Preparation method of milling cutter with open slots

An open-slot and milling cutter technology is applied in the field of preparation of open-slot milling cutters, which can solve the problems of insufficient fit between the shape of the blade and the surface contour of the workpiece, affecting the machining accuracy of the product, and increasing the reject rate of the product, so as to achieve a prominent processing effect. , The effect of improving machining accuracy and cutting speed, product accuracy and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

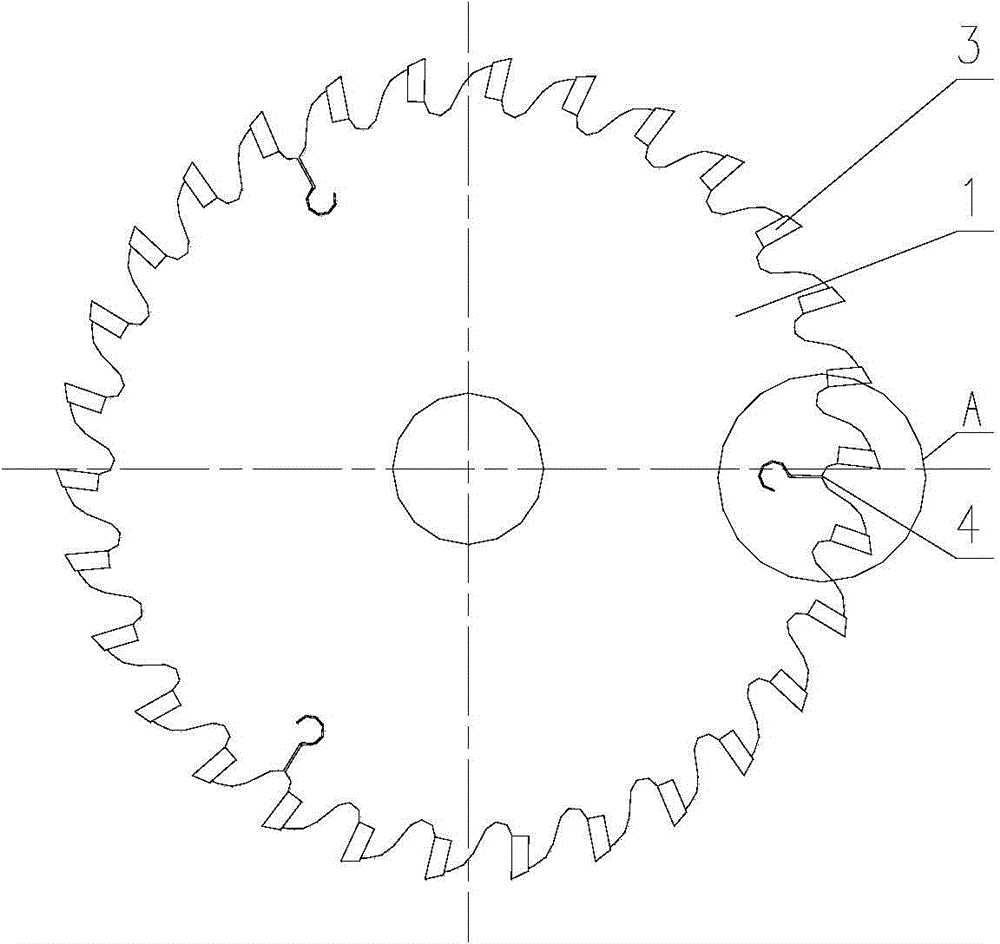

[0025] A method for preparing a milling cutter with an open slot, the production process includes: making a metal disc from a metal material, and cutting the outer circle of the metal disc into several serrated grooves in the same direction to form a cutter body, which is characterized in that : also includes the production steps:

[0026] ⑴ Distribute the groove bottom of the serrated groove along the center line of one side of the cutter body to make a plurality of open grooves, and then quench the oil and temper the cutter body;

[0027] ⑵Weld an alloy cutter head along the same direction on each sawtooth groove of the cutter body to form a milling cutter;

[0028] (3) The milling cutter made in step (2) is subjected to heat treatment in a vacuum furnace to complete the manufacturing process of the milling cutter with open slots of the present invention.

[0029] The present invention can also adopt following technical scheme:

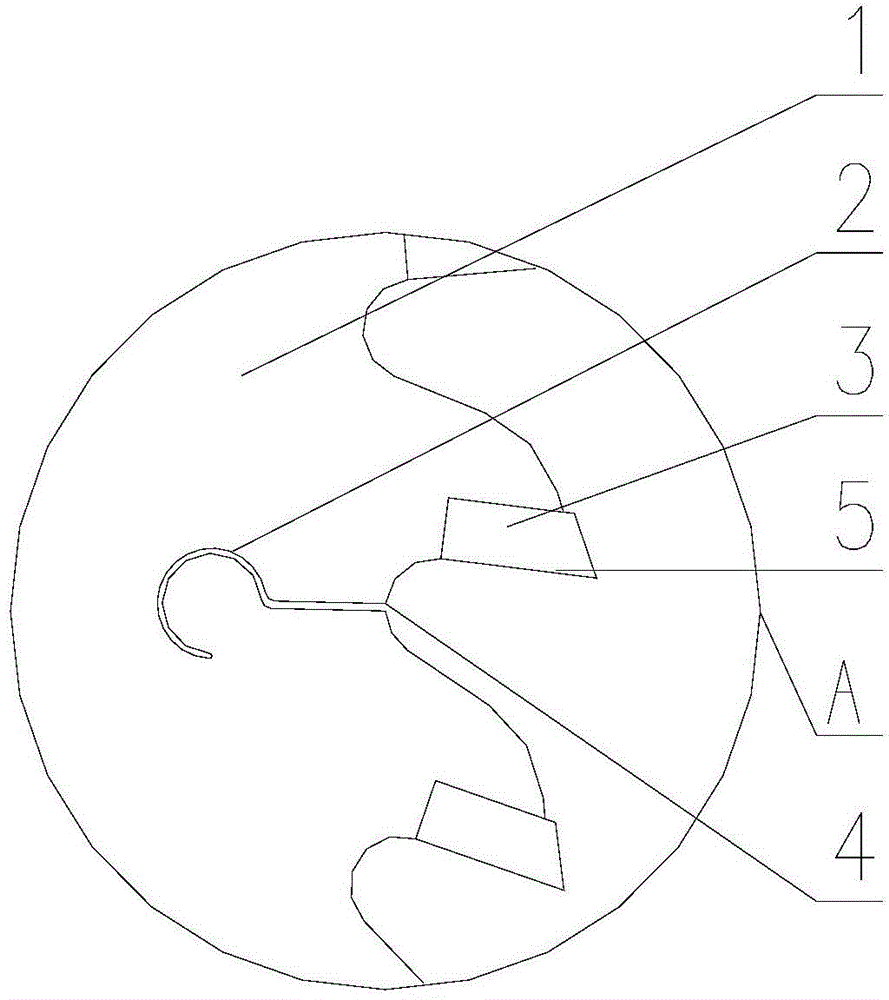

[0030] The open groove is a round hook-shap...

Embodiment

[0036] ⑴Choose 42Cr2Mo steel as the metal material for making the knife body 1, and make the 42Cr2Mo steel into a disc. According to the requirements of the knife shape, the outer circle of the 42Cr2Mo steel circle is uniformly cut into sawtooth grooves 4 that meet the number of knife shapes. The direction of the groove tip is clockwise (or counterclockwise) in the same direction; at the bottom of the serrated groove along the center line of one side of the cutter body, three round hook-shaped opening grooves 2 are scraped out at 120 degrees, and the round hook-shaped opening The groove gradually becomes narrower from the bottom of the serrated groove to the end of the hook point of the round hook. The direction of the hook tip of the round hook-shaped open groove is the same as the direction of the groove tip of the serrated groove, and the two sides of the knife body are initially ground;

[0037] ⑵Quenching and tempering at 860°C until the hardness of 42Cr2Mo steel is HRC32-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com