Homemade Forming Face Grooving Knife

A technology for forming knives and grooving knives, which is applied in the manufacture of tools, accessories for tool holders, tools for lathes, etc., can solve the problems of low processing efficiency and easy to break tools, and achieve high processing efficiency and reduce processing resistance. , Stable processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

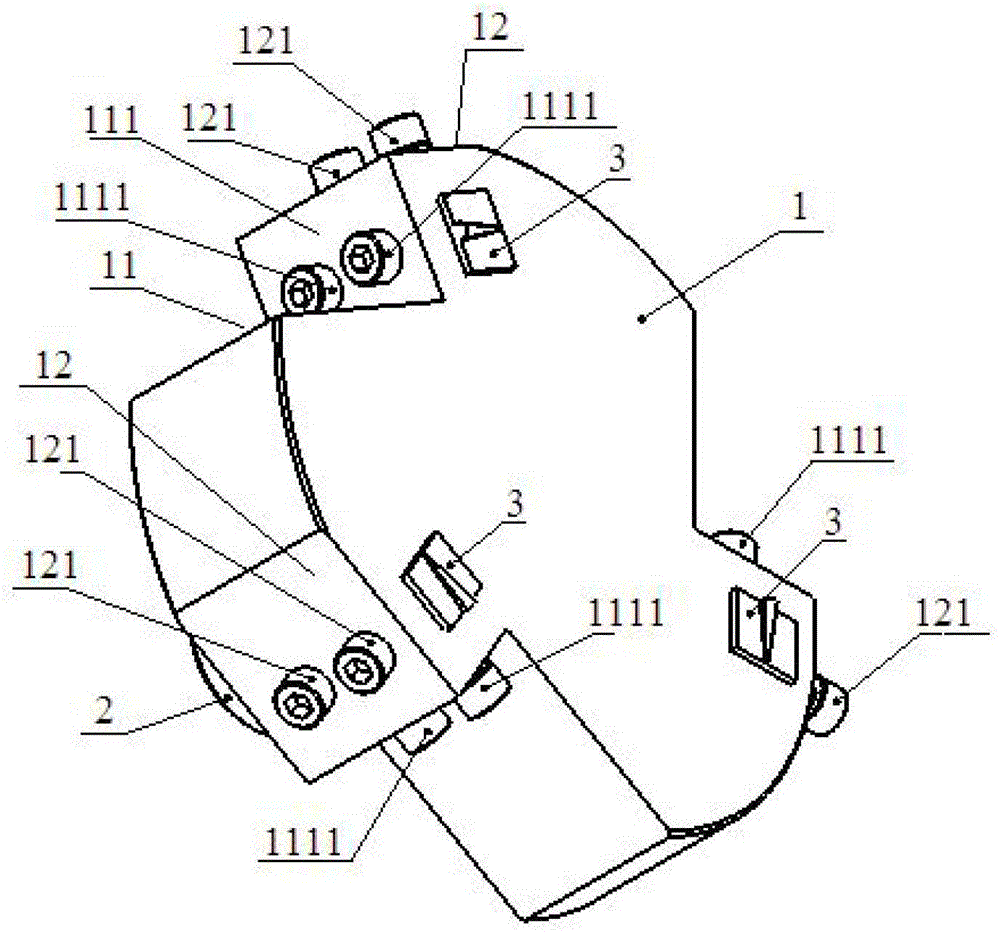

[0017] Further illustrate the present invention below in conjunction with accompanying drawing

[0018] Referring to the attached picture:

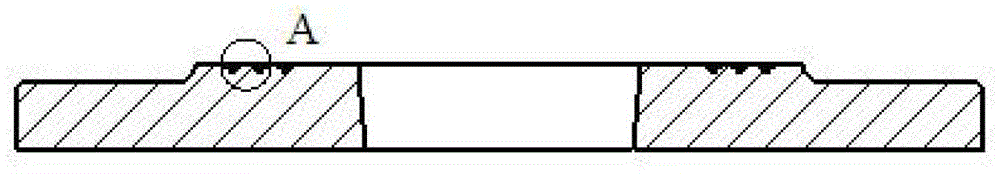

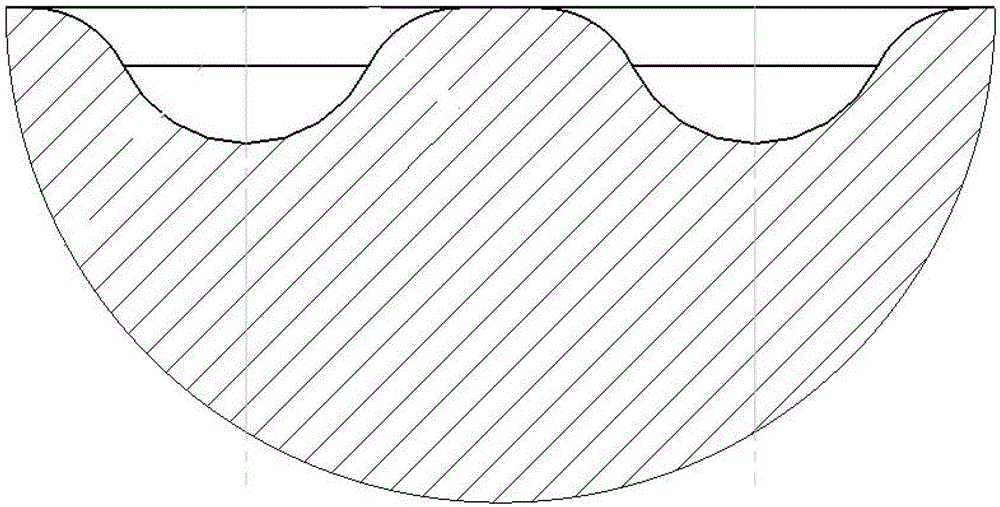

[0019] The self-made forming end face groove cutter of the present invention comprises a cutter body 1, a straight handle 2, and at least one forming cutter 3. The cutter body 1 is installed on the handle of a processing machine through the straight handle 2. The cutter body 1 is in the shape of a revolving body, the revolving body rotates around the central axis of the straight handle 12, the cutter body 1 is provided with notches 11 with the same number as the forming knives, and the notches 11 are in the form of the The center of the gyratory body is evenly arranged at the center, the first section 111 of the notch 11 is provided with a compression screw 1111, and the side of the gyratory intersecting with the first section 111 is provided with an adjusting screw 121 The second cut surface 12; the forming knife 3 includes a mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com