Pancake cooling equipment with automatic feeding-discharging function

A technology of automatic loading and unloading and cooling equipment, applied in packaging and other directions, can solve the problems of easy excessive loss of water, difficulty in controlling cooling time and humidity, and affecting taste, so as to achieve easy cooling time and humidity, control cooling time and humidity, and prevent Effects of Excessive Water Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

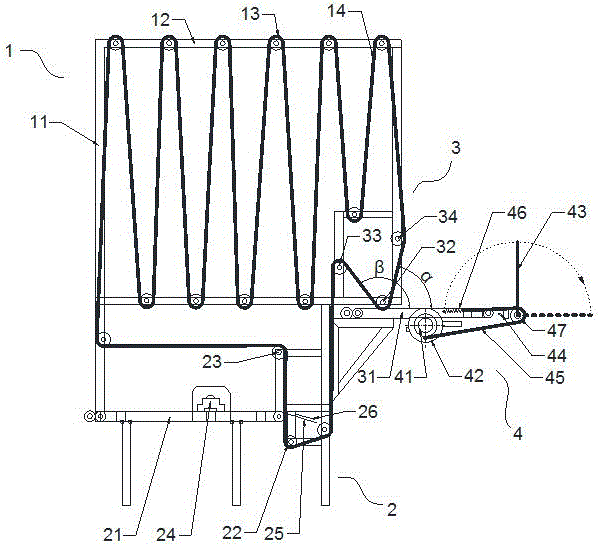

[0040] see figure 1 , figure 2 , The invention provides an automatic loading and unloading single cake cooling equipment. The equipment includes a cooling device 1, an automatic feeding device 2, an automatic unloading device 3 and a moisturizing device (not shown in the figure).

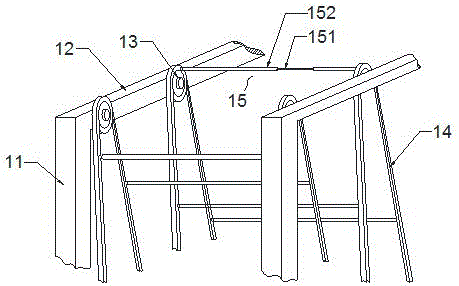

[0041] Described cooling device comprises the cooling frame 11 of rectangular parallelepiped frame structure, and two crossbeams 12 up and down on the same side of described cooling frame are a group, two groups of crossbeams 12 opposite inner sides are respectively symmetrically provided with several sprocket wheels 13, and the sprocket wheels 13 of the top crossbeam The chain wheels 13 of the lower beams are arranged at intervals, and there is an endless chain 14 around the outer side of the sprockets 13 on each set of beams. Several parallel cooling rods 15 are connected between the ring chains 14 on the two sets of beams 12. Adjacent cooling rods The spacing between them is equal. The coolin...

Embodiment 2

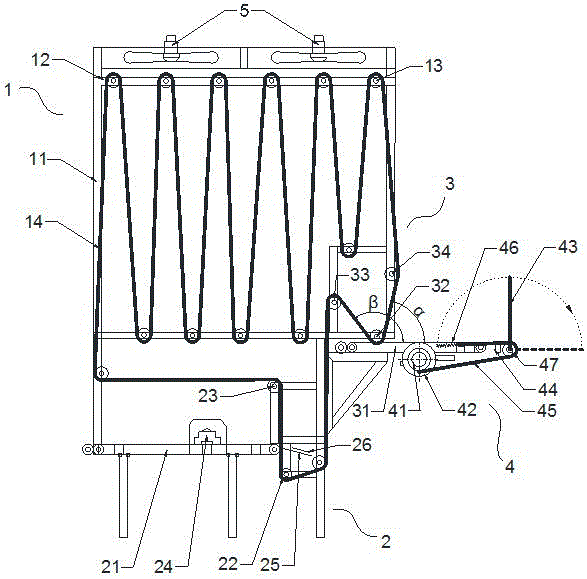

[0060] see image 3 , the present invention provides another automatic loading and unloading single cake cooling device. The similarities between this embodiment and the first embodiment will not be repeated, and only the differences will be described below.

[0061] In this embodiment, the automatic loading and unloading single cake cooling equipment also includes a fan 5, which is located at the top of the cooling frame 11, and the wind speed of the fan 5 is controlled by multi-stage or stepless speed change.

[0062] Equipped with fan 5 automatic loading and unloading single cake cooling equipment, it only takes 1-5 minutes for the hot cake to cool to room temperature, and the cooling efficiency is increased by 67%~93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com