Full corrosion-resistant connection structure of steel lining plastic composite pipeline

A composite pipeline and connection structure technology, applied in pipeline anticorrosion/rust protection, threaded connection, pipeline protection, etc., can solve the problem that the thread is easily corroded by fluid, and achieve the effect of reducing secondary pollution and eliminating rusty water at the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

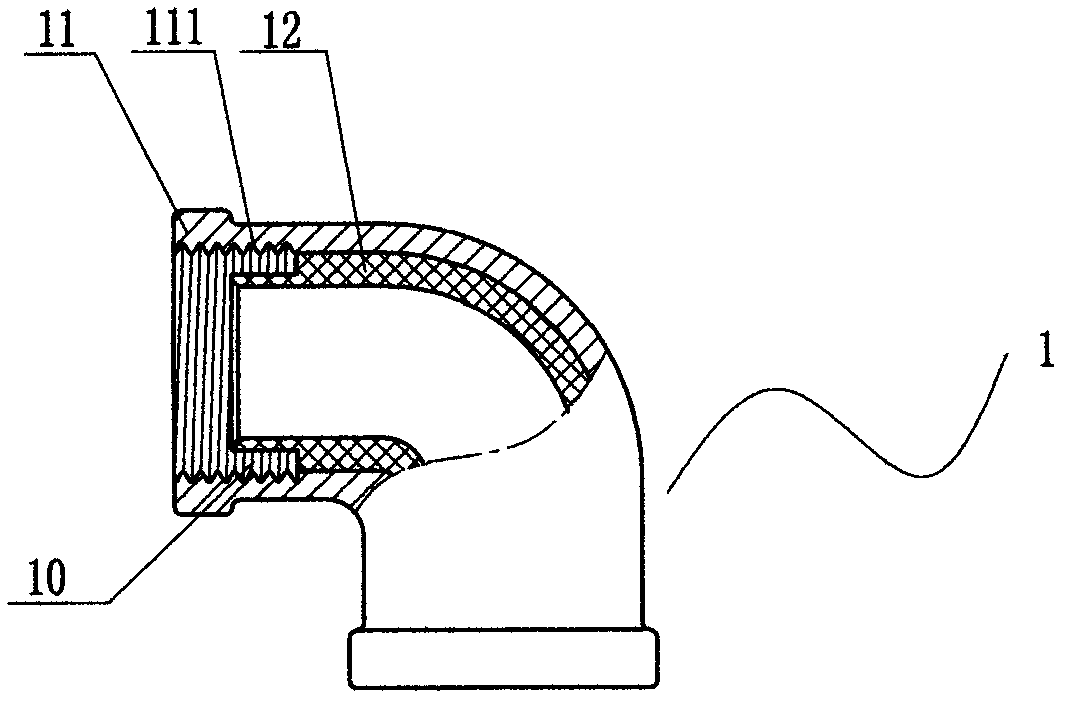

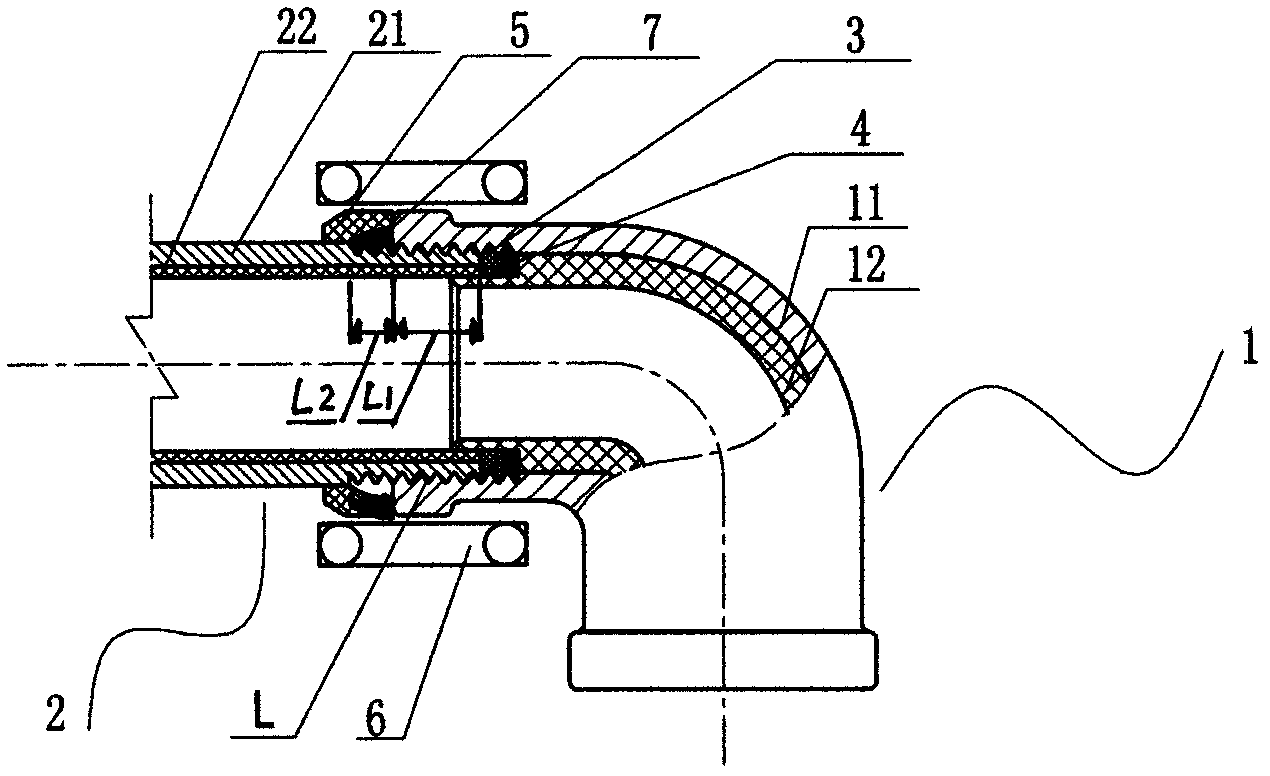

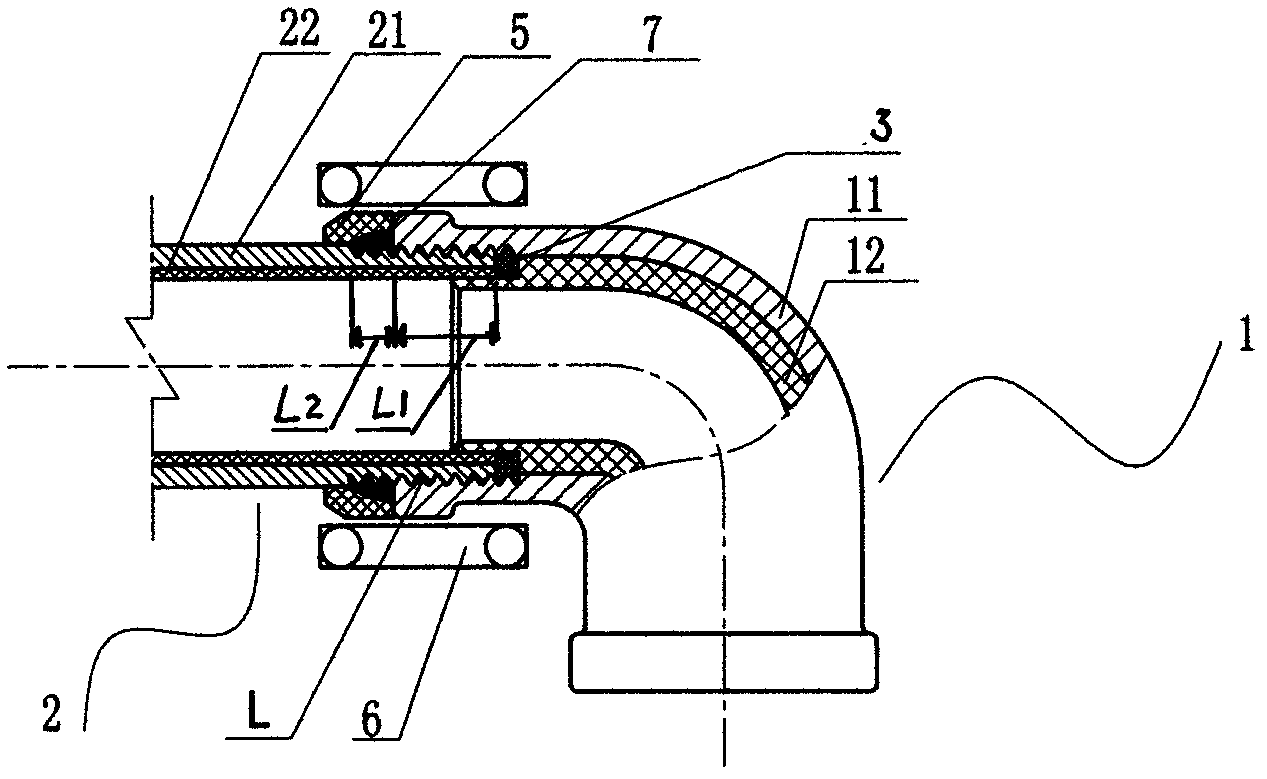

[0018] like image 3 As shown, the full anti-corrosion connection structure of the steel-lined plastic composite pipeline is mainly composed of a steel-lined plastic pipe fitting 1, a steel-lined plastic pipe 2, an anti-corrosion ring 5 and a solid hot melt adhesive 3. The steel-lined plastic pipe fitting 1 is composed of a steel outer ring 11 An integral part formed by compounding with the plastic inner ring part 12, the steel outer ring part 11 starts from its end, and an internal thread segment 111 is processed along the inner wall, and the steel outer ring part 11 and the plastic inner ring part 12 encircle to form an annular cavity 10. The steel-lined plastic pipe 2 is an integral part composed of a steel outer layer 21 and a plastic inner layer 22. The steel outer layer 21 starts from its end and processes a section of external thread L along the outer wall to form an external thread. The caliber of the steel-lined plastic pipe 2 after L matches the caliber of the annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com