Patents

Literature

53results about How to "Reduce process resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

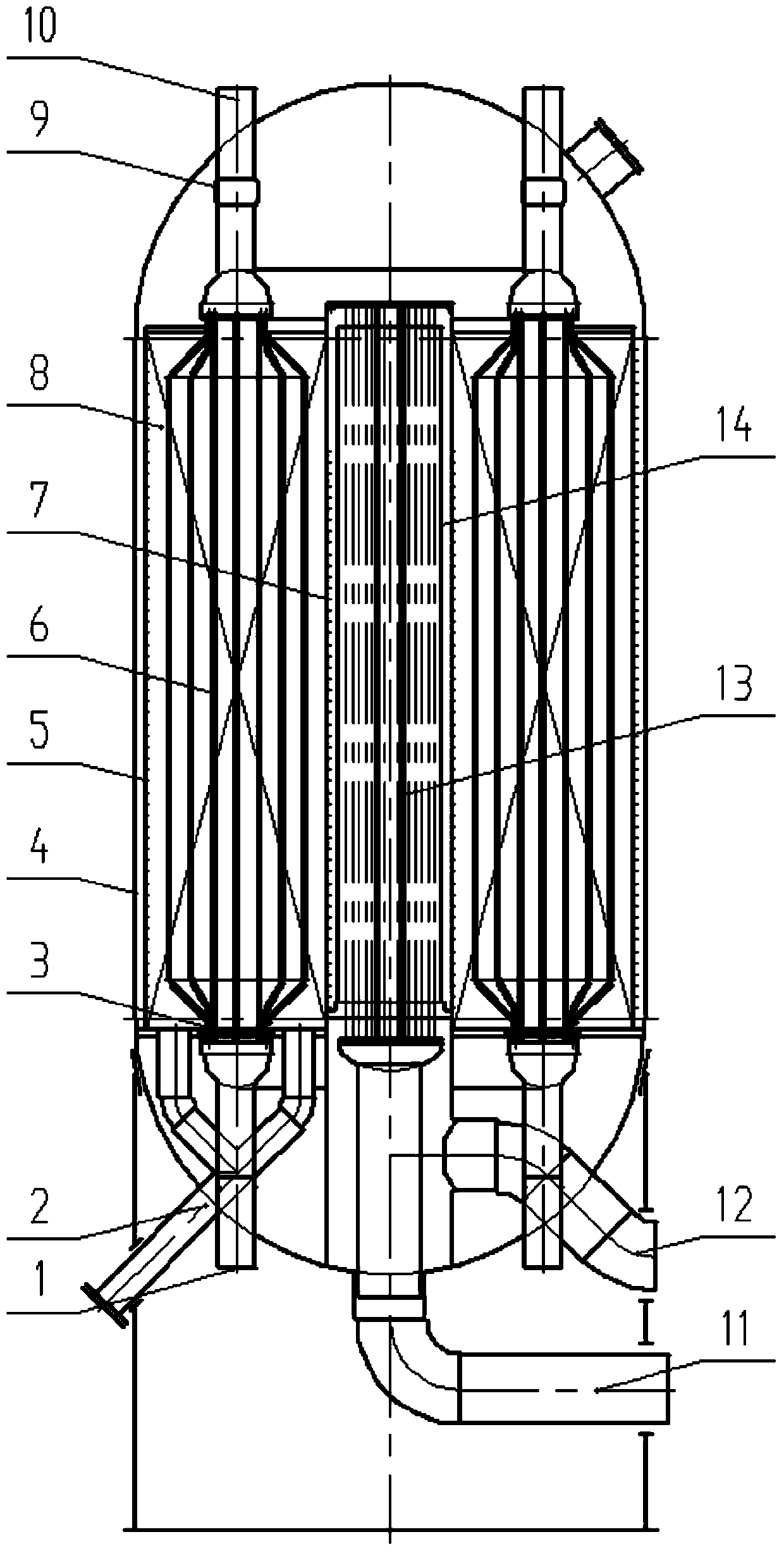

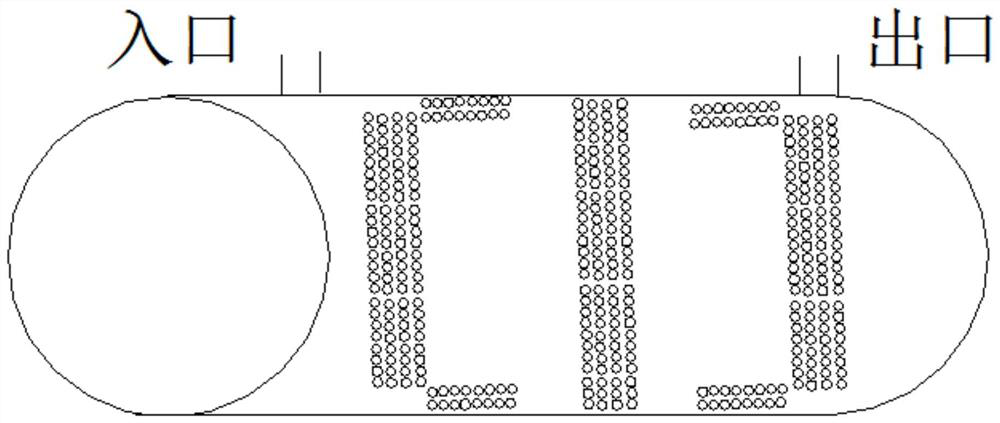

Pipe-bundle-builtin isothermal-shift reactor

ActiveCN105457563AFrom burningExtend your lifeHydrogenChemical/physical processesEngineeringHigh heat

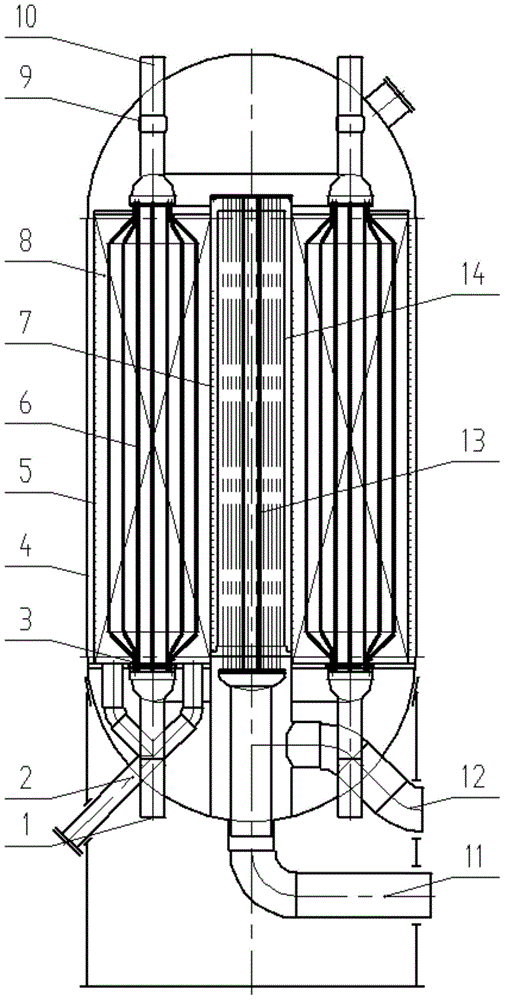

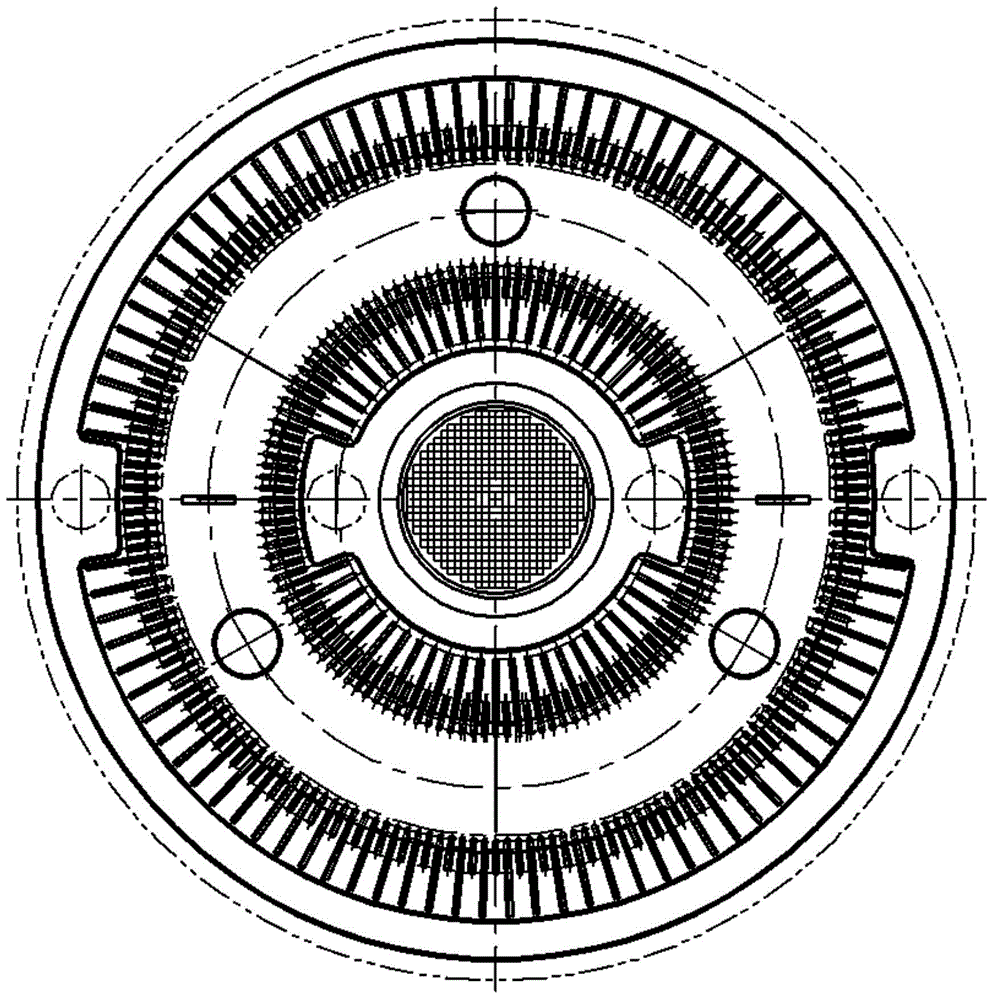

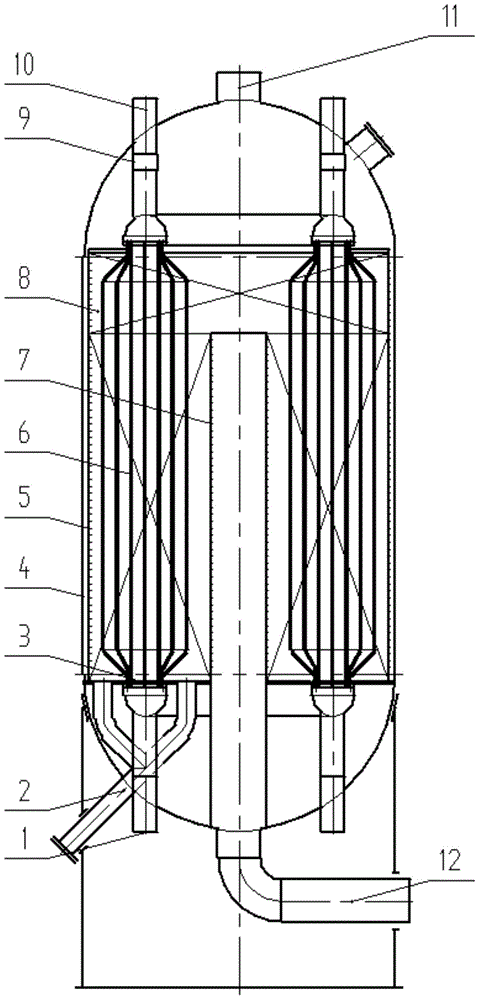

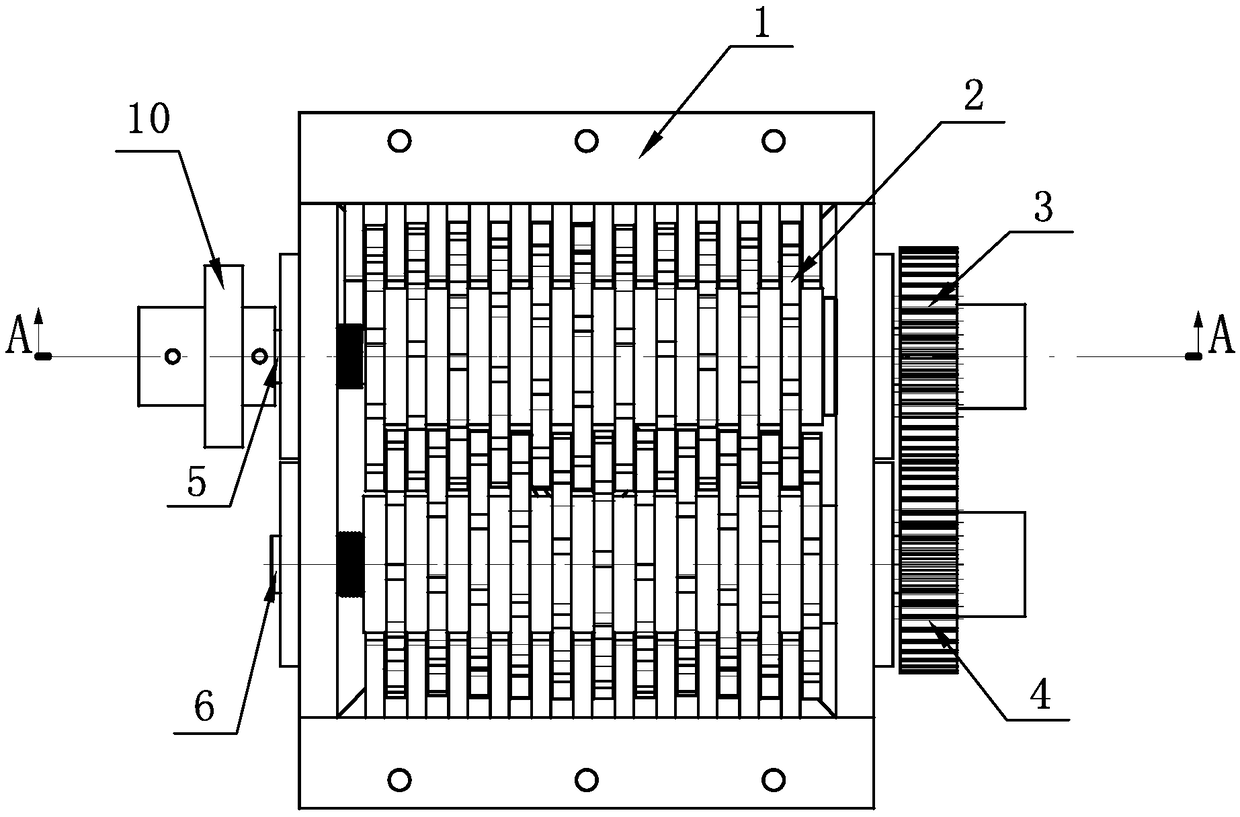

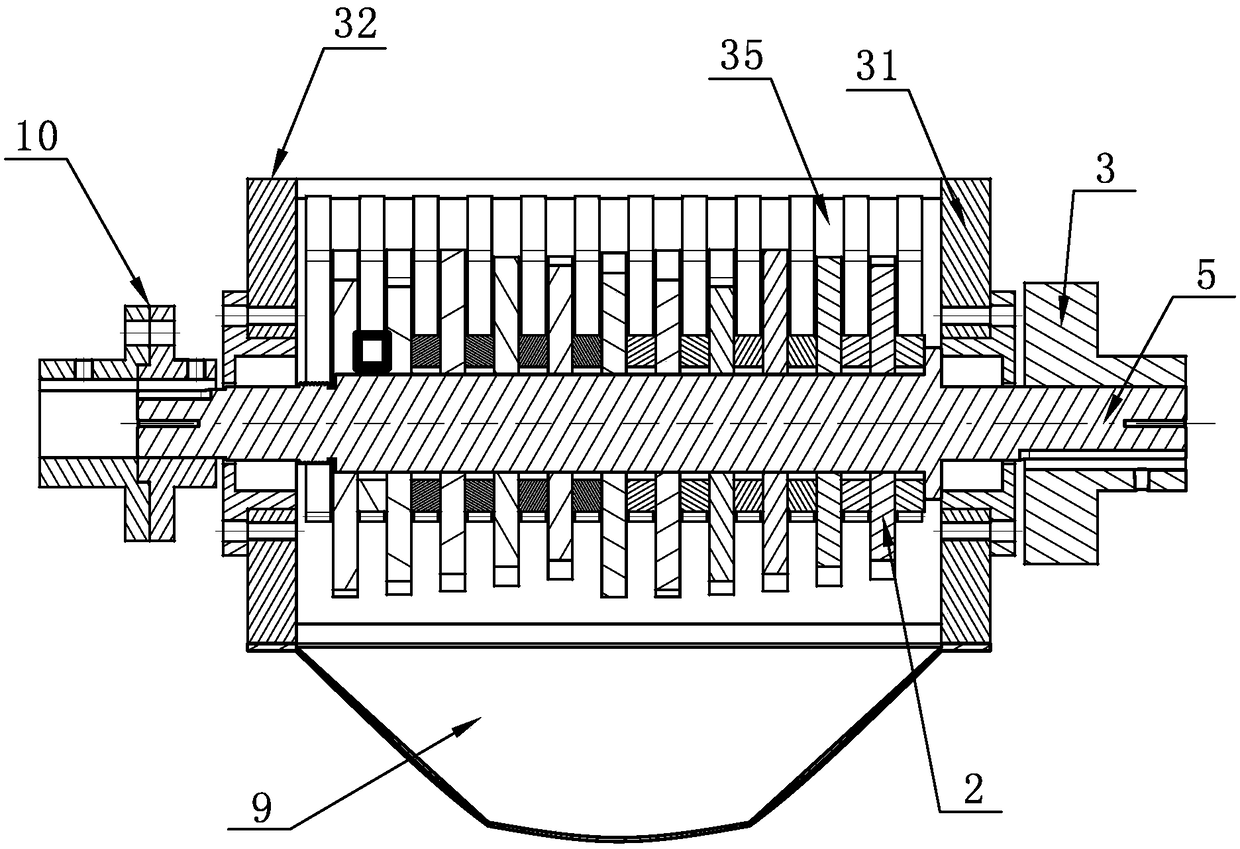

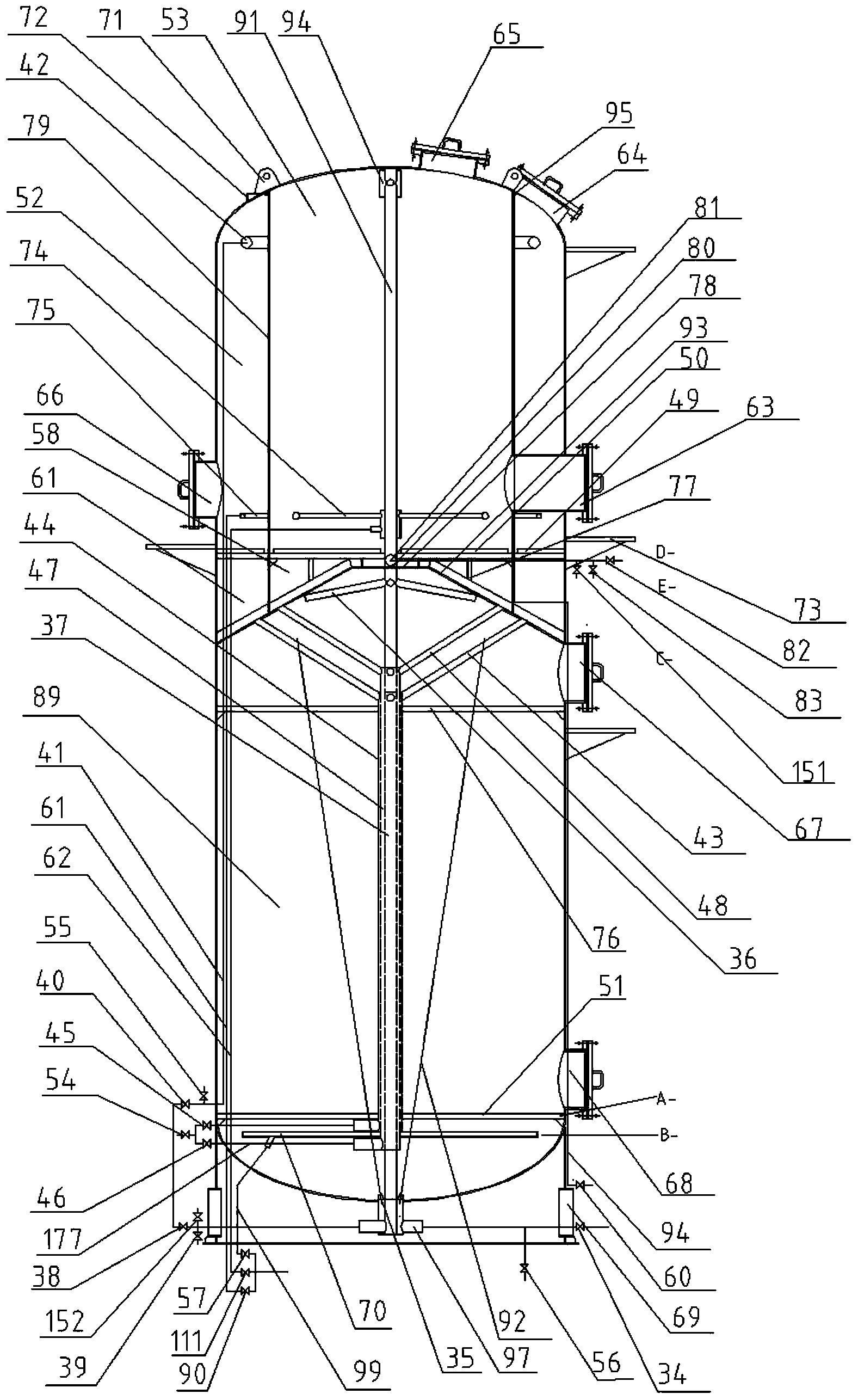

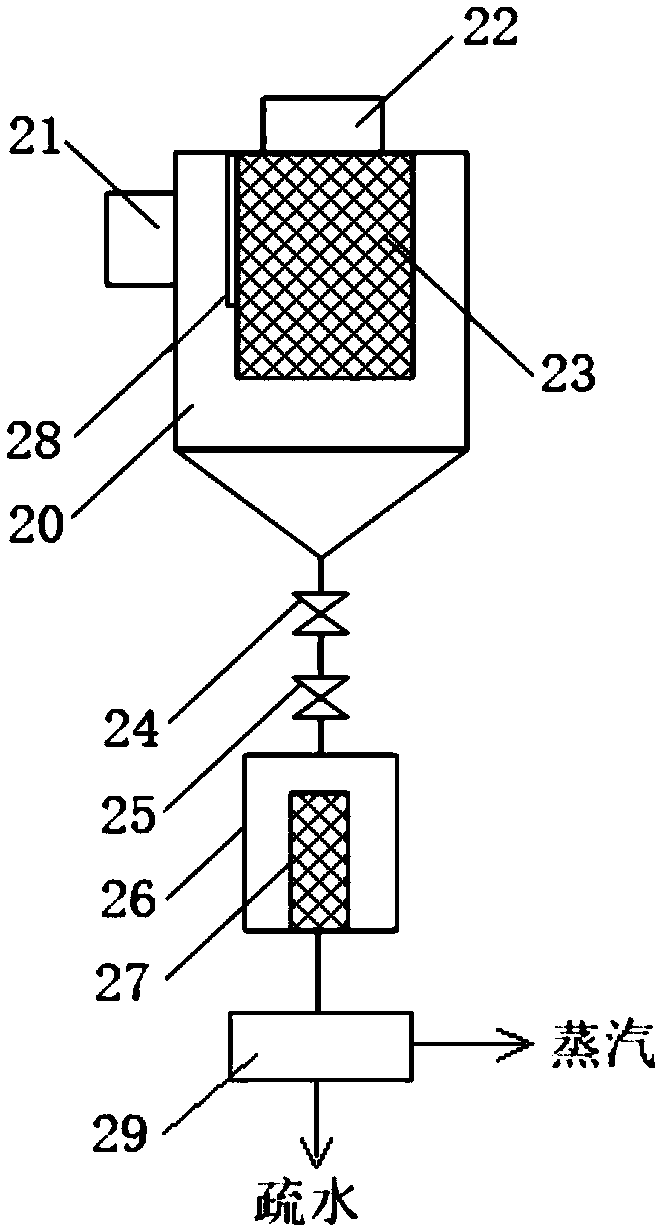

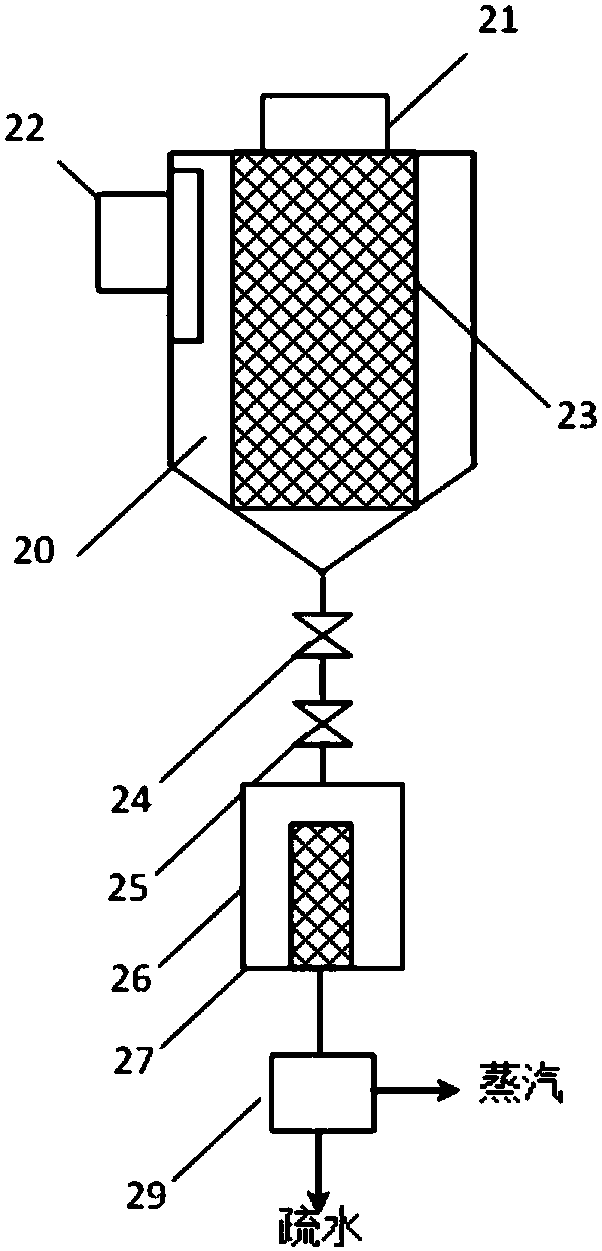

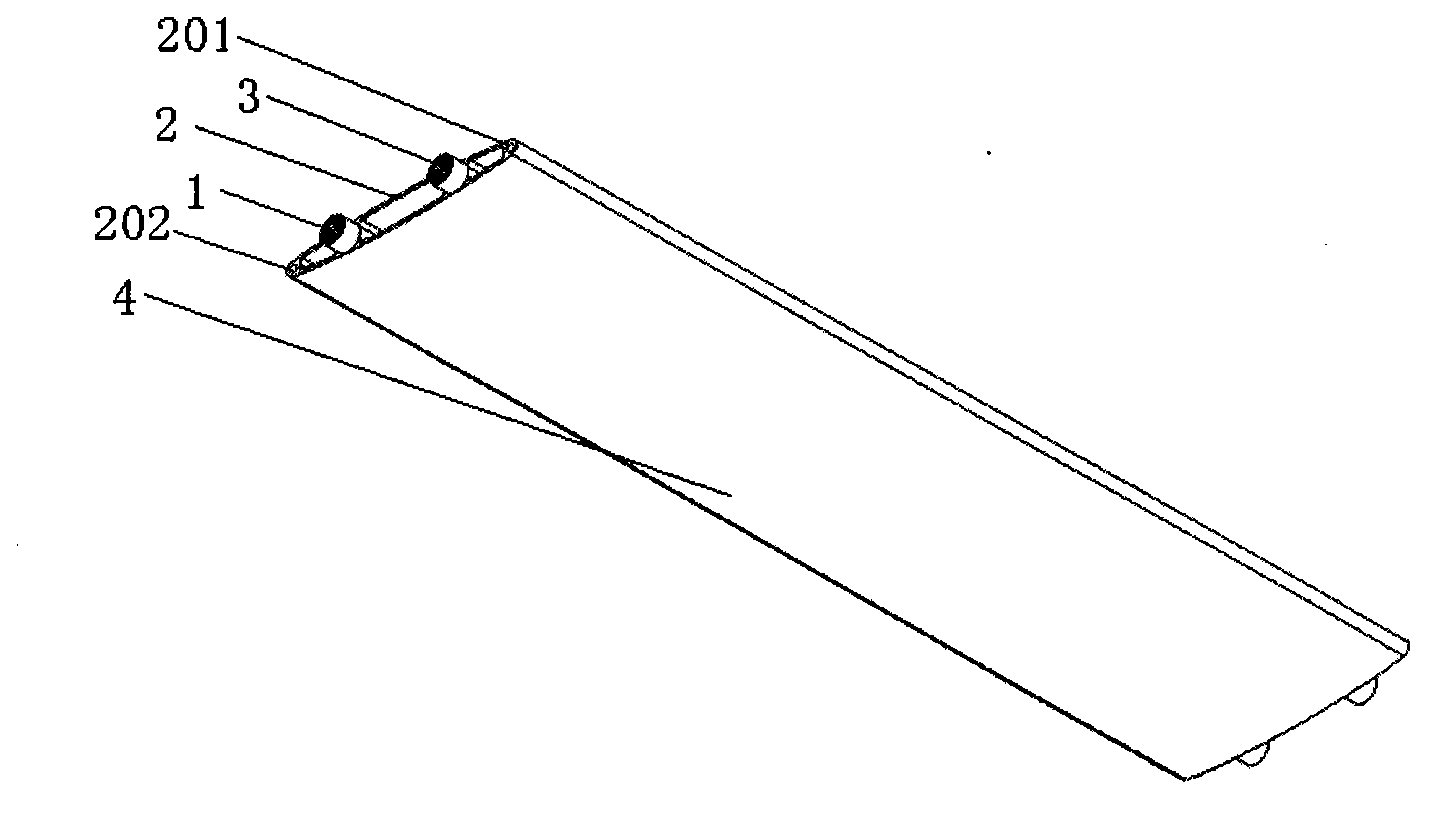

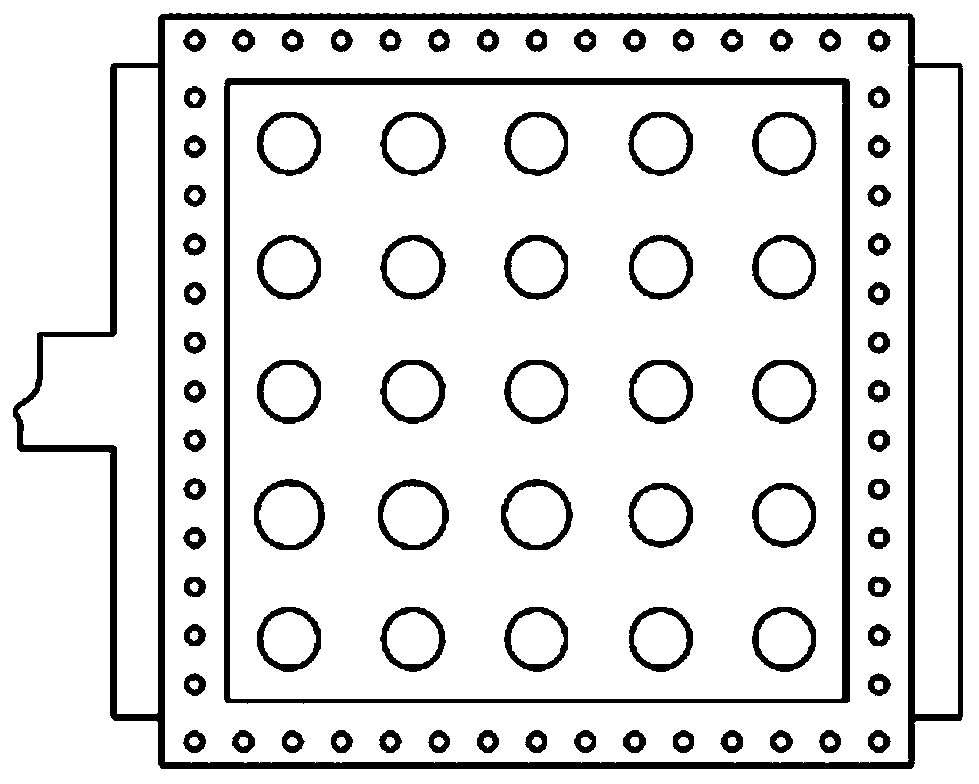

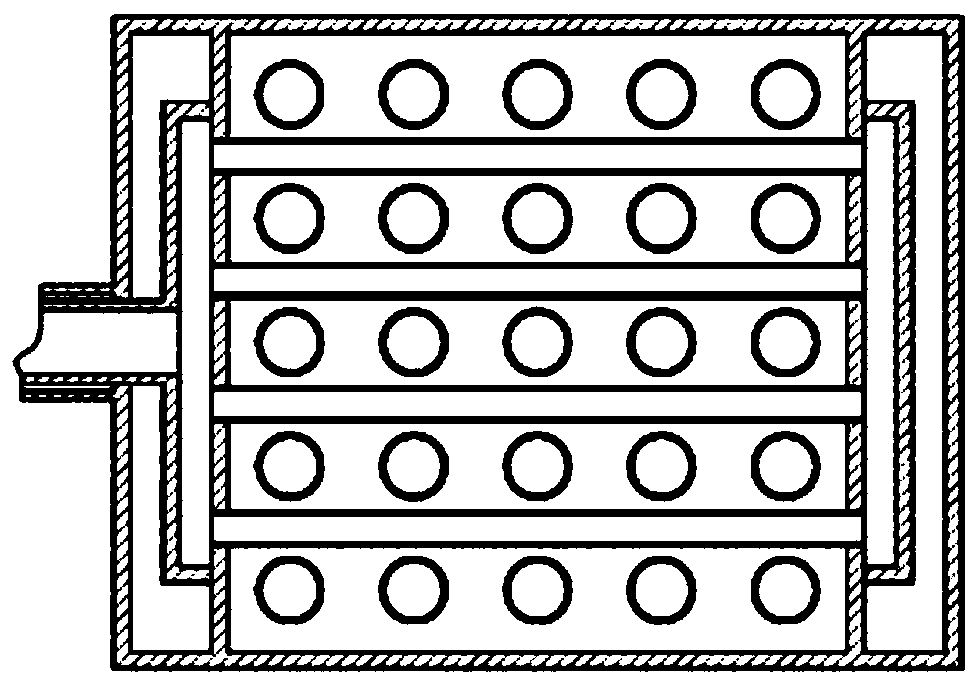

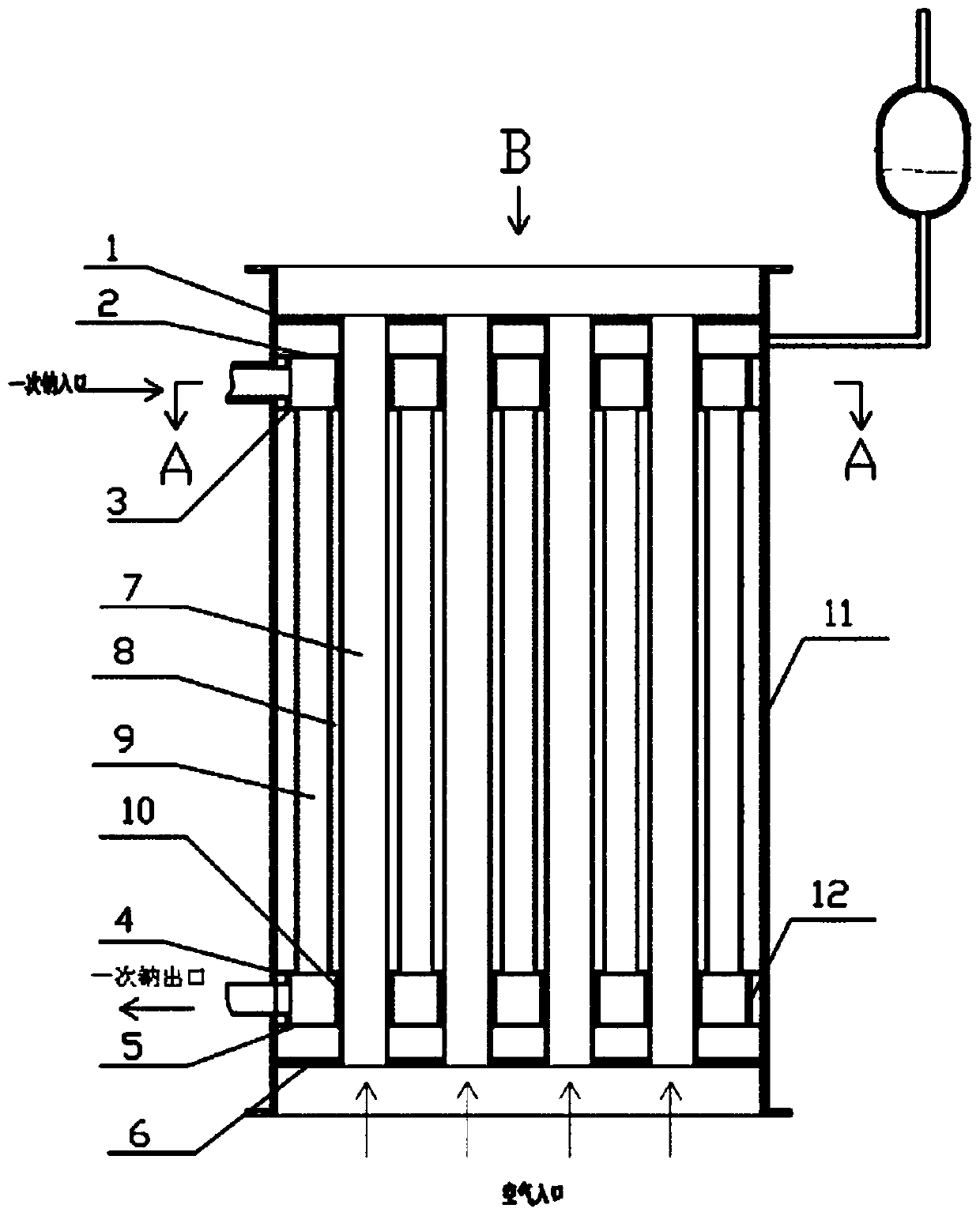

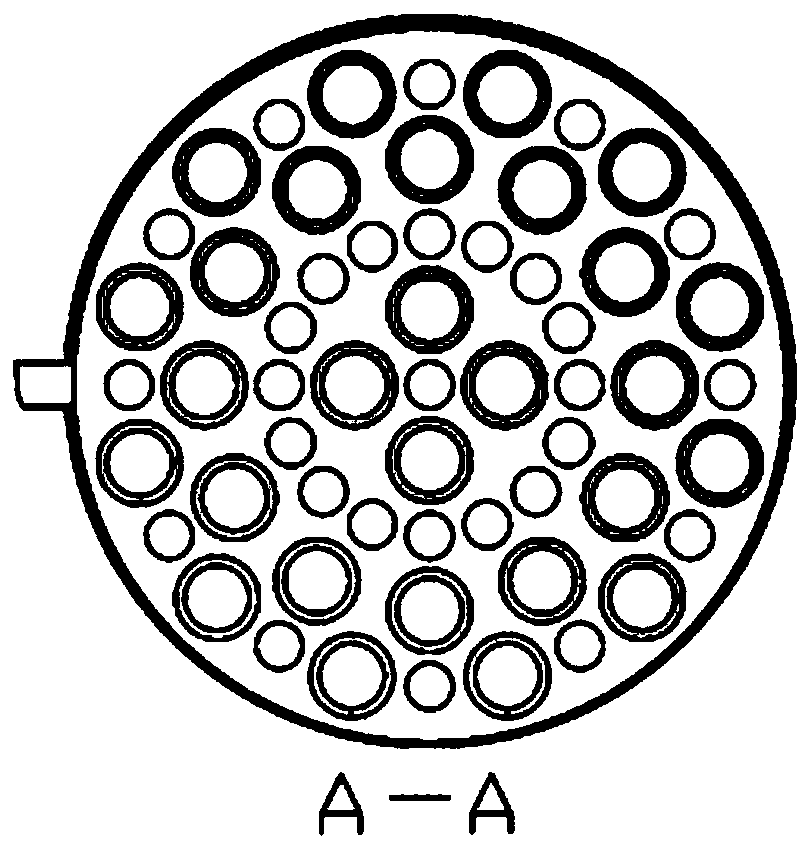

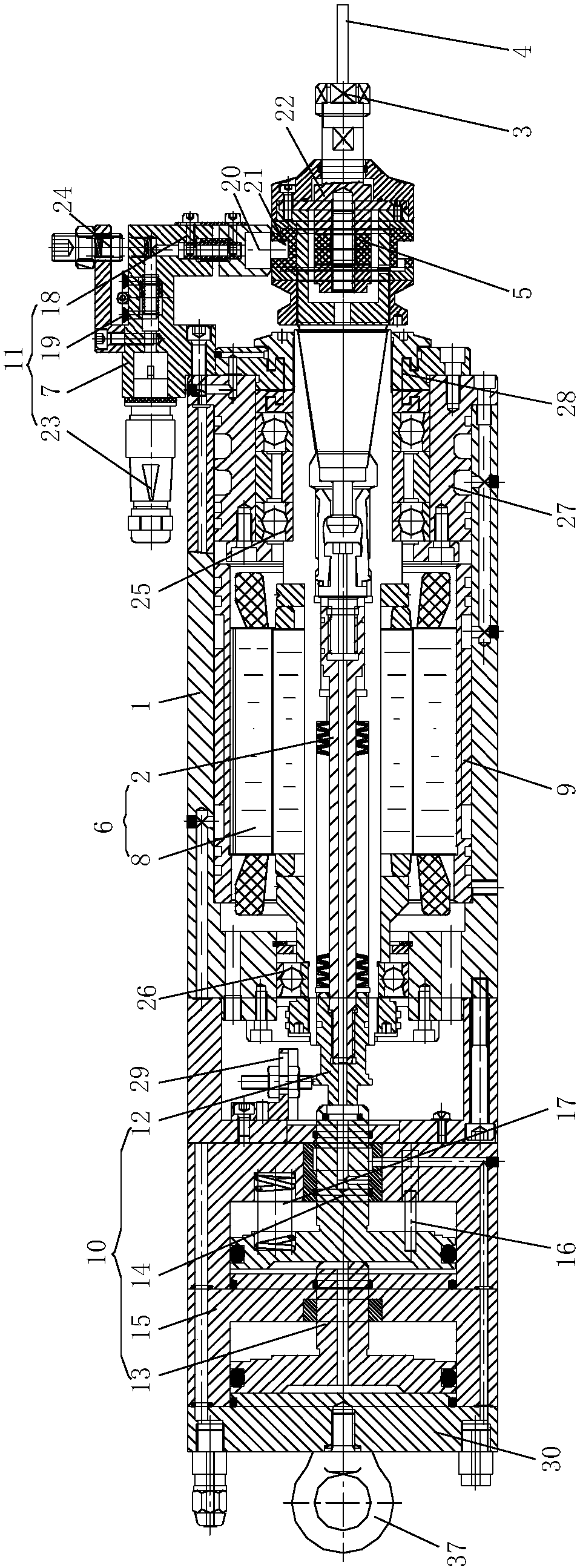

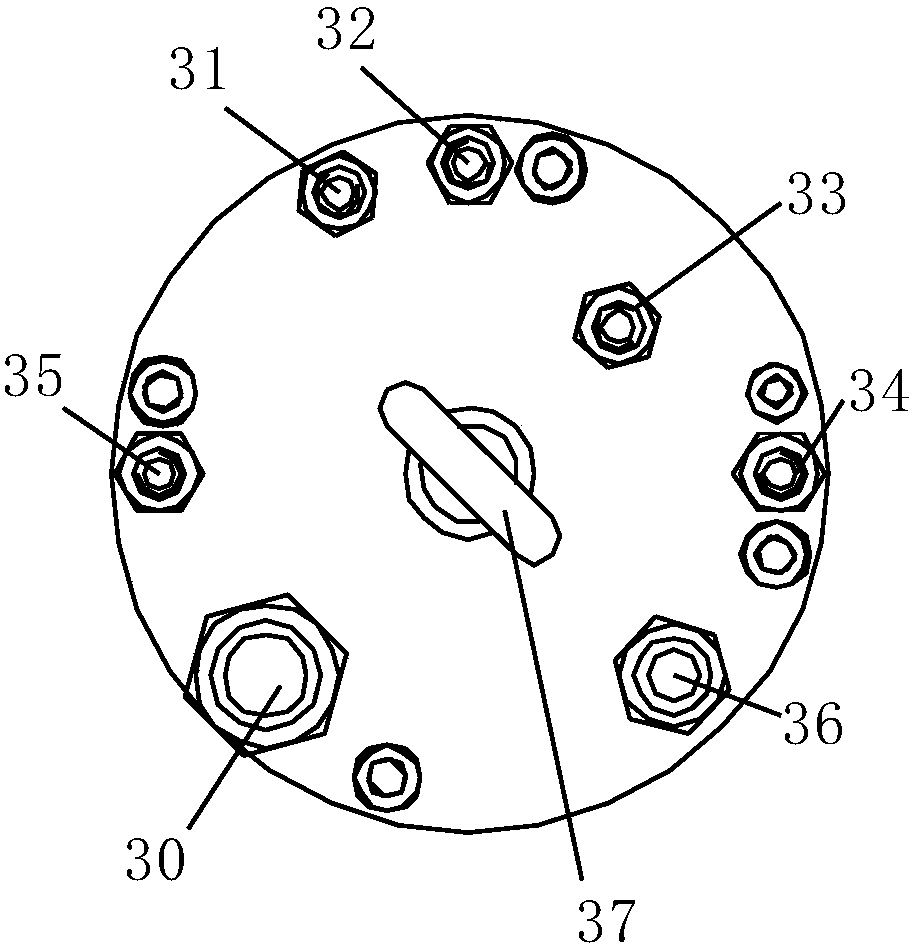

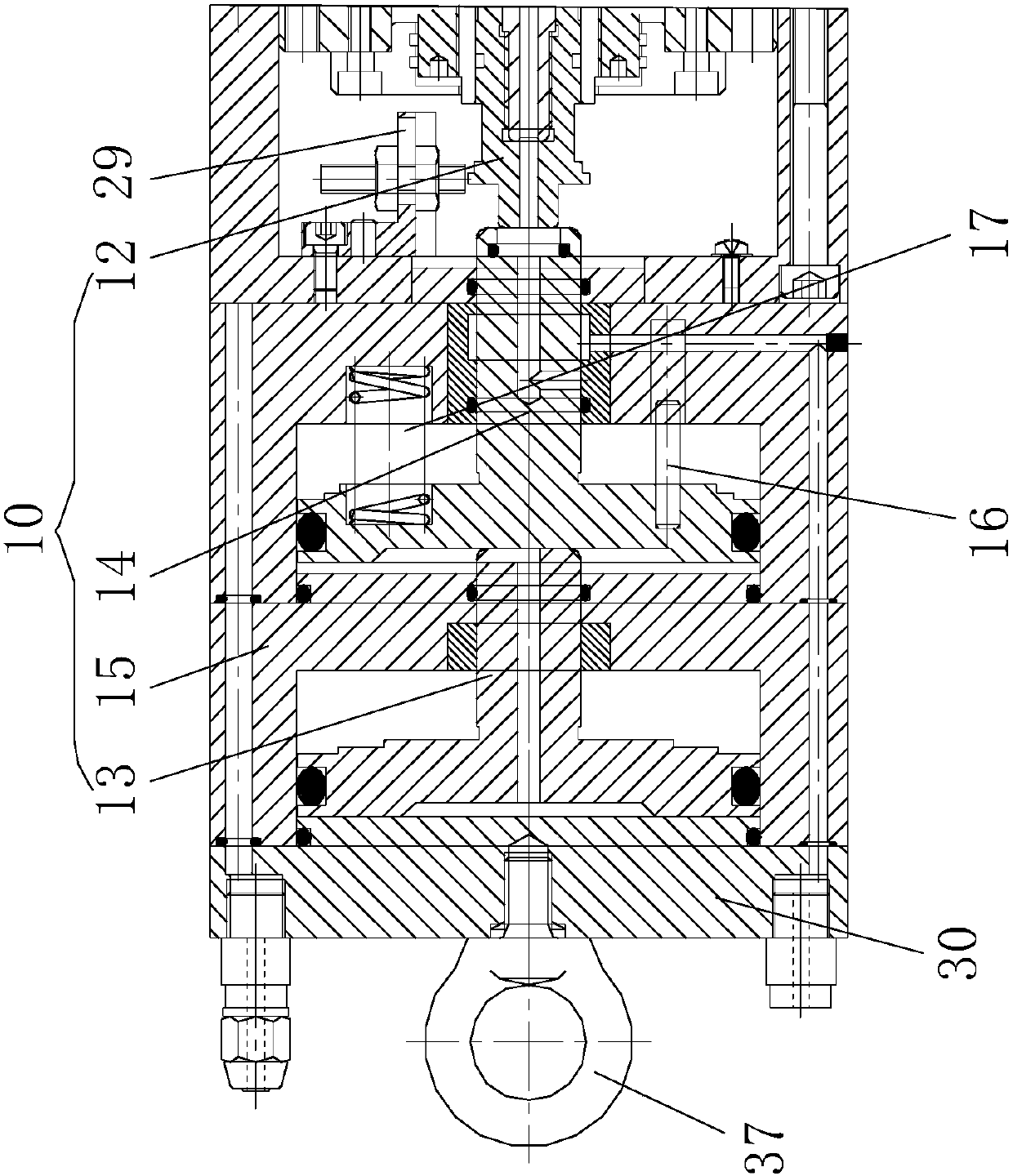

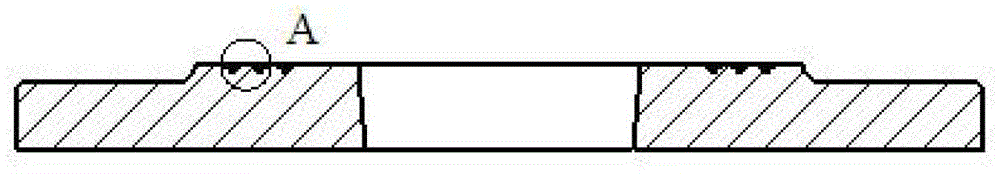

The invention relates to a pipe-bundle-builtin isothermal-shift reactor. According to the pipe-bundle-builtin isothermal-shift reactor, axial annular pipe bundles, which are builtin and are uniformly distributed in a catalyst bed layer along circumferential direction, are adopted to shift out heat of reaction, so as to realize isothermal shift; and a central pipe bundle which is built in a central pipe is adopted to preheat raw material gas entering the reactor, so as to realize the builtin of a gas-gas heat exchanger. The isothermal-shift reactor comprises a pressure-bearing shell, a catalyst basket, the axial annular pipe bundles, the central pipe and the central pipe bundle; and the axial annular pipe bundles consist of upper and lower annular pipe boxes, upper and lower annular pipe sheets and heat exchange tubes. According to the pipe-bundle-builtin isothermal-shift reactor, due to builtin pipe bundles, the manufacturing cost of equipment is effectively reduced; due to an end-part bent structure for the heat exchange tubes, the size of the pipe sheets is effectively reduced; due to a heat insulating layer laid between the pipe sheets and the high-temperature catalyst bed layer, the contact between pipe end weld spots and a bed layer high-temperature area is effectively isolated, the probability of leakage is lowered, and the reliability of equipment is improved; and the pipe-bundle-builtin isothermal-shift reactor is compact in structure, low in manufacturing cost, relatively easy in maintenance, high in reliability, complete in function and high in applicability.

Owner:CHANGZHENG ENG

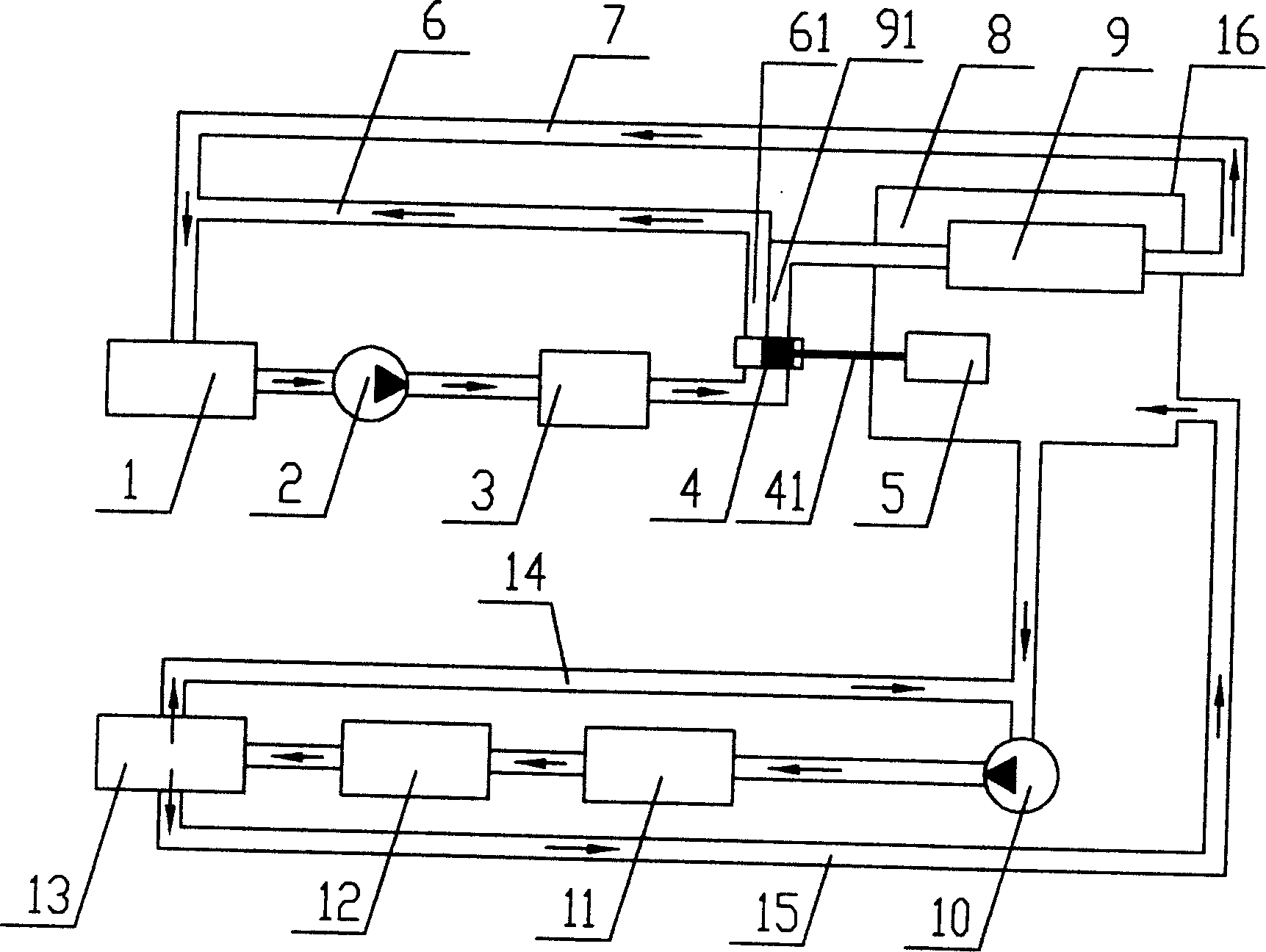

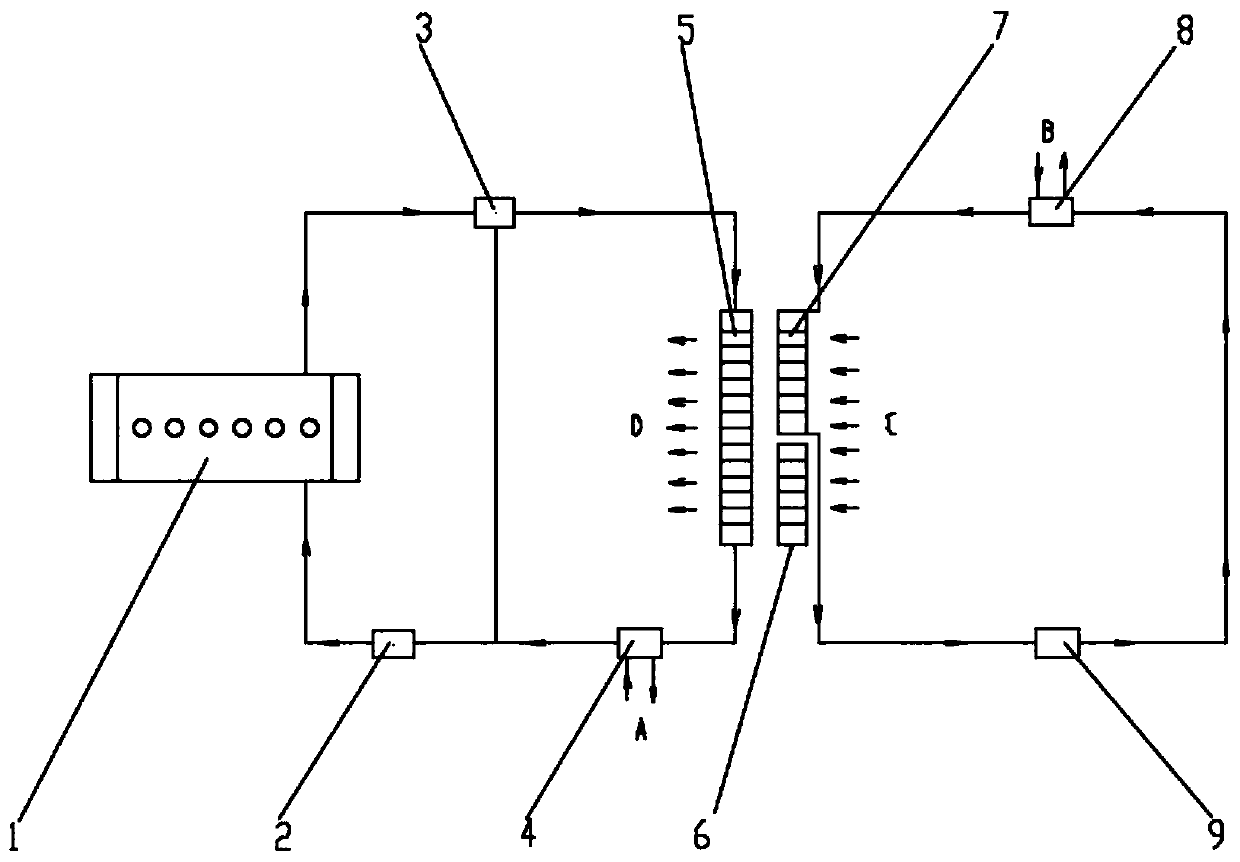

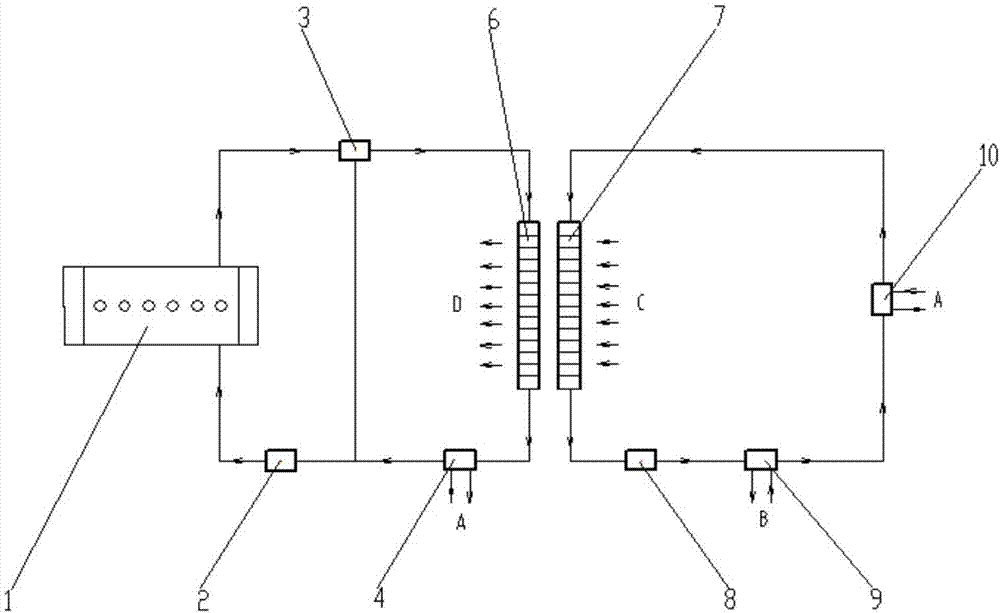

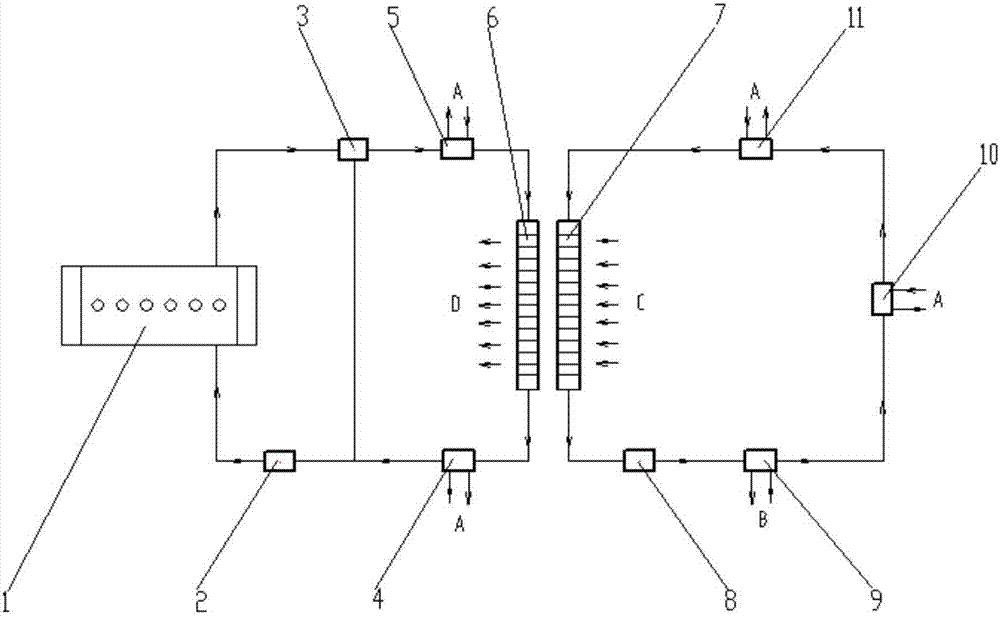

Engine dual-cycle forced cooling system

InactiveCN1891994AShorten the timeTake advantage ofLiquid coolingCoolant flow controlEngineeringControl valves

The invention discloses an engine double circulation forced cooling system, comprising internal circulation cooling subsystem and external circulation cooling subsystem, where the pipeline of the external circulation cooling subsystem connects to the external circulation water cavity of a heat exchanger and that of the internal circulation cooling subsystem connects to the internal circulation water cavity of the heat exchanger, the pipeline of the external circulation cooling subsystem is equipped with a flow control valve able to control the flow of external circulation cooling medium passing through the heat exchange, and a temperature sensing device sampling from the internal circulation water cavity, and the temperature sensing device drives the flow control valve; when a machine is in the 'warming-up' course, the temperature sensing device controls the flow control valve to control the quantity of external circulation cooling medium entering the heat exchanger so as to achieve the purposes of fully using heat energy, shortening warming-up time, and reducing heat energy losses.

Owner:WEICHAI POWER CO LTD

Novel combined vehicle double-circulation cooling system

InactiveCN110173336AReduce manufacturing costMeet cooling needsLiquid coolingInternal combustion piston enginesWorking temperatureIntercooler

The invention belongs to the technical field of vehicle cooling and heat dissipation, and discloses a novel combined vehicle double-circulation cooling system. The system is composed of a high-temperature circulating cooling system and a low-temperature circulating cooling system, a low-temperature radiator and a hydraulic oil radiator are arranged in parallel on a cooling air cooling flowing path, and then a high-temperature radiator is further arranged in a series mode on the path, so that a combined mode of arranging the radiators in the front row and the rear row is formed; the high-temperature circulating cooling system is mainly composed of an engine, an engine water pump, a transmission oil radiator and the high-temperature radiator; and the low-temperature circulating cooling system is mainly composed of the low-temperature radiator, a low-temperature circulating pump and a water-cooling intercooler. According to the system, the working temperature requirements of all the systems of a vehicle are considered, the cooling requirements of all heat sources are met, the radiators on the cooling air flowing path achieve heat exchange with cooling air in a series-parallel combination mode, the number of the radiators is reduced, the manufacturing cost of the cooling system is reduced, the cooling efficiency of the cooling air is improved, and the energy consumption of the vehicle cooling system is reduced.

Owner:JILIN UNIV +1

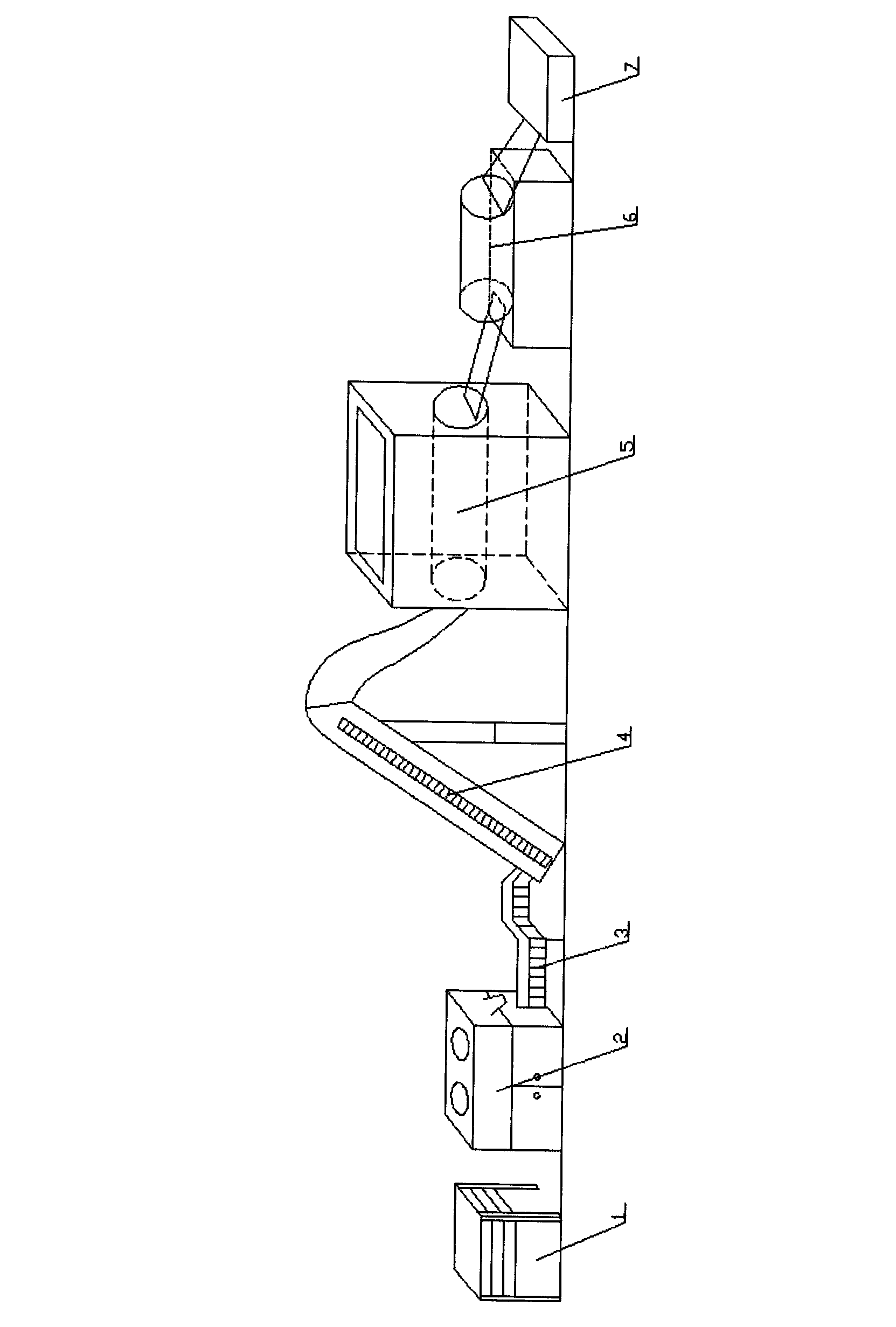

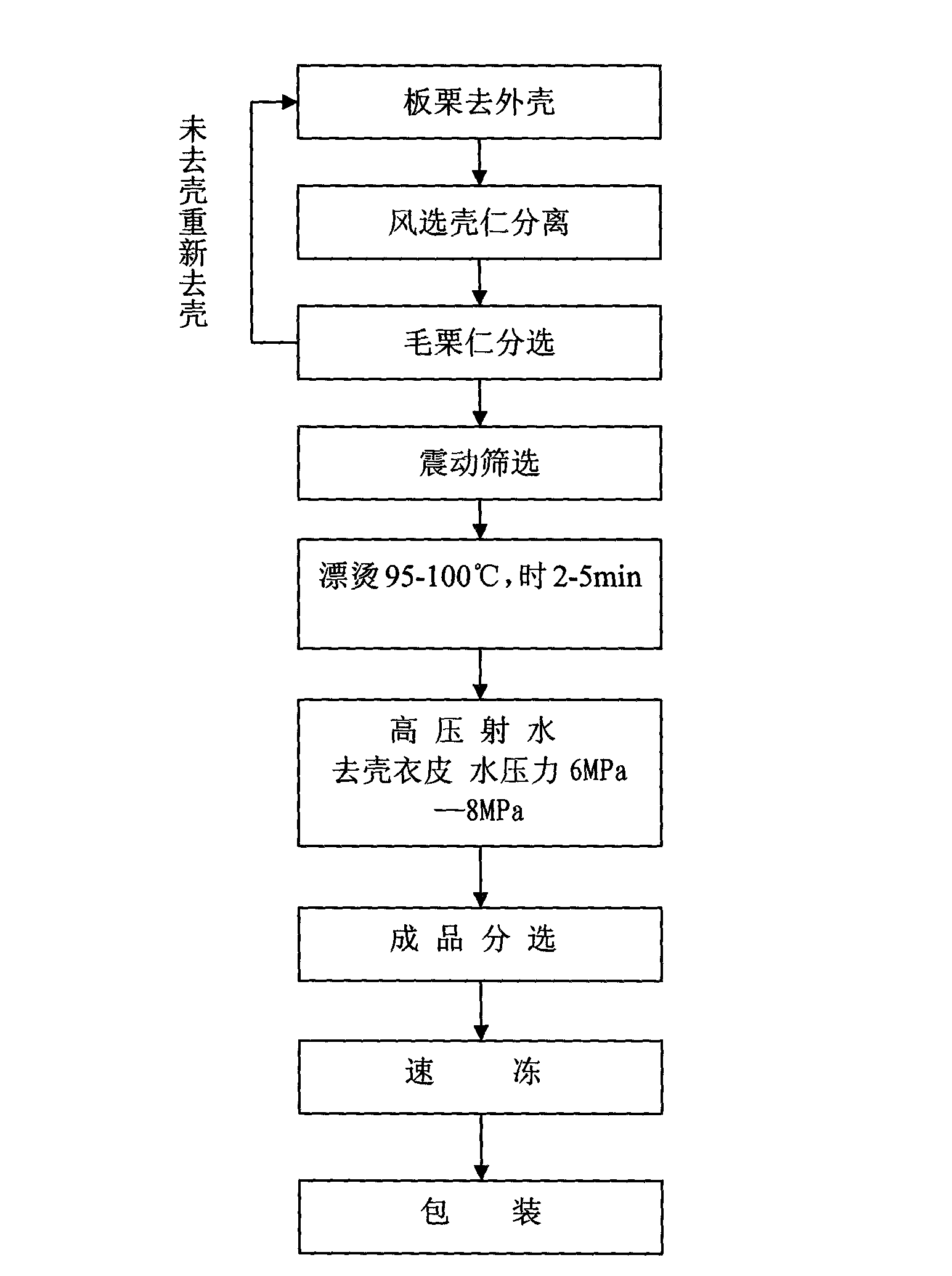

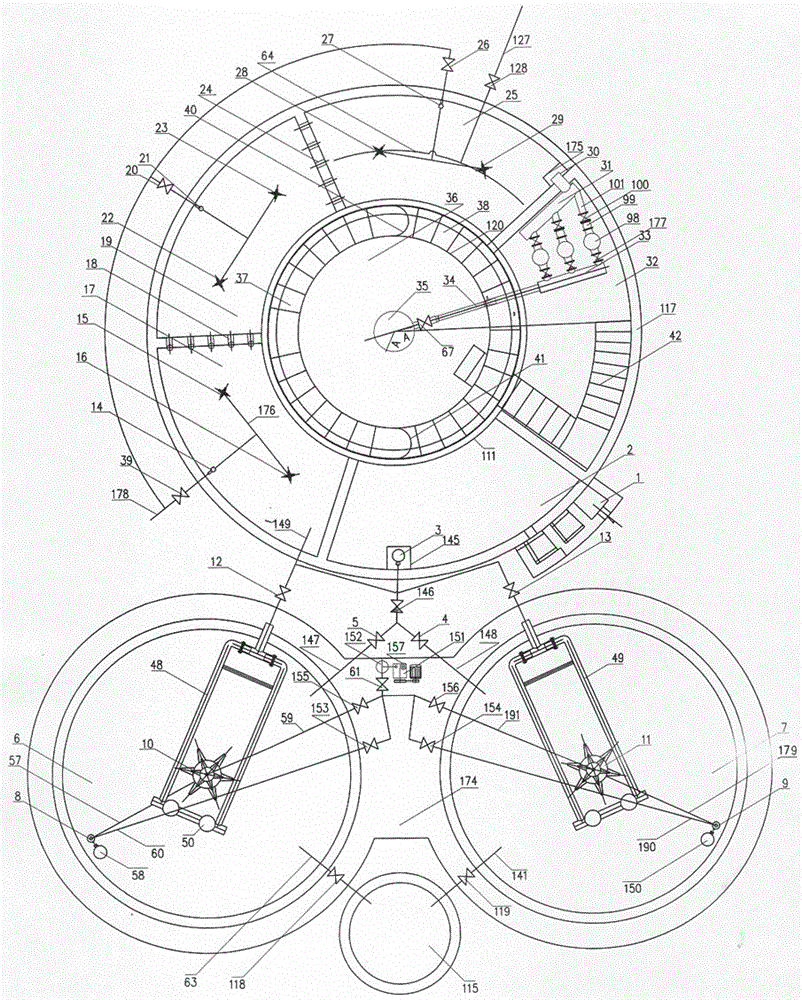

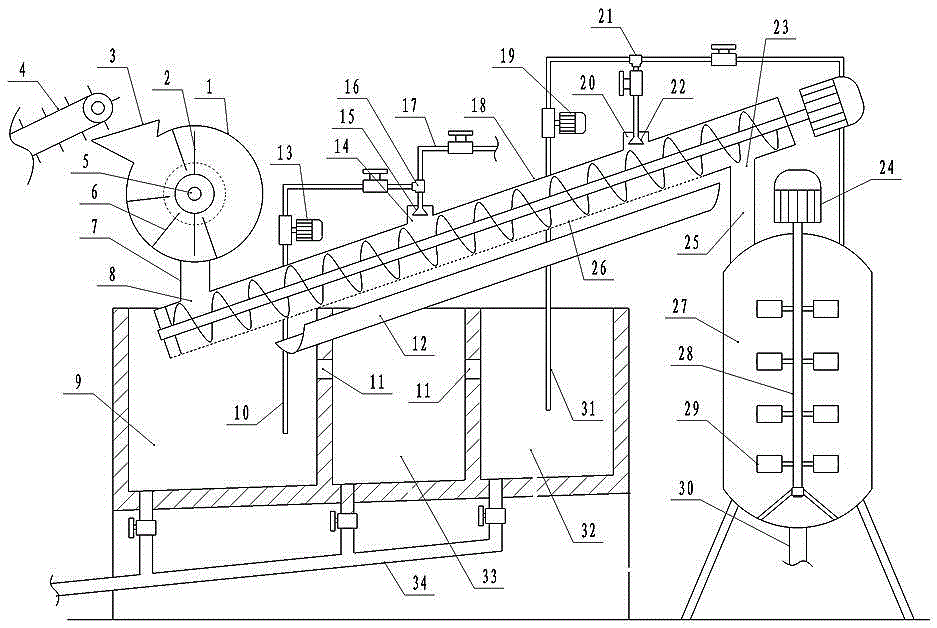

Chinese chestnut shelling equipment and shelling technology

The invention discloses Chinese chestnut shelling equipment, which is formed by sequentially connecting a Chinese chestnut grader, a shelling machine, a vibration screening machine, an elevator, a spiral blanching machine, a high-pressure sprayer and a cleaning machine. A shelling mechanism consists of a motor driven cutter head. The Chinese chestnut shelling equipment is characterized in that Chinese chestnuts are graded and shelled and then enter the bubble cleaning machine for bubble cleaning, and the cleaned Chinese chestnuts are elevated to the spiral blanching machine and the high-pressure sprayer; the high-pressure sprayer consists of a screen drum and a high-pressure water spray head; and the included angle between the water outlet of the high-pressure water spray head and the circumferential tangent of the drum is adjustable and is 15 to 20 degrees. The Chinese chestnut shelling equipment solves the problems that the conventional Chinese chestnut shelling machine cannot thoroughly remove the endothelium, damages the appearance of Chinese chestnut kernels and is high in loss and low in efficiency and the like; and through the equipment, manual shelling is replaced by mechanized production.

Owner:湖北绿润食品有限公司

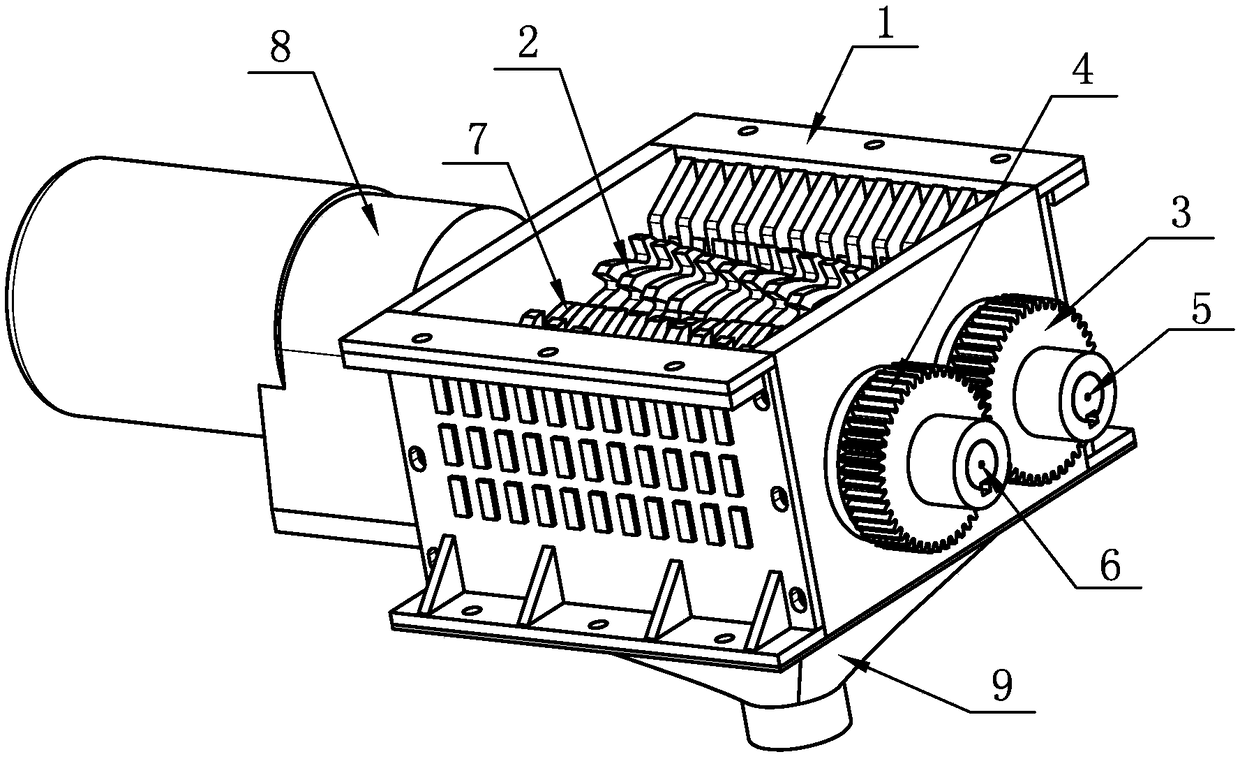

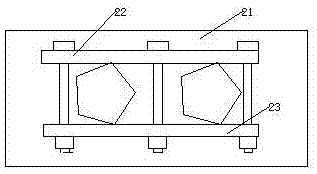

Tearing, milling and fragmenting device for machining hard solids in kitchen waste

The invention discloses a tearing, milling and fragmenting device for machining hard solids in kitchen waste. The tearing, milling and fragmenting device comprises a tearing box body, a drive knife assembly, a drive gear, a driven gear, a drive shaft, a driven shaft, a driven knife assembly and a tearing driving part; the drive knife assembly is fixedly installed on the drive shaft, the driven knife assembly is fixedly installed on the driven shaft, the drive shaft and the driven shaft are rotatably installed on the tearing box body in parallel, blades of the drive knife assembly and blades ofthe driven driven knife assembly are staggered in the axial direction, and the drive shaft is driven by the tearing driving part; and the drive gear is fixedly installed on the drive shaft, the driven gear is fixedly installed on the driven shaft, and the driven shaft achieves driving through the drive gear and the driven gear. According to the tearing, milling and fragmenting device for machining the hard solids in the kitchen waste, the hard solids such as big bones and shells in the kitchen waste can be effectively clamped, cut, torn, milled and fragmented, and the tearing, milling and fragmenting device is the premise ensuring smooth conduction of subsequent secondary crushing, extrusion type solid-liquid separating and solid stirring, heating, sterilizing and stir-frying and is an essential key device in on-site kitchen waste comprehensive processing complete equipment.

Owner:虞正洪

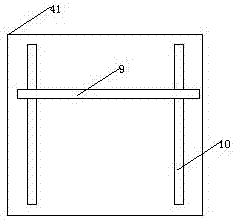

Multi-wire saw for cutting high-hardness materials

InactiveCN103600427ALarge swingSimple exerciseWorking accessoriesFine working devicesWire cuttingHardness

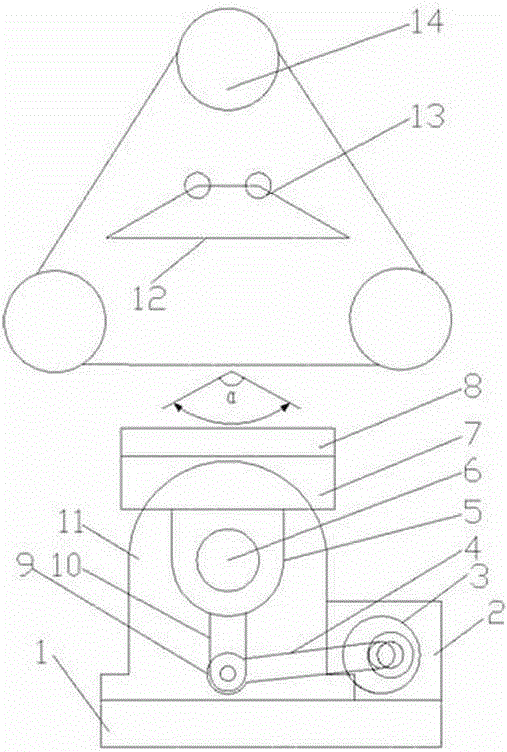

The invention discloses a multi-wire saw for cutting high-hardness materials. The multi-wire saw comprises a workbench capable of oscillating under driving of an oscillating component. A stock plate is placed on the workbench. A multi-wire cutting mechanism is arranged above the workbench and comprises three sheaves in triangular arrangement and wound with cutting wires. The oscillating component comprises a lifter and further comprises a rocker arm; the lifter is provided with provided with a pair of bearing blocks and two ends of a center shaft are mounted in the bearing blocks rotationally; the part, between the two bearing blocks, of the center shaft, is fixedly sleeved with a bearing bush, and the top end of the bearing bush is fixed with the bottom of the workbench; an oscillating rod is fixedly mounted at the bottom of the bearing bush and particularly mounted on an oscillating shaft, two ends of the oscillating shaft are rotationally mounted on a rocker arm support, and the rocker arm support is fixedly mounted on the lifter; one end of the rocker arm is connected to the oscillating shaft while the other end of the rocker arm is mounted on an eccentric shaft, and the eccentric shaft is driven by a motor which is fixedly mounted on the lifter.

Owner:SUZHOU QIMENG CRYSTAL MATERIAL PROD

Dual cycle cooling system for engineering vehicle

PendingCN107882624ASmall structure sizeImprove cooling efficiencyLiquid coolingInternal combustion piston enginesCirculator pumpIntercooler

The invention belongs to the technical field of cooling of vehicles and relates to a dual cycle cooling system for an engineering vehicle. The problems that in the prior art, the heat dissipation efficiency is low, the structure size is large, and cooling energy consumption is large are solved. The dual cycle cooling system is composed of a high-temperature cycle cooling system and a low-temperature cycle cooling system. The high-temperature cycle cooling system is composed of an engine, an engine water pump, a liquid-liquid radiator a and a high-temperature radiator. High-temperature cycle cooling liquid sequentially flows through an inner cooling cavity of the engine and the liquid-liquid radiator a. The low-temperature cycle cooling system is composed of a low-temperature radiator, a low-temperature cycle pump, a water cooling intercooler and a liquid-liquid radiator c. After low-temperature cycle cooling liquid passes through the low-temperature radiator, the low-temperature cyclecooling liquid sequentially flows through the water cooling intercooler and the liquid-liquid radiator c. Cooling air firstly flows through the low-temperature radiator and then flows through the high-temperature radiator, and heat exchange between heat of the systems of the vehicle and air is achieved. By means of the dual cycle cooling system for the engineering vehicle, the structural size of the radiators is reduced, the cooling efficiency of the cooling air is improved, and energy consumption of the vehicle cooling system is reduced.

Owner:JILIN UNIV +2

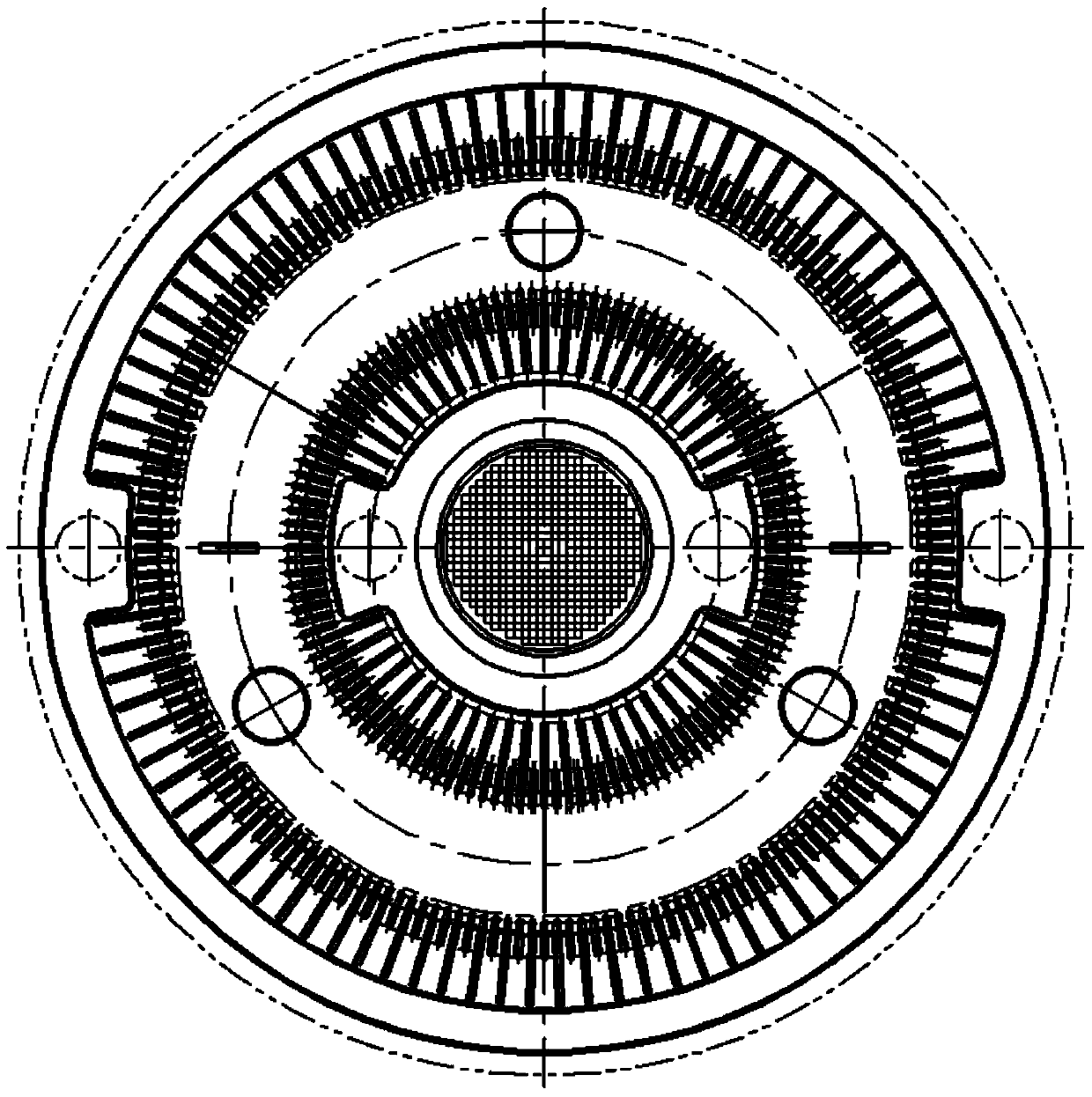

Vitrified super-abrasive-grain grindstone

ActiveUS20140349557A1Increase durabilityGood dispersionRevolution surface grinding machinesBonded abrasive wheelsWear particleGrindstone

A vitrified superabrasive grain grinding stone includes superabrasive grains including a CBN abrasive grain as a main abrasive grain and a diamond abrasive grain as an auxiliary abrasive grain bonded together by use of a vitrified bond. The auxiliary abrasive grain has an average grain diameter equal to ½ to 1 / 10 of that of the main abrasive grain, and the auxiliary abrasive grain has a toughness value of 0.4 to 1 when that of the main abrasive grain is given as 1.

Owner:NORITAKE CO LTD

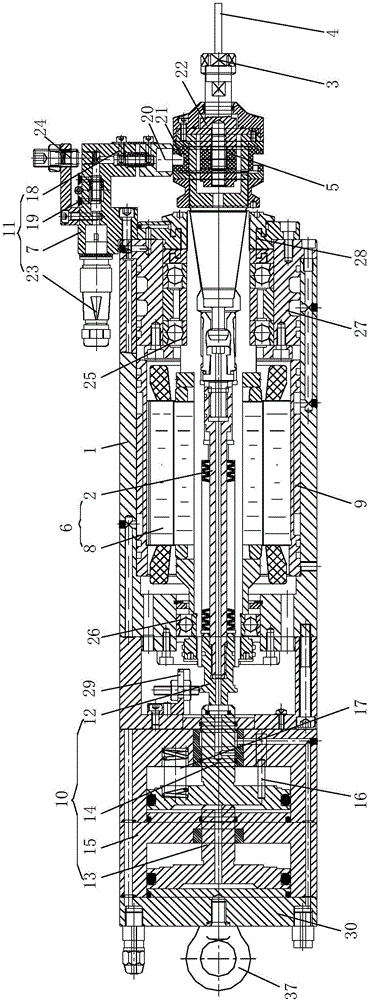

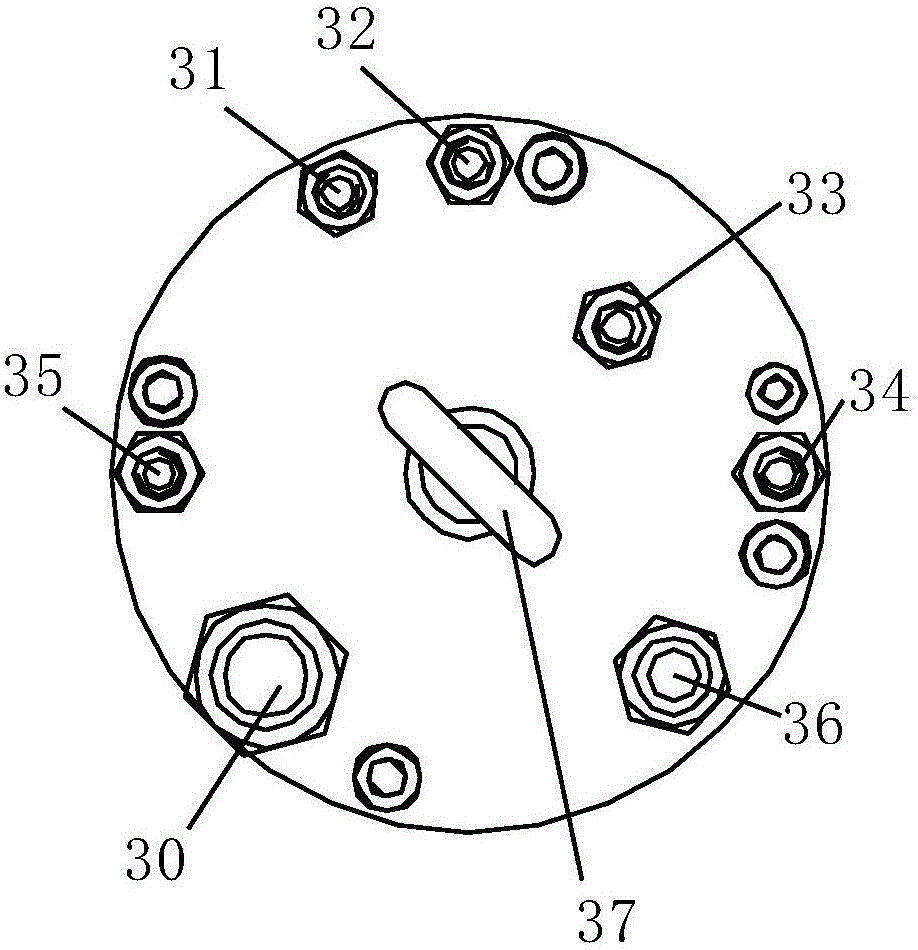

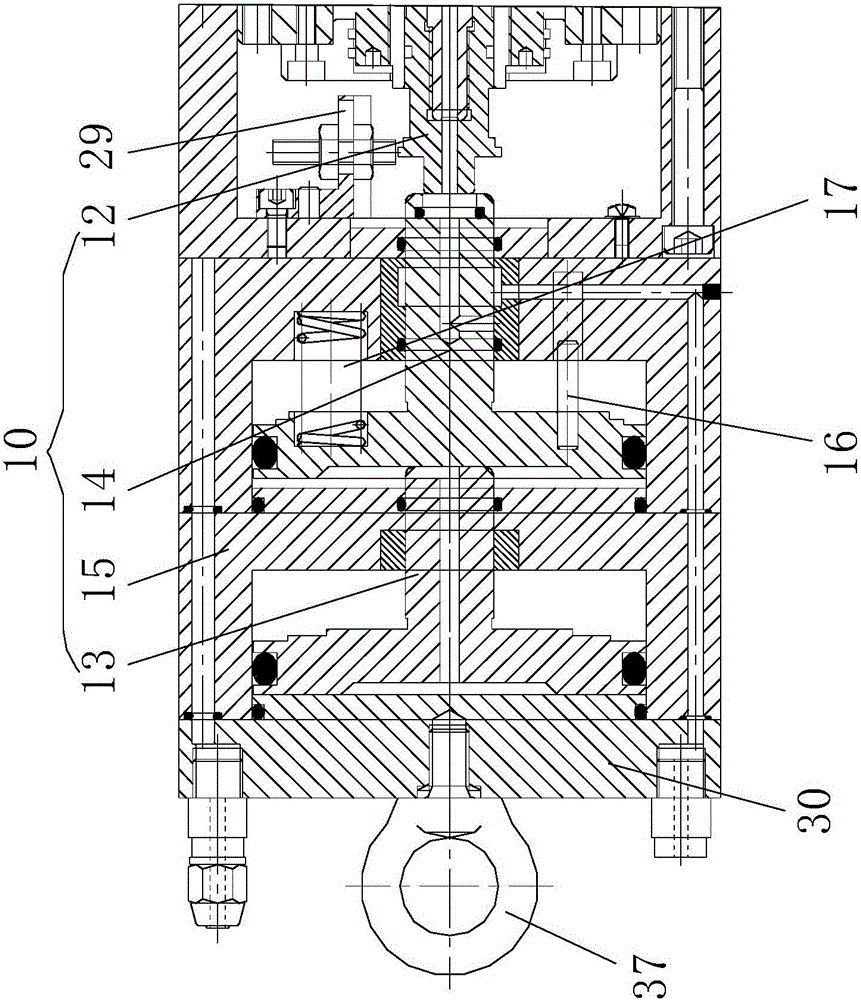

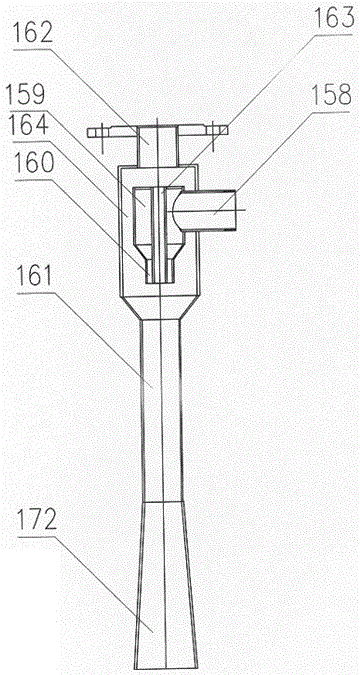

High-speed ultrasonic automatic tool changing motorized spindle

ActiveCN105921771AQuick tool changeEasy to processLarge fixed membersMetal working apparatusDrive motorEngineering

The invention relates to a high-speed ultrasonic automatic tool changing motorized spindle. The high-speed ultrasonic automatic tool changing motorized spindle is provided with an ultrasonic spindle body. The ultrasonic spindle body comprises a machine shell, a rotor shaft coaxially arranged with the machine shell, and a machining tool fixed to one end of the rotor shaft and connected with the end of the rotor shaft through nuts and an elastic contracting chuck. An ultrasonic tool handle is arranged at the front end of the rotor shaft. The rear end of the rotor shaft extends into the rear end of the machine shell. A built-in type assembly chamber is arranged in the ultrasonic tool handle. A built-in energy converter is detachably mounted in the built-in type assembly chamber. An ultrasonic generator is mounted on the upper portion of the ultrasonic tool handle and comprises an L-shaped combined support, a planar adjusting support and a vertical adjusting support, and the planar adjusting support and the vertical adjusting support are mounted on the combined support. The planar adjusting support passes through a fixed ring and then is coupled with a movable ring on the ultrasonic tool handle. A gap is formed between the fixed ring and the movable ring. A driving motor is directly connected with the ultrasonic spindle body and the ultrasonic tool handle, and the spindle has the characteristics that the ultrasonic spindle body and the ultrasonic tool handle are mutually independent, and application is convenient.

Owner:江苏翰琪电机股份有限公司

High temperature resistant insulation composite insulator

InactiveCN105001563AImprove corrosion resistanceGood oil resistanceRubber insulatorsSuspension/strain insulatorsRubber materialComposite insulators

The invention discloses a high temperature resistant insulation composite insulator which comprises an insulation core rod, an umbrella skirt and a metal fitting. The umbrella skirt coats the insulation core rod. The metal fitting coats two ends of the insulation core rod and is connected to two ends of the umbrella skirt. The umbrella skirt is made from a rubber material. The high temperature resistant insulation composite insulator is resistant to high temperature, has good electrical insulation property, high mechanical strength, corrosion resistance and radiation resistance, is simple and convenient to operate and has short processing time.

Owner:ANHUI CHUANGYU ELECTRIC POWER EQUIP CO LTD

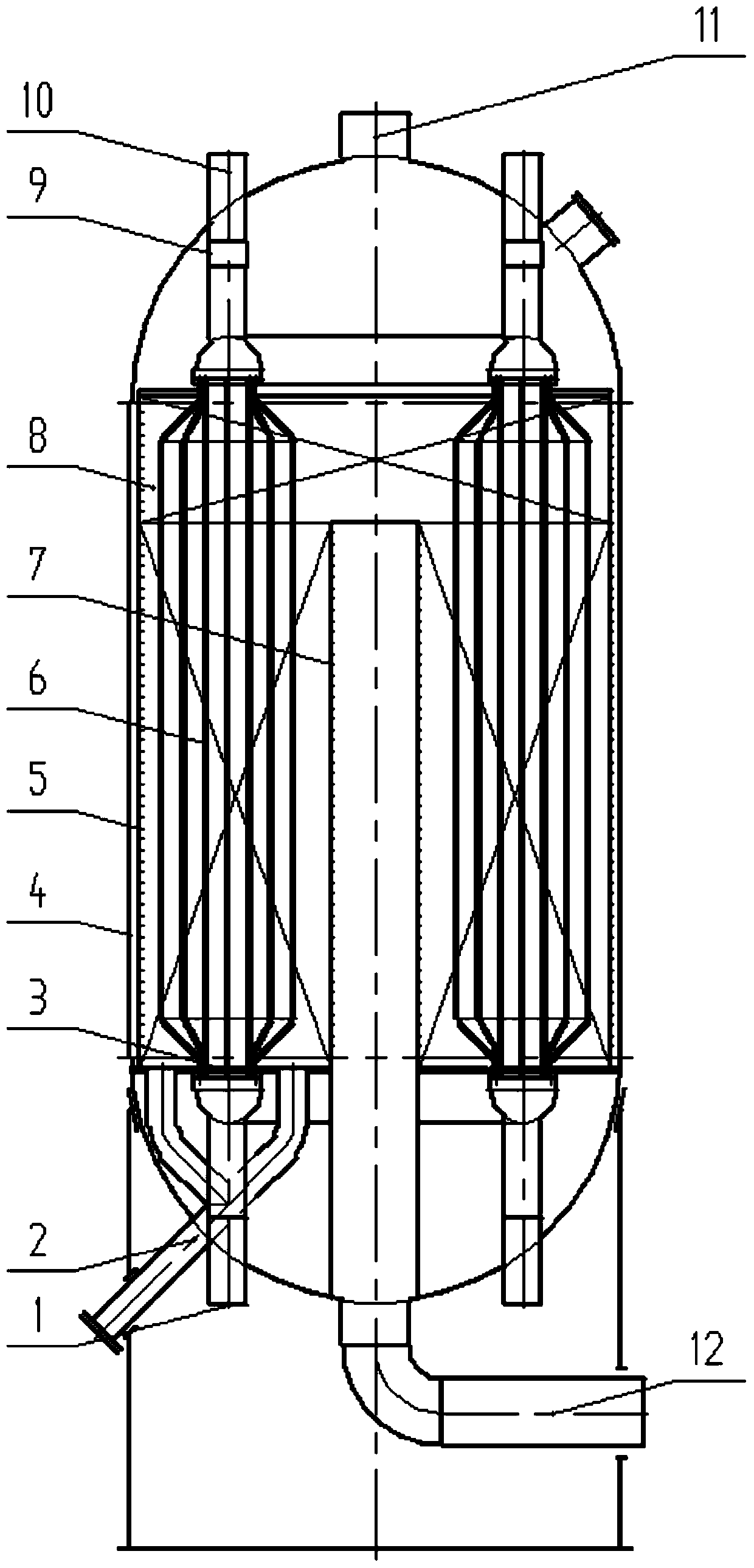

Sewage recycling harmless treatment integrated equipment

ActiveCN104370365AAchieve recyclingEliminate pollutionBiological treatment apparatusSustainable biological treatmentWater dischargeBiological activated carbon

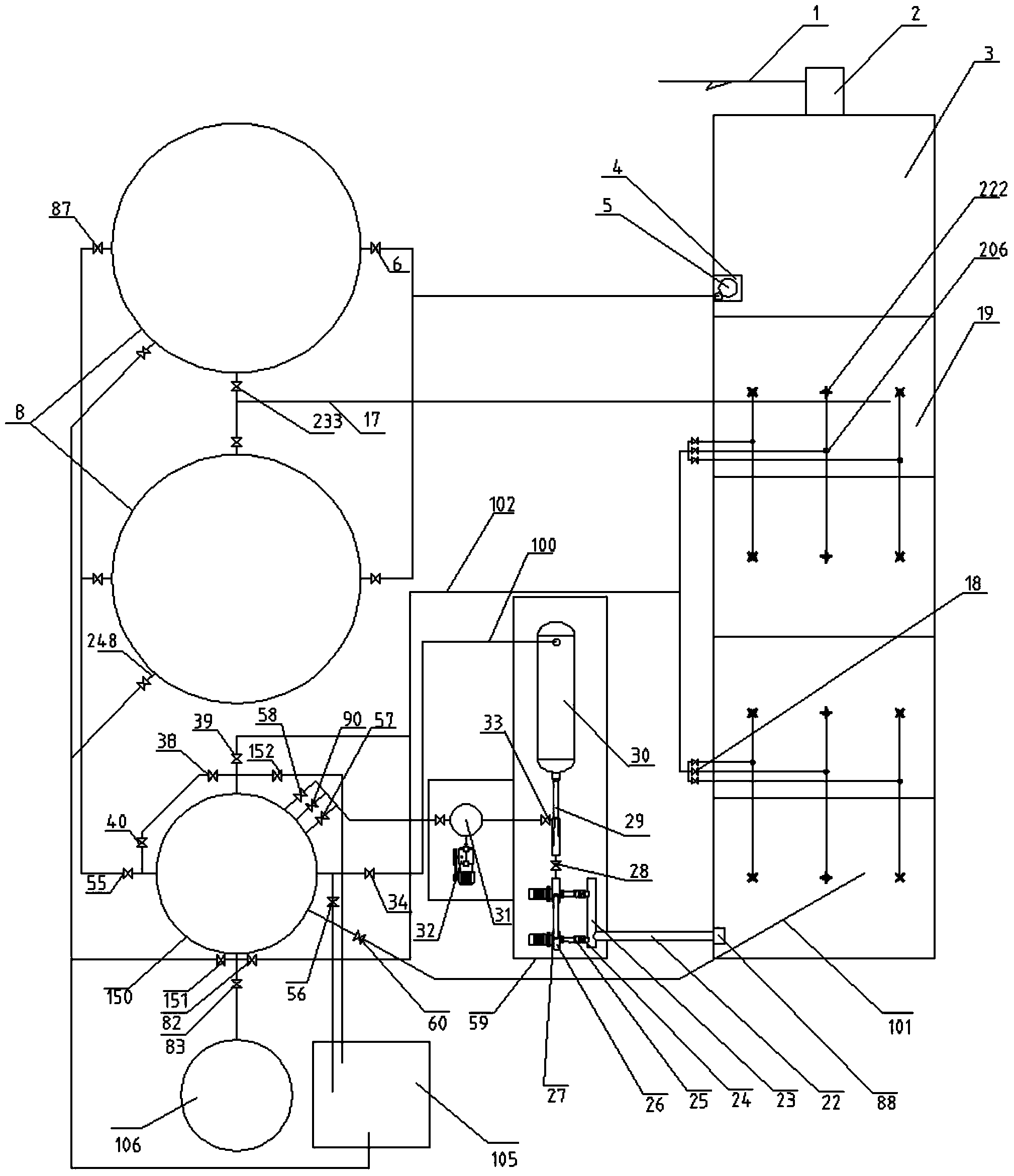

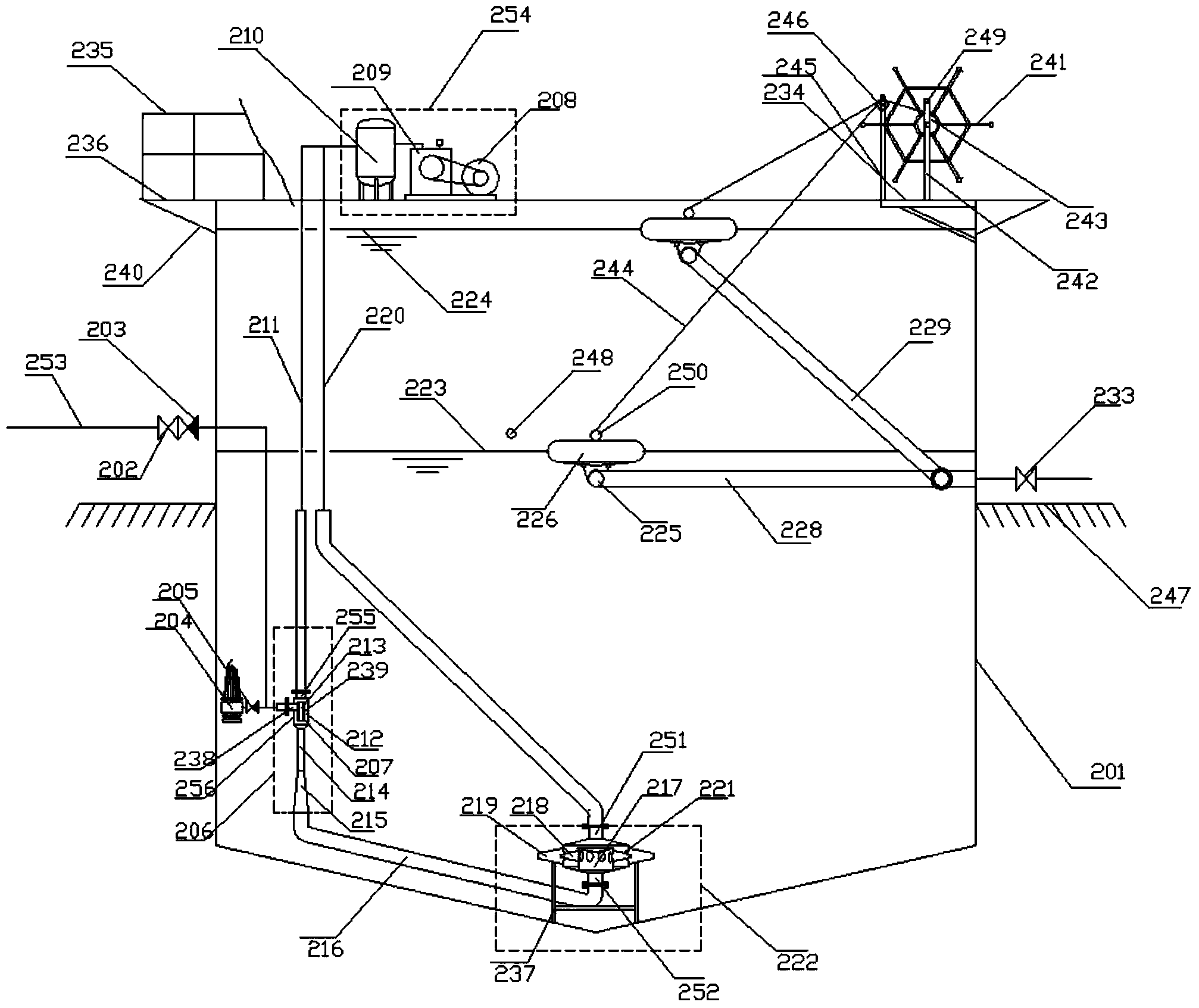

The invention relates to sewage recycling harmless treatment integrated equipment. A sewage biochemical treatment tower, a biological sand filter box and a biological activated carbon expanded bed are packaged into one pressure-bearing container and are separated into three sewage biochemical treatment units which can independently operate by virtue of conical and cylindrical separating plates, the three sewage biochemical treatment units are connected with a jet flow driving sequencing batch type biochemical reactor by virtue of a pipeline and a submersible sewage pump, the jet flow driving sequencing batch type biochemical reactor is connected with a biological contact filter chamber by virtue of a water decanter, the biological contact filter chamber is connected with the sewage biochemical treatment tower by virtue of a water pump and a jet flow gas mixing device, the sewage biochemical treatment tower is connected with the biological sand filter box by virtue of a water outlet valve of the sewage biochemical treatment tower, and the biological sand filter box is connected with the biological activated carbon expanded bed by virtue of a sand filter box water collecting pipe, a sand filter box water discharging pipe and a sand filter box water outlet valve. The sewage recycling harmless treatment integrated equipment has the advantages that sewage treatment recycling and harmless sewage treatment can be implemented, recycling of water source is realized, pollution of sewage to the environment is eliminated, and the water source is saved.

Owner:朱宇晴

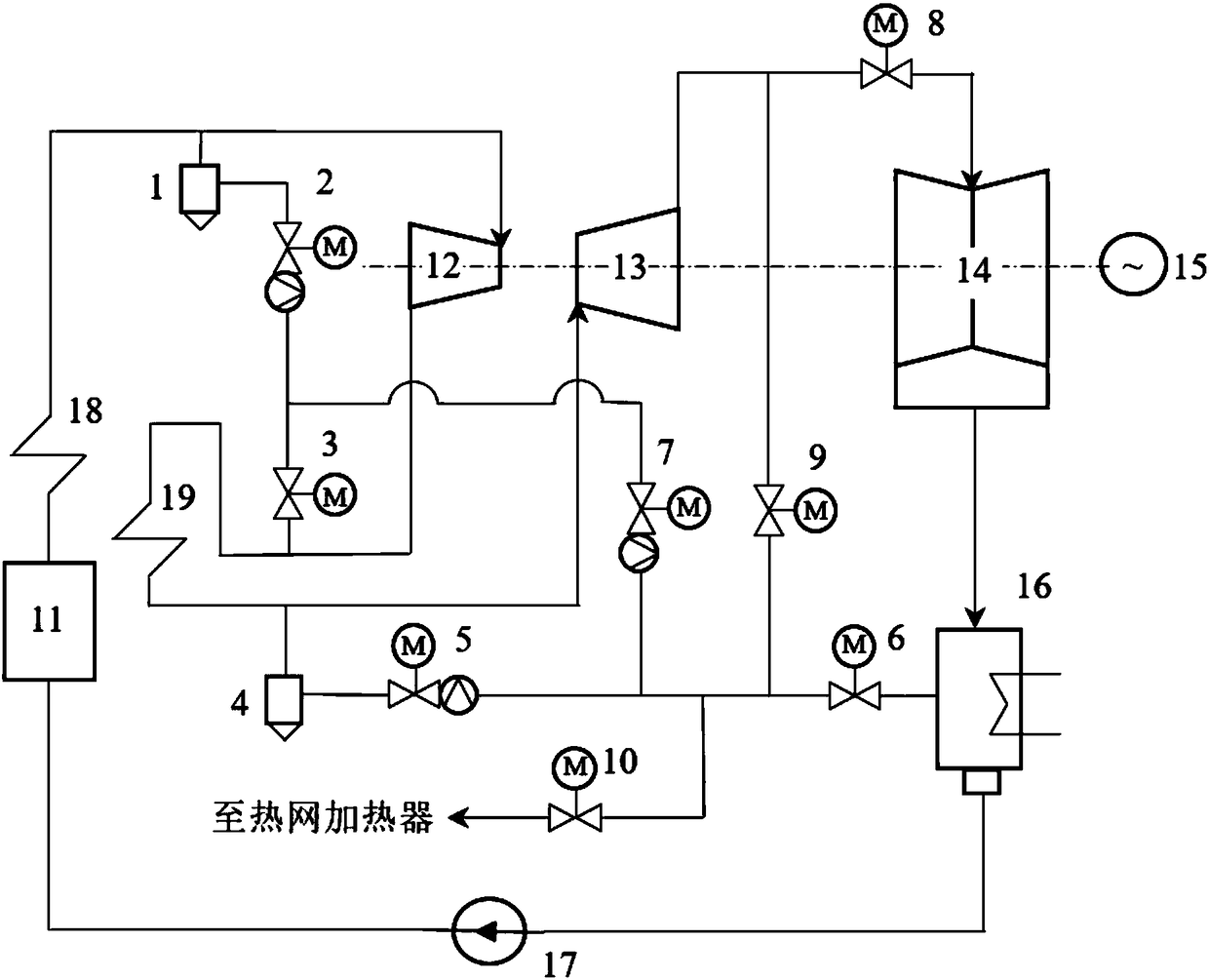

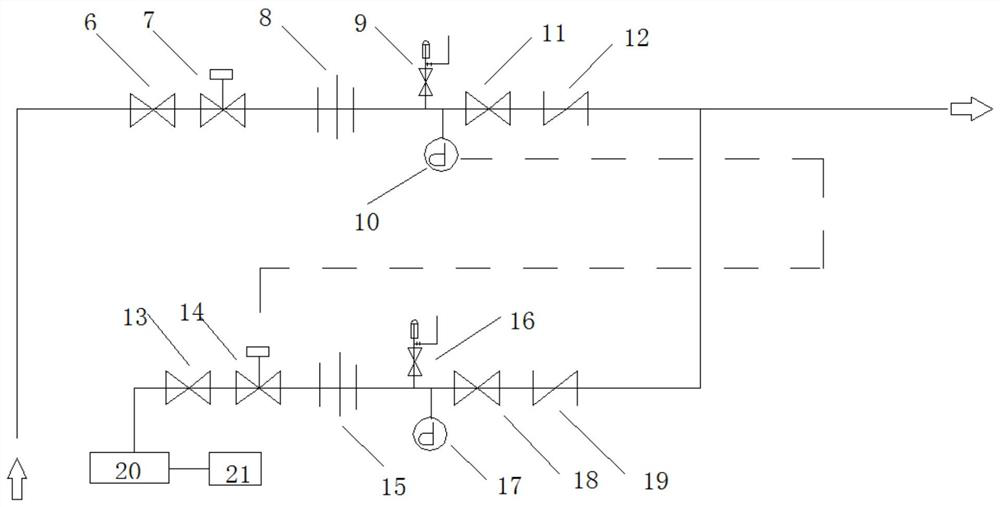

Generator set three-stage parallel serial connection bypass system and adjusting method thereof

PendingCN108301882AIncrease flexibilityIncreaseLighting and heating apparatusEngine componentsIsolation valveThree stage

The invention discloses a generator set three-stage parallel serial connection bypass system and an adjusting method thereof. The system comprises a high-pressure bypass system, a low-pressure bypasssystem and a low-low-pressure bypass system; the high-pressure bypass system comprises a high-pressure bypass filter, a high-pressure bypass valve and a high-pressure bypass isolation valve, the low-pressure bypass system comprises a low-pressure bypass filter, a low-pressure bypass valve and a low-pressure bypass isolation valve which are sequentially connected between a reheating steam heat segment pipeline and a condener, the low-low-pressure bypass system comprises a low-pressure cylinder isolation valve and a medium-pressure exhaust low-pressure bypass communication valve, the low-pressure cylinder isolation valve is arranged on an air guide pipe between a medium pressure cylinder and a low-pressure cylinder, an inlet pipeline of the medium-pressure exhaust low-pressure bypass communication valve is arranged on a medium-pressure cylinder exhaust pipeline, an outlet pipeline is arranged on a pipeline between the low-pressure bypass valve and the low-pressure bypass isolation valve,the high-pressure bypass system and the low-pressure bypass system are connected through a high and low pressure bypass communication valve, and a pipeline between the low-pressure bypass valve and the isolation valve is connected with a heat net heater through a low-pressure bypass heat supply adjusting valve.

Owner:XIAN THERMAL POWER RES INST CO LTD

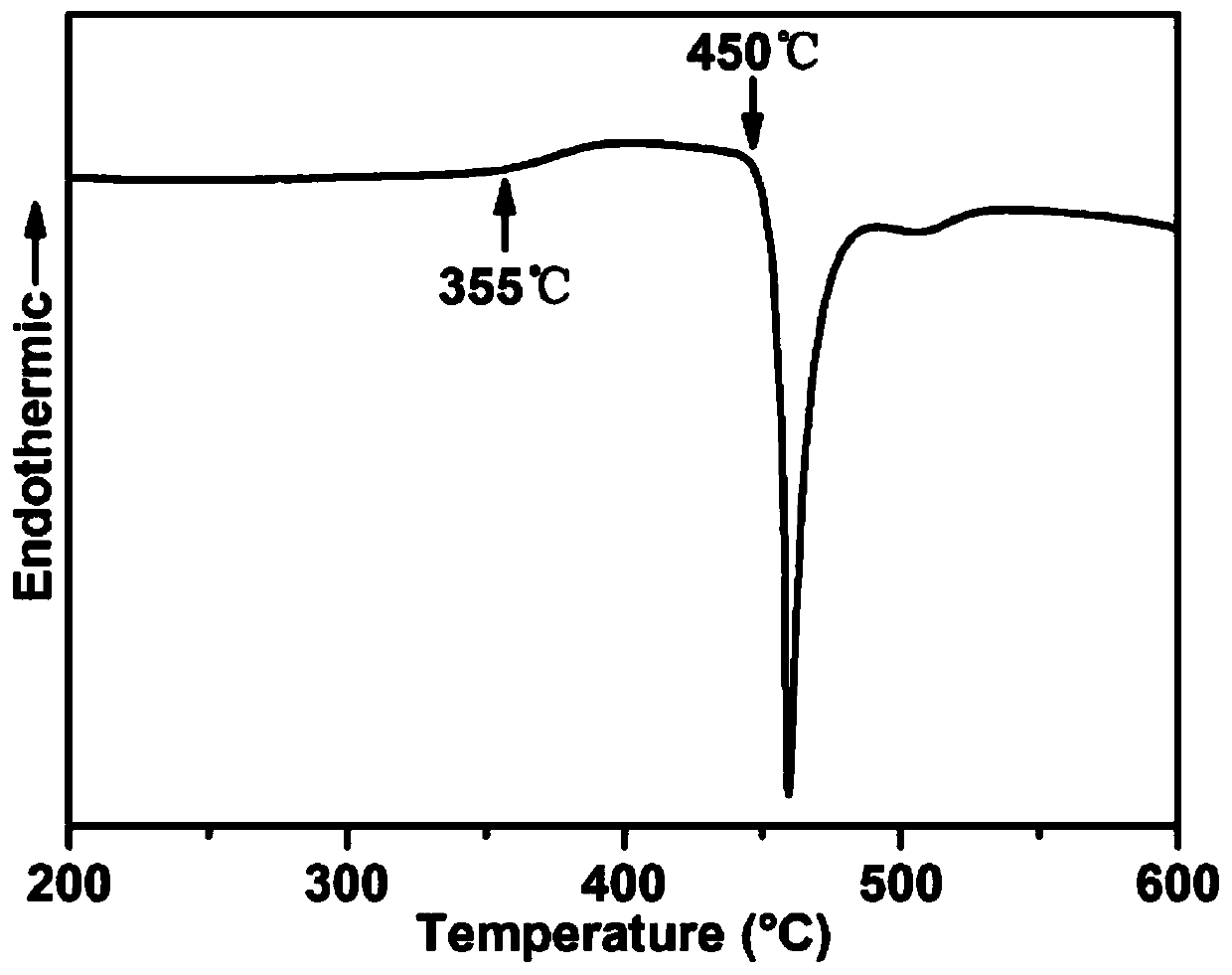

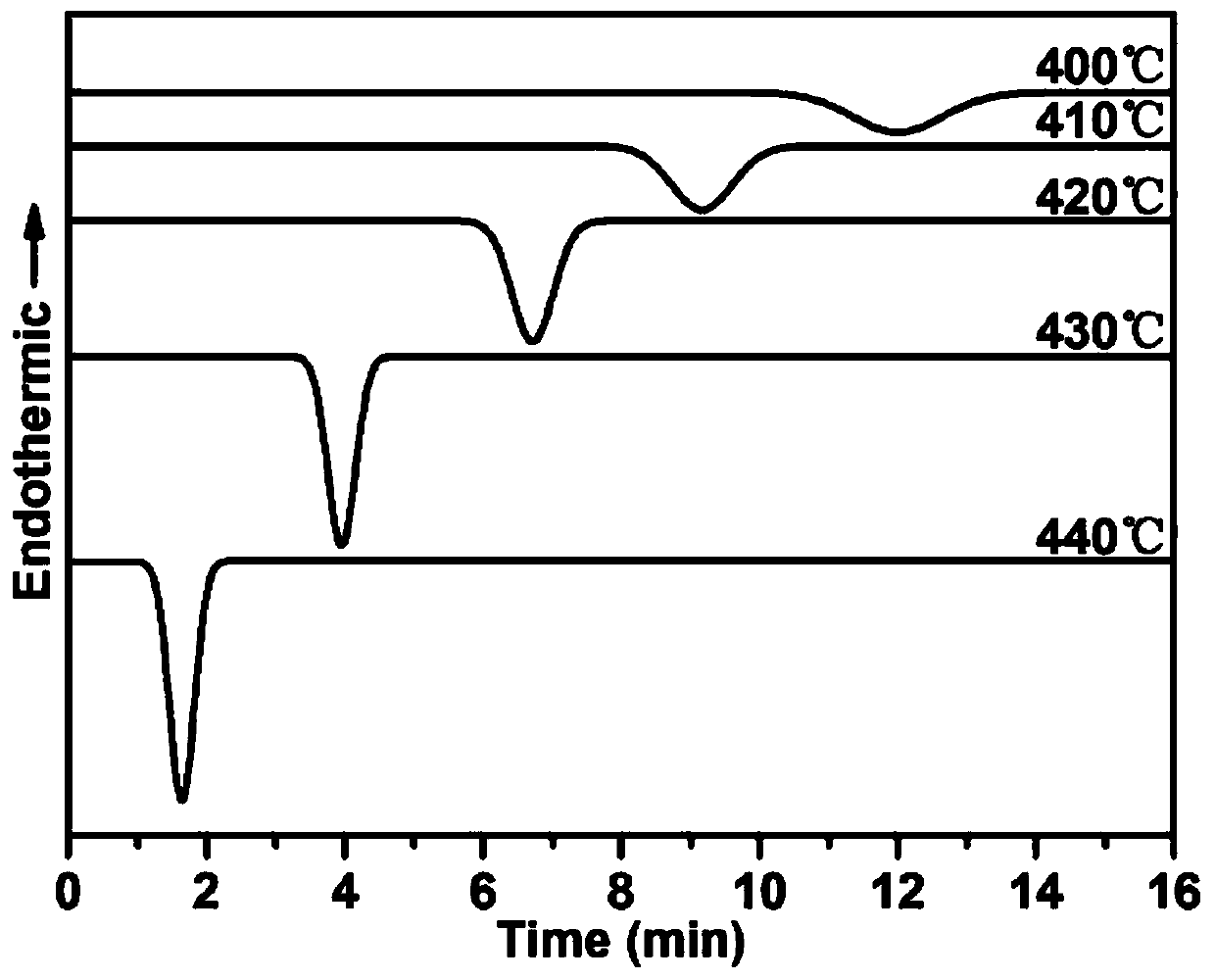

Processing method of amorphous alloy member

The invention discloses a processing method of an amorphous alloy member, and belongs to the technical field of amorphous alloy processing. The processing method comprises the following steps that theglass-transition temperature and the crystallization initial temperature of amorphous alloy under continuous heating conditions are measured; the crystallization starting time of the amorphous alloyunder the isothermal condition is measured; and the amorphous alloy is subjected to friction heat generation processing - rapid cooling, and amorphous alloy products are obtained. According to the processing method of the amorphous alloy member, the characteristic that the viscous resistance of the amorphous alloy is reduced in an overcooling liquid phase region is utilized to process the amorphous alloy, the problems that the amorphous alloy is difficult to machine at room temperature, long in processing period, high in cost and the like are solved, and feasibility is provided for the processing and application of the amorphous alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

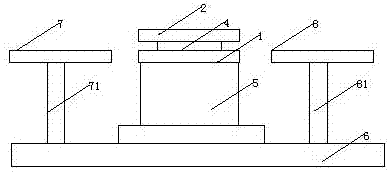

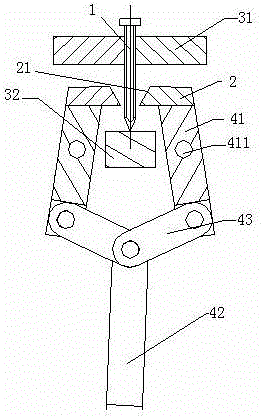

Tapping clamp used for nut machining

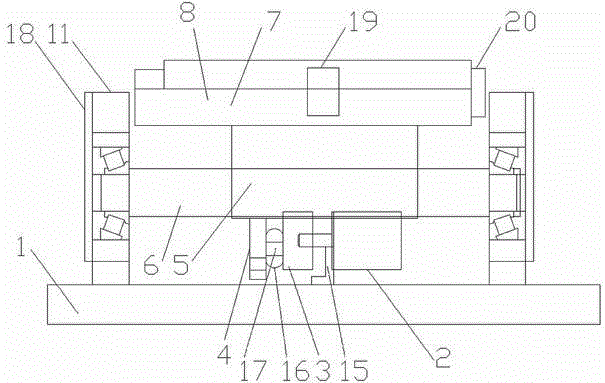

ActiveCN107414210AQuality improvementImprove qualityThread cutting machinesReciprocating motionEngineering

The invention belongs to the technical field of machining, and provides a tapping clamp used for nut machining. The tapping clamp used for nut machining comprises a supporting platform, a clamp structure and a mechanical arm, wherein the clamp structure is located above the supporting platform, a sliding structure is arranged between the clamp structure and the supporting platform, the clamp structure is guided by the sliding structure to do straight reciprocating motion, and the sliding structure is fixedly connected with the supporting platform. By means of the tapping clamp, nuts to be machined can be automatically replaced in the tapping work, the machining time is shortened, the amount of labor is reduced, the working efficiency is improved, and the quality of the nuts to be machined is improved.

Owner:安徽昕悦铸造科技有限公司

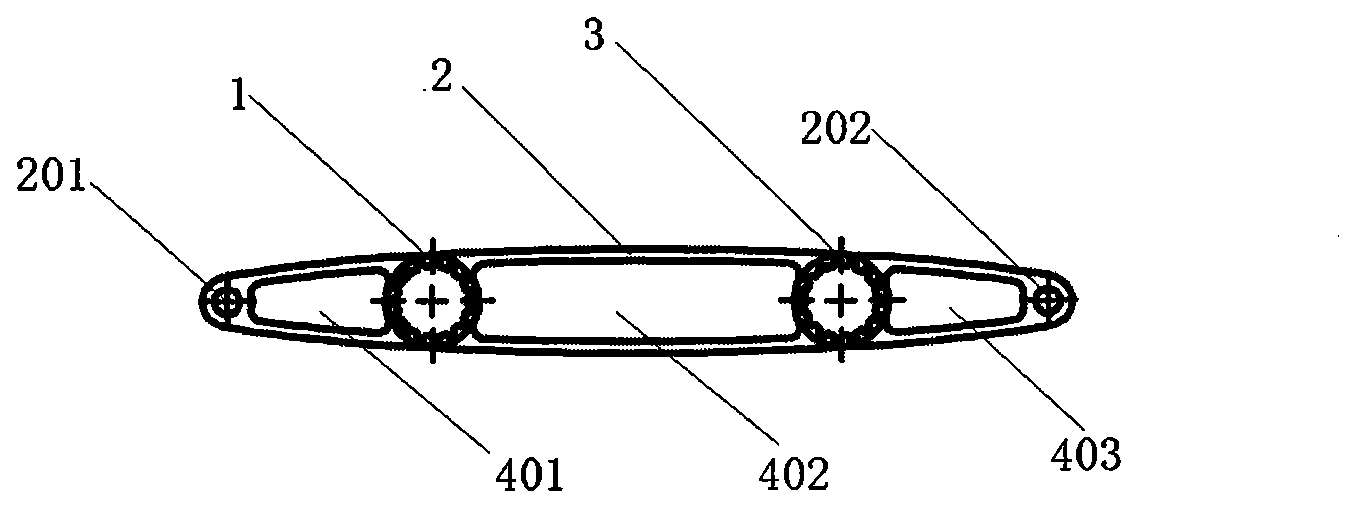

Flue gas waste heat recovery element and device capable of breaking through low temperature dew point

InactiveCN103245227AFully contactedImprove heat transfer efficiencyStationary tubular conduit assembliesCoatingsTemperature resistanceMaterials science

The invention relates to a flue gas waste heat recovery element and device capable of breaking through the low temperature dew point. The flue gas waste heat recovery element and device is characterized in that a heat exchange element is formed by an aluminum flat-oval-tube-shaped fin and aluminum fluid tubes; corrosion resistant, abrasion resistant and high temperature resistant ceramic glaze materials are composited on the surface of the heat exchange element; and an unsaturated contraction high polymer heat-shrink tube is wrapped on the outer surfaces of the ceramic glaze materials. The heat exchange element is fixed through an enameled steel plate to form a single module, a plurality of the single modules are combined in parallel connection mode to form a heat exchanger assembly, and all the fluid tubes of the heat exchange element are welded in series connection mode through bends. Liquid cold fluid is filled into the fluid tubes of the heat exchange element, three air cold fluid channels are arranged between the flat-oval-tube-shaped fin and the aluminum fluid tubes, and air hot fluid flows through the outer side of the flat-oval-tube-shaped fin. The flue gas waste heat recovery element and device has the advantages that a heat exchange tube is formed in once extruding mode, the fin is sufficiently contacted with the fluid tubes, accordingly heat exchange efficiency is improved and a large amount of labor work is reduced; the inner walls of the fluid tubes are designed to be tooth-shaped, the internal surface heat exchange areas of the fluid tubes are increased, and the heat exchange efficiency is led to be high; the heat exchange channels are additionally arranged so that use functions of a heat exchanger are increased; the surface is subjected to enameling processing and high polymer heat-shrink tube processing so that corrosion resistance, abrasion resistance and high temperature resistance are greatly improved; and the self-cleaning purpose is achieved, and normal and efficient heat exchange is ensured.

Owner:HANGZHOU YUANYUAN ENVIRONMENT TECH

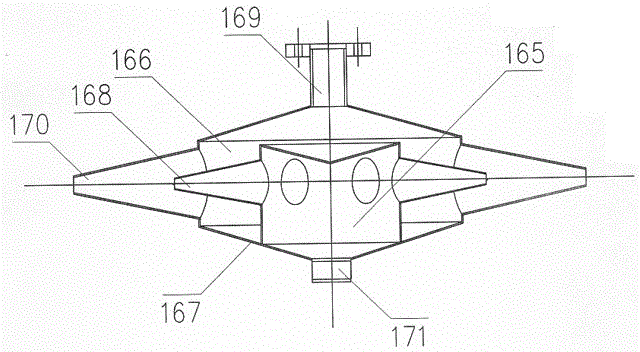

Cuboid sodium-sodium-air integrated heat exchanger

ActiveCN109727687AReduce the impactEasy to installNuclear energy generationCooling arrangementHeat transfer efficiencyEngineering

Owner:中核龙原科技有限公司 +1

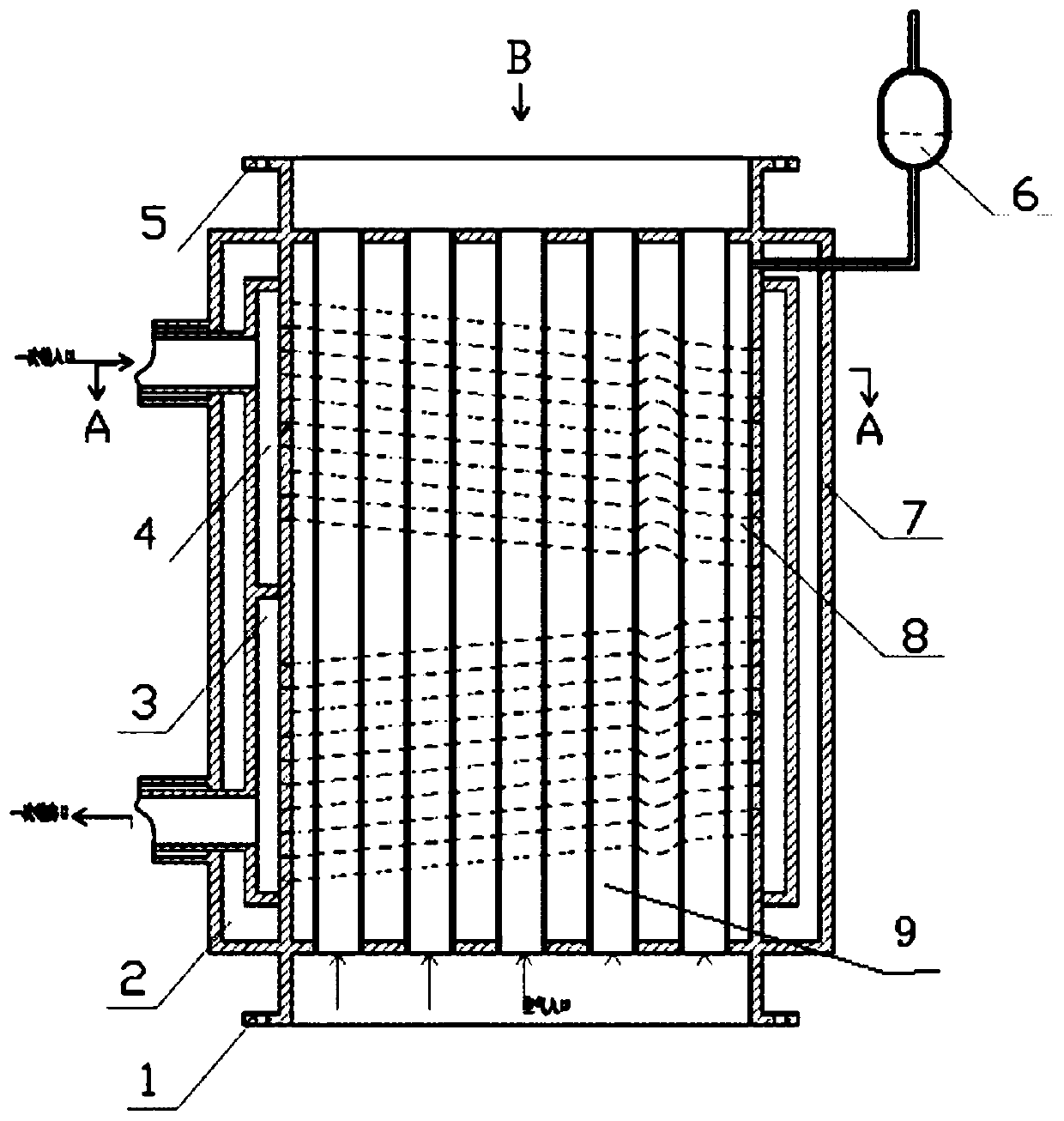

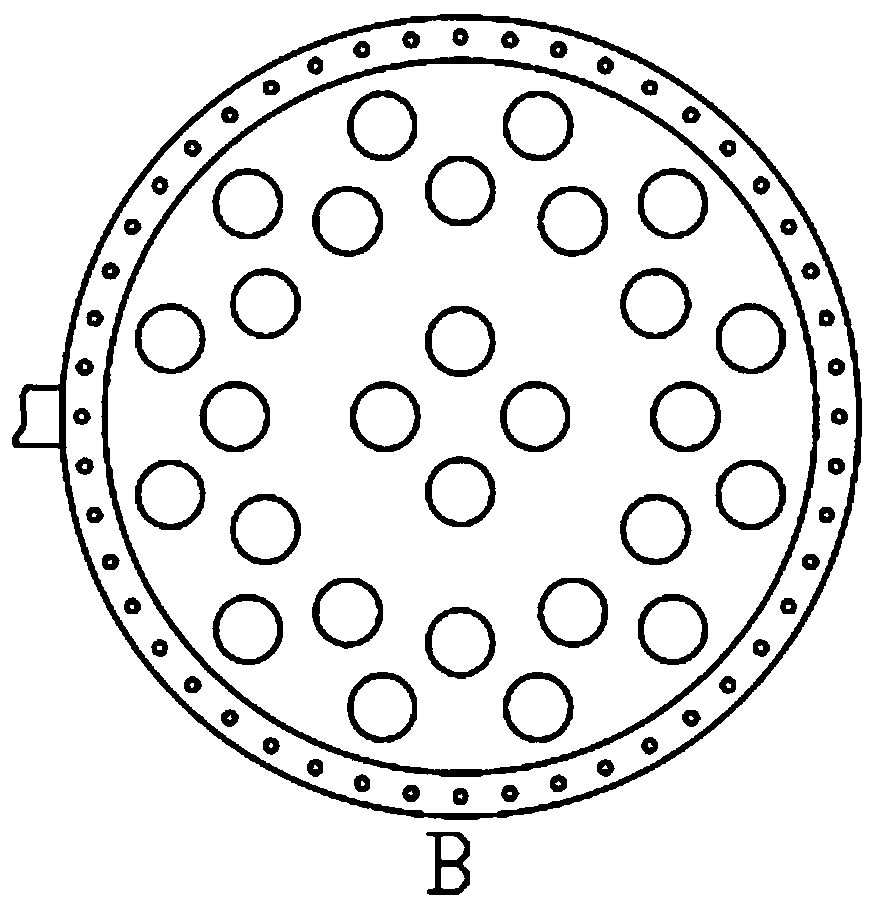

Cylindrical sodium-sodium-air integrated heat exchanger

ActiveCN109817355AEasy to installReduced radiation resistanceNuclear energy generationCooling arrangementHeat transfer efficiencyEngineering

The invention relates to the technical field of reactor accident after heat removal, and particularly discloses a cylindrical sodium-sodium-air integrated heat exchanger. According to the cylindricalsodium-sodium-air integrated heat exchanger, two layers of tube plates are arranged on the upper end surface and the lower end surface of a cylinder body in the heat exchanger, a plurality of sodium-air heat transfer tubes which are vertically distributed are arranged between the two layers of tube plates, so that a closed secondary side space is defined by the two layers of tube plates, the outerside walls of the sodium-air heat transfer tubes and the inner side wall of the cylinder body, a plurality of sodium-sodium heat transfer tubes are vertically arranged in the secondary side space, the side wall of the upper end of the cylinder body is provided with a primary sodium inlet, the primary sodium inlet is connected to the upper ends of the sodium-sodium heat transfer tubes, the side wall of the lower end of the cylinder body is provided with a secondary sodium outlet, the secondary sodium outlet is connected to the lower ends of the sodium-sodium heat transfer tubes, and the portion, outside the sodium-sodium heat transfer tubes, of the secondary side space is filled with sodium to form secondary side sodium. The heat exchanger is reduced to be a sodium-sodium-air heat exchanger, meanwhile, due to the fact that the heat exchanger is away from a reactor container with high neutron radiation, the requirements for the radiation resistance to equipment, manufacturing and installation are obviously lowered, and the heat transfer efficiency is improved.

Owner:中核龙原科技有限公司 +1

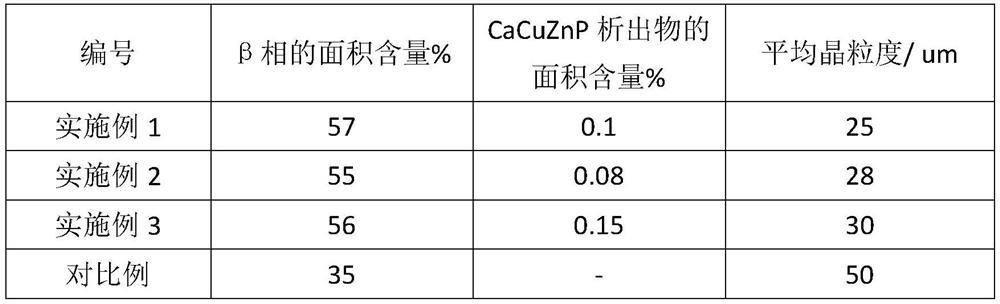

Brass bar and preparation method thereof

ActiveCN113584342AIncreased second phase contentHigh strengthProcess efficiency improvementHardnessUltimate tensile strength

The invention discloses a brass bar. The brass bar is characterized in that the brass is prepared from the following components including, by weight, 57% to 59% of Cu, 0.2% to 0.8% of Pb, 1.5% to 3.0% of Mn, 1.3% to 2.3% of Al, 0.2% to 0.8% of Si, 0.5% to 0.8% of P, 0.4% to 0.6% of Ca, 0.4% to 1.0% of Ni, 0.01% to 0.03% of B and the balance Zn and inevitable impurities. According to the brass bar, P, Ca, B and Ni are added on the basis of CW713R, the content of a second phase in a matrix is increased, so that the matrix structure is continuously cut off, when a cutter is used for machining, the contact with the matrix can be reduced, the machining resistance is reduced, the machinability is optimized, and the strength and hardness of the matrix are improved due to the existence of the second phase, so that the overall strength of the material is improved.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Sewage recycling and regenerating combined equipment

InactiveCN106830555AImprove recycling efficiencyReduce resistanceMultistage water/sewage treatmentBiological activated carbonSludge

The invention discloses sewage recycling and regenerating combined equipment which comprises a biochemical reactor, a cylindrical base, a platy base, a crypt machine room, an outer crypt machine room, an annular tank wall, a biological sand filter box, a semicircular partition, a biological activated carbon expanded bed, a water collection tank, SBRs, BAFs and a sludge concentration tank. Biochemical reaction, biological sand filtration and biological activated carbon biochemical degrading processes can be integrated in a combined pressure bearing tower, the combined pressure bearing tower can be assembled with the water collection tank, a jet-driven sequence batch biochemical reactor, a jet oxygenation biological contact filter and the sludge concentration tank to form the combined equipment, and the crypt machine room is arranged below the biochemical reactor, a biological sand filtration box and the biological activated carbon expanded bed. Flow pipelines and pipe fittings are reduced substantially, flow resistance is lowered, biochemical reaction efficiency is improved, land occupation area is compressed, construction cost is lowered, recycling and harmless sewage treatment is realized, recycling of water resources is promoted, and the water resources are saved.

Owner:海宁市双祥环保科技有限公司

A built-in tube bundle isothermal shift reactor

ActiveCN105457563BFrom burningExtend your lifeHydrogenChemical/physical processesPtru catalystMechanical engineering

The invention relates to a pipe-bundle-builtin isothermal-shift reactor. According to the pipe-bundle-builtin isothermal-shift reactor, axial annular pipe bundles, which are builtin and are uniformly distributed in a catalyst bed layer along circumferential direction, are adopted to shift out heat of reaction, so as to realize isothermal shift; and a central pipe bundle which is built in a central pipe is adopted to preheat raw material gas entering the reactor, so as to realize the builtin of a gas-gas heat exchanger. The isothermal-shift reactor comprises a pressure-bearing shell, a catalyst basket, the axial annular pipe bundles, the central pipe and the central pipe bundle; and the axial annular pipe bundles consist of upper and lower annular pipe boxes, upper and lower annular pipe sheets and heat exchange tubes. According to the pipe-bundle-builtin isothermal-shift reactor, due to builtin pipe bundles, the manufacturing cost of equipment is effectively reduced; due to an end-part bent structure for the heat exchange tubes, the size of the pipe sheets is effectively reduced; due to a heat insulating layer laid between the pipe sheets and the high-temperature catalyst bed layer, the contact between pipe end weld spots and a bed layer high-temperature area is effectively isolated, the probability of leakage is lowered, and the reliability of equipment is improved; and the pipe-bundle-builtin isothermal-shift reactor is compact in structure, low in manufacturing cost, relatively easy in maintenance, high in reliability, complete in function and high in applicability.

Owner:CHANGZHENG ENG

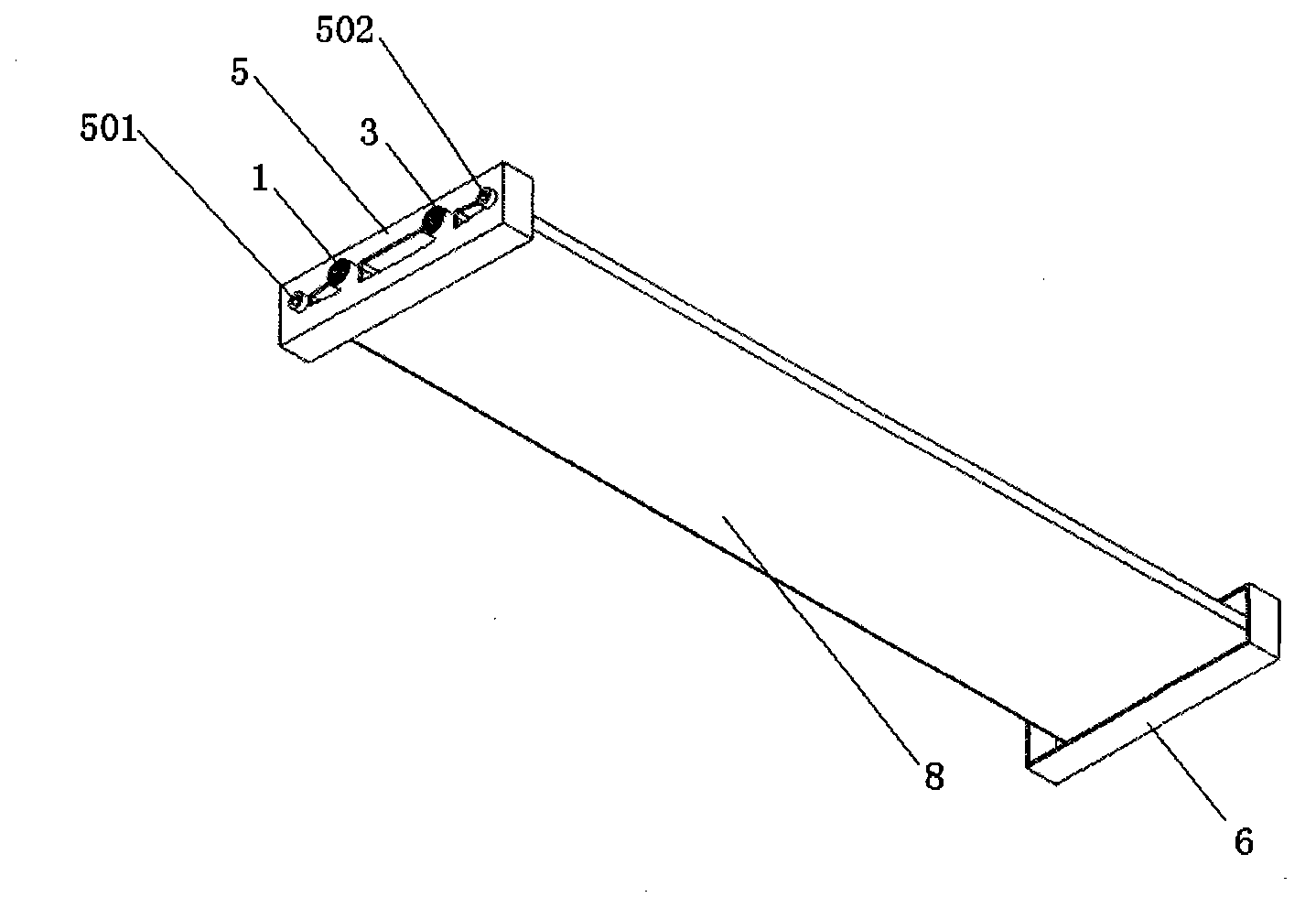

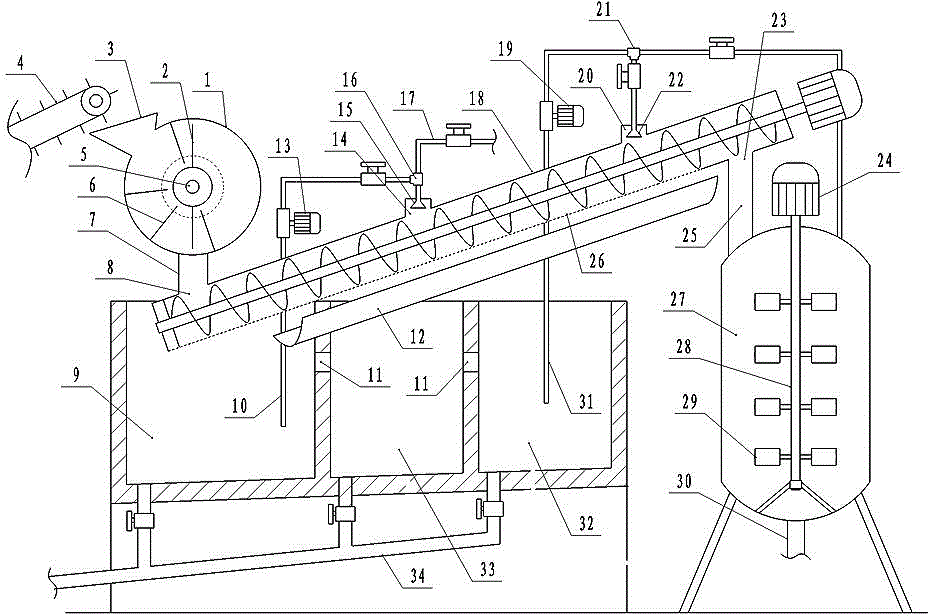

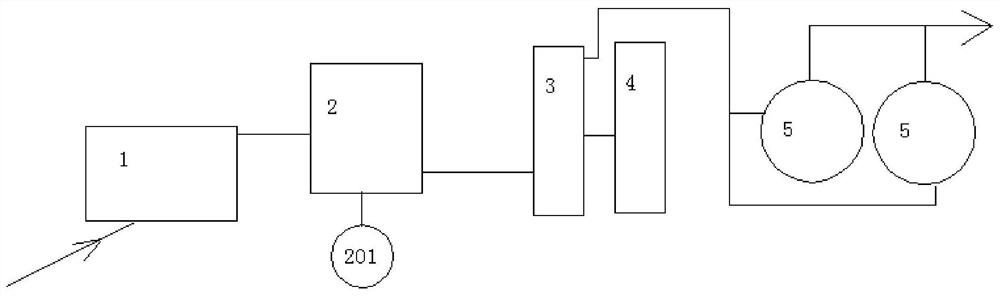

Chopping softening system for fresh fruit

ActiveCN104585841AReduce processing resistanceImprove cutting efficiencyJuice extractionThree levelWater resources

The invention relates to a chopping softening system for fresh fruit. The system comprises four parts, namely, a fresh fruit chopping device, a conveying device, a cleaning device and a pulp softening device, wherein a fixed cutter and a moveable cutter are mounted in a chopping cabin of the fresh fruit chopping device; the conveying device comprises a spiral conveying pipe; a filter hole is formed in a pipe wall on the lower side of the spiral conveying pipe; two water spraying holes are formed above the spiral conveying pipe; the cleaning device comprises three settling ponds; sprayers are arranged on water pumping pipes mounted on the settling ponds and are mounted in the water spraying holes; a stirring blade is mounted in a stirring cabin of the pulp softening device. The chopping cabin is adopted for chopping, so that the working efficiency is high and the working resistance is small; the conveying pipe is used for cleaning the residues, so that the difficulty in subsequent processing is reduced; the cleaning water is reused, so that the water resource is saved; the blade in the softening cabin is used for stirring and softening the raw materials, so that the basis for increasing the speed of the subsequent processing is established; the residues recycled in a three-level form through the settling ponds are respectively reutilized, so that the comprehensive utilization of the wastes is realized.

Owner:YUNNAN MAODUOLI GRP FOOD

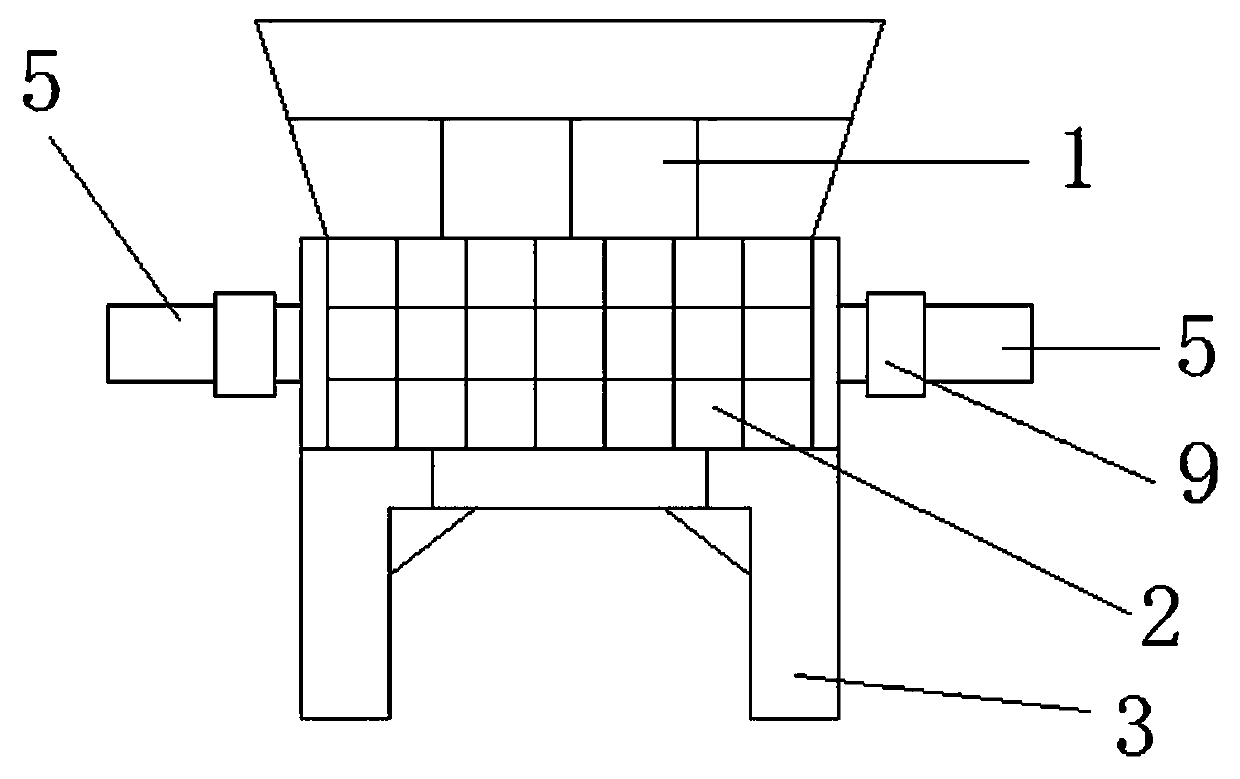

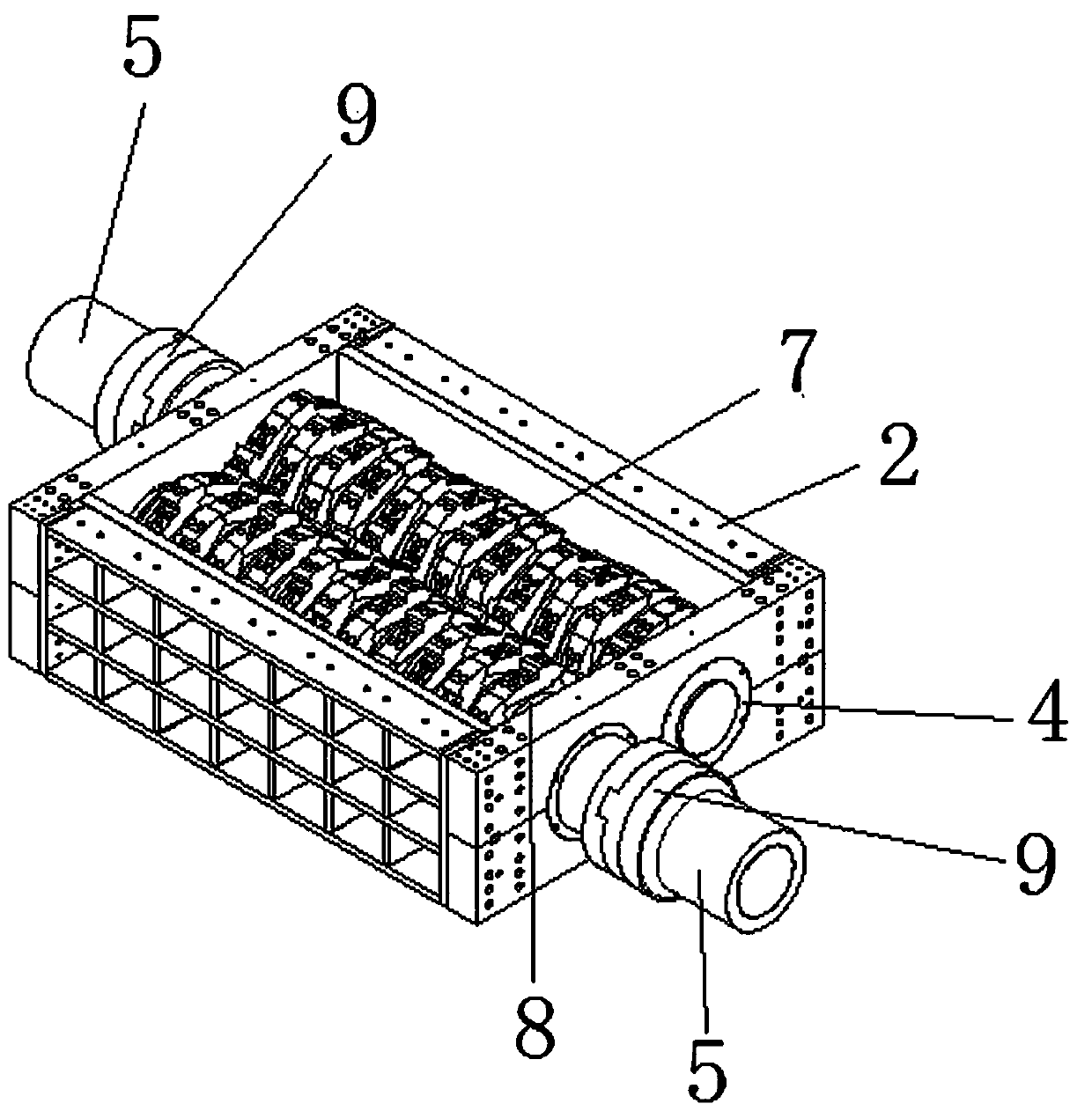

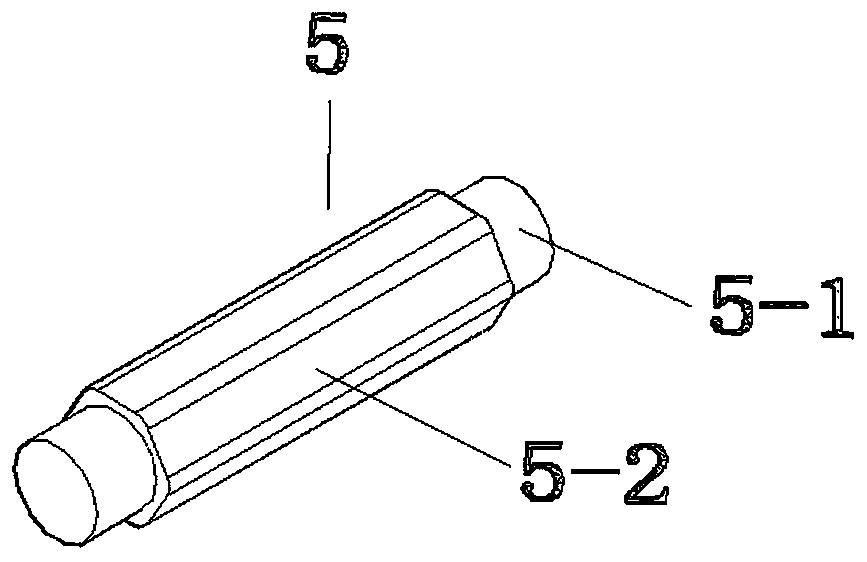

Waste automobile shell shredding recovery equipment

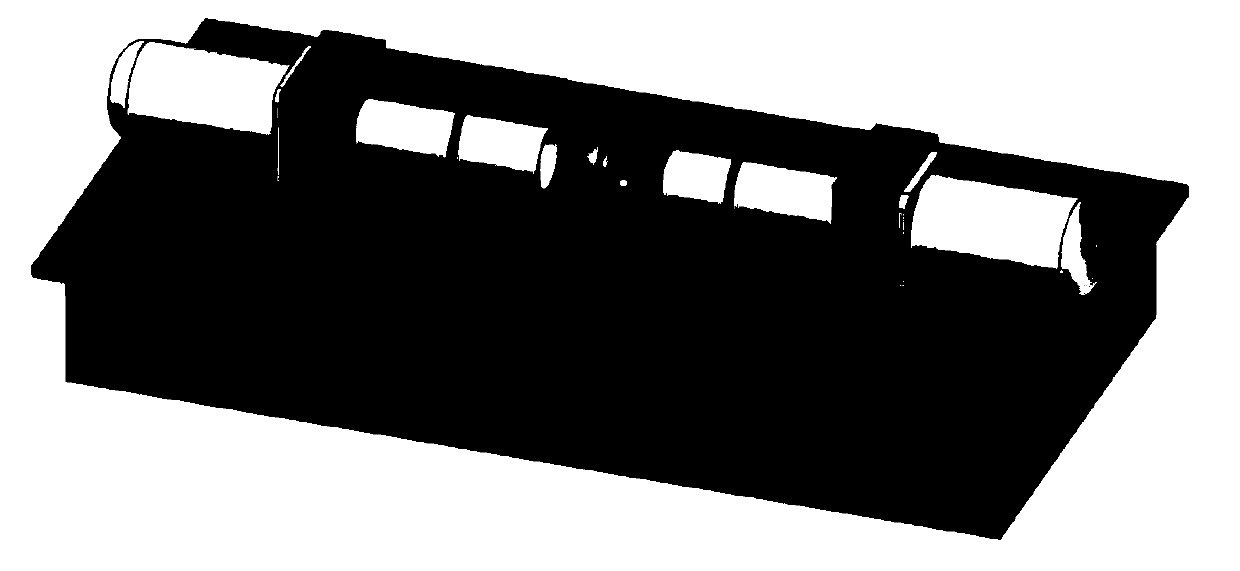

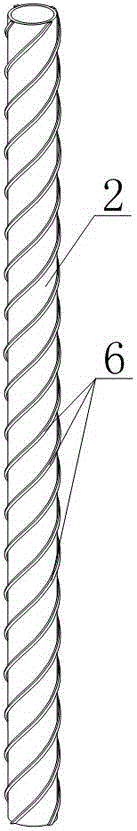

PendingCN110813473AEasy to replaceEasy to operateSolid waste disposalGrain treatmentsStructural engineeringMachining process

The invention discloses waste automobile shell shredding recovery equipment comprising a falling hopper (1), a smashing box (2), a rack (3) and a conveying line. The smashing box (2) is arranged abovethe rack (3). The falling hopper (1) is arranged above the smashing box (2). The conveying line is arranged below the smashing box (2). Two cutter shafts (5) are horizontally arranged in the smashingbox (2) in parallel through bearings (4) and rotate oppositely. Locating of the circumferential phase position is achieved between cutter bodies and the cutter shafts (5) in a hole shaft sleeved mode. A 15-degee included angle exists between axes of the cutter bodies, thus all the cutter bodies are installed behind the cutter shafts (5) sequentially in a sleeving mode, the connection line of blades (10-2) is a spiral line, through the specific cutter body structure, the effect that the blades on all the cutter bodies are distributed in a spiral line shape in the axial direction of the cuttershafts is ensured, in this way, in the machining process of a cutter set, different blades in the cutter set do not participate in shredding machining simultaneously, machining resistance is low, power consumption is low, shredding efficiency is high, and discharge sizes are uniform.

Owner:YUNNAN TAIBIAO NUMERICAL CONTROL MACHINE CO LTD

Centrifugal air compressor system for large-scale air separation

InactiveCN111947395AReduce energy consumptionTo achieve the goal of reducing emissionsSolidificationLiquefactionMolecular sieveCooling tower

The invention provides a centrifugal air compressor system for large-scale air separation. The system comprises a self-cleaning filter. The input end of the self-cleaning filter is communicated with an air inlet, and the output end of the self-cleaning filter is communicated with a centrifugal air compressor. The centrifugal air compressor is communicated with an air cooling tower. The air coolingtower is respectively communicated with a water cooling tower and a molecular sieve. The molecular sieve is communicated with an air outlet. According to the centrifugal air compressor system for thelarge-scale air separation, after a series of improvements such as equipment upsizing, an automatic emergency production protection system, a resistance-free drying system and the like, the economicbenefit is considerable, and the production is not influenced under special conditions. Zero emission is achieved by reducing technological process resistance, recycling waste nitrogen or recycling; the purposes of energy conservation and emission reduction are achieved by arranging an automatic yield-keeping emergency system; and the benefit is considerable.

Owner:RIZHAO STEEL HLDG GROUP

Fresh fruit cutting and softening system

The invention relates to a chopping softening system for fresh fruit. The system comprises four parts, namely, a fresh fruit chopping device, a conveying device, a cleaning device and a pulp softening device, wherein a fixed cutter and a moveable cutter are mounted in a chopping cabin of the fresh fruit chopping device; the conveying device comprises a spiral conveying pipe; a filter hole is formed in a pipe wall on the lower side of the spiral conveying pipe; two water spraying holes are formed above the spiral conveying pipe; the cleaning device comprises three settling ponds; sprayers are arranged on water pumping pipes mounted on the settling ponds and are mounted in the water spraying holes; a stirring blade is mounted in a stirring cabin of the pulp softening device. The chopping cabin is adopted for chopping, so that the working efficiency is high and the working resistance is small; the conveying pipe is used for cleaning the residues, so that the difficulty in subsequent processing is reduced; the cleaning water is reused, so that the water resource is saved; the blade in the softening cabin is used for stirring and softening the raw materials, so that the basis for increasing the speed of the subsequent processing is established; the residues recycled in a three-level form through the settling ponds are respectively reutilized, so that the comprehensive utilization of the wastes is realized.

Owner:YUNNAN MAODUOLI GRP FOOD

High-speed ultrasonic automatic tool change electric spindle

ActiveCN105921771BQuick tool changeEasy to processLarge fixed membersMetal working apparatusCoaxial lineDrive motor

The invention relates to a high-speed ultrasonic automatic tool changing motorized spindle. The high-speed ultrasonic automatic tool changing motorized spindle is provided with an ultrasonic spindle body. The ultrasonic spindle body comprises a machine shell, a rotor shaft coaxially arranged with the machine shell, and a machining tool fixed to one end of the rotor shaft and connected with the end of the rotor shaft through nuts and an elastic contracting chuck. An ultrasonic tool handle is arranged at the front end of the rotor shaft. The rear end of the rotor shaft extends into the rear end of the machine shell. A built-in type assembly chamber is arranged in the ultrasonic tool handle. A built-in energy converter is detachably mounted in the built-in type assembly chamber. An ultrasonic generator is mounted on the upper portion of the ultrasonic tool handle and comprises an L-shaped combined support, a planar adjusting support and a vertical adjusting support, and the planar adjusting support and the vertical adjusting support are mounted on the combined support. The planar adjusting support passes through a fixed ring and then is coupled with a movable ring on the ultrasonic tool handle. A gap is formed between the fixed ring and the movable ring. A driving motor is directly connected with the ultrasonic spindle body and the ultrasonic tool handle, and the spindle has the characteristics that the ultrasonic spindle body and the ultrasonic tool handle are mutually independent, and application is convenient.

Owner:江苏翰琪电机股份有限公司

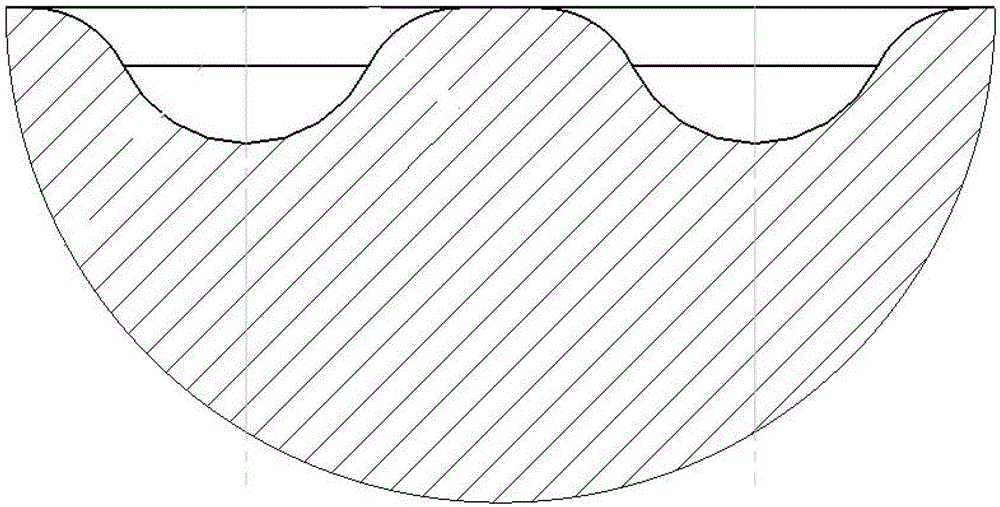

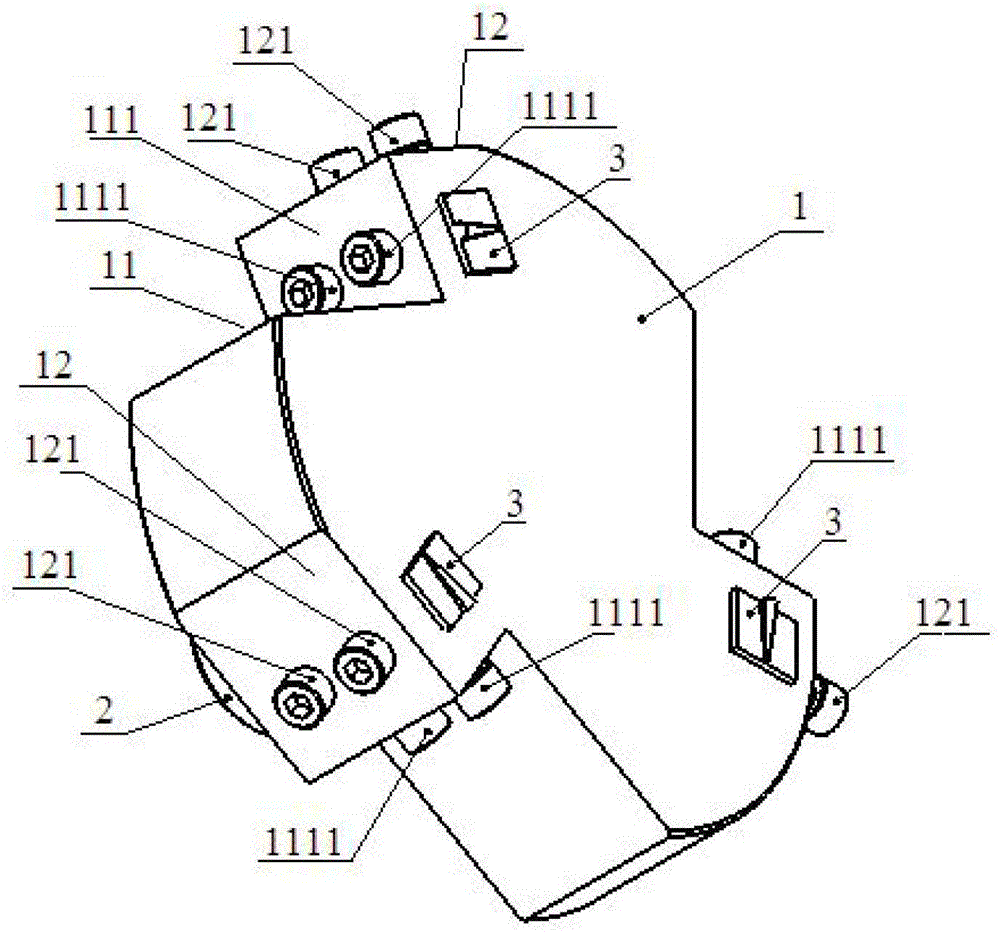

Homemade Forming Face Grooving Knife

The invention provides a self-made molding end face slot cutter. The self-made molding end face slot cutter comprises a cutter main body, a straight handle and at least one molding cutter, wherein the cutter main body is mounted on a cutter handle of a processing machine tool; the cutter main body is in a shape of a rotary body; the rotary body rotates around the middle axis of the straight handle; the cutter main body is provided with notches which are as many as the molding cutters; the notches are uniformly arrayed by taking the circle center of the rotary body as the center; pressing screw rods are arranged on first tangent planes of the notches and second tangent planes with adjusting screw rods are arranged on the side face of the rotary body, which is crossed with the first tangent planes; each molding cutter comprises a mounting part and a cutting edge; the cutting edges are arranged at one ends of the mounting parts; the mounting parts are fixed on the rotary body; front end tool noses and tail end curves of the cutting edges are connected through straight-line sections; the middle axis of each cutting edge is overlapped with the direction of the tangent, which passes the position of the cutting edge, of the rotary body, and is arranged along the rotary direction of the rotary body; the tool noses of the cutting edges of the molding cutters are on the same standard plane. The self-made molding end face slot cutter has the beneficial effects that the processing resistance is reduced, three-point equal-division cutting is realized, the stable processing is formed and the processing efficiency is high.

Owner:慈溪汇丽机电股份有限公司

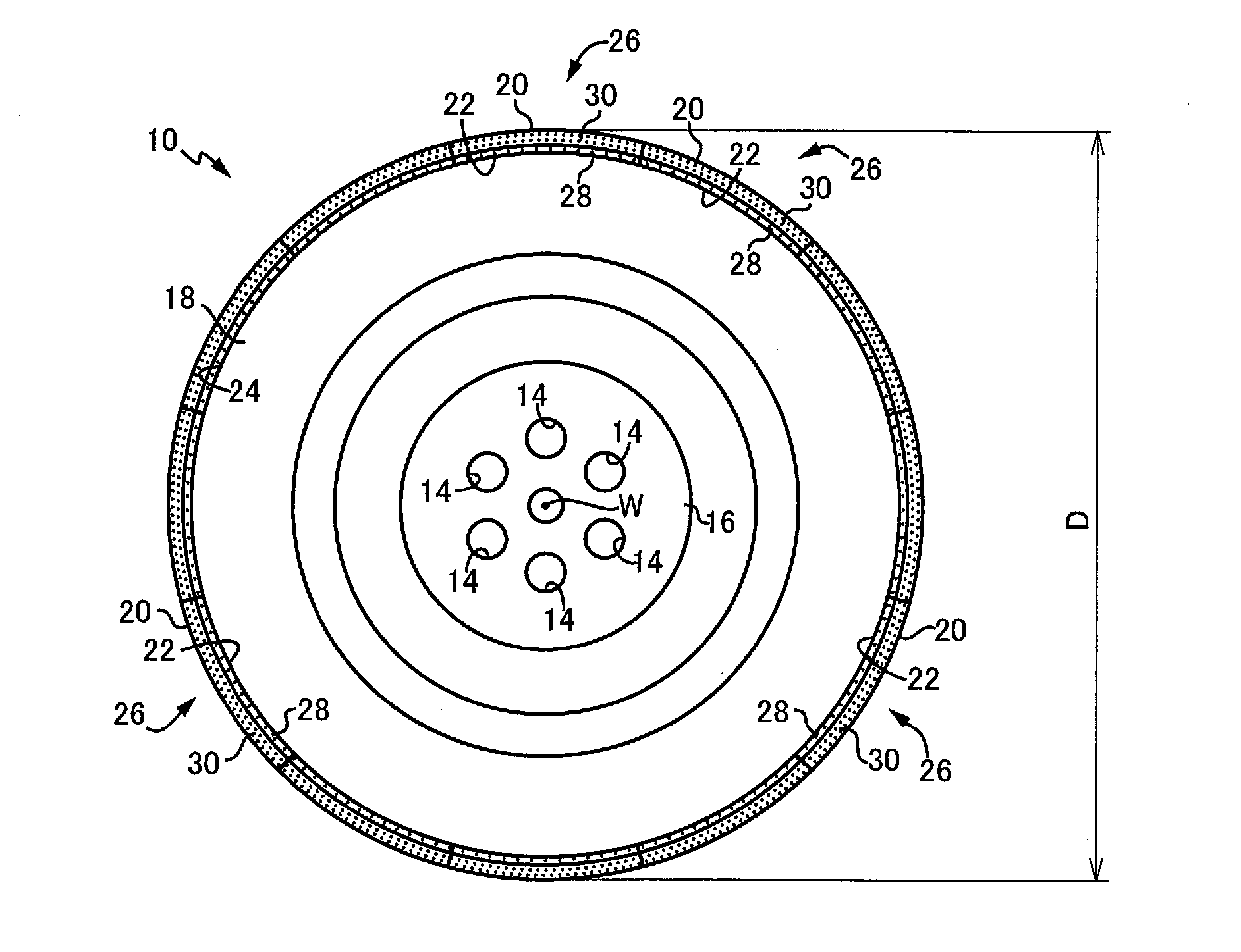

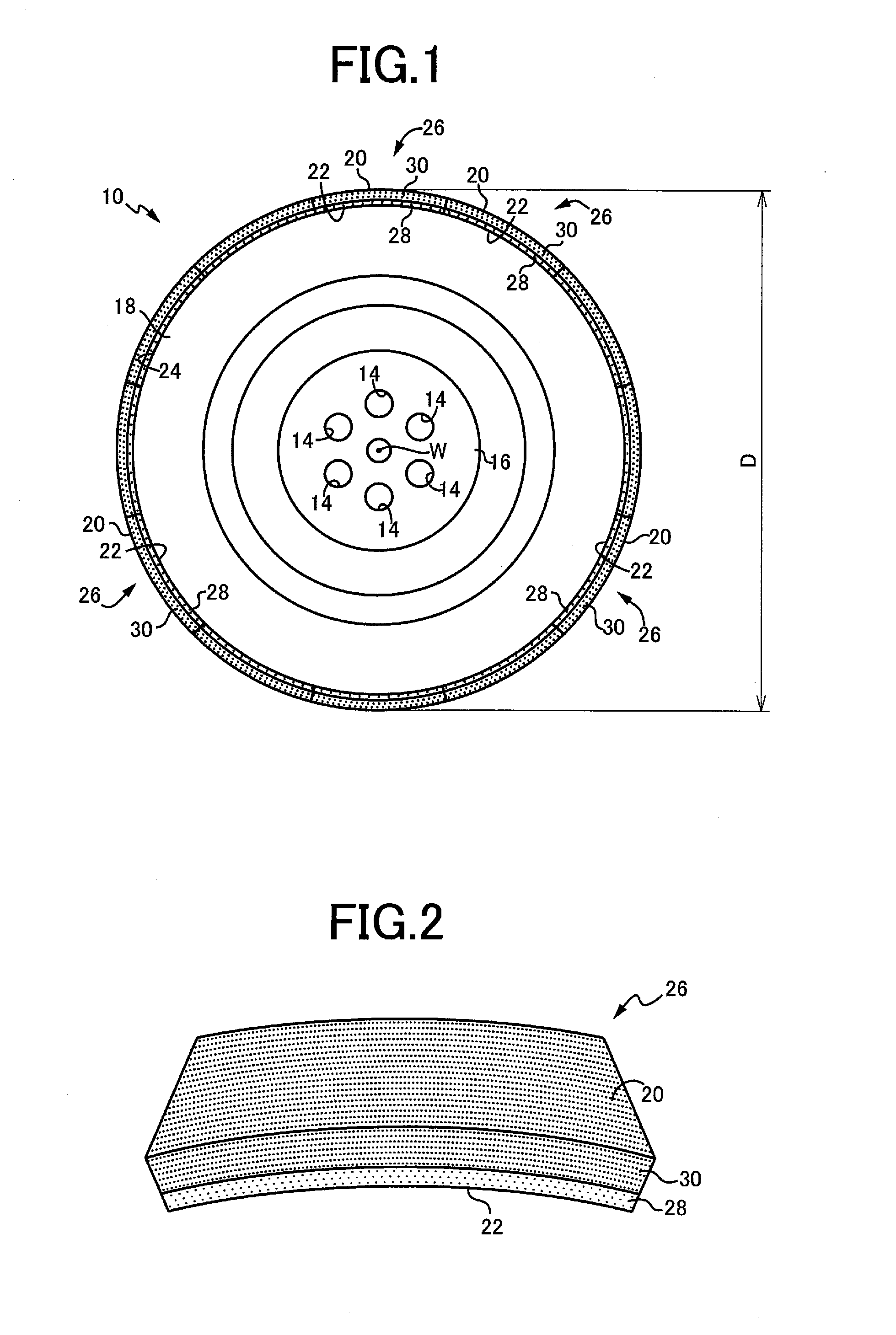

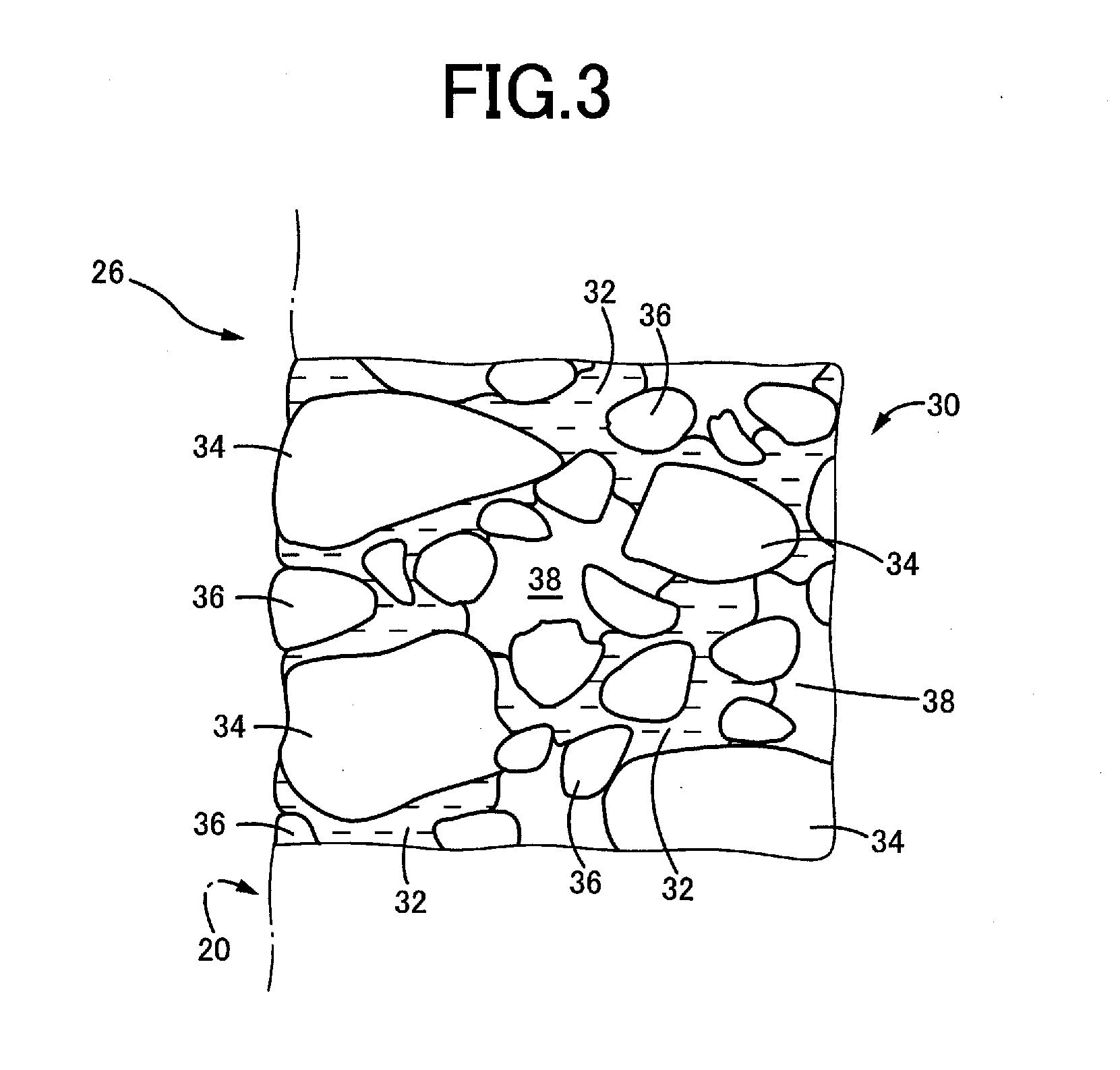

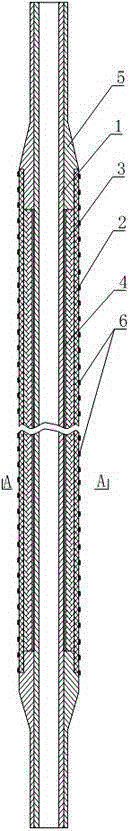

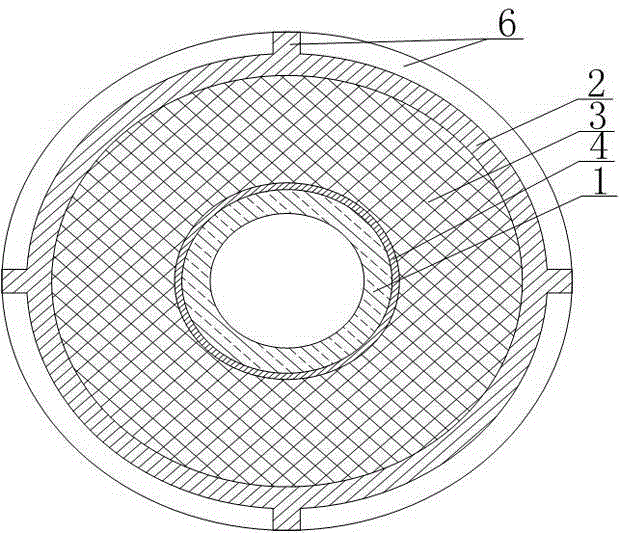

Improved Annular Fuel Element and Fuel Assembly of Supercritical Water Reactor

ActiveCN103106929BImprove manufacturing feasibilityEffective accommodationFuel elementsNuclear energy generationFully developedHeat transmission

The invention discloses an improved annular fuel element of a supercritical water reactor and a fuel component consisting of the fuel element. The improved annular fuel element comprises an inner wrapping shell and an outer wrapping shell coaxial with the inner wrapping shell, wherein granular fuel is filled between the inner wrapping shell and the outer wrapping shell; and a heat isolation coating layer is also arranged between the granular fuel and the inner wrapping shell. The fuel component consists of the annular fuel element, an upper heat isolation plate, a lower heat isolation plate, an upper flow guide plate and a lower flow guide plate which are matched with one another; a moderator on the inner side of the annular element and a coolant which is arranged on the outer side and flows in an opposite direction can be effectively shunted; no special control stick guide pipe is arranged in the component, so that the structural design of the component is simplified, the using amount of structural materials is reduced, and the economical property is improved; the advantages of uniformity in moderation of the annular fuel element, heat transmission on both sides, low fuel temperature and the like are fully developed; the engineering application feasibility is greatly improved; and therefore, the supercritical water reactor with relatively high economical property and safety can be designed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

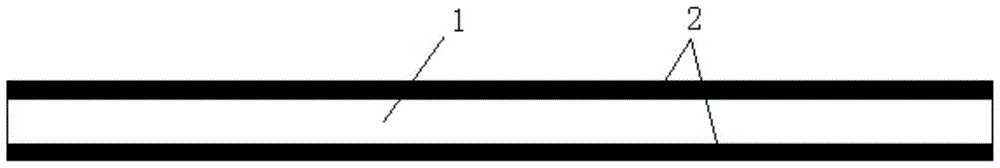

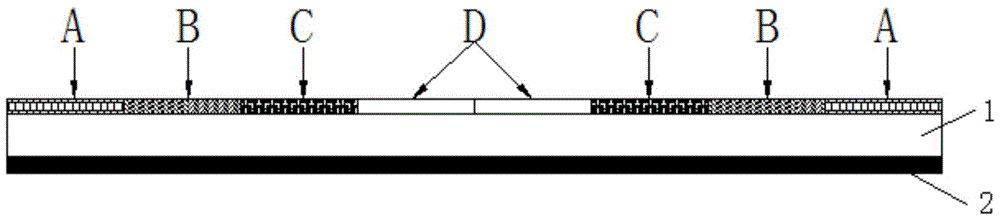

A kind of processing method of glass cover plate

Owner:KUNSHAN VISIONOX DISPLAY TECH

Barbing device

The invention relates to a barbing device comprising a fixing device, an extrusion block, and a drive mechanism. The fixing device is used for fixing a connector; the extrusion block is used for being arranged outside the extrusion block; the drive mechanism is used for driving the extrusion block to move towards or leave the connector; the extrusion block is provided with an extruding edge used for extruding the connector to form barbs on the connector. The existing connector can be directly barbed by the baring device. Barbing efficiency is significantly improved by the use of the barbing device.

Owner:HENAN UNIV OF SCI & TECH

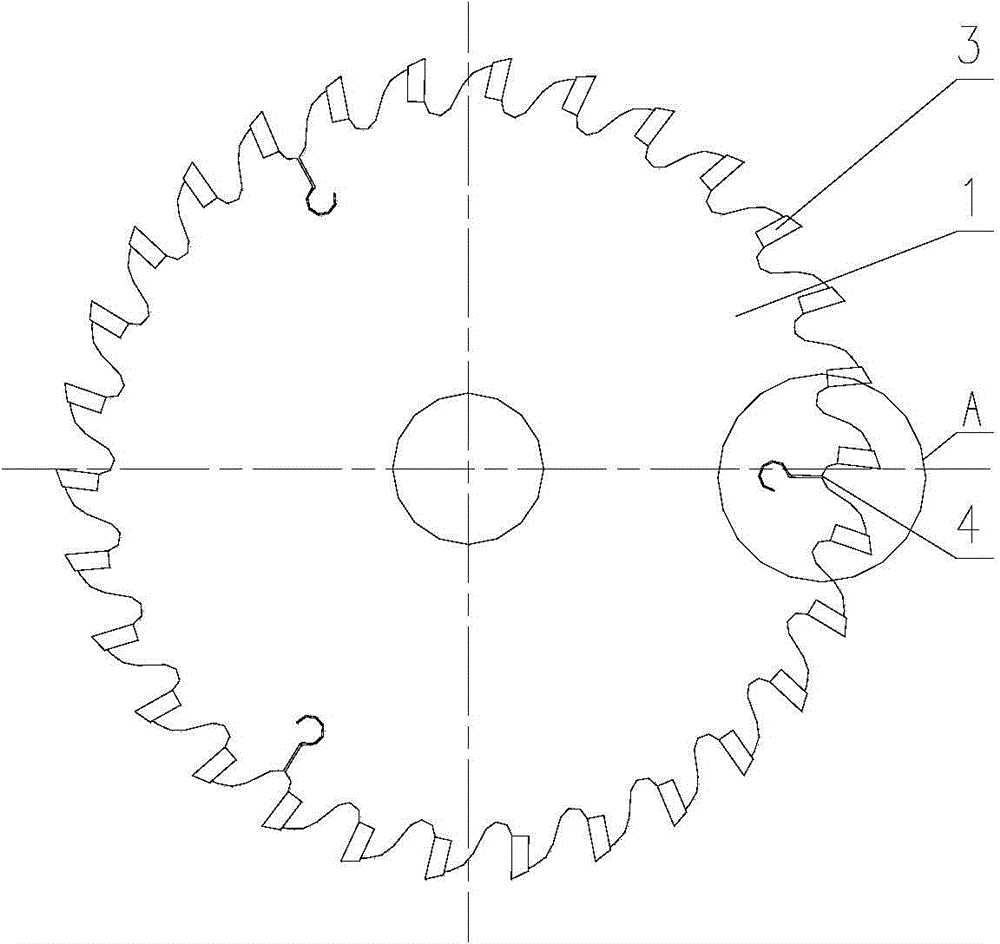

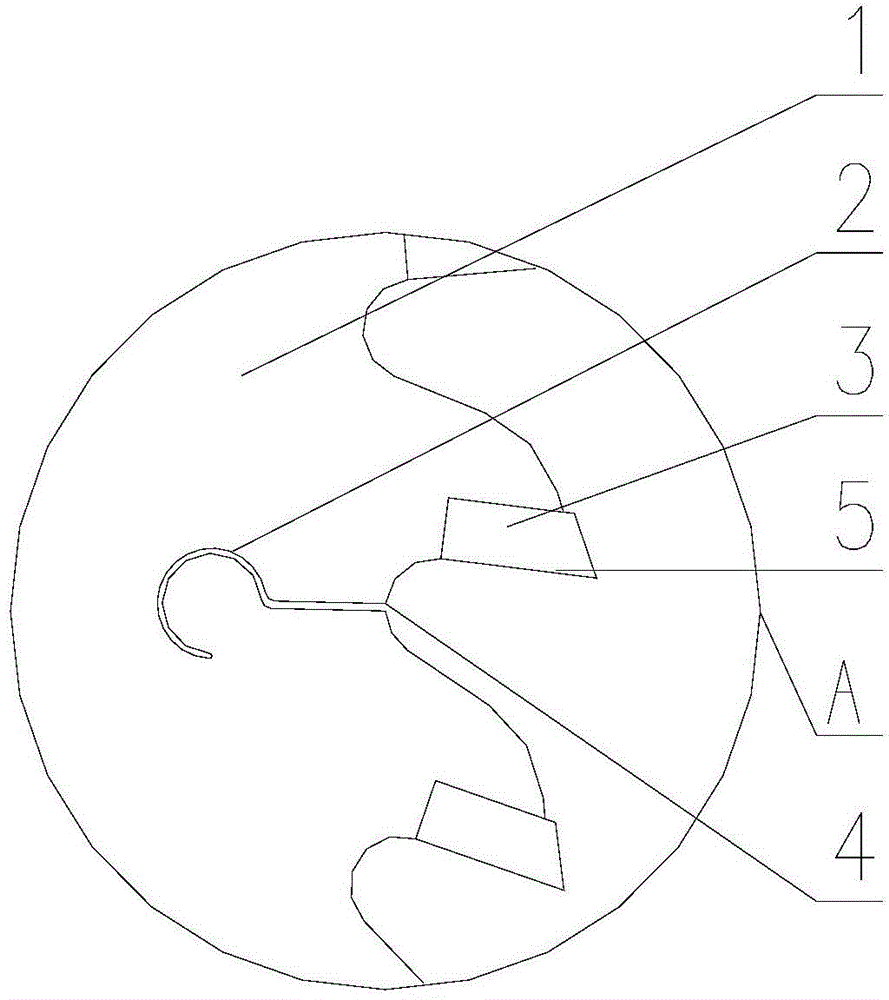

Preparation method of milling cutter with open slots

ActiveCN104668924ASolve the problem of machining chatterLess problems with machining chatterResonanceMilling cutter

The invention relates to a preparation method of a milling cutter with open slots, a manufacturing process comprises: the excircle of a metal disc is cut into a plurality of sawtooth grooves in the same direction in a uniformly distributed manner so as to form a cutter body, the method is characterized in that: (1) after a plurality of open slots are made at the bottom of the sawtooth grooves in a uniformly distributed manner along the center line direction of one surface of the cutter body, oil quenching and tempering treatments are carried out on the cutter body; (2) an alloy cutter head is welded on each sawtooth groove of the cutter body along the same direction, so as to form a milling cutter; (3) a vacuum furnace heat treatment is carried out on the milling cutter manufactured in step (2). According to the preparation method, the open slots are made in one surface of the cutter body, the internal stress of the cutter body is released during cutting, the vibration of the cutter body is eliminated, the problem that the milling cutter vibrates during working is solved, the processing resistance is reduced, the abrasion of a cutting edge is lowered, the phenomena of resonance, cutter blocking and cutter hitting generated when the milling cutter works are prevented, not only are the processing precision and the cutting speed enhanced, but also the waste of raw materials caused by the rejection rate of products is reduced by a large margin.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com