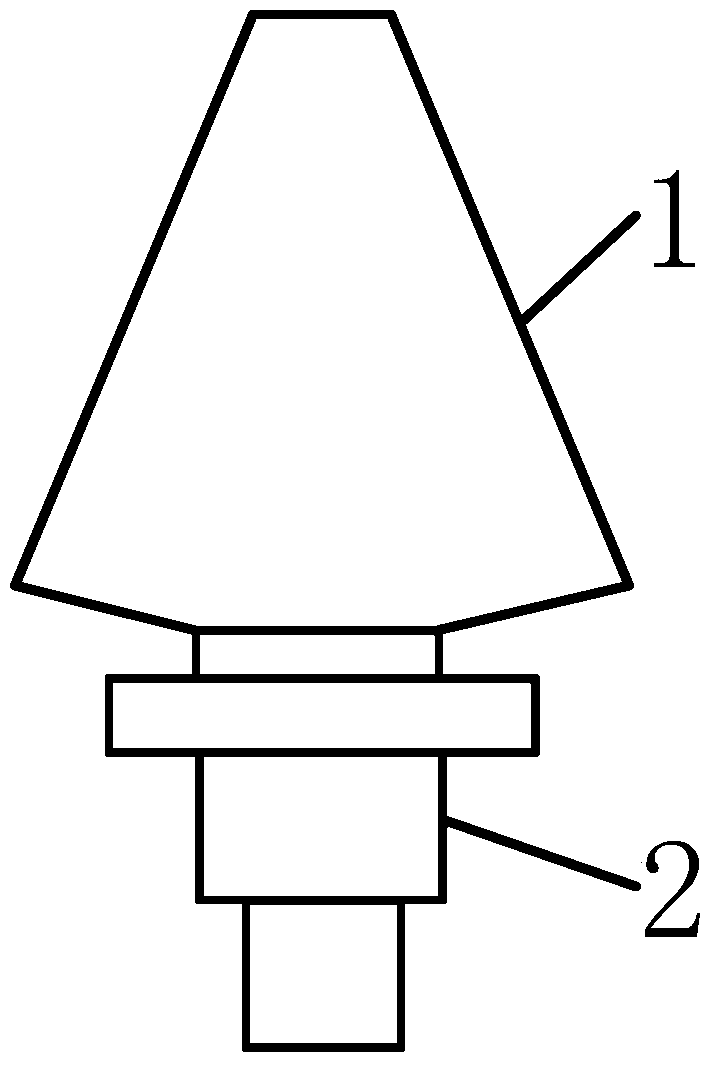

A method for machining microgrooves by shear-thickening abrasive flow compound grinding

ActiveCN113103070BQuality improvementAvoid secondary damageEdge grinding machinesPolishing machinesPolishingMachining

The invention discloses a method for composite grinding of microgrooves with shear-thickening abrasive streams, which comprises the following steps: adding abrasives to shear-thickening liquid and fully diffusing to form a thick suspension with shear-thickening effect; The thickened abrasive flow liquid is placed in the abrasive flow storage tank, the workpiece is clamped on the working platform, and the adjuster adjusts the inclination of the main shaft, so that the axis of the micro-grinding head forms a preset angle with the upper surface of the workpiece, and the workpiece and the micro-grinding head form a preset angle. At the same time, it is immersed in the shear-thickening abrasive flow liquid; the micro-grinding head is fed along the Y-axis and rotates at high speed in the shear-thickening abrasive flow liquid to form a flexible polishing head and produce a hydrodynamic pressure effect on the surface of the micro-groove; once After the machining is completed, the rotating work platform rotates the workpiece, the micro-grinding head is fed along the X-axis direction, and the end of the grinding head faces the other side of the micro-groove for abrasive flow compound grinding again, so as to obtain the same high-quality micro-groove surface on both sides. . The invention improves the surface quality of the workpiece while ensuring the machining dimensional accuracy, and is suitable for the machining of fine structures.

Owner:SOUTH CHINA UNIV OF TECH

Method and device for processing inlet guide vane of compressor

ActiveCN105382503BSolve the technological gap in processingGuaranteed roughnessOther manufacturing equipments/toolsEngineeringDimensional modeling

The invention relates to the field of mechanical processing, and discloses a method and device for processing an inlet guide vane of a compressor. By performing three-dimensional modeling on the inlet guide vane to be processed, and adjusting the processing coordinate system of the three-dimensional model of the inlet guide vane, the It is consistent with the coordinate system of the inlet guide vane in actual processing on the machine tool; according to the size requirements of the inlet guide vane, rough machining is performed on the inlet guide vane to be processed; heat treatment is performed on the inlet guide vane to make the inlet The guide vane reaches the preset hardness; semi-finishing the inlet guide vane to be processed; according to the three-dimensional model, the ball end mill is used to finish the inlet guide vane to be processed to process the required Curved surface; grinding rounded corners, rounded edges, deburring, and completing the processing of inlet guide vanes. The invention realizes a practical, high-efficiency and high-precision processing method of the inlet guide vane of the compressor, and solves the technical blank of the current inlet guide vane processing.

Owner:SHENYANG BLOWER GRP GEAR COMPRESSOR

An ultrasonic vibration processing device and method for aluminum-based silicon carbide composite materials

ActiveCN112548175BImprove quality and efficiencyImprove processing efficiencyMilling equipment detailsCarbide siliconMilling cutter

An ultrasonic vibration processing device and method for aluminum-based silicon carbide composite materials, comprising a computer, a laser-assisted heating part, an ultrasonic vibration processing part, a machine tool table, a machine tool spindle and a micro-blade milling cutter; the ultrasonic vibration processing part includes an ultrasonic generator , transducer and horn; the lower end of the machine tool spindle is connected to the transducer, the lower end of the transducer is connected to the horn, the upper end of the micro-blade milling cutter is clamped at the lower end of the horn, and the ultrasonic generator is connected to the transducer through a wire ; A clamper is arranged on the machine table, the workpiece of aluminum-based silicon carbide composite material is clamped on the clamper, and the clamper is connected with a three-way dynamometer; the laser-assisted heating part heats the part to be processed of the workpiece. During the milling operation, the invention can speed up chip discharge, eliminate tool chatter, reduce abrasive wear and adhesive wear, reduce milling force and cutting heat, ensure machining dimensional accuracy, improve workpiece surface quality and machining efficiency, and save machining costs.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com