A kind of processing method of glass cover plate

A technology of glass cover plate and processing method, which is applied in the field of glass cover plate processing, can solve the problems of low processing efficiency and difficulty in guaranteeing processing accuracy of arc-shaped glass cover plates, and reduce the difficulty of etching control and machining control, and achieve good results. The effect of increasing the rate and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

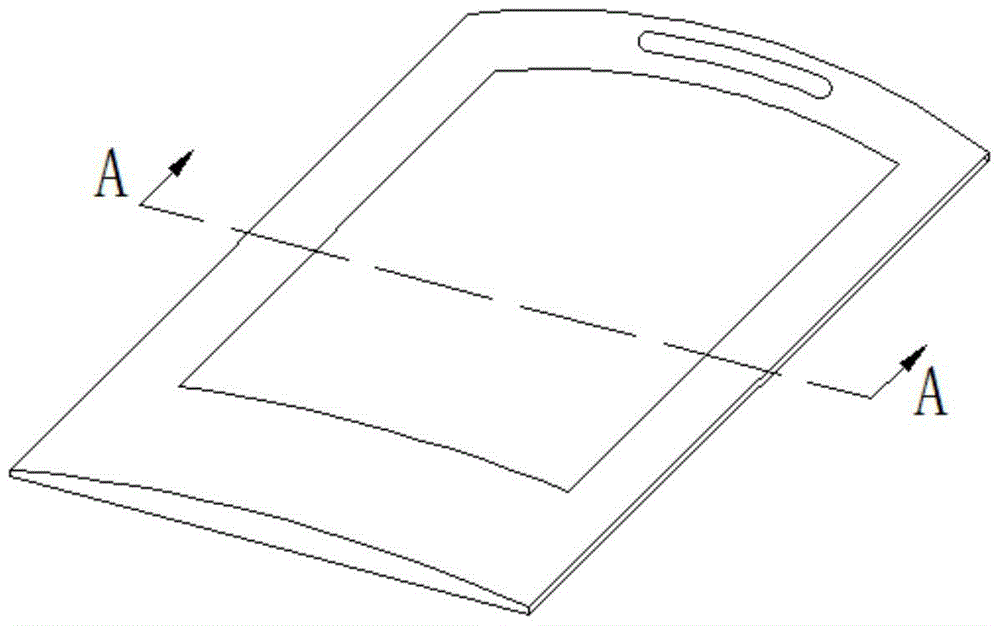

[0034] Figure 2-Figure 9 It is a processing method for a glass cover plate disclosed by the present invention, and it is finally processed into such as figure 1 A curved glass substrate is shown; it includes the steps of:

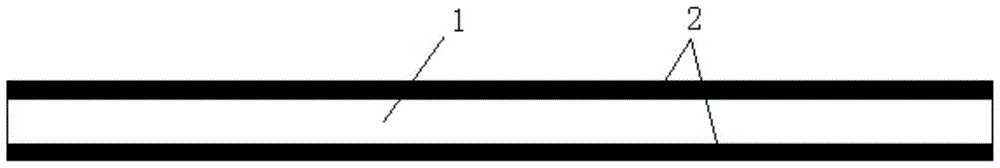

[0035] Step 1: Coat the top surface and the bottom surface of the rectangular glass cover plate 1 with a protective layer 2 respectively, such as figure 2 shown;

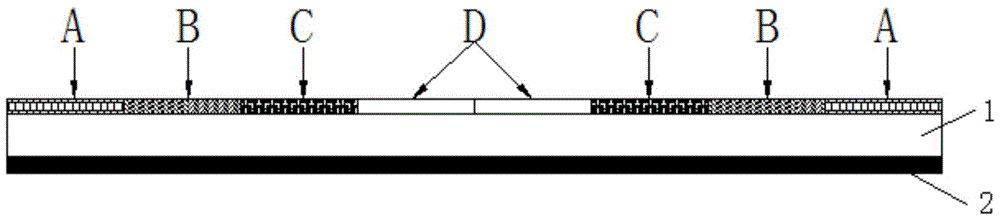

[0036] Step 2: According to the final radian of the glass cover 1, the top surface of the glass cover 1 is evenly and symmetrically divided into A, B, C, and D etching areas, such as image 3 As shown, make the final thickness difference e between adjacent etched regions equal;

[0037] Step 3: If Figure 4 As shown, after removing the protective layer of the etched area A with the smallest final thickness in the area to be etched by g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com