Patents

Literature

1420results about How to "Avoid resonance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

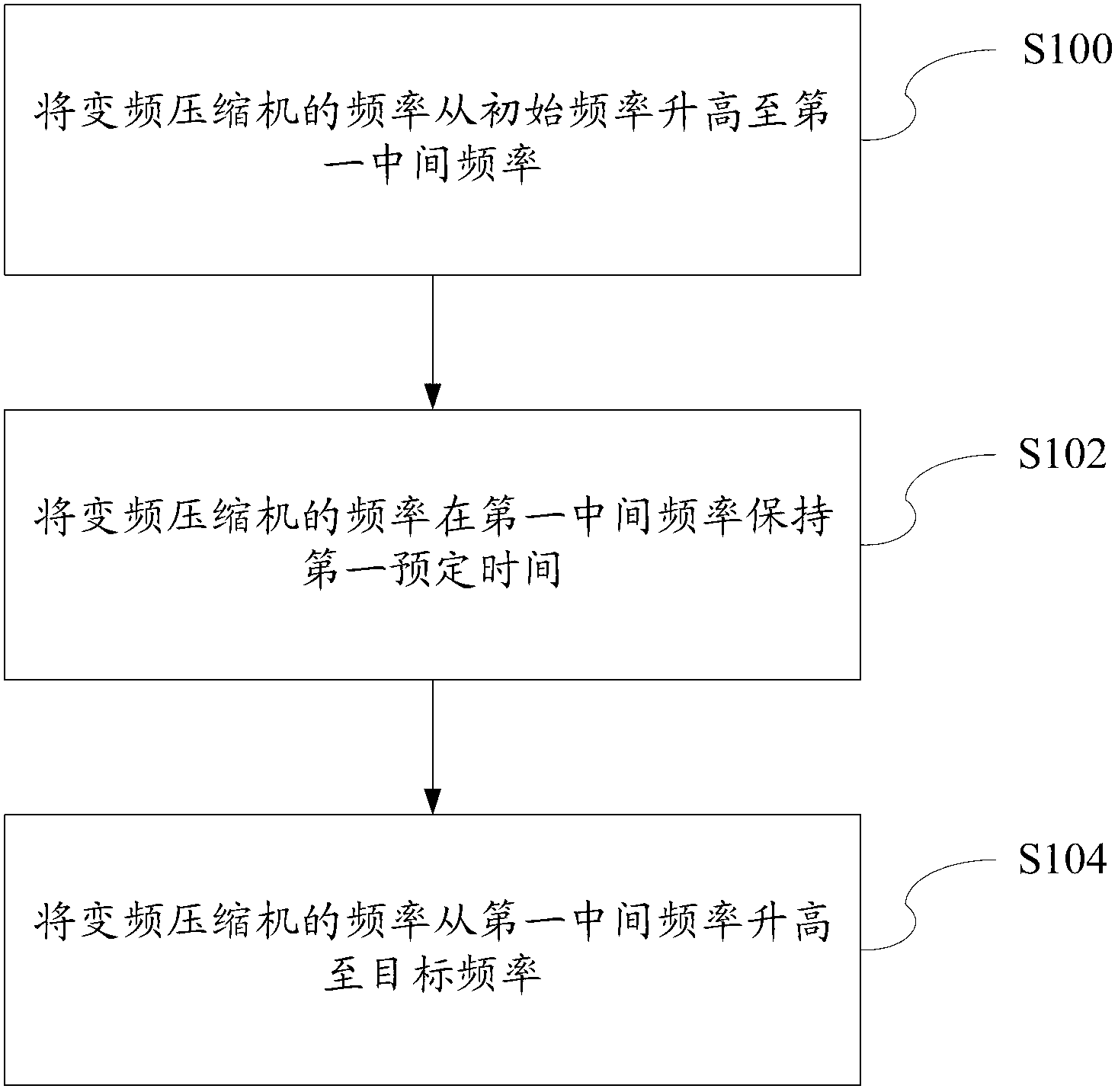

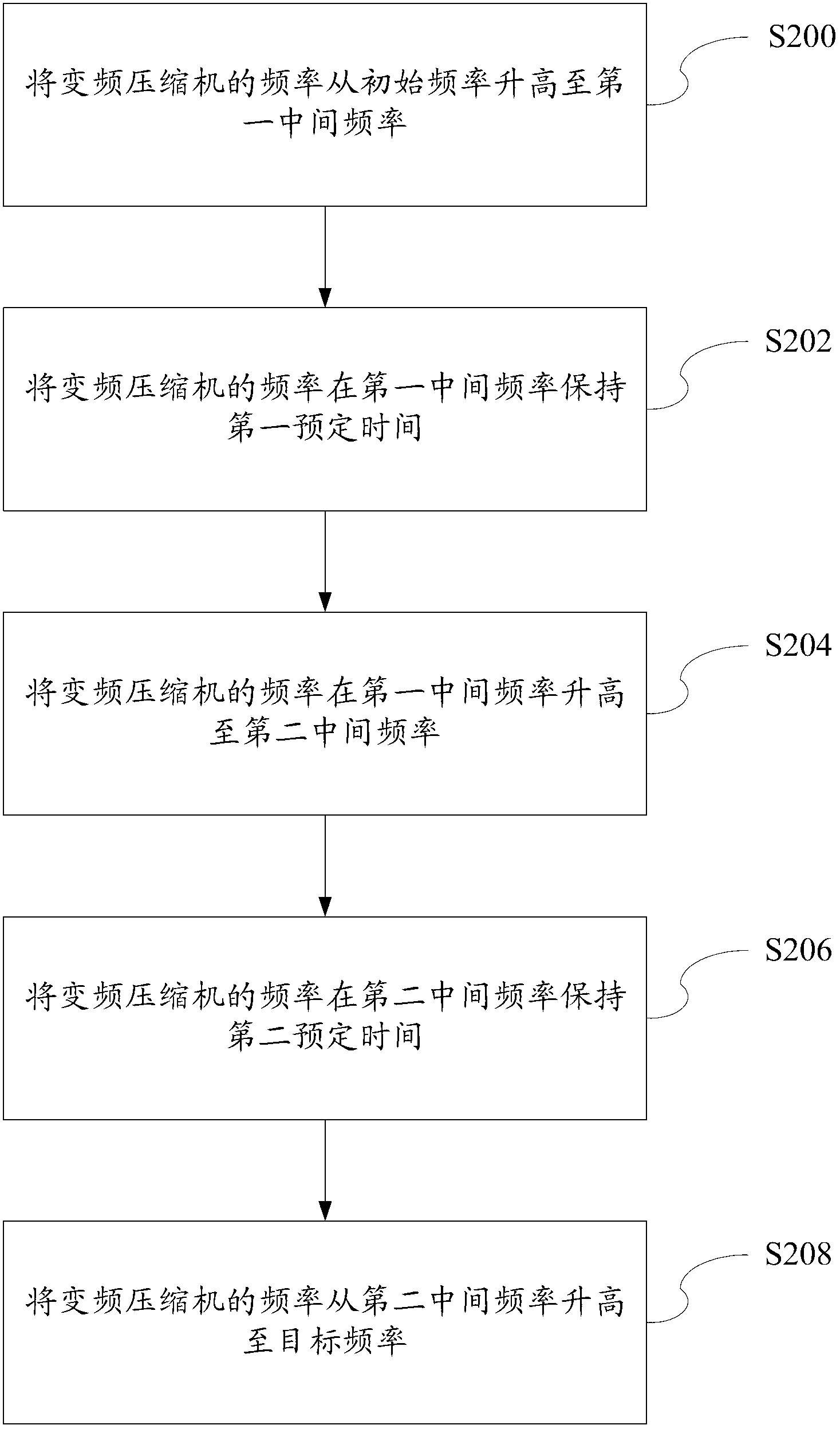

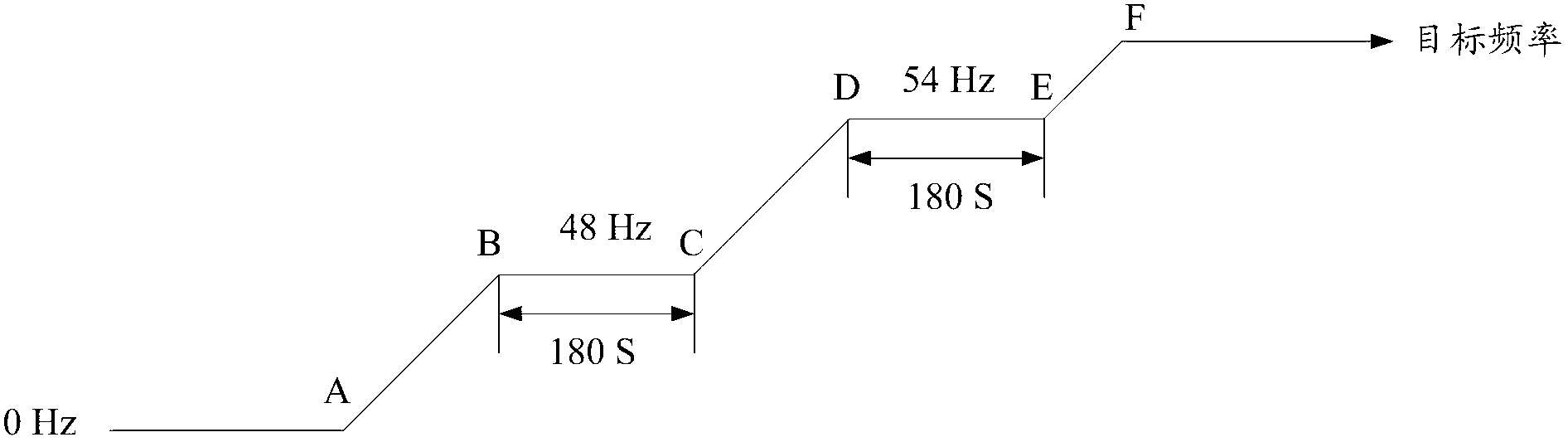

Method for starting variable frequency compressor

InactiveCN102705212AImprove reliabilityReduce wearPump controlPositive-displacement liquid enginesResonanceIntermediate frequency

The invention provides a method for starting a variable frequency compressor. According to the method, the frequency of the variable frequency compressor is raised to an intermediate frequency in the frequency raising process after the variable frequency compressor is started, and the intermediate frequency is kept for predetermined time, wherein the predetermined time is not shorter than the frequency modulation period of the variable frequency compressor. By the method for starting the variable frequency compressor, the reliability of the variable frequency compressor can be improved, abrasion of the variable frequency compressor is reduced, and the service life of the variable frequency compressor is prolonged; and by tripping certain frequency values of the variable frequency compressor in the starting process of the compressor, resonance between the compressor and a system pipeline is avoided, and the quality risk is avoided.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

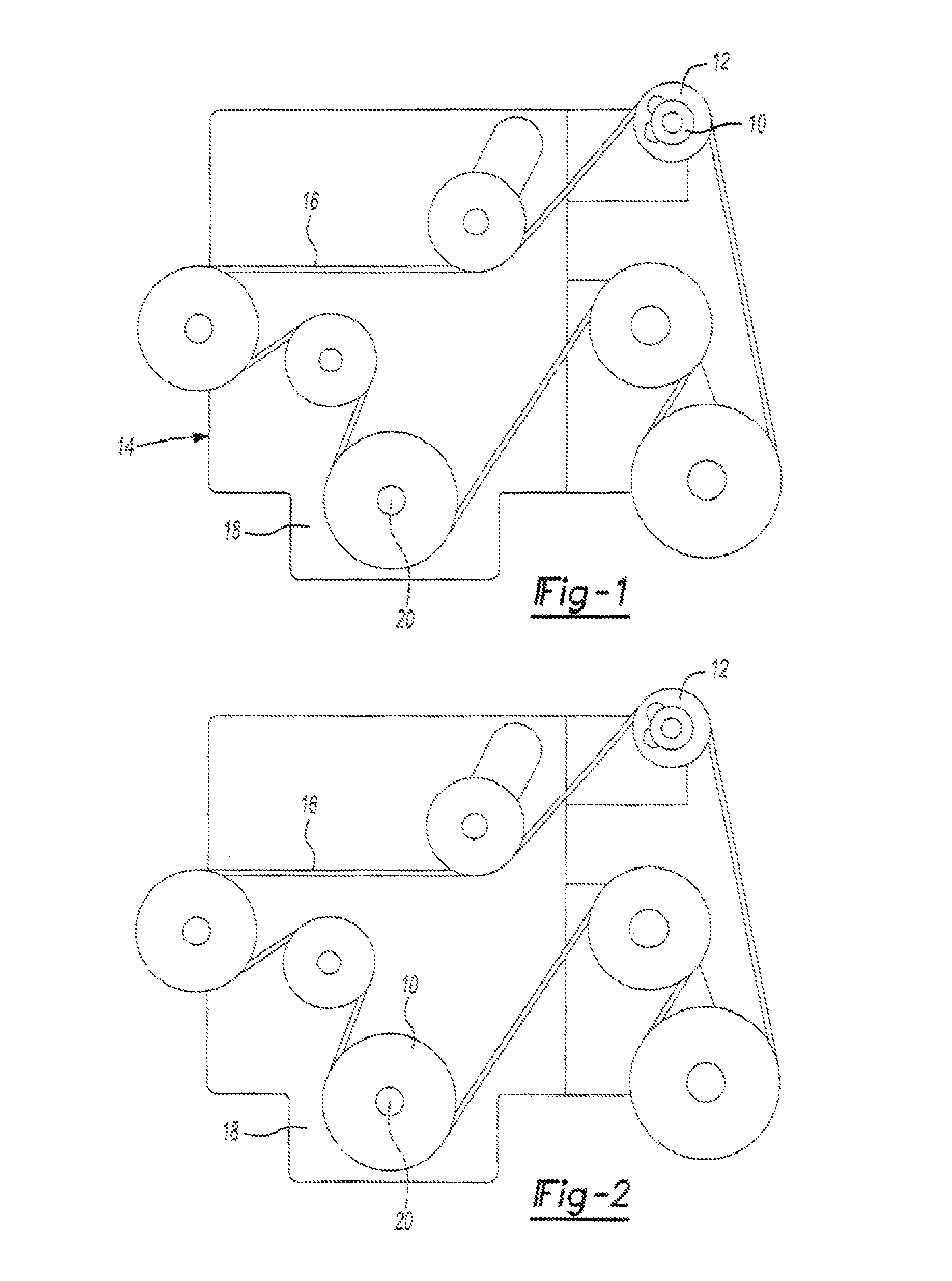

Receiver tube mounted trailer hitch cover

InactiveUS20050121880A1Lowering vehicle drag coefficientReduce turbulenceTowing devicesElectricityElectrical connection

This invention is an attractive cover for trailer hitch components which mounts on the receiver tube. It is especially useful for those vehicles whose trailer hitch is visible through an opening in the bumper fascia of the vehicle. These exposed components are generally unattractive. On these vehicles this invention will complete and fill-in the bumper fascia opening with a material that complements the vehicles own bumper covering. This invention mounts on the receiver tube and encloses and protects the receiver tube, safety chain anchors, electrical connections and other trailer hitch components. This invention will help to protect trailer components from blows and rough handling, corrosion, being clogged with mud and dirt and UV damage due to sunlight. It will prevent harm to people from striking the hitch and will smooth the outline of a vehicle reducing the turbulence around the vehicle and making it more gas efficient.

Owner:SANTANGELO ANTHONY

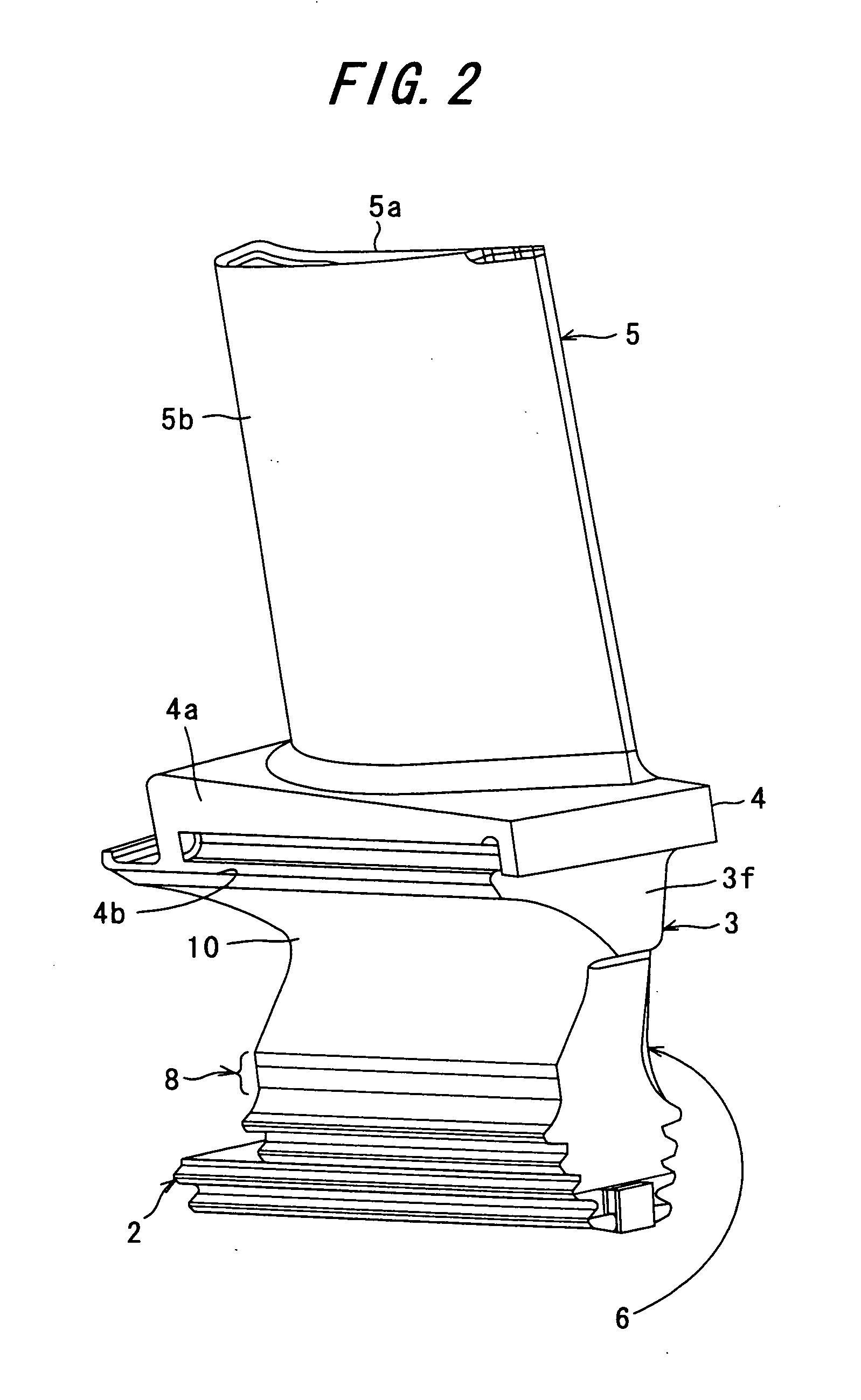

Moving blade and gas turbine using the same

ActiveUS20050186074A1Avoid stress concentrationUniform intensity distributionRotating vibration suppressionRotary propellersGas turbinesSpring system

In a gas turbine having a plurality of moving blades provided on a rotary shaft in a circumferentially adjoining condition, a seal pin is provided in a spacing between the shanks of the adjacent moving blades for preventing leakage of cooling air from a blade root portion side to an airfoil side; an arcuately depressed portion is formed on the shank of each of the moving blades; and vibration of each of the moving blades is suppressed in such a manner that the seal pin serves as a spring system while the airfoil portion, the platform, the shank, and the blade root portion serve as a mass system.

Owner:MITSUBISHI HEAVY IND LTD

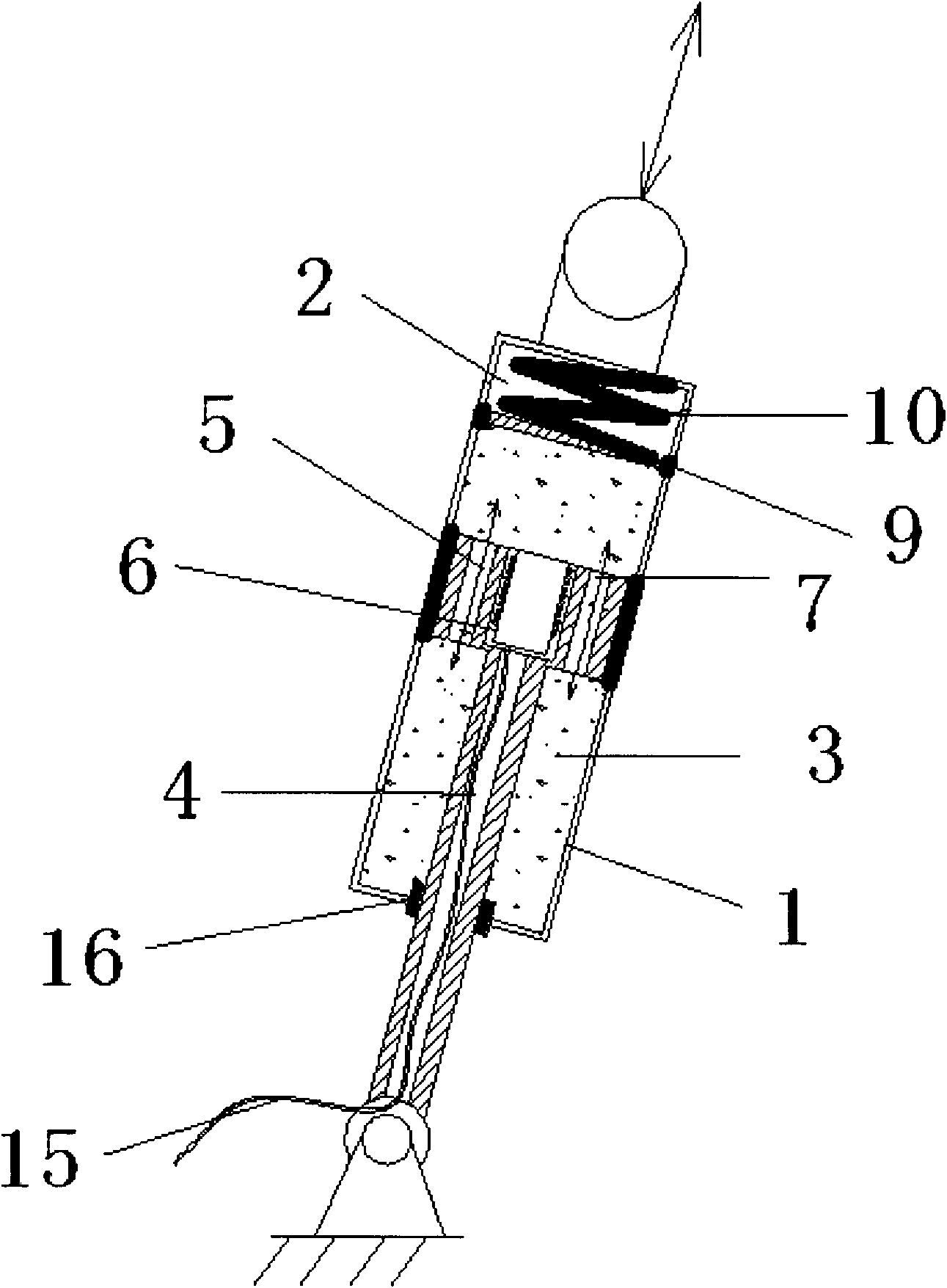

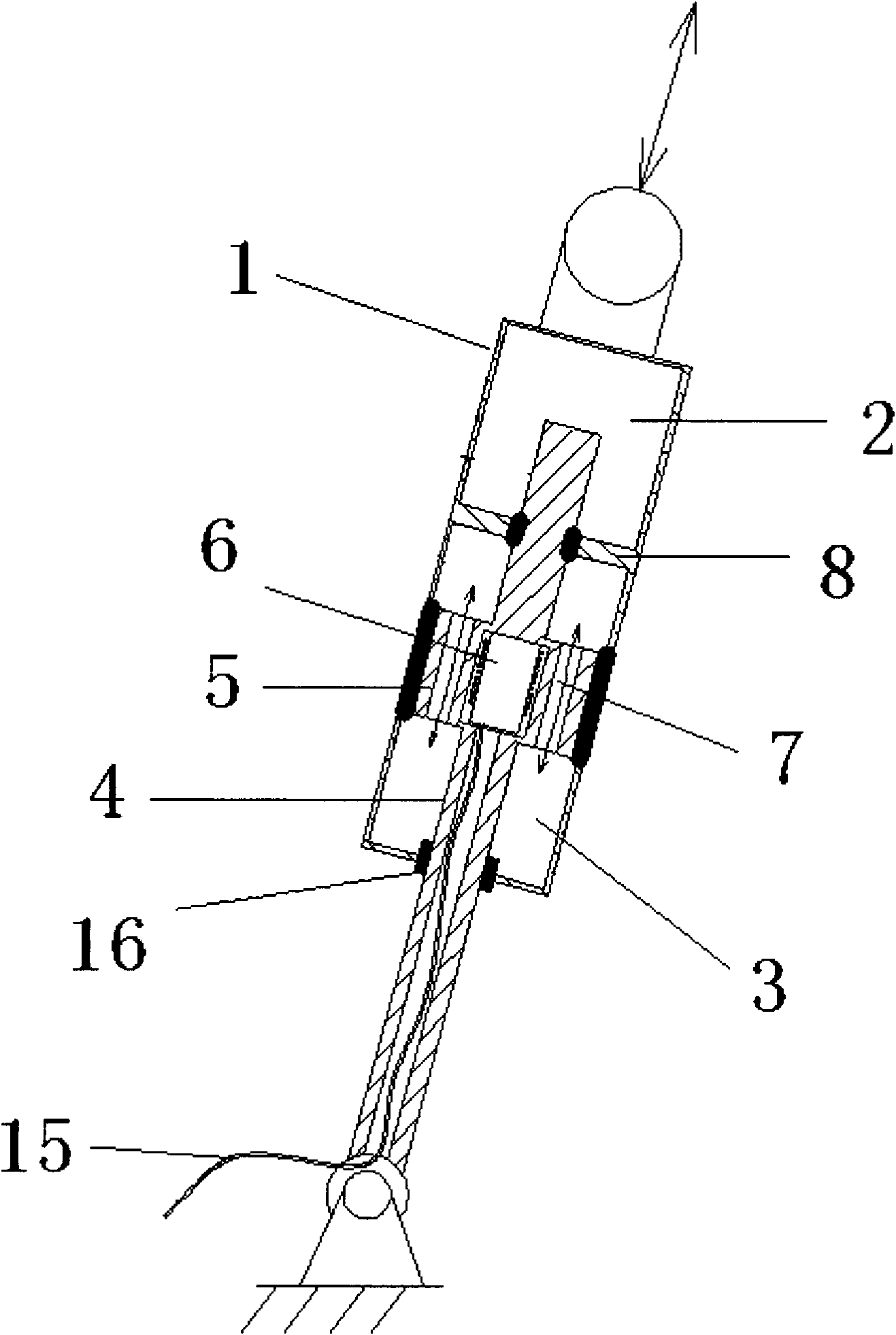

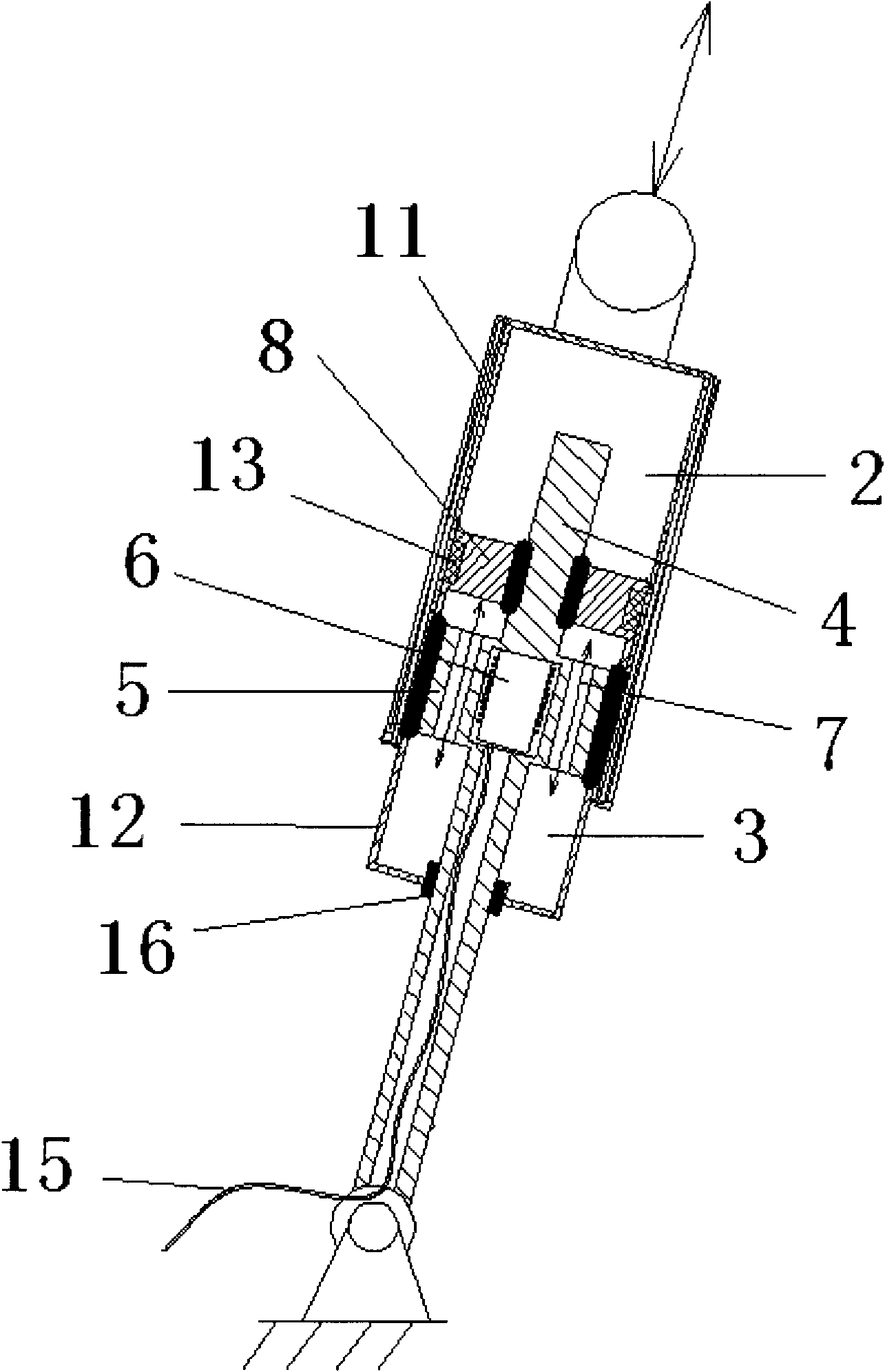

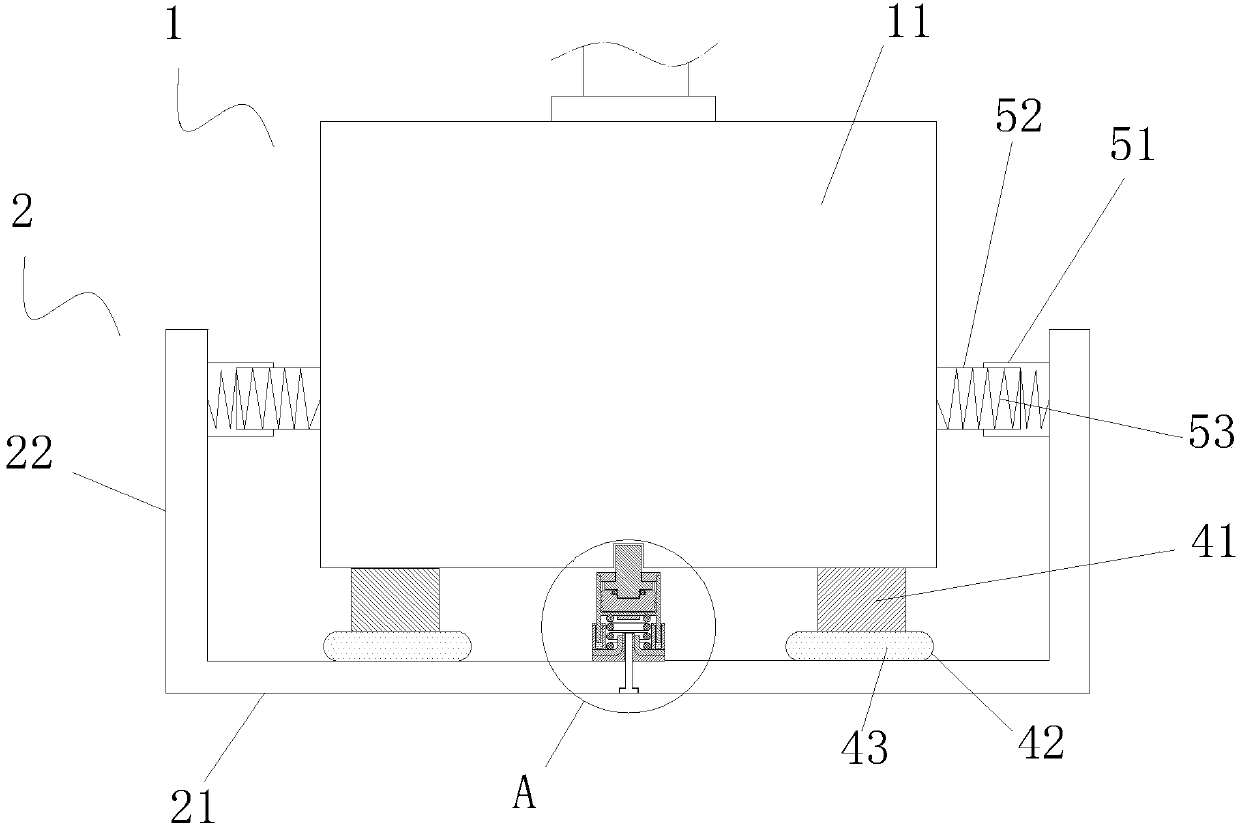

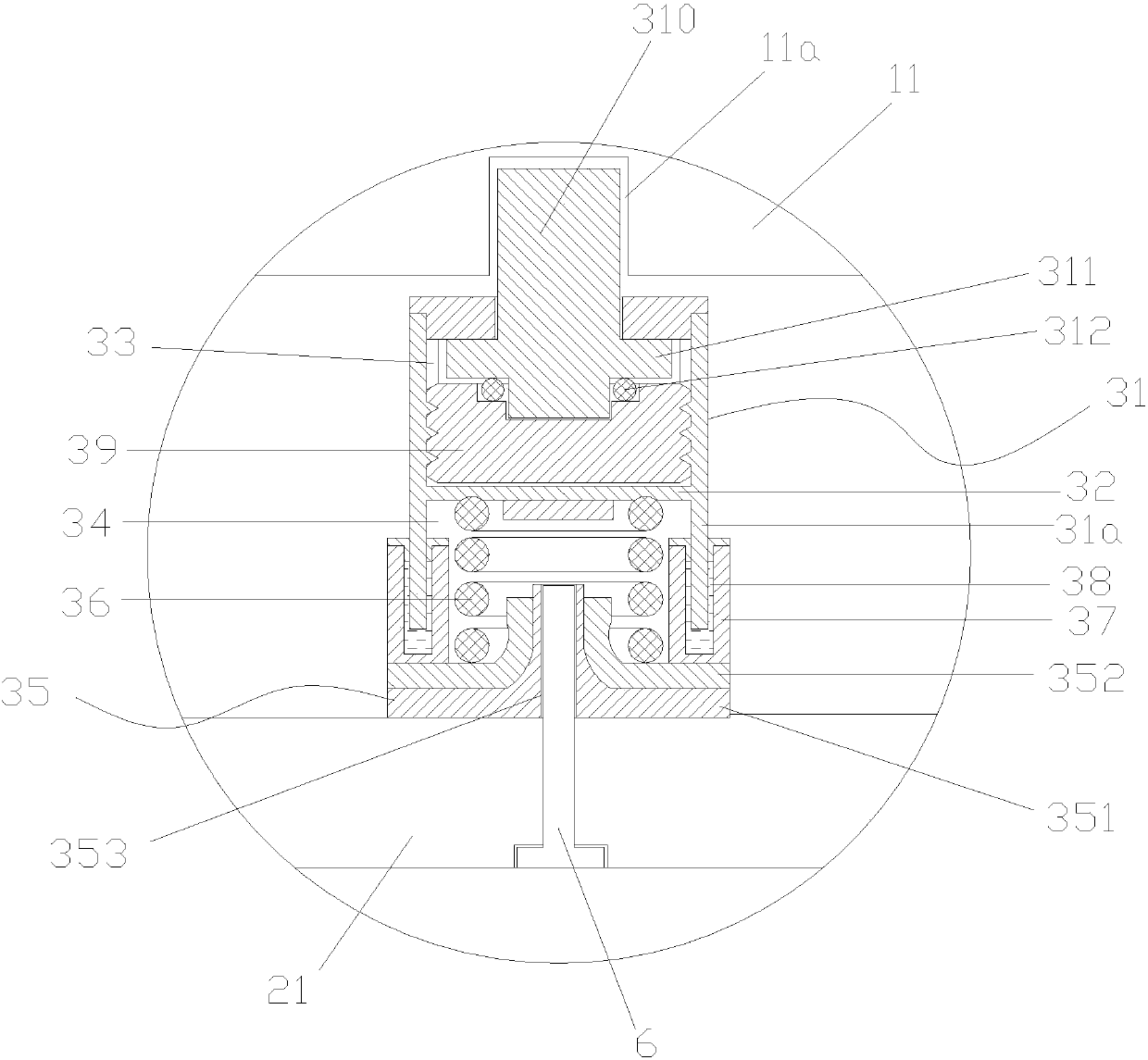

Variable damping shock absorber and drum washing machine using shock absorber

ActiveCN102162499AAvoid resonanceAvoid passingSpringsNon-rotating vibration suppressionPower flowEngineering

The invention discloses a variable damping shock absorber and a drum washing machine using the shock absorber. The shock absorber disclosed by the invention comprises a shock absorber barrel, a piston rod and a piston, wherein the shock absorber barrel comprises a damping cavity and a buffering cavity; the piston rod is inserted into the barrel; the piston is fixedly arranged on the piston rod in the damping cavity; the buffering cavity is communicated with the outside; the damping cavity is filled with magnetic fluid; an electric magnet and a throttling orifice for the magnetic fluid to pass through are arranged in the piston; the electric magnet is connected with a master controller through a wire in the piston rod; and the master controller changes the liquidity of the magnetic fluid by controlling the magnitude of current and utilizing the magnetism variation of the electric magnet, thereby realizing the purpose of adjusting the damping in real time. In the washing machine disclosed by the invention, the real-time damping adjustment can be realized according to the rotating speed of a motor through the shock absorber. The variable damping shock absorber and drum washing machine disclosed by the invention have the advantages of simple structure, high sensitivity and obvious shock absorption effect, and are suitable for being popularized and used.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

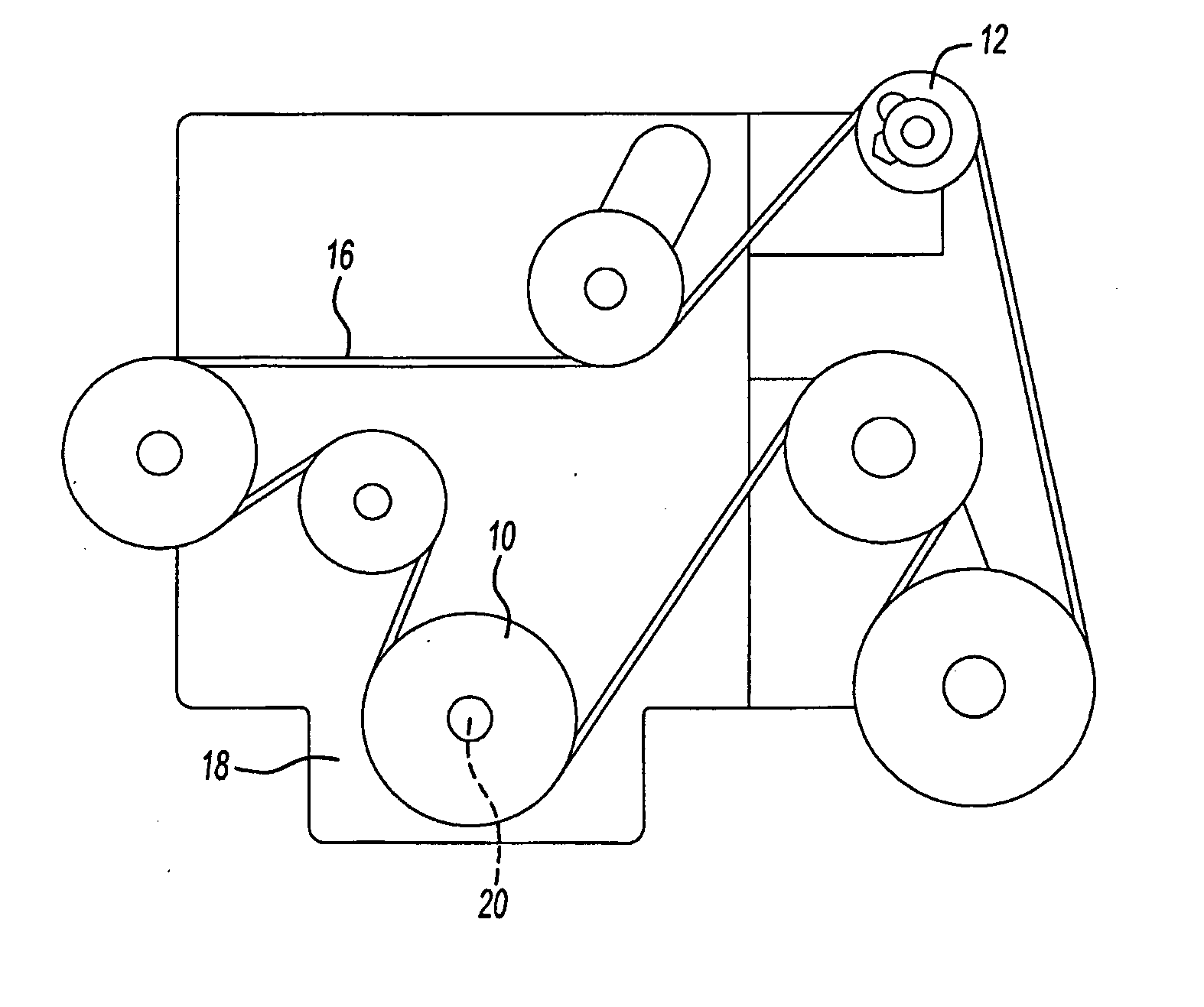

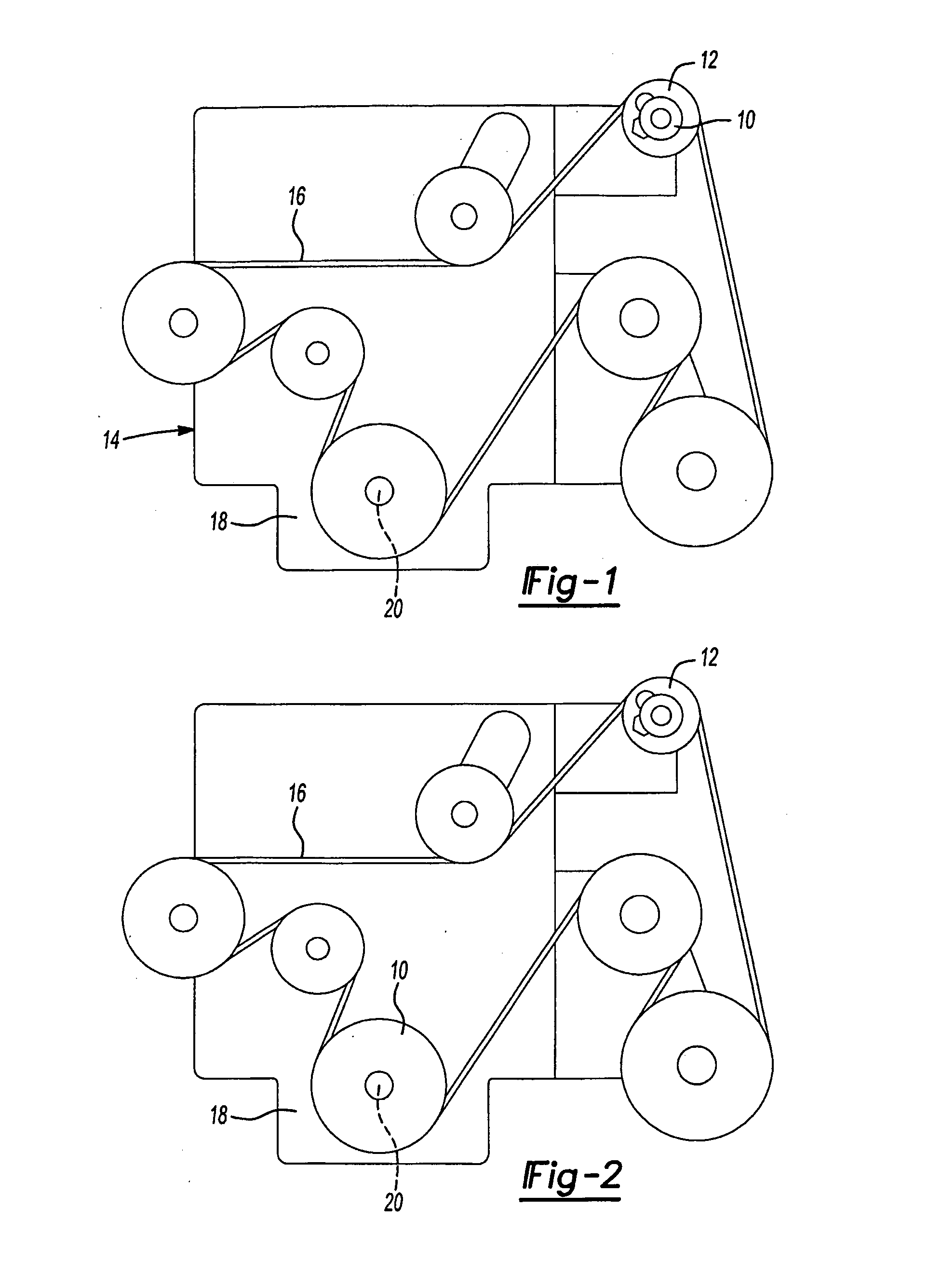

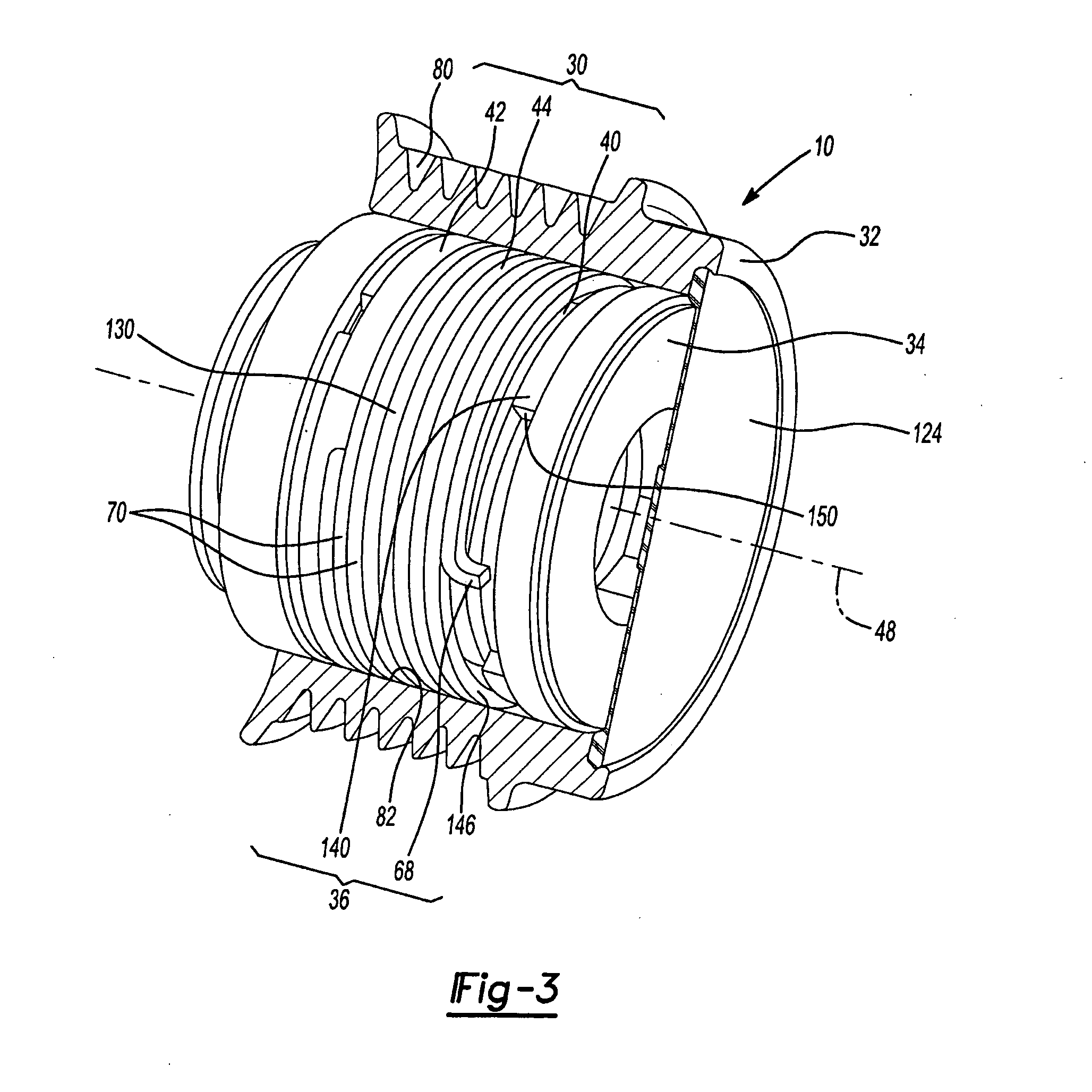

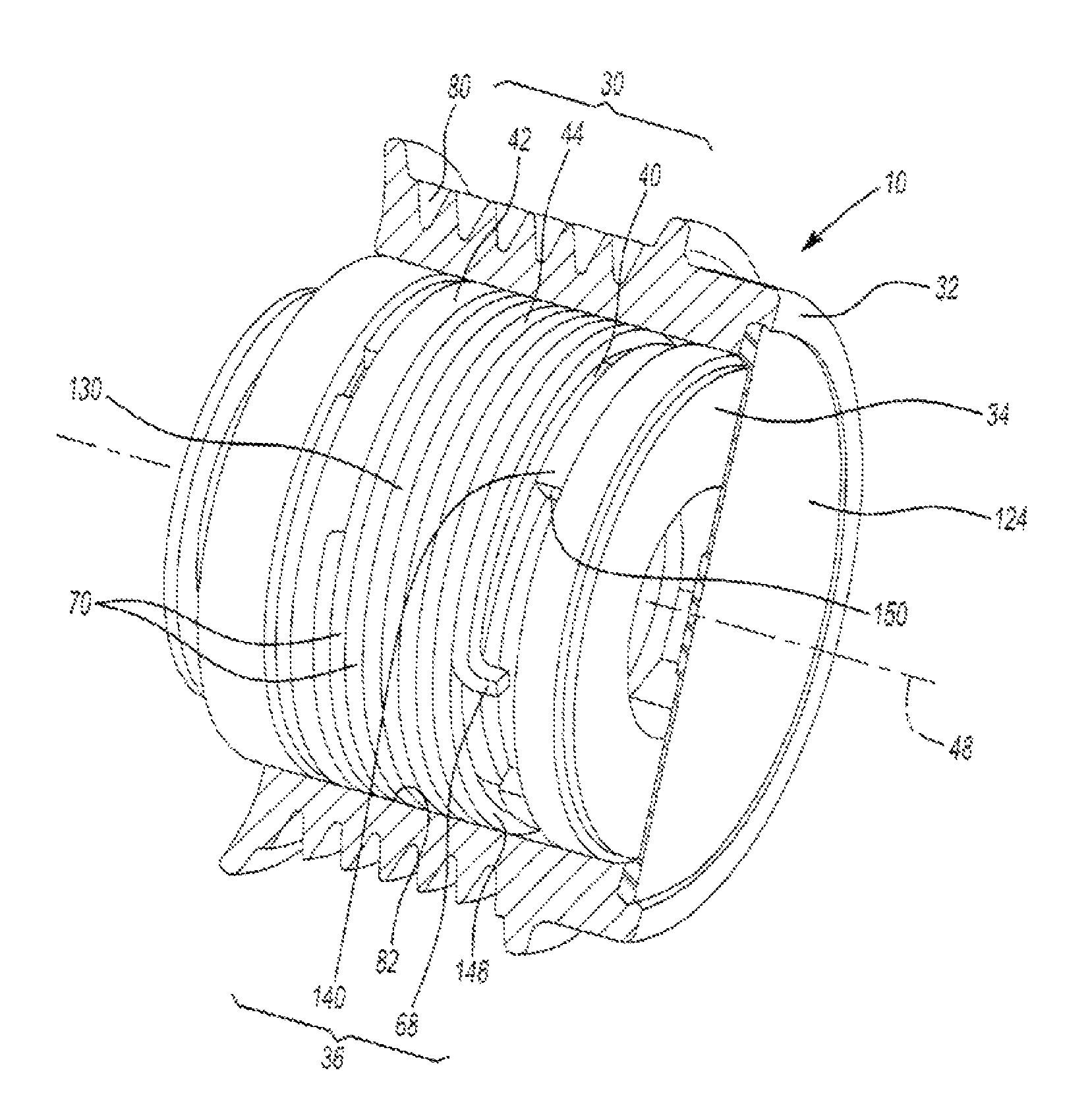

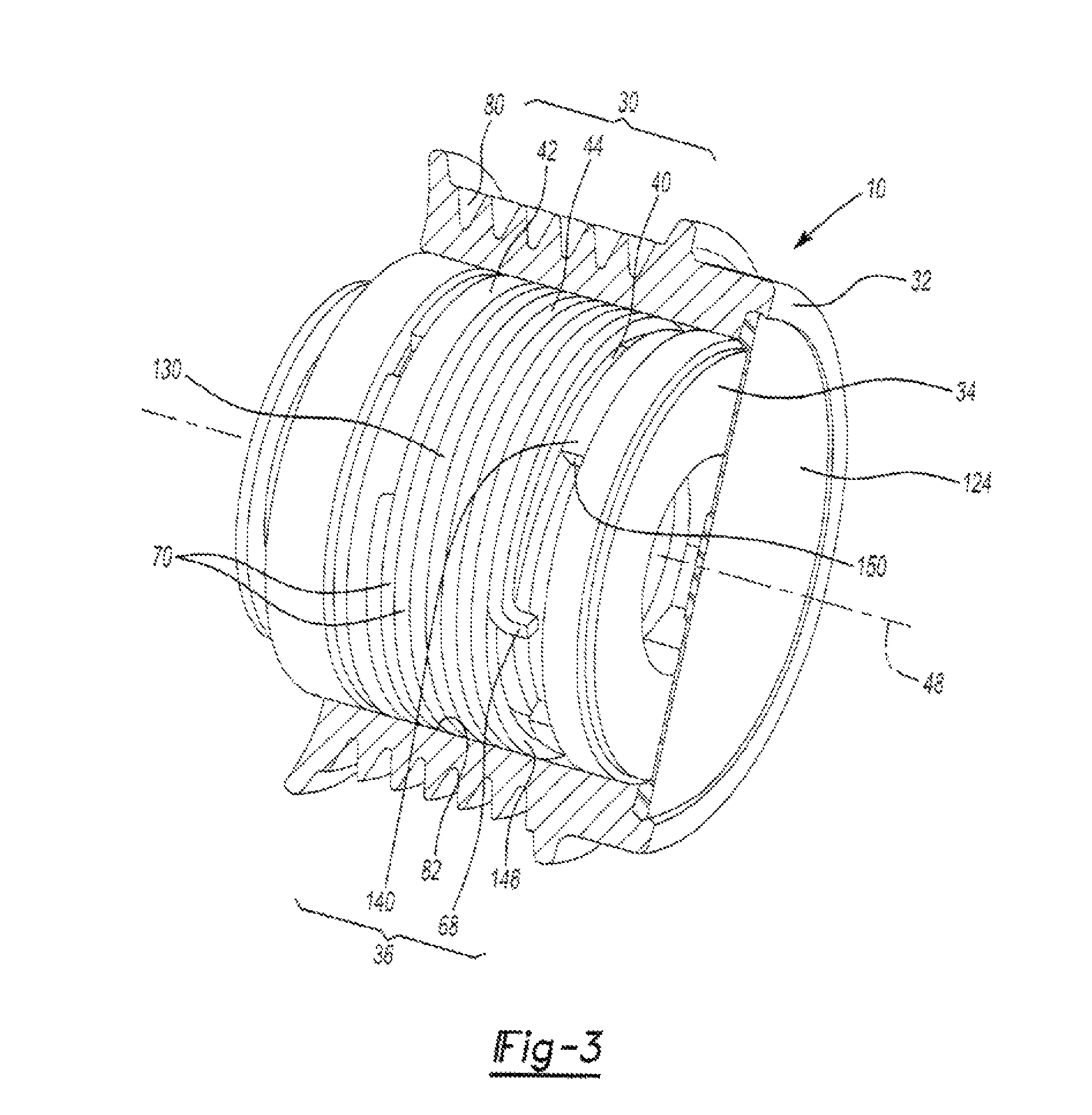

Over-Running Decoupler With Torque Limiter

ActiveUS20110224038A1Reduced fatigue lifeAvoid resonanceYielding couplingSlip couplingResonanceEngineering

A method for producing an over-running decoupler that is configured to transmit rotary power between a rotary member and a hub. The over-running decoupler includes a one-way clutch having a clutch spring, a carrier that is coupled to the clutch spring and at least one spring that resiliently couples the carrier to the hub. The method includes: establishing a desired fatigue life of the at least one spring; establishing a design deflection of the at least one spring during resonance, wherein deflection of the at least one spring at the design deflection during resonance does not reduce a fatigue life of the at least one spring below the desired fatigue life; and preventing resonance in the over-running decoupler by controlling a maximum deflection of the at least one spring such that the maximum deflection is less than or equal to the design deflection.

Owner:LITENS AUTOMOTIVE INC

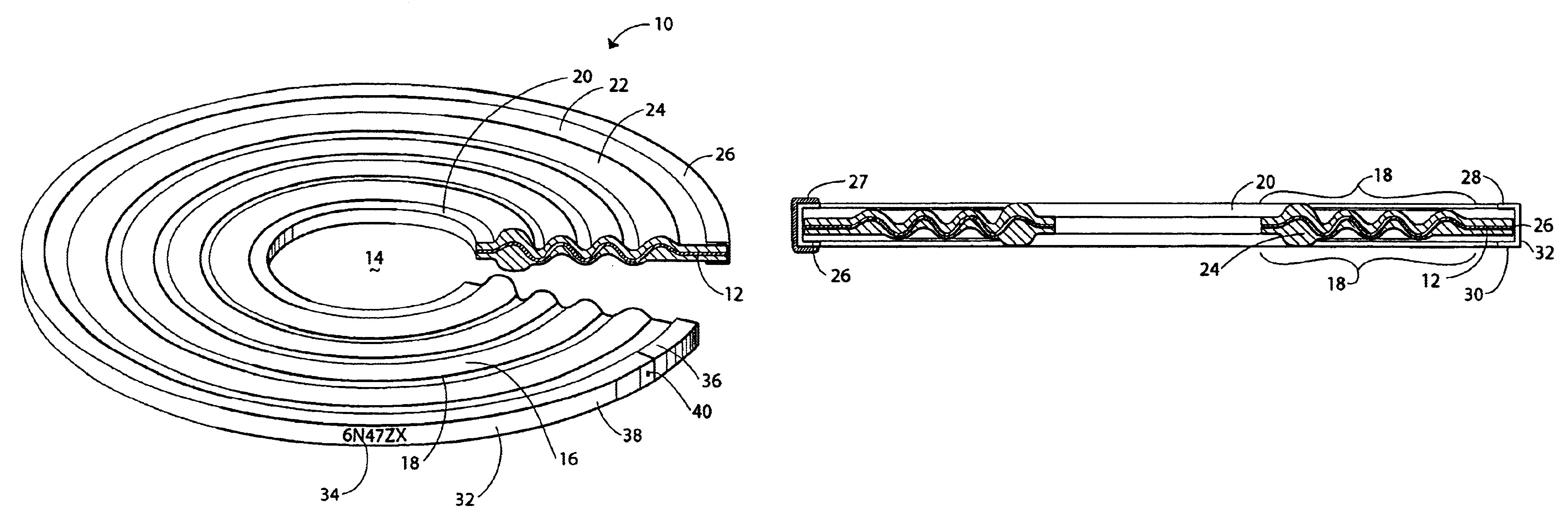

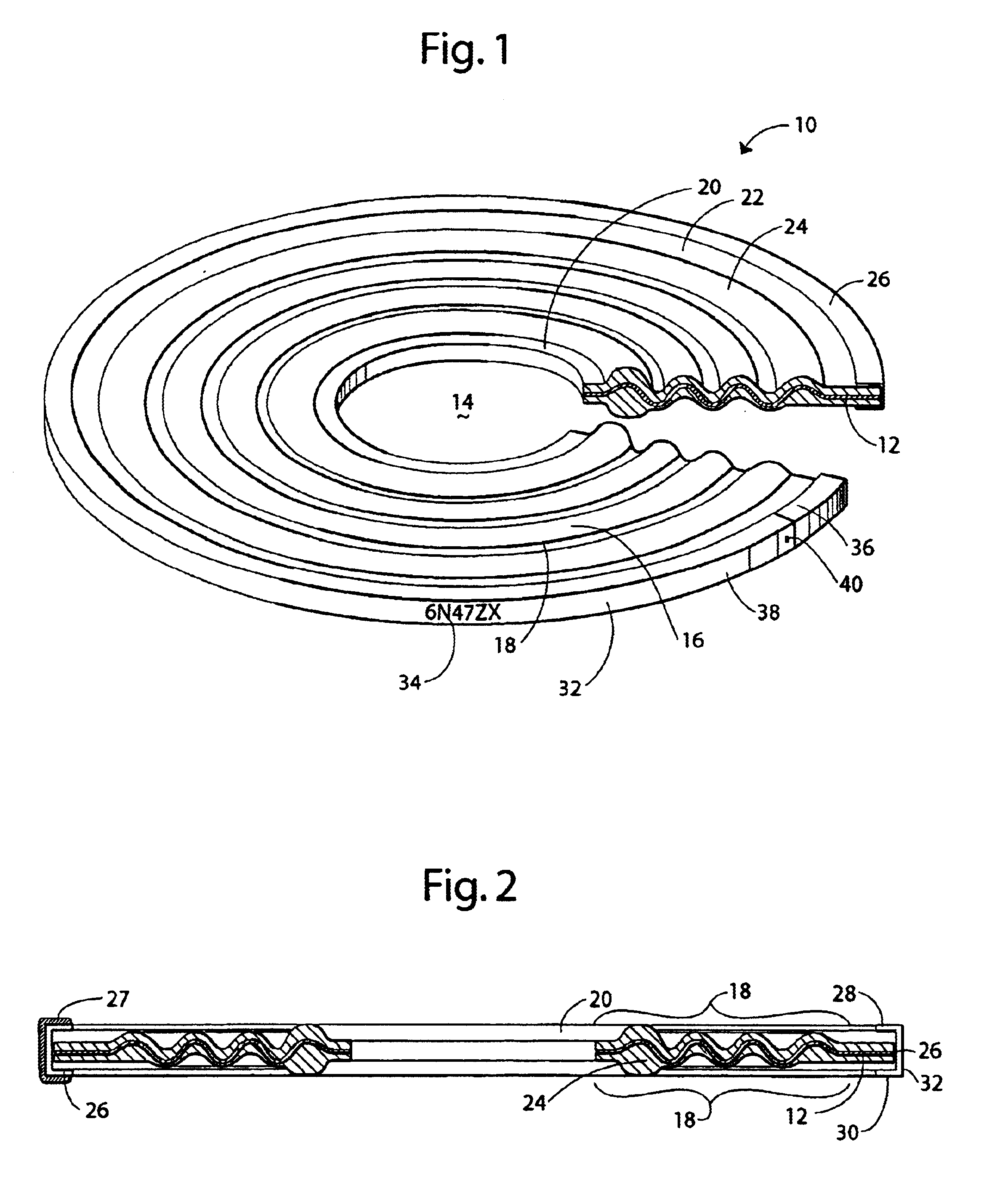

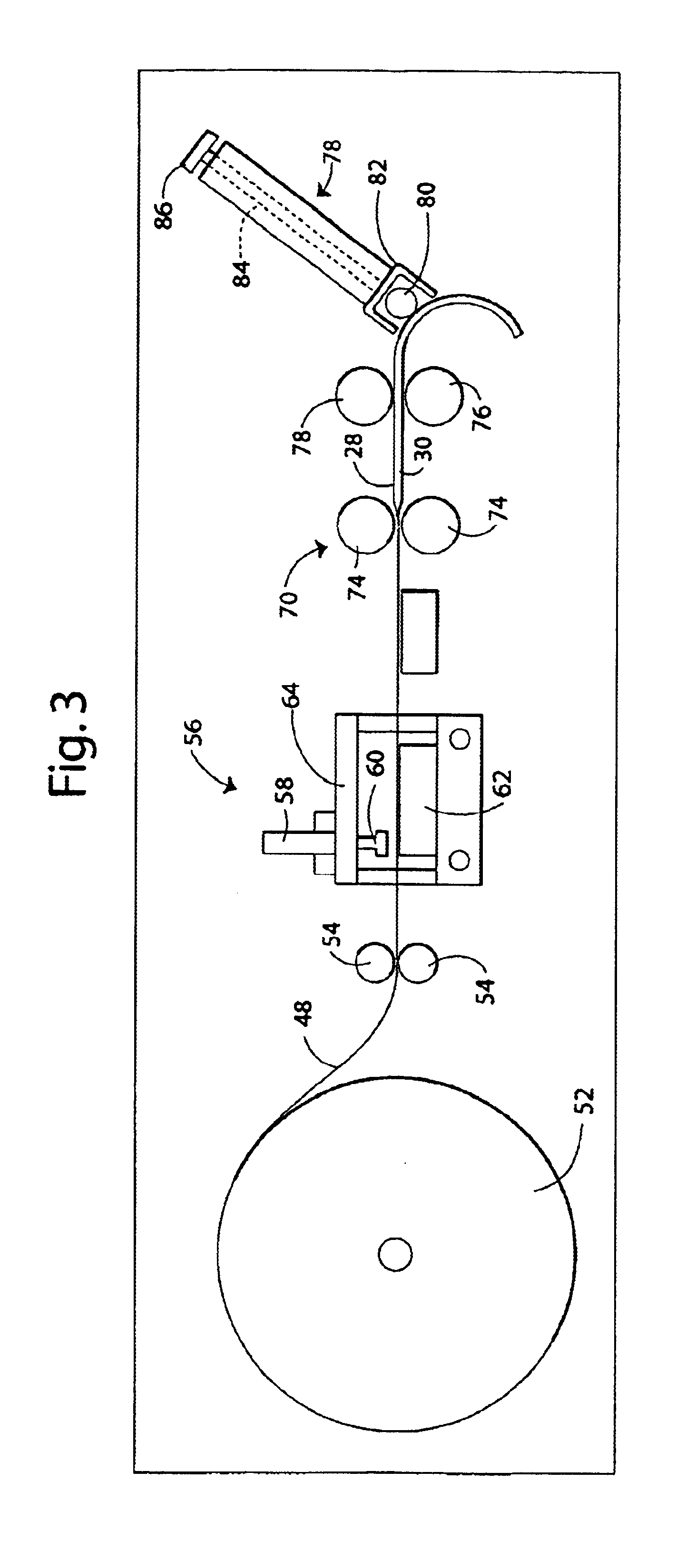

Gasket with outer edge damping channel and method and apparatus for manufacturing same

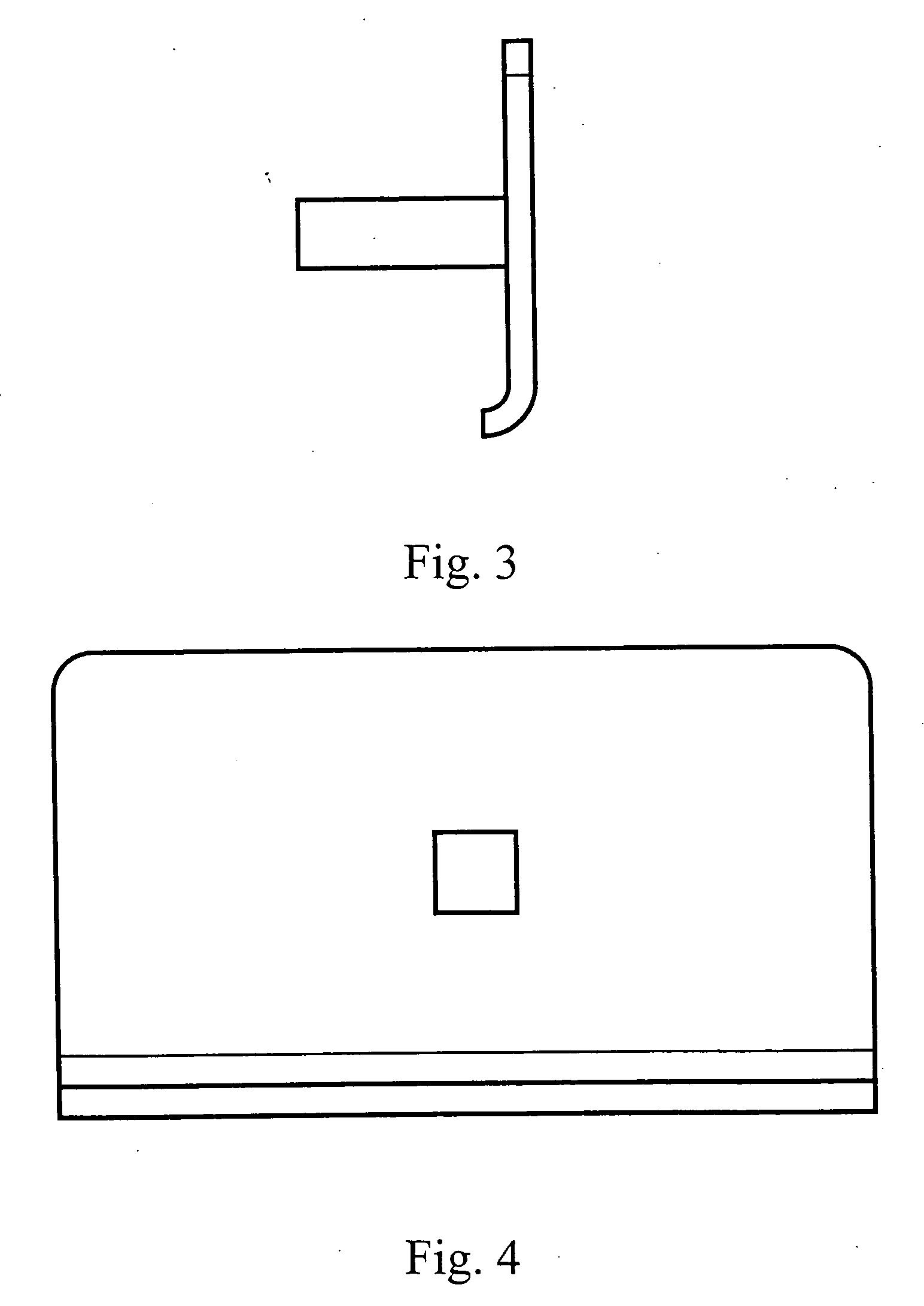

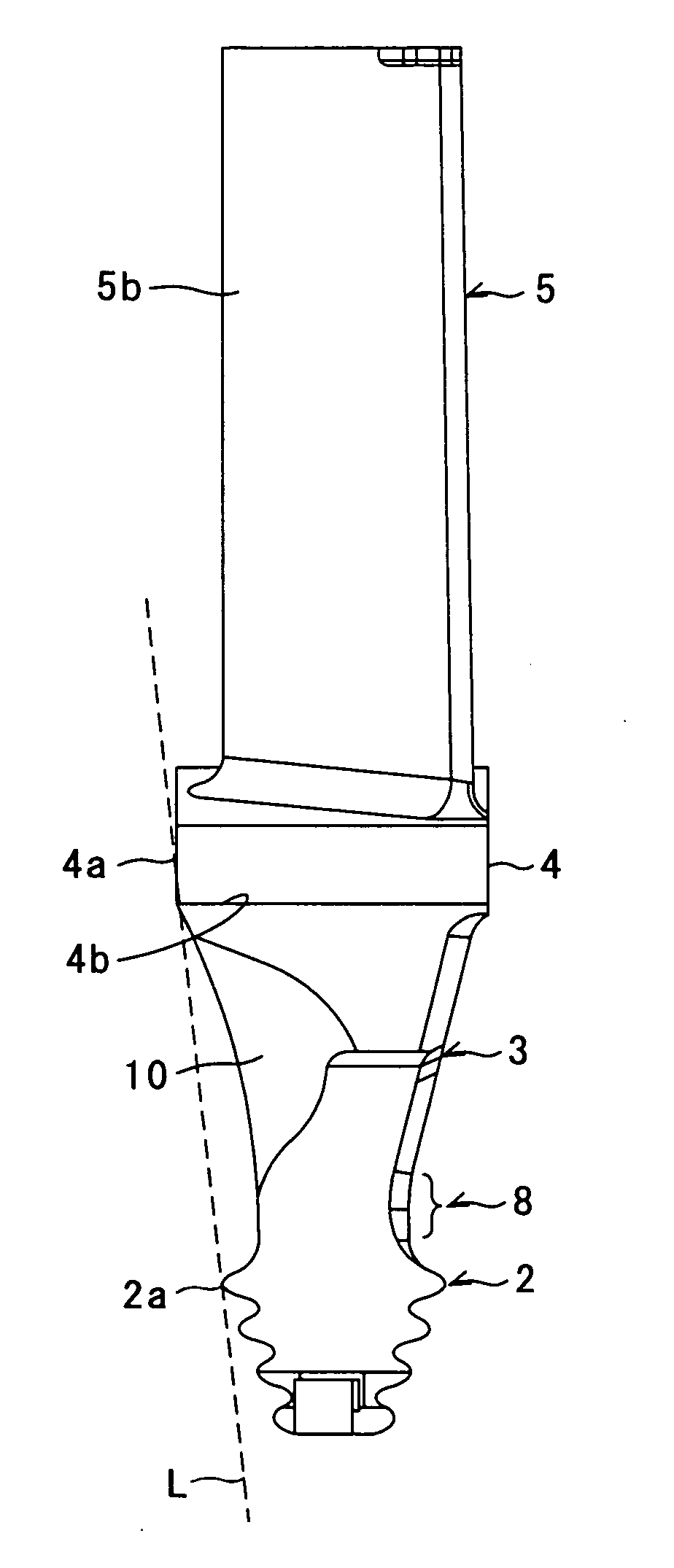

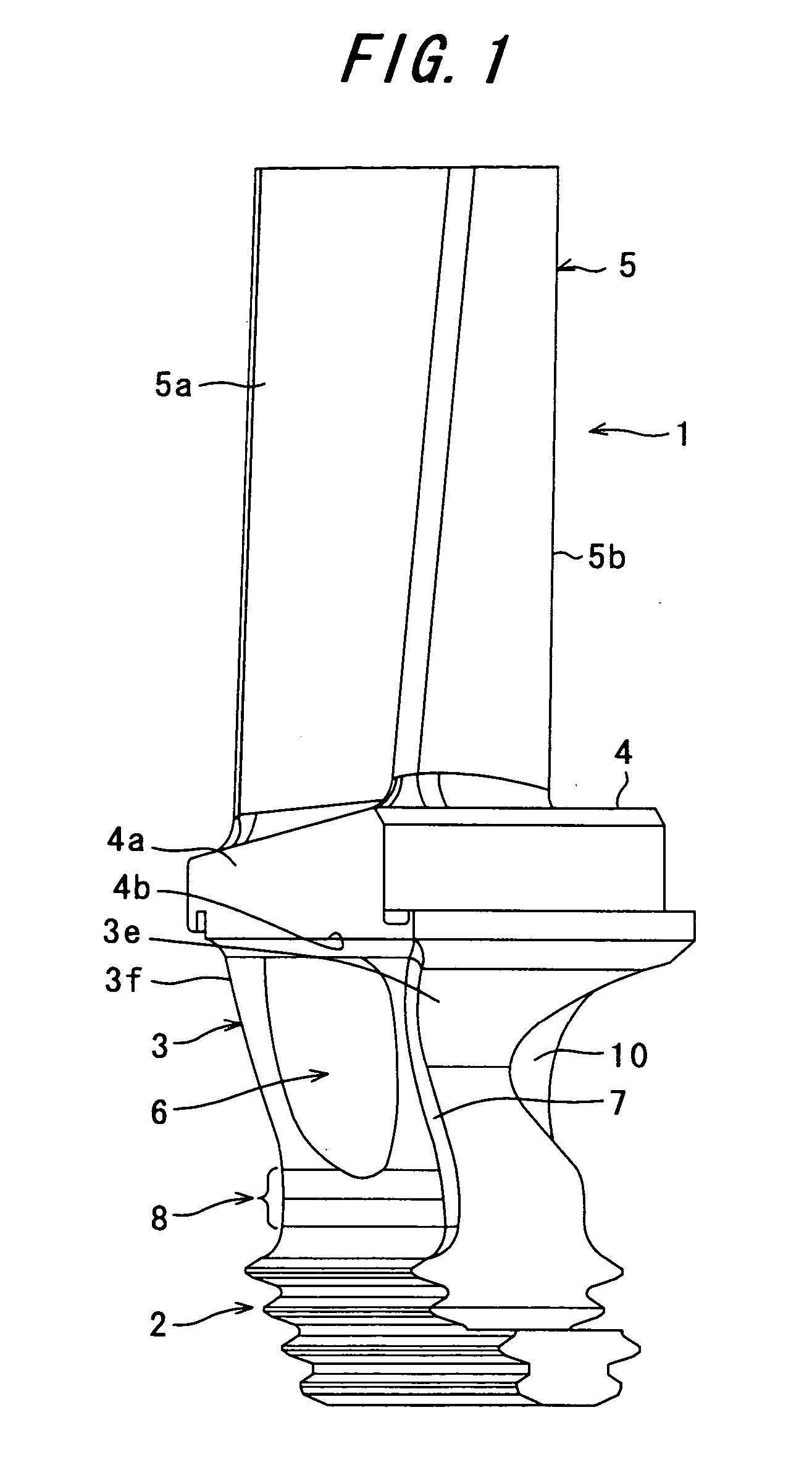

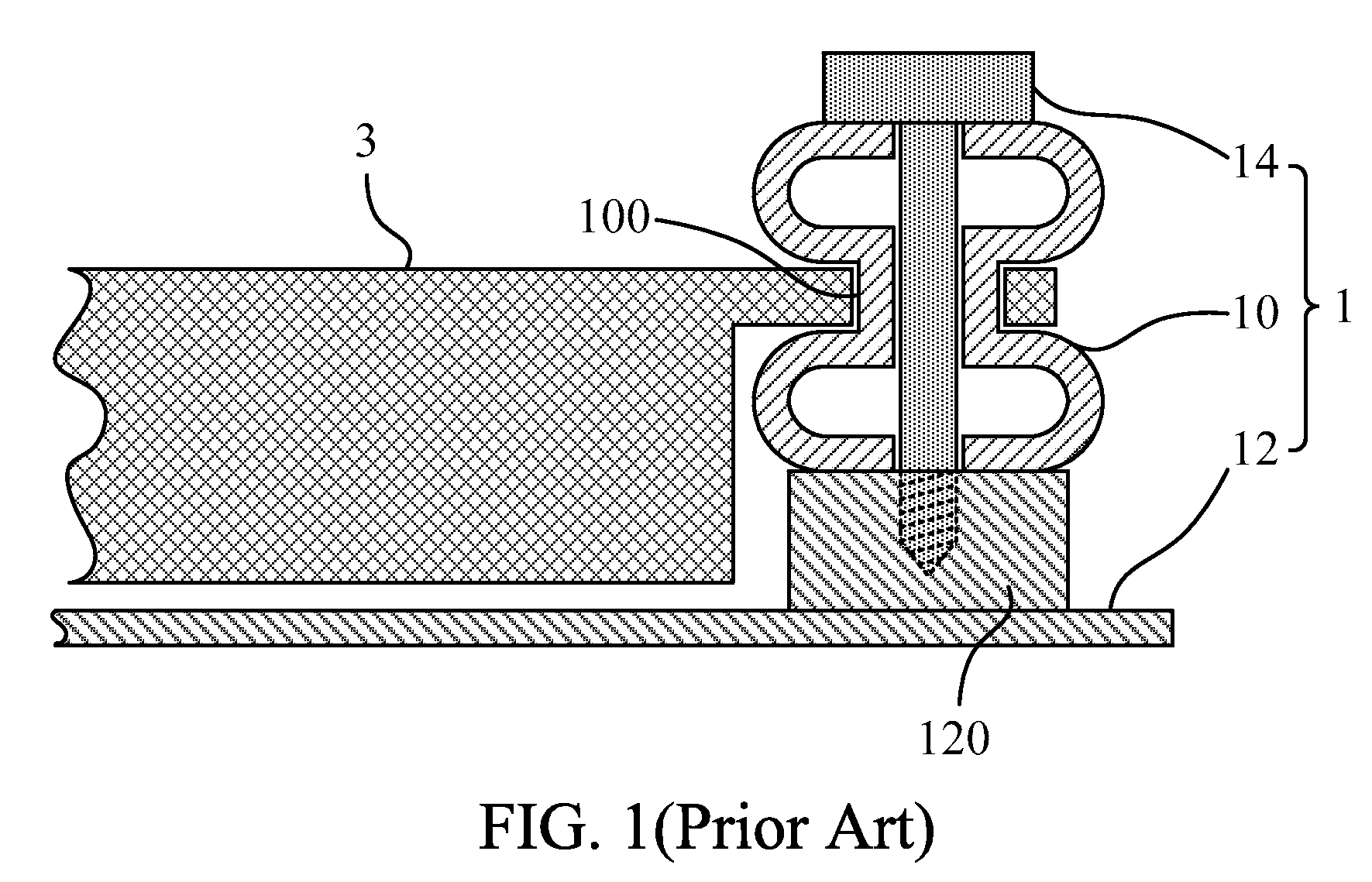

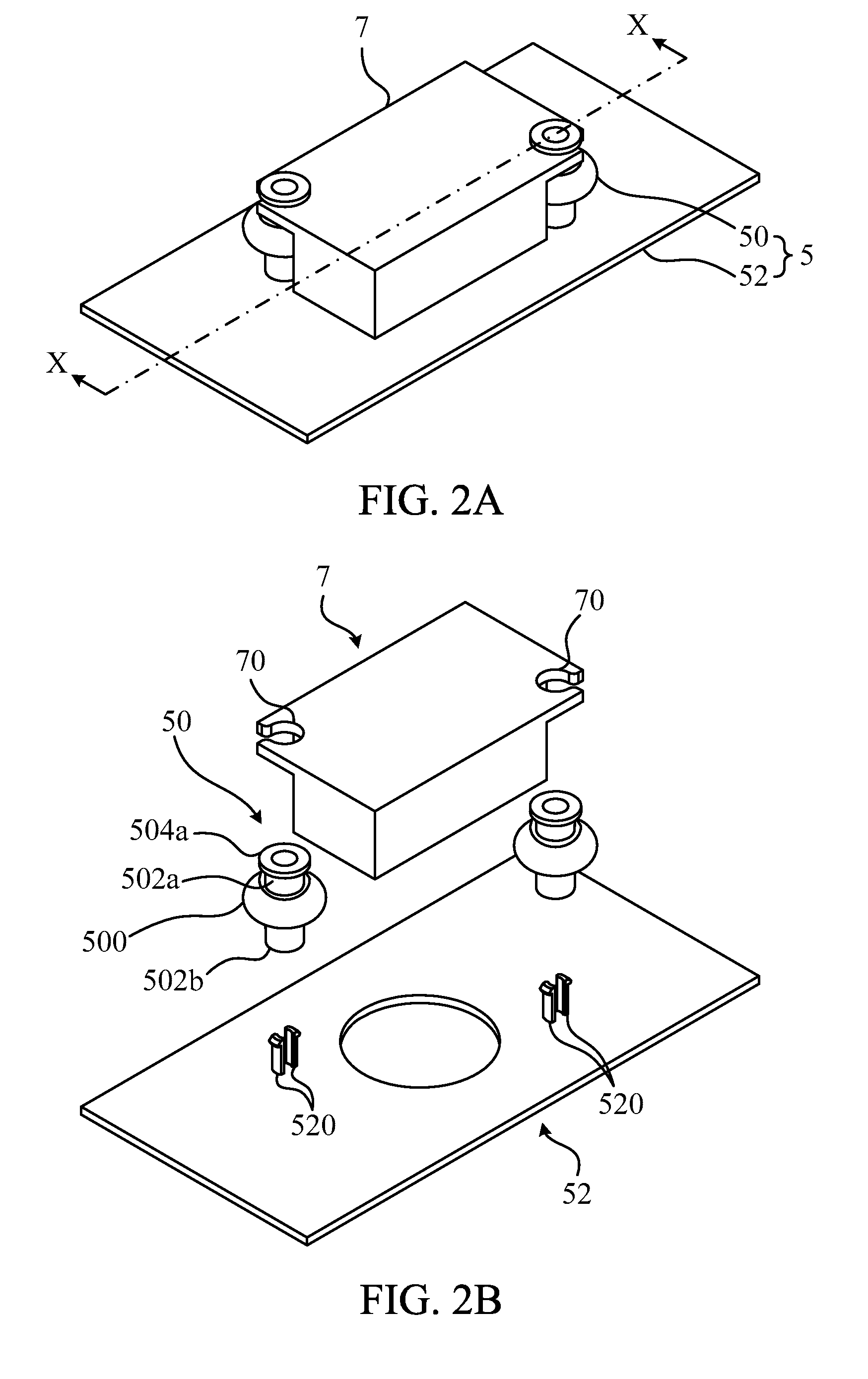

A gasket (10) for sealing flange connections in piping systems for media, while changing a natural frequency of the gasket to avoid resonance in the flange connection, comprising a plate (12) that defines a opening (14) for passage of media through the flange connection sealed with the plate, with opposing sealing surfaces (18) between an edge (20) of the opening and an outer perimeter edge (22) of the plate, and a channel (26) received around an outer perimeter edge of the plate and unloaded in the flange connection whereby the channel being unloaded but in engagement to the plate changes a natural frequency of the plate to avoid resonance in the flange connection.

Owner:ACADIA ELASTOMERS

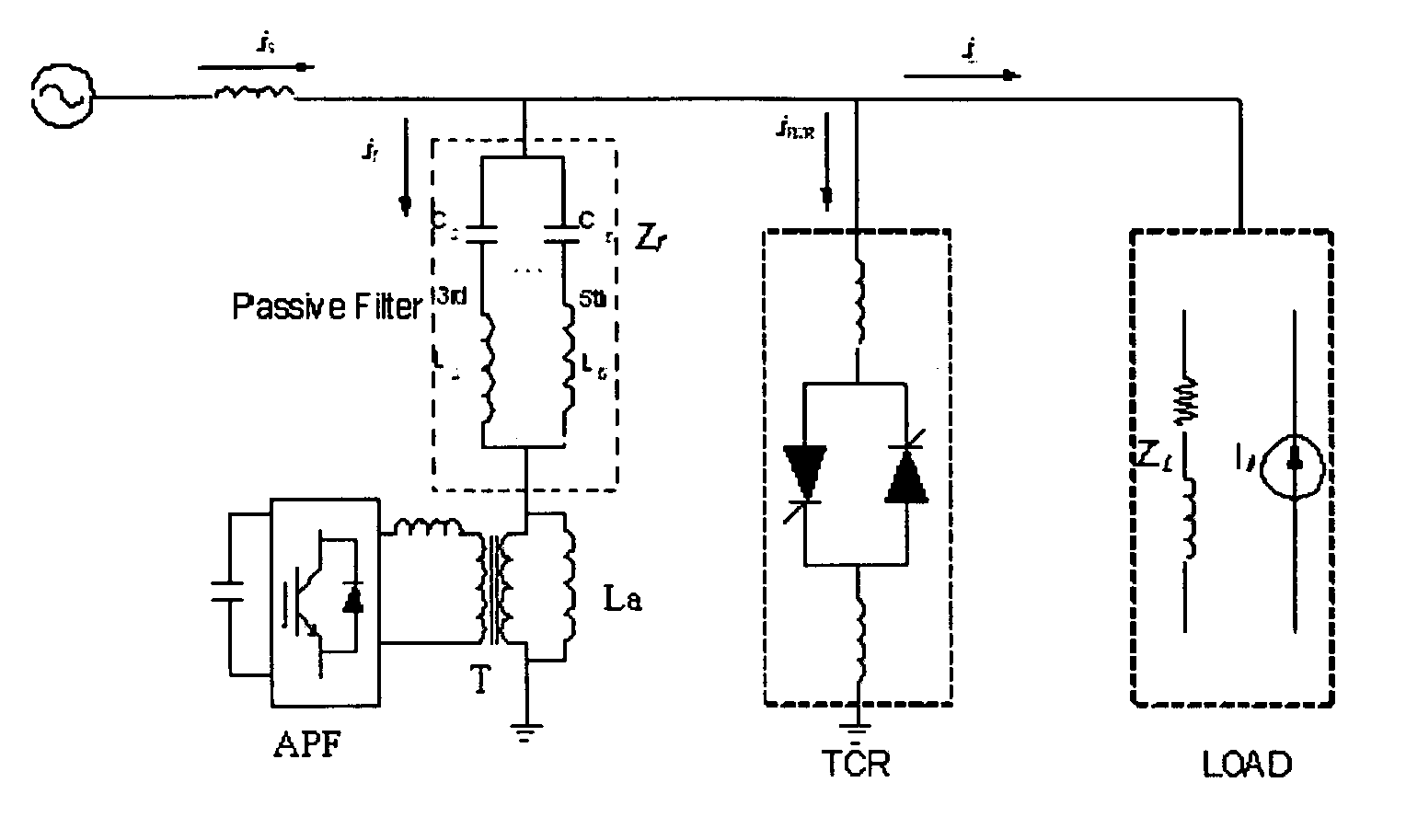

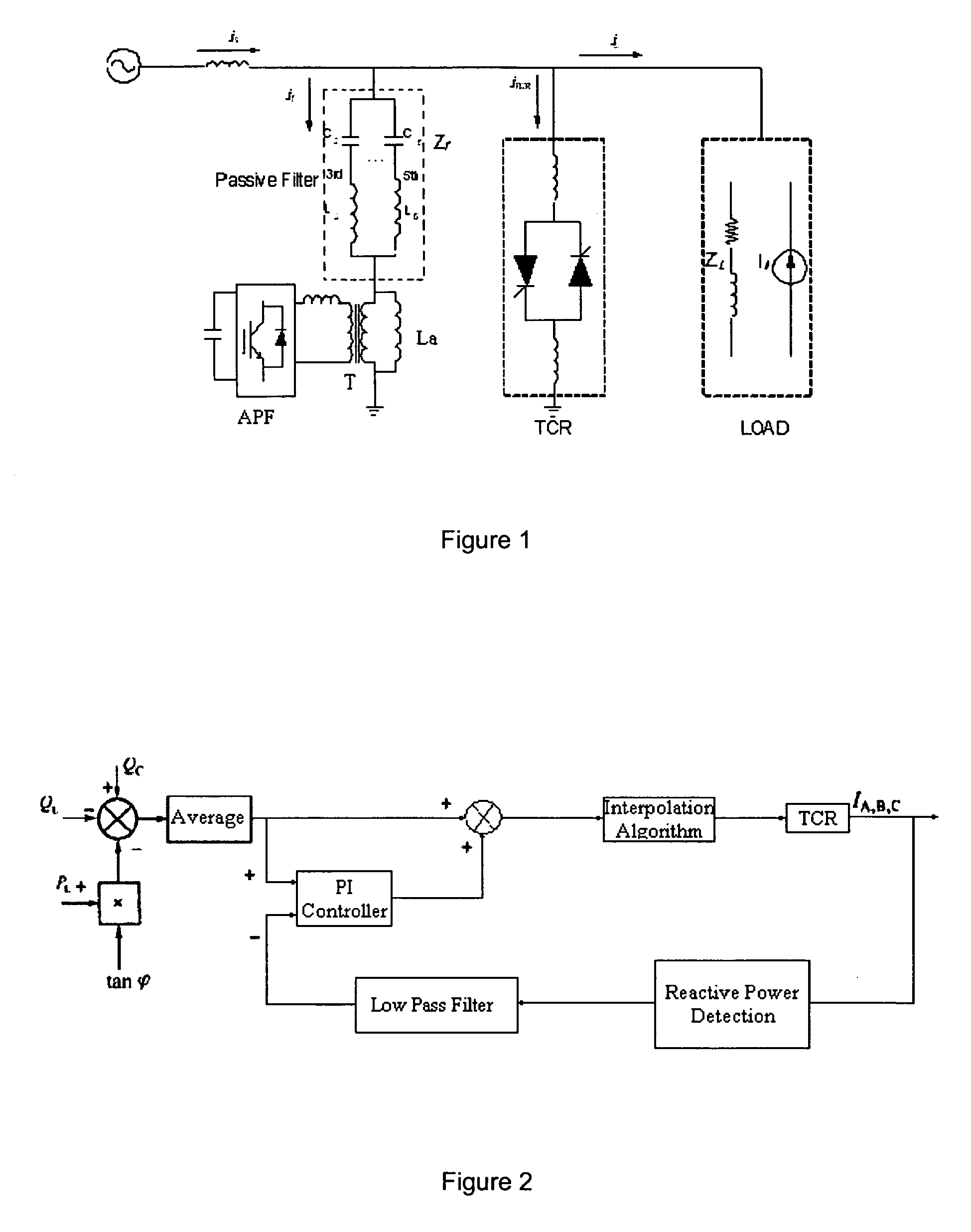

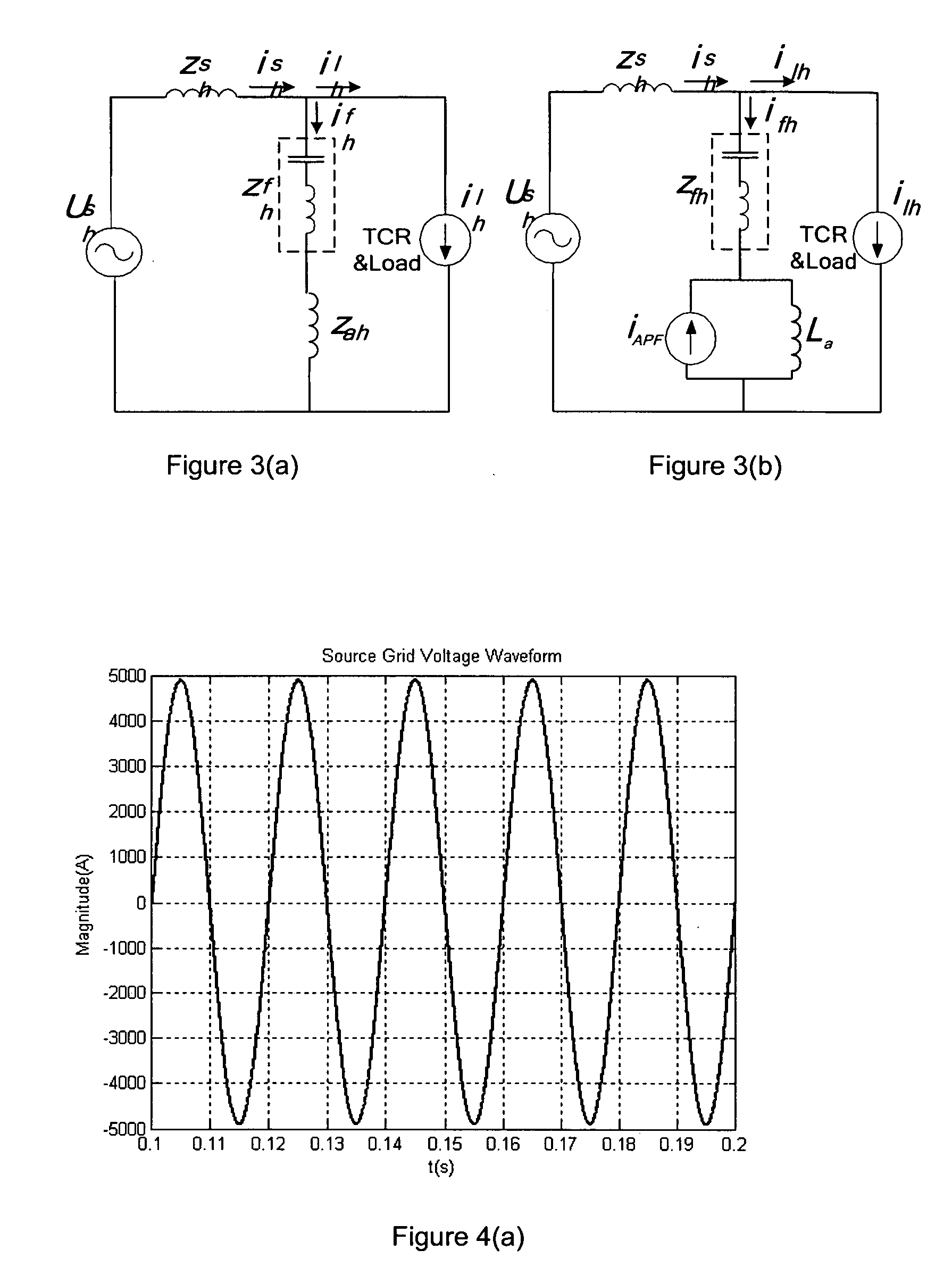

Comprehensive power quality controller for substation in power system

InactiveUS20070014132A1Small capacityCost muchFlexible AC transmissionActive power filteringPower gridPassive filtering

This invention disclosed is a comprehensive power quality controller for substation in the electric power system and includes a Thyristor Controlled Reactor (TCR), pure tuned passive filter Zf, additional inductor L active power filter (APF), and a coupling transformer. The Thyristor Controlled Reactor (TCR) provides inductive reactive power and controls the active power filter (APF) as the current source, it is connected with the additional inductor La in parallel via the coupling transformer, then connected to the passive filter Zf in serial to consist a hybrid power filter system, which is connected to the power grid via the circuit breaker or thyristor. The comprehensive filter system provides required capacitive reactive power and filters the harmonic produced by the load and TCR system itself. Because the capacity of the active power filter (APF) is very small which is less than 1% of the harmonic source capacity, so it is a solution with low cost but simple and reliable control mode. It can suppress influence on the passive filter by the “background harmonic” of the substation and prevent the resonance occurred between the passive filter and power grid impedance.

Owner:XI AN JIAOTONG UNIV

Over-running decoupler with torque limiter

ActiveUS8888619B2Suppress fluctuationsReduce and eliminate torsional loadYielding couplingSlip couplingResonanceTorque limiter

A method for producing an over-running decoupler that is configured to transmit rotary power between a rotary member and a hub. The over-running decoupler includes a one-way clutch having a clutch spring, a carrier that is coupled to the clutch spring and at least one spring that resiliently couples the carrier to the hub. The method includes: establishing a desired fatigue life of the at least one spring; establishing a design deflection of the at least one spring during resonance, wherein deflection of the at least one spring at the design deflection during resonance does not reduce a fatigue life of the at least one spring below the desired fatigue life; and preventing resonance in the over-running decoupler by controlling a maximum deflection of the at least one spring such that the maximum deflection is less than or equal to the design deflection.

Owner:LITENS AUTOMOTIVE INC

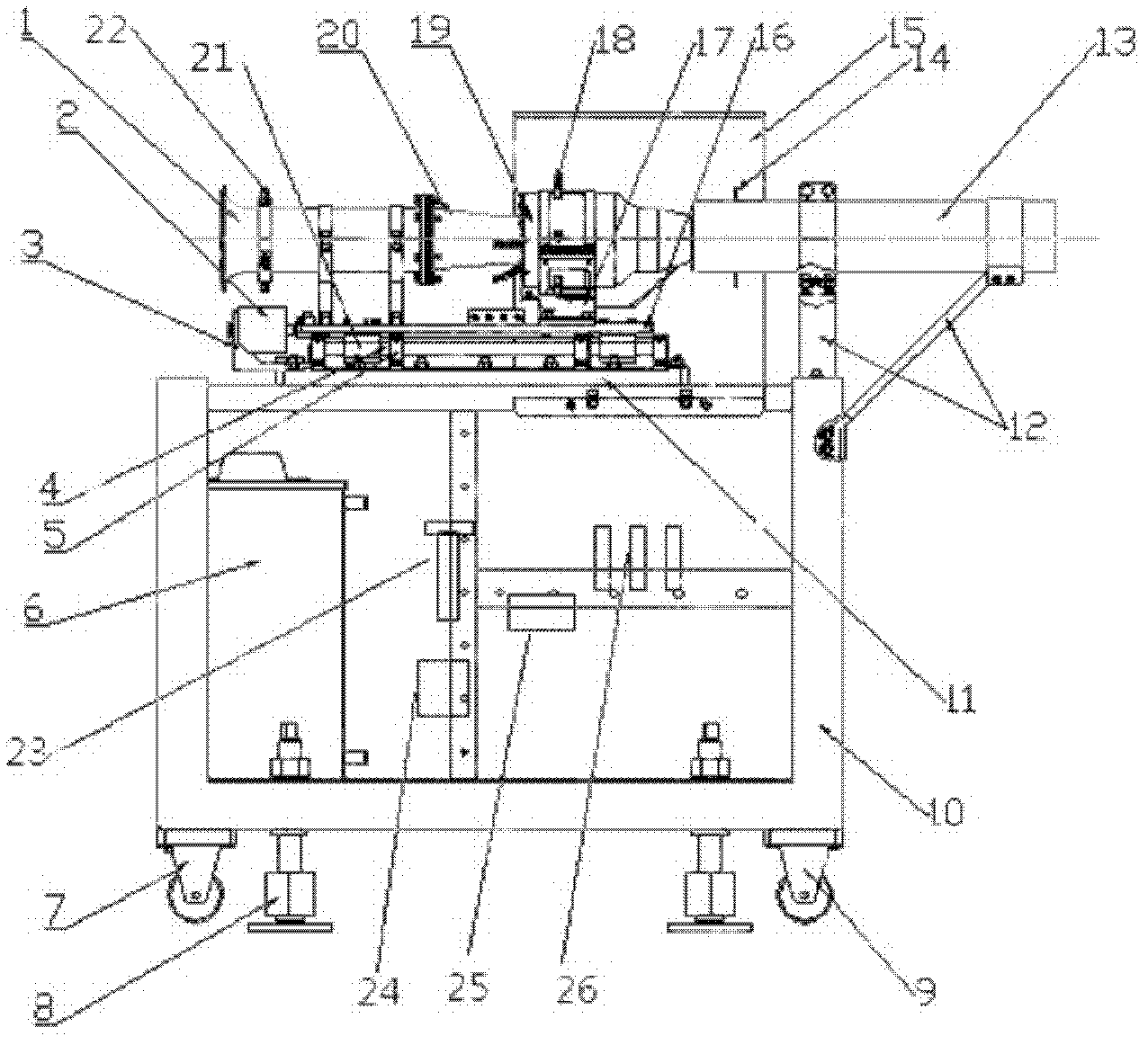

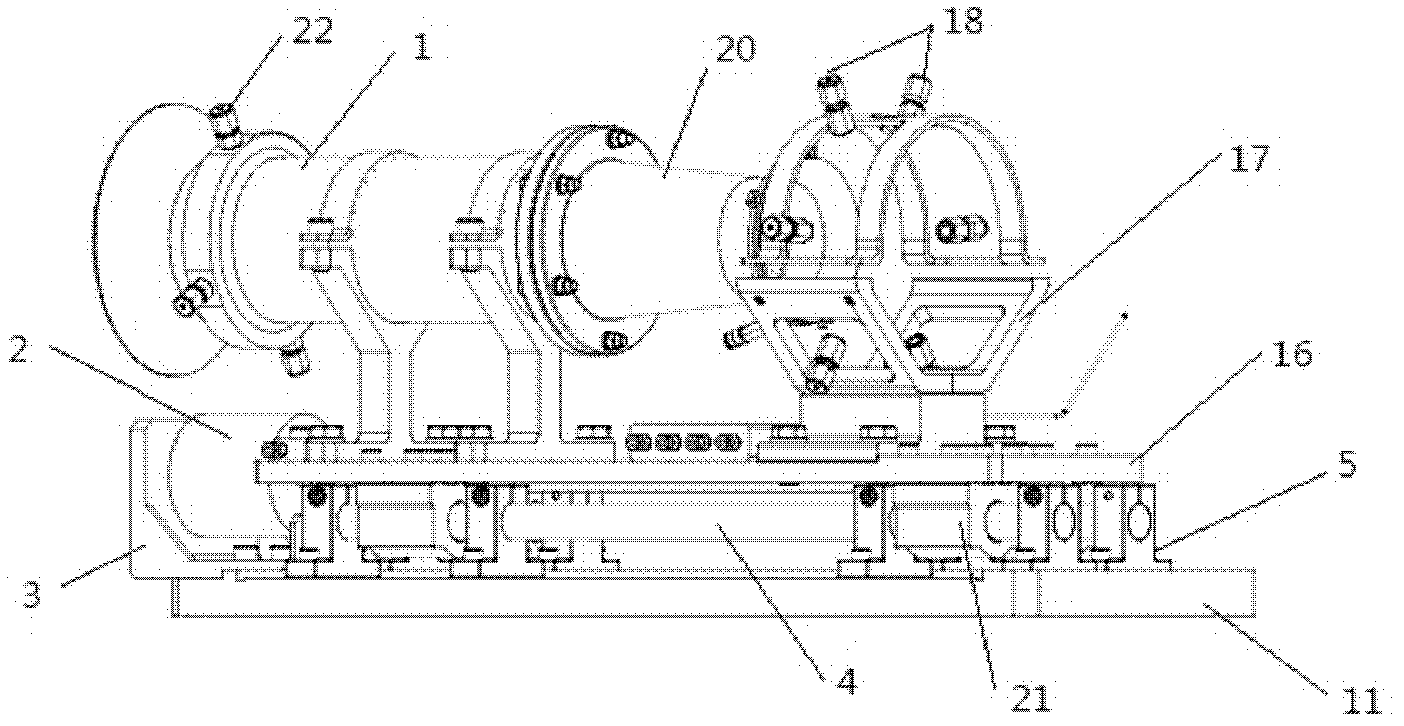

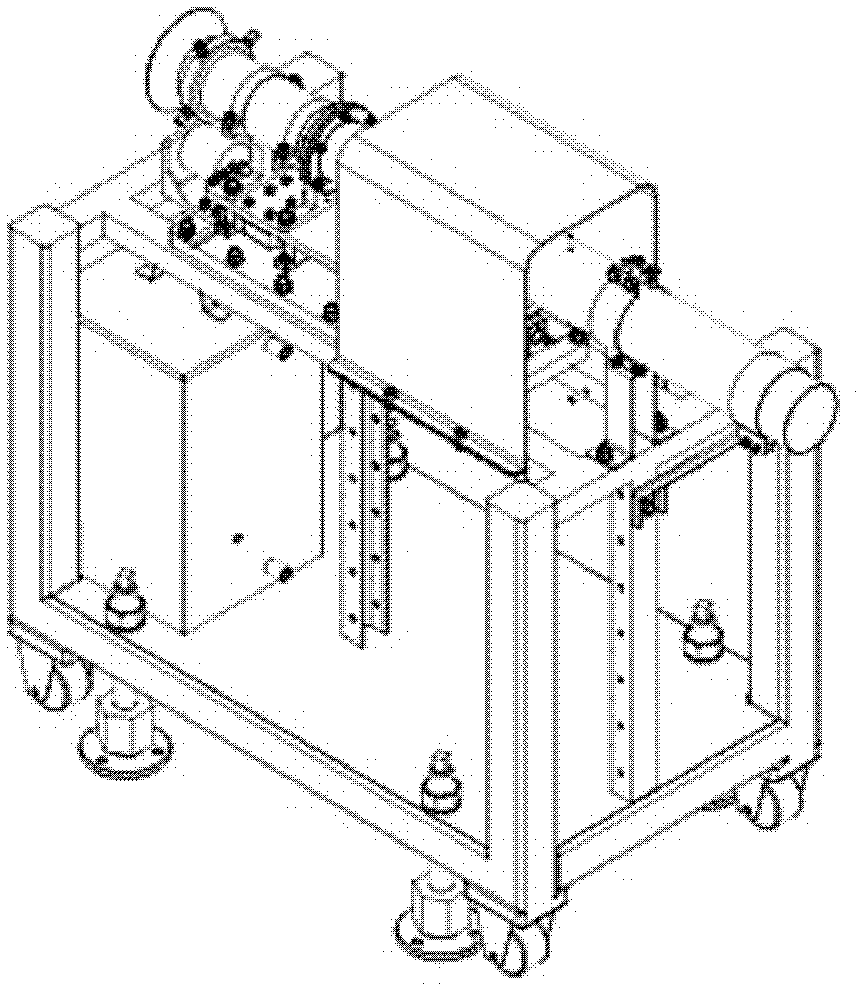

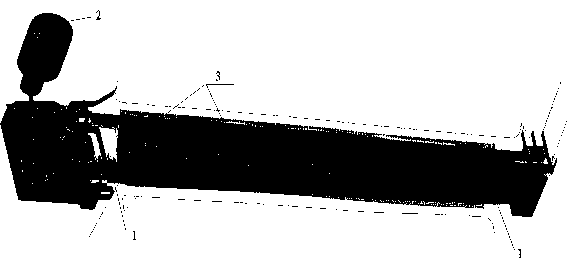

Movable micro turbine jet engine test bed

ActiveCN102507204AAccuracy meetsMeet the linearInternal-combustion engine testingDifferential pressureFuel tank

The invention relates to a movable micro turbine jet engine test bed, which consists of a test bed rack and a control cabinet. An engine to be tested and various measurement sensors are installed on the test bed rack. The test bed rack is connected with the control cabinet through conducting wires. Various meters and a computer are installed in the control cabinet. The control cabinet is used for receiving test data and controlling the running state of the engine. The test bed rack consists of a flow measuring pipe, a weighing sensor, a weighing sensor support, sliding rail shafts, sliding rail shaft supports, an oil tank, moving wheels, fixed wheels, lead screw supports, a main body support steel frame, a fixing plate, a tail jet pipe support, a tail jet pipe, temperature sensors, a protection cover, a sliding plate, an engine supporting base, a pressure measuring joint, the engine to be tested, a front inner flow guide cover, sliding plate connecting blocks, a flow meter, a micro differential pressure transmitter, an electronic control unit (ECU) and pressure transmitters. The control cabinet consists of a cabinet body, various meters, the computer, four corner wheels and an ECU control assembly. The movable micro turbine jet engine test bed is flexible and convenient, and provides an equipment support for the accurate determination of the performance of the micro turbine jet engine.

Owner:BEIHANG UNIV

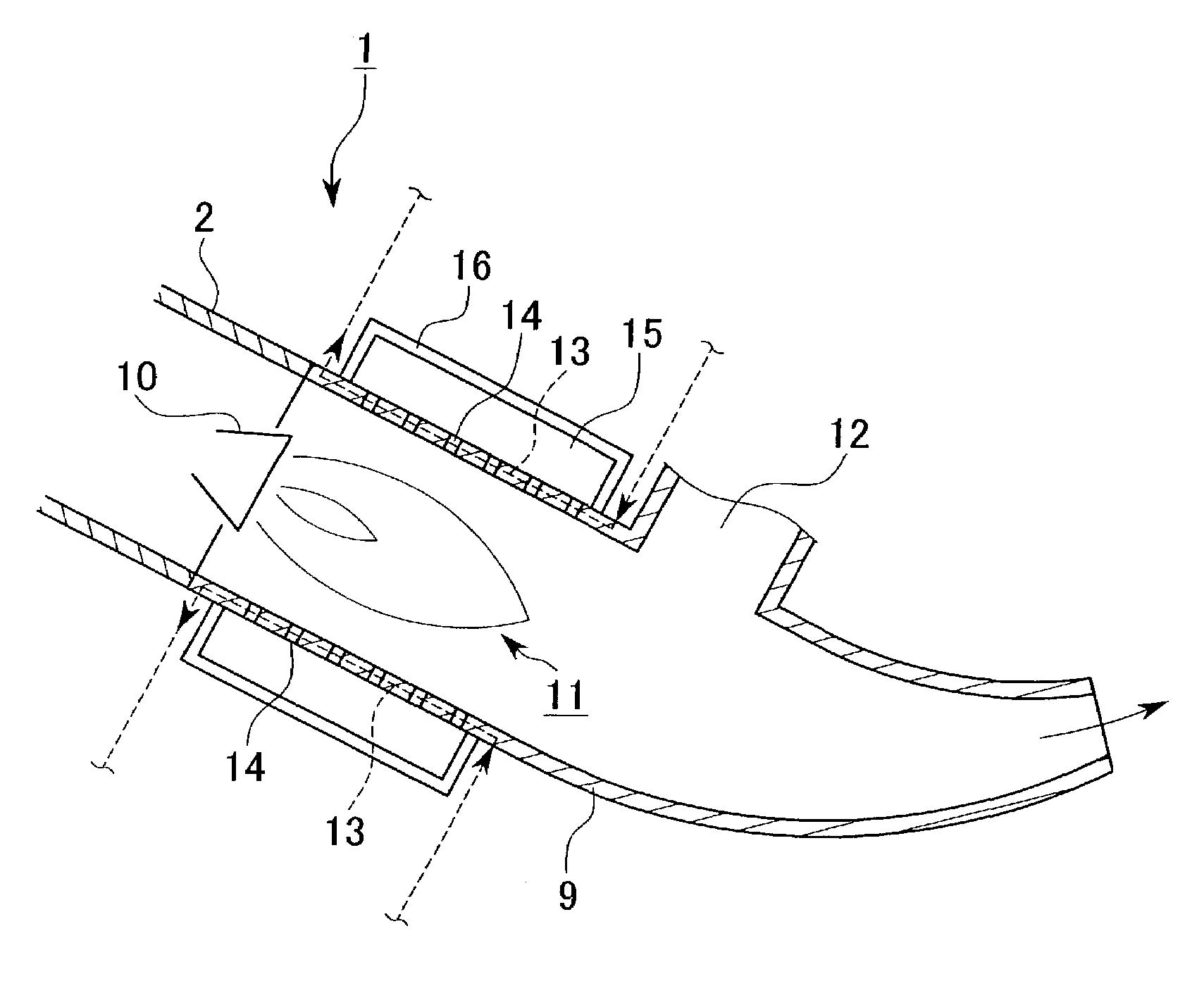

Gas turbine combustor, gas turbine, and jet engine

InactiveUS6973790B2Avoid resonanceReduce oscillationBurnersContinuous combustion chamberJet engineCombustor

For the purpose of reduced NOx gas emission, a gas turbine engine comprises a cylinder having a combustion region inside of the cylinder; a resonator having a cavity and provided around the surface of the cylinder and sound absorption holes formed on the cylinder and having opening ends on the cylinder.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

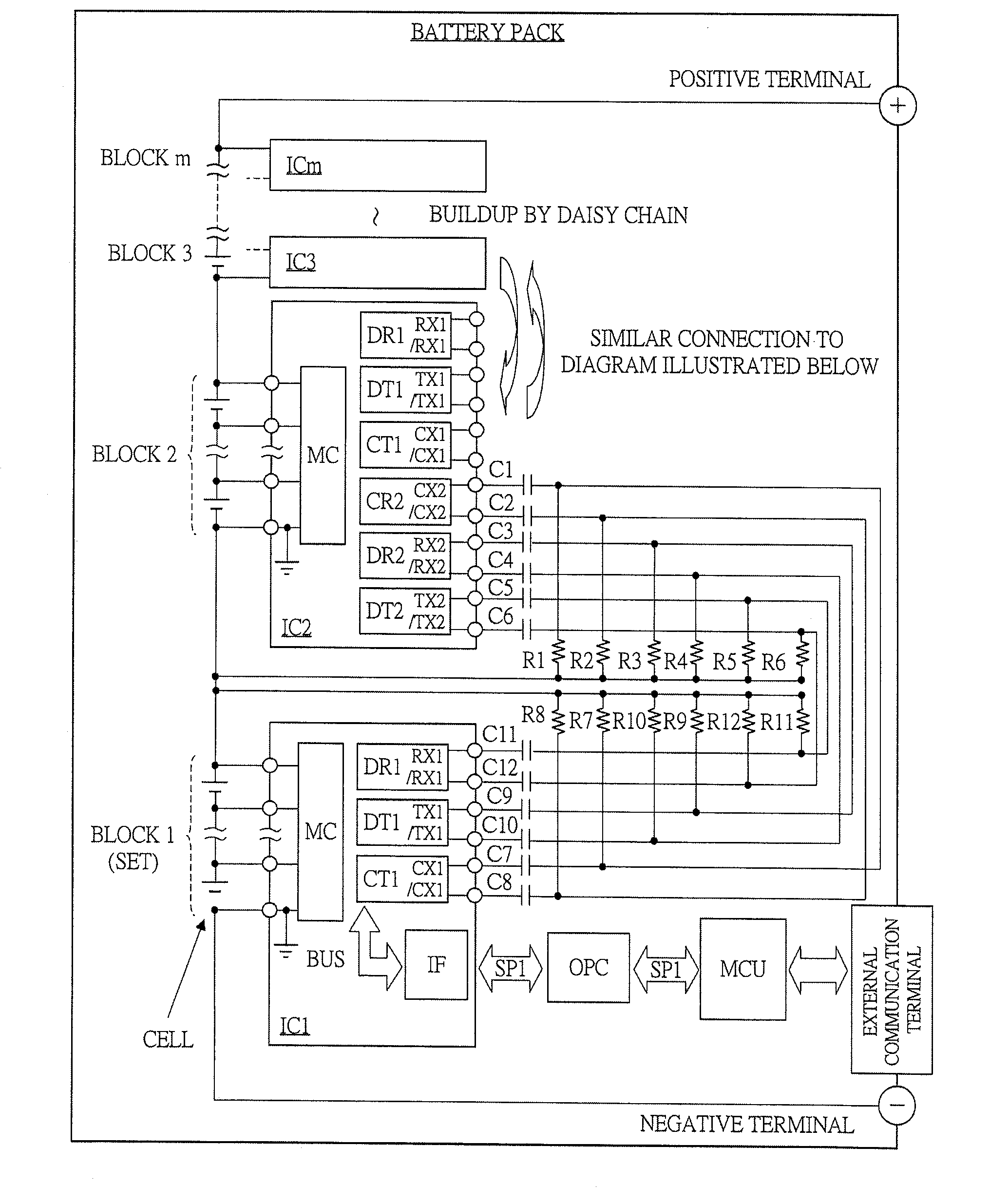

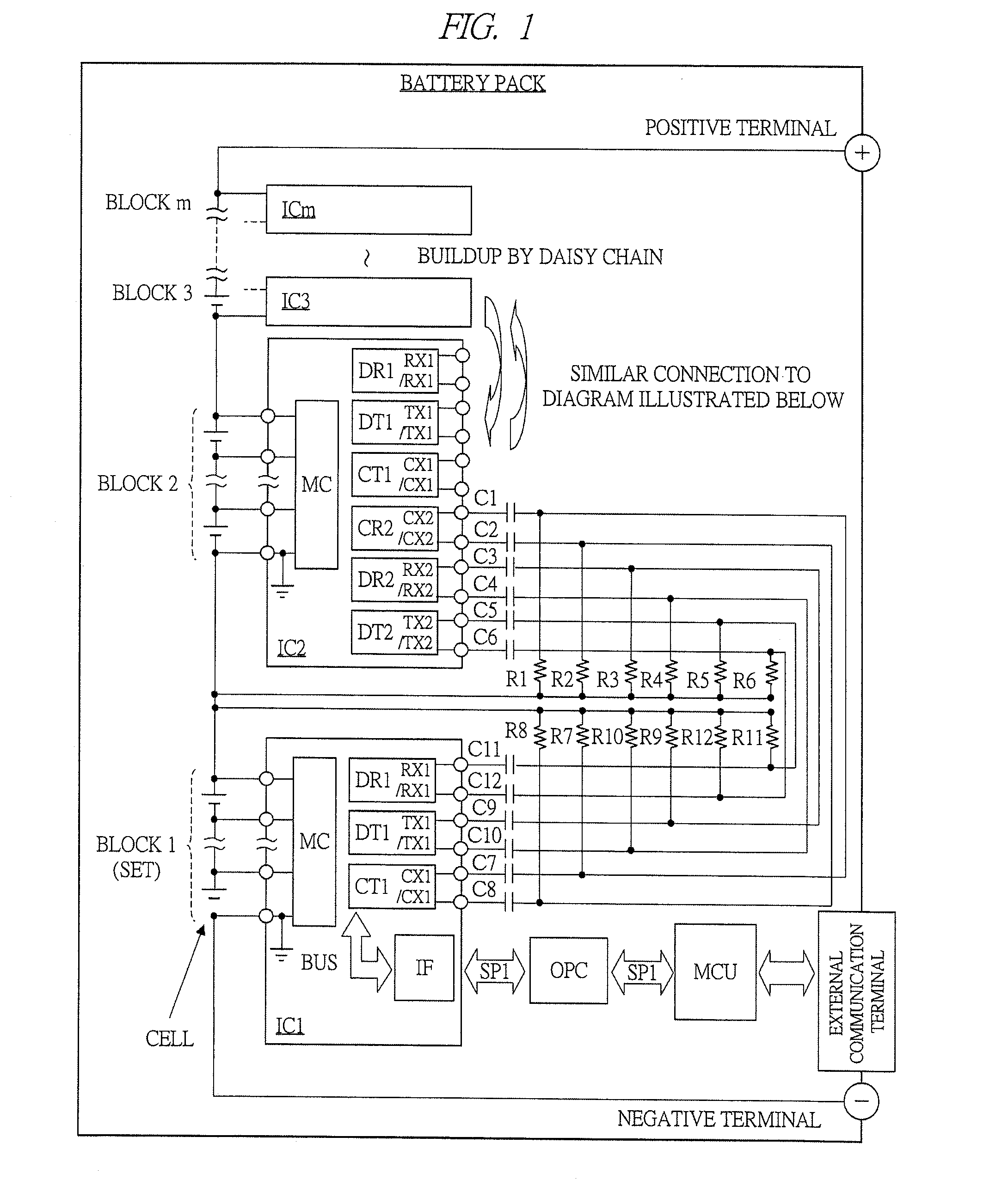

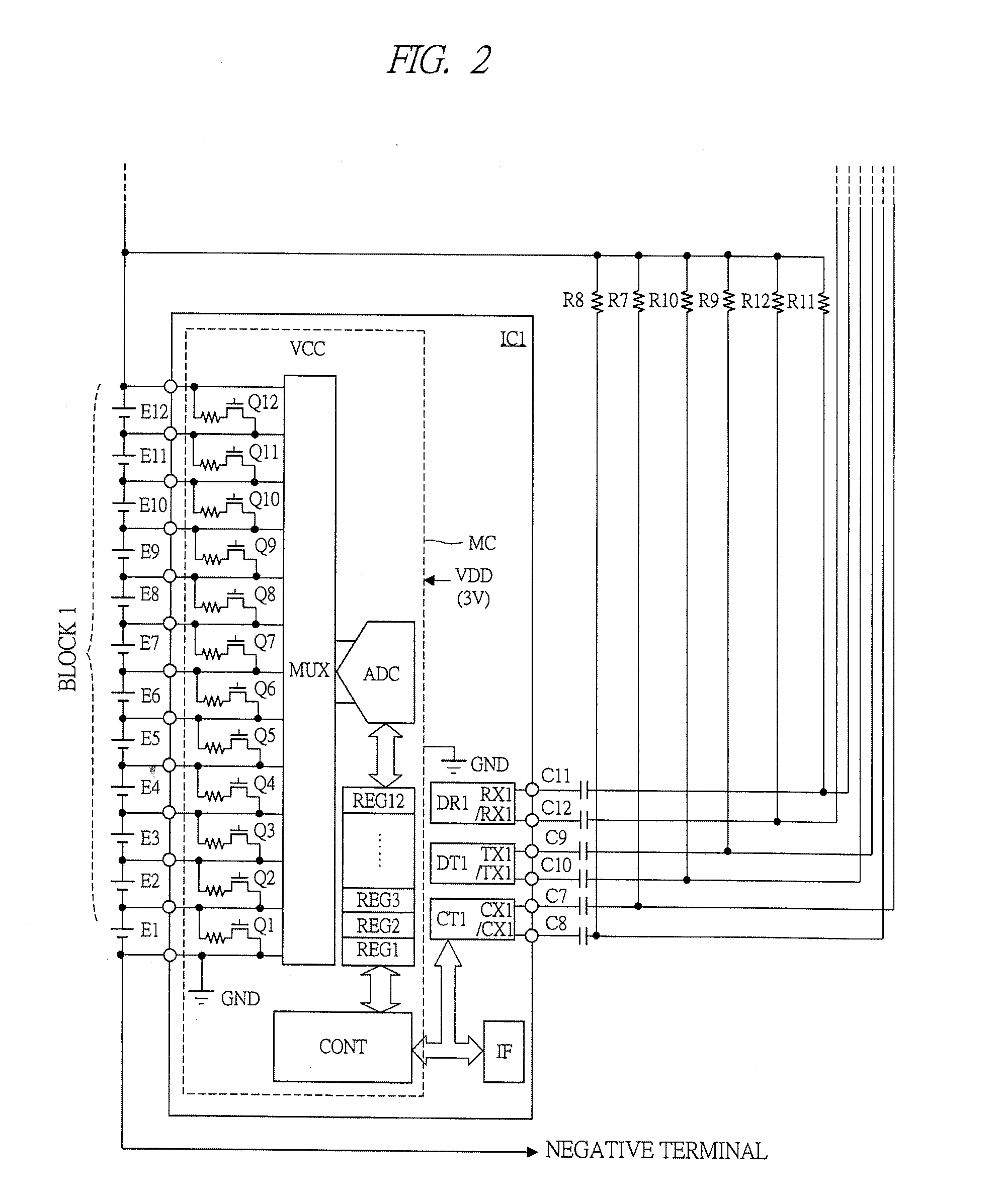

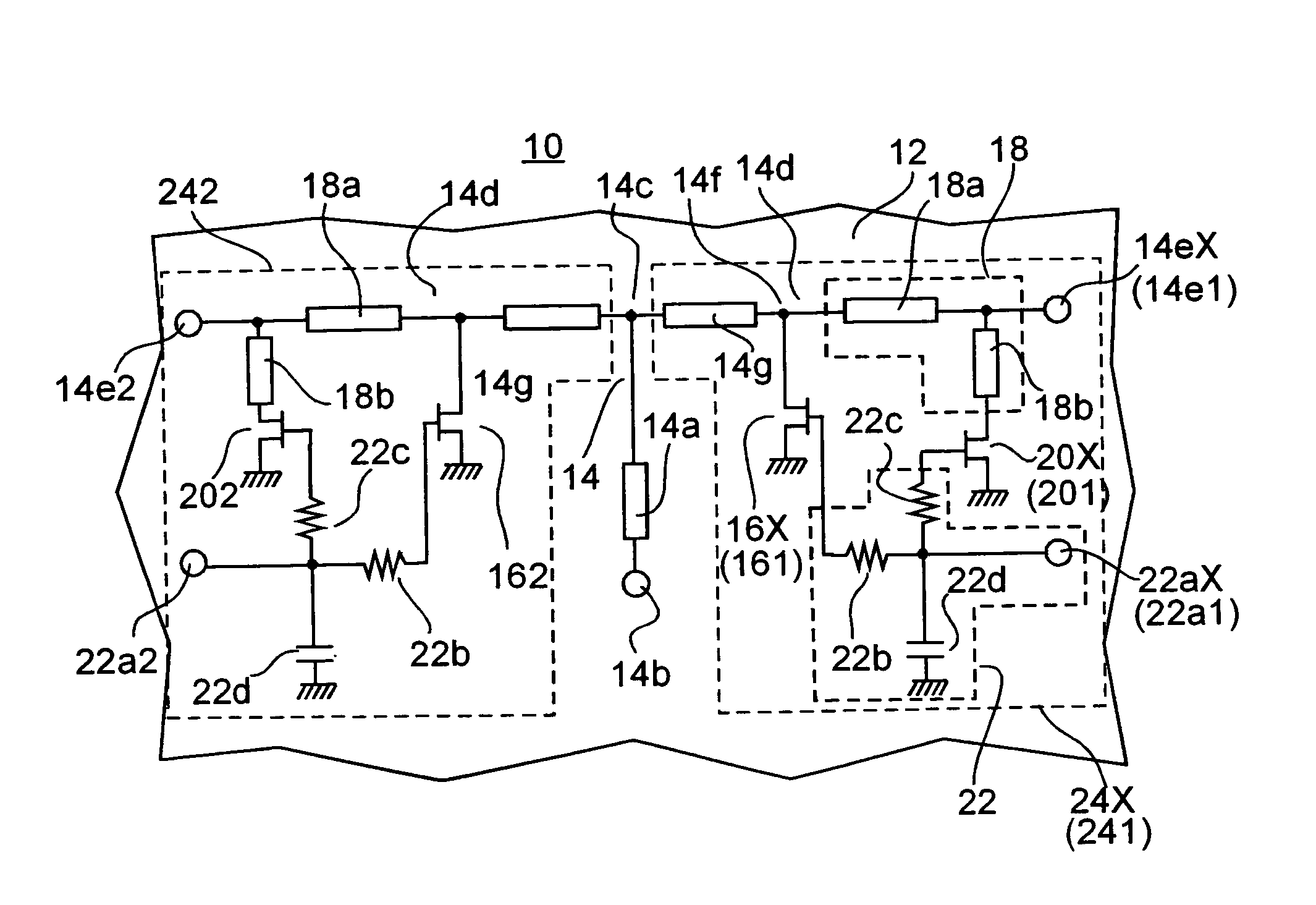

Charging/discharging monitoring device and battery pack

InactiveUS20130187610A1Avoid resonanceExclude influenceCircuit monitoring/indicationDifferent batteries chargingResonanceEngineering

A charging / discharging monitoring device of a battery pack, includes: a plurality of monitoring integrated circuits; a plurality of wiring boards on which the plurality of monitoring integrated circuits are mounted, respectively; and a plurality of signal transmission paths for, via corresponded respective capacitors, connecting between the plurality of wiring boards. The charging / discharging monitoring device is configured with a two-wire transmission path for connecting between terminals of an upstream-side monitoring integrated circuit of daisy chain connection and a downstream-side monitoring integrated circuit thereof, and a wire length of a wiring part which connects between the respective capacitors and terminals of the corresponding monitoring integrated circuits on the wiring boards is a length in which resonance is not caused by the electromagnetic wave noises in an electromagnetic wave noise environment under which the wiring boards are arranged.

Owner:HITACHI ULSI SYST CO LTD

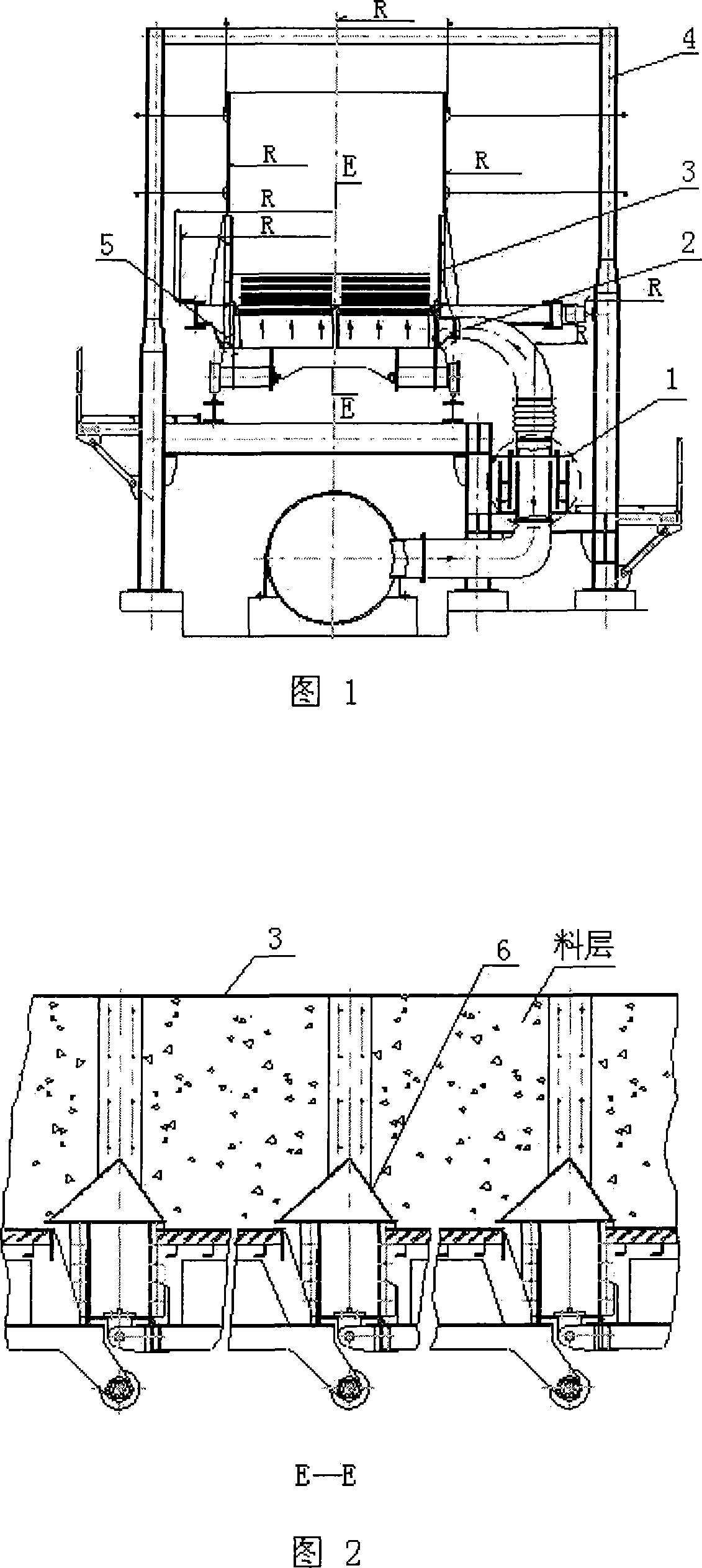

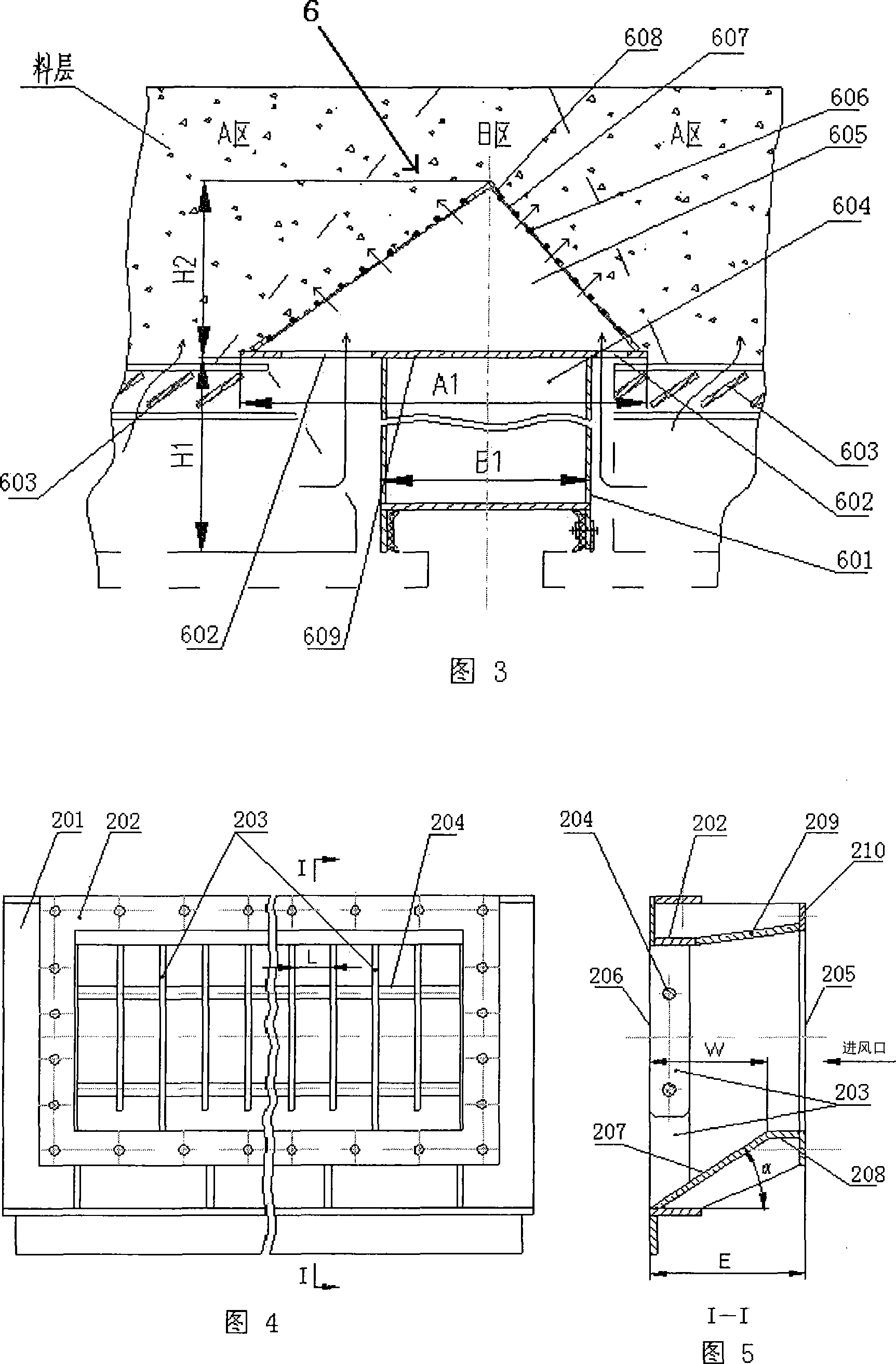

Improved blast circular cooling machine

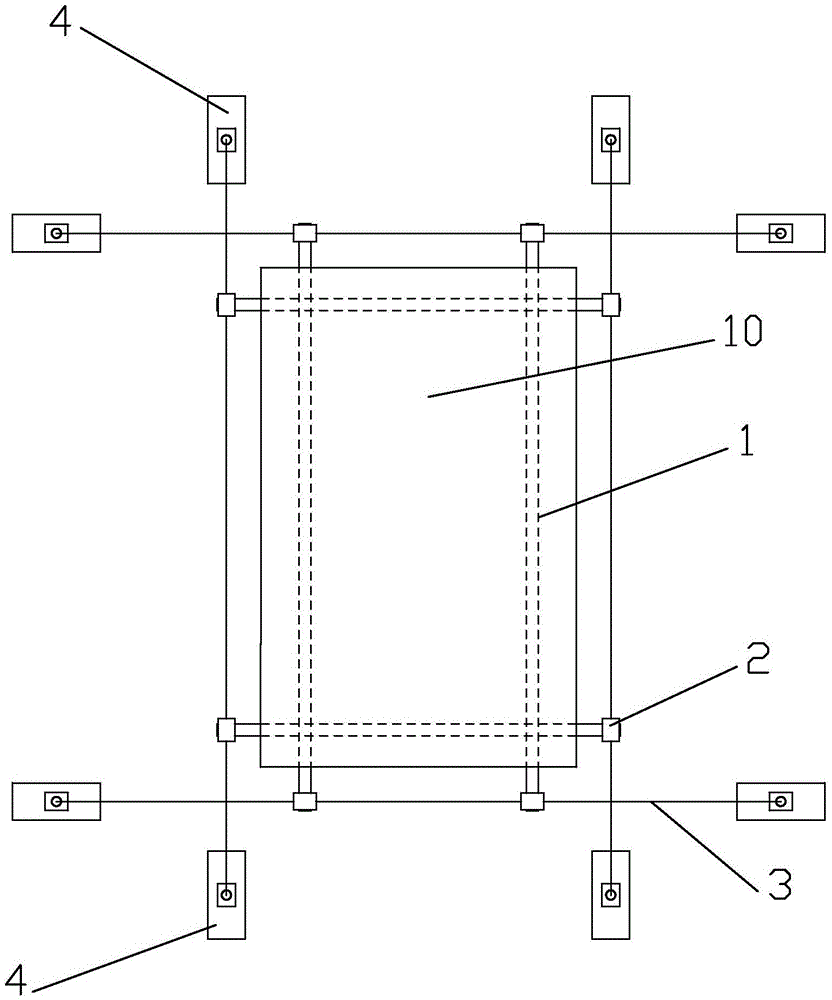

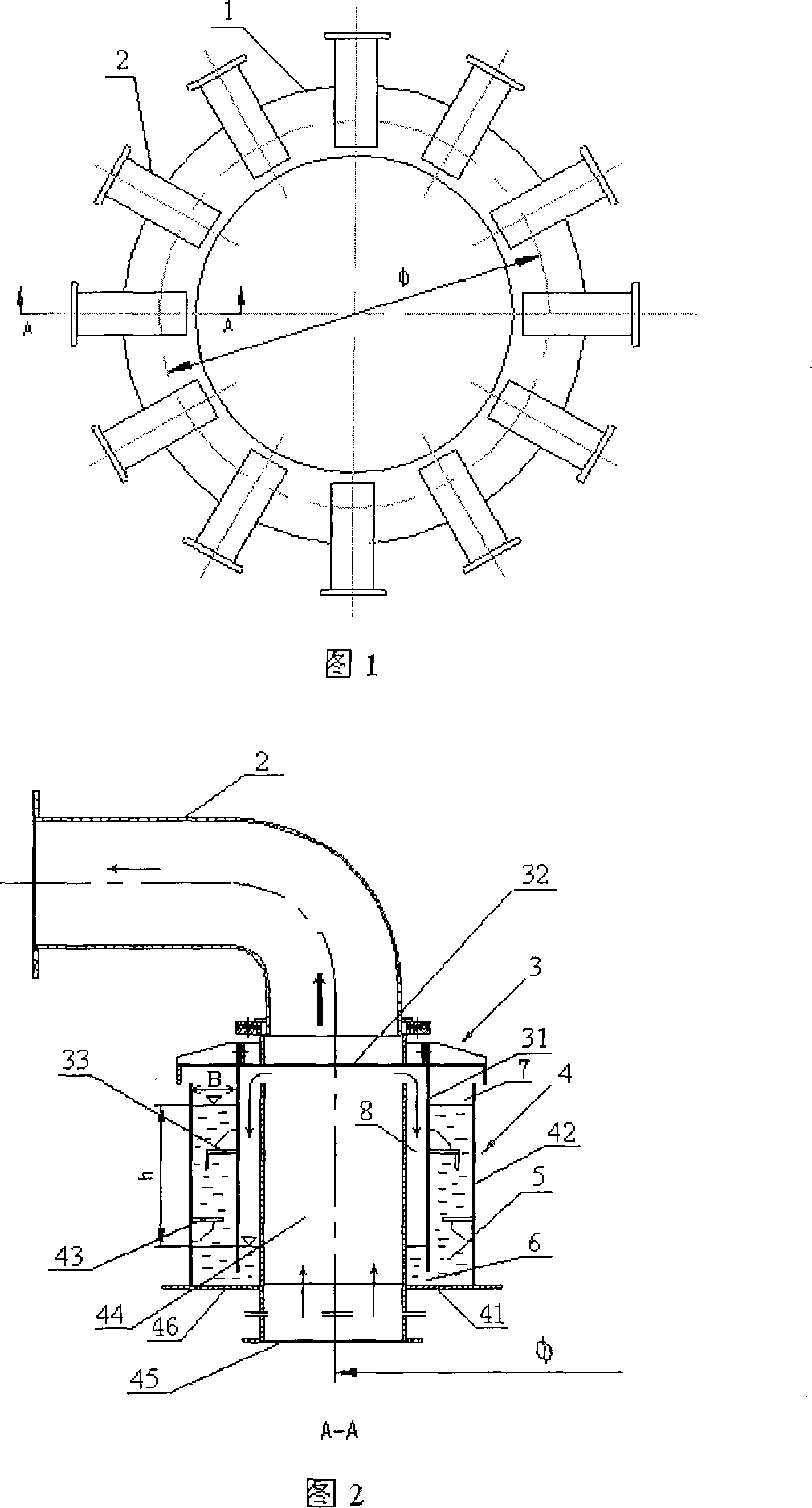

ActiveCN101118118AImprove cooling effectImprove sealingCharge manipulationFurnace typesForced-airEngineering

The present invention discloses an improved rotary forced-air cooler, which comprises a double layer trolley, a supporting beam structure, a material blocking proof air duct sealing plate arranged at the connecting part of the double layer trolley and an air supplying system, a double layer trolley unit static seal device and an air duct device. The supplying system structure is based on a rectangular beam, a triangle beam is arranged on the rectangular beam, and a plurality of ventilation channels are arranged on the bevel edge steel plates at the both waists; an air duct pipe is arranged on the air vent of the material blocking proof air duct sealing plate, an inclined plate inclining upwards from the air vent at the bottom part of the air duct pipe has a transition to a horizontal plate, a stopping ventilation fence is added to the air duct pipe at the side of the trolley; two rubber sealing parts with extended bottom edges are arranged at the outer sides of the lower parts of inner and outer sealing plates of the double layer trolley unit static seal device, an ash baffle plate which can move up and down is hung at the inner side; an air water sealing wave subduing device adopting a damping plate is arranged on the air duct device. The present invention further improves the sealing performance of the equipment, and reduces energy consumption and pollution.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

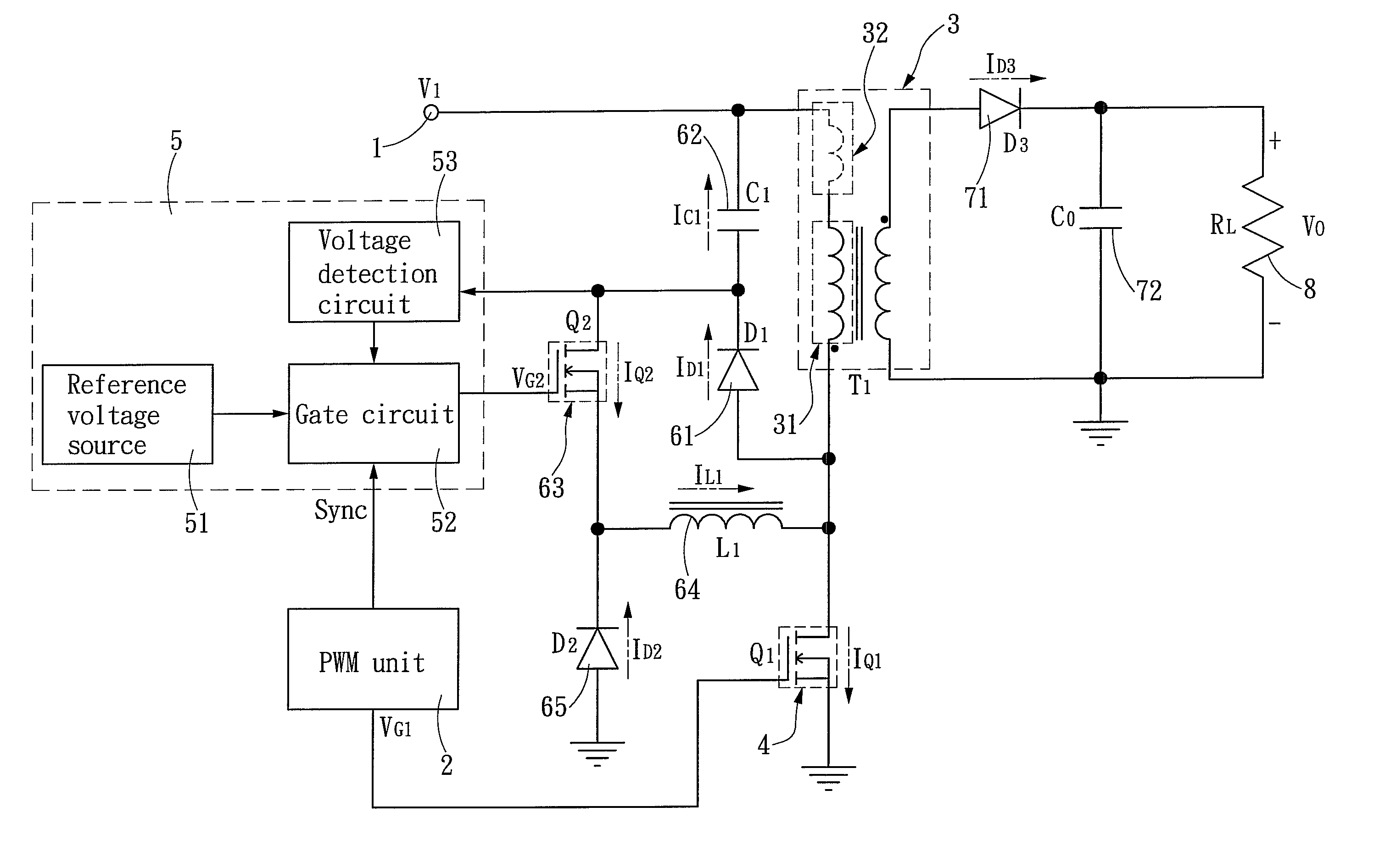

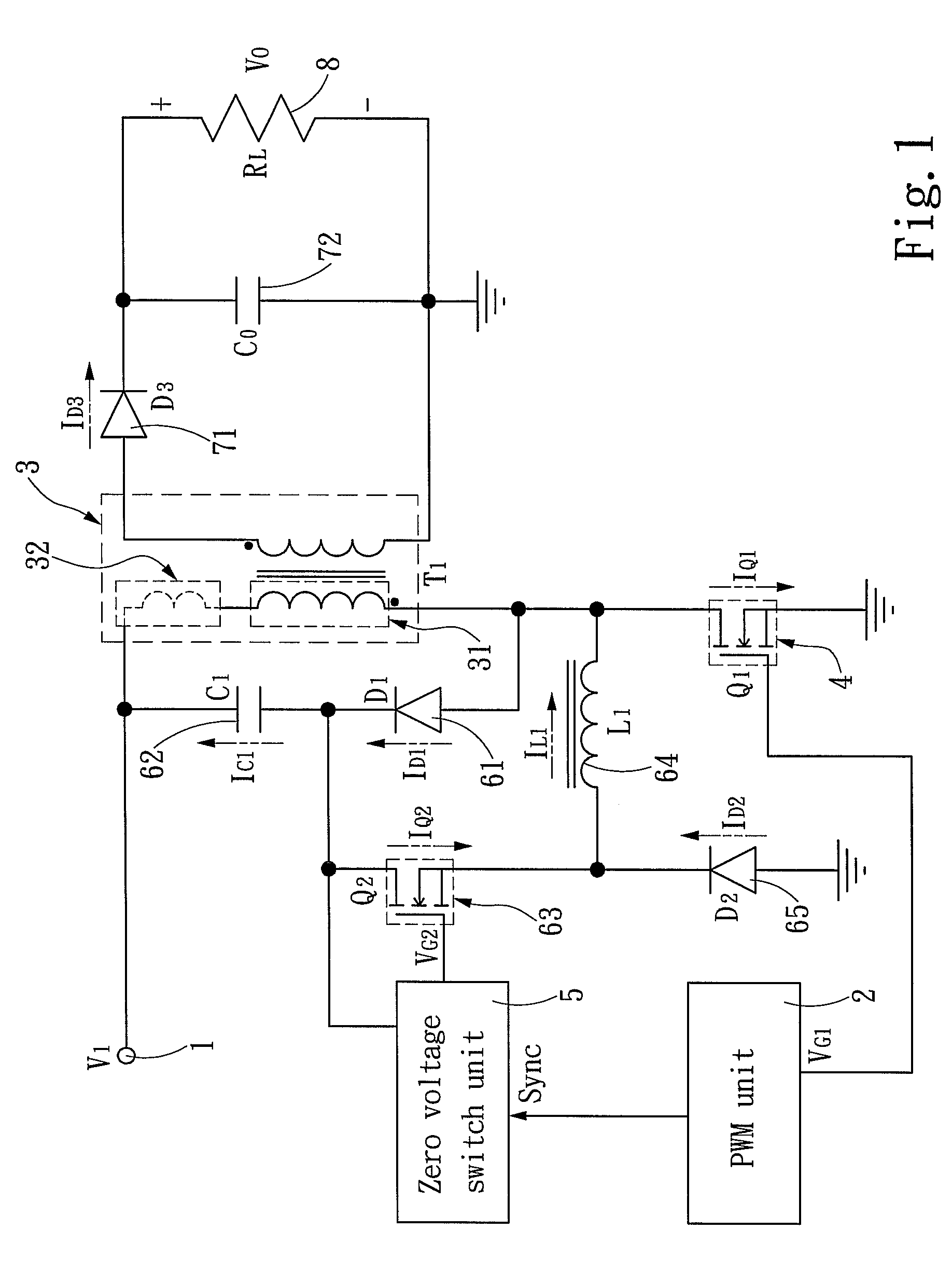

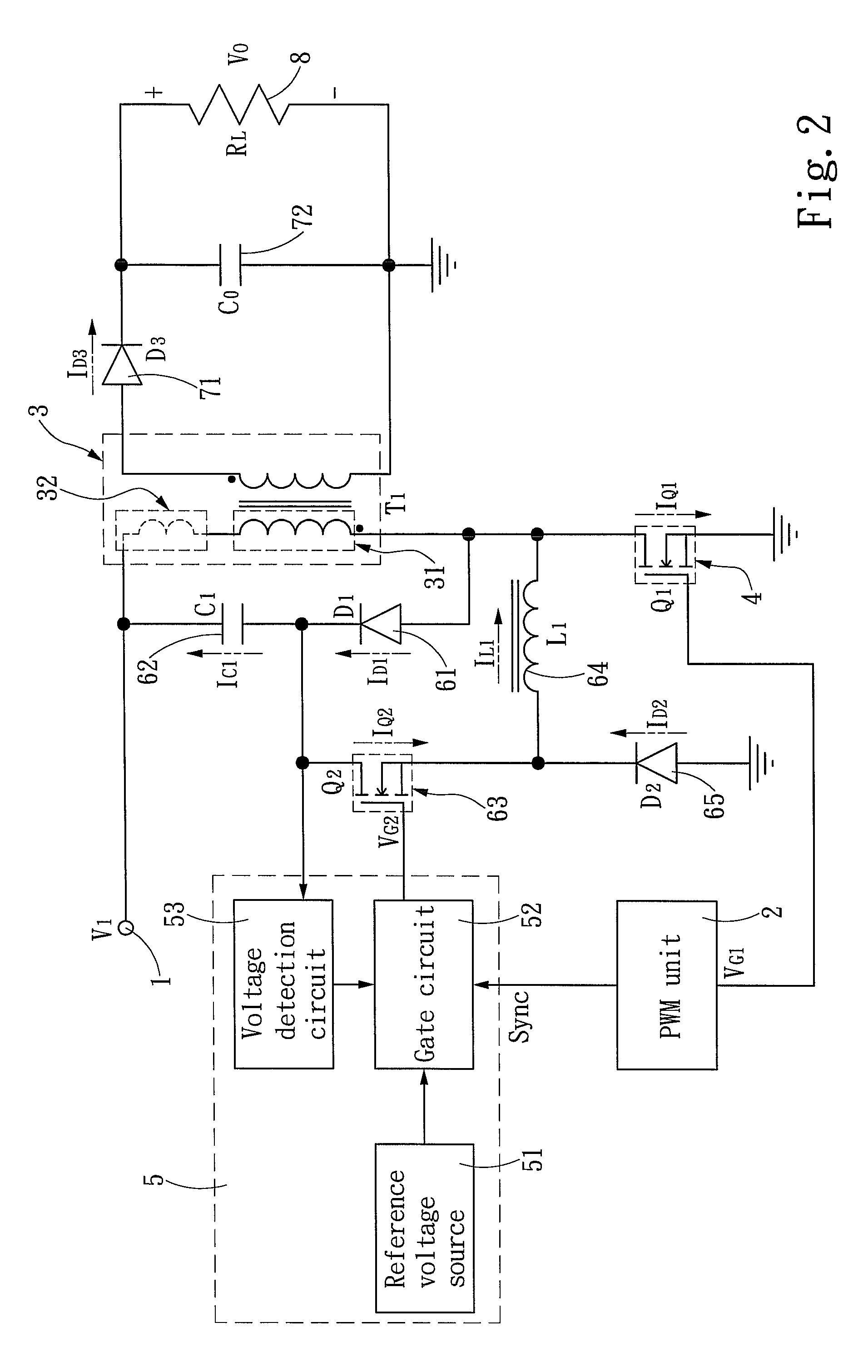

Flyback converter having an active snubber

ActiveUS7869235B2Total current dropAvoid resonanceEfficient power electronics conversionEmergency protective circuit arrangementsPower flowResonance

A flyback converter having an active snubber includes a transformer to receive input power. The transformer has a primary winding at a first side. The active snubber is coupled in parallel with two ends of the primary winding and has a first circumferential circuit coupling in parallel with the primary winding, a second circumferential circuit and a zero voltage switch unit. The second circumferential circuit is controlled by the zero voltage switch unit and incorporated with the first circumferential circuit to form double damping paths to reduce current and prevent resonance that might otherwise occur to a single circumferential circuit and the secondary side of the transformer.

Owner:SPI ELECTRONICS

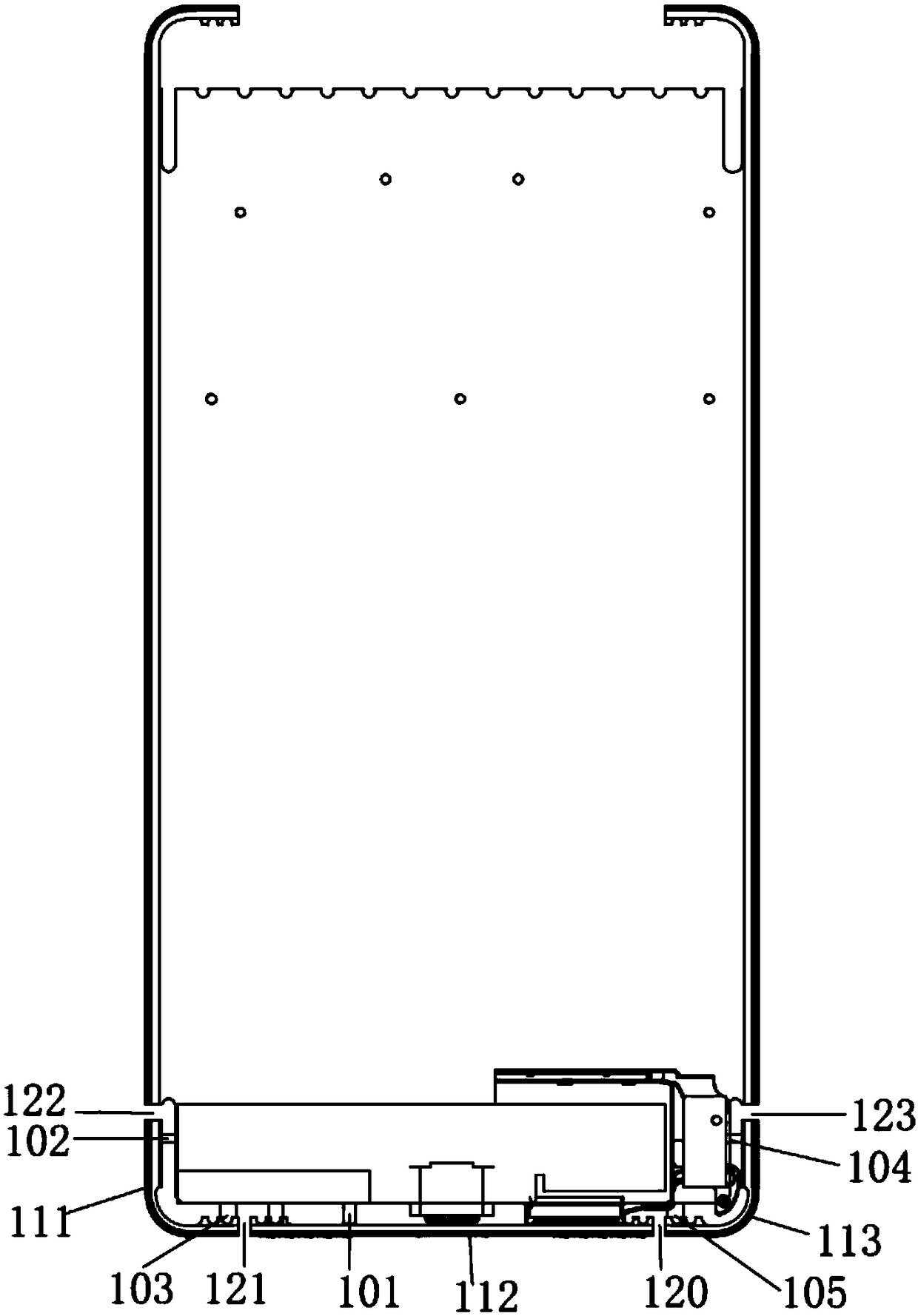

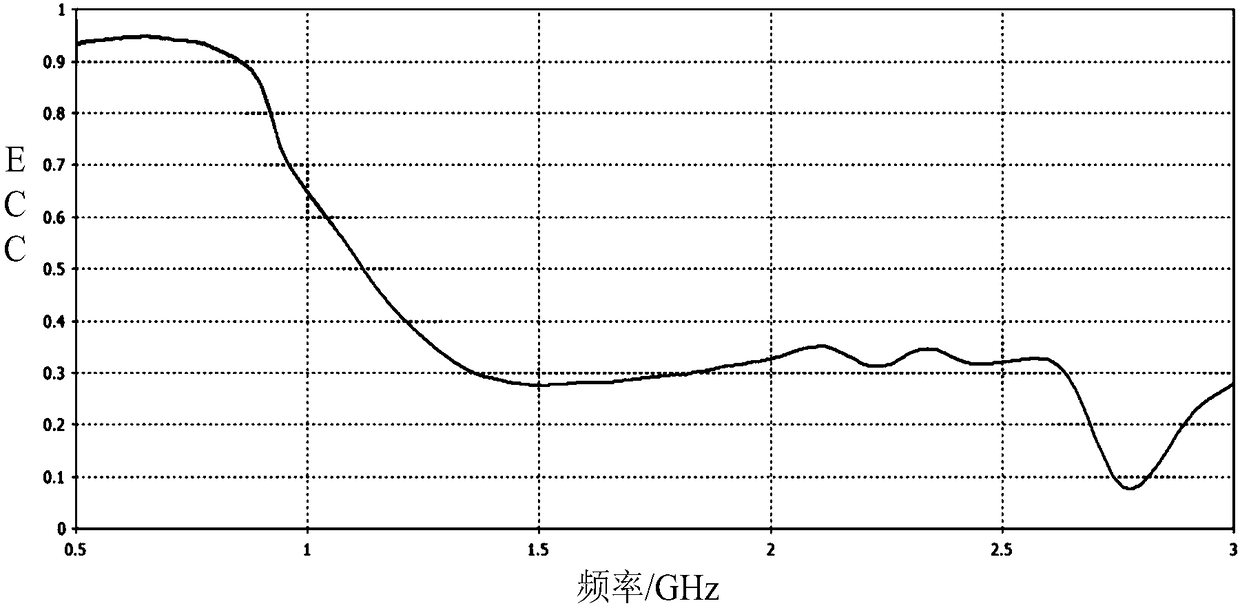

Antenna system and terminal

InactiveCN108199132AAffect the appearance sizeDoes not affect launchSimultaneous aerial operationsAntenna supports/mountingsCarrier signalFull band

The embodiment of the invention relates to the field of communication equipment and discloses an antenna system and a terminal. The antenna system comprises a first antenna, a second antenna, a firstfeeding point, a second feeding point and a first grounding point, wherein the first antenna and the second antenna are obtained through cutting a metal border of the terminal from a breaking joint, asecond breaking joint and a third breaking joint; the first antenna is located between the first breaking joint and the second breaking joint and connected with the first feeding point; the second antenna is located between the second breaking joint and the third breaking joint and connected with the second feeding point; the first grounding point is located at the edge position, close to the second breaking joint, of the first antenna; the first breaking joint and the second breaking joint are located on a short-edge side surface of the metal border of the terminal; the third breaking jointis located on a first long-edge side surface of the metal border of the terminal; and the first feeding point and the second feeding point are arranged on a printed circuit board. According to the antenna system, the terminal can work on a full band, the condition that a high frequency and a low frequency can simultaneously exist in different states is met and the requirements of carrier aggregation are met.

Owner:AAC PRECISE MFG TECH CHANGZHOU

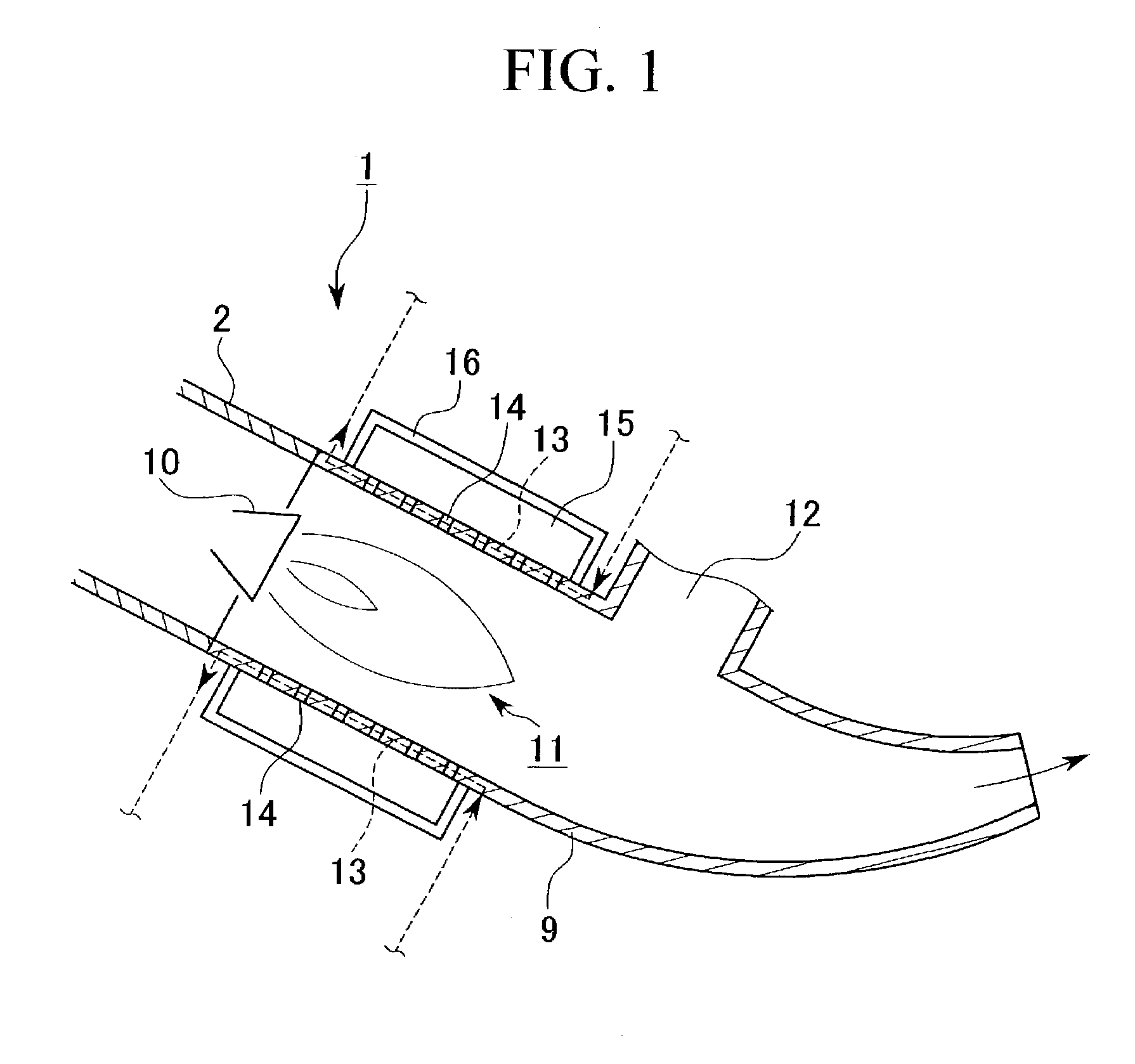

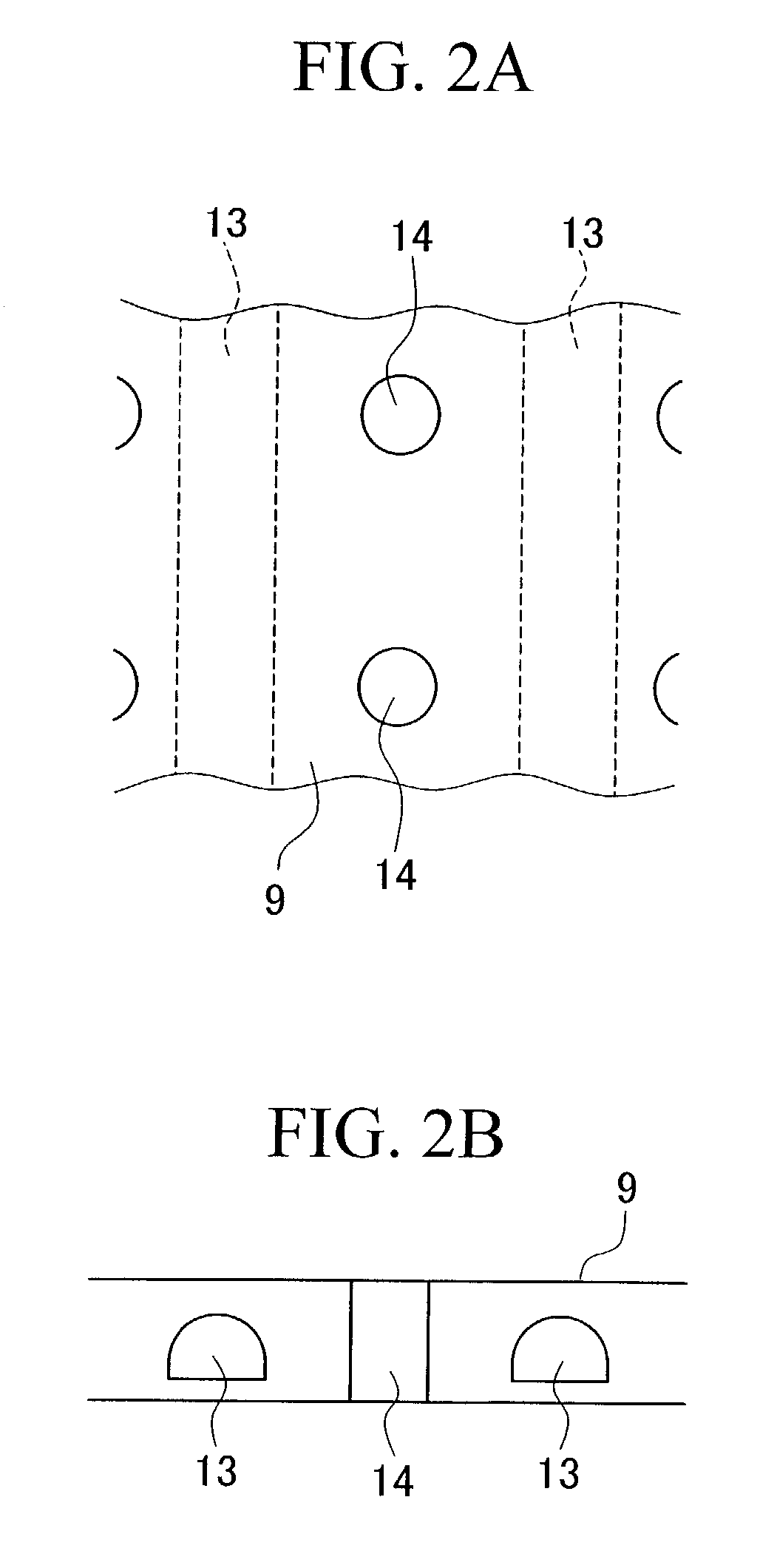

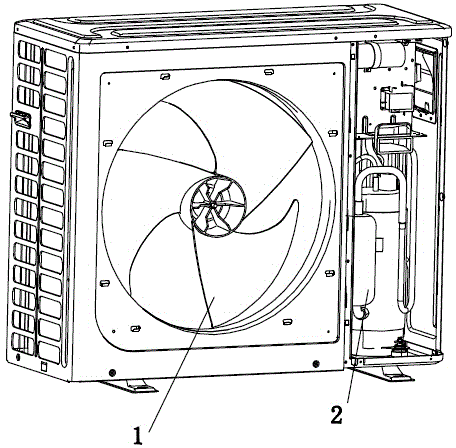

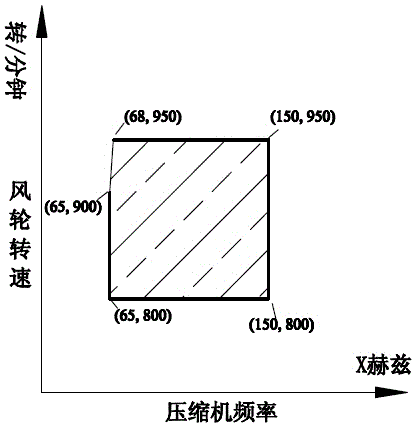

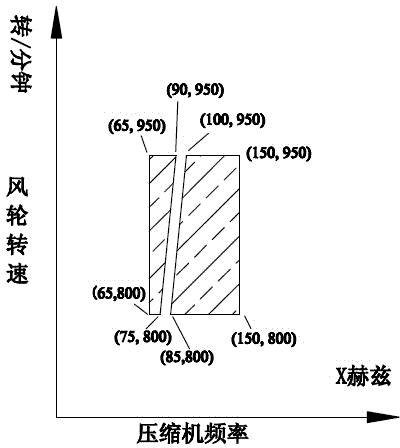

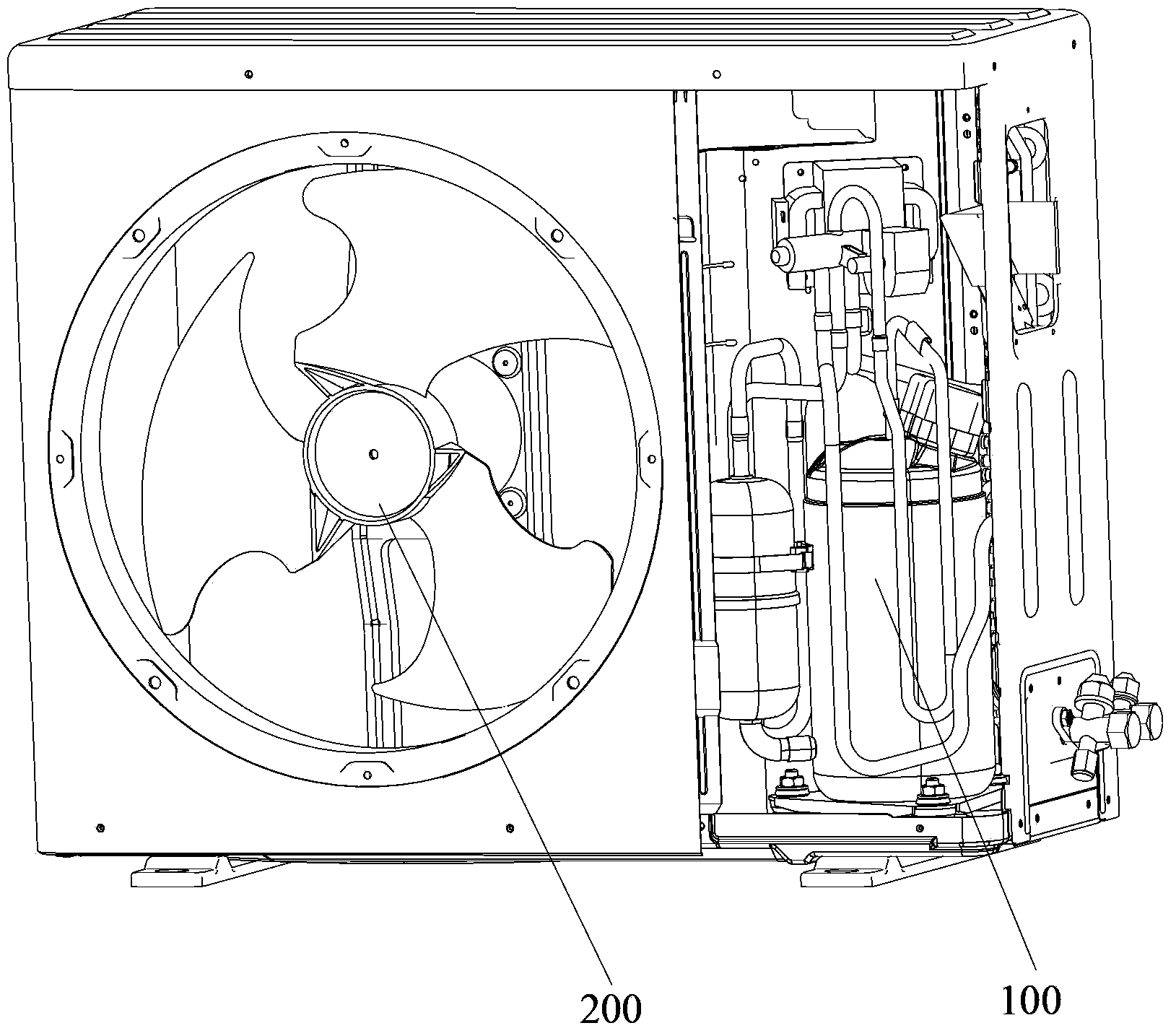

Method for controlling frequency inverter air conditioner outdoor fan and compressor vibration noise

ActiveCN102721120AImprove sound qualityImprove reliabilityLighting and heating apparatusAir conditioning systemsResonanceSuperimposition

The invention relates to a method for controlling frequency inverter air conditioner outdoor fan and compressor vibration noise. The rotation speed of a wind wheel (1) of an air conditioner outdoor fan is Y r / min. The number of the blade of the wind wheel (1) is Z. The rotation fundamental frequency of the blade of the wind wheel (1) is F1:F1=Z*Y / 60 Hz. The rotation frequency of a compressor (2) is X Hz. The method is characterized in that when the operation frequency of the compressor (2) X is between 65 Hz and 150 Hz, the rotation speed of the wind wheel (1) is in the range of 800 r / min to 950 r / min, and the following relationships exist: the absolute value of the difference between the rotation frequency of the compressor X and double rotation fundamental frequency of the blade of the wind wheel (1) is greater than 5 Hz, namely |X-2*F1|>5 Hz. The method provided by the invention can greatly weaken or completely eliminate the vibration formed by the superimposition of the wind wheel and the compressor rotation noise, thereby the sound quality the noise of the air conditioner outdoor unit is significantly improved, the sheet metal structure resonance can be effectively avoided, the vibration can be reduced, the sound quality can be improved, the noise can be reduced, and the reliability of the whole machine can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

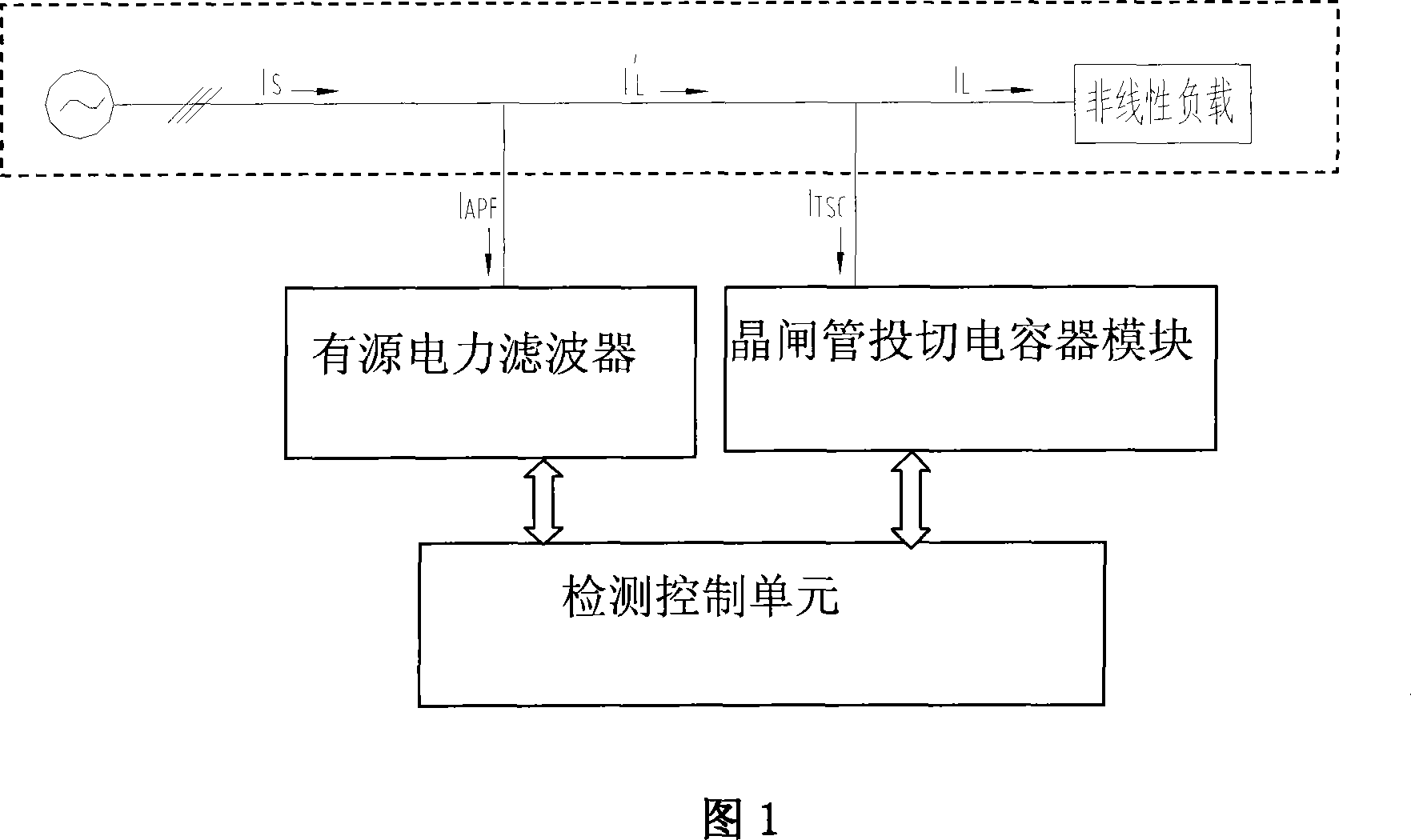

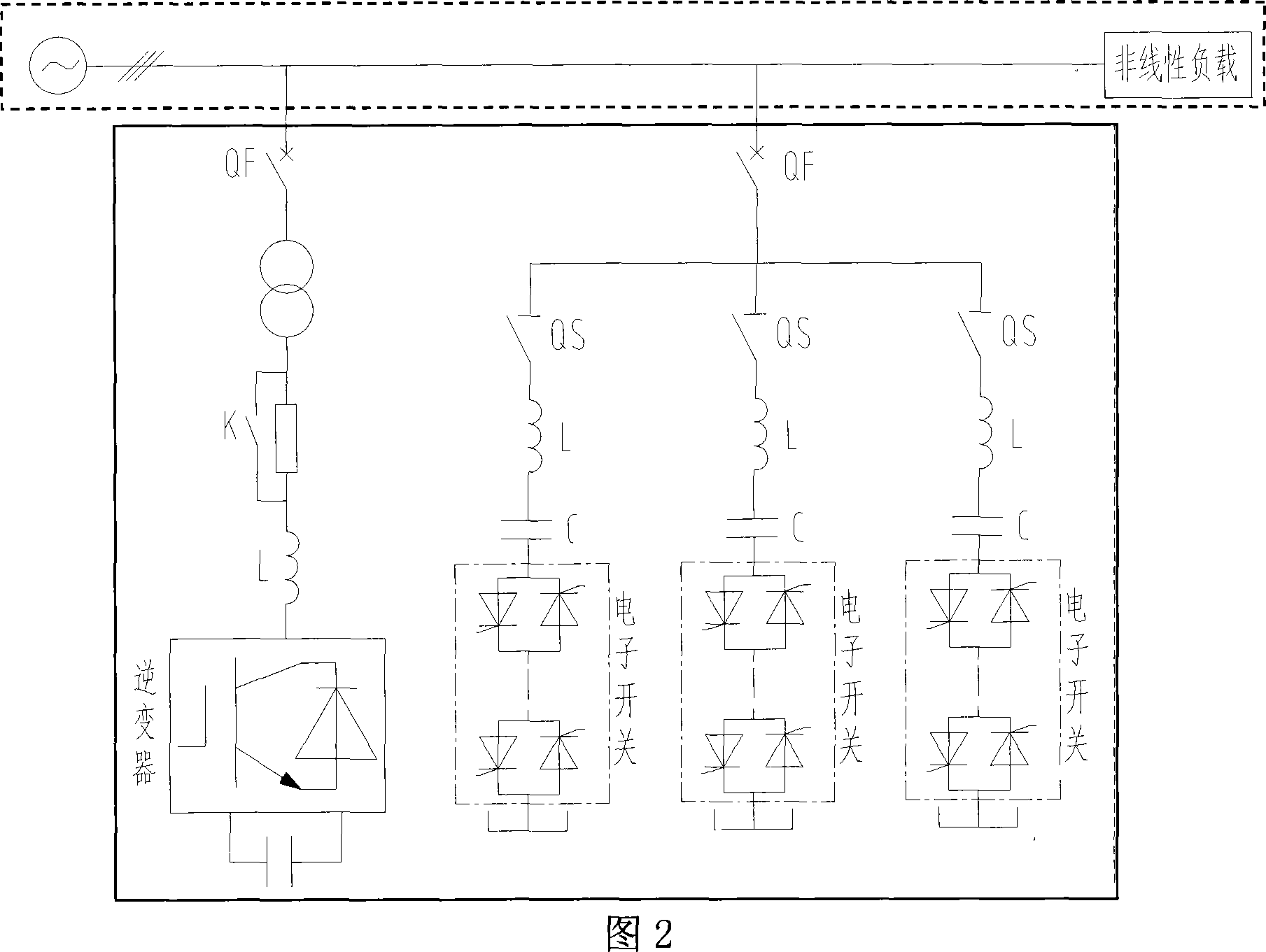

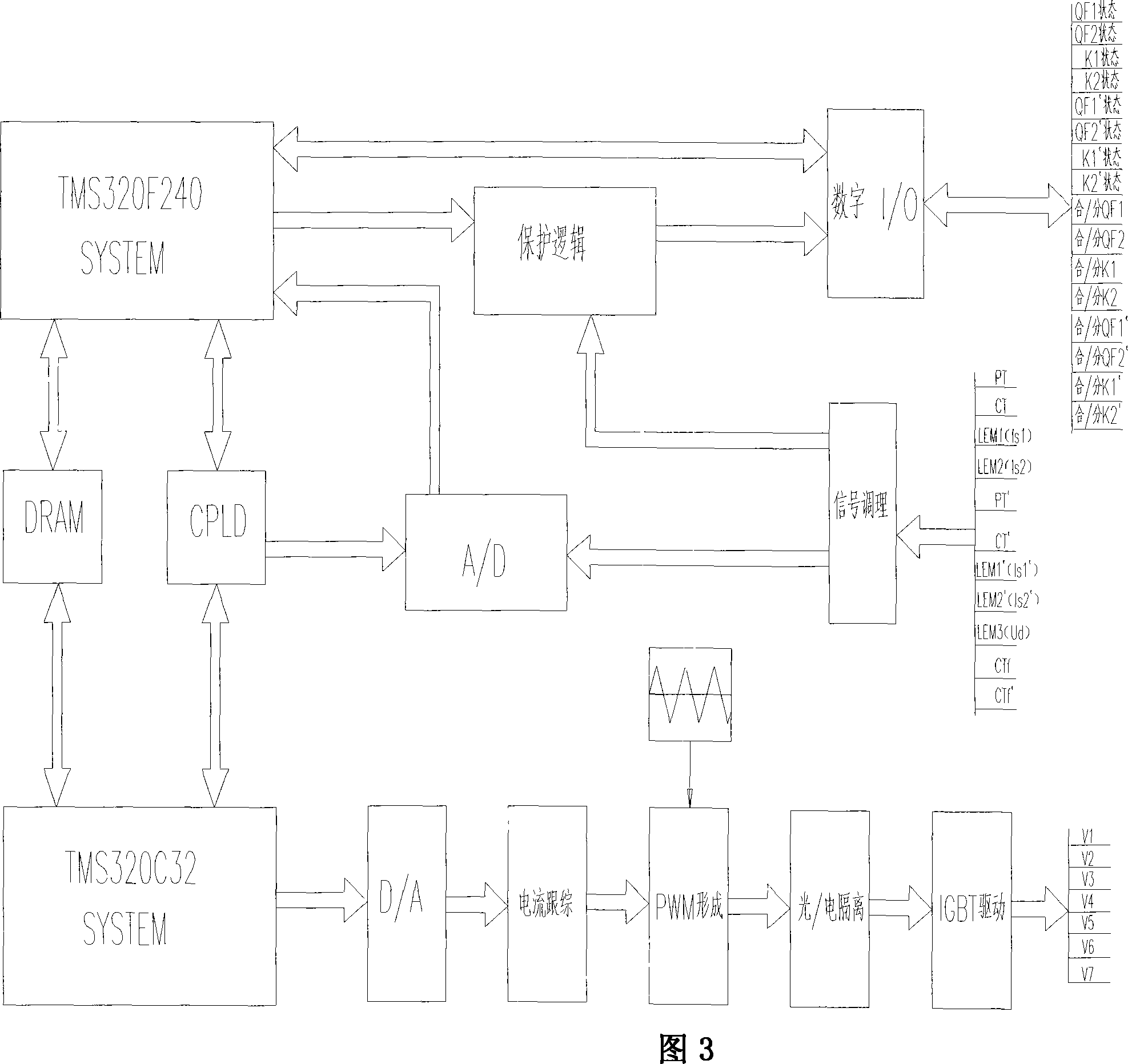

Comprehensive compensating device and method

ActiveCN101068082ASolve the problem of small compensation capacityLarge compensation capacityFlexible AC transmissionReactive power adjustment/elimination/compensationDriver circuitPower factor

An integrated compensation device consists of detection control unit, thyristor switched capacitor module connected to power network and active electric power filter. It is featured as calculating out reactive volume required to be compensated onto load by said device according load current and system voltage as well as object power factor then issuing different switching commands to thyristor switched capacitor module for realizing the switching operation of compensation branch and confirming command signal of compensation current on said filter to make actual output current of said filter track with variation of command current.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST +1

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

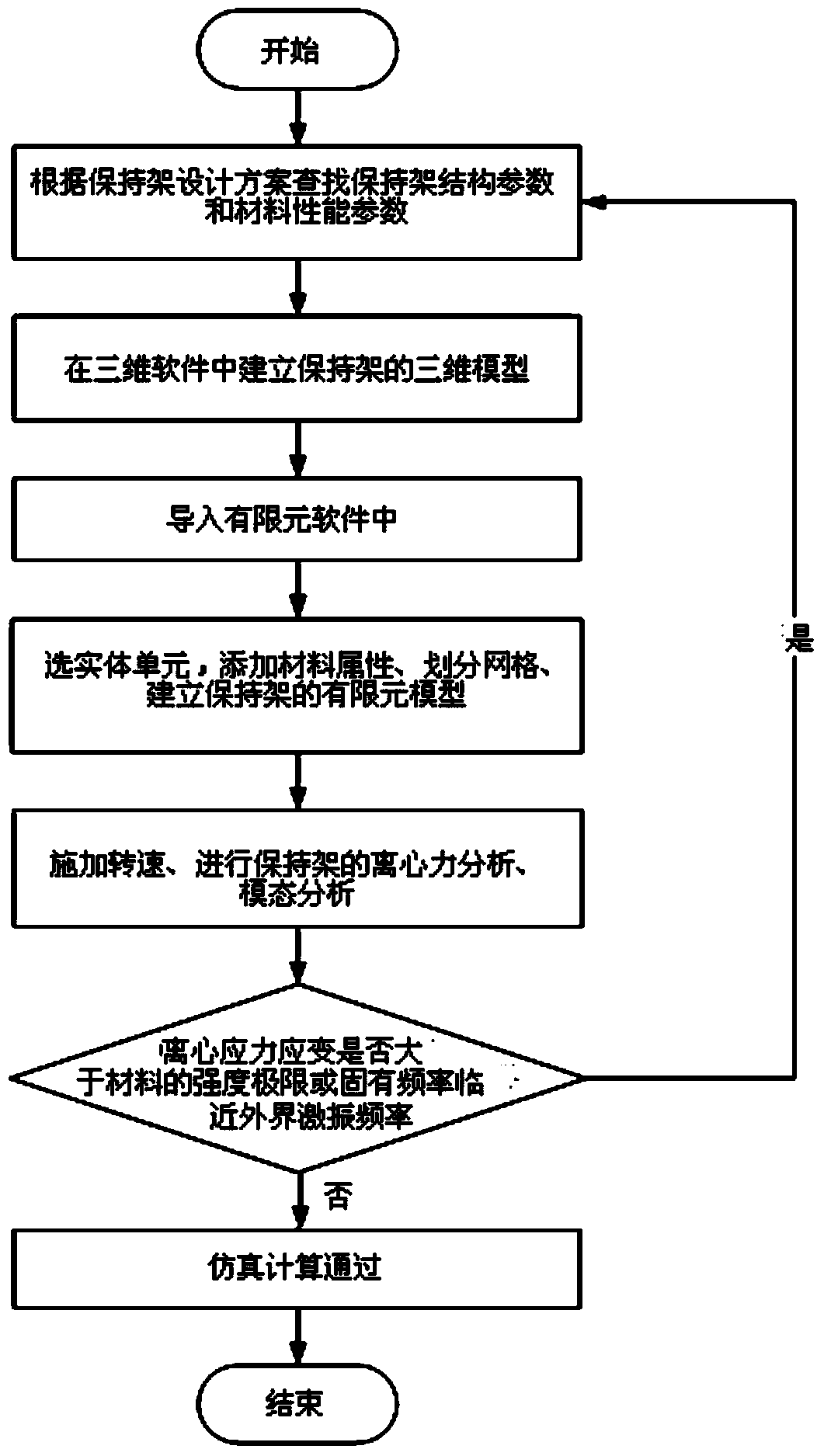

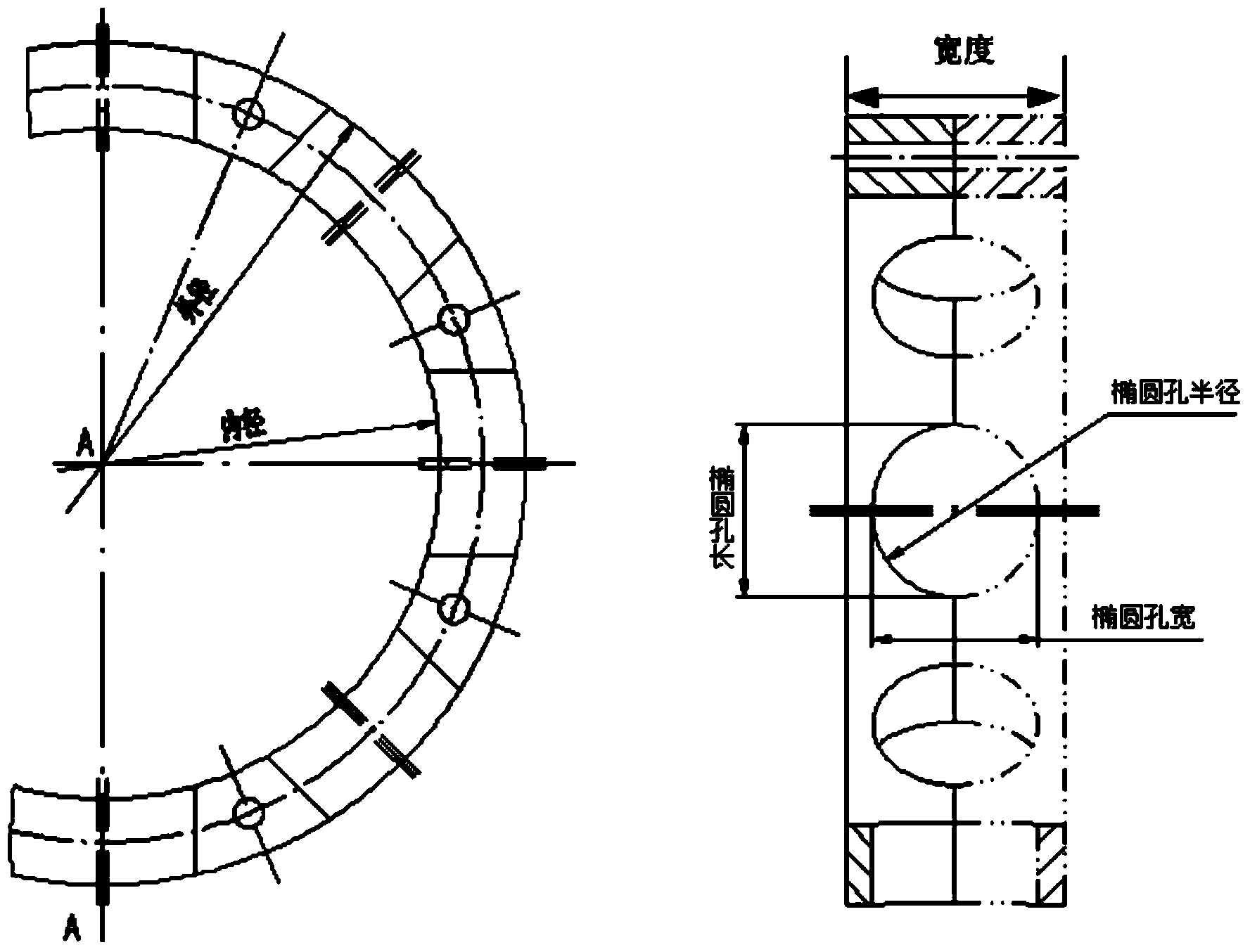

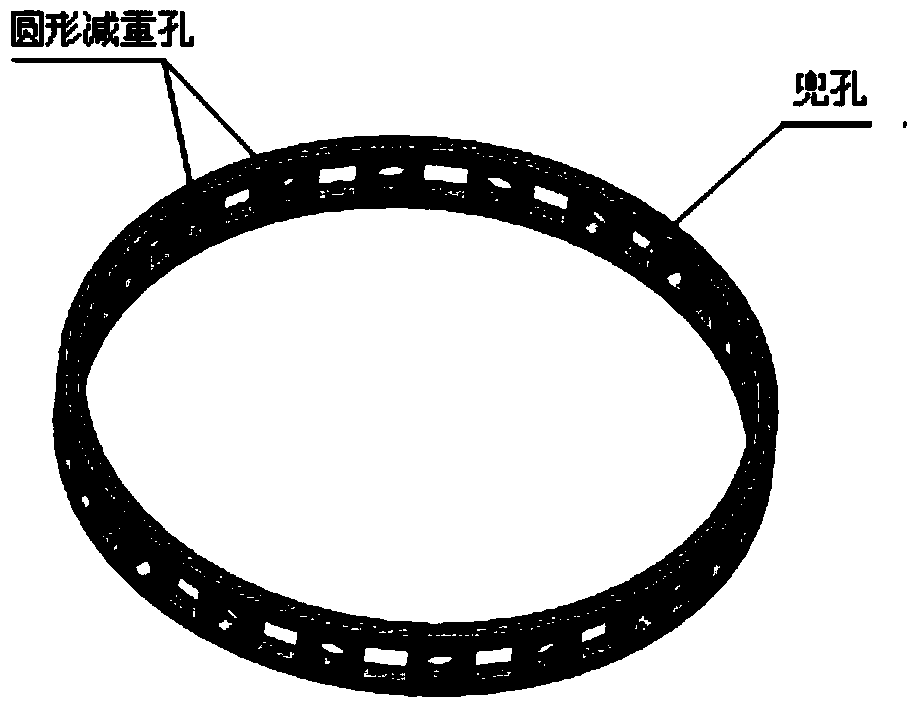

Method for analyzing vibration characteristics of bearing retainer based on finite elements

InactiveCN104268342AAvoid resonanceShorten the processing cycleSpecial data processing applicationsElement modelEngineering

The invention relates to a method for analyzing the vibration characteristics of a bearing retainer based on finite elements and aims at solving the problem that no automatic analysis procedure for the vibration characteristics of the bearing retainer is developed at present to prevent the frequency range of resonance of the bearing retainer of an aero-engine. The method is implemented through a step 1 of creating the three-dimensional model of the bearing retainer and saving the three-dimensional model under the working directory set by finite element software, a step 2 of establishing a finite element model and applying the rotating speed of the bearing to the finite element model for performing statics analysis and modal analysis, a step 3 of obtaining the stress and the strain as well as the inherent frequency and the corresponding formation thereof under the action of the rotating speed of the bearing, a step 4 of determining whether the stress and the deformation of the bearing retainer under the action of the centrifugal force meet the design requirements, and the like. The method for analyzing the vibration characteristics of the bearing retainer based on the finite elements is applied to the field of the vibration characteristics of the bearing retainers.

Owner:AVIC HARBIN BEARING

Construction method for reinforcing and repairing integral wall of ancient architecture

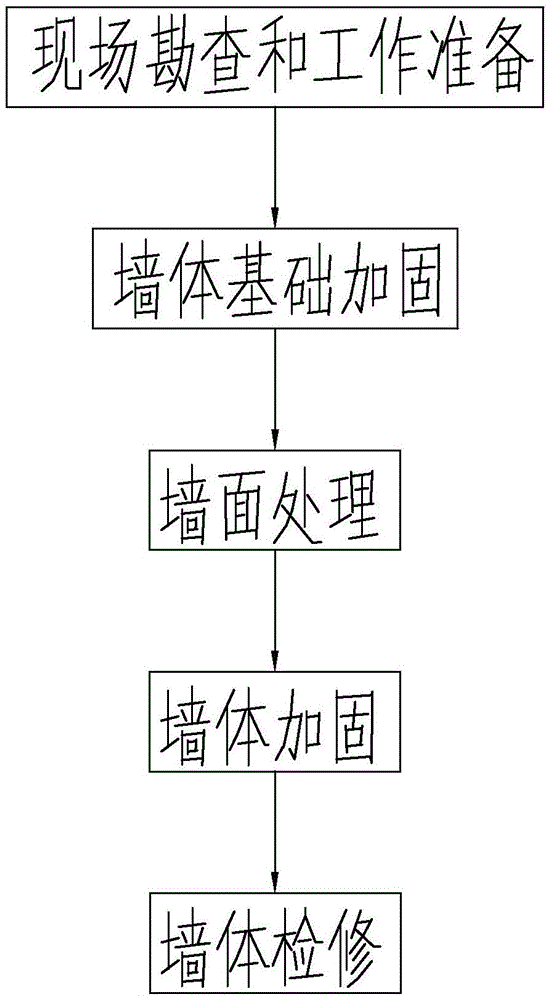

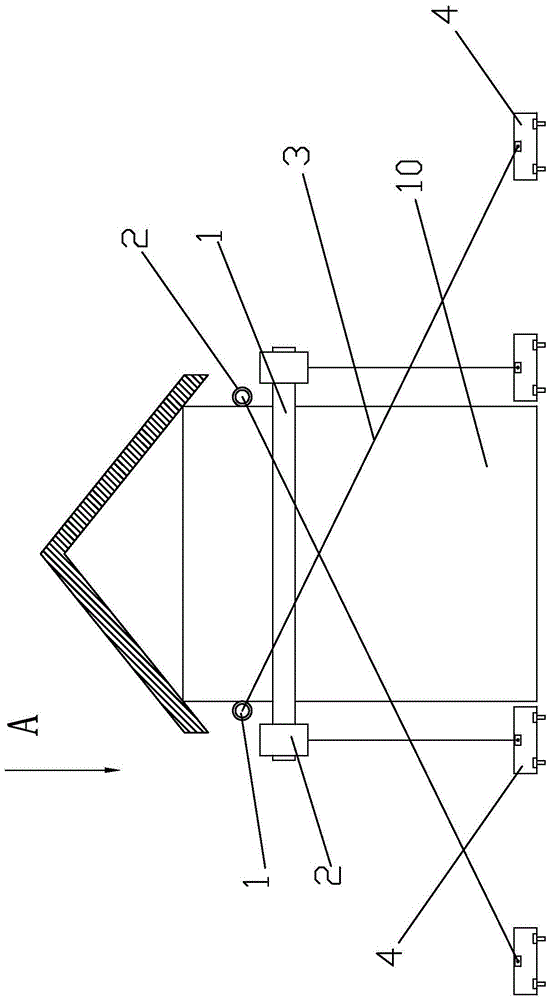

InactiveCN105604343ASimple construction methodEasy to implementBuilding repairsBearing capacityBuilding construction

The invention discloses a construction method for reinforcing and repairing an integral wall of ancient architecture. The construction method comprises the steps of site survey and work preparation, wall foundation reinforcement, wall surface treatment, wall reinforcement and wall maintenance. The construction method is simple and easy to implement, scientific and convenient, and has the advantages of fast construction progress, low construction cost, high working efficiency and wide application range. According to the principle of 'repairing the old as the old', the cultural relic value of ancient architectural elements is kept, only damaged parts are repaired and reinforced, and the whole wall does not need to be replaced. The ancient architecture wall is priceless in cultural relic value. By using the method, original parts can be kept when the ancient architecture wall is damaged and loses bearing capacity, and a bearing function is recovered; the method conforms to the principle of 'repairing the old as the old', and is of great significance to the protection of the national cultural relics.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

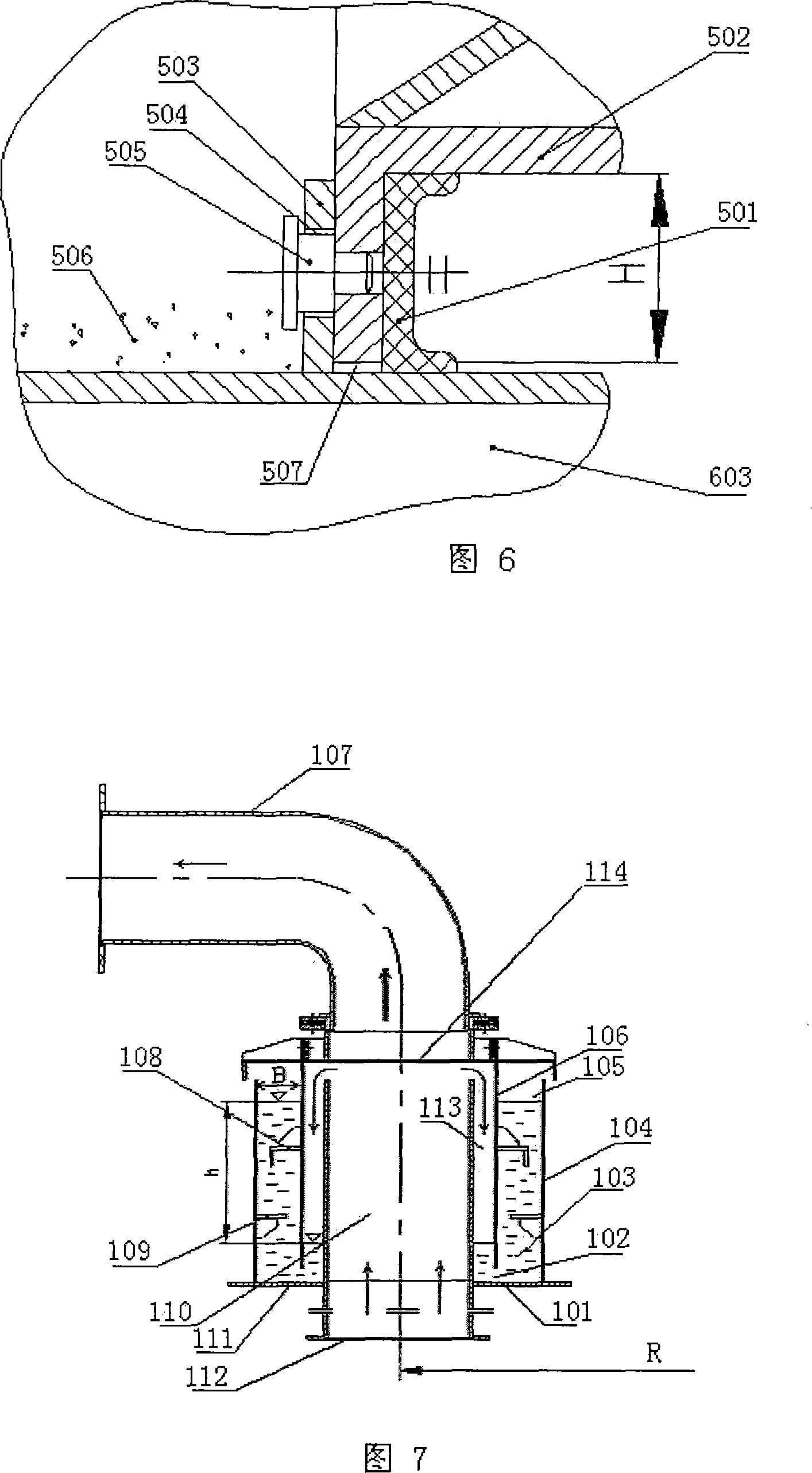

Air duct water sealing shock wave device used for ring cold machine

ActiveCN101118120AAvoid vibrationAvoid resonanceFurnace typesHandling discharged materialResonanceAtmospheric air

The present invention discloses an air water seal wave subduing device for a circular cooling machine, which comprises an inner ring-shape fluid bath, an outer ring-shaped fluid bath, and an inner water seal and an outer water seal composed of sealing plate devices with the radial cross section being in a door shape supported by a suspension. The inner water seal and the outer water seal are both composed of outer ring grooves connected with atmosphere and inner ring grooves connected with the air duct, a plurality of damping plates are fixed and arranged on the groove walls which form the water seal outer ring groove. Because damping plates are arranged in the water seal, under the good sealing effect of the ring-shape air duct, the vibration or resonance of the water in the water seal caused by wind in the air duct can be avoided, thus the circular cooling machine normal operation is ensured.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Wind power generation device

InactiveCN107588151AReduce vibrationHigh mechanical strengthNon-rotating vibration suppressionSupports/enclosures/casingsResonanceEngineering

The invention relates to the field of wind power generation, and particularly discloses a wind power generation device. The device comprises a generator and a square tank, the lower portion of the generator is located in the square tank, a vertical shock absorber is arranged between the bottom plate of the square tank and the bottom surface of the shell of the generator, and transverse shock absorbers are arranged between the four side plates of the square tank and the side surfaces of the shell of the generator; the vertical shock absorber comprises a first shock absorbing mechanism and second shock absorbing mechanisms, wherein the first shock absorbing mechanism comprises an outer sleeve cylinder, a base assembly and a fixing assembly; the second shock absorbing mechanisms comprise twoelastic shock absorbing plates symmetrically fixed to the shell of the generator and pouring bags arranged between the elastic shock absorbing plates and the bottom plate of the square tank, and the transverse shock absorbers comprise outer cylinders fixed to the side plates of the square tank and inner cylinders slidably arranged in the outer cylinders in a sleeved mode. By means of the wind power generation device, shock absorbing and noise reduction can be effectively conducted on the generator, occurrence of resonance between the generator and external environment is prevented, smooth andstable operation of the generation device is ensured, the noise produced by the generator during work is reduced, and the noise pollution is reduced.

Owner:长沙小新新能源科技有限公司

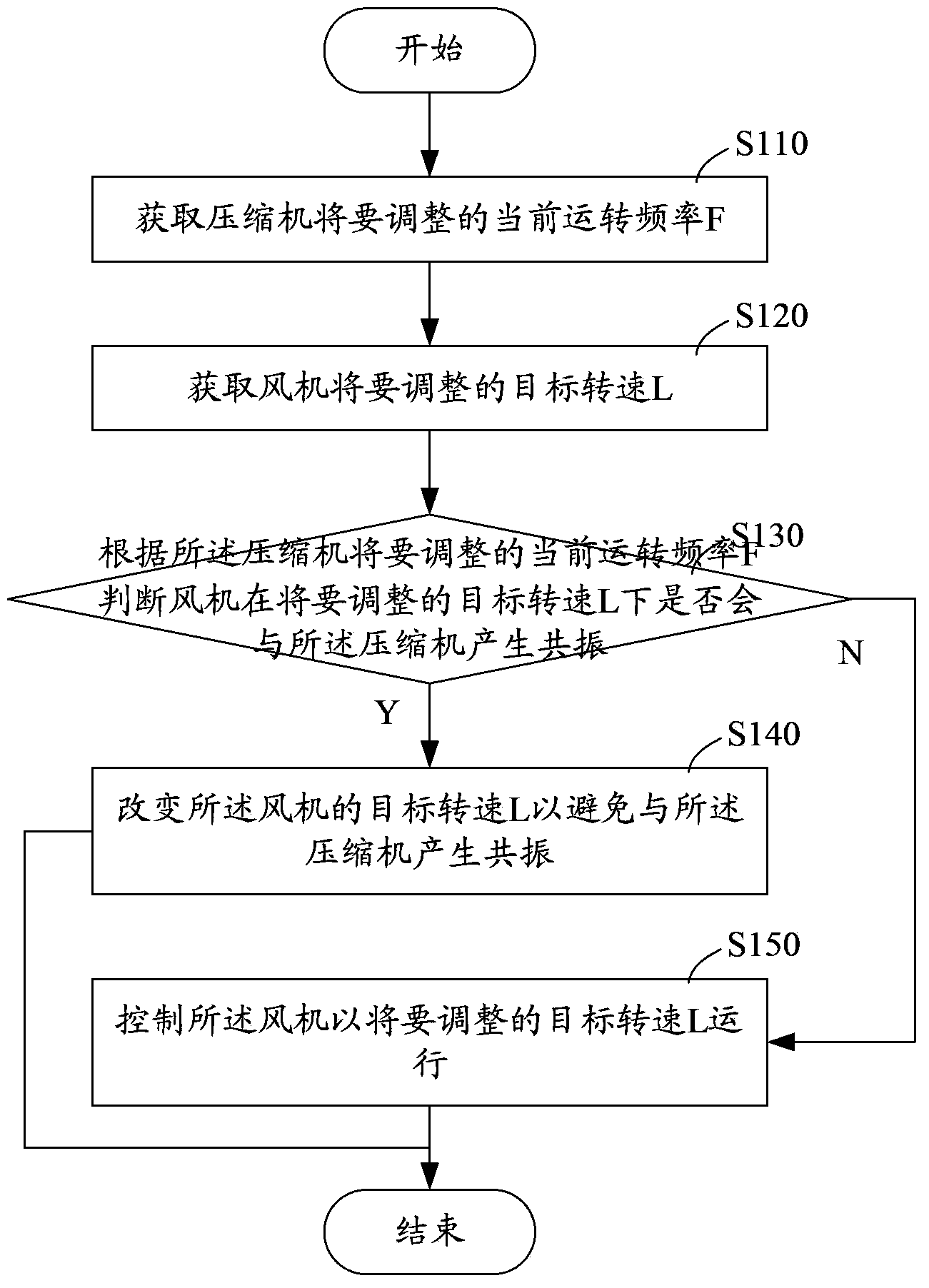

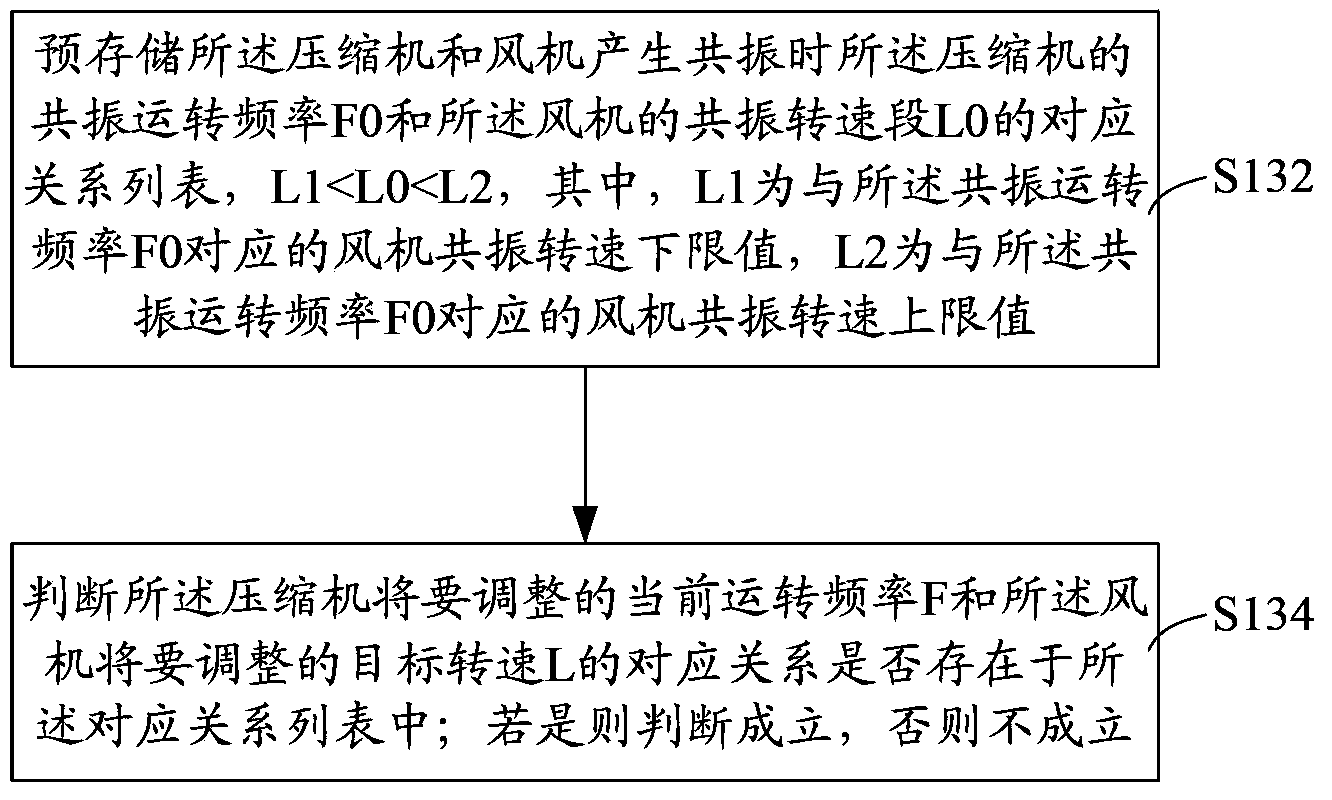

Method and system for controlling blower of refrigeration equipment

ActiveCN104048458AAvoid resonanceSolve low-frequency pulsating abnormal soundRefrigeration safety arrangementAutomatic controlResonance

The invention is applied to the field of the automatic control of refrigeration equipment and provides a method for controlling a blower of the refrigeration equipment. The method comprises the following steps: acquiring current operation frequency F to be regulated of a compressor; acquiring target rotating speed L to be regulated of the blower; judging whether the blower can be subjected to resonance with the compressor or not at the target rotating speed L to be regulated according to the current operation frequency F to be regulated of the compressor, and changing the target rotating speed L of the blower if the blower can be subjected to resonance with the compressor at the target rotating speed L to be regulated, so as to avoid the resonance with the compressor. According to the method, whether the acquired target rotating speed L is in a target rotating speed range Ln of the blower or not is judged according to the Ln which can be subjected to resonance with the compressor operating at the current operation frequency F, and the target rotating speed L of the blower is changed to avoid resonance if the acquired target rotating speed L is the Ln of the blower, so that the problem that an air conditioner emits low-frequency pulsating abnormal sound due to the resonance of the refrigeration equipment is solved, and the user comfort is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

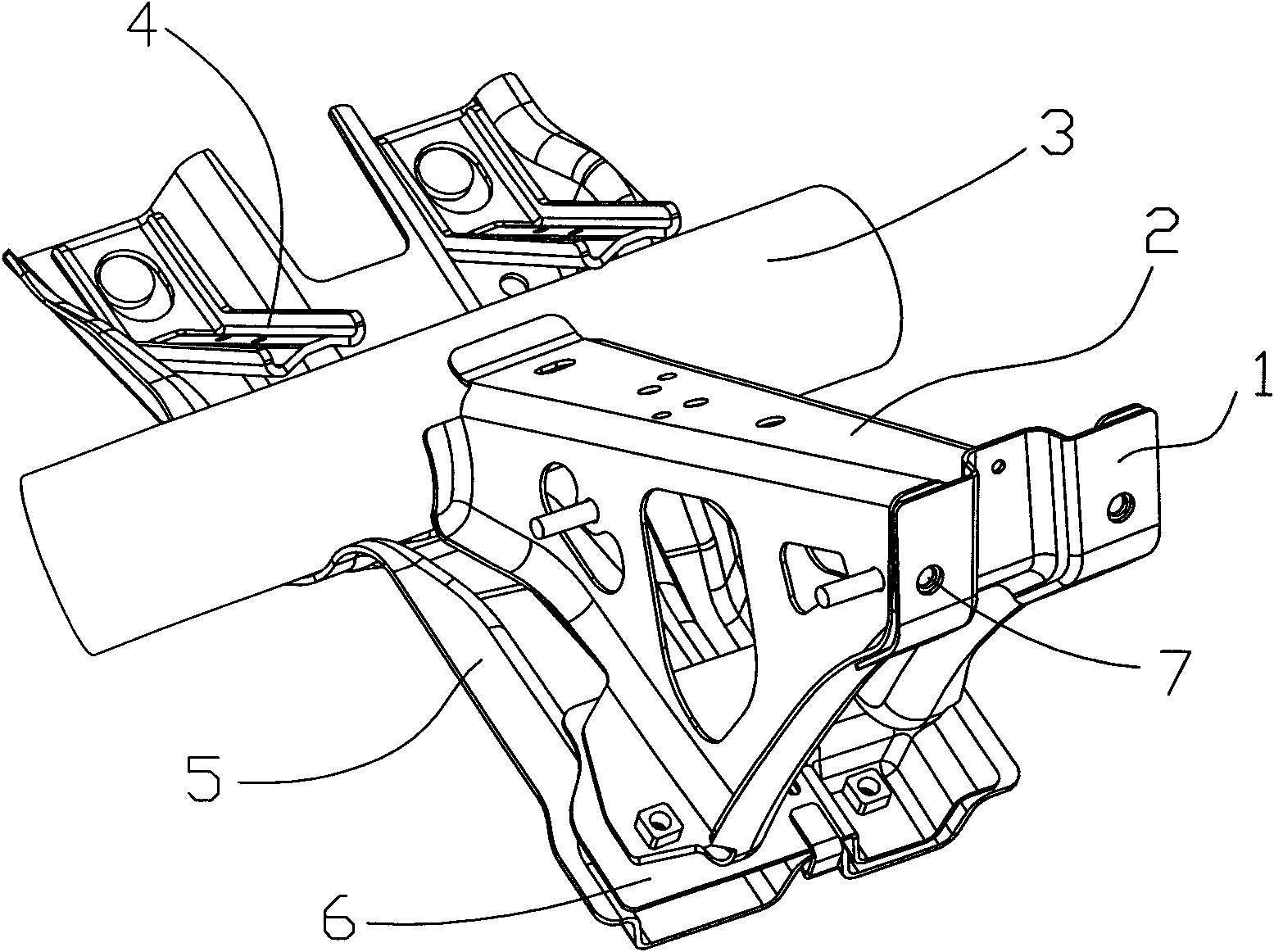

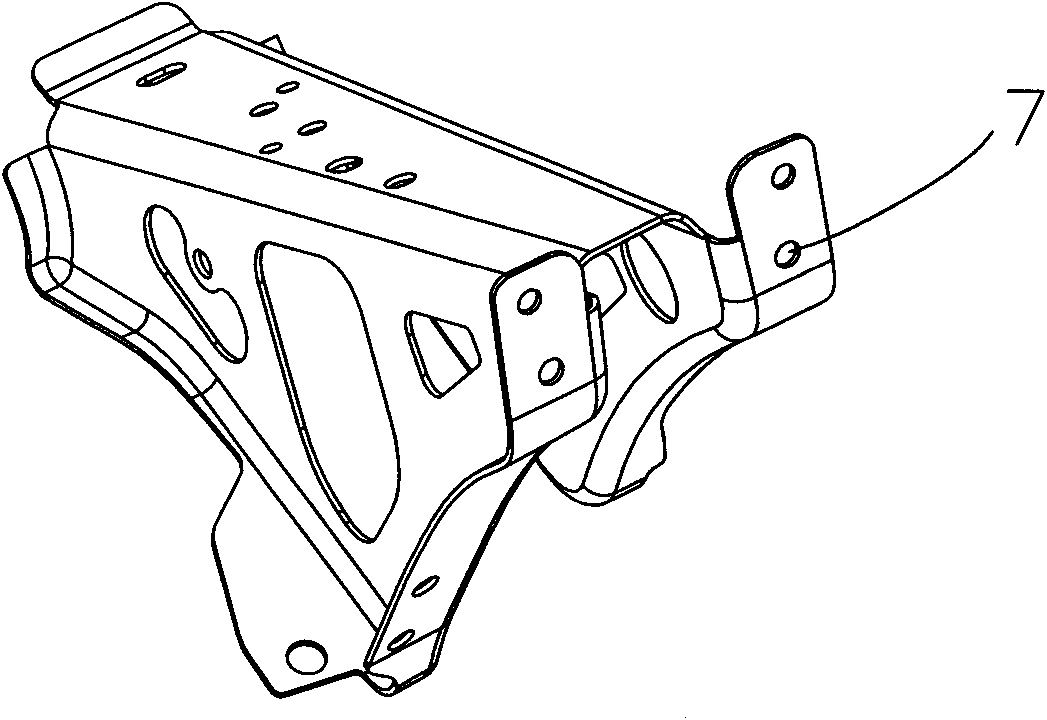

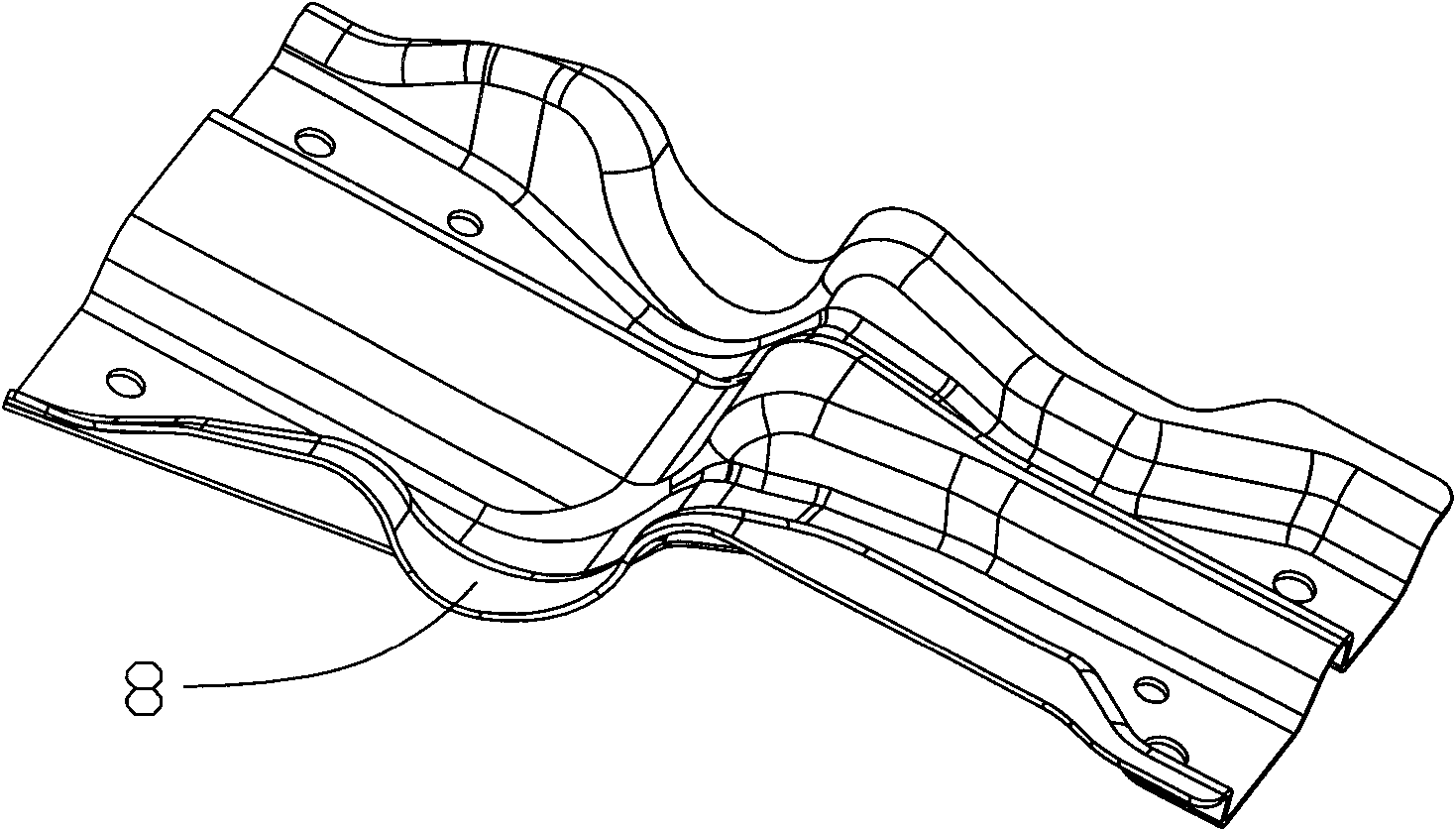

Connecting bracket assembly of steering support and front wall panel

ActiveCN101885348AImprove structural strengthReduce vibrationSuperstructure subunitsSteering columnsSteering columnResonance

The invention relates to a connecting bracket assembly of a steering support and a front wall panel for connecting the steering support of an automobile with the front wall panel of the vehicle body. The connecting bracket assembly comprises a steering support transverse pipe, and a steering column mounting bracket and a front wall panel connecting bracket which are welded with the steering support transverse pipe respectively; the front wall panel connecting bracket is a sheet metal part with U-shaped cross section, and the two side faces of the sheet metal part have triangular shapes; the front wall panel connecting bracket is welded with the steering support transverse pipe through a first top end of the triangular side face of the sheet metal part; and one edge, adjacent to the first top end, of the triangular side face is welded with the steering column mounting bracket. The connecting bracket assembly has high structural strength, improves the rigidity and the strength for the connection between the steering support of the automobile and the front wall panel of the vehicle body, and prevents the resonance with the low frequency vibration transferred from an engine compartment; and the connecting bracket assembly is directly connected with the steering column, and the front wall panel and the steering support simultaneously fix the steering column, so that the vibration of the steering column is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Two-stage series pressurization direct-driven centrifugal air compressor of fuel cell engine

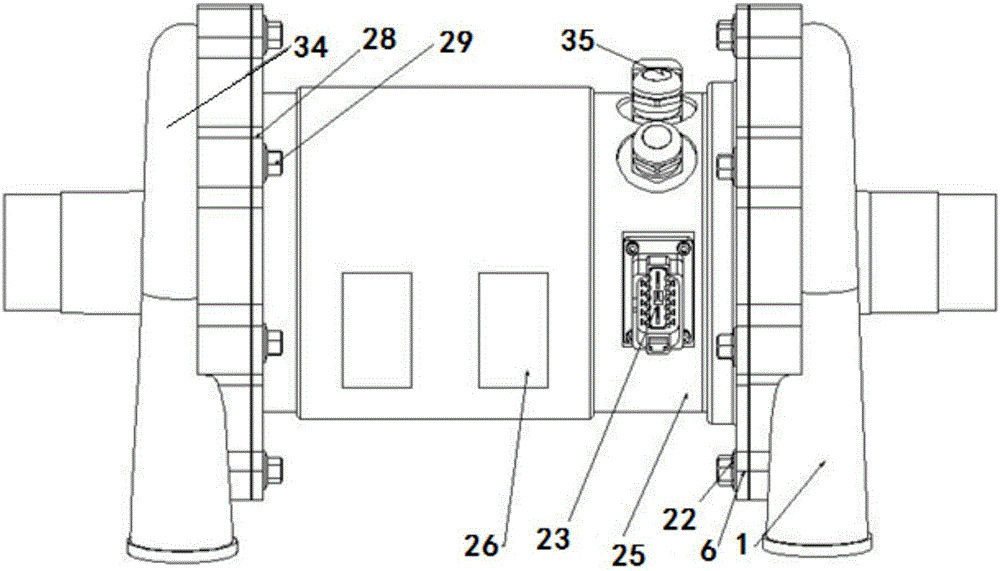

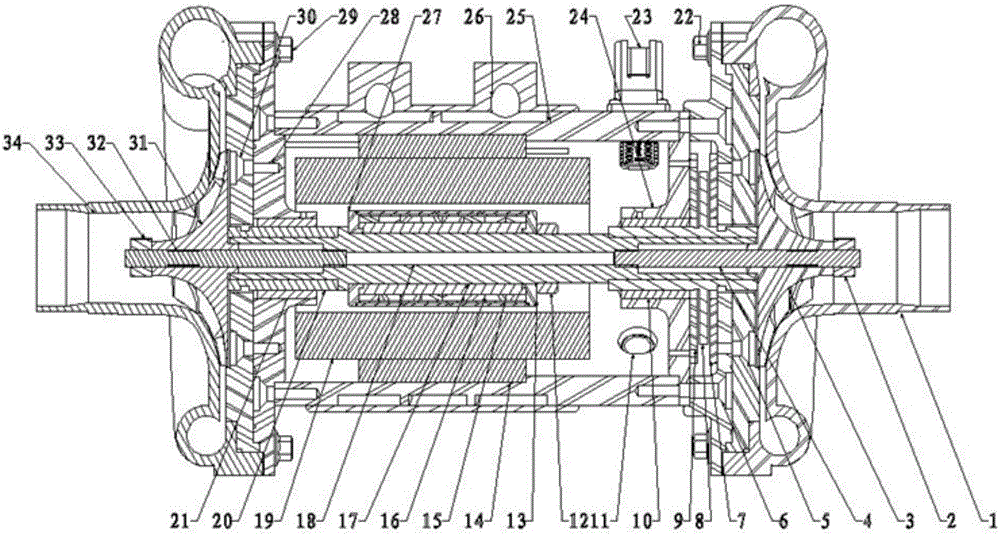

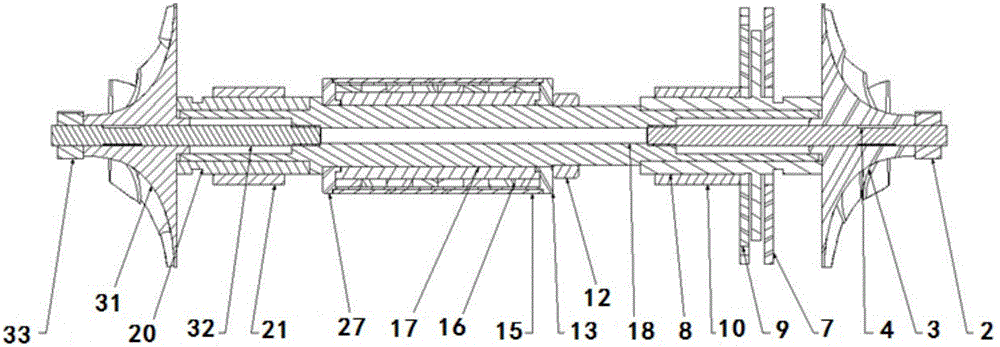

ActiveCN105889096AImprove reliabilityReduce volumeMagnetic circuit rotating partsPump componentsImpellerStator

The invention relates to a two-stage series pressurization direct-driven centrifugal air compressor of a fuel cell engine. The two-stage series pressurization direct-driven centrifugal air compressor comprises end covers, a spindle, volutes, impellers, a rotor, a stator and a driver. The spindle is supported by a left-end radial supporting air foil bearing, a left-end radial supporting air foil bearing bush, an air foil axial thrust bearing and a right-end radial supporting air foil bearing, wherein the left-end radial supporting air foil bearing and the left-end radial supporting air foil bearing bush are arranged on the left side, and the air foil axial thrust bearing and the right-end radial supporting air foil bearing are arranged on the right side of the spindle. The left-end radial supporting air foil bearing bush is arranged on the outer side of the spindle in a surrounding manner. The left-end radial supporting air foil bearing is fixed to the outer side of the left-end radial supporting air foil bearing bush. The air foil axial thrust bearing is fixed to the outer side of the spindle in a bush form. The right-end radial supporting air foil bearing is fixed to the outer side of the air foil axial thrust bearing. Compared with the prior art, the two-stage series pressurization direct-driven centrifugal air compressor is more suitable for the air inlet pressurization scene of the fuel cell engine with the high oilless air inlet requirement, and the durability and reliability of the air compressor of the fuel cell engine can be improved.

Owner:TONGJI UNIV

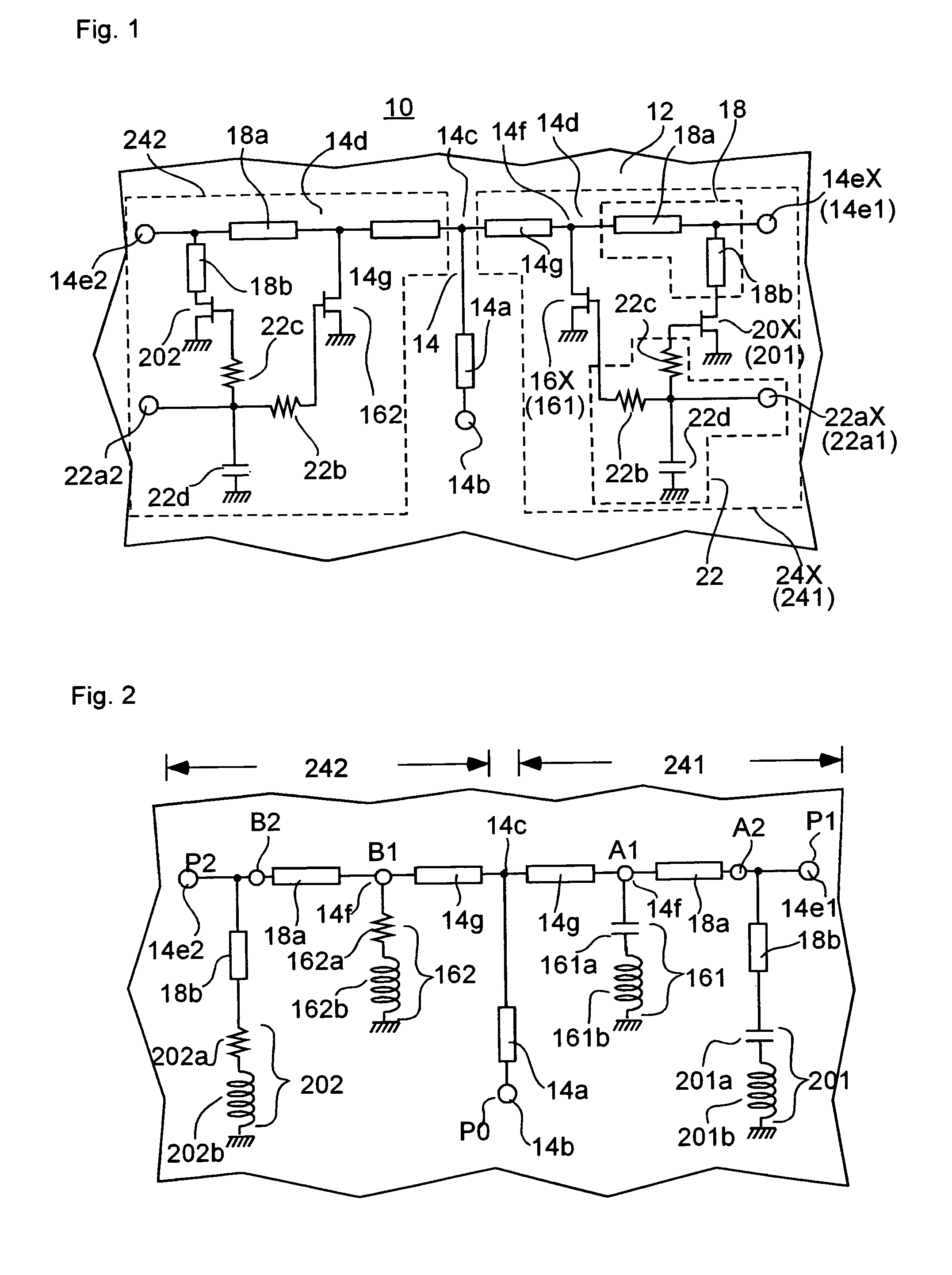

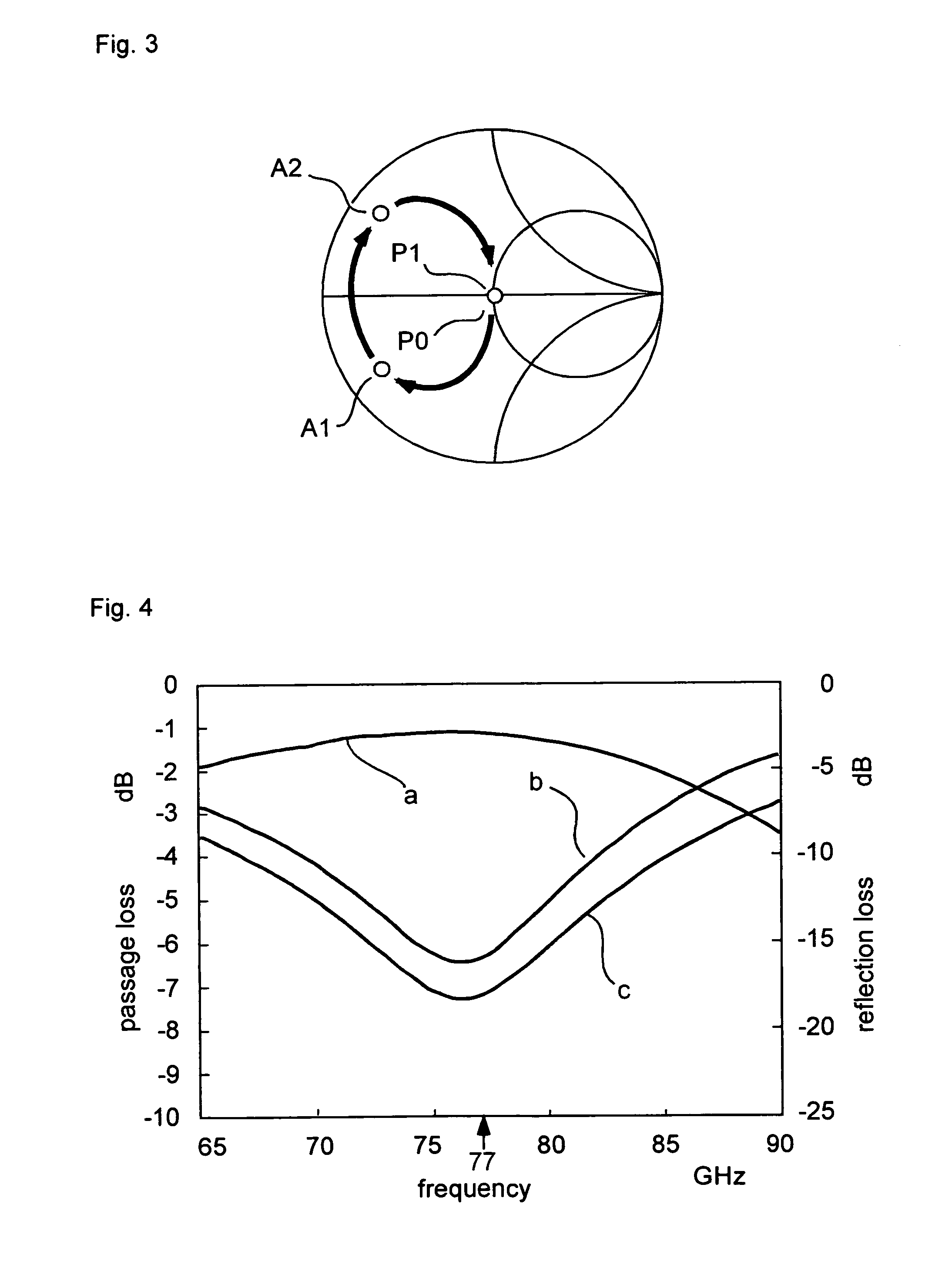

High-frequency switch

ActiveUS7411471B2Avoid resonanceReduce connectionsImpedence matching networksMultiple-port networksEngineeringWave band

A high-frequency switch operating in a millimeter wave band that includes a signal path having a λ / 4 transmission path, for part of two or more branch signal paths that branch from an input connection path via a branch point; an FET, which is shunt-connected between a grounding end and the branch signal paths that are positioned between the λ / 4 transmission path and a terminal end, as viewed from the branch point, and used to connect or disconnect the branch signal paths and the grounding end; an output matching circuit, which is positioned on the branch signal paths that are positioned between a terminal end and a connection point for the FET as viewed from the branch point, and includes a shunt-connected stub; and a matching FET, which is connected between the stub and the grounding end and used to connect or disconnect the stub and the grounding end in accordance with the FET's connection / disconnection.

Owner:MITSUBISHI ELECTRIC CORP

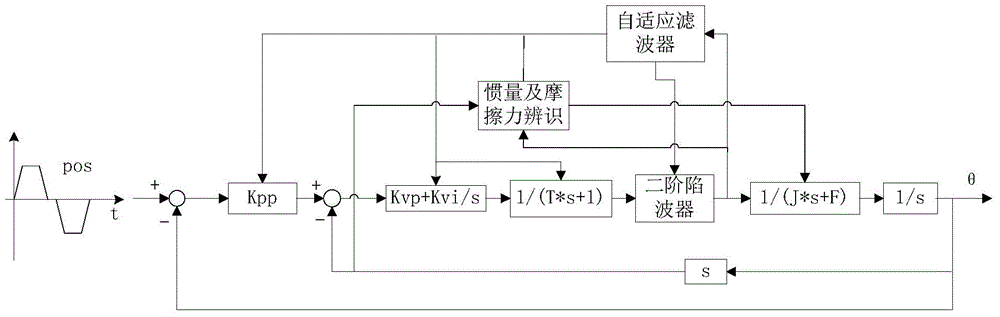

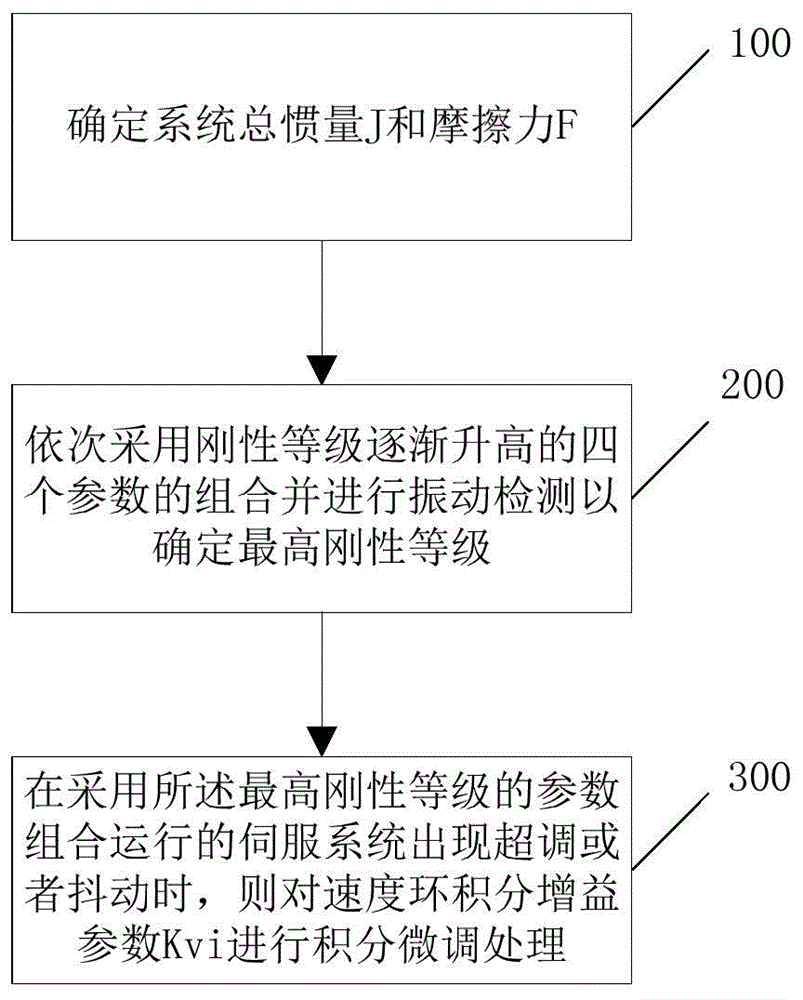

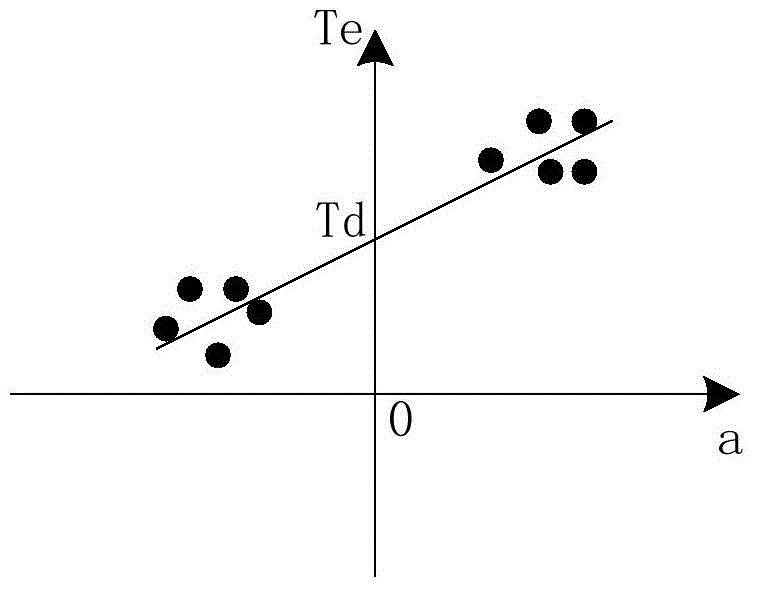

Servo motor system gain parameter automatically adjusting method and system

ActiveCN104617845AAvoid resonanceFind automatic fastElectronic commutation motor controlVector control systemsTime parameterSpeed loop

The invention discloses a servo motor system gain parameter automatically adjusting method and system. Gain parameters include position loop gain parameters Kpp, speed loop proportional gain parameters Kvp, speed loop integral gain parameters Kvi and low-pass filter time parameters T. The servo motor system gain parameter automatically adjusting method comprises, before a servo motor system works, establishing a rigidity table composed of Kpp, Kvp, Kvi and T, and dividing the rigidity table into a plurality of rigidity levels corresponding to the incremental change of the four parameters; during working of the servo motor system, performing the following steps of (a), according to the input of the servo motor system and the output of the encoder, performing vibration testing sequentially through combinations of the four parameters with the rigidity levels increasing gradually to determine the highest rigidity level, and (b) when overshoot or vibration occurs on a servo system working according to the parameter combination of the highest rigidity level, performing integral fine tuning on the Kvi. The servo motor system gain parameter automatically adjusting method saves manual adjustment of workers and can automatically and rapidly find appropriate gain parameters.

Owner:SUZHOU INOVANCE TECH CO LTD

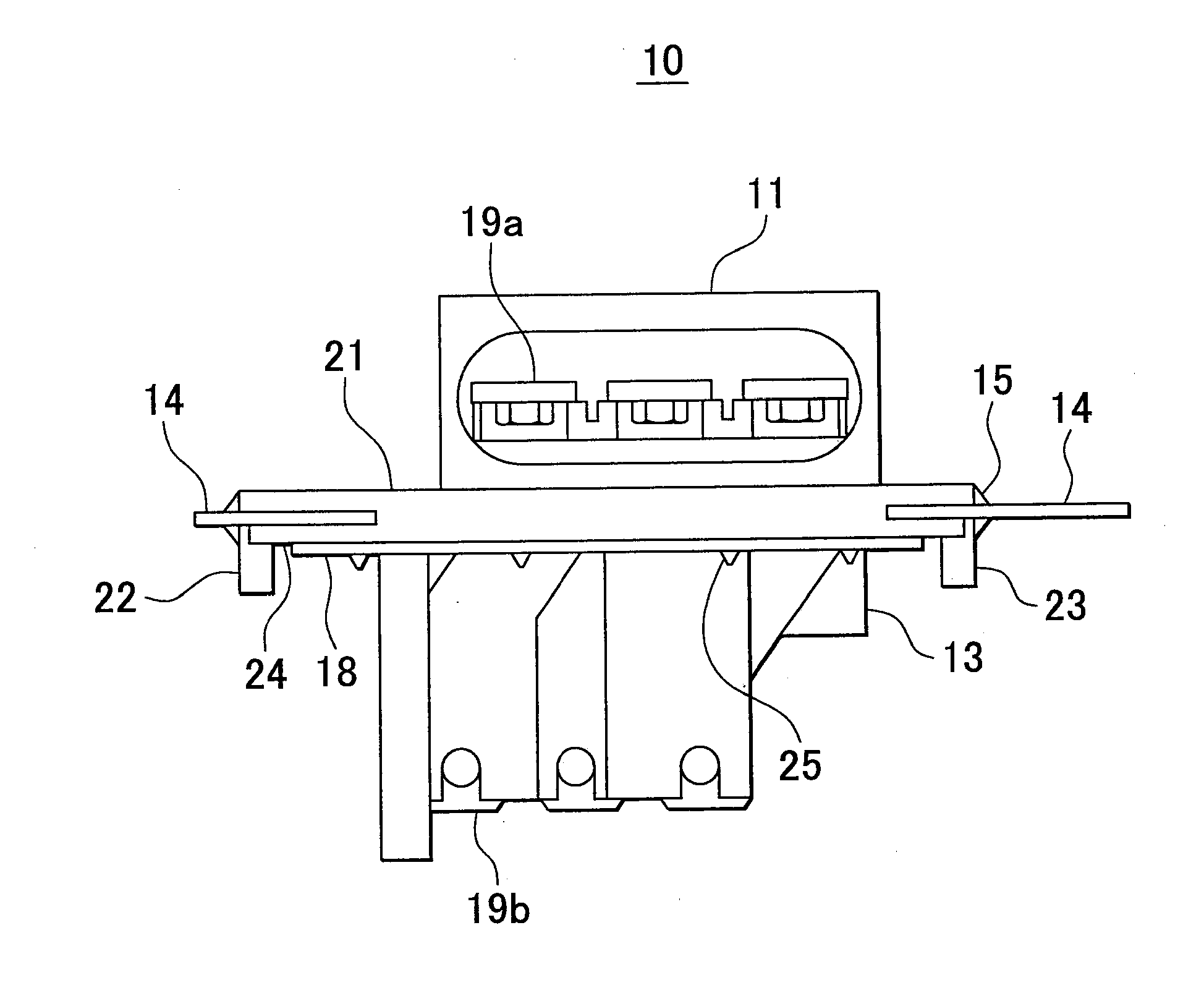

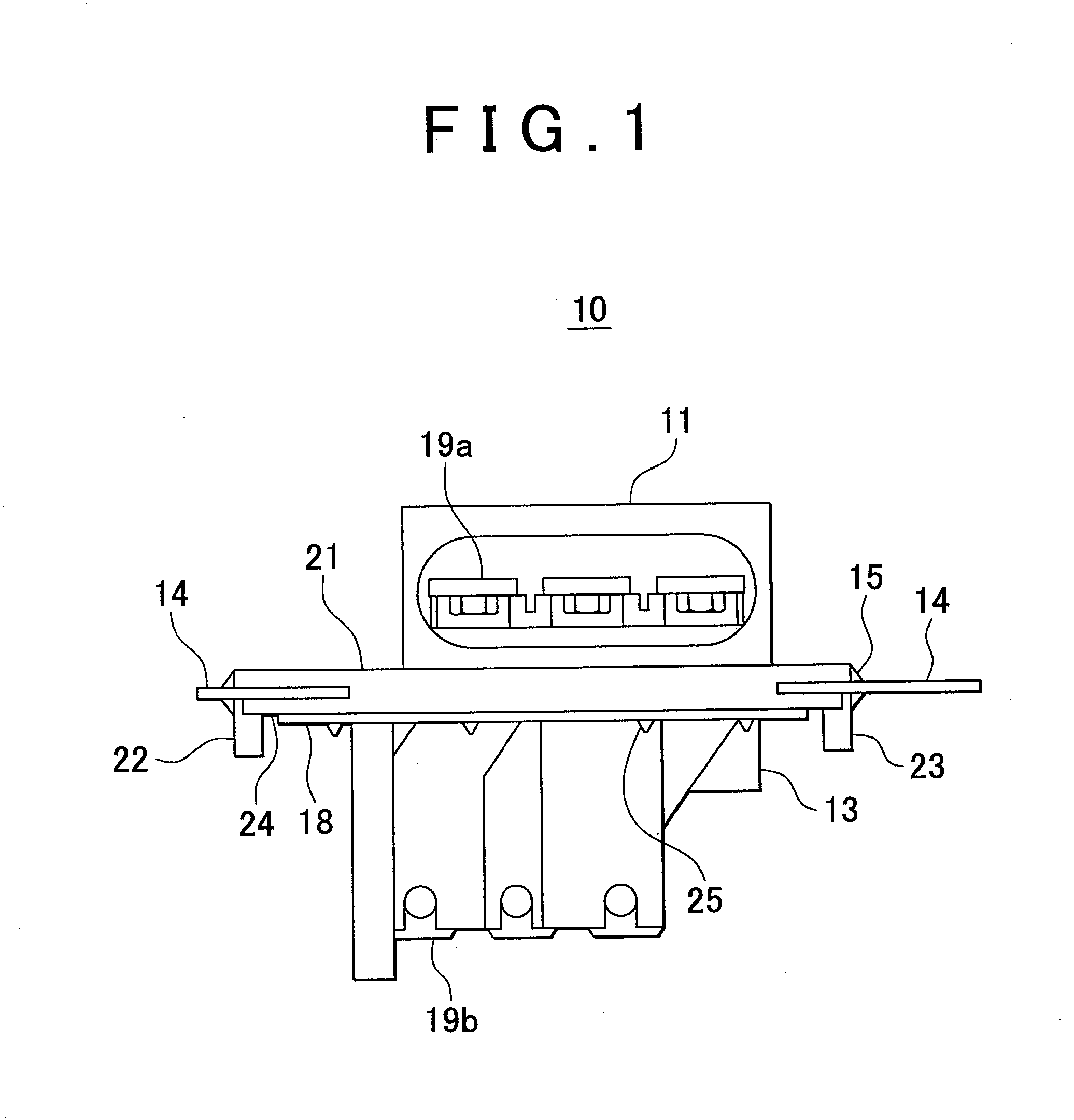

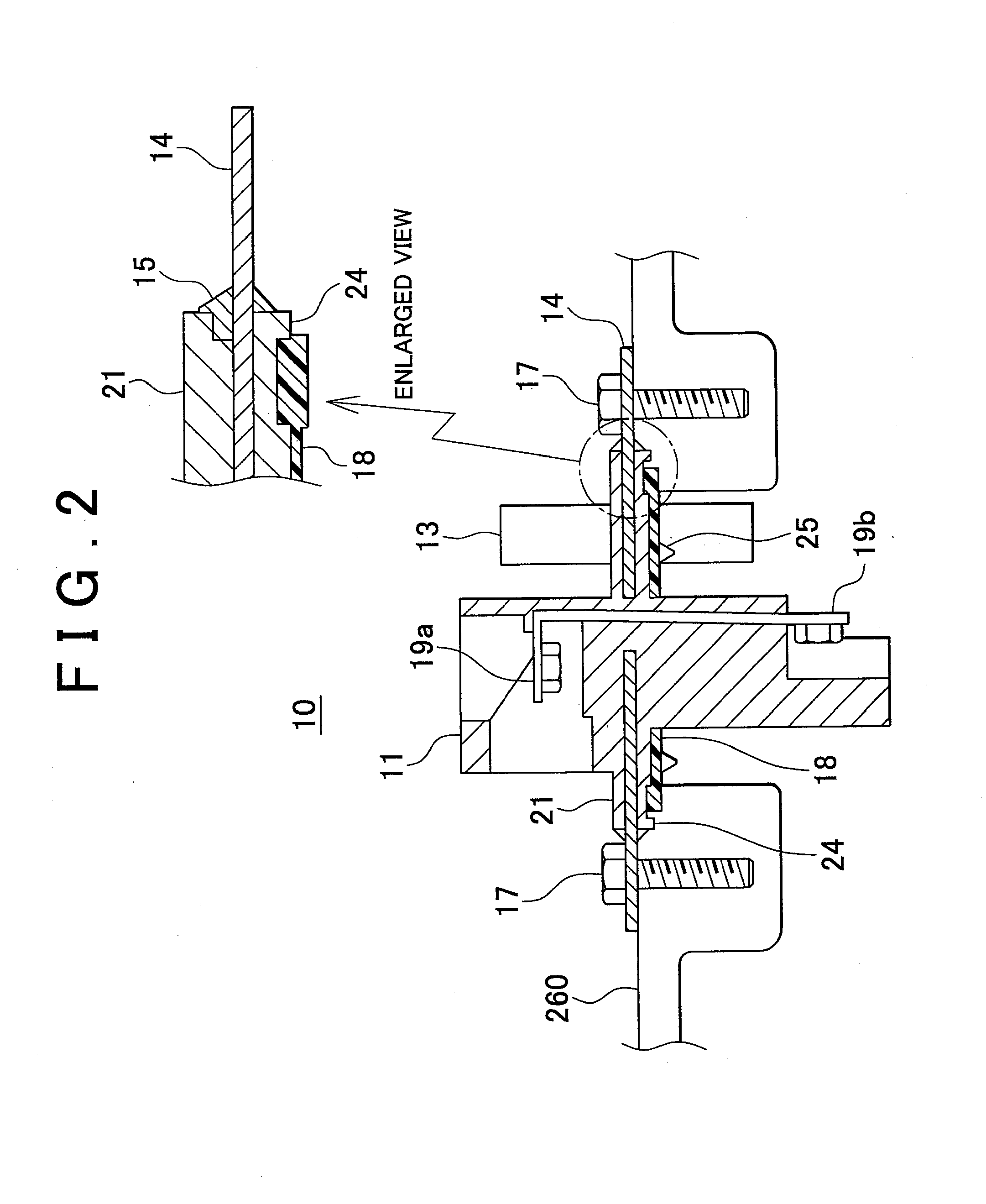

Terminal block for rotary electric machine

ActiveUS20110187213A1Avoid resonanceAvoid vibrationSupports/enclosures/casingsElectric machineEngineering

A rotary electric machine terminal block fits into an opening of a case that contains a rotary electric machine, and is fixed to the case by a plate. The rotary electric machine terminal block has: a mount that is formed by fixing the electric power line connector and the signal line connector to the steel-made plate and performing insert molding so that an anti-vibration plate is formed on an upper surface of the plate; projected portions of the plate which each have a fixture hole for fixing the plate to the case; an edge seal member that covers an edge of the projected portion; a face seal member for tight attachment of the mount to the case; and two positioning pins.

Owner:TOYOTA JIDOSHA KK +1

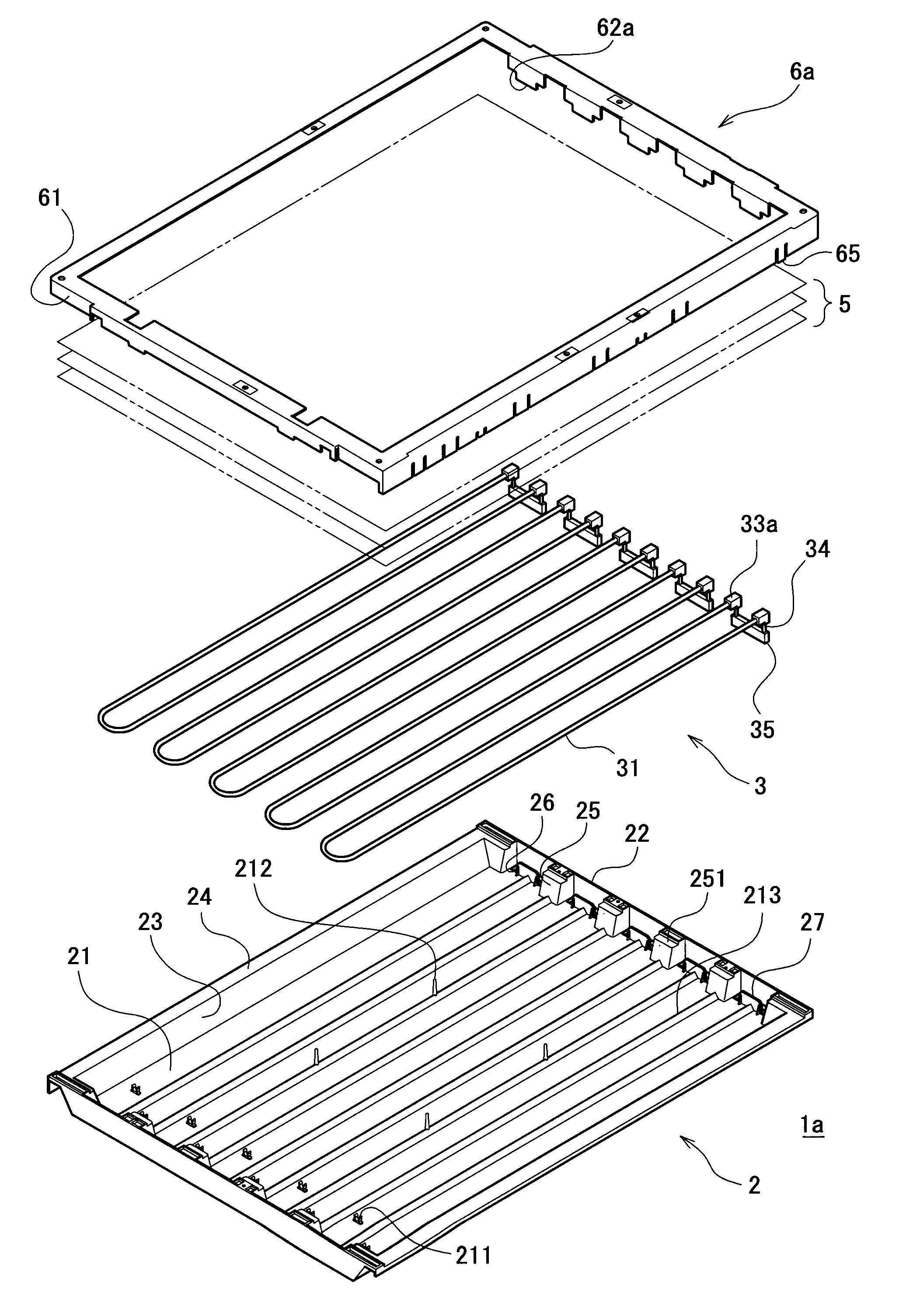

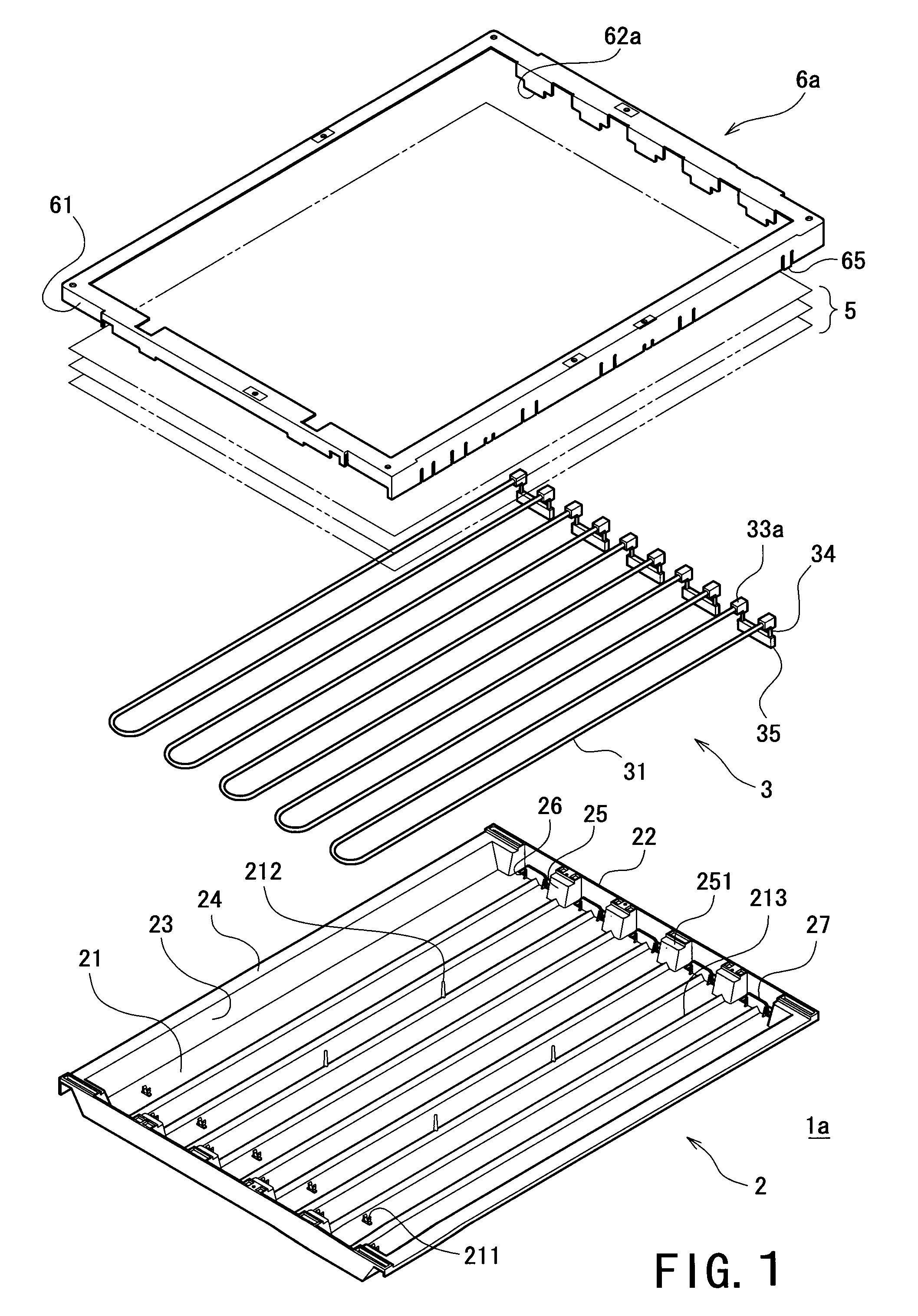

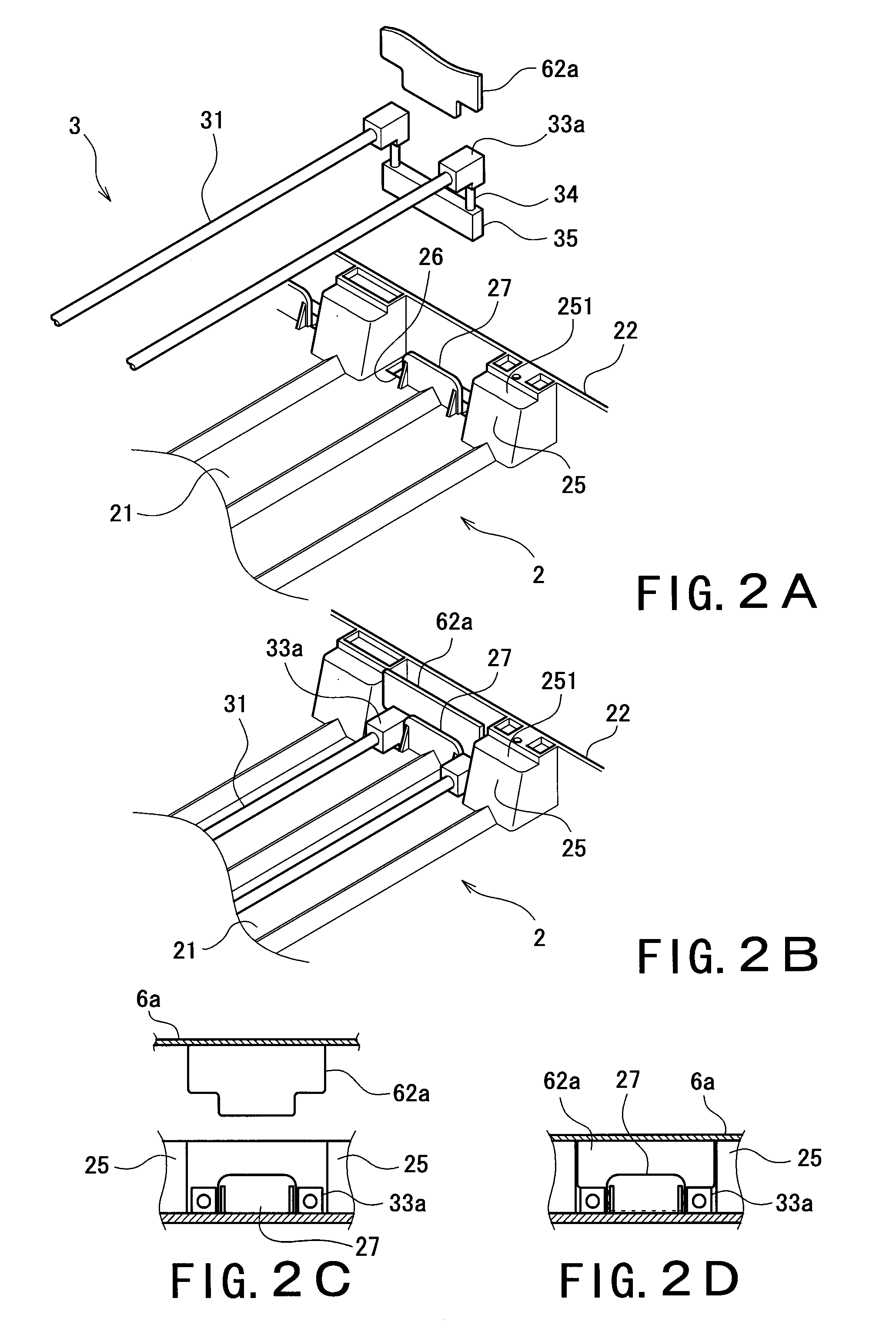

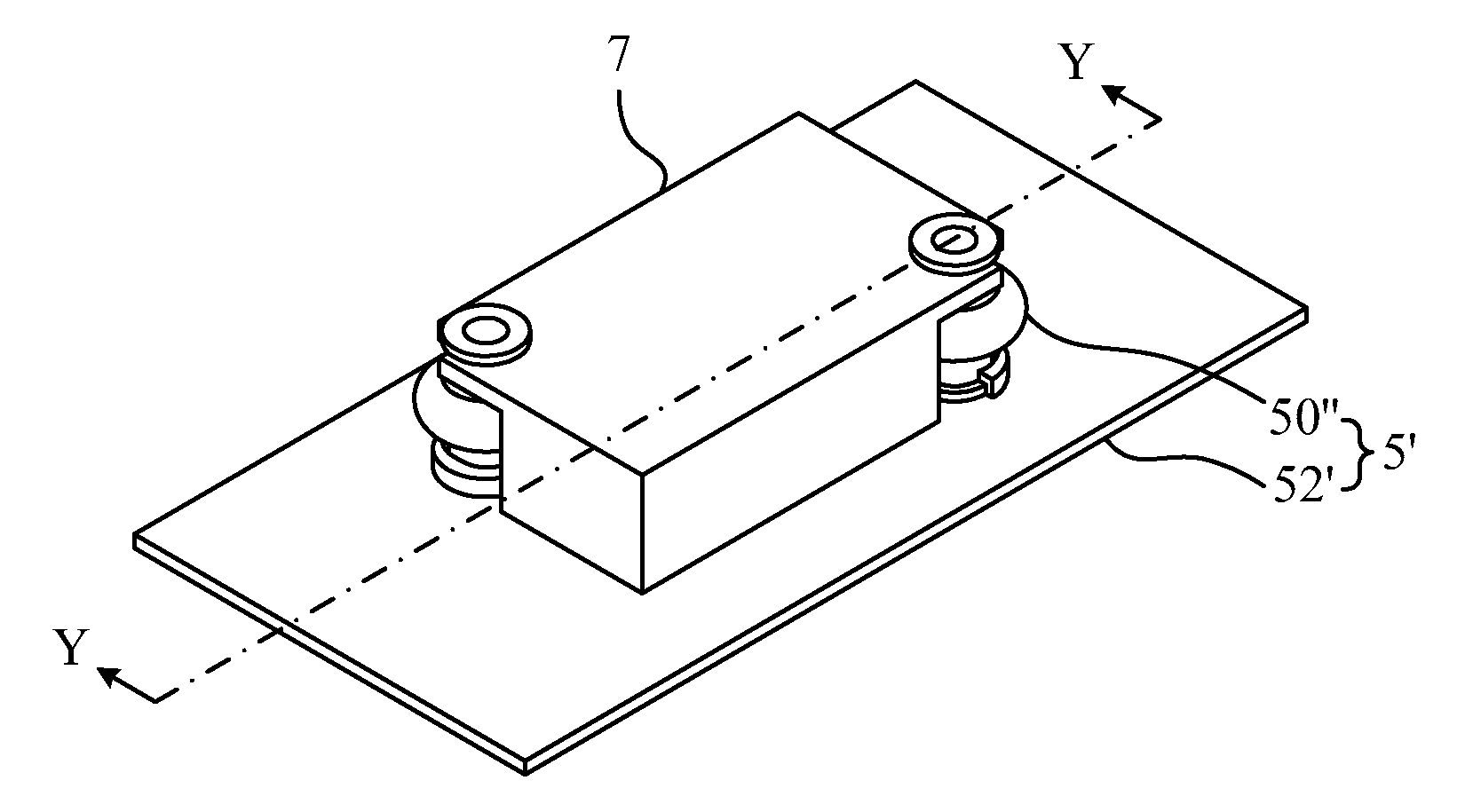

Support Structure for a Light Source, a Backlight Unit for a Display Device Having the Support Structure, and a Display Device

InactiveUS20080101074A1Preventing contact noiseAvoid noiseLighting support devicesElongate light sourcesDisplay deviceCold cathode

A support structure for a light source prevents the occurrence of a contact noise caused by contact of the light source with elements disposed around it due to vibrations. In the support structure, at the front of a backlight unit, cold cathode tubes as light sources and optical sheets for controlling the properties of light emitted from the cold cathode tubes are placed, and a frame substantially in the shape of a square with an opening is attached thereto from the front, so that rubber holders attached to the ends of the cold cathode tubes and the edges of the optical sheets are secured while disposed between the backlight unit and the frame.

Owner:SHARP KK

Damper and fixing device using the same

InactiveUS20090242322A1Resonance of the speaker and the casing is preventedSave materialSpringsNon-rotating vibration suppressionControl theoryLoudspeaker

The invention discloses a damper including a damping portion, a first pillar-shaped portion, a second pillar-shaped portion and a first block portion. The damping portion has a first end and a second end. The first pillar-shaped portion protrudes from the first end of the damping portion, and the second pillar-shaped portion protrudes from the second end of the damping portion. The first pillar-shaped portion has a third end away from the first end of the damping portion, and the first block portion protrudes from the third end. In the invention, the damper can fix a speaker to a base directly without screws.

Owner:PEGATRON

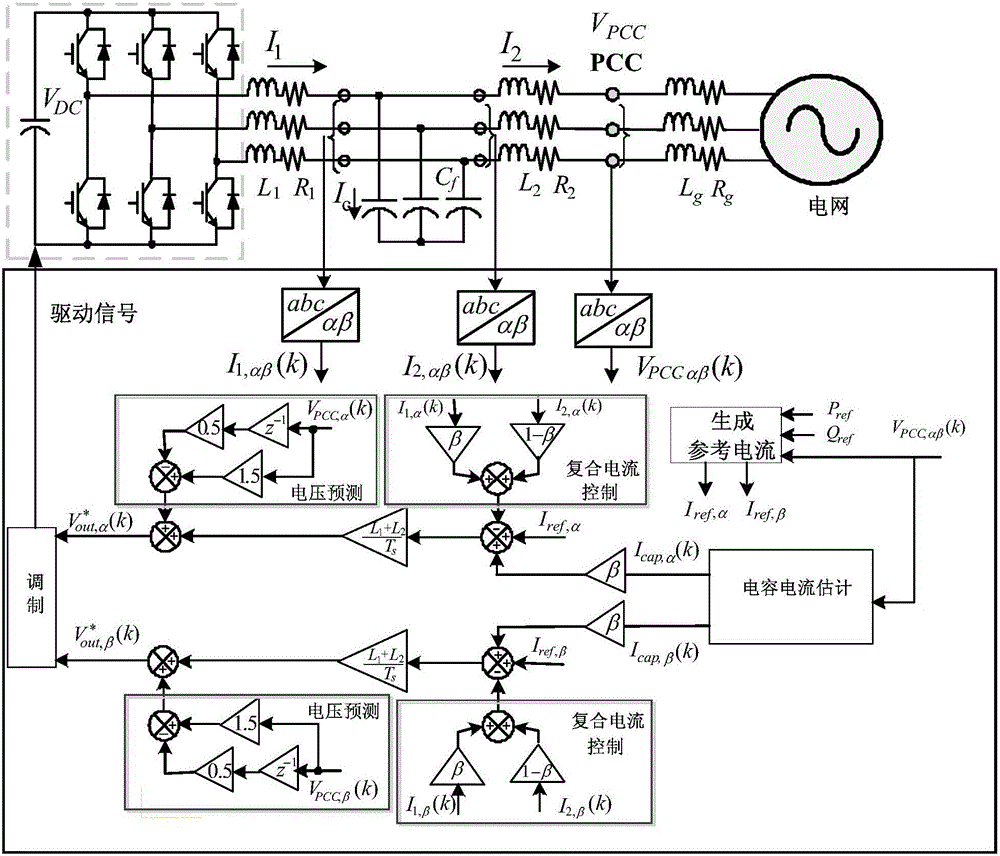

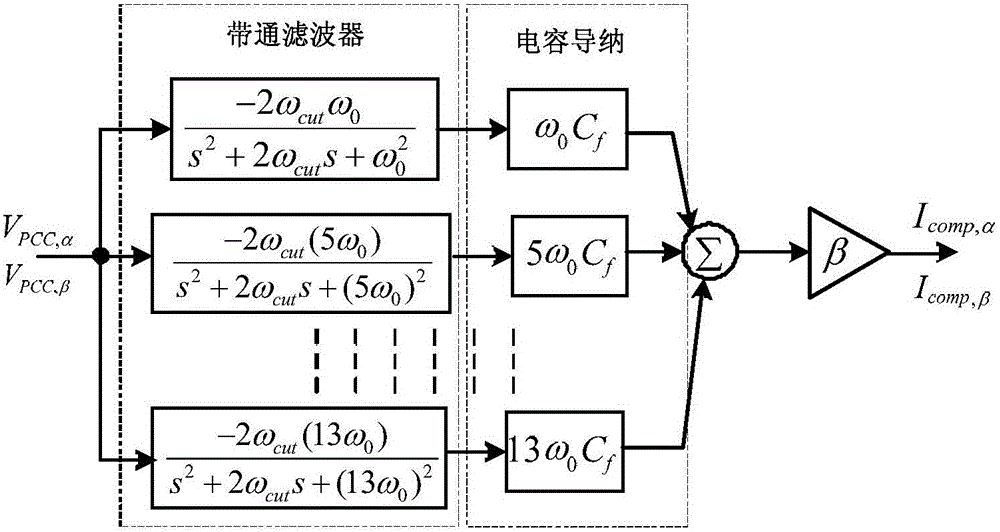

Inverter control method based on voltage feedforward and recombination current control

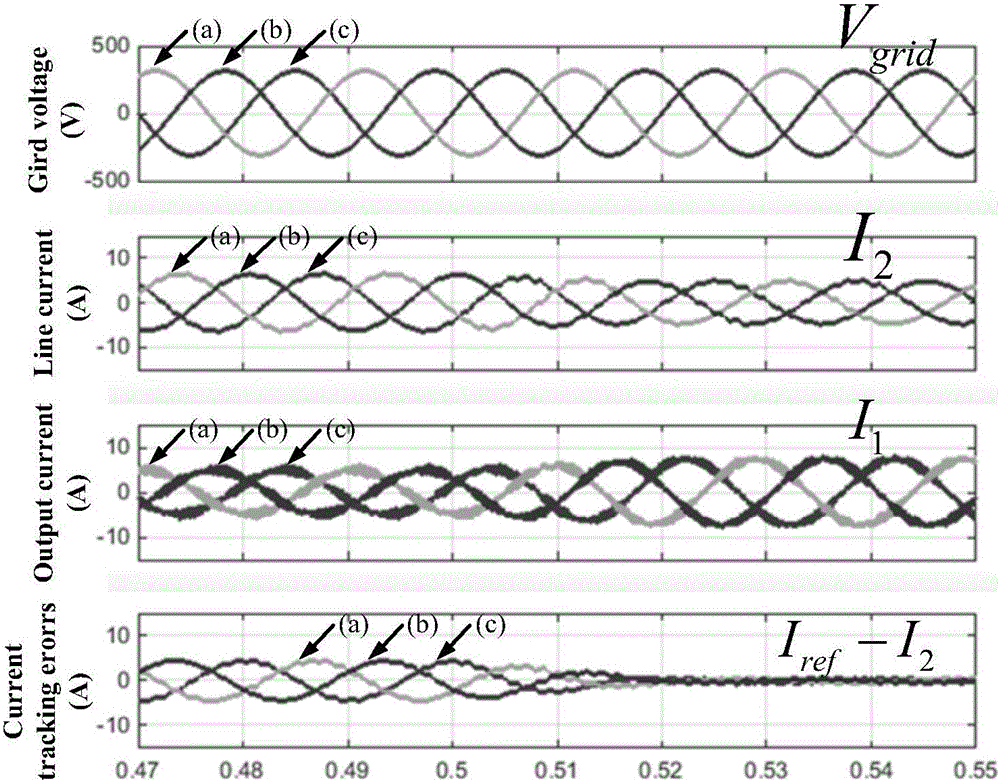

ActiveCN105763094AAvoid resonanceAccurate and effective outputAc-dc conversionSingle network parallel feeding arrangementsPower inverterPower grid

The invention discloses an inverter control method based on voltage feedforward and recombination current control. After signal collection is conducted, reference voltage can be obtained via dead beat control, duty ratio signals of a switch tube can be obtained via sine pulse width modulation or space vector pulse width modulation, and therefore switch-on and switch-off of the switch tube of the inverter can be controlled. According to the inverter control method disclosed in the invention, a predicted voltage value of a common connection point PCC is used as voltage feedforward in a procedure where the reference voltage is obtained via dead beat control, recombination current control is also adopted, an LCL wave filtering device can be prevented from resonance oscillation, and the control precision of a control algorithm can be improved. The control method cannot be affected by power grid voltage distortion, inverter grid connected current control precision can be effectively improved, the robustness of a control system can be improved, and system operation safety and stability can be ensured.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com