Brass bar and preparation method thereof

A brass bar and brass technology, applied in the field of copper alloys, can solve the problems of poor machining performance of CW713R, vulnerable knives, and unfavorable cutting, and achieve the effects of optimizing machinability, improving overall strength, and reducing machining resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

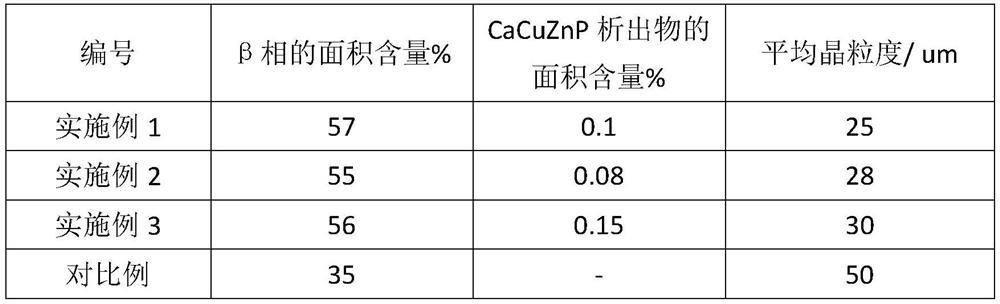

Examples

Embodiment 1

[0026] The mass percentage composition of the brass rod is Cu: 58.16wt%, Pb: 0.73wt%, Mn: 2.25wt%, Al: 2.05wt%, Si: 0.55wt%, P: 0.65wt%, Ca: 0.55wt% , Ni: 0.75wt%, B: 0.015wt%, and the balance is Zn.

[0027] The preparation steps of this embodiment are:

[0028] 1) Smelting: first put the electrolytic plate into the furnace, after the electrolytic plate is melted, increase the voltage to 600V, cover the liquid surface with charcoal, the covering height is more than 5mm, and the temperature reaches 1100℃~1150℃, metal aluminum, manganese, silicon , lead are added into the copper water in turn, stirred after melting, the voltage is raised to 400V, the temperature is lowered to 980 ° C ~ 1020 ° C, zinc is added to the copper water, and the temperature is kept for 3 minutes after melting. The copper-phosphorus alloy (the mass content of phosphorus is 7%), Copper-calcium alloy (the mass content of calcium is 10%) and metal nickel are added into the copper liquid with a pressure sp...

Embodiment 2

[0033] The mass percentage composition of the brass rod is Cu: 58.85wt%, Pb: 0.75wt%, Mn: 1.98wt%, Al: 1.48wt%, Si: 0.66wt%, P: 0.61wt%, Ca: 0.51wt% , Ni: 0.65wt%, B: 0.02wt%, and the balance is Zn.

[0034] The preparation steps of this embodiment are:

[0035] 1) Smelting: first put the electrolytic plate into the furnace, after the electrolytic plate is melted, increase the voltage to 610V, cover the liquid surface with charcoal, the covering height is more than 5mm, and the temperature reaches 1100 ℃ ~ 1150 ℃, metal aluminum, manganese, silicon , lead are added into the copper water in turn, stirred after melting, the voltage is raised to 410V, the temperature is lowered to 980 ° C ~ 1020 ° C, zinc is added to the copper water, and the temperature is kept for 3 minutes after melting. The copper-phosphorus alloy (the mass content of phosphorus is 7%), Copper-calcium alloy (the mass content of calcium is 10%) and metal nickel are added into the copper liquid with a pressure...

Embodiment 3

[0040] The mass percentage composition of the brass rod is Cu: 58.65wt%, Pb: 0.65wt%, Mn: 2.01wt%, Al: 1.58wt%, Si: 0.65wt%, P: 0.66wt%, Ca: 0.57wt% , Ni: 0.75wt%, B: 0.02wt%, and the balance is Zn.

[0041] The preparation steps of this embodiment are:

[0042] 1) Smelting: first put the electrolytic plate into the furnace, after the electrolytic plate is melted, increase the voltage to 600V, cover the liquid surface with charcoal, the covering height is more than 5mm, and the temperature reaches 1100℃~1150℃, metal aluminum, manganese, silicon , lead are added into the copper water in turn, stirred after melting, the voltage is raised to 400V, the temperature is lowered to 980 ° C ~ 1020 ° C, zinc is added to the copper water, and the temperature is kept for 3 minutes after melting. The copper-phosphorus alloy (the mass content of phosphorus is 7%), Copper-calcium alloy (the mass content of calcium is 10%) and metal nickel are added into the copper liquid with a pressure spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com