Patents

Literature

1172 results about "Liquid system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV Curable Silsesquioxane Resins For Nanoprint Lithography

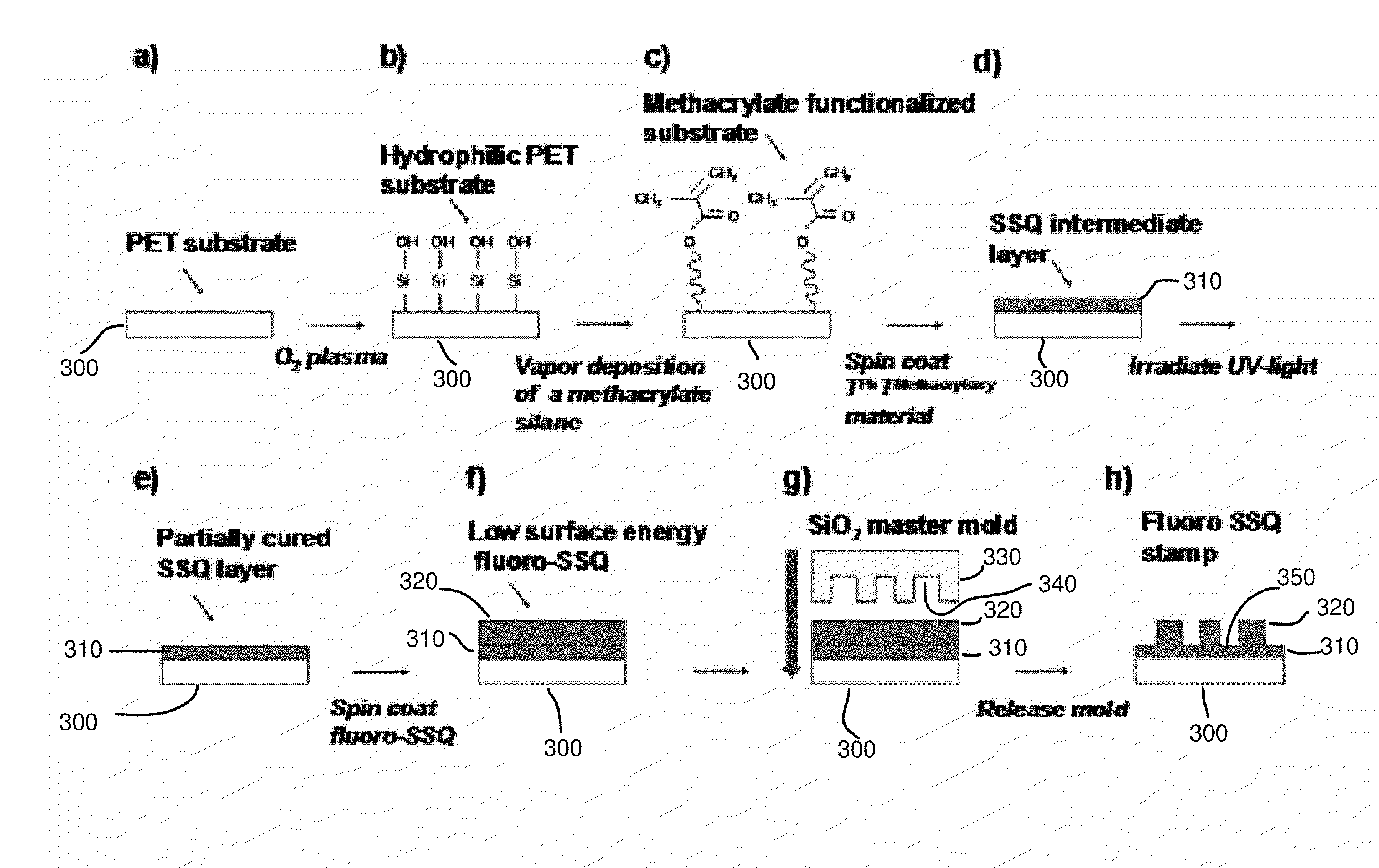

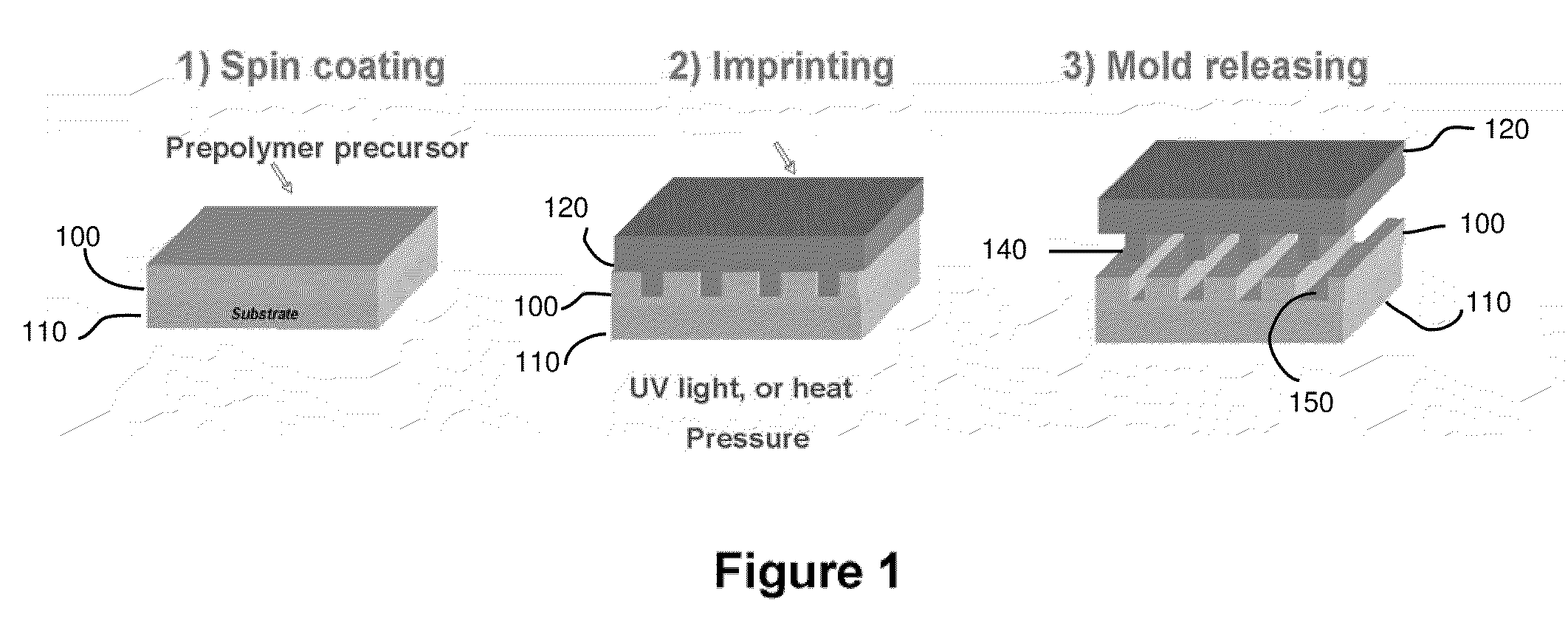

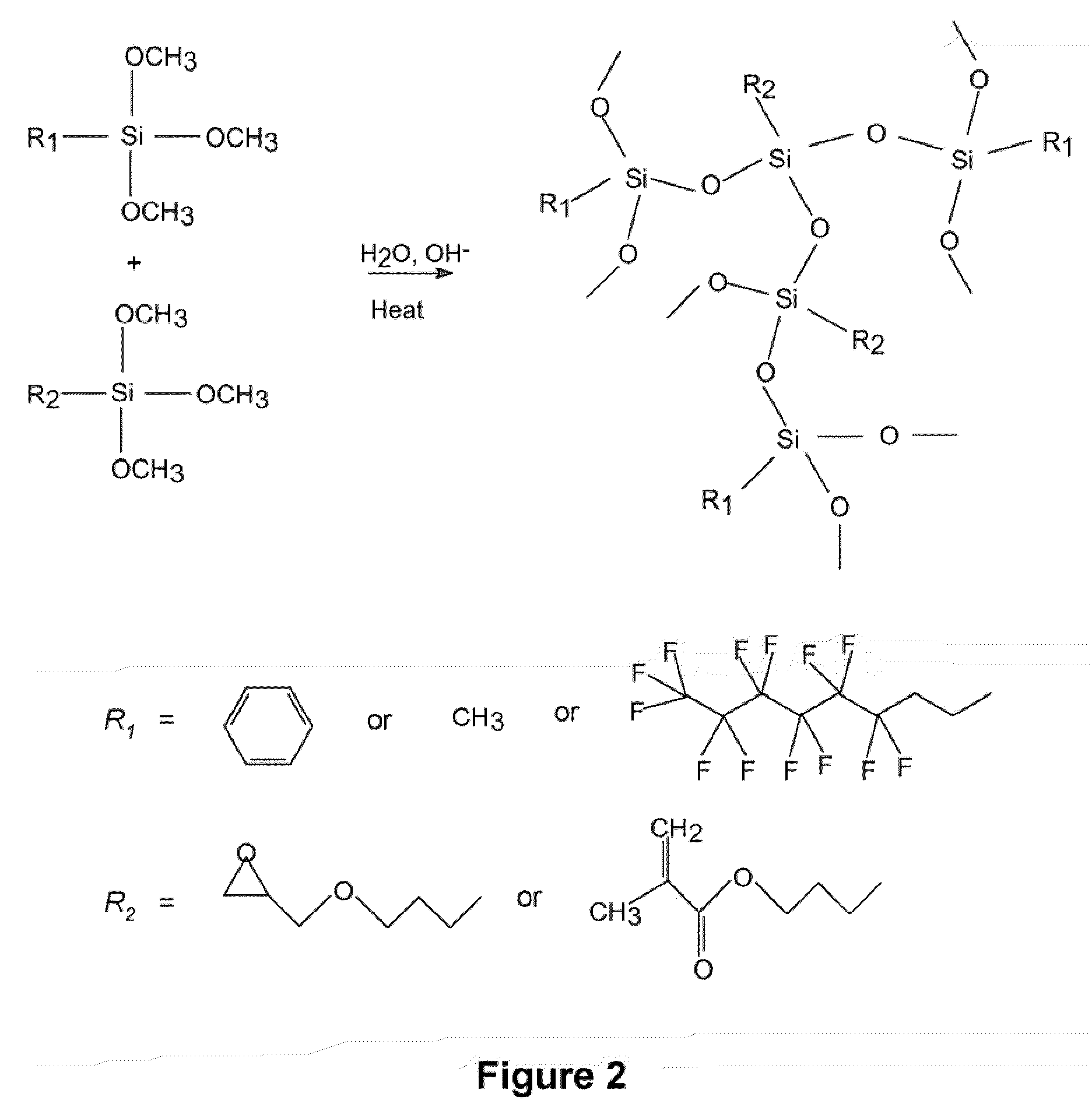

ActiveUS20090256287A1Simple compositionImprove methodPhotosensitive materialsNanoinformaticsNanolithographyResist

Radiation-curable silsesquioxane resin materials are employed for micro- and nanolithography. The resin materials can include a radiation-curable silsesquioxane resin and a photo-initiator having low viscosity. The low viscosity of the liquid system allows imprinting with low pressure and low temperature; e.g. room temperature. The resist's dry etching resistance is increased and the cured film is more easily separated from the mask. Due to its high modulus after cure, the material allows the fabrication of micro- and nano-features having high aspect ratios while providing a high throughput. Various pattern sizes, for example, ranging from tens of microns to as small as a few nanometers, may be achieved with the UV-curable material system.

Owner:RGT UNIV OF MICHIGAN

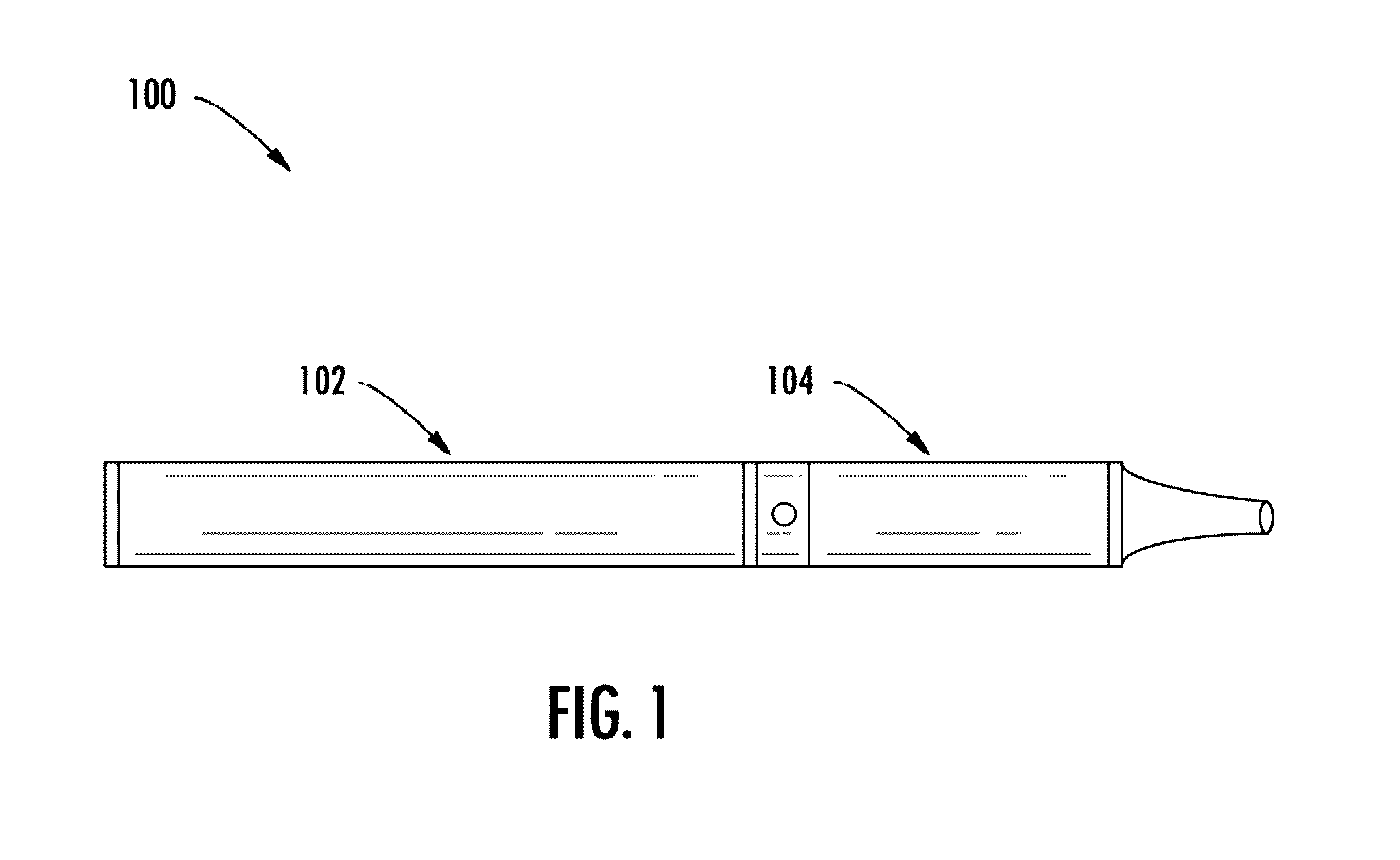

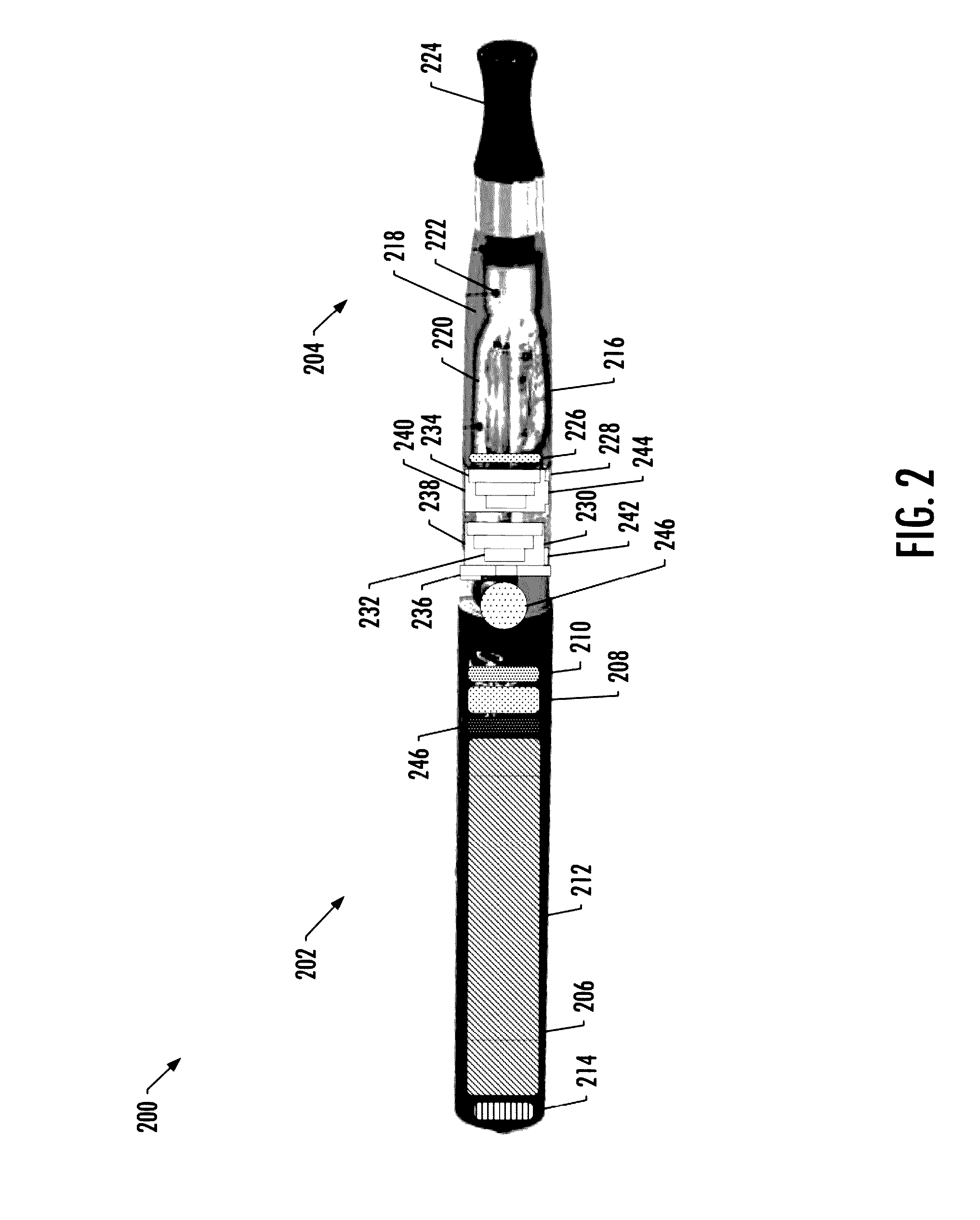

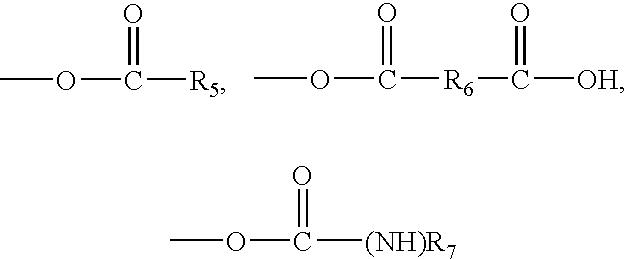

Contained liquid system for refilling aerosol delivery devices

A contained liquid system for use with a refillable aerosol delivery device is provided. The contained liquid system includes an aerosol delivery device having an adapter therein for receiving aerosol precursor composition within a reservoir of the aerosol delivery device, and a container of aerosol precursor composition having a corresponding adapter therein for transferring aerosol precursor composition from the container. The adapter and the corresponding adapter are removably, sealably connectable for refilling the aerosol delivery device with aerosol precursor composition. The adapter engages a valve of the corresponding adapter and includes a body defining separate and distinct filling airflow ports. The filling port transfers aerosol precursor composition from the container into the aerosol delivery device. The airflow port enables a flow of air through at least the portion of the aerosol delivery device when the adapter and valve are disengaged.

Owner:RAI STRATEGIC HLDG INC

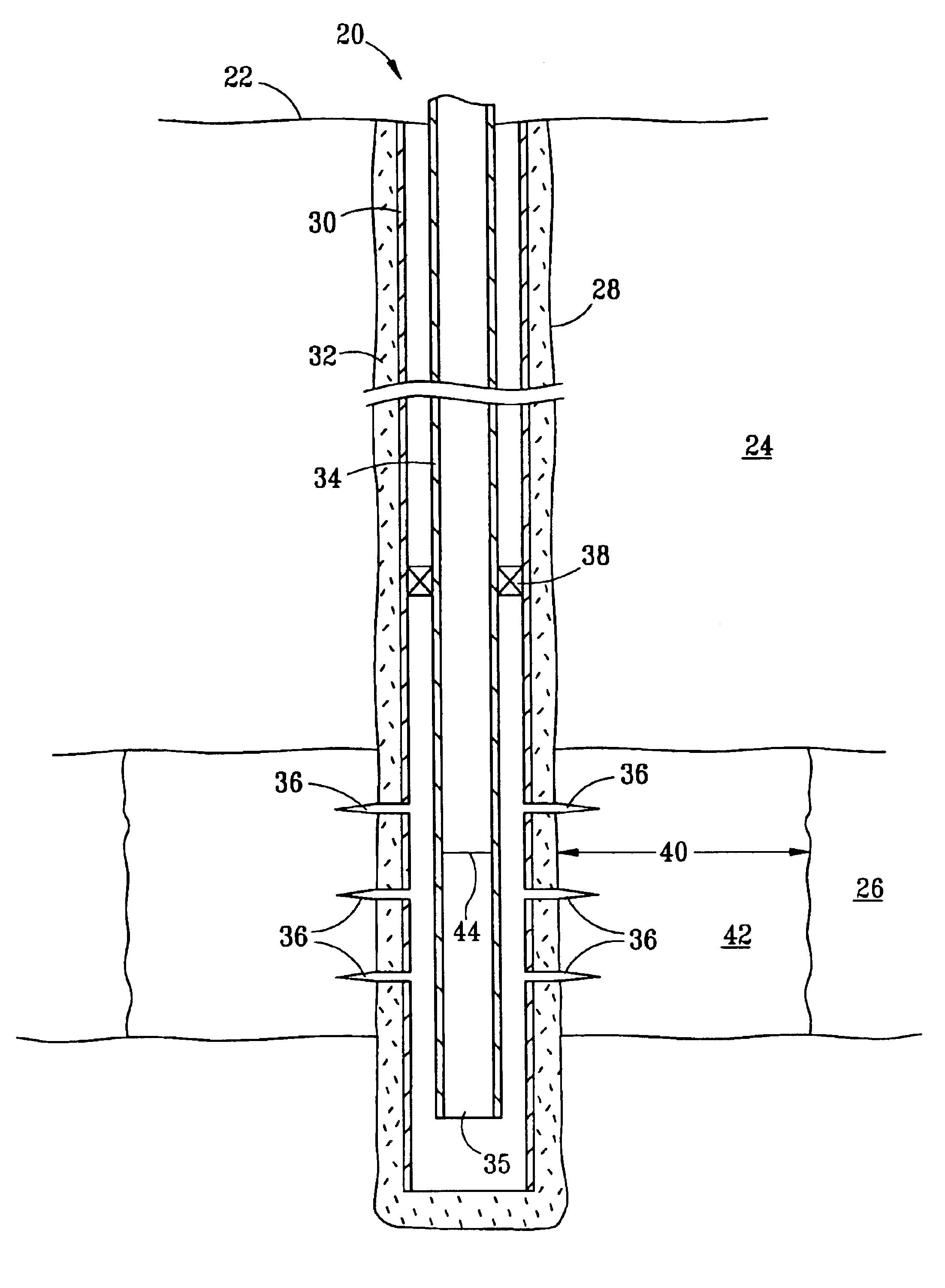

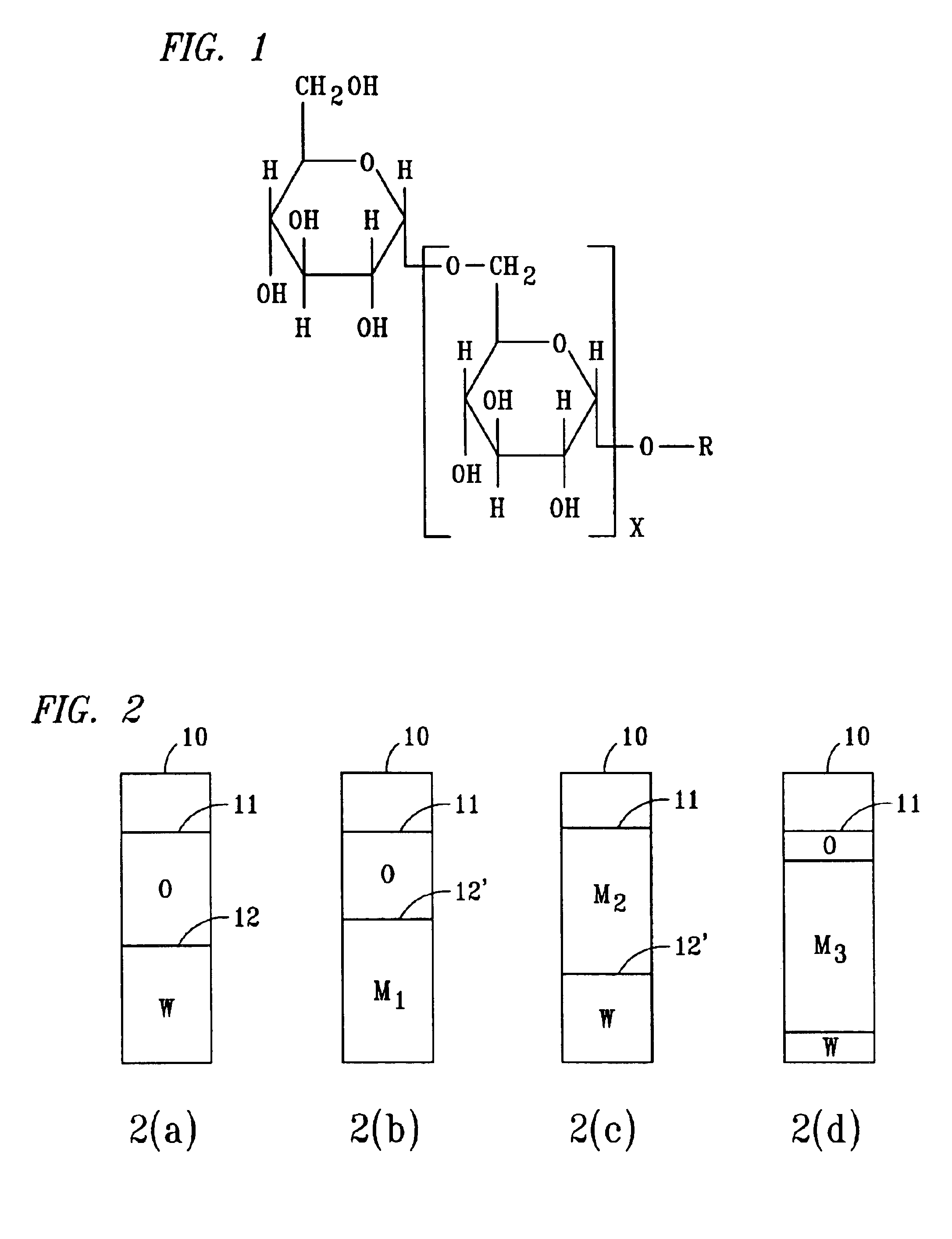

Water block removal with surfactant based hydrocarbonaceous liquid system

A composition, formulation, and method for removing water from a near-wellbore portion of a subterranean formation containing a crude oil and penetrated by a wellbore. The formulation contains alkylpolyglycoside, ethoxylated alcohol and linear alkyl alcohols. The composition contains a hydrocarbonaceous liquid, alkylpolyglycoside, ethoxylated alcohol and linear alkyl alcohol.

Owner:PHILLIPS 66 CO +1

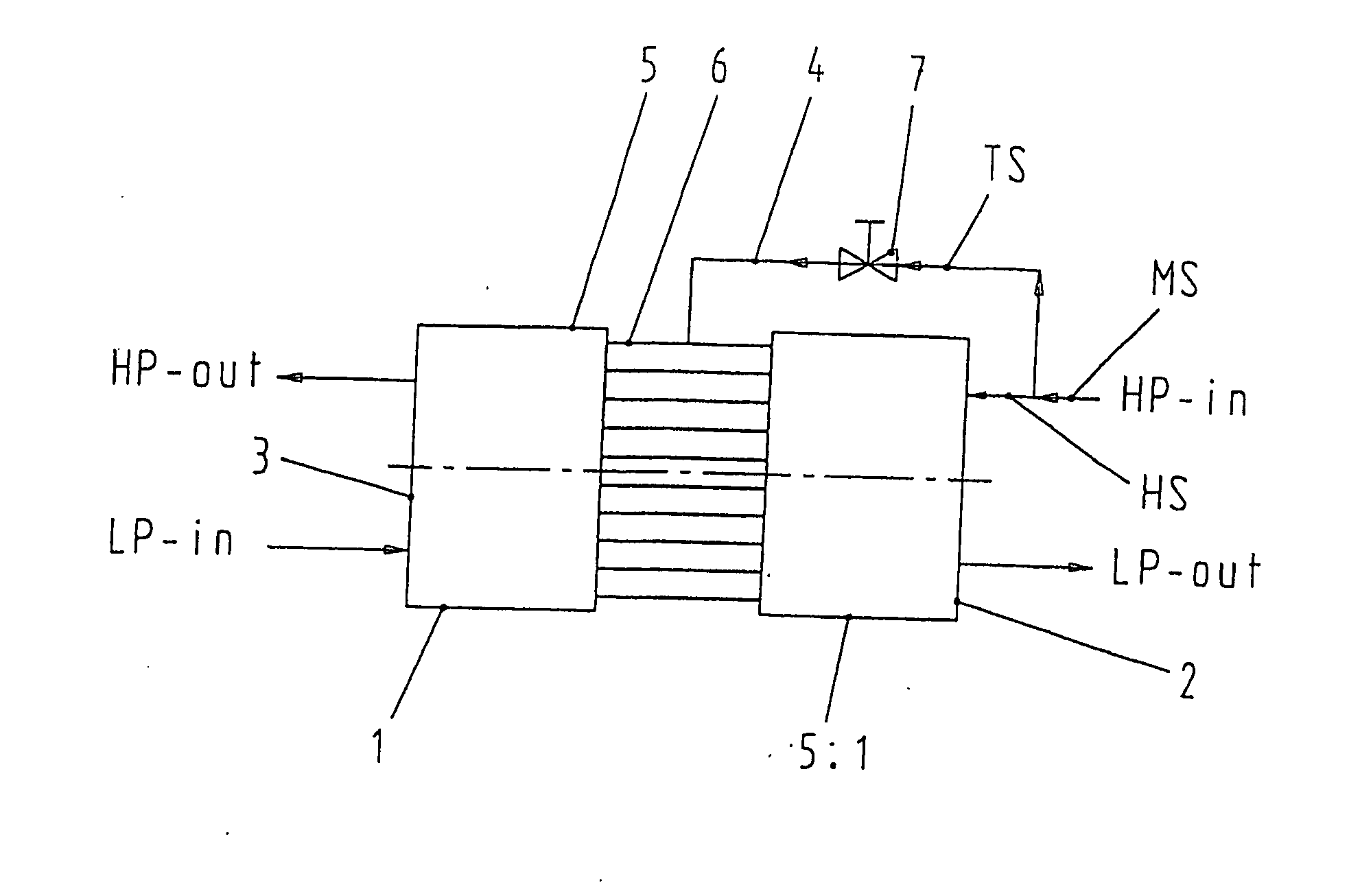

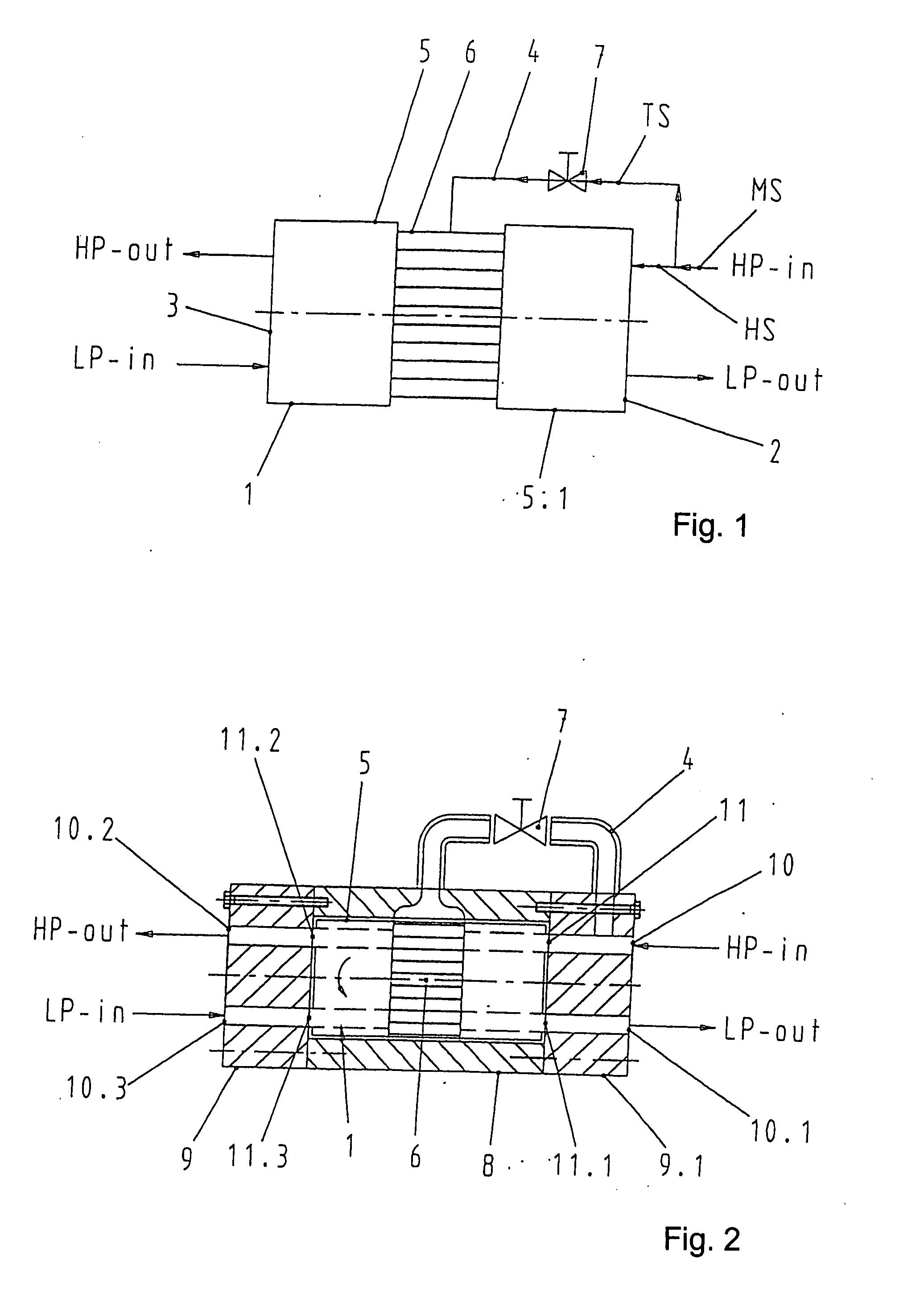

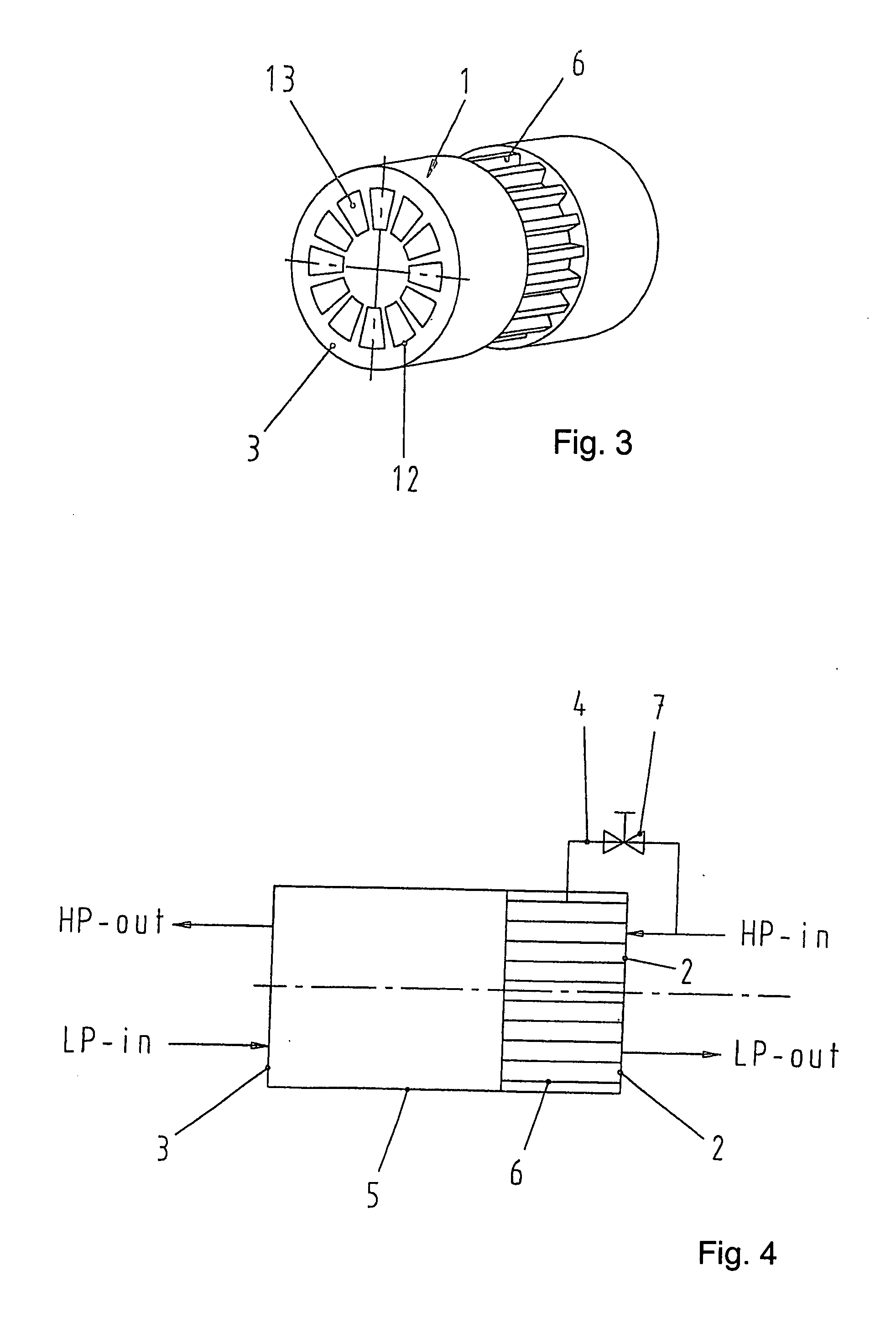

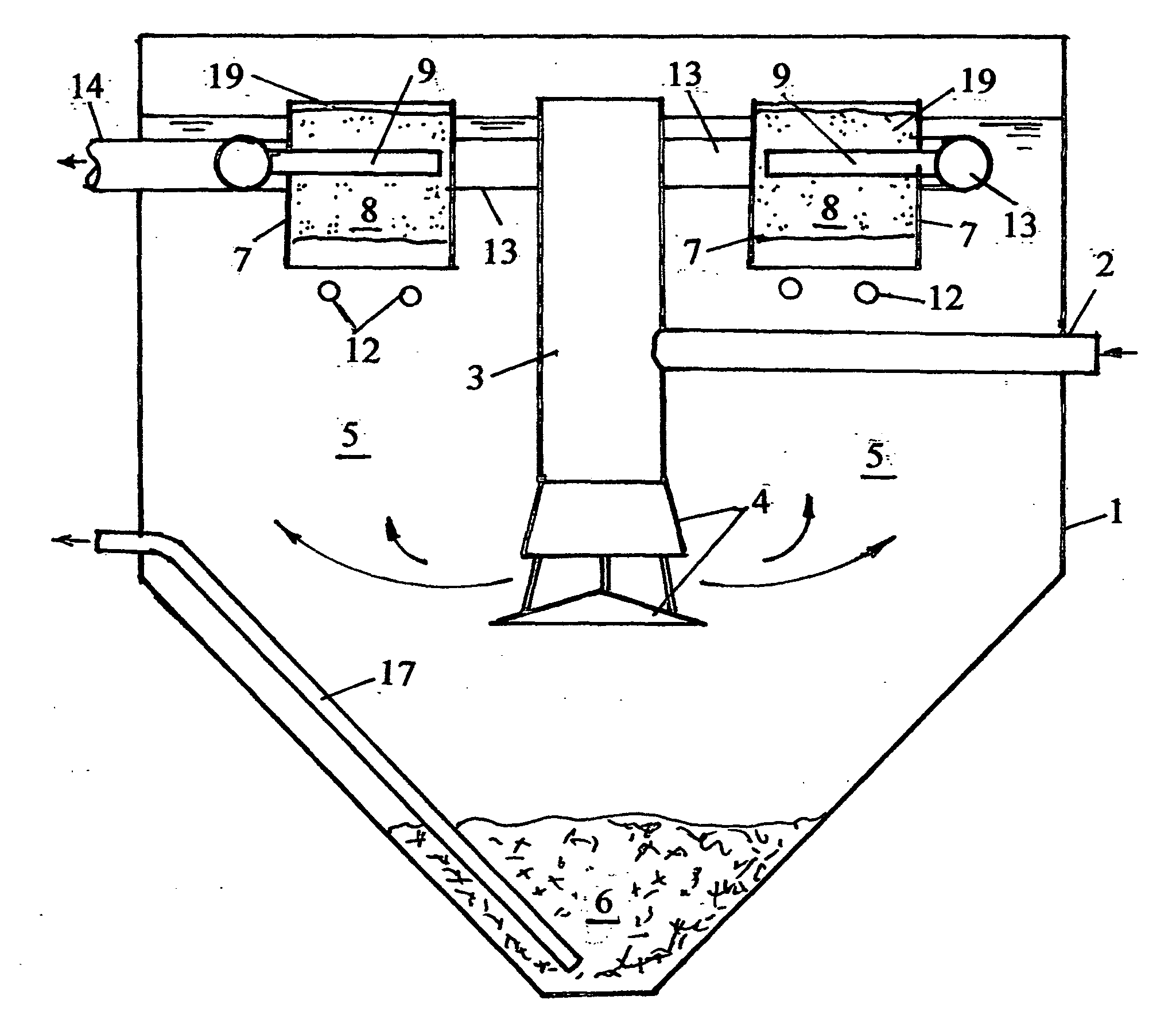

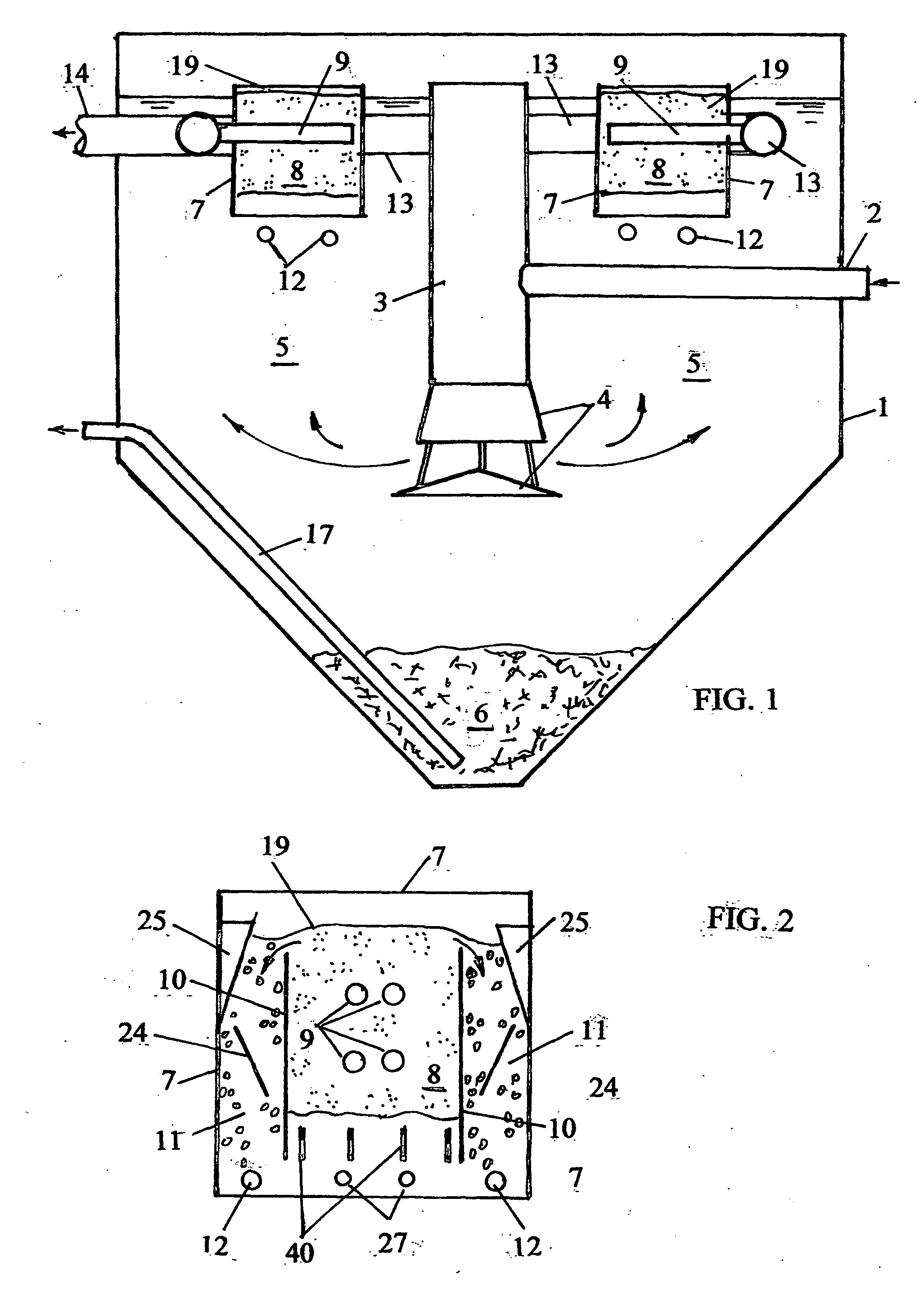

Speed-regulated pressure exchanger

InactiveUS20070137170A1Efficient operating stateMinimal mixing lossPump componentsGas turbine plantsMechanical engineeringPressure exchanger

A pressure exchanger for transferring pressure from a higher pressure liquid in a first liquid system to a lower pressure liquid in a second liquid system having a housing (8) with inlet and outlet connection openings (10-10.3) for each liquid and a rotor (1) arranged in the housing for rotation about a longitudinal axis. The rotor has a plurality of through channels (13) arranged around the longitudinal axis with openings (12) on axial end faces (2, 3) of the rotor. The rotor channels (13) are connected to the connection openings (10-10.3) through flow openings (11-11.3) in the housing such that during rotation of the rotor high pressure liquid and low pressure liquid are alternately supplied to the respective systems. A predominantly axially extending flow transition is formed between the flow openings (11-11.3) in the housing and the openings (12) of the rotor channels (13), and the flow openings in the housing form part of curved cavities (19) with each cavity (19) simultaneously covering several rotor channel openings (12) and having a shape which equilibrates the liquid flow speed in the vicinity of the housing flow openings (11-11.3). External surfaces (5-5.3) of the rotor (1) have an energy converting or energy transmitting configuration (6), and a partial flow (TS) of high pressure and / or flow energy impinging on the configuration (6) produces rotation of the rotor (1). A regulator (7) the varies the amount of the partial flow (TS) and the rotational speed of the rotor (1) and controls the rotational speed of the rotor for substantially shock-free admission of the mass flow into the rotor channels (13).

Owner:KSB AG

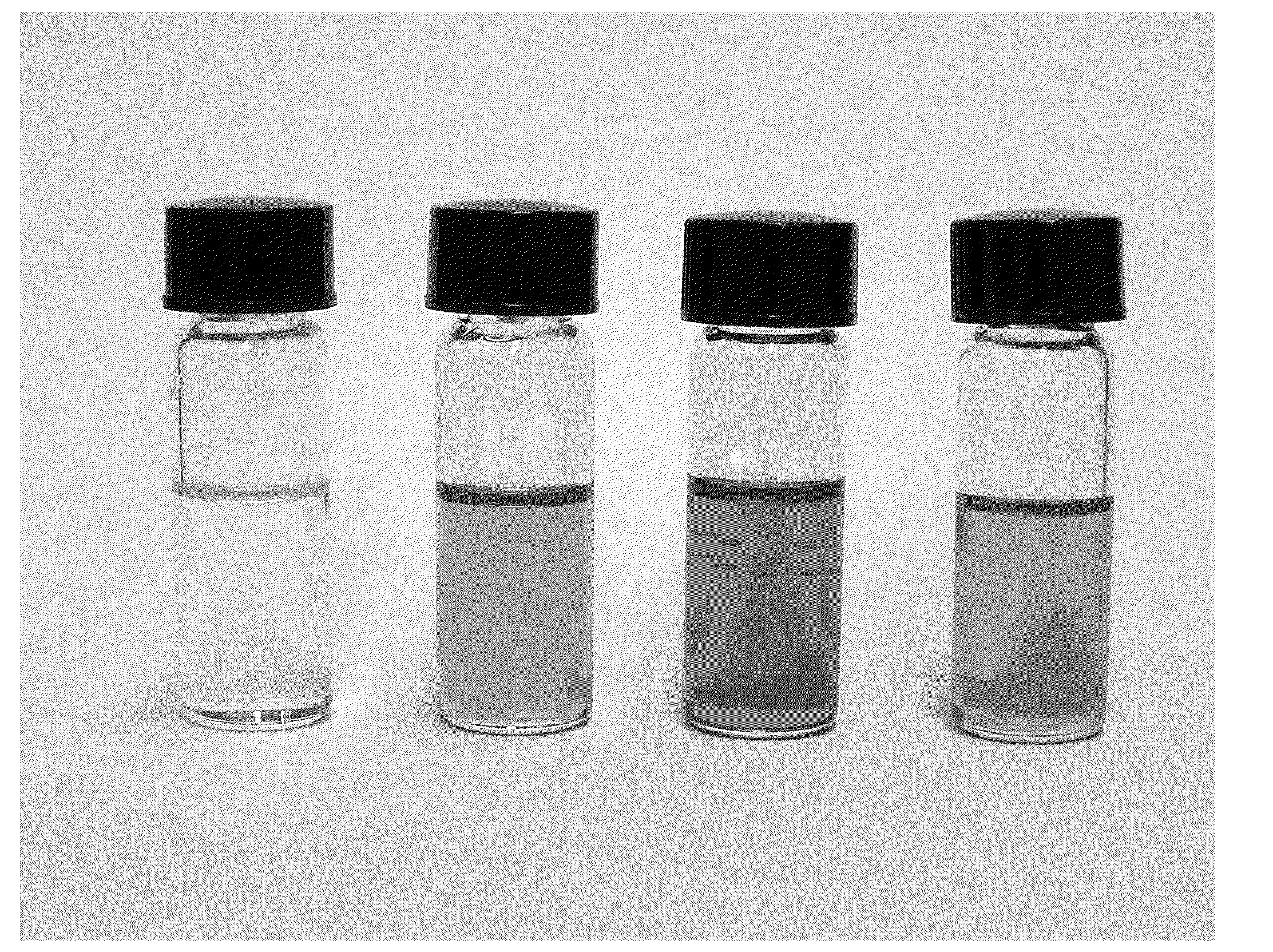

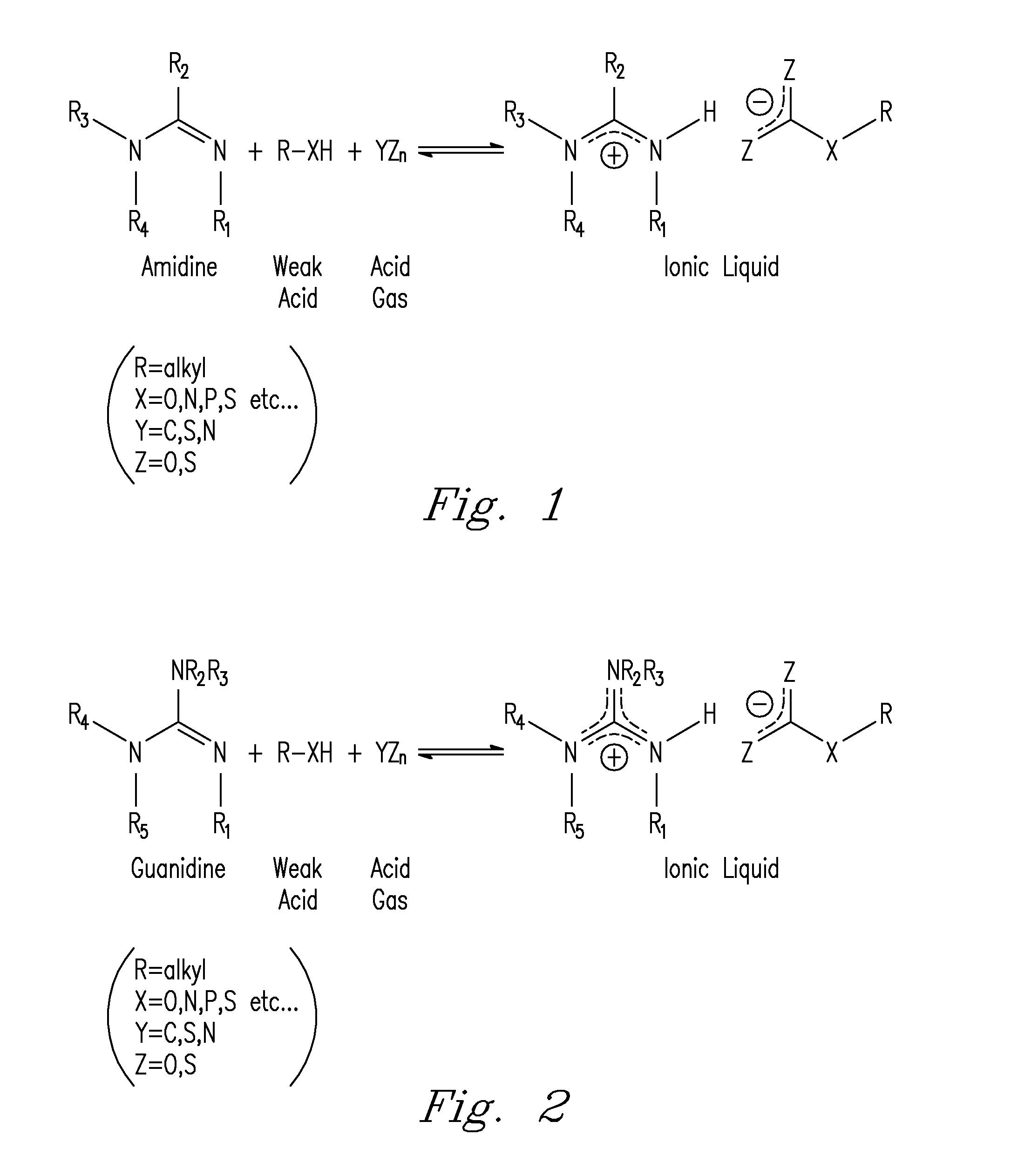

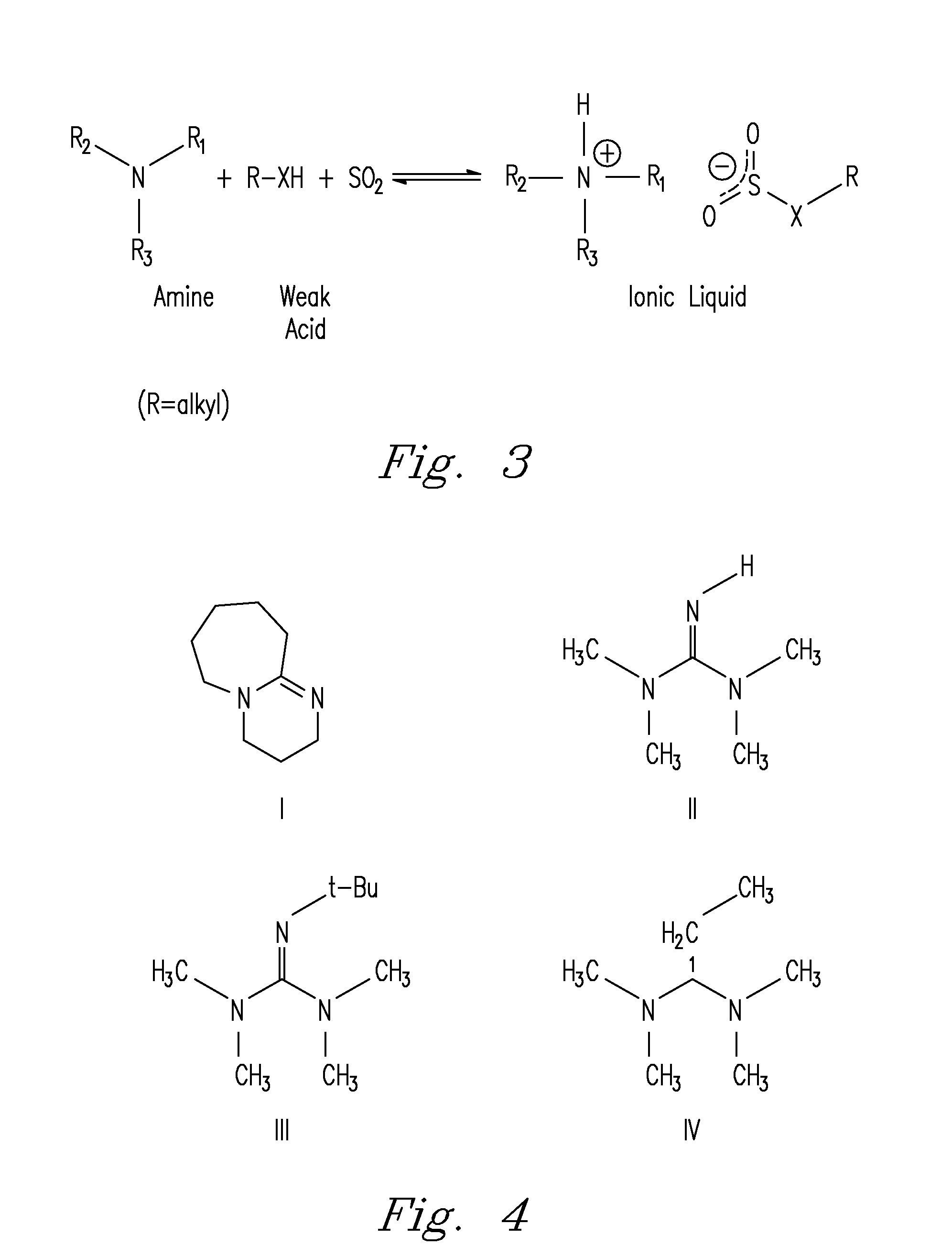

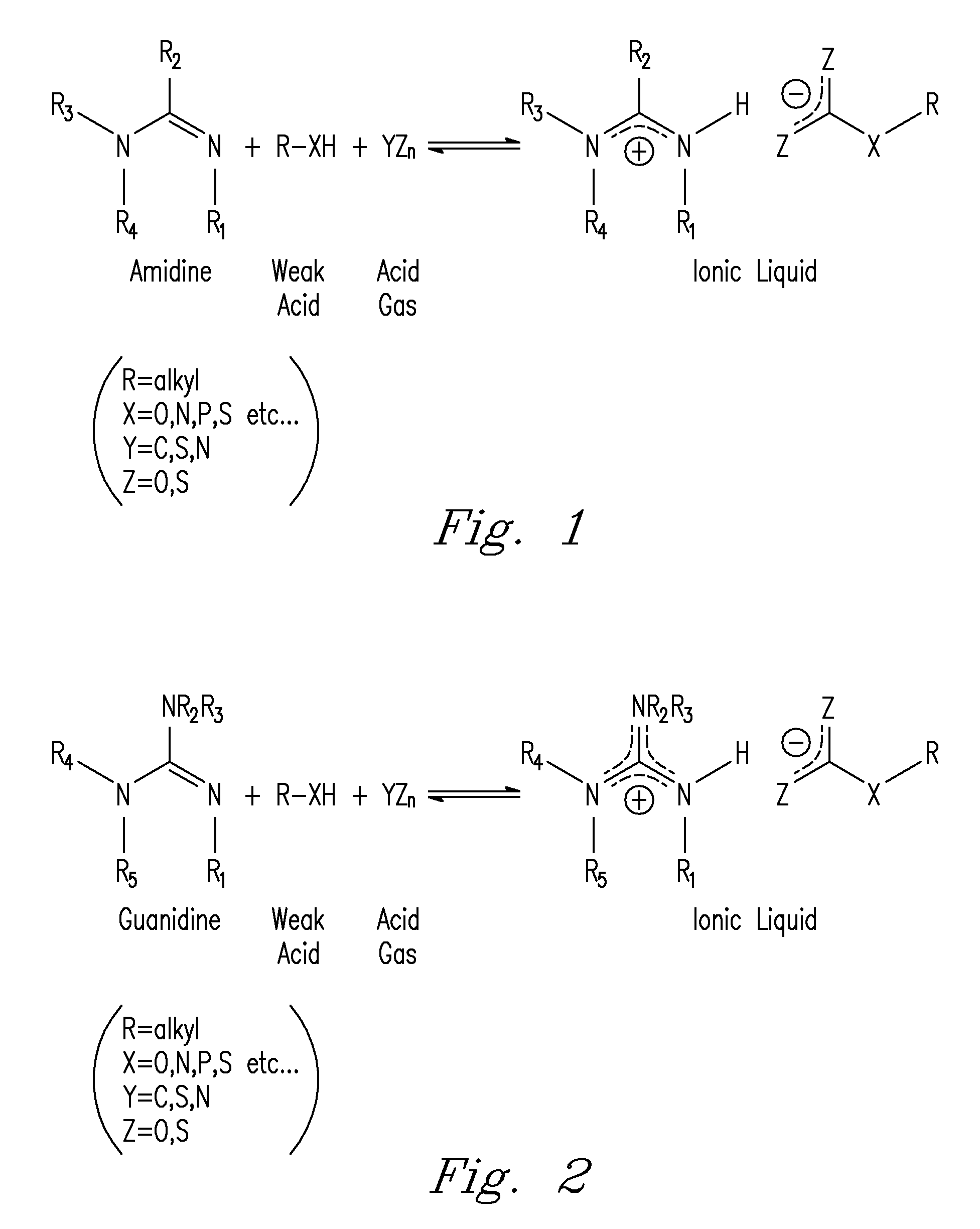

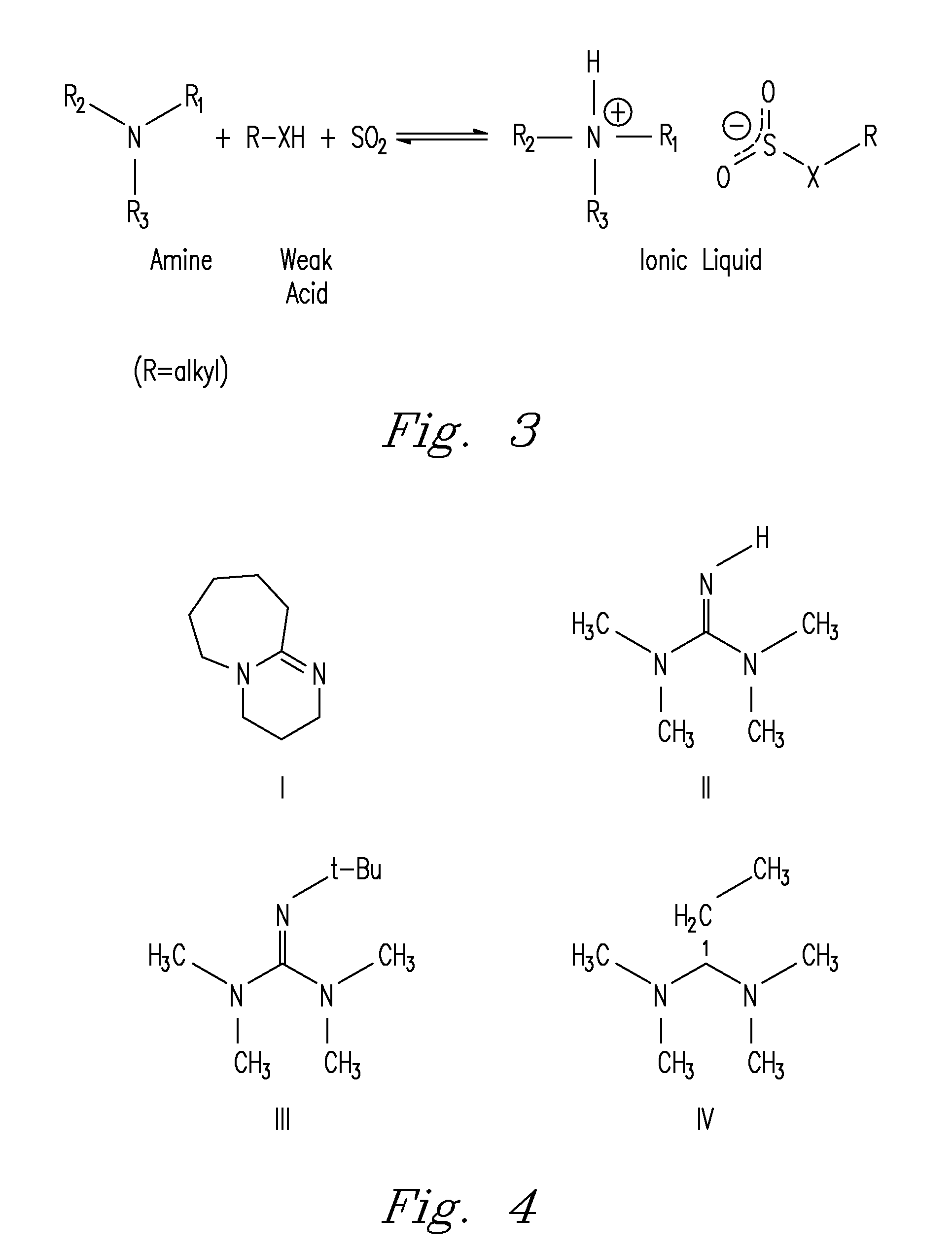

Capture and Release of Mixed Acid Gasses With Binding Organic Liquids

ActiveUS20090136402A1Reduced thermodynamic stabilityLess energy inputCombination devicesGas treatmentChemical reactionIonic liquid

Reversible acid-gas binding organic liquid systems that permit separation and capture of one or more of several acid gases from a mixed gas stream, transport of the liquid, release of the acid gases from the ionic liquid and reuse of the liquid to bind more acid gas with significant energy savings compared to current aqueous systems. These systems utilize acid gas capture compounds made up of strong bases and weak acids that form salts when reacted with a selected acid gas, and which release these gases when a preselected triggering event occurs. The various new materials that make up this system can also be included in various other applications such as chemical sensors, chemical reactants, scrubbers, and separators that allow for the specific and separate removal of desired materials from a gas stream such as flue gas.

Owner:BATTELLE MEMORIAL INST

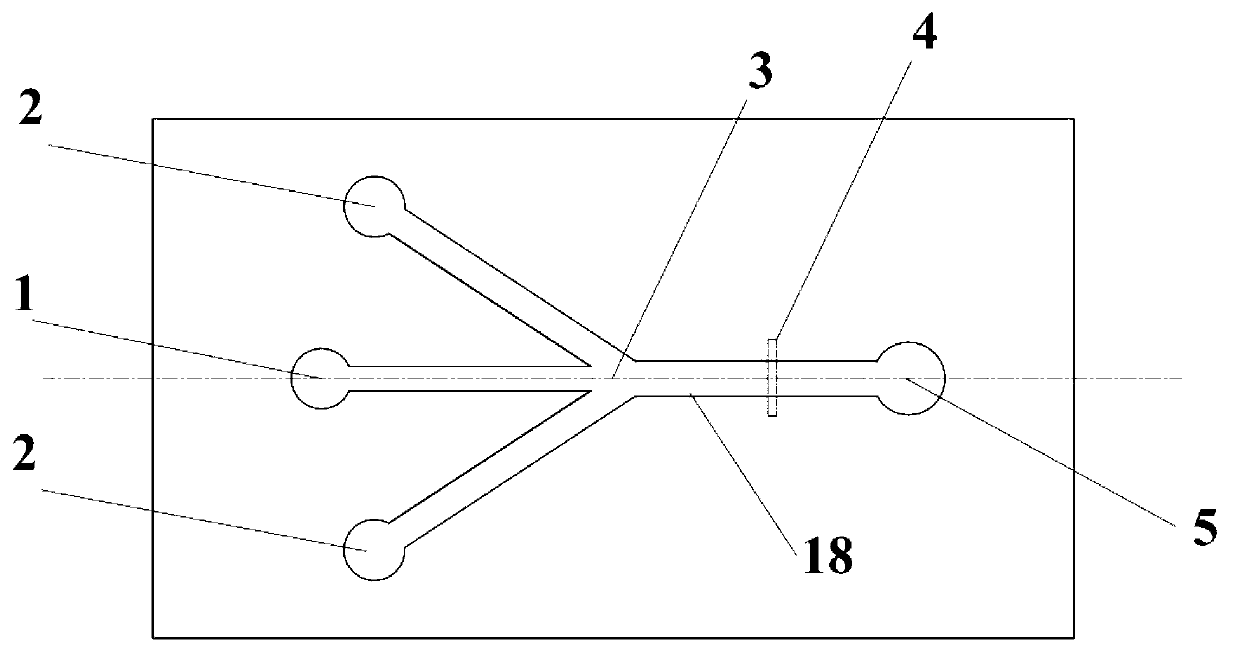

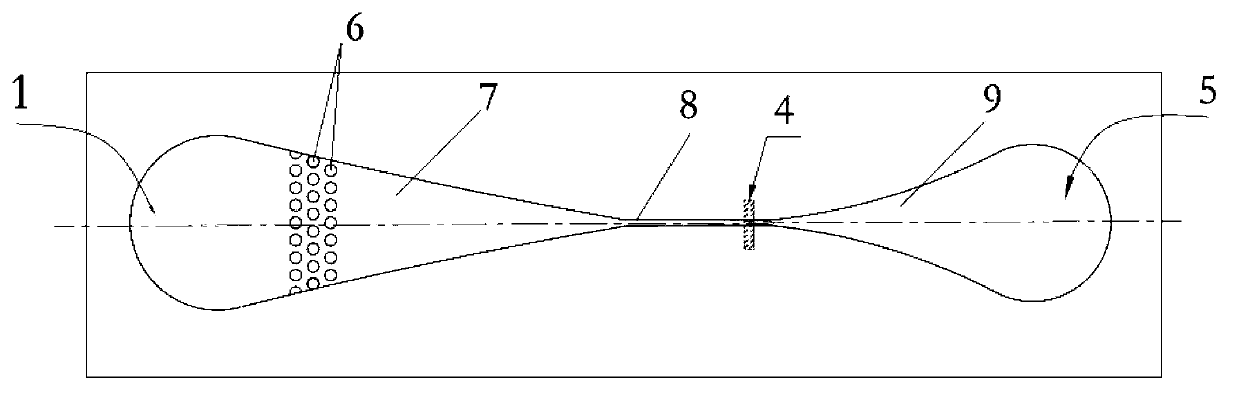

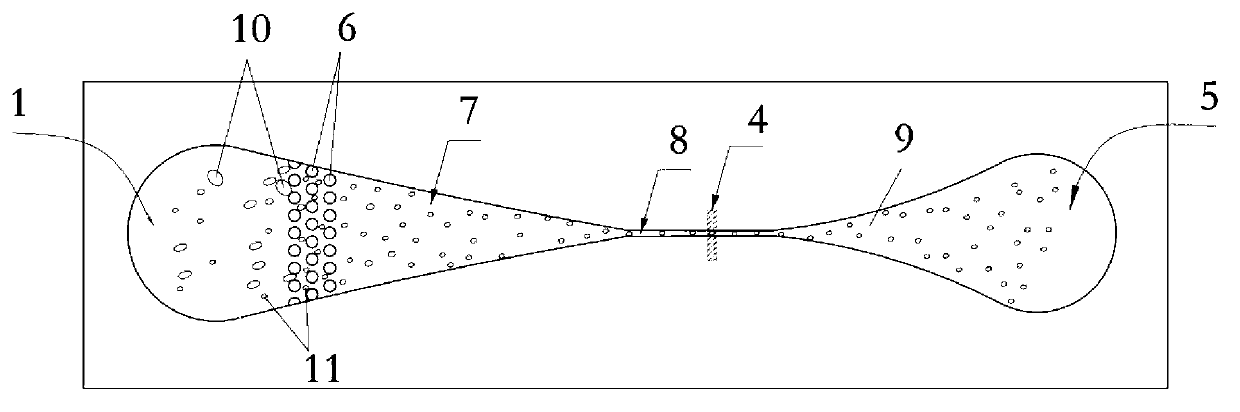

Micro-fluidic chip structure for flow cytometer, and preparation method of micro-fluidic chip

InactiveCN103341372ASimple processing methodEasy to processLaboratory glasswaresIndividual particle analysisBiocompatibility TestingImpurity

The invention discloses a micro-fluidic chip structure for a flow cytometer, and a preparation method a micro-fluidic chip. The chip comprises a sample liquid inlet 1, a column array structure 6, a conical focusing structure 7, a micro-channel 8, a detection zone 4, a flow expanding channel 9 and a waste liquid outlet end 5, wherein the column array structure 6 can play a role of filtering agglomerate protein impurities and other large biological solids inside sample liquid; and the conical focusing structure 7 has a focusing effect which is similar to that of the traditional sheath liquid system, so that cell granules flow inside the micro-channel 8 one by one; and the micro-channel 8 restricts the cells through the channel, so that the cells pass through the detection zone 4 one by one. By adopting the chip structure disclosed by the invention, the focusing effect without sheath flow liquid can be achieved; and blockage is not generated, so as to reduce use of the sheath flow liquid; and meanwhile, the situation that the cell granules pass through the detection zone one by one is ensured. The processing method of the micro-fluidic chip is convenient; the used bonding method is a common bonding method, and is simple and convenient to operate; and the used material PDMS (polydimethylsiloxane) is easy to process and has good biocompatibility.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

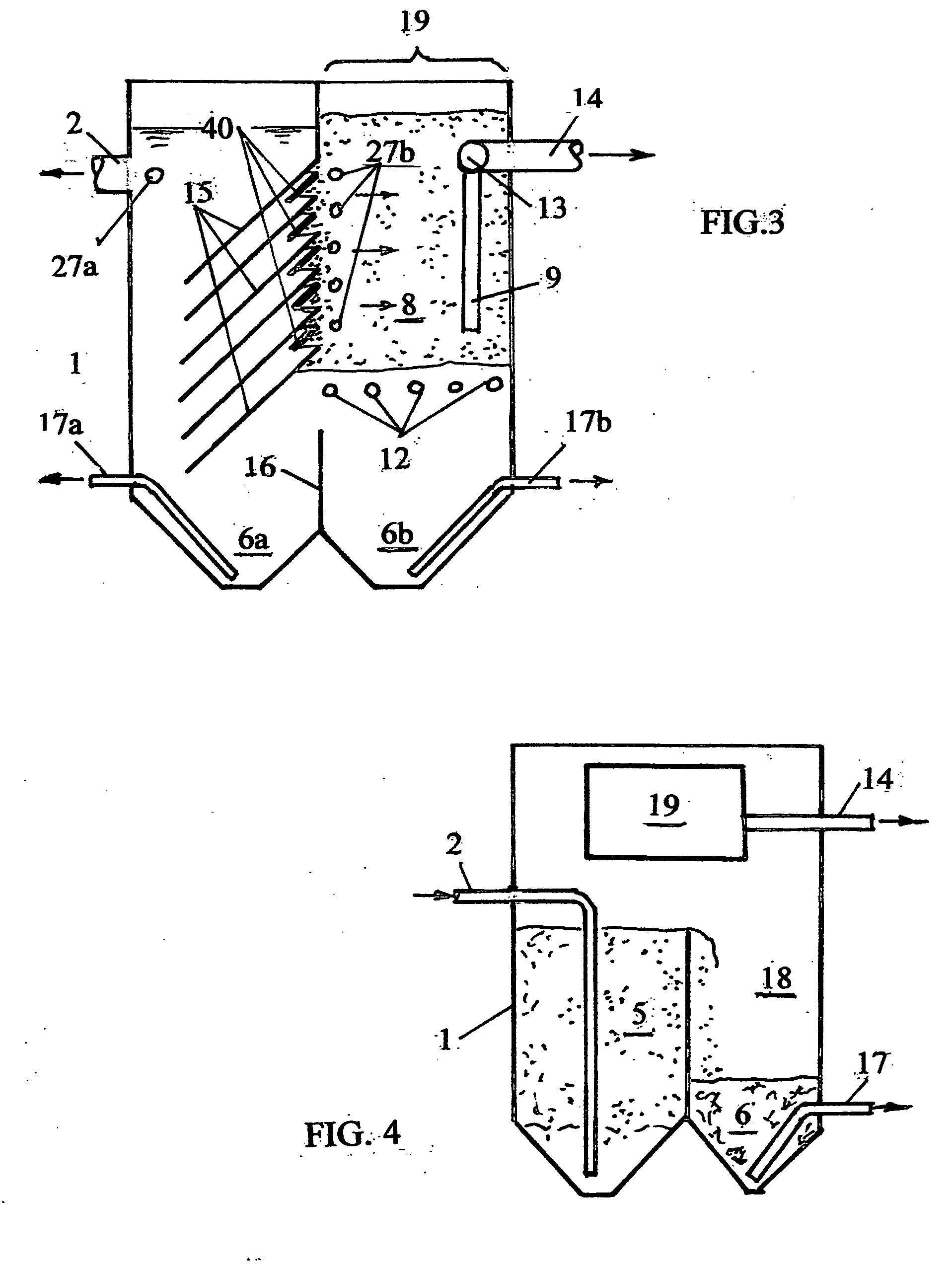

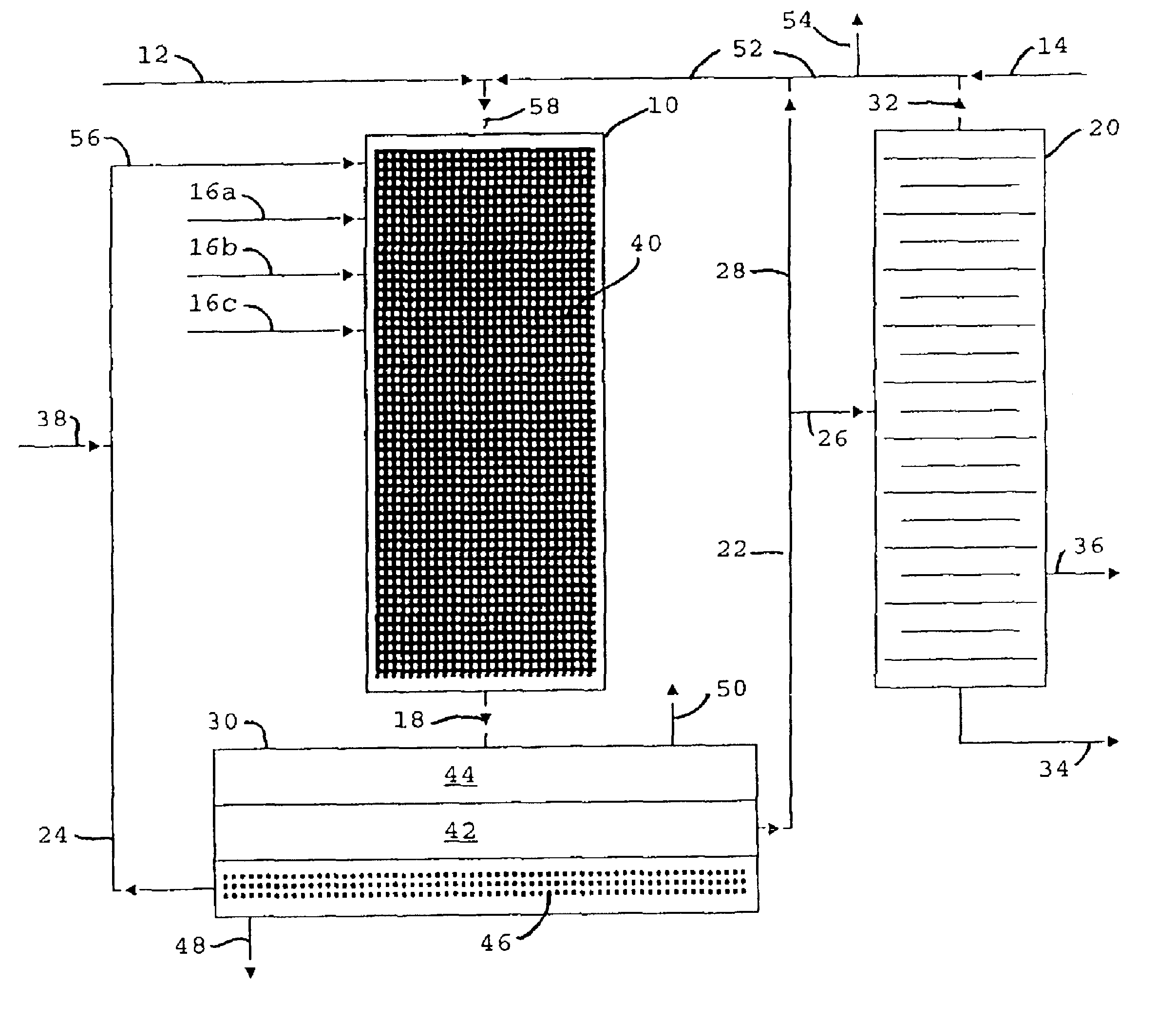

Combined gravity separation-filtration for conducting treatment processes in solid-liquid systems

InactiveUS20100133196A1Convenient to accommodateLower cost of capitalWaste water treatment from animal husbandryTreatment involving filtrationIon exchangeLiquid system

This is a method and apparatus for combined gravity separation-filtration for conducting physical, physical-chemical, chemical, and biological processes in solid-liquid systems; including but not limited to separation of dispersed solids from liquids, separation of alkalinity from the liquid stream, chemical acid-base interactions, chemical oxidation-reduction, chemical dissolution-precipitation, physical chemical adsorption, ion exchange, mass transfer in any combinations of multiple liquid-solid-gas phases, biological oxidation-reductions, biological growth, and combinations of these processes; gravity separation steps can be conducted in rectangular horizontal unidirectional flow clarifiers, rectangular or circular radial flow clarifiers, rectangular or circular vertical flow clarifiers, lamella clarifiers, suspended sludge blanket clarifiers, fluidized bed separators, and combinations thereof, wherein the filtration step is disposed in the upper portion of the combined process or side-by-side with clarification step; filtration steps are conducted in single or multiple attachment media filters, including particulate filter media either heavier than liquid or floating; liquid filtered through the attachment media is collected by holed pipes, screens, or membranes. Reagents can be introduced before the gravity separation and / or before filtration steps. This method and apparatus can be used for municipal and industrial water purification and wastewater treatment for removal of a broad range of admixtures including BOD / COD, suspended solids, nitrogen and phosphorus, organics imparting color, salts of hardness, heavy metals, and other constituents of admixture.

Owner:KHUDENKO BORIS MIKHAIL

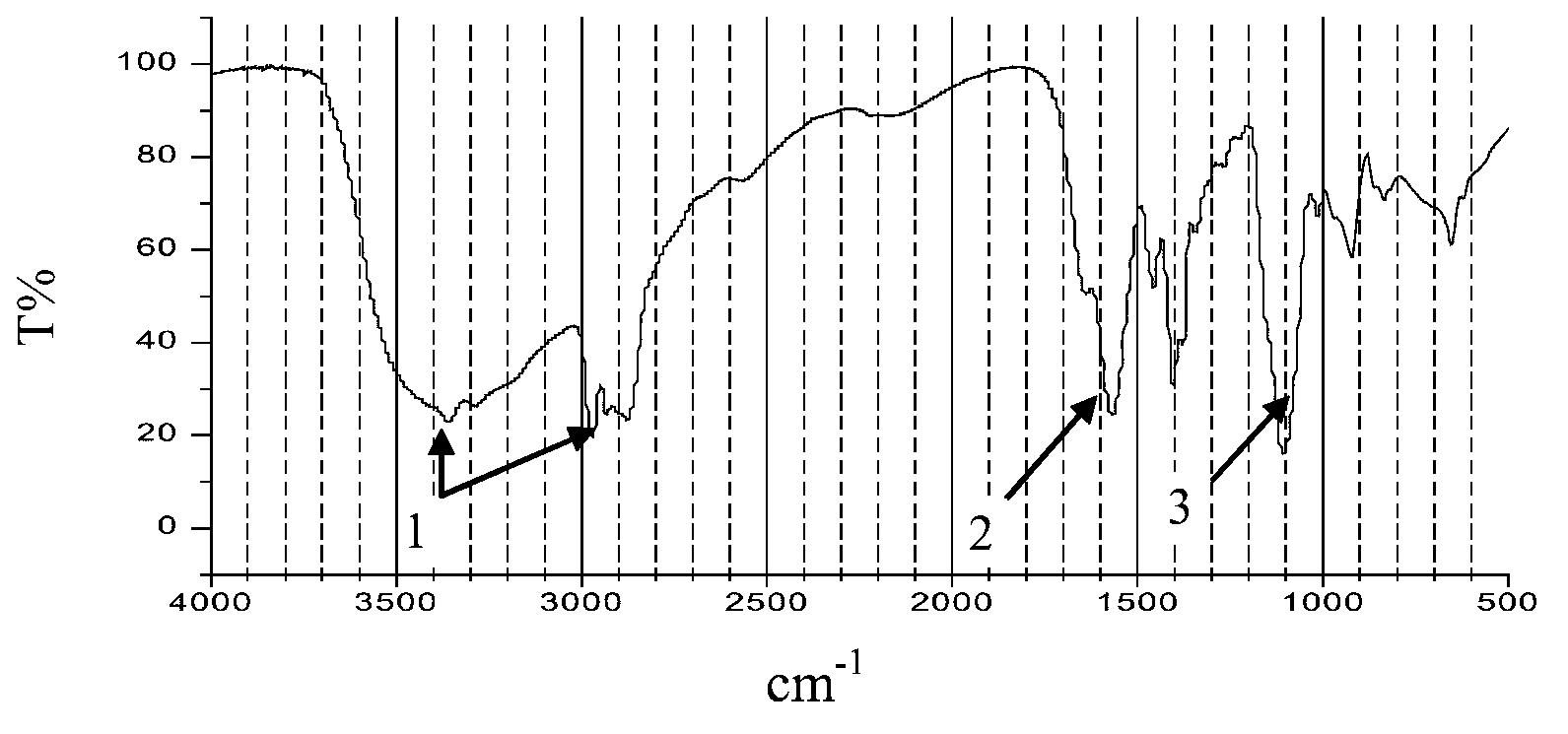

Nano suspension liquid concrete early strength agent and preparation method thereof

The invention provides a nano suspension liquid concrete early strength agent and a preparation method thereof. The nano suspension liquid concrete early strength agent is prepared from transition metal element doped nano calcium metasilicate suspension liquid, the suspension liquid is mainly composed of nanometer silicon particles, the chemical structure of the nanometer silicon particles is aCaO.bAl2O3.cZnO.SiO2.6H2O, 1<=a<=2, 0.50<=b<=1, and 0.25<=c<=0.50. The nanometer silicon particles are prepared from soluble calcium salt, soluble silicate, soluble aluminum salt, soluble zinc salt and a high polymer dispersing agent. On the one hand, the early strength agent contains no chlorine salt and has no corroding function on steel bars in concrete; on the other hand, an extremely stable suspension liquid system is achieved, adding is facilitated, and the early strength agent can be evenly dispersed easily in the concrete preparation process. The early strength of concrete can be remarkably improved, the early strength effect on concrete adopting highly-doped mineral admixtures is especially obvious, the early strength agent is especially suitable for production of precast concrete components, and a steam maintenance process can be effectively reduced and even omitted.

Owner:JIANGSU SOBUTE NEW MATERIALS

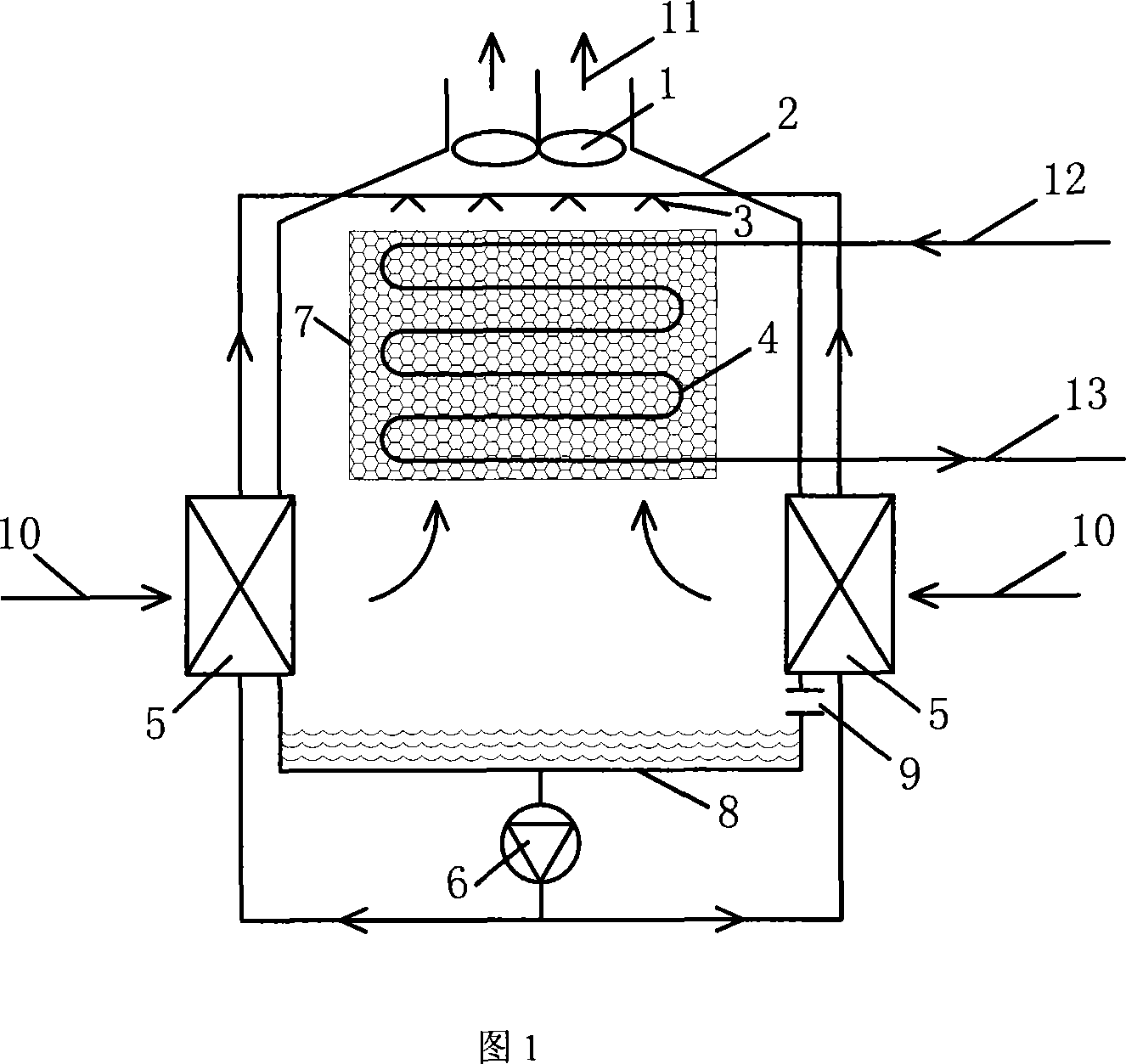

Paraffin alkylation

InactiveUS6858770B2Inhibit side effectsEasy to convertPhysical/chemical process catalystsCatalytic naphtha reformingParaffin waxAlkane

A process for the alkylation of alkane with olefin or olefin precursor such as an oligomer of tertiary olefin comprising contacting a liquid system comprising acid catalyst, isoparaffin and olefin in concurrent downflow into contact in a reaction zone with a disperser mesh under conditions of temperature and pressure to react said isoparaffin and said olefin to produce an alkylate product is disclosed. Preferably, the liquid system is maintained at about its boiling point in the reaction zone. Unexpectedly, the olefin oligomers have been found to function as olefin precursors and not as olefins in the reaction. Thus, for example, a cold acid alkylation using an oligomer of isobutene (principally dimer and trimer) with isobutane produces isooctane with the isobutane reacting with the constituent isobutene units of the oligomers on a molar basis. The product isooctane is essentially the same as that produced in the conventional cold acid process.

Owner:CHEM RES & LICENSING CO

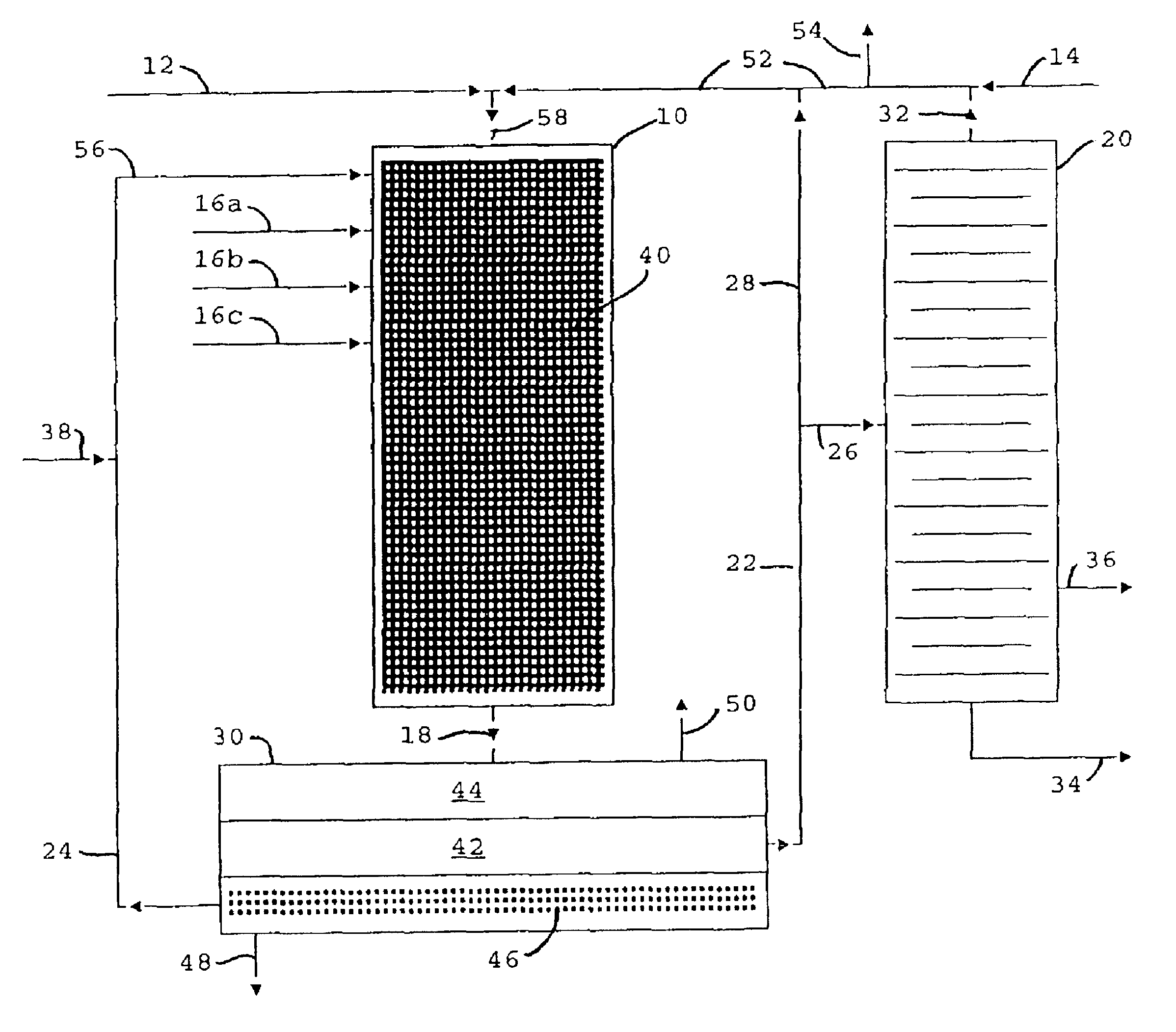

Indirect evaporation type cooling/condensing device

InactiveCN101169299AOutlet temperature dropsRealize energy-saving operationEvaporators/condensersTrickle coolersCooling towerEvaporation

An indirect evaporating cooling / condensing device comprises a blower, a shell body, a spraying machine, a dividing wall type heat exchanger, a wind inlet, a water pump and a water collecting plate, and an air-water heat exchanger which is arranged on the wind inlet. The water pump pumps water from the water collecting plate and sends to the water channel of the air-water heart exchanger, cools the environmental air inducted from the wind inlet enters the spraying machine after being cooled; the water which flows out from the spraying machine is sprayed on the outer surface of the dividing wall type heat exchanger, the water flows back to the water collecting plate depending on the gravity; and the cooled medium which enters into the dividing wall type heat exchanger from the entrance is cooled by the water sprayed from the spraying machine and then flow out from the cooled medium exit. The invention not only can be used as the enclosed type cooling tower, but also can be used as the evaporating type condenser; and compared with the prior art, the utility model can make the temperature of the out flowing liquid of the liquid with single-phase much lower in winter, and also can reduce the condensing temperature of the refrigerating and the chemical liquid system; the utility model has cooling / condensing function for the whole year and is useful for the energy saving running of air-conditions, refrigerating and chemical systems.

Owner:TSINGHUA UNIV

Preparation method of inorganic/organic hybridization antibacterial film

The invention relates to a preparation method of an inorganic / organic hybridization antibacterial film. The preparation method mainly comprises the steps of: (1) preparing a nano-silver-loaded molecular sieve germicide with stronger stability by ion exchange and a chemical reduction method; and preparing a molecular sieve / polymer hybridization antibacterial film loaded with nano-silver particles by a phase transformation film preparation process; and (2) taking N,N-dimethylformamide as a solvent and a reducing agent simultaneously, reducing silver ions to nano-silver serving as an antibacterial function body in a film casting liquid system in situ, and firmly loading the nano-silver in a polymer porous matrix material by a dispersion action and a coupling action of a coupling agent so as to form a nano-silver-loaded polymer porous film. The hybridization antibacterial film, provided by the invention, keeps excellent water flux, high retention rate and tough mechanical intensity, and has excellent antibacterial function, and can effectively solve the problems of loss of the silver ions of the silver-ion-loaded molecular sieve in the membrane filtration, loss of the nanometer inorganic particles in the polymer porous matrix, easy pollution of a separation film by microorganisms, and the like.

Owner:天津鼎芯膜科技有限公司

Liquid admixture composition

An admixture comprises an aqueous composition of a) a copolymeric dispersing component, b) an antifoaming agent component, c) a surfactant component, and d) water. The components may be a blend or physically or chemically attached and result in a stable liquid system that can be used as a dispersing agent for a calcium sulfate compound containing construction chemicals composition.

Owner:BASF CONSTR POLYMERS

Particle-based systems for removal of pollutants from gases and liquids

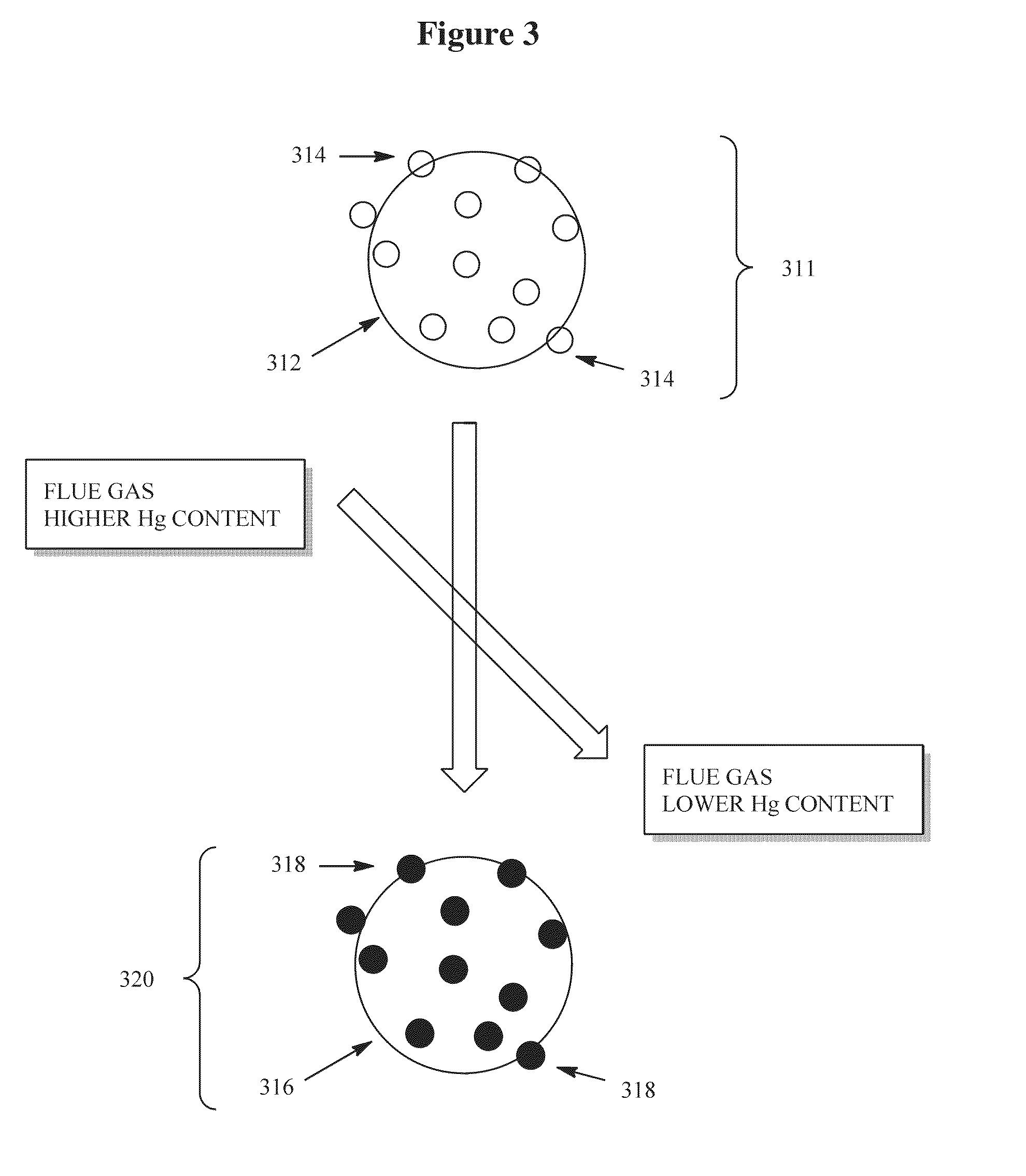

InactiveUS20140252270A1Reduce total mercury contentReduce contentCombination devicesGas treatmentPetrochemicalRefinery

Systems, compositions, and methods for removing a substance or substances from a material, such as a gas or liquid material, are described. The compositions can comprise composite removal particles. In some embodiments, the composite removal particles can be comprised of support particles made from an inexpensive carrier material, and a reactive particle borne on the support particle. The reactive particle reacts with the substance or substances in the material. The reacted composite removal particles can then be removed from the material, which reduces the amount of the substance or substances present in the material. The composite removal particles are useful for removing pollutants, such as mercury, from exhaust gases, such as flue gas from a power plant combustion unit, and from other materials such as natural gas, liquefied natural gas, fuels, hydrocarbons, petrochemicals, and refinery streams.

Owner:SDC MATERIALS

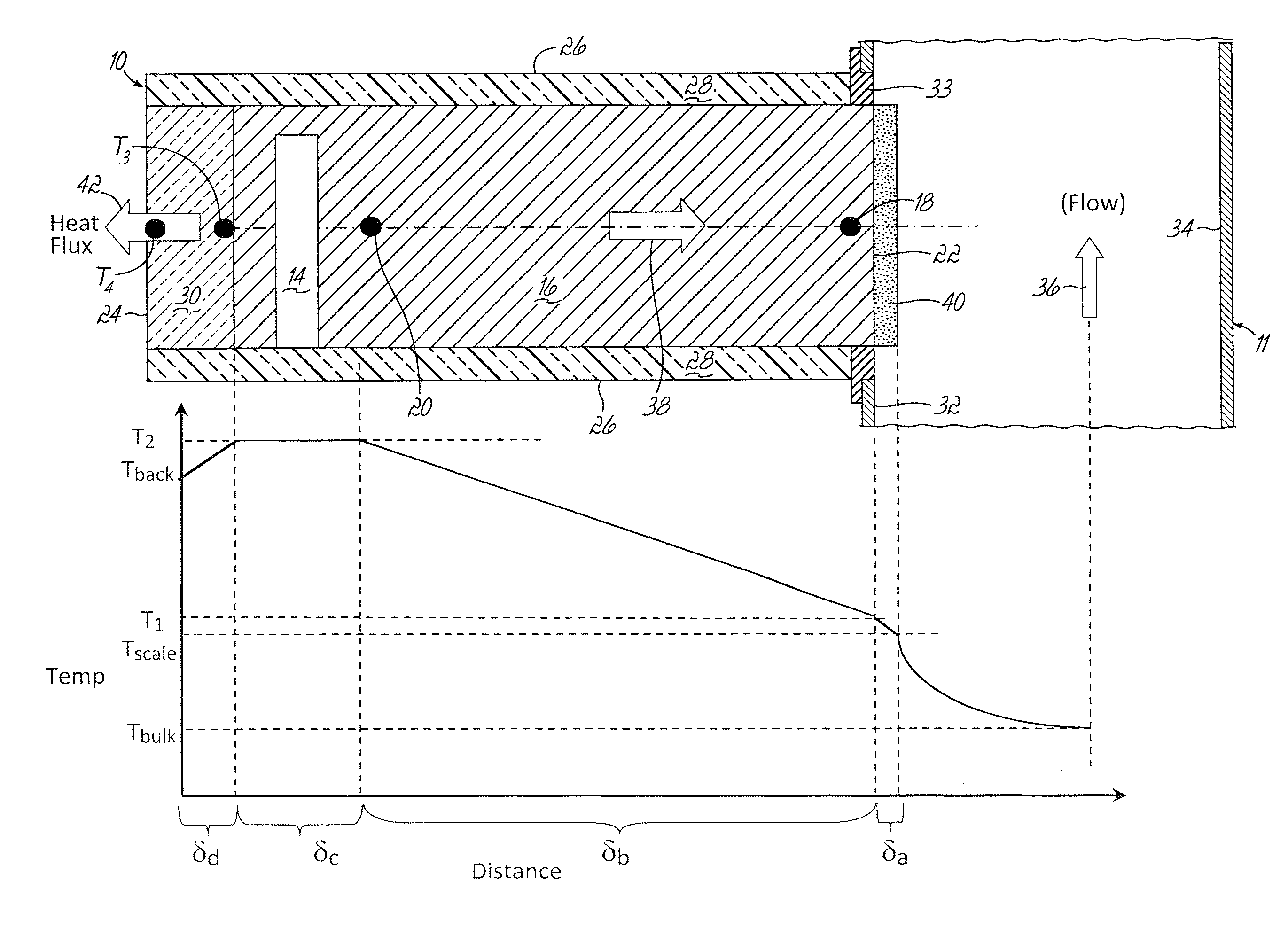

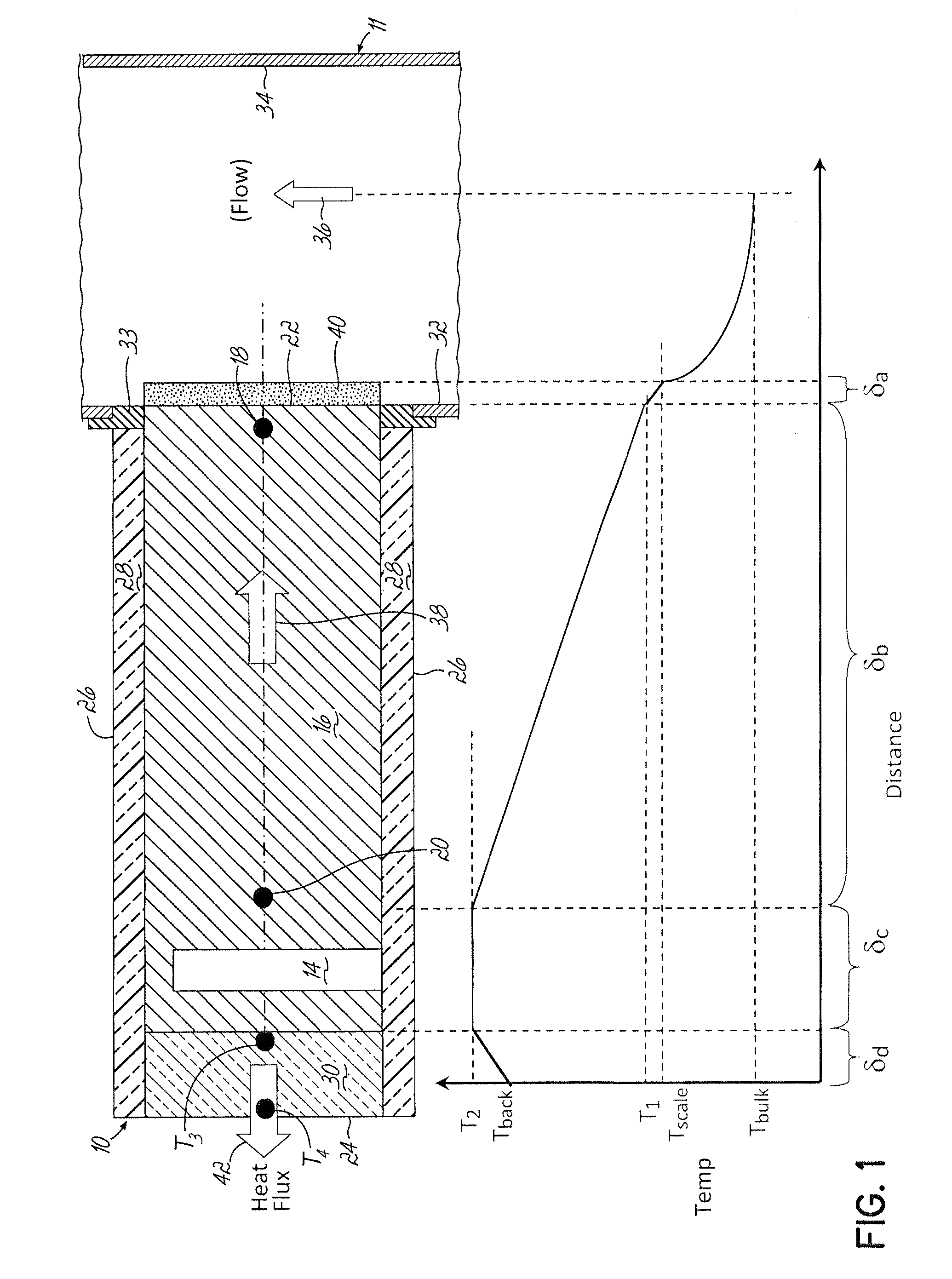

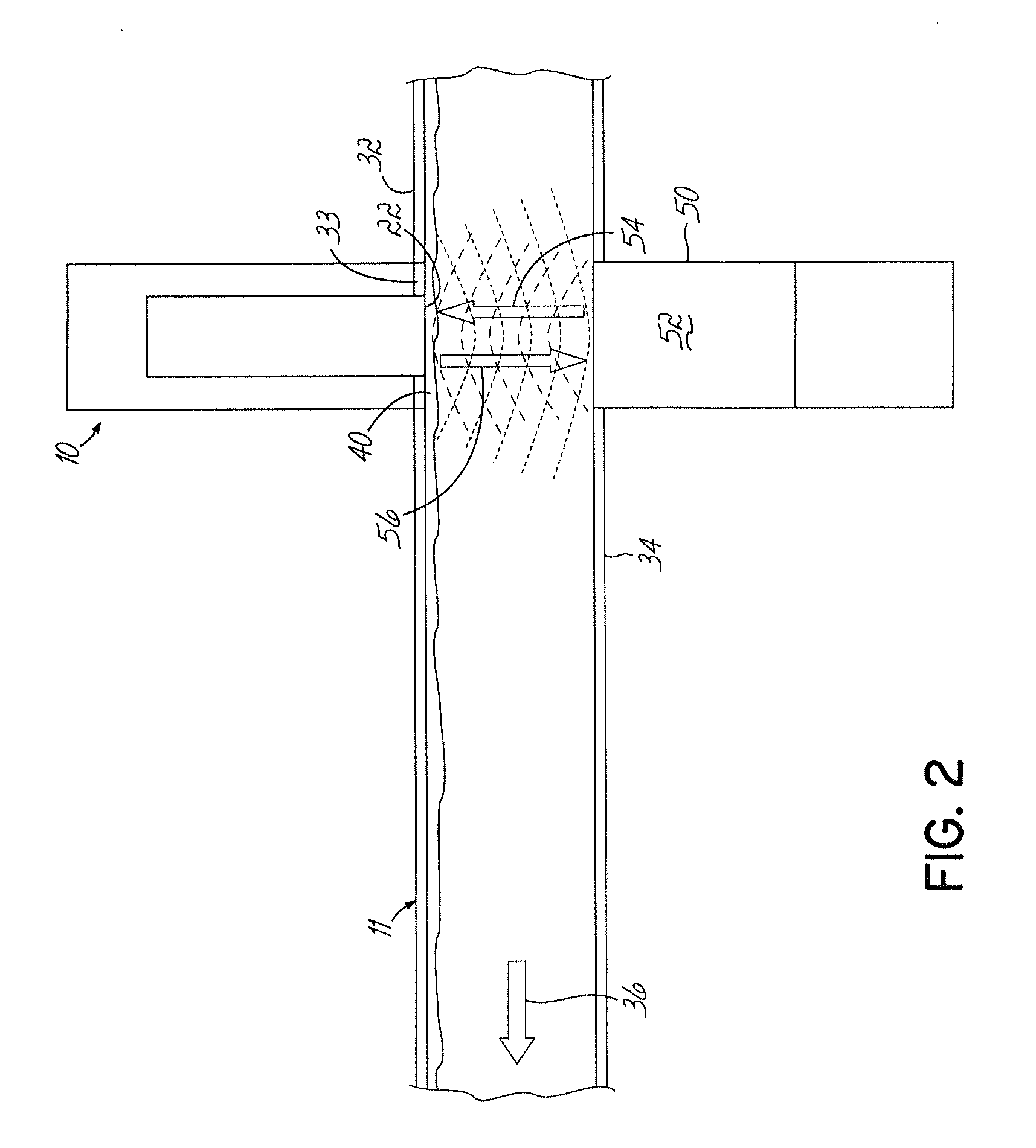

Method and apparatus for estimating fouling factor and/or inverse soluble scale thickness in heat transfer equipment

ActiveUS20140177673A1Accurately indicatedUseful insight natureThermometer detailsAir-treating devicesHeat fluxHeat flow

Scale deposition on a heat transfer surface in a liquid system such as a heat exchanger is estimated by directing of small portion of the liquid flow through a test cell, consisting of a sensor positioned on and projecting through a conduit wall. The sensor consists of a conductive block containing a heater and having a heated wetted test surface that is flush with the inside of the conduit wall and in contact with the flow through the conduit. Within the conductive block are two temperature sensors which are at different distances from the heated wetted test surface and the heater. The periphery of the apparatus is designed to reduce heat flow through the periphery and allow greater heat flow through the heated wetted test surface. By comparing the temperature differential between the two temperature sensors to the differential when no scale is present, the presence of and amount of scale can be determined, based on reduced heat transfer through the heated wetted surface caused by the accumulated scale. The change in the temperature differential is directly proportional to the scale thickness for a given type of scale. When the thickness of the scale is determined by another means, the nature of the scale can be implied. The sensitivity of the measurement can be adjusted to accommodate a very wide range of bulk liquid or ambient temperature via adjustment of the heat flux through the provided secondary heat flux path.

Owner:SOLENIS TECH CAYMAN

Forming active channel regions using enhanced drop-cast printing

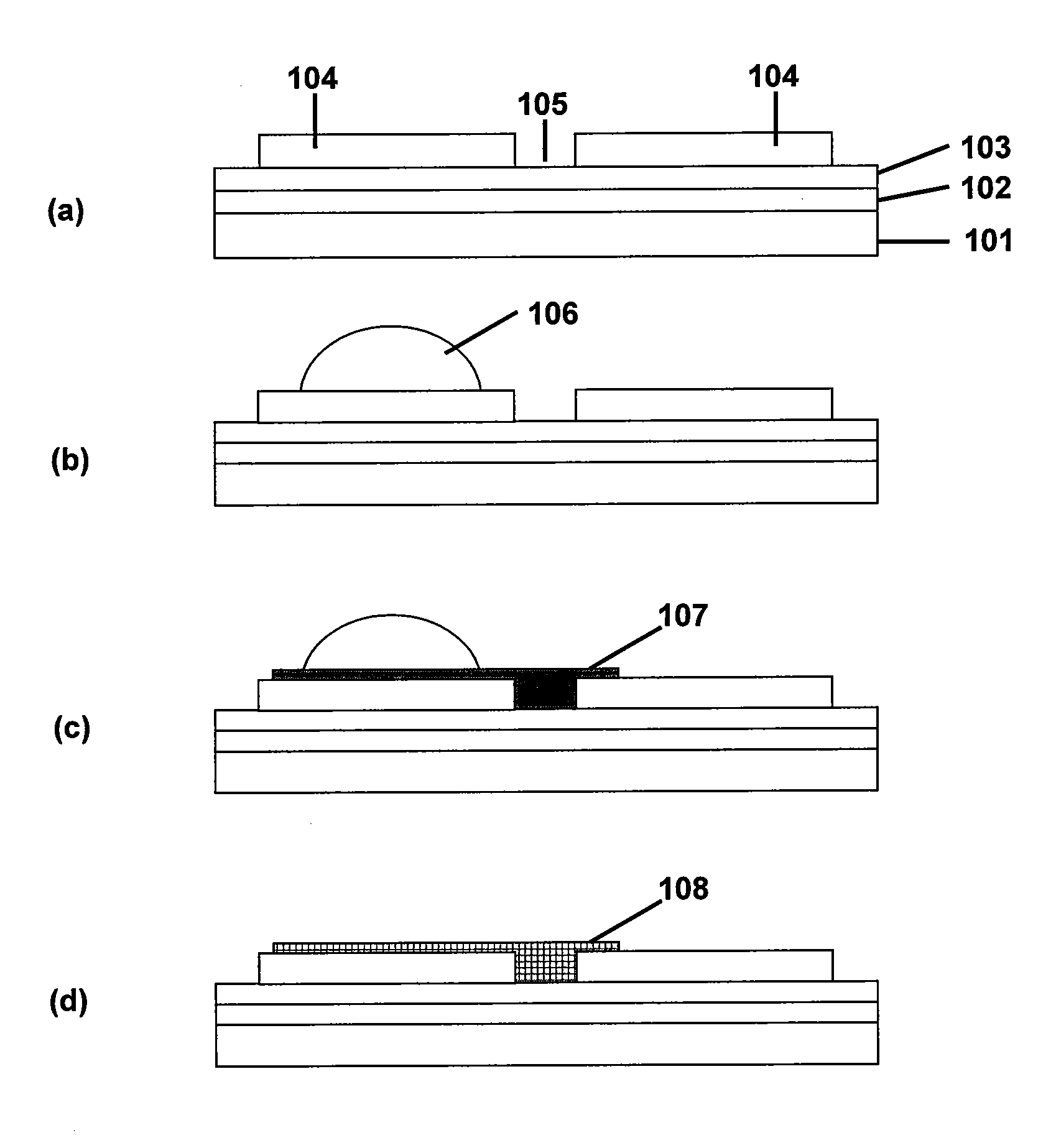

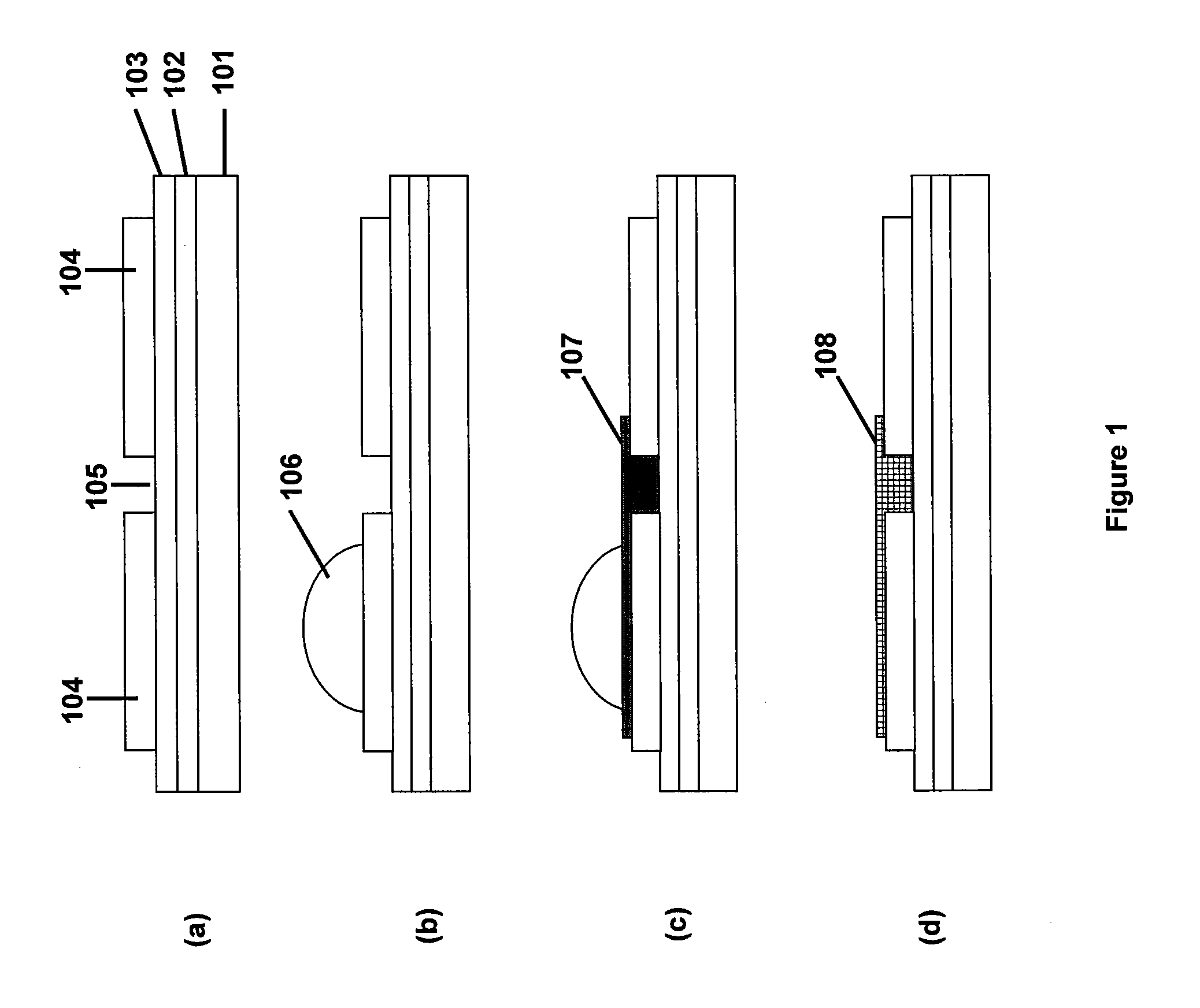

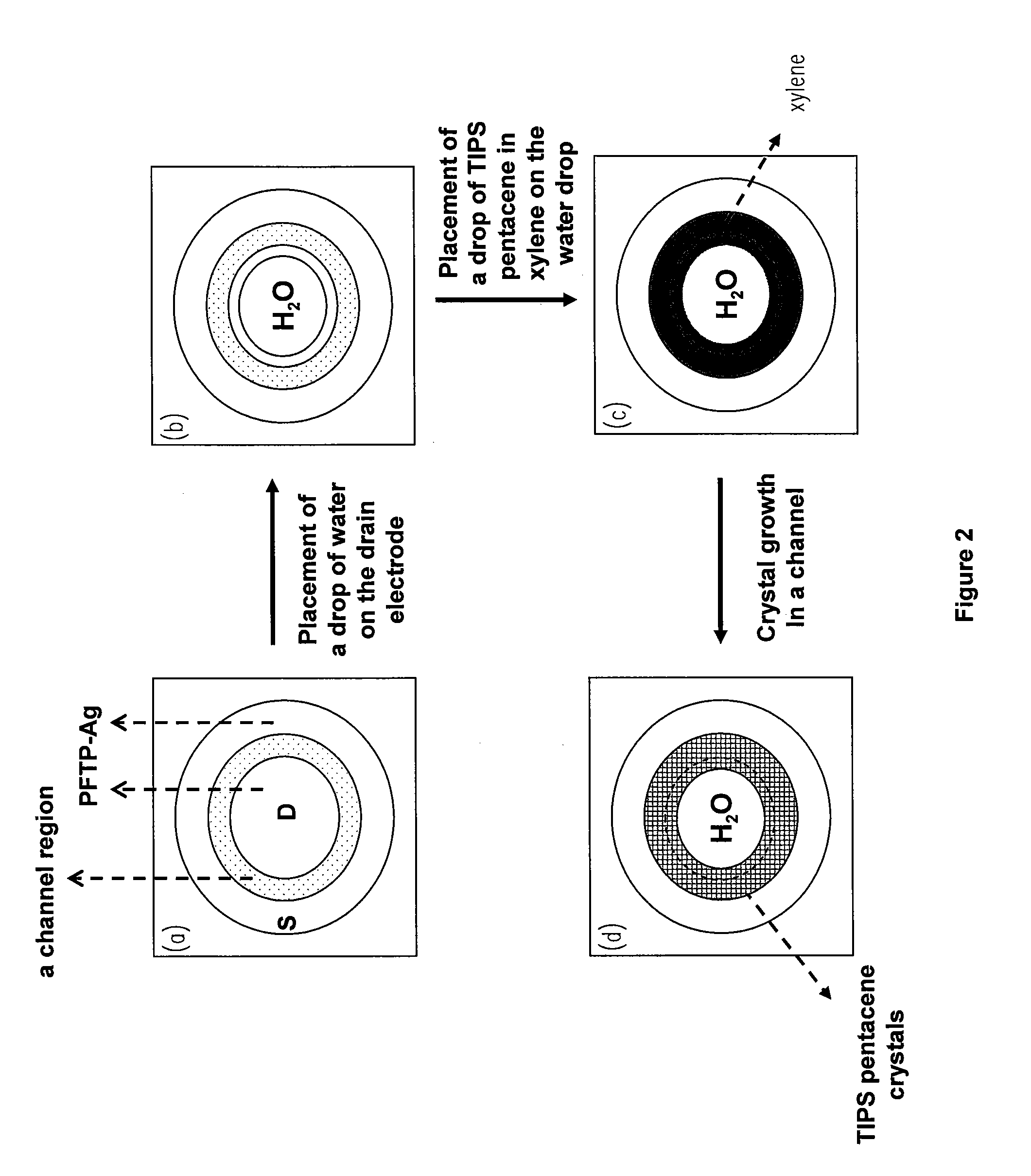

ActiveUS20100155710A1Improve solubilityImprove electrical performanceMaterial nanotechnologyElectroluminescent light sourcesOrganic field-effect transistorDisplay device

An active region or channel for printed, organic or plastic electronics or polymer semiconductors, such as organic field-effect transistors (OFETs), is obtained by using an enhanced inkjet drop-cast printing technique. A two-liquid system is employed to achieve the direct growth of well-oriented organic crystals at the active region of channel. High-performance electrical properties exhibiting high carrier mobility and low threshold voltage are obtained due to the proper orientation of molecules in the grown crystal in a highest mobility direction, due to the absence of grain boundaries, and due to low trap densities. The hydrophobic-hydrophilic interactions between the liquids utilized, which results in the fabrication of low-cost and mass-producible printable electronic devices for applications in flexible displays, electronic signages, photovoltaic panels, membrane keyboards, radio frequency identification tags (RFIDs), electronic sensors, and integrated electronic circuits.

Owner:SEOUL NAT UNIV R&DB FOUND

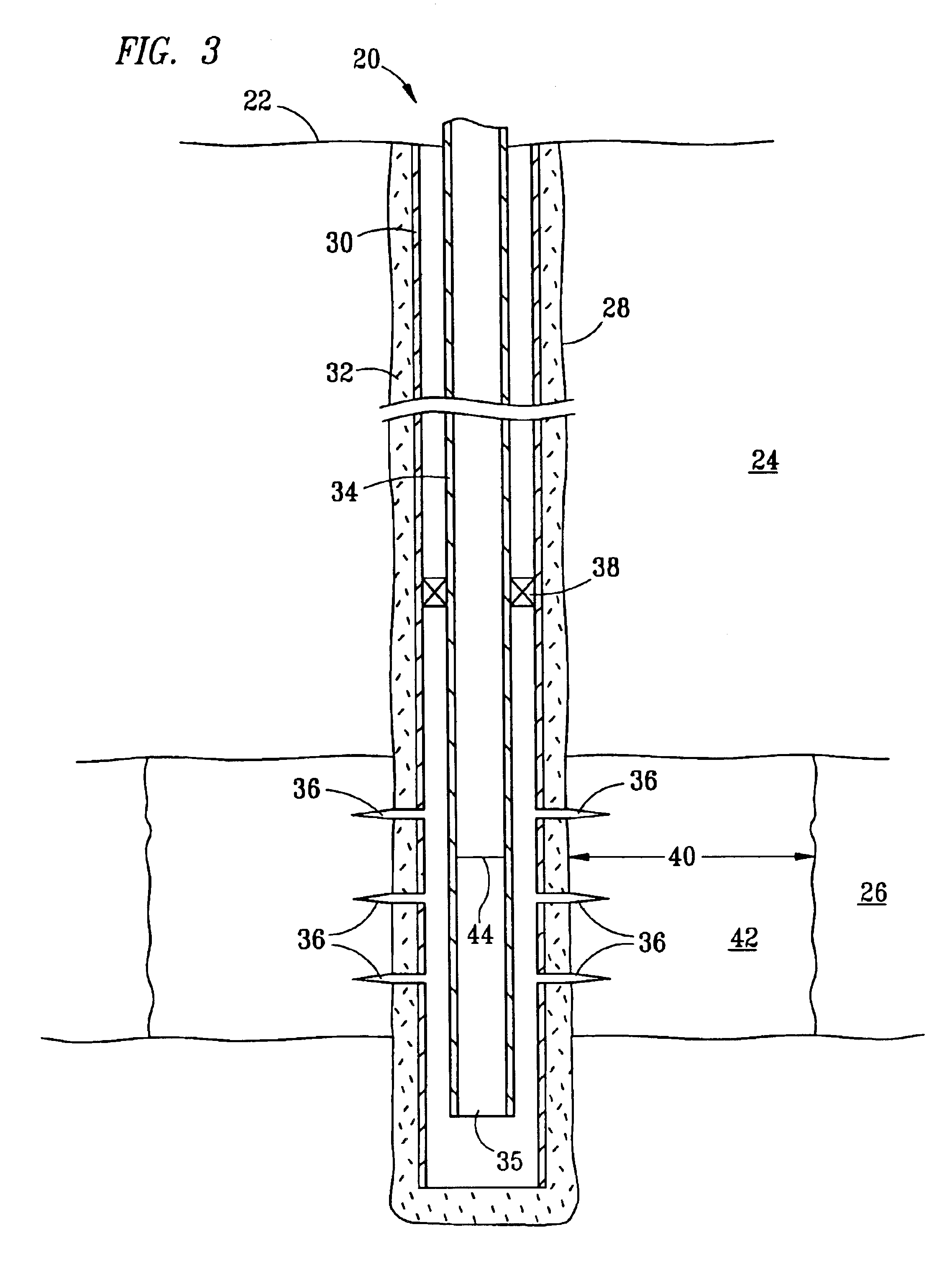

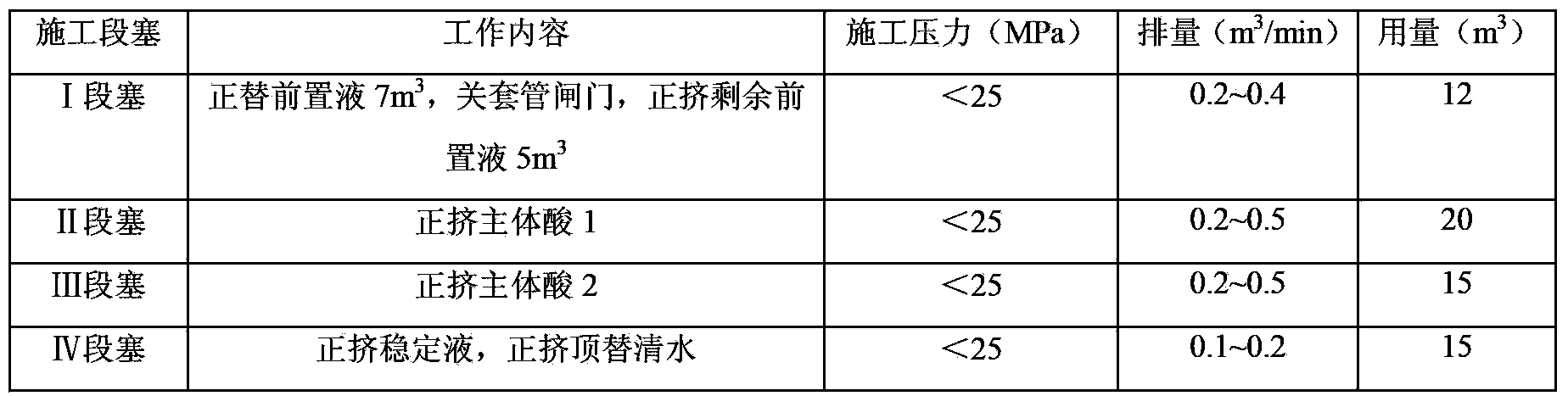

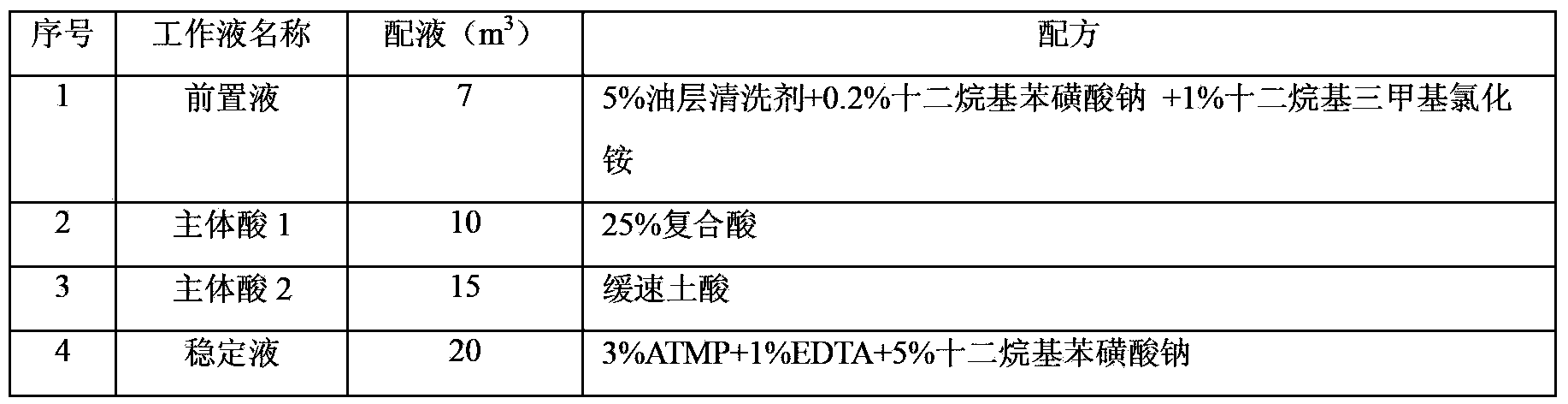

Deep blockage removal and injection increase method for water injection well of medium-and-high-permeability sandstone reservoir

InactiveCN104295275AImprove injection effectIncrease validity period of boosterCleaning apparatusFluid removalEffective dateSewage

The invention provides a deep blockage removal and injection increase method for a water injection well of a medium-and-high-permeability sandstone reservoir. The method mainly solves the problems of oil pollution, deep blockage removal of a ground layer and the like of a sewage injection well, which can not be solved in the existing conventional acidification method. In the method, the slug type injection technology of "washing-clearing-blockage removing-stabilizing" is adopted; and the injection increase effect can be improved and the injection increase effective date can be prolonged. The method comprises the following steps: during construction, firstly, the well is backwashed at high displacement, and impurities near a well bore and a bore hole are washed; secondly, organic blockages near an oil layer are washed; then, organic and inorganic blockages in the areas near the well and the deep part of the oil layer are removed in the mode of multistage injection and multiple acid liquid systems, so that the seepage capability is improved; and finally, stabilizing treatment is adopted for prolonging the injection increase effective date. Through the adoption of the slug type injection technology, blockage damage is removed in batches, and substrate treatment, scale prevention treatment and scale inhibition treatment are performed so that the injection increase effect is improved, the injection increase effective date is prolonged and a better blockage removal effect is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

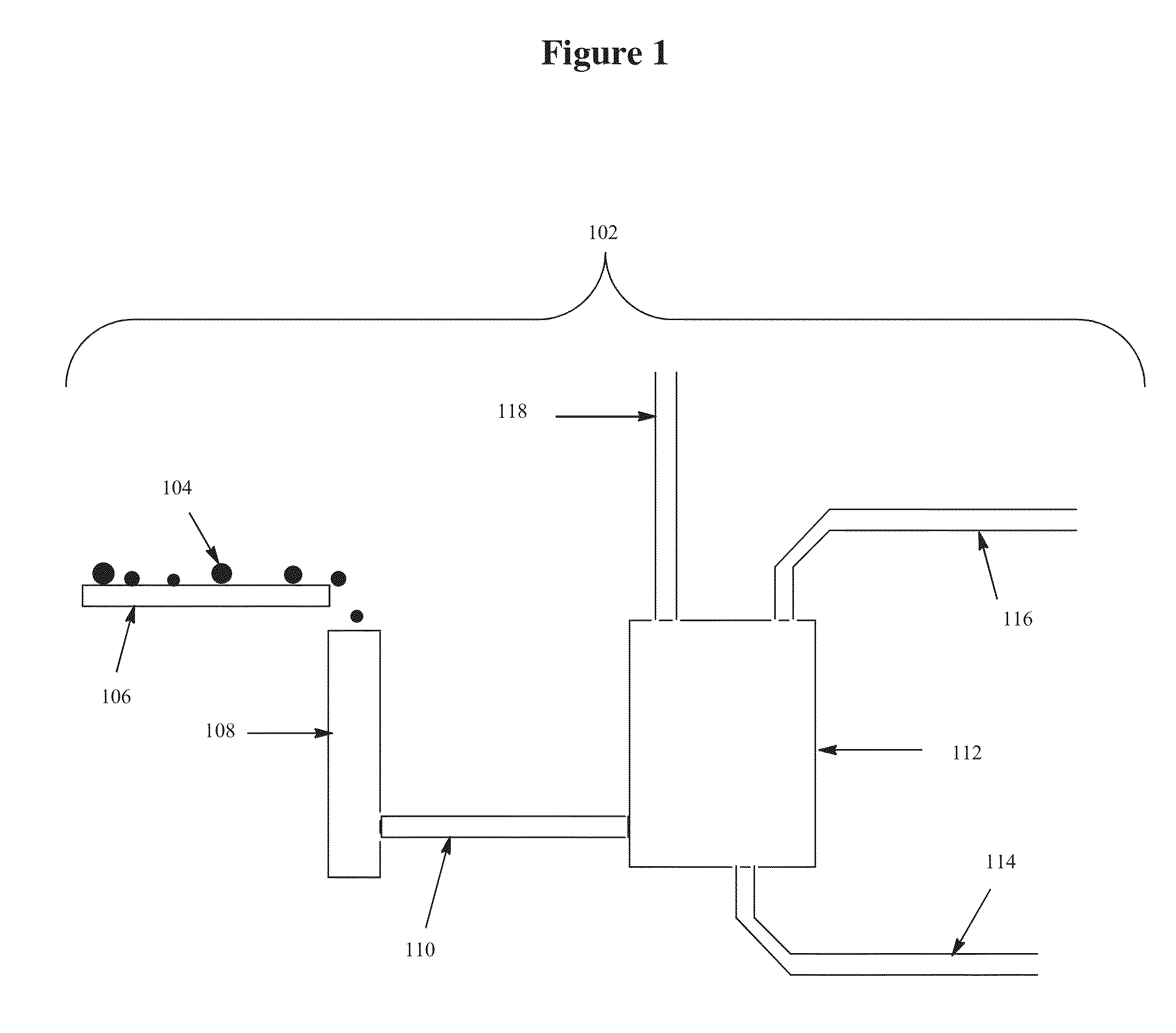

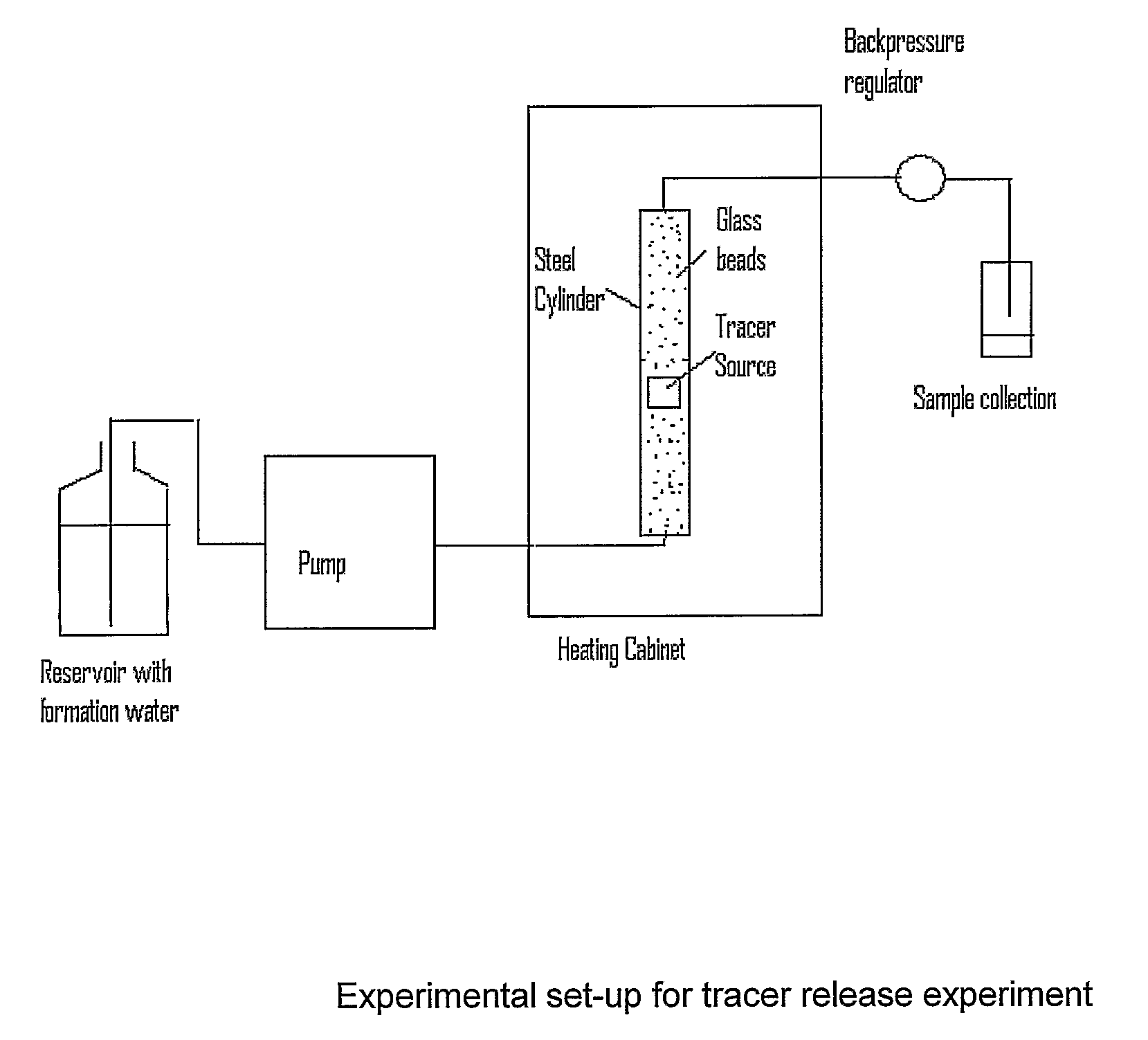

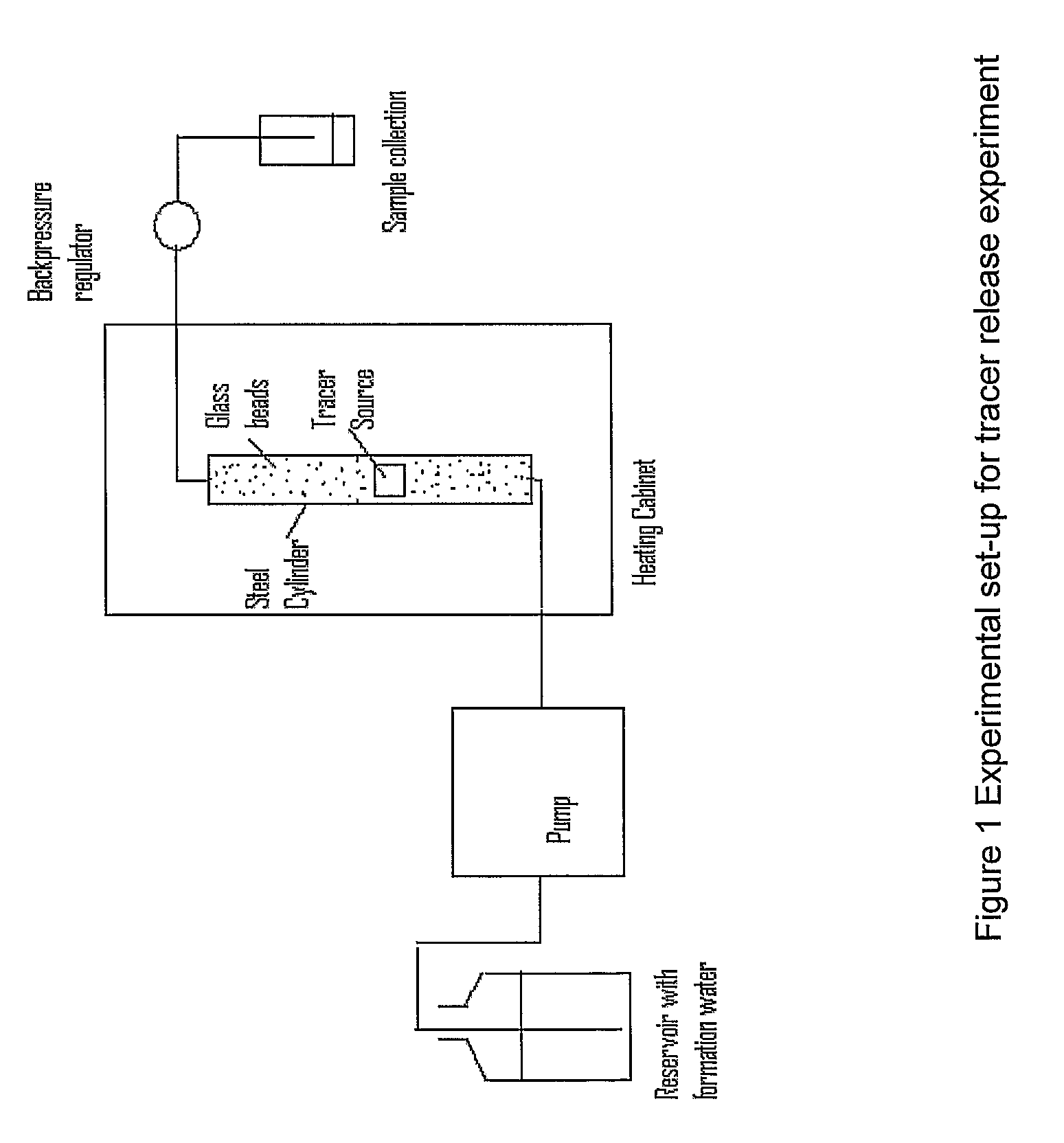

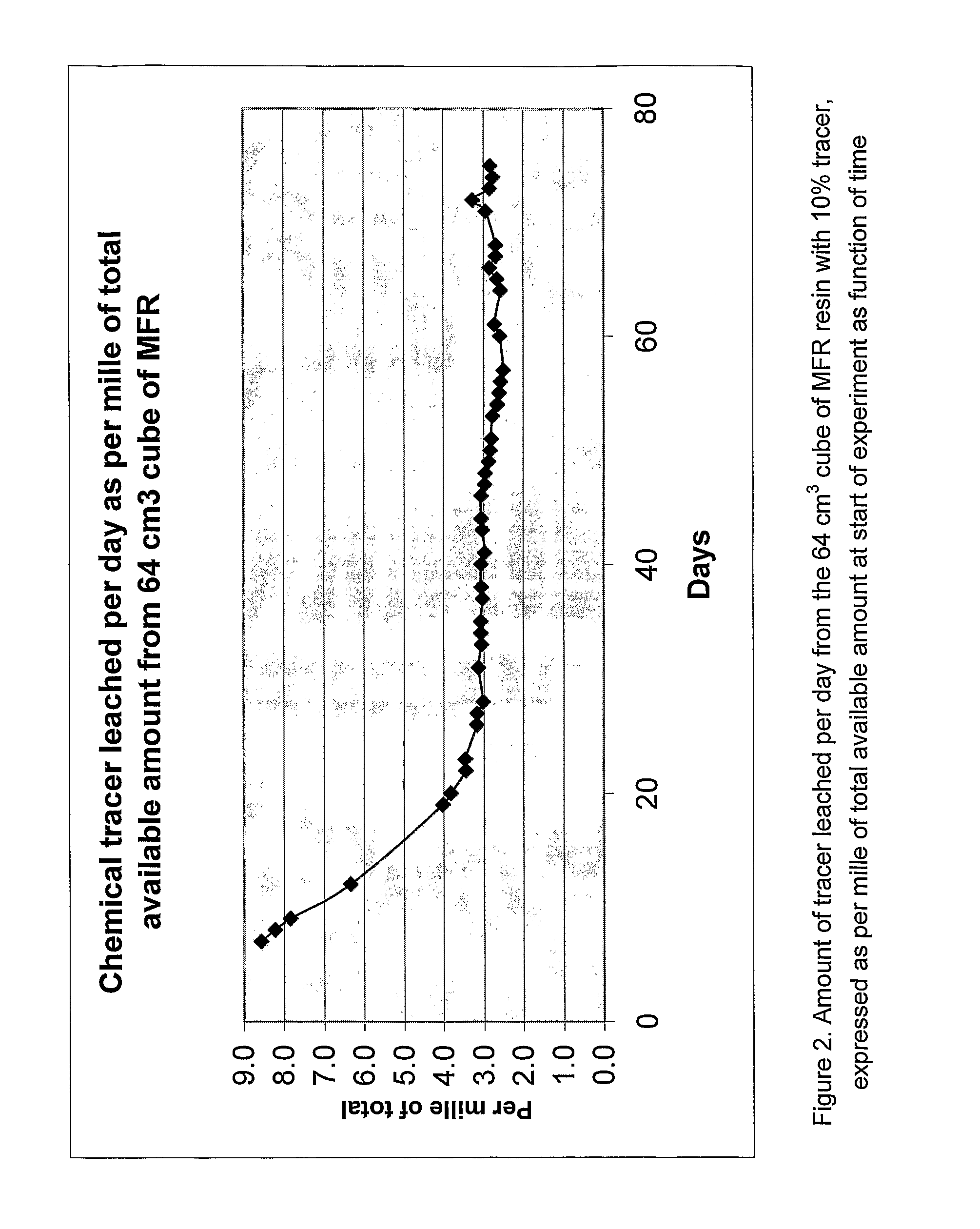

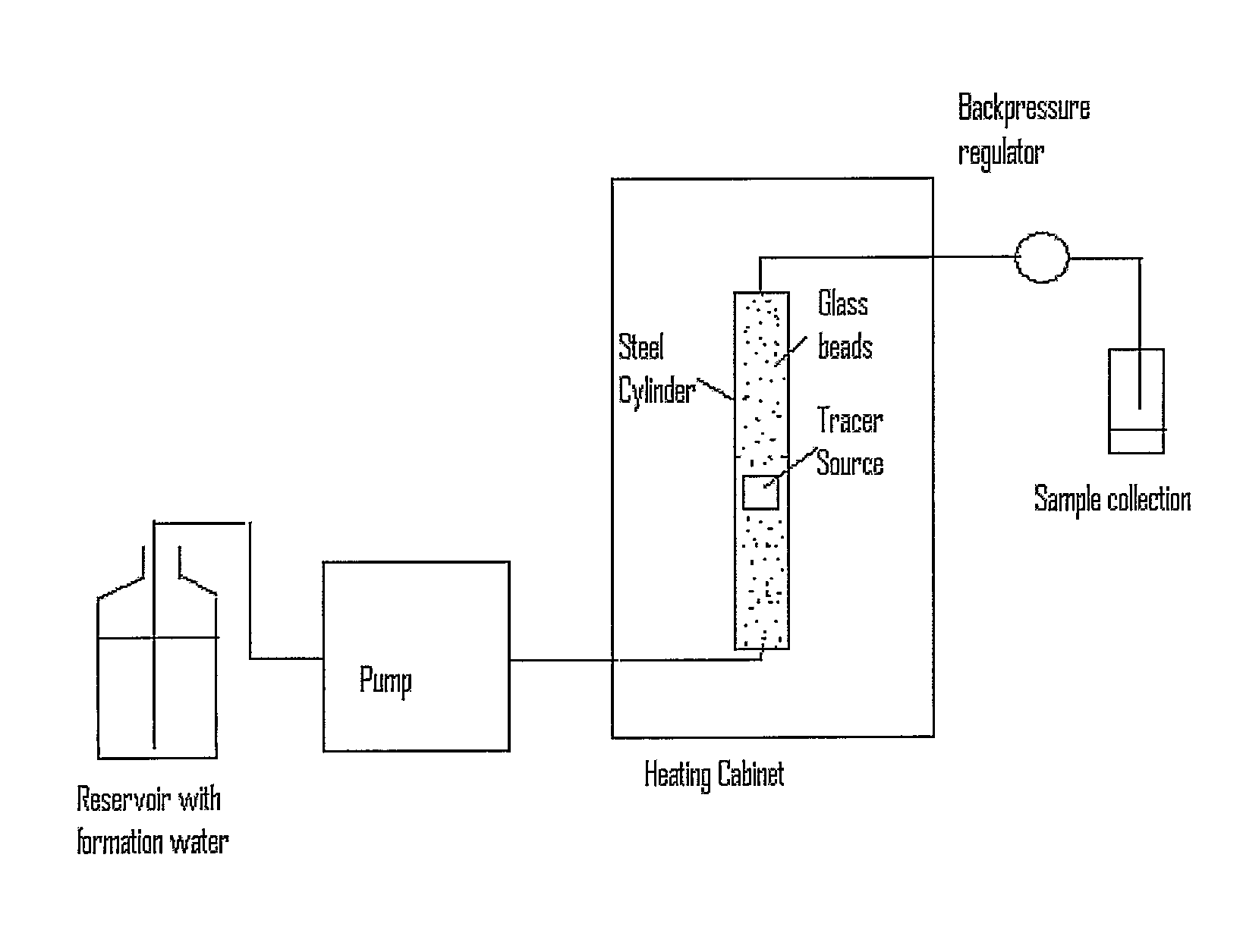

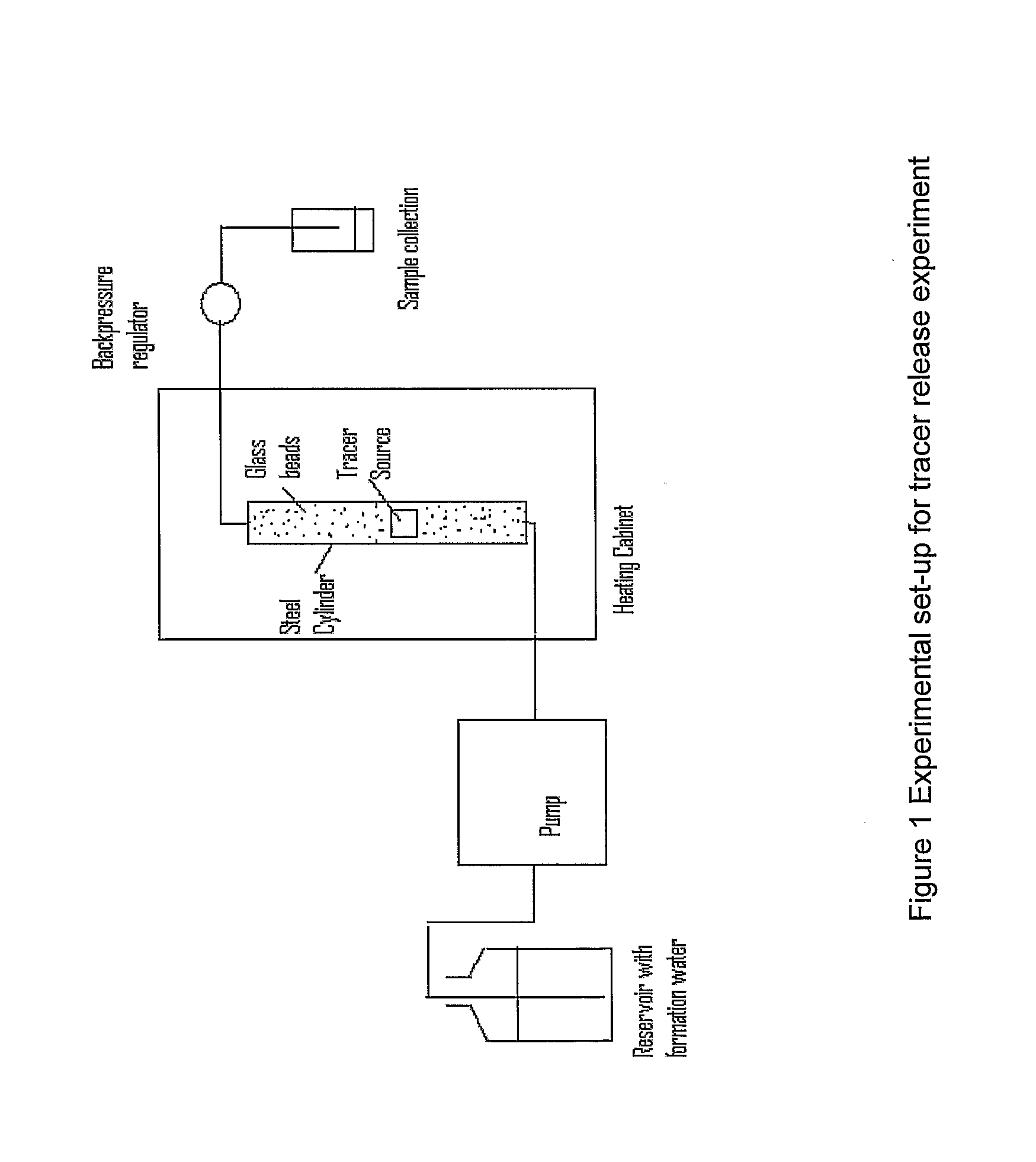

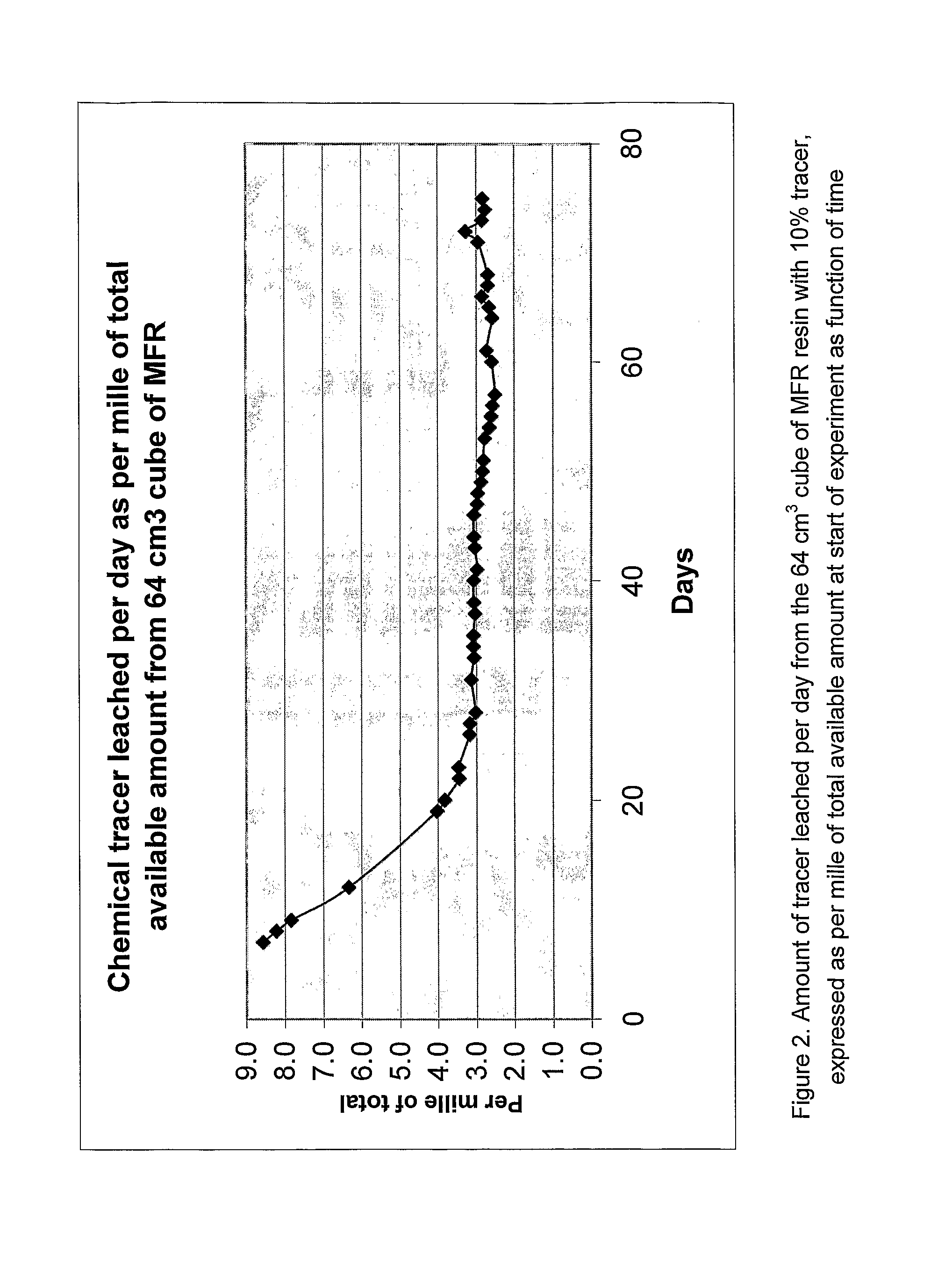

System for delivery of a tracer in fluid transport systems and use thereof

The present application describes a specific tracer delivery system that has been tested. The claimed system is composed of melamine formaldehyde resin (MFR) doped with various tracer materials. The MFR is used to slowly release tracer compounds into a liquid system. The MFR / tracer mixture is applied as part of a monitoring system where tracer is delivered from the MFR / tracer mixture at a specific location up-stream and detected at some location downstream, thereby verifying fluid flow from that specific location up-stream. The MFR can be doped with different types of tracers, thereby allowing placement of different tracers at several different positions upstream. Production from the various labelled zones can be verified through the analysis of one sample downstream.

Owner:RESMAN AS

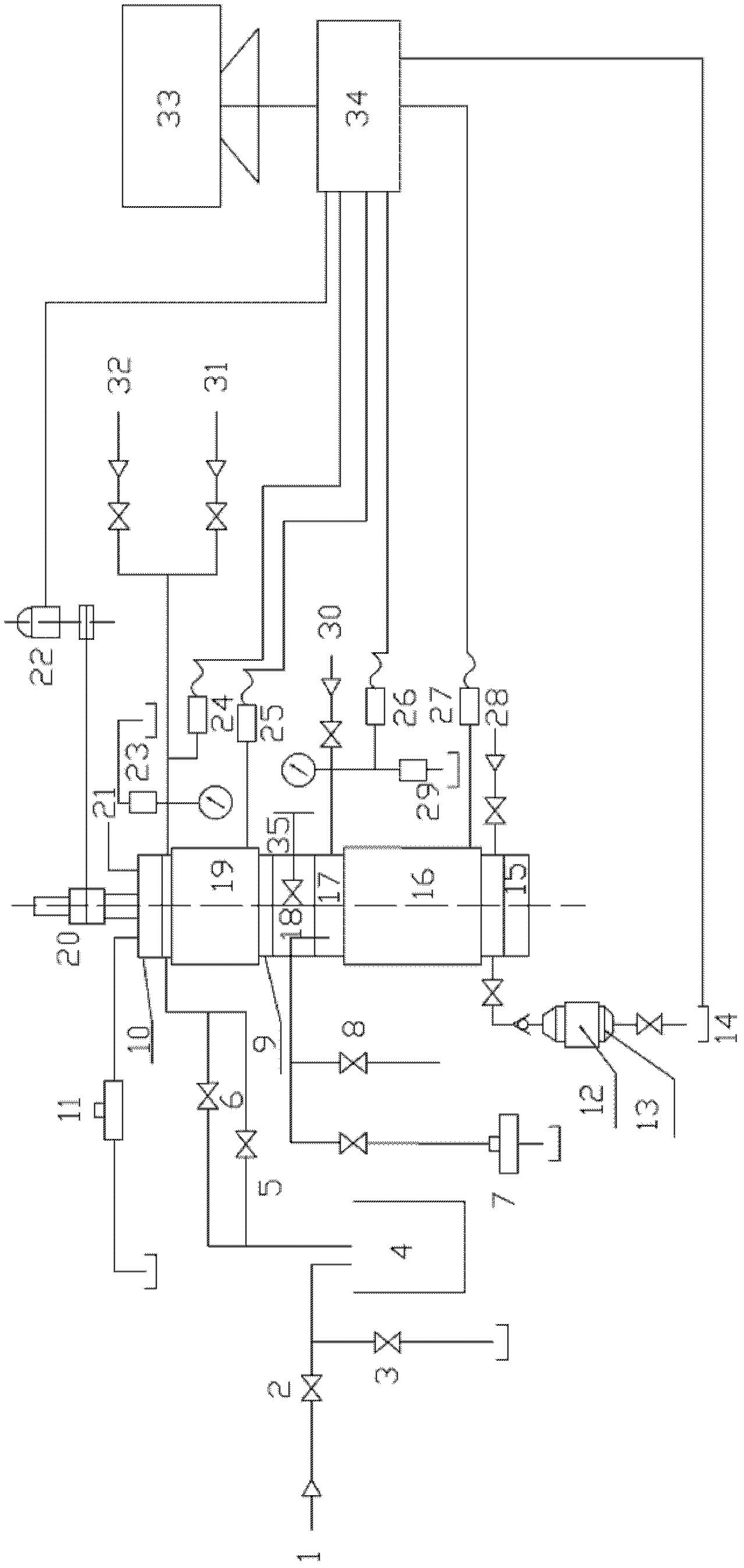

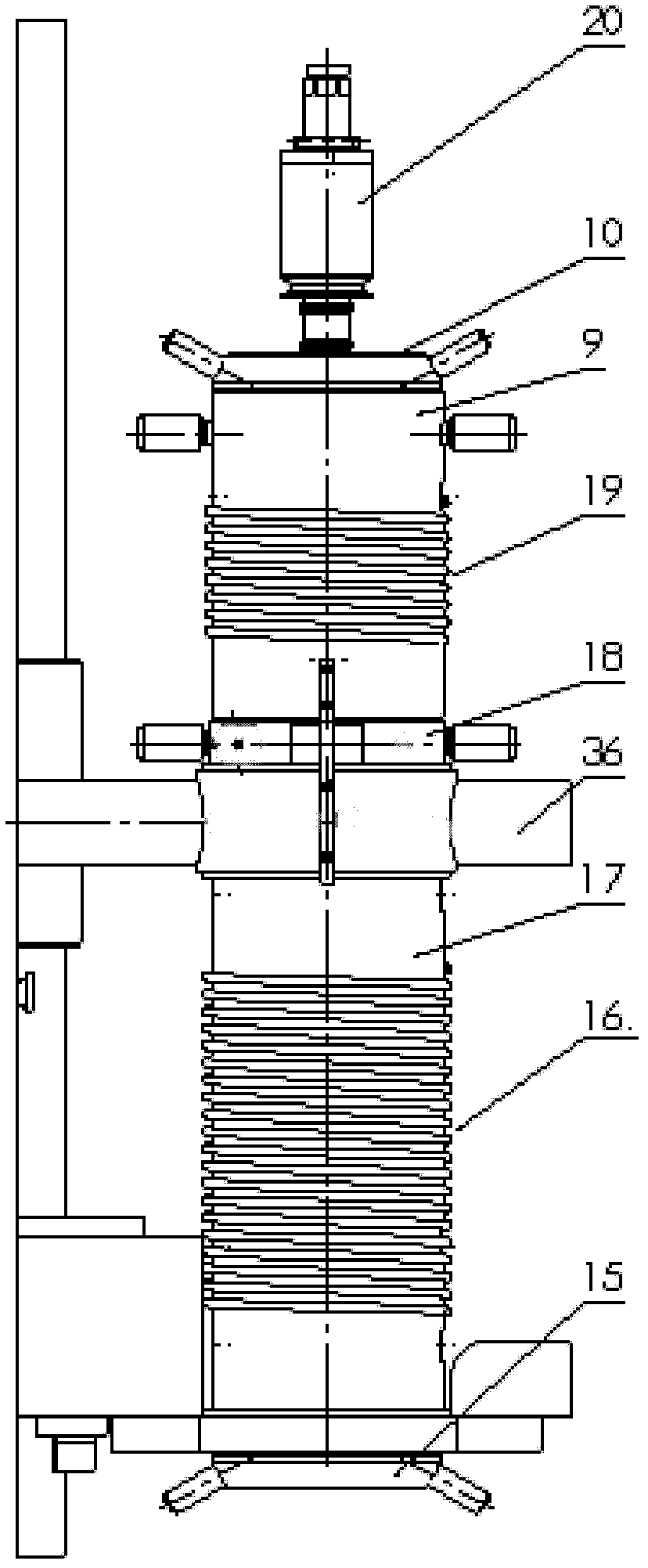

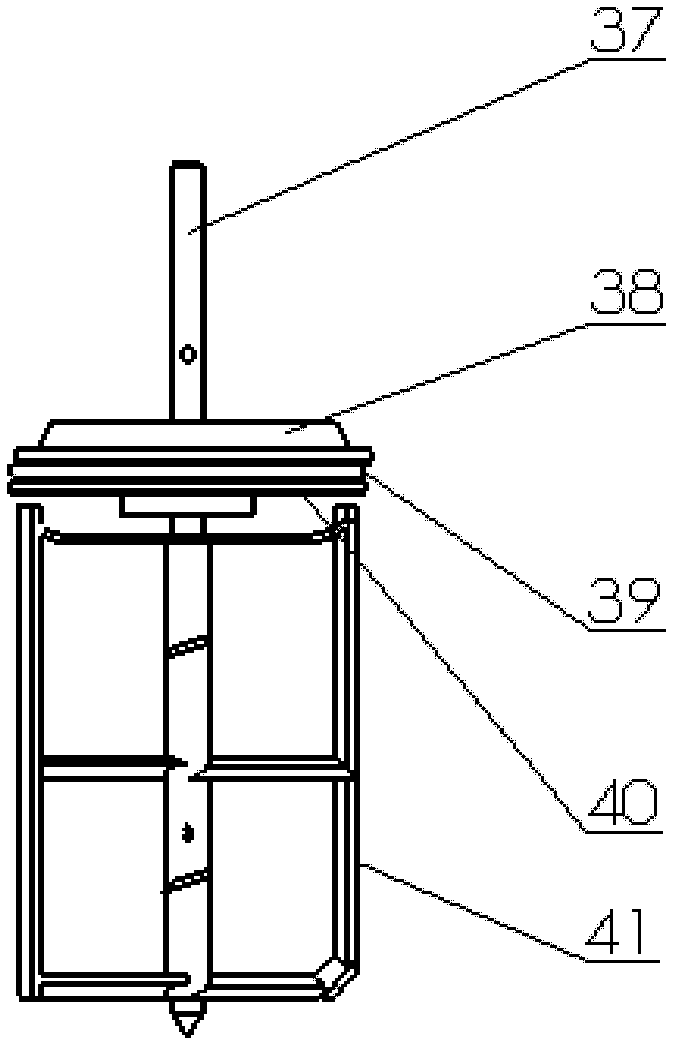

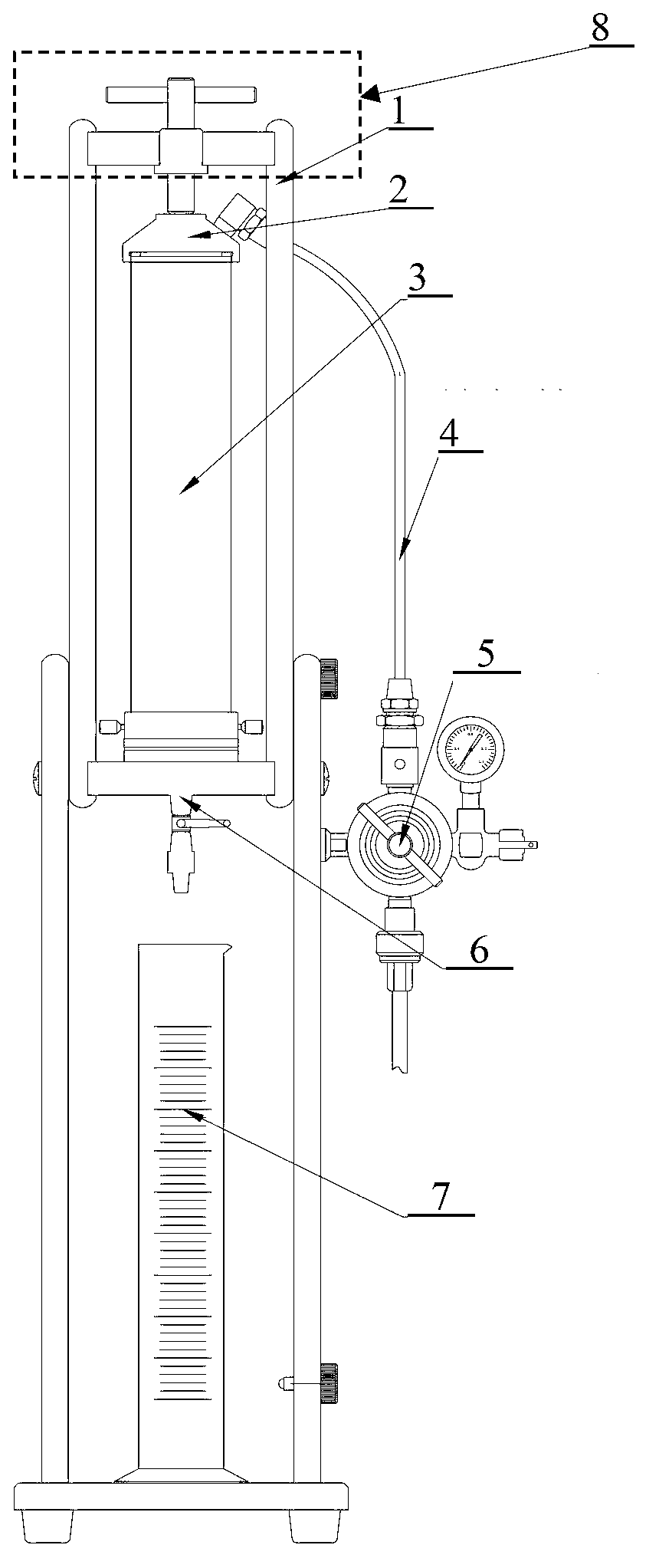

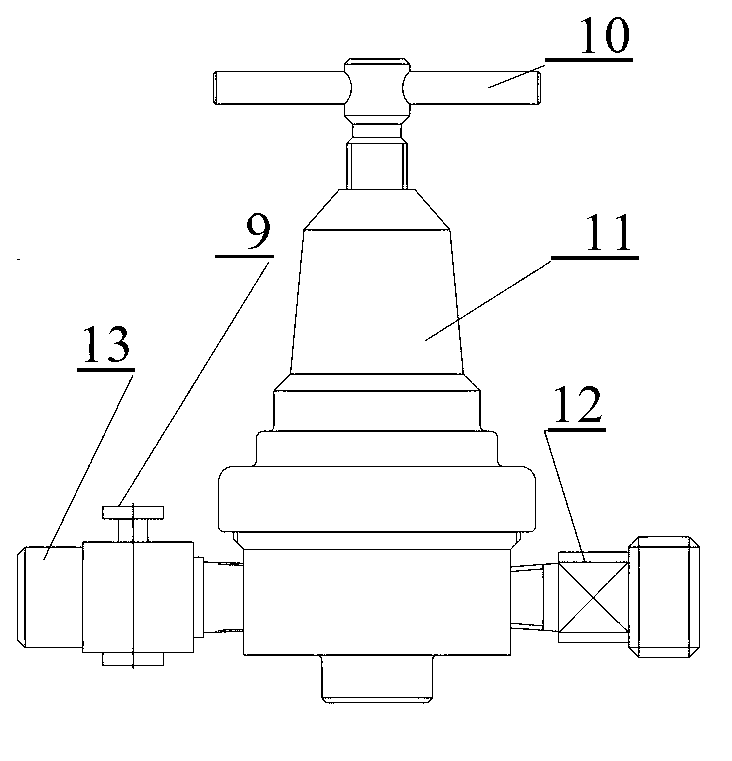

Test device capable of simulating plugging of high temperature and high pressure dropping strata

ActiveCN102518432ATest realization of blocking effectImplement testSealing/packingMagnetic tension forceWater source

The invention relates to a test device capable of simulating plugging of high temperature and high pressure dropping strata, which is mainly composed of a gas source, an oil tank, an upper kettle body, a lower kettle body, a water source, a magnetic force driver, a central processing system and a liquid collecting tank. The upper kettle body is connected with the oil tank and the gas source, the lower kettle body is connected with the water source, the upper kettle body and the lower kettle body are not only respectively connected with a pressure pump and a pressure-release pump, but also respectively connected with a pressure sensor and a thermalcouple, and the pressure sensor and the thermalcouple are connected with the central processing system. A blade is arranged in the upper kettle body, a blade rotary shaft is driven by a frequency converting motor to rotate through the magnetic force driver, and a simulation rock core is arranged in the lower kettle body and connected with theliquid collecting tank. The test device capable of simulating plugging of high temperature and high pressure dropping strata can simulate complex working conditions of drilling working liquid under stratum conditions with different well depth, temperature, pressure and dropping types, slurry body flow states, differential pressure under high temperature and high pressure between a shaft and the stratum and the like, can test relevant parameters of plugging to determine dropping plugging effects so as to preferably select a drilling working liquid system.

Owner:SOUTHWEST PETROLEUM UNIV

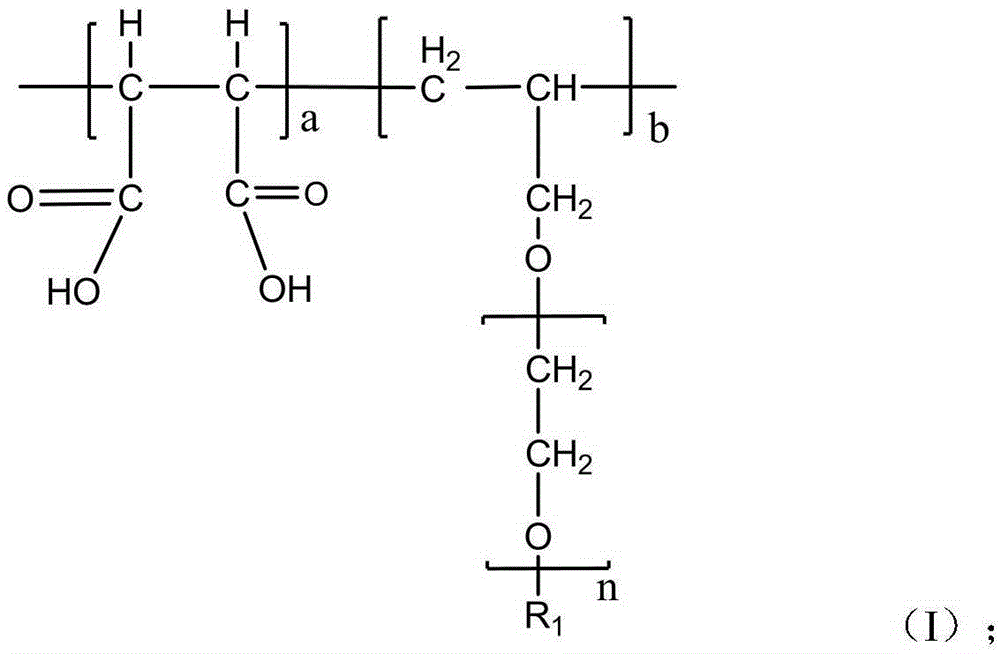

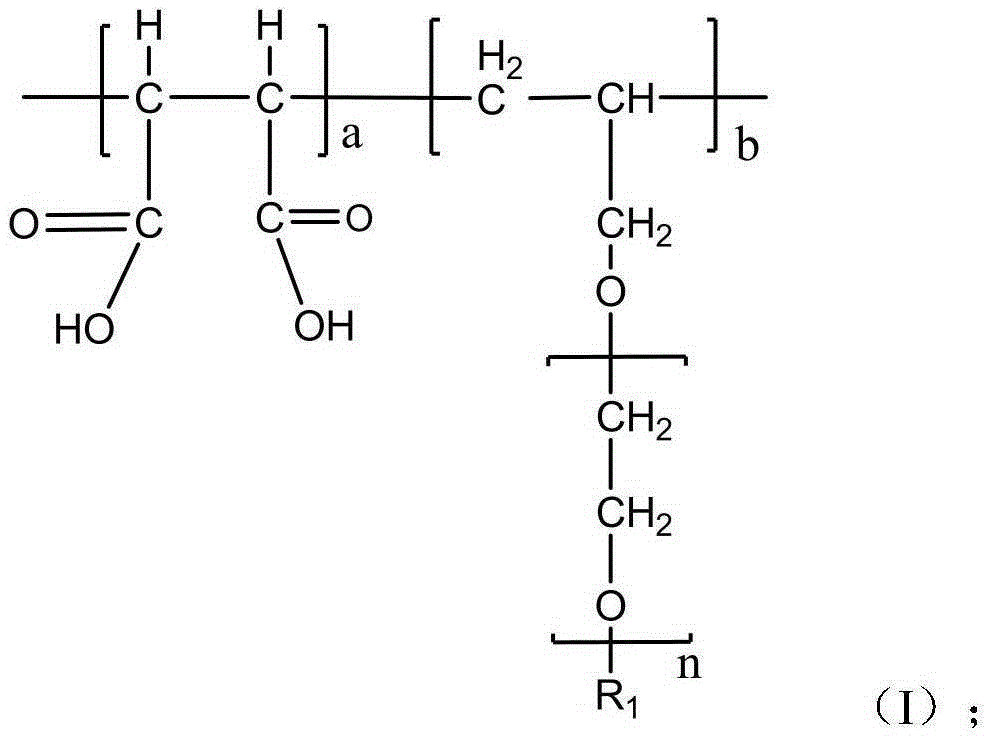

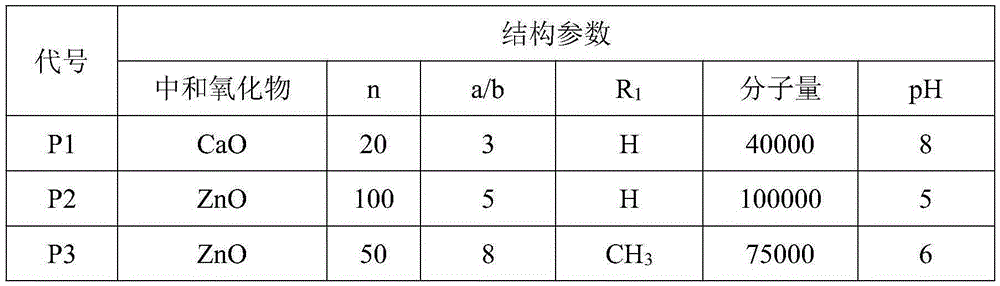

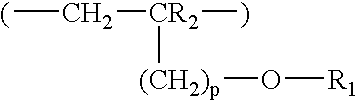

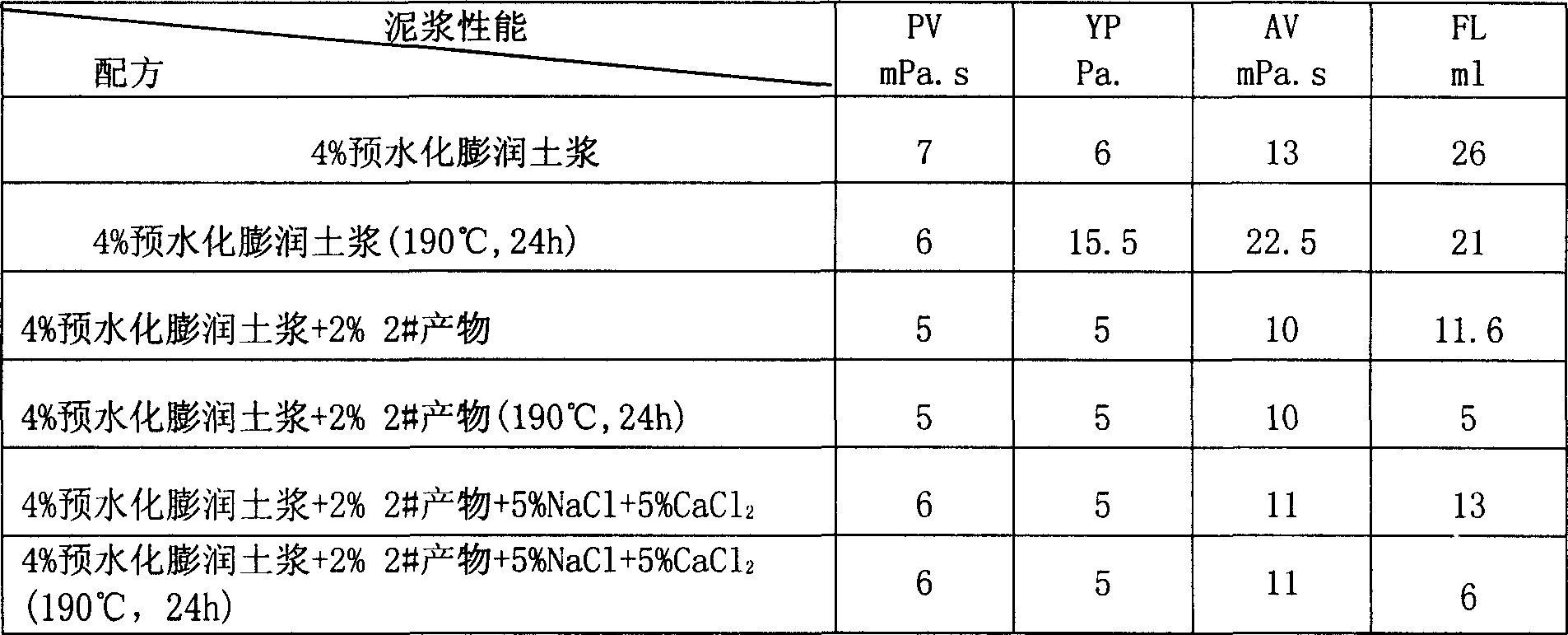

Strong-inhibition drilling fluid system

ActiveCN103013470AEnhanced inhibitory effectImprove stabilityDrilling compositionSlurryHigh pressure

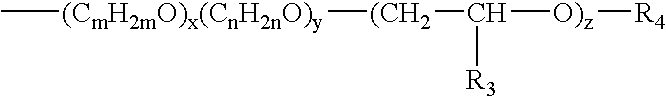

The invention relates to a strong-inhibition drilling fluid system, comprising the following components by mass percent of 2.5-4.5% of bentonite slurry, 0.1-0.3% of alkaline regulator, 0.3-2.0% of shale inhibitor, 0.2-0.4% of metal ion polymer, 2.0-5.0% of walchowite, 2.0-5.0% of sulfomethal phenolaldehy resin, 1.0-3.0% of cation emulsified asphalt, 0.5-3.0% of lubricating agent, 0.2-0.8% of emulsifier, 2.0-8.0% of crude oil, and 1.0-3.0% of calcium carbonate superfine powder according to 100% of water. The compound in a general formula (I) is also provided; R1 is H or CH3; R2 is H, CH3 or C2H5; and X is an integer between 2 and 20 and applied to the shale inhibitor. The compound and the cation emulsified asphalt are applied to the drilling liquid system; the drilling liquid system is strong in shale inhibition; the shale recovery rate can be up to 90.33% and is improved by over 35.02% in comparison with that of water shale; the high temperature resistance can be up to 150 DEG C; the lubricating friction coefficients before and after aging respectively are smaller than 0.1; the strong-inhibition drilling fluid system is strong in capacity of resisting poor soil, salt and calcium contamination, strong in rejection capability, and good in blocking effect; the API (American petroleum institute) water loss of the drilling fluid is smaller than 4.5mL, and the HTHP (high temperature and high pressure) water loss is smaller than 12mL.

Owner:CHINA PETROLEUM & CHEM CORP

Capture and release of mixed acid gasses with binding organic liquids

ActiveUS7799299B2Reduced thermodynamic stabilityPrevent excessive inputGas treatmentDispersed particle separationChemical reactionOrganic fluid

Reversible acid-gas binding organic liquid systems that permit separation and capture of one or more of several acid gases from a mixed gas stream, transport of the liquid, release of the acid gases from the ionic liquid and reuse of the liquid to bind more acid gas with significant energy savings compared to current aqueous systems. These systems utilize acid gas capture compounds made up of strong bases and weak acids that form salts when reacted with a selected acid gas, and which release these gases when a preselected triggering event occurs. The various new materials that make up this system can also be included in various other applications such as chemical sensors, chemical reactants, scrubbers, and separators that allow for the specific and separate removal of desired materials from a gas stream such as flue gas.

Owner:BATTELLE MEMORIAL INST

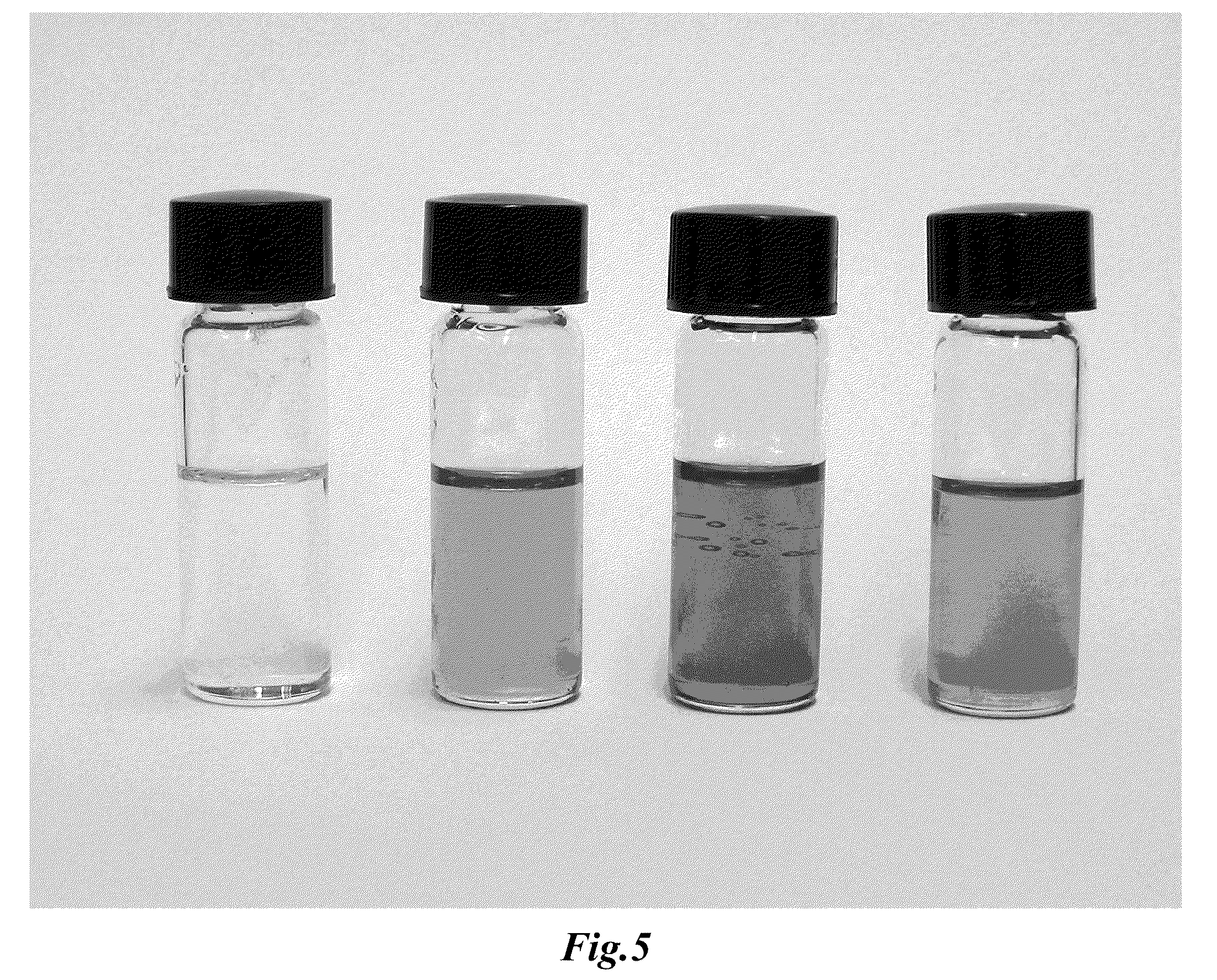

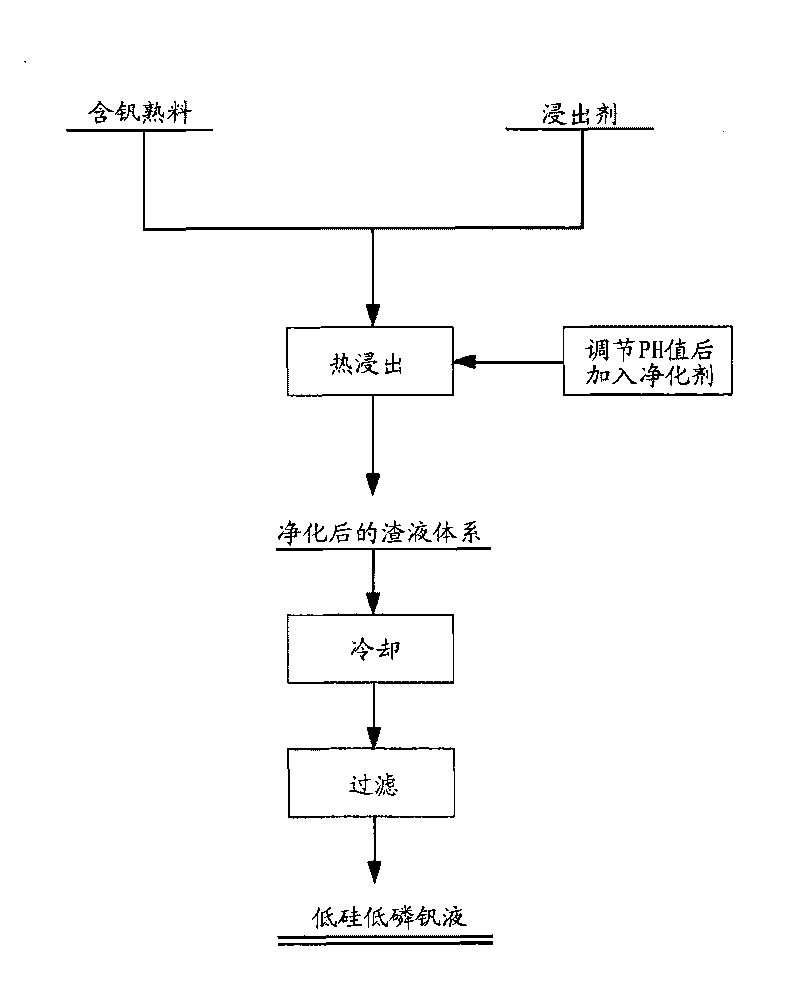

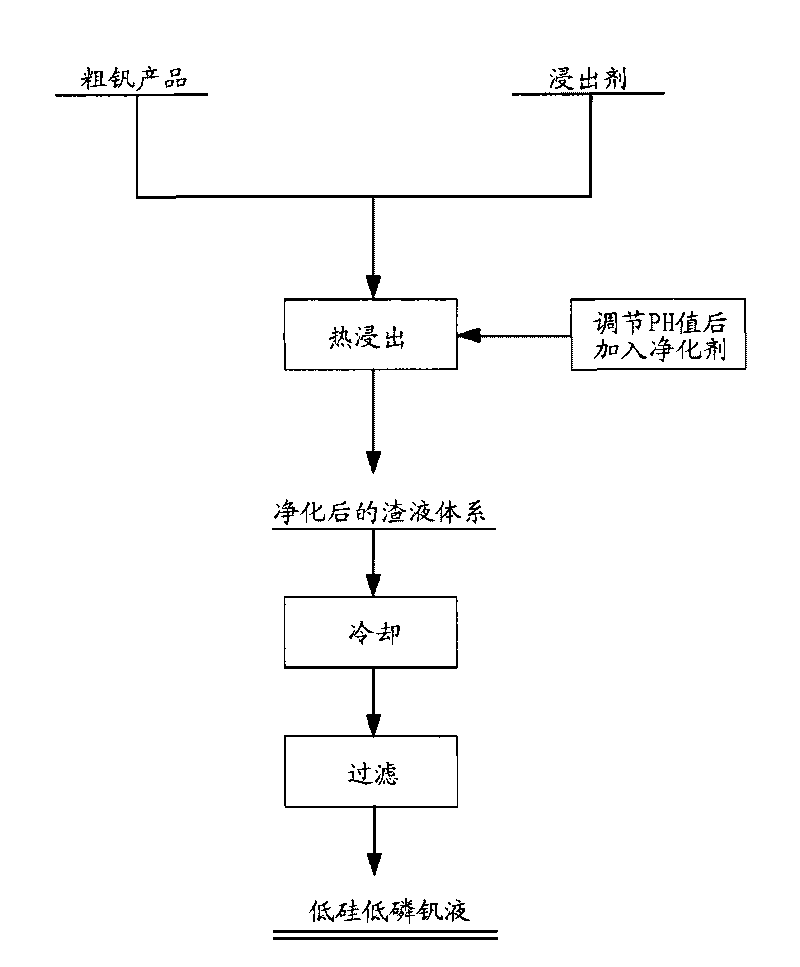

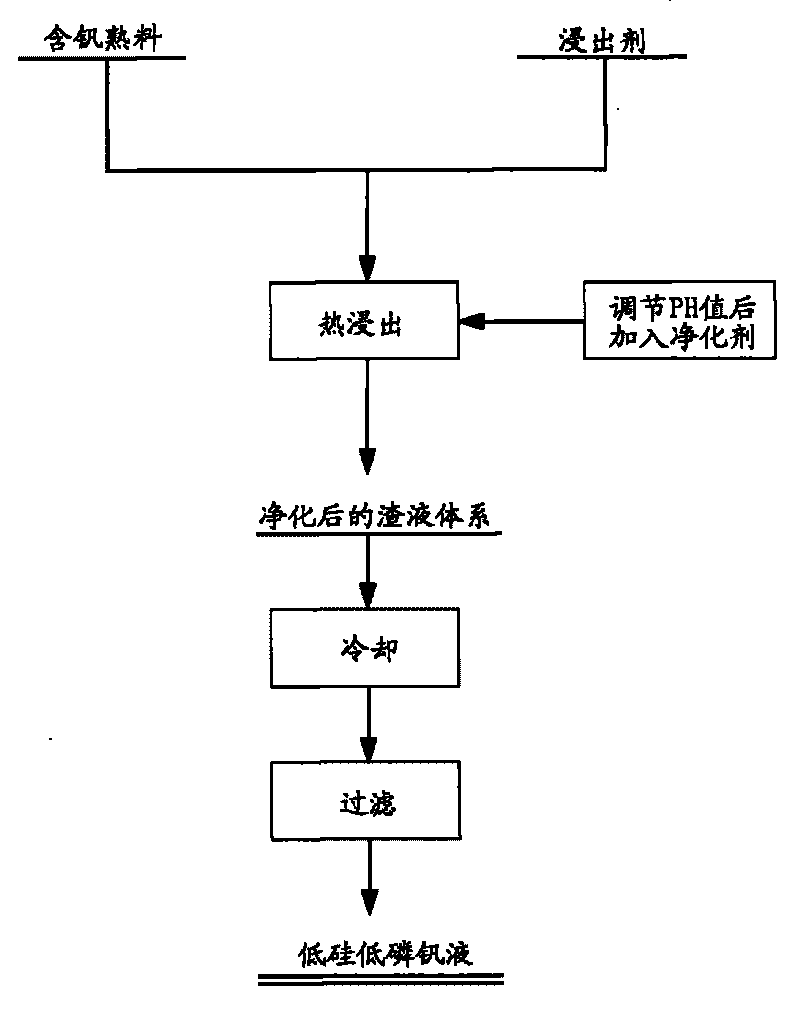

Method for preparing low-silicon and low-phosphorous vanadium liquid

The invention provides a method for preparing low-silicon and low-phosphorous vanadium liquid, which can be used for removing silicon and phosphorous by adding purifying agent into a vanadium liquid system in the process of leaching the vanadium liquid from vanadium-containing clinker or dissolving crude vanadium product. The method comprises the steps of: a. setting the leaching temperature of the vanadium-containing clinker or the dissolving temperature of the crude vanadium product to be any in the range between 60 DEG C to boiling temperature; b. using acid or alkali to adjust the corresponding vanadium liquid system obtaining in the step a to be alkaline, adding the purifying agent to remove silicon and phosphorous, and selecting at least one from aluminum salt, ferric salt and magnesium salt as the purifying agent; and c. after the step b, cooling, filtering and obtaining the low-silicon and low-phosphorous vanadium liquid. Compared with the existing vanadium extraction technique, the method has the advantages of being simple and easy use in technique, loose in content requirement of the vanadium liquid, low in equipment requirement, convenient for operation, low in cost and high in grade, synchronously removing silicon and phosphorous, etc.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Method for preparing nano aluminum oxide through vacuum freeze drying technology

InactiveCN101792164AThe production process is strictly controllableGood repeatabilityAluminium oxide/hydroxide preparationDispersityEmulsion

The invention relates to a method for preparing nano aluminum oxide with high specific surface area through vacuum freeze drying technology. The method comprises the following steps that: an organic phase is prepared, inorganic aluminum salt is mixed with the organic phase when agitation is conducted to obtain a micro-emulsion liquid system, and alkaline precipitant is added into the micro-emulsion liquid system for reaction to obtain aluminum hydroxide sediment; and after filtration and washing, vacuum freeze drying is conducted to the aluminum hydroxide sediment under conditions with temperature of negative 30 DEG C to negative 70 DEG C after pre-freezing, the freeze drying time is 2-96h to obtain aluminum hydroxide solid powder, and the aluminum hydroxide solid powder is calcined to finally obtain nano aluminum oxide. The preparation method of the invention combines the vacuum freeze drying technology with the reverse-phase micro-emulsion, the obtained nano aluminum oxide is gamma-aluminum oxide phase, the dispersity is good, the particles are even, the average grain size is 5-20nm, the specific surface area of the obtained nano aluminum oxide reaches 400-600m<2> / g and the pore volume is 1.5-2.5cm<3> / g. The invention has the advantages that the production process of the preparation method is controllable, the repetitiveness is high, the mass production can be realized, the stability is very high and the nano aluminum oxide can be used as the standard substance with high specific surface area.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

System for Delivery of a Tracer in Fluid Transport Systems and Use Thereof

The present application proposes a specific tracer delivery system that has been tested. The claimed system is composed of melamine formaldehyde resin (MFR) doped with various tracer materials. The MFR is used to slowly release tracer compounds into a liquid system. The MFR / tracer mixture is applied as part of a monitoring system where tracer is delivered from the MFR / tracer mixture at a specific location up-stream and detected at some location downstream, thereby verifying fluid flow from that specific location up-stream. The MFR can be doped with different types of tracers, thereby allowing placement of different tracers at several different positions upstream. Production from the various labelled zones can be verified through the analysis of one sample downstream.

Owner:RESMAN AS

Catalyst for polymerizing olefin and its prepn process

The present invention relates to catalyst for polymerization and copolymerization of olefin and its preparation process. The catalyst is obtained through dissolving magnesium halide in homogeneous solution of organic epoxy compound, organophosphorus compound and electron donor compound, and the reaction with the mixture solution of titanium halide or its derivative and liquid co-precipitant. Using the liquid co-precipitant intersoluble with titanium compound can omit the step of dissolving separating assistant, is favorable to the depositing separation of catalyst mother liquid system, raises the yield of the catalyst, avoids the residue of co-precipitant in catalyst product and raises the quality of polymer. The catalyst for polymerization and copolymerization of olefin has high activity and results in good polymer state.

Owner:CHINA PETROLEUM & CHEM CORP +1

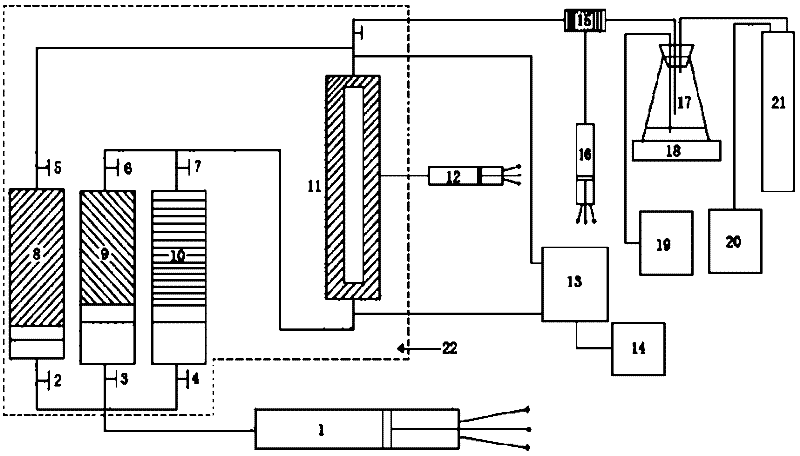

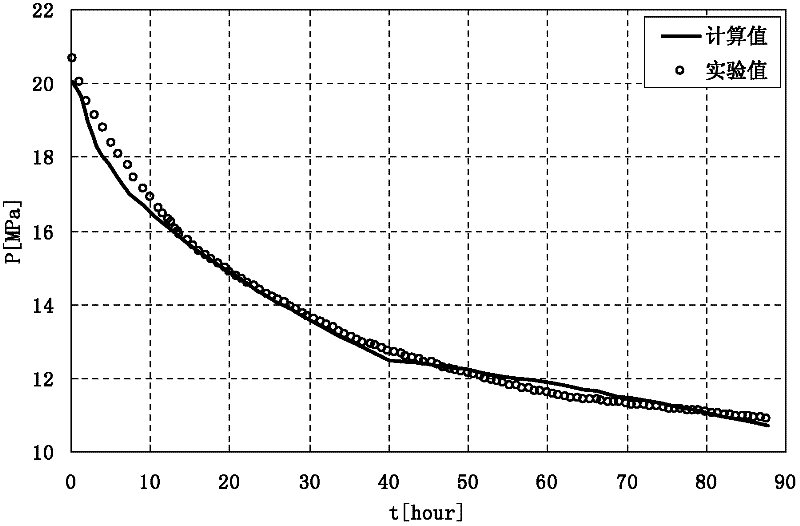

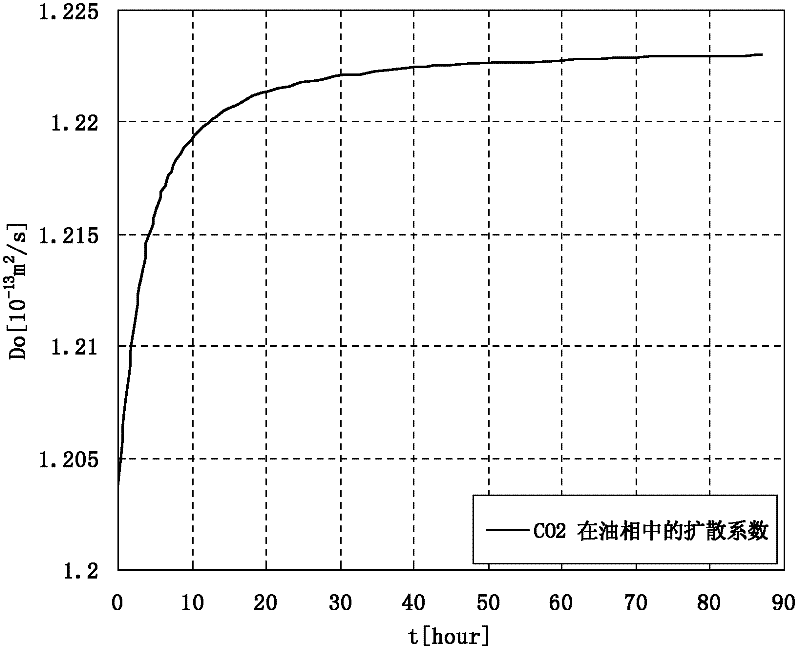

Device and method for determining molecular diffusion coefficient of multi-component gas-liquid system in rock core

ActiveCN102644459ARealize online testSimple test principleBorehole/well accessoriesRock coreGas phase

The invention relates to a device and method for determining a molecular diffusion coefficient of a multi-component gas-liquid system in a rock core. The device mainly comprises an inlet pump, a confining pressure pump, a pressure returning pump, an intermediate container, a rock core clamper, an oil-gas two-phase separator, a pressure sensor and a computer, wherein one end of the intermediate container is connected with the inlet pump; thee other end of the intermediate container is connected with the rock core clamper; the rock core clamper is connected with the pressure return pump, the confining pressure pump and the oil-gas two-phase separator; and two ends of the rock core clamper are connected with the pressure sensor and the computer. The method comprises the following steps of: transferring an oil sample and a gas sample into the rock core through the inlet pump; contacting an oil phase with a gas phase to generate diffusion and cause the reduction of the gas phase pressure; monitoring the pressure change of a gas phase zone; after the gas and liquid reach the balance, enabling the drained fluid in the rock core to enter the oil-gas two-phase separator; and analyzing and testing the gas phase composition and the property change. The device and method disclosed by the invention are reliable in principle and simple and convenient in operation; and the molecular diffusion coefficient of each component of the multi-component gas-liquid system in real rock core in the gas phase and oil phase can be determined under different temperature and pressure conditions of an oil reservoir and reasonable base data is provided for quantitatively evaluating the influence on the improvement on the recovery ratio caused by a molecular diffusion effect.

Owner:SOUTHWEST PETROLEUM UNIV

Melamine foam material for pipeline heat insulation and preparation method and use thereof

InactiveCN101423648ALight weightLow thermal conductivityThermal insulationPipe protection by thermal insulationFoaming agentSolid content

The invention provides a melamine foaming material for heat preservation of a pipeline, which consists of a foaming liquid system, wherein the foaming liquid system comprises a high solid content melamine resin, a foaming agent, a curing agent and an emulsifier, and the weight proportion of the high solid content melamine resin to the foaming agent to the curing agent to the emulsifier is 50-250 to 5-30 to 2.5-15 to 1-10. The invention also provides a method for preparing the melamine foaming material and application of the melamine foaming material. The melamine foaming material with adequate thickness is processed according to the shape of the pipeline and sleeved outside the pipeline, and the outside of the melamine foaming material is coated with a reinforced protective layer which is provided with a coating belt for fixation, so that the heat preservation effect of the pipeline can be achieved. The melamine foaming material has the advantages of low thermal conductivity coefficient, softness and moderation, easy machine shaping, simple construction, and firmness and reliability.

Owner:NO 91872 TROOPS PLA

Filtrate reducer for oil field well drilling fluid

ActiveCN101054512AImprove anti-slump inhibitionImprove collapse resistanceDrilling compositionFragilityMonomer

The invention relates to an oil field fluid loss additive for drilling liquid and its producing method and the application of the treating agent in the process of producing drilling liquid system. The treating agent utilizes the cation monomer dimethyl diallyl ammonium chloride can make the sodium lignin sulfonate and the sulfonated-methyl brown coal graft induced by FeCl3 so as to produce a new fluid loss agent with the resistance to salt and collapse at high temperature. The composed product integrates the brown coal and lignin. The cation introduction improves the resistance to collapse. The weak crosslinking function of the Fe3+ makes the heat resistance improved further based on the brown coal. Therefore, the product can be widely applied in different complicated conditions such as high temperature deep well, gypsum / slat bed, stratum with a bad water sensitivity, fragility stratum and etc. and has a good prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

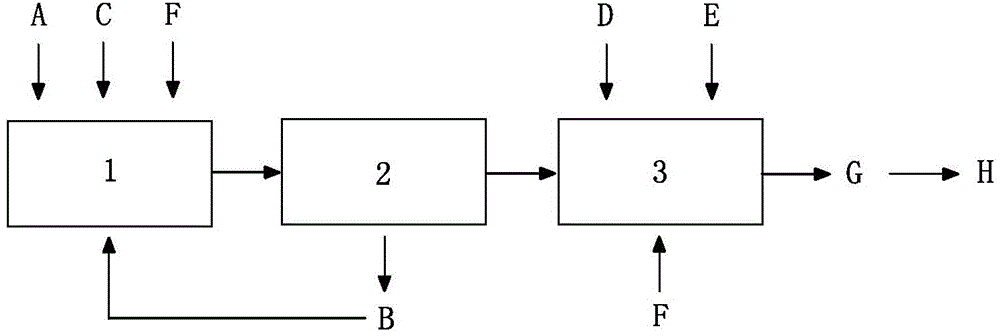

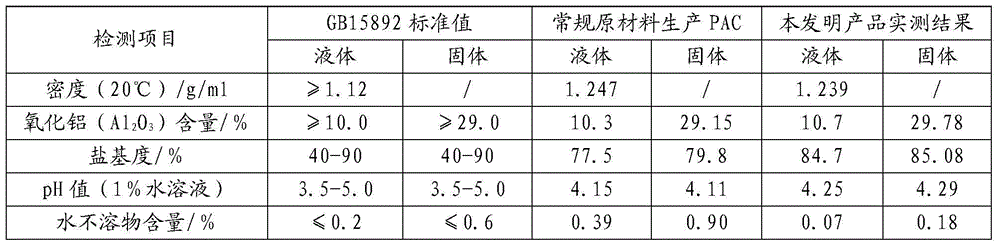

Recycling process of polyaluminium chloride filter residue

ActiveCN104402031AReduce manufacturing costReduce the dosing ratioAluminium chloridesLiquid densityProcess equipment

The invention discloses a recycling process of polyaluminium chloride filter residue; the process is as follows: adding water and hydrochloric acid into a first reaction kettle to prepare a 22-28% hydrochloric acid solution, adding the filter residue, stirring until the filter residue is dissolved; heating to 55 to 85 DEG C, adding aluminium-containing waste slag, after the addition, controlling the material liquid system temperature to be 92 to 118 DEG C for reacting for 2.5-5h; controlling the basicity of the material liquid after the reaction to be 27% + / -11% by adjustment of weight parts of the hydrochloric acid and the filter residue; separating the residue from the material liquid after the reaction, taking mother liquor, adding calcium aluminate powder; adjusting the material liquid density to be greater than or equal to 1.20g / ml, adding a synergist solution, reacting at 85-125 DEG C for 2.5-5h to obtain liquid polyaluminium chloride; and collecting and recycling the produced filter residue for reusing in production system to continue participating into the reaction. The recycling process achieves reuse of the filter residue in the polyaluminium chloride production system without addition of process equipment and other materials, greatly reduces the polyaluminium chloride production cost, reduces filter residue emissions, and conforms to environmental protection concepts of circular economy, energy saving and emission reduction.

Owner:蓝保(厦门)水处理科技有限公司

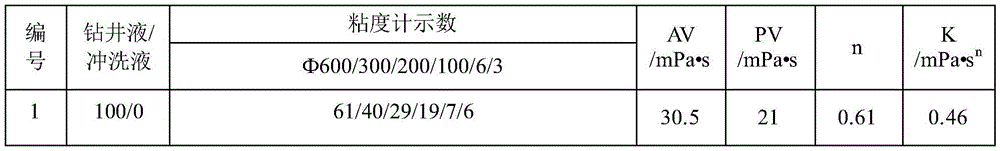

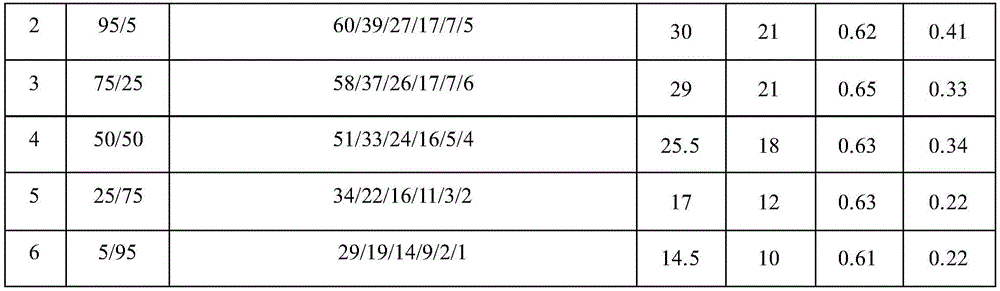

Well cementation flushing liquid system suitable for oil-based drilling fluid and preparation method thereof

InactiveCN105419758AReduce interfacial tensionImprove flushing effectDrilling compositionEngineeringVolumetric Mass Density

A well cementation flushing liquid system suitable for an oil-based drilling fluid and a preparation method thereof. The invention mainly solves the defects of low flushing efficiency, poor wetting conversion capability and poor interface cementing quality in the flushing liquids in the prior art. The flushing liquid system comprises the following components, by weight: 100 parts of clear water, 0.8-1.2 parts of an anionic surfactant, 0.6-0.8 parts of a nonionic surfactant, 0.7-1.0 part of a cosurfactant, 6.0-10.0 parts of an oil phase, 8.0-12.0 parts of a salt water phase, 0.15-5.0 parts of a polymer, 0.0-150 parts of a weighting agent and 1.0-2.5 parts of salt. The flushing liquid system is adjustable in density within 1.01-1.90 g / cm<3> and is 20-130 DEG C in available temperature range. The flushing liquid system can quickly remove residual oil-based drilling fluid, is strong in wetting conversion capability, ensures cementation between cement rings and an annular space, and is wide in application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

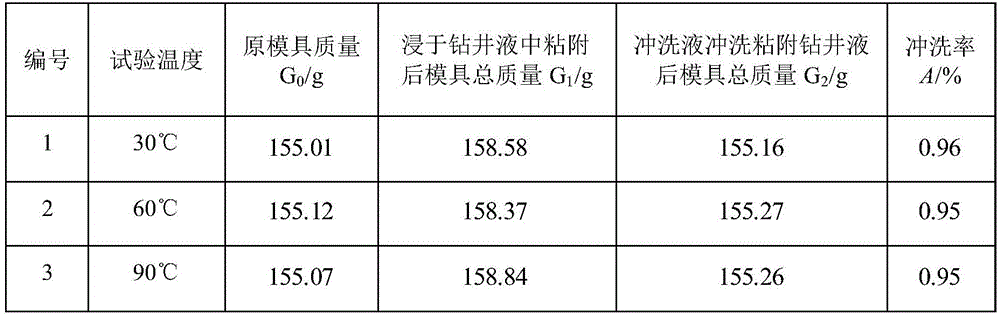

Mesoporous silica, mesoporous silica composite material, and processes for production thereof

A mesoporous silica has uniform mesopores and a periodic structure, which contains a Zr element in the form of a Si-O-Zr bond and wherein the Zr content in the Si-O-Zr bond, represented by [Zr / (Si+Zr)] is 0.05 to 20 mole %. The mesoporous silica is superior in alkali resistance and is suitably used particularly as a separation membrane (e.g. a ceramic membrane) and a catalytic support for solid-liquid system, in which an alkaline liquid may be used.

Owner:NGK INSULATORS LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com