Patents

Literature

3109results about "Screw threaded joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

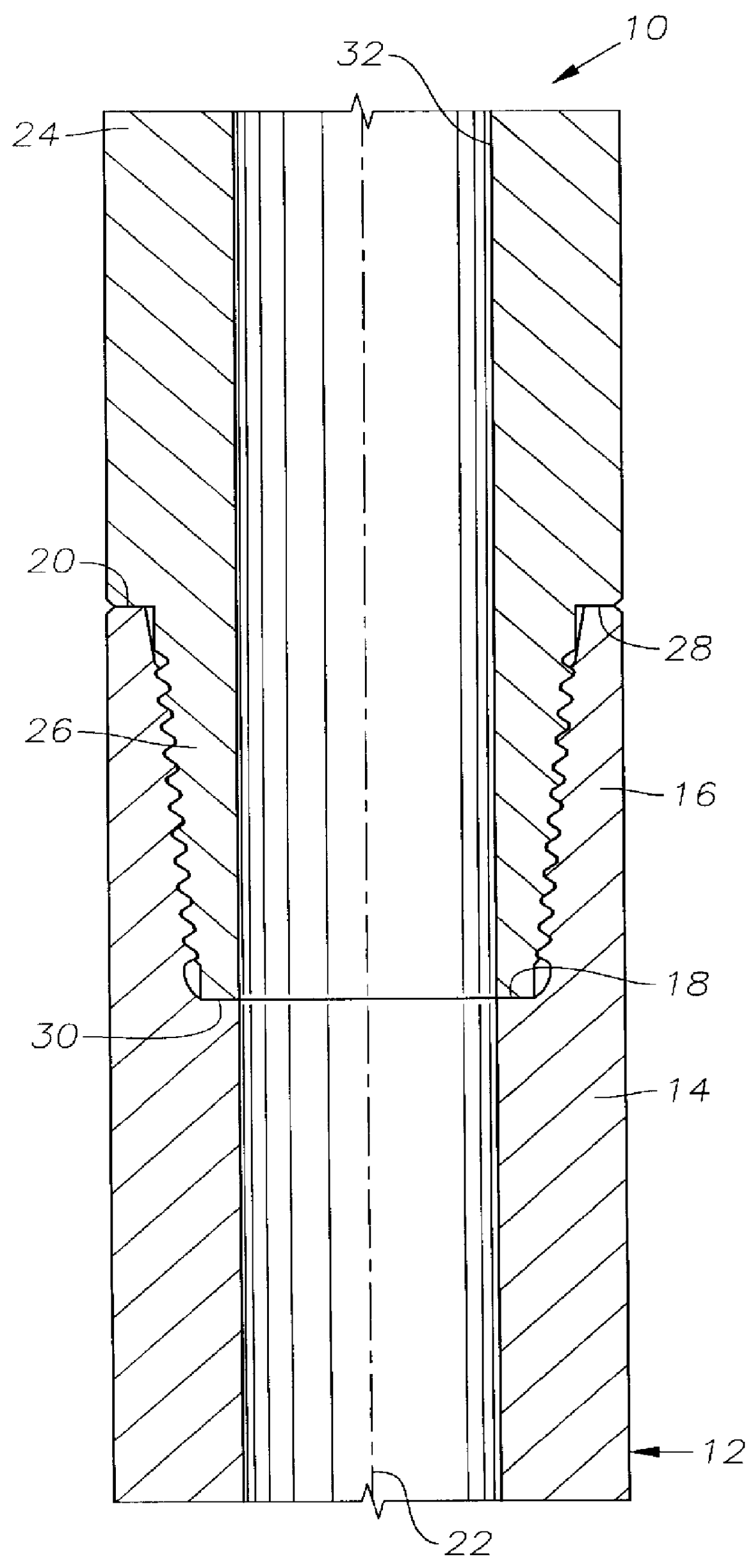

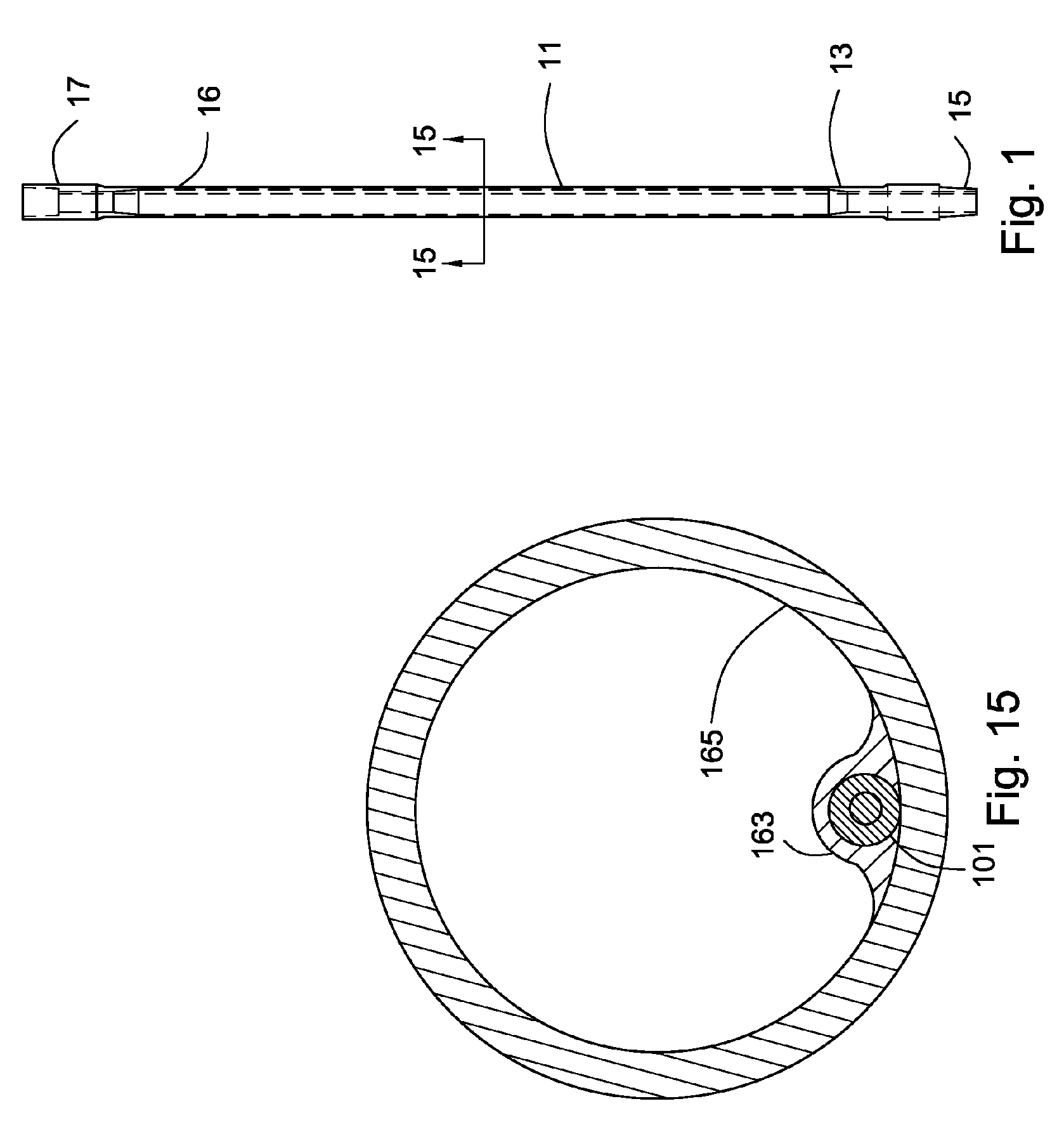

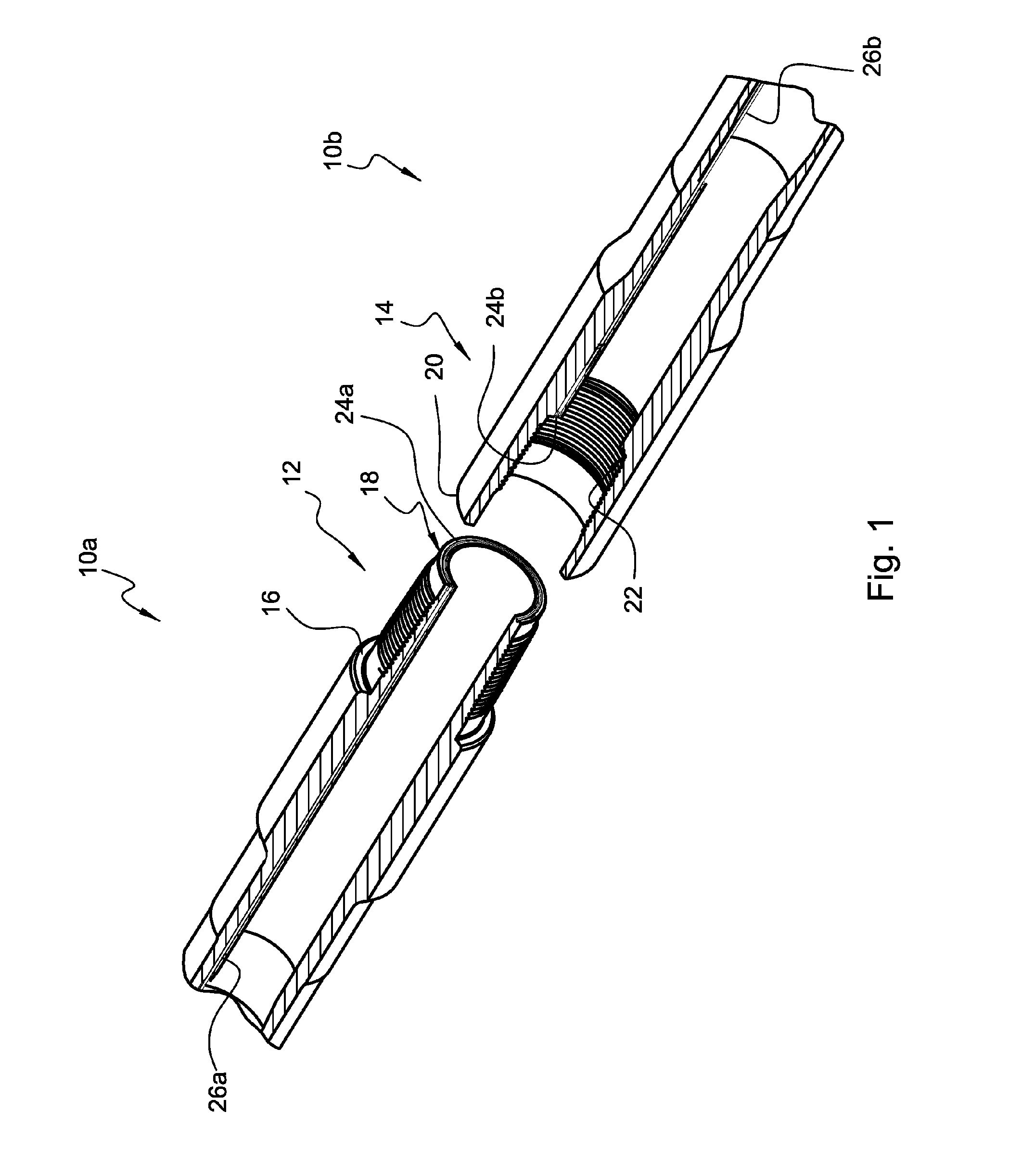

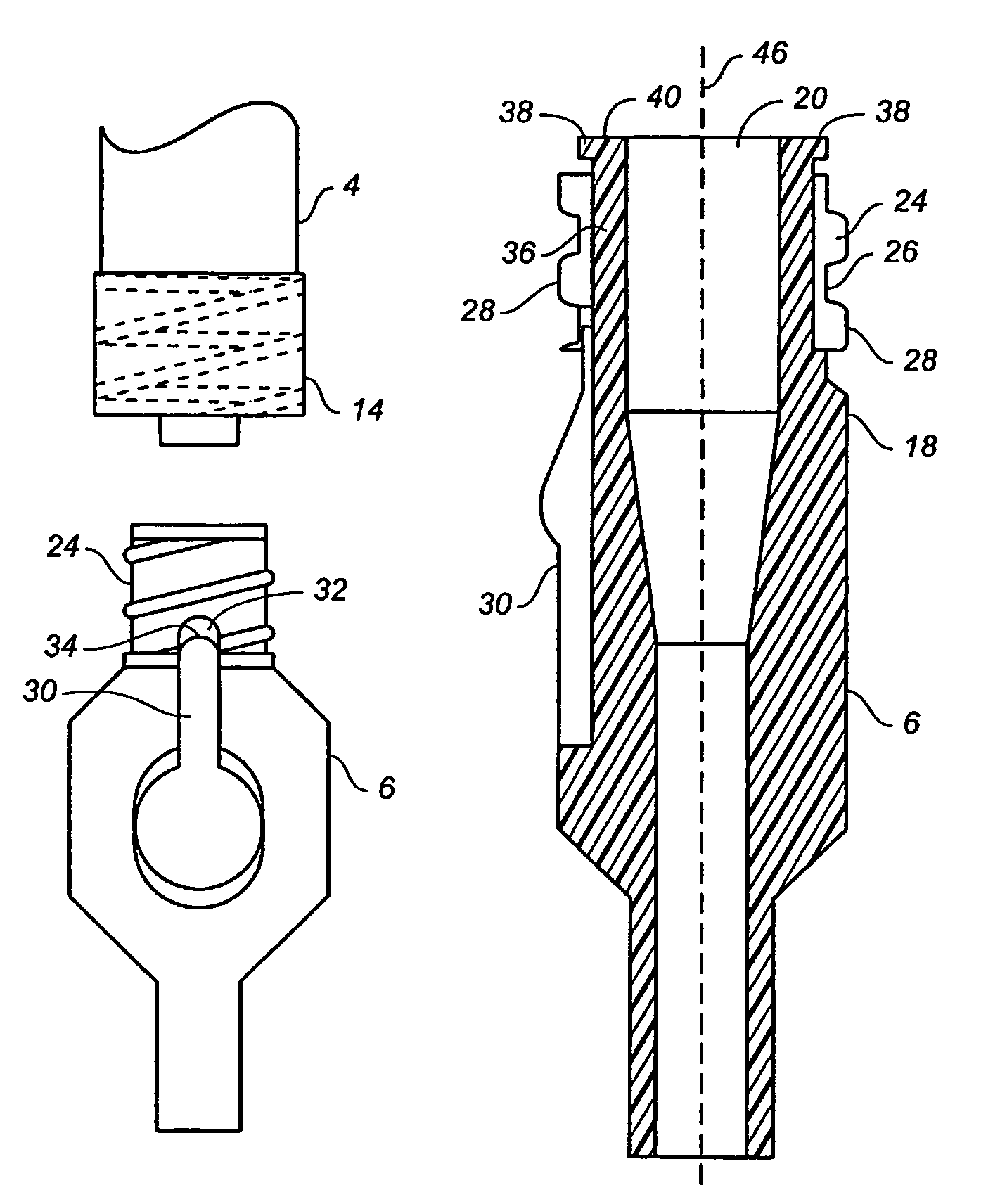

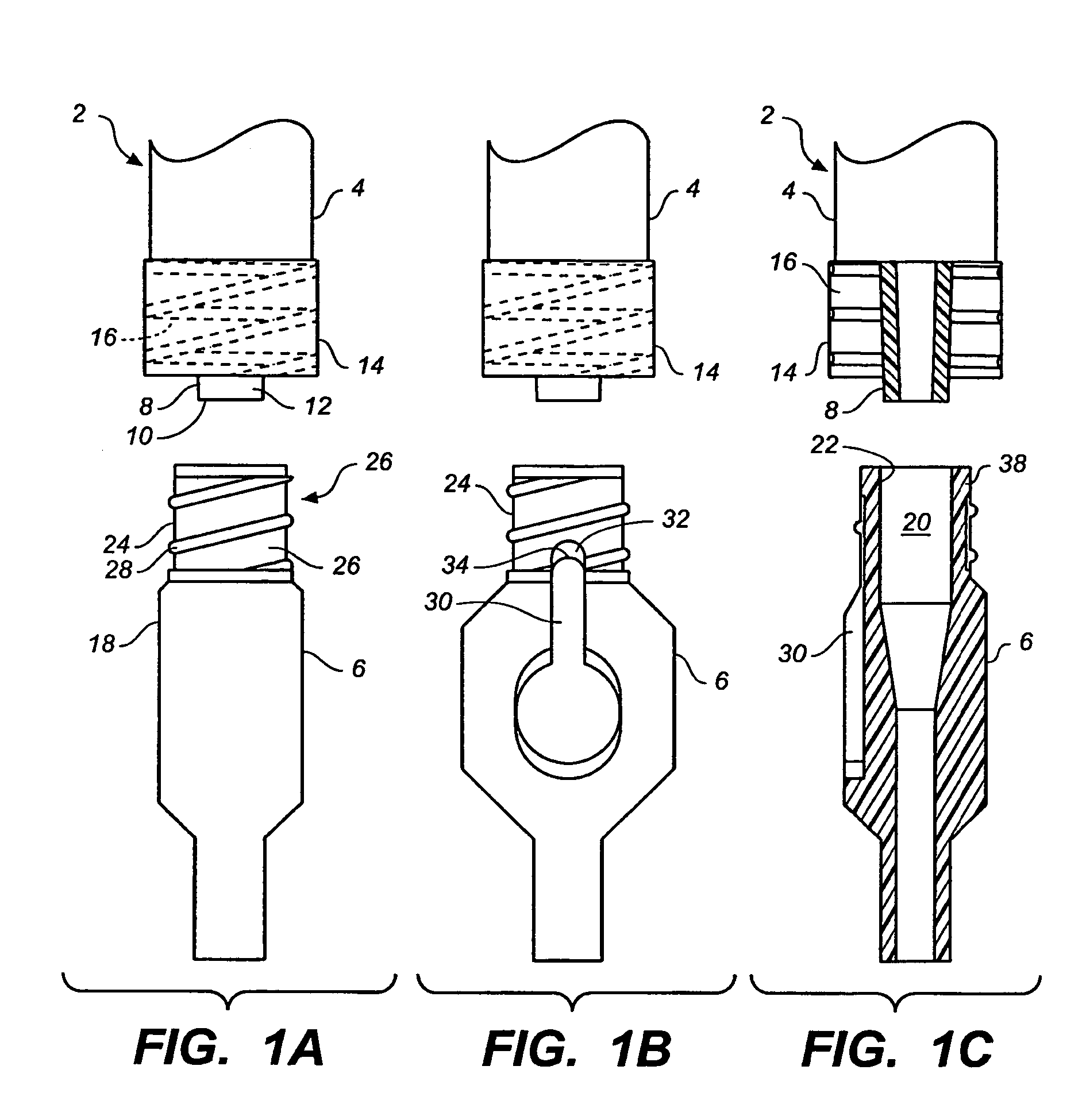

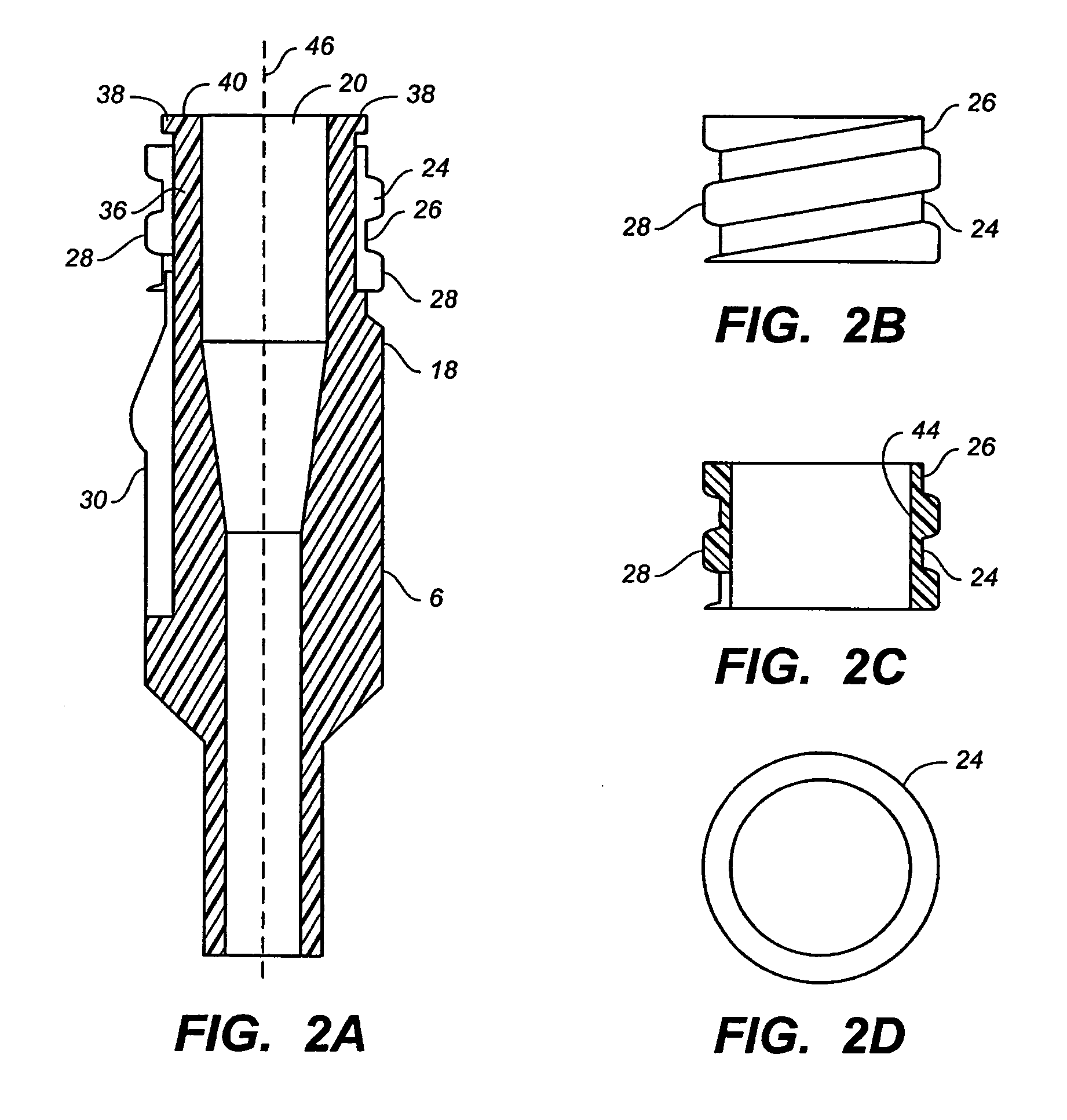

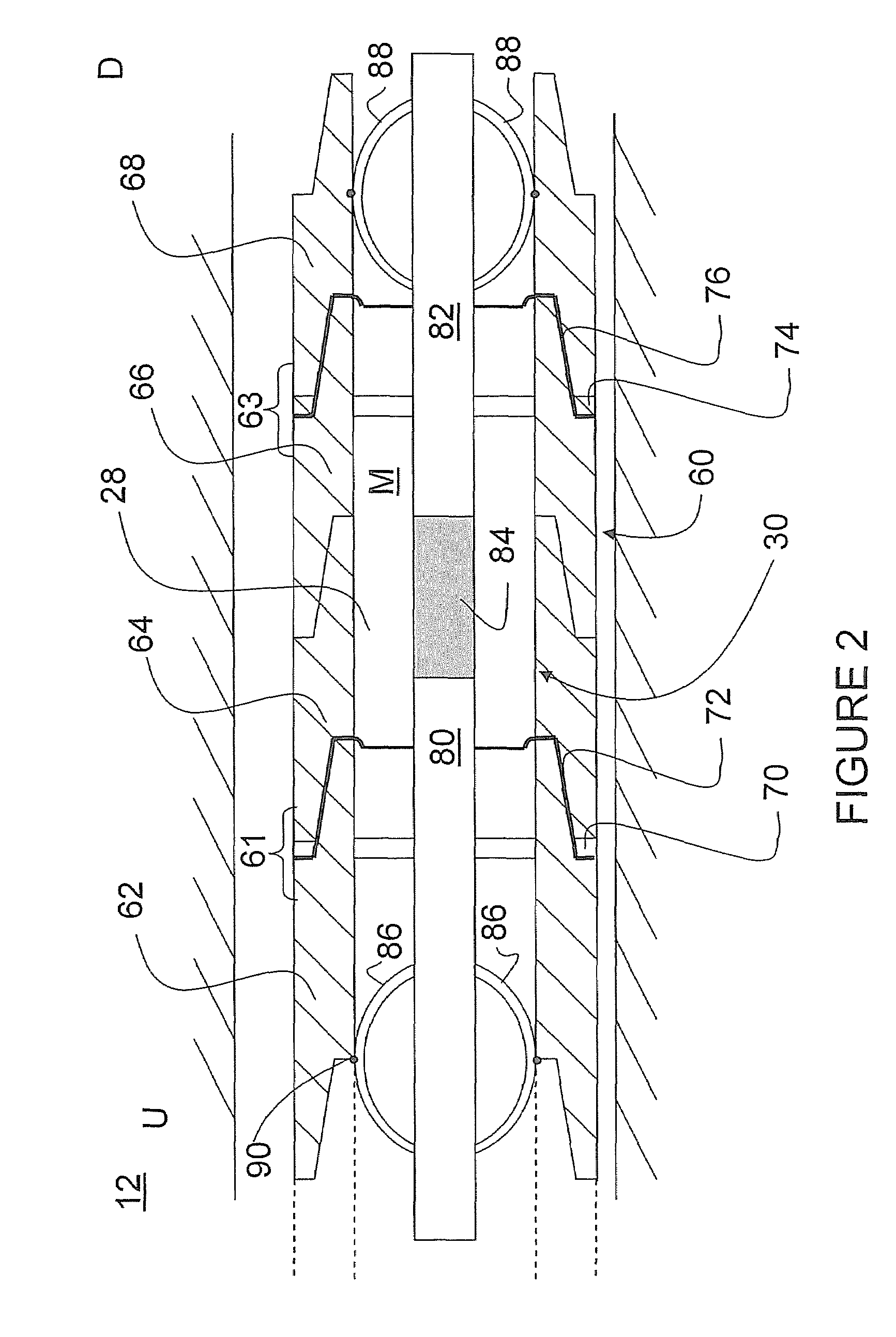

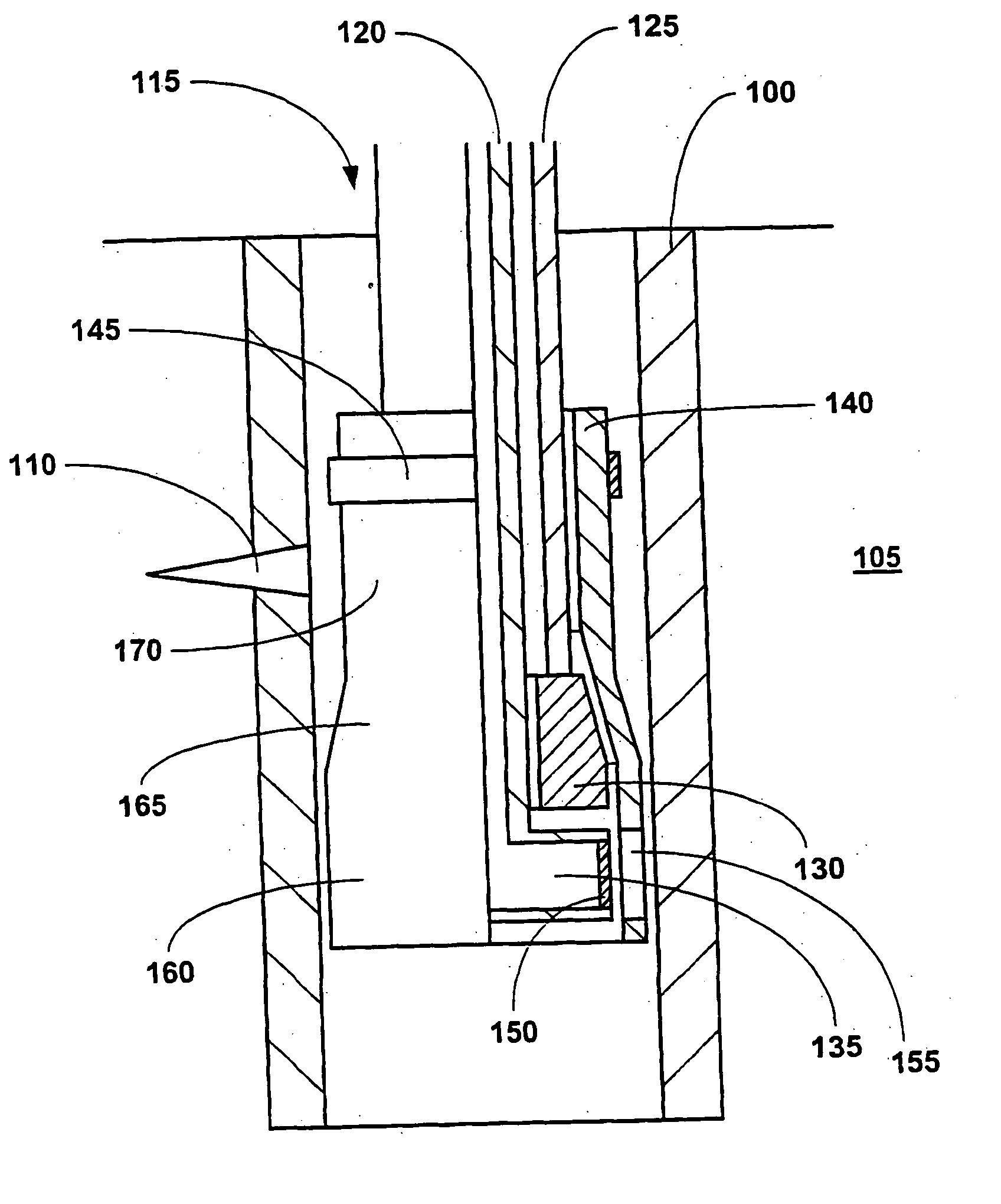

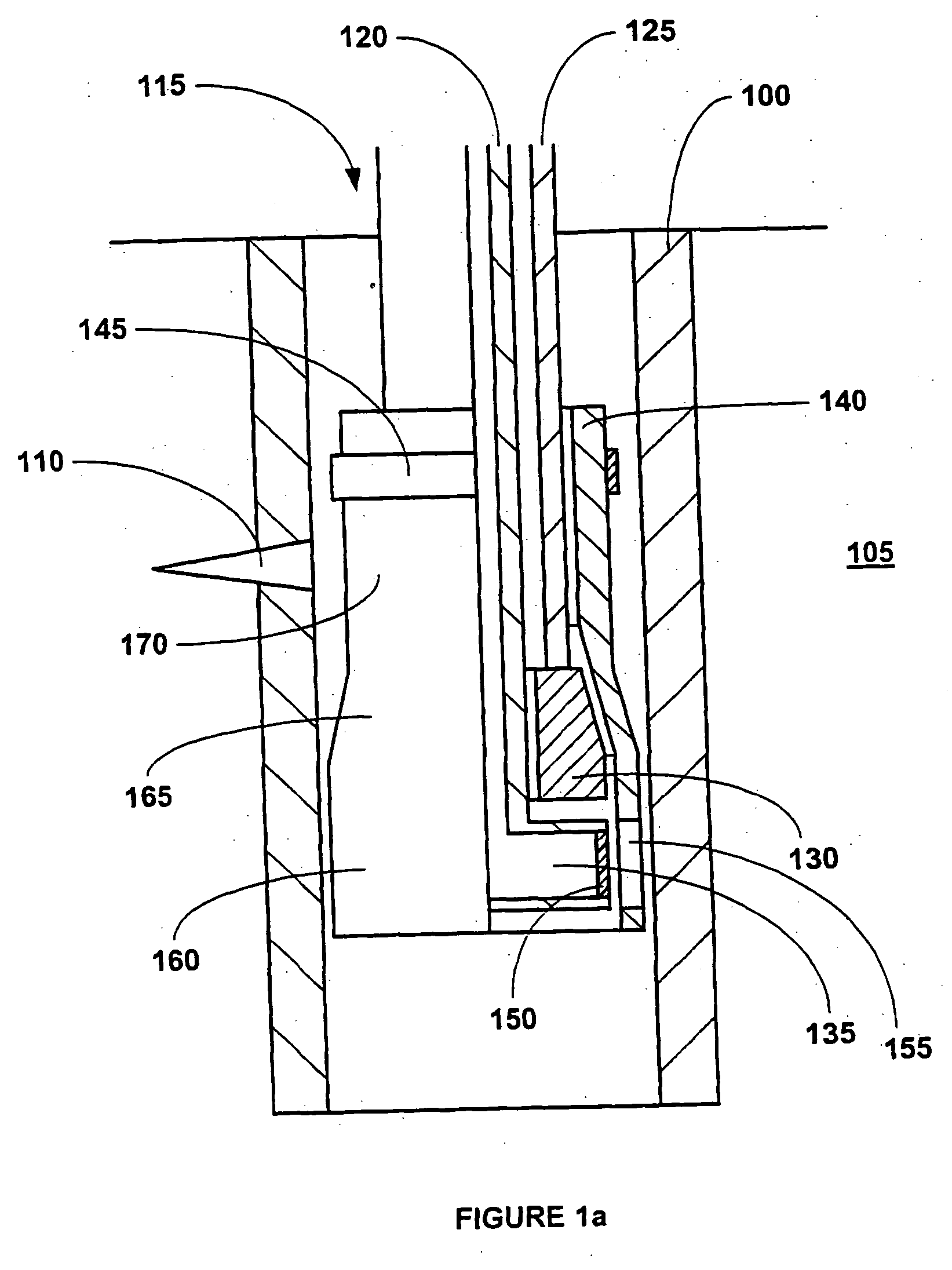

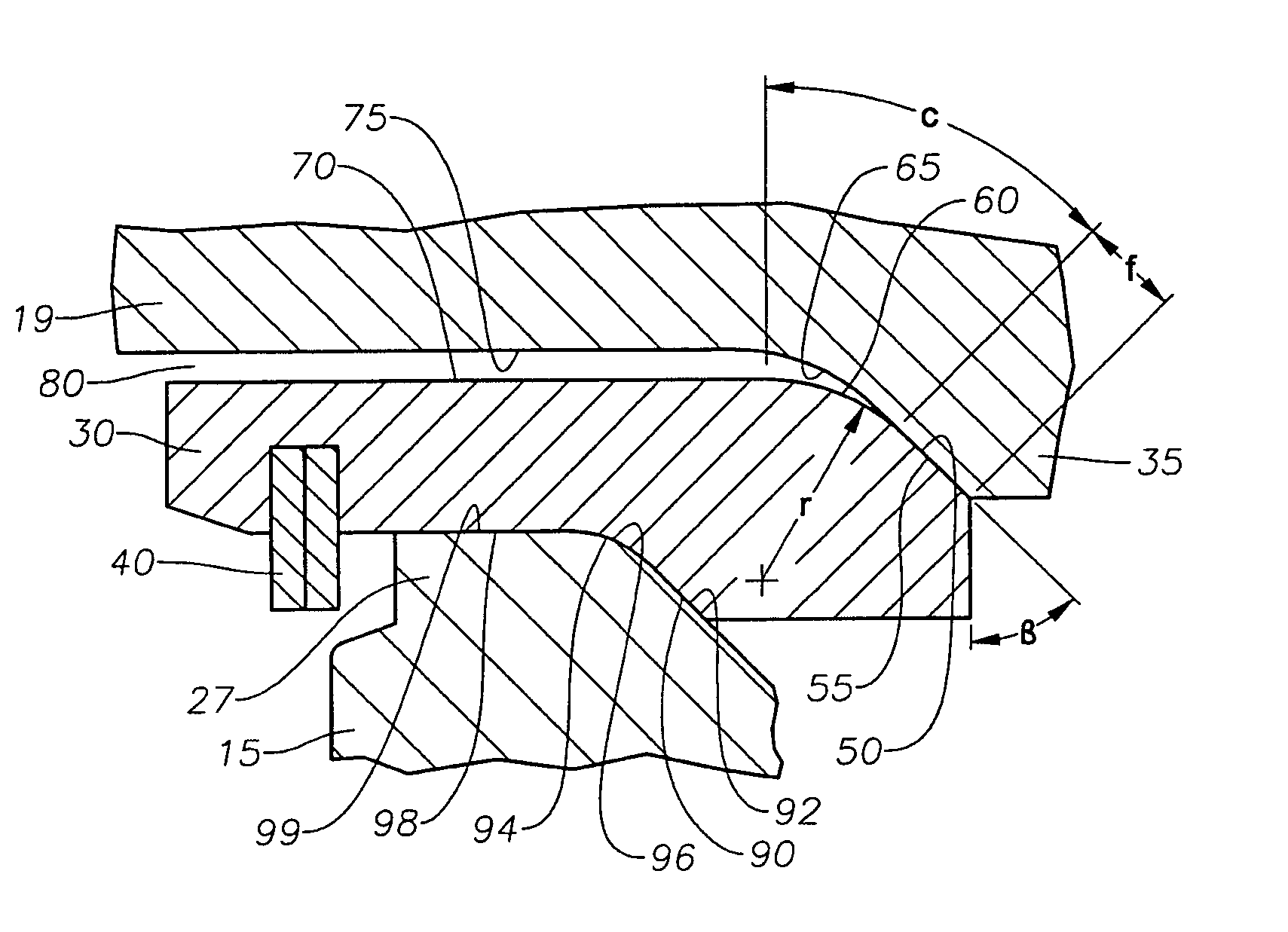

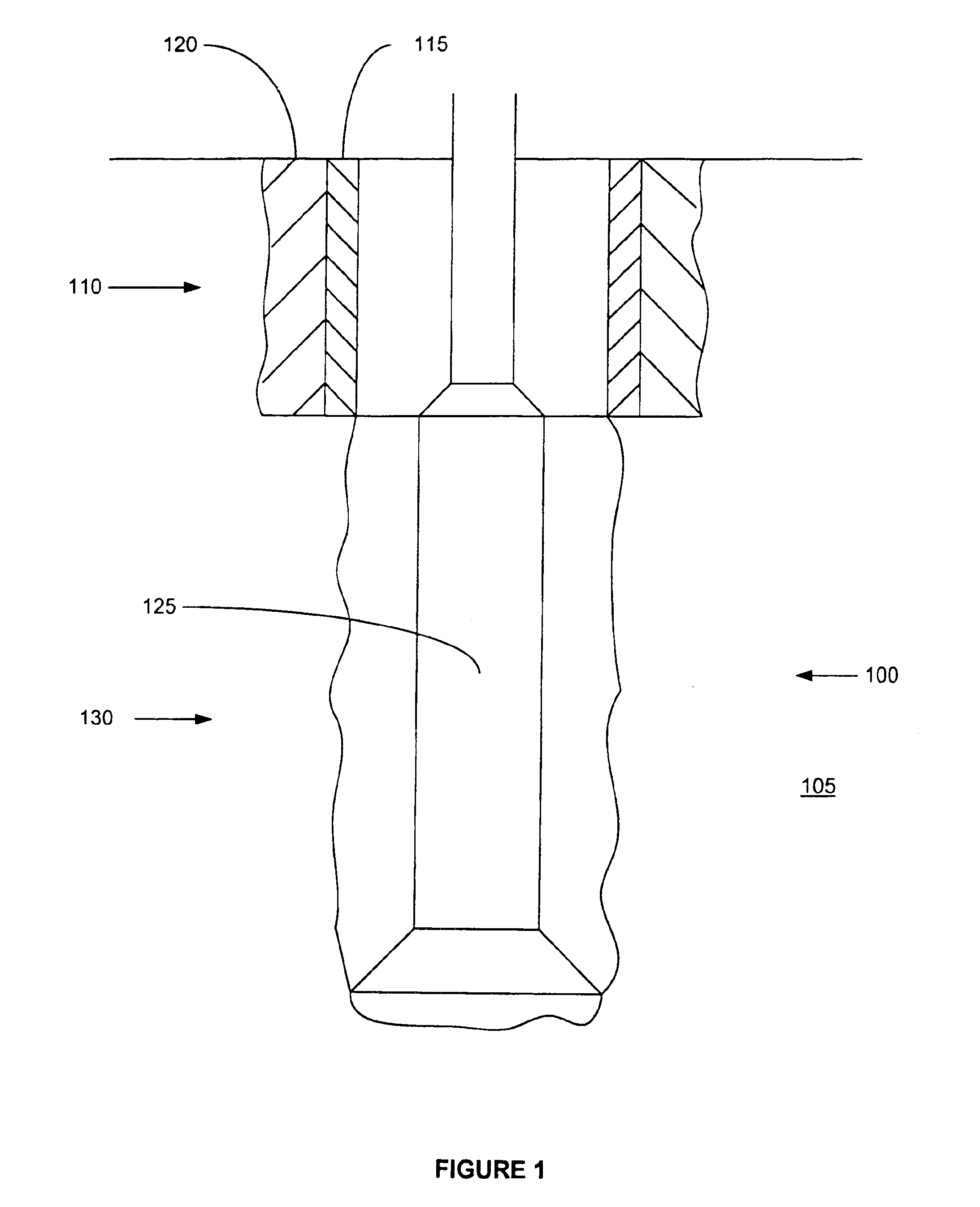

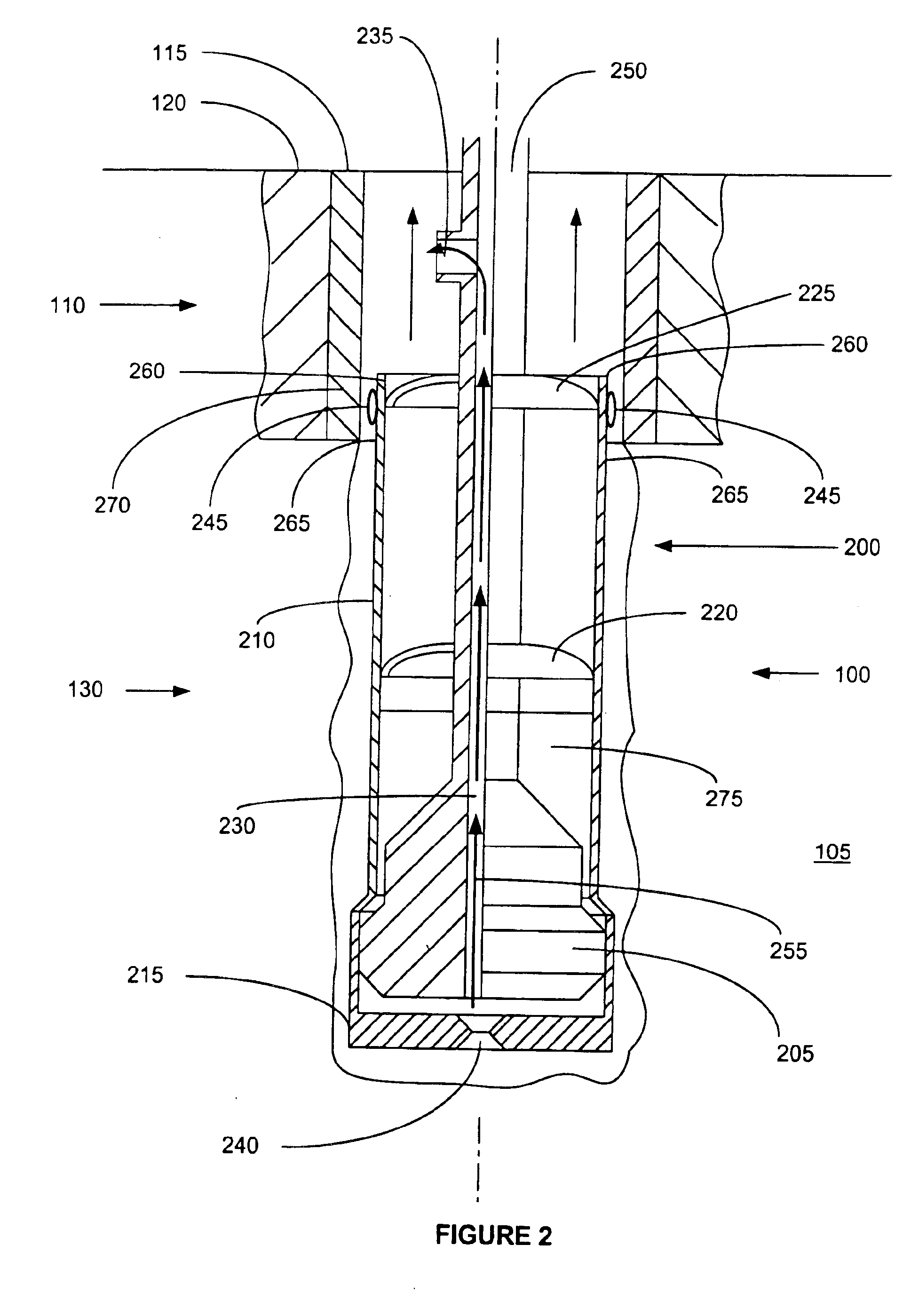

Expandable joint connector

InactiveUS6409175B1Lessen and eliminate radial engagementRadial expansionDrilling rodsCable inlet sealing meansEngineeringScrew thread

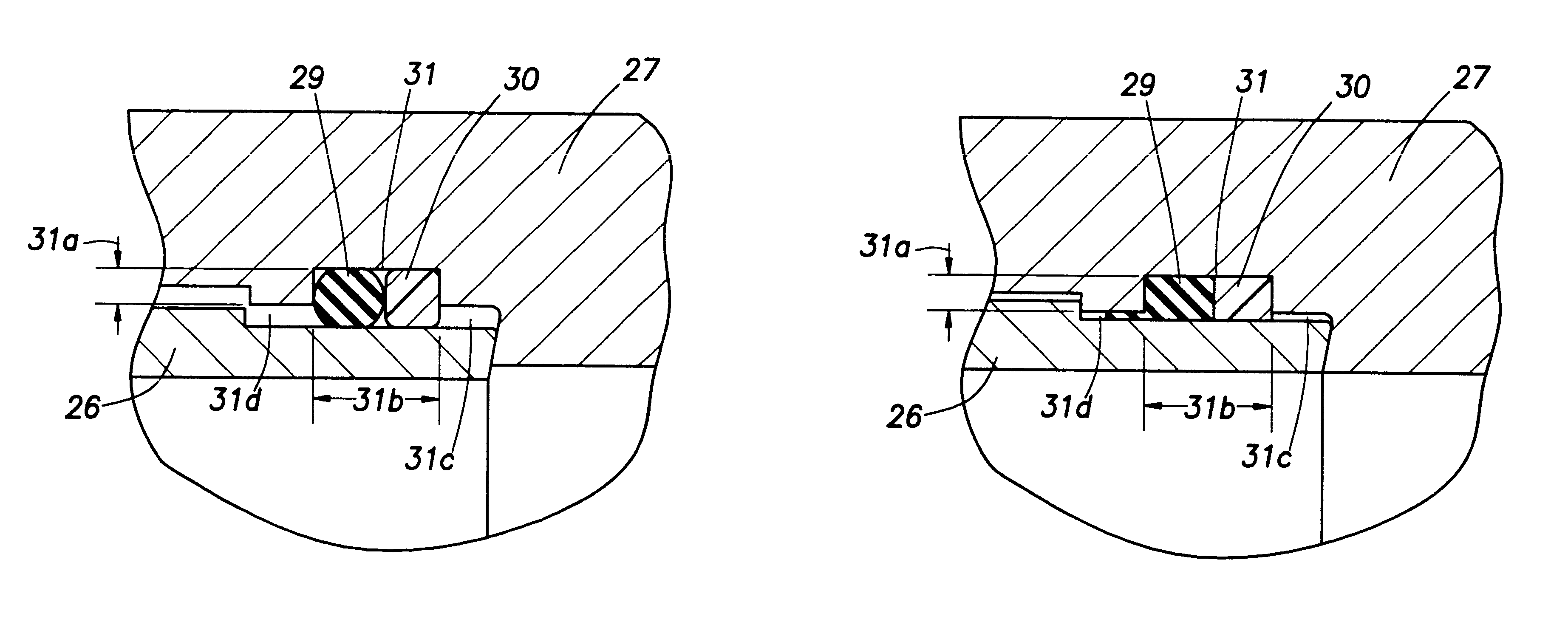

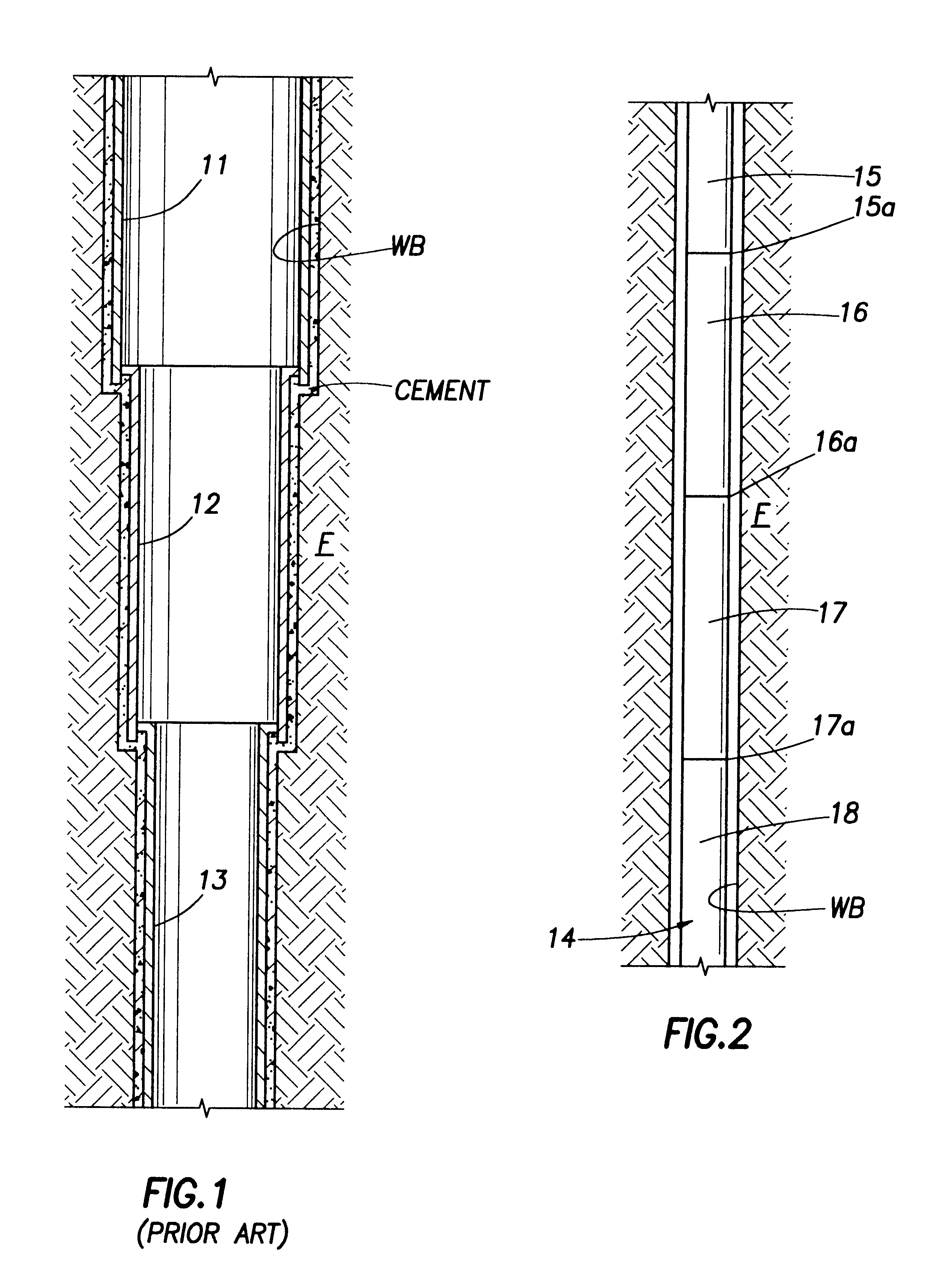

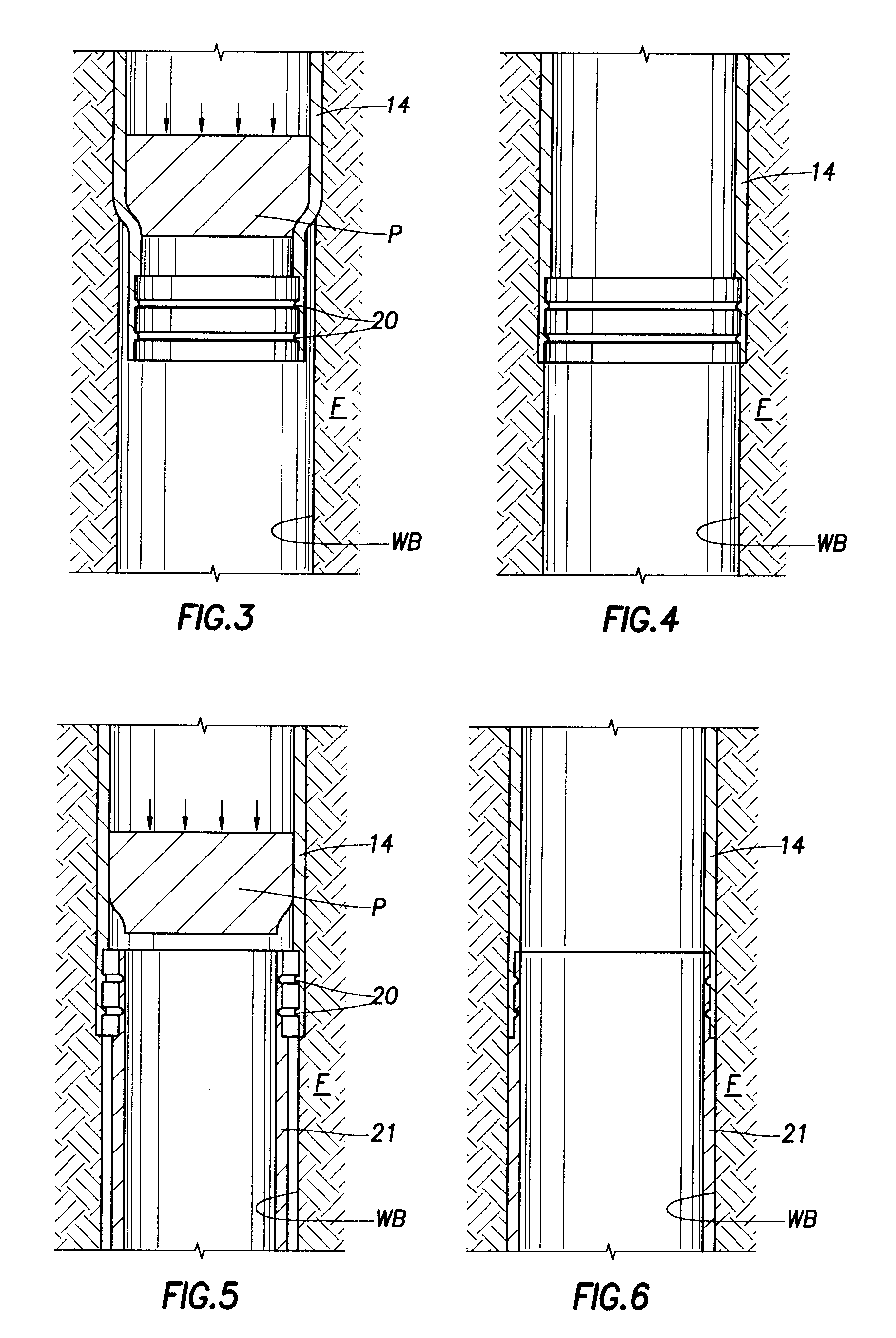

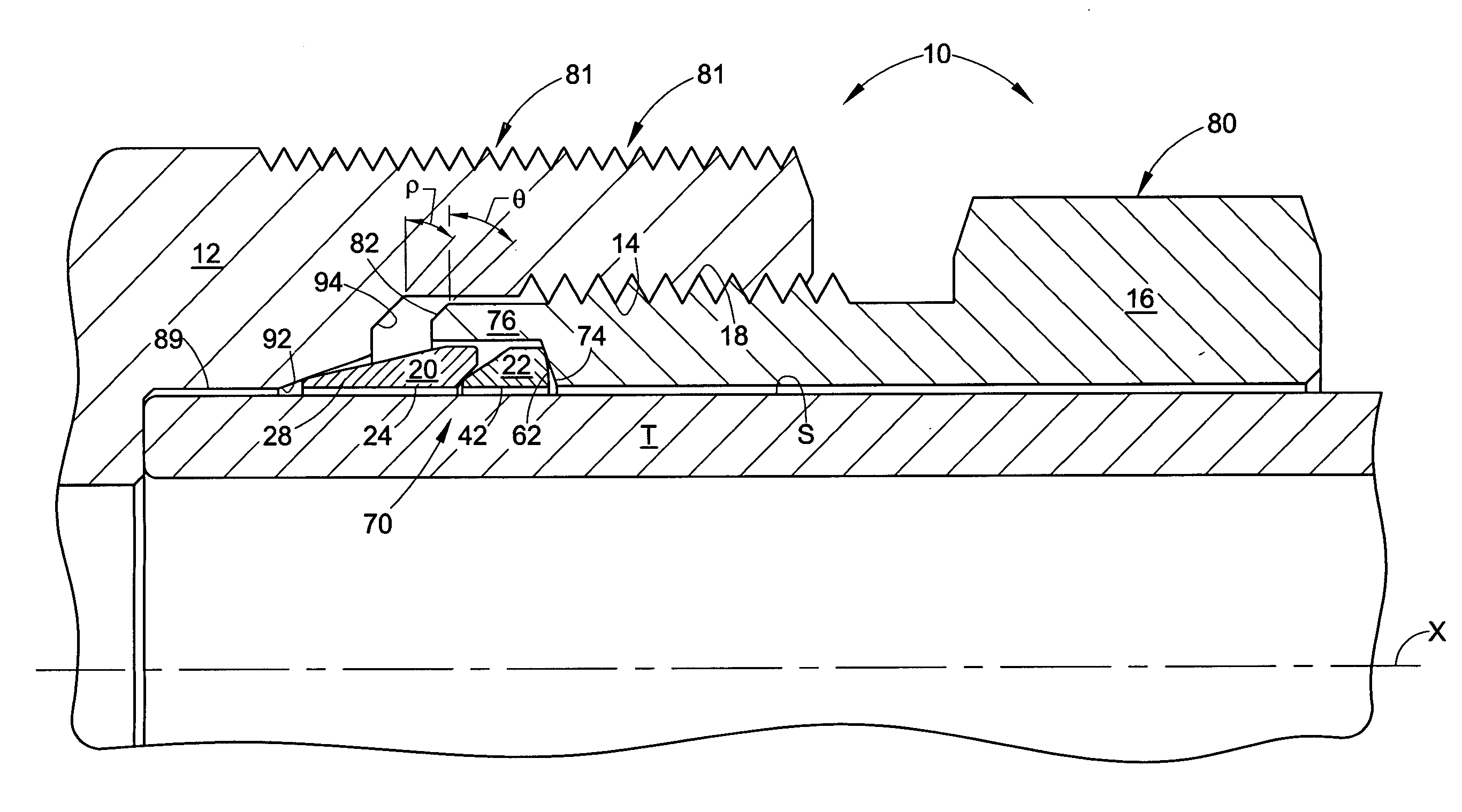

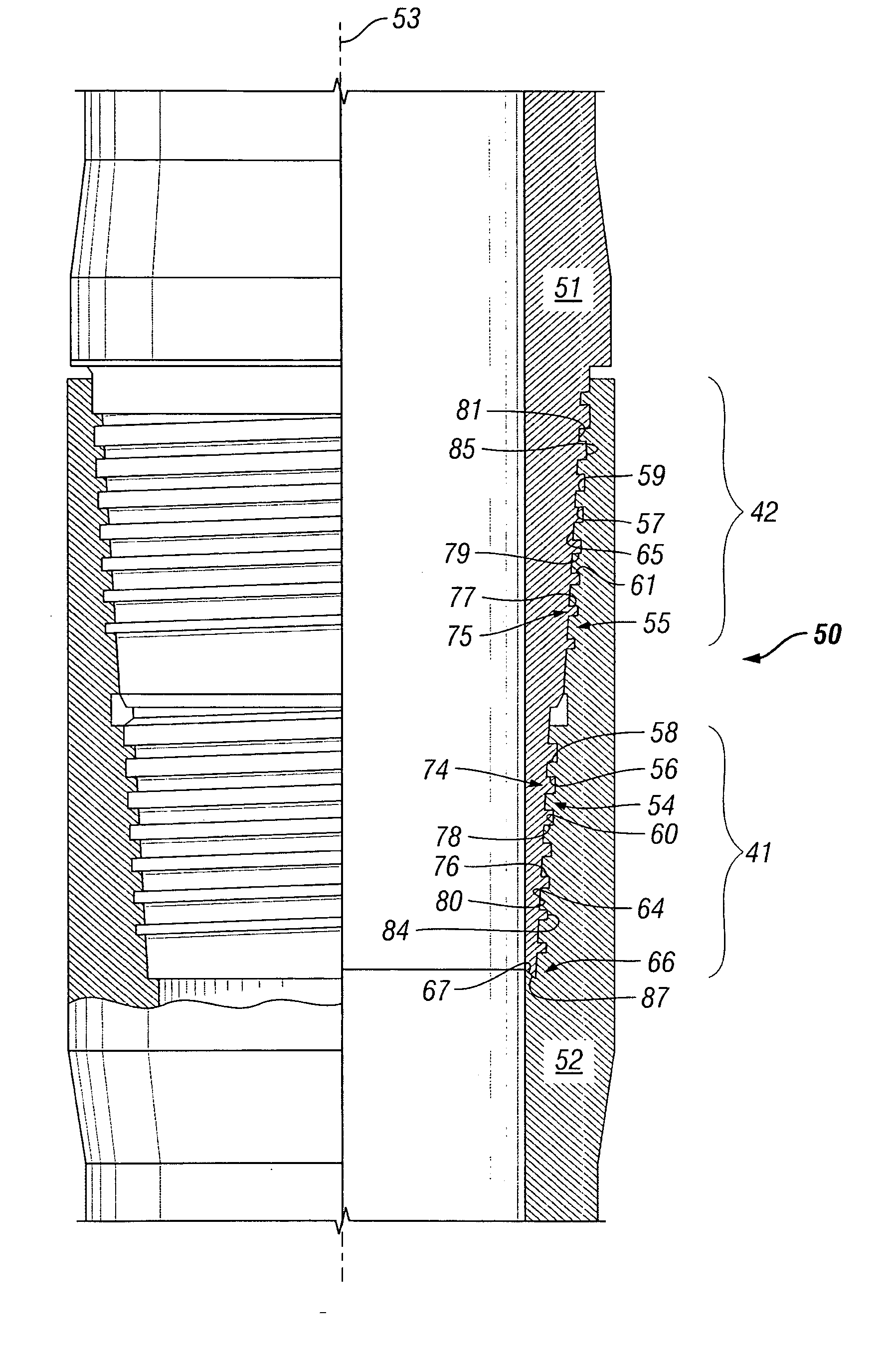

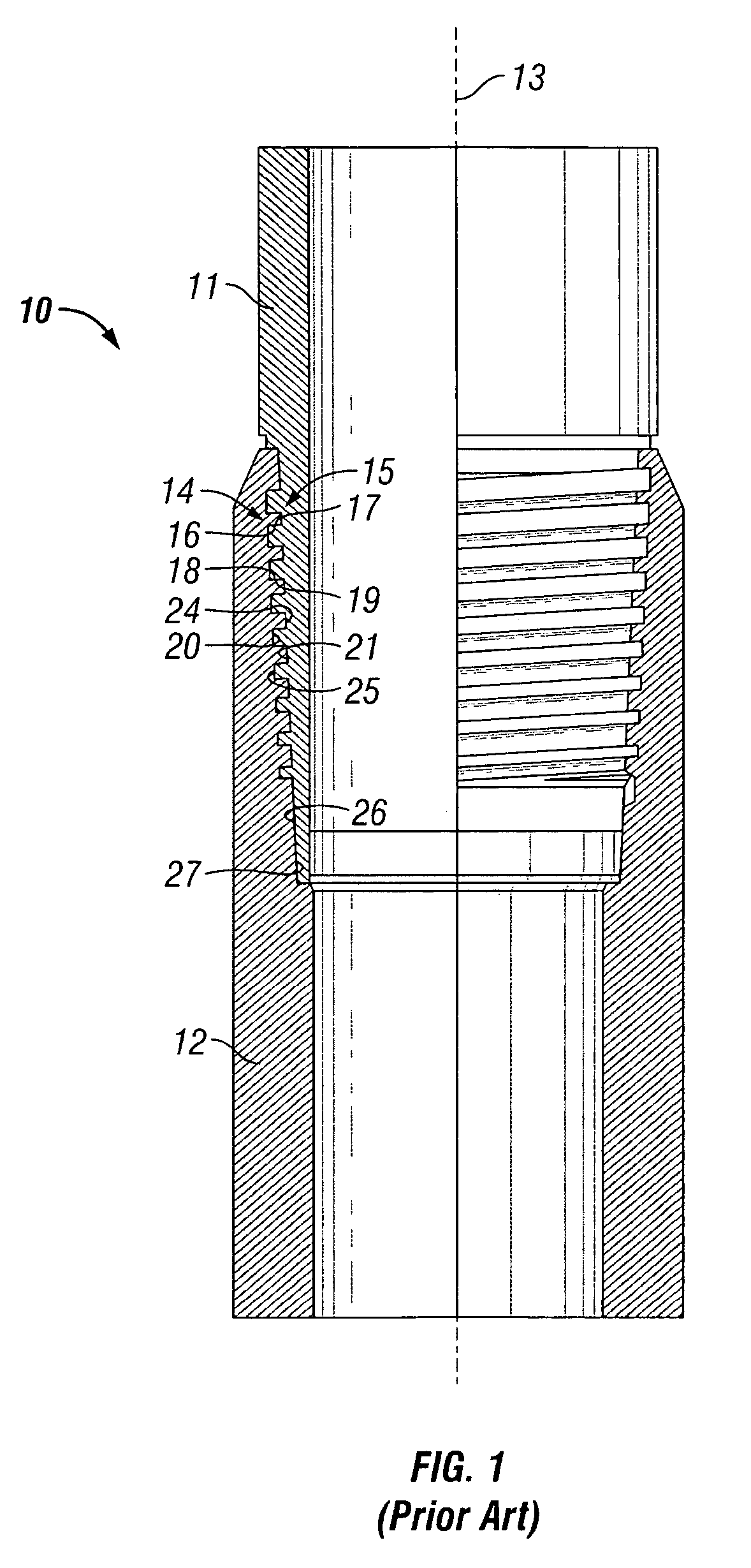

Methods and apparatus are provided for obtaining a secure mechanical connection and a pressure-tight seal in the overlapping area of two telescoping tubular bodies. The two bodies, including the overlapping area, are radially expanded to increase the inside diameter of the bodies. The expansion forces an annular seal in the overlapping area into a pressure-sealing engagement between the bodies. A string of pipe assembled from joints secured to each other by telescoping, threadedly engaged expanded pin and box connections may be radially expanded into a surrounding well bore to provide a cased well having an internal diameter greater than the original internal diameter of the pipe string. The seal in the connection comprises an annular elastomeric seal ring and an annular Teflon spacer ring carried in a specially dimensioned groove formed in either the box or the pin, or both members of the connection. Radial expansion of the connection causes axial contraction of the groove, which acts with the spacer ring to expand the seal ring radially to seal the annular space created between the expanded pin and box.

Owner:ENVENTURE GLOBAL TECH LLC

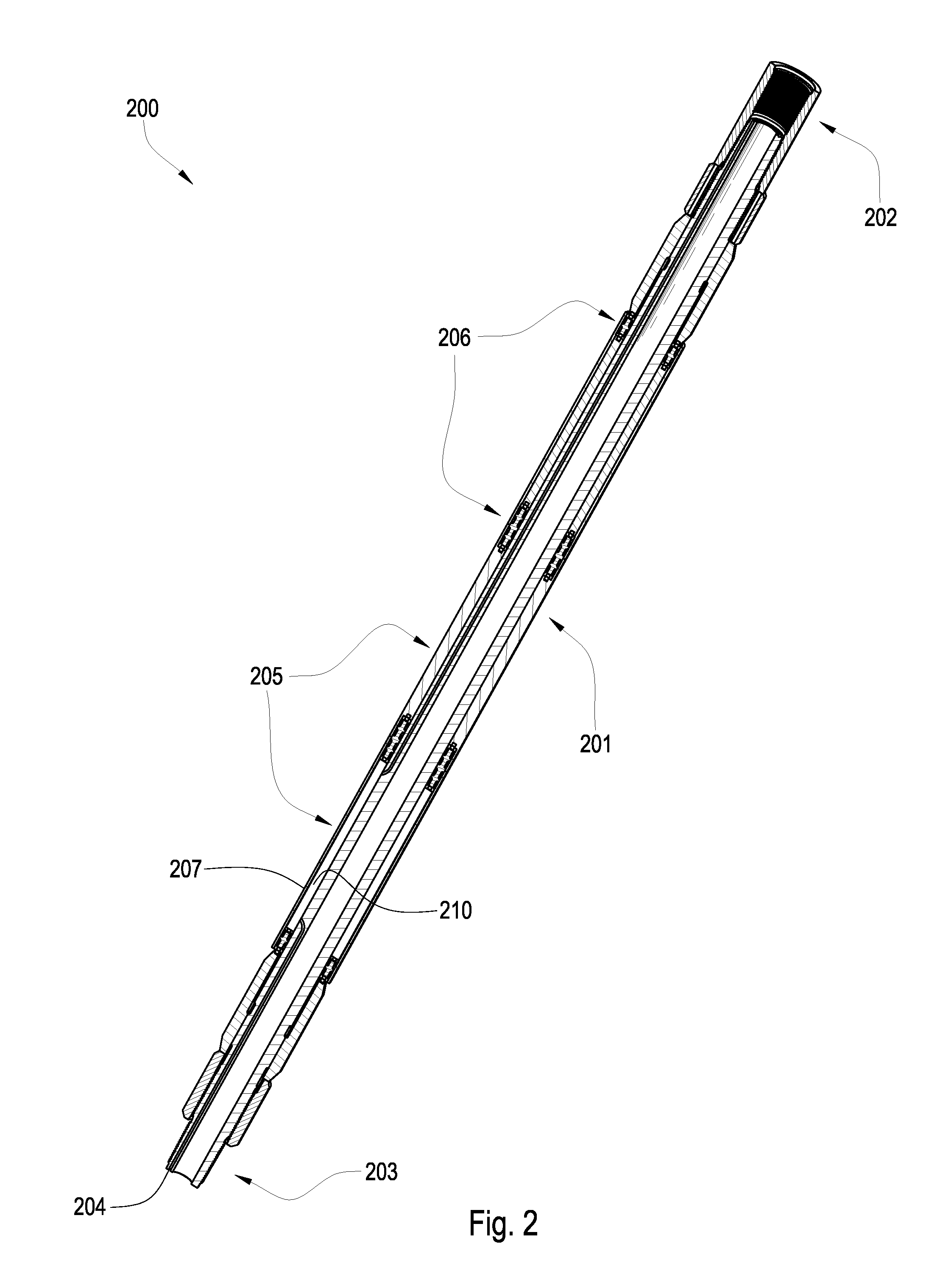

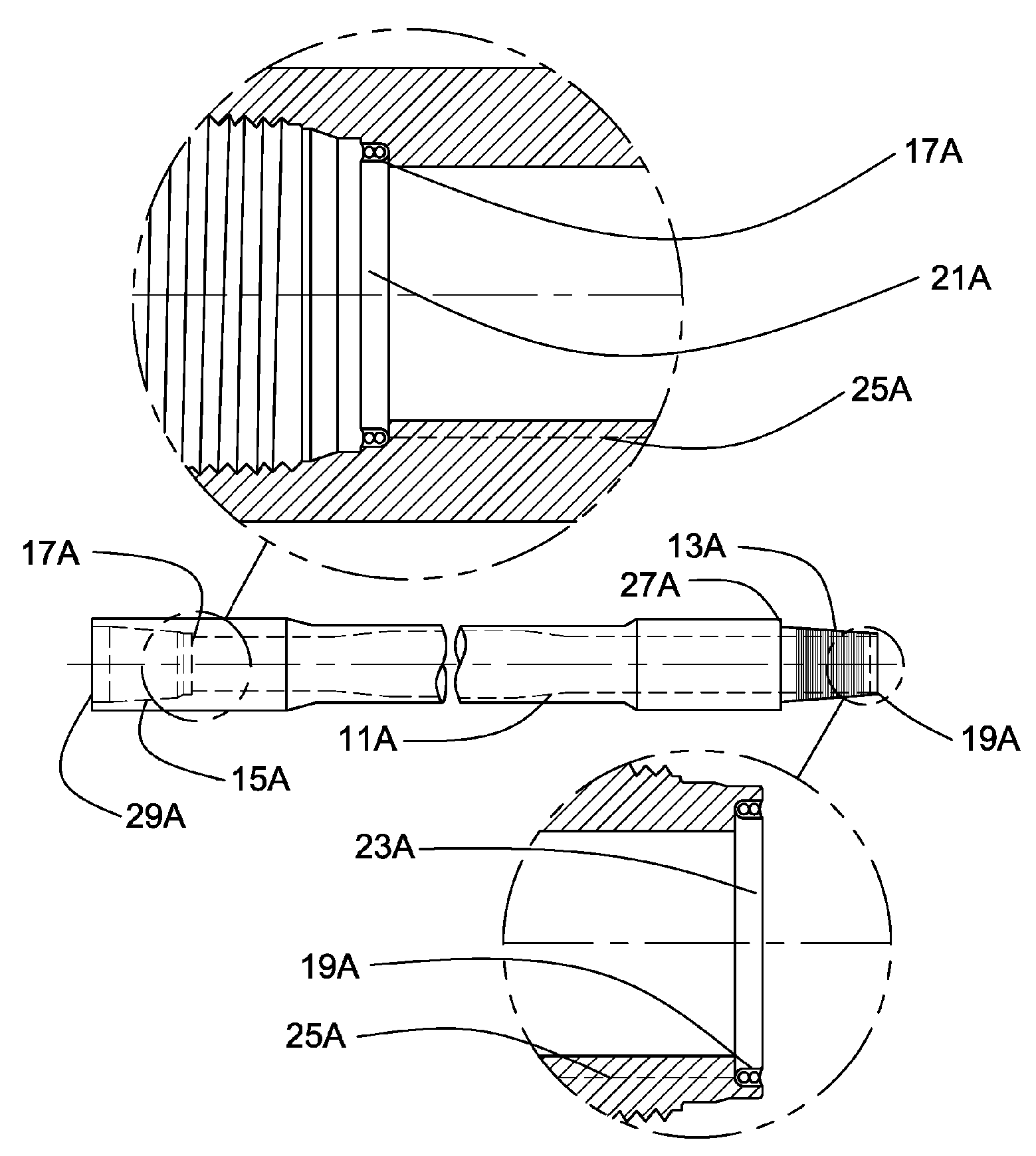

Downhole Coils

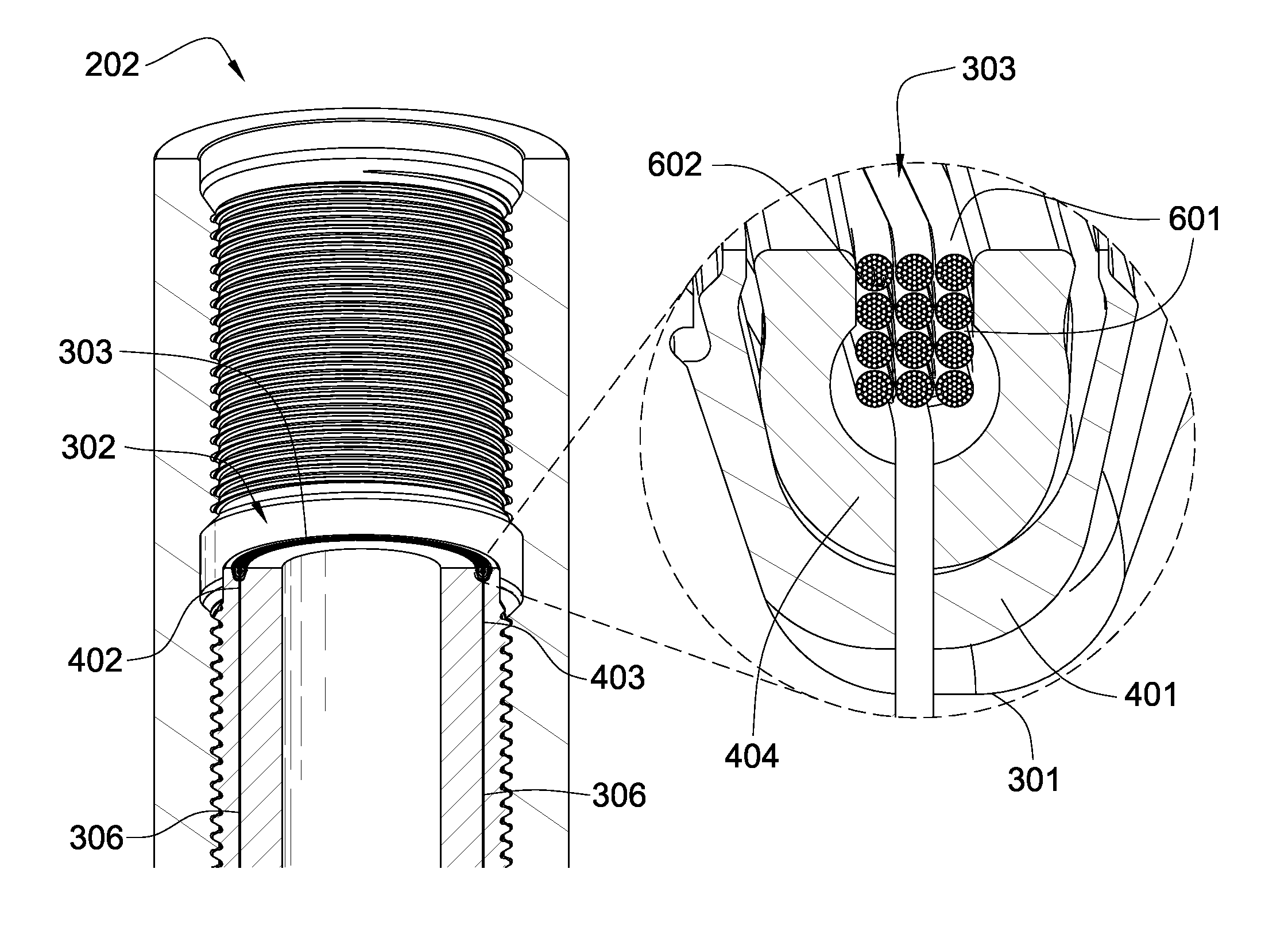

In one aspect of the invention, a downhole tool string component comprises a tubular body with at least one end adapted for threaded connection to an adjacent tool string component. The end comprises at least one shoulder adapted to abut an adjacent shoulder of an adjacent end of the adjacent tool string component. An annular magnetic coupler is disposed within an annular recess formed in the at least one shoulder, and the magnetic coupler comprises a coil in electrical communication with an electrical conductor that is in electrical communication with an electronic device secured to the tubular body. The coil comprises a plurality of windings of wire strands that are electrically isolated from one another and which are disposed in an annular trough of magnetic material secured within the annular recess.

Owner:SCHLUMBERGER TECH CORP

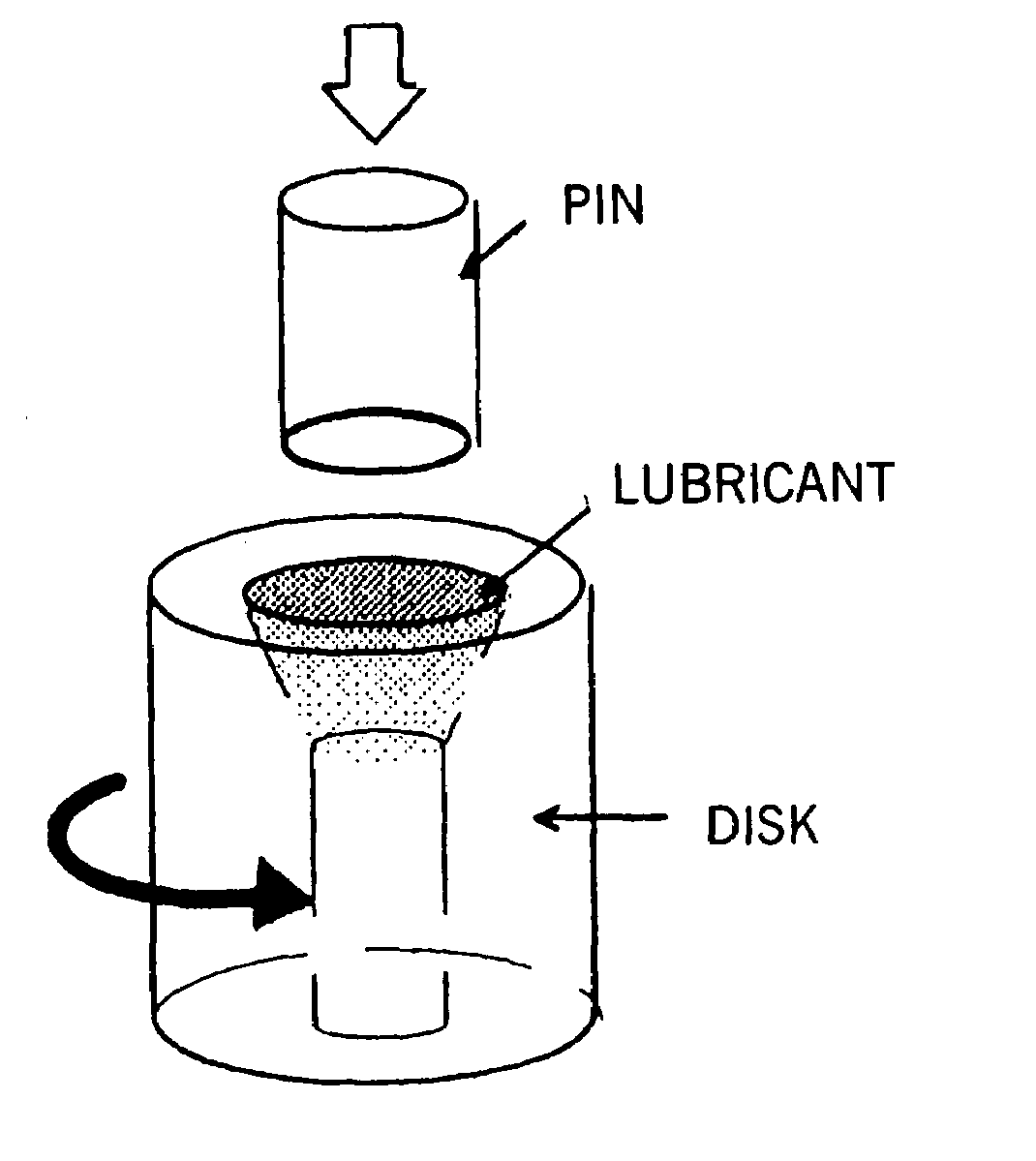

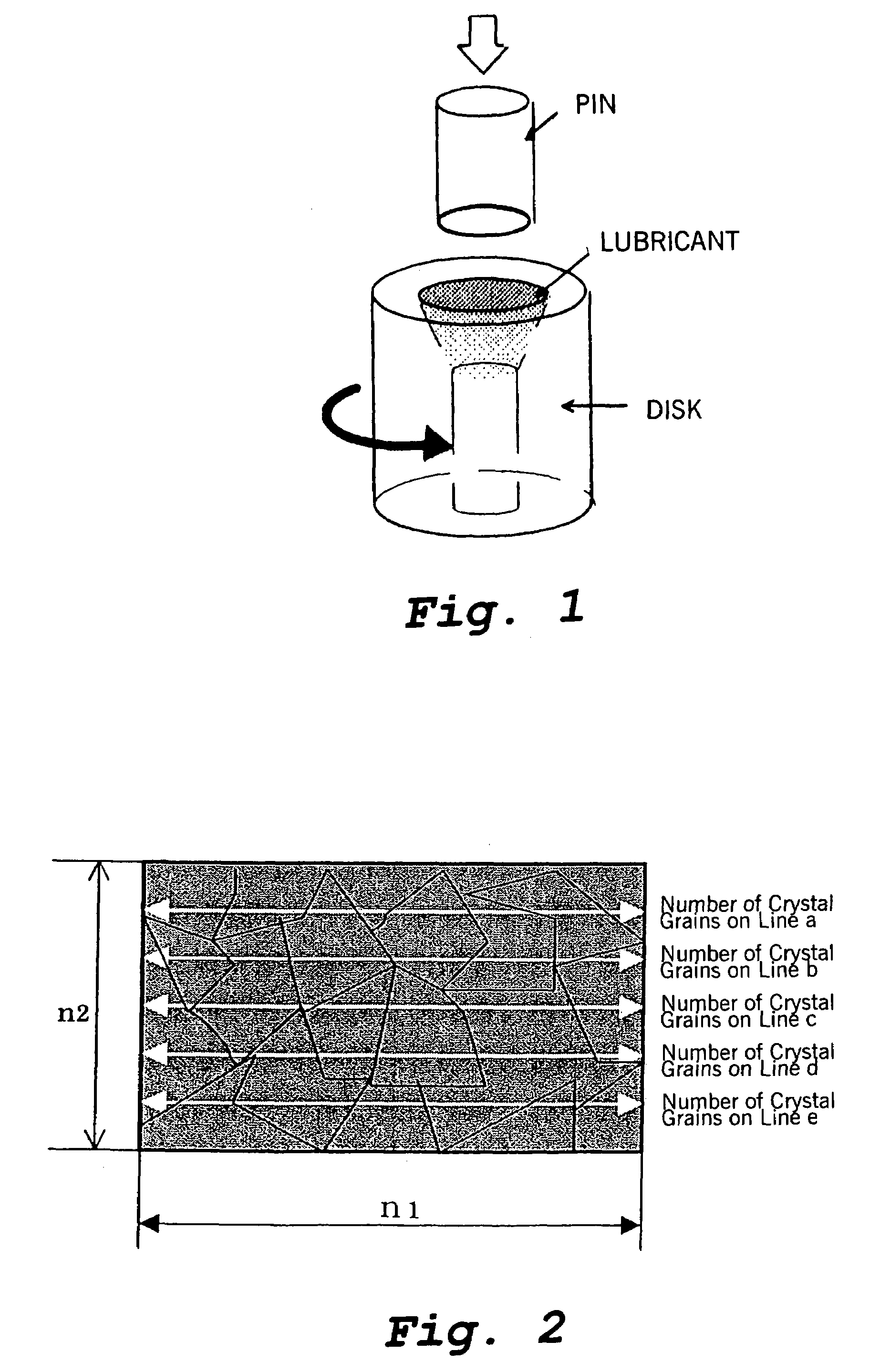

Joint for steel pipe having high galling resistance and surface treatment method thereof

InactiveUS6027145AShorten heating timeImprove the lubrication effectDrilling rodsPretreated surfacesEpoxyPolyamide

PCT No. PCT / JP95 / 02034 Sec. 371 Date May 23, 1997 Sec. 102(e) Date May 23, 1997 PCT Filed Oct. 4, 1995 PCT Pub. No. WO96 / 10710 PCT Pub. Date Apr. 11, 1996An object of the present invention is to provide galling resistance to a threaded joint used for an oil well pipe. On a thread portion and a metallic sealing portion of the joint, there is provided a manganese phosphate chemical formation coating layer, or alternatively there are provided a nitriding layer of 1 to 20 mu m thickness and a manganese phosphate chemical formation coating layer of 5 to 30 mu m thickness, and also there is coated a solid lubricant which contains powder of molybdenum disulfide or tungsten disulfide and also contains one of epoxy resin, furan resin and polyamide resin as an essential component, and a ratio of composition is maintained at a specific value, so that a solid lubricant coating layer of 10 to 45 mu m thickness can be formed by heating. Due to the above surface treatment, even when the frequency of repetition of fastening and unfastening of the joint is increased, the occurrence of galling can be prevented over a long period of time.

Owner:NSCT PREMIUM TUBULARS

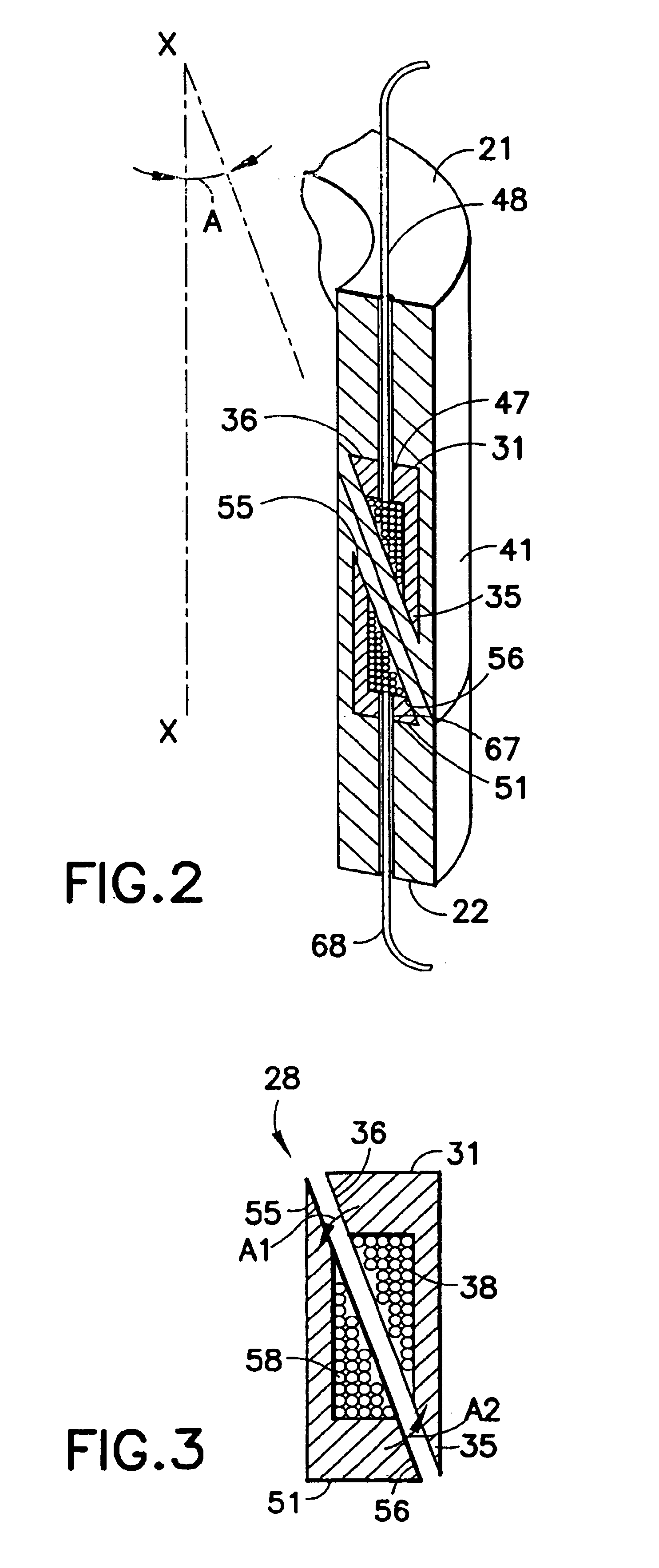

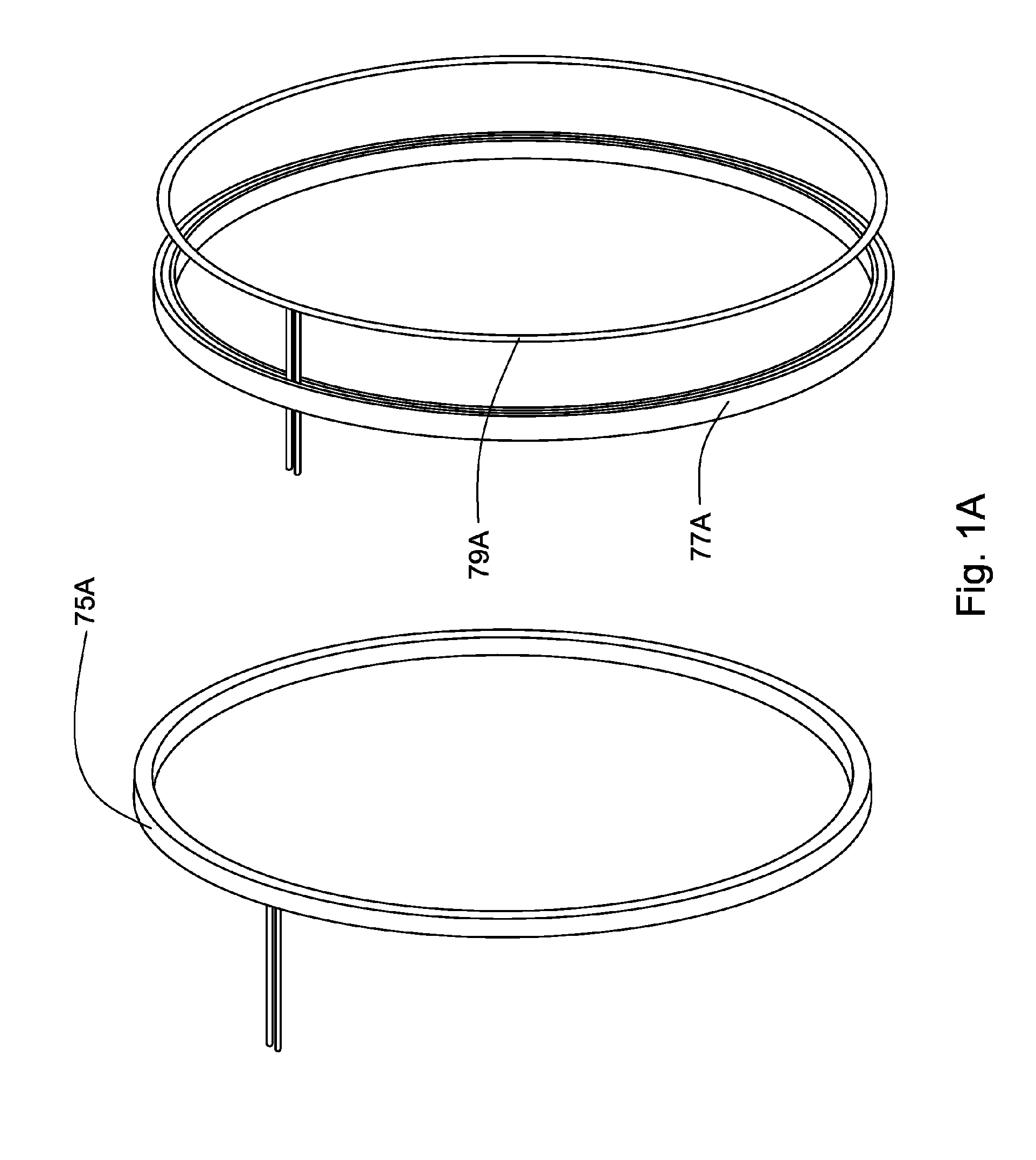

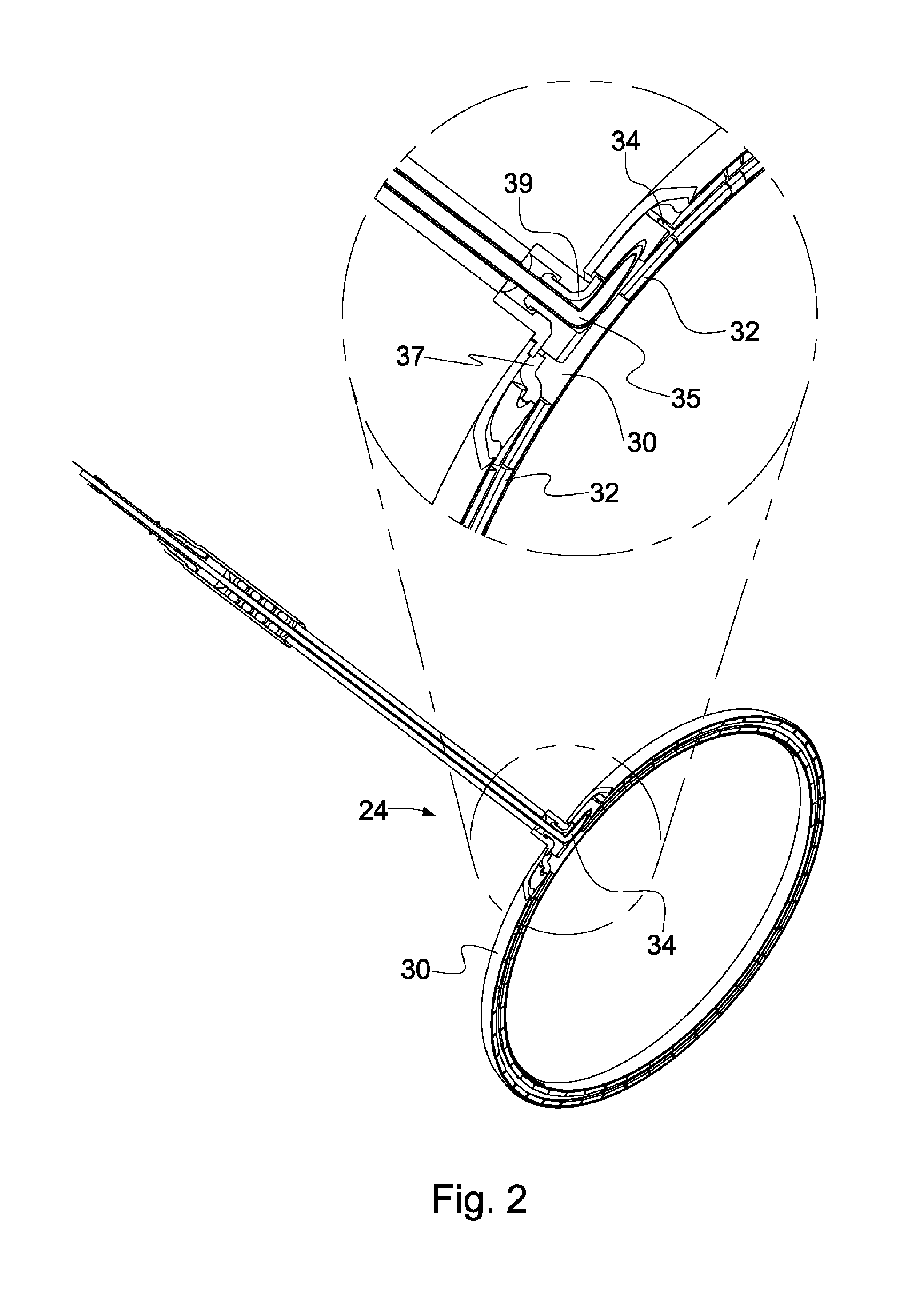

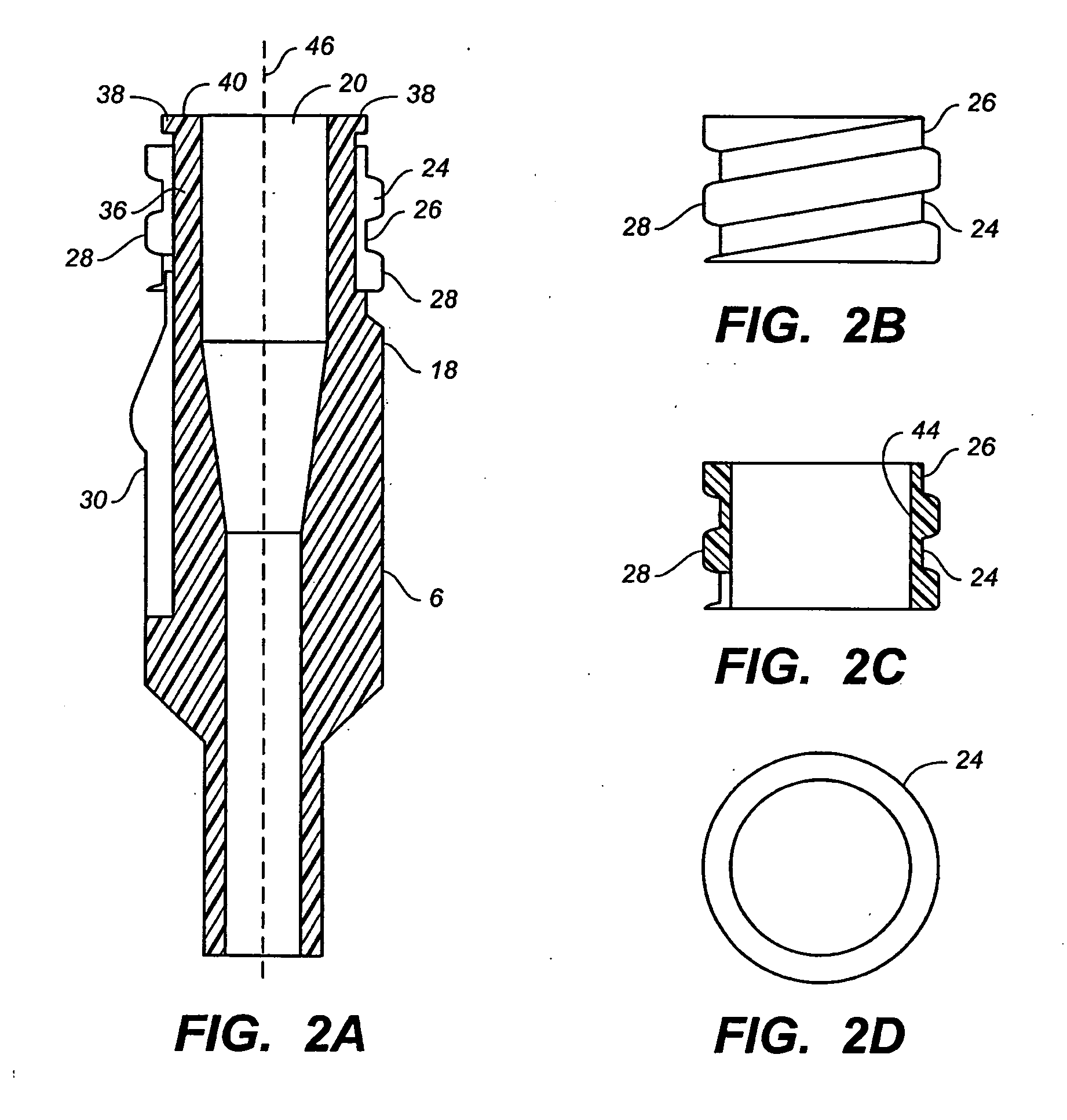

Low-loss inductive couplers for use in wired pipe strings

A first flux-loop inductive coupler element electrically couples with a second flux-loop inductive coupler element. The first flux-loop inductive coupler element comprises a first ring-like core having high magnetic permeability and a conical-section annular first face transverse to the plane of the first core. The first face has a first annular groove separating a first conical-section larger-diameter face and a first conical-section smaller-diameter face. A first coil is wound within the annular groove. The first and second cores form a low-reluctance closed magnetic path around the first coil and a second coil of the second flux-loop inductive coupler element.A first current-loop inductive coupler element electrically couples with a second current-loop inductive coupler element. The first current-loop inductive coupler element has a first high-conductivity, low-permeability shaped belt of a first end of a first pipe joint, a first ring-like core located at the first end, and a first electrically conductive coil wound about the first ring-like core. The first high-conductivity, low-permeability shaped belt partially encloses the first coil. It is shaped to cooperate with the second high-conductivity, low-permeability shaped belt of an adjacent second pipe joint having a second electrically conductive coil and a second high-conductivity, low-permeability shaped belt to create a closed toroidal electrical conducting path. The closed toroidal electrical conducting path encloses the first coil and the second coil when the first and second pipe joints are mated.

Owner:SCHLUMBERGER TECH CORP

Internal coaxial cable seal system

The invention is a seal system for a coaxial cable and is placed within the coaxial cable and its constituent components. A series of seal stacks including load ring components and elastomeric rings are placed on load bearing members within the coaxial cable sealing the annular space between the coaxial cable and an electrical contact passing there through. The coaxial cable is disposed within drilling components to transmit electrical signals between drilling components within a drill string. The seal system can be used in a variety of downhole components, such as sections of pipe in a drill string, drill collars, heavy weight drill pipe, and jars.

Owner:INTELLISERV

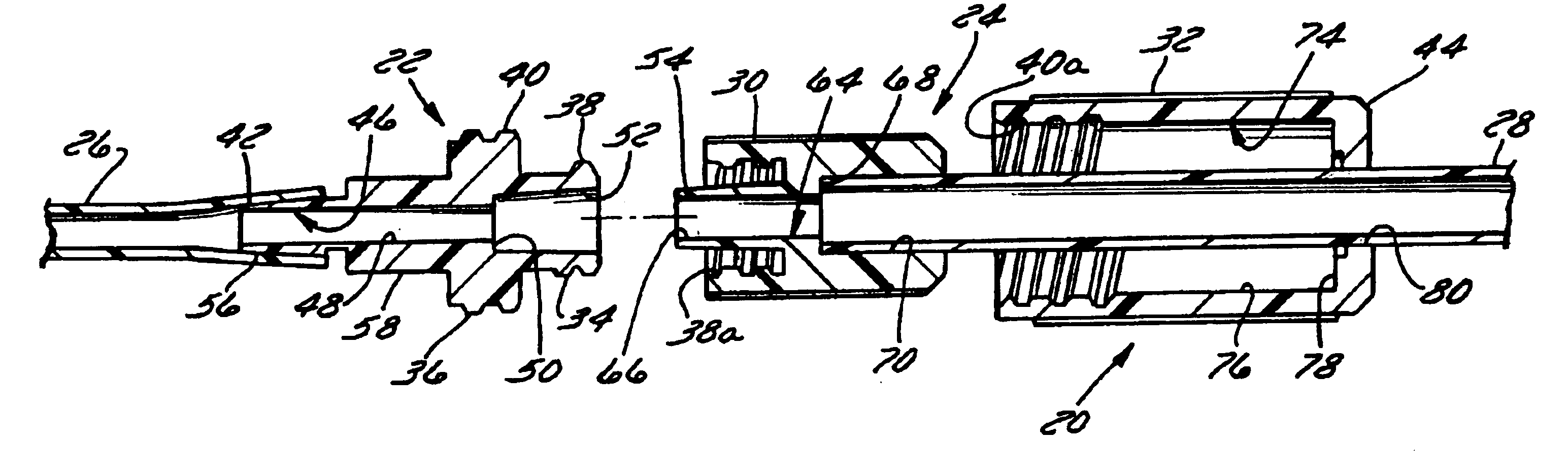

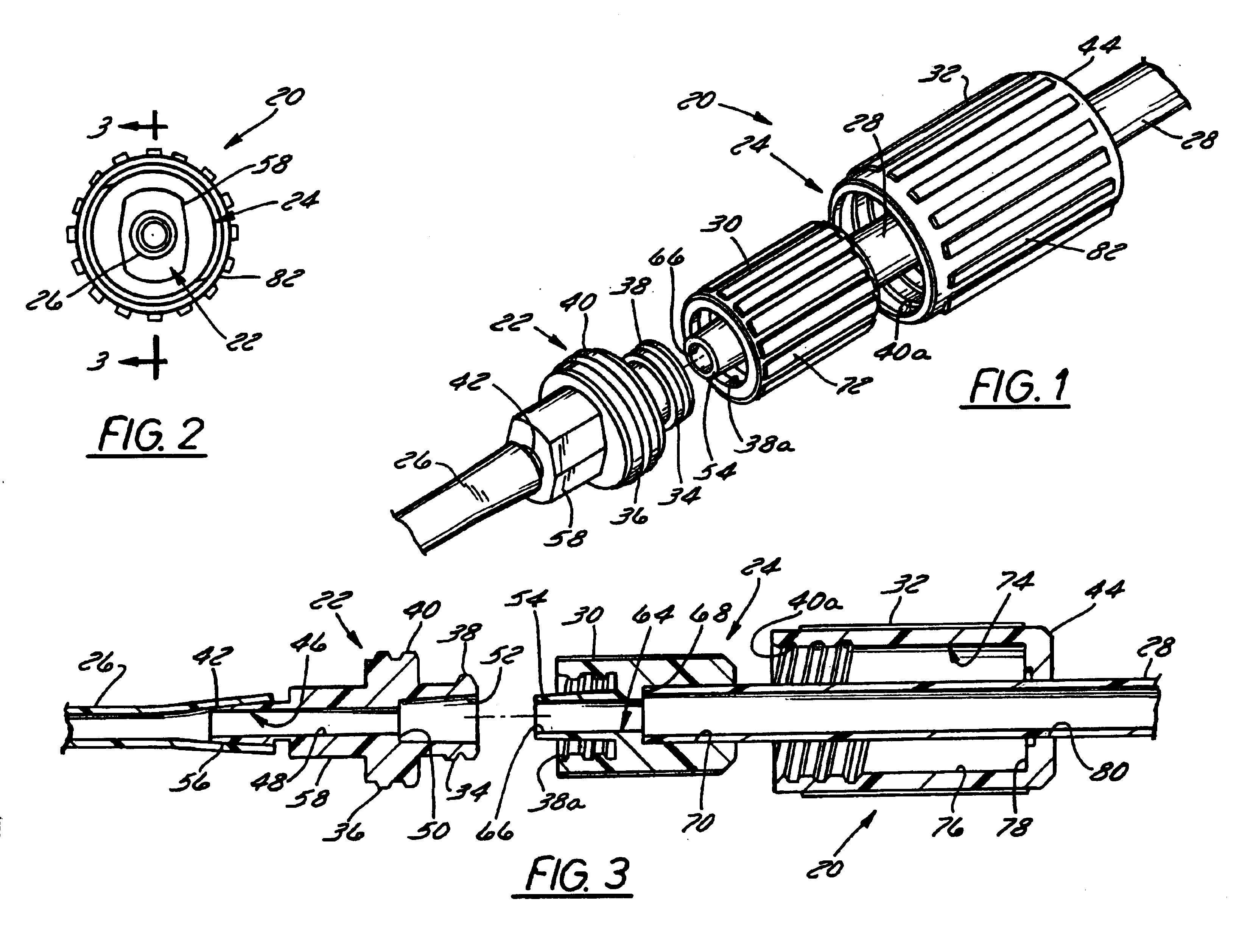

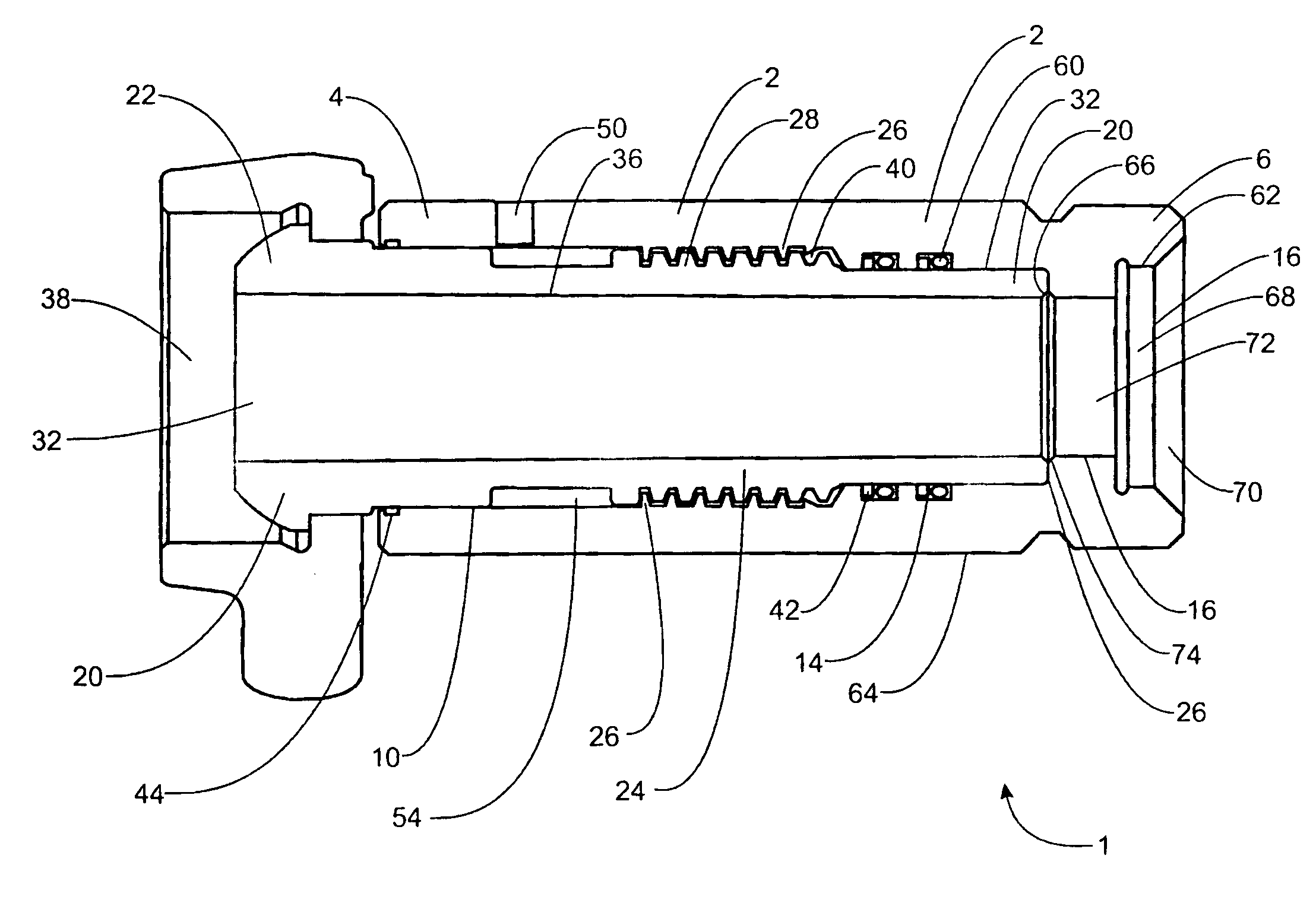

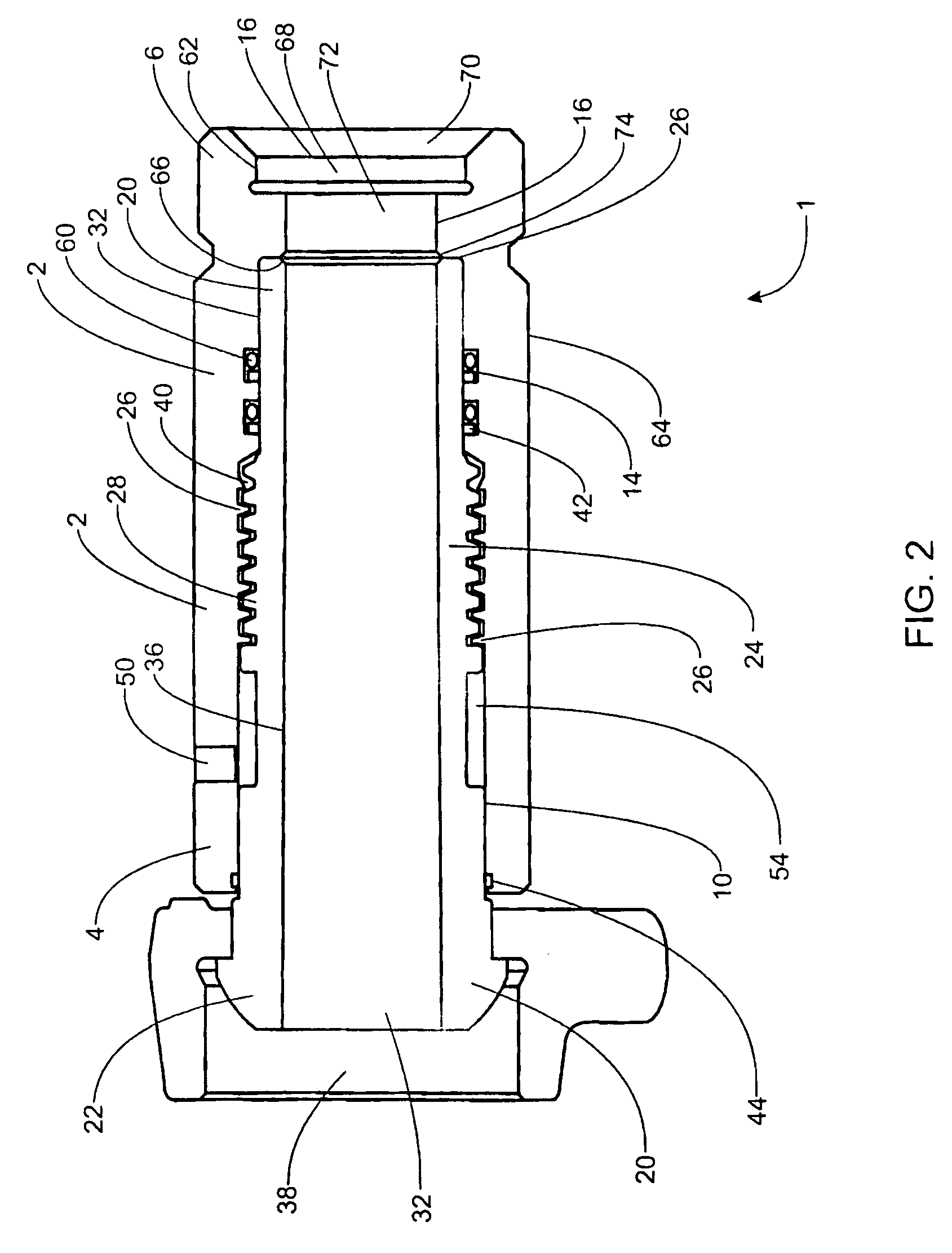

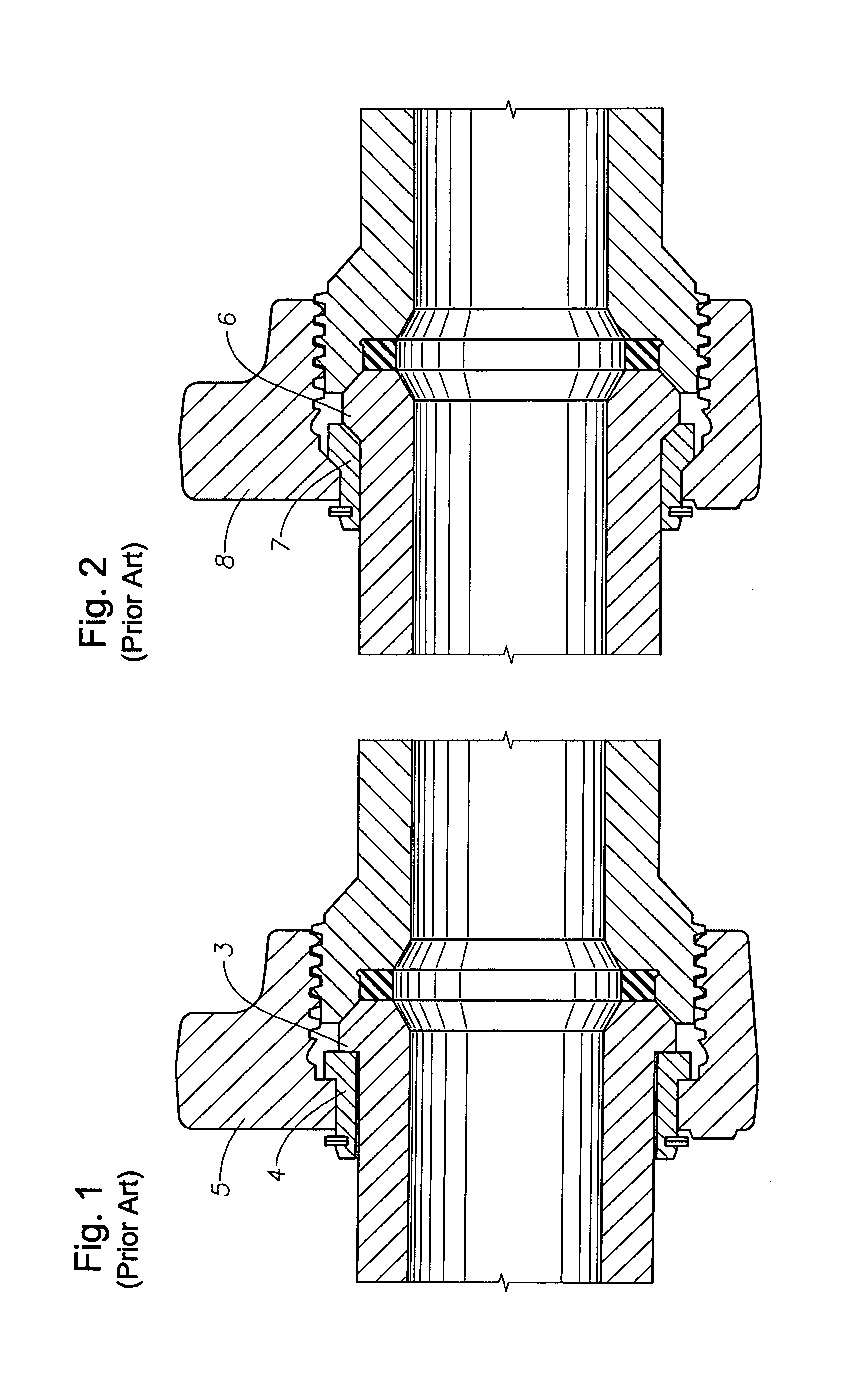

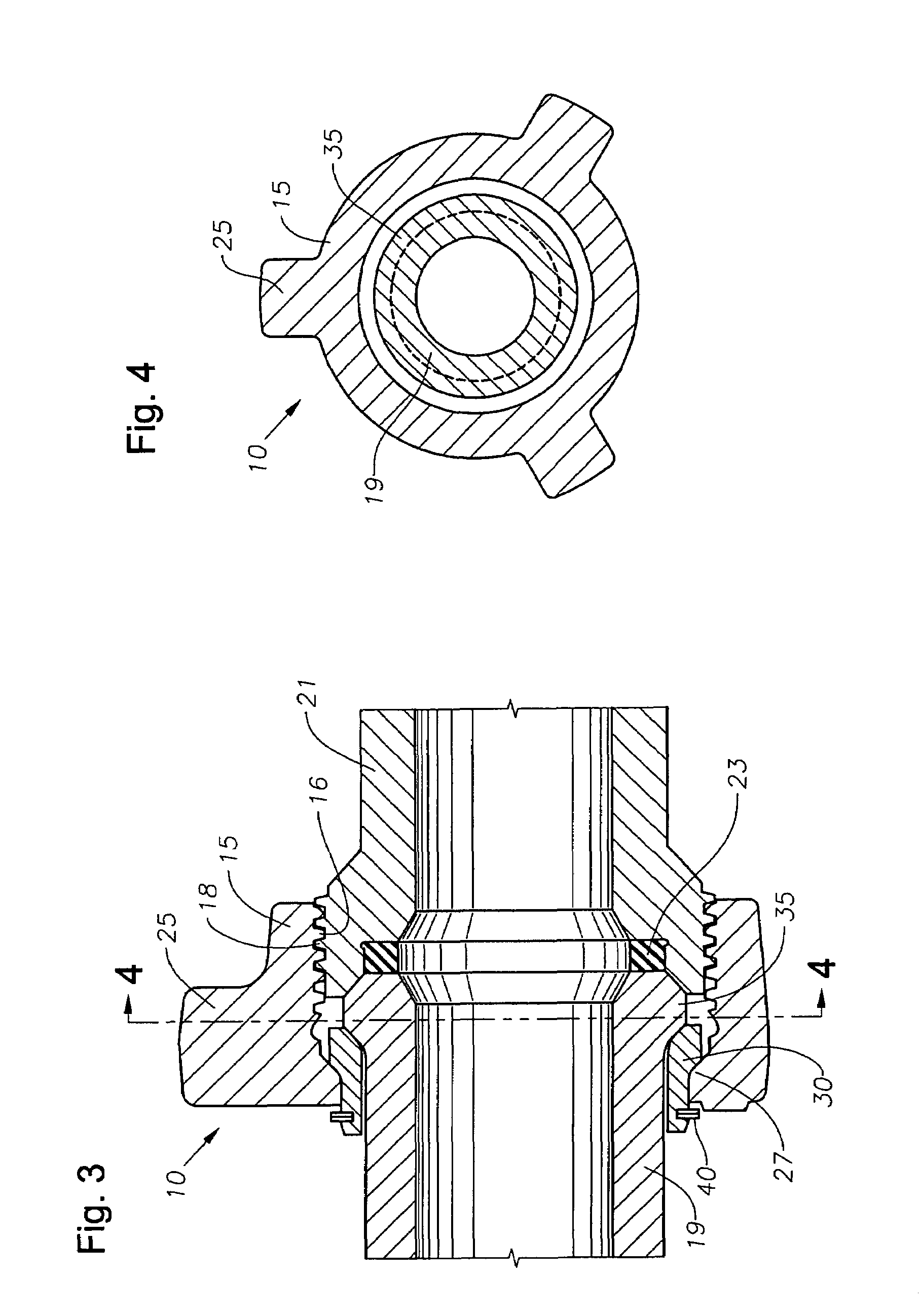

High torque threaded tool joint for drill pipe and other drill stem components

InactiveUS6030004AIncrease torqueEnhancing the torque resisting characteristicsDrilling rodsNutsStress concentrationRoot surface

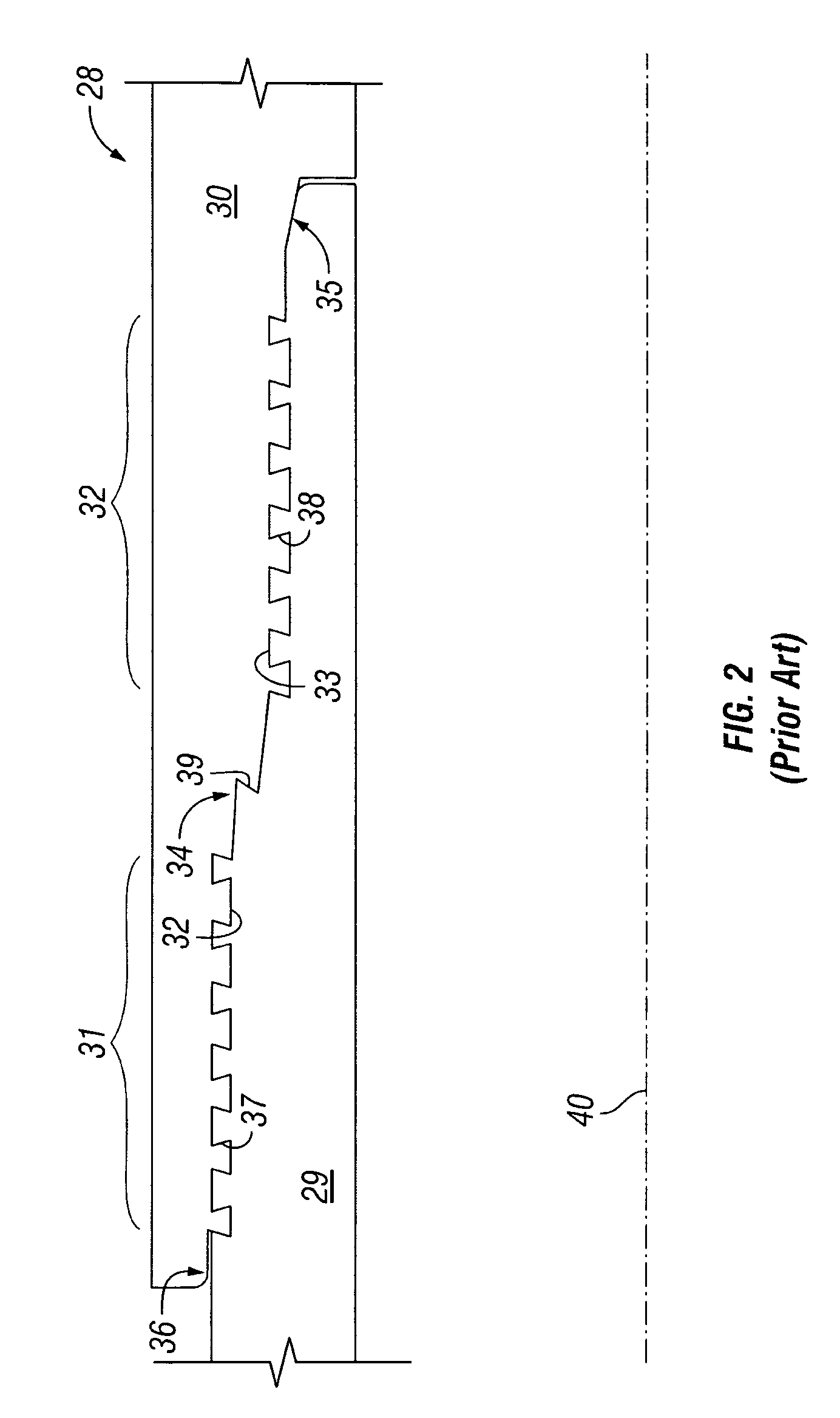

A double shouldered high torque resistance threaded connection for drill stem components having enhanced resistance to torque forces, tensile loads and material stress and fatigue is disclosed. The tool joint is provided with threads having a 75 DEG included angle between the thread flanks thereof and with generally elliptical root surfaces to minimize material stress and fatigue during operation under high torque and high tensile loads. When made up, the double intrerengaging shoulders of the threaded tool joint are in firm face to face engagement permitting torque forces and tensile loads to propagate through the tool joint in a manner that minimizes bending forces and minimizes high stress concentration so that the resulting service life of the tool joint is significantly enhanced.

Owner:VALLOUREC OIL & GAS FRANCE SAS

Medical tubing connector

A medical connector, usable to securely couple a first tubular medical device to a second tubular medical device, includes first and second fittings cooperating with the first and second medical devices, respectively. The first and second fittings may each include a nipple, a ferrule, or some other structure that is connected to the associated medical device and that is connectable to the other fitting. The second fitting may additionally include a tubular sleeve that slides over the second medical device and the ferrule or other component of the second fitting. The two components of the second fitting are sequentially connectable to the first fitting through distinctly different motions to provide a redundant, secure connection. For example, the first fitting may include a first set of left-handed threads and a second set of right-handed threads, and the components of the second fitting may have corresponding left-handed and right-handed threads.

Owner:A B KORKOR MEDICAL

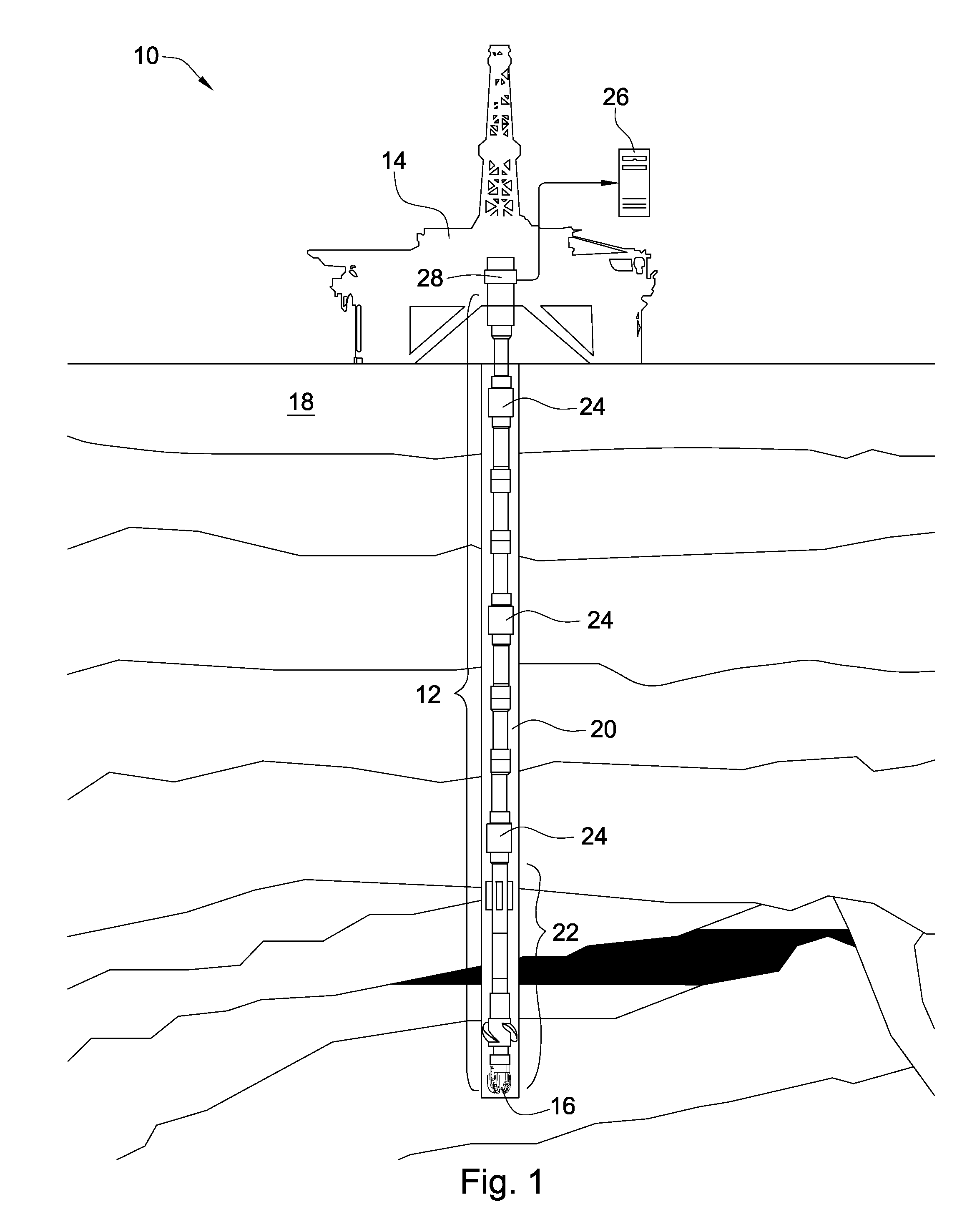

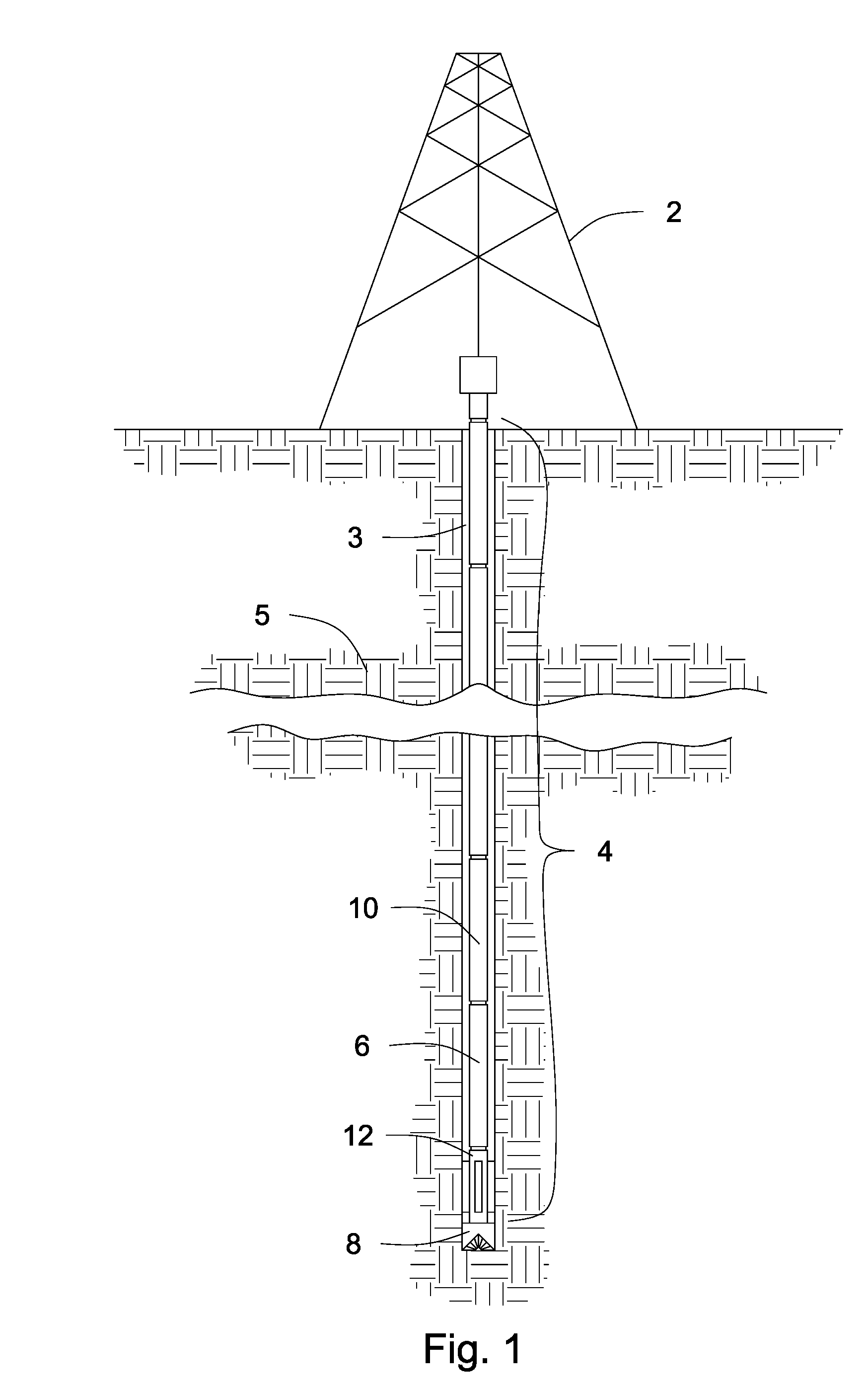

Downhole data transmission system

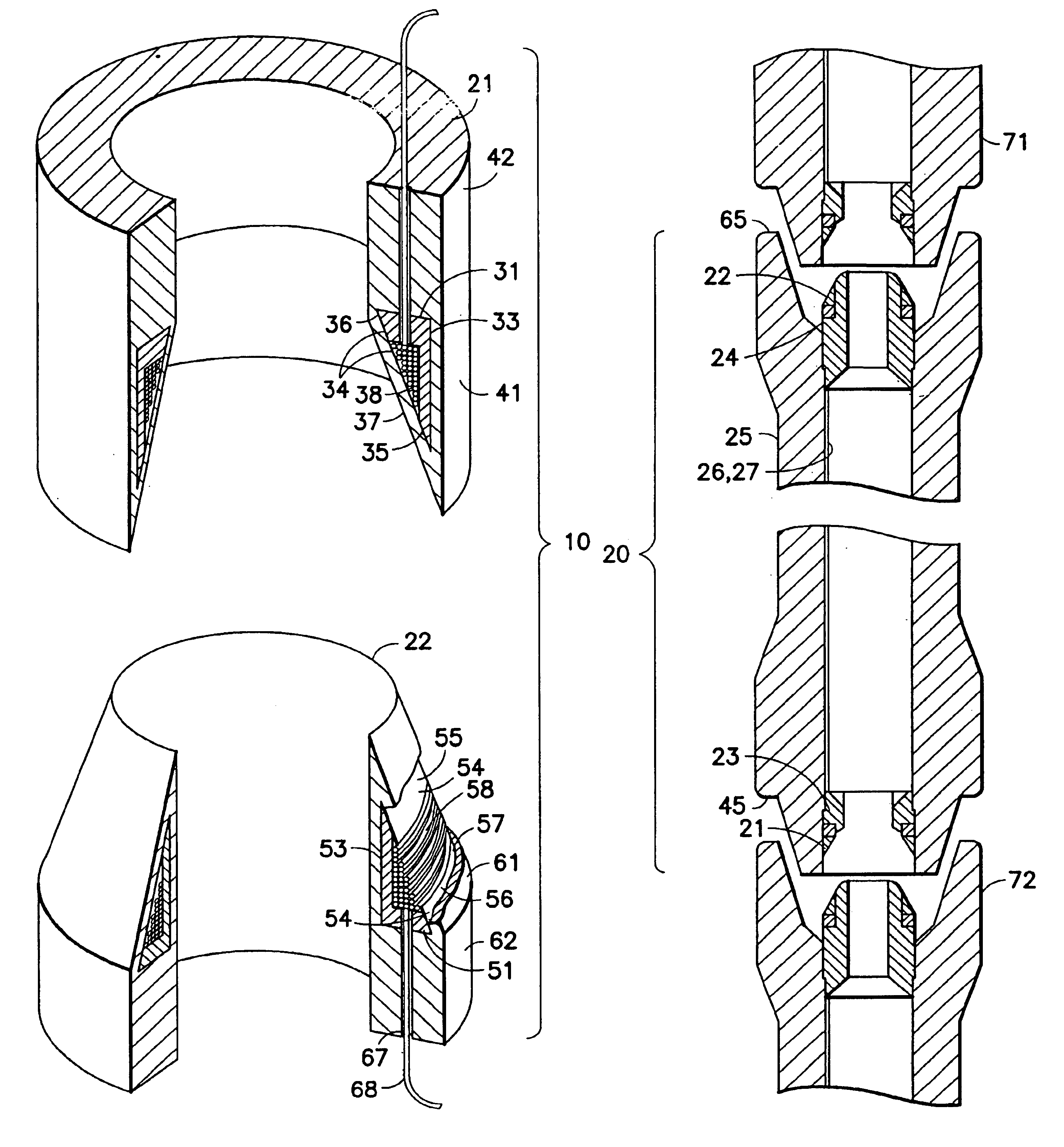

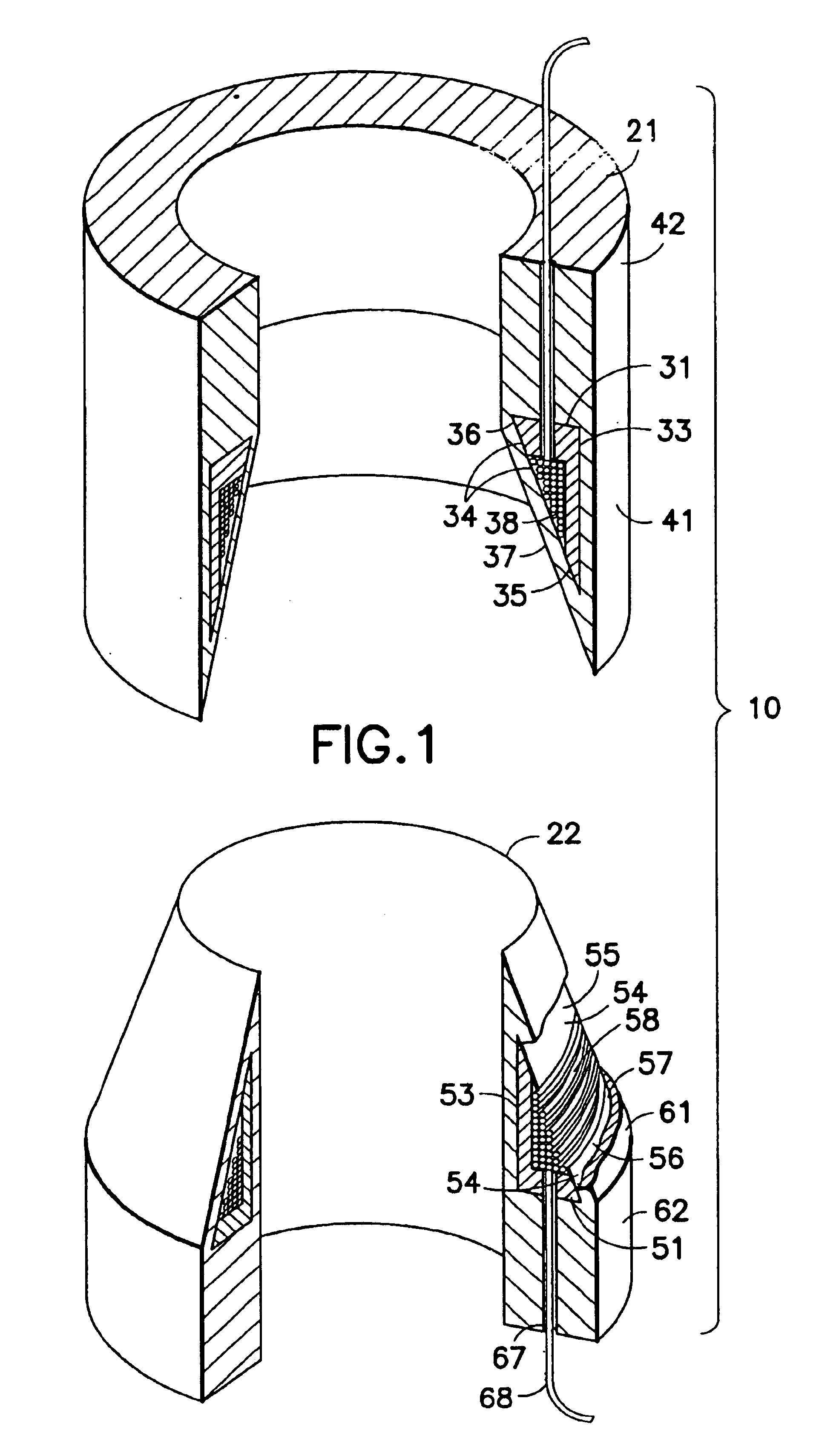

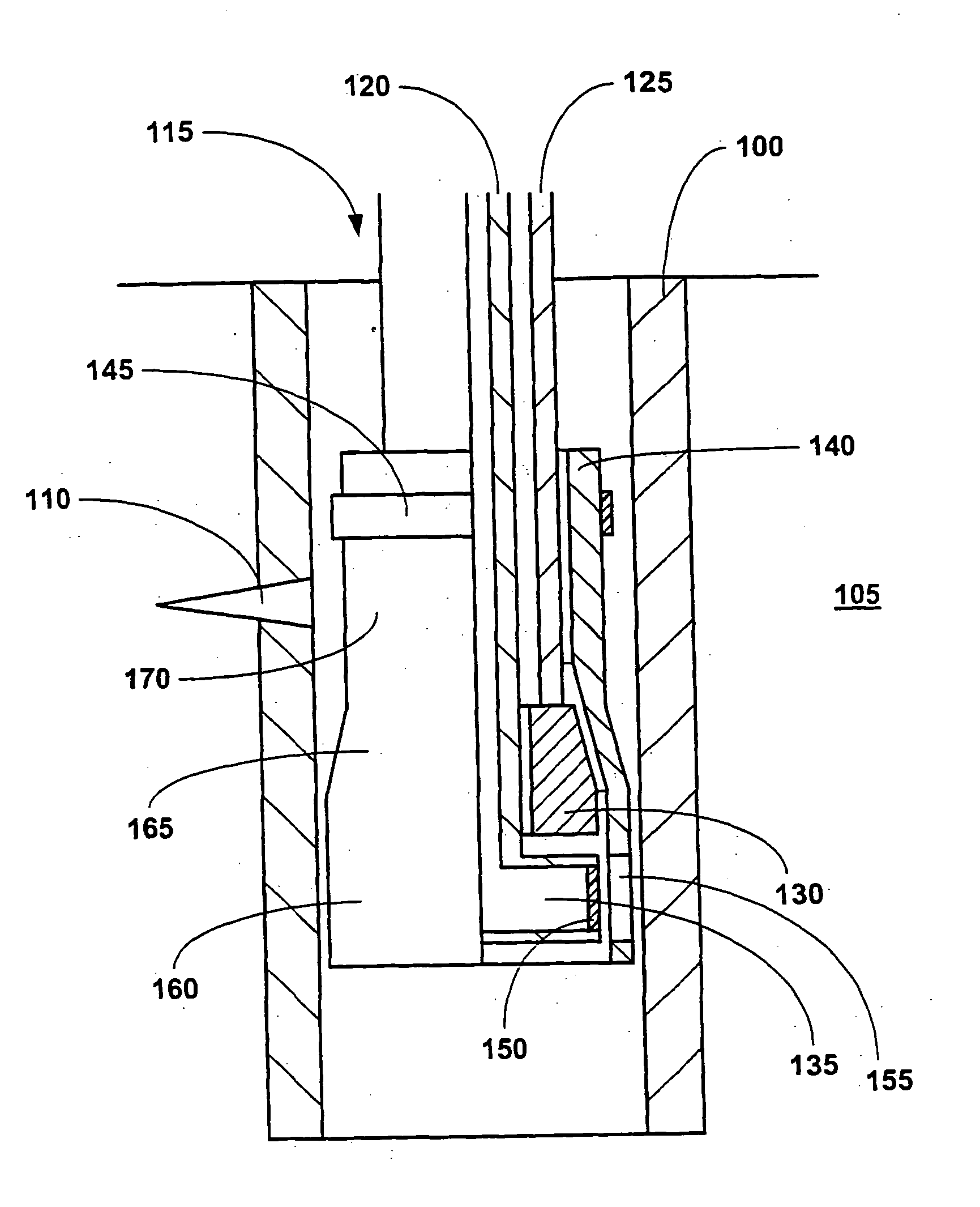

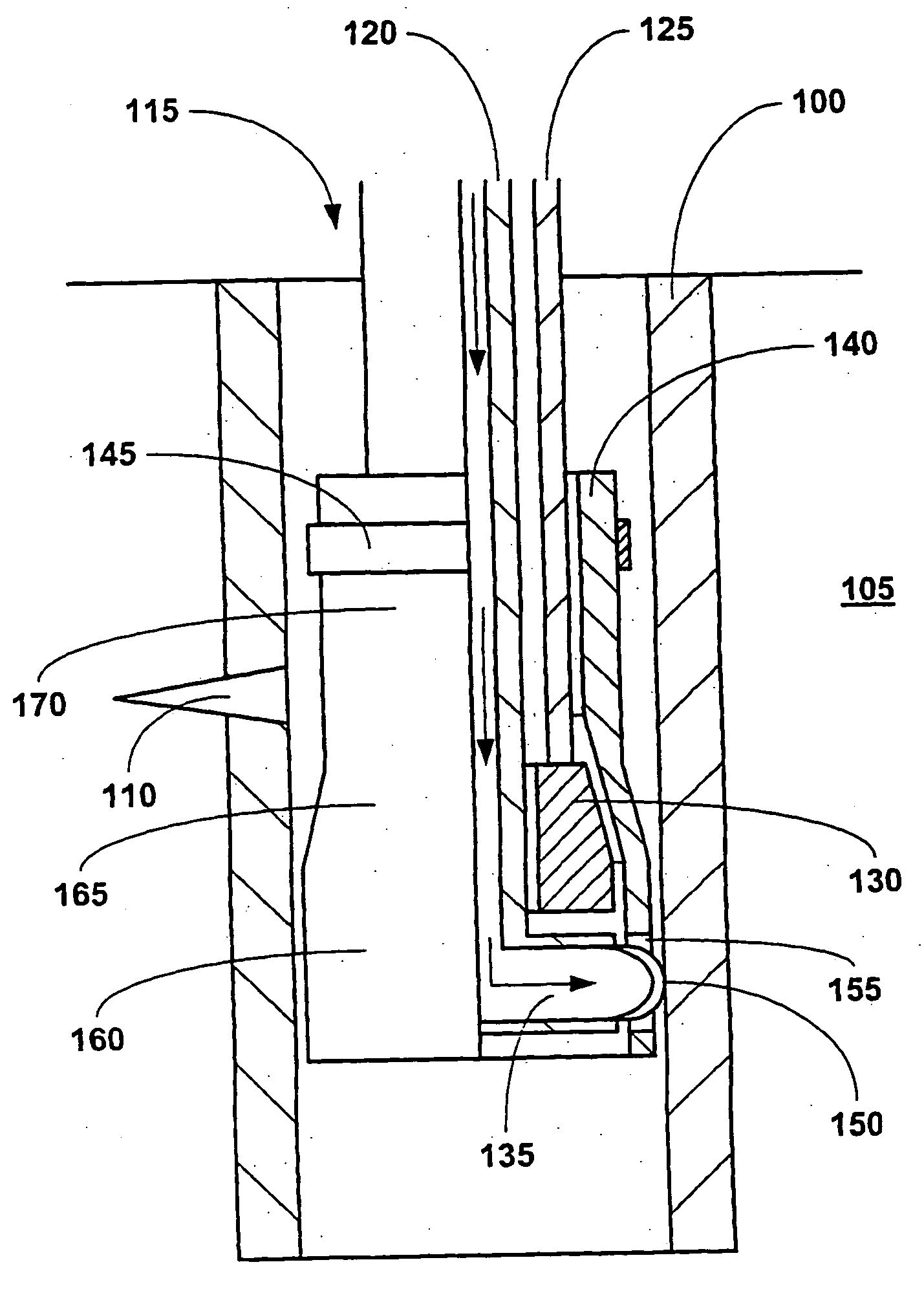

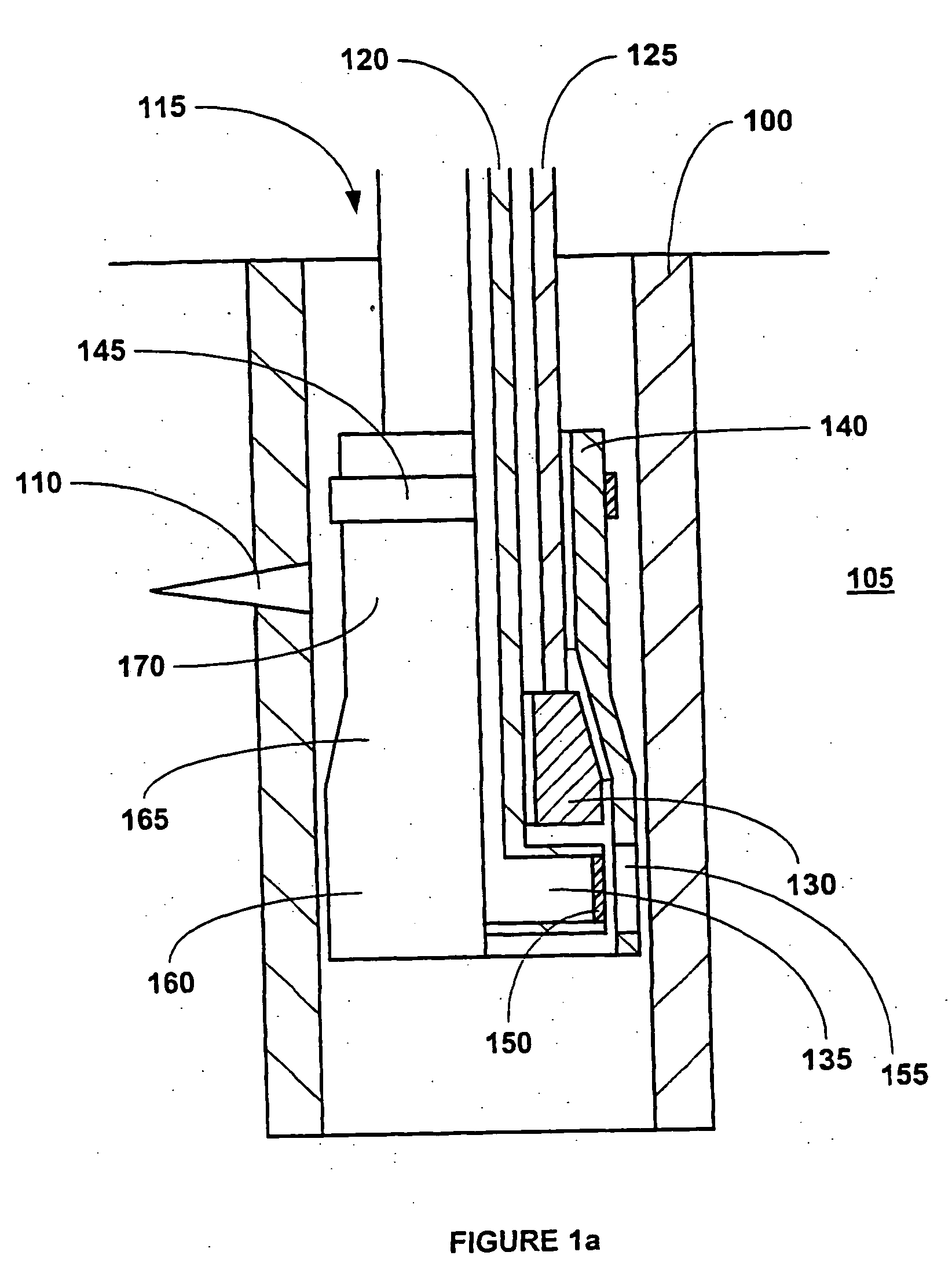

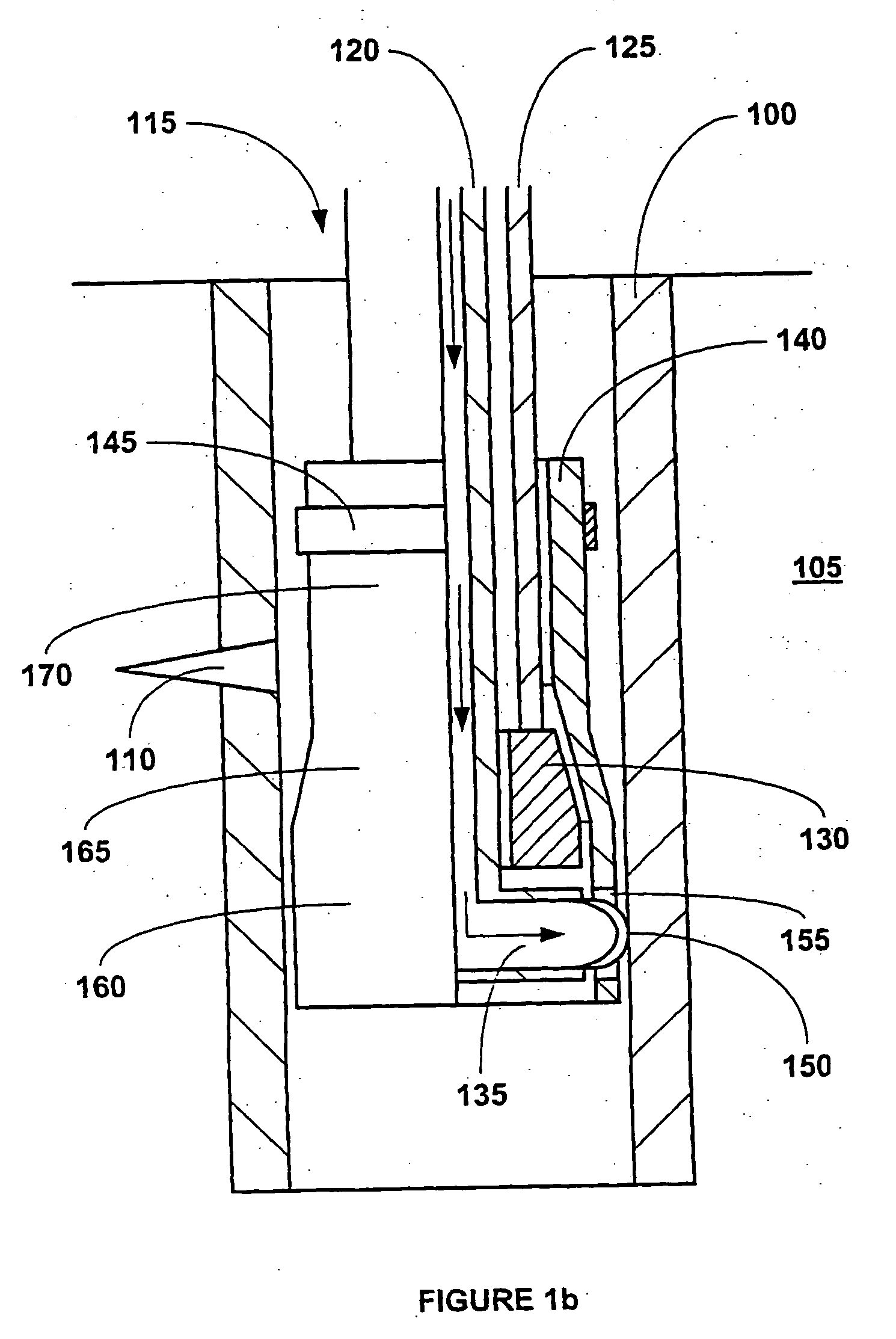

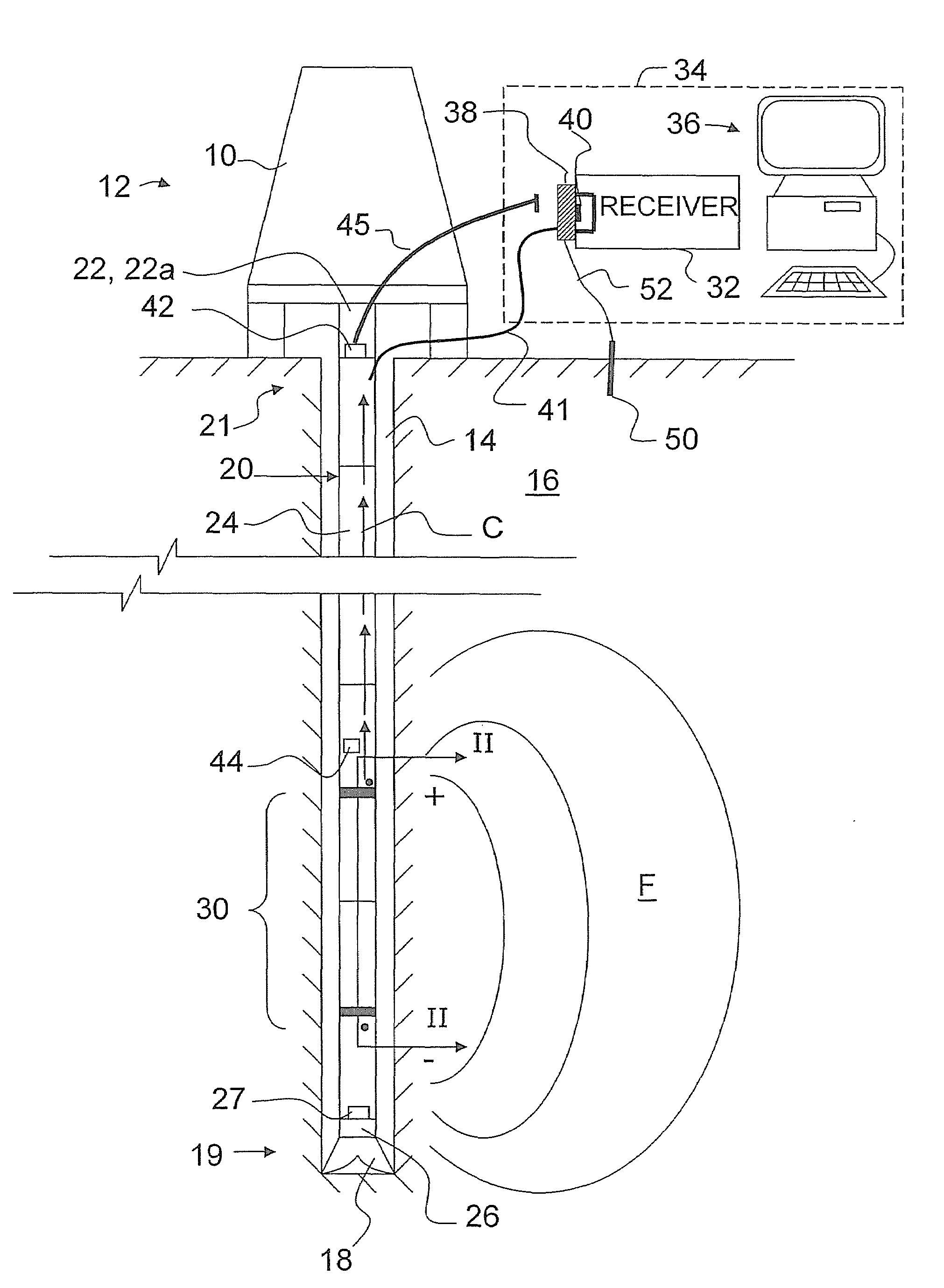

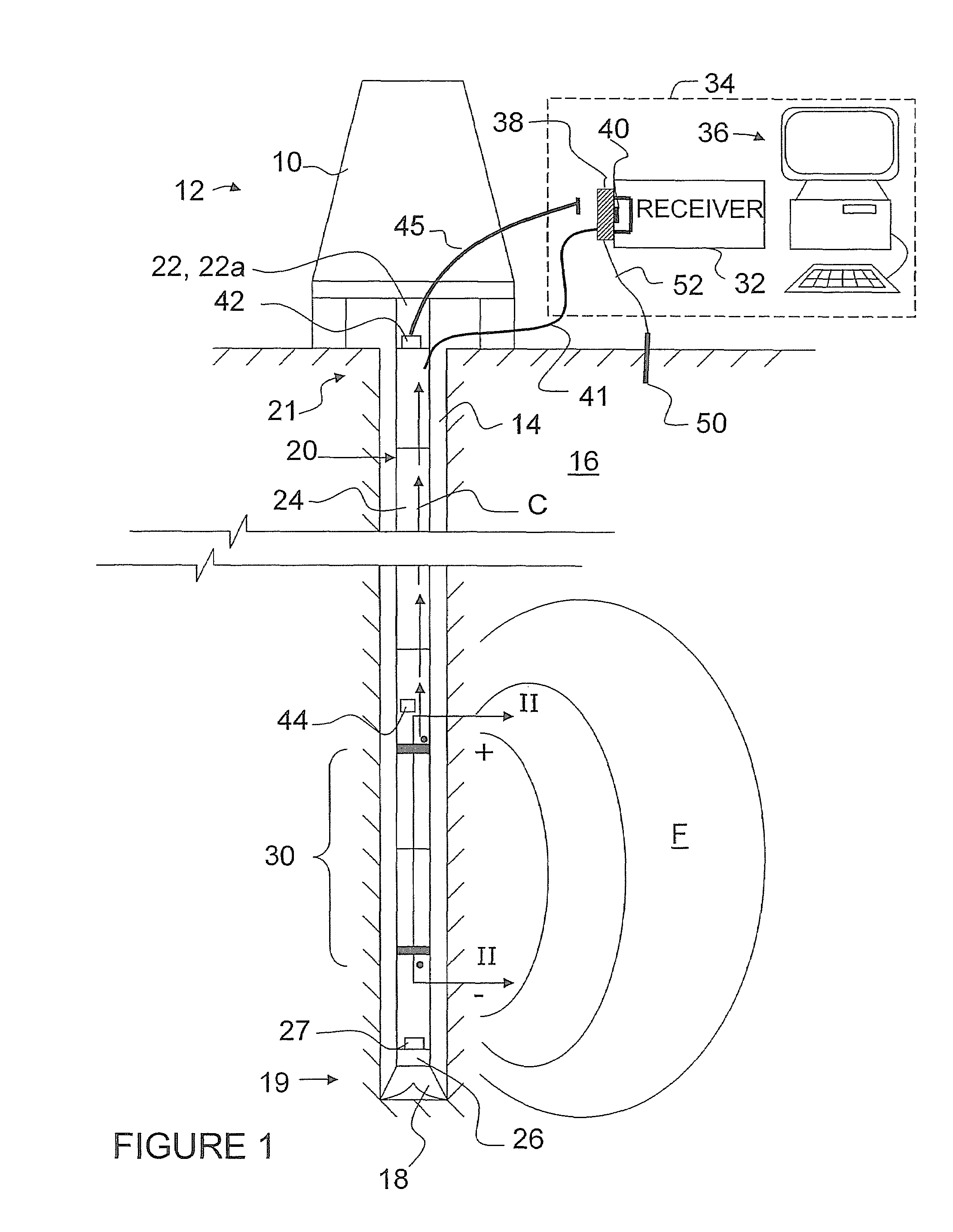

InactiveUS7064676B2Highly reliable communicationReduce complexityElectric signal transmission systemsSurveyElectricityElectrical conductor

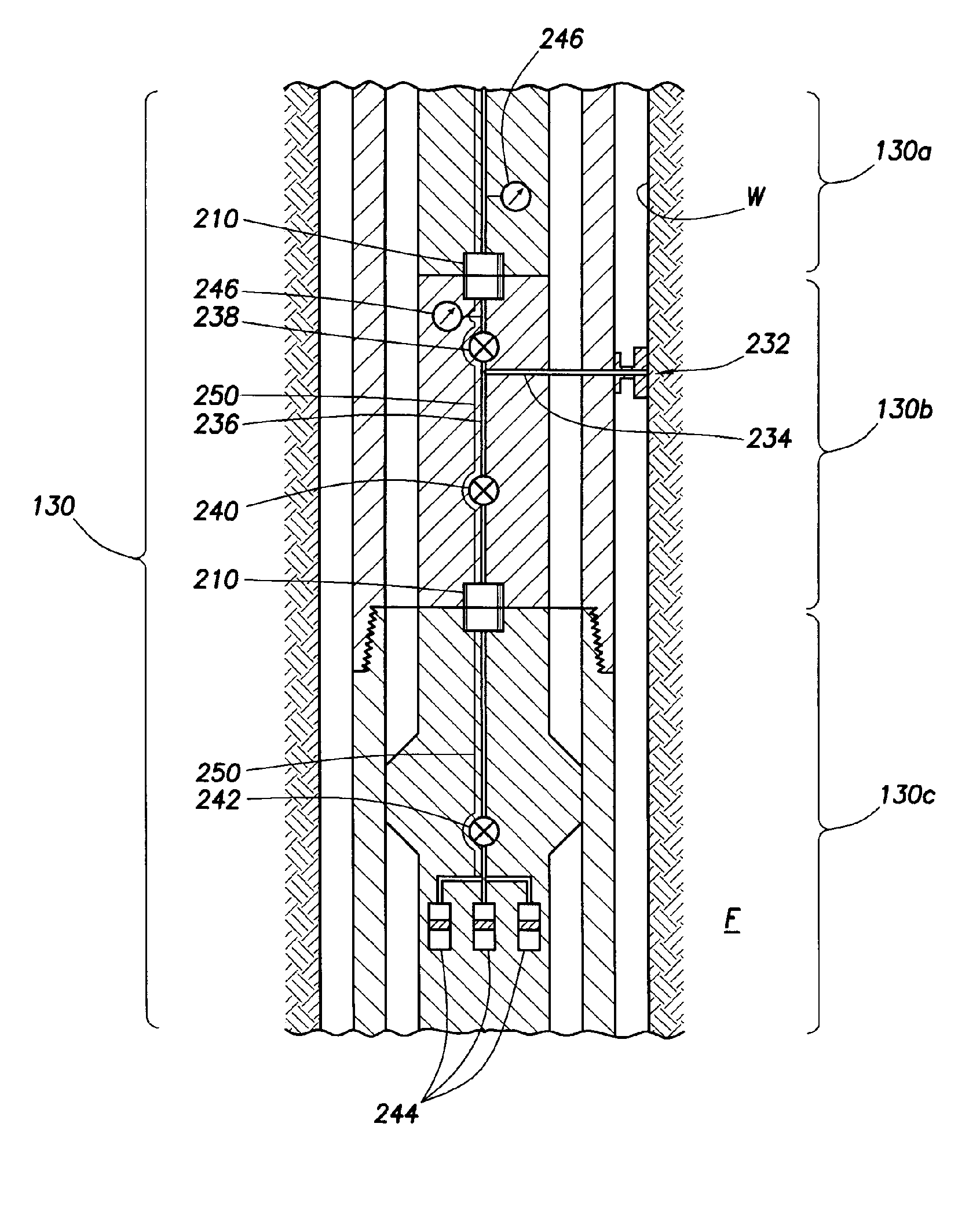

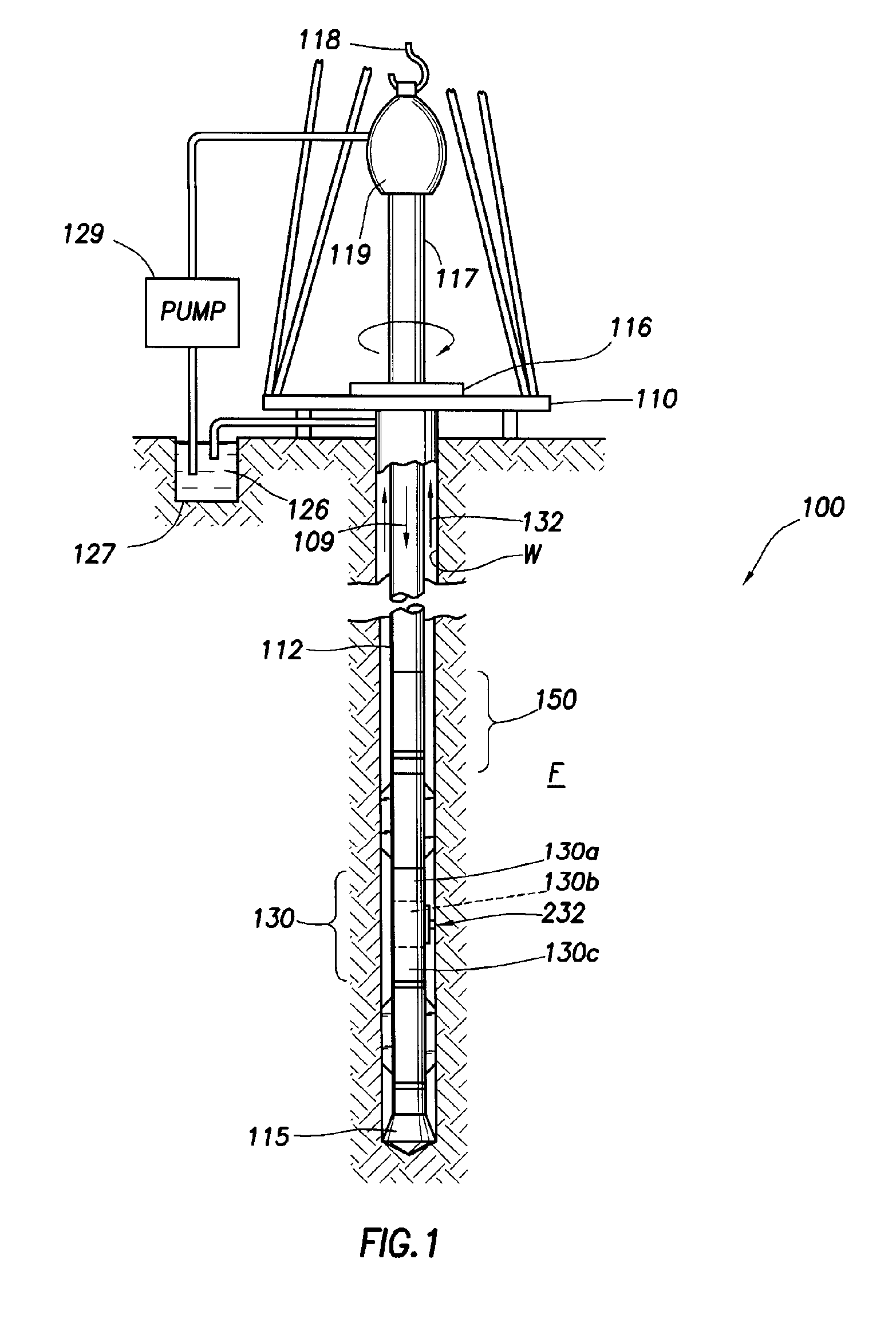

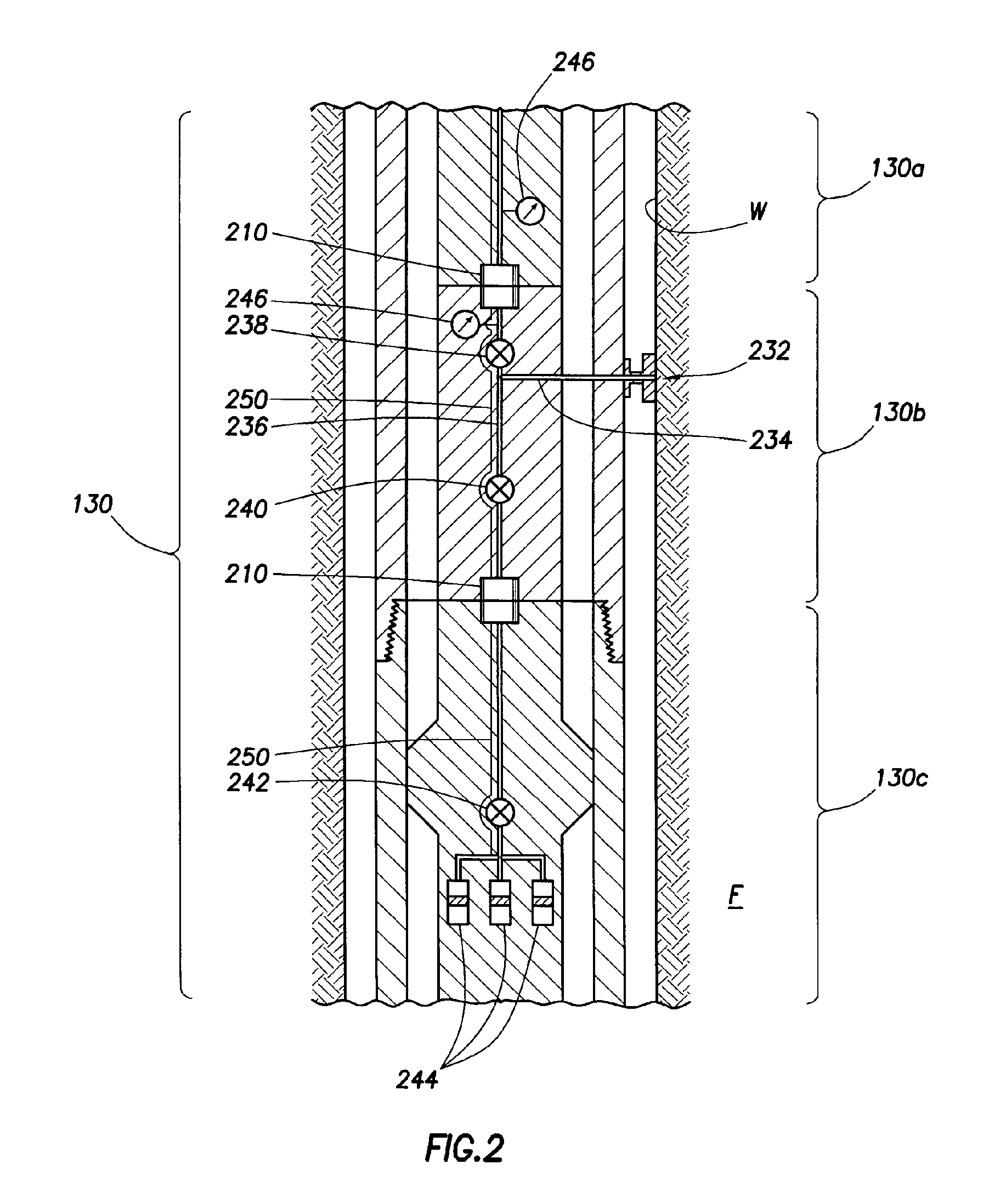

A system for transmitting data through a string of downhole components. In one aspect, the system includes first and second magnetically conductive, electrically insulating elements at both ends of the component. Each element includes a first U-shaped trough with a bottom, first and second sides and an opening between the two sides. Electrically conducting coils are located in each trough. An electrical conductor connects the coils in each component. In operation, a varying current applied to a first coil in one component generates a varying magnetic field in the first magnetically conductive, electrically insulating element, which varying magnetic field is conducted to and thereby produces a varying magnetic field in the second magnetically conductive, electrically insulating element of a connected component, which magnetic field thereby generates a varying electrical current in the second coil in the connected component.

Owner:INTELLISERV LLC

Corrosion-Resistant Downhole Transmission System

An apparatus in accordance with the invention may include a downhole tool and a data transmission path incorporated into the downhole tool. The data transmission path may include one or more contact surfaces providing electrical continuity to the data transmission path. To protect the contact surfaces from corrosion while maintaining electrical conductivity, a coating may be attached to one or more of the contact surfaces. The coating may include any of various materials that increase the corrosion-resistance of the underlying base metal, including but not limited to cobalt, nickel, tin, tin-lead, platinum, palladium, gold, silver, zinc, or combinations thereof.

Owner:INTELLISERV

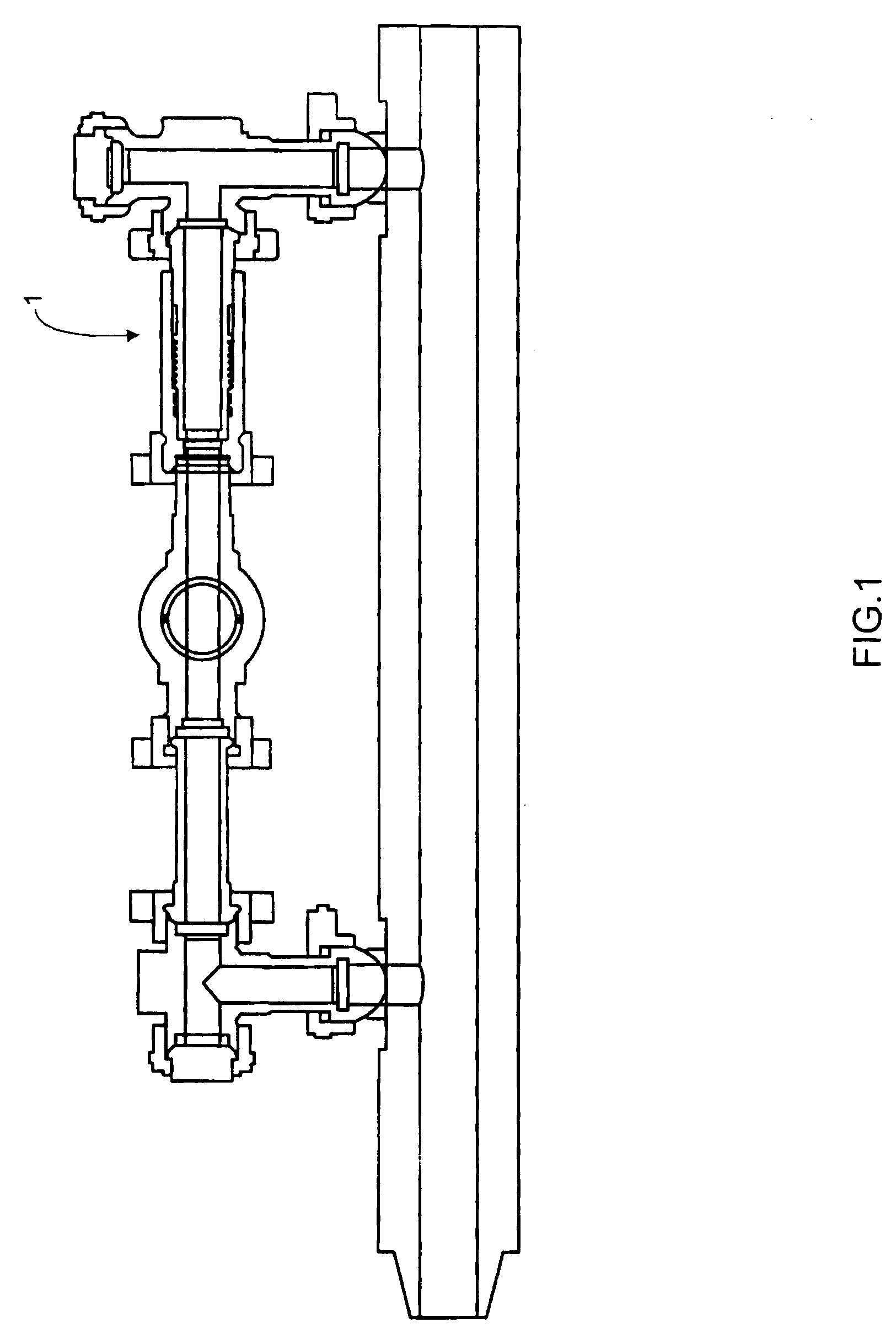

An Upset Downhole Component

InactiveUS20050093296A1Easy to useDrilling rodsNon-disconnectible pipe-jointsEngineeringMechanical engineering

A downhole component comprising a tube comprising an upset adapted for the passage of a transmission line. The tube of the downhole component further comprises an inside diameter, and the downhole component further comprises an elongate, generally cylindrical tool joint comprising a wall and a first interfacial surface. The upset is formed on an end of the tube and comprises a second interfacial surface and an effective inside diameter less than the inside diameter of the tube. The tool joint is attached to the upset on the tube at the first and second interfacial surfaces, and an opening formed within the wall of the tool joint is aligned with a passageway formed in the upset. The opening and the passageway cooperate to allow passage of a transmission line between the tool joint and the tube. The passageway in the upset may be formed at the time the upset is formed or afterwards.

Owner:INTELLISERV

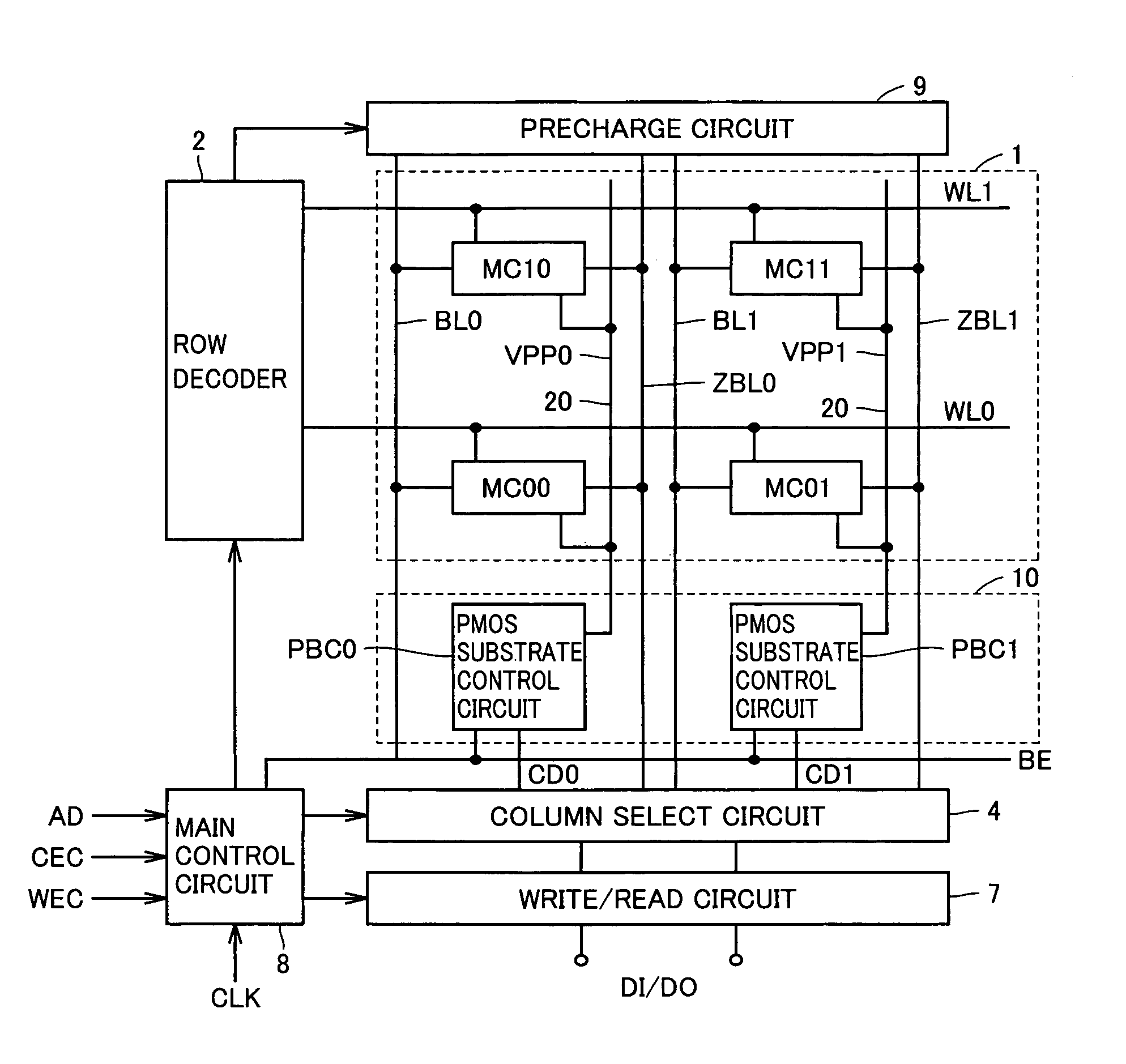

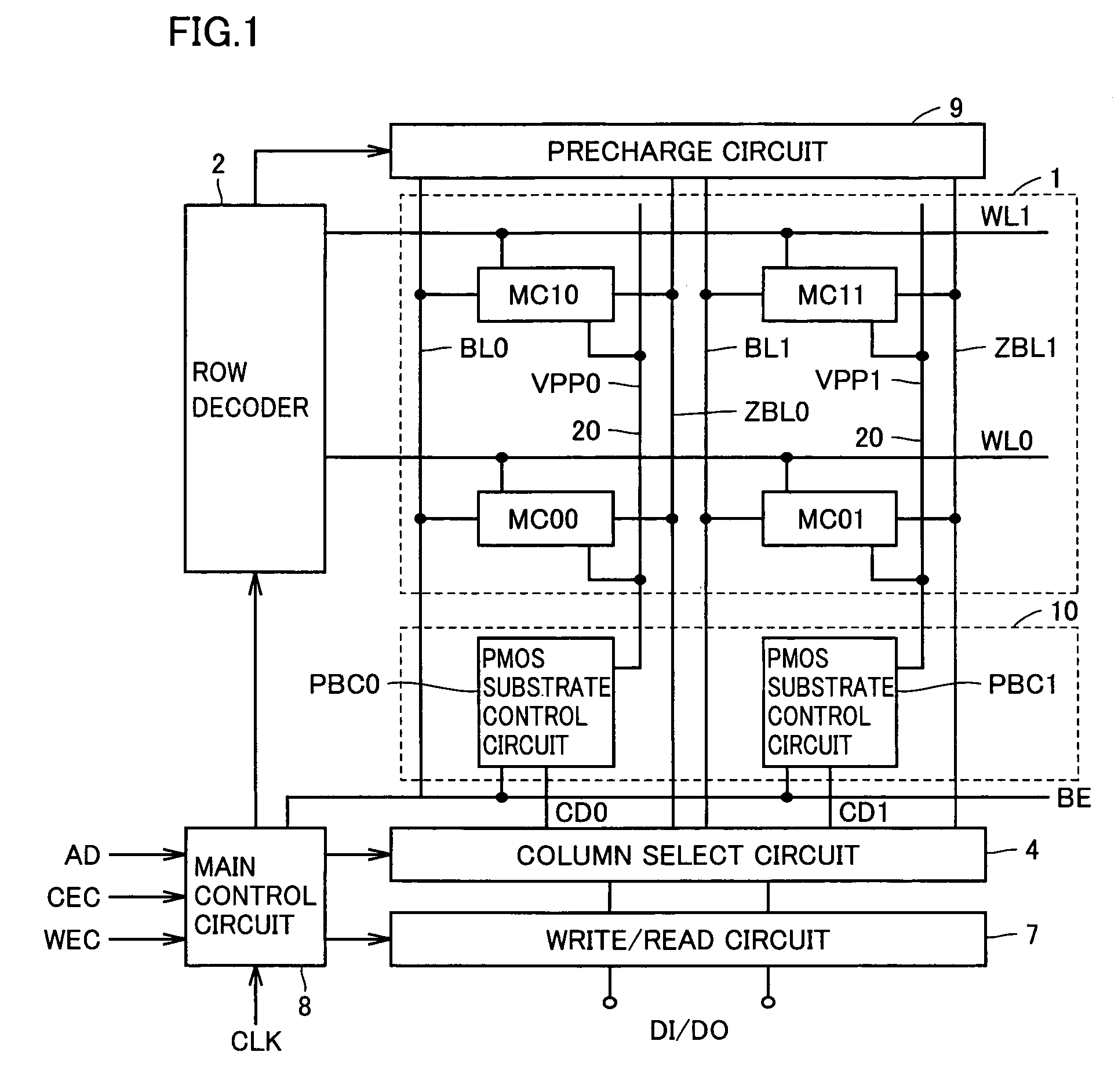

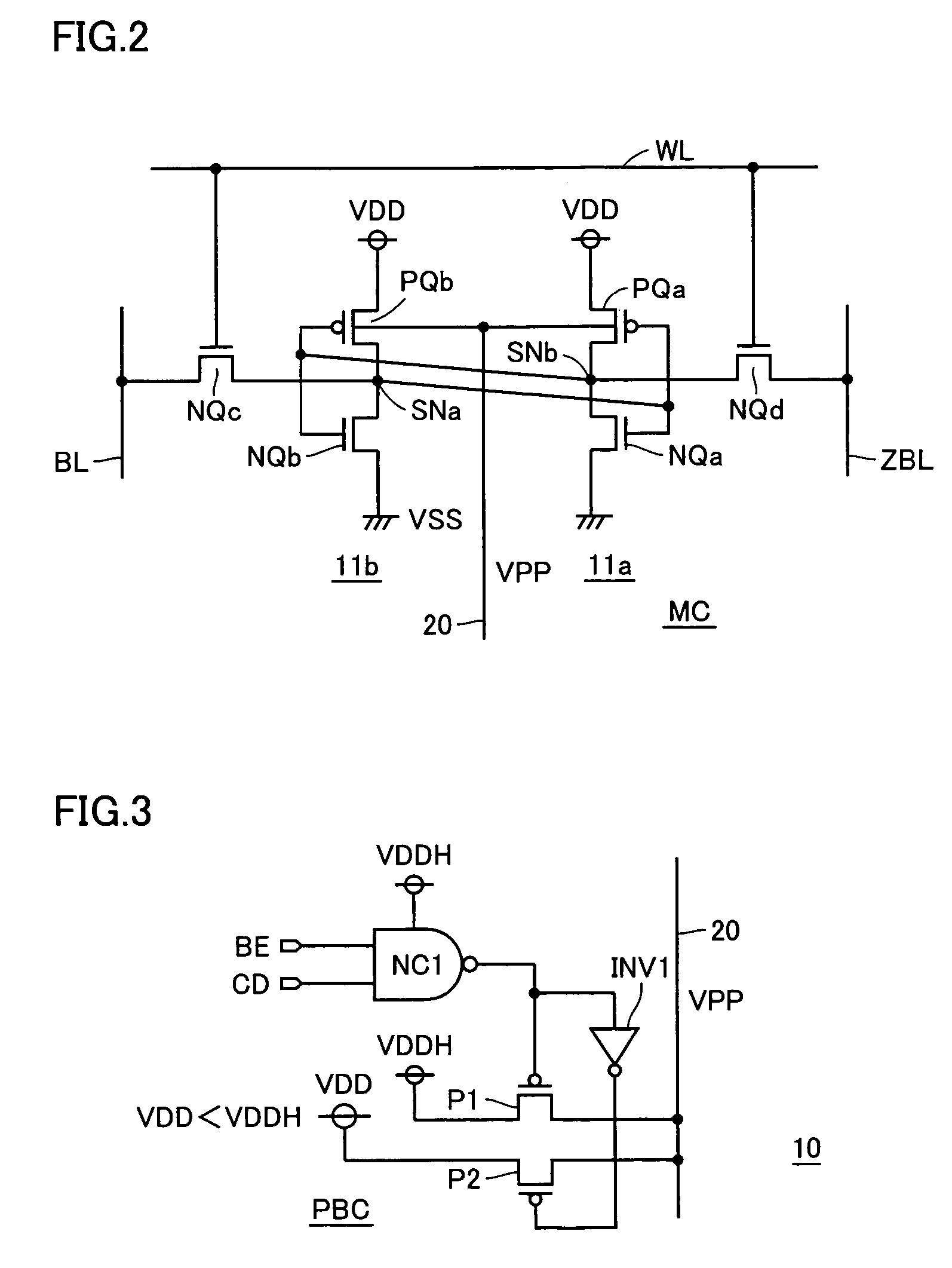

Semiconductor memory device with back gate potential control circuit for transistor in memory cell

ActiveUS7079413B2High-speed and stable data readingHigh-speed and stable and writingTransistorSolid-state devicesEngineeringStatic noise margin

A substrate potential setting circuits are provided which control substrate potentials in units of columns of a memory cell array at least in data writing. Upon data writing, the potential of the substrate region of memory cell transistors on a selected column is changed to reduce the data holding characteristics (static noise margin) to ensure high-speed data writing to the memory cells. Data writing is performed at high speed without impairing stability of data retention.

Owner:RENESAS ELECTRONICS CORP

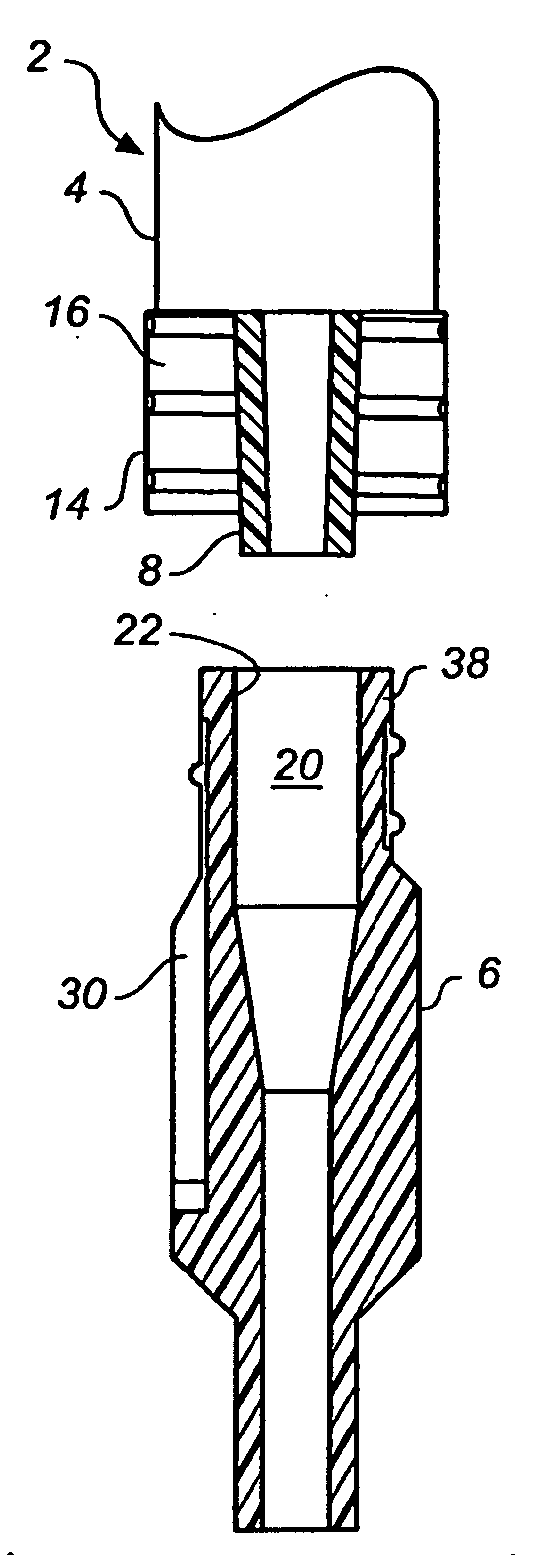

Locking luer fitting

InactiveUS7347458B2Avoid disconnectionPrevent rotationEngine sealsFluid pressure sealed jointsEngineeringCam

A locking luer fitting for connecting fluid lines. In one variation the connection interface includes a male luer connector and a corresponding female luer connector. The female luer connector includes a rotatable collar which engages the male luer connector. In another variation the female luer connector includes a cam configured to prevent inadvertent disconnection of the male luer connector. The locking luer fittings described herein may be implemented in various medical and industrial applications where secured fluid line connection interfaces are desirable.

Owner:CR BARD INC

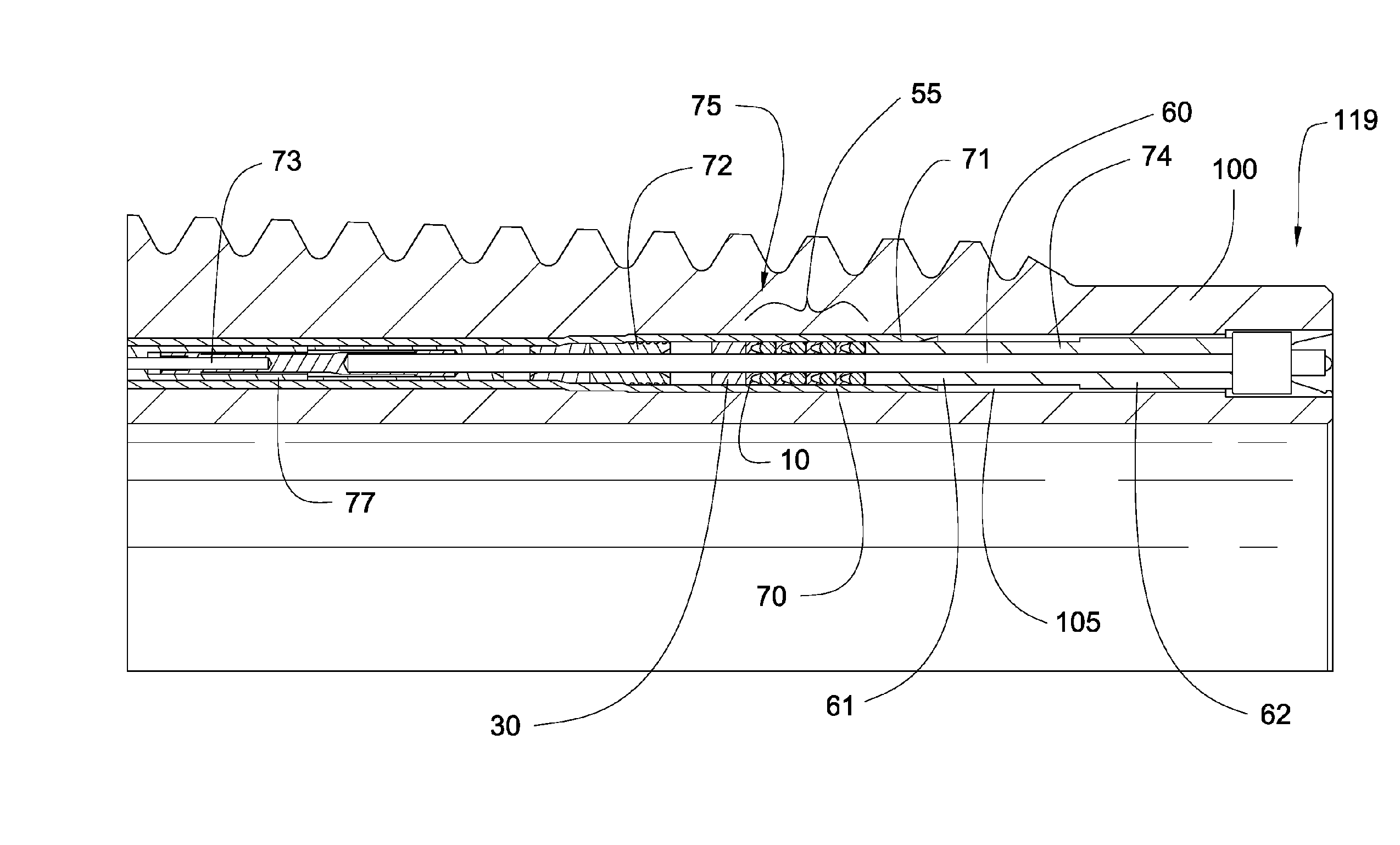

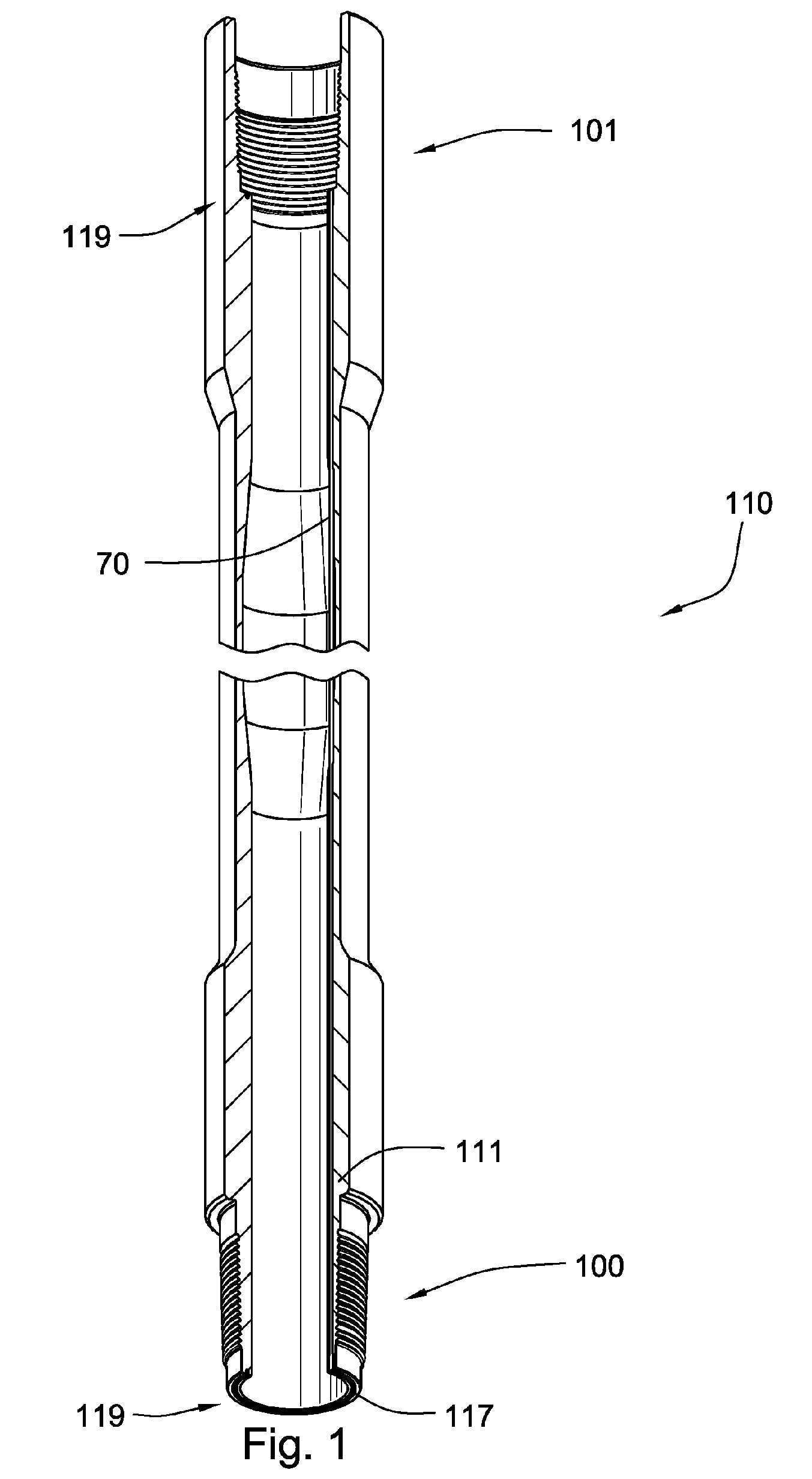

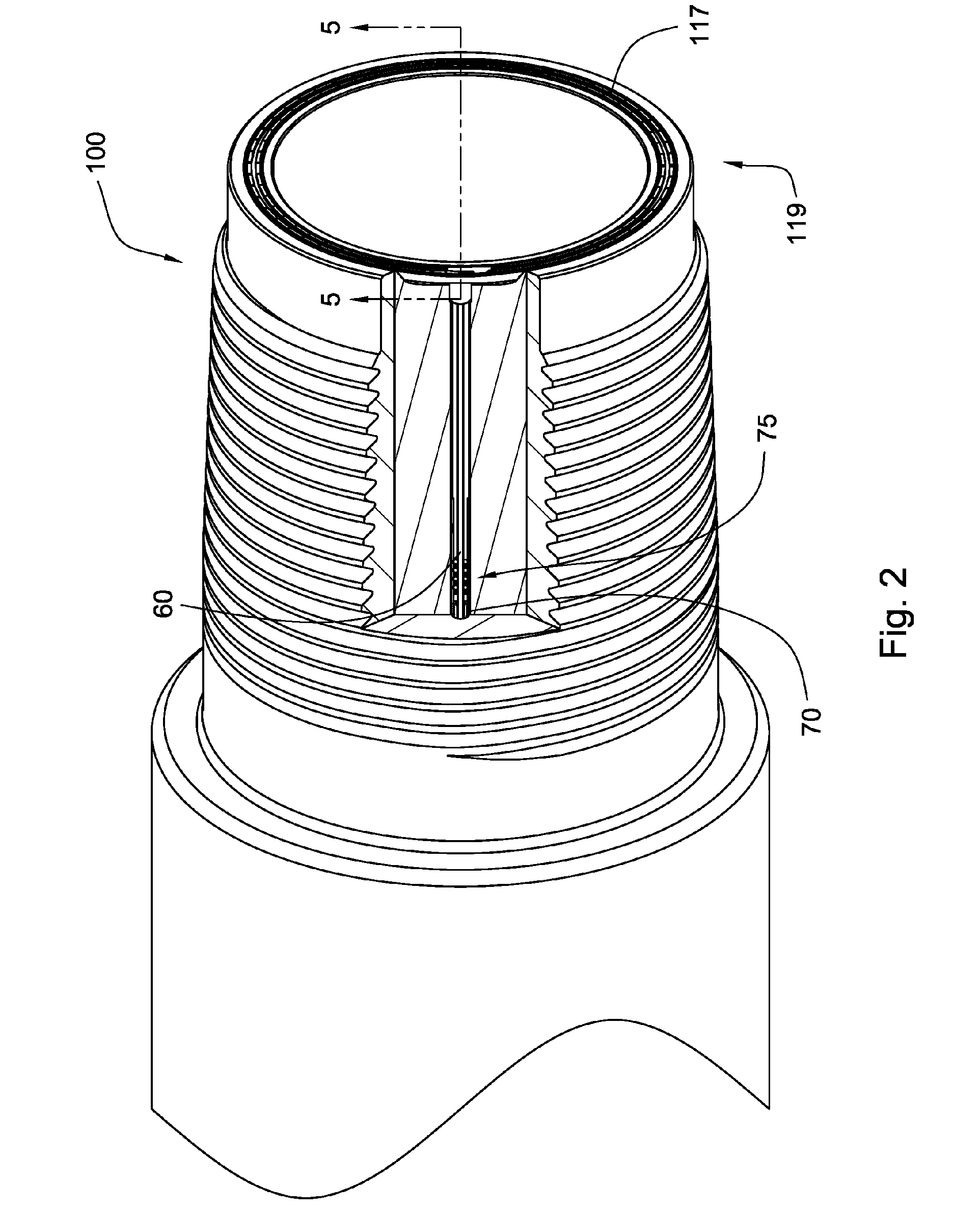

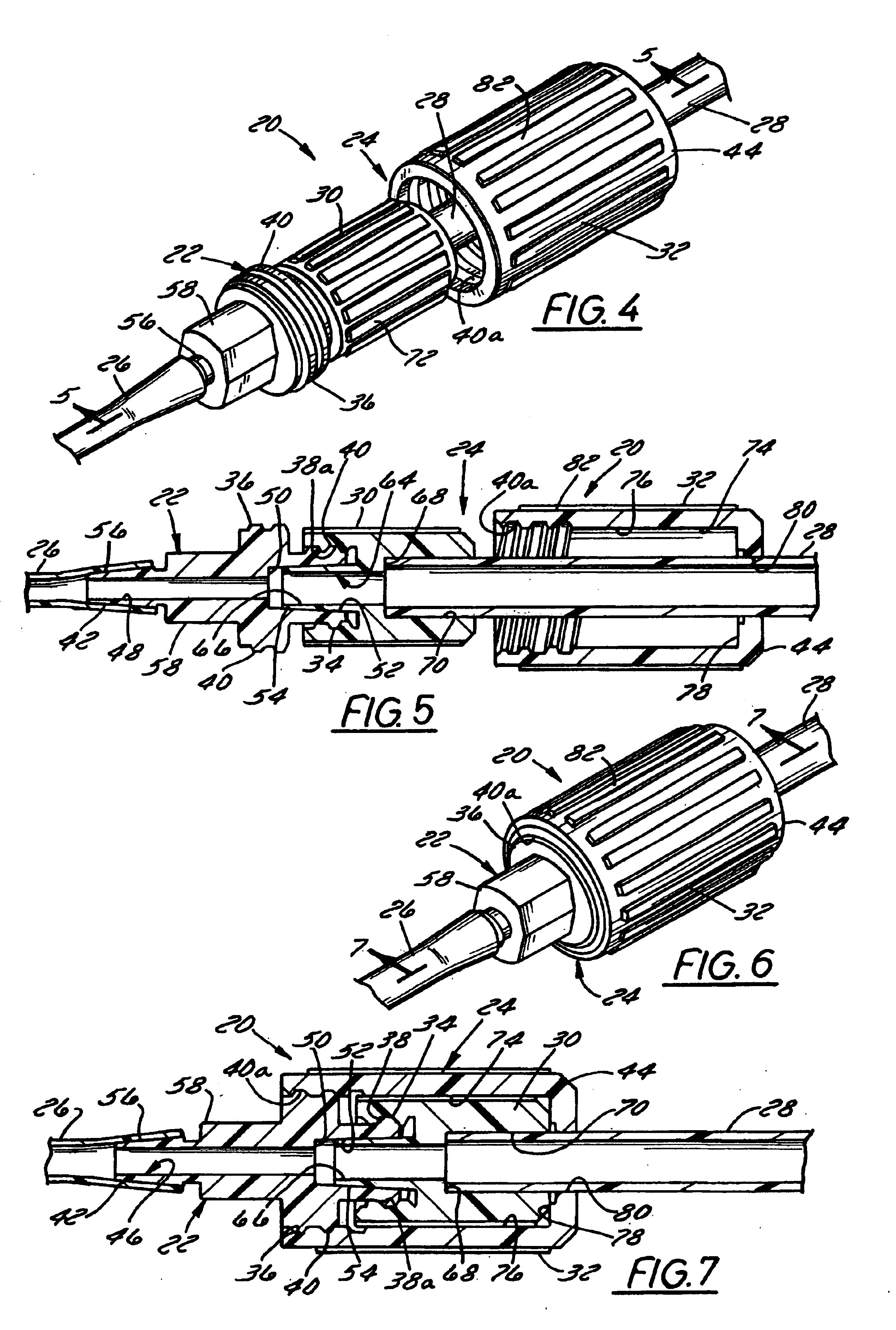

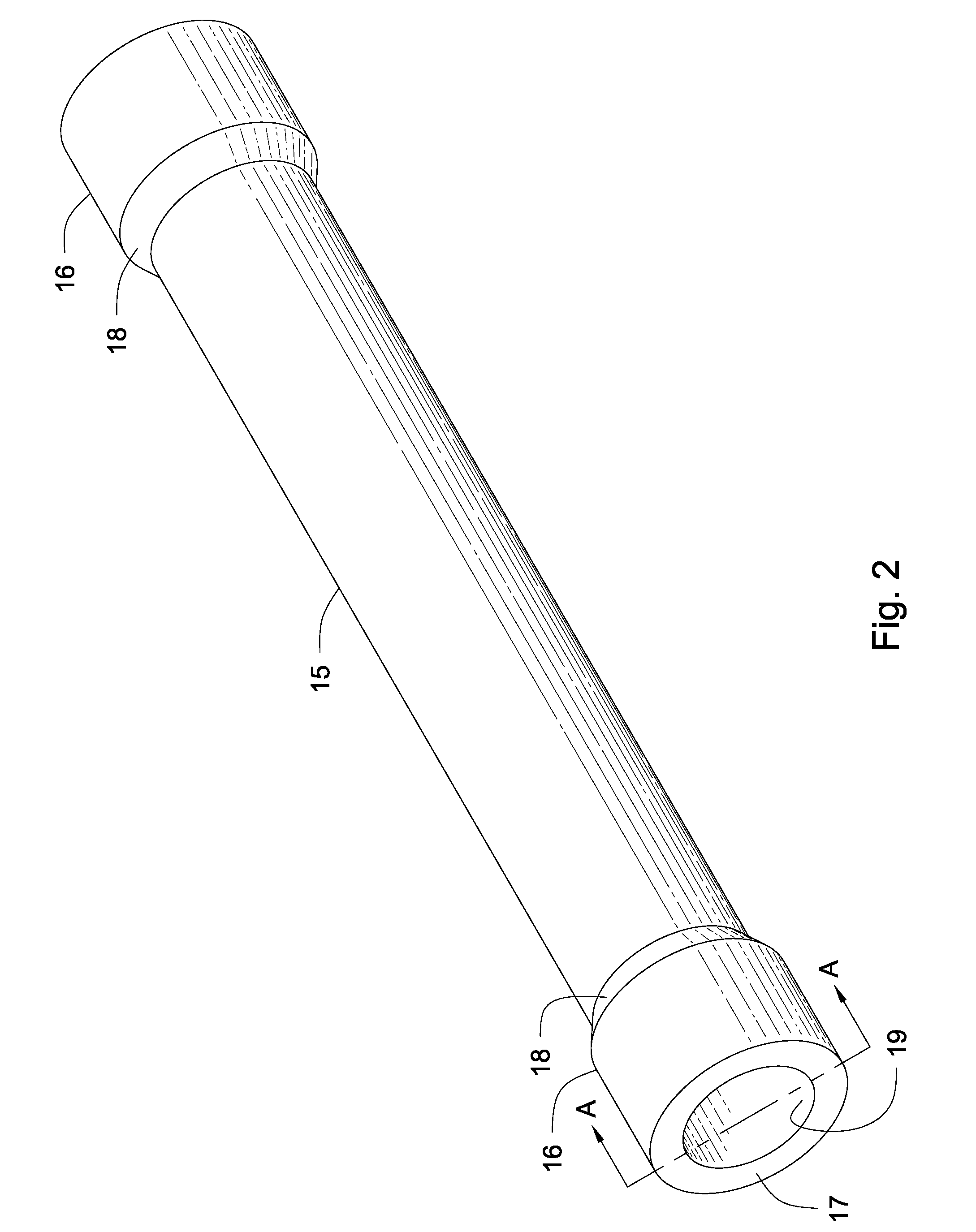

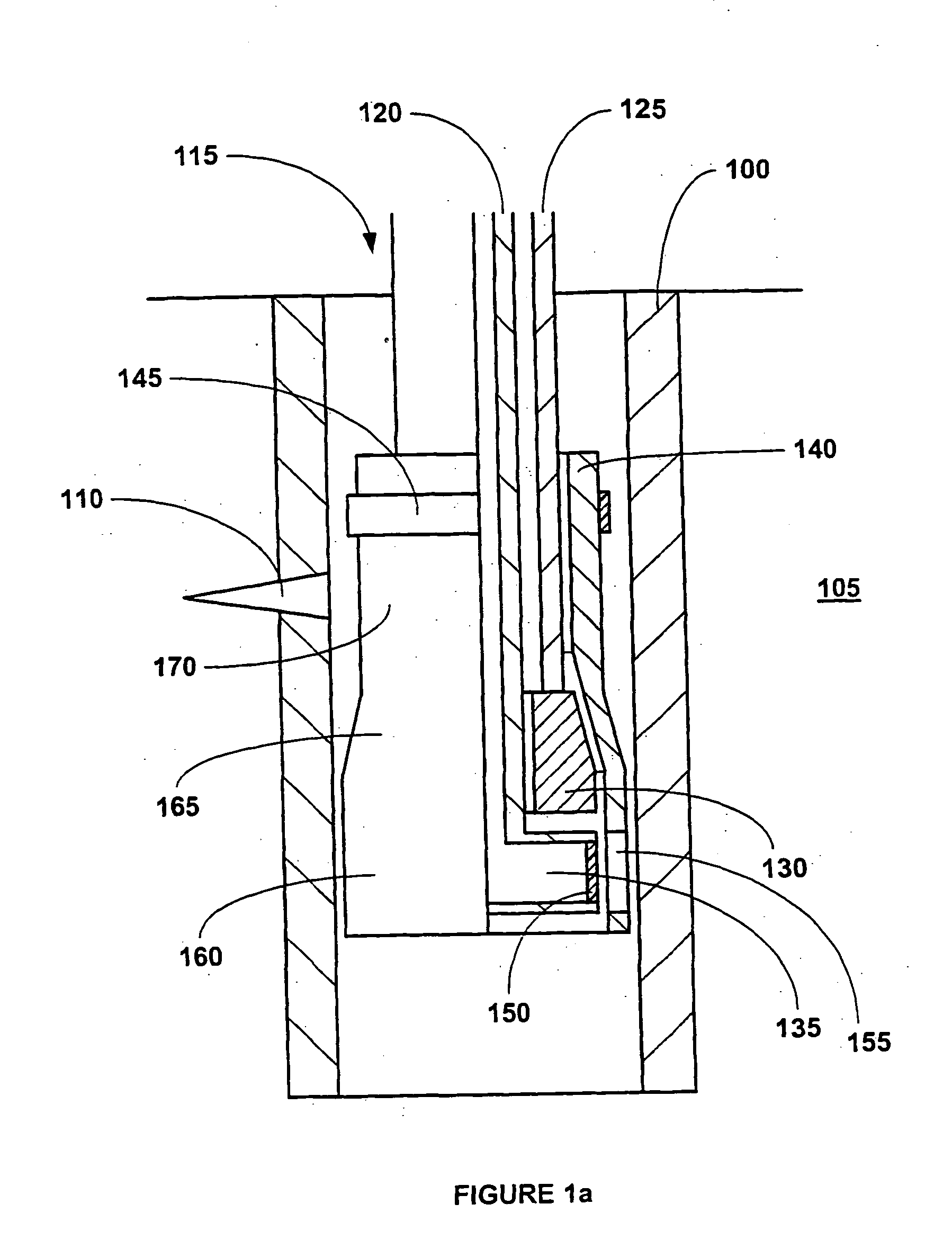

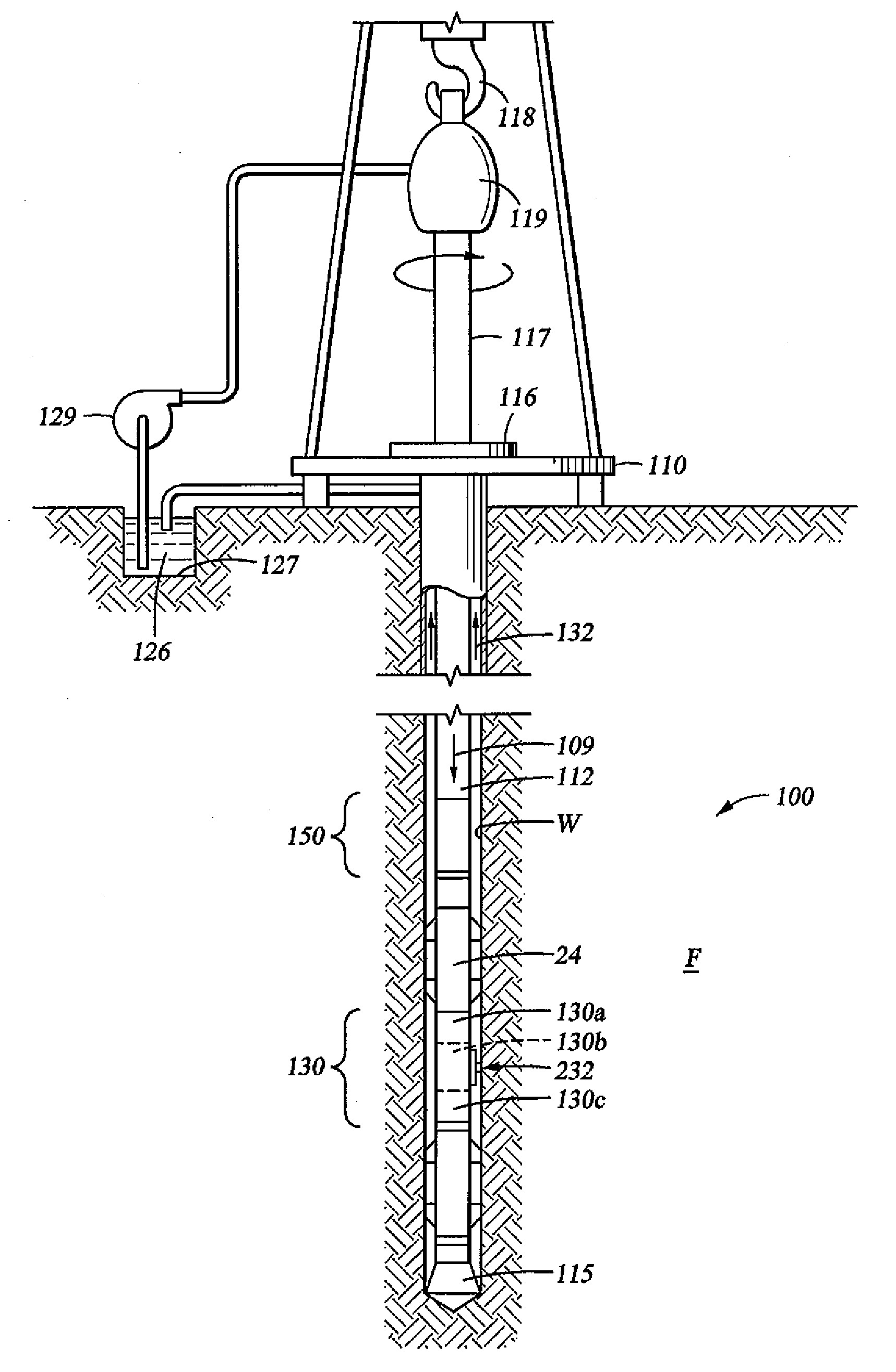

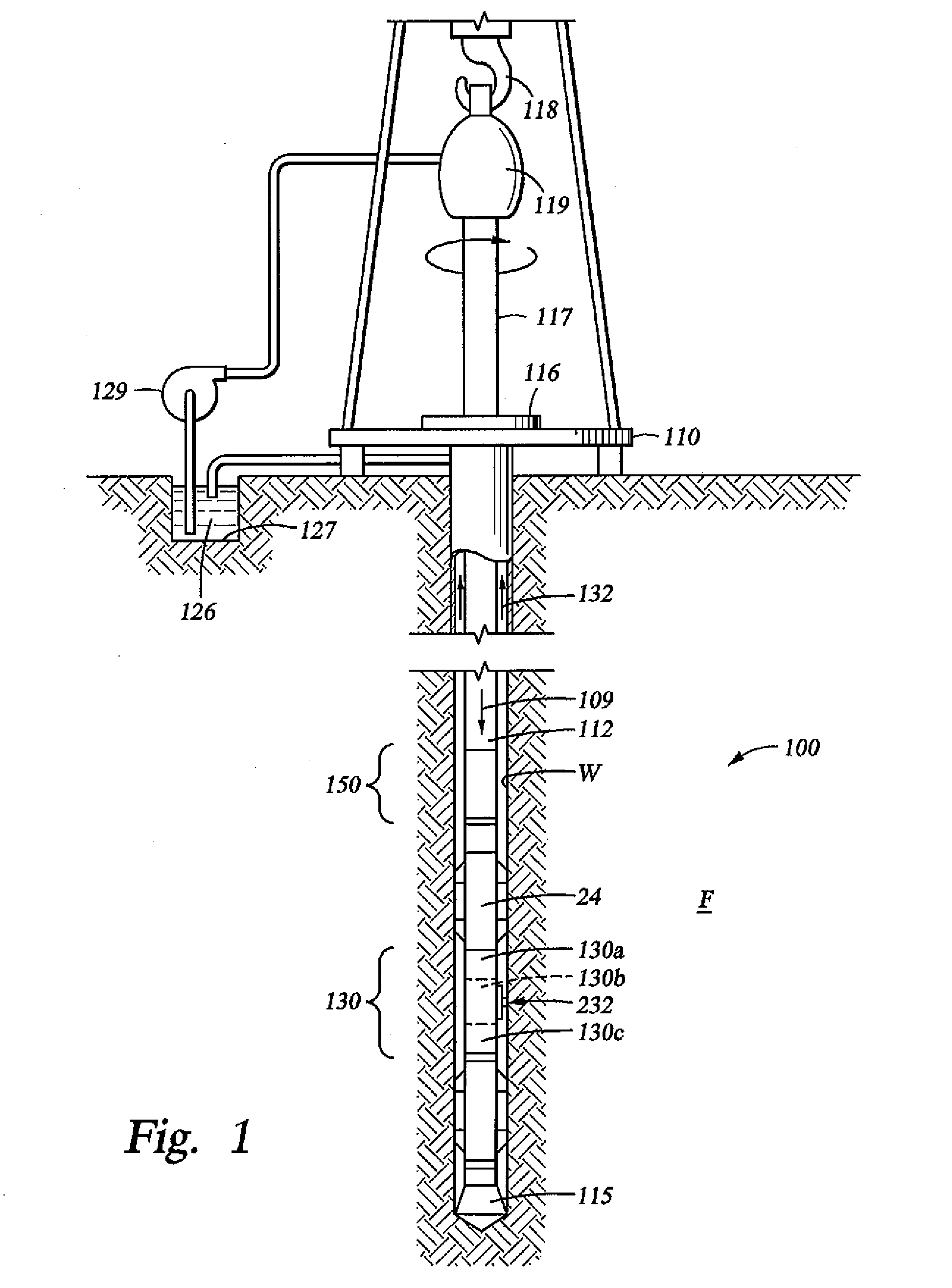

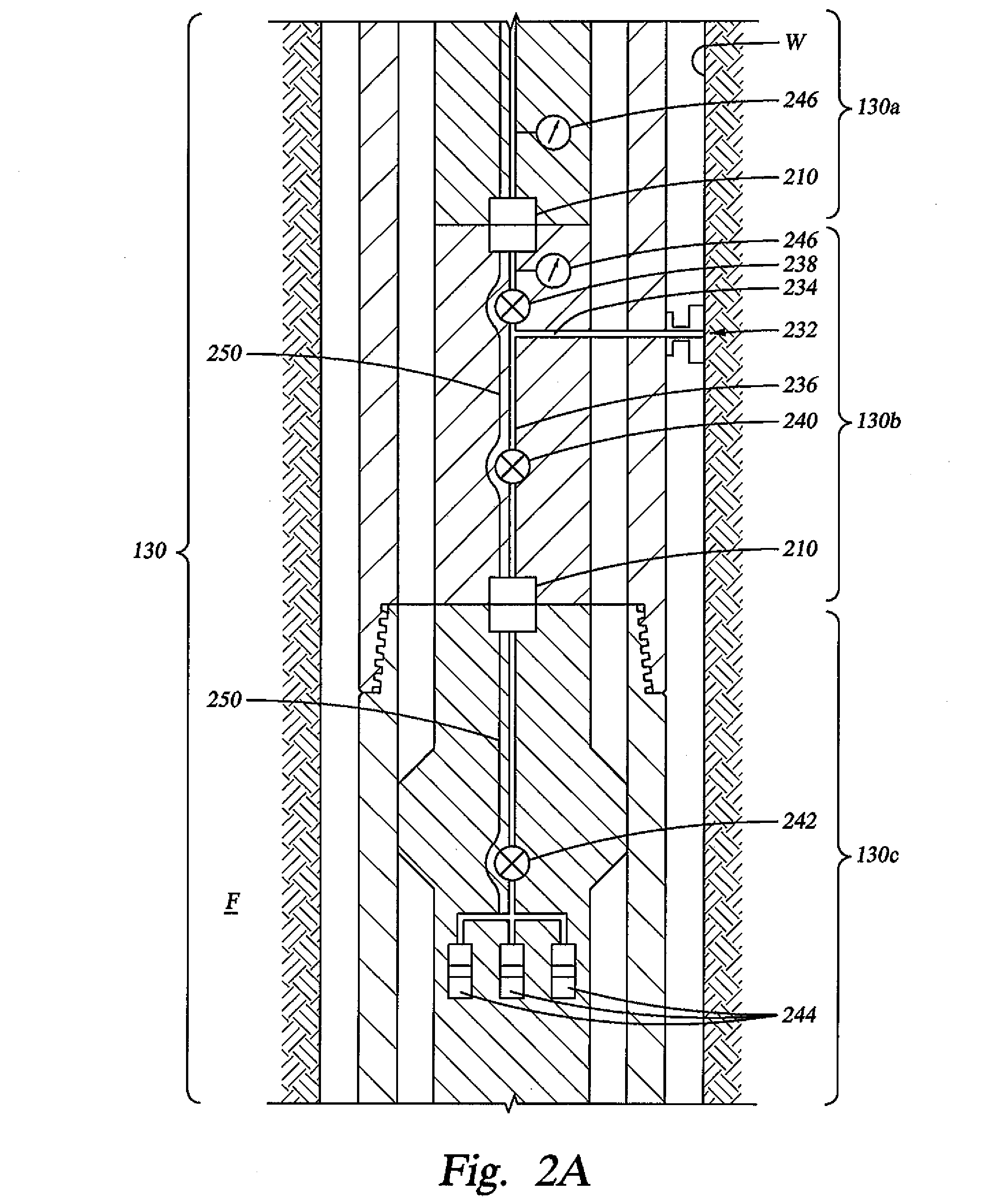

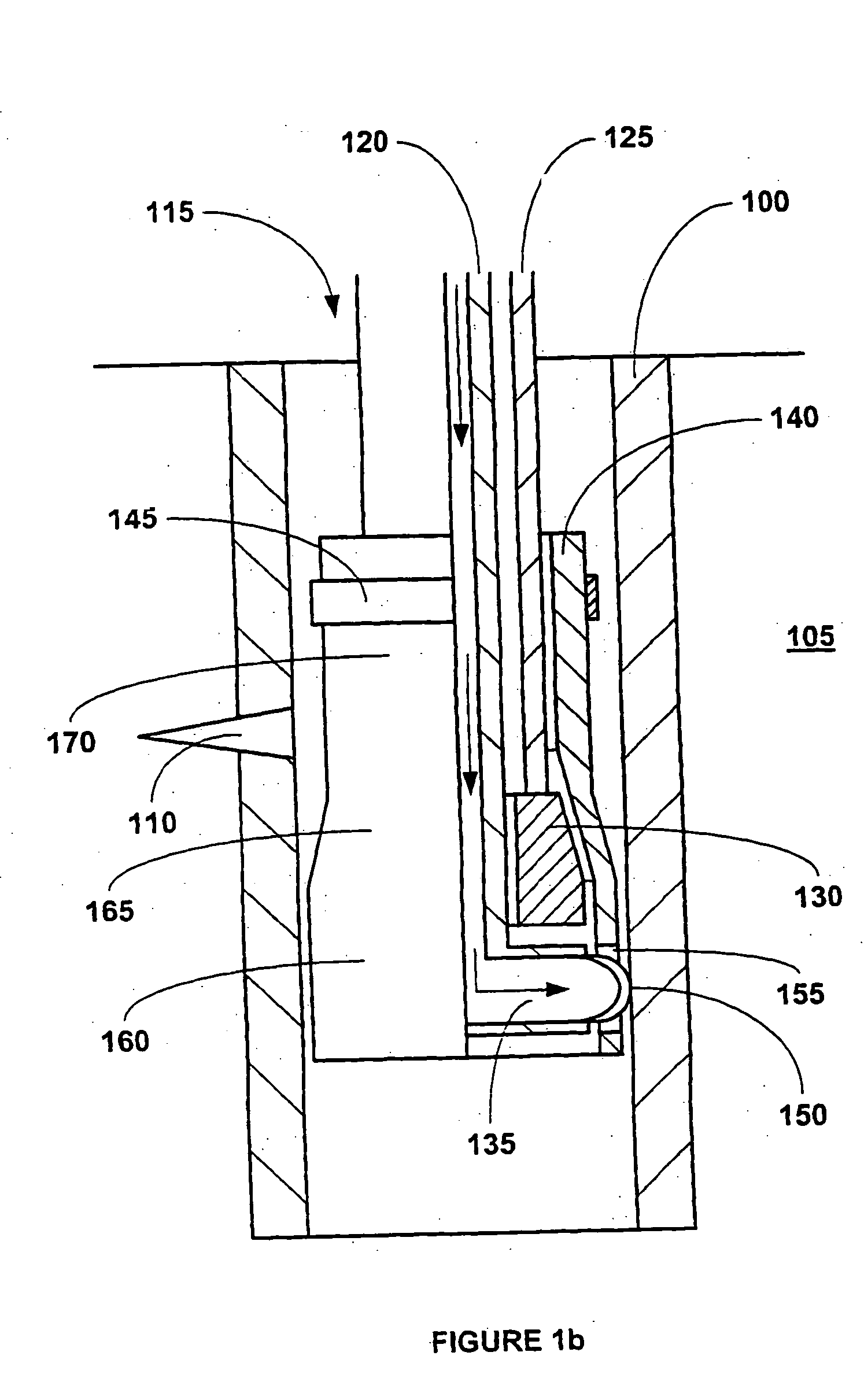

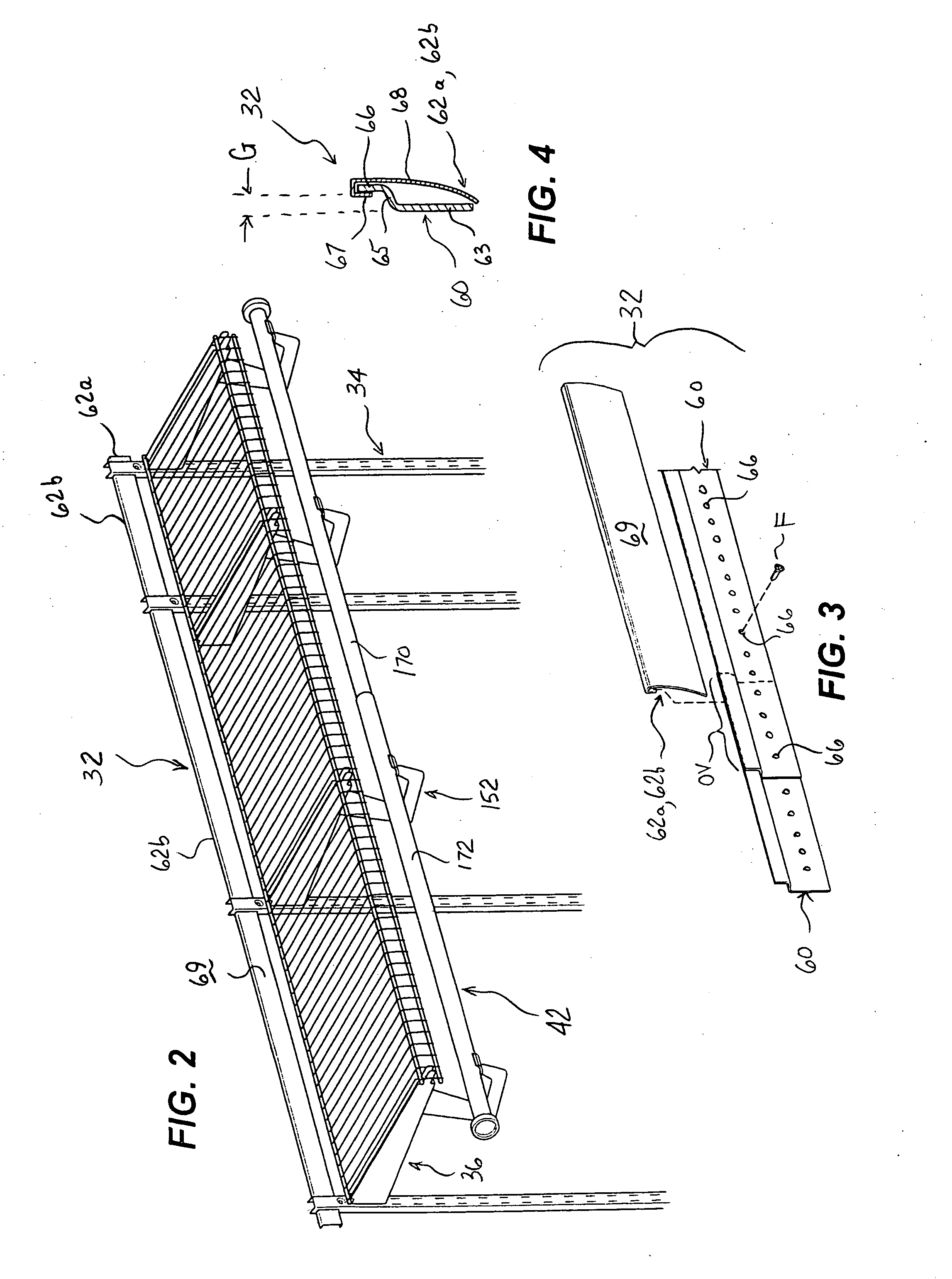

Radial expansion of tubular members

Owner:SHELL OIL CO

Locking luer fitting

InactiveUS20060157984A1Avoid disconnectionAvoid accidental disconnectionEngine sealsFluid pressure sealed jointsEngineeringCam

A locking luer fitting for connecting fluid lines. In one variation the connection interface includes a male luer connector and a corresponding female luer connector. The female luer connector includes a rotatable collar which engages the male luer connector. In another variation the female luer connector includes a cam configured to prevent inadvertent disconnection of the male luer connector. The locking luer fittings described herein may be implemented in various medical and industrial applications where secured fluid line connection interfaces are desirable.

Owner:CR BARD INC

Radial expansion of tubular members

Owner:ENVENTURE GLOBAL TECH LLC

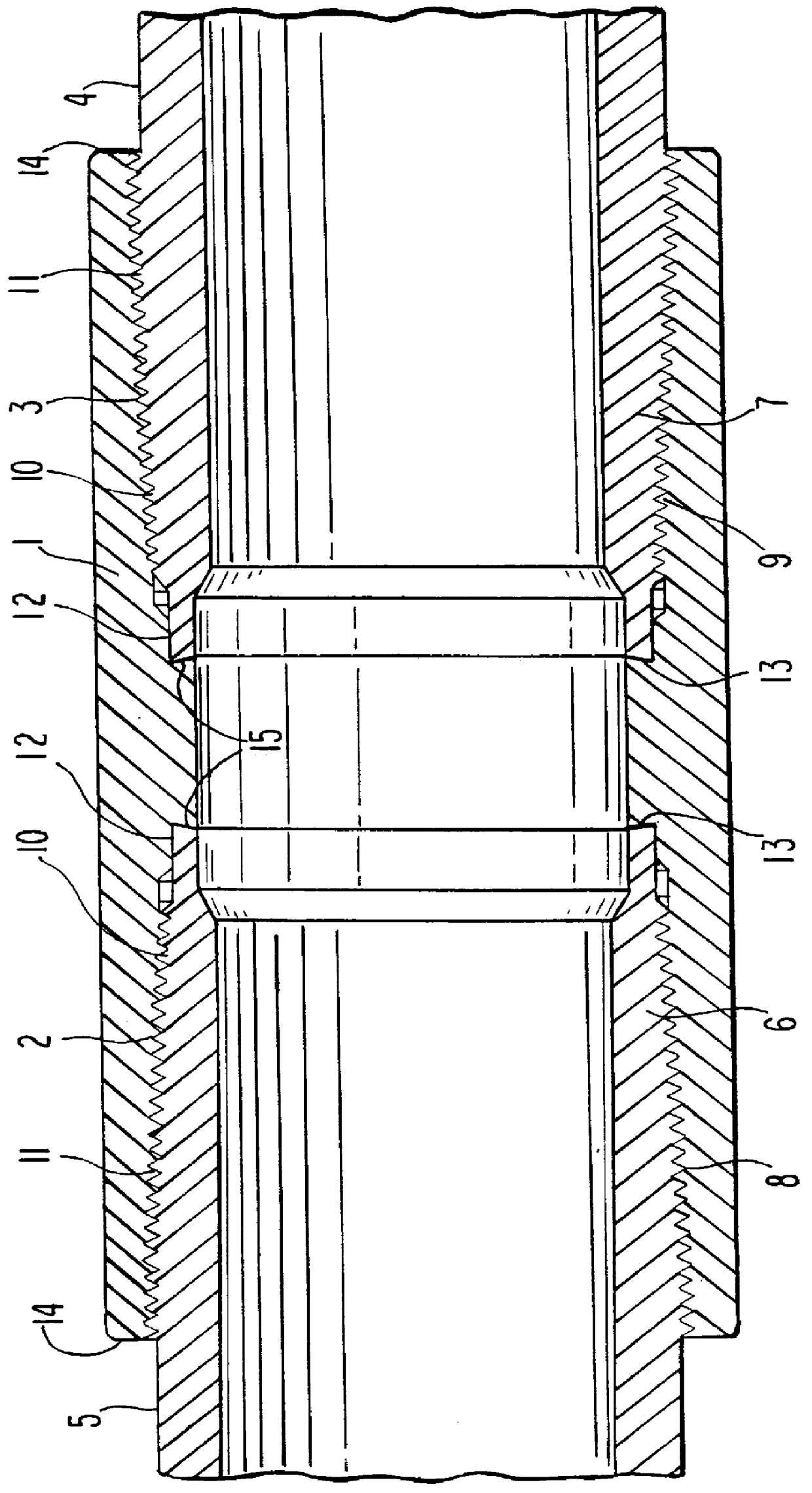

Threaded connection for oil country tubular goods and its method of manufacturing

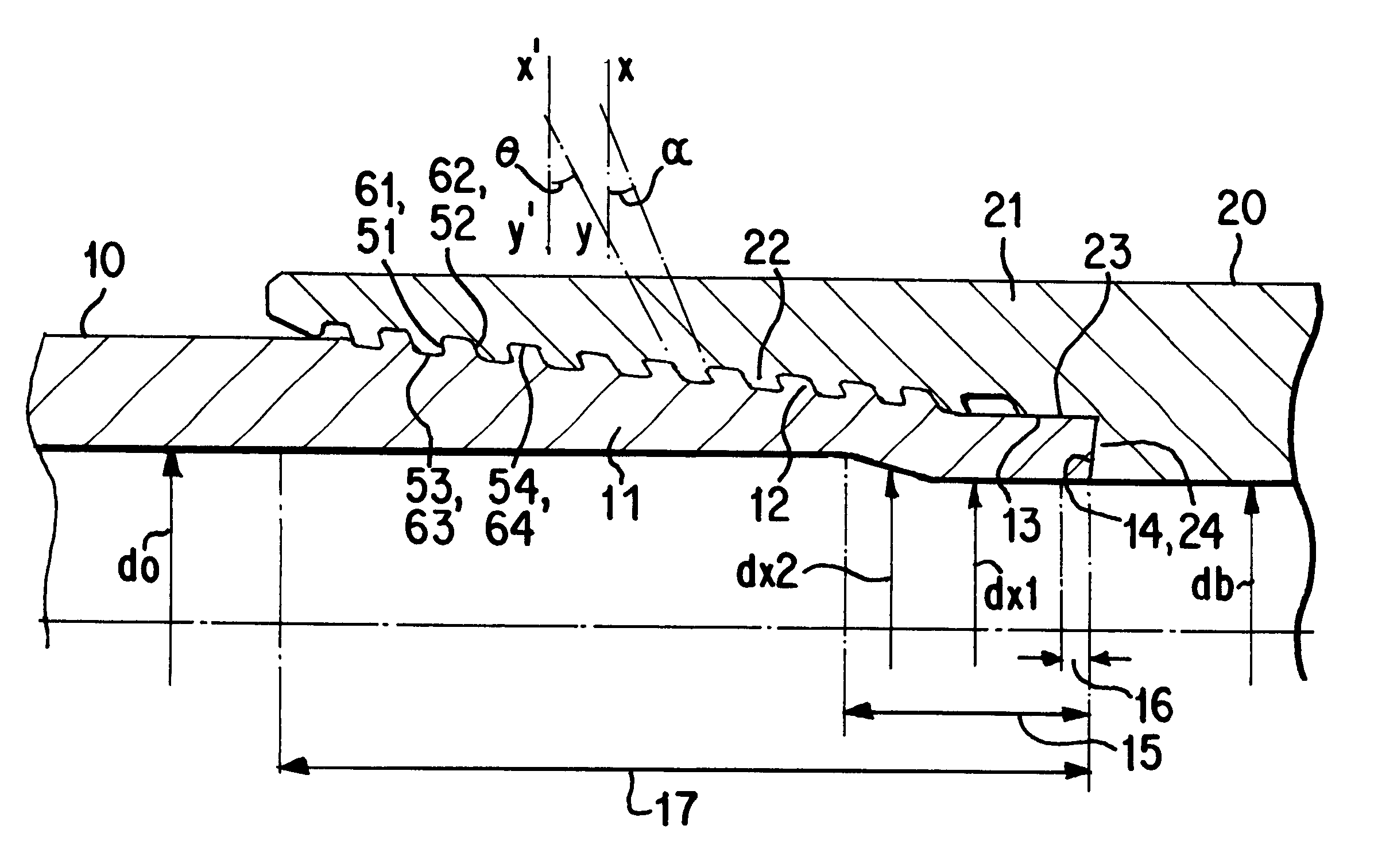

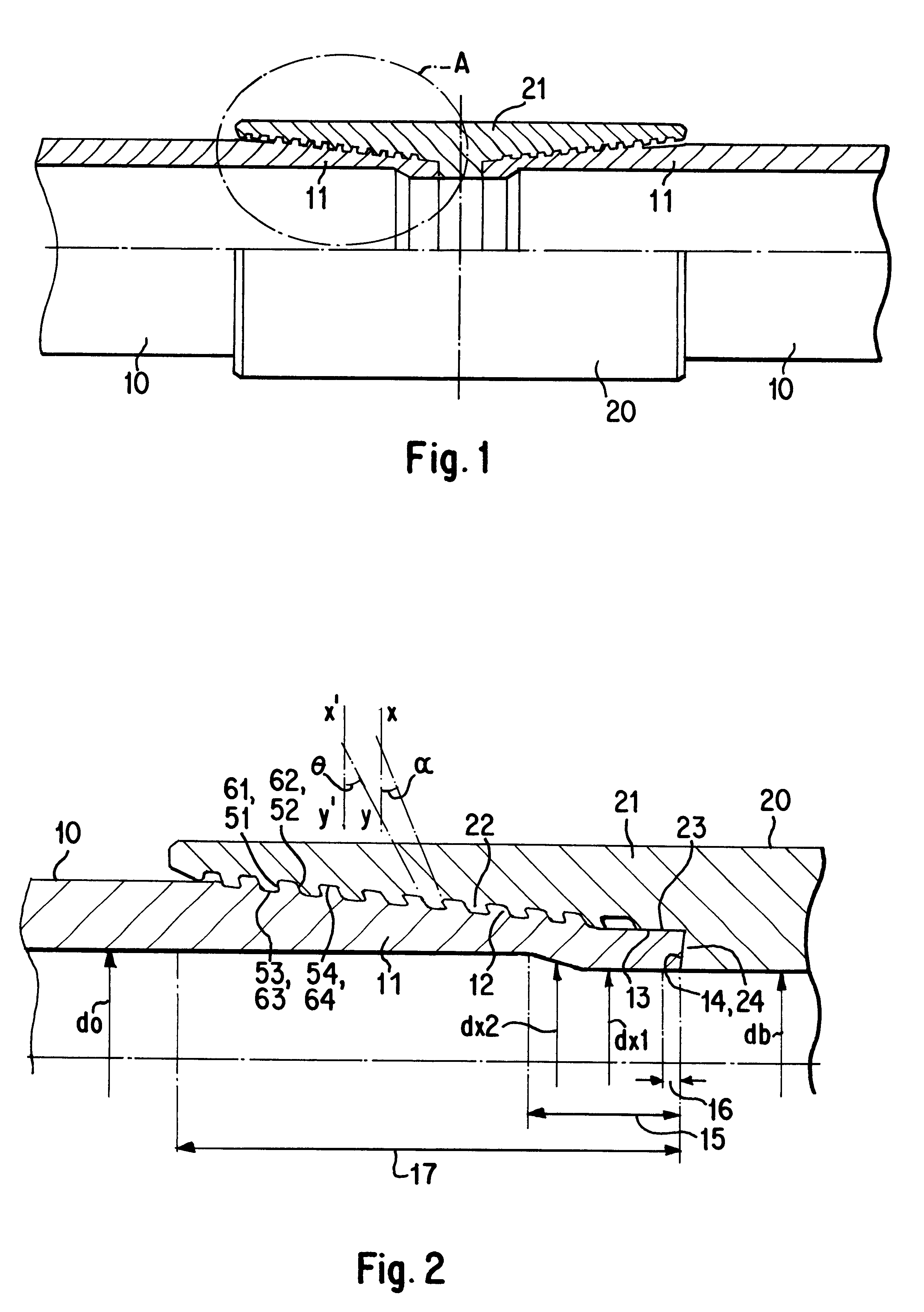

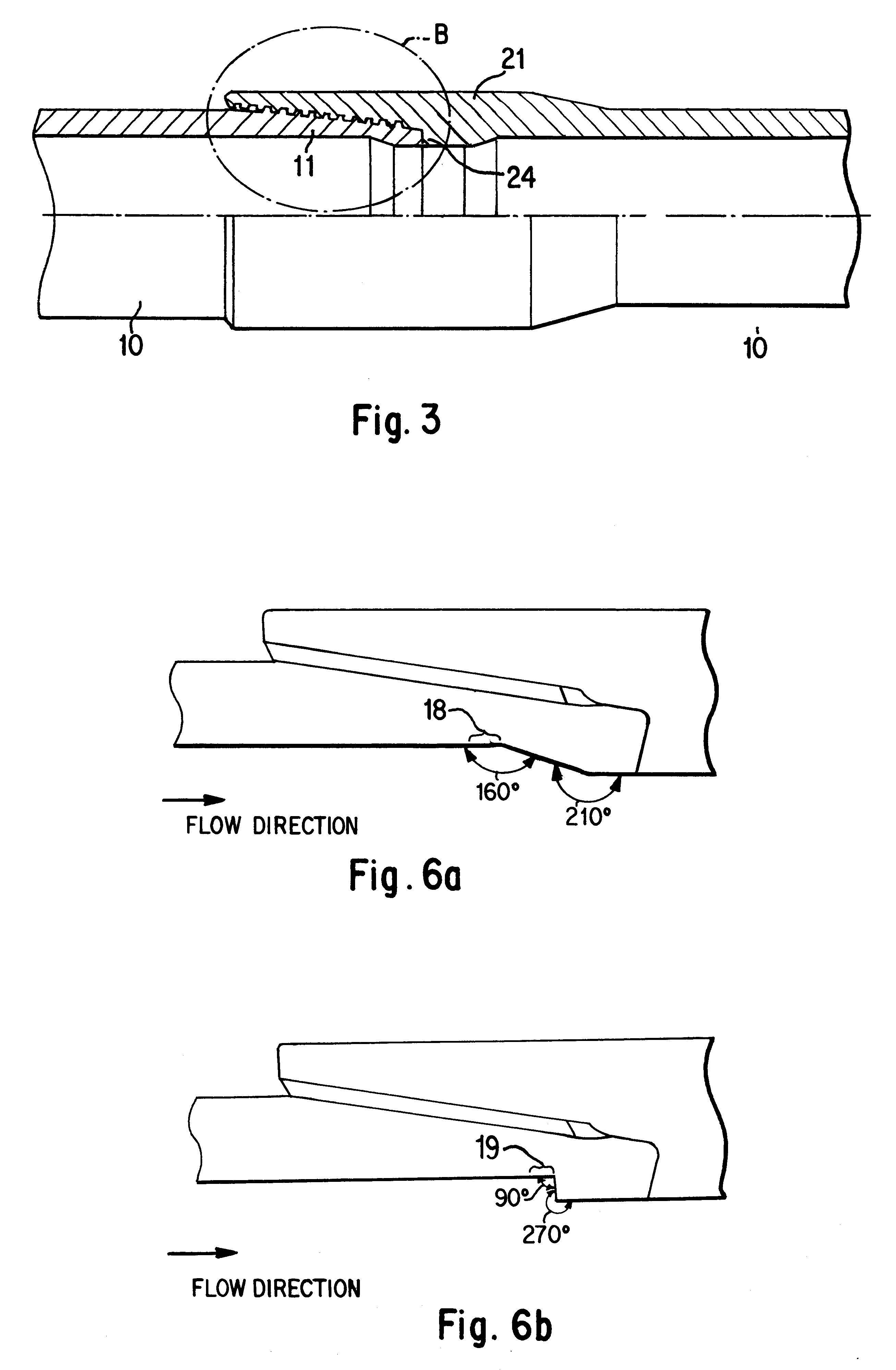

[Purpose]To provide a threaded connection capable of preventing deterioration of gas tightness from occurring when a tensile stress acts thereon after a compressive force in the direction of the axis of a pipe is applied.[Means of Solving Problems](1) A threaded connection for oil country tubular goods wherein a length (15) of a thick walled portion with a diameter defined in the formula (1), is longer than the length (16) from seal contact to the extremist of the pin section, shorter than a half of the length (17) of the pin section, the rest of inside diameter is equal to the inside diameter of pipe proper, having smooth tapered inner wall between thick walled portion and pipe proper. The inside diameter of the box section of torque shoulder section is the same as inside diameter of thick wall.Where dx(mm)=inside diameter of the thick walled portion of the pin section, and d0(mm)=inside diameter of the pipe proper.

Owner:SUMITOMO METAL IND LTD +1

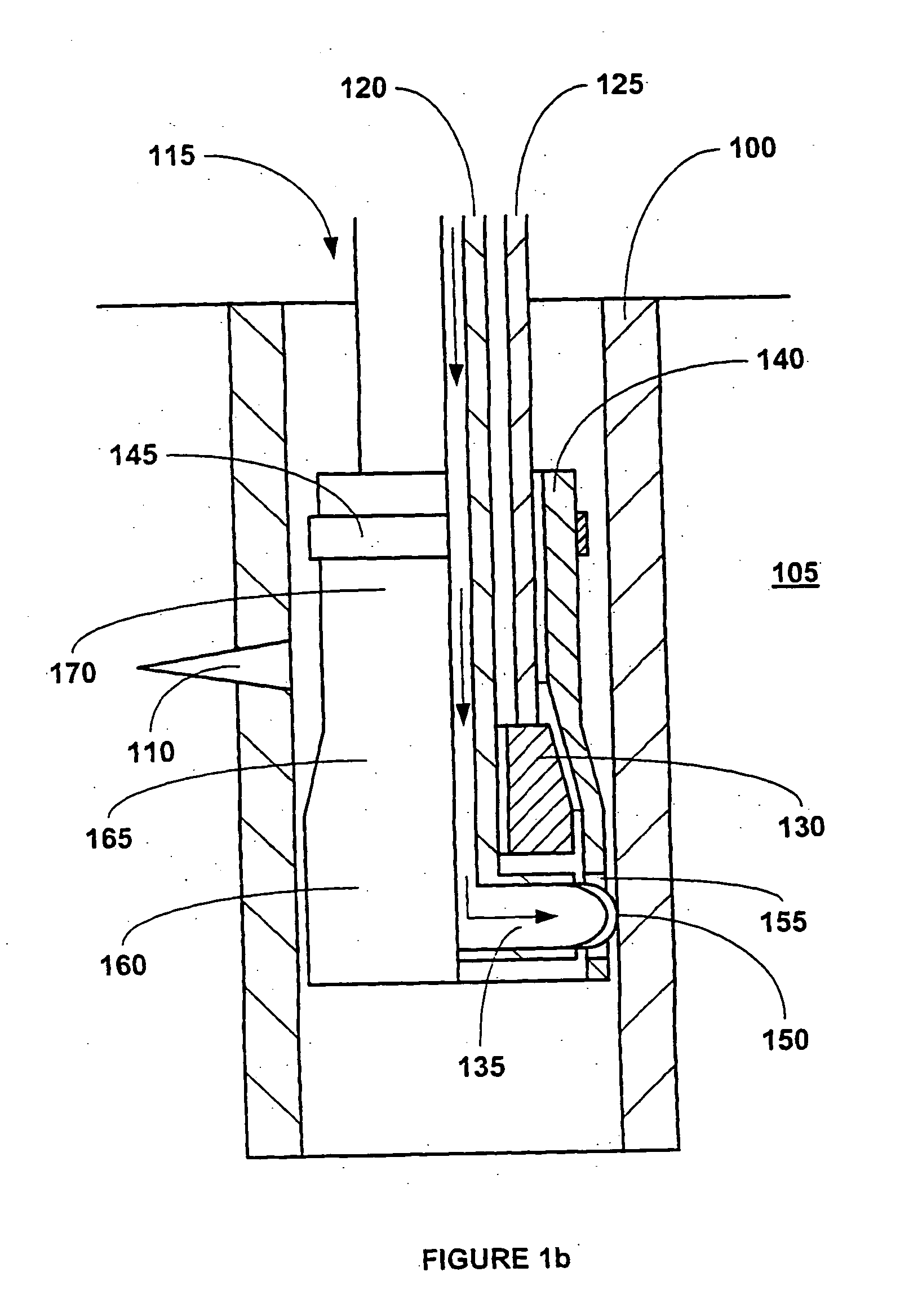

Fitting for tube and pipe

ActiveUS20050242582A1Shorten the lengthSecure retentionSleeve/socket jointsFluid pressure sealed jointsEngineeringHigh pressure

A fitting for a tube or pipe capable of functioning a high pressures having a first fitting component adapted to receive the conduit end; a conduit gripping device such as a ferrule or ferrules and a second fitting component that can be joined to the first fitting component to cause the conduit gripping device to grip the conduit and seal when assembled. In one aspect of the invention, the first fitting component is constructed from a material that is softer than the material used to construct the second fitting component. An additional aspect of the invention include a retaining portion on the second fitting component that constrains the tube gripping device against pressure. The retaining portion can also be configured to retain the tube gripping device to the second fitting component prior to installation and in a finger-tight condition. A further aspect of the invention includes a first fitting component in which an exterior portion of the component is work hardened radially outward from the tube gripping device. The fitting may optionally be provided with a structure to effect the pull-up by torque functionality.

Owner:SWAGELOK CO

System and method for downhole telemetry

A system and method are provided for providing electromagnetic (EM) measurement-while-drilling (MWD) telemetry capabilities using an existing mud-pulse MWD tool. An EM tool intercepts the output from the mud-pulse tool and generates an EM signal that mimics a mud-pulse pressure signal. The EM signal is intercepted at the surface by a receiver module that conditions the signal and inputs the signal into the existing pulse tool receiver. Since the EM signal mimics a mud-pulse signal, the pulse tool receiver does not require software or hardware modifications in order to process an EM telemetry mode. The EM tool can be adapted to also provide dual telemetry by incorporating a conventional pressure pulser that would normally be used with the pulse tool. A gap sub assembly for isolating the drill string is also provided that includes a pair of subs whose shoulders are separated by a non-conductive ceramic material and whose threads are separated by an insulative material, preferably a Kevlar™ cloth.

Owner:MOSTAR DIRECTIONAL TECH

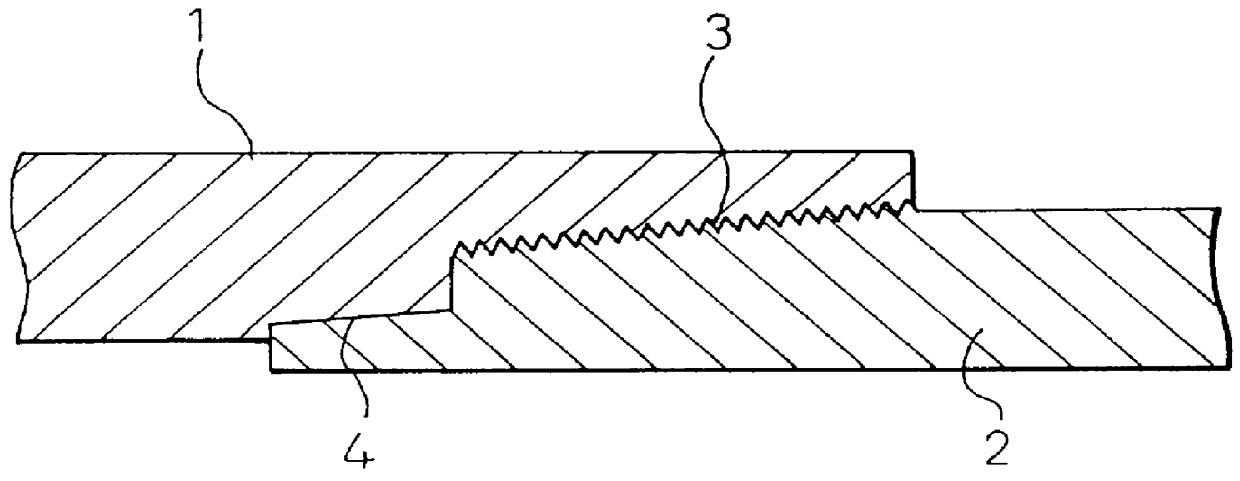

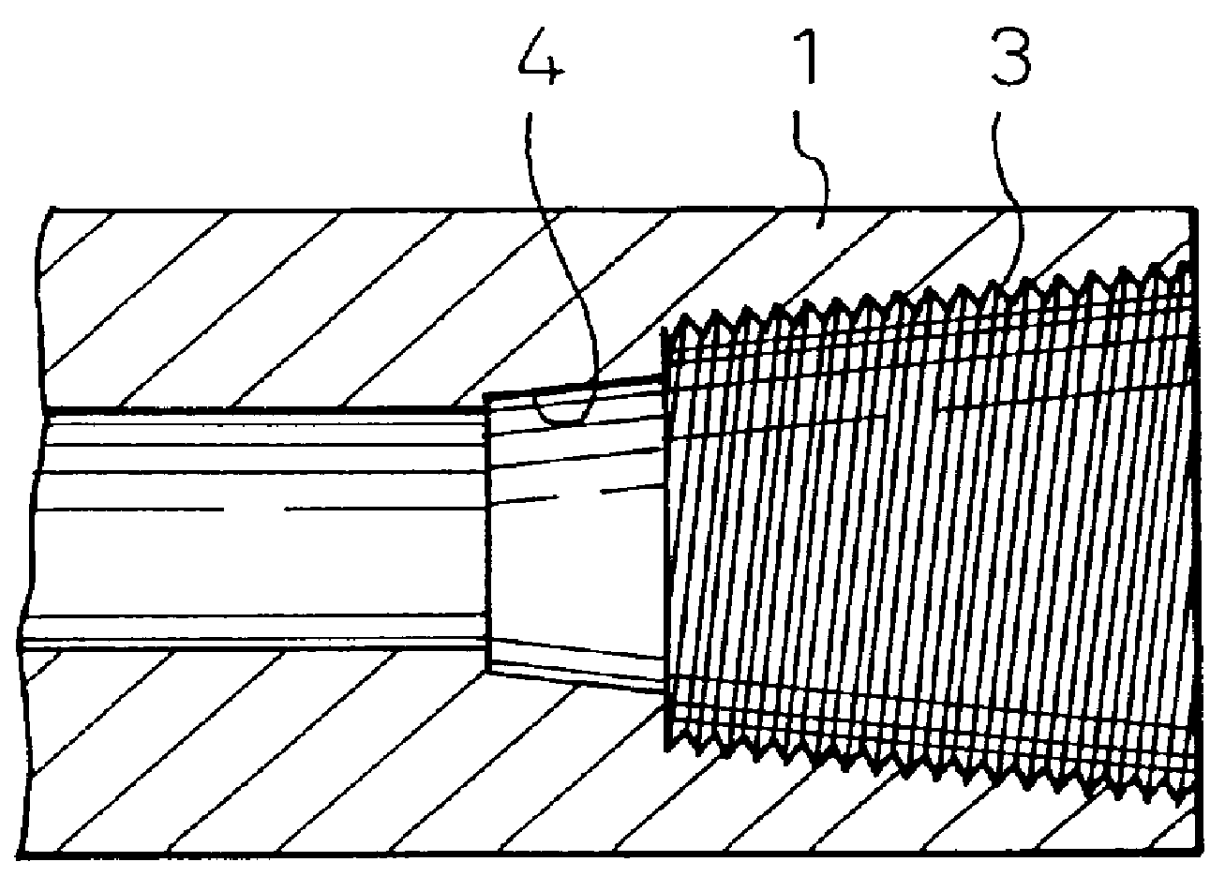

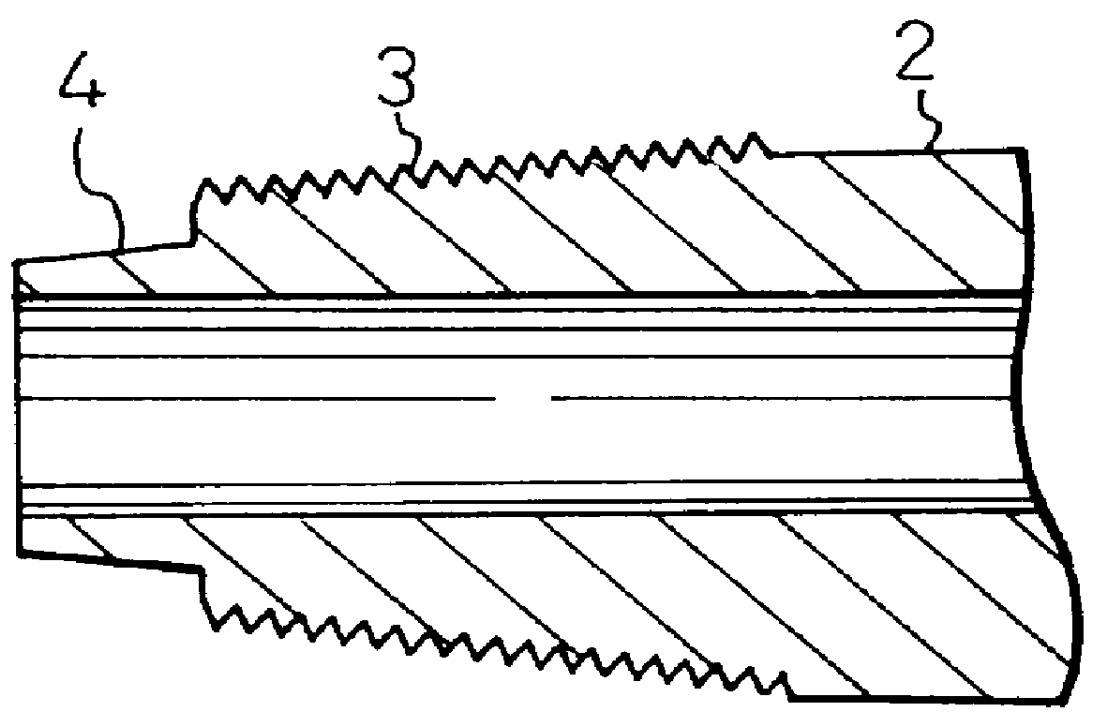

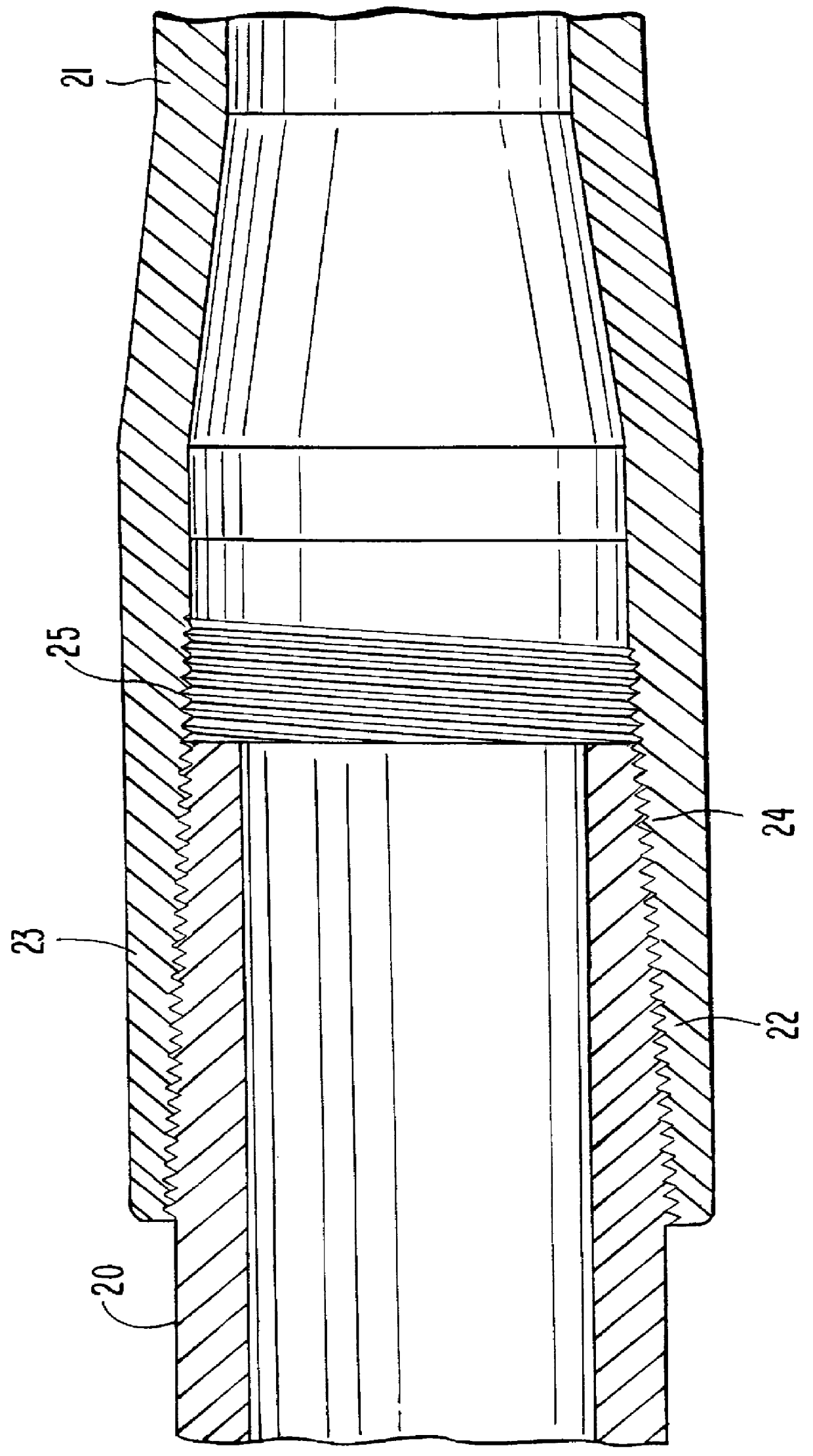

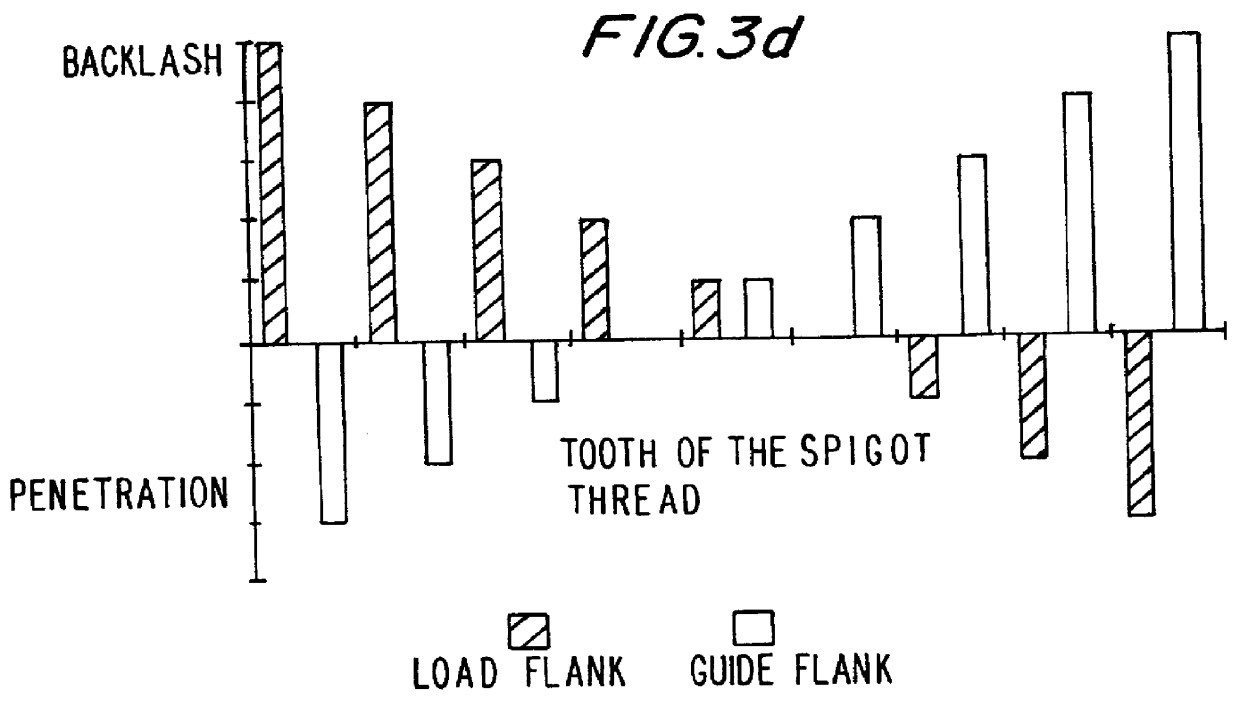

Pipe joint

PCT No. PCT / DE95 / 01059 Sec. 371 Date Apr. 2, 1997 Sec. 102(e) Date Apr. 2, 1997 PCT Filed Aug. 1, 1995 PCT Pub. No. WO96 / 07044 PCT Pub. Date Mar. 7, 1996A pipe joint with a sleeve element and with a spigot element configured to be threadedly connected together to collectively absorb the load experienced by the joint over the threaded sections of the sleeve and spigot. By suitably selecting the leads and tooth gaps in the sleeve or spigot, it is possible for the guide flank at one thread end to be braced against the load flank at the other thread end thereby effecting maximum bracing at the edges of the thread and decreasing toward the thread center.

Owner:MANNESMANN AG

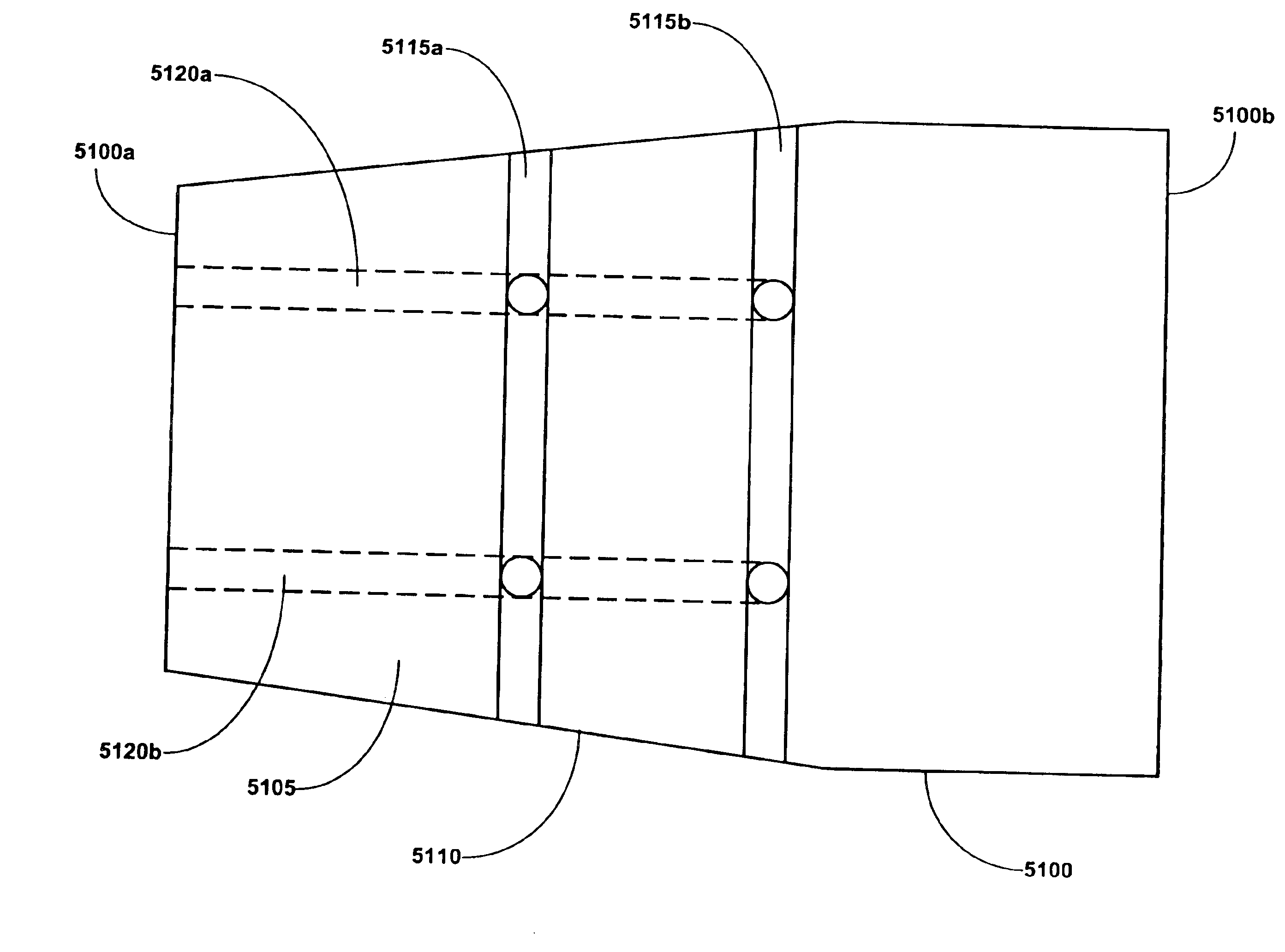

Modular connector and method

A modular tool for use in subterranean formations includes a first module, a second module and one or more connectors for connecting the first and second modules. In particular, the first module includes a first collar that at least partially defines an exterior of the tool and that includes a first engagement mechanism at a first end of the collar and a second engagement mechanism at a second end of the collar. The first module also includes a fluid passageway for passing drilling fluid therethrough. The second module has a similar configuration as includes similar architecture. The one or more connectors facilitate the connection of at least one flowline fluidly connected to an exterior of the tool, and an electrical pathway for transmitting power and / or data between the modules.

Owner:SCHLUMBERGER TECH CORP

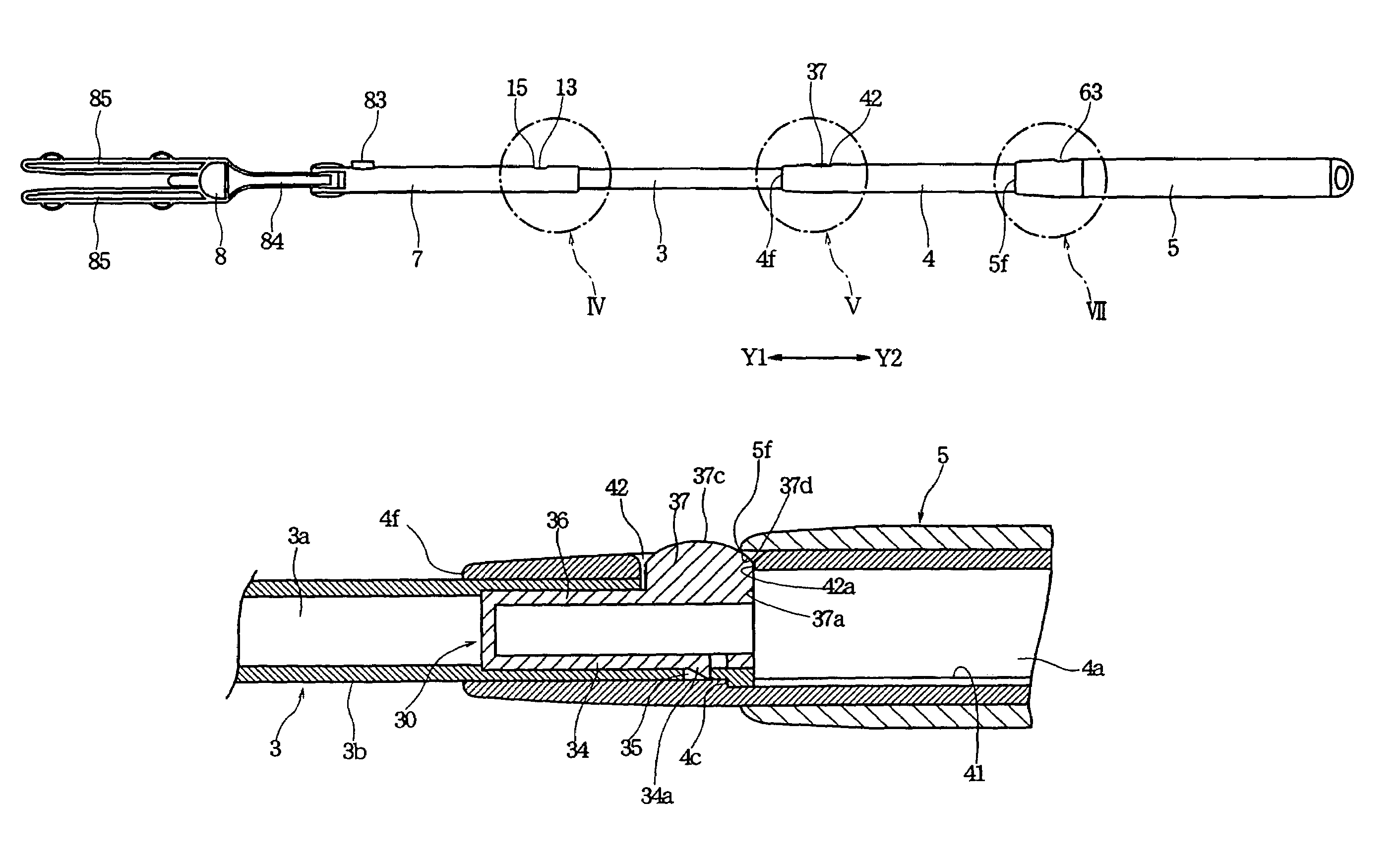

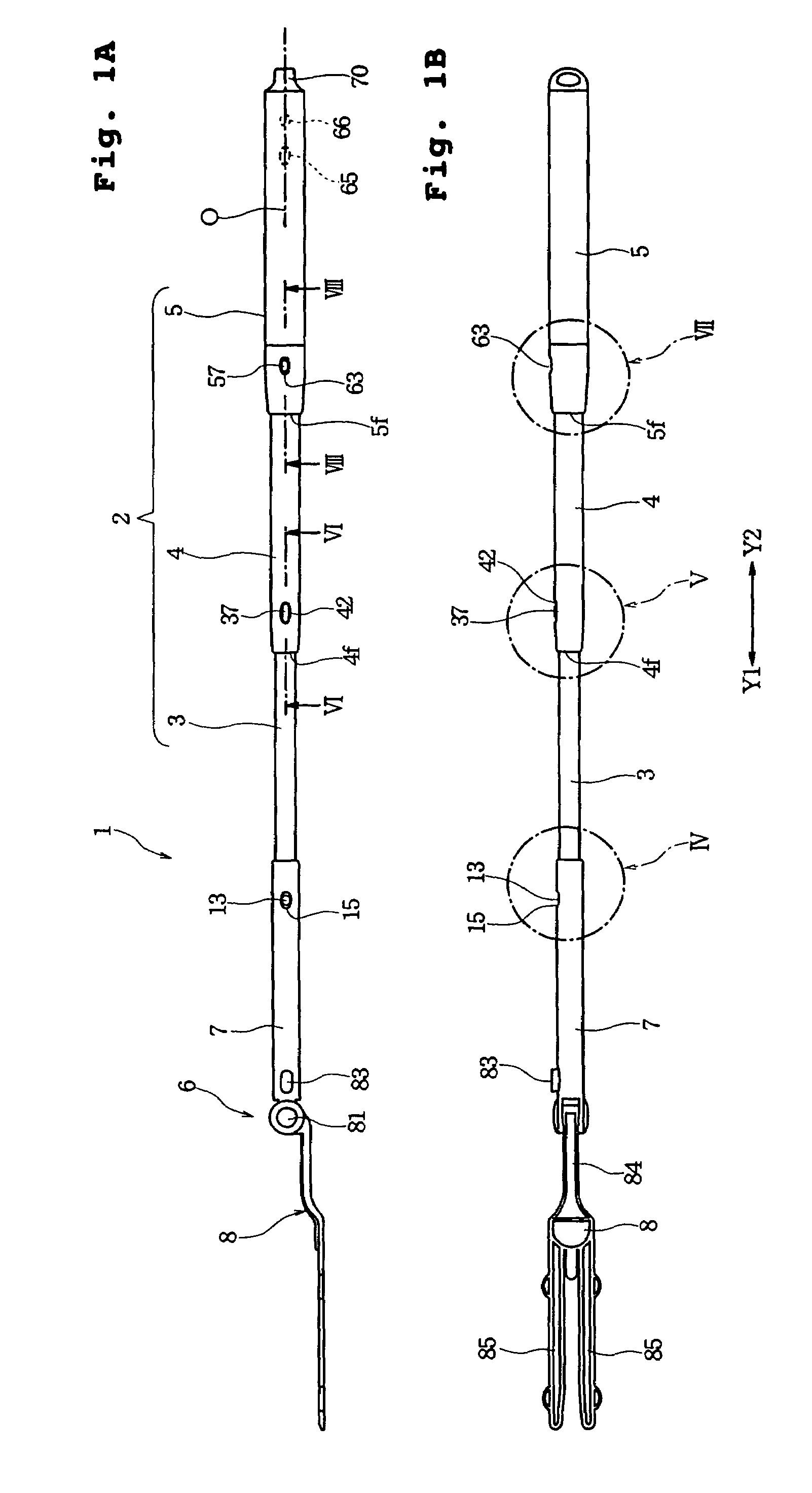

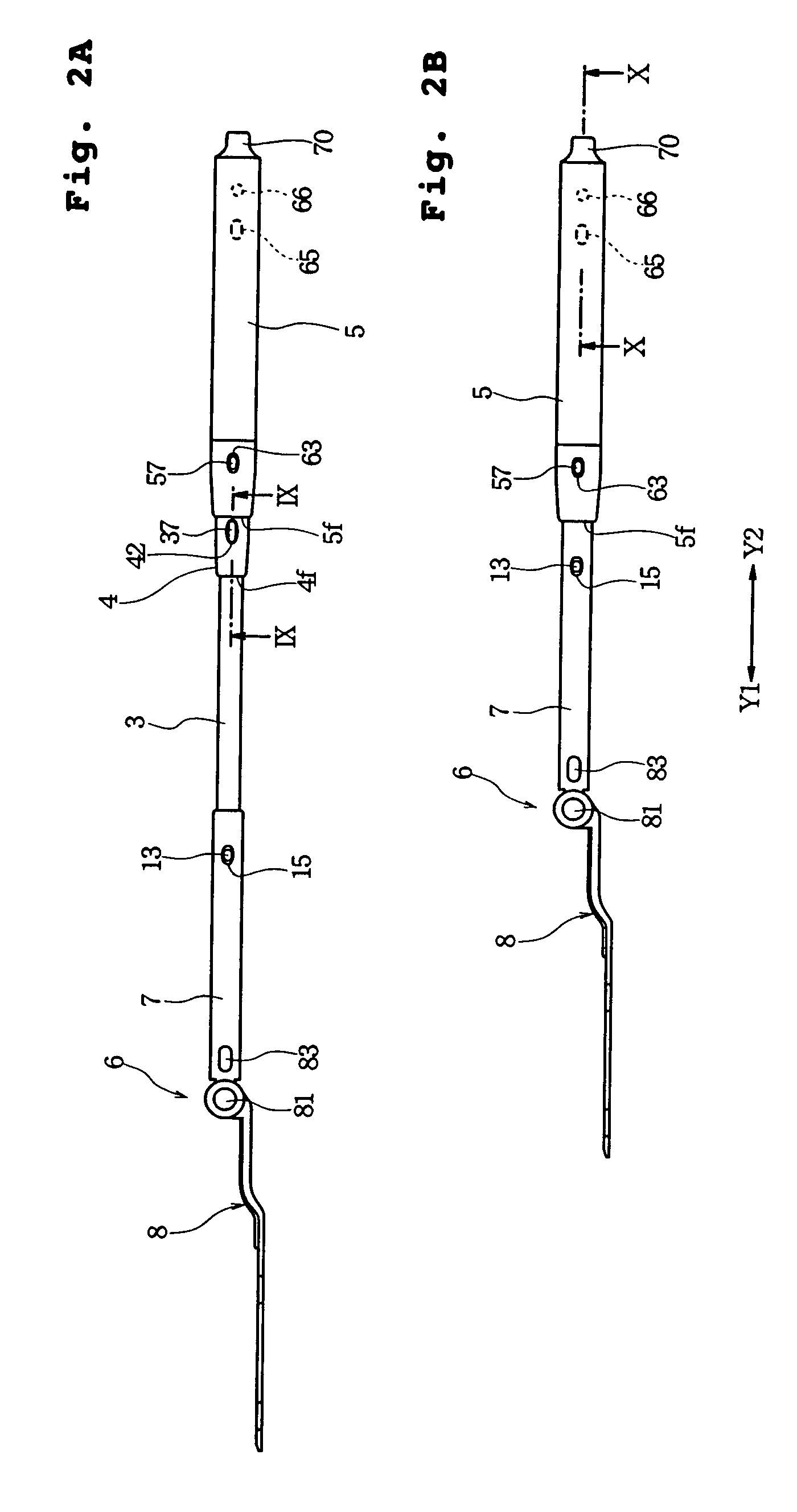

Holding device and cleaning tool with the holding device

InactiveUS7219386B2Easily be extended and retractedStable maintenanceTravelling carriersHoldersEngineeringFront and back ends

Disclosed is a holding device including: a telescopic handle having axially opposed front and rear ends and constructed of at least two separate shafts, of which a front-side separate shaft axially fits within a rear-side separate shaft being a hollow cylinder; and a support member provided at the front end of the telescopic handle for attachment of a cleaning wiper. The front-side separate shaft has an axially extending elastic arm and an engaging projection provided at a leading end of the elastic arm, while the rear-side separate shaft has a through-hole passing through a cylinder wall thereof, in which the engaging projection engages when the front-side separate shaft projects from the rear-side separate shaft by a predetermined length. Pressing the engaging projection, which engages in the through-hole, from outside the rear-side separate shaft permits release of the engaging projection from the through-hole.

Owner:UNI CHARM CORP

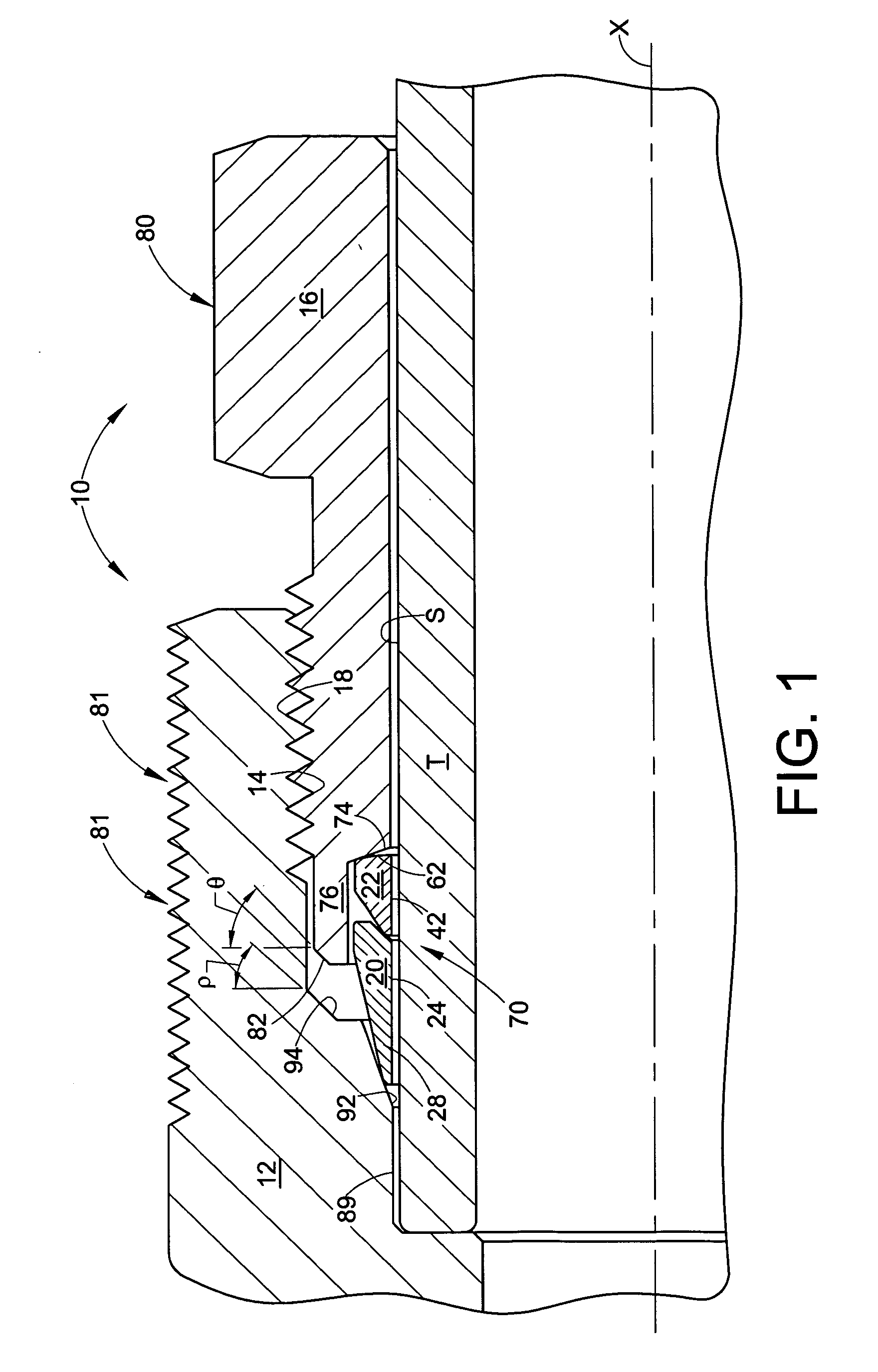

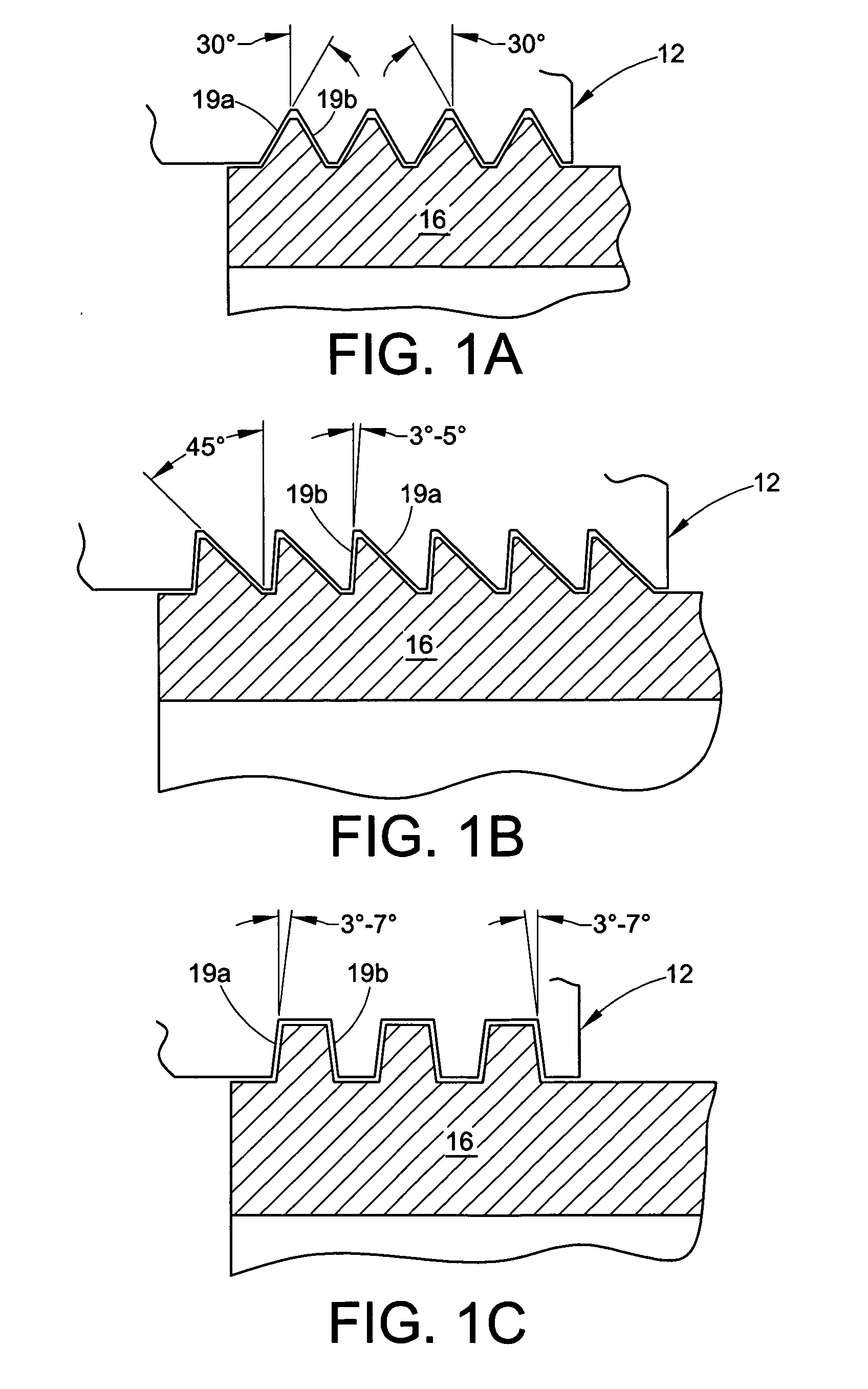

Radial expansion of tubular members

An apparatus and method for coupling a tubular member to a preexisting structure. The tubular member is anchored to the preexisting structure and an expansion member is displaced relative to the tubular member to radially expand the tubular member.

Owner:SHELL OIL CO

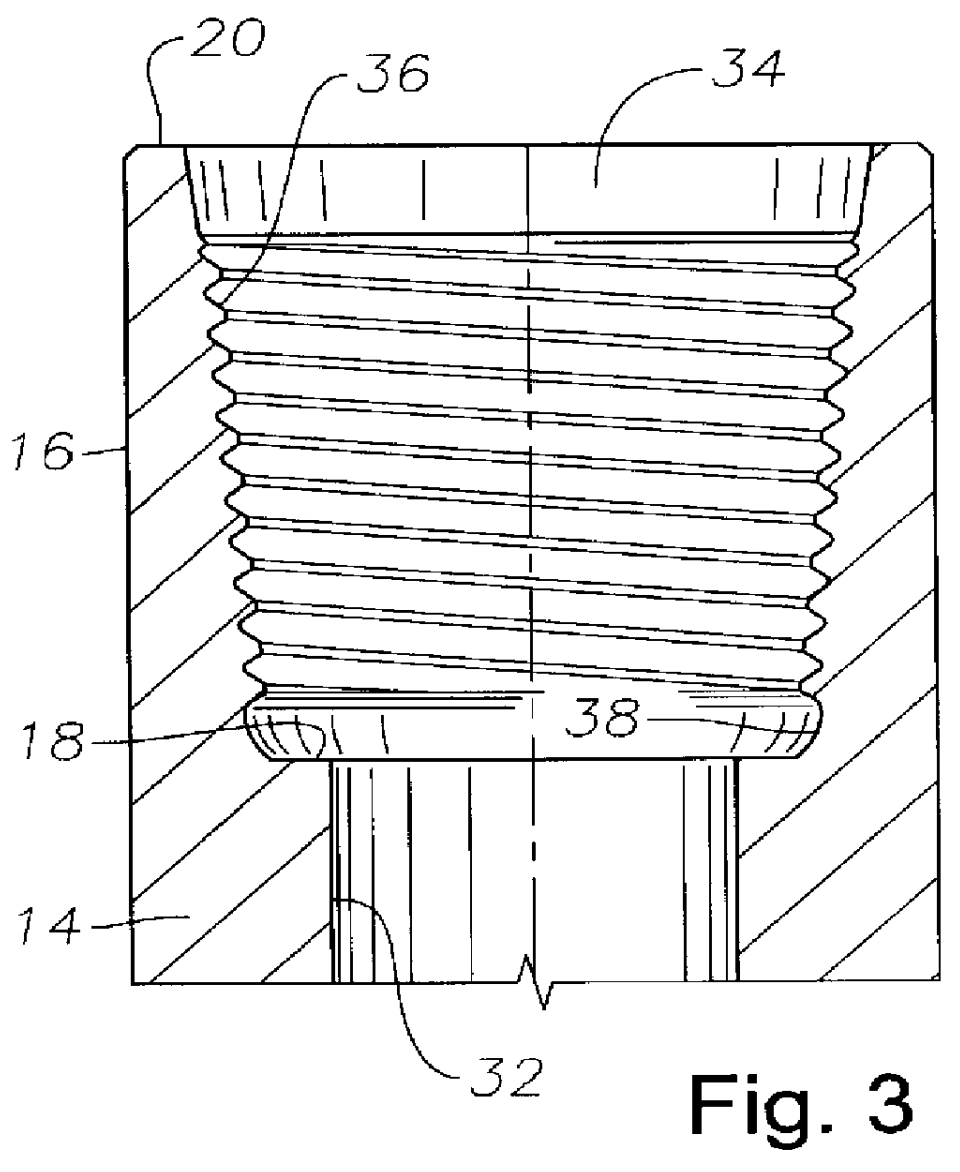

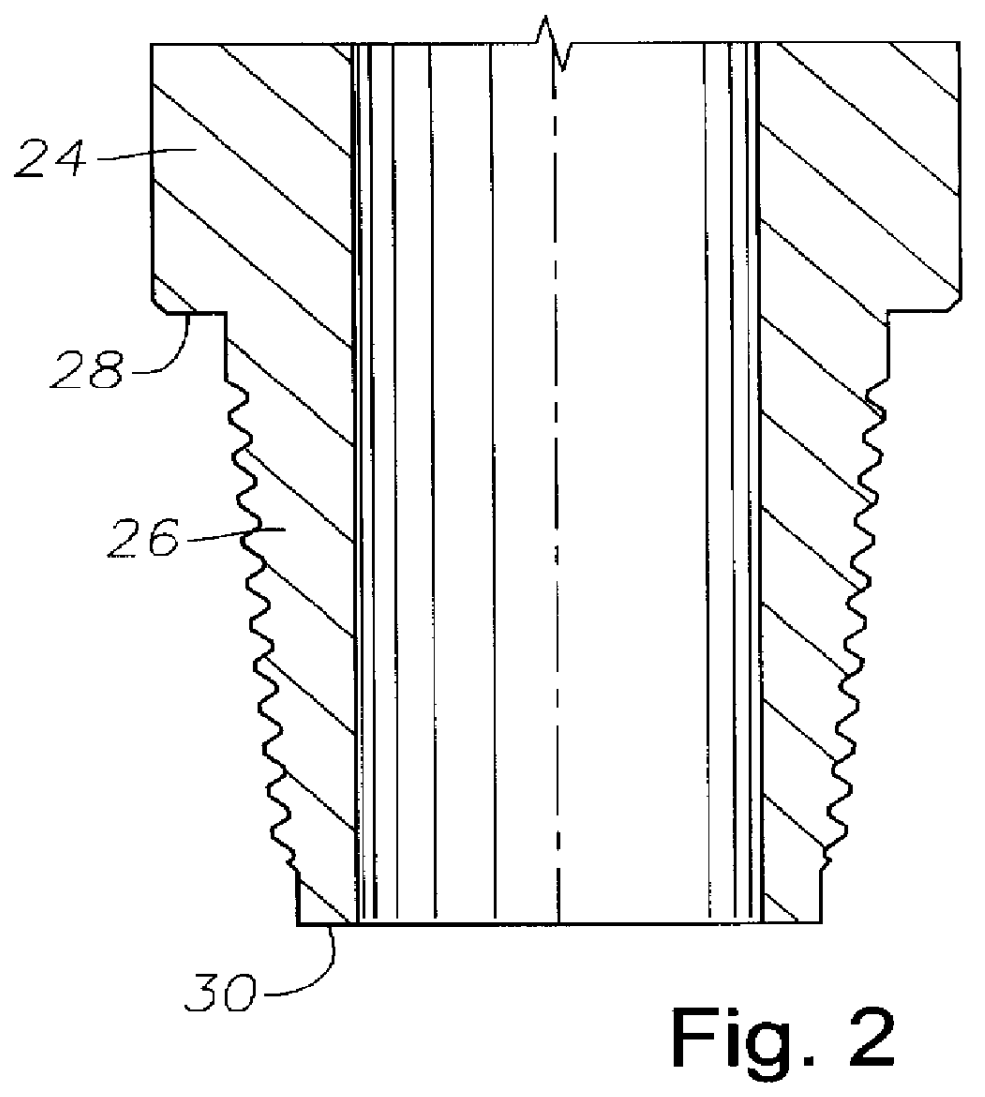

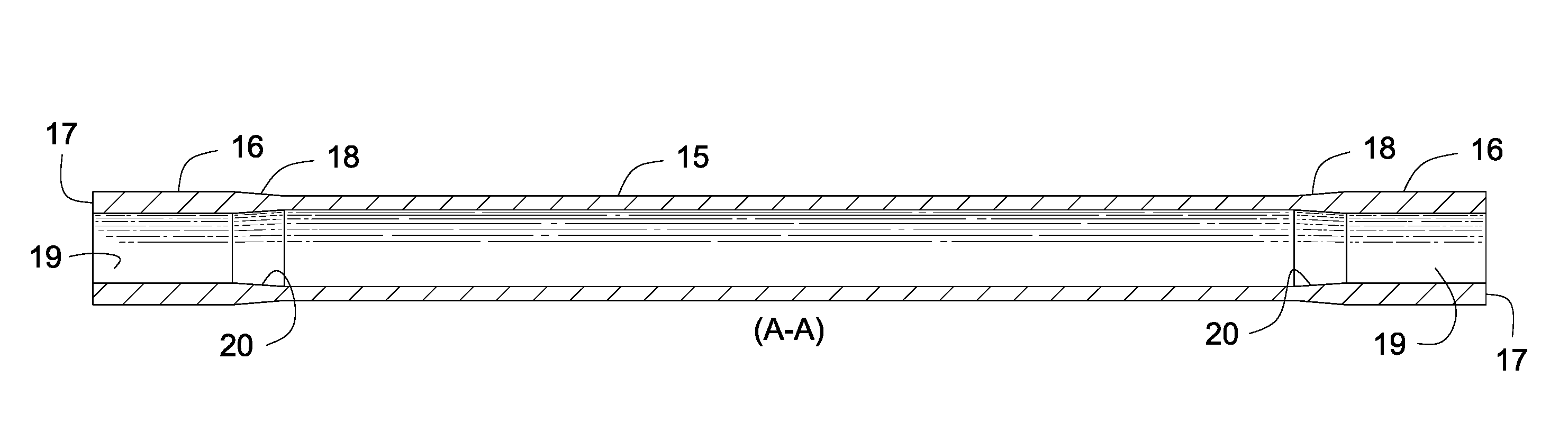

Adjustable Length Discharge Joint for High Pressure Applications

InactiveUS20090261575A1Adjustable lengthSleeve/socket jointsDrilling rodsInternal pressureEngineering

An adjustable length joint for high-pressure applications is described that includes rigid inner and outer tubes; both having passages there through. The rigid outer tube has at least one peripheral ring groove within its inner wall. The tubes have threads, which are adapted to adjustably engage with one another securely at a working pressure of at least about 10,000 psi. The rigid inner tube and the rigid outer tube are rotatable to enable adjustable engagement between the threads. The joint also includes an O-ring seated in each of the at least one peripheral ring grooves. When the rigid inner tube and the rigid outer tube are held in a selectable position, the first thread and the second thread overlap a sufficient distance necessary for the first thread and the second thread to withstand the forces exerted by the internal pressure within the joint at the working pressure.

Owner:HALLIBURTON ENERGY SERVICES INC

Enhanced durability hammer union

A union for connecting two tubular members. The first tubular member has an external flange, and the second tubular member has a set of external threads. An annular nut surrounds the first tubular member. The nut has an internal flange that surrounds the first tubular member, and a set of threads to engage the threads of the second tubular member. Arcuate segments are circumferentially mated between the internal flange of the nut and the external flange of the first tubular member. A flat conical surface on the inner side of the segment comes into contact with a flat conical surface on the outer side of the external flange. Curved conical surfaces tangentially align with and extend from the flat conical surfaces on the segment and the external flange. Cylindrical surfaces tangentially align and join the curved conical surfaces on the segment and the tubular member.

Owner:S P M FLOW CONTROL

Surface conditioning prior to chemical conversion treatment of a steel member

ActiveUS7666266B2Optimized diameterShort timeOther chemical processesCorrosion preventionPotassiumMaterials science

By subjecting a threaded joint for OCTG (oil country tubular goods) to surface conditioning with an aqueous solution of potassium tetraborate or sodium tetraborate prior to manganese phosphate chemical conversion treatment, a manganese phosphate chemical conversion coating having coarse crystal grains with an average crystal grain diameter of 10-110 micrometers is formed on the surface of the steel member which may be any steel including a high Cr steel. This manganese phosphate chemical conversion coating can hold a large amount of a liquid lubricant, and it is effective at preventing the occurrence of galling at the time of makeup of a threaded joint for OCTG.

Owner:NIPPON STEEL CORP

Expansion cone for radially expanding tubular members

Owner:SHELL OIL CO

Modular connector and method

A connector connects auxiliary flow lines—and, in some configurations, electrical lines—that extend through and terminate at or near opposing ends of two respective components of a downhole tool string. The connector comprises a body assembly for fluidly-connecting the auxiliary flow lines and electrically-connecting the electrical lines of the respective two components, and an assembly for adjusting the length of the body assembly. In particular embodiments, the two components are discrete modules of a unitary tool, or alternatively, are distinct tools. Additionally, the connector may include a mechanism for closing the auxiliary flow lines of one or both components upon disconnection of the fluid connection between the two components.

Owner:SCHLUMBERGER TECH CORP

Floating wedge thread for tubular connection

ActiveUS20060145480A1Reduce the amount requiredLarge applied makeup torqueDrilling rodsHose connectionsEngineeringWedge shape

Owner:HYDRIL CO

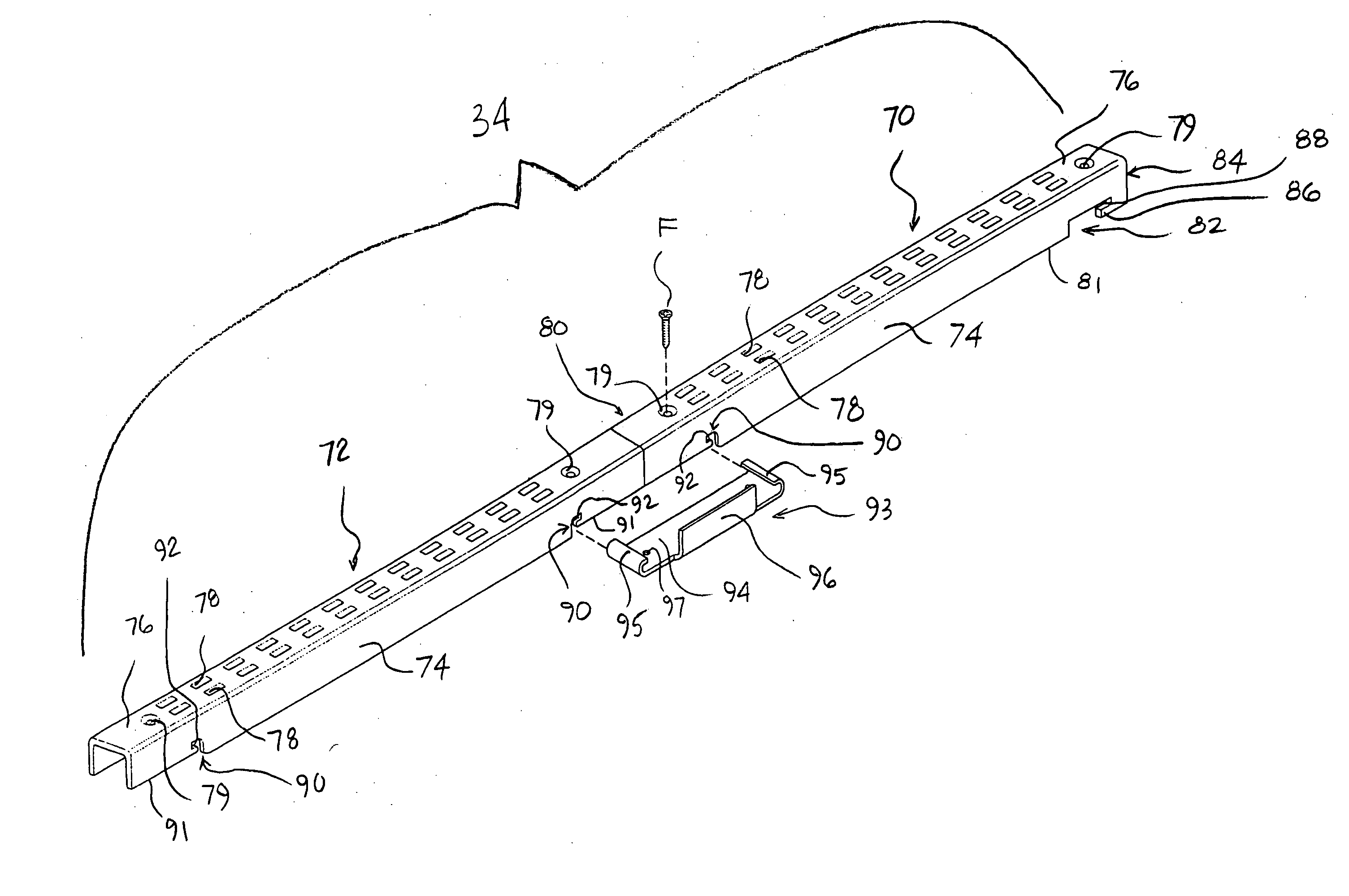

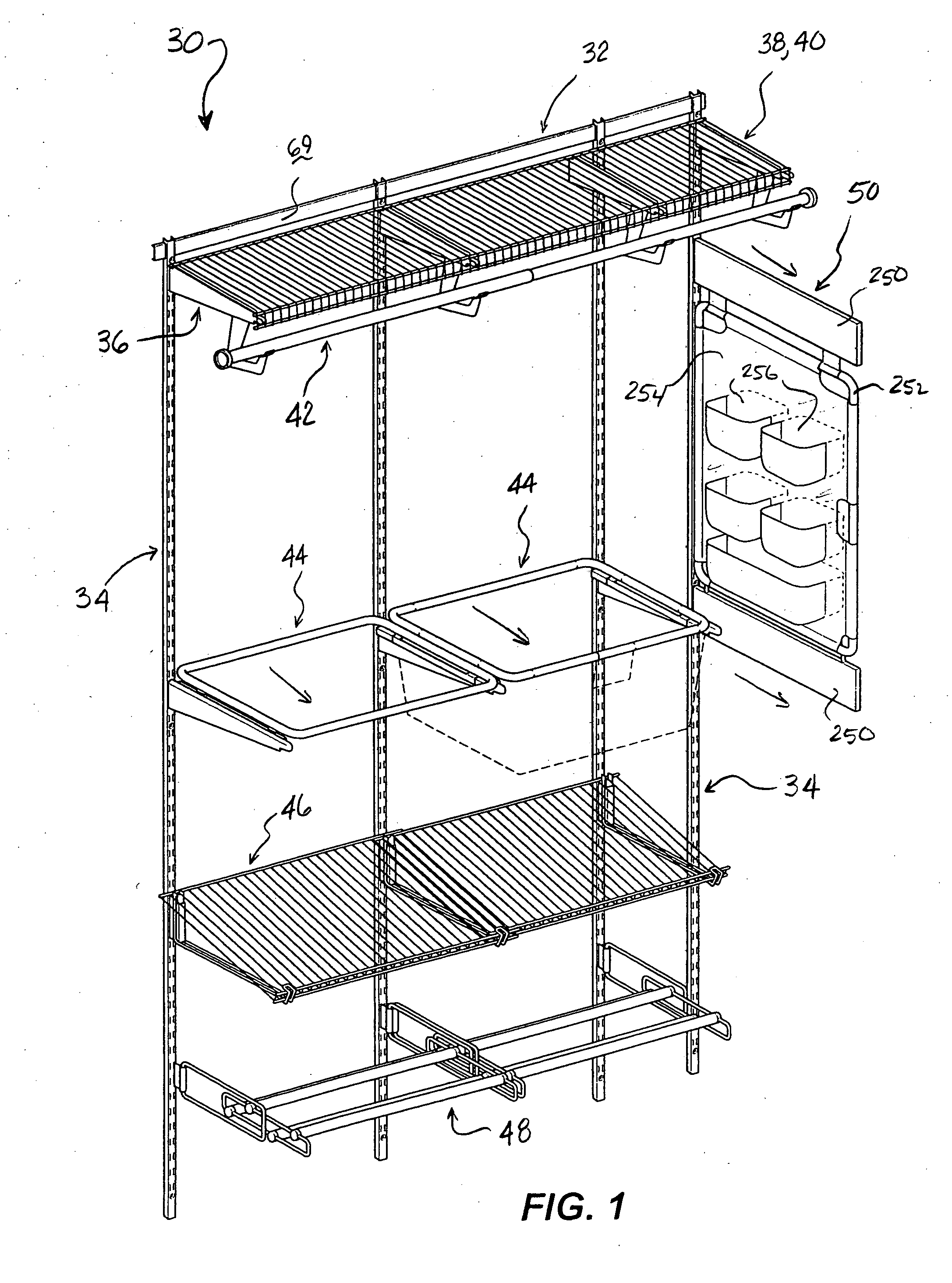

Mounting upright and clip for adjustable organizer system

A height adjustable upright for an adjustable organizer system has at least one first segment with a upper end configured to hang from a mounting rail and has a lower end. The upright also has at least one second segment with a pair of opposed ends, at least one of which being configured to connect end-to-end with the lower end of the first segment. A clip has a pair of opposed ends each configured to connect to the lower end of the first segment and to the one end of the at least one second segment to hang the second segment from the first segment.

Owner:RUBBERMAID

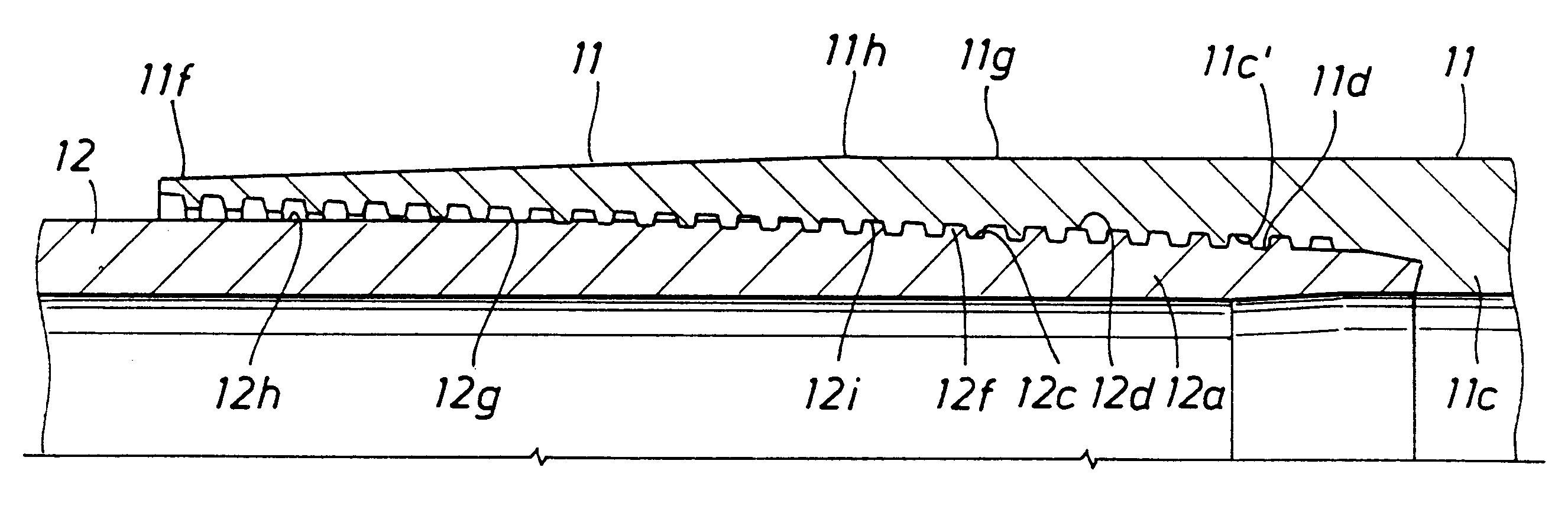

Threaded and coupled connection for improved fatigue resistance

InactiveUS6609735B1Reduce horizontal sizeReduce stress concentrationDrilling rodsFluid pressure sealed jointsCouplingEngineering

Threaded and coupled pipe connections are provided with a number of design features that increase resistance of the connection to fatigue failure from cyclical side loading. The features acting alone or in combination include the provision of a pin thread that is formed along a single taper and that vanishes at the surface of the pipe. The coupling engages the pin such that the threaded area of the coupling engages all of the pin threads and extends beyond the vanish point of the pin threads at the optimum coupling makeup position. The threads of the coupling and pipe may engage along both the stab and load flanks to distribute the side loading. The external surface of the coupling may be tapered from the center toward each coupling end to reduce the stiffness ratio of the connection, and the ends or faces of the coupling may be reduced in radial thickness to prevent coupling splitting. The coupling length may be extended to exceed standard coupling lengths to provide the additional threaded area and / or taper areas and / or reduced stiffness ratios.

Owner:DEUT BANK TRUST COMPANY AMERICAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com