Primary-sequence forming tool and forming method for omega-shaped elastic strip production

A technology for forming tooling and clips, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of the minimum size of the middle and tail of the clips, etc., to ensure the machining dimensional accuracy, simple operation, accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

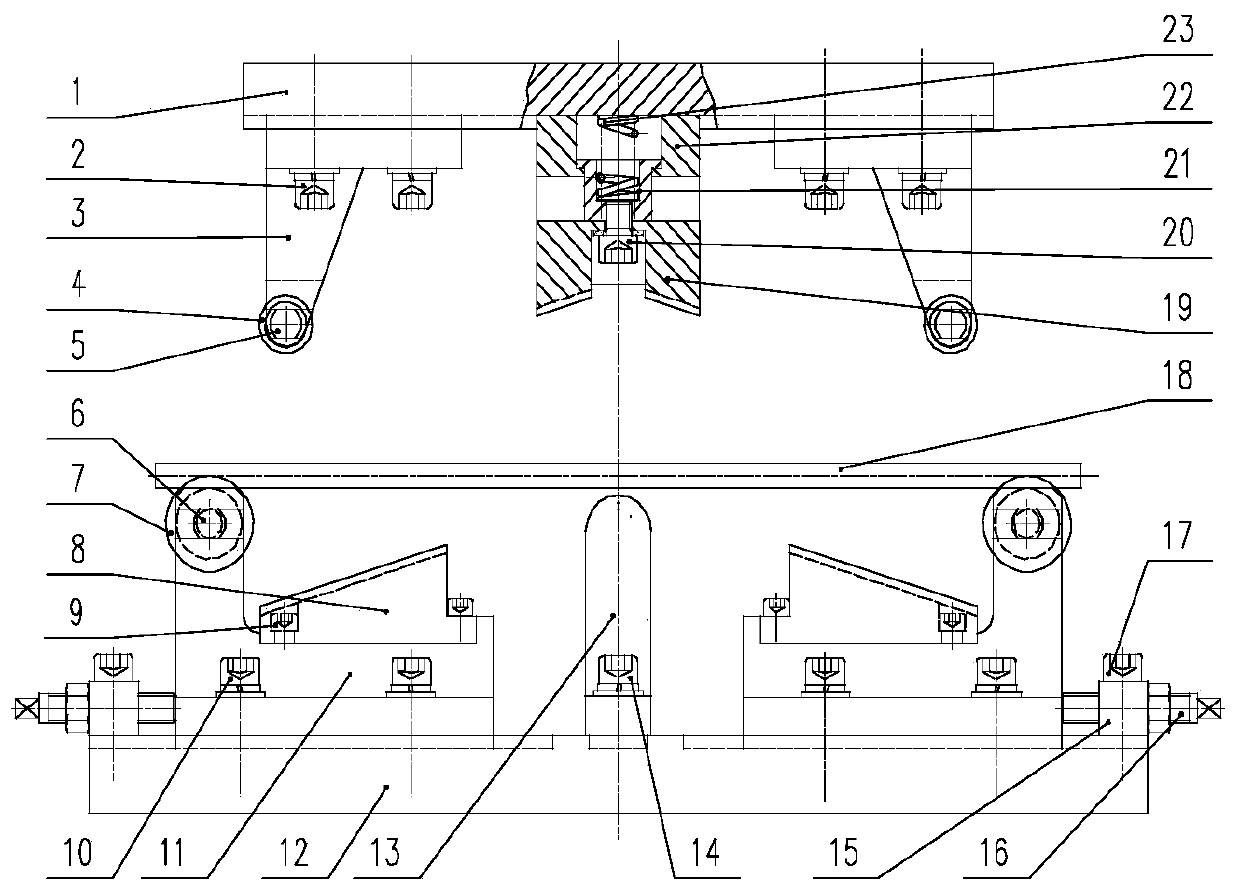

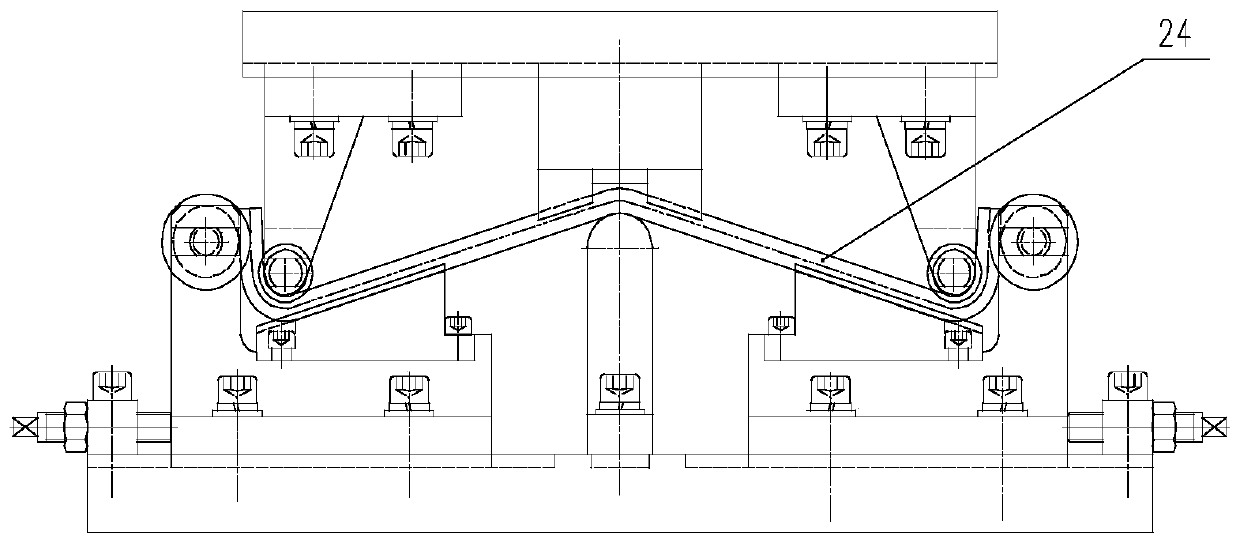

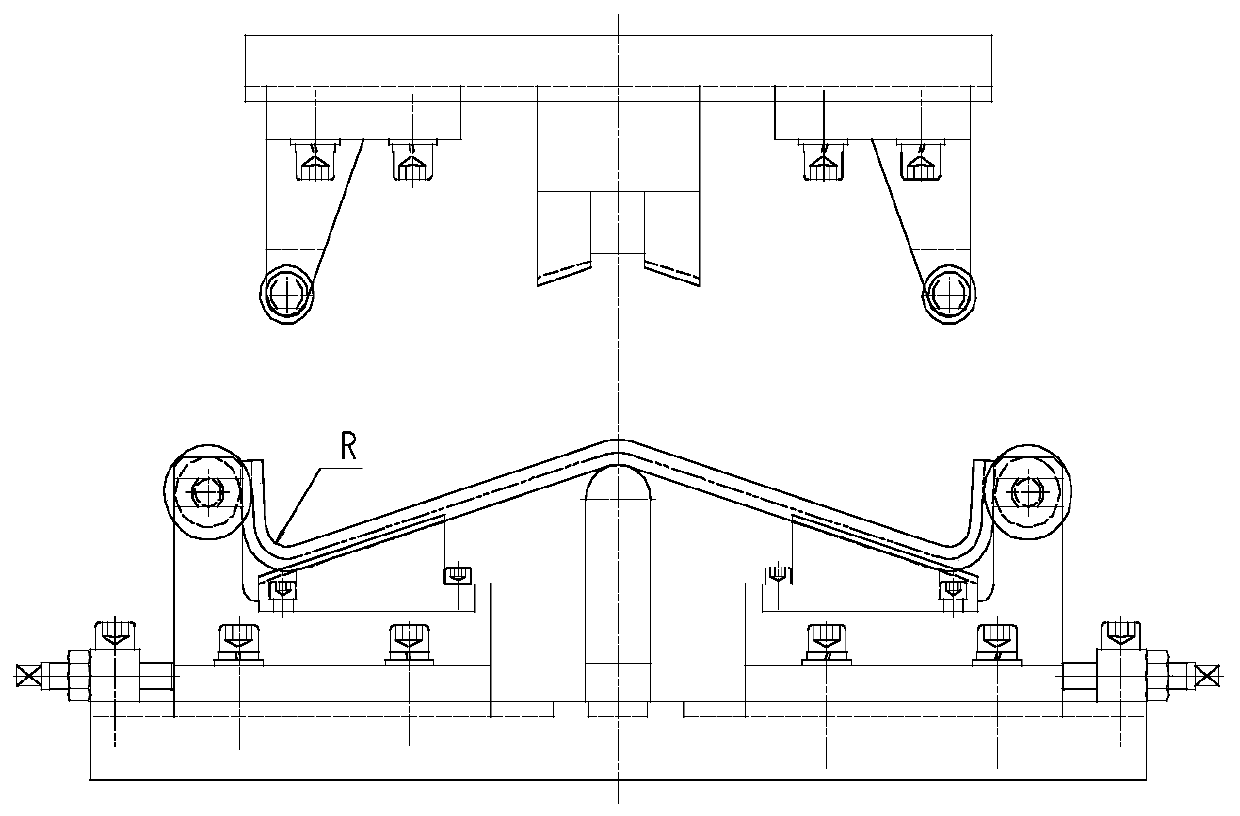

[0034] A one-step forming tool for the production of ω-shaped elastic strips, such as Figure 4 to Figure 6 As shown, it includes: lower template 1, left and right positioning blocks 2, nuts 3, inner six bolts 4, top wire 5, left lower mold base 6, upper mold roller 7, roller pin 8, left and right upper molds 9, inner six bolts 10, Upper template 11, middle and upper mold 12, inner six bolts 13, middle and upper mold roller 14, material receiving wheel 15, forming roller 16, right lower mold base 17, lower mold pad 18, inner six bolts 19, middle and lower mold 20 , inner six bolts 21, right positioning block 22, inner six bolts 23, pin shaft 24, roller 25, inner six bolts 26, inner six bolts 27, etc., wherein:

[0035] The left and right positioning blocks 2 are fixed on the lower formwork 1 by inner six bolts 4, and the top wire 5 is screwed on the left and right positioning blocks 2, and locked by nuts 3, and the left lower mold base 6 and right lower mold base 17 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com