A multi-station winding mold for manufacturing an intermediate pipe and a manufacturing method for the intermediate pipe

A multi-station and intermediate pipe technology, which is applied to the multi-station winding mold for manufacturing intermediate pipes and the manufacturing field of intermediate pipes, can solve the problems of waste of raw materials, high production cost, low production efficiency, etc., so as to reduce production costs and reduce Scrap rate and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

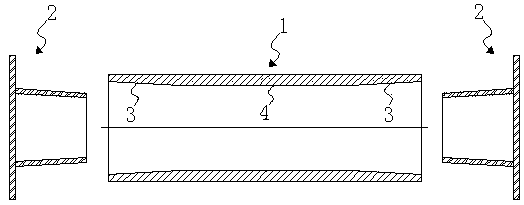

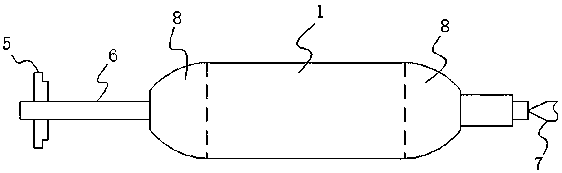

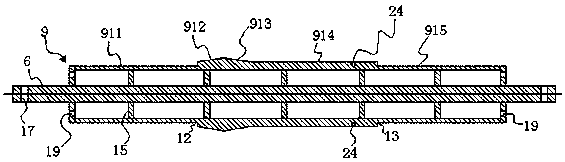

[0052] Embodiment 1: What this embodiment provides is a kind of three-station winding mold, such as Figure 1 to Figure 6 As shown, a three-station winding mold for manufacturing intermediate pipes includes a main mold cylinder 9 with a main shaft and two hollow secondary mold cylinders 10, and the main shaft 6 runs through the central axis of the main mold cylinder 9 The two ends of the main mold cylinder 9 and the two ends of the main mold cylinder 9 are exposed at the two ends of the main mold cylinder 9, and the multi-station winding mold also includes a special-shaped ring 11; the main mold cylinder 9 includes Main mold cylinder one 911, main mold frustum conical body one 912, main mold frustum conical body two 913, main mold cylinder two 914 and main mold cylinder three 915, the small end of main mold frustum conical body one 912 Be arranged on one end of the main mold cylinder one 911, the big end of the main mold frustum conical body one 912 is arranged on the big end ...

Embodiment 2

[0078] Embodiment 2: What this embodiment provides is a kind of four-station winding mold, such as Figure 9 and Figure 10 As shown, compared with Example 1, the difference is that: the multi-station winding mold includes two special-shaped rings 11, which are special-shaped ring 1 and special-shaped ring 2 respectively.

[0079] When the four-station winding mold is assembled, the special-shaped ring 1 and the special-shaped ring 2 are sequentially detachably fitted on the main mold cylinder 2 of the main mold cylinder.

[0080] After the four-station winding mold is assembled, the outer conical surface of the auxiliary mold truncated cone body 102 of the auxiliary mold cylinder, the outer cylindrical surface of the auxiliary mold cylinder two 103 and the outer surface of the main mold frustum cone one 912 of the main mold cylinder The conical surface constitutes a station for winding the intermediate pipe, using the outer conical surface of the secondary mold conical frust...

Embodiment 3

[0097] Embodiment 3: as Figure 11 and Figure 12 As shown, compared with Embodiment 1 and Embodiment 2, the difference is that: a main mold is also arranged between the big end of the main mold truncated cone 912 and the big end of the main mold truncated cone 2 913. Die cylinder four 916, that is, one end of main mold cylinder four 916 is arranged on the large end of main mold frustum one 912, and the other end of said main mold cylinder four 916 is arranged on main mold frustum two 913 On the big end, main mold cylinder 1 911, main mold frustum 1 912, main mold truncated cone 2 913, main mold cylinder 2 914, main mold cylinder 3 915 and main mold cylinder 4 916 are integral structures A hollow cylinder 113 (not shown in the figure) is also provided between the big end of the hollow cone one 111 of the special-shaped ring and the big end of the hollow cone two 112, the hollow cone one 111, the hollow cone two 112 and the hollow The cylinder 113 is an integral structure. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com