Water Filter Cartridge and Valve with Autobypass Feature

a technology of filter cartridge and valve, applied in the field of filters, can solve problems such as compromising the integrity of the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

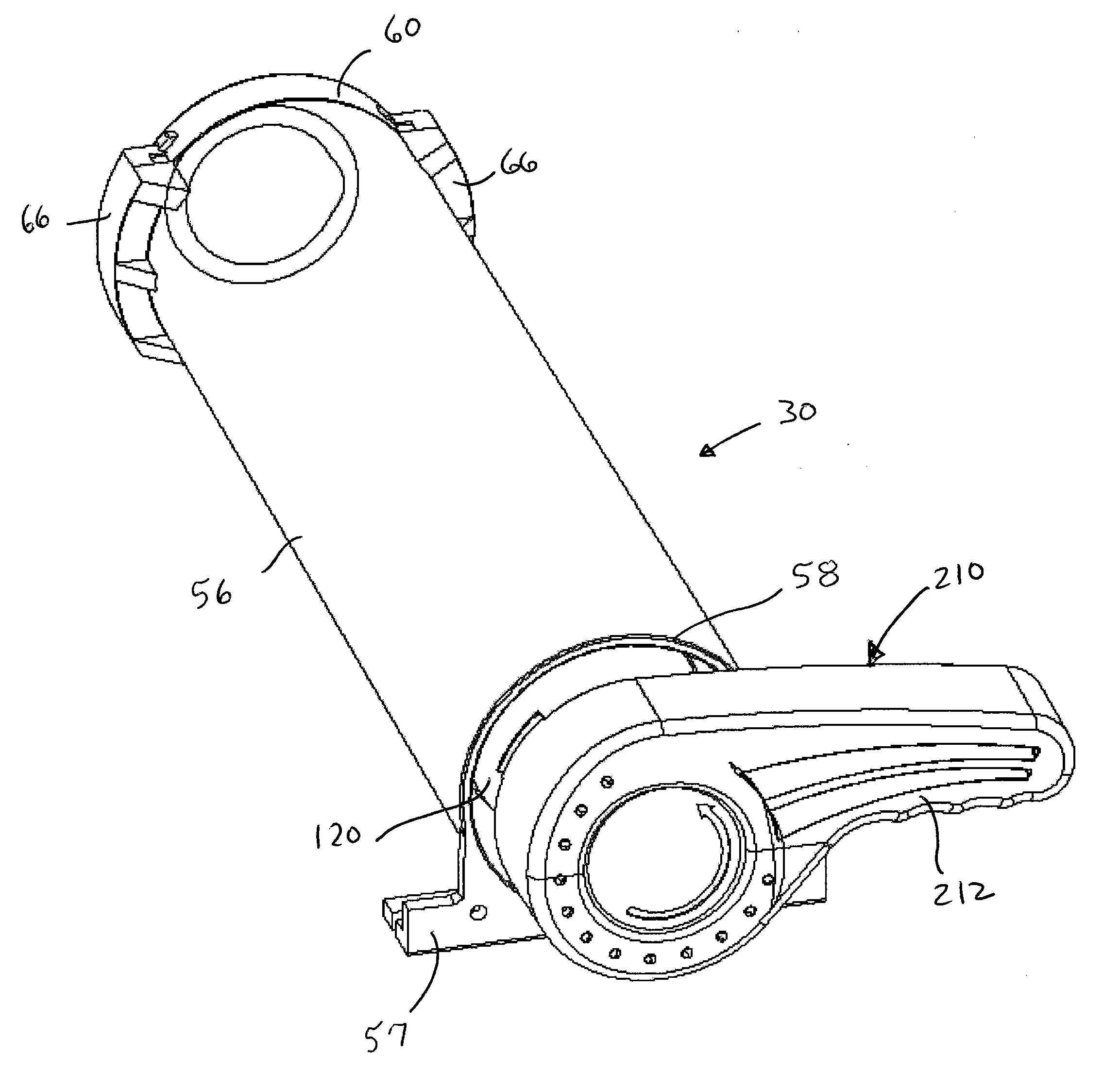

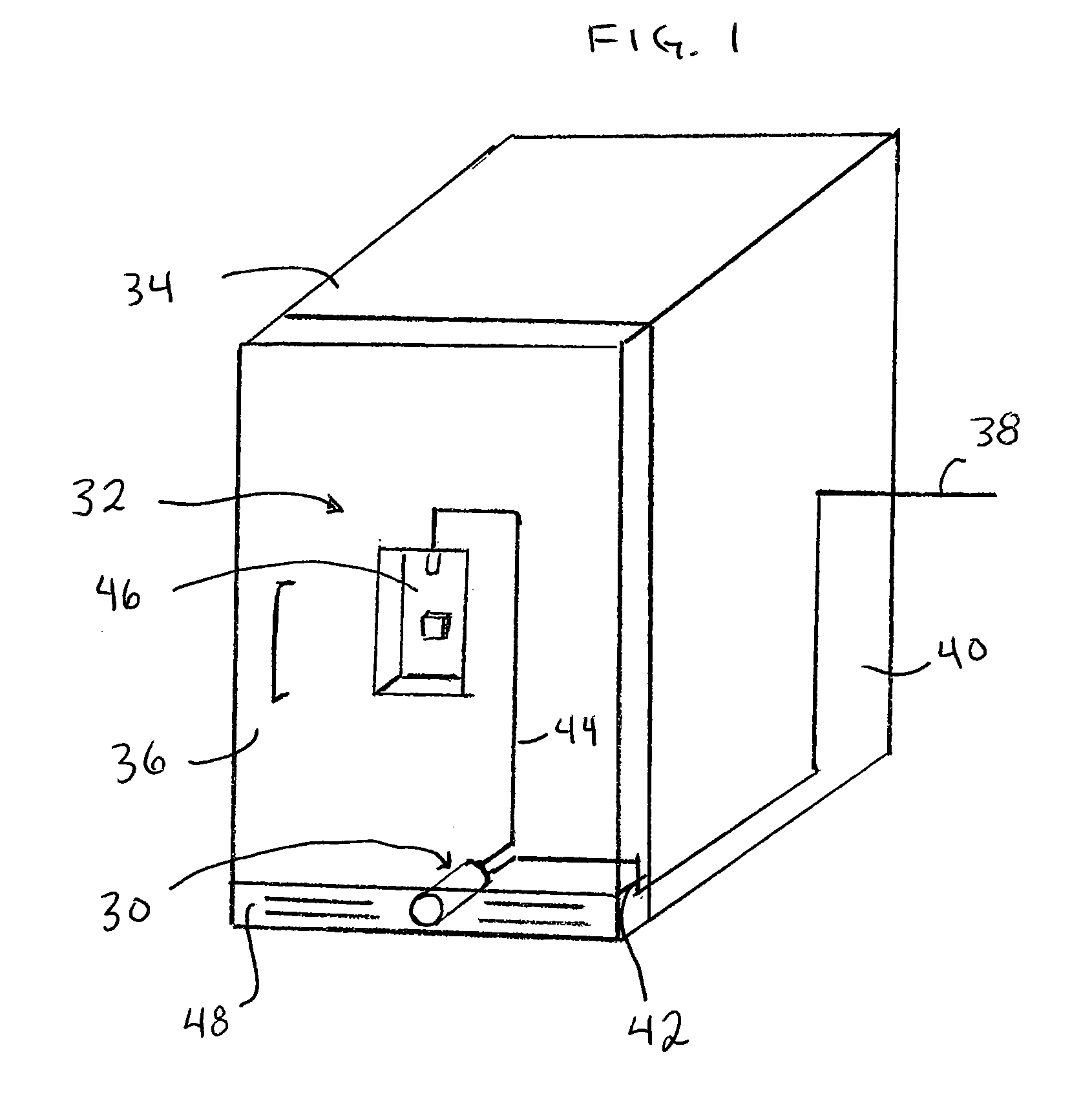

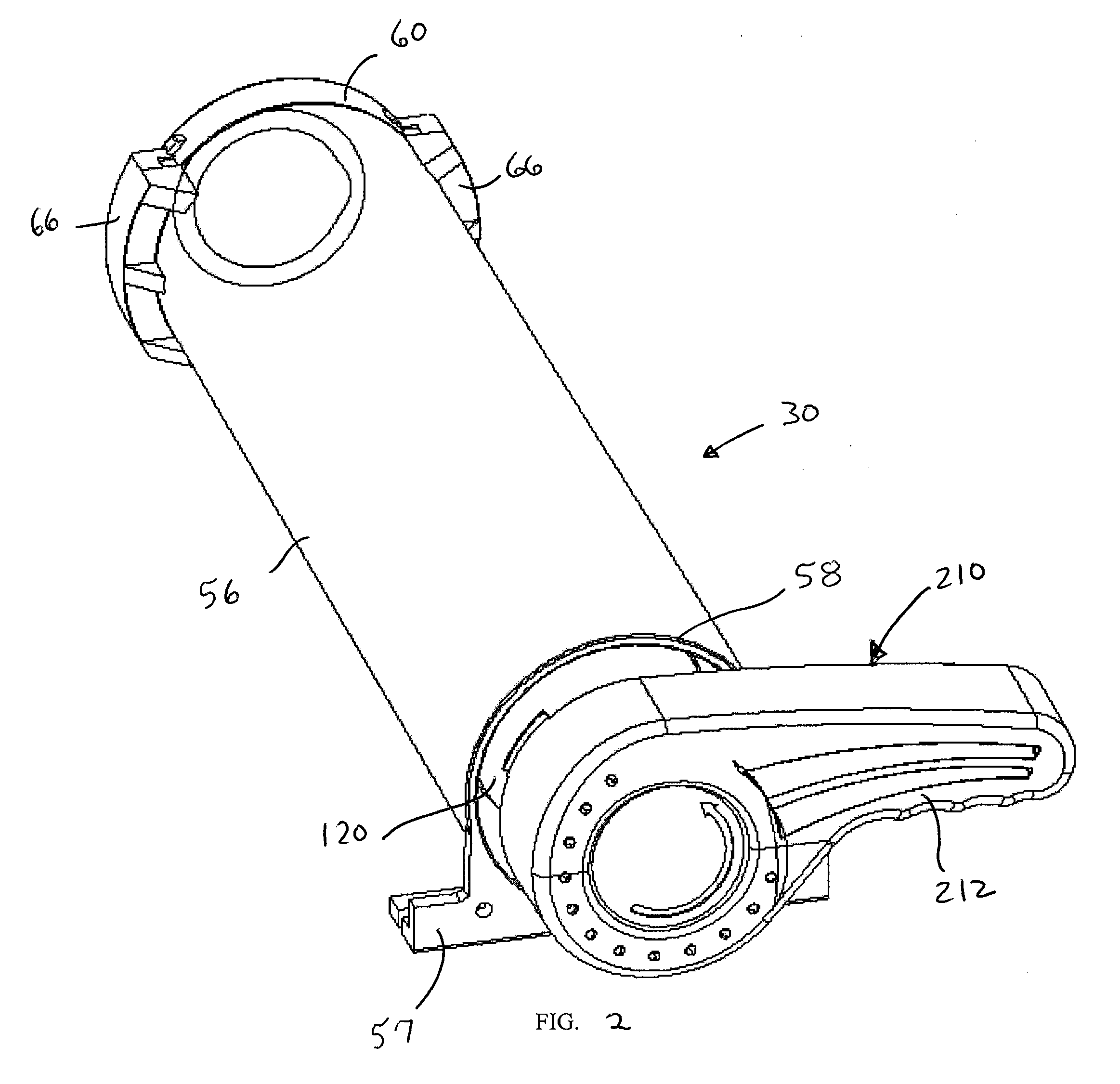

[0042]As schematically illustrated in FIG. 1, the present invention provides a water filter cartridge system 30, shown in isolation in FIG. 2, which may find particular utility in a water dispensing system 32, such as found in a refrigeration appliance 34. The present invention also has utility in other appliances and environments and for filtering liquids other than water. For purposes of disclosing an embodiment of the invention, it will be disclosed in the environment of a water dispensing system 32 in a domestic refrigerator 34 where the water is dispensed at a door 36 of the refrigerator. The water is supplied via a water line 38 plumbed into a building supply, and passes through a cabinet 40 of the refrigerator 34, and into the refrigerator door 36 at a hinge 42 for the door. The water line 38 in the door 36 is connected to the water filter cartridge system 30, and then a connecting water line 44 leads up to a water dispenser 46 accessible from an outside of the door. The wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

| lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com