Patents

Literature

325results about How to "Reduce processing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

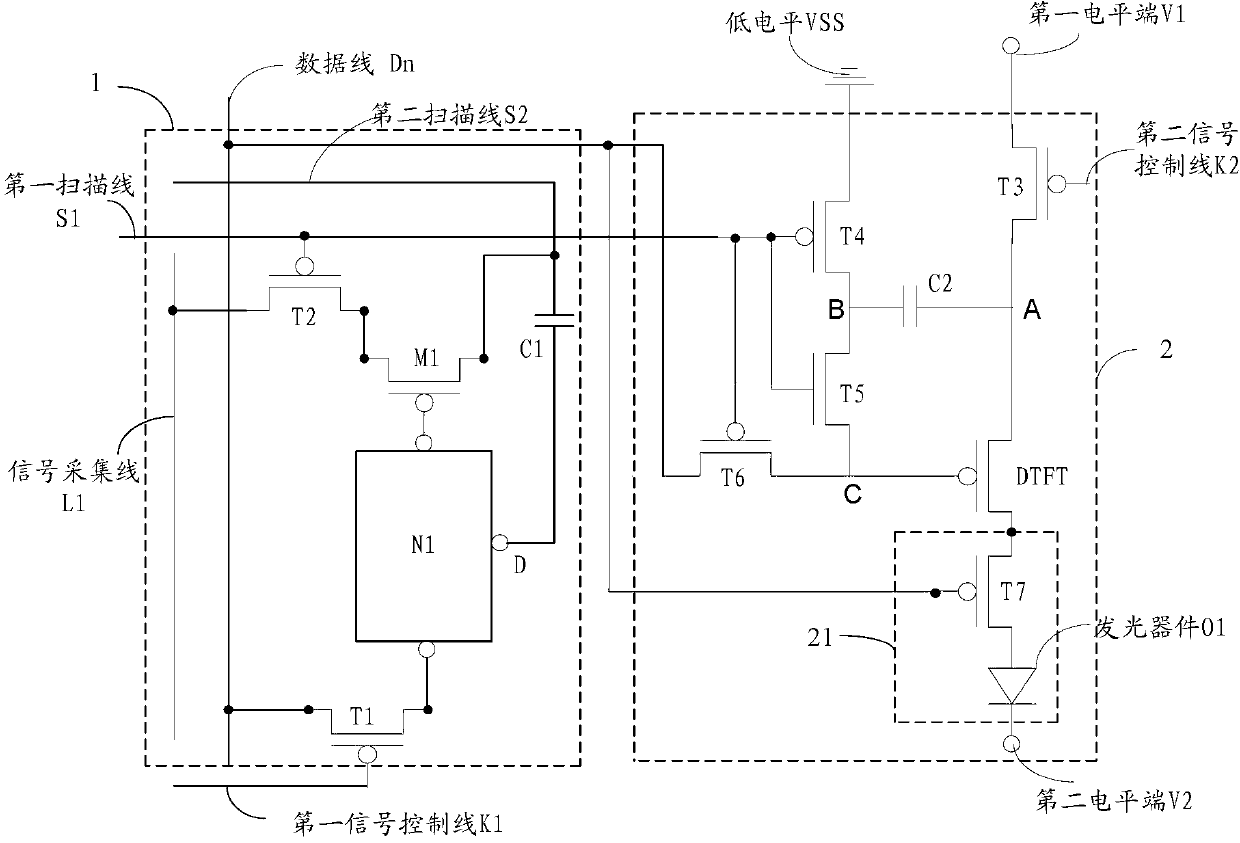

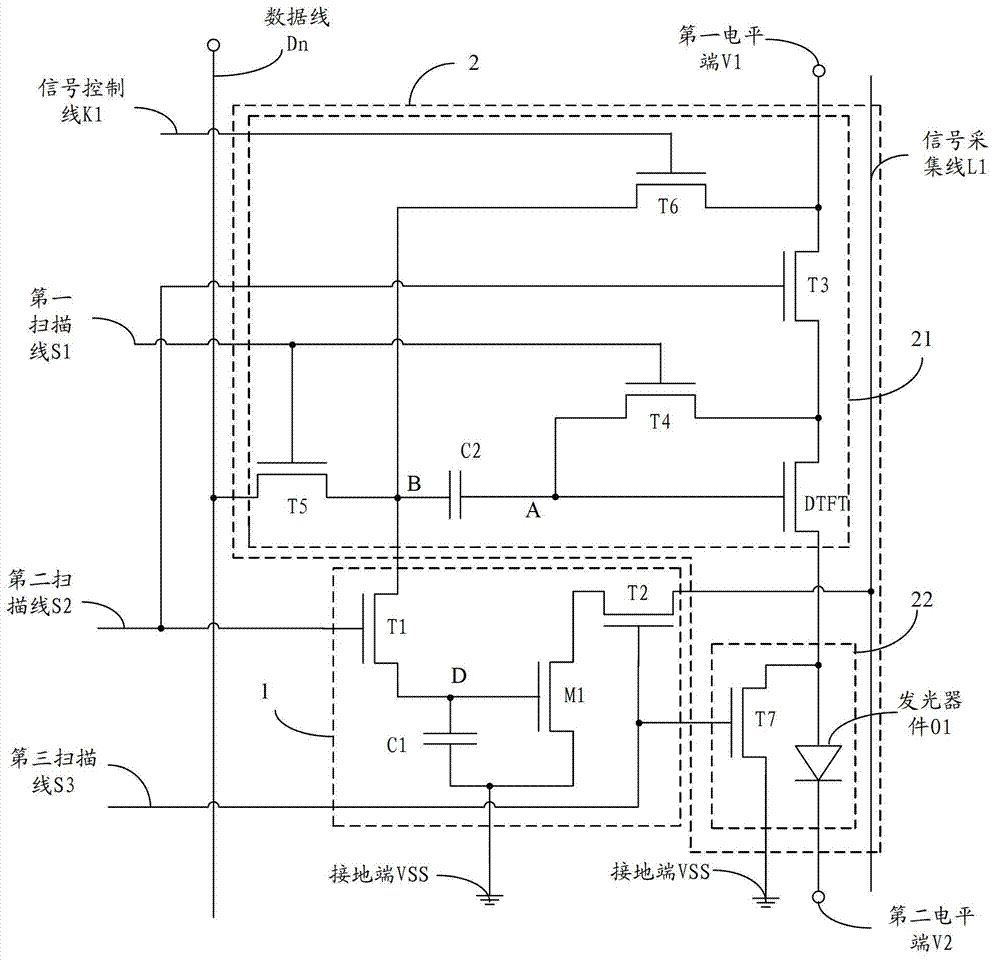

Touch control display circuit structure and driving method, array substrate and display device thereof

ActiveCN103135846AReduce process technologyLow costStatic indicating devicesInput/output processes for data processingControl lineData lines

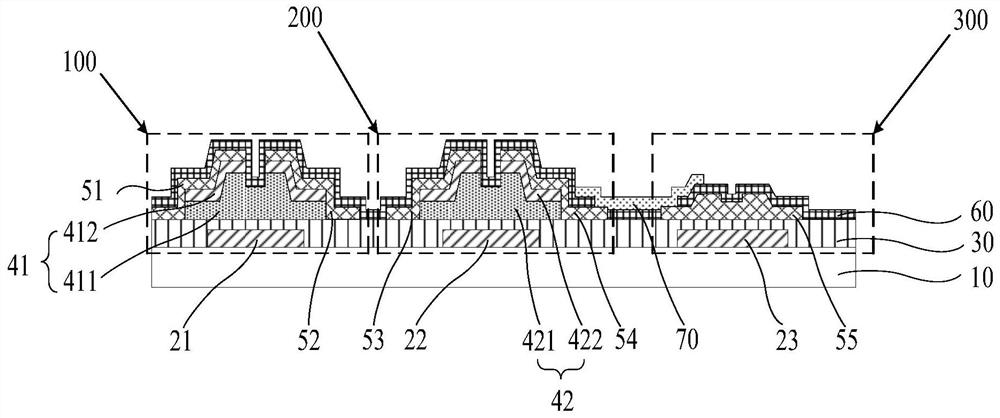

The invention discloses a touch control display circuit structure and a driving method, an array substrate and a display device thereof, and relates to the field of displayer manufacture. The touch control display circuit structure can reduce manufacturing processes during touch display product producing process, improves aperture opening ratio, and improves product additional value. The touch control display circuit structure comprises a touch control unit, a display unit, a data line, a first scanning line, a second scanning line, a signal collection line, a first signal control line, another one data line, another one first scanning line, another one second scanning line and another one signal control line, wherein the data line, the first scanning line, the second scanning line, the signal collection line and the first signal control line are connected with the touch control unit, and the another one data line, the another one first scanning line, the another one second scanning line and the another one signal control line are connected with the display unit. The touch control display circuit structure is applied to displayer manufacture.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

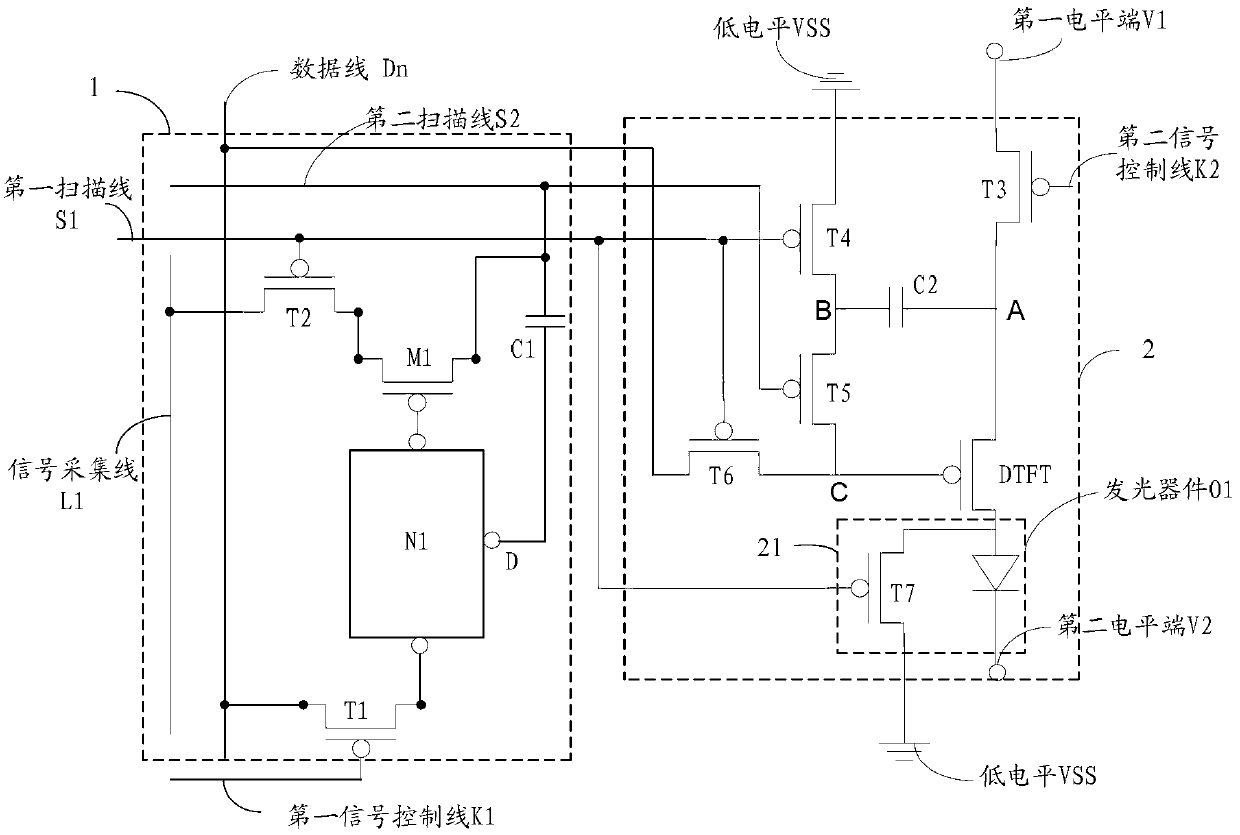

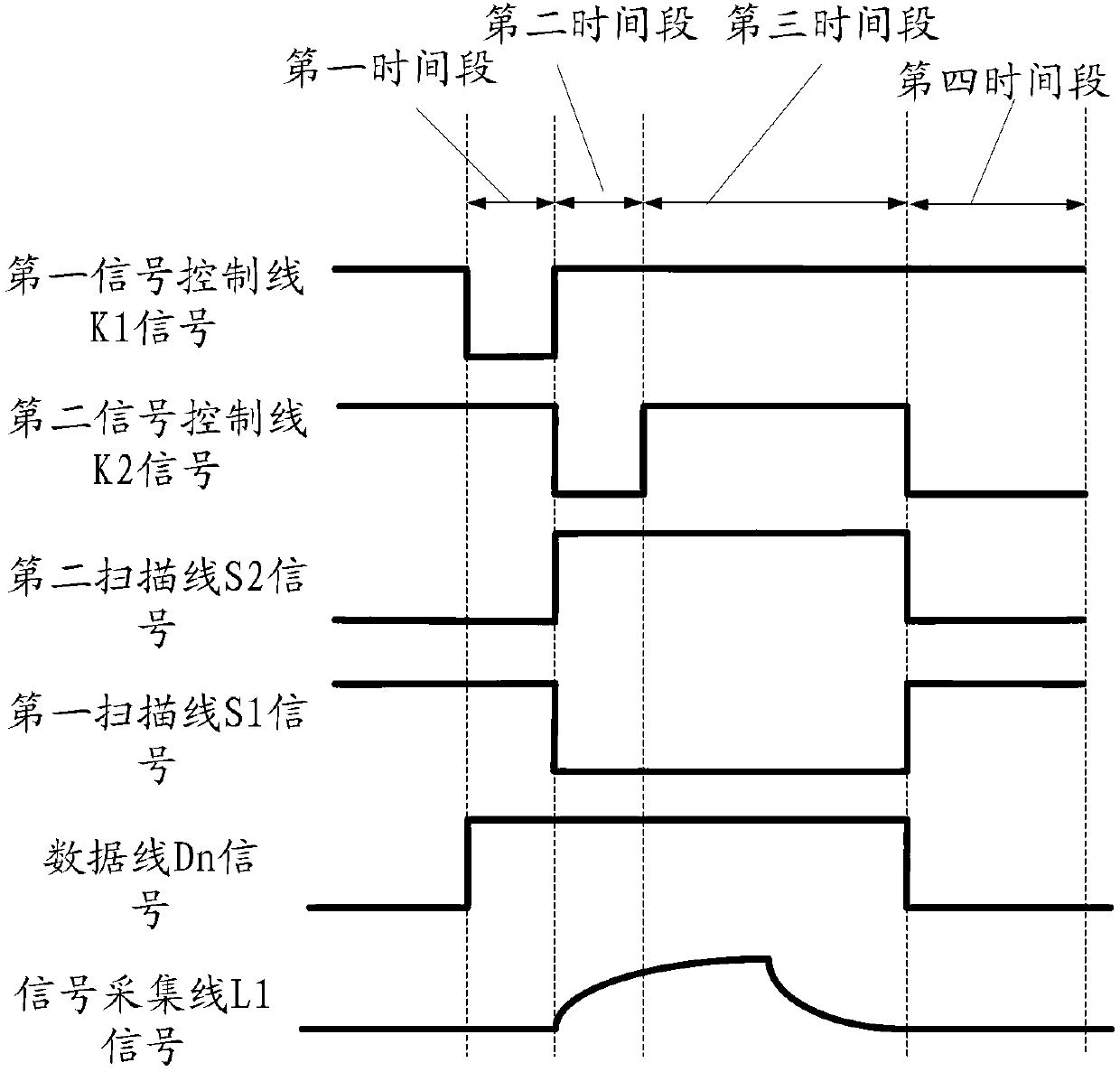

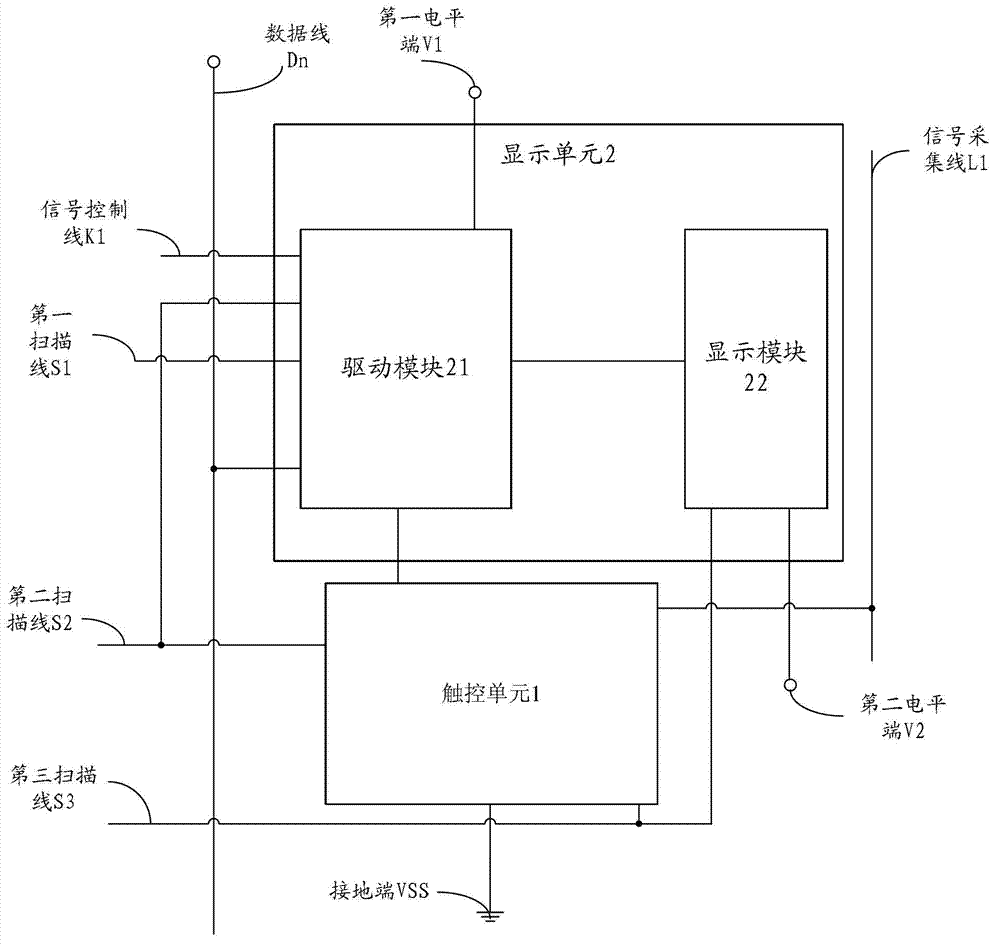

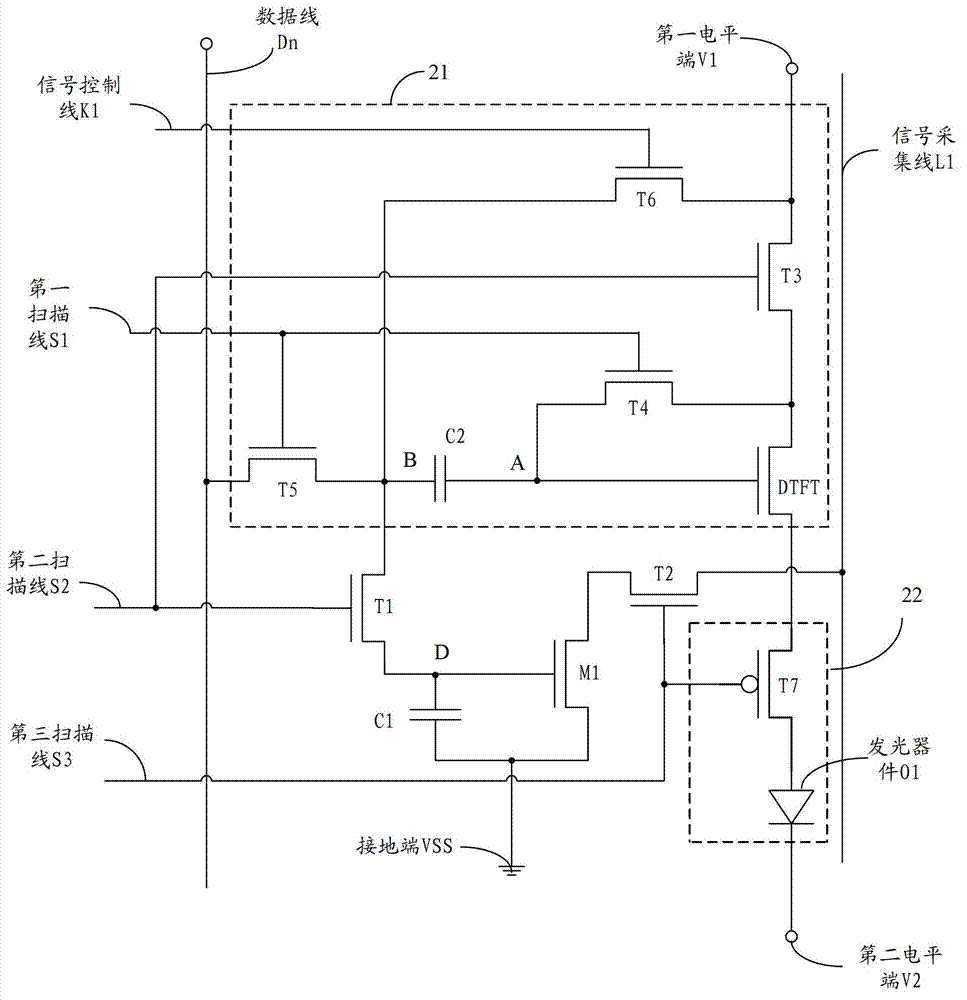

Touch display circuit structure and driving method thereof, array substrate and display device

ActiveCN103246396AReduce processing technologyLow costStatic indicating devicesInput/output processes for data processingDisplay deviceControl line

An embodiment of the invention discloses a touch display circuit structure and a driving method thereof, an array substrate and a display device, and relates to the field of display manufacture. The touch display circuit structure comprises a touch unit and a display unit which are connected with each other, a first scanning line, a second scanning line, a third scanning line, a signal control line, a data line, a first level end and a second level end, the second scanning line, the third scanning line and a signal acquiring line, wherein the first, second and third scanning lines, the signal control line, the data line, the first level end and the second level end are connected with the display unit, and the second and third scanning line and the signal acquiring line are connected with the touch unit. The touch display circuit structure, the driving method thereof, the array substrate and the display device in the embodiment are used for display manufacture, and manufacturing procedures during production of touch display products can be reduced, and aperture ratio and product additional value are increased.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

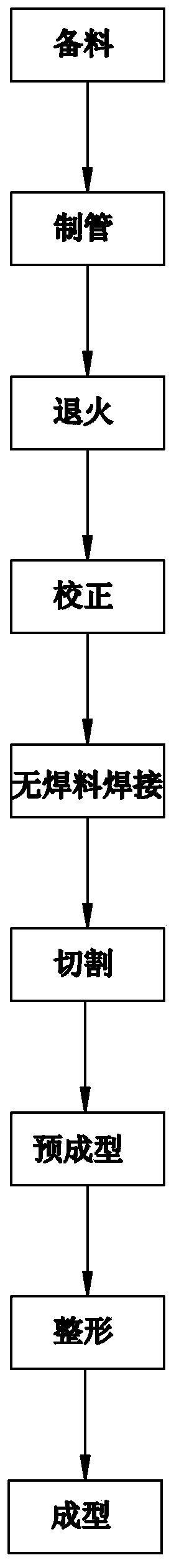

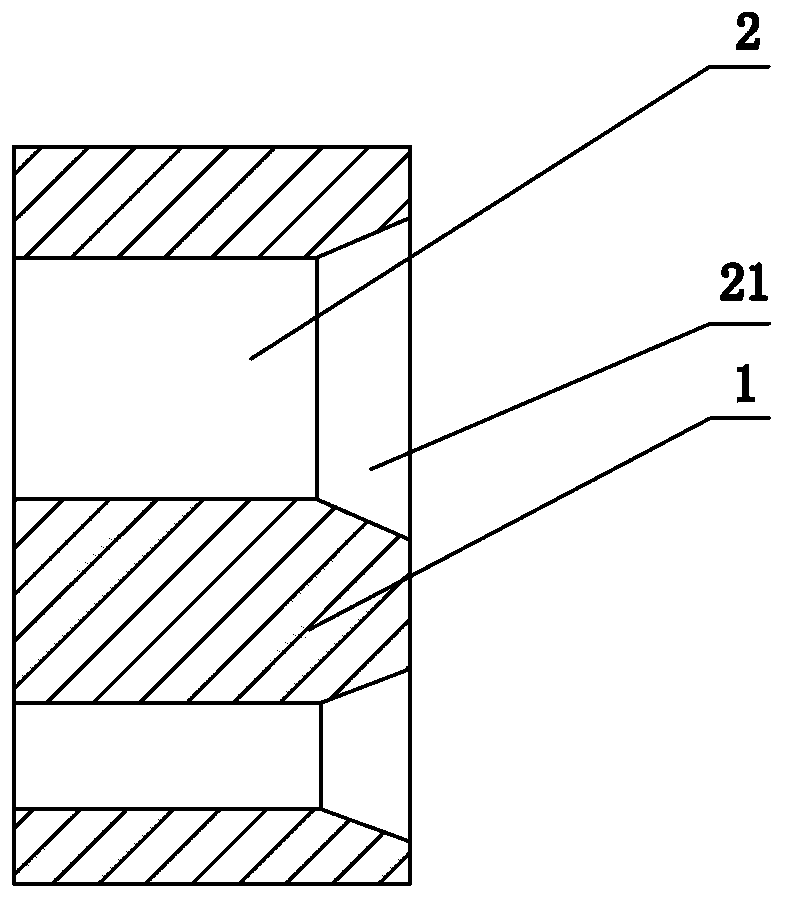

Gold and silver hollow bracelet processing technology

ActiveCN103416925AReduce processing technologyGuaranteed purity and colorJewelleryNanotechnologySheet material

The invention discloses a gold and silver hollow bracelet processing technology and belongs to the technical field of jewelry processing technologies. The processing technology comprises the following steps: preparing material: according to the specifications for processing gold and silver hollow bracelets, preparing sheet material with corresponding specifications; manufacturing a pipe: processing the sheet material into a round pipe with a gap and straightening the round pipe; annealing; calibrating: straightening the gap; welding without welding material: eliminating gap through high-temperature heating to form a gapless round pipe; cutting: cutting the gapless round pipe according to the finished size of a gold and silver hollow bracelet, and polishing two ends of the gapless round pip; pre-forming: processing the gapless round pipe into an open type circular ring, and forming a closed circular ring by performing high-temperature heating on the open type circular ring; shaping: shaping the shape of the closed circular ring until specified requirements are met; forming: processing the closed circular ring into a hollow bracelet with elliptic sections. Through the processing steps, since a only a piece of sheet material is needed, the hollow bracelet can be manufactured, the processing technology is reduced, the processing efficiency is improved, the forming effect is good, and meanwhile, the gap is closed automatically through high temperature, so that welding without welding material is achieved, and the purity and fineness are guaranteed.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD +1

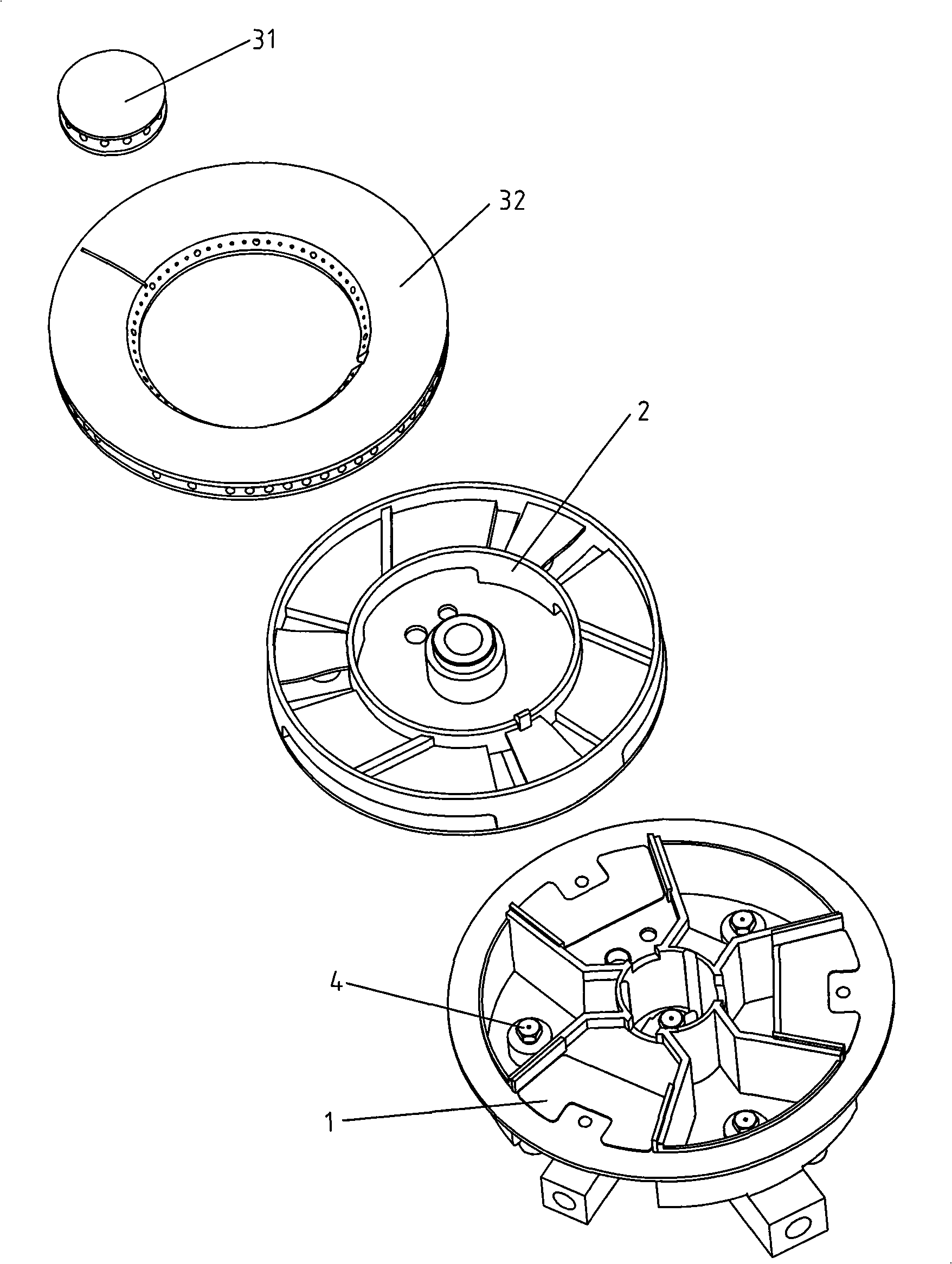

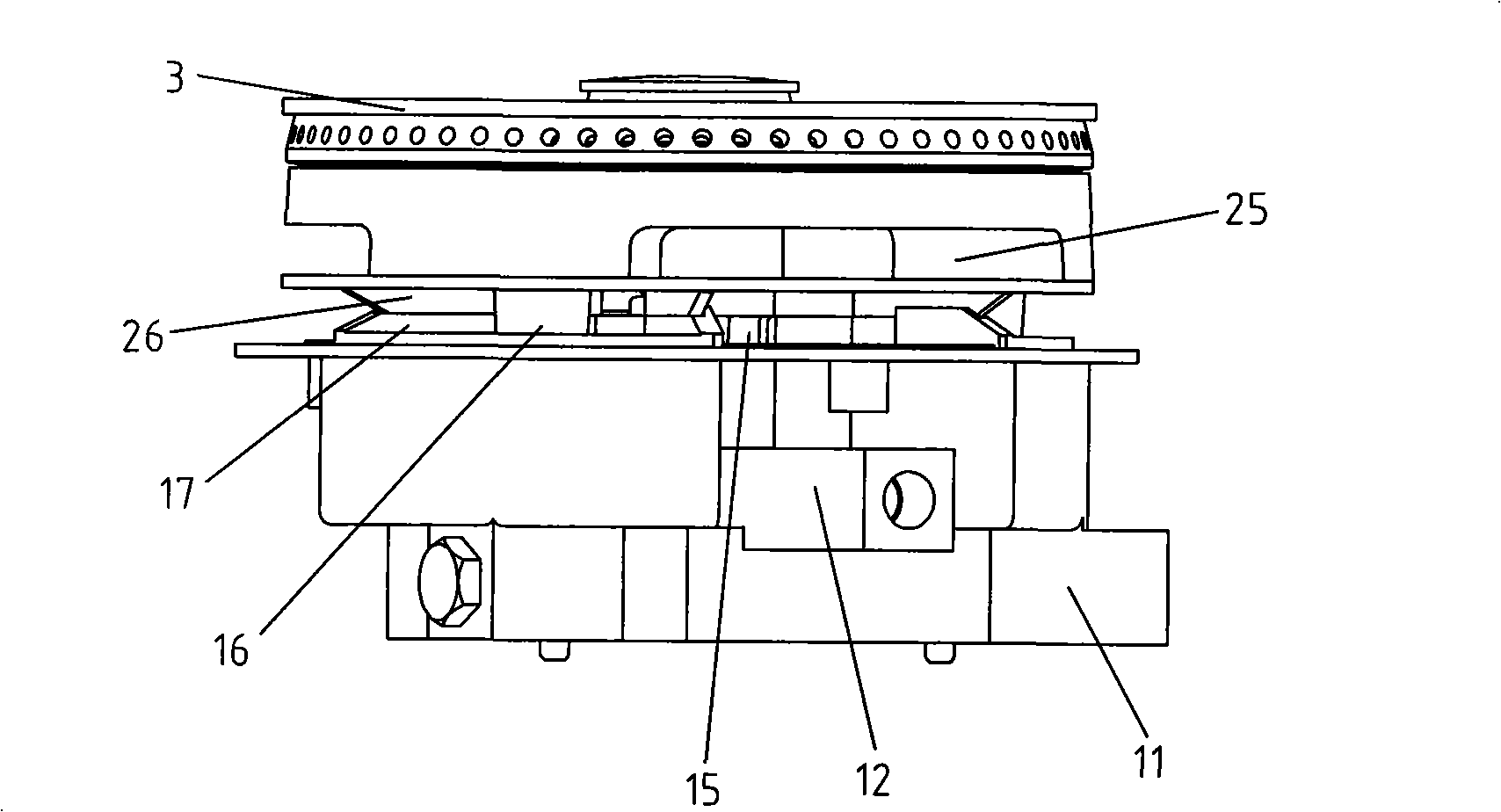

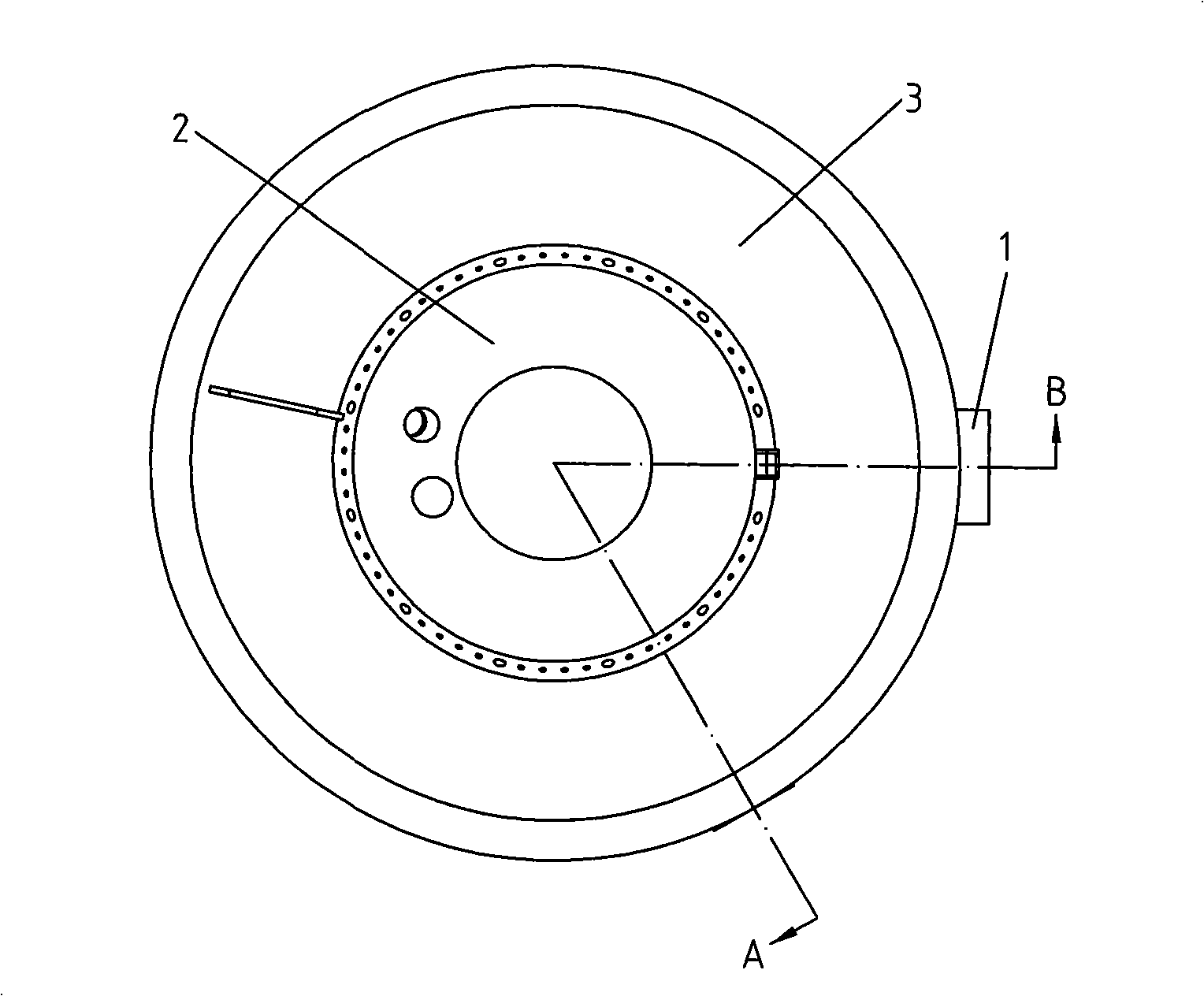

Household gas burner

The invention discloses a household gas burner, belonging to the part in the household gas kitchen range. The present household gas burner has the complex structure, poor processing precision and big accumulative error in assembling. The household gas burner comprises a nozzle, a gas distributing device, a gas mixing device and a fire lid, and characterized in that the gas distributing device and the gas mixing device are all the integrated structure, wherein the gas distributing device comprises a gas supplying pipe and a distributing chamber, a primary air inlet open is arranged on the distributing chamber, the nozzle is fixed on the orifice of the gas supplying pipe in the distributing chamber; the gas mixing device comprises a mixing pipe, a mixing chamber, a buffer baffle plate and a secondary air inlet slot, the mixing chamber is matched with the distributing chamber, the buffer baffle plate is arranged above the orifice of the mixing pipe in the mixing chamber, the secondary air inlet slot is arranged at the side surface of the gas mixing device. The gas distributing device and the gas mixing device in the invention have no accumulative error in assembling, simple assembling and safe and reliable use.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

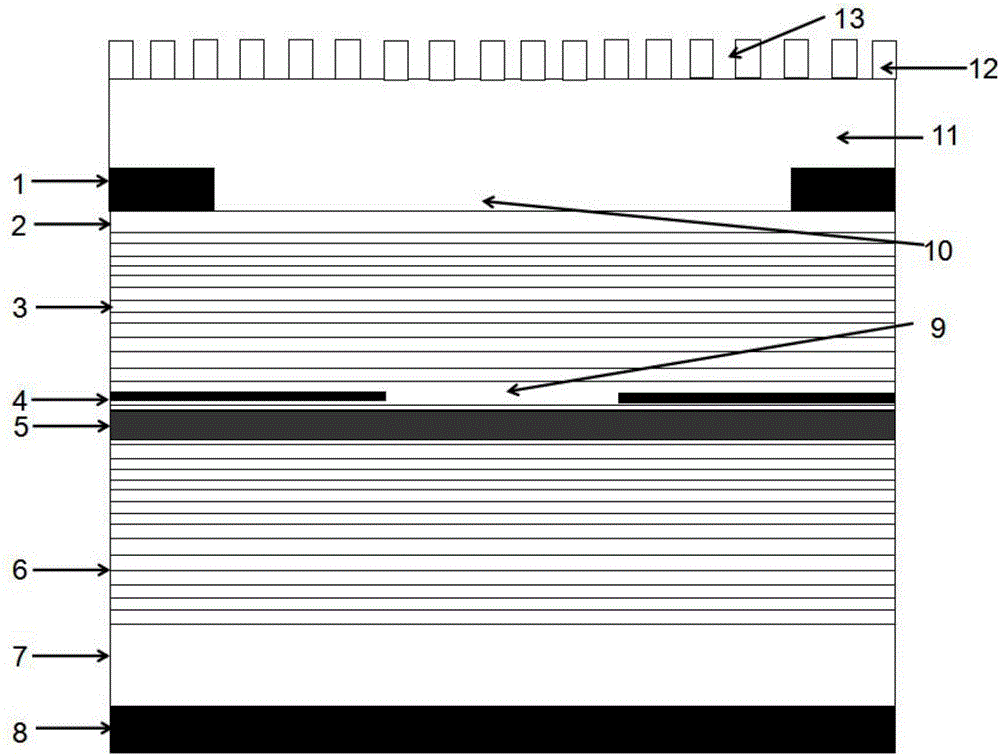

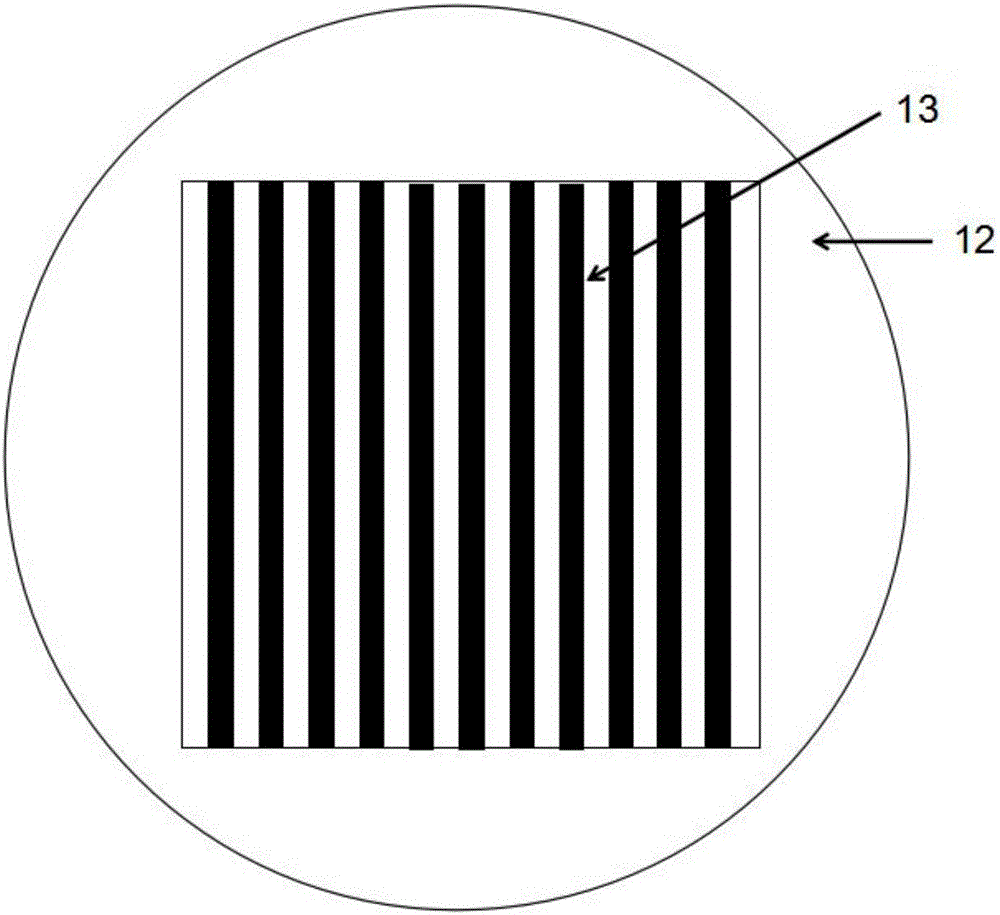

High-contrast-grating coupled-cavity narrow-spectral-line-width surface-emitting laser

ActiveCN106058642AReduce processing technologyImprove yieldLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserResonant cavity

The invention, which belongs to the technical field of the photoelectron, discloses a high-contrast-grating coupled-cavity narrow-spectral-line-width surface-emitting laser. A high-contrast grating having high reflectivity and large reflecting width is used as a reflector and is integrated to the top of a transverse-mode-based vertical-cavity surface-emitting laser; and on the basis of the high reflectivity of the high-contrast grating, emergent light of a device is fed back and photoinjection is carried out on the device, thereby obtaining a novel coupled-cavity integrated surface-emitting laser. Therefore, extension of an effective resonant cavity of the device is realized; and the spectral line width of the transverse-mode-based vertical-cavity surface-emitting laser is reduced to obtain a narrow-spectral-line-width surface-emitting laser. Because of utilization of the high-contrast-grating structure with support of the low refractive index, the integrated outer cavity preparation difficulty is reduced and the device processing process is simplified; the preparation process is a pure planar process, so that the yield and reliability of the device are improved effectively. The laser has advantages of large spectral line width adjusting range, obvious narrowing effect, and simple design and preparation process.

Owner:BEIJING UNIV OF TECH

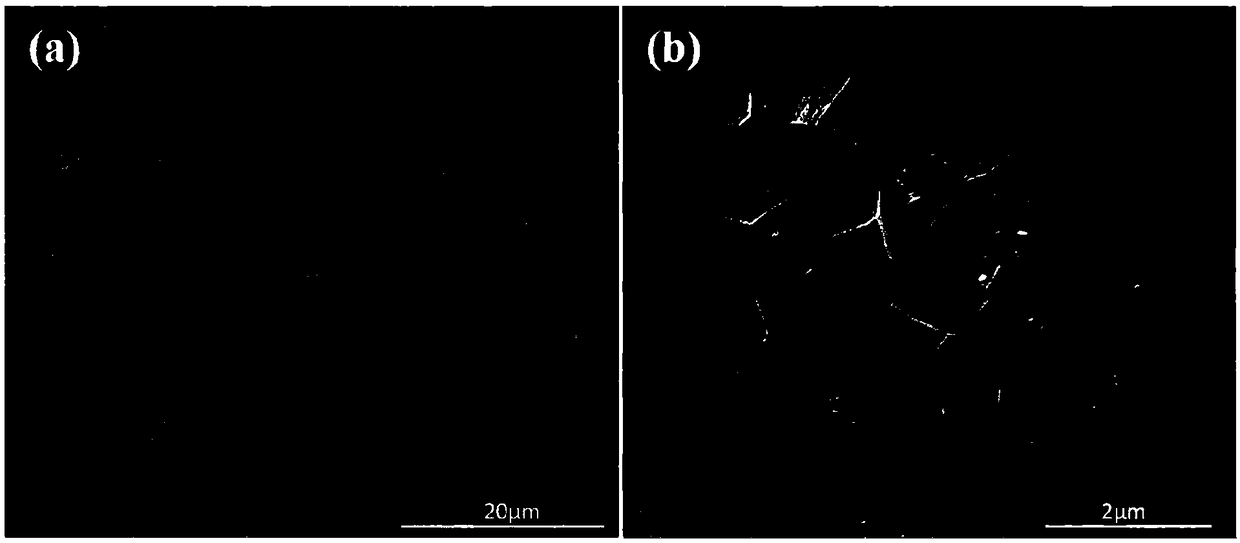

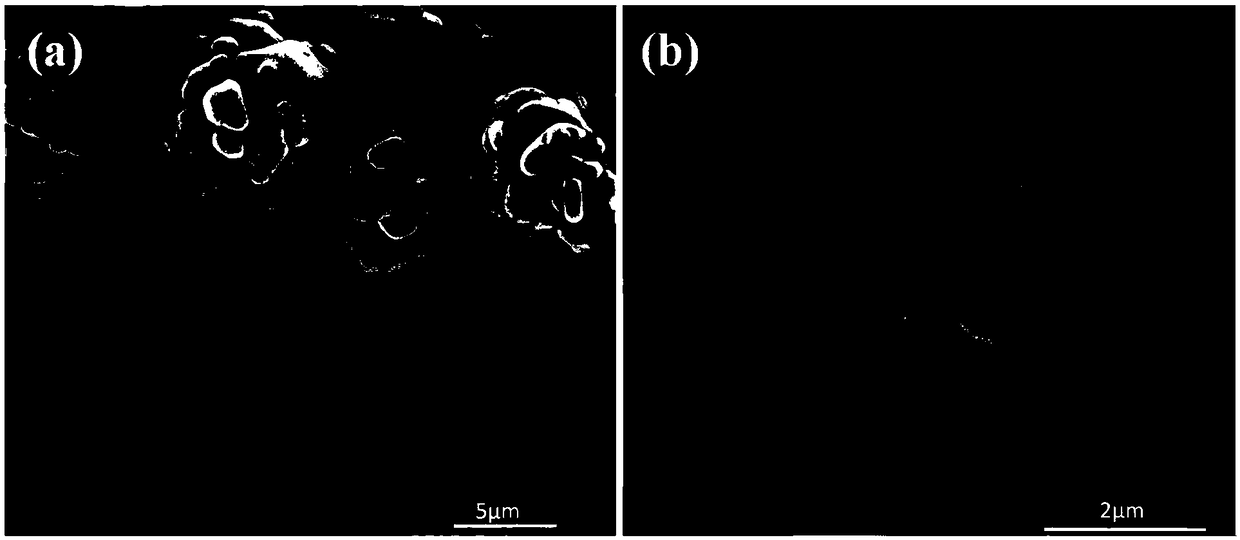

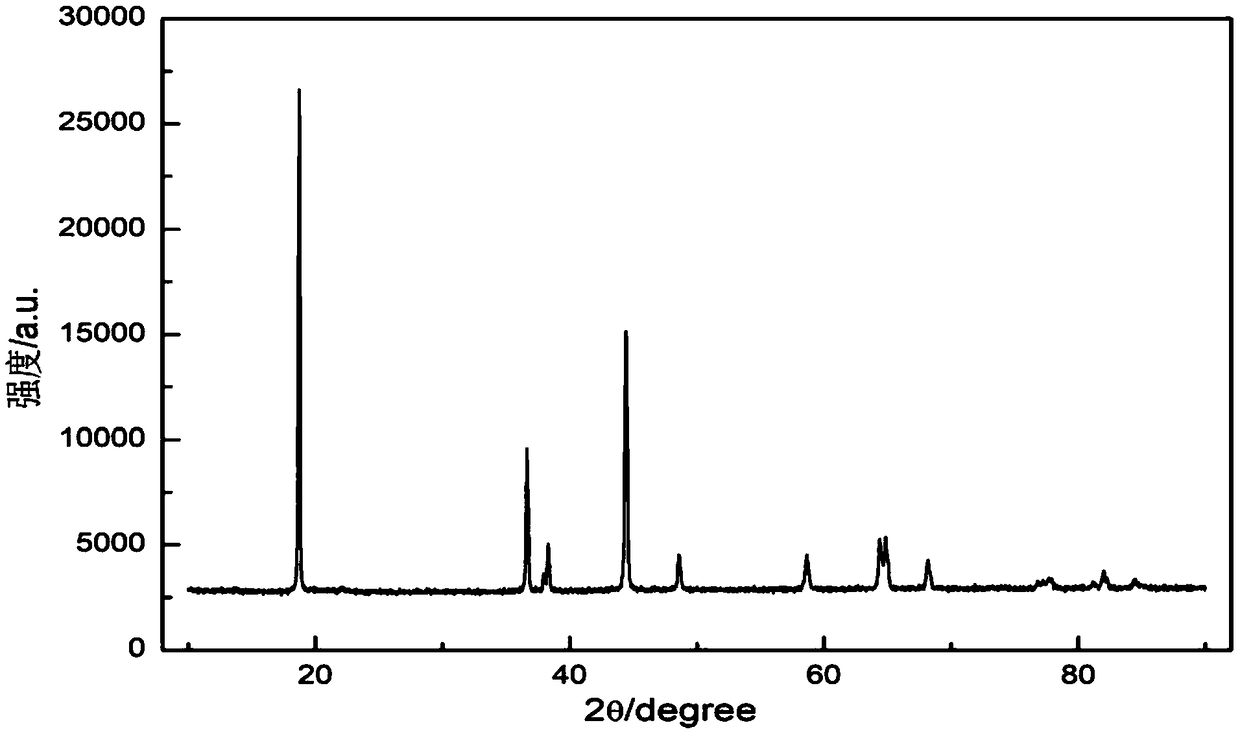

Ternary positive electrode material micron-sized platy monocrystal structure aggregate and preparation method thereof

The invention discloses a preparation method of a ternary positive electrode material micron-sized platy monocrystal structure aggregate. The method comprises the steps that an improved chemical coprecipitation method is adopted for preparing a micron spherical precursor formed by closely stacking nanometer sheets, wherein the size of the precursor D50 ranges from 6 micrometers to 8 micrometers; then the precursor is fully mixed with an appropriate amount of fluxing agent and lithium salt in sequence; finally, two-step high temperature sintering is conducted in a high temperature sintering furnace, and a ternary positive electrode material of the micron-sized platy monocrystal structure aggregate is obtained finally. The prepared positive electrode material combines the advantages of a monocrystal structure and an aggregate structure, on the one hand, a micron-sized platy monocrystal can make the positive electrode material tolerate high voltage and have better cycling stability and the high capacity and rate performance; one the other hand, the spherical structure ensures that the material has the high compaction density and excellent battery processing performance; therefore, theternary positive electrode material with the excellent performance is obtained.

Owner:圣戈莱(北京)科技有限公司

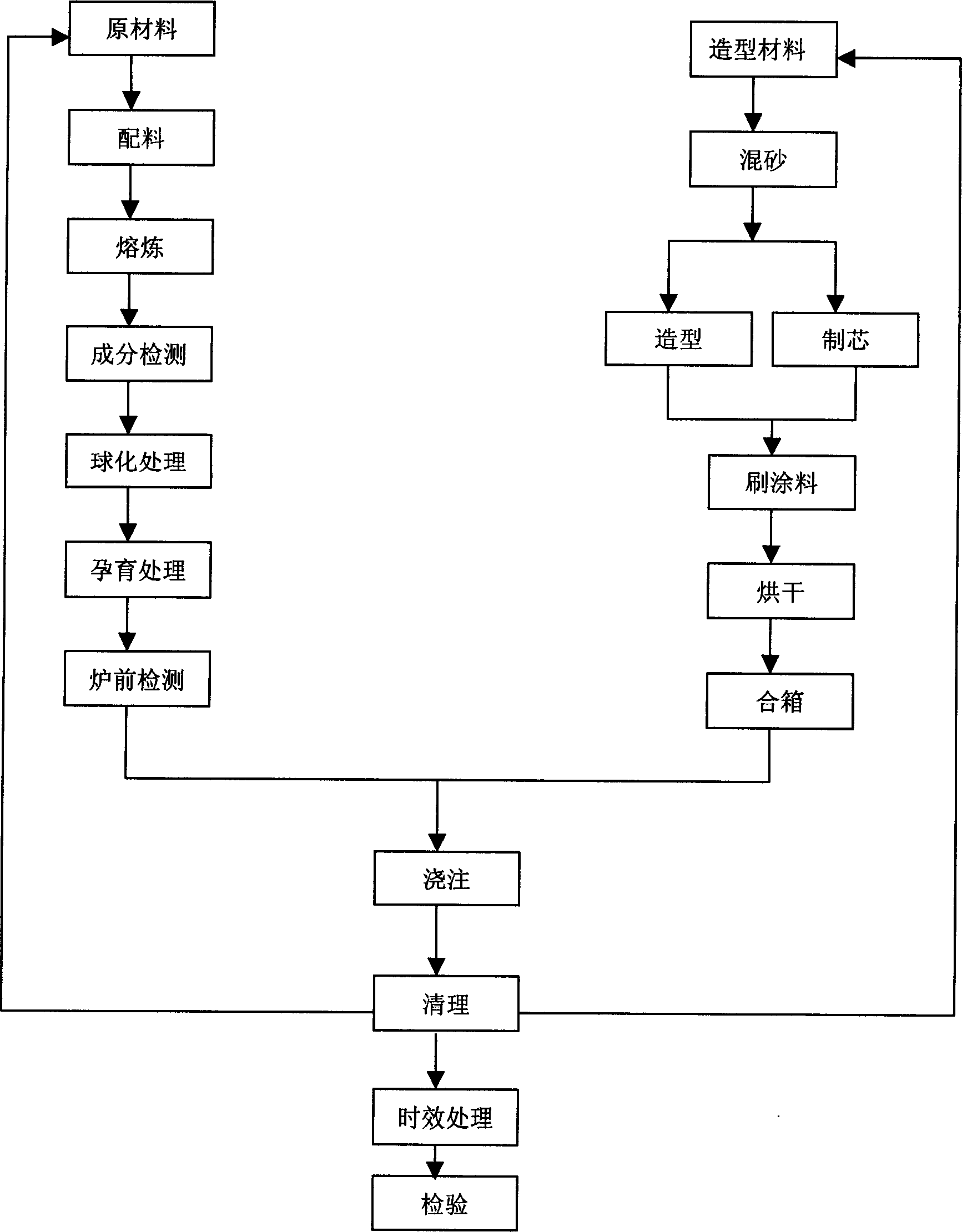

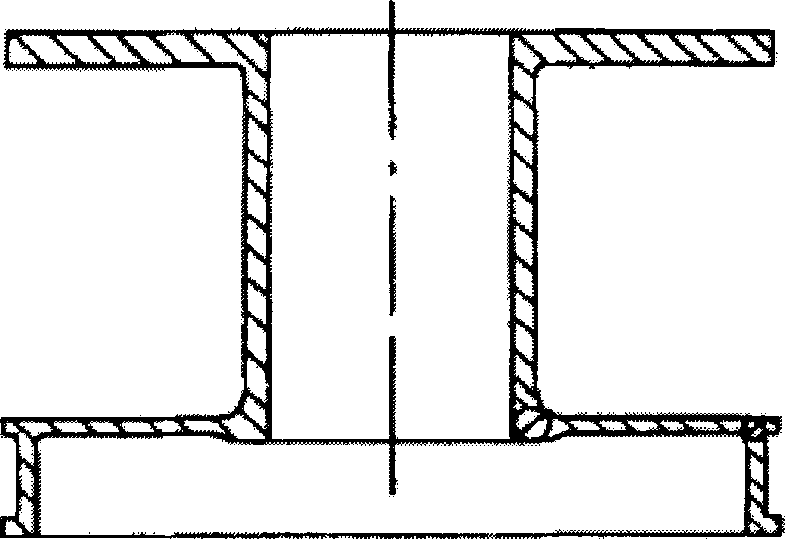

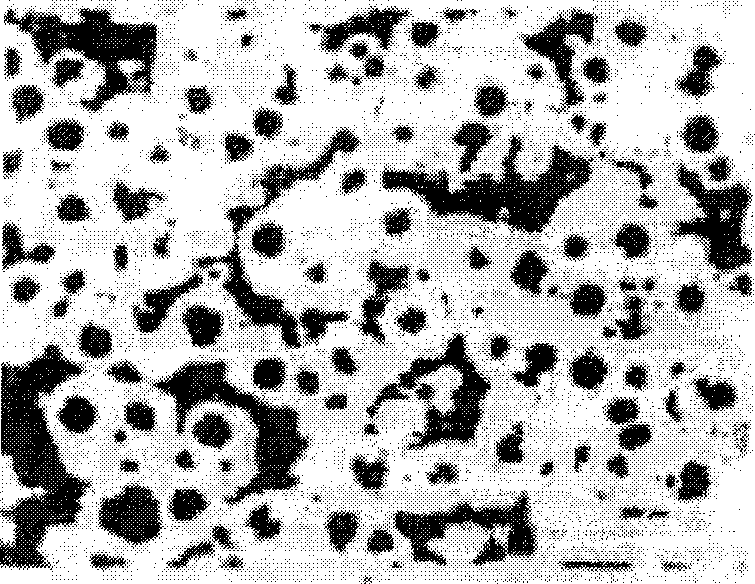

Manufacture process of high performance ductile iron roll

The present invention discloses manufacture process of high performance ductile iron roll, belongs to the field of crane roll making technology, and solves the problem of once casting formation. By means of the research on high performance cast ductile iron and the research on casting mold material, paint and casting process, the present invention has simplified roll manufacturing process, raised material utilization, low power consumption, obviously raised mechanical performance and use performance of the roll and obviously lowered production cost.

Owner:SHANDONG HUIFENG CASTING TECH

Anti-corrosive intelligent kitchen garbage barrel and manufacturing method thereof

ActiveCN106335723AEffective absorption and filtrationEffective shreddingRefuse receptaclesWastewaterSewage

The invention discloses an anti-corrosive intelligent kitchen garbage barrel and a manufacturing method thereof. The anti-corrosive intelligent kitchen garbage barrel comprises a barrel box, an end cover and a wastewater purifying device, wherein a stirring cavity, a cylinder body, a forming plate and a storage cavity are arranged inside the barrel body; a crushing mechanism is arranged in the stirring cavity; feeding mechanisms are symmetrically arranged on the outer side surface of the barrel boxy; the forming plate is positioned between the cylinder body and the storage cavity; a forming extrusion mechanism is arranged above the forming plate; and the wastewater purifying device is positioned on the bottom side surface of the barrel body. The manufacturing method comprises the following steps: (1) mounting of the storage cavity; (2) mounting of the forming plate and the forming extrusion mechanism; (3) mounting of the crushing mechanism; (4) mounting of the wastewater purifying device; (5) mounting of the feeding mechanisms; and (6) preliminary running debugging. The anti-corrosive intelligent kitchen garbage barrel disclosed by the invention is simple in structure and high in practicability; not only can kitchen garbage be crushed, but also the crushed kitchen garbage can be used for fish and poultry feeding; the garbage recovery efficiency is improved; and the environmental pollution caused by corrosion of the kitchen garbage is effectively prevented.

Owner:浙江融家科技有限公司

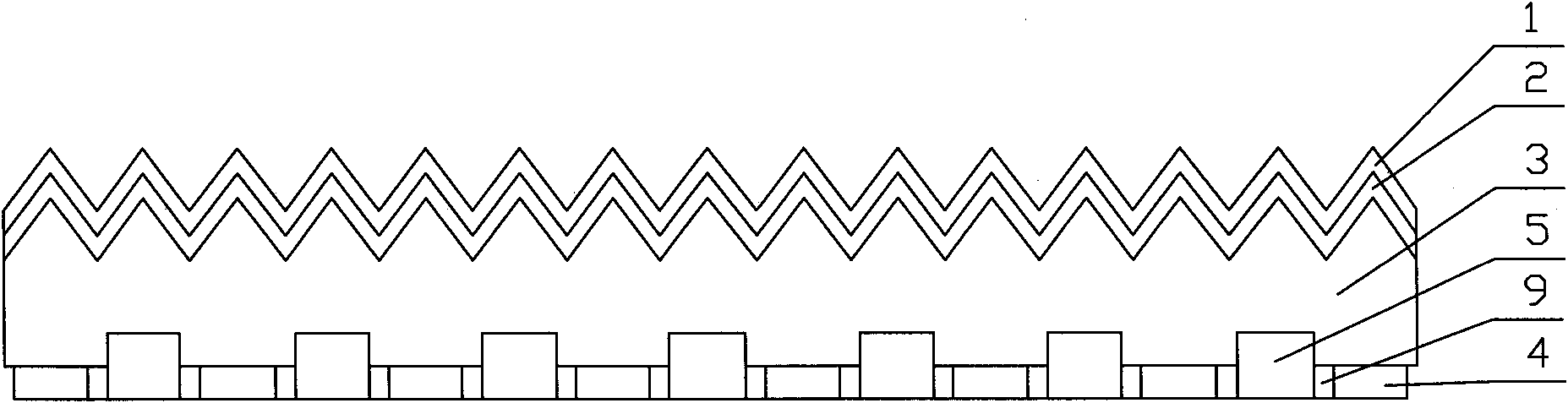

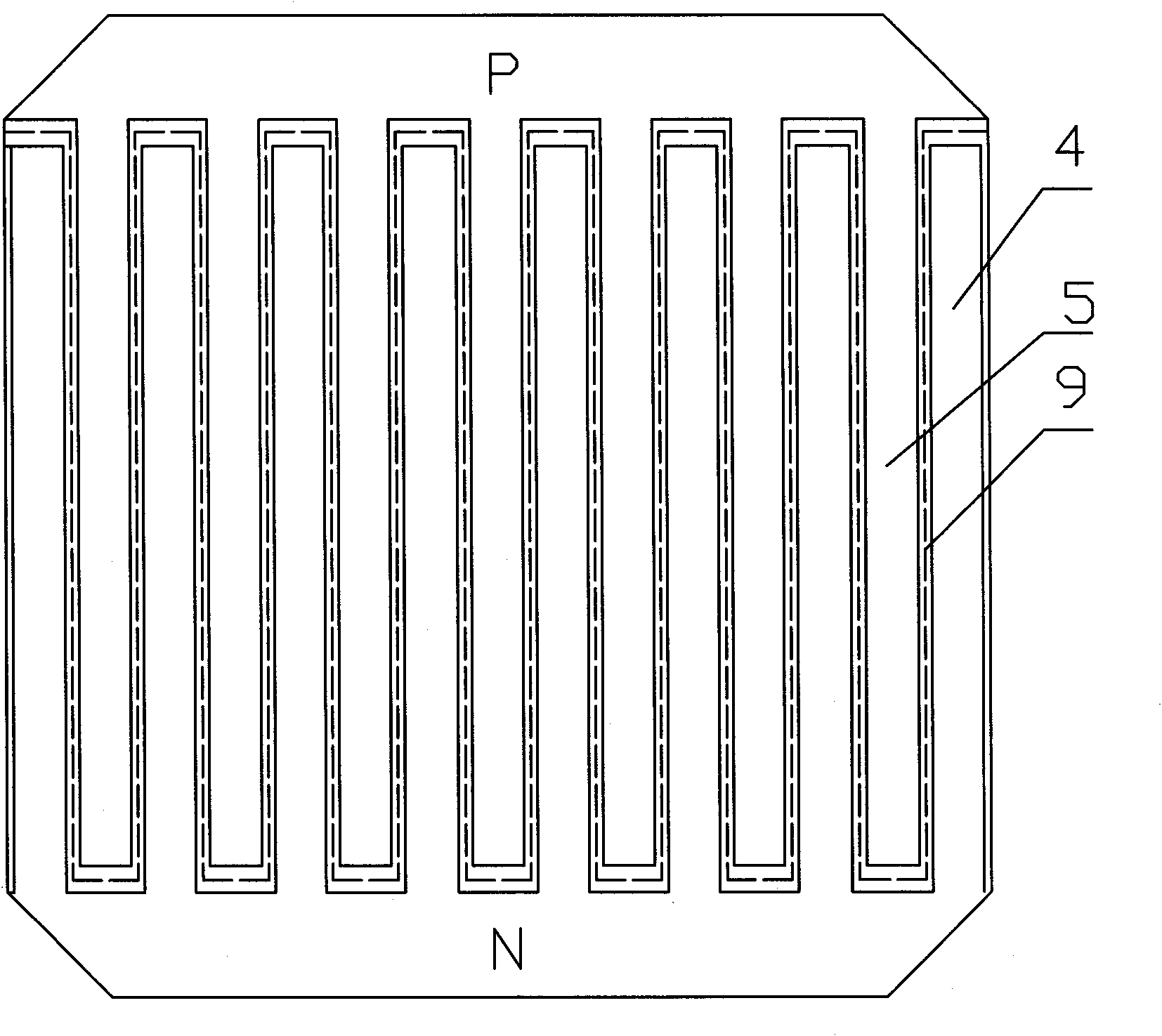

Schottky junction single-sided electrode crystalline silicon solar cell and preparation method thereof

InactiveCN101814540AIncrease effective lengthImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationAluminiumOhmic contact

The invention discloses a Schottky junction single-sided electrode crystalline silicon solar cell. In the cell, the backlight face of an N-type substrate is provided with a negative electrode which forms a Schottky junction together with the N-type substrate and a positive electrode which is matched with the negative electrode in shape, wherein the positive electrode and the N-type substrate are in ohmic contact; and a clearance is reserved between the negative electrode and the positive electrode. The invention also discloses a preparation method, which comprises: texturing the N-type substrate, and plating a light receiving surface with a passive layer and a reflective layer; forming the aluminum negative electrode on the backlight face of the N-type substrate by screen printing, wherein the aluminum negative electrode is shaped like a grid or comb; irradiating the aluminum negative electrode with strong laser to allow aluminum to permeate into a chip to form the Schottky junction; forming the metal positive electrode on the backlight face of the N-type substrate, which is crossed with the aluminum negative electrode and has the same shape as the aluminum negative electrode, by screen printing to form the positive electrode of the cell; and sintering the substrate to make the metal positive electrode in ohmic contact with the backlight face of the N-type substrate. The front face of the cell is not blocked and therefore can receive 10 to 20 percent of sunlight.

Owner:江苏华创光电科技有限公司

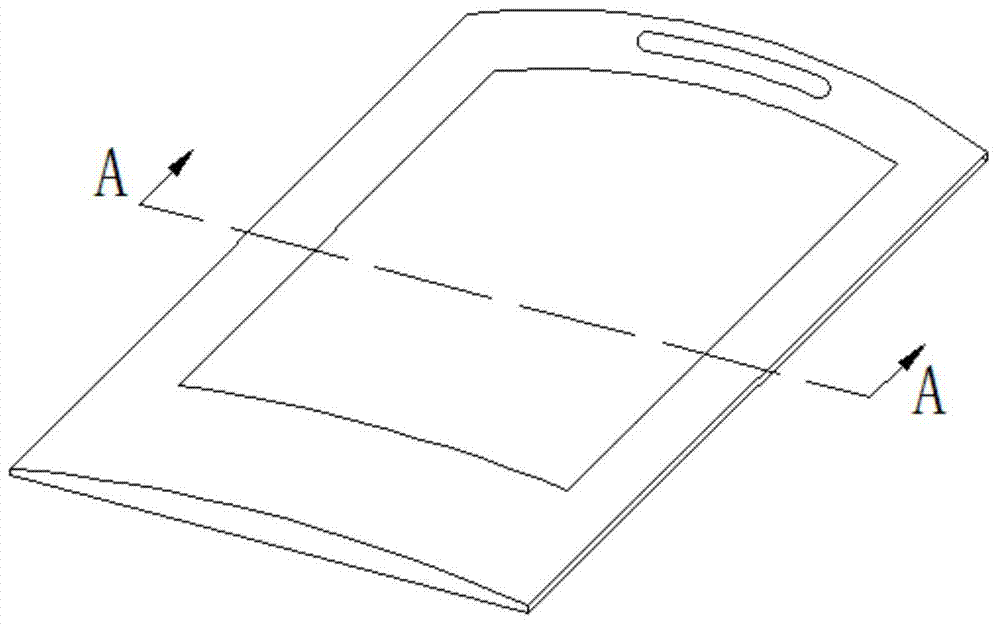

A processing method of a glass cover plate

A processing method of a glass cover plate is disclosed and belongs to the technical field of glass substrate moulding. The method includes dividing a surface to be processed of the glass cover plate into zones according to the final moulding thickness, etching the zones separately by an etching process according to an order from small thickness to large thickness of the zones, and grinding small sharp corners formed in adjacent zones after etching is completed to form the glass cover plate with a curved surface structure. Processing of the glass cover plate with the curved surface structure by the method is largely reduced in processing difficulty, and the yield is largely increased than the yield of numerical control machining. The method overcomes the problems of processing methods at present for arc-shaped glass cover plates, namely the processing efficiency is low and processing precision is not liable to ensure.

Owner:KUNSHAN VISIONOX DISPLAY TECH

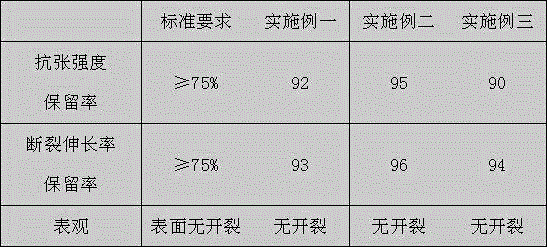

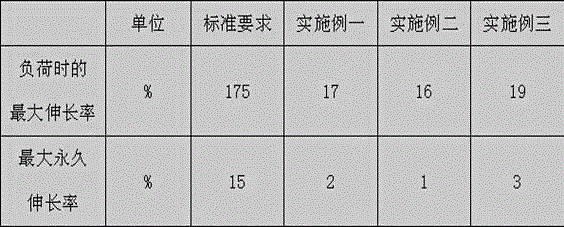

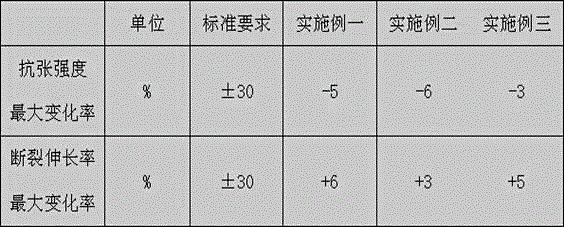

Whitening ultraviolet-proof cable insulating rubber and manufacturing method thereof

InactiveCN102977470AReduced decolorization abilityImprove heat aging resistancePlastic/resin/waxes insulatorsVulcanizationGas phase

The invention discloses whitening ultraviolet-proof cable insulating rubber and a manufacturing method of the rubber, and belongs to the field of cables. Raw materials comprises 12 parts of Keltan 5508, 8 parts of Keltan 21, 0.4-0.6 part of co-vulcanization agent TAIC, 0.5-0.8 part of vulcanizing agent DCP, 0.3-0.6 part of antiager MB, 0.1-0.2 part of antiager 2246, 0.8-1.2 parts of zinc oxide, 0.1-0.3 part of stearic acid, 1-1.5 parts of rutile type titanium dioxide, 10-12 parts of colloidal calcium carbonate, 10-12 parts of ultrafine talcum powder, 2-3 parts of cylinder oil of number 38, 2-3 parts of gas-phase-method silicon dioxide hydrate, 0.05-1 part of ultraviolet light absorber UV-326 and 0.1-0.3 part of coupling agent A-174. A filling agent, a reinforcing agent, a coloring agent, the antiager, the zinc oxide, the ultraviolet light absorber and the coupling agent are subjected to internal mixing first, ethylene propylene rubber is fed for mixing, rubber filtering, rolling, cooling are carried out, the stearic acid and the vulcanizing agent are fed for mixing, and then ethylene propylene rubber is fed for mixing, a triangular ladle is rammed, thin-passing process is carried out, and cutting and cooling are carried out for using. The insulating rubber is white in color, good in mechanical performance, good in ultraviolet light aging resistant performance and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

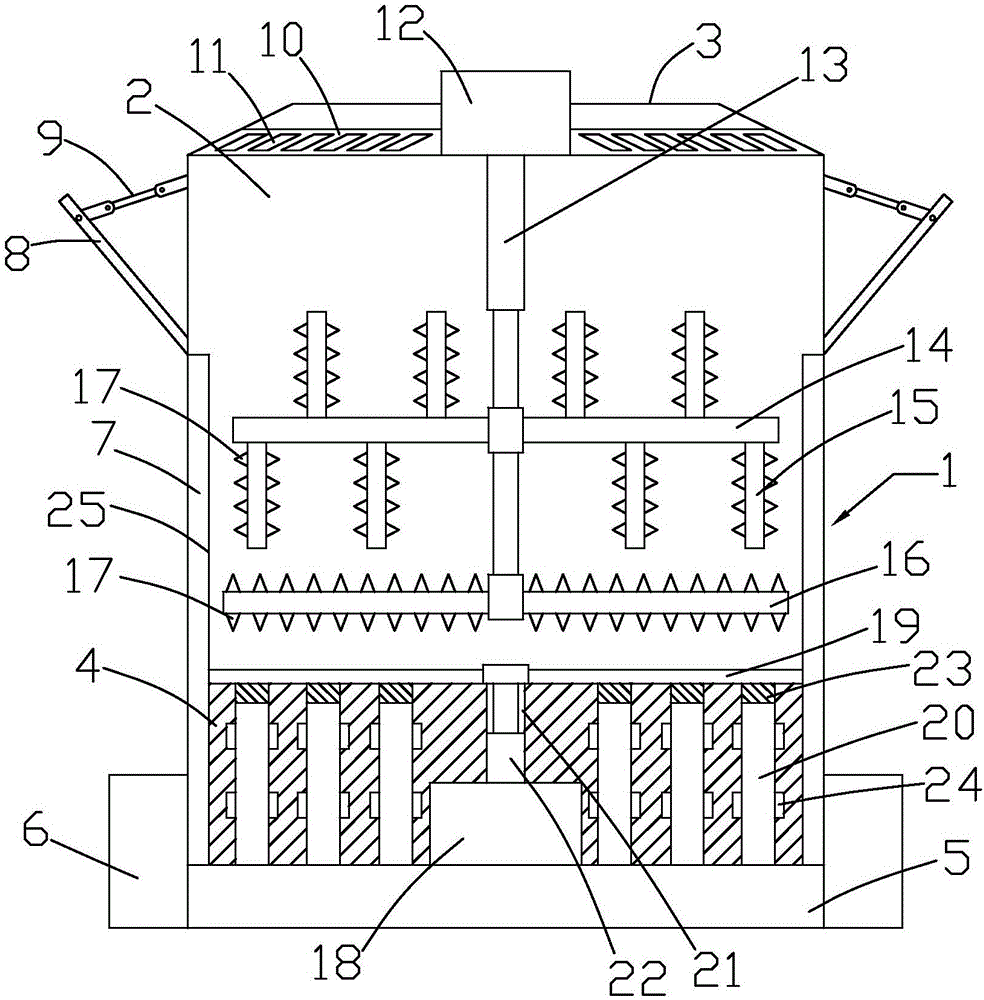

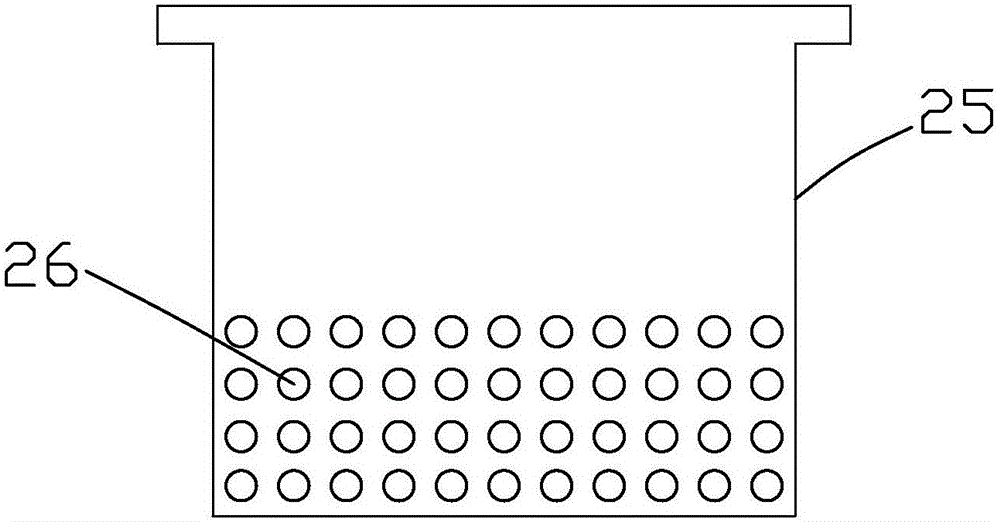

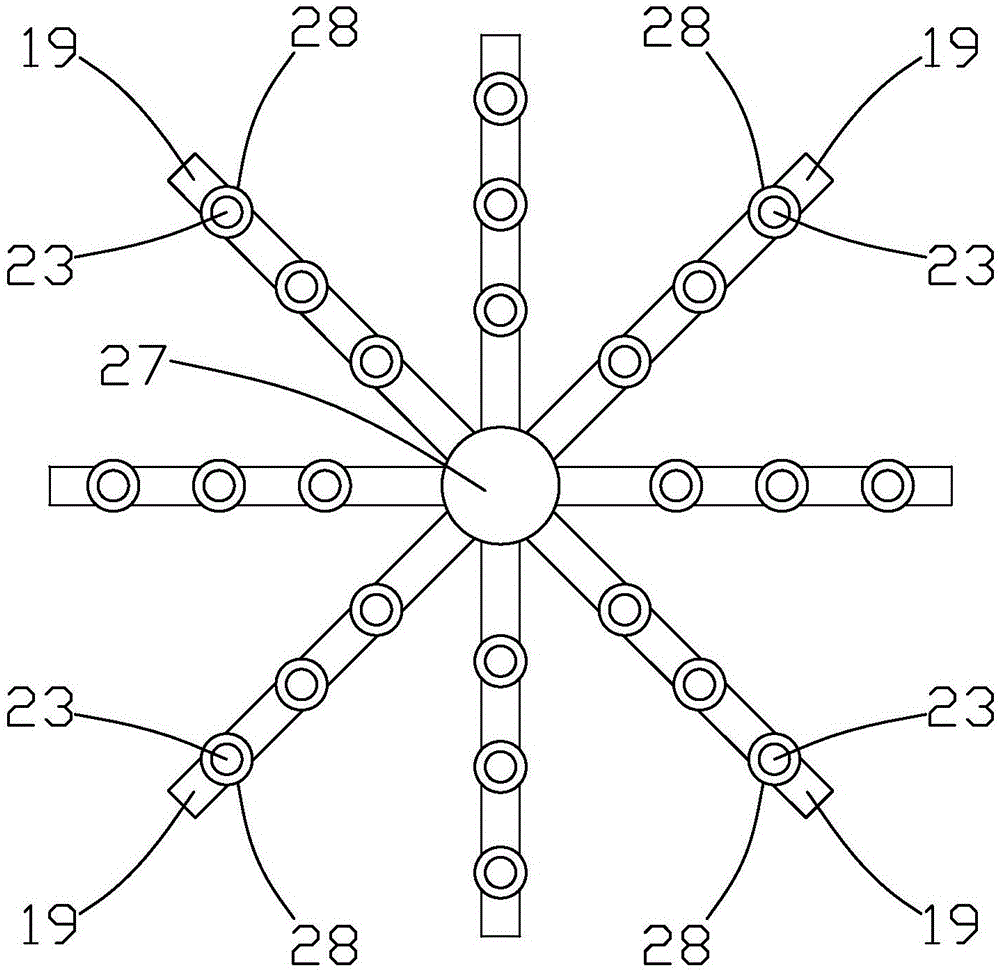

Multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit

InactiveCN104481411AImprove applicabilityImprove drilling efficiencyDrill bitsHigh pressure waterAlloy

The invention relates to a multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit, which is applicable to lubricating and cooling the drill bit and automatically drilling holes in a drilling process of a complex geological structure and has high drilling efficiency, long life and high applicability. The multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit comprises a special alloy crown part, and a diamond composite sheet is additionally arranged, so the wear degree of steel can be effectively relieved, the consistency in aperture is guaranteed, and the phenomenon of shrinkage is avoided. The high-pressure water jet of the drill bit is very beneficial for assisting in the drilling efficiency; the drilling diameter of the water jet is larger than the drilling diameter of the conventional mechanical rotary cut drilling, and the aperture of a soft coal seam at a local area can be increased by 20-30 times. The drill bit can be used for performing other drilling construction processes in combination with product characteristics when water circulates through a region drilled to meet the requirement of the process in a cut joint outside a fracturing breakage region, a hole collapse region, a hole blockage region, a gas accumulation region and a region with coal blast and spray holes, and the construction is integrally performed to save time and labor.

Owner:XUZHOU BOAN TECH DEV

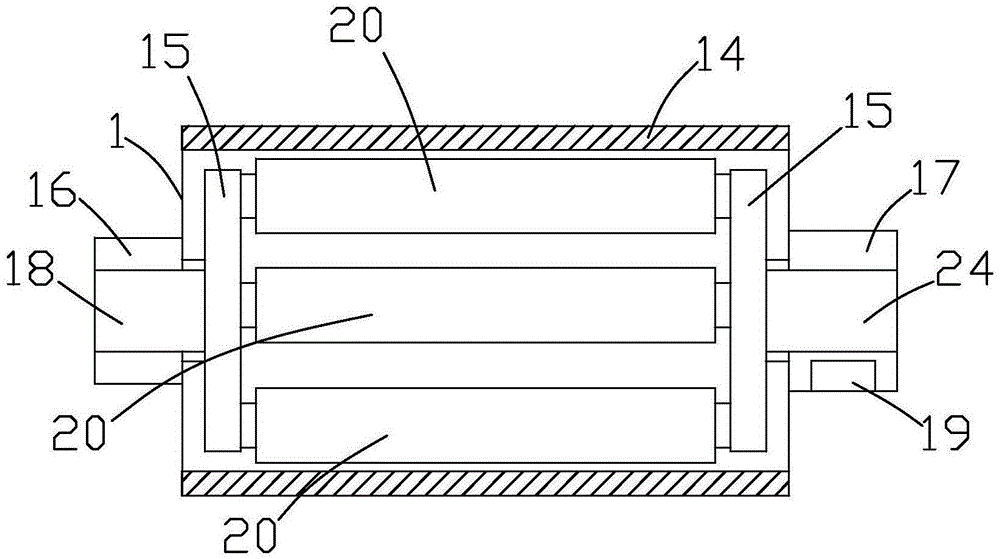

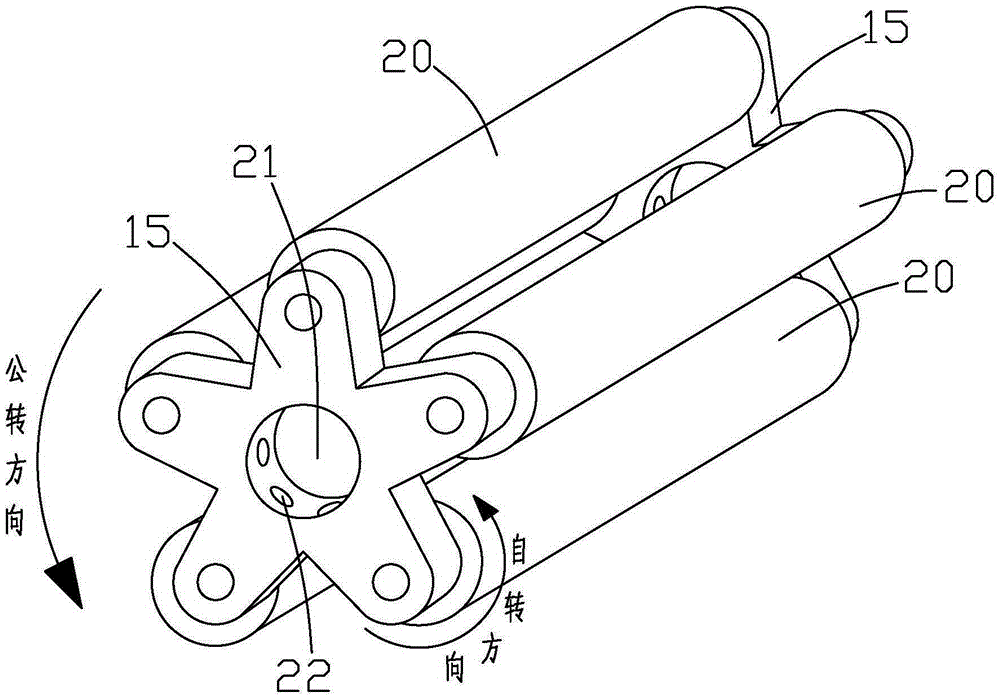

Ball mill used for producing graphite powder

InactiveCN105413813AExcellent crushing speedReduce crushing timeGrain treatmentsSynchronous motorGraphite

The invention discloses a ball mill used for producing graphite powder. The ball mill comprises a roller, a power drive device, a feeder and a dumping device, wherein two star brackets which are parallel to each other are arranged on the inner part of the roller; material distributing tubes are uniformly arranged on the inner parts of the star brackets; five cylindrical ball-milling tanks which are parallel to each other are uniformly distributed between the two star brackets; the two ends of each cylindrical ball-milling tank are provided with supporting tube racks; a synchronous motor is arranged on the inner parts of the star brackets; the cylindrical ball-milling tanks realize autoroatation around the star brackets; the two ends of the roller are respectively provided with a front positioning bearing and a rear positioning bearing; and the cylindrical ball-milling tanks realize rotation around the front positioning bearing and the rear positioning bearing. The ball mill is simple in structure, high in practicability, not only can realize autoroatation and rotation of the cylindrical ball-milling tanks and improve material crushing efficiency and material crushing quality, but also can pre-heat and crush materials, so that the materials are guaranteed to have certain temperature while being output, and therefore, crushing requirements of different materials are met.

Owner:SHENGZHOU SIGMA TECH

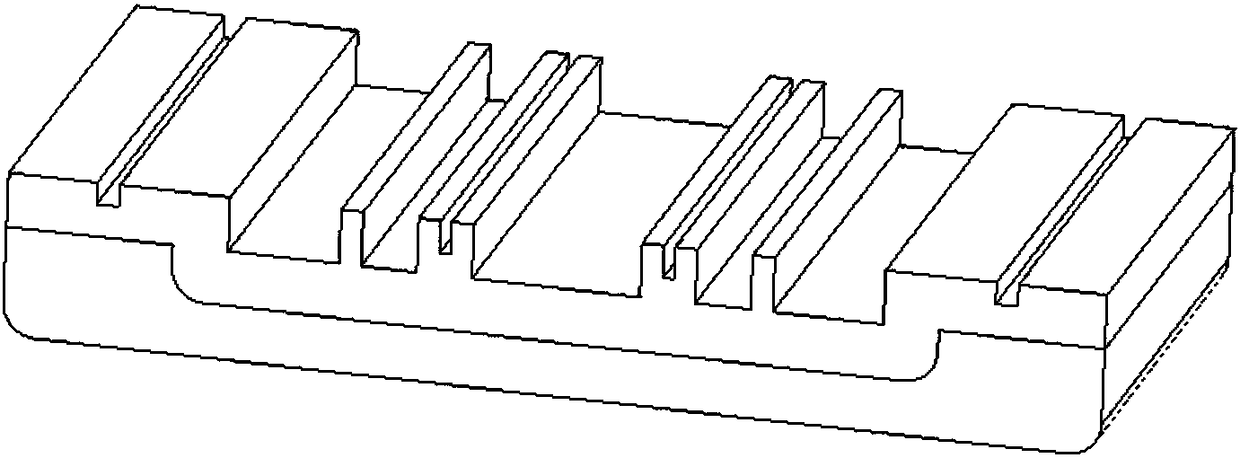

Machining method of steam seal measuring snap-gauge

ActiveCN105563040AGuaranteed dimensional accuracyGuaranteed size requirementsMechanical measuring arrangementsMachiningEngineering

The invention relates to a machining method of a steam seal measuring snap-gauge, and solves the problems that in the prior art, a steam seal measuring snap-gauge is high in manufacturing cost, and long in machining period. The machining method comprises the following specific steps: 1, preparing a blank; 2, roughly machining the side surfaces of the blank; 3, machining a circular arc on the upper surface of the blank; 4, conducting clean-up processing; 5, polishing; 6, drilling threaded holes; 7, finely machining the side walls of a straight slot; 8, roughly machining a measuring tooth; 9, chamfering; 10, conducting heat treatment on the measuring tooth; 11, polishing the measuring tooth; 1, finely machining the measuring tooth; 13, finely grinding the measuring tooth; 14, finely grinding the slope of the measuring tooth; and 15, chamfering and finely grinding the measuring tooth. The machining method is used in the machining field of steam seal measuring snap-gauges.

Owner:HARBIN TURBINE

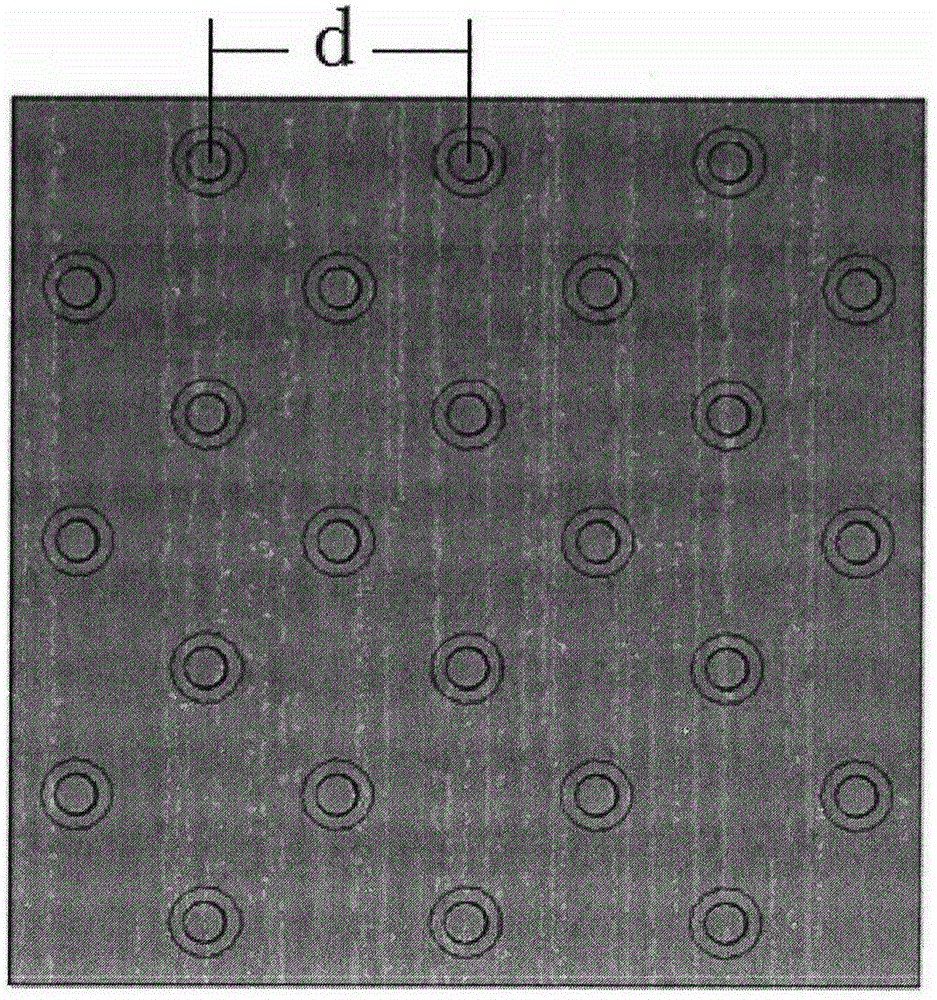

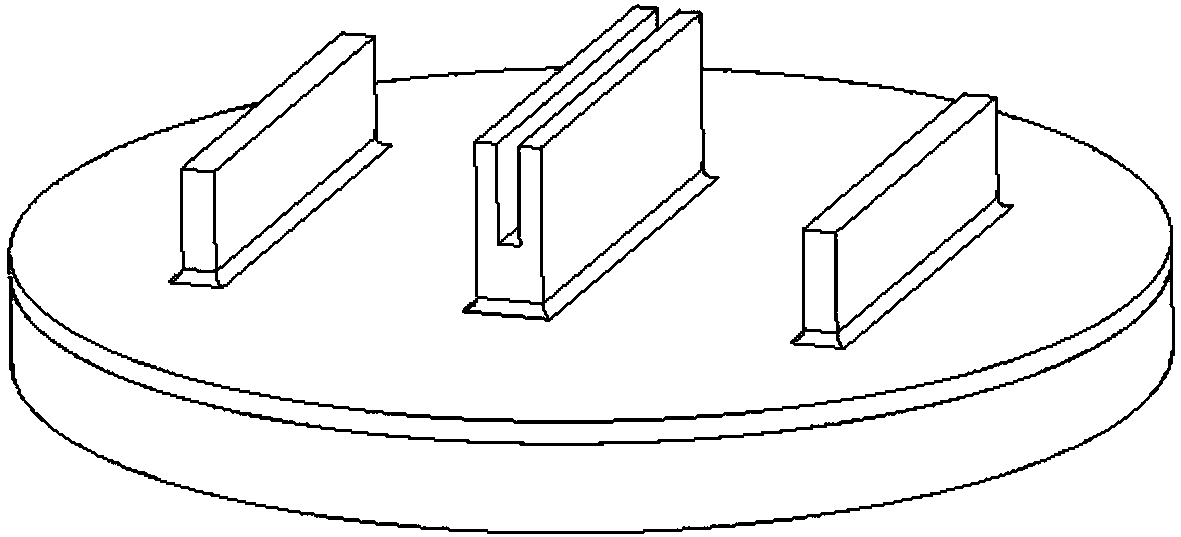

Surface source black body and manufacturing method thereof

The invention provides a surface source black body and a manufacturing method thereof. The surface source black body comprises a base plate and cones. The base plate is used for forming a support structure of the surface source black body. The predetermined number of cones is formed on the base plate. The cones are arranged on the base plate according to a predetermined mode. At least one part of the cones and the base plate form one body. And at least the other part of the cones is formed independently. The manufacturing of the surface source black body is simple. A processing technology is saved and cost is reduced. Manufacturing is convenient and the surface source black body is convenient to rapidly assemble. A large area of the surface source black body can be made. A high emissivity is possessed. And a verification demand of an infrared spectrum segment is satisfied.

Owner:NAT INST OF METROLOGY CHINA

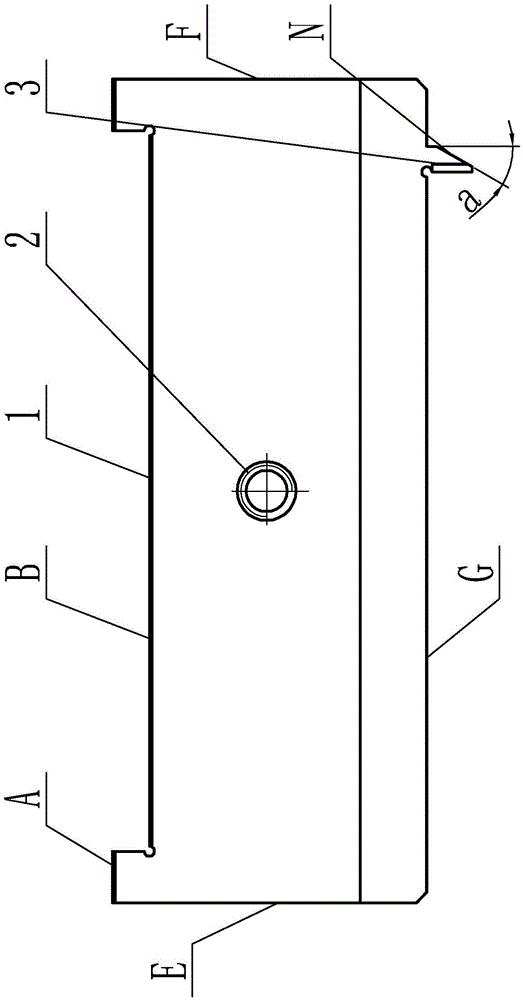

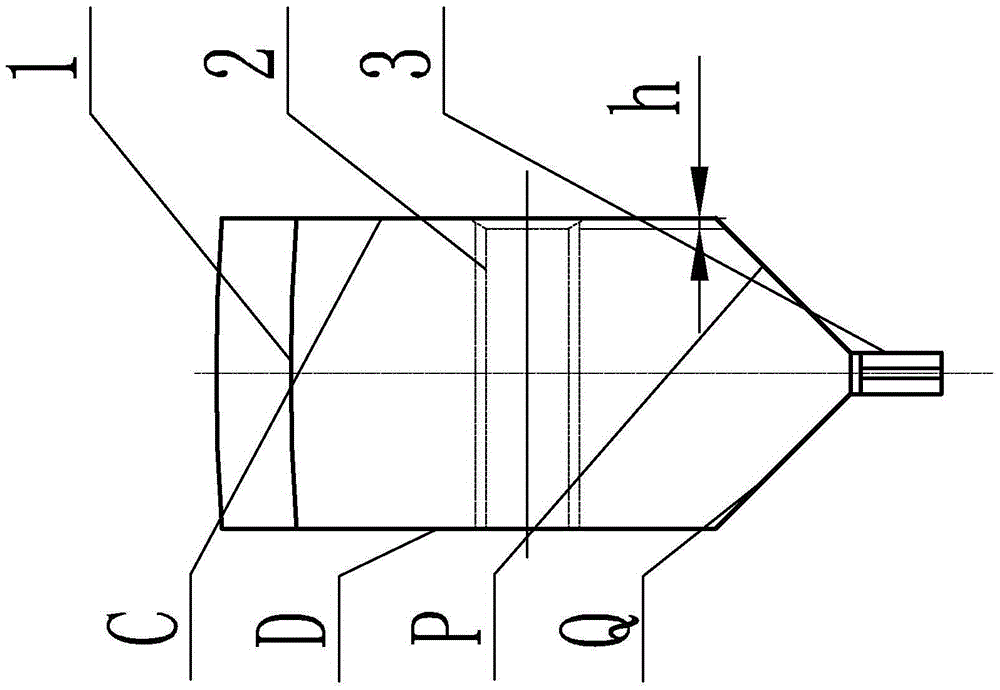

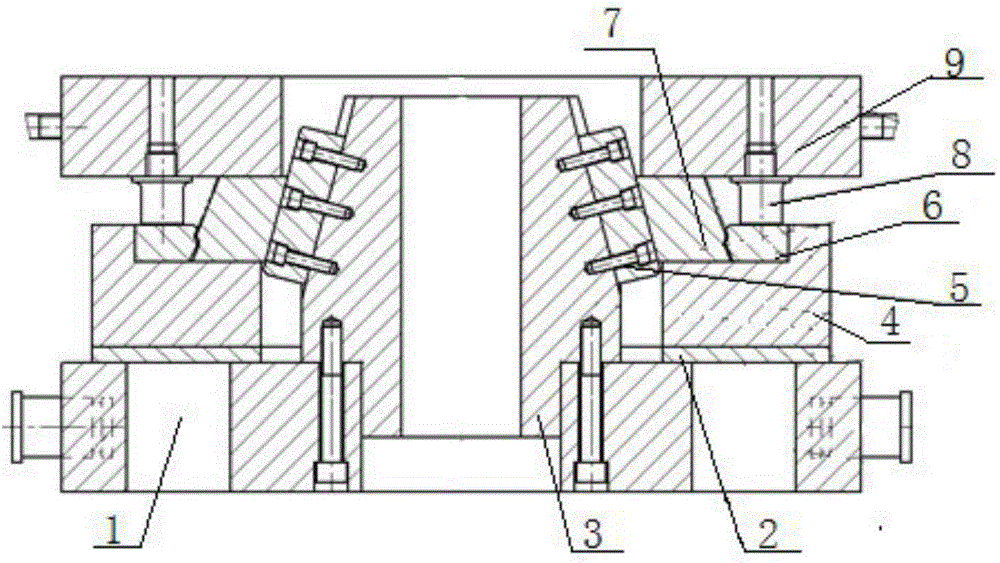

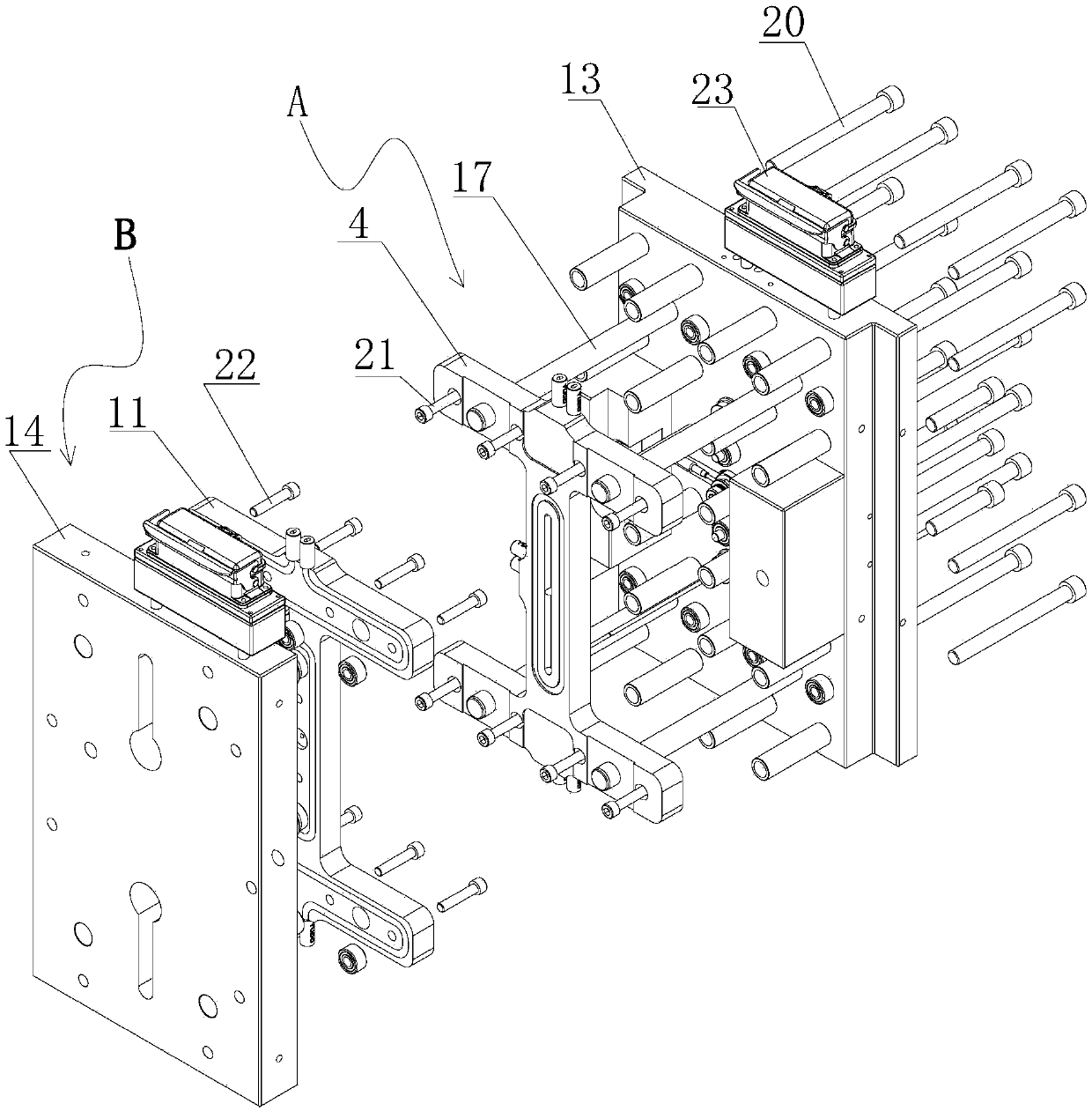

Processing method and tool for protruding ring-shaped high-temperature alloy thin-walled part

InactiveCN104550300AReduce processing technologyReduce raw material lossExtrusion diesExtrusion mandrelsThin walledMachining process

The invention relates to the technical field of mechanical parts and particularly relates to a processing method and a tool for a protruding ring-shaped high-temperature alloy thin-walled part. The processing method for the protruding ring-shaped high-temperature alloy thin-walled part comprises the following steps: in the processing process of the protruding ring-shaped high-temperature alloy thin-walled parts, processing the parts by using the tool and setting a bulging block on the tool, wherein the bulging block is between an upper template and a top plate and can radially move between a guide block and a concave die, so that the bulging block is further extruded to move outward to extrude a primary product of the part by virtue of a cone and the guide block; and leading the part to deform according to specification, wherein after the primary product of the circular part is attached to the die, the protruding ring-shaped high-temperature alloy thin-walled part is processed. The conventional processing process is changed, the labor intensity of the processing process of the protruding ring-shaped thin-walled parts is reduced, raw materials are saved, the yield of the protruding ring-shaped thin-wall part is improved, and the quality of the part is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Glass cutting and splitting processing method and device

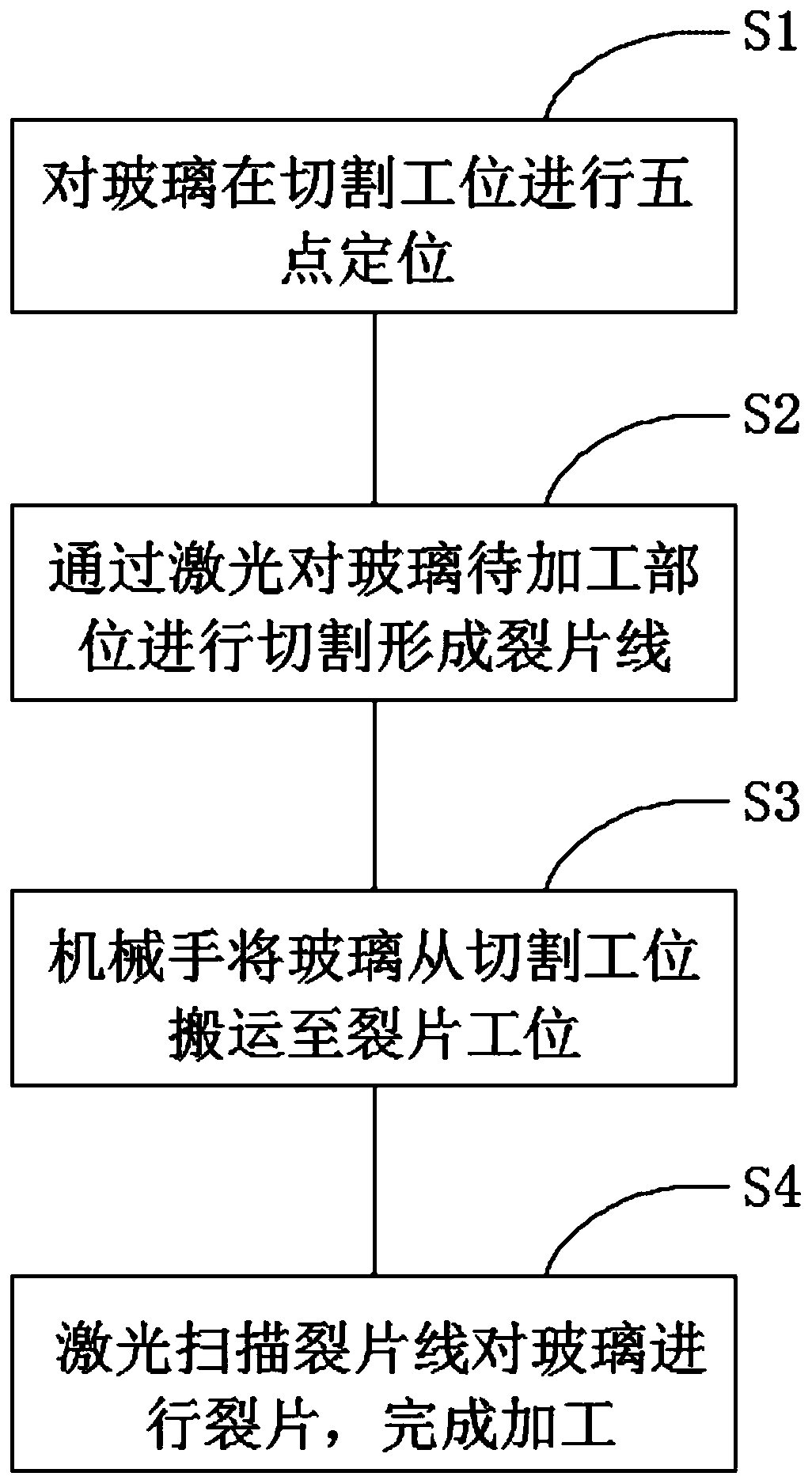

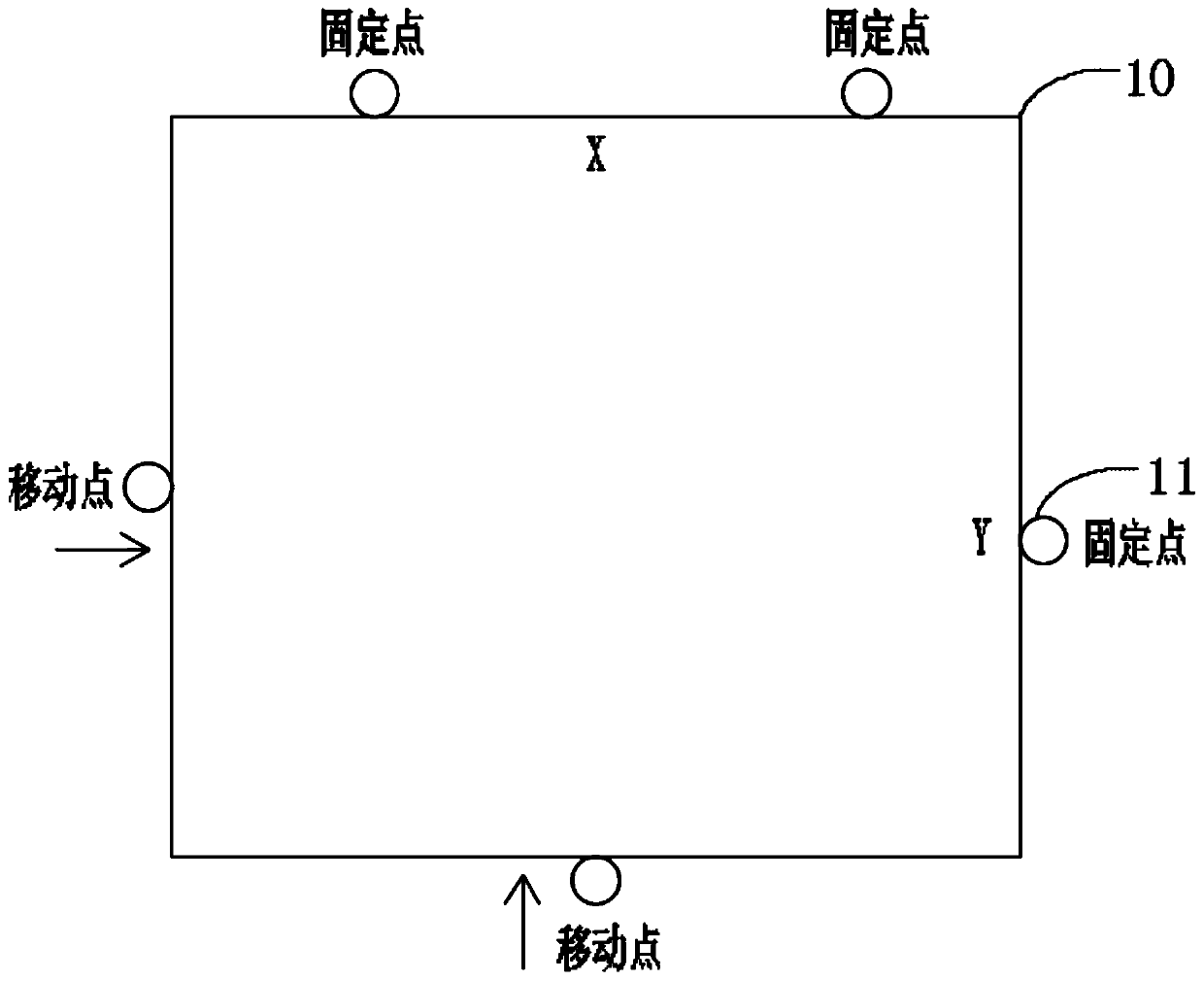

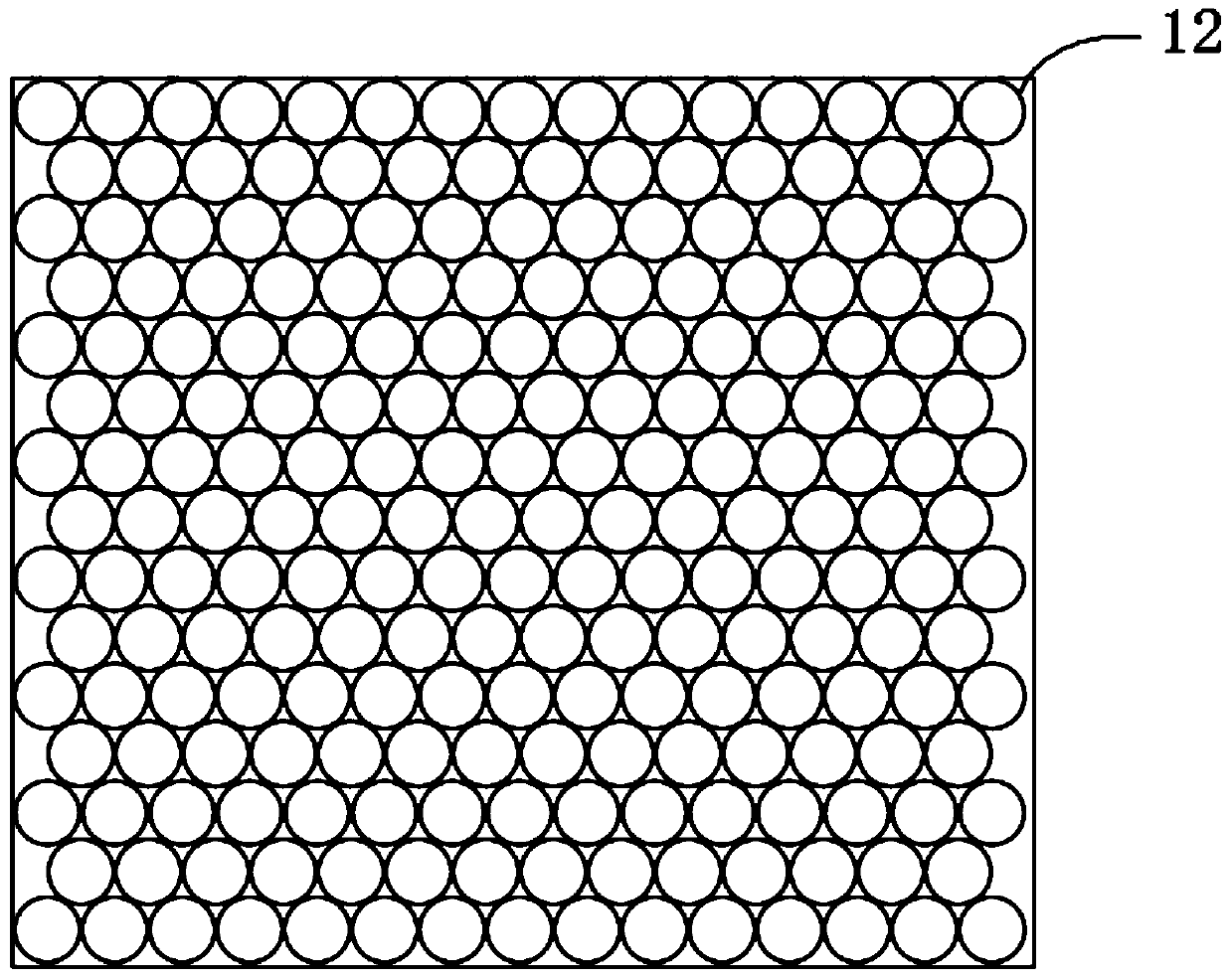

InactiveCN111393019AIncrease profitReduce labor costsGlass severing apparatusGlass productionLaser processingWatch glass

The invention relates to the technical field of laser processing, and discloses a glass cutting and splitting processing method and device, which are applied to watch glass laser cutting and splitting, and the method comprises the following steps: carrying out five-point positioning on watch cover glass at a cutting station; cutting and scribing the watch cover glass according to a set track to obtain a cutting line; using a transplanting manipulator for transplanting the watch cover glass from the cutting station to a splitting station; and generating laser thermal stress at the watch cover glass cutting line according to the set track so as to split the cut watch cover glass under the action of the laser thermal stress. According to the glass cutting and splitting machining method and device, watch cover glass cutting and splitting machining is integrated into circle cutting machining, only manual feeding and discharging are needed in the production process, the rest of cutting, splitting and carrying are all full-automatic machining, and the labor cost is reduced; compared with a traditional mode that a cutter wheel cuts square blocks and then CNC grinding is conducted to form circles, production efficiency is improved, machining processes are reduced, and the glass product utilization rate is increased.

Owner:深圳市青虹激光科技有限公司

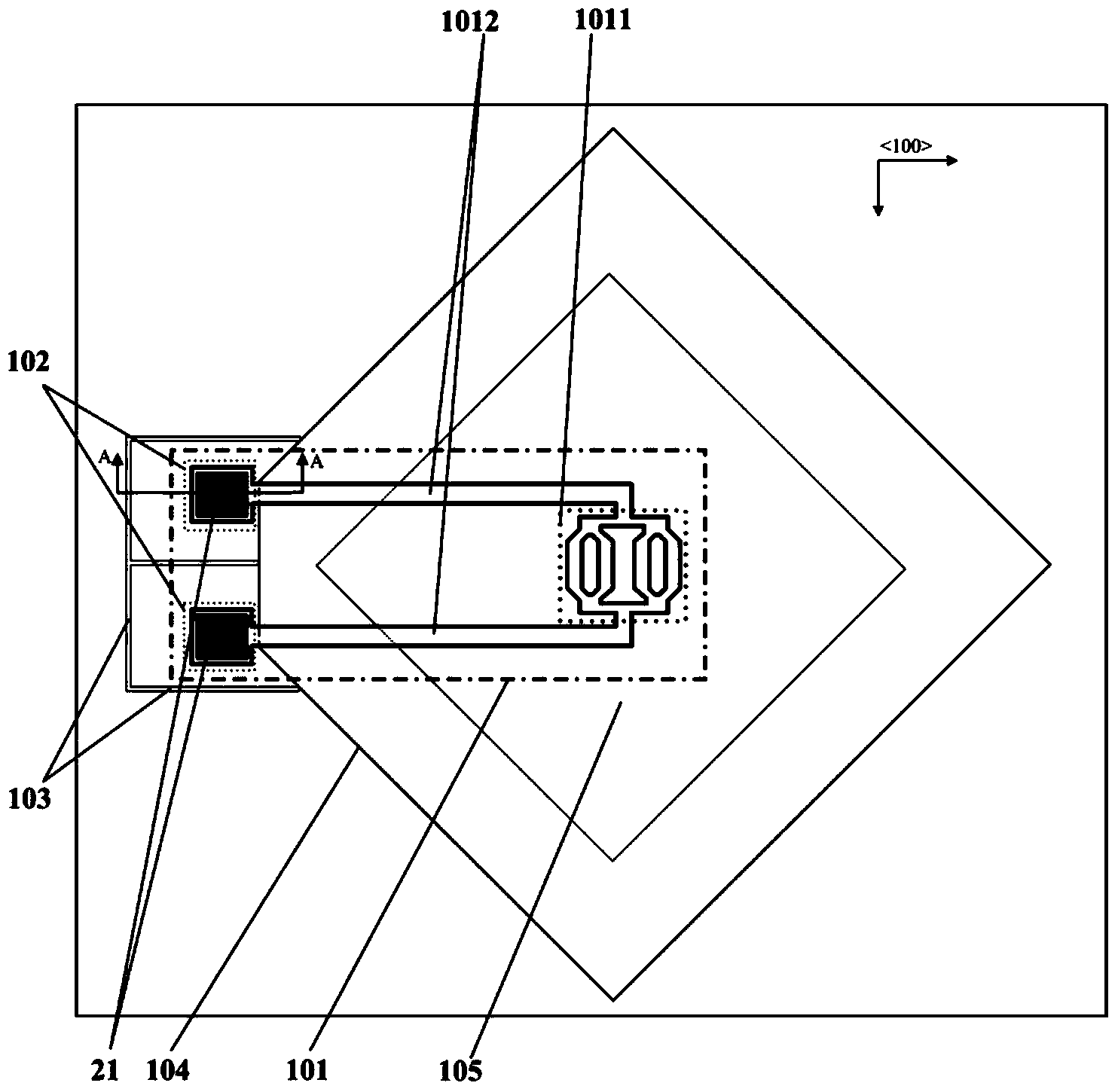

Silicon-heater-based MEMS (microelectromechanical system) methane sensor and preparation method and application thereof

InactiveCN104316576ALow costReduce processing technologyMaterial resistanceManufacturing technologyMicroelectromechanical systems

The invention discloses a silicon-heater-based MEMS (microelectromechanical system) methane sensor and a preparation method thereof, belongs to a methane sensor and a preparation method thereof, and particularly belongs to a methane sensor adopting a microelectromechanical system manufacturing technology and a preparation method and a methane detection method thereof. The methane sensor adopts an ordinary monocrystalline silicon wafer for manufacturing a silicon heater, the silicon heater is used as a methane-sensitive element, and a catalyst carrier and a catalyst material are not required; the preparation method of the methane sensor is compatible with a CMOS (complementary metal oxide semiconductor) technology; in case of batch production, the methane sensors have an advantage of low price and can be calibrated in batches; the methane sensor has the characteristics of low power consumption, high sensitivity , fast response, no influence on methane detection during oxygen shortage, and no influence from carbon deposition, poisoning and catalysts.

Owner:CHINA UNIV OF MINING & TECH

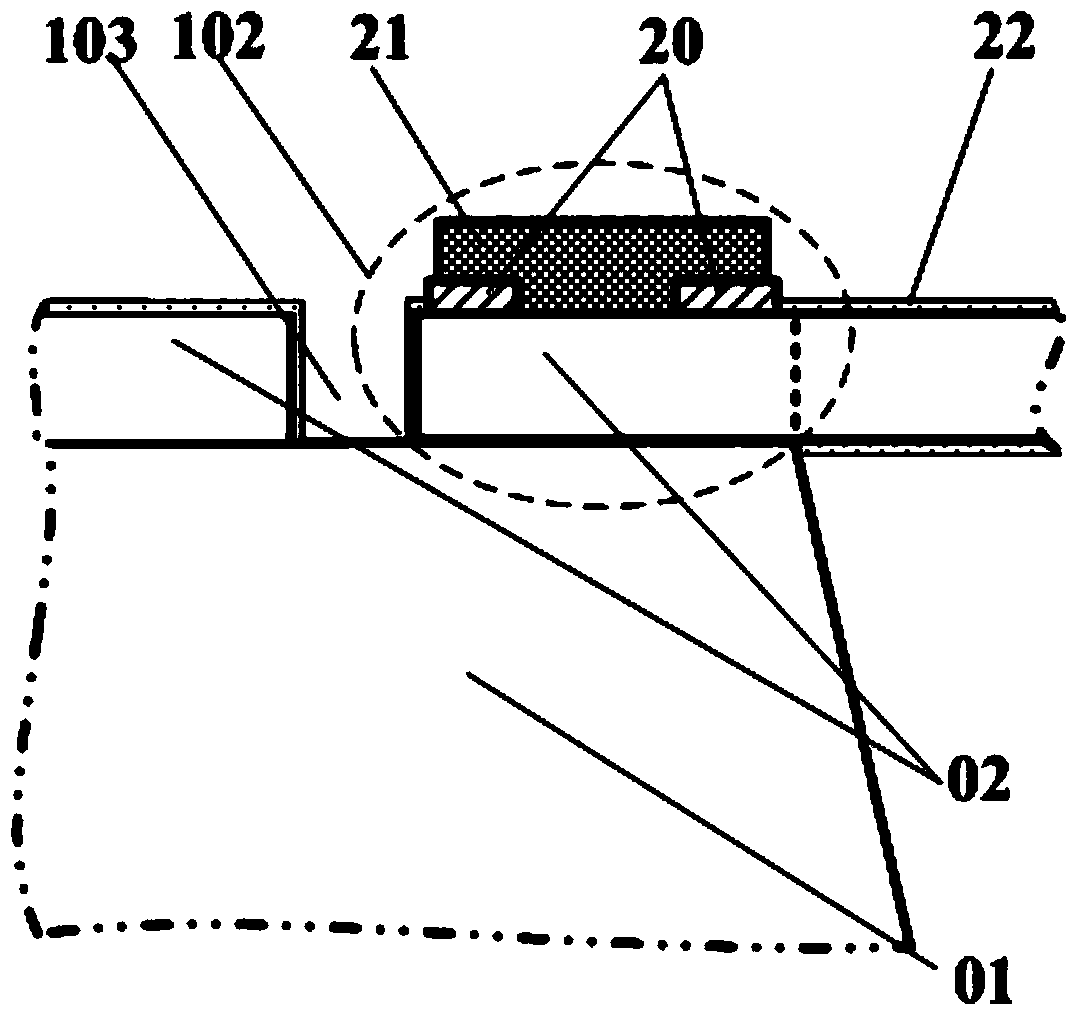

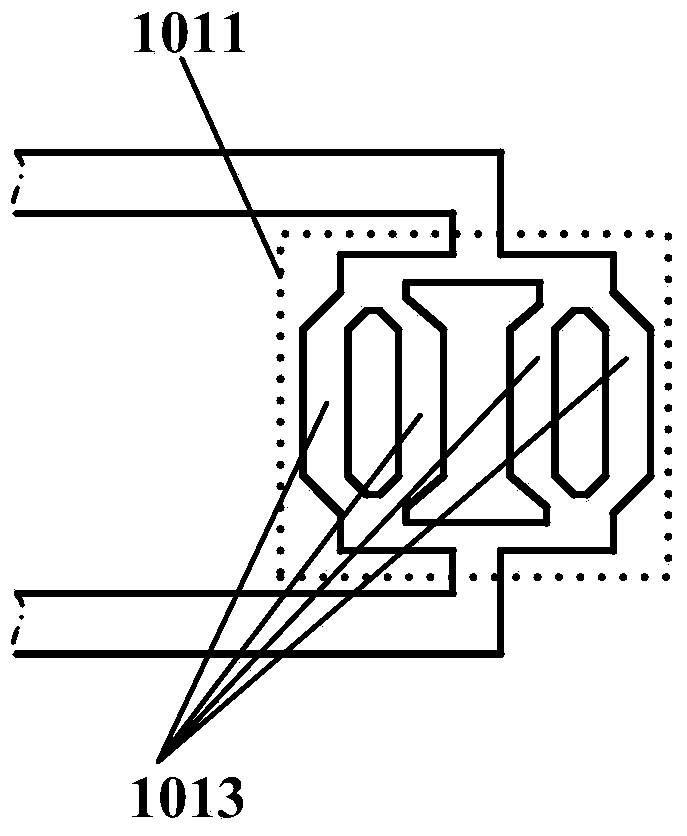

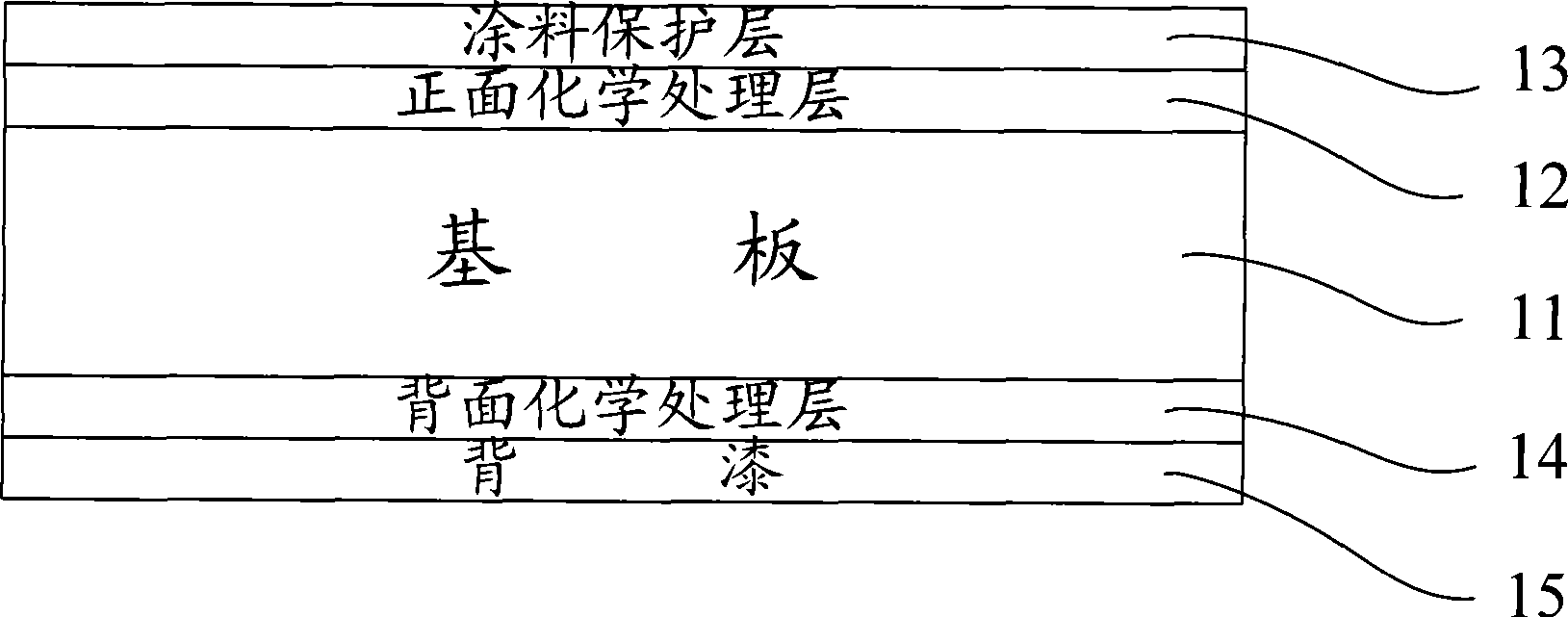

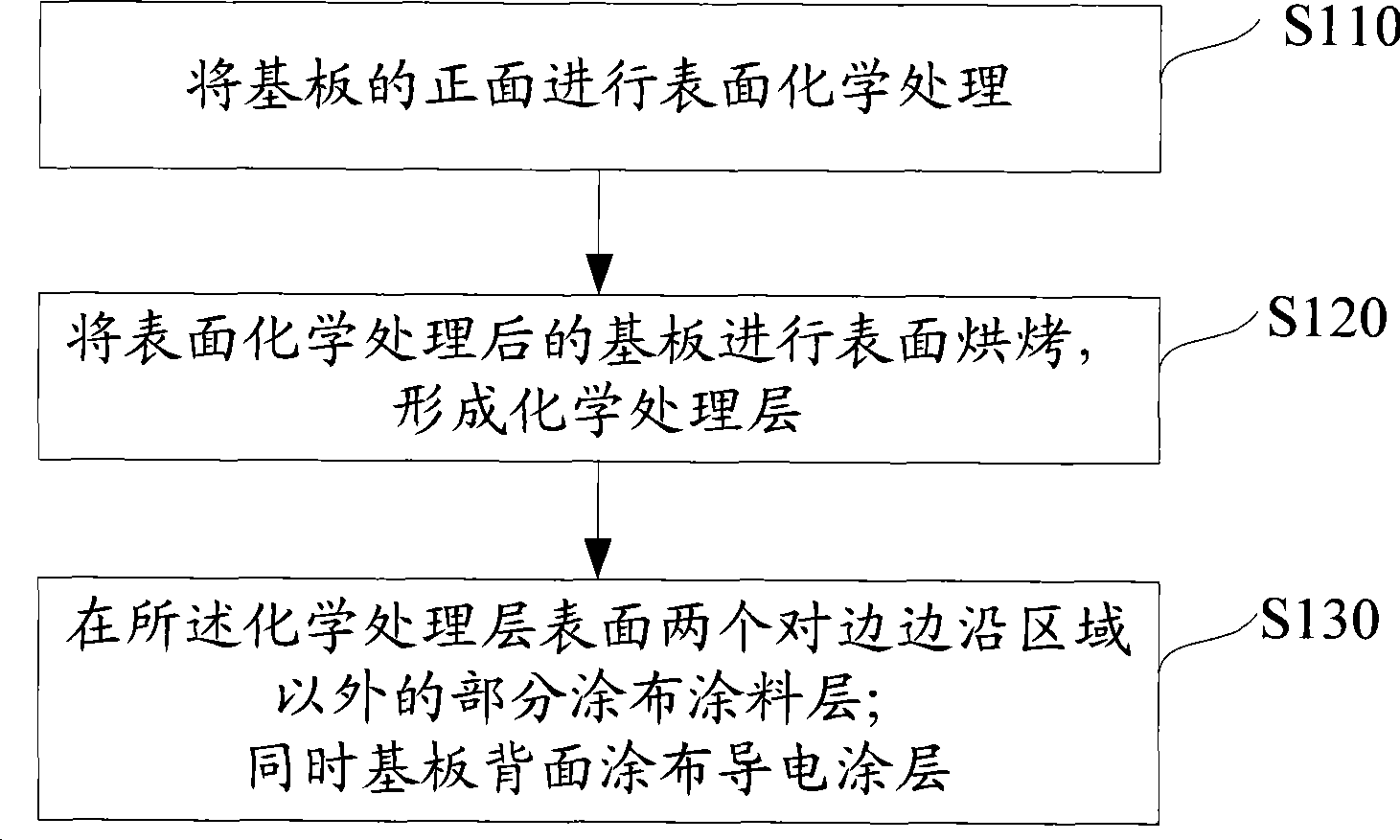

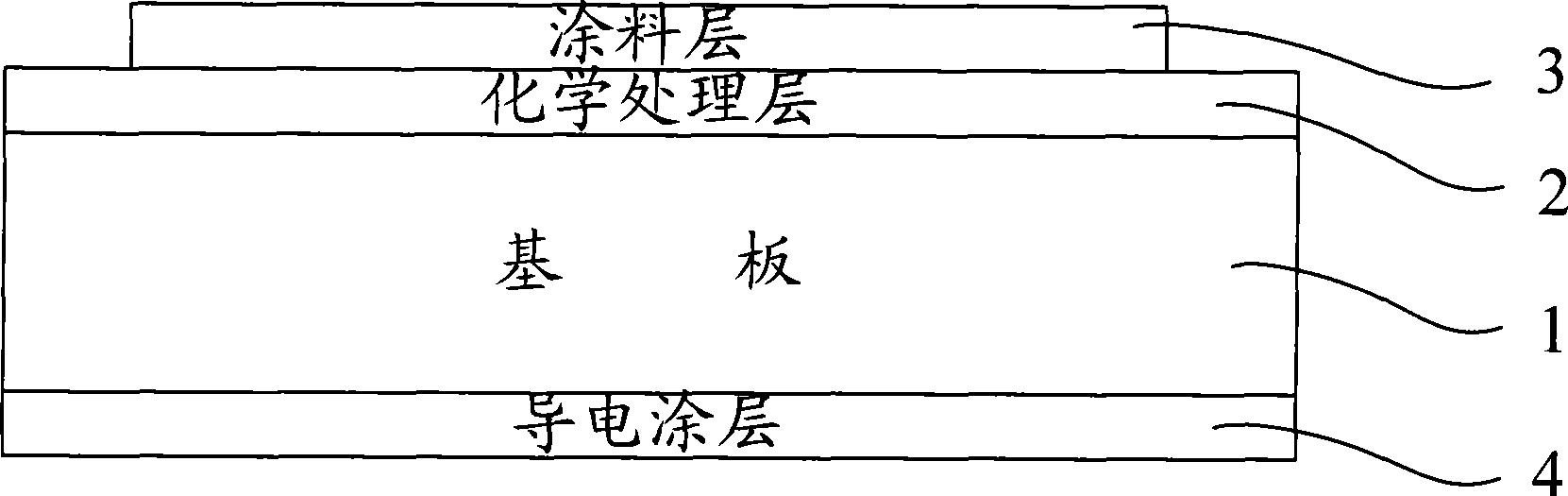

Method and equipment for processing coated metallic plate

InactiveCN101462104AMeet the requirements of electromagnetic interference testingSimple processPretreated surfacesCoatingsChemical treatmentConductive coating

The invention discloses a method for processing a coated metal plate, which comprises the following steps: performing surface chemical treatment on the facade of a substrate; coating a coating on the part outside edge areas of two opposite sides on the surface of a chemical treatment layer; and simultaneously coating a conductive coating on the rear of the substrate. The invention provides the method and a device for processing the coated metal plate, which are used for producing coated metal plates for shells of products such as computer cases subjected to an electromagnetic interference test.

Owner:HAIER GRP CORP +1

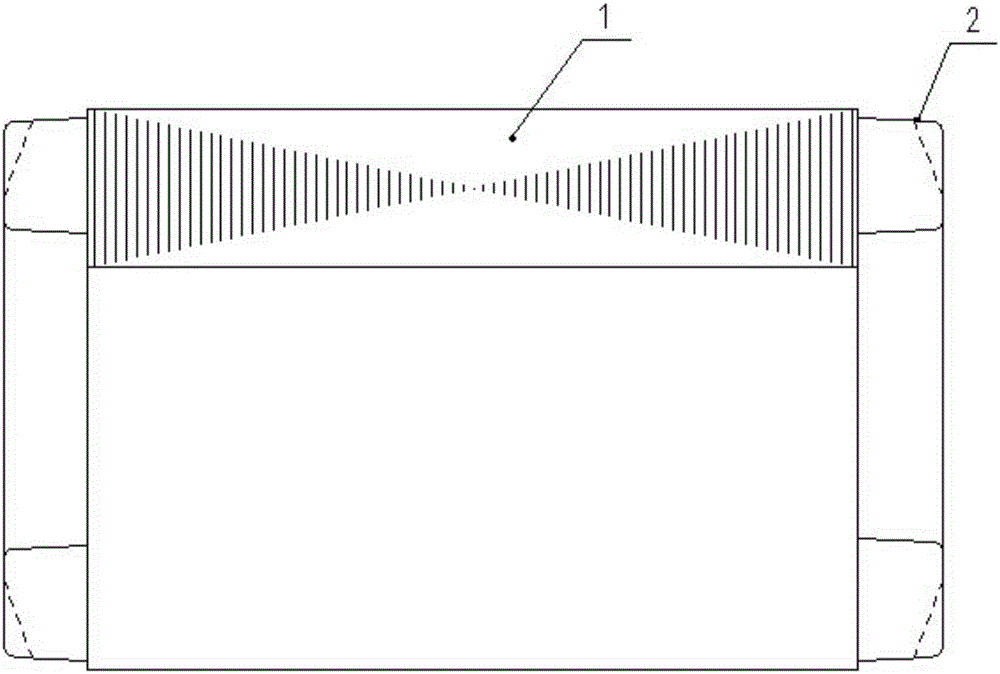

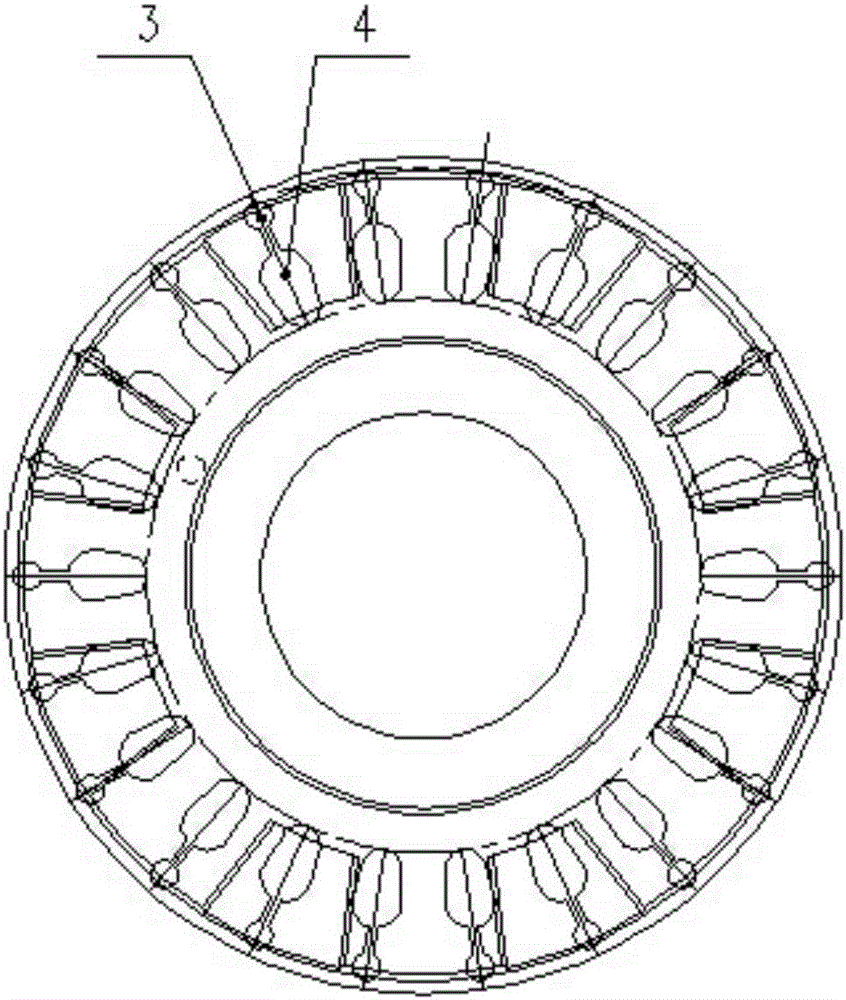

Highly-efficient composite cage bar motor rotor and preparation method thereof

InactiveCN106787554AMeet assembly requirementsIncreased assembly requirementsAsynchronous induction motorsManufacturing cage rotorsPunchingPower factor

The invention provides a highly-efficient composite cage bar motor rotor. The highly-efficient composite cage bar motor rotor comprises a rotor, and is characterized in that the rotor comprises a set of rotor punching sheets, inner and outer squirrel cage slots are formed in the rotor punching sheets; inner squirrel cage bars are inserted in the inner squirrel cage slots; a silicon aluminum outer squirrel cage which comprises outer squirrel cage bars and an end ring is cast in the outer squirrel cage slots once; the end ring comprises blades and balance columns; two ends of each of the inner squirrel cage bars and the outer squirrel cage bars are connected with the end ring integrally. The highly-efficient composite cage bar motor rotor disclosed by the invention is reasonable and simple in structure, scientific and advanced; when the highly-efficient motor rotor of high-speed pressed copper-aluminum double-squirrel cage composite cage bars is started, the starting current is concentrated on the outer squirrel cage due to a skin effect, equivalently, an effective section is small, the effective resistance is large, and power factors are increased, so that the starting current of a motor is reduced, and the starting torque is increased.

Owner:XUZHOU DAYUAN ELECTROMOTOR

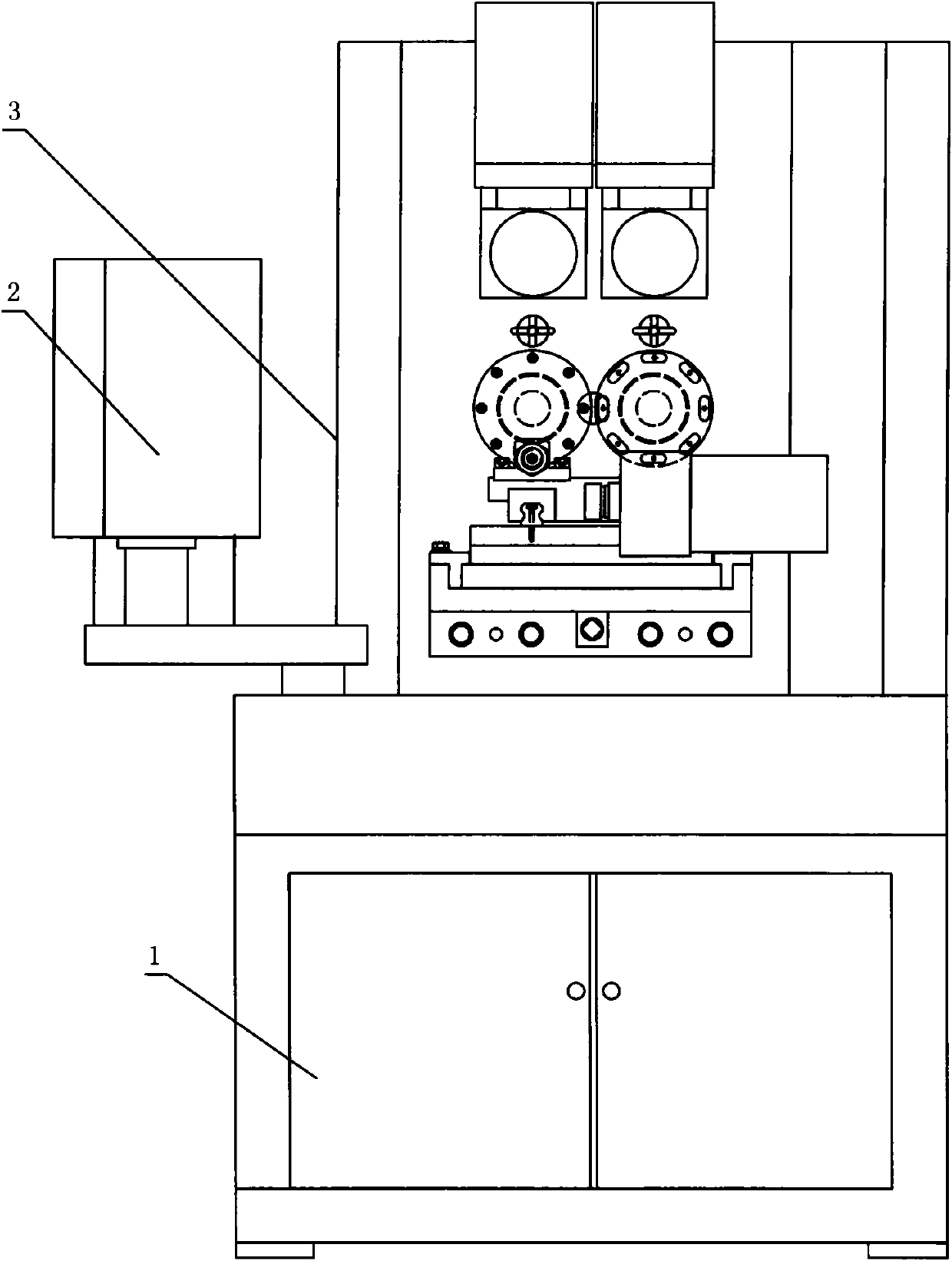

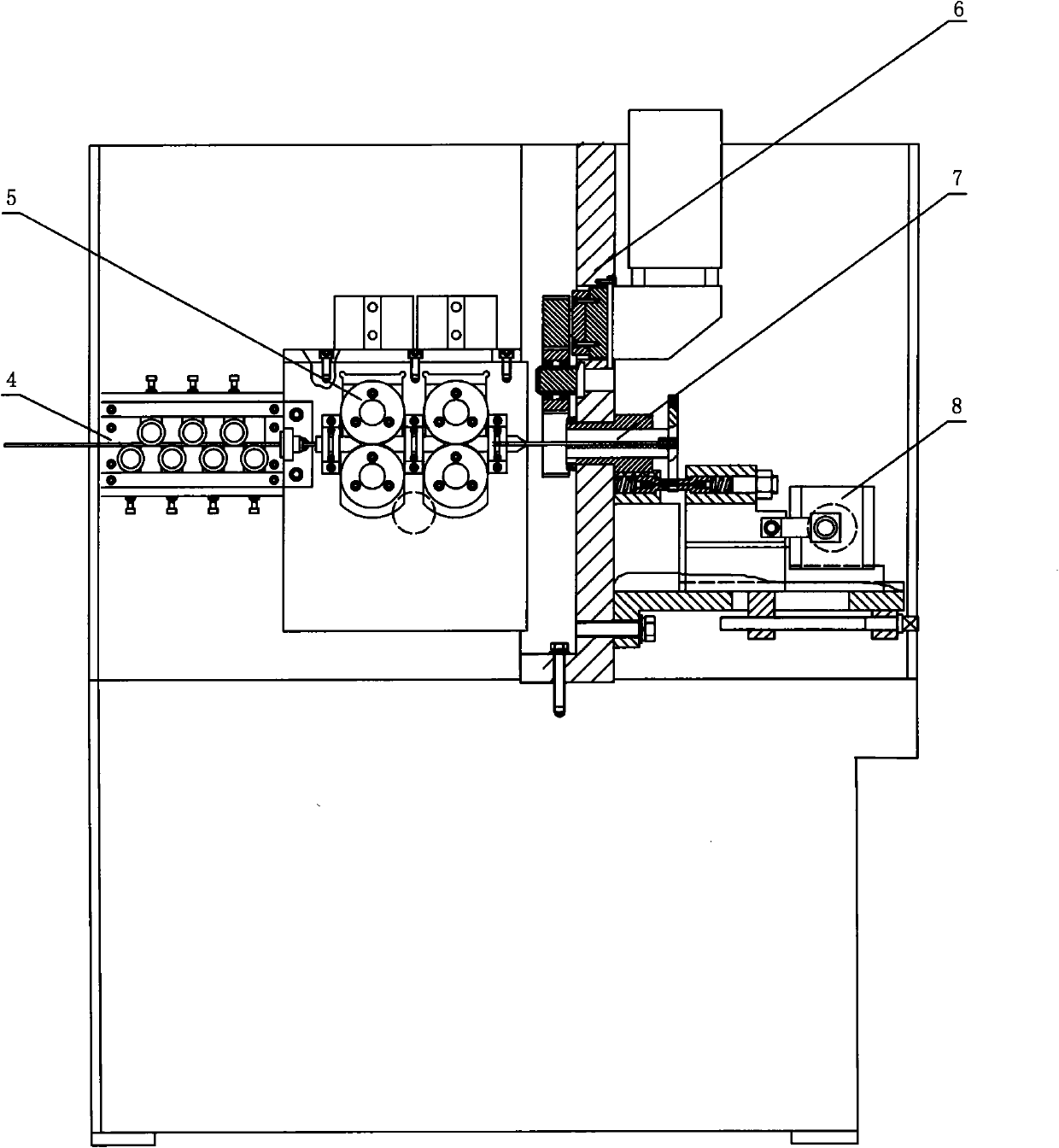

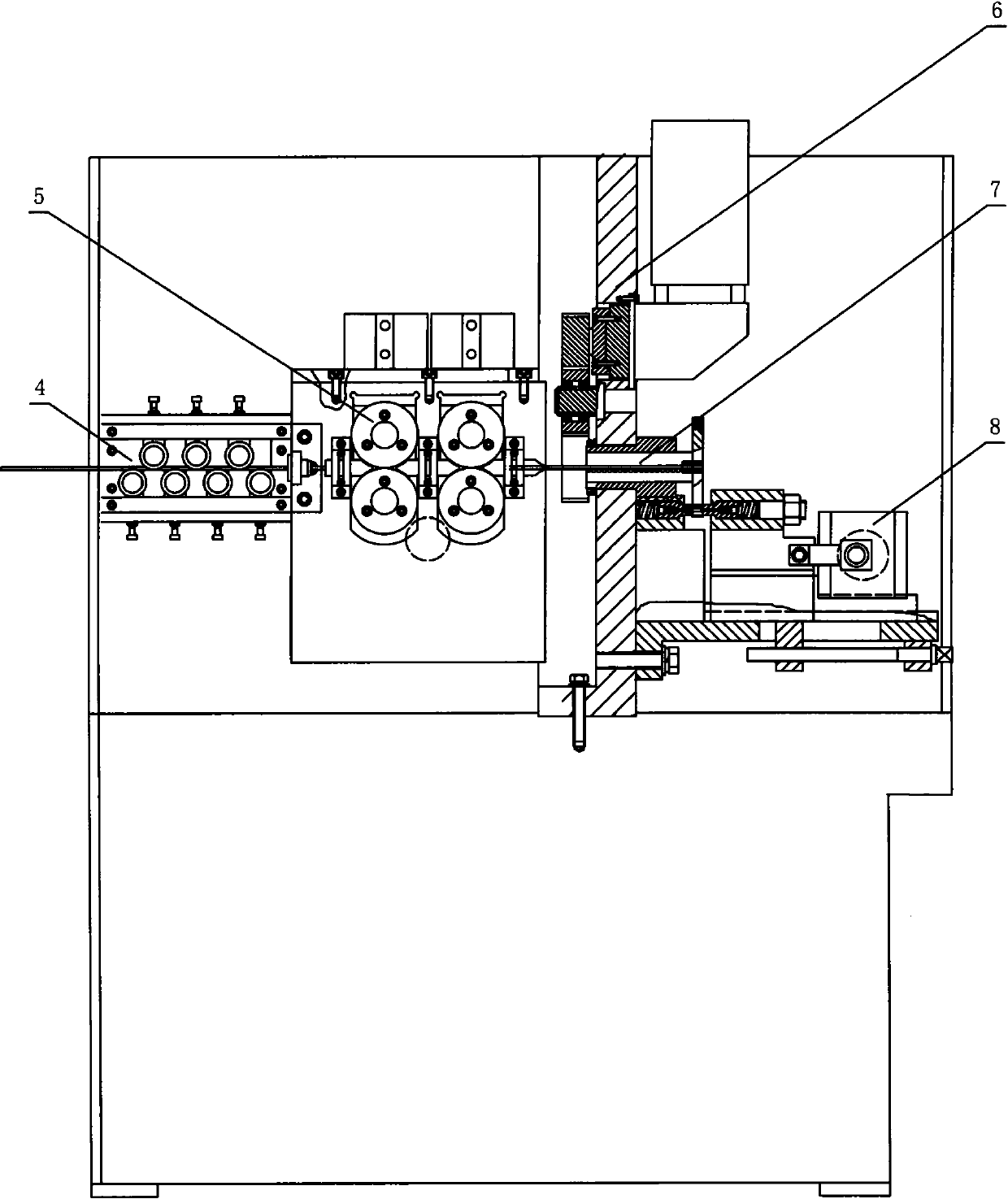

High-precision numerical control pin machine

InactiveCN102554625AAvoid pollutionOperational intelligenceOther manufacturing equipments/toolsNumerical controlControl system

A high-precision numerical control pin machine belongs to pin machining mechanical equipment and comprises a base, a computer control box, a machine tool body, a straightening mechanism, a wire feeding mechanism, a main wallboard, a cutting-off mechanism and an extrusion mechanism. The pin machine is designed by combining advanced driving technology, four-axis linkage numerical control technology and pneumatic technology, and is formed once by means of 'cutting off and chamfering'. Under the instruction of a control system, a steel wire on a rack enters a feeding wheel groove after passing through the straightening mechanism, the wire feeding mechanism drags the steel wire to the cutting-off mechanism and is cut off by a cutting-off die, the steel wire cut off according to a specified length enters the extrusion mechanism by means of moving along with the cutting-off die and is extruded by the extrusion mechanism, and a formed pin returns an original cutting-off position along with the cutting-off die and is pushed out by the steel wire entering the cutting-off die again. The procedures and actions are repeated, so that pins can be continuously machined. The pin machine is high in automation degree, low in production noise and safe and convenient in operation, production cost is reduced, energy conservation and emission reduction are realized, and product quality and production efficiency are improved.

Owner:盐城海旭数控装备有限公司 +1

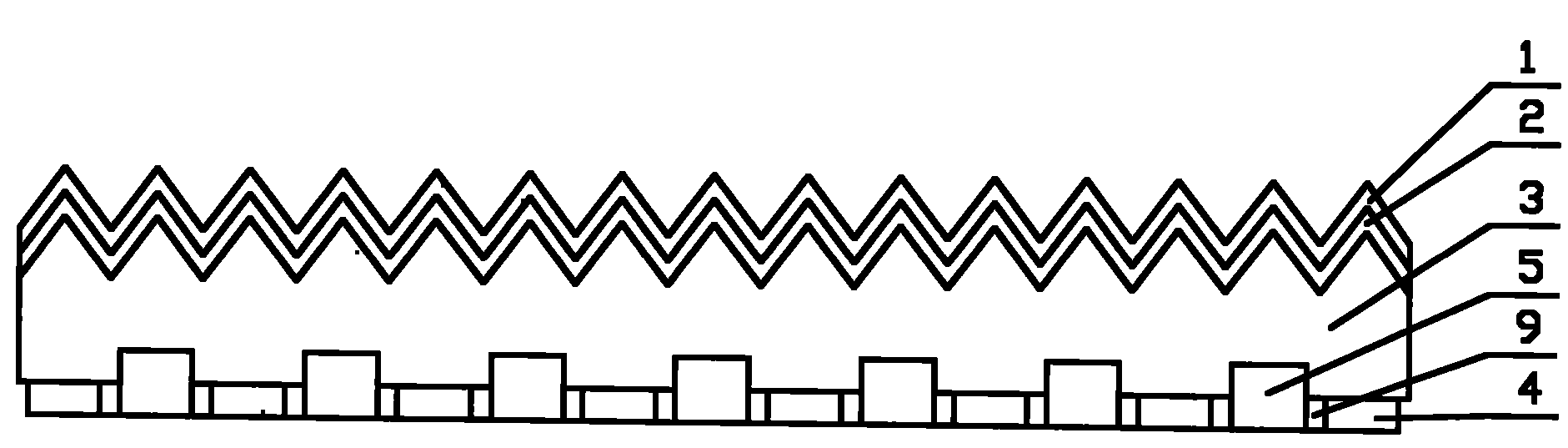

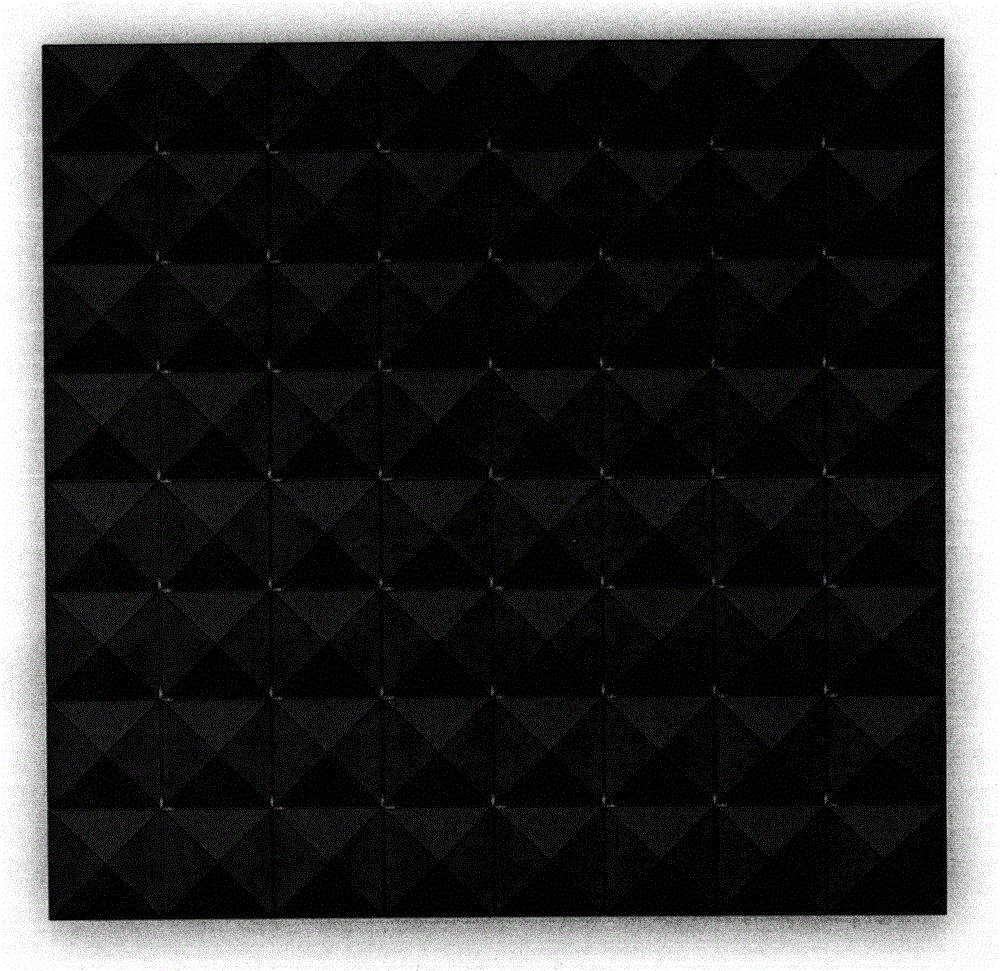

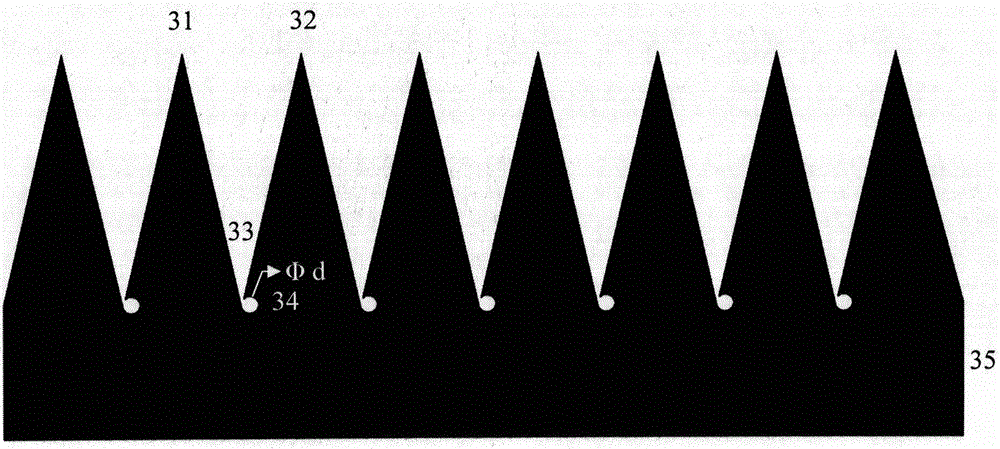

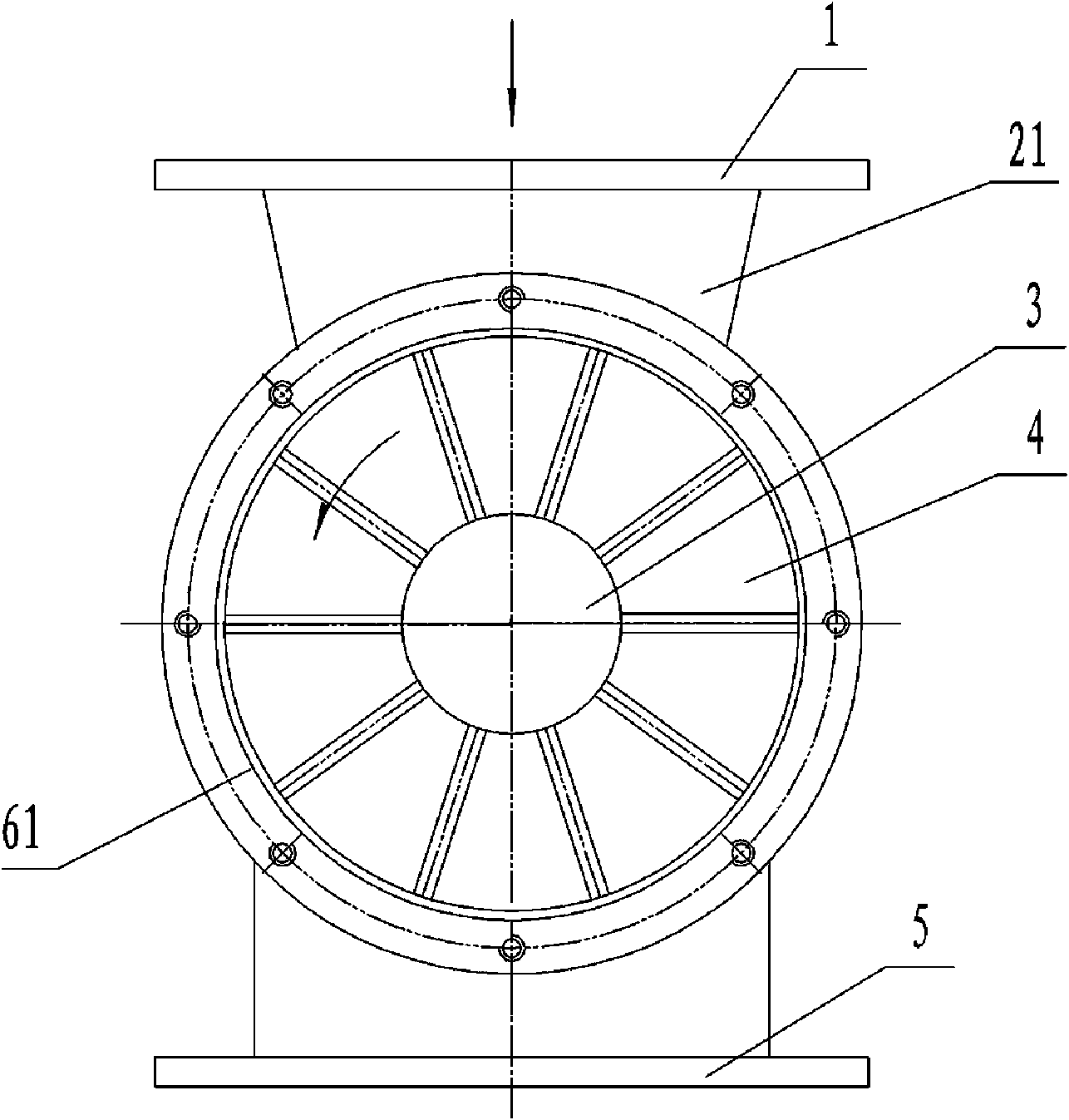

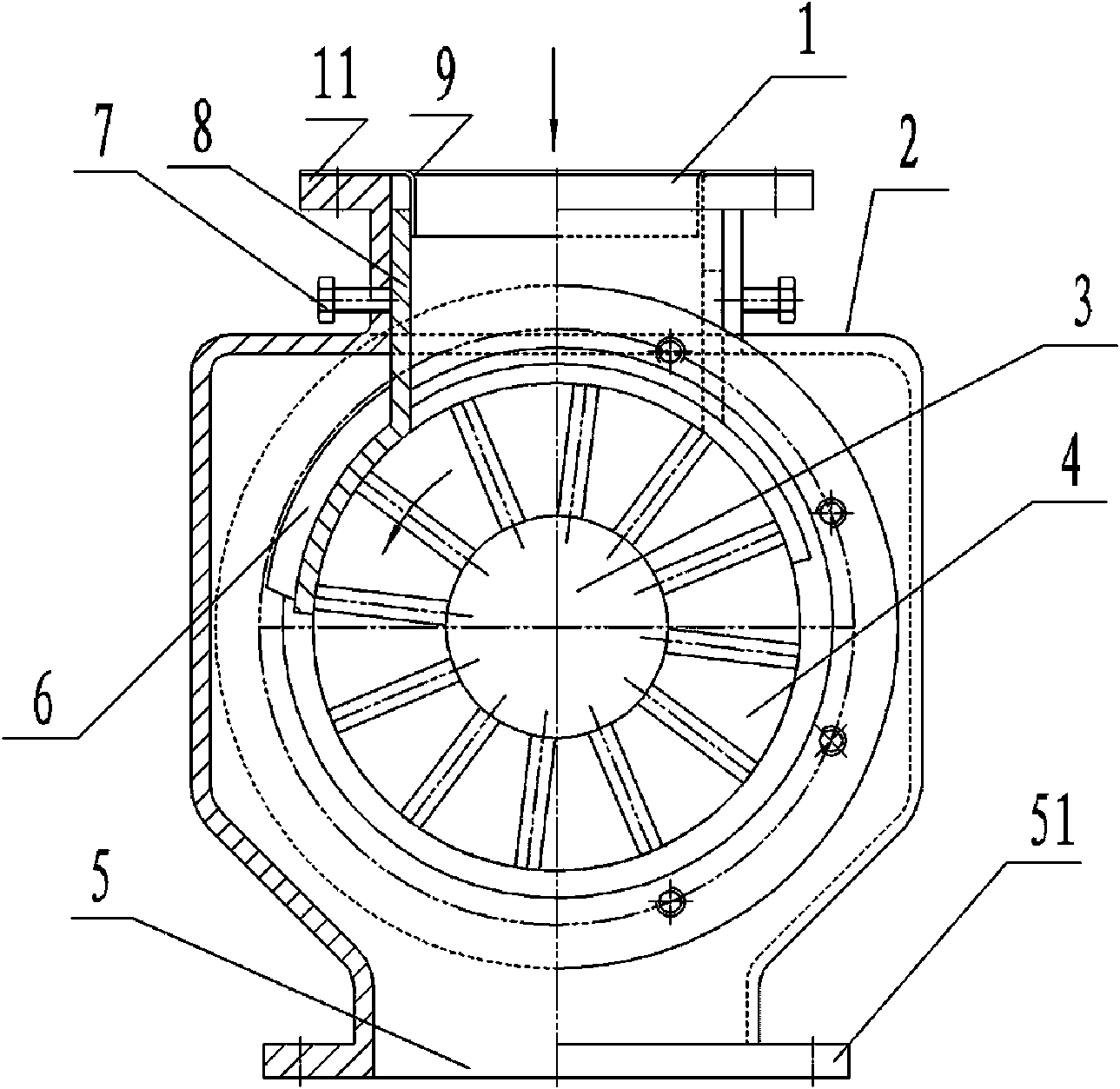

High-emissivity surface source black body radiator and manufacturing method thereof

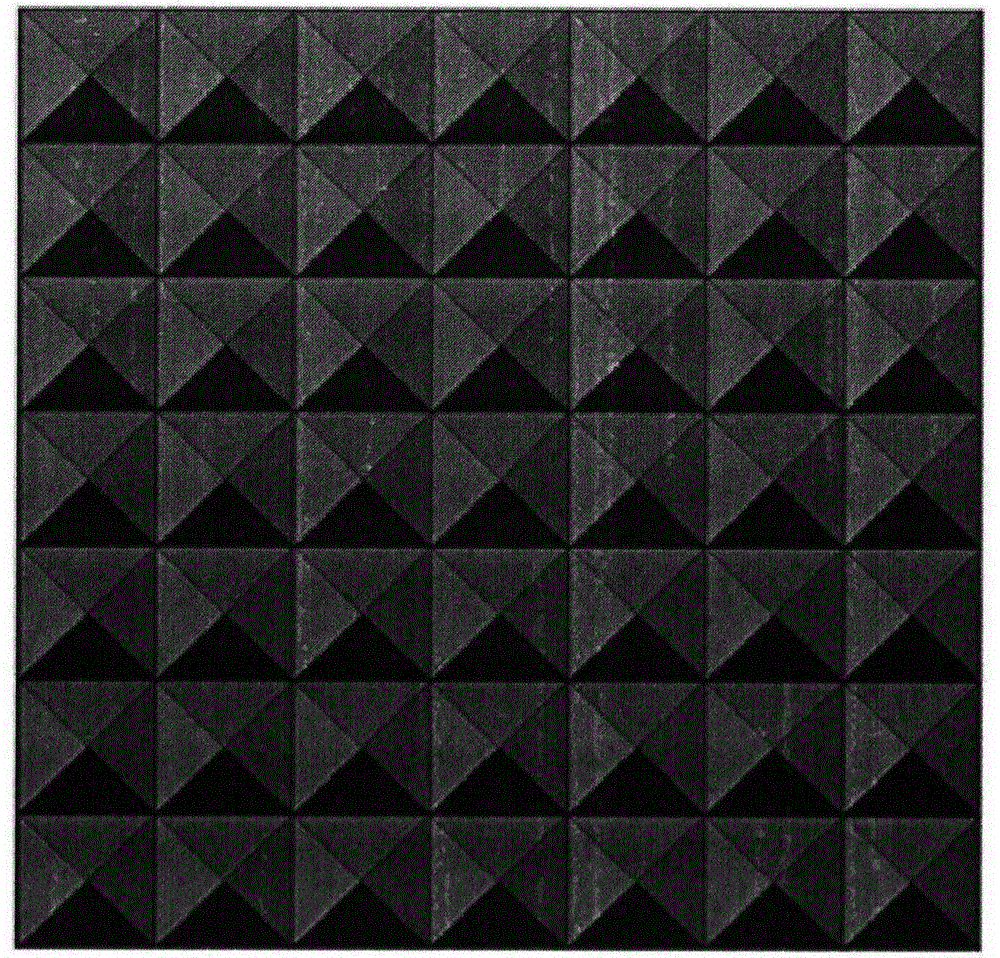

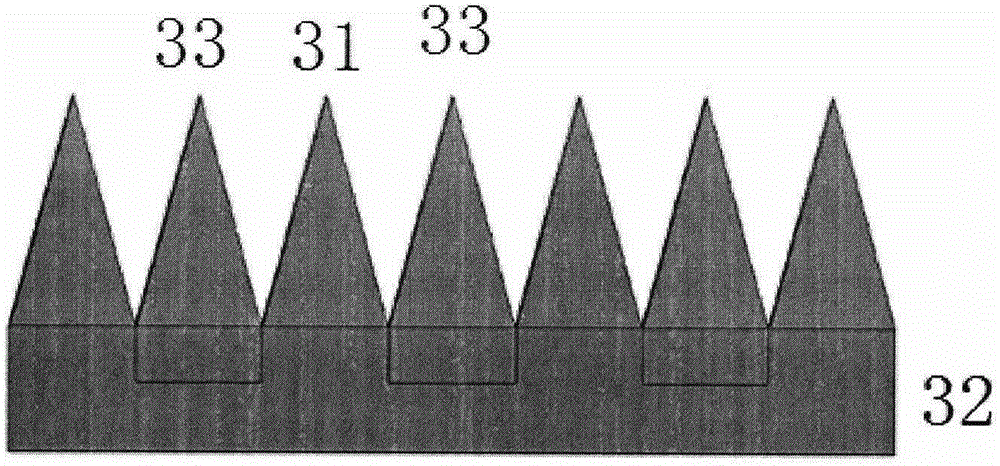

ActiveCN105910714AEasy to makeReduce processing technologyRadiation pyrometryEmissivitySpectral bands

The invention provides a high-emissivity surface source black body radiator and a manufacturing method thereof. The high-emissivity surface source black body radiator comprises the components of a base board which is used for forming the supporting structure of a surface source black body; a preset number of cones which are formed on the base board, wherein the cones are distributed on the base board in a preset manner. The cones and the base board are in an integrated structure. Conical grooves are arranged between the adjacent cones. The conical grooves are non-flat and concave. The high-emissivity surface source black body radiator has advantages of easy manufacture, effective machining process saving, effective cost reduction, convenient manufacture and convenient expansion. The high-emissivity surface source black body radiator can be manufactured to a large-area surface source black body and has high emissivity. Furthermore a calibration requirement for an infrared spectral band is satisfied.

Owner:NAT INST OF METROLOGY CHINA

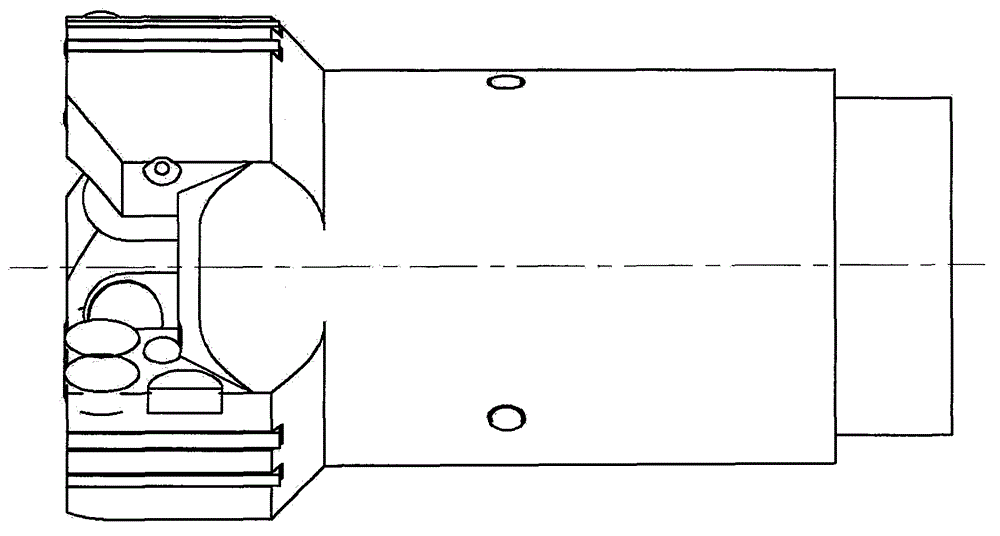

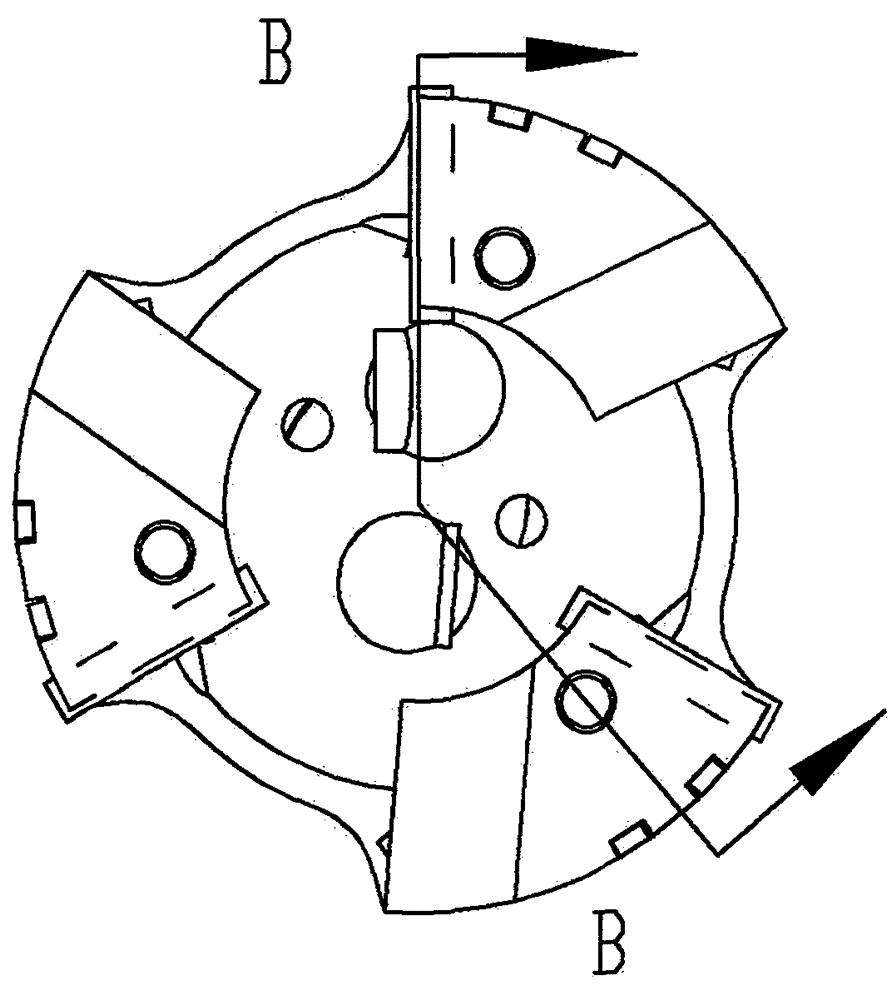

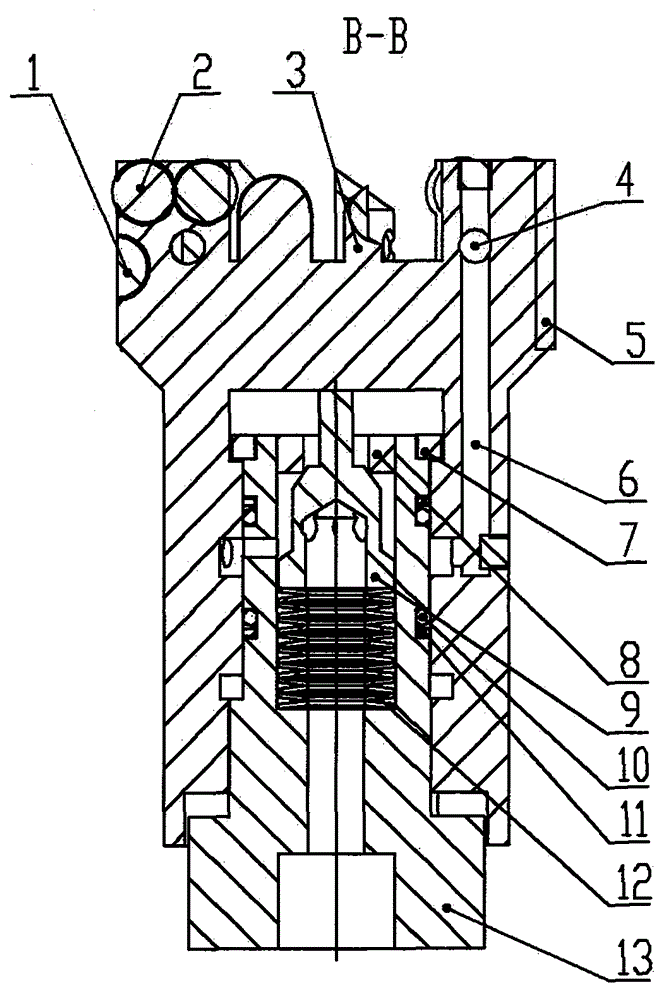

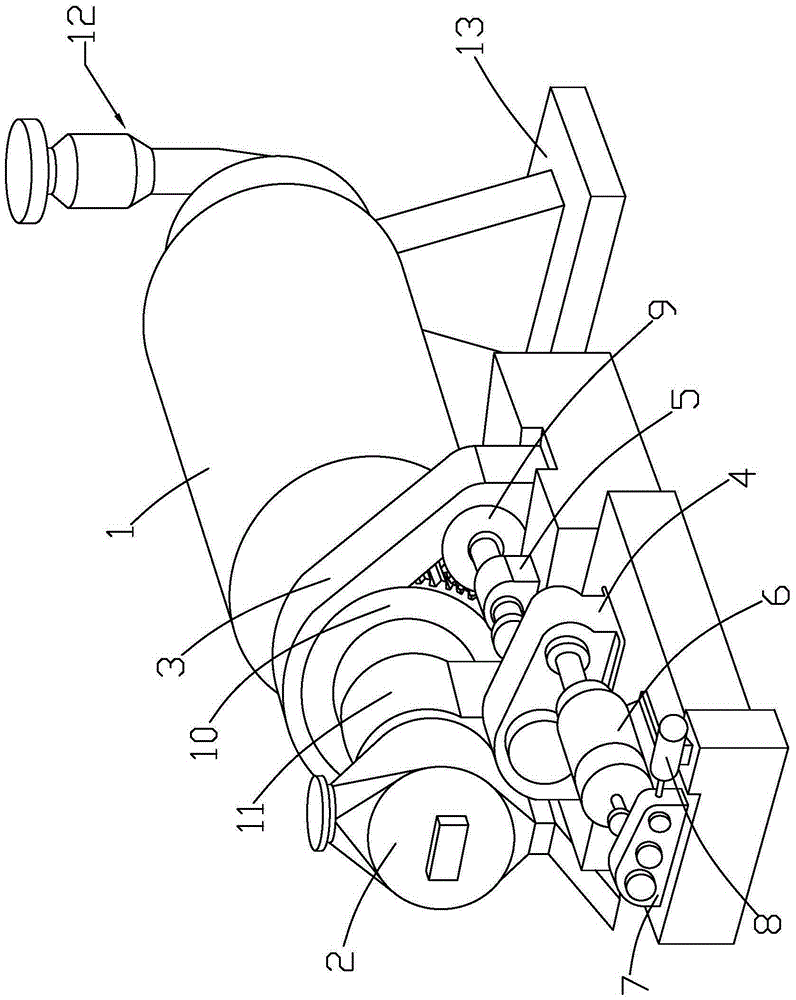

Adjustable sealing rotary valve

InactiveCN101670937AReduce processing technologyGuaranteed process requirementsRotary conveyorsMaintenance managementRotary valve

An adjustable sealing rotary valve mainly solves technical problems that the traditional rotary valve has short service life, heavy maintenance management workload, bad gas tightness, and when the rotary valve is used in the high temperature work conditions, equipment accidents easily happen, and the like. The adjustable sealing rotary valve has the technical solution that the rotary valve is formed by the combination of a rotary valve shell and a rotor (3), wherein the rotor (3) is provided with a rotor slot (4); the rotary valve shell is provided with a feeding hole (1) and a discharge hole(5); a feeding hole connecting piece (11) and a discharge hole connecting piece (51) are arranged on the feeding hole (1) and the discharge hole (5); the rotary valve shell (2) is internally sheathedwith a seal housing which is of a non-circular structure; the feeding hole (1) on the upper part of the rotary valve shell (2) is internally provided with a sliding sleeve (8) which is movably matched; the lower part of the sliding sleeve (8) is arc-shaped and sheathed between a sealing housing (6) and the rotor (3) in a matching way; by changing the structural style that the valve body of the traditional rotary valve directly contains the rotor, the valve body and a containing component of the rotor are separated, thus prolonging the service life thereof and increasing the gas tightness. Theadjustable sealing rotary valve is mainly used for powder or granule conveying devices.

Owner:XIANGXIANG MACHINERY FACTORY

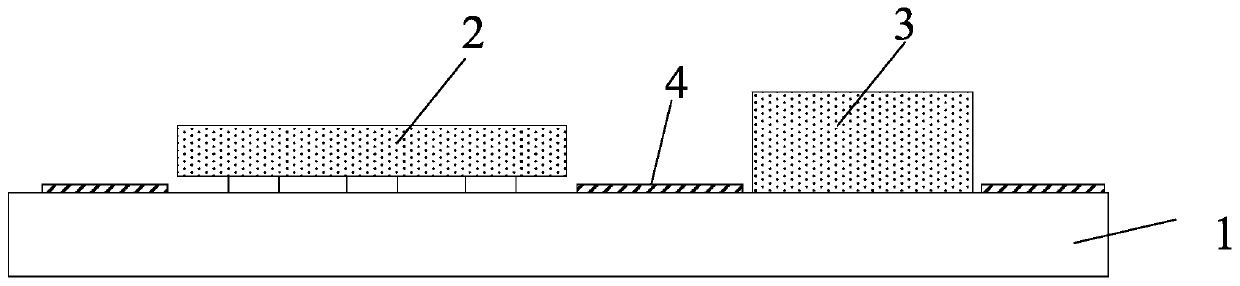

SIP module partition electromagnetic shielding package method

InactiveCN110010507AReduce areaEasy to absorb moistureSemiconductor/solid-state device manufacturingSputteringComputer module

The invention provides a SIP (System In Package) module partition electromagnetic shielding package method. The method comprises the steps of: providing a substrate, mounting a flip chip and a passiveelement at the first working surface of the substrate, wherein manufactured grounding bonding pads are arranged at the periphery of the chip mounting position of the first working surface of the substrate; performing plasma surface cleaning for the substrate, performing thin film plastic package for the first working surface of the substrate to form a plastic package film covering the first working surface of the substrate; employing a laser to perform slotting around the chip requiring partition shielding to expose the corresponding grounding bonding pads; performing sputtering for the firstworking surface of the whole substrate to form an inner metal shielding layer and achieve chip partition shielding; performing plasma cleaning for the substrate after sputtering, and performing plastic package for the first surface of the substrate to form an outer package body; and cutting the whole substrate to form each single SIP module. The SIP module partition electromagnetic shielding package method facilitates reduction of the module size, improves the reliability and improves the production efficiency.

Owner:中电海康无锡科技有限公司

Array substrate, preparation method thereof and liquid crystal display panel

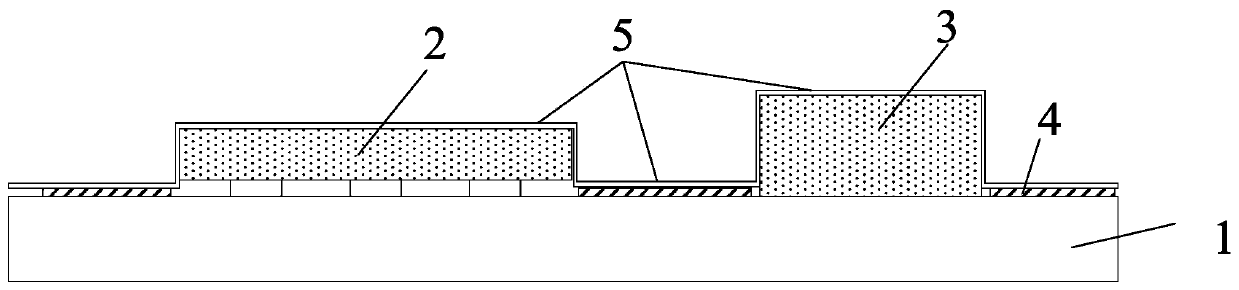

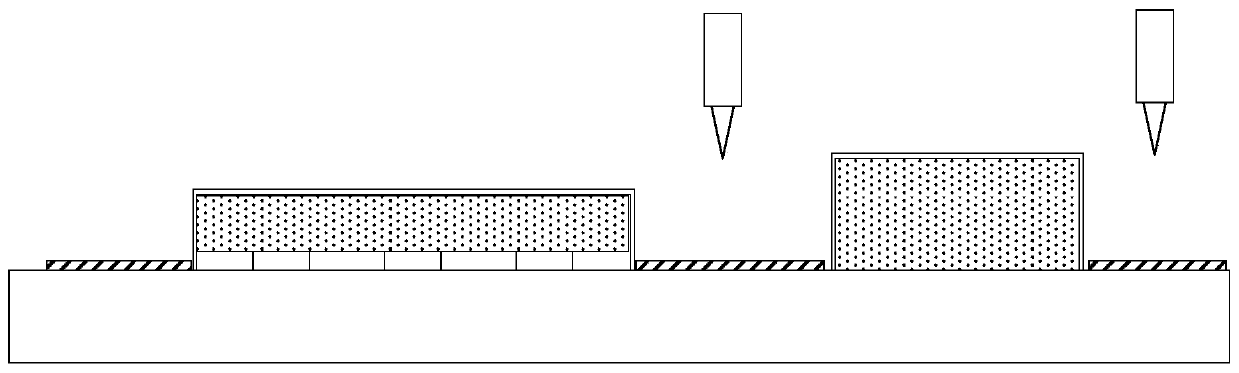

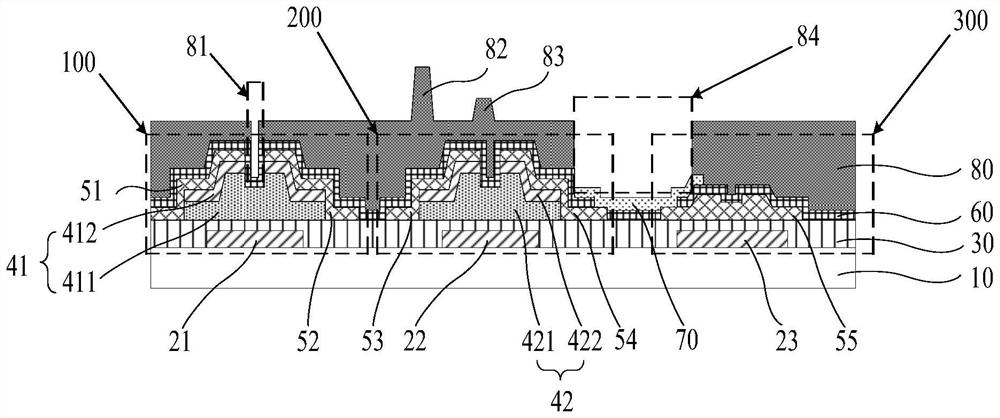

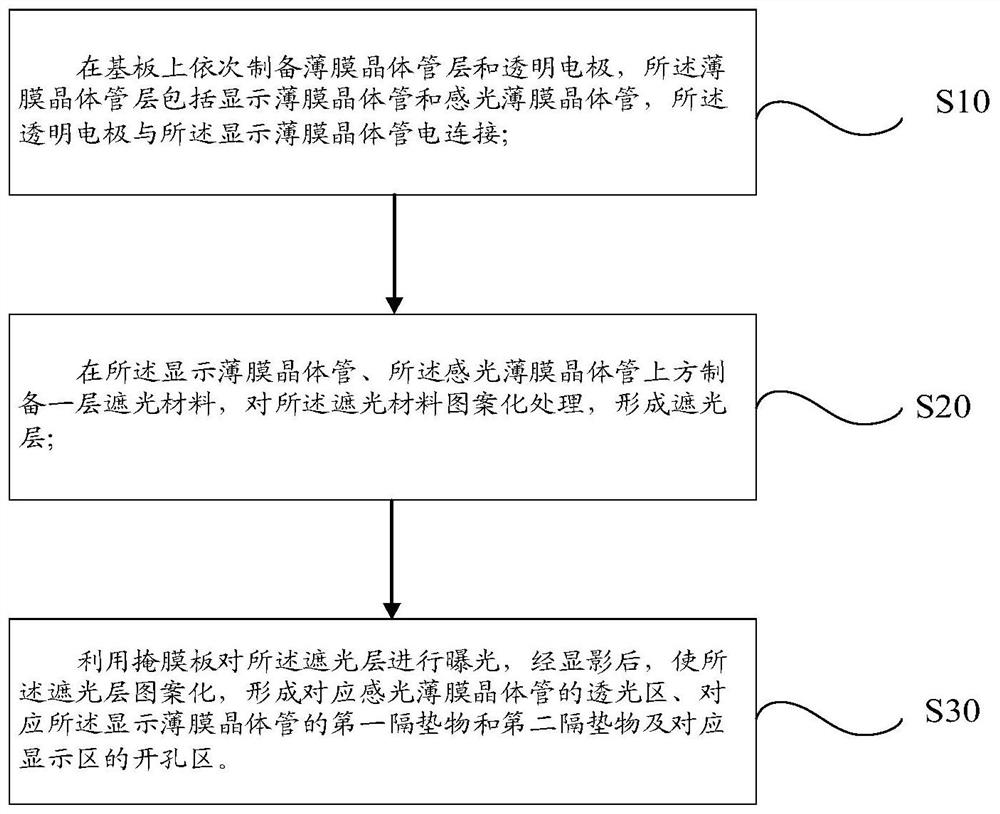

PendingCN112071861AReduce thicknessRealize the display functionSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The invention provides an array substrate, a preparation method thereof and a liquid crystal display panel. The array substrate comprises: a substrate body; display thin film transistors arranged on the substrate in an array manner; and a photosensitive thin film transistor arranged on the substrate, wherein the display thin film transistor and the photosensitive thin film transistor are arrangedon the same layer at intervals. The photosensitive thin film transistor and the display thin film transistors are prepared on the same substrate, so that the functions of integrated induction and display are achieved, and meanwhile, the thickness of the array substrate can be reduced; and the light-transmitting region and other light-shielding regions of a light-shielding layer are prepared by oneprocess, so that the process technology is saved, and the product cost is reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Wood composite floor and production method therefor

ActiveCN101016799AChange stressSmall deformation coefficientWood working apparatusWood layered productsSolid woodBrick

A recombination solid wood floor with its production method relates to a recombination construction art within three-ply boards, wherein a middle board layer comprises rectangular wood bricks in direct processing art which are connected to be a base block board, and at least one side of the base block board is recombined with a -shaped wood board of different fiber orientation, while the base block board is recombined with at least two rectangular wood bricks via bars between the every two rectangular wood bricks. The method comprises processing the rectangular wood bricks to be a base layer of floor in direct processing art, making the rectangular wood bricks to be base block boards, and recombining the connected base block boards with the wood boards of different fiber orientation, thereby making the block board of floor to be -shaped. The method has advantages of simple structure, easy processing art, good quality, low cost, convenience assembling, and good using effect.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

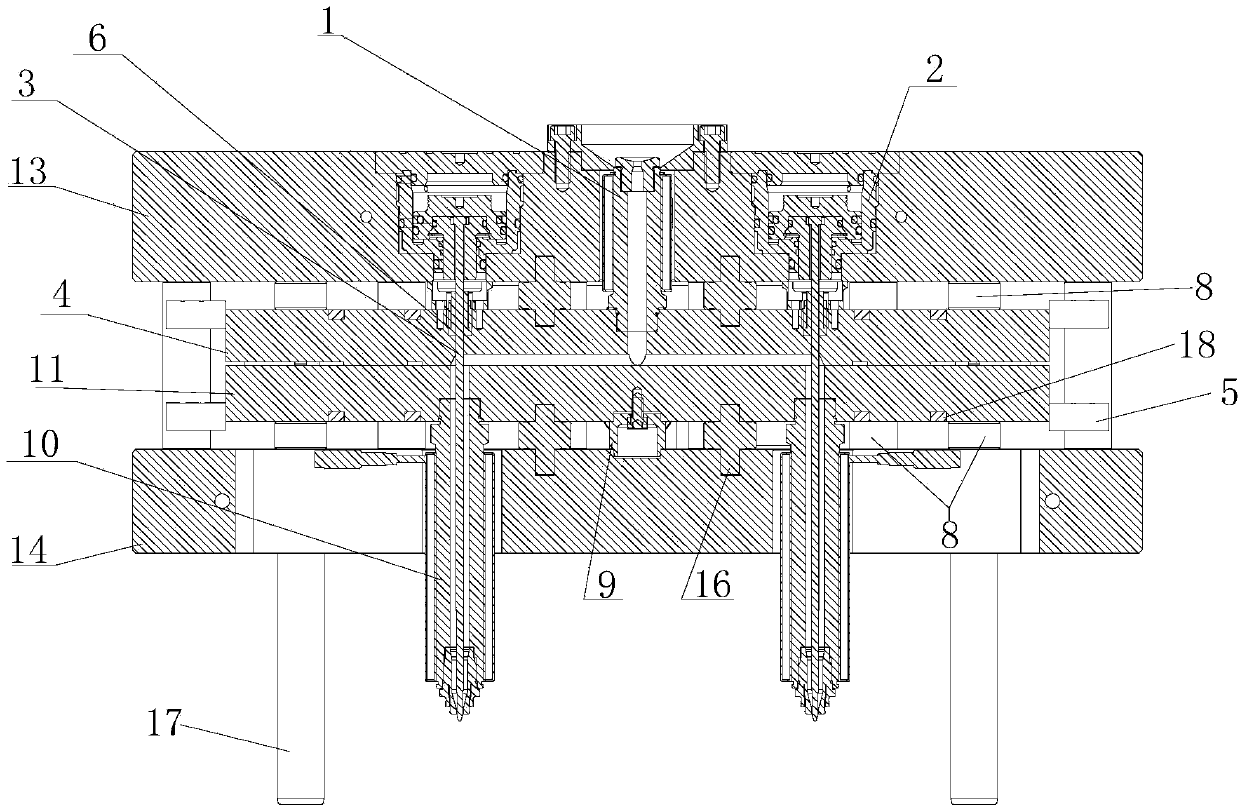

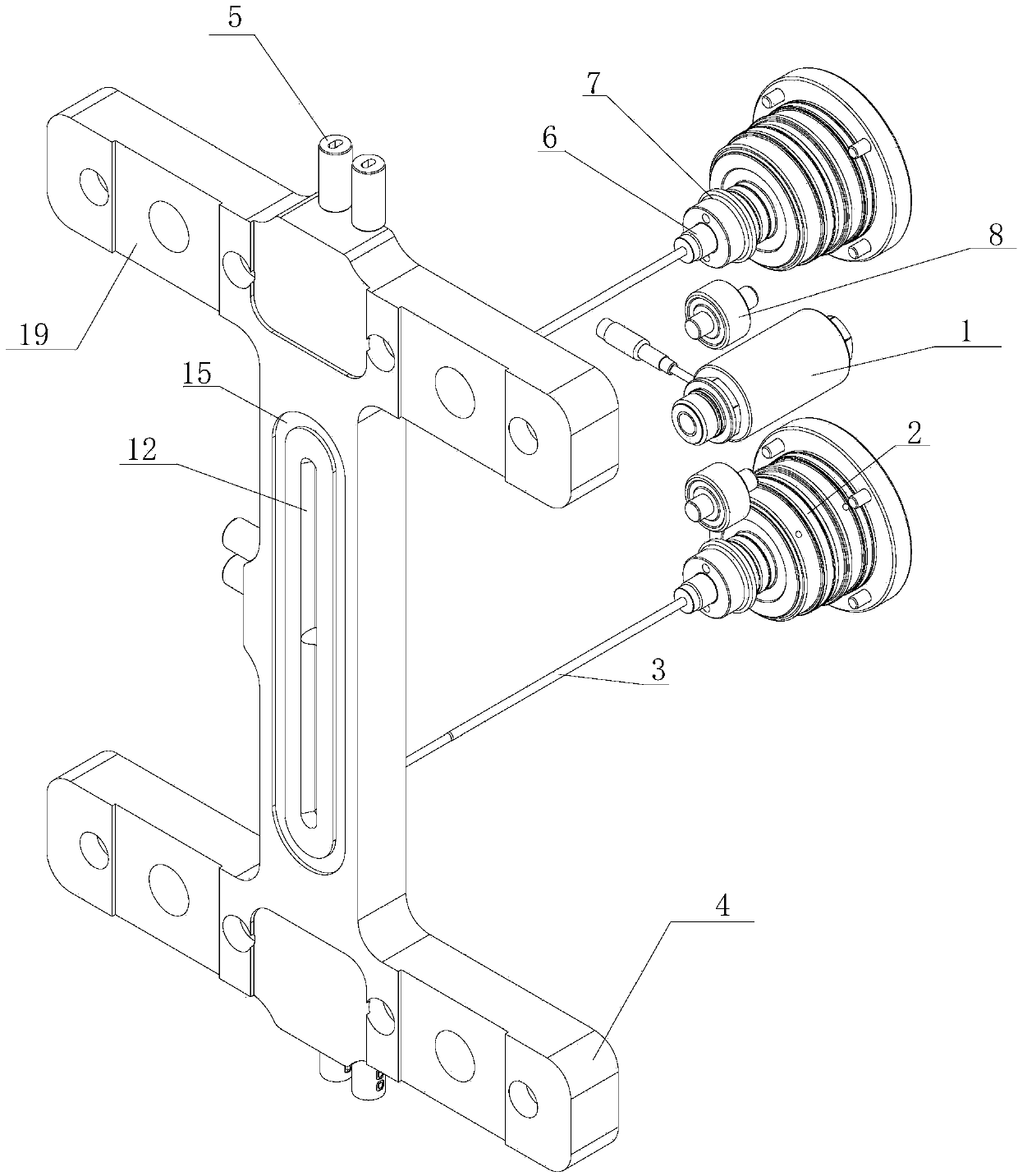

Overlapped and compressed type sealant hot runner system

The invention discloses an overlapped and compressed type sealant hot runner system. A manifold of the overlapped and compressed type sealant hot runner system is formed by overlapping a first manifold plate and a second manifold plate, and a runner is formed in the surface of the first manifold plate. According to the overlapped and compressed type sealant hot runner system, the runner is formed in the surface of the first manifold plate, so that the formed runner is smooth and free of dead angles, complicated nozzle runner distribution can be achieved, the pressure drop in the runner is reduced by 10%, the processing technology is reduced, and the cost is saved.

Owner:YUDO SUZHOU HOT RUNNER SYST

Pretreatment processing method of short flax fibers

InactiveCN104452263AIncrease the degree of splittingImprove spinnabilityDry-cleaning apparatus for textilesBleaching apparatusYarnEcological environment

The invention discloses a pretreatment processing method of short flax fibers. The pretreatment processing method comprises the following steps: with the short flax fibers as a raw material, carrying out procedures of peracetic acid pretreatment, warm washing, sodium percarbonate-peracetic acid scouring, hot washing, cold washing, dehydration and drying. The pretreatment processing method has the beneficial effects that most impurities such as pectin and lignin in the short flax fibers are removed by virtue of an ecological environment-friendly aid, so that wastewater pollution is avoided; processing conditions are relatively mild, so that the problem that the fiber strength is greatly damaged due to strong base and high temperature in a traditional process is remedied; the procedures of scouring and bleaching are simultaneously finished, so that impurity removal and bleaching are finished, the processing process is shortened, and the production efficiency is improved; original auxiliary projects and facilities can be utilized, so that the operation is easy, and the cost is low; the processed short fibers are pure white, soft, high in splitting degree and good in spinnability, so that the quality of finished yarns is beneficially improved, the technical requirements of the production of flax yarns for circular machine weft knitted single jersey are well met, and the grade of application range is promoted.

Owner:QIQIHAR UNIVERSITY

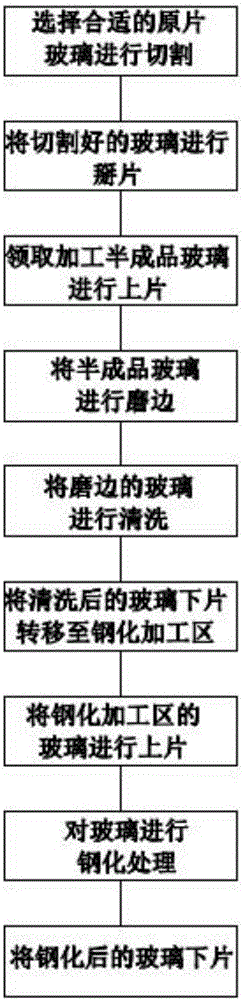

Method for manufacturing tempered glass of 5mm

InactiveCN106830656ASimple production methodReduce processing technologyGlass severing apparatusGlass tempering apparatusCutting glassWork in process

The invention discloses a method for manufacturing tempered glass of 5mm. The method comprises the following specific steps: selecting proper raw glass for cutting; breaking the cut glass; taking machined semi-finished glass for loading; polishing the edge of the semi-finished glass; cleaning the glass of which the edge is polished; transferring the cleaned glass to a tempering area; loading the glass in the tempering area; tempering the glass; unloading the tempered glass. By adopting the method, the glass tempering efficiency is increased, the yield of the tempered glass within unit time is increased, and meanwhile the problems of easiness in making mistakes and the like in a machining process are solved.

Owner:HUBEI SHALLPHA TECH CO LTD

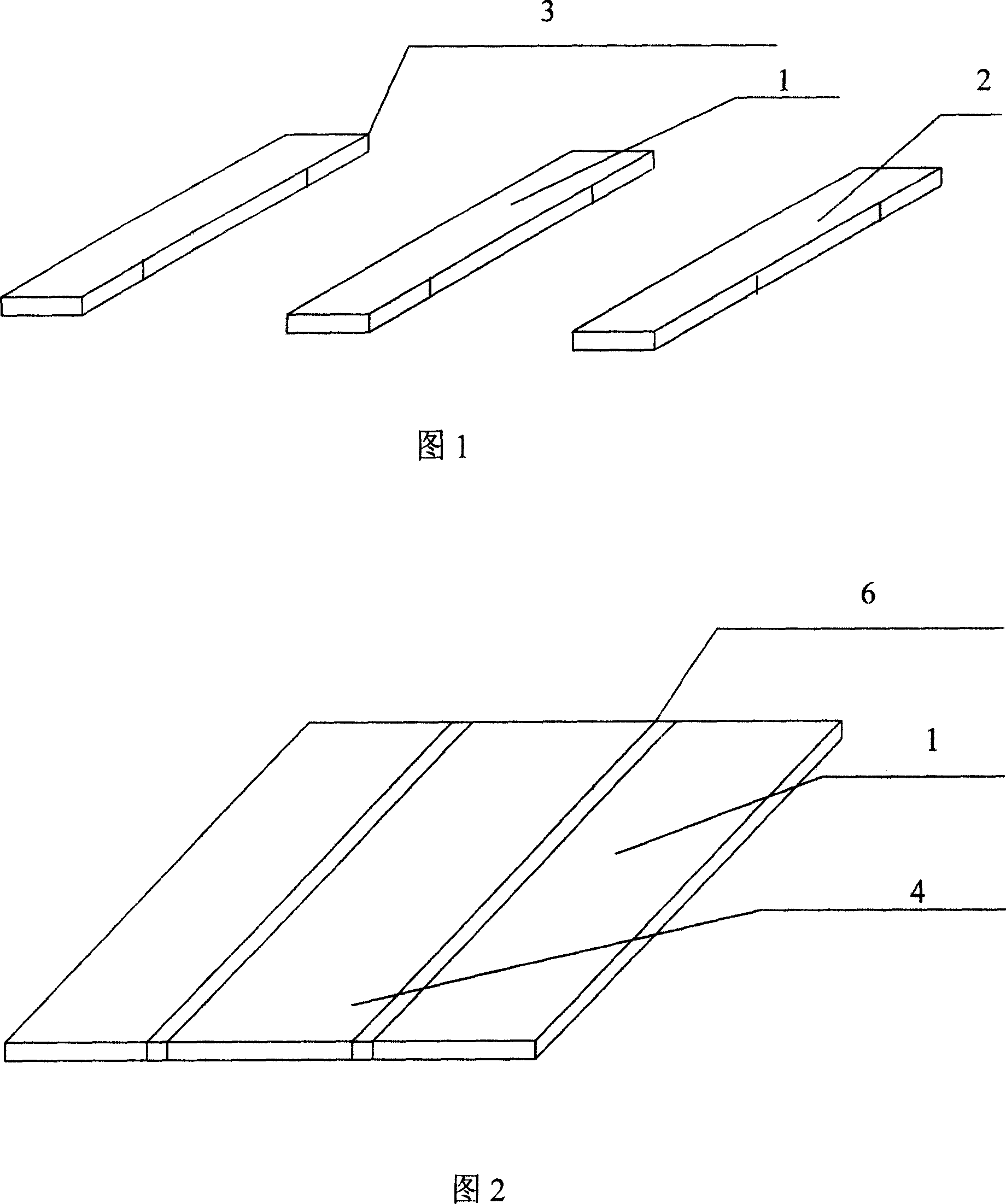

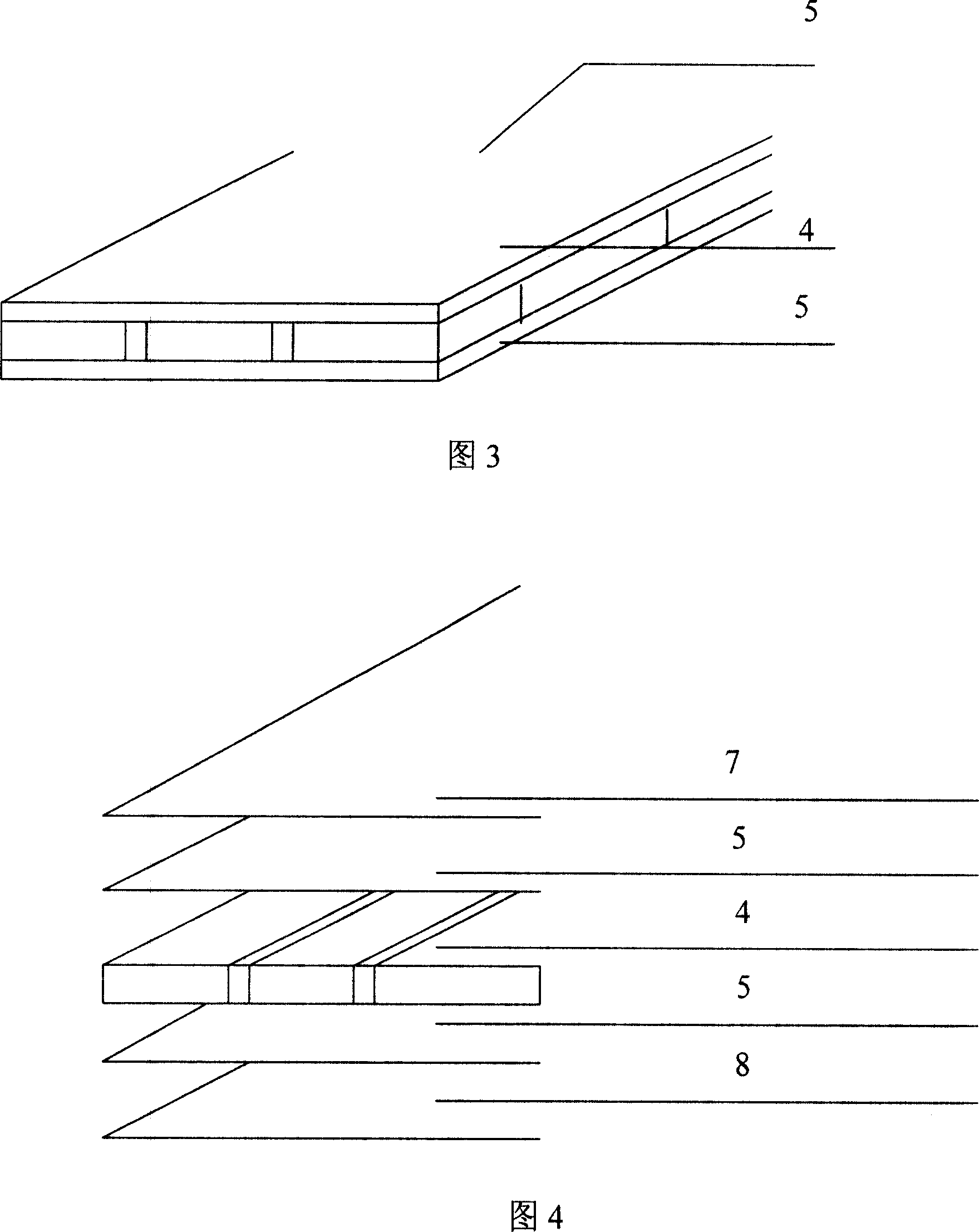

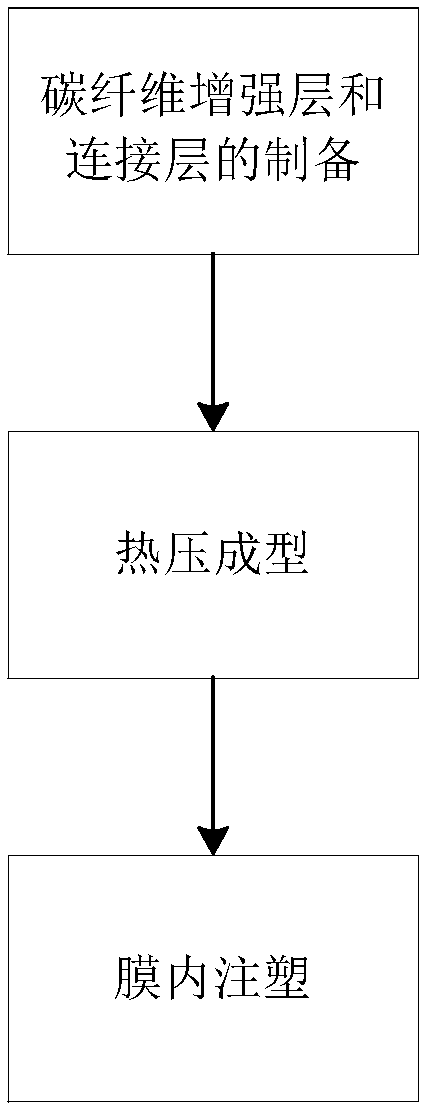

Preparation method of carbon fiber enhanced multilayered structure injection molding product and product of preparation method

The invention belongs to the field of injection molding product forming and discloses a preparation method of a carbon fiber enhanced multilayered structure injection molding product and a product ofthe preparation method. The preparation method comprises the following steps: a, preparing a carbon fiber enhancement layer and a connection layer through the electrostatic powder spraying technology;b, stacking the carbon fiber enhancement layer and the connection layer and then carrying out hot-press forming to form carbon fiber enhanced composite material, wherein the connection layer is stacked on the uppermost layer; and c, putting the carbon fiber enhanced composite material in a die and carrying out injection molding to obtain the required product. The invention further discloses the product prepared through the preparation method. Compared with the preparation method, a high-viscosity material composite material plate is obtained through the hot-pressing technology with low cost and high efficiency; in addition, the multilayered composite material structure is obtained by combining with the intramode injection molding technology, so that the high material cost is reduced and the surface decoration function is also played; and compared with the electronic engineering plastic with the same thickness, the product is high in mechanical strength.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com