Patents

Literature

1718 results about "Face seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A face seal is a seal in which the sealing surfaces are normal to the axis of the seal. Face seals are typically used in static applications and are used to prevent leakage in the radial direction with respect to the axis of the seal. Face seals are often located in a groove or cavity on a flange.

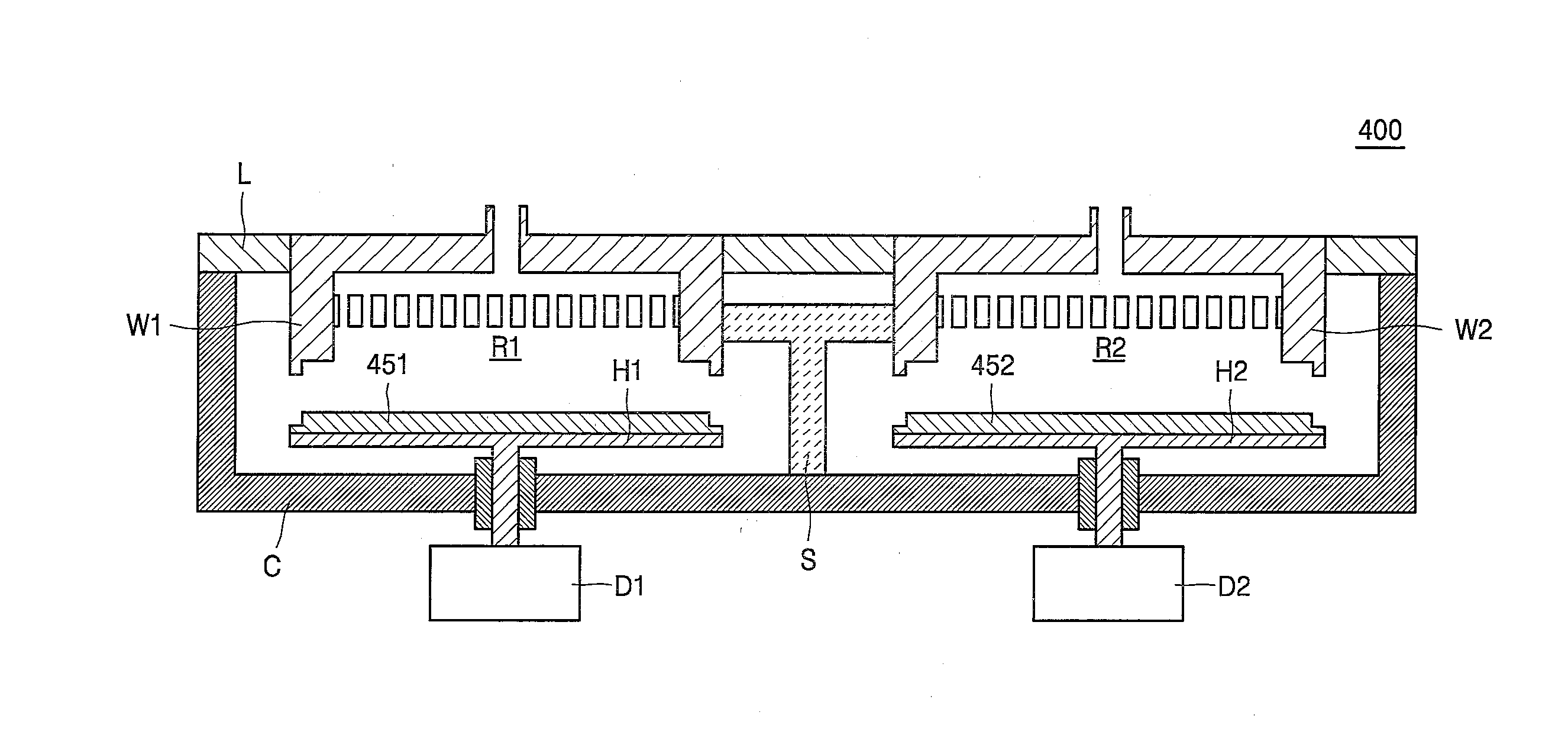

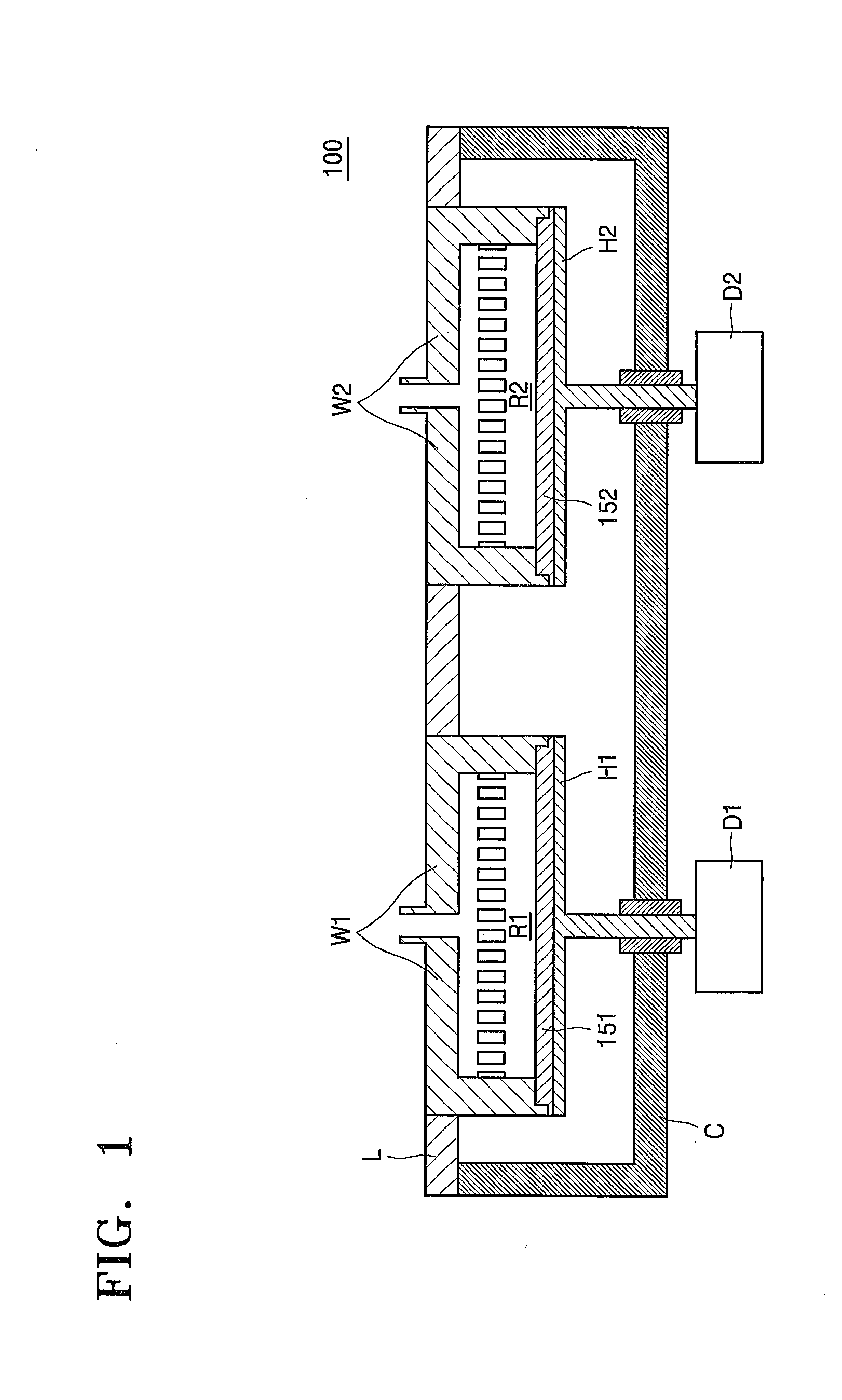

Thin film deposition apparatus

ActiveUS20170044666A1Reduce and prevent problemFrom chemically reactive gasesChemical vapor deposition coatingManufactured apparatusGas supply

Disclosed are a substrate holder and a semiconductor manufacturing apparatus including the substrate holder. The substrate holder provides a reaction region by making face-sealing contact with a reactor wall. The substrate holder has an elastic behavior when pressure is applied thereto while the substrate holder makes face-sealing contact with the reactor wall. The semiconductor manufacturing apparatus includes the substrate holder and a gas supply unit configured to supply gas to the reaction region provided by the reactor wall and the substrate holder.

Owner:ASM IP HLDG BV

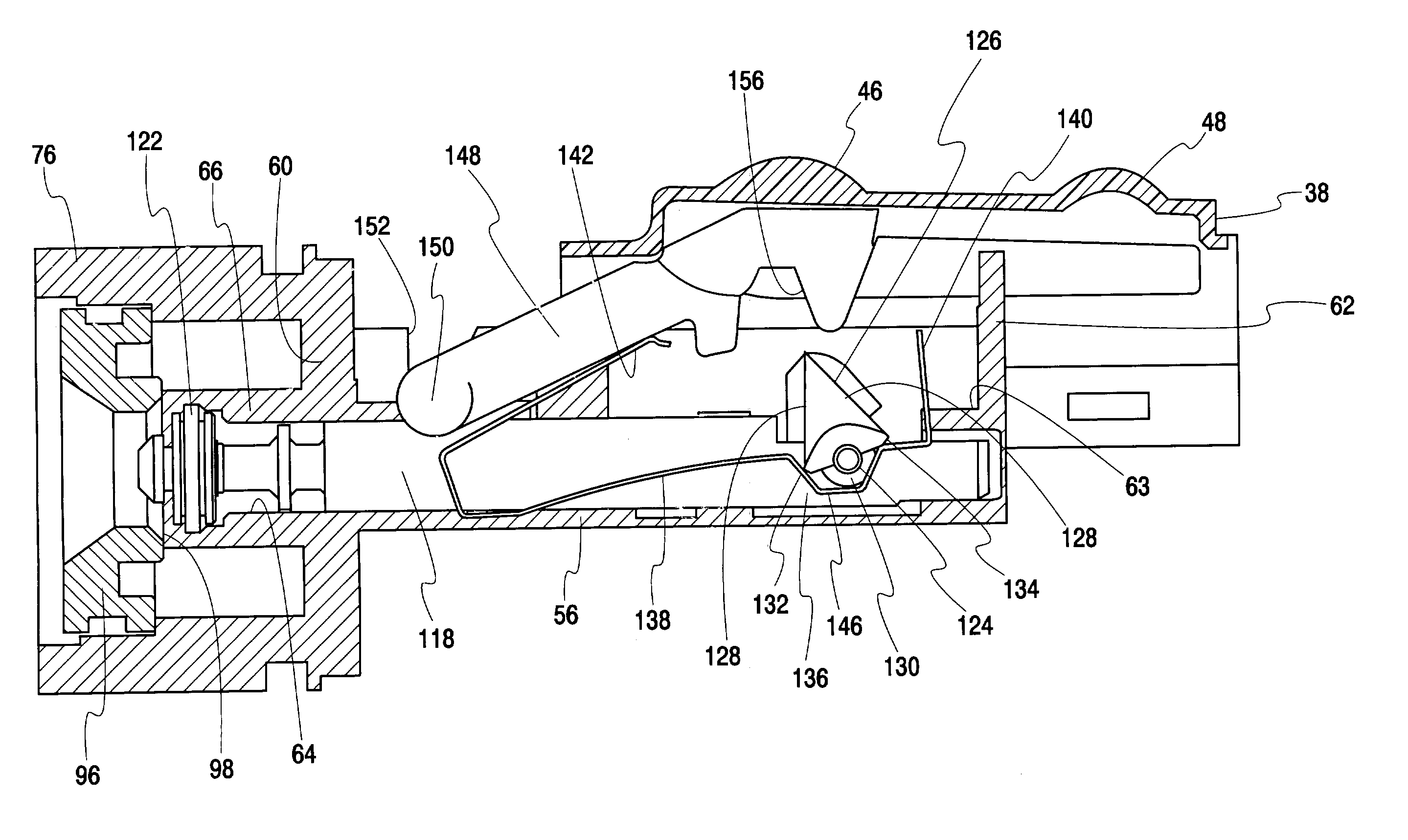

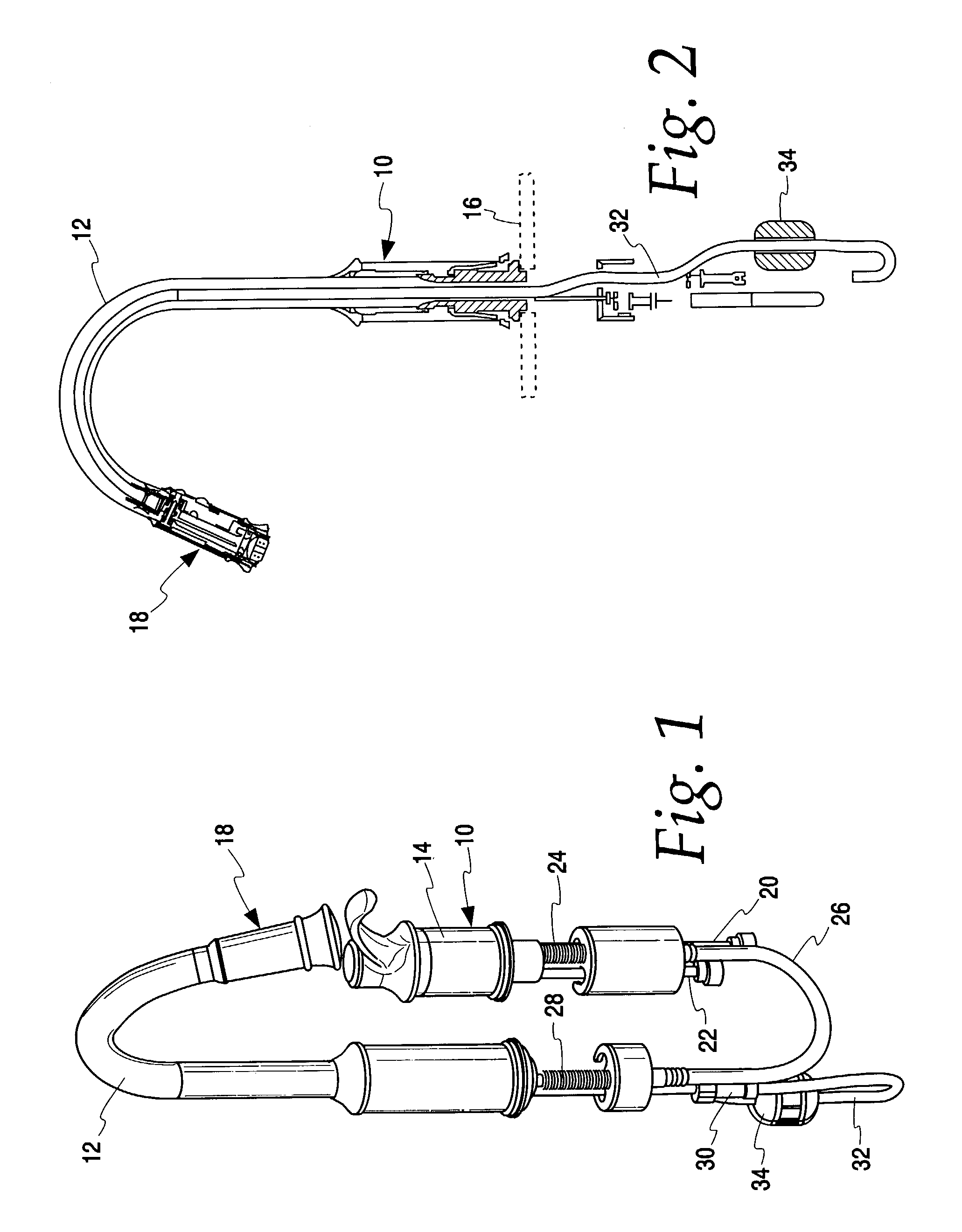

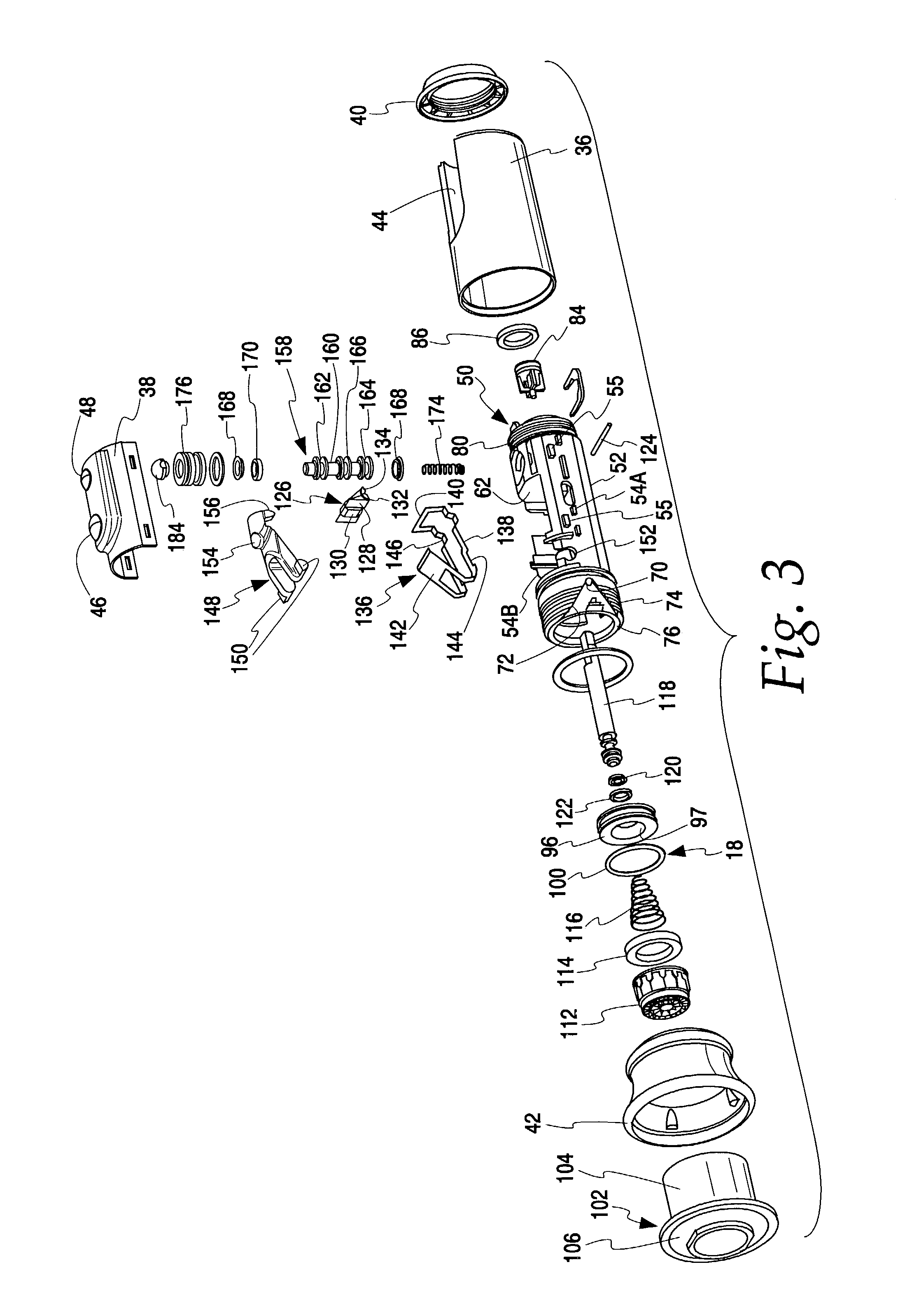

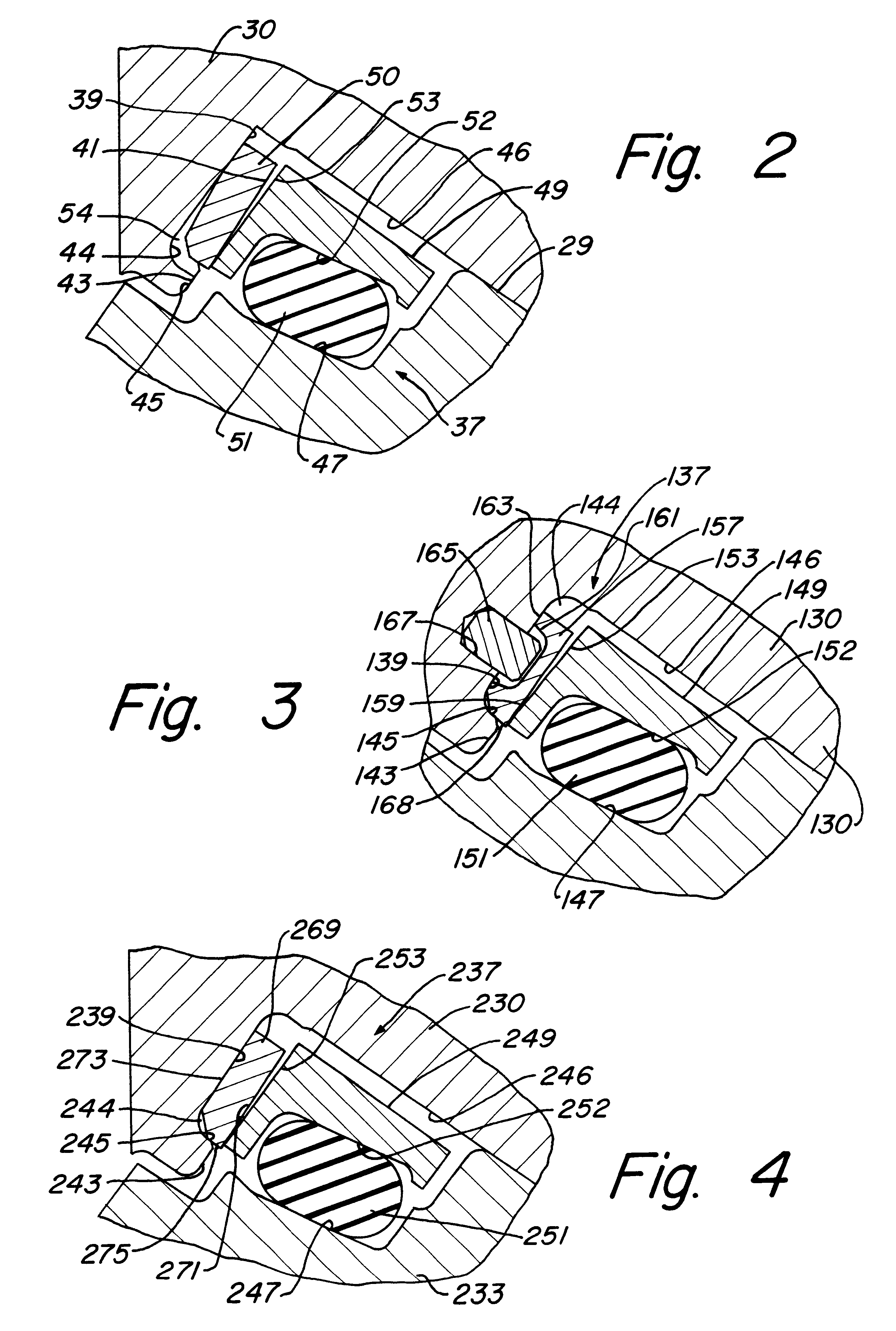

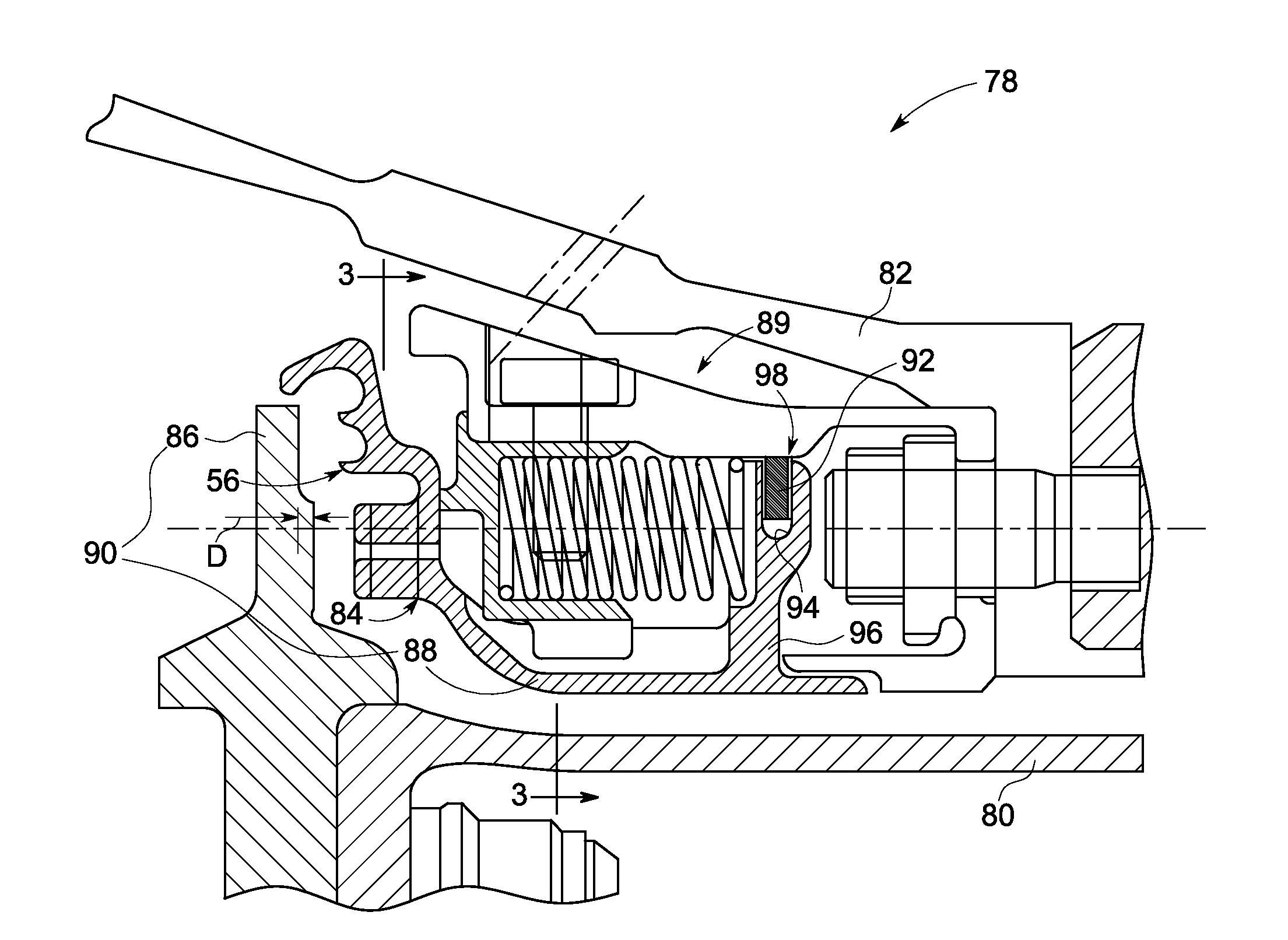

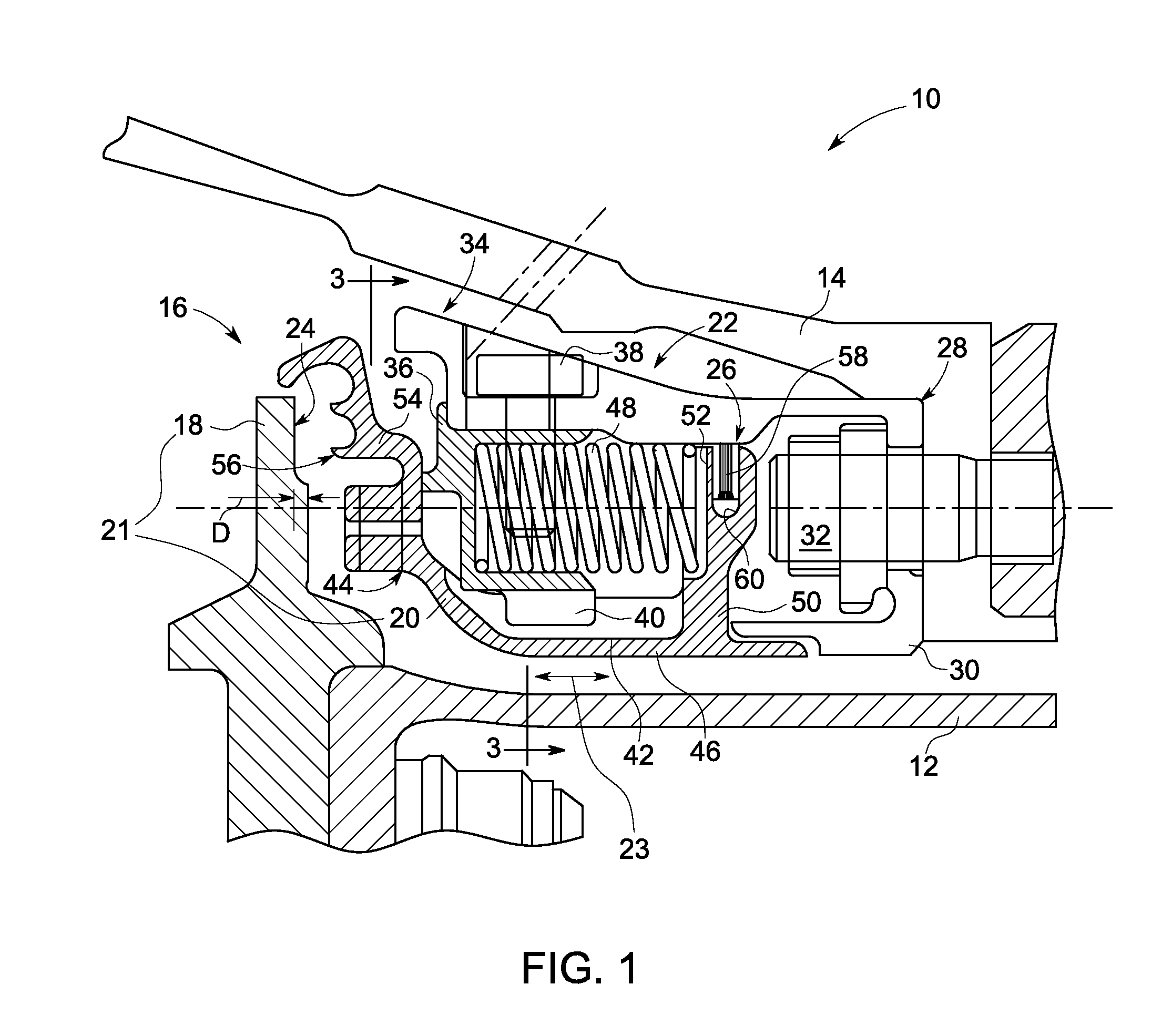

Pullout spray head with single-button mode selector

A spray head for a faucet or the like has a wand body defining a flow path from an inlet to first and second outlets. Diverter seats are provided so a face seal on a diverter spool can direct flow to the first or second outlet. The spool is positioned by a trigger acting on cam surfaces formed on a toggle. A spring biases the toggle to one of two stable states. Movement of the spool by the trigger causes the toggle to change states so subsequent actuation of the trigger causes the spool to move in the opposite direction. The wand body also has a pause button that reciprocates in a chamber that is part of the flow path. The chamber includes a valve seat and the pause button has a spool having a face seal that is engageable with the valve seat to shut off flow through the spray head. A return spring causes separation of the pause button's face seal upon release of pressure on the pause button. The pause button's seals in the chamber are arranged to have equal diameters and thus provide balanced hydraulic forces on the spool.

Owner:MOEN INC

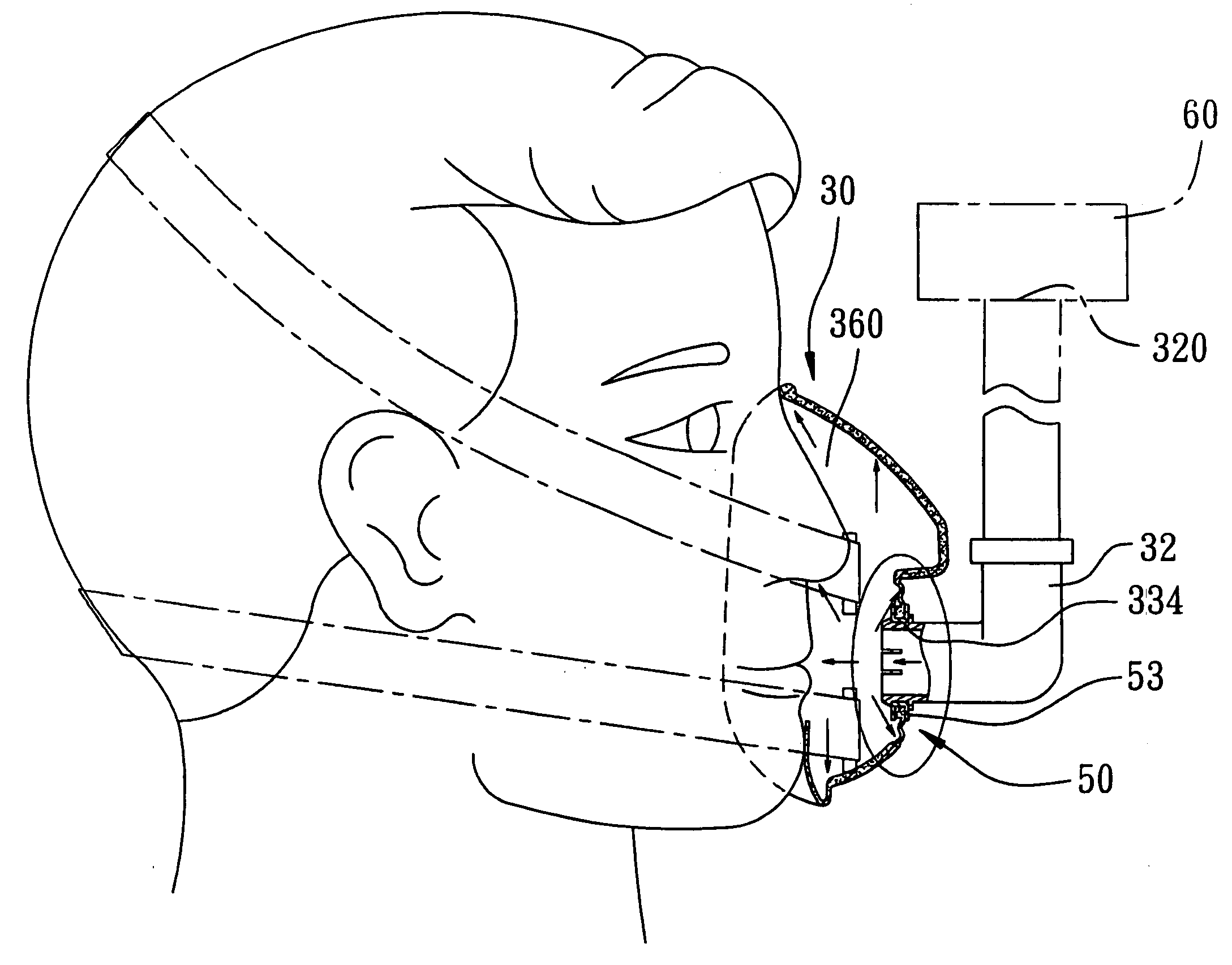

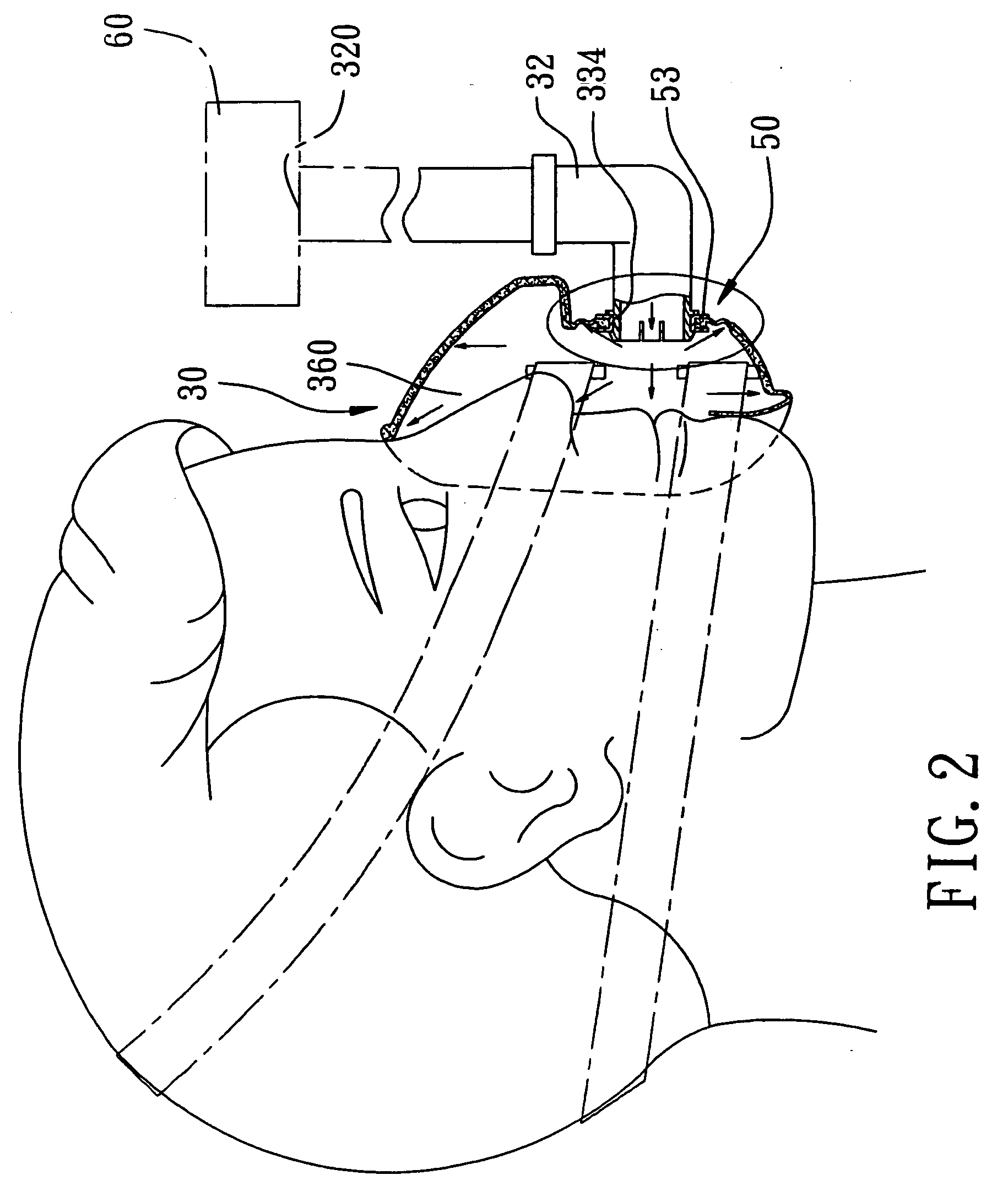

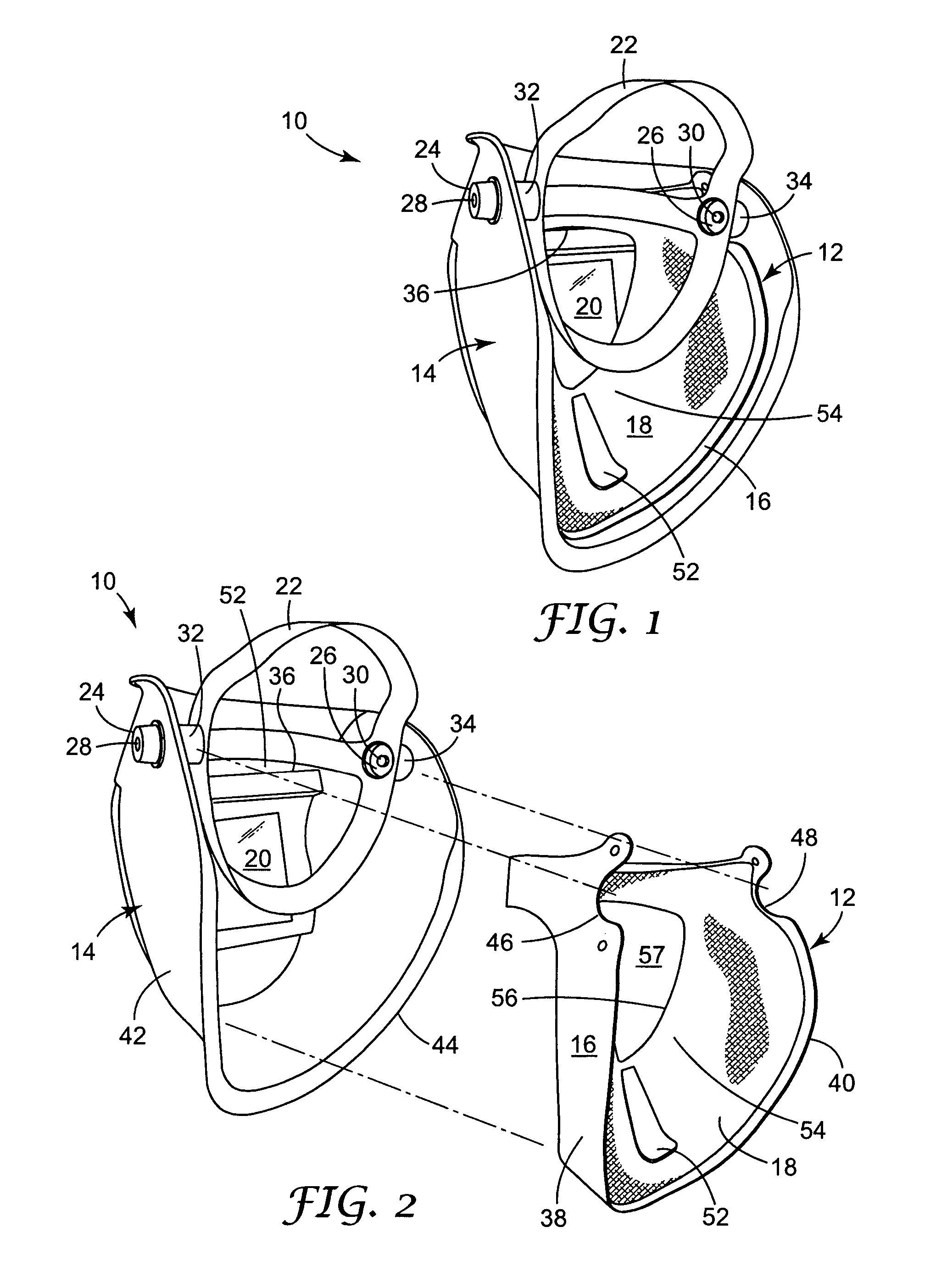

Full-face mask

InactiveUS20060254593A1Overcomes drawbackBreathing filtersRespiratory masksBiomedical engineeringMembrane configuration

A full-face mask includes a gas conduit, a membrane extending around the gas conduit and connected to one end of the gas conduit, a cap wall extending around and connected to the membrane and having a face-sealing edge opposite to the membrane, and at least one head attachment strap connected to the cap wall. The membrane is stretchable outward or foldable inward when there is a change in pressure inside the cap wall, or when the gas conduit is moved relative to the cap wall.

Owner:HSINER

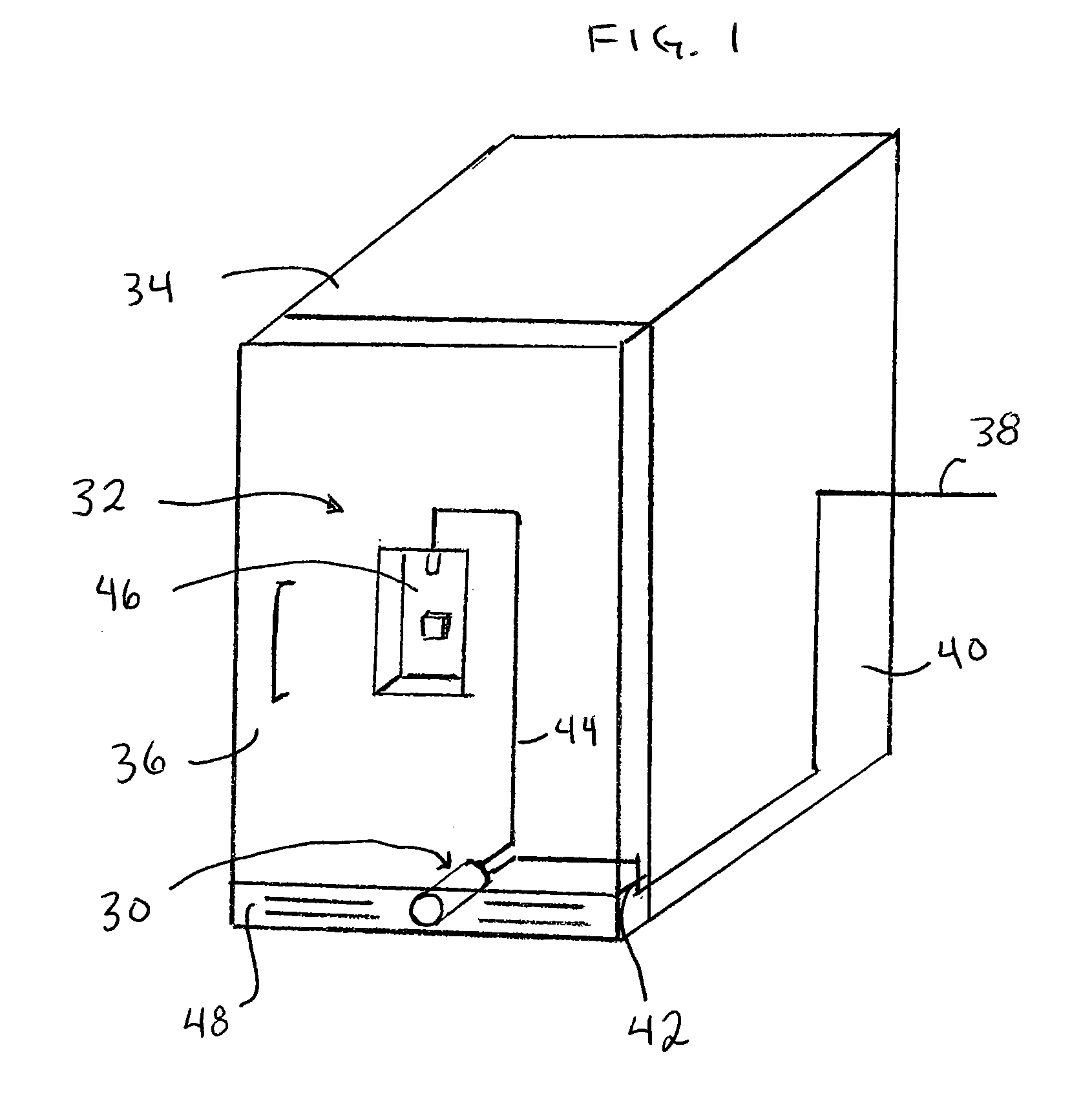

Water Filter Cartridge and Valve with Autobypass Feature

InactiveUS20080000820A1Avoid communicationSemi-permeable membranesOperating means/releasing devices for valvesWater filterValve actuator

A liquid filter cartridge system includes a housing, a valve body, a valve actuator, a filter, an inlet passage having a portion extending through each of the valve body and the valve actuator and into the filter, and an outlet passage having a portion leading out of the filter, and extending through each of the valve actuator and the valve body. An interface is located between the inlet passage portions in the valve actuator and the filter and an interface is located between the outlet passage portions in the valve actuator and the filter. The inlet passage interface and the outlet passage interface may lie in the same plane as each other. They may each comprise a face seal comprising an axial seal between the valve actuator and the filter. They may each comprise a seal between the valve actuator and the filter, wherein the two seals are sealed via compression and not via sliding contact.

Owner:WHIRLPOOL CORP

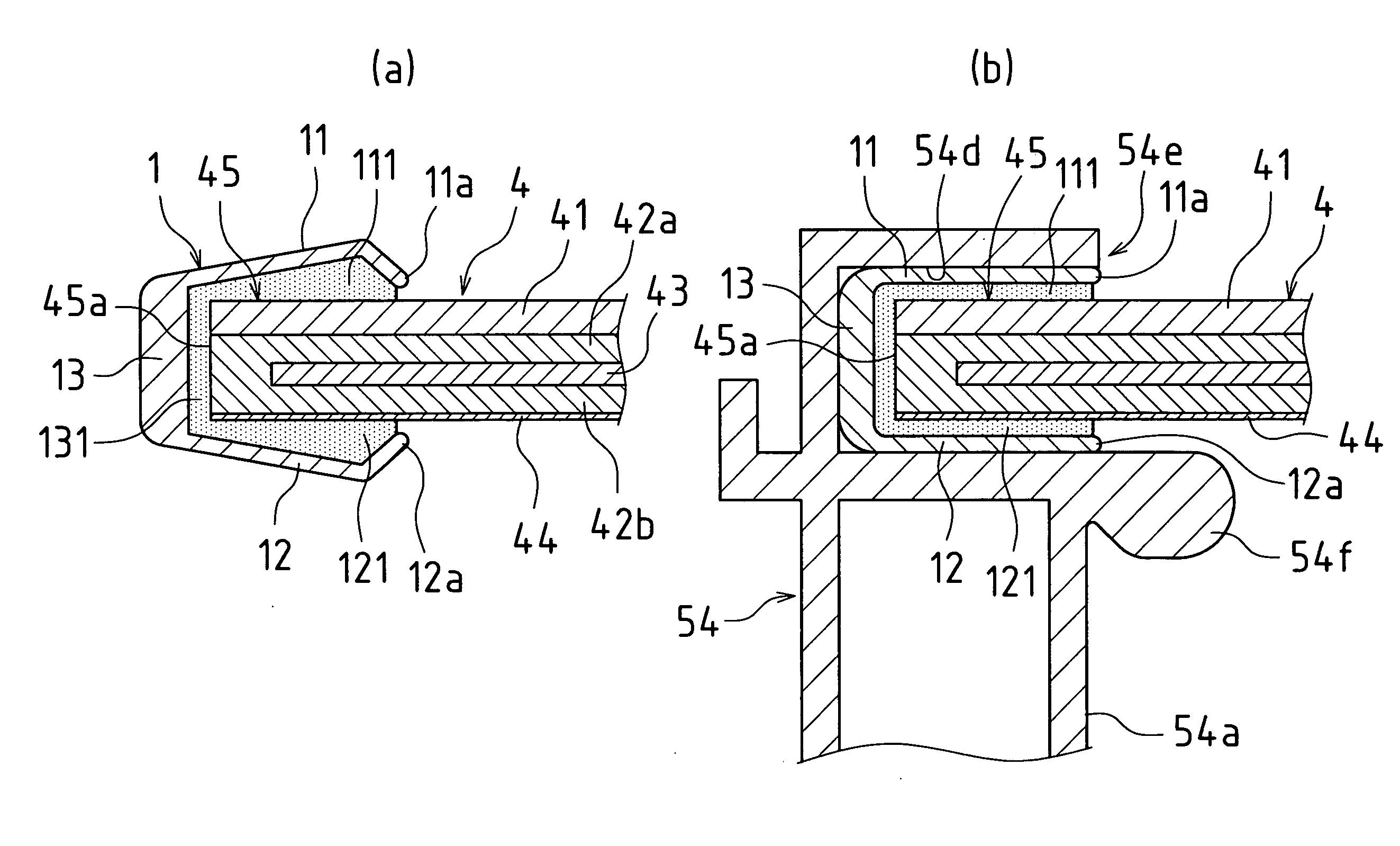

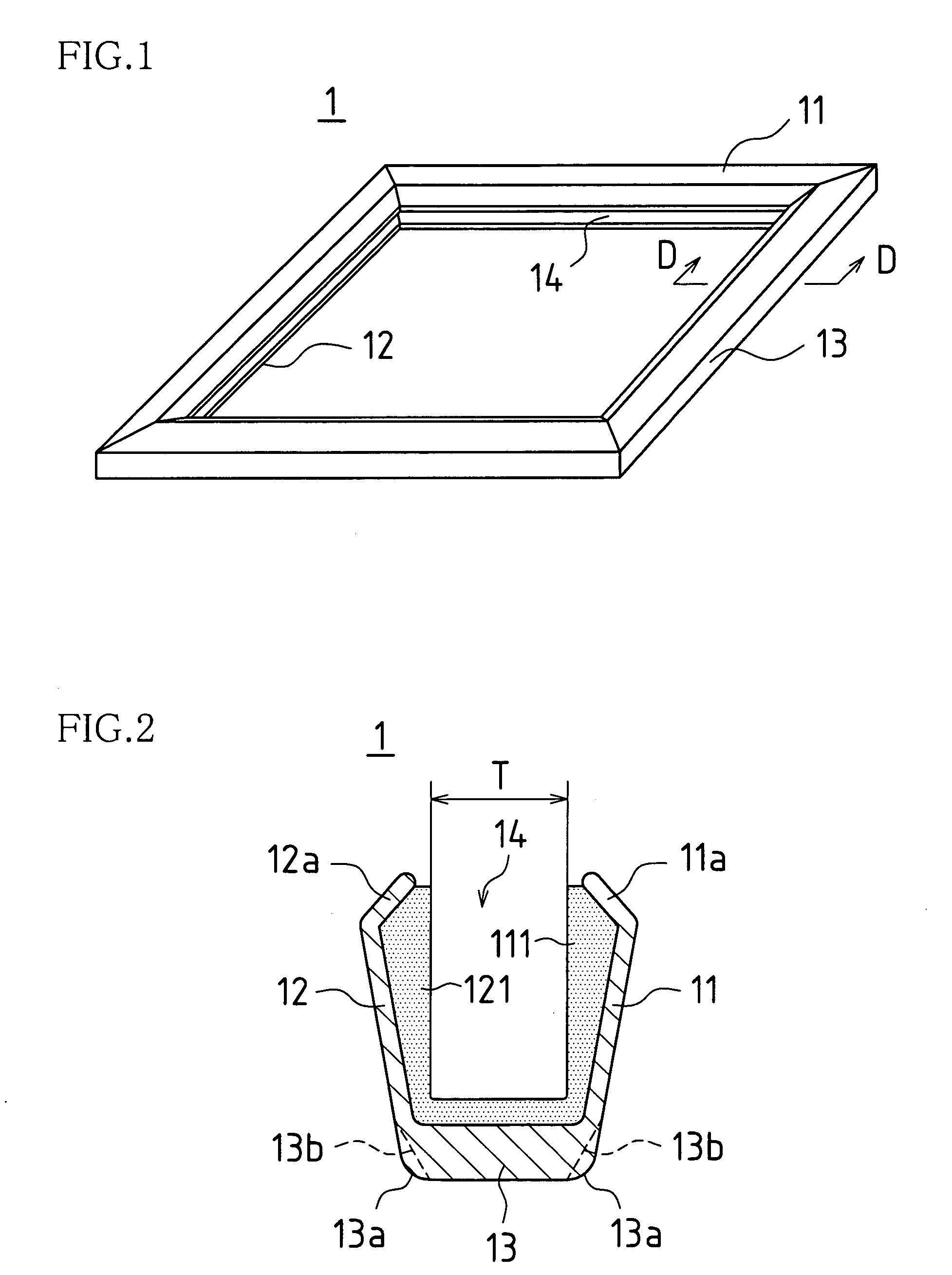

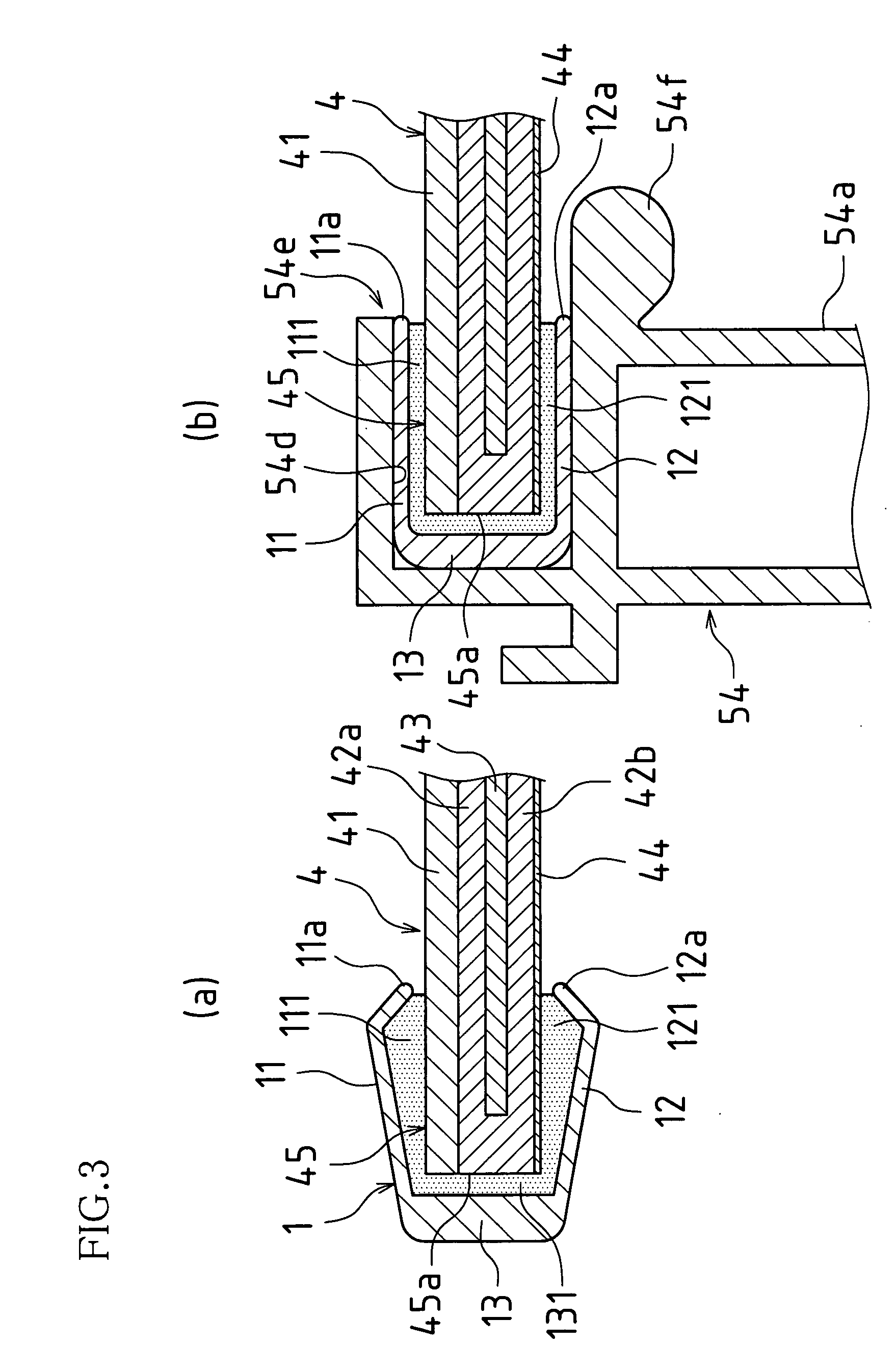

Solar cell module edge face sealing member and solar cell module employing same

InactiveUS20050115603A1Easy to operateImprove water tightnessPhotovoltaic supportsPV power plantsEngineeringHardness

Edge face sealing member(s) may be roughly c-shaped in cross-section, may be frame-like in shape and formed in more or less parallel fashion with respect to outer shape(s) of solar cell module body or bodies, may comprise upper sealing region(s) abutting front surface(s) of solar cell module body or bodies, may further comprise lower sealing region(s) abutting back surface(s) of solar cell module body or bodies, and may further comprise side sealing region(s) abutting edge face(s) of solar cell module body or bodies. Furthermore, sealing region(s) may be roughly c-shaped in cross-section; may comprise upper sealing region(s) abutting front surface(s) of solar cell module body or bodies, lower sealing region(s) abutting back surface(s) of solar cell module body or bodies, and side sealing region(s) abutting edge face(s) of solar cell module body or bodies; may be of two-layer construction; and outer layer(s) may be hard, hardness(es) of inner layer(s) being less than that of outer layer(s); as a result of which there may be intimate contact even with nonflat and / or nonsmooth glass surface(s), permitting sealing.

Owner:SHARP KK

Downhole plug

Owner:INTERWELL NORWAY AS

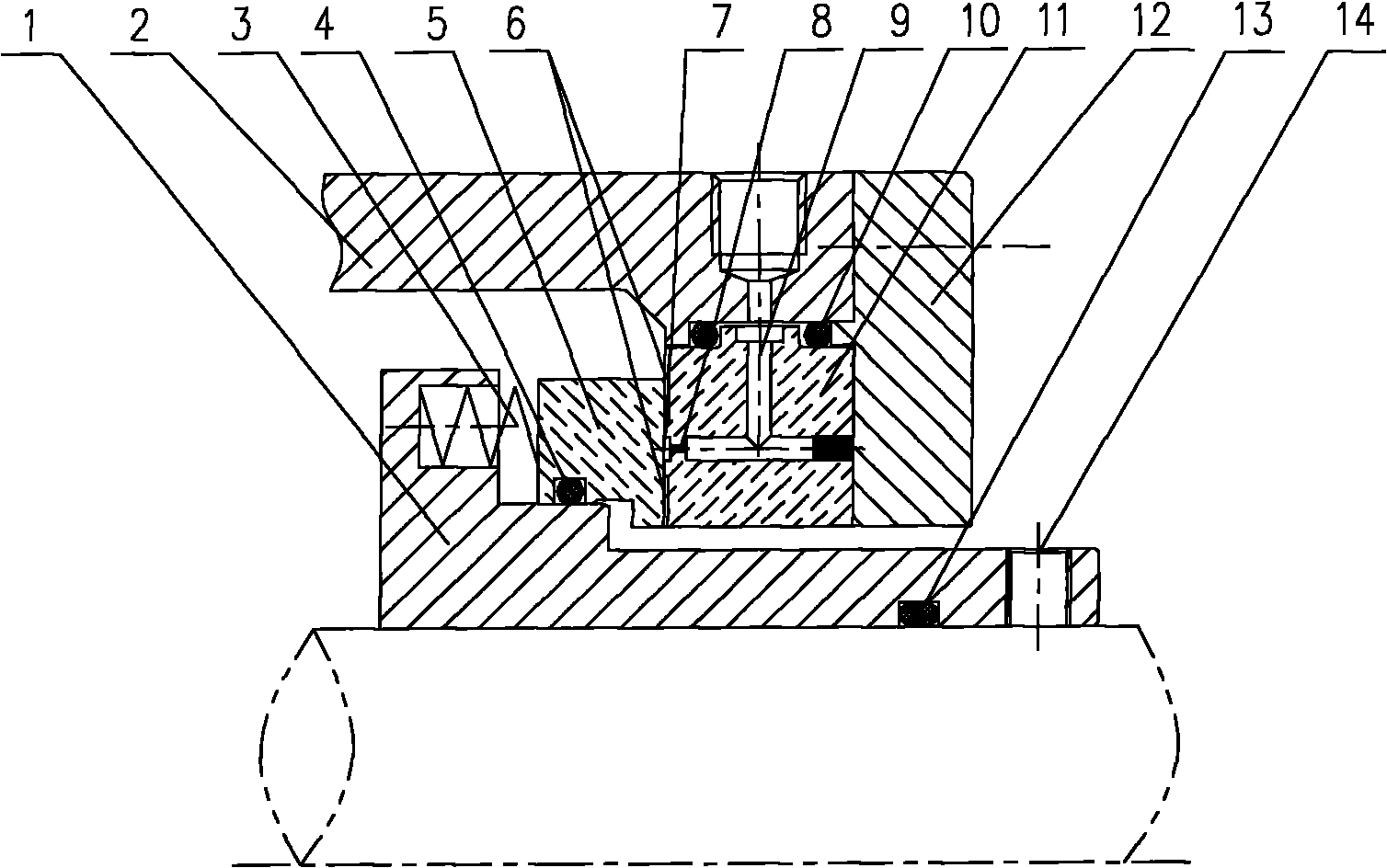

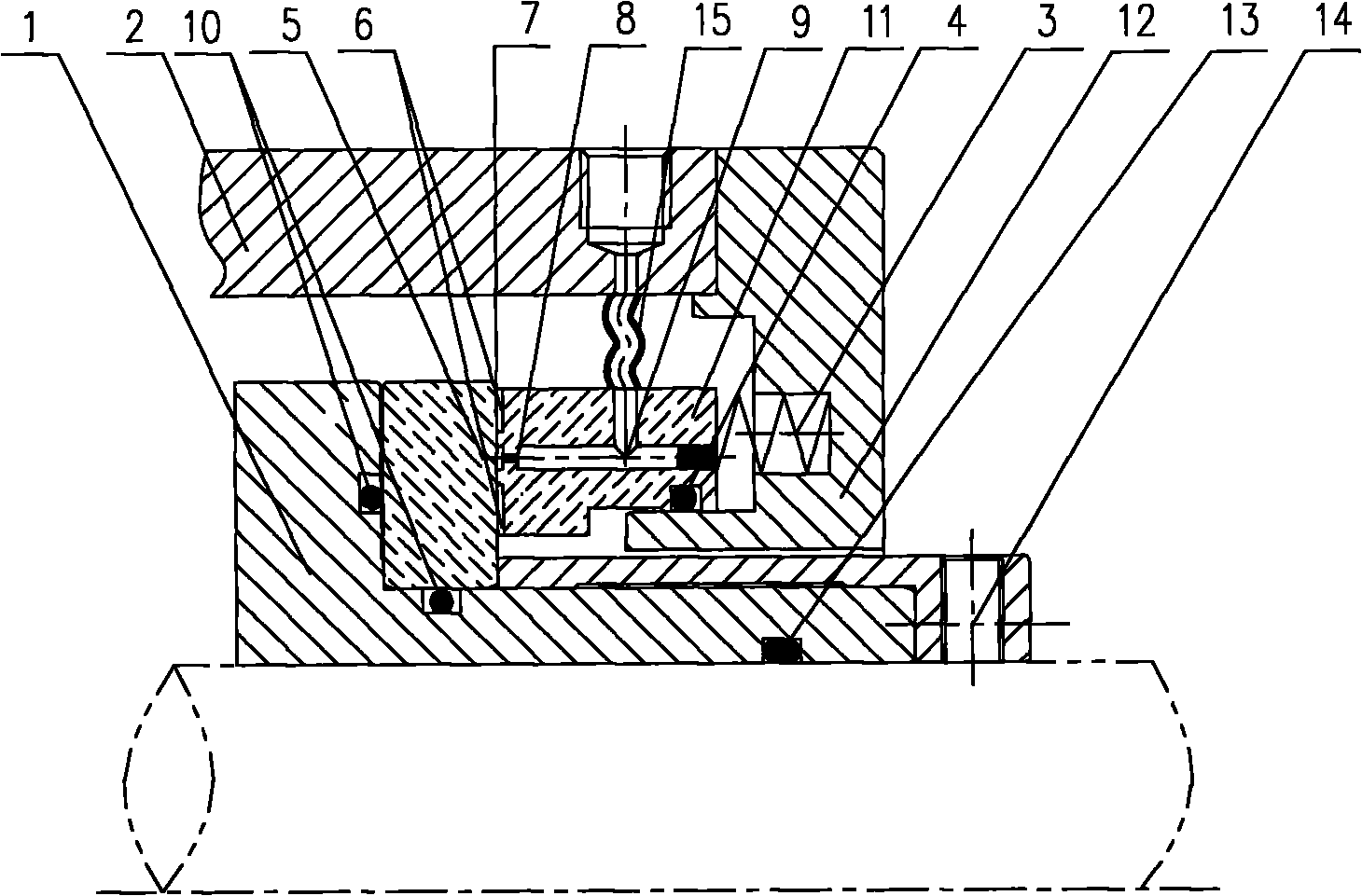

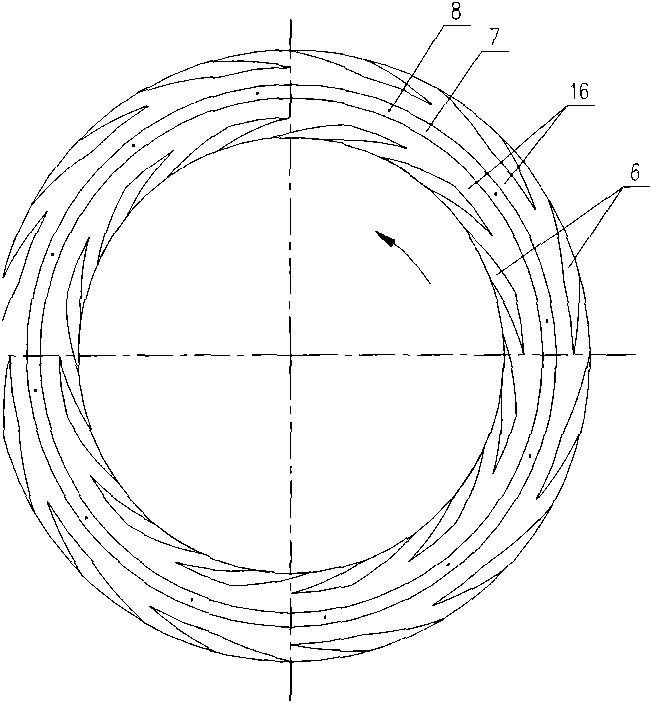

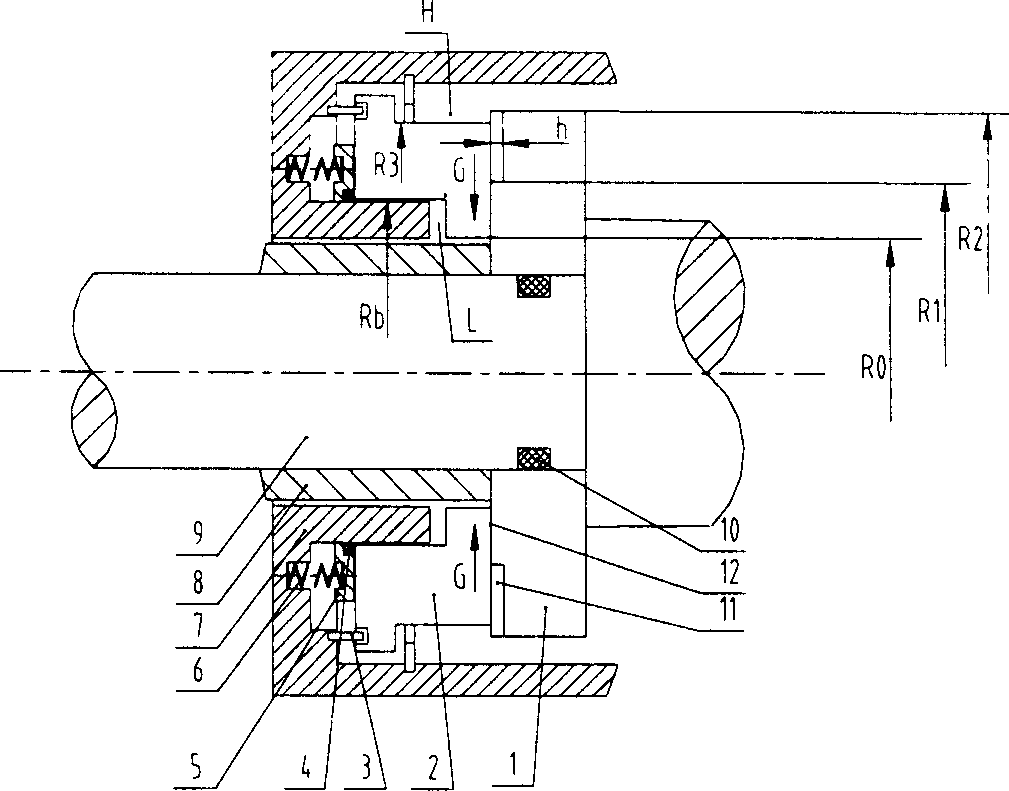

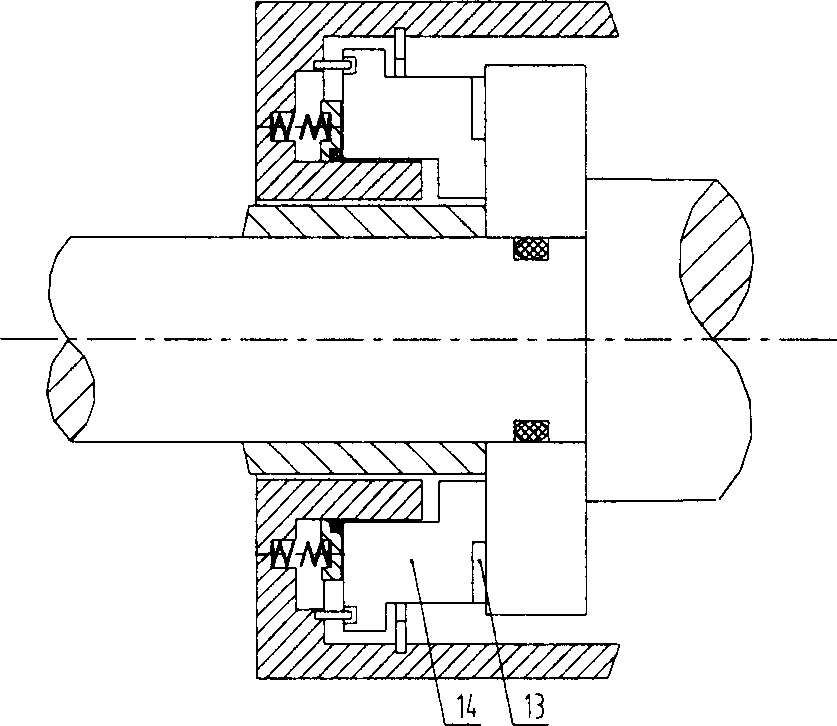

Outside pressurized type dynamic and static pressure gas lubricating and sealing device

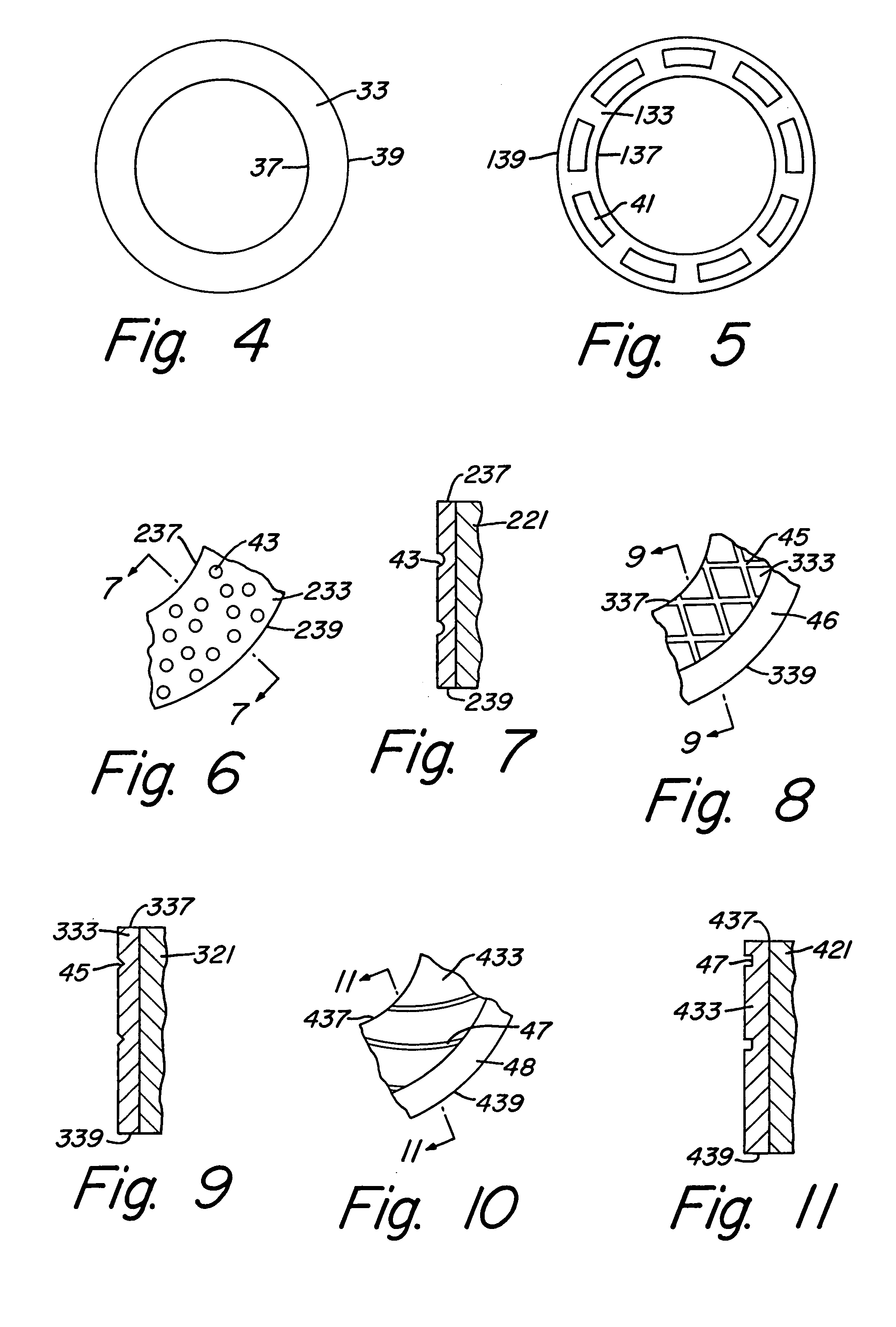

The invention discloses an outside pressurized type dynamic and static pressure gas lubricating and sealing device, which comprises a moving ring (5) and a seal static ring (11), wherein the moving ring (5) is fixed on a moving ring seat (1) and rotates along with a spindle, and the seal static ring (11) is fixed on a seal cavity (2) and a seal end cover (12); channels (9) for introducing outsidepressurized gas from outside are arranged in the seal static ring (11), and the channels (9) of certain numbers are distributed in the seal static ring (11) along circumference; throttle devices (8) are arranged in the channels (9), and pressure equalizing troughs (7) of certain depth are arranged at the outlets of the channels (9); various dynamic pressure troughs (6) having dynamic pressure effects are formed on the end face of the moving ring (5) or the seal static ring (11), and the inside and outside of the pressure equalizing troughs (7) are provided with seal dams not communicated withthe pressure equalizing troughs; and on-line monitoring is realized by adjusting the pressure of the outside pressurized gas. The pressurized type dynamic and static pressure gas lubricating and sealing device greatly lowers resistance moment and power consumption and improves the phenomenon that the traditional end face seal abrasion is severe.

Owner:BEIJING UNIV OF CHEM TECH

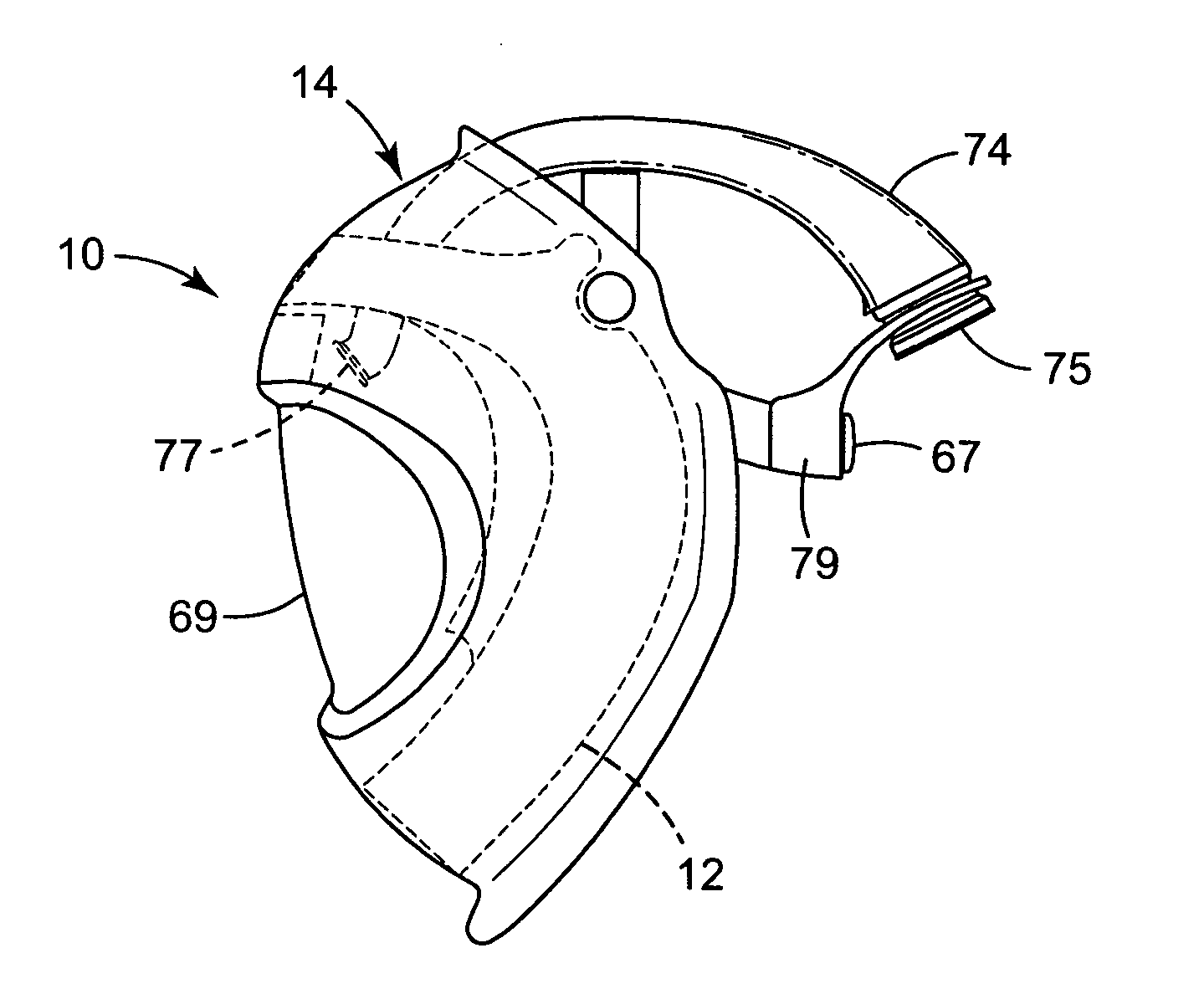

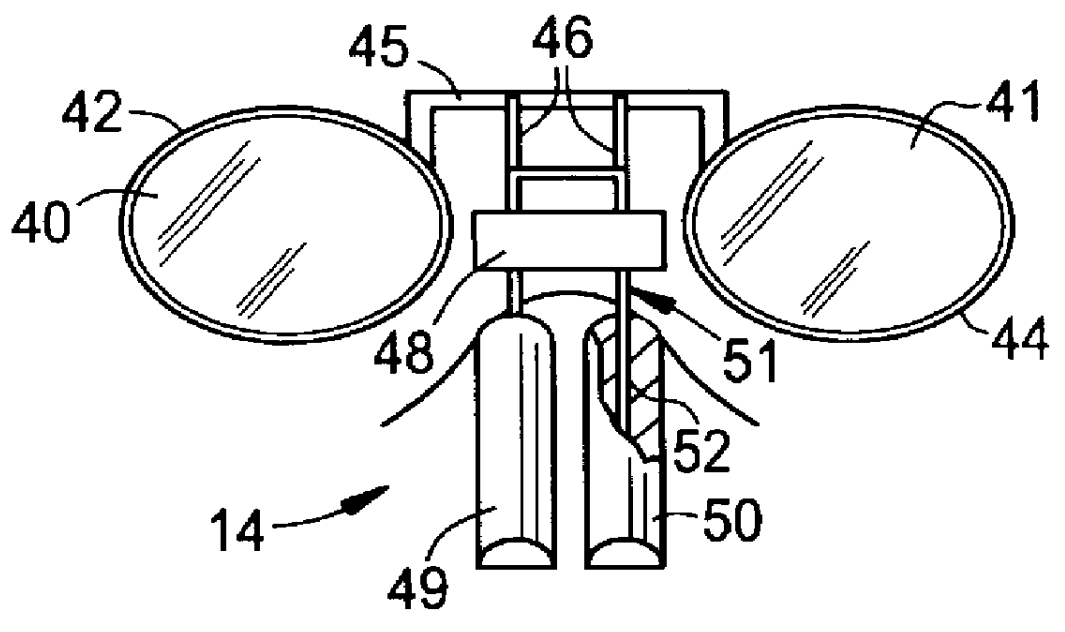

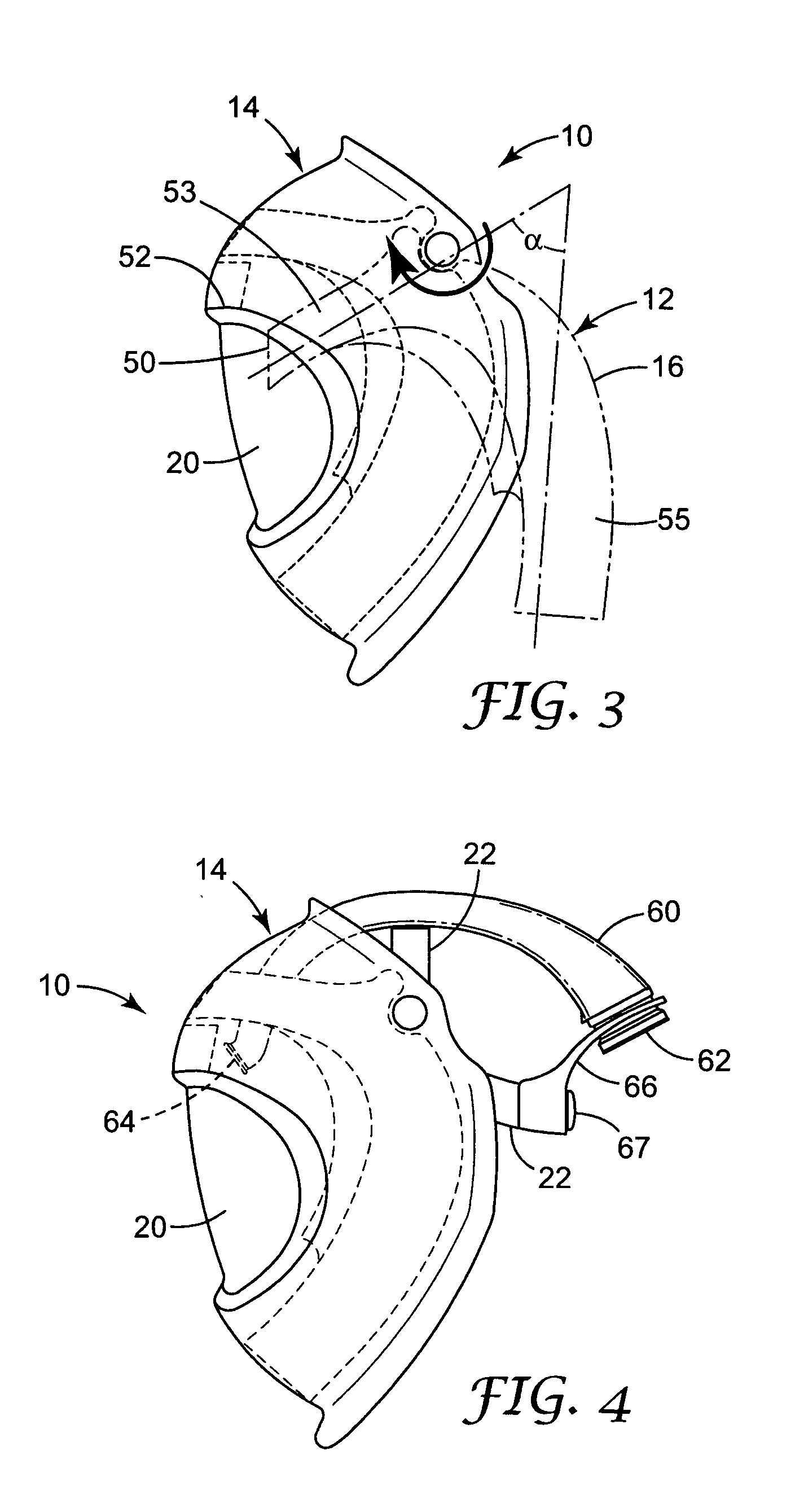

Supplied air helmet having a knitted face seal

InactiveUS20060107431A1Reduce the amount requiredSuppresses exhaustionChemical protectionHeat protectionEngineeringFace seal

A supplied air helmet 10 that has a visor 14 and a face seal 16. The face seal 16 is secured to the visor 14 and includes a sealing member 18 that comprises a knitted fabric. The knitted fabric is disposed on the face seal 16 in a location where the face seal 16 makes contact with a wearer's face. The use of a knitted fabric for the face seal 16 makes the supplied air helmet 10 more comfortable to wear and makes it more likely that helmet wearers will consistently use the face seal 16 while donning the supplied air helmet 10.

Owner:3M INNOVATIVE PROPERTIES CO

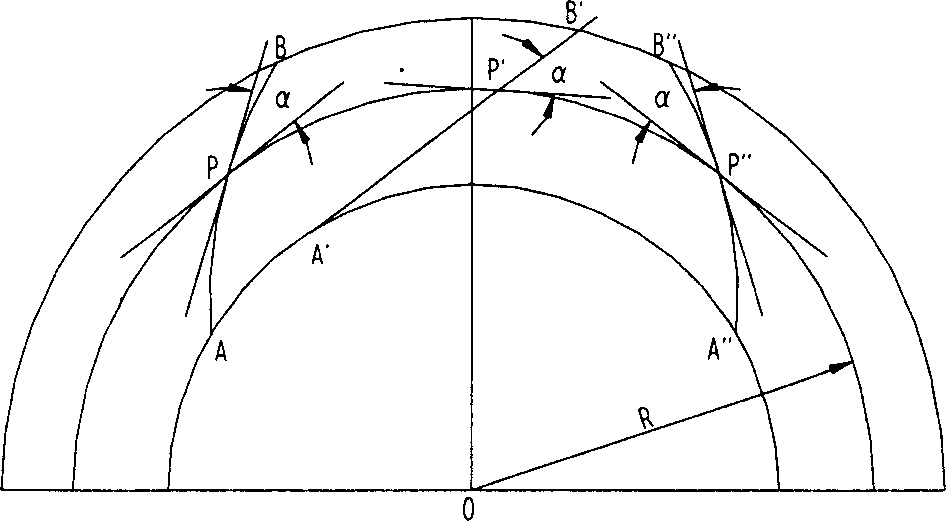

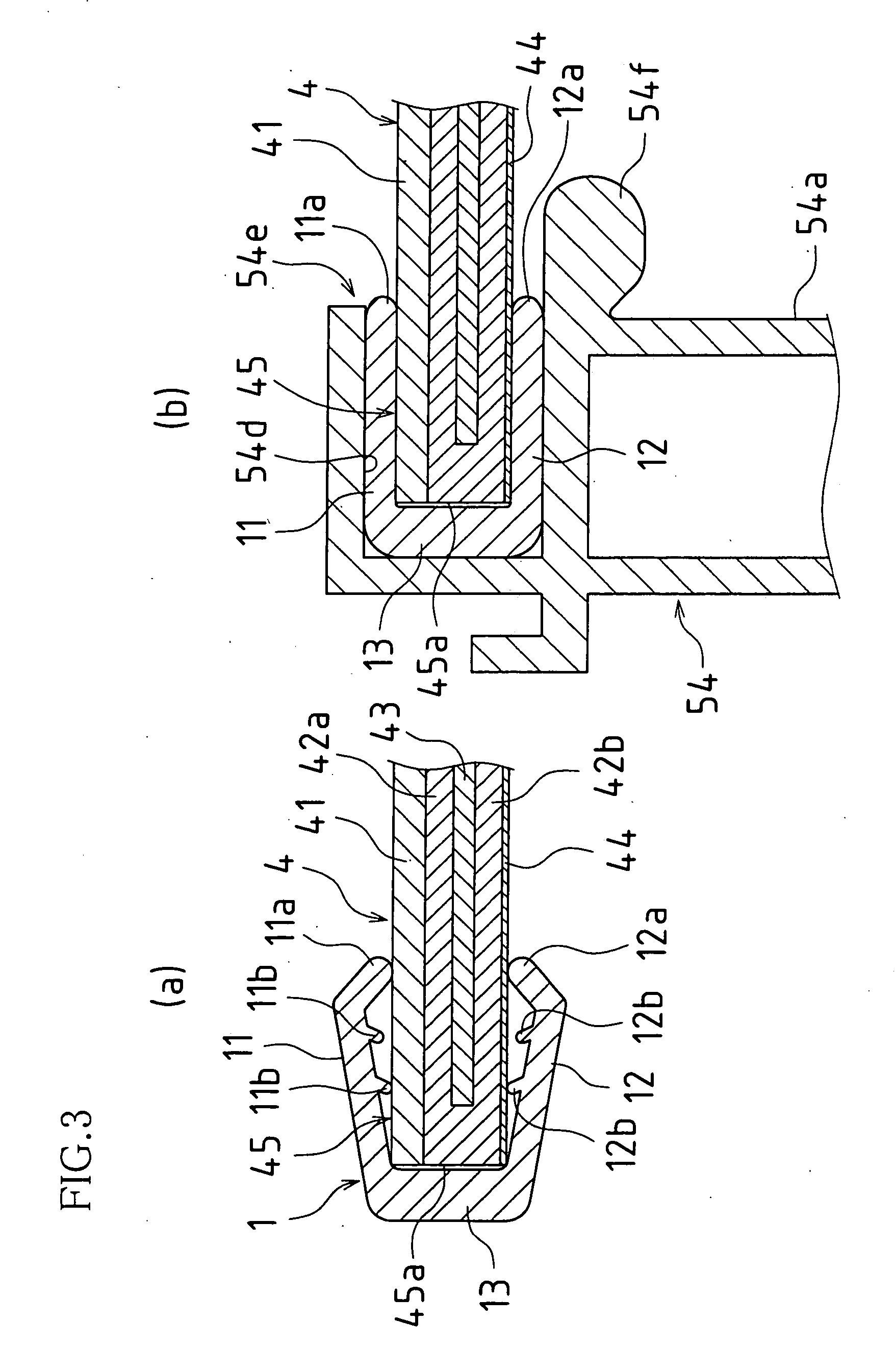

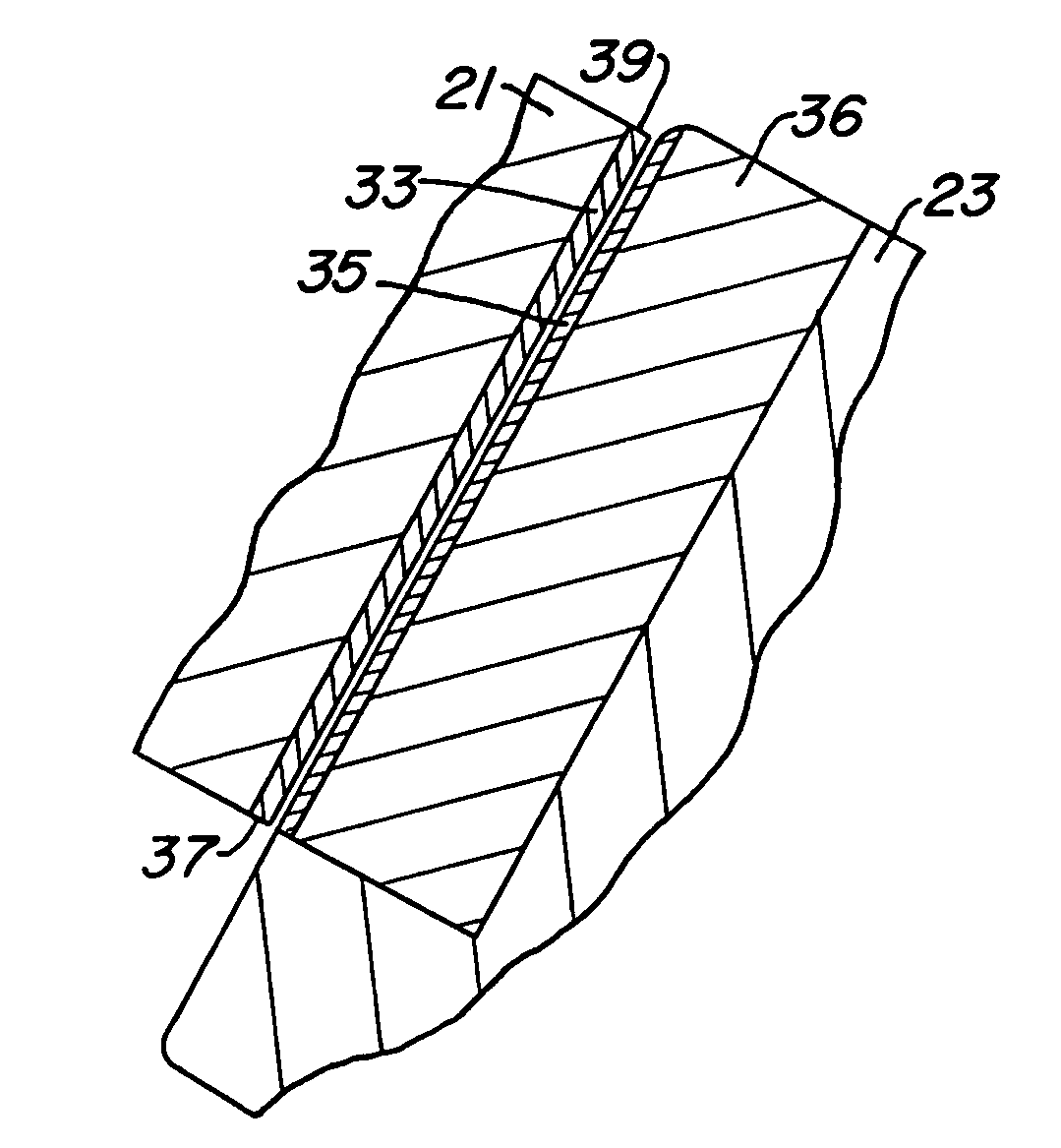

Unit for sealing end surface of 3D helical flute with double helix angles

InactiveCN1415877AImprove compression performanceIncreasing the thicknessEngine sealsFluteEngineering

Owner:JOHN CRANE TECH TIANJIN

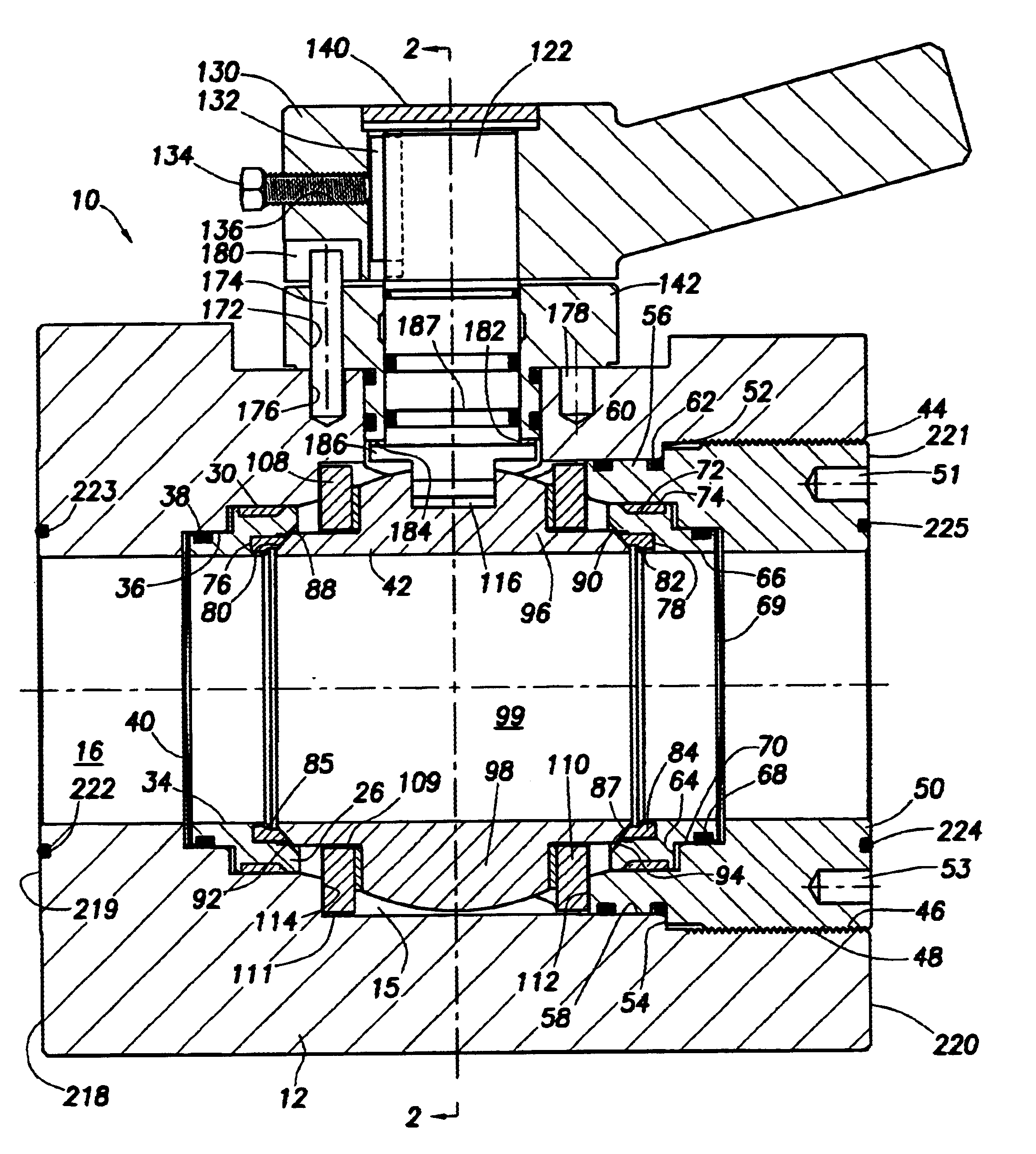

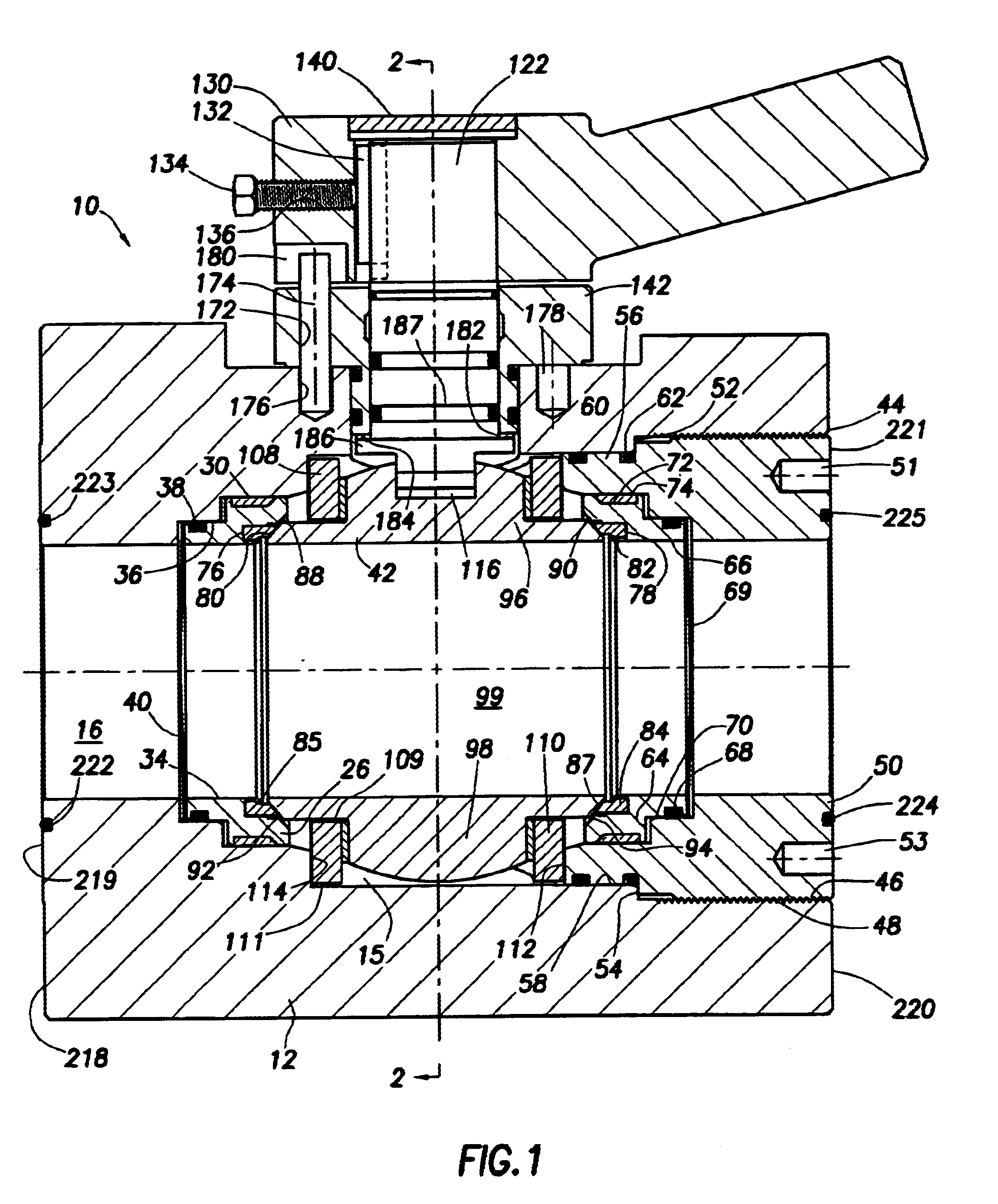

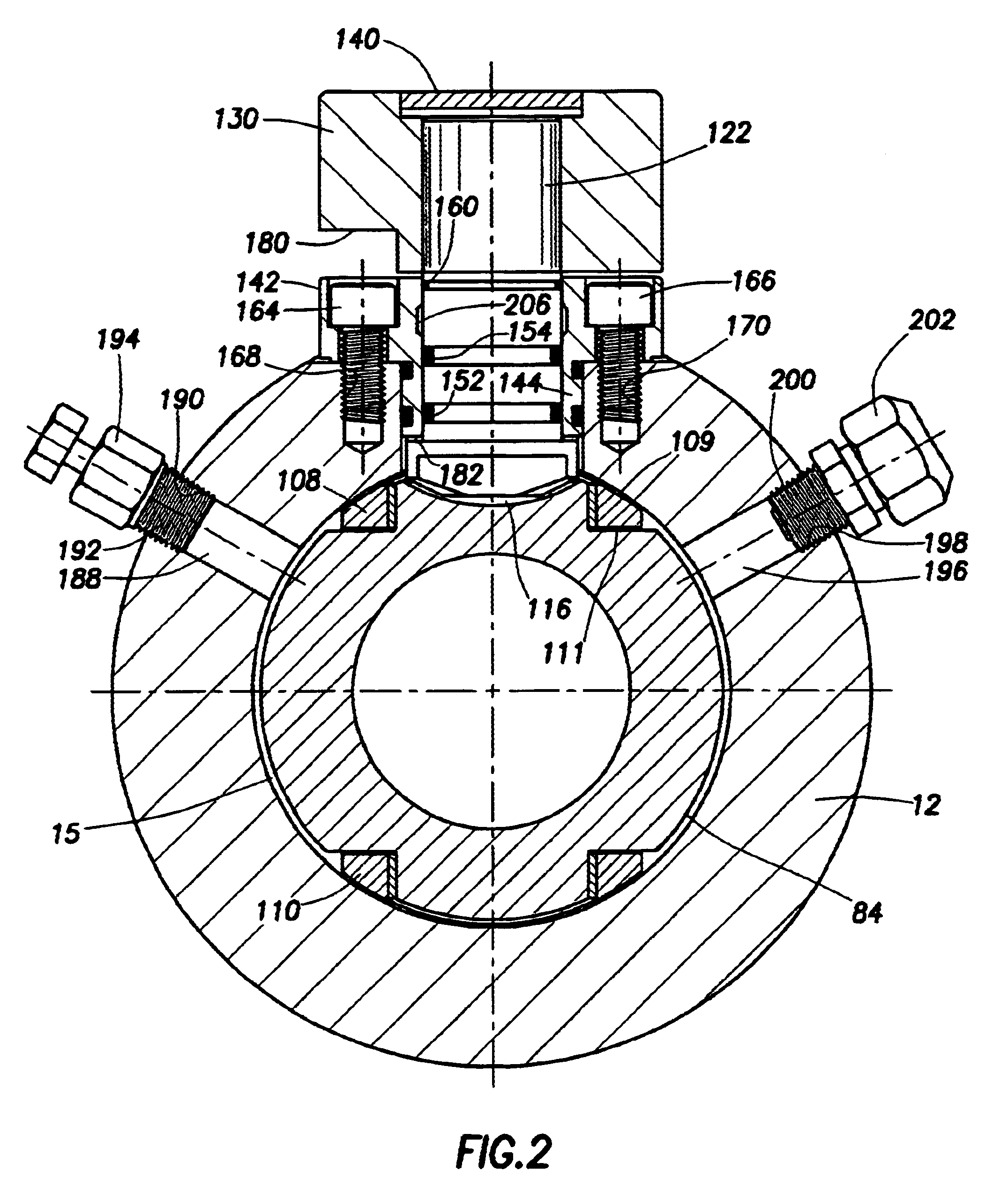

Compact manifold trunnion ball valve

A compact manifold ball valve having a valve body defining a valve chamber and having first and second ends and a first flow passage intersecting the valve chamber a cylindrical sealing surface defining a bonnet and valve stem passage also intersecting the valve chamber. A seat and ball retainer is threaded into the second end of the valve body and provides for support and positioning of a pair of trunnion support elements and a pair of seat assemblies. A valve ball having opposed trunnions is rotatable between open and closed positions within the valve chamber and is supported by the trunnion supports. A valve stem and bonnet assembly is secured and sealed to said valve body and is actuated to rotate the valve ball for opening and closing thereof. The valve seats are capable of metal-to-metal sealing with the valve ball in the event of heat destruction of said face seals to provide the valve with a fire-safe character. The seats incorporate high temperature graphite filament seals for fire-safe sealing between the valve seats and valve body in the event of heat destruction of said back seals. Other internal metal surfaces are arranged for metal-to-metal fire-safe sealing in the event the primary seals are destroyed by heat.

Owner:ARRAY HLDG

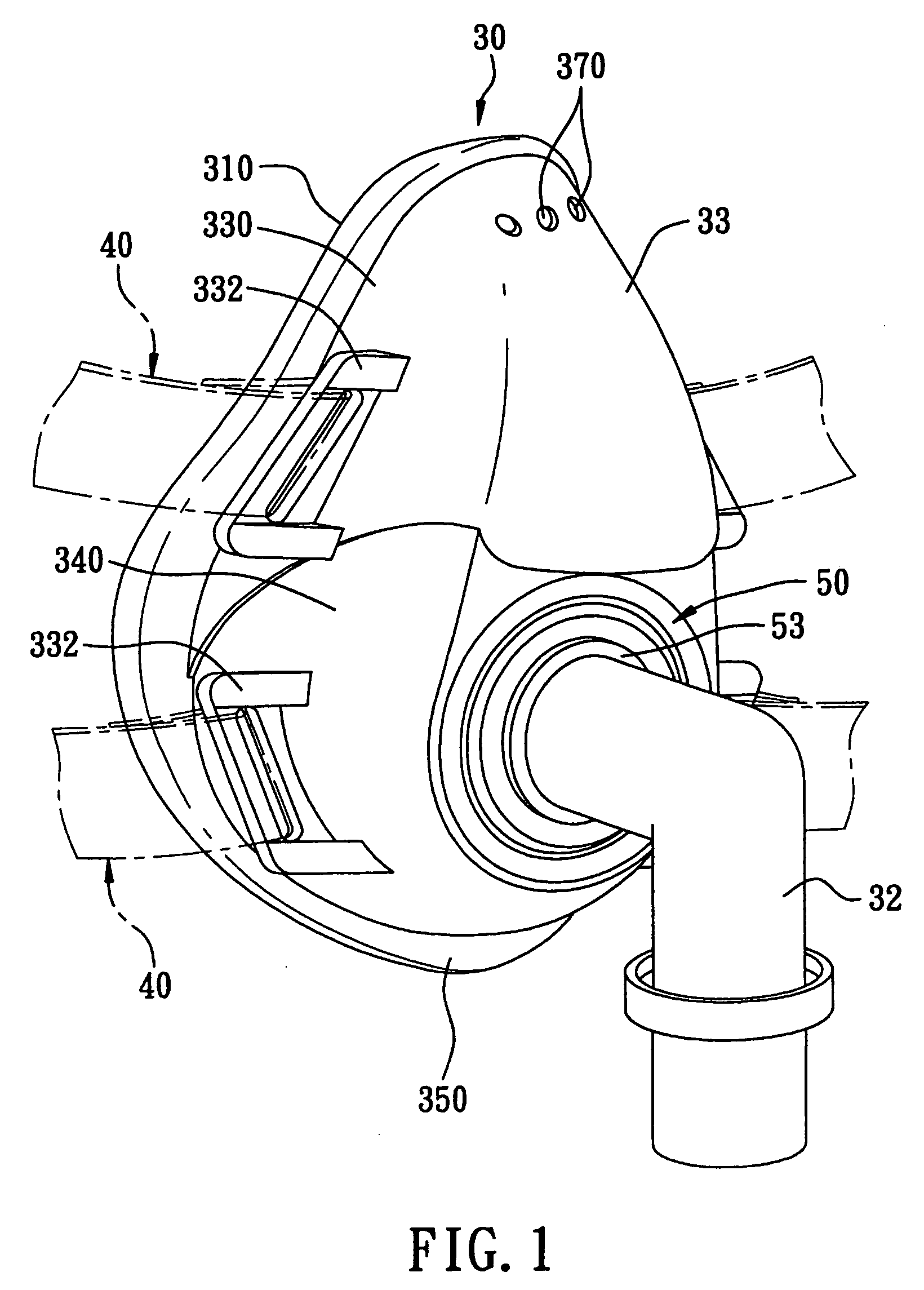

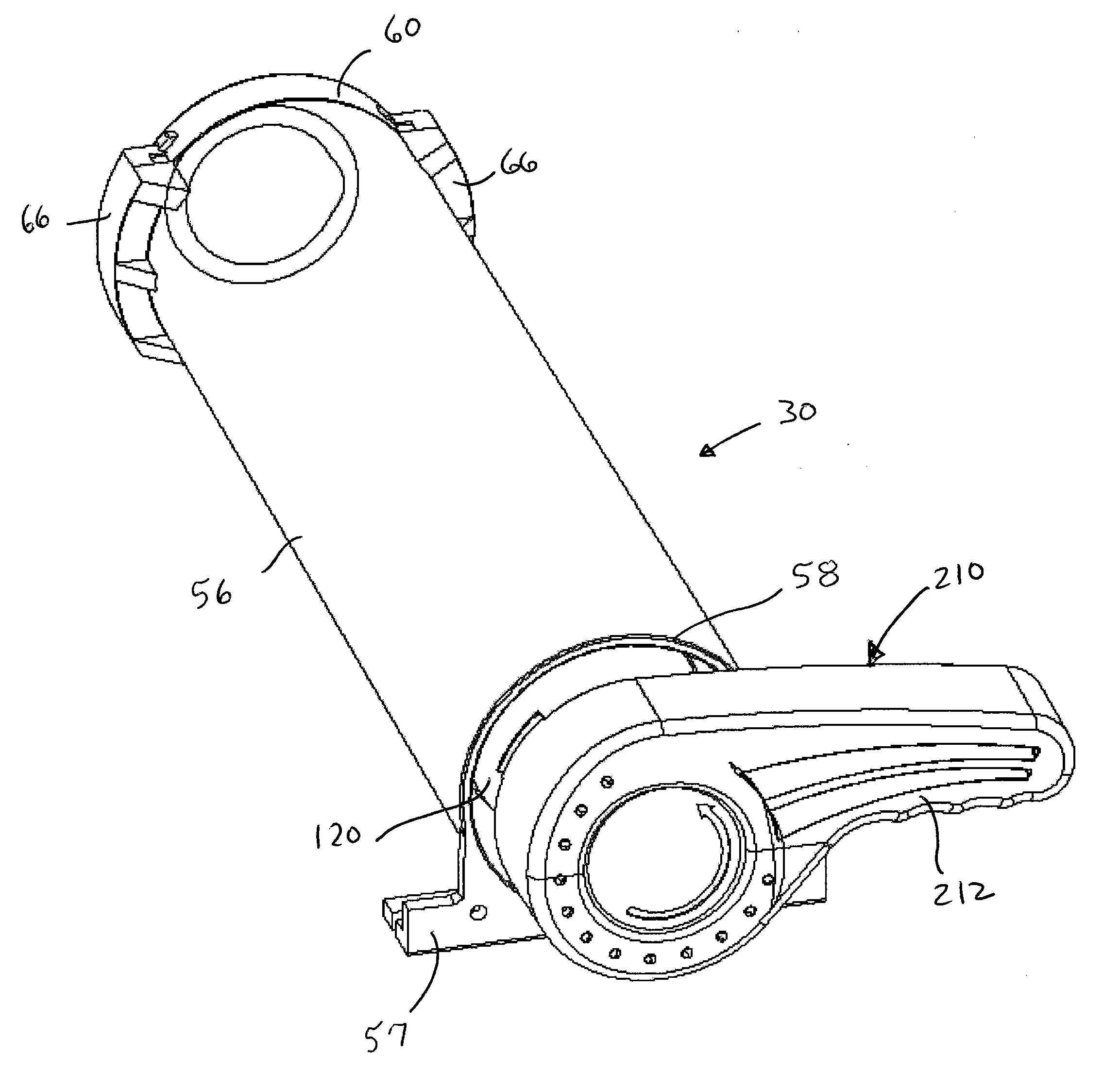

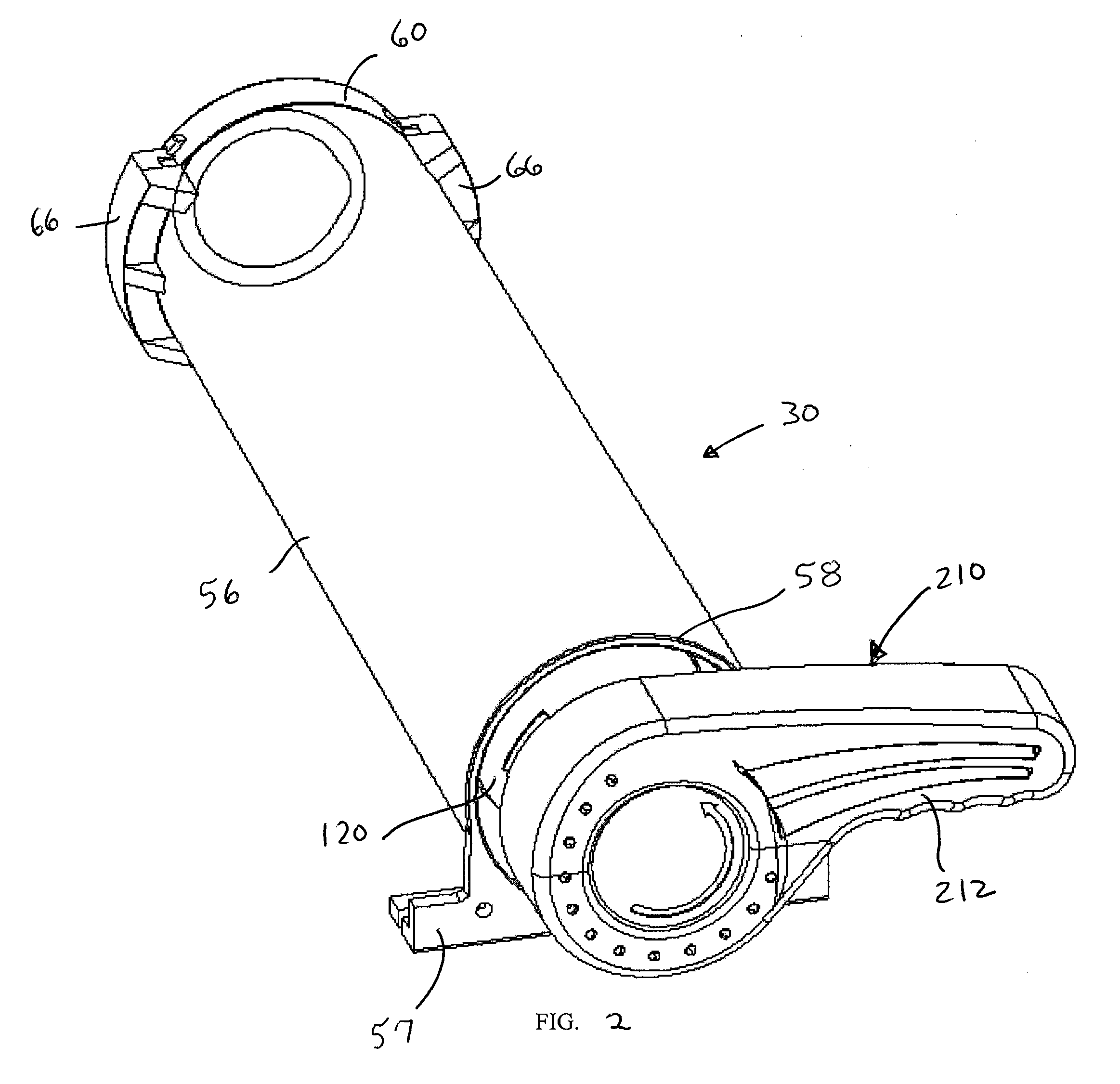

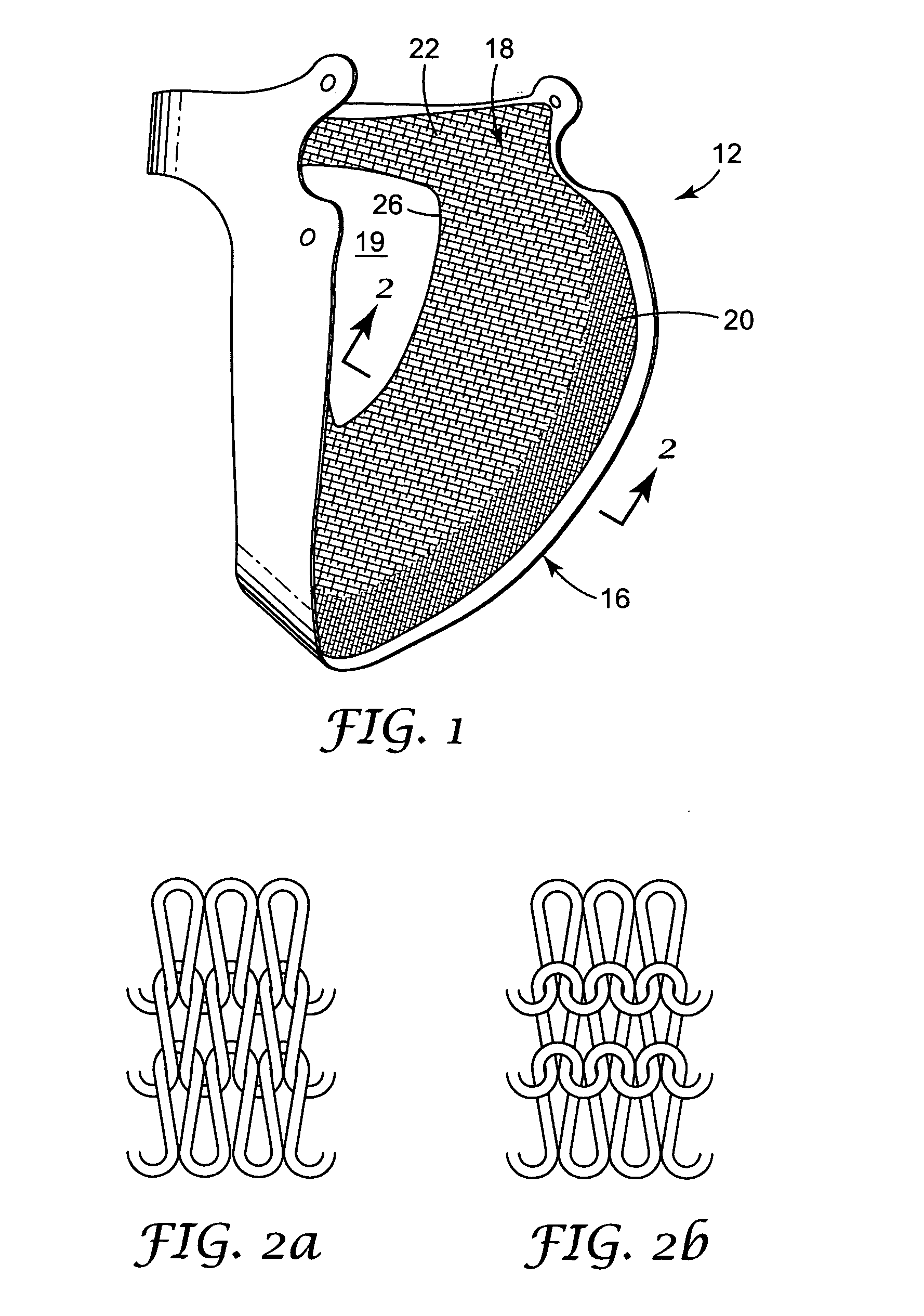

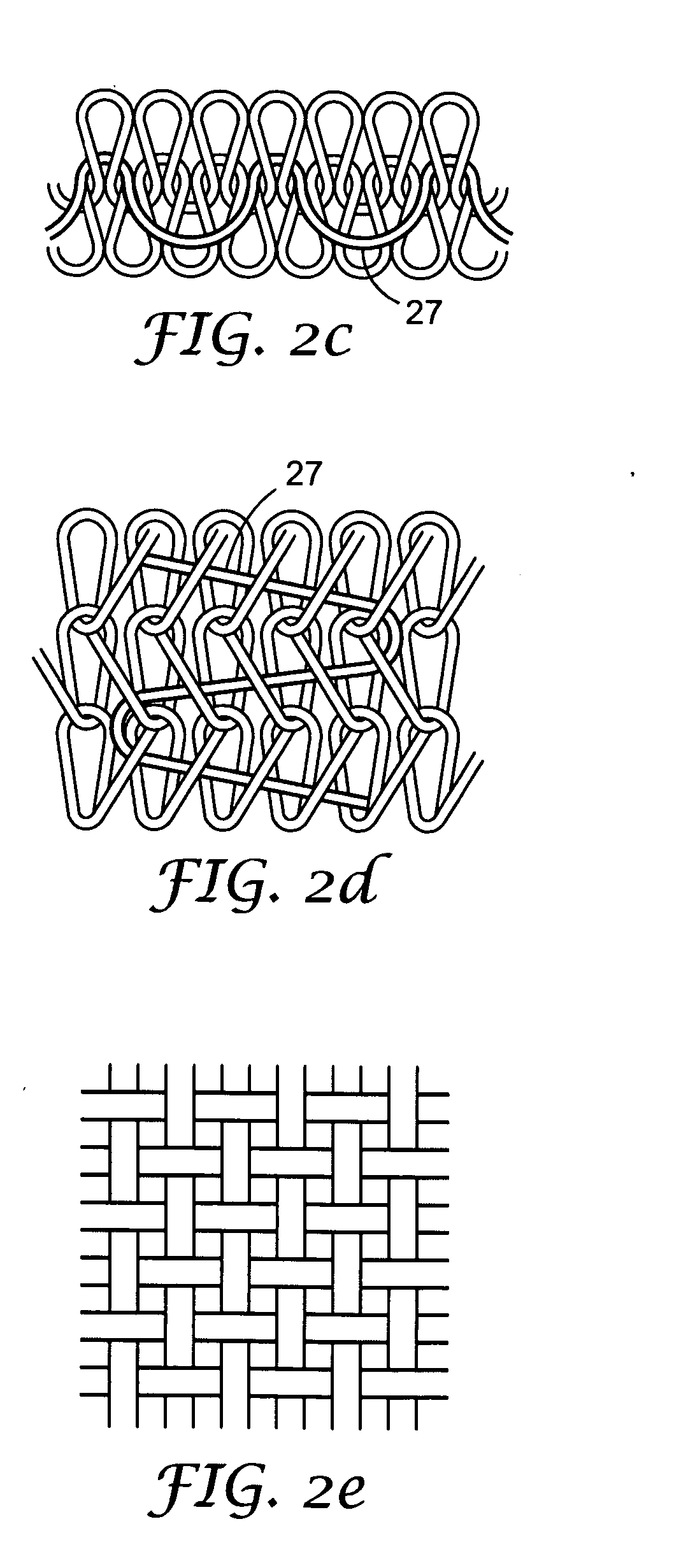

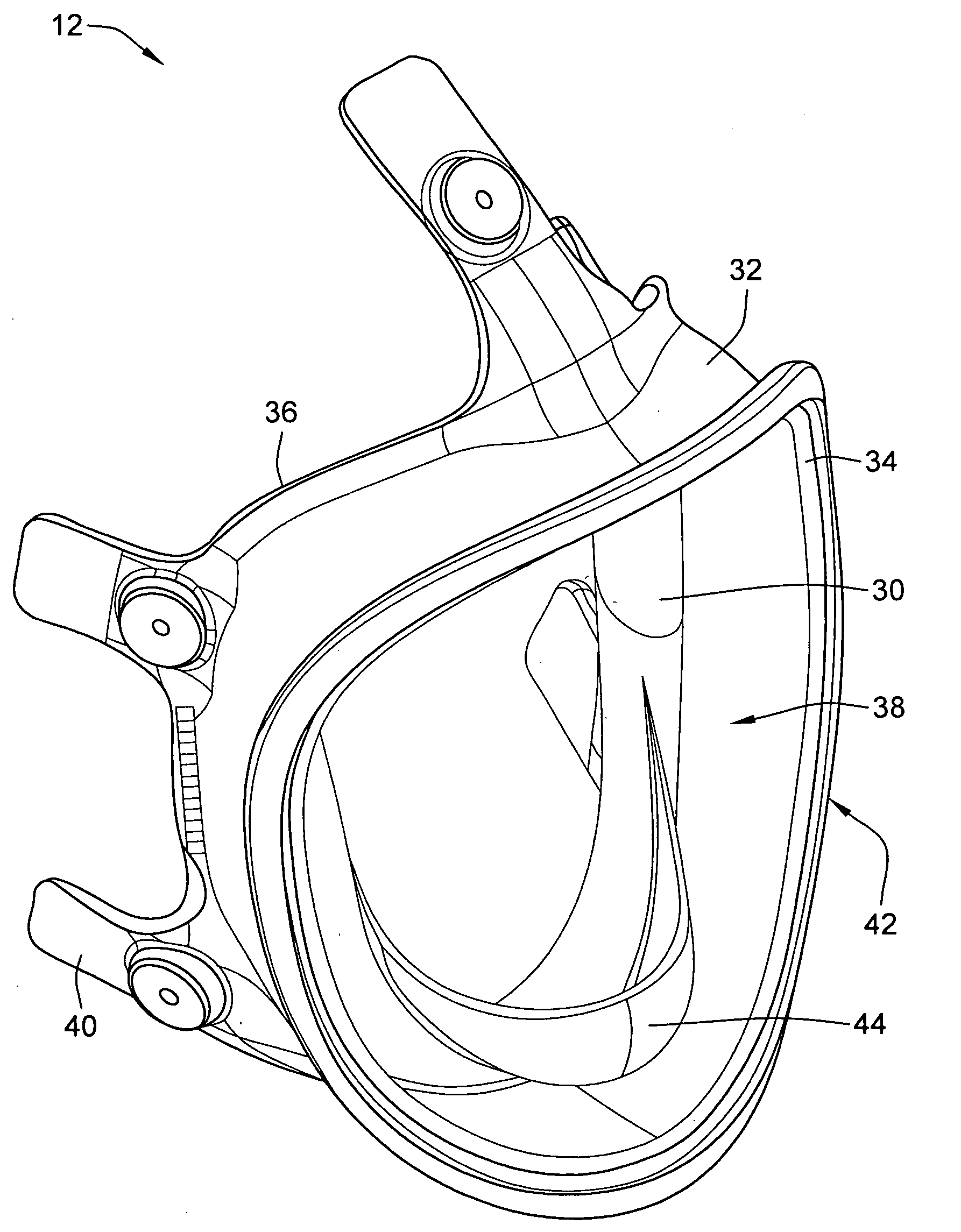

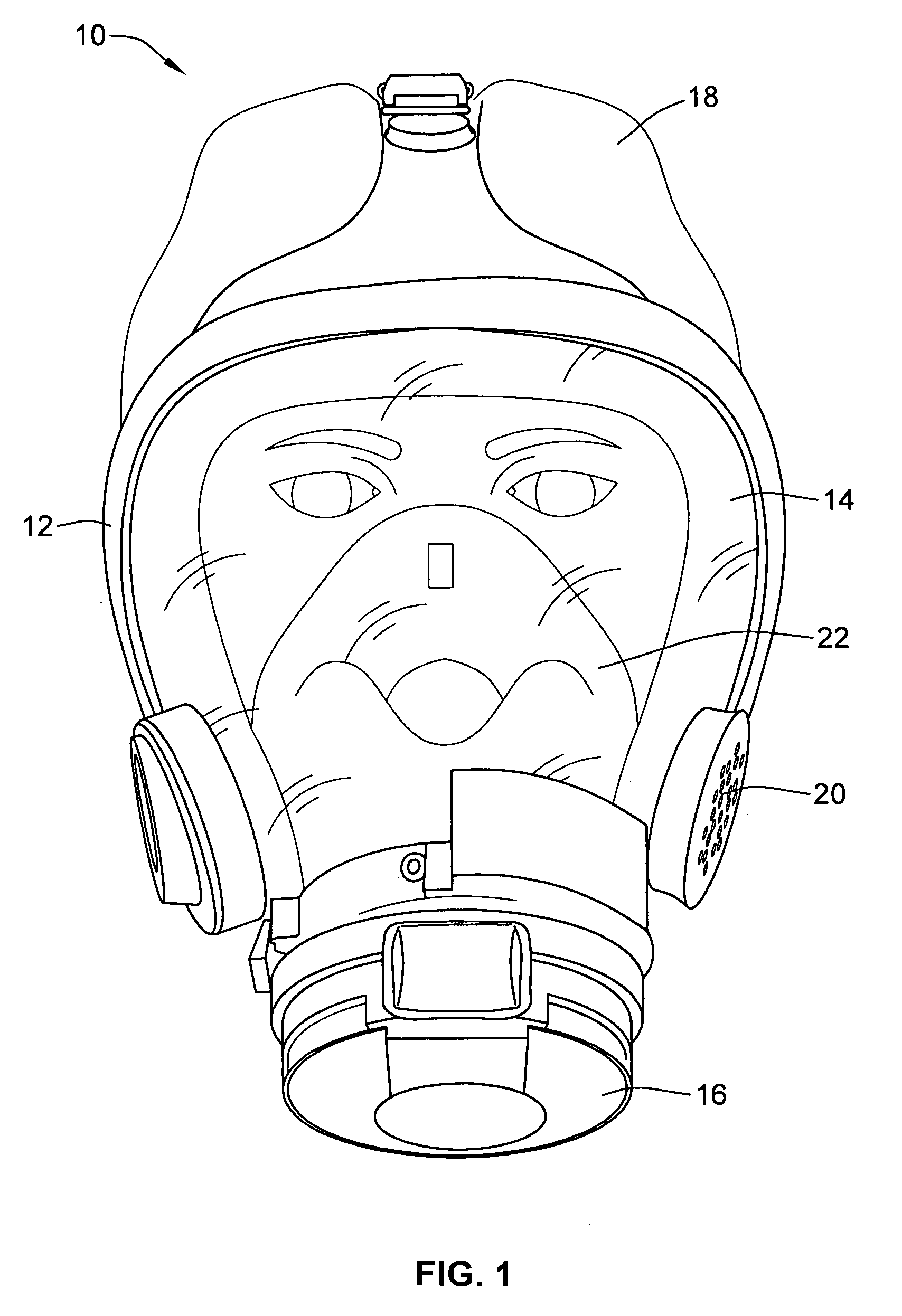

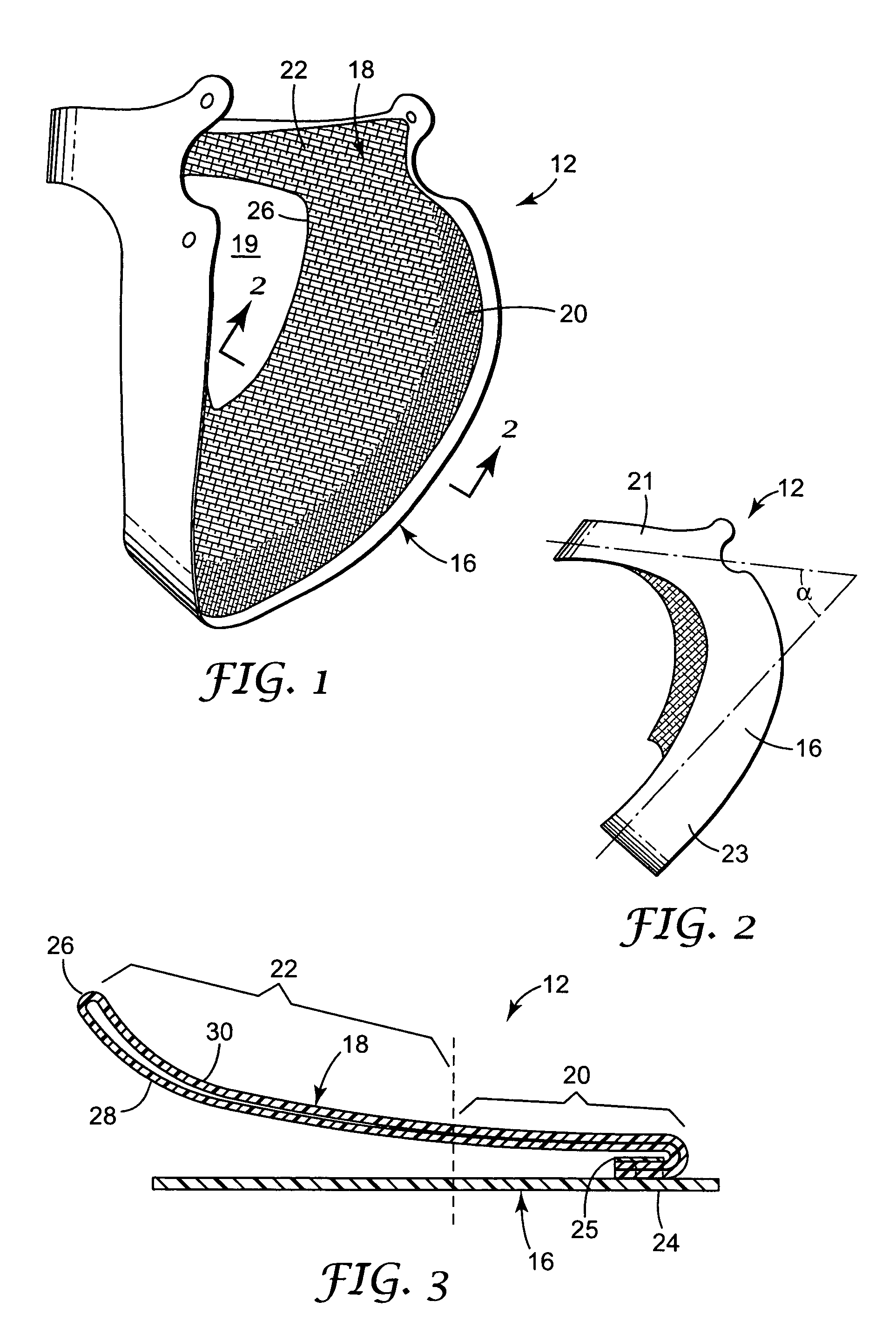

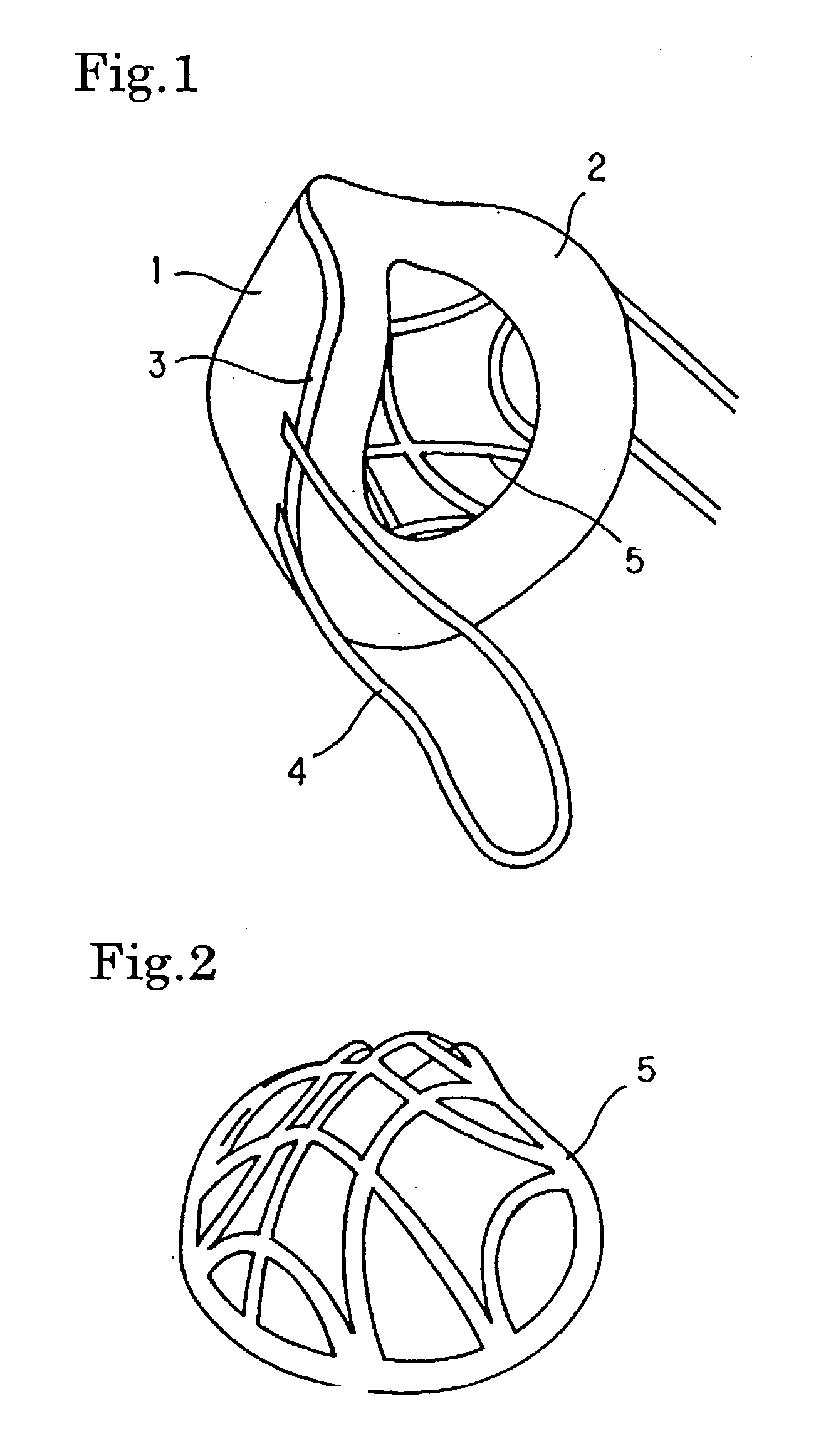

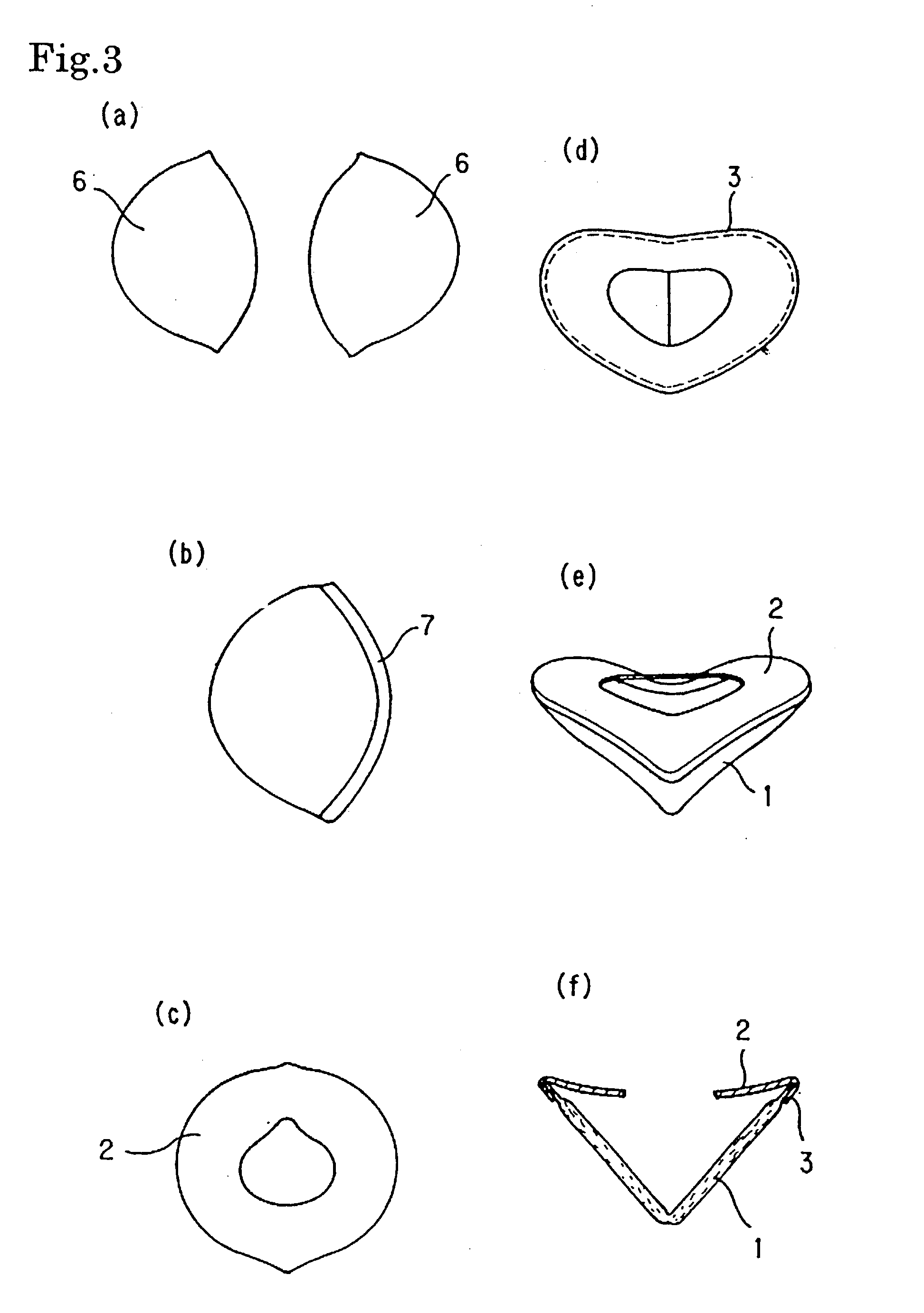

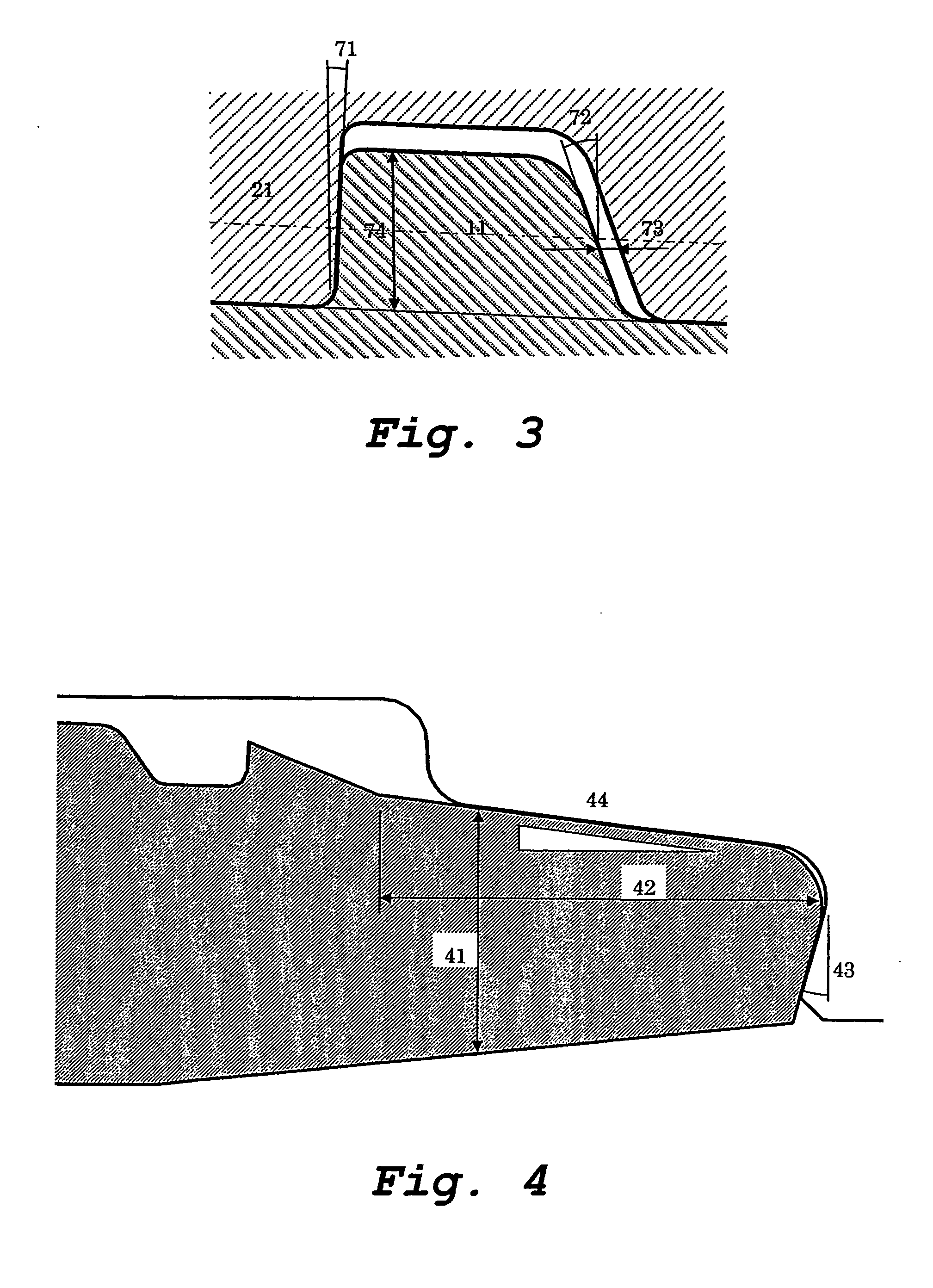

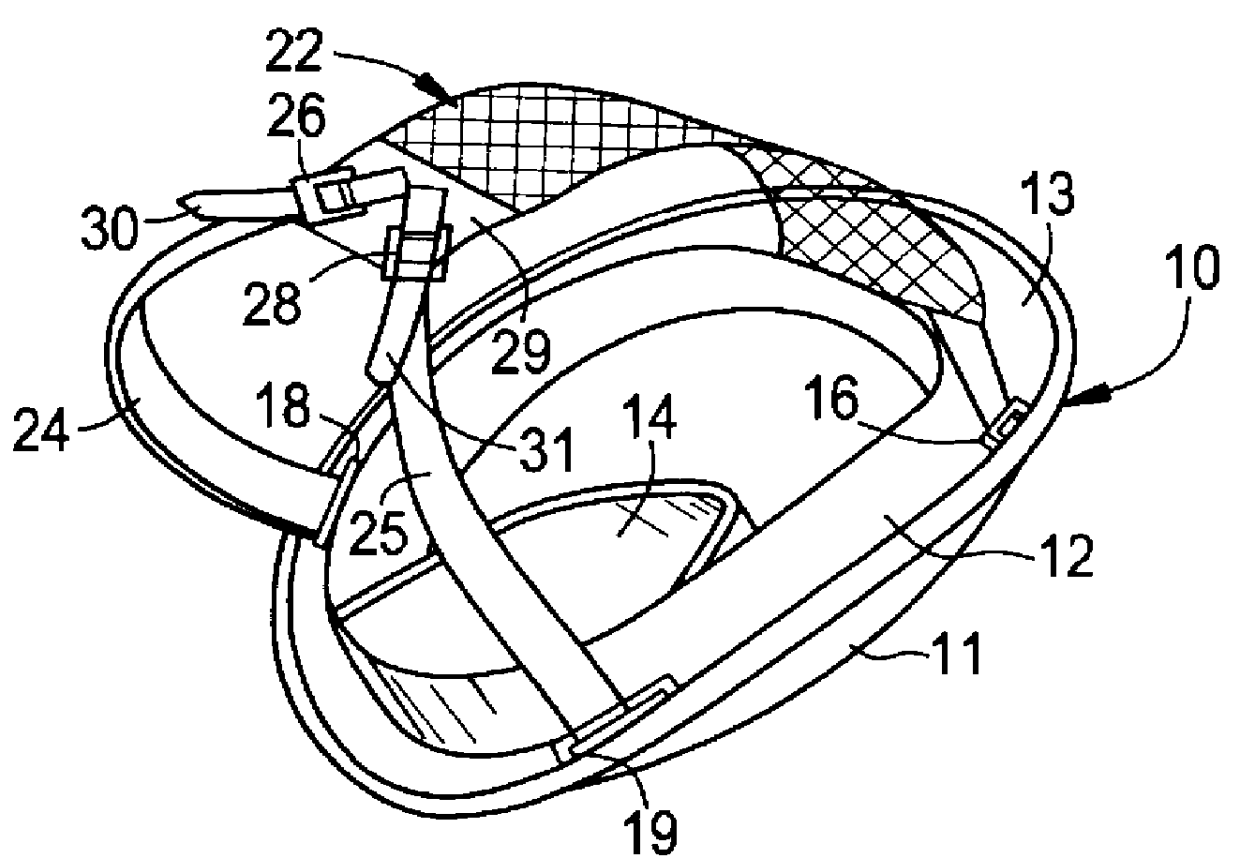

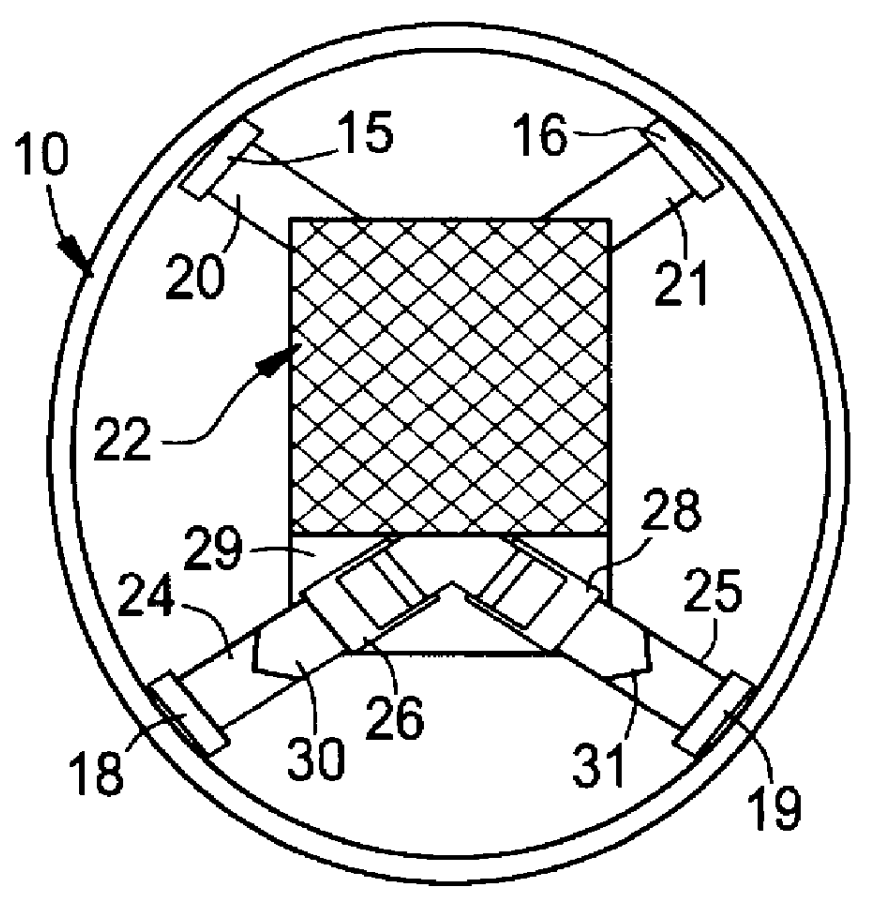

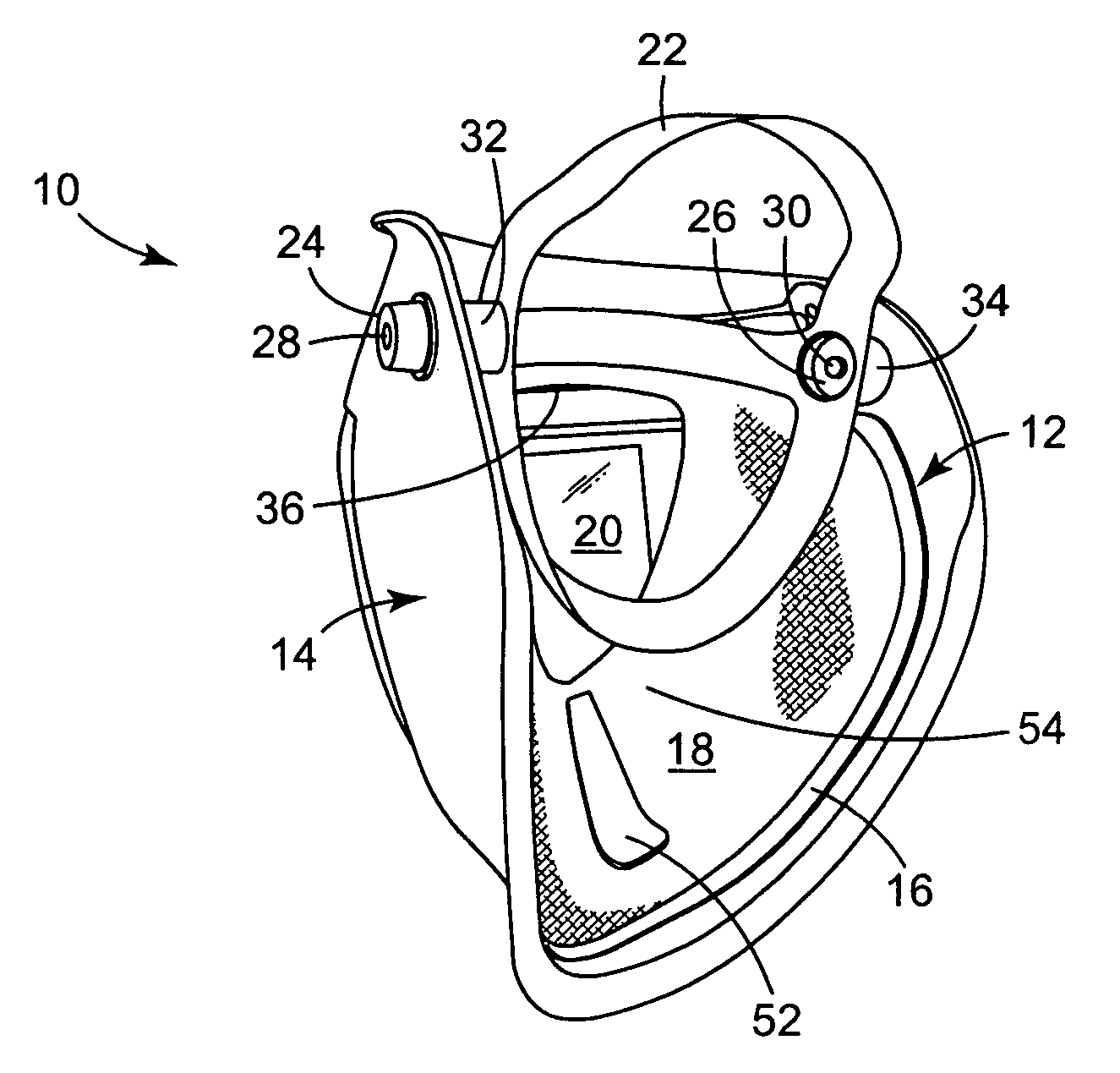

Face seals for respirators and method of manufacturing respirators

A respirator includes a mask having a body extending between a front edge and a rear edge, and a face seal extending inward from the body. The face seal has a first wall extending from the body and a second wall intersecting with the first wall at a sealing land. The sealing land is configured to contact a user's face to form a continuous circumferential seal. The face seal is folded over such that the first wall and the second wall both extend away from the sealing land in a common direction. Optionally, the face seal may be U-shaped.

Owner:SCOTT TECH INC

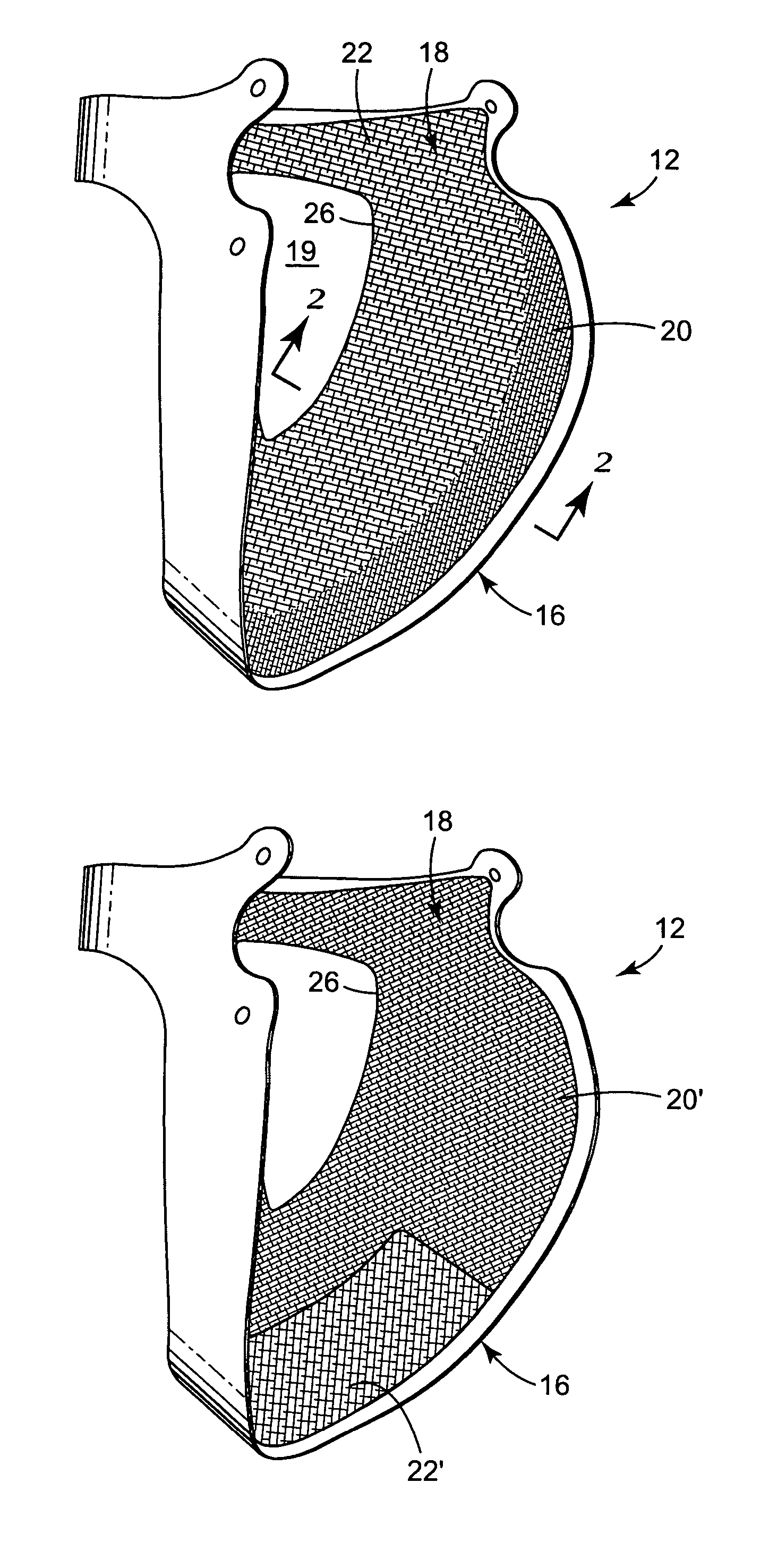

Supplied air helmet having face seal with differentiated permeability

InactiveUS7197774B2Less opportunityComfortable environmentChemical protectionLighting and heating apparatusEngineeringFace seal

A supplied air helmet 10 comprises a visor 14 and a face seal 12 that is secured to the visor. The face seal 12 includes a sealing member 18 and a frame member 16. The sealing member 18 extends radially inward from the frame member 16 and has first and second regions of permeability 20 and 22. The second region 22 has greater permeability than the first region 20. The use of a face seal 12 that has differentiated permeability allows for a controlled flow of air through the interior of the supplied air helmet 10.

Owner:3M INNOVATIVE PROPERTIES CO

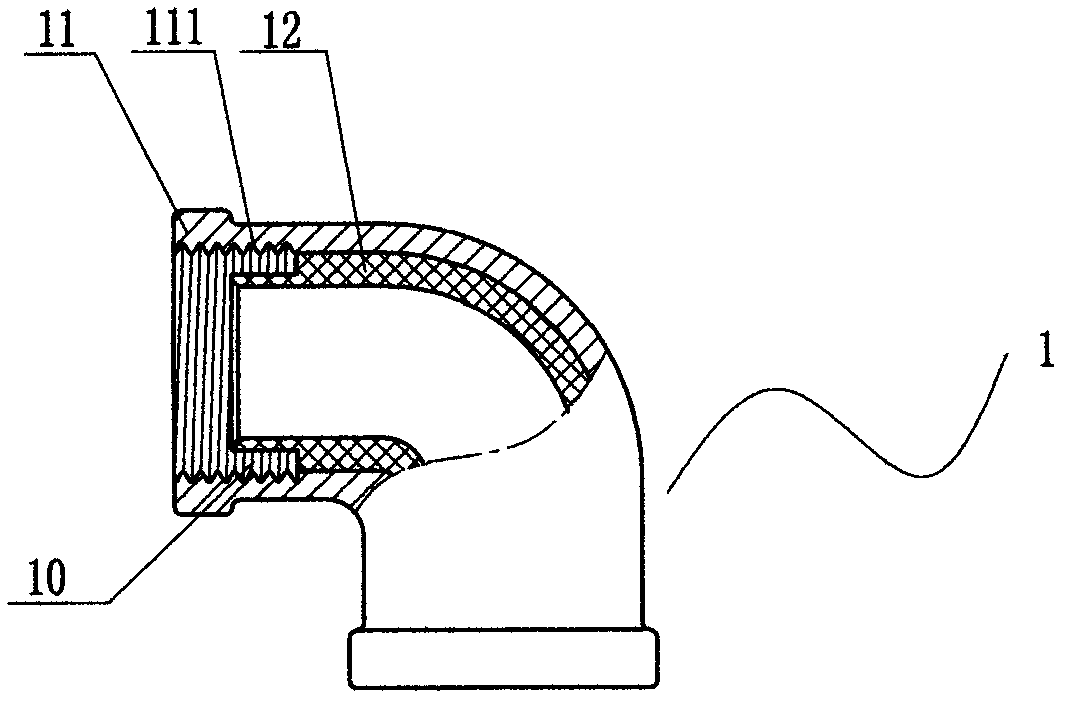

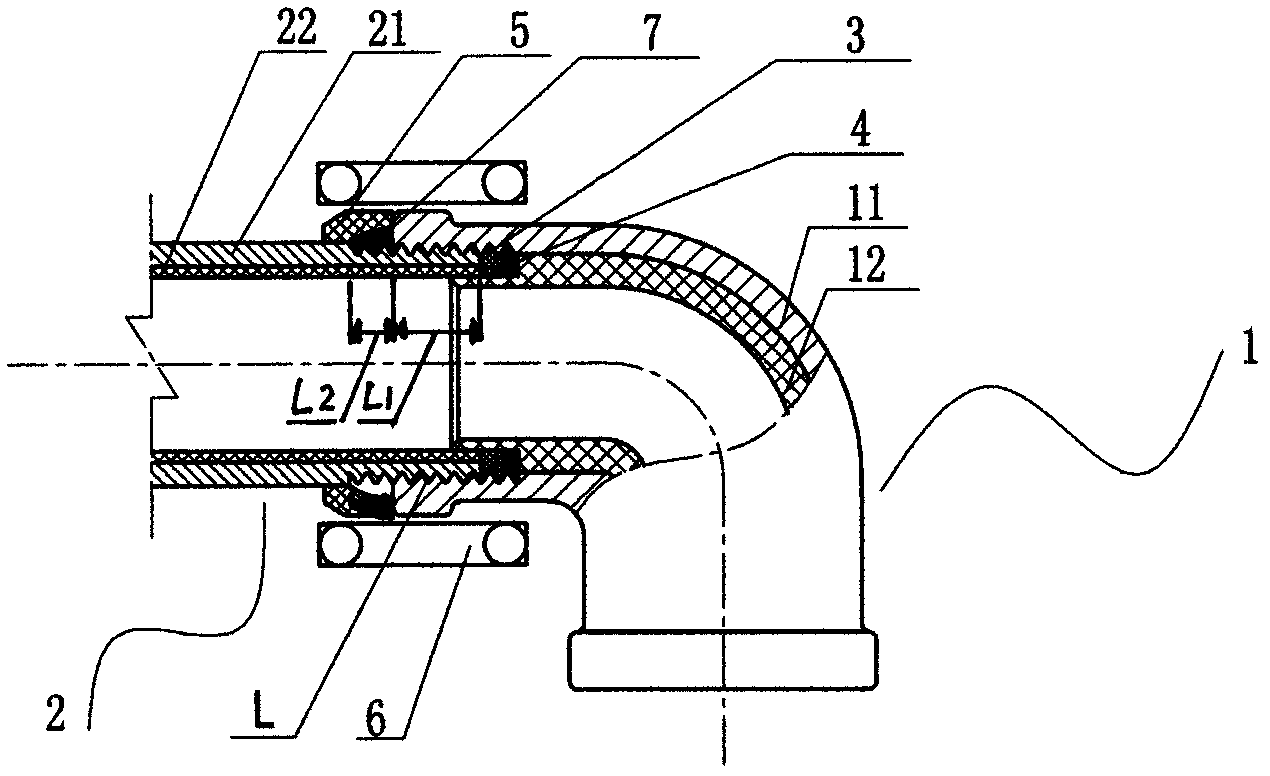

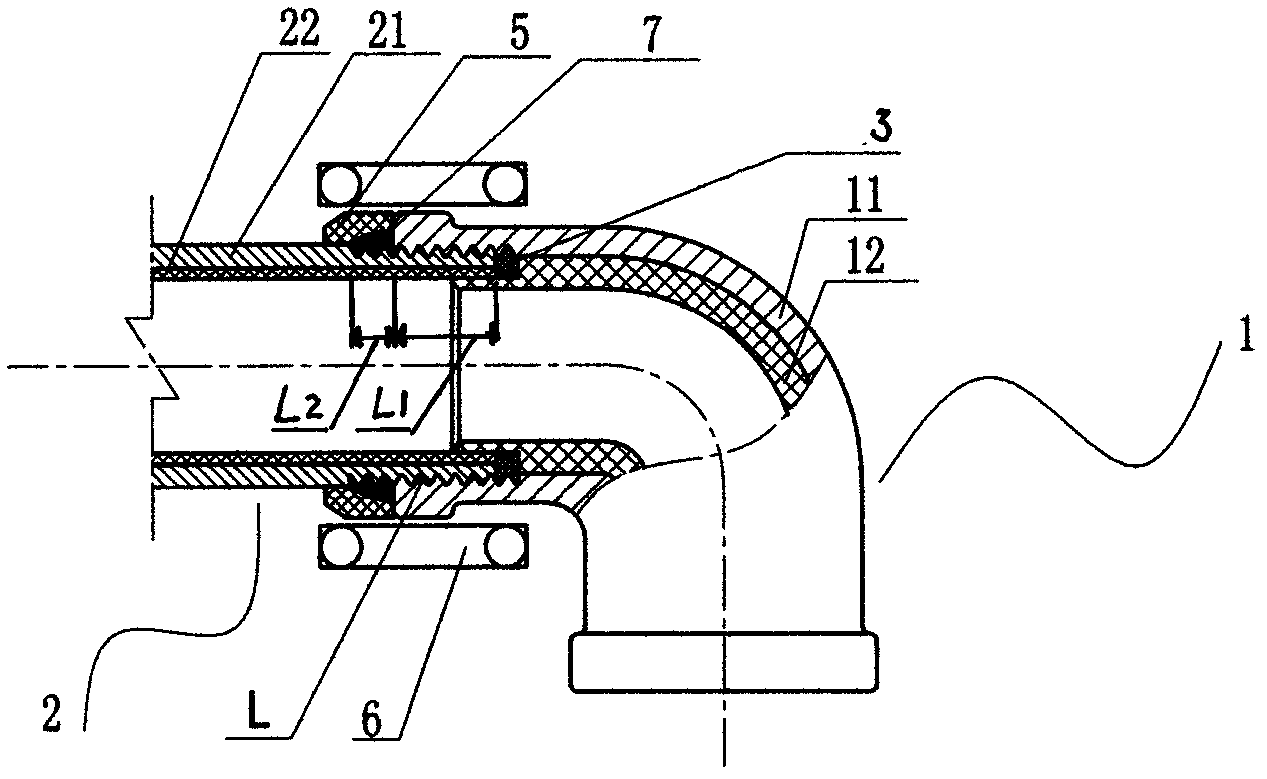

Full corrosion-resistant connection structure of steel lining plastic composite pipeline

InactiveCN102359697AReduce the chance of secondary pollutionEliminate interface rustCorrosion preventionPipe protection against corrosion/incrustationPipe fittingHot-melt adhesive

The invention discloses a full corrosion-resistant connection structure of a steel lining plastic composite pipeline, and belongs to the technical field of connection of the steel lining plastic composite pipeline. The structure comprises a corrosion-resistant ring sleeved on a non-meshing section of an external thread of a steel outer layer, a steel lining plastic composite pipe fitting consisting of a steel outer ring part and a plastic inner ring part, and a composite pipe consisting of the steel outer layer with the external thread, and a plastic inner layer, wherein the external thread consists of a meshing section and the non-meshing section; an annular cavity of which the inner wall is provided with an internal thread section is formed between the steel outer ring part and the plastic inner ring part; the pipe is in threaded connection with the pipe fitting; a solid hot melt adhesive is arranged in the annular cavity; when an alternating magnetic field is formed at the periphery of the joint of the pipe fitting and the pipe, the solid hot melt adhesive is in thread engagement with the steel outer ring part and in sealed connection with the end faces of the steel outer layer and the plastic inner layer; and the corrosion-resistant ring is in sealed connection with the non-meshing section of the pipe. After the scheme is adopted, the problem that the threads of the pipe and the pipe fitting are easily corroded and rusted is solved, and a full corrosion-resistant threaded connection effect is achieved.

Owner:HUAHUI CONSTR GROUP

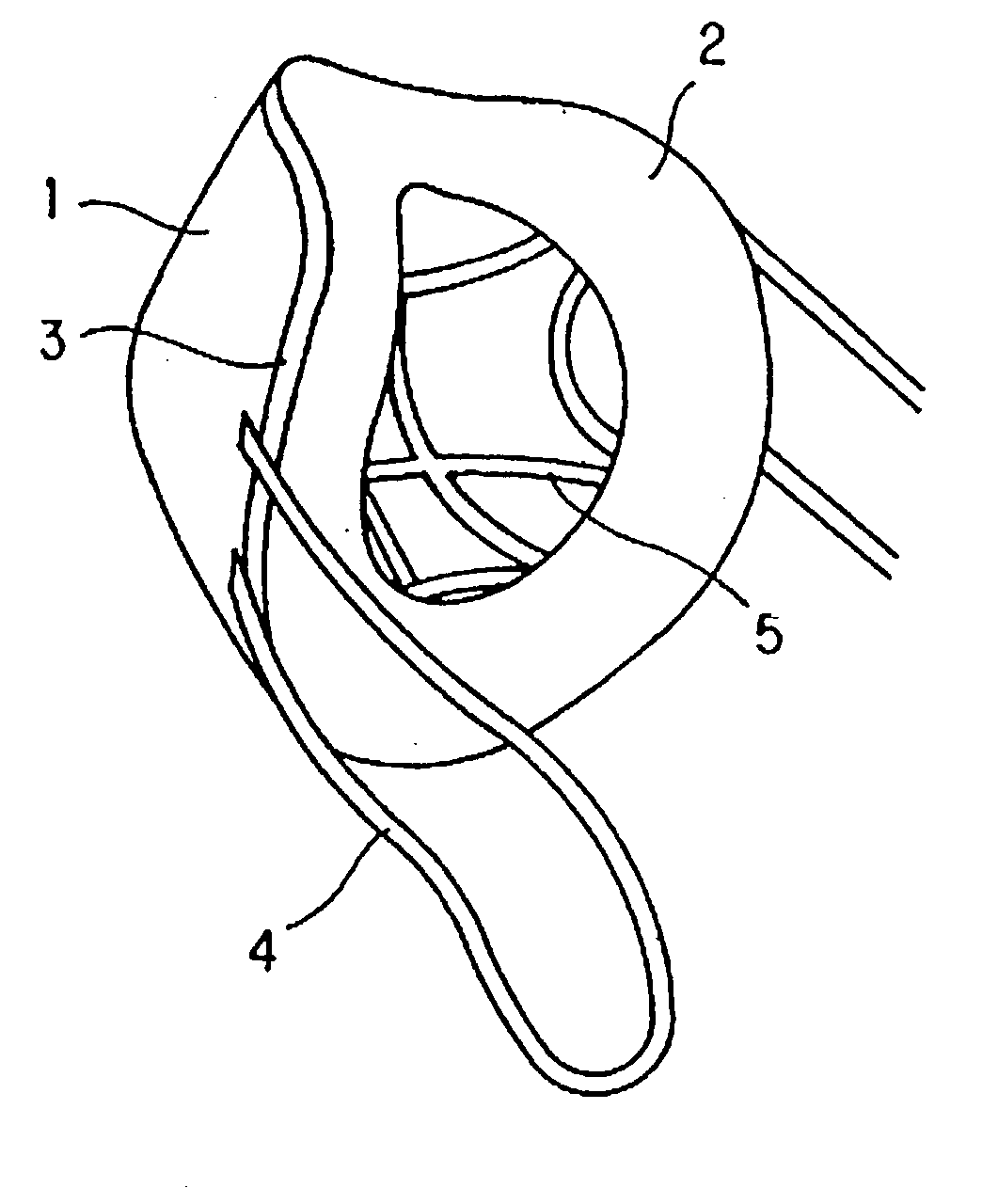

Mask

A mask comprising a mask main body and a face seal, wherein the outer periphery part of the main body and the outer periphery part of the face seal are adhered, said face seal is composed of a sheet prepared by laminating soft resin such as polyurethane resin on one surface of elastic fabric made of nylon or polyester fibers, and said laminated sheet is cut off to have a modified ring shape.

Owner:SHIGEMATSU WORKS CO LTD

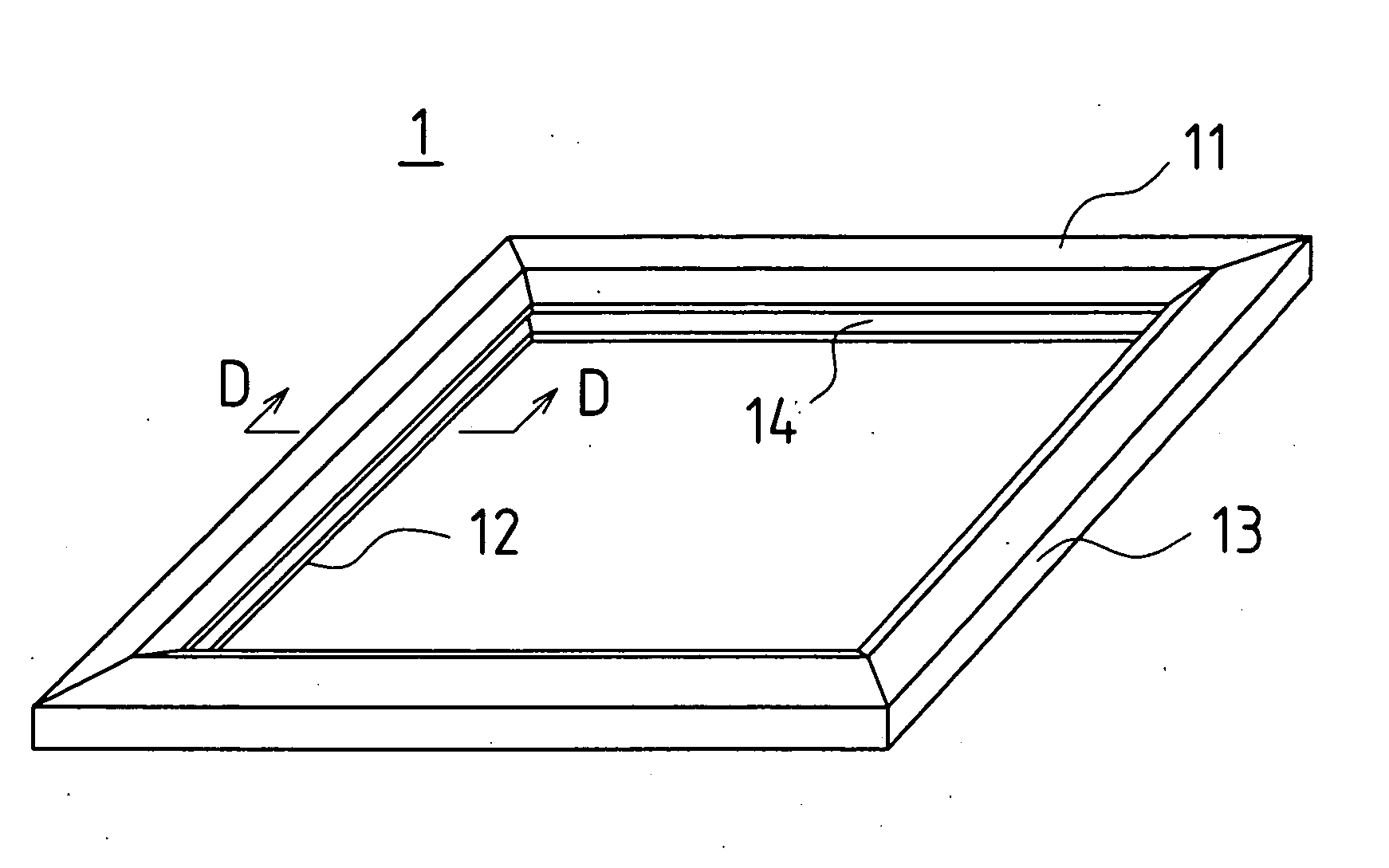

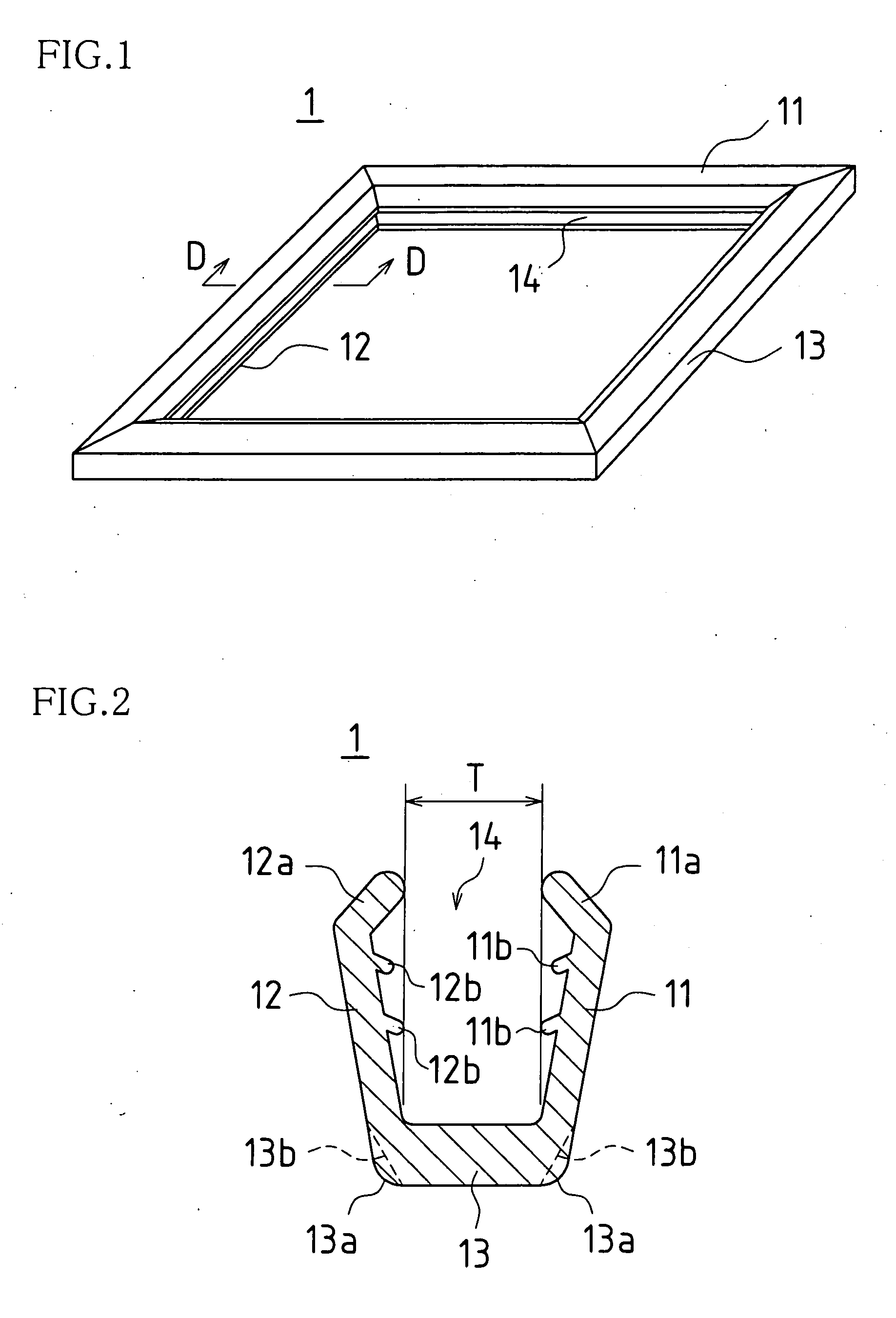

Solar cell module and edge face sealing member for same

InactiveUS20040084078A1Avoid yellowingPrevent degradationPhotovoltaic supportsRoof covering using slabs/sheetsElastomerPolystyrene

Edge face sealing member(s) 1 may be roughly c-shaped in cross-section, may be frame-like in shape and formed in more or less parallel fashion with respect to outer shape(s) of solar cell module body or bodies, may comprise upper sealing region(s) 11 abutting front surface(s) of solar cell module(s), may further comprise lower sealing region(s) 12 abutting back surface(s) of solar cell module(s), and may further comprise side sealing region(s) 13 abutting edge face(s) of solar cell module(s). Furthermore, respectively formed on facing surfaces of upper sealing region(s) 11 and lower sealing region(s) 12 there may be projections 11b, 12b. Furthermore, polypropylenic and / or polystyrenic elastomer resin(s) may be used as material(s) making up edge face sealing member(s) 1, and magnesium silicate may be present as additive(s) for prevention of yellowing of sealing resin layer(s) at solar cell module body or bodies.

Owner:SHARP KK

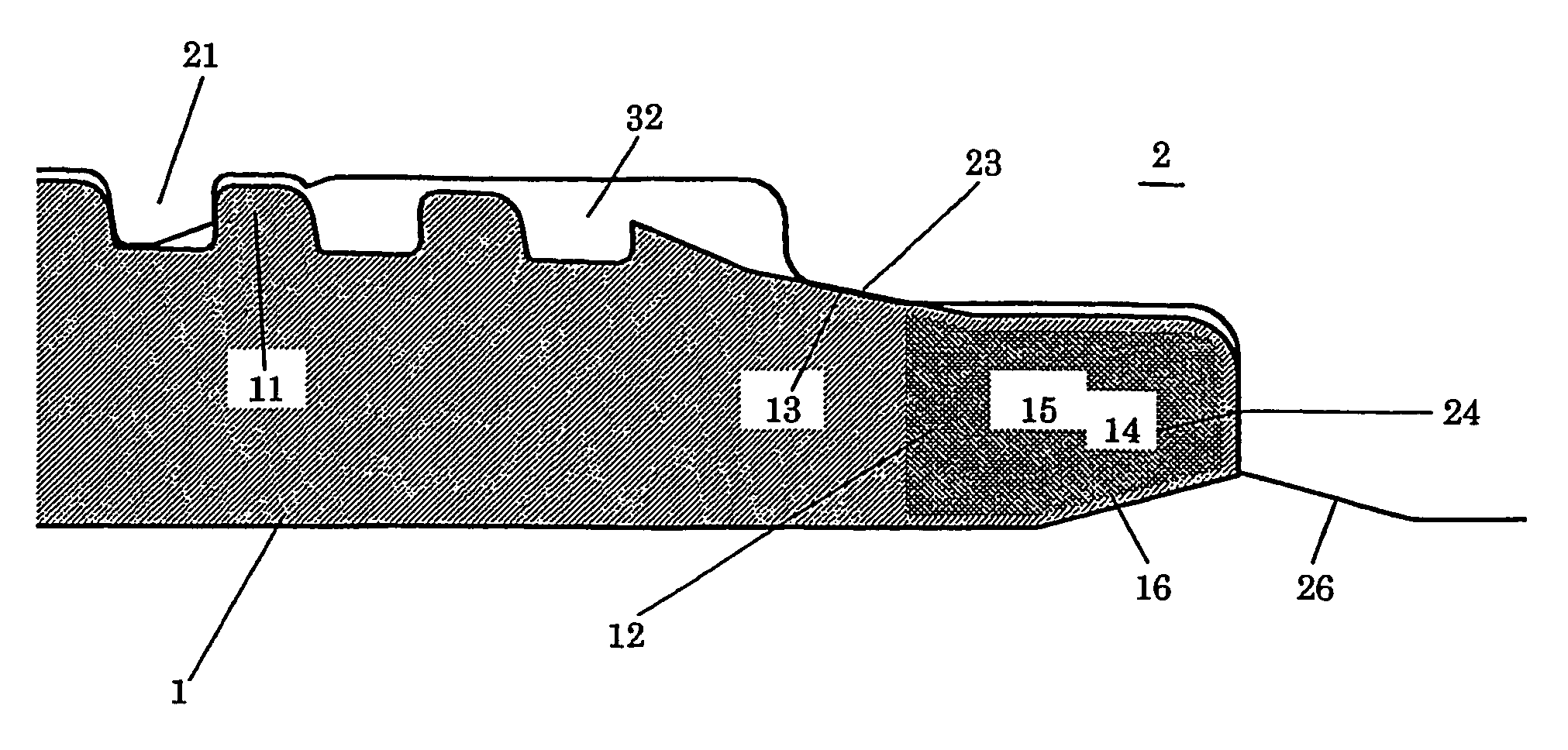

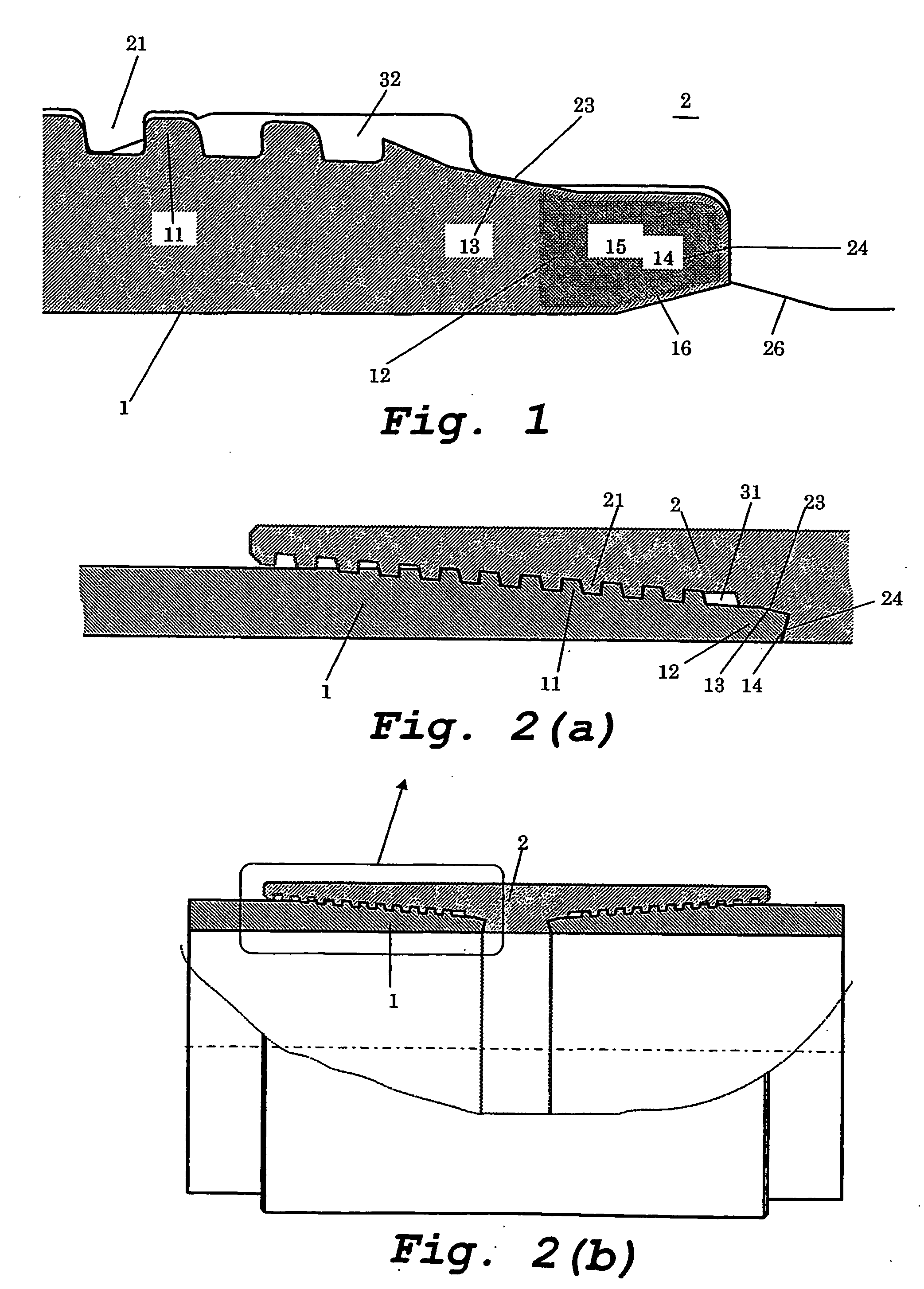

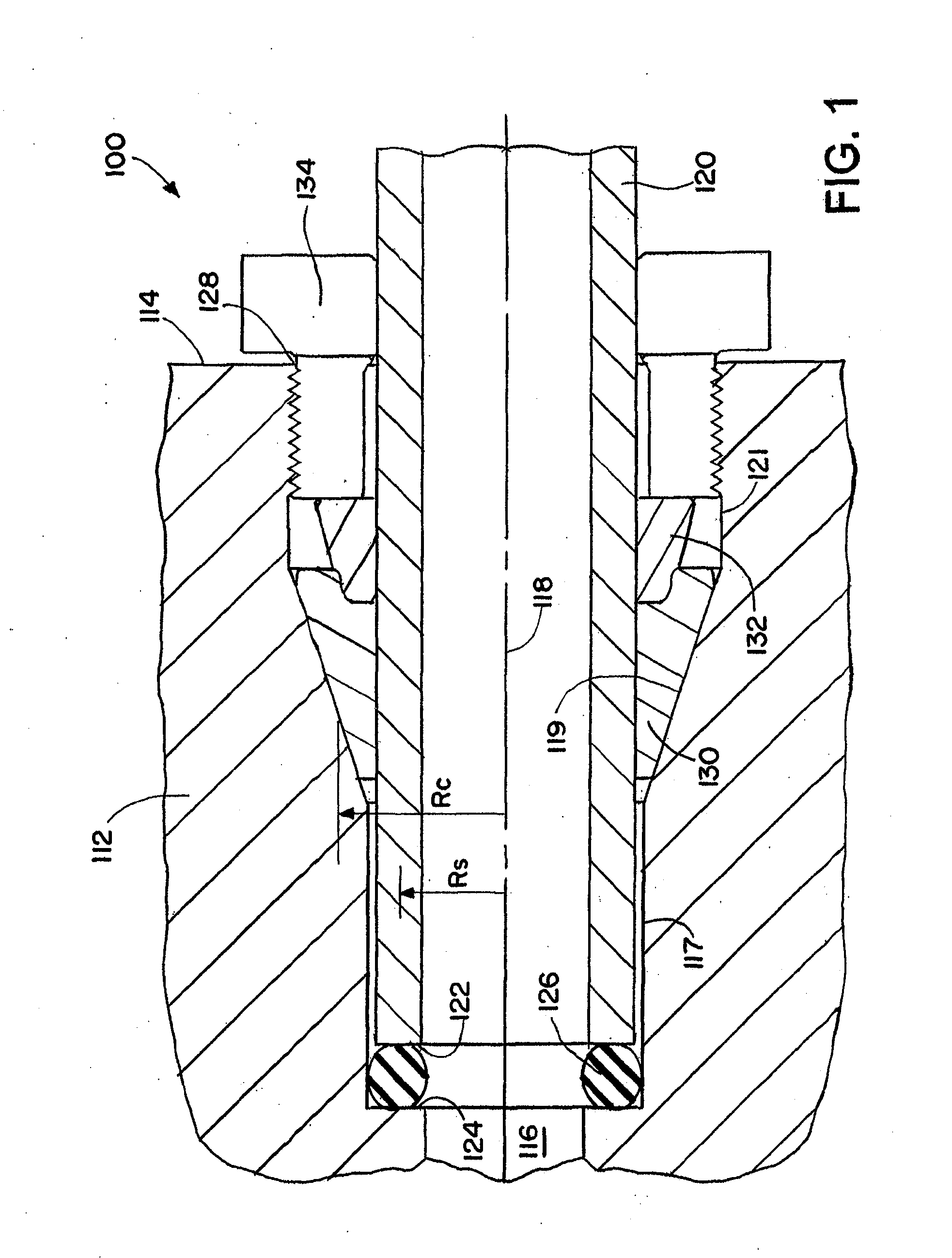

Threaded joint for steel pipes

ActiveUS20050248153A1Increase wall thicknessImprove sealingDrilling rodsHose connectionsEngineeringScrew thread

A threaded joint for steel pipes comprises a pin (1) and a box (2). The pin has male thread (11), a sealing surface (13), and a shoulder surface (14) located on the end face of the pin. Correspondingly, the box has female thread (21), a sealing surface (23), and a shoulder surface (24) which can mate or contact with the corresponding portions of the pin. The shoulder surface (14) of the pin (1) is provided at an end face of the pin. The sealing surface (13) of the pin (1) is located on a pipe end side near the male thread (11). A a nose portion (15) is provided on the pin (1) between the sealing surface (13) and the shoulder surface (14), the nose portion (15) being not in contact with a corresponding portion of the box (2).

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

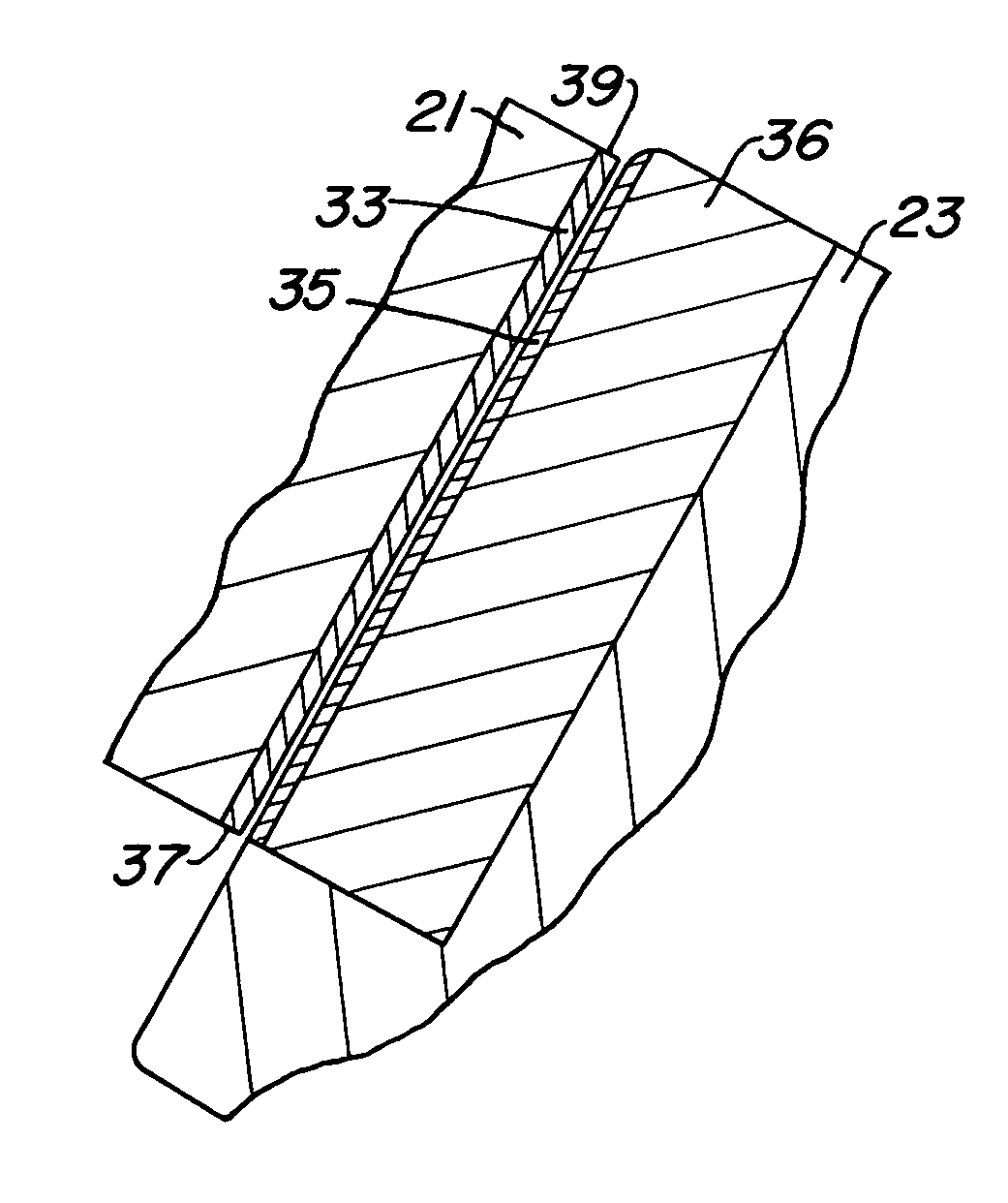

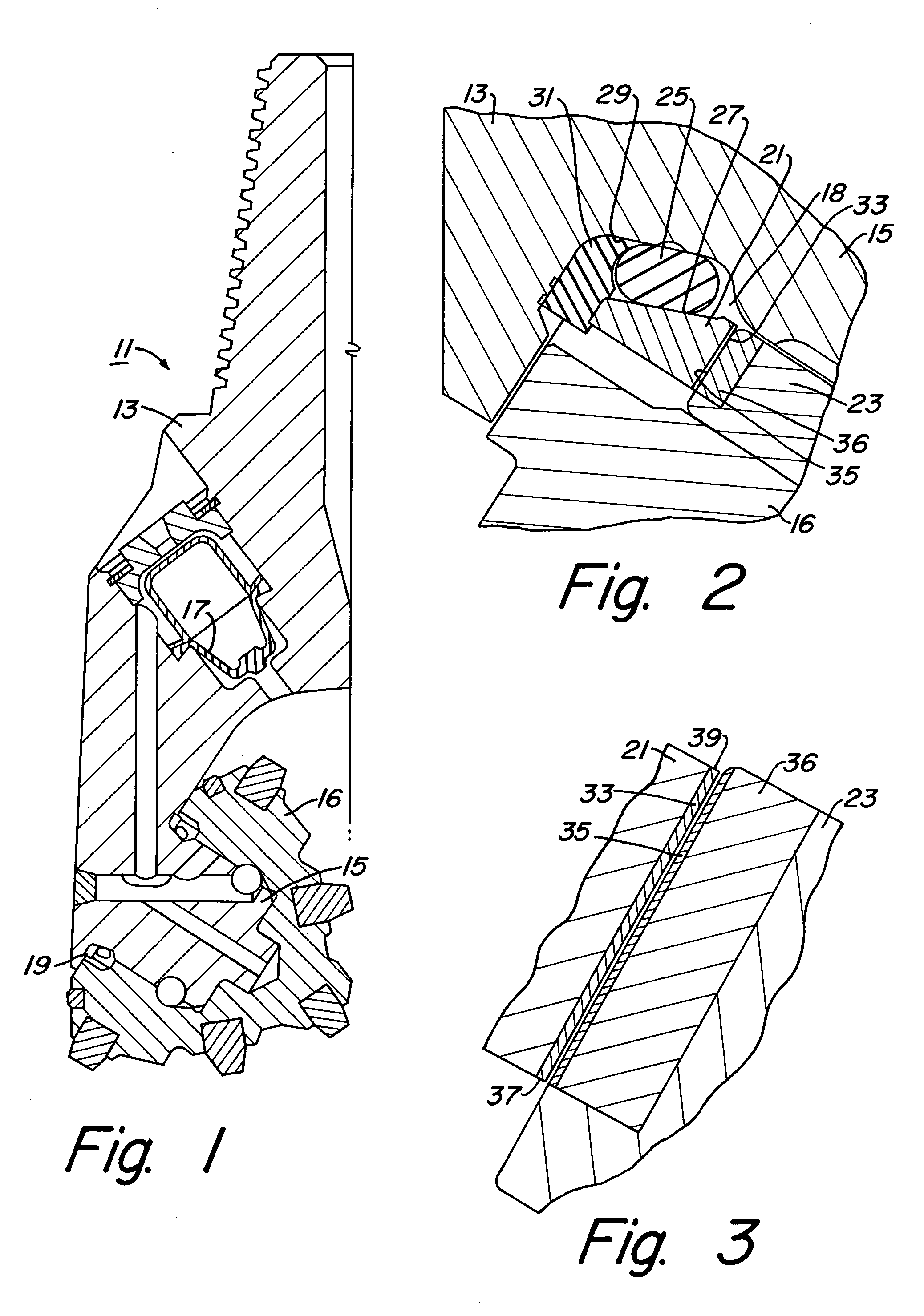

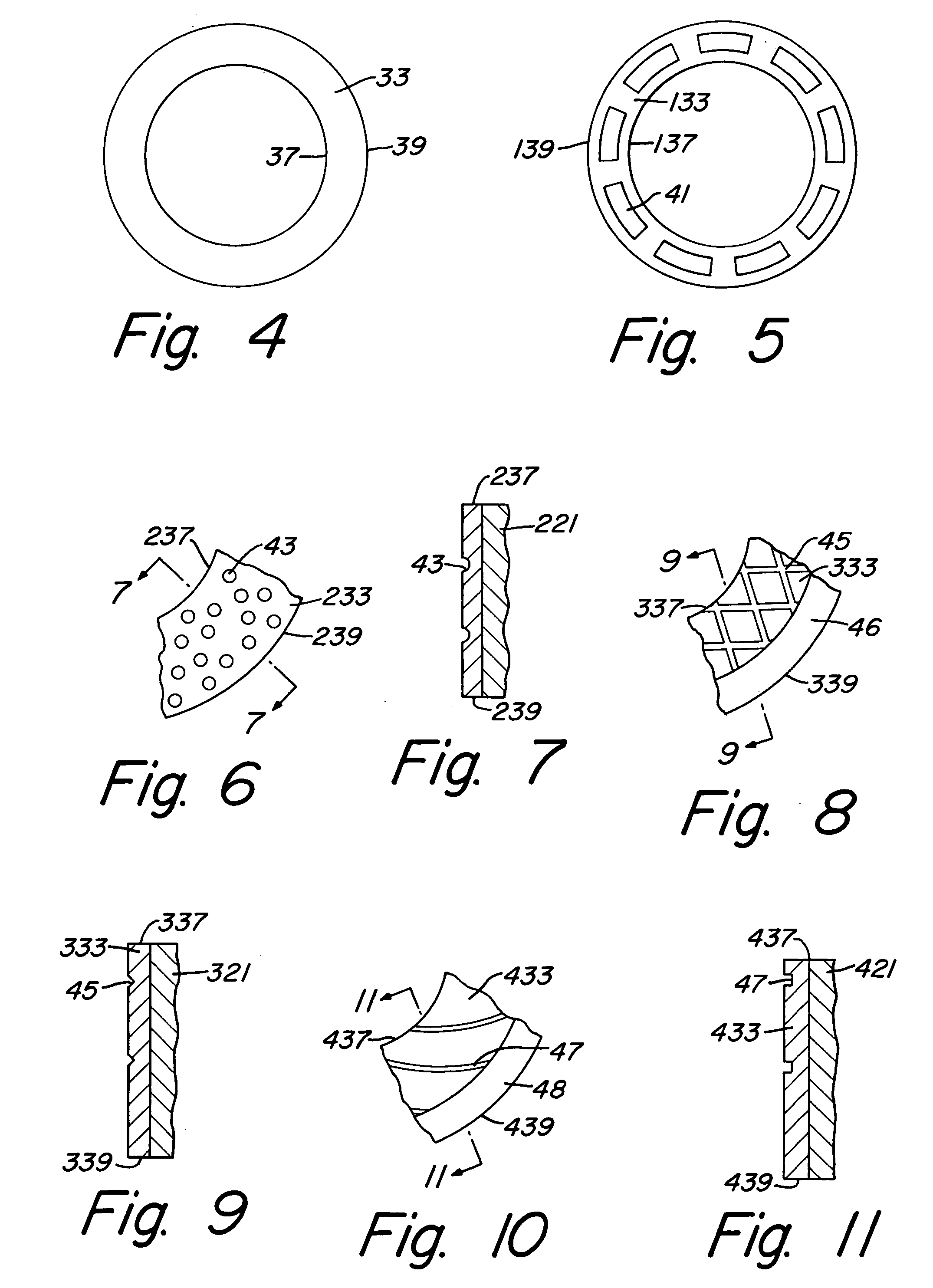

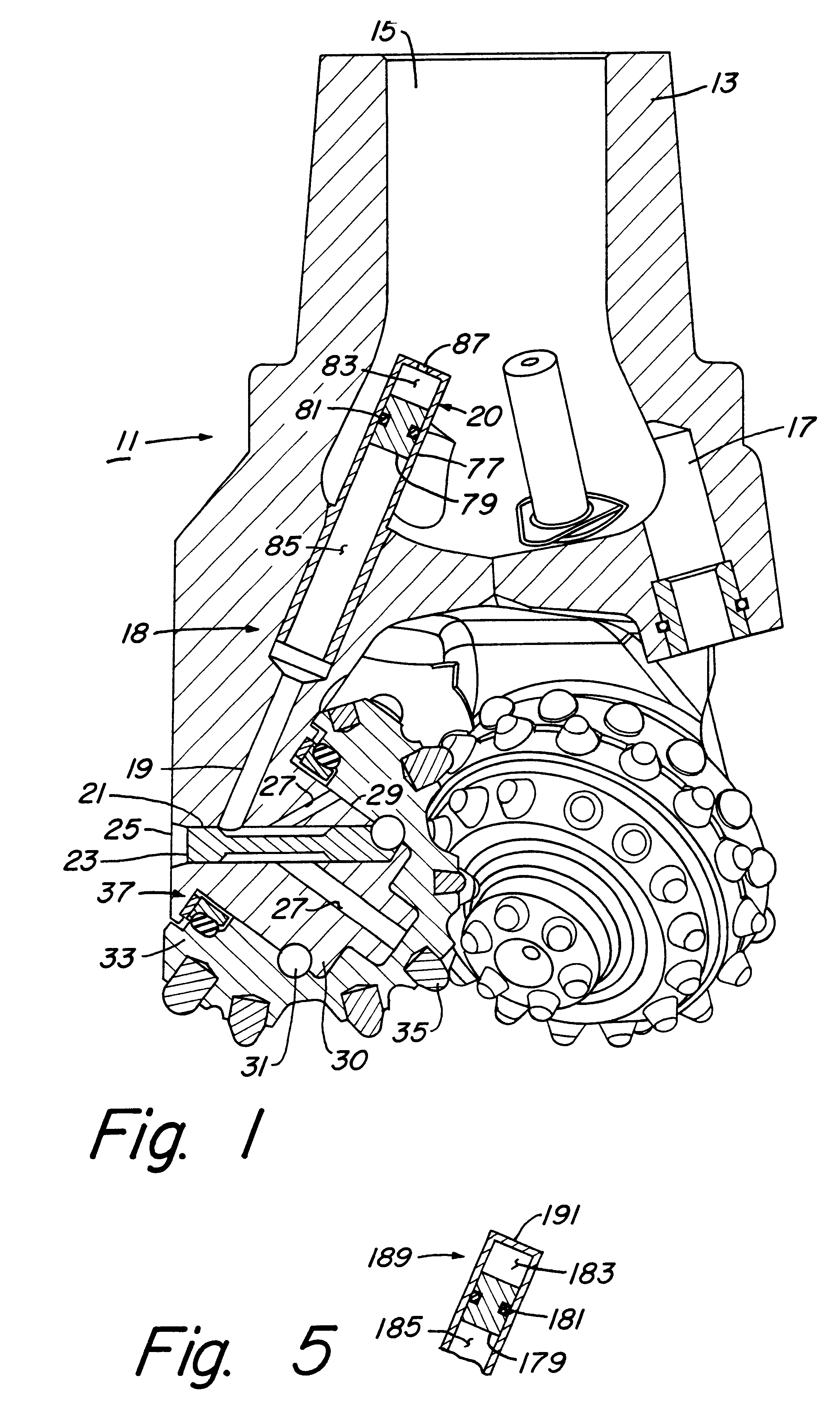

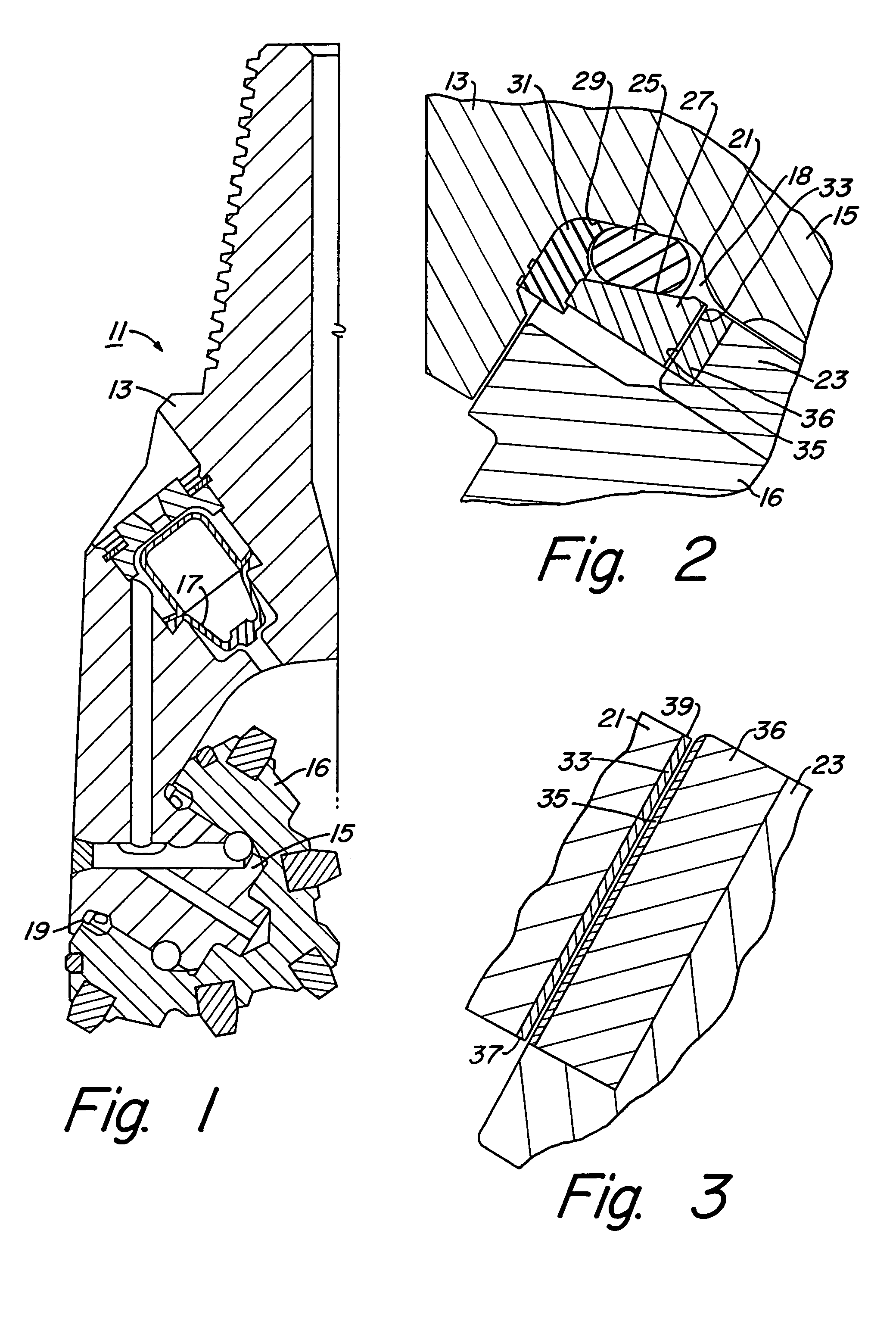

PCD face seal for earth-boring bit

Owner:BAKER HUGHES HLDG LLC

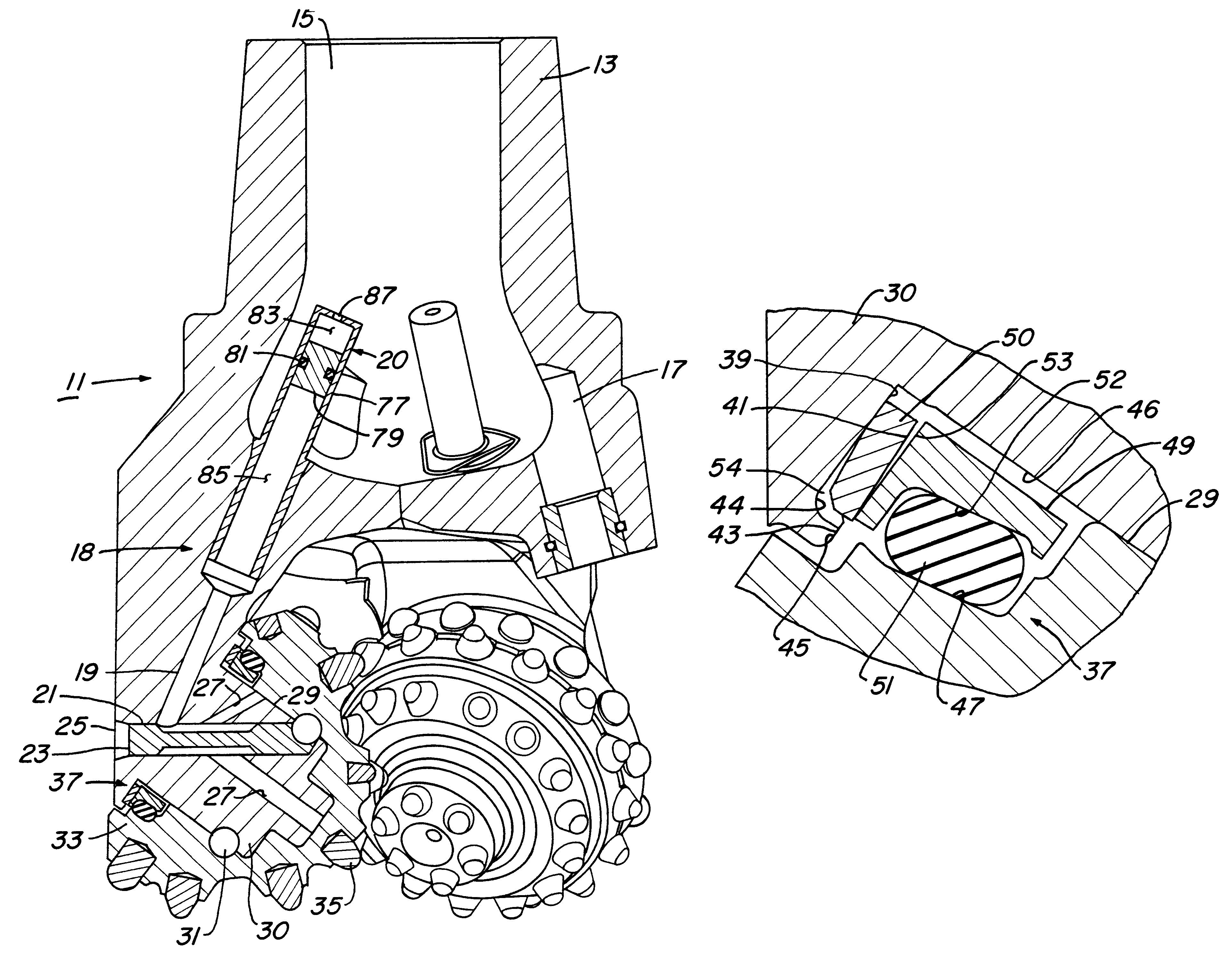

Metal-face-seal rock bit

A bit is provided having at least one leg extending downwardly and inwardly from the bit body. A cutter cone is rotatably mounted on a shaft extending inwardly from the lower portion of each leg. The annular space defined by the base of the shaft and the inner surface at the base of the cone forms a seal gland. An elastomeric o-ring sealingly engages an inner surface of the cone and a first rigid ring which rotates with the o-ring and cone. The o-ring energizes the first rigid ring for sealingly engaging a second rigid ring mounted to the leg of the bit near the base of the shaft. The second rigid ring is secured to and seals against a surface at the base of the shaft and is held stationary relative to the surface. A lubricant passage for lubricating the seal is pressurized by the drilling fluid pressure in the center of the bit body.

Owner:BAKER HUGHES INC

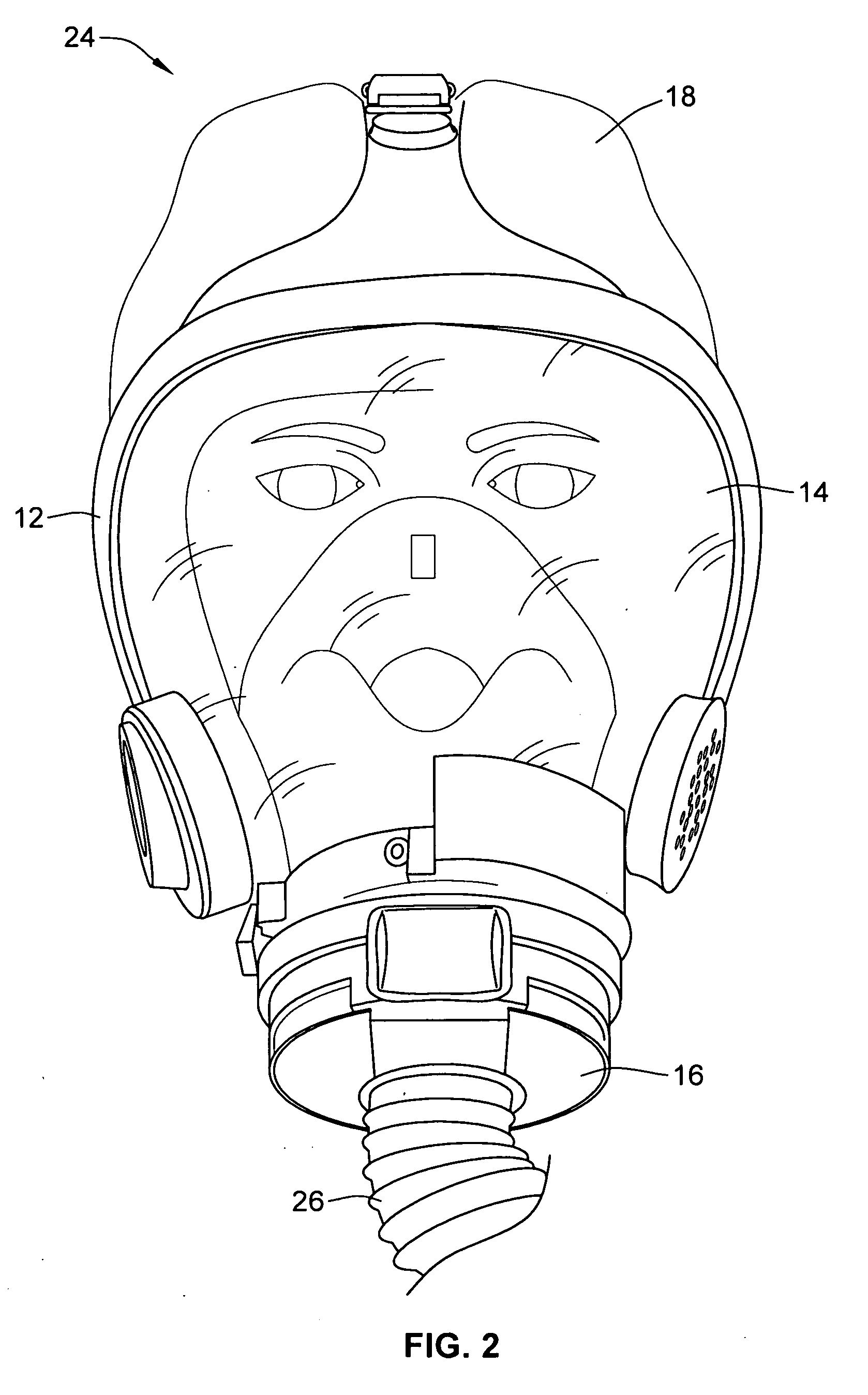

Face mask for self contained breathing apparatus

A face mask for a self contained breathing apparatus has two pairs of straps fixed to the frame of the mask, the straps being fixed to a net or woven head piece. The straps at the top of the head piece are fixed with respect to the mask, and the bottom straps are adjustable to tighten the mask against the face of the user. The nose cup has ribs that receive legs of a mounting member for eyeglasses. The eyeglasses include frames, with support arms that are slidably fixable to the mounting member. The mounting member moves towards and away from the eyes of the user, and the support arms move up and down with respect to the nose cup, for full adjustability of the eyeglasses. The nose cup of the face mask is adjustable by either removing a portion at the chin and shortening the mask, or simply removing the portion to allow the user's chin to extend beyond the nose cup while still inside the face seal. The seal for the mask has a single thickness in the forehead area for greater comfort while wearing a helmet, and is smaller at the temples for a tighter seal at the temples where users are frequently smaller.

Owner:AVON PROTECTION SYST

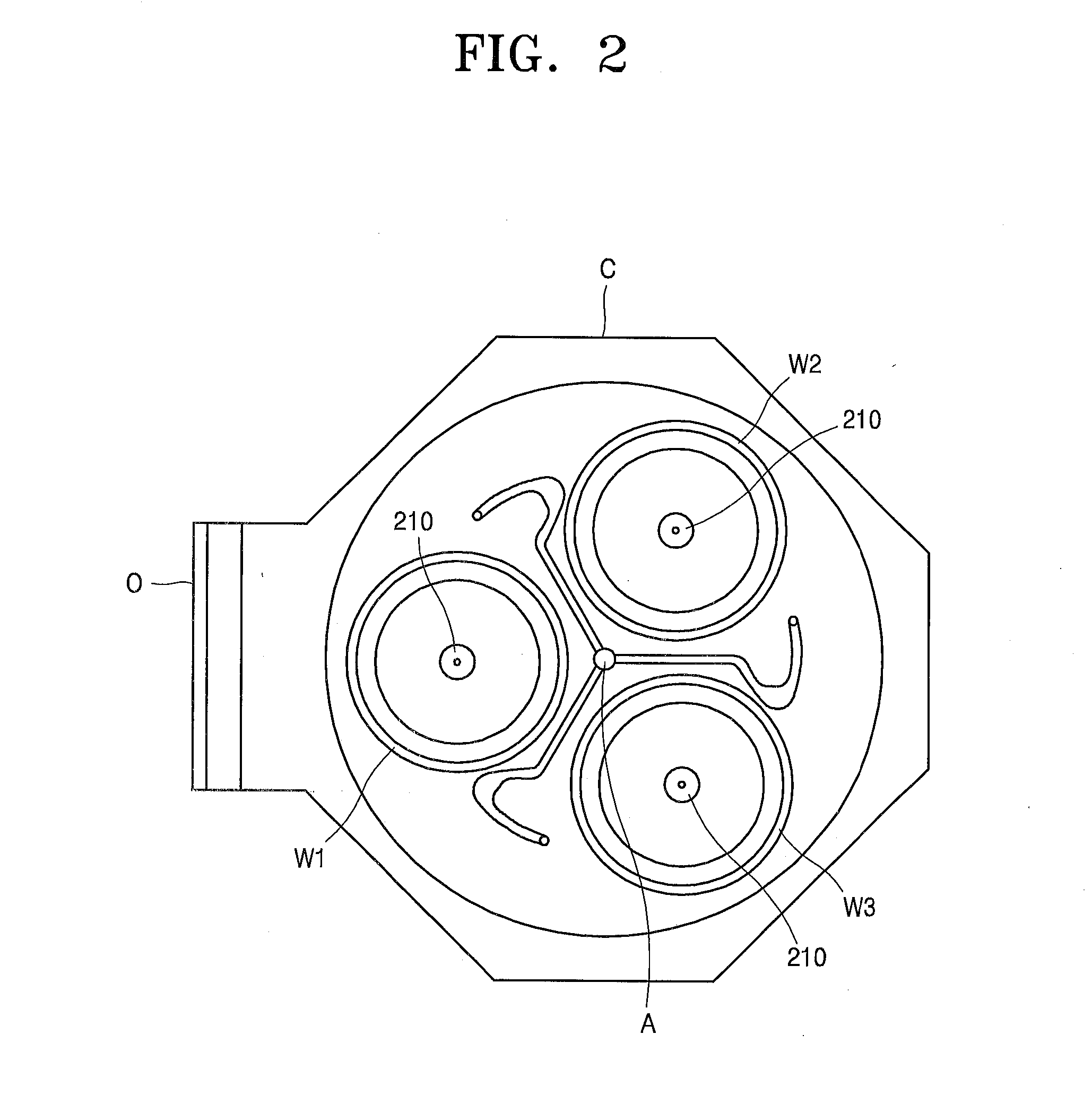

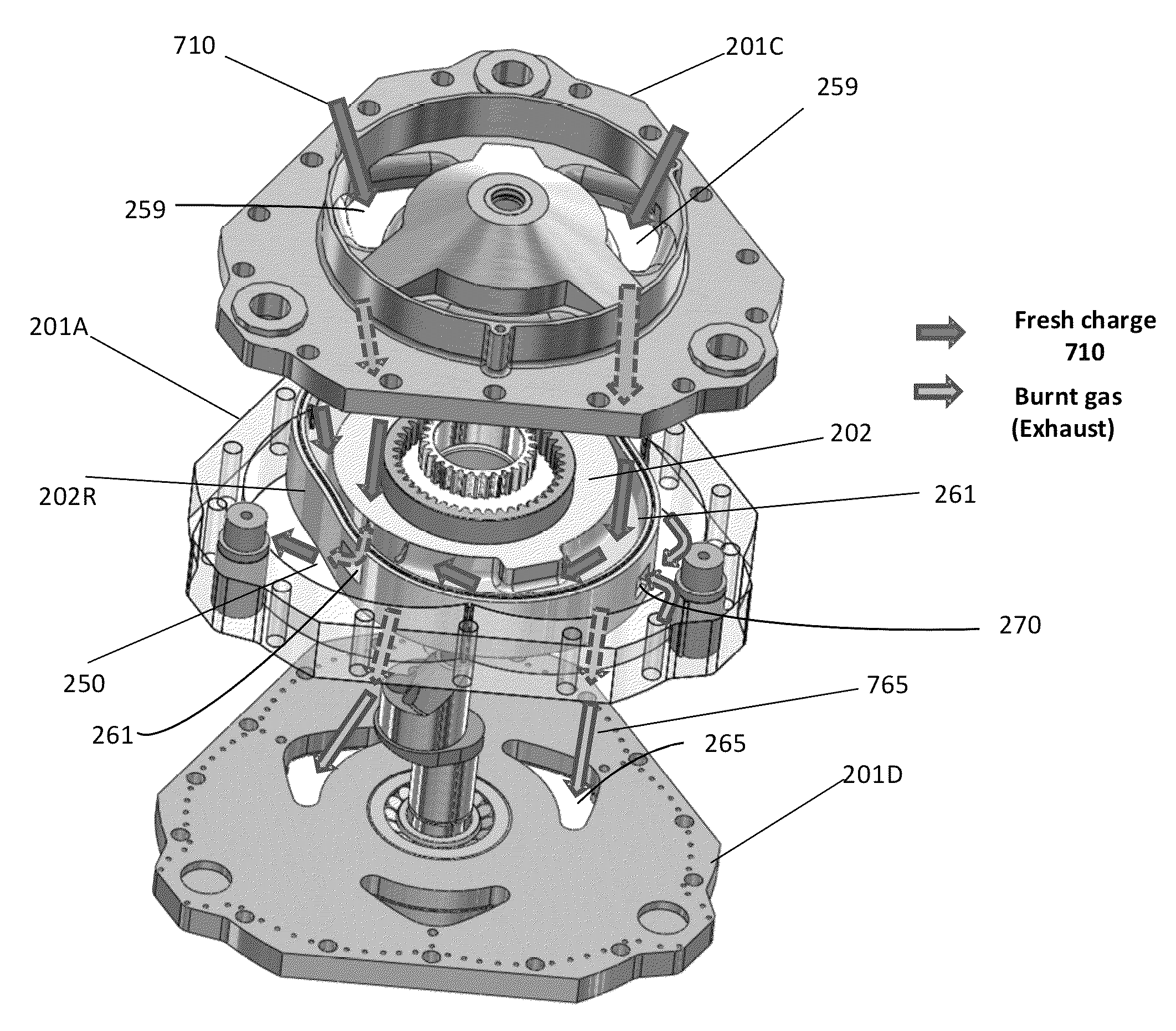

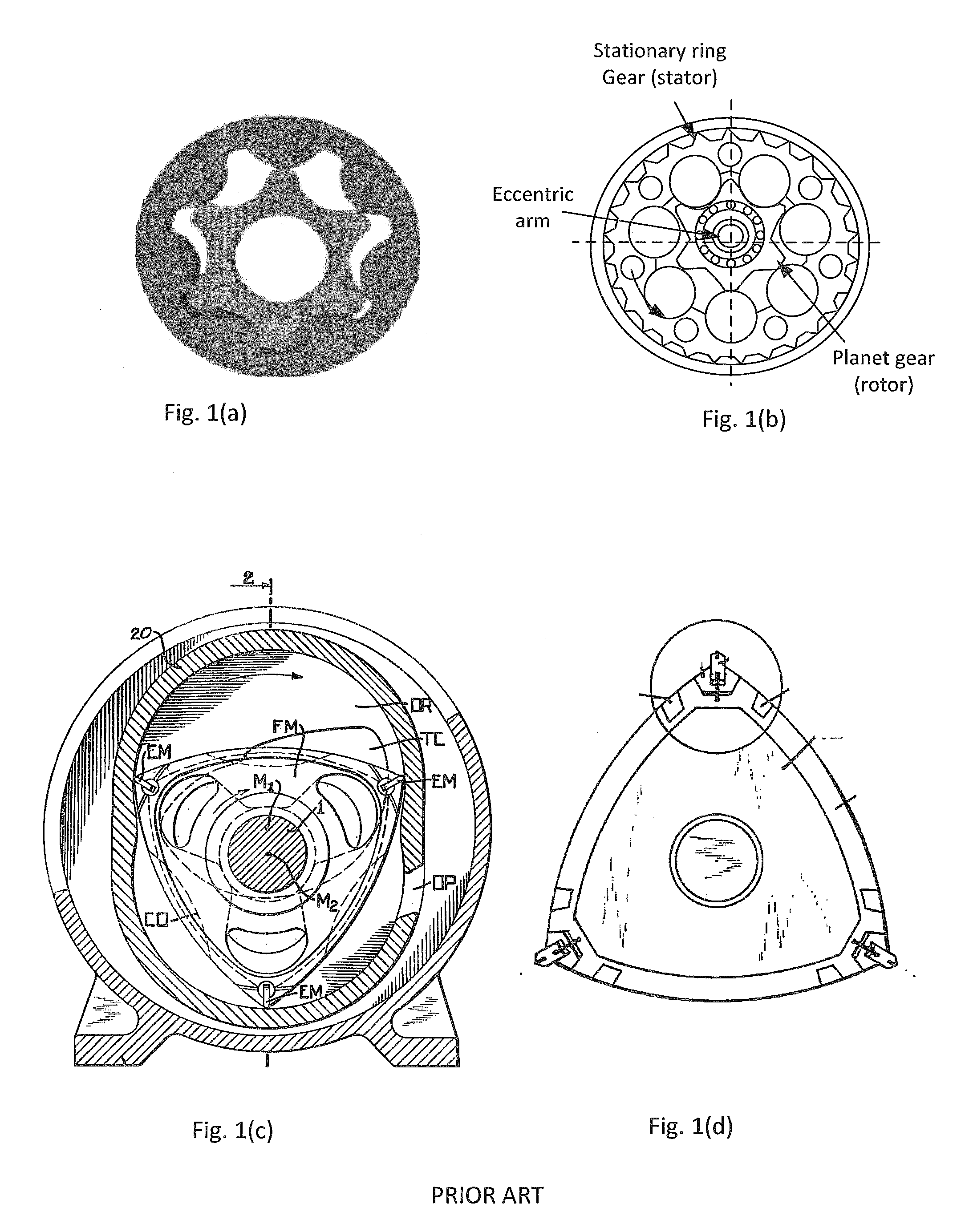

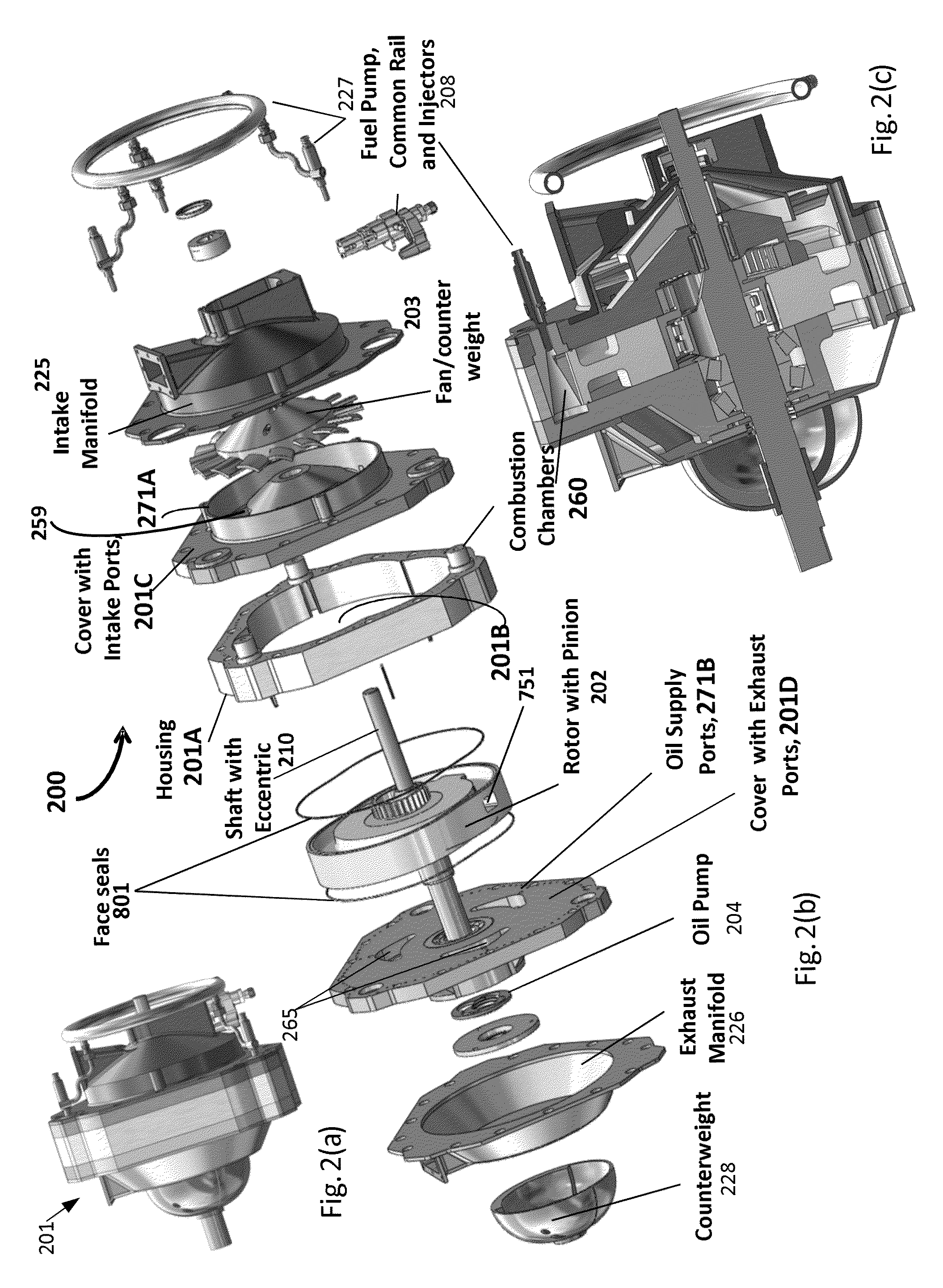

Cycloid rotor engine

ActiveUS8523546B2Internal combustion piston enginesEngine of arcuate-engagement typeRotary engineEngineering

Owner:LIQUIDPISTON INC

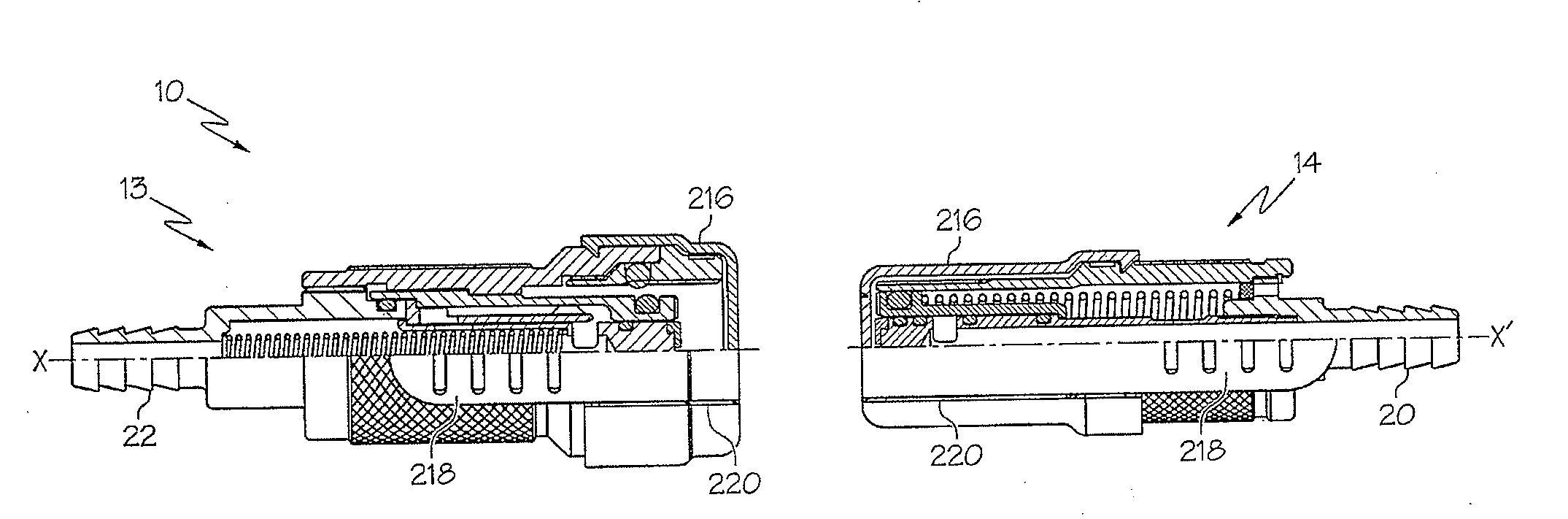

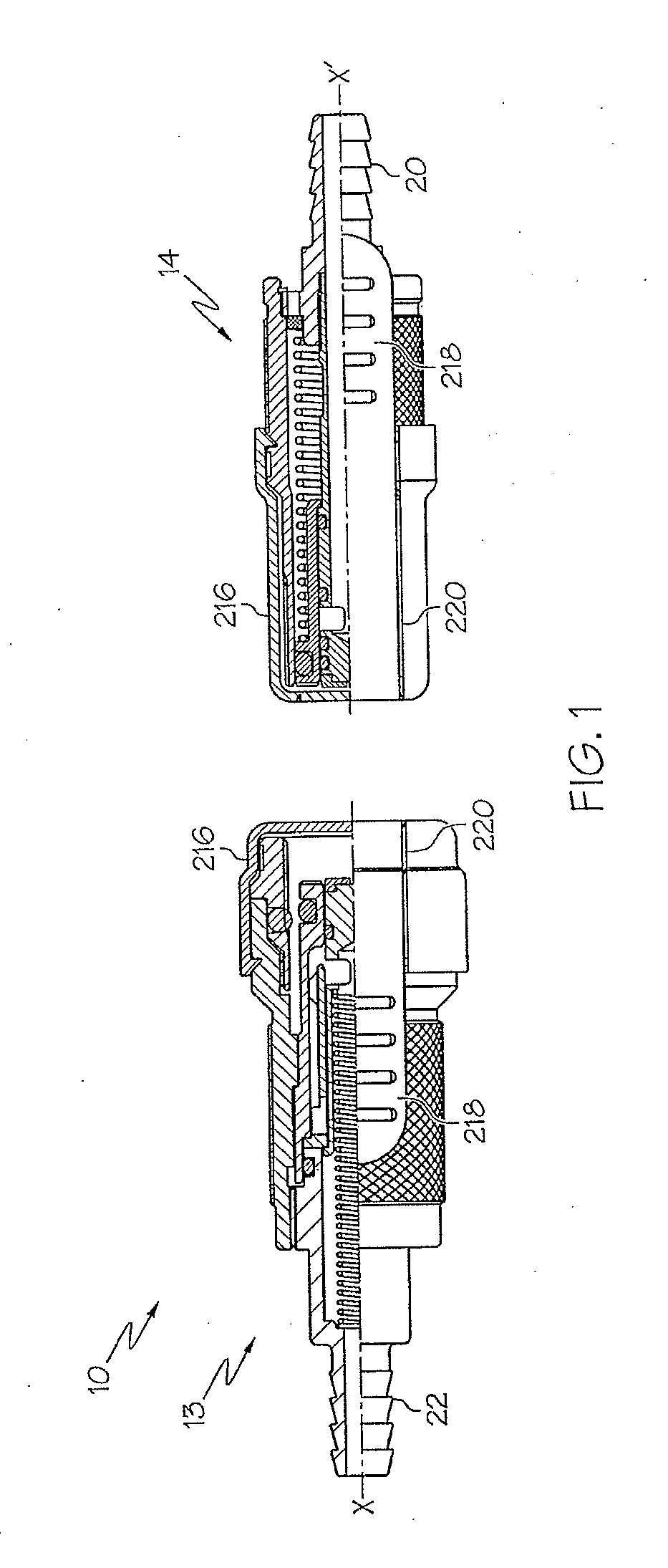

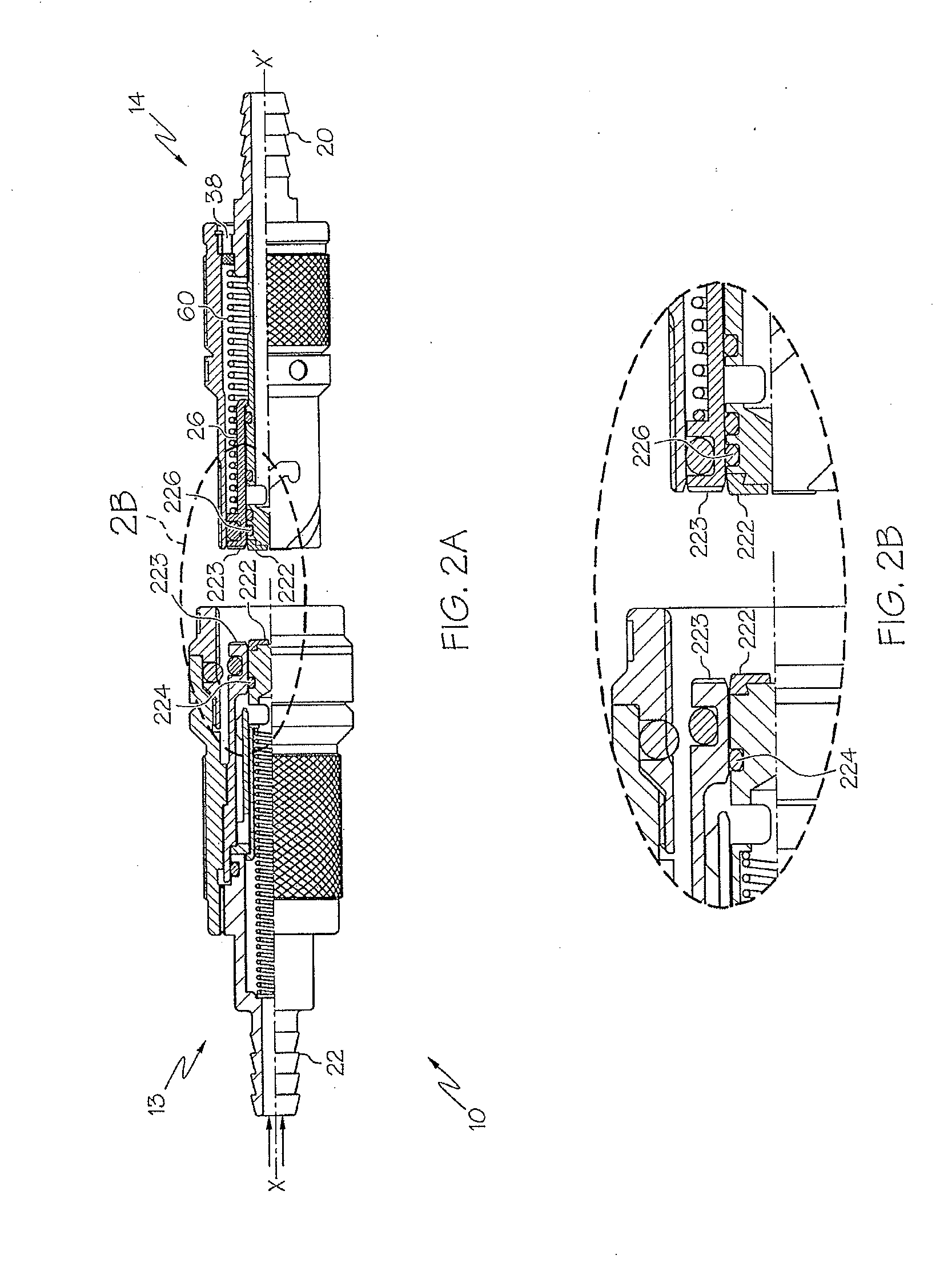

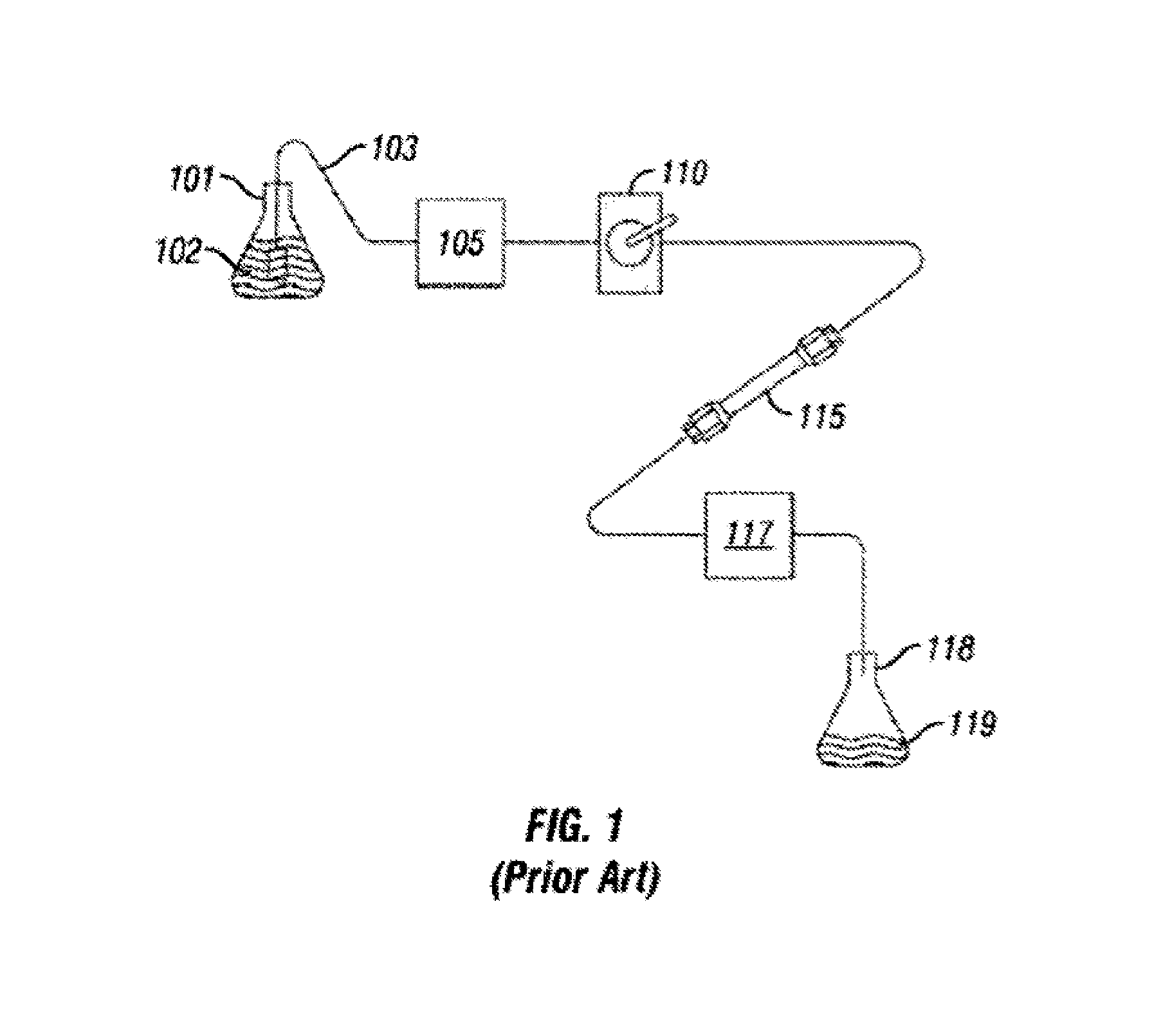

Chemical and biological clean air connector

A connector for use in a contaminated environment is provided. The connector includes first and second couplers which are coupled together to produce a fluid path through the connector. Prior to coupling of the first and second couplers, the first and second couplers include plastic caps for minimizing the contaminants on the couplers. Elastomer face seals which can be contaminated are mated against one another compressing to expel contaminants and trapping contaminants between the elastomer face seals. The elastomer face seals are captured between a pair of O-rings. Parts of the elastomer face seals are flushed with fluid as the connector is coupled to further reduce contamination. All internal passages and the elastomer face seals are treated with an antimicrobial compound. The connector vents to the atmosphere during engagement of the first and second couplers such that the connector can operate at a higher pressure with reduced engagement force.

Owner:AIR LOCK

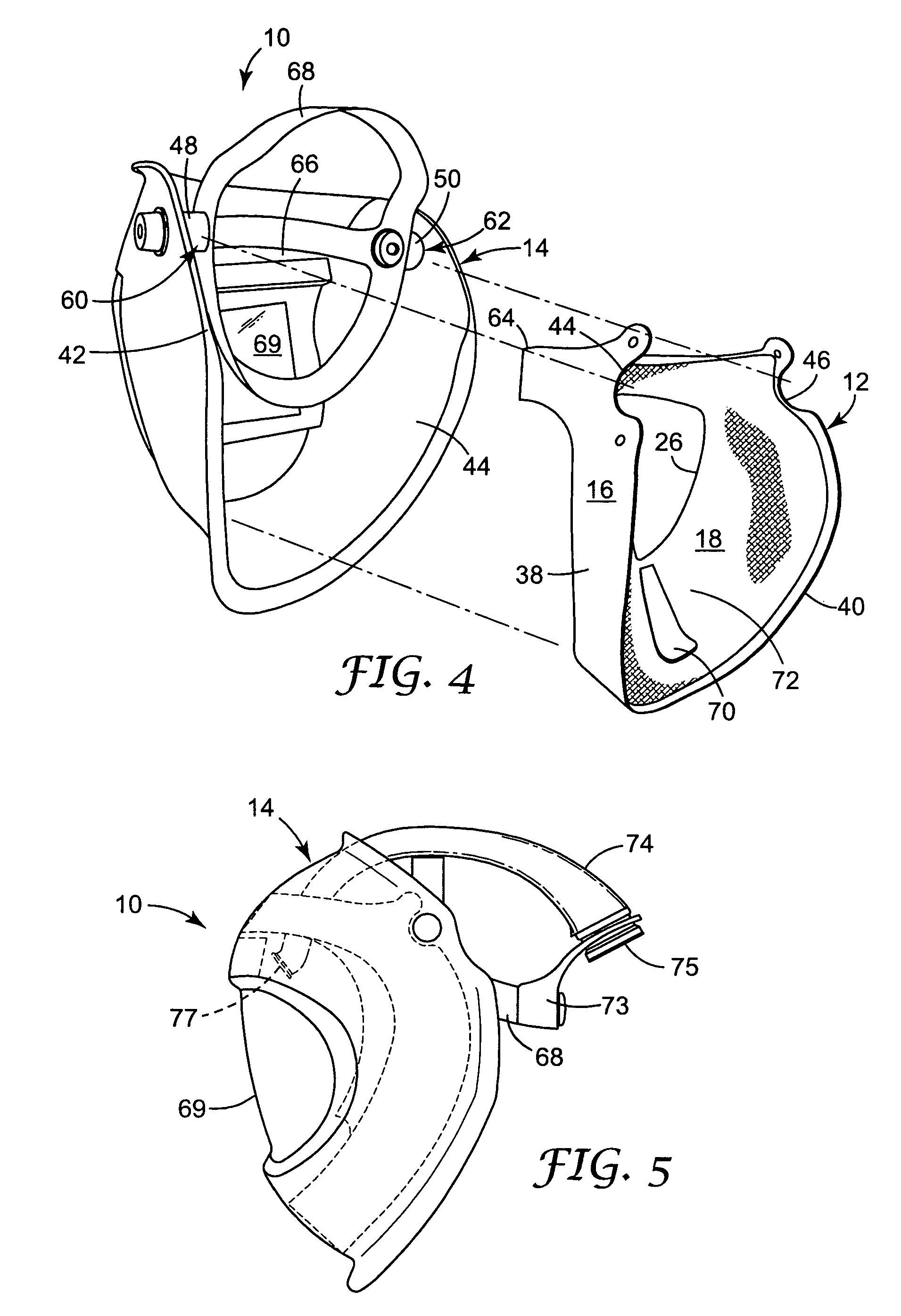

Frictionally engaged supplied air helmet face seal

InactiveUS20060101552A1Reduce the amount requiredReduce usageBreathing masksEye treatmentAdhesiveFace seal

A supplied air helmet 10 that has a visor 14, and a face seal 12 that includes a frame member 16 and a sealing member 18. The frame member 116 can be secured to the visor 14 by frictional engagement. The use of frictional engagement as opposed to pegs, adhesives, and hook and look type fasteners, may reduce the number of parts, may permit face seal installation and / or removal in a less onerous manner, and may reduce the opportunity for fastener failure.

Owner:3M INNOVATIVE PROPERTIES CO

PCD face seal for earth-boring bit

An earth-boring bit has a mechanical face seal assembly with PCD faces. The bit has a bearing shaft with a cone rotatably mounted on the bearing shaft. The seal locates between the bearing shaft and the cone for sealing lubricant therein. The seal includes at least one rigid seal ring having a cemented carbide body and an annular PCD face located on it. The mating face may also be of a PCD material. The cemented carbide body contains a binder that migrates into the PCD face while the PCD face is being formed. A binder-free region is leached on the surface of the PCD face.

Owner:BAKER HUGHES INC

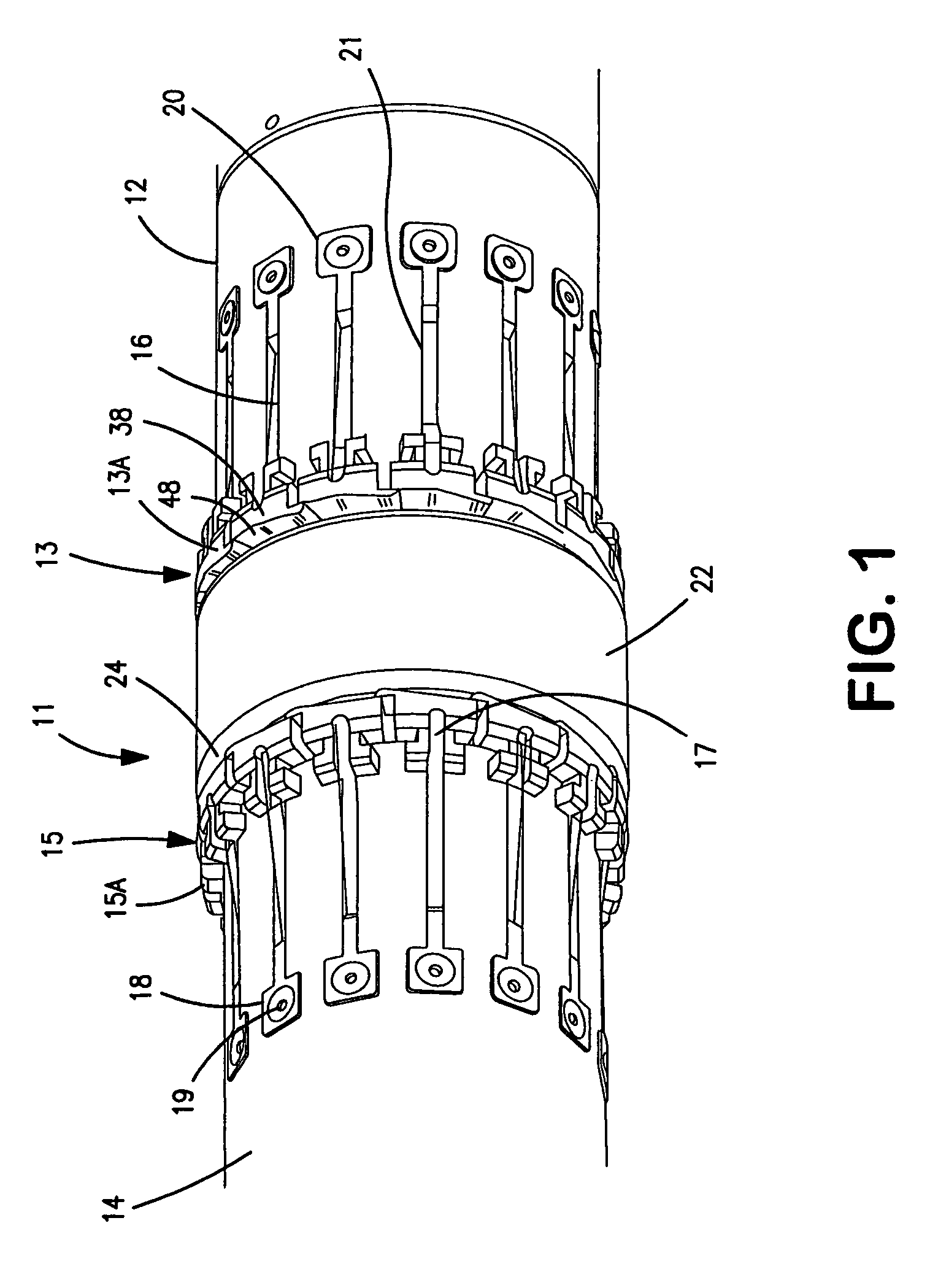

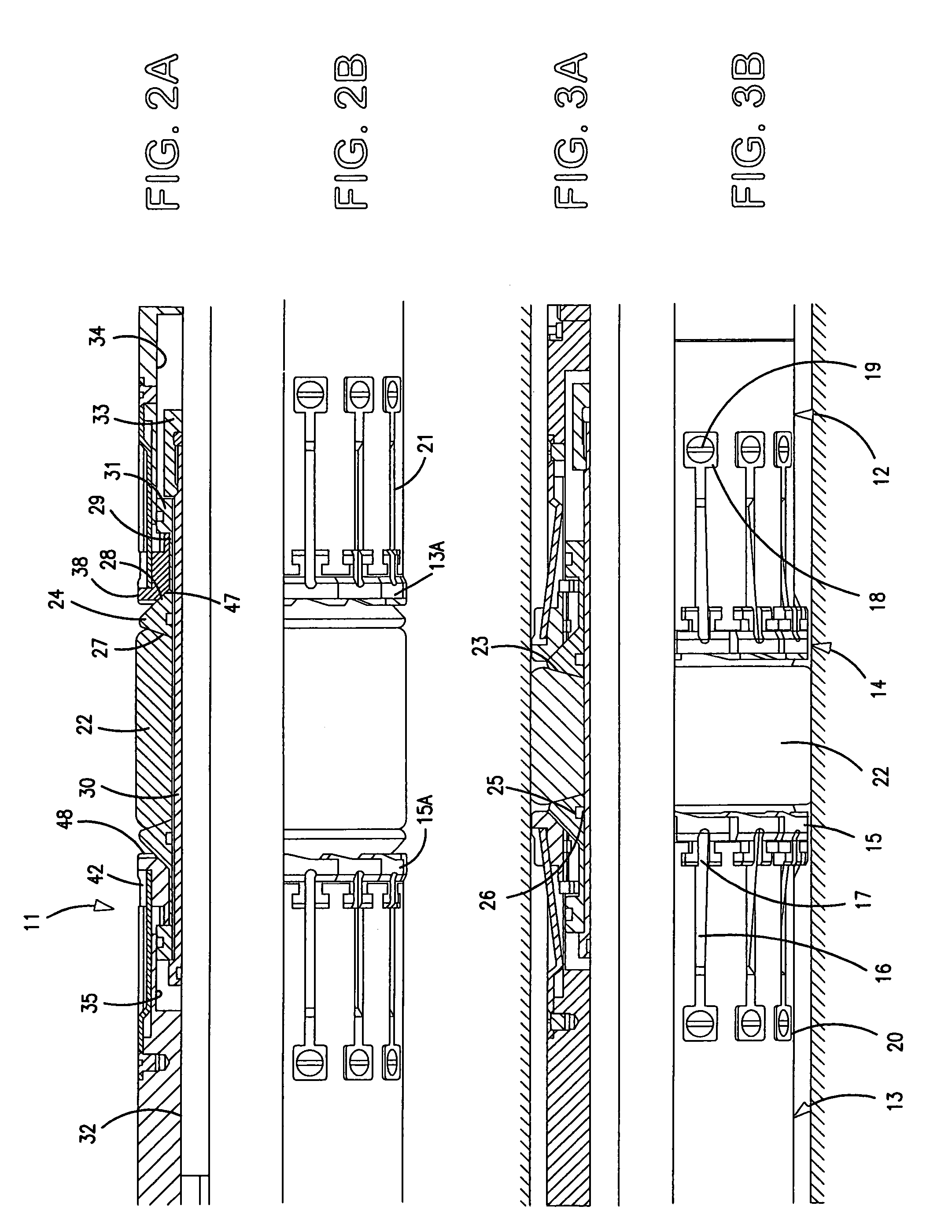

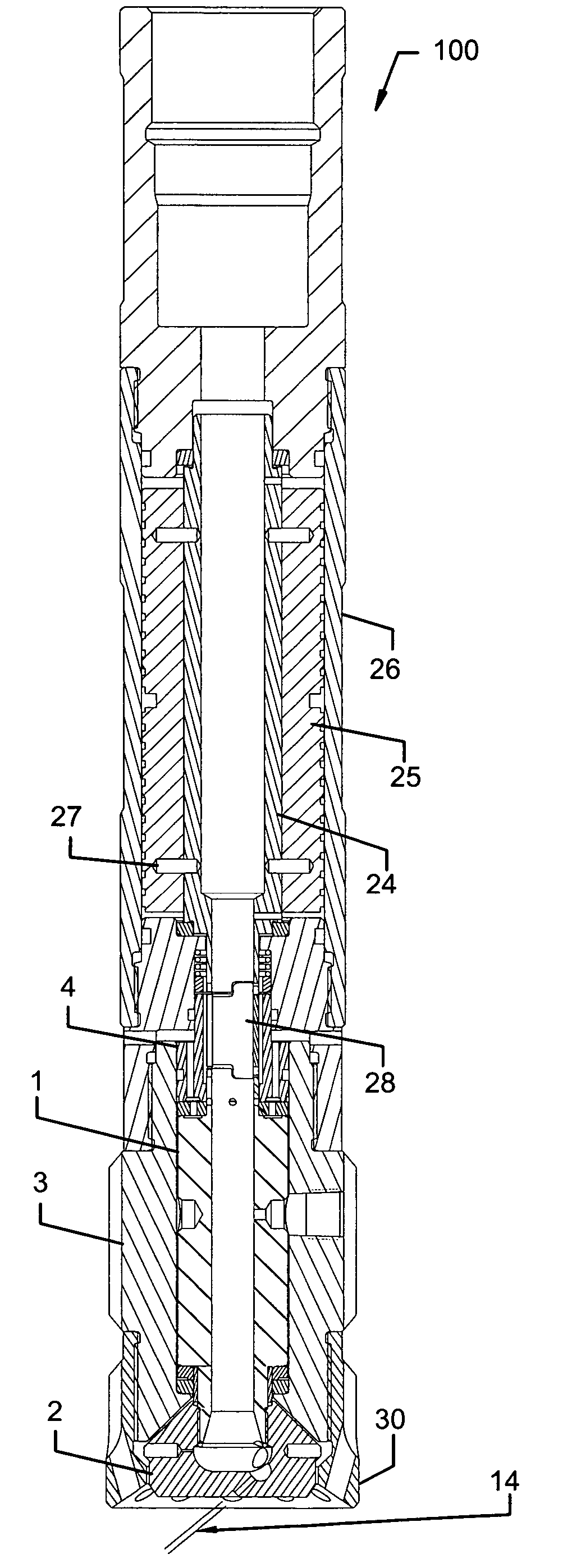

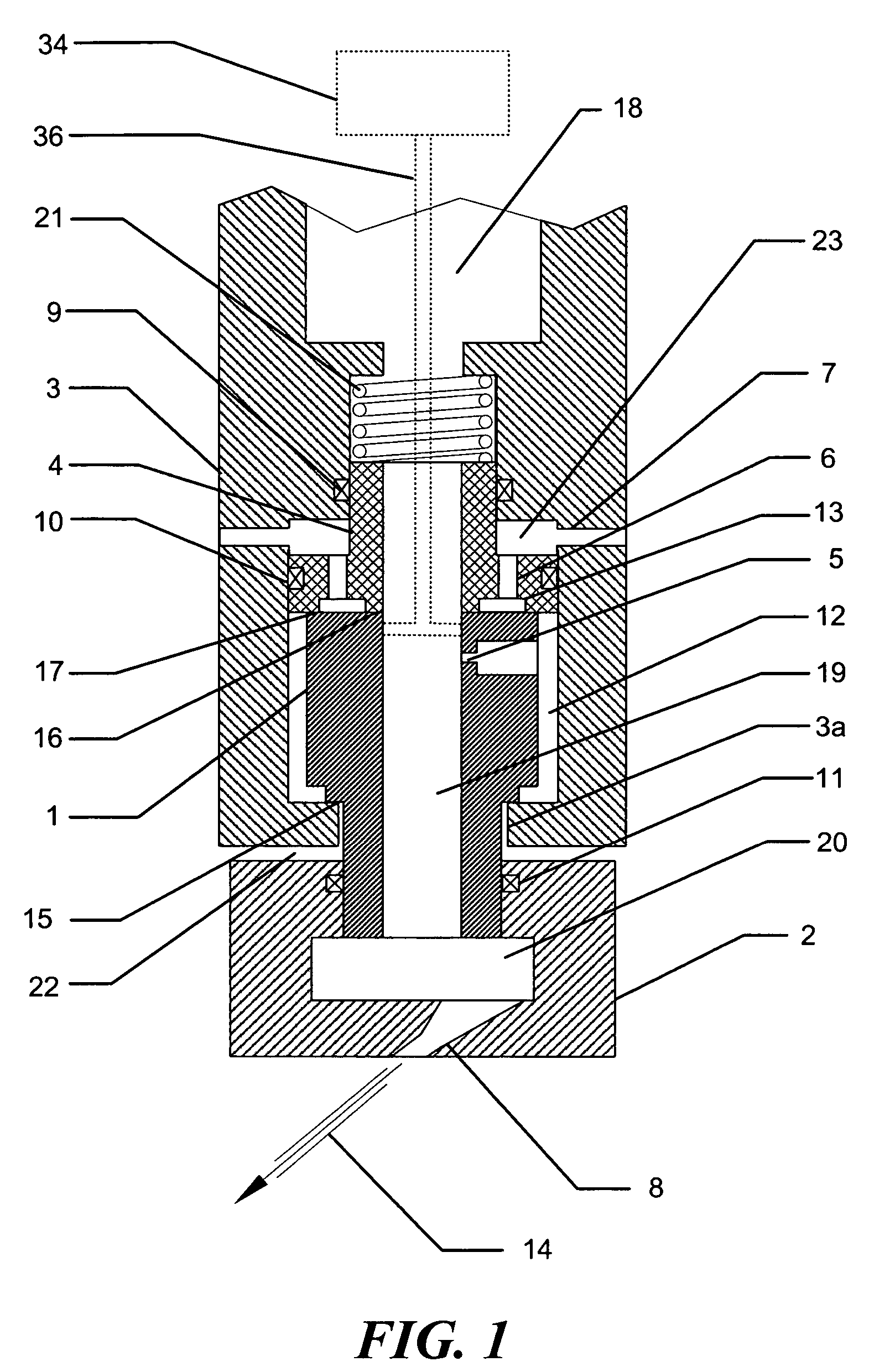

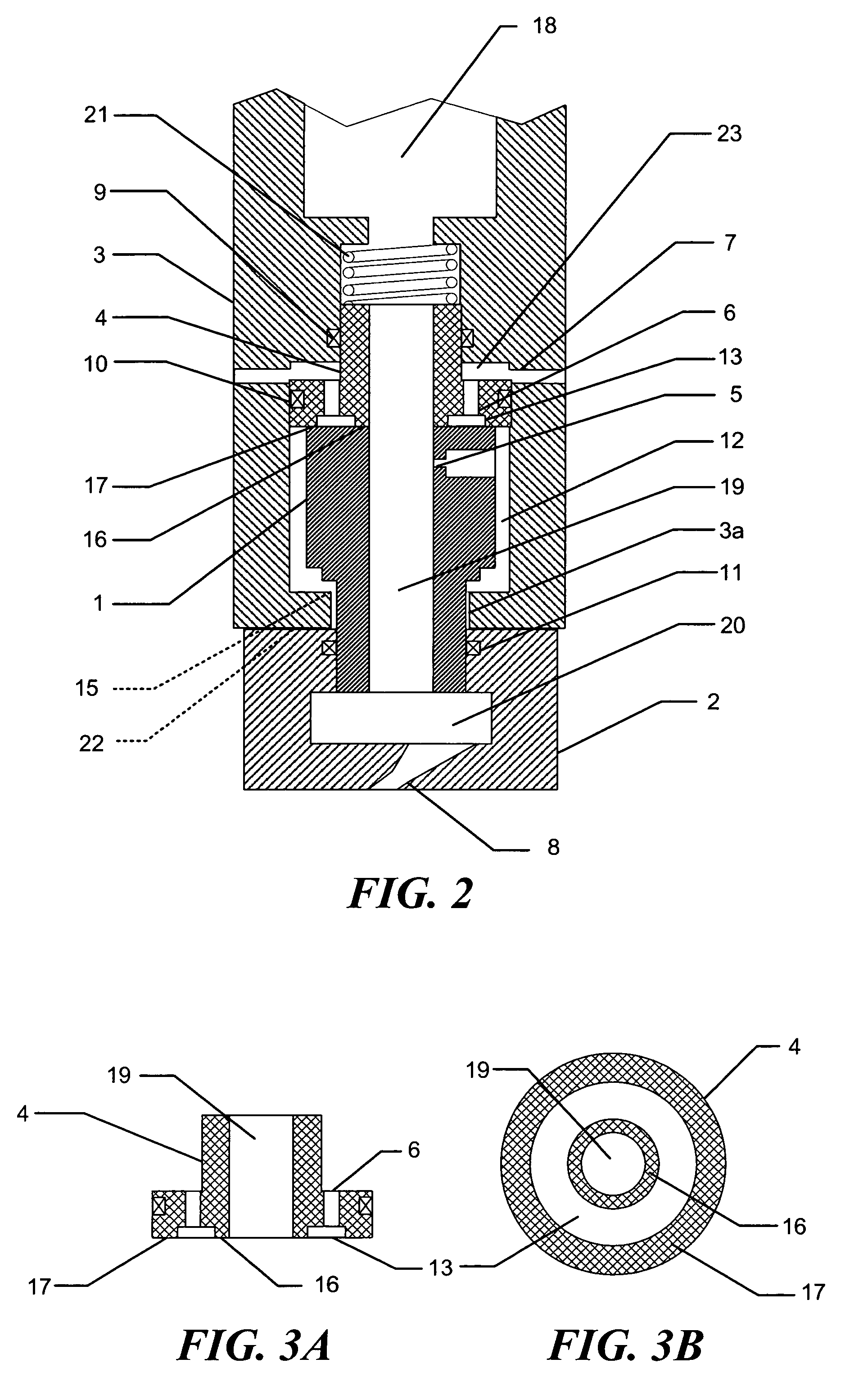

Low friction face sealed reaction turbine rotors

ActiveUS7201238B2Low starting torqueReduce torqueMovable spraying apparatusCleaning apparatusEngineeringPressure balance

Rotary jetting tool including a rotor with axially-opposed pressure-balanced mechanical face seals. Vented upper mechanical face seal enables the rotor to be operated with the relativity low starting torque achievable using reaction forces from offset jets energized with a pressurized fluid. When rotor is displaced axially due to set-down conditions, a pressure chamber exerts a pressure imbalance on the rotor, forcing the rotor to return to a normal operating position. Alternate structure to achieve low starting torque includes a volume disposed adjacent to a lower mechanical face seal, the volume being coupled in fluid communication with the pressurized fluid. Mechanical face seal surfaces are fabricated from ultra-hard materials, such as tungsten carbide, silicon carbide, and diamond. A gage ring designed to ensure the jets remove all of the material from the gage of the protective housing before the tool can advance can be incorporated.

Owner:WELLS FARGO BANK NAT ASSOC +1

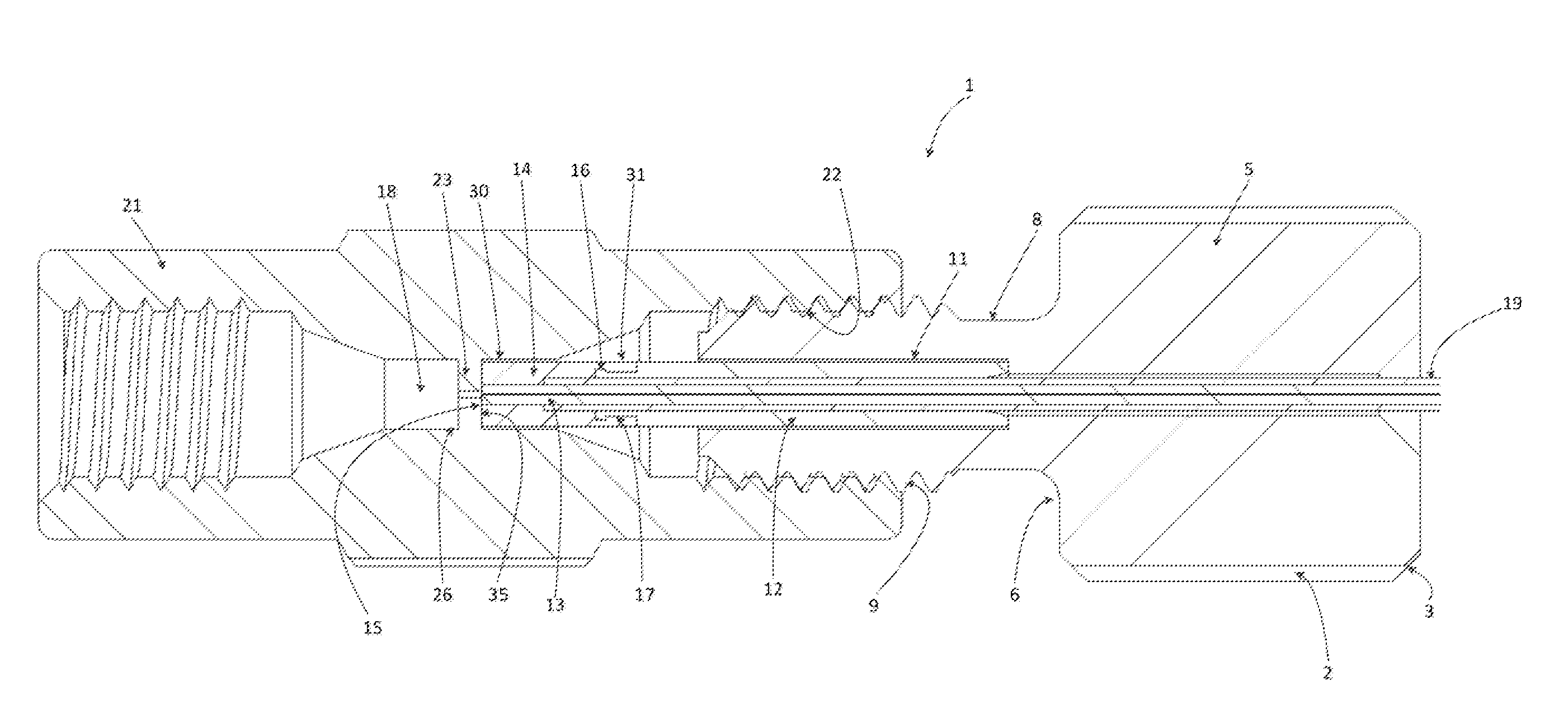

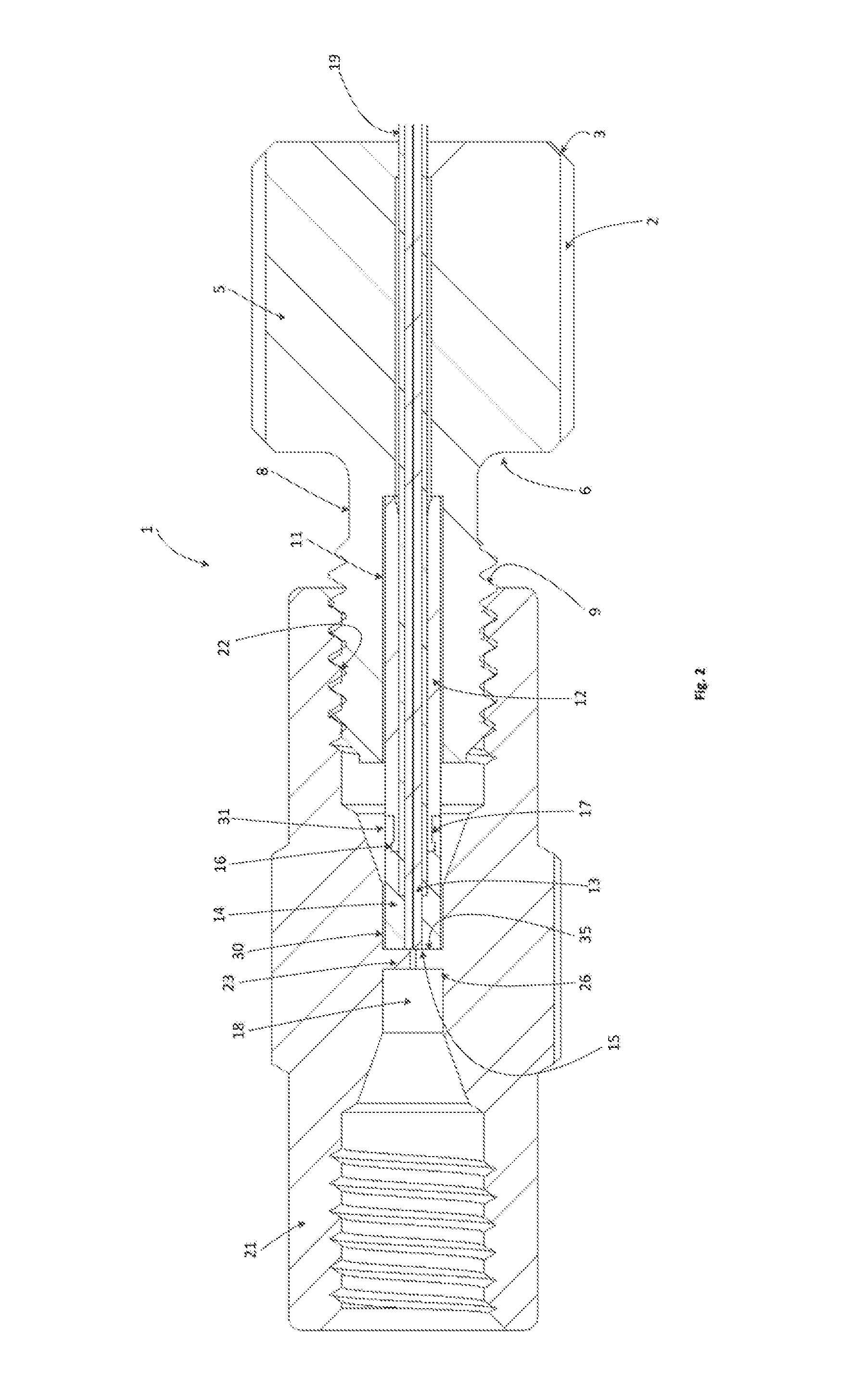

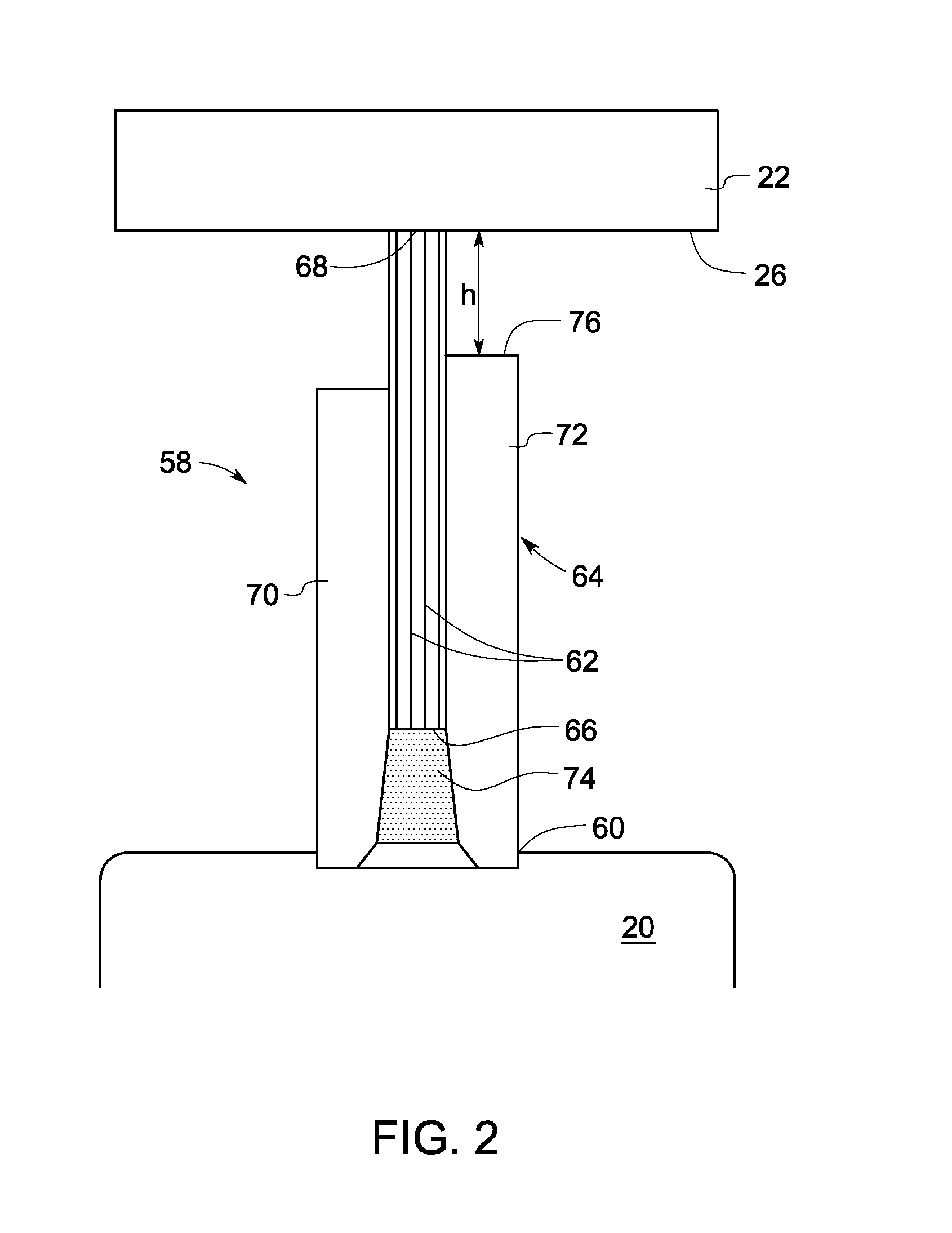

Face-Sealing Fluidic Connection System

ActiveUS20160116088A1Minimal torqueQuickly and easily and disconnectedComponent separationJoints with sealing surfacesInterference fitEngineering

A tubing or fitting assembly has an inner tube layer, an outer tube layer, a sleeve, a tip portion, and can have a nut. Each of the nut, sleeve, inner and outer tubing layers, and tip portion have a passageway therethrough, with at least the passageways in the sleeve, tip portion, outer tube layer, and nut adapted to allow the inner tube layer to pass therethrough or extend over the inner layer. The tip portion can be molded over an end portion of the inner tube layer and also over a portion of the sleeve. The sleeve may include a retention feature in the form of a lip which extends into the tip portion, and also a narrower portion so that the tip portion and sleeve remain coupled together. The inner and outer tubing layers can also be retained by an interference fit. The ends of the tip portion and inner layer together define a substantially flat surface which can form a seal in a flat-bottomed port of a component such as may be found in any one of a number of components in an analytical instrument system, including for example a liquid chromatography system. The nut, tube, ferrule, and transfer tube or liner tube may comprise biocompatible materials. In addition, the nut may have a slot, such as a slot adapted to allow the tube and the nut to be easily and quickly separated or to allow a portion of the tube to be easily and quickly inserted in the nut.

Owner:IDEX HEALTH & SCI

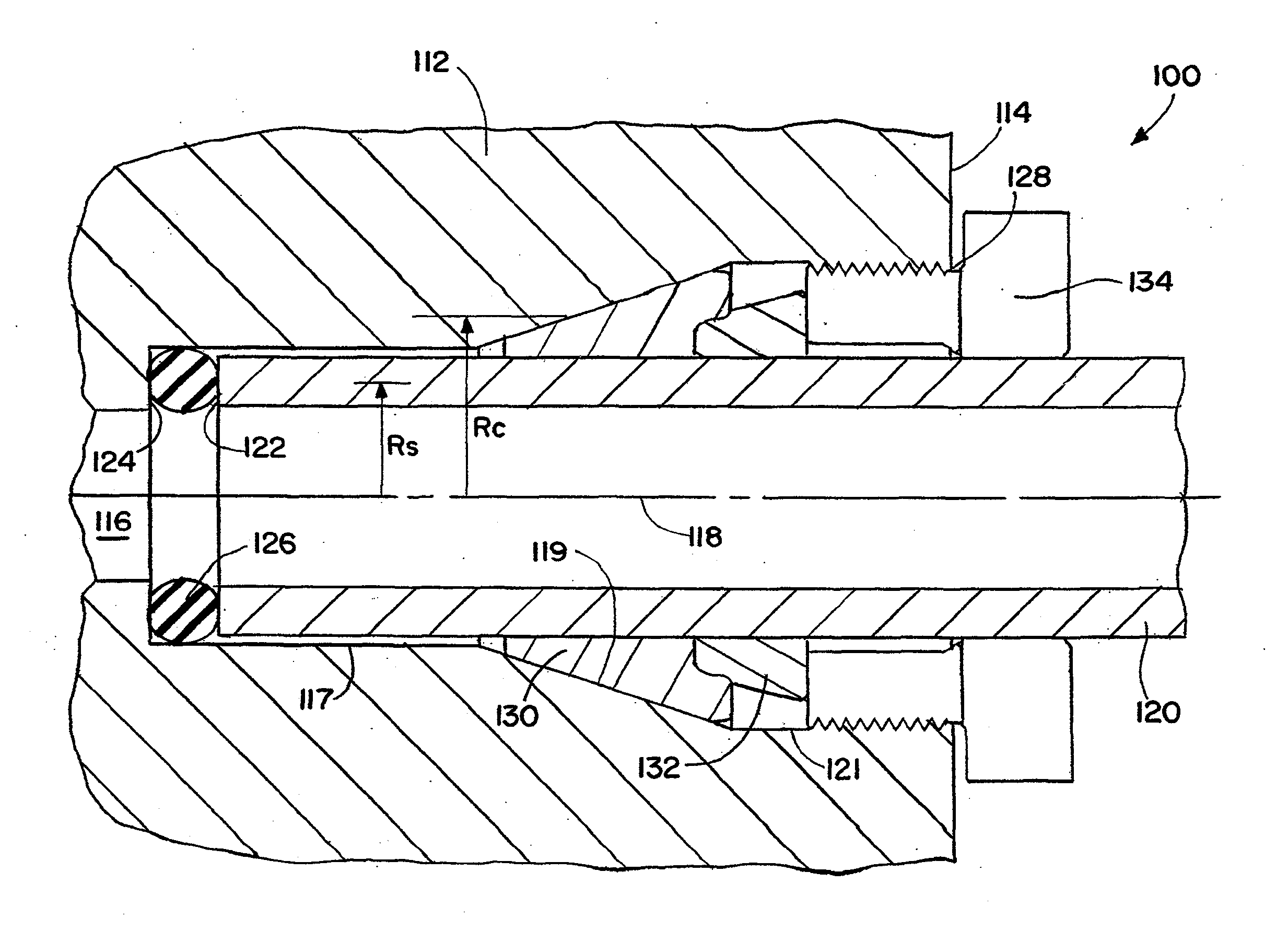

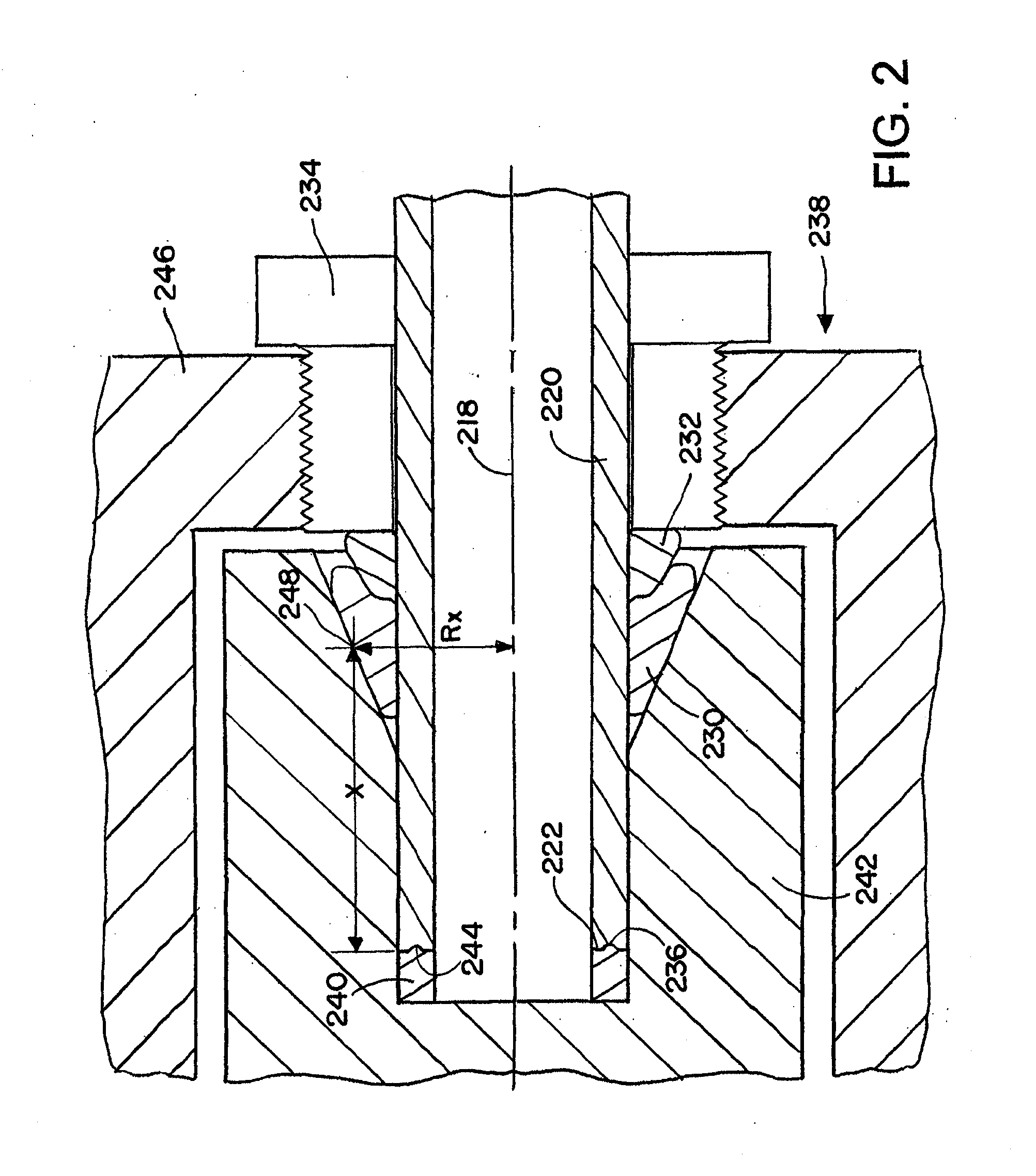

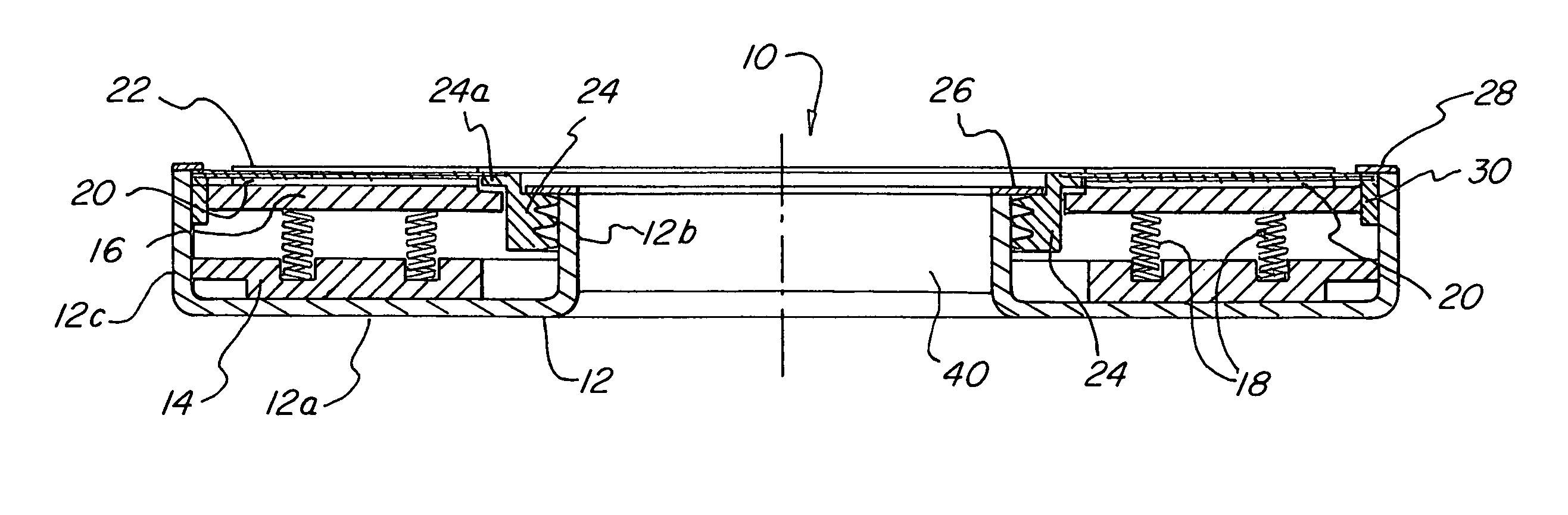

Tube and pipe end cartridge seal

InactiveUS20130043677A1Inexpensively and easily preparedMinimize forceFluid pressure sealed jointsJoints with sealing surfacesEngineeringHigh pressure

Described is a sealing system for use at high pressure. End-face seals minimize the sealing radius and therefore allow various fittings—including known ferrule fittings—to be used in high-pressure systems. End-face seals at such high pressure may require smooth surfaces. In order to reduce cost, an end-face preparation tool forges a dimple into the end face to mechanically deform and smooth the surface.

Owner:PARKER HANNIFIN CORP

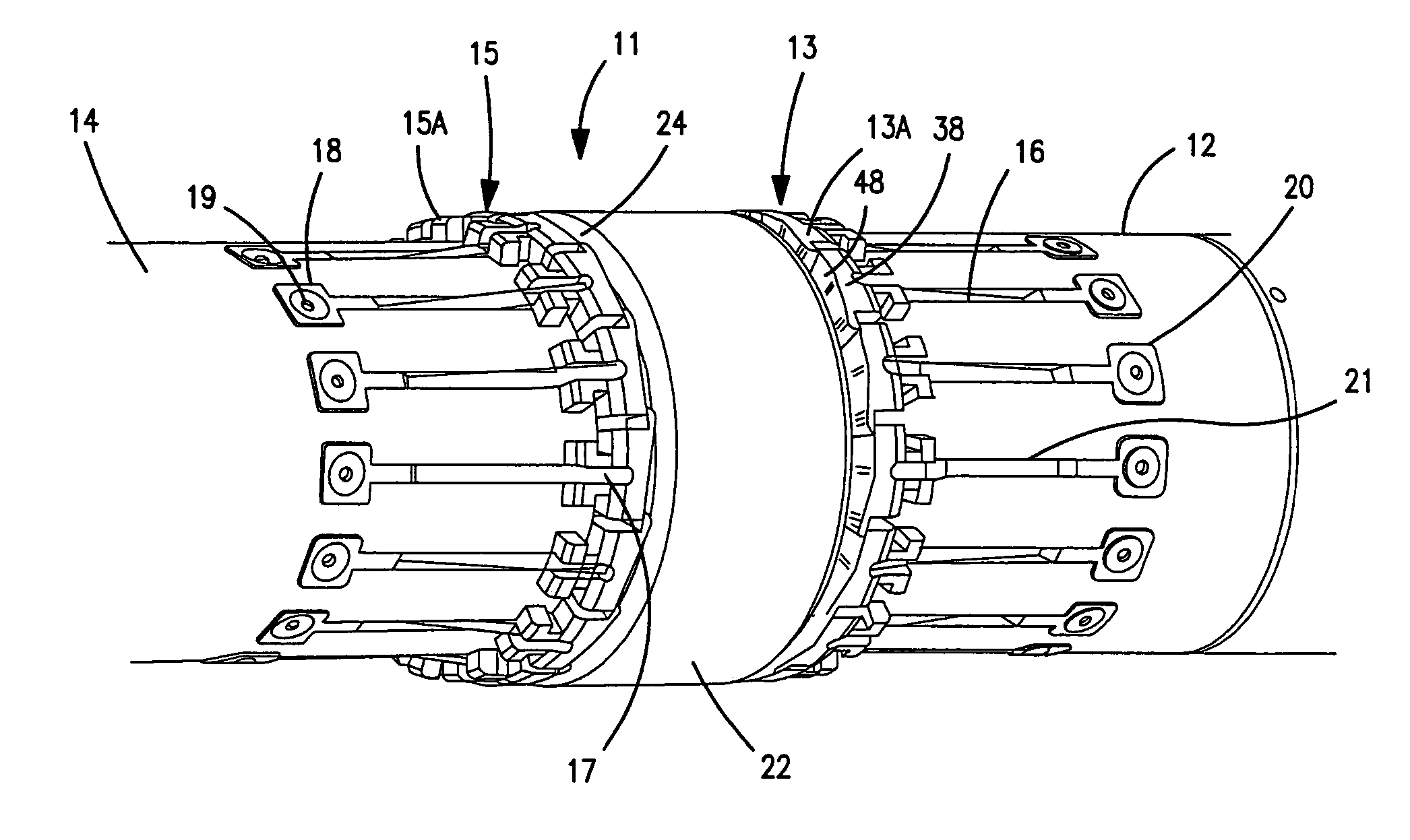

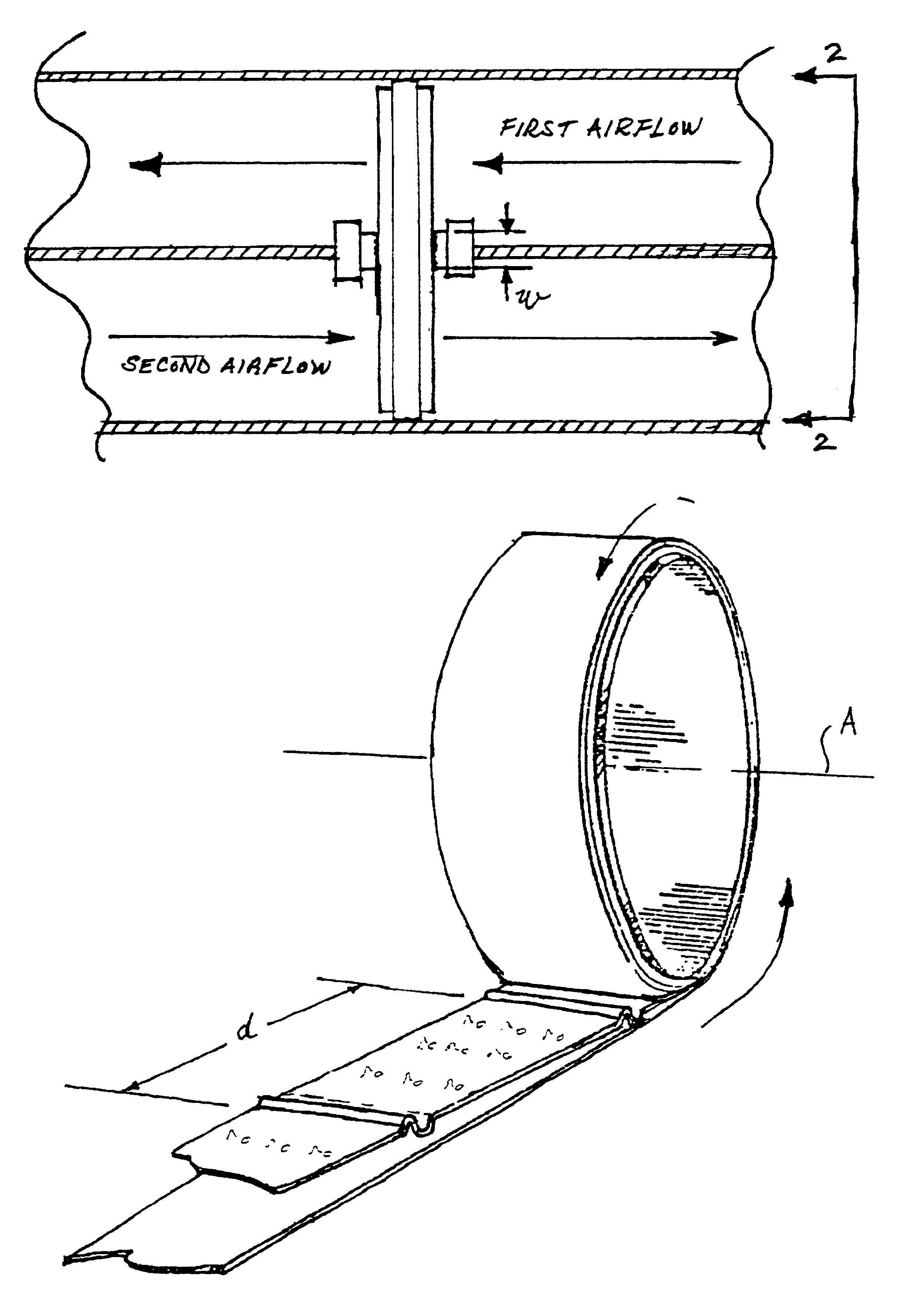

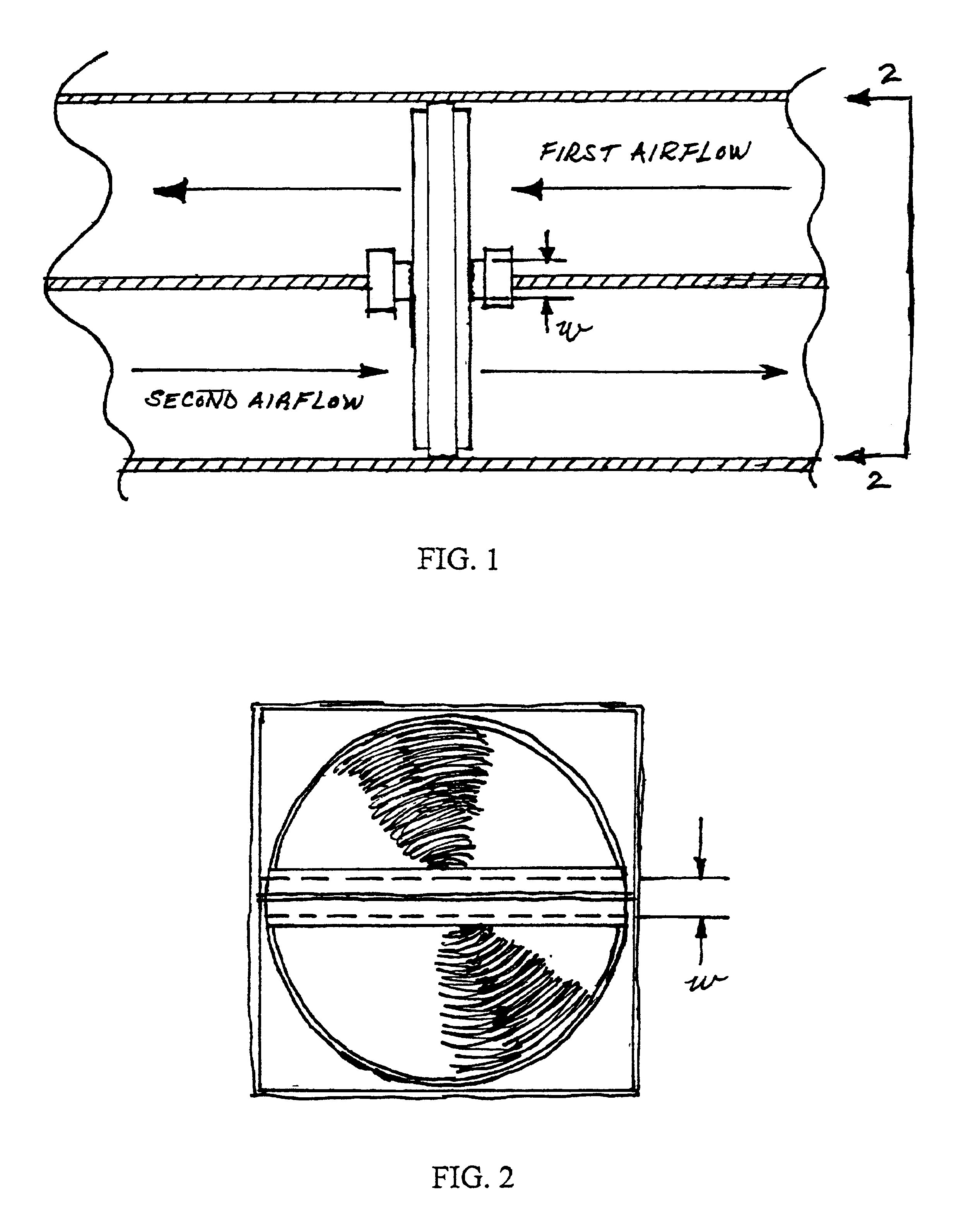

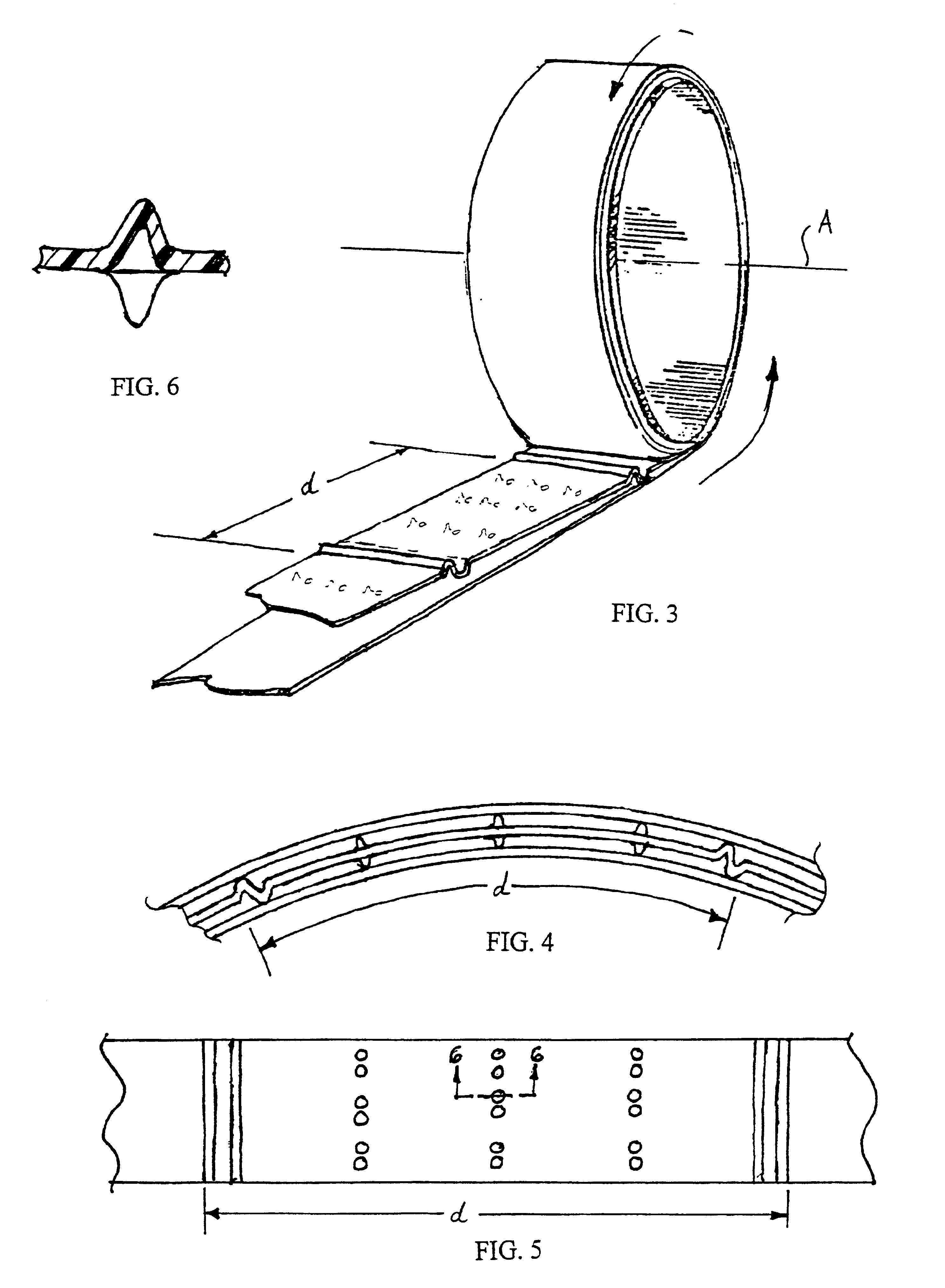

Embossed regenerator matrix for heat exchanger

InactiveUS6892795B1Uniform heightImprove heat exchange efficiencyAir treatment detailsCombustion processPlate heat exchangerCounter flow

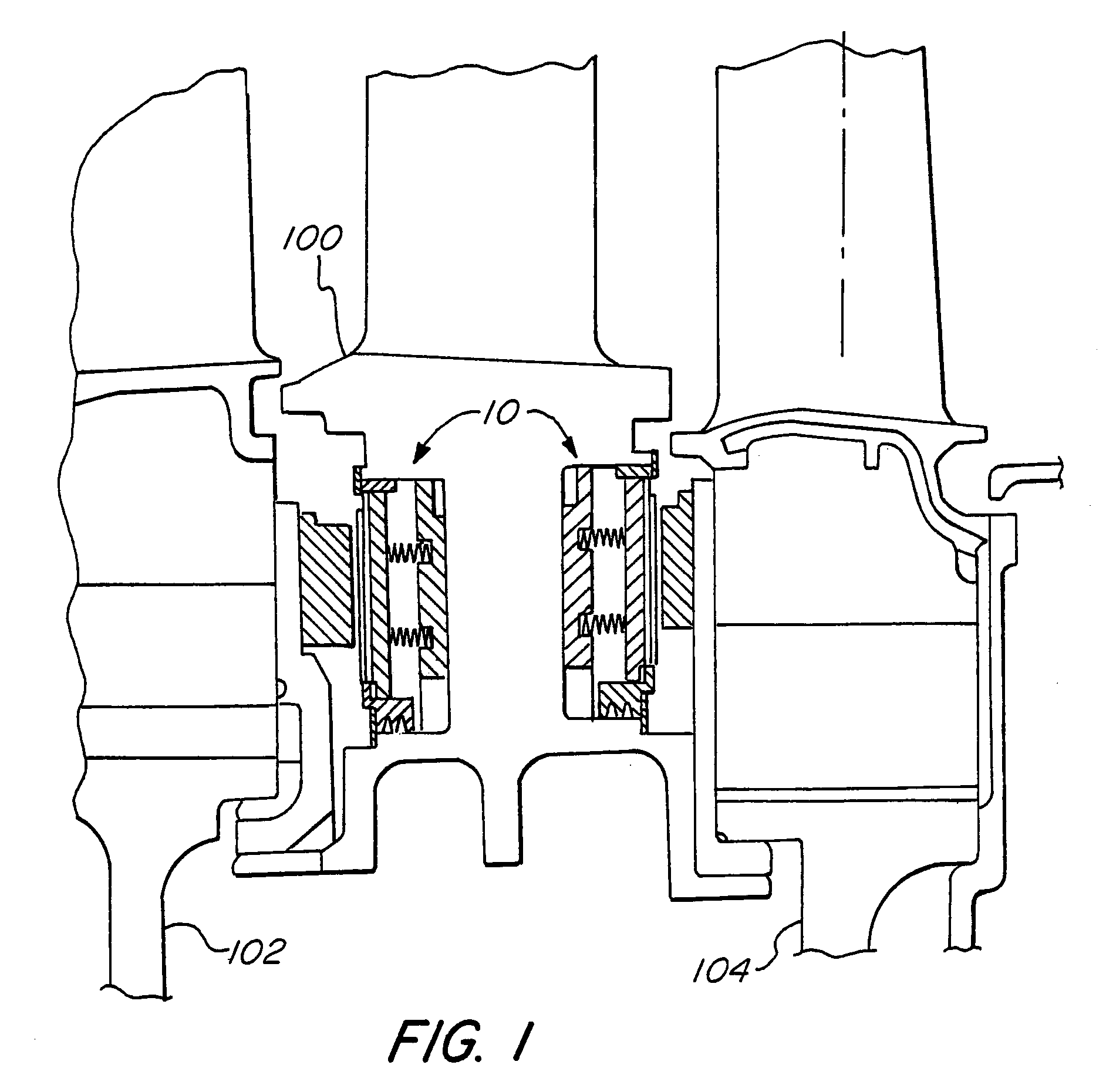

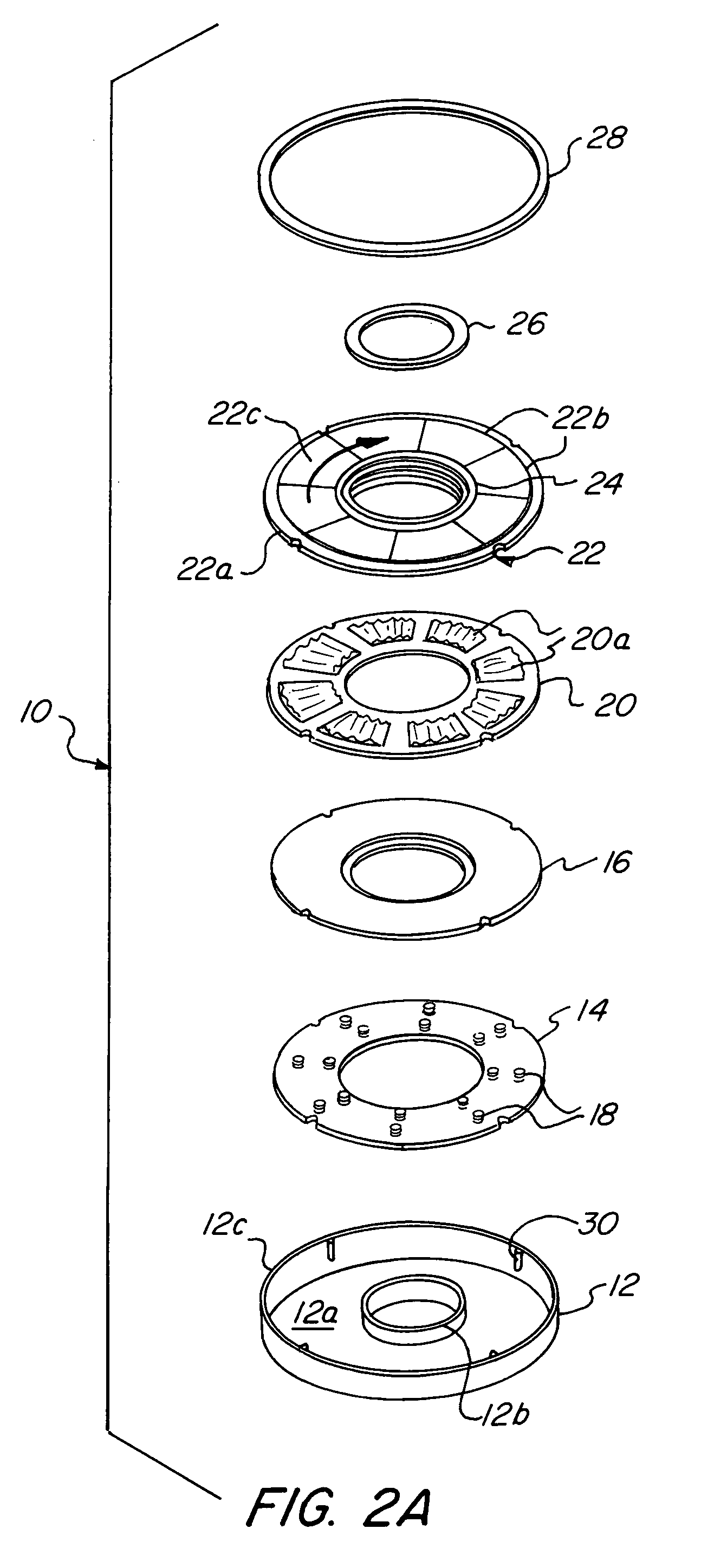

A regenerator matrix for effecting the transfer of heat between two counter-flowing air streams separated in part by face seals. The matrix includes strips of material wound about an axis so as to provide a plurality of layers. The matrix also includes embossments located on at least some of the layers and providing interlayer spaces between at least some of the layers, such that the interlayer spaces extend through the matrix substantially parallel to the axis. The embossments have a uniform height and include primary and secondary embossments. The primary embossments extend substantially parallel to the axis to divide the interlayer spaces into gas passageways and substantially resist circumferential gas leakage between the gas passageways. The primary embossments are also for aligning with the face seals to prevent circumferential gas leakage between the two counter-flowing air streams, and are successively spaced so that at most two successive primary embossments will align with the face seals. The secondary embossments maintain the interlayer spaces at a substantially uniform spacing between the primary embossments, yet allow circumferential gas flow within the gas passageways.

Owner:AIRXCHANGE

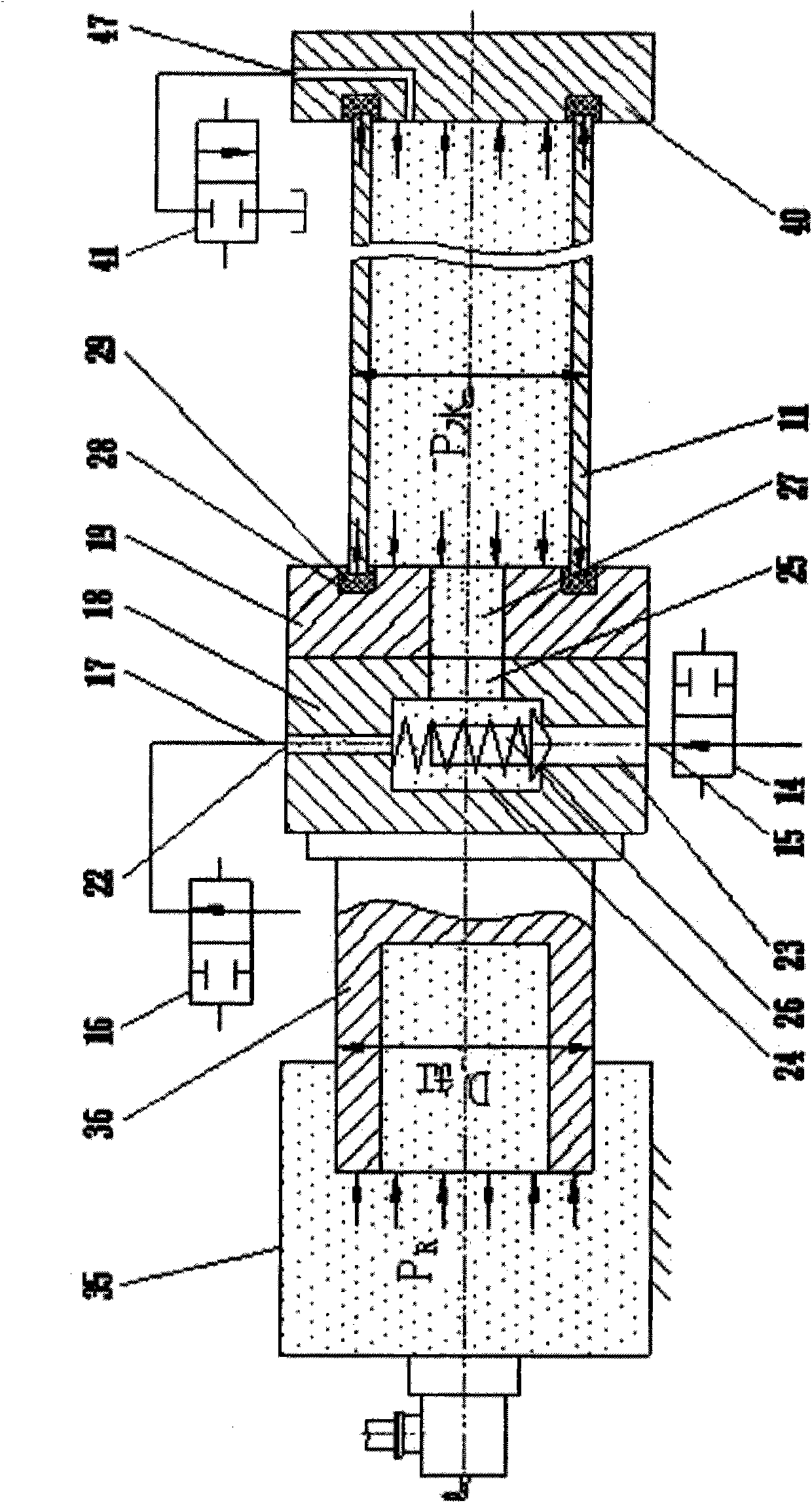

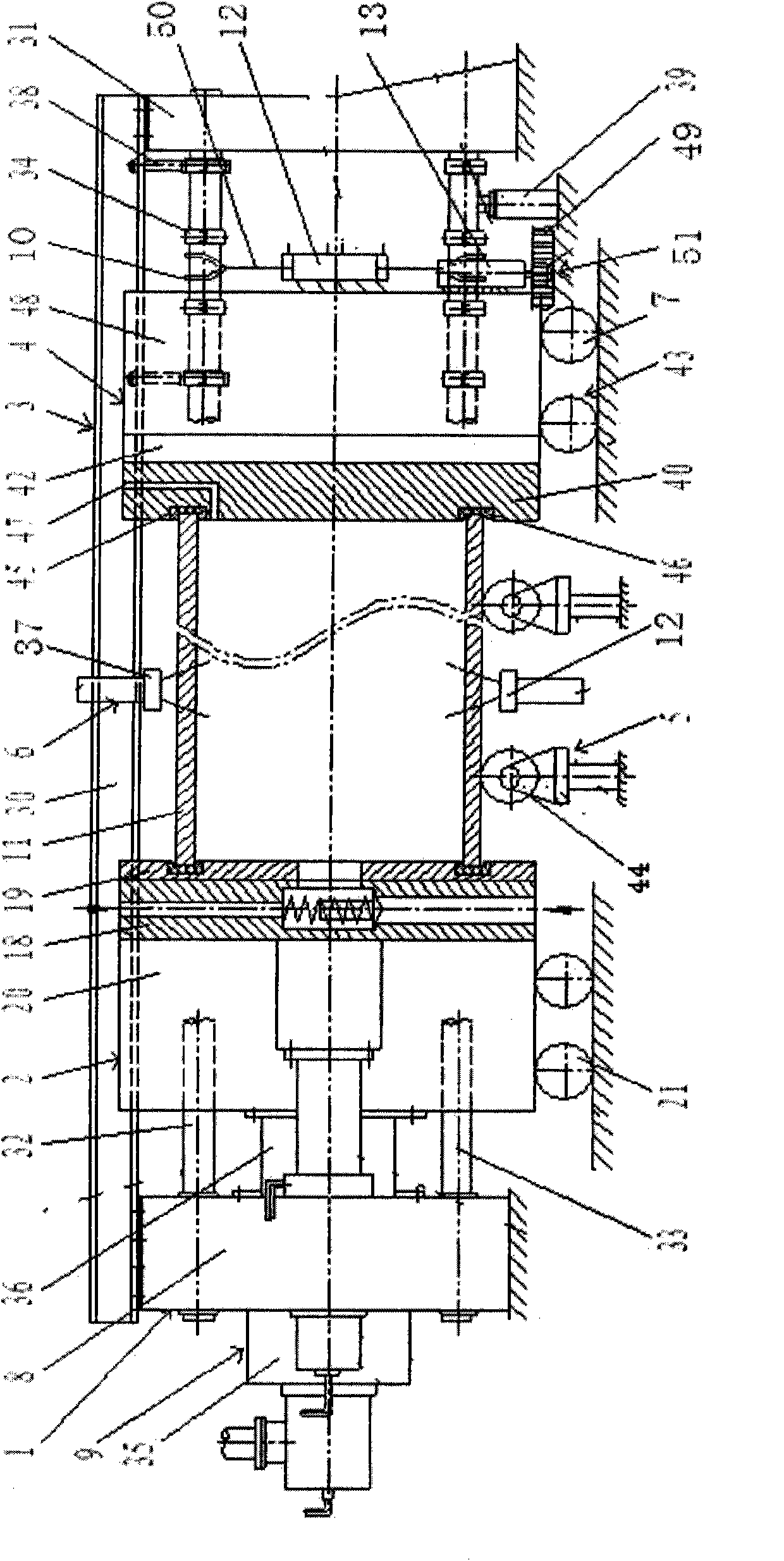

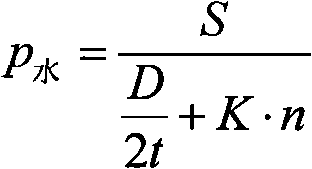

Method for detecting hydrostatic pressure of thin-wall steel pipe under end face seal condition

InactiveCN102042935AEasy to calculateCalculations are reliableMaterial strength using tensile/compressive forcesPore water pressureInlet valve

The invention relates to a method for detecting the hydrostatic pressure of a thin-wall steel pipe under the end face seal condition. Used equipment is an end face seal steel pipe hydrostatic pressure testing machine which comprises a testing machine body, a hydraulic system, a water pressure system and an electric control system. The method for detecting the hydrostatic pressure of the thin-wall steel pipe under the end face seal condition comprises the following steps of: 1) feeding the pipe and pre-clamping, namely respectively sealing the two pipe orifices of the pressure test thin-wall steel pipe by using two seal flat gaskets on a main pressure test head body and an auxiliary pressure test head body; 2) filling water, namely filling low-pressure water into the pressure test thin-wall steel pipe, exhausting, and closing a low-pressure water inlet valve, an exhaust port and a pressure relief port; 3) pressurizing, namely supplementing the water to the pressure test thin-wall steel pipe for pressurizing, pressurizing a main hydraulic cylinder synchronously, and determining a test pressure value according to a calculation formula; 4) stabilizing pressure, namely after the pressure of the water in the pressure test thin-wall steel pipe reaches a specified test pressure value, stabilizing the pressure until time specified by the test is up; and 5) relieving the pressure and discharging the water and the pipe. The detection method overcomes the defects of the conventional pipe making specifications, and the calculation process is simple, convenient and reliable.

Owner:马利芳

Aspirating face seal, and a related method thereof

An aspirating face seal includes a primary seal, a secondary seal, and a biasing device. The primary seal includes a first seal component and a second seal component. The first seal component is configured to be coupled to a rotor and rotatable with the rotor. The secondary seal includes a plurality of flexible elements and configured to be disposed between the second seal component and a stator housing. A biasing device is coupled to the second seal component such that the second seal component is biased along an axial direction away from the first seal component during a non-operating condition.

Owner:GENERAL ELECTRIC CO

Hydrodynamic foil face seal

A foil thrust bearing forms the primary rotating interface for a film riding face seal. This face seal includes a spring system that will allow the entire assembly to translate axially relative to a static attachment. The complete assembly will form a hybrid foil / film riding face seal that shows much promise at being sufficiently flexible to enable operation in a gas turbine engine. The seal includes a flexible top plate having a non-flat surface under its working conditions, and a spring support system to allow the top plate to accommodate axial excursions and out-of-flat distortions.

Owner:R & D DYNAMICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com