Method for preparing low-silicon and low-phosphorous vanadium liquid

A technology of phosphorus vanadium and vanadium liquid is applied in the field of preparing low silicon and low phosphorus vanadium liquid, which can solve the problems of reducing the yield of vanadium element, difficulty in filtration, affecting quality, etc., and achieves loose composition requirements of vanadium liquid and simple and easy-to-use process. , the effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

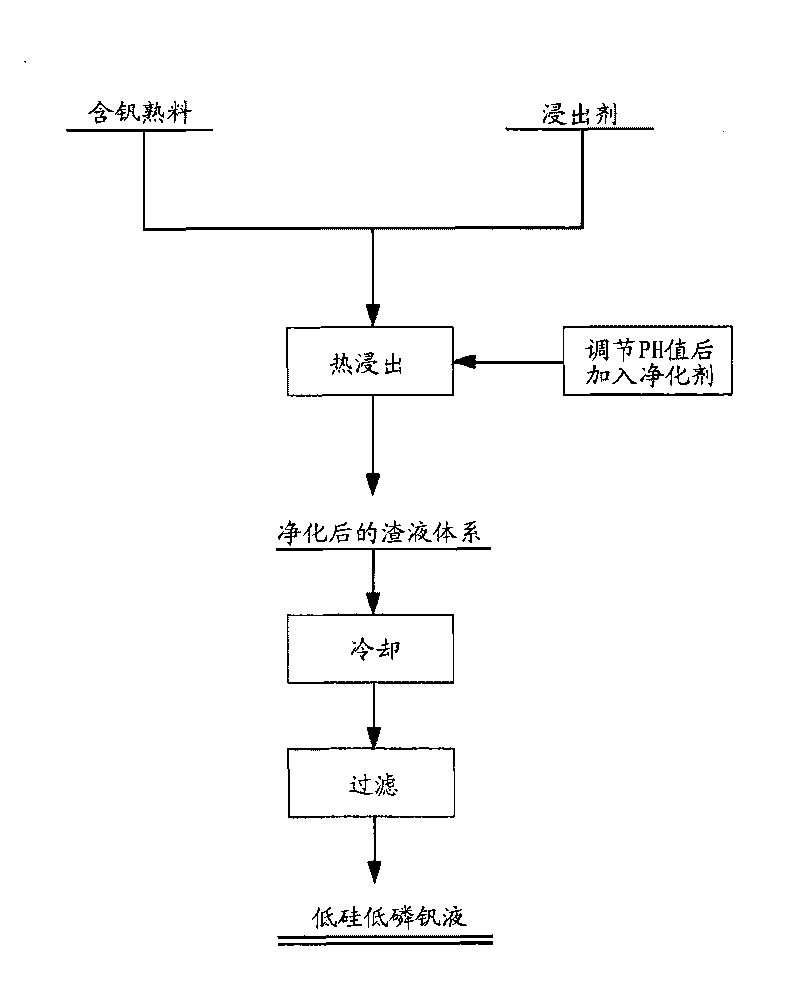

[0022] In this embodiment, a low-silicon and low-phosphorus vanadium solution is produced from vanadium slag clinker through the method for producing a low-silicon and low-phosphorus vanadium solution according to an exemplary embodiment of the present invention.

[0023] Add 400g of the vanadium slag clinker and 800mL of water whose elemental composition is shown in Table 1 to a 1000mL clean beaker, stir evenly, and heat the vanadium liquid system to 80°C. The vanadium liquid system mentioned here refers to the vanadium slag clinker The mixed material formed with water, because the pH value of the vanadium liquid system formed here is about 10, so there is no need to add acid or alkali to the vanadium liquid system. The agent is a solution made of 2.5g of anhydrous aluminum sulfate and an appropriate amount of water. After adding the purifying agent to the vanadium liquid system at 80°C for 1 hour, it is cooled to room temperature and filtered to obtain [Si]=0.0058g / L, [P]=0...

Embodiment 2

[0027] In this embodiment, a low-silicon and low-phosphorus vanadium solution is produced from vanadium slag clinker through the method for producing a low-silicon and low-phosphorus vanadium solution according to an exemplary embodiment of the present invention.

[0028] Add 400g of vanadium slag clinker and 800mL of water whose elemental composition is shown in Table 1 to a 1000mL clean beaker, stir evenly, and heat the vanadium liquid system to 60°C. The vanadium liquid system mentioned here refers to the vanadium slag clinker The mixed material formed with water, because the pH value of the vanadium liquid system formed here is about 10, so there is no need to add acid or alkali to the vanadium liquid system. The agent is a solution made of 1.5g of anhydrous aluminum sulfate, 1.5g of magnesium sulfate and an appropriate amount of water. After the vanadium liquid system at 60°C with purifying agent is added to react for 1 hour, it is cooled to normal temperature and filtered...

Embodiment 3

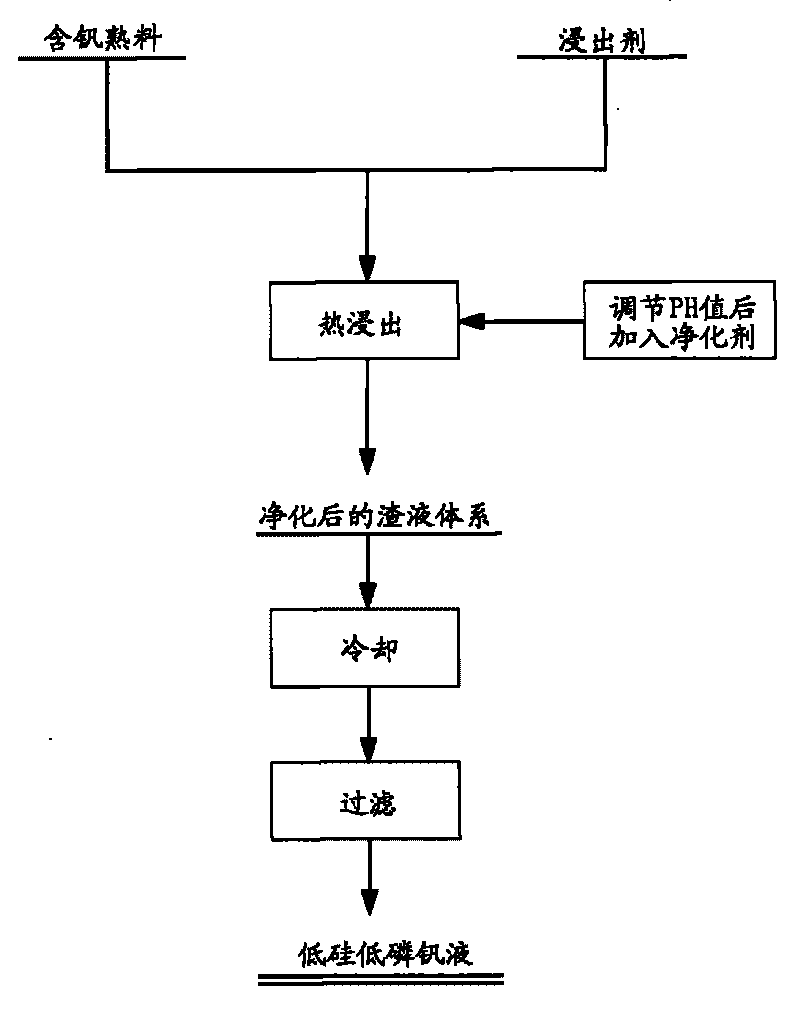

[0030] In this embodiment, a low-silicon and low-phosphorus vanadium solution is produced from vanadium slag clinker through the method for producing a low-silicon and low-phosphorus vanadium solution according to an exemplary embodiment of the present invention.

[0031] In the 5000mL clean beaker, add 2000g of vanadium slag clinker and 4000mL water with each element composition as shown in Table 1, stir evenly, and heat the vanadium liquid system to boiling. The vanadium liquid system mentioned here refers to the vanadium slag clinker and For the mixed material formed by water, since the pH value of the vanadium liquid system formed here is about 10, there is no need to add acid or alkali to the vanadium liquid system, and a purification agent is added to the boiling vanadium liquid system. It is a solution made up of 5g of anhydrous aluminum sulfate, 2g of magnesium chloride, 5g of ferric sulfate and an appropriate amount of water. After adding the boiling vanadium liquid sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com