Outside pressurized type dynamic and static pressure gas lubricating and sealing device

A gas lubrication and sealing device technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve single problems, achieve the effects of reducing friction and wear, expanding the use range of sealing, and improving sealing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

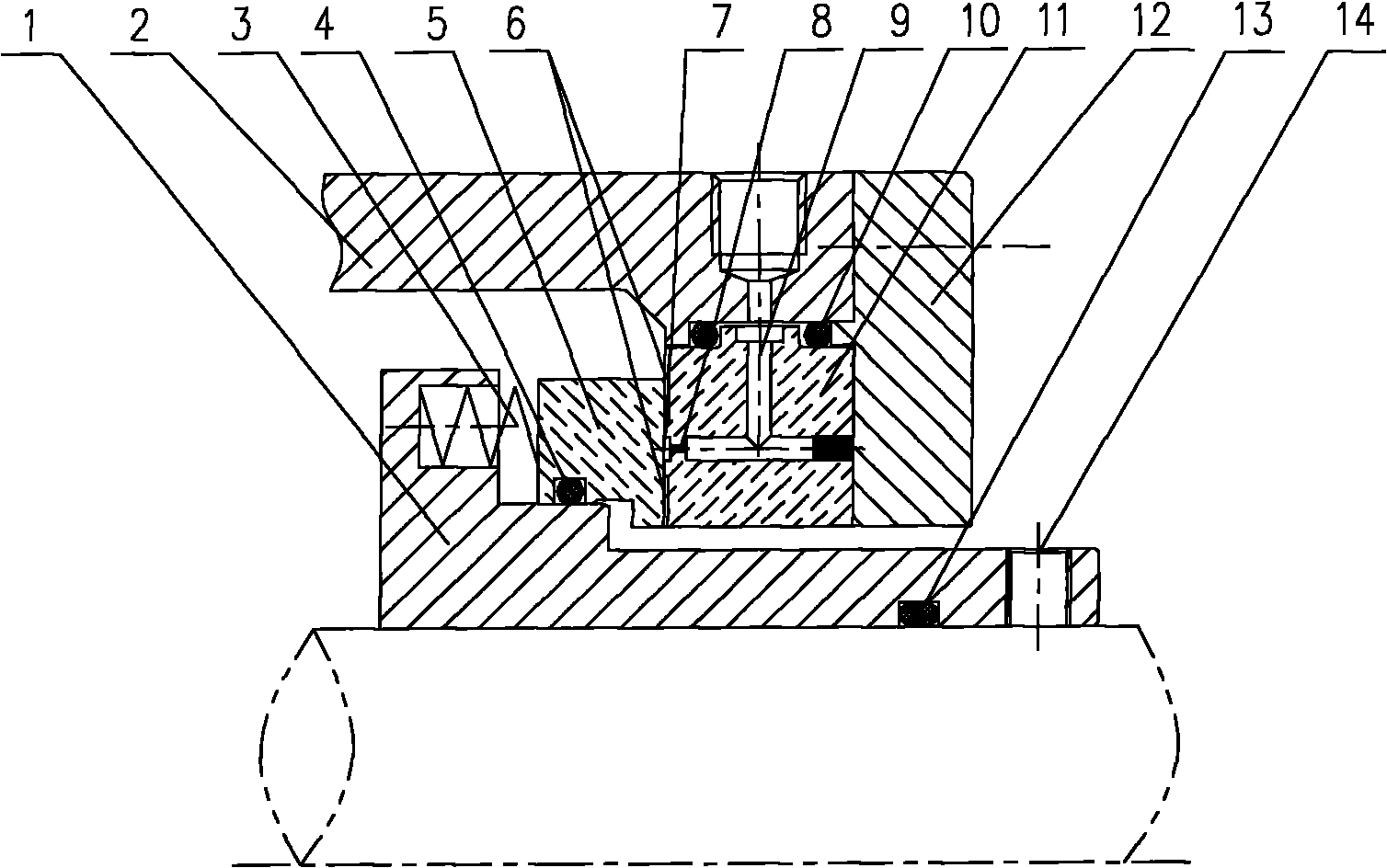

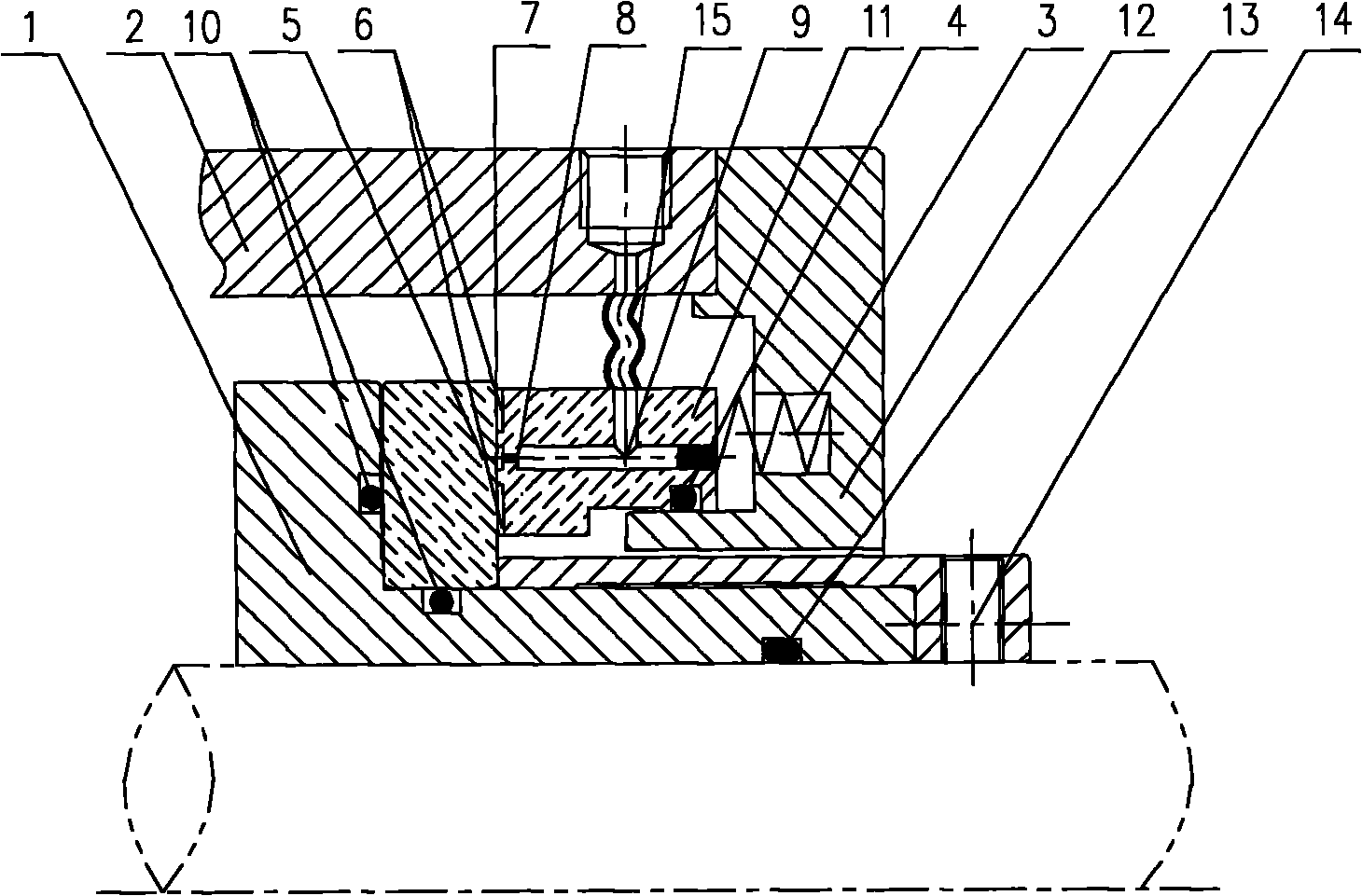

[0028] The content of the present invention will be further described in detail below in conjunction with the specific implementation manners shown in the accompanying drawings.

[0029] see figure 1 , figure 2 As shown, the way to introduce the external pressurized gas between the sealing end faces can be figure 1 As shown, the stationary sealing ring cannot be axially compensated, and is introduced into the sealing end face through the annular space formed by the sealing cavity 2 , the outer diameter of the stationary sealing ring 11 and the two O-rings 10 when it is stationary. When the static ring has axial compensation capability, that is, the spring 3 is stationary and does not rotate, it can be introduced between the sealing end faces through a flexible pipe 15 or a spiral ring tube, such as figure 2 shown.

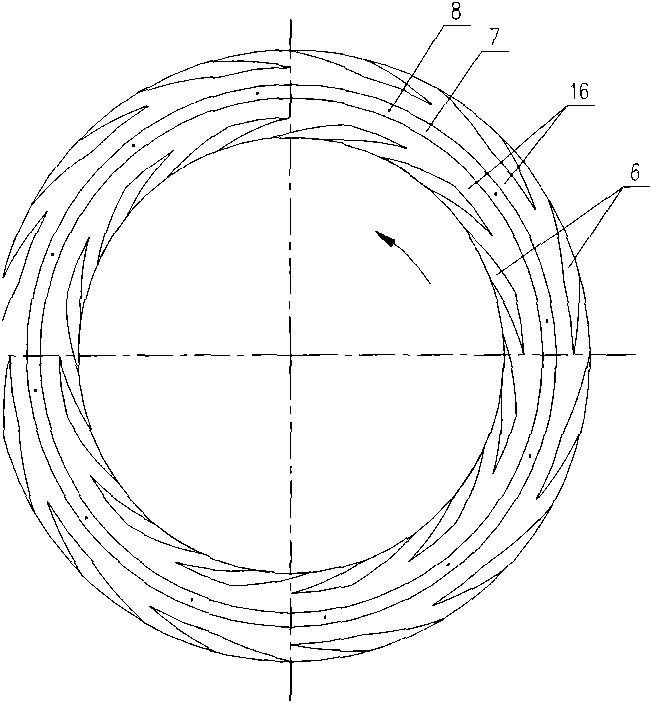

[0030] A throttling device, such as a small hole throttling, is arranged on the fluid passage introducing the externally pressurized gas in the static ring. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com