Frictionally engaged supplied air helmet face seal

a supplied air and face seal technology, applied in the direction of hats, breathing protection, protective garments, etc., can solve the problems of delamination of fasteners and cumbersome replacement process of face seals, and achieve the effect of reducing the amount of contaminants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In describing preferred embodiments of the invention, specific terminology is used for the sake of clarity. The invention, however, is not intended to be limited to the specific terms so selected, and it is to be understood that each term so selected includes all technical equivalents that operate similarly.

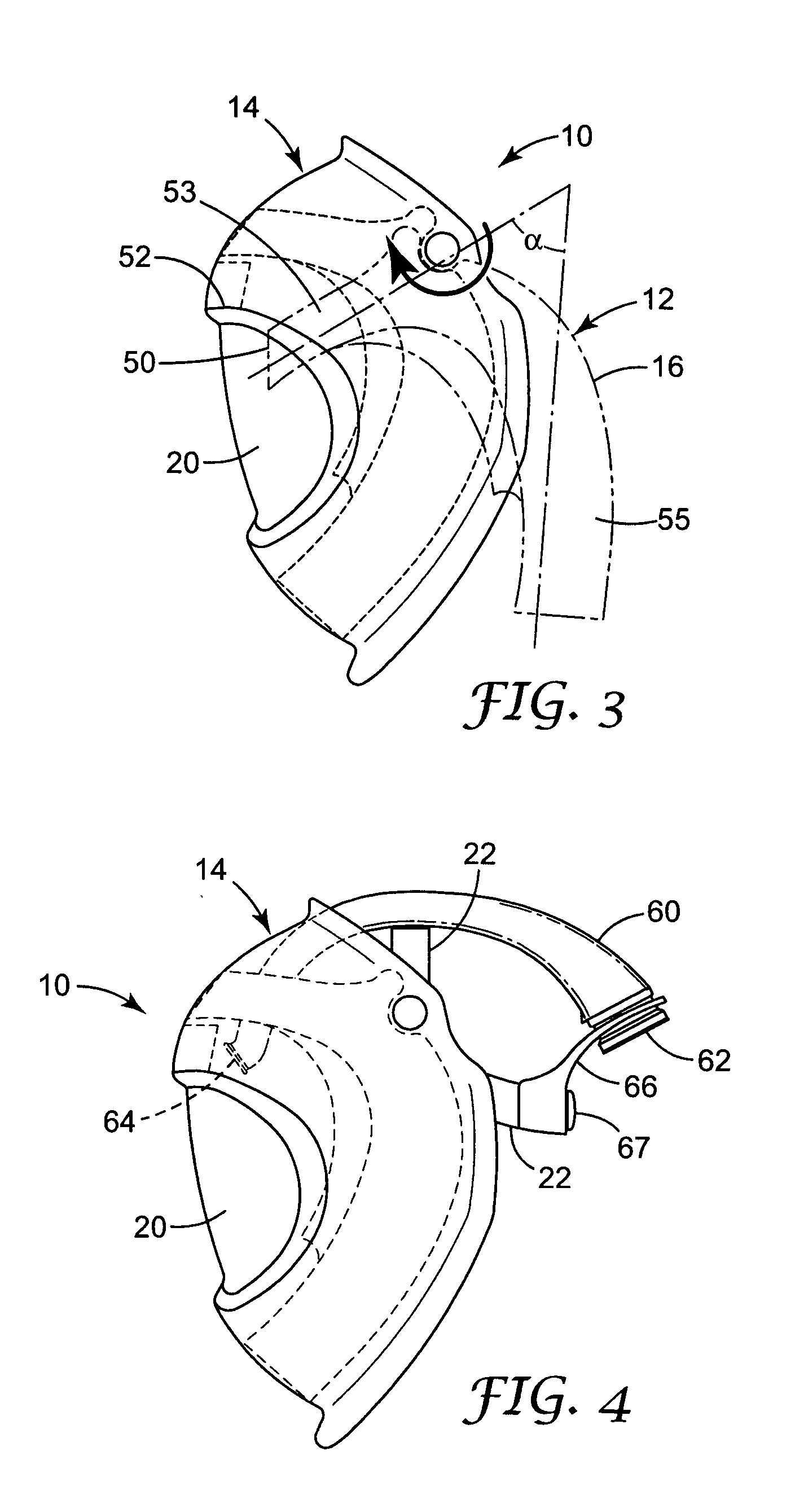

[0029] In the practice of the present invention, a new face seal is provided that can be frictionally secured to a visor of a supplied air helmet at multiple locations. The frictional securement enables less parts be used in the manufacture of the supplied air helmet and, as opposed to a commonly-used hook and loop fastening means, can provide a cleaner, more durable, and simpler form of engagement.

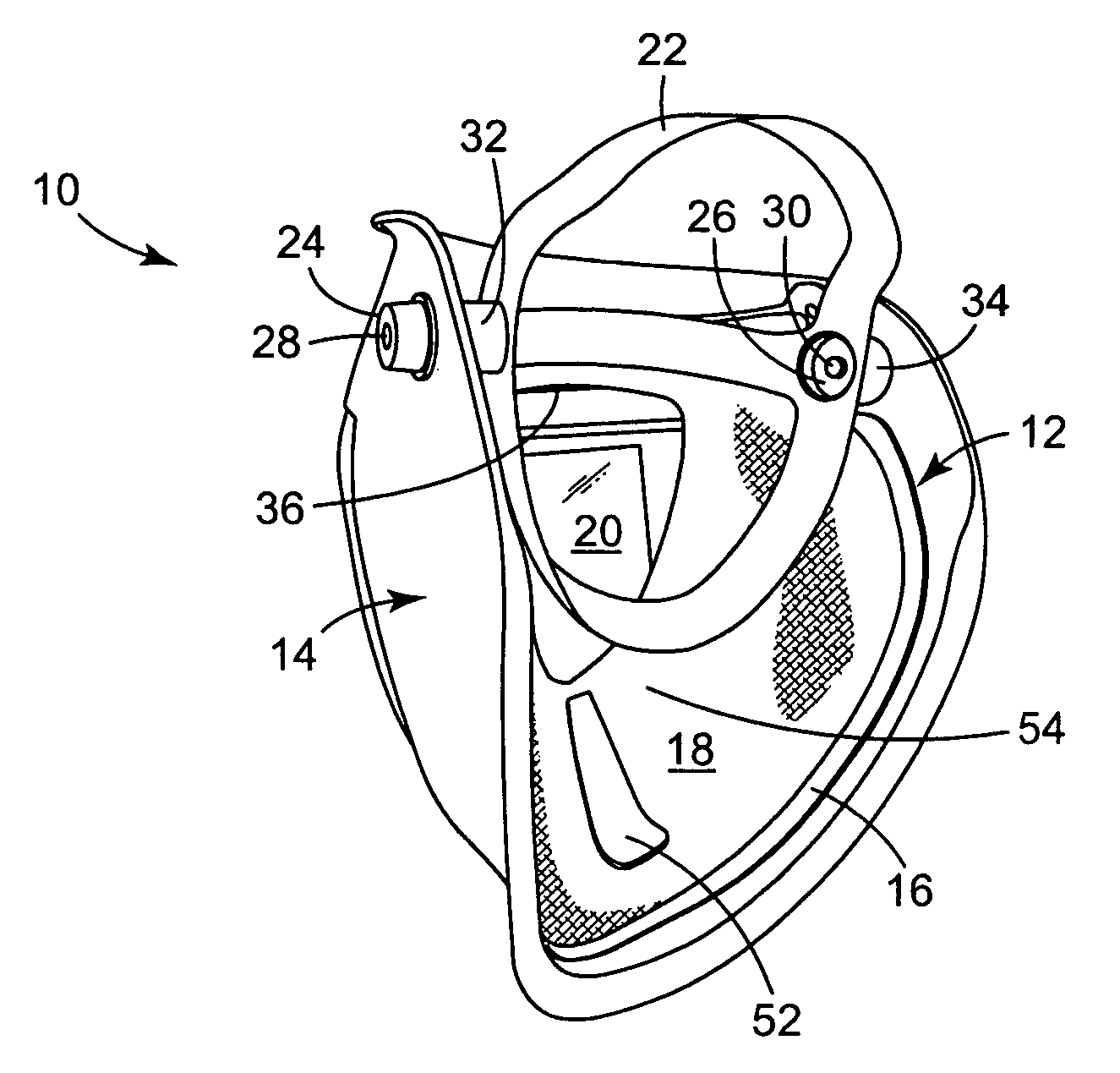

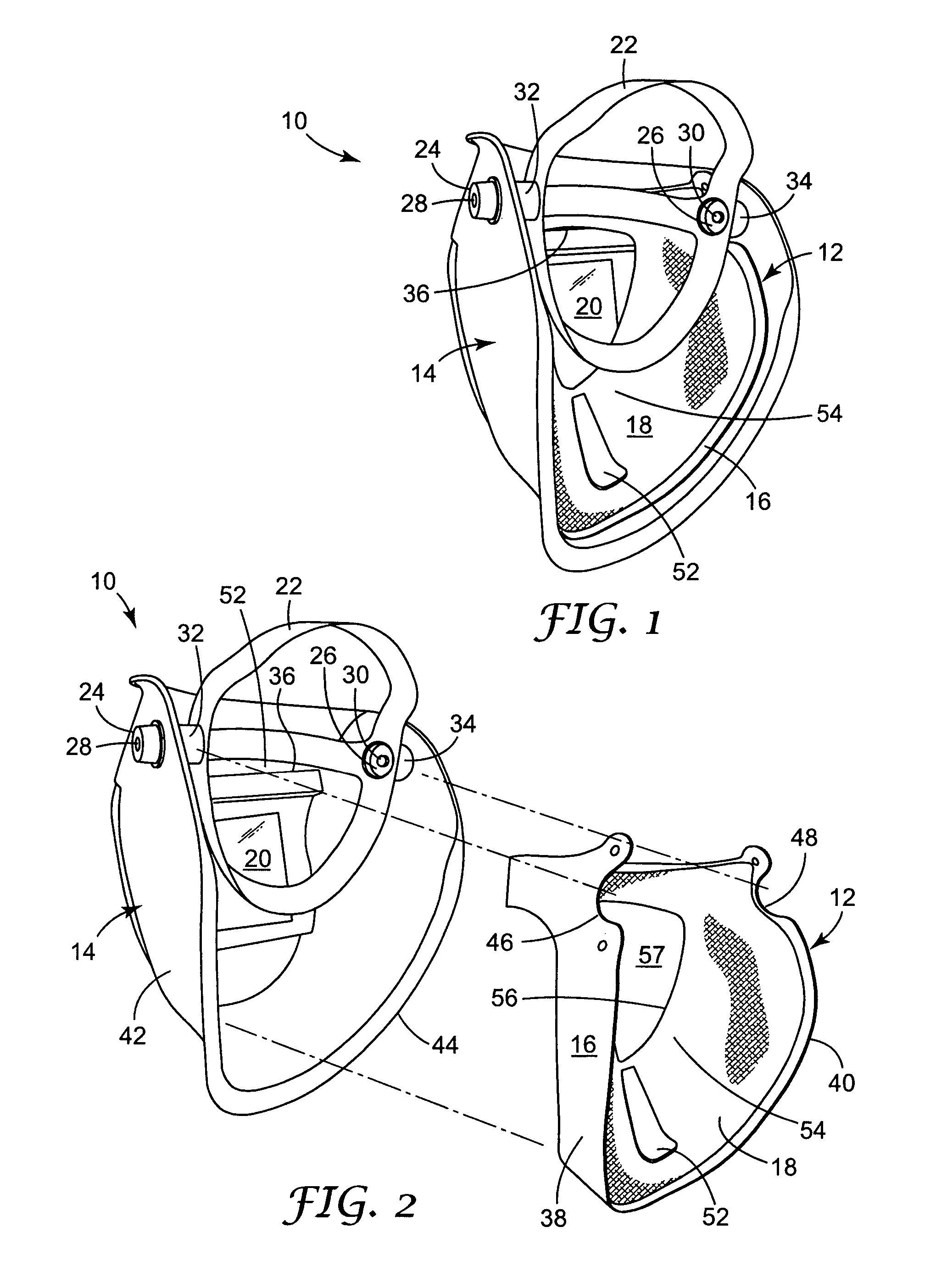

[0030]FIG. 1 illustrates a supplied air helmet 10 that includes a face seal 12 and a visor 14. The face seal 12 has a frame member 16 and a sealing member 18. A window or lens 20 is provided on visor 14 so that a wearer of the helmet 10 can see in the forward direction. If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com